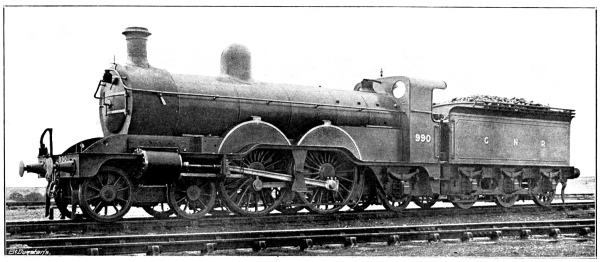

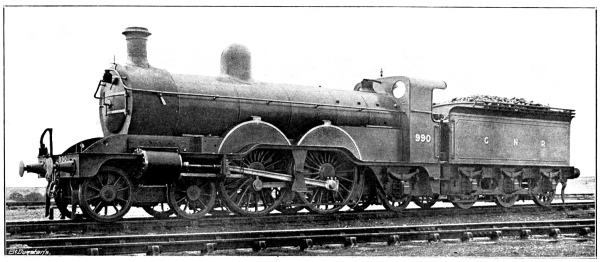

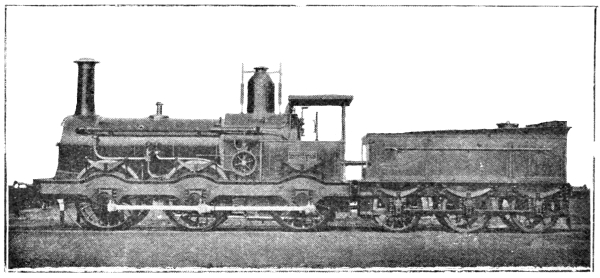

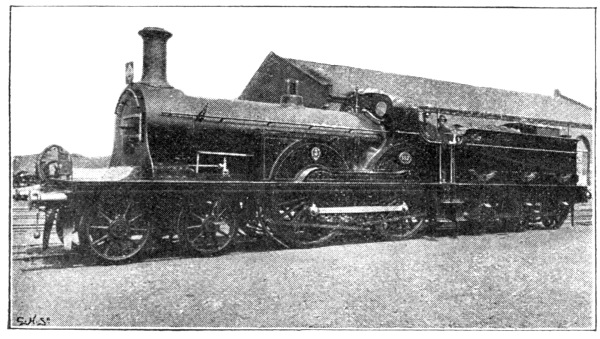

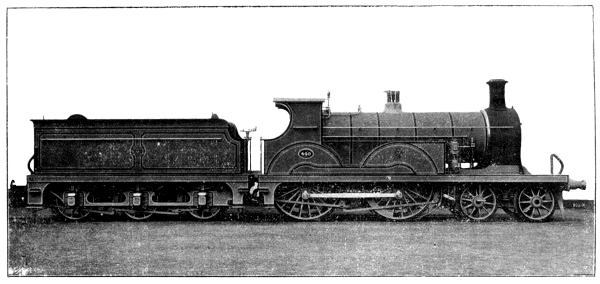

AN ENGLISH TEN-WHEELER,

DESIGNED BY MR H. A. IVATT, LOCO. SUPT.

BUILT AT THE G.N.R. LOCOMOTIVE WORKS,

DONCASTER

Title: The evolution of the steam locomotive (1803 to 1898)

Author: George Augustus Nokes

Release date: May 2, 2024 [eBook #73518]

Language: English

Original publication: London: The Railway Publishing Co, 1899

Credits: Peter Becker and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

AN ENGLISH TEN-WHEELER,

DESIGNED BY MR H. A. IVATT, LOCO. SUPT.

BUILT AT THE G.N.R. LOCOMOTIVE WORKS,

DONCASTER

(1803 TO 1898.)

BY

G. A. SEKON

Editor of the “Railway Magazine” and “Railway Year Book,”

Author of “A History of the Great Western Railway,” &c., &c.

London:

THE RAILWAY PUBLISHING CO., Ltd.,

79 to 83, Temple Chambers,

Temple Avenue, E.C.

1899.

[Pg iii]

In connection with the marvellous growth of our railway system there is nothing of so paramount importance and interest as the evolution of the locomotive steam engine.

At the present time it is most important to place on record the actual facts, seeing that attempts have been made to disprove the correctness of the known and accepted details relative to several interesting, we might almost write historical, locomotives.

In this work most diligent endeavours have been made to chronicle only such statements as are actually correct, without reference to personal opinions.

In a broad sense, and taken as a whole, the old works on locomotive history may be accepted as substantially correct.

From these, therefore, and from authentic documents provided by the various railways, locomotive builders, and designers, together with the result of much original research, has the earlier portion of this account of the evolution of the locomotive steam engine been constructed. The various particulars of modern locomotive practice have been kindly supplied by the locomotive superintendents of the different British railways, so that no question can arise as to the strict accuracy of this portion of the work.

Nearly forty years ago it was authoritatively stated: “That kind of knowledge of the locomotive engine which answers the purpose of a well-informed man has already become so popular that it almost amounts to ignorance to be without it. Locomotive mechanism is very simple in its elementary nature, and the mind is naturally disposed to receive and retain any adequate explanation of striking phenomena, whether mechanical or otherwise; and hence it is that there are thousands of persons who, although in no way concerned in the construction or working of railway engines, are nevertheless competent to give a fair general explanation of their structure and mode of working.”

If such were true at that time it is abundantly evident that it is more so at the threshold of the 20th century, considering the growth of inquiry into, and appreciation of, scientific and mechanical knowledge by an ever widening and increasing circle of general readers, which has been one of the marked signs of intellectual development during recent years. Under [Pg iv] such circumstances it is not surprising that the locomotive and its history have received a large share of public attention. Whilst railway officers, with the intelligence for which they are justly distinguished, have always evinced a proper desire to be acquainted with the evolution of the “steam horse,” the spread of education has increased and quickened a desire for knowledge concerning the locomotive amongst all classes in a remarkable manner. Many of the numerous illustrations that embellish the book have been specially collected for the purpose, and several will be quite new to the majority of readers. Special pains have been taken to admit only such illustrations the authenticity of which was known to the author, and for the same reason many otherwise interesting pictures, upon the accuracy of which suspicion rested, were excluded from the collection.

Despite these exclusions, we believe that no other book on locomotive history in the English language is so fully illustrated.

As it is proposed to deal with the railway locomotive only, it is not necessary to make more than a passing reference to the more or less crude proposals of Sir Isaac Newton, the Marquess of Worcester, Savery, Dr. Robinson, Leupold, and other writers and scientists, who hinted at the possibility of steam locomotion. Nor does the writer propose to discuss the alleged use of railways and steam locomotives in Germany at a date prior to their general introduction into England. The claims of Cugnot, Symington, Evans, Murdoch, and others as builders or designers of actual or model steam road locomotives will also be passed without discussion.

We take this opportunity of expressing our sincere thanks to the locomotive superintendents of British railways, who have all been so willing to assist the author, not only in supplying accurate data concerning the locomotives of their own design, but also for so kindly revising the portions of the volume that relate to the locomotive history of the particular railway with which each one of these gentlemen is connected.

In conclusion, we leave the “Evolution of the Steam Locomotive” to the kindly consideration of our readers, hoping that from a perusal of it they may derive both information and pleasure.

December, 1898.

[Pg v]

CONTENTS.

| page | |||

| Preface | iii. | ||

| List of | Illustrations | vi. | |

| Chapter | I. | 1 | |

| ” | II. | 10 | |

| ” | III. | 28 | |

| ” | IV. | 40 | |

| ” | V. | 56 | |

| ” | VI. | 66 | |

| ” | VII. | 82 | |

| ” | VIII. | 103 | |

| ” | IX. | 130 | |

| ” | X. | 156 | |

| ” | XI. | 185 | |

| ” | XII. | 205 | |

| ” | XIII. | 231 | |

| ” | XIV. | 260 | |

| ” | XV. | 294 | |

| Index | 321 | ||

[Pg vi]

| page | |

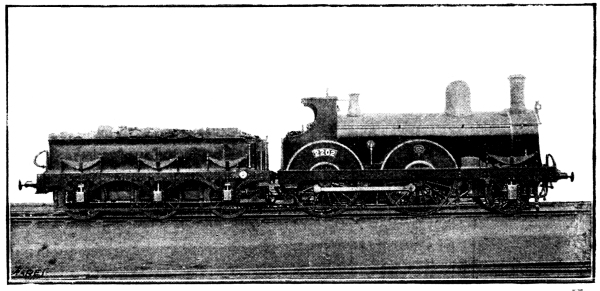

| “990,” the latest type of Great Northern Railway express engine | Frontispiece |

| The First Railway Locomotive of which authentic particulars are known | 3 |

| Locomotive built by Murray for Blenkinsopp’s Railway | 6 |

| Brunton’s “Mechanical Traveller” Locomotive | 8 |

| Hackworth’s “Wylam Dilly,” generally known as Hedley’s “Puffing Billy” | 11 |

| Hackworth’s or Hedley’s Second Design, used on the Wylam Rwy. in 1815 | 13 |

| Stephenson’s Initial Driving Gear for Locomotives | 15 |

| Stephenson and Dodd’s Patent Engine, built in 1815 | 16 |

| Stephenson’s Improved Engine, as altered, fitted with Steel Springs | 17 |

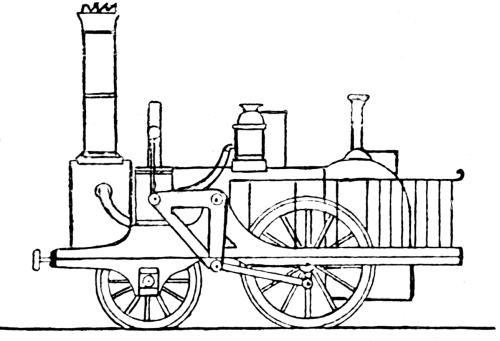

| “Locomotion,” the First Engine to Run on a Public Railway | 20 |

| The First Successful Locomotive, Hackworth’s “Royal George” | 23 |

| Hackworth’s Blast Pipe in the “Royal George” | 24 |

| Waste Steam-Pipe in Stephenson’s “Rocket” | 25 |

| The “Novelty,” entered by Braithwaite and Ericsson for the Rainhill Prize | 29 |

| Hackworth’s “Sanspareil,” one of the Competitors at Rainhill | 32 |

| Stephenson’s “Rocket,” the Winner of the Rainhill Prize of £500 | 35 |

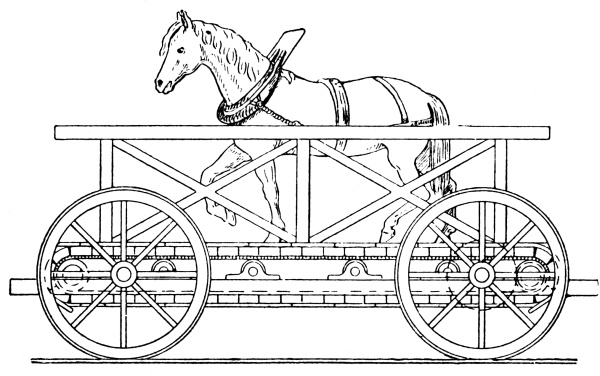

| Winan’s “Cycloped” Horse Locomotive | 38 |

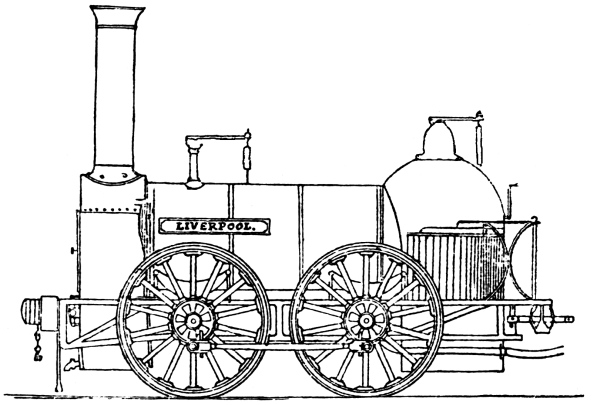

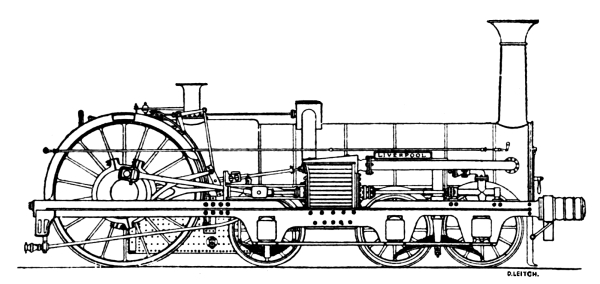

| Bury’s Original “Liverpool,” the First Engine with Inside Cylinders, etc. | 41 |

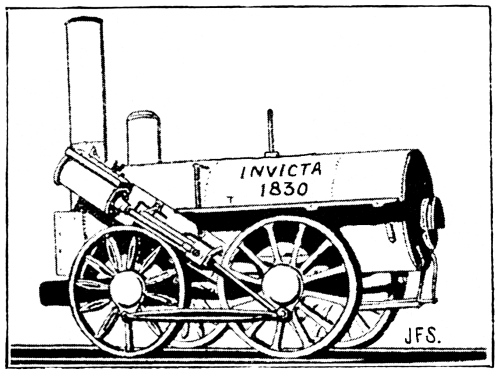

| The “Invicta,” Canterbury and Whitstable Railway, 1830 | 45 |

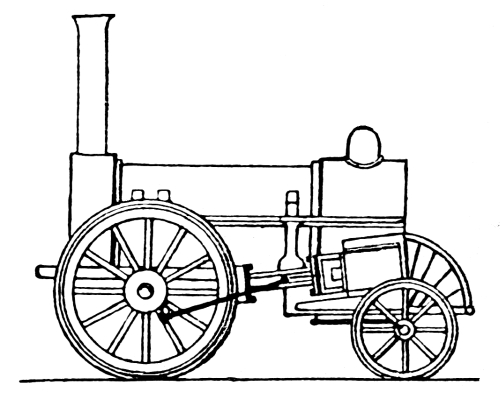

| The “Northumbrian,” the Engine that Opened the Liverpool | |

| and Manchester Rwy. | 46 |

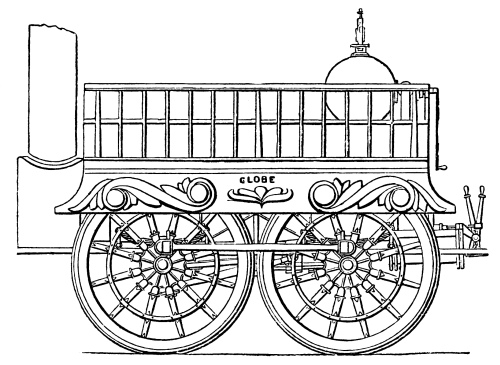

| Hackworth’s “Globe” for the Stockton and Darlington Railway | 48 |

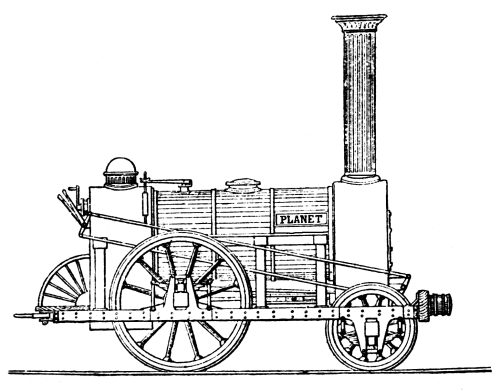

| Stephenson’s “Planet,” Liverpool and Manchester Railway | 49 |

| “Wilberforce,” a Stockton and Darlington Railway Locomotive | 53 |

| Galloway’s “Caledonian,” built for the Liverpool & Manchester Rwy. in 1832 | 54 |

| Roberto’s “Experiment,” with Verticle Cylinders, Bell-Cranks, etc. | 57 |

| Hawthorn’s “Comet,” First Engine of the Newcastle & Carlisle Rwy., 1835 | 59 |

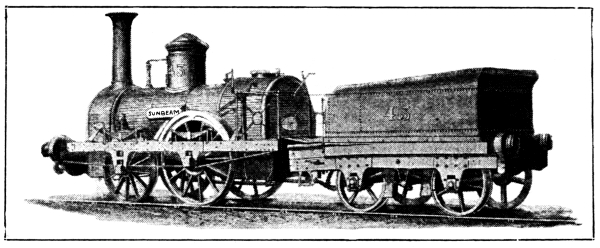

| “Sunbeam,” built by Hawthorn for the Stockton and Darlington Railway | 64 |

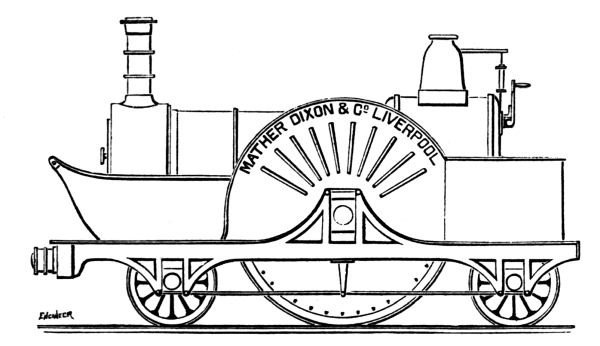

| The “Grasshopper,” with 10ft. driving wheels, built by | |

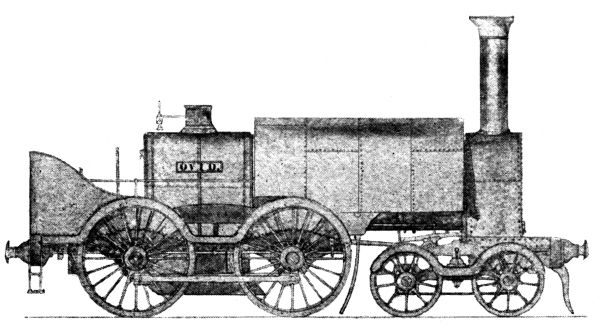

| Mather, Dixon & Co., for the G.W. Rwy. | 73 |

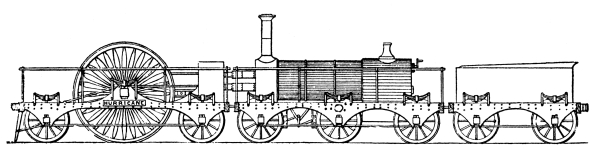

| The “Hurricane,” with 10ft. driving wheels, a Broad-Gauge Engine, | |

| built on Harrison’s System | 76 |

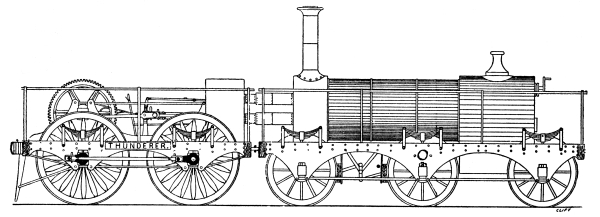

| The “Thunderer,” a geared-up Broad-Gauge Engine, built on Harrison’s Plan. | 78 |

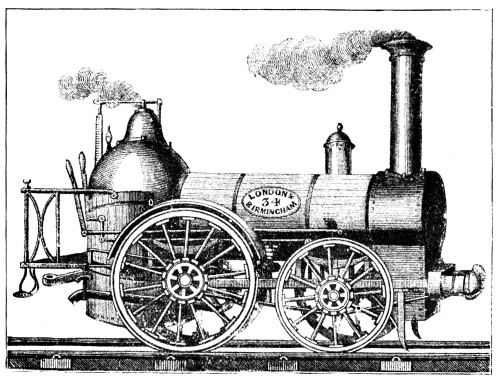

| Bury’s Standard Passenger Engine for the London and Birmingham Railway | 83 |

| “Garnet,” one of the First Engines of the London and Southampton Rwy. | 85 |

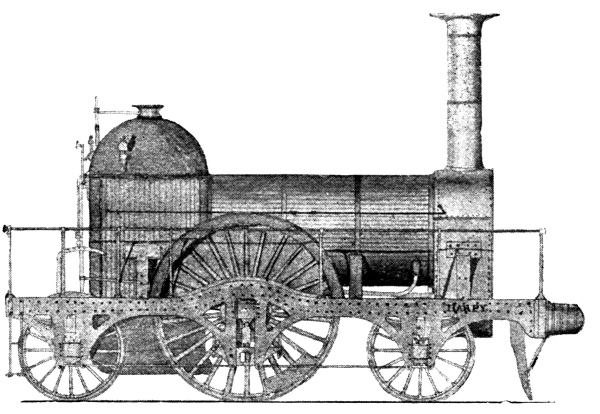

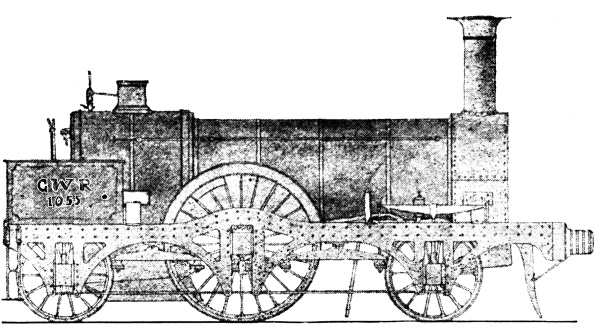

| “Harpy,” one of Gooch’s “Firefly” Class of Broad-Gauge Engines | 90 |

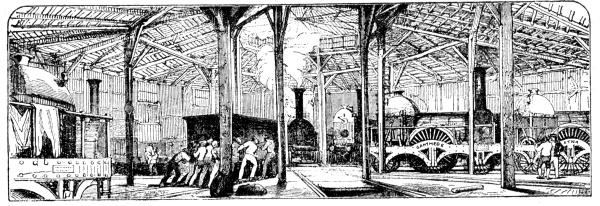

| Interior of Paddington Engine House, | |

| showing the Broad-Gauge Locomotives of 1840 | 92 |

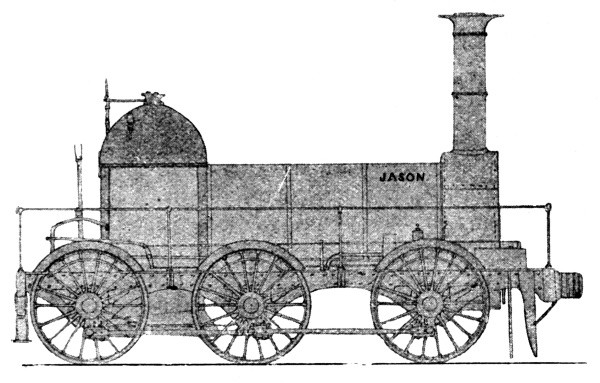

| “Jason,” one of Gooch’s First Type of Goods Engines for the G.W. Rwy. | 93 |

| Paton & Millar’s Tank Engine, for working on the Cowlairs Incline, Glasgow | 98 |

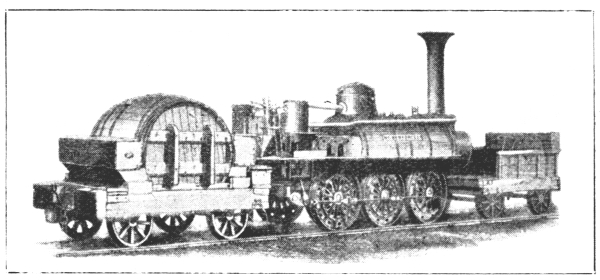

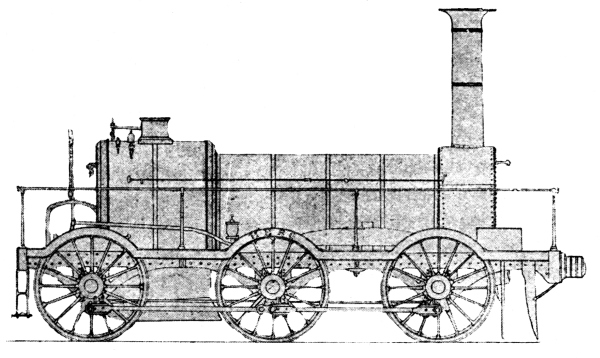

| Stephenson’s “Long Boiler” Goods Engine, Eastern Counties Railway | 104 |

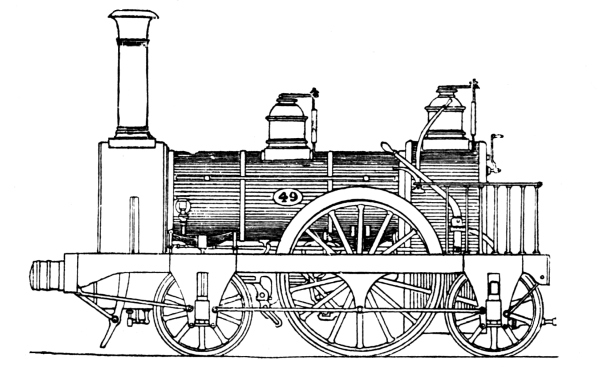

| Gray’s Prototype of the “Jenny Lind, No. 49”, London & Brighton Rwy. | 104 |

| ”Hero,” a Great Western Railway Six-Coupled Broad-Gauge Goods Engine | 106 |

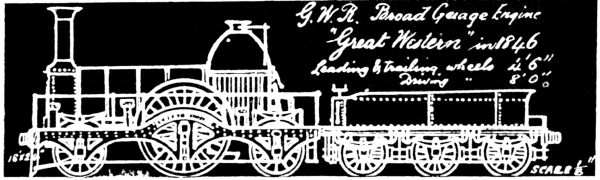

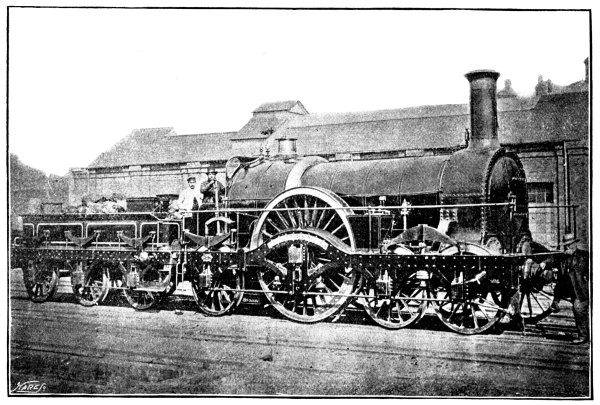

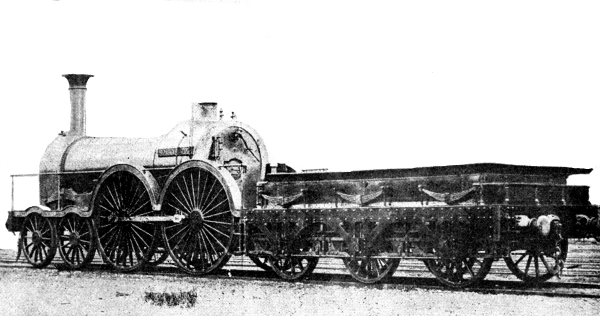

| The “Great Western” Broad-Gauge Engine as originally Constructed | 107 |

| The Original “Great Western,” as Rebuilt with Two Pairs of Leading Wheels | 109 |

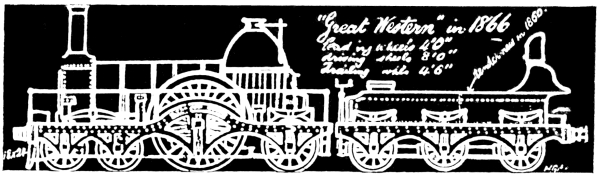

| The “Namur,” the First Engine built on Crampton’s Principle | 112 |

| Crampton’s “London,” First Engine with a Name, L. & N.W. Rwy. | 113 |

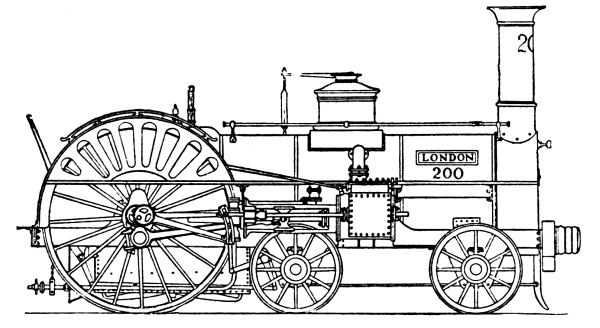

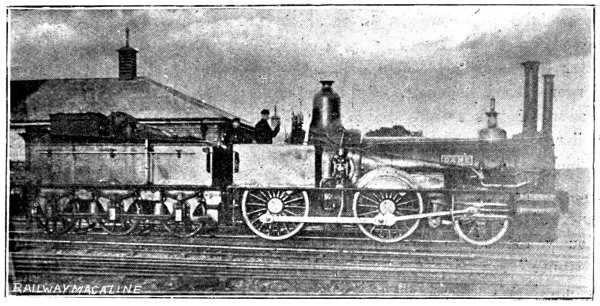

| “Great Britain,” one of Gooch’s Famous 8ft. “Singles,” G.W. Rwy. | 114 |

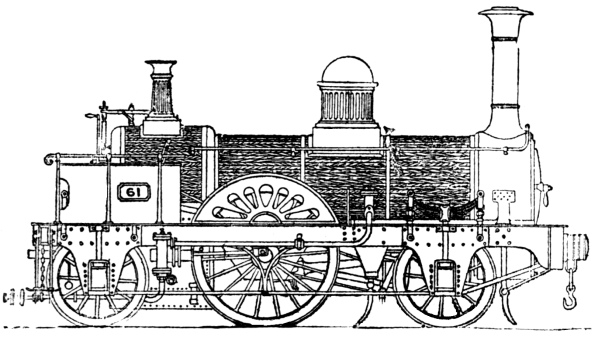

| “No. 61,” London and Brighton Railway. | 115 |

| The “Jenny Lind,” a Famous Locomotive, built by Wilson and Co. | 119 |

| Trevithick’s “Cornwall,” with 8ft. 6in. Driving Wheels, | |

| and Boiler below the Driving Axle | 120 [Pg vii] |

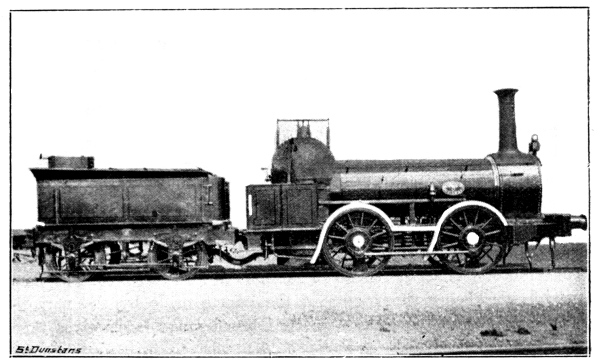

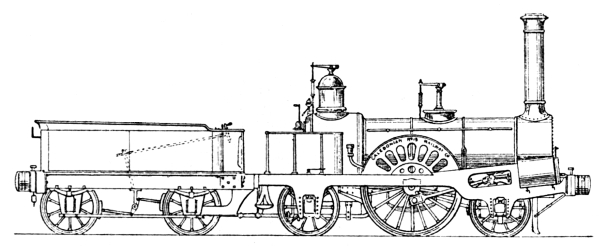

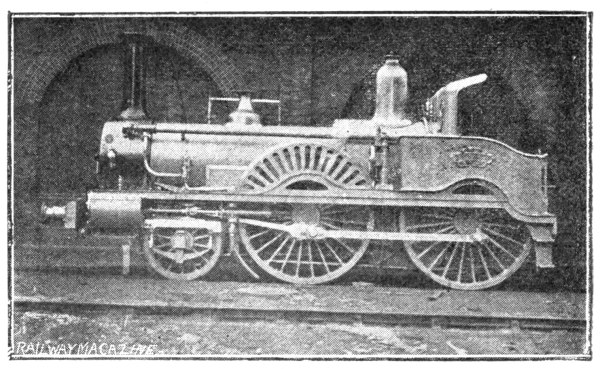

| Trevithick’s “Cornwall,” as now Running between Liverpool and Manchester | 121 |

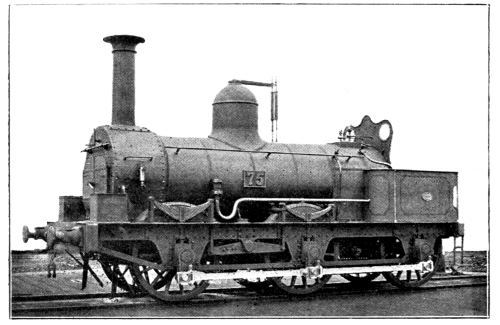

| “Old Copper Nob,” No. 3, Furness Rwy., Oldest Locomotive now at work | 123 |

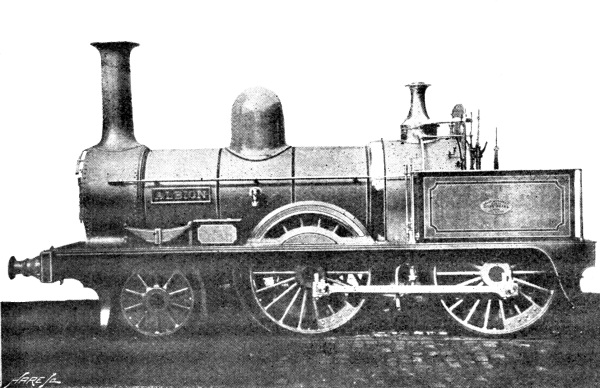

| The “Albion,” a Locomotive built on the “Cambrian” System | 127 |

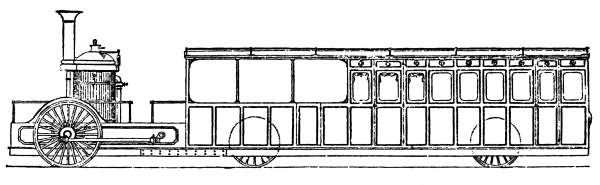

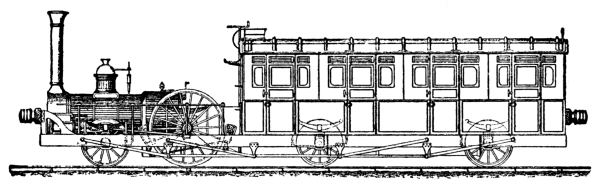

| The “Fairfield,” Adams’ Combined Broad-Gauge Engine and Train | 132 |

| The “Enfield,” Combined Engine and Train for the Eastern Counties Railway | 134 |

| “Red Star,” a 7ft. Single Broad-Gauge Saddle Tank Engine | 136 |

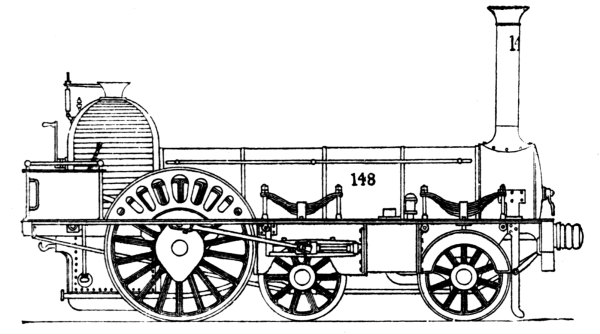

| “No. 148,” L. & N.W. Rwy.; Example of Stephenson’s “Long Boiler” Engines | 137 |

| Adams’ “Light” Locomotive for the Londonderry and Enniskillen Railway | 139 |

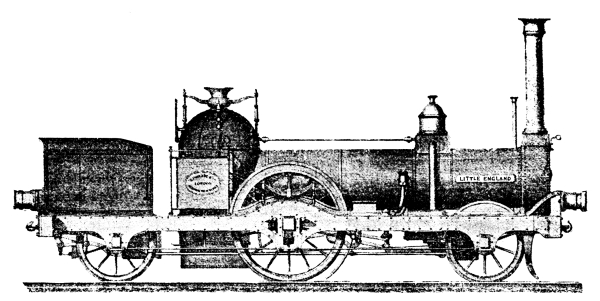

| England & Co.’s “Little England,” Locomotive-Exhibition, London, 1851 | 142 |

| Crampton’s “Liverpool,” London and North Western Railway | 145 |

| Timothy Hackworth’s “Sanspareil, No. 2” | 149 |

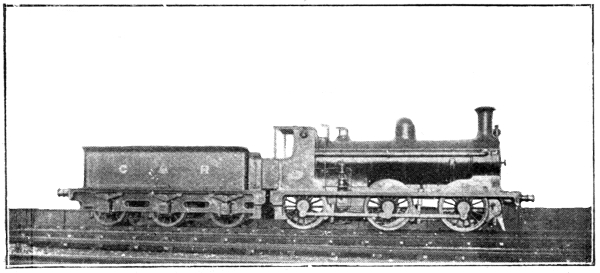

| Caledonian Railway Engine, “No. 15” | 153 |

| “Mac’s Mangle,” No. 227, London and North Western Railway | 154 |

| “President,” one of McConnell’s “Bloomers,” as originally built | 155 |

| One of McConnell’s “Bloomers,” as Rebuilt by Ramsbottom | 155 |

| The “Folkestone,” a Locomotive on Crampton’s System, | |

| built for the S.E.R., 1851 | 158 |

| One of J. V. Gooch’s “Single” Tank Engines, Eastern Counties Railway | 161 |

| “Ely,” a Taff Vale Railway Engine, built in 1851 | 163 |

| McConnell’s “300,” London and North Western Railway | 165 |

| Pasey’s Compressed Air Locomotive, Tried on the E.C. Rwy., 1852 | 170 |

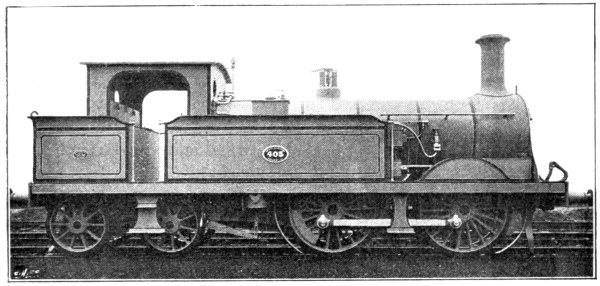

| The First Type of Great Northern Railway Passenger Engine, | |

| one of the “Little Sharps” | 171 |

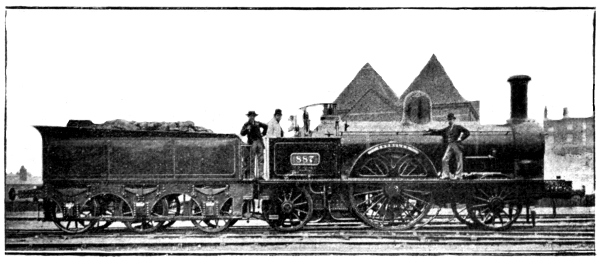

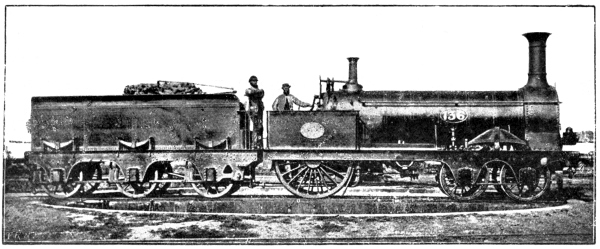

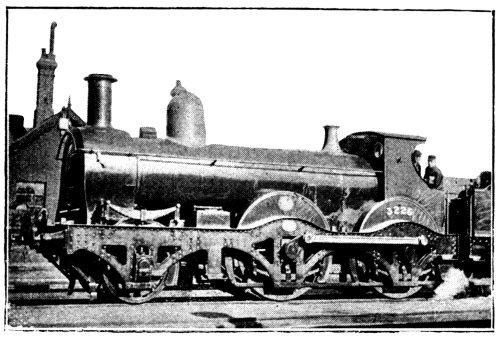

| Sturrook’s Masterpiece, the Famous Great Northern Railway, “215” | 172 |

| Pearson’s 9ft. “Single” Tank Engine, Bristol and Exeter Railway | 174 |

| One of Pearson’s 9ft. “Single” Tanks, taken over by | |

| the Great Western Railway | 176 |

| A Bristol and Exeter Railway Tank Engine, as Rebuilt | |

| (with Tender) by the G.W.R. | 178 |

| “Ovid,” a South Devon Railway Saddle Tank Engine, with Leading Bogie | 180 |

| “Plato,” a Six-Coupled Saddle Tank Banking Engine, South Devon Railway | 181 |

| The First Type of Narrow-Gauge Passenger Engines, Great Western Rwy. | 182 |

| “Robin Hood,” a Broad-Gauge Express Engine, | |

| with Coupled Wheels 7ft. in diameter | 183 |

| North British Railway Inspection Engine, No. 879 | 184 |

| The “Dane,” L. and S.W.R., fitted with Beattie’s Patent Apparatus | |

| for Burning Coal | 187 |

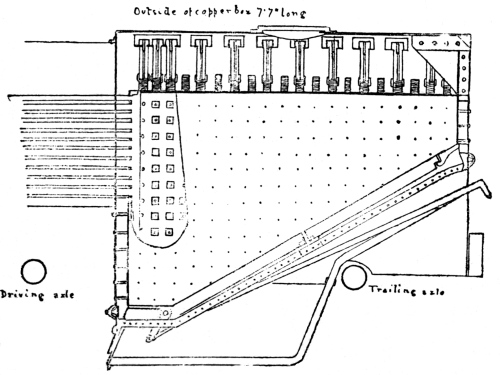

| Cudworth’s Sloping Fire-Grate, for Burning Coal, | |

| as fitted to S.E.R. Locomotives | 189 |

| “Nunthorpe,” a Stockton and Darlington Railway Passenger Engine, 1856 | 193 |

| Beattie’s Four-Coupled Tank Engine, London & South Western Rwy., 1857 | 194 |

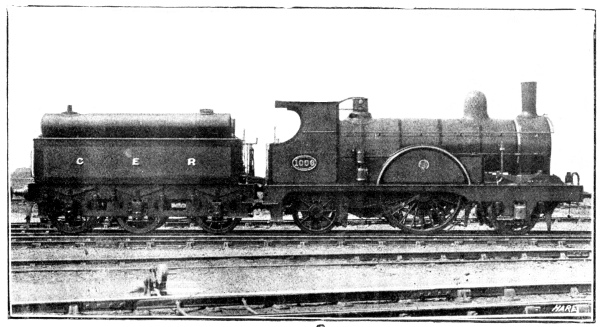

| Sinclair’s Outside Cylinder, Four-Coupled Goods Engine, | |

| Eastern Counties Railway (Rebuilt) | 196 |

| Six-Coupled Mineral Engine, Taff Vale Railway, built 1860 | 202 |

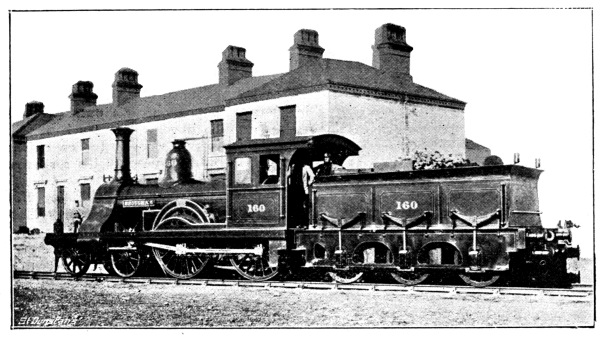

| “Brougham,” No. 160, Stockton and Darlington Railway | 206 |

| Conner’s 8ft 2in. “Single” Engine, Caledonian Railway (Rebuilt) | 208 |

| “Albion,” Cambrian Railways, 1863 | 210 |

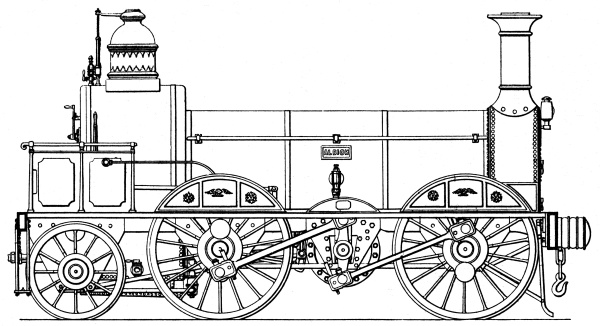

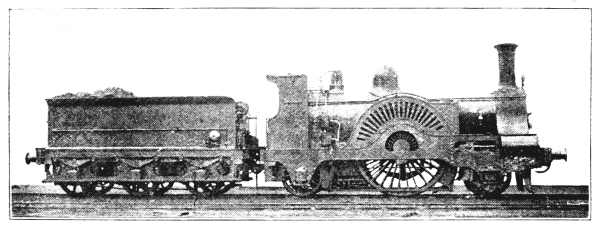

| A Great Northern Railway Engine, | |

| fitted with Sturrock’s Patent Steam-Tender | 218 |

| Sinclair’s Design of Tank Engine for the Eastern Counties Railway | 219 |

| Beattie’s Standard Goods Engine, London and South Western Railway, 1866 | 226 |

| Beattie’s Goods Engine, London and South Western Railway (Rebuilt) | 227 |

| Adams’ Passenger Tank Engine, N.L. Rwy., as Rebuilt by Mr. Pryce | 228 |

| Pryce’s Six-Coupled Tank Goods Engine, North London Railway | 229 |

| Locomotive and Travelling Crane, North London Railway | 230 |

| “Python,” a 7ft. 1in. Coupled Express Engine, L. and S.W. Rwy. | 232 |

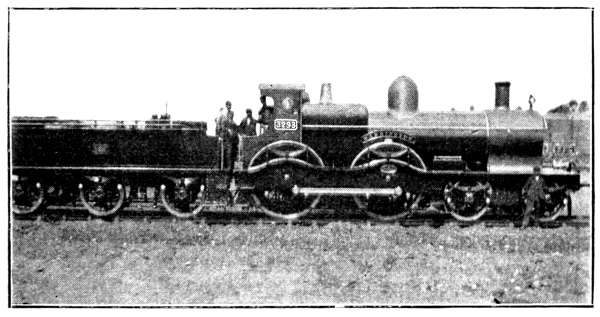

| 8ft. 1in. “Single” Express Engine, Great Northern Railway | 237 |

| “John Ramsbottom,” one of Webb’s “Precedent” Class, L. & N.W. Rwy. | 238 |

| “Firefly,” a London and South Western Outside Cylinder Tank Engine | 239 |

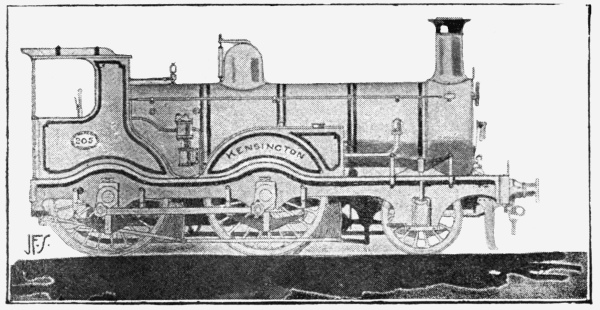

| “Kensington,” a Four-Coupled Passenger Engine, | |

| London, Brighton and South Coast Railway | 240 |

| “Teutonic,” a London and North Western Railway | |

| “Compound” Locomotive on Webb’s System | 244 |

| “Queen Empress,” one of Webb’s Compound Locomotives, L. & N.W. Rwy. | 245 [Pg viii] |

| “Black Prince,” L. & N.W. Railway, | |

| a Four-Coupled Four-Cylinder Compound Engine | 248 |

| Johnson’s 7ft. 9in. “Single” Engine, Midland Railway | 251 |

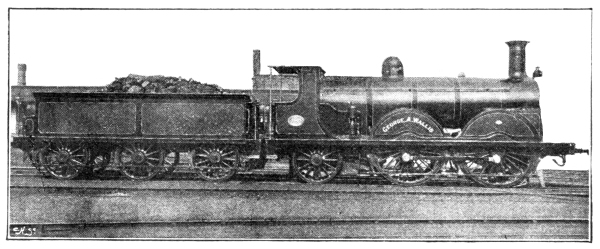

| “George A. Wallis,” an Engine of the “Gladstone” Class, | |

| L., B. and S.C. Railway | 252 |

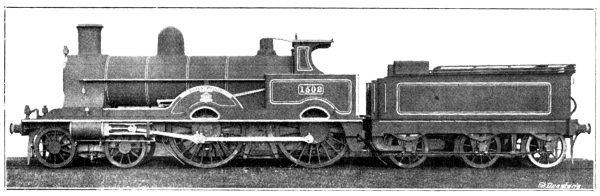

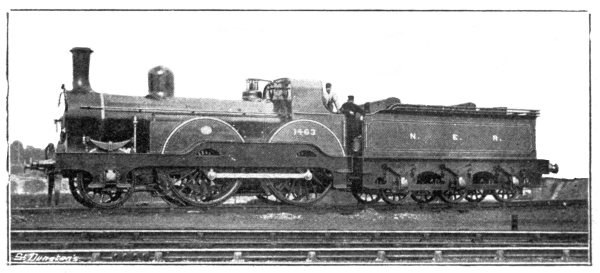

| “1463,” North Eastern Railway, one of the “Tennant” Locomotives | 253 |

| Holmes’s Type of Express Engines for the North British Rai | 254 |

| 7ft. “Single” Engine, Great Eastern Railway, | |

| fitted with Holden’s Liquid Fuel Apparatus | 256 |

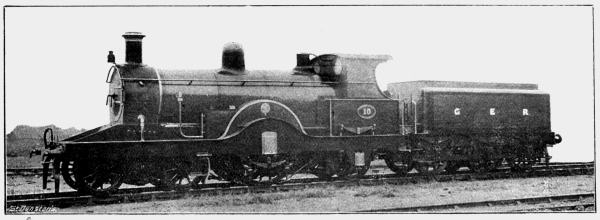

| “No. 10,” the Latest Type of Great Eastern Railway Express Engine, | |

| Fired with Liquid Fuel | 258 |

| “Goldsmith,” one of the new London, Brighton and South Coast | |

| Railway Express Passenger Engines | 261 |

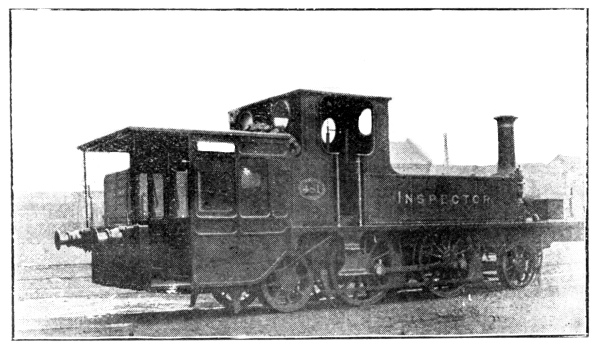

| “Inspector,” London, Brighton and South Coast Railway | 262 |

| “No. 192,” a Standard Express Passenger Locomotive, L.C. & D. Rwy. | 263 |

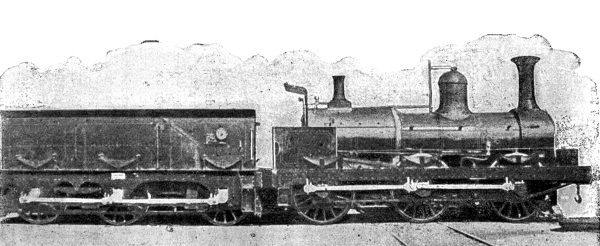

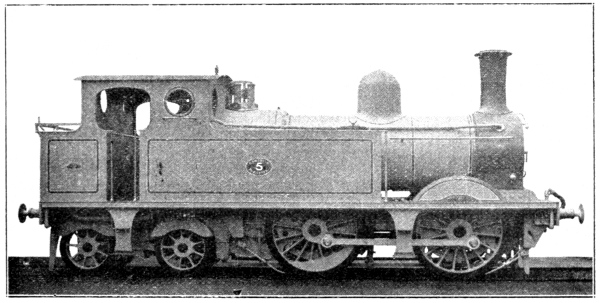

| Standard Express Passenger Engine, Cambrian Railways | 264 |

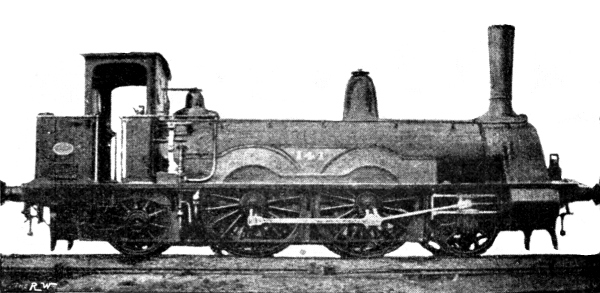

| Standard Passenger Tank Engine, Cambrian Railways | 265 |

| “No. 240,” the S.E. Railway Engine that obtained the Gold Medal, | |

| Paris Exhibition, 1889 | 267 |

| Standard Goods Engine, South Eastern Railway | 268 |

| Standard Passenger Tank Locomotive, South Eastern Railway | 269 |

| Latest Type of Express Passenger Engine, South Eastern Railway | 271 |

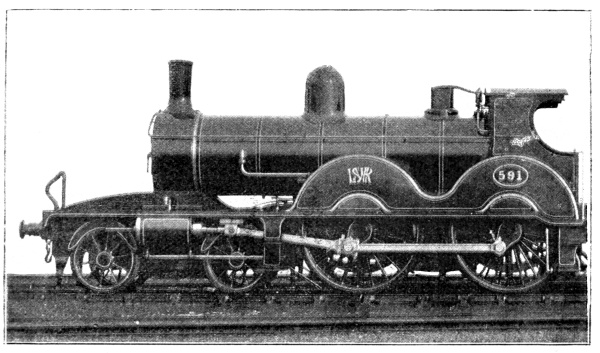

| Adams’ Standard Express Engine, London and South Western Railway | 273 |

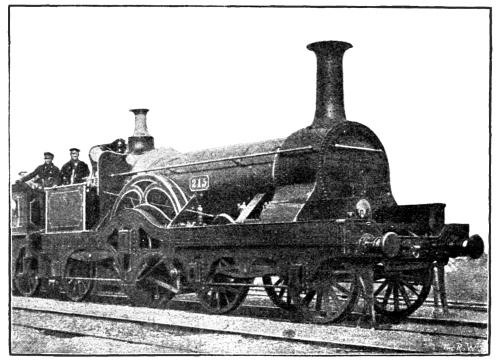

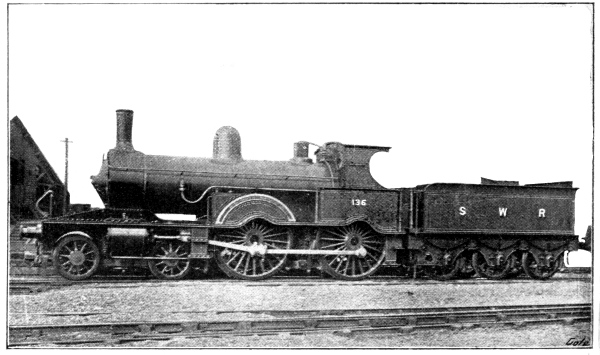

| A “Windcutter” Locomotive, “No. 136,” L. and S.W. Railway, | |

| fitted with Convex Smoke-Box Door | 274 |

| Drummond’s Four-Cylinder Engine, London and South Western Railway | 275 |

| Four-Coupled Passenger Engine with Leading Bogie, North British Railway | 277 |

| Holmes’s Latest Type of Express Engine, North British Railway | 279 |

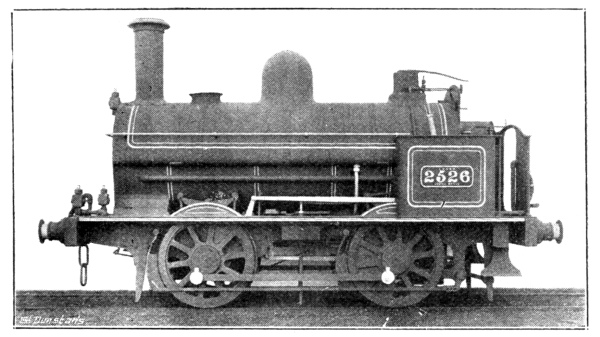

| Four-Wheels-Coupled Saddle Tank Engine, London & North Western Rwy. | 281 |

| Standard Express Passenger Locomotive, Lancashire and Yorkshire Railway | 282 |

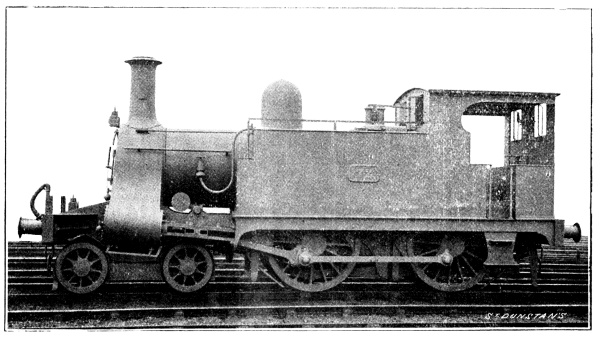

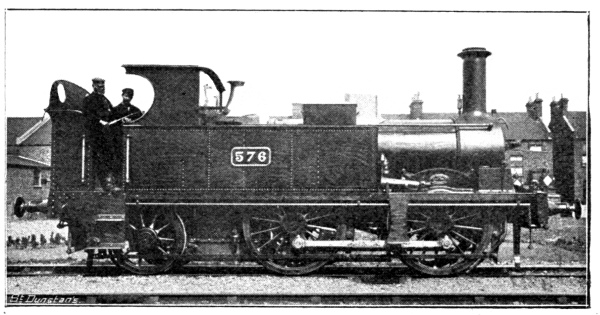

| Standard Eight-Wheel Passenger Tank Engine, Lancashire & Yorkshire Rwy. | 283 |

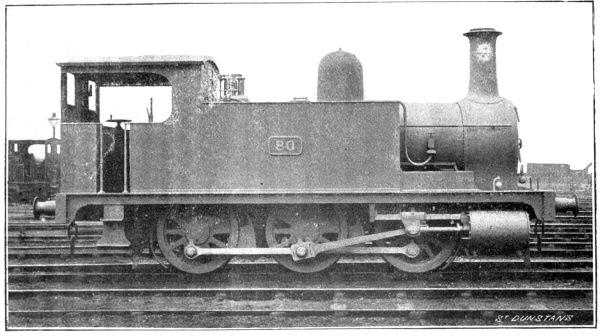

| Oil-Fired Saddle Tank Shunting Engine, Lancashire and Yorkshire Railway | 284 |

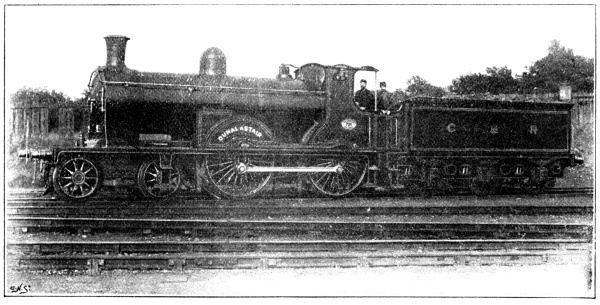

| “Dunalastair,” Caledonian Railway | 285 |

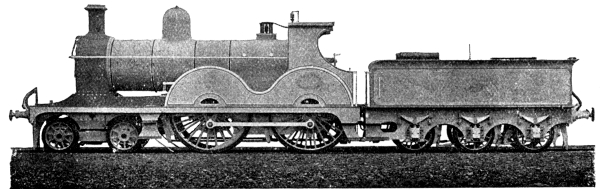

| One of McIntosh’s “Dunalastair 2nd” Caledonian Express Locomotives | 287 |

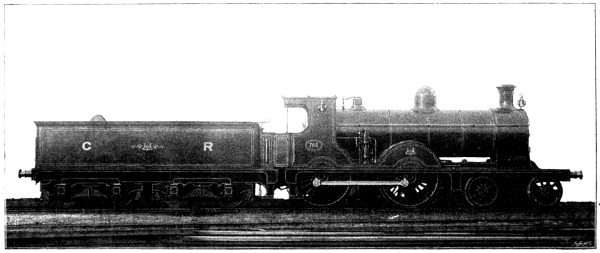

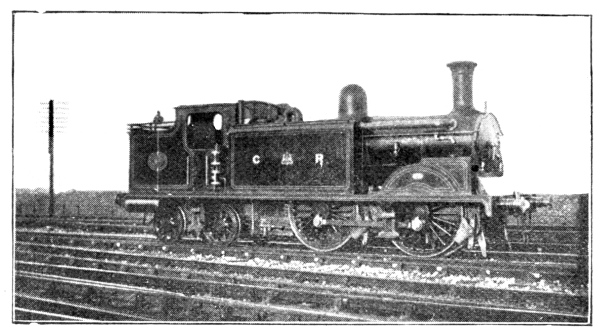

| Six-Wheels-Coupled Condensing Engine, Caledonian Railway | 288 |

| “Carbrook,” one of Drummond’s Express Engines for the Caledonian Railway | 289 |

| McIntosh’s 5ft. 9in. Condensing-Tank Engine, Caledonian Railway | 290 |

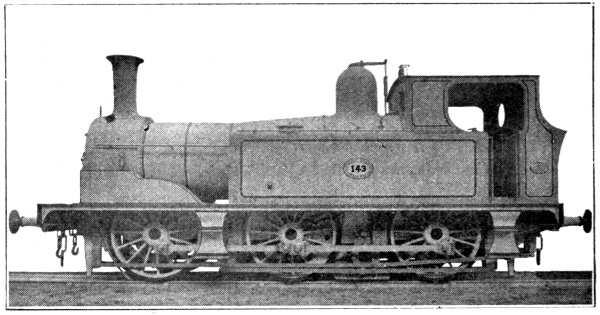

| “No. 143,” Taff Vale Railway Tank Locomotive, for working on incline | 292 |

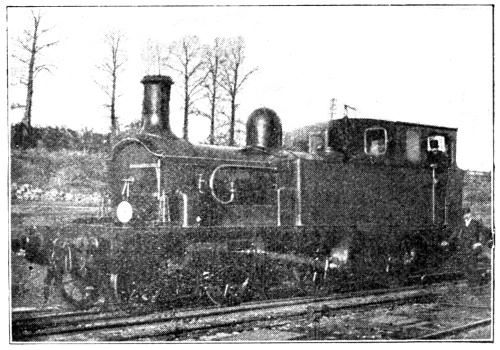

| A favourite Locomotive of the Isle of Wight Central Railway | 293 |

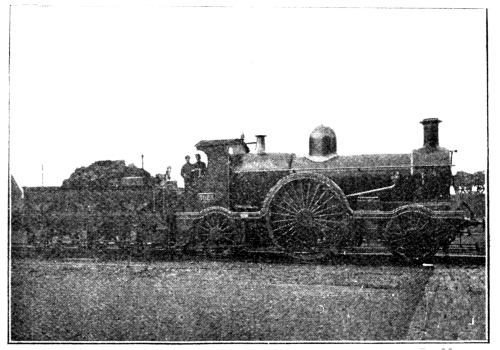

| 7ft. 8in. “Single” Convertible Engine, Great Western Railway | 295 |

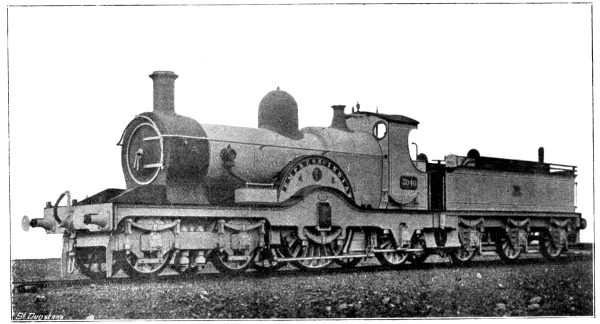

| “Empress of India,” Standard G.W. 7ft. 8in. “Single” Express Locomotive | 296 |

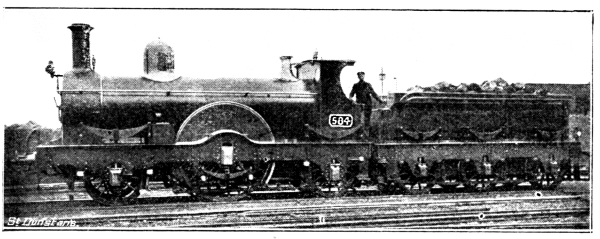

| “Gooch,” a Four-Coupled Express Engine, Great Western Railway | 297 |

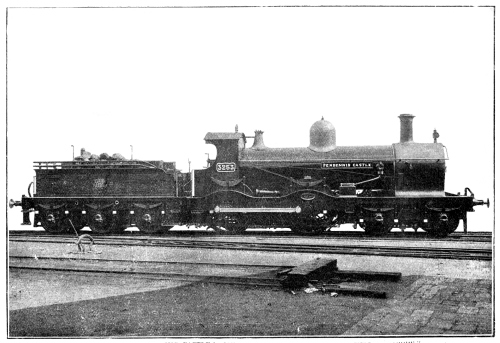

| “Pendennis Castle,” one of the Great Western “Hill Climbers” | 298 |

| “Single” Express Engine, Six-Wheel Type, Great Western Rai | 300 |

| 6ft. 6in. Four-Coupled Passenger Locomotive, Great Western Railway | 300 |

| 6ft. Four-Coupled Passenger Engine, Great Western Railway | 301 |

| “Barrington,” New Type of Four-Coupled Engine, Great Western Railway | 301 |

| Four-Coupled-in-Front Passenger Tank Engine, Great Western Railway | 302 |

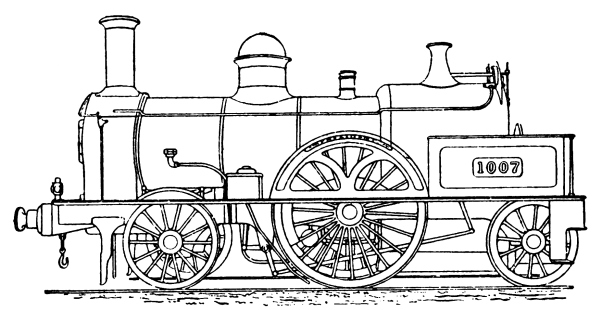

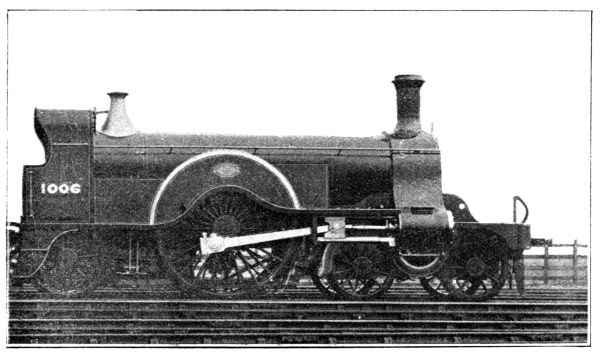

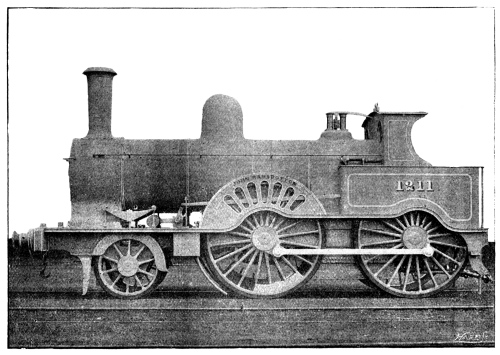

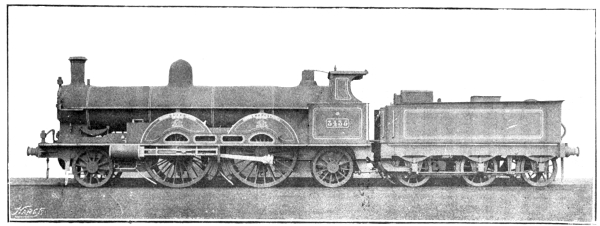

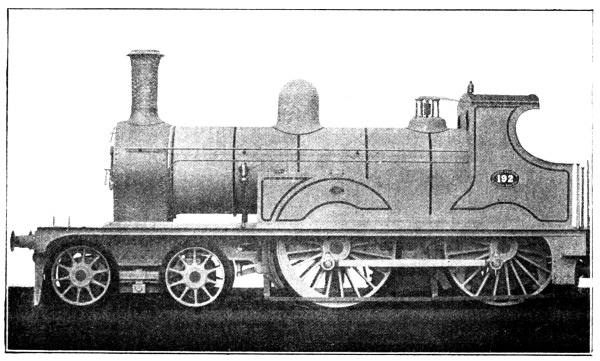

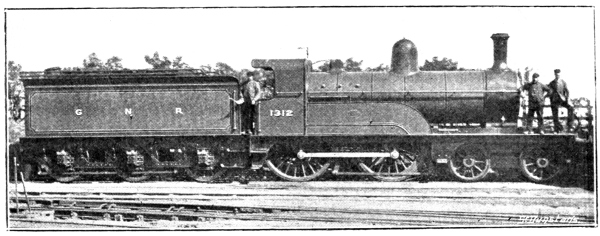

| “No. 1312,” one of Mr. Ivatt’s (1073) Smaller Class of | |

| Four-Coupled Bogie Engines, Great Northern Railway | 304 |

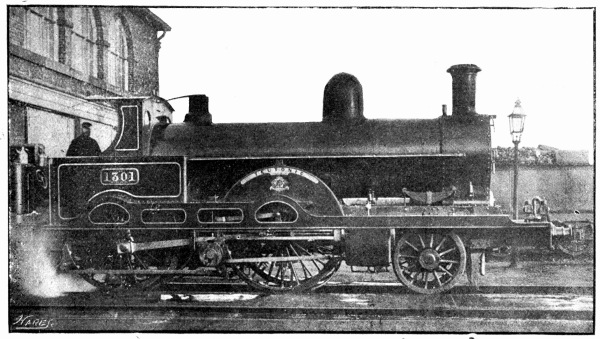

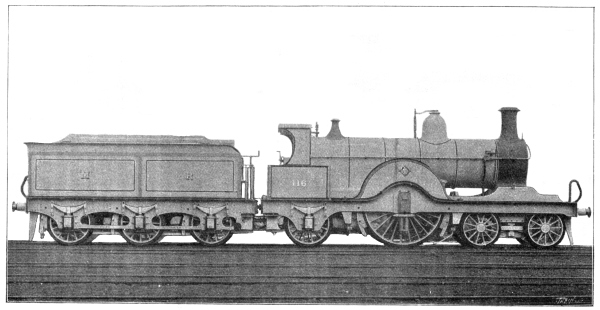

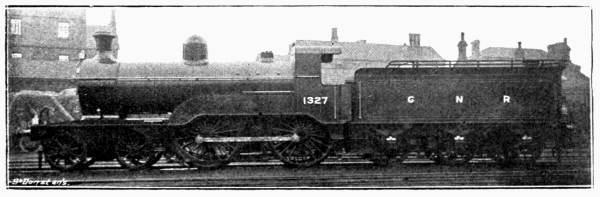

| The Latest Type of 6ft. 6in. Coupled Engine, Great Northern Railway | 305 |

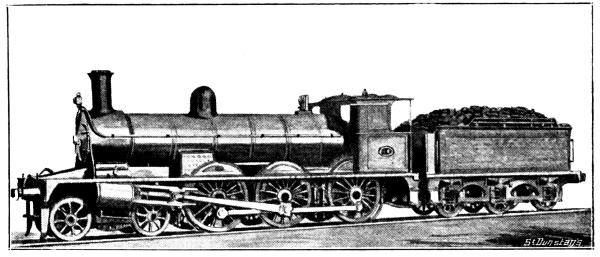

| Latest Type of G.N.R. Express Locomotive; 7ft. 6in. “Single,” | |

| with Inside Cylinders, etc. | 308 |

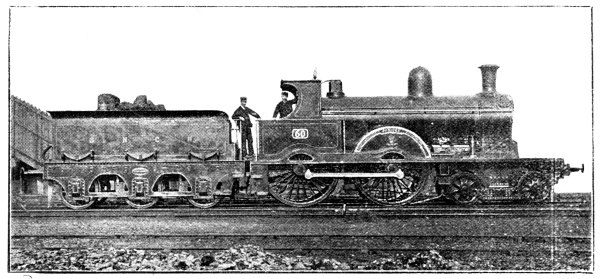

| “No. 100,” one of the “T” Class Four-Coupled Passenger Engines, | |

| Great North of Scotland Railway | 311 |

| Pettigrew’s New Goods Engine for the Furness Railway | 315 |

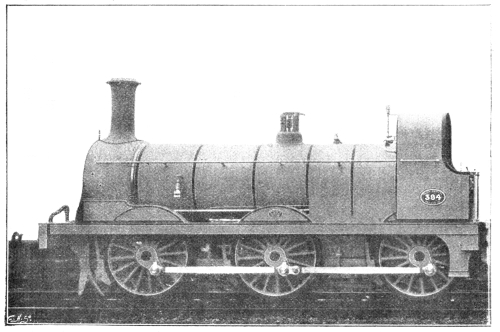

| Six-Wheels-Coupled Bogie Engine, with Outside Cylinders, | |

| Highland Railway | 316 |

| Liquid Fuel Engine, Belfast and Northern Counties Railway | 317 |

| “Jubilee,” Four-Wheels-Coupled Compound Locomotive, | |

| Belfast and Northern Counties Railway | 318 |

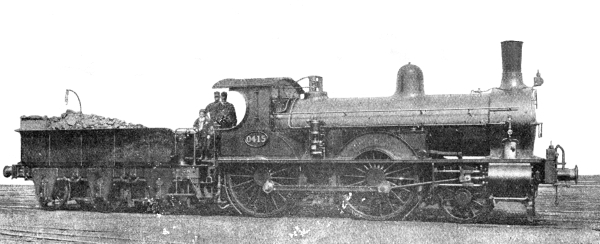

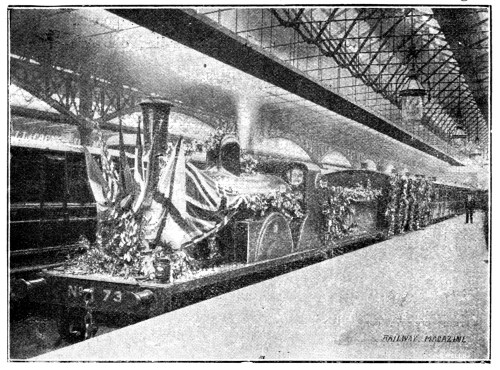

| “No. 73,” Standard Passenger Engine, Great Northern Railway (Ireland) | 318 |

| Four-Coupled Bogie Express Engine, Great Southern and Western Railway | 319 |

| “Peake,” a Locomotive of the Cork and Muskerry Light Railway | 319 |

[Pg 1]

EVOLUTION OF THE

STEAM LOCOMOTIVE.

Trevithick’s triumph; his first steam locomotives—Mistaken for the devil—The Coalbrookdale engine—A successful railway journey at Myrthyr Tydvil—Description of the engine—“Catch-me-who-can”—The locomotive in London— Blenkinsopp’s rack locomotive—Chapman’s engine—Did Chapman build an eight-wheel locomotive?—Brunton’s “steam horse”—Its tragic end.

To Richard Trevithick, the Cornish mine captain and engineer, belongs the honour of producing the first locomotive—true, his original essay was a road locomotive. As long ago as 1796 he constructed a model locomotive which ran round a room; and on Christmas Eve, 1801, he made the initial trip with his first steam locomotive through the streets of Camborne. This machine carried several passengers at a speed in excess of the usual walking pace of a man. Trevithick was joined in the enterprise by his cousin Vivian, who provided the money to build the steam engines, and to patent them, their first patent being dated 24th March, 1802. It is described as “for improving the construction of steam engines, and the application thereof for drawing carriages on rails and turnpike roads and other purposes.” It was claimed that their [Pg 2] engine would produce “a more equable rotary motion on the several parts of the revolution of any axis which is moved by the steam engine, by causing the piston-rods of two cylinders to work on the said axis by means of cranks, at a quarter turn asunder.”

Among other improvements claimed in the specification, mention should be made of the return tube boiler, bellows to urge the fire, and a second safety valve, not under the control of the driver.

A steam carriage with these improvements was constructed, and Vivian and Trevithick commenced a journey on it from Camborne to Plymouth, from which port it was shipped to London. On the road to Plymouth a closed toll-bar was met, and the steam carriage stopped for the gate to be opened. “What have us got to pay here?” demanded Vivian. The affrighted toll-keeper, shaking in every limb, and his teeth chattering, essayed to answer, and at last said, “Na—na—na—na.” “What have us got to pay, I say?” demanded Vivian. “Na—noth—nothing to pay, my de—dear Mr. Devil; do drive on as fast as you can. Nothing to pay.”

It must be remembered that to Cornishmen of a century ago the devil was a very real personage; and, seeing the horseless carriage proceeding with a fiery accompaniment, the poor toll-keeper thought he had at last seen his Satanic majesty. He also appears to have remembered that it is well “to be civil to everyone, the devil included; there is no knowing when you may require his good wishes.” Hence the toll-keeper’s reason for calling Vivian “my dear Mr. Devil.”

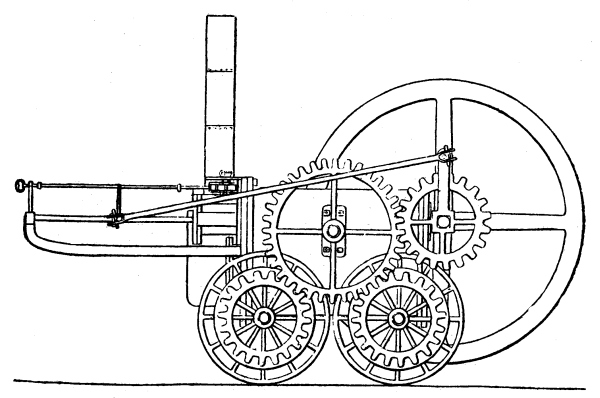

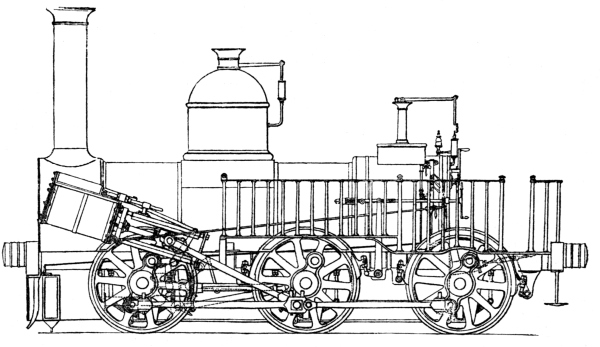

As early as August, 1802, R. Trevithick (according to his life, as written by his son, F. Trevithick) appears to have constructed a railway locomotive at Coalbrookdale. This engine had a boiler of cast-iron 1½in. thick, with an interior return wrought-iron tube. The length of the boiler was 6ft., and the diameter 4ft. The cylinder working this engine was 7in. in diameter, the stroke being 3ft. The next railway locomotive was that constructed for the Pen-y-darren Tramroad near Myrthyr Tydvil. Of this particular locomotive (Fig. 1) it is possible to obtain authentic particulars, although much that is legendary already clusters around this historic locomotive. For instance, we read that the locomotive in question had a brick chimney, and that it was demolished by colliding with an overhanging branch of a tree. Then the amount of the bet between Mr. Homfray, the owner of the tramroad, and his friend, as to whether the locomotive would successfully perform a journey from Pen-y-darren to the navigation at [Pg 3] Plymouth, is a variable quantity. The amount staked has been stated to be £500 a side, and also £1,000 a side.

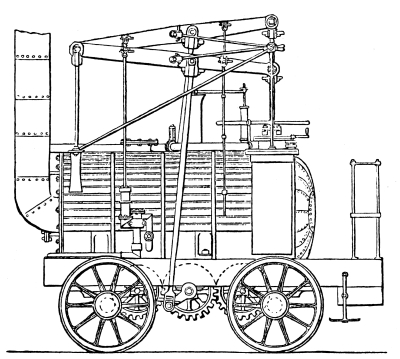

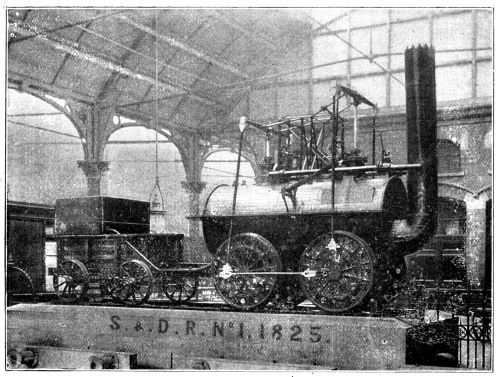

Fig. 1.—THE FIRST RAILWAY LOCOMOTIVE OF WHICH AUTHENTIC PARTICULARS ARE KNOWN

It is evident that some days prior to February 10th, 1804, the engine successfully performed the journey, and that overhanging trees and rocks considerably impeded the travelling, several stoppages having to be made whilst these obstacles were removed. Mr. Homfray, however, won the bet. On February 21st another trip was made by the locomotive. On this occasion the load consisted of 5 wagons, 10 tons of bar iron, and 70 passengers, the weight of the engine, with water and fuel, being 5 tons; the journey of nine miles being performed in 4 hours 5 minutes, including several stoppages; the average speed when travelling being five miles an hour. On the return journey the engine hauled the empty wagons up an incline of 1 in 18 at the rate of five miles an hour. Several of the tram-plates, which weighed only 28lb. per yard, were broken on the downward trip. Early in March the engine conveyed a load of 25 tons from the iron works to the navigation. [Pg 4]

It will be observed that this engine from the first decided the practicability of conveying loads by means of smooth wheels on smooth rails, simply by adhesion. Yet, strange to say, for several years after, it was the firmly-fixed belief of succeeding locomotive constructors that it was impossible to obtain sufficient adhesion between a smooth surface and a smooth rail to successfully work a locomotive. The result was the invention of many curious methods to overcome this apparent difficulty, which, as a fact, never existed, save in the minds of the designers of the early locomotives. These men do not seem to have been fully acquainted with the results of Trevithick’s experiments on the Pen-y-darren tramroad in 1804.

A description of this locomotive prototype is of interest. The boiler was cylindrical, with a flat end. The fire-door and chimney were both at the same end, an extended heating surface being obtained by means of the return tube; above the fire-door was the single horizontal cylinder, the diameter of which was 8¼in.; a considerable portion of the cylinder was immersed in the boiler, the exposed portion being surrounded by a steam jacket. The stroke was 4ft. 6in.! The piston-rod worked on a motion frame extending in front of the engine. At the other end of the boiler was a fly-wheel some 9ft. 6in. in diameter, the motion being conveyed to it by connecting-rods from the cross-head; a cog-wheel on the fly-wheel axle conveyed the motion by means of an intermediate wheel to the four driving wheels, which are stated to have been 4ft. 6in. in diameter. The exhaust steam appears to have been turned into the chimney, not for the purpose of a blast, but only as an easy method of getting rid of the vapour. It will be remembered that Trevithick, in his patent specification, specially mentioned bellows for urging the fire, and was, therefore, not acquainted with the nature of the exhaust steam blast. It is important to bear this in mind, as the reader will find in a later chapter. This engine is stated to have blown up through not being provided with a safety valve, though Trevithick specially ordered one to be fixed to the boiler, but his instructions do not appear to have been carried out.

Trevithick made another locomotive, called “Catch-me-who-can.” This ran on an ellipse-shaped railway specially laid down for it at Euston Square, London, and was visited by many people during the few days it was on view. Another locomotive was constructed from the drawings of [Pg 5] Trevithick’s Coalbrookdale locomotive of 1802, to the orders of Mr. Blackett, the owner of Wylam Collieries. This engine weighing 4½ tons, had a single cylinder 7in. diameter, 3ft. stroke, and, of course, a fly-wheel. For some reason or another this engine does not appear to have been used on the Wylam tramroad, but was used in a Newcastle foundry to blow a cupola. Mr. Armstrong, a former Locomotive Superintendent of the Great Western Railway, was acquainted with this engine of Trevithick’s at the time it was so employed at Newcastle.

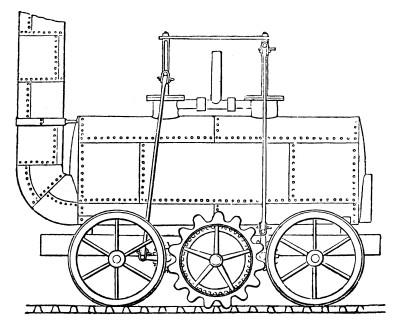

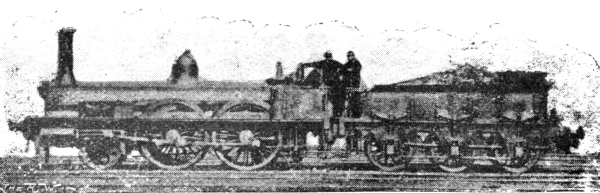

Having given an outline of Trevithick’s invention of the tramroad locomotive, and the other locomotive engines designed by him, we will deal with the locomotive built for J. Blenkinsopp (Fig. 2), of the Middleton Colliery, near Leeds, who, on April 10th, 1811, obtained a patent for a self-propelling steam engine, worked by means of a cog-wheel, engaging in a rack laid side by side with one of the rails forming the tramway.

The erroneous idea that the locomotive of itself had not sufficient adhesion between the smooth wheel and the surface of the rail to propel itself and draw a load was strongly entertained by Blenkinsopp, hence his patent rack and pinion system. Blenkinsopp having this opinion, which he published by means of his patent specification, caused succeeding inventors to fall into the same error regarding the adhesive properties of the locomotive, and consequently considerably retarded the development of the railway engine.

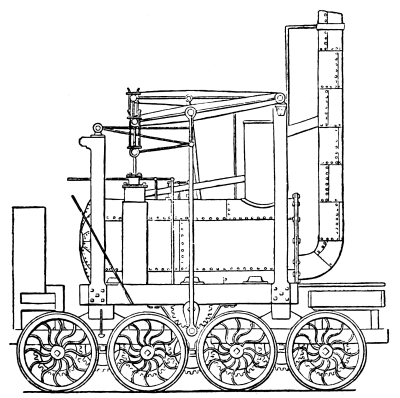

Although this engine is generally known as Blenkinsopp’s, it was constructed by Matthew Murray, the Leeds engineer. The boiler was cylindrical, with slightly convex ends, a single flue ran through it, which was in front turned upwards, and so formed the chimney; the fire-grate was at the other end of the flue, as in the modern locomotive.

This engine was provided with two cylinders, and was, in this respect, an improvement on Trevithick’s single cylinder engines. The cylinders were 8in. in diameter, and placed vertically, the major portion of them being placed within the boiler. The stroke was 20in., and the motion was conveyed by means of cross-heads, working connecting-rods; these came down to two cranks on either side below the boiler. The cranks worked two shafts fixed across the frames, on which were toothed wheels, both working into a centre toothed wheel, which was provided with large teeth, these engaged on the rack rail previously described. The cranks were set at right angles, so that one piston was exerting [Pg 6] power when the other was at its dead centre, and vice versâ. The engine was supported on the rails by four wheels 3ft. 6in. in diameter. The two cylinders were connected by a pipe which conveyed the exhaust steam and discharged it into the atmosphere through a vertical tube. The engine weighed 5 tons, burned 75lb. of coal per hour, and evaporated 50 gallons of water in the same time. This locomotive could haul 94 tons on the level at 3½ miles an hour, or 15 tons up an incline of 1 in 15; its maximum speed was 10 miles an hour. The engine cost £400 to construct, and worked from August, 1812, for a period of about 20 years, and in 1816 the Grand Duke Nicholas, afterwards Emperor of Russia, inspected the machine. The tramway on which it worked was about 3¾ miles long.

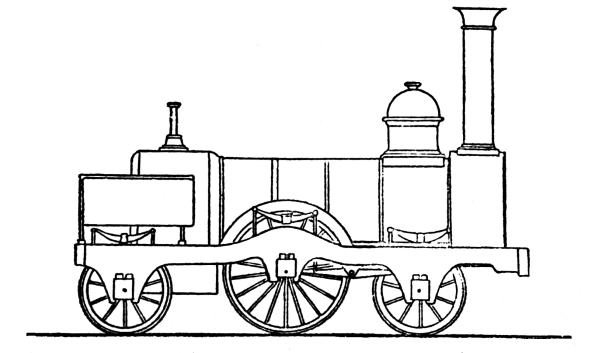

Fig. 2.—LOCOMOTIVE BUILT BY MURRAY FOR BLENKINSOPP’S RAILWAY

In September, 1813, Murray supplied two of Blenkinsopp’s engines to the Kenton Colliery.

On December 30th, 1812, a patent was granted to William and Edward Chapman for a method of locomotion. A chain was stretched along the [Pg 7] railway and fastened at each end; connected to the locomotive by spur gear was a barrel, around which the chain was passed. When the barrel rotated, the chain was wound over it, and since the chain was secured at either end, the engine was of necessity propelled. An engine on this principle was tried on the Heaton Colliery Tramroad, near Newcastle-on-Tyne. The machine was supported on wheels travelling on the rails. The boiler was of Trevithick’s design, and fanners were used to excite the combustion of the fuel. The weight of Chapman’s engine was 6 tons. After a few trials the scheme was abandoned, as it was found impracticable to successfully work such a system. Every eight or ten yards the chain was secured by means of vertical forks, which hold it when disengaged from the drum of the locomotive.

By this method the pressure of one engine on the chain was limited to the fork on either side of the drum instead of being spread over the whole length of the chain, and it would, therefore, have been possible for several engines to have used the chain at one and the same time.

According to Luke Herbert and Lieut. Lecount, Chapman also built an 8-wheel locomotive for the Lambton Colliery. This engine, it was stated, had vertical cylinders, and the motion was conveyed by means of spur wheels. It weighed 6 tons loaded, and drew 18 loaded wagons, of a gross weight of 54 tons, from the colliery to the shipping place on the Wear; with the above load it attained a speed of four miles an hour up an incline of 1 in 115. The dimensions and capabilities accredited to this engine appear suspiciously similar to those related of the first Wylam locomotive.

On May 22nd, 1813, Mr. W. Brunton, of the Butterfly Ironworks, obtained a patent for a novel method of steam locomotion. This locomotive inventor was also suffering from the common belief that it was impossible to obtain sufficient adhesion between a smooth rail and smooth wheels, despite the successes that had already been obtained in this direction by Trevithick. He therefore built an engine supported on four flanged carrying wheels, but propelled from behind by means of two legs. Indeed, another inventor considered the idea of steam legs so natural that he constructed a steam road-coach that was to be propelled by four legs, one pair partaking of the character and motion of the forelegs of a horse, and the other pair being fashioned on the model of the hind legs of the same quadruped. [Pg 8]

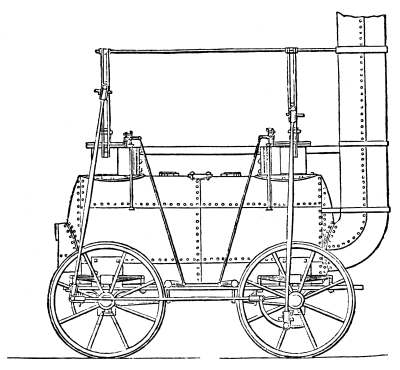

Fig. 3.—BRUNTON’S “MECHANICAL TRAVELLER” LOCOMOTIVE

In Brunton’s leg-propelled steam locomotive (Fig. 3) we find that the boiler was cylindrical, with a single horizontal tube passing through it, and turned up in front in a vertical position, thus forming the chimney. The motion was obtained from a single horizontal cylinder, fixed near the top of the boiler, the piston-rod projecting behind; the end of the piston-rod was attached to a jointed rod, the bottom portion of which formed one of the legs. The upper portion of this rod was attached to a framework fixed above the boiler of the engine, which formed a fulcrum, and then by an ingenious arrangement of levers, an alternate motion was given to the second leg. Each leg had a foot formed of two prongs at the bottom; these stuck in the ground, and prevented the legs from slipping. Upon steam being applied, the piston in the ordinary way would have travelled to the end of the cylinder, but the leg, having a firm hold of the ground, presented a greater resistance to the steam than did the weight of the engine, so the steam acting on the surface that presented the lesser resistance, caused the cylinder to recede, and with it the engine, to which it was, of course, firmly attached. By means of the reciprocating levers, a horizontal rod [Pg 9] travelled on the top of the boiler and over a cog-wheel; then on the other side of this cog-wheel was another horizontal rod, which, actuated by the cog-wheel, travelled in a contrary direction, and being attached to the other leg of the engine, as the machine receded from the first leg, it drew the second leg close up to the back of the engine. The second leg was now ready to propel the engine, which it did upon the steam being applied to the other side of the piston, and the process was alternated with each admission of steam to the front or back of the piston.

Whilst the legs were returning towards the engine the feet were raised by means of straps or ropes fastened to the legs and passing over friction-wheels, movable in one direction only by a ratchet and catch, and worked by the motion of the engine.

Brunton called his locomotive a “mechanical traveller,” and stated that the boiler was of wrought-iron, 5ft. 6in. long and 3ft. diameter, weighing 2¼ tons, stroke of piston, 2ft., and at 2½ miles per hour, with a steam pressure of 451b. per square inch, was equal in power to nearly six horses. This locomotive curiosity blew up at Newbottle in 1816, and about a dozen people were thereby either killed or seriously injured.

[Pg 10]

Who is entitled to the honour of constructing the Wylam locomotives?—The claims of Hackworth, Hedley and Foster—“Puffing Billy”—Rebuilt as an eight-wheel engine—Stewart’s locomotive—Sharp practice causes Stewart to abandon locomotive building—George Stephenson as a locomotive builder—His hazy views as to his first engine—“Blucher”—The German General proves a failure—Stephenson and Dodd’s engine—Stephenson’s third engine, with (so-called) steam springs—Competent critics condemn Stephenson’s engines—The “Royal William”—The “Locomotion”—Hackworth, General Manager of the Stockton and Darlington Railway—Horse haulage cheaper than Stephenson’s locomotives—Hackworth to the rescue—The “Royal George,” the first successful locomotive—The “exhaust” steam blast—Rival claimants and its invention—Locomotive versus stationary engine —“Twin Sisters”—“Lancashire Witch”—“Agenoria”—The “Maniac”, a Forth Street production.

We have now arrived at a point in the evolution of the steam locomotive where the claims of several men are in competition. The facts as to the experiments and construction of the engines at Wylam are not disputed. The question at issue is as to whom the honour of the success should be given. Christopher Blackett, of the Wylam Colliery, as previously stated, ordered a locomotive of Trevithick, but never used it. He, however, determined to make a trial of steam haulage on his plate way, and in 1811 some kind of experiments were made, having in view the above-mentioned object. At this time Timothy Hackworth was foreman of the smiths (he would now be called an engineer), and William Hedley was coal-viewer at Wylam. The friends of both Hackworth and Hedley claim for their respective heroes the honour of these early essays in locomotive construction. But it is probable the honours should be shared by both, as well as by Jonathan Foster, who also assisted in the experiments and construction of the Wylam locomotives.

Hedley was colliery-viewer at Wylam, and therefore, most likely, Hackworth was, to an extent, under his orders, and probably had to defer to, and act under, the instructions of Hedley.

But Hackworth’s position as foreman-smith did not preclude him from making suggestions and introducing improvements of his own into the locomotives under construction.

It is stated that Hedley was jealous because Hackworth obtained the [Pg 11] praise for building the Wylam locomotives (or “Timothy’s Dillies,” as they were locally called), and to force Hackworth to leave Wylam, Hedley required him to do some repairs to the machinery on Sundays. Now, Timothy was a fervent Wesleyan, and spent his Sundays in local preaching, so he naturally refused to violate his conscience by working on that day. Consequently Hackworth sought employment elsewhere.

Fig. 4.—HACKWORTH’S “WYLAM DILLY,” GENERALLY KNOWN AS HEDLEY’S “PUFFING BILLY”

On the other hand, it was a sore point with Hackworth that George Stephenson spent his Sundays at Wylam taking sketches and particulars of the locomotives at that time at work on the Wylam Railway, the result of which observations was apparent in the locomotive built by Stephenson at Killingworth in 1814.

The Wylam experimentalists in October, 1812, constructed a four-wheel vehicle driven by manual power working cranks connected with spur wheels. The carriage was loaded until sufficient weight had been placed upon it to cause the wheels to turn round without progressing. [Pg 12]

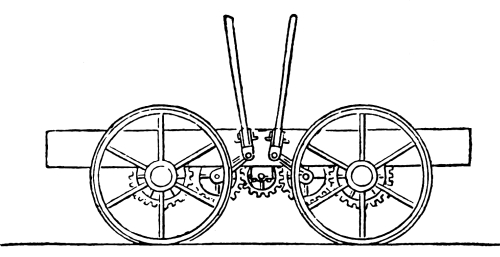

The experiment, however, satisfied Mr. Blackett that locomotive engines with smooth wheels could be employed in drawing loads on his tramroad; and the construction of an engine was immediately proceeded with. This was completed and put to work early in 1813. It had a cast-iron boiler, and a single internal flue; the solitary cylinder was 6in. in diameter, and a fly-wheel was employed after the model of Trevithick’s engine. The steam pressure was 50lb. This four-wheel engine drew six coal trucks at five miles an hour, and, therefore, did the work of three horses—not a very powerful example of a steam locomotive, it will be observed. This engine being somewhat of a failure, it was decided to build another, and one with a wrought-iron boiler and a return tube was constructed. In his engine (Fig. 4) it will be noticed the fire-box and chimney were both at the same end of the boiler. Two vertical cylinders were fixed over the trailing wheels of “Puffing Billy” (for it is this historical locomotive, now preserved in the South Kensington Museum, that is now being described). The piston-rods were connected to beams of the “Grasshopper” pattern, being both centred at the funnel end of the engine. The driving-rods were connected with these beams at about their centres, and passed down to spur wheels, which, by means of toothed wheels on either side, communicated the motion to the four carrying wheels. The spent steam was conveyed from the cylinders to the chimney by means of two horizontal pipes laid along the top of the boiler. It was soon discovered that the cast-iron tram-plates, which were only of four square inch section, were unable to bear the weight of “Puffing Billy,” and another change was decided upon.

The engine was therefore placed on two four-wheel trucks (Fig. 5), so that the weight was distributed on eight instead of four wheels, the same method of spur gearing was employed, and the whole of the wheels were actuated by means of intermediate cog-wheels. To prevent, as far as possible, the noise caused by the escaping steam, a vertical cylinder was fixed on the top of the boiler between the cylinders and the funnel. Into this chamber the spent steam was discharged, and from it the same was allowed to escape gradually into the chimney. In addition to the improvement of a return tube, with its extended heating surface, with which this class of engine was provided, the funnel was only 12in. in diameter, as compared with 22in. diameter as used by [Pg 13] Stephenson in his early engines. As already stated, the Wylam locomotives were locally called “Timothy’s Dillies,” after Timothy Hackworth, to whose inventive genius they were popularly ascribed. In 1830, the cast-iron plates on the road from Wylam to Leamington were removed, and the course was relaid with edge rails, so that the necessity for eight-wheel engines was at an end. “Timothy’s Dillies” were then reconverted to four-wheel locomotives, and continued at work on the line till about 1862.

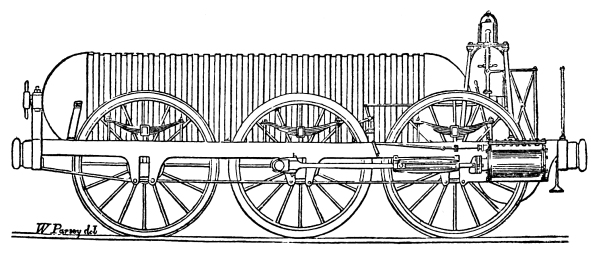

Fig. 5.—HACKWORTH’S OR HEDLEY’S SECOND DESIGN, AS USED ON THE WYLAM RAILWAY IN 1815

Not many locomotive writers are acquainted with the fact that in 1814 William Stewart, of Newport, Mon., constructed a locomotive for the Park End Colliery Company, which was tried on the Lydney Railway, and found to work in a satisfactory manner. The Park End Colliery Company were paying about £3,000 a year to contractors for horse haulage of their coal to the Forest of Dean Canal, and Stewart undertook to do the same by locomotive power for half that sum. The Company accepted his [Pg 14] terms, and he set about the construction of his engine. Whilst this was progressing the contractors who provided the horses were told at each monthly settlement that the Company were going to use a locomotive to haul the coal, as horse-power was too expensive. By means of these threats the contractors were induced each month to accept a less price than previously for “leading” the coal over the tramroad. Upon the specified date Stewart’s locomotive was duly delivered on the line, and accepted by the Park End Colliery Company for doing the work required; but the engineer was informed that the horse-power contractors were then only receiving £2,000 a year for the work, and that as Stewart had agreed to provide locomotive power at one-half of the sum paid for horses, he would only receive £1,000 a year.

Stewart was so highly indignant at this piece of sharp practice that he refused to have anything further to do with the Park End Colliery Company, and at once removed his locomotive off their tramroad, and took it back to Newport.

The earliest attempts of George Stephenson in connection with the evolution of the steam locomotive now deserve attention. Stephenson himself is not very clear about his first engine, for, speaking at Newcastle at the opening of the Newcastle and Darlington Railway in 1844, he said that thirty-two years ago he constructed his first engine. “We called the engine ‘My Lord,’ after Lord Ravensworth, who provided the money for its construction.” Both these statements are erroneous, for Stephenson did not build his first engine till 1814, and thirty-two years before 1844 would have been 1812. Then the engine could not have been called “My Lord,” after Lord Ravensworth, for the title did not exist in 1814, the gentleman alluded to being only Sir Thomas Liddell till the coronation of King George IV. in 1821, when he was created Lord Ravensworth.

The “Blucher,” as this engine was in fact usually called, was first tried on the Killingworth Railway on July 25th, 1814; she had a wrought-iron boiler, 8ft. long and 2ft. 10in. diameter, with a single flue 20in. diameter, turned up in front to form a chimney. The power was applied by means of two vertical cylinders located partly within the boiler, and projecting from its top, close together, and near the middle. The cylinders were 8in. diameter, the stroke 2ft. The motion was conveyed to the wheels by means of cross-heads and connecting-rods working on small spur wheels (Fig. 6), which engaged the four carrying wheels by means of cogged wheels fitted on the axles of [Pg 15] the flanged rail-wheels; these were only 3ft. in diameter, and were 3ft. apart. The spur wheels engaged another cogged wheel, placed between them, for the purpose of keeping the cranks at right angles. No springs were provided for the engine, which was mounted on a wooden frame, but the water barrel was fixed to one end of a lever, and also weighted; the other end of this lever was fixed to the frame of the engine. This arrangement did duty for springs!

Fig. 6.—STEPHENSON’S INITIAL DRIVING GEAR FOR LOCOMOTIVES

The best work done by “Blucher” was the hauling of loaded coal-wagons, weighing 30 tons, up an incline of 1 in 450, at about four miles an hour. This first effort of Stephenson had no original points about it; the method of working was copied from the Wylam engines, whilst Trevithick’s practice was followed with regard to the position of the cylinders—i.e., their location, partly within the boiler. The average speed did not exceed three miles an hour, and after twelve months’ working the machine was found to be more expensive than the horses it was designed to replace at a less cost. The absence of springs was specially manifested, for by this time the engine was so much shaken and injured by the vibration that the Killingworth Colliery owners were called upon a second time to find the money to enable Stephenson to construct another locomotive.

The second engine (Fig. 7) constructed by George Stephenson was built under the patent granted to Dodd and Stephenson on 28th February, 1815. In this engine vertical cylinders, partly encased in the boiler, were again employed; but their position was altered, one being placed at each extremity of the boiler over the wheels, the intermediate spur wheels formerly used for keeping the [Pg 16] cranks at right angles were abandoned, and the axles were cranked. A connecting-rod was fitted on these cranks, thus coupling the two axles. To give greater adhesion, the wheels of the tender were connected with those of the engine by means of an endless chain passing over cogs on the one pair of engine wheels, and over the adjoining pair of tender wheels; by these methods six pairs of wheels were coupled. The mechanics engaged were not, however, capable of forging proper crank axles, and these had to be abandoned, and an endless chain coupling employed for the engine wheels, similar to the one connecting the tender and engine, as previously described.

Fig. 7.—STEPHENSON AND DODD’S PATENT ENGINE, BUILT IN 1815

This engine had no springs, and, to avoid excessive friction arising from the bad state of the tramroad, Stephenson employed “ball and socket” joints between the ends of the cross-heads and the connecting-rods. In this way the necessary parallelism between the ends of the cross-heads and the axles was maintained. The spent steam in the engine was turned into the chimney, as in Trevithick’s Pen-y-darren locomotive. This locomotive commenced to work on 6th March, 1815.

George Stephenson constructed a third engine (Fig. 8), under a patent granted to Lock and Stephenson on 30th September, 1816; this patent covered several matters, the most important in connection with the engine being malleable iron wheels, instead of cast-iron, and what has [Pg 17] been described as “steam springs.” The patentees called them “floating pistons”; of this description Colburn says emphatically “they are not,” and the same authority continues, “and they (Lock and Stephenson) added, evidently without understanding the true action of the pistons, which were different in principle from the action of springs, that inasmuch as they acted upon an elastic fluid, they produced the desired effect, with much more accuracy than could be obtained by employing the finest springs of steel to suspend the engine. The whole arrangement was, on the contrary, defective in principle and objectionable on the score of leakage, wear, etc.; and, as a matter of course, was ultimately abandoned.”

Fig. 8.—STEPHENSON’S IMPROVED ENGINE, AS ALTERED, FITTED WITH STEEL SPRINGS (INVENTED BY NICHOLAS WOOD)

In the drawings attached to the patent specification this engine is shown with six wheels, and the chain coupling is employed. Lecount says: “The six wheels were continued in use as long as the steam springs were applied, and when steel springs were adopted they were again reduced to four.” So much praise has been given to Stephenson for the “great improvements” he is supposed to have introduced into the [Pg 18] construction of the locomotive, that it will not be uninteresting if we here reproduce the extremely pertinent remarks of Galloway, the well-known authority on the steam engine, which go far to prove that it was only the great success obtained by George Stephenson from the construction of the Liverpool and Manchester and other railways, that caused historians and biographers to either magnify his locomotive successes, or to gloss over the evident faults in the design and construction of his engines. In his “History of the Steam Engine,” published in 1827, Galloway says: These locomotive engines have been long in use at Killingworth Colliery, near Newcastle, and at Hilton Colliery on the Wear, so that their advantages and defects have been sufficiently submitted to the test of experiment; and it appears that, notwithstanding the great exertions on the part of the inventor, Mr. Stephenson, to bring them into use on the different railroads, now either constructing or in agitation, it has been the opinion of several able engineers that they do not possess those advantages which the inventor had anticipated; indeed, there cannot be a better proof of the doubt entertained regarding their utility than the fact that it has been determined that no locomotive engine shall be used on the projected railroad between Newcastle and Carlisle, since, had their advantages been very apparent, the persons living immediately on the spot in which they are used, namely, Newcastle, would be acquainted therewith.

“The principal objections seem to be the difficulty of surmounting even the slightest ascent, for it has been found that a rise of only one-eighth of an inch in a yard, or of eighteen feet in a mile, retards the speed of one of these engines in a very great degree; so much so, indeed, that it has been considered necessary, in some parts where used, to aid their ascent with their load, by fixed engines, which drag them forward by means of ropes coiling round a drum. The spring steam cylinders below the boiler were found very defective, for in the ascending stroke of the working piston they were forced inwards by the connecting-rod pulling at the wheel and turning it round, and in the descending stroke the same pistons were forced as much outwards. This motion or play rendered it necessary to increase the length of the working cylinder as much as there was play in the lower ones, to avoid the danger of breaking or seriously injuring the top and bottom of the former by the striking of the piston when it was forced too much up or down.” [Pg 19]

Stephenson must have felt himself to be a personage of some importance when he received an order from the Duke of Portland for a steam locomotive. The engine, which had six wheels, was duly built and delivered in 1817, when it was put to work on the tramroad connecting the Duke’s Kilmarnock Collieries with the harbour at Troon; but, after a short trial, its use was abandoned, as the weight of the engine frequently broke the cast-iron tram-plates. It has been stated that “this engine afterwards worked on the Gloucester and Cheltenham Tramroad until 1839, when the Birmingham and Gloucester Railway bought the line, and took up the cast-iron tram-plates.”

There is no doubt that a six-wheel engine with vertical cylinders partly encased in the top of the boiler, and called the “Royal William,” was actually at work on this line—the fact having been commemorated by the striking of a bronze medal; but there is nothing to show that the “Royal William” and the engine built for the Kilmarnock and Troon Tramroad were one and the same locomotive; whilst it is certain that the Gloucester and Cheltenham Tramroad was not purchased by the Birmingham and Gloucester Railway, but jointly by the Cheltenham and Great Western Union Railway and the Birmingham and Gloucester Railway, the price paid being £35,000.

It would appear from a letter written by George Stephenson, and dated Killingworth Colliery, 28th June, 1821, that he had but little idea to what a great degree the development of the steam locomotive would be carried. The letter, which was addressed to Robert Stevenson, the celebrated Edinburgh engineer, proceeded as follows: “I have lately started a new locomotive engine with some improvements on the others which you saw. It has far surpassed my expectations. I am confident that a railway on which my engine can work is far superior to a canal. On a long and favourable railway I would start my engine to travel 60 miles a day, with from 40 to 60 tons of goods.” Taking Stephenson’s “day” to mean twelve working hours, his idea of maximum speed did not exceed five miles an hour at that time. Before this—in December, 1824—Charles MacLaren had published in the Scotsman his opinion that by the use of the steam locomotive “we shall be carried at the rate of 400 miles a day,” or an average speed of 33⅓ miles an hour.

Yet such is the irony of fate, that MacLaren, the true prophet, is forgotten, and George Stephenson is everywhere extolled. [Pg 20]

The Hetton (Coal) Railway was opened on November 18th, 1822, and five of Stephenson’s “improved Killingworth” locomotives were placed upon the level portions. These engines were capable of hauling a train of about 64 tons, the maximum speed being four miles an hour.

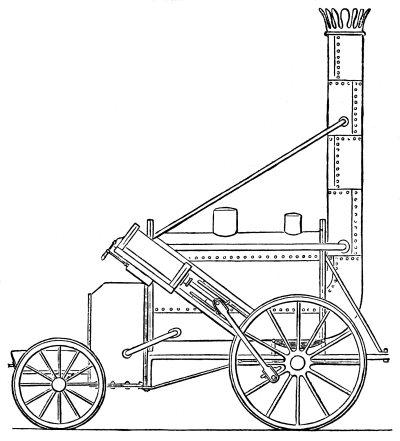

Fig. 9.—“LOCOMOTION,” THE FIRST ENGINE TO RUN ON A PUBLIC RAILWAY (THE STOCKTON AND DARLINGTON RAILWAY)

The Stockton and Darlington Railway, the first public railway, was opened on September 27th, 1825. The “Locomotion” (Fig. 9) was the first engine on the line. It was constructed at the Forth Street Works of [Pg 21] R. Stephenson and Co., at Newcastle-on-Tyne. At this early period these now celebrated Forth Street Works were little better than a collection of smiths’ forges.

Timothy Hackworth had been manager of these works, and he had a good deal to do with the construction of “Locomotion.” His improvement of the coupling-rods in place of the endless chain previously used for the purpose by Stephenson is worthy of passing notice. George Stephenson expressed a very strong desire that Hackworth should remain in charge of the Forth Street Works, and went so far as to offer him one-half of his (Stephenson’s) share in the business if he would remain. Hackworth agreed to do so if his name were added to that of the firm and he were publicly recognised as a partner; but this proposition was not accepted by Stephenson.

Hackworth then took premises in Newcastle, and intended to commence business as an engine-builder on his own account, he having already received several orders from the collieries, etc., where his skill was well known and appreciated. George Stephenson, having heard of Hackworth’s plans for carrying on a rival engine factory at Newcastle, saw Hackworth, and persuaded him to relinquish the proposition and accept the office of general manager and engineer to the Stockton and Darlington Railway.

Hackworth commenced these duties in June, 1825, and removed to Darlington. The “Locomotion” had four coupled wheels, 4ft. in diameter; two vertical cylinders, 10in. in diameter, placed partly within the boiler; the stroke was 24in.; steam pressure, 25lb. per square inch; weight in working order, 6½ tons. The tender was of wood, with a coal capacity of three-quarter ton, and a sheet-iron tank holding 240 gallons; weight loaded, 2¼ tons. The tender was supported on four wheels, each of 30in. diameter. This engine worked on the Stockton and Darlington Railway till 1850. In September, 1835, “Locomotion” engaged in a race with the mail coach for a distance of four miles, and only beat the horses by one hundred yards! She was used to open the Middlesbrough and Redcar Railway on June 4th, 1846, being under the charge of Messrs. Plews and Hopkins on this occasion, when she hauled one carriage and two trucks, and took thirty-five minutes to cover the eight miles. From 1850 to 1857 she was used as a pumping engine by Pease at his West Collieries, South Durham, after which she was mounted on a pedestal at North Road Station, Darlington. This engine was in steam upon the Darlington line during the celebration of the Stockton [Pg 22] and Darlington Railway jubilee in September, 1875. She has been exhibited as follows:—1876, at Philadelphia; 1881, Stephenson Centenary; 1886, Liverpool; and 1889, Paris. In April, 1892, she was removed from North Road to Bank Top, Darlington.

The Forth Street Works in 1826 supplied three more engines to the Stockton and Darlington Railway, named “Hope,” “Black Diamond,” and “Diligence.” These locomotives possessed many faults; indeed, they were frequently stopped by a strong wind, and the horse-drawn trains behind the locomotive-propelled ones were delayed because the engines could not proceed. “Jemmy” Stephenson (brother to George) was the principal engine-driver, and he was known far and near as most prolific in the use of oaths of a far from Parliamentary style.

“Jemmy” would be cursing his engine and the horsemen cursing “Jemmy” for the delay; and, indeed, the usual result was a general skirmish. We have already stated that Hackworth was a deeply religious man, and these scenes of lawlessness made a deep impression on his mind, so that he sought for some means to improve the locomotives, the radical fault of which was the shortness of steam—Hackworth knowing that if things progressed smoothly “Jemmy” would have fewer occasions to display his oratorical gift. After eighteen months’ working of the Stockton and Darlington Railway it was found that locomotive haulage was much more expensive than horse-power; indeed, for every pound spent on horse power about three pounds were paid for locomotive power for doing an exactly similar amount of work.

The £100 stock of the Stockton and Darlington Railway quickly fell to £50, and the shareholders began to get alarmed.

There were two opposite interests at stake—that of the general body of shareholders and that of the locomotive builders (Messrs. Pease and Richardson), who were also large shareholders in, and directors of the Stockton and Darlington Railway, as well as partners in the firm of R. Stephenson and Co. The question as to retaining the use of locomotive engines was fully discussed at a meeting of the principal proprietors, and Hackworth, as manager and engineer of the railway, was asked to give his opinion on the point. He replied: “Gentlemen, if you will allow me to make you an engine in my own way, I will engage that it shall answer your purpose.” To have refused him permission would have shown clearly to the other proprietors that Pease and Richardson did not care for the principles of steam locomotion, but that it was the [Pg 23] locomotives constructed at the Forth Street Works they wished to retain. Therefore, after some discussion, it was agreed that “as a last experiment Timothy shall be allowed to carry out his plan.”

Hackworth’s opportunity had now arrived, and the result was the production of the first really successful locomotive steam engine.

But although the shareholders “as a last experiment” gave Hackworth leave to build a locomotive on his own plan, they do not appear to have had much belief in the success of the venture, for the boiler of an old locomotive was given him to use in the construction of the new engine.

Fig. 10.—THE FIRST SUCCESSFUL LOCOMOTIVE, HACKWORTH’S “ROYAL GEORGE,” STOCKTON AND DARLINGTON RAILWAY, 1827

The engine was originally a four-wheel engine, provided with four cylinders, two to each pair of wheels, and it is stated to have been the first built in which a single pair of wheels was worked by two pistons actuating cranks placed at right angles to each other. She was built by Wilson, of Newcastle, and was the fifth engine supplied to the Stockton and Darlington Railway.

This boiler was a plain cylinder, 4ft. 4in. in diameter, and 13ft. long. A wrought-iron tube of [symbol] shape provided the heating surface, the vapour from the furnace travelling from the fire-grate up [Pg 24] and down the tube to the chimney, which was at the same end of the boiler as the grate; indeed, the chimney was an elongation of the tube continued through the end of the boiler and turned up vertically.

This return tube gave the new engine twice the heating surface of the ordinary engines, which were only provided with one straight tube. The locomotive was called the “Royal George” (Fig. 10), and was supported on six-coupled wheels, each of 4ft. diameter.

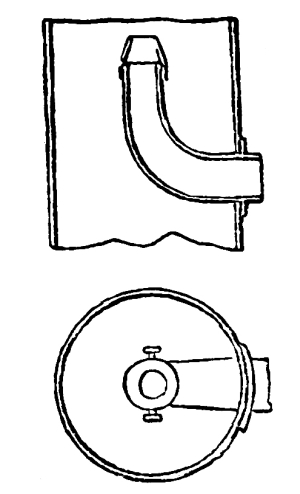

Fig. 11.—HACKWORTH’S BLAST PIPE IN THE “ROYAL GEORGE”.

The cylinders were placed in a vertical position over the pair of wheels farthest from the chimney. They were 11in. diameter, the stroke being 20in. Four of the wheels were provided with springs, but the pair connected to the pistons were not so fitted, the position of the cylinders rendering it impossible for springs to be used. The other improvements to be noted in the construction of the “Royal George” are:—

(1.) Springs instead of weights for the safety valves.

(2.) The short-stroked pumps.

(3.) Self-lubricating bearings fitted with oil reservoirs.

(4.) The cylinders placed central with the crank journals and the centre of its orbit.

(5.) The first example of six-coupled wheels.

(6.) The first really spring-mounted locomotive, the springs performing the double functions of “bearing springs” and “balance beams.”

(7.) A portion of the exhaust steam used as a jet beneath the fire-grate and part also for heating the feed-water; and last and most important—so important, indeed, that it has been described as the “life-breath of the high-pressure locomotive”—the Steam Blast. (Fig. 11.)

Trevithick, Nicholson, Stephenson, Gurney, and others have been credited with the production of this valuable contrivance, but an inquiry into the facts conclusively proves that before Hackworth built the “Royal George” the real nature of the exhaust steam blast was not understood by any of those who have since been credited with the invention.

Doubtless several locomotive experimentalists, after various endeavours to get rid of the spent steam, at last turned the escape pipe into the chimney, as the most practical way of discharging the exhaust steam. [Pg 25] Trevithick did so, and George Stephenson and others simply followed Trevithick’s example, but knew nothing of the value of the exhaust steam as a means of increasing the heating powers of the locomotive.

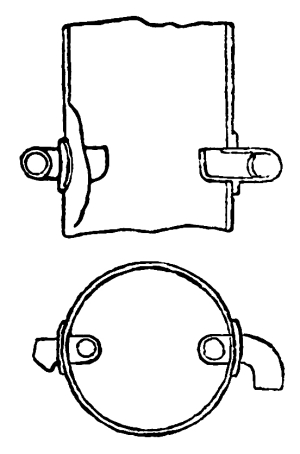

Fig. 12.—WASTE STEAM-PIPE IN STEPHENSON’S “ROCKET”

The claims of both Stephenson and Trevithick appear to be founded on the use of the words “steam blast” by N. Wood in his “Treatise,” when describing the exhaust steam arrangement. This he probably did, not understanding the true nature of the blast, or contracted orifice, as invented by Hackworth.

It is abundantly evident that Trevithick was absolutely ignorant of the effect of the blast on the fire, for in his patent (No. 2,599) no mention is made of it, although the specification is most minutely drawn; indeed, thirteen years later Trevithick actually patented “fanners, etc., for creating an artificial draught in the chimney.” Nicholson, in his patent (No. 2,990) dated November 22nd, 1806, also says, “The steam must be high pressure; the steam draught cannot be produced by exhaust steam”. This clearly shows he was not aware of the exhaust steam blast; indeed, he expressly states that exhaust steam cannot be used. With regard to George Stephenson, the fact that as late as July 25th, 1828, he wrote to Timothy Hackworth, “We have tried the new locomotive engine (‘Lancashire Witch’) at Bolton; we have also tried the blast to it for burning coke, and I believe it will answer. There are two bellows, worked by eccentrics underneath the tender.” It will, therefore, be observed that Stephenson’s “blast” was produced by bellows. This letter was written ten months after Hackworth had successfully used the steam blast in the “Royal George.”

It will be shown later that it was only at the Rainhill trials, in October, 1829, that Stephenson learned Hackworth’s secret of the blast pipe. Although Gurney, in 1822, used a coned pipe, he expressly states that the steam must be continuously ejected at a high velocity from a high-pressure boiler, which distinctly shows he did not use exhaust steam as Hackworth did.

Walker and Rastrick were the engineers engaged by the directors of the Liverpool and Manchester Railway to report on the advantages to be gained from the adoption of stationary or locomotive engines on the [Pg 26] Liverpool and Manchester Railway. They decided in favour of the former, but they stated in their report, “Hackworth’s engine (‘Royal George’) is undoubtedly the most powerful that has yet been made, as the amount of tons conveyed by it, compared with the other engines, proves.” The first year’s work of the “Royal George” consisted of conveying 22,442 tons of goods 20 miles, at a cost of only £466, whilst the same amount of work performed by horses cost £998, showing a saving by the use of the “Royal George” of £532 in one year. The “Royal George” was numbered, 1½, in the books of the S. and D. R.

This was the first time that a locomotive engine had worked for a whole year at a cheaper rate than horses. Upon this result being known to the Stockton and Darlington Railway directors, one of them exclaimed, “All we want is plenty of Timothy’s locomotives.” The “Royal George” worked night and day upon the Stockton and Darlington Railway until December, 1840, when she was sold to the Wingate Grange Colliery for £125 more than her original cost.

R. Stephenson and Co. in 1828 supplied a six-wheel coupled engine, “Experiment,” to the Stockton and Darlington Railway. This locomotive had inclined outside cylinders, 9in. diameter, with a stroke of 24in.; the wheels were 4ft. diameter. This engine did not give nearly so satisfactory results as Hackworth’s “Royal George.”

Reference must here be made to Stevenson’s locomotive, “Twin Sisters,” used in the construction of the Lancashire and Manchester Railway. She had two fire-boxes and boilers, and two chimneys; she was supported on six-coupled wheels of 4ft. diameter; the cylinders were outside in an inclined position. The “Lancashire Witch” (previously mentioned) was built by Stephenson and Co. in 1828 and sold to the Bolton and Leigh Railway. She was supported on four coupled wheels, 4ft. diameter; the cylinders were outside, 9in. diameter, fixed in an inclined position, projecting over the top and at the rear of the boiler. The engine is only mentioned for the purpose of noticing the fact that the fire was urged by means of bellows, worked by eccentrics fixed on the leading axle of the four-wheeled tender, which was specially built with outside frames for the purpose of allowing sufficient room to locate the bellows, etc. Yet some people have assurance enough to state that at the time Stephenson built this engine, and provided it with bellows for the purpose of urging the fire, he was fully acquainted with the nature and advantages of the steam blast!! [Pg 27]

In the South Kensington Museum there is preserved the “Agenoria,” a locomotive built for the Shutt End Railway by Foster, Rastrick and Co. in 1829, the engine being put to work on June 2nd in that year. It is a four-wheel engine, with vertical cylinders, 7½in. diameter, placed at the fire-box end; the stroke is 3ft., and the motion is taken from two beams fixed over the top of the boiler, which is 10ft. long and 4ft. diameter. The slide-valve eccentrics are loose upon the axle, and to enable the engine to work both ways a clutch is provided, as also is hand gear to the valves, to enable the axle to make a half turn, and so bring either the forward or backward clutch into action. The chimney was of abnormal height. The “Agenoria” worked for some thirty years.

In 1829 R. Stephenson and Co. supplied an engine named “Rocket,” No. 7, to the Stockton and Darlington Railway, similar in general design to “Experiment,” No. 6 (already referred to). This engine was delivered at the time Hackworth was attending the Rainhill locomotive contest, and a director of the Stockton and Darlington Railway wrote to Hackworth, describing the shortcomings of this engine as follows:—“The new one last sent was at work scarcely a week before it was completely condemned and not fit to be used in its present state. The hand gear and valves have no control in working it. When standing without the wagons at Tully’s a few day ago it started by itself when the steam was shut off, and all that Jem Stephenson could do he could not stop it; it ran down the branch with such speed that old Jem was crying out for help, everyone expecting to see them dashed to atoms; the depôts being quite clear of wagons, this would have been the case had not the teamers and others thrown blocks in the way and fortunately threw it off. A similar occurrence took place on the following day in going down to Stockton. As soon as the wagons were unhooked at the top of the run, away goes ‘Maniac,’ defying all the power and skill of her jockey, old Jem; nor could it be stopped until it arrived near the staiths. Had a coach been on the road coming up, its passengers would have been in a most dangerous position. The force-pump is nearly useless, having had, every day it was at work, to fill the boiler with pails at each of the watering-places. No fewer than three times the lead plug has melted out. This ‘Maniac’ was a Forth Street production, and at last was obliged to be towed up to the ‘hospital’ by a real ‘Timothy’ in front, on six wheels, and actually had twenty-four wagons in the rear as guard. It is now at headquarters at Shildon.”

Such was the opinion expressed by a director of the Stockton and Darlington concerning a Stephenson locomotive!

[Pg 28]

The Liverpool and Manchester Railway Locomotive Competition—The conditions of the contest—The competitors—The “Novelty”—The “Sanspareil”—The secret of the steam blast stolen—Mr. Hick’s history of the “Sanspareil”—The “Rocket”—Colburn’s comparison of the “Rocket” and “Sanspareil”—Booth’s tubular boiler fitted to the “Rocket”—The prize divided—History of the “Rocket”—The “Perseverance” wihtdrawn from competition—The “Cycloped” horse-propelled locomotive— Winan’s manumotive vehicles for the Liverpool and Manchester Railway—The directors purchase a dozen.

Although Walker and Rastrick had reported to the directors of the Liverpool and Manchester Railway in favour of stationary engines, there were some of them who were enlightened enough to be desirous of giving steam locomotives a fair trial. The Stephensons being locomotive engine builders, naturally were not behindhand in fully and frequently describing the superiority of locomotive traction. Finally, at the suggestion of Mr. Harrison, the directors offered a prize of £500, to be awarded to the locomotive that at the trial appeared to be the best machine competing. The following is a copy of the notice detailing the conditions of the competition:—

“Stipulations and Conditions on which the Directors of the Liverpool and Manchester Railway offer a premium of £500 for the most improved Locomotive Engine:—

“1st. The said engine must effectually consume its own smoke, according to the provisions of the Railway Act, 7, George IV.

“2nd. The engine, if it weighs six tons, must be capable of drawing after it, day by day, on a well-constructed railway, on a level plane, a train of carriages of the gross weight of twenty tons, including the tender and water-tank, at a rate of ten miles per hour, with a pressure of steam on the boiler not exceeding fifty pounds per square inch.

“3rd. There must be two safety valves, one of which must be completely out of the control of the engineman, and neither of which must be fastened down while the engine is working.

“4th. The engine and boiler must be supported on springs, and rest on six wheels, and the height from the ground to the top of the chimney must not exceed fifteen feet. [Pg 29]

“5th. The weight of the machine, with its complement of water in the boiler, must at most not exceed six tons; and a machine of less weight will be preferred if it draw after it a proportionate weight; and, if the weight of the engine, etc., does not exceed five tons, then the gross weight to be drawn need not exceed fifteen tons, and in that proportion for machines of still smaller weight; provided that the engine, etc., shall still be on six wheels, unless the weight (as above) be reduced to four-tons and a half or under, in which case the boiler, etc., may be placed on four wheels. And the Company shall be at liberty to put the boiler, fire-tube, cylinders, etc., to a test of pressure of water not exceeding 150 pounds per square inch, without being answerable for any damage the machine may receive in consequence.

“6th. There must be a mercurial gauge affixed to the machine with index rod showing the steam pressure above forty-five pounds per square inch.

“7th. The engine to be delivered complete for trial at the Liverpool end of the railway not later than the 1st of October next.

“8th. The price of the engine which may be accepted not to exceed £550, delivered on the railway, and any engine not approved to be taken back by owner.

“N.B.—The Railway Company will provide the engine tender with a supply of water and fuel for the experiment. The distance within the rails is four feet eight inches and a half.”

Fig. 13.—THE “NOVELTY,” ENTERED BY BRAITHWAITE AND ERICSSON FOR THE RAINHILL PRIZE

[Pg 30] At this period there were but few men who understood even the outlines of locomotive construction, and unfortunately all of these did not take part in the competition. The fifth condition, limiting the weight of the loaded locomotive to six tons, probably deterred some makers from competing. Others had commenced constructing locomotives for the competition, but were unable to finish them by the date mentioned in the conditions.

The actual entries were as follows: 1. Braithwaite and Ericsson’s “Novelty”; 2. Timothy Hackworth’s “Sanspareil”; 3. R. Stephenson’s “Rocket”; 4. Burstall’s “Perseverance”; and 5. Brandreth’s “Cycloped.”

The “Novelty” (Fig. 13) was far and away the favourite engine at Rainhill, its neat appearance and smartness attracting universal attention. It was a “tank” engine, and probably the first locomotive constructed to carry its supply of water and coal on the engine, being thus complete without a tender. This raised a difficulty in apportioning the load, as in the conditions it was arranged that the tender was to be counted as part of the load hauled. The machine with water and coal weighed 3 tons 17 cwt. 14 lb.; the allowance made for the tender and fuel reduced the theoretical weight of the “Novelty,” as an engine only, to 2 tons 13 cwt. 2 qr. 3½ lb.; the gross weight hauled, including the locomotive, being 10 tons 14 cwt. 14 lb.

The “Novelty” was first tried upon October 10th, 1829—she had not previously been upon a railway—and it was found necessary to make some alterations to her wheels. Timothy Hackworth, although he had an engine running in competition with the “Novelty,” generously offered to repair the defect, and he personally took out the broken portion, welded it, and replaced it in position with his own hands.

The trials were conducted upon a level portion of line at Rainhill, on a course only one and a half miles in length, and at either end an additional eighth of a mile was allowed for the purpose of getting up the speed and stopping after the run of a mile and a half. The engines had to make forty runs over the course, or a distance of sixty miles, in all, which was computed to be equal to a return journey between Liverpool and Manchester.

After running two trips of one and a half miles each, the pipe from the pump to the boiler burst, in consequence of the cock between the boiler and pump having, by accident, been closed. The “Novelty” and train covered the first trip in five minutes thirty-six seconds, and the [Pg 31] return in six minutes forty seconds; being at the rate of 16.07 and 13½ miles an hour respectively. After being repaired, the engine, with its train, made an unofficial trip, and developed a speed of 21 ⅙ miles an hour. Without a load the “Novelty” attained a speed of nearly thirty miles an hour.

The “Novelty” was again tried on October 14th, but upon its third trip part of the boiler gave way, and it was decided to withdraw the locomotive from competition.

The boiler of the “Novelty” was partly vertical and partly horizontal; the latter portion was about 12ft. long and 15in. in diameter. In the former was the fire-box, surrounded by water, coke being supplied through what at first might be mistaken for the funnel of a steam fire-engine. This was, however, kept air-tight, the fuel being introduced by means of a descending hopper. The area of the fire-grate was 1.8 sq. ft., the fire-box heating surface 9½ sq. ft., and the heating surface of the tubes, 33 sq. ft.

The air entered below the fire-bars by a pipe traversing the length of the engine, and connected with bellows fixed above the frame at the other extreme of the engine. The bellows were worked by the engine, so that the “Novelty” was provided with a forced draught. The heated air was forced through a tube, which made three journeys through the horizontal portion of the boiler, and was consequently 36ft. in length. It was 4in. in diameter at the grate end, and 3in. at the other extreme, where it was turned up as a chimney. The cylinders were located over the pair of wheels at the bellows end of the machine. They were fixed vertically, the diameter being 6in., and length of stroke 12in. The piston-rods worked through the top covers, and by means of cross-heads, side-rods, and bell-cranks the motion was conveyed to the crank axle beneath the vertical portion of the boiler, although, as previously mentioned, the cylinders were over the other pair of wheels. The wheels were 4ft. 2.1in. in diameter, and chains were provided for coupling the wheels together; but these were not used at Rainhill.