Title: Inventors at Work, with Chapters on Discovery

Author: George Iles

Release date: March 10, 2015 [eBook #48454]

Most recently updated: October 24, 2024

Language: English

Credits: Produced by Chris Curnow, Harry Lamé and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

Please see the Transcriber’s Notes at the end of this text.

Copyright by Park & Co., Brantford, Ontario.

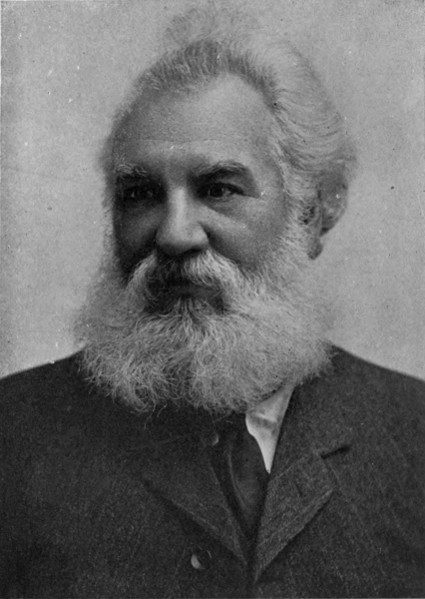

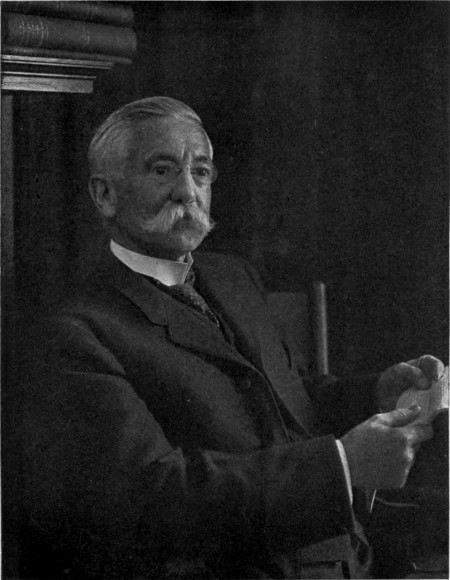

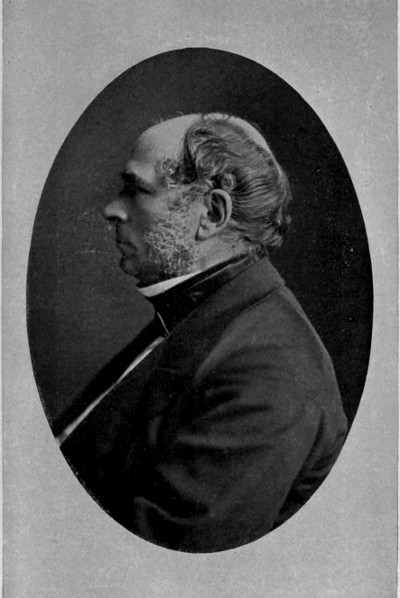

PROFESSOR ALEXANDER GRAHAM BELL.

Inventors at Work

With Chapters on Discovery

By George Iles

Author of “Flame, Electricity and the Camera”

Copiously Illustrated

New York

Doubleday, Page & Company

1907

Copyright, 1906, by

George Iles

Published October, 1906

All rights reserved, including that of translation into foreign languages, including the Scandinavian

TO MY FRIEND

JOSEPHUS NELSON LARNED

OF BUFFALO, NEW YORK

| PAGE | ||

| LIST OF ILLUSTRATIONS | xiii | |

| ACKNOWLEDGMENTS | xxi | |

| CHAPTER | ||

| I. | INTRODUCTORY | 1 |

| II. | FORM Form as important as substance. Why a joist is stiffer than a plank. The girder is developed from a joist. Railroad rails are girders of great efficiency as designed and tested by Mr. P. H. Dudley |

5 |

| III. | FORM CONTINUED. BRIDGES Roofs and small bridges may be built much alike. The queen-post truss, adapted for bridges in the sixteenth century, neglected for two hundred years and more. A truss replaces the Victoria Tubular Bridge. Cantilever spans at Niagara and Quebec. Suspension bridges at New York. The bowstring design is an arch disguised. Why bridges are built with a slight upward curve. How bridges are fastened together in America and in England |

18 |

| IV. | FORM CONTINUED. LIGHTNESS, EASE IN MOTION Why supports are made hollow. Advantages of the arch in buildings, bridges and dams. Tubes in manifold new services. Wheels more important than ever. Angles give way to curves |

39 |

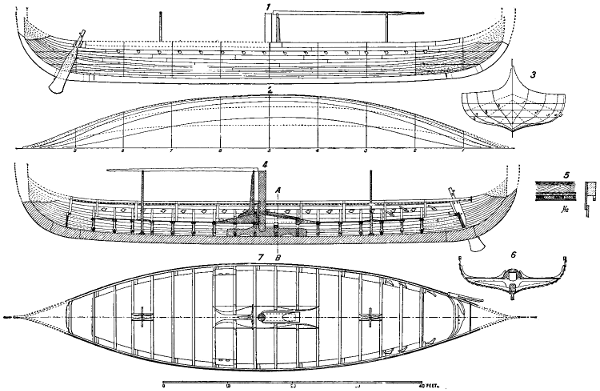

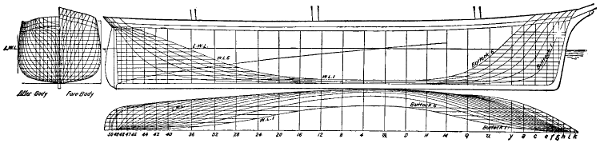

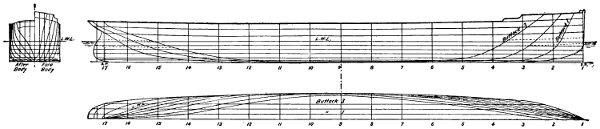

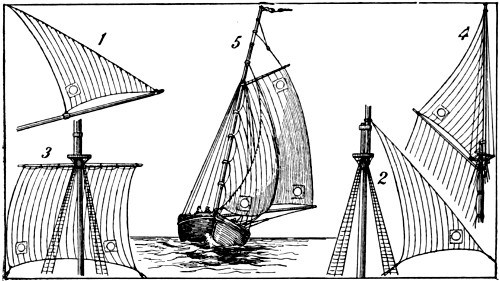

| V. | FORM CONTINUED. SHIPS Ships have their resistances separately studied. This leads to improvements of form either for speed or for carrying capacity. Experiments with models in basins. The Viking ship, a thousand years old, of admirable design. Clipper ships and modern steamers. Judgment in design |

52 |

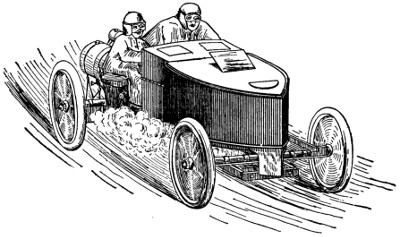

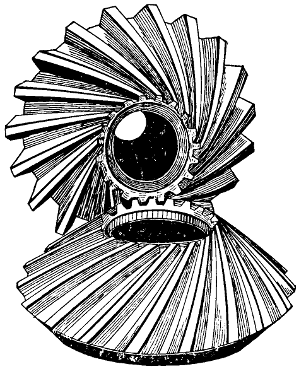

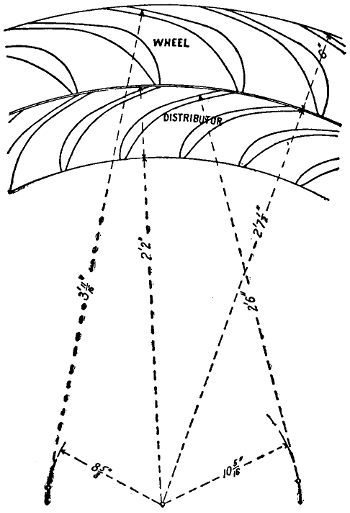

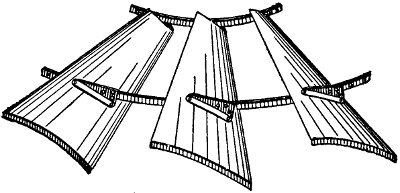

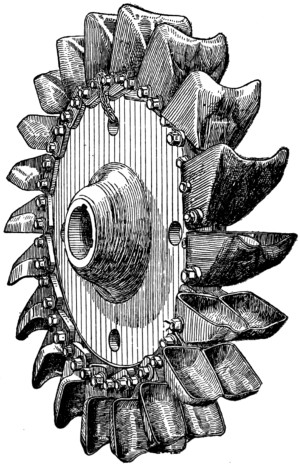

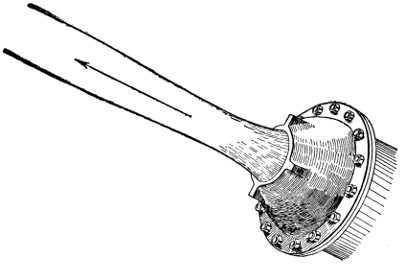

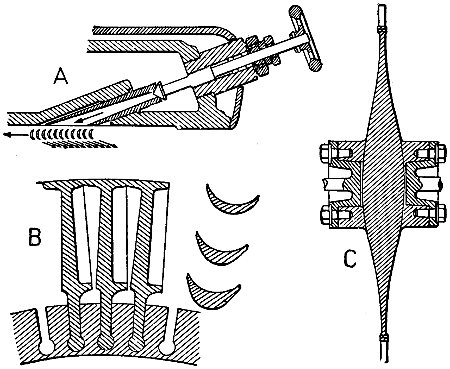

| VI.[viii] | FORM CONTINUED. RESISTANCE LESSENED Shapes to lessen resistance to motion. Shot formed to move swiftly through the air. Railroad trains and automobiles of somewhat similar shape. Toothed wheels, conveyors, propellers and turbines all so curved as to move with utmost freedom |

65 |

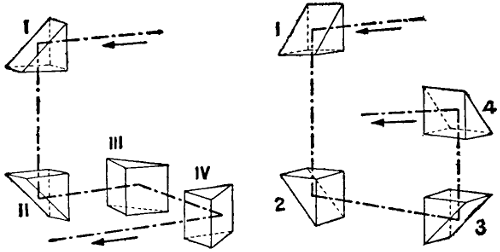

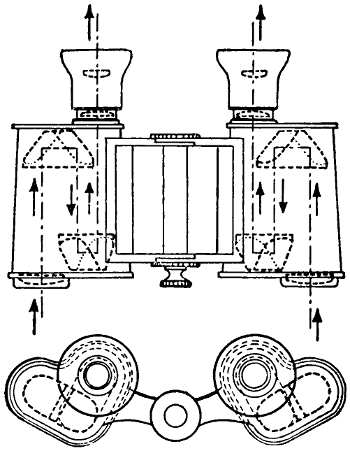

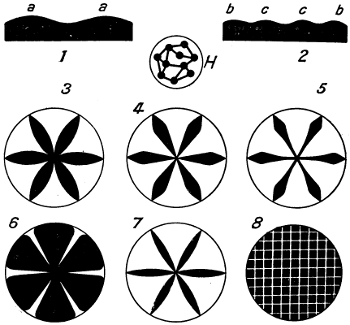

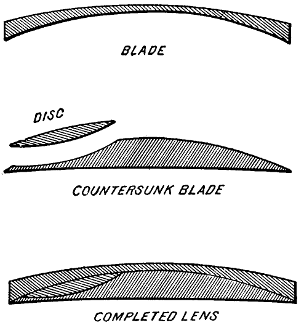

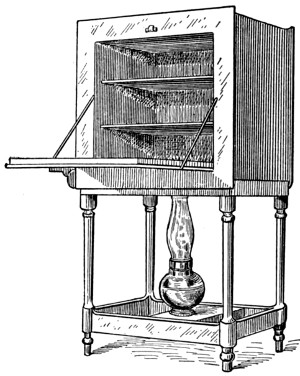

| VII. | FORM CONTINUED. ECONOMY OF LIGHT AND HEAT Light economized by rightly-shaped glass. Heat saved by well-designed conveyors and radiators. Why rough glass may be better than smooth. Light is directed in useful paths by prisms. The magic of total reflection is turned to account. Holophane Globes. Prisms in binocular glasses. Lens grinding. Radiation of heat promoted or prevented at will |

72 |

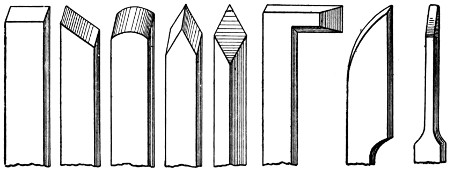

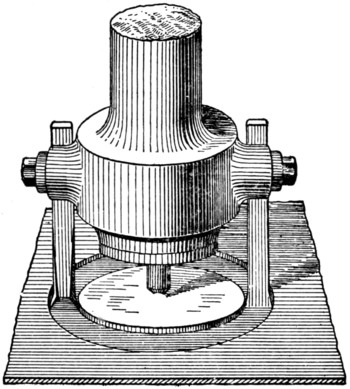

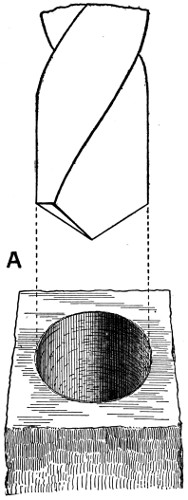

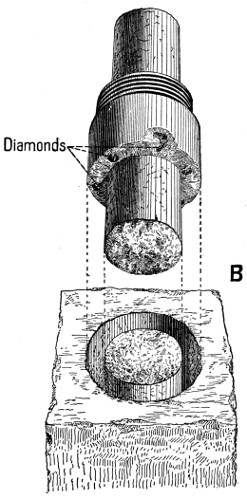

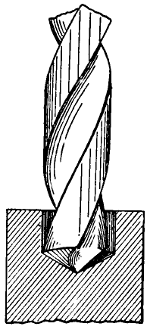

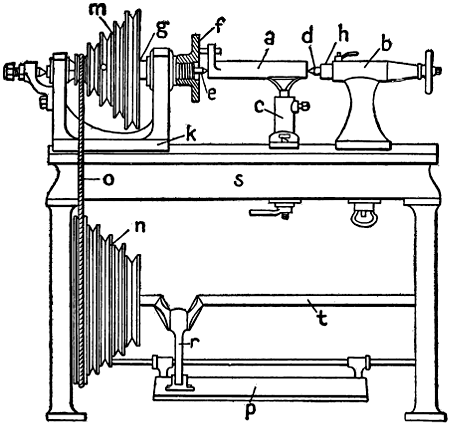

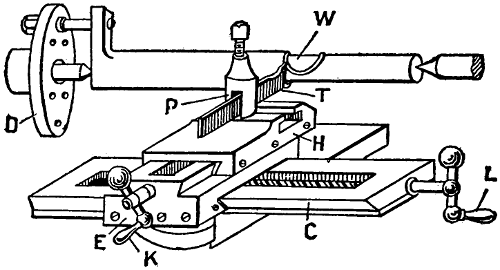

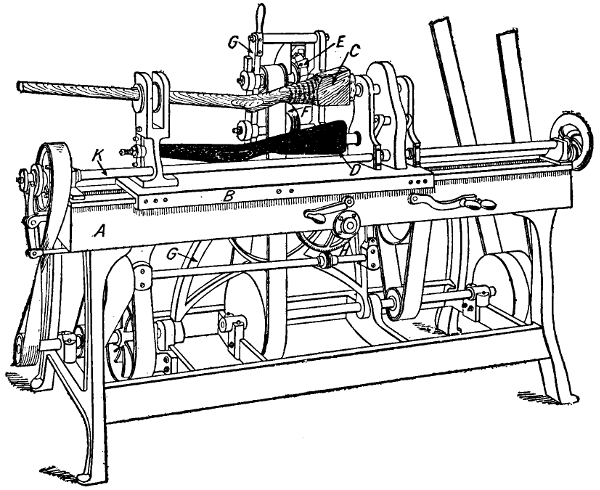

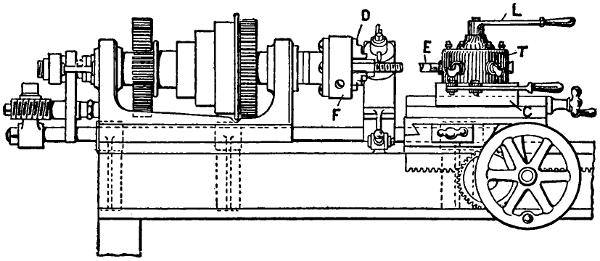

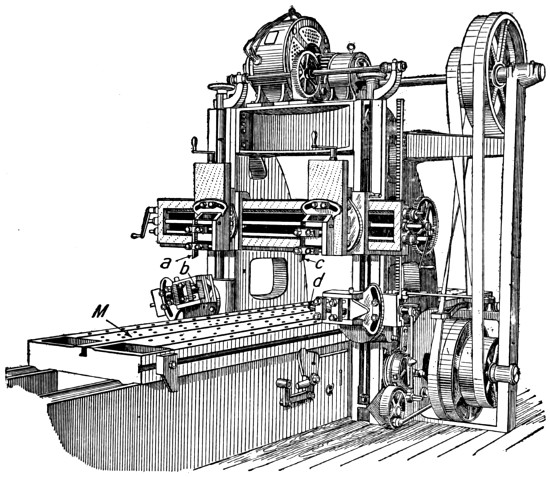

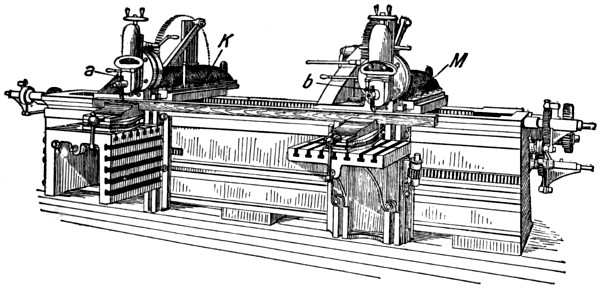

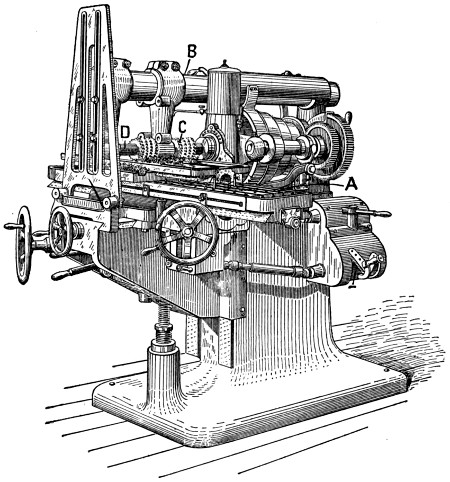

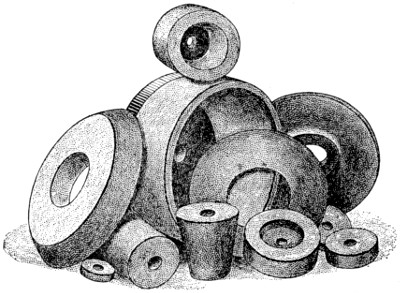

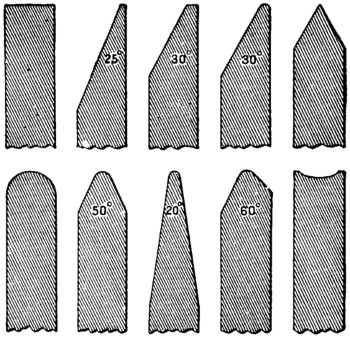

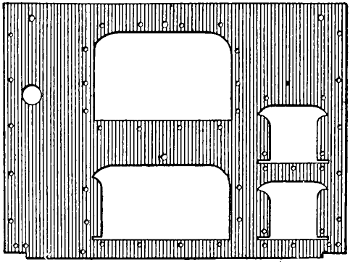

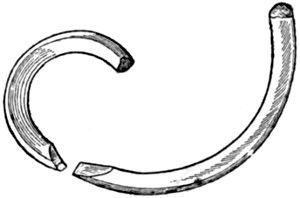

| VIII. | FORM CONTINUED. TOOLS AND IMPLEMENTS Tools and implements shaped for efficiency. Edge tools old and new. Cutting a ring is easier than cutting away a whole circle. Lathes, planers, shapers, and milling machines far out-speed the hand. Abrasive wheels and presses supersede old methods. Use creates beauty. Convenience in use. Ingenuity spurred by poverty in resources |

89 |

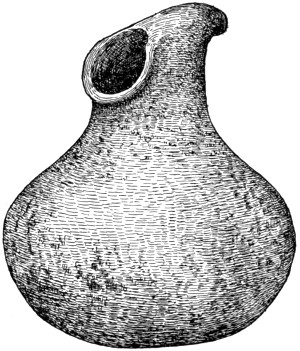

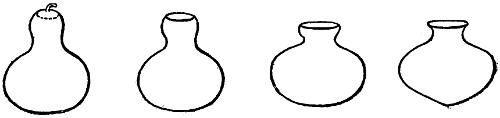

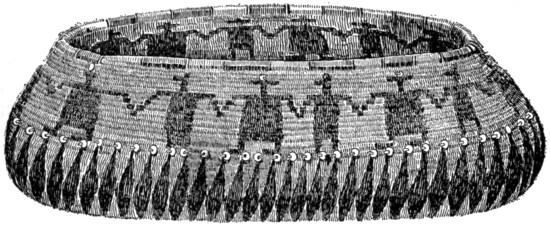

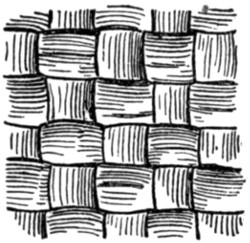

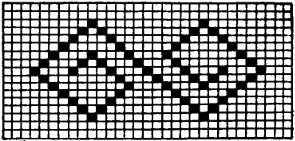

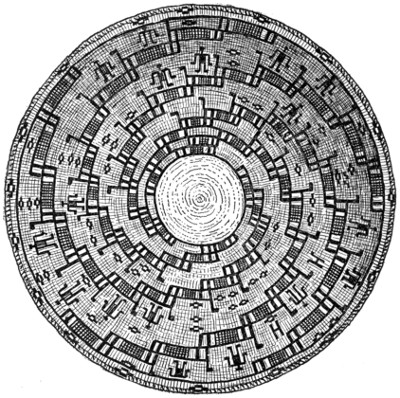

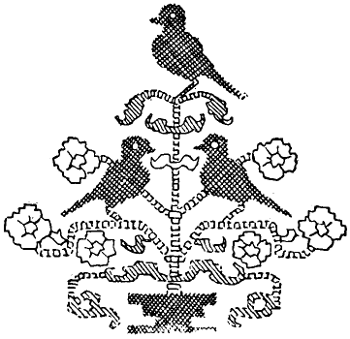

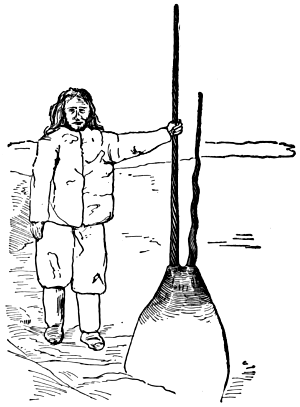

| IX. | FORM CONTINUED. ABORIGINAL ART Form in aboriginal art, as affected by materials. Old forms persist in new materials. Nature’s gifts first used as given, then modified and copied. Rigid materials mean stiff patterns. New materials have not yet had their full effect on modern design |

108 |

| X. | SIZE Heavenly bodies large and small. The earth as sculptured a little at a time. The farmer as a divider. Dust and its dangers. Models may mislead. Big structures economical. Smallness of atoms. Advantages thereof. Dust repelled by light |

120 |

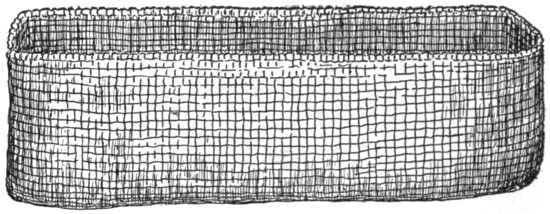

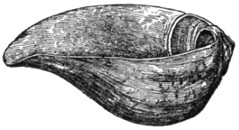

| XI. | PROPERTIES Food nourishes. Weapons and tools are strong and lasting. Clothing adorns and protects. Shelter must be durable. Properties modified by art. High utility of the bamboo. Basketry finds much to use. Aluminium, how produced and used. Qualities long unwelcome or worthless are now gainful. Properties created at need |

135 |

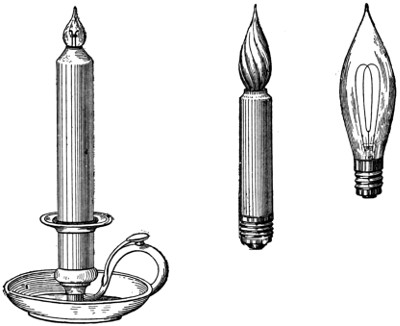

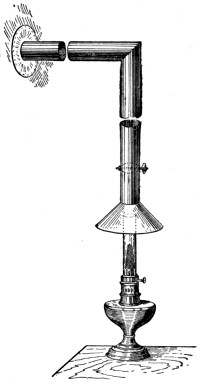

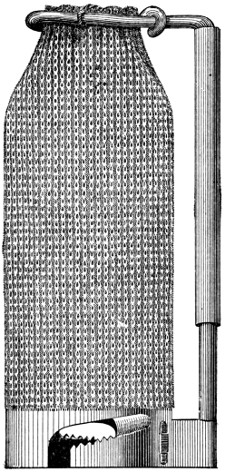

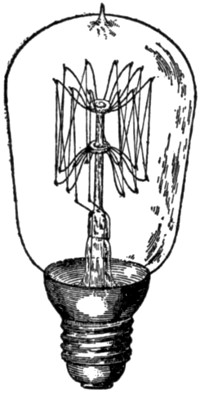

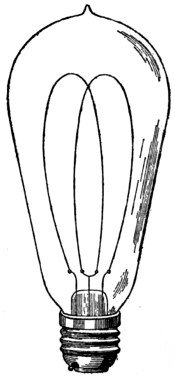

| XII.[ix] | PROPERTIES CONTINUED Producing more and better light from both gas and electricity. The Drummond light. The Welsbach mantle. Many rivals of carbon filaments and pencils. Flaming arcs. Tubes of mercury vapor |

154 |

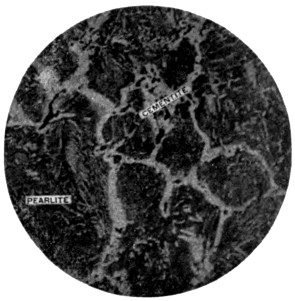

| XIII. | PROPERTIES CONTINUED Steel: its new varieties are virtually new metals, strong, tough, and heat resisting in degrees priceless to the arts. Minute admixtures in other alloys are most potent |

163 |

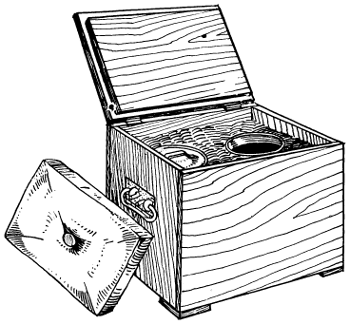

| XIV. | PROPERTIES CONTINUED Glass of new and most useful qualities. Metals plastic under pressure. Non-conductors of heat. Norwegian cooking box. Aladdin oven. Matter seems to remember. Feeble influences become strong in time |

180 |

| XV. | PROPERTIES CONTINUED. RADIO-ACTIVITY Properties most evident are studied first. Then those hidden from cursory view. Radio-activity revealed by the electrician. A property which may be universal, and of the highest import. Its study brings us near to ultimate explanations. Faraday’s prophetic views |

197 |

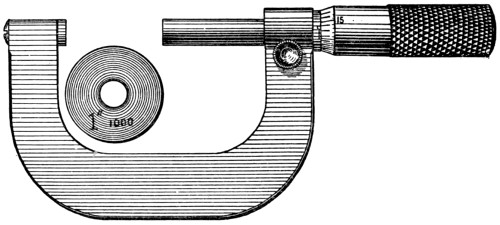

| XVI. | MEASUREMENT Methods beginning in rule-of-thumb proceed to the utmost refinement. Standards old and new. The foot and cubit. The metric system. Refined measurement as a means of discovery. The interferometer measures 15,000,000 inch. A light-wave as an unvarying unit of length |

208 |

| XVII. | MEASUREMENT CONTINUED Weight, Time, Heat, Light, Electricity, measured with new precision. Exact measurement means interchangeable designs, and points the way to utmost economies. The Bureau of Standards at Washington. Measurement in expert planning and reform |

219 |

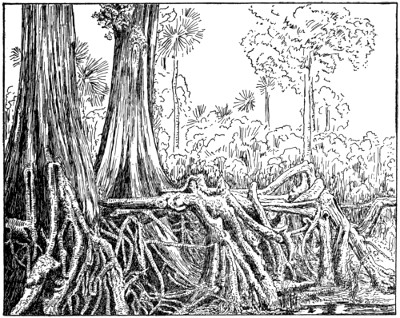

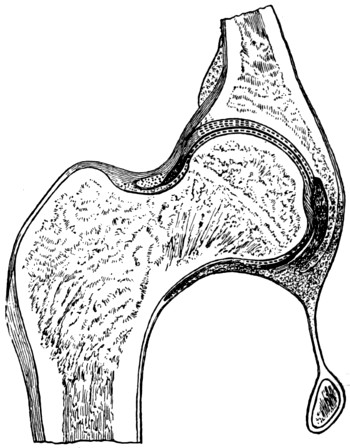

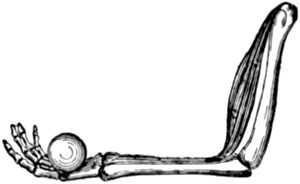

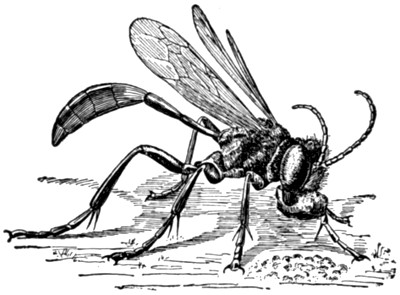

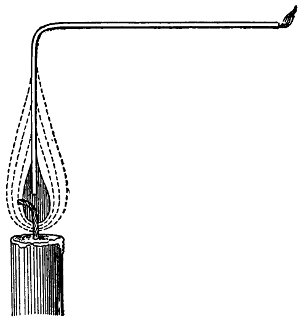

| XVIII. | NATURE AS TEACHER Forces take paths of least resistance. Accessibility decides where cities shall arise. Plants display engineering principles in structure. Lessons from the human heart, eyes, bones, muscles, and nerves. What nature has done, art may imitate,—in the separation of oxygen from air, in flight, in producing light, in converting heat into work: Lessons from lower animals. A hammer-using wasp |

245 |

| XIX.[x] | QUALIFICATIONS OF INVENTORS AND DISCOVERERS Knowledge as sought by disinterested inquirers. A plenteous harvest with few reapers. Germany leads in original research. The Carnegie Institution at Washington |

267 |

| XX. | OBSERVATION What to look for. The eye may not see what it does not expect to see. Lenses reveal worlds great and small otherwise unseen. Observers of the heavens and of seashore life. Collections aid discovery. Happy accidents applied to profit. Popular beliefs may be based on truth. An engineer taught by a bank swallow |

279 |

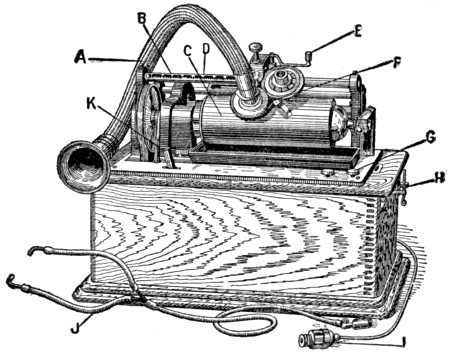

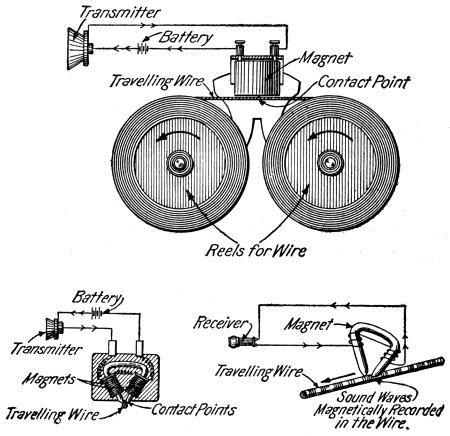

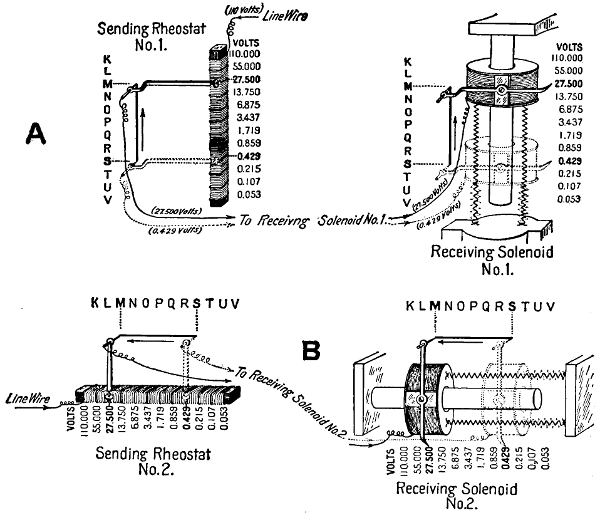

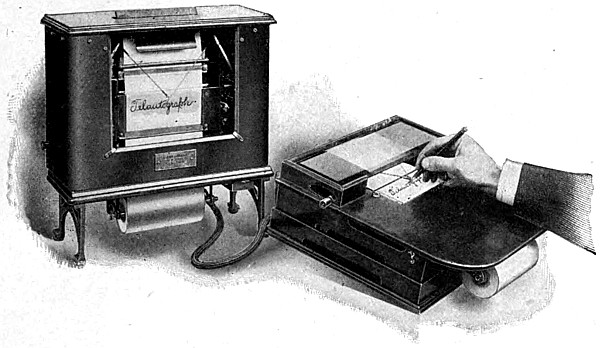

| XXI. | EXPERIMENT Newton, Watt, Ericsson, Rowland, as boys were constructive. The passion for making new things. Aid from imagination and trained dexterity. Edison tells how the phonograph was born. Telephonic messages recorded. Handwriting transmitted by electricity. How machines imitate hands. Originality in attack |

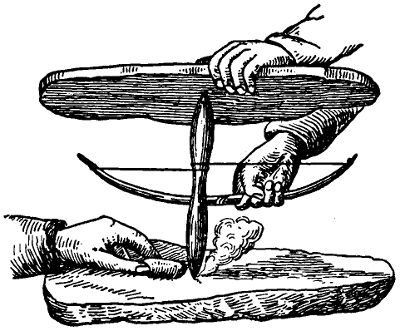

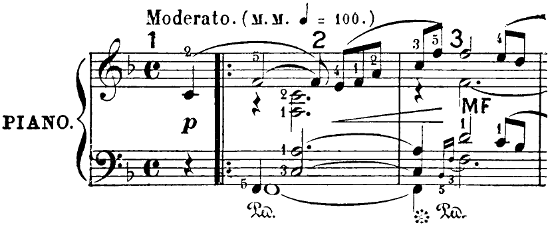

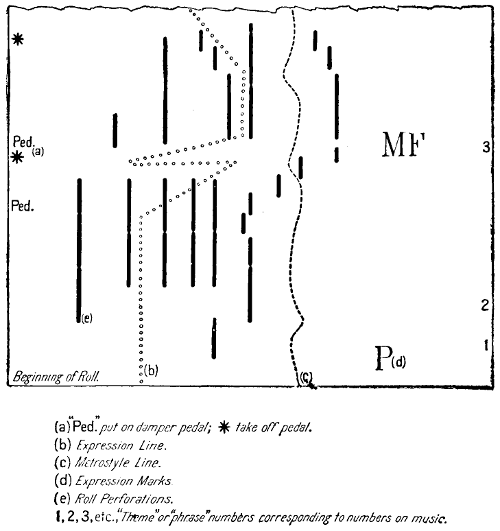

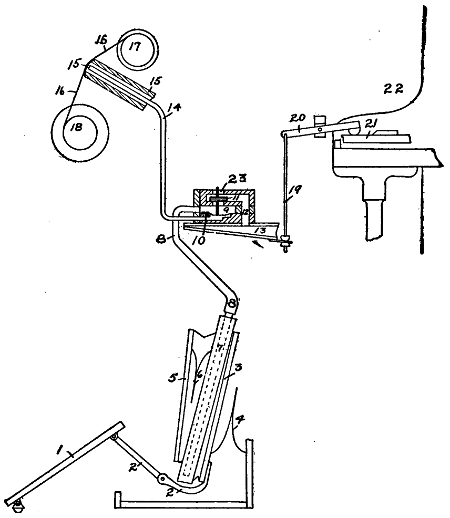

299 |

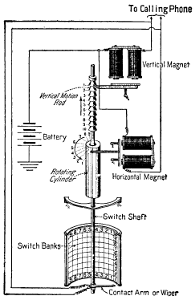

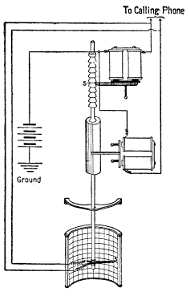

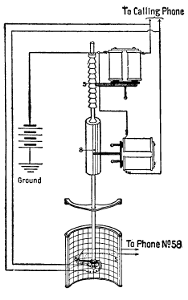

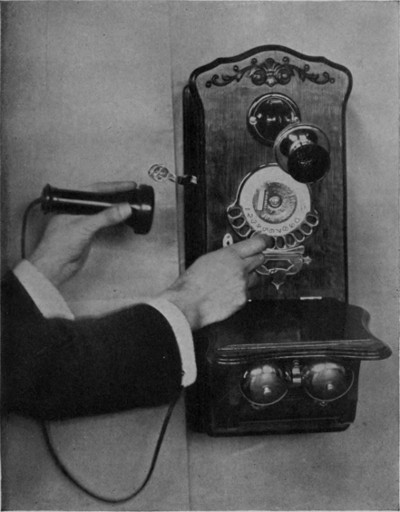

| XXII. | AUTOMATICITY AND INITIATION Self-acting devices abridge labor. Trigger effects in the laboratory, the studio and the workshop. Automatic telephones. Equilibrium of the atmosphere may be easily upset |

329 |

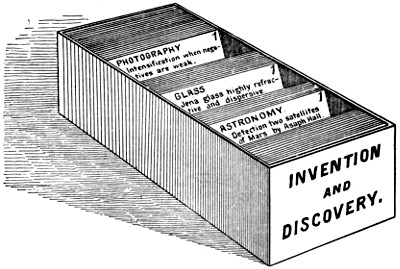

| XXIII. | SIMPLIFICATION Simplicity always desirable, except when it costs too dear. Taking direct instead of roundabout paths. Omissions may be gainful. Classification and signaling simpler than ever before |

340 |

| XXIV. | THEORIES HOW REACHED AND USED Educated guessing. Weaving power. Imagination indispensable. The proving process. Theory gainfully directs both observation and experiment. Tyndall’s views. Discursiveness of Thomas Young |

355 |

| XXV. | THEORIZING CONTINUED Analogies have value. Many principles may be reversed with profit. The contrary of an old method may be gainful. Judgment gives place to measurement, and then passes to new fields |

366 |

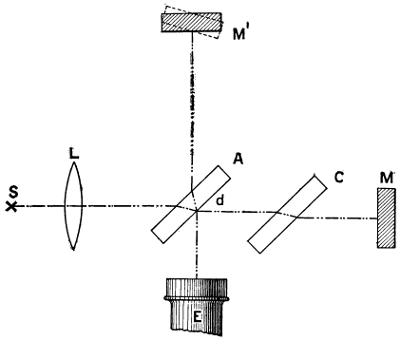

| XXVI.[xi] | NEWTON, FARADAY AND BELL AT WORK Newton, the supreme generalizer. Faraday, the master of experiment. Bell, the inventor of the telephone, transmits speech by a beam of light |

387 |

| XXVII. | BESSEMER, CREATOR OF CHEAP STEEL. NOBEL, INVENTOR OF NEW EXPLOSIVES Bessemer a man of golden ignorances. His boldness and versatility. The story of his steel process told by himself. Nobel’s heroic courage in failure and adversity. His triumph at last. Turns an accidental hint to great profit. Inventors to-day organized for attacks of new breadth and audacity |

401 |

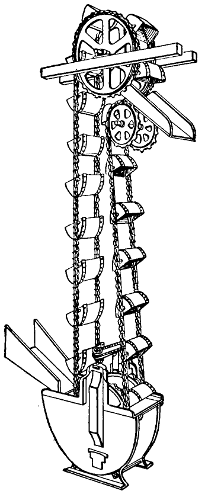

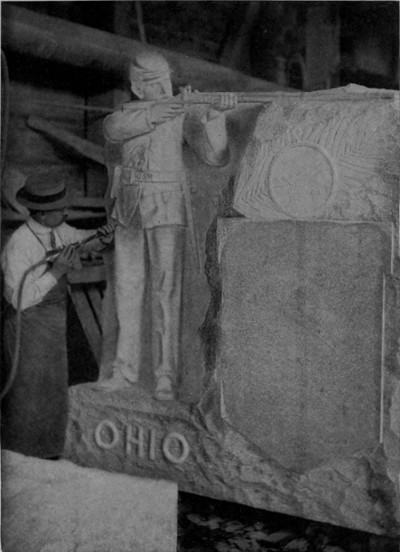

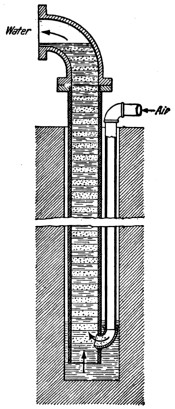

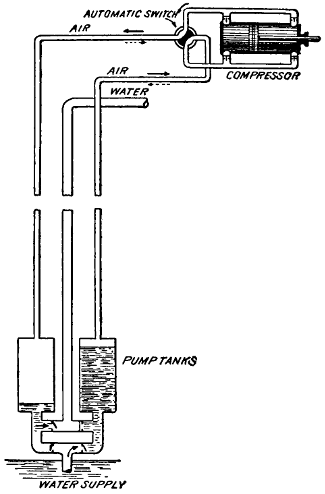

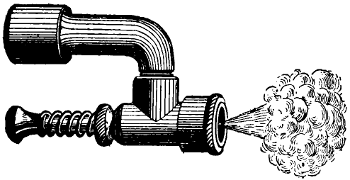

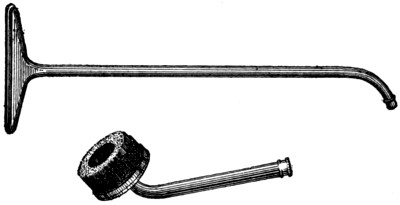

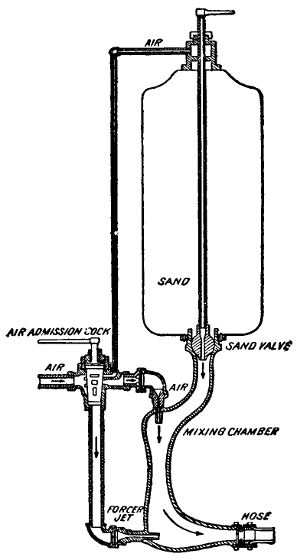

| XXVIII. | COMPRESSED AIR An aid to the miner, quarryman and sculptor. An actuator for pumps. Engraves glass and cleans castings. Dust and dirt removed by air exhaustion. Westinghouse air-brakes and signals |

417 |

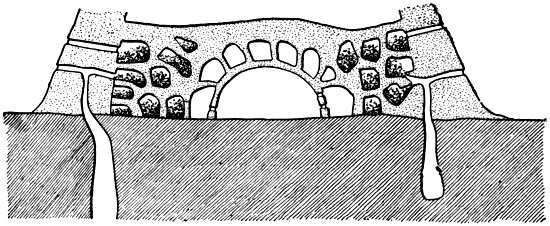

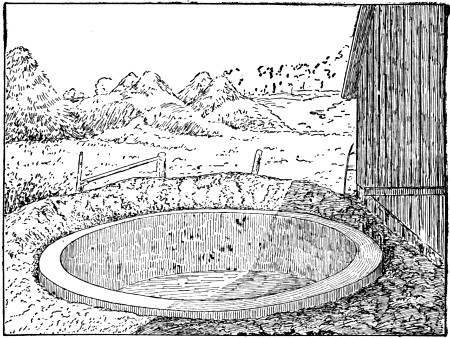

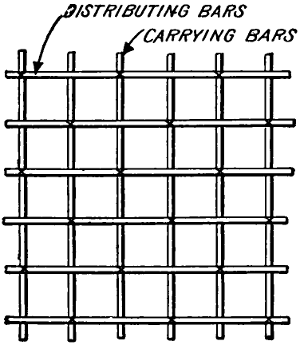

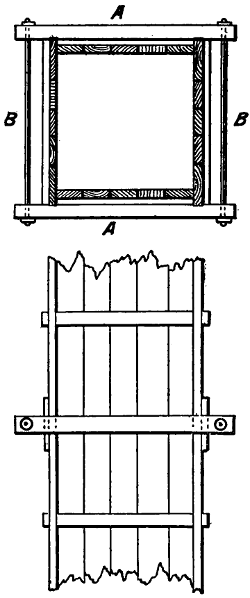

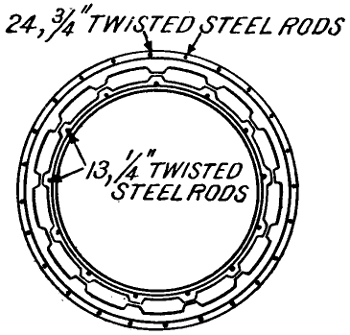

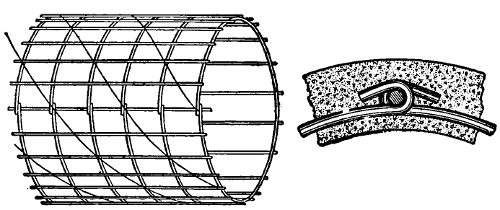

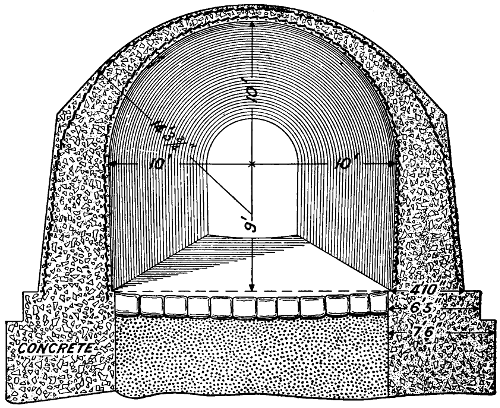

| XXIX. | CONCRETE AND ITS REINFORCEMENT Pouring and ramming are easier and cheaper than cutting and carving. Concrete for dwellings ensures comfort and safety from fire. Strengthened with steel it builds warehouses, factories and bridges of new excellence |

429 |

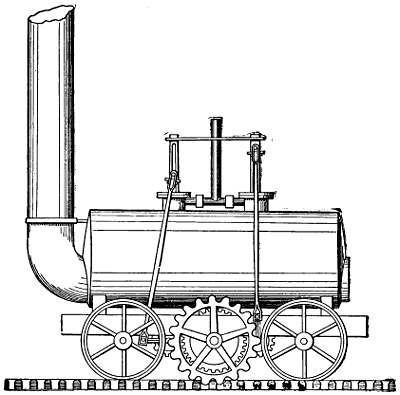

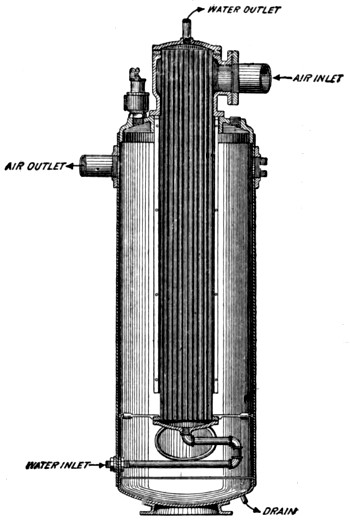

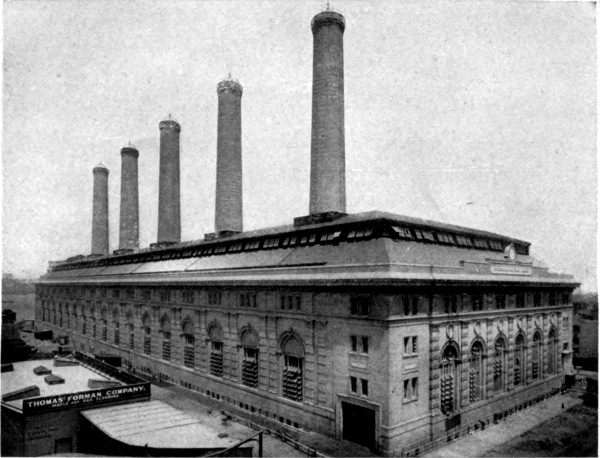

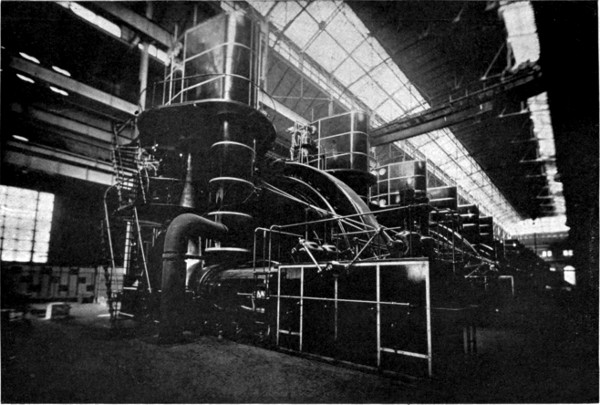

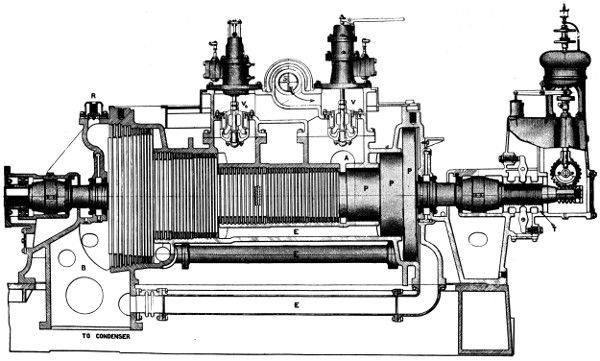

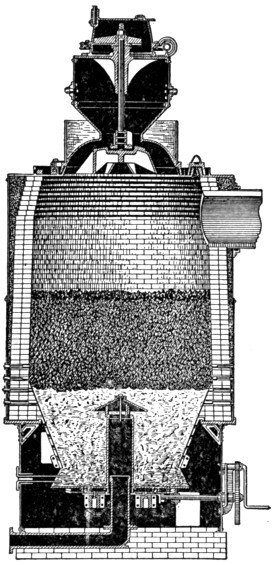

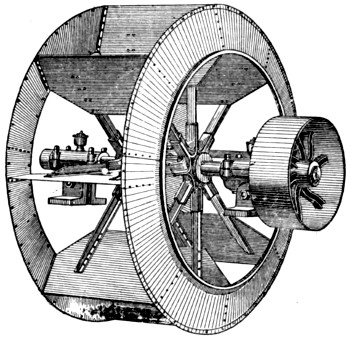

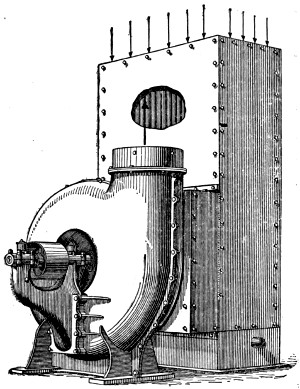

| XXX. | MOTIVE POWERS PRODUCED WITH NEW ECONOMY Improvements in steam practice. Mechanical draft. Automatic stokers. Better boilers. Superheaters. Economical condensers. Steam turbines on land and sea |

446 |

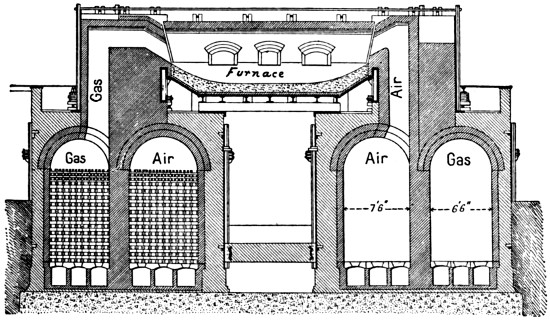

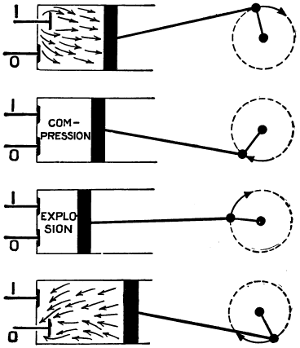

| XXXI. | MOTIVE POWERS, CONTINUED. HEATING SERVICES Producer gas. Mond gas. Gas engines. Steam and gas engines compared. Diesel engine best heat motor of all. Gasoline motors. Alcohol engines. Steam and gas motors united. Heat and power production together. District steam heating. Isolated plants. Electric traction. Gas for a service of heat, light and power |

457 |

| XXXII.[xii] | A FEW SOCIAL ASPECTS OF INVENTION Why cities gain at the expense of the country. The factory system. Small shops multiplied. Subdivided labor has passed due bounds and is being modified. Tendencies against centralization and monopoly. Dwellings united for new services. Self-contained houses warmed from a center. The literature of invention and discovery as purveyed in public libraries |

478 |

| INDEX | 489 | |

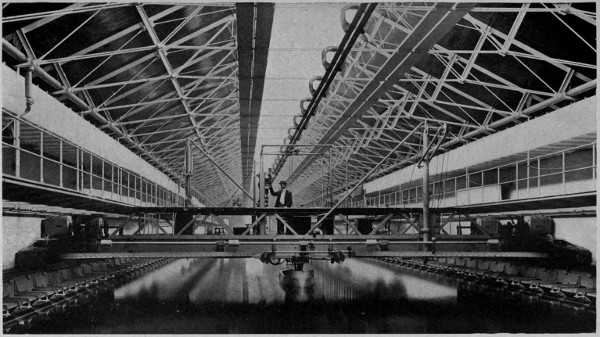

Aid in writing this volume is acknowledged in the course of its chapters. The author’s grateful thanks are rendered also to Dr. L. A. Fischer, of the Bureau of Standards at Washington, who has revised the paragraphs describing the work of the Bureau; to Mr. C. R. Mann of the Ryerson Physical Laboratory, University of Chicago, who corrected the paragraphs on the interferometer; to Mr. Walter A. Mitchell, formerly of Columbia University, New York, who revised most of the chapters on measurement. Mr. Thomas E. Fant, Head of the Department of Construction and Repair at the Navy Yard, Washington, D. C., gave the picture of the model basin here reproduced. Mr. Walter Hough of the National Museum, Washington, D. C., contributed a photograph of the Pomo basket also reproduced here. Mr. John Van Vleck and Mr. Henry G. Stott of New York, Mr. George R. Prowse and Mr. Edson L. Pease of Montreal, have furnished drawings and photographs for illustrations of unusual interest. Mr. George F. C. Smillie, of the Bureau of Engraving, Washington, D. C., Mr. Percival E. Fansler, Mr. Ernest Ingersoll, and Mr. Ashley P. Peck, of New York, have read in proof parts of the chapters which follow. Their corrections and suggestions have been indispensable.

Professor Bradley Stoughton, of the School of Mines, Columbia University, New York, has been good enough to contribute a brief list of books on steel, supplementing the chapter on that theme written with his revision. Had it been feasible, other chapters would have been supplemented in like manner by other teachers of mark. In 1902 the American Library Association published an annotated guide to the literature of American history, engaging forty critics and scholars of distinction, with Mr.[xxii] J. N. Larned as editor. It is hoped that at no distant day guides on the same helpful plan will be issued in the field of science, duly supplemented and revised from time to time.

In the present volume the author has endeavored to include in his survey the main facts to the close of May, 1906.

New York, September, 1906.

INVENTORS AT WORK

Inventors and discoverers are justly among the most honored of men. It is they who add to knowledge, who bring matter under subjection both in form and substance, who teach us how to perform an old task, as lighting, with new economy, or hand us gifts wholly new, as the spectroscope and the wireless telegraph. It is they who tell us how to shape an oar into a rudder, and direct a task with our brains instead of tugging at it with our muscles. They enable us to replace loss with gain, waste with thrift, weariness with comfort, hazard with safety. And, chief service of all, they bring us to understand more and more of that involved drama of which this planet is by turns the stage and the spectator’s gallery. The main difference between humanity to-day and its lowly ancestry of the tree-top and the cave has been worked out by the inventors and discoverers who have steadily lifted the plane of life, made it broader and better with every passing year.

On a theme so vast as the labors of these men a threshold book can offer but a few glances at principles of moment, to which the reader may add as he pleases from observations and experiments of his own. At the outset Form will engage our regard: first, as bestowed so as to be retained by girders, trusses and bridges; next, as embodied in structures which minimize friction, such as well designed ships; or as conducing to the efficiency of tools and machines; or deciding how best heat may be radiated or light diffused. A word will follow as to modes of conferring form, the influence on form of the materials employed, and the undue vitality of old forms that should long ago have bidden us good-by. Structures alike in shape may differ in size. Bigness has its economies, and so has smallness. Both will have brief attention, with a rapid survey of new materials which[2] enable a builder to rear towers or engines bolder in dimensions than were hitherto possible.

Substance, as important as form, will next receive a glance. First a word will be said about the properties of food, raiment, shelter, weapons and tools. Then, the properties of fuels and light-givers will be considered, as steadily improved in their effectiveness. How properties are modified by heat and electricity will be remarked, with illustrations from steels of new and astonishing qualities, and from notable varieties of glass produced at Jena. A few pages will recount some of the striking phenomena of radio-activity displayed by radium, thorium and kindred substances, phenomena which are remolding the fundamental conceptions of physics and chemistry.

A survey of form and properties, however cursory, must involve measurement, otherwise an inventor cannot with accuracy embody a plan in a working machine, or know exactly how strong, elastic, or conducting a rod, a wire, or a frame is. Measuring instruments will be sketched, their use delineated, and the results of precise measurement noted as an aid to the construction of modern mechanism, the interchangeability of its parts, the economy of materials and of energy in every branch of industry. Next will follow a chapter noting tasks which Nature has long accomplished, and which Art has still to perform, as in converting at ordinary temperatures within the human body fuel energy into work. Plainly, a broad field opens to future invention as it copies the function of plants and animals; functions to be first carefully observed, then explained and at last imitated with the least possible waste of effort.

The equipment and the talents for invention and discovery are now touched upon. First, knowledge, especially as the fruit of disinterested inquiry; Observation, as exercised by trained intelligence calling to its aid the best modern instruments; Experiment, as an educated passion for building on original lines. Then, in the mechanical field, we bestow a few glances at self-acting machines, at the simplicity of design which makes for economy not only in building, but in operation and maintenance. Either in designing a new machine, or in reaching a great truth, such as Universal Development, there is scope for Imagination upon[3] which we next pause for a moment. A succeeding chapter outlines how theories may be launched and tested, how analogy may yield a golden hint, the profit in rules that work both ways, or even in doing just the opposite of what has been done without question for ages past.

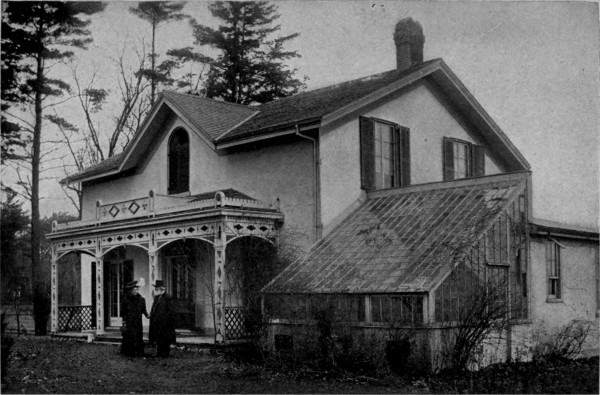

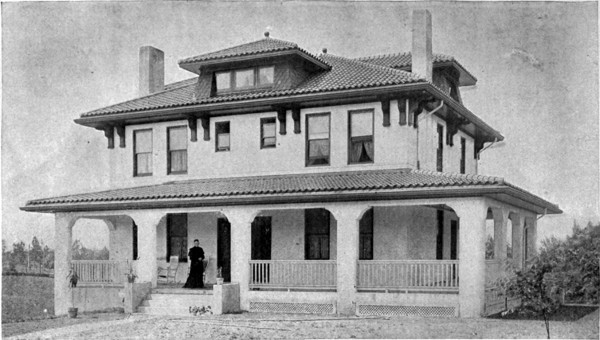

Copyright, 1906, by Park & Co., Brantford, Ontario, Canada

BELL HOMESTEAD, BRANTFORD, ONTARIO, CANADA.

Alexander Graham Bell and his Daughter in the Foreground.

Here the Telephone was Perfected in 1874.

Now the Home of the Bell Telephone Memorial Association.

From this brief consideration of method we now pass to a few men who have exemplified method on the loftiest plane; we come into the presence of Newton, the supreme generalizer, and observe his patience and conscientiousness, as remarkable as his resourcefulness in experiment, in mathematical analysis. Even greater in experiment, while lacking mathematical power, is Faraday, who next enlists our regard. This great man, more than any other investigator, laid the foundations of modern electrical science and art. Moreover he distinctly saw how matter might reveal itself in the ‘radiant’ condition now engaging the study of the foremost inquirers in physics.

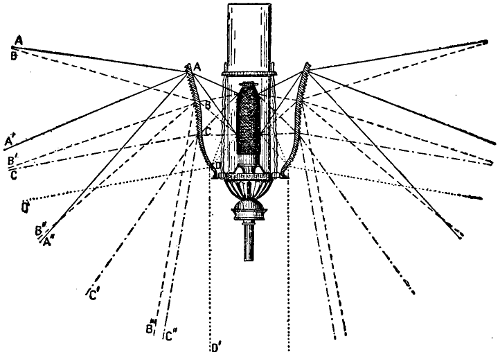

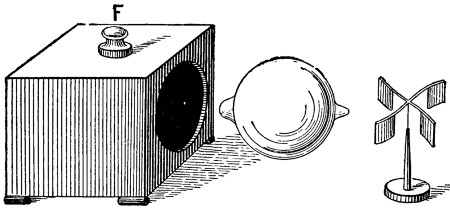

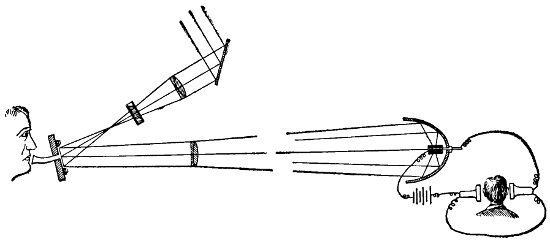

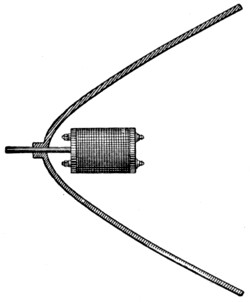

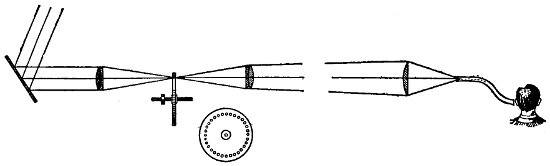

Electricity has no instrument more useful in daily life, or in pure research, than the telephone. Now follows a narration by its creator, Professor Bell, of his photophone which transmits speech by a beam of light. This recital shows us how an inventor of the first rank proceeds from one attempt to another, until his toil is crowned with success. Next we hear the story of the Bessemer process from the lips of Sir Henry Bessemer himself, affording us an insight into the methods and characteristics of a mind ingenious, versatile and bold in the highest degree. An inventor of quite other type is next introduced,—Nobel, who gave dynamite to the quarryman and miner, smokeless powder to the gunner and sportsman. His unfaltering heart, beset as he was by constant peril, marks him a hero as brave as ever fought hazardous and dreary campaigns to a victorious close.

Many advances in mechanical and structural art have been won rather through a succession of attacks by one leader after another, than by a single decisive blow from a Watt or an Edison. A great band of inventors, improvers, adapters, have accomplished notable tasks with no record of such a feat as Bessemer with his converter, or Abbe with Jena glass. A brief chapter deals with some of the principal uses of compressed air, an agent of steadily increasing range. As useful, in a totally different sphere—that of[4] building material—is concrete, especially as reinforced with steel. A sketch of its applications is offered. Then follows the theme of using fuels with economy, of obtaining from them motive powers with the least possible loss. This field is to-day attracting inventors of eminent ability, with the prospect that soon motive powers will be much cheapened, with incidental abridgment of drudgery, a new expansion of cities into the country, and the production of light at perhaps as little as one-third its present cost. A page or two are next given to a few social aspects of invention, its new aid and comfort to craftsmen, farmers, householders comparatively poor. It will appear that forces working against the undue centralization of industry grow stronger every day.

A closing word gives the reader, especially the young reader, a hint or two in case he wishes to pursue paths of study the first steps of which are taken in this book.

In 1900 was published the author’s “Flame, Electricity and the Camera,” in which are treated some of the principal applications of heat, electricity and photography as exemplified at the time of writing. That volume may supplement the book now in the reader’s hands.

Form as important as substance . . . Why a joist is stiffer than a plank . . . The girder is developed from a joist . . . Railroad rails are girders of great efficiency as designed and tested by Mr. P. H. Dudley.

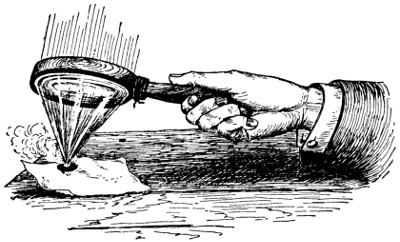

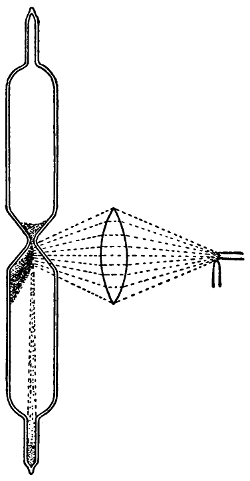

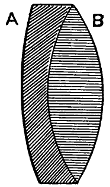

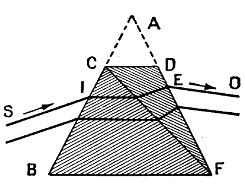

A lens of ice focussing a sunbeam.

One January morning in Canada I saw a striking experiment. The sun was shining from an unclouded sky, while in the shade a Fahrenheit thermometer stood at about twenty degrees below zero. A skilful friend of mine had moulded a cake of ice into a lens as large as a reading glass; tightly fastened in a wooden hoop it focussed in the open air a sunbeam so as to set fire to a sheet of paper, and char on a cedar shingle a series of zigzag lines. There, indeed, was proof of the importance of form. To have kept our hands in contact with the ice would have frozen them in a few minutes, but by virtue of its curved surfaces the ice so concentrated the solar beam as readily to kindle flame.[6] Clearly enough, however important properties may be, not less so are the forms into which matter may be fashioned and disposed. Let us consider a few leading principles by which designers have created forms that have economized their material, time and labor, and made their work both secure and lasting. We will begin with a glance at the rearing of shelter, an art which commenced with the putting together of boughs and loose stones, and to-day requires the utmost skill both of architects and engineers.

Building in its modern development owes as much to improvement in form as to the use of stronger materials, brick instead of clay, iron and steel instead of wood. A stick as cut from a tree makes a capital tent-pole, and will serve just as well to sustain the roof of a cabin. For structures so low and light it is not worth while to change the shape of a stick. By way of contrast let us glance at an office building of twenty-five stories, or the main piers of the new Quebec Bridge rising 330 feet above their copings. To compass such heights stout steel is necessary, and it must be disposed in shapes more efficient than that of a cylinder, as we shall presently see.

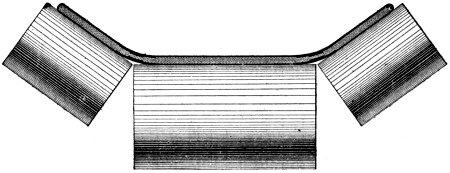

In most cases strength depends upon form, in some cases strength has nothing whatever to do with form; if we cut an iron bar in two its cross-section of say one square inch may be round, oblong, or of other contour, while the effort required to work the dividing shears will in any case be the same. But shearing stresses, such as those here in play, are not so common or important as the tension which tugs the wires of Brooklyn Bridge, or the compression which comes upon a pillar beneath the dome of the national capitol. When we place a lintel over a door or a window, we are concerned that it shall not sag and let down the wall above it in ruin: we ensure safety from disaster by giving the lintel a suitable shape. When we build a bridge we wish its roadway to remain as level as possible while a load passes, so that no hills and hollows may waste tractive power: levelness is secured by a design which is rigid as well as strong. If a railroad has weak, yielding rails, a great deal of energy is uselessly exerted in bending the metal as the wheels pass by. A stiff rail,[7] giving way but little, avoids this waste. To create forms which in use will firmly keep their shape is accordingly one of the chief tasks of the engineer and the architect.

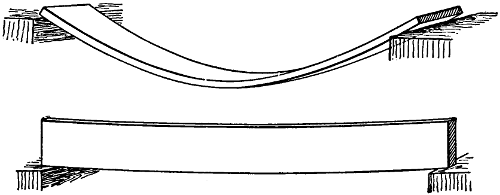

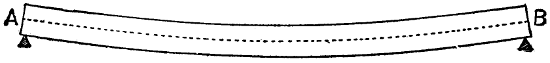

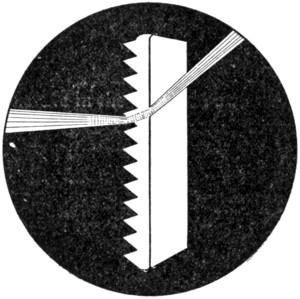

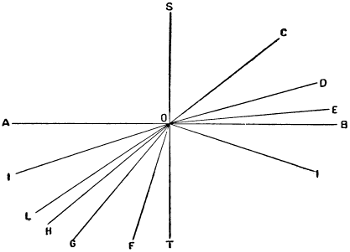

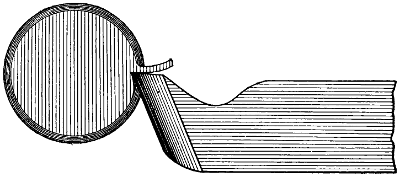

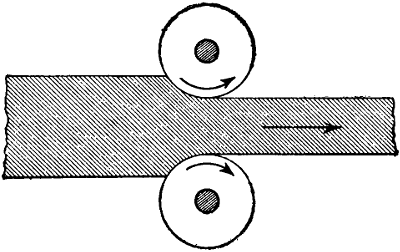

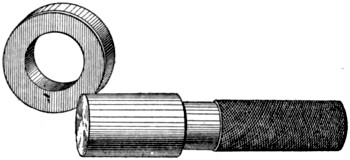

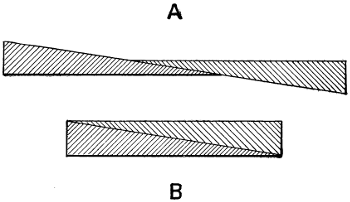

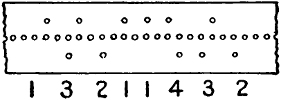

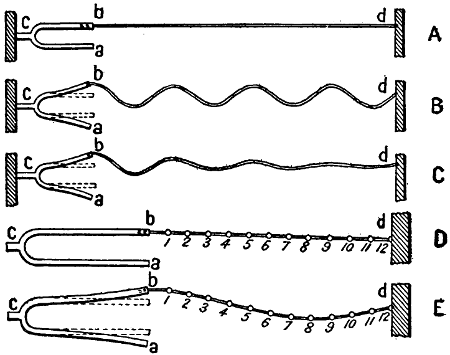

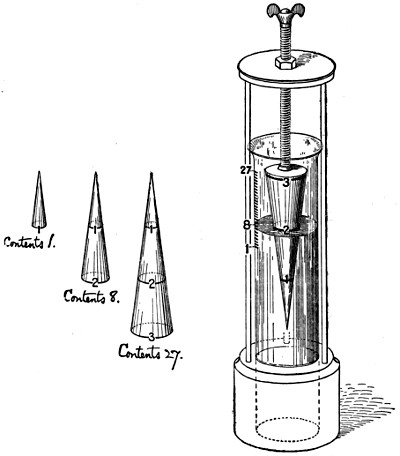

Rubber strip suspended plank-wise, and joist-wise.

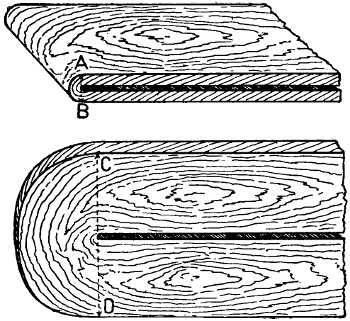

Board doubled breadthwise through small semi-circle AB, then edgewise through large semi-circle CD.

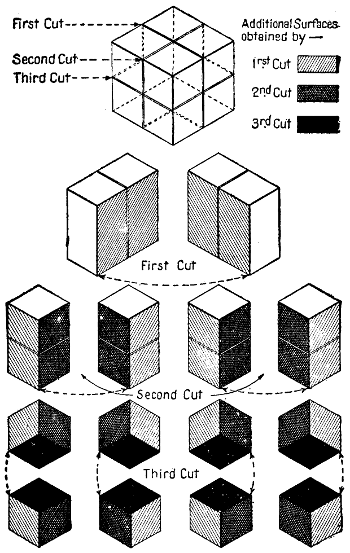

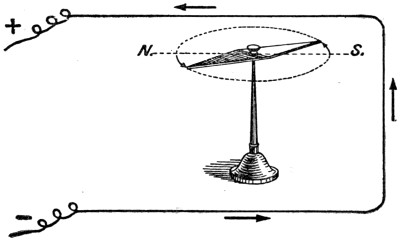

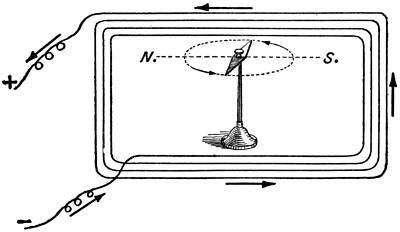

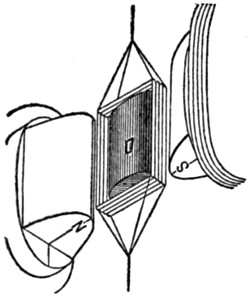

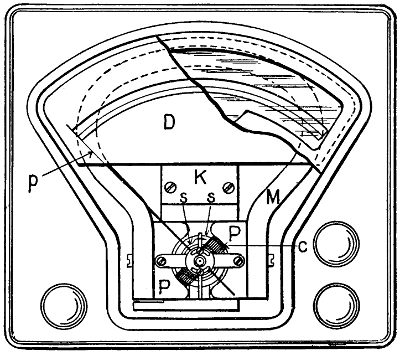

Forms of this kind, well exemplified in the steel columns and girders of to-day, have been arrived at by pursuing a path opened long ago by some shrewd observer. This man noticed that a plank laid flatwise bent much beneath a load, but that when the plank rested on its narrow edge, joist fashion, it curved much less, or hardly at all. Thus simply by changing the position of his plank he in effect altered its form with reference to the strain to be borne, securing a decided gain in rigidity. Let us repeat his experiment, using material much more yielding than wood. We take a piece of rubber eight inches long, one inch wide and one quarter of an inch thick. Placing it flatwise on supports close to its ends we find that its own weight causes a decided sag. We next place it edgewise, taking care to keep it perpendicular[8] throughout its length, when it sags very little. Why? Because now the rubber has to bend through an arc four times greater in radius than in the first experiment. Suppose we had a large board yielding enough to be bent double, we can see that there would be much more work in doubling it edgewise than flatwise. The rule for joists is that breadth for breadth their stiffness varies as the square of their depth, because the circle through which the bending takes place varies in area as the square of its radius. In our experiment with the rubber strip by increasing depth four-fold, we accordingly increased stiffness sixteen-fold; but the breadth of our rubber when laid as a joist is only one-fourth of its breadth taken flatwise, so we must divide four into sixteen and find that our net gain in stiffness is in this case four-fold.

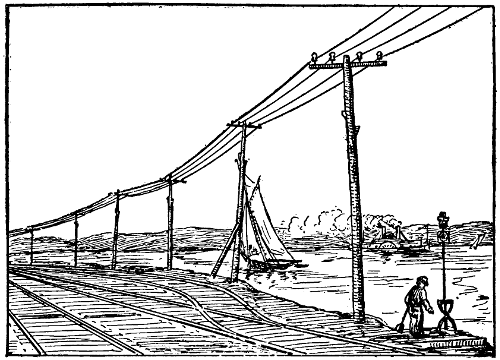

Telegraph poles under compression. Wires under tension.

Here let us for a moment dwell upon the two opposite ways in which strength may be brought into play, as either compression or tension is resisted. An example presenting both is a telegraph pole, with well-balanced burdens of wires. Its own weight and its load of wires, compress it, as we can prove by measuring the pole as[9] stretched upon the ground before being set in place, and then after it is erected and duly laden. Should this downward thrust be excessive, the pole would be crushed and broken down. The strung wires are not in compression, but in the contrary case of tension, and are therefore somewhat lengthened as they pass from one pole to the next. Now observe a mass first subjected to compression, and next to tension. In bearing a pound weight a rubber cylinder is compressed and protrudes; when the weight is suspended from this cylinder, the rubber is lengthened by tension. In each case the effect is vastly greater than with wood or steel, because rubber has so much less stiffness than they have.

Rubber

cylinder.

Flattened by

compression.

Lengthened

by tension.

Rubber

cylinder.

Flattened by

compression.

Lengthened

by tension.

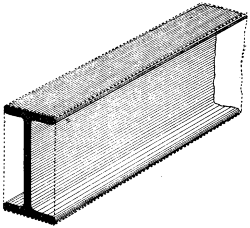

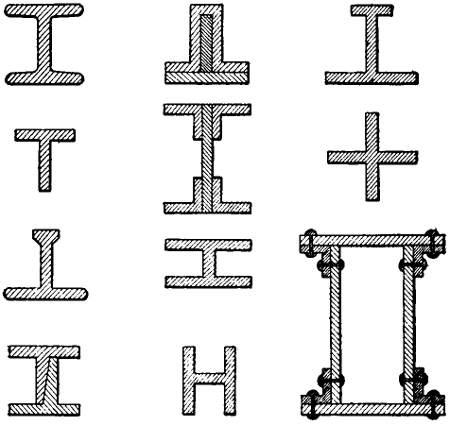

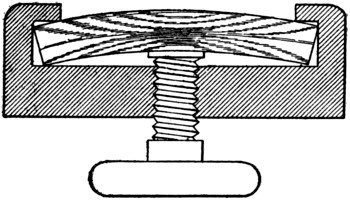

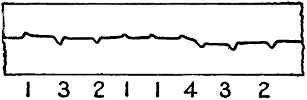

Both tension and compression are exhibited in our little rubber joist, which illustrates the familiar wooden support beneath the floors of our houses. This form in giving rise to the girder has been changed for the better. Let us see how. As the rubber joist sags between its ends, we observe that its upper half is compressed, and its lower half extended, the two effects though small being quite measurable. As we approach the central line, A B, this compression and tension gradually fall to zero; it is clear that only the uppermost and undermost layers[10] fully call forth the strength of the material, the inner layers doing so little that they may be removed with hardly any loss. Hence if we take a common joist and cut away all but an upper and lower flange, leaving just web enough between to hold them firmly together, we will have the I-beam which among rectangular supports is strongest and stiffest, weight for weight. In producing it the engineer has bared within the joist the skeleton which confers rigidity, stripping off all useless and burdensome clothing. An I-beam made of rubber when laid flatwise over supports at its ends will sag much; when laid edgewise it will sag but little, clearly showing how due form and disposal confer stiffness on a structure.

Rubber joist in section, compressed along the top, extended along the bottom.

Girder cut from joist.

Rubber I-beam suspended flatwise, and edgewise.

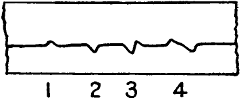

Simple girder contours.

Girder contours simple and built up.

Girder forms in locomotive draw-bars.

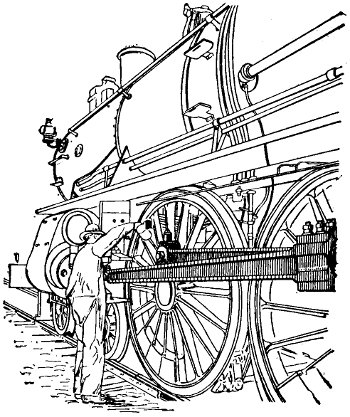

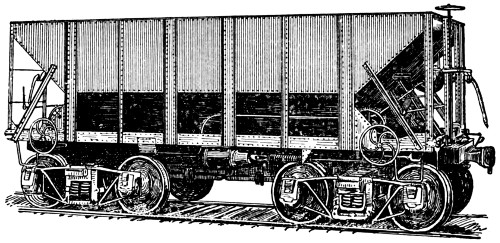

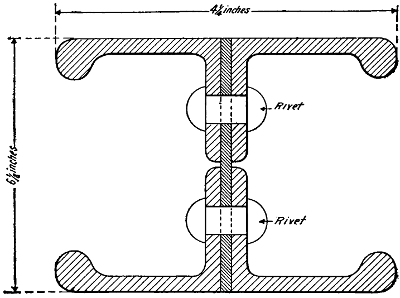

Girders of steel are rolled and riveted together at the mills in a variety of contours, each best for a specific duty, as the skeleton of a floor, a column, or a part of a bridge. Their lengths, if desired,[11] may far exceed those possible to wood. Their principal simple forms are the I-beam; T, the tee; L, the angle; C, the channel; and the Z-bar. Of these the I-beam is oftenest used; its two parallel flanges are at the distance apart which practice approves, they are united by a web just stout enough not to be twisted or bent in sustaining its[12] burdens. Crank shafts of engines, to withstand severe strains, are built in girder fashion; so are the side-bars of locomotives and the braces of steel cars. Plates riveted together may serve as compound girders or columns of great strength and rigidity. In the New York subway the riveted steel columns which support the roof have a contour which enlarges at the extremities.

100,000 pound steel ore car built by the Standard Steel Car Co., Pittsburg, for the Duluth, Missabe & Northern R. R. Of structural steel throughout. Weight unloaded, 32,200 pounds.

Section of standard bulb angle column, New York Subway.

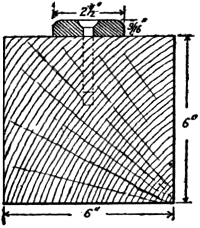

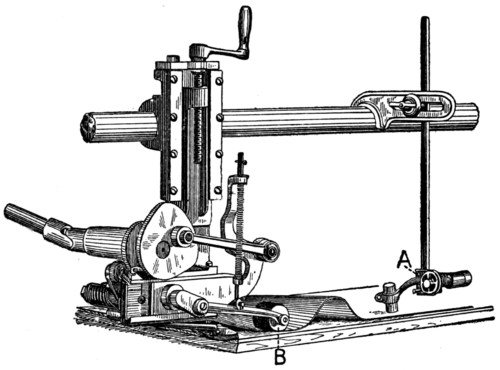

By all odds the most important girder is the rail in railroad service. Let us glance at phases of its development in America, as illustrating the importance of a right form to efficient service. At the outset of its operations, in 1830, the Mohawk & Hudson Railroad, now part of the New York Central & Hudson River Railroad, employed a rail which was a mere strap of iron two and one half inches wide, nine sixteenths of an inch thick, with upper corners rounded to a breadth of one and seven eighths inches; it was laid upon a pine stringer, or light joist, six inches square, and weighed about 14 pounds per yard. Thin as this rail was, its proportions were adequate to bearing a wheel-flange which protruded but half an inch or even less. Where the builders of that day sought rigidity and permanence was in the foundations laid beneath their stringers. Except upon embankments there were for each track two pits each two feet square, three feet from centre to centre, filled with broken stone upon which were placed stone blocks each of two cubic feet. On the heavy embankments cross-ties were laid; these were found to combine flexibility of superstructure with elasticity of roadbed, so that they were adopted throughout the remainder of the track construction and continue to this hour to be a standard feature of railroad building.

Cross Section

Top View

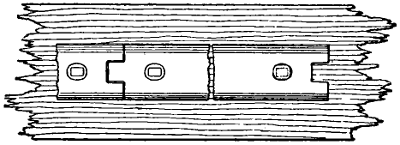

Strap rail and stringer, Mohawk & Hudson R. R., 1830.

It was soon observed that the surface of a track as it left the track-maker’s hands, underwent a depression more or less marked when a train passed over it. With a strap-iron rail this depression was so great that engines were limited to a weight of from three to six tons. Before long the strap form was succeeded by a rail somewhat resembling in section the rail of to-day. Year by year[14] the details of rolling rails were improved, so that sections weighing thirty-five to forty pounds to the yard came into service. These at length united a hard bearing surface for the wheel-treads, a guide for the wheel-flanges, and a girder to carry the wheel-loads and distribute them to the cross-ties. Thereupon the weights of engines and cars were increased, leading, in turn, to a constant demand for heavier rails. In 1865 a bearing surface was reached adequate for wheel-loads of 10,000 to 12,000 pounds, the rail weighing fifty-six to sixty pounds to the yard. But the metal was still only iron, and wore rapidly under its augmented burdens. Then was introduced the epoch-making Bessemer process and steel was rolled into rails four and one-half inches high, of fifty-six to sixty-five pounds to the yard, of ten to fifteen-fold the durability of iron. In design the early steel rails were limber so that they rapidly cut the cross-ties under their seats, pushing away the ballast beneath them. Because they lacked height they had but little stiffness, one result being that the spikes under the rails were constantly loosened, exaggerating the deflection due to passing trains. Throughout the lines every joint became low, and the rails took on permanent irregularities under the pounding of traffic, dealing harmful shocks to the rolling stock.

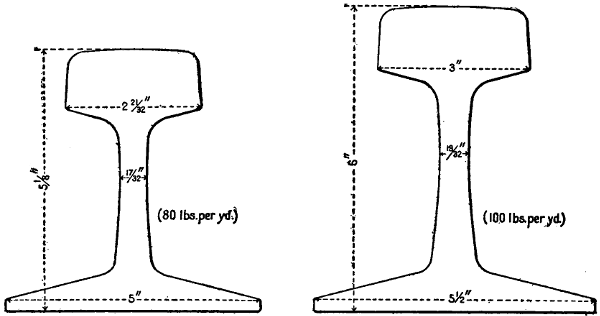

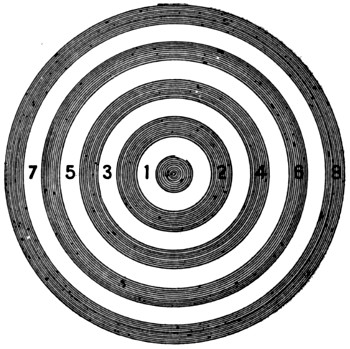

This was the state of affairs in 1880, when Mr. Plimmon H. Dudley invented his track-indicator. This apparatus, placed in a moving car, records by ever-flowing pens on paper every irregularity, however slight, in the track over which it passes. When railroad engineers first saw its records, they believed that the thing to do was to restore their roads to straightness by the labor of track-men. It was abundantly proved that the real remedy lay in using a rail of increased stiffness, that is, a rail higher and heavier. Mr. Dudley, in the light of records covering thousands of miles of running, added fifteen pounds to a rail which had weighed sixty-five pounds, and gave it a height of five inches instead of four and one half, while he broadened its upper surface. At a bound these changes increased the stiffness of the section sixty per cent., the gain being chiefly due to added height. Proof of this came when his improved rail was found to be much stiffer than that of the Metropolitan Railway, of London, which weighed[15] eighty-four pounds to the yard and had a base of six and three eighths inches, but a height of only four and one half inches. In July, 1884, the Dudley rail was laid in the Fourth Avenue viaduct, New York; so satisfactory did it prove that in less than two years five-inch rails were in service on three trunk lines. Then followed their introduction throughout America, their smoothness and stability as a track giving them acceptance far and wide.

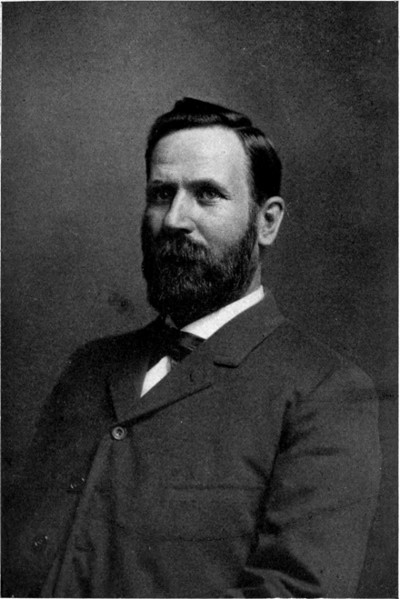

Photograph by F. M. Somers, Cincinnati, O.

PLIMMON H. DUDLEY

of New York.

The performance of the Dudley rail so impressed Mr. William Buchanan, Superintendent of Motive Power for the New York Central Railroad that in 1889 he planned his famous passenger engine, No. 870, which entered upon active duty in April, 1890. It carried 40,000 pounds upon each of its two pairs of driving wheels, instead of 31,250, as did its heaviest predecessor; its truck bore a burden of 40,000 pounds more; its loaded tender weighed 80,000 pounds, making a total of 100 tons, an advance of forty per cent. beyond the weight of the heaviest preceding engine and tender. Mr. Buchanan’s forward stride has been worthily followed up. Since 1890, passenger locomotives have nearly doubled in the weight borne upon their axles, while tractive power has increased in the same degree. Through express and mail trains have more than doubled in weight, and their speeds have increased thirty to forty per cent. The tonnage of an average freight train has been augmented four to six-fold, with reduction of the crews necessary to keep a given amount of tonnage in motion. This economy is reflected in a reduction of rates which are now in America the lowest in the world, and which steadily fall. In capacity for business united with stability of roadbed, mainly due to stronger and stiffer rails and to adapted improvement in rolling stock, railroad progress in the past fifteen years is equal to that of the sixty years preceding. With rails increased to a weight of 100 pounds to the yard there is shown, even in passing over the joints, an astonishing degree of smoothness as contrasted with the jolting action of rails comparatively low and light. Stiffness of rail reduces the destructive action of service, originally enormous, upon both equipment and track, lowering in a marked degree the cost of maintenance. Size of rail as well as form plays a part in this economy. A passenger train weighing[16] 378 tons has required 820 horse power on 65-pound rails, and but 720 horse power on 80-pound rails, the speed in both cases being 55 miles an hour; it is estimated that with 105-pound rails 620 horse power would have sufficed. In freight service Dudley rails have reduced the resistances per ton from between 7 and 8 pounds to one half as much; a further reduction, to 3 pounds, is in prospect. In passenger service, with rails of unimproved type the resistance at 52 miles an hour is 12 pounds per ton; with Dudley rails this resistance for heavy trains is not augmented when the speed rises to 65 or 70 miles an hour. Dudley rails, and rails derived from their designs, are now in use on three fourths of all the trackage of American railroads, effecting a vast economy. Seventy-five years ago the DeWitt Clinton locomotive and tender weighed only five sixths as much as the main pair of driving wheels, boxes, axle, and connecting rods of the present Atlantic type of engine. That such an engine can haul a heavy train at seventy miles an hour largely depends upon the production of that simple and important element in railroading, its rail.[1]

[1] Mr. Dudley’s rails, and those of other designers, are fully illustrated and discussed in “Railway Track and Track Work,” by E. E. Russell Tratman. Second edition. New York, Engineering News Publishing Co.

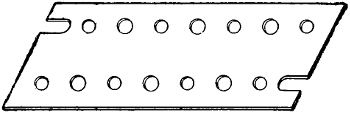

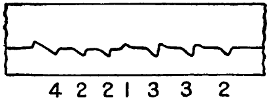

Dudley rails.

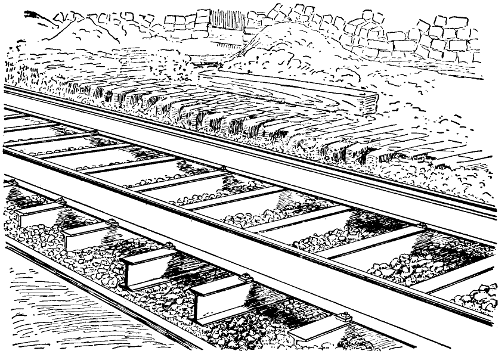

Steel cross-ties and rails.—Carnegie Steel Co., Pittsburg.

In Ninth Street, Pittsburg, the rails of the traction line are for some distance carried on steel ties similar in form, as here shown.

Roofs and small bridges may be built much alike . . . The queen-post truss, adapted for bridges in the sixteenth century, was neglected for two hundred years and more . . . A truss bridge replaces the Victoria Tubular Bridge . . . Cantilever spans at Niagara and Quebec . . . Suspension bridges at New York . . . The bowstring design is an arch disguised . . . Why bridges are built with a slight upward curve . . . How bridges are fastened together in America and England.

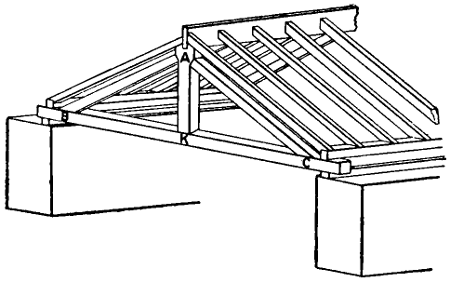

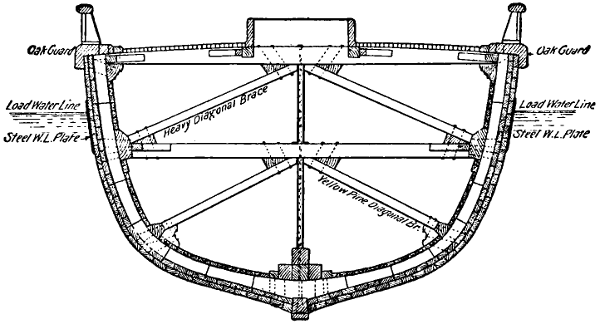

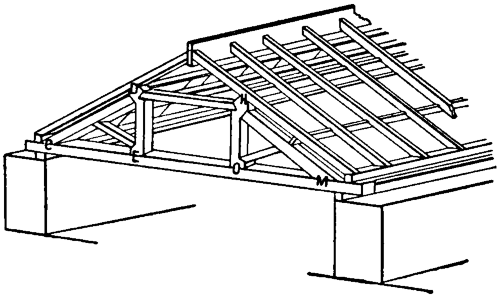

King-post truss. AK, king-post.

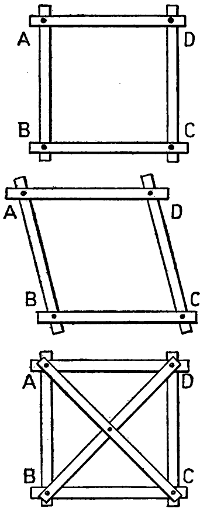

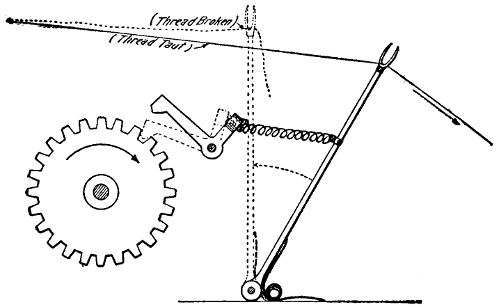

Rails are girders used by themselves: girders are often combined in trusses; of these much the largest and most important are employed for bridges. There is now under construction near Quebec a cantilever bridge whose channel span of 1,800 feet will be the longest in the world. See page 29. It will take us a little while to understand how so bold a flight as this was ever dared. We will begin with a glance at a truss of the simplest sort, such as we may find beneath the roof of an old-fashioned barn. A pair of rafters, AB and AC, are inclined to each other at an obtuse angle, and are fastened to the horizontal beam, BC, at B and C. Their apex, A, is joined to BC by the king-post, AK, which binds the three strongly and firmly. This whole structure makes up a triangle, and so does each of its halves, ABK and AKC. No other shape built of straight pieces will keep its form under strain. Take in proof say four pieces of lath and unite them with a freely turning pin at each corner to make the frame, ABCD; it is easily distorted by a slight pull or[19] push; but insert cross-pieces, AC and BD so as to divide the square into triangles, and at once the frame resists any strain not severe enough to break the wood or crush its fastenings. As the roof presses down the frame ABC, its sides, AB and AC, tend to slide away at their lower ends, B and C, but this is prevented by the horizontal beam, BC, which while it holds them in place is itself so stretched as to be held level and straight. This calling into play of tension constitutes the chief merit of the truss, and enables it in roofs and bridges to span breadths impossible to simple beams bending downward under compressive strains. Not only in houses, but in ships, the truss has great value; it was introduced in this field by Robert Seppings of Chatham, in England, about 1810. To resist the pressure of grinding ice, the “Roosevelt” is built with trusses of great strength. She sailed in 1905, under Commander Peary, for a voyage of Arctic discovery.

Frames of four sides. For rigidity diagonals are needed, AC, BD.

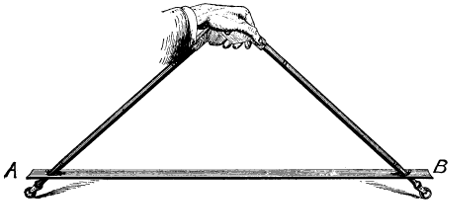

Were our barn roof flat instead of sloping to form a truss, its supporting timbers, under compression, would have a decided sag from which BC is free. When we fashion a small model of a king-post truss, its sides, AB and AC, must be of metal or wood because they will be in compression; the king-post, AK, and the base, BC, which will be under tension, may be of rubber or cord. Always as in this case the parts of a truss exposed to compression must be of rigid material. When a part may be of cord, rope or wire, we know that it is resisting tension.[2]

[2] A model easily put together illustrates the truss in its simplest form. Take a pair of wooden compasses, each half of which is 15 inches long, such as are sold for blackboard use by the Milton Bradley Co., Springfield, Mass., at 50 cents. At each tip fasten, by the ring provided with the compasses, a chair castor such as may be had at any hardware store. Join the tips of the castors by a rubber strip. Holding the compasses upright, and applying pressure from the hand, they will extend until the rubber will be so stretched as to become almost perfectly horizontal. Various weights may in succession be suspended from the compass-joint, replacing manual pressure, and serving to measure the exerted tensions.

Cross-section of the “Roosevelt,” Commodore Peary’s new Arctic ship. Reproduced by permission from the Scientific American, New York.

Pair of compasses stretch a rubber strip.

Wrought iron exerts about as much resistance to compression as to tension; so does steel. For this reason, and on account of their great strength, they have immense value in building. Cast[21] iron can bear only about one sixth as much tension as compression, so that it is useful as foundations, for the bed-plates of engines and machinery and the like, but is unsuitable for girders. Wood is much stronger under tension than compression; in white pine this proportion is as eight to one. In designing timber bridges the strains are, therefore, as far as possible, arranged for tension.

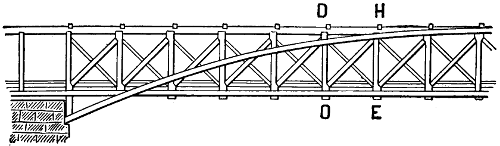

Queen-post truss.

DE, HO, queen-posts.

Upper part of a roof truss.

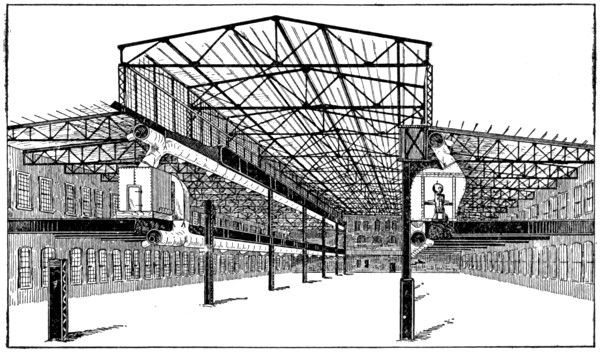

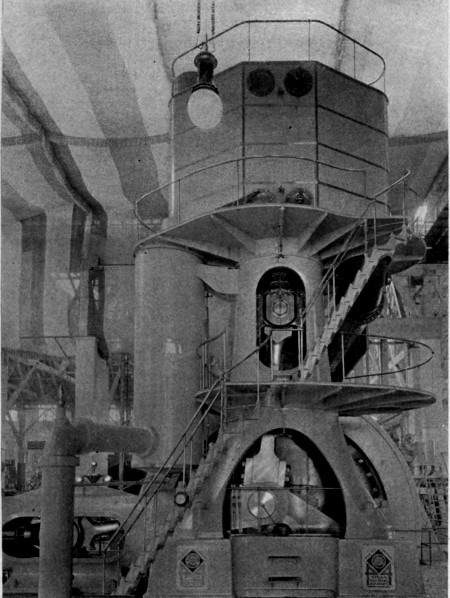

Interborough Power House, New York.

Let us now enter another barn, about one half wider than the first, and look upward at its rafters. We see its roof sustained by timbers disposed as DCMH, to avoid the undue weight necessary for a design resembling that of our first roof, ABC. Instead of one upright post, AK, as in that case, we have now two, DE and HO, called queen-posts, sustaining the horizontal beam, CM. In large modern roofs the simple queen-post is modified and multiplied, as in the main power house of the Interborough Rapid Transit Company, West 59th St., New York. Returning to our simple queen-post design, let us imagine a creek flowing between walls spanned by DCMH; that truss and a mate to it, parallel at a distance of say ten feet, would easily carry a roadway and give us a bridge. A truss for a bridge[22] must be much stronger than for a roof of equal span, because a bridge has to bear moving loads which may come upon it suddenly, giving rise not only to serious strains but to severe vibrations, all varying from moment to moment.

Two queen-post trusses form a bridge.

Palladio trusses.

The queen-post truss was remarkably developed by Palladio, a famous Italian architect of the sixteenth century. Two of his designs, here given in outline, are from his work on architecture published in 1570; their contours, little changed, are in vogue to-day. Strangely enough the trusses of Palladio, for all their merit, passed out of notice until their principles were revived and improved by[23] Theodore Burr, in 1804, in a wooden bridge over the Hudson at Waterford, New York. This bridge had spans respectively of 154, 160 and 180 feet, stretches impossible to single wooden beams. Professor J. B. Johnson, an eminent engineer, says that this is the most scientific design ever invented for an all-wooden bridge; during fifty years it stood unrivaled as a model for highway purposes in this country. The Burr bridges were usually covered in, so as to resemble the roofs we began by inspecting. In a truss bridge each part bounded by two adjacent uprights, as DOEH in the queen-post figure on page 21, is a panel; every part under compression, as DO, HE, is a strut, post, or column; every part subject to tension as DE, HO, is a tie.

Burr Bridge, Waterford, N. Y.

DO, HE, struts. DE, HO, ties. DHEO, panel.

In 1830 as the first American railroad train sped on its way, a new era dawned for the bridge builder as well as for his neighbors. At once sprang up a demand for bridges longer and stronger than those which in the past had served well enough. A score of wagons laden with wheat or potatoes were a good deal lighter than a locomotive followed by a train of loaded freight cars. A market-wagon, too, could easily be taken aboard a ferry-boat, but for an engine and its cars a bridge was imperative, if the stream were not so wide as to forbid all opportunity to the bridge builder. His response to the demands of the railroad was two-fold. First in the use of metal instead of wood, beginning with iron rods to bind together frames of timber. As iron became cheaper and its value more and more evident, he employed it for additional parts of his structure until at last he built the whole bridge of iron.

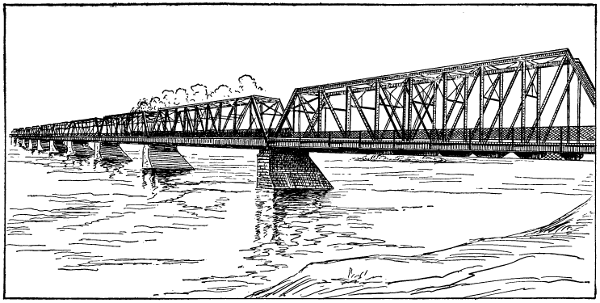

To-day good steel is so cheap that railroad bridges are seldom reared of anything else. Besides using stronger materials, the[24] designer has gradually improved the form of his structure, not only in its parts but as a whole, so that to-day, strength for strength, a bridge may be only one tenth as heavy as a bridge of fifty years ago. Advances in form have been due to experience as one type has been compared with another; meanwhile the mathematicians have carried their analysis of strains as far as the extreme complexity of their problems will allow, greatly to the betterment of designs.

In building a bridge, as in rearing many other structures, girders of various contours are used. In bridge building the I-beam is most employed. When the roadway proceeds on the top chord, as DH, in the queen-post figure, page 21, we have a deck bridge; when it is built on the bottom chord, as CM, we have a through bridge.

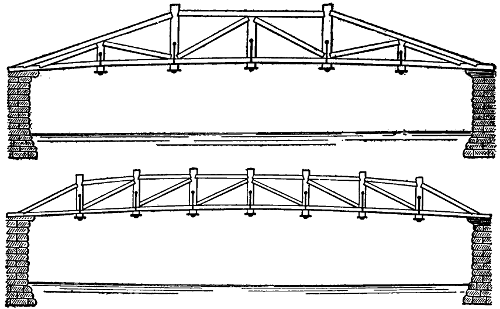

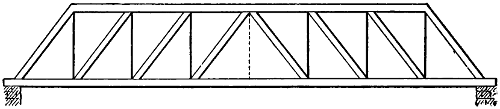

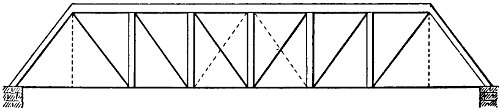

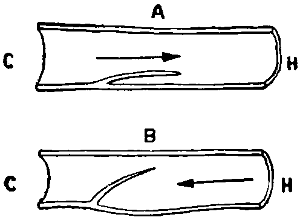

HOWE TRUSS

PRATT TRUSS

The Burr bridge of 1804, already mentioned, included an arch and was in part sustained by struts projecting from abutments. These features were omitted by William Howe in the bridge which he patented in 1840, and which was, as far as is known, the first successor to a design of Palladio in employing a simple truss for long spans. The Howe truss was built of wood, except its terminal tie-rods, which were of iron; it has been repeated thousands of times throughout the[25] world. In 1844 Thomas W. and Caleb Pratt patented a bridge which in design was the converse of Howe’s. Its diagonals of iron were used in tension, while its vertical struts of timber were in compression; in the Howe pattern the diagonals were in compression, the verticals in tension. This plan, by shortening the struts, diminished the cross-section necessary in a truss. When wrought iron took the place of wood for bridges, the Pratt design became the most popular of all, combining as it did more desirable features than any of its rivals. To-day for long spans the Baltimore truss is much in favor. Its stresses, that is, its resistances to change of form under strain, are readily ascertained; the shortness of its panels means strength; and its diagonals have the inclination which wide and varied experience has shown most desirable. The roadway, it will be observed, is upheld by sub-verticals, that is, by verticals which reach the floor from half the height of a panel.

Diagram of Baltimore truss.

Whipple Bridge.

An important study concerns itself with the intensity and distribution of strains, first in girders, next in trusses, and lastly, in bridges as units, all with intent to ensure the best possible designs throughout. In this field of inquiry the pioneer was Squire Whipple, a maker of mathematical instruments in Utica, N. Y., who published in 1847 his analysis of the strains in a truss bridge due to its own weight and to its moving loads. With the laws of these strains in mind he devised several bridges of great merit,[26] the most noteworthy being reared in 1852 on the Rensselaer & Saratoga Railroad, seven miles north of Troy, which did service until 1883; its sides or web system had ties extended across two panels in double intersection.

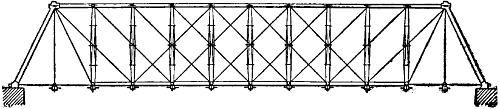

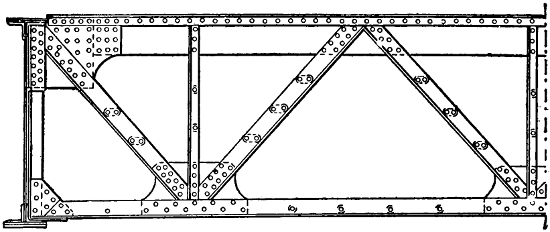

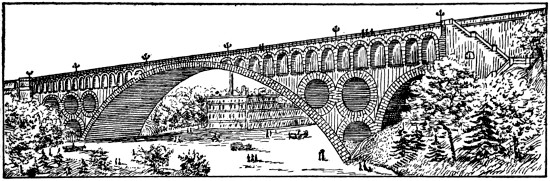

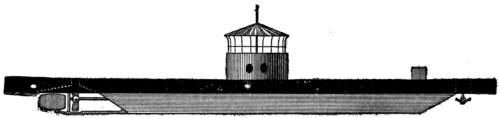

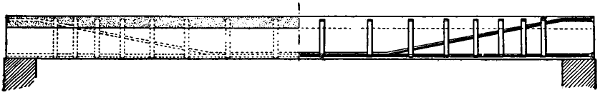

In a long truss bridge, which in its entirety may be regarded as a girder of the utmost size, the cross pieces between the main beams of the structure are much less heavy than if continuous plates, of no more strength. The original form of the Victoria Bridge at Montreal was that of a continuous tube of iron, square in section; it has given place to a truss bridge of five times greater capacity which weighs only twice as much. (Illustrations of both on pages 27 and 28.)

Thus to lessen weight in comparison with strength is a matter of great importance in a suspended structure, which must not only bear its own weight, but carry heavy moving loads.

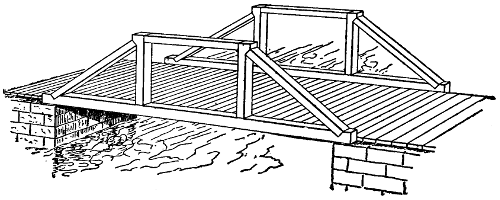

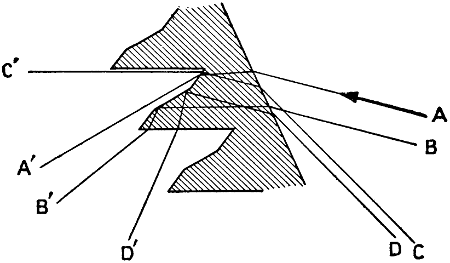

Simple cantilevers.

FG, HI, are first separate; then in contact; last are joined by a

plank laid above them.

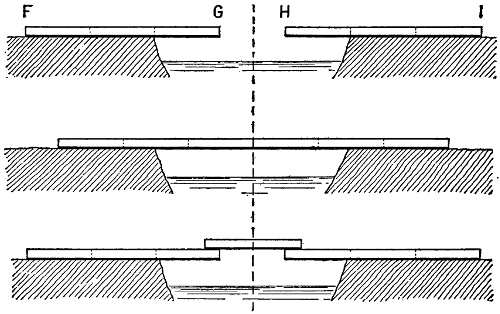

VICTORIA BRIDGE, MONTREAL.

Original tubular form designed by Robert Stephenson.

VICTORIA BRIDGE, MONTREAL,

Rebuilt with trusses.

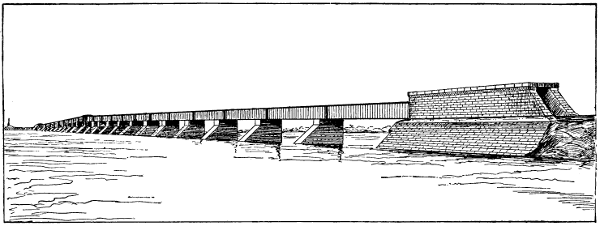

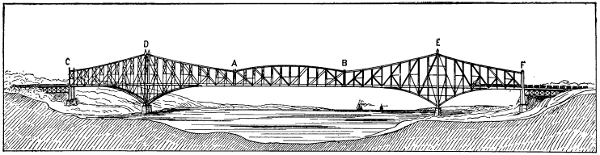

CANTILEVER BRIDGE ACROSS THE ST. LAWRENCE, NEAR QUEBEC.

Total length, CF, 3300 feet. Channel span, DE, 1800 feet. Central truss, AB, 675 feet.

In most cases a bridge crosses a valley or a river in a place

which permits the engineer to erect scaffolding to support his

trusses until they can be united and become

self-sustaining. In some places this course is

denied; a river such as the Ohio or the Mississippi

may have to be spanned at a point where the[27-

30]

waters in a single day may rise forty feet, bearing along trees and

timbers with destructive violence. As a rule the difficulty is met by

employing cantilever spans which require no scaffolding for their

construction. To understand their principle let us suppose that

on opposite banks of a creek we roll out to meet each other the

joists FG and HI, taking care that the parts over the water shall

always be lighter than the parts on land. When the joists at last

touch they are secured to each other as a continuous roadway. Or,

while they are at a moderate distance apart they may be joined

by a third timber laid across the gap from one to the other. In

practice the simple principle thus illustrated is developed and

varied in many ways, but in every application the one rule is that

the trusses as they stretch out from the two sides of a pier shall

balance each other, the shore ends being duly weighted down or

safely anchored to solid rock. And thus, at length, we come to

the wonderful bridge, six miles west of Quebec, whose channel

span of 1,800 feet will be the longest ever reared. See illustration,

page 29. From the cantilever arms, DA and BE, will be suspended

the central truss, AB, of 675 feet. A cantilever span may be much

longer than a simple truss because on a pier, as D of this bridge,

a part, DA, of the whole span, DE, is balanced either, as in this

case, by a shore span, CD, or by a corresponding part of the next[31]

span should that span not extend to the shore but pass from one

pier to another.

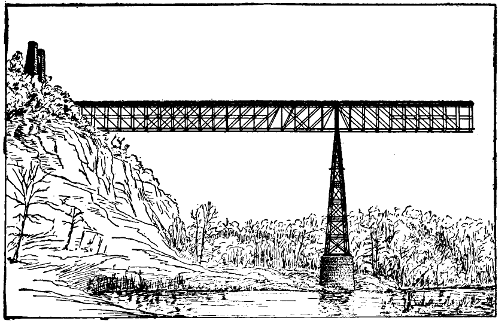

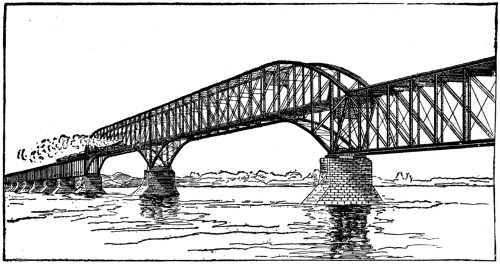

Kentucky river cantilever bridge

The first cantilever bridge in America was designed by C. Shaler Smith for the Cincinnati Southern Railroad, to cross the Kentucky River; it was built in 1876-7.

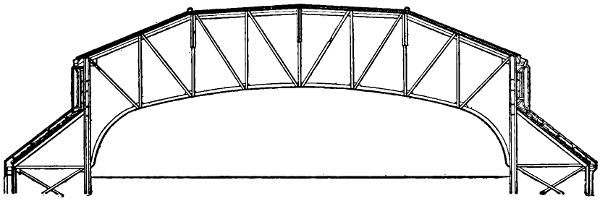

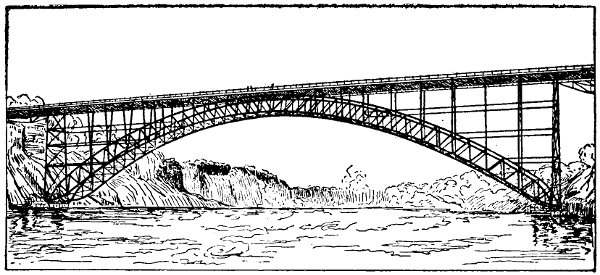

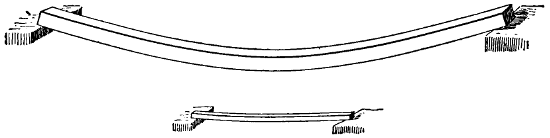

Arch bridge, Niagara Falls

Spanning the gorge of Niagara, close to the Falls, is an arch bridge of 840 feet in its central span, which, in its construction during 1898, followed the plan originated by James B. Eads in building the St. Louis bridge nearly thirty years before. As scaffolding was out of the question in both cases, each bridge was built out from its piers on the cantilever principle. An arch is sometimes disguised as a modified bowstring, as in the Burr design of 1804, a horizontal tie connecting the extremities of the arched rib and taking its thrust, dispensing with the abutments demanded by an arch. In the chords of such a pattern the strength comes as near to uniformity throughout as practical considerations permit, avoiding the losses of early days when one part of a bridge might be twice as strong as another. The bowstring was adopted for the great span of 5421⁄2 feet over the Ohio at Cincinnati built in 1888, and for the span of 5461⁄2 feet erected at Louisville in 1893. A bowstring 533 feet long, forming part of the Delaware river bridge of the Pennsylvania Railroad, built in 1896, in Philadelphia, is outlined on page 32. At Bonn, on the Rhine, there was completed in 1904 a bridge whose central span is a bowstring 6161⁄4 feet long.

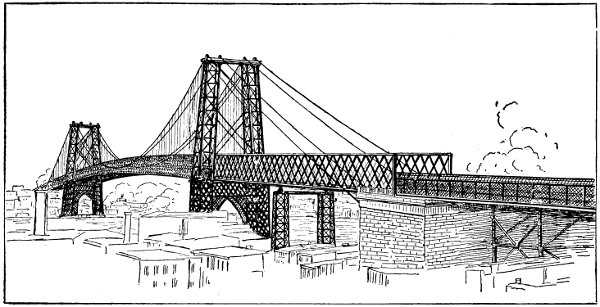

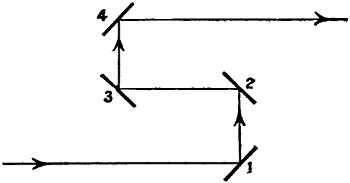

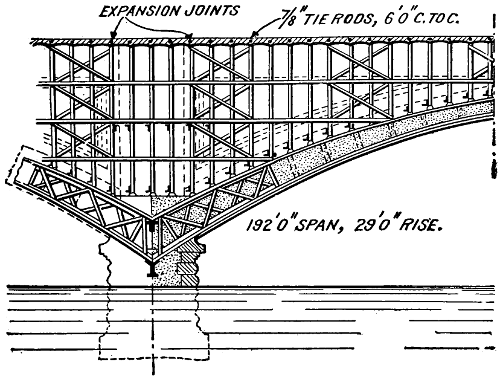

Bowstring Bridge, Pennsylvania R. R., Philadelphia.

If we take the design of an arch bridge and turn it upside down we have a contour such as that of the Williamsburg Suspension Bridge, opened in 1903 between Brooklyn and Manhattan, depicted on page 33. For the utmost length this is the only available span; it brings into play the tensile strength of wire, the strongest form that steel can take. A steel cable of suitable diameter, if it had to support only itself, might safely be three miles long. A suspension bridge has another advantage in employing an anchorage to bear strains which would break down a simple truss resting on piers. As first erected suspension bridges were liable to extreme and harmful vibration, in many cases being shaken to pieces by storms of no great violence. It was found that this vibration was checked and that safety was ensured by introducing stiffening trusses which, at the same time, benefited the bridge by distributing the load uniformly throughout the sustaining cables.

WILLIAMSBURG BRIDGE, NEW YORK CITY.

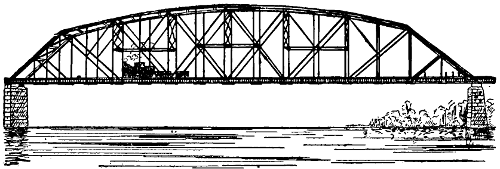

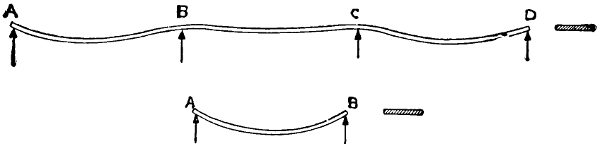

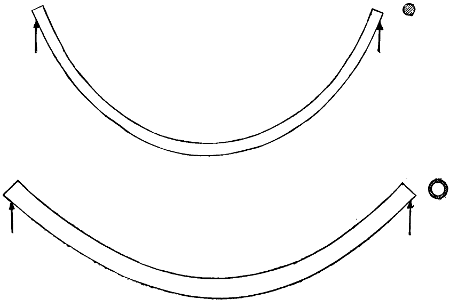

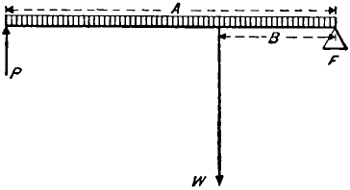

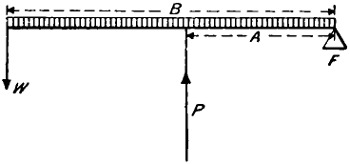

At Lachine, about eight miles west of Montreal, on the line of

the Canadian Pacific Railroad, a remarkable bridge crosses the

St. Lawrence river. Its design is that of a continuous girder of

four spans, the two side spans being 269 feet each in length, and

the two others each 408 feet. This type is discussed by Mr. Mansfield

Merriman and Mr. Henry S. Jacoby in Part IV, page 30, of

their work on Roofs and Bridges. One of the advantages presented

is that deflection under live load is less, and stiffness

greater than for simple, discontinuous girders, the harmful effect

of oscillation being thus diminished. Furthermore, less material

is required than for simple, discontinuous spans. Both these[33-

34]

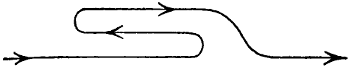

elements of gain are brought out in placing a strip of rubber, AD,

upon four equidistant points of support, when we find that BC,

the central third of the strip sags less than either AB or CD, the

first or last third. Cutting off one-third of the whole strip we

deprive the removed piece, at its surface of separation, of the

cohesion which did much to keep the whole strip, before cutting,

almost horizontal at that point. We take AB, our short removed

piece of rubber, and lay it at its ends on two points of support;

it now serves in a rough-and-ready way as a model of a simple

truss, all by itself; its decided sag shows it much less rigid than

when it formed a part of an unbroken and longer structure.

Continuous girders despite their advantages are seldom employed;

they are liable to serious difficulties; among these may

be mentioned that changes, often unavoidable, of level in piers[35]

and abutments cause them to suffer great reversals of stress, always

a source of danger; furthermore, variations of length due to

changes of temperature are, of course, much greater and more

troublesome to provide against than in the case of discontinuous

girders.

Continuous girder bridge, Canadian Pacific R. R., Lachine, near Montreal.

Rubber strip supported at 4 points, and at 2 points.

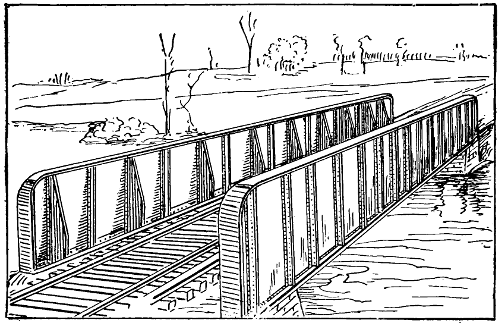

Plate girder bridge.

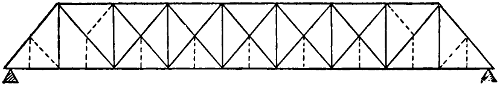

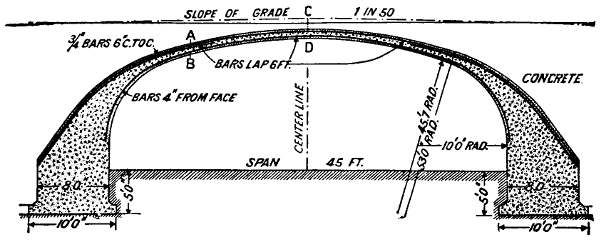

Whether spans are long or short, engineers are fairly well agreed as to the best proportions for girders and panels. They consider that a girder should have about one-twelfth to one-tenth as much depth as span; and that the weight of a web should be about equal to that of its flanges. They usually give panels twice as much depth as length, with a tendency to increase the proportion of depth to length, in order to minimize the deflections and oscillations which shorten the life of a structure. For definite lengths of span, particular types of construction are preferred; usually for lengths of from 20 to 125 feet, plate girders are chosen; for spans of 125 to 150 feet riveted lattice trusses are built; for spans of 150 to 600 feet pin-connected trusses are employed. Here we reach the economical limit of a length for simple trusses; beyond 600 feet the engineer is obliged to have recourse either to a cantilever or a suspension bridge.

Part of lattice girder bridge, showing rivets.

Whatever the breadth of the stream or the chasm over which he is to build a roadway, each case must be studied in the light of its special circumstances. There must be due regard to business as well as to engineering considerations; the designer will bear in mind that types of parts customarily turned out at great steel works are procurable in less time, and at less cost, than novel types requiring to be manufactured to order. Then, in speed of construction, he will remember that a pin-connected bridge can be built much faster than a riveted structure. Furthermore, every part must be vastly stronger than ordinary duty requires. Tempests and floods may suddenly arise; at any instant a derailment or a collision may create a strain of the utmost severity; and even under ordinary circumstances it must not be forgotten that train loads grow constantly heavier because economy lies that way.

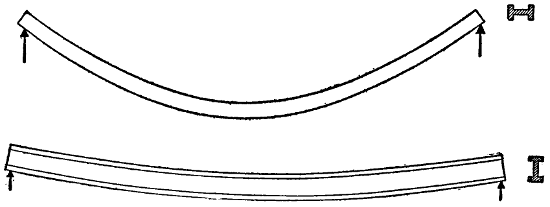

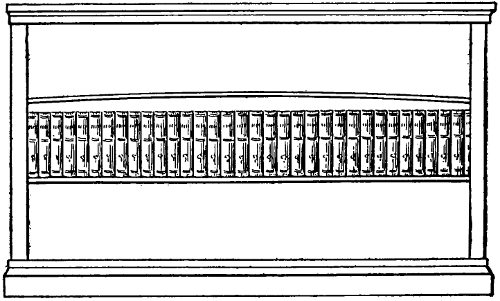

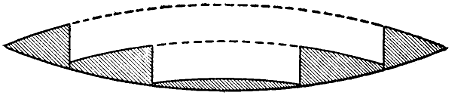

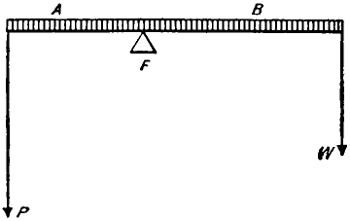

Upper shelf, unladen, has upward curve or camber.

Lower similar shelf is straightened by its load.

One detail of bridge design is worth a moment’s attention. When a book-shelf is a thin board, quite straight as manufactured, it sags in the middle when fully burdened. This downward dip may be avoided by making the shelf at first with a slight curve which brings the middle a little higher than the ends. In bridge building a like curve, or camber, is given to each span so that when fully loaded it will be level or nearly so. In a span of 500 feet it is found that a rise of half a foot at the centre is sufficient. In suspension bridges, for the sake of strengthening the structure, the camber far exceeds this ratio.

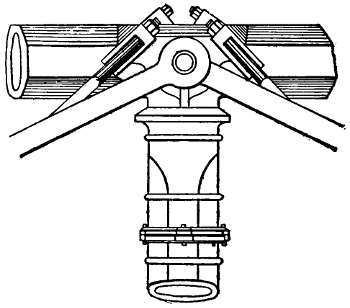

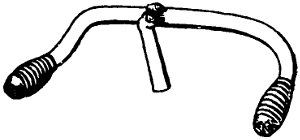

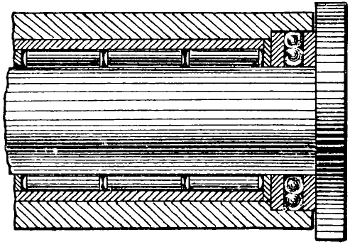

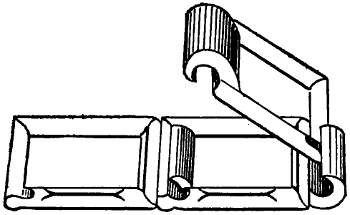

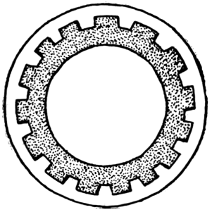

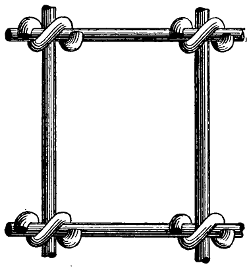

Pin connecting parts of a bridge.

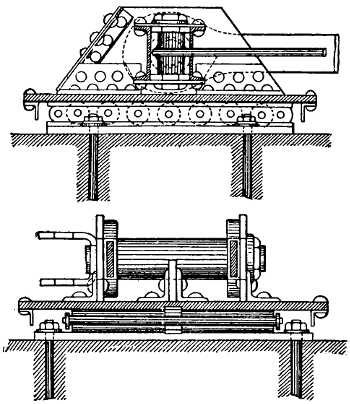

In fastening together the parts of a bridge the usual American practice, already mentioned, is to employ pins which pass through eye bars. In England riveting is preferred, as shown in the figure of the lattice truss, page 36. This difference in methods arose through the use of materials which differed. In the construction of bridges the English engineer started with the flanged girder of cast or rolled iron, or some other form of stiff beam, and as bridges increased in size so as to require the framing of a truss, his whole effort was directed toward making that truss as much like the original flanged or box girder as possible. The American engineer, on the other hand, had at first little or no iron or steel to work with, and of necessity used wood. As the necessary bridges were of considerable span, the only feasible method was to pin together small pieces of wood so as to form a connected series of triangles. To make rigid joints in wood was impracticable, and indeed rigid joints were not desired, because the strength of wood is slight when strains are applied in any direction other than that of the fibres of the piece, and the pin joint insures just this line of action. As a rule a riveted bridge requires more metal than a pin-connected[38] design, takes more time to build, but demands somewhat less skill. To provide for changes in length as a bridge is subjected to variations of temperature, friction rollers are used to support its extremities. In the first suspension bridge at Niagara Falls, built by Roebling, a little cement accidentally covered the friction rollers and prevented them from turning; fortunately the structure escaped the destruction to which it was thus exposed.

Bridge rollers in section and plan.

New York, Pennsylvania & Ohio R. R.

We have now taken a rapid survey of some of the methods by which the designer of bridges plans a structure which is at once safe and to the utmost extent economical of material. Step by step he has discovered how little steel he may use for designs all the bolder because his hand is so sparing of weight. His success began in adopting the girder, which we have seen to be in effect the working skeleton long concealed within the common joist; the cantilever span near Quebec, which compasses 1,800 feet in its flight, has been dissected out of preceding burden bearers in the same way. Its metal stands forth as so much sheer muscle kept to the most telling lines, unencumbered by a single pound of idle substance. A designer of such a fabric is an artist skilled in disengaging from masses of material every ounce that can be wisely removed. In some cases, as when Roebling linked together New York and Brooklyn, a bridge is created as much a thing of beauty as of use, as graceful as it is strong.[3]

[3] Mr. David A. Molitor has a chapter, copiously illustrated, on the esthetic design of bridges, beginning page 11 in the “Theory and Practice of Modern Framed Structures,” by Mr. J. B. Johnson and other authors, New York, John Wiley & Sons. Eighth edition, revised and enlarged. $10.00.

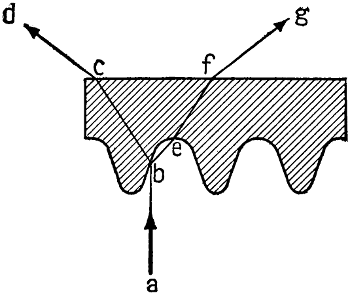

Why supports are made hollow . . . Advantages of the arch in buildings, bridges and dams . . . Tubes in manifold new services . . . Wheels more important than ever . . . Angles give way to curves.

Having glanced at methods by which forms, judiciously chosen, economize the materials of buildings and rails, of bridges diverse in type, we pass to further consideration of these and like shapes, to find that they effect a saving in material while they make feasible a new boldness of plan, and introduce new elements of beauty. We will also remark that judicious forms prevent waste of energy as structures are either set in motion, or serve to convey moving bodies. Incidentally we shall see that well chosen shapes insure a structure against undue hurt and harm.

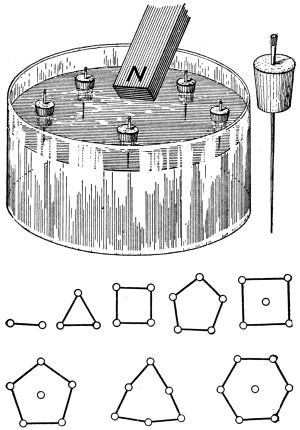

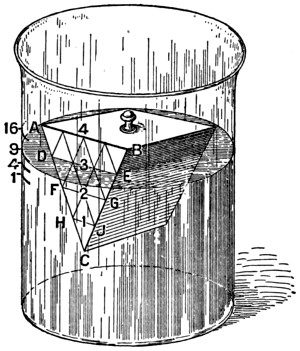

Square

Octagonal

16-Sided

Round

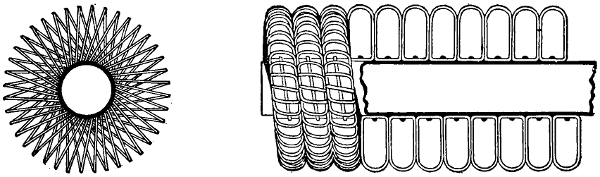

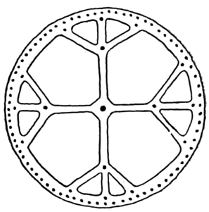

Girder sections.

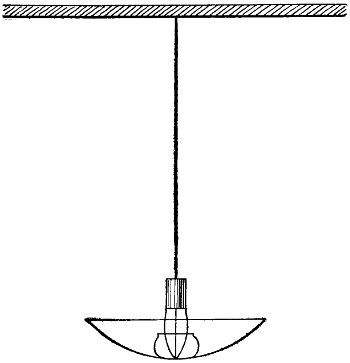

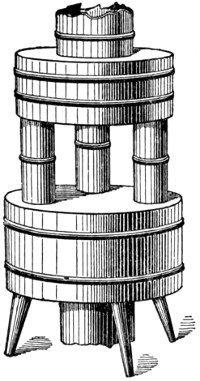

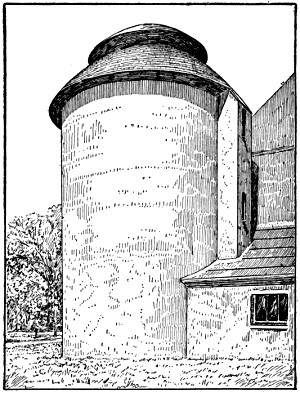

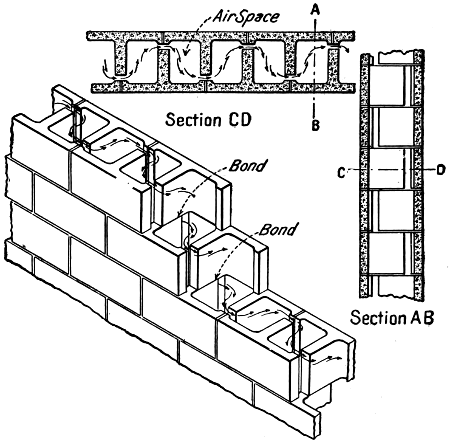

In lofty structures, the box girder is frequently employed as a column or a beam because it has even greater rigidity than the I-beam; usually it has four sides, but it may have eight, sixteen, or more, and thus step by step we come to a hollow cylindrical column which has, indeed, the best form that can be bestowed on supporting material. Chinese builders learned its economy on the distant day when they adopted the bamboo for their walls and[40] roofs. Comparison with a solid stick of timber of like weight and substance will show that an equal length of bamboo is decidedly preferable. The inner half of a round solid stick does comparatively little in holding up a burden; to remove that half is therefore as gainful as to strip from a joist the timber surrounding its working skeleton. At first the journals or axles of engines and large machines, as well as the axles of railroad cars and the shafts of steamships were solid; to-day, in a proportion which steadily increases, they are hollow. The advantage of this form comes out when we take two cylinders of rubber, alike in length and weight, one solid, the other hollow. Supporting both at their ends, the hollow form sags less than the solid form, proving itself to be the more rigid of the two.

Solid rubber cylinder sags much.

Hollow rubber cylinder sags less.

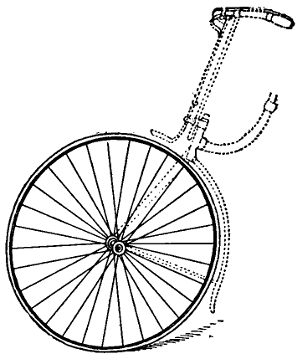

Handle-bar of bicycle in steel-tubing.

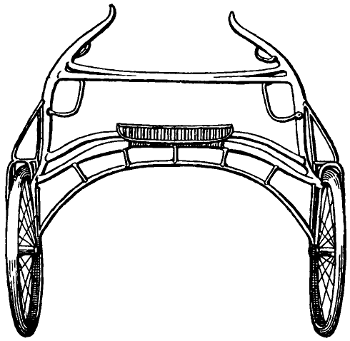

A sulky in steel tubing.

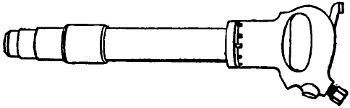

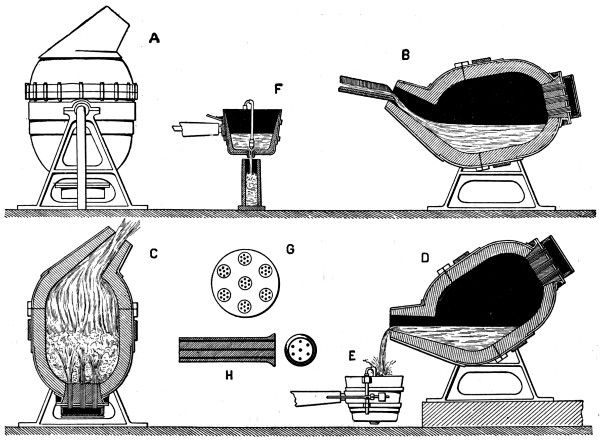

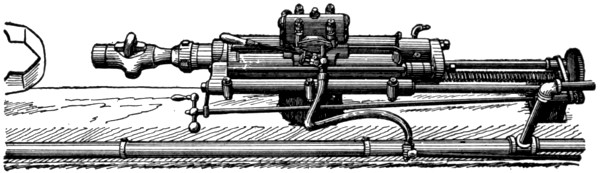

A pneumatic hammer, steel tubing.

Fishing-rod in steel tubing.

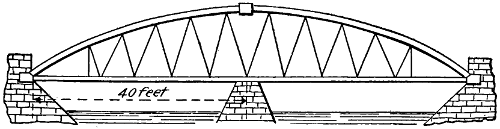

Bridge of steel pipe.

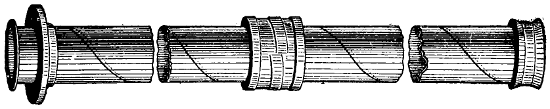

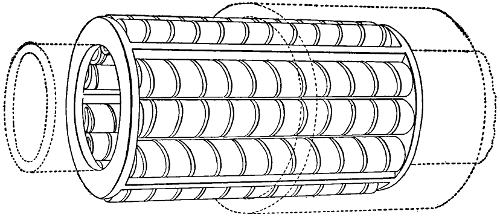

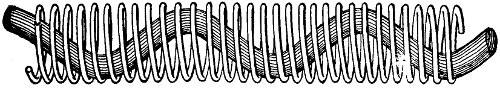

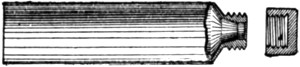

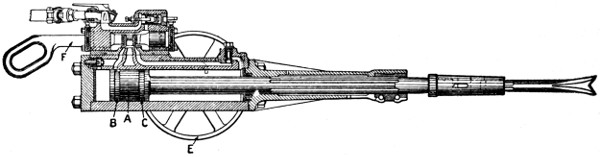

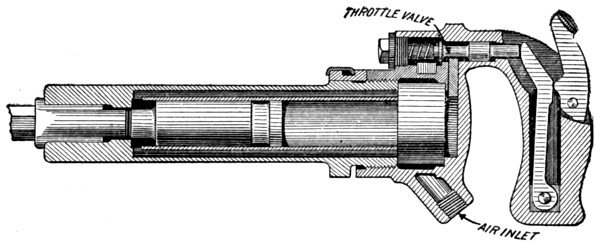

With like advantage seamless tubing is adopted for a broad variety of purposes. It builds bicycles and sulkies which far out-speed vehicles of solid frames; it is worked up into elevator cages, mangle rolls, pneumatic tools, fishing-rods, magazine-rifle tubes, inking rollers, farm machinery, poles, masts and much else where strength and lightness are to be united. Steel[41] tubing is readily bent into any needed contour, even when of considerable diameter. Mr. Egbert P. Watson has pointed out its availability for highway bridges of about forty feet span, no professional bridge-builders being needed for their construction. Near Saxonville, Massachusetts, a pipe-arch bridge, eighty feet long, provides a roadway across the Sudbury River, while carrying within its pipe a stream which forms part of the Boston water system. A bridge of similar form, 200 feet long, spans Rock Creek in the City of Washington. The Eads bridge crossing the Mississippi, at St. Louis, employs for each span eight steel tubes of nine inches exterior diameter. Tubes large and small have been strengthened by adopting the model of an old-fashioned fire-lighter, or spill, a bit of paper rolled spirally as a hollow tube. Blow sharply into it and you but tighten its joints. In like manner tubes and pipes of metal are all the tighter when their seams[42] are spiral instead of longitudinal. An eager quest for combined strength and lightness in the bicycle has ended in the choice of tubes spirally welded.

Arch bridge of steel pipe,

Sudbury River, near Saxondale, Mass.

Spiral fire-lighter.

Spiral weld steel tube.

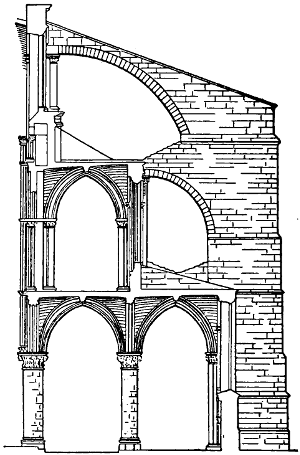

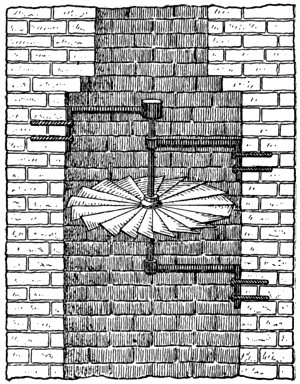

When builders of old began to rear masonry they repeated in stone or brick the forms they had constructed in wood. Accordingly the lintels of their doors and windows were flat. It was a remarkable step in advance when the arch was invented, probably by a bricklayer, spanning widths impossible to horizontal structures. A flat course of stone or brick presses downward only; an arch presses sidewise as well as downward. It is this sidewise thrust, calling into play a new resource, that gives the arch its structural advantage. In modern masonry the boldest arch is that of the bridge at Plauen, Germany, with its span of 2951⁄4 feet. Of[43] pointed arches the chief sustain the walls of Gothic cathedrals; it was to counteract the outward thrust of these arches that external buttresses were reared, either solid, as at St. Remy in Rheims, or flying, as at Notre Dame in Paris. The Saracenic arch, offering more than half of a circle, is not so strong as the Roman arch, but it has a grace of its own, fully revealed in the Alhambra, and in the incomparable mosque at Cordova. A chain of small links, a watch-chain, for example, freely hanging between two points of support strikes out a catenary curve; this Galileo suggested as the outline for an arch in equilibrium; it is adopted for suspension bridges.

Longest stone arch in the world, Plauen, Germany.

Church of St. Remy, Rheims, France.

Section across buttressed choir.

Curve of suspended chain.

Dam across Bear Valley, San Bernardino County, California.

“The arch,” says Mr. William P. P. Longfellow in “The Column and the Arch,” “was the great constructive factor in the architecture of the Roman Empire; it added enormously to the builder’s resources in planning, and to his means of architectural effect.[44] It gave him the means of spanning wide openings, and when expanded into the vault, of covering great spaces; it habituated him to curved lines and surfaces. Helped by it, and spurred by the new wants of the complex Roman civilization, he enlarged the scale of his buildings and greatly increased the intricacy of their plans. He used his new combinations with a boldness and fertility of invention that have been the wonder of the world from that age to ours, constructing on a scale that dwarfed[45] everything that had gone before except the colossal buildings of Egypt. Under a new stimulus, and with new means of effect, Roman building greatly outstripped that of the Greeks in extent, in variety, and magnificence.”

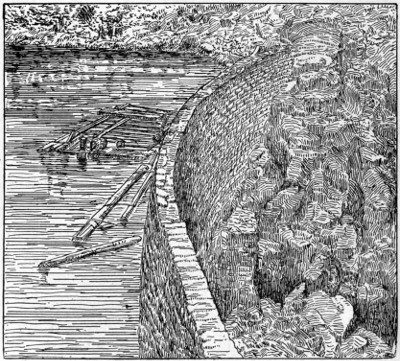

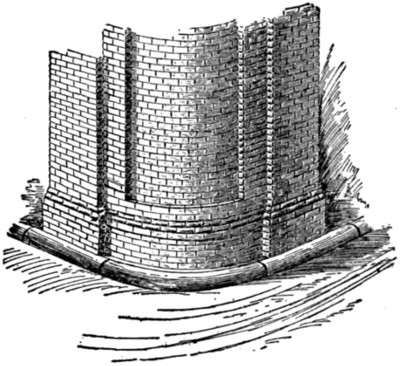

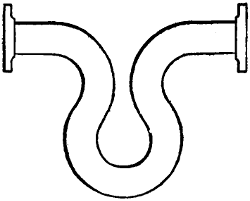

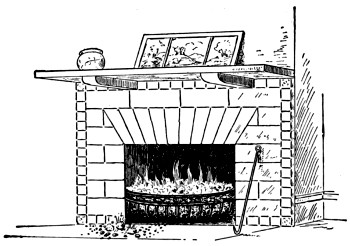

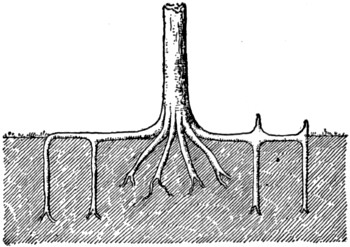

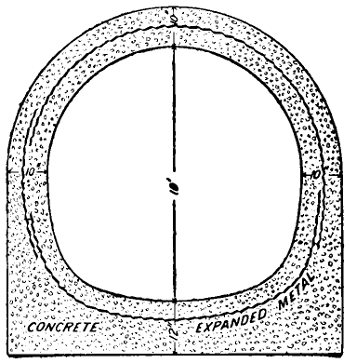

An arch built on its side, with its convexity upstream, and its ends braced against rocky banks, serves admirably as a dam. It has in many cases withstood floods much higher than those expected by its designers. Such dams must not be too long, or what is saved in thickness is more than lost in length. Arches inverted are used in many places as gulleys for drainage. Near Bristol, in England, they anchor the cables of the Clifton Suspension Bridge, at a depth of eighty-two feet below the surface of the ground. Many tunnels finished in masonry have outlines which are two arches united, the lower arch being inverted. The Cloaca Maxima, the famous sewer at Rome, is of this pattern; it is twenty-six feet high, sixteen feet broad, and is now in its twenty-fifth century of service.

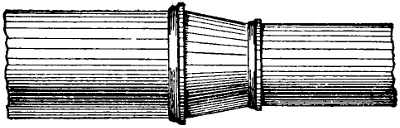

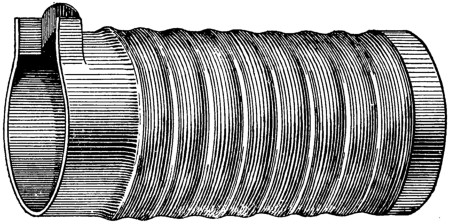

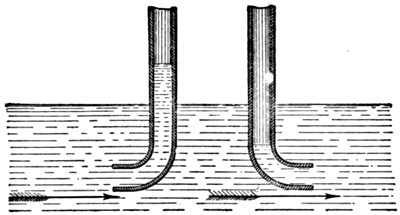

Ferguson locking-bar pipe. East Jersey Pipe Co,. Paterson, N. J.

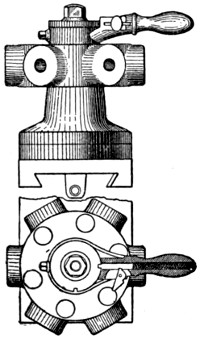

From arches, built of parts of circles, let us pass to the circle itself, and glance at the use of tubes of circular section as we begin to consider how resistances to motion may be minimized. The use of the bamboo not only for building, but for the carriage of water, began in the remote past. As structural material it was light and strong as we have noticed; laid upon the ground it was a ready-made water pipe of excellent form. When trees were hollowed out to convey water, when clay was modeled into tubes, the hollow cylindrical shape of the bamboo was in the mind of the Asiatic artisan, to be faithfully copied. That form has descended to all modern piping for water, steam, and gas, because the best that a pipe can take. No other shape has, proportionately to capacity, so little surface for friction inside or rust outside. A locking-bar water pipe, devised by Mephan Ferguson, of Perth, Australia, is made of two plates of equal width, curved into semi-circles which are pressed at their ends into channel bars of[46] soft steel. As the locking-bars and joints are opposite each other, their joints can be tightly closed by a simple machine which exerts pressure in a straight line. This construction may be used not only for pipes, but for hydraulic cylinders, air receivers, mud and steam drums, tubular boilers and boiler shells where high pressures are to be withstood.

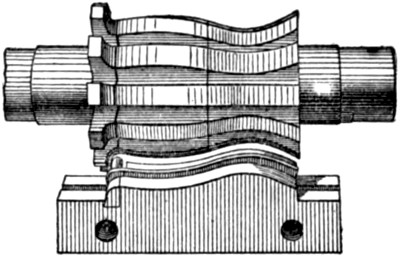

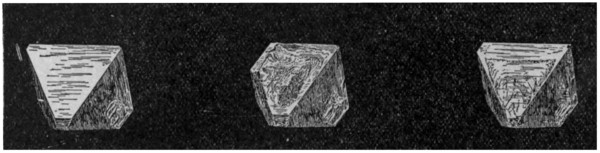

A steam boiler or other vessel under severe internal strains had best be spherical if equality to resistance is particularly desired. Usually a cylindrical shape is much more convenient, and no other is given to simple steam boilers or to the tubes of water-tube or fire-tube boilers. Tubes comparatively narrow, are readily manufactured without seam, so that they may be quite safe though thin; large boilers of plates riveted together, must be built of thick metal. It was estimated by Mr. F. Reuleaux, the eminent engineer, that if such boilers could be made in one continuous piece of metal by the Mannesmann process, so successful in tube-making, an economy in weight of at least one third would be feasible.

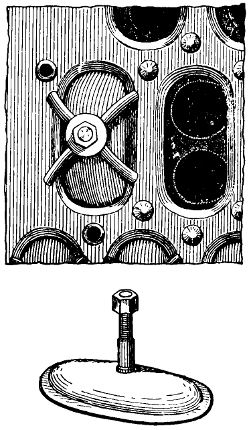

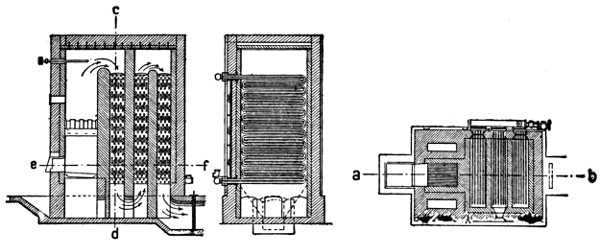

Hand-hole plates.

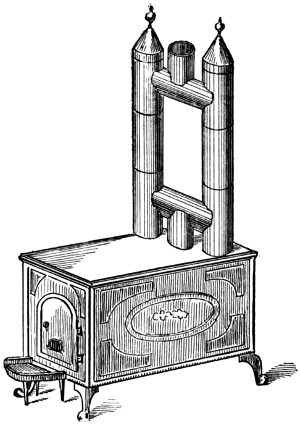

Erie City water-tube boiler.

In water-tube boilers a gainful departure from the circular form in a detail of their design is worthy of notice. In order that their tubes may be kept sound and clean they are rendered accessible by hand-holes which pierce the front and back of the boiler. Usually these hand-holes and their covers are round, a form which makes it necessary to put the cover outside the boiler where even a good joint, well stayed, may leak or give way under a pressure which tends to force apart the cover and its seat. In the Erie City boiler the covers are elliptical; they are readily passed through the hand-holes so as to rest not on the outside, but on the inside, of the boiler, where the steam pressure makes their joints all the tighter. A further advantage is[47] that each elliptical plate is large enough to give access to two tubes instead of one, lessening the lines of juncture along which leakage may occur.

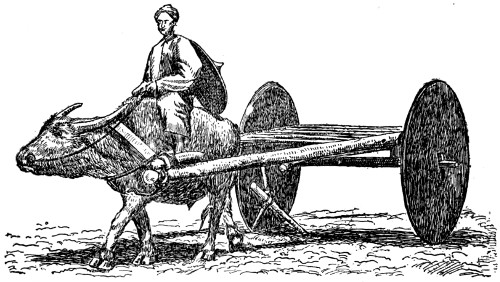

It was a memorable day when first a round log or stick was thrust under a burden, easing its motion and leading to the wheel by piecemeal improvements. A section cut off from the end of a round log is to-day the wheel for ox-carts in China and India. In its crudest form a roller enables a man to drag a load instead of carrying it, and he can readily drag much more than he can carry. Wheelwrights of old soon found that a wheel need not be solid, that strong spokes, a sound rim, and a metal tire embody the utmost strength and lightness. Roller and ball bearings much extend the benefits of simple wheels; they lessen friction in the best typewriters, bicycles, and elevators; in wagons, carriages, and automobiles roller bearings are so helpful that their use should be universal. Of notable efficiency is the Hyatt bearing, formed by winding a steel strip into a spiral roller. This device has a flexibility which enables it to conform to irregularities of motion much better than can a solid cylinder.

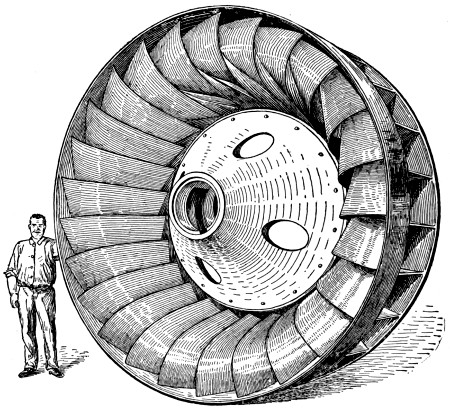

Bullock cart with solid wheels.

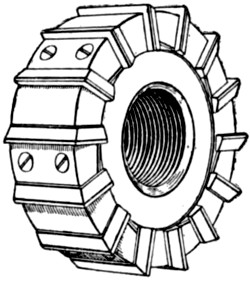

For machinery the wheel is indispensable. The hand does its work chiefly in moving to and fro, as in sawing and whittling. Machines outdo manual toil by moving swiftly and continuously[48] in a circle: instead of the smoothing iron we have the mangle, boards are planed by rotary knives, timber is divided by circular saws, and the steam turbine is displacing the steam engine which every moment has to check the momentum of huge reciprocating masses. Noteworthy in this regard is the perfecting press which prints a newspaper from a continuous roll, as contrasted with the old machine which demanded for each impression a distinct series of to and fro movements. The Harris Rotary Press for job printing is of like model. It feeds itself with 6,500 sheets an hour, printing from a stereotype or an electrotype curved upon its cylinder. The lathe, simple enough a century ago, has been developed into machines of great complexity, power, and variety, all with the original rotary mandrel as their essential feature. Milling machines, steadily gaining more and more importance, employ rotary cutters which dispense with the manual chipping and filing of former days.

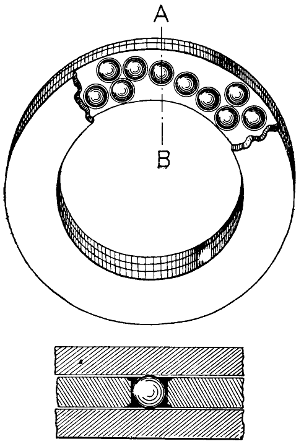

Section—A B

Ball thrust collar bearing.

Ball Bearing Co.,

Philadelphia.

Rigid bearings for driving axles

of automobiles.

Ball Bearing Co., Philadelphia.

Hyatt helical roller bearing.

Hyatt rollers supporting an axle.

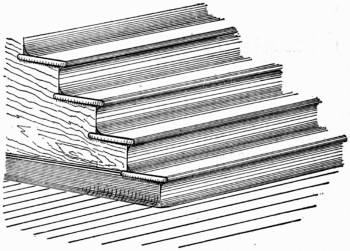

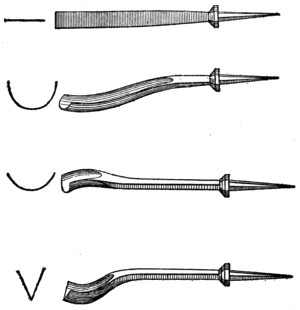

Treads and risers joined by curves.

Wood as commonly hewn, sawn, and planed; bricks as usually[49] molded; stone as it leaves an ordinary hammer, all have flat sides and square edges. Hence it has been easiest to build walls and floors which meet at right angles, and to leave sharp corners on outer walls, windows, doorways, and chimneys. This is being changed for the better; in staircases the boards on which we tread and those which join them together now meet in smooth curves; so do the walls of rooms as they reach ceilings and floors, conducing to ease and thoroughness in sweeping and cleansing. In outer walls, in doorways and windows, similar curves reduce liability[50] to hurt and harm. A wagon wheel easily knocks pieces from an angle of brickwork; it makes little impression on bricks retiring from the street line in a sweeping curve, as in the Madison Square Garden, New York. Factory chimneys have long been built round instead of square; to-day in the best designs the ducts to a chimney are also freely curved. In blast furnaces this is the rule for every part of the structure, ensuring gain in strength, lessening resistance to the flow of gases, and thus saving much fuel. When waterpipes varying in diameter are joined, the junction should be a gradual curve, otherwise retarding eddies will arise, wasting a good deal of energy; the same precaution is advisable in laying pipes for steam or gas. The elbows of pipes for gas, steam or water exert the least possible friction when given the utmost feasible radius. All the various parts of heavy guns are curved, since any sharpness of angle at a joint brings in a hazard of rupture under the tremendous strains of explosion.

Corner Madison Square Garden,

Madison Avenue and 26th Street,

New York.

Two pipes with funnel-shaped junction.

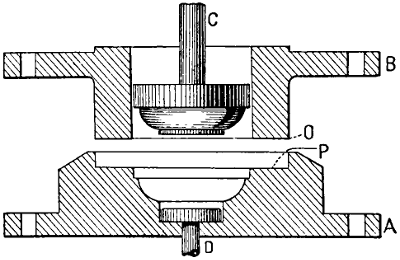

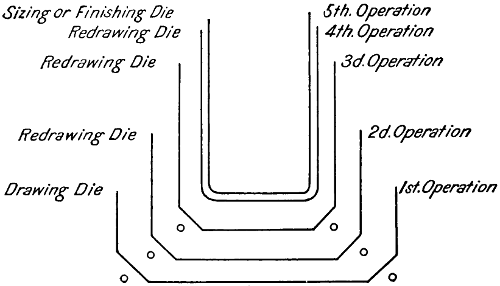

Embossing and stamping machines may either decorate a sheet of note paper or make a tub from a plate of steel. Whatever their size these machines have the edges of their dies nicely rounded, so as to avoid tearing the material they fashion. To ensure the utmost strength in the machines themselves they are contoured in ample curves. In hydraulic presses, subjected to strains vastly greater, the same shaping is imperative, otherwise a cylinder may part abruptly with disastrous effect. So, too, in the manufacture of magnets and electro-magnets, their terminals are well rounded[51] to ensure the closest possible approach to uniformity of field and of working effect.

A glance at a warship discovers her varied use of curves in defence; to deflect assailing shot and shell, her plates are given bulging lines, her turrets are built in spherical contours, and her casemates are convex throughout. On much the same principle fortifications are rendered bomb-proof, or rather bomb-shedding; while outworks are so inclined that bombs fall to distances at which they do little or no harm. As in war so in peace; there is gain in building breakwaters with an easy curve; to give their masonry and timbers a perpendicular face would be to invite damage, whereas a flowing contour like that of a shelving beach, slows down an advancing breaker and checks its shock. In rearing lighthouses to bear the brunt of ocean storms the outline of a breakwater is repeated to the utmost degree feasible. Often, however, the base supporting a lighthouse is too small in area for such an outline to be possible.

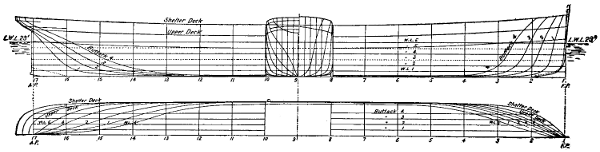

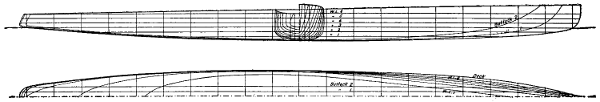

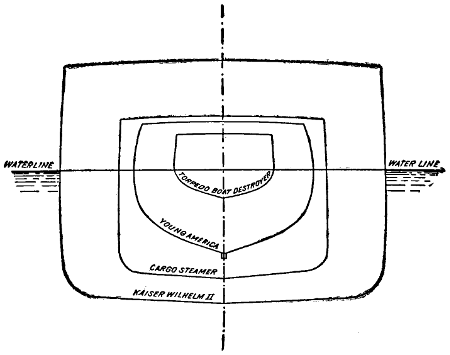

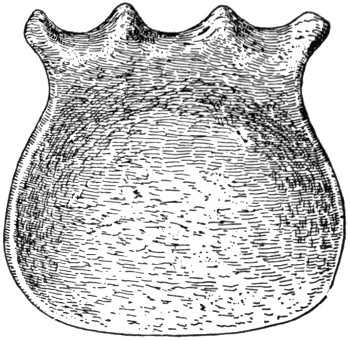

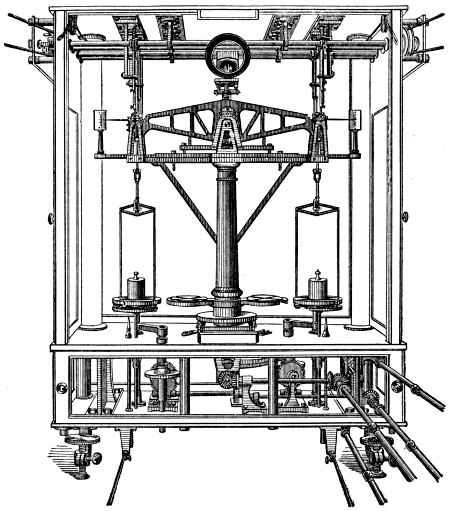

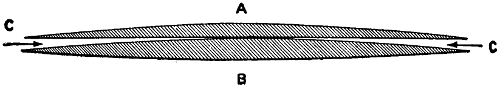

Ships have their resistances separately studied . . . This leads to improvements of form either for speed or for carrying capacity . . . Experiments with models in basins . . . The Viking ship, a thousand years old, of admirable design . . . Clipper ships and modern steamers. Judgment in design.