Title: The Romance of Modern Mechanism

Author: Archibald Williams

Release date: June 25, 2014 [eBook #46094]

Most recently updated: October 24, 2024

Language: English

Credits: Produced by Chris Curnow, Quentin Campbell and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

Transcriber's Note:

Minor typographical errors have been corrected. Printer's inconsistencies in the use of accents, hyphens, and punctuation have been retained unless otherwise noted. Archaic spellings have been left unchanged. For a complete list of corrections, please see the end of this document.

Note that left-clicking an illustration on some devices will display a larger version of it.

THE ROMANCE OF

MODERN MECHANISM

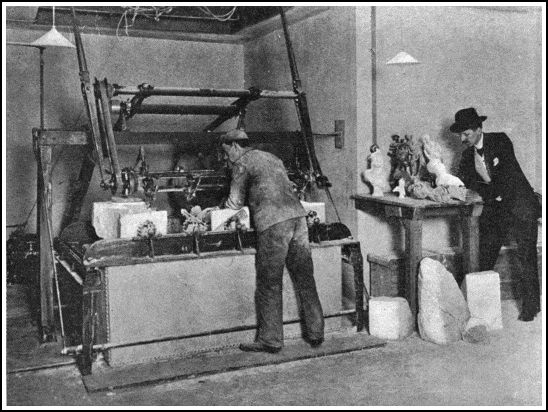

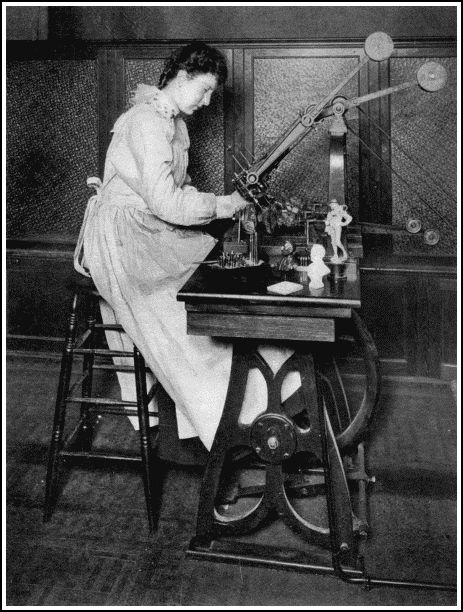

A MECHANICAL SCULPTOR

The lower illustration shows the Wenzel Sculpturing Machine at work on two blocks of stone ranged one on each side of a model. This machine can make four copies simultaneously from one original. The upper illustration shows the quality of work done by the automatic sculptor.

WITH INTERESTING DESCRIPTIONS IN NON-TECHNICAL LANGUAGE OF WONDERFUL MACHINERY AND MECHANICAL DEVICES AND MARVELLOUSLY DELICATE SCIENTIFIC INSTRUMENTS, &c., &c.

BY

ARCHIBALD WILLIAMS,

B.A., Oxon., F.R.G.S.

AUTHOR OF

"THE ROMANCE OF MODERN INVENTION," "THE ROMANCE OF MODERN

MINING," "THE ROMANCE OF MODERN ENGINEERING,"

"THE ROMANCE OF MODERN EXPLORATION,"

&c. &c.

WITH THIRTY ILLUSTRATIONS

LONDON

SEELEY AND CO. LIMITED

38 GREAT RUSSELL STREET

1910

UNIFORM WITH THIS VOLUME

THE LIBRARY OF ROMANCE

Extra Crown 8vo. With many illustrations. 5s. each

"Splendid volumes."—The Outlook.

"This series has now won a considerable and well deserved reputation."—The Guardian.

"Each volume treats its allotted theme with accuracy, but at the same time with a charm that will commend itself to readers of all ages. The root idea is excellent, and it is excellently carried out, with full illustrations and very prettily designed covers."—The Daily Telegraph.

By Prof. G. F. SCOTT ELLIOT, M.A., B.Sc.

THE ROMANCE OF SAVAGE LIFE

THE ROMANCE OF PLANT LIFE

THE ROMANCE OF EARLY BRITISH LIFE

By EDWARD GILLIAT, M.A.

THE ROMANCE OF MODERN SIEGES

By JOHN LEA, M.A.

THE ROMANCE OF BIRD LIFE

By JOHN LEA, M.A., & H. COUPIN, D.Sc.

THE ROMANCE OF ANIMAL ARTS AND CRAFTS

By SIDNEY WRIGHT

THE ROMANCE OF THE WORLD'S FISHERIES

By the Rev. J. C. LAMBERT, M.A., D.D.

THE ROMANCE OF MISSIONARY HEROISM

By G. FIRTH SCOTT

THE ROMANCE OF POLAR EXPLORATION

By ARCHIBALD WILLIAMS, B.A. (Oxon.), F.R.G.S.

THE ROMANCE OF EARLY EXPLORATION

THE ROMANCE OF MODERN EXPLORATION

THE ROMANCE OF MODERN MECHANISM

THE ROMANCE OF MODERN INVENTION

THE ROMANCE OF MODERN ENGINEERING

THE ROMANCE OF MODERN LOCOMOTION

THE ROMANCE OF MODERN MINING

By CHARLES R. GIBSON, A.I.E.E.

THE ROMANCE OF MODERN PHOTOGRAPHY

THE ROMANCE OF MODERN ELECTRICITY

THE ROMANCE OF MODERN MANUFACTURE

By EDMUND SELOUS

THE ROMANCE OF THE ANIMAL WORLD

THE ROMANCE OF INSECT LIFE

By AGNES GIBERNE

THE ROMANCE OF THE MIGHTY DEEP

By E. S. GREW, M.A.

THE ROMANCE OF MODERN GEOLOGY

By J. C. PHILIP, D.Sc., Ph.D.

THE ROMANCE OF MODERN CHEMISTRY

SEELEY & CO., LIMITED

In the beginning a man depended for his subsistence entirely upon his own efforts, or upon those of his immediate relations and friends. Life was very simple in those days: luxury being unknown, and necessity the factor which guided man's actions at every turn. With infinite labour he ground a flint till it assumed the shape of a rough arrow-head, to be attached to a reed and shot into the heart of some wild beast as soon as he had approached close enough to be certain of his quarry. The meat thus obtained he seasoned with such roots and herbs as nature provided—a poor and scanty choice. Presently he discovered that certain grains supported life much better than roots, and he became an agriculturist. But the grain must be ground; so he invented a simple mill—a small stone worked by hand over a large one; and when this method proved too tedious he so shaped the stones' surfaces that they touched at all points, and added handles by which the upper stone could be revolved.

With the discovery of bronze, and, many centuries later, of iron, his workshop equipment rapidly improved. He became an expert boat- and house-builder, and multiplied weapons of offence and defence. Gradually separate [vi] crafts arose. One man no longer depended on his individual efforts, but was content to barter his own work for the products of another man's labour, because it became evident that specialisation promoted excellence of manufacture.

A second great step in advance was the employment of machinery, which, when once fashioned by hand, saved an enormous amount of time and trouble—the pump, the blowing bellows, the spinning-wheel, the loom. But all had to be operated by human effort, sometimes replaced by animal power.

With the advent of the steam-engine all industry bounded forward again. First harnessed by Watt, Giant Steam has become a commercial and political power. Everywhere, in mill and factory, locomotive, ship, it has increased the products which lend ease and comfort to modern life; it is the great ally of invention, and the ultimate agent for transporting men and material from one point on the earth's surface to another.

Try as we may, we cannot escape from our environment of mechanism, unless we are content to revert to the loincloth and spear of the savage. Society has become so complicated that the utmost efforts of an individual are, after all, confined to a very narrow groove. The days of the Jack-of-all-trades are over. Success in life, even bare subsistence, depends on the concentration of one's faculties upon a very limited daily routine. "Let the cobbler stick to his last" is a maxim which carries an ever-increasing force.

The better to realise how dependent we are on the mechanisms controlled by the thousand and one classes [vii] of workmen, let us consider the surroundings, possessions, and movements of the average, well-to-do business man.

At seven o'clock he wakes, and instinctively feels beneath his pillow for his watch, a most marvellous assemblage of delicate parts shaped by wonderful machinery. Before stepping into his bath he must turn a tap, itself a triumph of mechanical skill. The razor he shaves with, the mirror which helps him in the operation, the very brush and soap, all are machine-made. With his clothes he adds to the burden of his indebtedness to mechanism. The power-loom span the linen for his shirts, the cloth for his outer garments. Shirts and collars are glossy from the treatment of the steam laundry, where machinery is rampant. His boots, kept shapely by machine-made lasts, should remind him that mechanical devices have played a large part in their manufacture, very possibly the human hand has scarcely had a single duty to perform.

He goes downstairs, and presses an electric button. Mechanism again. While waiting for his breakfast his eye roves carelessly over the knives, spoons, forks, table, tablecloth, wall-paper, engravings, carpet, cruet-stand—all machine-made in a larger or less degree. The very coals blazing in the grate were won by machinery; the marble of the mantelpiece was shaped and polished by machinery; also the fire-irons, the chairs, the hissing kettle. Machinery stares at him from the loaf on its machine-made board. Machines prepared the land, sowed, harvested, threshed, ground, and probably otherwise prepared the grain for baking. Machines ground his salt, [viii] his coffee. Machinery aided the capture of the tempting sole; helped to cure the rasher of bacon; shaped the dishes, the plates, the coffee-pot.

Whirr-r-r! The motor-car is at the door, throbbing with the impulses of its concealed machinery. Our friend therefore puts on his machine-made gloves and hat and sallies forth. That wonderful motor, the product of the most up-to-date, scientific, and mechanical appliances, bears him swiftly over roads paved with machine-crushed stone and flattened out by a steam-roller. A book might be reserved to the motor alone; but we must refrain, for a few minutes' travel has brought the horseless carriage to the railway station. Mr. Smith, being the holder of a season ticket, does not trouble the clerk who is stamping pasteboards with a most ingenious contrivance for automatically impressing dates and numbers on them. He strolls out on the platform and buys the morning paper, which, a few hours before, was being battered about by one of the most wonderful machines that ever was devised by the brain of man. Mr. Smith doesn't bother his head with thoughts of the printing-press. Its products are all round him, in timetables and advertisements. Nor does he ponder upon the giant machinery which crushed steel ingots into the gleaming rails that stretch into the far distance; nor upon the marvellous interlocking mechanism of the signal-box at the platform-end; nor upon the electric wires thrumming overhead. No! he had seen all these things a thousand times before, and probably feels little of the romance which lies so thickly upon them.

A whistle blows. The "local" is approaching, with [ix] its majestic locomotive—a very orgy of mechanism—its automatic brakes, its thousand parts all shaped by mechanical devices,—steam saws, planes, lathes, drills, hammers, presses. In obedience to a little lever the huge mass comes quickly to rest; the steam pump on the engine commences to gasp; a minute later another lever moves, and Mr. Smith is fairly on his way to business.

Arrived at the metropolis, he presses electricity into his service, either on an electric tram or on a subterranean train. In the latter case he uses an electric lift, which lowers him into the bowels of the earth, to pass him on to the current-propelled cars, driven by power generated in far-away stations.

His office is stamped all over with the seal of mechanism. In the lobby are girls hammering on marvellous typewriters; on his desk rests a telephone, connected through wires and most elaborately equipped exchanges with all parts of the country. To get at his private and valuable papers Mr. Smith must have recourse to his bunch of keys, which, with their corresponding locks, represent ingenuity of a high degree. All day long he is in the grasp of mechanism; not even at lunch time can he escape it, for the food set before him at the restaurant has been cooked by the aid of special kitchen machinery.

And when the evening draws on Mr. Smith touches a switch to turn his darkness into light, wrung through many wonderful processes from the stored illumination of coal.

Were we to trace the daily round of the clerk, artisan, scientist, engineer, or manufacturer, we should be brought [x] into contact with a thousand other mechanical appliances. Space forbids such a tour of inspection; but in the following pages we may rove here and there through the workshops of the world, gleaning what seems to be of special interest to the general public, and weaving round it, with a machine-made pen, some of the romance which is apt to be lost sight of by the most marvellous of all creations—Man.

The author desires to express his indebtedness to the following gentlemen for the kind help they have afforded him in connection with the gathering of materials for the letterpress and illustration of this book:—

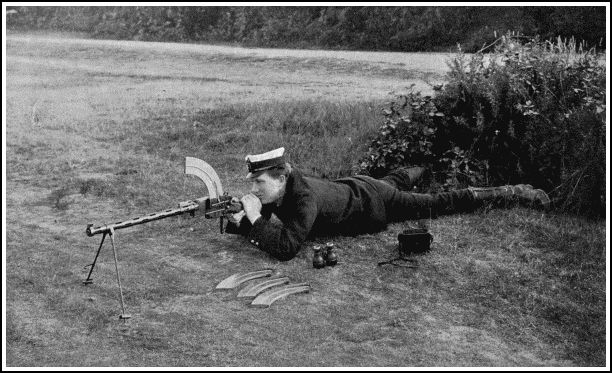

The proprietors of Cassier's Magazine, The Magazine of Commence, The World's Work, The Motor Boat; The Rexer Automatic Machine Gun Co.; The Diesel Oil Engine Co.; The Cambridge Scientific Instrument Co.; The Marconi Wireless Telegraphy Co.; The Temperley Transporter Co.; Messrs. de Dion, Bouton and Co.; Messrs. Merryweather and Sons; Mr. A. Crosby Lockwood; Mr. Dan Albone; Mr. J. B. Diplock; Mr. W. H. Oatway; The National Cash Register Co.; The Wenzel Sculpturing Machine Co.; Mr. E. W. Gaz; Sir W. G. Armstrong, Whitworth and Co.; The International Harvester Co. and Messrs. Gwynne and Co.

| PAGE | |

| INTRODUCTION | v |

| AUTHOR'S NOTE | xi |

| CHAPTER I | |

| DELICATE INSTRUMENTS — WATCHES AND CHRONOMETERS — THE MICROTOME — THE DIVIDING ENGINE — MEASURING MACHINES | 17 |

| CHAPTER II | |

| CALCULATING MACHINES | 42 |

| CHAPTER III | |

| WORKSHOP MACHINERY — THE LATHE — PLANING MACHINES — THE STEAM HAMMER — HYDRAULIC TOOLS — ELECTRICAL TOOLS IN THE SHIPYARD | 59 |

| CHAPTER IV | |

| PORTABLE TOOLS | 90 |

| CHAPTER V | |

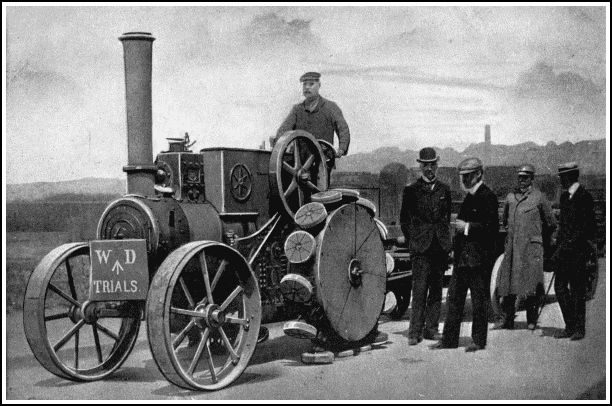

| THE PEDRAIL: A WALKING STEAM-ENGINE | 97 |

| CHAPTER VI | |

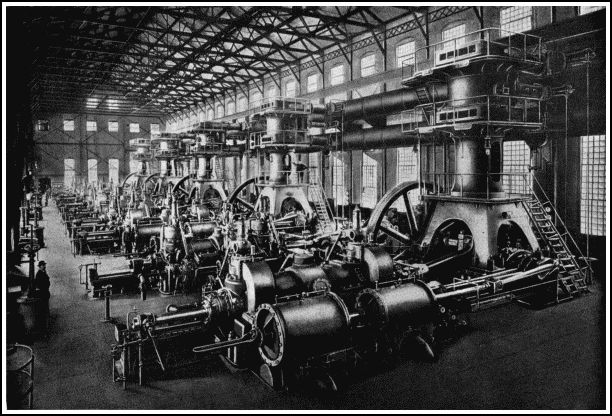

| INTERNAL COMBUSTION ENGINES — OIL ENGINES — ENGINES WORKED WITH PRODUCER GAS — BLAST FURNACE GAS ENGINES | 112 |

| CHAPTER VII | |

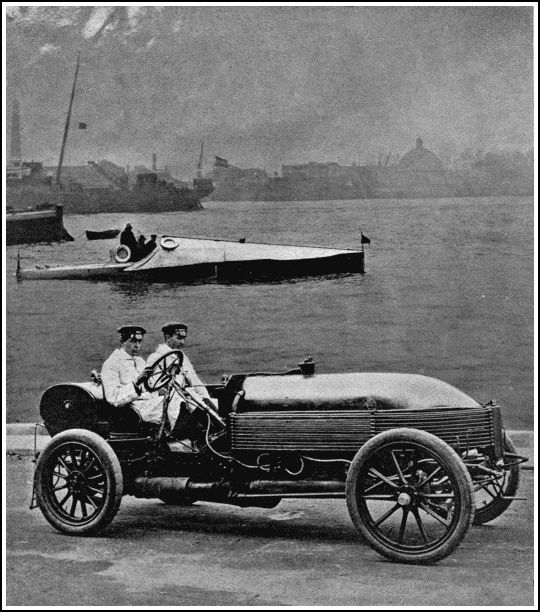

| MOTOR-CARS — THE MOTOR OMNIBUS — RAILWAY MOTOR-CARS | 130 |

| CHAPTER VIII | |

| THE MOTOR AFLOAT — PLEASURE BOATS — MOTOR LIFEBOATS — MOTOR FISHING BOATS — A MOTOR FIRE FLOAT — THE MECHANISM OF THE MOTOR BOAT — THE TWO-STROKE MOTOR — MOTOR BOATS FOR THE NAVY | 150 |

| CHAPTER IX | |

| THE MOTOR CYCLE | 175 |

| CHAPTER X | |

| FIRE ENGINES | 185 |

| CHAPTER XI | |

| FIRE-ALARMS AND AUTOMATIC FIRE EXTINGUISHERS | 191 |

| CHAPTER XII | |

| THE MACHINERY OF A SHIP — THE REVERSING ENGINE — MARINE ENGINE SPEED GOVERNORS — THE STEERING ENGINE — BLOWING AND VENTILATING APPARATUS — PUMPS — FEED HEATERS — FEED-WATER FILTERS — DISTILLERS — REFRIGERATORS — THE SEARCH-LIGHT — WIRELESS TELEGRAPHY INSTRUMENTS — SAFETY DEVICES — THE TRANSMISSION OF POWER ON A SHIP | 203 |

| CHAPTER XIII | |

| "THE NURSE OF THE NAVY" | 236 |

| CHAPTER XIV | |

| THE MECHANISM OF DIVING | 240 |

| CHAPTER XV | |

| APPARATUS FOR RAISING SUNKEN SHIPS AND TREASURE | 248 |

| CHAPTER XVI | |

| THE HANDLING OF GRAIN — THE ELEVATOR — THE SUCTION PNEUMATIC GRAIN-LIFTER — THE PNEUMATIC BLAST GRAIN-LIFTER — THE COMBINED SYSTEM | 252 |

| CHAPTER XVII | |

| MECHANICAL TRANSPORTERS AND CONVEYERS — ROPEWAYS — CABLEWAYS — TELPHERAGE — COALING WARSHIPS AT SEA | 258 |

| CHAPTER XVIII | |

| AUTOMATIC WEIGHERS | 274 |

| CHAPTER XIX | |

| TRANSPORTER BRIDGES | 277 |

| CHAPTER XX | |

| BOAT- AND SHIP-RAISING LIFTS | 283 |

| CHAPTER XXI | |

| A SELF-MOVING STAIRCASE | 295 |

| CHAPTER XXII | |

| PNEUMATIC MAIL TUBES | 301 |

| CHAPTER XXIII | |

| AN ELECTRIC POSTAL SYSTEM | 315 |

| CHAPTER XXIV | |

| AGRICULTURAL MACHINERY — PLOUGHS — DRILLS AND SEEDERS — REAPING MACHINES — THRESHING MACHINES — PETROL-DRIVEN FIELD MACHINERY — ELECTRICAL FARMING MACHINERY | 318 |

| CHAPTER XXV | |

| DAIRY MACHINERY — MILKING MACHINES — CREAM SEPARATORS — A MACHINE FOR DRYING MILK | 330 |

| CHAPTER XXVI | |

| SCULPTURING MACHINES | 335 |

| CHAPTER XXVII | |

| AN AUTOMATIC RIFLE — A BALL-BEARING RIFLE | 345 |

| PAGE | |

| A CARVING MACHINE | Frontispiece |

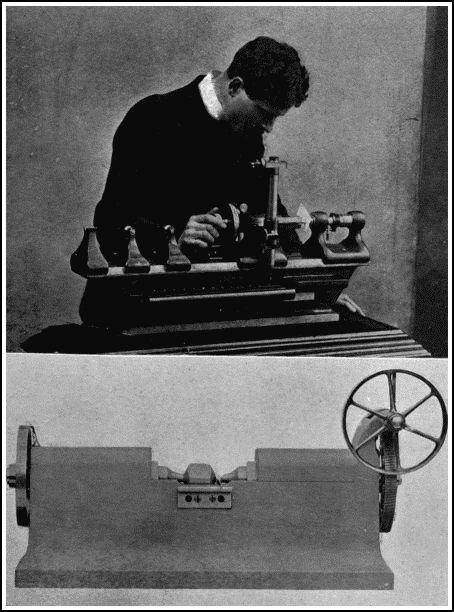

| MEASURING MACHINES | 34 |

| A CASH REGISTER | 45 |

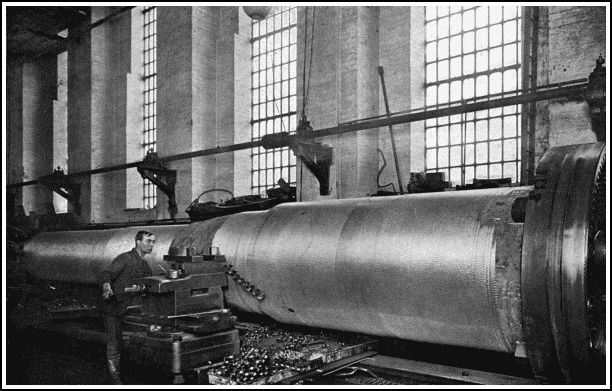

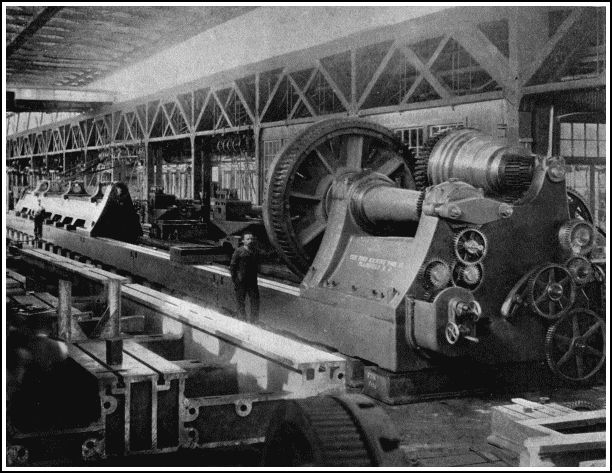

| LATHE TURNING A BIG GUN | 59 |

| LATHE FOR BORING 16-INCH GUN | 65 |

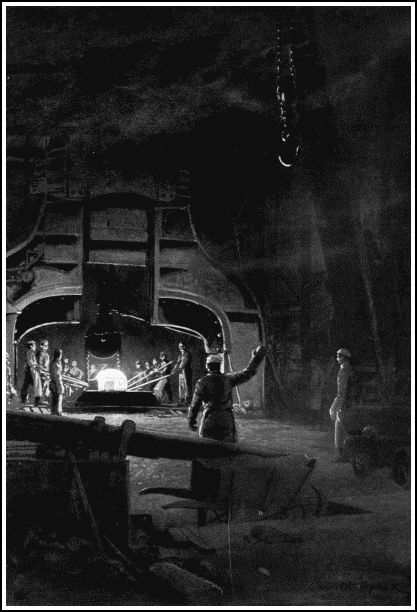

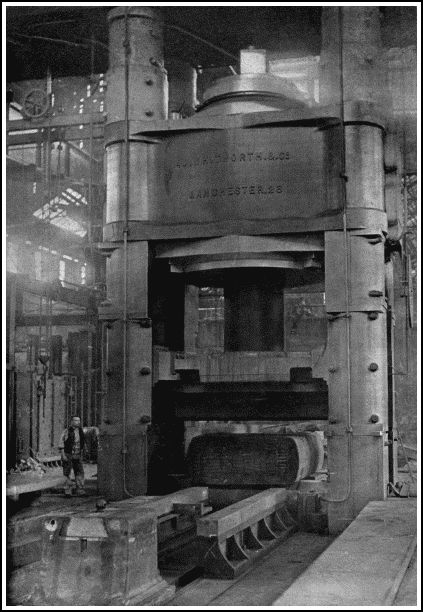

| A STEAM HAMMER | 72 |

| A HUGE HYDRAULIC PRESS | 82 |

| A PEDRAIL TRACTION ENGINE | 108 |

| GREAT GAS ENGINE FOR BLAST FURNACES | 128 |

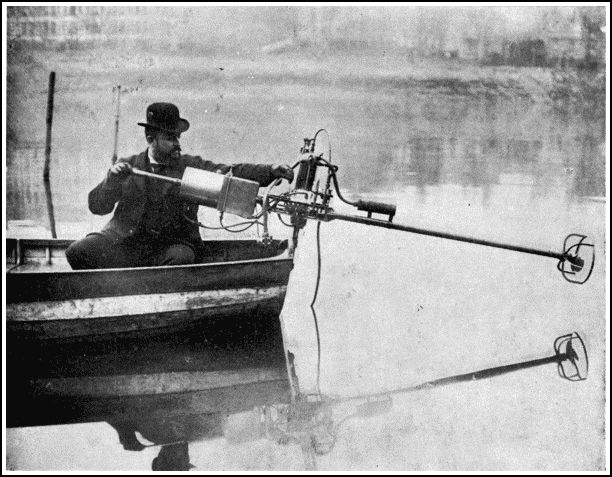

| MOTOR-CAR AND MOTOR-BOAT | 151 |

| A MOTOGODILLE | 156 |

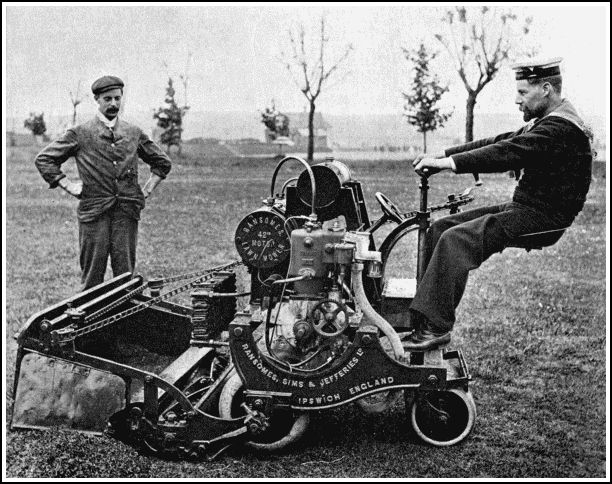

| A MOTOR LAWN MOWER | 182 |

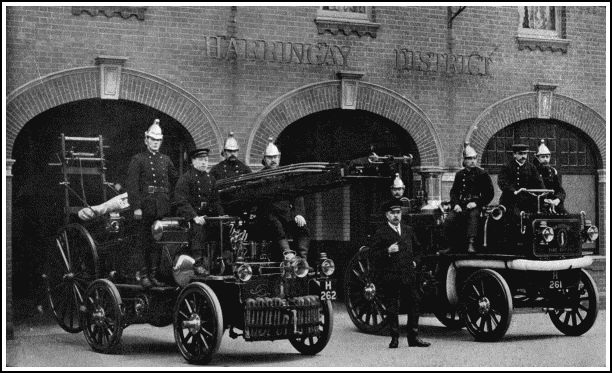

| UP-TO-DATE FIRE BRIGADE ENGINES | 186 |

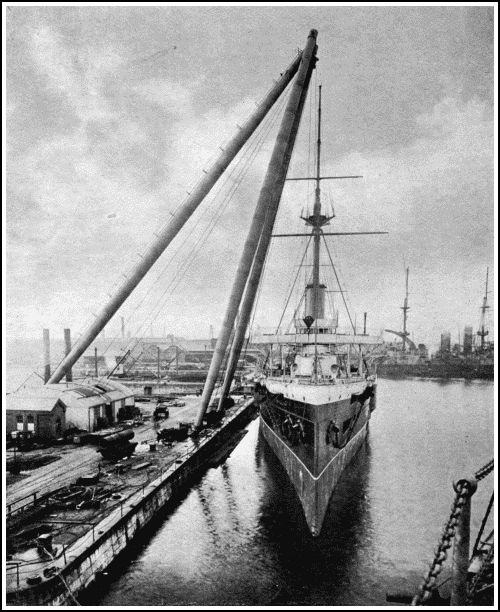

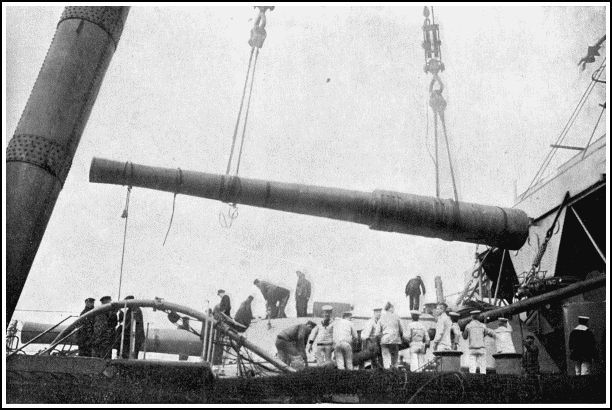

| HOISTING A HEAVY GUN ON BOARD MAN-OF-WAR | 204 |

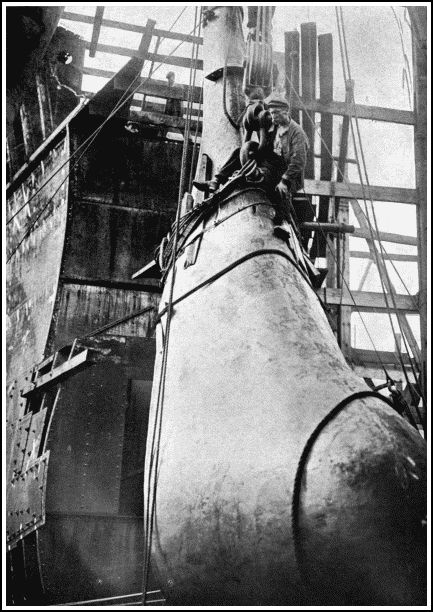

| FIXING A RAM TO A BATTLESHIP | 228 |

| A TRIPOD CRANE | 237 |

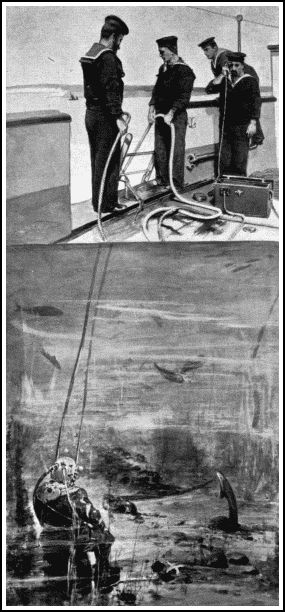

| MODERN DIVING APPARATUS | 245 |

| COALING AT SEA | 271 |

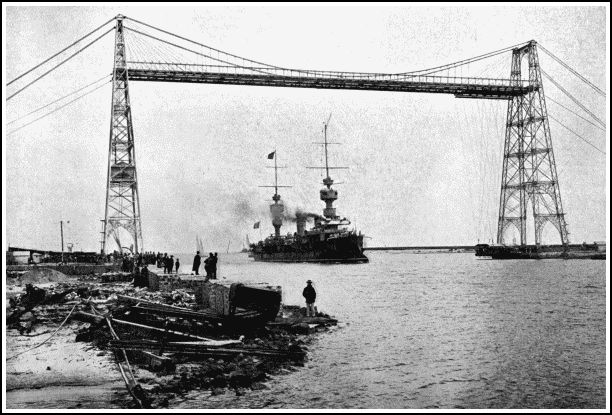

| A TRANSPORTER BRIDGE AT BIZERTA | 278 |

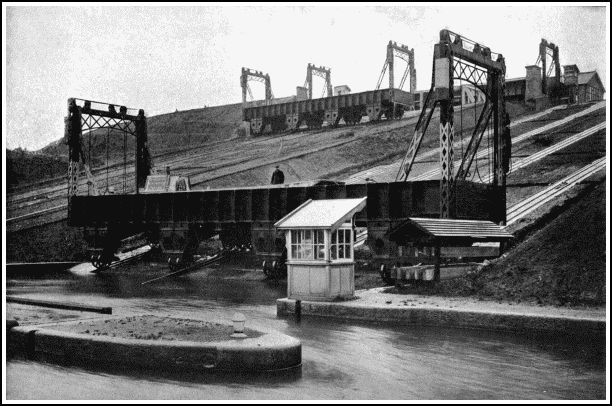

| A CANAL LIFT | 289 |

| AN AMERICAN CUTTER AND BINDER | 322 |

| A MOTOR PLOUGH | 327 |

| GIRL CARVING BY MACHINERY | 343 |

| THE REXER GUN | 352 |

WATCHES AND CHRONOMETERS — THE MICROTOME — THE DIVIDING ENGINE — MEASURING MACHINES

Owing to the universal use of watches, resulting from their cheapness, the possessor of a pocket timepiece soon ceases to take a pride in the delicate mechanism which at first added an inch or two to his stature. At night it is wound up mechanically, and thrust under the pillow, to be safe from imaginary burglars and handy when the morning comes. The awakened sleeper feels small gratitude to his faithful little servant, which all night long has been beating out the seconds so that its master may know just where he is with regard to "the enemy" on the morrow. At last a hand is slipped under the feather-bag, and the watch is dragged from its snug hiding-place. "Bother it," says the sleepy owner, "half-past eight; ought to have been up an hour ago!" and out he tumbles. Dressing concluded, the watch passes to its day quarters in a darksome waistcoat [18] pocket, to be hauled out many times for its opinion to be taken.

The real usefulness of a watch is best learnt by being without one for a day or two. There are plenty of clocks about, but not always in sight; and one gradually experiences a mild irritation at having to step round the corner to find out what the hands are doing.

A truly wonderful piece of machinery is a watch—even a cheap one. An expensive, high-class article is worthy of our admiration and respect. Here is one that has been in constant use for fifty years. Twice a second its little balance-wheel revolves on its jewelled bearings. Allowing a few days for repairs, we find by calculation that the watch has made no less than three thousand million movements in the half-century! And still it goes ticking on, ready to do another fifty years' work. How beautifully tempered must be the springs and the steel faces which are constantly rubbing against jewel or metal! How perfectly cut the teeth which have engaged one another times innumerable without showing appreciable wear!

The chief value of a good watch lies in its accuracy as a time-keeper. It is, of course, easy to correct it by standard clocks in the railway stations or public buildings; but one may forget to do this, and in a week or two a loss of a few minutes may lead to one missing a train, or being late for an important engagement. Happy, therefore, is the man who, having set his watch to "London time," can rely on its not varying from accuracy a minute in a week—a feat achieved by many watches.

The old-fashioned watch was a bulky affair, protected [19] by an outer case of ample proportions. From year to year the size has gradually diminished, until we can now purchase a reliable article no thicker than a five-shilling piece, which will not offend the most fastidious dandy by disarranging the fit of his clothes. Into the space of a small fraction of an inch is crowded all the usual mechanism, reduced to the utmost fineness. Watches have even been constructed small enough to form part of a ring or earring, without losing their time-keeping properties.

For practical purposes, however, it is advantageous to have a timepiece of as large a size as may be convenient, since the difficulties of adjustment and repair increase with decreasing proportions. The ship's chronometer, therefore, though of watch construction, is a big affair as compared with the pocket timepiece; for above all things it must be accurate.

The need for this arises from the fact that nautical reckonings made by the observation of the heavenly bodies include an element of time. We will suppose a vessel to be at sea out of sight of land. The captain, by referring to the dial of the "mechanical log," towed astern, can reckon pretty accurately how far the vessel has travelled since it left port; but owing to winds and currents he is not certain of the position on the globe's surface at which his ship has arrived. To locate this exactly he must learn (a) his longitude, i.e. distance E. or W. of Greenwich, (b) his latitude, i.e. distance N. or S. of the Equator. Therefore, when noon approaches, his chronometers and sextant are got out, and at the moment when the sun crosses the meridian the time is taken. If this moment happens to coincide with four o'clock on the chronometers [20] he is as far west of Greenwich as is represented by four twenty-fourths of the 360° into which the earth's circumference is divided; that is, he is in longitude 60° W. The sextant gives him the angle made by a line drawn to the sun with another drawn to the horizon, and from that he calculates his latitude. Then he adjourns to the chart-room, where, by finding the point at which the lines of longitude and latitude intersect, he establishes his exact position also.

When the ship leaves England the chronometer is set by Greenwich time, and is never touched afterwards except to be wound once a day. In order that any error may be reduced to a minimum a merchant ship carries at least two chronometers, a man-of-war at least three, and a surveying vessel as many as a dozen. The average reading of the chronometers is taken to work by.

Taking the case of a single chronometer, it has often to be relied on for months at a time, and during that period has probably to encounter many changes of temperature. If it gains or loses from day to day, and that consistently, it may still be accounted reliable, as the amount of error will be allowed for in all calculations. But should it gain one day and lose another, the accumulated errors would, on a voyage of several months, become so considerable as to imperil seriously the safety of the vessel if navigating dangerous waters.

As long ago as 1714 the English Government recognised the importance of a really reliable chronometer, and in that year passed an Act offering rewards of £10,000, £15,000, and £20,000 to anybody who should produce a chronometer that would fix longitude within sixty, forty, [21] and thirty miles respectively of accuracy. John Harrison, the son of a Yorkshire carpenter, who had already invented the ingenious "gridiron pendulum" for compensating clocks, took up the challenge. By 1761 he had made a chronometer of so perfect a nature that during a voyage to Jamaica that year, and back the next, it lost only 1 min. 54 1 2 sec. As this would enable a captain to find his longitude within eighteen miles in the latitude of Greenwich, Harrison claimed, and ultimately received, the maximum reward.

It was not till nearly a century later that Thomas Earnshaw produced the "compensation balance," now generally used on chronometers and high-class watches. In cheap watches the balance is usually a little three-spoked wheel, which at every tick revolves part of a turn and then flies back again. This will not suffice for very accurate work, because the "moment of inertia" varies at different temperatures. To explain this term let us suppose that a man has a pound of metal to make into a wheel. If the wheel be of small diameter, you will be able to turn it first one way and then the other on its axle quite easily. But should it be melted down and remade into a wheel of four times the diameter, with the same amount of metal as before in the rim, the difficulty of suddenly reversing its motion will be much increased. The weight is the same, but the speed of the rim, and consequently its momentum, is greater. It is evident from this that, if a wheel of certain size be driven by a spring of constant strength, its oscillations will be equal in time; but if a rise of temperature should lengthen the spokes the speed would fall, because the spring would have more [22] work to do; and, conversely, with a fall of temperature the speed would rise. Earnshaw's problem was to construct a balance wheel that should be able to keep its "moment of inertia" constant under all circumstances. He therefore used only two spokes to his wheel, and to the outer extremity of each attached an almost complete semicircle of rim, one end being attached to the spoke, the other all but meeting the other spoke. The rim-pieces were built up of an outer strip of brass, and an inner strip of steel welded together. Brass expands more rapidly than steel, with the result that a bar compounded of these two metals would, when heated, bend towards the hollow side. To the rim-pieces were attached sliding weights, adjustable to the position found by experiment to give the best results.

We can now follow the action of the balance wheel. It runs perfectly correctly at, say, a temperature of 60°. Hold it over a candle. The spokes lengthen, and carry the rim-pieces outwards at their fixed ends; but, as the pieces themselves bend inwards at their free ends, the balance is restored. If the balance were placed in a refrigerating machine, the spokes would shorten, but the rim-pieces would bend outwards.

As a matter of fact, the "moment of inertia" cannot be kept quite constant by this method, because the variation of expansion is more rapid in cold than in heat; so that, though a balance might be quite reliable between 60° and 100°, it would fail between 30° and 60°. So the makers fit their balances with what is called a secondary compensation, the effect of which is to act more quickly in high than in low temperatures. This could not well [23] be explained without diagrams, so a mere mention must suffice.

Another detail of chronometer making which requires very careful treatment is the method of transmitting power from the main spring to the works. As the spring uncoils, its power must decrease, and this loss must be counterbalanced somehow. This is managed by using the "drum and fusee" action, which may be seen in some clocks and in many old watches. The drum is cylindrical, and contains the spring. The fusee is a tapering shaft, in which a spiral groove has been cut from end to end. A very fine chain connects the two parts. The key is applied to the fusee, and the chain is wound off the drum on to the larger end of the fusee first. By the time that the spring has been fully wound, the chain has reached the fusee's smaller extremity. If the fusee has been turned to the correct taper, the driving power of the spring will remain constant as it unwinds, for it gets least leverage over the fusee when it is strongest, and most when it is weakest, the intermediate stages being properly proportioned. To test this, a weighted lever is attached to the key spindle, with the weight so adjusted that the fully wound spring has just sufficient power to lift it over the topmost point of a revolution. It is then allowed a second turn, but if the weight now proves excessive something must be wrong, and the fusee needs its diameter reducing at that point. So the test goes on from turn to turn, and alterations are made until every revolution is managed with exactly the same ease.

The complete chronometer is sent to Greenwich observatory to be tested against the Standard Clock, which, at [24] 10 a.m., flashes the hour to other clocks all over Great Britain. In a special room set apart for the purpose are hundreds of instruments, some hanging up, others lying flat. Assistants make their rounds, noting the errors on each. The temperature test is then applied in special ovens, and finally the article goes back to the maker with a certificate setting forth its performances under different conditions. If the error has been consistent the instrument is sold, the buyer being informed exactly what to allow for each day's error. At the end of the voyage he brings his chronometer to be tested again, and, if necessary, put right.

Here are the actual variations of a chronometer during a nineteen-day test, before being used:—

| Day. | Gain in tenths of seconds. |

Day. | Gain in tenths of seconds. |

|

| 1st | ½ | 11th | 4 | |

| 2nd | 3 | 12th | 3 | |

| 3rd | 4 | 13th | 3 | |

| 4th | 4 | 14th | 4 | |

| 5th | ½ | 15th | 5 | |

| 6th | 3 | 16th | 2 | |

| 7th | 0 | 17th | 3 | |

| 8th | 0 | 18th | 5 | |

| 9th | 4½ | 19th | 1 | |

| 10th | 3 |

An average gain of just over one quarter of a second per diem! Quite extraordinary feats of time-keeping have been recorded of chronometers on long voyages. Thus a chronometer which had been to Australia viâ the Cape and back viâ the Red Sea was only fifteen seconds "out"; and the Encyclopædia Britannica quotes the [25] performance of the three instruments of s.s. Orellana, which between them accumulated an error of but 2·3 seconds during a sixty-three-day trip.

An instrument which will cut a blood corpuscle into several parts—that's the Microtome, the "small-cutter," as the name implies.

For the examination of animal tissues it is necessary that they should be sliced very fine before they are subjected to the microscope. Perhaps a tiny muscle is being investigated and cross sections of it are needed. Well, one cannot pick up the muscle and cut slices off it as you would off a German sausage. To begin with, it is difficult even to pick the object up; and even if pieces one-hundredth of an inch long were detached they would still be far too large for examination.

So, as is usually the case when our unaided powers prove unequal to a task, we have recourse to a machine. There are several types of microtomes, each preferable for certain purposes. But as in ordinary laboratory work the Cambridge Rocking Microtome is used, let us give our special attention to this particular instrument. It is mounted on a strong cast-iron bed, a foot or so in length and four to five inches wide. Towards one end rise a couple of supports terminating in knife-edges, which carry a cross-bar, itself provided with knife-edges top and bottom, those on the top supporting a second transverse bar. Both bars have a long leg at right angles, giving them the appearance of two large T's superimposed one on the other; but the top T is converted into a cross by a fourth member—a sliding tube which projects forward towards a frame in which is clamped a razor, edge upwards.

The tail of the lower T terminates in a circular disc, pierced with a hole to accommodate the end of a vertical screw, which has a large circular head with milled edges. The upper T is rocked up and down by a cord and spring, the handle actuating the cord also shifting on the milled screw-head a very small distance every time it is rocked backwards and forwards. As the screw turns, it gradually raises the tail of the lower member, and by giving its cross-bar a tilt brings the tube of the upper member appreciably nearer the razor. The amount of twist given to the screw at each stroke can be easily regulated by a small catch.

When the microscopist wishes to cut sections he first mounts his object in a lump of hard paraffin wax, coated with softer wax. The whole is stuck on to the face of the tube, so as to be just clear of the razor.

The operator then seizes the handle and works it rapidly until the first slice is detached by the razor. Successive slices are stuck together by their soft edges so as to form a continuous ribbon of wax, which can be picked up easily and laid on a glass slide. The slide is then warmed to melt the paraffin, which is dissolved away by alcohol, leaving the atoms of tissue untouched. These, after being stained with some suitable medium, are ready for the microscope.

A skilful user can, under favourable conditions, cut slices one twenty-five thousandth of an inch thick. To gather some idea of what this means we will imagine that a cucumber one foot long and one and a-half inches in diameter is passed through this wonderful guillotine. It would require no less than 700 dinner-plates nine inches [27] across to spread the pieces on! If the slices were one-eighth of an inch thick, the cucumber, to keep a proportionate total size, would be 260 feet long. After considering these figures we shall lose some of the respect we hitherto felt for the men who cut the ham to put inside luncheon-bar sandwiches.

In the preceding pages frequent reference has been made to index screws, exactly graduated to a convenient number of divisions. When such screws have to be manufactured in quantities it would be far too expensive a matter to measure each one separately. Therefore machinery, itself very carefully graduated, is used to enable a workman to transfer measurements to a disc of metal.

If the index-circle of an astronomical telescope—to take an instance—has to be divided, it is centred on a large horizontal disc, the circumference of which has been indented with a large number of teeth. A worm-screw engages these teeth tangentially (i.e. at right angles to a line drawn from the centre of the plate to the point of engagement). On the shaft of the screw is a ratchet pinion, in principle the same as the bicycle free-wheel, which, when turned one way, also twists the screw, but has no effect on it when turned the other way. Stops are put on the screw, so that it shall rotate the large disc only the distance required between any two graduations. The divisions are scribed on the index-circle by a knife attached to a carriage over and parallel to the disc. The Dividing Engine used for the graduation of certain astronomical instruments probably constitutes the most perfect machine ever made. In an address to the Institution [28] of Mechanical Engineers,[1] the President, Mr. William Henry Maw, used the following words: "The most recently constructed machine of the kind of which I am aware—namely, one made by Messrs. Warner and Swasey, of Cleveland, U.S.A.—is capable of automatically cutting the graduations of a circle with an error in position not exceeding one second of arc. (A second of an arc is approximately the angle subtended by a halfpenny at a distance of three miles.) This means that on a 20-inch circle the error in position of any one graduation shall not exceed 1 20,000 inch. Now, the finest line which would be of any service for reading purposes on such a circle would probably have a width equal to quite ten seconds of arc; and it follows that the minute V-shaped cut forming this line must be so absolutely symmetrical with its centre line throughout its length, that the position of this centre may be determined within the limit of error just stated by observations of its edges, made by aid of the reading micrometer and microscope. I may say that after the machine just mentioned had been made, it took over a year's hard work to reduce the maximum error in its graduations from one and a-half to one second of arc."

The same address contains a reference to the great Yerkes telescope, which though irrelevant to our present chapter, affords so interesting an example of modern mechanical perfection that it deserves parenthetic mention.

The diameter of a star of the seventh magnitude as it appears in the focus of this huge telescope is 1 2,500 inch. The spiders' webs stretched across the object glass are [29] about 1 6,000 inch in diameter. "The problem thus is," says Mr. Maw, "to move this twenty-two ton mass (the telescope) with such steadiness in opposition to the motion of the earth, that a star disc 1 2,500 inch in diameter can be kept threaded, as it were, upon a spider's web 1 6,000 inch in diameter, carried at a radius of thirty-two feet from the centre of motion. I think that you will agree that this is a problem in mechanical engineering demanding no slight skill to solve; but it has been solved, and with the most satisfactory results." The motions are controlled electrically; and respecting them Professor Barnard, one of the chief observers with this telescope, some time ago wrote as follows: "It is astonishing to see with what perfect instantaneousness the clock takes up the tube. The electric slow motions are controlled from the eye end. So exact are they that a star can be brought from the edge of the field and stopped instantaneously behind the micrometer wire."

Dividing engines are used for ruling parallel lines on glass and metal, to aid in the measurements of microscopical objects or the wave-lengths of light. A diffraction grating, used for measuring the latter, has the lines so close together that they would be visible only under a powerful microscope. Glass being too brittle, a special alloy of so-called speculum metal is fashioned into a highly polished plate, and this is placed in the machine. A delicate screw arrangement gradually feeds the plate forwards under the diamond point, which is automatically drawn across the plate between every two movements. Professor H. A. Rowlands has constructed a parallel dividing engine which has ruled as many as 120,000 lines to the inch. [30] To get a conception of these figures we must once again resort to comparison. Let us therefore take a furrow as a line, and imagine a ploughman going up and down a field 120,000 times. If each furrow be eight inches wide, the field would require a breadth of nearly fourteen miles to accommodate all the furrows! Again, supposing that a plate six inches square were being ruled, the lines placed end to end would extend for seventy miles!

Professor Rowlands' machine does the finest work of this kind. Another very perfect instrument has been built by Lord Blythswood, and as some particulars of it have been kindly supplied, they may fitly be appended.

If a first-class draughtsman were asked how many parallel straight lines he would rule within the space of one inch, it is doubtful whether he would undertake more than 150 to 200 lines. Lord Blythswood's machine can rule fourteen parallel lines on a space equivalent to the edge of the finest tissue paper. So delicate are the movements of the machine that it must be protected from variations of temperature, which would contract or expand its parts; so the room in which it stands is kept at an even heat by automatic apparatus, and to make things doubly sure the engine is further sheltered in a large case having double walls inter-packed with cotton wool.

In constructing the machine it was found impossible, with the most scientific tools, to cut a toothed wheel sufficiently accurate to drive the mechanism, but the errors discovered by microscopes were made good by the invention of a small electro-plating brush, which added the thinnest imaginable layer of metal to any tooth found deficient.

During the process of ruling a grating of only a few square [31] inches area, the machine must be left severely alone in its closed case. The slightest jar would cause unparallelism of a few lines, and the ruin of the whole grating. So for several days the diamond point has its own way, moving backwards and forwards unceasingly over the hard metal, in which it chases tiny grooves. At the end the plate has the appearance of mother-of-pearl, which is, in fact, one of nature's diffraction gratings, breaking up white light into the colours of the spectrum.

You will be able to understand that these mechanical gratings are expensive articles. Sometimes the diamond point breaks half-way through the ruling, and a week's work is spoilt. Also the creation of a reliable machine is a very tedious business. Ten pounds per square inch of grating is a low price to pay.

The greatest difficulty met with in the manufacture of the dividing engine is that of obtaining a mathematically correct screw. Turning on a lathe produces a very rough spiral, judged scientifically. Some threads will be deeper than others, and differently spaced. The screw must, therefore, be ground with emery and oil introduced between it and a long nut which is made in four segments, and provided with collars for tightening it up against the screw. Perhaps a fortnight may be expended over the grinding. Then the screw must undergo rigid tests, a nut must be made for it, and it has to be mounted in proper bearings. The explanation of the method of eliminating errors being very technical, it is omitted; but an idea of the care required may be gleaned from Professor Rowlands' statement that an uncorrected error of 1 300,000 of an inch is quite sufficient to ruin a grating!

In the Houses of Parliament there is kept at an even temperature a bronze rod, thirty-eight inches long and an inch square in section. Near the ends are two wells, rather more than half an inch deep, and at the bottom of the wells are gold studs, each engraved with a delicate cross line on their polished surfaces. The distance between the lines is the imperial yard of thirty-six inches.

The bar was made in 1844 to replace the Standard destroyed in 1834, when both Houses of Parliament were burned. The original Standard was the work of Bird, who produced it in 1760. In June, 1824, an Act had been passed legalising this Standard. It says:—

"The same Straight Line or Distance between the Centers of the said Two Points in the said Gold Studs in the said Brass Rod, the Brass being at the temperature of Sixty-two Degrees by Fahrenheit's Thermometer, shall be and is hereby denominated the 'Imperial Standard Yard.'"

To provide for accidents to the bar, the Act continues: "And whereas it is expedient that the said Standard Yard, if lost, destroyed, defaced, or otherwise injured, should be restored to the same Length by reference to some invariable natural Standard: And whereas it has been ascertained by the Commissioners appointed by His Majesty to inquire into the subject of Weights and Measures, that the Yard hereby declared to be the Imperial Standard Yard, when compared with a Pendulum vibrating Seconds of Mean Time in the Latitude of London in a Vacuum at the Level of the Sea, is in the proportion of Thirty-six Inches to Thirty-nine Inches and one thousand three hundred and ninety-three ten-thousandth Parts of an Inch."

The new bar was made, however, not by this method, but by comparing several copies of the original and striking their average length. Four accurate duplicates of the new standard were secured, one of which is kept in the Mint, one in the charge of the Royal Society, one at Westminster Palace, and the fourth at the Royal Observatory, Greenwich. In addition, forty copies were distributed among the various foreign governments, all of the same metal as the original.

The French metre has also been standardised, being equal to one ten-millionth part of a quadrant of the earth's meridian (i.e. of the distance from the Equator to either of the Poles), that is, to 39·370788 inches. Professor A. A. Michelson has shown that any standard of length may be restored by reference to the measurement of wave lengths of light, with an error not exceeding one ten-millionth part of the whole.

It might be asked "Why should standards of such great accuracy be required?" In rough work, such as carpentry, it does not, indeed, matter if measurements are the hundredth of an inch or so out. But when we have to deal with scientific instruments, telescopes, measuring machines, engines for dividing distances on a scale, or even with metal turning, the utmost accuracy becomes needful; and a number of instruments will be much more alike in all dimensions if compared individually with a common standard than if they were only compared with one another. Supposing, for instance, a bar of exact diameter is copied; the copy itself copied; and so on a dozen times; the last will probably vary considerably from the correct measurements.

Hence it became necessary to standardise the foot and the inch by accurate subdivisions of the yard. This was accomplished by Sir Joseph Whitworth, who in 1834 obtained two standard yards in the form of measure bars, and by the aid of microscopes transferred the distance between the engraved lines to a rectangular end-measure bar, i.e. one of which the end faces are exactly a yard apart.

He next constructed his famous machine which is capable of detecting length differences of one millionth of an inch. Two bars are advanced towards each other by screw gearing: one by a screw having twenty threads to the inch, and carrying a graduated hand-wheel with 250 divisions on its rim; the other by a similar screw, itself driven by a worm-screw, working on the rim, which carries 200 teeth. The worm-screw has a hand-wheel with a micrometer graduation into 250 divisions of its circumference. So that, if this be turned one division, the second screw is turned only 1 250 × 1 200 of a division, and the bar it drives advances only 1 20 × 1 200 × 1 250 = 1 1,000,000 of an inch. The screw at the other end of the machine (which in appearance somewhat resembles a metal lathe) is used for rapid adjustment only.

DELICATE MEASURING MACHINES

The upper illustration shows a Pratt-Whitney Measuring Machine in operation to decide the thickness of a cigarette paper, which is one-thousandth of an inch thick. This machine will measure variations of length or thickness as minute as one hundredth-thousandth of an inch. The lower illustration shows a Whitworth Measuring Machine which is sensitive to variations of one-millionth of an inch.

"He (Sir J. Whitworth) obtained the subdivision of the yard by making three foot pieces as nearly alike as was possible, and working these foot pieces down until each was equal to the others, and placing them end to end in his millionth measuring machine; the total length of the three foot pieces was then compared with a standard end-measure yard. These three foot pieces were ground until they were exactly equal to each other, and the three [35] added together are equal to the standard yard. The subdivision of the foot into inch pieces was made in the same way."[2]

A doubt may have arisen in the reader's mind as to the possibility of determining whether the measuring machine is screwed up to the exact tightness. Would the measuring bars not compress a body a little before it appeared tight? Workmen, when measuring a bar with callipers, often judge by the sense of touch whether the jaws of the callipers pass the bar with the proper amount of resistance; but when one has to deal with millionths of an inch, such a method would not suffice. So Sir Joseph Whitworth introduced a feeling-piece, or gravity-piece. Mr. T. M. Goodeve thus describes it in The Elements of Mechanism: The gravity-piece consists of a small plate of steel with parallel plane sides, and having slender arms, one for its partial support, and the other for resting on the finger of the observer. One arm of the piece rests on a part of the bed of the machine, and the other arm is tilted up by the forefinger of the operator. The plane surfaces are then brought together, one on each side of the feeling-piece, until the pressure of contact is sufficient to hold it supported just as it remained when one end rested on the finger. This degree of tightness is perfectly definite, and depends on the weight of the gravity-piece, but not on the estimation of the observer.

In this way the expansion due to heat when a 36-inch bar has been touched for an instant with the finger-nail may be detected.

One of the most beautiful measuring machines commercially used comes from the factories of the Pratt-Whitney Co., Hartford, Connecticut, the well-known makers of machine tools and gauges of all kinds. It is made in different sizes, the largest admitting an 80-inch bar. Variations of 1 100,000 of an inch are readily determined by the use of this machine. It therefore serves for originating gauge sizes, or for duplicating existing standards. The adjusting screw has fifty threads to the inch, and its index-wheel is graduated to 400 divisions, giving an advance of 1 20,000 inch for each division: while by estimation this may be further subdivided to indicate one-half or even one-quarter of this small amount. Delicacy of contact between the measuring faces is obtained by the use of auxiliary jaws holding a small cylindrical gauge by the pressure of a light helical spring which operates the sliding spindle to which one of these auxiliary jaws is attached.

On one side of the "head" of the machine is a vertical microscope directed downwards on to a bar on the bed-plate, in which are a number of polished steel plugs graved with very fine central cross lines, each exactly an inch distant from either of its neighbours. A cross wire in the microscope tells when it is accurately abreast of the line below it. Supposing, then, that a standard bar three inches in diameter has to be tested. The "head" is slid along until the microscope is exactly over the "zero" plug line, and the divided index-wheel is turned until the two jaws press each other with the minimum force that will hold up the feeling-piece. Then the head is moved back and centred on the 3-inch line, and the [37] bar to be tested is passed between the jaws. If the feeling-piece drops out it is too large, and the wheel is turned back until the jaws have been opened enough to let the bar through without making the feeling-piece fall. An examination of the index-wheel shows in hundred-thousandths of an inch what the excess diameter is.

On the other hand, if the bar were too small, the jaws would need to be closed a trifle: this amount being similarly reckoned.

We have now got into a region of very "practical politics," namely, the subject of gauges. All large engineering works which turn out machinery with interchangeable parts, e.g. screws and nuts, must keep their dimensions very constant if purchasers are not to be disgusted and disappointed. The small motor machinery so much in evidence to-day demands that errors should be kept within the ten-thousandth of an inch. An engineer therefore possesses a set of standard gauges to test the diameter and pitch of his screw threads and nuts; the size of tubes, wires; the circumference of wheels, etc.

Great inconvenience having been experienced by American railroad-car builders on account of the varying sizes of the screws and bolts which were used on the different tracks—though all were supposed to be of standard dimensions—the masters determined to put things right; and accordingly Professors Roger and Bond and the Pratt-Whitney Co. were engaged to work in collaboration in connection with the manufacture of tools for minute measurements, viz. to 1 50,000 inch. "To give an idea of what is implied by this, let it be supposed [38] that a person should take a pair of dividing compasses and lay off 50,000 prick-marks 1 8 inch apart in a straight line. To do this the line would require to be over 520 feet, or nearly a tenth of a mile long. Imagine that many prick-marks compressed into the space of an inch, and you have an imperfect idea of the minuteness of the measurements which can now be made by the Pratt and Whitney Co."[3]

The standard taps and dies were supplied to tool-makers and engineers, who could thus determine whether articles supplied to them were of the proper dimensions. Nothing more was then heard of nuts being a "trifle small" or bolts "a leetle large." And so beautifully tempered were the dies made from the standards that one manufacturer claimed to have cut 18,800 cold-pressed nuts without any difference being perceptible in their sizes.

To appreciate what the difference of a thousandth of an inch makes in a true fit, you should handle a set of plug and ring gauges; the ring a true half-inch internally, the plugs half-inch, half an inch less one ten-thousandth of an inch, and half an inch less one-thousandth, in diameter.

The true half-inch plug needs to be forcibly driven into the ring on account of the friction between the surfaces. The next, if oiled, will slide in quite easily, but if left stationary a moment will "seize," and have to be driven out. The third will wobble very perceptibly, and would be at once discarded by a good workman as a bad fit.

For extremely accurate measurements of rods, calliper gauges, shaped somewhat like the letter Y, are used, the horns terminating in polished parallel jaws. Such a gauge will detect a difference of 1 20,000 inch quite easily.

So accurately can plug gauges be made by reference to a measuring machine, that a gold leaf 1 30,000 inch thick would be three times too thick to insert between the gauge and the jaws of the machine!

You must remember that in high-class workmanship these gauges are constantly being used. As time goes on, the "limit of error" allowed in many classes of machine parts is gradually lessened, which shows the simultaneous improvement of all machinery used in the handling of metal. James Watt was terribly hampered, when developing his steam-engine, by the difficulty of procuring a true cylinder for his pistons to work in with any approach to steam-tightness. His first cylinder was made by a smith of hammered iron soldered together. The next was cast and bored, but stuffing it with paper, cork, putty, pasteboard, and "old hat" proved useless to stem the leakage of steam. No wonder, considering that the finished cylinder was one-eighth of an inch larger in diameter at one end than at the other. Watt was in advance of his time. Neither machinery nor workmanship had progressed sufficiently to meet the requirements of the steam-engine. To-day an engineer would confidently undertake to bore a cylinder five feet in diameter with a variation from truth of not more than one five-hundredth of an inch.

Before passing from the subject of measuring machines, which play so important a part in modern mechanism, we [40] may just glance at the electrical method of Dr. P. E. Shaw. He discovered recently that two clean metal surfaces can, by means of an electric current, feel one another on touching with a delicacy that far transcends that of the purely mechanical machine. The mechanism he employs is thus devised: A finely cut vertical screw having fifty threads to the inch has a disc graduated into 500 parts. The screw can be turned by means of a pulley string from a distance, and it is thus possible to give the top end of the screw a movement of 1 25,000 inch, when a movement corresponding to one graduation is made.

This small movement is reduced by a train of six levers, the long arm of each bearing on the short arm of the one before it. The movement of the last lever of the train is thus reduced to 1 4,000 of that of the screw point, so a movement of 1 4,000 × 1 25,000 × = 1 1,00,000,000 inch is obtained!

How can such a movement be judged? A telephone and voltaic cell are joined to the last lever of the train and to the object whose movement is under examination. If they touch, the telephone sounds. An observer listens in the telephone, and if the object moves for any reason he can find out how much it moves by turning the screw until contact is made again.

Out of the many applications of this apparatus three may be given.

(1) A short bar of iron when magnetised elongates about 1 1,000,000 of its length. If further magnetised it contracts. These changes can readily be measured with the instrument.

(2) The smallest sound audible in the telephone is due to a movement of the diaphragm of the telephone by about 1 50,000,000 of an inch. This has been actually measured by Dr. Shaw and is by far the smallest distance ever directly recorded. It is about twice the diameter of the molecules of matter.

(3) Dispensing with levers, the screw alone is used for rougher work. Dr. Shaw has shown that one hundred-thousandth of an inch is the smallest dimension visible under a microscope. By fitting an electric measuring apparatus to the microscope carriage it becomes quite easy to measure minute distances. The microscope contains a cross wire which, when the object has been laid on the microscope stage, is centred on one side of the object. The electric contact screw is then advanced till it makes contact with the stage and a sound arises in the telephone. A reading of the screw disc having been taken, the screw is drawn in and the microscope stage is traversed sufficiently to bring the wire in line with the other side of the object. Once more the operator makes electrical contact and gets a second reading, the difference between the two being the diameter of the object. In this manner the bacillus of tuberculosis has been proved to have an average diameter of 31 250,000 of an inch.

The same method is employed to gauge the distance between the lines on a diffraction grating.

FOOTNOTES:

1. April 19th, 1901.

2. G. M. Bond in a lecture delivered before the Franklin Institute, February 29th, 1884.

3. Report on Standard Screw Threads, Philadelphia, 1884.

The simplest form of calculating machine was the Abacus, on which the schoolboys of ancient Greece did their sums. It consisted of a smooth board with a narrow rim, on which were arranged rows of pebbles, bits of bone or ivory, or silver coins. By replacing these little counters by sand, strewn evenly all over its surface, the abacus was transformed into a slate for writing or geometrical lessons. The Romans took the abacus, along with many other spoils of conquest, from the Greeks and improved it, dividing it by means of cross-lines, and assigning a multiple value to each line with regard to its neighbours. From their method of using the calculi, or pebbles, we derive our English verb, to calculate.

During the Middle Ages the abacus still flourished, and it has left a further mark on our language by giving its name to the Court of Exchequer, in which was a table divided into chequered squares like this simple school appliance.

Step by step further improvements were made, most important among them being those of Napier of Merchiston, whose logarithms vex the heads of our youth, and save many an hour's calculation to people who understand [43] how to handle them. Sir Samuel Morland, Gunter, and Lamb invented other contrivances suitable for trigonometrical problems. Gersten and Pascal harnessed trains of wheels to their "ready-reckoners," somewhat similar to the well-known cyclometer.

All these devices faded into insignificance when Mr. Charles Babbage came on the scene with his famous calculator, which is probably the most ingenious piece of mechanism ever devised by the human brain. To describe the "Difference Engine," as it is called, would be impossible, so complicated is its character. Dr. Lardner, who had a wonderful command of language, and could explain details in a manner so lucid that his words could almost always be understood in the absence of diagrams, occupied twenty-five pages of the Edinburgh Review in the endeavour to describe its working, but gave several features up as a bad job. Another clever writer, Dr. Samuel Smiles, frankly shuns the task, and satisfies himself with the following brief description:—

"Some parts of the apparatus and modes of action are indeed extraordinary—and, perhaps, none more so than that for ensuring accuracy in the calculated results—the machine actually correcting itself, and rubbing itself back into accuracy, by the friction of the adjacent machinery! When an error is made the wheels become locked and refuse to proceed; thus the machine must go rightly or not at all—an arrangement as nearly resembling volition as anything that brass and steel are likely to accomplish."[4]

Mr. Babbage, in 1822, entered upon the task of superintending the construction of a machine for calculating [44] and printing mathematical and astronomical tables. He began by building a model, which produced forty-four figures per minute. The next year the Royal Society reported upon the invention, which appeared so promising that the Lords of the Treasury voted Mr. Babbage £1,500 to help him perfect his apparatus.

He looked about for a first-rate mechanician of high intelligence as well as of extreme manual skill. The man he wanted appeared in Mr. Joseph Clement, who had already made his name as the inventor of a drawing instrument, a self-acting lathe, a self-centring chuck, and fluted taps and dies. Mr. Clement soon produced special tools for shaping the various parts of the machine. So elaborate was the latter, that, according to Dr. Smiles, "the drawings for the calculating machinery alone—not to mention the printing machinery, which was almost equally elaborate—covered not less than four hundred square feet of surface!"

You will easily imagine, especially if you have ever had a special piece of apparatus made for you by a mechanic, that the bills mounted up at an alarming rate; so fast, indeed, that the Government began to ask, Why this great expense, and so little visible result? After seven years' work the engineers' account had reached £7,200, and Mr. Babbage had disbursed an additional £7,000 out of his own pocket. Mr. Clement quarrelled with his employer—possibly because he harboured suspicions that they were both off on a wild-goose chase—and withdrew, taking all his valuable tools with him. The Government soon followed his example, and poor Babbage was left with his half-finished invention, "a beautiful fragment of [45] a great work." It had been designed to calculate as far as twenty figures, but was completed only sufficiently to go to five figures. In 1862 it occupied a prominent place among the mechanical exhibits at the Great Exhibition.

A MECHANICAL CASHIER

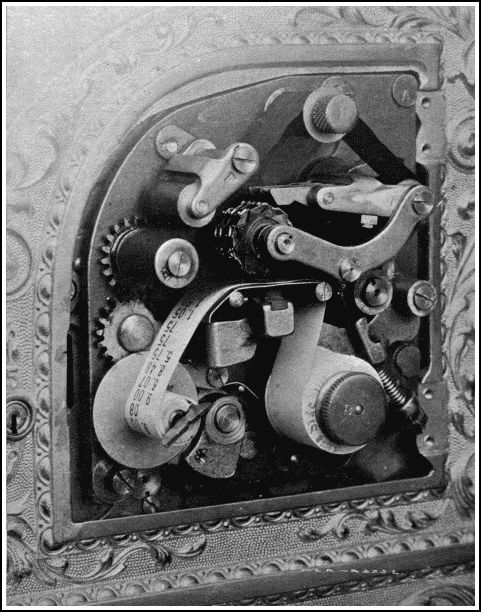

The printing apparatus of a National Cash Register. It impresses on a paper strip the amount and nature of every money transaction; and also prints a date, number, advertisement, money value, and nature of business done on a ticket for the customer.

We learn, with some satisfaction, that all this effort was not fated to be fruitless. Two scientists of Stockholm—Scheutz by name—were so impressed by Dr. Lardner's account of this calculating machine that they carried Babbage's scheme through, and after twenty years of hard work completed a machine which seemed to be almost capable of thinking. The English Government spent £1,200 on a copy, which at Somerset House entered upon the routine duty of working out annuity and other tables for the Registrar-General.

From Babbage's wonderfully and fearfully made machine we pass to a calculator which to-day may be seen at work in hundreds of thousands of shops and offices.

It is the most modern substitute for the open till; and, by the aid of marvellous interior works, acts as account-keeper and general detective to the money transactions of the establishment in which it is employed.

There are very many types of Cash Register, and as it would be impossible to enumerate them all, we will pass at once to the most perfect type of all, known to the makers and vendors as "Number 95."

This register has at the top an oblong window. Dotted about the surface confronting the operator are, in the particular machine under notice, fifty-seven keys; six bearing the letters A, B, D, E, H, K; three the words "Paid out," "Charge," "Received on Account"; and the others money values ranging from £9 to 1 4 d.

These are arranged in vertical rows. At the left end of the instrument is a printing apparatus, kept locked by the proprietor; at the right end a handle and a small lever. Below the register are six drawers, each labelled with an initial.

A customer enters the shop, and buys goods to the value of 6s. 11d. An assistant, to whom belongs the letter H, receives a sovereign in payment. He goes to the register, and after making sure that his drawer is pushed in till it is locked, first presses down the key H, and then the keys labelled "6s." and "11d." Suddenly, like two Jacks-in-the-box, up fly into the window two tablets, with "6s. 11d." on both their faces, so that customer and assistant can see the figures. Simultaneously a bell of a certain tone rings, drawer H flies open (so that he may place the money in it and give change, if necessary), and a rotating arm in the window shows the word "cash."

The assistant now revolves the handle and presses the little lever. From a slot on the left side out flies a ticket, on the front of which is printed the date, a consecutive number, the assistant's letter, and the amount of the sale. The back has also been covered with an advertisement of some kind. The ticket and change are handed over to the customer, the drawer is shut, and the transaction is at an end, except for an entry in the shop's books of the article sold.

A carrier next comes in with a parcel on which five-pence must be paid for transport. Mr. A. receives the goods, goes to the register, presses his letter, the key with the words "paid out" on it, and the key carrying [47] "5d.," takes out the amount wanted, and gives it to the carrier.

Again, a gentleman enters, and asks for change for half a sovereign. Mr. B. obliges him, pressing down his letter, but no figures.

Fourthly, a debtor to the shop pays five shillings to meet an account that has been against him for some time. Mr. K. receives the money and plays with the keys K, "Received on account," and "5s.," giving a ticket receipt.

Lastly, a customer buys a pair of boots on credit. Mr. D. attends to him, and though no cash is handled, uses the register, pressing the letter "Charge," and, say, "16s. 6d."

Now what has been going on inside the machine all this time? Let us lift up the cover, take off the case of the printing apparatus, and see.

A strip of paper fed through the printing mechanism has on it five rows of figures, letters, etc., thus—

| s. | d. | ||

| H | 6 | 11 | |

| Pd. | A | 0 | 5 |

| B | 0 | 0 | |

| Rc. | K | 5 | 0 |

| Ch. | D | 16 | 6 |

The proprietor is, therefore, enabled to see at a glance (1) who served or attended to a customer, (2) what kind of business he did with him, (3) the monetary value of the transaction. At the end of the day each assistant sends in his separate account, which should tally exactly with the record of the machine.

Simultaneously with the strip printing, special counting apparatus has been (a) adding up the total of all money taken for goods, (b) recording the number of times the drawer has been opened for each purpose. Here, again, is a check upon the records.

This ingenious machine not only protects the proprietor against carelessness or dishonesty on the part of his employés, but also protects the latter against one another. If only one drawer and letter were used in common, it would be impossible to trace an error to the guilty party. The lettering system also serves to show which assistant does the most business.

Where a cash register of this type is employed every transaction must pass through its hands—or rather mechanism. It would be risky for an assistant not to use the machine, as eyes may be watching him. He cannot open his drawers without making a record; nor can he make a record without first closing the drawers; so that he must give a reason for each use of the register. If he used somebody else's letter, the ear of the rightful owner would at once be attracted by the note of his particular gong. When going away for lunch, or on business, a letter can be locked by means of a special key, which fits none of the other five locks.

The printing mechanism is particularly ingenious. Every morning the date is set by means of index-screws: and a consecutive numbering train is put back to zero. A third division accommodates a circular "electro" block for printing the advertisements, and a fourth division the figure wheels.

The turn given to the handle passes a length of the [49] ticket strip through, a slot—prints the date, the number of the ticket, an advertisement on the back, the assistant's letter, the nature of the business done, and feeds the paper on to the figures which give the finishing touch. A knife cuts off the ticket, and a special lever shoots it out of the slot.

The National Cash Register Company, for prudential reasons, do not wish the details of the internal machinery to be described; nor would it be an easy task even were the permission granted. So we must imagine the extreme intricacy of the levers and wheels which perform all the tasks enumerated, and turn aside to consider the origin and manufacture of the register, which are both of interest.

The origin of the cash register is rather nebulous, because twenty-five years ago several men were working on the same idea. It first appeared as a practical machine in the offices of John and James Ritty, who owned stores and coalmines at Dayton, Ohio. James Ritty helped and largely paid for the first experiments. He needed a mechanical cashier for his own business, and says that, while on an ocean steamer en route to London the revolving machinery gave him the suggestion worked out, on his return to Dayton, in the first dial-machine. This gave way to the key-machine with its display tablet, or indicator, held up by a supporting bar moved back by knuckles on the vertical tablet rod.

The cut (Fig. 1) shows the right side of this key register, the action of which is thus described by the National Cash Register Company. The key A, when pressed with the finger at its ordinary position—marked [50] 1—went down to the point marked 2. Being a lever and pivoted to its centre, pressing down a key elevated its extreme point B. This pushed up the tablet-rod C, having on its upper part the knuckle D. This knuckle D, pushed up, took the position at E; that is, the knuckle pushed back the supporting-bar F, and was pushed past it and held above it. If the same operation were performed on another key, the knuckle on its vertical rod, going up, would again push the supporting bar back, which would release the first knuckled rod, and leave the last one in its place. This knuckled rod had on its upper end the display tablet, or indicator G. James and John Ritty claimed and proved that they invented this, but the attorney for the Dayton Company (formed by them) in the Supreme Court was compelled to admit that this mechanism was old. Yet if machines built like this were exhibited elsewhere, they were at most only [51] experimental models, and none of them had ever gone into practical or commercial use. In fact, at this time nothing had been really contributed which was useful to the public or used by the public.

The trouble was that the knuckles, being necessarily oiled, held dust and dirt which interfered with their free movement. And again, a "five-cent" or "ten-cent" key would be used more than others, and hence would become more worn. As a practical result the tablets did not drop when wanted, and the whole operation was thrown into confusion. When one tablet went up the other tablet stayed up, leaving a false indication. The most valuable modification now made by these Dayton inventors was to cease to rely on the knuckle to move back the supporting bar, and to supply the place of this function by what became known as "connecting mechanism," especially designed for this purpose. This was placed at the other, or say the left, side of the machine as you faced it. Cut No. 2 shows this new connecting mechanism. The keys, when pressed, performed the functions as before, on the right side of the machine, viz. to ring an alarm-bell, etc.; but on the other, or left, side the key, when pressed, operated the connecting mechanism marked M, N, O, P, and Q. The key pressed down by its leverage pushed back a little lever (Q), the further end of which pressed back the supporting bar F, and released the previously exposed indicator G, without relying on the knuckle to perform this function.

The Supreme Court of the United States said that the suggestion or idea to correct the old trouble and to drop the display tablet with certainty, and to accomplish this [52] by dividing the force used, and applying a portion of it to the new connecting mechanism on the left side of the machine, "was fine invention," and that "the results are so important, and the ingenuity displayed to bring them about is such that we are not disposed to deny the patentees the merit of invention. The combination described in the first claim was clearly new."

To revert for a moment to the origin of the invention. Mr. John Ritty gives an account differing from that of his brother; but the two can probably be reconciled by supposing that the first ideas occurred simultaneously and were worked out in common.

Late one summer night, before dispersing home, a group of men were in his store. One of them said to the proprietor, "If you had a machine there to register the cash received, you would get more of it," and to the statement both owner and his clerks assented. This raised a laugh. But Ritty who, in spite of a large business, which ranged over everything from a needle to a haystack, did not make much profit by his sales, took the suggestion seriously, and put on his thinking-cap, with the result that the first machine was patented, and profits became very greatly increased.

Before his machine had been perfected a rival was in the field. Mr. Thomas Carney, a man who had seen much life as a lumber merchant, captain during the Civil War, explorer, and railroad promoter, settled down in 1884, at Chicago, to the manufacture of coin-changers. "When in various businesses," he says, "we used gold and silver only, and it seemed to be a sheer necessity to have something of a money-changer to assist us in handling it [53] and making change. The custom then was to throw the different coins into a special receptacle marked for each. I invented, and in my own shop built this coin-changer, the keys of which, when touched, would, through the tube, drop the coin into the hand as wanted. At Chicago we made five or six hundred of these coin-changers, but by mistake placed the price too low, and after some conference I became assured that there was not enough money in it. A rich Chicago manufacturer had become familiar with the urgent need of a cash register, and the losses which followed in business without one. The National, at Dayton, had then been invented, but had not then been perfected as it has been since. Parties at Chicago agreed to put up the money if I would invent what would answer the purpose of a cash register and make a marketable machine. I went home and gave the matter some hard thinking, and talking with my son about the matter [54] one night, I looked up at the clock and said, 'Why, Harry, there is the right thing. Sixty minutes make an hour; one hundred cents make a dollar. All I have got to do is to change the wheels a little, put some keys into it, and there will be a thing which will register cents, dimes, and dollars, just as that clock will register time in minutes and hours.' In clocks the minute wheel, when it has revolved to its sixty point, throws its added result of sixty minutes over on to another wheel, which takes up the story, with one hour in place of the old sixty minutes. The first wheel then begins again and goes its round. A second complete revolution of the minute wheel throws another sixty minutes on to the hour, and gives one more hour registered, making two hours, and so on. I took some wheels, and with pasteboard made hands and a machine. It was very rough, but I took it to my friends and explained it to them. We went on, but encountering difficulties and obstacles, we merged our whole enterprise in the National. I followed it, and have since invented, worked, and helped along in the National Cash Register service. I developed the No. 35 machine which the company began on and uses yet. It is now in use in every civilised country, for it can be made to register English money and any decimal currency."

In 1883 Dayton contained five families. The following year Colonel Robert Patterson bought a large property in the neighbourhood, and helped to develop a small town, which has since grown into a thriving manufacturing centre. His two sons, John H. Patterson and Frank J. Patterson, bought out all the original proprietors of the National Cash Register, greatly improved [55] the machine's mechanism, and built the huge factory which employs about 4,000 men, women, and girls, and is one of the best-equipped establishments in the world to promote both an economical output and the comfort of the employés. The Company's buildings at Dayton cover 892,144 square feet of floor-space, and utilise 140 acres of ground. In convenience and attractiveness, and for light, heat, and ventilation, and all sanitary things, these structures are designed to be models of any used for factory purposes. A machine is made and sold every 2 1 2 minutes in the Dayton, Berlin, and Toronto factories collectively. According to its destination, it records dollars, shillings, marks, kronen, korona, francs, kroner, guildens, pesetas, pesos, milreis, rupees, or roubles. Registers are also made to meet the needs of the Celestials and the Japanese.

So necessary is it for these machines to be ever improving, that the Company, with a wisdom that prevails more largely, perhaps, in the United States than elsewhere, offer substantial rewards to the employé who records in a book kept specially for the purpose any suggestion which the committee, after due examination, consider likely to improve some detail of mechanism or manufacture. Five departments are entirely devoted to experiments carried out by a corps of inventors working with a special body of skilled mechanics. New patents accrue so fast as a result of this organised research that the National Company now owns 537 letters patent in the United States and 394 in foreign countries.

Many ideas come from outside. If they appear profitable they are bought and turned over to the Patents [56] Department, which hands them on to the experimenters. These build an experimental model, which differs in many respects from the types hitherto manufactured. A cash register must be above all things strong, so that it can bear a heavy blow without getting out of order, and must retain its accuracy under all conditions.

The model finished, it goes before the inspectors, who thump it, hammer it, almost turn it inside out, and send it back to the Factory Committee with reports on any defects that may have come to light. If the inspectors can only knock the machine out of time they consider that they have done their duty; for they argue that, if weaknesses thus developed are put right, no purchaser will ever be able to dislocate the machinery if he stops short of an actual "brutal assault with violence."