Steam Shovels

—AND—

STEAM SHOVEL WORK.

By E. A. HERMANN, M. Am. Soc. C. E.

1894.

ENGINEERING NEWS PUBLISHING CO.,

New York.

Copyright. 1894, by Engineering News Publishing Co.

CONTENTS.

| Pages. |

| Part 1.—Steam Shovels | 1-19 |

| "2.—Steam Shovel Work | 19-41 |

| "3.—Disposition of Material | 41-55 |

| "4.—Cost of Steam Shovel Work | 55-57 |

- Ballast, plowing, 48

- Blasting, 39, 52

- Brine, sprinkling earth, 52

- Cars, dump, 19, 41, 47

- Flat, 42

- Loading, 19

- Unloading, 42, 47

- Cost of work, 55

- Cuts, 28, 36, 39

- Time for, 17

- Widening, 19

- Explosives, 39, 52

- Fills, trestles for, 47

- Grades, construction track, 34

- Cutting down, 28

- Grading, 25

- Gravel train, 42, 45, 50

- Engines for, 50

- Unloading, 48

- Leveling, 53

- Loading cars, 19

- Gangs for, 21, 22, 23

- Operating, men for, 18

- Plow, Barnhart, 43

- Gravel, 42

- Plowing, cable for, 50

- Gravel train, 48

- Hauling engine for, 51

- Winter, brine for, 52

- Railways, construction, 33

- Reducing grades, 28

- Widening cuts, 19

- Railway work, 18, 28, 33

- Rapid unloader, 51

- Spreaders, 53

- Steam shovels, Barnhart, 6

- Boilers, 9

- Bucyrus, 4

- Clement, 10

- Daily capacity, 41

- Description, 5

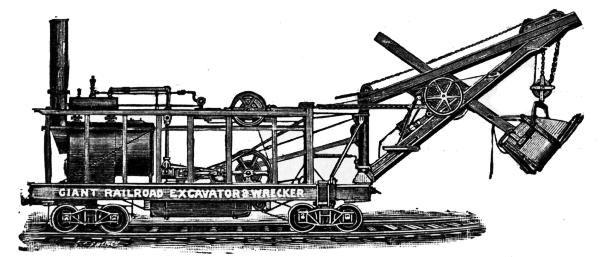

- Giant, 12

- Invention of, 1

- Little Giant, 12

- Industrial Works, 10

- Machinery of, 5

- Marion S. S. & Dredge Co., 6

- Number of men, 18

- Operation, 16

- Osgood, 2

- Otis-Chapman, 14

- Repairs, 19

- Souther's, 14

- Thompson, 4

- Toledo F. & M. Co., 8

- Types, 3

- Victor, 8

- Vulcan Iron Works, 12

- Tools, 16, 18

- Track, arrangement of, 19

- Narrow gage, 47

- Trains, dirt, handling, 19, 42, 45, 48, 50

- Trestles for fills, 47

- Widening cuts, 19

[1]

STEAM SHOVELS AND STEAM SHOVEL WORK.[1]

By E. A. Hermann, M. Am. Soc. C. E.

Part I.—Steam Shovels.

The following article originated in a short paper which was

read before a local society of civil engineers, and there were

so many requests made for this paper and the illustrations presented

with it that the author was led to believe that there was

a demand for such information. Believing that a better understanding

of the capabilities of these machines will serve a useful

purpose in economizing money, time and labor in the execution

of work to which they are adapted, the author presents in this

article the information learned by a long practical experience

in this special class of work. Descriptions of the various steam

shovels can readily be found in the trade catalogues of the different

manufacturers, but very little has been published on the

manner of using them in the execution of different classes of

work, and the disposition of the excavated material after it has

been loaded on cars or wagons. This part of the subject will

receive most attention, and although much of it may seem very

elementary to those who have had an extended experience in

operating steam shovels, it may be entirely new to the much

larger number who have had few or no opportunities for doing

work of this kind. It has been the aim of the author to condense

the reading matter as much as possible, making it a point

to use many illustrations in place of lengthy explanations, thus

presenting the subject more clearly than by extended descriptions.

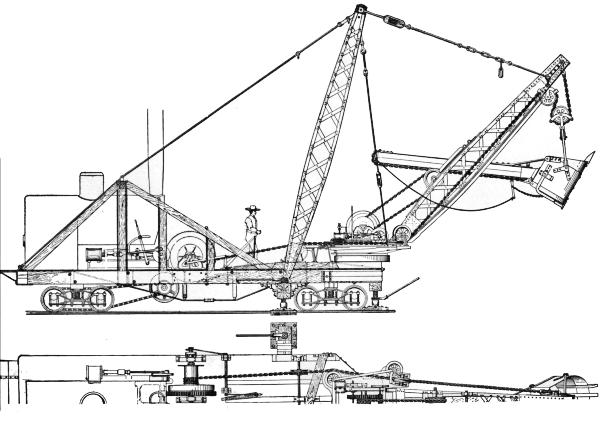

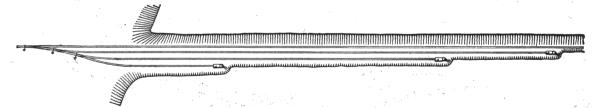

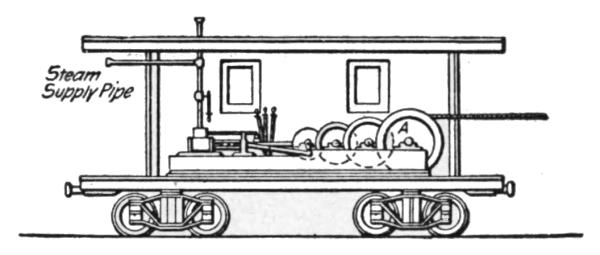

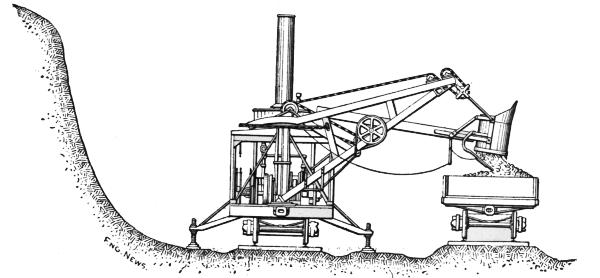

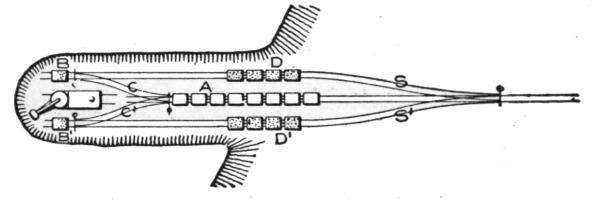

FIG. 1. ELEVATION AND HALF PLAN OF OSGOOD

STEAM SHOVEL; Osgood Dredge Co., Albany,

N. Y.

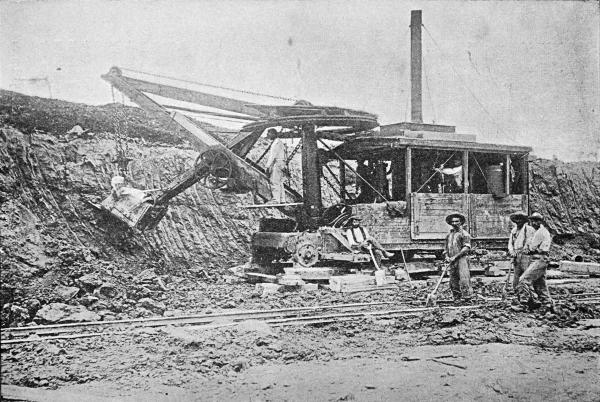

The steam shovel, or steam excavator, is a modified form

of dredge adapted for excavating material on dry land. It was

designed and patented by a Mr. Otis, about 1840, and like most

new inventions the first machine built was a very clumsy affair,[3]

but even in this crude state it possessed many advantages for

removing large masses of material. Its merits were recognized

in its earliest stages, and with increased experience in its operation

improvements were soon made which rendered it almost

indispensable on all works requiring large quantities of excavation.

It was not until 1865, however, that the machine came into

general use. About this time the largely increased railway construction

created an active demand for the steam shovel, which

demand was quickly supplied by several manufacturers, whose

machines vary in distinctive designs of various parts, but the

principles of operation are essentially the same in them all.

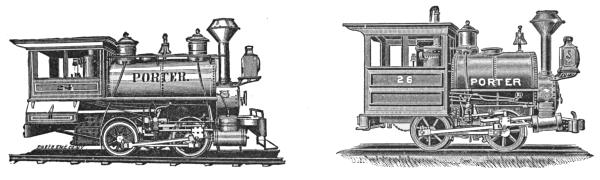

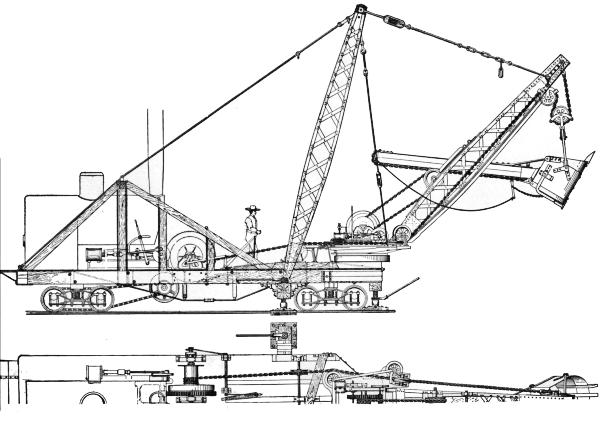

Types of Steam Shovels.—There are three types of steam

shovels: First; machines mounted on trucks of standard gage,

transported from place to place in freight trains (or propelled

by their own power), and intended for railway work only. Second;

machines mounted on wheels of other than standard gage,

transported in sections by boat or wagon, or loaded complete on

flat cars, and intended for both railway and other work. Third;

machines mounted on wheels fitted for transportation over

common roads, propelled by their own power, and intended for

railway and other work.

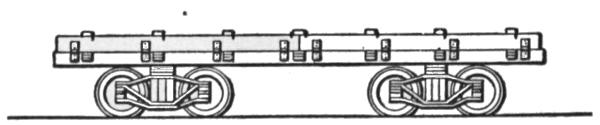

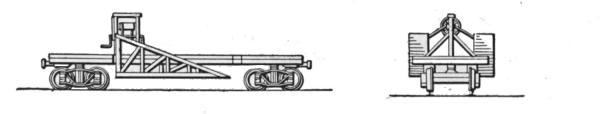

The first machines built were of the second type. As now

constructed they are mounted on a wide wooden frame or car

body, supported by four small wheels of 7 ft. to 8 ft. gage, thus

placing the machinery close to the ground, with a wide base of

support. In transporting this machine from one place to another,

not on the line of a railway, it is necessary to take it apart,

forward the sections and put them together again at the site of

the new work. The machine is built with a view to rapid dismantling

and re-erection, and for work requiring a large machine

for economical excavation, located in hilly country not

yet made accessible by rail, or requiring transportation by boat,

it is the machine most generally used. Its ready adaptability

to all kinds of work in any location has made it the favorite

machine with many general contractors whose work includes

large contracts for railway and other excavation. For transportation

by rail this machine is run onto an ordinary flat car,

only the crane being detached and loaded on a separate car.

With this manner of shipment the machine can be made ready

for railway work very quickly, but for exclusive railway work[5]

a machine of a later design has come into use and is now generally

preferred for this class of work.

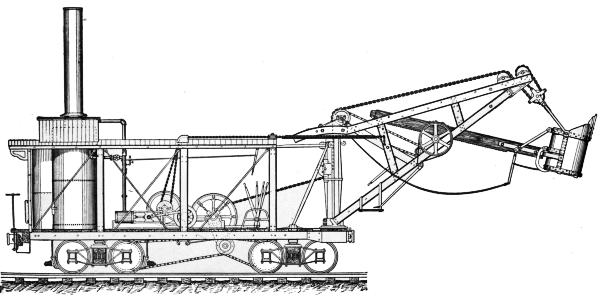

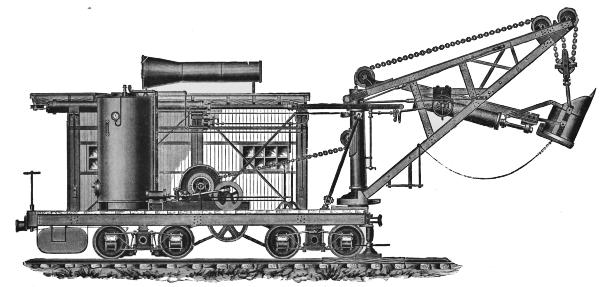

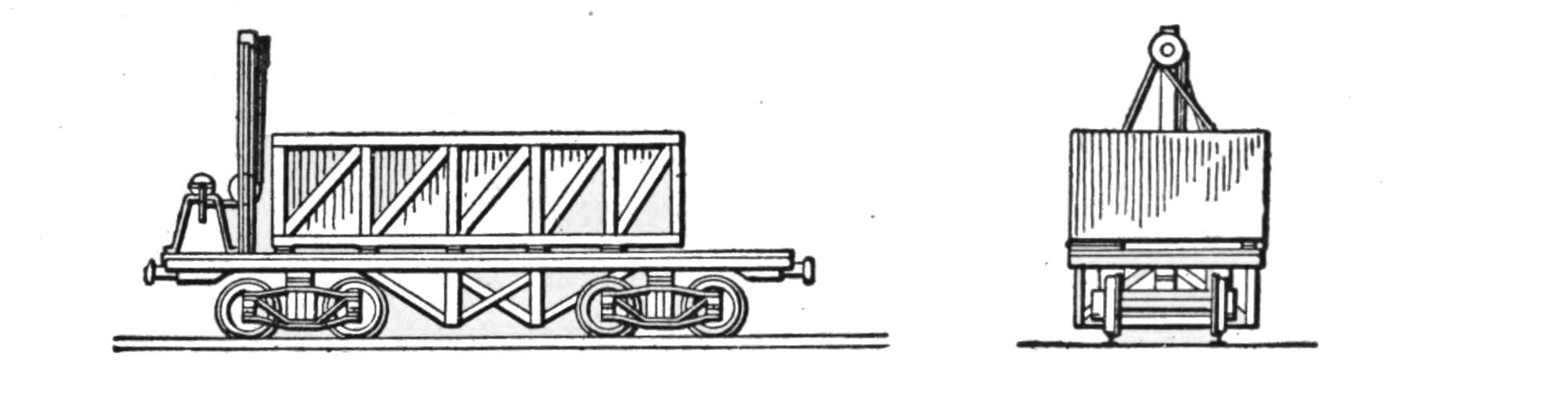

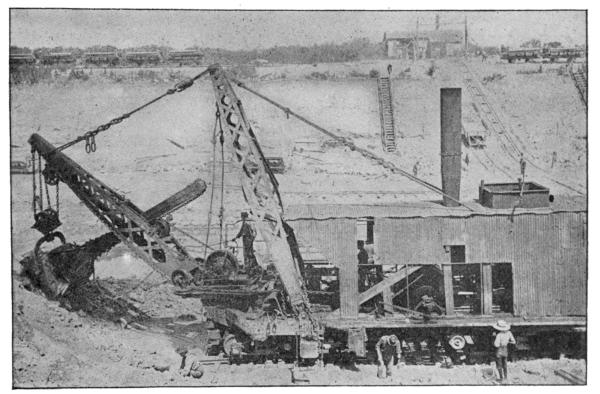

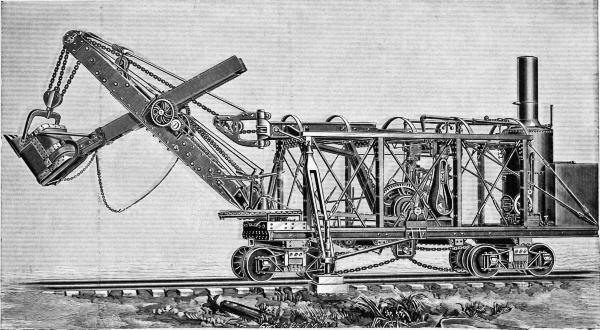

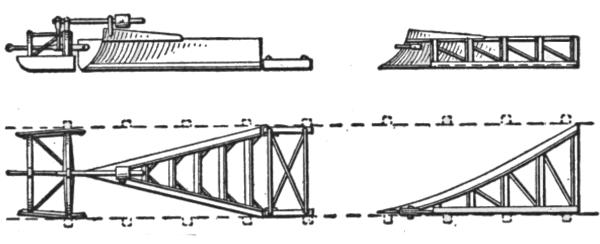

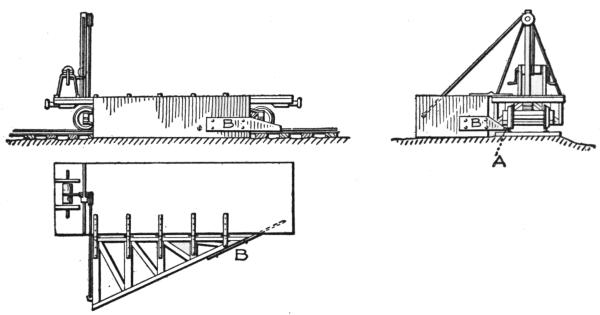

FIG. 2.—THOMPSON STEAM SHOVEL; Bucyrus

Steam Shovel & Dredge Co., South Milwaukee,

Wis.

This is the machine of the first type, resting on a wooden or

iron car body, supported on trucks of standard gage, with an

iron or steel crane from 18 to 26 ft. high over the track when

in working order, and which can be lowered to 14 ft. to permit

shipment through tunnels and under low overhead bridges.

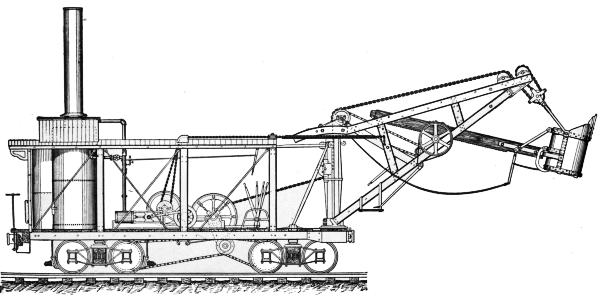

Machines of the third type are generally of smaller capacity

than the others; they have come into general use only within

the past few years, but are now multiplying rapidly in numbers

as their utility for nearly all kinds of work is better appreciated.

They are especially adapted to smaller jobs and work not readily

accessible by rail, but where common roads are available.

These three types are shown in Figs. 1 to 9, representing the

machines of seven of the principal manufacturers.

Steam shovels will excavate any kind of material except solid

rock, and they will load rock if it has been broken up by explosives

into pieces of not more than 3-4 cu. yd. in size. The

materials excavated by them are mostly sand, loose gravel, all

kinds of clay, cemented gravel, hardpan, clays mixed with

bowlders and other small stones, ore, phosphate rock, loose

rock and thin seams of slate, shale or sandstone.

These machines are used for excavating material, loading it

on cars or wagons for ballasting tracks; for filling trestles,

streets, roads, dams, lots and new city additions; for widening

embankments for double track, side tracks, yards,

shops and station grounds; for cutting down street, road

and railway grades; grading lots and new city additions, railway

yards, shop and station grounds; widening cuts, removing

land slides, stripping coal fields, ore beds and stone quarries;

digging canals and drainage ditches, loading clays for brick

yards, etc.

Construction of Steam Shovels.—The general plan of construction

of the machines, shown in Figs. 1 to 9, is essentially

the same in all, and consists of a strong frame, mounted on

wheels, forming the base to which all working parts are attached.

The boiler and machinery are placed near the rear end of the

frame, and the mast, or post, and crane at the front end. The

crane is made in two pieces connected only at the top or point,

and at the foot of the mast. Between these pieces, serving as

guides, is the dipper handle, carrying at its farther end the dipper[7]

or scoop. To the top of the post (or to the foot in some machines)

the swinging circle is secured.

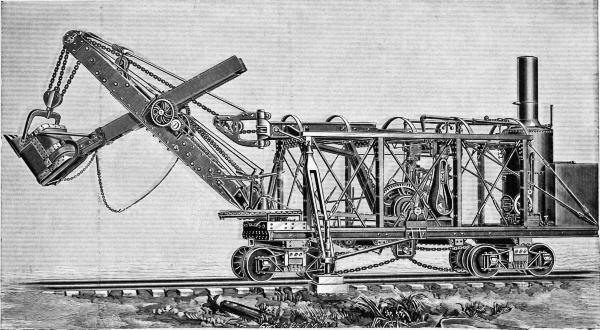

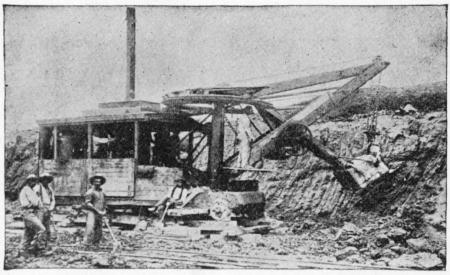

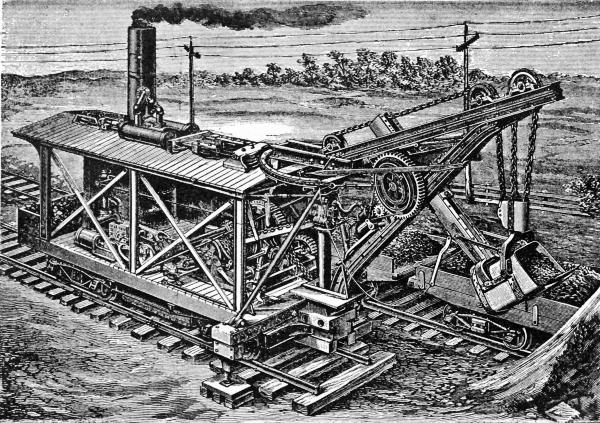

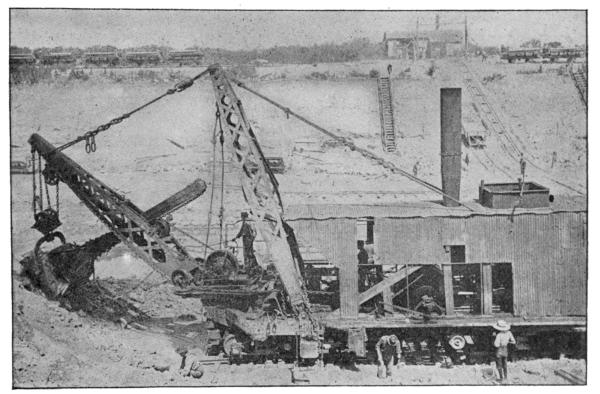

FIG. 3.—BARNHART STEAM SHOVEL; Marion Steam Shovel Co., Marion, O.

The most used, and hence the most important part of the

machinery of the steam shovel is the gearing imparting motion

to the hoisting drum, actuating the chains by which the dipper

is raised and lowered. It is in almost constant use, and is often

subjected to severe shocks in hard digging. Of all parts of the

machinery it is the most likely to break or rapidly wear out.

Naturally it has received the most attention of any part of the

steam shovel in all efforts to improve the design, strength and

durability of the machine. There are a number of different

gears in use, and essentially they are either friction clutches or

positive gearing. The use of the former subjects the machinery

and crane to less severe shocks, and can be thrown in and out

of gear more rapidly, but it wears out quicker, often causes delay

by heating, and requires frequent repairs. Positive gearing

exposes the machinery and crane to more severe shocks in hard

digging, and must be started slower, especially in hard material,

but while these machines are a little slower than those operated

with friction clutches, they are less subject to the expense of repairs

and delay due to the disarrangement of the hoisting gear,

so that their total output of material about equals, and sometimes

exceeds, the quicker moving friction gear machine.

The mechanism for thrusting the dipper into the bank is attached

to the crane, and the forms most generally used are as

follows:

1. A chain, one end of which is attached to the rear end of

the dipper handle, and the other end wound around a drum

receiving its motion by an endless chain passing over a sprocket

wheel connected to the axle of the sprocket wheel at the top of

the mast, over which the hoisting chain passes, thereby revolving

both wheels. This drum is thrown into gear by a friction

clutch, and its motion regulated by the cranesman's lever and

footbrake.

2. A rack on the dipper handle operated by a pinion attached

to a shaft revolved and regulated as above described.

3. A small double cylinder engine operating either a pinion

and rack as above described, or revolving a drum with a chain

attached to it, and the rear end of the dipper handle as described

in the first case.

4. A long steam cylinder attached to the dipper handle, whose[9]

piston rod is connected to the dipper, extending or withdrawing

it as desired.

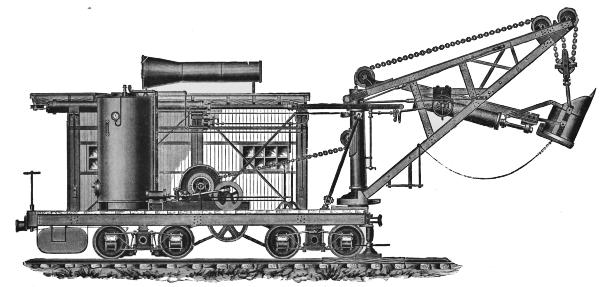

FIG. 5.—VICTOR STEAM SHOVEL; Toledo Foundry & Machine Co., Toledo, O.

The thrusting mechanism used in the last two cases imparts

a rapid, steady and powerful motion, but the extra engines or

steam cylinder and their connecting steam pipes involve a complication

which often more than balances their advantages.

Swinging the crane in a horizontal direction is generally accomplished

in one of the following three ways:

1. A chain passing around the swinging circle attached to

the post, and wound around drums connected to the engine by

positive gearing or friction clutches.

2. A wire rope passing round the swinging circle and connected

to the piston rods operated by two long steam cylinders.

3. A chain passing round the swinging circle and wound

around a drum connected to a small reversible engine.

The mechanisms used in the last two cases have the same advantages,

but also suffer from the same objections urged against

employing small engines or a steam cylinder for thrusting the

dipper into the bank.

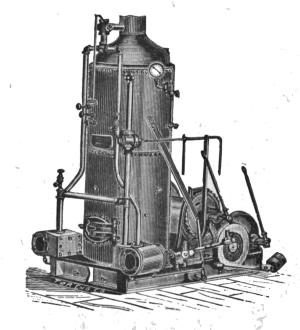

The engines are either of the upright type with a single steam

cylinder, or of the horizontal type, with double horizontal steam

cylinders. The size of the cylinders varies for machines of different

capacities, ranging from 8 by 10 ins. to 10 by 12 ins. for

the upright engines, and 6 by 8 ins. to 13 by 16 ins. for the

horizontal engines.

The upright type of boiler with submerged flues is usually

preferred, as it occupies only a small space. Horizontal boilers

of the locomotive type are used in a few machines, and are

more economical in the use of fuel, but occupy too large a floor

space. Forced draft is used in both types of boilers, and they

are generally worked to the limit of their capacity. The usual

working pressure is 90 lbs. per sq. in. The safety valve is generally

set to blow off at 120 lbs. per sq. in. The boiler is supplied

with water either from an upright circular sheet iron tank

located in a corner of the machine, behind the boiler, or from a

sheet iron box tank hung under the floor. These tanks usually

hold about 1,000 gallons of water, enough to run the machine

half a day. The water is obtained by a pump or siphon from the

tender of a locomotive on railway work, or is hauled to the

machine by wagon on other work.

FIG. 6.—CLEMENT STEAM SHOVEL; Industrial Works, Bay City, Mich.

In some machines the frame or car body is made of wood,[11]

generally oak, often incased with heavy plate iron. In others

it is constructed of iron or steel I-beams and channels. In all

machines it is strongly built and braced with a view to sustain

the weight of the working parts and to resist the shocks to which

it is subjected. The floor is usually of 3-in. oak plank.

The mast or post is made of cast or wrought iron, strongly

braced and guyed to the frame. It is the pivot about which the

crane swings, and easy working in its bearings is of great importance

for the rapid and economical operation of the machine.

In order to prevent breakage or delay it should never be permitted

to wabble by neglecting to promptly tighten its braces

and guys in case they should work loose. The post should

always stand vertical, or practically so, to insure the horizontal

motion of the crane and avoid unnecessary straining of the

swinging gear. For this reason the machine should be set

practically level before beginning operations; and using a small

mason's level is better than trusting to the eye, when blocking

under the track and adjusting the jack screws for this purpose.

The crane is secured to the post, and is made of wood, iron

or steel, strongly and compactly built to resist the shocks to

which it is often subjected. It is from 14 to 20 ft. high above

the track or ground, varying with machines of different sizes

and manufacture, and swings horizontally through an angle of

180 to 240 degrees, with a radius of 15 to 20 ft. In some machines

it must be detached from the post for shipment, in others

(mostly those made for railway use exclusively) it can be lowered

to a height of 14 ft. above the track, thereby permitting shipment

without detaching from the post.

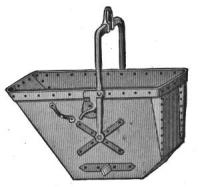

The dipper, scoop, or bucket is made of iron or steel, shaped

somewhat like a coal scuttle. Its cutting edge is protected by

four teeth made of steel or steel pointed. These teeth are easily

removed for sharpening or replacement. Dippers vary in size

from ½ cu. yd. to 2½ cu. yds. capacity. They also vary

somewhat in shape, according to the material to be excavated,

though no special provision is made for this unless there are

very large quantities of the same kind of material to be removed;

or for machines working in a certain class of material only, like

ore loaders. For general work in all kinds of materials the dipper

is seldom changed.

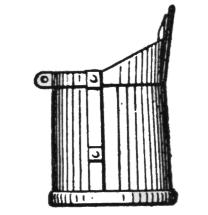

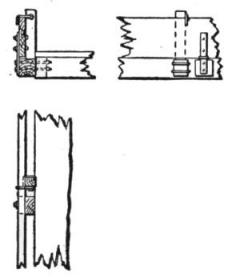

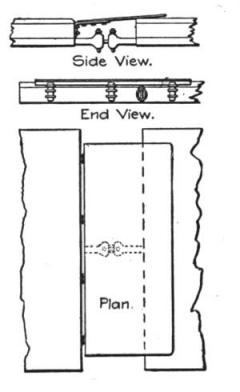

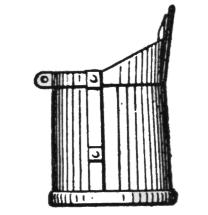

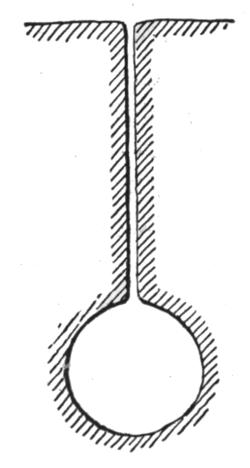

For soft, tenacious material, likely to adhere to the inner sides

of the dipper, and not drop out promptly when the bottom door[12]

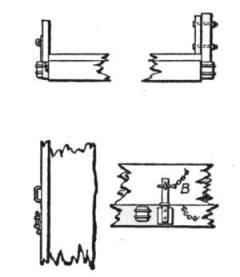

is opened for unloading, the dipper is shaped as shown in Fig.

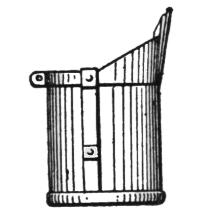

10, with a larger bottom than mouth. In hard, or dry soft material

the section shows parallel sides, as in Fig. 11. For general

use the bottom of the dipper should be slightly larger than

the mouth, as most materials contain more or less moisture

which is likely to produce a partial clogging of the dipper by

material sticking to the inner sides, especially between the teeth,

necessitating frequent cleaning out whenever the machine is

stopped while preparing to move forward, and sometimes

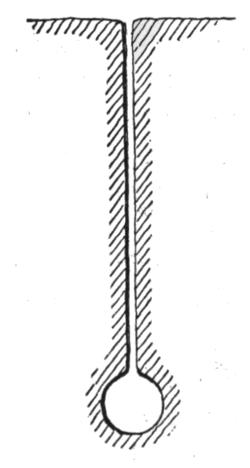

oftener. For ordinary clay, cemented gravel, and hard dry

materials, a dipper with a wide and shallow mouth, as shown in

plan in Fig. 12, is preferred to the one shown in Fig. 13, which

latter is better adapted for loose gravel, sand and other soft dry

materials where a deep cut can easily be made. For hardpan,

shale, loose rock and similar materials, ample strength of teeth

and dipper is of greater importance than its shape.

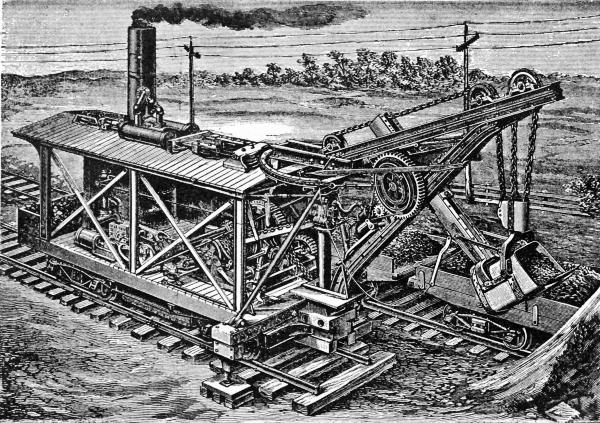

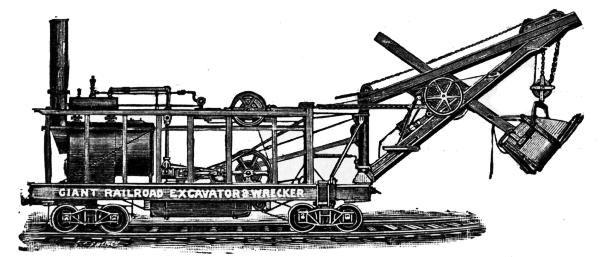

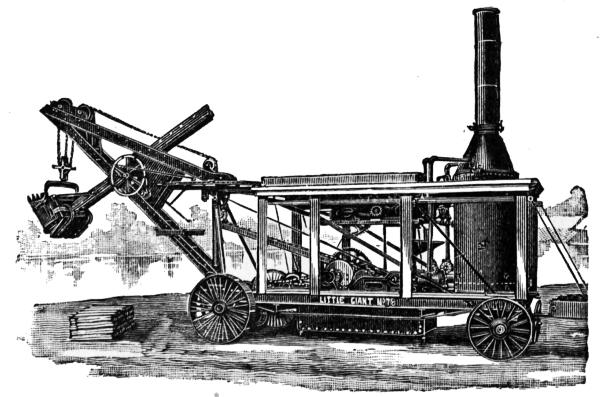

FIG. 7.—GIANT STEAM SHOVEL; Vulcan Iron Works Co., Toledo, O.

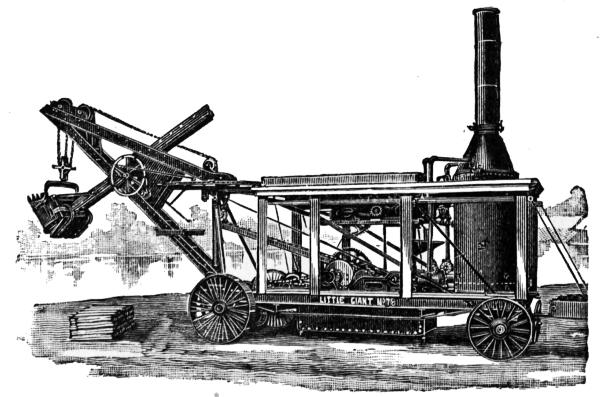

FIG. 8.—LITTLE GIANT STEAM SHOVEL; Vulcan Iron Works Co., Toledo, O.

[13]

To prevent tenacious material from sticking to the inner sides

of the dipper, and to allow it to drop out freely when the bottom

door is opened, it is often good economy to place a barrel

of water near the head of the machine from which a bucketful

can be taken and thrown into the dipper just before each cut.

The water acts as a lubricant and causes the material to drop out

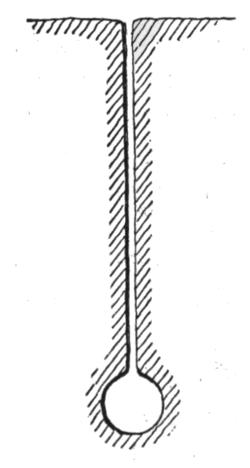

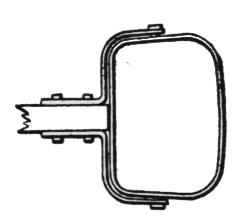

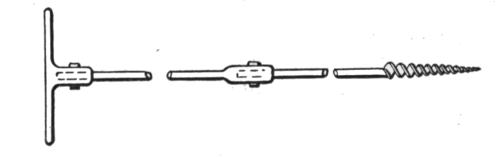

more readily. For cleaning the dipper, the tool shown in Fig.

14 is used.

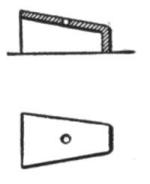

Fig. 10.

Fig. 11.

Fig. 12.

Fig. 13.

The chains have links of three-quarters-inch to one-inch

diameter, and are made of iron, sometimes of steel. Their constant

use necessarily subjects them to great wear, and as they are

also often exposed to severe shocks (especially the hoisting chain)

they must be made of the very best material and in the most

careful manner. At present iron chains are preferred to those

made of steel: they are more durable, and less likely to break

under severe shocks. Steel chains have suffered in reputation

through rapid wear and frequent breakages occurring within the

last few years, but with increased experience in their manufacture

and use they will undoubtedly be improved, and eventually

take the lead over iron chains.

The propelling mechanism consists of an endless chain connecting

one or more axles of the truck or supporting wheels

with the shaft of the hoisting drum by means of friction clutches

or positive gearing. The usual speed is five to six miles per

hour.

FIG. 9.—OTIS-CHAPMAN STEAM SHOVEL; John Souther & Co., Boston, Mass.

Steam shovels of seven of the most prominent manufacturers[15]

are shown in Figs. 1 to 9, and the general particulars of each

are given in condensed form in Table I. In each case the boiler

is upright.

TABLE I.—General Description of the Important Parts of the Most

Prominent Makes of Steam Shovels.

| | | <—Frame—> | |

| Fig. |

Shovel. |

Material. |

Size, ft. |

Running gear. |

Gage, ft. ins. |

B'l'r |

Eng-

ine |

Cylinder, ins. |

H'st'g gear. |

| 1. |

Osgood |

Wood |

10 × 34 |

2 trucks |

4 8½ |

V |

H |

2 |

10 × 12 |

F |

| |

" |

" |

10 × 30 |

" |

" |

" |

" |

" |

8¼ × 10 |

F |

| |

" |

" |

10 × 25 |

" |

" |

" |

" |

" |

7 × 10 |

F |

| 2. |

Thompson |

{I-be'm} |

10 × 32 |

" |

" |

" |

" |

" |

10 × 14 |

F |

| |

" |

{and} |

10 × 30 |

" |

" |

" |

" |

" |

8 × 12 |

F |

| |

" |

{chan- } |

10 × 28 |

" |

" |

" |

" |

" |

8 × 10 |

F |

| |

" |

{nels} |

10 × 24 |

" |

" |

" |

" |

" |

6 × 8 |

F |

| 3. |

Barnhart |

" |

10 × 28 |

" |

" |

" |

V |

" |

8 × 10 |

F |

| |

" |

" |

10 × 26 |

" |

" |

" |

H |

1 |

8 × 10 |

F |

| |

" |

" |

10 × 24 |

" |

" |

" |

V |

" |

8 × 10 |

F |

| |

" |

" |

10 × 22 |

" |

" |

" |

" |

" |

6 × 8 |

F |

| 5. |

Victor |

" |

10 × 30 |

" |

" |

" |

H |

2 |

8 × 10 |

F |

| 6. |

Clement |

" |

10 × 30 |

" |

" |

" |

" |

" |

8 × 10 |

P |

| 7. |

Giant |

" |

10 × 35A |

" |

" |

" |

" |

" |

13 × 16 |

F |

| |

" |

" |

10 × 35 |

" |

" |

" |

" |

" |

8 × 12 |

F |

| |

" |

" |

10 × 30 |

" |

" |

" |

" |

" |

7 × 11 |

F |

| 8. |

Little Giant |

" |

7 × 23 |

{4 r'd wh |

8 0 |

" |

" |

" |

7 × 11 |

F |

| |

" " |

" |

6 × 23 |

{4 r'd wh |

8 0 |

" |

" |

" |

6 × 8 |

F |

| 9. |

Otis-Ch'pm'n |

Wood |

10 × 22 |

{4 fl'ge wh |

7 10 |

" |

V |

1 |

10 × 12 |

P |

| |

" |

" |

10 × 18 | {4 fl'ge wh |

7 10 |

" |

" |

" |

8 × 10 |

P |

Transcriber's Note:

Boiler and Engine—V=Vert., H=Hor.

Hoisting Gear—F=Friction Clutch, P=Positive

| Fig. |

Thrusting Mechanism. | |

Swinging Mechanism. |

| | { | Reversible engines, 2 steam cylinders |

} | |

| 1. | { | each 6 × 8 ins. |

} | |

| | { | Do., do 5 × 6 ins. |

} | Chains attached to circle |

| | } | geared |

| 2. | { | Rack on dipper handle |

} | to hoisting drum. |

| | { | actuated by friction clutch |

} | |

| 3. | { | geared to hoisting drum. |

} | |

| |

| 5. | | Reversible engine, |

} | Wire ropes |

| | | 2 steam cyls. 6 × 8 ins. |

} | attached to circle |

| 6. | | Long st'm cyl., |

} | and pist'n rods |

| | | piston rod at'ch'd to dipper |

} | in long st'm cyl. |

| |

| 7. | { | Reversible engine, |

} | Reversible engine, 2 steam |

| | { | 2 steam cyls. 5 × 6 ins.; |

} | cylinders |

| 8. | { | 5 × 6 ins. |

} | except A, cylinders 7 × 9 ins. |

| |

| | { | Chains on dipper handle actuated by |

} | Chains attached to circle |

| 9. | { | friction clutch geared to |

} | geared to |

| | { | hoisting drum. |

} | hoisting drum |

| |

<————————Crane————————> |

|

| |

<—H'ght ab've—>

gr'nd or track. |

|

| Fig. |

Post

material. |

Material. |

Working order,

ft. |

Shipping order,

ft. |

Radius,

ft. |

Swinging

angle,

deg. |

Capacity

of dipper,

cu. yds. |

W'ht,

tons. |

| 1. |

{ | Wt. iron | } |

Wt. iron |

26 |

14 |

24 |

240 |

2 |

40 |

| | { |

A | } |

" |

24 |

14 |

24 |

240 |

1½ |

30 |

| | { |

frame | } |

" |

20 |

14 |

20 |

240 |

1 |

20 |

| |

| 2. | { |

Cast iron | |

" |

23 |

14 |

20 |

200 |

2½ |

45 |

| | { |

" | |

" |

18 |

14 |

18 |

200 |

1¾ |

40 |

| | { |

" | |

" |

18 |

14 |

16 |

200 |

1¼ |

30 |

| | { |

" | |

" |

16 |

14 |

12 |

200 |

¾ |

20 |

| |

| 3. | { |

Wt. iron | |

Wood |

26 |

14 |

20 |

200 |

1½ |

37 |

| | { |

" | |

" |

24 |

14 |

20 |

200 |

1 |

26 |

| | { |

" | |

" |

20 |

14 |

18 |

200 |

¾ |

16 |

| | { |

" | |

" |

18 |

14 |

18 |

200 |

½ |

12 |

| |

| 5. | { |

Hollow wt. ir. | |

Wt. iron |

19 |

14 |

20 |

200 |

2 |

40 |

| 6. | { |

Cast iron | |

" |

20 |

14 |

20 |

200 |

2 |

40 |

| |

| 7. | { |

Cast steel | |

Steel |

20 |

14 |

19 |

200 |

2½ |

70 |

| | { |

Cast iron | |

" |

20 |

14 |

19 |

200 |

1¾ |

45 |

| | { |

" | |

" |

18 |

14 |

17 |

200 |

1¼ |

30 |

| 8. | { |

" | |

" |

16 |

Detach'd |

15 |

185 |

1¼ |

20 |

| | { |

" | |

" |

15 |

" |

15 |

185 |

¾ |

18 |

| |

| 9. | { |

" | |

Wood |

20 |

" |

20 |

200 |

2½ |

26 |

| | { |

" | |

" |

16 |

" |

18 |

200 |

1¼ |

15 |

Makers: 1 (Osgood): Osgood Dredge Co., Albany, N. Y. 2 (Thompson): Bucyrus

Steam Shovel & Dredge Co., Bucyrus, O. 3, 4 (Barnhart): Marion Steam

Shovel Ca., Marion, O. 5 (Victor): Toledo Foundry & Machine Co., Toledo, O.

6 (Clement): Industrial Works, Bay City, Mich. 7 (Giant) and 8 (Little Giant):

Vulcan Iron Works Co., Toledo, O. 9 (Otis-Chapman): John Souther & Co.,

Boston, Mass.

[16]

Operation of Steam Shovels.—All movements of the steam

shovel are controlled by two men, the engineman and the cranesman.

The former is stationed near the engine, the latter

on a small platform attached to the crane. The engineman directs

the movements for raising and lowering the dipper, swinging

it into position for unloading, and moving the machine forward

or backward. The cranesman regulates the depth of the

cut made by the dipper, releases it from the bank when full or

near the top of the crane, and pulls the spring latch of the bottom

door of the dipper when in position for unloading, thereby

dumping its contents.

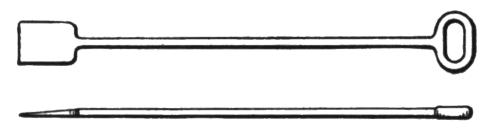

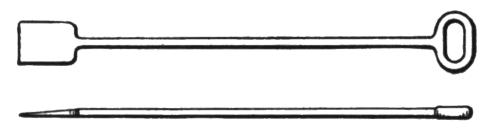

Fig. 14.—Spade for Cleaning Buckets.

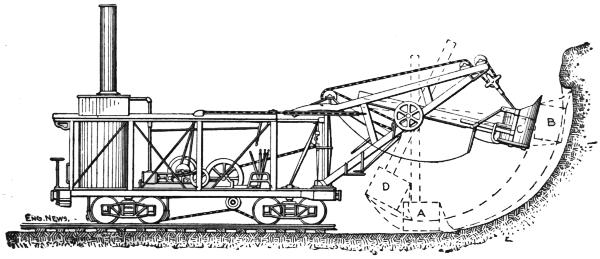

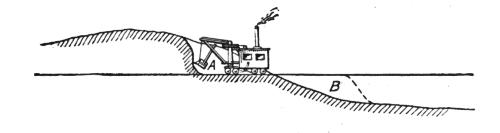

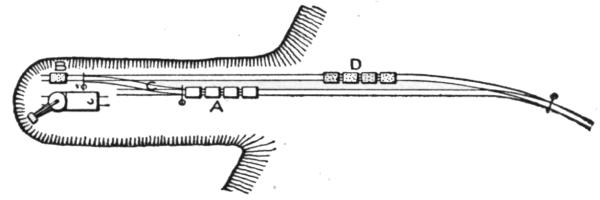

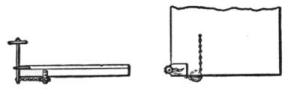

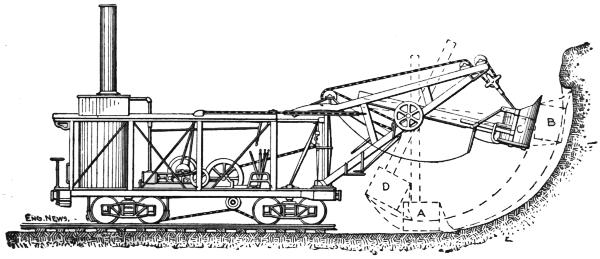

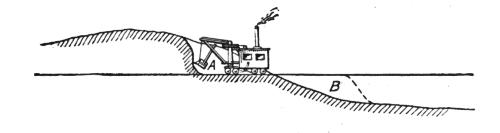

These motions are shown in Figs. 15 and 16. Beginning

with the dipper in the position shown at A, Fig. 15, the engineman

throws the hoisting drum into gear, and starting the engine

pulls the dipper upward, the cranesman at the same time thrusting

it forward, regulating the depth of the cut so that it will not

stop the engine or tip up the rear end of the machine. When

the dipper has reached the position B, near the top of the crane,

the engineman throws the hoisting drum out of gear, and holds

it in position with a foot brake; at the same time the cranesman

by easing his foot brake, allows the dipper to fall back to the

position C. The engineman then swings the dipper over the

car or wagon, as shown in Fig. 16, when the cranesman pulls

the latch rope, thereby opening the bottom door of the dipper

and dropping the contents. The engineman then swings the

crane back again to the next cut, at the same time releasing his

foot brake on the hoisting drum until the dipper has fallen to

a point near the ground, as at D, Fig. 15, where he holds it for

an instant with the foot brake, then drops it by releasing the

brake, while the cranesman (during this slight drop) regulates

the length of the radius of the dipper handle by releasing his

foot brake so as to bring the dipper into the position A again,

and adjoining the last cut. While the dipper is being lowered,

the bottom door closes and latches itself by its own weight, when

all is ready again for another cut.

[17]

These motions are very simple when taken separately, but

when performed together by two different men, experience and

quickness in both are required to carry on the work rapidly

and harmoniously, without breakages or delays. In loose

gravel one cut can be made in a half to three-quarters of a minute;

in hard materials one and a half to two minutes, seldom

more.

Fig. 15.—Showing Series of Operations for Excavating.

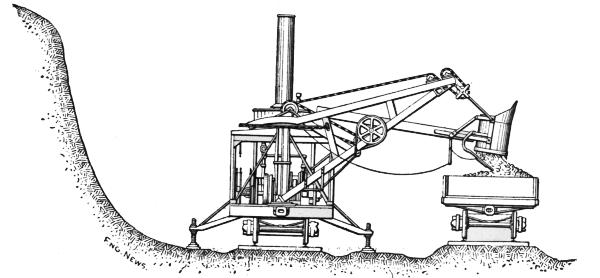

Fig. 16.—Loading Earth from Steam Shovel Onto Cars.

After all material within reach of the dipper has been removed,

an unoccupied section of track (generally about 4 ft. long) at the[18]

rear of the steam shovel is attached to the dipper by a chain

and dragged around the machine to the front (by swinging the

dipper horizontally) and there placed in position in line with the

sections of track under the machine. The screws at the ends of

the jack arm (a horizontal bar at the front end of the machine

used for steadying it when cuts are taken at right angles to the

steam shovel) are then released, and the machine moved forward

three or four feet by throwing the propelling gear into

motion. After placing the jack screws into their new position,

and tightening them, and blocking the supporting wheels of the

steam shovel, the machine is ready for another series of cuts.

The regular employees for operating a steam shovel are the

engineman, cranesman, fireman and four laborers. The latter

are under the supervision of the cranesman, and their duties are

to shovel forward any lumps or loose material which may roll

down and lodge too close to the front of the steam shovel to

be reached by the dipper, to level the surface of the ground in

front of the machine, preparing it for the next section of track,

to lay these sections of track, to attend to the jack screws and

blocking and to act as general utility men.

Fig. 17.—Pole for Breaking Down Edge of Excavation.

With this crew dry sand and loose gravel can readily be

loaded. In harder or more tenacious materials from two to

six extra men are required, depending upon the kind of material

to be excavated, and also upon good management of the

contractor or foreman in charge. Wet sand and fairly loose

gravel requires only two extra men, whose duty is to break

down the overhanging ledges of these materials which cannot

be reached by the dipper, and are liable to fall when the machine

has advanced, burying it or blocking the pit behind it. The

implement used by these men is a pole, Fig. 17, headed by an

iron point, resembling a surveyor's pole. With these poles

fairly loose gravel and sand can be readily broken down, sloped

at its natural angle, and fed into the pit in front of the steam

shovel. In harder materials three to four extra men are usually

sufficient, but in very hard or tenacious materials as many as[19]

six must be employed. These men break down overhanging

material in the face of the bank which cannot be reached by the

dipper, bore or drill holes for powder or dynamite when blasting

becomes necessary, cut and remove trees, etc.

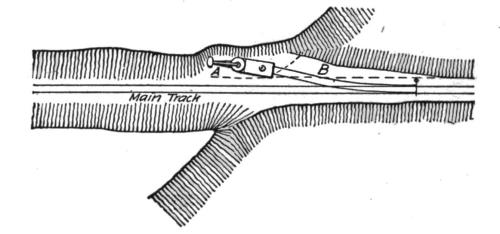

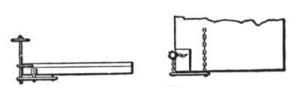

Fig. 18.

On all but very small pieces of railway work there are also

employed a blacksmith and helper, and two to five car repairers.

The blacksmith's work consists mostly of repairs about the cars,

mainly bent or broken aprons, sideboards, chains, etc. The

steam shovel occupies much the smaller part of his time. His

accommodation requires a small rough frame shop about 10 by

16 ft. (an old box car body is frequently used), with forge and

tools. Another rough frame shed of about the same size is

needed for the storage of tools, oils and supplies. The section-men

of the respective sections are occasionally called on for the

building and maintaining (or taking up) of the various side

tracks required during the progress of the work.

Part II.—Steam Shovel Work.

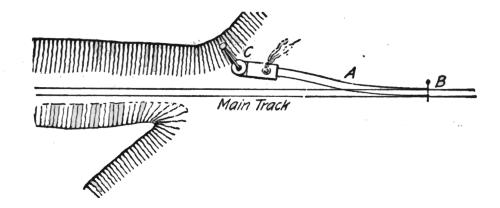

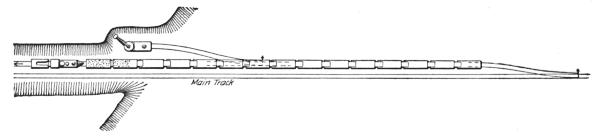

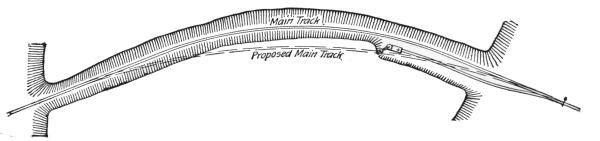

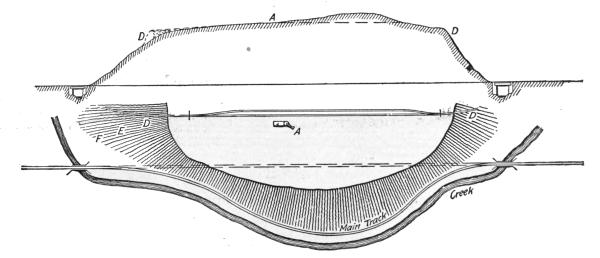

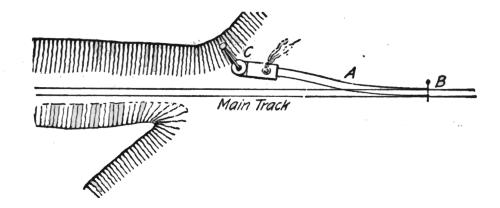

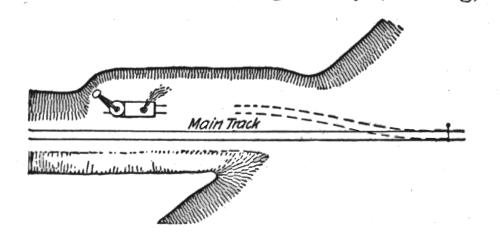

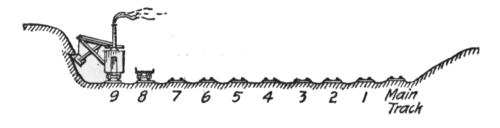

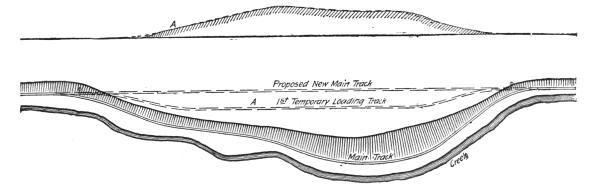

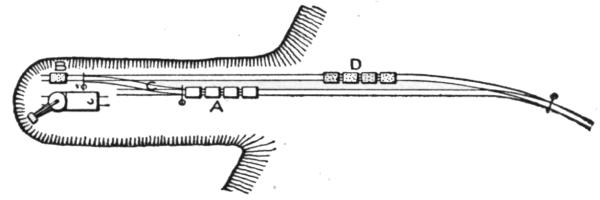

Widening a Cut; Loading on the Main Track.—The simplest

and one of the most frequent cases for the application of a steam

shovel is the widening of a single track railway cut. The manner

of doing this is shown in Fig. 18. A switch, A B, is put

in the main track just beyond the end of the cut and far enough

away to permit the steam shovel (when standing on the side

track) to clear cars on the main track. Cars are then placed

opposite it on the main track and the machine is ready for excavation.

Fig. 19.

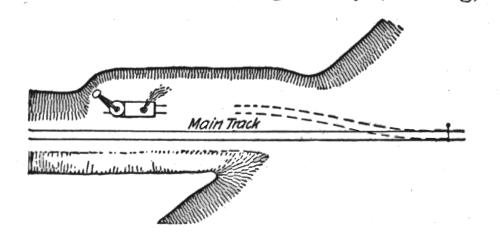

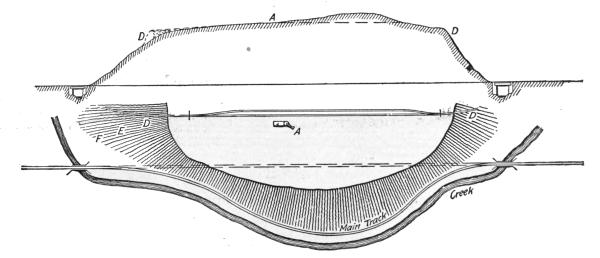

It very frequently happens that the end of the cut joins directly

on an embankment, as shown in profile, Fig. 19. In[20]

cases of this kind it would be necessary to widen the embankment

for the reception of the side track, near the end of

the cut, if the machine were to begin work at that point, C, Fig.

18. This is very seldom done; the usual method is to remove

the section, A, Figs. 19 and 20, to B by hand labor with wheelbarrows

or with teams and scrapers. The excavated material

is used to widen part of the embankment near the end of the

cut for the reception of the side track. Section A is made

barely long enough to provide a standing place for the steam

shovel and clear cars on the main track; it is seldom over 50 ft.

long, and averages about 30 ft. After placing the machine in

this space it is ready for work. Strings of 10 to 20 cars are

then drawn along the main track, and stopped opposite the machine

for loading.

Fig. 20.

Fig. 21.

When the machine has reached the end of the switch, it advances

on short sections of track, generally 4 ft. long, which are

placed in front of it, and again taken from its rear when it has

moved forward one section of track more than its own length.

When no more cuts are to be made for still further widening,

the switch is taken up again and the machine advances on its

own track sections, Fig. 21. When other cuts are to follow,

however, a loading track is needed for the next cut; the side

track is then extended for this purpose at convenient intervals,

generally about 300 ft. at a time though often after each space[21]

of a rail length (usually 30 ft.) is clear. The latter is by far the

best practice, as it permits the immediate withdrawal of the machine

in case of a threatened cave-in, sidehill slip, or other unforeseen

danger.

After all the cars have been loaded they are taken away for

unloading. Sometimes the steam shovel is left idle until the

train returns, which is a very wasteful method of working, even

where the haul to the dump is short, half a mile to two miles.

Two engines and crews should be furnished for hauls up to ten

miles; three engines and crews, or more, for longer hauls, or

where the traffic on the main line is very heavy, and delays to

the work trains are frequent. The material is generally utilized

in filling trestles, widening embankments for side tracks, double

tracks, yards, etc., thereby making two improvements at the

same time.

Fig. 22.

In widening a cut it is good policy to keep the grade of the

pit from 1 to 2 ft. below the surface of the subgrade of the main

track, as shown in Fig. 22, thereby providing for drainage of

the ballast and also providing a receptacle for the spreading of

loose material dropping off the cars and washing in from the

surface of the cut; there is nearly always considerable of this

loose material to roll or wash into the pit after the cut has

been completed; and unless room is provided for it, the accumulation

will soon reach the height of the track, washing mud on

it, and choking the drainage, thus injuriously affecting the main

track.

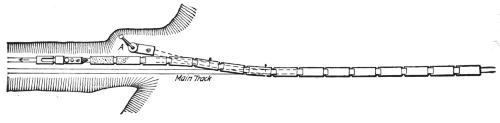

Widening a Cut; Loading on a Side Track Graded by Hand

or Steam.—The delays in loading on the main track of a railway

in operation, due to the clearing of the track for all trains, vary

from one to four hours per day of ten hours, and sometimes

amount to as much as seven hours, depending upon the density

of the traffic on the line. The first cut in a case such as the latter

is therefore necessarily an expensive one, and where the[22]

traffic is so heavy it is often cheaper to make a narrow cut for

the side track, on which the steam shovel is to load, either by

wagons and wheel scrapers, Fig. 23, or by hand with wheelbarrows

loading back on cars, Fig. 24.

Fig. 23. Fig. 23, a.

Fig. 24. Fig. 24, a.

The latter plan has the great disadvantage that only one car

at a time can be loaded and only a few men (six to ten) can be

employed. Therefore this plan is never adopted where quick

work is required, but is used only where ample time is available,

and mostly as an early spring preliminary job, preparing the

way for the operation of the steam shovel later in the season.

From three to six flat or coal cars are used, enough to require

a whole day for the gang of men employed to load; the material

from the face of the excavation is loaded on wheelbarrows, and

wheeled over the empty cars to the one farthest from the cut.

This car is loaded first, then the one next to it, etc. At night the

loaded cars are taken out of the switch by the first available

freight train and hauled to the nearest yard or side track where

widening of the embankment is wanted, or where the material

can be otherwise used to advantage, and there unloaded by a[23]

small gang of men on the following day; the cars to be returned

again the next night. Other empty cars are placed in the pit

track for loading next day, by a train bound toward the pit the

same night the loaded cars were taken out. The work can be

carried on from either one or both ends of the cut. Coal cars

should never be used if flats can possibly be obtained, as the

latter can be unloaded by a gang of men one-third as large as

would be necessary for unloading coal cars.

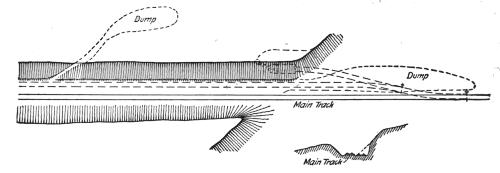

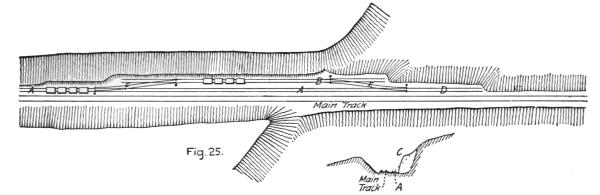

Fig. 25. Fig. 25, a.

Sometimes small dump cars are used, drawn by horses or

mules, and the material unloaded at the end of the cut, thereby

widening the embankment for a long side track, Fig. 25. The

narrow gage track, A, is laid over the ditch adjoining the main

track; the material for any slight excavation that may be necessary

for this track is shoveled on the slope of the cut, as at C,

on the cross section. The material is then loaded on small

dump cars standing on track A, and unloaded at D. The cars

are returned on track B. The cross-overs, E and F, are taken

up occasionally and relaid near the advancing ends of the cut

and dump.

In short cuts the narrow excavation necessary for placing

a side track in the cut for the steam shovel to load on is generally

taken out by carts and dumped at the ends of the cut,

widening the embankment for a long side track.

The plan of excavation with wagons or wheel scrapers for this

side track, shown in Fig. 23, is adopted where the traffic is too

heavy to permit loading on the main track; when the side track

is wanted at the earliest possible time; and in cuts not over 40

ft. deep. The material is dumped at the ends of the cut until

the haul becomes too long, then it is taken to the top of the

cut over sidehill driveways excavated for the purpose, and unloaded[24]

at a sufficient distance from the edge of the new cut to

prevent its washing back by rains.

These expedients are necessary only on railways where traffic

is very heavy. On most railways (on all where the total delay

does not exceed five hours per day) it is cheaper to load on the

main track until the first cut has been made. This necessarily

involves the delay due to running to and returning from the

nearest side track to get out of the way of every main line train,

until the pit track is long enough to contain the construction

train. This, however, seldom requires more than two weeks,

generally only one; the excavation of all of the first cut does

not often occupy more than a month, and is only a very short

time compared with the whole length of time that the steam

shovel is usually in operation on all but very small jobs.

Fig. 26.

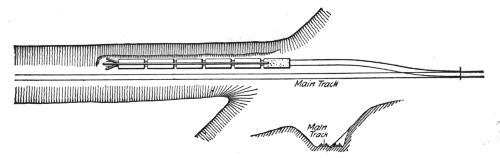

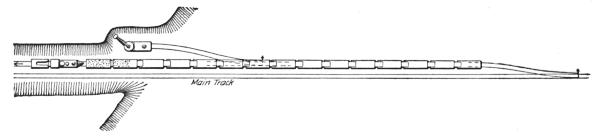

After a side track has been laid in the first cut made by one

of the methods described above, the steam shovel begins work

at A, Fig. 26, loading cars standing on the side track, and some

of them extending out on the main track. At first not more

than ten cars should be coupled to the engine, so that the train

can quickly run into the side track on the approach of a main

line train, and not delay its passage. After the steam shovel

has advanced a train-length, the full number of empty cars can

be coupled to the engine, as they will all be on the side track

while being loaded.

Fig. 27.

Where the embankment has been previously widened by the[25]

excavated material from the cut, Fig. 27, a sufficient length to

permit laying a side track long enough to hold the construction

train, the full number of cars can be used at once, a great advantage

in keeping the steam shovel at work without interruption

by passing trains, which is unavoidable when some of

the cars extend out on the main track.

After the machine has reached the other end of the cut it is

either withdrawn for other work, or placed on the other side

of the main track for widening the cut on that side. The steam

shovel begins at A, Fig. 28, loading cars standing on the main

track; the main line traffic being carried over a temporary main

track built in the excavation previously made by the steam

shovel on the other side of the main track. Only a few cars

at a time can be used for loading at first, unless the temporary

main track has been extended toward B a sufficient length to

clear the usual string of about 20 cars when the first car is being

loaded.

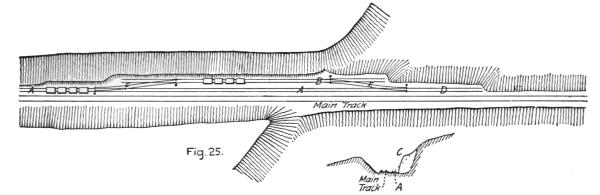

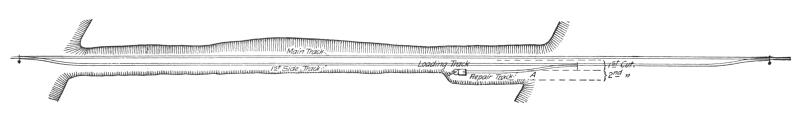

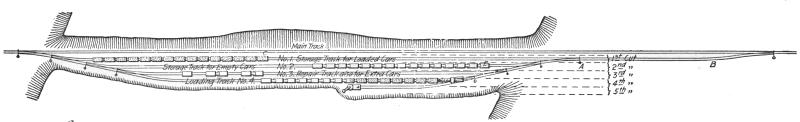

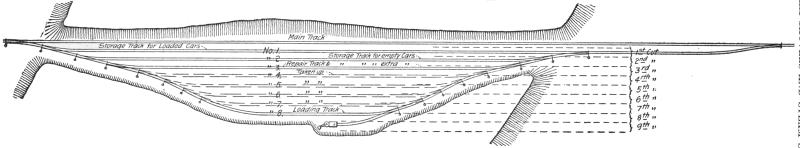

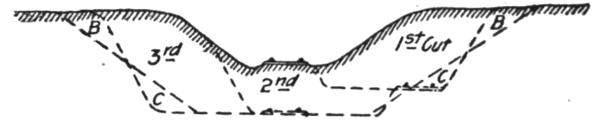

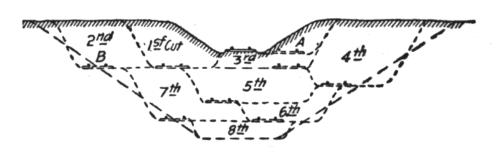

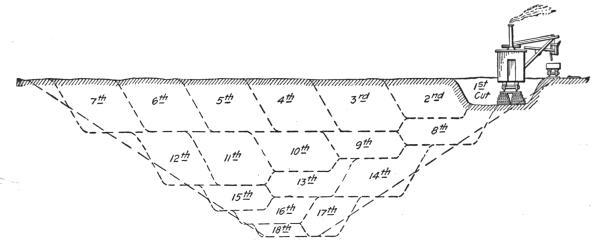

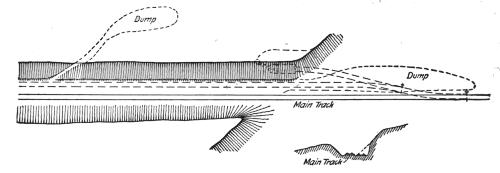

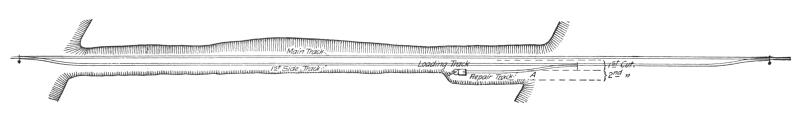

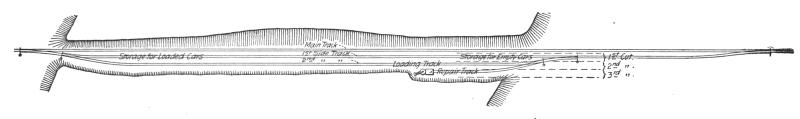

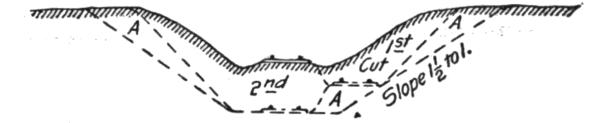

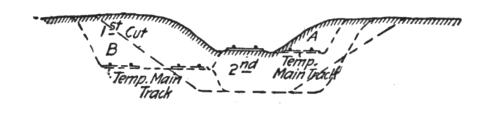

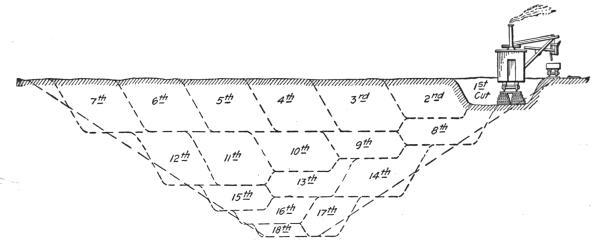

Grading Wide Areas.—In loading gravel for ballasting, or in

widening a cut for the purpose of grading yard, shop or station

grounds, the usual manner of doing the work is shown in Figs.

29 to 34. After the first cut has been made by one of the methods

already described the steam shovel is started in at A, Fig.

29, for the second cut. After its completion the first side track

becomes available for the storage of empty and loaded cars as

in Fig. 30, greatly increasing the convenience of handling the

cars and preventing delays by interferences between the strings

of empty and loaded cars, then the latter cannot be taken away

promptly on account of passing or shortly expected trains on

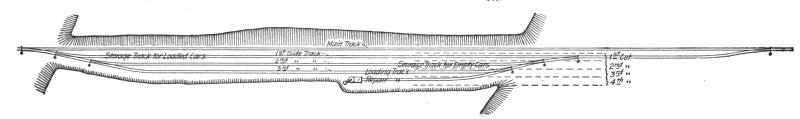

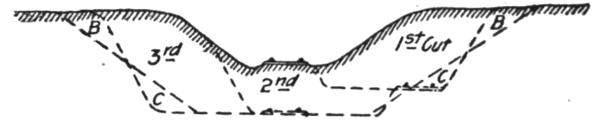

the main line. After the completion of the third cut, another

side track is available for cars, Fig. 31, the loaded cars are then

placed on the first inside track and the empty ones on the second.

The former are taken away by the road crew, and on their

return placed on track No. 2. The pit crew set their loaded

cars on track No. 1 for the road crew, and get their empties from

track No. 2. The pit track in the rear of the steam shovel is

used as a repair track for cars.

Fig. 28.

Fig. 29.

Fig. 30.

Fig. 31.

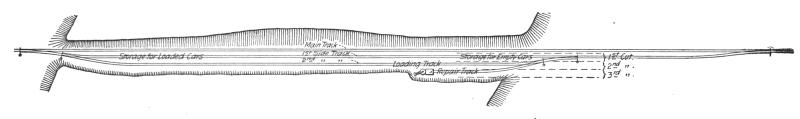

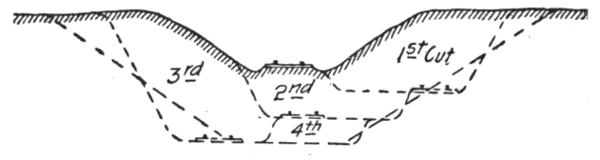

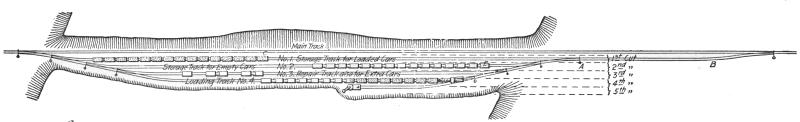

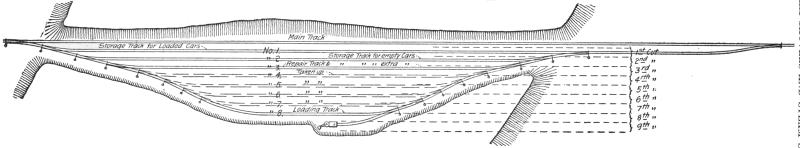

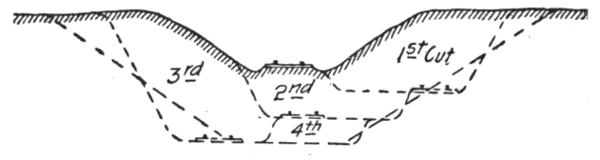

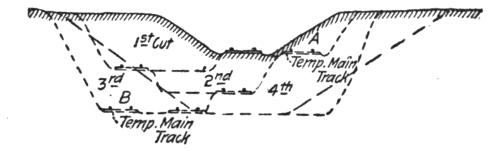

After the completion of the fourth cut, Fig. 32, track No. 3

is used for a car repair and extra storage track for loads or

empties, for which there may not be room in tracks 1 or 2.

Enough tracks have then been built for the most efficient and

economical handling of the loaded material, and if the empty[28]

cars are promptly returned the steam shovel can be kept almost

constantly at work. Each pit track, on which the steam shovel

advances, becomes a side track on the completion of that cut,

to be used as a loading track for the next cut up to the fourth

cut, after which the loading tracks are taken up on completion

of the cut for which they are used, Fig. 33, and relaid in the

pit of the next cut, to be used, taken up, and relaid as before

for the following cuts. In pits less than one-quarter mile in

length, it is sometimes necessary to retain more of these tracks

to provide ample storage space for all loaded and empty cars.

Fig. 32.

Fig. 33.

Fig. 35.

Fig. 36.

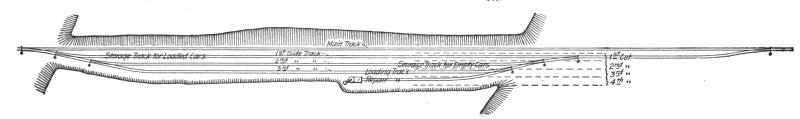

On all large pieces of work where the main line traffic is

heavy it is important that the first side track from A to B, Fig.

32, shall be of sufficient length (usually about 700 ft.) to hold

the engine and a full string of cars to avoid going on the main

track when switching loads to C, and obtaining empties from

D. If there is an embankment from A to B it can be widened

with material taken from the cut, either by wagon or cars.

Fig. 34.

Grading by this method for yard, shop and station grounds

occurs mostly near large cities where better terminal facilities

must be provided for. The width of the area excavated in this

manner seldom exceeds 200 ft. (eight cuts) except in old gravel

pits used for furnishing material for ballasting track, which are

sometimes 300 ft. (twelve cuts) or more in width.

Gravel pits and other wide areas excavated are seldom less

than one-quarter mile or more than one mile in length. One-half

to three-fourths of a mile is the most usual length; in exceptional

cases two miles have been reached. Long and narrow

pits can be worked more advantageously than short and wide

ones.

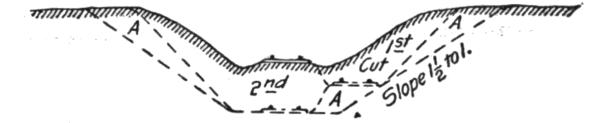

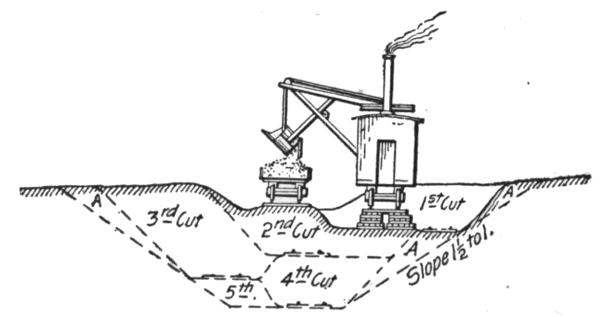

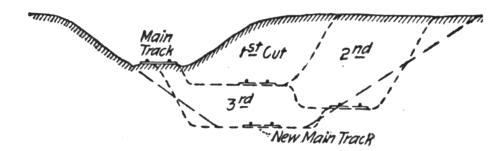

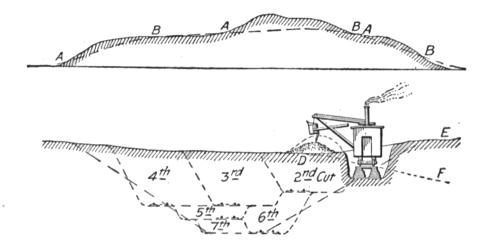

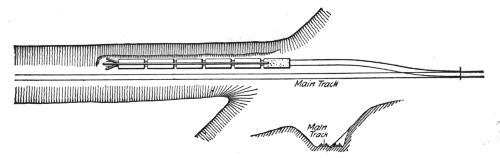

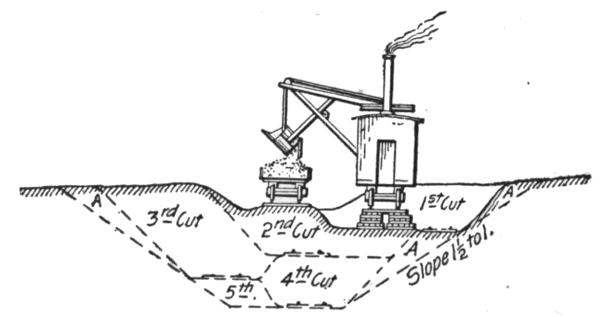

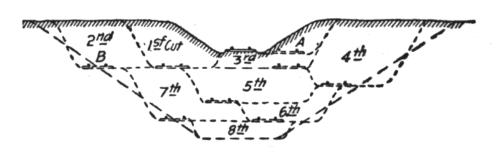

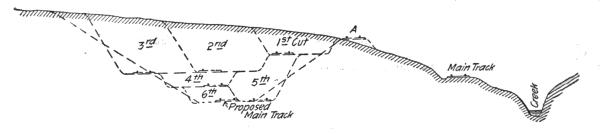

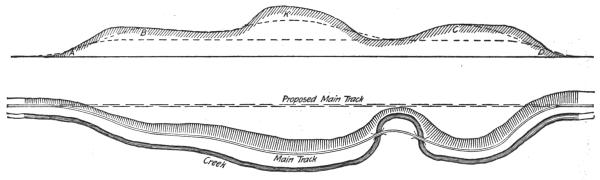

Cutting Down Grades.—For cutting down grades on railways

where the traffic is not too heavy to prohibit loading on

the main track, the usual plan of operations is shown in Figs.

35 to 42. The machine begins work at A, Figs. 35 and 36,

the beginning point of the new grade, loading cars on the main

track, cutting to the line of the new grade, and moving forward[29]

on the track on the surface of the pit as long as the height of

the crane permits raising the dipper high enough over the cars

to open the bottom door of the dipper and discharge its contents,

B, Fig. 35. This point is usually about 2 ft. below the

main track. The machine must then be gradually run upward

on a cribwork of wooden blocking, generally pieces of pine

6 by 12 ins. by 4 ft. long, with some longer track stringers for

supporting the sections of track on top of the blocking, and

some thinner pieces for attaining exact heights of blocking

when needed. As the machine moves forward the dipper still

continues cutting to the line of the new grade, while the machine

is gradually run upward on the blocking on a grade parallel

to the grade of the main track, and slightly below it, maintaining

a constant height between the top of the track on the

blocking and the highest point to which the dipper can be

raised on the crane to insure discharging its load on the cars.

When the dipper has cut as low as the length of the dipper

handle will permit, C, Fig. 35, the greatest depth to which the

machine will cut below the level of the main track has been

reached, and as the steam shovel advances the surface of the

pit will be on a grade parallel to the grade of the main track,

running upward to the summit, S, then downward, and continue

so until it cuts the new grade line at H, when the dipper

is made to cut on this grade, while the blocking under the machine

is gradually lowered as it was previously raised, until

the steam shovel reaches the end of the new grade at I, when

it is again on the surface of the pit.

Fig. 37.

Fig. 38.

Fig. 39.

Although the machine is gradually run upward and downward,

it is always blocked level after each forward move before[30]

beginning work, to insure quick and easy swinging of the

crane, as previously explained. Most machines will cut 5 ft.

below the main track and load on a flat car with 18 ins. side

boards. Some machines will cut as low as 8 ft., and they are

preferred to others on railways where much work of this kind

is done, as their use often avoids making an extra cut.

Fig. 40.

Fig. 41.

Fig. 42.

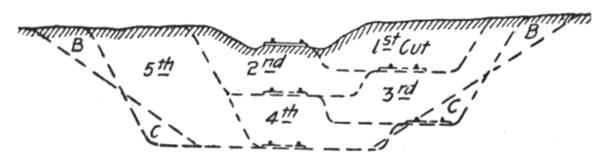

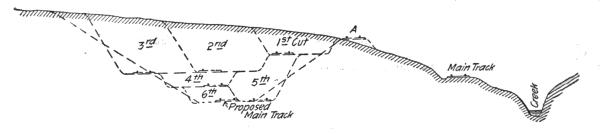

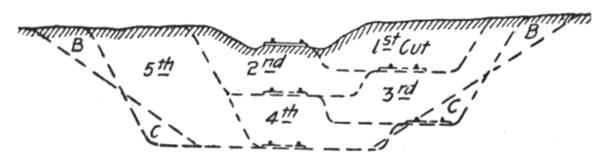

After the first cut has been completed, the pit track, A 1, Fig.

36, becomes the temporary main and loading track; the main

track is taken up from C to H, and the steam shovel run back

to C to begin the second cut, Fig. 42, excavating it in the same

way as the first, and loading on the temporary main track. This

track again is taken up after the second cut, the machine begins

at D and ends at G for the third cut and loads on the pit track

in the second cut; the fourth cut is made in a similar way, the

machine beginning at E and ending at F, Fig. 36. The fifth

and last cut is merely a widening cut, made by loading on the

track in the pit of the fourth cut. The material of each cut

after the first is loaded on the track laid in the preceding cut.

After the completion of the last cut, the permanent subgrade

having been reached, the main track is laid on the permanent

line, and the small quantity of material obtained from cutting

the ditches loaded on cars by hand and taken away for unloading.[31]

The most frequent depth of cut made at the summit of

grades is about 10 ft. (two cuts), Figs. 38 and 39.

Fig. 42½.

Fig. 43.

Fig. 44.

Fig. 45.

When the main track is on a curve, as frequently happens,

an extra cut can often be avoided by slightly changing the alinement

of the new main track, and at the same time reducing the

degree of curvature, as shown by Figs. 42½ and 43. This

is particularly applicable where an odd number of cuts must

be taken to reach the bottom of the new grades. The dipper

will cut to a slope of about 1 to 1. When greater slopes are required,

it must be done by hand or undercutting resorted to.

Sloping by hand is slow and expensive work, impracticably so

in all tenacious materials; it has therefore become the exception,

and undercutting the rule. Cuts made in the latter manner

sometimes present a rather ragged appearance when just completed,

but the irregularities soon merge into a smooth surface

as the action of the elements produces the natural slope of the

material; the smaller cost amply compensates for the temporary

lack of finished appearances. The amount of hand labor necessary[32]

where undercutting is not practiced is shown by the sections

A in Figs. 38 and 41. This can be entirely avoided by

undercutting the slopes, as shown in Figs. 39 and 42; the sections

B will slough off within a year or two and most of the

material lodge in the spaces C; a small part of this material

may roll to the bottom of the cut, and can be removed by loading

on cars by hand, or space may be provided for it by making

the cut a few feet wider at the bottom. In most cuts for reducing

grades this extra width must be cut out anyhow to

provide room for both steam shovel and loading track.

Fig. 46.

Fig. 47.

Fig. 48.

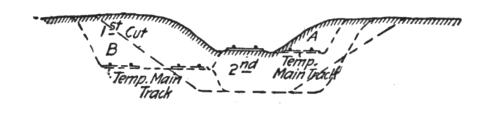

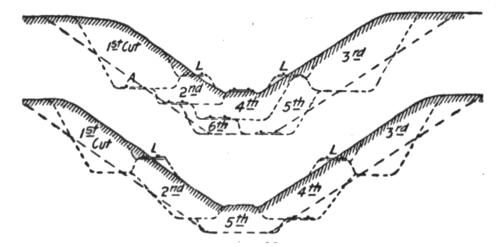

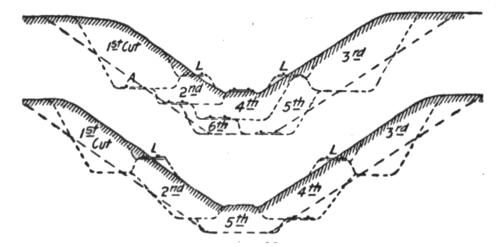

In reducing grades on railways with a traffic too heavy to

permit loading on the main track, a temporary main track

must first be built by one of the methods shown in Figs. 23, 24

and 25. The temporary main track, A, Figs. 44, 45 and 46, is

then laid, as shown in Fig. 28, to carry the traffic of the road

unobstructed. The main track then becomes the loading track

for the first cut, and the following cuts are made as shown in

Figs. 44, 45 and 46. The temporary main track, A, is moved

to a second position, B, when the material under it must be

cut away. Great care should be taken to arrange the cuts so

that the temporary main track will have to be moved as few

times as possible, and to attain the lowest level when it is

moved. In loose gravel or sandy materials wider bermes and

longer slopes must be allowed for the shelf on which the temporary

main track rests than are shown in the above figures,

but the method of doing the work is essentially the same.

[33]

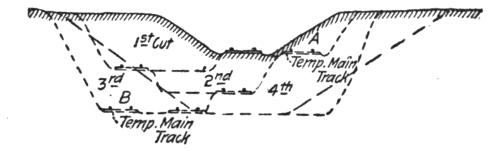

If the depth of the original cut in tenacious materials exceed

the height which the dipper can reach, and break down the material

above it, the cuts are arranged as shown in Figs. 47, 48

and 49. Temporary loading tracks, L, are built on the side of

the slope, and the first cut on each side made by loading on

them; the following cuts are then made, as shown on the

figures. If the main line traffic is very heavy, it is turned over

the temporary main track, A, Fig. 47, until the cut is completed.

Fig. 49.

The original cuts are not often more than 10 ft. deep, and the

section shown in Fig. 45 covers the majority of cases.

On double-track railways the traffic in both directions is generally

turned over one track for the length of the new cut,

thereby avoiding considerable expense in providing two temporary

main tracks.

Each different piece of work presents different conditions;

and while the same general principles apply to all, every case

requires disposition according to its own special circumstances.

Great care and study should be exercised in arranging the cuts,

to reduce them to the fewest possible number, and avoid shifting,

taking up and relaying tracks oftener than absolutely necessary.

Fig. 50.

Fig. 51.

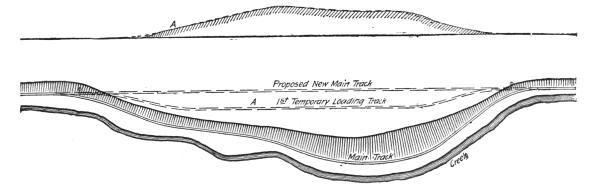

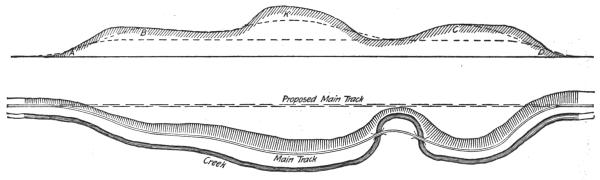

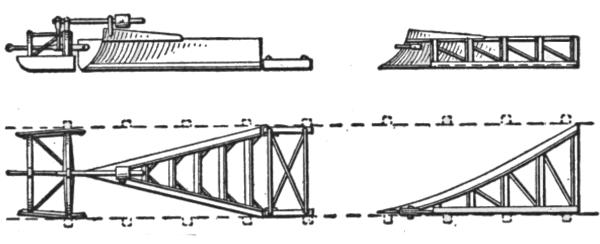

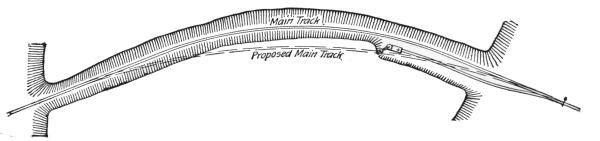

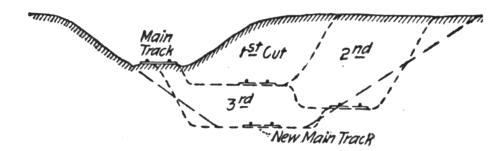

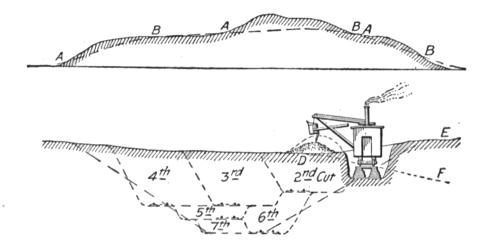

Construction Work.—On railways the steam shovel is used

mostly in connection with maintenance of way work: loading

gravel for ballasting the track, widening cuts, filling trestles, etc.,[34]

but it is also largely used for various construction work, particularly

re-alinements of the main track for reducing grades

and curvature. In excavation of this class, thorough cutting

should be avoided if possible, for reasons which will be subsequently

explained. The work is begun by laying a temporary

track, A, Figs. 50, 51 and 52, over the surface of the ground if

its natural grade is not too steep to permit operating construction

trains over it. Grades up to 6 per cent. (316.8 ft. per mile)

can be used. A mogul engine will draw six empty flats over

such a grade, a sufficient number of cars to start the work for

the short cuts near the summit. The cuts are then made as

indicated in Fig. 52.

Fig. 52.

Fig. 53.

Fig. 54.

If the grade of the ground is too steep to operate a track laid

on it, one of the three methods may be adopted to obtain a

grade for this track:

1. The steam shovel is made to cut a trench between the

points A and B, Fig. 53, where the slope of the ground is too

steep to permit operating a track laid on its surface, and varying

in depth from 5 to 10 ft. as may be necessary to attain the

desired grade. The excavated material is dumped at D, Fig.

54, to be removed with the next cut. The length of the crane

will not permit dumping at E a sufficient distance (20 ft. or

more) to obtain a berme and prevent the material washing back[35]

into the new cut in the course of time; it must, therefore, be

dumped at D and removed as described, unless the slope of

the ground is away from the cut, as indicated by the line D F,

Fig. 54; in such a case the excavated material can be dumped

at F.

2. By excavating the trench with teams and scrapers.

3. By through-cutting a trench with the steam shovel, loading

the material on small dump cars or wagons, and wasting

it at the nearest available place.

Fig. 55.

Fig. 56.

Fig. 57.

After the first loading track has been laid in this trench, the

cuts are made as indicated in Fig. 54.

[36]

When the slope of the ground is too steep to permit a track

to be laid on it which can be operated, or to cut a trench for

it, as frequently occurs when the excavation passes through a

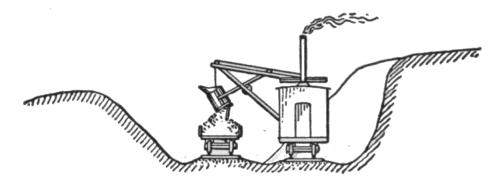

high spur or knoll, Figs. 55, 56 and 57, the steam shovel

mounted on standard gage railway tracks cannot be used, and

a machine independent of a railway track for transportation

must be employed. It is started at A, Figs. 56 and 57, loading

small dump cars drawn by horses, and dumping at the nearest

available place outside of the lines of the new cut, as at D, Figs.

56 and 57. Sometimes wagons are used if the cuts near the top

are short and not very deep, so that a temporary standard gage

track can soon be run through the cut, and the material loaded

on cars. The dumping track at D is changed to E F, etc., Fig.

57, as the machine cuts lower, maintaining a descending grade

from the steam shovel.

Fig. 58.

Fig. 59.

Fig. 60.

In cases of this kind it is often necessary to run the steam

shovel up a very steep grade to reach the point where it is to

begin work. This can readily be done by attaching one end

of a one and a half inch rope to a strong tree and winding the

other end around the driving axle. Then starting the running

gear the machine can be drawn up grades where it could not

otherwise propel itself. As a precautionary measure, it is advisable

to use at least two ropes.

[37]

A combination of all these methods sometimes becomes

necessary, as shown in Figs. 58 and 59. The material in the

knoll, K, Fig. 58, is loaded on small dump cars and unloaded

at the nearest available place. When this knoll has been cut

down sufficiently, and trenches cut between A B and C D,

the track A B C D is built, and the excavation proceeded with,

as heretofore described. The high points B, K and C are cut

down first until the grade of the loading track between B and

C is parallel to the grade of the proposed new main track. Cuts

nearly 100 ft. in depth and a mile in length have been excavated

in this manner. Two and often three steam shovels are employed

at the same time, working near the ends of the cut

until the through track has been laid, and then following each

other, as shown in Fig. 60. As soon as possible, a through

track should always be laid, as it greatly increases the capacity

for the prompt and efficient handling of the cars.

Fig. 61.

Fig. 62.

Enough side tracks for storing both empty and loaded cars

should be built close to the work, where they can be reached

without going out on the main track. Sometimes the pit tracks

behind the steam shovels are utilized for this purpose, but these

tracks are taken up too often, and should not be depended upon

for side tracks, though they may be used as such occasionally.

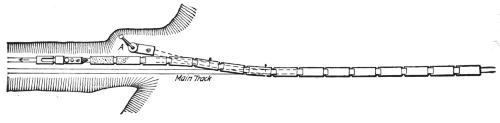

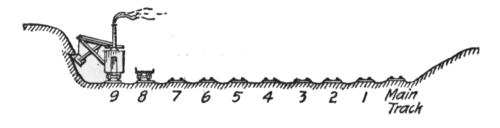

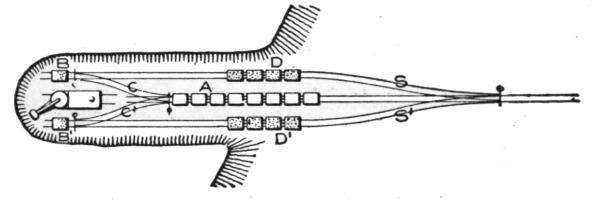

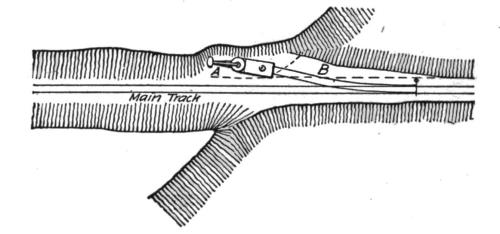

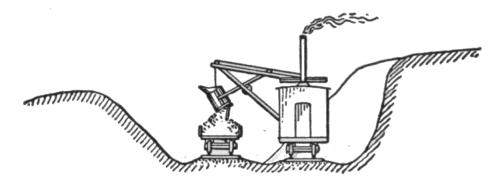

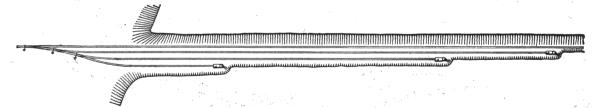

In through-cutting the material is loaded on small dump

cars running on tracks of about 3 ft. gage, drawn by horses,

and wasted on some side hill or other nearest available place;

this haul seldom exceeds a quarter of a mile in length. In Fig.

61, the empty dump cars standing at A are drawn over the

cross-over C by a horse, to be loaded at B; then run to D, and

when from four to six cars have been loaded they are taken to

the dumping place and unloaded; then returned to A.

[38]

In loose materials considerable time is lost in waiting from

the time the loaded car is run to D and the next empty brought

from A to B. In tenacious materials not nearly so much time

is lost, as the dipper cannot be filled so rapidly. This loss of

time is largely avoided by arranging double loading tracks,

Fig. 62, one on each side of the steam shovel, and connected

to a central track for empties by the cross-over C and C´ and

switches S and S´. Two horses are used, one on each side of

the central track, to bring forward the empty cars from A to

B, and A to B´, and return them to D and D´; these operations

are alternately performed, each empty car on one loading track

being brought forward while the other is being loaded. The

cross-overs C and C´ should be kept close to the rear of the

steam shovel, and as it advances they must be taken up and

relaid; this becomes necessary about once in three days in soft

materials and about once a week in hard stuff.

Portable sections of tracks, switches and cross-overs are generally

used between the points A and B, and can be relaid very

quickly.

Standard gage railway cars cannot be used in thorough cutting,

as the track cannot be laid in front of a point at right

angles to the post of the steam shovel, and when the track ends

there the crane cannot swing back far enough to load the car.

Thorough cutting should be avoided if possible, the cost due

to the loss of time in switching cars, relaying tracks, extra

horses and men, etc., makes it more expensive than excavating

from a side cut.

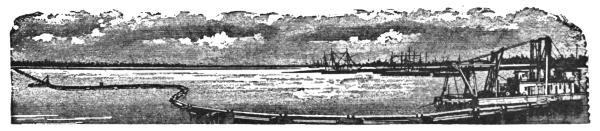

In excavating canals, harbor and dockwork, stripping coalfields,

stone quarries, grading for new city additions, and other

work not connected with a railway, as well as railway construction

and re-alinement work which is inaccessible to a railway

track in its early stages, the general manner of using the steam

shovel is the same as for railway work; varying only in details,

depending upon the means of disposing of the loaded material,

by wagons, carts or dump cars, and the use or waste of this material.

Although the steam shovel is employed mostly on railway

work, it is not exclusively a railway machine. It is already

largely used on other work, and its use in this direction is

rapidly extending, especially on the increasing number of extensive

public works in the vicinity of large cities.

[39]

The most economical height of cut varies greatly with the

nature of the material. In dry clay, loam and other dry materials

which can be broken down readily with a bar or iron

pointed pole (Fig. 17), cuts of 25 to 30 ft. in height are usually

taken. In harder and more tenacious materials it should not

exceed the height to which the dipper can be raised, 14 to 20 ft.,

varying with the size of the machine. In sand and loose gravel

which easily falls down to the machine heights up to 60 ft. are

common, and sidehill cuts in loose gravel up to 300 ft. in height

have been taken. In such cases, and also in the removal of

landslides, great care must be taken to avoid an avalanche of

the material burying the machine when the toe of the slope is

cut away. The pit track should always be kept close up to the

sections of track under the steam shovel, so that it can be

quickly withdrawn when necessary. As a general rule, the

higher the cut the better, as the machine can then load the greatest

amount of material between each advance, and lose the least

possible amount of time. Each forward move of the machine

requires from three to ten minutes, depending upon the height

of blocking, if any, it is working on; this is a dead loss, as no

cars or wagons can be loaded during that interval.

Powder and dynamite are frequently used to good advantage

to shatter the harder materials before excavating. When thus

broken up about twice the amount of these materials can be

loaded in a day. Great care must be exercised in the quantity

of the explosive used, and in the location of the drill holes to

prevent injury to the steam shovel. The explosives should be

stored in a safe place, preferably in a vault at some distance from

the place where they are to be used.

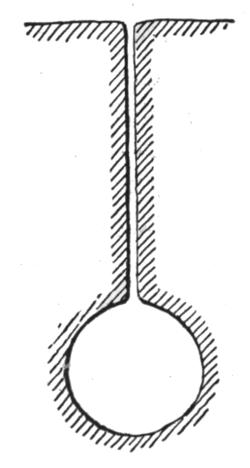

The use of dynamite is confined mostly to bowlders, ledges

of rock and stumps of trees, while powder is generally used for

hardpan, shale, slate, cemented gravel and hard clays. For the

latter materials dynamite is usually too powerful, as instead of

merely lifting and loosening them, as desired, it shatters shale

and slate into fragments, and compresses the other materials

about it, forming a "cistern" from 3 to 5 ft. in diameter, as shown

in Fig. 63. Sometimes small quantities of it are used specially

for this purpose to make room for a large charge of powder at

the bottom of the drill hole, where its explosion will have the

most effect in loosening the superincumbent material. A

charge of one-quarter to one-half of an ordinary dynamite cartridge[40]

will usually blow out a "cistern" large enough to contain

from one-half to one keg of powder, Fig. 64.

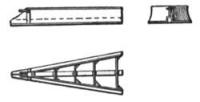

The depths of the drill holes in these materials vary from 4 to

20 ft.; they are made with a drill, or, in the softer materials, with

an auger similar to a plank auger, generally about 2 ins. diameter,

with extension pieces for deep holes, as shown in Fig.

65. Crowbars and wooden and iron wedges are also often used

in breaking down overhanging material when it cannot quite

be reached by the dipper.

The excavation of materials for which powder or dynamite

are used to loosen them requires a powerful machine, with a

strongly built, medium size dipper. A small or lightly built

machine giving good satisfaction in soft materials would prove

an utter failure here.

Fig. 63.

Fig. 64.

Fig. 65.

Assuming good management and a competent crew, the

daily output of a steam shovel depends mostly upon the nature

of the material excavated; it is also somewhat dependent upon

the height and width of the face of the cutting, and largely upon

the facilities for disposing of the loaded material, and keeping

the machine almost constantly at work by an ample supply of

empty cars and wagons. Although these varying conditions

differ on each piece of work, the probable output of a machine

for a given excavation can be closely estimated by good judgment[41]

based on previous experience with similar work. The

average daily output in different kinds of materials, and under

average, favorable and unfavorable conditions, as described

above, is shown in Table II.:

TABLE II.

| Capacity |

Delay. |

Sand. |

Loose gravel. |

Dry loam. |

Dry clay. |

Damp clay. |

| of dipper. |

hours.[2] |

Cu. yds. |

Cu. yds. |

Cu. yds. |

Cu. yds. |

Cu. yds. |

| 2½ cu. yds. |

1 |

Good |

2,400 |

2,400 |

2,000 |

1,800 |

1,200 |

| " |

5 |

Poor |

1,200 |

1,200 |

1,000 |

900 |

600 |

| " |

2½ |

Avg. |

1,800 |

1,800 |

1,500 |

1,350 |

900 |

| 1¾ cu. yds. |

1 |

Good |

1,600 |

1,600 |

1,200 |

1,000 |

800 |

| " |

5 |

Poor |

800 |

800 |

600 |

500 |

400 |

| " |

2½ |

Avg. |

1,200 |

1,200 |

900 |

750 |

600 |

| 1 cu. yd. |

1 |

Good |

1,000 |

1,000 |

800 |

700 |

500 |

| " |

5 |

Poor |

500 |

500 |

400 |

350 |

250 |

| " |

2½ |

Avg. |

750 |

750 |

600 |

525 |

375 |

TABLE II.—Continued.

| |

<————— Loosened by explosives.———> |

| |

|

Stiff blue |

Hard |

Mixed clay |

Loose |

Cemented |

| Capacity |

Delay. |

clay. |

pan. |

and boulders. |

rock. |

gravel. |

| of dipper. |

hours.[3] |

Cu. yds. |

Cu. yds. |

Cu. yds. |

Cu. yds. |

Cu. yds. |

| 2½ cu. yds. |

1 |

Good |

800 |

600 |

600 |

600 |

600 |

| " |

5 |

Poor |

400 |

300 |

300 |

300 |

300 |

| " |

2½ |

Avg. |

600 |

450 |

450 |

450 |

450 |

| 1¾ cu. yds. |

1 |

Good |

600 |

400 |

400 |

400 |

400 |

| " |

5 |

Poor |

300 |

200 |

200 |

200 |

200 |

| " |

2½ |

Avg. |

450 |

300 |

300 |

300 |

300 |

| 1 cu. yd. |

1 |

Good |

400 |

300 |

300 |

300 |

300 |

| " |

5 |

Poor |

200 |

150 |

150 |

150 |

150 |

| " |

2½ |

Avg. |

300 |

225 |

225 |

225 |

225 |

Part III.—Disposition of Material.

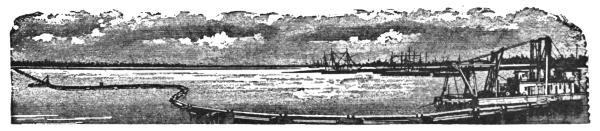

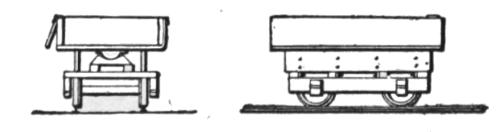

Loading the Material for Transportation.—The material excavated

by a steam shovel is loaded on cars, wagons or carts.

On railway work it is usually loaded on dump or flat cars. On

other construction work small dump cars are most generally

used, and sometimes wagons or carts.

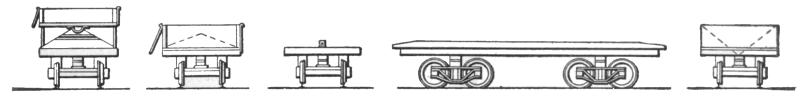

Fig. 66.Fig. 67.Fig. 68.

Fig. 69.Fig. 73.

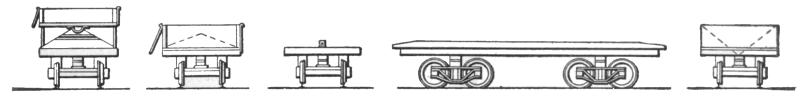

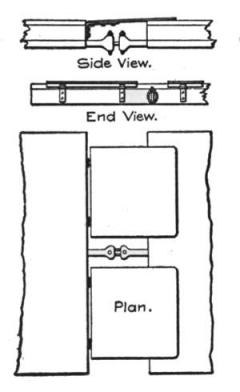

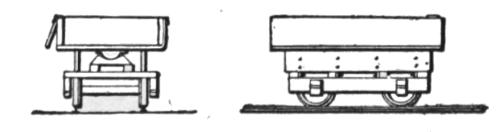

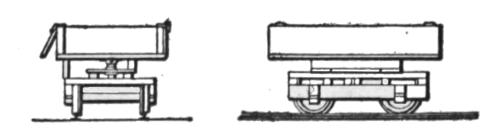

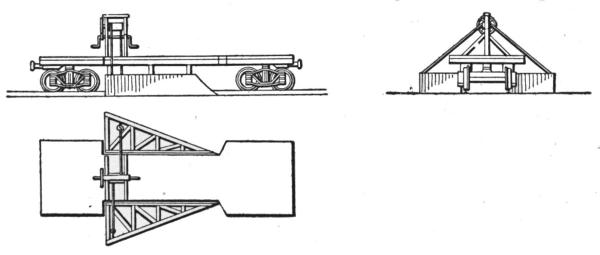

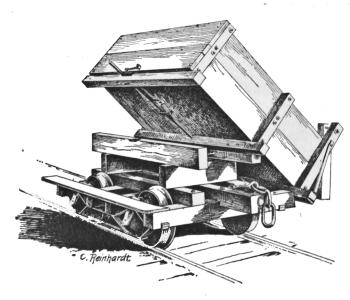

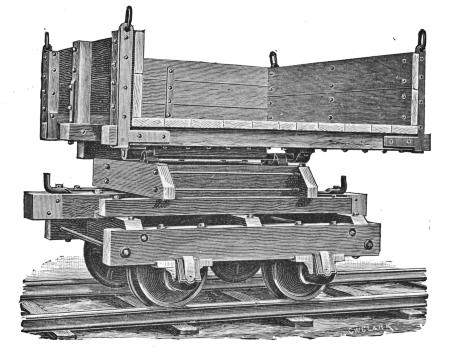

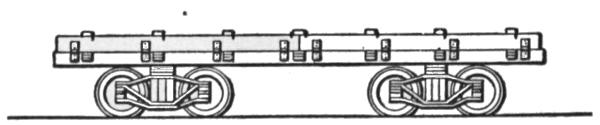

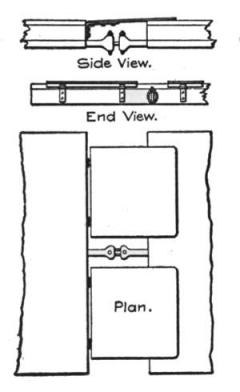

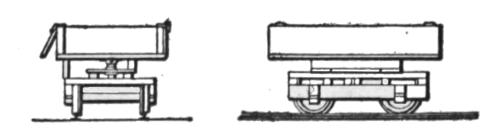

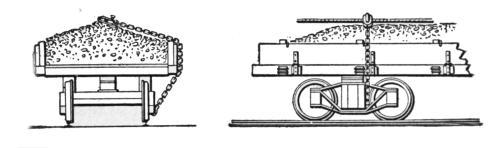

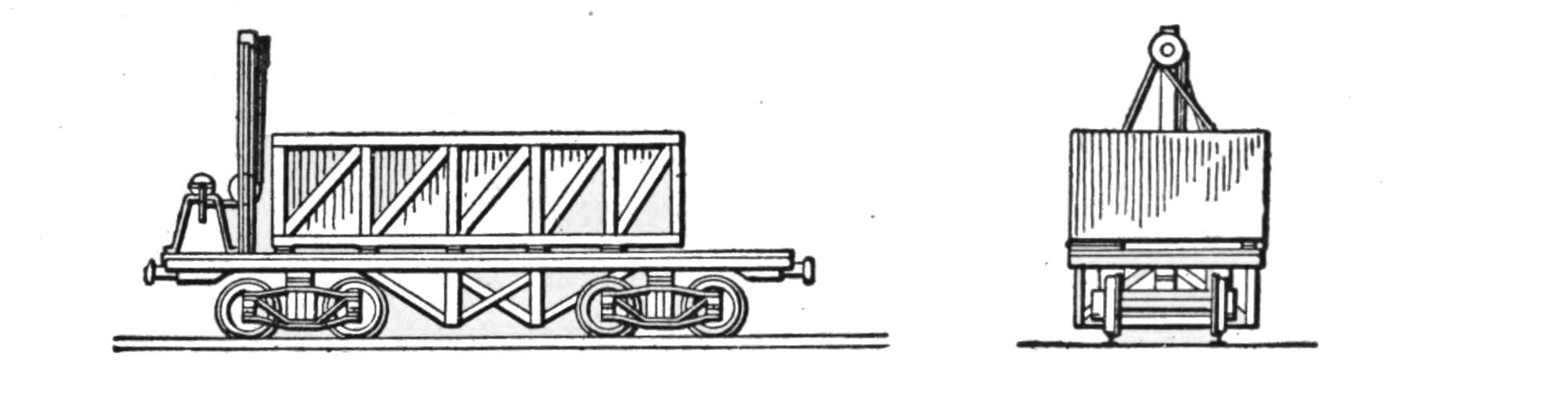

Standard gage railway dump cars, Figs. 66 and 67, have

nearly gone out of use. They were replaced by the center ridge

flat car, Figs. 68 and 69, and it in turn has been replaced by the

ordinary flat car. Dump cars are of two styles, dumping either

by tipping, Fig. 66, or by means of a hinged sideboard opening

on an inclined floor, Fig. 67. Both are heavy, clumsy, costly[42]

and can be used for scarcely any other purpose, often standing

idle from six to eight months of the year. They dump dry materials

very rapidly, but are often slow in discharging damp,

tenacious materials, especially in the hinged sideboard car,

whose floor slope is often not sufficient to permit the material

to slip out quickly, and the material must then be pushed out,

thus causing much delay. The greatest objection to these cars

is that they can be used for scarcely any other purpose, on most

railways for no other purpose; and there is not sufficient work

for them to justify keeping the necessary number on hand for

the ordinary work in this line. They were replaced by the

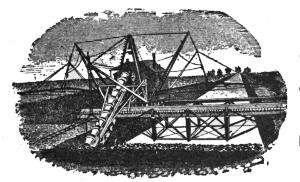

center ridge car, Figs. 68 and 69, as above noted, which is

merely an ordinary flat car with a timber 4 by 6 ins. bolted on

its floor along the center line, serving as a guide for a plow,

Fig. 70, drawn over it by the locomotive, thereby unloading the

material. The ridge timber is slightly pointed at both ends to

assist in guiding the plow onto the car as it passes from one

car to another. The top edges of the ridge are sometimes protected

by angle irons, as in Fig. 71, and the points by cast iron

caps, Fig. 72. By taking off the center ridge this car can

readily be restored to general service after completing the steam

shovel work. The center dump car, shown in Fig. 73, is used

only for gravel ballasting where the material is wanted delivered

between the rails.

Fig. 70.

Fig. 71.

Fig. 72.

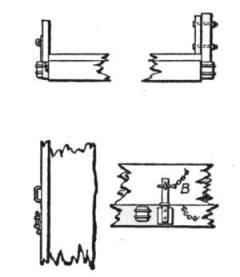

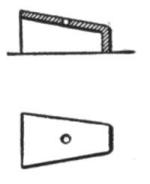

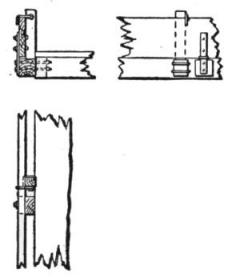

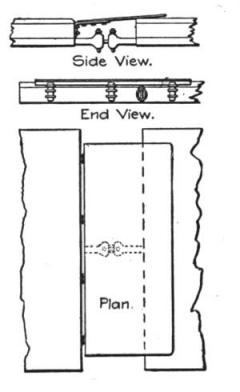

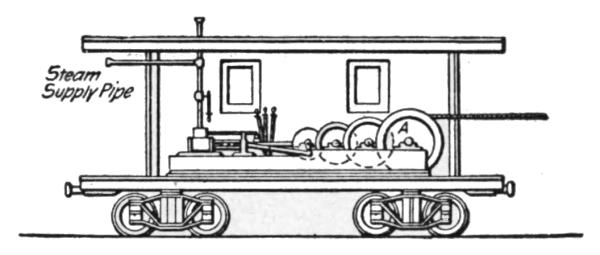

The brakes are placed on one side of the car, as shown in

Figs. 74 and 75. When boulders, loose rock, etc., are to be

unloaded, the brake staff is set in a socket, Fig. 76, and taken

out before the plow is started. This avoids bending or breaking

the staff in case any stone should be wedged between it and

the moving plow. Sometimes the socket is used with the brake

at its ordinary place at the end of the car; in such a case it

must always be taken out before the plow reaches it.

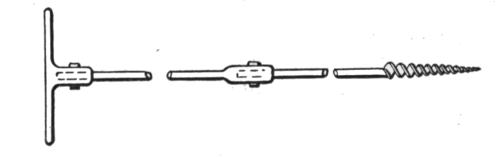

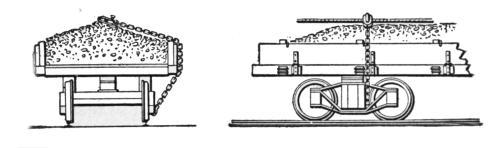

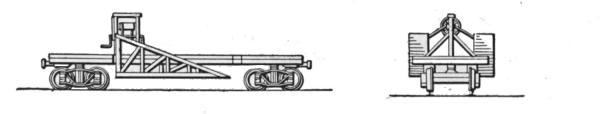

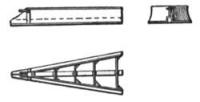

The plow, Fig. 70, is built of heavy plate and angle iron,

strongly braced, and headed by a cast steel point, to which the[43]

cable is attached. The sides are curved outward at the bottom,

working under the material and pushing it aside as the plow is

drawn along, and held down on the car by the weight of the

material and the partly downward pull of the cable at its point.

Short pieces of old rails and other scrap iron are also often

placed on the plow to help hold it down on the car when very

tenacious materials are to be unloaded. The groove extending

along the center line on the bottom fits over the ridge timber

on the car, and forms the guide by which its movement is directed.

Small stones, protruding bolts, slivered ridge timbers

and other obstructions in the groove of the plow sometimes

wedge the point fast, and before the engine can be stopped, the

plow is turned up on its point, and falling to either side, tumbles

off the car. The weight and elasticity of the cable is often sufficient

to draw the plow half a car-length after the engine has

been stopped, and it is often difficult to stop the plow quick

enough to prevent upsetting when obstructions occur, although

the speed is usually only two to three miles per hour. The unloading

nearly always occurs on trestles or embankments, and

when the plow is thrown off the car, its replacement often requires

much time and labor, sometimes even making the services

of the wrecking car necessary. This difficulty is very likely to

occur when unloading on curves, where one side of the point

of the groove presses against the ridge timber. This plow unloads

the material equally on both sides of the car, as it is

wanted in filling trestles, raising embankments, tracks, etc.; but

it cannot be used to advantage where the material is wanted on

one side only, as in widening embankments for double track,

side tracks, yards, station grounds, etc.

Fig. 74.

Fig. 75.

Fig. 76.

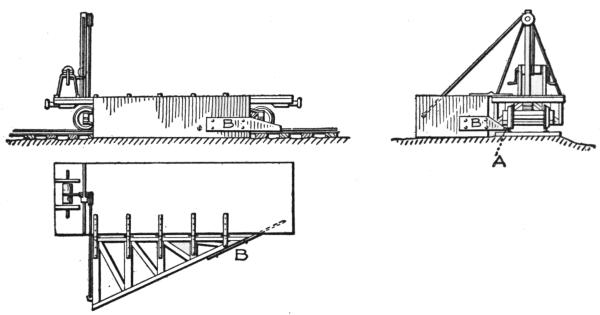

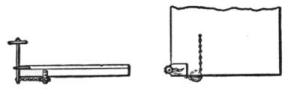

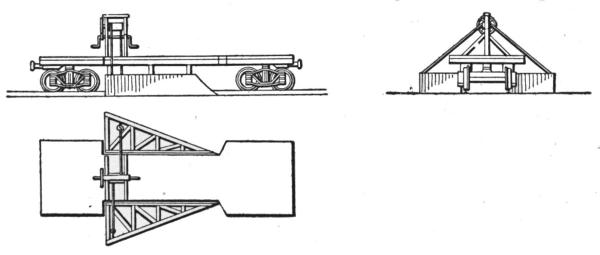

The many objections to the center ridge car are almost entirely

avoided by the use of the Barnhart plow, Fig. 77, employing

the ordinary flat car without any preparations except changing[44]

the brake staffs to one side or placing them in sockets at

their ordinary places and inserting short stakes in the stake

pockets, permitting the immediate use of the car for general

service if necessity should so require. This plow is also built of

heavy plate and angle irons, strongly braced, and headed by a

cast steel point to which the cable is attached; it is preceded

and followed by guiding sleds attached to it by adjustable hinges

and guided over the car by the stakes in the stake pockets,

which are indicated by the dotted lines. The usual speed at

which it is drawn over the car is about four miles per hour, but

in loose gravel it can safely be drawn at a speed of six miles

per hour. On straight track it is scarcely ever thrown off the

car unless carelessly handled, and it works equally well on

curves when the usual means are adopted to maintain a tangential

pull of the cable, as will be subsequently described. Two