Title: Scientific American Supplement, No. 711, August 17, 1889

Author: Various

Release date: October 31, 2005 [eBook #16972]

Most recently updated: December 12, 2020

Language: English

Credits: Produced by Juliet Sutherland and the Online Distributed

Proofreading Team at www.pgdp.net

A novel and interesting series of operations was carried out at Gibraltar a few weeks ago, with a view to test the promptitude with which the garrison of the famous Rock could turn out to resist a sudden attack by a powerful iron-clad fleet. The supposed enemy was represented by the Channel Squadron, under the command of Vice-Admiral Baird, and consisting of H.M.S. Northumberland (flag ship), the Agincourt, Monarch, Iron Duke, and Curlew. The "general idea" of the operations was that a hostile fleet was known to be cruising in the vicinity, and that an attack on the Rock might be made. The squadron left Gibraltar and proceeded to the westward, returning to the eastward through the Straits under cover of the night.

The Governor of Gibraltar, General the Hon. Sir Arthur Hardinge, issued orders for the whole garrison to stand to their arms at dawn, and subsequent days, until the attack should be made; but by his express command no batteries were to be manned, or any troops moved from their alarm posts, until the signal was given that an attack was imminent. The alarm signal ordered was that of three guns fired in rapid succession from the Upper Signal Station on the summit of the Rock, to be followed, after a short pause, by two more shots. It was a matter of complete uncertainty as to the direction from which the attack would be made.

Every detail was carefully carried out, as if the impending attack was a real affair. The telegraphic communication between the various parts of the Rock was supplemented by signalers; arrangements were made for the ready supply of reserve ammunition for all arms; and the medical authorities established dressing stations, at numerous points of the Rock, to render "first aid" to those who might chance to be numbered among the "wounded." Day broke with a "Levanter," and the heavy clouds hanging about rendered any distant view a matter of difficulty. However, before it had become actually daylight the alarm guns gave notice that the enemy had been sighted. The troops turned out with great promptitude, being all at their assigned stations in less than a quarter of an hour, and were shortly ordered to various points commanding the east side of the Rock. As day broke, the hostile ships were to be discerned steaming in single line ahead, from the northeast, along the back of the Rock, and about 5,000 yards from it. The flag ship, followed by the Monarch and the Agincourt, proceeded toward Europa Point, while the Iron Duke and the Curlew stood close in to the eastern beach, so as to engage the northern defenses of the fortress. The first shot was fired by the flag ship, shortly before six o'clock in the morning, at the southern defenses. It was replied to, in less than three minutes, by the Europa batteries, and very shortly the engagement became general. The plan of tactics employed by the squadron was that of steaming rapidly up and down, and concentrating their fire in turn on the various shore batteries. Later on, the whole squadron assembled off Europa Point, and fired broadsides by electricity as they steamed past at speed. The spectacle at this moment was a very fine one, the roar of the heavy guns of the ships being supplemented by the sharp, rapid report of the quick-firing guns, which were supposed to be sending a storm of small shell among the defenders of the Rock. The incessant rattle of the ships' machine guns was also heard in the intervals between the thundering broadsides of heavy ordnance. All the ships were, of course, cleared for action, with topmasts and yards sent down, and it is needless to say they looked exceedingly workmanlike and formidable.

The various batteries on the Rock replied with great vivacity, and the general effect produced as gun after gun was brought to bear on the ships, and the white smoke wreathed itself round the many crags and precipices of the grim old Rock, was a sight long to be remembered. The exercise afforded to both branches of the service was undoubtedly most instructive. Our illustration is a sketch by Captain Willoughby Verner from one of the batteries above the Europa Flats, at which point the governor took up his position to watch the operations.—Illustrated London News.

Notwithstanding that the political situation of Europe seems to be less threatening among its leading powers, still the uncertainty prevalent among those who are generally considered the arbiters of public affairs has had its influence in contracting the limits of speculative adventure, thereby circumscribing the general course of trade throughout the Mediterranean.

In renewing to the department my reports upon the navigation and general commerce of Gibraltar, I beg to state that there has been a tolerably fair current business prevailing in American produce during the past quarter, consisting chiefly in flour, tobacco, and refined petroleum in cases, imported direct from New York.

The steady demand for American petroleum confirms the fact that Russian petroleum so far receives but little attention in this market from the regular traders and consumers, so long as supplies from the United States can be regularly imported at reasonable prices. It, however, remains an open question, in the event of lower prices ruling in the Russian petroleum regions, whether American supplies may not later on experience some greater competitive foreign interference.

According to the statistical data, steam vessels of all nationalities have continued to make Gibraltar their port of call, not only for orders, but also for replenishing their stock of fuel and provisions, and in larger numbers than ever before, the number in 1888 having reached 5,712 steam vessels, measuring in all 5,969,563 tons, while in 1887 the number was only 5,187 steam vessels, with an aggregate tonnage of 5,372,962. This increase cannot but result in considerable benefit to the coal and maritime traffic, which now forms the most important portion of the general commerce of Gibraltar, in spite of the keen competition it experiences from other British and foreign coaling ports.

Freights have also advanced in favor of steamship interests, which, with higher prices in England for coal, have also caused an advance in the price of coal at this port, to the benefit of the coal merchants and others interested in this important trade. At present the ruling price for steam coal is 24s. per ton, deliverable from alongside of coal hulks moored in the bay. As near as I have been able to ascertain, the quantity of coal sold in this market during the past year for supplying merchant steam vessels has amounted to about 508,000 tons, which is an increase of about 20,000 tons over the year 1887.

Notwithstanding that plans have already been submitted to the British government for the construction of a dry dock in Gibraltar, the matter remains somewhat in suspense, since it meets with some opposition on the part of the British government, which, in face of the European fever for general arming, seems more inclined to utilize in another form the expense which such a work would entail upon the imperial government, by replacing the obsolete ordnance recently removed from this fortress and substituting new defenses and guns of the most approved patterns, a matter which has evidently been receiving, for some time past, the special attention of the British military authorities, not doubting that the recent visit to the fortress of the Duke of Cambridge has had some connection with it. In fact, it is reported that the duke has already expressed the opinion that this fortress requires a larger number of artillerymen than are quartered here at present to man its batteries, and it would seem that this recommendation is likely to be carried out.

It is yet somewhat too early to venture an opinion regarding the growing crops of cereals in this Spanish neighborhood, but the agricultural and manufacturing interests in Spain have suffered so much in the past years that the general feeling in Spain continues to tend toward establishing increased restrictions against foreign competition in her home markets. There is every probability that the provinces of Malaga and Granada may shortly be granted the privilege of cultivating the tobacco plant under government supervision, as an essay. If properly managed, it may form an important and lucrative business for those interested in land and agricultural pursuits.

After many consecutive years of heavy outlays, difficulties, and constant disappointments, a new English company has recently succeeded in commencing the construction of a railway from the neighboring Spanish town of Algeciras to join, via Ronda, the railway station of Bobadilla, on the railroad line toward Malaga. It is presumed that when this railroad will be in running order it will greatly benefit this community, especially if the Spanish government should decide to establish custom houses at Algeciras and the Spanish lines outside the gates of this fortress, similar to those existing on the frontiers of France and Portugal.

That some idea may be formed of the constant important daily intercourse which exists between this fortress and Spain, I may state that late police statistics show that 1,887,617 passes were issued to visitors entering this fortress on daily permits during the year 1888, 1,608,004 entering by the land route and 279,613 by sea. I must, however, observe that the larger portion of these visitors consists of laborers, coal heavers, market people, and others engaged in general traffic.

A new industry in cork has lately sprung up, in which leading Spanish and native commercial firms in Gibraltar are directly interested to a considerable extent. Extensive warehouses for the storing of cork wood and machinery for the manufacture of bottle corks have recently been established at the Spanish lines, about a mile distant from this fortress, in Spanish territory, where large quantities of cork have already been stored. The cork is obtained and collected from the valuable trees, which are owned by the representatives of some of the oldest nobility of Spain, who have sold the products of their extensive woods to private individuals for periods reaching as far on as ten years, for which concession large cash advances have already been made. The woods commence at a distance of about twelve miles from Gibraltar, and are of considerable extent.

The railway now in course of construction passes through these woods, which may ere long offer quite picturesque scenery for travelers, especially when the cork trees are bearing acorns, which form the principal food for the fattening of large herds of swine during certain seasons of the year, in this way, also, contributing to the value of this tree, which, like the other kinds of oak trees, is of long and tardy growth. The tree from which the cork is obtained is somewhat abundant in the mountainous districts of Andalusia. It grows to a height of about 30 feet, and resembles the Quercus ilex, or evergreen oak, and attains to a great age. After arriving at a certain state of maturity it periodically sheds its bark, but this bark is found to be of better quality when artificially removed from the tree, which may be effected without injury to the tree itself. After the tree has attained twenty-five years it may be barked, and the operation is afterward repeated once in every seven years. The quality of the cork seems to improve with the increasing age of the tree, which is said to live over one hundred and fifty years. The bark is taken off during July and August.

Cork dust is also obtained from this cork wood, and is much used in the packing of grapes, which fruit is largely shipped from the eastern coast of Spain, especially from Almeria, during the vintage seasons, for the American and British markets.—Reports of U.S. Consuls.

The point or rock known as Gibraltar is a promontory two and one-half miles long and from a quarter to three-quarters of a mile wide. It rises abruptly from the sandy shore to a height at its highest point of 1,408 ft. It is composed of gray limestone, honeycombed with caves and subterranean passages, some of which contain most beautiful stalactites in the form of massive pillars.

Gibraltar is emphatically a fortress, and in some respects its fortifications are unique. On the eastern side the rock needs no defense beyond its own precipitous cliffs, and in all other directions it has been rendered practically impregnable. Besides a sea wall extending at intervals round the western base of the rock, and strengthened by curtains and bastions and three formidable forts, there are batteries in all available positions from the sea wall up to the summit, 1,350 feet above the sea, and a remarkable series of galleries has been hewn out of the solid face of the rock toward the north and northwest. These galleries have an aggregate length of between two and three miles, and their breadth is sufficient to let a carriage pass. Portholes are cut at intervals of twelve yards, so contrived that the gunners are safe from the shot of any possible assailants. At the end of one of the galleries hollowed out in a prominent part of the cliff is St. George's Hall, 50 feet long by 85 feet wide, in which the governor was accustomed to give fetes. Alterations, extensions, and improvements are continually taking place in the defensive system, and new guns of the most formidable sort are gradually displacing or supplementing the old fashioned ordnance.

The whole population of Gibraltar, whether civil or military, is subjected to certain stringent rules. For even a day's sojourn the alien must obtain a pass from the town major, and if he wish to remain longer, a consul or householder must become security for his good behavior. Licenses of residence are granted only for short periods—ten, fifteen, or twenty days—but they can be renewed if occasion require. Military officers may introduce a stranger for thirty days. A special permit is necessary if the visitor wishes to sketch.

Though the town of Gibraltar may be said to date from the fourteenth century, it has preserved very little architectural evidence of its antiquity. Rebuilt on an enlarged and improved plan after its almost complete destruction during the great siege, it is still, on the whole, a mean-looking town, with narrow streets and lanes and an incongruous mixture of houses after the English and the Spanish types. As a proprietor may at any moment be called upon to give up his house and ground at the demand of the military authorities, he is naturally deterred from spending his money on substantial or sumptuous erections. The area of the town is about one hundred acres.

Gibraltar was known to the Greek and Roman geographers as Calpe or Alybe, the two names being probably corruptions of the same local (perhaps Phenician) word. The eminence on the African coast near Ceuta, which bears the modern English name of Apes' Hill, was then designated Abyla; and Calpe and Abyla, at least according to an ancient and widely current interpretation, formed the renowned pillars of Hercules (Herculis columnæ), which for centuries were the limits of enterprise to the seafaring peoples of the Mediterranean world.

The strategic importance of the rock appears to have been first discovered by the Moors, who, when they crossed over from Africa in the eighth century, selected it as the site of a fortress. From their leader, Tarik Ibn Zeyad, it was called Gebel Tarik or Tarik's Hill; and, though the name had a competitor in Gebel af Futah, or Hill of the Entrance, it gradually gained acceptance, and still remains sufficiently recognizable in the corrupted form of the present day. The first siege of the rock was in 1309, when it was taken by Alonzo Perez de Guzman for Ferdinand IV. of Spain, who, in order to attract inhabitants to the spot, offered an asylum to swindlers, thieves, and murderers, and promised to levy no taxes on the import or export of goods. The attack of Ismail Ben Ferez, in 1315 (second siege), was frustrated; but in 1333 Vasco Paez de Meira, having allowed the fortifications and garrison to decay, was obliged to capitulate to Mahomet IV. (third siege). Alphonso's attempts to recover possession (fourth siege) were futile, though pertinacious and heroic, and he was obliged to content himself with a tribute for the rock from Abdul Melek of Granada; but after his successful attack on Algeciras in 1344 he was encouraged to try his fortune again at Gibraltar. In 1349 he invested the rock, but the siege (fifth siege) was brought to an untimely close by his death from the plague in February, 1350. The next or sixth siege resulted simply in the transference of the coveted position from the hands of the King of Morocco to those of Yussef III. of Granada; and the seventh, undertaken by the Spanish Count of Niebla, Enrico de Guzman, proved fatal to the besieger and his forces. In 1462, however, success attended the efforts of Alphonso de Arcos (eighth siege), and in August the rock passed once more under Christian sway. The Duke of Medina Sidonia, a powerful grandee who had assisted in its capture, was anxious to get possession of the fortress, and though Henry IV. at first managed to maintain the claims of the crown, the duke ultimately made good his ambition by force of arms (ninth siege), and in 1469 the king was constrained to declare his son and his heirs perpetual governors of Gibraltar. In 1479 Ferdinand and Isabella made the second duke Marquis of Gibraltar, and in 1492 the third duke, Don Juan, was reluctantly allowed to retain the fortress. At length, in 1501, Garcilaso de la Vega was ordered to take possession of the place in the king's name, and it was formally incorporated with the domains of the crown. After Ferdinand and Isabella were both dead the duke, Don Juan, tried in 1506 to recover possession, and added a tenth to the list of sieges. Thirty-four years afterward the garrison had to defend itself against a much more formidable attack (eleventh siege)—the pirates of Algiers having determined to recover the rock for Mahomet and themselves. The conflict was severe, but resulted in the repulse of the besiegers. After this the Spaniards made great efforts to strengthen the place, and they succeeded so well that throughout Europe Gibraltar was regarded as impregnable.

In the course of the war of the Spanish succession, however, it was taken by a combined English and Dutch fleet under Sir George Rooke, assisted by a body of troops under Prince George of Hesse-Darmstadt. The captors had ostensibly fought in the interests of Charles Archduke of Austria (afterward Charles III.), but, though his sovereignty over the rock was proclaimed on July 24, 1704, Sir George Rooke on his own responsibility caused the English flag to be hoisted, and took possession in name of Queen Anne. It is hardly to the honor of England that it was both unprincipled enough to sanction and ratify the occupation and ungrateful enough to leave unrewarded the general to whose unscrupulous patriotism the acquisition was due. The Spaniards keenly felt the injustice done to them, and the inhabitants of the town of Gibraltar in great numbers abandoned their homes rather than recognize the authority of the invaders. In October, 1704, the rock was invested by sea and land; but the Spanish ships were dispersed by Sir John Leake, and the Marquis of Villadarias fared so ill with his forces that he was replaced by Marshal Tesse, who was at length compelled to raise the siege in April, 1705. During the next twenty years there were endless negotiations for the peaceful surrender of the fortress, and in 1726 the Spaniards again appealed to arms. But the Conde de la Torres, who had the chief command, succeeded no better than his predecessors, and the defense of the garrison under General Clayton and the Earl of Portmore was so effectual that the armistice of June 23 practically put a close to the siege, though two years elapsed before the general pacification ensued. The most memorable siege of Gibraltar, indeed one of the most memorable of all sieges, was that which it sustained from the combined land and sea forces of France and Spain during the years 1779-1783. The grand attack on the place was made on the 13th September, 1782, and all the resources of power and science were exhausted by the assailants in the fruitless attempt. On the side of the sea they brought to bear against the fortress forty-six sail of the line and a countless fleet of gun and mortar boats. But their chief hope lay in the floating batteries planned by D'Arcon, an eminent French engineer, and built at the cost of half a million sterling. They were so constructed as to be impenetrable by the red hot shot which it was foreseen the garrison would employ; and such hopes were entertained of their efficiency that they were styled invincible. The Count D'Artois (afterward Charles X.) hastened from Paris to witness the capture of the place. He arrived in time to see the total destruction of the floating batteries and a considerable portion of the combined fleet by the English fire. Despite this disaster, however, the siege continued till brought to a close by the general pacification, February 2, 1783. The history of the four eventful years' siege is fully detailed in the work of Drinkwater, who himself took part in the defense, and in the life of its gallant defender Sir George Augustus Eliott, afterward Lord Heathfield, whose military skill and moral courage place him among the best soldiers and noblest men whom Europe produced during the 18th century.

Since 1783 the history of Gibraltar has been comparatively uneventful. In the beginning of 1801 there were rumors of a Spanish and French attack, but the Spanish ships were defeated off Algeciras in June by Admiral Saumarez. Improvements in the fortifications, maintenance of military discipline, and legislation in regard to trade and smuggling are the principal matters of recent interest.

Another addition was made to the Austrian navy by the launching on May 18 of the ram cruiser Franz Josef I. from the yards of S. Rocco in the Stabilimento Tecnico Triestino. Her dimensions are: Length (over all), 103.7 meters; length (between perpendiculars), 97.9 meters; greatest breadth (outside), 14.8 meters; draught (bow), 5.28 meters; draught (stern), 6.05 meters; displacement on the construction water line, 4,000 tons. The armament consists of two 24-centimeter and six 15-centimeter Krupp breech loaders of 35 caliber length, two 7-centimeter Uchatius guns as an armament for the boats and for landing purposes, eleven Hotchkiss quick-firing guns, and several torpedo-launching ports; indicated horse power with natural draught 6,400, speed 17.5 knots; with forced draught 9,800, speed 19 knots.

The ship is built of steel, and constructed according to the "double bottom" system along the engine, boiler, and ammunition rooms. The vaulted armor deck, extending 1.25 meters below the water line and protecting the most vital parts of the ship, is 0.057 meter thick. There are more than 100 water tight compartments below and above the deck. A protecting belt of "cellulose" is provided for the engines and boilers, extending from the armor deck downward.

The two main guns, placed on Krupp's hydraulic carriages, occupy positions in front and rear, and are protected by stands 0.09 meter thick and 1.60 meters high. They fire en barbette with a lateral range each of 260 degrees at bow and stern—i.e., 130 degrees on either of the broadsides. The weight of the barrel of the gun is 25 tons, that of the steel shell 215 kilogrammes (about 430 lb.), that of the brown powder charge 100 kilogrammes; initial velocity of projectile, 610 meters; penetration, 0.524 meter iron; longest range, 17 kilometers (about 10½ English miles); range at 15 deg. elevation, 10 kilometers. The six 15-centimeter guns are placed in a kind of machicouli arrangement in two tiers on each of the broadsides, so that always four guns can fire in the direction of the keel to the front and rear. The weight of the barrel of the gun is each six tons, that of the steel shells 51 kilogrammes, that of the charge 22 kilogrammes; initial velocity, 610 meters.

The 11 quick-firing guns are partly placed along the broadsides, partly in the masts, of which there are two. The triple expansion engines, having each a bronze screw of 4.42 meters diameter, with three blades and a rise of 6.3 meters, make with natural draught 105 revolutions, and with forced draught 120. The pumping apparatus are able to lift in one hour 400 tons of water. The front boiler room contains a special cylindrical boiler for the working of the electrical apparatus, for hydraulic pumps of the artillery service, for anchor windlasses, ventilators, fire engines, etc. The whole engines weigh 890 tons. The bunkers have a capacity for 660 tons of coal, which allows for a run of 4,500 sea miles.

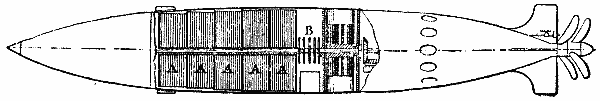

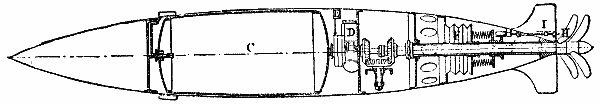

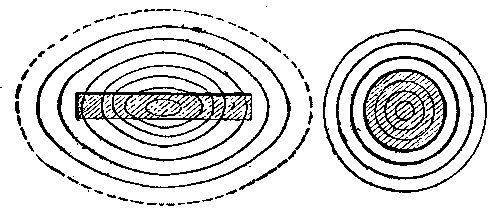

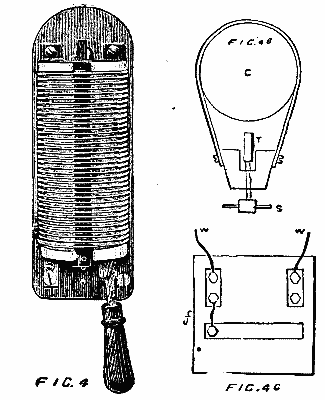

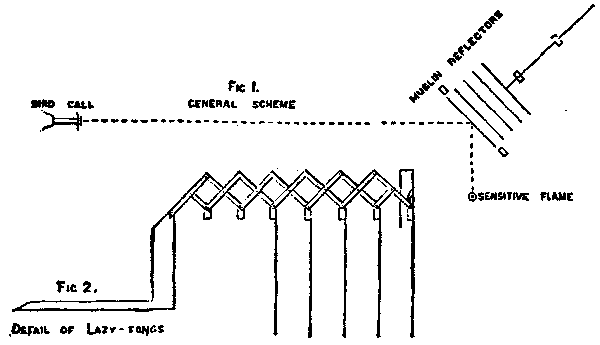

Figs. 1 and 2 represent, upon a scale of about 1/10, two types of torpedoes, the greatest number possible of the parts of which are made revolvable, so as to render the torpedoes as dirigible as the gyrating motion permits of.

Fig. 1 represents an electric torpedo actuated by accumulators, A A, keyed upon the shaft, and revolving along with the gearings. At the beginning of the running, the accumulators are not all coupled, but under the action of a clockwork movement which is set in motion at the moment of starting, metallic brushes descend one after another upon the collectors, B, and set in action new batteries for keeping constant or, if need be, accelerating the speed at the end of the travel.

Fig. 2 represents an air torpedo proposed by the same inventor. The air reservoir, C, revolves along with the gearings under the action of the pneumatic machine, D. The central shaft is hollow, so as to serve as a conduit. The admission of air into the slide valve of the machine is regulated by a clockwork which actuates a slide in an aperture whose form and dimensions are so calculated that the speed remains as constant as possible toward the end of the travel.

The trajectory of the two torpedoes is regulated by a cylindrical bellows, F, which gives entrance to the sea water. The springs shown in the figure balance the hydraulic pressure. The tension of these springs is regulated by the rod, H, according to the indications of the scale of depths, I.

When the torpedo reaches too great a depth, the action of the springs can no longer balance the increase of the hydraulic pressure, and the accumulation of the charge in the rear causes the front to rise toward the surface. When the torpedo reaches the surface, a contrary action is produced.—Revue Industrielle.

The accompanying engraving represents the remarkable steamboat that the unfortunate Marquis de Jouffroy constructed at Paris in 1816, after organizing a company for the carriage of passengers on the Seine. De Jouffroy, as well known, made the first experiment in steam navigation at Lyons in 1783, but the inventor's genius was not recognized, and he met with nothing but deception and hostility. With the obstinacy of men of conviction, he did not cease to prosecute his task. He assuredly had an inkling of the future in store for the invention that he was offering to humanity.

The paddle wheel boat that he constructed at Paris in 1816 did not succeed any better than its predecessors; it was remarkable nevertheless in appearance and structure.

The engine was forward, as shown in the engraving, which is copied from a composition of Dubucourt's.

The company organized by the marquis was ruined, and, as well known, the unfortunate inventor himself died in poverty in 1832, at the age of eighty-one years.—La Nature.

The American Institute of Electrical Engineers at its last meeting of the season, held June 25, again considered the subject of electrical traction, the paper presented by Mr. Leo Daft being based upon some recent electrical work on the elevated railroads and its bearing on the rapid transit problem. The Railroad Gazette gives the following abstract:

He introduced the subject with a tribute to the efficiency of the elevated railroad system as it is now operated by steam, with special reference to that section of it known as the Ninth Avenue line, upon which his experiments with the electric motor have been conducted, over which passengers are now conveyed a distance of five miles in 26 minutes for five cents, which he considered the best and cheapest municipal rapid transit in the world, and which is operated with a higher degree of safety than any other railroad in the world making an equal number of stops per 100 miles. On a recent holiday, April 30 last, 835,720 passengers were carried upon the entire system without noticeable detention or accident. The rapidly increasing traffic makes the demand for better facilities a pressing one, and as the average half million now carried daily will soon become a million, it appears doubtful if any method can be devised of providing for the growth by the use of steam motors on the present structures, which are now taxed to their utmost. To the mind of the mechanical engineer, having in view the ordinary coefficients of tractive ability, there is no remedy for this. The speaker stated that these coefficients were not entirely trustworthy. He reiterated his previously expressed opinion, based on frequent experiments, that there is a decided increase in traction gained by the passage of the electric current from the wheels to the rails, giving the details of one test where a motor with a load making a total of 600 lb. climbed a gradient of 2,900 ft. per mile, starting from a state of rest. He stated that some of those people who had ridiculed his statements had finally admitted that they were true.

The motor Ben Franklin, which had been used in making these tests on the elevated roads, weighed 10 tons, and performed service nearly equal to the steam motors weighing 18 tons. The object of these tests was the determination of coal economy. Tests with a Prony brake showed that the motor developed 128 H.P. The piece of track on which the experiments were conducted embraced 2,200 ft. of level track and 1-8/10 miles of gradients, varying from 11-3/10 to 98-7/10 ft. per mile, while at Thirtieth street the station is at the foot of the steepest grade, thus testing to the utmost the tractive capacity of the motor. The experiments were begun in October, 1888, and carried on between the hours of 9 P.M. and 4 A.M., beginning with one or two cars, the load being increased nightly until it was finally made up of eight coaches of 12 tons each, which were hauled up the 98 ft. grade at a speed of 7½ miles per hour, the entire distance being covered at the rate of 14-6/10 miles per hour. The maximum speed obtained on level with that train was 16.36 miles per hour. Seventy trips were subsequently made with a 70 ton train operated between the steam trains under 3 minutes headway, but the work was considered too critical on account of the absence of suitable brakes. A number of experiments made about this time showed that the mean speed with a three-car train running express on the up-town track was about 24 miles per hour, although the ability of the motor on a level with a similar train was nearly 28 miles per hour. This, however, was not the maximum speed, as the level track was not long enough to permit of its attaining the highest rate. It was the opinion of the speaker, however, that the speed attained could not be exceeded with prudence on the elevated structure.

The measurements of speed were made by dividing the track into 19 sections of 500 ft., each section being provided with a circuit-closing plate connected with a chronograph which was carefully tested. The indicator cards were taken at the central station by Mr. Idell and his assistants, and the dynamometer used was of the liquid type made by Mr. Shaw, of Philadelphia. The diagrams prepared from the data obtained were then explained by the speaker, who stated that there was not a marked difference between the 10 ton motor and the 18 ton locomotive in the initial effort on the level, as will be seen by comparing a run observed by a railroad officer on March 9 with a steam motor and a load of about 57½ tons. The steam motor required 1 min. and 29 sec. to make the distance from 14th to 23d streets, while the electric motor with a train of 70 tons made the same trip in 1 min. and 50 sec.; the absence of power brakes compelled the current to be taken off at 19th street, while it was probable that the throttle of the steam locomotive was not closed until it reached 23d street, this being the usual practice. The data obtained in these experiments shows that 29,940 h.p. is required to operate the Ninth avenue railroad for the 16 hours' service, or an average of 1,871 h.p. per hour, or 2,181 h.p., adding station friction. The varying requirements of the traffic during the day shows that the service could be advantageously divided up between four stationary engines of 800 h.p. each, there being but five hours of the day when all of them would be required. The fuel consumption per day, allowing 22 lb. of coal per h.p. per hour at $2.25 per ton, would make a total of $92.25 per diem for fuel, the coal being a mixture deliverable at the dock for about $1.80 per ton. The weight of coal used for the present locomotives is about the same, viz., 40 tons per day, but practice has shown it to be most economical to use coal of the best quality, costing $5 per ton, making the cost of fuel about double that required for the electric system. Without entering into other economies which the speaker claimed were in favor of electricity, and ignoring the plan suggested by Sir William Siemens of braking the train by converting the motor into a dynamo and thus utilizing the energy of momentum, he believed that the economy in fuel alone was sufficient to prove that the application of power by electricity was preferable to direct steam propulsion for the elevated railroad service.

There is perhaps no subject which at the present time can have a greater interest to the physicist, the electrician, and the electrical engineer than the one which heads this paper. The advances which have been made in the study from its purely theoretical or scientific side, and the great technical progress in the utilization of the known facts and principles concerning magnetic inductions, can but deepen and strengthen that interest.

On the side of pure theory we find the eager collection of experimental data to be submitted to the scrutiny of the ablest and brightest minds, to be examined and reasoned upon with the hope of finding some clew to satisfying explanations, and on the side of practice we find the search for new facts and relations no less diligent, though often stimulated by practical problems presented for solution. Indeed, the urgency for results is often the greater on the practical side, for theory can wait, practice cannot, at least in the United States.

We must look for continued triumphs in both directions, and the most welcome of all will be the framing of a theory or explanation which will enable us to interpret magnetic and electric phenomena. The recent beautiful experiments of Hertz on magnetic waves have opened a fertile region for investigation.

It would seem that the study of magnetism and electricity will give us the ability to investigate the ether of space, which medium has been theorized upon at great length, with the result of leaving it very much where it was before, a mysterious necessity.

Faraday says, speaking of magnetism:

"Such an action may be a function of the ether, for it is not at all unlikely that if there be an ether it should have other uses than simply the conveyance of radiations." 3,075. Vol. III., Exp. Res.

"It may be a vibration of the hypothetical ether, or a state of tension of that ether equivalent to either a dynamic or a static condition," etc. 3,263. Vol. III., Exp. Res.

Faraday again says, speaking of the magnetic power of a vacuum:

Modern views would seem to point that through a study of magnetic phenomena we may take a feeble hold upon the universal ether. Magnetism is an action or condition of that medium, and it may be that electrical actions are the expression of molecular disturbances brought about by ether strains or interferences. The close relations which are shown to exist between magnetism and light tend to strengthen such views. Indeed, it would not be too much to expect that if the mechanics of the ether are ever worked out, we should find the relation between sensible heat and electric currents to be as close as that of light to magnetism, perhaps find ultimately the forms of matter, the elements and compounds to be the more complex manifestations of the universal medium—aggregations in stable equilibrium. It is a difficult conception, I confess, and a most shadowy and imperfect one, yet facts and inferences which favor such views are not wanting.

Our science of electricity seems almost to be in the same condition that chemistry was before the work of Lavoisier had shed its light on chemical theory. Our store of facts is daily increasing, and apparently disconnected phenomena are being brought into harmonious relation. Perhaps the edifice of complete theory will not be more than begun in our time, perhaps the building process will be a very gradual one, but I cannot refrain from the conviction that the intelligence of man will, if it has time, continue its advance until such a structure exists.

I have been led to make these general allusions to electrical theory in order to emphasize the fact that in the present paper no unraveling of the mystery is to be attempted, but rather the presentation of some few considerations upon a subject of absorbing interest.

The conception of Faraday in regard to the existence of lines of magnetic force representing directions of magnetic strain or tension in a medium has not only lost nothing of its usefulness up to the present time, but has continually been of great service in the understanding of magnetic phenomena. We need spend no time in showing, as Faraday and others have done, that these lines are always closed circuits, polarized so that the direction of the lines cannot be reversed without reversal of the actions. Nor need we take time to show that in any medium the lines are mutually repellent laterally if of the same direction of polarization. Opposing this tendency to separation or lateral diffusion of magnetic force is the strong apparent tendency of the lines to shorten themselves in any medium. These actions are distributed by the presentation of a better medium, as iron instead of space or air. Lines of force will move into the better medium, having apparently the constant tendency to diminish the resistance in their paths.

The peculiar and mysterious nature of media, such as iron, is to permit an extraordinary crowding of lines on account of slight resistance to their passage through it. We need not, in addition, do more than refer to the other well-known facts of an electric current developing magnetic lines encircling the conductor, as being the general type, which includes all forms of magnetic field or electro-magnets, sustained by currents, and the fact of a development when magnetic lines or circuits and material masses are in relative movement of electromotive forces transversely to the direction of the lines of magnetism, and also transversely to the direction of relative movement, as in the case of electric conductors traversing or cutting through a field, or of a field traversing or being moved across a conductor. We must not forget that even insulators, as well as conductors, cutting lines of force, have the electromotive force developed in them. The action simply develops potential difference, and this generates the current where a circuit exists. While we are in the habit of saying that a conductor moved across a field of lines, or vice versa, generates electric current, I think the statement incomplete. The movement only sets up a potential difference, and the power expended in effecting the movement generates C × E. The current is energy less the potential, or the energy expended gives the two effects of potential or pressure and current or rate of movement. Consequently an insulator, or an open-circuited conductor, traversing a field, consumes no energy, potential difference only being produced. Nevertheless, as will be shown, the magnetic circuits or lines themselves may furnish the energy for their own movement across a conductor, and so develop current as well as potential.

This occurs in the effort of lines to shorten their paths, to lessen their density, to pass to better media. Indeed, a close examination will show that wherever power is expended in developing current in a circuit, cutting lines of force, the energy expended is first employed in stretching the lines, which thus receive the energy required to permit them, in shortening, to cut the conductor and set up currents in the electric circuit in accordance with the potential difference developed in that circuit and its resistance.

I think we may also say, though I do not remember to have seen the statement so put, that whenever electric potential is set up inductively, as in self-induction, mutual induction, induction from one circuit to another, and induction from magnets or magnetic field, it is set up by the movement of lines of force laterally across the body, mass or conductor in which the potential is developed, and that whenever current is set up in a wire or an existing current prolonged, or an existing current checked by induction, self-induction, or induction from magnets, the action is a transfer of energy, represented by strained lines of force shortening or lessening their resistance, or lengthening and increasing the resistance in their paths. The magnetic field is like an elastic spring—it can in one condition represent stored energy—it can be strained and will store energy—it can be made to relieve its strain and impart energy.

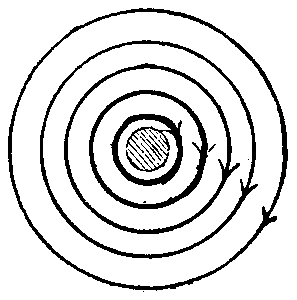

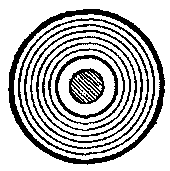

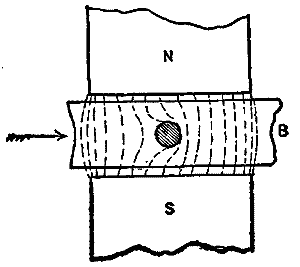

Fig. 1.

Fig. 1.

Let us examine some known phenomena in this light. Take the case of a simple wire, conveying current, say, in a line away from observer, Fig. 1. There exists a free field of circular magnetism (so called), shading off away from the wire, and which is represented by concentric circles of increased diameter. The superior intensity or strength of the lines near the wire may also be represented by their thickness. This is often shown also by crowding the lines near the wire, though I am disposed to regard Fig. 1 as more nearly expressing the condition, unless we are to regard the lines as simply indicating a sort of atmosphere of magnetic effect whose density becomes less as we proceed outward from the wire, in which case either form of symbol suffices. The direction of polarization of the lines may be indicated by an arrow head pointing in a direction of right-handed rotation in the path of the lines. This is the typical figure or expression for all forms of simple magnetic circuit—the form of the lines, their length, position, density, will depend on the shape of the conductor or conductors (when more than one) and the materials surrounding or in proximity to the wire or wires.

If the current traversing the conductor is constant, the magnetic field around it is stable and static, unless other influences come in to modify it. The cutting off of the current is followed by instability of the field whereby it can and must produce dynamic effects. I say must because the field represents stored energy, and in disappearing must give out that energy. To throw light on this part of the subject is one of the objects of the present paper. Cutting off the current supply in the case assumed leaves the developed magnetic lines or strains unsupported. They at once shorten their paths or circuits, collapsing upon the conductor as it were, and continuing this action, cut the section of the conductor, and apparently disappear in magnetic closed circuits of infinitesimal diameter but of great strength of polarization. It appears to me that we must either be prepared to give up the idea of lines of force or take the position that the magnetic circuits precipitate themselves in shortening their circuits and disappearing upon and cut the conductor. It was Hughes who put forward the idea that an iron bar in losing its apparent magnetism really short-circuits the lines in itself as innumerable strongly magnetized closed circuits among the molecules. In becoming magnetic once more these short circuits are opened or extended into the air by some source of energy applied to strain the lines, such as a current in a conductor around the bar.

May not this idea be extended, then, to include the magnetic medium, the ether itself? Does it contain intensely polarized closed circuits of magnetism which are ready to be stretched or extended under certain conditions by the application of energy, which energy is returned by the collapse of the extended circuits? This is doubtless but a crude expression of the real condition of things, for the lines are only symbols for a condition of strain in a medium which cannot be represented in thought, as we know nothing of its real nature. There is one point in this connection which I must emphasize. The strained lines, Fig. 1, are indications of stored energy in the ether, and the lines cannot disappear without giving out that energy. Ordinarily, it makes its appearance as the extra current, and adds itself so as to prolong the current which extended the lines when an attempt is made to cut off such current. Were it conceivable that the current could be cut off and the wire put on open circuit while the lines still remained open or strained, the energy must still escape when the field disappears. It would then produce such a high potential as to be able to discharge from the ends of the conductor, and if the conductor were of some section, part of the energy would be expended in setting up local currents in it. The field could not disappear without an outlet for the energy it represents. But we cannot cut off a current in a wire so as to leave the wire on open circuit with the lines of the magnetic circuit remaining around it without iron or steel or the like in the magnetic circuit. We can approach that condition, however, by breaking the circuit very quickly with a condenser of limited capacity around the break. This is done in the Ruhmkorff coil primary; the condenser forms a sort of blind alley for the extra current on its beginning to flow out of the primary coil. But the condenser charges and backs up and stops the discharge from the primary, even giving a reverse current. The lines of magnetic force collapse, however, and have their effect in the enormous potential set up in the secondary coil.

Take away the secondary coil so as to stop that outlet, the energy expends itself on the iron core and the primary coil. Take away the iron core, and the energy of magnetization of the air or ether core expends itself on the wire of the primary and, possibly, also on the dielectric of the condenser to some extent. The extra current becomes in this instance an oscillatory discharge of very high period back and forth through the primary coil from the condenser, until the energy is lost in the heat of C2 × R. This conversion is doubtless rendered all the more rapid by uneven distribution of current and eddy current set up in the wire of the coil.

The considerations just given concern the loss of field or the shortening and apparent disappearance of the magnetic lines or circuits, as giving rise to the self-induction or increased potential on breaking. Where the energizing current is slowly cut off or diminished the energy is gradually transferred to the wire in producing elevation of potential during the decrease; and the collapse and cutting of the wire by the collapsing circuits or lines is then only more gradual.

Let the current be returned to the wire after disappearance of magnetism, and the lines again seem to emanate from the wire and at the same time cut it and produce a counter potential in it, which is the index of the abstraction of energy from the circuit, and its storing up in the form of elastically strained lines of magnetism around the conductor. The effect is that of self-induction on making or upon increase of current, the measure of the amount being the energy stored in the magnetic circuits which have been extended or opened up by the current. The greater the current and the shorter the path for the lines developed around the axis of the conductor, the greater the energy stored up. Hence, a circular section conductor has the highest self-induction, a tube of same section less as its diameter increases, a flat strip has less as its width increases and thickness diminishes, a divided conductor much less than a single conductor of same shape and section. Separating the strands of a divided conductor increases the length of magnetic paths around it, and so diminishes the self-induction. A striking instance of this latter fact was developed in conveying very heavy alternating currents of a very low potential a distance of about three feet by copper conductors, the current being used in electric welding operations.

The conductors were built up of flat thin strips of copper for flexibility. When the strips were allowed to lie closely together, the short conductor showed an enormous self-induction, which cut down the effective potential at its ends near the work. By spreading apart the strips so as to lengthen a line around the conductor, the self-induction could be easily made less than 35 per cent. of what it had been before. The interweaving of the outgoing and return conductor strands as one compound conductor gets rid almost entirely of the self-inductive effects, because neither conductor has any free space in which to develop strong magnetic forces, but is opposed in effect everywhere by the opposite current in its neighbor.

Where a number of conductors are parallel, and have the same direction of current, as in a coil or in a strand, it is evident that statically the conductor may be considered as replaceable by a single conductor with the same external dimensions and same total current in the area occupied, the magnetic forces or lines surrounding them being of same intensity. But with changing current strength the distribution of current in the conductor has also a powerful effect on the energy absorbed or given out in accordance with the magnetism produced. Hence the self-induction of a strand, coil or conductor of the same section varies with the rapidity of current changes, owing to the conduction being uneven.

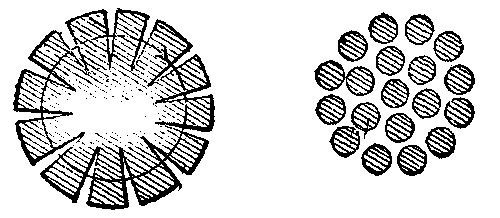

The uneven distribution of current, or its tendency to flow on the outer parts of a conductor when the rate of variation or alternation is made great, is in itself a consequence of the fact that less energy is transferred into magnetism in this case than when the current flows uniformly over the section, or is concentrated at the center. In other words, when a uniform current traverses a conductor of the same section, the circular magnetism, or surrounding magnetic lines, are to be found not only outside the conductor, but also beneath its exterior. Since in forming these lines on passage of current the middle of section would be surrounded by more lines than any other part of the conductor, the current tends to keep out of that part and move nearer the exterior in greater amount. Hence, in rapidly alternating currents the conductor section is practically lessened, being restricted largely to the outer metal of the conductor. If the round conductor, Fig. 2, were made of iron, the magnetism interior to it and set up by a current in it would be very much greater, the section of the conductor being filled with magnetic circuits or lines around the center. The total magnetism, external and internal, would be much greater in this case for a given current flow, and the energy absorbed and given out in formation and loss of field or the self-induction would be much increased. This could, however, be greatly diminished by slitting the conductor radially or making it of a number of separate wires out of lateral magnetic contact one with the other, Fig. 3. In these cases the resistance of the interior magnetic circuits would be increased, as there would be several breaks in the continuity around the center of the conductor. The total magnetism which could be set up by a current would be lessened, and the self-induction, therefore, lessened.

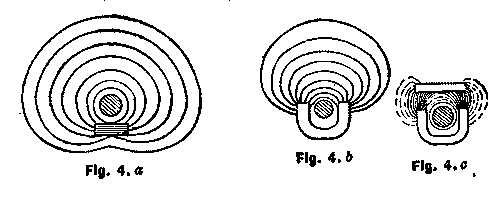

The moment we begin the bringing of iron into proximity with an electric conductor conveying current, we provide a better medium for the flow or development of magnetic lines or circuits. In other words, the lines may then be longer, yet equally intense, or more lines may be crowded into a section of this metal than in air or space. Figs. 4a, 4b, 4c show the effect brought about by bringing iron of different forms near to the conductor.

It shows, in other words, the development of the ordinary electro-magnet of the horseshoe form, and the concentration of the lines in the better medium. The lines also tend to shorten and diminish the resistance to their passage, so that attraction of the iron to the conductor takes place, and if there is more than one piece of iron, they tend to string themselves around the conductor in magnetic contact with one another.

When copper bars of 1 inch diameter are traversed by currents of 40,000 to 60,000 amperes, as in welding them, the magnetic forces just referred to become so enormous that very heavy masses of iron brought up to the bar are firmly held, even though the current be of an alternating character, changing direction many times a second.

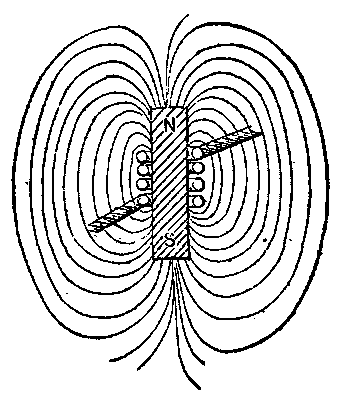

Fig. 5.

Fig. 5.

When a conductor is surrounded by a cast iron ring, as in Fig. 5, the current in such conductor has an excellent magnetic medium surrounding it. A large amount of energy is then abstracted on the first impulse of current, which goes to develop strong and dense magnetic lines through the iron ring and across the gap in it. On taking off the current the energy is returned as extra current, and its force is many times what would be found with air alone surrounding the conductor. We have then greatly increased the self-induction, the storing of energy and opposition to current flow at the beginning, the giving back of energy and assistance to the current flow on attempting to remove or stop the current. Let us now complete the ring, by making it of iron, endless, Fig. 6, with the conductor in the middle.

Fig. 6.

Fig. 6.

We now find that on passing current through the conductor it meets with a very strong opposing effect or counter potential. The evolution of magnetic lines, or the opening out of magnetic circuits, goes on at a very rapid rate. Each line or magnetic circuit evolved, and cutting the conductor, flies at once outward, and locates itself in the iron ring. This ring can carry innumerable lines, and they do not crowd one another. It permits the lines even to lengthen in reaching it, and yet, on account of its low resistance to their passage, the lengthening is equivalent to their having shortened in other media. We will suppose the current not sufficient to exhaust this peculiar capacity for lines which the iron has. Equilibrium is reached, the conductor has opened up innumerable closed circuits, and caused them to exist in the ring still closed; but in iron, not space or ether merely. The current passing has continued its action and storage of energy until to emit another line in view of the resistance now found in the crowded iron ring is impossible.

Now let us cut off the current. We are surprised to find a very weak extra current, a practical absence of self-induction on breaking, or, at least, a giving out of energy in nowise comparable to that on making. Let us put on the current as it was before. Another curious result. But little self-induction now on making energy not absorbed.

Now cut off the current again. Same effect as before. Now let us put on the current reversed in direction. At once we find a very strong counter potential or opposing self-induction developed.

The ring had been polarized, or retained its magnetic energy, and we are now taking out one set of lines and putting in reversely polarized lines of force. This done, we break the reversed current without much effect of self-induction. The ring remains polarized and inert until an opposite flow of current be sent through. Iron is then a different medium from the ether.

The ring once magnetized must, in losing its magnetism, permit a closure of the lines by shortening. This involves their passage from the iron across the space in the center of the ring, notwithstanding its great resistance to the lines of force. As passage from iron to air is equivalent to lengthening of the lines, it is readily seen that such lengthening may oppose more effect than a slight shortening due to leaving iron, for air or space may give in provoking a closure and disappearance of the lines. Looked at from another standpoint, the lines on the iron may actually require a small amount of initial energy to dislodge them therefrom, so that after being dislodged they may collapse and yield whatever energy they represent.

I must reserve for the future further consideration of the iron ring, but in thinking upon this matter I am led to think that the production of a magnetic line in an iron ring around a conductor may represent a sort of wave of energy, an absorption of energy on the evolution of the line from the conductor, and a slight giving out of energy on the line reaching that position of proximity to the iron ring, that its passage thereto may be said to be a shortening process or a lessening of its resistance.

The magnetism in air, gases, and non-magnetic bodies, being assumed to be that of the ether, this medium shows no such effects as those we get with the ring. It does not become permanently polarized, as does even soft iron under the condition of a closed ring. The iron possesses coercive force, or magnetic rigidity, and a steel ring would show more of it. The molecules of the iron or steel take a set. If we were to cut the soft iron ring, or separate it in any way, this introduction of resistance of air for ether in the magnetic circuit would cause the lines to collapse and set up a current in the conductor. The energy of the ring would have been restored to the latter. The curious thing is that physically the polarized ring does not present any different appearance or ordinary properties different from those of a plain ring, and will not deflect a compass needle. Its condition is discoverable, however, by the test of self-induction to currents of different direction. As a practical consideration, we may mention in this connection that a self-inductive coil for currents of one direction must be constructed differently from one to be used with alternating currents. The former must have in its magnetic circuit a section of air or the like, or be an imperfectly closed circuit, as it were. The latter should have as perfectly closed a magnetic circuit as can be made. We see here also the futility of constructing a Ruhmkorff core coil on the closed iron magnetic circuit plan, because the currents in the primary are interrupted, not reversed.

The considerations just put forward in relation to the closed iron ring, and its passive character under the condition of becoming polarized, are more important than at first appears. It has been found that the secondary current wave of a closed iron circuit induction coil or transformer, whose primary circuit receives alternating current, is lagged from its theoretical position of 90 degrees behind the primary wave an additional 90 degrees, so that the phases of the two currents are directly opposed; or the secondary current working lamps only in its circuit is one half a wave length behind a primary, instead of a quarter wave length, as might have been expected.

But when it is understood that the iron core polarized in one direction by the primary impulse does not begin to lose its magnetism when that impulse simply weakens, but waits until an actual reversal of current has taken place, it will be seen that the secondary current, which can only be produced when magnetic lines are leaving the core and cutting the secondary coil, or when the lines are being evolved and passing into the core from the primary coil, will have a beginning at the moment the primary reverses, will continue during the flow of that impulse, and will end at substantially the same time with the primary impulse, provided the work of the secondary current is not expended in overcoming self-induction, which would introduce a further lag. Moreover, the direction of the secondary current will be opposite to that of the primary, because the magnetic circuits which are opened up by the primary current in magnetizing the core, or which are closed or collapsed by it in demagnetizing the core, will always cut the secondary coil in the direction proper for this result. Transformers of the straight core type with very soft iron in the cores and not too high rates of alternation should approximate more nearly the theoretical relation of primary and secondary waves, because the magnetic changes in the core are capable of taking place almost simultaneously with the changes of strength of the primary current. This fact also has other important practical and theoretical bearings.

Fig. 7.

Fig. 7.

Let us assume a plain iron core, Fig. 7, magnetized as indicated, so that its poles, N, S, complete their magnetic circuits by what is called free field or lines in space around it. Let a coil of wire be wound thereon as indicated. Now assume that the magnetism is to be lost or cease, either suddenly or slowly. An electric potential will be set up in the coil, and if it has a circuit, work or energy will be produced or given out in that circuit, and in any other inductively related to it. Hence the magnetic field represents work or potential energy. But to develop potential in the wire the lines must cut the wire. This they can do by collapsing or closing on themselves. The bar seems, therefore, to lose its magnetism by gaining it all, and in doing so all the external lines of force moving inward cut the wire. The magnetic circuits shorten and short-circuit themselves in the bar, perhaps as innumerable molecular magnetic circuits interior to the iron medium. To remagnetize the bar we may pass an electric current through the coil. The small closed circuits are again distended, the free field appears, and the lines moving outward cut across the wire coil opposite to the former direction and produce a counter potential in the wire, and consequent absorption of the energy represented in the free field produced. As before studied, the magnetism cannot disappear without giving out the energy it represents, even though the wire coil be on open circuit, and therefore unable to discharge that energy. The coil open-circuited is static, not dynamic. In such assumed case the lines in closing cut the core and heat it. Let us, however, laminate the core or subdivide it as far as possible, and we appear to have cut off this escape for the energy. This is not really so, however. We have simply increased the possible rate of speed of closure, or movement of the lines, and so have increased for the divided core the intensity of the actions of magnetic friction and local currents in the core, the latter still receiving the energy of the magnetic circuit. This reasoning is based on the possibility in this case of cutting off the current in the magnetizing coil and retaining the magnetic field. This is of itself probably impossible with soft iron. That the core receives the energy when the coil cannot is shown in the well known fact that in some dynamos with armatures of bobbins on iron cores, the running of the armature coils on open circuit gives rise to dangerous heating of the cores, and that under normal work the heating is less. In the former case the core accumulates the energy represented in the magnetic changes. In the latter the external circuit of the machine and its wire coils take the larger part of the energy which is expended in doing the work in the circuit. In this case, also, the current in the coils causes a retardation of the speed of change and extent of change of magnetism in the iron cores, which keeps down the intensity of the magnetic reaction. In fact, this retardation or lag and reduction of range of magnetic change may in some machines be made so great by closing the circuit of the armature coils themselves or short-circuiting them that the total heat developed in the cores is much less than under normal load.

I wish now, in closing, to refer briefly to phenomena of moving lines of force, and to the effects of speed of movement. In order to generate a given potential in a length of conductor we have choice of certain conditions. We can vary the strength of field and we can vary the velocity. We can use a strong field and slow movement of conductor, or we can use a weak field and rapid movement of the conductor. But we find also that where the conductor has large section it is liable to heat from eddy currents caused by one part of its section being in a stronger field than another at the same time. One part cuts the lines where they are dense and the other where they are not dense, with the result of difference of potential and local currents which waste energy in heat. We cannot make the conductor move in a field of uniform density, because it must pass into and out of the field. The conditions just stated are present in dynamos for heavy current work, where the speed of cutting of lines is low and the armature conductor large in section.

But we find that in a transformer secondary we can use very large section of conductor, even (as in welding machines) 12 to 15 square inches solid copper, without meeting appreciable difficulty from eddy currents in it. The magnetic lines certainly cut the heavy conductor and generate the heavy current and potential needed. What difference, if any, exists? In the transformer the currents are generated by magnetic field of very low density, in which the lines are moving across the conductor with extreme rapidity. The velocity of emanation of lines around the primary coil is probably near that of light, and each line passes across the section secondary conductor in a practically inappreciable time. There is no cause then for differences of potential at different parts of the section heavy secondary. Then to avoid eddy currents in large conductors and generate useful currents in them, we may cause the conductor to be either moved into and out of a low density field with very great speed, or better, we must cause the lines of a very low or diffused field to traverse or cut across the conductor with very high velocity.

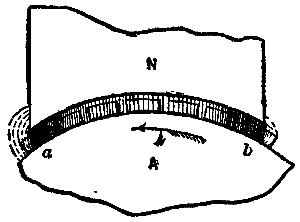

Fig. 8.

Fig. 8.

It is a known fact that, in dynamos with large section armature conductors, there are less eddy currents produced in the conductors when they are provided with iron cores or wound upon iron cores than when the conductors are made into flat bobbins moved in front of field poles. Projections existing on the armature between which the conductors are placed have a like effect, and enable us to employ heavy bars or bundles of wire without much difficulty from local currents. The reason is simple. In the armatures with coils without iron in them, or without projections extending between the turns, the conductor moves into and out of a very dense field at comparatively low velocity, so that any differences of potential developed in the parts of the section of conductor have full effect and abundant time to act in setting up harmful local currents. In the cases in which iron projects through the coil or conductor, the real action is that the lines of the magnetic circuits move at high speeds across the conductor, and the conductor is at all times in a field of very low density. Figs. 8 and 9 will make this plain. In Fig. 8 we have shown a smooth armature surface, having a heavy conductor laid thereon, and which is at a just entering a dense field at the edge of the pole, N, and at b leaving such field. It will be seen that when in such position the conductor, if wide, is subjected to varying field strength, and moves at a low speed for the generation of the working potential as it passes through the field, thus giving rise to eddy currents in the conductor.

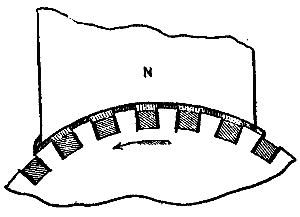

Fig. 9.

Fig. 9.

In Fig. 9 the conductors are set down between projections, in which case both armature and field poles are laminated or subdivided. As each projection leaves the edge of field pole, N, the lines which it had concentrated on and through it snap backward at an enormous speed, and cross the gap to the next succeeding projection on the armature, cutting the whole section of the heavy armature conductor at practically the same instant. This brisk transfer of lines goes on from each projection to the succeeding one in front of the field pole, leaving a very low density of field at any time between the projections. The best results would be obtained when the armature conductor does not project beyond or quite fill the depth of groove between the projections. Of course there are other remedies for the eddy current difficulty, notably the stranding and twisting of the conductor on the armatures so as to average the position of the parts of the compound conductor.

Fig. 10.

Fig. 10.

Perhaps the most extreme case of what may be called dilution of field by projections and by closed magnetic circuits in transformers would be that of a block of iron, B, Fig. 10, moved between poles, N and S, and having a hole through it, into and through which a conductor is carried. The path through the iron is so good that we can scarcely consider that any lines cross the hole from N to S; yet as B moves forward there is a continual snapping transfer of lines from the right forward side of the hole to the left or backward side, cutting the conductor as they fly across, and developing an electromotive force in it. I have described this action more in detail because we have in it whatever distinction in the manner of cutting the lines of the field is to be found between wire on smooth armatures and on projection armatures and modifications thereof; and also between flat, open coils passing through a field and bobbins with cores of iron. The considerations advanced also bring out the relation which exists between closed iron circuit transformers and closed iron circuit (projection) dynamos, as we may call them.

I had intended at the outset of this paper to deal to some extent with the propagation of lines of magnetism undergoing retardation in reference to alternating current motor devices, transformers with limited secondary current, or constant average current, an alternating motor working with what I may term a translation lag, etc.; but it was soon found that these matters must remain over for a continuation of this paper at some future time. My endeavor has been in the present paper to deal with the lines of force theory as though it were a symbol of the reality, but I confess that it is done with many misgivings that I may have carried it too far. Yet, if we are to use the idea at all it has seemed but right to apply it wherever it may throw any light on the subject or assist in our understanding of phenomena.

A paper read before the American Institute of Electrical Engineers, New York, May 22, 1889.

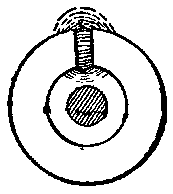

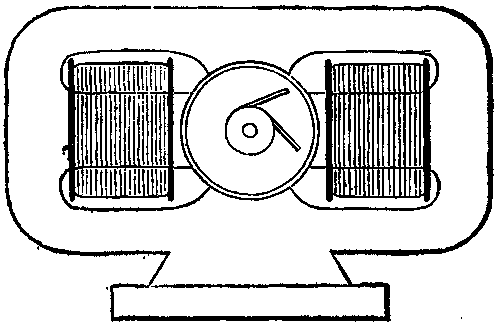

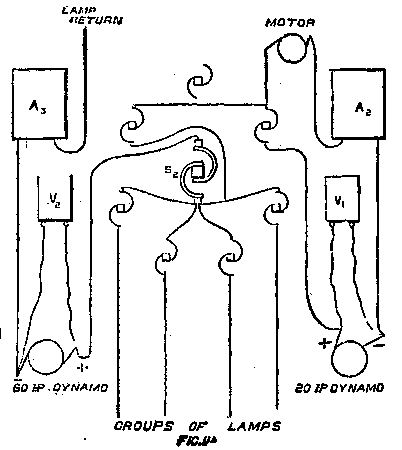

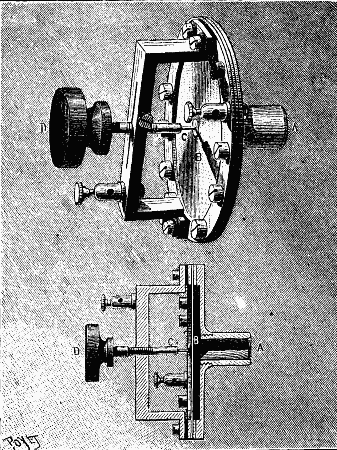

Immediately on entering the Machinery Hall by the galerie leading from the central dome, and occupying a prominent position at the commencement of the Swiss section, is a very important plant of dynamos, motors, and steam engines, put down by the Oerlikon Works, of Zurich. During the time the machinery is kept running in the hall, power is supplied electrically to drive the whole of the main shafting in the Swiss section and part of that in the Belgian section, amounting in all to some 200 ft., a large number of machines of various industries deriving their power from these lines of shafting, while during the evening a portion of the upper and lower galleries adjoining this section is lit by some twenty-five arc lamps run from this exhibit. Steam is supplied from the Roser boilers in the motive power court. The whole of the generating plant is illustrated in one view, and a separate view is given of the motor employed to drive the main shafting, this latter view showing the details of connection to the same. On the extreme right hand side of the first view is a direct coupled engine and dynamo of 20 horse power, a separate cut of which is given in Fig. 3. The engine is of the vertical single cylinder type, standing 5 ft. high, and fitted, as are the other two engines exhibited, with centrifugal governor gear on the fly wheel, acting directly on the throw of the cutoff valve eccentric. The two standards, supporting the cylinder and forming the guide bars, together with the entire field magnets and pole pieces of the dynamo, and the bed plate common to both, are cast in one piece.

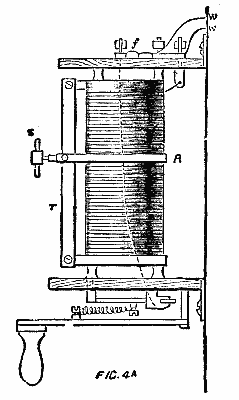

The machine is specially designed for ship lighting, and with the view of preventing any magnetic effect upon the ship's compass, the field is arranged so that the armature, pole pieces, and coils are entirely inclosed by iron. Any tendency to leakage of magnetic lines will therefore be within the machine, the iron acting as a shield. This build of field—shown in Fig. 3a—is also advantageous as a mechanical shield to the parts of the machine most likely to suffer from rough handling in transport, and it will be seen that the field coils are easily slipped on before the armature is mounted in its bearings.

FIG. 3A

FIG. 3A

The winding is compound, and in such a direction that the two opposite horizontal poles have the same polarity; it follows from this that there will be two consequent poles in the iron, these being opposite in name to the horizontal poles and at right angles to them, viz., above and below the armature. Opposite sections of the commutator are connected together internally as in most four-pole machines, so that only two brushes are necessary, at 90 deg. apart.

The section of iron in the field is 60 square inches and rectangular in form, and the whole machine measures 4 ft. 3 in. in length, and 2 ft. in height, without including the height of the bed plate. The armature is 17 in. in length and the same in diameter, measured over the winding, and develops at the machine terminals 70 volts and 200 amperes at 480 revolutions. The moving parts of the engine are well balanced, and run remarkably well and without noise at this high rate of speed.

This dynamo serves to develop power to run a motor in an adjoining inclosure, containing some fine specimens of lathes and machine tools constructed by the Oerlikon Works. These are driven by the motor through the medium of a countershaft, and the power and speed are controlled from the switch board seen at the left of the exhibit, and in Fig. 11. The resistance, R1, serves to vary the intensity of the shunt field of the dynamo, the volts being indicated by the voltmeter V1, and a resistance separate from the switch board is inserted in the main circuit of the two machines. The ammeter, A2, is directly connected to the dynamo, and therefore indicates the current, whatever circuit this machine is running.

A larger combined engine and dynamo, seen in the center of the stand, serves to run the lighting of the galleries. The engine is a 60 horse power compound, running at 350 revolutions, and fitted with a governor on the fly wheel, like that described above.

The dynamo is a two-pole machine, the upper pole and yoke being cast in one, and the lower pole, yoke, and combined bed plate forming a separate casting. The two vertical cores, over which the field bobbins are slipped, are of wrought iron, and are turned with a shoulder at either end, the yokes being recessed to fit them exactly. The cores are then bolted to the yokes vertically from the top and horizontally below. The field of this machine is shunt-wound, and in order to maintain the potential constant a hand-regulated resistance—R2 on the switch board—is added in circuit with the shunt field. The voltmeter, V2, immediately above this resistance, serves to indicate the difference of potential at the machine terminals. Both voltmeters are fitted with keys, so that they are only put in circuit when the readings are taken.

The main terminals of this machine are fitted on substantial insulating bases, fixed one at each end of the top yoke. These connect to the external circuit by a heavy cable—the machine being capable of developing 500 amperes—and to the shunt circuit, and regulating resistance by small wires; while the two connections to the brushes are by four covered wires in parallel on each side. This mode of connection is more flexible than a short length of heavy cable, and looks well, the wires being held neatly together by vulcanized fiber bridges. The dynamo is a low tension machine, the field being regulated to give 65 volts when running the lamp circuits.

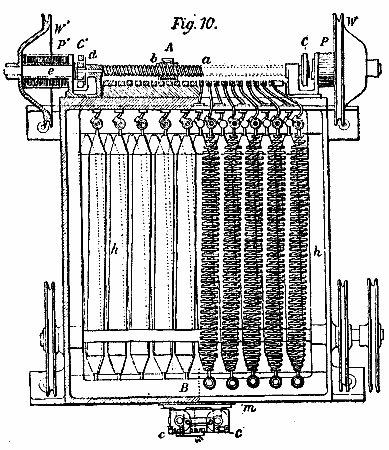

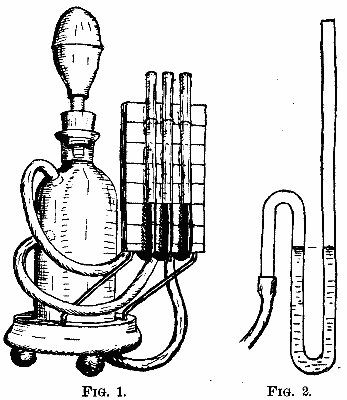

Fig. 10.

Fig. 10.

The illustration, Fig. 10, represents the automatic re-regulator—C.E.L. Brown's patent. Motion is imparted to the cores of two electro-magnets at the ends by the pulleys, W W1. The cores have a projection opposite to the spindle, a b, which latter is screw-threaded. By a relay one or other electro-magnet is put in action, and the rotating core, which is magnetized, causes rotation of the spindle by attraction, resulting in the movement of the contact along the resistance stops. The relay is acted upon directly by the potential of the dynamo, and the variable resistance is included in the shunt field of the machine, so that changes in the potential, resulting from changes in load or speed, are compensated for.