Title: Motorcycle, Solo (Harley-Davidson Model WLA)

Author: United States. War Department

Release date: January 27, 2016 [eBook #51058]

Most recently updated: October 22, 2024

Language: English

Credits: Produced by deaurider, Brian Wilcox and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

| 1TM 9–879 | ||

|---|---|---|

| RESTRICTED | ||

| TECHNICAL MANUAL No. 9–879 |

⎫ ⎬ ⎭ |

WAR DEPARTMENT Washington, 18 October 1943 |

Dissemination of restricted matter.—The information contained in restricted documents, and the essential characteristics of restricted materiel, may be given to any person known to be in the service of the United States, and to persons of undoubted loyalty and discretion who are cooperating in Government work, but will not be communicated to the public or to the press except by authorized military public relations agencies. (See also paragraph 18b, AR 380–5, 28 September 1942.)

| PART ONE—VEHICLE OPERATING INSTRUCTIONS | ||||

|---|---|---|---|---|

| Paragraphs | Pages | |||

| Section | I | Introduction |

1–2 | 3–6 |

| II | Description and tabulated data |

3–4 | 7–8 | |

| III | Controls and operation |

5–13 | 9–19 | |

| IV | First echelon, preventive maintenance services |

14–18 | 20–29 | |

| V | Lubrication |

19–20 | 30–34 | |

| VI | Tools and equipment stowage on the vehicle |

21–23 | 35–38 | |

| PART TWO—ORGANIZATIONAL MAINTENANCE | ||||

| Section | VII | Maintenance allocation |

24–25 | 39–44 |

| VIII | Second echelon preventive maintenance services |

26 | 45–59 | |

| IX | Organization tools and equipment |

27 | 60 | |

| X | Trouble shooting |

28–38 | 61–71 | |

| XI | Engine |

39–44 | 72–77 | |

| XII | Engine—removal and installation |

45–46 | 78–84 | |

| XIII | Clutch |

47–52 | 85–95 | |

| XIV | Transmission |

53–58 | 96–104 2 | |

| XV | Chains and sprockets |

59–66 | 105–114 | |

| XVI | Fuel system |

67–74 | 115–121 | |

| XVII | Intake and exhaust system |

75–81 | 122–128 | |

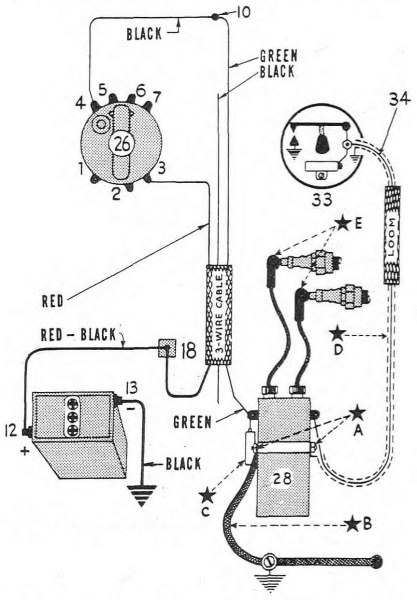

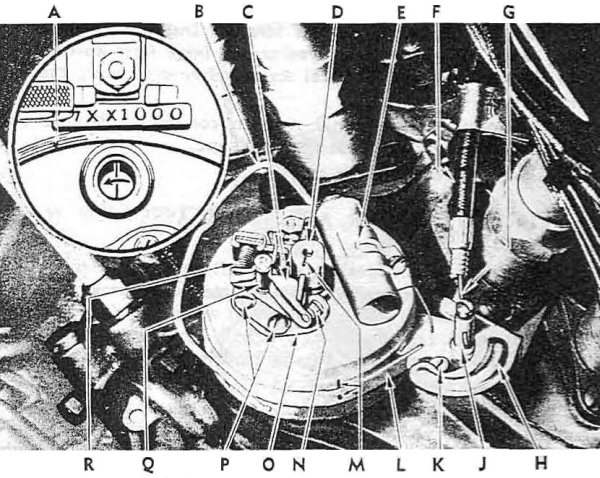

| XVIII | Ignition system |

82–89 | 129–141 | |

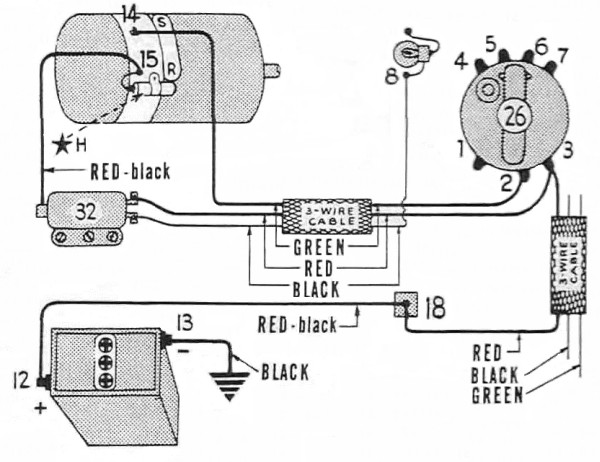

| XIX | Generating system |

90–95 | 142–148 | |

| XX | Brake system |

96–97 | 149–153 | |

| XXI | Steering control |

98–101 | 154–166 | |

| XXII | Sheet metal and equipment |

102–111 | 167–180 | |

| XXIII | Battery, lighting system, horn |

112–118 | 181–190 | |

| XXIV | Instrument panel |

119–121 | 191–192 | |

| XXV | Tires, wheels, and hubs |

122–127 | 193–199 | |

| References | 200 | |||

| Index | 201 | |||

a. This technical manual2 is published for the information and guidance of the using arm personnel charged with the operation, maintenance, and minor repair of this materiel.

b. In addition to a description of the Harley‐Davidson motorcycle, this manual contains technical information required for the identification, use, and care of the materiel. The manual is divided into two parts. Part One, section I through section VI, gives vehicle operating instructions. Part Two, section VII through section XXV, gives vehicle maintenance instructions to using arm personnel charged with the responsibility of doing maintenance work within their jurisdiction.

c. In all cases where the nature of the repair, modifications, or adjustment is beyond the scope or facilities of the unit, the responsible ordnance service should be informed so that trained personnel with suitable tools and equipment may be provided, or proper instructions issued.

a. This technical manual, together with TM 9–1879, supersedes and replaces the following Quartermaster Corps publications:

(1) TM 10–1175—Maintenance manual, motorcycle, solo, Harley‐Davidson (Model 42–WLA), 11 September 1941.

(2) TM 10–1177—Maintenance manual, motorcycle, solo, Harley‐Davidson (Models 1940–41–42), 11 September 1941.

(3) TM 10–1331—Maintenance manual, motorcycle, chain drive Harley‐Davidson (Model 42 WLA, solo).

(4) TM 10–1359—Instruction folder (45–A) motorcycles, solo, Harley‐Davidson (Model 1941 WLA 45), 25 November 1941.

(5) TM 10–1361—Instruction folder (45–B) motorcycle, solo, Harley‐Davidson (Model 1941 WLA 45), 25 November 1941.

2 To provide operating instructions with the materiel, this technical manual has been published in advance of complete technical review. Any errors or omissions will be corrected by changes or, if extensive, by an early revision.

a. This 2‐cylinder solo motorcycle is powered by a V‐type, air‐cooled gasoline engine, operating on conventional 4‐stroke, 4‐cycle principles. Air‐cooled engines rely upon movement of air over cylinder and head radiating fins, and upon circulation of oil for dissipation of excessive heat. Motorcycle engines, therefore, under no conditions should be operated for more than 1 minute when motorcycle is not in motion.

| a. Vehicle Specifications. | |

| Type of engine | 2‐cylinder, V‐type L‐head, air‐cooled |

| Cylinder bore | 2¾ in. |

| Stroke | 313⁄16 in. |

Engine number (serial) left side engine base, below front cylinder. |

|

| Wheelbase | 4 ft 11½ in. |

| Length over‐all | 7 ft 4 in. |

| Width over‐all (handle bars) | 3 ft 5 in. |

| Wheel size | 18 in. |

| Tire size | 4.00 × 18 in. |

| Tire type | Drop center |

Weight of vehicle (without rider or armament) | 540 lb. |

| Ground clearance (skid plate) | 4 in. |

| Kind and grade of fuel | Gasoline: 72 octane or higher |

| High gear ratio | 4.59:1 |

| Engine sprocket | 31‐tooth |

| Countershaft sprocket | 17‐tooth |

| Rear wheel sprocket | 41‐tooth |

| b. Performance. | |

| Maximum allowable speed | 65 mph |

| Miles per gallon (hard surface) | 35 |

| Cruising range (without refill) | 100 miles 8 |

| Fording depth (carburetor) | 18 in. |

| c. Capacities. | |

| Fuel capacity (left tank) | 33⁄8 U.S. gal |

| Oil tank capacity (right tank) | 11⁄8 U.S. gal |

| Transmission capacity | ¾ pt |

| Paragraph | |

|---|---|

| Controls | 5 |

| Engine prestarting instructions | 6 |

| Starting the engine | 7 |

| Stopping the engine | 8 |

| Operation of vehicle | 9 |

| Driving precautions | 10 |

| Stopping and parking vehicle | 11 |

| Towing vehicle to start engine | 12 |

| Running‐in new engine (or vehicle) | 13 |

a. Controls are peculiar to the motorcycle. The rider must become thoroughly familiar with the location and use of all control devices before attempting to operate vehicle.

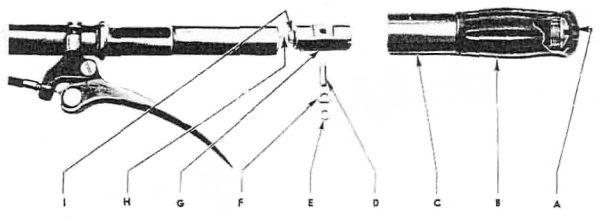

b. Gasoline Valve (figs. 5 and 6). Gasoline valve is located in left tank, forward. Valve is closed by turning to the right, finger tight. Turning to left opens valve. Valve is in normal operating position10 when turned to left, with valve head down. Lifting valve head releases emergency supply of fuel (3 quarts).

c. Throttle. The throttle is controlled by right handle bar grip. Turning grip inward opens throttle, turning it outward closes throttle.

d. Spark. Spark is controlled by left handle bar grip. Turning grip inward advances spark, turning it outward retards spark.

e. Clutch (fig. 7). Clutch is operated by left foot (rocker‐type) pedal, connecting with steel cable, which actuates clutch release lever. Pedal is located on left side of motorcycle above footboard. Forward downward (toe) position of pedal engages clutch. Rear downward (heel) position of pedal disengages clutch. Foot pedal provided with friction device to retain it in either engaged or disengaged position.

f. Service Brake (Rear Wheel). Foot pedal is located on right side of motorcycle at forward end of footboard.

g. Auxiliary Brake (Front Wheel). Auxiliary brake is operated by hand lever located on left handle bar. It is used in conjunction with service brake, as an emergency brake, or for holding vehicle while starting engine on grade. CAUTION: Brake is to be applied lightly and cautiously on wet and slippery roads.

h. Gear Shifter (fig. 8). Shifter lever is located on left tank, forward position, and operates within a guide. Shifter lever guide is notched for positive location of gears and each position is identified, front to rear: “1”—low gear; “N”—neutral; “2”—second gear; “3”—direct high gear.

i. Steering Damper. Steering damper is an adjustable friction device to damper turning action of forks, steady front wheel, and prevent wobble in rough terrain or at high speeds, and is located on top of steering head in center of handle bars. Move handle to right to apply desired friction.

j. Foot Starter Crank (fig. 1). The foot starter crank is located on right side of motorcycle. Gear shifter lever must be in neutral position, and clutch foot pedal in forward engaged position, before using foot starter crank. Starter crank normally is in upward position. Straddle motorcycle, place right foot on starter crank, and shift weight of body for forceful downward crank operation to start engine.

k. Ignition and Light Switch. Earlier models are provided with switch lock, later models are nonlocking. Switch is off in straight‐forward position. First position to right is for engine ignition only.13 Second position to right is for ignition and blackout lights. To use vehicle service lights, depress button to turn switch to third right position.

l. Instrument Panel Signal Lights. Instead of an ammeter and oil pressure gage, signal lights indicate generator charging, and engine oil pressure.

(1) Green light is located on left side of instrument panel. When engine is running, and light is out, it indicates generator is charging.

(2) Red light is located on right side of instrument panel. When engine is running, and light is out, it indicates engine oil is circulating.

m. Carburetor Choke (fig. 9). Choke lever is in full prime position when all the way up, and in normal running position when all the way down.

a. Before the engine is started, perform the Before‐operation Service outlined in paragraph 15. Special care must be taken during starting and warming‐up period to avoid unnecessary engine wear.

b. The rider must acquire correct motorcycle engine starting habits, and learn to do the job the quickest, easiest, and most dependable way. The following pointers will be helpful to the beginner as well as to a seasoned rider:

(1) Mount (straddle) motorcycle to obtain firm grip on handle bars.

(2) Leave side stand (jiffy stand) outward to support vehicle while operating foot starter crank with right foot.

(3) Engine starting will be benefited by use of front wheel, hand‐operated brake, to prevent vehicle from rolling or shifting during starting kicks. This is especially helpful if vehicle is parked on an incline or on soft, uneven surface.

c. The procedure outlined below is preparatory to starting either cold, warm, or hot engine:

(1) Place gear shifter lever in “N” (neutral) position (fig. 8).

(2) See that gasoline shut‐off valve is open (fig. 5).

(3) Engage clutch (fig. 7).

(4) Spark control (left) grip must be turned inward to fully advanced position, or nearly so.

(5) Foot starter crank may travel ½ way downward before starting engine. See that a full vigorous starter stroke is used. A vigorous kick, using a full swing (not a jab) of right leg and hip, is correct engine starting practice.

a. Procedure for starting cold, warm, or hot motorcycle engines differs. Therefore, following instructions are used with paragraph 6 c to cover correct procedure in all three cases.

b. Starting Cold Engine. When vehicle has not been operated for some time, and engine is normally cold, follow progressive procedure for easiest starting.

(1) Set carburetor choke lever in full upward (closed) position.

(2) Open throttle wide by turning right grip inward as far as it will go.

(3) Prime cylinders by operating foot starter crank one or two strokes.

(4) Set carburetor choke lever in ¼ to ½ closed position for mild weather starting: ¾ closed (or leave fully choked) for extremely cold weather starting. CAUTION: It is only in extremely cold weather that engine may start best with choke fully closed, and even then it will have to be moved from this position immediately after engine is started.

(5) Set throttle (right) grip to slightly open position.

(6) Turn ignition switch on, first right position.

(7) Start engine with vigorous strokes of foot starter crank.

(8) When engine starts, set throttle for moderate idling speed for warming up, or until ready to set vehicle in motion. Do not race engine unnecessarily.

(9) After engine warms up, and misfires due to an overrich mixture, gradually move choke lever downward. After engine has thoroughly warmed up, move choke lever to fully open (downward) position.

c. Starting Warm Engine. Following instructions apply to engine when halfway between hot and cold. With engine in this condition, carburetor choking must be handled cautiously.

(1) Lift choke lever to first upward position from normal (¼ closed).

(2) Set throttle (right) grip to fully closed (outward) position.

(3) Operate foot starter crank one or two strokes.

(4) Set throttle grip to between ¼ and 1⁄3 open position.

(5) Turn ignition switch on.

(6) Start engine with vigorous strokes of foot starter crank.

(7) Soon after engine starts, choke lever must be moved to fully open (downward) position.

(8) Turn throttle grip to control idling speed of engine.

d. Starting Hot Engine. If engine has been shut off for only a brief period and is near normal operating temperature, it is not necessary to use carburetor choke lever. With some engines, depending upon carburetor condition and adjustment, hot starting is easier and more dependable if foot starter crank is operated one stroke before turning ignition switch on.

(1) Close throttle grip by turning fully outward.

(2) Turn ignition switch on.

(3) Operate foot starter crank to start engine.

(4) When hot engine does not start readily after two or three strokes of the foot starter crank, it is usually due to an overrich (flooded) condition, and the proper procedure then is to open throttle wide so that more air can enter: close throttle quickly after engine starts. CAUTION: After engine has warmed up to a normal operating temperature, do not allow engine to stand idling for longer than a 1 minute interval.

e. Starting Engine with Dead Battery. See paragraph 12.

f. Behavior of Instrument Panel Signal Lights. Function of generator (green) signal light depends upon action of cut‐out relay; engine oil pressure (red) signal light depends upon action of oil feed pump. Rider must, therefore, thoroughly understand operating characteristics of both signal lights to judge condition of generator‐battery circuit and pressure in engine oil circulating system.

(1) When ignition light switch is turned to first (right) position, preparatory to starting engine, both green and red signal lights should go on. CAUTION: When switch is turned on, immediately after engine has been primed by cranking, red (oil pressure) signal light may not light at once, but will light after a few seconds, due to oil pressure built up by cranking, and is most likely to be noticed in cold weather.

(2) With engine started and running at medium idling speed, both signal lights should go off. CAUTION: Should oil pressure (red) signal light fail to go off at speeds above idling, conditions must be brought to attention of unit mechanic.

(3) At slow idle speed, or under approximately 20 miles per hour road speed (in high gear), generator (green) signal light will normally flash on and off, because at that speed generator voltage output is very low and unsteady. CAUTION: Should generator (green) signal light fail to go off at speed above approximately 20 miles per hour, generator is either not charging at all, or its current output is not up to normal, and generator should be given attention at once.

a. Stop engine only by turning ignition and light switch to off (straight‐ahead) position, to prevent discharge of battery through spark coil primary circuit.

a. Starting on Level Ground. The engine having been warmed up and checked for satisfactory operation, the vehicle (with operator in riding position) is put in motion as follows:

(1) Transfer body weight to right leg.

(2) Fold back side stand (jiffy stand).

(3) Disengage clutch by depressing clutch foot pedal with heel of left foot.

(4) Shift gear shifter lever into “1” (low) gear position.

(5) Slowly engage clutch by depressing clutch foot pedal with toe of left foot.

(6) When clutch starts to “take hold,” open throttle sufficiently to maintain engine speed.

(7) Accelerate gradually to between 12 and 15 miles per hour in low gear.

(8) Close throttle quickly.

(9) Disengage clutch.

(10) Shift through “N” (neutral) position into “2” (second) gear.

(11) Reengage clutch and accelerate to about 25 miles per hour.

(12) Close throttle quickly.

(13) Disengage clutch.

(14) Shift into “3” (high) gear.

(15) Reengage clutch and accelerate to desired speed.

b. Starting on Uneven or Soft Ground.

(1) If standing on an incline or in loose, heavy ground, more engine power will be required to start vehicle without stalling engine.

(2) It may be necessary to keep vehicle from rolling by keeping pressure on front brake hand lever. Brake pressure is released after vehicle starts in forward motion.

(3) Open throttle and engage clutch at same time to provide power needed for starting, without racing engine unnecessarily.

(4) Motorcycle starts should be made without excessive application of power, with consequent unnecessary spinning of rear wheel.

a. Practice will enable a rider to judge at what rate of speed the motorcycle should be moving before he shifts from a lower to higher17 gear, and engine should never be permitted to labor unduly, when a shift of gears, higher to lower, would improve operation.

(1) Operator must not look down at gear shifter when shifting gears, but keep his eyes on the road ahead. Do not ride the clutch. The operator’s foot should rest on clutch foot pedal only when he is operating it. When shifting gears, disengage clutch fully to avoid gear damage and shifting difficulties. CAUTION: Many transmissions are ruined through failure to disengage clutch fully when shifting gears.

b. Braking. Rear wheel service brake must be in such condition that medium‐hard application will cause rear wheel to lock. Application of service brake should be gradual, with just enough force to accomplish desired result.

(1) Auxiliary front wheel brake, when used in conjunction with service brake, must be applied with caution, especially on wet, muddy, or slippery roads.

(2) After passing through water, the brakes should be set slightly, and the vehicle operated for a short distance, until sufficient heat has been generated to dry the brakes.

c. Avoid Low Gear Operation. Always operate vehicle in highest gear possible, consistent with tactical situation, speed required, power required, and kind and nature of road substance, to prevent overheating of engine.

d. High Speed Tips. Only experienced riders should indulge in high‐speed riding. A motorcycle operated for long distances at high speed must be given closer than ordinary attention to avoid serious engine overheating with consequent damage. For better motorcycle service, apply the following suggestions:

(1) Develop habit of frequently snapping throttle shut for an instant when running at high speed. This draws additional lubrication to piston and cylinder and assists in cooling engine.

(2) In cool weather, operate engine slowly until it is thoroughly warmed up, to avoid damage to pistons, rings, cylinders, and other parts before oil is warm enough to circulate freely.

(3) If handle bar windshield and leg shields are used, engine is more likely to overheat with continued high‐speed riding. Watch this carefully.

(4) Adjust “steering damper” for best control of motorcycle consistent with riding speed and condition and nature of road.

a. Stopping Vehicle. Rider will make a “restart” easier and quicker if he will apply the following instructions upon stopping vehicle:

(1) Close throttle.

(2) Disengage clutch.

(3) Apply brake (or brakes) to slow vehicle without sliding rear tire.

(4) Just before coming to a complete stop, shift into “N” (neutral) position and engage clutch. CAUTION: If immediate restart is to be made, shift into “1” (low) gear and allow clutch foot pedal to remain in disengaged position. (Rider will be mounted on motorcycle with engine running.)

(5) Continue brake application to complete stop.

(6) After vehicle slows to point where it can no longer be balanced by steering, place left foot on ground to maintain balance until right foot can be removed from brake operating pedal. CAUTION: Do not idle engine longer than 1 minute.

(7) Stop engine by turning ignition switch off.

b. Parking Vehicle.

(1) Lean motorcycle on side (jiffy) stand.

(2) Shift into “1” (low) gear.

(3) Engage clutch so vehicle cannot roll.

(4) Shut off gasoline supply by turning valve (to right) finger‐tight against its seat.

a. In emergencies when engine cannot be started with foot starter crank, it can be started by towing the motorcycle.

(1) Set gear shifter lever in “2” (second) gear position.

(2) Disengage clutch.

(3) Choke carburetor.

(4) Turn ignition switch on.

(5) After momentum of the towed motorcycle reaches between 10 and 15 miles per hour, engage clutch, and continue procedure until engine starts.

b. Engine Starting with Dead Battery. Emergency engine starting with dead battery can be effected by making use of freshly charged battery, or by towing as outlined above. If vehicle with dead battery is to be towed for engine starting, proceed as follows:

(1) Disconnect battery negative wire from ground on right side of motorcycle.

(2) Tow motorcycle for engine starting.

(3) After engine is started, reconnect battery ground wire to frame to prevent damage to electrical system.

a. A new motorcycle engine or newly overhauled engine must be given proper “break‐in” consideration for at least the first 1,000 to 1,200 miles of service. Failure to do this may result in damage that will put engine out of active service within a short period of time.

b. At the first 250 miles, check front and rear drive chains to make sure they are receiving required amount of oil for ample lubrication. If necessary, have chain oilers adjusted by unit mechanic. Drive chains must be inspected for correct adjustment, and be given attention by unit mechanic as needed.

c. At first 500 miles, drain oil tank and refill with fresh oil. Check front and rear chains (step b above). Thereafter, follow instructions in Maintenance Operation section.

d. After a new motorcycle has been run 500 to 1,000 miles it needs to be thoroughly checked over and any loose screws and nuts tightened. Particular attention must be given engine and transmission mounting bolts and nuts, and to rear wheel mounting socket screws.

e. Following pointers must be observed when running‐in new engine or newly overhauled engine:

(1) Do not exceed 30 miles per hour during first 100 miles.

(2) Do not exceed 35 miles per hour during next 200 miles.

(3) Do not exceed 40 miles per hour during next 400 miles.

(4) Do not exceed 50 miles per hour during next 500 miles.

(5) Avoid use of low gears during break‐in operation as much as possible.

| Paragraph | |

|---|---|

| Purpose | 14 |

| Before‐operation service | 15 |

| During‐operation service | 16 |

| At‐halt service | 17 |

| After‐operation and weekly service | 18 |

a. To insure mechanical efficiency it is necessary that the vehicle be systematically inspected at intervals each day it is operated and weekly, so that defects may be discovered and corrected before they result in serious damage or failure. Certain scheduled maintenance services will be performed at these designated intervals. The services set forth in this section are those performed by driver or crew before operation, during operation, at halt, after operation, and weekly.

b. Driver preventive maintenance services are listed on the back of “Driver’s Trip Ticket and Preventive Maintenance Service Record,” W.D. Form No. 48, to cover vehicles of all types and models. Items peculiar to specific vehicles, but not listed on W.D. Form No. 48, are covered in manual procedures under the items to which they are related. Certain items listed on the form that do not pertain to the vehicle involved are eliminated from the procedures as written into the manual. Every organization must thoroughly school each driver in performing the maintenance procedures set forth in manuals, whether or not they are listed specifically on W.D. Form No. 48.

c. The items listed on W.D. Form No. 48 that apply to this vehicle are expanded in this manual to provide specific procedures for accomplishment of the inspections and services. These services are arranged to facilitate inspection and conserve the time of the driver, and are not necessarily in the same numerical order as shown on W.D. Form No. 48. The item numbers, however, are identical with those shown on that form.

d. The general inspection of each item applies also to any supporting member or connection, and generally includes a check to see whether the item is in good condition, correctly assembled, secure, or excessively worn.

(1) The inspection for “good condition” is usually an external visual inspection to determine whether the unit is damaged beyond safe or serviceable limits. The term “good condition” is explained further by the following: not bent or twisted, not chafed or burned,21 not broken or cracked, not bare or frayed, not dented or collapsed, not torn or cut.

(2) The inspection of a unit to see that it is “correctly assembled” is usually an external visual inspection to see whether it is in its normal assembled position in the vehicle.

(3) The inspection of a unit to determine if it is “secure” is usually an external visual examination, a hand‐feel, or a pry‐bar check for looseness. Such an inspection should include any brackets, lock washers, lock nuts, locking wires, or cotter pins used in assembly.

(4) “Excessively worn” will be understood to mean worn close to, or beyond, serviceable limits, and likely to result in a failure if not replaced before the next scheduled inspection.

e. Any defects or unsatisfactory operating characteristics beyond the scope of first echelon to correct must be reported at the earliest opportunity to the designated individual in authority.

a. This inspection schedule is designed primarily as a check to see that the vehicle has not been tampered with, or sabotaged since the After‐operation Service was performed. Various combat conditions may have rendered the vehicle unsafe for operation and it is the duty of the driver to determine whether or not the vehicle is in condition to carry out any mission to which it is assigned. This operation will not be entirely omitted, even in extreme tactical situations.

b. Procedures. Before‐operation Service consists of inspecting items listed below according to the procedure described, and correcting or reporting any deficiencies. Upon completion of the service, results should be reported promptly to the designated individual in authority.

(1) Item 1, Tampering and Damage. Look for any injury to vehicle in general, its accessories or equipment, that may have been caused by tampering, sabotage, collision, falling debris, or shell fire since parking vehicle. Look for loosened or damaged accessories, loose fuel or oil lines, or any disconnected linkage.

(2) Item 3, Fuel and Oil. Inspect tanks for fuel and oil levels, add oil and fuel as necessary. Any appreciable change in levels since performing After‐operation Service should be investigated and reported to designated authority.

(3) Item 4, Accessories and Drives. Examine all accessories such as carburetor, air cleaner, generator, and cut‐out relay for loose connections, loose mountings, or leaks. Examine rear chain (final drive) for free up‐and‐down movement (slack), midway between sprockets. Total up‐and‐down movement must not be more than 1 inch, nor less than ½ inch. Inspect rear chain for adequate lubrication.

(4) Item 6, Leaks, General. Examine vehicle and ground under vehicle for indications of fuel or oil leaks. Normally a few drops of waste oil from chains may be expected to drop from skid plate.

(5) Item 11, Glass. Clean glass on instruments; clean and adjust rear view mirror; inspect glass for breakage.

(6) Item 12, Lamps. If tactical situation permits, observe whether blackout and service lights operate with switch in its respective positions, and go out when switched off. Also see that lights are secure, and that lenses are clean and not broken. Observe whether both filaments of service headlight operate when dimmer switch on left handle bar is moved to its respective positions.

(7) Item 13, Wheels, Axle Nuts and Screws. Examine rear wheel mounting socket screws, front and rear axle nuts, and front fork rocker stud nuts for tightness. Observe rear chain adjusting screws for secure locking. Inspect spokes for good condition and tightness.

(8) Item 14, Tires. Examine tires for cuts or imbedded objects in treads or carcass. If time permits, check air pressure, which should be 18 pounds front, and 20 pounds rear (tires cold). Inspect valve caps for presence and secure mounting.

(9) Item 15, Springs and Suspension. Examine front fork springs for secure mounting and good condition. Push down rear of saddle to test for full action of saddle post spring.

(10) Item 16, Steering and Handle Bar Controls. Test steering head bearing adjustment by exerting strong upward pull at handle bar grips, and observing whether or not there is any noticeable play in bearing. Operate steering damper lever and observe that damper is compressed before lever reaches right‐side position, and is fully released with lever in left‐side position. Test handle bar grip controls for full, free action; also test for complete opening and closing of throttle, and full advance and retard of timer.

(11) Item 17, Fenders (Mudguards), Luggage Carrier, Safety Guards, and Stands. Examine these items for good condition and secure mounting.

(12) Item 21, Tools and Equipment. Inspect tools and equipment for presence, serviceability, and proper stowage. (See tool list in par. 21.)

(13) Item 7, Engine Warm‐up. Start engine, noting any tendency toward hard starting, or improper action of foot starter crank. Set throttle to moderate idle speed. Listen for unusual noises. Watch instrument indications and engine performance, such as misfiring. CAUTION: Do not idle engine longer than 1 minute with vehicle standing.

(14) Item 8, Choke. During idling of engine, reset choke as required to prevent excessive choking and dilution of engine oil.

(15) Item 9, Instruments. When switch is turned on and engine is idling at moderate speed both red light (indicating oil pressure) and green light (indicating generator action) should be out. At lower operating speeds generator‐indicating light may flicker. CAUTION: Do not operate engine with red light on (no oil pressure).

(16) Item 10, Horn. Tactical situation permitting, test horn.

(17) Item 22, Engine Operation. Engine should idle smoothly. Accelerate and decelerate, listening for any unusual noises that may indicate compression or exhaust leaks, worn, damaged, loose, or inadequately lubricated engine parts, or accessories. Note any unusual smoke from exhaust.

(18) Item 23, Driver’s Permit, Accident Report Form No. 26, and Vehicle Manual. These items must be present on vehicle and safely stowed.

(19) Item 25, During‐operation Service. The During‐operation Service should start immediately after vehicle is put in motion, in the nature of a road test.

a. While vehicle is in motion, listen for any sounds such as rattles, knocks, squeals, or hums that may indicate trouble. Be alert to detect any odor of overheated components or units such as generator, brakes, or clutch, fuel vapor from a leak in fuel system, exhaust gas, or other signs of trouble. Any time the brakes are used, gears shifted, or vehicle turned, consider this a test and notice any unsatisfactory or unusual performance. Watch the instruments constantly. Notice promptly any unusual instrument indication that may signify possible trouble in system to which the instrument applies.

b. Procedures. During‐operation Service consists of observing items listed below according to the procedures following each item, and investigating any indications of serious trouble. Notice minor deficiencies to be corrected or reported at earliest opportunity, usually at next scheduled halt.

(1) Item 27, Foot and Hand Brakes. The foot brake should operate smoothly and effectively, leaving reserve pedal travel of 1 inch. Normal free play before operation is 1 inch. Test hand brake lever for free play, which should be ¼ of total handle travel. Test for ease and smoothness of operation.

(2) Item 28, Clutch. Inspect clutch for disengagement at about ½ pedal travel. Clutch should not chatter, squeal, or slip.

(3) Item 29, Transmission. Gears should shift smoothly, operate quietly, and not jump out of mesh during operation. If transmission24 jumps out of mesh in any gear, this indicates need of shifter control adjustment.

(4) Item 31, Engine and Controls. Be alert for deficiency in engine performance such as lack of usual power, misfiring, unusual noise, stalling, indication of engine overheating, or unusual exhaust smoke. Notice whether engine responds to controls satisfactorily, whether controls appear to be in proper adjustment and are sufficiently tight.

(5) Item 32, Instruments. Observe instruments for indication of normal functioning of systems to which they apply.

(a) Speedometer and Odometer. Speedometer should indicate vehicle speed without excessive noise or fluctuation. Odometer should record trip and total mileage.

(b) Oil Pressure Signal Light. Red light should be off during operation. If light goes on, stop vehicle and investigate for oil pressure failure.

(c) Generator Signal Light. Green light should be off above 20 miles per hour. Battery discharge is indicated by green light being on.

(6) Item 33, Steering. Adjust steering damper to desired steering friction. Observe vehicle steering for wander, shimmy, leading to one side, or wheel hop.

(7) Item 34, Running Gear. Listen for any unusual noises from wheels, axles, or suspension parts that might indicate looseness or damage.

(8) Item 35, Chassis. Be alert for noises that might indicate loose accessories, controls, attachments, or equipment.

a. At‐halt Service may be regarded as minimum maintenance procedures and should be performed under all tactical conditions, even though more extensive maintenance services must be slighted or omitted altogether.

b. Procedures. At‐halt Service consists of investigating any deficiencies noted during operation, inspecting items listed below according to the procedures following the items, and correcting any deficiencies found. Deficiencies not corrected should be reported promptly to the designated individual in authority.

(1) Item 38, Fuel and Oil. Replenish fuel and oil as may be required to reach next refilling point. CAUTION: Left tank is for fuel; right tank is for oil. Filler caps should not be interchanged, as only fuel tank cap is vented.

(2) Item 39, Temperatures. Hand‐feel wheel hubs and brake drums for overheating.

(3) Item 40, Vents. Make sure that crankcase breather outlet and rear chain oil feed pipe are clear. Make sure grease drains in front and rear brake side covers are open and clean.

(4) Item 42, Springs and Suspensions. Look for broken springs in fork.

(5) Item 43, Steering. Investigate any difficulty developed during riding.

(6) Item 44, Wheels and Mounting Screws. Inspect wheels for broken, bent, or loose spokes. Also, look for loose axle nuts or rear wheel mounting screws. Inspect wheel rims for good condition.

(7) Item 45, Tires. Examine tires for low pressure or damage. Remove foreign matter from tire treads; inspect for cuts.

(8) Item 46, Leaks, General. Inspect vehicle for indication of fuel, oil, or battery leaks.

(9) Item 47, Accessories and Chain. Examine accessories for loose connections, loose mountings, or damage. Examine rear drive chain for broken rollers, broken link side plates, and broken or missing connecting link spring clips. Inspect chain for adequate lubrication.

(10) Item 48, Air Cleaner. Air cleaner must be secure, with air passages in good condition and clean. When operating under extremely dusty or sandy conditions, inspect air cleaner frequently and service as required.

(11) Item 49, Fenders (Mudguards), Luggage Carrier, Safety Guards, and Stands. Inspect these items for looseness or damage.

(12) Item 52, Appearance and Glass. Clean windshield, rear view mirror, and light lenses; inspect for good condition, secure attachment, and broken glass.

a. After‐operation Service is particularly important, because at this time the driver inspects his vehicle to detect any deficiencies that may have developed, and corrects those he is permitted to handle. He should report promptly, to the designated individual in authority, the results of his inspection. If this schedule is performed thoroughly, the vehicle should be ready to roll again on a moment’s notice. The Before‐operation Service, with a few exceptions, is then necessary only to ascertain whether the vehicle is in the same condition in which it was left upon completion of the After‐operation Service. The After‐operation Service should never be entirely omitted, even in extreme tactical situations, but may be reduced to the bare fundamental services outlined for the At‐halt Service, if necessary.

b. Procedures. When performing the After‐operation Service, the driver must remember and consider any irregularities noticed during26 the day in the Before‐operation. During‐operation, and At‐halt Services. The After‐operation Service consists of inspecting and servicing the following items. Those items of the After‐operation Services that are marked with an asterisk (*) require additional Weekly services, the procedures for which are indicated in step (b) of each applicable item.

(1) Item 54, Fuel and Oil. Fill fuel and oil tanks; fill oil tank within 1 inch of top; be sure to put oil in right tank and fuel in left tank; do not interchange caps. CAUTION: When operating under extremely dusty conditions, drain engine oil tank and refill with fresh oil as frequently as excessive contamination of the oil occurs.

(2) Item 55, Engine Operation. Test for satisfactory engine idle without stalling. Accelerate and decelerate engine, noting any tendency to miss or backfire, unusual noises, or vibration that may indicate worn parts, loose mounting, incorrect fuel mixture, or faulty ignition. Investigate any unsatisfactory engine operating characteristics noted during operation. Learn to recognize noise caused by loose primary (front) drive chain. Slack in excess of ½ inch total up‐and‐down motion can cause excessive noise which sounds like engine knock. Remove inspection cover for examination of chain.

(3) Item 57, Horn. If tactical situation permits, test horn.

(4) Item 59, Lights. If tactical situation permits, observe whether blackout and service lights operate with switch in its respective positions, and go out when switched off. Also see that lights are secure, and lenses clean and not broken. Observe whether both filaments of service headlight operate when dimmer switch on left handle bar is moved to its respective positions.

(5) Item 56, Instruments. Before stopping engine, inspect instruments to see that indicator lights are still out. Stop engine. After 30 seconds, turn on switch to see that oil pressure and generator signal lights turn on. CAUTION: Be sure to turn off ignition switch after this test.

(6) Item 58, Glass. Clean rear view mirror, windshield, instrument, and light glass. Examine for secure mounting and breakage.

(7) Item 62, *Battery.

(a) Inspect battery carrier for good condition and secure mounting. Inspect electrolyte level (should be 5⁄16 inch above plates). Inspect for any signs of leakage of electrolyte indicating battery has been overfilled, poorly sealed, or damaged. CAUTION: Do not add water unless actually needed.

(b) Weekly. Clean dirt from top of battery, remove battery caps, bring electrolyte level to 5⁄16 inch above plates, using clean, drinkable water. Clean terminals or posts if corroded; be sure felt washers are27 on terminals and properly oiled; tighten terminal bolts cautiously, if loose. Clean and paint battery carrier if corroded.

(8) Item 63, *Accessories and Chain.

(a) Inspect carburetor, air cleaner, generator, and cut‐out relay for loose connections, mountings, or damage. Examine rear drive chain for broken rollers, broken link side plates, and broken or missing connecting link spring clips. Examine rear chain (final drive) for free up‐and‐down movement (slack) midway between sprockets; maximum total allowable deflection is 1 inch, minimum, ½ inch.

(b) Weekly. Tighten any accessory connections found loose. Wipe excess dirt from rear chain. Check front chain for adjustment, and inspect for proper lubrication.

(9) Item 65, *Air Cleaner.

(a) Examine oil cup for excessive dirt and correct oil level. If air cleaner is excessively dirty, clean elements in dry‐cleaning solvent, refill cup with fresh oil. Dip elements in oil in oil cup, replacing elements and attaching oil cup immediately. If gaskets are damaged, replace. Under extremely dusty or sandy conditions it may be necessary to clean and refill the air cleaner more than once daily. Inspect hose for leaks.

(b) Weekly. Inspect air cleaner for proper oil level and excessively dirty oil. Clean and service air cleaner, tighten mounting and hose clamps. NOTE: Early‐type, round air cleaner does not have removable filter elements. Complete cleaner must be removed to wash element.

(10) Item 66, *Fuel Filter (Gasoline Strainer).

(a) Clean cap and screen of fuel filter.

(b) Weekly. Clean cap and screen of fuel filter, remove carburetor bowl drain plug, and drain off water and dirt. Be sure to replace plug, being careful to avoid cross threading.

(11) Item 67, Engine Controls. Examine throttle and spark controls for damage to wires or for disconnected linkage. Observe for lack of lubrication.

(12) Item 68, *Tires.

(a) Remove foreign matter such as nails, glass, or stones from tire treads. Inspect tires for abnormal tread wear, cuts, or bruises: also for presence and tightness of valve caps. Inflate tires to 18 pounds front, 20 pounds rear, with tires cool.

(b) Weekly. Replace badly worn or otherwise unserviceable tires.

(13) Item 69, *Springs and Suspension.

(a) Inspect front fork for broken or sagged springs, loose bolts, studs, and nuts.

(b) Weekly. Tighten wheel axle nuts and rear brake sleeve nut. Also tighten rear wheel mounting socket screws very securely.

(14) Item 70, Steering. Inspect steering head for proper adjustment of bearings. Examine steering damper for correct adjustment.

(15) Item 72, *Vents.

(a) Make sure that crankcase breather outlet and rear chain oil supply pipe are clear. Make sure grease drains in front and rear brake side covers are open and clean.

(b) Weekly. Clean crankcase breather outlet, rear chain oil supply pipe, and grease drains in front and rear brake side covers.

(16) Item 73, Leaks, General. Look around mechanism and beneath vehicle for indication of fuel, oil, and grease leaks. Examine around brake drums for evidence of grease in drums or on linings. Normally a few drops of oil may be expected to drip from skid plate.

(17) Item 74, Gear Oil Levels. Inspect transmission oil level with vehicle standing on rear stand (not jiffy stand); refill, if required, to level of filler plug opening with engine oil. CAUTION: Do not use gear oil.

(18) Item 76, Fenders (Mudguards), Luggage Carrier, Safety Guards, and Stands. Examine these items for good condition and secure mounting.

(19) Item 82, *Tighten.

(a) Inspect all frame and assembly nuts, bolts, and cap screws for tightness.

(b) Weekly. Tighten all vehicle assembly or mounting nuts. Driver is cautioned not to tamper with or tighten screws or nuts about the circuit breaker, as doing so may disturb ignition timing.

(20) Item 83, *Lubricate as Needed.

(a) Lubricate all parts where inspection reveals need for lubrication: wipe all dirt from fittings before applying lubricant. Report any missing fittings.

(b) Weekly. When vehicle has been driven a sufficient number of miles so that it is due for a regularly scheduled lubrication, lubricate according to Lubrication Guide in manual and current lubrication directives. Refrain from overlubricating wheel bearings, front brake side cover bushing, and front and rear brake operating lever camshafts.

(21) Item 84, *Clean Engine and Vehicle.

(a) Clean dirt and trash from vehicle and remove excess grease.

(b) Weekly. Wash vehicle if possible. If not, wipe off thoroughly. Do not rub lustreless paint enough to cause shine. If vehicle is washed in a stream, care should be taken that water or dirt does not get into bearings, breather valve, or brakes. CAUTION: It is extremely important29 that high‐pressure streams or steam should not be directed against wheel hubs, brakes, carburetor, air cleaner, or electrical units.

(12) Item 64, *Electrical Wiring.

(a) Inspect all ignition wiring to see that it is securely connected, clean, and not damaged.

(b) Weekly. Inspect all wiring to see that it is securely connected and supported, that insulation is not cracked or chafed, that loom, shielding, and condensers are in good condition and securely attached. Clean as required. Tighten any loose connections carefully. Radio shielding or bonding defects, except cleaning or tightening, must be referred to signal corps personnel.

(23) Item 85, *Tools and Equipment.

(a) See that all tools and equipment assigned to vehicle are present, in good condition, and properly stowed.

(b) Weekly. Check tools and equipment assigned to vehicle with vehicle stowage list (par. 21) to see that they are present. Inspect tools for good condition and proper stowage. Report missing or unserviceable items to designated authority.

a. Lubrication is an essential part of preventive maintenance, determining to a great extent serviceability of parts and assemblies.

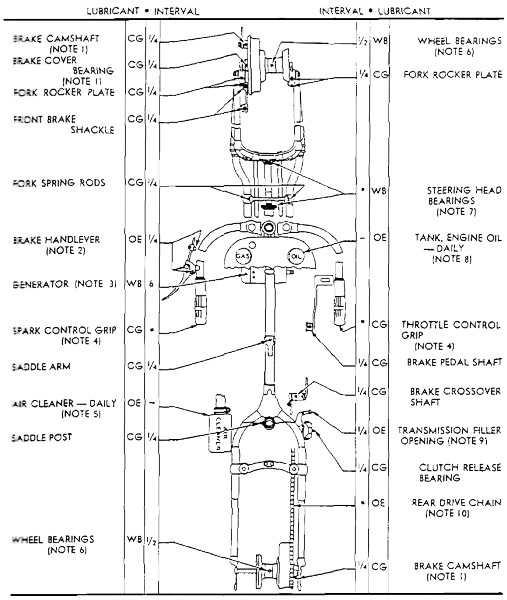

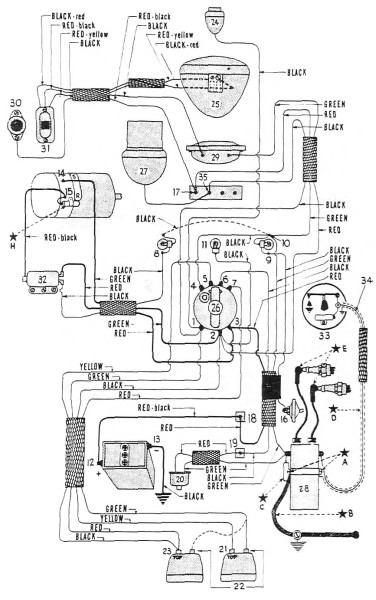

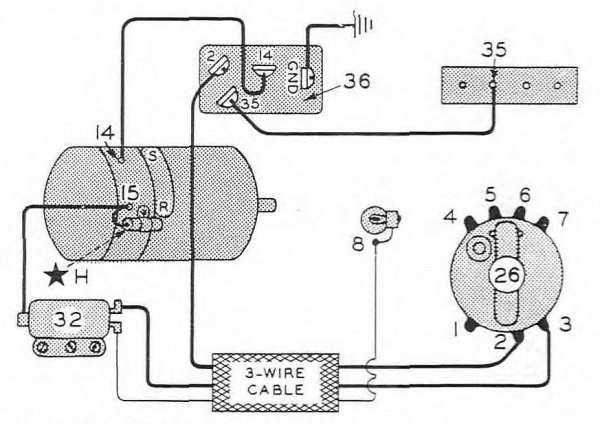

a. General. Lubrication instructions for this materiel are consolidated in a Lubrication Guide (fig. 10). These specify the points to be lubricated, the periods of lubrication, and the lubricant to be used. Intervals indicated on the guide are for normal service. For extreme conditions, high speed, heat, mud, snow, rough roads, dust, etc., change engine oil and lubricate more frequently. In addition to the items on the guide, brake, gear shifter, clutch control linkage, and hinges must be lubricated at frequent intervals.

b. Supplies. In the field it may not be possible to supply a complete assortment of lubricants called for by the Lubrication Guide to meet the recommendations. It will be necessary to make the best use of those available, subject to inspection by the officer concerned, in consultation with responsible ordnance personnel.

c. Lubrication Notes. The following notes apply to the Lubrication Guide (fig. 10). All note references in the guide itself are to the steps below having the corresponding number:

(1) Brake Fittings. Exercise caution when lubricating brake operating cams and front brake cover bushing, as excess grease working out of these bearings is likely to get onto brake lining, reducing brake efficiency. CAUTION: When using air‐operated grease gun, make sure not to overlubricate brake fittings.

(2) Brake Hand Lever Oilcan Points. Oil hand lever fittings and “oiler” mounted on cable housing. Oil front brake control cable at ends of control cable housing.

(3) Generator Commutator End Bearing. Hand‐pack with general

purpose grease, No. 2, at temperatures above zero. Below zero, use

lighter grease. This operation requires removal of generator end cover.

Bearing outer grease retainer must be loosened and swung aside for

access to bearing. If not convenient to grease bearing at specified

intervals, at least lubricate with a few drops of engine oil applied

to hole in outer grease retainer. Do not overlubricate. CAUTION:

Generator regulating brush plate must not be shifted while31

32 bearing

outer grease retainer is loose (par. 92). Generator drive end bearing

requires no attention, since it is lubricated by oil circulating

through engine.

| —— KEY —— | ||||||

|---|---|---|---|---|---|---|

| INTERVALS | ||||||

| LUBRICANTS | ¼ | — | 250 MILES | |||

| OE | — | OIL, ENGINE (CRANKCASE GRADE) | ½ | — | 500 MILES | |

| CG | — | GREASE, GENERAL PURPOSE | 1 | — | 1000 MILES | |

| No. 1 (ABOVE +32°) | 6 | — | 6000 MILES | |||

| No. 1 OR No. 0 (+32° TO +10°) | * L | — | SPECIAL LUBRICATION | |||

| No. 0 (BELOW +10°) | CHECK DAILY | |||||

| WB | — | GREASE, GENERAL PURPOSE (No. 2) | Air Cleaner | |||

| Engine Oil Tank | ||||||

| TABLE OF CAPACITIES WITH RECOMMENDATIONS AT TEMPERATURES SHOWN | ||||

|---|---|---|---|---|

| UNIT | CAPACITY | ABOVE +32° | +32° TO +10° | BELOW +10° |

| OIL TANK | 1 GALLON | OE S.A.E. 50 |

OE S.A.E. 30 |

OE S.A.E. 10 |

| TRANSMISSION | ¾ pint | OE S.A.E. 50 |

OE S.A.E. 30 |

OE S.A.E. 10 |

RA PD 310207

Figure 10—Lubrication Guide

(4) Spark and Throttle Control Grips. These grips require disassembly. Twice a year, or whenever grips do not turn freely, indicating need of lubrication, remove grips, clean parts, apply grease, and reassemble (par. 101).

(5) Air Cleaner. Examine oil cup daily for excessive dirt and correct oil level. Under extremely dusty or sandy conditions it may be necessary to clean and refill the air cleaner more than once daily. Refill oil cup to indicated level with engine oil. Drain, clean, and refill oil cup every 250 miles, depending upon operating conditions. Every 1,000 miles (oftener if necessary), remove air cleaner filter units, wash in dry‐cleaning solvent, lubricate, and reassemble (par. 76). NOTE: Early type round cleaner did not have removable filter element. Complete cleaner must be removed to wash element.

(6) Wheel Bearings. When wheel hubs are lubricated at regular 500‐mile interval, 1⁄8 ounce of grease with each greasing is sufficient. This amounts to about 15 shots of the standard 1‐pound air gun, or four strokes with a 1‐pound, hand‐operated gun. If vehicle has been operated in water, wheel hubs submerged, apply hub greasing service immediately afterward (or soon as situation permits). Do not overlubricate wheel hub bearings, as excess grease may work into brake linings, reducing brake efficiency. When using air‐operated grease gun, it is easy to overlubricate wheel hub bearings.

(7) Steering Head Bearings. Every 50,000 miles, repack upper and lower bearings, or whenever there is occasion to remove rigid fork for repair or replacement (par. 98).

(8) Tank, Engine Oil. Oil tank is located on right side of motorcycle. Empty tank holds 1 U. S. gallon. Check daily and add engine oil as necessary to refill tank within 1 inch of top. Oil level gage rod (dip stick) is located directly below tank cap. When oil level is down to “REFILL” mark on gage rod, 2 U. S. quarts may be added. Drain oil tank every 1,000 miles and refill with fresh engine oil. Drain plug located on underside of tank in forward position. In extremely dusty service, and in winter weather, change oil oftener.

(a) Winter Caution. Water is a by‐product of combustion in any internal combustion engine. In a condensed state, the water vapor formed would equal approximately the quantity of gasoline burned. Some of this water vapor escapes past the rings into the crankcase. When starting and warming up in cold weather, considerable vapor getting into crankcase condenses to water before crankcase is hot enough to exhaust the vapor, without inside condensation, through outside breather. If engine is driven enough to get crankcase thoroughly warmed up frequently, most of this water is again vaporized33 and blown out through outside breather. However, a moderately driven engine, making only short runs now and then, and seldom thoroughly warmed up, is likely to accumulate an increasing amount of water in oil tank. This water will, in freezing weather, become slush or ice and, if allowed to accumulate too long, may block oil lines with resulting damage to engine. Also, water mixed with oil for some time, forms a heavy sludge of considerable acid content that is very harmful to bearings and other internal engine parts. To sum it up briefly, an engine that is used only for short runs during freezing weather requires frequent oil changes along with thorough flushing of tank to remove any accumulated sludge.

(9) Transmission Filler Opening. Check oil level in transmission case every 250 miles and add engine oil as necessary to bring level up to filler opening. If motorcycle is run unusually long distances, inspect more frequently. Motorcycle must be on rear stand in straight upright position when checking oil level or filling transmission case. Use same grade of oil used in engine, summer, and winter. If gear shifting difficulty is caused by oil congealing in extremely cold weather, thin oil with small amount of kerosene or dry‐cleaning solvent. Every 1,000 miles, drain and refill transmission to level of transmission filler plug opening with specified grade of engine oil. Transmission holds ¾ pint of oil. To drain transmission case remove filler plug and lay motorcycle on right side. CAUTION: Do not leave motorcycle on side longer than two minutes.

(10) Drive Chains.

(a) Front and rear drive chains are automatically supplied with lubrication by engine oil pumps. Chain oilers are adjustable and may need occasional readjustment to meet lubrication requirements of varied operating conditions. Every 1,000 miles (or more often if operating conditions are extremely severe) inspect front primary drive chain for adequate lubrication (fig. 36).

(b) At every 1,000‐mile period rear drive chain should have additional lubrication as follows: Remove chain, wash thoroughly in dry‐cleaning solvent and hang it up to dry. Then soak chain in SAE 10 engine oil for a short period of time to allow oil to penetrate into all chain bearings. Drain chain and wipe off excess oil. Install rear chain (par. 63). (This attention is not required by front chain.) Readjustment of chain oilers must be made only by organization mechanic (par. 61). CAUTION: Inspect frequently and make sure that rear chain oiler supply pipe is clear, not bent or damaged.

d. Before Applying Lubricant. Always wipe dirt from the lubrication fittings or plugs so that dirt will not enter with the lubricant. Lubricate all chassis points after washing vehicle or after vehicle has been operated in streams or extremely muddy or slushy roads. CAUTION: It is extremely important that high‐pressure cleaning streams34 or steam should not be directed against ends of wheel hubs, brake side cover bearings, air cleaner, handle bar grips, or electrical system. To do so will seriously affect correct lubrication and functioning of these parts.

e. Oilcan Points. All brake, transmission, and clutch control points not fitted with grease connections should be lubricated with engine oil. Front brake control cable, spark, and throttle control wires must be oiled at the ends of their respective housings, especially after washing vehicle, or after operating it in wet weather. Keep battery terminal felt washers saturated with engine oil to prevent corrosion of connections.

f. Warning Light. Action of the engine oil feed pump is indicated by red signal light in instrument panel. Rider must be thoroughly familiar with operating characteristics of this signal light, to judge condition of engine oil circulating system (par. 7 f).

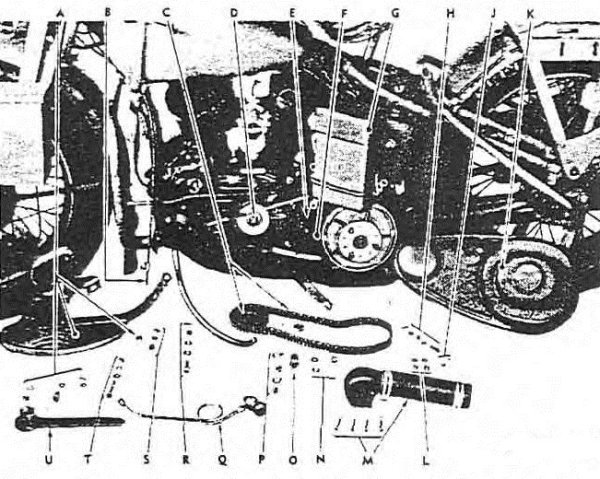

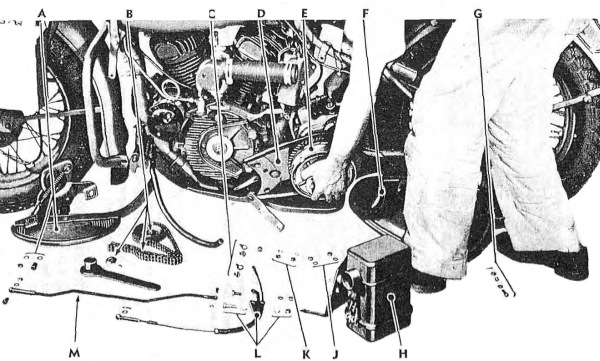

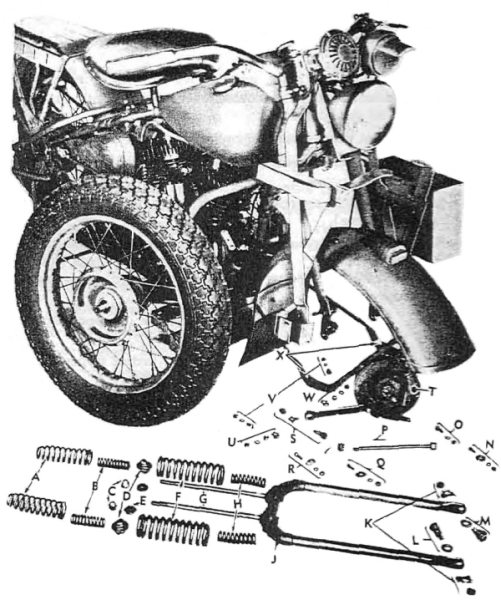

a. Kits. Included in the tool kit assembly are the following:

| Legend Letter for Fig. 11 |

Tool | Number Carried | Mfr’s Number | Federal Stock Number | Where Carried |

|---|---|---|---|---|---|

| A | Tool roll |

1 | 11819–44 | —— | In saddle bag |

| B | Irons, tire |

2 | 11551–X | 41–I–773–75 | In tool roll |

| *C | Handle, chain tool |

1 | 11817–40 | 41–H–1510–400 | In tool roll |

| D | Wrench, 5⁄8–in. by ¾–in. |

1 | 11804–44C | —— | In tool roll |

| E | Wrench, ½–in. by 9⁄16–in. |

1 | 11804–44B | —— | In tool roll |

| F | Wrench, 7⁄16–in. by ½–in. |

1 | 11804–44A | —— | In tool roll |

| G | Wrench, 5⁄16–in. by 3⁄8–in. |

1 | 11804–44 | —— | In tool roll |

| H | Wrench, ⅜–in. by 7⁄16–in. (valve tappet) |

1 | 11905–X | —— | In tool roll |

| I | Wrench, adjustable |

1 | 11813–44 | —— | In tool roll |

| *J | Wrench, ¾–in. by 1¾–in. (rear axle nut and trans.) |

1 | 11814–35 | 41–W–1989–850 | In tool roll |

| K | Gage, tire |

1 | 11562–43 | —— | In tool roll36 |

| *L | Tool, chain repair |

1 | 12039–38 | —— | In tool roll |

| *M | Washers, 0.002–in. thick (chain oiler adj.) |

4 | 674–32 | —— | In tool roll |

| *N | Wrench, 7⁄16–in. by 1⅜–in. (valve cover) |

1 | 11806–31 | 41–W–3617 | In tool roll |

| *O | Wrench, 7⁄16–in. by 11⁄8–in. (use with spark plug socket) |

1 | 11929–39 | —— | In tool roll |

| *P | Pliers, adjustable |

1 | 11812–44 | —— | In tool roll |

| *Q | Screwdriver |

1 | 11811–X | —— | In tool roll |

| R | Wrench, 9⁄16–in. socket (cyl. head bolt) |

1 | 12047–30A | 41–W01525 | In tool roll |

| *S | Wrench, wheel mounting |

1 | 11815–35 | 41–W–3825–400 | In tool roll |

| *T | Wrench, socket (spark plug; use with O) |

1 | 11805–40 | 41–W–3332 | In tool roll |

Pump, tire |

1 | 11553–41M | 8–P–4900 | On frame, left side | |

Grease gun (in case) |

1 | 11661–38A | —— | In saddle bag |

*EXCEPTION: Earlier models furnished with smaller tool roll and kit contain the items marked by asterisk.

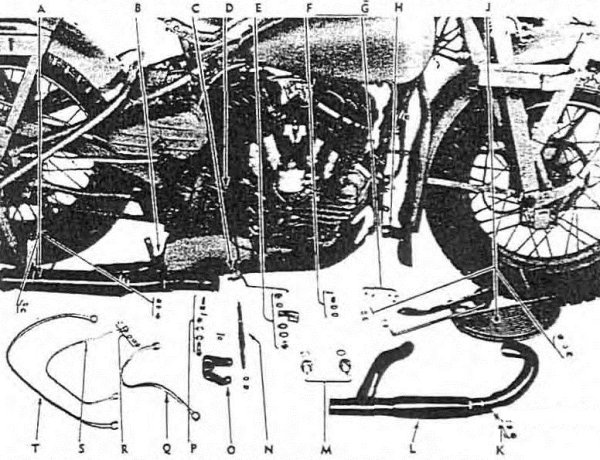

a. Attached to Vehicle.

| Item | Number Carried | Where Carried |

|---|---|---|

Saddlebags |

2 | On luggage carrier |

Mirror, rear view |

1 | On left handle bar |

Box, submachine gun ammunition |

1 | Front fender, left side |

Bracket, submachine gun carrier |

1 | Front fender, right side |

Guard, front safety |

1 | Attached to frame |

Guard, rear safety |

1 | Attached to frame |

Windshield, cpt |

1 | On handle bar |

Leg shields, cpt (right and left) |

2 | Attached to frame |

3a. Spare Parts.

| Item | Number Carried | Where Carried | |

|---|---|---|---|

| A | Roll, parts kit |

1 | In saddlebag |

| H | Plug, spark (and gasket) |

1 | In kit roll |

| F | Link, rear chain repair |

1 | In kit roll |

| G | Link, front chain repair |

1 | In kit roll |

| K | Lamp‐unit, tail blackout |

1 | In kit roll |

| J | Lamp‐unit, stop blackout |

1 | In kit roll |

| L | Lamp‐unit, tail and stop |

1 | In kit roll |

| B | Lamp bulk kit, head lamps, 5 bulbs |

1 | In kit roll |

| C | Kit, tire repair |

1 | In kit roll |

| I | Tape, friction |

1 | In kit roll |

| D | Caps, tire valve (5 in box) |

1 | In kit roll |

| E | Cores, tire valve (5 in box) |

1 | In kit roll |

3 EXCEPTION: No spare parts kit supplied with earlier models. Rear chain repair link only spare part furnished.

a. The scope of maintenance and repair by the crew and other units of the using arms is determined by the availability of suitable tools, availability of necessary parts, capabilities of the mechanics, time available, and the tactical situation. All of these are variable and no exact system of procedure can be prescribed.

a. Indicated below are the maintenance duties for which tools and parts have been provided for the using arm and maintenance personnel. Replacements and repairs which are the responsibility of ordnance maintenance personnel may be performed by using arm personnel when circumstances permit, within the discretion of the commander concerned. Echelons and words as used in this list of maintenance allocations are defined as follows:

| First and Second Echelon: Table III AR 850–15 |

Operating organization driver, operator or crew, companies and detachments, battalions, squadrons, regiments, and separate companies and detachments (first and second echelons, respectively). |

| Third Echelon: Table III AR 850–15 |

Technical light and medium maintenance units, including post and port shops. |

| Fourth Echelon: Table III AR 850–15 |

Technical heavy maintenance and field depot units including designated post and service command shops. |

| Fifth Echelon: Table III AR 850–15 |

Technical base units. |

| Service: (Including preventive maintenance) par. 24 a (2) and (3) in part AR 850–15 |

Checking and replenishing fuel, oil, grease, water and antifreeze, air, and battery liquid; checking and tightening nuts and bolts; cleaning. |

| Service: (Including preventive maintenance) par. 24 a (2) and (3) in part AR 850–15 |

Checking and replenishing fuel, oil, grease, water and antifreeze, air, and battery liquid; checking and tightening nuts and bolts; cleaning. |

| 40Replace: Par. 24 a (5) AR 850–15 |

To remove an unserviceable part, assembly, or subassembly from a vehicle and replace it with a serviceable one. |

| Repair: Par. 24 a (6) in part AR 850–15 |

To restore to a serviceable condition, such parts, assemblies or subassemblies as can be accomplished without completely disassembling the assembly or subassembly, and where heavy riveting, or precision machining, fitting, balancing, or alining is not required. |

| Rebuild: Par. 24 a (6) AR 850–15 |

Consists of stripping and completely reconditioning and replacing in serviceable condition any vehicle or unserviceable part, subassembly, or assembly of the vehicle, including welding, riveting, machining, fitting, alining, balancing, assembling, and testing. |

| Reclamation: AR 850–15 Par. 4 (c) in part CIR. 75, dated 16 March ’43 |

Salvage of serviceable or economically repairable units and parts removed from vehicles, and their return to stock. This includes the process which recovers and/or reclaims unusable articles or component parts thereof and places them in a serviceable condition. |

NOTES: (1) Operations allocated will normally be performed in the

echelon indicated by X.

(2) Operations allocated to the third echelon as indicated by E may

be performed by these units in emergencies only.

(3) Operations allocated to the fourth echelon by E are normally

fifth echelon operations. They will not be performed by the fourth

echelon, unless the unit is expressly authorized to do so by the

chief of the service concerned.

| ECHELONS | ||||

|---|---|---|---|---|

| CLUTCH | 2nd | 3rd | 4th | 5th |

| Bearings, clutch release—replace | X | |||

| Clutch—replace and/or repair (reline) | X | |||

| Hub, clutch—replace | X | |||

| Hub, clutch—repair | X | |||

| Sprocket assembly, clutch—replace | X | |||

| Sprocket assembly, clutch—repair | X | |||

| CONTROLS AND LINKAGE | ||||

| Controls and linkage—service and/or replace | X | |||

| Controls and linkage—repair | X | |||

| 41ELECTRICAL GROUP | ||||

| Battery—service (recharge) and/or replace | X | |||

| Battery—repair | X | |||

| Battery—rebuild | E | X | ||

| Cables, battery—replace and/or repair | X | |||

| Coil, ignition—replace | X | |||

| Head, speedometer—replace | X | |||

| Head, speedometer—repair | X | |||

| Head, speedometer—rebuild | X | |||

| Horn assembly—replace | X | |||

| Horn assembly—repair | X | |||

| Light assemblies—service and/or replace | X | |||

| Light assemblies—repair | X | |||

| Panel, instrument—replace | X | |||

| Panel, instrument—repair | X | |||

| Switch assemblies—replace | X | |||

| Switch assemblies—repair | X | |||

| Wiring—replace | X | |||

| ENGINE | ||||

| (V–45″–Twin Engine) | ||||

| Bearings, main—replace | E | X | ||

| Bearings, connecting rod—replace | E | X | ||

| Breaker assembly, circuit—replace | X | |||

| Breaker assembly, circuit—repair | X | |||

| Breaker assembly, circuit—rebuild | X | |||

| Carburetor—replace | X | |||

| Carburetor—repair | X | |||

| Carburetor—rebuild | X | |||

| Cleaner, air—service and/or replace | X | |||

| Cleaner, air—repair | X | |||

| Cleaner, air—rebuild | X | |||

| Cylinder assembly—replace | X | |||

| Cylinder assembly—repair | X | |||

| Cylinder assembly—rebuild (recondition) | E | X | ||

| Condenser—replace | X | |||

| Engine assembly—replace | *4 | X | ||

| 42 Engine assembly—repair | X | |||

| Engine assembly—rebuild | E | X | ||

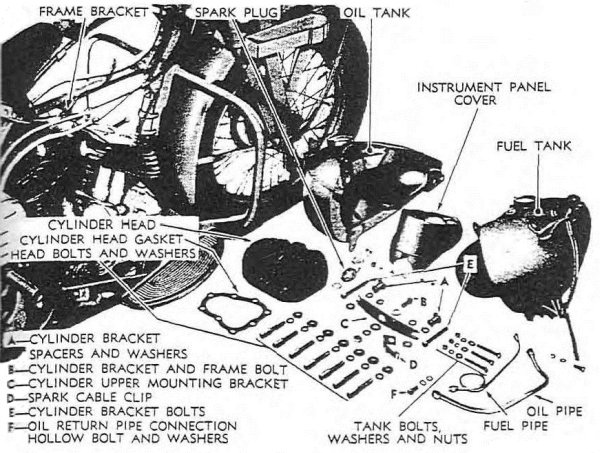

| Gasket, cylinder head—replace | X | |||

| Gears, timing—replace | E | X | ||

| Generator assembly—replace | X | |||

| Generator assembly—repair | X | |||

| Generator assembly—rebuild | X | |||

| Head, cylinder—replace and/or repair | X | |||

| Lines and connections—replace | X | |||

| Lines and connections—repair | X | |||

| Pistons, rings and pins assembly—replace | E | E | X | |

| Plug, spark—replace | X | |||

| Points, circuit breaker—service and/or replace | X | |||

| Pump assembly, feed—replace | X | |||

| Pump assembly, feed—repair | X | |||

| Pump assembly, feed—rebuild | X | |||

| Pump assembly, oil—replace | X | |||

| Pump assembly, oil—repair | X | |||

| Pump assembly, oil—rebuild | X | |||

| Pump assembly, oil scavenger—replace and/or repair | X | |||

| Pump assembly, oil scavenger—rebuild | X | |||

| Rod, connecting—replace and/or rebuild (recondition) | X | X | ||

| Sprocket, engine—replace | X | |||

| Strained gasoline—replace and/or repair | X | |||

| Valves—service | X | |||

| EXHAUST GROUP | ||||

| Muffler and exhaust pipe—replace | X | |||

| Muffler and exhaust pipe—repair | X | |||

| MISCELLANEOUS | ||||

| Bars, safety—replace | X | |||

| Bars, safety—repair | X | |||

| Boxes, ammunition, battery and tool—replace | X | |||

| Boxes, ammunition, battery and tool—repair | X | |||

| Carriers, luggage and scabbard—replace | X | |||

| Carriers, luggage and scabbard—repair | X | |||

| Frame—replace and/or rebuild | E | X | ||

| Guards, mud—replace | X | |||

| 43Guards, mud—repair | X | |||

| Plate, skid—replace | X | |||

| Plate, skid—repair | X | |||

| Saddle—replace | X | |||

| Saddle—repair | X | |||

| Saddle—rebuild | X | |||

| Springs, saddle post—replace | X | |||

| Tank, fuel—replace | X | |||

| Tank, fuel—repair | X | |||

| Tank, oil—replace | X | |||

| Tank, oil—repair | X | |||

| SUSPENSION (FRONT) | ||||

| Bars, handle—replace | X | |||

| Bars, handle—repair | X | |||

| Damper, steering—replace | X | |||

| Drum, brake—replace | X | |||

| Fork, front assembly—replace | X | |||

| Fork, front assembly—repair | X | |||

| Fork, front assembly—rebuild | X | |||

| Fork, spring—replace | X | |||

| Fork, spring—repair | X | |||

| Fork, spring—rebuild | X | |||

| Plate, rocker—replace | X | |||

| Plate, rocker—repair | X | |||

| Shoe assembly, brake—service and/or replace | X | |||

| Shoe assembly, brake—repair (reline) | X | |||

| Springs, cushion and rebound—replace | X | |||

| SUSPENSION (REAR) | ||||

| Chains, all—replace and/or repair | X | |||

| Drum, brake, rear—replace | X | |||

| Guards, chains—replace | X | |||

| Guards, chains—repair | X | |||

| Shoe assemblies, brake—service and/or replace | X | |||

| Shoe assemblies, brake—repair (reline) | X | |||

| Sprocket, rear—replace | X | |||

| Wheels—replace | X | |||

| Wheels—repair | X | |||

| Wheels—rebuild | E | X | ||

| 44 TIRES | ||||

| Casings and tubes—replace | X | |||

| Casings—repair | E | X | ||

| Tubes, inner—repair | X | |||

| TRANSMISSION | ||||

| Spring, kick starter—replace | X | |||

| Sprocket, transmission countershaft—replace | X | |||

| Starter, kick—replace | X | |||

| Starter, kick—repair | X | |||

| Transmission—replace | *4 | X | ||

| Transmission—repair | X | |||

| Transmission—rebuild | E | X | ||

| VEHICLE ASSEMBLY | ||||

| Motorcycle—service | X | |||

| Motorcycle—rebuild (with serviceable unit assemblies) | X | E | ||

4 The second echelon is authorized to remove and reinstall items marked by an asterisk. However, when it is necessary to replace an item marked by an asterisk with a new or rebuilt part, subassembly or unit assembly, the assembly marked by an asterisk may be removed from the vehicle by the second echelon only after authority has been obtained from a higher echelon of maintenance.

| Paragraph | |

|---|---|

| Second echelon preventive maintenance services | 26 |

a. Regular scheduled maintenance inspections and services are a preventive maintenance function of the using arms, and are the responsibility of commanders of operating organizations.

(1) Frequency. The frequencies of the preventive maintenance services outlined herein are considered a minimum requirement for normal operation of vehicles. Under unusual operating conditions such as extreme temperatures, and dusty or sandy terrain, it may be necessary to perform certain maintenance services more frequently.

(2) First Echelon Participation. The drivers should accompany their vehicles and assist the mechanics while periodic second echelon preventive maintenance services are performed. Ordinarily the driver should present the vehicle for a scheduled preventive maintenance service in a reasonably clean condition; that is, it should be dry, and not caked with mud or grease to such an extent that inspection and servicing will be seriously hampered. However, the vehicle should not be washed or wiped thoroughly clean, since certain types of defects, such as cracks, leaks, and loose or shifted parts or assemblies are more evident if the surfaces are slightly soiled or dusty.

(3) If instructions other than those contained in the general procedures in paragraph (4) or the specific procedures in paragraph (5) which follow, are required for the correct performance of a preventive maintenance service, or for correction of a deficiency, other sections of the vehicle operator’s manual pertaining to the item involved, or a designated individual in authority, should be consulted.

(4) General Procedures. These general procedures are basic instructions which are to be followed when performing the services on the items listed in the specific procedures. The second echelon personnel must be thoroughly trained in these procedures so that they will apply them automatically.

(a) When new or overhauled subassemblies are installed to correct deficiencies, care should be taken to see that they are clean, correctly installed, properly lubricated, and adjusted.

(b) When installing new lubricant retainer seals, a coating of the lubricant should be wiped over the sealing surface of the lip of the seal.

(c) The general inspection of each item applies also to any supporting member or connection, and usually includes a check to see46 whether the item is in good condition, correctly assembled, secure, or excessively worn. The mechanics must be thoroughly trained in the following explanations of these terms:

1. The inspection for “good condition” is usually an external visual inspection to determine whether or not the unit is damaged beyond safe or serviceable limits. The term “good condition” is explained further by the following: not bent or twisted, not chafed or burned, not broken or cracked, not bare or frayed, not dented or collapsed, not torn or cut.

2. The inspection of a unit to see that it is “correctly assembled” is usually an external visual inspection to see whether or not it is in its normal assembled position in the vehicle.

3. The inspection of a unit to determine if it is “secure” is usually an external visual examination, a hand‐feel, or a pry‐bar check for looseness; such an inspection should include any brackets, lock washers, lock nuts, locking wires, or cotter pins used in assembly.

4. “Excessively worn” will be understood to mean worn, close to or beyond serviceable limits, and likely to result in a failure if not replaced before the next scheduled inspection.

(d) Special Services. These are indicated by repeating the item numbers in the columns which show the interval at which the services are to be performed, and show that the parts, or assemblies, are to receive certain mandatory services. For example, an item number in one or both columns opposite a Tighten procedure, means that the actual tightening of the object must be performed. The special services include:

1. Adjust. Make all necessary adjustments in accordance with the pertinent section of the vehicle operator’s manual, special bulletins, or other current directives.

2. Clean. Clean units of the vehicle with dry‐cleaning solvent to remove excess lubricant, dirt, and other foreign material. After the parts are cleaned, rinse them in clean dry‐cleaning solvent, and dry them thoroughly. Take care to keep the parts clean until reassembled, and be certain to keep dry‐cleaning solvent away from rubber or other material which it will damage. Clean the protective grease coating from new parts, since this material is not a good lubricant.

3. Special lubrication. This applies both to lubrication operations that do not appear on the vehicle Lubrication Guide, and to items that do appear on such guides, but should be performed in connection with the maintenance operations, if parts have to be disassembled for inspection or service.

4. Serve. This usually consists of performing special operations, such as replenishing battery water, and draining and refilling units with oil.

5. Tighten. All tightening operations should be performed with sufficient wrench‐torque (force on the wrench handle) to tighten the nut according to good mechanical practice. Use torque‐indicating wrench where specified. Do not overtighten, as this may strip threads, or cause distortion. Tightening will always be understood to include the correct installation of lock washers, lock nuts, and cotter pins provided to secure the tightening.

(e) When conditions make it difficult to perform the complete preventive maintenance procedures at one time, these can sometimes be handled in sections, planning to complete all operations within the task if possible. All available time at halts and in bivouac areas must be utilized, if necessary, to assure that maintenance operations are completed. When limited by the tactical situation, items with special services in the columns should be given first consideration.

(f) The numbers of the preventive maintenance procedures that follow are identical with those outlined on W.D. AGO Form No. 463, which is the Preventive Maintenance Service Work Sheet for Motorcycles. Certain items on the work sheet that do not apply to this vehicle are not included in the procedures in this manual. In general, the numerical sequence of items on the work sheet is followed in the manual procedures, but in some instances there is deviation for conservation of the mechanic’s time and effort.

(5) Specific Procedures. The procedures for performing each item in the 1,000‐mile maintenance procedures are described in the following chart. Each page of the chart has a column at its left edge corresponding to the 1,000‐mile maintenance.

ROAD TEST

| 1000 Mile Maintenance | NOTE: If tactical situation does not permit a full road test, perform items 2, 3, 4, 5, 6, 7, 8, 9, 12, and 14, which require slight or no movement of the vehicle. When a road test is possible, it should be for preferably 5, and not over 10 miles. |

|---|---|

| 1 | Before‐operation Inspection. Perform Before‐operation Service listed on W.D. Form No. 418. “Driver’s Trip Ticket and Preventive Maintenance Service Record” (described in par. 15), to determine if vehicle is in a satisfactory condition to make the road test safely. |

| 2 | Ease of Starting. Start engine and observe action of starter. Note if engine responds readily. |

| 3 | Oil Circulation. Oil circulation is normally indicated by oil signal light (red light) in instrument panel being out. When red light is on, oil is not circulating. Observe for48 excess smoke in exhaust. CAUTION: If red light fails to go out after engine has been started, stop engine at once. Refer to paragraph 30 for possible causes. |

| 4 | Instruments. Observe instruments for proper or normal indication and functioning of system to which they apply. |