THE MAIN POST-OFFICE, PHILADELPHIA.

Title: The Pneumatic Despatch Tube System of the Batcheller Pneumatic Tube Co.

Author: Birney C. Batcheller

Release date: December 3, 2020 [eBook #63952]

Most recently updated: October 18, 2024

Language: English

Credits: deaurider, Brian Wilcox and the Online Distributed

Proofreading Team at https://www.pgdp.net (This file was

produced from images generously made available by The Internet

Archive)

Transcriber’s note:

The cover image was created by the transcriber and is placed in the public domain.

THE MAIN POST-OFFICE, PHILADELPHIA.

ALSO

FACTS AND GENERAL INFORMATION

RELATING TO PNEUMATIC

DESPATCH TUBES

BY

MECHANICAL ENGINEER

PHILADELPHIA

PRESS OF J. B. LIPPINCOTT COMPANY

1897

Copyright,

1896,

by

B. C. Batcheller.

| CHAPTER I. | |

|---|---|

A BRIEF HISTORICAL SKETCH. |

PAGE |

Early Records |

9 |

Practical beginning of the Art—The London Pneumatic Telegraph |

10 |

The Siemens Circuit System |

14 |

Recent Improvements in the London System |

16 |

An Underground Pneumatic Railway for Transportation of Mail | 19 |

The Berlin Pneumatic Telegraph |

20 |

The Paris Pneumatic Telegraph |

22 |

The Pneumatic Telegraph of other Cities |

25 |

Pneumatic Tubes in America |

25 |

| CHAPTER II. | |

THE PNEUMATIC TRANSIT COMPANY AND THE FIRST PNEUMATIC TUBES FOR THE TRANSPORTATION OF UNITED STATES MAIL. |

|

Organization |

28 |

Aim and Object of the Company |

28 |

The Clay-Lieb Patents |

30 |

Franchises and First Government Contract |

33 |

Search for Tubes |

34 |

Method of Manufacturing Tubes |

35 |

Laying and Opening the Tubes for Traffic |

37 |

| 4 Description of the Tubes, Method of Laying, etc. |

38 |

The Air-Compressor—Method of Circulating the Air |

40 |

Terminal Apparatus |

42 |

The Sender |

43 |

Sub-Post-Office Receiver |

44 |

Main Post-Office Receiver |

47 |

The Carrier |

50 |

Operation of the Tubes |

52 |

Benefits of the System |

54 |

| CHAPTER III. | |

THE SYSTEM AND APPARATUS OF THE BATCHELLER PNEUMATIC TUBE COMPANY. |

|

General Arrangement and Adaptability of the System |

57 |

The Size of Tubes |

64 |

System of very Large Tubes |

65 |

General Arrangement of Apparatus in the Stations—Two-Station, Two-Compressor Line |

69 |

Two-Station, One-Compressor Line |

72 |

Three- to Eight-Station Line |

74 |

Sending Apparatus |

79 |

Sending Time-Lock |

84 |

Intermediate Station Time-Lock |

88 |

Electro-Pneumatic Circuit-Closer |

91 |

The Open Receiver |

94 |

The Closed Receiver |

99 |

The Intermediate Station Receiving and Transfer Apparatus |

106 |

Carriers |

115 |

Air Supply |

117 |

Fans |

117 |

Blowers |

117 |

Air Compressors |

118 |

| 5 The Tube, Line Construction, etc. |

122 |

| CHAPTER IV. | |

FACTS AND GENERAL INFORMATION RELATING TO PNEUMATIC TUBES. |

|

Definitions |

124 |

Intermittent and Constant Air-Current |

125 |

Laws Governing the Flow of Air in Long Tubes |

126 |

Law of Pressure |

128 |

Uses of Pressure Curves |

130 |

Law of Velocity |

130 |

Characteristics of the Velocity Curve |

132 |

Uses of Velocity Curves |

133 |

Quantity of Air Used |

134 |

Temperature of the Air |

135 |

Horse-Power |

136 |

Efficiency |

137 |

Pressure and Exhaust Systems |

138 |

Laws expressed in Mathematical Formulæ |

141 |

Moisture in the Tubes |

142 |

Location of Obstructions in Tubes |

143 |

I have been prompted to prepare this book by the frequent inquiries made regarding the details of our system of pneumatic tubes. These inquiries have come from people interested in our company, from others interested in companies that have purchased the right to use our apparatus, from people desirous of becoming interested in a pneumatic-tube business, from would-be purchasers of pneumatic tubes, and from people interested in pneumatic tubes from a scientific, engineering, or mechanical point of view. This book is not intended to be a treatise on pneumatic tubes. In the first chapter I have given a brief sketch of what has been done in the application of pneumatic tubes from the earliest records to the present time. The second chapter contains a description of the postal tubes in Philadelphia, and the third chapter describes our system in detail. Following this is a short chapter explaining the theory of pneumatic tubes, or the theory of the flow of air in long pipes, stating the more interesting facts and relations in as plain and simple a8 manner as possible. Mathematical formulæ have been purposely avoided.

Several plates showing the Philadelphia postal line have been kindly loaned to me by the Engineers’ Club of Philadelphia. They formerly appeared in a paper read by Mr. A. Falkenau before that club. I have also to thank the and Drill Co., the B. F. Sturtevant Co., the Wilbraham-Baker Blower Co., and J. B. Stewart for the use of electrotypes of their machines.

B. C. B.

October 6, 1896.

—The earliest reference to pneumatic transmission of which we find any record is a paper presented to the Royal Society of London, by Denis Papin, in the year 1667, entitled “Double Pneumatic Pump.” His plan was to exhaust the air from a long metal tube by two large cylinders. The tube was to contain a piston, to which a carriage was attached by means of a cord. The “American Cyclopædia” goes on to say, “More than a century elapsed before any further effort in this direction was made. Paucbrouke’s ‘Dictionnaire Encyclopédique des Amusements des Sciences’ (1792) gives a description of a machine by M. Van Estin, by means of which a hollow ball holding a small package was propelled by a blast of air through a tube several hundred feet in length, and having many curves. This plan seems, however, to have been more an amusement than an attempt to introduce an industrial scheme. With more regard to practical results, Medhurst, an engineer of London, published a pamphlet on the subject in 1810. He proposed to move10 small carriages on rails in air-tight tubes or tunnels, by compressed air behind, or by creating a partial vacuum in front. In 1812 he published another pamphlet; but the plan was not put into successful operation, principally from insufficient means of exhaustion. About 1832 he proposed to connect the carriage inside such a tube with a passenger carriage running on the top of the tube; and, although the latter project has never been commercially successful, it was the first to be practically attempted. More than a score of patents were taken out on the Continent and in England and America, none of which met with any practical success. Returning to the original idea of Denis Papin, inventors attempted to accomplish pneumatic transmission by moving the load inside the tube, and in course of time achieved success. In France MM. Jarroux and Taisseau presented a project for atmospheric telegraphy before the Academy of Sciences, and they were succeeded in the same direction by MM. Brochet and Ardor.”

—London has the honor of being the first city to have a practical system of pneumatic telegraphy. The first tubes were installed by the Electric and International Telegraph Company, the work being planned and carried out by their engineer, Mr. Josiah Latimer Clark, in 1853 and 1854. The first tube to be laid was one and one-half inches in diameter, and extended from the central station, Founder’s Court, Lothbury, to the Stock Exchange, Throgmorton Street, a distance of two hundred and twenty yards. The tube was operated intermittently by connecting it to a vacuum chamber at the11 central station. Carriers were sent only in one direction. A steam-pump was used to maintain the vacuum. Much experience was gained from the use of this first tube. In 1858 some improvements were made by Mr. C. F. Varley, and I can best describe them by quoting from the discussion of Mr. Carl Siemens’s paper on “Pneumatic Despatch Tubes: The Circuit System” before the Institution of Civil Engineers, as recorded in the minutes of that society. “Later, about the year 1858, when a pipe two and one-fourth inches internal diameter was extended from Telegraph Street to Mincing Lane, thirteen hundred and forty yards in length, the traffic was so considerable that it was found desirable to have the power of sending messages in both directions. To effect that a smaller pipe, one and one-half inches in internal diameter, was laid between Telegraph Street and Mincing Lane, with a view to carrying the vacuum to the latter station, so as to take messages in the opposite direction. This smaller pipe was found to so wiredraw the current that the pipe would not work, the leakage past the carrier being too considerable; and accordingly a large chamber was built in the basement floor or kitchen at the corner of Mincing Lane and Leadenhall Street to collect power or vacuum for bringing the messages from Telegraph Street to Mincing Lane. This chamber was constructed of timber, fourteen feet by twelve feet broad and ten feet high, and was covered with lead. It was not strong enough to withstand the pressure; for one day, a carrier having stuck half-way, and when there was a higher vacuum than usual,—viz., twenty-three inches of mercury,—it collapsed with a loud report. At the time12 the landlord of the house happened to be dining in the next room, and he suddenly found himself, his table, dinner, and the door, which was wrenched off its hinges, precipitated into the room amongst the débris of the chamber. The windows were forced inwards, and those on the opposite side of Mincing Lane and Leadenhall Street were drawn outwards. The damage was considerable. This accident put an end, for a time, to the attempt to send telegraph messages by means of a vacuum conveyed through this smaller pipe. About that time he (Mr. Varley) became the engineer-in-chief of the Electric Telegraph Company, and got permission from the directors to introduce a new system,—viz., compressed air,—though many persons contended that it would be impossible to blow messages through a pipe, because all attempts to blow air through long pipes had utterly failed; while others said that, if messages were sent, they would go much slower than with the vacuum.... In his (Mr. Varley’s) apparatus, for he was the first to introduce compressed air, the reverse was found to be the case, and for this reason: the tube did not consume power until a message was about to be forwarded; and in a tube thirteen hundred yards in length, and two and one-fourth inches in diameter, fifteen seconds elapsed before the vacuum was felt at the distant end after communication had been established with the exhausted chamber at the engine end of the tube, consequently the carrier did not start until after fifteen seconds had elapsed. When a message was sent by compressed air, it was sent from the end at which the power was applied, and the carrier started at once, thus gaining a start of fifteen13 seconds; now, inasmuch as the air in the tube had to be compressed, it started at a very high velocity, and when it reached the other end the compressed air in expanding gave it a higher velocity. The result was, in thirteen hundred and forty yards, from Telegraph Street to Mincing Lane, the carriers were drawn by vacuum, on an average, in from sixty to seventy seconds, and were propelled by compressed air in about fifty or fifty-five seconds, the difference of pressure in each case being nearly equal.”

The first one and one-half inch tubes laid under the direction of Mr. Clark were of iron with screwed joints. They gave much trouble from roughness upon the interior, which wore the carriers very rapidly, and from water that was drawn in through leaky joints. When the extensions were made in 1858 and afterwards, two and one-fourth inch lead tubes were used with plumber’s joints made over a heated mandrel, which made the joints very smooth upon the interior. The carriers were of gutta percha in the form of a cylinder closed at one end and fitted with a cap at the other. The outside was covered with felt or drugget.

When a carrier was to be despatched, a signal was sent to an attendant at the pump end of the tube, who closed that end and connected the tube to an exhausted chamber by opening a valve. As soon as the carrier arrived, he closed the valve and opened the tube, which allowed the carrier to drop out. Mr. Varley improved the method of operating the valves by making the air pressure do the work by means of cylinders and pistons when the attendant pressed a button. He also improved the carriers by doing14 away with the cap and using in its place an elastic band to hold the messages in place.

We have seen that Mr. Clark designed the first tube used in connection with the telegraph, and that it was a single tube, operated in one direction only by vacuum, being operated only when there were messages to send. This was extended and improved by Mr. Varley, who increased the diameter of the tubes from one and one-half inches to two and one-quarter inches, and operated them in both directions, using vacuum for sending in one direction and compressed air for sending in the other. The air current was maintained in the tubes only when messages were sent.

Great credit is due to Sir Rowland Hill, who, in 1855, had a proposed method of conveying mails in the city of London, through nine- and thirteen-inch tubes, thoroughly investigated. It was decided at this time that the saving in time over that consumed by mail carts would not warrant the expense of installing such a system.

—The next progressive step was made by Siemens Brothers, of Berlin, who proposed a new system called the “circuit system,” in which two tubes were used, the up tube being connected to the down tube at the distant end. The air was compressed into one end of the circuit and exhausted from the other, and, furthermore, it was kept in constant circulation. Carriers were despatched by inserting them into the air-current without stopping it, in one direction in one tube or in the opposite direction in the other. Another feature of the Siemens system was the placing of three or more15 stations on one double line of tubes. Carriers could be stopped at an intermediate station by inserting in the tube an obstructing screen which the air would pass but which would stop a carrier. This system is described in detail in a paper read by Mr. Carl Siemens before the Institution of Civil Engineers, London, November 14, 1871, Vol. XXXIII. of the Proceedings. The Siemens apparatus for sending and receiving carriers consisted of two short sections of tube attached to a rocking frame so that either could be swung by hand into line with the main tube. One of the tube sections was open at both ends, and was used for despatching carriers. A carrier was placed in it, then it was swung into line with the main tube, when the air-current passing through swept the carrier along. The other tube section contained a perforated screen in one end and was used to receive carriers. When it was in line with the main tube and a carrier arrived, the carrier was stopped by striking the screen, then the tube section was swung to one side and the carrier pushed out with a rod. A by-pass was provided for the air around the apparatus so that its flow was not checked when the tube section was swung. When a carrier was despatched to an intermediate station, a signal was sent, and then the section of tube containing the screen was interposed in the line of the tube to stop the carrier upon its arrival. The carriers used by Mr. Siemens were made of gutta-percha, papier maché, or tin, closed at one end and fitted with a cover at the other. They were covered with felt, drugget, or leather. The front ends of the carriers were provided with thick disks of drugget or16 leather fitting the tube loosely, and the opposite ends were surrounded with pieces of the same material attached to them like the leather of an ordinary lifting pump.

In 1869 Messrs. Siemens Bros. received an order from the British government to install an experimental line of tubes between the central telegraph station and the general post-office. This was completed in 1870, and after a half-year’s test it was extended to Fleet Street, and finally to Charing Cross. The tubes were of iron, three inches in diameter, with flanged and bolted joints. It was found, after some experience, that there was no advantage in the circuit, so the up and down tubes were separated at Charing Cross Station and worked independently.

—In 1870 Mr. J. W. Wilmot designed a double sluice-valve by means of which carriers could be despatched continuously without stopping the flow of air in the tubes. Mr. Wilmot further increased the working capacity of pneumatic tubes when, in 1880, he invented an intermediate automatic signaller, by means of which a carrier signals the passage of a given point on its journey, showing that the section of the tube traversed is clear, thus allowing a second carrier to be despatched before the first has reached its destination.

From this beginning the English system developed into what has been termed a “radial system;” that is to say, one principal and several minor central pumping stations have been established, and from these radiate tubes to numerous sub-stations (see Fig. 2). Some of the stations are connected with double lines for sending in opposite directions. The out-going tube from the pumping station is worked17 by compressed air, and the incoming tube by exhaustion. Other stations are connected by single tubes, and they are operated alternately by compression and exhaustion. Intermediate stations are located on some of the lines. For the central station the Varley valves were found too expensive and troublesome to keep in order, so they were replaced by the Wilmot double sluice-valves, which are operated manually. In recent years the sluice-valves have been in turn replaced by what are termed D-boxes, a simpler form of apparatus. At the sub-stations the tube terminates in a box into which the carriers drop. As the system has been gradually extended, tubes two and three-sixteenths inches inside diameter have been used for short lines, and three-inch tubes for long lines. The tubes are of lead laid inside a cast-iron pipe which serves as a shield, protecting them from injury. They are laid in twenty-nine18 foot sections, the joints being made by soldering over a steel mandrel, which is afterwards drawn out by a chain. The joints in the cast-iron protecting pipe are made by caulking with yarn and lead. “Electric signals are used between the central and sub-stations, consisting of a single stroke bell and indicator, giving notice of the arrival and departure of carriers, and to answer the necessary questions required in working. Where there are intermediate stations the tubes are worked on the block system, as if it were a railway. Experience shows that, where great exactness of manipulation cannot be obtained, it is necessary to allow only one train in each section of a tube, whether worked by vacuum or pressure. But where there is no intermediate station, and where the tube can be carefully worked, carriers may be allowed to follow one another at short intervals in a tube worked by vacuum, although it is not perfectly safe to do so in one worked by pressure. In working by pressure it has been found that, notwithstanding a fair interval may be allowed, carriers are apt to overtake one another, for no two carriers travel in the same times, because of differences in fit, unless they are placed end to end. If signalling be neglected and a carrier happens to stick fast, being followed by several others, a block will ensue which it will be difficult to clear, while the single carrier could readily have been dislodged.” (Proceedings Institute of Civil Engineers, London, Vol. XLIII. p. 61.)

No changes have been made in the carriers from those used in the early experiments which have already been described.

The London system has grown until it now includes no less than forty-two stations and thirty-four miles of tubes. Similar systems have been established in connection with the telegraph in Liverpool, Manchester, Birmingham, Glasgow, Dublin, and New Castle. The tubes give a cheaper and more rapid means of despatching telegrams between sub-stations and central stations than transmission by telegraph, and local telegrams can be delivered in the sender’s handwriting.

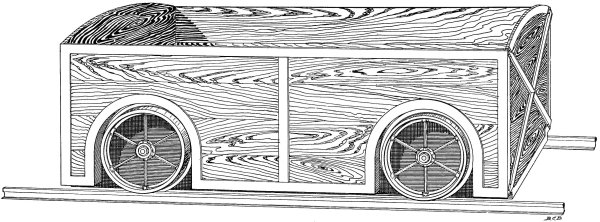

—Before describing the systems used in the cities on the Continent of Europe, we must notice a very large pneumatic tube, or more properly called a pneumatic tunnel railway, constructed in London for the transportation of mail from one of the railway stations. The first railway of this type was constructed in 1863 by the Pneumatic Despatch Company of London, and extended from Euston to the district post-office in Eversholt Street, a distance of about eighteen hundred feet. The tunnel was flat on the bottom, having a D-shaped cross-section two feet eight inches by two feet eight inches. The carriers or carriages were cradle-like boxes fitting the tunnel, and they moved at a speed of seventeen miles per hour, carrying fifteen mails daily. In 1872 two similar but larger tunnels were built from Euston Station to the general post-office, a distance of fourteen thousand two hundred and four feet, or two and three-quarters miles. One was for the up traffic, and the other for the down. The tunnels were four and a half feet wide by four feet high, the straight part being built of cast iron and the20 bends of brick. The line was operated by a fan twenty-two feet in diameter, which forced the air into one tunnel and exhausted it from the other, producing a vacuum of ten inches of water, or six ounces per square inch. The carriages occupied twelve minutes in traversing the tunnels, and there was one gradient of one to fourteen. The carriages were ten feet four inches long and weighed twenty-two hundredweight. “The system was able to transport over the whole line, allowing for delays, an average of a ton per minute.” The system was used to transport the mails in bulk, but it was found to be slow and unsatisfactory, and was very soon abandoned.

—In 1863 the Prussian government applied to the firm of Siemens and Halske, of Berlin, for a proposition to establish a system of pneumatic tubes in that city for the transmission of telegraph messages. A proposition was accordingly submitted, and the work was completed in 1865. This first line consisted of two parallel wrought-iron tubes, two and one-half inches in diameter, one tube being used exclusively to send in one direction, and the other in the opposite direction. They extended from the telegraph station to the Exchange, requiring a total length of five thousand six hundred and seventy feet of tube. The two tubes were looped together at the Exchange, and a continuous current of air was made to circulate in them by a double-acting steam air-pump, located at the telegraph station. Air was compressed into one end of the tube and exhausted from the other. With nine inches of mercury pressure and vacuum the passage was made in ninety-five seconds to the Exchange, and21 seventy-five seconds from the Exchange. It was similar to the line established in London by the same firm some years later, which we have already described, except that there was no intermediate station. After the line had been in use for a year and a half, the Prussian government had it extended, first, from the telegraph station to the Potsdam gate, with an intermediate station at the Brandenburg gate. After these preliminary experiments, further extensions were made until a net-work of tubes extended over the city of Berlin, including no less than thirty-eight stations and over twenty-eight miles of tubes; but in laying down this net-work a departure was made from the Siemens system. Air was no longer kept constantly circulating, but power was stored up in large tanks, some being exhausted and others filled with compressed air, which was used when required to send messages, usually at intervals of five or fifteen minutes. The exhausted tanks were permanently connected with the closed tubes, which were opened when required for use. The tanks containing compressed air were connected to the tubes when messages were sent. The internal diameter of the tubes was 2.559 inches. They were laid in circuits, including several stations in a circuit, and the carriers travelled only in one direction around the circuit. Some outlying stations were connected by a single tube with central pumping-stations, these single tubes being worked in both directions. Years of experience have shown the disadvantages of this circuit-system, and it has gradually been changed to the radial system, such as is used in London, until now nearly all the stations are grouped around the central pumping-stations, to which they are connected22 directly by radiating tubes. The Siemens apparatus has been replaced by simpler and less expensive valves and receiving-boxes, the latest form of which was designed and patented by Mr. Josef Wildemann.

—We will now glance at the system used in Paris, which has some novel features. In 1865 it was decided to establish a system, and the first experimental line, from Place de la Bourse to the Grand Hôtel, on the Boulevard des Capuciens, was laid in 1866. Instead of using a steam-engine to drive an air-compressor or exhaust-pump, air was compressed in tanks by displacement with water from the city mains. In 1867 this line was extended to Rue de Grennelle St. Germain, with an intermediate station at the Rue Boissy d’Anglais, and another line with stations at Rue Jean Jacques Rousseau, Hôtel du Louvre in the Rue de Rivoli, the Rue des Saints Pères, and terminating in the central station. In 1868 the system was changed to a polygonal or circuit system by removing the station in the Rue de Rivoli to the Place du Théâtre Français and connecting the latter directly with the Bourse. Other changes and extensions were made in 1870 and 1871, until three polygons or circuits were formed, with five or six stations in each circuit, and several outlying stations were connected by independent tubes. In the middle of the year 1875 seventeen stations had been connected and plans were made for twenty-one more. Instead of maintaining an air-current around each circuit by machinery located at one of the stations on the circuit, at least three of the five or six stations comprised in the circuit have means of supplying compressed air or23 of exhausting it, and each side of the polygon, or section of the circuit between two stations, is operated independently of the rest of the circuit (see Fig. 3). Carriers are sent on from station to station around the circuit, either by compressed air from the last station from which they were sent or by means of exhaustion at the next station towards24 which they are moving. The carriers are made up in trains of from six to ten, with a piston behind them that fits the tube closely and forces them ahead. Each carrier is addressed by means of a label for its destined station. Trains are despatched around the circuits at stated times, usually at fifteen-minute intervals. As they arrive at the various stations, carriers are taken out and others put in, and the trains sent on their way. The carriers consist of iron cylinders, closed at one end, with a leather case that slides over them and closes the open end. They weigh, when filled with thirty-five messages, twelve and one-half ounces, and they will travel about twelve hundred miles before the leather cover is so worn that it must be thrown away. The pistons are made of a wooden cone, covered with iron, and having a “cup-leather” upon the rear end that fits the tube closely. The sending and receiving apparatus consists of sections of tube closed at one end, having a door on the side, through which carriers are inserted or despatched. A peculiar form of fork is used for picking them out. The air is controlled by valves opened and closed by hand.

Several methods are used to compress and exhaust the air. The most novel method consists in having tanks in which a partial vacuum is produced by allowing water to flow out of them into the sewer, or in having the air compressed by allowing water from the city mains to flow into the tanks and displace the air. Water jets have also been used, operating similar to a steam-injector. At some of the stations water turbines drive the air-pumps, and at others steam-engines are used.

The tubes of the Paris system are of wrought iron, in lengths of from fifteen to twenty feet, the joints being made with flanges and bolts. The interior diameter is 2.559 inches with a maximum variation to 2.519 inches. The bends are made with a radius of from six to one hundred and fifty feet. Water frequently gives trouble by accumulating in the tubes. Traps are placed at low points to drain it off.

The speed of the trains of carriers in the Paris tubes is from fifteen to twenty-three miles per hour, and the average time that elapses from the receipt of a message until its delivery is from forty to forty-five minutes.

—A system similar to the one just described is used in Vienna. It differs some in details of apparatus, but the carriers are despatched around circuits in trains, stopping at each station, where some carriers are removed and others inserted. Brussels also is not without its system of pneumatic tubes for the transmission of telegrams.

—Turning our attention now to our own country, we cannot pass without mention some experiments of Alfred E. Beach with pneumatic railways, made nearly thirty years ago. His first experiment upon a large scale was made at the American Institute Fair held in New York City in 1867. Here he had constructed a circular wooden tube, one hundred and seven feet long and six feet in diameter. A car that would seat ten people ran upon a track laid down inside the tube, and was propelled by a helix fan ten feet in diameter, making two hundred revolutions per minute.26 He next tried his railway upon a practical scale, constructing an eight-foot tunnel for two hundred feet under Broadway, starting at the corner of Warren Street. A car was propelled by a large rotary blower located in the basement of a building near by. The blower was kept constantly running, and the car was sent alternately in one direction and then the other by changing valves at the blower. Few people know that this experimental line still exists under Broadway as Mr. Beach left it.

The most extensive use of small pneumatic tubes in this country has been in our large retail department stores for despatching cash to and from a centrally located cashier’s desk. Seamless brass tubes are usually used, and, since the tubes are short, the air is either compressed or exhausted by means of positive rotary blowers. At the outlying stations the tubes are usually open to the atmosphere, while at the central station simple forms of valves are used for sending and receiving. An outgoing and a return tube are always used, and the air is kept in constant circulation. The carriers are of metal with felt packing rings and open on the side. These cash-carrying systems have come into use during the past twenty-five years.

The Western Union Telegraph Company uses small tubes to transmit its messages to a considerable extent in some of our large cities. In 1876 four lines were laid in New York City from the main office on Broadway: two to the branch office at No. 14 Broad Street, one to 134 Pearl Street, and one to the Cotton Exchange. Since then this company has laid a double line about two miles in length under Broadway to its up-town office. It also uses27 tubes to send messages from the receiving desks to the operating rooms within the buildings.

Many of our large hotels use pneumatic tubes to transmit messages to the different floors and offices of the buildings, taking the place of messenger, or bell boys, who formerly did this service.

We call especial attention to the fact that in all the systems that we have mentioned which are in use both in this country and in Europe, none of the tubes are larger than three inches internal diameter; also that in all the systems, except in Paris where the carriers are despatched in trains, the carriers are so light and move so slowly that they can be stopped by allowing them to come in contact with some solid object, such as a box into which the carriers drop. Very few of the tubes are more than two miles in length, and most of them are less than one mile. A speed of more than thirty miles per hour has seldom been attempted, and usually it is much less than this.

—Early in the year 1892 several Philadelphia gentlemen organized a corporation and obtained a charter in the State of New Jersey to construct, lay, and operate pneumatic tubes for the transmission of United States mail, packages, merchandise, messages, etc., within the States of New Jersey and Pennsylvania. The corporation was styled the Pneumatic Transit Company. Mr. William J. Kelly was elected president, and the company is still under his management.

WM. J. KELLY,

President of the Pneumatic Transit Co.

Fig. 4.

Fig. 5.

SIX-INCH PNEUMATIC TUBES IN PROCESS OF BORING AT THE SHOP OF A.

FALKENAU, PHILADELPHIA, PA.

—When the Pneumatic Transit Company was formed, it was the aim and object of its promoters to construct an extensive system of underground tubes in the City of Philadelphia which would serve, first, for the rapid transmission of mail, second, for the quick delivery of merchandise from the large retail stores, third, for the transmission of telegrams or messages within the city limits, and, fourth, to conduct a general local express business with greater speed than can be done in any other manner. To accomplish this result sub-stations were to be located six or eight blocks apart throughout a large portion of the city, and a central station was to be established in the centre of the business29 section. Stations were also to be established in the more important retail stores and large office buildings, and all of the stations were to be connected by tubes forming one large system.

For the transmission of mail it was planned to connect the main post-office with the sub-post-offices by tubes of a size large enough to carry all of the first-class and most of the other classes of mail matter. The sub-post-offices would be divided into groups, all of the offices in one group being connected to the same line, which would terminate at the main post-office. Most of the business would be between the main and individual sub-offices; in addition to this there would be some local mail sent between the sub-offices which, for offices in the same group, could be despatched directly without passing through the main office. The advantages to be gained by the use of these tubes over the present wagon service are very apparent. It places all the sub-post-offices in almost instant communication with the main office and with each other.

It was a part of the general plan to lay tubes from the main post-office to the railway stations, thereby hastening the despatch and receipt of mails to and from the trains.

It was expected that the bulk of the business would consist in the delivery of parcels from the retail stores to the private houses in the residence sections of the city. Of course it would not be practicable to lay a tube to each house, but with a station not more than four or five blocks away, the parcels would be sent through the tube to the nearest station, and then delivered by messengers to the houses with a minimum loss of time. Ladies could do their30 shopping and find their purchases at home when they returned.

The same tubes used for parcel delivery would also be used for a district messenger service. With numerous public stations in convenient locations, all the advantages of the European system would be realized in the quick despatch of letters and telegrams. Every one knows how much time is consumed by district messenger-boys in the delivery of messages, especially when they have to go long distances, and no argument is required to show that this time would be very much reduced by the use of pneumatic tubes, besides prompt delivery would be made much more certain.

The tubes of this system were to be six or eight inches in diameter, with a few small tubes in localities where the message service is very heavy.

Without going more into detail, such were in brief the plans of the promoters of this new company; but before launching such an enterprise, involving a large amount of capital, there were many engineering and mechanical problems to be solved. It was not simply a question of obtaining tubes and laying them in the streets, but ways and means for operating them must be devised. Up to this time only small tubes had been used for the transmission of telegrams, messages, cash, and other light objects. Now it was proposed to transmit heavy and bulky material. There was no experience for a guide.

—The Pneumatic Transit Company at this time turned to the Electro-Pneumatic Transit Company, of New Jersey, a national company that31 had been in existence since 1886, and which claimed to own valuable patents, for the ways and means to carry out its new enterprise. The patents were those of Henry Clay and Charles A. Lieb, and the rights to use them in the State of Pennsylvania were procured by the Pneumatic Transit Company, under a contract entered into between the two companies. The patents claimed to cover a practical working system by which a large number of stations could be connected to a system of main and branch tubes, with electrically-operated switches at the junctions of the branches with the main lines. Any person who gives the subject a little thought will at once see the advantages of such a system if it could be made to operate. Up to the present time only single- or double-line tubes have been used, without branches. In the European systems, frequently several stations are located along a line, but the carriers must stop at each station, be examined, and if they are destined for another station, they must be redespatched. The cash systems used in many of our large stores have independent tubes running from the central cashier’s desk to each station about the store. It is plain to be seen that, if several of these stations could be connected by branches to a main tube, a large amount of tubing would be saved—a most desirable result. The advantages of such a system would be still greater for long lines of tube laid under the pavements, extending to stations located in different parts of a large city. It was such a result that the patents of Clay and Lieb aimed to accomplish.

In order to demonstrate the practicability of the system, the Electro-Pneumatic Transit Company had constructed32 in the basement of the Mills Building, on Broad Street, New York, a short line of small brass tubing, about two or three inches in diameter, with one branch, thus connecting three stations together. The tube was very short, probably not more than two hundred feet in length. The air-pressure required was very slight, probably not more than an ounce or two, being supplied by a small blower run by an electric motor.

At the junction of the branch and the main tube was located a switch that could be moved across the main tube and so deflect the approaching carrier into the branch. This switch was moved by an electro-magnet, or solenoid, that could be excited by pressing a button at the station from which the carrier was sent. When the carrier passed into the branch tube it set the switch back into its normal position, so that a second carrier, following the first, would pass along the main tube, unless the switch was again moved by pressing the button at the sending station.

This tube in the Mills Building worked well, but it was of a size only suited to the transmission of cash in a store or other similar service. It could not be said, because this tube worked well, that a larger and longer tube with numerous branches would work equally well. In fact, there are several reasons why such a tube would not operate satisfactorily. The method of operating the switches was impracticable. Suppose the branch tube had been located two miles away from the sending station and that it would take a carrier four minutes to travel from the sending station to the junction of the branch tube. Again, suppose that we have just despatched a carrier destined for a station33 on the main line beyond the junction, and that we wish to despatch the second carrier to be switched off into the branch tube, we must wait at least four minutes, until the first carrier has passed the junction, before we can press the button and set the switch for the second carrier which may be on its way. How are we to know when the first carrier has passed the junction, and when the second will arrive there, in order that we may throw the switch at the proper time? Must we hold our watch and time each carrier? It is plain that this is not practical. I take this as an illustration of the impracticability of the Clay-Lieb System as constructed in the Mills Building when extended to practical dimensions. I will not describe the mechanism and details of the system, which are ingenious, but will say in passing that the automatic sluice-gates, which work very well in a three-inch tube with carriers weighing an ounce or two and air-pressures of only a few ounces per square inch, would be useless and could not be made to operate in a six-inch tube with carriers weighing from eight to twenty-five pounds and an air-pressure of from five to twenty-five pounds per square inch. For further information the reader is referred to the patents of Clay and Lieb.

—In the spring of 1892 an ordinance was passed by Common and Select Councils, and signed by the Mayor of the City of Philadelphia, permitting the Pneumatic Transit Company to lay pneumatic tubes in the streets of that city. At the time this franchise was granted negotiations were in progress with the post-office department, in Washington, for the construction of a six-inch pneumatic34 tube, connecting the East Chestnut Street sub-post-office, at Third and Chestnut Streets, with the main post-office, at Ninth and Chestnut Streets, for the transmission of mail. This sub-post-office was selected because more mail passes through it daily than any other sub-office in the city, it being located near the centre of the banking district. Negotiations were delayed by various causes, so that the contract with the government was not signed until October, 1892.

—It was at this time that the writer was first employed by the Pneumatic Transit Company, as engineer, to superintend the construction of this line. The company commenced at once to carry out its contract with the United States government, both the post-office department and the company being very desirous of having the work completed before winter. The time was very short for such an undertaking, but wrought-iron tubes had already been ordered of a well-known firm who manufacture pipe and tubing of all kinds. After waiting four or five weeks the first lot of tubes were finished, but upon inspection it was found that they were not sufficiently accurate and smooth on the interior to permit of their being used for the purpose intended. The next thing that suggested itself was seamless drawn brass tubes. While they would be very expensive, the process of manufacture makes them eminently suited for the purpose, but they could not be obtained in time. A city ordinance prohibits the opening of the streets of Philadelphia during the winter months except in extreme cases. Accurate tubes must be had, and had quickly. It then occurred to the writer that it might be possible to bore a sufficient quantity35 of ordinary cast-iron water-pipe and fit the ends accurately together to answer our purpose. Inquiry was made at nearly all the machine-shops in the city, to ascertain how many boring-machines could be put upon this work of boring nearly six thousand feet of six-inch pipe. It was found impossible to get the work done in time, if it was to be done in the usual manner of boring with a rigid bar. At last a man was found in Mr. A. Falkenau, engineer and machinist, who was prepared to contract for the construction of twelve special boring-machines and to bore all the tubing required. Suffice it to say, that the machines were built, and about six thousand feet of tubes were bored, between November 8 and December 31.

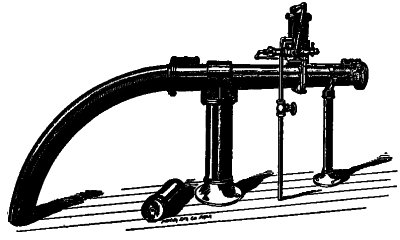

—The process of boring was novel in some respects, and might be termed reaming rather than boring. Figs. 4 and 5 show the interior of the shop and the twelve machines. Fig. 6 is a drawing of one of the machines. A long flexible bar rotated the cutter-head, which was pulled through the tube, in distinction from being pushed. In order to give the feeding motion, a screw was attached to the cutter-head and extended through the tube in advance of it. The feed-screw was drawn forward by a nut attached to a hand-wheel located at the opposite end of the tube from which the boring began. Since it was not necessary that the tubes should be perfectly straight, a method of this kind was permissible, in which the cutters could be allowed to follow the cored axis of the tube. Air from a Sturtevant blower was forced through the tubes during the process of boring, for the double purpose of clearing the chips from37 the cutters and keeping them cool. After the tubes were reamed, each piece had to be placed in a lathe, have a counter-bore turned in the bottom of the bell, and have the other end squared off and turned for a short distance on the outside to fit the counter-bore of the next section.

—The first tubes were laid about the middle of November, but December 1 came before the work was completed and special permission had to be obtained from the city to carry on the work after that date. All work was suspended during the holidays in order not to interfere with the holiday trade of the stores on Chestnut Street. Severe frosts prevailed at that season, so that when the work was begun again, after the holidays, bonfires had to be built in the streets to thaw out the ground in order to take up the paving-stones and dig the trench for the tubes. Several times the trench was filled with snow by unusually heavy storms. Notwithstanding all these delays and annoyances, the work was pushed forward, when a less determined company would have given it up, and was finally completed. A formal opening took place on February 17, 1893, when Hon. John Wanamaker, then Postmaster-General, sent through the tube the first carrier, containing a Bible wrapped in the American flag.

It was certainly a credit to the Pneumatic Transit Company and its managers that they were able to complete this first line of tubes so quickly and successfully under such trying circumstances. The tubes have been in successful operation from the opening until the present time, a period of nearly four years, and the repairs that38 have been made during that time have not required its stoppage for more than a few hours.

In the summer of 1895 the sub-post-office was removed from Chestnut Street to the basement of the Bourse (see Fig. 7). This required the abandonment of a few feet of tube on Chestnut Street and the laying of a slightly greater amount on Fourth Street, thus increasing the total length of the tubes a little. Wrought-iron tube, coated with some alloy, probably composed largely of tin or zinc, was used for this extension. The wrought-iron tube is not as good as the bored cast iron.

Fig. 7.

BOURSE BUILDING, PHILADELPHIA.

Fig. 8.

PNEUMATIC TUBES SUSPENDED IN THE BASEMENT OF THE MAIN POST-OFFICE.

—This Chestnut Street line consists of two tubes, one for despatching carriers from and the other to the main post-office. The distance between the two stations is two thousand nine hundred and seventy-four feet, requiring five thousand nine hundred and forty-eight feet of tube. The inside diameter of the tube is six and one-eighth inches, and it was made in sections each about eleven feet long, with “bells” cast upon one end, in order to join the sections with lead and oakum, calked in the usual manner of making joints in water- and gas-pipes, with this exception, that at the bottom of the bell a counter-bore was turned to receive the finished end of the next section. By thus machining the ends of each section of tube and having them fit accurately together, male and female, a practically continuous tube was formed with no shoulders upon the interior to obstruct the smooth passage of the carriers. Joints made in this way possess another great advantage over flanged and bolted joints, in that they are slightly yielding without39 leaking, and so allow for expansion and contraction due to changes of temperature. Each joint takes care of the expansion and contraction of its section, which is very slight, but if all were added together would amount to a very large movement. Another advantage of the “bell” joint is that it permits slight bends to be made in the line of tube without requiring special bent sections. Where short bends had to be made, at street corners, in entering buildings, and other similar places, brass tubes were used, bent to a radius of not less than six feet, or about twelve times the diameter of the tube. (One of the brass bends may be seen in Fig. 10.) The bends were made of seamless tubing, bent to the desired form and radius in a hydraulic machine. To prevent them from being flattened in the process of bending, they were filled with resin, which was afterwards melted out. Flanges were screwed and soldered to the ends of the bent brass tubes, and they were bolted to special flanged sections of the iron tube.

The tubes were laid in the trench and supported by having the ground firmly tamped about them. Usually one tube was laid above the other, with an iron bracket between, but frequently this arrangement had to be departed from in order to avoid obstructions, such as gas- and water-pipes, sewers, man-holes, etc. The depth of the tubes below the pavement varied from two to six feet, and in one place, in order to pass under a sewer, the extreme depth of thirteen feet was reached. At the street crossings it was frequently difficult to find sufficient space to lay the tubes. At the intersection of Fifth and Chestnut Streets a six-inch water-main had to be cut and a bend put40 in. A seven-strand electric cable, used for telephoning and signalling, was laid upon the top of one of the tubes, protected by a strip of “vulcanized wood,” grooved to fit over the cable. The cable and protecting strip of wood were fastened to the tube by wrought-iron straps and bolts.

The tubes enter the main post-office on the Chestnut Street side, through one of the windows, and are suspended from the ceiling along the corridor in the basement for a distance of nearly two hundred feet. Fig. 8 shows the tubes thus suspended. They terminate upon the ground floor about the centre of the building, and near the cancelling machines.

Fig. 9.

DUPLEX AIR-COMPRESSOR IN THE BASEMENT OF THE MAIN POST-OFFICE.

Fig. 10.

TANKS AND TUBE IN THE BASEMENT OF THE MAIN POST-OFFICE.

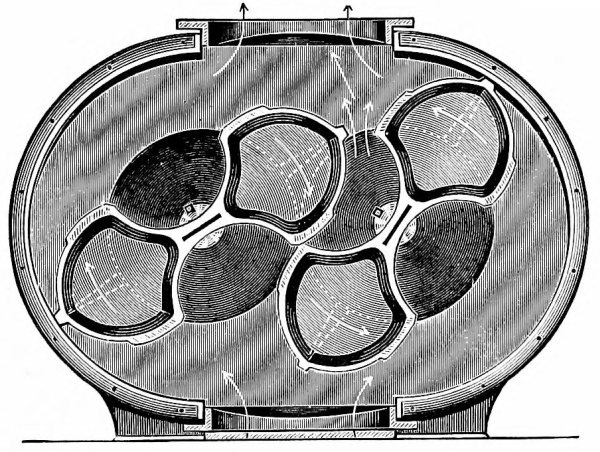

—The current of air that operates the tubes is supplied by a duplex air-compressor located in the basement of the main post-office. This machine is shown in Fig. 9, and requires no detailed description, as it does not differ materially from air-compressors used for other purposes. The stroke is twenty-four inches, the diameter of the steam-cylinders ten inches, and the air-cylinders eighteen inches. The air-cylinders are double acting, with poppet-valves, and have a closed suction. The speed of the machine varies slightly, being controlled by a pressure-regulator that maintains a practically constant pressure in the tank that feeds the tube. The engines develop a little over thirty horse-power under normal conditions. The pressure of the air as it leaves the compressor is usually six or seven pounds per square inch. Compressing the air heats it to about 156° F., but this is not sufficient to require water-jackets about the air-cylinders. From the compressor the air41 flows to a tank, shown on the right in Fig. 10, where any oil or dirt contained in the air is deposited. The principal purpose of the tank is, however, to form a cushion to reduce the pulsations in the air caused by the periodic discharge from the cylinders of the compressors, and make the current in the tube more steady. From this tank the air flows to the sending apparatus on the ground floor of the post-office and thence through the outgoing tube to the sub-post-office. At the sub-post-office, after flowing through the receiving and sending apparatus, it enters the return tube and flows back to the main office, passing through the receiving apparatus there and then to a tank in the basement,—the left tank in Fig. 10. The air-compressor draws its supply from this tank, so that the air is used over and over again. This return tank has an opening to the atmosphere, which allows air to enter and make up for any leakage or escape at the sending and receiving apparatus, thereby maintaining the atmospheric pressure in the discharge end of the tube and in the suction of the compressor. The tank serves to catch any moisture and dirt that come out of the tube. Fig. 11 is a diagram showing the direction and course of the air-current. It will be noticed that both the out-going and return tube are operated by pressure, in distinction from exhaust. The air is forced around the circuit by the air-compressor. There is no exhausting from the return tube. The pressure of the air when it enters the tube at the main post-office is, say, seven pounds per square inch; when it arrives at the sub-post-office the pressure is about three and three-quarters pounds, and when it gets back to the42 main office and enters the return tank, the pressure is zero or atmospheric. Thus it will be seen that the pressure becomes less and less as the air flows along the tube. This is not the pressure that moves the carriers, but the pressure of the air in the tube, a pressure that exists when there are no carriers in the tube. It is the pressure that would be indicated if you should drill a hole into the tube and attach a gauge.

—When the construction of this line was begun, it was the intention of the Pneumatic Transit Company to use the apparatus of the Electro-Pneumatic Transit Company, at both stations, for sending and receiving carriers, and so-called working-drawings were obtained for this purpose. The sending apparatus was constructed according to the designs furnished, but, upon examination of the drawings of the receiving apparatus, it was so apparent that it would not work as intended that it was never constructed.

The writer was asked to design an automatic receiver43 to stop the carriers without shock upon their arrival at the stations, and to deliver them upon a table without appreciable escape of air,—something that would answer the requirements of the present plant.

—The sending apparatus is for the purpose of enabling the operator to place a carrier in the tube without allowing the air to escape. In other words, it is a means of despatching carriers. The apparatus for this purpose, already referred to, is simply a valve. A side view and section of it are shown in Fig. 12. Fig. 15 is a view of the apparatus in the main post-office. The sending apparatus is seen on the left. Fig. 13 is a view of the sub-post-office apparatus, and here a man may be seen in the act of despatching a carrier. Referring to44 the section, Fig. 12, it will be seen that the sending apparatus consists of a short section of tube supported on trunnions and enclosed in a circular box. Normally this short section of tube stands in line with the main tube, and the air-current passes directly through it. It is shown in this position in the figure. When a carrier is to be despatched, this short section of tube is rotated by a handle until one end comes into coincidence with an opening in the side of the box. In this position the air flows through the box around the movable tube. A carrier can then be placed in the short section of tube and be rotated by the handle into line with the main tube. The carrier will then be carried along with the current of air. A circular plate covers the opening in the box where the carrier is inserted when the sending apparatus is closed.

At the sub-post-office this sending apparatus is placed in a horizontal position, but its operation is the same.

Fig. 13.

RECEIVING AND SENDING APPARATUS IN THE SUB-POST-OFFICE.

—We have already explained that the air-pressure in the tube at the sub-post-office is about three and three-quarters pounds per square inch. With such a pressure we cannot open the tube to allow the carriers to come out. They must be received in a chamber that can be closed to the tube after the arrival of a carrier and then opened to the atmosphere. Furthermore, this chamber must act as an air-cushion to check the momentum of the carriers. Fig. 13 shows the sub-post-office apparatus when a carrier is being delivered from the receiving apparatus, or, as we will name it for convenience, the receiver. Fig. 14 is a drawing of the same apparatus, partly in section, that shows more clearly its method of46 operation. This drawing shows the sending apparatus in a different position from Fig. 13, but that is immaterial. The receiver consists of a movable section of tube, about twice the length of a carrier, closed at one end, supported upon trunnions, and normally in a position to form a continuation of the main tube from which the carriers are received. When a carrier arrives it runs directly into the receiver, which being closed at the end forms an air-cushion that stops the carrier without shock or injury. Just before reaching the receiving chamber the current of air passes out through slots in the walls of the tube into a jacket that conducts it to the sending apparatus, as shown in Fig. 14. At the closed end of the receiving chamber, or air-cushion, is a relief valve, normally held closed by a spring. As the carrier compresses the air in front of it, this valve opens and allows some of the air to escape, which prevents the carrier from rebounding into the tube. Under the outer end of the receiving chamber is a vertical cylinder, E, Fig. 14, supported upon the base-plate containing a piston. The piston of this cylinder is connected by a piston- and connecting-rod to the receiving chamber. When air is admitted to the cylinder under the piston, the latter rises and tilts the receiving chamber to an angle of about forty degrees, which allows the carrier to slide out. The receiving chamber carries a circular plate, C, that covers the end of the main tube when it is tilted. A small piston slide-valve, F, located near the trunnion of the receiving chamber, controls the admission and discharge of air to and from the cylinder E, upon the arrival of a carrier. When a carrier arrives and47 compresses the air in the air-cushion or receiving chamber, a small portion of this compressed air is forced through pipe G, to a small cylinder containing a piston and located just above the piston slide-valve F. The increased pressure acting on the piston moves it downward, and it in turn moves the slide-valve F. Thus it will be seen that the stopping of the carrier causes the receiving chamber to be tilted and the carrier slides out on to an inclined platform, K. This platform is hinged at one end, and supported at the angle seen in the figure by a counterweight. When a carrier rests upon it, the weight of the carrier is sufficient to bear it down into a horizontal position; in this position the carrier rolls off on to a table or shelf. The platform, K, is connected by rods, bell-cranks, etc., to the piston slide-valve, so that when it swings downward by the weight of a carrier, the slide-valve is moved upward into its normal position, and this causes the receiving chamber to tilt back into a horizontal position ready to receive the next carrier. The time that elapses from the arrival of a carrier until the receiving chamber has returned to its horizontal position is not more than three or four seconds. Nothing could operate in a more satisfactory manner.

—At the main post-office we have a receiver of a different type. It will be remembered that the pressure in the return tube at the main post-office is nearly down to zero or atmospheric, so that we can open the tube to allow the carriers to pass out without noise or an annoying blast of air. Figs. 15 and 16 show the main-office apparatus, and Fig. 17 is a drawing of the same. Here the receiver consists of a section of48 tube closed by a sluice-gate, located at B, Fig. 17. The air-current passes out through slots in the tube into a branch pipe leading to the return tank in the basement. These slots are located about four feet back of the sluice-gate, so that the portion of the tube between the slots and the sluice-gate forms an air-cushion to check the momentum of the carriers. The sluice-gate is raised and lowered by a piston moving in a cylinder located just above the gate. The movement of this piston is controlled by a piston slide-valve in a manner similar to the apparatus at the sub-post-office. Air for operating the piston is conveyed through the pipe D, Fig. 17, from the pipe leading from the air-compressor to the sending apparatus. This air is at about seven pounds pressure per square inch.

Fig. 16.

RECEIVING APPARATUS AT THE MAIN POST-OFFICE.

When a carrier arrives, after passing the slots that allow the air-current to flow into the branch pipe, it compresses50 the air in front of it against the gate. This compression checks its momentum, and it comes gradually to rest. The air compressed between the carrier and the sluice-gate operates to move the piston slide-valve, thereby admitting air to the gate cylinder under the piston, which rises, carrying with it the sluice-gate. The tube is now open to the atmosphere, and there is just sufficient pressure in the tube to push the carrier out on to a table arranged to receive it. As the carrier passes out of the tube it lifts a finger out of its path. This finger is located at E, Fig. 17, and when it is lifted by the passing carrier it moves the piston slide-valve, and the sluice-gate is closed. A valve is located in the branch-pipe that conducts the air to the return tank in the basement. If the pressure in the tube is not sufficient to push the carrier out on to the table, this valve is partially closed, thereby increasing the pressure to a desired amount.

Fig. 18.

CARRIER.

Fig. 19.

CARRIER.

—We have frequently spoken of the carrier, which contains the mail and other parcels that are transported from one office to the other. In Fig. 13, showing the sub-post-office apparatus, we see one of these carriers being despatched by the attendant and another being delivered from the tube. In Fig. 15 several carriers may be seen standing on the floor. Fig. 18 shows a carrier with the lid open, ready to receive a charge of mail, and Fig. 19 shows the same closed, ready for despatching. The construction of the carrier is shown by the drawing, Fig. 20. The body of the carrier is steel, about one-thirty-second of an inch in thickness. It is made from a flat sheet, bent into a cylinder, riveted, and soldered. The51 length outside is eighteen inches, and the inside diameter is five and one-quarter inches. The front end is made of a convex disk of steel, stamped in the desired form, and secured to the body of the carrier by rivets, with the convex side inward. It is necessary to have a buffer upon the front end of the carrier to protect it from blows that it might receive, and this buffer is made by filling the concave side of the front head with felt, held in place by a disk of leather and a central bolt. The leather disk is made of two pieces, riveted together, with a steel washer between. The steel washer is attached to the head of the bolt. The carrier is supported in the tube on two bearing-rings, located on the body of the carrier a short distance from each end. The location of these rings is so chosen that it permits a carrier of maximum length to pass through a bend in the tube of minimum radius without becoming wedged. This is a very important feature in the construction of carriers, but does not appear to have been utilized in other systems.

The bearing-rings are made of fibrous woven material, especially prepared, and held in place by being clamped between two metal rings, one of which is riveted to the52 body of the carrier. Of course these rings wear out and have to be replaced occasionally, but their usual life is about one thousand miles. The rear end of the carrier is closed by a hinged lid and secured by a special lock. The lock consists of three radial bolts that pass through the body of the carrier and the rim of the lid. These bolts are thrown by three cams, attached to a short shaft that passes through the lid and has a handle or lever attached to it upon the outside of the lid. This cam-shaft is located out of the geometrical centre of the lid in such a position that when the lever or handle is swung around in the unlocked position, it projects beyond the periphery of the lid, and in this position the carrier will not enter the tube. When the lid is closed and locked, the lever lies across the lid in the position shown in Fig. 19, and when the carrier is in the tube it cannot become unlocked, for the lever cannot swing around without coming in contact with the wall of the tube. This insures against the possibility of the carriers opening during transit through the tube. The empty carriers weigh about nine pounds, and when filled with mail, from twelve to fifteen pounds. They have a capacity for two hundred ordinary letters, packed in the usual manner.

—The tubes are kept in constant operation during the day, and six days of the week. The air-compressor is started at nine o’clock in the morning and runs until seven in the evening, except during the noon hour, the air flowing in a constant steady current through the tubes. When a carrier is placed in the tube it is carried along in the current without appreciably affecting the load on the compressor. Carriers may be despatched53 at six-second intervals, and when they are despatched thus frequently at each office, there will be eighteen carriers in the tube at the same time. If ten carriers per minute are despatched from each office, and each carrier contains two hundred letters, the tube has a carrying capacity of two hundred and forty thousand letters per hour, which is far beyond the requirements of this office. About five hundred carriers a day are despatched from each office. This varies considerably on different days and at different seasons of the year. Experience has taught that a certain period of time should elapse between the despatching of carriers, in order that they may not come in contact with each other, and that the receivers may have time to act. With the present plant this period is made about six seconds. In order to make it impossible for carriers to be despatched more frequently than this, time-locks are attached to the sending apparatus. One of these locks may be seen in Fig. 13, connected to the handle of the sending apparatus. It is so arranged that when a carrier is despatched a weight is raised and allowed to fall, carrying with it a piston in a cylinder filled with oil. While the weight is rising and falling the sending apparatus is locked, but becomes unlocked when the weight is all the way down. A by-pass in the cylinder permits the oil to flow from one side of the piston to the other, and the size of this by-pass can be regulated, thus determining the time that the weight shall take in descending. This makes a simple and effective time-lock that does not get out of order.

The time required for a carrier to travel from the main to the sub-post-office is sixty seconds, and from the sub- to54 the main post-office, fifty-five seconds. This difference of time in going and returning is due to the expansion of the air in the tube, as will be explained more fully in another place. The distance between the offices being two thousand nine hundred and seventy-four feet, gives an average speed of about fifty-two feet per second, or 35.27 miles per hour. Of course the speed can be increased by increasing the air-pressure, but this speed is found in practice to be ample for all requirements. In order to give some idea of the energy possessed by one of these carriers travelling at this speed, it may be said that if the end of the tube were left open and turned upward, an emerging carrier would rise about forty feet into the air. It is easy to imagine how apparatus, depending for its operation upon impact with a moving carrier, would be soon destroyed, as well as the carriers themselves. This is why receiving apparatus used with small tubes and light carriers cannot be applied to large tubes with heavy carriers.

No serious trouble has ever been experienced from carriers getting wedged in any part of these tubes.

—The advantages to the post-office department by the adoption of this system have been numerous, and the post-office officials who are familiar with the operation of the tubes frequently speak in high terms of their usefulness. Formerly the mail was transported from one office to the other by a wagon making a trip every half-hour. Considerable time has been saved by the greater speed of transit, but even more time is gained by keeping the mail moving instead of allowing it to accumulate and then despatching it in bulk. With the55 pneumatic system a letter posted in the sub-post-office will reach its destination just as quickly as if posted at the main office, and sometimes more quickly. Let us take an example, first, with the old wagon service. Suppose that you drop a letter in the sub-post-office; it lies there, say, fifteen minutes waiting for the departure of the next wagon; it is put into a pouch with hundreds of other letters, and ten minutes are consumed in transporting it to the main office. When it arrives there the pouch is thrown on the floor at the entrance of the building; in a few minutes, more or less, a clerk takes the pouch, throws it on a truck and wheels it around to the cancelling machines, where it may lie for five or ten minutes more before being opened, and then perhaps five minutes will elapse before your letter reaches the cancelling machine. It would not be unusual for three-quarters of an hour to elapse from the time you dropped your letter in the office until it was cancelled. Now with the pneumatic tube service forty minutes of this time will be saved; for immediately after you drop your letter in the office it will be despatched through the tube and delivered on the table in front of the cancelling machines. Soon after the tubes were installed the postmaster’s attention was called to an instance where letters from the sub-office were sent through the tube and were despatched to New York City one train earlier than they could have been had the old wagon service been in use. People frequently post letters requesting that they be sent through the tube; of course they would be sent in that way if the request was not made, but it shows that the public recognize the better56 service. Formerly mail was collected from the street boxes in the banking section of the city and the collectors carried it to the main office. After the tubes were installed this mail was carried to the sub-post-office to be sent through the tube, and the time formerly occupied in walking to the main office was then utilized in having the men face up the letters ready for the cancelling machines,—a double saving in time besides making their labor much lighter and enabling them to do more useful work.

Since the sub-office has been established in the Bourse, it has been made a distributing as well as receiving office. At least two more deliveries of mail are made each day in the Bourse building than in any other office building in the city.

All letters mailed in the sub-office with a special delivery stamp are despatched through the tube immediately.

It is now nearly four years since the system was put into operation. During that time more than thirty-five million letters have been transported, and all the repairs to the system have not required it to be stopped for more than a few hours. During the first year the Pneumatic Transit Company operated the tubes at their own expense, agreeing at the end of that time to take them out if the government so requested. Since the first year the government has paid the running expenses.

Such is the history of the first United States pneumatic postal system. Such is the history of the first pneumatic tubes of sufficient size to carry all the first class and most of the lower classes of mail, in this or any other country, so far as the writer knows.

—The experience gained in the construction and operation of the Philadelphia post-office tubes has naturally suggested improvements that can be made in future construction, and, furthermore, it has taught us what the requirements will be of an extensive system of tubes laid in the streets of our cities, both for the transmission of mail and for a general commercial business. Since the Philadelphia post-office tube was completed, we have been busily engaged in working out all the details of a system of many stations so connected together that carriers can be despatched in the most direct manner possible from any station to any other. It is the purpose of the present chapter to describe this system.

While the Pneumatic Transit Company has ample field in the State of Pennsylvania to carry out the work which it has mapped out, a field broad enough to yield a good profit for the capital invested, there is no reason why the system should be limited to one State. So, in order to obtain a broader charter, covering all places where pneumatic service may be needed, a new corporation was formed and styled the Batcheller Pneumatic Tube Company.

It is impossible to lay down a rigid system equally well58 adapted to all places and purposes. We must accommodate ourselves somewhat to circumstances. For example, the post-office department may require one size of tube, arranged to operate in a particular way, while the requirements of a parcel delivery business would be utterly different. The geographical location of the stations will have much to do with the general arrangement; also the condition of the streets. Some of the streets of our large cities are so filled with water- and gas-pipes, electrical conduits, sewers, steam-pipes, etc., etc., that it is almost impossible to find space for pneumatic tubes, especially of large diameter. Railway or water facilities have much to do with the location of a central pumping station, on account of the coal supply. All of these and many other things have to be taken into consideration in planning a system for any locality.

We have an example of a peculiar location and conditions in a proposed line of tubes over the New York and Brooklyn bridge connecting the main post-offices of those cities. This would be in many respects a unique plant. Two air-compressors would be used, one at each office.

In order to give a general idea how a large number of stations can be connected into one system, the diagram Fig. 21 has been drawn.

We have already referred to the attempts of Clay and Lieb to devise means whereby several stations could be located along a main line and carriers be sent from any station to any other through the main line. Their method was to use branch tubes leading off from the main line with switches at the junctions. They deflected the air-current59 into the branch by placing an automatic closed valve in the main line just beyond the junction, returning the air from the branch to the main line just beyond the valve. The carriers were to open and close this valve automatically as they passed.