Title: Plain Concrete for Farm Use

Author: T. A. H. Miller

Release date: April 28, 2019 [eBook #59379]

Language: English

Credits: Produced by Tom Cosmas compiled from images made available

by The Internet Archive.

U. S. DEPARTMENT OF AGRICULTURE

FARMERS' BULLETIN No. 1279

PLAIN

CONCRETE

for

FARM USE

THE successful and economical use of concrete involves the selection of suitable materials, the correct proportioning of mixtures in the development of qualities to meet specific requirements, the proper placing and the care of the green concrete.

A concrete of great strength is uneconomical if a weaker mixture will serve and a cheap or weak concrete is costly if it does not fulfill all requirements. The cost of concrete depends not only upon the price of the materials and labor but also upon the judicious use of the two. Lack of foresight in locating the mixing plant, in the design of forms, and in planning the successive operations may cause unnecessary expense, while neglect of any one of the precautions which should be observed is likely to result in unsatisfactory work.

The bulletin discusses the requirements of good concrete and describes the making and placing of plain concrete according to the best practice.

Agricultural Engineer, Division of

Agricultural Engineering, Bureau of Public Roads.

| Page. | |

| Introduction | 1 |

| Materials | 1 |

| Proportioning the materials | 6 |

| Quantities of materials required | 7 |

| Consistency | 8 |

| Estimating | 9 |

| Forms | 10 |

| Mixing | 13 |

| Placing | 18 |

| Care of concrete | 21 |

| Protection from freezing weather | 21 |

| Contraction and expansion joints | 23 |

| Lintels | 23 |

| Surface finish | 24 |

| Concrete exposed to fire | 25 |

| Water-tight concrete | 26 |

PORTLAND CEMENT concrete is the mass formed by mixing Portland cement, sand, gravel (or particles of other suitable materials), and water.

The quality of concrete may be made to conform to certain requirements which vary with the purpose of the structure in which the material is to be used; economy, strength, water-tightness, fire resistance, or resistance to wear and shock may be the chief requisite. The character of the constituent materials, the proportions in which they are used, the consistency, the method of mixing, and the placing and curing of the concrete are important factors in securing the desired qualities of the finished product.

Total failure or a product which does not give the service expected is often the result of the nonobservance of practices recognized as necessary in the preparation and use of concrete. This bulletin is intended to assist the inexperienced in making and using concrete suitable for general farm construction and is confined to a discussion of the rudiments of plain (not reinforced) concrete work.

Portland cement is used because it is the only kind adapted to general construction. Other cements are manufactured but they possess individual characteristics that restrict their use. The word Portland is not a trade name, but signifies the kind and distinguishes it from the slag, natural, and other cements.

A number of brands of Portland cement are manufactured, most of which are made to meet the requirements of a fixed standard adopted by the United States Government and the American Society for Testing Materials. Cement always should be tested for use in important work, but this is impractical for the user of small amounts and it is generally safe practice to omit the test if a reliable brand of Portland cement of American manufacture is selected, especially if the dealer's or manufacturer's guaranty that it meets the standard is secured.

The following simple test for soundness is easily made and is on the side of caution. Make a ball, about 11/2 inches in diameter, if neat cement and water; place it under a wet cloth and keep it moist for 24 hours, then put the ball in a vessel of water; allow the water to come to the boiling point slowly and to boil for 3 hours. A good cement will not be affected, but an inferior one will check, crack, or go to pieces entirely.

Portland cement is shipped in paper bags, cloth sacks, and wooden barrels (sometimes in bulk). For the average user the cloth sack is the best container, as it is easier to handle; and while the manufacturers charge more for this kind of package, they allow a rebate for the return of the sacks in good condition. A sack of Portland cement weighs 94 pounds and a barrel contains the equivalent of four sacks.

As cement readily absorbs moisture from the atmosphere, it should be stored in a dry place; if exposed to dampness it soon becomes lumpy, or even a solid mass, and in this condition it is useless and should be thrown away. The lumps caused by pressure in piling the sacks are not injurious. They can be pulverized easily, thus distinguishing them from those due to dampness.

Cement never should be stored on the ground. Build a raised platform for it and keep it away from the sides of the shelter. As it is heavy, care should be taken not to overload the supporting floor.

All grains, small pebbles, or particles of broken stone are considered as sand if they will pass through a wire screen with one-fourth inch meshes. The particles or grains should be hard and well graded and should vary in size, as a stronger concrete is thus obtained than when the size of the grains is nearly uniform. If a large proportion of the sand is very fine an extra quantity of cement should be used and if exceptionally fine it is advisable to use 25 per cent more cement.

The sand should be clean; that is, free from vegetable matter, loam, or any considerable amount of clay. If the hands are soiled « 3 » when a small quantity of sand is rubbed between them the following test should be made: Put 4 inches of sand into a pint preserving jar, fill with clear water to within an inch of the top, fasten the lid, and shake the jar vigorously until the whole is thoroughly mixed. Set the jar aside and allow the contents to settle. The sand will settle to the bottom with the clay and loam on top of it. If more than three-eighths of an inch of clay or loam shows, the sand should be rejected or washed. The difference in fineness and color shows clearly the line of division between the clay or loam and the sand.

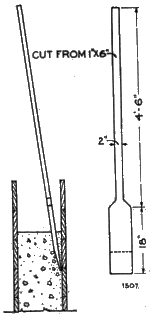

Should sand require washing the simplest way for small quantities is to build a loose board platform from 10 to 15 feet long, with one end higher than the other. On the lower end and sides nail 2 by 6 inch boards. Spread the sand over the platform in a layer 3 or 4 inches thick and wash with water. The water may be supplied by any means which will cause agitation of the sand and allow the lighter material to run off with the water. When pressure or a head is obtainable the water is most easily applied by means of a garden hose. The washing should be started at the higher end and the water allowed to run through the sand and over the 2 by 6 inch piece at the bottom. Figure 1 illustrates a convenient trough for washing larger quantities.

A small amount of clay, provided it is not in lumps, does not injure sand, but amounts over 10 per cent should be washed out.

The larger particles used in concrete may be gravel, broken stone, air-cooled blast-furnace slag, or other suitable materials. The coarse aggregate should be sound and clean, that is, free from disintegrated or soft particles, loam, clay, or vegetable matter. Air-cooled blast-furnace slag should weigh at least 70 pounds per cubic foot. The best results are obtained from a mixture of sizes graded from those retained on a one-fourth inch screen to those passing a three-fourths to 2 inch ring, depending upon the work. Ordinarily the greatest dimension of any particle should not be over one-fourth of the thickness of the concrete work.

Gravel which is too dirty for use usually can be detected by observation. It may be washed in the same manner as sand. Lumps of clay should be eliminated and care should be taken to see that the gravel is not coated with a film of clay or loam which will prevent the bonding of the cement.

Broken stone should be clean, hard, and of a size suited to the character of the work, and the same care in grading should be exercised as in the case of gravel. Trap, granite, hard limestone, and hard sandstone are commonly used. The composition and physical character of the stones should be considered, as some possess qualities that limit their use under certain conditions (see Substitutes for gravel).

Field stones are common in many localities and their use, when crushed, may be economical. The finer particles, after the dust is removed, can be used as sand. Small stone crushers, operated by three or four horsepower gasoline engines, can be purchased at a relatively low price and may prove profitable if a large quantity of stone is needed.

Bank or creek gravel, which will answer the purpose of sand and gravel combined, sometimes can be obtained, and frequently it is used in small jobs of concrete work just as it comes from the pit or creek. Although such gravel occasionally contains nearly the right proportions of sand and gravel, in the majority of sand pits and gravel banks there is a great variation in the sizes of the grains and pebbles or gravel and in the relative quantity of each. It is advisable to screen the sand and gravel and to remix them in the correct proportions, as well-graded aggregates make stronger concrete and, ordinarily, enough cement will be saved to pay for the cost of screening.

Experience has shown that it is advisable to screen bank gravel twice; first over a screen with large meshes to eliminate particles too large for use. The size of the mesh will depend upon the nature of the work involved (see Coarse aggregate); then the material which has passed through this screen should be sifted again over a screen with one-fourth inch meshes. All material which passes the latter screen may be considered sand and should conform to the characteristics discussed under "Fine aggregate."

For general work gravel or broken stone always is preferred to other coarse aggregate. Other materials at times are easier to obtain and, when used with discretion, will provide a satisfactory concrete.

Broken terra cotta, brick, and old concrete, if hard and strong, may be used for unimportant work where no great strength is required, but special care should be taken that the particles do not show on the finished surface.

The maxim that a chain is only as strong as its weakest link applies to concrete. If the coarse aggregate is weaker than the cement mortar, as in the case of some sandstones, it should be used with caution. The aggregate may have properties that render it unsuitable for use under certain conditions; for instance, cinders should not be used if water-tightness or strength is expected, but they are useful for fireproofing. Material that disintegrates or flakes when heated is undesirable in places exposed to high temperature; thus marble and some limestones should not be used in fireplaces. Some aggregates when exposed at the surface of concrete are apt to cause discolorations, and when this would be objectionable aggregates of this type should be avoided. Flat or elongated slab-like fragments should be avoided, as particles of this shape do not bond well; slate and shale are examples.

Cinders should be composed of hard, clean, vitreous clinkers, free from sulphides, soot, and unburned coal or ashes. As a precaution against the presence of small amounts of detrimental substances, cinders should be soaked thoroughly with water 24 hours before being used. If clean they will not discolor the hands when a small quantity is rubbed between the palms.

Cinder concrete, on account of its light weight, commonly is used for filling between sleepers of floors and grading roofs, and frequently for fireproofing, for which it is very effective. Cinders should never be used when the concrete is to be subjected to heavy loads or abrasion.

Lava rock varies widely in chemical composition and physical qualities. In some instances lavas are so light and frothy or contain so large a proportion of easily oxidizable material that they are wholly unsuited for concrete work. In general, the lava rock found in the Northwestern States is a suitable substitute for gravel. Rhyolite, a light colored volcanic rock, and many of the darker colored basaltic lavas can well be used for concrete for building purposes.

Water should be clean and free from strong acid and alkali. Sea or brackish water should not be used if fresh water can be obtained.

In mixing concrete various proportions of cement, sand, gravel, and water are employed, depending upon the purpose for which the concrete is to be used. The ideal mixture is one in which all the spaces or voids between the grains of sand are filled with the cement and all the voids in the gravel are filled with the cement-sand mortar. This perfection is seldom attained, because the voids in each lot of gravel and sand vary slightly, and in order to be absolutely safe a little more sand and cement than will just fill the voids are used.

The strongest concrete is not required in every structure, and, in many instances, the cost of it would be unwarranted. For important work involving large quantities of materials of unknown qualities, tests should be made to determine the best proportions. Such tests, being rather complicated, are made usually in a laboratory, and are not practical for the user of small quantities of concrete. Various proportions have been tested by experienced engineers to determine which, under average conditions, will develop the greatest strength, best resist wear, and assure greatest impermeability or water-tightness. The mixtures given below have been found to meet the requirements indicated, and having been adopted as arbitrary standards, are recommended for use in farm concrete work. The amount of water required is discussed under "Consistency."

Rich mixture.—Used for concrete subject to high stresses or where exceptional water-tightness and resistance to abrasion are desired: 1:11/2:3; i. e., 1 part cement, 11/2 parts sand, and 3 parts gravel.

Standard mixture.—Used generally for reinforced concrete and water-tight work: 1:2:4; i. e., 1 part cement, 2 parts sand, and 4 parts gravel.

Medium mixture.—Used for plain concrete of moderate strength: 1:3:5; i. e., 1 part cement, 3 parts sand, and 5 parts gravel.

Leaner mixtures are sometimes used after a test has proved them to be suitable for the work at hand.

It will be noticed that always in indicating the proportions the first number refers to the cement, the second to the sand, and the third to the gravel. The three materials must be measured by volume, using the same unit. The cubic foot is a convenient measure, because a sack of cement, weighing 94 pounds, is considered to contain 1 cubic foot.

When the coarse aggregate (gravel, etc.) is omitted the mixture is generally spoken of as mortar and the proportions are indicated thus, 1:2, meaning 1 part cement and 2 parts sand. Mortar is used for plastering, stucco, top coats of floors, and for laying masonry.

More concrete can be made from given volumes of aggregates if the gravel used is graded from fine to coarse than if the particles are too nearly of one size, because the small stones help to fill the voids between the larger ones and less sand-cement mortar is required. The extra mortar thus adds to the volume of the concrete.

A common mistake to be guarded against is to assume that the volume of concrete produced is equal to the quantity of sand plus the gravel as indicated in the proportion. For instance a 1:2:4 mixture will not produce 6 cubic yards of concrete, if 2 yards of sand and 4 yards of gravel are used, because the sand will lodge in the voids between the pebbles. If 6 cubic yards of concrete are desired it will be necessary to use 2.7 cubic yards of sand and 5.34 cubic yards of gravel.

Table 1 shows the quantity of cement, sand, and gravel required under average conditions for the indicated proportions.

Table 1.—Materials for 1 cubic yard of rammed concrete.

| Proportions. | Cement. | Sand. | Gravel. | ||

| Cement. | Sand. | Gravel. | |||

| Sacks. | Cu. yds. | Cu. yds. | |||

| 1 | 1 | --- | 19.20 | 0.74 | --- |

| 1 | 2 | --- | 13.48 | 1.00 | --- |

| 1 | 21/2 | --- | 11.00 | 1.01 | --- |

| 1 | 3 | --- | 10.40 | 1.16 | --- |

| 1 | 1 | 2 | 10.52 | .39 | 0.78 |

| 1 | 11/2 | 3 | 7.64 | .42 | .85 |

| 1 | 2 | 4 | 6.04 | .45 | .89 |

| 1 | 21/2 | 5 | 4.96 | .46 | .92 |

| 1 | 3 | 5 | 4.64 | .52 | .86 |

| 1 | 3 | 6 | 4.24 | .47 | .94 |

The quantity of water used in mixing has a very great influence on the strength of the concrete. An excess of water weakens the concrete, while an insufficient amount prevents thorough mixing.

Therefore, only sufficient water should be used to produce a workable or plastic mixture.

Recent tests have proved that to secure the greatest strength the concrete should be mixed considerably drier than has heretofore been customary. Of course, for thin walls containing closely placed reinforcement, or for water-tightness, a fairly wet mix is necessary. A little experience will show the proper amount of water to use.

A very rough estimate of the quantity of water required in mixing for general work is 4 to 5 gallons to each sack of cement.

Three degrees of consistency (corresponding to different proportions of water) are used in general practice, namely, wet, medium, and dry. In the light of recent investigations it is thought the wet mixture of present-day practice contains too much water. The following definitions are therefore recommended:

Wet mixture. One that does not flow readily and yet can not be piled up. It is recommended for thin sections when reinforcement is closely placed.

Medium mixture. One that is between the wet and dry mixture. This consistency is recommended for general work.

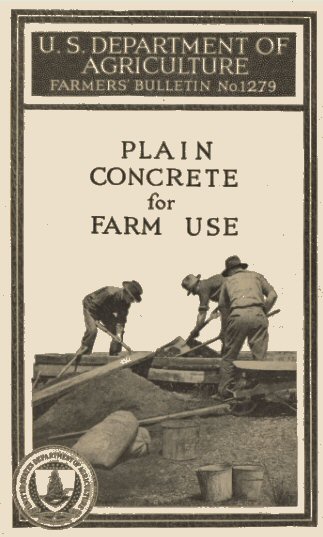

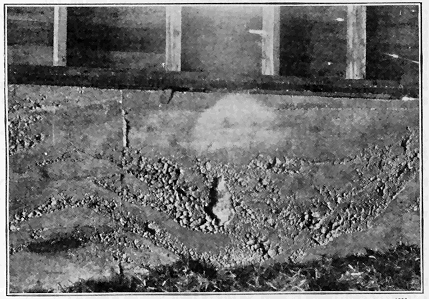

Dry mixture. One about like damp earth. If a handful is squeezed it will retain its shape. This consistency requires thorough ramming to eliminate voids and is used when forms are to be removed immediately, but should not be used where a water-tight job is expected. The porous structure of the concrete in Figure 2 is due to the fact that it was placed as a dry mixture.

In estimating the amount of concrete in a given piece of work and the quantities of materials required, the unit of measurement is usually the cubic yard (27 cubic feet). The following examples will explain best the method of determining the quantities required:

Example 1.—A wall 9 inches thick, 12 feet high, and 30 feet long has a door opening 3 feet wide and 6 feet high, also a footing 18 inches wide and 9 inches deep. The concrete is to be mixed in the proportions of 1:2:4.

The volume of the footing is found by multiplying together the dimensions expressed in feet, thus, 11/2 ×3/4 × 30 = 333/4 cubic feet. Similarly, the volume in the wall is3/4 × 12 × 30, less the door opening3/4 × 3 × 6 = 2561/2 cubic feet.

The total volume in footing and wall is 2901/4 cubic feet = 103/4 cubic yards.

To find the quantity of cement, sand, and gravel, multiply the amounts for 1 cubic yard, indicated in line 7 of Table 1, by 103/4, and it will be found that 65 sacks of cement, 4.83 cubic yards of sand, and 9.56 cubic yards of gravel are necessary to build the wall.

Example 2.—A pavement 27 feet long, 4 feet wide, and 6 inches thick has a 5-inch base mixed in the proportions of 1:3:5 and a 1-inch surface mixed in the proportions of 1:2.

The volume in the base is 27 × 4 ×5/12 = 45 cubic feet = 12/3 cubic yards.

The volume in the top is 27 × 4 ×1/12 = 9 cubic feet =1/3 cubic yard.

Multiplying the quantities in line 9 of Table 1 by 12/3 and those in line 2 by it is found that the base requires 7.74 sacks cement; 0.86 cubic yard sand; 1.43 cubic yards gravel; and the top requires 4.49 sacks cement; 0.33 cubic yard sand.

Example 3.[1]—A tank 9 feet inside diameter has walls 6 inches thick and 4 feet high (above the floor). The floor is 6 inches thick, the concrete is to be 1:2:4.

[1] A practical rule in finding the area of a circle is to multiply one-half the diameter (radius) by itself and the product by22/7. In finding the volume in the wall of a circular structure, such as a silo or tank, the area of the circle formed by the inside circumference is deducted from the area of the circle formed by the outside circumference and the remainder is multiplied by the height.

The volume in the floor is10/2 ×10/2 ×22/7 ×1/2 = 392/7 Cubic feet.

The area of the larger circle is 5 × 5 ×22/7 = 784/7 cubic feet.

The area of the smaller circle is 41/2 × 41/2 ×22/7 = 634/7 cubic feet.

The area of the wall, therefore, is 15 cubic feet and the volume is 15 × 4 = 60 cubic feet.

The total volume in the structure is 992/7 cubic feet or 32/3 cubic yards. Multiplying the quantities in line 7 of Table 1 by 32/3, it is found that the following material is needed: 22.14 sacks of cement; 1.65 cubic yards of sand; 3.27 cubic yards of gravel.

Forms are required to hold the concrete in place until it has attained sufficient strength to sustain itself and the initial loads to which it may be subjected. Concrete is plastic and will assume the shape of the form, thus any imperfection or impression on the face of the forms will be reproduced.

Wood is commonly used for forms, as it can be easily worked into different shapes, though various other materials sometimes are better adapted to special conditions. Cast iron, for instance, is suitable for casting small objects that are to be reproduced in quantities, such as concrete block or tile; plaster of Paris, glue, or moist sand are employed for casting ornaments or to produce a fine, smooth surface; sheet metal is suitable when the forms can be used repeatedly or for such circular structures as silos. When the sides of an excavation are not likely to cave in the earth may serve as a form.

Wood for forms must be of a kind that is easily worked and that will retain its shape when exposed to the weather. White pine is the best wood, but is seldom used because of its cost. Spruce, yellow pine, and fir are satisfactory woods for forms and are best, used partially green or unseasoned.

The edges of boards should be surfaced, tongued and, grooved, or beveled in order to obtain a tight form, so that the soft mortar will not ooze out. A better surface* is secured if the boards are dressed on one side and are free of loose knots or other imperfections.

As forms must be removed, they should be so planned that they can be taken down without destroying the lumber, especially if the boards are used for sheathing or again for forms. Therefore the nailing of the boards to the support should be only sufficient to keep them in place until the concrete has hardened. Greasing the surface next to the concrete with crude oil, soap solution, or linseed oil will prevent the concrete from adhering and facilitate removal.

Metal forms can be used to advantage when the work involved is to be repeated many times. If it is known or if it is probable that the forms may have to be altered, the relative costs of wood and metal forms should be carefully determined.

Metal forms of various types and designs may be purchased. Although the first cost may be high, yet their use may lower the total cost when the work is such as to warrant it.

Circular forms may be built as shown in Figure 3. The sheathing is generally of wood 4 to 6 inches wide, or sheet metal, and, if of wood, is laid perpendicular to the battens. In forms of small diameter, sheet metal sheathing is necessary if a smooth surface is desired, as the 4-inch boards can not be made to conform to a true circle. The radius used for cutting the battens of the inner circle should be the thickness of the sheathing less than the inside radius of the structure and the same amount greater than the outer radius for the outside battens.

The period of time after which forms may be removed varies according to conditions. Rich and dry mixtures set quickly, and warm weather tends to hasten the setting of concrete. The character of the structural member and the loadings also must be considered.

Thus, an unloaded wall 12 inches or more thick may be stripped of forms in from 1 to 3 days, while the forms of thinner walls should remain in place from 2 to 5 days. Slab forms and the sides of beam and girder forms may be removed in from 6 to 14 days if the span is not over 7 feet. The bottoms of beam and girder forms, even though of a span less than 7 feet, should remain in place and braced form 10 to 14 days and even longer. Experience is the best guide to the time of removal, but if there is any doubt ample time should be allowed, especially in cold weather.

Concrete, while plastic, exerts a great pressure on the confining walls, necessitating rigid tying and bracing of the forms to keep them from bulging out of alignment. The effect of the bulging of a form is corrected only at a considerable expense; hence it is advisable to pour the concrete to a depth of not more than 21/2 or 3 feet, allowing it to set or harden before pouring more.

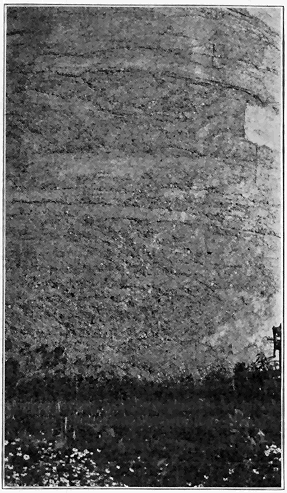

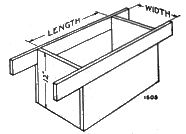

The form most used in concrete construction is that for a straight wall. The methods of building such a form apply in general to the forms for most structural work, though modifications may be necessary to meet particular conditions.

The straight wall form may be built continuous (Figs. 4 and 5), or in panels of a size convenient to handle, and from stock lengths of lumber (Fig. 6). Generally the face boards are placed horizontally and secured to studs or posts. The face boards may be 1 or 2 inches thick and from 6 to 10 inches wide, preference being given to the narrower widths, which are less liable to cup or warp. The thickness depends upon the spacing of the studs, the number of times the forms are to be used, and the depth of pouring. Ordinary sheathing, if the joints are made tight, is satisfactory for foundations of dwellings, etc., and the studs, if 2 by 4 inches, should be spaced 18 inches on centers. The studs for a long, high form had best be 4 by 4 inches or 2 by 6 inches, spaced from 2 to 3 feet « 13 » center to center. The studs of the inside and outside forms must be tied together to prevent spreading; this is conveniently done with No. 10 wire, as shown in Figure 4, or with one-half or three-quarter inch bolts, which is the more expensive method. Bolts should be greased to facilitate removal. Temporary spacers of wood, 1 by 2 inches, of a length equal to the thickness of the wall, should be used to prevent drawing the forms together when the wire or bolt is tightened. They should be spaced at the ties, but need not be at every wire, and are knocked out and removed as the concreting progresses.

The ties should be spaced on each stud about 21/2 feet vertically. If more than 3 feet of concrete is poured at one time the ties should be closer together, vertically, at the bottom of each pouring. The thickness of the wall does not affect the number of ties. On removing the forms the wires should be clipped close to the face of the concrete and punched back, unless the surface is to be stuccoed. If a pit hole is caused by punching back the wire it should be pointed up with mortar, which then should be rubbed to make it blend with the general surface.

Before starting to mix, annoyance and money may be saved by planning the location of the mixing plant with regard to convenience in depositing the concrete in the forms and ease of access to the materials. Often the board can be located so that by moving « 14 » it once or twice the bulk of the concrete may be shoveled directly into the forms. It is more economical to wheel material a distance of from 10 to 25 feet than to carry it in shovels. Eight feet is about as far as it is profitable to shovel.

When material is to be wheeled, runways of planks should be provided, because more material can be handled in a given time, and the wear and tear on men and equipment is not so great. The planks used in the runways should be thick enough to sustain the weight passing over them and should be 10 to 12 inches wide to permit foot room. They should be anchored securely and made rigid, as springy or loose boards retard progress of the work. Smooth joints in the planking will prevent bumping and stumbling.

The number of men required is determined by the amount of concrete to be placed in a given time, the method of mixing, and the size of the batch; that is, the number of bags of cement mixed at one time. The amount of concrete one man can mix by hand in a day depends upon the experience of the man, the layout of the work, and other duties required of him. One man should average 11/2 to 13/4 cubic yards of concrete in eight hours, including mixing and wheeling not more than 50 feet.

The gang for a one-bag batch may consist of 3 men, but a larger number make a more efficient force, for when the concrete is mixed by hand the men can take turns at the various tasks and will not tire so easily. The assigning of tasks so that each man's time fits into that of the others requires considerable study and is one of the chief factors making for loss or profit.

Good concrete can be mixed by hand or machine. The quantity of concrete work in prospect is the factor that determines the more economical method. A small amount (say 100 to 200 cubic yards) does not warrant the purchase of a machine, but it is often feasible and economical to hire a machine from a neighbor or contractor if the quantity of concrete to be placed is more than 15 cubic yards.

A mixer should be purchased only after careful consideration of the amount and character of the work to be done and the conditions affecting its use.

The two types of mixers most used are the batch mixer, which mixes and dumps a definite quantity, and the continuous, which discharges a constant stream of concrete. The continuous type is not adapted to farm work unless the concrete can be handled as fast as it is mixed, thus permitting the machine to work continuously.

There are numerous types and various sizes of batch mixers. A one-bag batch machine is most suitable for general work, though there are smaller mixers that may prove handy. Some of the smallest sizes are operated by hand, but the medium and large sizes are power operated. Mixers can be had with or without the power plant attached and may be stationary or on wheels, which facilitate moving to different sites. Engines used for sawing wood, the larger ones used for pumping water, and tractors furnish sufficient power to operate an average mixer. Figure 7 shows a homemade mixer built of discarded farm implement parts and operated by the farm engine.

Directions for operating a mixer are generally furnished with the machine. The tendency is to use too much water in mixing concrete in a machine. The consistency of the mixture should be as described under the heading "Consistency" on page 8. The mixing should be continued for at least a minute after the drum has been charged, but a better mixture is secured if two minutes are allowed. At the end of each day's work the machine should be thoroughly washed, and when not in use it should be well greased and covered.

Hand mixing is the more economical on the farm unless a large amount of work is to be done at one time. Few tools need be purchased, and, as a rule, only farm help need be employed. The following tools will be needed in mixing and placing plain concrete: Two or more square-end short-handled shovels, 1 heavy garden rake, 1 sprinkling can or bucket (if a hose is not available), 1 52-gallon barrel, 2 wheelbarrows with metal trays, 1 sand screen (Fig. 8), 1 tamper (Fig. 9), 1 wood float or trowel (Fig. 10), measuring boxes (Fig. 11), mixing board (Fig. 12), 1 spader (Fig. 13). The number of shovels and wheelbarrows needed will depend upon the size of the batch, number of men mixing, and the layout of the work. Long-handled pointed shovels will be found more convenient at the sand and gravel piles.

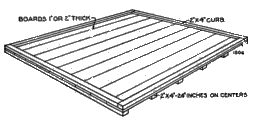

A bottomless box is necessary for convenient and accurate measurement of the sand and gravel. Where wheelbarrow measurement of materials is practiced, as in charging a mixer, the capacity of the wheelbarrow should be determined by use of a measuring box. The box may be made as illustrated in Figure 11, from boards 12 inches wide. The dimensions in Table 2 are of boxes for use in measuring quantities for mixtures of various proportions, assuming that one bag of cement is used in a batch. If two bags are used in a batch the boxes should be filled twice.

Fig. 10.—Wooden float.

|

Fig. 9.—Tampers.

|

Fig. 13.—Spading tool.

|

|

||

|

Fig. 11.—Measuring box.

Fig. 12.—Mixing Board.

|

||

Table 2.—Inside dimensions of measuring boxes for various proportions.

[1-bag batch, box 12 inches deep.]

| Proportion. | Box for sand. | Box for gravel. | ||||

| Feet. | Feet. | |||||

| 1:1:2 | 1 | by | 1 | 1 | by | 2 |

| 1:11/2:3 | 1 | by | 11/2 | 1 | by | 3 |

| 1:2:4 | 1 | by | 2 | 2 | by | 2 |

| 1:21/2:5 | 11/4 | by | 2 | 2 | by | 21/2 |

| 1:3:5 | 11/2 | by | 2 | 2 | by | 21/2 |

| 1:3:6 | 11/2 | by | 2 | 2 | by | 3 |

A tight platform should be provided similar to that illustrated in Figure 12 upon which to mix the concrete. For mixing 1 or 2 bag batches a platform 9 by 10 feet will serve.

The mixing board should be located in convenient relation to the supply of materials and the work and should be level. The sand box is placed on the board, about 2 feet from one of the longer sides, and filled level with sand; the box is then lifted away and the sand spread in a 3 or 4 inch layer. The cement is spread as evenly as possible on' top of the sand. Two men with shovels, standing on opposite sides of the pile, turn the sand and cement in such a way that the materials axe thoroughly mixed. In turning the material it should not be simply dumped off the shovel, but should be shaken off the ends and sides, so that the two constituents will be mixed as they fall. The mass should be turned two or three times, or until it is of uniform color and there are no streaks of either sand or cement. A man with a hoe or rake may assist by raking the top over as the two men turn. When the sand-cement mixture is of a uniform color it should be spread out carefully in a layer and the gravel box placed on top. The box is filled with gravel and then removed, the gravel being spread over the sand-cement mixture. The mass is soaked with about one-half the quantity of water to be used, care being taken not to wash away any of the cement. The materials then should be turned over in much the same manner as was the sand-cement, except that instead of shaking them off the end of the shovel the whole load should be dumped and dragged back toward the mixer with the square end of the shovel. The wet gravel picks up the sand and cement as it rolls over when dragged back. The mixing should be continued until the mass is uniform, water being added to the dry spots during the mixing until the desired consistency is obtained.

Experience counts considerably in mixing concrete with the least amount of labor; ordinarily three or four turnings are required to mix the materials thoroughly. After the final turning the concrete should be shoveled into a compact pile and then is ready for placing in the forms.

The mixed concrete should be deposited in the forms within from 20 to 30 minutes from the time the water is added to the cement, as it begins to set or harden after this time. To disturb the concrete after the set has begun is risky, as it will lose some of its strength, the extent of the injury depending upon the seriousness of the disturbance.

Concrete which has set before it can be placed in the forms should not be tempered or softened with water, but should be discarded.

To prevent delay in placing, all forms should be examined before the mixing is begun to see that they are properly braced, that all chips or loose particles are removed, that the surface of concrete which has set has been properly roughened and wetted to assure a bond, as described on page 20, and that all reinforcement, bolts, inserts, etc., are properly located and secured.

At the lunch' period, or at the end of a day's work, the mixing board and equipment should be thoroughly washed, for if this is not done many pounds of heavy concrete are needlessly carried around by the men and the addition of a pound in the weight of tools will lower the efficiency of the workers. Moreover, it will save time and wear and tear of equipment incident to cutting the surplus concrete away with a cold chisel.

In depositing concrete in the forms care should be taken that the materials do not separate.

If the mixing is done close to the place of depositing, the concrete may be shoveled into the forms directly or through a chute. If it is necessary to lift or transport the concrete, buckets and wheelbarrows are convenient containers. The concrete should be deposited in horizontal layers, preferably not over 6 inches thick, and a spade or paddle should be worked up and down against the forms to push the coarse material away from the surface, as illustrated in Figure 13. The object of the spading is to eliminate impounded air that may form pockets in the mass and to insure a smoother and more « 20 » impervious surface. In addition to being spaded, stiff concrete should be rammed until water flushes to the surface. Tapping the forms with a hammer is a very effective way of securing a smooth surface. Figure 14 shows the result of improper spading.

Fresh concrete will riot bond readily to concrete that has hardened and a seam may be formed that will permit water to trickle through. When bonding fresh concrete to that which has been in place for a short time it is usually sufficient to roughen the hardened surface with a pick or by other means so as to expose the gravel or stone, and to clean off all loose particles. The hardened concrete should be soaked with water, the excess water removed, and the surface then given a coat of grout (a mixture of cement and water) of the consistency of cream just before the new concrete is deposited.

When pouring of a wall is to be discontinued for some time, provision for the bonding of future work should be made. This may be done by placing short steel dowels in the concrete when it is poured, or a rebated joint or groove may be made, as shown in Figure 15. In bonding a new wall to old concrete, holes should be drilled for the dowels, which should be grouted in, and the old surface should be roughened, cleaned, and wetted; or a groove may be cut in the old wall to receive the new concrete.

Concrete can be placed under still water if proper precautions are taken. It should never be placed, while soft, in running water unless a form or cofferdam is used, as the cement will be washed out. When concrete is to be placed under water a form of tube or chute, known as a tremie (Fig. 16), may be used advantageously. The tube should be of sheet metal, about 8 inches in diameter, with a hopper on top, and means should be provided for quickly raising and lowering it without jolts, so that the concrete will feed out at the bottom without breaking the seal. The lower end of the tube should rest on the bottom or on the concrete as it is built up and a continuous flow of concrete, mixed somewhat soft so that it will flow easily, should be maintained.

Scum or laitance is likely to form on concrete when placed under water, and unless all of the concrete is! poured in one operation and brought to a little above the water surface, seams or planes of weakness will occur.

After the concrete has been poured, care should be taken that it does not dry out too quickly, and in hot weather it must be protected from the sun. Exposed surfaces and objects made of dry concrete should be sprayed thoroughly with water twice or oftener each day for a week or 10 days. Sometimes surfaces are shielded with canvas, paper, boards, or layers of moist sand.

If suitable methods are used, good concrete work can be done in cold weather, but with more difficulty and at somewhat greater cost than when the weather is warm. Ordinarily it is best not to attempt to do concrete work during freezing weather. However, the extra cost at times may be warranted by urgent need of the structure or the fact that other farm work is not so pressing during the winter and the concrete work may be carried on without seriously interfering with regular farm operations.

Concrete must be protected from alternate freezing and thawing until it has set. Cold retards the setting and hardening of concrete; therefore, even though the temperature is not at the freezing point, the concrete should be protected and special care taken not to subject it to loads. The forms should be kept in place until there is no doubt that the concrete has properly hardened. Hot water should be poured on the concrete to make sure that apparent hardness is real and not due to a frozen condition. Just before « 22 » the concrete is placed all ice and frost should be removed from the forms and reinforcement, if used, by warming the surfaces with steam or by other means.

Concrete that has been frozen once may, with proper care, attain its ultimate strength, but should it freeze a second time the chances of saving the work are very slight. Exposed surfaces are apt to scale or pit if the concrete is allowed to freeze before it is thoroughly hardened.

Pleating the materials, protecting the green concrete, and the use of salt are precautions generally taken to prevent freezing.

The use of salt is objectionable, as it forms a white efflorescence on exterior surfaces and is liable to corrode the steel in reinforced concrete work. The quantity of salt required varies with the temperature, but it should not exceed 10 per cent of the weight of the water used in mixing. A 10 per cent solution is eight-tenths (approximately 13 ounces) of a pound of salt per gallon of water and will prevent freezing at a temperature of 22° F. Lower temperatures would require a greater proportion of salt, which would impair the strength of the concrete, and hence is not practicable.

A rule, frequently advocated, for varying the percentage of salt is to use 11/3 ounces per gallon of water for each degree Fahrenheit below freezing. Since it is impossible to foretell the exact drop in temperature, the exact quantity of salt can not be predetermined, so that provision should be made for several degrees lower than anticipated. The salt should be dissolved in the mixing water, and in order that the proportion be correct the amount of water required for each batch should be determined by trial and this quantity used throughout the work.

Perhaps the most satisfactory method of preventing freezing of concrete is to heat the materials and to inclose or cover the completed work for a few days or until most of the water has disappeared and sufficient strength has developed. In extreme weather protection may be needed for five or six days. When the weather is cold but not freezing, heating the materials will be sufficient. If a freeze is expected the concrete work should be protected by wood inclosures, paper, or canvas, over which, if the surface is horizontal, may be spread a 6 or 8 inch layer of straw. Manure should not be used to protect fresh concrete, since the acids in it are destructive and cause unsightly stains. Splits or other openings in coverings may admit cold, which may freeze parts of the work. As the temperature drops (to about 20° F.) it will be necessary to arrange the covering so « 23 » that live steam can be turned in between it and the concrete or that heat may be supplied from stoves or salamanders.

Mass work, except in very cold weather, will not require as careful protection as thin sections and, as a rule, the forms are sufficient if the exposed parts are covered.

The water can be heated sufficiently for use in concrete (approximately 150° F.) in kettles on stoves or by steam from a boiler.

A metal smokestack placed horizontally with a fire in one end makes an efficient heater for the sand and gravel. The materials are piled over the stack, but not so high that their weight will crush the pipe. Small quantities of sand and gravel may be heated on top of metal plate with a fire under it. If a small boiler is available it may be economical to use steam for heating the sand and gravel. Steam is effective when forced from nozzles into the piles or circulated through perforated pipes placed under the material. Covering the piles with canvas or other material will retain much of the heat.

Concrete expands and contracts with changes in temperature, causing cracks to appear. Contraction cracks occur in thin sections exposed to wide variations in temperature and are common in sidewalks; therefore, large stretches of concrete should not be laid without breaks or spaces to allow for the changes in size. The spaces should be filled with tar or some similar material that will yield or give when the concrete expands. A joint like that shown in Figure 17 is frequently used for thick walls. A section of the wall is poured and before the next is poured the abutting end is covered with tar and paper, the thickness of the covering depending upon the length of the section and the exposure. Sidewalks and similar work, when not cast in alternate blocks, should have a one-fourth inch space left at intervals of 40 feet. The joint may be filled with tar paper or tar. Steel is used to take care of contraction in long or high walls and water-tight work. Important structures in which temperature reinforcement is necessary should be designed by one experienced in concrete design.

The subject of reinforced concrete is not within the province of this bulletin, but as openings of various widths are required in the « 24 » walls of most farm structures, a general explanation is given of the reinforcement of lintels or that portion of concrete immediately above an opening, such as a floor or window.

A lintel is a beam, and when a beam bends the lower part is stretched or pulled while the upper portion is compressed. Good concrete will stand great pressure but is not capable of resisting any great pulling or tensile stress. For this reason steel is used in the lower portion to take care of the tensile or pulling force.

It will be found generally satisfactory, where no heavy or concentrated load occurs over an opening and the span is not more than 4 feet, to place two rods three-eighths of an inch in diameter in the bottom of the lintel, so that there will be 1 inch of concrete below them. Two diagonal rods should be placed at each top corner of a window or door, as shown in Figure 18. When the opening is between 4 and 8 feet the rods should be bent up as shown in Figure 19 and when between 8 and 12 feet, three one-half inch rods should be used, two of them being bent.

Barbed wire, old fencing, and scrap or rusty iron is not suitable for reinforcement. Loose rust should be cleaned off the rods and they should be free of grease and oil.

Joints and imperfections in the forms are reproduced on the concrete surfaces. Patches of honeycomb and rough places are left where the mortar has run out of the forms or where the concrete has not been properly placed. Such imperfections do not necessarily affect the strength of the concrete, but they do detract from the appearance « 25 » (see Fig. 14). Too of ten the finishing of the concrete work in even the more important farm buildings is neglected. With little extra trouble exposed surfaces can be given a finish which will add to the attractiveness and hence the value of the completed work. Rubbing off the form marks and pointing up depressions or holes greatly improves the appearance of the work. The rubbing may be done with a wooden float or hard-burned brick, using a little sand and water as an abrasive and a 1:2 mortar for pointing up. The surface can be worked best if the forms are removed within 24 hours or before the concrete has set too hard. After the concrete has hardened it may be necessary to use a carborundum block for rubbing.

A pleasing finish can be secured by scrubbing the surface with a stiff fiber or wire brush, using plenty of water to wash off the loosened particles. The work must be done while the surface is workable for if the concrete is too green or soft the aggregate will break out and if too hard the work can not be done effectively.

Artistic effects can be secured by picking or tooling the surface with a bush hammer, toothed chisel, or pick. For such treatment the concrete should be two or three weeks old to prevent breaking out the aggregate. Other finishes may be obtained by etching with acid to expose selected colored aggregates and by the application of stucco. The limitations of the bulletin do not permit of a discussion of these more elaborate treatments.

Concrete is practically fireproof in that it can not be consumed by fire, but unless properly made and of the right materials it will disintegrate, at least on the surface.

To resist fire concrete should be mixed fairly rich, say, 1:11/2:3, or 1:2:4 and special care should be taken to grade the sand and gravel to secure a dense mixture.

The aggregates should be selected with a view to their fire-resisting properties. The sand should be siliceous and the larger aggregate should not disintegrate when heated; hence, marble, granite, limestone, materials containing quartz, and some gravels are unsuitable. Cinders are specially valuable, due to their non-conductivity, but can not be used where strength is required. Trap rock will resist destruction by heat and produce a strong concrete. Blast furnace slag is very good for this purpose.

Fireplaces and chimneys of dwellings[2] may be constructed of ordinary concrete but the back, jambs, and inner hearth, which are directly exposed to the heat of the fire, should be made of specially prepared concrete as described above or should be lined with firebrick, although concrete made with broken hard-burned brick or terra cotta has been used successfully. If suitable large-sized aggregate is not available a mixture of one part cement and three parts sand may be used.

[2] See Farmers' Bulletin No. 1230, Chimneys and Fireplaces, U. S. Department of Agriculture.

Practical water-tightness in concrete may be secured by using a fairly rich mixture properly proportioned. Foreign ingredients, membrane and surface coatings, or other means need not be used, except where poor workmanship is likely or where considerable damage and inconvenience may result in case of leakage. Under such circumstances the membrane treatment used in addition to a properly proportioned concrete, while the most expensive method of waterproofing, probably will give the most reliable results. This treatment consists of layers of burlap or tar paper cemented to the surface and together with tar or asphalt. Where the membrane is subject to injury it is sometimes protected by a coating of cement mortar or brick backing.

First-class workmanship and special attention to details are required to secure water-tightness. The essential requisite is that the voids be filled. A lean mixture may be made more impervious by using hydrated lime which tends to fill the voids and makes the concrete flow easily. A little more cement in the mixture would serve the same purpose. The lime should not be in excess of 10 per cent of the weight of the cement and under no circumstances should unslaked lime be used.

The materials for water-tight concrete must be well graded, so as to obtain a maximum density; that is, enough sand must be used to fill the spaces between the gravel or stone and enough cement to fill the spaces between the grains of sand. A 1:2:4 concrete will prove practically impermeable in ordinary construction, but if a head or pressure of water is to be resisted a 1:2:3 or richer mixture may be necessary. The consistency is very important. A sluggishly flowing consistency is best, for if the concrete is too wet the mortar may flow away from the stone, leaving leaky places and, if too dry, the mass may prove porous. The proportions and consistency must be accurately maintained for each batch and the concrete must be exceptionally well mixed.

It is necessary to exercise great care in the placing of the concrete. Where practicable, the structure or object should be poured in one operation to avoid leaky joints, but when this is not possible precautions should be taken to secure a tight joint between concrete « 27 » of different ages. The surface of concrete which has set must be cleaned of dirt and scum down to the true concrete. This surface then should be well whetted and painted immediately with a creamy mixture of cement and water before placing the new concrete. A good plan, when discontinuing work on structures intended to hold liquids, is to embed a 6 or 8 inch strip of tin or thin sheet metal to half its width in the concrete so that the other half will project into the new concrete.

A wall thick enough to resist the stresses put upon it will generally resist percolation of water, but 6 inches may be considered as a minimum.

Contraction and expansion must be controlled to avoid the occurrence of leaks. To guard against cracks due to unequal settlement or other causes, most concrete designed for water-tightness should be reinforced. In some mass work, special contraction joints, as described on page 23 may be necessary. Rules for the use of reinforcement and contraction joints can not be given, as the requirements in each case vary with the conditions to be met.

October 21, 1929

| Secretary of Agriculture | Arthur M. Hyde. |

| Assistant Secretary | R. W. Dunlap. |

| Director of Scientific Work | A. F. Woods. |

| Director of Regulatory Work | Walter G. Campbell. |

| Director of Extension Work | C. W. Warburton. |

| Director of Personnel and Business Administration |

W. W. Stockberger. |

| Director of Information | M. S. Eisenhower. |

| Solicitor | R. W. Williams. |

| Weather Bureau | Charles F. Marvin, Chief. |

| Bureau of Animal Industry | John R. Mohler, Chief. |

| Bureau of Dairy Industry | O. E. Reed, Chief. |

| Bureau of Plant Industry | William A. Taylor, Chief. |

| Forest Service | R. Y. Stuart, Chief. |

| Bureau of Chemistry and Soils | H. G. Knight, Chief. |

| Bureau of Entomology | C. L. Marlatt, Chief. |

| Bureau of Biological Survey | Paul G. Redington, Chief. |

| Bureau of Public Roads | Thomas H. MacDonald, Chief. |

| Bureau of Agricultural Economics | Nils A. Olsen, Chief. |

| Bureau of Home Economics | Louise Stanley, Chief. |

| Plant Quarantine and Control Administration | C. L. Marlatt, Chief. |

| Grain Futures Administration | J. W. T. Duvel, Chief. |

| Food, Drug, and Insecticide Administration | Walter G. Campbell, Director of Regulatory Work, in Charge. |

| Office of Experiment Stations | E. W. Allen, Chief. |

| Office of Cooperative Extension Work | C. B. Smith, Chief. |

| Library | Claribel R. Barnett, Librarian. |

This bulletin is a contribution from

| Bureau of Public Roads | Thomas H. MacDonald, Chief. |

| Division of Agricultural Engineering | S. H. McCrory, in Charge. |

U. S. GOVERNMENT PRINTING OFFICE: 1929

Transcriber Notes

All illustrations were moved so as to not split paragraphs.