Title: Hawkins Electrical Guide v. 03 (of 10)

Author: N. Hawkins

Release date: August 24, 2015 [eBook #49769]

Most recently updated: October 24, 2024

Language: English

Credits: Produced by Juliet Sutherland, tallforasmurf and the Online

Distributed Proofreading Team at http://www.pgdp.net

In transcribing this book, the proofreaders found and corrected several minor typographical errors which did not affect the sense of the text. In the caption to Figure 541, the equation for the voltage of a Weston cell at different temperatures was missing a digit "1" and this has been corrected. There is a reference to a Figure 619 but no such figure exists in the original text. There are references to a Figure 119 and a Figure 443; these presumably exist in one of the preceding volumes of the series.

COPYRIGHTED, 1914,

BY

THEO. AUDEL & CO.,

New York.

Printed in the United States.

Action of compass needle--simple galvanometer--difference between galvanoscope and galvanometer--sensibility--action of short and long coil galvanometers--classes of galvanometer--astatic galvanometer--tangent galvanometer--graduation of tangent galvanometer scale--table of galvanometer constants--mechanical explanation of tangent law--sine galvanometer--table of natural sines and tangents--comparison of sine and tangent galvanometers--differential galvanometer--ballistic galvanometer--kick--damping effect--use of mirrors in galvanometers--lamp and scale--damping--D'Arsonval galvanometer: construction, operation; uses--galvanometer constant or figure of merit--shunts.

TESTING AND TESTING APPARATUS 465 to 536

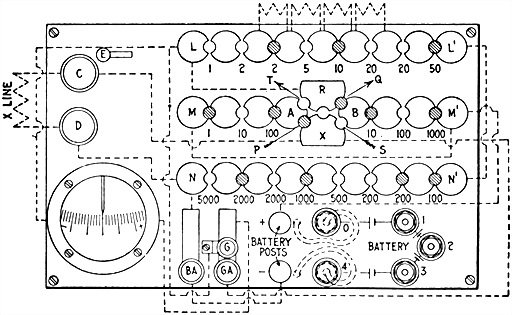

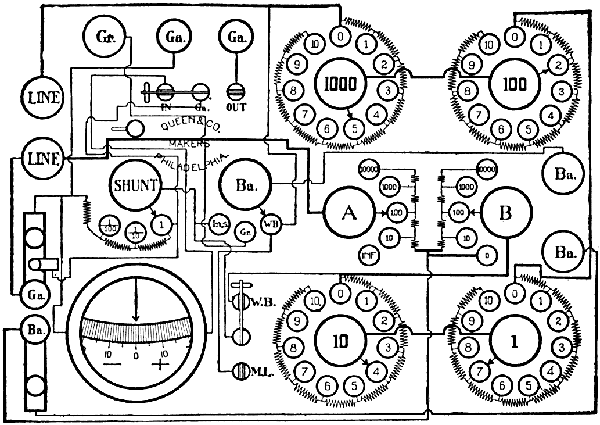

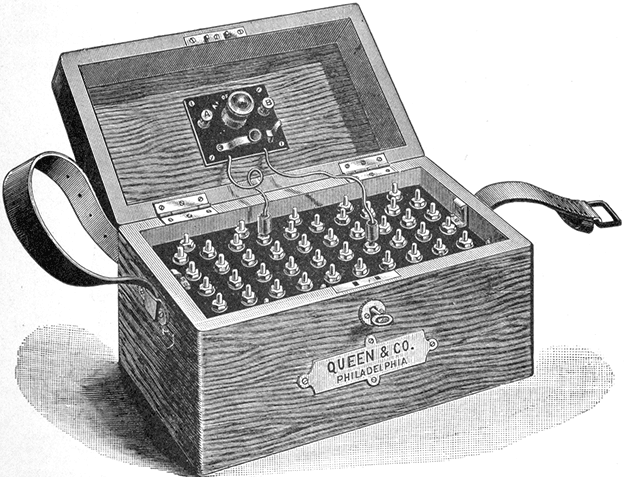

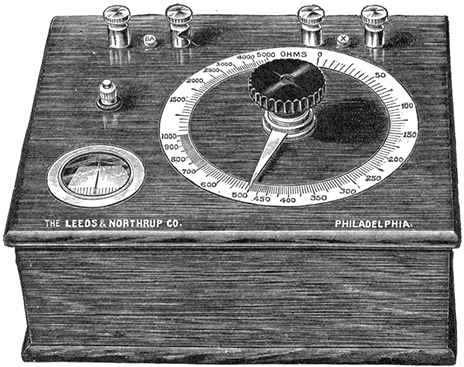

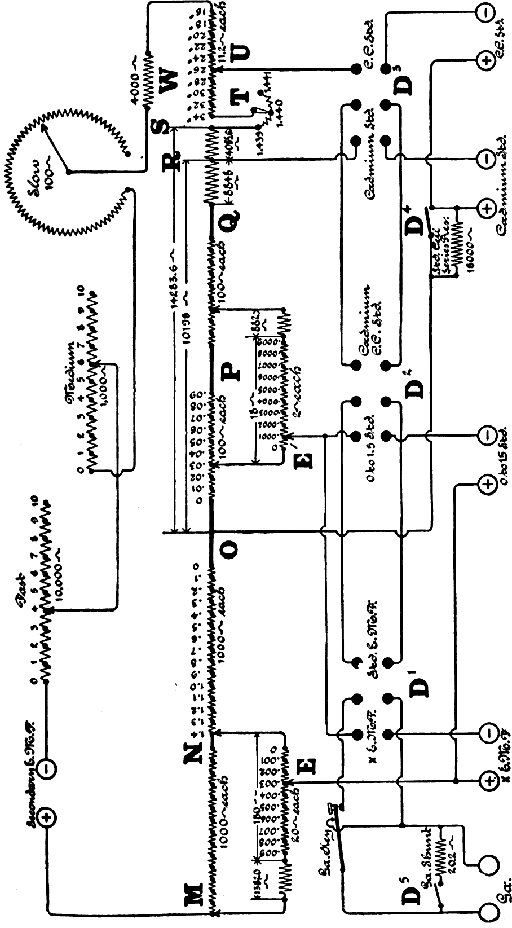

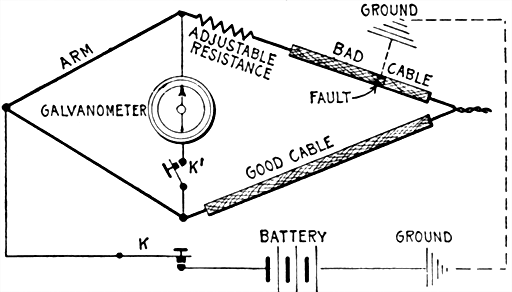

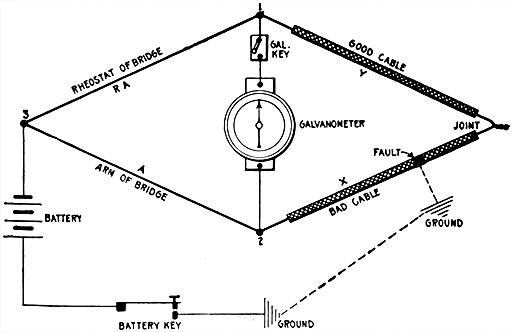

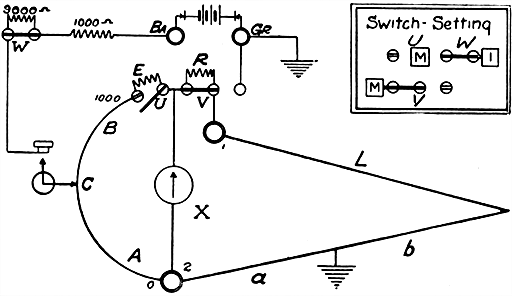

Pressure measurement--Clark cell--Weston cadmium cell--pressure measurement error with ordinary voltmeter--International volt--hydraulic analogy of amperes--coulombs--current measurement--International ampere--voltameters--Ohm's law and the ohm--International ohm--ohm table--practical standards of resistance--various methods of resistance measurement--direct deflection method--method of substitution--resistance box--fall of potential method--differential galvanometer method--drop method--voltmeter method--Wheatstone bridge--usual arrangement of resistances of Wheatstone bridge--ratio coils of Wheatstone bridge--the decade plan--two plug arrangement--"plug out" and "plug in" type of resistance box--testing sets--direct deflection method with Queen Acme set--[typo:ohmeter:ohmmeter]--fall of potential method with Queen Acme set--apparatus for measuring low resistances--how to check a voltmeter--Kelvin wire bridge--internal resistance measurement--Evershed portable ohmmeter set--L and N fault finder--ammeter test--diagram of Queen standard potentiometer--diagrams illustrating loop testing--the Murray loop--the Varley loop--special loop--the potentiometer--location of opens--to pick out faulty wires in a cable--voltage of cell measurement with potentiometer--care of potentiometer--location of faults where the loop is composed of cables of different cross sections.

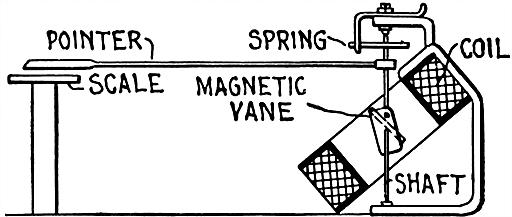

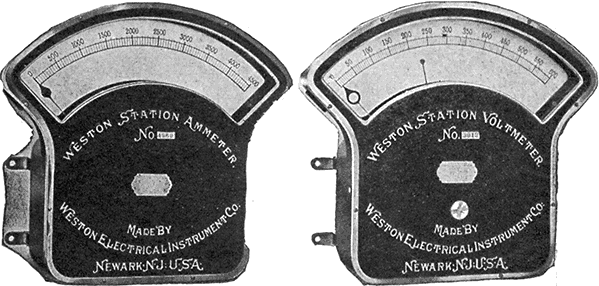

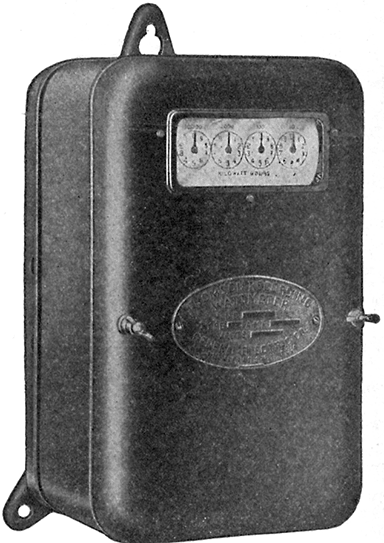

AMMETERS, VOLTMETERS, AND WATTMETERS 537 to 572

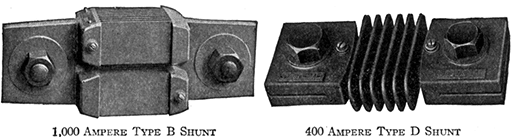

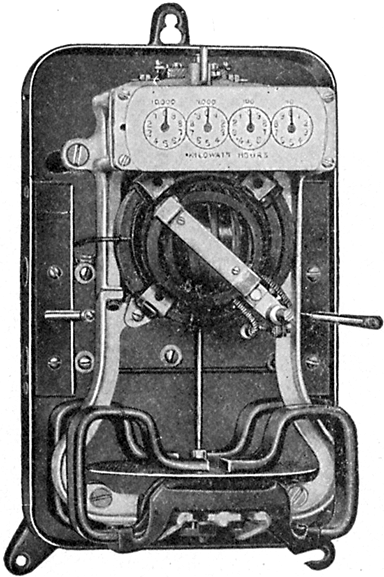

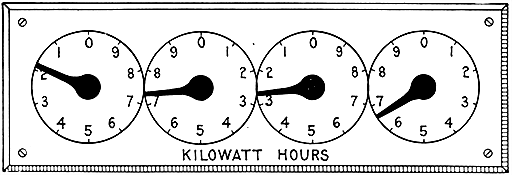

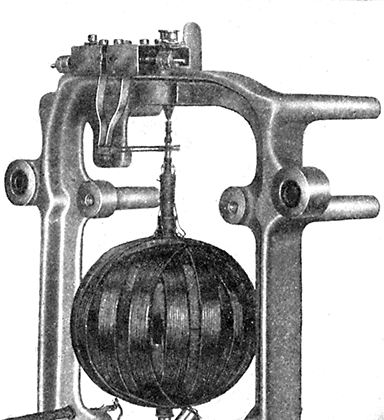

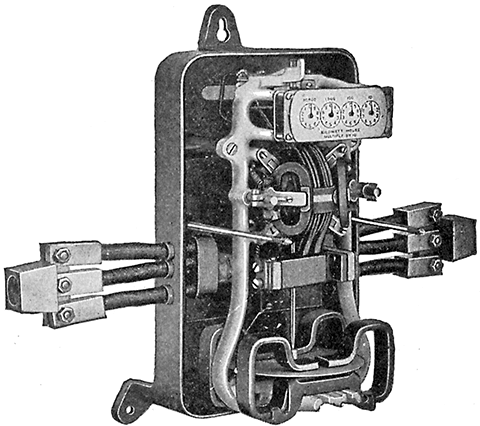

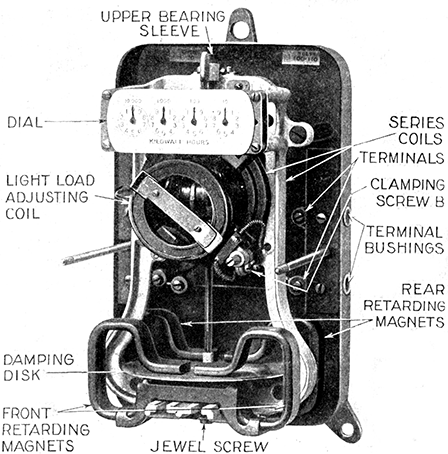

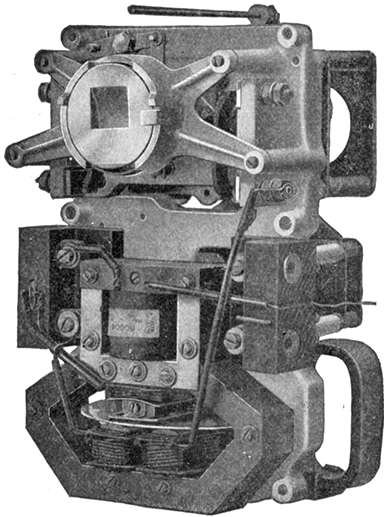

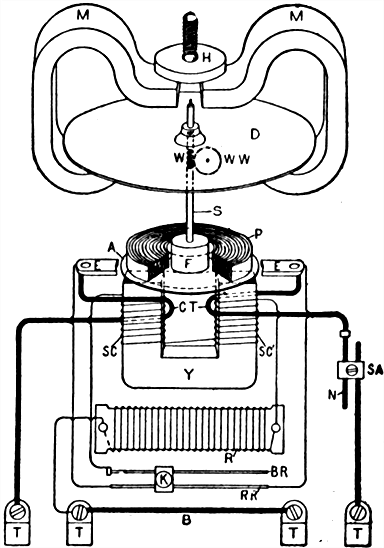

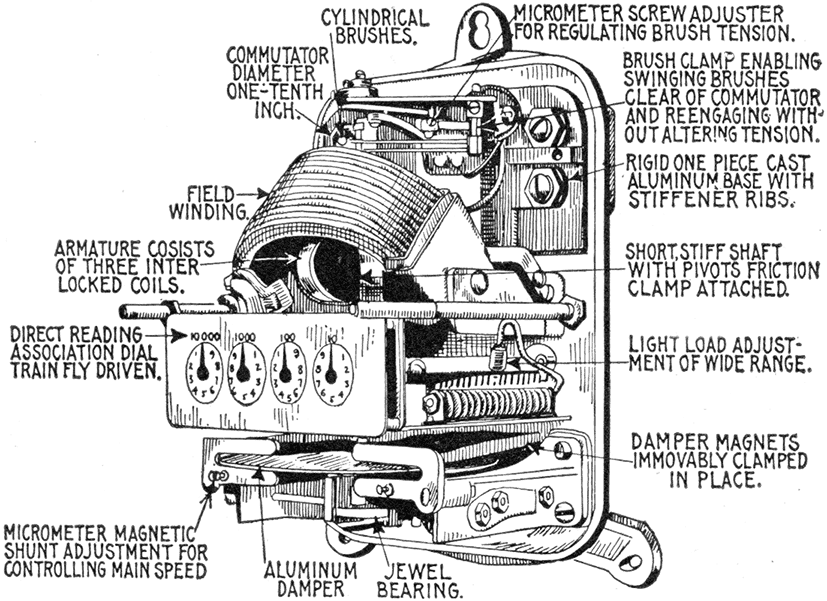

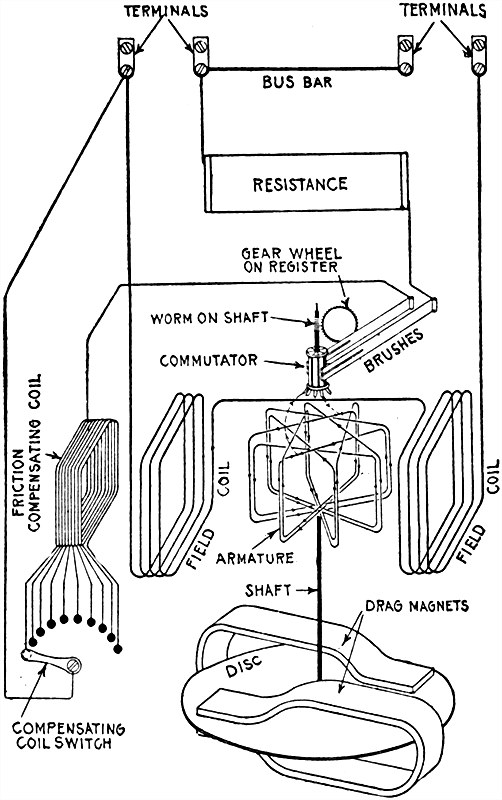

Definition of ammeter--classification of ammeter and voltmeters--moving iron type instrument--Keystone voltmeter--winding in ammeters and volts--connections for series and shunt ammeters--voltmeter connections--Westinghouse ammeter shunts--various types of instrument--plunger type instrument--magnetic vane instrument--inclined coil instrument--Whitney hot wire instruments--principle of electrostatic instruments--multipliers--portable shunts--Siemens electro-dynamometer--station instruments--Thompson watt hour meter--how to read a meter--installation of wattmeters--Westinghouse watt hour meter--Thompson prepayment watt hour meter--how to test a meter--Sangamo watt hour meter--Columbia watt hour meter--Duncan watt hour meter.

OPERATION OF DYNAMOS 573 to 596

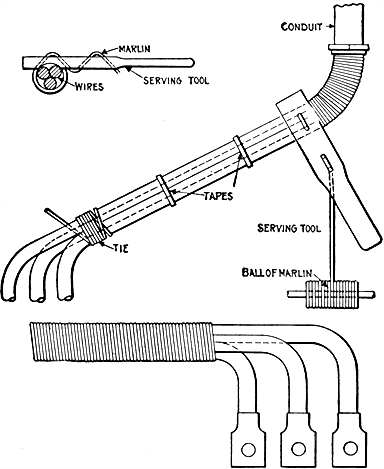

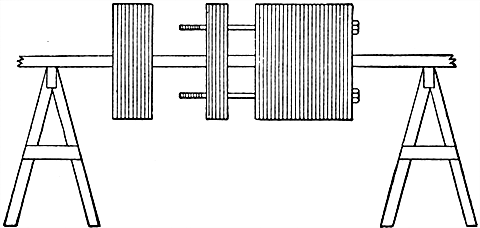

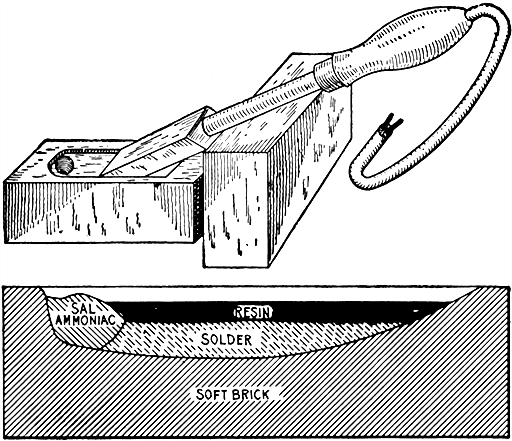

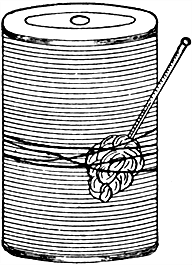

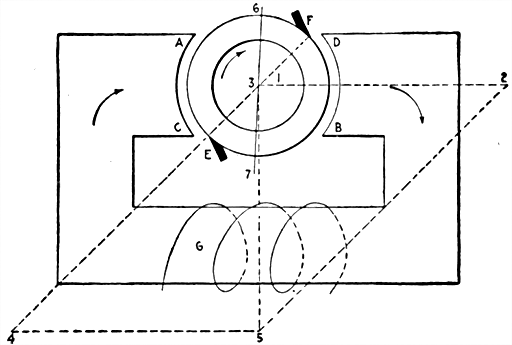

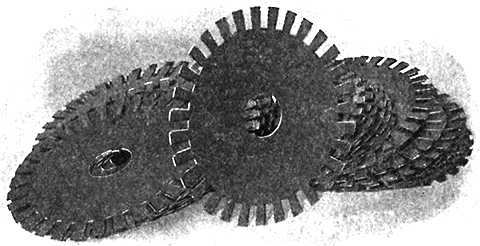

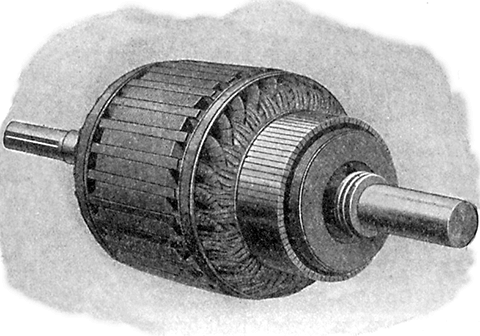

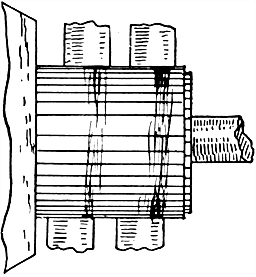

Before starting a dynamo--adjusting the brushes--brush position--how to set the brushes--method of soldering cable to carbon brush--brush contact pressure--direction of rotation--method of winding cables with marlin--method of assembling core discs--starting a dynamo--tinning block for electric soldering tool--shunt dynamos in parallel--shunt dynamos on three wire system--how to start a series machine--the term "build up"--how to start a shunt or compound machine--"picking up"--indication of reversed connections--how to correct reversed polarity--finding the reversed coil--loss of residual magnetism--remedy for reversed dynamo--attention while running--lead of brushes--method of taking temperature--lubrication--oils--allowable degree of heating--attention to brushes and brush gear.

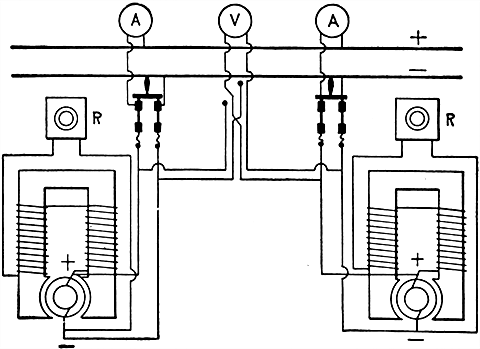

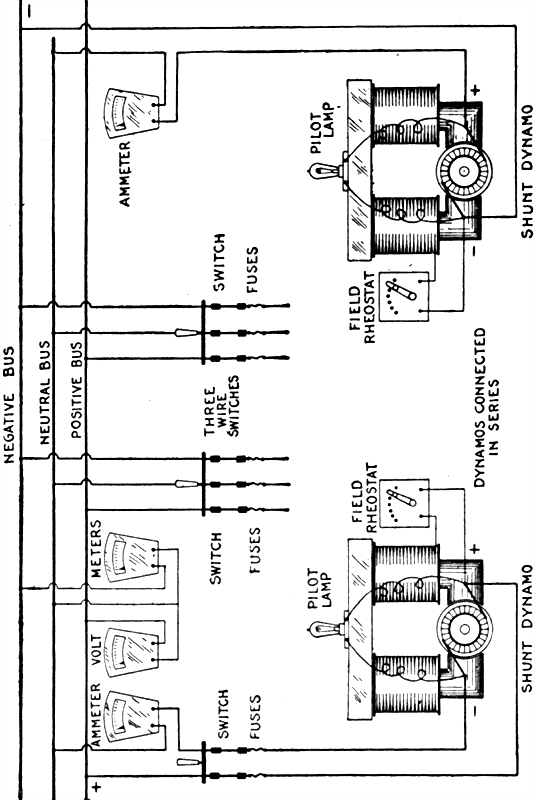

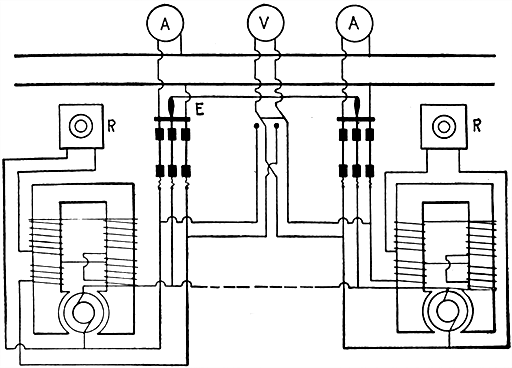

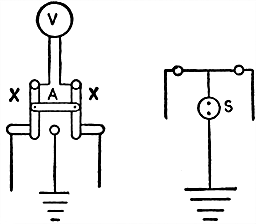

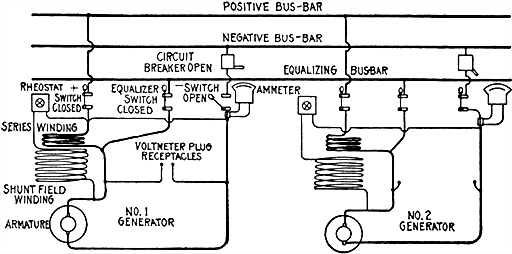

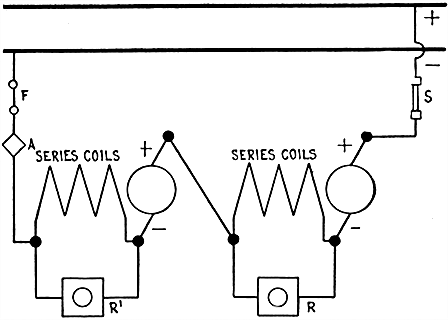

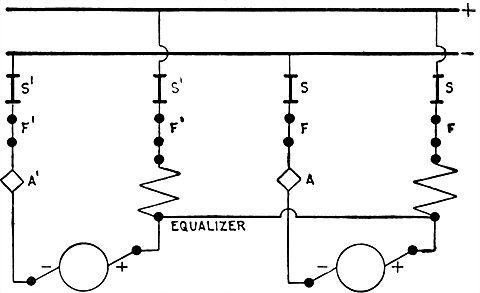

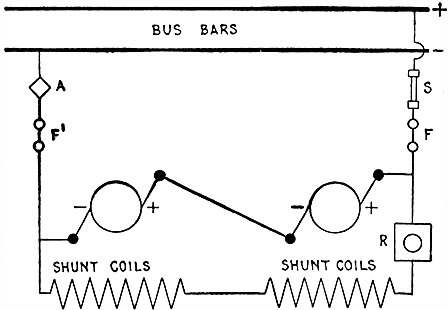

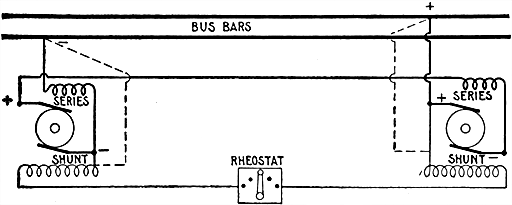

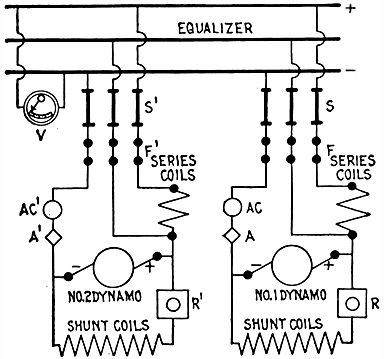

COUPLING OF DYNAMOS 597 to 610

Series and parallel connections--coupling series dynamos in series; in parallel--equalizer--shunt dynamos in series; in parallel--switching dynamo into and out of parallel--to cut out a machine--dividing the lead--compound dynamos in series; in parallel--equalizer connection--switching a compound dynamo into and out of parallel--equalizing the load--shunt and compound dynamos in parallel.

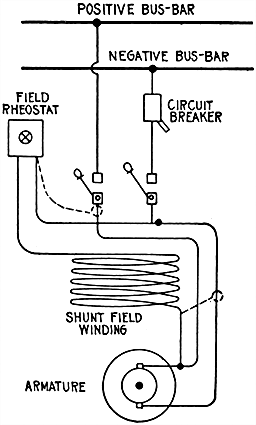

DYNAMO FAILS TO EXCITE 611 to 622

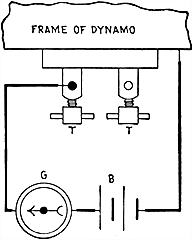

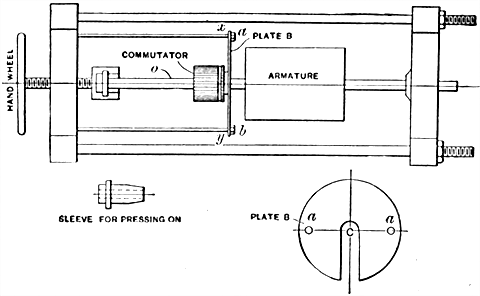

Various causes--brushes not properly adjusted--defective contacts--incorrect adjustment of regulators--speed too low--testing for break--insufficient residual magnetism; remedy--open circuits--test for field circuit breakers--probable location of breaks--Watson armature discs--Fort Wayne commutator truing device--short circuits--Watson armature--wrong connections--reversed field magnetism.

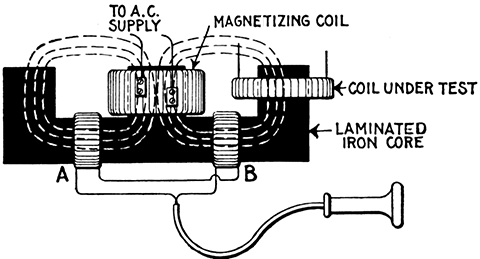

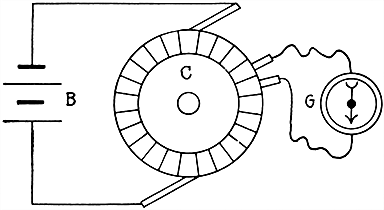

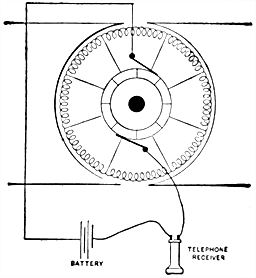

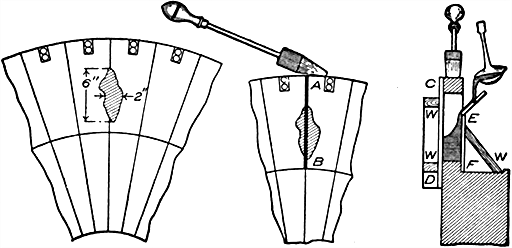

Causes--how avoided--various faults--short circuit in individual coils--location of faulty coil--test for break in armature lead--bar to bar test for open or short circuit in coil or between segments--short circuits between adjacent coils--alternate bar test for short circuits between sections--short circuits between sections through frame or core of armature; between sections through binding wires--partial short circuits in armatures--method of testing for breaks--burning of armature coils--Watson field coils--grounds in armatures--method of locating grounded armature coil--magneto test for grounded armatures--method of binding armature winding--breaks in armature circuit.

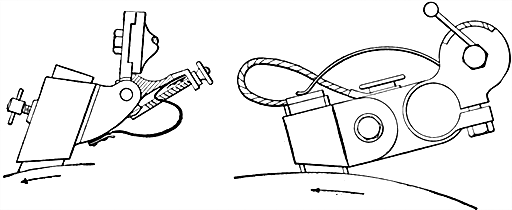

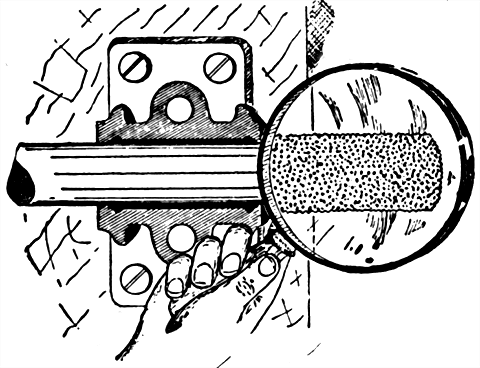

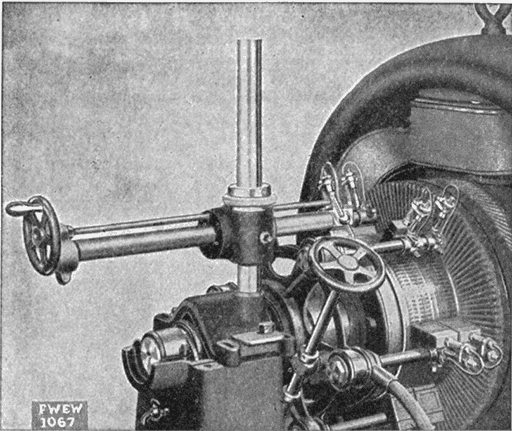

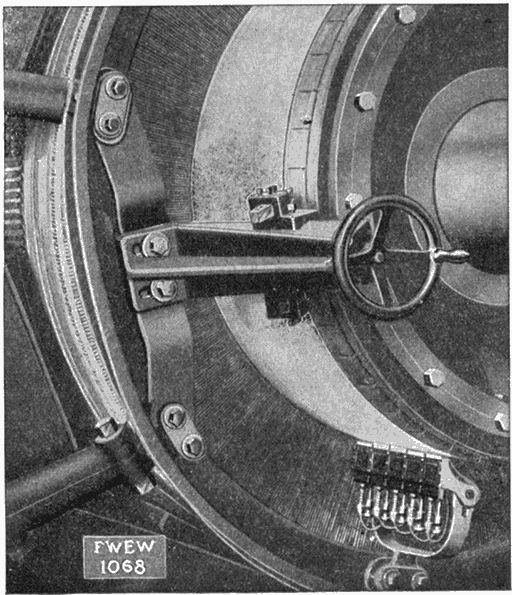

CARE OF THE COMMUTATOR AND BRUSHES 635 to 652

Conditions for satisfactory operation--oil for commutator--attention to brushes--Bissell brush gear--two kinds of sparking--commutator clamp--causes of sparking--bad adjustment of brushes--rocking--bad condition of brushes--brushes making bad contact--bad condition of commutator--detection of untrue commutator--high segments--"flats"--causes of flats; remedy--method of repairing broken joint between commutator segment and lug--segments loose or knocked in--how to re-turn a commutator--Bissell commutators--overload of dynamo--method of repairing large hole burned in two adjacent bars of a commutator--operating dynamos with metal brushes--indication of excessive voltage--method of smoothing commutator with a stone--causes of excessive voltage--loose connections, terminals, etc.,--breaks in armature circuit--sandpaper holder for commutator--short circuits, in armature circuits; in field--breaks in field--sandpaper block--short circuits in commutator.

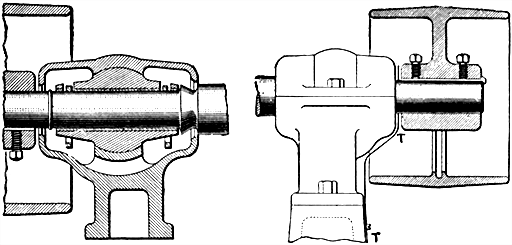

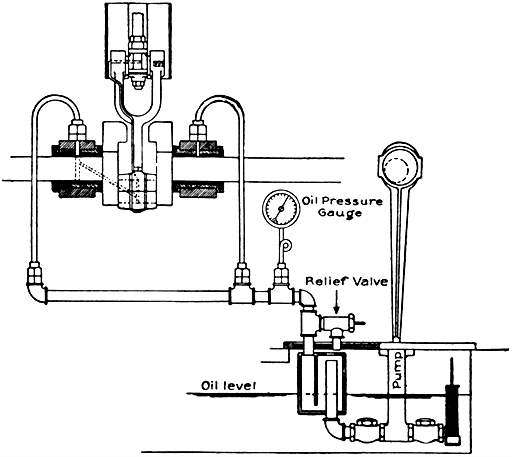

Various causes--how detected--procedure--heating, of connections; of brushes, commutator and armature--excessive heating--ventilated commutator--self-oiling bearing--some causes of hot bearing--effect of hot bearings--points relating to hot bearings--operation above rated voltage and below normal speed--forced system of lubrication--heating of field magnets--causes of eddy currents in pole pieces--detection of moisture in field coils--indication of short circuits in field coils.

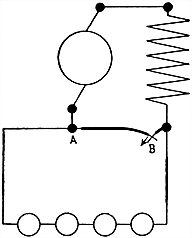

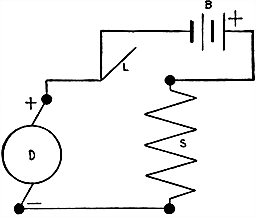

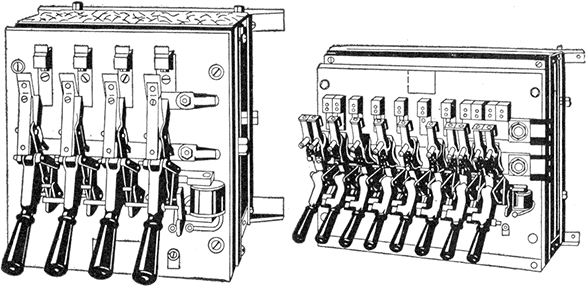

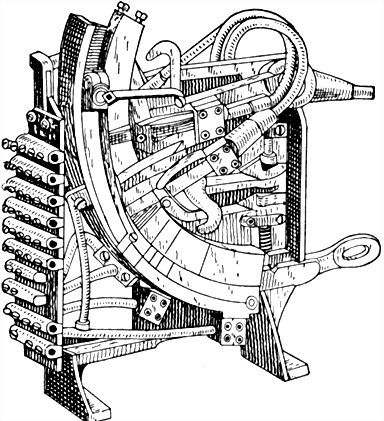

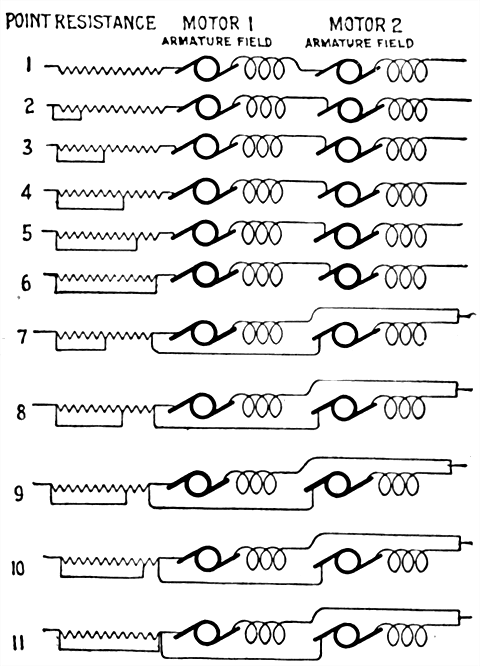

OPERATION OF MOTORS 663 to 696

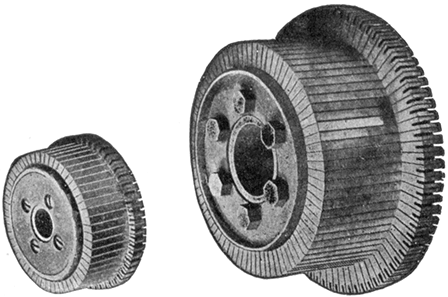

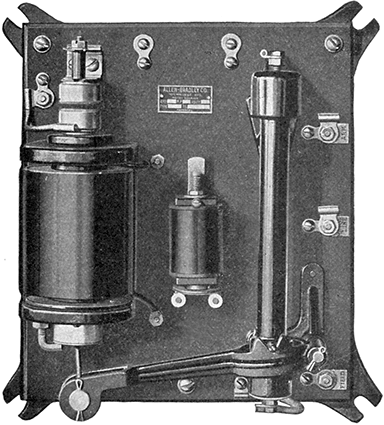

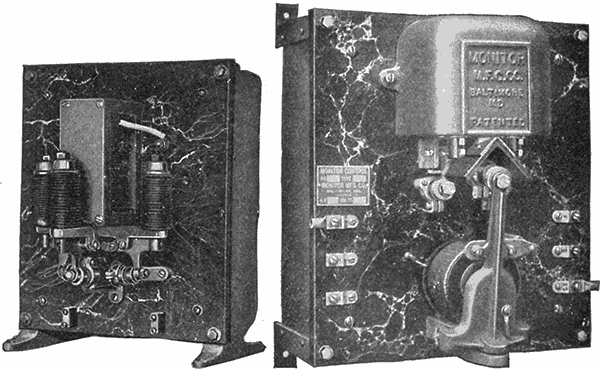

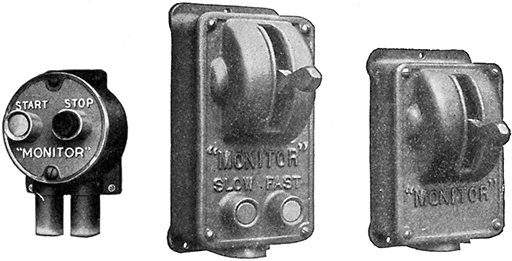

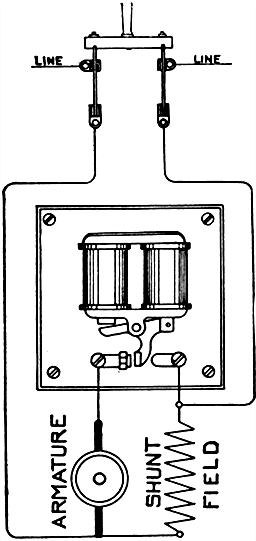

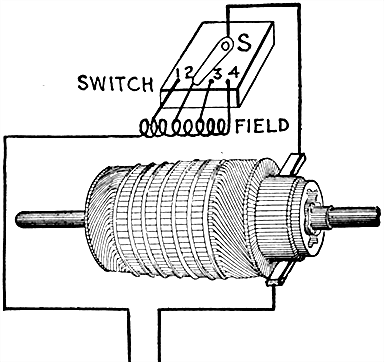

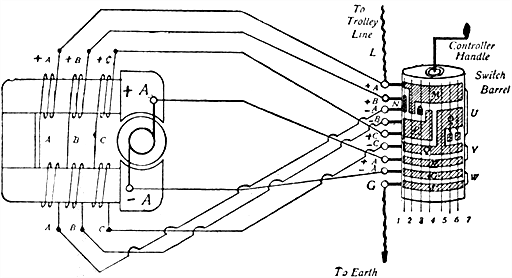

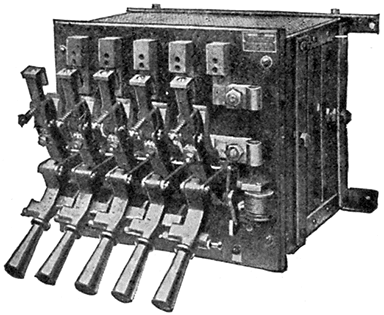

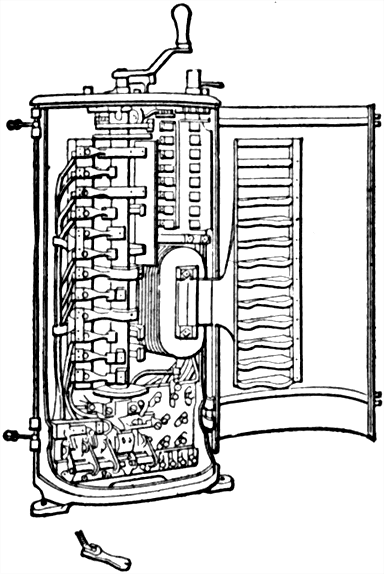

Before starting a motor--starting a motor--various starting resistances--starting boxes--speed regulators--Cutler Hammer starter--time required to start motor--how to start--sliding contact starters--series motors on battery circuits--starting a shunt motor--multiple switch starters--effect of reverse voltage--rheostat with no voltage and overload release--failure to start--starting panel--Cutler Hammer starting rheostats--Allen Bradley automatic starter--Monitor starter with relay for push button control--a remote control of shunt motors--regulation of motor speed; various methods--Monitor printing press controller--speed regulation of series motor, by short circuiting sections of the field winding--varying the speed of shunt and compound motors--Cutler Hammer multiple switch starter--regulation by armature resistance--Compound starter--regulation by shunt field resistance--Holzer Cabot instructions for shunt wound motor--Reliance adjustable speed motor--Cutler Hammer reversible starter--combined armature and shunt field control--selection of starters and regulators--Watson commutators--organ blower speed regulator--General Electric controller--speed regulation of traction motors--controller of the Rauch and Lang electric vehicles--two motor regulation--controller connection diagrams--stopping a motor.

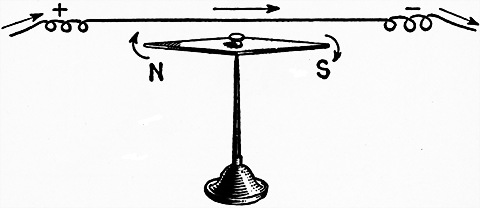

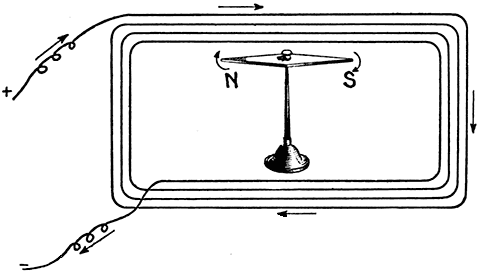

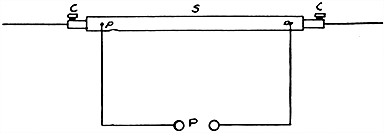

If a compass needle be allowed to come to rest in its natural position, and a current of electricity be passed through a wire just over it from north to south, the north seeking end of the needle will be deflected toward the east. If the wire be placed under the needle and the current continued from north to south the needle will be deflected toward the west. Again, if the current be passed from north to south over the needle, and back from south to north under the needle, as shown in fig. 504, the magnetic effect will be doubled, and the needle deflected proportionately. Upon these phenomena depend the working of galvanometers.

Fig. 503.--Effect of neighboring current upon a magnetic needle. Above the needle and parallel to it is a conductor carrying an electric current, the current flowing in the direction indicated by the arrow. This causes the north pole of the needle to turn toward the east. If the conductor be held below the needle, its north pole will turn in the opposite direction or toward the west. These movements are easily determined by Ampere's rule as follows: If a man could swim in the conductor with the current, and turn to face the needle, then the north pole of the needle will be deflected toward his left hand.

[432] Ques. Describe a simple galvanometer.

Ans. It consists essentially of a magnetic needle suspended within a coil of wire, and free to swing over the face of a graduated dial.

Ques. What is a galvanoscope and how does it differ from a galvanometer?

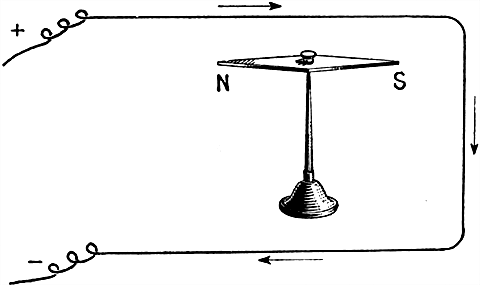

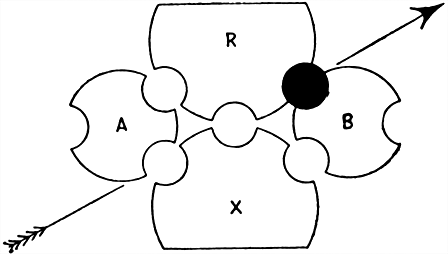

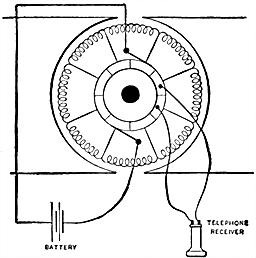

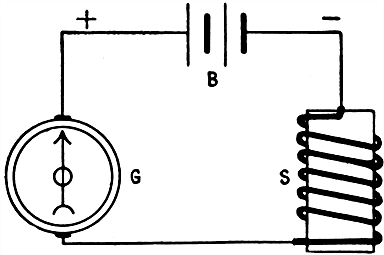

Ans. A galvanoscope, as shown in fig. 504, serves merely to indicate the presence of an electric current without measuring its strength. It is an indicator of currents where the movement of the needle shows the direction of the current, and indicates whether it is a strong or a weak one. When the value of the readings has been determined by experiment or calculation any galvanoscope becomes a galvanometer.

Fig. 504.--Effect upon a magnetic needle of a neighboring current in a loop. In this arrangement the same conductor is simply carried back beneath the needle and hence both the upper and lower portions tend to turn it in the same direction, while the side branch or vertical section is ineffective. In accordance with Ampere's swimming rule, the upper wire causes the N pole of the needle to turn to the left, while if a man can imagine himself swimming in the lower wire in the direction of the current, and facing the needle (that is, swimming on his back), the N pole of the needle will turn to his left--that is to the east. The effect of the loop then has double the effect of the single wire in fig. 503.

[433] Ques. For what use are galvanometers employed?

Ans. They are used for detecting the presence of an electric current, and for determining its direction and strength.

Ques. How is the direction and strength of the current indicated?

Ans. When a galvanometer is connected in a circuit, the direction of the current is indicated by the side towards which the north pole of the needle moves, and the current strength by the extent of the needle's deflection.

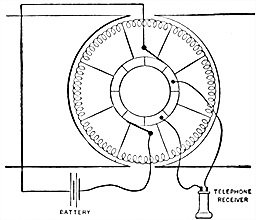

Fig. 505.--Effect upon a magnetic needle of a neighboring current in a coil. The coil as shown, is equivalent to several loops, that is, the force tending to deflect the needle is equal to that of a single loop multiplied by the number of turns. Hence, by using a coil with a large number of turns, a galvanometer may be made very sensitive so that the needle will be perceptibly deflected by very feeble currents. An instrument, as shown in the figure is called a galvanoscope. When it is accurately constructed, and supplied with a scale showing how many degrees the needle is deflected it is then called a galvanometer.

Ques. How should a galvanometer be set up before using?

Ans. When no current is flowing, the coil should be parallel to the magnetic needle when at rest.

[434] Ques. What is a "sensitive" galvanometer?

Ans. One which requires a very small current or pressure to produce a stated deflection.

It does not follow that a galvanometer which is sensitive for current measurement will also be sensitive for pressure measurement.

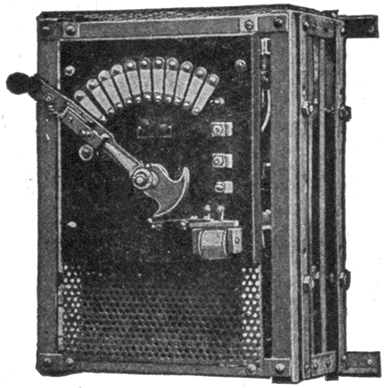

Fig. 506.--Bunnell simple detector galvanometer. It has middle clamps and scale divided into degrees.

Ques. Define the term "sensibility."

Ans. With reference to mirror reflecting galvanometers it may be defined in three ways. First, in megohms, the sensibility being the number of megohms through which one volt will produce a deflection of one millimeter with the scale at one meter distance. Second, in micro-volts, the sensibility being the number of micro-volts which applied directly to the terminals of the galvanometer will produce a deflection of one millimeter on a scale one meter from mirror. The sensibility is best stated in megohms for high resistance galvanometers and in micro-volts for low resistance galvanometers, and is frequently given both for galvanometers for intermediate resistance. Third, in [435] micro-amperes, the sensibility being the number of micro-amperes that will give one millimeter deflection with scale at a distance of one meter.

Ques. Upon what does the sensibility depend?

Ans. 1, Upon the number of times the current circulates around the coil, 2, the distance of the needle from the coil, 3, the weight of the needle, 4, the current strength, and 5, the amount of friction produced by its movement.

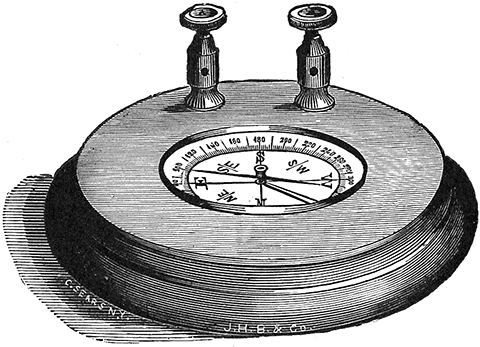

Fig. 508.--Bunnell horizontal galvanometer. It has two coils, one of which is of zero resistance and one of fifty ohms resistance adapting it to a variety of test.

The needle is usually quite small, and often a compound one. In very sensitive galvanometers, the coils are wound with thousands of turns of very fine wire, and shunts are generally used in connection with them.

NOTE.--Strong currents must not be passed through very sensitive galvanometers, for even if they be not ruined, the deflections of the needle will be too large to give accurate measurements. In such cases the galvanometer is used with a shunt, or coil of wire arranged so that the greater part of the current will flow through it, and only a small portion through the galvanometer.

Ques. What two kinds of coil are used?

Ans. The short coil and the long coil.

[436] Ques. What is the difference between a short coil and a long coil galvanometer?

Ans. A short coil galvanometer has a coil consisting of a few turns of heavy wire; a long coil galvanometer is wound with a large number of turns of fine wire.

Fig. 509.--Bunnell galvanometer for measurements of instruments, lines, batteries, wires and any object from 1/100 to 10,000 ohms or more.

Ques. What is the action of short and long coil galvanometers?

Ans. With a given current, the total magnetizing force which deflects the needle is the same, but with a short coil, it is produced by a large current circulating around a few turns, instead of a small current circulating around thousands of turns as in the long coil. The short coil being of low resistance is used to measure the current, and the long coil with high resistance, is suitable for measuring the pressure. Hence, a short coil instrument with its scale directly graduated in amperes is an ammeter, and the long coil type with graduation in volts is a voltmeter.

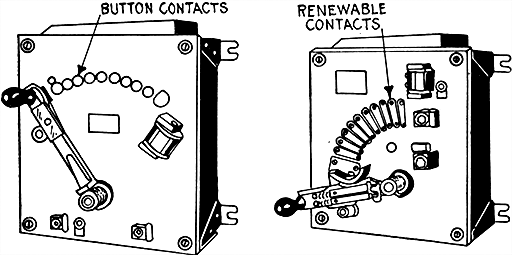

[437] Classes of Galvanometer.--There are numerous kinds of galvanometer designed to meet the varied requirements. According to construction, galvanometers may be divided into two classes, as those having:

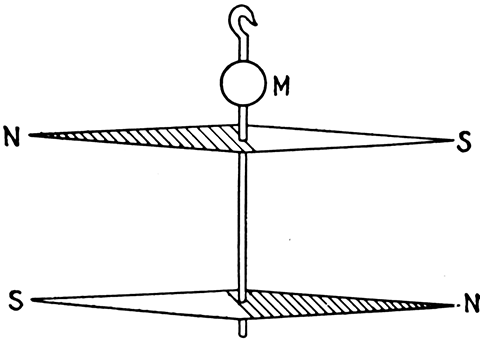

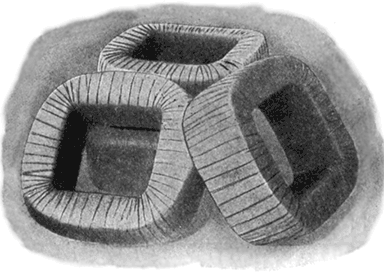

Fig. 510.--Astatic needles. Two magnetic needles of equal moment are mounted in opposition on a light support. The whole system is suspended by a delicate fibre, and when placed in a uniform magnetic field such as that of the earth, there will be no tendency to assume any fixed direction, the only restraining influence on the needles being that due to torsion in the suspension fibre.

Either type may be constructed with short or long coil, and there are several ways in which the deflections are indicated. The principal forms of galvanometer are as follows:

[438] Astatic Galvanometer.--It has been pointed out how a compass needle is affected when a wire carrying a current is held over or under it, the needle being turned in one direction in the first instance, and in the opposite direction for the second position of the wire.

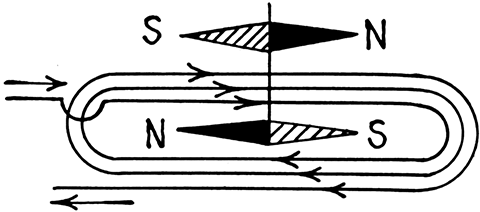

Fig. 511.--Connections of single coil astatic needles. The coil surrounds the lower needle and the direction of the current between the two needles tends to turn them the same way.

The earth's magnetism naturally holds the compass needle north and south. The magnetic field encircling the wire, being at right angles to the needle (when the wire itself is parallel therewith), operates to turn it from its normal position, north and south, so as to set it partially east and west. However, on account of the fact that the earth's magnetism does exert some force tending to hold the needle north and south, it is evident that no matter how strong the current, the latter can never succeed in turning the needle entirely east and west. The accomplishment of this is further prevented by the reason of the points of the needle, where the magnetic effect is greatest, quickly passing out of the reach of the magnetic field, where it is now practically operated on only in a slight degree. Thus it would take quite a powerful current to hold the needle deflected any appreciable distance. The use of a shorter needle is, therefore, more desirable.

[439] It is evident in this style of instrument that the effect of the current cannot be accurately measured, because it acts in opposition to the earth's magnetism, and as this is constantly varying, some method must be employed which will either destroy the earth's magnetism or else neutralize it.

In the astatic galvanometer, the earth's magnetism is neutralized by means of astatic needles. These consist of a combination of two magnetic needles of equal size and strength, connected rigidly together with their poles pointing in opposite and parallel directions, as shown in fig. 510. As the north pole of the earth attracts the south pole of one of the needles, it repels with equal strength the north pole of the other needle, hence, the combination is independent of the earth's magnetism and will remain at rest in any position.

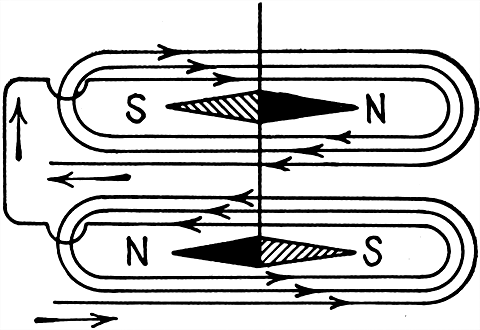

Fig. 512.--Connections of double coil astatic needles. With this arrangement, the direction of current in both coils will tend to turn the system in the same direction, making the needles more sensitive than with a single coil as in fig. 511.

If one of the needles be surrounded by a coil, as shown in fig. 511, the magnetic effect of the current will be correctly indicated by the deflection of the needle.

[440] Sometimes each needle is surrounded by a coil, as in fig. 512, the coils being so connected that the direction of current in each will tend to deflect the needles in the same direction.

Ques. For what use is the astatic galvanometer adapted?

Ans. For the detection of small currents.

It is used in the "nil" or zero methods, in which the current between the points to which the galvanometer is connected is reduced to zero.

Fig. 513.--Queen reflecting astatic galvanometer. It is mounted on a mahogany base with levelling screws. A plain mirror is attached above the upper needle. The entire combination of mirror and needles is suspended by unspun silk from the interior of a brass tube, which also carries a weak controlling magnet. A dial 4 inches in diameter and graduated in degrees, enables the deflections of the needle to be accurately read. The mirror can be used with a reading telescope and scale, or by means of a lantern, the image of a slit may be reflected from the mirror to a screen. Resistance, .5 to 1,000 ohms.

Ques. Upon what does the movement of the needles depend?

Ans. Upon the combined effect of the magnetic attraction of the current which tends to deflect the needles, and the torsion [441] in the suspension fibre which tends to keep the needle at the zero position.

Ques. Does the astatic galvanometer give correct readings for different values of the current?

Ans. When the deflections are small (that is, less than 10° or 15°), they are very nearly proportional to the strength of the currents that produce them.

Thus, if a current produce a deflection of 6° it is known to be approximately three times as strong as a current which only turns the needle through 2°. But this approximate proportion ceases to be true if the deflection be more than 15° or 20°.

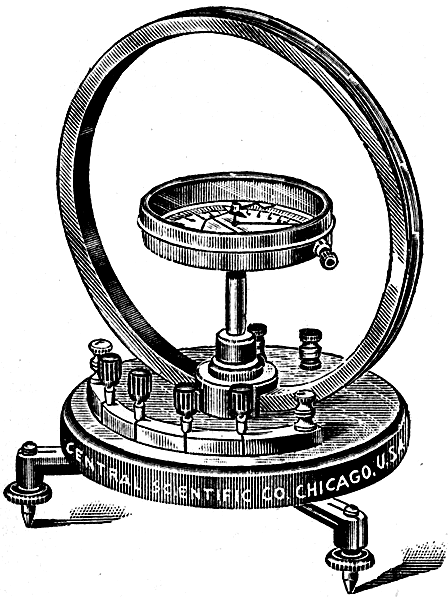

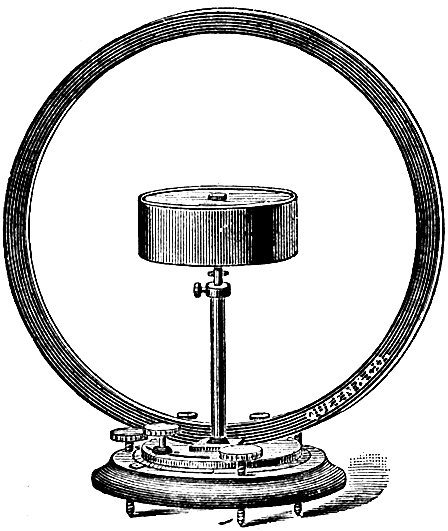

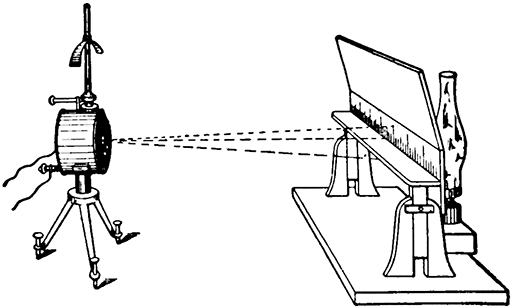

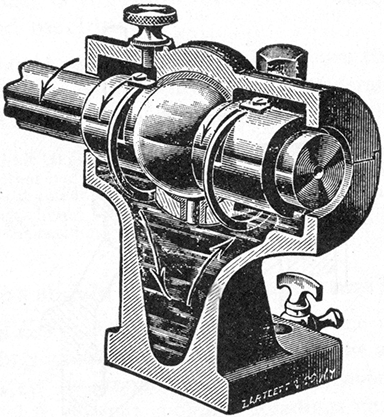

Fig. 514.--Central Scientific Co. tangent galvanometer. A 9 inch brass ring is mounted on a mahogany base which rotates on a tripod provided with levelling screws. The needle has an aluminum pointer and jewelled bearing. The winding consists of 300 turns of magnet wire so connected to the plugs in front that 20, 40, 80, or 160 turns or any combination of these numbers may be used. For heavy currents a band of copper is used by connecting to the extra pair of binding posts in the rear of the instrument.

Ques. Why does the instrument not give accurate readings for large deflections?

Ans. The needles are not so advantageously acted upon by the current, since the poles are no longer within the coils, but [442] protrude at the side. Moreover, the needles being oblique to the force acting on them, part only of the force is turning them against the directive force of the fibre; the other part is uselessly pulling or pushing them along their length.

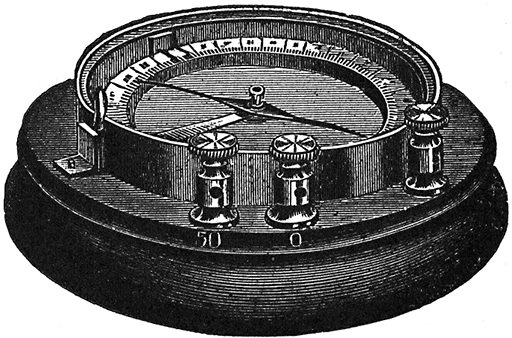

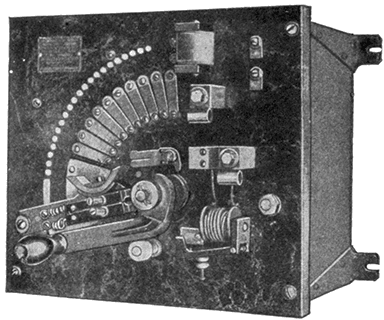

Fig. 515.--Bunnell tangent galvanometer. This instrument is mounted on a circular hard rubber base, 7-3/8 inches diameter, provided with levelling screws and anchoring points. The galvanometer consists of a magnetized needle 7/8 inch in length, suspended at the center of a rubber ring six inches in diameter, containing the coils. There are five coils of 0, 1, 10, 50 and 150 ohms resistance. The first is a stout copper band of inappreciable resistance; the others are of different sized copper wires, carefully insulated. Five terminals are provided, marked, respectively, 0, 1, 10, 50 and 150. The ends of the coils are so arranged that the plug inserted at the terminal marked 50 puts in circuit all the coils; marked at the terminal 50--all except the 150 ohm coil; and so on, till at the zero terminal only the copper band is in circuit. Fixed to the needle, which is balanced on jewel and point, is an aluminum pointer at right angles, extending across a five inch dial immediately beneath. One side of the dial is divided into degrees; on the other side, the graduations correspond to the tangent of the angles of deflection.

Ques. How may correct readings be obtained?

Ans. The instrument may be calibrated, that is, it may be ascertained by special measurements, or by comparison with a [443] standard instrument, the amounts of deflection corresponding to particular current strengths.

Thus, if it be once known that a deflection of 32° on a particular galvanometer is produced by a current of 1/100 of an ampere, then a current of that strength will always produce on that instrument the same deflection, unless from any accident the torsion force or the intensity of the magnetic field be altered.

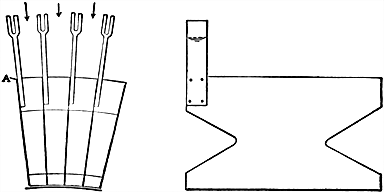

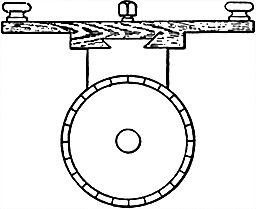

Fig. 516.--Tangent galvanometer. It consists of a short magnetic needle suspended at the center of a coil of large diameter and small cross section. In practice, the diameter of the coil is about 17 times the length of the needle. If the instrument be so placed that, when there is no current in the coil, the suspended magnet lies in the plane of the coil, that is, if the plane of the coil be set in the magnetic meridian, then the current passing through the coil is proportional to the tangent of the angle by which the magnet is deflected from the plane of the coil, or zero position--hence the name: "tangent galvanometer."

The Tangent Galvanometer.--It is not possible to construct a galvanometer in which the angle (as measured in degrees of arc) through which the needle is deflected is proportional throughout its whole range to the strength of the current. But it is possible to construct a very simple galvanometer in which the tangent of the angle of deflection shall be accurately proportional to the strength of the current.

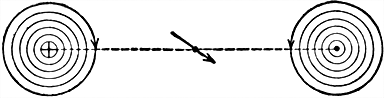

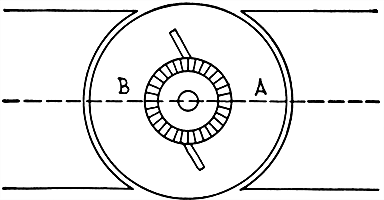

Fig. 517.--Horizontal section through middle of tangent galvanometer, showing magnetic whirls around the coil and corresponding deflection of needle.

A simple form of tangent galvanometer is shown in fig. 516. The coil of this instrument consists of a simple circle of stout copper wire from ten to fifteen inches in diameter. At the center is delicately suspended a magnetized steel needle not exceeding one inch in length, and usually furnished with a light index of aluminum. When the galvanometer is in use, the plane of the ring must be vertical and in the magnetic meridian. A horizontal section through the middle of the instrument is shown in fig. 517. For simplicity, the coil is supposed to have but a single turn of wire, the circles surrounding the wire representing the magnetic lines of force. By extending the lines of force until they reach the needle, it will be seen that with a short needle, the [445] deflecting force acts in an east and west direction when the galvanometer is placed with its coil in the magnetic meridian.

If, in fig. 518, ab represent the deflecting force acting on the N end of the needle, the component of this force that acts at a right angle to the needle will be

in which, x is the angle of the deflection.

The controlling force is

and when the needle is in equilibrium, the component ae = H sin x is equal and opposite to ac, hence

from which

Since ab is proportional to the current,

[446] in which k is a constant depending upon the instrument. For any other current C',

hence

This means that the currents passing through the coil of a tangent galvanometer are proportional, not to the angle of deflection, but to the tangent of that angle.

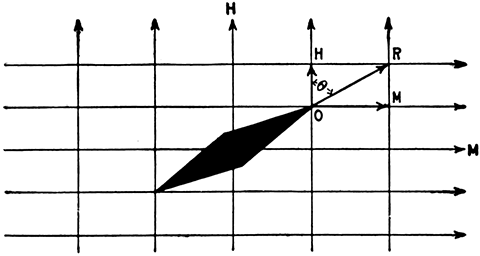

Fig. 519.--Diagram illustrating the tangent law. This is the law of the combined action of two magnetic fields upon a magnetic needle. If two magnetic fields be at right angles in direction as indicated in the figure, the resultant field is obtained by the parallelogram of forces and it makes an angle θ with one of the component fields such that tan θ = M + H where M and H are the strengths of the component fields. In the tangent galvanometer this principle is employed in the measurement of currents. A magnetic needle is pivoted in a field of known strength. The current to be measured is passed round a coil (or coils) which generates a field at right angles to the original field. The needle then lies along the direction of the resultant field, and by finding the tangent of its angle of deflection, and knowing the field strength produced by unit current in the coil, the current strength can be found.

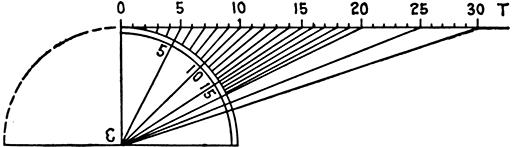

Fig. 520.--Graduation of tangent galvanometer scale with divisions representing tangent values. In the figure let a tangent OT be drawn to the circle, and along this line let any number of equal divisions be set off, beginning at O. From these points draw lines back to the center. The circle will thus be divided into a number of spaces, of which those near O are nearly equal, but which get smaller and smaller as they recede from O. These unequal spaces correspond to equal increments of the tangent. If the scale were divided thus, the readings would be proportional to the tangents.

Ques. Upon what does the sensibility of a tangent galvanometer depend?

Ans. It is directly proportional to the number of turns of the coil and inversely proportional to the diameter of the coil.

Ques. How may the tangent galvanometer be used as an ammeter?

Ans. The strength of the current may be calculated in amperes by the formula given below when the dimensions of the instrument are known.

The needle is supposed to be subject to only the earth's magnetism and to move in a horizontal plane. The current is calculated as follows:

amperes = ((H × r)/N) tan x(1)

[447] in which

The constant H, given in the following table represents the horizontal force of the earth's magnetism for the place where the galvanometer is used. Each value has been multiplied by (2π )/10 so that the formula (1) for amperes is correct as given.

Table of Galvanometer Constants.--Values of H.

| Boston | .699 |

| Chicago | .759 |

| Denver | .919 |

| Jacksonville | 1.094 |

| London | .745 |

| Minneapolis | .681 |

| New York | .744 |

| New Haven | .731 |

| Philadelphia | .783 |

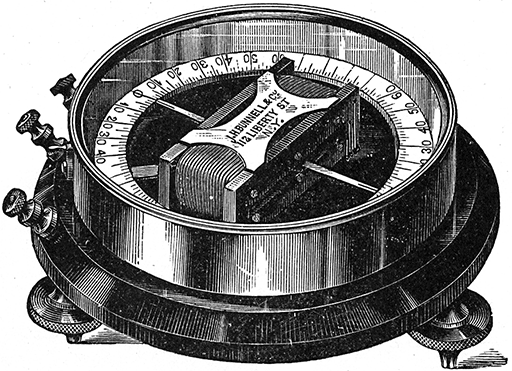

| Portland, Me. | .674 |

| San Francisco | 1.021 |

| St. Louis | .871 |

| Washington | .810 |

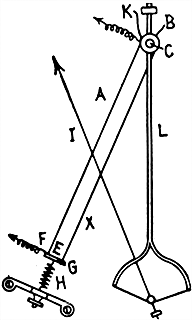

Fig. 521.--Mechanical explanation of the tangent law. Construct an apparatus as shown in the figure. The short wooden block, NS, represents the magnetic needle. This piece of wood turns around its center, C, which may be an ordinary nail. It will now be seen that two different forces act upon N; namely, the weight, G (one or two ounces), and the changeable weights which are placed in the scoop, W (made of cardboard). The height of the roll, or wheel, R, is such that the cord, RN, runs horizontally, when NS stands vertically, i.e., when there is no weight in the little scoop. If the wheel, R, be placed sufficiently far from NS, the string RN, will always remain almost horizontal, even if NS be deviated. The thin hand on NS moves over a vertical scale, which is divided into equal parts, as shown. This scale may be made of cardboard. If the hand point to division 1 when one ounce is placed in the scoop, it will point to 2 for two ounces, to 3 for three ounces, etc. At 45° the needle is deviated at its greatest angle, and this is, therefore, the sensitivity angle of the tangent galvanometer. The deviating values are, therefore, proportionate to the scale parts 01, 02, and 03, and so on; and, inasmuch as these themselves are tangents, the tangent law will hold good.

[448] Ques. How is the tangent galvanometer constructed to give direct readings?

Ans. To obviate reference to a table, the circular scale of the instrument is sometimes graduated into tangent values, as in fig. 520, instead of being divided into equal degrees.

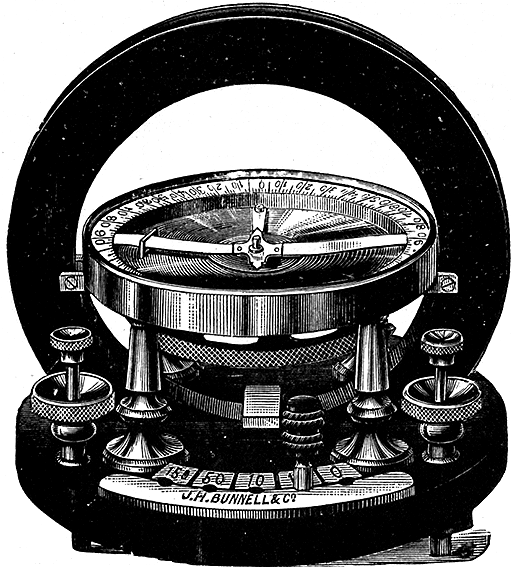

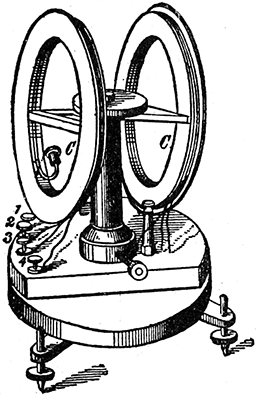

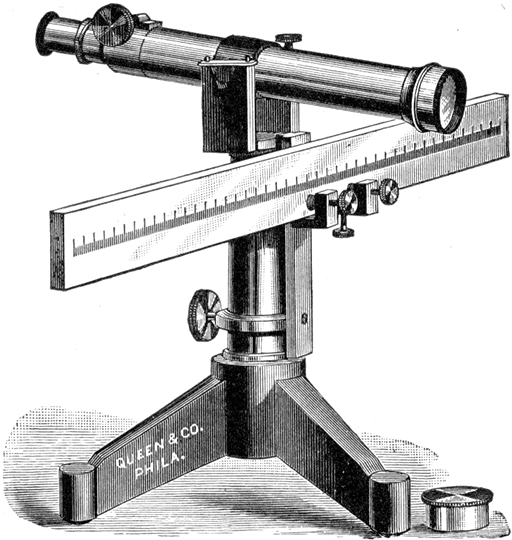

Fig. 522.--Queen tangent and sine galvanometer. This instrument properly adjusted can be used as a standard instrument for laboratory work. The brass ring is 12 inches in diameter, and the grooves in which the wire is wound are carefully turned so as to be of true rectangular cross section, thus allowing the constant of the instrument to be accurately calculated and compared with the constant as obtained by other methods. The compass box is 5 inches in diameter and is so held in position that it may be raised or lowered, rotated on its vertical axis, shifted out of the plane of the coil, etc., thus enabling the operator to acquire proficiency with the instrument and to meet all cases of derangement possible. The dial is graduated to single degrees, and the needle is suspended by a very light cocoon fibre. The whole instrument can be turned about its vertical axis, and a quadrant graduated in degrees upon the base allows the amount of rotation to be accurately measured, and the laws of the sine galvanometer investigated. The instrument is wound to measure .25 ampere to 8 amperes.

Ques. What is the objection to the scale with tangent values?

Ans. It is more difficult to divide an arc into tangent lines with accuracy than into equal degrees.

Ques. What disadvantage has the tangent galvanometer?

Ans. The coil being much larger than the needle, and hence far away from it, reduces the sensitiveness of the instrument.

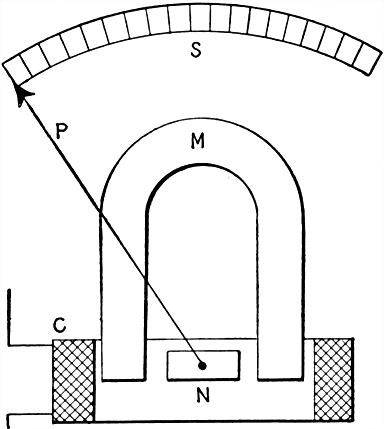

[449] The Sine Galvanometer.--This type of instrument has a vertical coil which may be rotated around a vertical axis, so that it can be made to follow the magnetic needle in its deflections.

In the sine galvanometer, the coil is moved so as to follow the needle until it is parallel with the coil. Under these circumstances, the strength of the deflecting current is proportional to sine of angle of deflection.

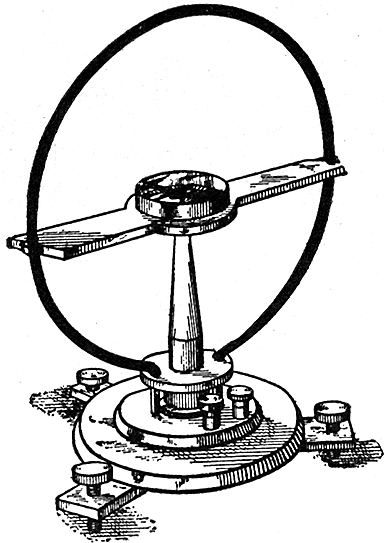

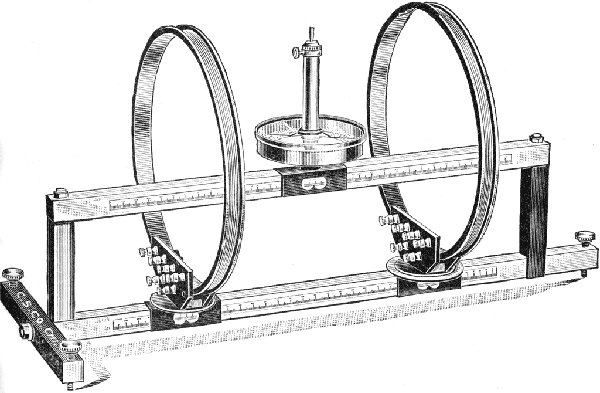

Fig. 523.--Central Scientific Co. universal tangent galvanometer. This instrument may be used as a tangent, Gaugain, Helmholtz-Gaugain, sine, cosine, Wiedemann or detector galvanometer. The coils, which slide on a beam parallel to the one carrying the needle box, are wound on brass rings 12 inches in diameter. On each ring are wound two coils of 48 turns each, connected to separate binding posts, and double wound so as to be of equal resistance. The coils and needle box are each provided with an indicator for reading their position on the scale. The needle box is swivelled and removable and one coil may be rotated about its vertical axis and its position read on a disc graduated in degrees. Currents may be measured ranging from .000002 ampere to 100 amperes.

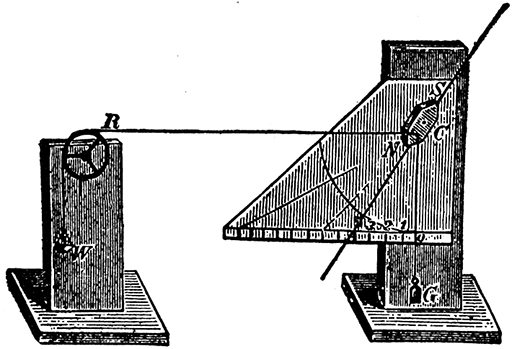

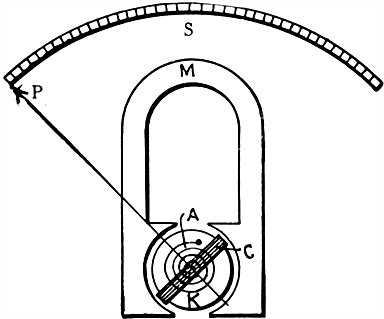

Ques. Describe the construction of a sine galvanometer.

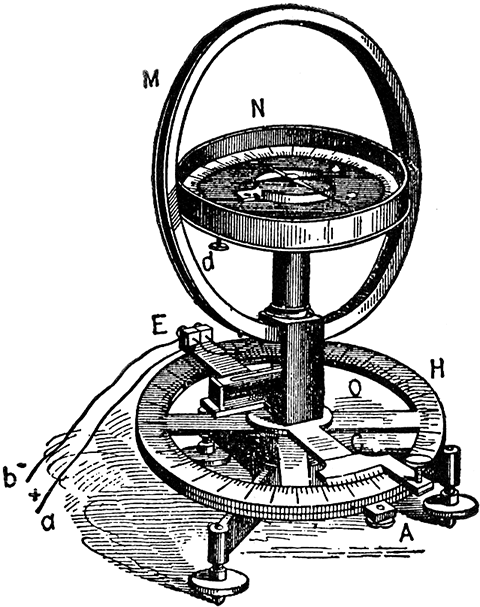

Ans. A form of sine galvanometer is shown in fig. 524. The vertical wire coil is seen at M. A needle of any length less than the diameter of the coil M, moves over the graduated circle N. The coil M, and graduated circle N may be rotated on a vertical [450] axis, and the amount of angular movement necessary to bring the needle to zero, measured on the graduated circle H.

Ques. How is the current strength measured?

Ans. It is proportional to the sine of the angle measured on the horizontal circle H, through which it is necessary to turn the coil M, from the plane of the earth's magnetic meridian to the plane of the needle when it is not further deflected by the current.

Fig. 524.--Sine galvanometer. It differs from the tangent galvanometer in that the vertical coil and magnetic needle are mounted upon a standard free to revolve around a vertical axis, with provision for determining the angular position of the coil. The needle may be of any length shorter than the diameter of the coil. In the figure the parts are: M, coil; N, graduated dial of magnetic needle; H, graduated dial by which the amount of rotation necessary to bring the needle to zero is measured; E, terminals of the coil; O, upright standard carrying coil and graduated dial of magnetic needle; C, base with levelling screws.

Ques. How is the sine galvanometer operated?

Ans. In using the instrument, after the needle has been set to zero, the current is sent through the coil, producing a deflection of the needle. The coil is then rotated to follow the motion [451] of the needle, the current being kept constant, the rotation being continued until the zero on the upper dial again registers with the needle. The current then is proportional to the sine of the angle through which the coil has been turned, as determined by the lower dial.

Ques. Has the sine galvanometer a large range?

Ans. For a given controlling field, it does not admit of a very large range of current measurement, since, for large deflection, on rotating the coil the position of instability is soon reached.

TABLE OF NATURAL SINES AND TANGENTS

| Angle | Sin. | Tan. |

| 0° | .0000 | .0000 |

| 1 | .0175 | .0175 |

| 2 | .0349 | .0349 |

| 3 | .0523 | .0524 |

| 4 | .0698 | .0699 |

| 5 | .0871 | .0875 |

| 6 | .1045 | .1051 |

| 7 | .1219 | .1228 |

| 8 | .1392 | .1405 |

| 9 | .1564 | .1564 |

| 10° | .1736 | .1763 |

| 11 | .1908 | .1944 |

| 12 | .2079 | .2126 |

| 13 | .2250 | .2309 |

| 14 | .2419 | .2493 |

| 15 | .2588 | .2679 |

| 16 | .2756 | .2867 |

| 17 | .2924 | .3057 |

| 18 | .3090 | .3249 |

| 19 | .3256 | .3443 |

| 20° | .3420 | .3640 |

| 21 | .3584 | .3839 |

| 22 | .3746 | .4040 |

| 23 | .3907 | .4245 |

| 24 | .4067 | .4452 |

| 25 | .4226 | .4663 |

| 26 | .4384 | .4877 |

| 27 | .4540 | .5095 |

| 28 | .4695 | .5317 |

| 29 | .4848 | .5543 |

| 30° | .5000 | .5774 |

| 31 | .5150 | .6009 |

| 32 | .5299 | .6249 |

| 33 | .5446 | .6494 |

| 34 | .5592 | .6745 |

| 35 | .5736 | .7002 |

| 36 | .5878 | .7265 |

| 37 | .6018 | .7536 |

| 38 | .6157 | .7813 |

| 39 | .6293 | .8098 |

| 40° | .6428 | .8391 |

| 41 | .6561 | .8693 |

| 42 | .6691 | .9004 |

| 43 | .6820 | .9325 |

| 44 | .6947 | .9657 |

| 45 | .7071 | 1.0000 |

| 46 | .7193 | 1.0355 |

| 47 | .7314 | 1.0724 |

| 48 | .7431 | 1.1106 |

| 49 | .7547 | 1.1504 |

| 50° | .7660 | 1.1918 |

| 51 | .7771 | 1.2349 |

| 52 | .7880 | 1.2799 |

| 53 | .7986 | 1.3270 |

| 54 | .8090 | 1.3764 |

| 55 | .8192 | 1.4281 |

| 56 | .8290 | 1.4826 |

| 57 | .8387 | 1.5399 |

| 58 | .8480 | 1.6003 |

| 59 | .8572 | 1.6643 |

| 60° | .8660 | 1.7321 |

| 61 | .8746 | 1.8040 |

| 62 | .8829 | 1.8807 |

| 63 | .8910 | 1.9626 |

| 64 | .8988 | 2.0503 |

| 65 | .9063 | 2.1445 |

| 66 | .9135 | 2.2460 |

| 67 | .9205 | 2.3559 |

| 68 | .9272 | 2.4751 |

| 69 | .9339 | 2.6051 |

| 70° | .9397 | 2.7475 |

| 71 | .9455 | 2.9042 |

| 72 | .9511 | 3.0772 |

| 73 | .9563 | 3.2709 |

| 74 | .9613 | 3.4874 |

| 75 | .9659 | 3.7321 |

| 76 | .9703 | 4.0108 |

| 77 | .9744 | 4.3315 |

| 78 | .9781 | 4.7046 |

| 79 | .9816 | 5.1446 |

| 80° | .9848 | 5.6713 |

| 81 | .9877 | 6.3138 |

| 82 | .9903 | 7.1154 |

| 83 | .9925 | 8.1443 |

| 84 | .9945 | 9.5144 |

| 85 | .9962 | 11.43 |

| 86 | .9976 | 14.30 |

| 87 | .9986 | 19.08 |

| 88 | .9994 | 28.64 |

| 89 | .9998 | 57.29 |

Ques. What is the position of instability?

Ans. The position of the needle beyond which the rotation of the coil will cause it to turn all the way round.

Ques. How may the range be increased?

Ans. By an adjustable controlling field or a shunt.

[452] Ques. What advantage has the sine galvanometer over the tangent instrument?

Ans. Its advantage is in the case where the relative values of two or more currents are required to be measured, or where the constant of the instrument is obtained by comparison with a standard measuring instrument and not calculated from the dimensions of the coil, because all galvanometers thus used follow the sine law independently of the shape of the coil, while only circular coils will follow the sine law.

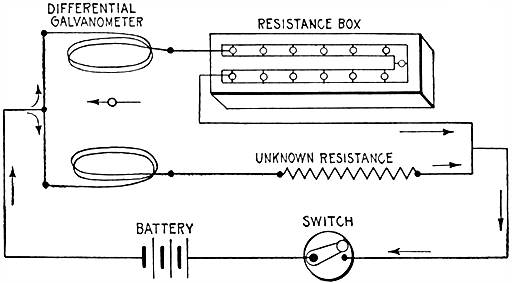

Fig. 525.--Differential galvanometer. It consists of two coils of wire, so wound as to have opposite magnetic effects on a magnetic needle suspended centrally between them. The needle of a differential galvanometer shows no deflection when two equal currents are sent through the coils in opposite directions, since, under these conditions, each coil neutralizes the effect of the other. Sometimes the current is so sent through the two coils, that each coil deflects the needle in the same direction. In this case the instrument is no longer differential in action. If, when this condition obtains, the magnetic needle be suspended at the exact center of the line which joins the centers of the coils, the advantage is gained by obtaining a field of more nearly uniform intensity around the needle. When the needle is suspended by a silk fibre, a final and most delicate adjustment can be obtained by raising or lowering one of the levelling screws slightly, so as to tilt the needle nearer to or farther from one of the coils.

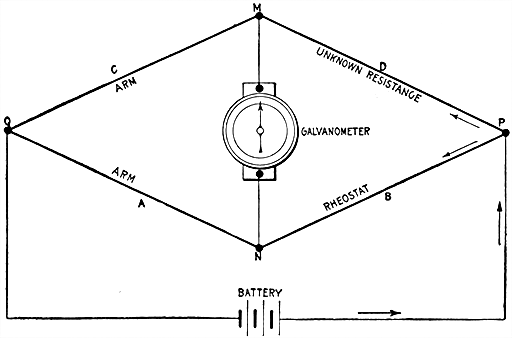

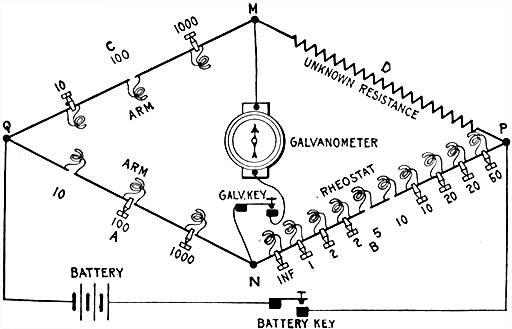

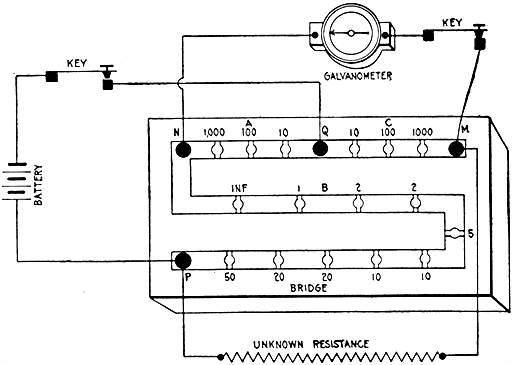

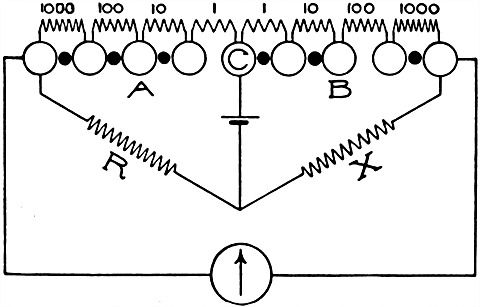

The Differential Galvanometer.--This is a form of galvanometer in which a magnetic needle is suspended between two coils of equal resistance so wound as to tend to deflect the needle in opposite directions. The needle of a differential galvanometer [453] shows no deflection when two equal currents are sent through the coils in opposite directions, since under these conditions, each coil neutralizes the other's effects. Such instruments may be used in comparing resistances, although the Wheatstone bridge, in most cases, affords a preferable method.

Ques. What is the special use of the differential galvanometer?

Ans. It is used for comparing two currents.

Ques. What is the method of comparing currents?

Ans. If two equal currents be sent in opposite directions through the coils of the galvanometer, the needle will not move; if the currents be unequal, the needle will be deflected by the stronger of them with an intensity corresponding to the difference of the strengths of the two currents.

Ques. How are the coils adjusted?

Ans. This is done by coupling them in series in such a way that they tend to turn the needle in opposite directions, and when a current is passing through them, they are moved nearer to the needle or farther from it until the needle stands at zero with any current.

If the coils be not movable, a turn or more can be unwound from the coil giving the greatest magnetic effect until a balance is obtained, the wire so unwound can then be coiled in the base of the instrument.

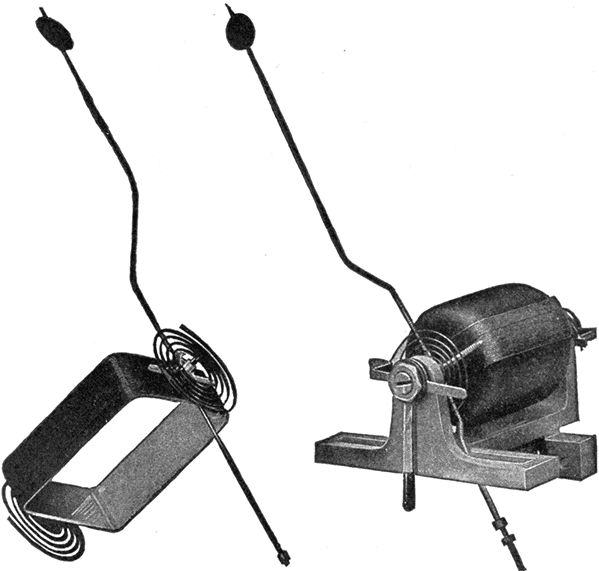

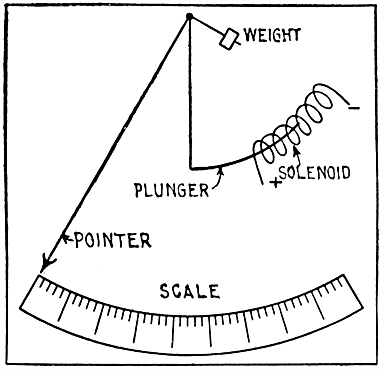

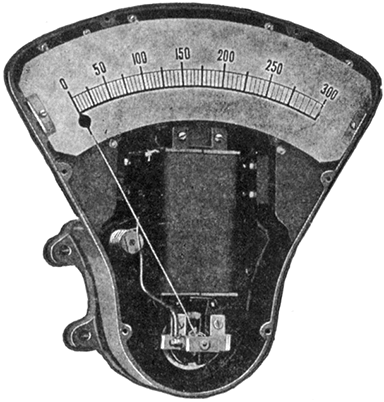

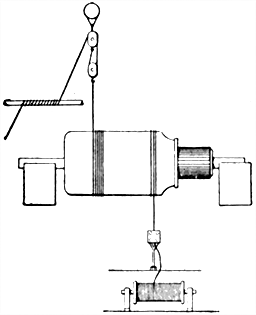

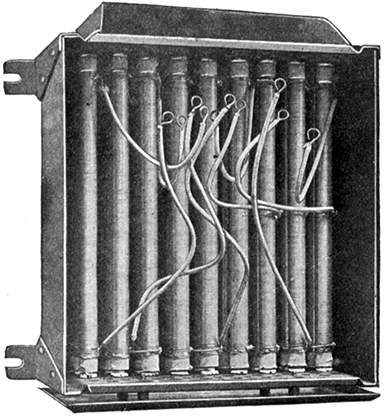

Ballistic Galvanometer.--This type of galvanometer is designed to measure the strength of momentary currents, such for instance, as the discharge of a condenser. In construction the magnetic system is given considerable weight, and arranged to give the least possible damping effect.

[454] The term "damping effect" means the offering of a retarding force to control swinging vibrations, such as the movements of a galvanometer needle, and to bring them quickly to rest.

If a momentary current be passed through a ballistic galvanometer, the impulse given to the needle does not cause appreciable movement to the magnetic system until the current ceases, owing to the inertia of the heavy moving parts, the result being a slow swing of the needle.

Fig. 526.--Queen dead beat and ballistic reflecting galvanometer. As illustrated, the coils are easily removable and enclose a heavy block of copper fixed in a central fork. In a cylindrical hole bored in this block hangs the bell magnet which with its mirror is suspended by a long cocoon fibre, and the eddy currents induced in the copper bring the system quickly to rest after a deflection. By lifting the copper block out of the frame the instrument is made ballistic. The instrument is made with coils of any desired resistance up to 1,000 ohms.

Ques. What name is given to the swing of a ballistic galvanometer needle?

Ans. It is called the kick.

Ques. How is the current measured?

Ans. As the needle swings slowly around it adds up, as it [455] were, the varying impulses received during the passage of the momentary current, and the quantity of electricity that has passed is proportional to the sine of half the angle of the first swing or kick.

If a reflecting method be used with a straight scale, the observed deflection depends upon the tangent of twice the angle of movement of the needle. For small deflections, however, the change of flux can be taken as directly proportional to the observed deflection.

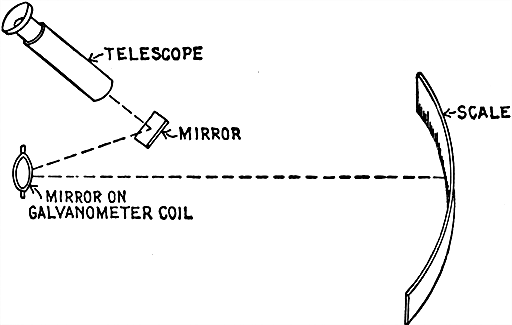

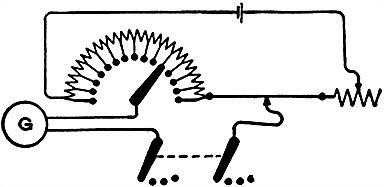

Fig. 527.--Thompson galvanometer with mirror reflecting system for reading the deflections of a galvanometer needle by the movements of a spot of light reflected from a mirror attached to the needle or movable magnetic system.

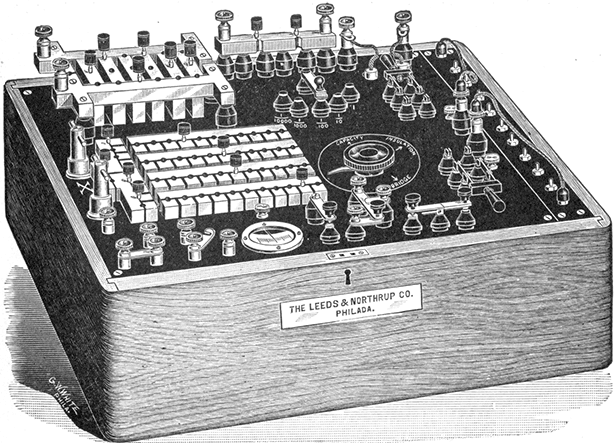

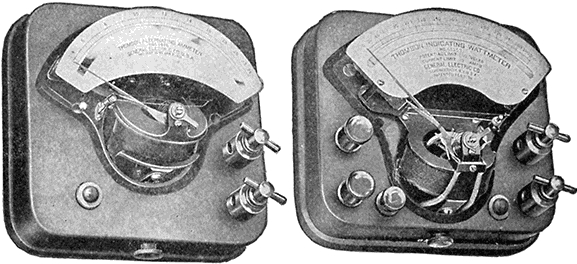

Use of Mirrors in Galvanometers.--In order that small currents may be measured accurately, some means must be provided to easily read a small deflection of the needle. Accordingly, it is desirable that the pointer be very long so that a large number of scale divisions may correspond to small deflections. In construction, since sensitive galvanometers must be made with the moving parts of little weight, it would not do to use a long needle, hence a ray of light is used instead, which is reflected on a distant scale by a small mirror attached to the moving part.

[456] In the Thompson mirror reflecting galvanometer, as shown in fig. 528, a small vertical slit is cut in the lamp screen below the scale, and the ray of light from the lamp, passing through the slit, strikes the mirror which is about three feet distant, and which reflects the beam back to the scale. It should be noted that the angle between the original ray of light and the reflected ray is twice the angle of the deflection of the mirror; the deflections of the ray of light on the scale, however, are practically proportional to the strength of currents through the instrument. The mirror arrangement as shown in fig. 528, requires a darkened room for its operation, but such is not necessary when a telescope is used as in fig. 529. Here the scale readings are reflected in the mirror and their value observed by the telescope without artificial light.

Fig. 528.--Telescope method of reading galvanometer deflections by reflection of scale reading in mirror. Here two mirrors are used, but in most cases the telescope is pointed directly toward the mirror on galvanometer shown in fig. 527, because the two mirror system, as illustrated in the figure, is used on portable galvanometers since it is the more compact.

Damping.--This relates to the checking or reduction of oscillations. Thus, a galvanometer is said to be damped when so constructed that any oscillations of the pointer which may be started, rapidly die away. Galvanometers are frequently provided with damping devices for the purpose of annulling these [457] oscillations, thus causing the moving part to assume its final position as quickly as possible.

Sometimes the instrument is fitted with a damping coil, or closed coil so arranged with respect to the moving system that the oscillations of the latter give rise to electric currents in the closed coil, whereby energy is dissipated. Again, air vanes are employed, but anything in the nature of solid friction cannot be used.

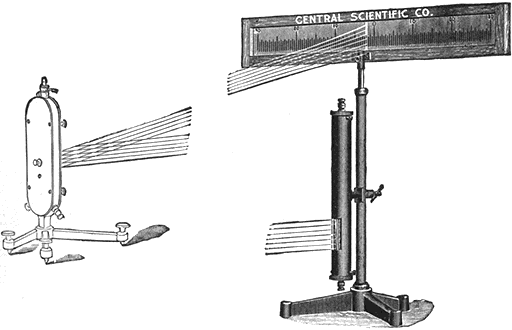

Figs. 529 and 530.--Galvanometer lamp and scale for individual use. The scale is etched on a ground glass strip 6 centimeters wide by 60 centimeters long with long centimeter divisions and short millimeter divisions the entire length, reading both ways from zero in the center. It is mounted in an adjustable wooden frame. A straight filament lamp (110 volts) is enclosed in a metal hood japanned black to cut out all reflected light. This form of filament makes a single brilliant line on the scale, enabling closer readings than the "spot of light" arrangement. The lamp hood is adjustable to any desired height on the support rod.

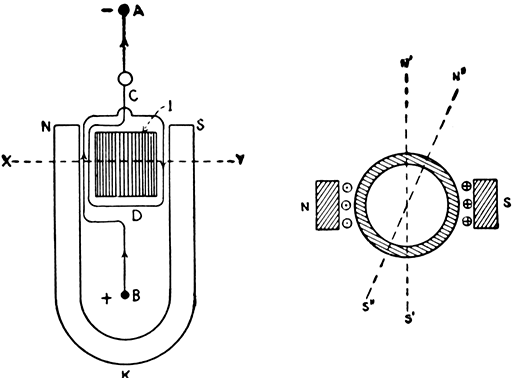

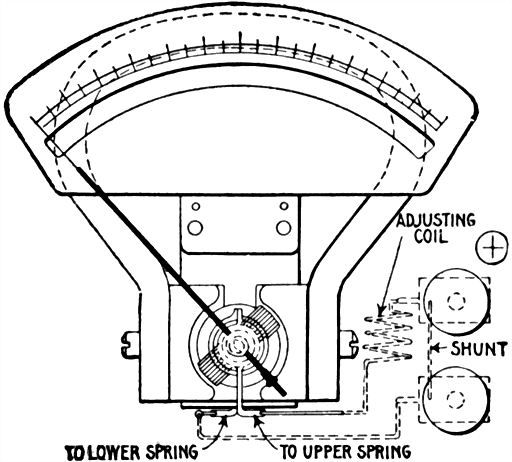

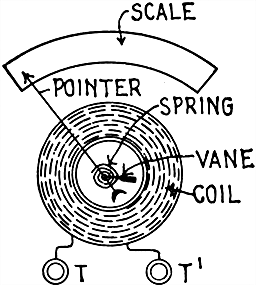

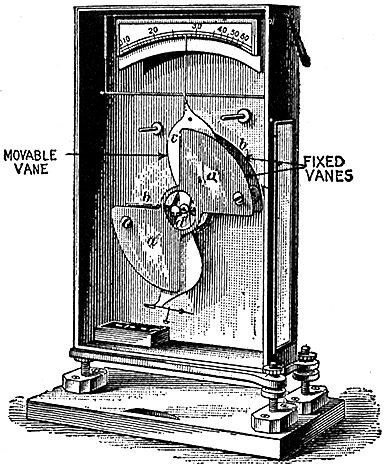

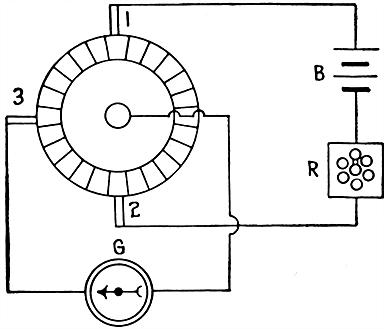

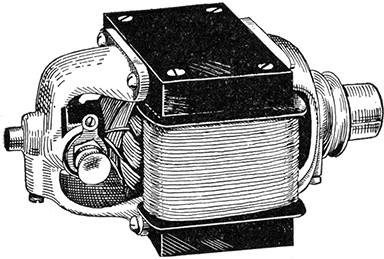

D'Arsonval Galvanometer.--This instrument has a movable coil in place of a needle, and its operation depends upon the principle that if a flat coil of wire be suspended with its axis perpendicular to a strong magnetic field, it will be deflected whenever a current of electricity passes through it.

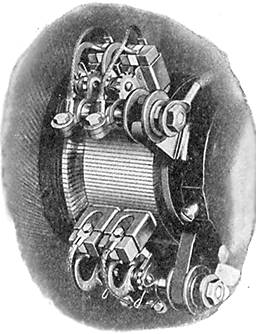

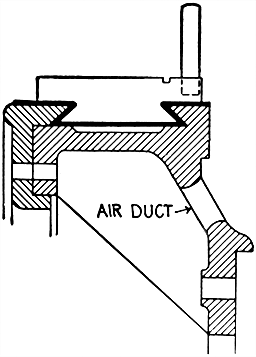

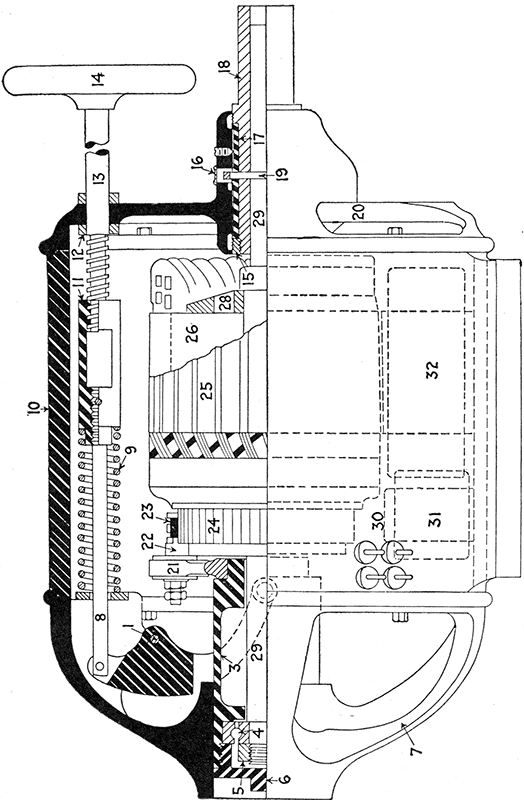

[458] Ques. Describe the construction of a D'Arsonval galvanometer.

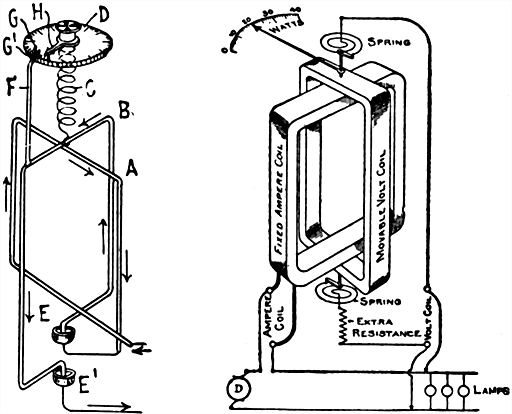

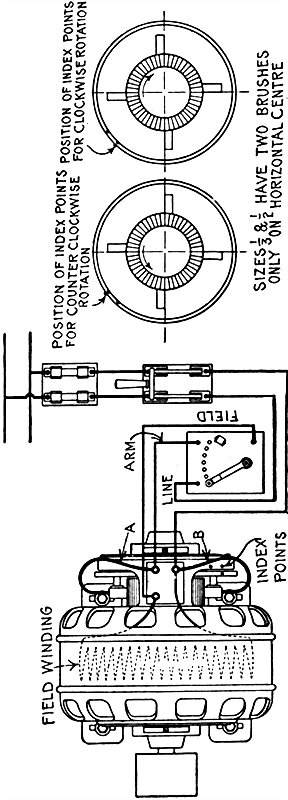

Ans. The essential features are shown in figs. 532 and 533. The coil, which is rectangular in section is wound upon a copper form, and suspended between a permanent magnet by fine wires to the points A and B. The magnet has its poles at N and S. It is a soft iron cylinder fixed between the poles in order to intensify the magnetic field across the air gaps in which the coil moves.

Fig. 531.--Queen reading telescope. This arrangement is utilized to measure the deflections of a galvanometer having suspended mirror moving system. It consists of a reading telescope mounted as illustrated with a millimeter scale, having a length of 50 centimeters. In use, the image of the scale is seen in the galvanometer mirror through the telescope. The eye piece of the telescope has a cross hair which acts as a reference line so that by noting the particular division on the scale when the galvanometer is at rest, the amount of deflection can be readily observed when the galvanometer is deflected. The instrument has all the necessary adjustments to set it up quickly and for bringing the cross hair and scale in focus. It is generally placed at a distance of one meter from the galvanometer mirror.

Ques. Explain its operation.

Ans. An enlarged horizontal cross section of the galvanometer on line XY is shown in fig. 533. The current is flowing in the coil as in fig. 532, up on the left side and down on the right. [459] The position of the coil when no current is flowing is indicated by n' s'. By applying the law of mutual action between magnetic poles, it is seen that when the current is applied, the poles developed at n' s' will move into the position n'' s''. See fig. 119.

Ques. How is the coil affected by a change in the direction of the current?

Ans. The polarity of the coil is reversed and consequently the direction of the deflection.

Figs. 532 and 533.--Diagrams showing essential features of construction and principle of operation of D'Arsonval galvanometer.

Ques. Upon what does the sensitiveness of the instrument depend?

Ans. Upon the strength of the field of the permanent magnet, the number of turns in the suspended coil, and the torsion of the wires by which it is suspended.

Ques. When is this galvanometer called "dead beat"?

Ans. When the construction is such that the moving part comes quickly to rest without a series of diminishing vibrations.

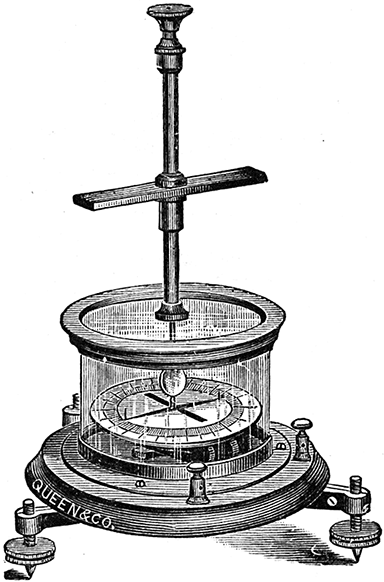

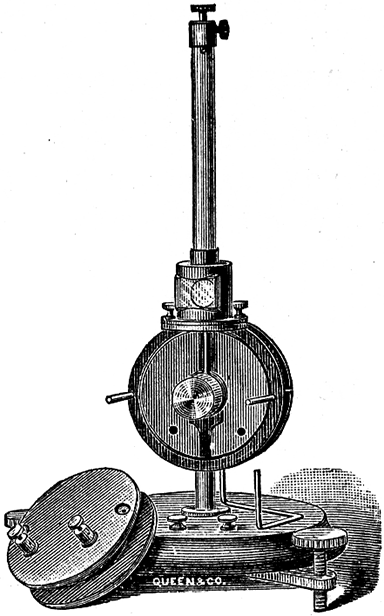

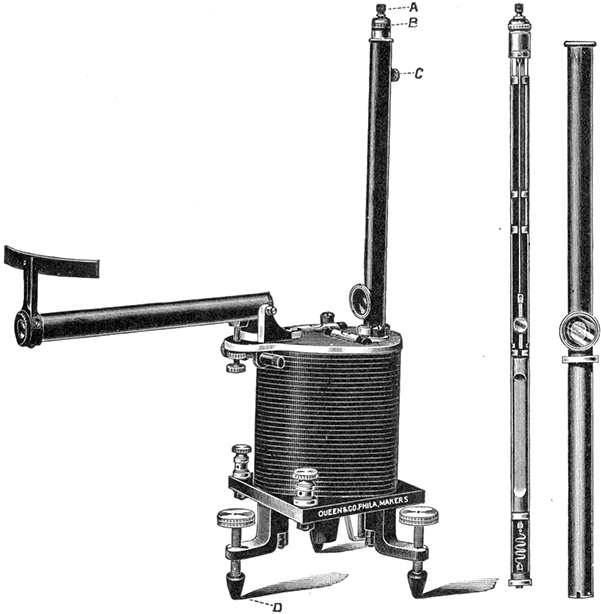

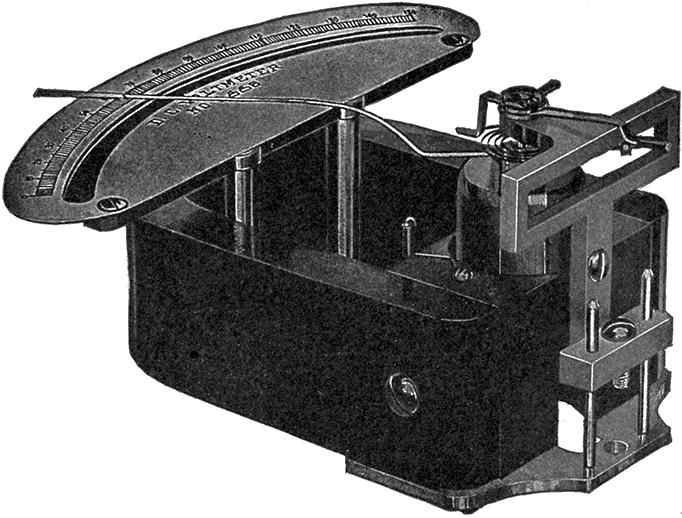

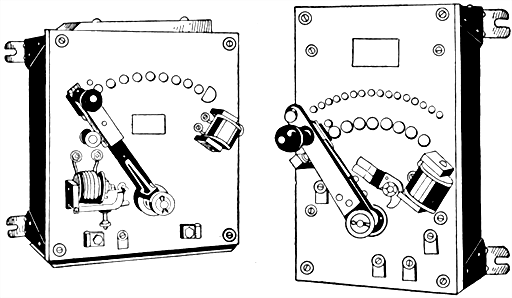

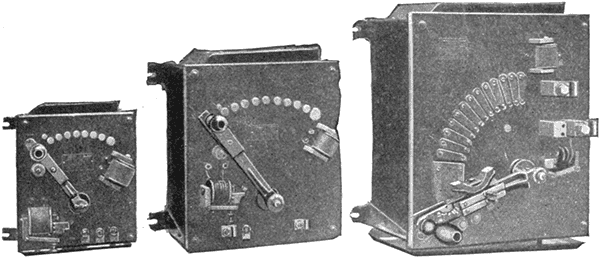

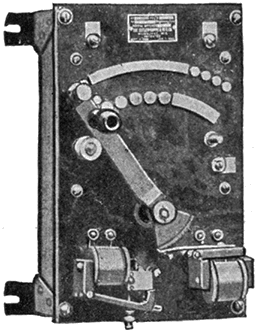

Figs. 534 to 536.--Queen horizontal magnet D'Arsonval galvanometer with telescope and scale. It is very sensitive and is used in many electrical measurements, including commercial testing, such as measuring insulation of cables, fault location, etc. It is not affected by surrounding magnetic disturbances, and may, therefore, be used in proximity to dynamos and switchboards. The instrument has a pair of binding post terminals, one of which connects to a bottom spiral of the system and the other forms a junction with the top of the tube holding the system, forming a complete circuit through the coil. The tube containing the system may be readily removed from the magnet and another tube having a different system inserted as is required for various kinds of electrical measurement. The entire system with its suspension may be inspected by the removal of a thumb screw. To inspect interior of tube first be sure that the screw B is turned so that the coil is clamped. Entirely remove screw C, and, holding the outside tube near the window, press firmly with the finger on the extreme top of the suspension support. The inside rib, with complete suspension, will draw from the tube, and the working parts can be fully inspected. Carefully return same to its original position in tube, setting tight the screw C. The galvanometer is designed so that the coil is clamped in position when the galvanometer must be transported. The insulation of the galvanometer terminals and binding posts is such as to guard against any possible leakage. As a further protection, each levelling screw is provided with a hard rubber insulator. This feature is essential since, in making insulation measurements, the operator wishes to be assured that the deflection being obtained is the result of leakage upon the cable or wire being measured and not leakage between the galvanometer terminals. The galvanometer is provided with an attached telescope and scale for noting the deflections. The deflections produced by this galvanometer are proportional to the current. To facilitate quickly setting up the instrument, two way levels are provided.

[461] Ques. What causes this?

Ans. The instrument is made dead beat by winding the coil on a copper or aluminum frame, so that when in operation, currents are induced in the frame by the motion of the coil in the magnetic field; these currents oppose the motion of the coil.

Ques. For what service is the D'Arsonval galvanometer adapted?

Ans. It is desirable for general use as it is not much affected by changes in the magnetic field. It may be made with high enough period and sensibility to be satisfactory as a ballistic instrument, but for extreme sensibility an instrument of the astatic type is more generally used.

Galvanometer "Constant" or "Figure of Merit."--In order that a galvanometer shall be of value as a measuring instrument, the relation between the current and the deflection produced by it must be known. This may be obtained experimentally by determining the value of the current required to produce one scale division. The galvanometer constant then may be defined as the resistance through which the galvanometer will give a deflection of one scale division when the current applied is at a pressure of one volt.

Accordingly, the deflection as indicated on the scale must be multiplied by its constant or figure of merit, in order to obtain the correct reading. If the scale readings be not directly proportional to the quantity to be measured, the law of the instrument must also be considered.

Thus in a tangent galvanometer as previously explained

where I = current, φ the deflection or scale reading, and K the galvanometer constant.

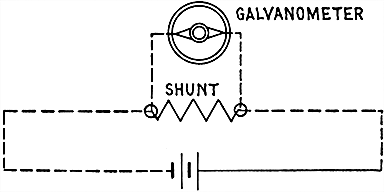

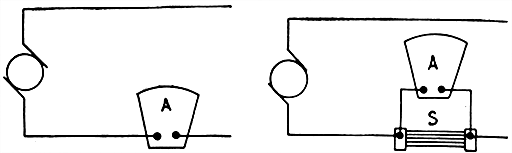

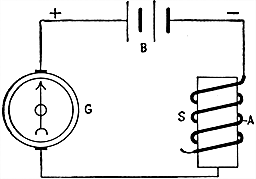

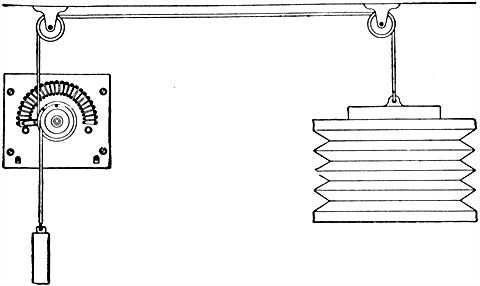

Fig. 537.--Diagram showing method of connecting galvanometer shunt. By the use of a shunt the range of measurement of a galvanometer can be greatly increased.

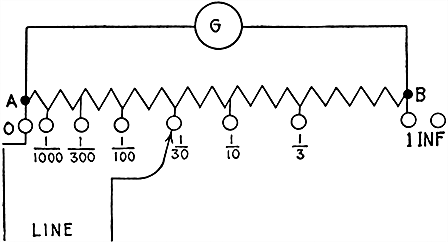

Fig. 538.--Diagram of a form of universal shunt box for use with galvanometers of widely different resistances. The galvanometer, as indicated at G, is connected across the ends of a series of resistances AB. The main wires are connected, one to end A of the series and the other to a travelling point whose position is varied by means of plugs or by a dial switch.

Galvanometer Shunts.--The sensitiveness of a galvanometer used for measuring current may be reduced to any desired extent by connecting a resistance of known value in parallel with it. Thus, if it be desired to measure a current greater than can be [463] measured directly by the galvanometer, a part of the current can be sent through the resistance or shunt, and the total value of the current calculated.

A galvanometer shunt bears a definite ratio to the resistance of the galvanometer, being usually adjusted so that only .1, .01, or .001 part of the current passes through the galvanometer.

The degree in which a shunt increases the range of deflection of a galvanometer is called its "multiplying power."

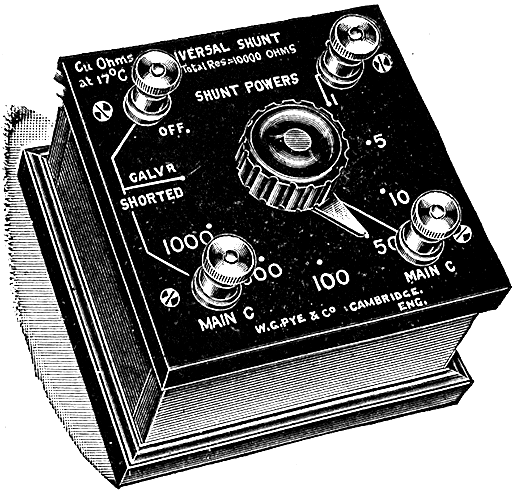

Fig. 539.--Ayrton-Mather universal shunt. This shunt may be used with any galvanometer. The total resistance is 10,000 ohms, with shunt powers of 1, 5, 10, 50, 100, 500, and 1,000. It is also fitted with positions in which the galvanometer is shorted and off. The coils are of constantan wire.

If .1 of the current flowing, passed through the galvanometer and .9 through the shunt, then the current in the circuit would be ten times that through the galvanometer. Accordingly the current in the galvanometer must be multiplied by the multiplying power of the shunt to obtain the true value of the current in the circuit.

In order to determine the resistance necessary to be used with a certain galvanometer, the resistance of the latter is to be divided by the multiplying power desired less one.

[464] EXAMPLE.--What must be the resistance of a shunt for a galvanometer of 2,000 ohms resistance where only one fifth of the current is to pass through the galvanometer?

The multiplying power less one is

and the required resistance is

When it is essential that the total resistance of the circuit should not be altered by an alternation of the galvanometer shunt, a compensating box should be used which automatically inserts a resistance for each shunt in series with the shunted galvanometer to bring the total resistance up equal to the unshunted value. Thus the current in the main circuit is not altered.

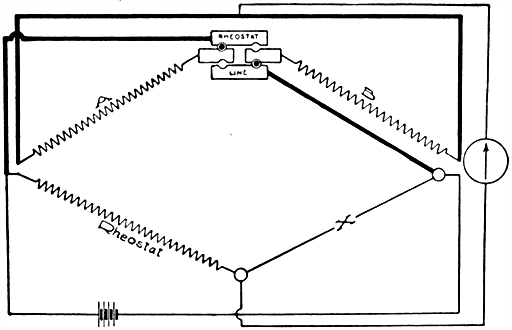

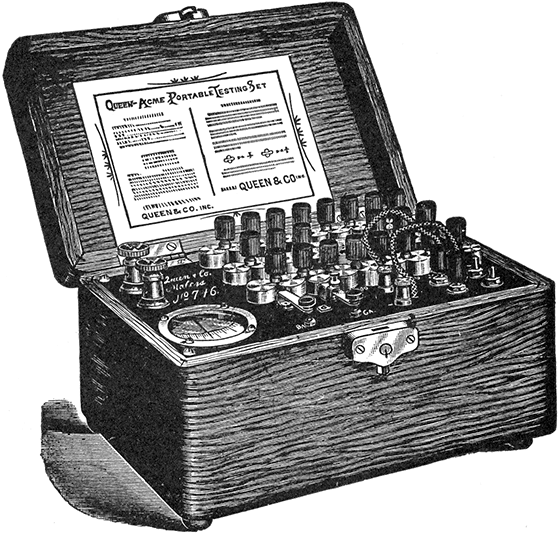

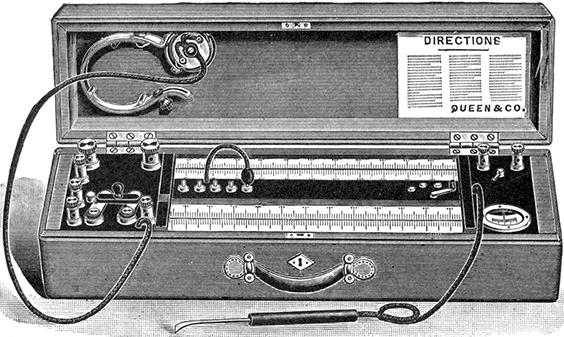

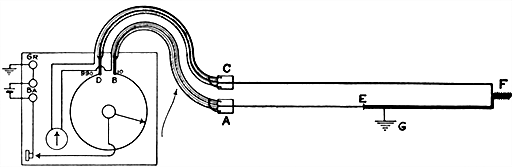

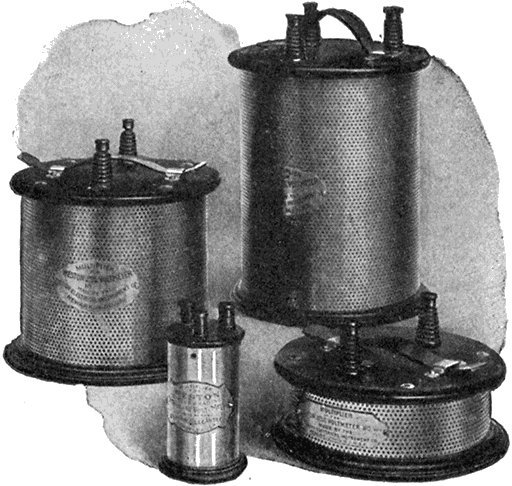

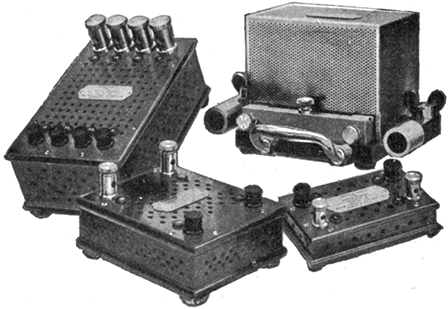

The practical electrician frequently has to make tests of various kinds which require the rapid and accurate measurement of voltage, current and resistance. It is therefore essential that he understand the methods employed in testing and the operation of the instruments used.

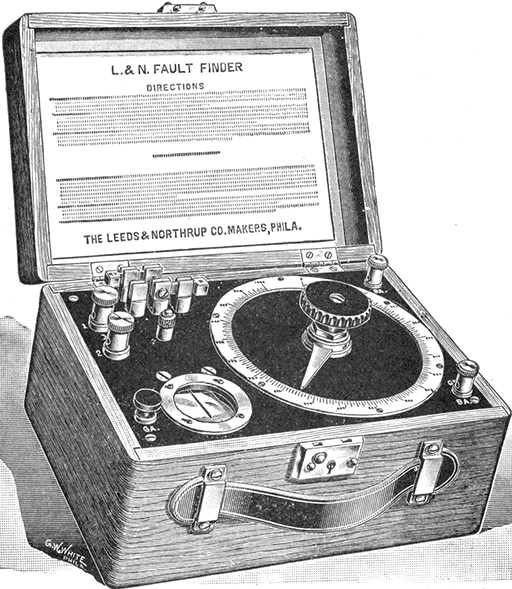

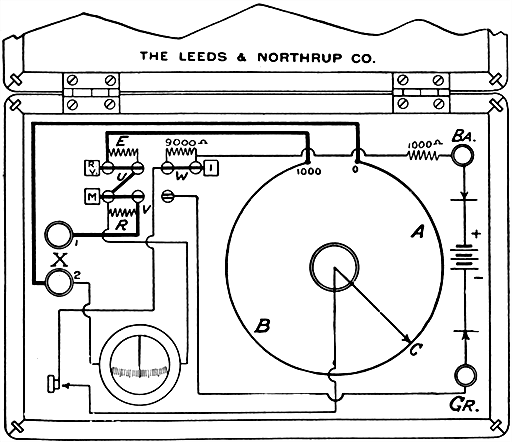

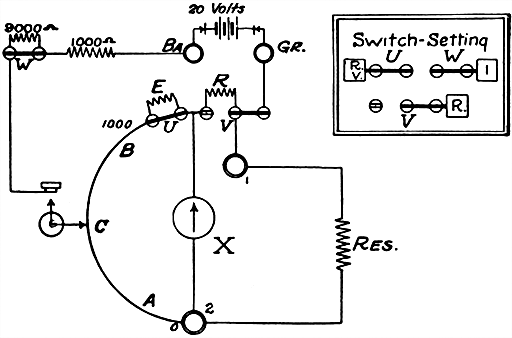

Most tests are made with a galvanometer, and the devices, such as resistances, switches, etc., which are used in connection with the galvanometer may be obtained put up in a neat and substantial box together with the galvanometer, the combination being called a "testing set." Numerous forms of testing set are illustrated in this chapter.

The construction, use, and operation of the various types of galvanometer have been explained in chapter twenty-six. Ammeters and voltmeters, which are simply special forms of galvanometer, and which are largely used are fully described in the preceding chapter.

Pressure Measurement.--An electromotive force has been defined as that which causes or tends to cause a current; it is analogous to water pressure; potential difference corresponds to difference of level. The total electromotive force of a circuit is [466] independent of resistance or current, and cannot be limited to mean the fall of pressure between any two points, as for instance the terminals of a battery.

If the pressure of a battery be two volts when measured on open circuit by a static voltmeter, there will still be two volts on closed circuit, but there will now be a loss of pressure through the internal resistance of the battery and the voltage across the terminals will be less than the total voltage. The static voltmeter, never closing the circuit, actually measures the total voltage.

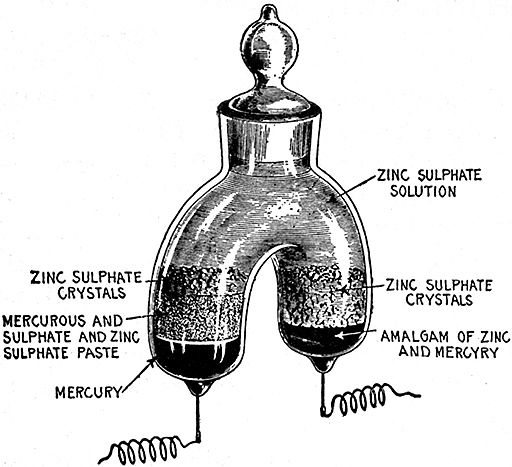

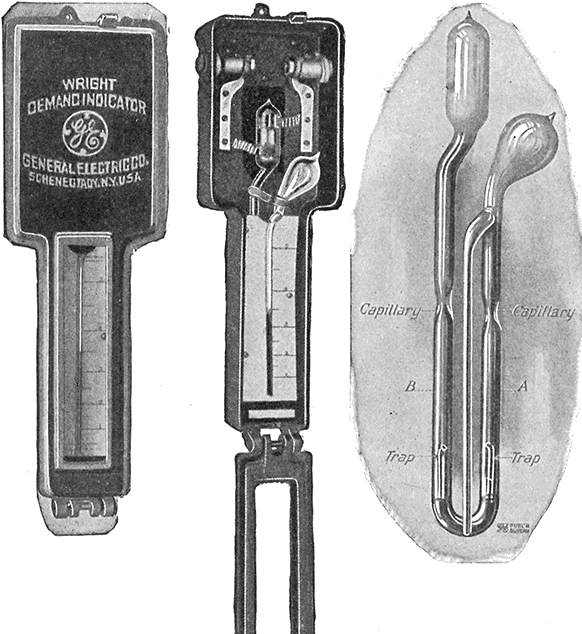

Fig. 540.--Clark cell (Kahle's modification of the Rayleigh H form), the standard for the International volt. The cell has for its positive electrode, mercury, and for its negative electrode, amalgamated zinc. The electrolyte consists of a saturated solution of zinc sulphate and mercurous sulphate. The pressure is 1.434 volts at 15°C., and between 10°C. and 25°C. the pressure decreases .00115 of a volt for each increase of 1°C. The containing glass vessel consists of two limbs, closed at bottom and joined above to a common neck fitted with a ground glass stopper. The diameter of the limbs should be at least 2 cms., and their length at least 3 cms. The neck should be not less than 1.5 cms. in diameter. At the bottom of each limb a platinum wire of about .4 mm. in diameter is sealed through the glass. To set up the cell, place mercury in one limb, and in the other hot liquid amalgam, containing 90 parts mercury and 10 parts zinc. The platinum wires at the bottom must be completely covered by the mercury and the amalgam, respectively. On the mercury, place a layer 1 cm. thick of the zinc and mercurous sulphate paste. Both this paste and the zinc amalgam must be covered with a layer of the neutral zinc sulphate crystals 1 cm. thick. The whole vessel must then be filled with the saturated zinc sulphate solution, and the stopper inserted so that it shall just touch it, leaving, however, a small bubble to guard against breakage when the temperature rises. Before finally inserting the glass stopper a strong alcoholic solution of shellac is applied to the upper edge, after which the stopper is pressed firmly in place.

[467] Ques. What error is introduced in measuring the pressure of a battery with an ordinary voltmeter?

Ans. Since the measurement is made on closed circuit the reading does not give the total pressure of the battery.

The error is very slight because the resistance of the voltmeter is very high and the current so small that the loss of pressure in the battery can be neglected.

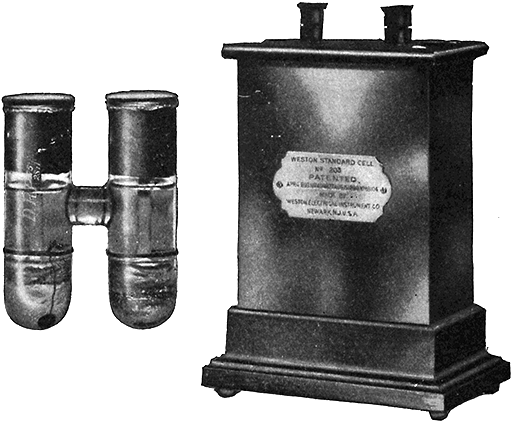

Fig. 541.--Weston Cadmium Cell. It is made in two forms; one known as the Weston normal cell, in which the solution of cadmium sulphate is saturated at all temperatures at which the cell may be used. The other, known as the Weston standard cell, in which the cadmium sulphate solution is unsaturated at all temperatures above 4°C. The Weston normal cell, or saturated form is slightly affected by changes in temperature, but, on account of the fact that it can be accurately reproduced, it was adopted by the London Conference in 1908, as a convenient voltage standard. The value of its voltage suggested by the committee of the London Conference on Electrical Units and Standards, and adopted by the Bureau of Standards at Washington, Jan. 1st, 1911, is 1.0183 International volts at 20°C. At any other temperature its voltage is:

Et = E20 - 0.0000406(t-20) - 0.00000095(t-20)2 + 0.00000001(t-20)3

The Weston standard cell, or unsaturated form is practically unaffected by changes in temperature and is the form most commonly used for laboratory work and general testing. The average pressure of this form is 1.0187 Int. volts.

[468] Ques. Define the International volt.

Ans. It is the electromotive force that, steadily applied to a conductor whose resistance is one International ohm, will produce a current of one International ampere, and which is represented sufficiently well for practical use by 1,000/1,434 of the voltage between the poles of the Clark cell at a temperature of 15° C., when prepared as in fig. 540.

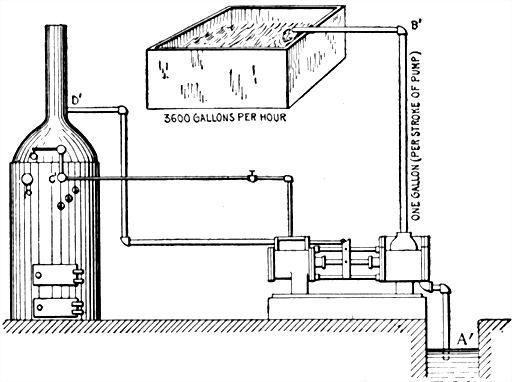

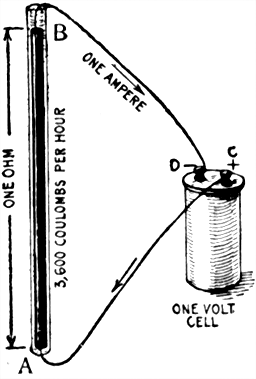

Figs. 542 and 543.--Diagrams showing hydraulic analogy illustrating the difference between amperes and coulombs. The rate of current flow of one ampere in fig. 543 may be compared to the rate of discharge of a pump as in fig. 542. Assuming the pump to be of such size that it discharges a gallon per stroke and is making 60 strokes per minute, the quantity of water discharged per hour (coulombs in fig. 543) is 1 × 60 × 60 = 3,600 gallons. Following the analogy further (in fig. 543), the pressure of one volt is required to force the electricity through the resistance of one ohm between the terminals A and B. In fig. 542, the boiler must furnish steam pressure on the pump piston to overcome the friction (resistance) offered by the pipe and raise the water from the lower level A' to the higher level B'. The difference of pressure between A and B in the electric circuit corresponds to the difference of pressure between A' and B'. The cell furnishes the energy to move the current by maintaining a difference of pressure at its terminals C and D; similarly, the boiler furnishes energy to raise the water by maintaining a difference of pressure between the steam pipe C and exhaust pipe D'.

Fig. 543. If the current strength in fig. 543 be one ampere, the quantity of electricity passing any point in the circuit per hour is 1 × 60 × 60 = 3,600 coulombs.

[469] Current Measurement.--It is necessary to adopt some arbitrary standard in order to compare currents of different strengths. The term strength of a current, or current strength means the rate of flow past any point in the circuit in a given unit of time. The unit of current, called the ampere, is defined as the unvarying current which, when passed through a solution of nitrate of silver in water (15 per cent. by weight of the nitrate) deposits silver at the rate of .001118 gramme per second.

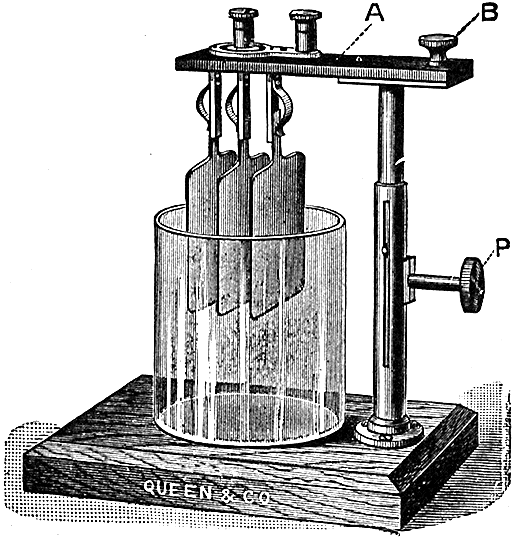

Fig. 544.--Queen weight voltameter for determining the strength of current by the weight of metal deposited in a given time. The two outside plates form the anode and are joined together and to one binding post, while the cathode is placed between them and connected to the other binding post. The cathode thus receives a deposit on both sides. An adjustable arm serves to lower the plates into the electrolyte. To calculate the strength of an unknown current which has passed through a weight voltameter, divide the gain in weight by the number of seconds the current flows through the instrument and by the weight deposited by one ampere in one second. That is, current strength in amperes = gain in weight ÷ (time in seconds × .0003286).

Ques. How much copper or zinc will one ampere deposit in one second?

Ans. .0003286 gramme of copper in a copper voltameter, or .0003386 gramme of zinc in a zinc voltameter.

[470] Ques. What is the difference between an ampere and a coulomb?

Ans. An ampere is the unit rate of flow of the current, and a coulomb is the unit quantity of electricity, that is, the ampere is the rate of current flow that will deposit .0003286 grammes of copper in one second and a coulomb is the quantity of electricity that passes a given point in one second when the current strength is one ampere. In other words a coulomb is one ampere second.

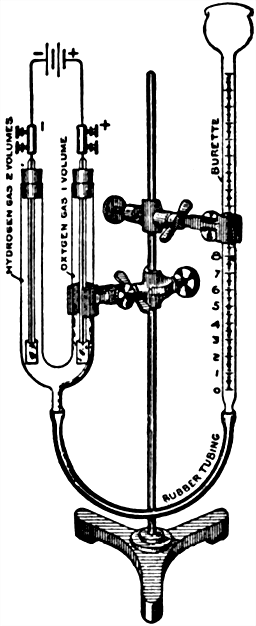

Fig. 545.--Gas voltameter for determining the strength of current by the volume of gas evolved. To use, connect up as shown in the illustration. Adjust so that the zero position of the burette is about one-half inch below the level of the top of the U tube. Pour acidulated water into the mouth of the burette till the water in the U tube is about one-half inch from the top. With the electrodes inserted through the corks, carefully place each one in position by giving a slight twist to the right as the cork enters. The water level in the U tube and burette should now be the same, or further adjustment must be made to attain this result. The level in the burette does not necessarily have to correspond with the zero graduation, but must not be below it. Unclamp the burette and hold it nearly horizontal. The liquid will not run out if the corks be tight, so that this is the air leakage test. Attach the connectors and wires from the current source (which should have a pressure of 2 or more volts) placing a switch in the circuit. When the switch is closed, bubbles of gas will rise in the U tube from both electrodes, displacing the water and forcing it up the burette. Hydrogen will be liberated over the negative electrode, and oxygen over the positive electrode in the proportion of twice as much hydrogen as oxygen. To calculate the current strength, divide the volume of gas liberated by the time in seconds, and by the volume of gas liberated (in cubic centimeters) by one ampere in one second and by .1733; that is: amperes = volume of gas liberated ÷ (time in seconds × .1733).

EXAMPLE.--If an arc lamp require a current of 8 amperes, how much electricity does it consume per hour?

Since one coulomb = one ampere second, the quantity of electricity consumed per hour is

8 amperes × ( 60 × 60 ) = 28,800 coulombs.

[471] Voltameter.--A voltameter is an electrolytic cell employed to measure an electric current by the amount of chemical decomposition the current causes in passing through the cell. There are two classes of voltameter:

Ques. What is the difference between these two classes of voltameter?

Ans. In one, the current strength is determined by the weight of metal deposited or weight of water decomposed, and in the other by the volume of gas liberated.

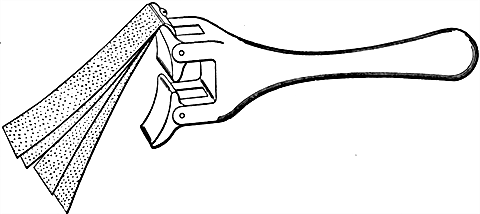

Ques. How should the plates of a weight voltameter be treated before use?

Ans. They must be thoroughly cleaned and polished with sandpaper, the sand being afterwards removed by placing them in running water. The fingers must not be placed on any part of the plate which is to receive the deposit.

Ques. What form of voltameter has been selected to measure the International ampere?

Ans. The silver voltameter arranged as here specified:

The cathode on which the silver is to be deposited shall take the form of a platinum bowl, not less than 10 cms. in diameter, and from 4 to 5 cms. in depth.

The anode shall be a disc or plate of pure silver some 30 sq. cms. in area, and 2 or 3 cms. in thickness. This shall be supported horizontally in the liquid near the top of the solution by a silver rod riveted through its center.

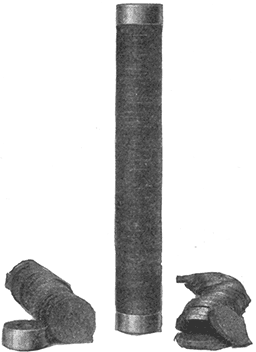

To prevent the disintegrated silver which is formed on the anode falling upon the cathode, the anode shall be wrapped around with pure filter paper, secured at the back by suitable folding.

The liquid shall consist of a neutral solution of pure silver nitrate containing about 15 parts by weight of the nitrate to 85 parts of water.

[472] Ques. What is the value of the International ampere as measured with the silver voltameter?

Ans. The International ampere is represented sufficiently well for practical use by the unvarying current which, when passed through a silver voltameter (as described above) deposits silver at the rate of .001118 gramme per second.

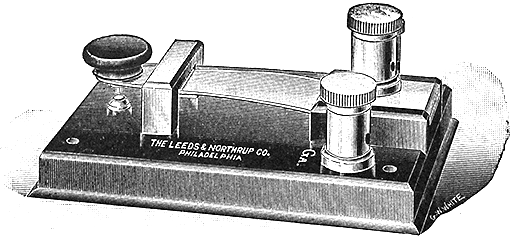

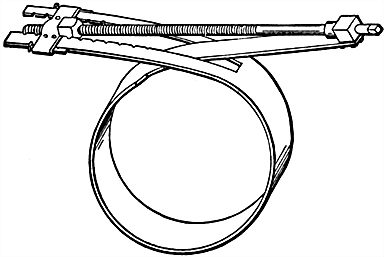

Fig. 546.--Single contact and short circuiting key. This key is intended especially for use with D'Arsonval galvanometers in zero deflection methods. The key is connected in circuit with the galvanometer so that whenever the key is not depressed, the galvanometer is short circuited, and its oscillations quickly damped out by the currents induced in its coil. The back end of the spring is held in a slot in a rubber block attached to the base.

Ohm's Law and the Ohm.--The various tests here described depend for their truth upon the definite relation existing between the electric current, its pressure, and the resistance which the circuit offers to its flow. This relation was fully investigated by Ohm in 1827. Using the same conductor, he proved not only that the current varies with the pressure, but that it varies in direct proportion.

Ohm's law has already been discussed in a previous chapter and the several ways of expressing it are repeated here for convenience:

| 1. | Amperes | = | voltsohms ; |

| [473] | |||

| 2. | Volts | = | amperes × ohms ; |

| 3. | Ohms | = | voltsamperes . |

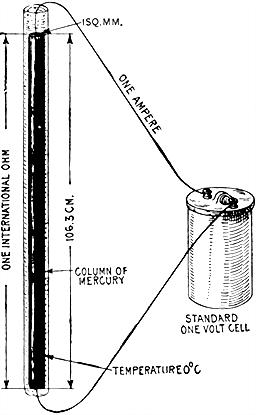

Various values have been assigned, from time to time, to the ohm or unit of resistance, the unit in use at the present time being known as the International ohm. This was recommended at the meeting of the British Association in 1892, was adopted by the International Electrical Congress held in Chicago in 1893, and was legalized for use in the United States by act of Congress in 1894. The International ohm in graphically defined in fig. 548. The previous values given to the ohm which were more or less generally accepted are as follows:

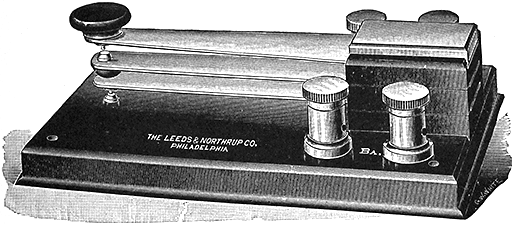

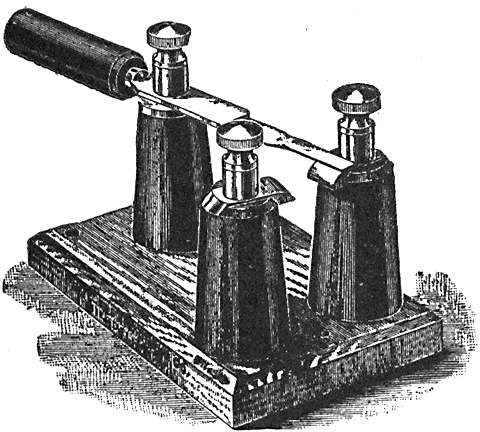

Fig. 547.--Double contact key. It is of especial value in connection with a Wheatstone bridge. When used with the latter it forms a combination battery and galvanometer key. The battery is wired to the top leaves of the key and the galvanometer to the lower leaves. Hence, when operated, the battery circuit will be closed before the galvanometer circuit, as it is desirable to avoid undue disturbance of the needle.

[474] The Siemens' Ohm.--A resistance due to a column of mercury 100 cm. long and 1 sq. mm. in cross section at 0° C.

B. A. (British Association) Ohm.--A resistance due to a column of mercury approximately 104.9 cm. long and 1 sq. mm. in cross section at 0° C.

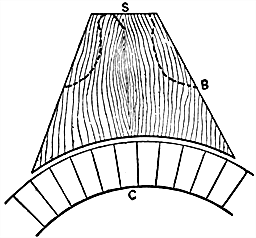

Fig. 548.--The international ohm. It is defined as the resistance of 14.452 grammes of mercury in the form of a column of uniform cross section 106.3 centimeters in length, at a temperature of 0° C. This is approximately equivalent to a column 106.3 cm. long, having a uniform cross section of 1 sq. mm. In the figure the international ohm is defined graphically. The resistance of the external circuit and the standard one volt cell is assumed to be zero.

Legal Ohm.--A resistance due to a column of mercury 106 cm. long and 1 sq. mm. in cross section at 0° C. This unit was adopted by the Paris conference of 1884.

OHM TABLEA

| Date | International Ohm | Legal Ohm | B. A. Ohm | Siemens' Ohm | |

| International Ohm | 1893-4 | 1.0000 | 1.0028 | 1.0136 | 1.0630 |

| Legal Ohm | 1884 | .9972 | 1.0000 | 1.0107 | 1.0600 |

| B. A. Ohm | 1864 | .9866 | .9894 | 1.0000 | 1.0488 |

| Siemens' Ohm | .9407 | .9434 | .9535 | 1.0000 |

[A] NOTE.--In the above table to reduce, for instance, British Association ohms to International ohms, multiply by .9866, or divide by 1.0136; to reduce legal ohms to International ohms, multiply by .9972, or divide by 1.0028, etc.

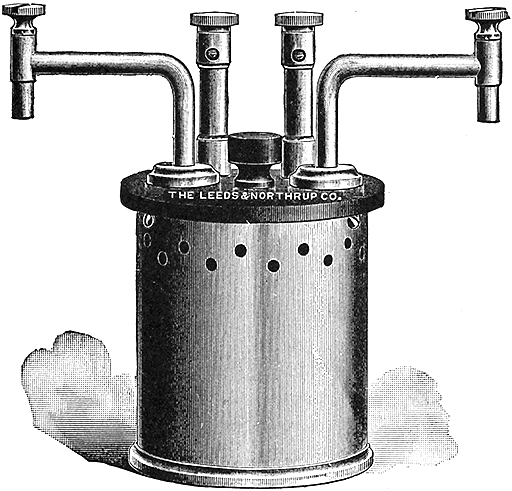

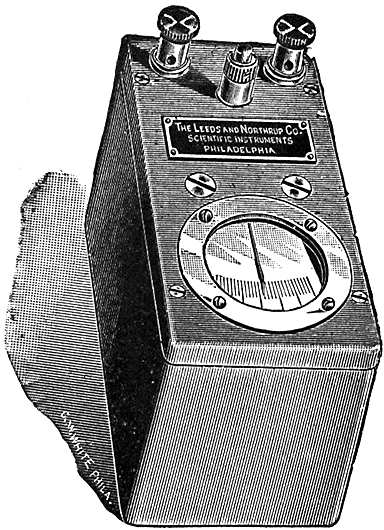

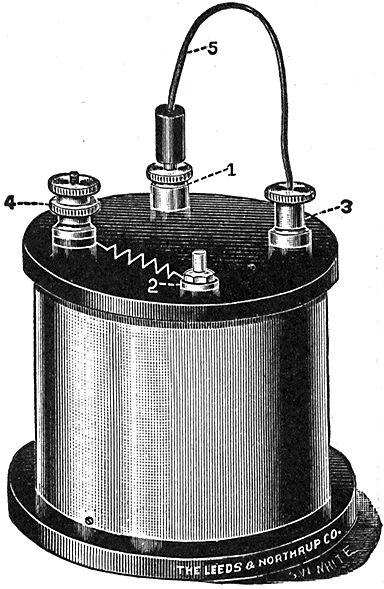

Fig. 549.--Leeds and Northrup one ohm standard resistance (Reichsanstalt form); adjusted at 20° C. Low resistance standards may be properly divided into two classes: 1. those which are designed primarily as resistance standards, and 2. those designed as current carrying standards. Those of the first mentioned class are often used to measure currents up to their capacity. The above standard has both pressure and current terminals. The binding posts for the former are mounted on high posts so as to be easily accessible when the standard is immersed in oil. When used as a resistance standard of precision, it should not be subjected to a current of more than one ampere, and when used as a current carrying standard of lesser accuracy, a current of 2 or 3 amperes may be used.

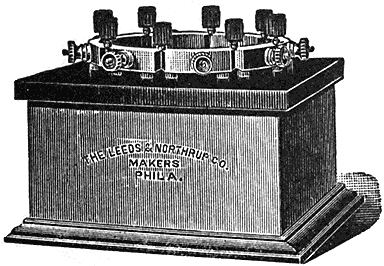

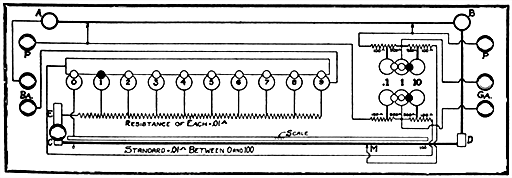

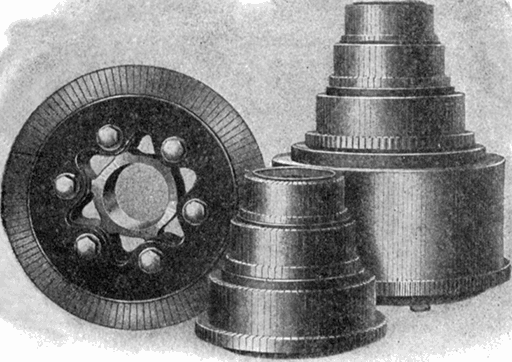

[476] Practical Standards of Resistance.--The column of mercury as shown in fig. 548, is the recognized standard for resistance, however, in practice, it is not convenient to compare resistances with such a piece of apparatus, and therefore secondary standards are made up and standardized with a great degree of precision. These secondary standards are made of wire. The material generally used being manganin or platinoid.

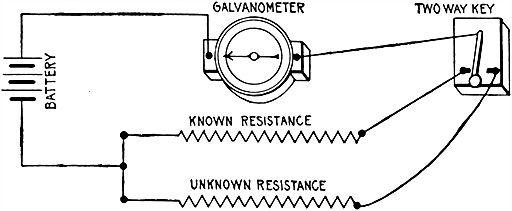

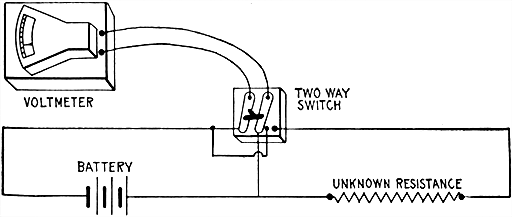

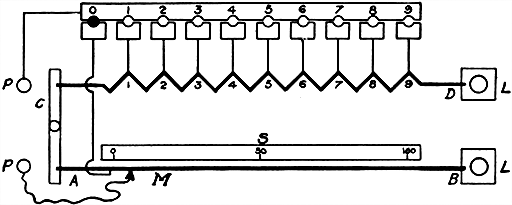

Fig. 550.--Direct deflection method of testing resistances; a useful and simple method which may be used in numerous tests. Galvanometer readings are taken through the known, and unknown resistances, and the current being proportional to the deflections, the value of the unknown resistance is easily calculated.

Resistance Measurement.--Resistance is that which offers opposition to the flow of electricity. Ohm's law shows that the strength of the current falls off in proportion as the resistance in the circuit increases. This gives a basis for measuring resistance.

There are various methods by which an unknown resistance may be measured, as by the:

Direct Deflection Method.--This method is based on the fact that the greater the current through a galvanometer the greater the deflection of the needle; it is a simple method and is capable of extended application.

The apparatus required consists of battery, galvanometer, known resistance, and double contact key. The connections are made as in fig. 550. The known resistance is put in circuit with the galvanometer and after noting the deflection, the key is moved so as to cut out the known resistance and throw into circuit the unknown resistance. The deflection of the galvanometer is again noted and compared with the first deflection.

Fig. 551.--Charge and discharge key, adapted to condenser testing where the condenser is to be alternately charged and discharged. The insulated handle enables the key to be used without insulating the body.

Fig. 552.--Pohl commutator. This is equivalent to a two pole double throw switch. The depressions in the base are filled with mercury into which the contacts dip in closing the circuit.

If the deflections be proportional to the current, the unknown resistance will be as many times the known resistance as the deflection with the known resistance is greater than the deflection with the unknown resistance.

[478] Method of Substitution.--This is the simplest method of measuring resistance. The resistance to be measured is inserted in series with a galvanometer and some constant source of current, and the galvanometer deflection noted. A known adjustable resistance is then substituted for the unknown and adjusted till the same deflection is again obtained. The value of the adjustable resistance thus obtained is equal to that of the resistance being tested.

Fig. 553.--Substitution method of testing resistances. The connections and apparatus are the same as in fig. 550, except that a resistance box is used in place of the known resistance. In making the test, first note deflection with unknown resistance in circuit, then press key so that the current will pass through the resistance box, and adjust the resistance in the box so that the deflection of the galvanometer is about the same as with the unknown. Now switch from one circuit to the other, changing the resistance in the box until equal deflections are obtained. When this obtains, the resistance in the box is the same as the resistance being tested.

Ques. What kind of adjustable resistance is used in making the above test?

Ans. A resistance box.

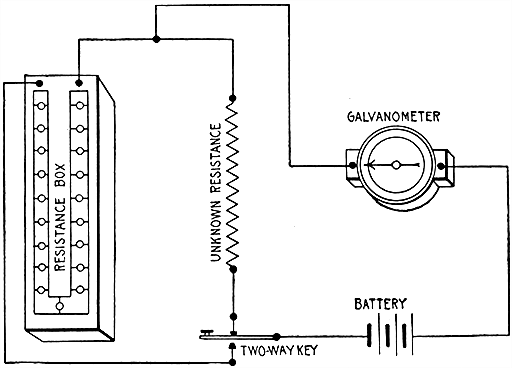

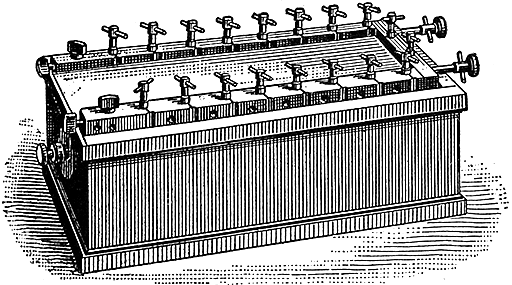

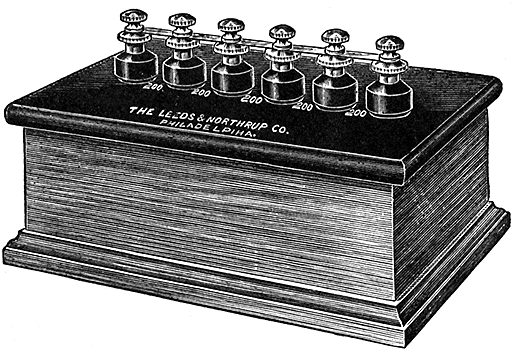

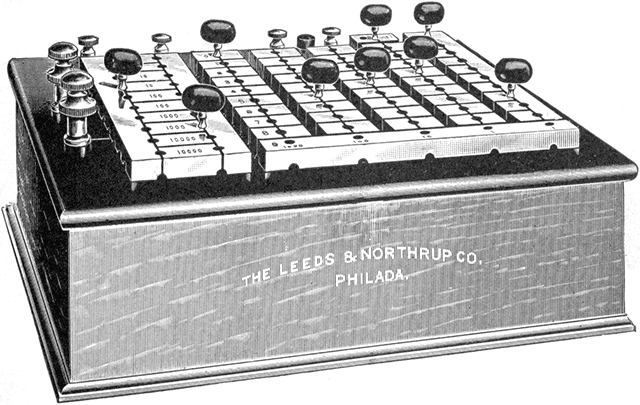

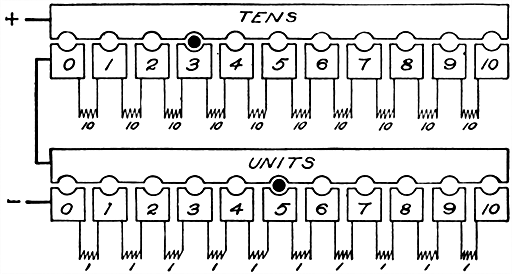

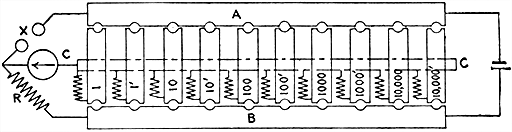

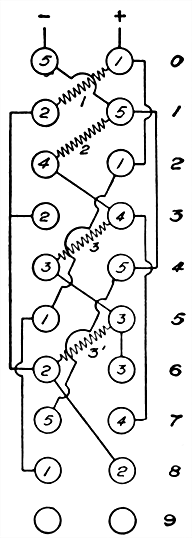

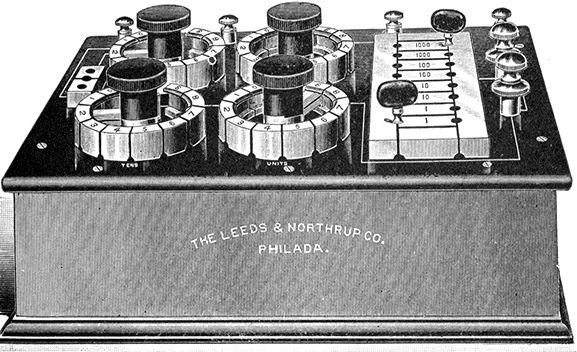

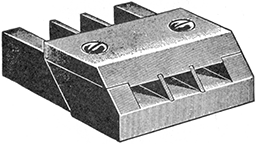

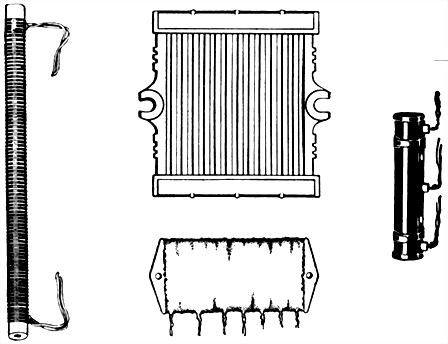

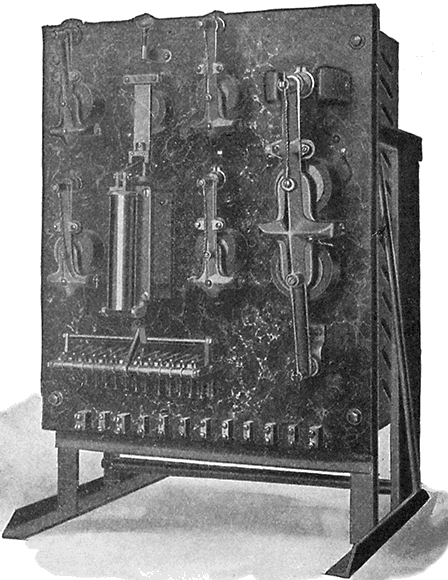

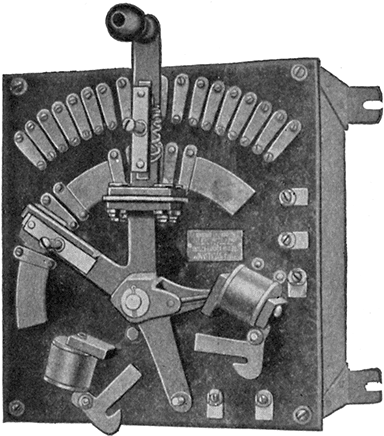

[479] Ques. Describe a resistance box.

Ans. It consists of a box containing numerous resistance coils with their ends connected to terminals and provided with plugs so that they may be thrown into or out of circuit at will, thus varying the resistance in the circuit.

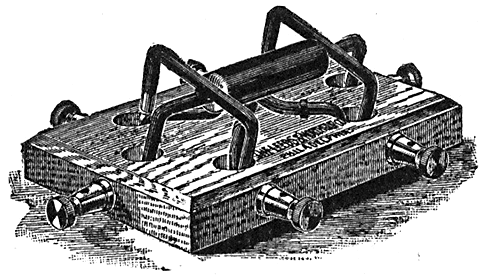

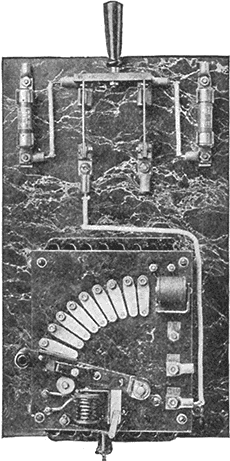

Fig. 554.--Ordinary resistance box. It contains sets of standard resistances consisting of coils of insulated wire having low conductivity and small temperature coefficient. The ends of the coils are joined to the section of the bar between the plugs. The insertion of a plug cuts out a coil. In using, care should be taken to put the plugs in with a slight twist so that there shall be no resistance introduced by poor contact.

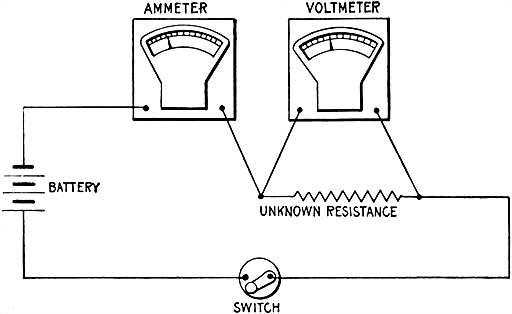

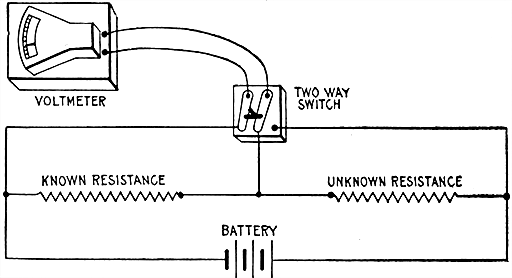

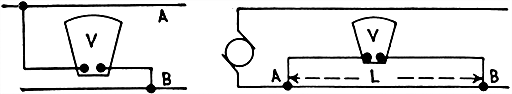

Fall of Potential Method.--This is a very simple method of measuring resistances, and one that is convenient for practical work in electrical stations because it requires only an ammeter, voltmeter, battery and switch--apparatus to be found in every station. The connections are made as shown in fig. 555.

In making the test the ammeter and voltmeter readings are taken at the same time, and the unknown resistance calculated from Ohm's law. Accordingly, since:

solving for the resistance,

Fig. 555.--Fall of potential method of testing resistances; a convenient method for testing at stations, requiring only the usual instruments to be found at a station. The resistance of the voltmeter must be very high, otherwise the test must be made as in fig. 556.

EXAMPLE.--If in fig. 555 the readings show 6 volts and 2 amperes how many ohms is the resistance being tested?

Substituting in formula (2)

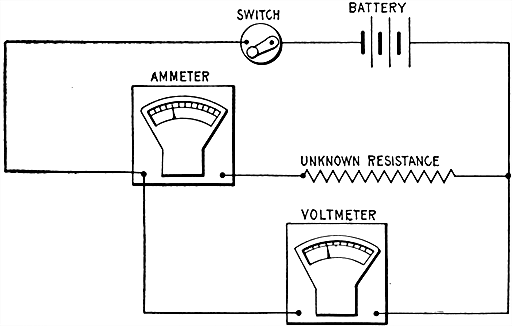

[481] Ques. Can this test be made with any kind of voltmeter?

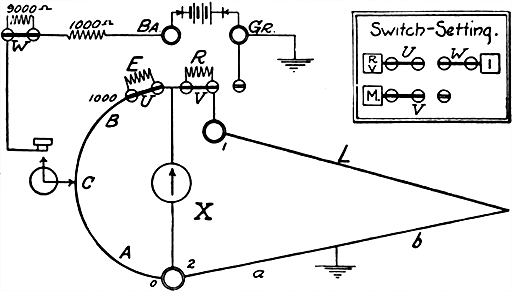

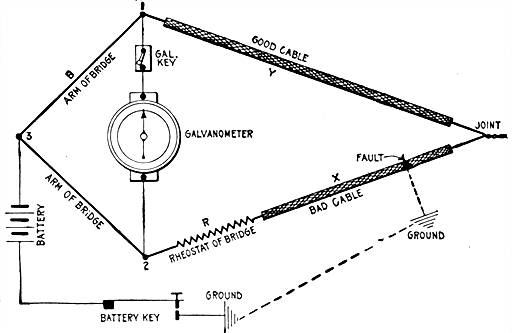

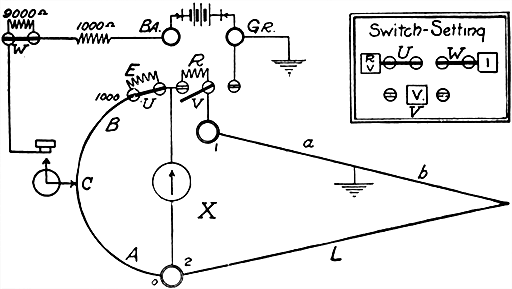

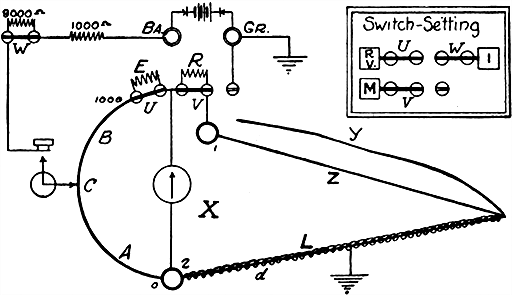

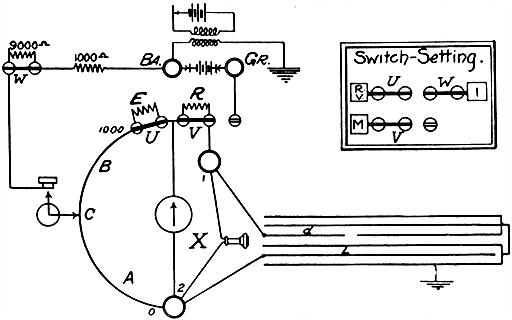

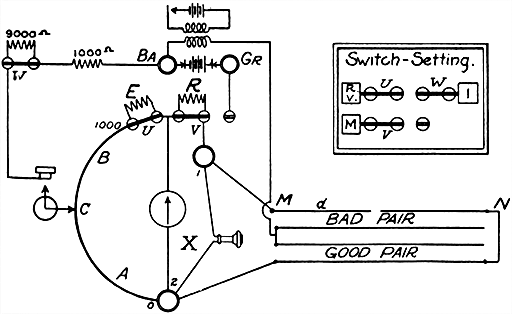

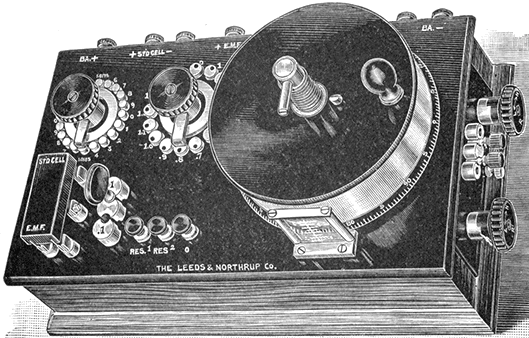

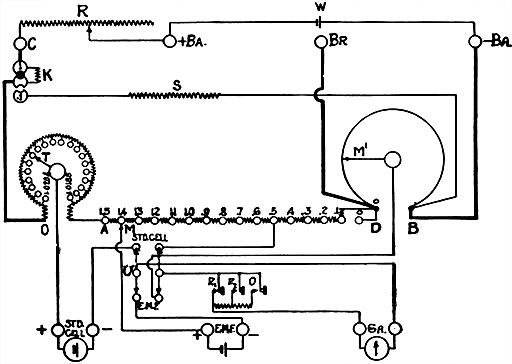

Ans. Its resistance must be very high to avoid error. When a voltmeter having small resistance is used, it should be connected so as to measure the fall of pressure across both ammeter and unknown resistance as shown in fig. 556.