Title: Dyes and dyeing

Author: Viscount Exmouth Charles E. Pellew

Release date: February 6, 2025 [eBook #75302]

Language: English

Original publication: New York: Robert M. McBride & Company, 1913

Credits: Aaron Adrignola, A Marshall and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

Footnote anchors are denoted by [number], and the footnotes have been placed at the end of the paragraph.

Some minor changes to the text are noted at the end of the book.

BY

CHARLES E. PELLEW

Formerly Adjunct Professor of Chemistry

at Columbia University

NEW YORK

ROBERT M. McBRIDE & COMPANY

1918

[Pg iii]

Copyright, 1913, by

McBRIDE, NAST & COMPANY

Copyright, 1918, by

ROBERT M. McBRIDE & COMPANY

New and enlarged edition

Published, January, 1918

[iv]

| PAGE | ||

| Chapter I—INTRODUCTION | 5 | |

| Dyes of the Ancients—Dyes of Our Ancestors—Animal, Vegetable and Mineral Dyes—Outfit for Practical Dyeing. | ||

| Chapter II—MODERN DYESTUFFS | 40 | |

| Discovery of the Aniline or Coal-Tar Colors—Their Properties and Uses—How Obtained—How Named—Classification of Coal-Tar Colors for Craftsmen. | ||

| Chapter III—THE DIRECT COTTON OR SALT COLORS | 53 | |

| Discovery, Properties and Uses of the Salt Colors; with Lists of Selected Dyestuffs, and Dying Directions for Cotton and Linen—Fastness to Light and Washing—After-treatment. | ||

| Chapter IV—THEORY AND PRACTICE OF COLOR DYEING | 71 | |

| Even and Shaded Dyeing with the Primary Colors—Experiments with Secondary Colors—Matching Shades. | ||

| Chapter V—THE SULPHUR COLORS | 85 | |

| Discovery—Properties and Uses of the Sulphur Colors—List of Selected Dyestuffs, and Dyeing Directions for Cotton and Linen. | ||

| Chapter VI—THE INDIGO OR VAT COLORS | 91 | |

| Natural and Synthetic Indigo—Properties and Application—Vat Dyeing, Old and Modern—Dyeing Directions—The Modern Vat Colors—Their Properties and Uses—Selected Dyestuffs—Fastness to Light and Washing—Dyeing Directions for Cotton, Linen and Silk.[v] | ||

| Chapter VII—THE BASIC COLORS | 108 | |

| History, Properties, and Application to Cotton, Wool, Silk, etc.—Disadvantages—Not Fast to Light—Dyeing Directions for Straw, Raffia, etc. | ||

| Chapter VIII—THE ACID COLORS | 123 | |

| History, Properties, Uses, and List of Selected Dyestuffs—Dyeing Directions for Wool. | ||

| Chapter IX—DYEING FEATHERS | 131 | |

| The Dye-bath—The Dyeing Method—The Finishing Process—Dry and Wet Starching—Dyeing in the Starch—Black Dyeing of Feathers—Painting Feathers. | ||

| Chapter X—LEATHER AND LEATHER DYEING | 141 | |

| History—Preparation of Leather—Oil, Mineral and Bark Tanning—Dyeing, Staining and Finishing Leather. | ||

| Chapter XI—SILK I | 156 | |

| History, Origin and Varieties of Silk—Preparing Silk for Dyeing—Piece Dyeing—Skein Dyeing—Dyeing Wild Silks. | ||

| Chapter XII—SILK II | 168 | |

| Black Dyeing of Silk—Coal-Tar Colors—Logwood—Weighting of Silk—Properties and Tests for Weighted Silk—Dyeing Silk with Colors Fast to Washing. | ||

| Chapter XIII—IMITATION AND ARTIFICIAL SILK | 181 | |

| History, Preparation and Properties of Mercerized Cotton—History, Preparation and Properties of Artificial Silk—Precautions to be Taken in Dyeing and Finishing. [vi] | ||

| Chapter XIV—TIED AND DYED WORK | 192 | |

| As Used in South America, India, Philippines and U.S.—Variations in Tying Process—How Dyed—Tied and Discharged Work. | ||

| Chapter XV—STENCILS AND STENCILLING | 211 | |

| Japanese Practice—U.S. Practice—Knives, Brushes, Paper, etc.—Colors for Leather, Silk, and Cotton—Stencilling with Aniline Black Paste. | ||

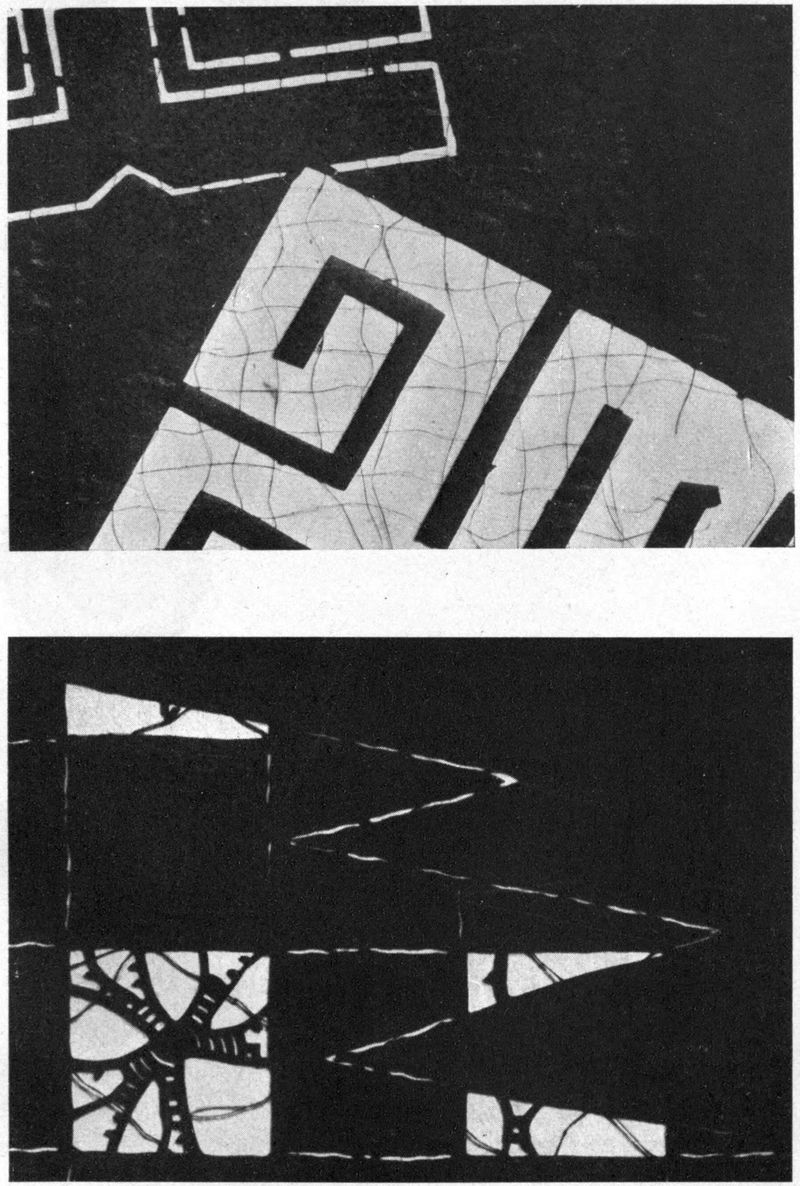

| Chapter XVI—RESIST AND DISCHARGE STENCILLING | 228 | |

| Japanese Practice—Resist Paste and the Sulphur Colors—Discharge Stencilling with Bleaching Powder and Hydrosulphite. | ||

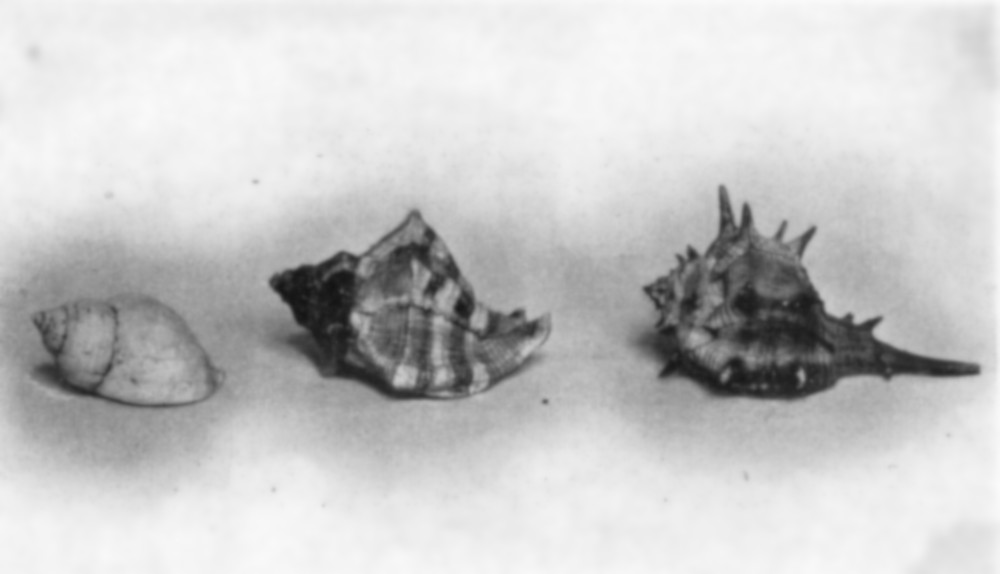

| Chapter XVII—BATIK OR WAX RESIST | 241 | |

| Javanese Practice—Modern Practice and Apparatus—Dyeing of Batiked Goods—Use of Batik Process on Cotton, Linen, Silk, Leather, Wood, Bone, etc. | ||

| Chapter XVIII—THE INFLUENCE OF THE WAR UPON THE DYESTUFF INDUSTRY | 260 | |

| Rise of the German Dyestuff Monopoly—Ruin of the English Dyestuff Industry—Dyestuff Industry in the United States—Changed Conditions Due to the War—Lists of Best Dyestuffs. | ||

THE ILLUSTRATIONS

PLATES IN COLOR

| PLATE | |||

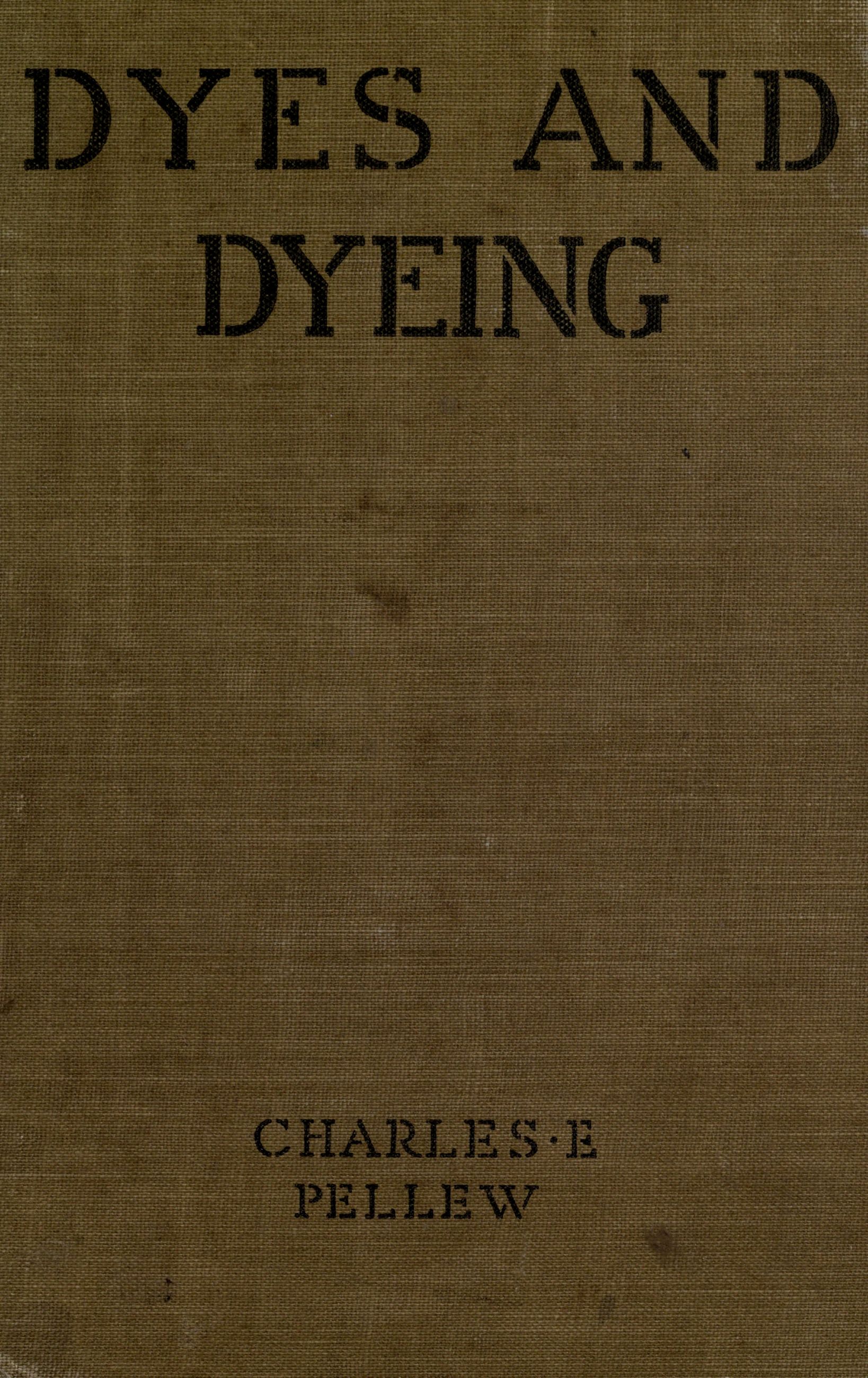

| I | Indigo dyed batik from Madras | Frontispiece | |

| FACING PAGE | |||

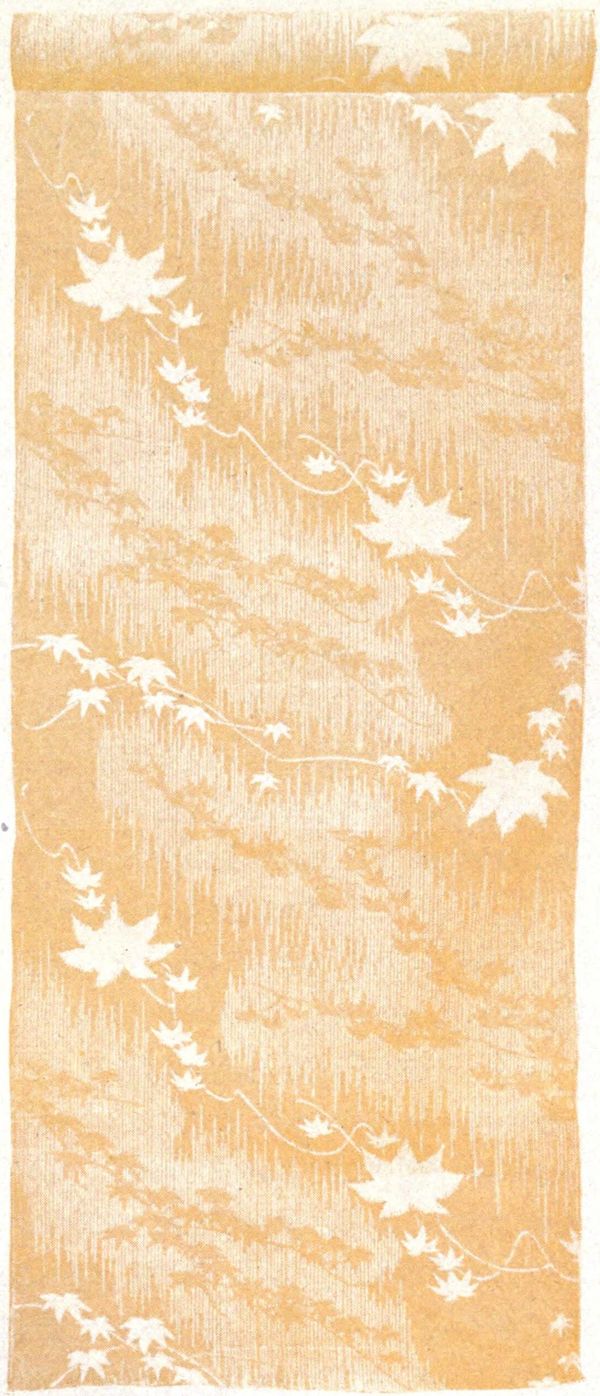

| II | Japanese towelling, showing impression of fresh damp leaves | 26 | |

| III | Same towelling after immersion in iron spring | 30 | |

| IV | (a) Example of tied and dyed work (b) Example of tied and discharged work |

} | 210 |

| V | Japanese towelling stencilled in resist and dyed by immersion in iron spring | 230 | |

ILLUSTRATIONS IN HALF-TONE

| FIG. | |||

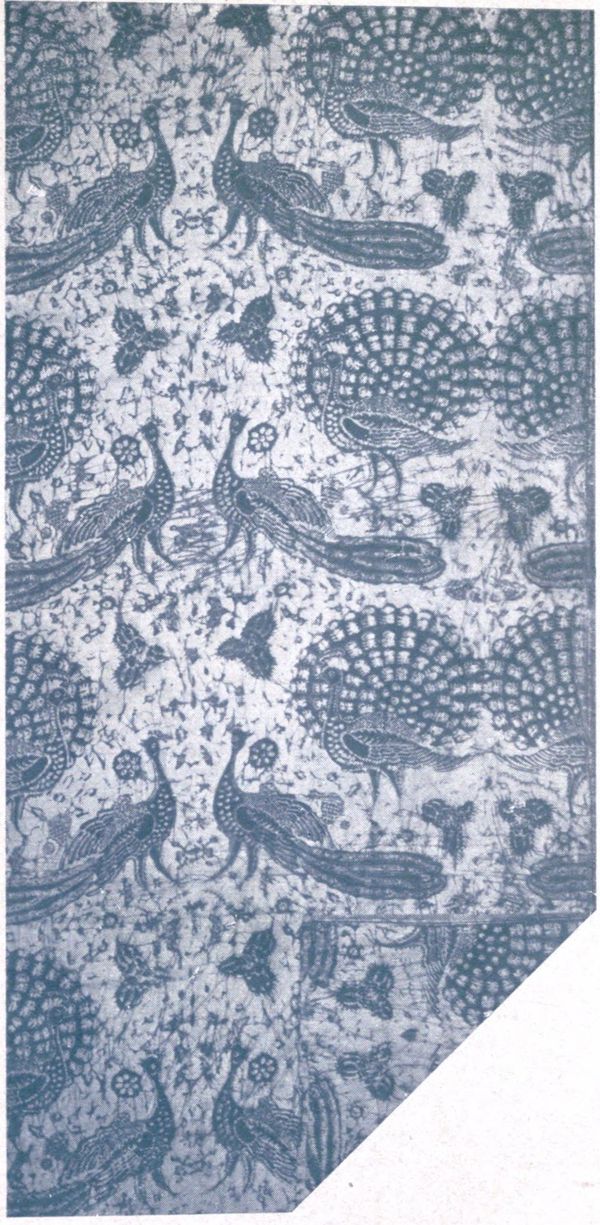

| 1 | Shellfish used by the ancients for Tyrian purple | 12 | |

| Sir W. H. Perkin | 42 | ||

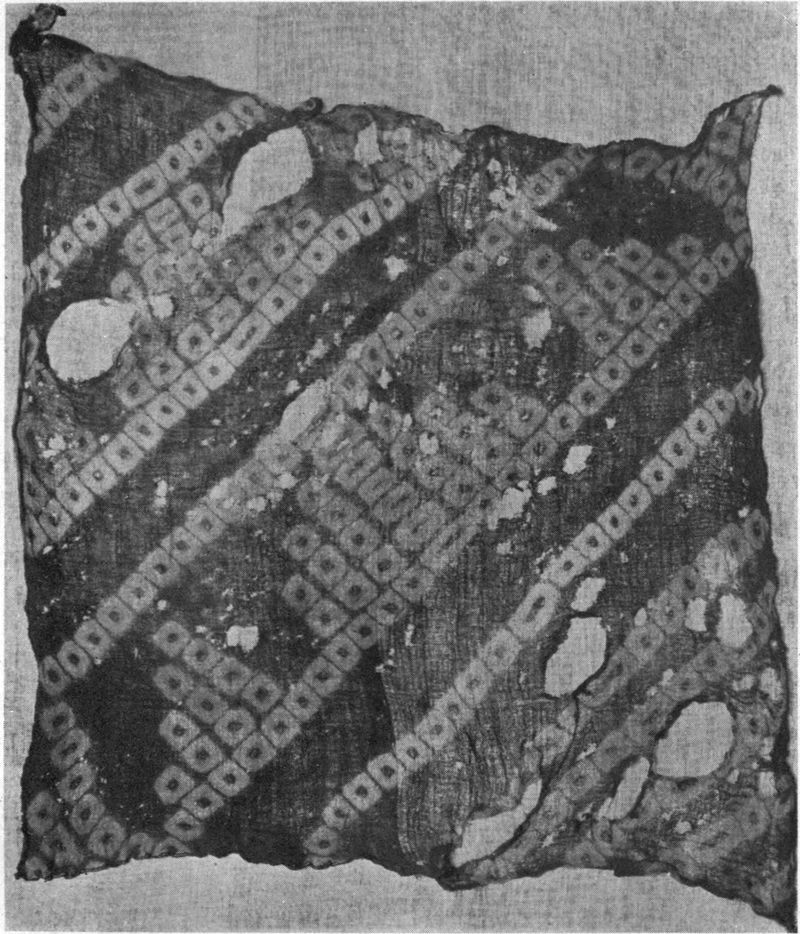

| 2 | Tied and dyed headdress from an Inca tomb in Peru | 192 | |

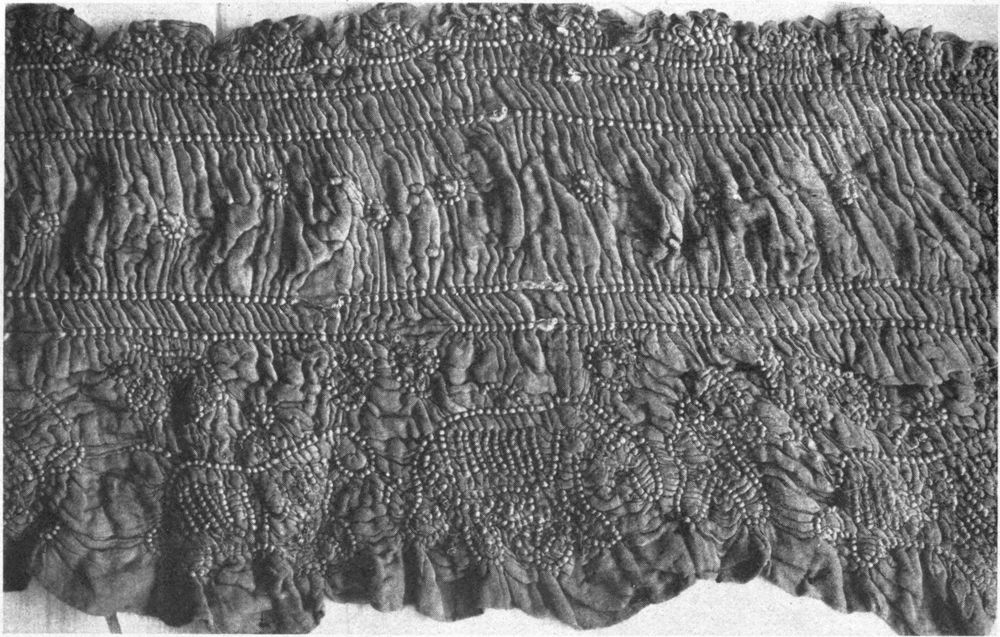

| 3 | Shikar chundri, from Rajputana, with knots still untied | 196 | |

| 4 | Same chundri untied and shaken out | 198 | |

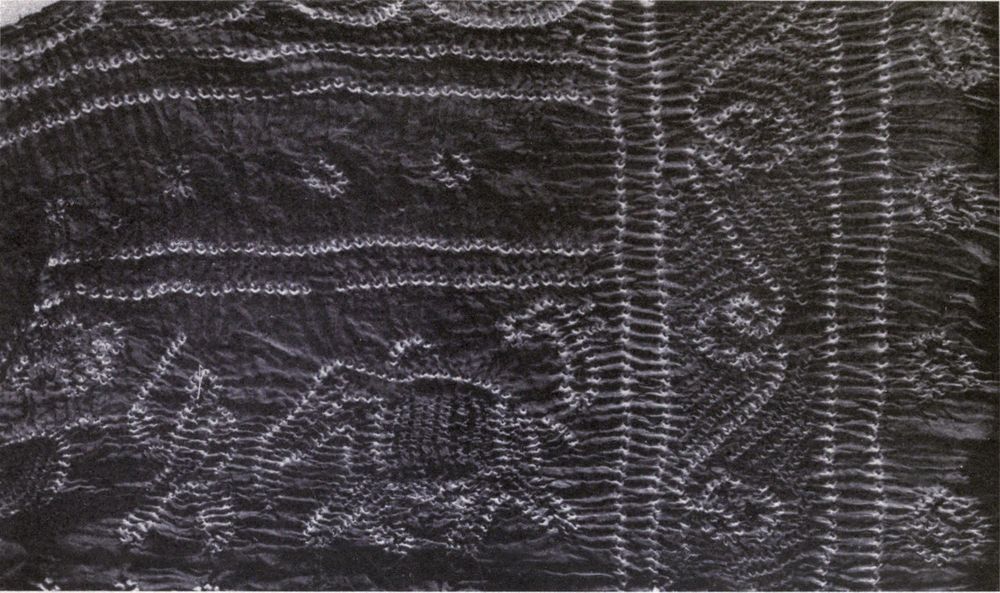

| 5 | Bagobo headdress from the Island of Mindanao | 200 | |

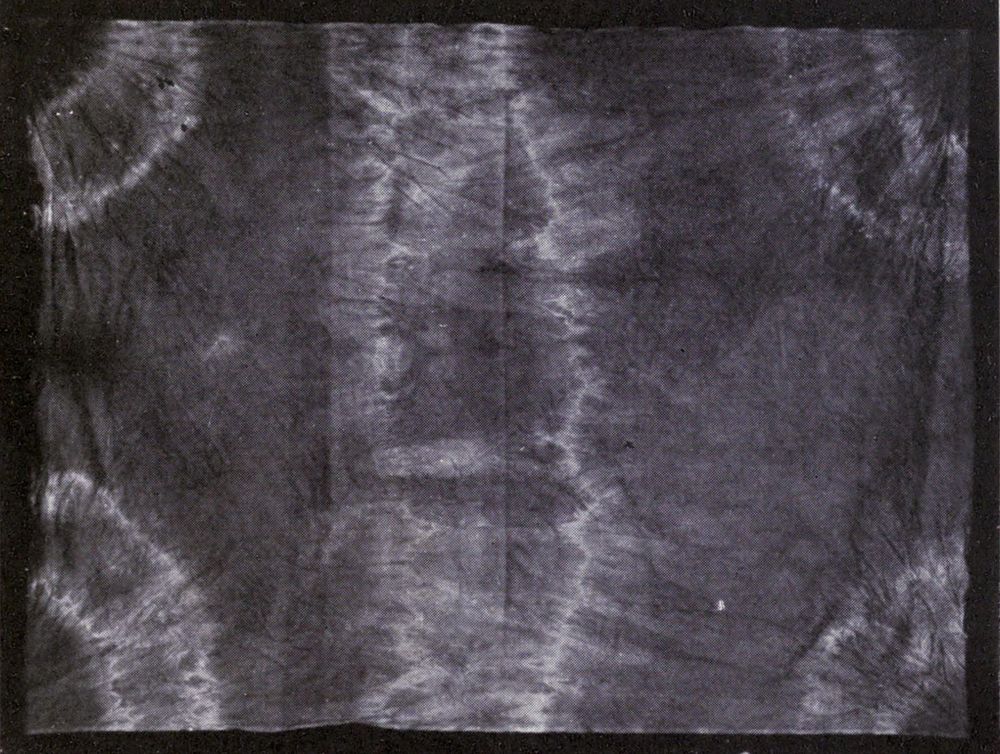

| 6 | Sample of tied and dyed work, “tied on itself” | 202 | |

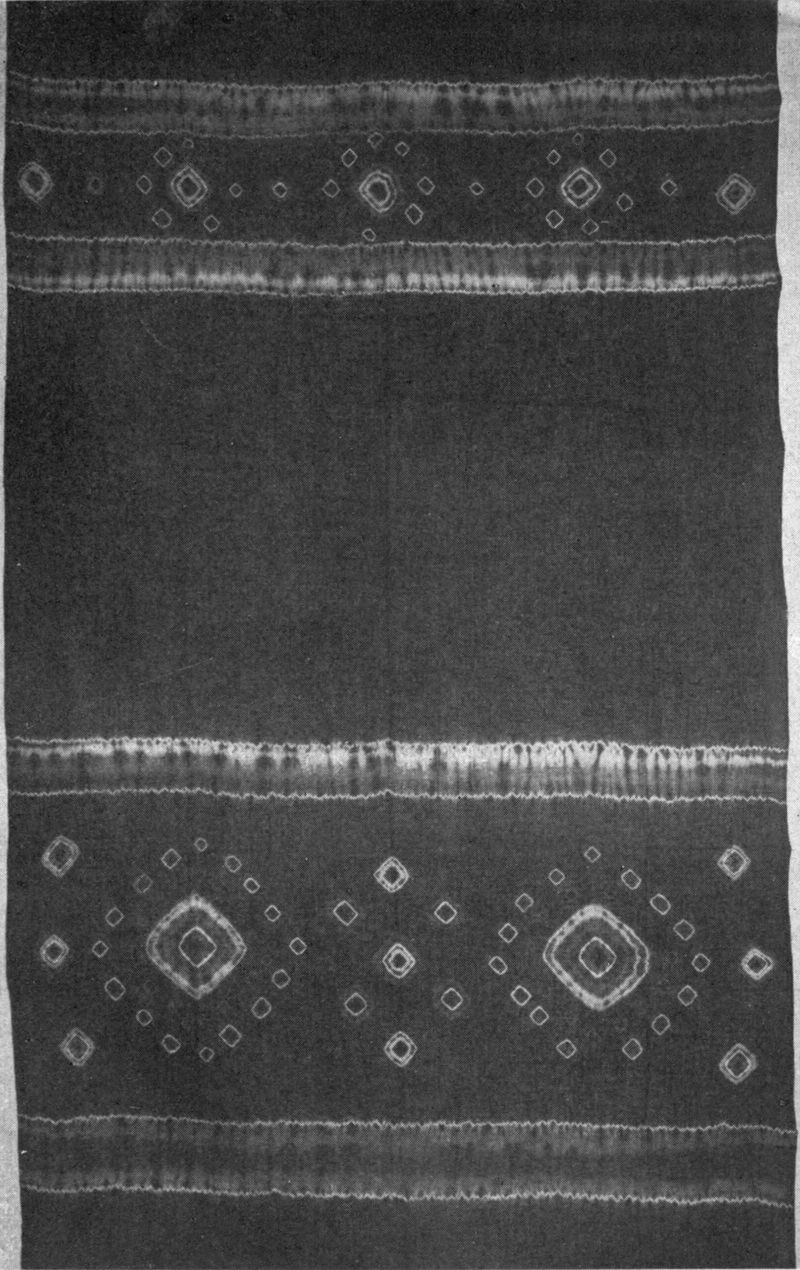

| 7 | Sample of tied and dyed work, “tied in bands” | 204 | |

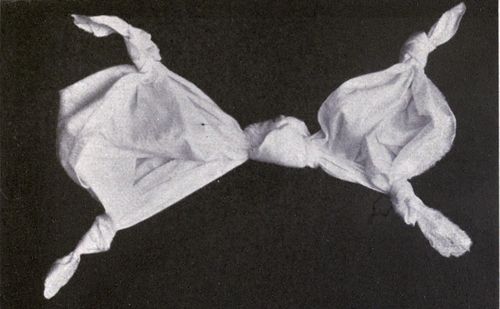

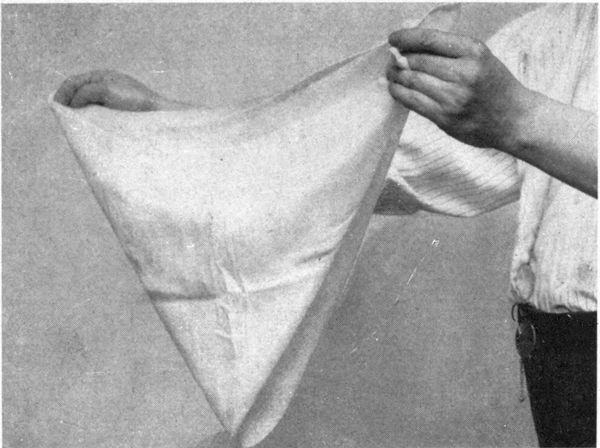

| 8 | Tied and dyed work—Folding the cloth | 206 | |

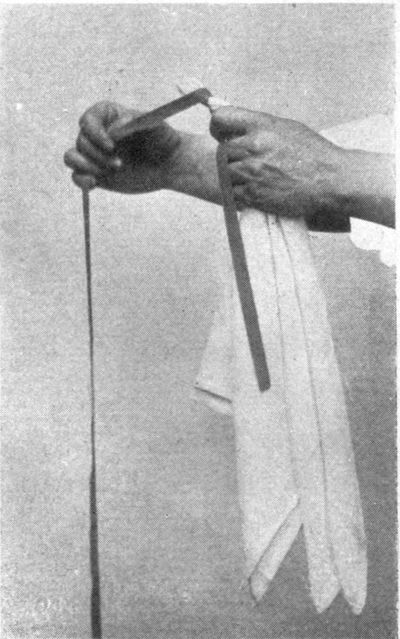

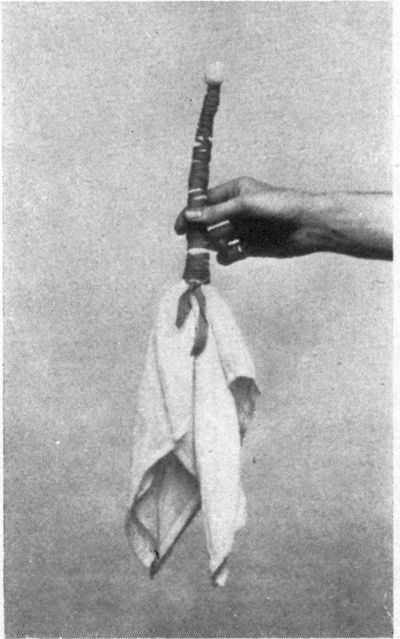

| 9 | Starting to tie | 206 | |

| 10 | Centre portion tied | 206 | |

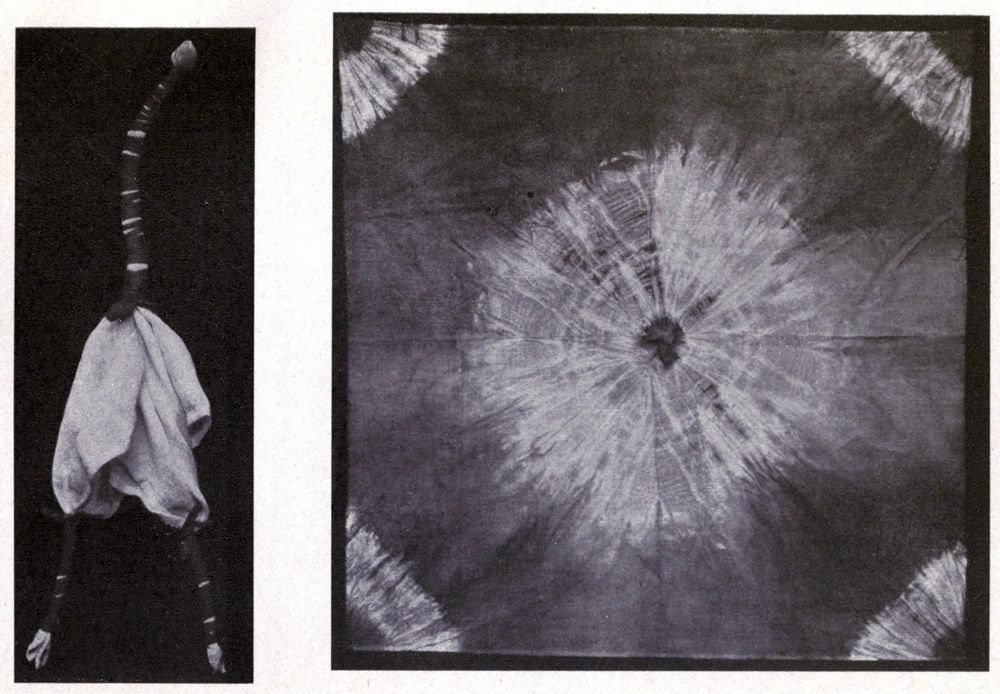

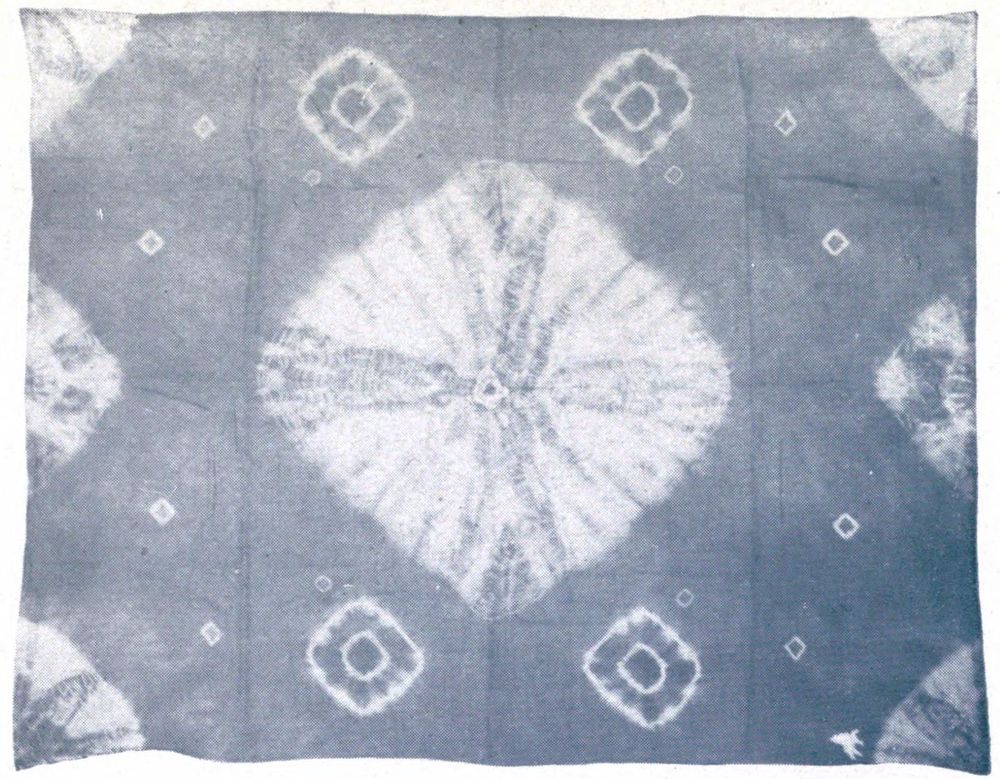

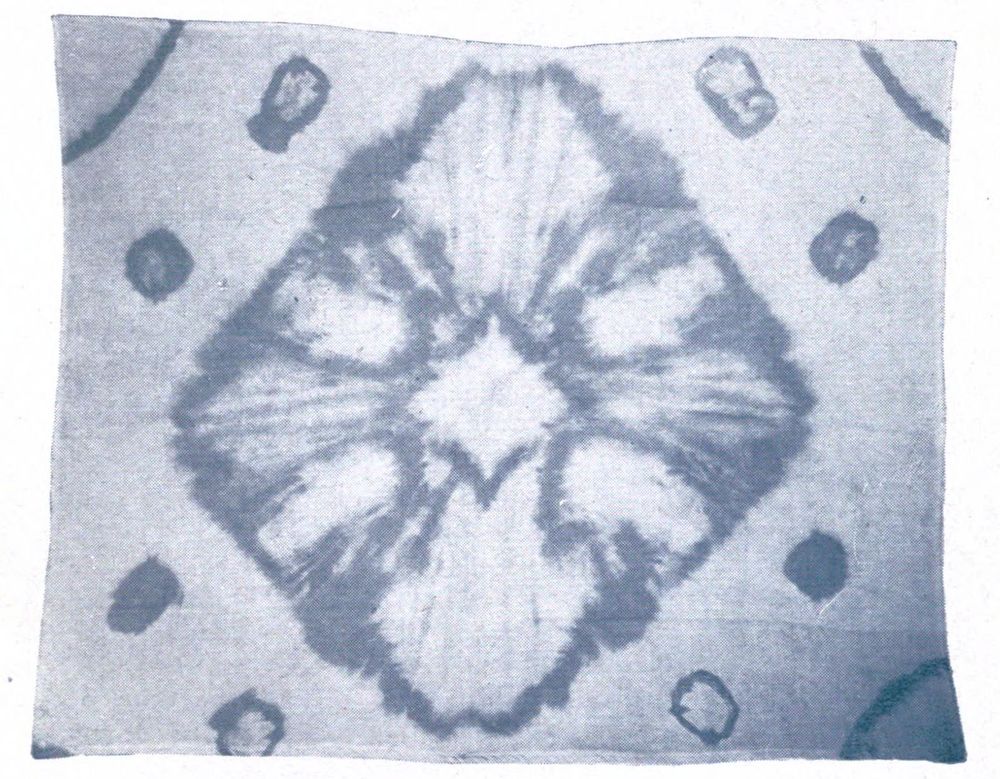

| 11 | Centre and corners tied | 208 | |

| 12 | Dyed, untied and shaken out | 208 | |

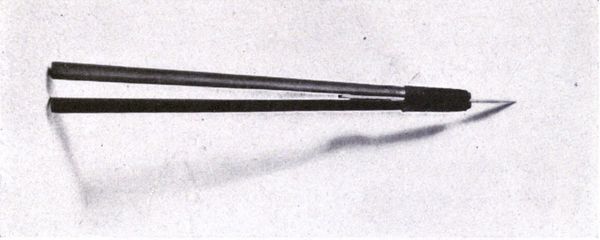

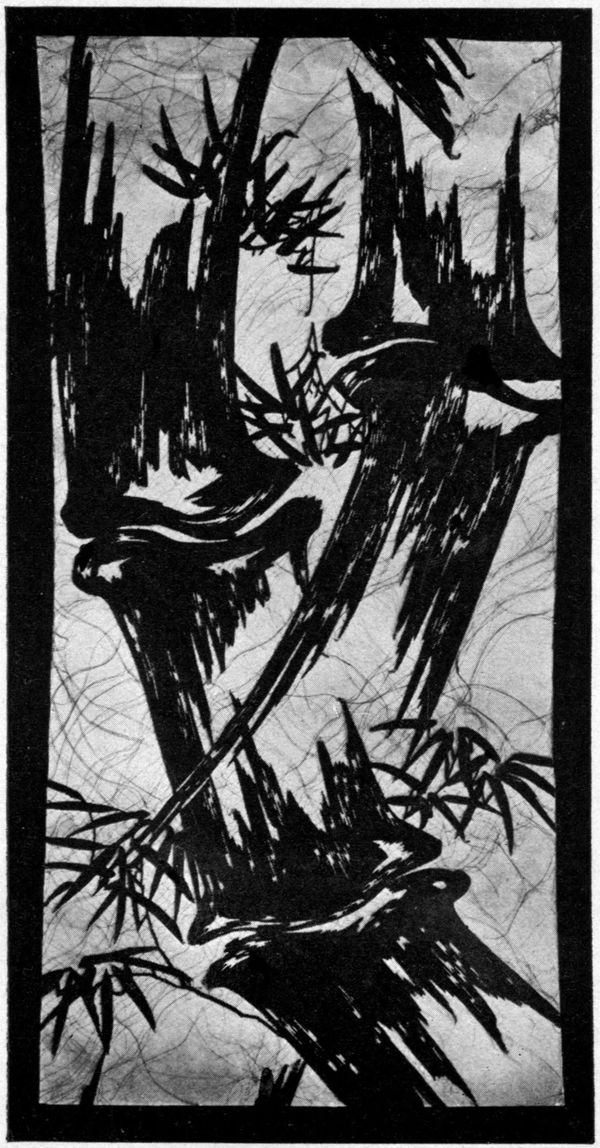

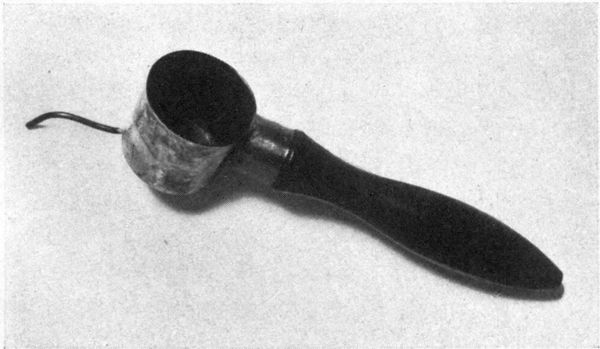

| 13 | Japanese stencil knife | 212 | |

| 14 | Japanese stencil brushes | 212 | |

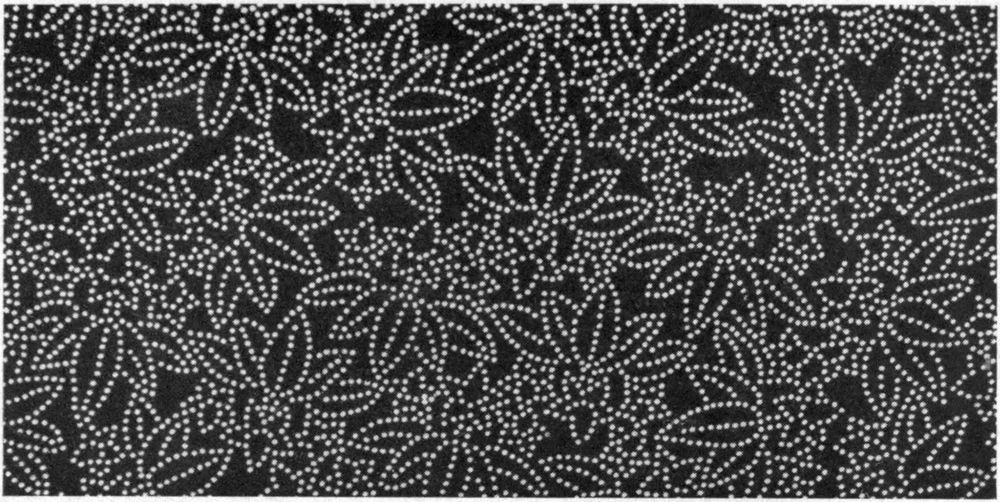

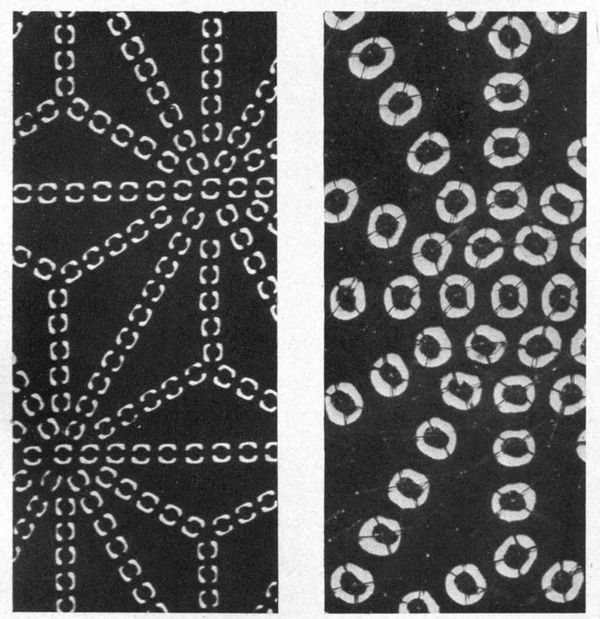

| 15 | Japanese stencil, showing holes punched by hand tool | 216[viii] | |

| 16 | Japanese stencil, showing use of stops | 216 | |

| 17 | Japanese stencil, showing use of sewing instead of stops | 216 | |

| 18 | Japanese stencils, showing use of both stops and net | 218 | |

| 19 | Large and handsome Japanese stencil, showing use of net | 224 | |

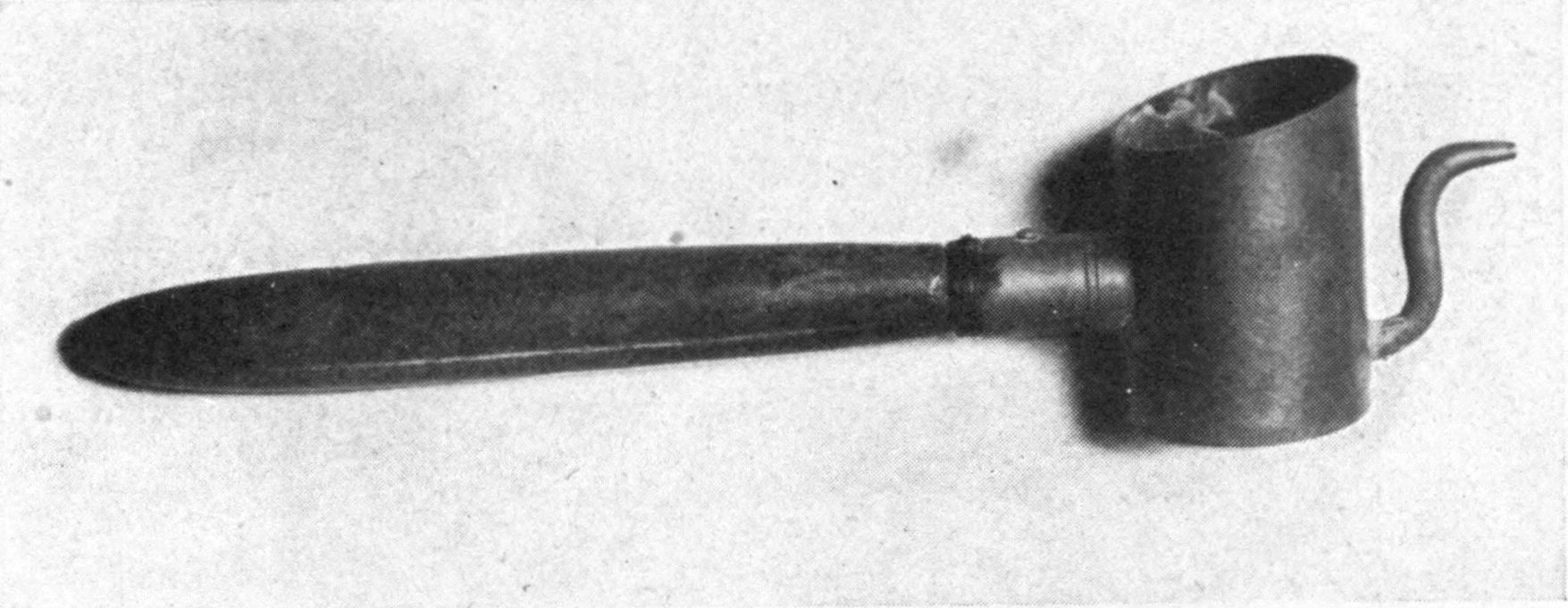

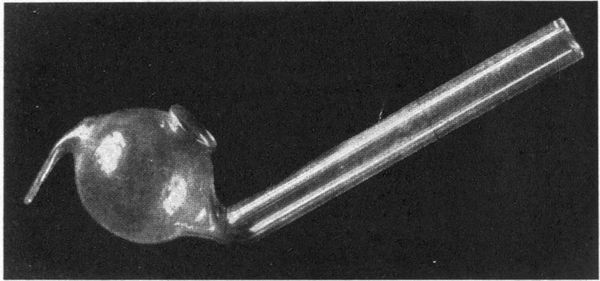

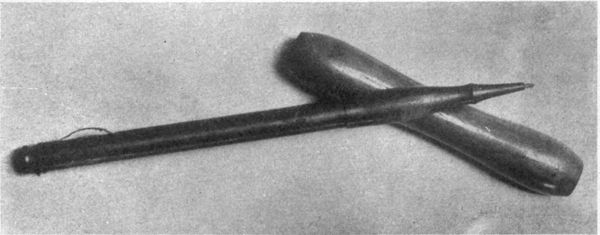

| 20 | “Teapot” model of tjanting | 248 | |

| 21 | Walther glass tjanting | 248 | |

| 22 | “Wax pencil” model of tjanting | 248 | |

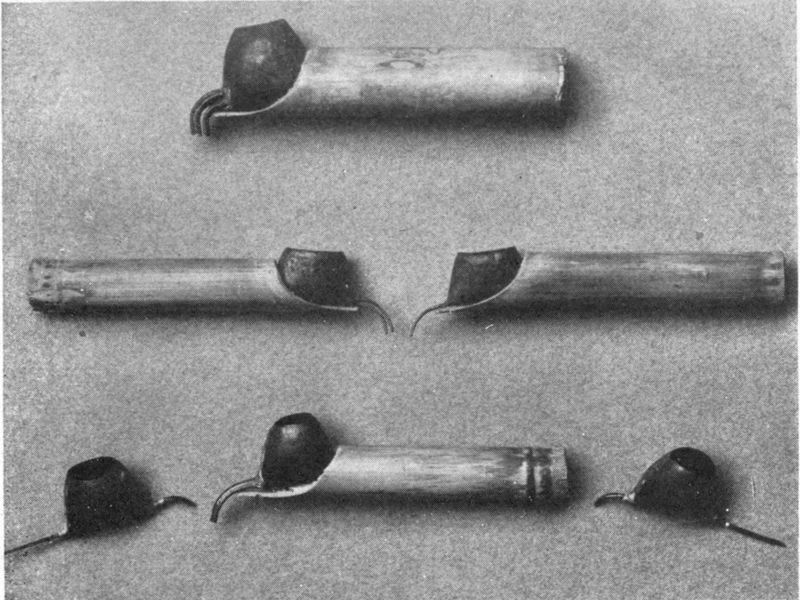

| 23 | Javanese tjantings | 250 | |

| 24 | American modification of Javanese tjanting | 250 | |

DIAGRAMS IN THE LETTERPRESS

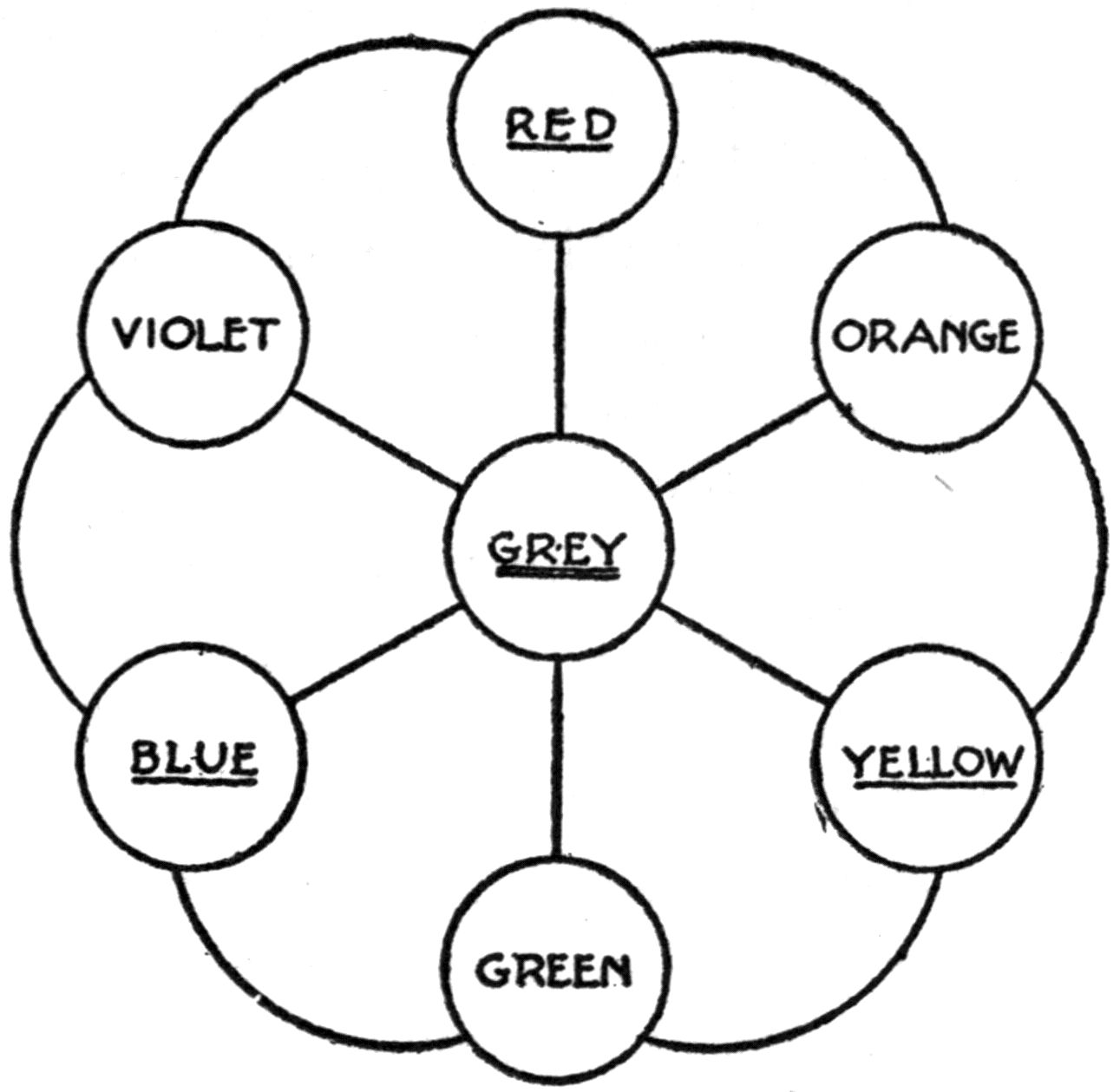

| Primary Colors | 73 | |

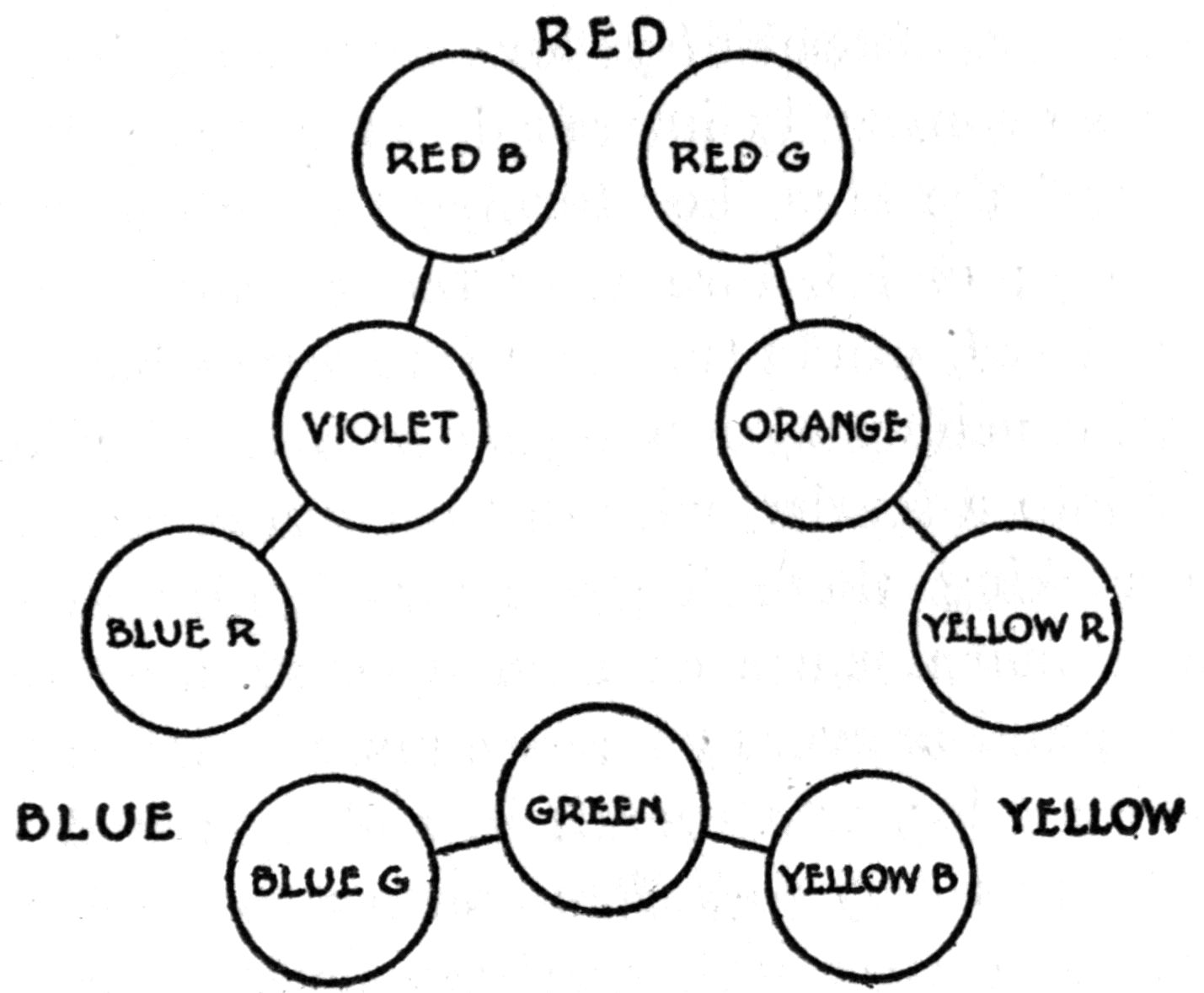

| Mixed Colors | 79 |

[1]

When a new text-book is offered to an innocent and long-suffering public about such an ancient subject as Dyes and Dyeing, it is, perhaps, the very least that the author can do, to explain briefly his reasons for hoping that his particular book may prove of some special usefulness.

As a matter of fact this book is intended for the use of craftsmen and others who are trying to dye and stain textiles by hand and on a small scale, rather than for professional dyers or dyeing chemists who are interested in factory dyeing, conducted on a large scale. For the latter there is little or no difficulty in getting any information that they desire, either from the large and carefully written text-books or, still better, from the many excellent dyeing manuals and books of directions issued at frequent intervals by the great color houses.

But for craftsmen and their like, the amateur dyers as opposed to the regular professionals, the required information is not easy to obtain. Their leaders and teachers, as a rule, profess a scorn of the wonderful discoveries which, in the last half century, have revolutionized the art of dyeing more, perhaps, than any other branch of handicraft. And the dyeing chemists and writers have devoted themselves almost exclusively to the far larger and more important and more profitable[2] field of commercial or professional dyeing, and only here and there is one found who has given any special attention to the dyes and processes needed by those working only on a small scale.

For my own part, after teaching the principles and practice of modern dyeing to class after class of chemical students at Columbia, my attention was called to this particular branch of the subject by finding, one spring, that some friends had started a hand-weaving industry at a settlement house in which I was interested, but had not made any arrangement for a dyehouse at the same time. This was a serious omission because it is almost impossible to buy in the market raw materials for hand-woven rugs, table-covers, and the like, that are dyed just the right shade and, at the same time, are fast to both light and washing; and, unless this last is guaranteed, there is little or no excuse for charging the large prices necessary to pay for the extra expense of the hand labor.

Wishing, therefore, to help out my friends, I offered to assist as far as possible in this part of the work. That summer was spent on the St. Lawrence, where it was possible to study some of the textile work of the Frenchhabitants whose dyeing processes, designs, and looms had descended from mother to daughter since the old Colonial days; and in the autumn I fitted up a little dyehouse and started with a small but intelligent class of neighbors who were working at the looms.

Of course, it was foolish to attempt to teach them the scientific chemical formulæ used by my students[3] uptown. The processes must be short and simple—must give the desired shades on cotton, linen, wool, and silk in the course of an hour or an hour and a half at the outside, counting from the time when the class was called to order. And the colors must be absolutely fast to light, and, wherever possible, to washing also.

The work was very interesting and proved successful enough, at least as far as the dyeing went. After a few months some visiting reporter, in an article on Greenwich House and its industries, mentioned the dyeing, in a magazine, and stated that the colors resulting were not only beautiful but fast. Immediately I was bombarded with letters from all over the country, begging for information about permanent dyestuffs to be used for hand-woven textiles. Requests came from friends and acquaintances to help them in various side branches of the subject, such as feather dyeing, leather dyeing and staining, stencilling, tied and dyed work, and, above all, Batik. And it soon became a source of much interest to look up some old process of dyeing, originating perhaps in the East, perhaps among the ancient Egyptians, and to work it out with the best modern dyestuffs.

Finally, my correspondence grew so burdensome that I arranged with the well-known New York magazine, The Craftsman, for a series of articles upon “Modern Dyestuffs and Dyeing Processes for the Use of Craftsmen”; and from these articles the present book is a natural result.

It is hoped that it will prove useful, not only for[4] individuals who are trying, under considerable difficulties, to get satisfactory results, by means of long-abandoned processes, upon textile materials of many sorts and kinds, but also for teachers of art in our public as well as private schools. Much attention is being given now to training the hands of children in various drawing and decorating and weaving processes. But the modern dyestuffs give a much greater opportunity to train their eyes to a sense of color and to its beauties, as well as giving them an introduction into an art which can be used at home for most useful as well as beautiful purposes.

My hearty thanks are due to many friends, notably, to Mr. Philip Clarkson, head chemist of H. A. Metz & Co., to Dr. Ludwig, of the Cassella Color Co., and to many other expert dyeing chemists, who have most kindly helped me with advice and information about many widely varying branches of the subject. Also to many of my craftsman friends, notably Mrs. C. L. Banks, of Bridgeport, Conn., and Mrs. Charlotte Busck, of this city, who have been of the greatest assistance in working out many of the problems involved in stencilling and Batik; and to Miss Mary Grey, of Hackettstown, N. J., who has kindly allowed me to insert an illustration of some of her interesting and well-designed tied work (Fig. 7). It is my earnest hope that the information contained in this book may encourage and assist other craftsmen throughout the country to come up to the high standard of these skilled textile workers.

C. E. P.

[5]

There has been so much said and written about the beauty and value of the old-fashioned dyestuffs and dyeing processes and their superiority to the modern coloring matters, that many well-meaning people of artistic tastes have never ceased to deplore the discovery and introduction of the so-called aniline or coal-tar dyes, and to regard them as a serious detriment to the art of dyeing.

Some, indeed, have gone so far as to decry the discoveries not only of the last fifty years, but also of the last nineteen or twenty centuries. These quote with approval the great John Ruskin, founder and original leader of the whole Arts and Crafts movement in England, if not in the world, as having said, “There has been nothing discovered of the slightest interest in the tinctorial art” (the art of dyeing) “since the days of the ancient Greeks and Romans.”

To suppose for an instant that this important and highly specialized art has not advanced during nearly two thousand years is, on the face of it, absurd. A very little knowledge of dyestuffs forces recognition of the fact that many of the very best, fastest, and most beautiful of the dyes of our ancestors—such as cochineal, with which they dyed practically all of their[6] fast pinks and scarlets; logwood, with which silk as well as wool was, and is still dyed black; fustic, which was used for fast yellows on wool and cotton, and several others—were natives of America, and therefore only known to the world at large since the seventeenth century.

Indeed, as we shall see, the art of dyeing, based as it is on chemical processes, discovered one by one, but never properly explained or understood until the last sixty or seventy years, is, perhaps, the one art above all others in which not only the ancient world, but the world of comparatively a few years ago, was very distinctly inferior to that of the present day.

In drawing, sculpture, painting, architecture, ceramics, wood-carving, lacemaking, metal working, and almost every other art that can be mentioned, the craftsman of the Middle Ages, if not indeed of ancient Rome or Greece, could still hold his place against modern competitors. Even in such a modern art as book printing, the lover of books will claim, with considerable reason, that no more beautiful or more nearly perfect specimen of the printer’s art has ever been produced than the Gutenberg Bible, the first product of the European printing press.

The art of dyeing, however, has been changing and developing so much from century to century, that, even before the wonderful discoveries of the last fifty years, the effects produced by any one generation of dyers would have been totally impossible for their ancestors of a few generations before them.

It would seem hardly worth while to dwell further[7] upon this subject, were not the idea so fixed in the minds of craftsmen in general that to get permanent and artistic effects in dyeing we must go back to the colors of our ancestors, if not to those of the ancient world. To this day we hear of new industries being started in the lines of hand-made tapestries, hand-woven linens, homespun cloths, and the like, where, as a great inducement to prospective purchasers, the goods are loudly proclaimed as dyed with “pure vegetable colors”; and the first question commonly asked about a pretty piece of dyed work is, “Are you sure that it is fast? Did you use the vegetable dyes?”

As a result of this ignoring and scorning of the wonderful results of modern science in its application to this most important industry, the work of textile craftsmen all over the world is far behind the times, and comparatively far behind other lines of craftwork.

Nobody expects a modern sculptor to do his carving with the bronze tools used by the old Athenians; nor do we consider that the present day worker in metals should refrain from using the modern gas furnace, or limit his products to the few metals and alloys known in the Middle Ages, ignoring those which modern chemistry has developed. And yet, all over the world, craftsmen are still pottering with long since obsolete dyestuffs and obscure and antiquated formulæ, instead of spending their energies in getting, with the minimum expenditure of time and trouble, results of a quality never dreamed of by the most skilful dyers of half a century ago.

[8]

As a matter of fact, so far from Mr. Ruskin’s estimate of the value of ancient dyes being correct, it is actually no more than fair to say that hardly a single dyeing process, known and used more than fifty years ago, is of the slightest practical importance now to any one.

So far as we can tell, the art of dyeing is an extremely ancient one. It seems to have developed in every country and to have been practised by every race of mankind, as soon as that race ceased to rely exclusively upon the skins of fur-bearing animals for clothing and coverings. Wherever we find people using woven goods, whether vegetable, like cotton or linen, or animal, like wool or silk—or wherever, as in the case of the North American Indians, they have learned the art of dressing skins so as to make them soft, pliable, and with a comparatively smooth surface, we find at least the rudiments of the process of dyeing, in the staining of these materials to add to their beauty and interest.

Vegetable Dyes.—The earliest dyes were probably of vegetable origin, discovered by accidentally staining garments with juices of fruits or plants. Thus, for instance, in the Bible we read of “garments dyed in the blood of grapes”; and we can all call to mind fruits in common use—blackberries, huckleberries, peaches, and the like, whose juice could be used, if nothing better presented itself, to dye or stain light-colored fabrics.

[9]

In most cases, as in those just mentioned, the colors would be fugitive, and after a short time become dull and uninteresting. But in the process of time vegetable dyes were discovered, in one part and another of the world, which, in the hands of those who knew how to work with them, gave colors both fast and beautiful. And thus grew and developed the art of the professional dyer.

For instance, in many widely separated countries, such as India, Java, South and Central America, plants are found, known asindigoferae, whose juices, yellow when fresh, rapidly turn blue when exposed to the air. These juices impart a rich and permanent blue stain to objects moistened with them while they are still yellow; and this blue is the coloring matter known as indigo. The plants bearing it have been cultivated for hundreds, if not, indeed, thousands of years, and used for dyeing.

Garments and blankets found in the so-called Inca graves in Peru and Chili, dating from long before the Spanish conquest, as well as the oldest specimens of Hindoo workmanship, and even some of the textiles found in the tombs of Egypt, all show examples of this same dyestuff. It was so valuable that, in small quantities and at vast expense, it was imported by the Romans from India, as is shown by its Latin name, Indicum (Indian), from which its present name, indigo, is directly derived.

But, curiously enough, exactly the same dyestuff, but in a very impure form, and derived from an entirely different plant, theisatis tinctoria, commonly[10] known aswoad, has been discovered and used in Western Europe from time immemorial. And when Julius Cæsar, nearly two thousand years ago, led a Roman army for the first time across the channel into England, he found the native Britons adorning themselves by smearing their bodies with a dirty blue dyestuff obtained from this source.

So, little by little, the knowledge of these natural dyestuffs and their application grew and expanded. But as a matter of fact, so far at least as can be gathered from the old writers, those known and used by the ancient Greeks and Romans were few in number and of comparatively little interest.

For blues they were obliged to use the inferior color derived, as above mentioned, from the native woad, excepting when, for some special purposes, a little indigo was imported from the East at enormous expense.

Their principal yellow dyestuff was saffron, which is derived from the flowers of the common yellow crocus. This gives pleasant, warm shades of golden yellow, not fast, however, to either light or washing. This same saffron, though long since entirely abandoned as a dyestuff, is still used in small quantities for staining candy and foodstuffs, and occasionally for medicinal purposes.

The ancients are believed to have discovered the dyeing properties of the roots of madder—rubia tinctorum—(the dyer’s root), and to have used it in small quantities for producing purple and brown and, possibly, even red shades, on cotton and wool. Whether,[11] however, the art of dyeing the brilliant crimson and scarlet shades known as Turkey red was ever worked out before the Middle Ages, is extremely doubtful.

Animal Dyes.—Unquestionably the best red dyes known to the people of those early times were of animal origin, and were used for various shades of red and of purple.

Kermes.—One of these, called kermes, is very closely related to the more important and, up to a few years ago, the very generally used, cochineal, and to the lac dye.

These three dyestuffs—kermes, cochineal, and lac—come to the market in the form of little dark colored grains, which, when ground up with hot water, give a bright red solution called carmine, which contains a considerable amount of a coloring known as carminic acid. When wool or silk that has been previously mordanted—that is, impregnated with chemical agents; in this case salts of tin, aluminium, iron, or copper—is boiled in one of these solutions, it becomes scarlet, crimson, purple, or claret color, according to the mordant employed. From the appearance and form, as they come to market, of these dyestuffs, the shades thus derived are commonly known as the “grain colors.”

When these granules are soaked for some time in warm water they swell, and their true character becomes apparent. They consist of the dried bodies of small insects, known as “cocci” (berries), which are carefully cultivated on particular kinds of trees or shrubs and when full grown are brushed off and dried[12] for market. They are very small—the cochineal grains, which are the most important, running about 70,000 to the pound.

Kermes, which was the only one of the three known to the old Greeks and Romans, consists of the dried bodies of the “coccus ilicis,” a variety of the insect which lives on a species of oak, and which, it is said, is still occasionally used in Southern Europe, and in Morocco, for dyeing leather and wool.

Tyrian Purple.—The most highly prized ancient dyestuff, and one concerning which much interest has always been felt, was the so-called “Tyrian purple.” This was obtained from the juices of certain species of snails found in the waters of the Mediterranean Sea, and, indeed, in the ocean waters of many other warm climates. Two species of this class—themurex Brandaris and themurex trunculus—were used extensively by the ancients, and great mounds of their shells, such for instance as the so-called Monte Testaccio at Tarentum, are still found along the shores at places famous, in old days, for their dyeing establishments.

Other shellfish of the same general type, known aspurpura lapillus, are found quite abundantly, not only in the Mediterranean, but also on our own coast and along the shores of Central and South America. They have been used by the natives in Nicaragua and elsewhere, from time immemorial, for obtaining a similar color.

Purpura lapillus Murex trunculus Murex Brandaris

These shellfish were so much sought after in the old days that, by the time of the early Middle Ages,[13] they were almost exterminated, and the dye disappeared from commerce entirely. But, long before that, in the early days of the Roman Empire, the coloring matter was so expensive that fabulous sums were paid for cloth or yarns dyed with it, and its use was practically confined to the imperial family. In fact one of the imperial titles in the Eastern empire—purpureogenitus, “born to the purple”—was due to this fact.

Some interesting information upon the value set on this dyestuff by the ancients is afforded by the so-called Edict of Diocletian, fragments of which, engraved on stone tablets, have been found in different parts of the old Roman Empire, ranging from Egypt to Asia Minor. By this edict, issued in A.D. 301, the emperor Diocletian attempted to fix the market price of the principal articles of commerce, for the Eastern empire. According to this, the price of wool, heavily dyed with this color, was worth about $350 a pound, in gold.

The dyestuff, as we learn from the description of the process by ancient writers, was obtained from a whitish or yellowish liquid found, two or three drops at a time, in a particular vein in the body of these animals. This juice, when exposed to air and especially to sunshine, forms the purple or violet color, much in the some manner that the blue color of indigo is formed from the yellow juice of the indigo plant.

The shellfish in question, having for many centuries been left undisturbed, are now quite common in the waters of the Mediterranean, and are occasionally[14] to be found in the poorer quarters of Venice and other Italian seaports, exposed for sale as food.

A year or two ago a German color chemist, famous for his discovery of the brilliant and extremely permanent reddish violet dyestuff, known as Thio Indigo red B., made a careful investigation to see whether, by any chance, this color of his might happen to be the same as the famous old Tyrian purple.

He managed to secure some twelve thousand specimens ofmurex Brandaris, and, with an immense amount of labor, obtained from these twelve thousand specimens about twenty-one grains of pure dyestuff. This he carefully analyzed and experimented with, until finally he was able to prove that, while it was not identical with his own Thio Indigo red dyestuff—which, as the name shows, is a compound of indigo and sulphur—the Tyrian purple was a similar compound of the same indigo dyestuff, with the comparatively rare acid element, bromine. In fact it is what the chemists would call a brom-indigo; and this same famous chemist, Dr. Friedlaender, of Biebrich on the Rhine, after discovering its composition, amused himself by manufacturing some of it artificially; and, with the artificial reproduction of the ancient Tyrian purple, he dyed some skeins of silk, as an illustration to his article detailing his discovery.

Now, if there were any truth in the theory of the superlative value and beauty of these ancient dyestuffs, it is evident that this rediscovery of the true and genuine Tyrian purple would have been a matter[15] of great practical importance. On the assumption that one pound of dyestuff would color at least twenty pounds of wool, this would put the price of the dye itself, in Diocletian’s day, at a pretty high figure.

It can now be manufactured, at a profit, for not over one one-thousandth of what it cost in those days, not allowing, either, for the difference in value of money between then and now. And yet this famous dye, which was so highly esteemed and of which so much has been written, is so inferior in color and tone to several of the modern dyestuffs that it probably would not pay to put it on the market. Dr. Friedlaender’s samples were, indeed, fast to both light and washing, but their color showed dull and, to modern eyes, distinctly uninteresting shades of violet. And there are already on the market several violet, red and blue dyes of the same general class—the indigo or vat dyes—which are quite as fast to light and washing, and far superior in beauty and brilliancy of shade.

It is only proper, however, to state that Dr. Friedlaender’s investigation did not completely clear up the subject, though there is no question but that he really discovered the true Tyrian purple; and the color of the specimens dyed and exhibited by him corresponded very closely to some still surviving from antiquity.

Among the fine collections of textiles from the Egyptian tombs that are in the Metropolitan Museum of Art in New York City, are some excellent examples of Tyrian purple. These are what the Greeks[16] used to call “di-bapha,” or double dyed—i.e., dyed very deep, full shades of dark purple. While a wonderful example of the lighter, violet, shades of the same dye can be seen in a famous manuscript, known as “The Golden Gospels,” now in Mr. J. Pierpont Morgan’s collection in the same city, but which was given about 1520, by Pope Leo X to King Henry VIII. This was written, in golden characters, upon vellum dyed with Tyrian purple, and the shades of the latter correspond quite closely with the violet of the artificial brom-indigo compound.

On the other hand there is evidence to show that the ancients were also able to obtain, with the same Tyrian purple dye, perhaps from the shellfishpurpura lapillus, fast and brilliant shades of scarlet, as well as these rather dull tones of violet and purple. In the days of the Roman Empire, as above mentioned, the use of “purple” garments was denied to all but the imperial family; but later, after the rise of the Christian Church, the ecclesiastics gained sufficient power to obtain this privilege for themselves. And to this day the cardinals of the Roman Catholic Church are called “porporati” on account of the “purple” or, as we would say, scarlet, color of their characteristic robes. So, whenever we see the red robes of a high dignitary of the church we are probably looking at one of the tints of the real old Tyrian purple, although the art of actually producing it has long since been lost; and, if rediscovered, would probably be of as little practical value as Dr. Friedlaender’s remarkable investigation.

[17]

Between the days of the ancient Greeks and Romans, and the discovery of the first aniline dye in 1856, many and important additions were made to the list of available dyestuffs, some of which have continued in use, for special purposes, up to the present day.

Indian Dyes.—The opening of trade to the Far East, due to the discovery of the sea route round the Cape of Good Hope, brought to Europe the free use of some of the Indian dyestuffs. Indigo, for instance, was introduced for the first time in considerable quantities, and, after much opposition, completely took the place of the much inferior native dyestuff, woad.

For yellow, the old saffron dye was superseded by the more powerful, but still rather fugitive, turmeric, or Indian saffron. This came from the root of the curcuma tinctoria, a plant freely grown to this day in both India and China. The safflower was also imported from India; this is a kind of thistle,carthamus tinctorum, the dried heads of flowers of which were largely used for dyeing pretty shades of pink upon cotton,directly—that is, without any mordanting process. This color, too, is comparatively fugitive to light, and has almost disappeared from sight.

Of more importance were the so-called red woods, which came partly from India and partly from the east and west coasts of Africa; and of which the most important are the sandal wood, bar wood, and cam wood. The wood of each of these trees probably[18] contains the same coloring matter. The color is not very easy to extract, but when used with mordants of chromium, aluminium, or tin salts, it dyes wool various shades of red and reddish-brown. These colors are very fast to milling—in other words to the action of alkalies when the wool is finished in the manufacture of broadcloth; but they are not particularly fast to light, and for this reason, as well as because of their greater expense, they have been for the most part abandoned.

From India, too, were introduced the well-known brown dyes known as cutch (catechu) and gambier. These come to the market in the form of dark colored pastes, formed by evaporating infusions of leaves, seed pods, nuts, and sometimes the wood of various species of acacia and areca trees. They contain large amounts of a peculiar variety of the substance known as tannin or tannic acid, which is widely distributed among many plants, and which is very useful in dyeing, as will be described later. The brown coloring matter has been isolated, and is called catechin. Both cutch and gambier will dye cotton and wool rich shades of brown, which are quite fast to light when after-treated with copper or chromium salts.

Dyes from the New World.—The discovery of America, and the colonizing and opening to trade of South America and the West Indies, in the sixteenth and seventeenth centuries, still further enlarged the field for dyers.

Cochineal.—One of the first dyes introduced from there was cochineal, a “grain color,” similar to[19] kermes, already described, consisting of the dried bodies of an insect known ascoccus cacti, because it lives upon certain kind of cactus which are native to Mexico and Central America.

This dyestuff was largely used for dyeing wool and silk goods, and produced fairly fast shades of crimson or of scarlet, according to the mordant employed. But it has been replaced almost entirely now by the various acid dyes, to be described later, which are cheaper, are much easier to apply, and are of equal and, in many cases, of much greater, fastness to light.

One of the few cases where cochineal is still used on a large scale is in England, where the scarlet coats of the British regulars are dyed with this color, on a tin mordant. It is believed, however, that this is not due to any real or fancied superiority of the old dye over many of the modern colors, but simply to the terms of an old “perpetual” contract, which, a hundred and fifty years or more ago, gave the privilege of dyeing the English “redcoats” to one particular firm and their successors, on condition that they use this dye and none other. Although both dyers and government would profit by the use of modern dyes, the terms of the old contract are still rigidly adhered to for fear of losing the monopoly.

Lac Dye.—The similar dyestuff called lac dye, which had been known and used in India for hundreds of years, was introduced into Europe towards the end of the eighteenth century. It also is the body of a small insect, thecoccus laccae, which lives on the twigs of[20] the banyan tree, and other varieties of fig trees. When these twigs are broken off and dried to kill the insect, there is found present on them, along with the coloring matter, a large amount of a peculiar resinous or gummy substance, which, when extracted and purified, is known and widely used, as “shellac.”

Lac dye was used in practically the same way as cochineal, and produced, upon wool, scarlet, orange, and crimson shades, which were faster and more solid, but not as brilliant, as the cochineal. It is now used but rarely, even in the East, having been largely superseded, there, by brilliant but, unfortunately, in many cases, cheap and worthless modern dyestuffs.

Fustic.—From America, also, came the excellent yellow dyestuff, “fustic,” yielded by the tree commonly called yellow wood, Cuba wood, etc. Its true botanical name, however, ischlorophora tinctoria, and it was largely used for dyeing, either directly in the form of chips, or as a solid or liquid extract made from the wood.

It was principally used with mordants of aluminium or tin salts, for dyeing wool bright, fast shades of yellow, or, with the aid of bichromate of potash as a mordant, for obtaining mixed shades, in conjunction with indigo, cutch, madder, and logwood. It has been almost entirely replaced now by fast modern dyestuffs.

Logwood.—The most important of all these dyestuffs, and the only one still used on a large scale, is logwood, a dye extracted from the wood of quite a large tree, thehaematoxylon Campechianum (the “blood-red[21] wood from Campeachy”), which grows freely in the West Indies and Central American states.

It was discovered and used by the Spaniards early in the sixteenth century, and in Queen Elizabeth’s reign was introduced into England, much against the wishes of the older school of dyers who furiously denounced it as producing fugitive colors, and had its use prohibited by Act of Parliament. It was over a hundred years before the real value of the dyestuff was appreciated, and this law was repealed.

The operation of extracting the coloring matter from the wood itself, of which it forms only some three per cent. by weight, is a troublesome and delicate one. The logs are chipped or rasped into fine pieces, then moistened and piled in heaps and the color developed by a process of fermentation. Accordingly, extracts of logwood have been put on the market by various large firms, especially of late years, and, while the use of the wood itself by dyers has for the most part been abandoned, these extracts are widely used for dyeing blacks upon silk, in spite of there now being many excellent acid blacks.

The dyeing process, too, is rather complicated, for the goods must be carefully mordanted before dyeing, with salts of iron, chromium, or tin. For this reason wool is rarely dyed with logwood. It is, however, still used for silk dyeing, partly because it gives very full, deep, permanent shades of black, but principally because, by using one mordant after another before dyeing, it is possible to increase enormously the weight of the dyed silk, at very moderate expense.

[22]

Turkey Red.—The use of madder which, as before mentioned, was probably known to the ancients, was greatly developed during the sixteenth and seventeenth centuries, owing to the introduction from the near East of the so-called Turkey red process for obtaining, upon cotton and wool, very fast and very brilliant shades of scarlet.

The process took some three months, and consisted of an elaborate series of mordanting operations, before the dyeing proper began. The goods were first soaked in a bath of some fatty material, such as milk or, later, rancid olive oil, and then dried carefully. After this they were soaked in a bath of alum and then in limewater, or a chalk bath—and these operations were repeated over and over, with various manipulations in between.

Finally, the mordanted material was dyed by boiling it in a bath containing the finely-ground madder root, and then “brightened” by washing out, in a boiling soap bath, all the loose color and the unfixed mordant. This process was repeated until the proper shade was reached.

During the early part of the nineteenth century, various extracts of madder were made, by treating the ground root with strong sulphuric acid and other agents, which destroyed the woody tissues and other inert matter, without injuring the coloring matter. The dyeing process also was greatly simplified and shortened. Later the real active principles of the madder root were investigated, and found to be two crystalline bodies named alizarine and purpurine, respectively.[23] And finally, several years after aniline dyestuffs had been discovered and manufactured, two German chemists, Graebe and Liebermann, discovered a method for making these very identical substances out of coal tar.

Since that time the cultivation and use of madder has disappeared almost entirely. But real Turkey red is manufactured to-day, and in very large quantities—and, though freely imitated by inferior products, the modern Turkey red is just as fast to light and to washing as it ever was in the past, and possesses a brilliance and a lustre which never could have been obtained formerly. The process, however, is completed now in hours, not days, and instead of yielding a few shades of red and purple, the alizarine colors have been added to until they cover a large range of blues, purples, reds, oranges, yellows, and browns, all of them as fast as the original Eastern products, and all of them made from coal tar.

The dyes already mentioned were the ones which, after hundreds of years of experiment, proved to be of distinct value. Many of them were expensive in themselves and, in almost every case, the process of dyeing with them was a quite complicated one, worked out by generations of practical dyers, and passed down from father to son as a precious trade secret.

Besides these there were, in almost every community, certain special formulæ and recipes for obtaining, by comparatively simple methods, dyes of varying degrees of value from more or less common vegetable materials. Some of these are occasionally[24] met with to this day. Thus, in the province of Quebec, well down on the St. Lawrence, the French Canadian women still dye their homespun worsteds an orange shade of yellow, of very moderate fastness to light, by boiling them with the skins of the yellow or brown onions. And they get a pretty, but fugitive, shade of golden yellow by using the dried flowers of the goldenrod.

Some recipes from the mountain districts of North Carolina, where the sheep are raised and sheared, and the wool carded, spun, dyed, and woven into homespun, are unique, and wool dyed with them shows extremely good color. Thus, for green, we are told to “Git blackjack or black oak bark, and bile it right good, and put in a li’l piece of alum. This makes the pur’tiest green, mighty nigh, that ever was.” And for purple and black the instructions are to “git maple bark and bile it. Throw in a grain of copperas and put in your wool. Bile it just so long if you want purple, and longer if you want black. The longer you bile it the darker it gits.”

Recipes like these can be picked up in country districts all over the land to this day, and where no other coloring agents can be obtained, they may still be of some use. They are to be compared, however, to the somewhat similar recipes of the herb or “yarb” doctor, now almost extinct, who concocted various brews and teas and messes from roots and leaves, and administered them as valuable remedies.

Useful these brews undoubtedly were in their day, when it was impossible to get better medicines at[25] any price, and the available drugs, even in large cities, were few and costly and but little understood. But who of us would now prefer to treat a serious illness with herb tea when within reach of even a third-class drug store?

And so to-day, when modern dyestuffs, even if not of the very best varieties, can be bought in packages at the nearest grocery or druggist, who has time to waste upon the laborious processes and messy, uncertain formulæ of former and unscientific ages?

Tribes and nations in different parts of the world seem, at a comparatively early date, to have found out the art of coloring and staining textiles with mineral compounds. Iron springs, containing iron salts in solution, are found in many countries; and such springs are always noteworthy from the taste of the waters, and the color of the sediments left when the water stands exposed to the air.

Therefore discovery of the fact that those waters would impart a permanent and quite pleasing orange or reddish-brown color to textiles was perfectly natural.

Iron Buff.—Accordingly, in different parts of the world, people learned to dip cloths in these springs and then expose them to the air, thus dyeing them this iron rust color, commonly called by dyers “iron buff.” When iron became a common metal, it was found that any soluble salt of iron would act as a[26] dyeing solution, just as well as a natural iron spring; and hence we find use made, in widely separated countries, of iron salts for dyeing.

This iron buff is used to this day, though of course it has lost the importance it had in the past. The red sails of the fishermen in the Mediterranean show this color; and it is a useful and interesting dye for weavers of hand-made rugs, curtains, and the like, because of its pleasing tone and great permanence. On the other hand, it is very likely to rub; and it fills the fibre of the cloth with mineral matter, thereby making the material stiff and hard to sew or cut.

Preparation.—Our colonial ancestors made this color cheaply enough. They carefully saved all the scraps of iron and steel that they could find—old horseshoes, broken knife blades, etc., etc.—and placed them in a barrel half filled with vinegar and water. Little by little the iron dissolved in the acid and, when it was strong enough, the housewife would soak her homespun cloth, or other material, in the solution, warming and stirring it, and making it absorb as much of the liquor as possible. Then she would take it out, wring it thoroughly, rinse it slightly, and dip it for a minute or two in another barrel half filled with a water extract of wood ashes.

After removing from the solution and wringing again, the goods were shaken out and exposed to the air for some minutes, during which time the color would develop—in other words, would make its final change to yellow or orange, or even to brownish-red, according to the amount of iron absorbed by the fibre.

[27]

The process, nowadays, is much the same, excepting that, for the first or iron bath, it is cheaper and easier to use a solution of the green crystalline iron salt, known as copperas, or asferrous (iron)sulphate. This can be obtained at, or through, any drug store at a very low price, as it is not necessary to buy a chemically pure product. The ordinary commercial salt is as pure as the work requires; this dissolves quite readily in warm water.

The amount of copperas to be used, to dye a particular lot of material a particular shade, can only be determined by experience and experiment. It is always easy to build up a color, i.e., to deepen its shade if it is too light, by dipping the fabric over again in the same dye-bath. Indeed there is a general rule to be observed in dyeing all colors like this iron buff or the manganese brown—as well as the sulphur and indigo colors, which will be described later—that are developed, or fixed, by exposure to the air. Whenever dark shades of these colors are desired, they should be produced by successive dippings in weak baths, rather than by one or two dippings in strong baths. This avoids rubbing, as far as possible, and lessens the injury to the cloth fibre. In general, it is best to start with a dye-bath containing some three or four tablespoonfuls of copperas to one gallon of hot water.

For the second, or fixing, bath—that is, the alkali bath—it is now customary to use a solution of soda instead of the extract made from wood ashes. Either cooking soda (bicarbonate of soda) or the stronger[28] washing soda or soda crystals, known to the chemist as carbonate of soda, will be satisfactory, and instead of soda the corresponding potash salts may be used, though these are usually more expensive. It is possible, too, to use a bath of the so-called caustic soda, or caustic potash, known to the chemist as hydroxide of soda and hydroxide of potash. But these, as the name implies, must be handled with care because, when strong, they are likely to burn the hands and clothes. Careful analyses of dyed mummy cloths show that the ancient Egyptians were accustomed to use for their second or fixing bath, a solution of slaked lime, or lime water.

Khaki.—By mixing in the first bath of copperas or other iron salt an equal quantity of chrome alum, and then fixing and developing as above, a certain amount of greenish chromium oxide is deposited in the fibre along with the oxide of iron. This gives rise to the shade known as “khaki.” Sometimes shaded a little with manganese brown, this was the regular dye for the army uniforms, until the recent introduction of the extremely fast and very satisfactory vat dyes.

Uses.—Iron buff is chiefly used for cotton, linen, and other vegetable fabrics; on them it gives pleasant, warm shades of orange and reddish-brown. But on wool, and especially on silk, it is not so satisfactory, owing to its tendency to roughen and injure the fibre. Indeed, in the case of silk, it is likely to greatly diminish, or even to destroy, the lustre. On cotton and linen, however, it has great fastness to light and to washing. Indeed, every one who has tried to get rust[29] stains out of a garment or a piece of table linen knows how hard a matter it is to get rid of the color.

Another important reason for using this dye is that the coloring agents are very cheap, and are easily obtained in any quantities. It has, however, some serious disadvantages, one of which is that the color, especially in dark shades, is very liable to rub. This can best be obviated by building up the shades with successive dippings; and by thoroughly washing the finished goods in a hot soap bath. The dyed goods are pretty certain to be a little stiff, and therefore hard to sew or cut, owing to the fact that the final color is composed of iron rust. When vegetable fibres are filled with a mineral matter they are naturally stiffer and harder than they were originally.

Then there is the final objection on the part of professional dyers to this color, as well as to all the other developed colors, i.e., those colors fixed by exposure to the air. It is not easy to get a smooth, even color with them, and it is very difficult to dye to shade. For handicraft work, where these two points are of minor importance as compared with the beauty of the color, this objection is not so serious, but where it is necessary to dye large amounts of yarn or cloth to a definite shade with this, or similar, dyes, it is, as a rule, far easier to use a dyestuff which does not materially change its shade after the goods leave the dye-bath.

Iron Grey.—Soon after the discovery, in different localities, of the iron buff color, it was discovered that by the action of various vegetable extracts upon the iron salts, dark grey stains could be produced which,[30] under certain conditions, would be fairly fast to light and washing.

This color was, later, found to be due to the combination with iron of the peculiar vegetable acid called tannic acid or tannin. This is found in small quantities in the juices of twigs and leaves of many varieties of plants, and, until the introduction of the modern dyestuffs, this process offered the chief method of obtaining grey or black shades upon cotton. At present it is rarely, if ever, used for that purpose, but the compound is still the basis of most of the writing inks on the market.

To make this color, the cloth is soaked for some time in a solution of an iron salt—nitrate of iron, formed by boiling a solution of copperas for a minute or two with a few drops of nitric acid, is preferable to the untreated copperas—and then, after being wrung and slightly rinsed, it is plunged into a bath containing tannic acid. This can be made by dissolving a few tablespoonfuls of the dry tannic acid in some water, or by making a hot infusion of the leaves, twigs, or bark of any plant or tree containing it. Tea leaves contain much tannin, and so do unripe English walnuts and butternuts. Acorns, oak leaves with nut galls on them, the green twigs of alders, and hazelnut bushes, have all been used to form this color.

The grey color quickly develops and, after rinsing, the material can be dried and pressed, or dipped again to obtain a deeper shade, first into the iron and then into the tannin bath. The color is a pleasant, soft shade of grey or, if dyed deeply, a black. It is fast[31] to washing, and fairly so to light, though it may become rusty on standing; like the iron buff, it is not fast to acids.

Some interesting examples of the dyeing of cotton cloth with iron buff and iron grey are shown in Plate I. They came from the mineral springs at Arima, near Kobe in Japan, where the waters are so saturated with iron salts, that comparatively short immersion, and exposure to air, will bring out a deep orange shade. The Japanese, not content with dyeing their goods plain colors, have for many generations utilized these springs in the production of figures and designs on the cloth. Plate V is an example of stencil work, where the white patterns are made by covering parts of the cloth with a “resist paste” which protects whatever it is in contact with from the action of the coloring agent.

Plate II shows a piece of soft calico on which impressions of leaves have been made by placing fresh juicy leaves between two pieces of cloth, and beating them with wooden mallets.

Plate III shows the same piece of cloth as in Plate II, after immersion in the iron spring, and exposure to air. The tannin from the leaf juice converts some of the iron oxide into iron grey; while the white figures are made by tying the cloth with string or tape (Tied and Dyed work) before dyeing it.

So far as we can tell, these two were the only mineral colors known to the ancients. Several other mineral colors, however, were in common use by the cotton dyers in the days preceding the introduction[32] of modern dyestuffs, but it is hardly worth while to dwell here on many of them. Yellow and orange shades were obtained by impregnating cloth with lead salts, and then developing with a bath of chromate or bichromate of potash, with more or less caustic alkali added for the darker shades.

Prussian blue, too, was used as a substitute for the more expensive indigo. This was formed by using the nitrate of iron for the first bath, and then developing the color with a bath of yellow prussiate (ferrocyanide) of potash. These colors, however, are so far inferior in their application, and in fastness to light and to rubbing, to the colors now at our command, that they have disappeared entirely for textile work, though they are still widely used for pigments.

Manganese Bronze (Manganese Brown, Bistre).—There is one good mineral color, however, which came into use early in the last century and which, while hardly ever used by professional dyers, is of interest to craftsmen. This color, in its chemical composition, greatly resembles the iron buff. It is quite cheaply produced by first impregnating the cloth to be dyed with a solution of a manganese salt (manganese chloride is the cheapest), and then, by means of a second bath of alkali, forming a deposit on the fibre of pink manganese hydroxide—corresponding to the greenish ferrous hydroxide—which, on exposure to the air, absorbs oxygen and forms the final brown color.

Unfortunately the alkali used in this case must be caustic alkali—potassium hydroxide orsodium hydroxide—and not one of the mild alkalies like the[33] carbonates or bicarbonates, which will do for the iron color. And, therefore, although it is rather more expensive, and is somewhat liable to weaken the fabric, it is generally more convenient to obtain this color by a one-bath process. A purple solution of the salt known aspermanganate of potash, is prepared and the cloth dipped. After being immersed it is wrung carefully and shaken out, and the red or purplish color gradually changes into the final brown. As soon as this change has taken place the goods should be plunged into a hot soap bath and thoroughly scoured, both to remove any loosely adhering particles of color which cause rubbing, and to prevent tendering of the cloth.

The latter danger, however, is always present with this process and, therefore, full shades should not be dyed excepting on heavy, strong goods like rugs or very coarse yarns or cloth. Even then it should be done carefully and by successive dippings, with a careful washing, after the color has been developed in the air, between each bath.

This injury to the cloth which, hitherto, has been the great drawback to the permanganate process, can be avoided by dipping the goods, as soon as possible after leaving the dye-baths, into a solution containing glucose, as, for instance, two or three spoonfuls of Karo (corn syrup) or molasses in each gallon of hot water. Directly the purple-stained cloth touches this solution the color changes to brown, without affecting the strength of the materials.

This color, like the other mineral colors, is rarely,[34] if ever, to be used on silk, being altogether too likely to injure the texture and the lustre of the material.

In at least one instance, however, it has been used on animal fibres with considerable success. During the critical part of the Boer war, it was at one time necessary for England to put as many of her troops as possible—especially her mounted troops—into the field. Among others the Scots Greys, distinguished at Waterloo and made famous in many other bloody campaigns as a fine old fighting regiment, were ordered to the front. There is a tradition, dating back over two hundred years, that the horses of this regiment must all be either white or grey in color. Some heaven-sent genius at the Horse Guards—the English War Department—hinted quite forcibly to the authorities that to send out a cavalry regiment on white horses to face the Boer sharpshooters, was rather a dangerous experiment. The authorities, therefore, consulted a well-known dyeing chemist. He advised them to send down, on the troopship, some kegs of permanganate; and to instruct the officers and men to sponge each horse with a weak solution of the salt, every day at “Stables.” This was done, and, in consequence, long before reaching Cape Town, the skin and hair of every horse was thoroughly colored a soft, quiet shade of brown.

The color produced by permanganate varies, according to the strength of the solution, or rather with the number of dips in comparatively weak solutions, from a light brownish tan to a full, rich, soft, seal brown. Pleasant shades, too, can be obtained by dyeing first[35] with the iron rust dye and then covering with the permanganate. This color is discharged, not only from textiles but from the hands, by soaking in a solution ofsodium hydrosulphite (commonly used in dyeing indigo) and then washing.

Before proceeding to the practical dyeing instruction it is well to say a few words about the equipment needed for the work.

Fortunately no elaborate or expensive outfit is necessary, even for the beginner. And after one has had a little experience, it is astonishing what an amount of interesting, and even important work can be turned out with a few of the very simplest utensils. The essentials may be set down as follows:

Dye-pots.

Heating devices.

Stirring rods, or dye-sticks.

Wringers.

Drying arrangements.

Dye-pots.—For this purpose, common agateware vessels are best and most convenient. There should be varying sizes to accommodate different amounts of material to be dyed. The so-called “miner’s cups,” which are agateware cups holding a pint or more, are large enough for practical work, when single skeins are being dyed. For large pieces use the wash boilers[36] which vary in capacity from one to five gallons. It is always best, especially for amateurs, to dye in one batch enough material to complete the work on hand, whether rug, portière, or piece of tapestry. This avoids the necessity of exactly matching the shade afterward.

For three and a half to four pounds of cotton rags, such as are used in making rag carpets, three and one-half gallon pots are about the right size. This amount of material will be about enough for the filling for one rug about 6×4 feet, woven on a hand loom.

Heating Devices.—Work may be done over any flat-topped stove that burns wood or coal; gas is, of course, an advantage and so is an oil stove, as with these the heat may be regulated very exactly and much time saved. For actual work, a stove with space for four or five pots is the most convenient type to use.

There should always be one large pot set aside for heating water, another for boiling out the raw goods, and still a third for boiling out and brightening the finished materials with soap, when very fast colors are used on cotton or linen; and each of these pots should be reserved for its special purpose andnot used for dyeing. This will avoid the danger of staining the goods.

The top of a kitchen range will do for heating, but whenever possible, it is best to have a separate stove, so placed that the top of it will not be more than about twenty-four inches from the ground or floor. This enables the operator to look down into[37] the dye-pot and so avoid strain, and the consequent excessive fatigue while stirring the goods.

Stirring Rods.—While the material is being dyed, it should be kept in constant motion. When working with small amounts of material, or with goods such as straw, raffia, muslin, or silk in skeins, which are delicate and easily spoiled, it is far more satisfactory in every way to use heavy glass rods for stirring. These are rather expensive. They are about fifteen inches in length and well rounded at the ends. If carefully handled and thoroughly washed, they are always clean and smooth. Care must, of course, be exercised in their use, as sudden variations of heat and cold may cause them to crack or chip, and lifting or stirring large quantities of heavy materials—anything above five pounds—is liable to break them. In these cases, it is best to use wooden dye-sticks. Broomsticks or dowel sticks, cut into two-foot lengths, with the ends rounded carefully by whittling with a sharp penknife, are excellent substitutes. For careful work it is necessary to have several sets of wooden dye-sticks—two for each main color at least—and these must be carefully washed each time after using, or they will stain cloth that is being dyed light shades. They are bound to get soft and rotten before very long, from the action of the alkali in the dye-baths, but they are easily replaced.

Good rubber gloves are extremely useful while dyeing, to protect the hands not only from being stained and discolored by the dyes, but also from the action of the chemicals—especially while dyeing with indigo[38] and other dyes wherein the caustic alkalies are employed.

After some experience in the use of dye-sticks, however, it will be found comparatively easy to handle the materials, in and out of the dye-baths, with the sticks, without at any time taking hold of them with the hand. Nothing demonstrates more clearly the skill of the dyer than the ability to carry, immerse in the dye-bath, stir, take out, wring, and rinse the materials without getting stains on either clothes or fingers. On the other hand, the amount of slopping that can be accomplished by a careless, but enthusiastic, amateur must be lived with to be thoroughly appreciated.

Wringers.—Both before and after dyeing it is very important to have at hand a good clothes wringer, preferably with metal frame. In fact, for very careful work there should be two wringers; one to wring out the raw materials after boiling them in soap and water, or, if clean, in plain water, to insure that they are thoroughly and evenly wet; and the other to wring out the excess of dye-liquor from the goods before rinsing, or, as in some cases, before hanging up to oxidize. The rubber rolls of these wringers should be kept clean by scouring with soap and sapolio immediately after finishing the day’s work, and by carefully rinsing free from dye-liquor.

It is always well to keep on hand near the wringer a supply of clean blotting paper, or cheap filter paper, or even soft, dry cheesecloth or muslin. For by wrapping the materials that have just been dyed, in any[39] of these, and then running them backwards and forwards through the wringer, it is possible to dry them with a minimum of time and exposure. This is particularly important in the case of natural and artificial silks, either in skeins or scarfs, of ostrich feathers, and of other light and fragile materials.

Drying Arrangements.—Sufficient room should be provided for hanging up the cloth to dry. An ordinary clothes-line, conveniently fastened, is the best means of support. For special purposes, where the material handled is very delicate or where the work is done in a classroom, a simple clothes-horse made of thick glass tubing, one inch or so in diameter and supported on a wooden frame, will occupy the least possible space and give the best support.

[40]

The whole art and practice of dyeing was completely revolutionized once and forever, by the discovery in 1856 of the artificial dyestuff named mauveine, or, more commonly, mauve, a name, by the way, derived from the French name of the violet-colored mallow flower.

The discovery was made accidentally, by a young chemical student, William Henry Perkin, while experimenting in a very crude and simple way, with a view to forming artificial quinine from a curious oily body known as aniline. This aniline was originally prepared by distilling indigo in a dry retort, and it had received its name from the native Javanese word “anil,” meaning indigo. While thus prepared it was, of course, very expensive. But about this time methods were invented for obtaining this same compound in practically unlimited quantities from coal tar—that heavy, foul-smelling refuse of gas works—which, up to that time, had been not only useless but actually a source of annoyance and expense to the gas companies.

Perkin conceived the idea that, by partially burning or oxidizing it, this aniline might be changed into[41] quinine. He made the experiment and there resulted a black molasses-like mass, very far removed from the white crystals he was hoping for. But by testing this with various chemicals, he found that hot alcohol dissolved part of it, and turned it into a violet liquid which had the power to dye silk and wool the same bright color. Finding that the color was fairly fast to light, and that it could be produced without too much expense, he took out a patent and, with the aid of his father and brother, set up near Manchester, England, the first factory for artificial dyestuffs.

His discoveries were at once published, and chemists all over the world began to manufacture and experiment with the new dyestuffs. Great factories were started all over Europe. From this beginning the manufacture of coal-tar dyestuffs, and more recently all their allied compounds, has become one of the most important and most profitable of all chemical industries.

The dyes first discovered, the so-called “Basic dyes,” were of great brilliancy and strength; but they were not of any particular beauty when used individually. Compared with the vegetable colors which preceded them, and especially the same shades we are accustomed to see in nature, these dyes were hard, coarse, crude, and very inartistic. This could be remedied, however, by mixing two or three of them together, such mixture tending to soften the different colors and blend all into pleasant and delicate shades.

A more serious difficulty was the fact that those early dyestuffs were usually quite fugitive to light or,[42] at any rate, far less fast than the best of the vegetable dyes that preceded them. Besides, they did not fade true. In other words, a piece of cloth might to-day be a bright red, and after a few days of exposure to the sunlight, the exposed portions might turn a yellow, a white, or even some dark color; and, in any case, the change would entirely spoil the original color scheme.

By 1868, however, the artificial manufacture of alizarine, first by two German chemists, and then by Perkin himself, served to open up another whole class of new dyestuffs, which, when submitted to the proper tests, proved to be exceedingly fast both to light and to washing. In consequence, within a few years after this discovery, the commercial use of madder was everywhere abandoned. Chemists could now produce on cotton, linen, wool, and silk, practically the whole range of colors, brilliant and dull, hard and soft, light and dark, not only of a beauty, but of a fastness to light and to washing, never before surpassed, if indeed equalled.

| AT THE AGE OF 14 | AT THE AGE OF 22 |

AT THE TIME OF THE COAL-TAR COLOR JUBILEE—50 YEARS AFTER HIS DISCOVERY OF MAUVEINE

Since that time, not a year has gone by without scores of new dyestuffs being put on the market by some of the great color houses. Of late years special efforts have been made to simplify dyeing processes, and at the same time to insure the fastness as well as the beauty of the colors. At the present time it is possible for the veriest amateur, with practically no previous knowledge of chemistry or of dyeing, and with only intelligence enough to follow some simple directions, to get, in one bath,[43] with very little expenditure of time, an immense variety of shades that are exceedingly fast to light and to washing. A very few years ago this result could not possibly have been obtained, except by some expert dyer, and then only after long and tedious, as well as difficult, processes.

We are all familiar with the constant complaint that it is now impossible to get goods dyed or printed in good, fast colors. For instance, take the brilliant scarlet calico commonly known as Turkey red. In the days of our grandfathers a piece of cloth dyed Turkey red would stand rain and sun, washing and scouring, and thefibre would wear out before thecolor would fade. But nowadays, if you buy Turkey red cloth for the purpose of covering cushions for a piazza-lounge, you will be fortunate if the color does not begin to change after three or four days in the open air.

The reason is simple. In the old days theonly way to get that particular shade was by dyeing the cloth with ground-up madder root, through a series of operations lasting the best part of two months. Now any capable dyer would be able to dye cotton that exact shade with any of, say, twenty different colors, most of which would not require more than one or two hours to dye. Out of these twenty dyestuffs, four or five, rather more expensive than the rest, would give just as fast, just as brilliant, and just as strong color as the good old madder color. But the rest, which are distinctly cheaper and easier to apply, would furnish goods which wouldlook exactly[44] the same to the average purchaser, but which might notlast any time at all.

Naturally, the average manufacturer carefully instructs his dyer to furnish him with the “cheap and nasty” goods, not only because it costs less money, but also, unfortunately, because he reasons that “it will be good for business.” The manufacturer has the greatest sympathy with the inclination of the fastidious housewife to throw away anything that looks faded, and to buy in its place something new and fresh. Curtains or portières that hold their original shade indefinitely, he has little or no patience with. A calico dress that keeps its color so that it can be worn for a second summer, is an abomination not to be endured. And in every case, when complaint is made, it is always said to be the fault of the chemist who produced and put on the market such “horrid, fugitive dyes.”

As a matter of fact, it is simply a case of picking and choosing. There have been discovered, so far, several thousand different coal-tar dyestuffs of all sorts and kinds. Out of these, probably one hundred, or less, can be considered really fast to both light and washing. The remaining ones, most of which never were considered valuable enough to put on the market, vary in degrees of fastness, the poorest being simply stains which will “bleed” indefinitely with moderate washing, and which will turn almost any color after exposure for a few hours to sun and weather.

In the following pages, considerable pains will be taken to emphasize the names and properties of the[45] very best and fastest dyestuffs in the different classes,[1] so that the results of work done with them can be depended upon.

[1] In some classes there are no absolutely fast dyestuffs.

Perhaps the most interesting thing, in connection with the whole subject of the artificial dyestuffs, is the enormous influence that they have had upon the life of the whole human race. This influence was but slightly appreciated, even by the chemists themselves, until a few years ago. The awakening dates from the time of the fiftieth anniversary of the discovery of mauveine, when from one end of the world to the other, honors were showered upon Sir William Henry Perkin, then grown old and nearing the end of his useful and prosperous life. It was then announced, and was for the first time generally recognized as true, that no one of the great discoveries of the nineteenth century—the steam locomotive, the steamship, the telephone, the telegraph, the gas light, the electric light, and the rest—had been more important to the world at large than the discovery of the first coal-tar dye. And probably never in the history of the world have such enormous results been produced from a single discovery, during the lifetime of the discoverer himself.

The artificial dyestuffs form such a large body of complicated chemical compounds, that at first glance it would seem hopeless for any one who is not a trained[46] chemist, to attempt to get any clear or definite ideas about them. This, indeed, would be the case if any attempt were made to study them chemically, i.e., with reference to their composition, or their method of manufacture; but when it comes to the application of them to the various textile fabrics and other materials, for which dyes are valuable, we soon find that the problem is not so very difficult after all.

To be sure there are many hundreds of different dyes on the market now, great numbers of which are known under three or four different trade names, according to the trade-mark of each particular manufacturer. But besides the great manufacturers, and their accredited agents, there are numerous retail agencies all over the country, large and small, which make a business of distributing dyes made by the great concerns. Some of these are very energetic, and have pushed the sale of artificial dyestuffs in ten- and fifteen-cent packages, until in almost every village, large enough to boast of a decent country store, these dyes can be obtained.

It is common to hear these dyes sneered at and abused. They are frequently referred to, especially by those of “artistic tastes,” as harsh and crude in color, fugitive to light and washing, and, in short, generally inferior and worthless products. This is not the case. They are, in some cases, individual dyestuffs, and in other cases, mixtures, generally belonging to the class of colors next to be described, the Salt dyes; and very good, if not indeed the very best specimens of that class. These Salt dyes, until[47] the last few years, were far from fast, either to light or washing; but the more recent members of the class are much more satisfactory, and these colors, too, are found in the fifteen-cent packages.

Nor, too, can objection be fairly taken to the shades as being crude and harsh. That is all a matter of taste and skill on the part of the dyer. There is no better practice in dyeing than to take the very hardest, clearest, most brilliant red, blue, and yellow colors that can be found at the corner grocery and, following the directions on the packages, proceed to dye yarn or cheesecloth with them, at first using the individual dyes, and afterwards modifying the shade of one dye with traces of each of the other two. The softness and richness of the tones that can be thus obtained will satisfy the most critical.

The real objection to these widely distributed popular dyes is a very different one. They are not sold under their own names, and therefore it is almost impossible to identify them. To be sure, from the accompanying directions it is possible for a trained dyer to recognize at once the class to which the dyestuff belongs. But it is impossible for him, excepting after a long, tedious and often very troublesome analysis, to tell just what member or members of that particular class is contained in any given package. For this reason the dyer who has to depend on them for an important piece of work is in much the same position as a doctor would be who had to treat a difficult case with patent medicines compounded after secret formulæ.

[48]

In the following chapters, a discussion of each class of dyestuffs, and an explanation of their application and general properties will be followed by lists of three or four of the very best colors, sold by the New York agents of six of the largest and most reliable color manufacturers.

Workers wishing to obtain these dyes in comparatively large quantities, say one pound and upwards, can get them by writing directly to the addresses in the following table:

Badische— The Badische Anilin & Soda Fabrik,

128 Duane St.,

N. Y. City.

Cassella— The Cassella Co.,

184 Front St.,

N. Y. City.

Elberfeld—The Farbenfabriken of Elberfeld Co.,

117 Hudson St.,

N. Y. City.

Kalle— Kalle & Co.,

530 Canal St.,

N. Y. City.

Klipstein—A. Klipstein & Co.,

Agent for Society of Chemical Industry of Basle,

654 Greenwich St.,

N. Y. City.

Metz— Farbwerke-Hoechst Co., formerly H. A. Metz & Co.,

Agent for the Meister Lucius & Bruning Co.,

122 Hudson St.,

N. Y. City.

N. B. Further information concerning dyestuffs, apparatus, textiles, chemicals, etc., connected with this work may be obtained on writing to the author at 7 West 43rd St., New York.

[49]

It is important to remember that, in order to identify a color by name, it is necessary to know three things: first, the trade name; second, the shade, or distinguishing, letter; and third, the manufacturer or agent. The trade name sometimes bears a reference to the class, properties, or color of the dye, as “fast acid blue”; or to its chemical composition, as “methylene blue,” or “diamine red”; but in most cases it is simply an arbitrary name, given by the original discoverer when the patents were issued, or assigned later by the manufacturer or his local agents.