Title: The Construction of the Small House

Author: H. Vandervoort Walsh

Release date: April 20, 2020 [eBook #61880]

Most recently updated: October 17, 2024

Language: English

Credits: Produced by ellinora, Paul Marshall and the Online

Distributed Proofreading Team at https://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive/American Libraries.)

A SIMPLE AND USEFUL SOURCE OF INFORMATION

ON THE METHODS OF BUILDING SMALL AMERICAN HOMES,

FOR ANYONE PLANNING TO BUILD

BY

H. VANDERVOORT WALSH

INSTRUCTOR OF CONSTRUCTION IN

THE SCHOOL OF ARCHITECTURE,

COLUMBIA UNIVERSITY

WITH ILLUSTRATIONS BY

THE AUTHOR

NEW YORK

CHARLES SCRIBNER’S SONS

1923

Copyright, 1923, by

CHARLES SCRIBNER’S SONS

Printed in the United States of America

Published February, 1923

| CHAPTER | PAGE | |

| I. | Present-Day Economic Troubles | 1 |

| II. | General Types and Costs | 7 |

| III. | Essential Standards of Quality in Building Materials | 20 |

| IV. | Types of Wooden-Frame Construction | 38 |

| V. | Construction of the Masonry and Wood Dwelling | 49 |

| VI. | Safeguards Against Fire in Dwellings | 69 |

| VII. | Poor Methods of Construction Employed by | |

| Unscrupulous Builders | 81 | |

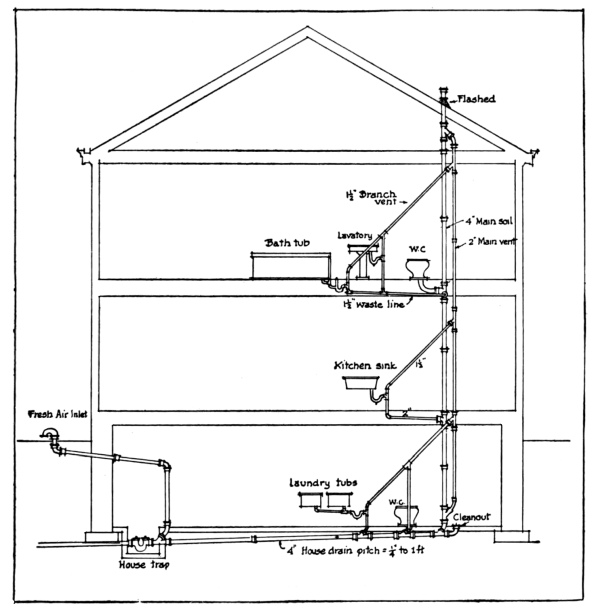

| VIII. | Essential Features of Good Plumbing | 94 |

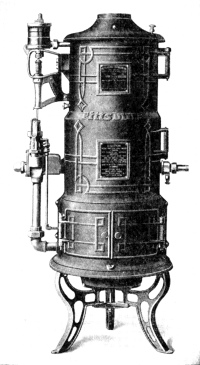

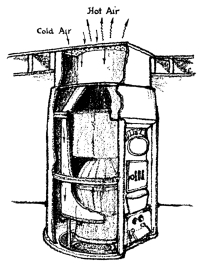

| IX. | Methods of Heating | 109 |

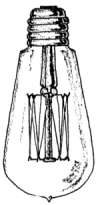

| X. | Lighting and Electric Work | 121 |

| XI. | Construction of the Trim | 130 |

| XII. | Lessons Taught by Depreciation | |

| XIII. | Selecting Materials from Advertisements | 150 |

| XIV. | Roofing Materials | 158 |

| XV. | Painting and Varnishing the House | 177 |

| XVI. | Labor-Saving Devices for the Home | 185 |

| XVII. | Concrete Work Around the House | 197 |

| XVIII. | Classification and Construction of the Architectural | |

| Motifs Used in Small-House Designing | 208 | |

| XIX. | Traditions of Building from Which Our Modern Methods | |

| Are Derived | 219 | |

| XX. | Traditions of the Construction of Doors and Windows | 236 |

| XXI. | Building the Setting for the House | 245 |

| XXII. | Financing the Construction Work | 258 |

CONSTRUCTION OF THE

SMALL HOUSE

Immediately after the war the housing shortage made itself very evident, because the landlords discovered that it existed, and realized that they had it within their power to exact extortionate rents. Statisticians got busy and put their heads together and informed the public that within the next five years there would have to be built some 3,300,000 new homes to properly house the people. The building magazines likewise were predicting great things in construction, and all in the building industry were looking for fat years of prosperity, for here was the need and there was the pressure of the high rents. Why should not the thousands of families that had waited build now, when they saw their money going to waste in high rents? All kinds of advertisements were sent out to urge the public to build, and own-your-own-home shows sprang up in every large city, and one could find plenty of builders who would say that one should build immediately, before prices went higher.

And seeing the poor, unprotected home-builder, the greed of human nature seized all in the building industry as it had entangled all [Pg 2] other business lines, and the price of materials leaped into the air, and the cost of labor became swollen, and all had that bloated and enlarged look which comes over the face of him who is sure of his meal.

Before the war he planned for this

At the end of 1918 the average cost of all building materials was up to 175 per cent over that of 1913, but by the first quarter of 1920 they had gotten up to 300 per cent increase over 1913 prices. Lumber had gone up 373 per cent. Labor had also risen to 200 per cent.

Mr. Average Citizen found that the home he had been saving his money to build had flown from his hand, like a bird. The sketches and plans he had prepared for a nice little $10,000 home now represented an investment of $20,000 or more. In fact, if he expected to build at all, he had to be reconciled to a small house of six or seven rooms, which [Pg 3] would cost him not less than $10,000 or more, or as much as the large house which he had planned originally to build.

Then what happened? Mr. Average Citizen did not build. The confidently predicted building boom which the building material manufacturers had looked for did not materialize. Prices were too high, and the public could not be made to believe that they would not come down, and the public was right.

Now his plans have shrunk to this

The light began to break as well as the prices, and we find the cost of building materials dropping suddenly. By the end of 1920 they had reached the 200 mark. By March, 1922, they had reached the 155 level, and are still going down with slight fluctuation.

But during all of this time we heard all kinds of theories as to how the problem should be met. Some architects went so far as to predict that people could no longer build individual houses for themselves; that the day of the small house was over. They claimed that the only solution was in the construction of group houses. Such groups would eliminate much of the expensive street paving as ordinarily required, and cut to a minimum the water supply-lines and sewage systems. Semi-detached houses in groups were capable of saving the cost on one [Pg 4] outside wall, one chimney, one set of plumbing pipes for each house in the group. The heating could also be reduced to a community basis, and the land so distributed that the best air and light could be had with the minimum waste.

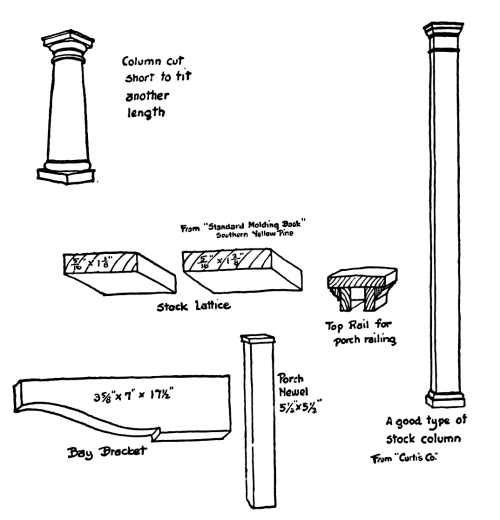

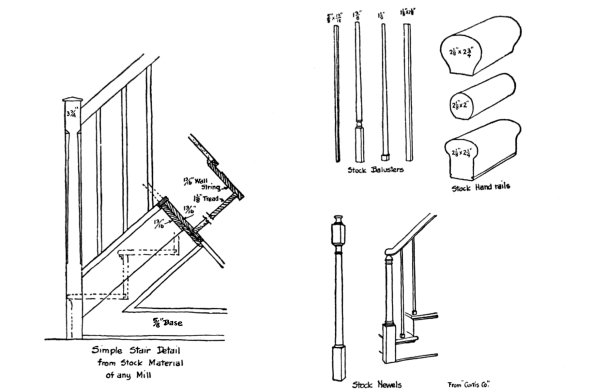

Many architects conscientiously tried to reduce the cost of construction of the small house by inventing cheaper ways and methods of building. However, the estimates came in just as high, because the average small contractor who builds the small house was afraid of innovations, since there was too great an element of risk, and he was conservative. To meet this difficulty some architects attached to their office organization construction departments by means of which they were able to build according to their economical plans and secure the advantage of the saving in cost. This was held by many to be unprofessional. Other architects secured lower bids by having a written agreement with the various contractors who were competing that, if they received the contract, the owner would be responsible for and pay for any increase in labor or material prices which might take place during the period of erection. Likewise the contractor agreed to give the owner the benefit of any reduction in prices which might take place during the time of erection. This simple understanding seemed to relieve the contractor of nervousness, and his bids were often lower. Still other architects claimed that the cost of construction could only be reduced by standardizing all of the parts. Certain mills had secured high-class talent to design stock doors, cornices, windows, columns, and the like, and the results were very satisfactory, both artistically and economically.

This problem of the cost of the small house was very acute, and, although it has been relieved somewhat by the decreasing prices at this [Pg 5] time, yet it will always be an integral part of the problem of building the small house.

In fact, to properly design the small house and build it economically requires the greatest care for detail. Many well-established architects will not bother with this architectural problem, for the time required to consider all these small details is greater than they can afford to give in proportion to the fee they receive. For this reason most of this work is done by the young architect or by the speculative builder, who generally shows very bad taste in selecting his design, while the young architect is apt to be somewhat inexperienced in his knowledge of construction.

The very first thing that must be considered in the problem of the building of the small house is the question of money, because this determines what kind of a lot can be purchased, how large the house can be, and of what type of construction it can be built. Experts on financing say that the cost of the house should be such that it can be paid off in full within fifteen years. This means that the cost of the proposed home must be arranged to come within definite limits. Methods of approximately determining the cost of a house in its preliminary sketch stages will be considered later, but it is sufficient to say here, that once this first problem is solved carefully, other matters are much easier to take care of. If one knows the cost, the question of borrowing money is made easier, and one is not misled into wild fancies of larger houses than possibly the pocketbook could afford. The worst mistake that a young architect can make is to lead his client to believe that he can have a certain design for less money than will actually be the case. It is always best to overestimate the cost in the beginning than to underestimate it. [Pg 6]

“But,” says the client, “I can buy a house and lot at ‘Heavenly Rest Real Estate Park’ for that price, and on the instalment plan, too. I don’t see why the cost of a house built from your plans should be so much greater than this.”

And that is a big question to answer, one which this volume will attempt to make clear, one to which only a knowledge of construction can give a real and satisfactory answer. It is the old story, that a well-built article is bound to cost more than a poorly built one; but how to know the well-built article!

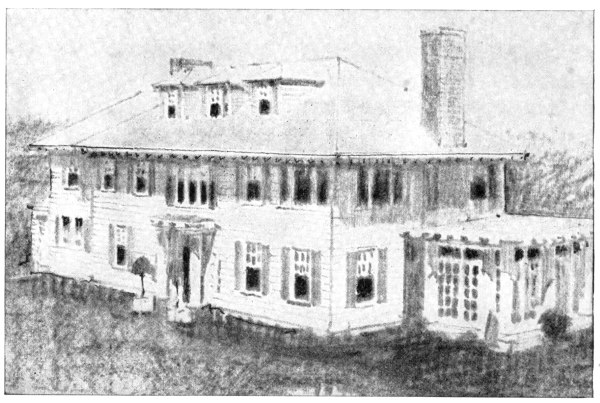

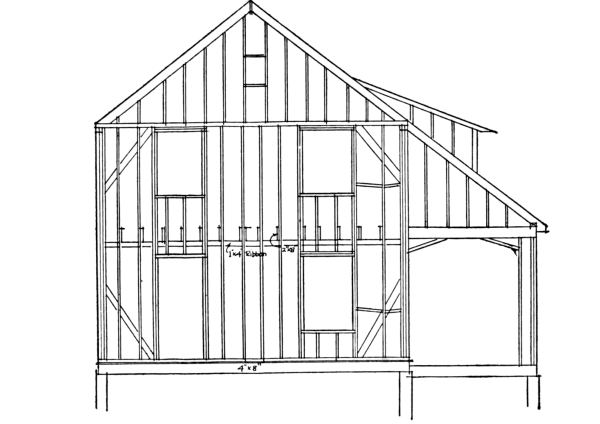

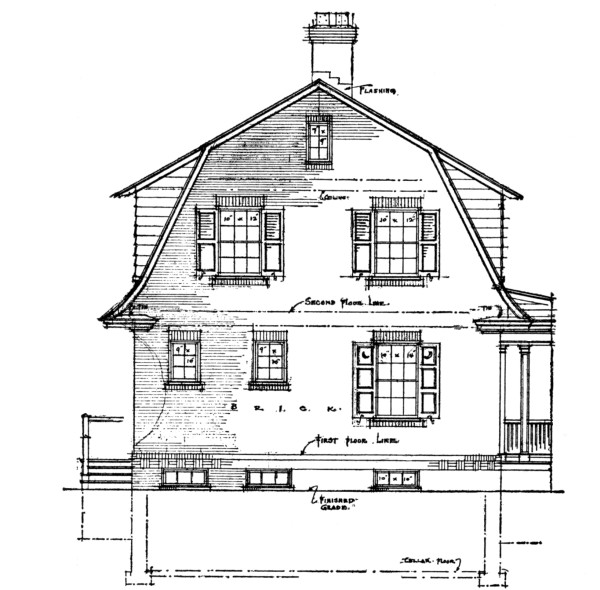

Type I Wooden Frame

All small houses may be classified into four types, according to their construction. The first type is the commonest and is the wooden frame structure. This has exterior walls and interior partitions built of light wooden studs, and the floors and ceilings framed with wooden joists. The exterior walls may be covered with clapboard, shingles, stucco, brick veneer, or stone veneer. The roof is generally covered with wooden shingles, although slate, tile, asbestos, and asphalt [Pg 8] shingles are often used. These houses are the most numerous, because the cost of wood in the past has been so much less than other materials that they appealed to the average builder’s financial sense. However, the cost of such dwellings to the country as a whole has been very high, for they are extremely dangerous when attacked by fire. More than twenty-two millions of dollars are wasted by fire each year in these houses. They also cost us a great deal in up-keep. It would be interesting to see what was the total cost per year to repaint them and keep the roofs in order. It certainly would run into the millions. Although wood increased from about $30.00 per thousand board feet to about $85.00 in the Eastern markets from pre-war days, and is now dropping below $55.00, yet the wooden house is still listed as the cheapest, for the cost of other materials has also increased, as brick from $10.00 per thousand to $23.00 until very recently, and cement from $2.00 to $3.25 per barrel. In any comparison of cost the wooden frame building is taken as the base or cheapest type of construction, although it is the most expensive in up-keep and fire-hazard of all. Until the price of wood increases in excessive proportion to other materials, there is no doubt that this type of house will be the commonest. However, there is much that can be done to make them more fire-resisting, and, although we cannot look to the speculative builders to use such methods, since they increase the costs slightly, yet the architect should not overlook them.

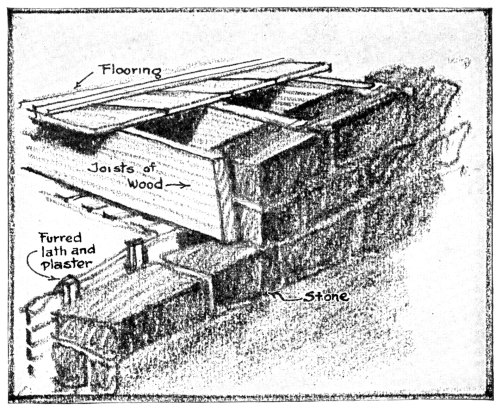

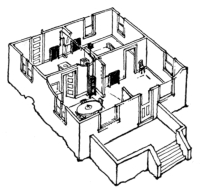

Type II Masonry and Wood

The second type of dwelling which is next in vogue has exterior walls of stone, brick, concrete, or terra-cotta, and interior floors, [Pg 9] partitions, and roof of wooden frame construction. These are very slightly more fireproof than the wooden frame structure, and as a class they are more costly in the beginning, but require less expense in up-keep. They resist attack from external fires better than the wooden frame building, but if the fire starts within, they will burn just as readily. Although the fire loss per year of this class is not nearly as great as for the first type, yet it must be appreciated that there are not so many of them. The chief advantage of the masonry house of this second type lies in the lowered cost of up-keep, longer life, and saving of heating-fuel in the winter. A great deal of literature has been circulated by brick, cement, and hollow terra-cotta tile manufacturers by which the public has been educated to believe that this type of structure is much more fire-resisting than it is. Of course this campaign of education was intended to stimulate interest in their product, and it had no unselfish motive back of it. The result of this propaganda is evident in the public belief that such houses are fireproof houses, while as a matter of fact they are not. [Pg 10]

Type II · Masonry walls · Interior·Wood

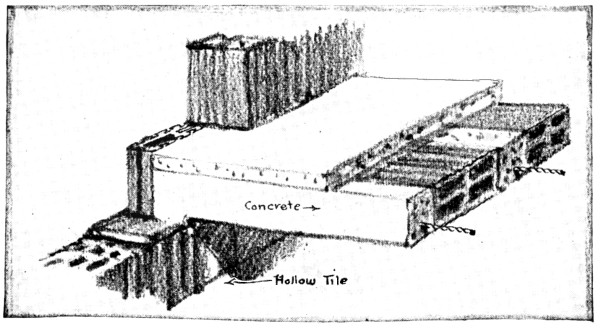

The third class of dwelling is quite rare, and very few small houses are built that could be classified under it. Some builders call them fireproof houses, although this is erroneous. These buildings have walls, roofs, floors, and partitions built of incombustible materials, but the finished floors, the trim, windows, and doors are of wood. The exterior walls are of masonry construction, and the construction of the floors and roofs consists of steel beams with terra-cotta arches or concrete floor slabs, spanning in between them, and the partitions are of terra-cotta, gypsum, metal lath and plaster, or other similar materials. They may also be built of reinforced concrete throughout, or any other combination of these materials. There have been very few [Pg 11] examples of this kind of construction used in the small house. It is an unfortunate condition that it is more adaptable to the costly mansion than to the average house of the middle-class citizen, for the high cost of construction of this character, in most cases, permits it to be used only by the wealthy man. Examples where such houses have been built generally show an investment of $30,000 or more, or, if they were built to-day, $50,000 or more. Those attempts to use this form of construction in the small house have been made by large building corporations, and have been chiefly represented by concrete houses of very ugly design.

Type III. Walls, floors, partitions fireproof, but windows, doors and trim of wood.

The fourth and last type of dwelling is the ideal fireproof house, but it is so costly that very few examples exist. This type can be termed fireproof with accuracy, for all structural parts, including doors, windows, and trim, are of incombustible materials. Metal trim is used or wood that has been treated to make it fire-resisting. This latter [Pg 12] class of construction is so out of the reach of the average home-builder, on account of its cost, that its value cannot be thoroughly appreciated. Practically the only examples in existence are large mansions, built by wealthy clients.

Cost Does Not Indicate Fire-Resistance.—In this classification of buildings it would almost seem that the cost of a building indicated its fireproof qualities. This is not true, however. There are many expensive dwellings which are just as great fire-traps as the less expensive ones. In both cases the fire hazards are the same, if they are built of the same type of construction. In fact, we could build a $60,000 dwelling according to Type II, and also a $10,000 one according to Type II, and make the latter more fire-resisting than the former by using certain precautions of construction in which the spread of fire is retarded.

Except in unusual cases, the construction of the ordinary dwelling will be either according to the first or second type, and any fire precautions that are desirable must be applicable to them. Most comparisons of relative costs are made between the dwellings included under these two types, and the difference will be mostly a difference in the kind of exterior walls used in the construction. In fact, if any comparisons are made between different kinds of buildings, as to their relative costs, it is essential that only one feature be made variable and that all others be kept the same.

Ever since the closing of the war the problem of knowing the cost of the construction of the small house has been a very intricate one, and no sure estimates could be made, until the plans were completed and let out for bids. Previous to the war, when costs were somewhat stabilized, [Pg 13] it was possible to predict with a reasonable amount of accuracy the cost of the dwelling when the plans were still only roughed in.

In order to show the fluctuation in prices, an example of a seven-room frame house of Type I can be mentioned. This house was practically 30 by 34 feet, and had a cubical contents of about 29,100 cubic feet and an area of 2,640 square feet. In 1914 this house cost $5,529.00, but at the peak of prices in 1920 this house cost $12,815.00, which was an increase of 131 per cent. In the spring of 1922 this same house cost $9,502.00 to build, which was about 71 per cent over that of pre-war prices.

With a heavy pressure of needed construction in dwellings, the cost of materials seems to be settling down to a very gradual decrease in cost, so that the present rates show a more stable curve of decline than those of the latter part of 1920 and during 1921. The unfortunate factor which is noticeable is that certain building interests believe that a building boom is inevitable, and therefore that it is the time to hold up prices again. Wherever this has happened a building boom has been headed off.

The average client, in spite of the difficulties above mentioned, insists upon securing from the architect an approximate idea of how much of a house he can have for $12,000.00, etc., or whatever sum he has been able to save for his small home. In order to approximate this figure, the architect must use the cubic-foot system of estimating. Now under changing conditions of prices this system is rather inaccurate, so that it should be used with great care. Any figures which are given here are bound to be only approximations, due to the fact that they are more or less of a local nature and must be given at this time of writing. The only satisfactory way of using the cubic-foot system of [Pg 14] estimating is to secure prices from one’s own locality on work recently finished.

Type II

If the approximate cost of a house of Type I is desired, observe some recently erected house of that same character, secure its dimension, and calculate its cubical contents and then its cost per cubic foot. In order to be consistent, the method of computing the cubage must be the same in all cases. The following is recommended as a uniform basis: [Pg 15]

1. Determine total area of the building on the ground floor, including all projections.

2. Determine the average height of the building from the cellar floor to the average height of the roof.

3. Multiply the above together for the cubical contents.

4. Open porches may be added at one-quarter their cubical contents, and closed ones at their full value.

Type II

Prices per Cubic Feet Near New York for Two-Story Dwellings,

June, 1922

| Type I | 32 to 38 cents per cubic foot |

| Type II | 38 to 42 cents per cubic foot |

From what has been previously stated, it will be noticed that, as a rule, the architect in selecting the kind of material with which he will build his house is limited on account of expense to the first two types of construction—namely, the frame dwelling and the masonry house with wood interior. The latter two fire-resisting types are better fitted to the larger mansions, where expense is not so important an item. Undoubtedly the comparative costs between the various kinds of exterior walls will have much to do with the selection; but more often the local conditions will outweigh these considerations. In some places a house built of stone will be the best and most economical; in others, where there is an abundance of good sand, the cement house will be suitable, while those located near brick centres will find this material adaptable.

The ideal method, of selecting a material of construction purely from an æsthetic point of view, is not always possible. But, after all, is not the most abundant local material the most harmonious to use for any one locality? Nature adapts her creations to the soil and the scenery into which she places them. All her animals are marked with colors which harmonize with the woods or fields in which they live. In fact this harmony is their protection, and in the war we imitated it in our camouflage painting. It is astonishingly evident, in the New York Museum of Natural History, how far more beautiful are animal tableaux which are set in painted scenery, representing accurately their natural habitat, than those which are exhibited alone in the cases, without a suggestion of their surroundings. Their marks and colorings seem [Pg 17] ridiculous when they are separated from their natural surroundings. The same principle holds true in selecting the material for the small house. A stone house, built of native stone, in a stony, rugged region, is the most harmonious of all. A cement house in a flat, sandy country always seems in accord with the scene. A brick house in hills of clay most certainly appears the best, and a wooden house, near the great outskirts of the timber-land, is a part of the inspiring picture. Why are so many of the old colonial houses so charming? One of the reasons is the careful use of local materials.

In the first architectural studies of the house, since this problem of cost is ever with us, it is well to be familiar with some of those broad and general principles of economical design.

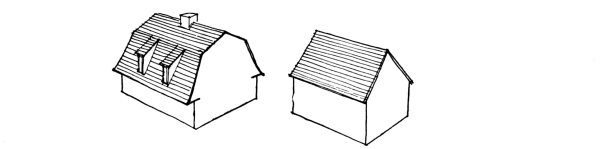

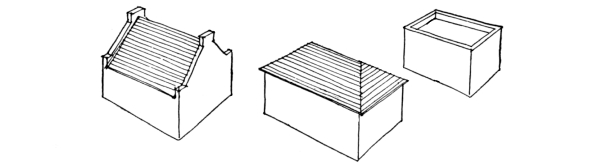

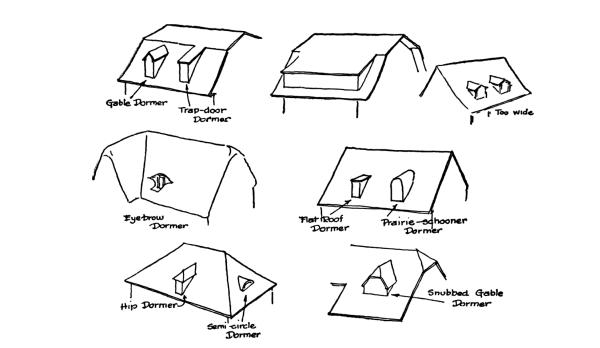

The lower we keep our house to the ground, the less will be the expense of labor, for, when work must be done above the reach of a man’s hands, it means the construction of scaffolds and the lifting by special hoists of the materials. This is not so important a consideration with the light wooden frame building as it is with the masonry house. Wherever we have brick, stone, or concrete exterior walls, for the sake of economy they should be built low. Mr. Ernest Flagg has found this to be so very true that, in houses which he is constructing at Dongan Hills on Staten Island, he has carefully limited the height of all walls to one story, and starts the construction of his roof from this level. Of course, at the gable end of the house, it is necessary to carry them up much higher. Now, the starting of the roof from the top of the first floor makes all the second floor come within the roof, and [Pg 18] this heretofore has been impracticable, on account of the great heat generated under the roof and the inability of dormer-windows to ventilate the rooms properly. Mr. Flagg has solved this problem by inventing a simple roof ventilator which is located on the ridge of the roof, and serves the purpose of both lighting and ventilating. So successful has this been, that the space which in most houses is called the attic, and is wasted, has been made available and livable. What he has accomplished by these ventilators is the ability to start the roof at the top of the first floor, and thus lower the exterior walls and set the attic in the place of the second floor and make it very livable. Not only does this principle of design save considerable money, but it follows one of those great laws of beauty, so prevalent in nature. It makes the house low and nestling in the landscape, thereby harmonizing it with the surroundings. The house of the uncultured speculator stares blatantly at you and is proud of its complete isolation and difference from the landscape; but the house of those who have taste is modestly in harmony with the surroundings. The ugly house thrusts into the air without close connection with the ground, while the comely one cuddles in nature’s lap. Is it not strange that this principle of economy is a law of beauty?

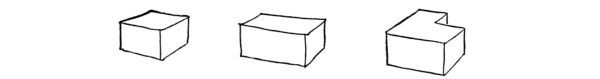

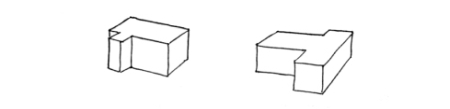

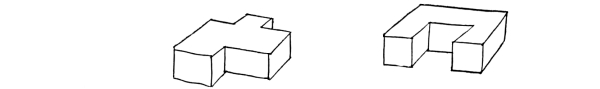

There are other features of economy in design which should be observed. The simpler and more straightforward the design, the cheaper it is and the more beautiful it can be made in the hands of the good artist. Simplicity is the highest art, as it is also the most economical thing. Likewise the cost of a house can be reduced by shaping as nearly to a square as possible, and reducing the outside walls to the minimum. The semi-detached house in the group plan accomplishes this in the best [Pg 19] manner, and gives to the whole structure that low, long skyline that is so very pleasing. This also makes one soil-line and one chimney do for both houses, a great point in economy. Some architects believe these group houses are the only economical solution of the problem of the small house.

It will be remembered that the commonest types of small houses are the wooden frame house and the masonry-and-wood house. Now it is essential that certain definite qualities be required of all materials of construction which enter into the building of these houses, and although there are many facts covering the standard qualities and methods of manufacture, yet one cannot expect to remember all of them. It is sufficient if one knows those qualities which mean satisfactory building and durability when applied to the structure.

Of the large number of materials which enter into the construction of a house, the following are the most important and should be maintained at a high standard: wood, clay products, cementing materials, metals, glass, and paint.

It is possible to enter into a long discussion of the classes, qualities, methods of conversion, defects of wood and similar subjects, but these are not pertinent to the main idea, namely, the essential qualities of woods which are used in the construction of the small house. There is a prevalent impression abroad that the supply of wood is becoming so depleted that it will in the future be used only for [Pg 21] special ornamental features. This is wrong, for we still have enough virgin forests left to supply the country for several generations, and with the growth of forestry we will maintain a certain source of supply.

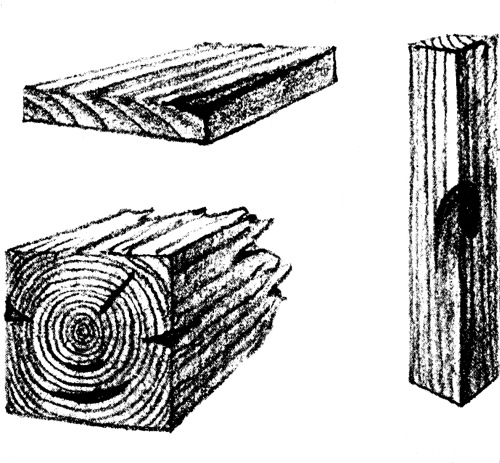

Waney edges

Star and ring shakes

Common timber defects

We have two classes of woods on the market which are used in different parts of the structure, according to their special qualities. These are commercially known as hard and soft woods, although this is not a very scientific distinction, since some of the soft woods are harder than some of the hard woods, and vice versa. Scientists have more accurate names than these, but as the above are so well established, there is no doubt as to what is meant.

In the market, lumber is not only classified according to the above, but according to the species of tree it comes from, and also according to certain standard grades of the same kind. These grades are determined by the presence of certain defects. The recognized defects are knots, shakes, checks, splits, streaks, pitch-pockets, stain, rot, wane, warp, cupping, mineral streaks, pith on the face of the board, and worm-holes.

Various large lumber associations issue rules governing standard sizes [Pg 22] and classifications for woods to be used in construction. The best and the next best are the usual grades which are used for the interior and exterior trim of houses. These grades have many designations, as “clears” and “selects,” or “A” and “B,” or “No. 1” and “No. 2,” or “firsts” and “seconds.”

The grades used for the rough framing, such as studs, joists, rafters, subfloors, and sheathing, are not so good. They are designated as “No. 1 common” and “No. 2 common.” A poorer grade still, known as “No. 3 common,” is sometimes used for cheap temporary structures.

For the details of grading and standard sizes of lumber, one should possess Circular 64 of the United States Department of Agriculture on “How Lumber is Graded.”

Next to the grading of timber, the most important factor of quality is the relative durability of the various woods, for upon this depends to a large extent the choice of them for special places. The table on page 23 is taken from a government classification.

From this table it will be noticed that the soft woods as a class are relatively more durable than the hard woods. This is true, because of the fact that the structure of soft woods is simple, while that of the hard woods is complex. When the former become wet and expand and then dry out and shrink, the structure is not stressed internally as much as is that of the hard woods, and they are therefore much more capable of withstanding the action of the weather. Also certain of the soft woods have natural properties of resisting dry or wet rot.

Certain species of woods are, therefore, selected for particular parts of the house according to the needs of durability, strength, appearance, and local supply. [Pg 23]

Rough wooden framing requires a wood that is fairly abundant and strong. The soft woods are generally used, and those which are classified as durable in the table are the most used.

| The Soft Woods | |||

|---|---|---|---|

| very durable | durable | intermediate | non-durable |

| Northern white cedar. | Douglas fir. | Eastern hemlock. | True firs. |

| Western red cedar. | Tamarack. | Western hemlock. | Spruces. |

| Cypress. | Western larch. | Loblolly-pine. | |

| Redwood. | Long-leaf yellow pine. | Norway pine. | |

| Eastern white pine. | Short-leaf yellow pine. | ||

| Sugar-pine. | |||

| Western white pine. | |||

| Western yellow pine. | |||

| The Hard Woods | |||

| Chestnut. | Black cherry. | White ash. | Basswood. |

| Black walnut. | White oak. | Butternut. | Beech. |

| Black locust. | Red gum. | Birch. | |

| Yellow poplar. | Buckeye. | ||

| Red oak. | Cottonwood. | ||

| White elm. | |||

| Hard maple. | |||

| Soft maple. | |||

| Sycamore. | |||

| Cotton gum. | |||

For rough underflooring and sheathing the cheapest and most abundant local wood is used. Durability is not essential.

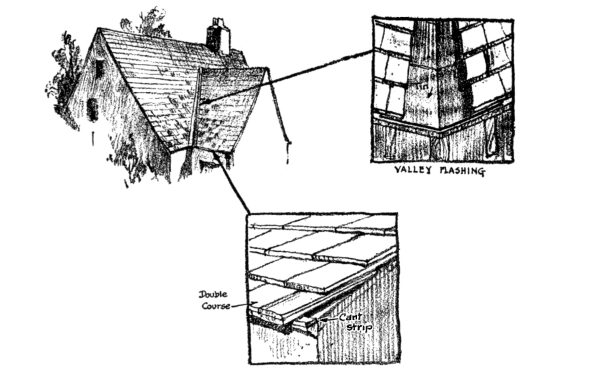

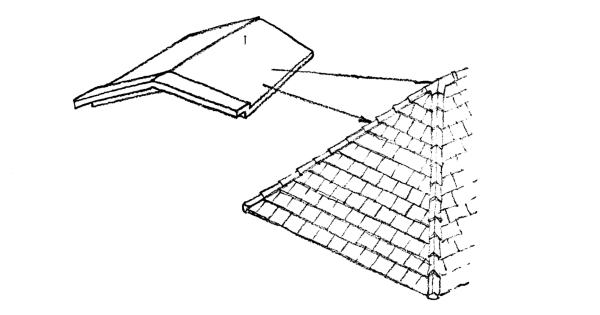

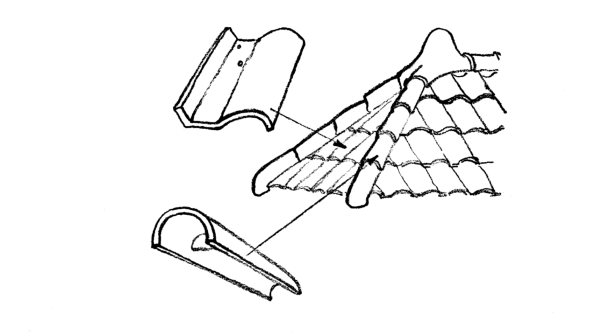

For shingles the most durable woods must be used, such as cypress, cedar, and redwood.

Lath are generally cut from waste slabs, and should be of some soft [Pg 24] wood like spruce or of one of the softer hard woods. Siding should be made from one of the soft woods, especially those which are classed as durable in the table.

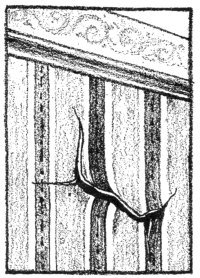

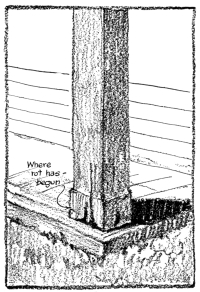

Porch columns and the like require very durable woods. They should be hollow except for very small ones. Built-up columns of interlocking type are usually specified, but the lumber used should be thoroughly kiln-dried so that the joints will not open.

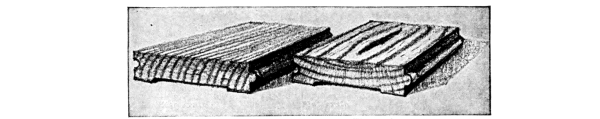

| Edge grain | Flat grain |

| Difference in the cut of flooring boards. |

The flat grain in the softer woods is not durable. |

Flooring should be capable of resisting wear and should not splinter. The hard woods as a class are more adaptable than the soft woods, although yellow pine and Douglas fir are used a great deal on account of their cheapness. These latter are divided into two grades: “flat grain,” in which the annual rings are almost parallel to the surface, and “edge grain,” in which the annual rings run almost perpendicular to the surface. The latter is more desirable, since it wears better. The flat grain splinters off, due to the layers of soft spring wood and hard summer wood. Oak flooring comes plain and quarter sawn, which is practically the same as the cut of yellow pine, but since oak is strong either way, the wearing qualities are not very different. Maple is also an excellent wood for flooring, since it is hard and smooth.

Door and window frames may be made from many kinds of wood, although [Pg 25] the soft and more durable woods are generally accepted as the best. Specially hard and durable woods should be used for the thresholds.

Doors which are to be used on the exterior should be of a soft and durable wood. The choice of wood for interior doors is limited only by the taste of the designer. The doors which stand best the warping effect of steam-heat in the winter are constructed of white pine cores with a veneer on the exterior made from some hard wood.

Sash and blinds require a soft and durable wood. Sash are subject to the drying of steam-heat on the interior and cold and dampness on the exterior. Sash built of yellow pine sapwood have rotted in a few years, and while soft maple, birch, and basswood have been used, they are not durable, although easily worked. White pine is considered to be the best for sash and blinds.

The selection of woods for interior trim depends only upon the designer’s taste, since neither relative durability nor strength is a requirement. The harder woods in the past have been used more extensively for interior trim than the soft, because of their supposedly better and richer appearance, but this is not so true to-day, for new methods of treating such woods as cypress and yellow pine have shown them to be fitted for the best artistic places. Of course hard woods are not dented from knocks by furniture as easily as the soft woods, and in this way retain their appearance longer.

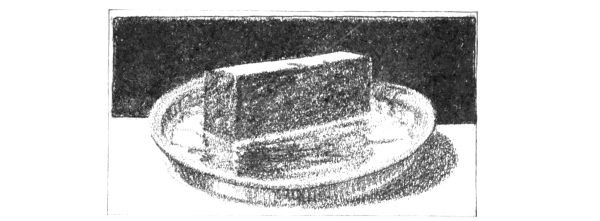

Bricks.—In considering the essential qualities of bricks for the small house it must be appreciated that those bricks which are used on [Pg 26] the exterior must be able to resist the effects of weather and produce the best artistic results, while those which are in the interior of walls or chimney need not be held up to such rigid standards. The determination of the resistance of bricks to frost and weather action is quite simple. A brick which struck by a hammer gives a clear ring is one which has been well burned and has no soft spots, cracks, or weak places. Such a brick can be said to be satisfactory for exterior use, provided that it has the proper form and color desired and is not so overburned as to be twisted and warped. Another requirement sometimes specified is that the face brick made from soft clay should not show a percentage of absorption in excess of 15 per cent, and for the stiff-moulded or dry-pressed bricks not more than 10 per cent. This, however, cannot be a hard-and-fast rule, due to the variation of clays.

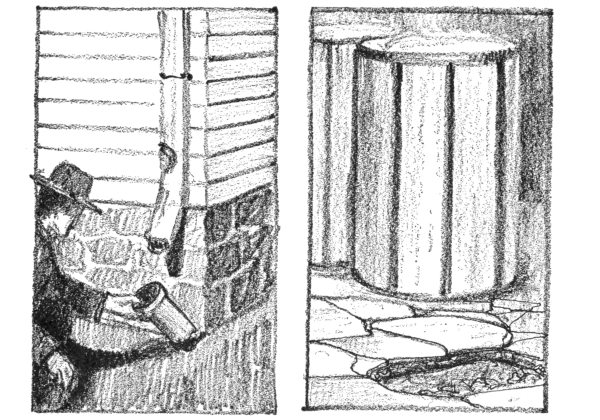

Certain red bricks, unless they are burned very hard, show, when built into the wall, a very ugly white surface discoloration, called “whitewash” or efflorescence. This is not entirely due to the brick, since the mortar that is used may sometimes produce it. If it is due to the brick it can be discovered before the brick is used in the wall, by placing a sample brick on edge in a pan containing one inch of either rain or distilled water. As the water is absorbed by the brick, the white discoloration will develop on the top surface after several days of standing if it contains the salts which will cause the whitewash. Those bricks which have been very hard-burned will not discolor under any circumstances. If after passing this test the brick wall should develop whitewash, it can be laid to the mortar. In order to prevent any such occurrence it is necessary to waterproof the joints around window-sills and between the foundations and the wall, so that the [Pg 27] minimum amount of water will be soaked up into the wall when it rains. An expensive addition of 2 per cent of barium carbonate to the mortar will tend to fix the soluble salts which cause this efflorescence.

Method of testing a sample brick to see whether

it will have a tendency to whitewash

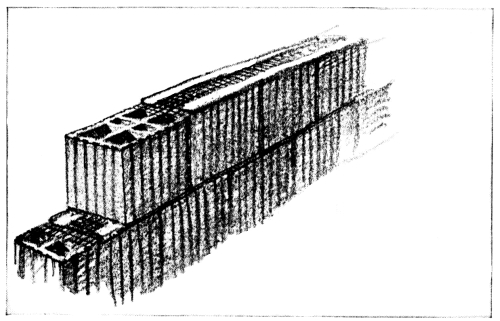

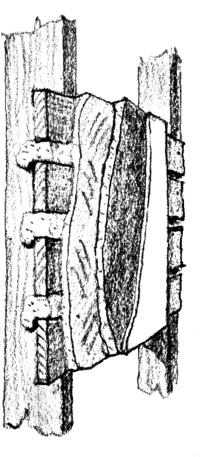

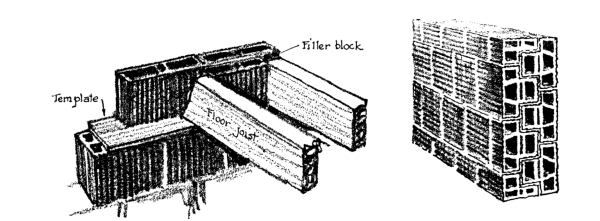

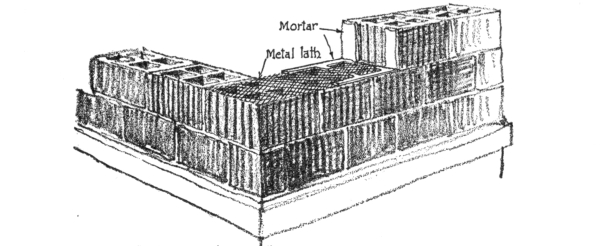

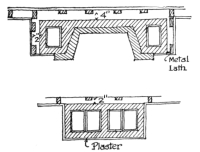

Hollow Tiles.—Hollow terra-cotta tiles covered with stucco or brick veneer are being used more extensively than ever, due to the cheaper cost of laying them, since they are larger units, and also to the fact that they build a cellular wall. Wherever these tiles are used for bearing walls it is important that they be hard-burned, but the softer ones may be permitted in non-bearing partitions. Tiles for use in outer walls should be hard-burned, free from cracks, straight, and should not show a greater absorption of water than 10 per cent. As these tiles are intended to support loads from floor-joists, it is essential that they should have the correct proportion of voids to solid shells and webs. The maximum width of any voids should not exceed 4 inches and the thickness of any shells or webs should not be less than 15 per cent of this measurement. In tests it has been shown that tiles laid with webs vertical are stronger than those with webs horizontal, but this [Pg 28] difference in strength is not of very great importance in the small house, where the loads are very light. The chief thing to avoid in the setting of tile, when they are vertical webbed, is the dripping of mortar to the bottom and the insufficient spreading of it over the ends of the webs and shells. This can be overcome by laying wire lath over each course, and then buttering the mortar on the inside and outside edges. The mortar is prevented from falling out of place by the lath, and because it is not continuous through the wall, any penetration of moisture through it is stopped.

Showing the use of metal lath in the joints of vertically

webbed hollow-tile, to prevent the dropping of the mortar

into the voids and also allow the separation of mortar joint

The most important cementing materials which enter into the construction of the small house are lime, cement, gypsum, and their various mixtures, as mortar, plaster, and concrete.

The various technical requirements for good lime and cement are very strict and detailed, and for the small house it is customary to cover [Pg 29] their qualities in the briefest manner by referring to the standard specifications of the American Society for Testing Materials.

Slaked lime should be made from well-burned quicklime, free from ashes, clinker, and other foreign materials.

Dry hydrated lime should be the finely divided product resulting from mechanically slaking pure quicklime at the place of manufacture.

The specifications of the American Society for Testing Materials covering the quality of cement should be followed where large purchases are made. Where small quantities are to be used, the reliability of the dealer must be the basis of purchase.

As mortars and concretes made from these materials are as important as the cements or limes, it is essential to have definite standards for them.

Lime mortar should be made of 1 part by volume of slaked lime putty or dry hydrated lime and not more than 4 parts by volume of sand. The use of hydrated lime is recommended, since the poor qualities which are apt to develop from careless slaking of quicklime are thus avoided. It also comes in smaller packages, and if the entire quantity is not used at once it may be stored without deterioration. It is only necessary to mix the hydrated lime with water until it becomes a paste, and then add the necessary sand. The purpose of adding sand is to increase the bulk and to reduce the shrinkage which pure lime paste will develop as it hardens. Pure lime paste, without sand, will shrink, crack, and develop very little strength. By introducing sand this contraction is reduced, but the addition of too much will decrease the strength slightly. However, this decrease of strength is very little. A mortar made of 1 part lime to 6 parts sand is nearly as strong as one made from 1 part [Pg 30] lime and 3 parts sand. The maximum amount of sand to be used is generally governed by the ease of working, and not so much by the strength. A lime which is too sandy will not spread easily on the trowel.

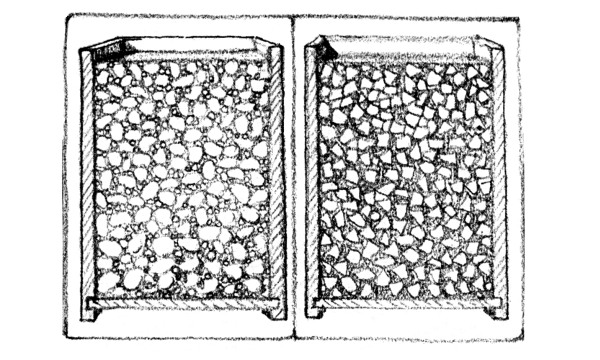

Cement mortar is, of course, a stronger material and can be used in damp places where lime mortar would deteriorate. The theory of mixtures of both cement mortar and concrete is to proportion the materials so that they produce the most compact substance. For instance, in the cement mortar the cement should just fill the voids between the particles of sand, and in concrete this cement mortar should just fill the voids in between the larger aggregate, and this larger aggregate should be so graded in size that it makes the most compact body. It used to be thought that certain definite numerical proportions, as laid down by theory, of the various ingredients would hold true for all kinds of sands and aggregates. For instance, the proportion of 1 part of cement, 3 parts of sand, and 6 parts of aggregate was thought to be the best for ordinary use under all conditions. But extensive tests by the government have shown that the only real way to determine the correct proportions of mixtures is to experiment with the particular sand and gravel that will be used, and to test them to see what ratios give the most compact mass. It has also been found that round aggregates, like pebbles, produce the strongest concrete, since the particles flow into place better than the sharper aggregates, which formerly were considered necessary because of the supposed idea that they made a better mechanical bond with one another. The proportion of water is also important, a quaking mixture producing the best results. [Pg 31]

It is customary in small work, however, where no experiments can be made on various mixtures to determine their proper proportions, to follow the old rules of thumb for amounts.

Cement mortar should be made of cement and sand in the proportions of 1 part of cement and not more than 3 parts of sand by volume.

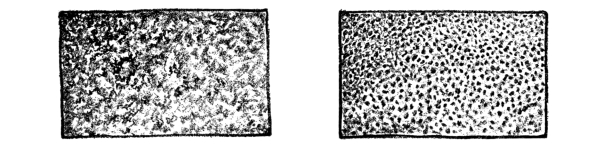

| Good. Very compact | Bad. Not compact because of poor grading of aggregate |

Good and bad concrete |

|

If cement-lime mortar is to be used it should not have more than 15 per cent by volume of the cement replaced by an equal volume of dry hydrated lime. The addition of hydrated lime to cement mortar improves its working qualities, making it slide more readily on the trowel and also increasing its waterproofness. Its strength is not decreased within the limits prescribed.

In concrete work it is as important to have good sand and aggregate as cement. Sand should be sharp, clean, coarse quartz. The sand used should not, when it is rubbed in the hand, leave the palm stained. [Pg 32]

Gravel which is used as an aggregate should be free from clay or loam, except such as naturally adheres to the particles. If there is too much clay or loam, it should be washed with water. When bank gravel is used the best results will be obtained if it is screened from the sand and remixed in the proper proportions for fine and coarse aggregate. For ordinary mass concrete the size of aggregate should vary from ¼ inch to 2 inches, and in reinforced work should not exceed 1¼ inches.

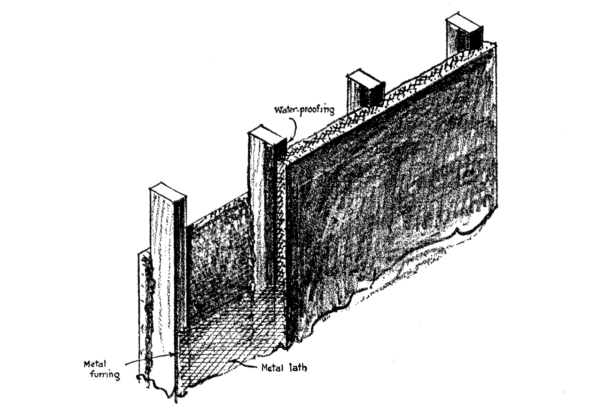

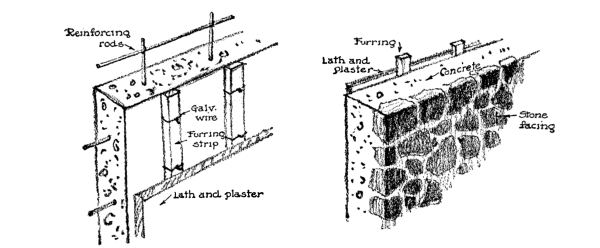

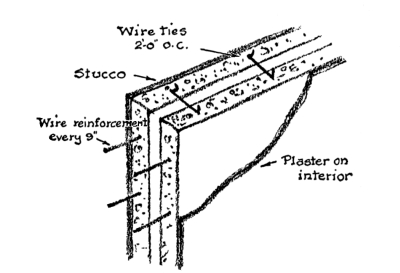

STUCCO ON METAL LATH OVER WOOD STUDS

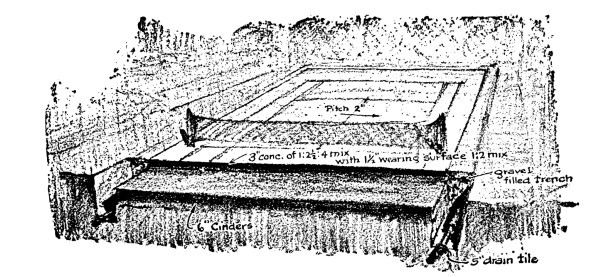

The best proportion of parts to use must vary according to the requirements, but for the small house good results will be obtained by using 1 part of cement, 2 parts of sand, and 4 parts of gravel or broken stone.

Stucco Work.—Stucco is really a Portland-cement plaster used on the exterior, and its success depends a great deal upon the quality of materials employed and workmanship. All stucco to a greater or less [Pg 33] degree cracks, but the problem is to make the cracks as small as possible. The government is carrying on an extensive investigation of the problem of stucco through experiments on fifty-six exterior panels which have been under observation since 1915. Each one of these panels has been spread upon a different base or made with different proportions. So far only two panels have been found to be entirely free from cracks, although many are practically uninjured by the small cracks which have developed. It is therefore quite evident that as a rule it must be assumed that the stucco will crack to a certain extent, and in order to cover such defects a rough surface is the best. As to proportions of mixtures, there is a great variation of opinion. The commonest is 1 part of cement, 2½ parts of sand, to which is added about ¹/₁₀ part of hydrated lime by weight of cement. For a more detailed account on stucco, send for the Progress Report issued by the Bureau of Standards on the Durability of Stucco and Plaster Construction.

Plastering.—The qualities of internal plaster depend upon the construction of the wall, the methods of application of the plaster, and the quality of the plastering material.

Scratch coat is for bonding;

brown coat for plasticity;

finished coat for appearance

The walls and ceiling to which plaster is to be applied must be so constructed as to be practically rigid under the loads that they will carry. Since plaster is not elastic, any slight change in shape of the surface will cause it to crack. The common backings which are satisfactory for plastering are wood lath, metal lath, and masonry, such as concrete, terra-cotta tile, brick, plaster board, etc. Wood lath makes the least rigid back of all, and for this reason is not considered the best, although it is the cheapest. Unless the wood laths are wet before the plaster is applied, they will absorb the moisture [Pg 34] from the plaster and swell, thus cracking the wall. Metal lath for this reason is superior. Masonry walls should be made rough to give the necessary key for the plaster to cling to. In brick walls the joints are raked out, in concrete walls the surface is picked, and the outside of terra-cotta tile is marked with grooves for this purpose.

The best results in plaster are secured with three coats. The first coat is called the scratch coat, and is intended to form a bond between the wall itself and the plaster. It should be pressed into the apertures between the lath to secure a good bonding key, and its surface should be scratched with a tool to give the required bond between it and the next coat, or brown coat. The brown coat forms the main body of the plaster and averages about ¾ inch to ⅞ inch thick. The finished coat is then added on top of this and is intended to develop a plane surface with the desired color. Each coat should be allowed to dry out and then be wet before the next one is added. If wood lath is used, this drying and wetting will cause the lath to shrink and swell, so that cracks will be developed in the scratch and brown coats. These should be filled in before the finished coat is added.

The materials which should be used in the various coats depend upon the [Pg 35] requirements which are necessary for each one. As the most important characteristic of the scratch coat is strength, and that of the brown plasticity, and the final coat appearance, the materials must be proportioned accordingly.

| SCRATCH-COAT PROPORTIONS | |||

| Hydrated lime | 133 | parts | by weight |

| Sand | 400 | “ | “ |

| Hair | 1 | part | “ |

| BROWN COAT | |||

| Hydrated lime | 100 | parts | “ |

| Sand | 400 | “ | “ |

| Hair | ½ | part | “ |

| FINISHED COAT | |||

| Smooth Finish | |||

| 1 part by volume of calcined gypsum. | |||

| 3 parts“lime paste. | |||

The most used metal in the small house is the so-called tin-plate or roofing tin. It is not a true tin-plate, for it contains 75 per cent lead and 25 per cent tin, applied to a base of soft steel or wrought iron. It comes in two grades, IX and IC, the former being No. 28 gauge and the latter No. 30 gauge. The lighter is used for roofing and the heavier for valleys and gutters. The tin does not entirely protect the base metal, so that it is necessary to paint both sides before it is applied.

Galvanized iron is another form of sheet metal which is extensively used for work on the small house. It consists of sheet iron or steel, covered with zinc. This coating should be free from pinholes or bare spots, and of a thickness to prevent cracking or peeling. If the coating is sufficient and well done, it is superior in lasting quality to the ordinary tin-plate. [Pg 36]

Copper, since the war, has come back into use again as a sheet metal for the small house, for its cost has dropped within reason. In order to meet a certain popular demand a light grade of copper sheet roofing has been placed on the market, although it has generally been considered that sheets weighing less than 16 ounces per square foot were not suitable for roofs.

There are two kinds of window-glass used, double thick and single thick. The former is ⅛ inch thick or less, and the latter is ¹/₁₂ inch thick. It is customary to use double thick in all window-panes over 24 inches in size. The grading is AA, A, and B, according to the presence of defects, such as blisters, sulphur stains, smoke stains, and stringy marks.

Plate glass is used only where the expense will permit. It is different from window-glass in that the latter is made from blown glass, while plate glass is made from grinding and polishing down sheets of rolled glass.

There are quite a number of other minor materials which enter into the construction of the small house, but they are more or less identified with the mechanical equipment and the finishing, and will be considered under these headings.

Sheet lead weighing 5 to 6 pounds per square foot is often used for counter-flashing. Leaders and leader heads of cast lead have been made practical by one company, which has developed a method of hardening the lead.

Zinc, like copper, is again being urged upon the public by the manufacturers since the war demand is over. Zinc spouts are usually made from No. 11 zinc gauge, which is equal in thickness to No. 24 steel gauge. [Pg 37]

There is hardly any need to mention the durable qualities of copper, zinc, or lead. Wherever the cost permits, one cannot deny that materials of such durable nature are the proper ones to use.

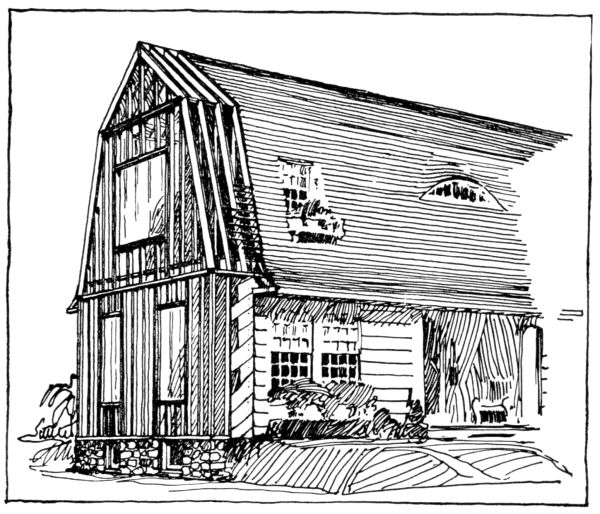

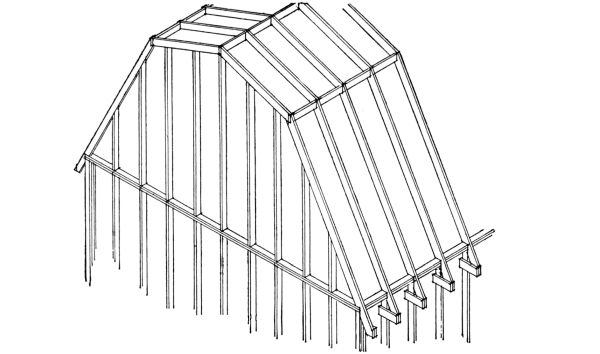

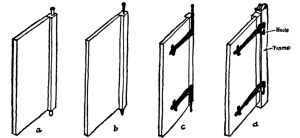

There are no sharp distinctions between the various types of wooden frame construction. But in order to classify certain tendencies, we will arbitrarily define four types. To these we will give the names of braced-frame, balloon-frame, combination-frame, and platform-frame.

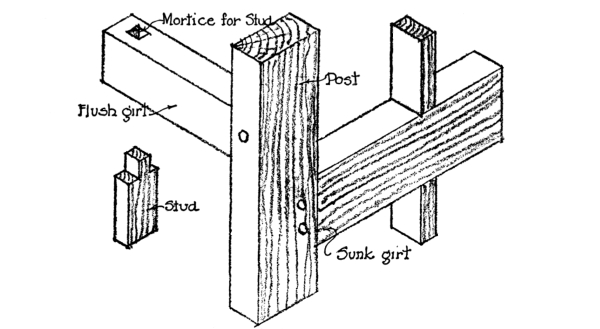

The braced-frame is the oldest type, and originated in Colonial days in New England. It was developed under the influence of a tradition of heavy, European half-timber construction, and also nourished by the abundance of wood directly at hand. The fact that nails were not made, except by hand, urged the carpenters to use methods of fastening which required as few as possible. Because of these factors, then, certain definite characteristics of this type of wooden frame construction manifest themselves in the use of timbers, far larger than necessary for safety, and joints consisting of mortises and tenons. [Pg 39]

As the sawmill became mechanically more rapid, and as nails were being turned out by machines more plentifully, the Yankee who went West on adventuresome trips, and cared little for a permanent dwelling, devised a system of light-frame construction which became known as the balloon-frame. This was put together with the greatest speed, and required only nails for fastening all joints. The timbers which were used were standardized to one size, namely, 2 inches by 4 inches.

CORNER CONSTRUCTION OF BRACED-FRAME

MORTICE & TENON JOINTS

Now, both of these types had advantages and disadvantages which were bound to influence later builders. Those who had been accustomed to build according to the braced-frame system found that lumber was becoming scarcer, and that nails were cheaper than they formerly were. Certain features of the balloon-frame appealed to them, such as its greater speed of construction, its smaller timbers, and lightness. On the other hand, those people who had lived in houses constructed according to the balloon system of framing found that they were very [Pg 40] flimsy, that fires quickly consumed them, that rats and vermin could travel freely through the walls, and that, after all, they were only the most temporary sort of shelter. These folks looked back at the old methods of building, and saw the good features of solidity and permanence. We had, therefore, the growing together of the two systems of construction into a type which we call the combination-frame dwelling.

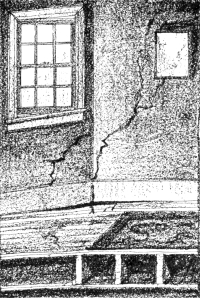

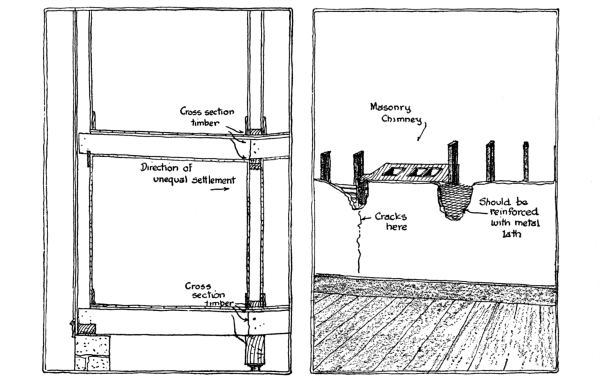

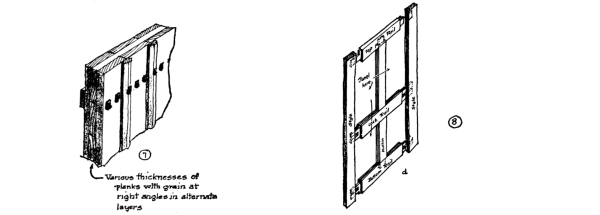

However, progress did not stop at this point. The houses built according to this newly devised system were found to settle unevenly, which cracked plaster ceilings and walls and made doors and windows into leaning parallelograms. The cause of this was [Pg 41] found to be due to the natural shrinkage of wood as it dried out. Now, all wood shrinks mostly across the grain, and not with it, so that the amount of settlement of any wooden wall depends upon the amount of cross-section of wood which it contains. If there is more in the interior partitions than in the exterior, it is certain that the floor-joists will settle down on the inside ends more than the outside. This is exactly what happened. It occurred not only in the combination-frame but in the braced and balloon frame. Various devices were introduced to avoid this defect, but all were more or less incomplete. Nevertheless, it all led gradually to the development of the fourth type of construction, which is called the platform-frame, for lack of a better name. This frame solves the problem of uneven settlement in the wooden structure. It also makes the location of the windows of the second floor independent of those of the first floor, which is not the case with the balloon-frame, for in this type the studs extend in one piece from the sill to the plate, requiring the centring of the windows of the second floor over those on the first.

The methods which are used in constructing the small house of to-day are not as simply classified as the previous description would lead one to believe. The old New England braced-frame has practically gone out of existence, yet many of its features remain. The balloon-frame is used only in the cheapest sort of structures, yet many of its details are found in the modern dwelling; The combination-frame in all its many varied forms can be called the advanced type.

The illustrations show the four types in their entirety. But in order [Pg 42] to fully understand the combination-frame, it is necessary to know what features of the braced-frame and balloon-frame are used to-day.

1. The use of the girt, because it permits the location of the second-floor windows at any point irrespective of the first floor windows. This cannot be done when a ribbon-board is used, for this requires studs which extend continuously from sill to plate, and if any windows are to be located on the second floor, they must be placed directly over those on the first floor. The ribbon-board does not act as a stop for either vermin or fire, as does the girt. However, fire-stops can be introduced in connection with the ribbon-board, if the extra expense is no hindrance.

2. The use of the sill, because it serves as a firm foundation for the outside studs and first tier of floor-joists. The balloon-frame has [Pg 43] no sill, for the floor-joists are set directly upon the top of the foundation-wall, and the exterior studs are built on top of them.

3. The use of the corner braces, because they stiffen the frame.

TYPICAL FRAMING OF “WAR HOUSES.”

1. The use of small timbers, or the standardization of the 2 by 4 for all parts except the sill, because of economy. The corner-posts are made of three 2 by 4’s, and the plate is made of two 2 by 4’s.

2. The use of the nailed joint, because of its cheapness and its greater strength. It will not rattle loose when the timber seasons, as does the mortise and tenon joint in the braced-frame.

3. The use of the ribbon-board, in place of the girt, for those houses which are to be stuccoed, and a rigid, outside wall-frame is desired from sill to plate.

4. The use of diagonal sheathing-boards, to brace the frame instead of the corner-pieces. The reasons for this are not very certain, since diagonal bracing with sheathing is not always effective, while it is extremely wasteful.

The combination-frame includes all of the present-day methods which make use of selected features of both the braced-frame and balloon-frame, such as were noted above. There are no rules to follow. In certain sections of the country one type is favored more than the other. Where a house is to be covered with stucco, the balloon-frame is a better type to use than the braced-frame, since it gives a stiffer outside wall as a backing for the stucco.

It will be noticed in the illustration how different is the amount of cross-section of wood in exterior and interior walls of the [Pg 44] combination-frame, a thing which causes the unequal settlement previously alluded to. In order to reduce this to a minimum, it is often specified that the studs of all interior partitions be carried down to the top of the cap of the partition below or to the top of the supporting girder, thus reducing the amount of cross-section timber. This is not a complete cure, however, although it is a big improvement.

The real solution of the difficulty lies in the use of the platform system of construction. In this system the first floor is built on top of the foundation-walls, as though it were a platform. A sill, called the box-sill, is constructed for the exterior support of the ends of the floor-joists by laying down a timber the same size as the joists and setting another one on the extreme edge in a vertical position. The angle thus formed makes a resting-box into which the floor-joist can be framed. The interior ends of the floor-joists should be supported upon a steel I-beam upon which has been placed a 2-inch-thick timber. The I-beam should be supported upon steel-tube columns which have been filled with concrete. On top of the floor-joists should be nailed the underflooring, laid diagonally. The first floor then appears as a perfectly smooth platform. Now wherever there is to be erected an interior or exterior partition, a 2 by 4, called the sole piece, is [Pg 45] nailed directly on top of the rough flooring. This serves as a sill for the studs of the partition, which are now erected vertically upon them and capped with double 2 by 4’s on the top. Now the second floor is built on top of the partitions in the same manner as the first, and a new platform is constructed, so to speak. Upon this is then erected the partitions of the second floor, and on this the floor of the attic. In fact, this construction proceeds floor by floor, and each floor is an independent platform. If the drawings are examined it will be noticed that the amount of cross-section of wood in any one bearing partition is identically the same as in any other. The dwelling built in this way, then, cannot settle unevenly, and the cracked plaster and twisted doors will be eliminated. [Pg 46]

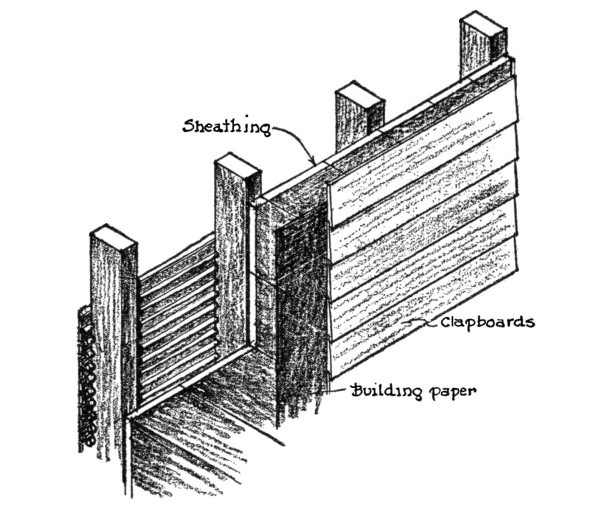

CLAPBOARDS OVER WOODEN STUDS

There are certain features which are common to all types of frames. For instance, the framing around all doors and windows requires the use of double 2 by 4’s or the use of one 4 by 4.

These framing studs around the window are set 5 inches higher and 8 inches wider than the dimensions of the finished window. Those about the door-openings are set 2 inches higher and 4 inches wider.

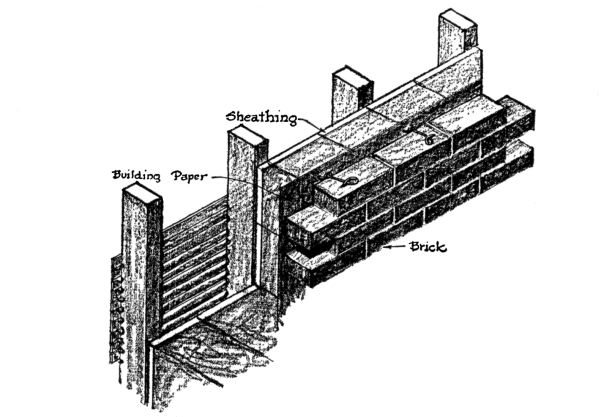

BRICK VENEER OVER WOODEN STUDS.

All use sheathing-boards of ⅞-inch stock to cover the outside of the studs, and these are usually 6 inches to 8 inches wide.

The usual spacing of studs is 16 inches on centres, and they are generally of 2 by 4’s, although where any pipes or flues are run through the partition they should be 2 by 6’s. [Pg 47]

Interior stud partitions should be bridged or braced once in their height, and partitions which run parallel to the floor-joists should have a capping-board, so that the proper nailing for lath can be secured. In fact, at all intersections of partitions care should be exercised that the required nailing for lath is provided.

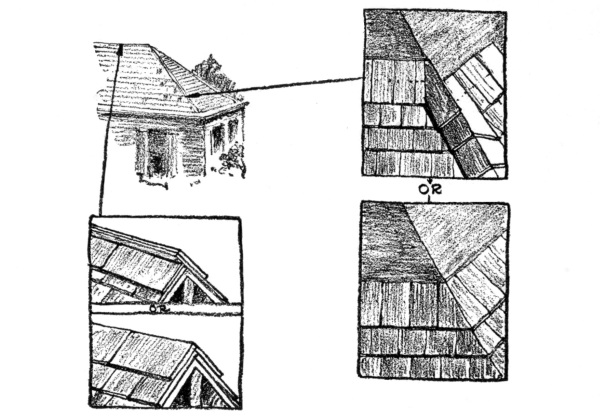

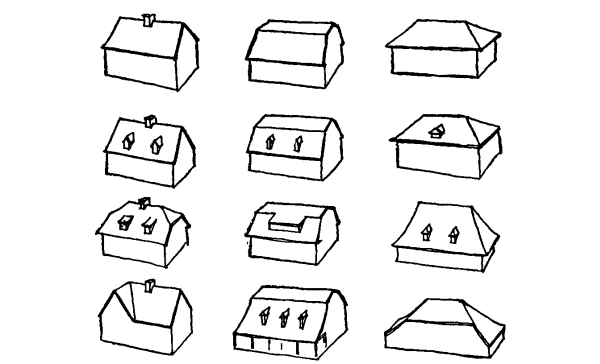

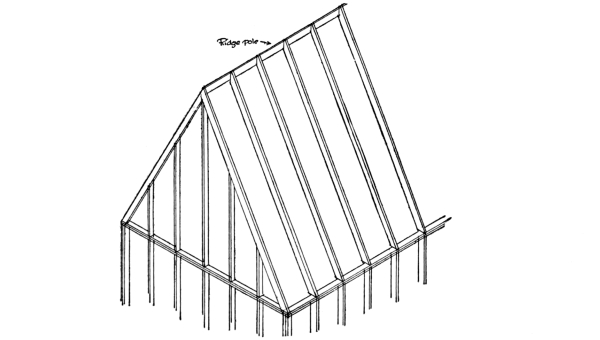

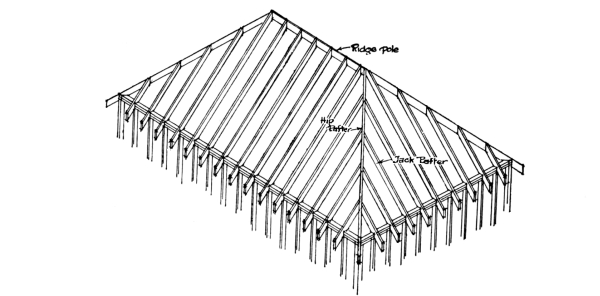

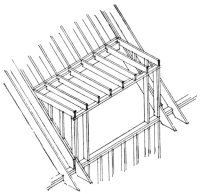

In the construction of roofs the average spacing of rafters is 20 inches on centres. They should be doubled around all openings. The ridge is usually of a 1-inch by 10-inch piece. The size of the rafters varies with the length of span and load. They are usually 2 inches by 6 inches for short spans and light loads, and 2 inches by 8 inches or 2 inches by 10 inches for long spans and comparatively heavy loads. Valley rafters must always be deeper and heavier than the rafters and should be designed as a girder. The hip rafters do not carry any great load, but are often made deeper to fit the incline cut of the jack rafters.

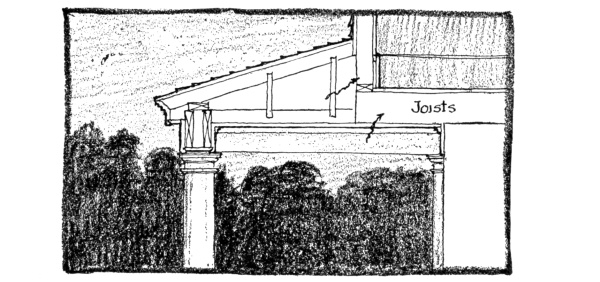

All floor-joists are spaced 16 inches on centres, and should be bridged. The following is the table commonly followed for good house construction, although lighter work is most often specified:

| SPAN | TIMBER | |

|---|---|---|

| 12' and under | 2" × 10" | cross-bridged once. |

| 12' to 15' | 2" × 10" | doubled every other one, if good stiffness |

| is desired, and bridged twice. | ||

| 15' to 20' | 3" × 12" | and of long-leaf yellow pine, crowned at |

| centre ½", and bridged three times. | ||

| 20' to 25' | 3" × 14" | of long-leaf yellow pine, crowned at the |

| centre 1" for the 25' spans, and bridged four times. | ||

Floor-joists should be doubled around all openings larger than 3 feet, and joists should be hung from the header beam by metal straps. [Pg 48]

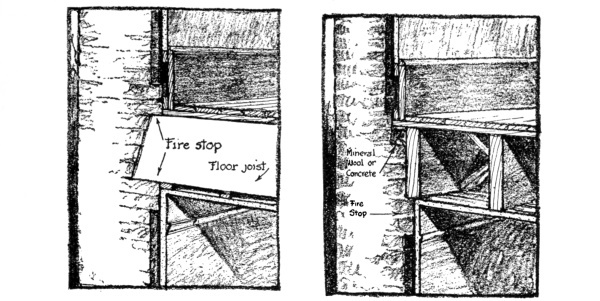

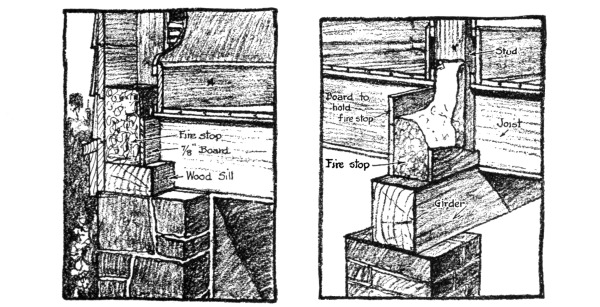

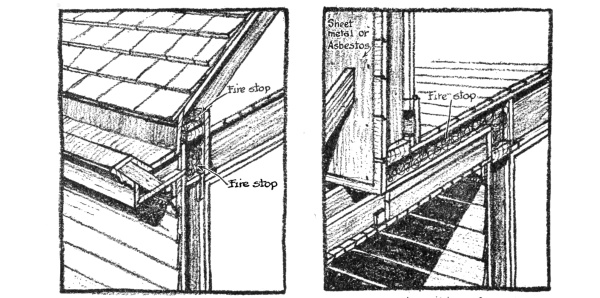

There are many precautions which should be taken to prevent the spread of fire in the wooden frame house, but those will be considered as a special subject. Likewise the discussion of certain defects of construction which are commonly found in the speculative house will be dealt with later.

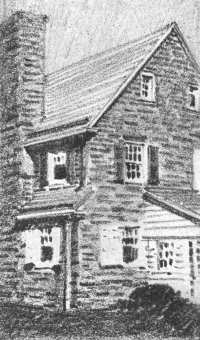

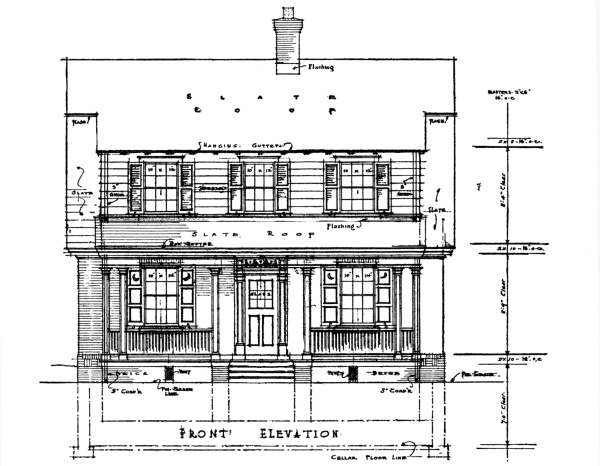

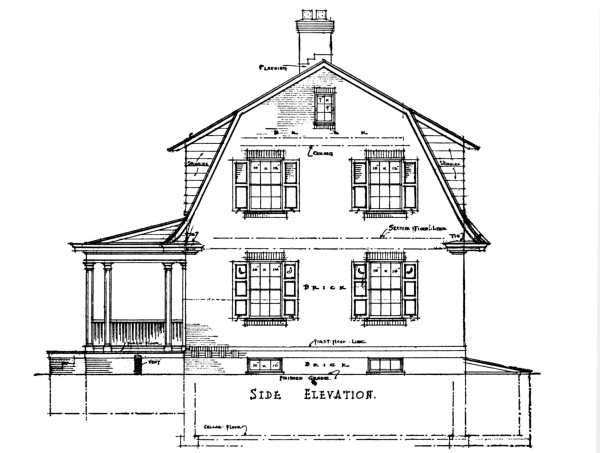

In one of the previous chapters it was pointed out that the type of construction next in general use to that of the wooden frame house was the dwelling of masonry and wood. This was designated as Type II, and defined as a building with exterior walls of stone, brick, concrete, or terra-cotta, and interior floors and partitions of wooden frame construction.

The difference in construction between the wooden frame structure and the masonry-and-wood building is mostly in the material used for the exterior walls. The interiors of both types are constructed in practically the same way, the floors being of light wooden joists and the partitions of wooden studs.

The oldest varieties of the masonry houses in America are represented by the stone and brick dwellings of Colonial days. These are so substantially built, and often so artistic in conception, that they have become common models from which to draw inspiration. The concrete house of the monolithic or block type, and that of hollow terra-cotta tile, is a modern development.

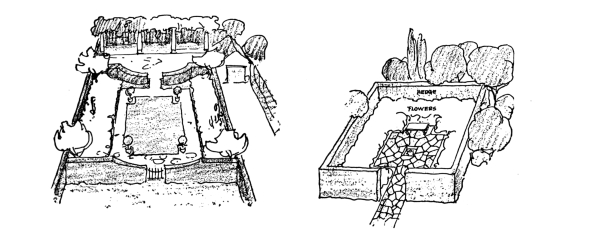

The stone house is very adaptable to all those regions where this material can be secured from the excavation of the cellar or from some neighboring road improvement. Sometimes an old stone wall serves as a [Pg 50] source of supply. Because of the native character of this material it will always be in harmony with the landscape.

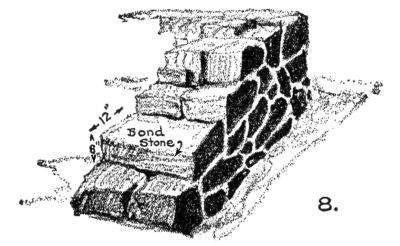

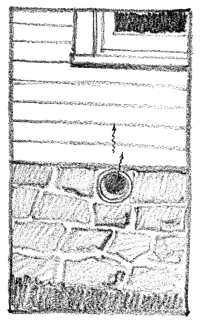

In building the wall of stone there are a number of things to be observed, where success is desired. The wall should be well bonded together, the lintels over the windows should be strong, the foundations should be adequate to prevent cracks, the method of laying should be artistic, and the form of jointing in harmony with it.

All native stones used for rubble wall construction have certain characteristics of color and formation. Certain stones will split easily into long, flat shapes, others seem to have very little lamination and break into jagged, irregular patterns, while others are so soft that they lend themselves to easy shaping in squared blocks of regular size. Sometimes, even, the neighborhood may be filled with round field stones, which can be used to imbed into the face of the wall and produce a surface of round bumps. Whatever is the character of the native stone, it should be used in its simplest form and not forced into imitation of some other type. The soft brown sandstones which are seen in some Colonial houses are easily cut and squared; but to cut up a hard stone into such carefully shaped blocks, in imitation of this Colonial work, would not only be a waste of money but a waste of artistic effect.

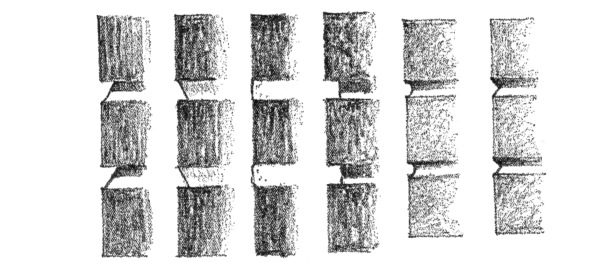

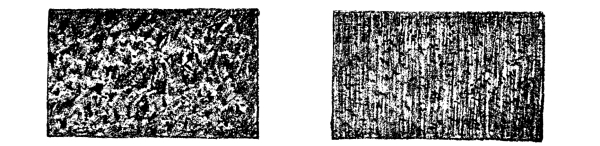

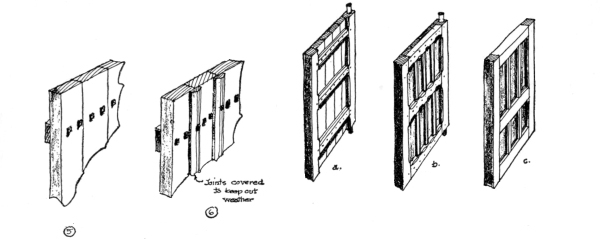

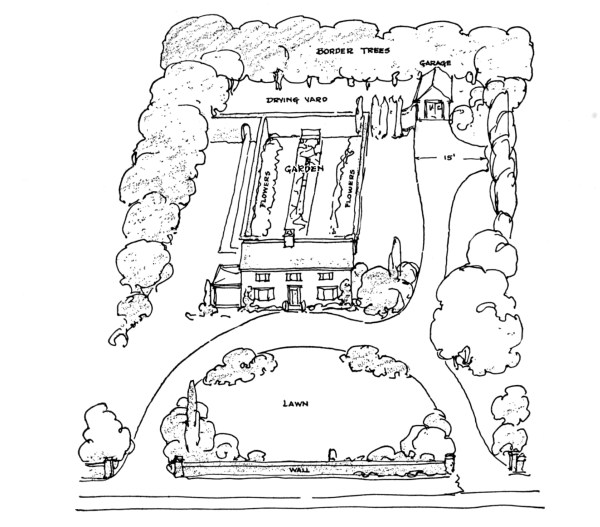

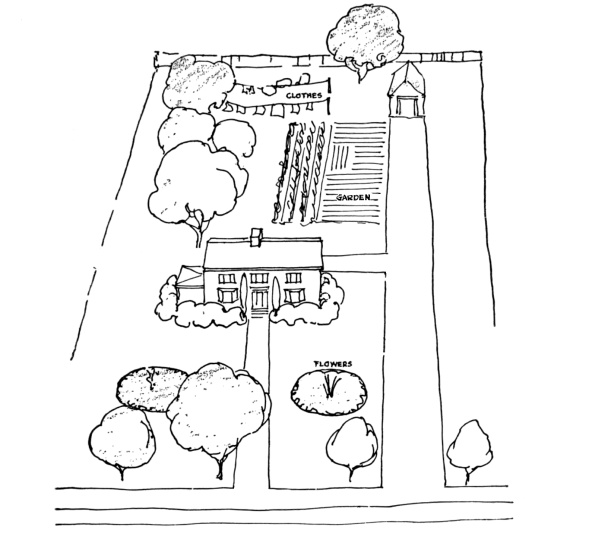

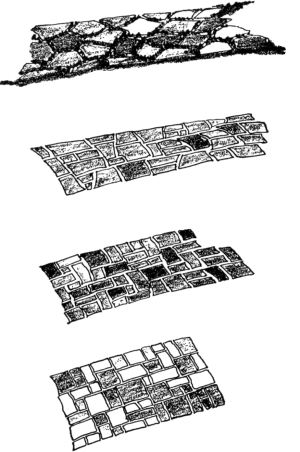

According to the way in which the stone naturally lends itself, we have various types of rubble walls. The commonest is the rough rubble wall in which the stones have neither regular shapes nor regular sizes, or even courses. The wall is composed of large stones and small stones (the latter are called spalls, and fill in the interstices between the larger stones). The joints of mortar between the stones may be plastered roughly over the surface, covering much of the face of the stones themselves, or they may be roughly but neatly pointed with white mortar, or the joints may be raked out. Where the stone has a natural tendency to cleave into long, flat shapes, the rough rubble may become more regularly coursed in appearance. All of these types are respectively illustrated in Figures 1, 2, 3, and 4. [Pg 51]

[Pg 52] A softer stone, which can be dressed with the hammer, may be treated in two different ways: It may be shaped to fit closely, without using any spalls to fill up the interstices, and, thus, appear as a cut-out puzzle; this is called “cobweb rubble.” However, the more dignified treatment is the squared, uncoursed rubble, in which the blocks are cut to rectangular shape and the joints pointed with a tool. Figures 5 and 6 illustrate these.

A wall built entirely of field stone depends upon the mortar for its strength. It appears the best when the joints of the surface are raked out, permitting a large part of the stones to project outward. Figure 7 illustrates this kind of rubble wall. [Pg 53]

When the rubble wall is built with very carefully squared stones, and in regular courses, it partakes more of the monumental character of ashlar work and draws away from the rustic value of rubble. In determining the amount of cutting which is to be done, the character of the building should be considered, remembering that the smoother and more finished the wall, the more monumental is its appearance.

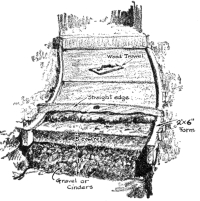

Bond stone every 2' in ht. and 3' in length

Thickness of

rubble-stone wall

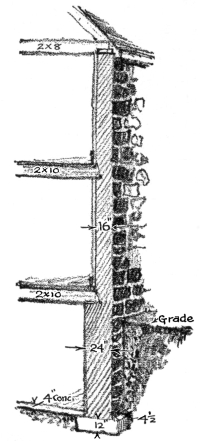

The kind of mortar which should be used for the rubble wall depends upon its location and desired appearance. All foundation-walls, and all walls which are subject to dampness, should be built with Portland-cement mortar. Lime mortar may be used in walls above grade, although cement mortar, or cement-lime mortar is superior. As the strength of a rubble wall depends more upon the mortar than the bond, it is well to use the best. However, care should be taken that the wall is well bonded. A wall which consists of two faces, not bonded together, should not be built. A bond stone which carries through from one face to the other should be set into the wall every 2 feet in [Pg 54] height, and every 3 feet in length. This bond stone should be flat and about 12 inches in width and 8 inches thick. The usual thickness of walls for dwellings not over three stories in height is 16 inches, and the foundation-walls are made 8 inches thicker than the wall above or 2 feet.

The footings under a stone wall should be of concrete, not less than 12 inches thick, and should rest upon solid ground at a depth equal to, or greater than, the frost-line below the surface, unless solid rock occurs above this point. The width of the footings should be such that it projects outward on both sides of the wall at least 4½ inches.

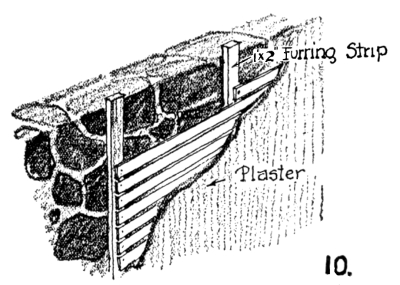

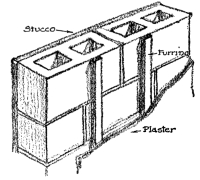

The interior of all stone walls, and in fact all masonry walls, will show condensation of moisture over the interior surface, and if they are plastered directly on the interior the decorations will be ruined by the collection of so much water. The cause of this condensation is the same as that which forms sweat on the exterior surface of a glass of cold water. In order to eliminate this disagreeable feature, all masonry walls are furred on the interior before the lath and plaster is applied. The furring makes an air space between the wall and the plaster, and all dampness is prevented from penetrating to the interior [Pg 55] surface of the plaster. To further increase the damp-proof qualities of a masonry wall they are sometimes built hollow, as, for example, the hollow brick wall, or the hollow terra-cotta tile wall. This air space also serves as an insulator for heat, preventing the escape of heat from the interior of the building in winter and the penetration of it into the structure in the summer.

Furring Strip

The commonest type of furring is the 1-inch by 2-inch wooden strip, nailed to the joints of the masonry or to wall plugs inserted in the joints. Metal furring strips are also extensively used, and occasionally hollow terra-cotta furring blocks.

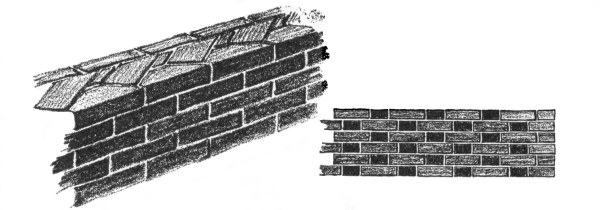

Like the stone house, the brick dwelling is one of the oldest types in this country. Examples of early brick houses show a taste for good brick, which later died out on account of the introduction of the first American machine-made bricks. These early machine-made bricks were extremely ugly, due to their perfection of geometric shape, smoothness of surface, and monotony of red color. Later improvements in the manufacture of brick have released this material for extensive artistic use. The surface was given a varied color and texture, and the form was not made so machine-like. To-day we have a variety of bricks which range in colors through reds, yellows, buffs, greens, blues, and even dark violets. Textures of wire-cut bricks are rich and varied, and, if properly handled, can produce the very finest architecture. [Pg 56]

| 11. | 14. | |

| Running Bond and method of Bonding |

Flemish Bond |

12.

English Bond

13.

Dutch Bond or

English Cross Bond

The thickness of brick walls for dwellings not higher than three stories ought to be 12 inches, although 8 inches is considered by many experts to be quite thick enough for small houses. If the foundation walls are of rubble-stone they should be 8 inches thicker, and if of brick or concrete they should be 4 inches thicker. Usually the walls [Pg 57] will be faced with some variety of face brick, in which case they should be bonded into the wall. If a running bond is used, the face brick should be bonded into the backing at every sixth course by cutting the corners of each brick in that course of face brick and putting in a row of diagonal headers behind them, and also using suitable metal anchors in bonding courses at intervals not exceeding 3 feet. Where Flemish bond is used, the headers of every third course should be a full brick and bonded into the backing. If the face brick is of different thickness to that of the common brick backing, the courses of the exterior and interior should be brought to a level bed at intervals of about eight courses in height of face brick, and the face tied into the backing by a full header course or other suitable method. [Pg 58]

FISKLOCK BRICK

It is very easy to understand the bonds in brickwork if the fundamental forms are known. There are, in reality, but two real bonds: namely, the English and the Flemish bond. The so-called running bond is no bond at all; while the common bond is found only in common brick walls, and uses a bonding course of headers every sixth course. The Dutch bond is only a slightly altered arrangement of the English bond, and is produced by merely shifting the centring of vertical joints of the stretcher course. By arranging these fundamental bonds in varying manners a decorative pattern can be produced on the wall of brick.

15.

Brick Joints

Here, again, as in the stone wall, the mortar joint plays a great part in the final effect of the design. It can be safely set forth as a rule [Pg 59] that the rougher the texture of the brick used, the rougher and wider should be the joint. For the smooth-faced brick the joint should be small and finished with a tool. For a rough-faced brick the joint should be large and rough in texture. The various forms of brick joints in common use are shown in the illustrations.

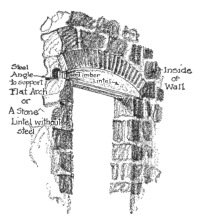

16.

Lintel Construction

In the construction of lintels in either the wall of brick or stone, the introduction of either wood or steel is necessary for strength. Where the openings are less than 4 feet in width, timber lintels are used at the back of the lintel or arch, which are cut to serve as a centre for a rowlock or keyed arch. Any face brick may be supported by using a small steel angle. Where lintels are wider than 4 feet, steel I-beams, channels, or angles must be used. Where the span is more than 6 feet, it is necessary to build in bearing plates for the support of the ends of lintels.

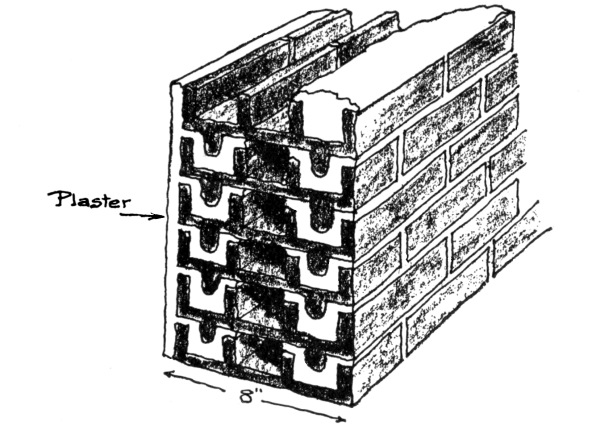

It would be well to mention here the new type of brick wall which is being advertised widely by the Common Brick Manufacturers Association. This wall is claimed to be very suited to the small house, and no doubt it would be, if it were possible to secure the co-operation of the local mason. [Pg 60]

This type of brick wall is built hollow, and arranged as shown in the drawings. There are no continuous mortar joints from the exterior to the interior through which moisture can penetrate. There are many features of advantage which the following table shows, but, unfortunately, not all mason contractors will give the owner the advantage of the reduction in cost which this wall permits.

| 8" IDEAL WALL | 12" IDEAL WALL | |

| COMMON BRICK | ||

For 100 square feet of wall, 8 inches thick, the following materials are required:

| FOR SOLID BRICK WALL | |

| 1,233 | bricks. |

| 2.6 | sacks of cement. |

| 2.9 | bags of hydrated lime. |

| .7 | cubic yards of sand. |

| 9 | hours of a bricklayer’s time. |

| 10 | hours of a mason’s helper’s time. |

| FOR IDEAL ALL ROLOK WALL | |

| 904 | bricks. |

| 1 | sack of cement. |

| 1.2 | sacks of hydrated lime. |

| .3 | cubic yards of sand. |

| 8 | hours of bricklayer’s time. |

| 6 | hours of a mason’s helper’s time. |

The past decade has seen an increasing use of hollow terra-cotta tile as a building material for the walls of the small house. It has many advantages which have made its popularity increase, such as its larger and lighter construction unit, reducing the labor of setting, its cellular wall features, and its availability. There is much information published by the manufacturers describing the correct construction, but always, of course, with an eye to advertising the material.

However, there has been much conflicting testimony made concerning the practicability of hollow-tile construction, and some of the disadvantages should be noted. As a rule, they have proved to be strong enough to support the weight of the structure imposed upon them, but in the Southwest, where tornado winds are prevalent, these walls have been criticised because of their lack of stability and their porosity. Hollow-tile walls have been thrown down while those constructed of brick have stood, and driving rain-storms frequently make the inside of the walls wet.

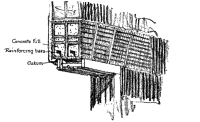

The stability can be increased by filling them with concrete, but the allowable strength cannot be considered to have been raised. Tests have shown that this filling does not increase the strength, because of the difference in the elasticity of the two materials.

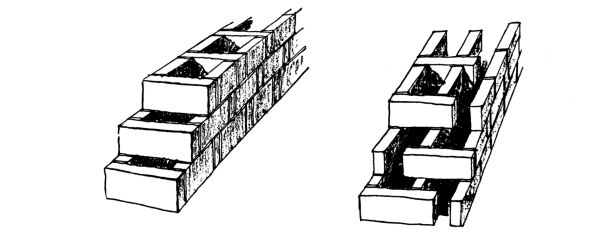

There are two types of hollow terra-cotta blocks, one which builds with cells vertically and the other which builds with cells horizontally. [Pg 62] This latter is generally an interlocking tile. The strongest wall for vertical-load resistance is built with vertical-cell tiles.

| 20. | 18. | |

| Support of floor-joists | Hollow-tile wall Cells Horizontal |

All hollow-tile should be laid in Portland-cement mortar, and the webs should be arranged so that they build over one another. The bearing of floor beams and girders on walls, built with blocks of vertical cells, should be made by covering the tile with templates of terra-cotta slabs, filling them with concrete or protecting them with plates of steel. Where chases are required for pipes they should not be cut into the wall, but special blocks should be used to build around them. All lintels under 5 feet should be constructed with tile arches, reinforced with concrete and steel rods inside of their webs.

17.

Vertical cell Hollow-tile wall

21.

Construction

of lintel

Brick Veneered

Hollow-tile wall

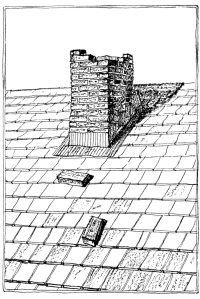

In order to prevent the penetration of moisture the mason should butter all joints on the inside and outside edges, leaving an empty space between, in order to insulate against the transmission of moisture through the joint. To prevent the collection of mortar in the cells of the tile, due to droppings during construction, the spreading of metal [Pg 63] lath over the top of each course of tile will accomplish this and also make the strength of the wall greater. Although it is often recommended that hollow-tile be plastered directly upon the interior, yet this is not safe in those sections of the country where there are driving rain-storms. For this reason it is advisable to fur them on the interior. It is also recommended that a waterproofing compound be added to the stucco applied to the exterior. Another fact should be observed: namely, that all door and window frames, since they are of wood, will tend to shrink and thus open up the joints and permit the leakage of rain-water. Oakum should be stuffed behind all brick moulds to prevent this. Care should also be taken to make drips under all sills, so that no water will leak into the interior of the wall. All belt courses [Pg 64] should also have steep washes. Stucco should not be carried down to the grade level, but a course of solid material, like brick, concrete, or stone, should be built at this point.

It is sometimes customary to veneer walls of hollow-tile with brick, especially those tiles which are of the interlocking type, since a better bond can be secured. In any case, any brick veneer should be bonded to the backing with a row of headers every 16 inches, or be attached with metal ties. This veneering should not be considered as part of the required thickness of wall.

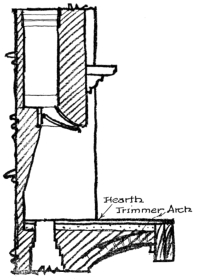

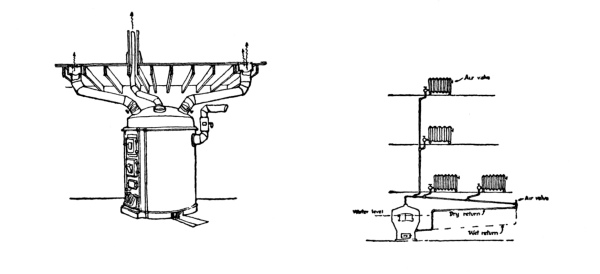

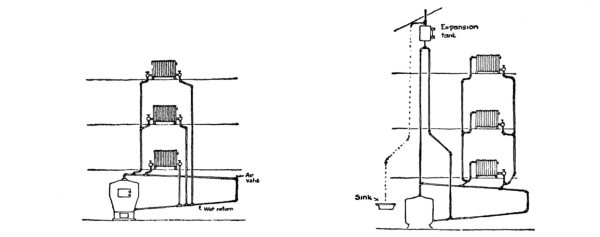

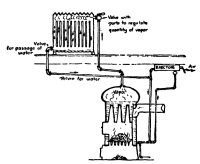

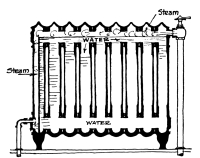

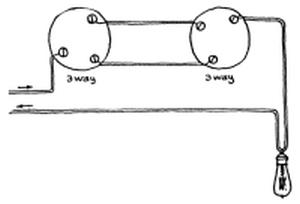

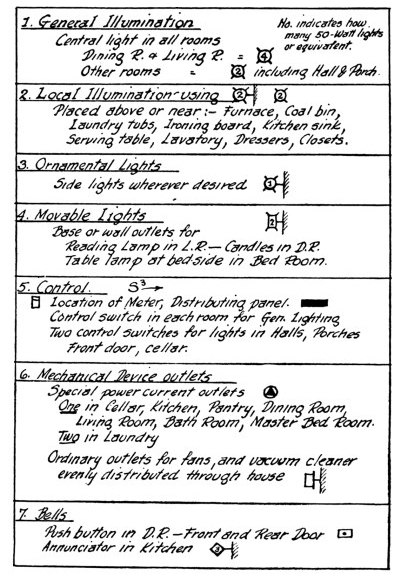

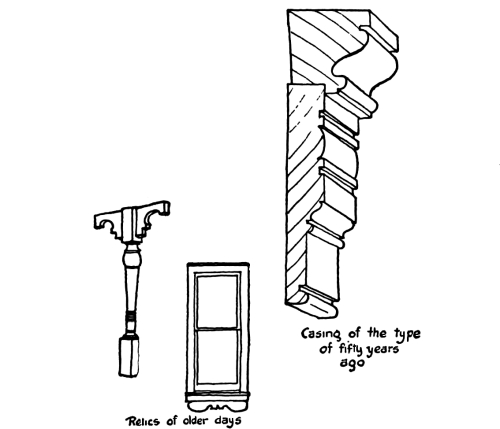

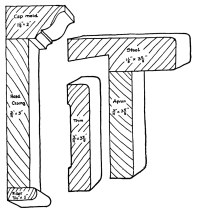

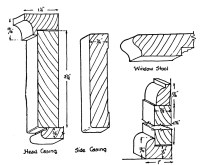

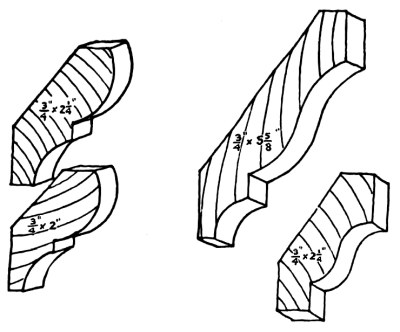

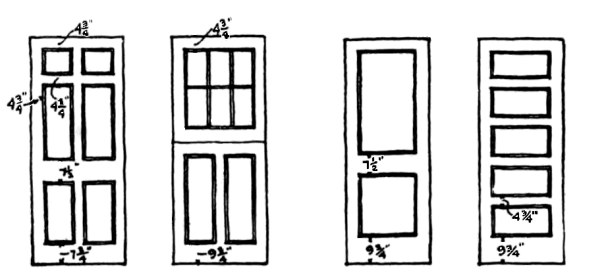

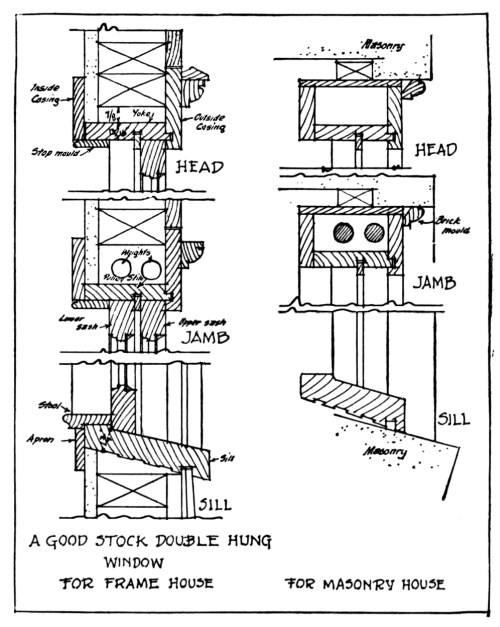

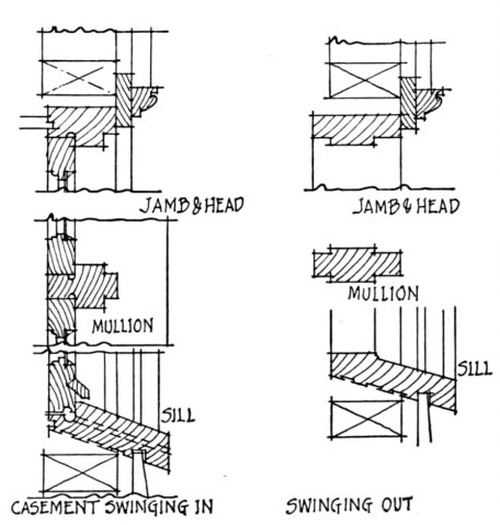

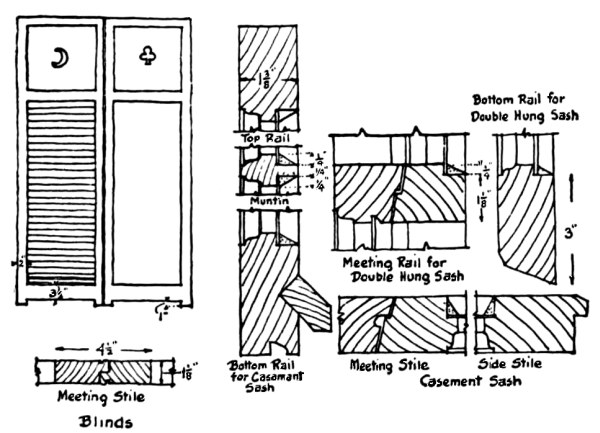

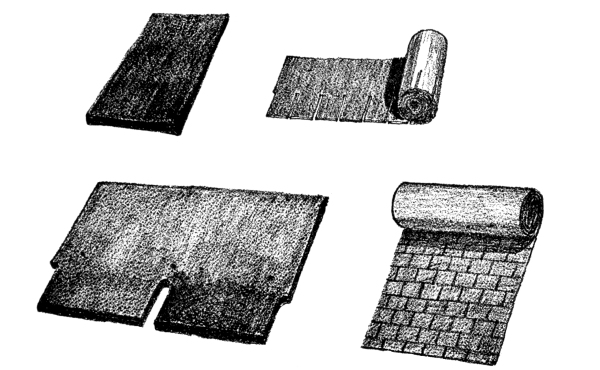

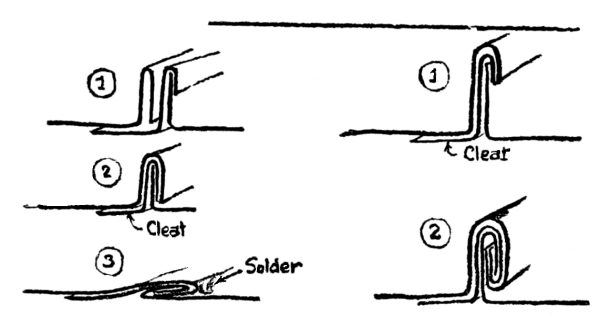

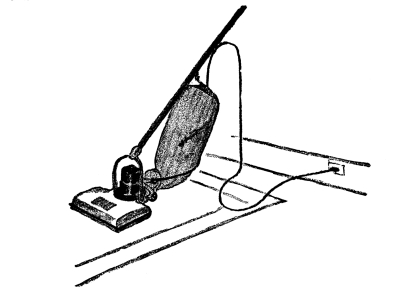

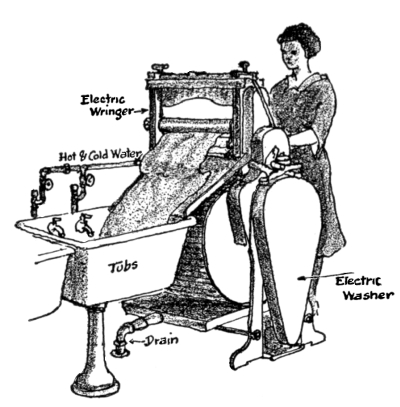

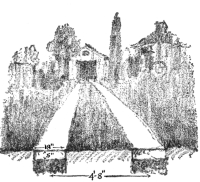

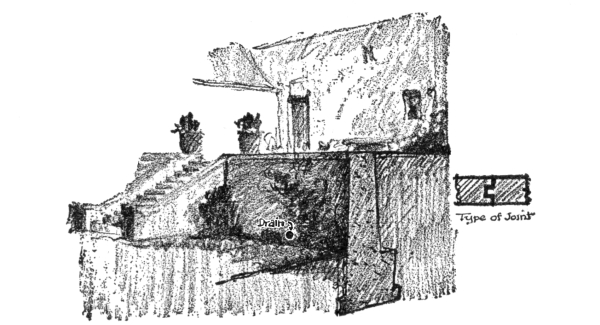

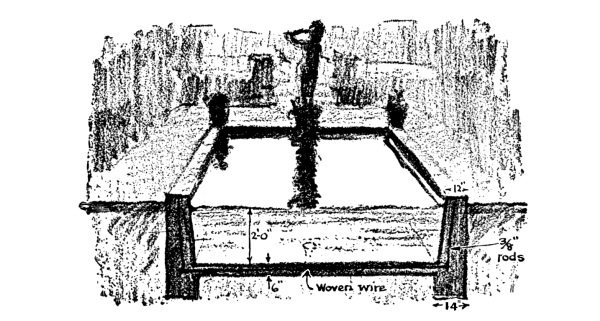

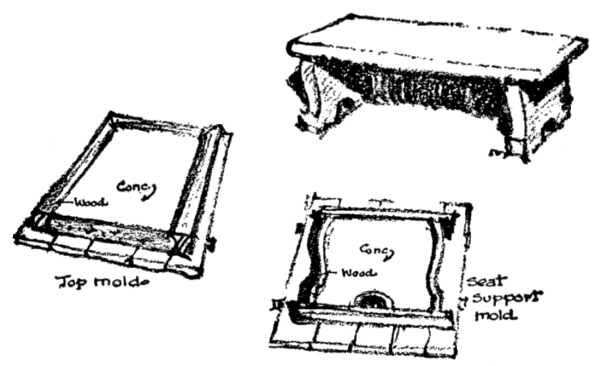

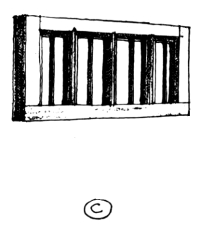

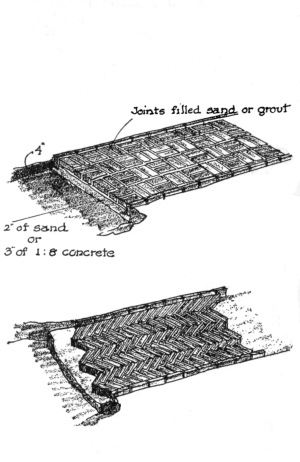

The thickness of hollow-tile walls should be the same as for walls of brick. The construction of light 10-inch and 8-inch walls, while strong enough as a substitute for a frame dwelling, is not strong against weather or fire. The only justification for thin walls is the slightly reduced cost of materials. Hollow blocks, as a rule, are not used for foundations, although they are satisfactory under buildings not higher than 40 feet. It is better to fill such walls with concrete and waterproof them on the exterior.