Title: Pneumatic conveying

Author: Ernest George Phillips

Release date: December 2, 2023 [eBook #72290]

Language: English

Original publication: London: Sir Isaac Pitman & Sons, 1921

Credits: Bob Taylor, deaurider and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

PITMAN’S TECHNICAL PRIMER SERIES

Edited by R. E. NEALE, B.Sc., Hons. (Lond.)

A.C.G.I., A.M.I.E.E.

PNEUMATIC CONVEYING

PITMAN’S TECHNICAL PRIMERS

Edited by R. E. NEALE, B.Sc. (Hons.), A.C.G.I., A.M.I.E.E.

In each book of the series the fundamental principles of some sub-division of engineering technology are treated in a practical manner, providing the student with a handy survey of the particular branch of technology with which he is concerned. Each 2s. 6d. net.

THE STEAM LOCOMOTIVE. By E. L. Ahrons, M.I.Mech.E.

BELTS FOR POWER TRANSMISSION. By W. G. Dunkley, B.Sc.

WATER-POWER ENGINEERING. By F. F. Fergusson, A.M.I.C.E.

PHOTOGRAPHIC TECHNIQUE. By L. J. Hibbert, F.R.P.S.

HYDRO-ELECTRIC DEVELOPMENT. By J. W. Meares, M.Inst.C.E.

THE ELECTRIFICATION OF RAILWAYS. By H. F. Trewman, M.A.

CONTINUOUS-CURRENT ARMATURE WINDING. By F. M. Denton.

MUNICIPAL ENGINEERING. By H. Percy Boulnois, M.Inst.C.E.

FOUNDRYWORK. By Ben Shaw and James Edgar.

PATTERNMAKING. By Ben Shaw and James Edgar.

THE ELECTRIC FURNACE. By Frank J. Moffett, B.A., M.I.E.E.

SMALL SINGLE-PHASE TRANSFORMERS. By E. T. Painton, B.Sc.

PNEUMATIC CONVEYING. By E. G. Phillips, M.I.E.E., A.M.I.Mech.E.

BOILER INSPECTION AND MAINTENANCE. By R. Clayton.

ELECTRICITY IN STEEL WORKS. By W. Macfarlane, B.Sc.

MODERN CENTRAL STATIONS. By C. W. Marshall, B.Sc.

STEAM LOCOMOTIVE CONSTRUCTION AND MAINTENANCE. By E. L. Ahrons, M.I.Mech.E., M.I.Loco.E.

HIGH TENSION SWITCHGEAR. By H. E. Poole, B.Sc., A.C.G.I.

HIGH TENSION SWITCHBOARDS. By the Same Author.

POWER FACTOR CORRECTION. By A. E. Clayton, B.Sc., A.K.C.

TOOL AND MACHINE SETTING. By P. Gates.

TIDAL POWER. By A. Struben, O.B.E., A.M.I.C.E.

SEWERS AND SEWERAGE. By H. G. Whyatt, M.Inst.C.E. M.R.S.I.

ELEMENTS OF ILLUMINATING ENGINEERING. By A. P. Trotter, M.Inst.C.E.

COAL-CUTTING MACHINERY. By G. E. F. Eagar, M.Inst.Min.E.

GRINDING MACHINES AND THEIR USE. By T. R. Shaw, M.I.Mech.E.

ELECTRO-DEPOSITION OF COPPER. By C. W. Denny, A.M.I.E.E.

DIRECTIVE WIRELESS TELEGRAPHY. By L. H. Walter, M.A.

TESTING OF CONTINUOUS-CURRENT MACHINES. By C. F. Smith, D.Sc., M.I.E.E.

ELECTRICAL TRANSMISSION OF ENERGY. By W. M. Thornton, D.Sc.

STEAM ENGINE VALVES AND VALVE GEAR. By E. L. Ahrons, M.I.Mech.E.

MECHANICAL HANDLING OF GOODS. By C. H. Woodfield.

INDUSTRIAL AND POWER ALCOHOL. By R. C. Farmer, D.Sc.

POSITION AND DIRECTION FINDING. By L. H. Walter, M.A., A.M.I.E.E.

HIGH TENSION TRANSFORMERS. By W. T. Taylor, M.Inst.C.E.

LONDON: SIR ISAAC PITMAN & SONS, LTD.

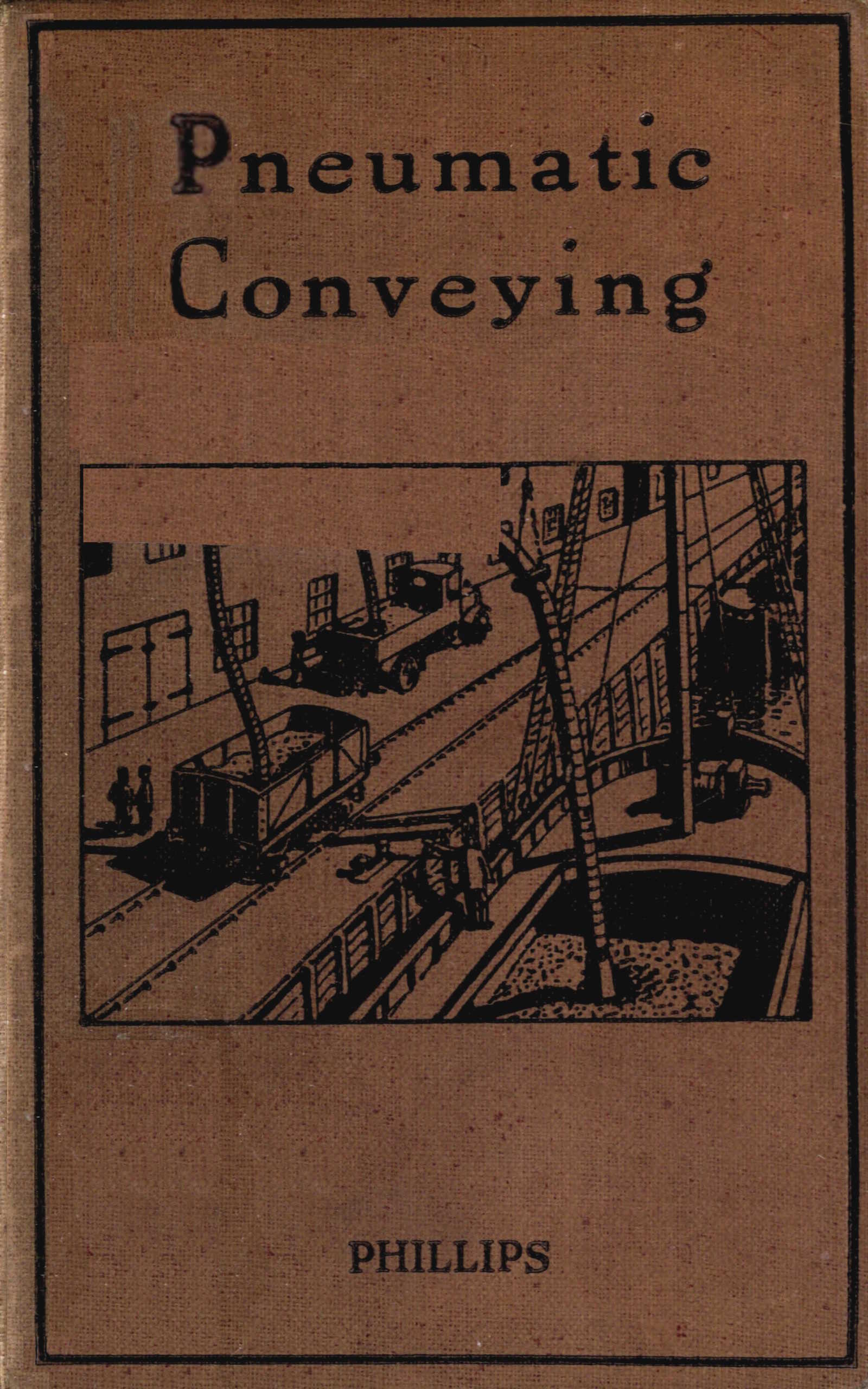

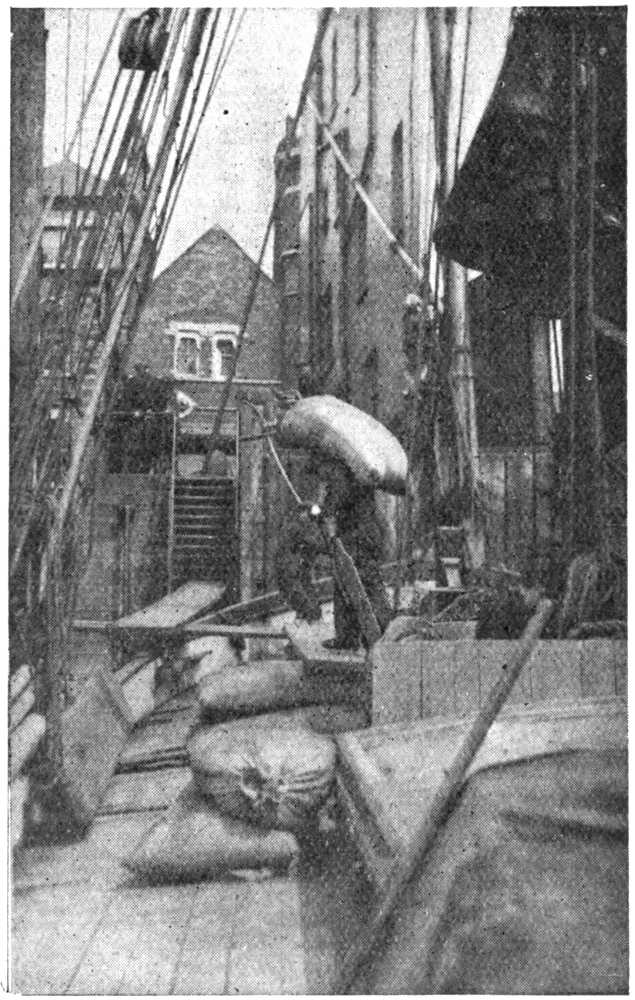

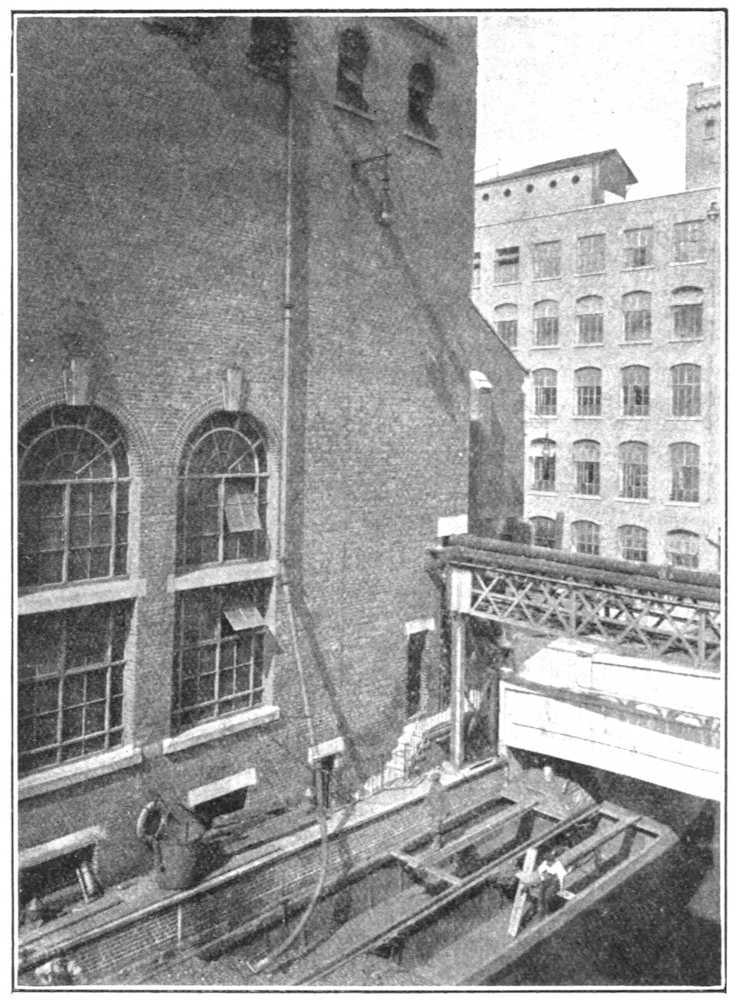

Frontispiece

Intake End of Pneumatic Conveyor.

Adjustable to follow rise and fall of vessel on tidal waters.

A CONCISE TREATMENT OF THE

PRINCIPLES, METHODS AND APPLICATIONS

OF PNEUMATIC CONVEYANCE OF MATERIALS

WITH SPECIAL REFERENCE TO THE CONVEYING

AND ELEVATING OF HEAVY SOLID MATERIALS

FOR ENGINEERS, WORKS MANAGERS,

AND STUDENTS

BY

E. G. PHILLIPS

M.I.E.E., A.M.I.Mech.E.

LONDON

SIR ISAAC PITMAN & SONS, LTD.

PARKER STREET, KINGSWAY, W.C.2

BATH, MELBOURNE, TORONTO, NEW YORK

1921

Printed by

Sir Isaac Pitman & Sons, Ltd.

Bath, England

[Pg vii]

Pneumatic Conveying has recently attracted great and widespread interest amongst engineers and others interested in the economical handling of materials. The information hitherto available on the subject has, however, been so meagre and so indefinite that the author offers this concise treatment of principles, methods and applications in order that those who are anxious to avail themselves of this flexible means of transportation may know just how, and why, it is worthy of their attention.

The high cost of labour, coupled with the desire to improve the condition of the worker who has had to work in a dust-laden atmosphere of an objectionable, or even poisonous nature, will create such a demand for pneumatic conveying plant that present day methods of transportation will be revolutionized in many branches of industry.

The author has had three years’ experience with one of the first pneumatic plants erected in this country, for use with coal, ashes, and flue dust, and he has conducted numerous experiments on other materials, such as sand, oxide, potatoes, various chemicals, etc., and has endeavoured to add his quota to the information available for the benefit of other engineers and works managers.

Experiments proved that with certain materials[Pg viii] the discharger was the weak link in the chain, as wet sticky materials entering at a high velocity “packed” tight and would not discharge freely. This led to experiments which, with the valuable assistance of Mr. H. B. Clarke, A.M.I.E.E., resulted in overcoming this difficulty by means which are described fully in Chapter VI.

No attempt has been made to go fully into the questions of domestic vacuum cleaners, removing dust from manufacturing processes, etc. The chief aim has been rather to bring into prominence the flexibility and other advantages of moving air as a means of conveying and elevating heavy solid materials which hitherto it has been thought could not be handled in this manner.

The author gladly acknowledges the interest and information given by the following firms and individuals Mr. H. B. Clarke, A.M.I.E.E.; Messrs. Ashwell & Nesbit; Boby, Ltd.; H. J. H. King & Co., Ltd.; The Lamson Store Service Co.; and the Sturtevant Engineering Co., Ltd.

E. G. PHILLIPS.

Nottingham.

[Pg ix]

| CHAP. | PAGE | |

| PREFACE | vii | |

| I. | SYSTEMS AND APPLICATIONS OF PNEUMATIC CONVEYING | 1 |

| II. | DETAILS OF PLANT—PUMPS, EXHAUSTERS AND AIR FILTERS | 10 |

| III. | DETAILS OF PLANT (CONTD.)—DISCHARGERS, PIPE LINES AND SUCTION NOZZLES | 28 |

| IV. | TYPICAL INSTALLATIONS FOR GRAIN | 45 |

| V. | PNEUMATIC COAL HANDLING PLANTS | 54 |

| VI. | THE INDUCTION CONVEYOR | 62 |

| VII. | STEAM JET CONVEYORS | 72 |

| VIII. | MISCELLANEOUS APPLICATIONS OF PNEUMATIC CONVEYING | 80 |

| BIBLIOGRAPHY | 105 | |

| INDEX | 107 |

[Pg x]

[Pg xi]

| FIG. | PAGE | |

| Intake end of Pneumatic Conveyor, with rise and fall adjustment | Frontispiece | |

| 1. | King’s pneumatic system. Steam-driven air pump | 12 |

| 2. | Sturtevant rotary blower | 17 |

| 3. | Nash “Hydro-Turbo” exhauster | 19 |

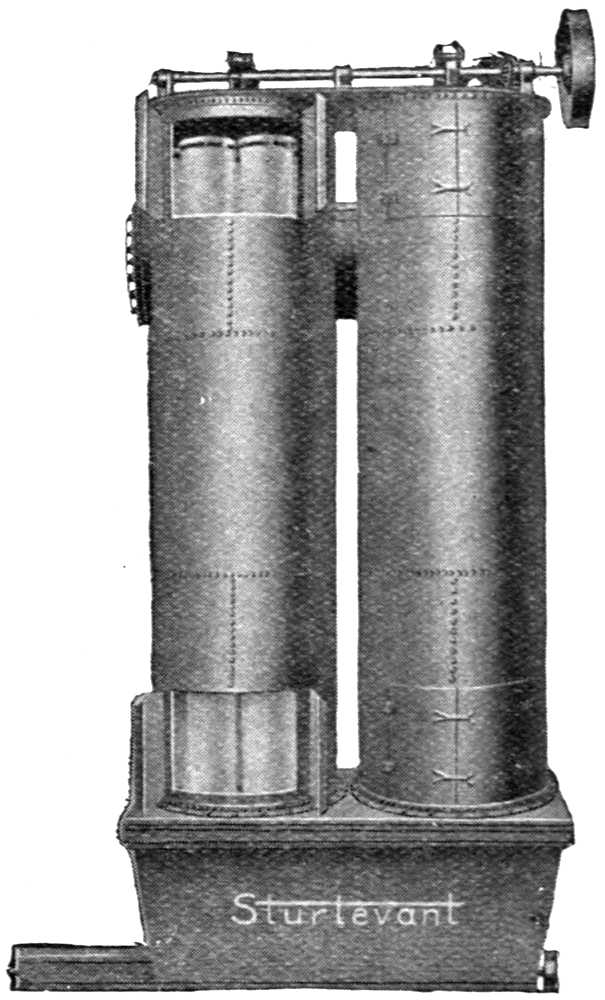

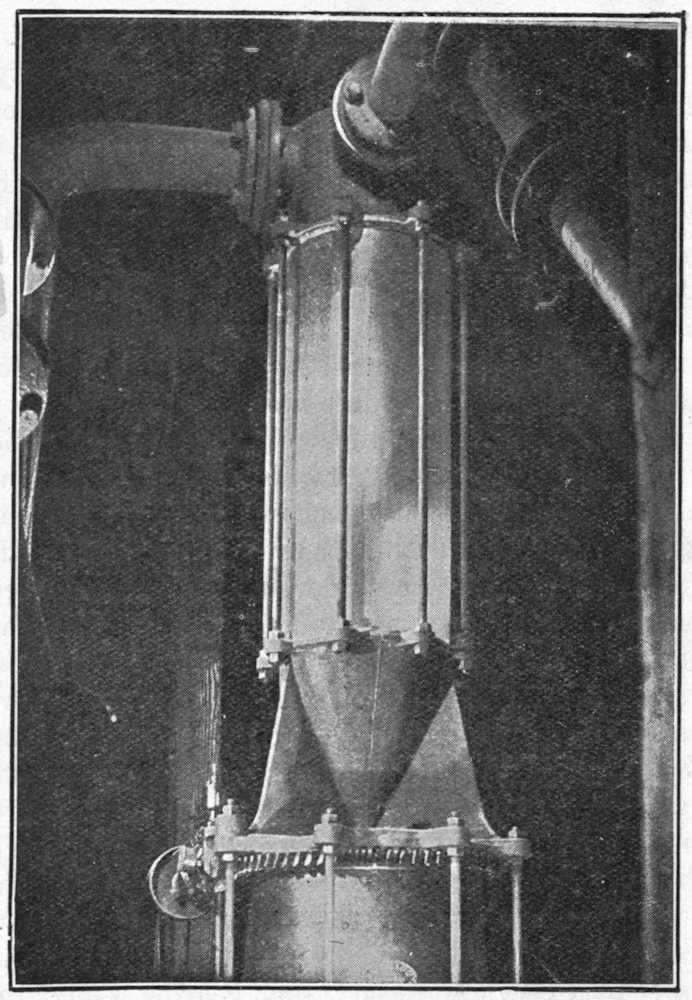

| 4. | Sturtevant “Cyclone” dust separator | 21 |

| 5. | Automatic bag filter | 23 |

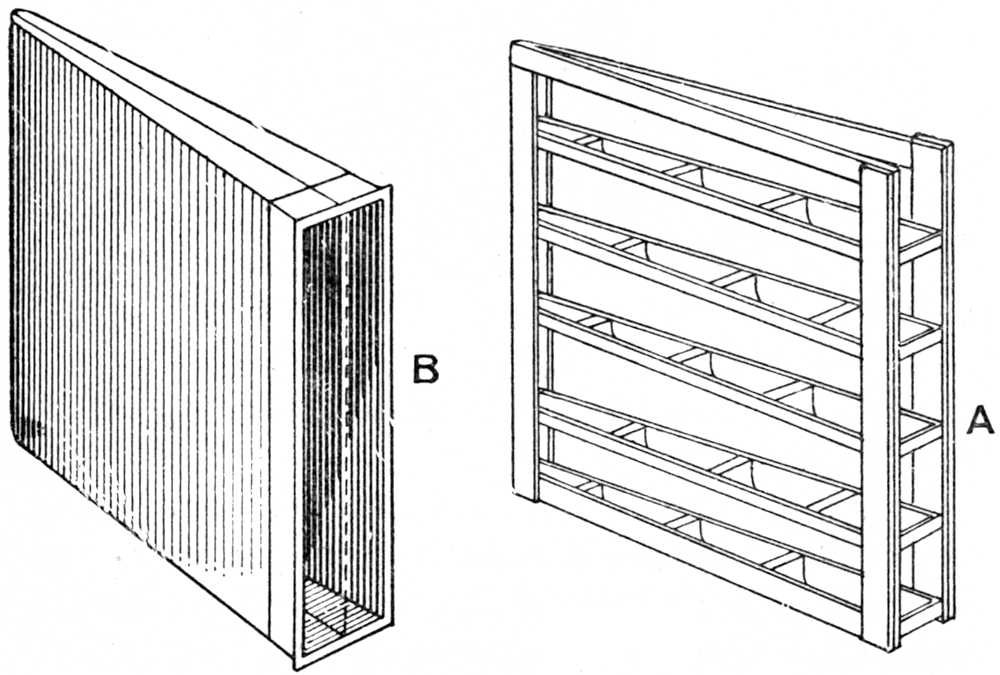

| 6. | Mollers’ air filter | 24 |

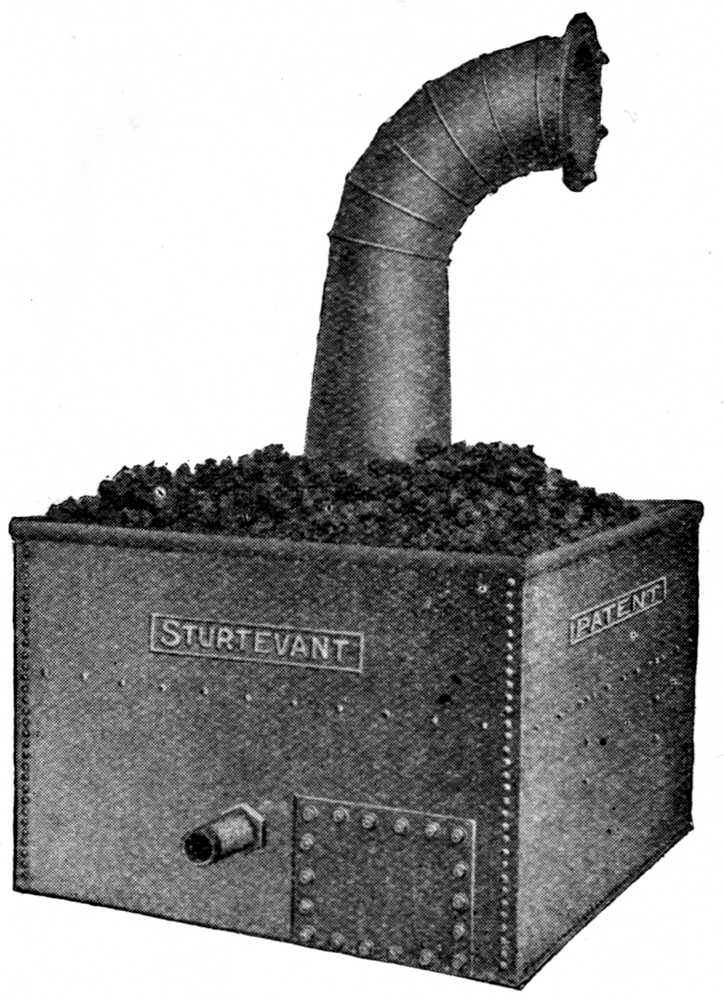

| 7. | Sturtevant wet filter | 26 |

| 8. | Fixed discharger with glass receiver | 30 |

| 9. | Sturtevant patent junction | 33 |

| 10. | Course taken by material round bend | 35 |

| 11. | Segment-back bend | 35 |

| 12. | Lobster bend | 35 |

| 13. | King full-way junction valve | 37 |

| 14. | Suction nozzles for high pressure systems | 40 |

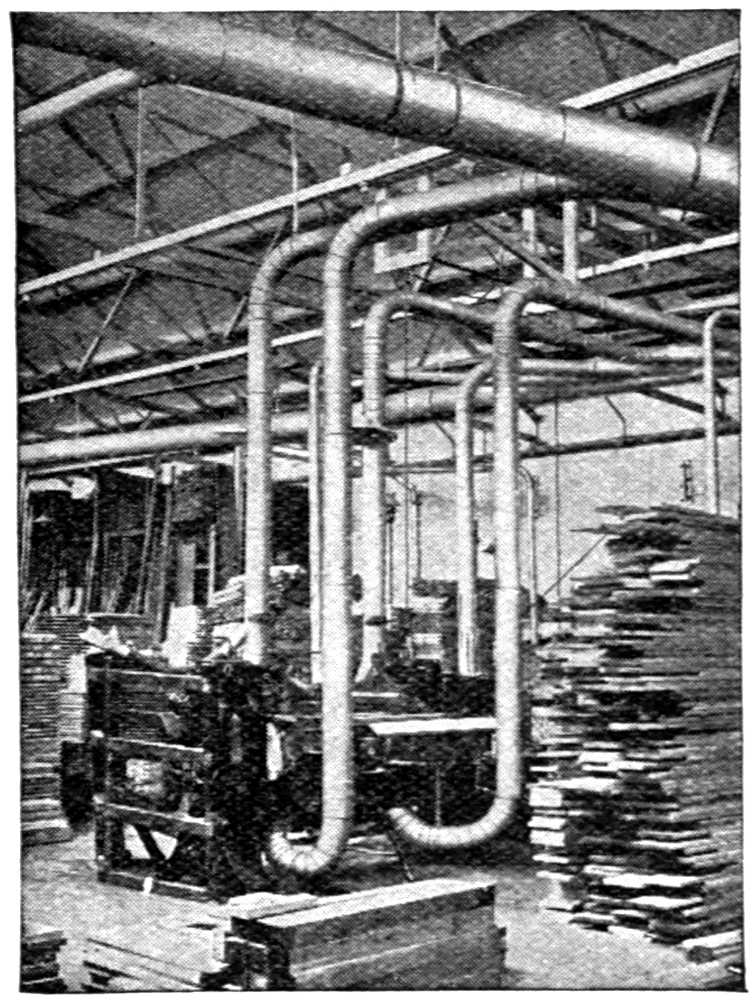

| 15. | Sturtevant equipment removing wood refuse from double tenoning machine | 41 |

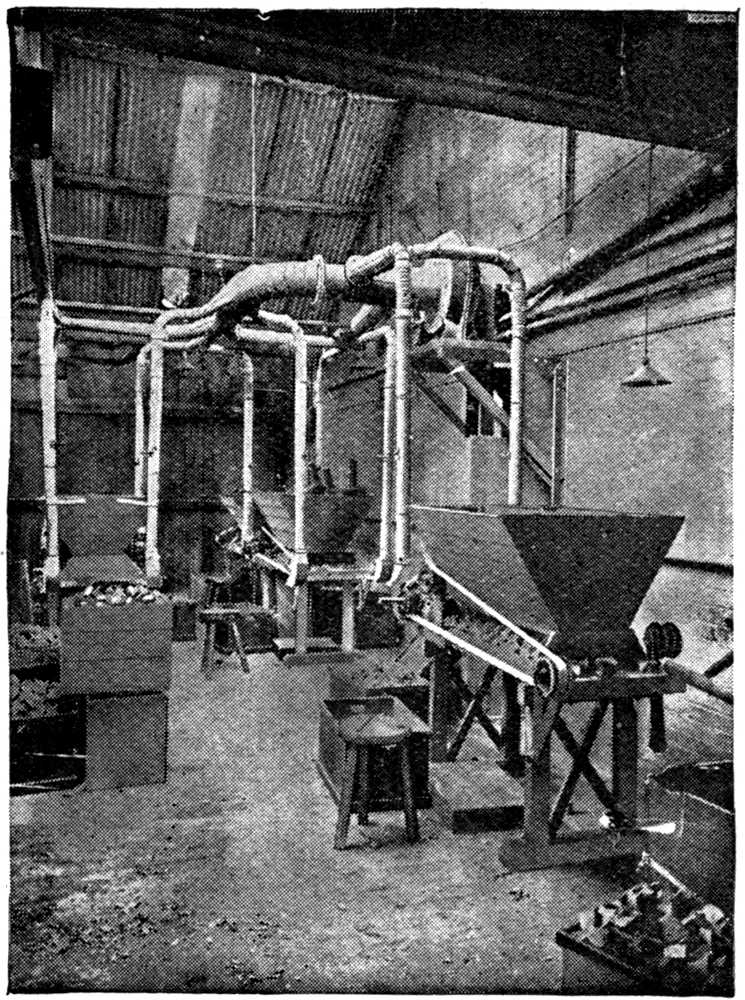

| 16. | Sturtevant equipment removing dust from sand papering machines | 42 |

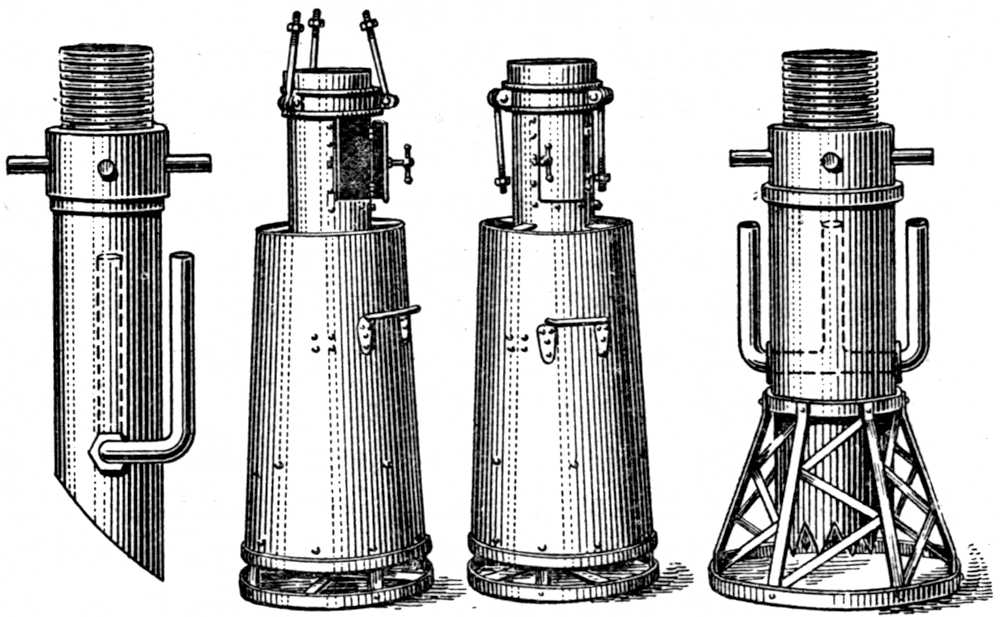

| 17, 18. | Ancient and Modern | 46 |

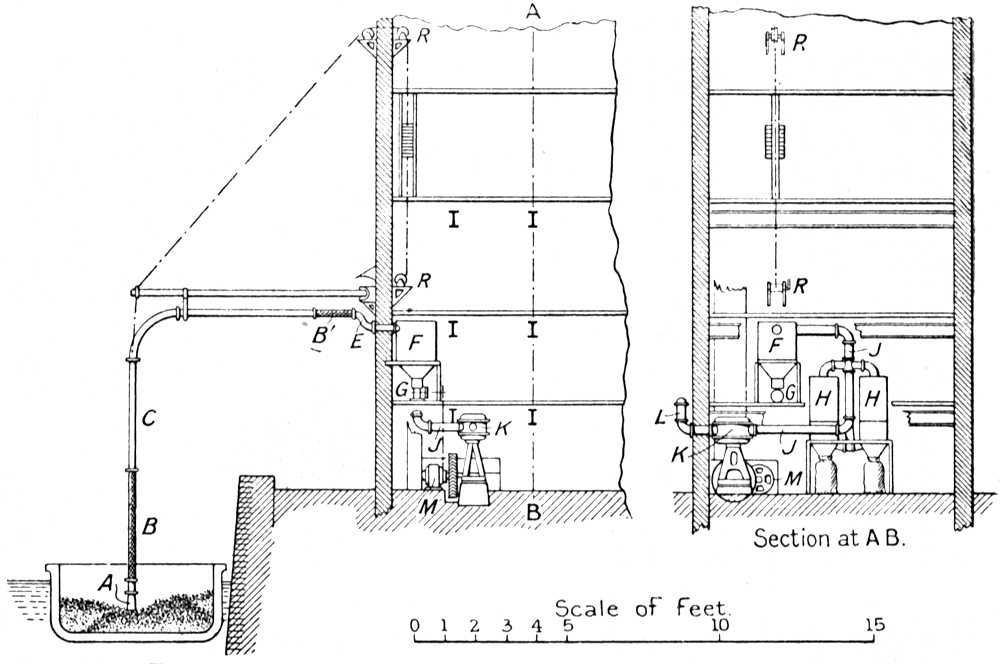

| 19. | Typical grain-handling plant | 47[Pg xii] |

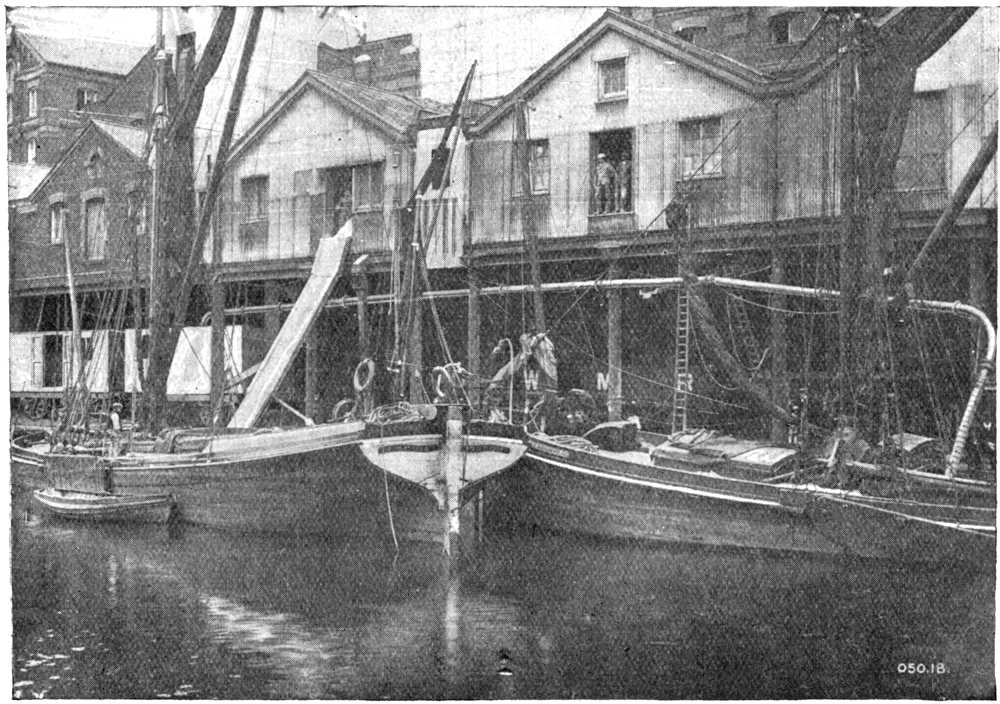

| 20. | Floating pneumatic transport plant | 49 |

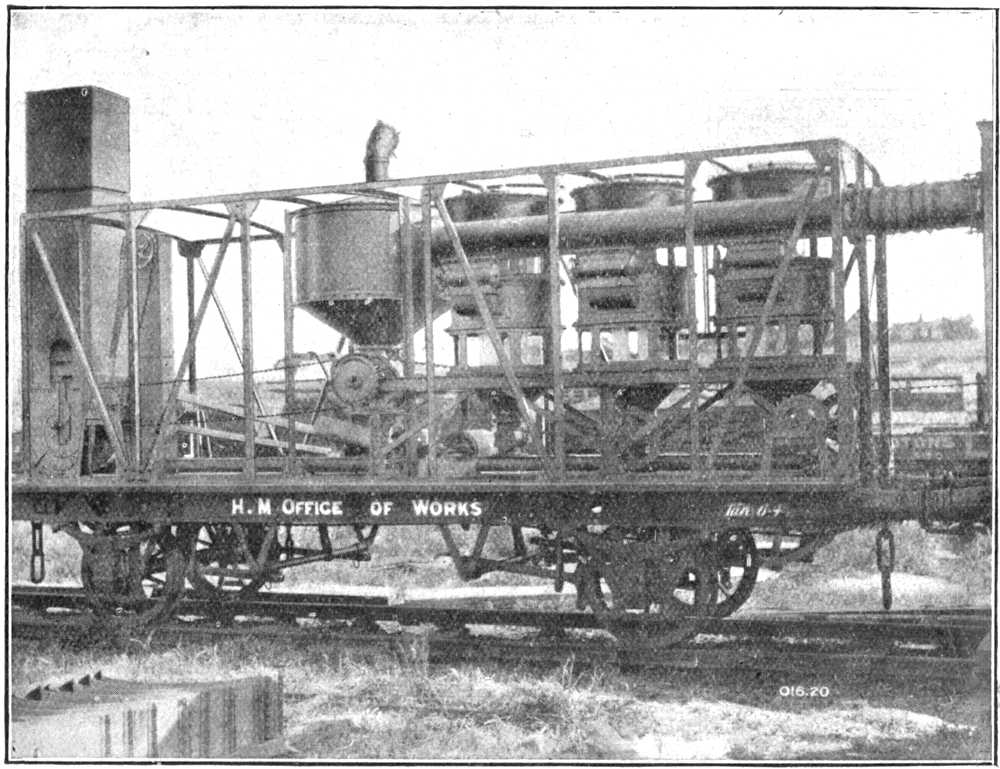

| 21. | Portable pneumatic plant on railway truck | 50 |

| 22. | Portable railway plant in operation | 52 |

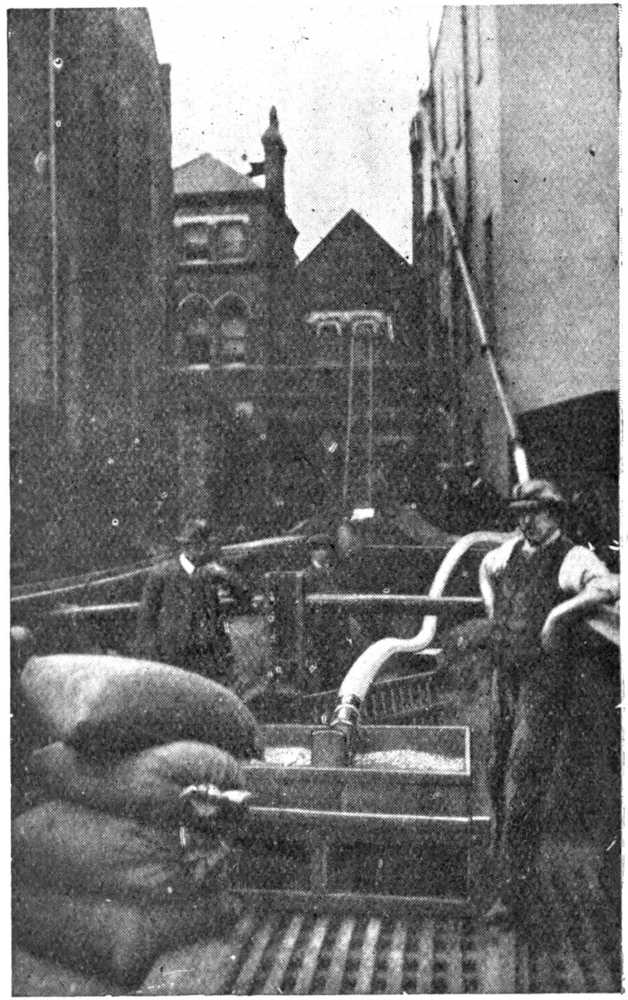

| 23. | Pneumatic unloading of coal | 55 |

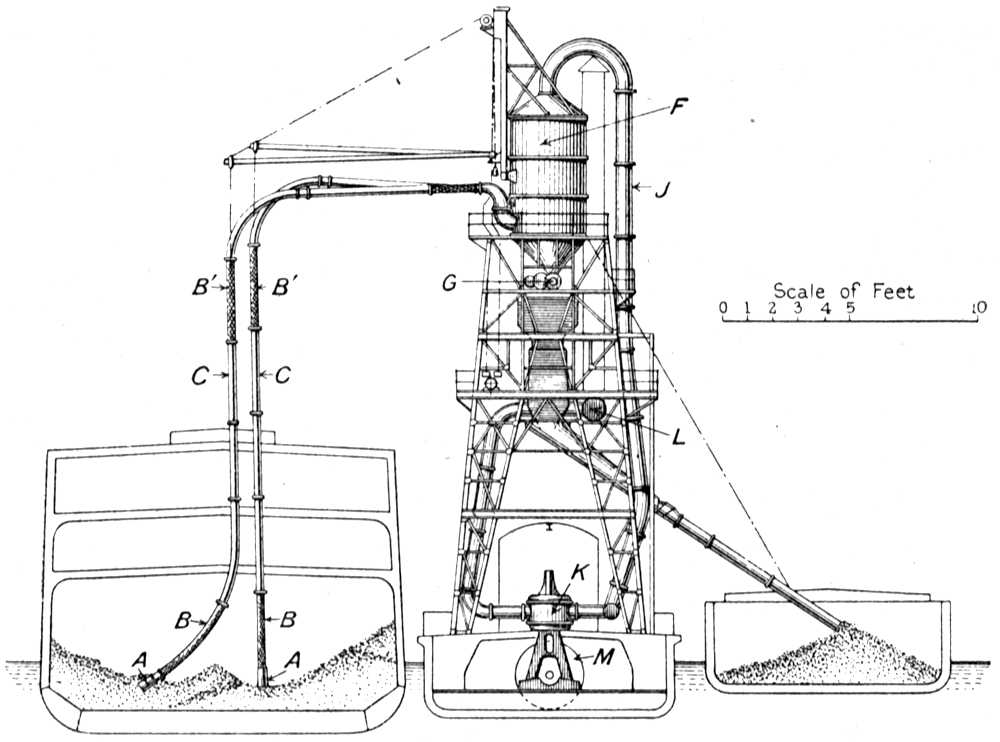

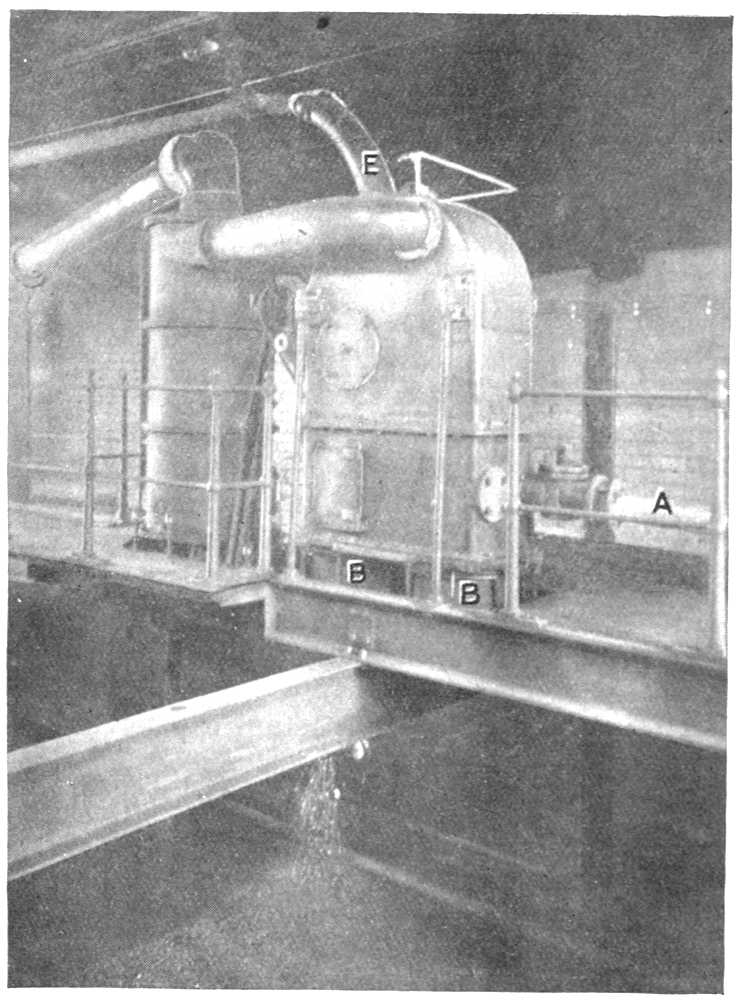

| 24. | Discharger for coal conveying plant | 57 |

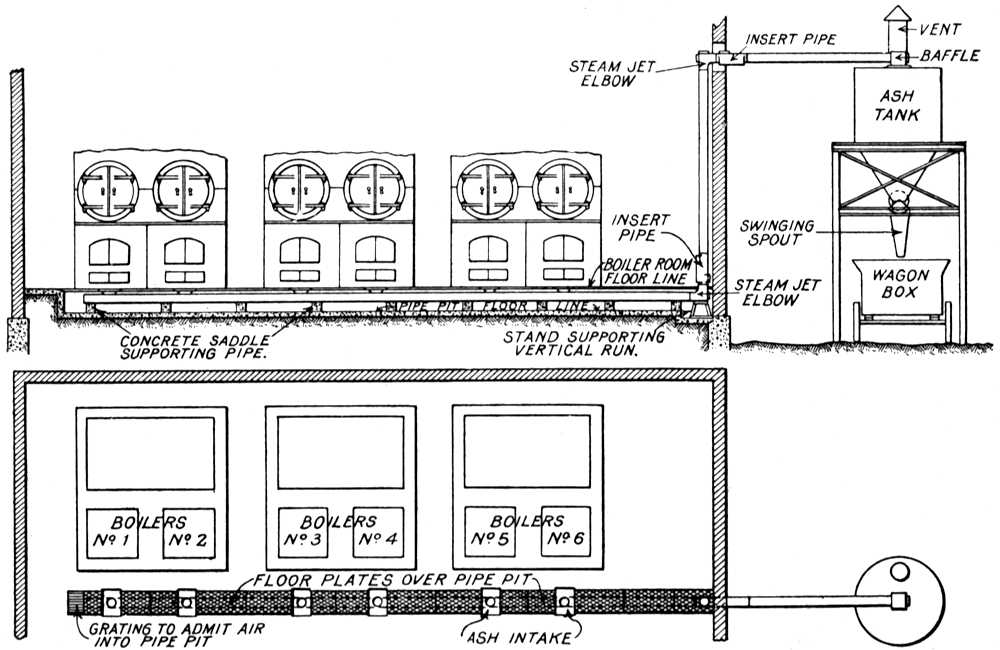

| 25. | Brady steam jet ash conveyor | 75 |

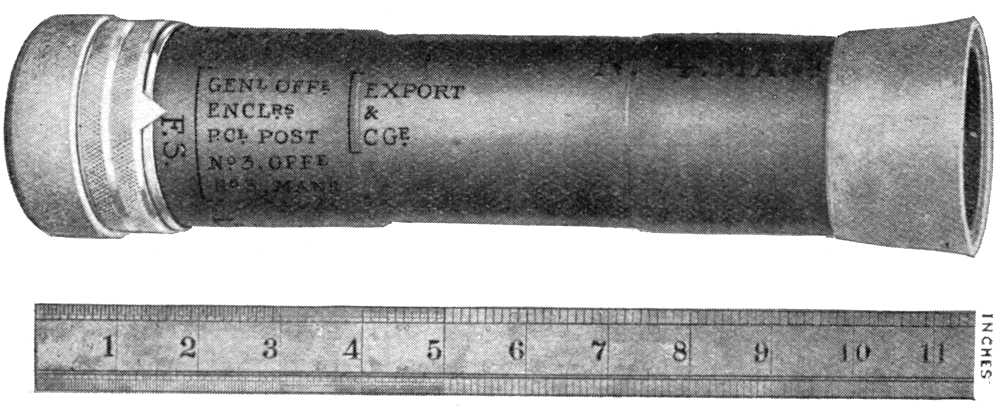

| 26. | Typical Lamson inter-communication carrier | 82 |

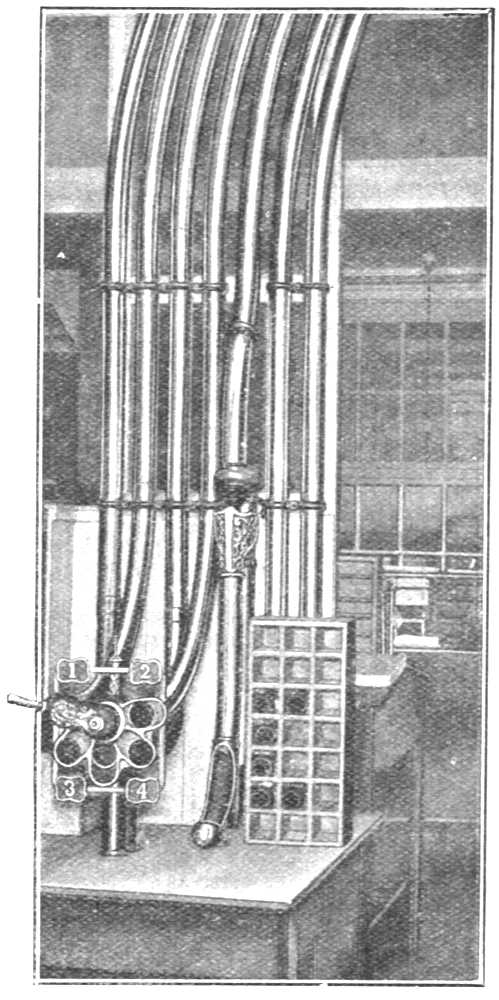

| 27. | Tube central in wholesale drug house | 87 |

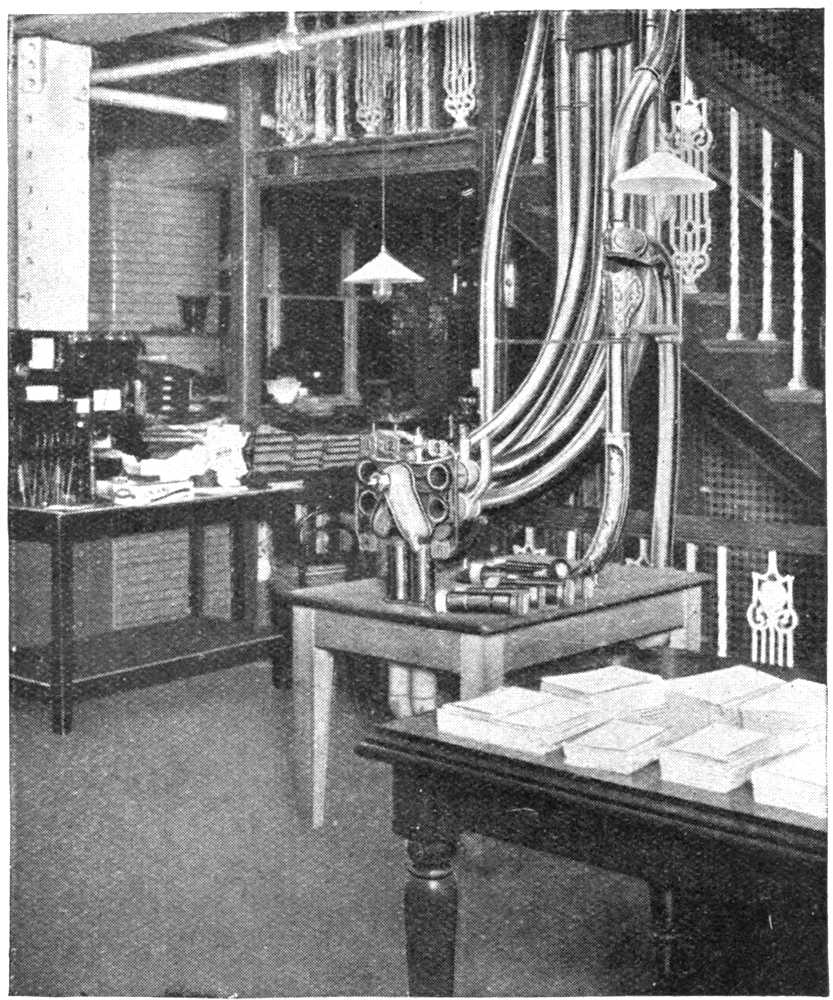

| 28. | Lamson distributing station | 88 |

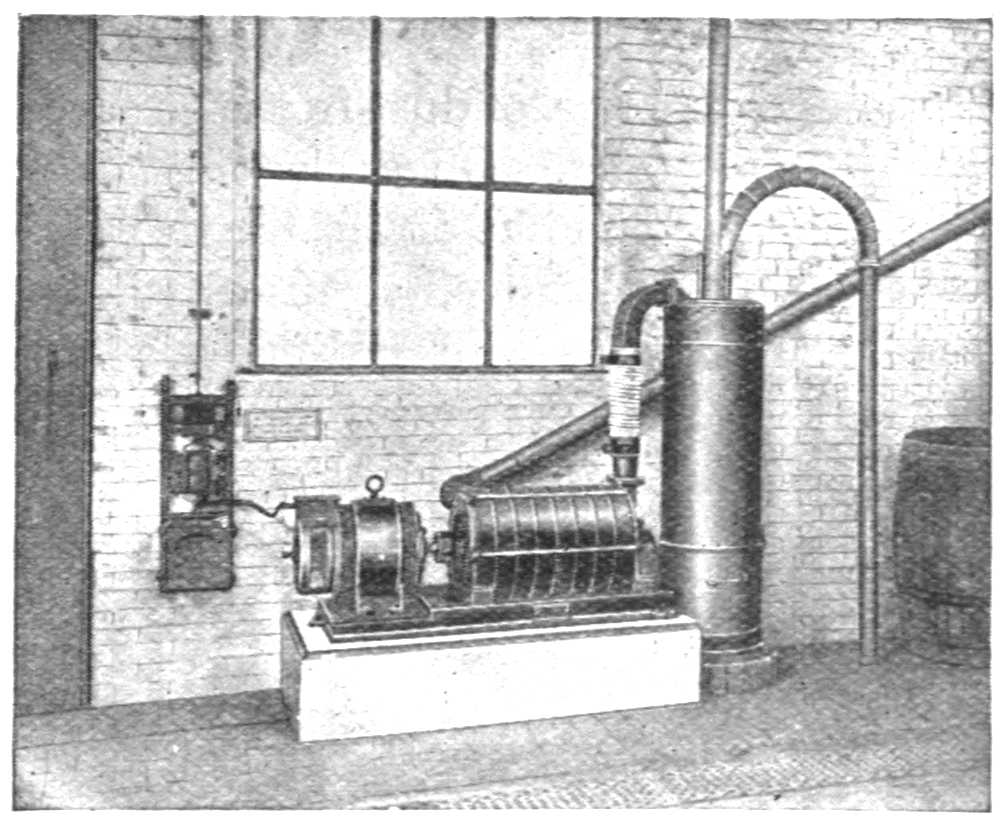

| 29. | Stationary turbo-exhauster with dust separator | 91 |

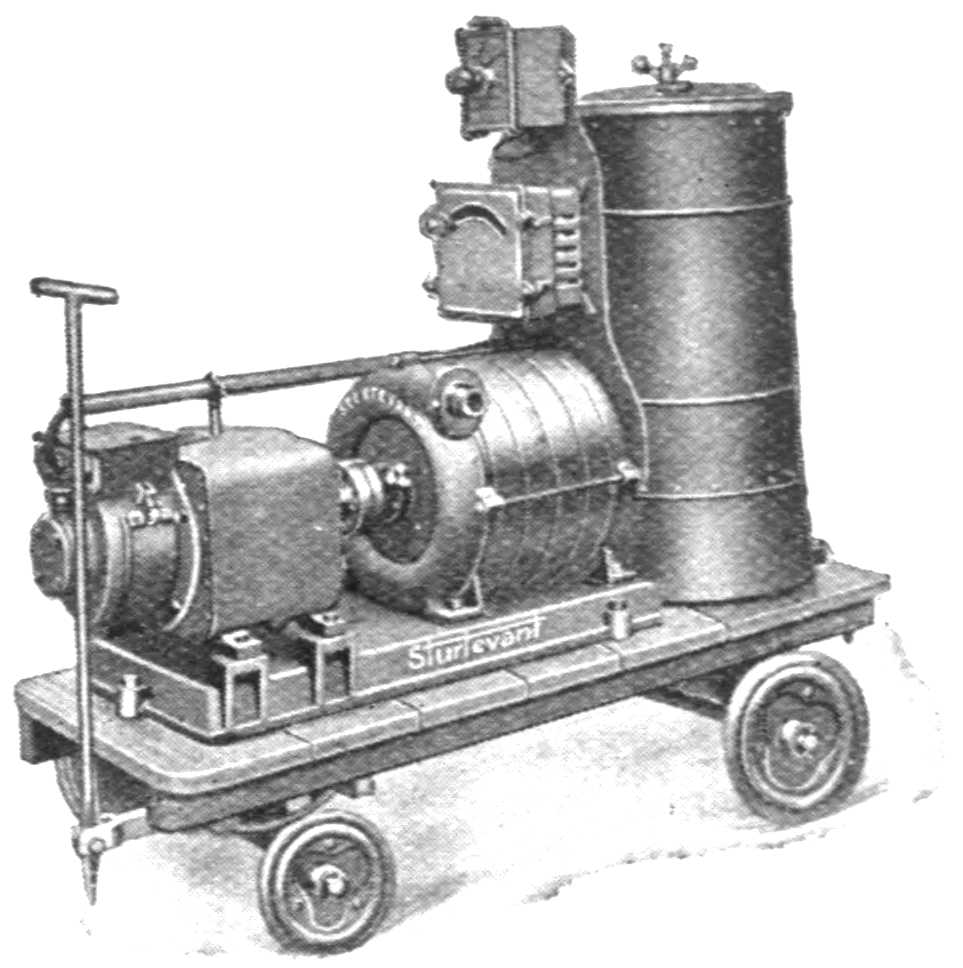

| 30. | Portable turbo-exhauster | 91 |

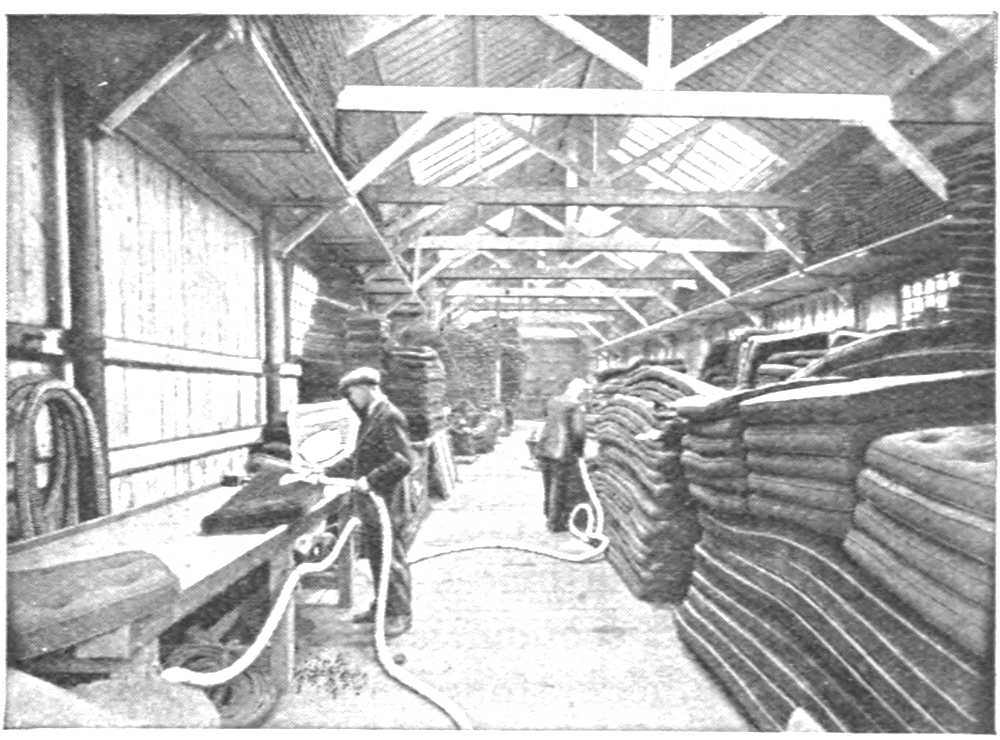

| 31. | Suction cleaning for railway carriage cushions | 93 |

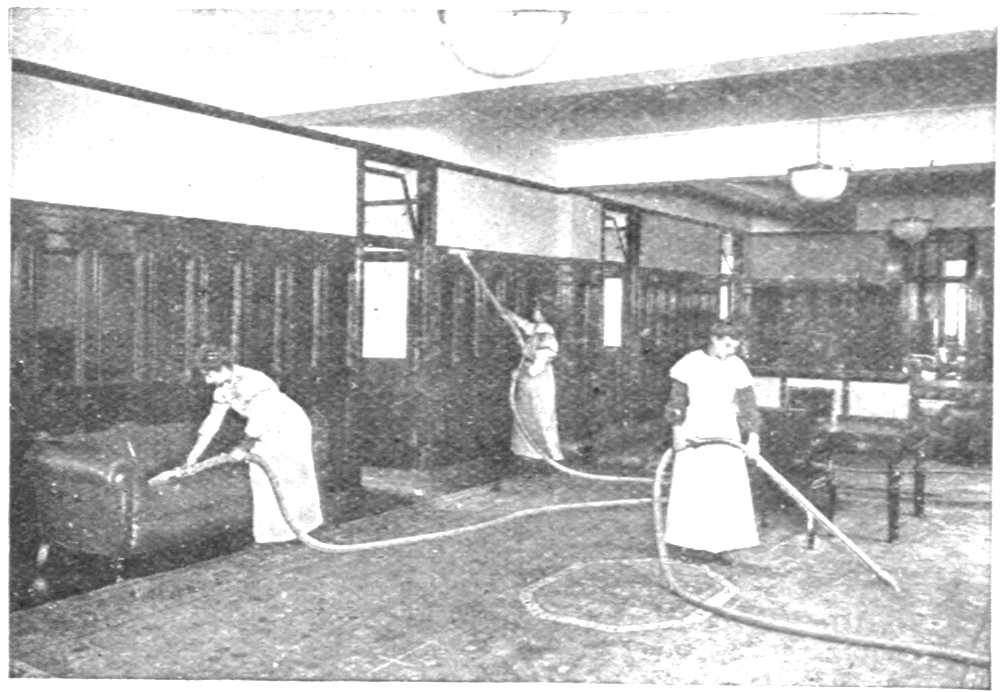

| 32. | Sturtevant equipment for office cleaning | 93 |

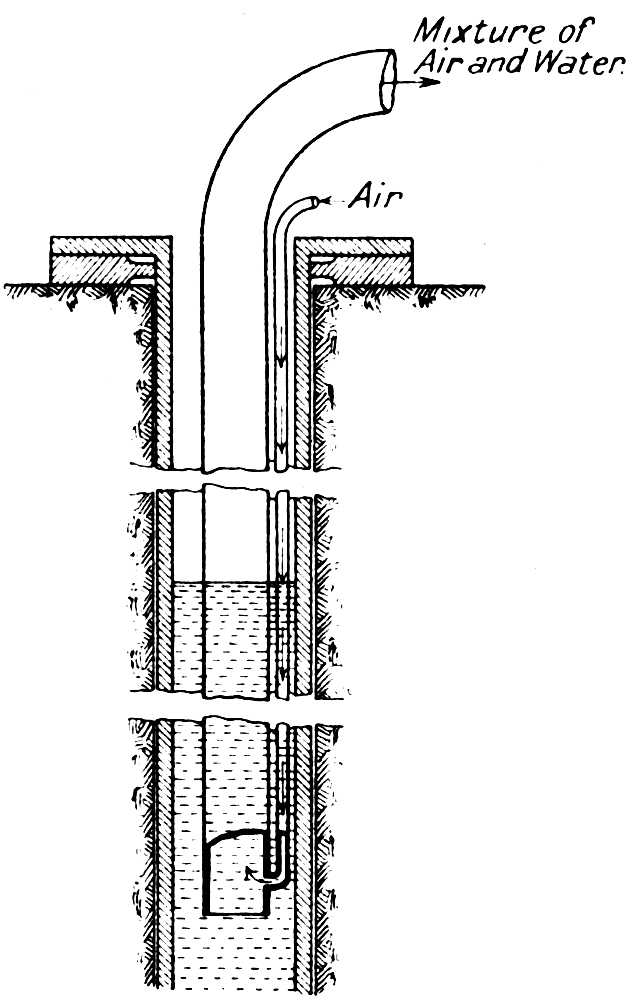

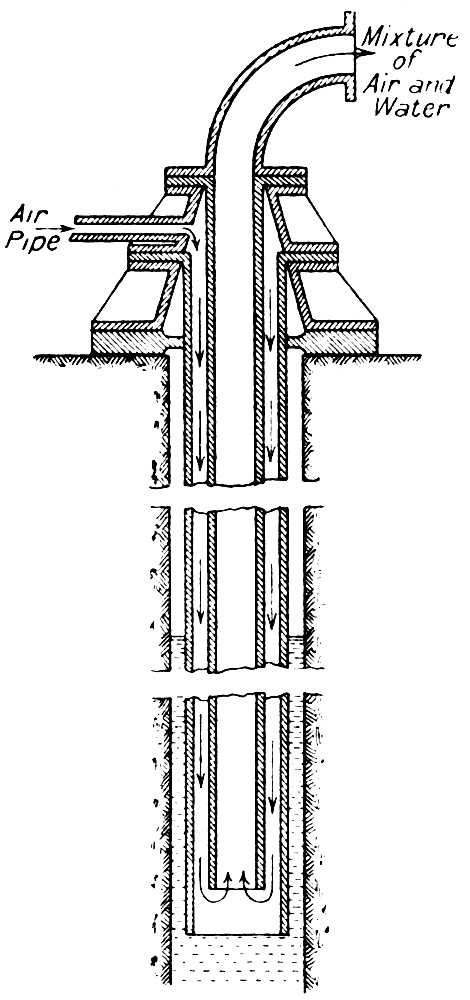

| 33, 34. | Air-lift pumping | 98 |

[Pg 1]

PNEUMATIC

CONVEYING

Conveying by mechanical means has existed for many centuries, and is one of the earliest forms of man’s ingenuity towards labour saving as we know it to-day. The pneumatic conveyance of materials from one position to another, either horizontally or vertically, is the most recent form of automatic handling of solid substances.

Genesis and Applications of Pneumatic Conveying. The need of water for human consumption and for irrigation purposes caused the ancient inventor to carry out nearly all his experiments with that substance, and the first instance we have of anything approaching pneumatic conveying is the well known injector in which steam is passed through one pipe, placed at right angles to a second pipe, at such a velocity as to reduce the pressure in the second pipe to below the atmospheric pressure. The excess of atmospheric pressure over[Pg 2] the reduced pressure in the second pipe then drives up the latter the material (in this case water) in which the end of the pipe is submerged. This invention is about a century old, if it emanated from the Marquis Mammonry d’Eclet, in 1818, as is usually believed.

The first practical application of this invention to other than liquid materials is supposed to have been in connection with the conveying of cotton in a loose form, as an improvement upon the manual shifting of large bales. This development was made about 1867, and after this date great progress was made, principally in connection with the handling of grain, wheat, malt, etc., and largely owing to the work of an American named A. K. Williams.

At the present day it is hardly possible to enumerate all the successful schemes for the pneumatic handling of materials. In addition to installations for the conveyance of materials such as those mentioned above is the pneumatic tube, for conveying papers, messages and cash in offices and between shop counter and cash desk, etc. Also, there is the suction cleaner, ranging in application from the handling of refuse and dust from saw mills and woodworking machinery to the removal of fine abrasive and poisonous particles in certain manufacturing processes. Small suction cleaners are, of course, now quite familiar domestic appliances. The sand-blasting machine is really another example of a self contained pneumatic conveyor on a small scale.

[Pg 3]

Ashes, coal, oranges, sugar, chemicals, spent oxide, iron ore, spent tanning bark, and many other materials are now actually transported, elevated or conveyed pneumatically, and it must here be acknowledged that the first really successful plant in this country was due entirely to the initiative and inventive genius of Mr. Frederic Eliot Duckham, late Chief Engineer to the Millwall Dock Co., who in 1888 commenced experiments in grain-handling by suction. In 1892 he produced a very successful floating plant for unloading ships into land silos, and this installation was the prototype of many similar plants which were placed in commission all over the world. Many improvements have been carried out and numerous patents issued for pneumatic handling apparatus, but the original scheme as designed by Mr. Duckham has never been departed from seriously.

Fundamental Principles and Components. The pneumatic conveyance of materials along pipes is most easily understood when the equipment is considered as a pump producing a high velocity stream of air in which the material to be transported is floating, and with which it is carried through the pipe system. It is necessary fully to understand this, as it is otherwise difficult to realize how it can be possible to lift solids at the rate of 100 tons or more per hour, several hundred feet up a pipe in which the vacuum does not exceed about 7 inches mercury column (say, 11 lb. per sq. in. absolute).

[Pg 4]

A modern pneumatic conveying plant of the suction type comprises: (1) An exhauster, or an air pump, of either the reciprocating or the rotary type. (2) A suction nozzle. (3) A discharger, whereby the material is extracted from the pipe line at the desired position, without “breaking” or losing the vacuum. (4) One or more appliances for filtering the air and extracting any foreign material which may have been carried over from the discharger and which would damage the cylinder walls of the exhauster if allowed to enter the plant.

It is necessary here to mention that all pneumatic conveying is not done by exhausting, but frequently by the use of pressure, that is, that the air is not sucked along the transport line but is actually blown in under pressure by fans, air compressors, or rotary blowers, according to the circumstances.

The suction system is preferable when it is required to convey materials from several outlying points to one central storage bunker or area. On the other hand, the pressure system is less expensive in first cost, when it is required to transport from one central point to numerous outlying plants in the area to be served. A combination of the suction and pressure systems is now being developed for the handling of materials in cases where neither the “suction” nor the “blowing” scheme alone can be said to be successful. This combined system is known as the induction system and is discussed in Chapter VI.

[Pg 5]

Advantages over Mechanical Conveyors. The reasons why pneumatic methods for elevating and conveying are now receiving such attention are to be found in the advantages of pneumatic over mechanical conveying. These may be summarized as follows: Economy in labour; flexibility of plant both in design and operation; elimination of dust and its harmful effects on the employees; and in many instances the recovery of dust which is valuable and which would otherwise represent a serious financial loss. Wear and tear on moving parts is reduced to a minimum. All obstacles such as buildings, roads, rivers, railways, etc., can be overcome easily since the conveyor is “only a pipe.” Should circumstances not permit of a straight single run for such appliances as bucket elevators, it is usually necessary to bag and cart the material from one position to another, but this is avoided by pneumatic elevating and conveying, because the pipe can be carried up or down, round corners, over or under roads, etc.

Hundreds of instances still exist in which loose material in barges is shovelled into bags, which are lifted by an ordinary friction hoist into a building over the quay-side. The sacks are wheeled by manual labour into the building, and emptied into hoppers or silos, the empty bags being lowered again for a further cycle of operations. This costly multiple handling may be obviated by the erection of a small pipe line which will automatically feed itself at one end, and discharge evenly and continuously into the receptacle[Pg 6] provided. The whole of the “moving parts” may be situated in one position, which enables them to be carefully inspected, oiled and kept in repair, etc.

Cranes, hoists, telphers, and belt conveyors all have their special spheres of usefulness, but no other plant can claim all the advantages of the pneumatic system as outlined above.

Pneumatic Conveying Systems. As mentioned above there are three main systems of pneumatic conveying, viz.—

(1) Conveying by air above atmospheric pressure.

(2) Conveying by air below atmospheric pressure.

(3) Conveying by air above and below atmospheric pressure, by a combination of (1) and (2), known as the induction system.

Although these are the main headings under which the subject may be considered, they must be sub-divided further as follows—

(1) Conveying above Atmospheric Pressure. (a) Low pressure systems using single-stage centrifugal fans, and suitable for conveying such materials as wool, cotton, bark, chopped straw, paper clippings, sawdust, shavings, jute, and fibrous materials of many kinds.

(b) High pressure systems using multi-stage fans and blowers of the rotary type or positive design, and suitable for conveying materials of a denser nature such as dry sand, sugar, etc., also for pneumatic despatch tubes.

[Pg 7]

(2) Air Suction Systems. (a) Large pipe systems using ordinary steel plate centrifugal fans, and applied to handling the waste products and injurious dust in many industries, such materials being sawdust and shavings from woodworking machinery; emery dust from grinding wheels; dust and lint from polishing mops; leather dust from heel and sole scouring plants; starch dust in confectionery works; colour dust in works manufacturing pigments; and bronze dust in printing works. Many other examples will no doubt occur to the reader.

(b) Small pipe systems using multi-stage centrifugal fans or rotary blowers. Under this section the most important plants are undoubtedly those for domestic vacuum cleaning. Large stationary plants for this purpose are installed in many hotels, offices, buildings, workshops, theatres, large private houses, etc.

(c) Heavy commercial systems in which the fan is replaced by a reciprocating exhauster, producing currents of air suitable for conveying such materials as coal, ashes, sugar, leather tanning bark, ores, granite chippings, wood blocks, oranges, etc., which it would be impossible, or undesirable, to pass through a fan.

(3) Induction System. A compressed air injector is used to produce a partial vacuum on the suction or inlet end of the pipe system, and to produce a pressure above atmospheric at the delivery end, thus avoiding the necessity for a discharger. This[Pg 8] system, which is suitable for use with heavy sticky materials—such as hot sugar, saturated sand, finely ground heavy ores, spent oxide as used in gas works, etc.—is now being developed so as to make possible pneumatic conveyance of all manner of materials which are unsuitable for passing through the discharger, or air lock, of a suction system.

Factors influencing Design. In the strict sense of the term, “pneumatic conveying” really implies the conveyance of a quantity of material from one point to another, using air as the conveying agent. As will be seen from the above, the subject also embraces the removal of comparatively light dust produced in many industrial processes. Although the same name is implied in both cases, the methods to be adopted vary, and each case must be considered on its own merits.

With regard to a conveying plant proper, the points for consideration in the initial stages are as follows—

(1) The nature of the material to be handled and the quantity required in a given time.

(2) The size of the largest and smallest pieces of materials and the density of the material.

(3) The distance over which the material is to be conveyed.

(4) The difference in level between the point at which the material is fed into the system, and the point where it is delivered.

[Pg 9]

(5) The method and regularity of feeding the material into the system.

(6) The means to be adopted for separating the material from the conveying air at the desired point of delivery.

There is a very important distinction between plants in which the material passes through the fan or blower and those in which the conveying is carried out entirely under suction.

The latter system has many advantages, but it carries with it the necessity of providing automatic delivery of the material without seriously impairing the suction. In order to accomplish this, some form of “air lock” is required, and a necessary feature of this is a device with close-fitting surfaces or more or less air-tight valves. The simpler plan is undoubtedly to pass the material through the fan, as there is then no question of breaking the suction in order to get the material out of the system. It is common practice to convey for long distances such materials as wood chippings and sawdust, cotton, jute, wool, esparto grass, paper chippings and many other materials. In all cases, however, the designer is confronted with the problem of separating the material from the air, and in many instances to do this satisfactorily is more difficult than the actual conveying; especially is this so with certain sticky materials or materials which will readily “pack” or build up when entering any mechanical discharger at the high velocity necessary in the suction system.

[Pg 10]

A pneumatic conveying plant of practically any type comprises the following five main components: (1) A pump or exhauster to create a partial vacuum in the pipe line and so induce a high velocity air current in which the material will be conveyed. (2) An air filter in which any light dust carried over beyond the receiver is trapped, to prevent its entering the exhauster where it would quickly damage the piston rings and cylinder walls of reciprocating pumps. (3) A main receiver or discharger, and occasionally one or more subsidiary receivers, in which the conveyed material is extracted from the system and discharged into the receptacle or on to a dump as required. (4) The pipe line, junctions, etc., to connect the point of supply with the desired point of delivery. (5) The suction nozzle through which the material enters the system, together with the “free air” which is to act as the conveying medium.

Pumps and Exhausters. The type of apparatus used for creating the flow of air varies according to the ideas of the numerous makers of the plants. It must be remembered that for a pump working under the conditions required for pneumatic plants it is not a high vacuum that is required; the most[Pg 11] important function is to handle very large quantities of air at a comparatively low vacuum.

The most efficient type of plant for dealing with large quantities of air is certainly the reciprocating pump, although several makers are now devoting a lot of attention to the multi-stage turbine type of blower, or exhauster. The probability is that this type may shortly be as efficient as the reciprocating pump, and if so it is almost sure to be used extensively, as it has distinct advantages in other directions compared with the cylinder and piston type. This remark has special reference to the high pressure system for conveying sand, coal, sugar, etc., and does not apply to the “small pipe system” detailed later.

In dealing with ashes, flue dust, crushed iron ore, and similar abrasive materials, it is essential that the air passing through the pump should be filtered thoroughly so that no dust should enter the cylinders and cut the walls and piston rings. The turbo-blower, having no rubbing surfaces, would suffer little or no damage from a small percentage of dust, hence the filtering equipment might be less elaborate and less costly. No lubrication would be necessary in the rotary pump (except, of course, at the bearings), hence no difficulties would arise owing to oil acting as a dust trap, as is sometimes the case in reciprocating pumps with defective air filters.

[Pg 12]

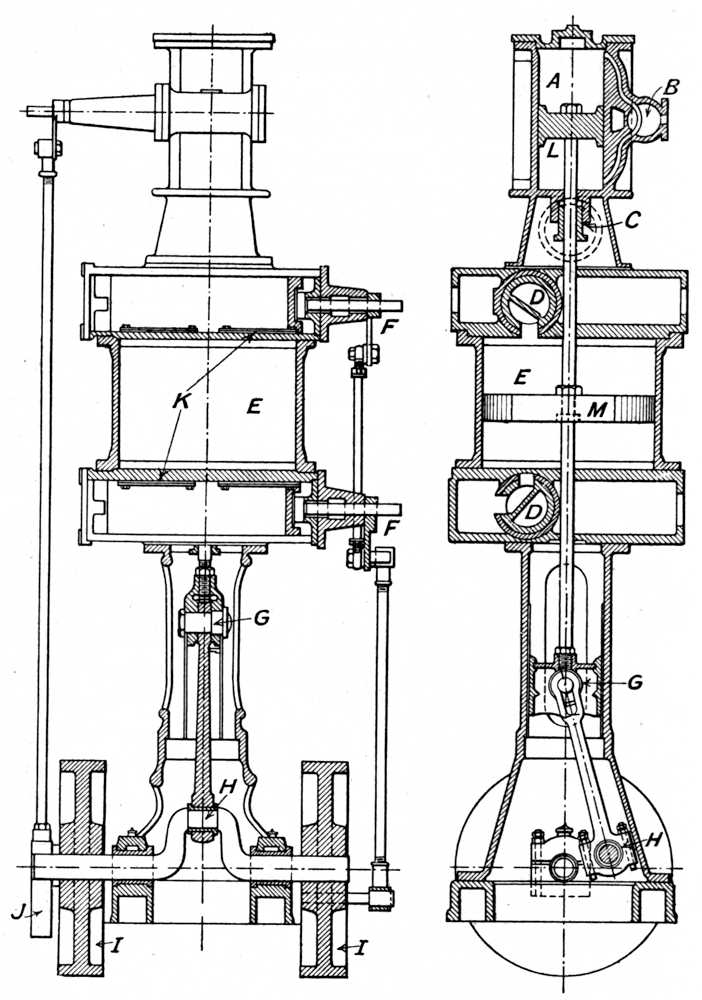

Fig. 1.—King’s Pneumatic System. Steam-driven Air Pump.

[Pg 13]

Key to Fig. 1.

A = cylinder of double-acting steam engine driving the whole machine.

B = semi-rotary valve controlling admission of steam to A.

C = steam gland for piston rod connecting L and M.

D = Corliss-type air-inlet valves with semi-rotary motion. These valves are alternately open to the pipe system and the air cylinder E when the piston is travelling in one direction, and are closed (both to cylinder and air pipe) directly the piston reverses its travel.

E = cylinder of double-acting air pump.

F = valve gear for operating the Corliss valves, D this gear is driven by a pin out of centre on the flywheel.

G = cross-head and slide.

H = big-end bearing and crank.

I = flywheels on the main shaft.

J = eccentric and strap operating the valve, B, on the steam cylinder.

K = leather air-outlet valves held on two sides by metal strips. The leathers are opened by air pressure on the exhaust stroke, and are drawn on to their gridiron seatings during the inlet stroke.

L = steam piston.

M = air piston.

Note.—If preferred, the steam cylinder may be omitted and the air pump driven by electric motor direct-coupled or geared to the main shaft. Belt drive on to the flywheels or special pulley is possible but not advisable.

Typical Reciprocating Pump. Fig. 1 shows the general construction of a vertical steam-driven air pump such as is generally used in present day plants. The pump shown has a stroke of 14 ins., with an air-cylinder diameter of 28 ins. The machine is a dry air pump, and is fitted with Corliss inlet valves and special leather exhaust valves: it is fitted with ring-oiling bearings and automatic continuous lubrication, and under test it shows a mechanical efficiency of 78 per cent. from power input to air horse-power delivered. Such a pump is suitable for a plant handling 20 to 25 tons per hour and, if preferred, the pump may be driven through gearing from an electric motor on the same bed-plate.

Rotary Blowers and Exhausters. The turbine blower and exhauster depend entirely upon centrifugal force for their power to compress or exhaust air or gas, etc. The use of centrifugal force makes this type of machine resemble the centrifugal water-pump, but radical differences in design have to be introduced, seeing that water is not compressible, whereas air is capable of compression, and alterations are also necessary, due to the great difference in specific gravity of the two substances.

Owing to the very low specific gravity of air, the machine must run at a much higher speed than would be required with water to develop a given pressure. The high speed of the steam turbine has given impetus to the design of large exhausters on the turbine principle.

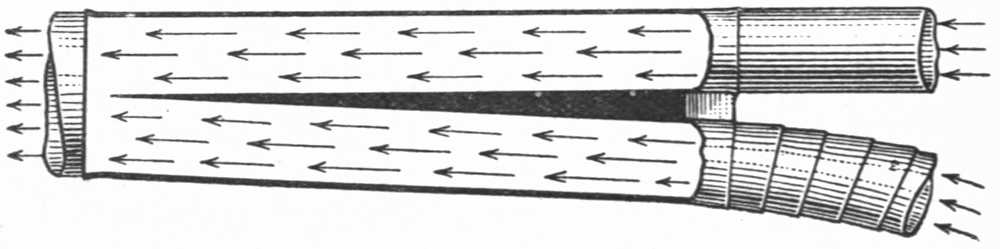

It will be recognized that, when air is made to[Pg 15] flow steadily along a conduit or pipe of gradually diminishing cross-sectional area, the velocity of the air must increase correspondingly, in order that the constant quantity may flow through the smaller section of pipe. Increasing the velocity will diminish the pressure due to the greater kinetic energy to increase the velocity. The converse is the result of passing air at constant pressure through a channel gradually increasing from a smaller to a larger area, the velocity being then reduced and the pressure increased.

Now if a number of impellers be mounted turbine fashion on a high speed shaft, and the casing be so designed that the area between stages gradually increases, the air will enter the first stage and will be caught up by the impeller and accelerated until it leaves No. 1 impeller at a higher pressure and velocity. Leaving the casing through a diffuser which gradually increases in area the velocity is transformed into pressure in the diffuser. The air therefore travels to the second stage with its initial pressure plus the pressure due to the conversion of velocity in the first diffuser. This process may be repeated stage by stage until almost any desired pressure is obtained.

As there are no rubbing surfaces in this type of machine it is particularly suitable for the work under consideration, and when developed for efficient running in small sizes it will be very effective in “booming” pneumatic conveying.

[Pg 16]

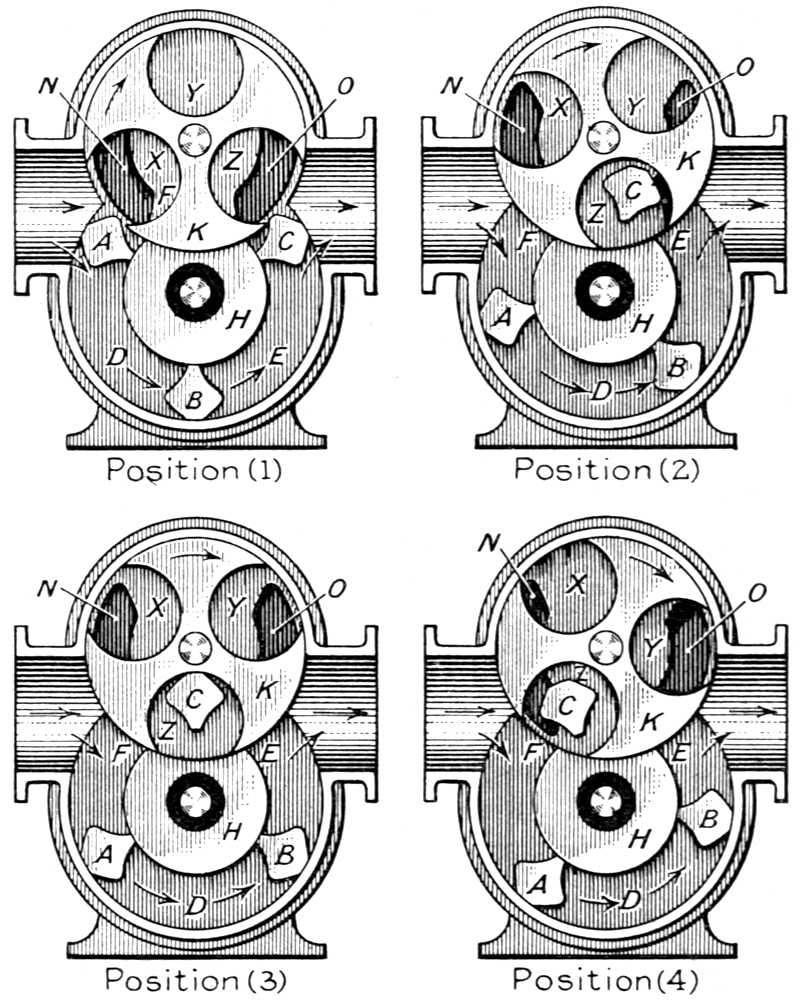

Sturtevant Blower or Exhauster. The Sturtevant Engineering Co., Ltd., has developed a special rotary blower or exhauster suitable for use with pneumatic conveying installations and, although this machine has not a water-seal for surfaces under pressure (as in the Nash Hydro-Turbo described below), it has a number of distinctive points, and the discharge of the air, or the intake of air, as the case may be, occurs at a more nearly constant pressure and with smaller pulsations than with any other rotary blower known to the writer.

The sectional diagrams (Fig. 2) show the four successive stages in the movement of the rotors. In position (1), chamber D has been filled with air, while chamber E is discharging air against pressure in the delivery pipe. In position (2), chamber D is cut off from the inlet, and the air in it is being carried round. Blade C has entered pocket Z, which is filled with air under pressure; this air, however, in turn is released into pocket Y through leakage passage O. Continued rotation carries the rotors A, B and C to position (3), and the remaining pressure in Z is now being transferred to X by leakage passage N.

As the fourth position is reached, chamber F is filling and pocket Y is discharging its air. When further rotation brings impeller blade B into the discharge passage, the air in space D will be delivered from the blower. After leaving position (4), the rotors again reach a position similar to that shown at (1), and the cycle is then repeated.

[Pg 17]

Fig. 2.—Sturtevant Rotary Blower.

A study of the above will convince the reader [Pg 18]that this blower is ingenious and very suitable for the class of work under investigation.

For certain conditions the Roots blower and the multifarious types of drum pumps or blowers can be used, seeing that it is quantity rather than pressure that is required, but it is essential that the most reliable and efficient exhauster should be installed in accordance with the conditions for each installation, bearing in mind always the questions of dust, speed, lubrication, etc.

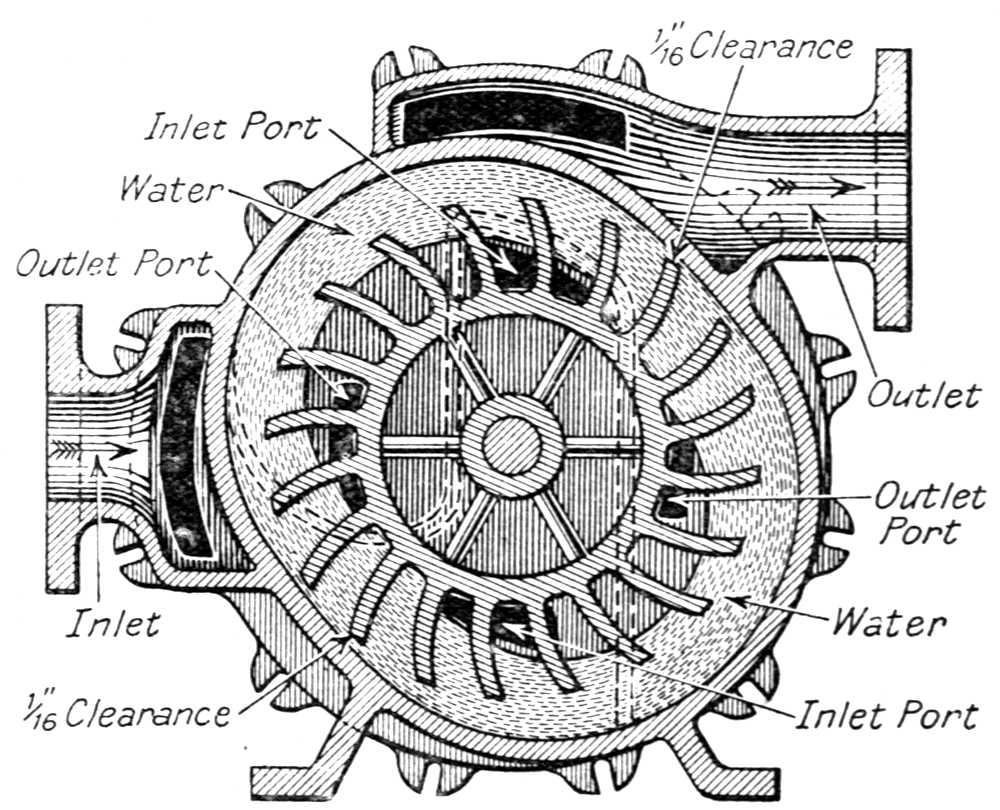

Nash Hydro-Turbine. An entirely new type of rotary exhauster was recently illustrated in the Chemical Age, and a study of Fig. 3 will show the principle of this pump. This pump was built just before the war by Messrs. Siemens-Schuckert, and similar pumps are now being introduced by the Nash Engineering Co. (U.S.A.), and are known as the Nash Hydro-Turbine.

This exhauster has a cylindroid external casing, inside which is a shaft carried on the two end brackets and having mounted upon it a crude type of water-wheel. It should be noted here that this arrangement has the effect of bringing the edges of the wheel into a position of eccentricity in relation to the inside of the external casing.

The wheel shaft is connected directly to a high speed electric motor, and when the pump is running the water which is fed into the casing is thrown by centrifugal force to the periphery of the casing and thus forms certain air pockets into which the air of the system is drawn. The air is now locked[Pg 19] between the hub of the wheel and the sheet of water surrounding the outside of the wheel. As the wheel revolves, the air in each pocket in turn is compressed into a smaller capacity and eventually, when it arrives opposite the outlet point, it at once escapes into the atmosphere due to its additional pressure.

Fig. 3.—Nash “Hydro-Turbo” Exhauster.

Tracing the wheel right round we then find that another pocket is formed into which the air is again sucked, and so the cycle of operations continues, two compressions and extractions occurring per revolution of the spindle. For many materials such a pump has the great advantage that the water acts as a wet filter and traps all[Pg 20] the dust in suspension which can be washed out in the form of sludge. Where the dust is valuable this characteristic would be a disadvantage, but it is very useful in plants dealing with corrosive and abrasive materials.

Lubrication. The lubrication of cylinders in the reciprocating type of pump has been mentioned in connection with the necessity for taking special care in filtering all dust from the air pulled over from the discharger. Ordinary oil makes a sticky surface to which any dust adheres readily, and the two combined make an abrasive mixture which will quickly score and damage the walls of the cylinders. One firm, at least, has gone a long way towards removing this trouble by inserting pieces of solid graphite into the piston: this provides dry lubrication and produces a very smooth surface on which dust finds great difficulty in obtaining a “footing.”

The use of “Aquadag” is also fairly successful: this lubricant consists of deflocculated graphite in such very fine particles that they will remain in suspension in water even without mechanical agitation. “Aquadag” is fed into the cylinders in the same way as oil and deposits its graphite in the pores of the cylinder walls, whilst the water is atomized and blown out with the air.

The turbine exhauster solves the problem by eliminating the necessity for internal lubrication, and the perfect filtering of the air is then not so important.

[Pg 21]

Air Filters. It is impossible to deal with practically any granular material without carrying over more or less dust beyond the discharger, and to obviate the damage and inconvenience which would result from allowing this to enter the exhauster, an air filter is fitted between the discharger and the pump. Many types of air filters have been introduced, and representative examples are described below.

Fig. 4.—Sturtevant “Cyclone” Dust Separator.

“Cyclone” Separators. For such materials as grain, malt, etc., the ordinary type of cyclone separator is frequently mounted inside the receiver. This separator consists of an inverted cone: the dust laden air enters at the top and the heavy material circulates inside, and gradually falls to[Pg 22] the bottom from which it is discharged into suitable containers (see Fig. 4).

The cyclone is an excellent separator, and has the advantage that it is self-cleaning, and offers little or no resistance to the flow of air, but so large a cone would be required to separate very fine dusts that it frequently becomes impossible to use this type of plant.

Bag Filters. An alternative type of air filter is the ordinary bag filter, which consists of a number of closely woven fabric “stockings” in a cast iron container. The air is led into the casing so that it passes down through the inside of the tubes, through the fabric, where it deposits the greater proportion of the dust, and then out to the atmosphere.

Naturally, after working a certain period, the fabric becomes choked with deposited dust, and it is then necessary to dislodge the dust by shaking the “stocking” somewhat violently. This is usually carried out by a mechanically operated vibrating apparatus, but cleaning is done more effectively and time is saved if the air is shut off from the filter while the dust is dislodged. This is done most conveniently by having two similar filters installed, working in parallel; then, when cleaning becomes necessary, all the air is passed through each filter in turn, whilst the other is cleaned.

The bags or tubes hang vertically in the casing, and as the air is brought in at the top and[Pg 23] discharged in a downward vertical direction, it naturally discharges the heavier material straight into the bottom of the casing, owing to the inertia of the heavy particles and the high velocity of the incoming air.

Fig. 5.—Automatic Bag Filter.

Showing filter bags through the open access doors

Fig. 5 illustrates a Sturtevant automatic bag filter. In this case the air is brought in at the bottom. The cleaning of the bags is effected automatically. At frequent intervals and in rotation, each section of bags is cut off automatically[Pg 24] from the supply of dust-laden air by closing the outlet valve of that section. At the same time, that section is opened to the atmosphere at the top, causing a reverse current of air downwards. The bags are then agitated automatically and the dust adhering to the fabric drops, and is blown into the discharge hopper below. The opening and closing of the valves is accomplished by a simple mechanism driven by the pulley shown at the top of the illustration. Where the amount of dust to be handled is large and continuous it can be extracted from the hopper by a worm or screw conveyor, or, as in some other patterns, by a rotary valve placed in the bottom of the hopper.

Fig. 6.—Mollers’ Air Filter.

Mollers’ Air Filter. This apparatus consists of separate fabric pockets mounted on a frame. The[Pg 25] pockets are rectangular and taper towards the top. Referring to Fig. 6, A is the frame on which the fabric is stretched, and B is the fabric pocket. As many of these units as necessary are mounted side by side in an adjustable frame, each unit having fixing and tension bolts. This arrangement permits a filter of any desired capacity to be built up quickly, and facilitates repairs and cleaning of filter bags.

Wet Filters. The type of filtering apparatus used for dealing with poisonous material, emery dust from grinding wheels, sand from sand-blasting apparatus, etc., is usually of the wet type, of which Fig. 7 is a good example. This apparatus consists of a tank having a wire shelf on which a layer of coke is supported. The tank is partially filled with water, the level of which is regulated by an overflow.

The dust-laden air impinges on the surface of the water, and the major portion of the dust is trapped by being driven actually into the water. The dust particles too light to be brought into contact with the water are compelled to pass through the coke screen and are there arrested. If necessary, the scheme can be made to deal with finer dusts by having the coke constantly sprayed with water. The dust is reclaimed from the tank in the form of sludge or mud through the door or valve provided for that purpose.

Fig. 7.—Sturtevant Wet Filter.

Another type of air filter which might be developed in connection with the pneumatic handling of[Pg 26] material consists of a very slowly revolving drum or cylinder, which is fitted with a continuous corrugated tape running spirally from the centre to the extreme edge of the casing. The space between the corrugated sheets is very small, and as a stream of water is continually running over and around the divisions, the air passing through the very tortuous path provided is bound to come into contact with these wet surfaces and give up its dust or other contamination, which is washed off when it arrives at the bottom of the[Pg 27] cylinder. Naturally, this or any other wet filter would not be used where the recovery of dust in dry form was desired.

Another form of wet filter consists of a chamber of suitable proportions (according to the amount of air to be cleansed), fitted with racks in which are placed strips of glass at an angle of 45° to the flow of air, and at 90° to one another. The glass strips have a serrated or prismatic face, and the air carries the dust forward into the angles of the glass. A very fine water spray keeps the glass moist and eventually trickles down to the drain channels, washing the glass in its course.

The development of apparatus for air-washing has received considerable attention during recent years, owing to the necessity of having pure, dust-free air for ventilating turbo-generators, etc., and no difficulty should present itself in obtaining satisfactory results for pneumatic conveying plants, except in cases when the collection and retention of dust is required. In these cases the bag or fabric sheet filter is the only type available.

[Pg 28]

Dischargers. The advocates of “blowing” material, instead of “sucking” it through the pipe, often lay great stress on the alleged difficulties of extracting the material from the system without allowing air leakage. This, however, has been overcome successfully by several designers and is not the serious difficulty so frequently suggested, providing that the material is suitable for this means of treatment. The only exception to this is, when the high velocity at which the material enters the discharger—say, 45 to 50 ft. per sec.—causes it to pack or bind so that it will not fall by gravity into the rotary valves and then out into the storage bins.

The function of the discharger is to cause the incoming material to lose its velocity and to fall into a compartment which can eventually be discharged after it has been moved from the low pressure to which the chamber itself is subjected.

This is best accomplished by the use of a rotary valve, somewhat similar to a paddle-wheel, which is revolved slowly but continuously. This wheel can be placed either vertically or horizontally at[Pg 29] the bottom of the receiving chamber; the material enters the large chamber above, loses its velocity, drops by gravity, is caught in the box formed by the revolving paddle-wheel, and gradually is carried forward out of the chamber, eventually passing over an aperture through which it again gravitates to the bunker, silo, or other container. Probably the horizontal type of rotary valve is preferable because, owing to the increased surface exposed to the vacuum, the “suction” effect assists in holding the valve up to its seat.

When dealing with such materials as malt and grain, it is an advantage to be able to inspect the material entering the receiver, and at least one maker secures this advantage by constructing the chamber of a glass cylinder to which are bolted cast iron top and bottom pieces carrying the necessary pipe connections and discharge valves. Fig. 8 illustrates this construction and also shows fairly clearly the method of driving or revolving the discharge valves. The top flange of the valve has a worm wheel tooth cut around its periphery and the actuating worm engages in this wheel, thereby obtaining a large reduction in speed. In other words, the worm can be driven by a light, high speed belt and pulley, and still revolve the valve at a very low speed; such gearing is smooth, silent running, and altogether admirable for such a purpose as the one under consideration.

Fig. 8.—Fixed Discharger with Glass Receiver.

A very common form of separator, which is used almost invariably on plants dealing with wood shavings, sawdust and similar materials, [Pg 31]is known as the cyclone or centrifugal separator. This is usually constructed with a sheet steel body with the inlet for the dust-laden air at the top, and so arranged that the air enters tangentially. Inside there is a smaller cylinder of sheet steel forming an air outlet, and the laden air sweeps round the annular space between the body and the inner cylinder. This results in a whirling action and the material entrained in the air is projected by centrifugal force against the side of the separator body. In some instances an internal ledge, or plate of “corkscrew” form, leads the material downwards towards the outlet at the bottom of the separator.

In the case of some of the denser materials which can be conveyed by air, it is sufficient to connect the discharge pipe to an open bin or chamber, the material in such cases being heavy enough to separate itself by the action of gravity.

Mr. Gordon S. Layton, describing dischargers in his paper, before the Engineering Group of the Society of Chemical Industry (Birmingham, April, 1920), stated—

“There are two types of dischargers in use: The first consists of a large steel box divided into two compartments. This box is arranged to oscillate about a horizontal axis, so that each compartment alternately is brought under the lower opening of the receiver vessel.

“The other type of discharger consists of a bucket wheel rotating continuously inside a closely fitting casing. The material which is[Pg 32] being conveyed falls into the pockets of the bucket wheel when these are on the top of their revolution, and is passed out through an opening in the lower side of the casing.

“It will be obvious that the working of both types is liable to be interrupted by the jamming of a foreign body (such as a piece of wood or a bolt) in the working parts; in each case, special mechanism for driving the discharger has been devised, to avoid the interruption resulting from such blocking, and to enable the discharger to keep on working continuously.”

The rotary type of discharger is preferable to the tipping box type, for the following reasons: because the rotary discharger is more easily kept air-tight, works without vibration, and gives a practically continuous stream, whereas the discharge from the tipping box occurs as large isolated masses of material.

It is impossible to give specific details concerning the discharger because, in all cases, the conditions under which the plant has to work affect the whole design. For instance, where the working is only intermittent, e.g. the removal of ashes from a boiler-house, the discharger can be eliminated, provided that the ash bunker is large enough to hold the quantity of ashes to be dealt with at each operation. In such a case, the ash container would be capable of being exhausted, and the material entering as before would simply drop by gravity into the container and remain there until the pump was shut down; it would then be[Pg 33] allowed to gravitate into the truck or other conveyance for disposing of the ashes.

Hand-holes for cleaning, and easy access to the interior are essential in the design of a discharger, especially if the material to be handled is liable to “pack” when entering at a high velocity.

Pipe Lines. One of the most important points in the designing of a pneumatic conveying system is the correct lay-out of the pipe line.

Fig. 9.—Sturtevant Patent Junction.

A fatal mistake often made in low pressure and exhausting systems is that the numerous branch pipes are added to or altered after the makers have left the original installation. Almost invariably, branches thus added are made to approach the main trunk at too great an angle, with the result that eddies and whirlpools are created within the pipe, seriously reducing the output of the main trunk. So essential is it that this junction should be correct and that the two streams should run as nearly parallel as possible, that the Sturtevant Engineering Co. has patented a special junction (Fig. 9) to bring together the two streams of air in the main and the branch pipe practically parallel, as shown.

[Pg 34]

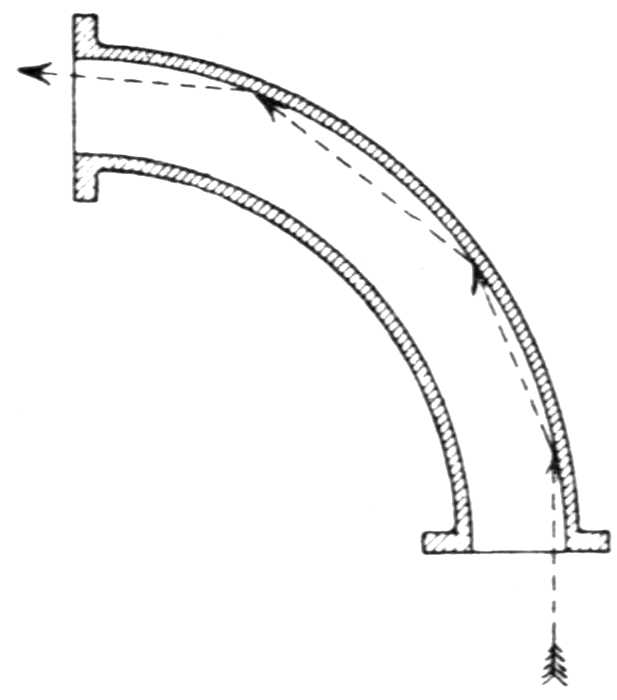

Bends. In connection with high pressure systems, the following points are of great importance. All vertical and horizontal straight lengths may be of a light section constructed in steel. Bends should be avoided whenever possible, and those which are inevitable should be made in hard cast iron, with every possible provision for easy replacement of wearing parts.

The wear takes place at the point of actual contact which, in elbows, is practically confined to one place only. The material rushes to the end, strikes the bend, and—suddenly changing its direction of travel—whirls off down the next straight length. The impact and the resulting wear on the pipe, as well as the breaking of the material conveyed, are naturally much greater in elbows than in easy bends, but if the breaking of the material is not detrimental, elbows should be employed, as they are less costly and can be replaced more quickly and easily.

Certain raw materials—such as salt, soda, lime and various chemicals—which have to be ground before use, may be prepared to a considerable extent for this operation by the use of elbows. On the other hand, easy bends should be employed for material which it is desired to convey without damage, e.g. malt, coal, and granular substances, which are finally required in granular form and not as powder.

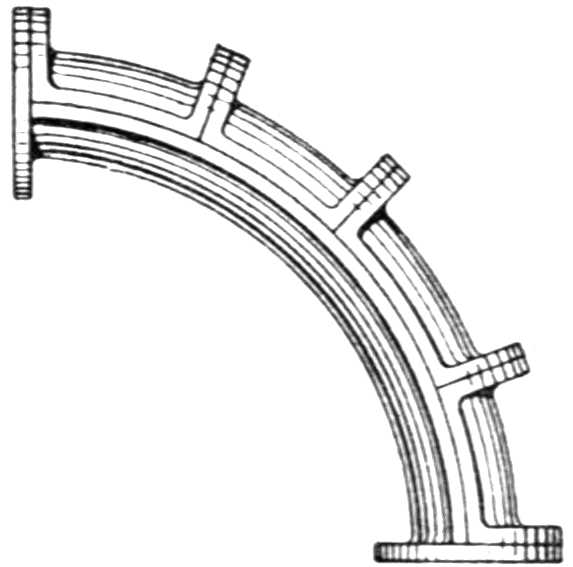

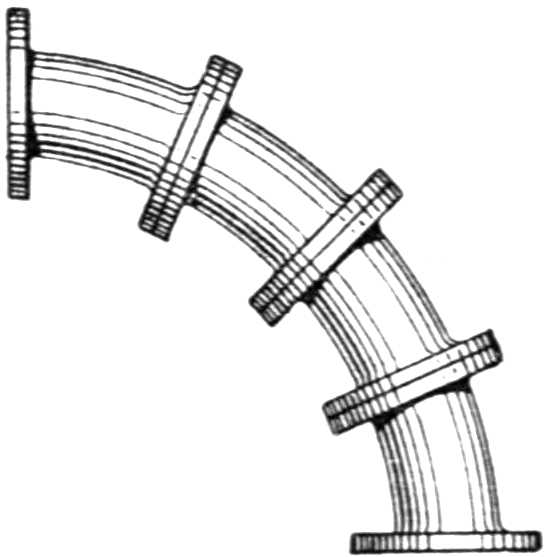

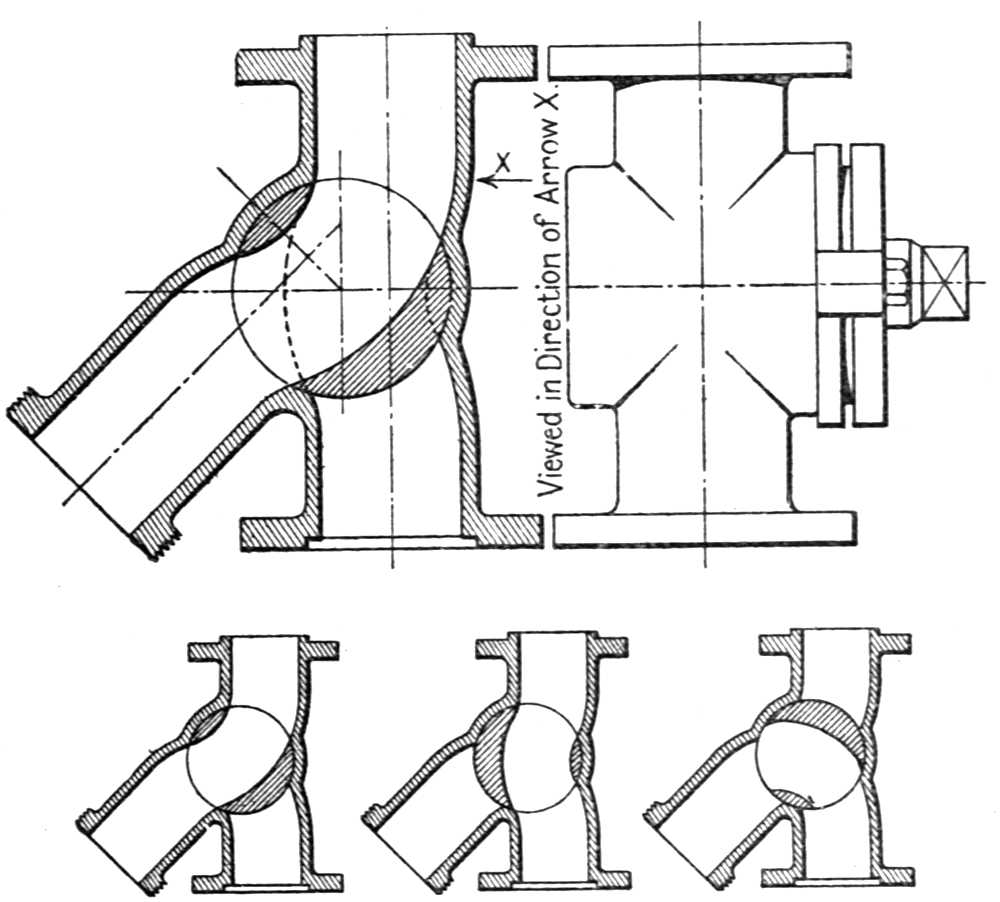

The wear in bends is only on the external radius of the bend, and then is inclined to be localized at certain points rather than distributed[Pg 35] over the full sweep of the bend (see Fig. 10); this being so, it is often desirable so to construct the bends that the back is in segments which can be renewed easily (see Fig. 11). Alternatively, the bend may be constructed on the “lobster” principle (Fig. 12), only the worn sections being replaced when overhauling. It is not necessary always to take a bend at an angle of 90°, and if the small short angle sections are interchangeable, then almost any angle can be constructed by building up with the necessary number of sections.

Fig. 10.

Fig. 11.

Fig. 12.

Fig. 10.—Course taken by Material Round Bend.

Fig. 11.—Segment-Back Bend.

Fig. 12.—Lobster Bend.

With regard to the straight lengths of pipe, it is necessary to ensure a smooth internal bore, especially at the joints. It is therefore desirable that the joints should be self-aligning as, if this is not the case, eddies will be formed which will cause the material to deviate from the centre of the pipe, striking the side at one or more definite[Pg 36] points where holes will eventually be worn through the pipe.

In vertical pipes the evidence of wear is negligible, in fact the conveyed material presumably does not touch the pipe at all, but travels up the centre of it as a core.

Capacity of Pipes. The velocity of the air passing up the pipe should be from 40 to 50 ft. per sec., equivalent to about 35 miles per hour.

The conveying capacity of an efficient pipe line is approximately 15 per cent. of the total capacity: in other words, if the total cross-sectional area of the pipe be taken as 100, the effective cross-sectional area as regards conveying is 15.

Flexible Connections. The flexible connections attached to the permanent pipes may be ordinary tubing, as made by the Flexible Metallic Co. Phosphor bronze and other metals have been tried, but the extra cost is not justified. A loose screw collar connection makes possible easy fixing, and permits the flexible connection to be removed easily to prevent damage when not in use. Rubber tubing, reinforced with steel wires, would be best where it is important that the material conveyed should not be damaged, but the wear on such tubing is so rapid that the extra cost is not recovered by the saving in damage to ordinary materials. The length of the flexible pipe should be such that the movement over the greatest area to be covered does not put too great a strain[Pg 37] on the bending properties of the tubing. On the other hand, unnecessary increase in the length of the flexible pipe merely increases the cost of one of the shortest lived portions of the plant, the “scrap value” of which is almost negligible.

Showing Three Positions of the Valve.

Fig. 13.—King Full-way Junction Valve.

Valves, etc. For use where branches are inserted in the main pipe line for convenience in either lifting over, or discharging over, a large area, special appliances have been designed and these should be used, as they do not create eddies or[Pg 38] increase the pipe friction appreciably, or reduce the carrying capacity of the pipe line. The King patent full-way junction valve is an excellent example, and is shown in Fig. 13, from which it will be seen that a full bore circuit can be completed in any of three directions. This valve has no corners where the material can collect, hence the pipes are sucked perfectly clean the moment the feed is shut off.

Another convenient fitting of this description is the Boby patent pipe switch. This device is similar to a switch as used on a railway track, and by its use three separate side positions may be connected with one part on the main transport line. When the switch is thrown over so as to connect to any one particular branch, all other branches are disconnected.

Telescopic Pipes. When the unloading of ships is carried out by “suction” it is necessary to make provision for lengthening or shortening the vertical suction pipe, or pipes (see Frontispiece), because the ship will rise as relieved of its cargo, and the suction nozzle will simultaneously move towards the bottom of the hold as the cargo is discharged.

A still greater difficulty is encountered in tidal rivers, where the rise and fall may be many feet and must be allowed for continuously. This is best done by the introduction of telescopic pipes in the vertical downright pipes. These must be so constructed that while it is fairly easy to increase[Pg 39] or decrease their length, the pipes must remain air-tight at the joints and connections.

Where the rise and fall is small the difference in level may be compensated by a ball and socket joint, and a counter balance on the jib arm, but this method has its limitations.

Pipes for High Pressure Systems. Coming now to the “small pipe,” high pressure systems as used for vacuum cleaning plants, the pipe lines must be designed and installed carefully and on a liberal basis. It is mistaken policy to attempt to economize by using a smaller main on branch pipes. Small diameter pipes cause excessive losses by friction, and naturally are less efficient as regards power consumption.

The frictional losses in a system of this description vary directly as the length of the pipe, and inversely as the fifth power of the diameter. Large pipes are therefore very desirable, not only because of their greater carrying capacity—which is very desirable—but also because such things as matches, hairpins, etc., are picked up every day by an installation as fitted in hotels, restaurants and theatres. Such material quickly clogs small pipes and causes endless trouble and delay.

The flexible hose should be as short as is consistent with ease of working, because the frictional losses in this class of tubing are very great. It would be preferable to increase the number of wall plugs, rather than have to use very long lengths of flexible hose.

[Pg 40]

Fig. 14.—Suction Nozzles for High Pressure Systems.

Suction Nozzles. Probably more patents have been taken out on new suction nozzles than on any other portion of a pneumatic suction plant. The chief desiderata for a nozzle on a high pressure system for wheat, coal, ashes, etc., are that it be of light construction to allow of easy manipulation by the operator, and that it have some means of allowing a “free air” inlet, making it impossible to choke the nozzle by burying the end. It is an advantage to be able to regulate the free air inlet according to the conditions existing with different materials. The same nozzle that will act best while dealing with a large bulk of material, may be quite unsuitable when it becomes necessary to “clean up” in the corners of the hold or waggon. Fig. 14 shows different types of nozzles for high pressure plants, but as the efficiency[Pg 41] and capacity of the plant can be affected seriously by the design of this portion of the apparatus, it is highly advisable to allow the designer to have a free hand and to make use of the experience already gained.

Fig. 15.—Sturtevant Equipment Removing Wood Refuse from Double Tenoning Machine.

Nozzles designed for low pressure systems, dealing with dust, shavings, etc., have to be built to suit the machine to which they are attached, and they therefore vary indefinitely in details of design and construction. The same remarks apply to the nozzles for use on suction cleaning plants. Figs. 15 and 16 show how the suction nozzles are adapted to the machines.

[Pg 42]

Fig. 16.—Sturtevant Equipment Removing Dust from Sand-papering Machines.

It must be remembered that in low pressure systems handling shavings, dust, etc., the problem is quite different from that in high pressure systems handling wheat, etc. In the case of removing dust or shavings from a machine, the material is already in motion, and only requires drawing forward and into the pipe system, but in the case of conveyors for wheat, coal, etc., and in the case of suction cleaners, the material to be moved is heavy and stationary and has to be lifted[Pg 43] and started in motion before it can be carried away. This necessitates a much higher air velocity through the collecting nozzles.

Idle Nozzles should be Closed. It is perhaps advisable to draw attention at this point to the disadvantages of using more than one suction nozzle on one receiver at one and the same time. The reader is asked to recall the fact that the material is not lifted by vacuum, but that the production of a partial vacuum causes a stream of air to pass up the pipe at high velocity. The material to be conveyed is entrained with the air, and due to the frictional contact between the particles of air and the particles of material, the latter is lifted and carried forward.

If the conveying plant is to be efficient and of reasonable capacity, the pipes must be relatively large, and in order that the desired partial vacuum may be maintained in them (establishing a vigorous air current) without the use of an unduly large pump, it is important that air be admitted only through those nozzles which are actually in use. Also, when more than one nozzle is in use at the same time, it is necessary to keep each nozzle covered with material to such an extent that the same amount of air passes into each pipe. Unless this is done a large quantity of air will pass up one pipe, and a small quantity up the other, and the amount of material taken in at each nozzle will vary as the quantity of air varies. To consider an extreme case, suppose that the man operating at[Pg 44] one of the pipes allows his nozzle to become exposed. Air will rush in at this nozzle to the full capacity of the pump, with the result that little or no air will pass up the second pipe, and consequently no material either. Thus, if one man is sufficiently neglectful to leave his nozzle idle and open, he renders practically useless the other nozzle or nozzles on the same main.

Even with care this is bound to occur to a certain extent, as is shown by the figures given by makers for the estimated power consumption, viz., about 1 h.p. per ton on single-nozzle plants, and 1½ h.p. on double-nozzle plants.

Under these conditions it should be considered whether it is more advisable to install one large plant with two nozzles, or two small plants, each with only one nozzle. The decision depends upon the extra cost of power for the double-nozzle plant compared with the higher capital charges on the two single-nozzle plants.

[Pg 45]

The pneumatic principle has been applied to the handling of grain in bulk to a much greater extent than to any other material. As previously stated, the original successful plant invented and designed by Mr. Frederic Duckham was for the handling of wheat for the Millwall Docks Co., and the success of this plant was such that it was imitated by engineers in this country and abroad with equally satisfactory results.

Grain lends itself admirably to pneumatic transport because it is easy of flow, regular in size, and practically self-feeding. Also, the removal of dust, which is incidental to pneumatic conveying, is a special advantage where grain is concerned. Figs. 17 and 18 show clearly the advantages of pneumatic conveying in point of simplicity and labour saving.

Typical Quayside Plant. Fig. 19 shows a typical lay-out for a comparatively small plant handling 50 tons per hour. The diagram is almost self explanatory.

A represents the special suction nozzle through which the grain enters the system, together with the “free air” which acts as the conveying medium.

[Pg 46]

Fig. 17.—Ancient.

Fig. 18.—Modern.

[Pg 47]

Fig. 19.—Typical Grain-Handling Plant; 50 Tons per hour.

[Pg 48]

B is a length of flexible pipe to enable the nozzle to sweep the width of the barge, the length being dealt with by moving the boat to within the radius of the swivel arm E.

C is a permanent pipe carried on the jib arm which is mounted on a swivel joint; B is another short flexible pipe to permit of the swivelling already mentioned.

F indicates the receiver into which the grain is deposited, and G the special rotary valves, for releasing the material from the system without interfering with the vacuum of the conveying line.

H illustrates the twin air filters which are provided with valves, so that each of the filters can be isolated in turn from the rest of the plant for cleaning of the fabric tubes, without interrupting the continuous working of the plant.

J indicates the connecting pipes between the receiver, air filters, and pump, and it should be noted they are considerably larger than those on the suction end C, this being necessary to allow for the expansion of the air under vacuum.

K is the reciprocating air pump, driven electrically by the motor M through large helical gear wheels, which act as flywheels and are helpful in equalizing the torque required by the pump.

L is the outlet pipe for the air as it is exhausted from and by the pump.

[Pg 49]

Fig. 20.—Floating Pneumatic Transport Plant; 200-250 Tons per hour.

Fig. 21.—Portable Pneumatic Plant on Railway Truck.

This plant is simple, but every possible modification can be added that circumstances make desirable; such as discharging on to a belt [Pg 51]conveyor, for feeding the silos or other storage bins.

Where grain is bought by bulk it would be necessary to check the weight, and in this case an automatic weigher would be installed, into which the material would be discharged from the receiver. With a bag filter the collected dust can also be weighed, the total weight being then obtained by addition.

Typical Floating Plant. The most popular development of the above type of plant is the floating plant, designed for erection on a hulk, or barge, and intended to suck grain from an ocean-going steamer and discharge it into barges or lighters on the other side of the discharging plant, as indicated in Fig. 20. The plant shown is one of many in actual operation and its construction may be followed by reference to the description of the plant shown in Fig. 19, the same index letters being used in each case. One great advantage of floating plants is that the difference in height due to tides is of no consequence.

Portable Plants. Still another modification consists of a complete quay-side plant mounted like a travelling crane, so that it can be moved longitudinally along steel rails on the quay-side. This plant is particularly useful where large cargo ships have to be emptied and then allowed to remain at their berth until reloaded with another cargo.

Fig. 22.—Portable Railway Plant in Operation.

Complete plants have also been mounted on [Pg 53]railway trucks, the engine and pump in this case being on a second waggon (see Figs. 21, 22). In such a case the plant has to be mounted very low, and it is necessary to lift from the under-side of the truck to, say, a railway waggon, by means of an adjustable belt or bucket elevator (shown at the extreme left of Fig. 21).

Many other applications will suggest themselves to the reader, and sufficient has been said to prove that for the handling of wheat the pneumatic system is distinctly flexible and convenient; also, it effects a great saving in labour, which is an important consideration nowadays. “Bushelling,” conveying, and weighing by hand used to cost well over a shilling per ton, which figure was reduced to just over 1½d. per ton by pneumatic conveying; these are pre-war costs in both instances, but the relative saving effected by pneumatic conveying is certainly not less under present conditions.

All the previous remarks also apply to linseed and cotton seed in bulk, maize, oats, and in fact all cereals. Such materials have to be accepted as and when the ships arrive irrespective of convenience, and it is an important advantage of pneumatic conveying that the material can be lifted and discharged in the most convenient position; also, when the barge or ship has departed the same apparatus can be utilized to lift the material from its position in store to the cleaning or grinding plant.

[Pg 54]

The writer was directly interested in the erection and installing of one of the first plants installed in this country for the elevation and conveying of coal, and a description of the various details may give a good idea of a complete plant, handling coal on a commercial scale.

The conditions to be complied with are as follows: 20 tons of “slack” per hour, to be raised 90 ft. above canal level or 80 ft. above road level.

The coal is brought alongside the power-house by canal barges of 25 tons capacity, or by tipping steam waggons from the railway sidings, a distance of one mile away. In both cases the coal is required to be elevated into overhead bunkers of 600 tons capacity placed vertically over the boilers.

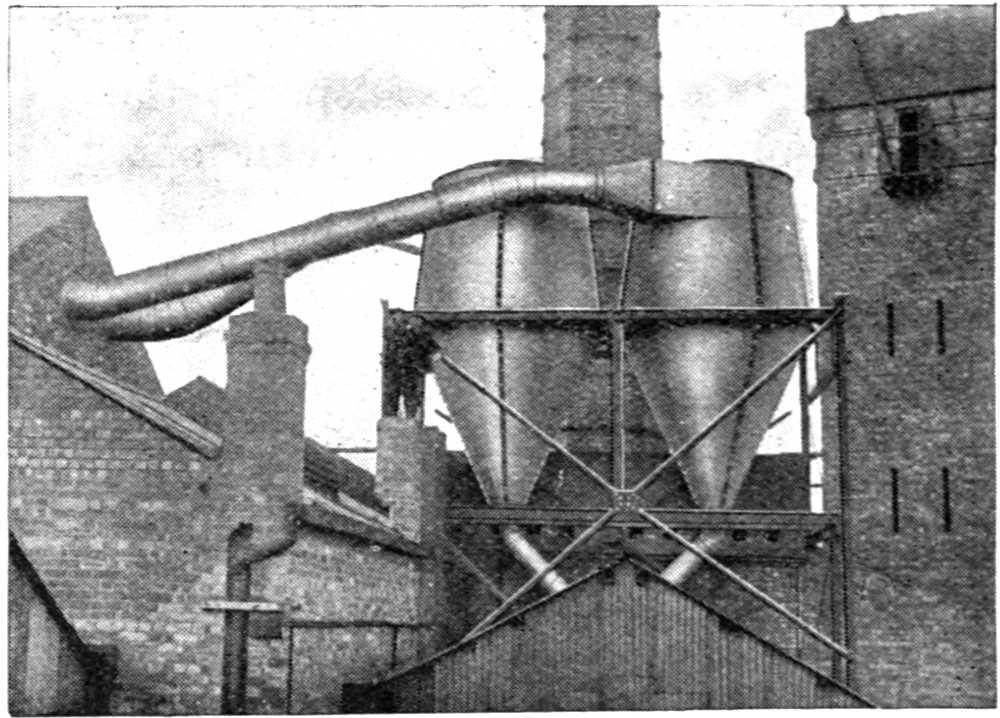

Fig. 23.—Pneumatic Unloading of Coal at Messrs. Boots, Ltd. (Nottingham).

In the first case, immediately the barge is alongside, the flexible suction pipe is lowered into the barge (Fig. 23), and coal immediately begins to rise in the pipe and is discharged as required. Little or no handling of the coal is required after the suction nozzle has once reached the bottom of the barge; all that it is necessary to do is to bring the barge gradually up to the nozzle, the coal then “avalanching” down to the nozzle. [Pg 56]Fig. 24 shows the discharger placed on girders over the bunkers into which it discharges continuously. The coal enters at A and the major portion of the fuel is discharged through the rotary valves B.

The coal discharger itself consists of a cast iron vessel with two King’s patent rotating valves. These are designed in the form of a slightly conical taper divided into four sections, one portion of the circular valve being under vacuum, and the other under ordinary atmospheric pressure. The outlet of the valves is larger than the inlet to allow the coal which is in the valve to drop out easily. Over each valve is also provided a four-armed sweeper to prevent any damp coal from forming a cone inside. The discharger is provided with two inlets with full-way bored valves, so that the coal can be drawn either from the water side or from the land side at will. After the coal has been deposited in the main discharger, there is provided a supplementary discharger consisting of a vessel 6 ft. high by 30 ins. diameter, with two inlet pipes of 8 ins. diameter, to provide a contra-flow, so that any particles of coal dust in the air will meet one another in the 30 ins. box at equal velocity and be deposited. The small particles are delivered by a supplementary rotary discharge valve which is set to run very much slower than the main discharger valves.

[Pg 57]

Fig. 24.—Discharger for Coal Conveying Plant.

The main discharger valves are driven by worm gearing, the latter having one right-hand thread and one left-hand thread, so that the end thrust [Pg 58]on the worms is neutralized. Ball bearings are provided and the small motor which drives all three valves is coupled up with an electrical device designed by the author. This device ensures that if anything happens to the top discharge valves—so that the 3 h.p. motor driving them cuts out, owing to an overload or other cause—then the main motor also is cut out by the opening of its circuit breaker. This prevents any “flooding” of the pipes and dischargers.

It may be mentioned that the valves are so designed that a portion of the weight of each valve is carried by the vacuum, so that the vertical wearing lift on the valves when at work is very slight.

The intake pipes for the coal are 5 ins. diameter, and they are provided with heavy cast iron bends, having extra thick metal on the outside radius to allow for the wearing effect of coal passing at the rate of 20 tons per hour.

The pipe into the barge is provided with a flexible steel pipe at the suction nozzle end, for convenience of handling. India-rubber piping has been tried, but the extra cost does not justify its continued use.

The nozzle is made as light as possible for convenience of handling, and is fitted with a special “free air” inlet for the regulation of the amount of air necessary to blend with the coal.

Ash Handling. In addition to unloading coal, the above plant is capable of dealing with hot ashes which are first crushed in a portable clinker[Pg 59] breaker, electrically driven, which runs under all the ash hoppers of the boilers. The ash when crushed gravitates into funnel-topped tee-pieces, inserted in the main ash-conveying pipe, whence it is immediately sucked up into an overhead ash hopper to await the convenience of the waggons which dispose of it on the “tips.”

Flue Cleaning. A 3 in. suction pipe has been run round the boiler-house in such positions that flexible hose can be attached for flue cleaning purposes. In this case the cleaners simply use an enlarged nozzle such as is supplied with a domestic equipment and the dust is removed from the flues, economizer soot chambers, etc., into the ash hopper without trouble or dust.

The success of this plant is best indicated by the fact that, at the moment of writing, a duplicate plant is being erected. Owing to the growth of the business, and its demand for power and steam, the original plant has to be worked continuously on coal, so that the ash and flue dust problem has become acute again.

Portable Floating Plant. A third plant ordered by the same firm is of considerable interest. This is intended to be mounted in a barge so as to be portable. Owing to lack of space in close proximity to the power-house, considerable difficulty is found in keeping adequate stocks of coal on the site except the 600 tons in the overhead bunkers. In order to secure continuity of working,[Pg 60] it is essential that as much fuel as possible be stored, and for this purpose a coal pile has been made about half a mile away from the works, adjoining the canal. Ashes can be disposed of on certain fields a few miles outside the city in swamps and pools caused by subsidences, due to colliery workings.

The portable plant is therefore arranged to operate as follows: the barge is self-propelled by a 30 h.p. paraffin engine which can be coupled by clutches to either the propeller or a Roots blower, the latter being the exhauster for the portable suction plant.

The barge is loaded with ashes for disposal, and then proceeds under its own power to the site where they are to be dumped. The clutch is operated disconnecting the propeller and operating the blower. The suction side of the blower is coupled up with the pipe line in the boat and the barge feeds the plant by means of the flexible hose: the discharge pipe is raised over the towing path so as not to interfere with passing traffic, and the ashes are blown out into the swamps previously mentioned. It will readily be recognized how simple this unloading becomes compared with trying to dig out the ashes with either a spade or a fork.

The empty barge then returns to the coal pile and takes up a load of coal in a similar manner, then proceeding to the power-house under its own power and being unloaded by the original fixed pneumatic installation in the ordinary way.

[Pg 61]

The coal arriving by road is tipped into a concrete hopper excavated below the ground level, and so designed with sloping sides that it is self feeding into a suction pipe connected to the bottom of the hopper. The same procedure occurs except that in this case the coal enters the main discharger at the top (E, Fig. 24).

It is interesting to note that the very fine dust collected from the air filter is eagerly sought after by the foundry trade, and what would at first appear to be a waste product impossible to burn, is actually a valuable by-product of the plant.

[Pg 62]

Numerous means have been devised to cause the necessary current of air to flow along the conveyor pipe, but the ideal method is probably yet to seek. Probably the most satisfactory and economical system, until recently, was the positive pump exhausting a vacuum chamber; the latter receiving the material, and discharging it into the receptacle provided for that purpose.

The difficulties arising in practice, however, incited the inventive genius of engineers responsible for the operation of these plants, and a number of attempts were made to induce an air current by other means.

Ejector Systems. Steam ejectors were fitted to the closed tank provided for the reception of the material, thus converting the tank into a vacuum chamber, and eliminating the discharger. In other cases injectors, also operated by steam, were placed at intervals along the conveyor pipe, usually at such convenient points as 90° bends, and the slight vacuum created by the condensation of the steam and also by the velocity of the jet, induced an air current which swept the material along with it into the receiver chamber.

Although both these methods are in practical[Pg 63] use, their applications are strictly limited to materials which do not suffer by contact with heat and moisture; the methods are therefore used principally for conveying ashes and soot from boiler furnaces and flues. Ashes formed by the combustion of coal contain large amounts of abrasive matter, and it is very important that all this matter should be extracted from the air, before entering the exhauster of the suction system. The steam jet cuts out the exhauster entirely, but absorbs an excessive amount of power in the form of steam. It has the advantage, however, of quenching the ashes on their way to the settling tank. For flue dust, however, the steam jet is unsuitable, as the condensed vapour causes the material to cake in the pipes, and the latter rapidly become choked, involving considerable delay and trouble in cleaning out. The ejector system is used for this material, the tank being of the closed type, and the necessary vacuum being created by a steam ejector fixed in a branch at the side near the top, the dust striking a baffle and falling by gravity to the bottom of the tank. A special air-tight gate or valve is opened to empty the tank.

Air Induction. The cardinal feature of the induction system is the ease with which materials may be handled which cannot be conveyed by the suction method.

Sand, sugar, salt, soda ash, and many other substances of a granular nature, which are very[Pg 64] troublesome when conveyed by the suction method, may be dealt with economically by the induction system and, although the latter is only in its experimental stages at the moment of writing, it is possible that it may displace all other systems in the near future.

The induction system differs from the suction system in that the air flow along the pipe is induced by a jet of air, at very high velocity, fixed at any convenient distance from the intake nozzle of the conveyor pipe, and the material conveyed is discharged either from an open end into an open container, or by some form of cyclone. The closed discharger or container, with its baffles and rotary valves or air locks, is eliminated, and the substance to be handled has a free and unrestricted flow throughout the length of the pipe.

Advantages of the Induction System. The advantages of the induction conveyor may be summarized as follows: (1) Low first cost, the power unit being the only expensive item. (2) Low maintenance cost, there being no moving parts and little wear. (3) Low labour cost, practically no attendance being required. (4) Flexibility and ease of handling. (5) High efficiency of power unit and reliability of system. (6) Ability to handle materials which are easily damaged.

In the case of a suction plant handling grain or coal, the intake end of the conveyor is fairly flexible, and the nozzle may be operated over a fairly large radius, say, all over the floor of a[Pg 65] vessel’s hold. The discharge end, however, is fixed, unless a cumbersome and expensive gantry is provided to permit of the discharge apparatus being moved about. Even should the discharger be mounted on rails, the area over which it can operate is limited by the rails on which it runs. With a large plant, this would mean that a number of dischargers would be required to lift from a ship into a warehouse or store, from the latter into bunkers or silos, or perhaps into trucks or waggons. Each discharger would require a separate exhauster and a separate intake, and valuable space would be occupied by the plant and expense incurred for machinery which would not be in use for a considerable part of the time.

The induction system, however, is flexible at both intake and discharge ends of the pipe. It is only necessary to lower the nozzle into the material to be removed, and to place the delivery pipe over the receptacle for the material, and to turn on the air jet. The delivery may be handled easily while working, and the material distributed where required; or suitable valves and branches may be fixed, and a number of discharge pipes used in turn to deliver into different bins or into various floors.

The source of power for the operation of the induction conveyor is the air compressor. As every operating engineer is well aware, all machinery is kept in better condition and runs more economically, when it is housed in proper environment and receives skilled attention. The compressor, in this[Pg 66] case, need not be erected near the work, but may be placed some distance away, preferably in the power station, as the pipe line connecting the conveyor with the machine will have a very small bore, compared with the air pipe to the exhauster on a suction plant, and will also be inexpensive to erect and maintain. In the instance quoted above, where a number of suction and delivery points are required, only these small pipes need be run from a common main, and turned on and off as needed, the compressor running continuously at or near its most economical load.

Construction of Induction Plant. The induction conveyor may be said to be a compromise between the suction and blowing methods. The air jet is fixed in the conveyor pipe at a suitable angle, some distance above the intake nozzle, and a stream of air at high velocity is passed along the pipe in the direction of the discharge. This air jet is designed carefully for the duty it has to perform, and its discharge entrains the free air in the pipe, causing it to move in the required direction. A partial vacuum is created in the conveyor pipe, behind the jet, and free air rushes in at the intake, carrying the material along with it.