Title: Shafting, Pulleys, Belting and Rope Transmission

Author: Hubert E. Collins

Release date: January 6, 2020 [eBook #61123]

Most recently updated: October 17, 2024

Language: English

Credits: Produced by deaurider, Alan and the Online Distributed

Proofreading Team at http://www.pgdp.net (This file was

produced from images generously made available by The

Internet Archive)

THE POWER HANDBOOKS

The best library for the engineer and the man who hopes to be one.

This book is one of them. They are all good—and they cost

$1.00 postpaid per volume. (English price 4/6 postpaid.)

SOLD SEPARATELY OR IN SETS

By PROF. AUGUSTUS H. GILL

OF THE MASSACHUSETTS INSTITUTE OF TECHNOLOGY

ENGINE ROOM CHEMISTRY

By HUBERT E. COLLINS

| BOILERS | KNOCKS AND KINKS | |

| SHAFT GOVERNORS | PUMPS | |

| ERECTING WORK | SHAFTING, PULLEYS AND | |

| PIPES AND PIPING | BELTING |

By F. E. MATTHEWS

REFRIGERATION. (In Preparation.)

HILL PUBLISHING COMPANY

505 PEARL STREET, NEW YORK

6 BOUVERIE STREET, LONDON, E. C.

THE POWER HANDBOOKS

Shafting, Pulleys, Belting

AND

Rope Transmission

COMPILED AND WRITTEN

BY

HUBERT E. COLLINS

Published by the

McGraw-Hill Book Company

New York

Successors to the Book Departments of the

| McGraw Publishing Company | Hill Publishing Company |

| Publishers of Books for | |

| Electrical World | The Engineering and Mining Journal |

| The Engineering Record | Power and The Engineer |

| Electric Railway Journal | American Machinist |

Copyright, 1908, by the Hill Publishing Company

All rights reserved

Hill Publishing Company, New York, U.S.A.

INTRODUCTION

This handbook is intended to furnish the reader with practical help for the every-day handling of shafting, pulleys and belting. These are allied in the operation of plants and it is a pretty generally conceded fact that all three are much neglected by many operators.

A close perusal of these pages will enable the reader to determine the best course to pursue in the most common instances and in various troubles, and in all articles there are suggestions for similar cases which may arise.

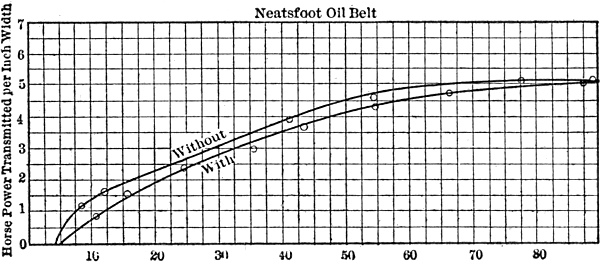

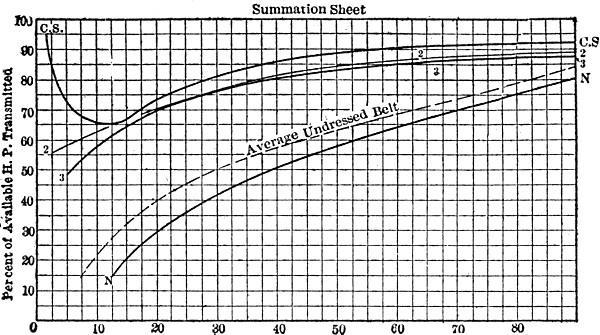

For instance, the need of belt dressing as a preservative, now generally conceded by most authorities, is fully covered in Chapter XI and the result of a test made by disinterested parties to find the degree of efficiency of four of the best known dressings is given. The results are of importance to all belt users.

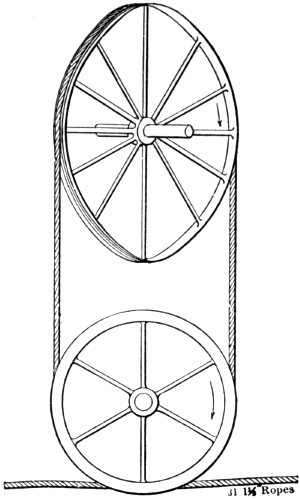

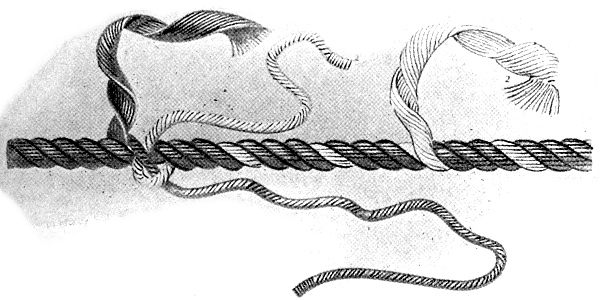

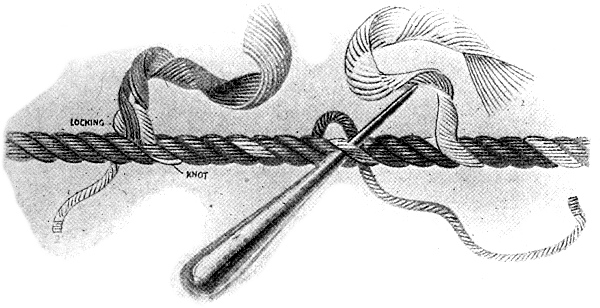

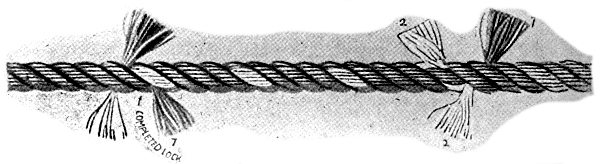

A portion of the book is also given to rope transmission which is in more general use to-day than ever before, and in this connection some advice is offered by experts as to the selection and care of the rope. Rope splices and how to make them will also prove valuable to many engineers.

The author wishes to make acknowledgment to various contributors to Power whose articles are used[Pg vi] herein, and to some special contributors, from whose articles small portions have been taken. Acknowledgment is also made to Stanley H. Moore, the author of "Mechanical Engineering and Machine Shop Practice" for the section on splicing.

Hubert E. Collins.

New York, November, 1908.

CONTENTS

| CHAP. | PAGE | |

| I | Shafting Hints | 1 |

| II | Shafting Hints | 21 |

| III | Shafting Hints | 32 |

| IV | Truing up Line Shafting | 49 |

| V | Apparatus for Leveling and Lining Shafting | 54 |

| VI | Some Practical Kinks | 61 |

| VII | Practical Methods of Loosening Pulleys | 65 |

| VIII | Splicing Leather Belts | 72 |

| IX | Care and Management of Leather Belts | 89 |

| X | Belting—Its Use and Abuse | 99 |

| XI | A Comparative Test of Four Belt Dressings | 102 |

| XII | Belt Creep | 106 |

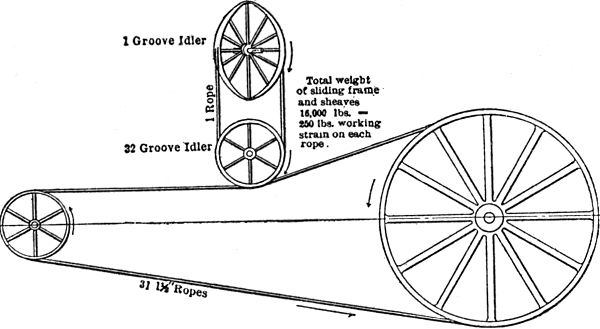

| XIII | Rope Drives | 108 |

| XIV | A New Scheme in Rope Transmission | 115 |

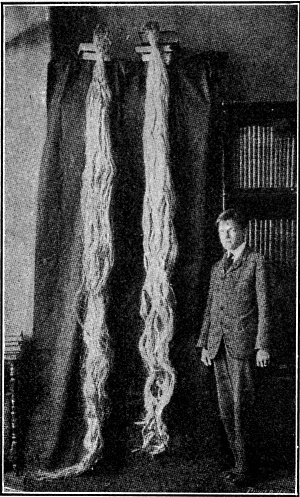

| XV | How to Order Transmission Rope | 122 |

| XVI | A Belting and Pulley Chart | 129 |

| XVII | Splicing Rope | 135 |

| XVIII | Wire Rope Transmission | 143 |

I

In the installation, maintenance and repair of shafting, as in all other things, there is a right and a wrong way; and though the wrong way ranges in its defects from matters causing trivial inconvenience to absolute danger, the right too often—owing to lack of knowledge or discernment—finds but scant appreciation.

[1] Contributed to Power by Chas. Herrman.

Where, as is often the case, the end of a shaft is journaled to admit of the use of an odd, small-bore pillow block or wall-box hanger, the journaled part should equal in length twice the length of the hanger bearing plus the length of the collar. The hanger can thus readily be slid out of the wall box, and the necessity of uncoupling this shaft length and removing it before access to the bearing for purposes of cleaning or repair is done away with.

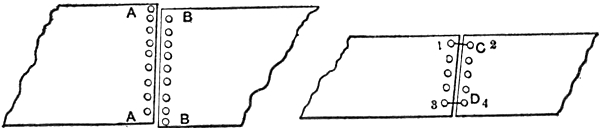

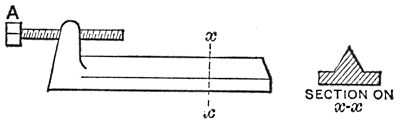

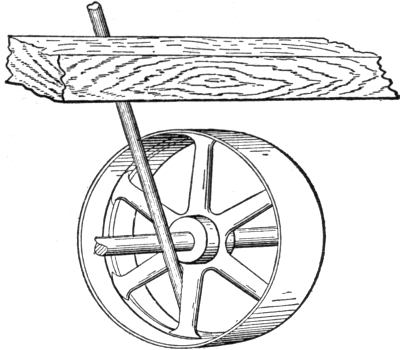

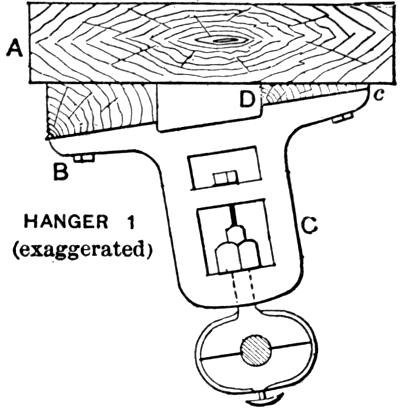

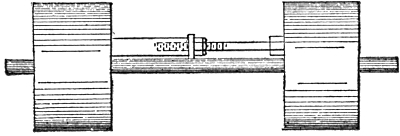

A plank or board A (Fig. 1), about ¼ to ½ inch longer than the distance from the bottom of the shaft to the floor, can be used to good advantage at such times to free the hanger of the shaft's weight, and to prevent the shaft's springing from its own weight and the pulleys it may be carrying.

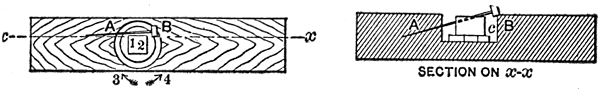

Should it become necessary to place a pulley with[Pg 2] half the hub on and half off the journaled part, this can readily be done by the use of a split bushing, as shown in sectional view of Fig. 1.

Very often a small-sized bearing is used and the shaft journaled off to act as a collar. Of this procedure it can only be said that if done with the idea of making a "good job" it signally fails of its object; if of necessity (a collar being insufficient), then the shaft is heavily overloaded and serious trouble will result, because of it.

It is advisable to center punch, or otherwise mark, the ends of both shafts held by a compression coupling close up against the coupling, and both edges of the coupling hub should have a punch mark just opposite and close to the shaft punch marks. These marks will serve at all times to show at a moment's glance any end or circumferential slippage of the shafts within the coupling. The same method can be resorted to for proof of pulley slippage.

When a new line of shafting is put up, the foot position of each hanger should be clearly marked out on their respective timbers after the shaft has been brought[Pg 3] into alinement. Hangers can thus be easily put back into their proper place should timber shrinkage or heavy strains cause them to shift out of line. This idea can be applied to good advantage on old lines also, but before marking out the hanger positions the shaft should be tried and brought into perfect alinement.

Hangers that do not allow of any vertical adjustment should not be used in old buildings that are liable to settle. Shafting so run pretty nearly always gets out and keeps out of level.

In flanged bolt couplings (Fig. 1) no part of the bolt should project beyond the flanges. And where a belt runs in close proximity to such a coupling, split wood collars should be used to cover in the exposed coupling flanges, bolt heads and nuts. Countershafts have been torn out of place times innumerable by belts getting caught and winding up on the main line.

Whenever possible a space of 8 to 10 inches should be left between the end of a shaft line and the wall. A solid pulley or a new coupling can thus readily be put on by simply uncoupling and pushing the two shaft lengths apart without taking either down. Ten inches does not represent the full scope of pulleys admissible, for so long as the pulley hub does not exceed a 10-inch length the pulley face (the more readily in proportion to the larger pulley diameter) can be edged in between the shafts.

Fig. 2 is an instance of bad judgment in locating the bearings. In one case this bearing overheated; the remedy is either to re-babbitt the old box or replace it with a new one.

Both pulleys were solid and the keys—headless ones—had been driven home to stay. The rims of both pulleys almost touched the wall, and the circumferential position on the shaft of both these pulleys was such as to preclude the possibility (owing to an arm of a being in a direct line with key B1 and arm of b with key a1) of using anything but a side offset key starting drift.

An effort was made to loosen b (which was farthest from the wall) by sledge-driving it toward the wall, hoping that the pulley might move off the key. The key, as was afterward found out, not having been oiled when originally driven home had rusted in place badly; though the pulley was moved by sledging, the key, secure in the pulley hub, remained there.

Ultimately one of us had to get into pulley b, and, removing cap c, hold the improvised side offset, long, starting drift D in place against B1 at b2 while the other swung the hand sledge at a. The entering end of the key, not having been file chamfered off, as it should have been (see E), our starting drift burred it up; so, after having started it, we had the pleasure of getting[Pg 5] into b to file the key end b2 into shape so as to admit of getting it out.

The solid pulley b has since been replaced with a split pulley.

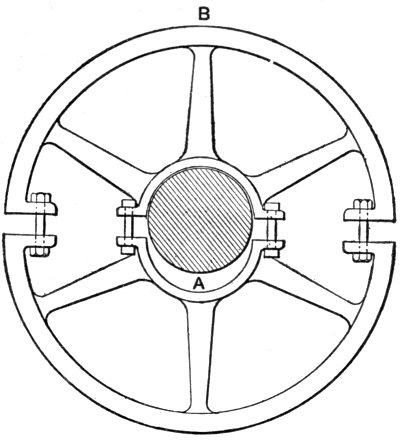

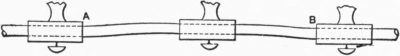

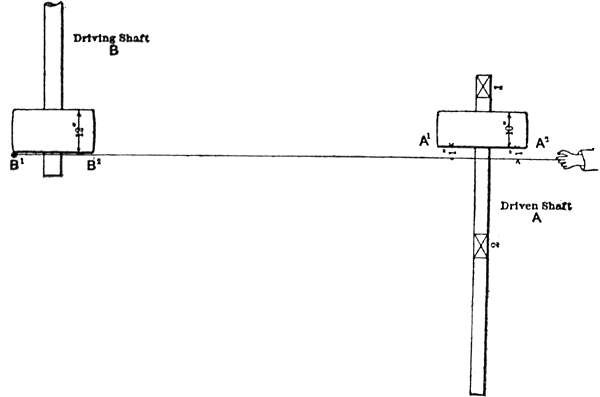

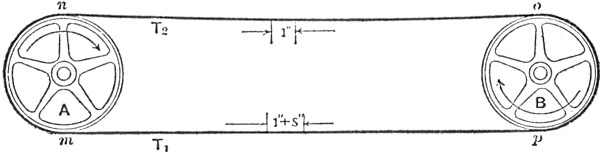

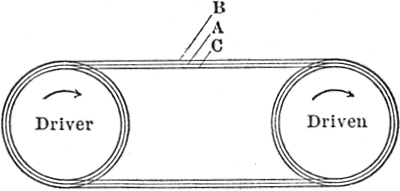

By the arrangement, as shown in Fig. 3, of the rim-friction clutch on the driven main shaft B and the driving pulley on the engine-connected driving main shaft A, no matter whether B shaft is in use or not—i.e., whether the clutch be in or out of engagement—so long as A shaft is in motion the belt C is working.

Main line belts come high, and the more they are used the sooner will they wear out. By changing the clutch from shaft B to A and the pulley D from A to B, belt C will be at rest whenever B is not in use. Where, however, these shafts are each in a separate room or on a different floor (the belt running through the wall or floor and ceiling, as the case may be) the clutch, despite belt wear, should be placed directly on the[Pg 6] driven shaft (as B), so as to provide a ready means for shutting off the power in cases of emergency.

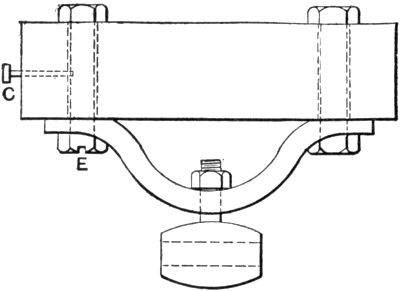

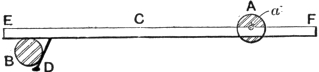

Figs. 4, 5 and 6 represent a dangerous mode, much in vogue, of driving an overhead floor. An extremely slack belt connects the driving shaft A and the driven shaft B; when it is desired to impart motion to the driven shaft the belt tightener C is let down and belt contact is thus secured.

This tightener system is called dangerous advisedly, for few are the shops employing it but that some employee has good cause to remember it. Unlike a clutch—where control of the power is positive, instantaneous and simple—the tightener cannot be handled, as in emergency cases it has to be.

In any but straight up and down drives with the driven pulley equal to or larger (diametrically) than the driver, unless the belt have special leading idlers there is more or less of a constant belt contact with its resultant liability to start the driven shaft up unexpectedly. When the tightener is completely off, the[Pg 7] belt, owing to heat, weight or belt fault, may at any time continue to cling and transmit power for a short space, despite this fact.

These tighteners are usually pretty heavy—in fact, much heavier than the unfamiliar imagines when on the spur of emergency he grapples them, and trouble results.

Tightener (in Fig. 5) A is held in place by two threaded rods B—as shown by slot a in A1—and regulated and tightened by ring-nuts C working along the threaded portion of B. C (of Fig. 4) is also a poor arrangement. Fig. 6 is the best of them all.

Apropos of clutches, great care must be exercised in tightening them up while the shafting is in motion, for if the least bit overdone the clutch may start up or, on being locked for trial (according to the clutches' structure), continue running without possibility of release until the main source of power be cut off. Nothing can exceed the danger of a clutch on a sprung shaft.

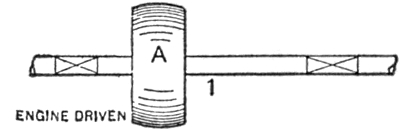

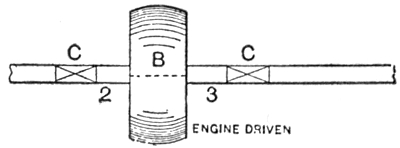

Heavily loaded shafting runs to much better advantage when center driven than when end driven, and what often constitutes an overload for an end drive is but a full load for a center drive. To illustrate, here is one case of many: The main shaft—end driven—was so overloaded that it could be alined and leveled one week and be found out one way or the other, frequently both ways, the next week. Being tired of the ceaseless tinkering that the condition under which that shaft was working necessitated, the proprietors were given the ultimatum: A heavier line of[Pg 8] shafting which would be sure to work, or a try of the center drive which, owing to the extreme severity of this case, might or might not work.

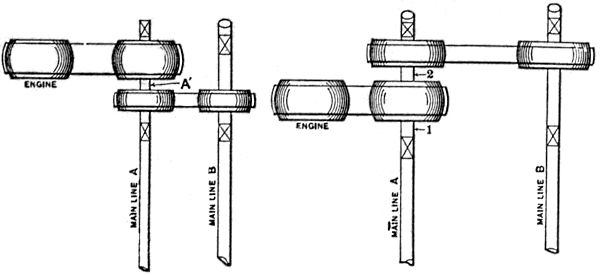

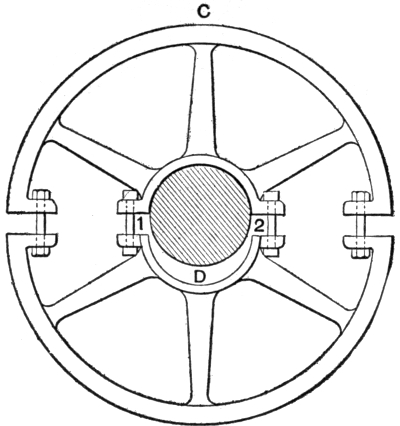

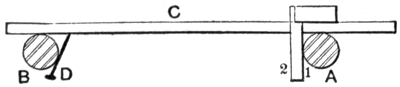

Fig. 7.

Fig. 8.

A center drive, being the cheapest, was decided upon. Pulley A, Fig. 7, which happened to be a solid, set-screw and key-held pulley, was removed from the end of the shaft. The split, tight-clamping-fit pulley B, Fig. 8, was put in the middle of the shaft length; the gas engine was shifted to accommodate the new drive, and hanger C1 was put up as a reinforcement to hanger C and as a preventive of shaft springing. After these changes the shaft gave no trouble, so that, as had been hoped, the torsional strain that had formerly all been at point 1 must evidently have been divided up between points 2 and 3.

When a main shaft is belted to the engine and to a countershaft, as shown in Fig. 9, the pulley A1 gets all the load of main and countershafts. In the arrangement shown in Fig. 10 point 1 gets A's load and 2 gets B's load and is the better arrangement.

Fig. 9——Fig. 10.

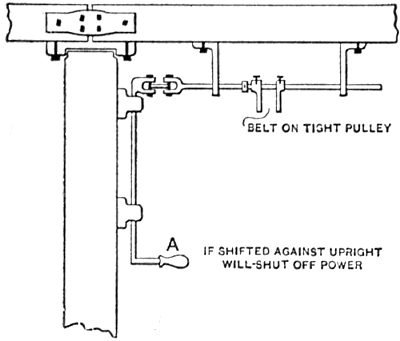

Where a machine is situated close to one of the columns or timber uprights of the building it is very customary to carry the belt shifter device upon the column, as in Fig. 11. The sudden stoppage of a machine seldom does any damage, whereas an unexpected starting may cause irreparable damage and often even endanger the limb and life of the machine operative.

Fig. 11.

To avoid the possibility of some passing person brushing up against the shifting lever and thus starting the machine, the tight and loose pulleys of the countershaft should be so placed that when A is exposed—that is, away from the column—its accidental shifting shall stop the machine. Fig 12 makes this point clear.

Fig. 12.

This arrangement is often used to save a collar (at A). The oil runs out between the loose pulley and the bearing, especially if the latter be a split bearing; the loose pulley, instead of being totally free when the belt is on the tight pulley, acts more or less, in proportion to the end play of the shaft, as a buffer between the tight pulley and the bearing; finally, the tight pulley is deprived of the support (which, when under load, it can use to good advantage) a nearer proximity to the hanger would give it.

The shafts of light-working counters should not be needlessly marred with spotting or flats for collar set-screws, nor should cup or pointed set-screws (which mar a shaft) be used. If the collar be sharply tapped with a hammer, diametrically opposite the set-screw, while it is being tightened up, all slack is taken out of the collar; and the hold is such that, without resource[Pg 11] to the same expedient when loosening the collar, a screwdriver will scarcely avail against a slotted set-screw.

When required to sink the head of a bolt into a timber to admit of the timbers lying snug in or against some spot, if allowable, the bolt's future turning can be guarded against by cutting the hole square to fit the bolt head. But where a washer must be used, the only positive and practical way to prevent the bolt from turning is to drive a nail (as shown) into A (Fig. 13) far enough for the nail head to flush B; now bend the head down behind the bolt toward c. It is evident that if the bolt tries to turn in the direction of 3 the nail end (wood held) will prevent it; if toward 4, the nail head will be forced against the wood and catch hold of the bolt head.

Fig. 13.

Large belts of engines, dynamos, motors, etc., when in need of taking-up are usually attended to when the plant is shut down; that is, nights, Sundays or legal holidays. At such times power is not to be had; and if the spliced part of the belt, which must be opened, shortened, scraped, re-cemented and hammered, happens to be resting against the face of one of the pulleys, is up between some beams or down in a pit, the chances of the job, if done at all, being any good are very slim.

The spliced part of a large belt should be clearly[Pg 12] marked in some permanent and easily recognizable way (a rivet, or where the belt is rivet-held at all its joints some odd arrangement of rivets is as good a way as any). This marking will minimize the possibility of mistake and enable the engineer to place the belt splice in the position most favorable for the belt-maker's taking-up.

In wire-lacing a belt, very often, despite all efforts and care, the edges of the belt (A, B) get out of line, as shown in Fig. 14, and make the best of jobs look poor. By securing the belt in proper position by two small pieces of wire passed through and fastened at 1, 2, 3 and 4, Fig. 15, the lacing can be more conveniently accomplished and the edge projection is avoided. When the lacing has progressed far enough to necessitate the removal of wires c d, the lacing already in place will keep the belt in its original position.

Fig. 14——Fig. 15.

A wire lacing under certain conditions will run a certain length of time to a day. On expensive machinery whose time really is money it pays to renew the lacing at regular intervals so as to avoid the loss of time occasioned by a sudden giving out of the lace.

Never throw a belt on to a rim-friction or other kind of clutch while the shaft is in full motion. Belts, when being thrown on, have a knack, peculiarly their own,[Pg 13] of jumping off on the other side of the pulley. And should a belt jump over and off on the wrong side and get caught in the clutch mechanism, as the saying goes, "there will be something doing" and the show usually comes high. It pays to slow down.

A mule belt (transmitting in the neighborhood of or considerably over 25 horse-power) that runs amuck through the breaking down of the mule can make enough trouble in a short time to keep the most able repairing for a long while.

Fig. 16.

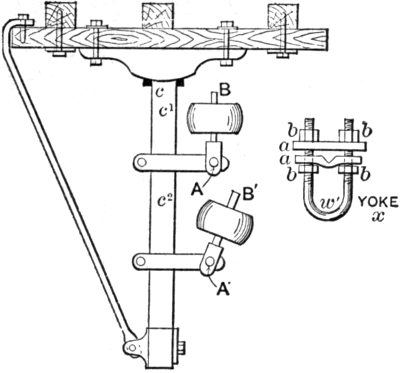

No matter what the pulley shafts holding arrangement and adjusting contrivance may be, all of the strain due to belt weight, tension, and the power transmitted falls mainly at points A, A1, Fig. 16; and it is here that, sooner or later, a pin, set-screw or bolt gives way and the belt either gets badly torn up, rips[Pg 14] something out of place, or a fold of it sweeping to the floor slams things around generally until the power is shut off.

The remedy is obvious: Reinforce A, A' by securing B, B' to the supporting shaft c at c1, c2. The yoke x is a reliable and practical means to this end. Straps a held by the nuts b hold the yoke securely on the supporting shaft c, while the pulley-shaft ends B, B' are held in the U of the yoke at w' at any desired distance from c by means of the adjustment provided by the nuts b.

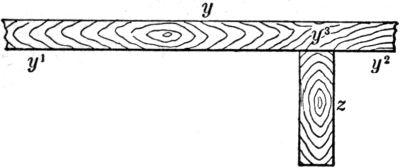

The end of a hanger bearing was badly worn (Fig. 17). The cap could be lifted out by removing bridge A, but the shaft interfered with the lifting of the bottom out, owing to its being held in the hanger slides. It had to be removed and we were called upon to put it into shape by re-babbitting.

Being a newspaper plant, money was no object; the time limit, however, was three hours, or hands off.[Pg 15] Opening the 30-inch engine belt and removing the interfering shaft length was out of the question in so short a time. So the job was done as follows: The shaft was braced against down sag and engine pull along the line B C by a piece of timber at A, and against pull on B D by timber arrangement X; timber y's points y1 and y2 resting against the uprights at 1 and 2, timber z wedged in between y at y3 and the shaft at 4, thus acting as the stay along line B D. The nuts and washers a, a were removed; the bolts driven back out of the bracket; the end of a rope was thrown over the shaft at b, passed through the pulley and tied to the bracket and hanger which, as one piece, were then slid endways off the shaft and lowered to the floor. The bearing was cleaned, re-babbitted and scraped, everything put back, stays removed and the shaft running on time with a half-hour to the good.

TIMBER ARRANGEMENT X

When desirable to keep a shaft from turning while chipping and filing flats, spotting in set screws or moving pulleys on it, it can be done by inserting a narrow strip of cardboard, soft wood or several thicknesses of paper between the bearing cap and the top of the shaft and then tightening the cap down.

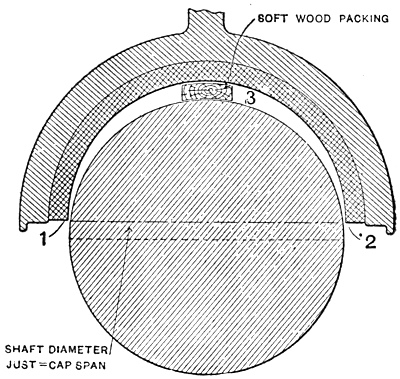

The packing, 1/16 to 3/16 inch thick and about as[Pg 16] long as the bearing, must be narrow; otherwise, as may be deduced from Fig. 18 (which shows the right way), by the use of a wide strip in the cap the shaft is turned into a wedge, endangering the safety of the cap when forced down. At point 3 packing does no harm, but at 1 and 2 there is just enough space to allow the shaft diameter to fit exactly, with no room to spare, into the cap bore diameter.

Fig. 18.

As a very little clamping will do a good deal of holding the clamping need not be overdone. A shaft can also be held from turning, or turned as may be desired, by holding it with a screw (monkey) wrench at any flat or keyway, as shown in sectional view, Fig. 19.

When a shaft breaks it is either owing to torsional strain caused by overload, springing through lack of[Pg 17] hanger support at the proper interval of shaft length, the strain of imperfect alinement or level, or a flaw.

An immediate temporary repair may be effected by taking some split pulley that can best be spared from another part of the shaft and clamping it over the broken part of the shaft, thus converting it, as it were, into a compression coupling. The longer the pulley hub the better the hold; spotting the set-screws—that is, chipping out about 1/8-inch holes for their accommodation into the shaft—is also a great help.

Fig. 19.

If when the shaft breaks it has not been sprung by the sudden dropping of itself and the pulleys that were on it, a permanent repair can be effected, after correcting the cause of the break, by the use of a regular key-less compression coupling.

If it has been sprung, a new length comes cheapest in the wind-up; and if overload was the original cause of the trouble, only a heavier shaft or a considerable lightening of the load will prevent a repetition.

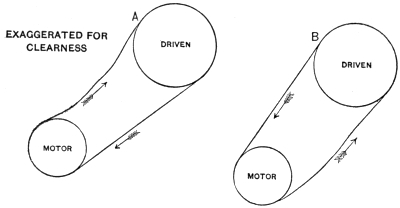

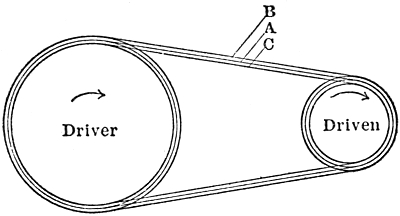

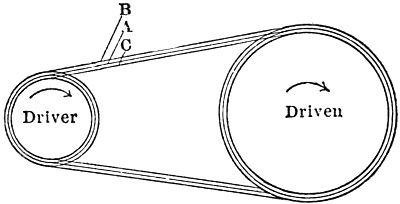

In Fig. 20 A shows how to drive to make belt weight count in securing extra contact. In B this weight causes a loss of contact. Bearing in mind that B is not only a loss from the normal contact but also a loss of the extra contact that A gives, it will readily be seen how important a power-saving factor the right sort of[Pg 18] a drive is—especially on high-speed small-pulley machines, such as dynamos, motors, fans, blowers, etc.

Fig. 20.

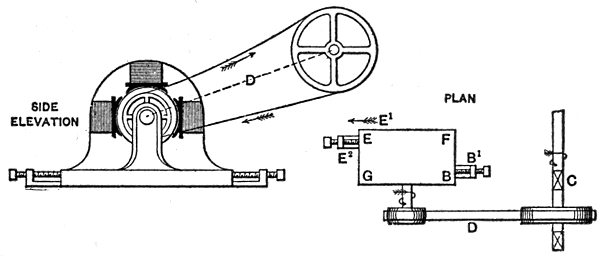

A good many electrical concerns mount some of their styles of dynamos and motors (especially the light duty, small size) upon two V-shaped rails, Fig. 21 (the bottom of the motor or dynamo base being V-grooved for the purpose). The machine's weight and the screws A are counted on to keep it in place. If the machine be properly mounted on these rails, as regards screws A in relation to its drive, the screws reinforce the machine's weight in holding it down and also permit a surer adjustment through this steady holding of the machine.

Fig. 21.

Fig. 22 shows the machine properly mounted. The belt tension and pull tend to draw B corner of the machine toward the shaft C; and screw B1 is there to resist this pull. Owing to this resistance and the pull along line D, E tends to lift and slew around in E1 direction; screw E2 is, however, in a position to overcome both these tendencies. If the screws are both in front, there is nothing but the machine's weight to keep the back of it from tilting up. The absurdity of placing the screws at F and G, though even this is thoughtlessly done, needs no demonstration.

Fig. 22.

When putting a new belt on a motor or dynamo, both the driver and the driven are often needlessly strained by the use of belt-clamps, in the attempt to take as much stretch out of the belt as possible. On being loosely endlessed it soon requires taking up; and if only laced, when the time for endlessing comes the belt is botched by the splicing in of the piece which, owing to the insufficiency of the original belt length, must now be added to supply enough belt to go around, plus the splice.

The proper mode of procedure is: Place the motor on its rails or slides 5 inches away from its nearest possible approach to the driven shaft or machine and wire-lace it (wire-lacing is a very close second to an endless belt). Let it run for a few days, moving the motor back from the driven shaft as the belt stretches. When all reasonable stretch is out, move the motor back as close to the driven shaft as possible.

The 5 inches forward motion will give 10 inches of belting, which will be amply sufficient for a good splice; and, further, the machine will be in position to allow of tightening the belt up, by simply forcing the motor back, for probably the belt's lifetime.

II

The bolts, set-screws, pulleys, bearings, shafting and clutches of a plant, although among the foremost factors in its efficiency, are very often neglected until they reach the stage where their condition absolutely compels attention.

[2] Contributed to Power by Chas. Herrman.

Very often this lack of proper attention is due to surrounding difficulties of an almost insurmountable and most discouraging nature. At other times it is due to a lack of proper appreciation of the damage resultant from seemingly insignificant neglects. How to overcome some of these difficulties is the object of this chapter.

Fig. 23 shows a case of a turning bolt. The head is inaccessible and the bolt's turning with the nut, owing to burrs or rust, prevents either the tightening or the loosening of the nut. One to three fair-sized nails driven through the timber as at C, hard up against, or, better still, forced into a tangent with the bolt, will often suffice to hold it while the nut is being turned. In iron girders, beams, etc., the nail method being impossible, a slot E can easily be cut with a hack-saw through the lower end of both the nut and bolt, so[Pg 22] that the bolt may be held by a screwdriver while the nut is turned with a wrench.

Where an extra strong screwdriver must be used, the use of two blades at the same time in the hack-saw frame will give a slot of the requisite width. Where the bolt's end projects beyond the nut and it is desired to tighten the nut, a Stillson wrench is often, though inadvisedly, called into service. This tends to spoil the lower threads of the bolt and thus prevents any future loosening, except by the cutting off of the projecting end.

Fig. 23.

As the alinement and level of shafting depend on the power of their hold, bolts, lag-bolts and set-screws should, when they are tightened, be so in fact and not in fancy.

The proper way to use a wrench, especially a screw wrench, so as to avail yourself of every ounce of power, not of your biceps only but of your whole body, is as follows: Place your shoulders on a level with the object to be tightened, secure the wrench jaws well upon it,[Pg 23] grasp the jaws with the left hand and the wrench handle with the right, holding both arms straight and tense; swing the upper part of the body to the right from the hip, backing the force of your swing up with the full force of your legs, steadying yourself the while with your left-hand grip on the wrench jaws, which are the center of your swing. Several such half turns, at the wind-up, will cause an extremely hard jam with comparative ease.

In tightening up a split-pulley, the expedient of hammering the bolts tight, by means of an open-ended bolt-wrench and a small sledge, is often resorted to. If the head of the bolt be lightly tapped while the nut is being tightened, even a light hammering, except in the extremest cases, becomes unnecessary.

Split-pulleys are invariably better held in place by a good clamping fit than by set-screws. It must also be borne in mind that, for good holding, set-screws must be spotted into the shaft, and this defaces and often materially weakens the shaft. Split-pulleys, like solid ones, are sometimes subject to stoppage, owing to excessive strain. Set-screws, at such times, cut a shaft up pretty badly; whereas, if clamped, only a few slight scratches would result.

Where packing with paper, cardboard, emery cloth or tin becomes necessary to secure a good clamping fit, care should be taken to put an equal thickness of packing into both halves of the pulley; otherwise it will wabble and jump when running.

Emery cloth, on account of its grittiness, is preferable for packing where the duty done by the pulley[Pg 24] is light. When the duty done is extra heavy, emery cloth, despite its grittiness, will not do; tin or sheet iron, owing to body, must be used.

The following is the most practical way of packing a split-pulley to a good clamping fit, assuming that emery cloth is to be used:

The thickness of the emery cloth to be used, and whether to use one or more folds, can readily be ascertained by calipering the shaft diameter and pulley bore, or by trial-clamping the pulley by hand. In both of these instances, however, due allowance must be made for the compressiveness of the packing used. If the packing be too thin, the pulley will not clamp strongly enough; if too thick, the chances of breaking the lugs when drawing the bolts up are to be apprehended.

Having determined the proper thickness of emery cloth to be used, place the pulley on the shaft, as shown in Fig. 24. Into the lower half C, in space A, which is out of contact with the shaft, place a sheet of emery with the emery side toward the hub and the smooth side toward the shaft. The width of the emery should be a little less than half of the shaft's circumference, and it should be long enough to project about one-half of an inch to an inch on each side of the hub.

Now turn the pulley on the shaft so that the position of the halves shall become reversed (Fig. 25), C on top, B on bottom. See that the emery cloth remains in its proper position in half-hub, the smooth side being toward the shaft; the projecting length beyond the pulley hub will help you to do this.

Into half-hub B (space D) insert a similar sized piece of emery cloth, smooth side toward the hub and the emery side toward the shaft. Draw up on your bolts to clamp the pulley into position. Be sure, however, that no emery cloth gets in between the half-hubs or lugs at points 1 and 2, Fig. 25, as this would prevent their coming properly together; the width of the emery being less than half of the shaft's circumference will be a help to this end.

Fig. 24.

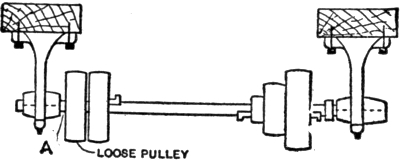

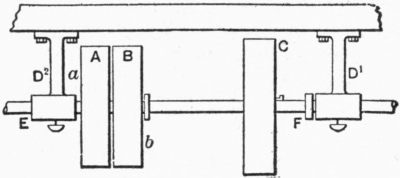

It often happens, owing to downright neglect or unwitting neglect, through the oil hole or oiler being blocked up, that a loose pulley, running unlubricated, cuts, heats, and finally, through heat expansion, seizes. It then becomes necessary to take the countershaft[Pg 26] down, force the loose pulley off and file and polish the shaft up before it can be put back into place.

Fig. 25.

The following method avoids the taking down and putting back, provides an easy means for loosening up the pulley that has seized, and improvises, as it were, a lathe for filing and polishing the shaft.

Fig. 26.

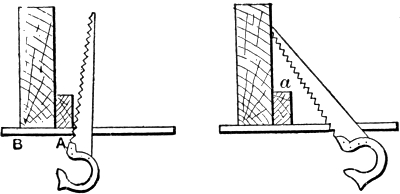

In Fig. 26, A is the loose pulley that has seized.[Pg 27] Throw off both the belt that leads from the main shaft to pulleys A, B and the belt that leads to the driven machine from the driving pulley C. Tie, or get somebody to hold, an iron bar in pulley A at side a, as shown in Fig. 27, over an arm of the pulley, under the shaft, and resting against the timber, ceiling, wall or floor, in such a way as to prevent the pulley from turning in one direction, as shown in Fig. 27. Now, with another bar, of a sufficient length to give you a good leverage, take the grip under a pulley arm and over the shaft in the tight pulley B at b, which will enable you to work against the resistance of the bar in the loose pulley A.

Fig. 27.

With enough leverage, this kind of persuasion will loosen the worst of cases. Take the bars out and move B sufficiently to the right to allow A to take B's former position. Secure B by means of its set-screws in its new position and, by means of a piece of cord, fasten[Pg 28] an arm of A to one of B's. It is evident that by throwing the main-shaft belt on to A it will, through A's cord connection with B, which is screwed to the shaft, cause the shaft to revolve, thus enabling you to file up and polish that portion of it formerly occupied by A. To prevent the countershaft from side-slipping out of hanger-bearing D1, get somebody to hold something against hanger-bearing D2 at E; or fasten a piece of wire or cord on the countershaft at F and the hanger D1, so as to prevent side-slipping while not interfering with revolution.

Filing, polishing, a cleaning out of the oil hole or oiler, and the taking of proper precaution against future failure of lubrication will put everything into first-class order. When the loose pulley is, as it is best for it to be, farthest away from the bearing, held in its place by the tight pulley and a collar, not only is the tight pulley better adapted for carrying its load, owing to additional support resultant from its proximity to the bearing, but such matters of small repair as come up are much simplified.

Fig. 28.

Fig. 28 in some degree, aside from the cutting up and heating of the bearings, illustrates the breaking strain, in addition to the usual torsional strain, which becomes enhanced in direct proportion with the increase of breaking strain, to which an out-of-line or out-of-level[Pg 29] shaft is subject. The bends are exaggerated for illustration.

In this instance, the fact of one hanger-bearing being out of line or level subjects the shaft to a severe breaking strain. The shaft being both out of line and level does not, if both at the same point, aggravate matters, as might at first be supposed.

It is true that the full torsional strength of a shaft is only equal to the weakest portion of it, so that three weak spots more or less can, theoretically, make no difference one way or the other. But, practically, there is the undue strain and wear of the bearings at these points, and if a pulley transmitting any considerable amount of power is situated anywhere along the length A B it is sure to be unpleasantly in evidence at all times.

Only an eighth or a quarter out, but oh, what shaft-breaking stories that fraction could tell!

The following is a simple method for testing the alinement and level of a line of shafting that is already up.

As in Fig. 29, stretch a line C so that it is exactly opposite the shafting. Set it equidistant from the shaft end centers G and F and free from all contact along its entire length except at its retaining ends A and[Pg 30] B. Now, it is self-evident, as line C is straight and set equidistant from the shaft end centers G and F, that if you set the entire center line of the shafting at the same distance from line C, as G and F, you are bound to get your shafting into perfect alinement.

In leveling a line of shafting that is already up, you can, by the use of a level and perseverance, get it right.

Placing the level at A, you are just as likely to raise the first hanger as to lower the middle one. Look before you jump, even if compelled to climb to the top of the fence to do so. When you find a length of shafting out of level, try the two adjacent lengths before acting, and your action will be the more intelligent for it.

On exceptionally long lines of shafting the following method, in which the level and a line constitute a check upon and a guide for each other, can be used to great advantage. Stretch a line so that it is exactly above, or, if more convenient, below the shafting to be leveled. With the level find a length of shafting that is level and adjust your line exactly parallel with this length. Your line now, free of contact except at its retaining ends, and level owing to its parallelism to the level shaft length, constitutes a safe hight level guide while the level itself can serve to verify the accuracy of the finished job.

In lining, whether for level or alinement, unless the shafting line consists of the same diameter of shafting throughout its entire length, though of necessity measuring from the shaft circumference to the line, always[Pg 31] base your calculations on the shaft centers. The figures in Fig. 29 will make this point clear.

The manner of securing the ends of the line under different circumstances must be left to individual ingenuity. Only be sure that the line is so placed that the shafting adjustment shall not affect its original position with reference to the end shaft centers.

Coupling clutches, i.e., those joining two lengths of shafting into one at option, will fail, utterly or partially, if the respective shafts which bear them are out of line or level with each other. Such a condition should not be tolerated on account of the danger entailed by the inability to shut off the power in cases of emergency.

As a general rule, it is most advisable to set a clutch to take as hard a grip as it can without interfering with its releasing power. Where a clutch grips weakly, it is subject to undue wear owing to slippage, whereas a strongly regulated clutch absolutely prevents slippage wear.

III

Engineers, machinists and general mechanics are often called upon to turn their hands to a shafting job. We recognize that all of the following cannot prove new or even suggestive to most of our readers; still, some of it for all, and, mayhap, all for some, may not come amiss.

[3] Contributed to Power by Chas. Herrman.

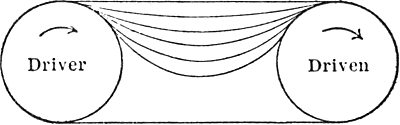

We all know that to have belting run rightly on pulleys located upon parallel lines of shafting the shafting must be in absolutely correct parallel. The slightest deviation, even to a 1/16 inch, often imparts a marring effect, through poorly running belts, to an otherwise faultless job.

Fig. 30.

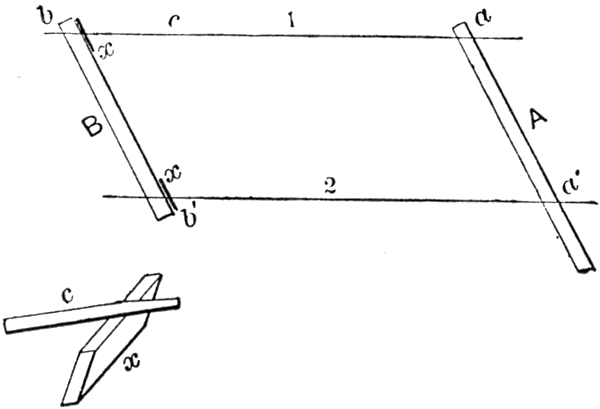

Fig. 30 shows how to line a countershaft as regards parallelism with the driving shaft when the countershaft's end-centers are availably situated for thus measuring. A is the countershaft, B the main shaft, C is a stick of proper length about 1½ inches in thickness[Pg 33] and width, D a heavy nail—about 20-penny will do—driven into C far enough from its end E to allow of C's resting squarely upon the top of the shaft B.

Rest the measuring rod upon the main shaft, keeping the nail in touch with the shaft, so that when the F end is in contact with the end of the countershaft the stick shall be at right angles to the main shaft, and then mark the exact location a of the countershaft's end-center on the stick. Do the same at the other end of the countershaft. If both marks come at the same spot, your counter is parallel; if not, space between these two marks will show you how much and which way the counter is out.

It may only be necessary to shift one end in or out a little; and then, again, it may be that to get into line you will have to throw one end all the way in one direction and the other all or some in the opposite direction. But, whichever it be, do not rest content until you have verified the correctness of your adjustment by a re-measurement.

The nail should be well driven into C, so that its position will not readily change, and it should, preferably, be slant driven (as shown in Fig. 30), as it thus helps to keep the stick down in contact with the shaft.

Where an end-center is not available or where there is no clear space on the main shaft, opposite a center, the method shown in Fig. 31 can generally be used.

Rest C on top of both shafts and at right angles to the driving shaft B. With D pressed against B, place a square on stick C, as shown (stock in full contact with the top of the rod, and the tongue running down the[Pg 34] side of it). Slide along C toward A until the side of the tongue touches the shaft the other side of A. Now mark a line on the stick down tongue. Do the same at the other end of your countershaft and the two resultant marks will be your parallel adjustment guides.

Fig. 31.

It often happens that a counter, or even line shaft, is end driven from the extreme end of the main or jack driving shaft with its other end running beyond the reach of the driving shaft, as shown in Fig. 32.

Fig. 32.

It is evident that neither method 1 nor 2 can here be applied to solve the alinement problem. If the[Pg 35] driving pulley B and the driven pulley A are both in place, the following method can be used to advantage.

Fasten, or let somebody hold, one end of a line against pulley B's rim at B1; carry the line over to A at A2; now sweep the loose A2 end of the line toward pulley A until the line just touches pulley B's rim at B2. When the line so touches—and it must just barely touch or the measurement is worthless—A1 and A2 of pulley A must be just touched by or (if B and A are not of a like face width, as in Fig. 32) equidistant from the line.

A single, two-hanger-supported length of shafting thus lined is bound to be in parallel; but where the so adjusted shaft line consists of two or more coupling-joined lengths supported by more than two hangers, only pulley A's supporting portion of the shaft between its immediate supporting hangers 1 and 2 is sure to be lined; the rest may be more or less out.

To make a perfect job, fix a string in parallel with shaft length 1 and 2, stretching along the entire length of the adjusted shaft, and aline the rest of the shaft length to it.

When there are no pulleys in place to go by, or when, as occasionally happens, the wabbly motion of pulley B (when running) indicates that, having been inaccurately bored or bushed, or being located on a sprung shaft length, its rim line is not at right angles to the shaft line, the method shown in Fig. 33 can be resorted to.

Instead of the nail used in methods 1 and 2, use a board about 8 to 12 inches long and of a width equal to considerably more than half of shaft B's diameter.[Pg 36] By nailing this board x to the measuring rod c at any suitable angle, you will be enabled to reach from the end a well into the shaft B, as at b, and from bâ² well into A, as aâ². By keeping the board x along its entire length in full contact with the shaft B at both 1 and 2, the angular position of rod C is bound to be the same in both instances, and you will thus (by the use of a square, as in Fig. 31) be enabled to aline A parallel with B.

Fig. 33.

In all instances of parallel adjustment here cited it is assumed that both the alined and the alined-to shafts have been, as to secure accuracy of result they must be, properly leveled before starting to aline.

The above methods apply to cases where the shafting is already in place. Where, however, shafting is being newly installed before the work can be proceeded with, it is necessary, after determining on the location for the shafting, to get a line on the ceiling in parallel with the driving shaft to which to work to. Mark that point A which you intend to be the center line for the proposed shafting upon the ceiling (Fig. 34).

Rest your measuring rod upon the driving shaft and at right angles to it, with the nail against it. Hold your square with the stock below and the tongue against the side of the measuring stick, so that its tongue extremity touches the ceiling mark A, and then mark a line on the rod along the tongue side A. Move your rod along the driving shaft to the point where the other end of the proposed shafting line is to be, and, squaring your stick to the driving shaft with the tongue side A on the marked line of the stick, mark your section point on the ceiling. Draw a line or stretch a string between these points, and you have a true parallel to work to.

Fig. 34.

Owing to the supporting timber B's interference, a square had to be used; but where the ceiling is clear the rod can be cut to proper length or the nail be so located as to allow of using the stick extremity C for a marking point.

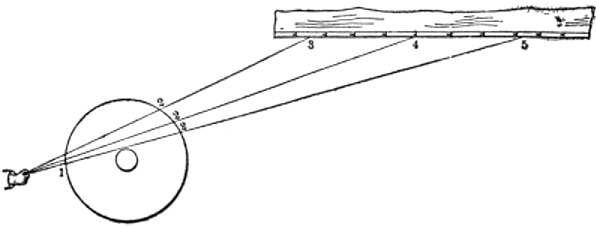

When a pulley is handily situated on the driving shaft, the method shown in Fig. 35 can be used to advantage.

Let somebody hold one end of a line at 1, and when you have got its other end so located on the ceiling that the line just touches the pulley rim at 2, mark that ceiling point (we will call it 3). In the same way get your marks 4 and 5, each farther back than the other[Pg 38] and, for the better assurance of accuracy, as to just touching at 2, remove and readjust the line separately each time. If now a straight line from 3 to 5 cuts 4, your line 3, 4, 5 is at right angles to the driving shaft and a line at right angles to this will be parallel to the shaft.

Fig. 35.

The plumb-bob method is so familiar and, where not familiar, so easily thought out in its various applications, that we deem it useless to touch upon it.

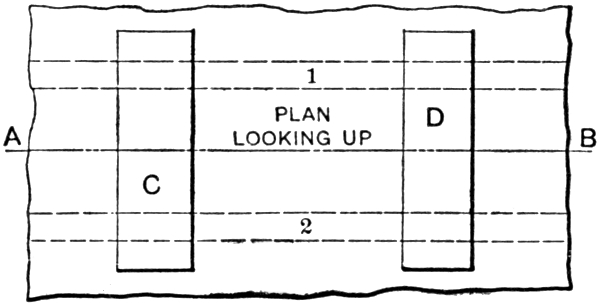

The stringers or supporting timbers of drop hangers should be equal in thickness to about one-fifth of the hanger drop.

Where the stringers run with the hangers and crosswise of the shaft, both feet of a hanger base are bolted to the same stringer, and this should be from 1¼ to 1½ times the width of the widest portion of the hanger base. As the hanger is securely bolted to its stringer, this extra width is in effect an enlargement of the hanger base, and thus enables it the better to assist the shaft's end motion.

Where the stringers run with the shaft and crosswise of the hangers, the two feet of the hanger base are each fastened to a separate timber, and these should[Pg 39] be equal in width to the length of one hanger foot, plus twice the amount of adjustment (if there be any) the hanger's supporting bolt slots will allow it. In reckoning hanger adjustment, be sure to figure in the bolt's diameter and to bear in mind that to get the utmost adjustment for the countershaft the bolts should originally be centered in the slot; thus a 13/16 à 1½-inch slot, as it calls for a ¾-inch bolt, leaves a ¾-inch play, and this play, with the bolt in the center of the slot, allows of 3/8-inch adjustment either way. Without this extra width addition any lateral adjustment of the hanger would result in leaving a part of the hanger's feet without stringer support. Such jobs look poorly, and often run still more poorly. Fig. 36, in its two views, will make the above points clear.

In the stringing of countershafts whose hangers have no adjustment it often happens, despite all care[Pg 40] in the laying out, that they come 1/8 to ¼ inch out of parallel. A very common and likewise very dangerous practice at such times is to substitute a smaller diameter supporting bolt instead of the larger size for which the hanger foot is cored or drilled, and to make use of the play so gained for adjustment.

That shafting so carried does not come down oftener than it does is due solely to the foresight of the hanger manufacturers. They, in figuring the supporting bolt's diameter as against the strain and load to be sustained, are careful to provide an ample safety margin for overload, thus enabling the bolt substituted to just barely come within the safety limit under easy working conditions.

The largest-sized bolt that a hanger will easily admit should invariably be used, and for alinement purposes either of the following slower but safer methods should be used.

Rebore the hanger-supporting bolt holes in the stringers to a larger size, and use the play so gained for adjustment. It is not advisable, however, to rebore these holes any larger than to one and three-quarter times the diameter of the bolt to be used; and the diameter of the washers to be used on top of the stringers should be diametrically equal to at least twice the size of the rebored holes. That the washers used, under such conditions, must be of a good proportionate thickness goes without saying.

When the reboring method cannot be used—as when the hangers are carried by lag screws, lag-bolts, bolts screwed directly into supporting iron girders,[Pg 41] etc.—it is evident that hanger adjustment can be secured by packing down one foot of the hanger base, as shown in Fig. 37.

Fig. 37.

The piece of packing (necessarily wedge-shaped) between the hanger foot B and the stringer A tilts the bottom of the hanger forward. The size of the wedge regulates the amount of adjustment. Wedge-shaped space D, at foot C, should also be packed out so as to avoid throwing undue strain upon C's extremity c. If now, the foot c of the countershaft's other supporting hanger (No. 2) be similarly and equally packed, as B of No. 1 hanger, the shaft will have been thrown forward at one end and back at the other, and thus into line. The equal division of the adjusting wedge packing between the opposite feet of the two hangers enables a limited packing to do considerable adjusting without any undue marring effect; and, further, insures the shaft's remaining level, which evi[Pg 42]dently would not be the case if only one hanger were packed down.

After so adjusting, be sure to get your hangers squarely crosswise of the shaft as readjusted, so that the hanger bearings will lie in a true line with the shaft and not bind it. At all times be sure to have your hangers hang or stand plumb up and down; as, if the bearings are not so pivoted as to be horizontally self-adjusting, excessive friction will be the lot of one end of the bearing with not even contact for the rest of it. The bearing being self-adjusting all ways, square crossing of the shaft line by the hanger line and plumb still remain eminently desirable for appearance's sake.

Before a countershaft can be put up on a ceiling whose supporting timbers are boarded over, or in a modern fireproof structure whose girders and beams are so bricked and plastered in as not to show, it is necessary to positively locate those of them which are to carry the stringers.

It is in the earnest endeavor to properly locate these that the unaccustomed hand turns a wood ceiling into a sieve and a brick one into a wreck. To avoid kitchen and house razing effects, try the following recipe:

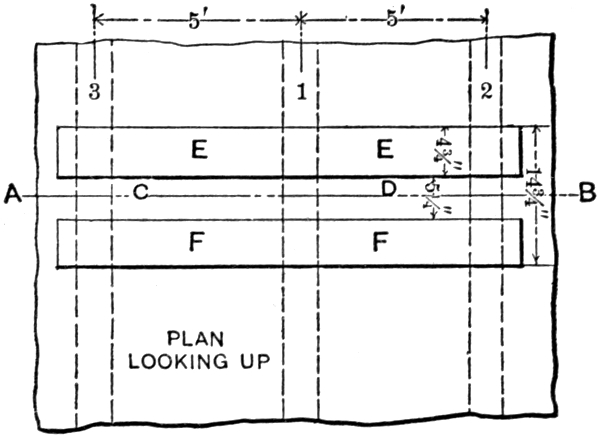

We will assume that line A B, Fig. 38, laid out by one of the methods previously described, is the center line of the proposed countershaft. The hanger's base length, lateral adjustment and individual foot length call for stringers 4¾ inches wide, placed 5¼ inches apart or 14¾ inches outside (as per sketch). The floor position of the machine to be driven, or the driving point of the main shaft, is so located with reference to the counter[Pg 43]shaft that one of the supporting hangers must go at or very near C, and the countershaft's length brings the other hanger at or very near D.

Now between points C D and with due reference to the center line A B, lay out the position which your stringers are to occupy. It is self-evident that by confining your beam prospecting to the stringer spaces E and F, ultimately, when the countershaft is in place, all the cut-up portions of the ceiling will be hidden from view.

Fig. 38.

Generally the necessary supporting beams will not all be found within the shaft's length distance C D; in such cases continue your cutting in the same parallel line to A B, as at E or F, going from C D outwardly until you strike the sought-for beams. Having located beams, say 1 and 2, we find by measurement that they are 5 feet apart, and, as beams are generally uniformly spaced, we may start 4 feet 6 inches (go 4 feet 6 inches and not 5 feet, to make sure not to skip beam 3 and[Pg 44] thus make a cut that will not be covered by the stringers) from 1 to cut outwardly for the location of beam 3.

Where the building's beams run parallel to the shaft, Fig. 39, mark the counter's-center line A B, and then mark the spaces—as determined by the countershaft length, floor position of the driven machine or the driving point on the main shaft—to be occupied by the stringers C D, and, starting from the center line A B, cut outwardly each way to the desired beams 1 and 2.

Fig. 39.

Where the center line as laid out (before the position of the ceiling beams was known) brings it close to or directly under a supporting beam, it is generally advisable where possible to step the counter back or forward to a central position between the beams.

Where shafting is already in place in a building, no matter on what floor, valuable measurements as to beam location can thus be had from the plainly in sight and the reasonably deducible. Lacking in-place-shafting to go by, the walls, columns and main girders always clearly indicate the crosswise or parallel run of the ceiling beams to the proposed shafting line.

In the usual method of locating the timbers of a boarded-over ceiling, a brace and bit, or a nail, can be used for the purpose. If shy of an awl, and in preference the other two ways, force or drive a chisel (cold chisel or wood) in between a tongue and groove of the ceiling boards in stringer space (Fig. 38) E or F, and thus spring the boards sufficiently apart to insert a compass saw. With the extremity of a 12-inch saw a very little cutting (along the tongue and groove, as this shows least) will enable you to locate a beam, since they generally run 8, 12, 16, 20, 24 and 30 inches apart.

Always, on locating your beam, run the point of your compass saw down the whole of the timber's width, so that any nailed-on pieces will not lead you into a false estimate of the beam's thickness.

Fig. 40...........Fig 41.

Figs. 40 and 41 make this point and its object clear. The saw, in Fig. 40, being stopped by A, naturally leads to the inference that A B is the timber's thickness. By running down the timber, as in Fig. 41, the saw's point sticking at a acts as a sure detector. This precaution should be taken on both sides (B and A) of the timber, and then, when the lags are screwed in,[Pg 46] they can be sent home safe and true in the center of the timber.

It often happens that in boring for the lag screws the bit strikes a nail and further progress at that point seems out of the question. When so situated, take your bit out, and running the lag screw up as far as it will go, by sheer force swing it three or four turns up further than the point where your bit struck. Removing the lag and replacing the bit, it will be found that the nail has been forced aside and the way is now clear.

Fig. 42.

Hook bolts (Fig. 42) or—as our across-the-sea cousins call them—"elbow bolts," despite all assertions to the contrary, are an easy, safe and economical stringer fastener or suspending device.

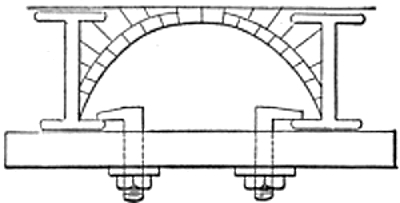

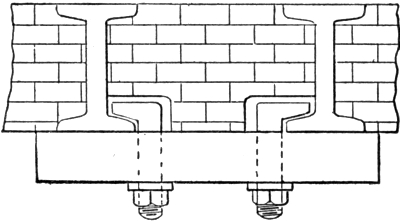

Figs. 43 and 44 illustrate two very common abuses of the hook bolt. In the one (Fig. 43), instead of the bolt proper lying snug up against the beam flange with the whole of its hook resting squarely upon the beam's flange, its supporting countershaft is turned into a menace to limb and life by this "chance it" kind of[Pg 47] erection. In the other (Fig. 44), though the bolts do lie snug against the flange, the hook being out of sight and no means being provided for telling whether the hook lies, as it should, at right angles to the web of the beam, even if properly placed at installation, timber shrinkage, vibration or a slight turn of the bolt when tightening the nut, all constitute dangerous factors tending to loosen or entirely loosen the hook's grip upon the beam flange.

Fig. 43.

Fig. 44.

Fig. 43 suggests its own remedy. As to Fig. 44, a screwdriver slot (made by a hacksaw) at the nut end of the hook bolt and running in the same direction as[Pg 48] the hook, Fig. 45, will at all times serve to indicate the hook's position and, allowing as it does of a combined use of screwdriver and wrench, it can be used to prevent the bolt's turning when being tightened.

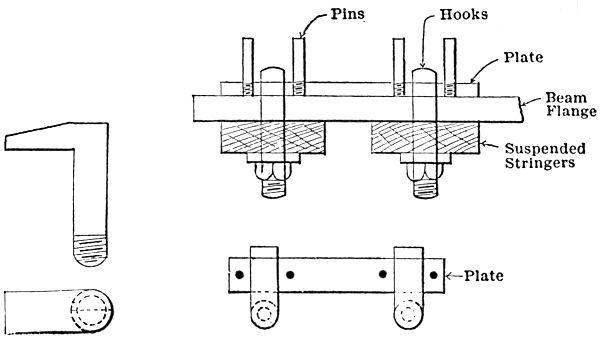

Fig. 45............Fig. 46.

Where two or more hook bolts are placed close together on the same beam flange, a plate, preferably wrought iron with properly spaced confining pins for the hooks, may be placed between the beam flange and the hooks as in Fig. 46. Its benefits are obvious and so likewise is the use of a small, square, wrought-iron plate with a bolt hole through its center instead of hook bolts.

The various styles of beam clamps carried by the hardware and supply trade all have their good points, and though the C of their cost may seem to loom large, it is not a whit more emphatic, taken all in all, than the W of their worth.

IV

It is assumed, for the purposes of this description, that the modern style of shafting, increasing in diameter by the ½ inch, is used, and that all pulleys and belts are in place. We will take a line composed of sizes ranging between 3 15/16 and 2 7/16 inches. This gives us four sizes, 3 15/16, 3 7/16, 2 15/16 and 2 7/16 inches in the line.

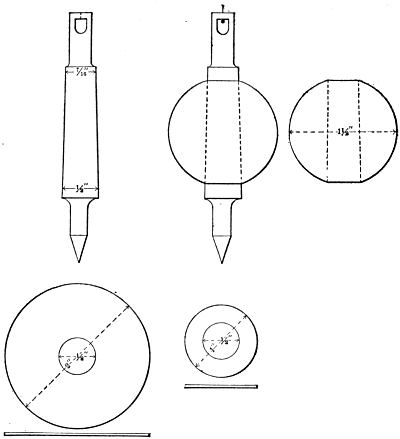

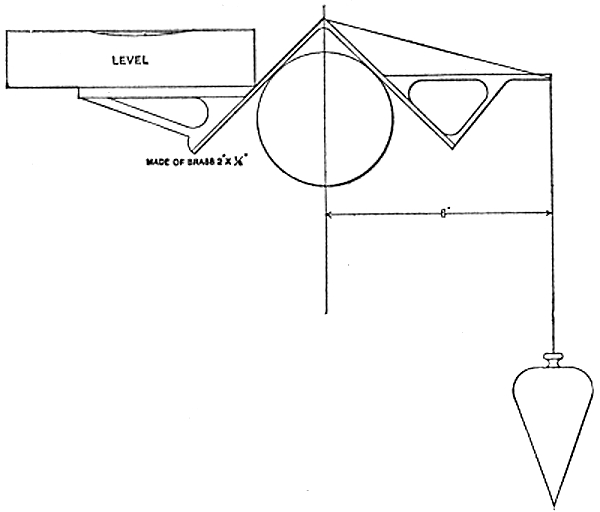

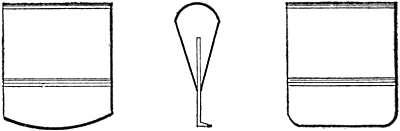

We will first consider the plumb-bob. The accompanying sketch, Fig. 47, illustrates a good one.

The ball is 1½ inches diameter, and the large end of the tapered stem ½ inch in diameter, turned parallel for a short distance at the lower end. The two thin sheet-steel disks, 1 and 2 inches in diameter, are drilled to fit snugly when pushed on to the ½-inch part of the stem, and stay there until pulled off. These disks are turned true. This arrangement of plumb-bob and disks enables us to deal with five sizes on one line, and there are not many lines that contain more.

Now having our plumb-bob ready, we will stretch the line. The stretchers should be set horizontally by nailing a strip of wood, say 1 à 1½ à 12 inches, with a piece at each end to form a space between it and the wall, or place of location in line with the edge of the shaft, as in Fig. 48. The top of this stretcher should[Pg 50] be low enough to clear the largest pulley, and high enough to clear the hat of your tallest man. You would perhaps find it convenient to go between the spokes of a large pulley.

Fig. 47.

Now having located your stretcher, find approximately the position of your line, and drive a nail a foot or more below it in a vertical line, and another nail anywhere for convenient winding. The advantage of this plan is that the line can be easily adjusted as it[Pg 51] merely passes over the stretcher, and is free to respond to movement either way; then when the final adjustment is made, and is ready for its final stretch, it is only necessary to pinch the line to the nail with one hand, while the other is at liberty to unwind, stretch and rewind the line without fear of its shifting.

Fig. 48.

The line being adjusted over the stretchers, we will now proceed to set it. Begin at the 2 7/16-inch end, by throwing your plumb line over the shaft and setting your line at that end, right with the center point of your bob. Having done so, go to the other or 3 15/16 end of your line, and set the line so that the edge of the ball of your bob just touches it. Now go back to the 2 7/16 end and see that the necessary adjustment did not alter it. Having proved this, give your line the final stretch and try if it is right at both ends. You now have a center line (though the edge instead of the center of the[Pg 52] shaft is used) that may remain up for days if necessary without fear of disturbance.

It is best to go over the whole line first, before disturbing anything; so starting at the first hanger at the 2 7/16-inch end, throw your plumb line over the shaft, and record on the floor in chalk beneath it whether it is O. K. or wants to go either way, and how much; then go to the next hanger, and so on to the end. A short study of the conditions enables one to correct the faults, with a knowledge of the requirements, and consequently in the least time and with the least trouble.

Now suppose we start at the 2 7/16-inch end to inspect the line, we use the center point of the bob on the line so long as we are testing 2 7/16 inches.

When we get to the 2 15/16-inch part, which is ½ inch larger, we use the half diameter of the stem, the edge of which should just touch the line.

When we come to the 3 7/16-inch part, 1 inch larger than 2 7/16, we use the 1-inch disk, slip it on to the stem, and when it just touches the line with its edge it is O. K.

The 3 15/16-inch, being 1½ inches larger than the 2 7/16-inch, will be right when the ball of the bob is in light contact with the line.

The 2-inch disk would be suitable for the next size, and other disks or modifications of the bob proper might be made to suit circumstances.

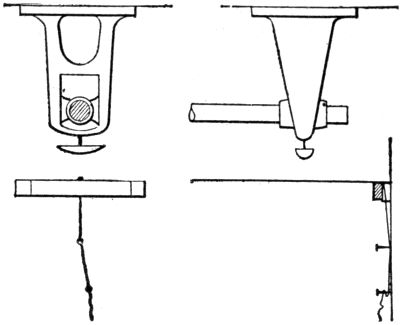

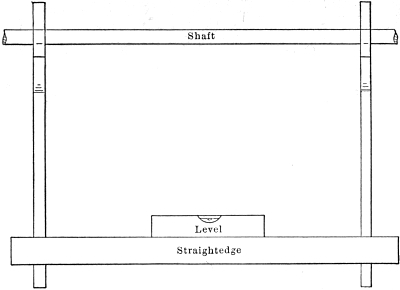

Now having straightened the line, the next process is to level it. As in some cases your pulleys will be too close to place your level where you want, make a[Pg 53] light iron frame as per Fig. 49, making the suspending members of sufficient length to admit of your reading the level conveniently when standing on the floor. Hang your frame on the shaft, and put your level on the straight-edge below; in this way travel along the shaft, placing your frame where convenient. Be sure that one end of your frame does not rest on a shaft of different diameter, a key, keyseat, or anything to distort the reading.

Fig. 49.

Never be content with trying your level, especially an adjusting level, one way; always reverse it and try again; for if it is out of truth at the start, you might want to go through the roof or down cellar at the finish. Get into a habit of reversing your level, and so prove your work as you proceed.

V

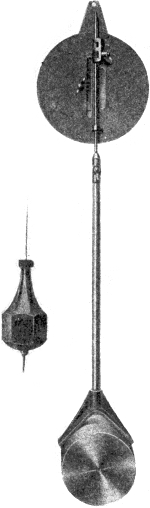

The first apparatus explained in this chapter was designed by the late Chas. A. Bauer, and is a highly perfected instrument.

For those who have lined and leveled shafting with an engineer's transit and level it is unnecessary to say anything of the advantages of that method over the cruder methods usually employed. It is not only done much more rapidly and economically, but the greater accuracy with which the work is done goes on paying dividends in decreased friction and loss of power and in lessening of wear.

Fig. 50.

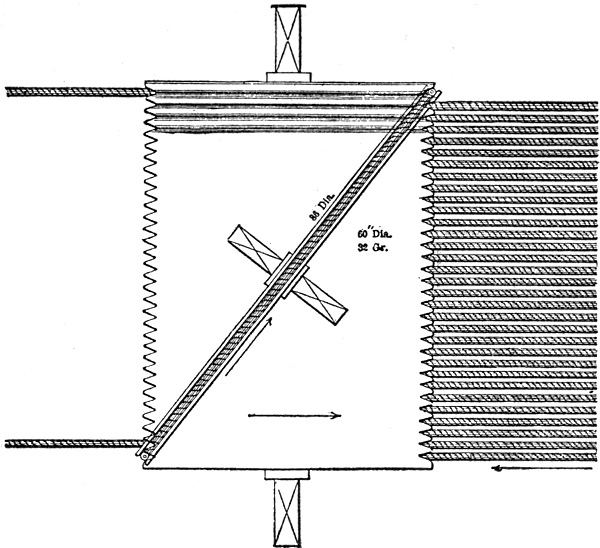

The apparatus we now illustrate (Fig. 50) has at

the top a hook, which is passed over the shaft, as indicated;

on the straight portion of this hook are two

sliding jaws which are so set that the shaft will just

pass between them. Set into the face of this hook is

a commercial 6-inch steel rule which facilitates the

setting of the jaws, and they are of course so set that

the tubular portion of the hook or leveling rod is centered

vertically under the shaft. Within the outer tube,

which is about 1 inch outside diameter and nicely

japanned, is another tube, and inside this a third tube,[Pg 55]

[Pg 56]

these being arranged à la telescope slide, and clamps

being provided so that the length or distance from the

shafting to the target may be anything desired from

4 to about 10 feet. At the lower end of the third or

inner tube is a swiveling head to which the target is

attached, and nurled nuts at this point give means of

adjusting the sighting point of the target to the exact

hight of the transit or level sighting line.

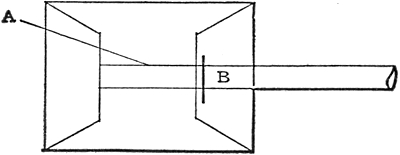

The target is a brass plate 5½ inches diameter, on the face of which is a recess milled for the reception of a second commercial steel rule, which in this case is vertical and can be moved vertically and clamped in any desired position with reference to a line drawn upon the target. At the center of this scale is a very small hole through which the light of a hand flash lamp may shine to form the sighting point. The slot through the target at the right of the scale is provided with a single thickness of white cloth, which permits enough light to pass through it to help in finding the target in the field of the telescope.

The object of providing a vertical adjustment for the rule on the target is so that when passing from one diameter of shafting to another in the same line, as sometimes happens, the scale can be moved up or down just half the difference of diameter and the sighting point thus be kept at a constant hight.

Fig. 51.

The target is readily detached from the rod, and may

then be placed upon the small standard (Fig. 51) which

has at its base a V adapted to go over the shaft. The

standard is tubular and the wire (about 1/8 inch diameter)

may be adjusted and clamped at the desired hight. The[Pg 57]

[Pg 58]

target fits over the wire as shown (rear view of target)

for leveling lines of shafting that may be near the floor,

or, with the target removed, the V and wire form

a sort of length gage or caliper with which the shaft

may be made parallel to a line or wire stretched at the

side of it. Two different lengths of wire are provided

for this purpose.

The plumb-bob shown is part of the equipment and is a very superior article. A new feature it possesses is in having its larger portion hexagonal instead of round, so when laid down upon a plank or scaffolding it will lie there instead of promptly rolling off and falling to the floor. The entire apparatus is, we think, very well designed for its purpose.

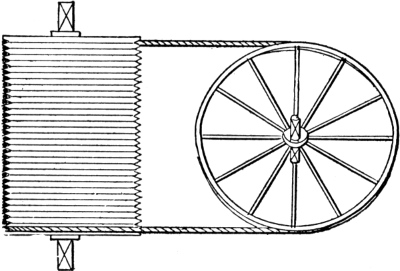

Tool for Leveling Shafting

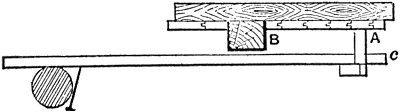

The instrument shown in Fig. 52 is a good one for use in leveling up shafting. It can be made to fit several sizes of shaft, or all the sizes ordinarily found in a factory.

When the instrument is placed on any piece of shaft and leveled up with the attached level, the plumb line will hang exactly the same distance from the shaft center every time. In this case the distance of line from center is 6 inches.

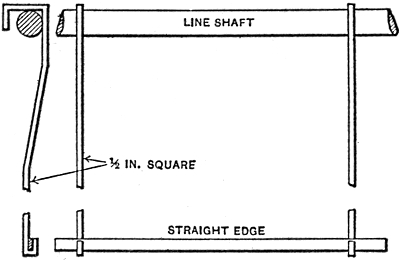

A handy apparatus for use in leveling up long lines of shaft can be made as follows.

Fig. 52.

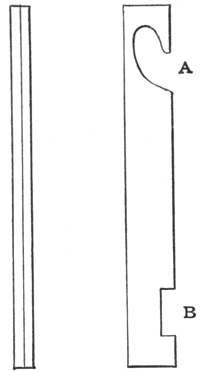

Fig. 53.......Fig. 54

Take two pieces of finished material, fasten together as in Fig. 53 and cut out as shown at A and B in Fig. 54. The opening A is made so that the piece can be hung over the shaft, and the opening B is made for the reception of a wooden straight-edge.

Make the straight-edge out of 1¼-inch stuff. Be sure that the edges are parallel, the width just enough less than the width of opening B, Fig. 55, to enter it, and the length 6 or 8 feet, to suit convenience. Use the apparatus with a level, as in Fig. 55, taking care that the suspension pieces are always on the same size shaft.

Fig. 55.

VI

Fig. 56.

A pulley on one of the motors at a certain plant had been giving some trouble by becoming loose and working its way along the shaft toward the motor bearing. Each time the pulley became loose, the set-screw was loosened, the pulley put back in position, the set-screw made tight and the motor started. After a few trials it was found that this would not prevent the pulley from working its way along the shaft. In order to overcome this difficulty the pulley was placed in its proper position, a line was drawn around the shaft close to the hub and, after the line was scribed, the pulley was removed and the shaft was burred upon the line as shown at B, Fig. 56. The pulley was then put back and driven close up to the burred line, the [Pg 62]set-screw made tight and the pulley is now running without any apparent tendency to travel from its proper position. It will be seen that the position of the set-screw as indicated by the line at A is a poor one and calculated to give plenty of trouble at the most inopportune time.

[4] Contributed to Power by Wm. Kavanagh.

Not long ago a cast-iron pulley had to move along a countershaft in order to make room for a pulley of another diameter. The pulley had not been on the shaft long, so it was thought that little work would be required to move it. A heavy bar was placed against the hub and a sledge hammer was used to strike the bar. After an hour and a half of heavy work the pulley was not moved over 1 inch (it had to be moved 16 inches), so it was suggested that a Bunsen burner be attached to a gas pipe by means of a hose and placed beneath the hub. The plan was immediately adopted. The burner was placed beneath the hub, the gas lit and allowed to heat the hub. After about twenty-five minutes it was found that a blow from the bar was sufficient to move the pulley. The pulley was moved the 16 inches inside of twenty minutes.

Fig. 57.

A very handy arrangement for moving pulleys is a bolt and nut. Fig. 57 shows the bolt and nut with[Pg 63] a piece of pipe attached. A piece of pipe can be cut to suit the distance between the nut and hub of one pulley while the bolt head is against the other hub. The nut is screwed back upon the bolt as far as possible. A washer is then placed against the nut, and a piece of pipe cut to suit. Of course, the pipe must be large enough in diameter to fit over the bolt. If we screw back upon the nut, a powerful strain can be brought to bear between the hubs and in all probability the pulley will move.

Fig. 58.

In taking down solid pulleys from main or counter shafting it sometimes happens that a hanger must be removed to permit the pulley to be taken off. A first-rate plan is to make a couple of long bolts hooked at the end as shown in Fig 58; pass the hook around the shaft and the threaded end through a hole in the stringer. By screwing up the nut as shown, the shaft[Pg 64] and remaining pulleys can be kept in position, obviating the use of tackle, not to mention the labor required to hoist back the shaft into position. The application of this contrivance is especially valuable where heavy cone pulleys are required to be lowered or changed. It will be seen that if we employ a pipe thread we will be enabled to suit almost any condition of length that may arise between the shaft and stringer.

VII

When a solid pulley is to be removed from a piece of shaft for any reason, it is not good policy to use sledge hammers on the spokes or hub to do it. Cast iron in pulleys is too liable to break or crack under repeated blows.

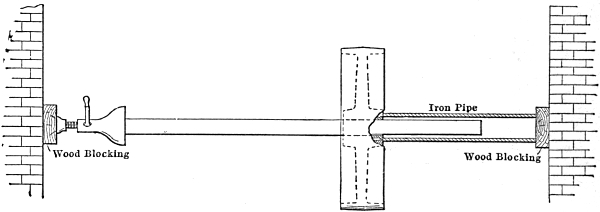

Fig. 59.

In Fig. 59 one ready method is illustrated by which the pulley may be removed. When a place between two walls can be found that will admit of this arrangement, proceed as shown to force the shaft through the pulley, substituting longer pieces of pipe as the shaft is forced through farther.

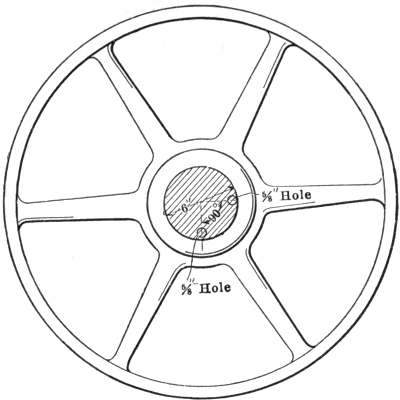

In one case where a large pulley was stuck on a 7-inch

shaft and its removal was imperative, the shaft was

sawed off (with large hack-saws) close up to the pulley

hub and two 5/8-inch holes were drilled into the shaft

parallel to its axis, as shown in Fig. 60. These holes

were drilled so that they were 90 degrees apart and

came within 1/16-inch of the hub of the pulley. The

hub was 14 inches through and these holes were 8 inches

deep; but that was enough to loosen up the shaft

so that when the pulley was laid over on beams with[Pg 66]

[Pg 67]

the shaft hanging through, a sledge hammer applied

on the shaft end soon drove it out.

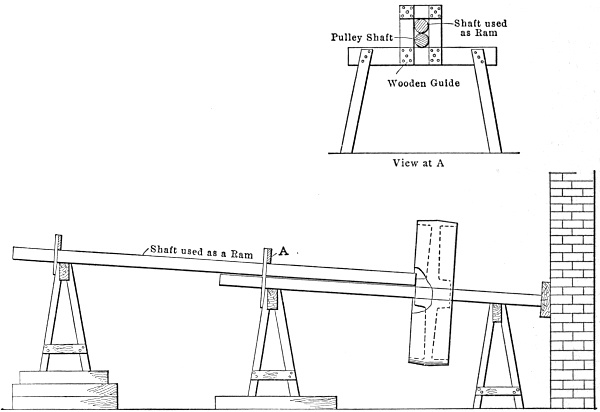

Another way to remove a pulley is shown in Fig. 61, where a ram is used. The ram is another piece of old shaft. To prevent its damaging the pulley hub and also to have its force applied most advantageously, it should be used in a direct line with the direction of removal. To do this, the method shown in Fig. 61 is self-explanatory.

Fig. 60.

Another good method of removing an obdurate

pulley is illustrated in Fig. 62, where the bolts W, W

must have long threads and the work is done by pulling

up on the nuts A, A. This method can be used only

when the end of the shaft can be reached and used as

shown. In using this method, care must be exercised

[Pg 68]

[Pg 69]

[Pg 70]in the pulling up on the bolts W, W, keeping the strain

equally divided between the two by pulling a little

at a time on each.

Fig. 61.

If the pulley comes extra hard, it can be assisted when the strain is on the bolts by striking at X with a sledge.

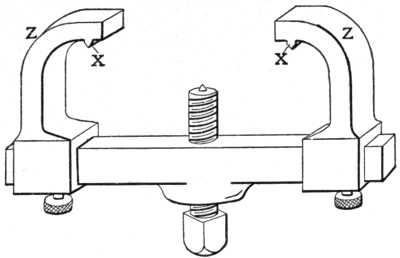

A good device for removing motor and generator pulleys that are near the shaft end is shown in Fig. 63. The arms Z, Z are adjustable to take hold of hub or arms, and the screw applied to the shaft center will do the rest.

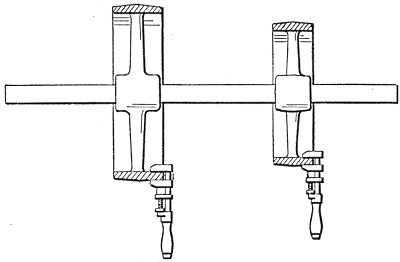

To run a pulley off a shaft without injury to the hands, use a monkey wrench on the rim of each pulley, as shown in Fig. 64. One pulley on the shaft can be selected for a hold-back; one monkey wrench there will hold the shaft from turning, while the other will turn around the shaft the pulley which it is intended to remove.

Fig. 63.

Fig. 64.

VIII

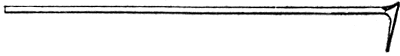

The first thing is the tools for the different kinds of work. These may be usually changed somewhat to suit the taste of the user, but in the main the style and kind herein shown in attached drawings cannot be very much improved upon.

[5] Contributed to Power by Walter E. Dixon, M. E.

Fig. 65........Fig. 66.

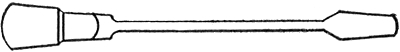

Figs. 65 and 66 show a splice opener for heavy belts.

It is made of ½-inch tool steel with the point spread out

about 2 inches wide and well tempered, after which it

is ground to a good sharp edge, and then an oil stone

run over the edge until it has been dulled so that it will

not cut. The right kind of an edge can only be secured

by trying; it is one of the tools that is very hard to

get just right. You will notice that the manner in

which this splitter is built may seem to be rather too

much work to bestow on such a simple tool, but the

reasons for so doing are as follows: in opening a 36-inch

belt an old splice opener that was driven into

the handle like an ordinary file was used and the

handle split; that sharp point came back through the

handle, and when it finally stopped it had gone about

2 inches into the palm of the operator's hand. Some

½-inch hexagon steel was turned down 6 inches, just[Pg 73]

[Pg 74]

enough to round it up; then a solid brass washer was

turned out 1¼ inches in diameter and 1 inch thick,

a hole bored through it that was a driving fit on the

piece of steel and was driven down to the shoulder.

Washers were cut out of old pieces of belt and put on

with a liberal coat of glue on both sides; when the

handle was filled, a steel washer which was 1/2 inch

thick was screwed down hard on the leather washers,

and when it had dried well the whole was turned down

to size shown in the sketch. Two of these tools were

made, one for belts up to 18 inches, and another that

will reach through a 40-inch belt. The tool shown in

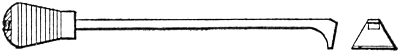

Fig. 67 is an ordinary heavy screwdriver with the point

rounded nicely, and it is used to raise the thin points

that the larger tool will sometimes tear.

Fig. 67.

Fig. 68.

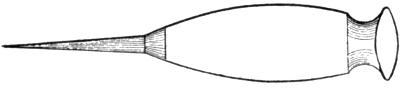

Fig. 68 shows a handle made almost like the one in Fig. 65, with the exception that the brass washer referred to in Fig. 65 is here turned down to ¾ inch, commencing ½ inch from the large end, which is 1 inch in diameter. The leather washers are slipped on over the small part until it is filled, and then a washer is screwed on the small end and the whole turned as shown[Pg 75] in the sketch. A hole that will tap out 3/8 inch is bored in the large end of the brass center, and then tools made with threaded ends on them that will fit into it. These tools are made of 3/8-inch tool steel with scraping ends, as shown. These scrapers are used only for removing glue that is too hard and too thick to be removed by the scraper shown in Fig. 69.

Fig. 69......Fig. 69a......Fig. 69b.

Figs. 69, 69a and 69b show views of the only tool that is hardly worth being referred to as a leather-cutting tool. It is made of a thin piece of steel, about 18 gage, or any old hand-saw will make the very best scrapers that can be secured. They should be about 4 inches square, perhaps a little smaller, and fixed in a hardwood handle (usually of hard maple), simply by sawing about 2½ inches into the handle and then driving the blade in. The saw cut should be just a trifle thinner than the piece of steel. Should they get loose from use, a piece of paper folded over the back of the blade and forced back into the handle with the blade will usually tighten it all right.

This is the tool that will ordinarily worry the novice more than all the rest to keep in proper condition. Fig. 70 shows an exaggerated view of how the blade[Pg 76] should look when properly finished. It should be hooked considerably.

Fig. 70.

Fig. 71 shows a small steel for sharpening the scraper after it is turned, and it should be absolutely smooth.

Fig. 71.

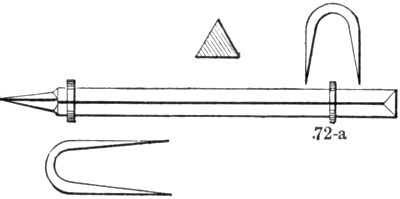

Fig. 72.

Fig. 72 shows the equipment for turning the edge of the scrapers. A large three-cornered file, about 12 inches long, which has all the teeth ground carefully off of it and then nicely polished, is fastened to a piece of good clean belt leather by means of the staples shown.

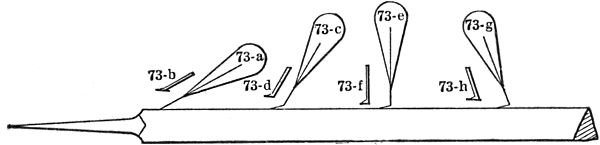

Fig. 73.

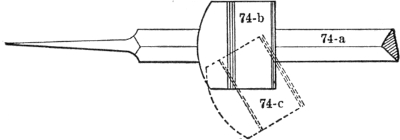

Fig. 73 shows the method employed in turning the edge of the scraper, which is as follows: After the blade has been set firmly in the handle, grind the edge rounding, as is shown in Fig. 69; then grind sharp with a good long taper of about 3/8, and grind from both sides just as you would an ordinary axe. After you have a good smooth edge on it, put it on an oil or water stone and put as fine an edge as possible on it, then put on a smooth piece of leather and hone it down until it would shave you. You will then have a tool that will do a world of work for you, "if you will turn it right." The method shown in Fig. 73, if properly carried out, will do the trick for you; the thing to be remembered is that at no time in the turning of the scraper must the cutting edge bear on the smooth file. The first position is not shown right; the handle should be allowed to touch the file the first few times it is passed over, and then gradually raise the handle and keep on passing the blade from side to side, as is shown in Fig. 74; allowing it to slip off on the leather every time you cross the file; this is to keep the corners in proper shape. Another thing to remember is to bear down on the blade as it is passed over the file; you can't bear too hard; the only thing to look out for is not to raise[Pg 78] the handle too fast. An ordinary blade can be turned in about fifty strokes across the file. The edge turned over should be at least 1/16 inch long and should be well hooked, as is shown in Fig. 73.

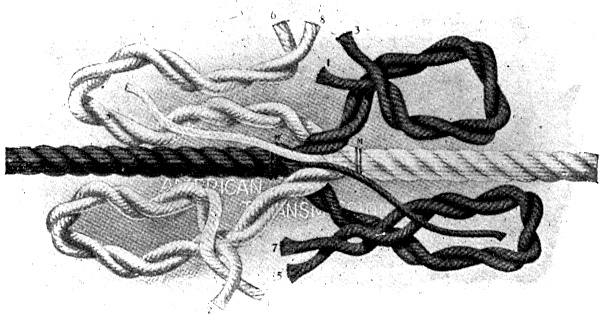

Fig. 74.