Red. Orange. Yellow. Green.

Blue. Indigo. Violet.

Title: The Dyer's Guide

Author: Thomas Packer

Release date: December 23, 2016 [eBook #53797]

Most recently updated: October 23, 2024

Language: English

Credits: Produced by Deaurider, Chris Pinfield and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

Transcriber's Note.

Apparent typographical errors have been corrected. The use of hyphens has been rationalised.

THE DYER'S GUIDE.

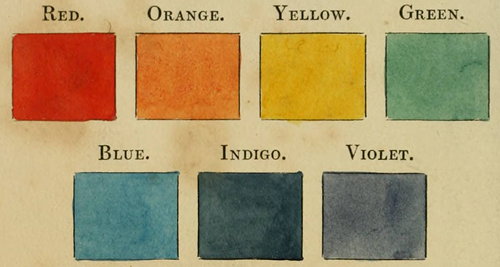

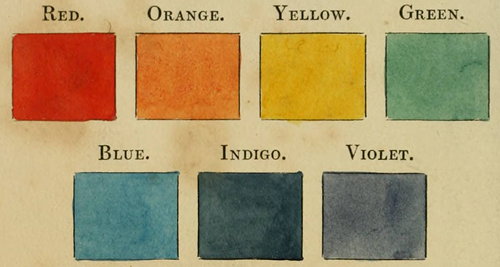

Colours obtained by Sir Isaac Newton's method of decomposing the rays of light, the least refrangible being placed first, the most refrangible last. See p. 18.

Red. Orange. Yellow. Green.

Blue. Indigo. Violet.

THE DYER'S COLOURS AND THEIR CHIEF COMPOUNDS.

SIMPLE COLOURS.

Blue, Yellow, Red, Black[1].

Red includes Crimson, Scarlet, Maroon, Pink, &c.

COMPOUND COLOURS.

Green is made with Blue and Yellow.

Orange with Red and Yellow.

| Purple | ⎫ | |

| Violet | ⎬ | with Blue and Red. |

| Lilac | ⎭ |

Greys with Black, Blue, and Red.

| ⎧ | Blue, Yellow, and Black; | |

| Olives with | ⎨ | or |

| ⎩ | Blue, Yellow, and Red; |

[1] Black according to the theory of Newton, denotes the absence, and White the presence of all colours.

BEING A

COMPENDIUM OF THE ART OF DYEING

LINEN, COTTON, SILK, WOOL, MUSLIN, DRESSES,

FURNITURE, &c. &c.

WITH THE METHOD OF

SCOURING WOOL, BLEACHING COTTON, &c.

AND

DIRECTIONS FOR UNGUMMING SILK, AND FOR WHITENING

AND SULPHURING SILK AND WOOL.

AND ALSO

AN INTRODUCTORY EPITOME OF THE LEADING FACTS IN CHEMISTRY,

AS CONNECTED WITH THE ART OF DYEING.

By THOMAS PACKER,

DYER AND PRACTICAL CHEMIST.

SECOND EDITION,

CORRECTED AND MATERIALLY IMPROVED.

LONDON:

PRINTED FOR SHERWOOD, GILBERT, AND PIPER,

PATERNOSTER-ROW.

1830.

To insist on the utility of the present Manual is, assuredly, superfluous. The favourable reception of the first edition, sometime since out of print, has stimulated the author to revise the work throughout, and to render it more deserving the public approbation. The Appendix to the first edition now forms a part of the Introductory Chapter, to which it naturally belongs; to the whole have been added such improvements as the present advanced state of knowledge, and particularly chemical knowledge, has rendered absolutely necessary; and which the practical dyer will find of considerable importance and much utility.

The following letter from the late Sir Humphry Davy, the first chemist of the age, appeared in the Preface to the first edition; it is here again reprinted as some proof of the sufficiency of that learned man's judgment, at least concerning the chemical theory of the art of dyeing.

I am very much obliged to you for your liberal communication on a subject of my Lectures: I will attend to the information you are so good as to give me in the next Edition.

The author has only to add, that an Index is now appended to the work, by which every article may be most readily and conveniently found.

Page 22, line 3, for proximate read ultimate.

| CHAPTER I. INTRODUCTORY. |

PAGE |

| On the different branches of dyeing— On the drugs used in dyeing—On vegetable and animal substances—On substantive and adjective colours, and mordants—And on the leading facts of chemical science as connected with the art of dyeing—On the calico printer's mordant for yellow and red, and on compound colours—On bleaching—On the theory of fast and fugitive colours—On dye-houses and water—Miscellaneous observations. | 1 |

| CHAPTER II. ON DYEING COTTON. |

|

| To dye cotton a Saxon or chemic blue—Sulphate of Indigo—Saxon or chemic green—To set a cold indigo vat—Another Indigo vat—To dye cotton a fast green with the cold indigo vat and weld—Another cold blue vat for linen and cotton—solution of indigo for penciling printed muslin, &c.—To dye cotton a fast buff—To dye cotton pink. | 47 |

| CHAPTER III. ON DYEING SILK. |

|

| To alum silk—The blue vat of indigo for silk—Another blue vat for silk—To dye silk violet, royal purple, &c.—To dye silk lilac—Another process for lilac—Another process for dyeing muslin, &c. lilac—To dye silk a violet or purple with logwood—To dye silk violet with Brazil wood and logwood—To dye silk violet or purple with Brazil wood and archil. | 63 |

| CHAPTER IV. ON SCOURING AND DYEING WOOL. |

|

| On the action of alum and tartar upon wool—A pastil or woad vat for blue—To prepare the indigo mentioned in the preceding directions—Rules to judge of the state of the vat—Indications when a vat has had too much or too little lime—To work a vat which is in proper order—On the putrefaction of the woad vat—Methods of dyeing blues—To dye wool with lac-dye, scarlet, or crimson—To dye worsted yarn a crimson—A preparation of archil to finish the crimson—on dyeing wool scarlet—To dye wool maroon—To dye wool yellow—To dye wool brown or of a fawn colour—To dye wool purple, &c.—To dye wool green—A chemic vat for green woollen—A chemic vat for blue woollen—To dye wool orange, gold colour, &c.—To dye wool black—Another process for black without a blue ground—To dye wool a grey—Mixture of black or grey with red and blue—On browns, fawns, greys, &c.—On the yellow of Quercitron bark—On a full bright yellow from the same bark—Bancroft's murio-sulphate of tin—To dye wool buff—To dye wool peach—To set an indigo vat for worsted, serge, &c. | 70 |

| CHAPTER V. ON DYEING SILK AND COTTON BLACK. |

|

| To dye silk black for velvets—To dye silk black London process—On dyeing cotton black at Rouen—To dye cotton black, London process—For dyeing black, particularly cotton velvets, at Manchester—On dyeing silk and cotton black with a blue ground—Another iron liquor—To dye cotton black by using the preceding solution—to dye cotton violet—To dye cotton red—To dye cotton an Adrianople or Turkey red—Miscellaneous observations relative to Adrianople red. | 105 |

| CHAPTER VI. ON DYEING COTTON AND SILK. |

|

| To dye skein cotton yellow—On dyeing and re-dyeing cotton furniture yellow—to dye cotton skein a duck's wing green and olive—Of browns, maroons, coffee colours, &c.—Observations on silk—On ungumming and boiling silk—Whitening—Sulphuring—On aluming silk—Skein silk for yellow—Preparation of annatto for aurora or orange, moidore, gold colour, and chamois—To dye silk aurora or orange—To dye moidore—Process for orange—To dye silk poppy or coquelicot—A cheaper poppy with annatto and Brazil wood—On dyeing, silk a fine crimson—Composition for dyeing silks scarlet or crimson with cochineal—Another process for crimson—Another process for crimson by Brazil wood—Of fine violet—Observations on crimson and scarlet upon silk—On dyeing silk green—On olives—On dyeing silk grey—Nut grey—Black greys—Iron greys—On dyeing silk of a Prussian blue colour—Chromate of lead for yellow on silk or cotton—Conclusion. | 123 |

| Index | 153 |

THE

DYER'S GUIDE.

On the different branches of dyeing—On the drugs used in dyeing—On vegetable and animal substances—On substantive and adjective colours and mordants, and on the leading facts of chemical science, as connected with the art of dyeing—On the Calico-Printers' mordant for yellow and red, and on compound colours—On bleaching—On the theory of fast and fugitive colours—On dye-houses and water—Miscellaneous observations.

The trade of a Dyer is, in this country, subdivided into several distinct branches. Thus we have woollen dyers, who are occupied solely in the colours obtained from cochineal, such as scarlet, crimson, orange, buff, &c.; likewise purple, or royal purple, obtained from cochineal and indigo. They are called, also, grain dyers, from the circumstance of the colouring material, cochineal, {2} being in small grains[2]. Yet it ought to be observed, that the term dyed in grain is applied by the public generally in a very different sense, namely, to those cloths the raw material of which is dyed previously to being spun into thread, or at least before woven into cloth; and hence such dyes are usually more permanent than those which are dyed after the materials are woven into cloth. This class of dyers generally dye cloth in the piece, or a number of pieces of cloth tacked together, and worked over a winch in a suitable copper.

There are dyers who likewise dye worsted and woollen yarn of those grain colours, but they are generally a distinct branch. The yarn is dyed in hanks, upon sticks; and, when in the copper, the hanks are changed end for end, so that they may be kept even; such changing being performed five or six times to each turning in.

There are also silk dyers who are grain dyers. These dye in the skein, chiefly for new goods. Some silk, and some mixed silk and worsted goods, are dyed in the piece.

In dyeing cotton, the Adrianople or Turkey Red is, in many cases, a branch of itself, and comes the nearest to what may be called grain or scarlet dyeing upon cotton, because cochineal cannot be applied to cotton to any advantage; yet cotton is occasionally dyed with this material.

In woollen another branch consists of the woad dyers. These often superintend the black dye on woollen cloth, {3} as well as the blue from woad and indigo. There is the same distinction among worsted yarn dyers, they having likewise to do slates, greys, &c. Nearly the same may be said of the silk skein dyers.

In many places, particularly in the country, browns, drabs, stone-colours, &c. constitute a branch in woollen. The same colours form also a branch in calico and muslin; but black, in calico and muslin, is a distinct branch.

The dyers (whether in London or provincial towns) who keep shops, and take in garments, furniture, &c. to be dyed, are termed by the trade Rag-dyers.

There are a few dyers in the metropolis who dye black on woollen, silk, cotton, &c. for the dye-shops, many of these putting all their black out to be dyed.

There are one or two dyers famous for dyeing silk stockings black; these constitute a particular branch. Dyeing bombasins black is also another branch.

The following constitute also particular branches: black hats,—hats of fancy colours,—fur,—chip and straw,—feathers,—leather, Morocco and Spanish, and kid leather for shoes and gloves. Many other branches of the dye-trade might be enumerated, but more detail does not appear necessary.

Concerning all these different branches, one general observation will suffice; namely, that those who are concerned in them have, for the most part, obtained, their knowledge of the art of dyeing, not from theories adapted to explain the different processes, but from practice in that branch in which they are occupied. They usually, therefore, perform those processes which {4} they have been shewn and told, without any inquiry into the causes which produce the results. There are, it is admitted, exceptions to this, men of general information and knowledge being occasionally found in the various branches of dyeing, but they are so few, that it may be questioned, when compared with the great body employed in the art, whether they amount to one in a thousand. This is not, however, to be attributed to any indifference in such persons to acquire a correct knowledge of the art, but is chiefly owing to a deficiency of the ready means of acquiring such information; which information it is the design of the present Treatise to supply; there not being, as far as the present writer knows, any such work, at a moderate price, to be obtained in the English language.

It is true many of the Cyclopædias furnish us with much useful information on the subject of dyeing: one of these, Jennings's Family Cyclopædia, may be particularly mentioned as containing such; but it is scattered about in these dictionaries in various ways, at once troublesome and unpleasant to obtain. Dr. Bancroft's work on the philosophy of Permanent Colours, in two octavo volumes, will also supply much valuable information; so also will the edition, some time since published, of Berthollet's Elements of the art of Dyeing, with the addition of valuable Notes by Dr. Ure. Dr. Ure's Chemical Dictionary is also very useful to the dyer, us well as many detached papers in several of our English publications. A Treatise on Printing and Dyeing Silks, &c. lately published by H. M'Kernan, is also valuable, and should be consulted by the curious in this {5} art. But all these works are expensive, and such as few dyers will be disposed to obtain; hence the necessity of the present Manual, the author of which has not servilely followed the directions or recommendations of any previous writer; but from his own practice, a practice of more than thirty years, has laid down such rules as he knows to be at once practical and efficient. At the same time he thinks it right to state, that he has not only consulted all the works mentioned above, but also Hellot, Macquer, &c. adopting all that appeared essential in these, and giving such additions as accord with the present improved state of chemistry and dyeing; and, as far as was possible, in the limits prescribed for this work, so that it may be within the reach of every dyer in the kingdom, as well as every journeyman and apprentice in all the various branches of this truly extensive and mysterious art, as carried on in London, Norwich, Yorkshire, Gloucestershire, and various other parts of the British dominions.

The author has, in treating of the various matters to be dyed, adopted nearly the same arrangement as that which appears in the Title, taking Cotton first, in consequence of its having the least affinity for dyeing bodies. He has taken Silk next, which has a greater affinity for many dyes, and, when dyed, yields colours more permanent than cotton.

Wool he has not placed entirely last, although many of the colours which it receives from the dyer are complex. The black dyeing of cotton and silk is placed after the processes of black for wool, as likewise the Turkey red, &c. these being naturally difficult to perform.

{6} White and black have been considered colours by dyers, and with propriety, black forming a part of slate, grey, &c. White is seldom pure; in proportion to its clearness and purity will the colours be with which it is dyed.

In regard to black dye, and particularly cotton black dye, the author does not know any simple and concise theory, consistent with chemical principles. He flatters himself, however, that from his extensive experience, his observations are founded on interesting facts. Cotton, for instance, will take fast blues from the cold indigo vat; this vat, with the combination of iron, and in a heat no greater than the hand can bear, will easily produce all shades of grey, slate, &c. Many of these colours may be done by logwood instead of the blue vat, and in the same heat of the dye bath; so cotton likewise, whether in pieces or skeins, may be dyed brown, fawn, drab, &c. in consequence of the great affinity which cotton has for acetate and sulphate of iron.

With respect to black, it should be also observed, that few substances are known which yield by themselves a good black. The juice of the cashew nut communicates, however, a black colour, which resists not only washing, but even boiling with soap and alkaline leys. It is used for marking linen. The Toxicodendron yields a juice which produces nearly the same effect. Some other vegetables also produce black dyes, but all of them in such small quantities as not to be available for the purposes of art; nor do they, besides, produce blacks equal to those formed in the dye-house.

Blue, red, and yellow are admitted to be three distinct {7} colours. In many of the browns, red and yellow are combined naturally in the drugs from which they are produced, and so they are in logwood. Blue, red, and yellow, are developed by iron, whether in the state of an acetate or sulphate.

It may be useful, before we proceed any farther in noticing the theories of dyeing, to give a brief description of the

Alum, or Potash-sulphate of alumina, is a concrete salt, composed of alumina or clay, potash, and sulphuric acid. It is found native in some places; but the greatest part of the alum of commerce is prepared by a peculiar management of schistose pyritic clays, usually denominated alum ores. Alum is made at Civita Vecchia, in Italy, and also at many other places on the continent; at Hurlett near Glasgow, at Whitby in Yorkshire, &c. Its form and appearance are both too well known to need being described. Its chemical composition is as follows: sulphate of alumina, 36.70; sulphate of potash, 18.88; and water, 44.42—together 100. The alum called in commerce Roch alum, said to be obtained from Roccha, in Syria, is in smaller crystals than common alum, and has a reddish hue, but does not appear to be essentially different from the common alum. Common alum requires sixteen parts of water, at a temperature of 60°. to dissolve one of it; but there is another kind not generally made or known, containing soda instead of potash, and hence with propriety named soda-sulphate of alumina, which is soluble in less than its {8} own weight of water, and which, on this account, may become valuable in some processes of dyeing.—Ure.

Acetate of Alumina is prepared in large quantities for the calico printers, by decomposing alum with acetate of lead, or more economically with aqueous acetate of lime, having a specific gravity of about 1.050, a gallon of which, equivalent to nearly half a pound avoirdupoise of dry acetic acid, is employed for every 2½ lbs. of alum. A sulphate of lime is formed by complex affinity which precipitates, and an acetate of alumina floats.—Ure.

Archil, Archilla, Rocella, Orseille, or Litmus, is said to be a whitish lichen growing upon rocks in the Canary and Cape Verd islands, which yields a rich purple tincture, fugitive, but extremely beautiful. It is brought to this country as it is gathered; it is prepared here for the dyer, by grinding it between stones, so as thoroughly to bruise but not to reduce it into powder; it is moistened occasionally with a strong spirit of urine, or urine itself, mixed with quicklime; in a few days it acquires a purplish red, and at length a blue colour; in the first state it is called archil, in the latter lacmus or litmus. The dyers rarely employ this drug by itself, on account of its dearness and the perishableness of its beauty. Its chief use is to give a bloom to other colours, as pinks, &c.

Cudbear is also manufactured in this country from archil, and is in repute for dyeing various shades, from pink and crimson to a mazarine blue; it is said these colours are very permanent.

Argol, or Tartar, is a crystalline substance deposited in wine casks during the fermentation of the wine, {9} from the juice of the grape, in which it exists in considerable abundance. It is an impure supertartate of potash; that is, potash combined with a superabundant quantity of tartaric acid. Algol is found in commerce of two colours, white and red. Cream of tartar is the same substance freed from colouring and other extraneous matter.

Blood. See Adrianople red.

Bran acts in some peculiar way on colouring matter, but scarcely on the mordants. It seems to loosen and remove the colouring matter; as also to alter its hue in some cases, an effect obvious in the bran pinks.—Ure.

Chlorine. See Oxymuriatic acid.

Cochineal is the female insect of the coccus cacti found on the cactus coccinellifer and cactus opuntia, Prickly pear or Indian fig, natives of South America, the West Indies, and other tropical regions. The female of the insect is the true cochineal; in her full sized, pregnant, and torpid state, she bears so small a proportion to her former or creeping state, that her antennæ, legs and proboscis are scarcely discernible; her whole appearance is that of a whitish berry, and so it was formerly regarded. This insect is found in a wild state in Mexico, Georgia, South Carolina, and some of the West India Islands, feeding on several species of the cactus; but in some of the Spanish settlements, as well as in Mexico, the insect is domesticated, and fed on the cactus coccinellifer, which is cultivated for the purpose, on which it attains a much larger size than in its wild state. Cochineal is also obtained from the East Indies; but East Indian cochineal has not yet attained the quality of that produced {10} in the West Indies and America. Its use, as a colour for dyeing many shades of red, &c. is great and important.

Copper is also used in dyeing, in the state of a sulphate or blue copperas, a nitrate, and also as an acetate. See Verdigris.

The Gall or Bile of ANIMALS consists of a saponaceous bitter, yellowish fluid, secreted by the liver, and found in the sac usually called the gall-bladder. It is sometimes preferred to soap for cleansing cloths by the dyer and the scourer.

Galls are excrescences produced on the quercus infectoria, a species of oak growing throughout Asia Minor. The gall grows on the shoots of the young boughs, and is produced by an insect, the cynips quercusfolii; this insect punctures the tender shoot with its sting and deposits its egg in the puncture; the egg is soon hatched, and the irritation of the maggot feeding on the plant produces the wen or gall-nut. When the nuts are gathered before the worm within changes to a fly, and not yet having eaten its way out, they are of a dusky green colour, and are called in commerce blue galls, and are by far the best. Those collected after the fly has eaten its way out have a hole in each, are of a whitish yellow colour, considerably lighter than the blue-galls, and of an inferior quality: they are brought to this country chiefly from Aleppo. They are used in large quantities in the arts, principally for dyeing, and making ink. They contain a large quantity of Tannin and Gallic acid.

Indigo is a well known deep blue substance, obtained {11} from the Indigofera tinctoria or Indigo bearing plant, a native of the East Indies, which is propagated by seed and will thrive in most tropical climates; hence we have good indigo from South America, the East Indies, Carolina, &c. The chief criterion of the goodness of indigo is, if, when cut with a knife, it exhibits a reddish copper-like appearance; where this shade is not, or only very slight, the indigo is of inferior value. It is prepared by macerating the leaves in water, whence is obtained the blue feculence or indigo. Indigo is insoluble in water, but soluble in sulphuric acid, hence a solution of it in this acid, forming a sulphate of indigo, is well known in the art of dyeing.

The best indigo is that called Flora, which floats in water, all the other kinds sink in that fluid.

The constituent parts of indigo are Carbon, 73.22, Nitrogen 11.26, Oxygen 12.60, and Hydrogen, 2.92, = 100.

When indigo is digested in concentrated sulphuric acid, it is converted into a peculiar blue substance, commonly called sulphate of indigo; this colouring matter has been, however, lately named Cerulin, by Mr. W. Crum, who has made many experiments on it; (see notes to Bertholet, vol. ii. p. 357. et seq.) he observes that cerulin dissolves more abundantly in sulphuric acid than water; but this does not prove the formation of a compound entitled to be called sulphate of indigo; that, such a solution differs in no respect from that of resins in acids or in alcohol. Another substance has been also obtained from indigo by Mr. Crum, of a purple colour, which he calls Phenicin; it dissolves both in water and alcohol.

{12} Iron rarely in its metallic state enters into the manipulations of dyeing, but its sulphate, muriate, acetate, &c. as well as its oxides contribute largely to the dyer's art.

Sulphate of Iron, or green copperas, as it is commonly called, is too well known to need description; it is in green crystals of different sizes, and is used for various purposes in dyeing, &c.

Peracetate of Iron, or Acetate of Iron, forms a reddish-brown uncrystallizable solution, much used by the calico printers, and is prepared by keeping iron turnings or pieces of old iron for six months immersed in redistilled pyrolignous acid. It may be also prepared in a more expeditious way by boiling filings of iron with the acid.

Lac dye and LAC LAKE are two articles now regularly imported from the East Indies, and employed for dyeing scarlet. They both appear to be the colouring matter of seed-lac, obtained from it in India by a process not generally known. Both these articles are in lumps or cakes of a dark-reddish or blackish colour.

Muriatic acid, or spirit of salt, as it was formerly called, is obtained from common salt or muriate of soda, by distillation with sulphuric acid. When this acid is pure it is perfectly colourless, but it generally has a yellow hue arising from a little iron. It gives out, at all temperatures, a large quantity of a fuming suffocating gas of a peculiar smell. Its usual specific gravity is about 1.160. For the basis of this acid see Oxymuriatic acid.

Nitric acid is composed of oxygen and nitrogen: it is usually obtained from nitre, (the chemical name of which {13} is nitrate of potash,) by distilling three parts of it with two of sulphuric acid. When pure, nitric acid is a colourless, extremely sour, and corrosive liquor. Its specific gravity is 1.42; it always contains more or less water, which modifies its specific gravity. It is usually coloured with nitrous acid gas. It forms a variety of compounds with numerous other bodies. Aqua fortis is this acid diluted more or less with water; when strong it is called double, when weak single aqua fortis. For Nitrogen, see forwards.

Nitro-muriatic acid, or AQUA REGIA, is a mixture of nitric and muriatic acids. It is usually made by dissolving sal ammoniac or common salt in nitric acid. When the former is employed the usual proportion is one of the salt to four of the acid; but equal parts will be necessary to dissolve platinum. Aqua regia is the only menstruum which will dissolve gold.

Orpiment, REALGAR, or SULPHURET of ARSENIC has been lately applied to the purposes of dyeing a yellow colour. Sulphur may be combined with arsenic in different proportions. Realgar is red, and occurs native in Germany and Switzerland; it is also produced by art. Orpiment is commonly produced by art and is of a yellowish colour; native orpiment is also occasionally found; it is of a bright lemon colour.

Oxymuriatic acid, or as it is now more correctly termed CHLORINE, from its yellowish green colour, is an elastic gaseous fluid of a pungent disagreeable smell, and highly injurious to animal life, even when largely diluted with atmospheric air. Mixed with hydrogen, and exposed to light, they combine and produce a sour compound {14} called muriatic acid gas; this gas is greedily absorbed by water, which takes up 480 times its bulk, and has its specific gravity increased from 1 to 1.210. Thus dissolved in water it forms the liquid muriatic acid mentioned in a preceding article.

Chlorine forms combination, besides, with several other bodies; many of its combinations are termed oxymuriates, or more properly, chlorides: some of these are extremely useful in bleaching, dyeing, &c. The muriatic acid appears to be the only acid of any consequence into which oxygen does not enter.

Oxide is the combination of oxygen with some base, without being in the state of acid; it is most commonly applied to the combination of oxygen with metals; most of the different rusts of metals are oxides. As oxygen combines with the metals and other bodies in different proportions, its combinations are distinguished by different prefixes, thus: protoxide denotes an oxide containing the least quantity of oxygen: deutoxide the next larger quantity; tritoxide the next; and peroxide the largest possible quantity of oxygen in the compound when it is not acid. For Oxygen see forwards.

Pot-ashes and Pearl-ashes (one of the fixed alkalies) are both impure carbonates of potash obtained from the ashes of innumerable vegetables, over which water is poured which dissolves the salts, and by evaporating the water leaving the salt, a dry powdery white mass is obtained. The chief difference between pot-ashes and pearl-ashes consists in the superior whiteness of the latter, and in the former being of a more dirty colour, and more caustic than the latter; hence it is not so highly {15} saturated with carbonic acid. For many purposes in the arts such caustic potash is to be preferred.

Quercitron, or American-bark is obtained from the quercus nigra or black oak, a native of North America. It is used for dyeing yellow, and was brought into notice by Dr. Bancroft, who obtained the exclusive privilege of using it as a dye by an Act of Parliament, passed in the 25th year of the reign of George III.

Safflower, bastard-saffron or carthamus, is obtained from one or two plants, species of the carthamus genus, natives of the South of Europe and the Mediterranean coasts. This dyeing material consists of two colouring substances, a yellow and a red. The former is of little value, the latter which is soluble in alkalies forms, by precipitation with acids, a beautiful red pigment sometimes used for silk dyeing, but more commonly in the preparation of rouge.

Soda, called sometimes mineral alkali, is another of the fixed alkalies; it forms the basis of common salt, that being a muriate of soda; soda, under the name of barilla, is used in making soaps, and also in dyeing.

Sulphur, or Brimstone, is scarcely used for dyeing in its crude state, but when combined with oxygen forming sulphuric acid, as well as when that acid is combined with various bases, as iron, alumina, &c. it becomes of great importance in this art; see Sulphuric acid.

Sulphate of Iron, see Iron above.

Sulphuric Acid was for many years, and still is called by the vulgar, oil of vitriol, because it was formerly obtained from green vitriol or sulphate of iron, but the more simple and ingenious processes of modern chemistry {16} have superseded the old methods; sulphuric acid is now obtained by burning sulphur with a certain portion of saltpetre in large leaden cisterns. The acid fumes sink into the water placed at the bottom of the cistern, the water being afterwards boiled away: the acid is afterwards purified by retorts, placed in a sand heat. The specific gravity of good sulphuric acid should be 1.85.

Sumach is the production of the rhus coriaria, a shrub which grows naturally in Syria, Palestine, Spain, and Portugal. It is cultivated in the two last countries with great care. Its shoots are cut down every year quite to the root, and after being dried are reduced to powder, and thus prepared for the purposes of dyeing, &c. Sumach bears a great resemblance, as an astringent, to galls. Sumach alone gives a brown and a fawn colour, but cotton stuffs impregnated with acetate of alumina take a durable yellow from it.

Tartar, see Argol.

Tin, dissolved in nitric or muriatic acid, forms solutions of great importance in many processes of dyeing, particularly scarlet. These solutions are called respectively nitrate and muriate of tin.

Turmeric is a root obtained from a plant growing both in the East and West Indies. The root is used chiefly for dyeing yellow; but it is a fugacious colour.

Verdigris is a crude acetate of copper, obtained by exposing copper plates to the husks, &c. of grapes, which containing considerable acetic acid, the acid combines with the surface of the copper plates, forming a blueish green rust, which is scraped off, and forms the verdigris of commerce. A still more complete acetate of {17} copper is obtained in distilled verdigris, which is in elegant green crystals. The best verdigris is made in France; some is now also made in this country.

Weld, sometimes called improperly Woulds, dyer's-weed, or Reseda luteola, is a plant found wild, in this country, but cultivated for the purposes of the dyer; it is much used for yellows.

Woad, or Pastel, is obtained from a plant growing in various parts of Europe and also in this country; it is the Isatis tinctoria, and is cultivated with care for the dyeing matter which it affords, and which is obtained from the leaves of the plant, collected and prepared in a particular manner. Woad gives a full-bodied and fast blue to wool, yet not very bright, so that it is usually mixed with indigo[3].

Besides the preceding substances we may mention that annatto is used for dyeing several colours; kermes, madder, and Brazil wood for reds; logwood for purple and black; peach-wood for maroon, &c.; fustic, dyer's-broom, saw-wort, French-berries, &c. for yellow; walnut-root, and the outside green shell of the nuts for browns. We may also mention prussiate of potash, acetate of lead, commonly called sugar of lead, and oxide of manganese, as occasional articles used for various purposes by the dyer. Several other substances are also used in dyeing, which we cannot enumerate; some are mentioned in the subsequent pages. We may, however, name cam-wood, bar-wood, redsanders, and myrobolans. We ought also {18} to observe that how desirable soever it may be to have all woods for dyeing, in powder, in order to obtain the greatest quantity of colouring matter from them by decoction or otherwise, yet, as in a powdered state they are much more likely to be adulterated than in chips, it is most advisable to purchase them in this last state; logwood in particular ought never to be purchased in powder.

In order more correctly to understand the theory and practice of dyeing, it is essential that the pupil should become acquainted with the nature of the substances upon which and with which he must necessarily operate. We shall not enter into the theories of light and of colours, as propounded by Sir Isaac Newton, as well as many illustrious chemists, who have already done so much for the art of dyeing, but shall simply refer to such writers as Ure, Bancroft, Berthollet, Brande, &c. from whom may be learnt what is of most importance to be known concerning this curious subject.

We may just add, however, in regard to light, that Sir Isaac Newton proved it consists of rays differing from each other in their relative refrangibilities. By causing light to pass through a hole in a window-shutter into a darkened room, and receiving that light on a glass prism, the rays, in passing through the prism, not only became refracted, that is, thrown out, of the rectilinear direction, but also separated into seven distinct colours, namely, red, orange, yellow, green, blue, indigo, and {19} violet. The red being the least refracted and violet the most. If these prismatic, or primary colours, as they are usually called, be divided into 360 equal parts, the red rays will occupy 45 of these parts, the orange 27, the yellow 48, the green 60, the blue 60, the indigo 40, and the violet 80, and, what is very remarkable, these colours, when mixed in the proportions here set down, produce white. This may be readily proved by mixing seven powders of the colours and quantity mentioned, or by painting a wheel with the same proportions of the different colours and making it revolve rapidly. But it should be noted, that, in either case, the white will not be so pure and delicate, as that produced by the mixture of the rays of light. Upon these phenomena is founded the Newtonian theory of colours. Thus green bodies reflect the green rays and absorb the others. All the rays are reflected by white bodies, and absorbed by those which are black.

It is, notwithstanding, highly necessary that the learner should know that portion of modern chemistry which will lead him to the best secrets of his art, and hence assure him of that which was only before conjecture. And it cannot be sufficiently impressed upon him, that if our theory be not true, we work from wrong data; we may, it is true, approach the truth; be right in some things and wrong in others, and our uncertainty and mistakes will be accordingly; yet the most complete dyer must be he, who with extensive practice combines a knowledge of the true principles of his art, to which modern chemistry is, doubtless, the key.

It is scarcely necessary to insist further on the importance {20} of a knowledge of the constituent parts of vegetable and animal bodies, as well as those inorganic substances with which chemistry has so largely to deal; but it will be seen, in the course of our subsequent observations, what difficulty there is in dyeing cotton of a red colour, similar to that produced by cochineal on wool; how, in dyeing cotton yarn an Adrianople red, the intestinal liquor of the sheep, and the dung and the blood of the same animal are used, and have been found so important by the dyers of Asia; hence the colour is called the Adrianople or Turkey red.

It is found by experience, and particularly in hot climates, that substances containing ammonia (volatile alkali) quite developed, have the property of raising and rendering more intense the red colours. It has been found, too, that the bones of animals retain the colour of madder very strongly, when they have been given that colouring material; and the vivacity of the colour has been attributed in such cases, it is presumed with truth, to the ammonia which the bones contain.

There are, therefore, in regard to vegetables in particular, some things, the nature and properties of which it is absolutely necessary that the dyer should understand: for want of a knowledge of one of them, it is a fact that losses are very often sustained to a serious amount. It may seem surprising, but the author has not seen in any writer on dyeing or chemistry, a proper method of working the pastil or woad vat; nor how to renew and work it down, again and again, with an assurance that it will be neither decomposed nor spoiled; and which, for want of a proper knowledge, it has often {21} been. We shall therefore endeavour to give some directions by which those fatal and expensive disasters may be avoided.

Although, at first sight, it seems easy to distinguish the three kingdoms of nature from each other, yet there is such an imperceptible transition from one to the other, that it will be difficult to give such a definition as shall embrace all the individuals of each, and, at the same time, exclude those of the other kingdoms. On examination, indeed, we do find that there is in fact no natural distinction of this kind; and that there is scarcely a function common to vegetables and minerals which some of the animal tribe do not enjoy, and vice versâ. Yet it must, however, be noted, that most animals have the power of voluntary loco-motion, and are thus rendered peculiarly different from all other bodies which we find upon or in the earth.

The substances constituting vegetable differ from those constituting mineral bodies, in their being of a more complex kind; and though vegetables are extremely susceptible of decomposition in various ways, not one can be, by any art, synthetically produced. Yet, although what are called by chemists the proximate constituents of vegetables are numerous, such are water, starch, sugar, gum, gluten, wax, oil, camphor, resins, colouring matter, extractive matter, several acids, &c. &c. all of which are capable of being decomposed, the ultimate constituents of vegetables are very few; the chief are carbon, hydrogen, and oxygen; some afford nitrogen; in some are traces of sulphur, potassa, lime, soda, magnesia, {22} silica, &c.; in nearly all vegetables are traces of iron; in many manganese.

As the ultimate principles of vegetables are chiefly carbon, hydrogen, and oxygen, it will be useful to inquire how vegetables obtain these materials. Water, which is composed of hydrogen and oxygen, is a ready source whence both its constituents may be obtained; and it is concluded that it is decomposed in the glands of vegetables, assisted by solar light, and becomes fixed in them in the state of oil, extract, mucilage, &c. The greatest part, however, of vegetables consists of carbon, or, to make ourselves more intelligible, pure charcoal; the carbon, notwithstanding its solidity in the shape of charcoal, most readily combines with oxygen, and hence it forms, as carbonic acid, a small portion of atmospheric air, from which source the carbon of plants is in part at least derived. Another source from which plants derive their carbon is the earth, and decaying vegetable matters; the dung of animals supplies also some of the constituents of vegetables. Indeed, in the application of dung and other matters, so as to promote the healthy and vigorous growth of vegetables, does the science of agriculture chiefly consist. It appears, however, that nourishment is received principally, if not entirely, by plants in a liquid or gaseous form. It should be noticed too, that few, if any, healthy vegetables will grow any where except in light, a powerful stimulant at all times, not only to plants but to animals; such are its effects, that many dyes in cloth are materially altered, nay, sometimes destroyed by it.

{23} Animal substances thus differ from vegetables: they afford a considerable quantity of ammonia, (which is, it is now known, a compound body consisting of hydrogen and nitrogen), and very fetid products, either by the action of fire, or by the putrid fermentation. They also putrify more readily and speedily than vegetables, and give out a very disagreeable smell. They also contain a considerable quantity of nitrogen, the presence of which constitutes the most striking peculiarity of animal compared with vegetable bodies; but as some vegetables contain nitrogen, so there are certain animal principles into the composition of which nitrogen does not enter. The chief ultimate principles then of animal matter are carbon, hydrogen, oxygen, and nitrogen; but phosphorus and sulphur are also often contained in it. Lime also exists in animal bones and shells in considerable quantity, usually, however, in combination with the phosphoric and the carbonic acid. The chief proximate principles of animal matter are blood, albumen, gelatine, colouring matter, milk, bile, lymph, urine, skin, muscle, horn, hair, fat, cerebral substance, shell, and bone, &c.

The differences between vegetable and animal bodies appear to depend upon animal matter containing nitrogen in much greater abundance than it is found in vegetables; and hence the decomposition of animal matter by destructive distillation is characterized by the presence of ammonia, which is formed by the union of the hydrogen with the nitrogen; and it is sometimes so abundantly generated as to be the leading product: thus when horns, hoofs, or bones are distilled by themselves, a quantity of solid carbonate of ammonia and of the same substance {24} combined with a fœtid oil, and dissolved in water, are obtained. Hence the preparations called salt and spirit of hartshorn and animal oil.

The principal animal fluids are blood, milk, and bile. The blood, soon after it is taken from the living animal, separates into two parts, one called the crassamentum, which is red, and the other serum, which is a fluid, and of a pale straw-colour; the crassamentum is a more firm and consistent mass than the serum, by which it is usually, when cool, surrounded. Milk consists of serum or whey, butter, which while floating on the milk is called cream, and curd or cheese, which has the leading properties of coagulated albumen. The bile, as has been before stated, is a saponaceous fluid consisting chiefly of albumen, soda, a bitter resin, water, and some other saline matter. Fat, in the dead animal, is merely animal oil in a concrete or hardened state.

The principal animal solids besides bone, are albumen, gelatine, and fibrin. These substances, in certain states of concretion and combination, form all the solids of animals, and are separable from each other by easy analysis.

By whatever means we deprive animal substances of their nitrogen, we reduce them to a state similar to that of vegetables. The muscular fibre, or flesh as it is usually called, when excluded from the air, but particularly if in contact with water, parts with its nitrogen, and is converted into a substance resembling spermaceti, which in its analysis agrees with vegetable expressed oil.

When vegetables and animals are deprived of life, their various parts, and especially their fluids, sooner or {25} later, spontaneously assume processes which terminate in their total decomposition. The earlier stages which lead to their decomposition are termed fermentation. Of this there are three kinds; the first, or vinous fermentation, takes place in vegetable juices which contain a considerable quantity of sugar, such are the juices of the grape forming wine, of the apple forming cyder, &c. In this fermentation a considerable quantity of carbonic acid gas is disengaged; this gas is very destructive to animal life, no one can live for a minute in it. If, after the vinous fermentation is completed, the liquor be exposed for some time to atmospheric air, another fermentation takes place, oxygen is absorbed, and the liquor becomes vinegar, hence called the acetous fermentation. The putrid fermentation generally takes place in animal bodies very soon after death, so that neither of the other processes, certainly not the vinous, the acetous rarely, becomes a condition of animal matter.

The chief product of the vinous fermentation is an intoxicating, colourless, volatile, and highly inflammable liquor called alcohol; in common language rectified spirits of wine. It may be obtained by distillation from wine, cyder, perry, brandy, &c. &c.; and from whatever liquor it be obtained, when freed from extraneous matter, it is in every case the same. Alcohol consists of hydrogen, carbon, and oxygen. Its usual specific gravity is 825, water being 1000.

After vegetables have passed through these fermenting processes, the decomposition continuing, unless checked by extraneous means, the remainder of their constituents become separated, many of them being volatilized in the {26} form of gas, and nothing remains but a black or brown residuum called mould, consisting of carbon, some salts, a little oil, and extractive matter.

In the decomposition of animal substances, we perceive the union of hydrogen and nitrogen forming ammonia; the combination of carbon with oxygen produces carbonic acid; and nitric acid arises from the union oxygen and nitrogen. A quantity of hydrogen is also extricated in the form of gas, carrying off with it sulphur and phosphorus, which produce together the disagreeable smell arising from animal putrefaction. Nothing now remains but a portion of carbon mixed with phosphate of soda and phosphate of lime.

Hence we see that, by the processes of fermentation, complex bodies are converted into more simple substances, and that nature restores, in the new combinations, the principles which she had borrowed from the atmosphere for the formation of both animals and vegetables; and that she accomplishes a perpetual circle of ever-changing being, at once demonstrating the fecundity of her resources, and the grandeur and simplicity of her operations.

The substances commonly dyed are either animal, as wool, silk, hair, leather, and skins of all kinds; or vegetable, as cotton, flax, hemp, &c. Great differences exist between the affinities for colouring matter possessed by {27} these substances, so that a process which perfectly succeeds in dyeing wool may fail when applied to cotton. Wool has generally the strongest affinity for colour; silk and other animal substances come next; cotton next, and hemp and flax last.

Of the numerous known dyes, few can be applied to either animal or vegetable fibre without some preparation beyond that of cleansing the stuff, and immersing it in the dyeing liquor. When colours can be fixed on cloth without any previous preparation, they are called substantive colours, such is indigo; when they cannot be so fixed, but require to be saturated with some preparation, such as acetate of alumina, or a metallic oxide, &c. they are called adjective colours; of this kind are madder, cochineal, &c. The substances with which cloths are impregnated, previously to being dyed, are called mordants, because they are supposed to bite or lay hold of the colour which is applied.

The chief difference between vegetable and animal substances is, that animal (as for instance wool) contains a small portion of carbon, and a large quantity of hydrogen and nitrogen; while vegetables contain a very large proportion of carbon, less hydrogen, and, in general, no nitrogen.

It is the interest of every dyer to acquire as much information as possible concerning the nature of alum, iron, carbon, nitrogen, hydrogen, the alkalies, acids, &c. in order to prevent or obviate the consequences of an incorrect application of these agents in the various departments of his art, and also to apply them with the greatest success. We shall, therefore, enter a little into {28} the nature and combinations of some of these bodies, and state some of the leading facts with which the modern discoveries in chemistry have made us acquainted.

Carbon, or charcoal, is considered an elementary body, because, as yet, no means have been found adequate to decompose it; it forms the skeleton of vegetables or their woody fibre.

We must now direct the attention of the reader to oxygen gas, the discovery of which was made by Dr. Priestley in the year 1774, and by him called dephlogisticated air; the most important discovery that was, perhaps, ever made in chemistry. When a metal is exposed to atmospheric air, at almost every temperature, it loses its metallic lustre, and acquires the form and appearance of an earthy substance. If this change be produced in a given quantity of air, the oxidation can only be carried on to a certain degree; and on examining the air which remains, we shall find that it has lost the whole of its oxygen, and that nothing remains but nitrogen gas. What was formerly called the calcination of metals is nothing but the process of their union with oxygen, which is now therefore properly called their oxidation.

If charcoal be mixed with the metallic oxide, and a suitable heat be applied to the mixture, it will unite with the oxygen and form carbonic acid, which will fly off in the form of gas, while the metal will assume its metallic form. From this we learn that oxygen is a part of atmospheric air, and that nitrogen constitutes another portion of the same air. Ammonia is a combination of nitrogen and hydrogen. Combustion, or the burning of any combustible body, cannot take place, at least under {29} ordinary circumstances, without the presence of oxygen. Nitrogen gas, (called by its discoverers azotic gas), constitutes about three fourths of atmospheric air; the other fourth consists of oxygen, besides a small fraction of carbonic acid gas. Oxygen decomposes and destroys all fugitive colours. Oxygen is, besides, the basis of almost all the acids, and hence is one of the most universal agents in nature.

Hydrogen, formerly called inflammable air, was discovered by Mr. Cavendish in 1767; it is called hydrogen, because it is one of the component parts of water; or, more properly, it is the base of water. It is obtained in the most pure state from the decomposition of water by means of metals, thus: pass one hundred parts of water through a red hot iron tube, a gun barrel for instance, fifteen parts of hydrogen gas will be produced, while the inside of the tube will be found converted into an oxide, and to have gained eighty five parts in weight.

Again, when eighty five parts of oxygen gas are burned with fifteen of hydrogen gas, both gases vanish, and one hundred parts of water are the result. Hydrogen gas, when in a pure state, is about fifteen times lighter than atmospheric air; hence its use for inflating balloons. Hydrogen, if inhaled, destroys animal life; combined with nitrogen, it forms ammonia, or the volatile alkali, as we have before stated.

We have mentioned the fixed alkalies in a preceding section. We may add here, that by the discoveries of Sir Humphry Davy, in the year 1807, the base of caustic, or pure potash, is now known to consist of a light, white metallic substance, to which the name of potassium has been {30} given; it is of the consistence of soft wax; at a freezing temperature it is hard, brittle, and solid; when thrown upon water it instantly takes fire, hydrogen gas escapes, and an oxide of potassium, or caustic pot-ash, is produced. The potash and pearl-ash of the shops we must not forget, are combinations of carbonic acid and pot-ash, hence they effervesce with all the acids; but caustic pot-ash, containing no carbonic acid, combines with any of the acids without effervescence.

The SODA, as obtained from barilla, is a carbonate of soda; pure soda, or caustic soda, was, till the discoveries of Sir Humphry Davy, supposed to be, as well as potash, a simple substance. It is now, however, known to consist of a metallic substance of the colour of lead, but, nevertheless, lighter than water; upon which, when thrown, it produces, like potassium, violent action, yet does not, in general, like potassium, inflame. It is called sodium; pure soda consists therefore of sodium and oxygen, hence it is an oxide of sodium. These discoveries of the composition of the fixed alkalies are of infinite importance in the arts. The alkalies contain some very striking properties:

Their taste is acrid, burning and urinous. They generally change the blue colours of vegetable infusions green. When mixed with silex or flint, by exposure to great heat they form glass, and they render oils miscible with water, and hence combine with them forming soaps. They effervesce (when combined with carbonic acid,) with many other acids, and form neutral salts with all the acids. The volatile alkali or ammonia, on exposure to air, flies entirely away. Pot-ash, either in its caustic {31} state, or in that of a carbonate, absorbs moisture from the air, and liquifies. While soda, on the contrary, and many of its combinations, effloresce in the air; they, nevertheless, effervesce, and combine with the acids in a similar way to pot-ash.

We have mentioned how pot-ash is obtained in a preceding section. Soda is commonly procured from the ashes of marine plants; the barilla of commerce is obtained, it is said, in Spain, chiefly from many species of the salsola, or salt-wort. Barilla is an impure subcarbonate of soda, it is used largely in the manufacture of soap.

We now proceed to notice the nature of acids.

They excite a particular sensation on the palate, which we call sour. They change the blue colour of vegetables red. All of them, except the carbonic acid, effervesce with the volatile as well as the fixed alkalies when in the state of carbonates, as they are most commonly found in commerce. Oxygen is the principle of almost all acids; their difference depends upon the base combined with the oxygen: thus oxygen combined with carbon or pure charcoal, forms carbonic acid; with nitrogen the nitric acid; with sulphur the sulphuric acid, &c. &c.

Gas is a term implying the same as air; but as the term air, when used, is liable to be misunderstood for the air of the atmosphere, which is, as we have seen, a compound body, the term gas is more appropriately applied to all elastic fluids of a specific kind. Thus we say carbonic acid gas, oxygenous gas. The difference between carbonic acid and carbonic acid gas, and oxygen and oxygenous gas, consists in the latter being combined {32} with heat only, and in the state of air, while in the former they are fixed in some body, as in carbonate of pot-ash and oxide of lead, in both which cases the carbonic acid exists in a fixed state, or combined with the pot-ash, and the oxygen is in a fixed state, or combined with the lead.

We may now treat of carbonic acid gas, which is thus produced, as well as in many other ways: when charcoal is burned in oxygen gas, exactly sufficient for its combustion, both the charcoal and oxygen disappear, and an elastic fluid is found in the vessel, which is equal in weight to both. This air or gas is carbonic acid gas; it combines with lime, the alkalies, and pure or burnt magnesia: it constitutes a considerable portion of the weight of chalk, limestone and marble, as is readily seen by comparing these bodies before and after their conversion into quicklime. It is frequently combined with hydrogen. The gas with which the streets are now lighted is chiefly carburetted hydrogen.

Carbonic acid gas has the following properties. It extinguishes flame, and, like nitrogen and hydrogen, kills animals immersed in it. It is heavier than common air, and may therefore be poured out of one vessel into another like water. Cider, wine, beer and other fermented liquors owe their briskness to the carbonic acid which they contain; soda-water also owes its briskness entirely to the quantity of carbonic acid gas which it contains, a small quantity of heat being sufficient to give the acid the gaseous state.

Sulphur has been mentioned before; it is well known to be a very combustible substance; it is found in great quantities {33} throughout nature; the sulphur of commerce comes either from Italy or Sicily; or from the isle of Anglesea, where it is obtained from the smelting of sulphuret of copper; the best, however, comes from Sicily. It is, sometimes, found pure; but often combined with some of the metals, forming sulphurets. It is also frequently obtained by the decomposition of animal and vegetable substances; it is sometimes found combined with hydrogen (hence called sulphuretted hydrogen), in the human stomach, more frequently in the intestines. Sulphur combined with a small dose of oxygen, forms a volatile suffocating acid, called the sulphureous acid; with a large dose it forms sulphuric acid, or oil of vitriol.

For the nitric and muriatic acids, see a preceding section. We may, however, mention here, that nitric acid has the peculiar property of staining the scarf skin of the human body a dull yellow, of such permanence, that it can scarcely, by any means, be destroyed, it usually remaining till the skin wears or peels off.

The principal vegetable acids are the tartaric and the acetic. The tartaric acid exists in superabundance in tartar, and particularly in cream of tartar, which is nothing more than a purified tartar. See argol in a preceding section.

The acetic acid constitutes the vinegar both common and distilled; it is found in a very concentrated state in the shops, under the name of aromatic vinegar. It is also now obtained in large quantities, and of great strength from wood by distillation, or burning, in vessels, adapted for the purpose, hence called the pyrolignous acid, but essentially the acetic acid. This last is now used by {34} Calico-Printers to make acetate of iron. See a preceding section.

Alumina, or earth of alumina, sometimes called argil, is soft to the touch, adheres to the tongue, and hardens in the fire, contracting its dimensions: it constitutes the greatest part of clays. With sulphuric acid and pot-ash, it forms the common alum of the shops. Alum dissolves in about sixteen times its weight of cold water. For acetate of alum see alum in a preceding section.

Agriculturists and agricultural chemists know that alumina constitutes three eighths or more of a fruitful soil; some vegetables, likewise, contain this earth in their composition. Iron is also a component part of many soils, particularly those in which a red colour is predominant; hence it is, probably, a component part of all drugs used for browns, fawns, and blacks. It will be seen what affinity cotton has for iron in the dye of buff[4] upon cotton; and it seems reasonable to conclude that this metal not only produces the black, grey, and brown hues, but, with lime, forms a component part of the drugs themselves which give the brown dyes. It may be here also mentioned, that the red colour of the blood has been by many chemists supposed to arise from the iron which it contains; Mr. Brande, however, does not, from his own experiments, conclude this to be the fact. The blood of animals is, nevertheless, occasionally used for dyeing, as will be seen under Adrianople red. See {35} Kirwan on Manures, &c. and Davy's Agricultural Chemistry.

From the acids or oxygen combined with alkalies, earths, or metals, almost innumerable mordants, as we have seen, are formed; and upon the correct and proper application of these to the cloth or other matters to be dyed, depends the goodness and permanence of the colours. The dyer cannot, therefore, be too scrupulously attentive to this portion of his art.

In dyeing the student ought also to remember, that the material to be dyed combines intimately, in numerous instances, with alumina or other mordants; in the case of alumina it, in some instances, takes up from one twelfth to one fourth of its weight of alum, leaving the alum bath nearly tasteless. So also will rich extract of American bark, or even weld, when the proportion of weld is in weight more than two to one of the wool, form a triple compound with the cloth and alum, of permanent duration.

All these preliminaries the author considers of the first importance to be understood, and he has, therefore, mentioned them again and again. For so doing he is sure that he shall be excused in the dye-house, although not perhaps by the critics, whose candour he nevertheless respectfully solicits.

We now proceed to the application of mordants. In regard to muslins and calicoes, the alum is to be mixed with gum and carried to the piece, as will be described below in the Calico-Printers' mordant, and then immersed in the dye-bath: it thus receives the base or mordant. If the base be alum and the dye-bath madder, then, where the block strikes the pattern with the alumine {36} base, the colour will come out red; the other parts will clean and bleach white. If alum and iron form the base, the colour will be purple; if iron alone be applied, and galls, sumach, logwood, &c. are the component parts of the dye-bath, then it will be black.

Take one gallon of soft and pure water, of a heat of 150°, three pounds of common alum, one pound and a half of sugar (acetate) of lead; mix these together, and let them stand for two or three days, so that they may incorporate, often stirring them during that interval; then add two ounces of pearl-ash, and the same quantity of clean powdered chalk or whiting. After a time the clear liquor, now become an acetate of alum, must be drawn off. When used, it is thickened either with paste, flour, or gum arabic, or senegal; four pounds of either of the gums to each gallon of liquor[5]. A block or a press similar to a copper-plate press for paper, but much larger, and having the copper plates in proportion, is employed to spread the acetate of alum from a utensil {37} called a sieve, which is, however, not porous, while a boy or girl called a Teerer, works it smooth; when smooth on the sieve, the printer applies his block, and charges it with the acetate of alum; the block thus charged, is correctly put on the cotton cloth, which is laid upon a blanket spread upon a table; it is then struck with a mallet once or twice, by which, or by the pressure of the rolling-press, if copper-plate, the acetate of alum is driven into the pores of the cloth. The cloth thus prepared, is hung up in a hot stove, and dried by a high degree of heat. The goods are now ready, if for red, for the madder; and if for yellow, for the weld copper. Sometimes, however, lately, the colour is previously prepared, and applied at once in more instances than are prudent. To the above mordant, M'Kernan adds three ounces of sulphate of copper, omitting the potash; and he adds, "When the colour is wanting on the scarlet cast, omit the sulphate of copper."

Wool readily takes the alum at a boiling heat; common alum is in many instances proper for wool; and in others, where it might be improper, it is corrected by the use of argol or cream of tartar.

Yellow and red produce orange; red and blue, purple; but upon cotton, a scarlet, purple, or crimson cannot be produced in any way equal to those colours in wool or silk. Yellow and blue form the green.

We cannot enter with much minuteness into this part of the subject, more especially as the art of bleaching is {38} usually a separate one from that of dyeing. Yet as in fact the arts of dyeing and of bleaching depend in a great degree on the same principles, some notice of bleaching, in a treatise on dyeing, seems absolutely necessary.

Linen, cotton, and other cloths, were for ages deprived of their colour, in other words, bleached, rendered white, by a tedious process. Thus, the article to be bleached being boiled in a solution of pot-ash, was washed, and then spread on the grass in a field, watered occasionally, and, thus exposed to the atmosphere for two or three months, became white. This method is, however, in part, if not now entirely, dispensed with. M. Berthollet, an ingenious French chemist, to whose valuable work on dyeing we have before alluded, employed what was then called oxygenated muriatic acid, now chlorine, to perform in a few days what before took months to accomplish. His method was as follows. To six pints of powdered oxide of manganese he added sixteen of muriate of soda, (common salt) and twelve of concentrated sulphuric acid diluted with an equal quantity of water. These were placed in a leaden retort and distilled: the product was oxygenated muriatic acid, or chlorine, which being conducted to a vessel containing the material to be dyed, produced the same effects as the former tedious process, and bleached as much, in two or three days, as was before done in two or three months. This process has been since much further improved by the use of a combination of chlorine with lime, called chloride, or oxymuriate of lime. This article is at present used in almost all the bleaching grounds in the United Kingdom. It appears, therefore, that upon the use of the agent, chlorine, does the expedition {39} and whiteness of modern bleaching principally depend. Yet it ought, nevertheless, to be stated, that although, in the hands of scientific and judicious persons, chlorine is one of the most powerful agents in bleaching that ever was discovered, still, in the hands of bungling and avaricious persons, it may contribute greatly to the destruction of the cloth; and therefore, even now, a demand is occasionally heard for the old method of bleaching.

These processes constitute the art of the bleacher; the dyer has seldom any thing to do with them except in piece-goods or rough cambric, which he has sometimes to dye black as they come from the bleacher's in a state which they call once boucked; and sometimes he has them just as they come from the weaver; in which case, if for black, they need not be bleached white, but should be boiled in pot-ash, to take out the grease, &c.

Many attempts have been made by chemical philosophers to account for the permanence or want of permanence of various colours, when imparted to cloths and other bodies as a dye. Among these, Hellot, D'Apligny, and others of the old, and Berthollet, Bancroft, Henry, and others of the modern school, may be mentioned.

The power of resisting vegetable acids, alkalies, and soap, and, above all, the action of air and light, constitutes the durability of a colour. But this property has a very unequal standard, according to the nature of the colour and the species of the stuff.

{40} There is no obscurity in the action of water, alkalies, acids, and soap: for a solution is effected by means of these agents, or a small portion of acid or alkali unites to the combination, which forms the colour. But this is not the case with the action of light and air. Till lately, however, it was not known in what this action consisted.

Of the two principles which compose atmospheric air, it is only the oxygen gas which acts on the colouring particles. It combines with them, and thus impairs their colour or makes them fade. But its action is soon chiefly exerted on the hydrogen which enters into their composition, and it thereby forms water. This effect may be compared to a feeble combustion. Hence the carbon, which enters into the composition of the colouring particles, becomes predominant, and the colour usually passes to yellow, dun, or brown, or other appearances.

Light promotes this decomposition of the colouring particles, which frequently takes place only with its concurrence, and thus it contributes to the destruction of the colour. Heat also favours the same result, but less efficaciously so, unless it have a certain intensity.

It is concluded, therefore, that colours are more or less fixed in the air, according to the greater or less tendency which the colouring particles have to undergo this change[6]. Hence the utility of mordants in rendering fugitive colours fast.

The natural proofs of a dye's being effectual, are exposure to the air, to the sun, or to rain. If the colour be not changed by such exposure after twelve or fourteen days, it may be considered as fixed. These proofs are not, however, adapted to every colour: for some resist the action of air, light, and rain, yet are nevertheless injured by certain acids. There are also colours which do not resist the natural proofs and yet remain unchanged by acids.

Colours may be arranged in this respect in three classes: the first class is tried with alum, the second with soap, the third with tartar. For the proof with alum, half an ounce of this salt must be dissolved in a pint of water in an earthen pipkin, and into this liquor is to be put half a quarter of an ounce of the dyed thread or stuff, the whole being boiled about five minutes; it is then to be washed clean with water. Thus are tried crimson, scarlet, flesh-colour, violet, ponceau, peach-blossom, different shades of blue, and other colours bordering on these.

The next proof consists in boiling a quarter of an ounce of soap in a pint of water, with half a quarter of an ounce of the dyed stuff or thread for five minutes. With this proof all sorts of yellow, green, madder-red, cinnamon, and similar colours are to be tried.

The proof with tartar consists in boiling one ounce of that salt, previously powdered very fine, with a quarter of an ounce of dyed thread or stuff, in a pint of water for five minutes. This proof is used for all colours bordering {42} upon fallow, or hair-brown.—Journal of Science, vol. xxii. 219.

But notwithstanding these general rules may be given for dye-tests, yet so many are the niceties in this art, that, after all, nothing but long practice combined with scientific knowledge, will enable the dyer to become in this respect, a complete and successful artist.

The dye-house should be as spacious as possible, according to the quantity of work intended to be done in it; it should be also as near as possible to a clear running stream. The floor should be a mixture of lime and cement, and sufficiently inclining, so that water, the old contents of the vats, &c. &c. may run off freely when thrown down.

A dyer cannot be too particular in regard to the water which he uses. Some pump, well, and other spring waters, contain iron; this is injurious to many colours, while for black, brown, slates, and grey, it is very advantageous. It has been supposed that some dyers succeed in dyeing even the very same colour in a superior manner, in consequence of the peculiar purity or other properties of the water which they use.

To discover whether water contains iron or not, a little tincture of galls or prussiate of potash must be dropped into it; if a purple or blue tinge be produced in the water, we may be assured that it does contain iron.

For dyeing delicate colours, the water, which ought to be chosen for such purpose the purest and best, should {43} be heated with bran in a bag, when much of the contents of the water inimical to dyeing will rise to the top in the form of a scum, and should be taken off just before the water boils. Instead of bran, a little alum will answer the same purpose when it is not inimical to the colour intended to be dyed.

The boiling point of water is at the degree of 212° of Fahrenheit's thermometer; the freezing point is at 32° of the same instrument; blood heat is at 98°.

The limits and price of this manual preclude the possibility of our giving plates to explain some of the machinery and utensils which are now employed in dyeing. To inform a dyer what kind of coppers, casks, and vats are necessary, would seem to be superfluous; and the pupil may soon acquire such knowledge in the dye-house. Should a dyer find it his interest to undertake a branch of his art of which he has not any previous knowledge, he had better engage a man who understands it; if, however, he thinks himself competent to manage it, but is unacquainted with the best modern utensils appropriated to that particular branch, he had better get a dyer's labourer who has been used to it; a man of sufficient intelligence may be found with due encouragement to perform this part. It may just be added, that Ure's Berthollet and Mr. M'Kernan's work, both contain numerous explanatory plates of the utensils and machinery which are described and recommended in those works.

{44} All solutions and decoctions of Brazil wood, logwood, fustic, &c. should always be prepared in the same quantity and proportion, and one measure be invariably set apart for each. This observation is meant more particularly to apply to drugs in stock, always kept in a state of preparation ready for any process or work which may occur. The drugs just named may be kept in a prepared state; but weld boiled will not keep, nor will some others which are mentioned in the body of the work.

Weld, as it will not keep, should be used thus: a copper in proportion to the size of the work should always be used; and as weld will bear boiling and re-boiling, it can be boiled by the half bundle or more according as it may be wanted, whether you work little or much. If you are exact and near in your estimate, practice will soon render you perfect in any branch. It should be observed too, that to dye to pattern cannot be the result of a receipt, without a great latitude be left for the judgment.

The most difficult part of dyeing is that of light drabs, stone drabs, &c.

Nothing but practice will qualify you for this and all pattern dyeing: the way, and the only good way to obtain practice, is to work with all possible regularity. In the dyeing of fancy cloths in the clothing districts of Yorkshire, Gloucestershire, and other fine cloth manufactories, the manufacturers who dye their own cloths, as well as dyers of the greatest eminence, always number, measure, weigh, and time all the component parts of their various processes of dyeing. Such in fact ought {45} to be the universal practice; and then a person of ordinary abilities may soon be able to perfect his processes and obtain the best results.

Hence, however, it is very necessary that the dyer should have a competent knowledge of chemistry and drugs, that he may be able to judge of the goodness of the articles which he uses, and of the numerous and extraordinary combinations into which they enter. To chemistry, in particular, every able and scientific dyer must be largely indebted; for this reason it is that we have endeavoured, in this introductory chapter, to sketch some of the most important facts in this universal and interesting science.

In possession of these qualifications, and working upon the above plan, the dyer can never be far from the desired result in all his processes. His deviations, if any, will be few, as from his knowledge, he will soon perceive the first approach of any incorrectness, and be able to adjust it generally without much inconvenience.

The chemical terms now introduced into treatises on dyeing are chiefly taken from the Greek language, and are used in such a manner as to convey, by their etymology, an idea of the nature of the substances to which they are applied. Oxygen implies the producer of acid: hydrogen, the producer of water; nitrogen, the producer of nitre, &c. The term gas has been explained above. Caloric is a term used by chemists for heat; but caloric is used in a more extensive signification than the term heat, thus: although a gas might possess no sensible heat, yet being in a gaseous state, it is assumed to contain a certain portion of caloric which keeps it in its {46} gaseous state; the same observation will apply to liquids whether aqueous, oleous, or metallic.

All the measures mentioned in this work unless otherwise described, are those usually called in this country WINE MEASURE, and not those which have been introduced by a late act of parliament, called IMPERIAL MEASURES.

[2] Cochineal was at first supposed to be a grain, which name it still retains by way of eminence among dyers. Ure.

[3] For the cultivation of Woad in England, see Parish's paper in vol. xii. of the Bath Society's Report, or Tilloch's Mag. vol. xxxviii.

[4] What are called iron moulds in cotton, linen, &c. are, it is well known, nothing but the marks of a buff colour, usually left by ink and other matters which contain iron: acids, of course, dissolve, and discharge these buff colours; the oxalic acid does so without decomposing the cloth.

[5] "Acetate of Alumina is now most frequently made for the Calico-Printers by dissolving alum in a solution of crude acetate of lime, (pyrolignite); a gallon of the acetate, of specific gravity, 1.050 or 1.060, being used with two pounds and three-quarters of alum. A sulphate of lime is formed, which precipitates, while an acetate of alumina mixed with some alum floats above. The acetate of alumina employed as a mordant for chintz, is still commonly made by the mutual decomposition of alum and acetate of lead."—Ure's Berthollet, vol. ii. p. 331.

[6] Berthollet.

To dye cotton a Saxon or chemic blue—Sulphate of indigo—Saxon or chemic green—To set a cold indigo vat—Another indigo vat—To dye cotton a fast green with the cold indigo vat and weld—Another cold blue vat for linen and cotton—Solution of indigo for penciling printed muslin, &c.—To dye cotton a fast buff—To dye cotton pink.

We refer the reader to the preceding chapter for many observations relative to cotton, with which, in order to understand correctly the best method of dyeing this material, it is necessary that he should become acquainted: indeed, the whole of that chapter ought to be well studied by every one desirous of becoming an expert dyer.