Title: Scientific American Supplement, No. 446, July 19, 1884

Author: Various

Release date: March 1, 2004 [eBook #11385]

Most recently updated: December 25, 2020

Language: English

Credits: Produced by Jon Niehof, Don Kretz, Juliet Sutherland, Charles Franks

and the DP Team

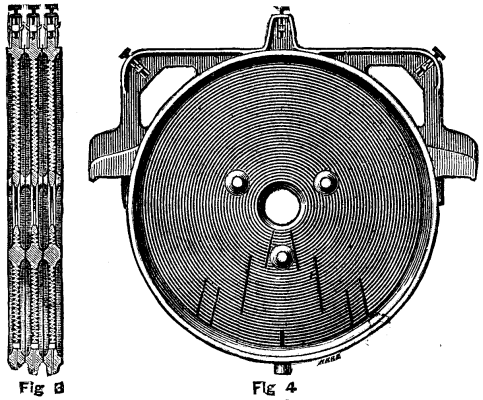

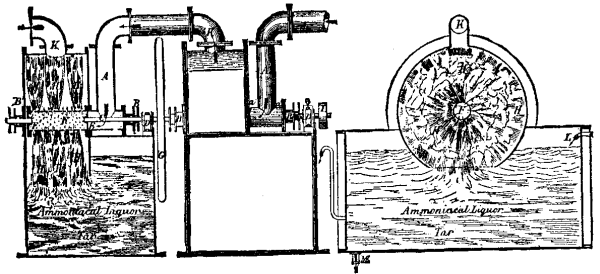

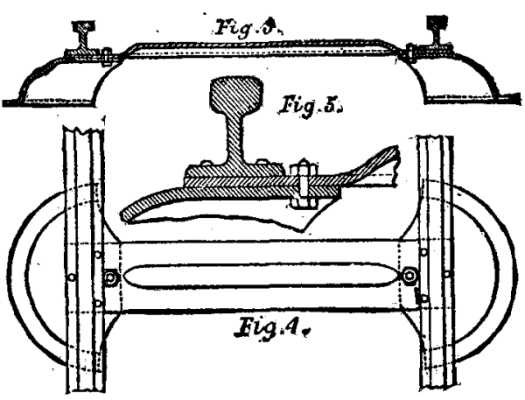

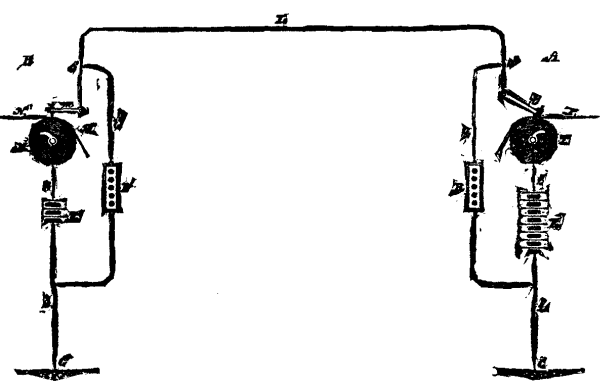

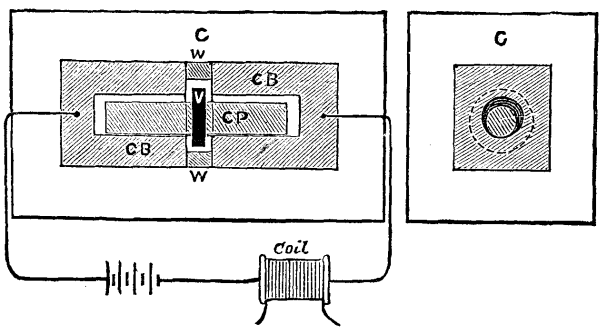

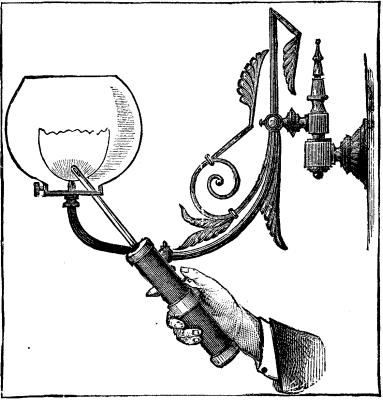

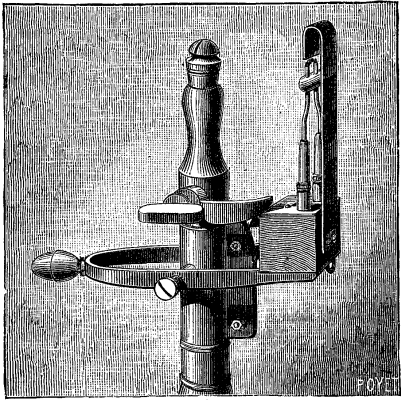

Hitherto it has been found that of all the appliances and methods for separating the liquid from the solid matters, whether it is in the case of effluents from tanneries and other manufactories, or the ocherous and muddy sludges taken from the settling tanks in mines, some of which contain from 90 to 95 per cent. of water, the filter press is the best and the most economical, and it is to this particular process that Messrs. Johnson's exhibits at the Health Exhibition, London, chiefly relate. Our engravings are from The Engineer. A filter press consists of a number of narrow cells of cast iron, shown in Figs. 3 and 4, held together in a suitable frame, the interior frames being provided with drainage surfaces communicating with outlets at the bottom, and covered with a filtering medium, which is generally cloth or paper. The interior of the cells so built up are in direct communication with each other, or with a common channel for the introduction of the matter to be filtered, and as the only exit is through the cloth or paper, the solid portion is kept back while the liquid passes through and escapes by the drainage surfaces to the outlets. The cells are subjected to pressure, which increases as the operation goes on, from the growing resistance offered by the increasing deposit of solid matter on the cloths; and it is therefore necessary that they should be provided with a jointing strip around the outside, and be pressed together sufficiently to prevent any escape of liquid. In ordinary working both sides of the cell are exposed to the same pressure, but in some cases the feed passages become choked, and destroy the equilibrium. This, in the earlier machines, gave rise to considerable annoyance, as the diaphragms, being thin, readily collapsed at even moderate pressures; but recently all trouble on this head has been obviated by introducing the three projections near the center, as shown in the cuts, which bear upon each other and form a series of stays from one end of the cells to the other, supporting the plates until the obstruction is forced away. We give an illustration below showing the arrangement of a pair of filter presses with pneumatic pressure apparatus, which has been successfully applied for dealing with sludge containing a large amount of fibrous matter and rubbish, which could not be conveniently treated with by pumps in the ordinary way. The sludge is allowed to gravitate into wrought iron receivers placed below the floor, and of sufficient size to receive one charge. From these vessels it is forced into the presses by means of air compressed to from 100 lb. to 120 lb. per square inch, the air being supplied by the horizontal pump shown in the engraving. The press is thus almost instantaneously filled, and the whole operation is completed in about an hour, the result being a hard pressed cake containing about 45 per cent. of water, which can be easily handled and disposed of as required. The same arrangement is in use for dealing with sewage sludge, and the advantages of the compressed air system over the ordinary pumps, as well as the ready and cleanly method of separating the liquid, will probably commend itself to many of our readers. We understand that from careful experiments on a large scale, extending over a period of two years, the cost of filtration, including all expenses, has been found to be not more than about 6d. per ton of wet sludge. A number of specimens of waste liquors from factories with the residual matters pressed into cakes, and also of the purified effluents, are exhibited. These will prove of interest to many, all the more so since in some instances the waste products are converted into materials of value, which, it is stated, will more than repay for the outlay incurred.

Fig. 3. Fig 4.

Another application of the filter press is in the Porter-Clark process of softening water, which is shown in operation. We may briefly state that the chief object is to precipitate the bicarbonates of lime and magnesia held in solution by the water, and so get rid of what is known as the temporary hardness. To accomplish this, strong lime water is introduced in a clear state to the water to be softened, the quantity being regulated according to the amount of bicarbonates in solution. The immediate effect of this is that a proportion of the carbonic acid of the latter combines with the invisible lime of the clear lime water, forming a chalky precipitate, while the loss of this proportion of carbonic acid also reduces the invisible bicarbonates into visible carbonates. The precipitates thus formed are in the state of an impalpable powder, and in the original Clark process many hours were required for their subsidence in large settling tanks, which had to be in duplicate in order to permit of continuous working. By Mr. Porter's process, however, this is obviated by the use of filter presses, through which the chalky water is passed, the precipitate being left behind, while, by means of a special arrangement of cells, the softened and purified water is discharged under pressure to the service tanks. Large quantities can thus be dealt with, within small space, and in many cases no pumping is required, as the resistance of the filtering medium being small, the ordinary pressure in the main is but little reduced. One of the apparatus exhibited is designed for use in private mansions, and will soften and filter 750 gallons a day. In such a case, where it would probably be inconvenient to apply the usual agitating machinery, special arrangements have been made by which all the milk of lime for a day's working is made at one time in a special vessel agitated by hand, on the evening previous to the day on which it is to be used. Time is thus given for the particles of lime to settle during the night. The clear lime water is introduced into the mixing vessel by means of a charge of air compressed in the top of a receiver, by the action of water from the main, the air being admitted to the milk of lime vessel through a suitable regulating valve. A very small filter suffices for removing the precipitate, and the clear, softened water can either be used at once, or stored in the usual way. The advantages which would accrue to the community at large from the general adoption of some cheap method of reducing the hardness of water are too well known to need much comment from us.

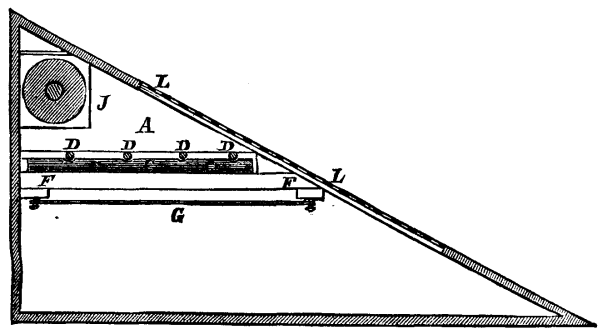

According to K. Lintner, the worst features of the present system of malting are the inequalities of water and temperature in the heaps and the irregular supplies of oxygen to, and removal of carbonic acid from, the germinating grain. The importance of the last two points is demonstrated by the facts that, when oxygen is cut off, alcoholic fermentation--giving rise to the well-known odor of apples--sets in in the cells, and that in an atmosphere with 20 per cent. of carbonic acid, germination ceases. The open pneumatic system, which consists in drawing warm air through the heaps spread on a perforated floor, should yield better results. All the processes are thoroughly controlled by the eye and by the thermometer, great cleanliness is possible, and the space requisite is only one-third of that required on the old plan. Since May, 1882, this method has been successfully worked at Puntigam, where plant has been established sufficient for an annual output of 7,000 qrs. of malt. The closed pneumatic system labors under the disadvantages that from the form of the apparatus germination cannot be thoroughly controlled, and cleanliness is very difficult to maintain, while the supply of oxygen is, as a rule, more irregular than with the open floors.

IMPROVED PNEUMATIC FILTERING PRESSES.

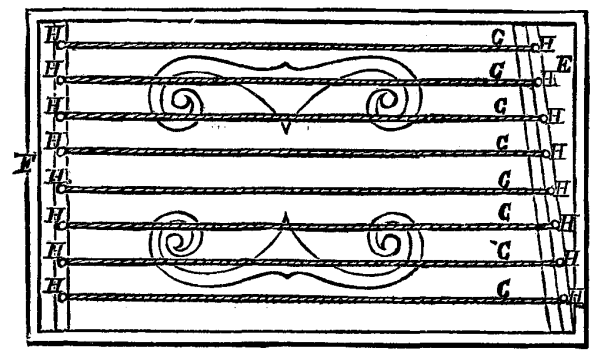

The washer is an appliance intended to condense and clean gas, which, on leaving the hydraulic main, holds in suspension a great many properties that are injurious to its illuminating power, and cannot, if retained, be turned to profitable account. This cleaning process is not difficult to carry out effectually; and most of the appliances invented for the purpose would be highly efficacious if they did not in other respects present certain very serious inconveniences. The passage of the gas through a column of cold water is, of course, sufficient to condense it, and clear it of these injurious properties; but this operation has for its immediate effect the presentation of an obstacle to the flow of the gas, and consequently augmentation of pressure in the retorts. In order to obviate this inconvenience (which exists notwithstanding the use of the best washers), exhausters are employed to draw the gas from the retorts and force it into the washers. There is, however, another inconvenience which can only be remedied by the use of a second exhauster, viz., the loss of pressure after the passage of the gas through the washer--a loss resulting from the obstacle presented by this appliance to the steady flow of the gas. Now as, in the course of its passage through the remaining apparatus, on its way to the holder, the gas will have to suffer a considerable loss of pressure, it is of the greatest importance that the washer should deprive it of as little as possible. It will be obvious, therefore, that a washer which fulfills the best conditions as far as regards the cleaning of the gas will be absolutely perfect if it does not present any impediment to its flow. Such an appliance is that which is shown in the illustration on next page. Its object is, while allowing for the washing being as vigorous and as long-continued as may be desired, to draw the gas out of the retorts, and, having cleansed it perfectly from its deleterious properties, to force it onward. The apparatus consequently supplies the place of the exhauster and the scrubber.

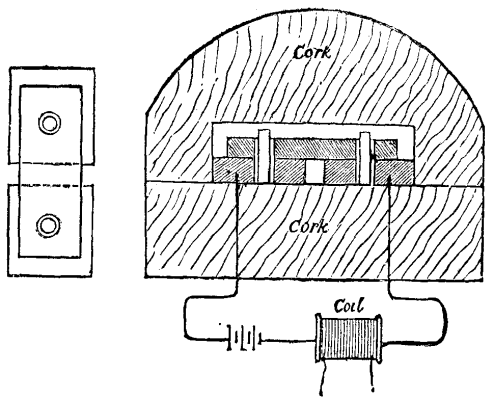

The new washer consists of a rectangular box of cast iron, having a half-cylindrical cover, in the upper part of which is fixed a pipe to carry off the gas. In the box there is placed horizontally a turbine, the hollow axis of which serves for the conveyance of the gas into the vessel. For this purpose the axis is perforated with a number of small holes, some of which are tapped, so as to allow of there being screwed on to the axis, and perpendicularly thereto, a series of brooms made of dog grass, and having their handles threaded for the purpose. These brooms are arranged in such a way as not to encounter too great resistance from contact with the water contained in the vessel, and so that the water cast up by them shall not be all thrown in the same direction. To obviate these inconveniences they are fixed obliquely to the axis of the central pipe, and are differently arranged in regard to each other. A more symmetrical disposition of them could, however, be adopted by placing them zigzag, or in such a way as to form two helices, one of which would move in a particular direction, and the other in a different way. The central pipe, furnished with its brooms, being set in motion by means of a pulley fixed upon its axis (which also carries a flywheel), the gas, drawn in at the center, and escaping by the holes made in the pipe, is forced to the circumference of the vessel, where it passes out.

The effect of this washer is first, to break up the current of gas, and then force it violently into the water; at the same time sending into it the spray of water thrown up by the brooms. This double operation is constantly going on, so that the gas, having been saturated by the transfusion into it of a vigorous shower of water (into the bulk of which it is subsequently immersed), is forced, on leaving the water, to again undergo similar treatment. The same quantity of gas is therefore several times submitted to the washing process, till at length it finds its way to the outlet, and makes its escape. The extent to which the washing of the gas is carried is, consequently, only limited by the speed of the apparatus, or rather by the ratio of the speed to the initial pressure of the gas. This limit being determined, the operation may be continued indefinitely, by making the gas pass into several washers in succession. There is, therefore, no reason why the gas should not, after undergoing this treatment, be absolutely freed of all those properties which are susceptible of removal by water. In fact, all that is requisite is to increase the dimensions of the vessel, so as to compel the gas to remain longer therein, and thus cause it to undergo more frequently the operation of washing. These dimensions being fixed within reasonable limits, if the gas is not sufficiently washed, the speed of the apparatus may be increased; and the degree of washing will be thereby augmented. If this does not suffice, the number of turbines may be increased, and the gas passed from one to the other until the gas is perfectly clean. This series of operations would, however, with any kind of washer, result in thoroughly cleansing the gas. The only thing that makes such a process practically impossible is the very considerable or it may be even total loss of pressure which it entails. By the new system, the loss of pressure is nil, inasmuch as each turbine becomes in reality an exhauster. The gas, entering the washer at the axis, is drawn to the circumference by the rotatory motion of the brooms, which thus form a ventilator. It follows, therefore, that on leaving the vessel the gas will have a greater pressure than it had on entering it; and this increase of pressure may be augmented to any desired extent by altering the speed of rotation of the axis, precisely as in the case of an exhauster.

Forcing the gas violently into water, and at the same time dividing the current, is evidently the most simple, rational, and efficient method of washing, especially when this operation is effected by brooms fixed on a shaft and rotated with great speed. Therefore, if there had not been this loss of pressure to deal with--a fatal consequence of every violent operation--the question of perfect washing would probably have been solved long ago. The invention which I have now submitted consists of an arrangement which enables all loss of pressure to be avoided, inasmuch as it furnishes the apparatus with the greatest number of valuable qualities, whether regarded from the point of view of washing or that of condensation.

Longitudinal Section. Elevation. Transverse Section.

Referring to the illustration, the gas enters the washer by the pipe, A, which terminates in the form of a [Symbol: inverted T]. One end (a) of this pipe is bolted to the center of one of the sides of the cylindrical portion of the case, in which there is a hole of similar diameter to the pipe; the other (a') being formed by the face-plate of a stuffing-box, B, through which passes the central shaft, C, supported by the plummer-block, D, as shown. This shaft has upon its opposite end a plate perforated with holes, E, which is fixed upon the flange of a horizontal pipe, F. This pipe is closed at the other end by means of a plate, E', furnished with a spindle, supported by a stuffing-box, B', and carrying a fly-wheel, G. The central pipe, F, is perforated with a number of small holes. The gas entering by the pipe, A, makes its way into the central pipe through the openings in the plate, E, and passes into the cylindrical case through the small holes in the central pipe, which carries the brooms, H. These are caused to rotate rapidly by means of the pulley, I; and thus a constant shower of water is projected into the cylindrical case. When the gas has been several times subjected to the washing process, it passes off by the pipe, K. Fresh cold water is supplied to the vessel by the pipe, L; and M is the outlet for the tar.--Journal of Gas Lighting.

[Footnote: A paper read before the Engineers' Club of St. Louis, 1884.]

In the history of the world the utilization of the wind as a motive power antedates the use of both water and steam for the same purpose.

The advent of steam caused a cessation in the progress of wind power, and it was comparatively neglected for many years. But more recently attention has been again drawn to it, with the result of developing improvements, so that it is now utilized in many ways.

The need in the West of a motive power where water power is rare and fuel expensive has done much to develop and perfect wind mills.

Wind mills, as at present constructed in this country, are of recent date.

The mill known as the "Eclipse" was the first mill of its class built. It is known as the "solid-wheel, self-regulating pattern," and was invented about seventeen years ago. The wind wheel is of the rosette type, built without any joints, which gives it the name "solid wheel," in contradistinction to wheels made with loose sections or fans hinged to the arms or spokes, and known as "section wheel mills."

The regulation of the Eclipse mill is accomplished by the use of a small adjustable side vane, flexible or hinged rudder vane, and weighted lever, as shown in Plate 1 (on the larger sizes of mills iron balls attached to a chain are used in place of the weighted lever). The side vane and weight on lever being adjustable, can be set to run the mill at any desired speed.

Now you will observe from the model that the action of the governing mechanism is automatic. As the velocity of the wind increases, the pressure on the side vane tends to carry the wind wheel around edgewise to the wind and parallel to the rudder vane, thereby changing the angle and reducing the area exposed to the wind; at the same time the lever, with adjustable weight attached, swings from a vertical toward a horizontal position, the resistance increasing as it moves toward the latter position. This acts as a counterbalance of varying resistance against the pressure of the wind on the side vane, and holds the mill at an angle to the plane of the wind, insuring thereby the number of revolutions per minute required, according to the position to which the governing mechanism has been set or adjusted.

If the velocity of the wind is such that the pressure on the side vane overcomes the resistance of the counter weight, then the side vane is carried around parallel with the rudder vane, presenting only the edge of the wind wheel or ends of the fans to the wind, when the mill stops running.

This type of mill presents more effective wind receiving or working surface when in the wind, and less surface exposed to storms when out of the wind, than any other type of mill. It is at all times under the control of an operator on the ground.

A 22-foot Eclipse mill presents 352 square feet of wind receiving and working surface in the wind, and only 9½ square feet of wind resisting surface when out of the wind.

Solid-wheel mills are superseding all others in this country, and are being exported largely to all parts of the world, in sizes from 10 to 30 feet in diameter. Many of these mills have withstood storms without injury, where substantial buildings in the immediate vicinity have been badly damaged. I will refer to some results accomplished with pumping mills:

In the spring of 1881 there was erected for Arkansas City, Kansas, a 14-foot diameter pumping wind mill; a 32,000-gallon water tank, resting on a stone substructure 15 feet high, the ground on which it stands being 4 feet higher than the main street of the town. One thousand four hundred feet of 4-inch wood pipe was used for mains, with 1,200 feet of 1½-inch wrought iron pipe. Three 3-inch fire hydrants were placed on the main street. The wind mill was located 1,100 feet from the tank, and forced the water this distance, elevating it 50 feet. We estimate that this mill is pumping from 18,000 to 20,000 gallons of water every twenty-four hours. We learned that these works have saved two buildings from burning, and that the water is being used for sprinkling the streets, and being furnished to consumers at the following rates per annum: Private houses, $5; stores, $5; hotels, $10; livery stables, $15. At these very low rates, the city has an income of $300 per annum. The approximate cost of the works was $2,000. This gives 15 per cent. interest on the investment, not deducting anything for repairs or maintenance, which has not cost $5 per annum so far.

Plate 2. THE ECLIPSE WIND MILL.

In June, 1883, a wind water works system was erected for the city of McPherson, Kansas, consisting of a 22-foot diameter wind mill on a 75-foot tower, which pumps the water out of a well 80 feet deep, and delivers it into a 60,000-gallon tank resting on a substructure 43 feet above the ground. Sixteen hundred feet of 6-inch and 300 feet of 4-inch cast iron pipe furnish the means of distribution; eight 2½-inch double discharge fire hydrants were located on the principal streets. A gate valve was placed in the 6-inch main close to the elbow on lower end of the down pipe from the tank. This pipe is attached to the bottom of the tank; another pipe was run up through the bottom of tank 9 feet (the tank being 18 feet deep), and carried down to a connection with the main pipe just outside the gate valve. The operation of this arrangement is as follows:

The gate valve being closed, the water cannot be drawn below the 9-foot level in tank, which leaves about 35,000 gallons in store for fire protection, and is at once available by opening the gate valve referred to. The tank rests on ground about 5 feet above the main streets, which gives a head of 57 feet when the tank is half full. The distance from tank to the farthest hydrant being so short, they get the pressure due to this head at the hydrant, when playing 2-inch, or 1-1/8-inch streams, with short lines of 2½-inch hose; this gives fair fire streams for a town with few if any buildings over two stories high. It is estimated that this mill is pumping from 30,000 to 38,000 gallons on an average every twenty-four hours. There is an automatic device attached to this mill, which stops it when the tank is full, but as soon as the water in the tank is lowered, it goes to pumping again. The cost of these works complete to the city was a trifle over $6,000.

In November last a wind mill 18 feet in diameter was erected over a coal mine at Richmond, in this State. The conditions were as follows:

The mine produces 11,000 gallons of water every twenty-four hours. The sump holds 11,000 gallons. Two entries that can be dammed up give a storage of 16,500 gallons, making a total storage capacity of 27,500 gallons. It takes sixty hours for the mine to produce this quantity of water, which allows for days that the wind does not blow. The average elevation that the water has to be raised is 65 feet, measuring from center of sump to point of delivery. A record of ninety days shows that this mill has kept the mine free from water with the exception of 6,000 gallons, which was raised in the boxes that the coal is raised in. The location is not good for a wind mill, as it stands in a narrow ravine or valley a short distance from its mouth, which terminates at the bottom lands of the Missouri River. This, taken in connection with the fact that the grit in the water cuts the pump plunger packing so fast that in a short time the pump will not work up to its capacity, accounts for the apparent small amount of power developed by this mill.

There has been some discussion of late in regard to the horse power of wind mills, one party claiming that they were capable of doing large amounts of grinding and showing a development of power that was surprising to the average person unacquainted with wind mills, while the other party has maintained that they were not capable of developing any great amount of power, and has cited their performance in pumping water to sustain his argument. My experience has has led me to the conclusion that pumping water with a wind mill is not a fair test of the power that it is capable of developing, for the following reasons:

A pumping wind mill is ordinarily attached to a pump of suitable size to allow the mill to run at a mean speed in an 8 to 10 mile wind. Now, if the wind increases to a velocity of 16 to 20 miles per hour, the mill will run up to its maximum speed and the governor will begin to act, shortening sail before the wind attains this velocity. Therefore, by a very liberal estimate, the pump will not throw more than double the quantity that it did in the 8 to 10 mile wind, while the power of the mill has quadrupled, and is capable of running at least two pumps as large as the one to which it is attached. As the velocity of the wind increases, this same proportion of difference in power developed to work done holds good.

St. Louis is not considered a very windy place, therefore the following table may be a surprise to some. This table was compiled from the complete record of the year 1881, as recorded by the anemometer of the United States Signal Office on the Mutual Life Insurance Building, corner of Sixth and Locust streets, this city. It gives the number of hours each month that the wind blew at each velocity, from 6 to 20 miles per hour during the year; also the maximum velocity attained each month.

Complete Wind Record at St. Louis for the Year 1881.

_______________________________________________________________________________

|No. |No. |No. |No. |No. |No. |No. |No. |

|hours |hours |hours |hours |hours |hours |hours |hours |Maximum

|wind |wind |wind |wind |wind |wind |wind |wind |velocity

YEAR |blew 6 |blew 8 |blew 10|blew 12|blew 14|blew 16|blew 18|blew 20|during

1881. |miles |miles |miles |miles |miles |miles |miles |miles |each

MONTHS|or over|or over|or over|or over|or over|or over|or over|or over|month.

______|_______|_______|_______|_______|_______|_______|_______|_______|____

|H. M.|H. M.|H. M.|H. M.|H. M.|H. M.| H. M.| H. M.|

Jan. | 545 45| 429 45| 289 00| 198 15| 131 30| 87 15| 56 00| 38 45| 31

Feb. | 619 30| 533 15| 449 15| 374 15| 287 00| 207 15| 151 15| 110 30| 32

March.| 604 15| 534 30| 449 45| 368 45| 296 30| 243 45| 191 00| 158 45| 37

April.| 577 15| 468 45| 342 45| 359 30| 175 00| 121 00| 62 45| 36 00| 28

May. | 553 00| 375 00| 226 15| 138 00| 74 45| 42 30| 23 45| 11 30| 31

June. | 614 15| 463 45| 303 30| 215 15| 123 45| 76 30| 29 45| 17 45| 32

July. | 556 45| 378 00| 228 15| 136 15| 55 30| 22 30| 6 00| 2 30| 22

Aug. | 536 30| 345 00| 176 00| 80 30| 35 45| 22 15| 17 15| 15 00| 34

Sept. | 564 15| 445 45| 326 45| 224 45| 145 30| 96 45| 70 00| 46 45| 30

Oct. | 617 30| 501 45| 368 45| 363 00| 170 00| 93 45| 40 30| 27 45| 27

Nov. | 642 45| 537 30| 428 45| 328 30| 226 00| 151 45| 100 30| 74 00| 30

Dec. | 592 15| 516 30| 390 00| 308 45| 224 45| 167 45| 110 45| 67 00| 30

------+-------+-------+-------+-------+-------+-------+-------+-------+-----

Totals|7,024 |5,529 |3,981 |2,995 |1,946 |1,335 | 868 | 606 | --

| 00| 30| 00| 45| 00| 00| 30| 15|

Max. | | | | | | | | |

for | ----- | ----- | ----- | ----- | ----- | ----- | ----- | ----- | 37

year | | | | | | | | |

______|_______|_______|_______|_______|_______|_______|_______|_______|____

The location of a mill has a great deal to do with the results attained. Having had charge of the erection of a large number of these mills for power purposes, I will refer to a few of them in different States, giving the actual results accomplished, and leaving you to form your own opinion as to the power developed.

In 1877 a 25-foot diameter mill was erected at Dover, Kansas, a few miles southwest of Topeka. It was built to do custom flour and feed grinding, also corn shelling, and is in successful operation at the present time. We have letters frequently from the owner; one of recent date states that it has stood all of the "Kansas zephyrs," never having been damaged as yet. On an average it shells and grinds from 6 to 10 bushels of corn per hour, and runs a 14 inch burr stone, grinding wheat at the same time. During strong winds it has shelled and ground as high as 30 bushels of corn per hour. Plate 2 is from a photograph of this mill and building as it stands. One bevel pinion is all the repairs this mill has required.

In the spring of 1880 there was erected a 25-foot diameter mill at Harvard, Clay County, Neb. After this mill had been running nineteen months, we received the following report from the owner:

"During the nineteen months we have been running the wind mill, it has cost us nothing for repairs. We run it with a two-hole corn sheller, a set of 16-inch burr stones, and an elevator. We grind all kinds of feed, also corn meal and Graham flour. We have ground 8,340 bushels, and would have ground much more if corn had not been a very poor crop here for the past two seasons; besides, we have our farm to attend to, and cannot keep it running all the time that we have wind. We have not run a full day at any time, but have ground 125 bushels in a day. When the burr is in good shape we can grind 20 bushels an hour, and shell at the same time in the average winds that we have. The mill has withstood storms without number, even one that blew down a house near it, and another that blew down many smaller mills. It is one of the best investments any one can make."

The writer saw this mill about sixty days ago, and it is in good shape, and doing the work as stated. The only repairs that it has required during four years was one bevel pinion put on this spring.

The owner of a 16-foot diameter mill, erected at Blue Springs. Neb., says that "with a fair wind it grinds easily 15 bushels of corn per hour with a No. 3 grinder, also runs a corn-sheller and pump at the same time, and that it works smoothly and is entirely self-regulating."

The No. 3 grinder referred to has chilled iron burrs, and requires from 3 to 4 horse-power to grind 15 bushels of corn per hour. Of one of these 16-foot mills that has been running since 1875 in Northern Illinois, the owner writes: "In windy days I saw cord-wood as fast as the wood can be handled, doing more work than I used to accomplish with five horses."

The owner of one of these mills, 20 feet in diameter, running in the southwestern part of this State, writes that he has a corn-sheller and two iron grinding mills with 8-inch burrs attached to it; also a bolting device; that this mill is more profitable to him than 80 acres of good corn land, and that it is easily handled and has never been out of order. The following report on one of these 16-foot mills, running in northern Illinois, may be of interest: This mill stands between the house and barn. A connection is made to a pump in a well-house 25 feet distant, and is also arranged to operate a churn and washing machine. By means of sheaves and wire cable, power is transmitted to a circular saw 35 feet distant. In this same manner power is transmitted to the barn 200 feet distant, where connection is made to a thrasher, corn-sheller, feed-cutter, and fanning-mill. The corn-sheller is a three horse-power, with fan and sacker attached. Three hundred bushels per day has been shelled, cleaned, and sacked. The thrashing machine is a two horsepower with vibrating attachment for separating straw from grain. One man has thrashed 300 bushels of oats per day, and on windy days says the mill would run a thrasher of double this capacity. The saw used is 18 inches diameter, and on windy days saws as much wood as can be done by six horses working on a sweep power. The owner furnishes the following approximate cost of mill with the machinery attached and now in use on his place:

1 16-foot power wind mill, shafting, and tower. $385

1 Two horse thrasher. 70

1 Three horse sheller. 38

1 Feed grinder. 50

1 18-inch saw, frame and arbor. 40

1 Fanning mill. 25

1 Force pump. 27

1 Churn. 5

1 Washing machine. 15

Belting, cables, and pulleys. 45

----

Total. $700

The following facts and figures furnished by the owner will give a fair idea of the economic value of this system, as compared with the usual methods of doing the same work. On the farm where it is used, there are raised annually an average of sixty acres of oats, fifty acres of corn, twenty acres of rye, ten acres of buckwheat.

Bushels. The oats average, say 30 bushels per acre. 1,800 Corn " 30 " " 1,500 Rye " 20 " " 400 Buckwheat " 20 " " 200 Grinding for self and others. 1,000

It will cost to thrash this grain, shell the corn, and grind the feed with steam power. $285 And sawing wood, 12½ cords. 18 Pumping, one hour per day, 365 days. 36 Churning, half hour per day, 200 days. 10 Washing, half day per week, 26 days. 26 ---- Total. $375

This amount is saved, and more too, as one man, by the aid of the wind mill, will do this work in connection with the chores of the farm, and save enough in utilizing foul weather to more than offset his extra labor, cost of oil, etc., for the machinery. The amount saved each year is just about equal to the cost of a good man. Cost of outfit, $700--just about equal to the cost of a good man for two years, consequently, it will pay for itself in two years. Fifteen years is a fair estimate for the lifetime of mill with ordinary repairs.

The solid-wheel wind mill has never been built larger than 30 feet in diameter. For mills larger than this, the latest improved American mill is the "Warwick" pattern.

A 30-foot mill of this pattern, erected in 1880, in northwestern Iowa, gave the following results, as reported by the owner:

"Attachments as follows: One 22-inch burr; one No. 4 iron feed-mill; one 26-inch circular saw; one two-hole corn-sheller; one grain elevater; a bolting apparatus for fine meal, buckwheat and graham, all of which are run at the same time in good winds, except the saw or the iron mill; they being run from the same pulley can run but one at a time. With all attached and working up to their full capacity, the sails are often thrown out of the wind by the governors, which shows an immense power. The machines are so arranged that I can attach all or separately, according to the wind. With the burr alone I have ground 500 bushels in 48 consecutive hours, 100 bushels of it being fine meal. I have also ground 24 full bushels of fine meal for table use in two hours. This last was my own, consequently was not tolled. This was before I bought the iron mill, and now I can nearly double that amount. I saw my fire wood for three fires; all my fence posts, etc. My wood is taken to the mill from 12 to 15 feet long, and as large as the saw will cut by turning the stick, consequently the saw requires about the same power as the burrs. With a good sailing breeze I have all the power I need, and can run all the machinery with ease. Last winter I ground double the amount of any water mill in this vicinity. I have no better property than the mill."

A 40-foot mill, erected at Fowler, Indiana, in 1881, is running the following machinery:

"I have a universal wood worker, four side, one 34-inch planer, jig saw, and lathe, also a No. 4 American grinder, and with a good, fair wind I can run all the machines at one time. I can work about four days and nights each week. It is easy to control in high winds."

A 60-foot diameter mill of similar pattern was erected in Steel County, Minnesota, in 1867. The owner gives the following history of this mill:

"I have run this wind flouring mill since 1867 with excellent success. It runs 3 sets of burrs, one 4 feet, one 3½ feet, and one 33 inches. Also 2 smutters, 2 bolts, and all the necessary machinery to make the mill complete. A 15-mile wind runs everything in good shape. One wind wheel was broken by a tornado in 1870, and another in 1881 from same cause. Aside from these two, which cost $250 each, and a month's lost time, the power did not cost over $10 a year for repairs. In July, 1833, a cyclone passed over this section, wrecking my will as well as everything else in its track, and having (out of the profits of the wind mill) purchased a large water and steam flouring mill here, I last fall moved the wind mill out to Dakota, where I have it running in first-class shape and doing a good business. The few tornado wrecks make me think none the less of wind mills, as my water power has cost me four times as much in 6 years as the wind power has in 16 years."

There are very few of these large mills in use in this country, but there are a great many from 14 to 30 feet in diameter in use, and their numbers are rapidly increasing as their merits become known. The field for the use of wind mills is almost unlimited, and embraces pumping water, drainage, irrigation, elevating, grinding, shelling, and cleaning grain, ginning cotton, sawing wood, churning, running stamp mills, and charging electrical accumulators. This last may be the solution of the St. Louis gas question.

In the writer's opinion the settlement of the great tableland lying between the Mississippi Valley and the Rocky Mountains, and extending from the Gulf of Mexico to the Red River of the North, would be greatly retarded, if not entirely impracticable, in large sections where no water is found at less than 100 to 500 feet below the surface, if it were not for the American wind mill; large cattle ranges without any surface water have been made available by the use of wind mills. Water pumped out of the ground remains about the same temperature during the year, and is much better for cattle than surface water. It yet remains in the future to determine what the wind mill will not do with the improvements that are being made from to time.

It is here shown as mounted on a torpedo launch and ready for action. The shell or projectile is fired by compressed air, admitted from an air reservoir underneath by a simple pressure of the gunner's finger over the valve. The air passes up through the center of the base, the pipe connecting with one of the hollow trunnions. The valve is a continuation of the breech of the gun. The smaller cuts illustrate Lieutenant Zalinski's plan for mounting the gun on each side of the launch, by which plan the gun after being charged may have the breech containing the dynamite depressed, and protected from shots of the enemy by its complete immersion alongside the launch; and, if necessary, may be discharged from this protected position. The gun is a seamless brass tube of about forty feet in length, manipulated by the artillerist in the manner of an ordinary cannon. Its noiseless discharge sends the missile with great force, conveying the powerful explosive within it, which is itself discharged internally upon contact with the deck of a vessel or other object upon which it strikes, through the explosion of a percussion fuse in the point of the projectile. A great degree of accuracy has been obtained by the peculiar form of the projectile.

PNEUMATIC DYNAMITE GUN TORPEDO VESSEL.

The projectile consists of a thin metal tube, into which the charge is inserted, and a wooden sabot which closes it at the rear and flares out until its diameter equals that of the bore of the gun. The forward end of the tube is pointed with some soft material, in which is embedded the firing pin, a conical cap closing the end. A cushion of air is interposed at the rear end of the dynamite charge, to lessen the shock of the discharge and prevent explosion, until the impact of the projectile forces the firing pin in upon the dynamite and explodes it. Many charges have been successfully fired at Fort Hamilton, N.Y. As the center of gravity is forward of the center of figure in the projectile, a side wind acting upon the lighter rear part would tend to turn the head into the wind and thus keep it in the line of its trajectory. A range of 1¼ miles has been attained with the two inch gun, with a pressure of 420 lb. to the square inch, and one of three miles is hoped for with the larger gun and a pressure of 2,000 lb.

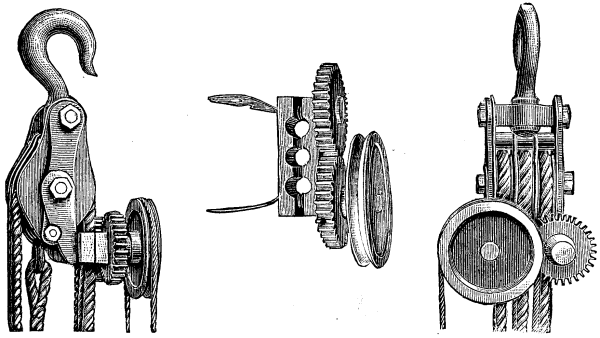

A novel device in connection with rope pulley blocks is illustrated in the annexed engravings, the object of the appliance being to render it possible to leave a weight suspended from a block without making the tail of the rope fast to some neighboring object. By this arrangement the danger of the rope slipping loose is avoided, and absolute security is attained, without the necessity of lowering the weight to the ground. The device itself is a friction brake, constructed in the form of a clip with holes in it for the three ropes to pass through. It is made to span the block, and is secured partly by the pin or bolt upon which the sheaves run, and partly by the bottom bolt, which unites the cheeks of the block. Thus the brake is readily attachable to existing blocks. The inner half of the clip or brake is fixed solidly to the block, while the outer half is carried by two screws, geared together by spur-wheels, and so cut that although rotating in opposite directions, their movements are equal and similar. One of the screws carries a light rope-wheel, by which it can be rotated, the motion being communicated to the second screw by the toothed wheels. When the wheel is rotated in the right direction the loose half of the clip is forced toward the other half, and grips the ropes passing between the two so powerfully that any weight the blocks are capable of lifting is instantly made secure, and is held until the brake is released.

A light spiral spring is placed on each of the screws, in order to free the brake from the rope the moment the pressure is released. The hand rope has a turn and a half round the pulley, and this obviates the need of holding both ends of it, and thus leaves one hand free to guide the descending weight, or to hold the rope of the pulley blocks. Engineering says these brakes are very useful in raising heavy weights, as the lift can be secured at each pull, allowing the men to move hands for another pull, and as they are made very light they do not cause any inconvenience in moving or carrying the blocks about. Manufactured by Andrew Bell & Co., Manchester.

We have from time to time given accounts in this journal of the system of towage by hauling on a submerged wire rope, first experimented upon by Baron O. De Mesnil and Mr. Max Eyth. On the river Rhine the system has been for many years in successful operation; it has also been used for several years on the Erie Canal in this State. We publish from Engineering a view of one of the wire rope tug boats of the latest pattern adopted for use on the Rhine.

The Cologne Central Towing Company (Central Actien-Gesellschaft für Tauerei und Schleppschifffahrt), by whom the wire rope towage on the Rhine is now carried on, was formed in 1876, by an amalgamation of the Rührorter und Mulheimer Dampfschleppshifffahrt Gesellschaft and the Central Actien-Gesellschaft fur Tauerei, and in 1877 it owned eight wire rope tugs (which it still owns) and seventeen paddle tugs. The company so arranges its work that the wire rope tugs do the haulage up the rapid portion of the Rhine, from Bonn to Bingen, while the paddle tugs are employed on the quieter portion of the river extending from Rotterdam to Bonn, and from Bingen to Mannheim.

ROPE PULLEY FRICTION BRAKE.

The leading dimensions of the eight wire rope tugs now worked by the company are as follows:

Tugs No. I. to Tugs No. V. to

IV. VIII.

Meters. ft. in. Meters. ft. in.

Length between

perpendiculars 39 = 126 0 42 = 137 10

Length over all 42.75 = 140 3 45.75 = 150 1

Extreme breadth 7.2 = 28 8 7.5 = 24 5

Height of sides 2.38 = 7 11 2.38 = 7 11

Depth of keel 0.12 = 0 5 0.15 = 0 6

All the boats are fitted with twin screws, 1.2 meters (3 feet 11¼ inches) in diameter, these being used on the downstream journey, and also for assisting in steering while passing awkward places during the journey up stream. They are also provided with water ballast tanks, and under ordinary circumstances they have a draught of 1.3 to 1.4 meters (4 feet 3 inches to 4 feet 7 inches), this draught being necessary to give proper immersion to the screws. When the water in the Rhine is very low, however, the water ballast is pumped out and the tugs are then run with a draught of 1 meter (3 feet 3 3/8 inches), it being thus possible to keep them at work when all other towing steamers on the Rhine are stopped. This happened in the spring of 1882.

Referring to our engraving, it will be seen that the wire rope rising from the bed of the river passes first over a large guide pulley, the axis of which is carried by a substantial wrought iron swinging bracket, this bracket being so pivoted that while the pulley is free to swing into the line on which the rope is approached by the vessel, yet the rope on leaving the pulley is delivered in a line which is tangential to a second guide pulley placed further aft and at a lower level. This last named guide pulley does not swing, and from it the rope is delivered to the clip drum, over which it passes. From the clip drum the rope passes under a third guide pulley; this pulley swings on a bracket having a vertical axis. This third pulley projects down below the keel of the tug boat, so that the rope on leaving it can pass under the vessel without fouling. Suitable recesses are formed in the side of the tug boat to accommodate the swinging pulleys, while the bow of the boat is sloped downward nearly to the water line, as shown, so as to allow of the rising part of the rope swinging over it if necessary.

The hauling gear with which the tug is fitted consists of a pair of condensing engines with cylinders 14.17 inches in diameter and 23.62 inches stroke, the crankshaft carrying a pinion which gears into a spur wheel on an intermediate shaft, this shaft again carrying a pinion which gears into a large spur wheel fixed on the shaft which carries the clip drum. In the arrangement of hauling gear above described the ratio of the gear is 1:8.44, in the case of tugs Nos. I. to IV.; while in tugs Nos. V. to VIII. the proportion has been made 1:11.82. In tugs I. to IV. the diameter of the clip drum is 2.743 meters (9 feet), while in the remaining tugs it is 3.056 meters (10 feet).

From some interesting data which have been placed at our disposal by Mr. Thomas Schwarz, the manager of the Central Actien-Gesellschaft fur Tauerei und Schleppschifffahrt, we learn that in the tugs Nos. I. to IV. the hauling machine develops on an average 150 indicated horse, while in the tugs No. V. to VIII. the power developed averages 180 indicated horse power. The tugs forming the first named group haul on an average 2,200 tons of cargo, contained in four wooden barges, at a speed of 4½ kilometers (2.8 miles) per hour, against a stream running at the rate of 6½ kilometers (4.05 miles) per hour, while the tugs Nos. V. to VIII. will take a load of 2,600 tons of cargo in the same number of wooden barges at the same speed and against the same current. In iron barges, about one and a half times the quantity of useful load can be drawn by a slightly less expenditure of power.

The average consumption of coal per hour is, for tugs Nos. I. to IV., 5 cwt, and for tugs Nos. V. to VIII., 6 cwt.; and of this fuel a small fraction (about one-sixth) is consumed by the occasional working of the screw propellers at sharp bends. The fuel consumption of the wire rope tugs contrasts most favorably with that of the paddle and screw tugs employed on the Rhine, the best paddle tugs (with compound engines, patent wheels, etc.) burning three and a half times as much; the older paddle tugs (with low pressure non-compound engines), four and a half times as much; and the latest screw tugs, two and a half times as much coal as the wire rope tugs when doing the same work under the same circumstances. The screw tugs just mentioned have a draught of 2½ meters (8 feet 2½ inches), and are fitted with engines of 560 indicated horse power.

During the years 1879, 1880, and 1881, the company had in use fourteen paddle tugs and ten eight-wire rope tugs, both classes being--owing to the state of trade--about equally short of work. The results of the working during these years were as follows:

================================================================

| | Freight | Cost of | Degree

| | hauled | haulage in | of

Class of tugs. | Year. | in | pence per | occupation.

| | ton-miles. | ton-mile. |

----------------------------------------------------------------

Paddle | 1879 | 31,862,858 | 0.1272 | 0.686

" | 1880 | 31,467,422 | 0.1305 | 0.638

" | 1881 | 28,627,049 | 0.1245 | 0.537

Wire Rope | 1879 | 15,407,935 | 0.1167 | 0.614

" | 1880 | 17,289,706 | 0.1056 | 0.615

" | 1881 | 17,593,181 | 0.0893 | 0.536

================================================================

The last column in the above tabular statement, headed "Degree of Occupation," may require some explanation. It is calculated on the assumption that a tug could do 3,000 hours of work per annum, and this is taken as the unit, the time of actual haulage being counted as full time, and of stoppages as half time. The expenses included in the statement of cost of haulage include all working expenses, repairs, general management, and depreciation. The accounts for 1882, which are not completely available at the time we are writing, show much better results than above recorded, there being a considerable reduction of cost, while the freight hauled amounted to a total of 54,921,965 ton-miles.

WIRE ROPE TUG BOAT, RIVER RHINE.

As regards the wear of the rope, we may state that the relaying of the first rope between St. Goar and Bingen was taken in hand in September, 1879, while that between Obercassel and Bingen was partially renewed the same year, the renewal being completed in May, 1880, after the rope had been in use since the beginning of 1876. The second rope between Bonn and Bingen, a length of 74¾ miles, is of galvanized wire, has now been 2¾ years in use, during which time there have been but three fractures. The first rope laid was not galvanized, and it suffered nine fractures during the first three years of its use. The first rope, we may mention, was laid in lengths of about a mile spliced together, while the present rope was supplied in long lengths of 7½ miles each, so that the number of splices is greatly reduced. According to the report of the company for the year 1880, the old rope when raised realizes about 16 per cent. of its original value, and allowing for this, it is calculated that an allowance of 18.7 per cent. per annum will cover the cost of rope depreciation and renewals. Altogether the results obtained on the Rhine show that in a rapid stream the economic performances of wire rope tugs compare most favorably with those of either paddle or screw tug boats, the more rapid the current to be contended against the greater being the advantage of the wire rope haulage.

Hay-ropes are used for many purposes, their principal use being in the foundry for core-making; but they also find a large application for packing ironmongery and furniture. The inventor is James Pollard, of the Atlas Foundry, Burnley.

HAY ROPE MACHINE.

The chief part of the mechanism is carried in an open frame, having journals attached to its two ends, which revolve in bearings. The frame is driven by the rope pulley. The journal at the left hand is hollow; the pinion upon it is stationary, being fixed to the bracket of bearing. The pinion gearing into it is therefore revolved by the revolution of the frame, and through the medium of bevel wheels actuates a transverse shaft, parallel to which rollers, and driven by wheels off it, is a double screw, which traverses a "builder" to and fro across the width of frame. The builder is merely the eye through which the band passes, and its office is to lay the band properly on the bobbin. The latter is turned to coil on the band by a pitch chain from the builder screw, the motion being given through a friction clutch, to allow for slip as the bobbin or coil gets larger, for obviously the bobbin as it gets larger is not required to turn so fast to coil up the band produced as when it is smaller. If the action is studied, it will be seen that the twist is put in between the bobbin and the hollow journal, and every revolution of the frame puts in one turn for the twist. The hay is fed to the machine through the hollow journal already mentioned. By suitably proportioning the speed of feed-rollers and the revolutions of the frame, which is easily accomplished by varying the wheels on the left hand of frame, bands of any degree of hardness or softness may be produced. The machine appears to be simple and not liable to get deranged. It may be after a little practice attended to by a laborer, and is claimed by its maker to be able to produce 400 yards of band per hour. The frame makes about 180 revolutions per minute, that is, this is the number of turns put into the twist in this time. The machine can make a bundle about 200 yards long, which can be removed off the bobbin without unwinding with the greatest facility.--Mech. World.

The river Lee flows through the city of Cork in two branches, which diverge just above the city, and are reunited at the Custom House, the central portion of the city being situated upon an island between the two arms of the river, both of which are navigable for a short distance above the Custom House, and are lined with quays on each side for the accommodation of the shipping of the port.

The Anglesea bridge crosses the south arm of the river about a quarter of a mile above its junction with the northern branch, and forms the chief line of communication from the northern and central portions of the city to the railway termini and deep-water quays on the southern side of the river.

THE NEW ANGLESEA BRIDGE, CORK.

The new swing bridge occupies the site of an older structure which had been found inadequate to the requirements of the heavy and increasing traffic, and the foundations of the old piers having fallen into an insecure condition, the construction of a new opening bridge was taken in hand jointly by the Corporation and Harbor Commissioners of Cork.

The new bridge, which has recently been completed, is of a somewhat novel design, and the arrangement of the swing-span in particular presents some original and interesting features, which appear to have been dictated by a careful consideration of the existing local conditions and requirements.

On each side of the river, both above and below the bridge, the quays are ordinarily lined with vessels berthed alongside each of the quays, and as the river is rather narrow at this point, the line of fairway for vessels passing through the bridge is confined nearly to the center of the river. This consideration, together with some others connected with the proposed future deepening of the fairway, rendered it very desirable to locate the opening span nearly in the center of the river, as shown in the general plan of the situation, which we publish herewith. At the same time it was necessary to avoid any encroachment upon the width of the existing quays, which form important lines of communication for vehicular and passenger traffic along each side of the river, and to and from the railway stations. Again, it was necessary to preserve the full existing width of waterway in the river itself, which is sometimes subjected to heavy floods.

These considerations evidently precluded the construction of a central pier and double-armed swing bridge, and on the other hand they also precluded the construction of any solid masonry substructure for the turntable, either upon the quay or projected into the river. To meet these several conditions the bridge has been designed in the form of a three-span bridge, that is to say, it is only supported by the two abutments and two intermediate piers, each consisting of a pair of cast-iron cylinders or columns, as shown by the dotted circles upon the general plan.

The central opening is that which serves for the passage of vessels. The swing bridge extends over two openings, or from the north abutment to the southern pier, its center of revolution being situated over the center of the northern span, and revolves upon a turntable, which is carried upon a lower platform or frame of girders extending across the northern span of the bridge. The southern opening is spanned by an ordinary pair of lattice girders in line with the girders and superstructure of the swing bridge.

We propose at an early date to publish further details of this bridge, and the hydraulic machinery by which it is worked.

We present a perspective view of the bridge as seen from the entrance to the exhibition building, which is situated in close proximity to the southern end of the bridge.--Engineering.

[Footnote: Paper read before the Institution of Mechanical Engineers.]

Narrow gauge railways have been known for a very long time in Great Britain. The most familiar lines of this description are in Wales, and it is enough to instance the Festiniog Railway (2 feet gauge), which has been used for the carriage of passengers and goods for nearly half a century. The prosperous condition of this railway, which has been so successfully improved by Mr. James Spooner and his son, Mr. Charles Spooner, affords sufficient proof that narrow gauge railways are not only of great utility, but may be also very remunerative.

In Wales the first narrow gauge railway dates from 1832. It was constructed merely for the carriage of slates from Festiniog to Port-Madoc, and some years later another was built from the slate quarries at Penrhyn to the port of Bangor. As the tract of country traversed by the railways became richer by degrees, the idea was conceived of substituting locomotives for horses, and of adapting the line to the carriage of goods of all sorts, and finally of passengers also.

But these railways, although very economical, are at the same time very complicated in construction. Their arrangements are based upon the same principles as railways of the ordinary gauge, and are not by any means capable of being adapted to agriculture, to public works, or to any other purpose where the tracks are constantly liable to removal. These permanent narrow gauge lines, the laying of which demands the service of engineers, and the maintenance of which entails considerable expense, suggested to M. Decauville, Aîne, farmer and distiller at Petit-Bourg, near Paris, the idea of forming a system of railways composed entirely of metal, and capable of being readily laid. Cultivating one of the largest farms in the neighborhood of Paris, he contemplated at first nothing further than a farm railroad; and he contrived an extremely portable plant, adapted for clearing the land of beetroot, for spreading manure, and for the other needs of his farm.

From the beginning in his first railroads, the use of timber materials was rigidly rejected by him; and all parts, whether the straight or curved rails, crossings, turntables, etc., were formed of a single piece, and did not require any special workman to lay them down. By degrees he developed his system, and erected special workshops for the construction of his portable plant; making use of his farm, and some quarries of which he is possessed in the neighborhood, as experimental areas. At the present time this system of portable railways serves all the purposes of agriculture, of commerce, of manufactures, and even those of war.

Within so limited a space it would be impossible to give a detailed description of the rails and fastenings used in all these different modes of application. The object of this paper is rather to direct the attention of mechanical engineers to the various uses to which narrow gauge portable railways may be put, to the important saving of labor which is effected by their adoption, and to the ease with which they are worked.

The success of the Decauville railway has been so rapid and so great that many inventors have entered the same field, but they have almost all formed the idea of constructing the portable track with detachable sleepers. There are thus, at present, two systems of portable tracks: those in which the sleepers are capable of being detached, and those in which they are not so capable.

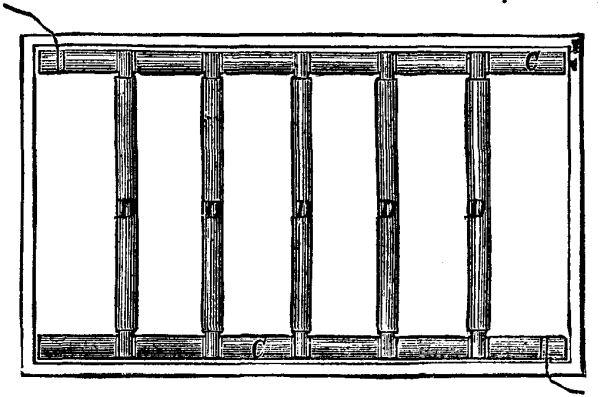

The portable track of the Decauville system is not capable of so coming apart. The steel rails and sleepers are riveted together, and form only one piece. The chief advantage of these railways is their great firmness; besides this, since the line has only to be laid on the surface just as it stands, there are not those costs of maintenance which become unavoidable with lines of which the sleepers are fixed by means of bolts, clamps, or other adjuncts, only too liable to be lost. Moreover, tracks which are not capable of separation are lighter and therefore more portable than those in which the sleepers are detachable.

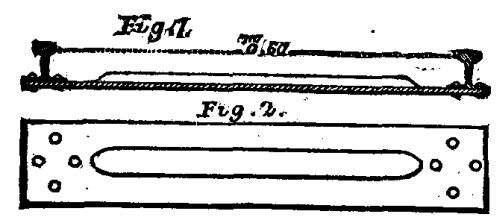

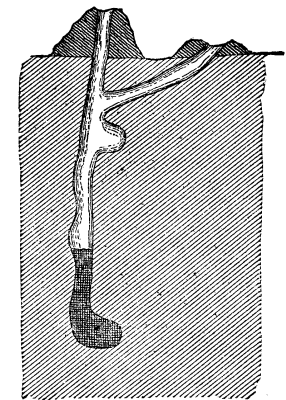

With regard to sleepers, a distinction must be drawn between those which project beyond the rails and those which do not so project. M. Decauville has adopted the latter system, because it offers sufficient strength, while the lines are lighter and less cumbersome. Where at first he used flat iron sleepers, he now fits his lines with dished steel sleepers, in accordance with Figs. 1 and 2.

Fig. 1. Fig. 2.

This sleeper presents very great stiffness, at the same time preserving its lightness; and the feature which specially distinguishes this railway from others of the same class is not only its extreme strength, but above all its solidity, which results from its bearing equally upon the ground by means of the rail base and of the sleepers.

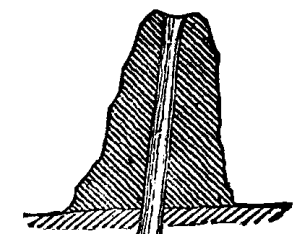

In special cases, M. Decauville provides also railroads with projecting sleepers, whether of flat steel beaten out and rounded, or of channel iron; but the sleeper and the rail are always inseparable, so as not to lessen the strength, and also to facilitate the laying of the line. If the ground is too soft, the railway is supported by bowl sleepers of dished steel, Figs. 3 and 4, especially at the curves; but the necessity for using these is but seldom experienced. The sleepers are riveted cold. The rivets are of soft steel, and the pressure with which this riveting is effected is so intense that the sleepers cannot be separated from the rails, even after cutting off both heads of the rivets, unless by heavy blows of the hammer, the rivets being driven so thoroughly into the holes made in the rails and sleepers that they fill them up completely.

The jointing of the rails is excessively simple. The rail to the right hand is furnished with two fish-plates; that to the left with a small steel plate riveted underneath the rail and projecting 1¼ in. beyond it. It is only necessary to lay the lengths end to end with one another, making the rail which is furnished with the small plate lie between the two fish-plates, and the junction can at once be effected by fish-bolts. A single fish-bolt, passing through the holes in the fish-plates, and through an oval hole in the rail end, is sufficient for the purpose.

With this description of railway it does not matter whether the curves are to the right or to the left. The pair of rails are curved to a suitable radius, and can only need turning end for end to form a curve in the direction required. The rails weigh 9 lb., 14 lb., 19 lb., and 24 lb. per running yard, and are very similar to the rails used on the main railways of France, except that their base has a proportionally greater width. As to the strength of the rail, it is much greater in proportion to the load than would at first sight be thought; all narrow-gauge railways being formed on the principle of distributing the load over a large number of axles, and so reducing the amount on each wheel. For instance, the 9 lb. rail used for the portable railway easily bears a weight of half a ton for each pair of wheels.

The distance between the rails differs according to the purpose for which they are intended. The most usual gauges are 16in., 20 in., and 24in. The line of 16 in. gauge, with 9 lb. rails, although extremely light, is used very successfully in farming, and in the interior of workshops.

Fig. 3. Fig. 4. Fig. 5.

A length of 16 ft. 5 in. of 9 lb. steel rail, to 16 in. gauge, with sleepers, etc., scarcely weighs more than 1 cwt., and may therefore be readily carried by a man placing himself in the middle and taking a rail in each hand.

Those members of the Institution who recently visited the new port of Antwerp will recollect having seen there the portable railway which Messrs. Couvreux and Hersetit had in use; and as it was these works at the port of Antwerp that gave rise to the idea of this paper, it will be well to begin with a description of this style of contractor's plant.

The earth in such works may be shifted by hand, horsepower, or locomotive. For small works the railway of 16 in. gauge, with the 9 lb. rails, is commonly used, and the trucks carry double equilibrium tipping-boxes, containing 9 to 11 cubic feet. These wagons, having tipping-boxes without any mechanical appliances, are very serviceable; since the box, having neither door nor hinge, is not liable to need repairs.

This box keeps perfectly in equilibrium upon the most broken up roads. To tip it up to the right or the left, it must simply be pushed from the opposite side, and the contents are at once emptied clean out. In order that the bodies of the wagons may not touch at the top, when several are coupled together, each end of the wagon is furnished with a buffer, composed of a flat iron bar cranked, and furnished with a hanging hook.

Plant of this description is now being used in an important English undertaking at the port of Newhaven, where it is employed not only on the earthworks, but also for transporting the concrete manufactured with Mr. Carey's special concrete machine.

These little wagons, of from 9 to 11 cubic feet capacity, run along with the greatest ease, and a lad could propel one of them with its load for 300 yards at a cost of 3d. per cube yard. In earthworks the saving over the wheel-barrow is 80 per cent., for the cost of wagons propelled by hand comes to 0.1d. per cube yard, carried 10 yards, and to go this distance with a barrow costs ½d. A horse draws without difficulty, walking by the side of the line, a train of from eight to ten trucks on the level, or five on an incline of 7 per cent. (1 in 14).

One mile of this railway, 16 in. gauge and 9 lb. steel rail, with sixteen wagons, each having a double equilibrium tipping box containing 11 cubic feet, and all accessories, represents a weight of 20 tons--a very light weight, if it is considered that all the materials are entirely of metal. Its net cost price per mile is 450l., the wagons included.

Large contracts for earthwork with horse haulage are carried on to the greatest advantage with the railway of 20 in. gauge and 14 lb. rails. The length of 16 ft. 5 in. of this railway weighs 170 lb., and so can easily be carried by two men, one placing himself at each end. The wagons most in use for these works are those with double equilibrium tipping boxes, holding 18 cubic feet. These are at present employed in one of the greatest undertakings of the age, namely, the cutting of the Panama Canal, where there are used upward of 2,700 such wagons, and more than 35 miles of track.

A mile of these rails of 20 in. gauge with 14 lb. rails, together with sixteen wagons of 18 cubic feet capacity, with appurtenances, costs about 6601., and represents a total weight of 33 tons.

This description of material is used for all contracts exceeding 20,000 cubic yards.

A very curious and interesting use of the narrow-gauge line, and the wagons with double equilibrium tipping-box, was made by the Societe des Chemins de Fer Sous-Marins on the proposed tunnel between France and England. The line used is that of 16 in. gauge, with 9 lb. rails.

The first level of the tunnel, which was constructed by means of a special machine by Colonel Beaumont, had only a diameter of 2.13 m. (7 ft.); the tipping boxes have therefore a breadth of only 2 ft., and contain 7¼ cubic feet. The boxes are perfectly balanced, and are most easily emptied. The wagons run on two lines, the one being for the loaded trains, and the other for the empty trains.

The engineers and inspectors, in the discharge of their duties, make use of the Liliputian carriages. The feet of the travelers go between the wheels, and are nearly on a level with the rails; nevertheless, they are tolerably comfortable. They are certainly the smallest carriages for passengers that have ever been built; and the builder even prophesies that these will be the first to enter into England through the Channel Tunnel.

One of the most important uses to which a narrow gauge line can be put is that of a military railway. The Dutch, Russian, and French Governments have tried it for the transporting of provisions, of war material, and of the wounded in their recent campaigns. In Sumatra, in Turkestan, and in Tunis these military railroads have excited much interest, and have so fully established their value that this paper may confine itself to a short description.

The campaign of the Russians against the Turcomans presented two great difficulties; these were the questions of crossing districts in which water was extremely scarce or failed entirely, and of victualing the expeditionary forces. This latter object was completely effected by means of 67 miles of railway, 20 in. gauge, 14 lb. steel rails, with 500 carriages for food, water, and passengers. The rails were laid simply on the sand, so that small locomotives could not be used, and were obliged to be replaced by Kirghiz horses, which drew with ease from 1,800 lb. to 2,200 lb. weight for 25 miles per day.

In the Tunisian war this railroad of 20 in. gauge, 14 lb. rail, was replaced by that of two ft. gauge, with 14 lb. and 19 lb. rails. There were quite as great difficulties as in the Turcoman campaign, and the country to be crossed was entirely unknown. The observations made before the war spoke of a flat and sandy country. In reality a more uneven country could not be imagined; alternating slopes of about 1 in 10 continually succeeded each other; and before reaching Kairouan 7½ miles of swamp had to be crossed. Nevertheless the horses harnessed to the railway carriages did on an average twelve to seventeen times the work of those working ordinary carriages. In that campaign also, on account of the steep ascents, the use of locomotives had to be given up. The track served not only for the conveying of victuals, war material, and cannon, but also of the wounded; and a large number of the survivors of this campaign owe their lives to this railway, which supplied the means of their speedy removal without great suffering from the temporary hospitals, and of carrying the wounded to places where more care could be bestowed upon them.

The carriages which did duty in this campaign are wagons with a platform entirely of metal, resting upon eight wheels. The platform is 13 ft. 1 in. in length, and 3 ft. 11 in. in width. The total length with buffers is 14 ft. 9 in. This carriage may be at will turned into a goods wagon or a passenger carriage for sixteen persons, with seats back to back, or an ambulance wagon for eight wounded persons.

For the transport of cannon the French military engineers have adopted small trucks. A complete equipage, capable of carrying guns weighing from 3 to 9 tons, is composed of trucks with two or three axles, each being fitted with a pivot support, by means of which it is made possible to turn the trucks, with the heaviest pieces of ordnance, on turntables, and to push them forward without going off the rails at the curves.

The trucks which have been adopted for the service of the new forts in Paris are drawn by six men, three of whom are stationed at each end of the gun, and these are capable of moving with the greatest ease guns weighing 9 tons.

The narrow-gauge railway was tested during the war in Tunis more than in any preceding campaign, and the military authorities decided, after peace had been restored in that country, to continue maintaining the narrow-gauge railways permanently; this is a satisfactory proof of their having rendered good service. The line from Sousse to Kairouan is still open to regular traffic. In January, 1883, an express was established, which leaves Sousse every morning and arrives at Kairouan--a distance of forty miles--in five hours, by means of regularly organized relays. The number of carriages and trucks for the transport of passengers and goods is 118.

The success thus attained by the narrow-gauge line goes far to prove how unfounded is the judgment pronounced by those who hold that light railways will never suffice for continuous traffic. These opinions are based on certain cases in the colonies, where it was thought fit to adopt a light rail weighing about 18 lb. to 27 lb. per yard, and keeping the old normal gauge. It is nevertheless evident that it is impossible to construct cheap railways on the normal gauge system, as the maintenance of such would-be light railways is in proportion far more costly than that of standard railways.

The narrow gauge is entirely in its right place in countries where, as notably in the case of the colonies, the traffic is not sufficiently extensive to warrant the capitalization of the expenses of construction of a normal gauge railway.

Quite recently the Eastern Railway Company of the province of Buenos Ayres have adopted the narrow gauge for connecting two of their stations, the gauge being 24 in. and the weight of the rails 19 lb. per yard. This company have constructed altogether six miles of narrow-gauge road, with a rolling stock of thirty passenger carriages and goods trucks and two engines, at a net cost price of 7,500l., the engines included. This line works as regularly as the main line with which it is connected. The composite carriages in use leave nothing to be desired with regard to their appearance and the comforts they offer. Third-class carriages, covered and open, and covered goods wagons, are also employed.

All these carriages are constructed according to the model of those of the Festiniog Railway. The engines weigh 4 tons, and run at 12½ miles per hour for express trains with a live load of 16 tons; while for goods trains carrying 35 tons the rate is 7½ miles an hour.

Another purpose for which the narrow-gauge road is of the highest importance in colonial commerce is the transport of sugar cane. There are two systems in use for the service of sugar plantations:

1. Traction by horses, mules, or oxen.

2. Traction by steam-engine.

In the former case, the narrow gauge, 20 in. with 14 lb. rails, is used, with platform trucks and iron baskets 3 ft. 3 in. long.

The use of these wagons is particularly advantageous for clearing away the sugar cane from the fields, because, as the crop to be carried off is followed by another harvest, it is important to prevent the destructive action of the wheels of heavily laden wagons. The baskets may be made to contain as much as 1,300 lb. of cane for animal traction, and 2,000 lb. for steam traction. In those colonies where the cane is not cut up into pieces, long platform wagons are used entirely made of metal, and on eight wheels. When the traction is effected by horses or mules, a chain 14½ ft. long is used, and the animals are driven alongside the road. Oxen are harnessed to a yoke, longer by 20 in. to 24 in. than the ordinary yoke, and they are driven along on each side of the road.

On plantations where it is desirable to have passenger carriages, or where it is to be foreseen that the narrow-gauge line maybe required for the regular transport of passengers and goods, the 20 in. line is replaced by one of 24 in.

The transport of the refuse of sugar cane is effected by means of tilting basket carts; the lower part of which consists of plate iron as in earthwork wagons, while the upper part consists of an open grating, offering thus a very great holding capacity without being excessively heavy. The content of these wagons is 90 cubic feet (2,500 liters). To use it for the transport of earth, sand, or rubbish, the grating has merely to be taken off. In the case of the transport of sugar cane having to be effected by steam power, the most suitable width of road is 24 in., with 19 lb. rails; and this line should be laid down and ballasted most carefully. The cost of one mile of the 20 in. gauge road, with 14 lb. rails, thirty basket wagons, and accessories for the transport of sugar cane, is 700l., and the total weight of this plant amounts to 35 tons.

Owing to the great lightness of the portable railways, and the facility with which they can be worked, the attention of explorers has repeatedly been attracted by them. The expedition of the Ogowe in October, 1880, that of the Upper Congo in November, 1881, and the Congo mission under Savorgnan de Brazza, have all made use of the Decauville narrow-gauge railway system.

During these expeditions to Central Africa, one of the greatest obstacles to be surmounted was the transport of boats where the river ceased to be navigable; for it was then necessary to employ a great number of negroes for carrying both the boats and the luggage. The explorers were, more or less, left to the mercy of the natives, and but very slow progress could be made.