Title: Scientific American Supplement, No. 392, July 7, 1883

Author: Various

Release date: August 1, 2005 [eBook #8742]

Most recently updated: October 9, 2012

Language: English

Credits: Produced by Olaf Voss, Don Kretz, Juliet Sutherland, Charles

Franks and the Distributed Proofreaders Team

The continuous current and the alternating current generators invented by Dr. J. Hopkinson and Dr. Alexander Muirhead are peculiarly interesting as being probably the first in which the bobbins of the armature were wound with copper ribbon and arranged on a disk armature much in the same way as was afterward done by Sir William Thomson and by Mr. Ferranti. In the Muirhead-Hopkinson machine the armature coils are attached to a soft iron ring, whereas in the Ferranti the iron core is dispensed with, and a gain of lightness in the armature or rotating part effected; this advantage is of considerable importance, though Messrs. Hopkinson and Muirhead can of course reduce the weight of this iron core to insignificant proportions.

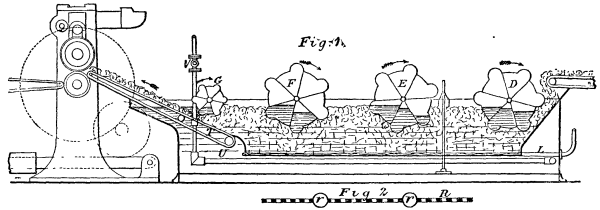

[Illustration: HOPKINSON & MUIRHEAD'S DYNAMO-ELECTRIC GENERATOR.]

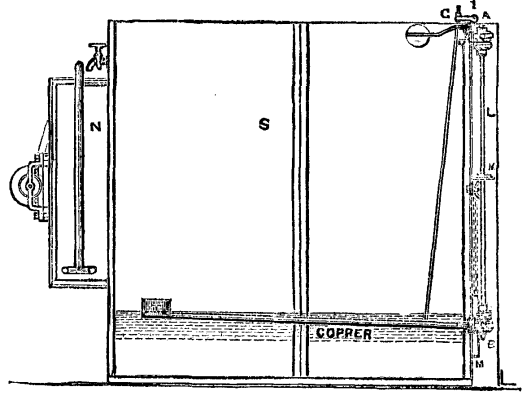

The general form of this generator is clearly shown by the side and end elevation.

The armature is made by taking a pulley and encircling it with a rim of sheet-iron bands, each insulated from the other by asbestos paper. On one or both sides of the rim thus formed, radial slots are cut to admit radial coils of insulated copper wire or ribbon, so that they lie in planes parallel to the plane of the pulley. In the continuous current machine coils are placed on both sides of the iron rim and arranged alternately, that on the one side always covering the gap between two on the other side. In this way, when a coil on one side of the rim is at its "dead point" and yields its minimum of current, the corresponding coil on the other side is giving out its maximum.

The field magnets are made in a similar manner to the armature and run in circles parallel to the rim of the latter. The cores may be built up of wrought iron as the rim of the armature is; but it is found cheaper to make them of solid wrought or cast iron. To stop the local induced currents in the core, however, Messrs. Muirhead and Hopkinson cut grooves in the faces of the iron cores, and fill them up with sheet-iron strips insulated from each other, similar to the sheet-iron rim of the armature.

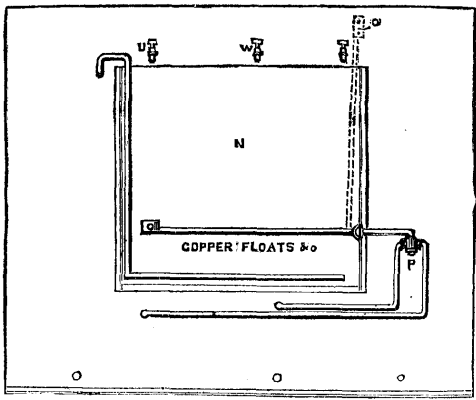

The coils, both in the armature and electro-magnets, are packed as closely as they may to each other, and have thus a compressed or quadrilateral shape. The arrangement is shown in Figs. 1 and 2, which represent, in side view and plan, the armature pulley with the soft iron rim and coils attached. There a is the pulley which is keyed to the shaft of the machine, and is encircled with bands of sheet iron, b, insulated from each other by ribbons of asbestos paper laid between every two bands. When the rim has been built up in this way, radial holes are drilled through it from the outer edge inward, and the whole rim is bound together by bolts, d, inserted in the holes and secured by cottars, e. Radial slots are then cut on each side of the rim all round, and the coils of wire mounted on them.

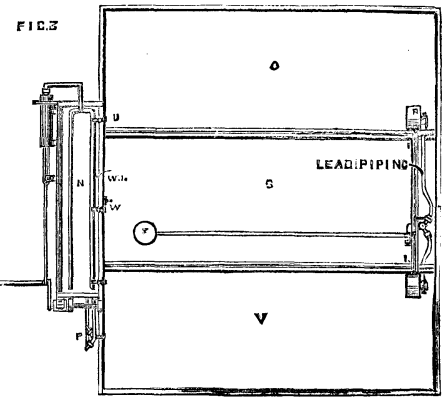

Figs. 3 and 4 show the armature of the continuous current dynamo, with the coils on one side of the rim, half way between the coils on the other side, so as to give a more continuous current. In the alternating current machine the slots on the opposite faces are face to face.

Figs. 5 and 9 illustrate the complete continuous current machine, Fig. 9 showing the internal arrangement of the field magnets, and Fig. 5 the external frame of cast iron supporting them. In these figures a is the armature already described, b b are the cores of the electro-magnets with a strong cast iron backing, c c; d d are the exciting coils or field magnets, so connected that the poles presented to the armature are alternately north and south, thus bringing a south pole on one side of the armature opposite a north pole on the other side.

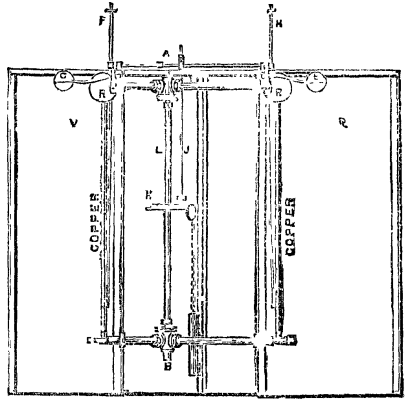

The commutator, e, is arranged to prevent sparking when the brushes leave a contact piece. This is done by splitting up the brushes into several parts and inserting resistances between the part which leaves the contact piece last and the rest of the circuit. This resistance checks the current ere the final rupture of contact takes place.

Figs. 6 and 7 will explain the structure of the commutator. Here a a a are the segments or contact pieces insulated from each other, and b' b b are the collecting brushes carried on a spindle, c c'. One of these brushes, b', is connected to the spindle, c, through an electrical resistance of plumbago, arranged as shown in Fig. 7, where d e are metal cylinders, d being in contact with the brush, b', while e is in contact with the spindle, c. The space, f, between these two cylinders, d e, is filled with a mixture of plumbago and lampblack of suitable resistance, confined at the ends by ivory disks. The brush, b', is adjusted by bending till it remains in contact with any segment of the commutator for a short time after the other brushes have left contact with that segment, and thus instead of sudden break of circuit and consequent sparking, a resistance is introduced, and contact is not broken until the current has been considerably reduced.

The contact segments are supported at both ends by solid insulating disks; but they are insulated from each other by the air spaces between them, where the brushes rub upon them.

The alternating current dynamo of Drs. Hopkinson and Muirhead differs little in general construction from that we have described; except that the commutator is very much simplified, and the armature bobbins are placed opposite each other on both sides of the rim. Instead of forming the coils into complete bobbins, Dr. Muirhead prefers to wind them in a zigzag form round the grooved iron rim after the manner shown in Fig. 8, which represents a plan and section of the alternating current armature. This arrangement is simpler in construction than the bobbin winding, and is less liable to generate self-induction current in the armature. Sir William Thomson has adopted a similar plan in one of his dynamos. In Fig. 8, a is the pulley fixed to the spindle of the machine, b b is the iron rim, and c c are the zigzag coils of copper ribbon. The field magnets are also wound in a similar manner.

It will be seen from our description that Drs. Hopkinson and Muirhead have scarcely had sufficient credit given them for this interesting machine, which so closely approximates to the Ferranti. One of their alternating dynamos has been built, and was shown at the Aquarium Exhibition. It works well, and is capable of supporting 300 Swan lights, while in size and appearance it resembles the Ferranti machine in a very striking manner. Drs. Muirhead and Hopkinson have also designed a magneto-electric alternating current machine; but as it closely resembles the machines described, with the exception that permanent magnets are employed as field magnets, we need not dwell upon it further.--Engineering.

The Leclanche battery is distinguished for its simplicity, its small internal resistance (0.7 to 1.0 Siemens unit), and that all chemical action ceases when the current is broken, that it is not sensitive to external influence, and by the self-renewal of the negative electrodes. But on the opposite side the action is not very great (= 1.20 or 1.48 D.), and the zinc as well as the sal ammoniac are converted into products that cannot be utilized.

I replace the solution of sal ammoniac by one of caustic potash or soda (12 to 15 per cent.), and the thin zinc rods by zincs with larger surfaces. In this manner, I obtain a powerful and odorless battery, having all the valuable qualities of the Leclanche, and one that permits of a renewal of the potash solution as well as of the negative electrode.

The electromotive power of this element may be as high as 1.8 D. The same pyrolusite (binoxide of manganese) cylinder used with the same thin rod of zinc will precipitate 75 per cent. more copper from solution in an hour when caustic potash is used than when sal ammoniac is employed. But by replacing the thin zinc rod by a zinc cylinder of large surface, 2½ times as much copper is precipitated in the same time.

The more powerful action of such a pair is explained by the stronger excitation and more rapid regeneration that the negative electrodes undergo from the oxidizing action of the air in the potash solution, as well as by the fact that this solution is a better conductor than the sal ammoniac solution. The potash solution does not crystallize easily, hence the negative electrode remains free from crystals and does not require filling up with water. Zinc dissolves only while in contact with negative bodies, hence there is no unnecessary consumption of zinc either in the open or closed circuit.

When the potash lye has become useless, I regenerate it by removing the zinc in the following manner: I pour the solution from the cells, put it in a suitable vessel, where I add water to replace that already evaporated, and then shake it up well at the ordinary temperature with hydrated oxide of zinc (zincic hydrate). Under this treatment the greater portion of the zinc that had been chemically dissolved by the potash is precipitated in the form of zinc hydrate, along with some carbonate. The liquid is now allowed to settle, and the clear supernatant solution is poured back again into the battery cells. The battery has rather greater electromotive force when this regenerated lye is used, because certain foreign matters from the carbon, like sulphur, chlorine, sulphuric acid, etc., are removed by this treatment.

The regeneration of the (brown coal) carbon goes on of itself, beneath the lye, through the oxidizing action of the atmospheric air; it is advantageous to have a part of the carbon sticking out of the liquid. Of course the regeneration takes place much more quickly if the electrodes are taken out and exposed to the air. In this case the carbon electrode need not be very thick, and can be flat or of tubular form. In the former case it must have a large volume, and the massive cylindrical form is recommended. The zinc electrode must be kept covered deeply with potash. The cells must have free access of air, and the potash must be replaced as soon as it is exhausted.--Chem. Zeit.

[Concluded from SUPPLEMENT No. 390, page 6217.]

[Footnote: Paper lately read before the Society of Telegraph Engineers and Electricians.]

The apparatus needed for researches upon evident external polarity requires no very great skill or thought, but simply an apparatus to measure correctly the force of the evident repulsion or attraction; in the case of neutrality, however, the external polarity disappears, and we consequently require special apparatus, together with the utmost care and reflection in its use.

From numerous researches previously made by means of the induction balance, the results of which I have already published, I felt convinced that in investigating the cause of magnetism and neutrality I should have in it the aid of the most powerful instrument of research ever brought to bear upon the molecular construction of iron, as indeed of all metals. It neglects all forces which do not produce a change in the molecular structure, and enables us to penetrate at once to the interior of a magnet or piece of iron, observing only its peculiar structure and the change which takes place during magnetization or apparent neutrality.

The induction balance is affected by three distinct arrangements of molecular structure in iron and steel, by means of which we have apparent external neutrality.

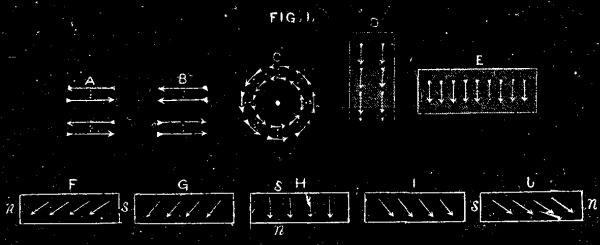

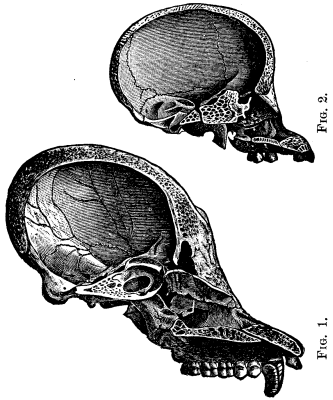

Fig 1 shows several polar directions of the molecules as indicated by the arrows. Poisson assumed as a necessity of his theory, that a molecule is spherical; but Dr. Joule's experimental proof of the elongation of iron by one seven-hundred and-twenty-thousandth of its length when magnetized, proves at least that its form is not spherical; and, as I am unable at present to demonstrate my own views as to its exact form, I have simply indicated its polar direction by arrows--the dotted oval lines merely indicating its limits of free elastic rotation.

In Fig. 1, at A, we have neutrality by the mutual attraction of each pair of molecules, being the shortest path in which they could satisfy their mutual attractions. At B we have the case of superposed magnetism of equal external value, rendering the wire or rod apparently neutral, although a lower series of molecules are rotated in the opposite direction to the upper series, giving to the rod opposite and equal polarities. At C we have the molecules arranged in a circular chain around the axis of a wire or rod through which an electric current has passed. At D we have the evident polarity induced by the earth's directive influence when a soft iron rod is held in the magnetic meridian. At E we have a longitudinal neutrality produced in the same rod when placed magnetic west, the polarity in the latter case being transversal.

In all these cases we have a perfectly symmetrical arrangement, and I have not yet found a single case in well-annealed soft iron in which I could detect a heterogeneous arrangement, as supposed by Ampere, De la Rive, Weber, Wiedermann, and Maxwell.

We can only study neutrality with perfectly soft Swedish iron. Hard iron and steel retain previous magnetizations, and an apparent external neutrality would in most cases be the superposition of one magnetism upon another of equal external force in the opposite direction, as shown at B, Fig. 1. Perfectly soft iron we can easily free, by vibrations, from the slightest trace of previous magnetism, and study the neutrality produced under varying conditions.

FIG. 1.

If we take a flat bar of soft iron, of 30 or more centimeters in length, and hold it vertically (giving while thus held a few torsions, vibrations, or, better still, a few slight blows with a wooden mallet, in order to allow its molecules to rotate with perfect freedom), we find its lower end to be of strong north polarity, and its upper end south. On reversing the rod and repeating the vibrations, we find that its lower end has precisely a similar north polarity. Thus the iron is homogeneous, and its polarity symmetrical. If we now magnetize this rod to produce a strong south pole at its lower portion, we can gradually reverse this polarity, by the influence of earth's magnetism, by slightly tapping the upper extremity with a small wooden mallet. If we observe this rod by means of a direction needle at all parts, and successively during its gradual passage from one polarity to the other, there will be no sudden break into a haphazard arrangement, but a gradual and perfectly symmetrical rotation from one direction to that of the opposite polarity.

If this rod is placed east and west, having first, say, a north polarity to the right, we can gradually discharge or rotate the molecules to zero, and as gradually reverse the polarity by simply inclining the rod so as to be slightly influenced by earth's magnetism; and at no portion of this passage from one polarity to neutrality, and to that of the opposite name, will there be found a break of continuity of rotation or haphazard arrangement. If we rotate this rod slowly, horizontally or vertically, taking observations at each few degrees of rotation of an entire revolution, we find still the same gradual symmetrical change of polarity, and that its symmetry is as complete at neutrality as in evident polarity.

In all these cases there is no complete neutrality, the longitudinal polarity simply becoming transversal when the rod is east and west. F, G, H, I, J, Fig. 1, show this gradual change, H being neutral longitudinally, but polarized transversely. If, in place of the rod, we take a small square soft iron plate and allow its molecules freedom under the sole influence of the earth's magnetism, then we invariably find the polarity in the direction of the magnetic dip, no matter in what position it be held, and a sphere of soft iron could only be polarized in a similar direction Thus we can never obtain complete external neutrality while the molecules have freedom and do not form an internal closed circle of mutual attractions; and whatever theory we may adopt as to the cause of polarity in the molecule, such as Coulomb's, Poisson's, Ampere's, or Weber's, there can exist no haphazard arrangement in perfectly soft iron, as long as it is free from all external causes except the influence of the earth; consequently these theories are wrong in one of their most essential parts.

We can, however, produce a closed circle of mutual attraction in iron and steel, producing complete neutrality as long as the structure is not destroyed by some stronger external directing influence.

Oersted discovered that an external magnetic needle places itself perpendicular to an electric current; and we should expect that, if the molecules of an iron wire possessed inherent polarity and could rotate, a similar effect would take place in the interior of the wire to that observed by Oersted. Wiedermann first remarked this effect, and it has been known as circular magnetism. This circle, however, consists really in each molecule having placed itself perpendicular to the current, simply obeying Oersted's law, and thus forming a complete circle in which the mutual attractions of the molecules forming that circle are satisfied, as shown as C, Fig. 1. This wire becomes completely neutral, any previous symmetrical arrangement of polarity rotating to form its complete circle of attractions; and we can thus form in hard iron and steel a neutrality extremely difficult to break up or destroy. We have evident proof that this neutrality consists of a closed chain, or circle, as by torsion we can partially deflect them on either side; thus from a perfect externally neutral wire, producing either polarity, by simple mechanical angular displacement of the molecules, as by right or left handed torsion.

If we magnetize a wire placed east and west, it will retain this polarity until freed by vibrations, as already remarked. If we pass an electric current through this magnetized wire, we can notice the gradual rotation of the molecules, and the formation of the circular neutrality. If we commence with a weak current, gradually increasing its strength, we can rotate them as slowly as may be desired. There is no sudden break or haphazard moment of neutrality: the movements to perfect zero are accomplished with perfect symmetry throughout.

We can produce a more perfect and shorter circle of attractions by the superposition of magnetism, as at B, Fig. 1. If we magnetize a piece of steel or iron in a given direction with a strong magnetic directing power, the magnetism penetrates to a certain depth. If we slightly diminish the magnetizing power, and magnetize the rod in a contrary direction, we may reduce it to zero, by the superposition of an exterior magnetism upon one of a contrary name existing at a greater depth; and if we continue this operation, gradually diminishing the force at each reversal, we can easily superpose ten or more distinct symmetrical arrangements, and, as their mutual attractions are satisfied in a shorter circle than in that produced by electricity, it is extremely difficult to destroy this formation when once produced.

The induction balance affords also some reasons for believing that the molecules not only form a closed circle of attractions, as at B, but that they can mutually react upon each other, so as to close a circle of attractions as a double molecule, as shown at A. The experimental evidence, however, is not sufficient to dwell on this point, as the neutrality obtained by superposition is somewhat similar in its external effects.

We can produce a perfectly symmetrical closed circle of attractions of the nature of the neutrality of C, Fig. 3, by forming a steel wire into a closed circle, 10 centimeters in diameter, if this wire is well joined at its extremities by twisting and soldering. We can then magnetize this ring by slowly revolving it at the extremity of one pole of a strong permanent magnet; and, to avoid consequent poles at the part last touching the magnet, we should have a graduating wedge of wood, so that while revolving it may be gradually removed to greater distance. This wire will then contain no consequent points or external magnetism: it will be found perfectly neutral in all parts of its closed circle. Its neutrality is similar to C, Fig. 3; for if we cut this wire at any point we find extremely strong magnetic polarity, being magnetized by this method to saturation, and having retained (which it will indefinitely) its circle of attractions complete.

I have already shown that soft iron, when its molecules are allowed perfect freedom by vibration, invariably takes the polarity of the external directing influence, such as that of the earth, and it does so even with greater freedom under the influence of heat. Manufacturers of electro-magnets for telegraphic instruments are very careful to choose the softest iron and thoroughly anneal it; but very few recognize the importance as regards the position of the iron while annealing it under the earth's directing influence. The fact, however, has long since been observed.

Dr. Hooke, 1684, remarked that steel or iron was magnetized when heated to redness and placed in the magnetic meridian. I have slightly varied this experiment by heating to redness three similar steel bars, two of which had been previously magnetized to saturation, and placed separately with contrary polarity as regards each other, the third being neutral. Upon cooling, these three bars were found to have identical and similar polarity. Thus the molecules of this most rigid material, cast steel, had become free at red heat, and rotated under the earth's magnetic influence, giving exactly the same force on each; consequently the previous magnetization of two of these bars had neither augmented nor weakened the inherent polarity of their molecules. Soft iron gave under these conditions by far the greatest force, its inherent polarity being greater than that of steel.

I have made numerous other experiments bearing upon the question of neutrality, but they all confirm those I have cited, which I consider afford ample evidence of the symmetrical arrangement of neutrality.

Knowing that by torsion we can rotate or diminish magnetism, I was anxious to obtain by its means a complete rotation from north polarity to neutrality, and from neutrality to south polarity, or to completely reverse magnetic polarity by a slight right or left torsion.

I have succeeded in doing this, and in obtaining strong reversal of polarities, by superposing one polarity given while the rod is under a right elastic torsion, with another of the opposite polarity given under a left elastic torsion, the neutral point then being reached when the rod is free from torsion. The rod should be very strongly magnetized under its first or right-hand torsion, so that its interior molecules are rotated, or, in other words, magnetized to saturation; the second magnetization in the contrary sense and torsion should be feebler, so as only to magnetize the surface, or not more than one-half its depth; these can be easily adjusted to each other so as to form a complete polar balance of force, producing, when the rod is free from torsion, the neutrality as shown at B, Fig. 1.

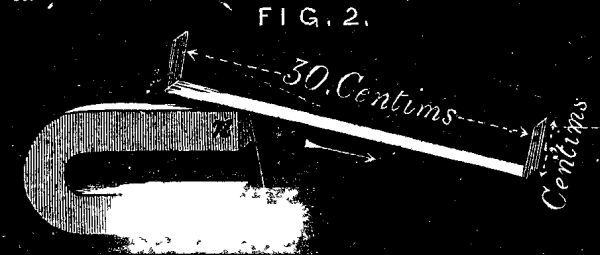

The apparatus needed is simply a good compound horseshoe permanent magnet, 15 centimeters long, having six or more plates, giving it a total thickness of at least 3 centimeters. We need a sufficiently powerful magnet, as I find that I obtain a more equal distribution of magnetism upon a rod or strip of iron by drawing it lengthwise over a single pole in a direction from that pole, as shown in Fig. 2; we can then obtain saturation by repeated drawings, keeping the same molecular symmetry in each experiment.

In order to apply a slight elastic torsion when magnetizing rods or wires, I have found it convenient to attach two brass clamp keys to the extremities of the rods, or simply turn the ends at right angles, as shown in the following diagram, by which means we can apply an elastic twist or torsion while drawing the rod over the pole of the permanent magnet. We can thus superpose several and opposite symmetrical structures, producing a polar north or south as desired, greatly in excess of that possible under a single or even double magnetization, and by carefully adjusting the proportion of opposing magnetisms, so that both polarities have the same external force, the rod will be at perfect external neutrality when free from torsion.

FIG. 2.

If we now hold one end of this rod at a few centimeters distance from a magnetic directive needle, we find it perfectly neutral when free of torsion, but the slightest torsion right or left at once produces violent repulsion or attraction, according to the direction of the torsion given to the rod, the iron rod or strips of hoop-iron which I use for this experiment being able, when at the distance of five centimeters from the needle, to turn it instantly 90° on either side of its zero.

The external neutrality that we can now produce at will is absolute, as it crosses the line of two contrary polarities, being similar to the zero of my electric sonometer, whose zero is obtained by the crossing of two opposing electric forces.

This rod of iron retains its peculiar powers of reversal in a remarkable degree, a condition quite different to that of ordinary magnetization, for the same rod, when magnetized to saturation under a single ordinary magnetism, loses its evident magnetism by a few elastic torsions, as I have already shown; but when it is magnetized under the double torsion with its superposed magnetism, it is but slightly reduced by variations or numerous torsions, and I have found it impossible to render this rod again free from its double polar effects, except by strongly remagnetizing it to saturation with a single polarity. The superposed magnetism then becomes a single directive force, and we can then by a few vibrations or torsions reduce the rod to its ordinary condition.

The effects of superposed magnetism and its double polarity I have produced in a variety of ways, such as by the electro-magnetic influence of coils, or in very soft iron simply by the directive influence of the earth's magnetism, reversing the rod and torsions when held in the magnetic meridian, these rods when placed magnetic west showing distinctly the double polar effects.

It is remarkable, also, that we are enabled to superpose and obtain the maximum effects on thin strips of iron from ¼ to ½ millimeter in thickness, while in thicker rods we have far less effect, being masked by the comparatively neutral state of the interior, the exterior molecules then reaching upon those of the interior, allowing them to complete in the interior their circle of attractions.

I was anxious to obtain wires which would preserve this structure against the destructive influence of torsion and vibrations, so that I could constantly employ the same wires without the comparatively long and tedious process of preparation. Soft iron soon loses the structure, or becomes enfeebled, under the constant to and fro torsions requisite where we desire a constant change of polarity, as described later in the magnetic bells. Hard steel preserves its structure, but its molecular rigidity is so great that we obtain but mere traces of any change of polarity by torsion. I have found, however, that fine cast drill steel, untempered, of the kind employed by watchmakers, is most suitable; these are generally sold in straight lengths of 30 centimeters. Wires 1 millimeter in diameter should be used, and when it is desired to increase the force, several of these wires, say, nine or ten, should be formed into a single rod or bunch.

The wire as sold is too rigid to give its maximum of molecular rotation effect. We must therefore give it two entire turns or twists to the right, and strongly magnetize it on the north pole of the magnet while under torsion. We must again repeat this operation in the contrary direction, after restoring the wire to its previous position, giving now two entire turns to the left and magnetizing it on the south pole. On restoring the wire to its original place, it will be extremely flexible, and we may now superpose several contrary polarities under contrary torsions, as already described.

The power of these wires, if properly prepared, is most remarkable, being able to reverse their polarity under torsion, as if they were completely saturated; and they preserve this power indefinitely if not touched by a magnet. It would be extremely difficult to explain the action of the rotative effects obtained in these wires under any other theory than that which I have advanced; and the absolute external neutrality that we obtain in them when the polarities are changing, we know, from their structure, to be perfectly symmetrical.

I was anxious to show, upon the reading of this paper, some mechanical movement produced by molecular rotation, consequently I have arranged two bells that are struck alternately by a polarized armature put in motion by the double polarized rod I have already described, but whose position, at three centimeters distant from the axis of the armature, remains invariably the same. The magnetic armature consists of a horizontal light steel bar suspended by its central axle; the bells are thin wine glasses, giving a clear musical tone loud enough, by the force with which they are struck, to be clearly heard at some distance. The armature does not strike these alternately by a pendulous movement, as we may easily strike only one continuously, the friction and inertia of the armature causing its movements to be perfectly dead beat when not driven by some external force, and it is kept in its zero position by a strong directive magnet placed beneath its axle.

The mechanical power obtained is extremely evident, and is sufficient to put the sluggish armature in rapid motion, striking the bells six times per second, and with a power sufficient to produce tones loud enough to be clearly heard in all parts of the hall of the Society. As this is the first direct transformation of molecular motion into mechanical movement, I am happy to show it on this occasion.

There is nothing remarkable in the bells themselves, as they evidently could be rung if the armature was surrounded by a coil, and worked by an electric current from a few cells. The marvel, however, is in the small steel superposed magnetic wire producing by slight elastic torsions from a single wire, one millimeter in diameter, sufficient force from mere molecular rotation to entirely replace the coil and electric current.

During these researches I have remarked a peculiar property of magnetism, viz., that not only can the molecules be rotated through any degree of arc to its maximum, or saturation, but that, while it requires a comparatively strong force to overcome its rigidity or resistance to rotation, it has a small field of its own through which it can move with excessive freedom, trembling, vibrating, or rotating through a small degree with infinitely less force than would be required to rotate it permanently on either side. This property is so marked and general that we can observe it without any special iron or apparatus.

Let us take a flat rod of ordinary hoop iron, 30 or more centimeters in length. If, while holding this vertically, we give freedom to its molecules by torsions, vibrations, or, better still, by a few blows with a wooden mallet upon its upper extremity, we find, as is well known, that its lower portion is strongly north, and its upper south. If we reverse this rod, we now find it neutral at both extremities. We might here suppose that the earth's directing force had rotated the molecules to zero, or transversely, which in reality it has done, but only to the limit of their comparatively free motion; for if we reverse the rod to its original position, its previous strong polarity reappears at both extremities, thus the central point of its free motion is inclined to the rod, giving by its free motion great symmetrical inclination and polarity in one direction, but when reversed the inclination is reduced to zero.

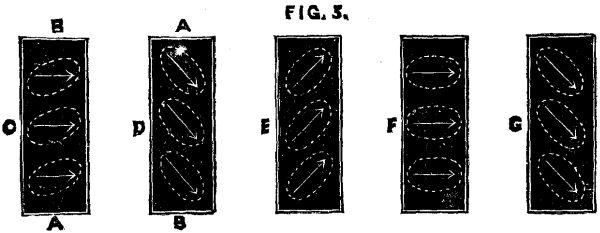

In Fig. 3, D shows the bar of iron when strongly polarized by earth's magnetic influence, under vibrations, with a sufficient force to have rotated its elastic center of action. C shows the same bar with its molecules at zero, or transversal, the directing force of earth being insufficient without the aid of mechanical vibration to allow them to change. The dotted lines of D suppose the molecule to be in the center of its free motion, while at C the molecules have rotated to zero, as they are prevented from further rotation by being at the extreme end of its free motion.

If, now, we hold the rod vertically, as at C, giving neutrality, and give a few slight blows with a wooden mallet to its upper extremity, we can give just the amount of freedom required for it to produce evident polarity, and we then have equal polarity, no matter which end of the bar is below, the center of its free rotation here being perfect, and the rod perfectly neutral longitudinally when held east and west. If, on the other hand, we have given too much freedom by repeated blows of the mallet, its center of free motion becomes inclined with the molecules, and we arrive at its first condition, except that it is now neutral at D and polarized at C. From this it will be seen that we can adjust this center of action, by vibrations or blows, to any point within the external directing influence.

FIG. 3.

We can perceive this effect of free rotation in a limited space in all classes of iron and steel, being far greater in soft Swedish iron than in hard iron or steel. A similar phenomenon takes place if we magnetize a rod held vertically in the direction of earth's magnetism. It then gives greater polarity than if magnetized east or west, and if magnetized in a contrary sense to earth's magnetism, it is very feebly magnetized, or, if the rod is perfectly soft, it becomes neutral after strong magnetization. This property of comparative freedom, and the rotation of its center of action, can be demonstrated in a variety of ways. One remarkable example of it consists in the telephone. All those who are thoroughly acquainted with electro-magnetism, and know that it requires measurable time to charge an electro-magnet to saturation (about one-fifteenth of a second for those employed in telegraphy), were surprised that the telephone could follow the slightest change of timbre, requiring almost innumerable changes of force per second. I believe the free rotation I have spoken of through a limited range explains its remarkable sensitiveness and rapidity of action, and, according to this view, it would also explain why loud sounding telephones can never repeat all the delicacy of timbre that is easily done with those only requiring a force comprised in the critical limits of its free rotation. This property, I have found, has a distinct critical value for each class of iron, and I propose soon to publish researches upon the molecular construction of steel and iron, in which I have made use of this very property as a guide to the quality of the iron itself.

The elastic rotation (in a limited space) of a molecule differs entirely from that known as mechanical elasticity. In perfectly soft iron we have feeble mechanical elasticity, while in tempered steel we have that elasticity at its maximum. The contrary takes place as regards molecular elasticity. In tempered steel the molecules are extremely rigid, and in soft iron its molecular elasticity is at its maximum. Its free motion differs entirely from that given it by torsion or stress. We may assume that a molecule is surrounded by continuous ether, more of the nature of a jelly than of that of a gas; in such a medium a molecule might freely vibrate through small arcs, but a rotation extending beyond its critical limit would involve a much greater expenditure of force.

The discovery of this comparatively free rotation of molecules, by means of which, as I have shown, we can (without in any degree disturbing the external mechanical elasticity of the mass) change the axes of their free motion in any direction desired, has led me into a series of researches which have only indirectly any relation with the theory of magnetism. I was extremely desirous, however, of finding an experimental evidence which in itself should demonstrate all portions of the theory, and the following experiment, I believe, answers this purpose.

Let us take a square soft iron rod, five millimeters in diameter by thirty or more centimeters in length, and force the molecules, by aid of blows from a wooden mallet, as previously described, to have their centers of free motion in one direction; the rod will (as already shown) have polarity at both ends, when held vertically; but if reversed, both ends become completely neutral.

If now we turn the rod to its first position, in which it shows strong polarity, and magnetize it while held vertically, by drawing the north pole of a sufficiently powerful permanent magnet from its upper to its lower extremity, we find that this rod, instead of having south polarity at its lower portion, as we should expect from the direction of the magnetization, is completely neutral at both extremities, but if we reverse the rod its fullest free powers of magnetization now appear in the position where it was previously neutral. Thus, by magnetization, we have completely rotated its free path of action, and find that we can rotate this path as desired in any direction by the application of a sufficient directing power.

If we take a rod as described, with its polarities evident when held vertically, and its neutrality also evident when its ends are reversed in the same magnetic field, we find that its polarity is equal at both ends, and that it is in every way symmetrical with a perfect magnet. If we gradually reverse the ends and take observations of its condition through each degree of arc passed over, we find an equal symmetrical diminution of evident external polarity, until we arrive at neutrality, when it has no external trace of inherent polarity; but its inherent polarity at once becomes evident by a simple return to its former position. Thus the rod has passed through all the changes from polarity to neutrality, and from neutrality to polarity, and these changes have taken place with complete symmetry.

The limits of this paper do not allow me to speak of the numerous theoretical evidences as shown by the use of my induction balance. I believe, however, that I have cited already experimental evidences to show that what has been attributed to coercive force is really due to molecular freedom or rigidity; that in inherent molecular polarity we have a fact admitted by Coulomb, Poisson, Ampere, De la Rive, Weber, Du Moncel, Wiedermann, and Maxwell; and that we have also experimental evidence of molecular rotation and of the symmetrical character of polarity and neutrality.

The experiments which I have brought forward in this paper, in addition to those mentioned in my paper read before the Royal Society, will, I hope, justify me in having advanced a theory of magnetism which I believe in every portion allows at least experimental evidences of its probable truth.

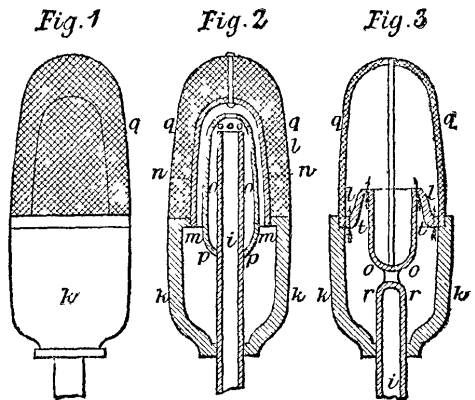

Below we illustrate the main parts of the Westinghouse brake as applied to a vehicle. The supplementary reservoir brake cylinder and triple valve are shown in position, and as fitted upon the engine, tender, and each vehicle of the train. Air compressed by a pump on the locomotive to, say, 70 lb. or 80 lb. to the square inch fills the main reservoir on the engine, and flowing through the driver's brake valve and main pipe, also charges the supplementary reservoirs throughout the train. When a train is running, uniform air pressure exists throughout its length--that is to say, the main reservoir on the engine, the pipe from end to end of train, the triple valves and supplementary reservoirs on each vehicle, are all charged ready for work, the brake cylinders being empty and the brakes off. The essential principle of the system is, that maintaining the pressure keeps the brakes off, but letting the air escape from the brake pipe, purposely or accidentally, instantly applies them. It follows, therefore, that the brake may be applied by the driver or any of the guards, or if necessary by a passenger, by the separation of a coupling, or the failure or injury to a vital part of the apparatus, whether due to an accident to the train or to the brake; and as the brake on each vehicle is complete in itself and independent, should the apparatus on any one carriage be torn off, the brake will nevertheless remain applied for almost any length of time upon the rest of the train.

The triple valve, as will be seen, is simply a small piston, carrying with it a slide valve, which can be moved up or down by increasing or decreasing the pressure in the brake pipe. As soon as the air from the main reservoir is turned into the brake pipe, by means of the driver's valve, the piston is pushed up into the position shown, and air is allowed to feed past it through a small groove into the reservoir. At the same time the slide valve covers the port to the brake cylinder, and is in such a position that the air from the latter may exhaust into the atmosphere. The piston has now the same air pressure on both sides; but if the pressure in the brake pipe is decreased, the piston and slide valve are forced down, thereby uncovering the passage through which air from the reservoir flows into the brake cylinder between the pistons, thus applying the brakes. The brake pipe is shut off as soon as the triple valve piston passes the groove. To release the brakes, the piston and slide valves are again moved into the position shown, by the driver turning air from the main reservoir into the brake pipe. The air in the brake cylinder escapes, and at the same time the reservoir is recharged.

THE WESTINGHOUSE BRAKE.

Fig. 2 represents two Westinghouse couplings connected. They are exactly alike in all respects, and an air tight joint is made between them by means of the rubber washers. These couplings are so constructed that the air pressure within serves to tighten the joint, and they may be pushed apart by the separation of the train without any injury. Such an occurrence as already explained leads to the instant application of all the brakes on the train.

By closing the small tap shown between the brake pipe and the triple valve, the brake on any vehicle, if out of order, can be cut out of the system. A release valve is also placed upon each cylinder as shown, so that in the event of the brakes being applied by the separation of the train, or the breaking of a pipe, or when the locomotive is not attached, they can be released by allowing the air to escape from each brake cylinder direct. The Westinghouse brake has been made to comply thoroughly with the Board of Trade conditions. Many people, however, do not appear to understand all that is involved in the second requirement, which runs as follows: In case of accident, to be instantaneously self-acting. This clearly implies: First, that accident to the train, or to any of its vehicles, shall cause the instant application of the brakes to the wheels of every vehicle in the train without the intervention of the driver or guards. Secondly, that any injury, however caused, which may impair the efficiency of the brake apparatus, shall, in like manner, lead to the instant application of all the brakes on the train. It then becomes impossible for a driver to run his train in ignorance of any defect in his brake apparatus because such defect at once discloses itself by applying the brakes and stopping the train. Thirdly, that each vehicle shall carry its own brake power in such a manner that the destruction of the brake apparatus on one or more of the carriages shall not affect the efficiency of the brakes upon any of the others. No continuous brake which does not comply with such conditions can ever be satisfactory.--The Engineer.

[Footnote: Read at Buffalo meeting of the American Water-Works Association May 15,1883.]

What I have to say in relation to elevators and motors will be mostly in regard to questions that their uses necessarily bring up for settlement at the water-works office; also to show how I have been able in a measure to overcome some of the many difficulties that have presented themselves, as well as to discuss and seek information as to the best way of meeting others that still have to be dealt with. At the outset, therefore, let me state that I am not an hydraulic engineer, nor have I sufficient mechanical knowledge to undertake the discussion of the construction or relative merits of either elevators or motors. This I would respectfully suggest as a very proper and interesting topic for a paper at some future meeting by some one of the many, eminent engineers of this association.

The water-works of Kansas City is comparatively young, and my experience only dates back six or seven years, or shortly after its completion. At this time it was deemed advisable on account of the probable large revenue to be derived from their use, to encourage the putting in of hydraulic elevators by low water rates. With this end in view a number of contracts were made for their supply at low special rates for a period of years, and our minimum meter rate was charged in all other cases, regardless of the quantity of water consumed. In most instances these special rates have since been found much too low, parties paying in this way being exceedingly extravagant in the use of elevators. However, the object sought was obtained, and now they are very extensively used. In fact, so much has their use increased, that the question is no longer how to encourage their more general adoption, but how to properly govern those that must be supplied. A present our works furnish power to about 15 passenger and 80 freight elevators, and the number is rapidly increasing.

Before going into details it seems proper to give at least a brief description of our water-works, as my observations are to a great extent local.

On account of the peculiar topography of Kansas City (and I believe it has more topography to the square foot than any city in the country) two systems of water supply have been provided, the high ground being supplied by direct pumping, and a pressure of about 90 pounds maintained in the business portion, and the lower part of the city being supplied by gravity, from a reservoir at an elevation of 210 feet, thus giving the business portions of the city, on high and low ground, about the same pressure. By an arrangement of valves, a combination of these two systems is effected, so that the Holly machinery can furnish an increased fire pressure at a moment's notice, into either or both pipe systems. Thus at some points the pressure is extremely high during the progress of fires, causing difficulties that do not exist where the gravity system of works is used exclusively.

Elevators have become an established institution, and in cities of any commercial importance are regarded as a necessity, hotels, jobbing houses, factories, and office buildings being considered as far behind the times when not thus provided, as a city without a water supply or a community without a "boom." The use of elevators has made it practicable and profitable to erect buildings twice as high as were formerly thought of. Perhaps some of the most notable examples of this are in New York city, where such structures as the Mills building, the buildings of the Tribune, Evening Post, and Western Union Telegraph Co.. tower high above the surrounding blocks, monuments of architecture, that without this modern invention would reflect little credit upon their designers. It is now found less labor to go to to the fifth, sixth, or even tenth floors of these great buildings than it was to reach the second or third, before their use. In these days, merchants can shoot a ton of goods to the top of their stores in less time than it would take to get breath for the old hoist or "Yo, heave O" arrangement. Thousands of dollars are sometimes expended on a single elevator, the cars are miniature parlors, and the mechanism has perhaps advanced to nearly the perfection of the modern steam engine. If then they have become such a firmly established institution, their bearing upon the water supply of cities is a subject to be carefully considered.

As before intimated, there are many questions involved in the use of hydraulic elevators, that particularly concern towns supplied by direct pumping, and perhaps other places where the supply by gravity is somewhat limited. In a few larger cities supplied by ample reservoirs and mains, some of the difficulties suggested are not serious. Very little power is necessary to perform the actual work of lifting, with either steam or hydraulic elevators, but on account of the peculiar application of the power, and the great amount of friction to be overcome, a very considerable power has to be provided. It has been estimated, by good authorities, that not more than one-quarter of the power expended in most cases is really utilized.

With all hydraulic elevators of which I have cognizance, as much water is required to raise the empty cars as though they were loaded to maximum capacity. Still, to be available for passenger purposes elevators must have capacity of upward of 2,500 pounds, particularly in hotels, where the cars are often arranged with separate compartments underneath for baggage. In general use it is exceptional that passenger elevators are fully loaded; on the contrary less than half a load is ordinarily carried, and for this reason it would appear that no actual benefit is derived from at least one-half of the water consumed. In this connection it has occurred to me that passenger elevators could be built at no great additional cost, with two cylinders, small and large, the two piston rods of which could be connected so as to both operate the same cable, either or both furnishing power, the smaller cylinder to be used for light loads, the larger for heavy work, and the two together for full capacity, this independent valve arrangement to be controlled by a separate cable running through the car. Whether this plan is practicable or not must be left to elevator manufacturers, but it seems to me that with the Hale-Otis elevator for instance (which is conceded to be one of the best) it could easily be accomplished. Certainly some such arrangement would effect a great saving of water, and perhaps bring water bills to a point that this class of consumers could afford to pay.

Hydraulic elevators where the water is used over and over again, by being pumped from the discharge to elevated tanks, cut little or no figure in connection with a city's water supply. When fuel, first cost, attendance of an engineer, and the poor economy of the class of pumps usually employed to perform this work are considered, the cost of operating such elevators is greatly in excess of what it would be if power were supplied direct from water mains, at any reasonable rate. The following remarks will then relate almost exclusively to that class of hydraulic elevators supplied with power directly from the water mains.

Let us now consider whether they are a desirable source of revenue, and in this my knowledge does not exceed my actual experience. Few elevator users appreciate the great quantity of water their elevators consume. Even in Kansas City, where, on account of the high pressure carried, much smaller cylinders than ordinarily are required, it is found that passenger elevators frequently consume 500,000 to 800,000 gallons of water per month, which will make a very considerable bill, at the most liberal rates. I have, therefore, concluded that the quantity of water was so large that, unless liberal concessions were made, it would be a hardship to consumers to pay their water bills, and have therefore made a special schedule, according to quantity, for elevators and motors, these rates standing below our regular meter rates, and running to the lowest point at which we think we can afford to furnish the water. This schedule brings the rate below what we would receive for almost any other legitimate use of water; and, in view of our rapidly increasing consumption, and the probability of soon having to increase all our facilities, it is an open question whether this will continue a desirable source of revenue.

In Kansas City we have elevators of various manufacture: the Hale-Otis, Ready, Smith & Beggs, O'Keefe, Kennedy, and perhaps others, each having its peculiarities, but alike demanding large openings in the mains for supply. These large openings are objectionable features with any waterworks, and especially so with direct pumping. An occurrence from this cause, about two years ago, is an experience I should not like repeated, but is one that might occur whenever the pressure in the mains is depended upon to throw fire streams. In this instance a large block of buildings occupied by jobbing houses and having three elevators was burned down, and the elevator connections broken early in the fire, allowing the water to pour into the cellars in the volume of about twelve ordinary fire streams. This immense quantity of water had to be supplied from a 6-inch main, fed from only one end, which left little pressure available for fighting the fire, and as a matter of course failure to subdue the fire promptly was attributed to the water-works. We have since had up hill work to restore confidence as to our ability to throw fire streams, although we have demonstrated the fact hundreds of times since.

From this time we have been gradually cutting down on the size of openings for elevator supply, but under protest of the elevator agents, who have always claimed that they should be allowed at least a 4-inch opening in the mains, until we have found that under 80 to 90 pounds pressure two to four 1-inch taps will answer the purpose, provided the water pipes are of ample size.

The "water hammer" produced by the quick acting valves of elevators has always been objectionable, both in its effect at the pumping-house and upon water mains and connections. To obviate this, Engineer G. W. Pearson has suggested the use of very large air chambers on the elevator supply, and still smaller openings in the mains, his theory being that the air chambers would not only materially decrease the concussion or "water hammer," but that they would also act as accumulators of power (or water under pressure) to be drawn from at each trip of the elevator, and replaced when it was at rest. This plan I have never seen put to actual test, but believe it to be entirely practicable, and that we will have to ultimately adopt it.

All things considered, the plan of operating elevators from tanks in the top of buildings, supplied by a small pipe connected with the water-mains and arranged with a float valve to keep the tank filled, I believe to be the best manner of supply, except for the great additional cost of putting up such apparatus. By this arrangement the amount of water consumed is no less, in fact it would ordinarily be more than with a direct connection with the mains, but it has the advantage of taking the water in the least objectionable manner. Still, if this mode of supply were generally enforced, the large first cost, an additional expense of operating, would undoubtedly deter many from using elevators.

Another evil in connection with the use of elevators, and which no doubt is common, is the habit many parties have of keeping a key or wrench to turn on and off the water at the curb. This we have sought to remedy by embracing in our plumbers' rules the following: "All elevator connections in addition to the curb stop for the use of the Water Company must be provided with another valve where the pipe first enters the building for the use of occupants of the building." Without this extra valve it was found almost impossible to keep parties from using the curb valve. In most cases the persons were perfectly responsible, and as there was no intent to defraud the company by the act, they would claim this privilege as a precaution against the pipes bursting or freezing. This practice was very generally carried on, and was the direct cause in at least two cases of very serious damage. In the instances referred to, the pipes burst between the elevator and the area wall of buildings, and the valves outside had become so worn from frequent use that they would not operate, allowing the water to literally deluge the basements before the water main could be turned off.

One of the greatest causes of waste from elevators is the wearing out of the piston packing, this being particularly troublesome in most of the Western cities, where the water supplied is to a large extent from turbid streams, carrying more or less fine sand or "grit," which cuts out the packing of the pistons very rapidly. The only practicable remedy for this is close inspection, to see that the pistons do not allow water to pass, a fact that can readily be determined from the noise made in the cylinder when the elevator is in motion going upward.

I have reserved one of the most annoying features of elevator supply for the last, hoping to work myself into a mood to do the subject justice, but doubt if it can be done in language proper to use before this dignified body. I remember on one occasion the mayor of our city, in discussing a job of plumbing, said that it seemed to him "that even a plumber ought to know something about plumbing." Now it would seem that even elevator agents ought to know something about elevators, but from the following incident, which is but one of many, I am led to believe that they are not infallible to say the least. Only a short time since, one of these very reliable (?) agents reported at our office that he had just attached a new indicator to the elevator of a leading hotel. He was asked: "What does it register?" and promptly replied, "Cubic feet." In this case our inspector had already made an examination, and had correctly reported as follows: "Hale elevator; indicator started at zero February 28; internal diameter of cylinder, 12 inches; travel of piston for complete trip 30¼ feet; indicator registers for complete trip, 4."

When it is understood that we had for a long time been assuming that elevator agents knew about all there was to know on the subject, a comparison of statements of this agent and our inspector is somewhat startling. Now let us see what the difference amounted to: At the end of the month the indicator had registered 12,994; calling it cubic feet, this register would equal 97,195 gallons. According to our inspector, this same register would equal 578,233 gallons, or a difference of nearly half a million of gallons for a single month. Our experience with the agents in Kansas City has shown that they will, if allowed, put any kind of an indicator on the most convenient point of any sort of an elevator, without the slightest regard as to what it was intended to indicate; then report it as registering cubic or lineal feet, whichever they find the indicator marked. On the same principle they could as well change the fulcrum of a Fairbanks scale, and then claim it weighed pounds correctly, because pounds were marked upon the bar. We have lately prepared a blank, upon which these agents are required to make a detailed report upon the completion of an elevator before the water will be turned on, which it is hoped will to some extent correct this trouble.

I have come to regard an elevator indicator with a feeling of wonder. Some years ago, when the "planchette" first came out, I remember that it acquired quite a reputation as a particularly erratic piece of mechanism, but for real mystery and innate cussedness, on general principles, commend me to the indicator. Why, I have known an indicator after registering a nice water bill, to deliberately and without provocation commence taking it all off again, by going backward. This crab-like maneuver the agent readily explained by saying the "ratchet had turned over," but even he was unable to show us how to make the bills after these peculiar gyrations. I also find that it is quite a favorite amusement for indicators to stop entirely, like a balky horse, after which no amount of persuasion will bring them to a realizing sense of their duty.

Even at the best, these indicators are very apt to get out of order, necessitating greater watchfulness in supplying elevators than for any other purpose for which water is furnished.

Accidents in connection with the use of elevators are common throughout the country, and in Kansas City had, until within a short time, become of altogether too frequent occurrence. The great cause of this I believe to be due to the fact that the parties who usually operate elevators are the very ones who know least about them; the corrosion of pistons, crystallization and oxidation of cables, and many other disorders common to elevators, being matters they do not comprehend. The frequency and fatality of these accidents in Kansas City finally led the city authorities to appoint an Elevator Inspector, who is under heavy bond, and whose duty is to examine every elevator at least once a month, and to grant license to run only such as he deems in safe condition. Thus far since the establishment of this office we have had no serious accidents, which leads me to the belief that in most cases a monthly examination will discover in time the causes of many terrible casualties; also that it is not safe to operate elevators unless so inspected by some competent person.

The hatchways of elevators in large buildings are points greatly feared by firemen. They well know that when a fire once reaches this shaft, it takes but a moment for it to be carried from floor to floor, until the building is soon past saving. Although this great danger is well known, it is the exception rather than the rule to provide elevators with fire-proof hatches. A properly constructed elevator should, it seems to me, be provided with hatches, or better still, built within brick fire-proof walls, with openings to be kept closed when not in use. In this way costly buildings, valuable merchandise, and many lives would be saved from fire every year.

Although considerable has been said on the subject of elevators, I am aware that the ground has not been covered, and that difficulties have been pointed out more than remedies suggested. There is much yet to be brought out by the engineers, to whom the subject more properly belongs.

In the mean time, although elevators claim many of the objectionable features in the business of water supply, most of them are not of a nature that should condemn their use; on the contrary, I hope that with the joining of our experience there will be an improvement in the methods of their supply. Inasmuch as they must be furnished with water, all that can be done is to adopt such rules and fix such rates as will compensate in some degree for their objectionable qualities.

My remarks on this subject I trust will be more to the have been point than they upon the questions already discussed. Certainly my ideas are more decided, so far at least as supplying water motors is concerned.

In many respects I believe water motors furnish as nearly perfect power as it is possible to attain. A motor, for instance, properly connected and supplied by the even pressure from a reservoir is probably the most reliable and steady power known, not excepting the most improved and costly steam engines. The convenience and little attendance necessary in operating make them especially desirable for many purposes. Where only small power is required, or even where considerable power for only occasional use is desired, they are particularly well adapted, and can be driven at small expense. Even for greater power they possess advantages over steam engines which, to a considerable extent, compensate for the large water rates that ought to be paid for their supply. These advantages are in the first cost of a motor, as compared with a steam engine, the saving in attendance and fuel, the convenience and cleanliness, and in some cases a saving in insurance by reason of their being no fire risks attendant upon its use. At just what point steam becomes preferable, however, is a question depending considerably upon water rates, but to some extent on other circumstances, leaving it largely a question of judgment. As with elevators, there are difficulties involved in their supply that unless carefully guarded make water motors anything but a desirable source of revenue. How often is the argument advanced: "Why, I only use water for a quarter of an inch jet!" Showing how little people who use motors or elevators or fountains realize the quantity of water they consume. This class of consumers may be placed on one footing, to wit, a class who, in spite of the fact that they are supplied with water for much less than any other, feel that they are imposed upon, and cannot be made to think otherwise.

Though not as large as for elevator supply, water motors require liberal openings in the mains, and frequently the fault of having too small supply pipes is sought to be remedied by openings in the water mains much larger than needful. A table prepared by an engineer who had given the matter study, or by some motor manufacturer, showing the size of taps, or openings, for the proper supply of motors, with the various jets, under different pressures, would be of general use to water-works people. In order to use water to the best advantage, the full pressure in the main, so far as practicable, should be had at the jet, but in order to accomplish this it is not necessary to use as large taps as are ordinarily demanded, but to provide supply pipes of sufficient capacity to deliver the water to the point of discharge with the least possible friction. Lately this theory has been put in practice to some extent by us, and the result has shown that in this manner we are able to supply motors through smaller taps than beforehand with as satisfactory results.

It is a general practice throughout the country to make annual or monthly rates for water motors, and from my observation I believe I can safely venture the assertion that in three-quarters of the cases the rates charged will not equal 50 per cent. of the lowest meter rates in force in these places. Although the Kansas City Water-Works has not perhaps been generally accorded the reputation of being the most liberal "monopoly" in the country, still I have had occasion at times to make some such claims as an inducement to its generous support. But with all its liberality, I am free to say that we cannot begin to meet the rates for motors that parties claim to have paid almost everywhere else.

The St. Louis Water-Works, where the rates are substantially the same as in Kansas City, have been quoted as having the following motor rates, but whether correct or not my inquiries have failed to determine:

"On the supposition that motors are to be used ten hours per day for 300 days per year, motors are assessed for--

___________________________________

1/4 inch jets | $120 per annum. |

3/8 " | 198 " " |

1/2 " | 300 " " |

----------------+-----------------+

These rates based upon a charge of 50 cents per 1,000 gallons."

From Col. Flad's Report as Engineer of Public Works, May 1, 1876, p.70, it is found that with 42 pounds pressure a ½ inch orifice will discharge 2,160 gallons per hour, 21,600 gallons in 10 hours, or 6,480,000 gallons in 300 days, which at 20 cents per 1,000 gallons would amount to $1,296, for which they assess the rate $300. From all of which I would conclude that there must be a lack of harmony somewhere between the engineering and office departments.

I have made some estimates myself for water motors, basing rates upon the number of hours it was claimed the motors would be in use, and afterward supplied the same motors by meter measurement; in every case found that at least twice as much water was used as had been estimated. Although estimates were carefully made upon what was believed to be a reliable basis, these repeated similar results have led me to the conclusion that the only way to supply motors is to make it an object to the users of them to be economical. In other words, I believe the way to supply water motors is upon an estimate that they will run 24 hours per day and 365 days per year, or, more properly still, supply them only by meter measurement. At all events this is henceforth my policy; or, in other words, "on this rock I stand," believing it the only equitable way out of this difficulty.

That class of motors or water engines operated by water pressure in close cylinders upon pistons as with steam in a steam engine, I believe could be easily supplied by measurement of water without a meter. This could be accomplished by the use of "revolution counters" or indicators, as the amount of water required per revolution could be readily determined, and when once computed the cylinders would measure out the water as accurately as a meter. The only objection to this plan is the expense of counters, which is considerable; and as to indicators, it may have been observed that I have little faith in their reliability. With cheap revolution this class of motors would be free from many of the objections raised in regard to motors generally.

The practical conclusion that I would draw from a consideration of this subject is that the question of whether the supply of hydraulic elevators and motors is desirable in its effects upon the water supply is one that hinges so delicately upon their being carefully governed, connected, and restricted, that while on the one hand they may be made the source of large profit, and at the same time a public benefit, on the other hand, unless all the details of their supply be carefully guarded by the wisest rules and greatest watchfulness, their capacities for waste are so great and the rates charged necessarily so low, that they may become the greatest source of loss with which we have to contend. I therefore trust that this discussion will be continued until an interest is felt that will result in our all receiving much useful information upon two most important factors of our business.

As this paper has been long for the information contained, I will close with the earnest wish that it may at least be of service in bringing these important but often neglected subjects to the attention of the thinking and intelligent body of men, of whom many have had much longer and more general experience in relation to these matters, and whose views when expressed will consequently be of more interest and have greater weight. Thus as a result may we all derive the benefit of whatever useful information there is to be gained by this annual interchange of experiences in the all-important business of public water supply.

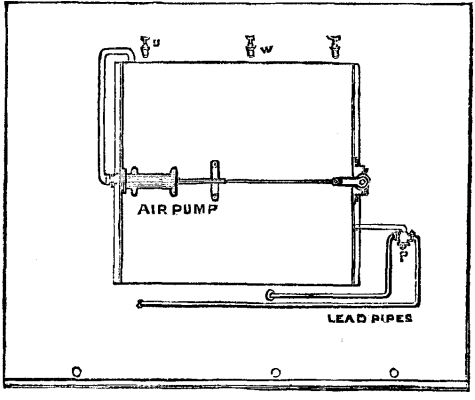

We now describe the new waterworks lately erected for supplying the town of Cougleton, Cheshire. The population is about 12,000, and the place is a seat of the silk manufacture. After various expensive plans had been suggested, in the year 1879 a complete scheme for the supply of the town with water was devised by the then borough surveyor, Mr. Wm. Blackshaw, now borough surveyor of Stafford. These we now illustrate above by a general drawing, and a separate drawing of the tower. With respect to the mechanical arrangements, the Corporation called in Mr. W. H. Thornbery, of Birmingham, consulting engineer, to decide on the best design of those submitted, and this, with modifications made by him, was carried out under his inspection. The water, for the supply by pumping, is obtained from springs situated at the foot of Crossledge Hill, about a mile from the town. It does not at present require filtering, but space enough has been allowed for the construction of duplicate filtering beds without in any way interfering with the present appliances. These filter beds are shown in our perspective illustration, but they are not yet built or required.

WATER SUPPLY OF SMALL TOWNS--CONGLETON WATERWORKS.

The waterworks are situated very near the springs, from which they are only separated by a road, under which the collecting pipes run. There are two circular collecting tanks of brickwork, two pumping wells, engine-house, boiler-house, chimney stack, and engine-driver's dwelling-house, all inclosed by a wall. On the top of Crossledge Hill is erected a circular brick water tower 35 ft. high to the underside of the service tank, which is of cast iron 30 ft. internal diameter, supported on rolled girders. The tank is capable of containing 50,000 gallons of water, and it is provided with the usual rising and service mains, overflow and washout pipes. There is an arrangement for pumping direct into the mains in case the tank should require cleaning or repairing.

The pumping machinery is in duplicate, and each set consists of a horizontal condensing engine, with cylinder 18 in. diameter, stroke 30 in., fitted with Meyer's expansion gear, governor, fly-wheel 12 ft. diameter, weighing 4 tons, jet condenser with a single acting vertical air pump, situated below the engine room floor, and between the end of the cylinder and the main pump. Each main pump is 10 in. diameter, horizontal, double-acting, worked by a prolongation backward of the piston-rod. The valves and seats are of gun metal, 8½ in. diameter. The capacity is 350 gallons per minute, raised 206 ft. The air vessel is 21 in. internal diameter and 6 ft. high, and is fitted with a hand pump for renewing the supply of air if necessary. The rising main from the air vessel to the service tank is 9 in. diameter, and 307 yards long, laid up the steep slope of the hill on which the water tower is built. The boilers, two in number, are of the ordinary Cornish single-flued type, 5 ft. diameter by 18 ft. long, with flue 2 ft. 9 in. diameter, with three Galloway tubes. They were made by Messrs. Hill & Co., of Manchester. The engines and pumps were made by Mr. Albert Scragg, of Congleton, and the brick, stone, and builder's work was executed by Mr. Thomas Kirk. The waterworks were opened in the autumn of 1881, and since then have constantly afforded an abundant supply of water. There is also an independent gravitation system, also arranged by Mr. Blackshaw, for supplying an outlying part of the town. The cost of the works was exceedingly moderate, being not more than £12,000, including the water mains for distribution.

The available water of many villages and small towns is that of the chalk beds, but it is invariably very hard, and should be softened. We have received so many inquiries respecting a simple means of carrying out Clarke's water-softening process, that the following description of a set of apparatus devised for this purpose by Messrs. Law and Chatterton, MM.I.C.E., may interest many besides those who contemplate the construction of small waterworks supplied by the chalk springs.

The apparatus, as made in various sizes by Messrs. Bowes, Scott, and Read, of Broadway-chambers, Westminster, we illustrate by the accompanying engravings.

Softening hard water.--The disadvantages attending the use of hard water either for drinking purposes, steam generation, lavatory purposes, and for many manufacturing purposes, are well known, but as there are several methods of softening waters which are hard in different degrees by different substances, we may be pardoned if we here reproduce, for the convenience of some of our readers, a few passages from the sixth report of the River Pollution Commission, 1874, pages 21 and 201-16, which give some very valuable information on the relative merits of hard and soft waters in domestic and trade uses. "Some of the mineral substances which occur in solution in potable waters communicate to the latter the quality of hardness. Hard water decomposes soap, and cannot be efficiently used for washing. The chief hardening ingredients are salts of lime and magnesia. In the decomposition of soap these salts form curdy and insoluble compounds containing the fatty acids of the soap and the lime and magnesia of the salts. So long as this decomposition goes on the soap is useless as a detergent, and it is only after all the lime and magnesia salts have been decomposed at the expense of the soap, that the latter begins to exert a useful effect. As soon as this is the case, however, the slightest further addition of soap produces a lather when the water is agitated, but this lather is again destroyed by the addition of a further quantity of hard water. Thus the addition of hard water to a solution of soap, or the converse of this operation, causes the production of the insoluble curdy matter before mentioned. These facts render intelligible the process of washing the skin with soap and hard water. The skin is first wetted with the water and then soap is applied; the latter decomposes the hardening salts contained in the small quantity of water with which the skin is covered, and there is then formed a strong solution of soap which penetrates into the pores, and now the lather and impurities which it has imbibed require to be removed from the skin by wiping the lather off with a towel or by rinsing it away with water. In the former case the pores of the skin are left filled with soap solution; in the latter they become clogged with the greasy, curdy matter which results from the action of the hard water upon the soap solution which had previously gained possession of the pores of the cuticle. As the latter process of removing the lather is the one universally adopted, the operation of washing with soap and hard water is analogous to that used by the dyer and calico printer for fixing pigments in calico, woolen, or silk tissues. The pores of the skin are filled with insoluble greasy and curdy salts of the fatty acids contained in the soap, and it is only because the insoluble pigment produced is white, or nearly so, that so repulsive an operation is tolerated. To those, however, who have been accustomed to wash in soft water, the abnormal condition of skin thus induced is for a long time extremely unpleasant.