Title: Scientific American Supplement, No. 799, April 25, 1891

Author: Various

Release date: March 1, 2004 [eBook #11649]

Most recently updated: December 26, 2020

Language: English

Credits: Produced by by Don Kretz, Juliet Sutherland, Charles Franks and the

DP Team

In time of war the dispatch boats are the eyes of the fleet. It is their duty to reconnoiter and ascertain the strength of the enemy and to carry the orders of the commander. For this service great speed is of the utmost importance. As all nations have increased the speed of their war ships during the last few years, it has become necessary to build faster dispatch boats. Although our new vessels of this class, Blitz, Pfeil, Greif, Jagd, and Wacht, fulfill the requirements, still greater speed was deemed requisite, and steps were taken for the construction of the Meteor, which was launched at Kiel in 1890. This vessel is 262 ft. long, 31 ft. wide, and has a draught of 13 ft., and a displacement of 950 tons. There are two independent engines, each of which develops 2,500 h.p., making a total of 5,000 h.p.; and each engine drives a screw. When both engines are running with their full power, the Meteor has a speed of 24 knots (over 27½ miles) an hour, which is equal to the speed of a freight train.[1] As the resistance of the water increases greatly with an increase in the speed of the vessel, the engines of the Meteor are very large in comparison with the size of the vessel. The largest armored vessel in the navy, the Konig Wilhelm, for example, has a displacement of 9,557 tons, and its engines develop 8,000 h.p., driving the vessel at a rate of 14 knots an hour; that is, 0.84 h.p. to each ton of displacement, while in the Meteor there is 5.26 h.p. to each ton of displacement. The Meteor has a crew of 90 men, and an armament of eight light guns, and has no rigging; only one mast for signaling. Steam power is used for raising the anchor, removing the ashes from the engine room, and for distilling water. The vessel is lighted with electricity, and is also provided with electrical apparatus for search lights.—Illustrirte Zeitung.

THE NEW GERMAN DISPATCH BOAT METEOR.

Shortly after the recovery of the Ulunda, below described, the North American and West Indian squadron of the Royal Navy visited Halifax, Nova Scotia. The simple and novel means adopted for raising the ship attracted considerable attention among the officers of the fleet, and by way of stimulating the studies of the junior officers in this branch of their duties, a prize was offered for the best essay on the subject, to be competed for by the midshipmen of the various ships. The essays were adjudicated upon by Captain W.G. Stopford, of the flag ship—H.M.S. Bellerophon—and the first prize was awarded to the following paper, written by Mr. A. Gordon Smith, of H.M.S. Canada. The article needs no apology, but it is only just, says the Engineer, to mention the fact that the writer is not yet eighteen years of age.

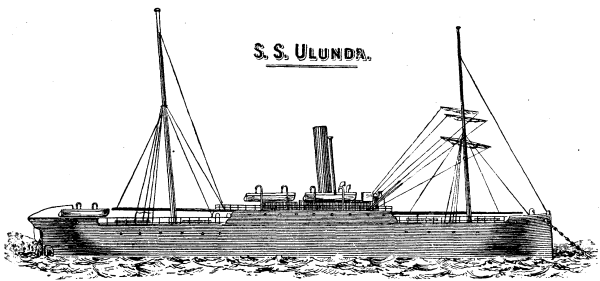

The steamship Ulunda, on the remarkable raising and recovery of which this paper is written, is an iron screw ship of 1,161 tons, until lately belonging to the Furness line. It is a sister ship to the Damara, of the same company, and was built and engined by Alex. Stephens, shipbuilder and engineer, at Glasgow, being fitted with compound vertical engines, of 200 nominal horse power, having two cylinders of 33 inches and 66 inches diameter respectively, which are capable of sixty-five revolutions per minute, and give a speed of twelve knots an hour.

For supplying steam to the engines there are two return-tube boilers, each having three furnaces, and there is also a donkey boiler, which is used in harbor for working the four steam winches on deck.

She is divided into seven watertight compartments by athwartship bulkheads. The foremost one is the usual collision bulkhead. Between this and the foremost engine room bulkhead are Nos. 1 and 2 holds, separated by a watertight bulkhead. Abaft the after engine room are two more holds, divided in the same manner as the forward ones, and astern is another compartment, in which all stores are kept. Coal bunkers form a protection for the engines and boilers. Fore and aft the ship, as low down as possible, are a number of ballast tanks, which can be filled with or emptied of water as occasion requires to alter the trim of the ship. Extending over all holds there is a strong iron lower deck, about 8 feet below the upper deck, which is pierced with a hatch over each hold immediately under a corresponding hatch in the upper deck, for stowing and unstowing cargo.

In the engine room there are six steam pumps, two of them bilge pumps, worked by the main crossheads, for clearing the engine room of water. For pumping out the ballast tanks there are two more, which have their own independent engines. The remaining two are for various purposes. Besides these there are several hand pumps on the upper deck.

Having been built in 1885, the Ulunda is almost a new ship, and has been used principally as a cargo steamer, though she is provided also with a saloon and staterooms for a few passengers. She was on her way from St. John, New Brunswick, to Halifax, when during a thick fog she struck on Cowl Ledge, a reef between Bryer and Long Islands, on the southwest coast of Nova Scotia, about half a mile from the shore. The cause of the disaster was probably one of the strong tide eddies which exist in the Bay of Fundy, and which had set her in toward the shore. It was calm at the time, and she was making seven knots an hour; and, being close to the shore, leads should have been going in the chains. Had this precaution been taken, very probably she would have been able to stop or anchor in time to avert this catastrophe. There was no cargo on board, it being intended to ship one at Halifax for London.

When ashore on this reef she was sold by public auction at Halifax, and fell to a syndicate of private individuals for £440. These gentlemen at once decided to raise her if possible, transport her into dock, and repair her. They commissioned Captain Kelly, of the Princess Beatrice, a ship then in harbor, to visit her and see what could be done for that purpose. He went with a hired crew to Annapolis, and from thence proceeded to the steamer by means of a tug, a distance of about forty miles. When they arrived they found the Ulunda with her head to sea, and her stern in only 2 ft. of water at low tide, with a list of 30 deg. to port and her foremast broken short off. At high tide the water flowed over the upper deck. On examination, the engine room was found full of water, which did not rise and fall with the tide, showing that it had been filled at high tide through its skylight. No. 3 hold was also full, but had a slight leak, which was shown by the water falling slowly at low tide and rising in the same manner at high water. The other three holds were hopelessly leaky.

Upon investigation, it was decided to pump out the engine room compartment and No. 3 hold, and to make the iron lower deck watertight over the remaining holds. For this purpose three powerful pumps, with the necessary boilers, were obtained from Halifax, sent by rail to Annapolis, and then shipped on board a tug, from which they were hoisted into the Ulunda by means of the derricks on the mainmast. These were centrifugal pumps, capable of discharging 2,000 gallons a minute each. One was placed in the engine room, another with its suction in No. 3 hold, and when these two compartments were pumped dry, it was found that in No. 3 hold the leak was easily kept under, while in the engine room there was no leak at all. The third pump was not used.

In the two foremost holds 2,000 large casks were then placed, and all the hatches over the leaky holds—Nos. 1, 2, and 4—were battened down, and made airtight with felt, pitch, tow, etc. A small hole was then made in Nos. 1 and 2 hatches, about 2 ft. square. When the tide had sunk its farthest, these two holes were closed and made perfectly airtight, in the same manner as the hatches had been.

Before this took place the whole of the lower deck over the badly damaged holds had been prevented from bursting up by means of wooden shores, which were placed in rows about 4 ft. apart, and wedged firmly into position. The wood for the shores was obtained from Annapolis, and the casks from St. John. The ship went ashore on August 26, 1890. This work was commenced on September 8, and completed ten days afterward.

The labor of repairing her could only be carried out at low tide, and only then with the greatest difficulty, as the decks were very slippery with weeds, etc., and inclined at an angle of 30 deg. Everything was ready for floating her off at high tide on the 18th, and the hatches were closed up on that day.

She was raised off the rocks by the water rising and compressing the air in the two foremost holds, assisted by the buoyancy of the engine room and No. 3 compartments. At high water the bow was afloat, but she was aground by the stern. When, however, she was taken in tow by three tugs, she slowly slid down the reef and floated into deep water. One tug was placed on each bow, and the third was ahead. In this state she was towed into West Port, a distance of four miles, and there beached on a sheltered stretch of sand.

The casks performed no part in floating the ship off, but were only there in case the great pressure of air should cause the escape of some of it, in which event all the space underneath the lower deck would soon have been occupied with water instead of air. These casks would then, of course, have served to displace a large amount of this water, and so keep her afloat. Luckily the deck did not leak, and the barrels were thus not instrumental in the raising.

When beached the hatches were taken off, the casks removed, and a false deck was built about 7 ft. below the lower deck, and about 10 ft. above the keel. This was used as the bottom of the ship to take her round to Halifax, and was built in the following manner: A kind of iron platform, about 2 ft. wide, runs along the sides of the holds in the Ulunda for strengthening purposes, braced at intervals of 15 ft. by iron beams across the ship.

On this was built the wooden deck. Beams for this deck were constructed of three 3 in. planks, and were laid down on the iron platform about 3½ ft. apart, and firmly wedged into the ship's side. On these beams a layer of 3 in. planks was placed in a fore-and-aft direction and nailed down; on this were three layers of felt, and on this again more planks were laid down in the same direction as before.

The whole deck was then carefully calked and the sides made watertight with Portland cement. This deck only extended to the engine room bulkhead through the two foremost holds. It was prevented from bursting up by the pressure on the bottom of it, by means of shores, in the same manner as the iron deck had been served before. Shores were, therefore, connecting the three decks—the upper deck, lower deck, and wooden deck—this being done to equalize the pressure on the extemporé deck and the two permanent decks, and thus gain additional strength.

No deck was built in either of the after compartments, inasmuch as No. 3 hold was kept clear of water as before by its pump, and in No. 4 the deck was not necessary. To have built one there, as in the two foremost ones, although it would have given a little more reserve of buoyancy to the ship, would have raised the stern higher than the bows, and so would have increased the upward pressure on the wooden deck, and thus have increased the liability to burst up. For the same reason, when raising the ship off the rocks, no compressed air was used in the after hold to lift the ship. The anchors and cables were in both cases transferred aft, for the same purpose, namely, to diminish the upward pressure forward. In the case of the wooden deck leaking, 200 of the same casks were placed between it and the lower deck in the foremost hold to retain some of the buoyancy of the forepart, which would otherwise be lost. No decks were built in the compartment before the collision bulkhead, as very little buoyancy was lost by that space being full of water, and all that was there was confined to that compartment by the bulkhead and the iron lower deck.

While all these foregoing arrangements were being made for the exclusion of water from the inside of the ship, the engineers and firemen were employed clearing the engine room of some fifty tons of coal which had been washed from the open bunkers into the machinery by the sea, when the engine room was full and the ship on the reef. The greatest difficulty was experienced in digging out and excavating the engines from the coal and dirt, and still greater was the labor of cleaning all the mechanism and putting everything once more in an efficient steaming condition. But all was finished soon after the decks had been completed, and on October 12 she was ready for sea. On the following day she was floated off and started on her perilous voyage to Halifax, using her own engines, and making about five and a half knots an hour. Her steam pumps were by this time all ready for service to assist the big ones on deck in an emergency. She anchored once on her way round, at Shelburne, on the coast of Nova Scotia, arriving at Halifax at 1 p.m. on October 17. The trip round was a very anxious time for all hands, more especially when they were overtaken by a fresh gale in the Atlantic, for the forward deck was very liable to be burst up with the increased pressure on it caused by the pitching of the ship; also the rudder was entirely unable to bear any strain on it, because the lower part of the rudder post was unconnected with the stern post, part of the stern framing which connects the two having been broken off. Any heavy sea was therefore likely to carry away the rudder altogether, or the same accident might happen if the helm was put down too hard, rendering the ship unmanageable.

She was placed in dry dock as soon as she arrived at Halifax, and it was not until then that the full extent of the damages, caused by the pounding on the rocks, could be fully realized. The first 20 feet of the keel had been torn completely out, and about 30 feet from the stern there was an immense hole, with the thick plates torn and bent like paper, the framing and stanchions being twisted into all sorts of shapes almost beyond recognition. Under the foremast the bottom of the ship was bent up in the form of an arch, having been raised 4 feet above its natural position, with an immense hole punctured on the starboard side, besides several smaller ones. Also the aftermost 20 feet of keel was torn and jagged, with several small holes in the skin, and the lower portion of the stern framing was broken off, leaving the rudder post to hang down unsupported at its extremity. It would strike one on looking at these gaping wounds that it would be nearly impossible to place the Ulunda in an efficient condition again, but the work of renewing the damaged plates is being carried out at a great rate, and in three months' time it is hoped that all the repairs necessary will be completed and the ship once more doing her duty. She has already cost her owners some $10,000, and $40,000 are estimated to cover all future repairs.

The foremast was snapped off in a somewhat novel manner. She was pivoted on the rocks by her bows, and at high tide, the day after she struck, a breeze sprang up and turned her round; the tide sinking again, the whole weight of the ship came on the bottom of the ship where she was then touching, namely, just on the spot where the foremost was stepped, and right astern, leaving the center portion of the ship unsupported. This caused the foremast to rise, and it being held down by wire rigging, it snapped in several places, at the same time tearing up the shrouds from the deck. This accounts also for the arch-like bulge in the bottom at that spot and for the damages astern; also for the fact that Captain Kelly discovered the ship with her head to sea.

Another incident happened when the ship was just rising off the rocks, which nearly resulted in a catastrophe. When the ship was just beginning to lift, the leak in No. 3 compartment was found to be gaining on its pump. A diver was at once sent down to ascertain the cause, and he found that a small hole, about 6 inches square, had been punctured in the skin, which until then had been kept tight by the rock that had caused it. It was necessary to close this leak at once. An iron bolt, which was screwed for a nut at one end, was obtained and passed through a strong piece of wood about 2 feet square. The inside of this board was cushioned with canvas and oakum, and it was taken down outside the ship by the diver and placed over the hole, with the feathered end of the bolt sticking through the hole; the diver was then sent down inside the hold, and with a nut set up the whole cushion until the flow of water was stopped. The leak was thus stopped which had threatened the arrangements for floating the ship with failure.

It has been seen that the method of raising the Ulunda was very simple. She was floated off by the rising tide. If there had been only a small instead of an 18 foot rise, some other mode would have to have been adopted. No attempt was made to stop any of the leaks, except the one just stated, but a deck above the lacerations was made water-tight, and this, together with the sides of the ship hanging down, formed a kind of diving bell, the pressure of air in which, caused by the water outside, acting on this deck, being the principal means of buoying up the ship, assisted by the buoyancy of the two water-tight compartments. The deck afterward built was only necessary for the safety of the ship, she being able to float without it; but it would have been suicidal to trust the ship on the Atlantic in the state she was in when raised, since with any swell on, the compressed air would escape and its place be taken by water, the buoyancy necessary for keeping her afloat being thus lost.

It only remains to be said that the risks run in steaming around to Halifax by herself were, as it was, very great, and had the wind and sea been less favorable, the undertaking would probably have proved a disastrous failure.

Up to recent years there was no reason for putting the question that forms the title of this article, for it was admitted by all that the conversion of thermic energy, or heat produced by the combustion of coal, into mechanical energy or work could no longer be effected economically except by having recourse to steam. In ordinary language, and even to manufacturers, steam engine was the equivalent of thermic motor, and it would not have occurred to any one to use anything else but steam to effect the transformation.

The progress that has been made during the last twenty years in the thermatic study and construction of gas motors (without speaking of hot air motors) has shown that the use of steam is not absolutely indispensable for the production of work, and it has demonstrated that, as regards dynamic product, the gas motor preserves the advantage, although the relatively high price of the illuminating gas employed in the production of the motive power generally renders the use of this combustible more costly than steam, especially for high powers.

The economic truth of twenty years ago, when gas motors absorbed 1,500 liters per horse hour and exceeded with difficulty an effective power of from 8 to 10 horses, has become less and less certain, when the consumption has successively descended to 1,200, 1,000, 800 and even to 600 liters of gas per horse hour, the power of the motors rising gradually to 25, 50 and 100 horses with a motor having a single cylinder of a diameter of 57 centimeters.

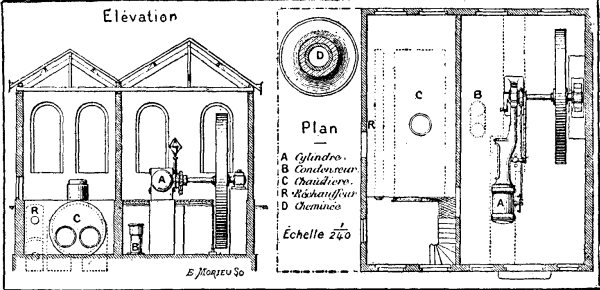

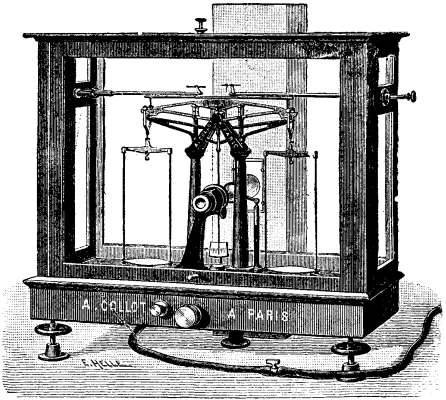

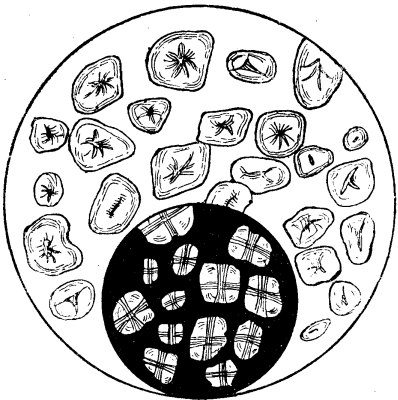

FIG. 1.—CORLISS ENGINE AND BOILER OF 100

INDICATED H.P.—ELEVATION AND PLAN.

A, cylinder; B, condenser; C, boiler; R, feed water heater; D,

chimney.

But these results did not suffice, and it was desired to do better still by dispensing with the use of high priced illuminating gas. An endeavor was made to obviate the difficulty by manufacturing a special gas for the motive power, as steam is produced for the same object, by distilling coal, carbureting air, producing water gas by the Dowson process, and by other equivalent processes.

The strides made in this direction were finally crowned with success, and the results obtained in the recent experiments due to Mr. Aimé Witz, an undoubted authority in the matter, permit of affirming that now and hereafter, in many circumstances, a gas generator supplying a gas motor will be able to advantageously dethrone a steam boiler supplying a steam engine of the same power.

These conclusions, which tend to nothing less than to limit the reign of the steam engine, are confirmed on the one hand by an experiment carried on for the last two years in the Barataud flour mill of Marseilles, where a 50 h.p. "Simplex" motor has been running day and night for several months without stopping, and consuming but about 500 grammes of English anthracite per effective horse hour, and, on another hand, by some personal experiments of Mr. Witz's, to which we shall shortly advert, and whence there results a sensibly equivalent production for a motor of 100 indicated h.p., corresponding to a power of 75 effective horses.

Before establishing, with Mr. Witz, a comparison of the two systems in pressure, steam or gas, let us state in a few words in what the latter consists, the steam engine and the boiler that supplies it being so well known that no description is necessary.

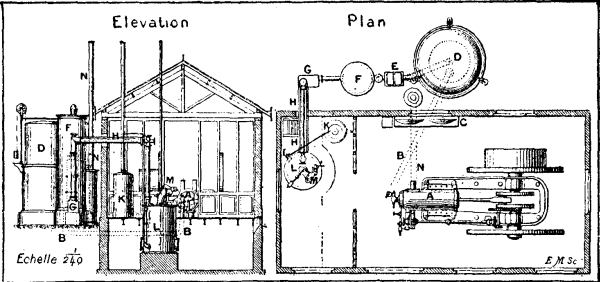

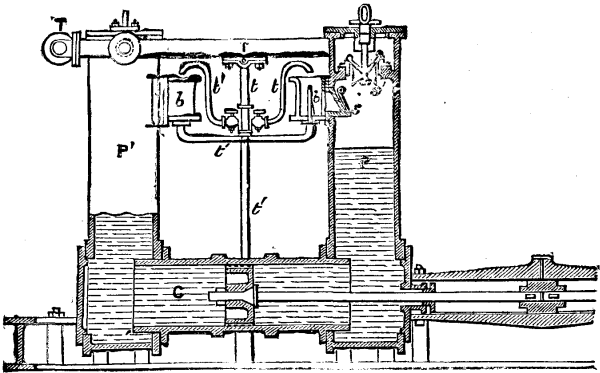

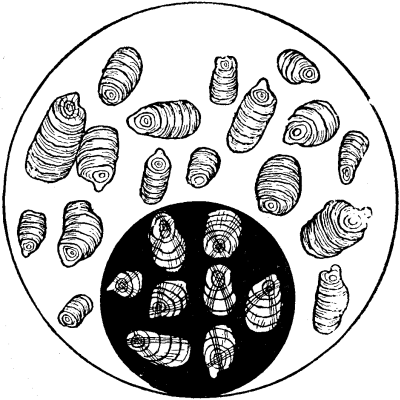

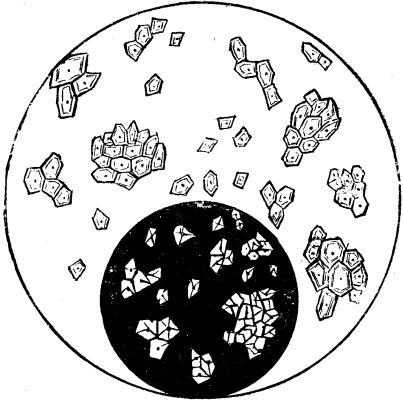

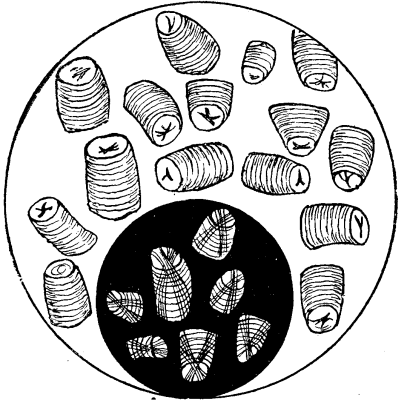

The Dowson gas generator does not differ essentially from the numerous generators devised during recent years for the manufacture of gaseous combustibles, the use of which is so often convenient. The motor that it supplies is the most powerful single cylinder one that has hitherto been constructed. It is of 100 indicated h.p., and its normal angular velocity is 100 revolutions per minute. On trial it has yielded 112 indicated h.p., and 76.8 effective h.p., corresponding to an organic rendering of 69 per cent. This motor, elaborated by Messrs. Delamare-Bouteville & Malandin, of Rouen, operates by compression and in four periods, according to the Beau de Rochas cycle. We give the aspect of it in Fig. 3. In the first period the mixture of air and gas is sucked in, in the second it is compressed, in the third it is ignited, and in the fourth the products of combustion are expelled.

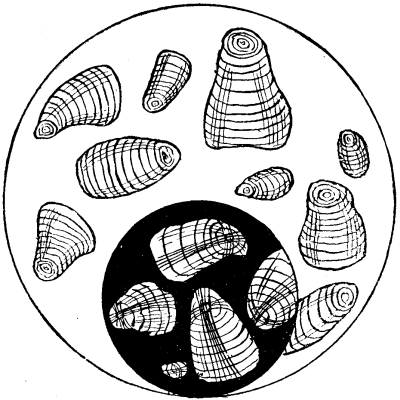

FIG. 2.—SIMPLEX MOTOR, DOWSON GENERATOR OF

100 INDICATED H.P.—ELEVATION AND PLAN.

A, cylinder; B, gas conduit; C, rubber pockets; D. gasometer;

E, purifier; F, scrubber; G, hydraulic main; H, cooling pipe;

I steam injector; K, steam boiler and superheater; L, gas

generator; M, charger; N, discharge of the motor.

Ignition is effected electrically by a series of sparks playing between two platinum points in the slide valve, and this permits of regulating the instant of ignition through the edges of the orifices. The angular velocity is regulated by a Watt's governor, which secures an isochronism of the motion independently of the charge.

The setting in motion of so powerful an engine is effected very easily by means of an arrangement that permits of introducing into the cylinder, while the piston is in the center of the stroke, a mixture of air and gas whose pressure is sufficient at the arrival to expel the inert products. After this the ignition takes place, and the explosion is sufficient to set the motor in motion.

The trials made by Mr. Witz with the motor represented in Fig. 3 gave the following results, deduced from an experiment of 68 hours. The figures relate to one effective horse power, measured with the brake upon the shaft of the motor.

Consumption of anthracite. 516 grammes.

" " coke. 96 "

Consumption of water for the injection

of steam. 0.487 liters.

Consumption of water for cooling

the cylinder. 50.0 "

Consumption of oil for lubricating

the cylinder. 3.74 grammes.

Consumption of grease. 0.45 "

Consumption of gas reduced to

0° C. and to 760 mm. 2,370 liters.

This last figure will appear very high, but the fact must not be lost sight of that it is a question of poor gas, the net cost of which varies between one and two centimes per cubic meter, and the calorific power of which is but 1,487 heat units per cubic meter of constant volume, and supposing the steam condensed. This combustion of 612 grammes of combustible per effective horse hour is remarkable, and fully shows what may be expected of the gas motor supplied by a gas generator in putting to profit certain improvements that will hereafter be possible, such, for example, as the lightening of the movable parts of the motor, the bettering of its organic rendering (now quite feeble), the use of better oils, the reduction of the consumption of water, the superheating of the steam injected into the gas generator, etc.

A well constructed steam engine, carefully kept in repair and as much improved as it is possible to make it, would certainly consume twice as much coal to produce the same quantity of effective work, say at least 1,200 grammes per horse hour. But, as has been objected with reason, it does not suffice to compare the figures as to the consumption of fuel in order to institute a serious comparison between the steam engine and the motor using poor gas.

The gas generator requires the use of English anthracite, while a steam boiler is heated with any kind of coal. The prices of unity of weight are therefore very different. Moreover, the gas motor necessitates an immense amount of water for the washing of the gas and the cooling of the cylinder, through circulation in the jacket. It is well to keep this fact in view. On another hand, the lubrification of the cylinders requires a profusion of oil whose flashing point must be at a very high temperature, else it would burn at every explosion and fill the cylinder with coom. Such oil is very costly.

Does not the expenditure of oil in large motors largely offset the saving in coal? And then, gas motors are sold at high prices, as are gas generators, and this installation necessarily requires the addition of a large gasometer, scrubbers, etc. The wear of these apparatus is rapid, and if we take into account the interest and amortization of the capital engaged, we shall find that the use of steam is still more economical. The obstruction caused by bulky apparatus is another inconvenience, upon which it is unnecessary to dwell. In a word, the question is a very complex one. We look at but one side of it in occupying ourselves only with the coal consumed, and we shall certainly expose those who allowed themselves to be influenced by the seductive figures of consumption to bitter disappointment.

To answer such objections Mr. Aimé Witz has established a complete parallel between the two systems, in which he looks at the question from a theoretical and practical and scientific and financial point of view. Considered as a transformation apparatus, a steam motor burning good Cardiff coal in a Galloway boiler with feed water heaters will consume (with a good condensing engine utilizing an expansion of a sixth) from 1,100 to 1,250 grammes of coal per effective horse hour, which corresponds to a rough coefficient of utilization of 9.7 per cent. A gas generator supplying a gas motor burning Swansea anthracite and Noeux coke, medium quality, will consume 516 grammes of anthracite and 90 of coke to produce 2,370 liters of gas giving 1,487 heat units per cubic meter. Of the 3,524 heat units furnished to the motor by the 2,370 liters of gas, the motor will convert 18 per cent. into disposable mechanical work.

With the boiler, the gross rendering of the whole is 7 per cent. With the gas generator it reaches 12.7 per cent. From a theoretical point of view the advantage therefore rests with the gas generator and gas motor. In order to compare the net cost of the units of work, from an industrial point of view, it is necessary to form estimates of installation, costs of keeping in repair, interest and amortization.

Figs. 1 and 2 represent, on the same scale, the installations necessary in each of these systems. The legends indicate the names of the different apparatus in each installation. The following table shows that, as regards the surface occupied, the advantage is again with the gas generator and gas motor:

Steam Engine. Gas Motor.

Surface covered. 85 sq. m. 72 sq. m.

Surface exposed. 33 " 43 "

--- ---

Total surface. 118 " 115 "

The estimates of installation formed by Mr. Witz set forth the expense relative to the capital engaged exactly at the same figure of 32,000 francs for a motive power of 75 effective horses. The expenses of keeping in repair, interest, etc., summed up, show that the cost per day of 10 hours is 47.9 francs for the steam engine and 39.6 for the gas motor, say a saving of 8.3 francs per day, or about 2,500 francs for a year of 300 days' work.

The gas motor, therefore, effects a great saving, while at the same time occupying less space, consuming less water and operating just as well.

With Mr. Witz we cheerfully admit all the advantages that he so clearly establishes with his perfect competency in such matters, but there still remain two points upon which we wish to be enlightened. Are not the starting up, the operation and the keeping in repair of a gas generator actually more complicated and more delicate than the same elements of a steam engine? Does not the poor gas manufactured in a gas generator present, from a hygienic point of view, danger sufficiently great to proscribe the use of such apparatus in many circumstances?

Such are the points upon which we should like to be enlightened before unreservedly sharing Mr. Witz's enthusiasm, which, however, is justified, economically speaking, by the magnificent results of the experiments made by the learned engineer.—La Nature.

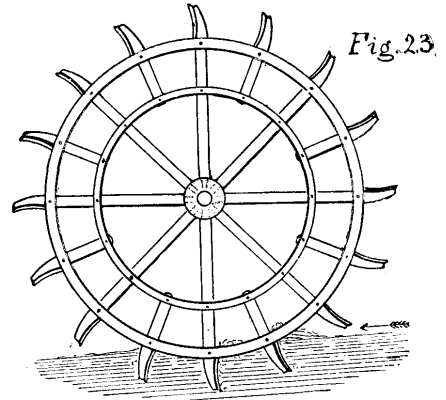

FIG. 3.—GAS MOTOR OF 100 INDICATED HORSE POWER.

We publish illustrations of a Thwaites suspension pneumatic power ½ cwt. hammer of a new design, for planishing pipes and plates, for which we are indebted to Engineering. As indicated in the perspective view (Fig. 1) the mechanism is supported at the center of a cross girder resting on two cast iron square pillars, box section, each bolted down to the foundations by four 1¼ in. diameter bolts. The measurements of these columns and girders are given in Figs. 2 and 3, the former an elevation of the hammer and the latter a plan, partly in section, of the cross girder, while Fig. 4 is a cross section showing the arrangements for operating the hammer. In the center is a cast iron guide for working the ram, the guide being extended on two sides to receive the disk crank journals, 2 in. in diameter by 3½ in. long. The disk cranks are connected to a hollow steel ram by a connecting rod. The ram is divided inside into two compartments, each having a phosphor bronze air piston. These are connected together by a steel piston rod, the top air piston forming a connection for the small end of the connecting rod. The outside diameter of the ram is 3¾ in., and the diameter of the air pistons 2¾ in. and 2-7/8 in. respectively. Cottered into the bottom of the ram is a steel pallet holder with a dovetail, so that the pallet can be renewed or exchanged for one of another shape when required. Keyed on to the crankshaft is a flanged pulley 10 in. in diameter by 3¼ in. between flanges. There is also an overhead countershaft with strap shifting arrangement. At the side of one of the columns a hand lever and quadrant are provided, as shown in the perspective view and in Fig. 2, for working an arrangement for tightening the belt when the machine is working. To this arrangement is connected a powerful brake which stops the machine in a few revolutions. It will be seen that the brake is applied as the belt is slackened for stopping the machine. For planishing pipes or tubes a long wrought iron mandrel is provided mounted on two cast iron carriages, each having four flanged wheels for running on rails. The hammer is arranged so that tubes 4 feet in diameter can be worked for planishing plates. A pallet is fastened on the top of one of the mandrel carriages, Figs. 5 to 8 showing the details of the carriages. The general dimensions are: Distance between pillars, 6 feet; height under girder, 5 feet; height from ground to top of mandrel, 4 feet 1¾ in.; and length of stroke, 5 in. This machine is capable of delivering 500 blows per minute. The constructors are Messrs. Thwaites Brothers, Limited, Bradford, Yorkshire.

FIG. 1.

SUSPENSION PNEUMATIC POWER HAMMER.

I cannot but realize as I stand before you that I would be very much more at home were I in your midst. I feel but little older and so very much less wise than when I sat in the class room an undergraduate of the University of Pennsylvania, that I trust I may expect you to give me this afternoon, not only your attention, but your sympathy.

The present situation is not without suggestions of my own experience. I recall a lecture in the ordinary course, given by our professor of mining, whose struggles with the English language were quite as conspicuous as were our efforts to tell what he was driving at. He was describing an ordinary windlass hoist used at the shaft of a mine. He said "There is a windlass at de top of de shaft around which is coiled a rope, on de two ends of which is fastened two er—er—pans, one of which is a bucket and de oder a platform." I mention this because I shall ask you to attribute my shortcomings in this lecture, not so much to my lack of familiarity with my native tongue, as to—well, because I was not educated at Cornell University.

We all know what free air is. You who are privileged to live upon these beautiful hills overlooking Ithaca and the lake, doubtless know more about free air than we do who are choked in the dusty confines of New York City. Compressed air is simply air under pressure. That pressure may be an active one, as in the case of the piston of an air compressor; or passive, as with the walls of a receiver or transmission pipe. It is usual to define compressed air as air increased in density by pressure, but we know that we may produce compressed air by heat alone. A simple illustration of this is the pressure which will blow a cork from an empty bottle when that bottle has been placed near the fire. Here we have pressure, or compressed air, in the bottle produced by heat alone.

Having defined compressed air, we must next define heat; for in dealing with compressed air, we are brought face to face with the complex laws of Thermodynamics. We cannot produce compressed air without also producing heat, and we cannot use compressed air as a power without producing cold. Based on the material theory of heat, we would say that when we take a certain volume of free air and compress it into a smaller space, we get an increase in temperature because we have the heat of one volume occupying less space, but no one at this date accepts the material theory of heat. Your distinguished director, Professor Thurston, in discussing "Steam and its Rivals," in the Forum, said: "The science of Thermodynamics teaches that heat and mechanical energy are only different phases of the same thing, the one being the motion of molecules, and the other that of masses." This is the accepted theory of heat. In other words, we do not believe that there is any such thing as heat, but that what we call heat is only the sensible effect of motion. In the cylinder of an air compressor the energy of the piston is converted into molecular motion in the air and the result, or the equivalent, is heat. A higher temperature means an increased speed of vibration, and a lower temperature means that this speed of vibration is reduced. If I hold an open cylinder in my left hand and a piston in my right, and place the piston within the cylinder, I here have a confined volume of air at the temperature and the pressure of this room. These particles of air are in motion and produce heat and pressure in proportion to that motion. Now if I press the piston to a point in the center of the cylinder, that is, to one-half the stroke, I here decrease the distance between the cylinder head and the piston just one-half, hence each molecule of air strikes twice as many blows upon the piston and head in traveling the same distance and the pressure is doubled. We have also produced about 116 degrees of heat, because we have expended a certain amount of work upon the air; the air has done no work in return, but we have increased the energy of molecular vibration in the air and the result is heat.

But what of this heat? What harm does it do? If I instantly release the piston which I hold at one-half stroke it will return to its original position, less only a little friction. I have, therefore, recovered all, or nearly all, the power spent in compressing the air. I have simply pressed a spring, and have let it recover. We see what a perfect spring compressed air is. We see the possibility of expending one horse power of energy upon air and getting almost exactly one horse power in return. Such would be the case provided we used the compressed air power immediately and at the point where the compression takes place. This is never done, but the heat which has been boxed up[1] in the air is lost by radiation, and we have lost power. Let us see to what extent this takes place.

Thirteen cubic feet of free air at normal temperature and barometric pressure weigh about one pound. We have seen that 116 degrees of heat have been liberated at half stroke. The gauge pressure at this point reaches 24 pounds. According to Mariotte's law, "The temperature remaining constant, the volume varies inversely as the pressure," we should have 15 pounds gauge pressure. The difference, 9 pounds, represents the effect of the heat of compression in increasing the relative volume of the air.

FIG. 1.: CURVES OF COMPRESSION ILLUSTRATEDIN VOLUMES, PRESSURES, AND TEMPERATURES.

The specific heat of air under constant pressure being 0.238, we have 0.238 × 116 = 27.6 heat units produced by compressing one pound or thirteen cubic feet of free air into one-half its volume. 27.6 × 772 (Joule's equivalent) = 21,307 foot pounds. We know that 33,000 foot pounds is one horse power, and we see how easily about two-thirds of a horse power in heat units may be produced and lost in compressing one pound of air. I would mention here that exactly this same loss is suffered when compressed air does work in an engine and is expanded down to its original pressure. In other words, the heat of compression and the cold of expansion are in degree equal.

Experiments made by M. Regnault and others on the influence of heat on pressures and volumes of gases have enabled us to fix the absolute zero of temperature as -461 degrees Fahrenheit. This point, 461 degrees below zero, is the theoretical point at which a volume of air is reduced to nothing. The volume of air at different temperatures is in proportion to the absolute temperature, and on this basis Box gives us the following table:

TABLE l.—OF THE VOLUME AND WEIGHT OF DRY AIR AT DIFFERENT TEMPERATURES UNDER A CONSTANT ATMOSPHERIC PRESSURE OF 29.92 INCHES OF MERCURY IN THE BAROMETER (ONE ATMOSPHERE), THE VOLUME AT 32° FAHRENHEIT BEING 1.

Temperature Volume in Weight of a

in degrees. cubic feet. cubic foot in lb.

32 1.000 0.0807

42 1.020 0.0791

52 1.041 0.0776

62 1.061 0.0761

72 1.082 0.0747

82 1.102 0.0733

92 1.122 0.0720

102 1.143 0.0707

112 1.163 0.0694

122 1.184 0.0682

132 1.204 0.0671

142 1.224 0.0660

152 1.245 0.0649

162 1.265 0.0638

172 1.285 0.0628

182 1.306 0.0618

192 1.326 0.0609

202 1.347 0.0600

212 1.367 0.0591

230 1.404 0.0575

250 1.444 0.0559

275 1.495 0.0540

300 1.546 0.0522

325 1.597 0.0506

350 1.648 0.0490

375 1.689 0.0477

400 1.750 0.0461

450 1.852 0.0436

500 1.954 0.0413

550 2.056 0.0384

600 2.15[2] 0.0376

650 2.260 0.0357

700 2.362 0.0338

750 2.464 0.0328

800 2.566 0.0315

850 2.668 0.0303

900 2.770 0.0292

950 2.872 0.0281

1,000 2.974 0.0268

1,100 3.177 0.0254

1,200 3.381 0.0239

1,300 3.585 0.0225

1,400 3.789 0.0213

1,500 3.993 0.0202

1,600 4.197 0.0192

1,700 4.401 0.0183

1,800 4.605 0.0175

1,900 4.809 0.0168

2,000 5.012 0.0161

2,100 5.216 0.0155

2,200 5.420 0.0149

2,300 5.624 0.0142

2,400 5.828 0.0138

2,500 6.032 0.0133

2,600 6.236 0.0130

2,700 6.440 0.0125

2,800 6.644 0.0121

2,900 6.847 0.0118

3,000 7.051 0.0114

3,100 7.255 0.0111

3,200 7.459 0.0108

The effect of this heat of compression in increasing the volume, and the heat produced at different stages of compression, are shown by the following table:

TABLE 2.—HEAT PRODUCED BY COMPRESSION OF AIR.

--------+-----------------------+----------+------------+-------------

| Pressure. | | |

Atmo- +-----------+-----------+ Volume |Temperature | Total

spheres.|Pounds per |Pounds per | in Cubic | of the Air | Increase of

|Square Inch|Square Inch| Feet. | throughout | Temperature.

| above a |above the | |the Process.| Degrees.

| Vacuum. |Atmosphere | | Degrees. |

| |(Gauge | | |

| |Pressure). | | |

--------+-----------+-----------+----------+------------+-------------

1.00 | 14.70 | 0.00 | 1.0000 | 60.0 | 00.0

1.10 | 16.17 | 1.47 | 0.9346 | 74.6 | 14.6

1.25 | 18.37 | 3.67 | 0.8536 | 94.8 | 34.8

1.50 | 22.05 | 7.35 | 0.7501 | 124.9 | 64.9

1.75 | 25.81 | 11.11 | 0.6724 | 151.6 | 91.6

2.00 | 29.40 | 14.70 | 0.6117 | 175.8 | 115.8

2.50 | 36.70 | 22.00 | 0.5221 | 218.3 | 158.3

3.00 | 44.10 | 29.40 | 0.4588 | 255.1 | 195.1

3.50 | 51.40 | 36.70 | 0.4113 | 287.8 | 227.8

4.00 | 58.80 | 44.10 | 0.3741 | 317.4 | 257.4

5.00 | 73.50 | 58.80 | 0.3194 | 369.4 | 309.4

6.00 | 88.20 | 73.50 | 0.2806 | 414.5 | 354.5

7.00 | 102.90 | 88.20 | 0.2516 | 454.5 | 394.5

8.00 | 117.60 | 102.90 | 0.2288 | 490.6 | 430.6

9.00 | 132.30 | 117.60 | 0.2105 | 523.7 | 463.4

10.00 | 147.00 | 132.30 | 0.1953 | 554.0 | 494.0

15.00 | 220.50 | 205.80 | 0.1465 | 681.0 | 621.0

20.00 | 294.00 | 279.30 | 0.1195 | 781.0 | 721.0

25.00 | 367.50 | 352.80 | 0.1020 | 864.0 | 804.0

--------+-----------+-----------+----------+------------+-------------

A cubic foot of free air at a pressure of one atmosphere (equal to 14.7 pounds above a vacuum) at a temperature of 60 degrees, when compressed to twenty-five atmospheres, will register 367.5 pounds above a vacuum (352.8 pounds gauge pressure), will occupy a volume of 0.1020 cubic foot, will have a temperature of 864 degrees, and the total increase of temperature is 804 degrees.

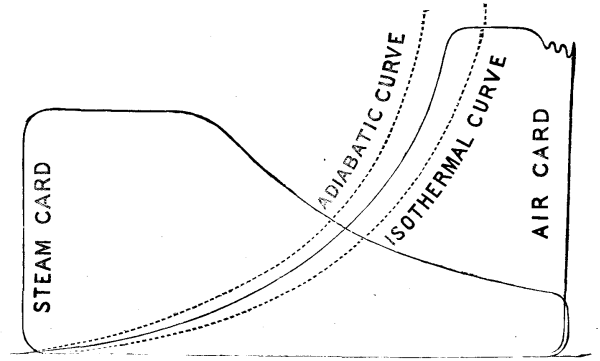

The thermal results of air compression and expansion are shown by the accompanying diagram.

The horizontal and vertical lines are the measures of volumes, pressures and temperatures. The figures at the top indicate pressures in atmospheres above a vacuum, the corresponding figures at the bottom denote pressures by the gauge. At the right are volumes from one to one-tenth. At the left are degrees of temperatures from zero to 1,000 Fahrenheit. The two curves which begin at the upper left hand corner and extend to the lower right are the lines of compression or expansion.

The upper one being the Adiabatic curve, or that which represents the pressure at any point on the stroke with the heat developed by compression remaining in the air; the lower is the Isothermal, or the pressure curve uninfluenced by heat. The three curves which begin at the lower left hand corner and rise to the right are heat curves and represent the increase of temperature corresponding with different pressures and volumes, assuming in one case that the temperature of the air before admission to the compressor is zero, in another sixty degrees, and in another one hundred degrees.

Beginning with the adiabatic curve, we find that for one volume of air when compressed without cooling the curve intersects the first vertical line at a point between 0.6 and 0.7 volume, the gauge pressure being 14.7 pounds. If we assume that this air was admitted to the compressor at a temperature of zero, it will reach about 100 degrees when the gauge pressure is 14.7 pounds. We find this by following down the first line intersected by the adiabatic curve to the point where the zero heat curve intersects this same line, the reading being given in figures to the left immediately opposite. If the air had been admitted to the compressor at 60 degrees, it would register about 176 degrees at 14.7 pounds gauge pressure. If the air were 100 degrees before compression, it would go up to about 230 degrees at this pressure. Following this adiabatic curve until it intersects line No. 5, representing a pressure of five atmospheres above a vacuum (58.8 lb. gauge pressure), we see that the total increase of temperature on the zero heat curve is about 270 degrees, for the 60 degree curve it is about 370 degrees, and for the 100 degree curve it is about 435 degrees. The diagram shows that when a volume of air is compressed adiabatically to 21 atmospheres (294 lb. gauge pressure), it will occupy a volume a little more than one-tenth; the total increase of temperature with an initial temperature of zero is about 650 degrees; with 60 degrees initial temperature it is 800 degrees, and with 100 degrees initial it is 900 degrees. It will be observed that the zero heat curve is flatter than the others, indicating that when free air is admitted to a compressor cold, the relative increase of temperature is less than when the air is hot. This points to the importance of low initial temperature.

We have now seen that the economical production of compressed air depends upon the following conditions:

(1) A low initial temperature.

(2) Thorough cooling during compression.

It has been demonstrated by experiments made in France that the power required to compress moist air is less than that for dry air. A table showing the power required to compress moist and dry air has been prepared from the data of M. Mallard and shows that for five atmospheres the work expended in compressing one pound of dry air is 58,500 foot pounds, while that for moist air is 52,500 foot pounds. In expansion also moisture in the air adds to the economy, but in both cases the saving of power is not great enough to compensate for the many disadvantages due to the presence of water. Mr. Norman Selfe, of the Engineering Association of N.S.W., has compiled a table which shows some important theoretical conditions involved in producing compressed air.

So much for the theory of compression. We now come to the practical production of compressed air.

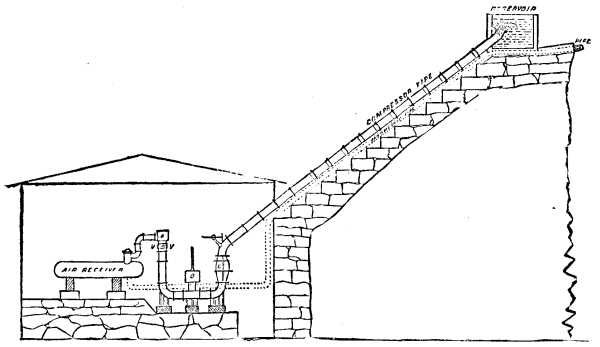

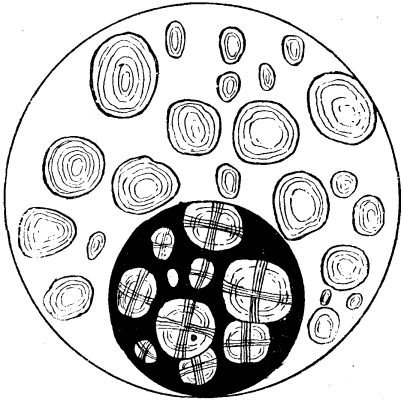

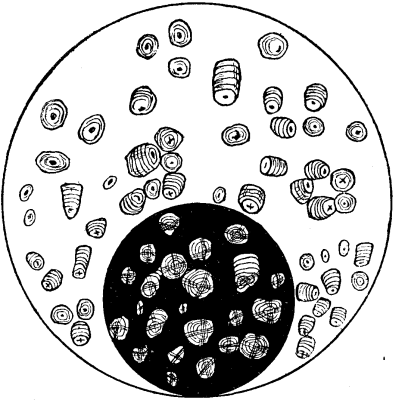

The first record that we have of the use of an air compressor is at Ramsgate Harbor, Kent, in the year 1788. Smeaton invented this "pump" for use in a diving apparatus. In 1851, William Cubitt, at Rochester Bridge, and a little later an engineer, Brunel, at Saltash, used compressed air for bridge work. But the first notable application of compressed air is due to Professor Colladon, of Geneva, whose plans were adopted at the Mont Cenis tunnel. M. Sommeiller developed the Colladon idea and constructed the compressed air plant illustrated in Fig. 2.

FIG. 2.

The Sommeiller compressor was operated as a ram, utilizing a natural head of water to force air at 80 pounds pressure into a receiver. The column of water contained in the long pipe on the side of the hill was started and stopped automatically, by valves controlled by engines. The weight and momentum of the water forced a volume of air with such shock against a discharge valve that it was opened and the air was discharged into the tank; the valve was then closed, the water checked; a portion of it was allowed to discharge and the space was filled with air, which was in turn forced into the tank. The efficiency of this compressor was about 50 per cent.

At the St. Gothard tunnel, begun in 1872, Prof. Colladon first introduced the injection of water in the form of spray into the compressor cylinder to absorb the heat of compression.

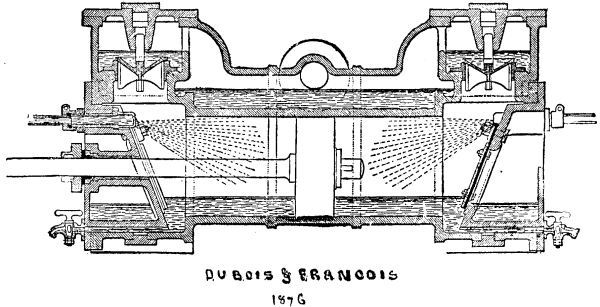

FIG. 3.

Fig. 3 illustrates the air cylinder of the Dubois-Francois type of compressor, which was the best in use about the year 1876. This compressor was exhibited at the Centennial Exposition and was adopted by Mr. Sutro in the construction of the Sutro tunnel. A characteristic feature seems to be to get as much water into the cylinder as possible. The water which flooded the bottom of the cylinder arose from the voluminous injection; this water was pushed into the end of the cylinder and some of it escaped with the air through the discharge valve.

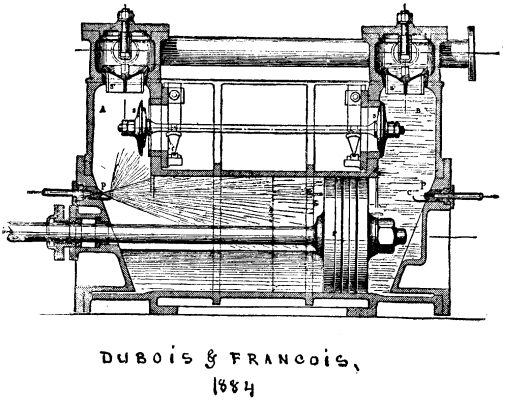

An improved pattern of this compressor is shown in Fig. 4.

FIG. 4.

These illustrations are interesting from an historical point of view, as indicating the line of thought which early designers of air-compressing machinery followed. As the necessity for compressed air power grew, inventors turned their attention to the construction of air-compressing engines that would combine efficiency with light weight and economy of space and cost. The trade demanded compressors at inaccessible localities, and in many cases it was preferred to sacrifice isothermal results to simplicity of construction and low cost.

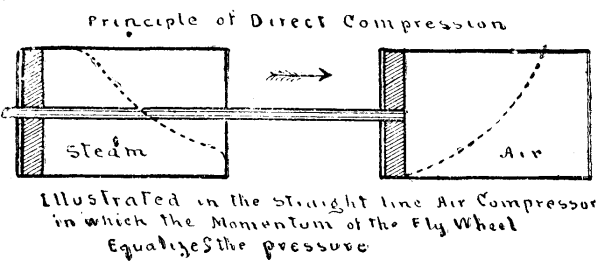

It is evident that an air compressor which has the steam cylinder and the air cylinder on a single straight rod will apply the power in the most direct manner, and will involve the simplest mechanics in the construction of its parts. It is evident, however, that this straight line, or direct construction, results in an engine which has the greatest power at a time when there is no work to perform. At the beginning of the stroke steam at the boiler pressure is admitted behind the piston, and, as the air piston at that time is also at the initial point in the stroke, it has only free air against it. The two pistons move simultaneously, and the resistance in the air cylinder rapidly increases as the air is compressed. To get economical results it is, of course, necessary to cut off in the steam cylinder, so that at the end of the stroke, when the steam pressure is low, as indicated by the dotted line (Fig. 5), the air pressure is high, as similarly indicated. The early direct-acting compressor used steam at full pressure throughout the stroke. The Westinghouse pump, applied to locomotives, is built on this principle, and those who have observed it work have perhaps noticed that its speed of stroke is not uniform, but that it moves rapidly at the beginning, gradually reducing its speed, and seems to labor, until the direction of stroke is reversed. This construction is admitted to be wasteful, but in some cases, notably that of the Westinghouse pump, economy in steam consumption is sacrificed to lightness and economy of space.

FIG. 5.

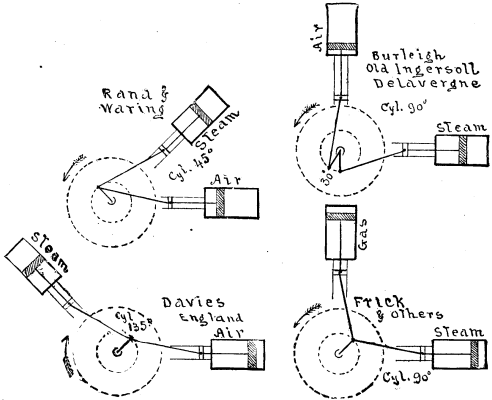

Many efforts were made to equalize the power and resistance by constructing the air compressor on the crank shaft principle, putting the cranks at various angles, and by angular positions of steam and air cylinders. Several types are shown in Fig. 6.

FIG. 6.

Angular positions of the cylinder involve expensive construction and unsteadiness. Experience has conclusively proved that it does not pay to build air compressors with vertical cylinders, and moreover we have found out that there is nothing in the apparent difficulty in equalizing the strains in a direct-acting engine. It is simply necessary to add enough weight to the moving parts, that is, to the piston, piston rod, fly wheel, etc., to cut off early in the stroke and secure rotative speed with the most economical results and with the cheapest construction. It is obvious that the theoretically perfect air compressor is a direct-acting one with a conical air cylinder, the base of the cone being nearest the steam cylinder. This, from a practical point of view, is impossible. Mr. Hill, in referring to the fallacious tendencies of pneumatic engineers to equalize power and resistance in air compressors, says: "The ingenuity of mechanics has been taxed and a great variety of devices have been employed. It is usual to build on the pattern of presses which do their work in a few inches of the end of the stroke and employ heavy fly wheels, extra strong connections, and prodigious bed plates. Counterpoise weights are also attached to such machines; the steam is allowed to follow full stroke, steam cylinders are placed at awkward angles to the air-compressing cylinders and the motion conveyed through yokes, toggles, levers; and many joints and other devices are used, many of which are entire failures, while some are used with questionable engineering skill and very poor results."

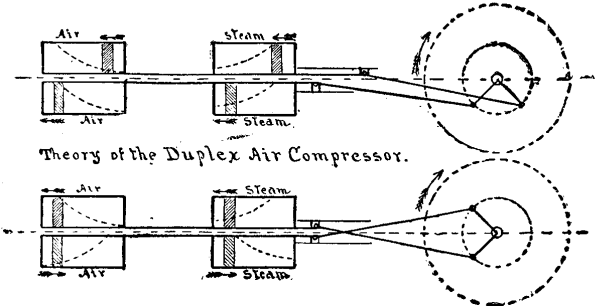

FIG. 7.

Fig. 7 illustrates the theory of Duplex Air Compressors. The hydraulic piston or plunger compressor is largely used in Germany and elsewhere on the Continent of Europe, but the duplex may be said to be the standard type of European compressor at the present time. It is also largely used in this country. Fig. 7 shows the four cylinders of a duplex compressor in two positions of the stroke. It will be observed that each steam cylinder has an air cylinder connected directly to the tail rod of its piston, so that it is a direct-acting machine, except in that the strains are transmitted through a single fly wheel, which is attached to a crank shaft connecting the engines. In other words, a duplex air compressor would be identical with a duplex steam engine were it not for the fact that air cylinders are connected to the steam piston rods. The result is, as shown in Fig. 7, that, at that point of the stroke indicated in the top section, the upper right hand steam cylinder, having steam at full pressure behind its piston, is doing work through the angle of the crank shaft upon the air in the lower left hand cylinder. At this point of the stroke the opposite steam cylinder has a reduced steam pressure and is doing little or no work, because the opposite air cylinder is beginning its stroke. Referring now to the lower section, it will be seen that the conditions are reversed. One crank has turned the center, and that piston which in the upper section was doing the greatest work is now doing little or nothing, while the labor of the engine has been transferred to those cylinders which a moment before had been doing no work.

There are some advantages in this duplex construction, and some disadvantages. The crank shafts being set quartering, as is the usual construction, the engine may be run at low speed without getting on the center. Each half being complete in itself, it is possible to detach the one when only half the capacity is required. The power and resistance being equalized through opposite cylinders, large fly wheels are not necessary. Strange to say, the American practice seems to be to attach enormous fly wheels to duplex air compressors. It is difficult to justify this apparently useless expense in view of the facts shown in Fig. 7. A fly wheel does not furnish power, nor does it add to the economy of an engine except in so far as it enables it to cut off early in the stroke, and to equalize the power and resistance. In other words, a fly wheel is not a source of power, and in many cases it is only a means by which we accomplish rotative speed. It takes power to move matter, and assuming that other conditions are equal, every engine that carries a fly wheel that is larger than is necessary consumes a certain number of foot pounds in turning so much metal around through space. Were it possible to cut off at the same point and rotate as positively without a fly wheel, it would be done away with entirely. Some straight line air compressors are so constructed that the momentum of the piston and other moving parts is nearly sufficient to equalize the strains without a fly wheel; but the fly wheel is there because it insures a definite length of stroke, and because it enables us to operate eccentrics and to regulate the speed of the engine uniformly.

Objections to the duplex construction are: The strains are indirect, angular and intermittent. It is necessary therefore to largely increase the strength of parts; to add a crank shaft of large diameter with enormous bearings, and to build expensive and very secure foundations. Should the foundations settle at any point, excessive strains will be brought upon the bearings, resulting in friction and liability to breakage. A steam engine meets with a resistance on its crank shaft that is uniform throughout the stroke; while an air compressor is subject to a heavy maximum strain at the end of the stroke, hence the importance of direct straight line connection between power and resistance.

FIG. 8.

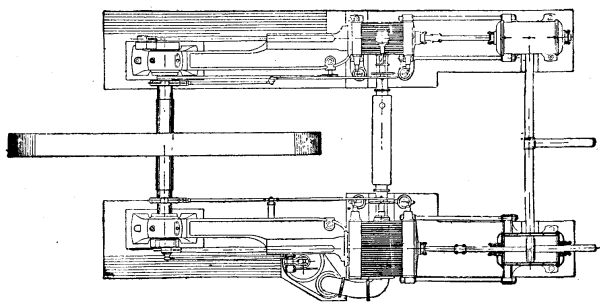

The friction loss on a duplex compressor seldom gets lower than 15 per cent., while straight line compressors show as low a loss as 5 per cent. Fig. 8 illustrates the Rand Duplex Air Compressor, a machine largely used in America, especially in the Lake Superior iron mines. Fig. 9 illustrates a Duplex Compound Condensing Corliss Air Compressor built by the Ingersoll-Sergeant Drill Company. This is a compressor made of the best type of Corliss engine, with air cylinders connected to the tail rods of the steam cylinders. One of these machines, of about 400 horse power capacity, is now at work furnishing compressed air power for the Brightwood Street Railway in Washington, D.C. Fig. 10 illustrates the Norwalk direct-acting straight line air compressor, with compound air cylinder. The chief purpose of compounding is to reduce the maximum strain. This construction also adds to isothermal economy. The large cylinder to the left determines the capacity of the compressor, the air being compressed first to a low pressure (ordinarily about 30 pounds per square inch), afterward passing through an intercooler, by which its temperature is reduced, and then it is compressed still higher, even to 5,000 pounds per square inch if desired. The terminal strain, which is so severe in air compressors, is here considerably reduced, as in this case it is only equal to the area of the initial air piston multiplied by its low air pressure.

FIG. 9.

Economical results are attained with this compressor at low cost of construction. The fly wheels are small, and the bearings narrow, because the maximum strain is less, and the momentum of the piston and other moving parts is such that most of the high initial steam power is taken up in starting these parts and is afterward given out at the end of the stroke, when the steam pressure is low. The strains are direct, and expensive foundations are not required. Fig. 11 illustrates the Ingersoll-Sergeant Compound Straight Line Air Compressor. This differs from the one just described chiefly in that it is single-acting, while the other is double-acting.

FIG. 10.

By single-acting is meant that the air cylinders compress their respective volumes of air once every revolution. The air is admitted to the large cylinder through the piston, is compressed to about 30 pounds, and on the return stroke the pressure is raised to almost any point required, and in proportion to the diameter of the smaller cylinder. Though single-acting, the capacity of one of these compressors is about equal to that of the double-acting machine of the same cost of construction. The initial air cylinder is made large enough to correspond with the capacity of the smaller double-acting cylinder. The strains are equalized because the area of the large cylinder multiplied by its low pressure is exactly equal to that of the small cylinder multiplied by its high pressure. The maximum strains are reduced considerably below those which exist in compressors that do not compound the air.

FIG. 11.

The advantage of the single-acting air cylinder over the double is that it compresses a volume of free air only once every revolution, hence there is a better chance to cool the air during compression. The cylinders have time to impart to the water jackets the heat produced by compression and are kept cooler. The large air head of the initial cylinder is jacketed, also adding to isothermal economy.

FIG. 12.

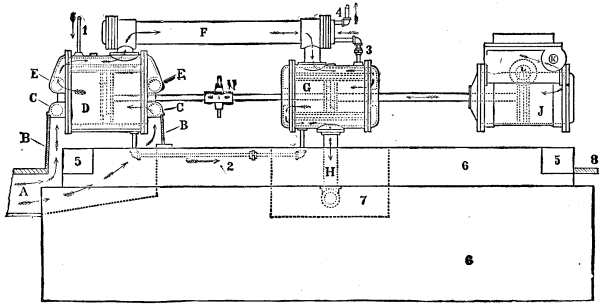

Fig. 12 illustrates the Ingersoll-Sergeant Piston Inlet Cold Air Compressor. This a straight line direct-acting engine, with steam and air pistons connected to a single rod through a crosshead which connects with two fly wheels. The strains are direct and the power and resistance are equalized by the inertia of the crosshead, piston, rods, and fly wheels. The Meyer's adjustable cut-off is used on the steam cylinder. The air cylinder is provided with a tail rod tube through which all the air is admitted into the cylinder.

FIG. 13.—AN AUTOMATIC AND ADJUSTABLE REGULATOR

AND UNLOADING DEVICE

APPLIED TO INGERSOLL-SERGEANT AIR COMPRESSORS.

Fig. 13 illustrates an unloading device and regulator applied to the Ingersoll-Sergeant compressor.

The purpose of this unloading device is to maintain a uniform air pressure in the receiver and a uniform speed of engine, notwithstanding the consumption of the air, and to do this without waste of power or attention on the part of the engineer. A weighted valve of safety valve pattern is attached to the air cylinder, and is connected with the air receiver, and with a discharge valve on each end of the air cylinder, also with a balanced throttle valve in the steam pipe. When the pressure of the air gets above the desired point in the receiver, the valve is lifted and the air is exhausted from behind the discharge valves, thus letting the compressed air at full receiver pressure into the cylinder at both ends, and balancing the engine. At the same instant the compressed air is exhausted from the little piston connected with the balanced steam valve and the steam is automatically throttled, so that only enough steam is admitted to keep the engine turning around, or to overcome the friction, no work being done.

FIG. 14.

When the compressor is unloaded, it is evident that the function of the air piston is merely to force the compressed air through the discharge valves and passages from one end to the other until more compressed air is required, this being indicated by a fall in the receiver pressure. The weighted valve now closes and the small connecting pipes are instantly filled with compressed air; the steam valve automatically opens, and the compression goes on in the regular way. Another function of this device is to prevent the compressor from stopping or getting on the center. Direct-acting compressors are liable to center when doing work at slow speed.

FIG. 15. PISTON INLET VALVE OPERATED BY THE NATURAL LAWS OF MOMENTUM.

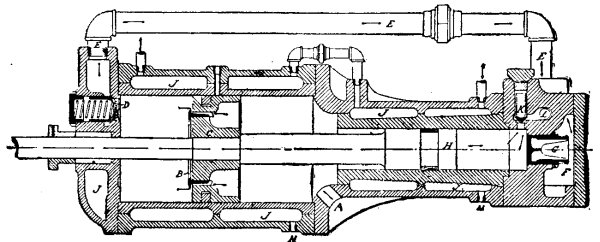

Fig. 15 illustrates the Ingersoll-Sergeant Air Cylinder and Piston.

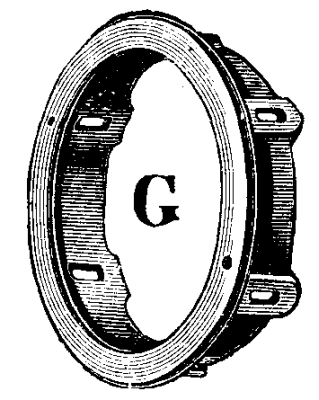

Fig. 16 shows the piston inlet valve, situated at G in Fig. 15. Two of these valves are placed in each piston of a double-acting air cylinder, the piston being hollow and the free air being admitted through a tail-rod pipe, letter E, Fig. 15. JJ are water jacket passages for cooling the air during compression. Owing to the absence of inlet valves, large water jackets are provided, not only around the cylinder itself, but through the heads. As the heat of compression is greater near the end of the stroke, the advantage of a cool head is manifest. H H are the discharge valves through which the compressed air is forced.

FIG. 16. PISTON INLET VALVE OPERATED BY THE NATURAL LAWS OF MOMENTUM.

The most interesting feature of this cylinder is the piston inlet valve. It is evident that this valve being attached to the piston needs no springs or other connections, but is opened and closed exactly at the right time by its natural inertia. With only about ¼ of an inch throw of valve a large area is opened, through which the free air is drawn. The valve is made of a single piece of composition metal and is practically indestructible. Its construction is such that it fills the clearance spaces to a greater extent than is usual in air compressors. A singular feature is that indicator cards taken on these cylinders show a free air line in some cases a little above the atmospheric line. Poppet valve compressors almost invariably show a slight vacuum, due to several causes, mainly the duty performed in compressing the springs of the valves, but the vacuum is also influenced by insufficiency of valve area, hot air cylinders, etc. This cylinder gives its full volume of air, and apparently a little more at times, because the air is admitted by a concentrated inlet in which free air is always moving in one direction. After it has been started, the speed of the compressor is such that the air attains a momentum due to its velocity and density; this serves a useful purpose in piling up the free air in the cylinder before the inlet valve closes on the return stroke.

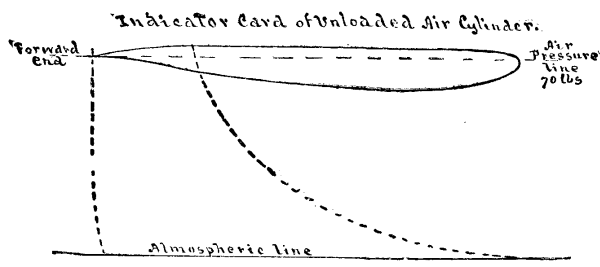

FIG. 17.—COMBINED STEAM AND AIR INDICATOR

CARD:

Taken from a 16x18 Sergeant piston inlet air compressor,

meyer's cut-off at 3/10. Steam at 58 lb.; air pressure,

77 lb.; total engine friction, 5 per cent.

Fig. 17 illustrates a combined steam and air indicator card taken from one of these cylinders. It will be observed that with steam and air cylinders equal in diameter and stroke, an air pressure of 77 pounds is reached with a steam pressure of only 58 pounds. The reason for this is plainly shown in the cards, their areas being nearly equal. What is made up in the air card by high pressure is represented in the steam card by greater volume. The indicated efficiency deduced from these cards is 95 per cent., that is, the area of the air card divided by the area of the steam card, representing the resistance divided by the power, results in 95 per cent. While several cards have been taken on the cylinders showing a loss by friction of only 5 per cent., yet on the average the best practice shows a loss of 6 per cent. or an efficiency of 94 per cent. This result indicates an almost perfect proportion between power and resistance, and good workmanship in air-compressing machinery. It is difficult to conceive an engine of this size being worked with a less expenditure for friction than 5 or 6 per cent. Were it possible to retain the heat which is in the air, and which is represented by the space between the dotted isothermal curve and the actual curve, we might attain high efficiency in using compressed air power, but it is evident that the power represented by the area of this space will be lost by radiation of heat before it is used in an engine situated several hundred feet away.

These indicator cards show at a glance that heat is responsible for the important air losses, and that so far as the design of the compressing engine is concerned, we have attained a point very near perfection. All the devices, past, present and future, on which inventors spend so much time, and in the development of which capitalists are innocently inveigled, aim to save this six per cent. loss! We hear a good deal about "Centrifugal Air Compressors," "Rotaries," "Plunger Pumps," etc., designs involving expensive complications without any heat advantage, and which seem to be based upon the "iridescent dream" of a large loss in the present method of compressing air. Here we have a simple engine, compact and complete in itself, capable of high speed without injury, constructed on the basis of our best steam engine practice, which produces compressed air power at a loss of only six per cent.

Clearance is not taken into consideration in the foregoing figures, but clearance is very much more of a bete noir in theory than in practice. The early designers, as shown in the "Dubois-Francois" illustrations, Figs. 3 and 4, regarded clearance loss as a very serious matter. Even at the present time some air compressor manufacturers admit water through the inlet valves into the air cylinder, not so much for the purpose of cooling as to fill up the clearance space. A long stroke involving expensive construction is usually justified by the claim that a large saving is effected by reduced clearance loss. Let us see what the effect of this clearance is. Assuming that we have an air compressor which shows an isothermal pressure line, there would be some loss of power due to clearance space, because we would have a certain volume of air upon which work was done and heat produced, that heat having been absorbed and the air being retained in the cylinder and not serving any useful purpose. But let us assume that we have a compressor which shows an adiabatic pressure line. We now have the air in the clearance space acting precisely as a spring, compressed at each stroke, retaining its heat of compression, and giving it out against the air piston at the point when the stroke is reversed. There is no loss of power in such a case as this, but, on the contrary, the air spring is useful in overcoming the inertia of the piston and moving parts. The best air compressors give a result about midway between the isothermal and the adiabatic, and the net loss of power directly due to clearance is so small as to be practically unworthy of consideration.

It must not be inferred from the preceding remarks that the designer of an air compressor may neglect the question of clearance. On the contrary, it is a very important consideration. If we assume a large clearance space in the end of an air cylinder of a compressor which is furnishing air at a high pressure, we may readily conceive that space to be so large, and that pressure so high, that the entire volume of the cylinder would be filled by the air from the clearance space alone, and the compressor would take in no free air and would, of course, produce no compressed air.

Loss in capacity of air compressors by clearance is in direct proportion to the pressure.

Owing to the loss of capacity by clearance space at high pressures, it is important that compound air cylinders should be used for furnishing air at high pressure. With compound air cylinders the air is compressed to alternate stages of pressure in the different cylinders, and the clearance loss is thus reduced because of the reduced density of the air in the clearance spaces. In ordinary practice air compressors deliver the air at less than 100 pounds pressure, so that with a properly designed air cylinder the clearance space is so small that the capacity of the compressor is not materially affected.

Two systems are in use by which the heat of compression is absorbed, and the difference between one and the other is so distinct that air compressors are usually divided into two classes (1) wet compressors, (2) dry compressors.

A wet compressor is that which introduces water directly into the air cylinder during compression.

A dry compressor is that which introduces no water into the air during compression.

Wet compressors may be subdivided into two classes.

(1) Those which inject water in the form of a spray into the cylinder during compression.

(2) Those which use a water piston for forcing the air into confinement.

The injection of water into the cylinder is usually known as the Colladon idea. Compressors built on this system have shown the highest isothermal results, that is, by means of a finely divided spray of cold water the heat of compression has been absorbed to a point where the compressed air has been discharged at a temperature nearly equal to that at which it was admitted to the cylinder. The advantages of water injection during compression are as follows:

(1) Low temperature of air during compression.

(2) Increased volume of air per stroke, due to filling of clearance spaces with water and to a cold air cylinder.

(3) Low temperature of air immediately after compression, thus condensing moisture in the air receiver.

(4) Low temperature of cylinder and valves, thus maintaining packing, etc.

(5) Economical results, due to compression of moist air (see table 3).

TABLE 3.—SHOWING THE RELATIVE QUANTITY OF WORK REQUIRED TO COMPRESS A GIVEN VOLUME AND WEIGHT OF AIR, BOTH DRY AND MOIST—ALSO RELATIVE VOLUMES WITH AND WITHOUT INCREASE OF TEMPERATURE FROM COMPRESSION.

_______________________________________________________________________________________ | | | |Compression at |Compression | |a Constant |with | |Temperature. |Increase of | |Mariotte's Law. |Temperature. | __|________________|__________________________________|________________________________ | | | | | | | | | | | | | | | 1|0.1 | | | | | | 20 | 68 |1.0 | | | 68 | | | 2|0.5 | 7199|1468|0.612| 7932|1618| 85.5|186 |1.222| 733|0.092|111 |3.0|23500|22500 3|0.333|11356|2316|0.459|13360|2725|130.4|267 |1.375|2004|0.150|135.5|4.0|37000|35000 4|0.25 |14260|2909|0.374|17737|3618|165.6|330 |1.495|3477|0.196|153.5|4.8|48500|45000 5|0.200|16580|3383|0.320|21209|4326|195.3|384 |1.595|4629|0.213|167 |5.4|58500|52500 6|0.167|18475|3768|0.281|24310|4959|220.5|429 |1.681|5835|0.240|179 |6.0|67000|60000 7|0.143|20038|4087|0.252|27048|5517|243.2|470 |1.758|7040|0.260|190 |6.4|75000|66000 8|0.125|21422|4370|0.229|29518|6021|263.6|506.5|1.828|8096|0.274| | | | 9|0.111| | |0.210| | |282 |539.6|1.891| | | | | | 10|0.100| | |0.195| | |299 |570.2|1.950| | | | | | _______________________________________________________________________________________ | | | | | | | | | | | | | | | 1| 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14| 15 | 16 __|_____|_____|____|_____|_____|____|_____|_____|_____|____|_____|_____|___|_____|_____

Column Heading 1 Tension in Atmospheres. 2 Volume. 3 Work of Compression. Cubic Meters in Kilogram-meters. 4 Work of Compression. Cubic Feet in Foot Pounds. 5 Volume. 6 Work of Compression. (Dry.) Cubic Meters in Kilogram-meters. 7 Work of Compression. (Dry.) Cubic Feet in Foot Pounds. Deduced from 6. 8 Temperatures. (Dry.) Cent. 9 Temperatures. (Dry.) Fah. 10 Ratio of Greater to Less Temperature. Absolute. 11 Loss of Work in Compressing one Cubic Meter in Kilogram-meters. By Increase of Temperature alone. 12 Percentage of Work of Compression Converted into Heat and Lost. By Increase of Temperature alone. 13 Final Temperature if Water is used in Compression. Fah. 14 Percentage of Water to Air Required. 15 Foot Pounds to Compress One Pound Air. Dry. 16 Foot Pounds to Compress One Pound Air. With sufficient Moisture.

The first advantage is by far the most important one, and is really the only excuse for water injection in air compressors. We have seen (table 3) that the percentage of work of compression which is converted into heat and loss when no cooling system is used is as follows:

Compressing to 2 atmospheres loss 9.2 per cent. " " 3 " " 15.0 " " " " 4 " " 19.6 " " " " 5 " " 21.3 " " " " 6 " " 24.0 " " " " 7 " " 26.0 " " " " 8 " " 27.4 " "

We see that in compressing air to five atmospheres, which is the usual practice, the heat loss is 21.3 per cent., so that if we keep down the temperature of the air during compression to the isothermal line, we save this loss. The best practice in America has brought this heat loss down to 3.6 per cent. (old Ingersoll Injection Air Compressor), while in Europe the heat loss has been reduced to 1.6 per cent. Steam-driven air compressors are usually run at a piston speed of about 350 feet per minute, or from 60-80 revolutions per minute of compressors of average sizes, say 18" diameter of cylinder. Sixty revolutions per minute is equal to 120 strokes, or two strokes per second. An air cylinder 18" in diameter filled with free air once every half second, and at each stroke compressing the air to 60 pounds, and thereby producing 309 degrees of heat, is thus, by means of water injection, cooled to an extent hardly possible with mere surface contact. The specific heat of water being about four times that of air, it readily takes up the heat of compression.

A properly designed spray system must not be confused with the numerous devices applied to air cylinders, by means of which water is introduced. In some cases the water is merely drawn in through the inlet valves. In others it passes through the center of the piston and rod, coming in contact with the interior walls of the air cylinder between the packing rings. Introducing water into the air cylinder in any other way, except in the form of a spray, has but little effect in cooling the air during compression. On the contrary, it is a most fallacious system, because it introduces all the disadvantages of water injection without its isothermal influence. Water, by mere surface contact with air, takes up but little heat, while the air, having a chance to increase its temperature, absorbs water through the affinity of air for moisture, and thus carries over a volume of saturated hot air into the receiver and pipes, which on cooling, as it always does in transit to the mine, deposits its moisture and gives trouble through water and freezing. It is, therefore, of much importance to bear in mind that unless water can be introduced during compression to such an extent as to keep down the temperature of the air in the cylinder, it had better not be introduced at all.

If too little water is introduced into an air cylinder during compression, the result is warm, moist air, and if too much water is used, it results in a surplus of power required to move a body of water which renders no useful service. The following table deduced from Zahner's formula gives the quantity of water which should be injected per cubic foot of air compressed in order to keep the temperature down to 104 degrees Fah.

_________________________________________________________________________

| | |

| |Weight of water |Weight of water

| |to be injected at |to be injected at

|Heat units devel-|68° Fah. to keep |68° Fah. to keep

Compression |oped in 1 lb. |the temperature at|the temperature at

by atmosphere |free air by |104° Fah. in lbs. |104° Fah. in lbs. of

above a volume.|compression. |of water and per |water for 1 cubic

| |lb. of free air. |foot of free air.

_______________|_________________|__________________|____________________

| | |

2 | 3.702 | 0.734 | 0.056

3 | 5.867 | 1.664 | 0.089

4 | 7.406 | 1.469 | 0.113

5 | 8.598 | 1.701 | 0.131

6 | 9.570 | 1.891 | 0.145

7 | 10.398 | 2.063 | 0.158

8 | 11.109 | 2.204 | 0.167

9 | 11.740 | 2.329 | 0.179

10 | 12.301 | 2.440 | 0.188

11 | 12.813 | 2.542 | 0.195

12 | 13.278 | 2.634 | 0.202

13 | 13.706 | 2.719 | 0.209

14 | 14.102 | 2.798 | 0.215

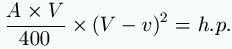

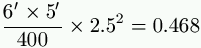

15 | 14.471 | 2.871 | 0.223