Title: A New Century of Inventions

Author: James White

Release date: June 15, 2013 [eBook #42951]

Most recently updated: October 23, 2024

Language: English

Credits: Produced by Chris Curnow, Harry Lamé and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

Please see Transcriber’s Notes at the end of this text.

Note that all Plates the text refers to may be found at the end of the book (starting here), as in the original work. For ease of reading, (parts of) the plates have been copied to that part of the text where they are described. The Plates at the end of the book provide links to larger scale plates (not available in all formats); many reference letters will only be visible in these larger scale plates.

By JAMES WHITE, Civil Engineer.

Connoissons le principe—

Nourrissons nous des Elemens.

Girard Syn. fr.

Manchester:

PRINTED FOR THE AUTHOR, BY LEECH AND CHEETHAM, WRIGHT’S-COURT, MARKET-STREET.

AND SOLD BY

W. AND W. CLARKE, MARKET-PLACE; E. THOMSON, MARKET-STREET; T. SOWLER, ST. ANN’S-SQUARE, MANCHESTER.

G. WILSON, 49, ESSEX-STREET, STRAND; LONGMAN, HURST, REES, ORME, AND BROWN, PATERNOSTER-ROW, LONDON.

AND BY THE PRINCIPAL BOOKSELLERS IN THE UNITED KINGDOM.

1822.

Entered at Stationers’ Hall.

It has been my lot, during a long and eventful passage through life, to have my attention forcibly drawn to a multitude of Mechanical Subjects; the present review of which permits me to hope, that in making them publicly known, I should render an important service to the Arts and to Society. But the manner of doing this has been so long a question with me, that I have sometimes feared my ability would be extinct before I could do it at all. The reasons, however, that urge me to make the attempt acquire strength with the lapse of time: and whenever my declining health bespeaks the approach of that “night in which no man can work,” I feel deep regret, that this tribute should not have been thrown into the treasury of human knowledge while yet, by the favour of a good Providence, the means of doing it were more fully at my disposal.

I have determined therefore to publish these Inventions. Not because they have been matured into a regular System of Mechanical truth;[iv] but because they consist of many distinct objects of immediate application:—coupled with some ideas of a more comprehensive nature, that may probably extend the usefulness of this admirable study, in the hands of Artists yet unborn.

The form, or rather the title of this work, has but one example, that of the illustrious Marquis of Worcester; whose name may, perhaps, prolong the remembrance of mine: an event the rightful anticipation of which, I confess, would give me pleasure. Not that I either covet or regard what is commonly called popular applause: but the approbation of the wise and good I do regard, and aspire to obtain; since that alone seems to fulfil the adage—“Vox populi vox dei.”

On the subject of our respective Inventions, my views are somewhat different from those of the Noble Marquis; whose description of his labours, as the custom then was, seems chiefly calculated to excite the desire of knowing them better: whereas my wish is to infuse, at once, the knowledge of my subjects into every head capable of receiving it.

This Work then, treats less of Theory than Practice. What are called Principles in Mechanics, are, and must be, founded on numerous suppositions; to present which to “the mind’s eye” requires often a forest of signs, which some readers will not, and others can not penetrate; so that, for many, Theory might as well not exist. This evil is increased when, as it sometimes happens, these suppositions are laid so far from reality, as to leave the result, though correctly deduced, further from the truth than the point to which a sound understanding unassisted by science, would have carried it. To this extreme discrepance of views between theoretical and practical men, may be ascribed their well-known antipathy to each other—in indulging which, they are alike to blame! since no theory inconsistent with fact can be complete; nor any fact be adduced, that a perfect theory will not account for and confirm.

Happily these discussions do not affect my present purpose. For although I shall offer nothing contrary to sound theory, I do not consider that as my subject; but make it my business to[vi] present rational methods of producing useful effects.—In other words to describe these Inventions as connected with immediate Practice. And if, hereafter, it should become desirable to resume the discussion of any principle relating to these subjects, I shall cheerfully enter upon it; but hasten, mean while, to do what seems more important—to place the subjects themselves beyond the danger of being wholly lost, whatever may befall me in the course of those events which are still among the secrets of Heaven.

In the pursuit of knowledge, in general, it is often desirable to trace it from its upper source; and to know all the circumstances that have attended its progress, down to the very moment when it falls under our observation. Nor is it a matter of indifference to examine the minutest form which talent assumed, in the young mind whose subsequent efforts have engaged our attention, or gratified us with more varied and solid productions. In this view I have presumed to think myself justified in commencing this Work, by a succinct reference to those feeble efforts which[vii] marked my first steps in this career. Young I then was, and my musings puerile indeed! But they were original: they were the links of a chain which time has not yet snapt asunder—and of which my honoured Father saw the connection with my subsequent labours, long before I thought, myself, of any thing but working for the purposes of amusement; or, in the childish phraseology, of “playing at work.”

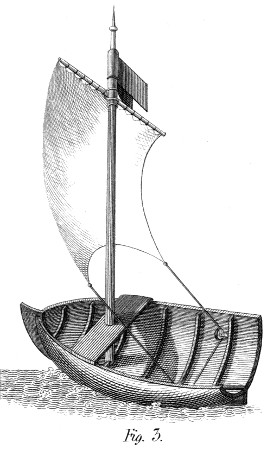

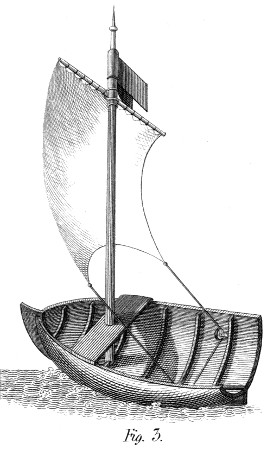

Should any reader then enquire what were my first avocations? the answer would be, I was (in imagination) a Millwright, whose Water-wheels were composed of Matches. Or a Woodman, converting my chairs into Faggots, and presenting them exultingly to my Parents: (who doubtless caressed the workman more cordially than they approved the work.) Or I was a Stone-digger, presuming to direct my friend the Quarry-man, where to bore his Rocks for blasting. Or a Coach-maker, building Phætons with vaneer stripped from the furniture, and hanging them on springs of Whalebone, borrowed from the hoops of my Grandmother. At another time, I was a Ship Builder, constructing[viii] Boats, the sails of which were set to a side-wind by the vane at the mast head; so as to impel the vessel in a given direction, across a given Puddle, without a steersman. (See Plate 2. Fig. 3.) In fine, I was a Joiner, making, with one tool, a plane of most diminutive size, the [relative] perfection of which obtained me from my Father’s Carpenter a profusion of tools, and dubbed me an artist, wherever his influence extended. By means like these I became a tolerable workman in all the mechanical branches, long before the age at which boys are apprenticed to any: not knowing till afterwards, that my good and provident Parent had engaged all his tradesmen to let me work at their respective trades, whenever the more regular engagements of school permitted.

Before I open the list of my intended descriptions, I would crave permission to exhibit two more of the productions of my earliest thought—namely, an Instrument for taking Rats, and a Mouse Trap: subjects with which, fifty years ago, I was vastly taken; but for the appearance of which, here, I would apologize in form, did I not hope the considerations[ix] above adduced would justify this short digression. If more apology were needful.... Emerson himself describes a Rat-trap: and moreover, defies criticism, in a strain I should be sorry to imitate! my chief desire being to instruct at all events, and to please if I can: without, however, daring to attempt the elegant Problem, stated and resolved in the same words—“Omne tulit punctum, qui miscuit utile dulci.”

The town of Cirencester (my native place) is intersected by several branches of the river Churn, whose waters are pure and transparent, and whose banks, formerly, were much perforated by the industry of the Rats that had made them their residence. These holes had generally two openings; one at or near the surface of the ground, and the other near the bottom of the river: so that the rats could range the fields from the former, and dive into the water from the latter—where they were often seen gliding along the bottom, either up or down the stream. The Instrument for taking them in these circumstances, was no other than my Father’s Walking-stick, (represented at A. Fig. 1.[x] Plate 2.) connected with the curve B by the joint C; the curve having a string fastened to it, which, passing through the body of the stick, rose to the hand at D, for the purpose of closing the fork at the proper moment. The Machine, thus constructed, was put over the rat’s back while in the act of diving; and by pulling the string C D, he was sufficiently pinched to be drawn out of the water, where a Dog stood ready to dispatch him.

On the Mouse-trap (Fig. 2. and 4.) more thought was bestowed. It appeared adviseable (I remember) to lay the deceptive plan rather deep: and to lull the little animal into a false security till the snare had taken full effect; and even then to hide from her some of its horrors till she was far enough from this vestibule of misery, not to deposit there any of those tokens of distress that might deter other mice from following her example. The trap then, consisted of a long passage, formed spirally round the surface of a Cone, like the figures we have of the Tower of Babel. This passage is uncovered in Fig. 4 to shew the entrance E, and the subsequent gates F G H, &c. which like the valves of a pump, gave easy entrance to the victim, but forbade her return. At the length[xi] of a mouse from the outer gate E, was placed the first bait N, say a small rind of cheese, well toasted to allure, but nailed down to prevent its removal. Its position was further indicated by a train of meal reaching from it to the outer gate E; which latter was nicely hung on pivots inclined a little to the perpendicular, so as to open with ease but never fail to close itself again. It had besides an horizontal plate O, fixed to its bottom on the inside, so that if the mouse attempted to open it that way, she trode on this plate and destroyed the result of her own efforts.

When, therefore, the little wretch had passed this barrier, she was in reality taken: but unconscious yet of danger, she nibbled the first bait with pleasure, and then skipped forward in search of more substantial food: but to obtain this she must pass more of these faithless gates, F G H, &c. which with progressive effort she opened, and at length found the inner compartments replete with good things, on which she fed to satiety, and then only began to think of her situation. Nor yet, with much alarm: for at the end of this labyrinth, so easy of access, she hoped to find an easy exit. But alas, these[xii] hopes were illusive. Instead of light, she found the dark gallery O; the least evil of which was to be too narrow for two mice abreast, since it overhung a tremendous cavern, Q, that entirely occupied the Cone below, and was filled with water deep enough to drown her, were she to fall, or be jostled into it. And one of these disasters she could hardly escape! for other mice would not fail to be beguiled into this cruel Bastille; to reach the same spot; and finally, to plunge her into this watery grave.

Having endeavoured to recollect the substance of these youthful attempts to unite cause and effect, or to fulfil a given purpose by preconcerted means, I now turn to things of greater importance, and more worthy to be the theme of my readers’ attention. The subjects to be presented will observe a miscellaneous order; since they have not only originated at different periods, but offer likewise different degrees of interest—to equalize which throughout the Work, appears a desirable attempt. As to the manner of treating each subject, it will be, generally, to describe the Machines by a reference to the Figures; and then to add some remarks on their date, construction, properties, and uses.

A NEW CENTURY OF

Inventions.

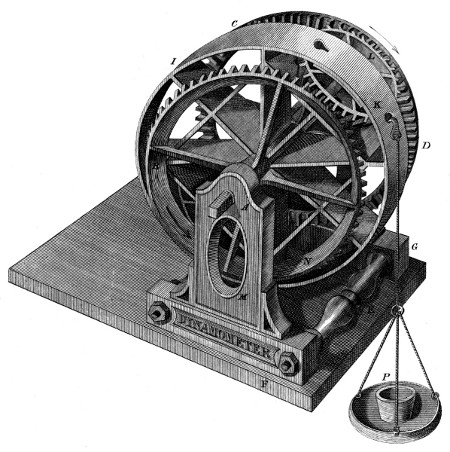

Dynamics being a science that relates to bodies in motion—comprehending not their weight only, or their velocities only, but the product of the one by the other; so the Dynamometer is a mean of measuring both these circumstances together, and thus of making known the momentum of a power or resistance in motion. As this Machine has a connection more or less intimate with almost every other, it seems entitled to the first place in this collection. Its description follows:

In Plate 3, Fig. 1 and 3, M M, represent two cheeks, standing parallel to each other, and forming a cage or frame by means of the cross bars E and the nuts F G. A P, Fig. 2, is the principal axis of the Dynamometer, fixed to the wheel R N of which it is the centre of motion. It has a square end A, formed to receive the wheels and other supplemental parts, to be mentioned below. After the square A, comes a bearing E, to fit the steps in the frame; and beyond the wheel R N is a cylindrical part O, fitted to the hollow axis T of the wheel or frame I K, (Fig. 4); and in fine the form P of this shaft fits and turns in the cannon of[16] the axis B H, of the wheel C D; so as, when put together and connected with the frame I K, to assume the form C R F G of the third figure. L P, Fig. 3 and 4, are two intermediate wheels (thus placed to balance each other on the common centre T) whose axes turn on proper steps in the frame I K; and which by their teeth connect the motion of this frame with that of both the wheels R N, and C D.

Such are the parts of the Dynamometer properly so called; and they are shewn as in their places in Plate 1, where the parts above described, as far as visible, are marked with the same letters. Moreover, this figure shews a scale-bason P, to receive the weights used to measure equable powers, as will be seen hereafter.

Plate 4 contains some of the auxiliary parts of this Machine. But before we proceed to describe them, it may be proper to observe that the measuring power, by the action of which at K, (Plate 1) the energy of the force is transmitted to the resistance, must, to meet every case, be susceptible of change, according as the resistance or force to be measured is uniform or convulsive. For example, in a mill grinding corn, driven by a fall of water, the whole process is sensibly uniform, and a weight at P is the proper measurer. But if it were desired to measure the effect of a pump driven by water, or of a tilt hammer worked by a Steam Engine, then the measuring power at P must be a spring: for in these cases the vis inertiæ of[17] a weight would add to its force of gravity when suddenly raised, or detract from it when the resistance should suddenly give way. Whenever therefore, the force and resistance are both equable, a weight will best measure them; and when either is convulsive, a spring: but a spring so equalized as to offer the same resistance at every degree of tension it may have to sustain.

In the 6th. and 7th. Figures, (Plate 4) these demands are fulfilled. The first represents a barrel-spring, similar to that of a watch, but surrounded by a fusee, the increasing radii of which compensate for the increased tension of the spring in the barrel G; so that the action of the system on the chain is always the same.

The 7th. Figure exhibits a spring adapted to heavier purposes. It is a cylinder nicely bored and hermetically closed at bottom; in which works a Piston P plunged in oil, which when forcibly drawn up forms a vacuum in the cylinder, into which the atmosphere endeavouring to enter, acts like a spring on the Piston; and preserves the same stress whatever be the height of this Piston in the cylinder.

This then, is also an equalized Spring, such as these experiments require; but it is not my invention. I first saw a vacuum used, as a spring, by my noble Patron, the late Earl Stanhope: to whose mechanical attainments, I owe this tribute of applause on the present occasion.

In the three Figures of this Plate, 8, 9, 10, are shewn two of the means I use for creating those factitious resistances that are sometimes wanted in the process of measuring power. In Fig. 8, E H F, is a gripe or brake, such as millers use to stop their wind-mills with; fixed under L, it surrounds the wheel E H, and is then fastened to the end F of the lever K L. The brake is thus pressed with greater or less force against the wheel, as the weight I is placed more or less distant from the fulcrum L of the lever. By these means a resistance of the equable kind is produced, capable of being adapted to any power it may be wished to measure; which makes this Dynamometer a real tribometer or measurer of friction.

The second kind of resistance brought forward in this Plate, is a Pendulum P (Fig. 9 and 10,) set a vibrating by a pallet-wheel A B, connected with the axis of resistance; and working in the pallets N. It appears besides, in the Figure, that the times of vibration can be changed by the mechanism T N R, which raises or lowers the ball P. This then, is another resistance, such as we sometimes want: but it is also a mean of finding the quantity of resistance that a vibrating body opposes to motion, when oscillating in times not those due to its length as a pendulum. In other words it is a mean of measuring vis inertiæ itself—which an astounding modern writer declares does not exist!

I hasten to give a description of certain other parts relating[19] to the measuring system: and some methods of connecting with the Dynamometer the several kinds of forces it may be desirable to examine.

In Plate 5, Fig. 12, A X represents a Crank or Handle with a variable radius, the intent of which is to adapt a man’s strength to the velocity and intensity of any resistance he may have to overcome. The manner is this: B is a Screw pressing on the quadrant, and fixing the arm C X to any required angle with the part A C: thus determining the virtual radius of the handle.

Fig. 14, shews a method of applying to the Machine the force of a man pumping: for the catch N permits the handle O to rise alone, but carries round the wheel R, at every downward stroke, while the fixed catch C secures all the forward motion thus given. The same Figure shews, at B, the force of a man in the act of rowing: for the catch M permits the lever V M to recede when the man fetches his stroke, and carries the wheel round when he takes it. An operation, by the bye, which I think the best mode of employing human strength, if every possible advantage is taken of the method.

The 13th. Figure shews the last method I shall now offer of adapting power to the Dynamometer. T S represents the Piston of a Steam Engine, the rod of which is formed of two bars, including between them the chains F G and F D, the first of which is single, merely to carry back the acting wheel; and the[20] last double, to draw round the ratchet wheel E, by the catch O, at every stroke of the Piston.

I must obviate here an objection that may strike some readers. This Piston T S, acts only one way, like that of an atmospheric engine, a thing now quite out of date! I answer that this figure is chiefly intended to give the idea; and shew a rotatory Steam Engine that might act without a fly. I will add, that it is my intention some day to bring forward a method of using these suspended actions, better than by a mere ratchet wheel: and especially without incurring danger from the length of the ratchet teeth, or the blow they suffer at the beginning of the strokes. But of this more hereafter.

A short description will suffice for the mechanism of the 18th. figure (Plate 6), which is intended to convert the alternate pressure of a man’s feet into rotatory motion, and then to measure his power. To do this two catches A B, take into the teeth of the same wheel M, and each catch carries an arm, P, embracing somewhat stiffly the boss of the wheel. The treadles have a common centre at E, and are fastened to the same rope going over a pulley, F, so as for the depression of the one to raise the other. Again, the pulling bars C D, are connected with the treadles, and from the form of the catches, it is evident (since the levers move with some stiffness), that the first effect of an ascending motion will be to draw the rising catch out of the teeth, and keep it out until arrived at its greatest height; when[21] the very beginning of its descending motion will bring the catch into the teeth again, and thus carry round the wheel at every downward movement of the treadle;—a method this of making a ratchet work without rattling upon the wheel.

The mechanism shewn in figure 19, is intended to produce another of our factitious resistances; and it serves likewise to make experiments on the resistance of the air. It is a fly, meeting with an equable resistance as does the fly in the striking train of a clock. The wheel W, is put on the axis of resistance of the Dynamometer; and its teeth geer in those of the vertical shaft L H. This latter is perforated from above, and has an open mortice all along its body, which a small bar penetrates, meeting at bottom the ring H, to which it is fastened by a pin going through the mortice. Again, this ring H, is moved, downward, by the rollers of the sliding bracket P, which has its motion from the wheel and rack G: and finally, the leaves I K slide in the horizontal frame; and when the machine turns would obey the centrifugal force and fly outward; but are withheld by the cords N O, which passing over the pulleys N O, and under those L M, are then fixed to the frame above L. When, now, this Machine is used, and the fly made to revolve swiftly, the leaves I K, oppose a certain resistance to the rotatory motion; and if this be too feeble, the key G must be turned backward, which will permit the ring H to rise, and the wings I K to recede from the centre. But if this resistance is already too strong, the key G must be turned forward, and the wings brought nearer: between[22] which extremes, a point will easily be found where the resistance of the air will expend just power enough to balance that brought into the Dynamometer through the power-axis; and thus to keep the measuring weight in the position required for any given experiment.

There remains only one part to be described as belonging to this Machine. It is represented in Plate 5, fig. 15, and is a graduated bar, made to fit in the holes K, of the measuring cylinder I K Plate 1: and to carry one of the arcs A A, which thus serves to extend, virtually, the radius of that cylinder to any required dimension.

It is now time to shew something of the manner of using this Dynamometer in the measurement of forces. Let the object then be to measure the power expended by a Horse in drawing a Carriage.

To do this, we fix a Drum (see fig. 16,) of equal radius with the measuring cylinder, on the power axis A; and a similar Drum to the resisting axis H. After firmly fixing the Machine, we place the Carriage at a distance behind it in the plane of the Drum H; and carry a rope from that Drum to the Carriage: on the other hand, we fill the first Drum A, with a coil of rope, to which the Horse is harnessed; and while he travels in the plane of the Drum A, the scale P (Plate 1,) is loaded with weights, until the Carriage follows the horse’s motion without[23] any (or with little) agitation to the scale P: at which moment the power employed is equal to one half the weight at P, multiplied by the space gone through both by the Horse and the Carriage.

If it were now desired to find the power of a man turning a crank or handle, we should take that given in the figure 12, and fix it to the power-axis A. We should also take the fly-system shewn in fig. 19, and place it on the axis-of-resistance H. Then causing the man to turn the Machine, we should put twice as much weight into the scale P, as his strength was thought able to bear. Then if he thought the work too heavy, we should draw inward the leaves of the fly, and take away part of the weight P, until the man were satisfied he could work with convenience: and when, as before, the weight P should overcome the resistance of the fly I K, without either rising or falling, (sensibly) then the power expended would be one half of the weight P, multiplied by the space described by the man’s hand in the act of turning the handle.

It may occur to some of my readers that in these experiments the whole effect is not actually measured: since the space described by the horse or the man’s hand, must be determined after the experiment. I answer that these quantities, necessarily variable, must bear an inverse proportion to the weight P: and in all cases, this weight multiplied by that space, must give the power or momentum required. Besides, it is most easy to add a piece[24] of mechanism that shall count the number of turns, and express them in space, by the inspection of a graduated scale. Nor need we stop here. The duration, in time, of any experiment, may also be recorded by the Machine itself. These are things so naturally connected with the subject, that I cannot feel it necessary, with so much before me, to attempt exhausting them. But this I engage to do: if any serious difficulty should actually stop any reader in this career of investigation, I will obviate such difficulty at some convenient future period. And mean while those persons who have aptitude for such subjects, will find in this Machine, ample scope for extending their enquiries; and comparing many mechanical realities with the deductions of Theory, thus amending and conciliating the conclusions both of Theory and Practice.

I have said above, that the weight or spring acting on the measuring cylinder at K, must be equalized: but in reference to some applications of this Machine to real use, I would modify that precept a little. I should, indeed, always like the principal action to be of a constant nature: with a supplementary part of less intensity, prepared to add something to the former; and this, for the purpose of meeting spontaneously the case of any unexpected addition of the moving power. Thus in Plate 1, if P be a weight nearly adapted to a given resistance, I would (to prevent accident, from its being overraised by any sudden jerk of the power,) hang one or more heavy chains under the scale, which drawn from the ground to a certain length, would add[25] a known quantity to the measuring power; and transmit with a certain softness to the work, the unequal action of the mover.

One word on the friction of this Machine. All friction must of course be avoided as much as possible; but as it will be nearly the same in every class of experiments, it is not of great importance. The same may be said of the vis inertiæ of the parts, in convulsive motions. The parts would, of course, be made as light as a proper strength would permit. My mechanical readers will easily supply these small items of foresight; to anticipate the whole of which would make this Work interminable.

Although this invention does not properly constitute a new Spring, yet it produces effects both new and important. It protracts almost indefinitely the action of a barrel Spring, and thus reduces considerably the number of wheels in a clock or other spring-driven machine. This effect is produced by setting the two ends of the spring at variance; or making them act one against another: for as these opposite tendencies can be made nearly equal, one end of the spring will be wound up almost as much as the other end runs down: thus prolonging the effect in any desired proportion. It will be making known the principle, to describe the first motion of a clock founded upon it.

In Plate 7, fig. 1, A is the spring barrel, to which is fixed a wheel, B, of 96 teeth, working in C, a pinion of 17. E is another wheel of 92 teeth, working in F, a pinion of 22: both pinions being fixed on the same arbor, I G. The smaller wheel E, turns on a round part of the axis H D; and is connected with its motion in the backward direction only, by a ratchet wheel R, fixed on a square part of the same arbor. As usual, this latter has a cylindrical boss within the barrel A, to which the inner end of the spring is hooked; as its outer end is, to[27] the rim of the barrel; and thus does the wheel B (when the clock is wound up) tend to turn forward as shewn by the arrow B; while the wheel E, tends to turn backward in the direction of E, the second arrow. But these opposite tendencies are not equal; because the wheel B is larger, and acts disadvantageously on C, the smallest pinion; while the wheel E is smaller, and acts to advantage on the larger pinion F: so that there is a decided tendency in the whole to turn backward. Now, to find precisely what is the effect of that tendency, we observe that when the barrel and the larger wheel B, have made one revolution round the common axis H D, the pinions C and F will both have made 96⁄17 of a revolution (being the quotient of the division of the wheel B by the pinion C:) and since the larger pinion of 22 teeth, works in the smaller wheel of 92 teeth; this latter wheel in the same time will have made 96⁄17 of 22⁄92 of a revolution, or 1,350 of a turn very nearly. The difference then between this quantity and unity, namely the decimal 0,350, is what the spring has really gone down during one turn of the barrel. And as the whole number of coils in the spring are 10, the number of turns of the barrel to uncoil it entirely, will be 10⁄0,350 or 10000⁄350 equal to 28,57 nearly: instead of ten revolutions which it would have been on the common principle.

It is almost superfluous to add that this prolongation of the time might have been greater, had I not been confined to the above numbers, for want of others more nearly alike, and having a common difference, on my engine.

An important remark here presents itself, viz. that the best properties of this invention are unattainable by the use of the common geering—the friction of whose teeth would have absorbed the small rotatory tendency thus retained; and in which system, also the working diameters of the wheels could not have been defined with sufficient exactitude. This then, is one of the cases in which (as I have observed in a former work) my late Patent System of Geering has “given rise to machines that could not have existed without it,”—which it does by possessing exclusively the property of realizing (sensibly) the whole calculated effect; and working without commotion or assignable friction. It may please some of my readers to be informed that this System, and the means of executing it in every dimension, will hold a prominent place in some future page of this essay.

Referring again to the figure 1, the teeth X X, Y Y, are there placed to give a first idea of this principle: and they are unaccompanied by others, to avoid the confusion of lines that would have arisen from attempting to shew all the teeth, in their due position, on so small a scale. These things will claim all our attention when the System itself comes under examination.

The above representation of this Machine may leave a technical difficulty on the minds of clock makers relative to the winding up of this spring; which, in the present state of things, will suspend, for the time, it’s action on the pendulum: for in[29] order to effect it, (in a reasonable number of turns) the introduction of the key must, by a proper check-piece, be made to stop the wheel B, and leave it again at liberty when the key is taken out: in which case ten turns of the key will effect the winding, although the Machine should be calculated to give out forty turns in the uncoiling of the spring. But if the wheels B and E had changed places; that is, if E had been fixed to the barrel A, and B been connected with the ratchet wheel R, then the act of winding up would have taken place in the opposite direction; or in that which tends to keep up the motion of the pendulum, in which case, however, the machinery of the clock must have borne the whole stress of the spring during the act of winding, instead of the small portion it sustains when the two ends counteract each other.

But I anticipate another objection to this method of employing a barrel spring: which is the inequality of stress, when the spring is much or little wound. The answer is, that many clocks and watches are made to go well without fusees; either by modifying the thickness of the springs, or employing only a few of the middle coils. My Invention may, perhaps, help to nurse this System to perfection: if not, its influence will be the more confined, but in no wise destroyed.

A B, Plate 7, fig. 2 and 3, is a ring or wheel fixed to the frame C D; and having all round it’s inside, teeth directed to the centre. F is a wheel of half the diameter, and exactly half the number of teeth of the wheel A B. It turns on a Crank-arm, E F, whose radius is equal to one quarter of the diameter of the fixed wheel A B—in the centre of which the axis of this Crank finds it’s due position. The latter, therefore, so conveys the wheel F round the inside of the fixed wheel A B, that the teeth of both are constantly geering to a proper depth: and a stud being fixed on the face of the wheel F, opposite the middle of any tooth, a, directly over the centre of the Crank E, this stud describes the perpendicular diameter of the large wheel: and will either receive motion from the rod R of a Steam Engine Piston, so as to give the fly I K, a rotatory motion; or communicate to a Pump-piston a reciprocating motion, drawn from the rotatory one of the fly, when that is the effect desired to be produced.

This Invention will be remembered, as having procured me a remunerating Medal from the late Napoleon Bonaparte, then first Consul of the French Republic. That period, however,[31] (1801) was not the real date of this production, although then first made public. I have proof, on the contrary, of its existence with me several years before; and it is generally ascribed to me by the publicists. I might quote in particular Doctor Gregory: who likewise mentions its having been executed by Messrs. Murray and Wood, of Leeds, subsequently to it’s exhibition at Paris. The Doctor commits, however, a small error in calling me an Anglo-American; but this is accounted for by my then living in a country where to be an Englishman was itself a crime! and where some kind friends, wishing to hide me from the relentless decrees of the day, felt justified in using this sort of pious fraud in my favour: a resource from which, though I did not authorize it, I reaped no small advantage; and still think of with gratitude, though not with unmixed approbation.

I think it a duty more imperious than agreeable, to expostulate a little with Messrs. Lanz & Betancourt, on their apparent partiality in giving an account of this Machine. In their work on the construction of machines, art. 97, page 37, they make M. de la Hire the inventor of it, by the terms in which they introduce his treatise on Epicycloids: and they leave me the thread-bare merit of having “presented a model of this movement at the last exposition but one,” &c. Now, although I do not attach great importance to this kind of misrepresentation, I cannot but observe, that neither my Machine or their description of it can be called a Theorem! nor especially a theorem relating solely to the Epicycloid, as M. de la Hire’s was. These[32] Gentlemen knew that he insisted principally on the application of this curve to the teeth of wheels, with which my Invention has nothing to do. On the contrary, my Machine is a combination of two curves at least, on which de la Hire says absolutely nothing. Is this then inadvertency? or is it uncandid nationality? I hope, the former.

A further remark on the utility of this System as a first motion, may be of use in this place. It respects the geering of the fixed and moveable wheels A B, and F, on the perfection of which depends the truth of the statement, that the stud, a, describes a diameter of the large wheel. Now, perfection is too much to be expected from common teeth when of the necessary strength; so that my Patent Geering is an indispensable complement to this Invention: as by its use, the principle is made practically true; this line becoming really straight, and this motion, under proper circumstances, being unattended with noise or commotion. In a word, I cannot move a step in this mechanical field, without meeting with instances where the new System shews its superiority to the old: whence it becomes a duty for me to commence the consideration of this subject in the very next part of this publication.

These Pulleys have been frequently described since I first entered my specification at the Patent Office. The Authors of the Encyclopedia Britannica; the Rev. Mr. Joyce, in his juvenile philosophy; and Dr. Gregory in his mechanics, have all adverted to them. In the latter work, I find the following quotation from my own description, thus introduced:

A very considerable improvement in the construction of pulleys has been made by Mr. James White, who obtained a Patent for his Invention, of which he gives the following description: “Fig. 4, Plate 7, of this work, shews the Machine, consisting of two pullies, Q and R; the former fixed, the other moveable. Each of these has six concentric grooves, capable of having a line put round them, and thus of acting like as many different pulleys having diameters equal to those of the grooves. Supposing then, each groove to be a distinct pulley, and that all these diameters were equal, it is evident, that if the weight 144 were to be raised by pulling at S, till the pulleys touched each other, the first pulley must receive the length of line as many times as there are parts of the line hanging between it and the lower pulley.[34] In the present case there are 12 lines, b, d, f, &c. hanging between the two pulleys, formed by its revolution about the six upper and six lower grooves. Hence as much line must pass over the uppermost pulley as is equal to 12 times the distance of the two. But, from an inspection of the figure, it is plain that the second pulley R S, cannot receive the full quantity of line by as much as is equal to the distance betwixt it and the first. In like manner, the third pulley receives less than the first, by as much as is equal to the distance between the first and the third; and so on to the last which receives only 1⁄12 of the whole: for this receives it’s share of line n, from a fixed point in the upper frame which gives it nothing: while all the others in the same frame receive the line partly by moving to meet it, and partly by the line coming to meet them.”

“Supposing now these pulleys to be equal in size, and to move freely as the line determines them, it appears from the nature of the system, that the number of their revolutions, and consequently their velocities, must be in proportion to the number of suspending parts, that are between the fixed point above-mentioned, (n) and each pulley respectively. Thus the outermost pulley would go twelve times round in the time that the pulley under which the part n of the line passes, (if equal to it) would revolve only once; and the intermediate times and velocities would be a series of arithmetical proportionals of which, if the first term were[35] l, the last would always be equal to the whole number of terms. Since then, the revolutions of equal and distinct pulleys are measured by their velocities, and that it is possible to find any proportion of velocity on a single body running on a centre, viz. by finding proportional distances from that centre; it follows, that if the diameters of certain grooves in the same body be exactly adapted to the above series, (the line itself being supposed inelastic and of no magnitude) the necessity of using several pulleys in each frame will be obviated, and with that some of the inconveniences to which the use of the common pulley is liable.”

“In the figure referred to the coils of rope, by which the weight is supported, are represented by the lines a, b, c, &c. a is the line of traction commonly called the fall, which passes over and under the proper grooves, until it is fastened to the upper frame just above n. In practice, however, the grooves are not arithmetical proportionals; nor can they be so, for the diameter of the rope employed must be deducted from each term, without which, the small grooves to which the said diameter bears a greater proportion than to the larger ones, will tend to rise and fall faster than the latter, and thus introduce worse defects than those which they were intended to obviate.”

“The principal advantage of this kind of pulley is, that it destroys lateral friction, and that kind of shaking motion which are so inconvenient in the common pulley; and lest, says[36] Mr. White, (I quote Dr. Gregory) this circumstance (of a long pin) should give the idea of weakness, I would observe, that to have pins for pulleys to run upon, is not the only, nor perhaps the best method: but that I sometimes use centres fixed in the pulleys, and revolving on a short bearing in the side of the frame, by which strength is increased, and friction much diminished: for to the last moment of duration, the motion of the pulley is circular, and this very circumstance is the cause of it’s not wearing out in the centre as soon as it would, assisted by the ever increasing irregularities of a gullied bearing.—These pullies when well executed, apply to Jacks and other Machines of that nature with great advantage: both as to the time of their going and their own durability: and it is possible to produce a System of pulleys of this kind, composed of six or eight parts only, and adapted to the pocket, which by means of a skain of sewing silk, would raise more than a hundred weight.”

There are several real and solid advantages attending the use of this pulley; some of which are only hinted at in this description. I have thought, therefore, it might be useful to introduce here an account of some trials which the System underwent a few years ago at Portsmouth,—at the request of an Officer of the Navy, who had re-invented it with some ingenious additions to my ideas. Not being at present in correspondence with that Gentleman, I hardly think myself at liberty to mention his name; but fully so to give an extract from the report which followed these experiments—in which the superiority of the[37] System in respect of power, is made evident, although some less favourable circumstances prevented its adoption on that occasion.

“With a view to comparison, it was settled with Lieutenant S. that his blocks should be made to correspond with the treble and double 16 inch blocks of a 24 gun ship, which carry a 41⁄2 inch rope. The sheeves in the new blocks are fixed upon the pin, revolving therewith, and are of different diameters proportioned to the velocity of the parts of the rope that pass over them; they are also reeved with a double rope so that there are two grooves of each size, the diameter of the smallest groove in this tackle being 28⁄12, and of the largest 15 inches. The diameter of the sheeves of the common blocks would have been (as usually made) 91⁄8 to the bottom of the grooves, but were reduced at the request of Lieutenant S. in the treble block to 81⁄8, and in the double block to 87⁄8, in order that the sum of the diameters of the sheeves in each tackle should be the same. The Lieutenant intending in the first instance, to have used a roller under the pin, for the purpose of diminishing friction, but afterwards laying aside this idea on account of it’s complication, was the reason that he had not made his sheeves in the same proportion with the common blocks: the weight and length of the respective blocks are as follows:

| Weight. | Length. | ||||

|---|---|---|---|---|---|

| Lieutenant S.’s | treble blocks | 131 | lbs. | 24 | Inches. |

| Common | ditto | 78 | „ | 16 | „ |

| Lieutenant S.’s | double block | 73 | „ | 21 | „ |

| Common | ditto | 60 | „ | 16 | „ |

| Lieutenant S.’s | single block | 22 | „ | 17 | „ |

| Common | ditto | 34 | „ | 16 | „ |

“Lieutenant S.’s blocks were reeved with a 21⁄2 inch double rope, and the common block with a 41⁄2 inch single rope, and both tackles suspended from a beam, and their respective falls let over the single blocks, so as to keep the weight applied as a power, just clear of the weight to be lifted, thus forming a power of six to one; the following experiments were made:

| Weight very slowly lifted. |

Power required with Lieutenant S.’s blocks. |

Power required with the common blocks. |

|---|---|---|

| ℔s. | ℔s. | ℔s. |

| 336 | 88 | 124. |

| 672 | 169 | 252. |

| 1344 | 312 | 448. |

| 2688 | 588 | 808. |

| 5376 | 1101 | 1344. |

“After reeving the common blocks with a 31⁄2 inch rope in lieu of a 41⁄2 inch rope, it was as follows: 5376 1101 1232.

“It must be observed, that the double 21⁄2 inch rope in Lieutenant[39] S.’s blocks, is not of equal strength with the single 41⁄2 inch rope first used in the common blocks; and that his blocks had an undue advantage in the first experiment over the common blocks, in respect to the pliability of the rope. The rope should therefore, be taken larger in the one or smaller in the other case, on this account: The common blocks were reeved in the last experiment, with a 31⁄2 inch rope, which is as near as may be of the same strength as the double 21⁄2 inch rope.

“In these experiments it was observable, that the tar was much more squeezed out of the parts of the rope that passed over the smallest sheeves in Lieutenant S.’s blocks, than out of those passing over the larger sheeves, or out of those passing over the sheeves of the common blocks; by which, as well as by the nature of the thing, we judge that with blocks requiring such small sheeves, the ropes would be more crippled and broken than by the common blocks, especially if any constant strain or weight in motion, as on ship board, should be held by them. In regard to our opinion of the merits of the blocks proposed by Lieutenant S. compared with common blocks, we beg leave to submit, that the mechanical principle of them is very inviting, and it is not to be wondered that an ingenious person should pursue the idea; yet allowing there would be a saving of power, which is attained in so great a degree with the common blocks, but considering the greater complication, weight, and expence of[40] these blocks, and their greater disposition to cripple the ropes, we do not perceive any application of them on ship board, for which we could recommend them in preference to common blocks; neither do we perceive any purposes on shore, for the services of the dock yards in which to recommend their application in preference to the other powers in use.”

To this account of the result of these experiments, I beg leave to add what seems to be a great improvement of this System: namely, a method by which the diameters of the larger pulleys are considerably lessened; and thus the principal, if not the only objection, obviated. It has been before observed, that the larger pulleys, as Q R, are the ultimate terms of an arithmetical progression, beginning at unity; and that consequently they cannot be very small, even though the first terms should be so. If a first pulley were only one inch in diameter, the twelfth pulley would be twelve inches,—where we see a large and inconvenient difference. But this evil I now obviate, by placing at the beginning of the series, one or more loose pulleys, over which to reeve the cord, before the concentric or fixed grooves begin; thus lowering the ratio of the progression, and keeping the larger pulleys within bounds. For example, the smallest fixed pulley (supposed as before, to be one inch in diameter) I now make the second of the series instead of the first: and therefore, the second fixed pulley is to the first as 3 to 2, instead of being as 2 to 1; for the same reason, the third fixed pulley is to the second as 4 to 3; and[41] in a system of 12 pulleys, (with one loose one) the respective terms will be as follows:

| Terms | 1 | — | 2 | — | 3 | — | 4 | — | 5 | — | 6 | — | 7 | — | 8 | — | 9 | — | 10 | — | 11 | — | 12 |

| loose; | 2⁄2; | 3⁄2; | 4⁄2; | 5⁄2; | 6⁄2; | 7⁄2; | 8⁄2; | 9⁄2; | 10⁄2; | 11⁄2; | 12⁄2 |

or 6 inches for the largest pulley, instead of 12 inches given by the last progression.

So likewise, if we take two loose pulleys, (which will not add much to the complication of the Machine) and make the third term 1 inch, the fourth will become 4⁄3, shewing the ratio of the progression to be 1⁄3, so that the series of 12 terms will stand thus:

| Terms, | 1 | — | 2 | — | 3 | — | 4 | — | 5 | — | 6 | — | 7 | — | 8 | — | 9 | — | 10 | — | 11 | — | 12 | |

| loose; | loose; | 1; | 4⁄3; | 5⁄3; | 6⁄3; | 7⁄3; | 8⁄3; | 9⁄3; | 10⁄3; | 11⁄3; | 12⁄3; | or, |

four inches for the largest groove in the concentric part of the System.

Now we saw before, that the first and last pulley were in diameter to each other, as 1 to 12; whereas, here, with only two loose pulleys, these extremes are but as 1 to 4: dimensions much more convenient and manageable. The 5th. figure of the Plate 7, is intended to shew graphically, the effect of this modification of the principle. In that figure, if the line a, be the diameter of the first pulley, that of the sixth pulley will be shewn by the line b c; but if the same line a be made the second pulley, the diameter of the sixth will be shewn by the line e d; only 2⁄3 of the former. And in fine, if the same a, be the third pulley, the sixth will have it’s diameter reduced to the line f g,[42] only one half of what it was in the first case. In a word, the more loose pulleys are put before the fixed ones begin, the nearer to cylindrical will the general form become; and the more conveniently may pulleys be used for general purposes. I might even assert, that if one, or at most two loose pulleys had been used in the above-mentioned experiments, the result would have been as favourable to the System, with respect to the weight of the tackle and stress on the ropes, as it was in respect of power; where it’s advantages were important and undeniable.

This Wheel (see Plate 8, fig. 1,) is technically called a Bucket-wheel. It is plunged almost entirely in water, oil, mercury (or other heavy fluid) contained in the vessel A B. It’s axis carries a waved wheel a b, on which rolls a friction-pulley p, running on a pin in the mortice of the bar c d. This bar works the pump f; which by the descent of it’s loaded Piston, drives cold air (or gas) into the tube g, communicating with several collateral ones placed across the vessel, so as to convey the air to h, below and beyond the centre of the wheel. A fire being made at F under this vessel, the water (or other fluid) is brought to a proper heat; and if then the pump f, be made to give a stroke or two, air will be forced from the tubes at h, which having been heated in the passage, will bubble up into the buckets h, i, k, &c. and turn the wheel so as to perpetuate it’s own supplies from the Pump, and furnish a surplus of power for other purposes. This results from the fact, that air (for example) in rising to the temperature of boiling water, expands, under the pressure of the atmosphere, to about three times the volume it occupied at the mean temperature: so that it resists the entrance into the vessel as unity, and acts (when[44] heated) as 3: leaving a power of two, in the form of a rotatory motion.

It will occur to many readers, that azotic gas or nitrogen, might be used with advantage to turn this wheel: only adding to the Machine a long returning tube, leading from the top of the vessel, through air or water, to the suction valve of the pump f; and that in order to bring down the temperature of the gas from the heat it had acquired in the vessel, to the mean temperature; at which this gas is said to occupy only 1⁄7 of the space it fills when at the heat of boiling water.

I have now to observe that this invention was executed in 1794, of which abundant proof remains. Since then, it has been proposed by other persons, and is I think, patentized either in France or England: but a different method is employed of introducing the cold air, namely an inverted screw of Archimedes, whose manner of working I do not entirely recollect. What I here wish to observe is, that this concurrence of idea between others and myself, gives me no pain; since it would be more strange if it did not happen, while so many active minds are ransacking nature for the very purpose of unveiling her secrets. Only I think it incumbent upon me to use every method, consistent with truth and honour, to avoid being thought unjust enough to purloin other people’s ideas, and call them my own.

This Machine is represented in Plate 8, fig. 2 and 3. It is composed of two barrels A B, both of them forming part of the column of water to be raised; connected together by a crooked tube C, of equal diameter, out of which the lower Piston-rod passes through a stuffing box into the air: as does the upper Piston-rod at D, where the column leaves the Pump to pass upward. The two Pistons fixed to the rods E and F, are of the bucket kind; made as thin and light as possible; their valves opening upwards and their motions being such, generally, that when one of them is drawn up, the water rises through the other, then descending: But here lies both the novelty and utility of this Machine; these upward and downward motions are not reciprocal: Both Pistons fall faster than they rise, and thus leave an interval of time when they both rise together; during which their valves, respectively, close by their own weight before the column of water falls upon them. In such manner, indeed, that the column never falls at all. By this important arrangement, the work is constantly going on, and no commotion occurs to absorb Power uselessly, or to destroy, prematurely, the Machine; circumstances which constantly attend every Pump Machine acting by merely reciprocal motion.

This non-reciprocity then, I produce by several methods; one of which (perhaps the most easily understood) is that shewn in fig. 2: There, A B are two friction-rollers, made as large as possible, rolling on the curves C X, the ascending and descending parts of which are essentially unequal. For example, the rising part of the curve occupies 2⁄3 of the whole circumference; and the falling part 1⁄3 only; so that both curves recede from the centre at the same time, during 1⁄6 of a revolution, at the two opposite positions, A C and X Y. Applying then, these curves and levers to the Pump-barrels represented in fig. 3, we obtain that continuity of uniform motion, which is necessary to doing the greatest quantity of work with the least power; and to securing the greatest durability of the Machine. Having hinted at a minimum of power, I must add here that this Machine appears to promise that result, much more credibly than any reciprocating pump whatever; especially if to this continuity of motion we add a certain largeness of dimension that shall produce the required quantity of water, with the slowest possible motion of each particle; and even here this continuative principle helps us much; since pistons and valves of the largest dimensions may be used without introducing any convulsive, or (what is synonymous) any destructive effects.

One particular remains to be noticed in fig. 2. It relates to the means by which the perpendicularity of the motion in the Piston-rods is secured. The arcs M are portions of cylinders having the bolts Z, for their centres, and which, rolling up[47] and down against the perpendicular plane O N, secure a similar motion to the bolts. The tenons P, are cycloidal, on their upper and lower surfaces; and work in square or oblong holes in the plane N O, being kept in their holes by the action of the two springs on a pin let through these tenons: and thus is the motion of the point Z of the levers M B, a perpendicular one; and that of the friction rollers A B, very nearly so.

My object in this work, is to make known the principles, and some of the forms of these Inventions, but my limits will not permit their being dilated on; else I could give several more useful forms of this Machine: but, to make room for other subjects, I must hasten forward—reserving to some future period, many hints respecting the adaptation of those ideas to particular cases. Those of my readers who love to speculate on the doctrine of permutations, will anticipate how much may be done by the combination of a hundred Machines with each other: and they will give me credit for detached items of knowledge—useful in themselves, though too minute to be severally brought forward. Should, however, the degree of patronage I have already experienced, be proportionably extended as the work advances, I can and will follow it up with many useful hints, tending to shew the extent of some of my present subjects, and the amplitude of the sphere in which they roll.

It should be observed, in concluding this article, that the present Machine was executed in France, in 1793, and also[48] proposed to the Government, as a substitute for the celebrated Machine of Marly. In the report then published, it was preferred to the whole multitude of former projects; but left in equilibrio with one modern Machine,—a competition which prevented it’s adoption for the moment—and indeed till I was glad to escape the notice, instead of courting the favour of the then rapidly succeeding governments.

Let A, Fig. 4 Plate 8, be the barrel-wheel of a Clock, or other Machine, already in use, and driven by a weight; and let the similar barrel B be added to the former; the motion of both being connected by the unequal wheels C D. The rope or chain E F, is then led from the barrel A under the pulley P to the barrel B: By which arrangement, when the weight has occasioned one revolution of the barrel and wheel A C, those B D, will have made a lesser portion of a revolution in the ratio of the wheel C and D; (namely as 22 to 24,) and that motion will have taken up 11⁄12 of the line which the barrel A has given off. By these means, the motion of the whole may be prolonged almost indefinitely. This System may appear to some persons open to the objection that the friction of the wheels C D, will absorb so much of the power, as to leave the rotatory tendency too feeble for it’s intended purpose. But I again take refuge in the well proved property of my patent geering,—of not impeding (sensibly) the motion of any Machine in which it is used.

Should it further be suggested, that this is only an awkward parody on the differential wheel and axle, ascribed by Dr. Gregory[50] (in the introduction to his work, page 4,) to the celebrated George Eckhardt: I would answer, that I made that invention also; though doubtless after Mr. Eckhardt; and especially after the date of the figure given by the Doctor, as coming from China, “among some drawings of nearly a century old;” Of course then, I do not pretend to priority of invention: but truth herself authorises me to say, that I did invent this Machine also, in the night between the 17th. and 18th. of January, 1788, and drew it in bed by moonlight, that it might not escape me! It was the result of a previous fit of close thinking: and of the conclusion I then drew, that in whatever way, slowness of motion is obtained by the connection of two movements, power is invariably gained for the same reason, and in the same proportion. The fact is, that all my ideas respecting differential motions, have flowed from this source; as will be evident to the attentive reader of these pages.

It is a known property of an angle such as g d f (plate 9 fig. 1) when touching two fixed points g f, and gliding from one of these points to the other, to describe a portion of a circle g d f. My object in this instrument is to determine, by inspection, the radius of such circle in all cases.

To do this, I connect with the jointed rule m d n, another rule like itself but shorter g e f, so as that the figure g d e f shall be a perfect parallelogram: and I then say that knowing the distance of the points d and e, (the distance d f being given) I know the radius of the circle of which g d f is a portion. To prove this, a little calculation is necessary: In the circles A B and a b (fig. 6) draw the lines E D; f d, d g, g f, g e, and g D; and bearing in mind the known equation of the circle, let d n = x, g n = y; and g D = a, the absciss, ordinate, and radius respectively. The equation is 2ax - x² = y²: from which we get a = (y² + x²)/2x the denominator of this fraction being the line d e. But further its numerator (y² + x²) is equal to the square of the chord g d of the angle E D g, which chord I call c. This gives a = c²/(line d e); from which equation we derive this proportion[52] a : c ∷ c : line d e; Putting then the chord c = 1 (one foot for instance) this proportion becomes a : 1 ∷ 1 : 1/a; whence we draw this useful conclusion, that, whatever portion of a foot is contained in the line d e, (expressed by a fraction having unity for its numerator) the radius of the circle will be expressed in feet by the denominator of that fraction. Thus if the line d e, be 1 inch or 1⁄12 of a foot (and the line g d or d f be 1 foot) the radius of the circle will be 12 feet; and so for every other fraction. Now in the instrument itself the two points d and e, are connected by a micrometer-screw (not here drawn) of the kind described in a subsequent article, and by which an inch is divided in 40,000 parts, each of which therefore is the 1⁄3333.33, &c. part of a foot: so that if the distance d e, were only one of these parts, we should produce a portion g d f of a circle of 3333.33, &c. feet radius—being more than half a mile.

I had omitted to observe, that the points or studs, against which the rulers m n slide, to trace the curve (by a style in the joint d,) that these studs I say are fixed to a detached ruler o p, laid under the parallelogram on the paper, and having two stump points to hold it steady: one of the studs being moveable in a slide, in order that it may adapt the distance f g, to any required distance of the points d e: We note also that the dotted curve g d f is not the very circle drawn, but one parallel to it and distant one half the width of the rulers. In fact the mortices of these rulers are properly the acting lines, and not their edges. I expect, for several reasons, to resume the subject of this instrument before the work closes.

My principal inducements for giving this Wheel the form represented, by a section, in fig. 3, (see Plate 9) were to save horizontal room; and to gain speed by a Wheel smaller than a common horse-walk,—and yet requiring less obliquity of effort on the part of the horse. With this intention, the horse is placed in a conical Wheel A B, more or less inclined, and not much higher than himself: where, nevertheless, his head is seen to be at perfect liberty out of the cone as at C. The horse then walks in the cone, and is harnessed to a fixed bar introduced from the open side where, by a proper adjustment of the traces, he is made to act partly by his weight, so as to exert his strength in a favourable manner. This Machine applies with advantage where a horse’s power is wanted, in a boat or other confined place: and it is evident, by the relative diameters of the wheel and pinion A B and D, (as well as by the small diameter of the wheel) that a considerable velocity will be obtained at the source of power,—whence, of course, the subsequent geering to obtain the swifter motions, will be proportionately diminished.

In fig. 2, of Plate 9, (which offers an horizontal section of the Machine), A B is an axis, to the cylindrical part of which the wheels C D are fitted, so as to turn with ease in either direction. Each of these wheels, C and D, has two rims of teeth, a b, and c d; and between those b d are placed an intermediate pinion W, connected by it’s centre with the arm x, which forms a part of the axis A B. There is likewise a fourth wheel or pinion Z, working in the outer rims a c of the wheels C and D. It appears from the figure itself, that the action of this Machine depends on the greater or lesser difference between the motion forward of the wheel C, and the motion backward of the wheel D; for if these opposite motions were exactly alike, the wheels would indeed all turn, but produce no effect on the arm x, or the axis A B: whereas this motion is the very thing required. Since then the motion of the bar x, and finger g depends on the difference of action of the wheels C and D on the intermediate pinion W, we now observe, that in the present state of things, the rims a, b, c, d, have respectively 99, 100, 100, and 101 teeth: and that when one revolution has[55] been given to the wheel C, the rim b of this wheel has acted, by 100 of its teeth, on those of the intermediate pinion W; insomuch that if the opposite wheel D had been immoveable, the arm x would have been carried round the common centre a portion equal to 50 teeth, or one half of it’s circumference (which effect takes place because the pinion W rolls against the wheels C and D, it’s centre progressing only half as fast as it’s circumference.) But instead of the wheel D standing still, it has moved in a direction opposite to the former, a space equal to 99⁄100 of a revolution, and brought into the teeth of the pinion W, 99⁄100 of 101 teeth; that is, 99 teeth, and 99 hundredths of one tooth: so that the account between the two motions stands thus:

| The forward motion by the wheel C, is equal to | 100,00 | teeth. | |

| And the backward motion by the wheel D, is | 99,99 | „ | |

| And the difference in favour of the forward motion is | 00,01 | of 1 tooth. | |

Or, dividing the whole circumference into 101 parts (each one equal to a tooth of the rim d,) this difference becomes 1⁄100 part of 1⁄101 = 1⁄10100 of a revolution of the axis A B, for each revolution of the wheel C. But we have observed, that the arm x progresses only half as much, on account of the rolling motion: whence it appears that the wheel C, must make 20200 turns to produce one turn of this axis A B. And if, with 20 teeth in the pinion Z, we suppose the movement to be given by the handle y, this handle must make more than 20200 revolutions, in the proportion of 99 (the teeth in the wheel) to 20, the teeth in the pinion Z. Thus the said 20200 turns must be multiplied by the fraction 99⁄20 which gives 99990 turns of the handle, for one of the axis[56] A B. And finally, if instead of turning this Machine by the handle and pinion y Z, we turned it by an endless screw, taking into the rim c, of 100 teeth; the handle of such screw must revolve 2020000 times to produce one single revolution of the axis A B; or to carry the finger g, once round the common centre.

The above calculations are founded on the very numbers of a Machine of this kind I made in Paris: and of which I handed a model to a public man nearly thirty years ago. I need not add that this kind of movement admits of an almost endless variety: since it depends both on the numbers of the wheels and their differences; nay, on the differences of their differences. I might have gone to some length in these calculations had I not conceived it more important to bring other objects into view, than to touch at present the extensive discussions this subject invites and will doubtless suggest to many. Suffice it now to say, that here is a simple Machine which gains power (or occasions slowness), in the ratio of two millions and twenty thousand to one; giving, (if executed in proper dimensions) to a man of ordinary strength, the power of raising, singly, from three to four hundred millions of pounds. It may be useful to observe that using this Machine for an opposite purpose, that of gaining speed, extreme rapidity may be caused by a power acting very slowly on the axis A B; only in that case, the difference must be enlarged, and the diameters and numbers of the wheels be calculated on the principles of perfect geering—which is as easy in this Machine as in any other.

Doctor Gregory (in his Mechanics 2d. volume page 157,) thus introduces the description of this Crane, and the observations with which he tags that description.

“The several Cranes described in this article, as preferable to the common walking Crane, while they are free from the dangers attending that Machine, lose at the same time one of it’s advantages, that is, they do not avail themselves of that addition to the moving power which the weight of the men employed may furnish: yet this advantage has been long since insured by the mechanists on the continent: who cause the labourers to walk upon an inclined plane, turning upon an axis, after the manner shewn in the figure referred to under the article foot-mill,—where we have described a contrivance of that kind, well known in Germany nearly 150 years ago. The same principle has been lately brought into notice (probably without knowing it had been adopted before) by Mr. Whyte, (White) of Chevening in Kent: His Crane is exhibited,—fig. 2 and 4, Plate 10, as it was described in the Transactions of the Society for the Encouragement of Arts.”

“A, Plate 9, fig. 4, (of this Work) is a circular inclined plane, moving on a pivot under it, and carrying round with it the axis E. A person walking on this plane at A, and pressing against a lever, throws off a gripe or brake, and thus permits the plane to move freely, and raise the weight G by the coiling of the rope F, round the axis E. To shew more clearly the construction and action of the lever and gripe, a plan of the plane connected with them, is added in fig. 5, where B represents the lever, and D the gripe: where it is seen that when the lever B is in the situation in which it now appears, the brake or gripe D, presses against the periphery of the plane; but when the lever B is driven out to the dotted line H, the gripe D is detached, and the whole Machine left at liberty to move: a rope or cord of a proper length, being fastened to B, and to one of the uprights in the frame, to prevent this lever from being pushed too far towards H, by the man working at the Crane.”

“The supposed properties of this Crane, (says Dr. Gregory) for which the premium of forty guineas was adjudged by the society to the Inventor, are as follows:”

“‘1. It is simple, consisting merely of a wheel and axle:

“‘2. It has comparatively little friction, as is obvious from the bare inspection of the figure:

“‘3. It is durable from the two properties above mentioned:

“‘4. It is safe: for it cannot move but during the pleasure[59] of the man, and while he is actually pressing on the gripe lever:

“‘5. This Crane admits of an almost infinite variety of different powers; and this variation is obtained without the least alteration of any part of the Machine. If in unloading a vessel, there should be found goods of every weight, from a few hundreds to a ton and upwards, the workman will be able so to adapt his strength to each, as to raise it in a space of time, (inversely) proportionate to it’s weight, he walking always with the same velocity as nature and his greatest ease may teach him.’”

“‘It is a great disadvantage in some Cranes, that they take as long a time to raise the smallest weight as the largest; unless the man who works them turn or walk with such velocity as must soon tire him. In other Cranes, perhaps, two or three powers may be procured; to obtain which, some pinion must be shifted, or fresh handle applied or resorted to. In this Crane on the contrary, if the labourer find his load so heavy as to permit him to ascend the wheel without turning it, let him only move a step or two towards the circumference, and he will be fully equal to the task. Again, if the load be so light as scarcely to resist the action of his feet, and thus to oblige him to run through so much space as to tire him beyond necessity, let him move laterally towards the centre, and he will soon feel the place where his strength will suffer the least fatigue by raising the load[60] in question. One man’s weight applied to the extremity of the wheel would raise upwards of a ton: and it need not be added that a single sheaved block (at the jib) would double that power. Suffice it to say that the size of the machine may be varied in any required degree, and that this wheel will give as great advantage at any point of its plane as a common walking wheel of equal diameter; as the inclination can be varied at pleasure, as far as expediency may require. It may be well to observe that what in this figure is the frame and seems to form a part of the Crane, must be considered as part of the house in which it is placed; since it would be mostly unnecessary should such cranes be erected in houses already built: and with respect to the horizontal part, by walking on which, the man who attends the jib, occasionally assists in raising the load, it is not an essential part of this invention, when the crane and jib are not contiguous: although, when they are, it would certainly be convenient and economical.’”

The Doctor continues: “Notwithstanding, however, the advantages which have been enumerated, Mr. Whyte’s (White’s) Crane is subject to the theoretical objection, that it derives less use than might be wished from the weight of the man or men: for a great part of that weight (half of it if the inclination be 30 degrees,) lies directly upon the plane, and has no tendency to produce motion. Besides, when this Crane is of small dimensions, the effective power of the men is very[61] unequal; and the barrel too small for winding a thick rope: when large, the weight of the materials, added to that of the men, put it out of shape and give it the appearance of an unwieldy moving floor.”

The Doctor continues: “We know one large Crane of this construction, which has an upright post near the rim on each side, to support it, and keep it in shape; and as much as possible to prevent friction, each post had a vertical wheel at it’s top.” (N. B. I never saw, or heard, before, of this monster.)—“We were informed this Crane was seldom used; and that it was soon put out of order. Nor, moreover, is it every situation that will allow the Crane-rope to form a right angle with the barrel on which it winds; and when this angle is oblique, the friction must be much increased. The friction arising from the wheels at the top of the vertical crutches might indeed be got shut off, by making the inclined wheel very strong; but this would add greatly to the friction of the lower gudgeon of the oblique shaft, and considerably increase the expence of the Machine.”

“There remains then (says Dr. Gregory) another stage of improvement with regard to the construction of Cranes, in which the weight of the labourers shall operate without diminution, at the end of an horizontal lever; and in which the impulsive force thus arising, may be occasionally augmented[62] by the action of the hands, either in pulling or lifting”—and then follows the conclusion. “This step in the progress has been lately effected by Mr. David Hardie, of the East India Company’s Bengal warehouse!”

I cannot follow the author (whoever he be) of the glowing picture next given of Mr. Hardie’s Invention, (to which the obloquy thrown on my poor abortion is clearly the foil) as my readers must already be anxious to “get shut” of such unmitigated Bathos, bestowed on so trivial a theme. With respect to my Crane, I shall only say that it fulfilled the conditions required by the Society, and obtained the Premium: and if on the one hand, the language in which, thirty years ago, I described it, exhibits the impetuosity of youth, untempered with the moderation of age, I will say on the other, that if impartial criticism, mechanical acumen, or comprehensive science are essential components of a mechanical work of high pretensions,—these qualities were seldom more wantonly abandoned or abused, than in the paragraphs above quoted: except, perhaps, in the attack of the same work, on the labours and character of the justly celebrated Watt, whose merits had this author known how to appreciate, he could not thus have attempted to lessen in the public esteem.

But to return, this Diatribe begins by comparing my Crane to a foot mill: and kindly supposes I did not know that its principle existed in Germany 150 years ago. But the fact is,[63] my object was nothing like that of the author of the mill in question: the very figure of which, proves that he had no view to the variation of power by change of place on the wheel: whereas that is the principal use I make of this “unwieldy moving floor,” as the Doctor heavily terms it. Again, this author asserts that by making men walk on an inclined plane, I derive less use than might be wished from their weight; and yet! a page before he told us that “the mechanists on the Continent had long since insured the advantage of availing themselves of that addition to the moving power which the weight of the men may furnish;” so that poor I have the merit of imitating them without knowing it, and yet of not drawing the same advantages as they from the self same principle!

But again, “a great part of the weight of the man (half of it, if the inclination be 30 degrees) lies directly on the plane, and has no tendency to produce motion,” which one sided truism is placed there to give relief to the portentous dictum, which follows:—that “there remains then another stage of improvement with regard to the construction of Cranes, in which the weight of the labourers shall operate without diminution at the end of an horizontal lever: and that stage has been effected by Mr. D. H. of the East India Company’s Bengal warehouse.”