The Boy Mechanic

Vol. 1

700 Things for Boys to Do

800 Illustrations Showing How

[Transcriber's note: Image sizes are limited to the browser window size. To expand an image, right click on the image and select "view image" or "open image in new tab". Then click on the new image to see it full size. You could also just use you favorite image viewer directly.

Many projects are of contemporary interest—magic, kites and boomerangs for example. Try a "Querl" for starters.

There are many projects of purely historical interest, such as chemical photography, phonographs, and devices for coal furnaces.

Another class of projects illustrate the caviler attitude toward environment and health in 1913. These projects involve items such as asbestos, gunpowder, acetylene, hydrogen, lead, mercury, sulfuric acid, nitric acid, cadmium, potassium sulfate, potassium cyanide, potassium ferrocyanide, copper sulfate, and hydrochloric acid. Many references to these have been highlighted in red.

Projects requiring extra skill and care that involve high voltage, melting metals, or other hazards, have the title highlighted.

Please view these as snapshots of culture and attitude, not as suggestions for contemporary activity.

Be careful and have fun, or simply read and enjoy a trip into yesterday.]

The Boy Mechanic

Vol. 1

700 Things for Boys to Do

800 Illustrations Showing How

How to Make a Glider

(See page 171)

How To Construct

Wireless Outfits, Boats, Camp Equipment,

Aerial Gliders, Kites,

Self-propelled Vehicles Engines, Motors,

Electrical Apparatus, Cameras

And

Hundreds Of Other Things Which Delight Every Boy

With 800 Illustrations

Copyrighted, 1913, By H. H. Windsor

Chicago

Popular Mechanics Co.

Publishers

Engine Details

The accompanying sketch illustrates a two-cylinder single-acting, poppet valve steam engine of home construction.

The entire engine, excepting the flywheel, shaft, valve cams, pistons and bracing rods connecting the upper and lower plates of the frame proper, is of brass, the other parts named being of cast iron and bar steel.

The cylinders, G, are of seamless brass tubing, 1-1/2 in. outside diameter; the pistons, H, are ordinary 1-1/2 in. pipe caps turned to a plug fit, and ground into the cylinders with oil and emery. This operation also finishes the inside of the cylinders.

The upright rods binding the top and bottom plates are of steel rod about 1/8-in. in diameter, threaded into the top plate and passing through holes in the bottom plate with hexagonal brass nuts beneath.

The valves, C, and their seats, B, bored with a countersink bit, are plainly shown. The valves were made by threading a copper washer, 3/8 in. in diameter, and screwing it on the end of the valve rod, then wiping on roughly a tapered mass of solder and grinding it into the seats B with emery and oil.

The valve rods operate in guides, D, made of 1/4-in. brass tubing, which passes through the top plate and into the heavy brass bar containing the valve seats and steam passages at the top, into which they are plug-fitted and soldered.

The location and arrangement of the valve seats and steam passages are shown in the sketch, the flat bar containing them being soldered to the top plate.

The steam chest, A, over the valve mechanism is constructed of 1-in. square brass tubing, one side being sawed out and the open ends fitted with pieces of 1/16 in. sheet brass and soldered in. The steam inlet is a gasoline pipe connection such as used on automobiles.

The valve-operating cams, F, are made of the metal ends of an old typewriter platen, one being finished to shape and then firmly fastened face to face to the other, and used as a pattern in filing the other to shape. Attachment to the shaft, N, is by means of setscrews which pass through the sleeves.

{2}The main bearings, M, on the supports, O, and the crank-end bearings of the connecting rods, K, are split and held in position by machine screws with provision for taking them up when worn.

The exhausting of spent steam is accomplished by means of slots, I, sawed into the fronts of the cylinders at about 1/8 in. above the lowest position of the piston's top at the end of the stroke, at which position of the piston the valve rod drops into the cutout portion of the cam and allows the valve to seat.

All the work on this engine, save turning the pistons, which was done in a machine shop for a small sum, and making the flywheel, this being taken from an old dismantled model, was accomplished with a hacksaw, bench drill, carborundum wheel, files, taps and dies. The base, Q, is made of a heavy piece of brass.

The action is smooth and the speed high. Steam is supplied by a sheet brass boiler of about 3 pt. capacity, heated with a Bunsen burner.

Contributed by Harry F. Lowe, Washington, D. C.

Wax Hand on Board and Electrical Connections

The magic hand made of wax is given to the audience for examination, also a board which is suspended by four pieces of common picture-frame wire. The hand is placed upon the board and answers, by rapping, any question asked by members of the audience. The hand and the board may be examined at any time and yet the rapping can be continued, though surrounded by the audience.

The Magic Wand, London, gives the secret of this spirit hand as follows: The hand is prepared by concealing in the wrist a few soft iron plates, the wrist being afterwards bound with black velvet as shown in Fig. 1. The board is hollow, the top being made of thin veneer (Fig. 2). A small magnet, A, is connected to a small flat pocket lamp battery, B. The board is suspended by four lengths of picture-frame wire one of which, E, is connected to the battery and another, D, to the magnet. The other wires, F and G, are only holding wires. All the wires are fastened to a small ornamental switch, H, which is fitted with a connecting plug at the top. The plug can be taken out or put in as desired.

The top of the board must be made to open or slide off so that when the battery is exhausted a new one can be installed. Everything must be firmly fixed to the board and the hollow space filled in with wax, which will make the board sound solid when tapped.

In presenting the trick, the performer gives the hand and board with wires and switch for examination, keeping the plug concealed in his right hand. When receiving the board back, the plug is secretly pushed into the switch, which is held in the right hand. The hand is then placed on the board over the magnet. When the performer wishes the hand to move he pushes the plug in, which turns on the current and causes the magnet to attract the iron in the wrist, and will, therefore, make the hand rap. The switch can be made similar to an ordinary push button so the rapping may be easily controlled without detection by the audience.

Fig.1, 2, 3—Forming the skis

During the winter months everyone is thinking of skating, coasting or ski running and jumping. Those too timid to run down a hill standing upright on skis must take their pleasure in coasting or skating.

The ordinary ski can be made into a coasting ski-toboggan by joining two pairs together with bars without injury to their use for running and jumping. The ordinary factory-made skis cost from $2.50 per pair up, but any boy can make an excellent pair for 50 cents.

In making a pair of skis, select two strips of Norway pine free from knots, 1 in. thick, 4 in. wide and 7 or 8 ft. long. Try to procure as fine and straight a grain as possible. The pieces are dressed thin at both ends leaving about 1 ft. in the center the full thickness of 1 in., and gradually thinning to a scant 1/2 in. at the ends. One end of each piece is tapered to a point beginning 12 in. from the end. A groove is cut on the under side, about 1/4 in. wide and 1/8 in. deep, and running almost the full length of the ski. This will make it track straight and tends to prevent side slipping. The shape of each piece for a ski, as it appears before bending, is shown in Fig. 1.

The pointed end of each piece is placed in boiling water for at least 1 hour, after which the pieces are ready for bending. The bend is made on an ordinary stepladder. The pointed ends are stuck under the back of one step and the other end securely tied to the ladder, as shown in Fig. 2. They should remain tied to the ladder 48 hours in a moderate temperature, after which they will hold their shape permanently.

The two straps, Fig. 3, are nailed an a little forward of the center of gravity so that when the foot is lifted, the front of the ski will be raised. Tack on a piece of sheepskin or deer hide where the foot rests, Fig. 4.

{4}

Fig. 4—The Toe Straps

The best finish for skis is boiled linseed oil. After two or three applications the under side will take a polish like glass from the contact with the snow.

Fig. 5—Ski-Toboggan

The ski-toboggan is made by placing two pairs of skis together side by side and fastening them with two bars across the top. The bars are held with V-shaped metal clips as shown in Fig. 5.

Contributed by Frank Scobie, Sleepy Eye, Minn.

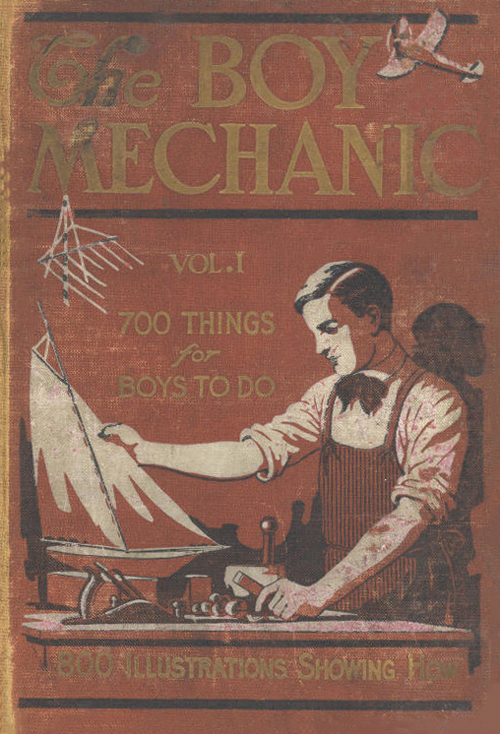

Fig. 1, Fig. 2—Inner Tube and Cover

Procure an inner tube of a bicycle tire, the closed-end kind, and fold it in four alternate sections, as shown in Fig. 1. Cut or tear a piece of cloth into strips about 1/2 in. wide, and knot them together. Fasten this long strip of cloth to the folded tube and weave it alternately in and out, having each run of the cloth about 4 in. apart, until it is bound as shown in Fig. 1. Make a case of canvas that will snugly fit the folded tube when inflated. The straps that hold the preserver to the body may be made of old suspender straps. They are sewed to the case at one end and fastened at the other with clasps such as used on overall straps. The tube can be easily inflated by blowing into the valve, at the same time holding the valve stem down with the teeth. The finished preserver is shown in Fig. 2.

Bending and Cutting the Wood

When the ice is too thin for skating and the snow is not right for skis, about the only thing to do is to stay in the house. A boomerang club will help to fill in between and also furnishes good exercise for the muscles of the arm. A boomerang can be made of a piece of well seasoned hickory plank. The plank is well steamed in a wash boiler or other large kettle and then bent to a nice curve, as shown in Fig. 1. It is held in this curve until dry, with two pieces nailed on the sides as shown.

After the piece is thoroughly dried out, remove the side pieces and cut it into sections with a saw, as shown in Fig. 2. The pieces are then dressed round. A piece of plank 12 in. wide and 2 ft. long will make six boomerangs. To throw a boomerang, grasp it and hold the same as a club, with the hollow side away from you. Practice first at some object about 25 ft. distant, and in a short time the thrower will be able to hit the mark over 100 ft. away. Any worker in wood can turn out a great number of boomerangs cheaply.

Contributed by J. E. Noble, Toronto, Ontario.

Laying the Snow Bricks

Playing in the snow can be raised to a fine art if boys and girls will build their creations with some attempt at architectural skill and not content themselves with mere rough work. Working in snow and ice opens a wide field for an expression of taste and invention, but the construction of houses and forts out of this plastic material provides the greatest amount of pleasure to the normally healthy boy or girl.

The snow house of the Eskimo is probably the unhealthiest of buildings made by any savage to live in, but it makes an excellent playhouse in winter, and represents at the same time a most ingenious employment of the arch system in building. The Eskimos build their snow houses without the aid of any scaffolding or interior false work, and while there is a keystone at the top of the dome, it is not essential to the support of the walls. These are self-supporting from the time the first snow blocks are put down until the last course is laid.

The snow house is of the beehive shape and the ground plan is that of a circle. The circle is first laid out on the ground and a space cleared for it. Then a row of snow blocks is laid on the ground and another course of similar blocks placed on top. The snow blocks are not exactly square in shape, but about 12 in. long, 6 in. high and 4 or 5 in. thick. Larger or smaller blocks can be used, according to size of the house and thickness of the walls.

First, the snow blocks must be packed and pressed firmly into position out of moist snow that will pack. A very light, dry snow will not pack easily, and it may be necessary to use a little water. If the snow is of the right consistency, there will be no trouble in packing and working with it. As most of the blocks are to be of the same size throughout, it will pay to make a mold for them by forming a box of old boards nailed together, minus the top, and with a movable bottom, or rather no bottom at all. Place the four sided box on a flat board and ram snow in it, forcing it down closely. Then by lifting the box up and tapping the box from above, the block will drop out. In this way blocks of uniform size are formed, which makes the building simpler and easier.

While one boy makes the blocks another can shave them off at the edges and two others can build the house, one inside of the circle and the other outside. The Eskimos build their snow houses in this way, and the man inside stays there until he is completely walled in. Then the door and a window are cut through the wall.

Each layer of snow blocks must have a slight slant at the top toward the center so that the walls will constantly curve inward. This slant at the top is obtained better by slicing off the lower surfaces of each block before putting it in its course. The top will then have a uniform inward slant.

{6}The first course of the snow house should be thicker than the others, and the thickness of the walls gradually decreases toward the top. A wall, however, made of 6-in. blocks throughout will hold up a snow house perfectly, if its top is no more than 6 or 7 ft. above the ground. If a higher house is needed the walls should be thicker at the base and well up toward the middle.

The builder has no mortar for binding the blocks together, and therefore he must make his joints smooth and even and force in loose snow to fill up the crevices. A little experience will enable one to do this work well, and the construction of the house will proceed rapidly. The Eskimos build additions to their houses by adding various dome-shaped structures to one side, and the young architect can imitate them. Such dome-shaped structures are shown in one of the illustrations.

Three-Room Snow House

A fact not well understood and appreciated is that the Eskimo beehive snow house represents true arch building. It requires no scaffolding in building and it exerts no outward thrust. In the ordinary keystone arch used by builders, a, temporary structure must be erected to hold the walls up until the keystone is fitted in position, and the base must be buttressed against an outward thrust. The Eskimo does not have to consider these points. There is no outward thrust, and the top keystone is not necessary to hold the structure up. It is doubtful whether such an arch could be built of brick or stone without scaffolding, but with the snow blocks it is a simple matter.

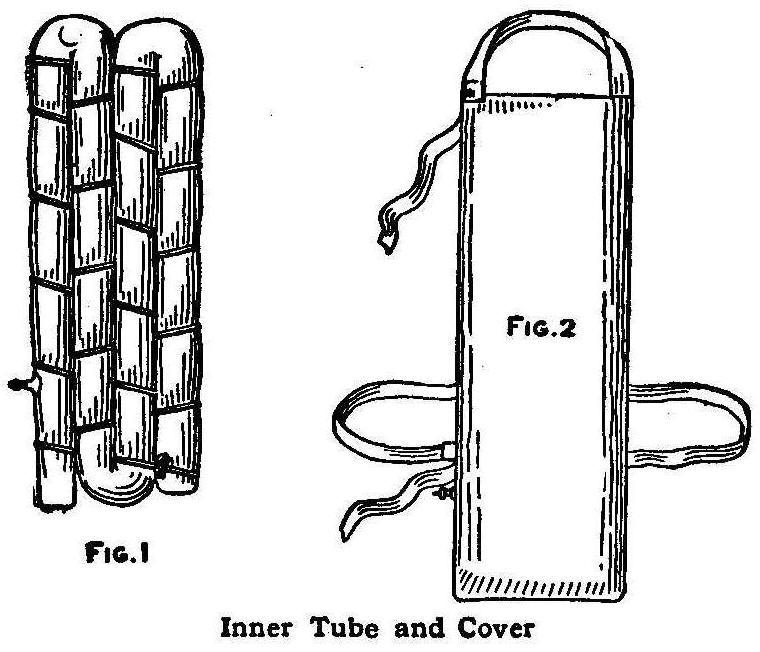

Fig. 1, Fig. 2, Fig. 3—The Lock Parts

The sketch shows the construction of a lock I have on a door which is quite a mystery to those who do not know how it operates. It also keeps them out. The parts of the lock on the inside of the door are shown in Fig. 1. These parts can be covered so that no one can see them.

The ordinary latch and catch A are attached to the door in the usual manner. The latch is lifted with a stick of wood B, which is about 1 ft. long and 1 in. wide, and pivoted about two-thirds of the way from the top as shown. The latch A is connected to the stick B with a strong cord run through a staple to secure a right-angle pull between the pieces. A nail, C, keeps the stick B from falling over to the left. The piece of wood, D, is 6 or 8 in. long and attached to a bolt that runs through the door, the opposite end being fastened to the combination dial. Two kinds of dials are shown in Fig. 2. The piece D is fastened on the bolt an inch or two from the surface of the door to permit placing a spiral spring of medium strength in between as shown in Fig. 3. The opposite end of the bolt may be screwed into the dial, which can be made of wood, or an old safe dial will do. A nail is driven through the outer end of the piece D and the end cut off so that it will pass over the piece B when the dial is turned. When the dial is pulled out slightly and then turned toward the right, the nail will catch on the piece B and open the latch.

Contributed by Geo. Goodbrod, Union, Ore.

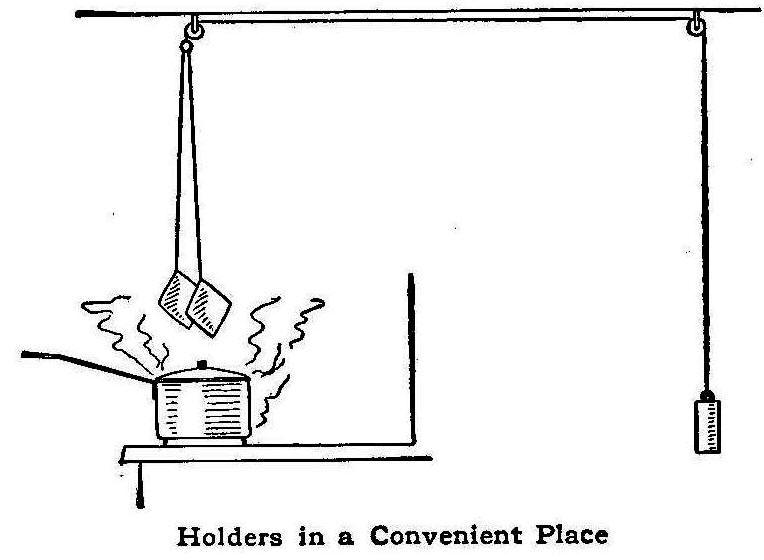

Holders in a Convenient Place

When taking hot dishes from the stove, it is very convenient to have holders handy for use. For this purpose I screwed two screw eyes into the ceiling, one in front of the stove directly above the place where the holder should hang, and the other back of the stove and out of the way. I next ran a strong cord through the two eyes. To one end of the cord I attached a weight made of a clean lump of coal. The cord is just long enough to let the weight hang a few inches above the floor and pass through both screw eyes. I fastened a small ring to the other end to keep the cord from slipping back by the pull of the weight. I then fastened two pieces of string to the ring at the end of the cord and attached an iron holder to the end of each string. The strings should be just long enough to keep the holders just over the stove where they are always ready for use, as the weight always draws them back to place.

Contributed by R. S. Merrill, Syracuse, New York.

Box with Hinges and Lock.

The things required to make this trick are a heavy packing box with cover, one pair of special hinges, one or two hasps for as many padlocks and a small buttonhook, says the Sphinx. The hinges must be the kind for attaching inside of the box. If ordinary butts are used, the cover of the box must be cut as much short as the thickness of the end board. The hinges should have pins that will slip easily through the parts.

Before entering the box the performer conceals the buttonhook on his person, and as soon as the cover is closed and locked, and the box placed in a cabinet or behind a screen, he pushes the pin or bolt of the hinge out far enough to engage the knob end with the buttonhook which is used to pull the pin from the hinge. Both hinges are treated in this manner and the cover pushed up, allowing the performer to get out and unlock the padlocks with a duplicate key. The bolts are replaced in the hinges, the box locked and the performer steps out in view.

When sifting flour in an ordinary sieve I hasten the process and avoid the disagreeable necessity of keeping my hands in the flour by taking the top from a small tin lard can and placing it on top of the flour with its sharp edges down. When the sieve is shaken, the can top will round up the flour and press it through quickly.

Contributed by L. Alberta Norrell, Augusta, Ga.

An automobile horn with the bulb and reed detached makes a good funnel. It must be thoroughly cleaned and dried after using as a funnel.

Manner of Forming the Plates

To protect the corners of blotting pads such as will be found on almost every writing desk, proceed as follows:

First, make a design of a size proportionate to the size of the pad and make a right-angled triangle, as shown in Fig. 1, on drawing paper. Leave a small margin all around the edge and then place some decorative form therein. Make allowance for flaps on two sides, as shown, which may later be turned back and folded under when the metal is worked. It should be noted that the corners of the design are to be clipped slightly. Also note the slight overrun at the top with the resulting V-shaped indentation.

To make a design similar to the one shown, draw one-half of it, then fold along the center line and rub the back of the paper with a knife handle or some other hard, smooth surface, and the other half of the design will be traced on the second side. With the metal shears, cut out four pieces of copper or brass of No. 22 gauge and with carbon paper trace the shape and decorative design on the metal. Then cut out the outline and file the edges smooth.

Cover the metal over with two coats of black asphaltum varnish, allowing each coat time to dry. Cover the back and all the face except the white background. Immerse in a solution of 3 parts water, 1 part nitric acid and 1 part sulphuric acid. When the metal has been etched to the desired depth, about 1-32 of an inch, remove it and clean off the asphaltum with turpentine. Use a stick with a rag tied on the end for this purpose so as to keep the solution off the hands and clothes. The four pieces should be worked at the same time, one for each corner.

It remains to bend the flaps. Place the piece in a vise, as shown in Fig. 2, and bend the flap sharply to a right angle. Next place a piece of metal of a thickness equal to that of the blotter pad at the bend and with the mallet bring the flap down parallel to the face of the corner piece, Fig. 3. If the measuring has been done properly, the flaps ought to meet snugly at the corner. If they do not, it may be necessary to bend them back and either remove some metal with the shears or to work the metal over farther. All the edges should be left smooth, a metal file and emery paper being used for this purpose.

If a touch of color is desired, it may be had by filling the etched parts with enamel tinted by the addition of oil colors, such as are used for enameling bathtubs. After this has dried, smooth it off with pumice stone and water. To keep the metal from tarnishing, cover it with banana-oil lacquer.

The following hints will be found useful when boring holes in cork. In boring through rubber corks, a little household ammonia applied to the bit enables one to make a much smoother hole and one that is nearly the same size at both openings. The common cork, if rolled under the shoe sole, can be punctured easily and a hole can be bored straighter. The boring is made easier by boiling the cork, and this operation insures a hole that will he the desired size and remain the size of the punch or bit used.

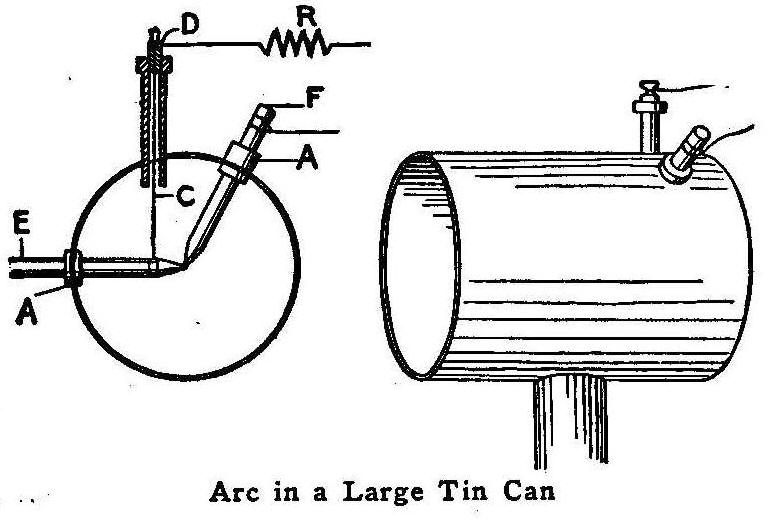

Arc in a Large Can

A practical and easily constructed self-lighting arc searchlight can be made in the following manner: Procure a large can, about 6 in. in diameter, and cut three holes in its side about 2 in. from the back end, and in the positions shown in the sketch. Two of the holes are cut large enough to hold a short section of a garden hose tightly, as shown at AA. A piece of porcelain tube, B, used for insulation, is fitted tightly in the third hole. The hose insulation A should hold the carbon F rigidly, while the carbon E should rest loosely in its insulation.

The inner end of the carbon E is supported by a piece of No. 25 German-silver wire, C, which is about 6 in. long. This wire runs through the porcelain tube to the binding post D. The binding post is fastened to a wood plug in the end of the tube. The tube B is adjusted so that the end of the carbon E is pressing against the carbon F. The electric wires are connected to the carbon F and the binding post D. A resistance, R, should be in the line.

The current, in passing through the lamp, heats the strip of German-silver wire, causing it to expand. This expansion lowers the end of the carbon E, separating the points of the two carbons and thus providing a space between them for the formation of an arc. When the current is turned off, the German-silver wire contracts and draws the two carbon ends together ready for lighting again. The feed can be adjusted by sliding the carbon F through its insulation.

A resistance for the arc may be made by running the current through a water rheostat or through 15 ft. of No. 25 gauge German-silver wire.

Contributed by R. H. Galbreath, Denver, Colo.

Take an ordinary collapsible drinking cup and place a cake of shaving soap in the bottom ring. This will provide a shaving mug always ready for the traveler and one that will occupy very little space in the grip.

Made from Barrel Staves

Secure four light barrel staves and sandpaper the outside smooth. Take two old shoes that are extra large and cut off the tops and heels so as to leave only the toe covering fastened to the sole. Purchase two long book straps, cut them in two in the middle and fasten the ends on the toe covering, as shown in Fig. 1. The straps are used to attach the snowshoe to the regular shoe. When buckling up the straps be sure to leave them loose enough for the foot to work freely, Fig. 2. Fasten the barrel staves in pairs, leaving a space of 4 in. between them as shown in Fig. 3, with thin strips of wood. Nail the old shoe soles to crosspieces placed one-third of the way from one end as shown.

Contributed by David Brown, Kansas City, Mo.

Bell and Battery in a Box

Watching a fish line set in a hole cut in the ice on a cold day is very disagreeable, and the usual method is to have some kind of a device to signal the fisherman when a fish is hooked. The "tip ups" and the "jumping jacks" serve their purpose nicely, but a more elaborate device is the electric signal. A complete electric outfit can be installed in a box and carried as conveniently as tackle.

An ordinary electric bell, A, Fig. 1, having a gong 2-1/2 in. in diameter, and a pocket battery, B are mounted on the bottom of the box. The electric connection to the bell is plainly shown. Two strips of brass, C, are mounted on the outside of the box. The brass strips are shaped in such a way as to form a circuit when the ends are pulled together. The box is opened and set on the ice near the fishing hole. The fish line is hung over a round stick placed across the hole and then tied to the inside strip of brass. When the fish is hooked the line will pull the brass points into contact and close the electric circuit.

A floor polisher is something that one does not use but two or three times a year. Manufactured polishers come in two sizes, one weighing 15 lb., which is the right weight for family use, and one weighing 25 lb.

A polisher can be made at home that will do the work just as well. Procure a wooden box such as cocoa tins or starch packages are shipped in and stretch several thicknesses of flannel or carpet over the bottom, allowing the edges to extend well up the sides, and tack smoothly. Make a handle of two stout strips of wood, 36 in. long, by joining their upper ends to a shorter crosspiece and nail it to the box. Place three paving bricks inside of the box, and the polisher will weigh about 16 lb., just the right weight for a woman to use. The polisher is used by rubbing with the grain of the wood.

Contributed by Katharine D. Morse, Syracuse, N. Y.

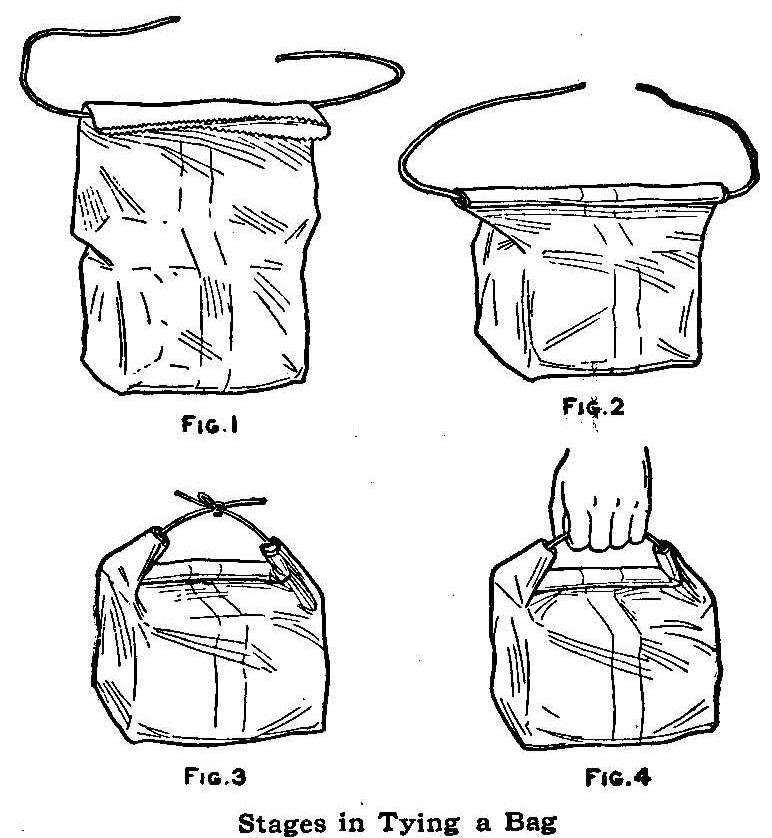

Stages in Tying a Bag

In tying the ordinary paper bag, the string can be placed in the paper in such a way that it will form a handle to carry the package, and also prevent any leakage of the contents. The bag must be long enough for the end to fold over as shown in Fig. 1. The folds are made over the string, as in Fig. 2. The string is then tied, Fig. 3, to form a handle, Fig. 4.

Contributed by James M. Kane, Doylestown, Pa.

Warping the Aeroplane Wings

On one of my model aeroplanes I placed an equilibrator to keep it balanced. The device was attached to a crosspiece fastened just below the propeller between the main frame uprights. A stick was made to swing on a bolt in the center of the crosspiece to which was attached a weight at the lower end and two lines connecting the ends of the planes at the upper end. These are shown in Fig. 1. When the aeroplane tips, as shown in Fig. 2, the weight draws the lines to warp the plane so it will right itself automatically.

Contributed by Louis J. Day, Floral Park, N. Y.

Small glass ornaments for Christmas tree decorations are very easily broken on the line shown in the sketch. These can be easily repaired by inserting in the neck a piece of match, toothpick or splinter of wood and tying the hanging string to it.

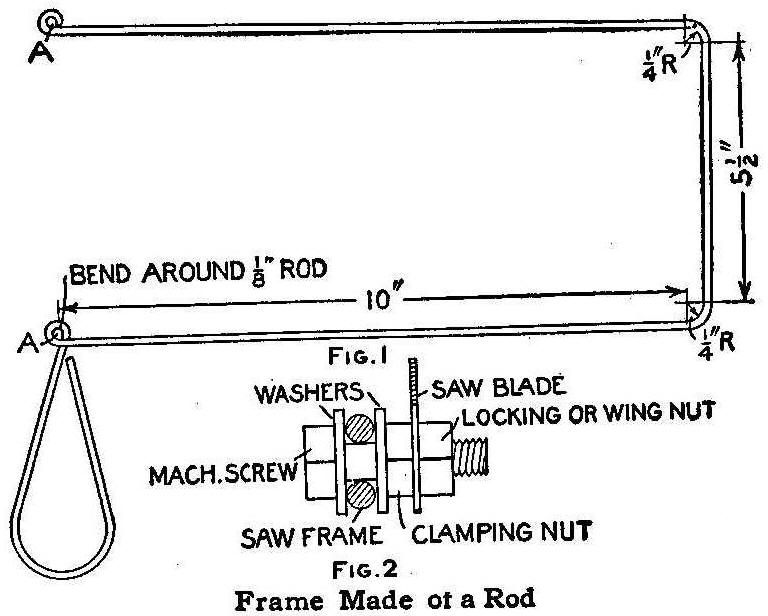

Frame Made of a Rod

A scroll saw, if once used, becomes indispensable in any home carpenter chest, yet it is safe to say that not one in ten contains it. A scroll saw is much more useful than a keyhole saw for sawing small and irregular holes, and many fancy knick-knacks, such as brackets, bookracks and shelves can be made with one.

A simple yet serviceable scroll saw frame can be made from a piece of cold-rolled steel rod, 3/32 or 1/4 in. in diameter, two 1/8-in. machine screws, four washers and four square nuts. The rod should be 36 or 38 in. long, bent as shown in Fig. 1. Place one washer on each screw and put the screws through the eyelets, AA, then place other washers on and fasten in place by screwing one nut on each screw, clamping the washers against the frame as tightly as possible. The saw, which can be purchased at a local hardware store, is fastened between the clamping nut and another nut as shown in Fig. 2.

If two wing nuts having the same number and size of threads are available, use them in place of the outside nuts. They are easier to turn when inserting a saw blade in a hole or when removing broken blades.

Contributed by W. A. Scranton, Detroit, Michigan.

Watch Fob

The fixtures for the watch fob shown—half size—may be made of either brass, copper, or silver. Silver is the most desirable but, of course, the most expensive. The buckle is to be purchased. The connection is to be of leather of a color to harmonize with that of the fixtures. The body of the fob may be of leather of suitable color or of silk. Of the leathers, green and browns are the most popular, though almost any color may be obtained.

Make full size drawings of the outline and design of the fixtures. With carbon paper trace these on the metal. Pierce the metal of the parts that are to be removed with a small hand drill to make a place for the leather or silk. With a small metal saw cut out these parts and smooth up the edges, rounding them slightly so they will not cut the leather or silk. Next cut out the outlines with the metal shears. File these edges, rounding and smoothing with emery paper. The best way of handling the decorative design is to etch it and, if copper or brass, treat it with color.

For etching, first cover the metal with black asphaltum varnish, on the back and all the parts that are not to be touched with the acid. In the design shown, the unshaded parts should not be etched and should, therefore, be covered the same as the back. Apply two coats, allowing each time to dry, after which immerse the metal in a solution prepared as follows: 3 parts water, 1 part nitric acid, 1 part sulphuric acid. Allow the metal to remain in this until the acid has eaten to a depth of 1/32 in., then remove it and clean in a turpentine bath, using a swab and an old stiff brush. The amount of time required to do the etching will depend upon the strength of the liquid, as well as the depth of etching desired.

For coloring silver, as well as brass and copper, cover the metal with a solution of the following: 1/2 pt. of water in which dissolve, after breaking up, five cents worth of sulphureted potassium. Put a teaspoonful of this into a tin with 2 qt. of water. Polish a piece of scrap metal and dip it in the solution. If it colors the metal red, it has the correct strength. Drying will cause this to change to purple. Rub off the highlights, leaving them the natural color of the metal and apply a coat of banana-oil lacquer.

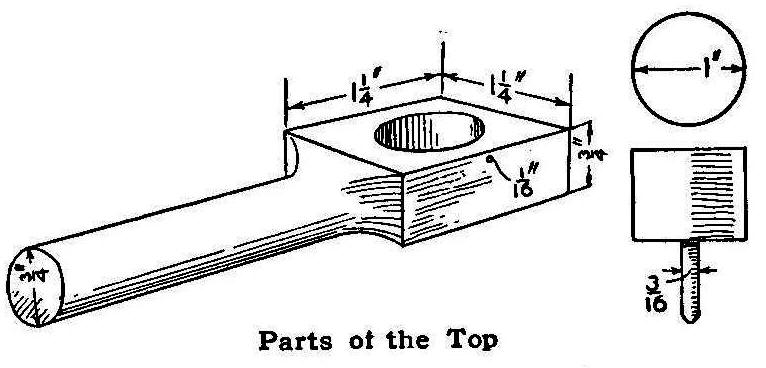

Parts of the Top

All parts of the top are of wood and they are simple to make. The handle is a piece of pine, 5-1/4 in. long, 1-1/4 in. wide and 3/4 in. thick. A handle, 3/4 in. in diameter, is formed on one end, allowing only 1-1/4 in. of the other end to remain rectangular in shape. Bore a 3/4-in. hole in this end for the top. A 1/16-in. hole is bored in the edge to enter the large hole as shown. The top can be cut from a broom handle or a round stick of hardwood.

To spin the top, take a piece of stout cord about 2 ft. long, pass one end through the 1/16-in. hole and wind it on the small part of the top in the usual way, starting at the bottom and winding upward. When the shank is covered, set the top in the 3/4-in. hole. Take hold of the handle with the left hand and the end of the cord with the right hand, give a good quick pull on the cord and the top will jump clear of the handle and spin vigorously.

Contributed by J.F. Tholl, Ypsilanti, Michigan.

Pockets for Thread

A detachable pocket for holding thread when sewing is shown herewith. The dimensions may be varied to admit any number or size of spools. Each pocket is made to take a certain size spool, the end of the thread being run through the cloth front for obtaining the length for threading a needle. This will keep the thread from becoming tangled and enable it always to be readily drawn out to the required length.

Contributed by Miss L. Alberta Norrell, Augusta, Ga.

Beat up the whites of three eggs carefully and use a piece of flannel to rub it well into the leather which will become clean and lustrous. For black leathers, some lampblack may be added and the mixture applied in the same way.

Baking Pan without Sides

When making cookies, tarts or similar pastry, the housewife often wishes for something by which to lift the baked articles from the pan. The baking tray or pan shown in the sketch not only protects the hands from burns but allows the baked articles easily to slip from its surface. The pan is made from a piece of sheet iron slightly larger than the baking space desired. Each end of the metal is cut so that a part may be turned up and into a roll to make handles for the pan.

A wire or small rod is placed between the handles as shown. This wire is fastened at each end and a loop made in the center. The pan can be removed from the oven by placing a stick through the loop and lifting it out without placing the hands inside the hot oven. The baking surface, having no sides, permits the baked articles to be slid off at each side with a knife or fork.

A. A. Houghton, Northville, Mich.

A very simple and effective device for holding a broom when it is not in use is shown in the sketch. It is made of heavy wire and fastened to the wall with two screw eyes, the eyes forming bearings for the wire. The small turn on the end of the straight part is to hold the hook out far enough from the wall to make it easy to place the broom in the hook. The weight of the broom keeps it in position.

Contributed by Irl Hicks, Centralia, Mo.

A string for drawing electric wires into bent fixtures can be easily inserted by rolling it into a small ball and blowing it through while holding one end.

Darkroom Lantern

Procure an ordinary 2-qt. glass fruit jar, break out the porcelain lining in the cover and cut a hole through the metal, just large enough to fit over the socket of an incandescent electric globe, then solder cover and socket together, says Studio Light. Line the inside of the jar with two thicknesses of good orange post office paper. The best lamp for the purpose is an 8-candlepower showcase lamp, the same as shown in the illustration. Screw the lamp into the socket and screw the cover onto the jar, and you have a safe light of excellent illuminating power.

When you desire to work by white light, two turns will remove the jar.

If developing papers are being worked, obtain a second jar and line with light orange paper, screw into the cover fastened to the lamp and you have a safe and pleasant light for loading and development. By attaching sufficient cord to the lamp, it can be moved to any part of the darkroom, and you have three lamps at a trifling cost.

Many housekeepers do not know that there is a simple way to prevent potatoes from burning and sticking to the bottom of the pot. An inverted pie pan placed in the bottom of the pot avoids scorching potatoes. The water and empty space beneath the pan saves the potatoes. This also makes the work of cleaning pots easier as no adhering parts of potatoes are left to be scoured out.

Folding Clothes Rack

A clothes-drying rack that has many good features can be made as shown in the illustration. When the rack is closed it will fit into a very small space and one or more wings can be used at a time as the occasion or space permits, and not tip over. The rack can be made of any hard wood and the material list is as follows:

1 Center post. 1-1/4 in. square by 62 in.

4 Braces. 1-1/4 in. square by 12 in.

16 Horizontal bars. 1 by 1-1/4 by 24 in.

4 Vertical pieces. 1/4 by 1 by 65 in.

Attach the four braces for the feet with finishing nails after applying a good coat of glue.

The horizontal bars are fastened to the vertical pieces with rivets using washers on both sides. The holes are bored a little large so as to make a slightly loose joint. The other ends of the bars are fastened to the center post with round head screws. They are fastened, as shown in the cross-section sketch, so it can be folded up.

Contributed by Herman Fosel, Janesville, Wis.

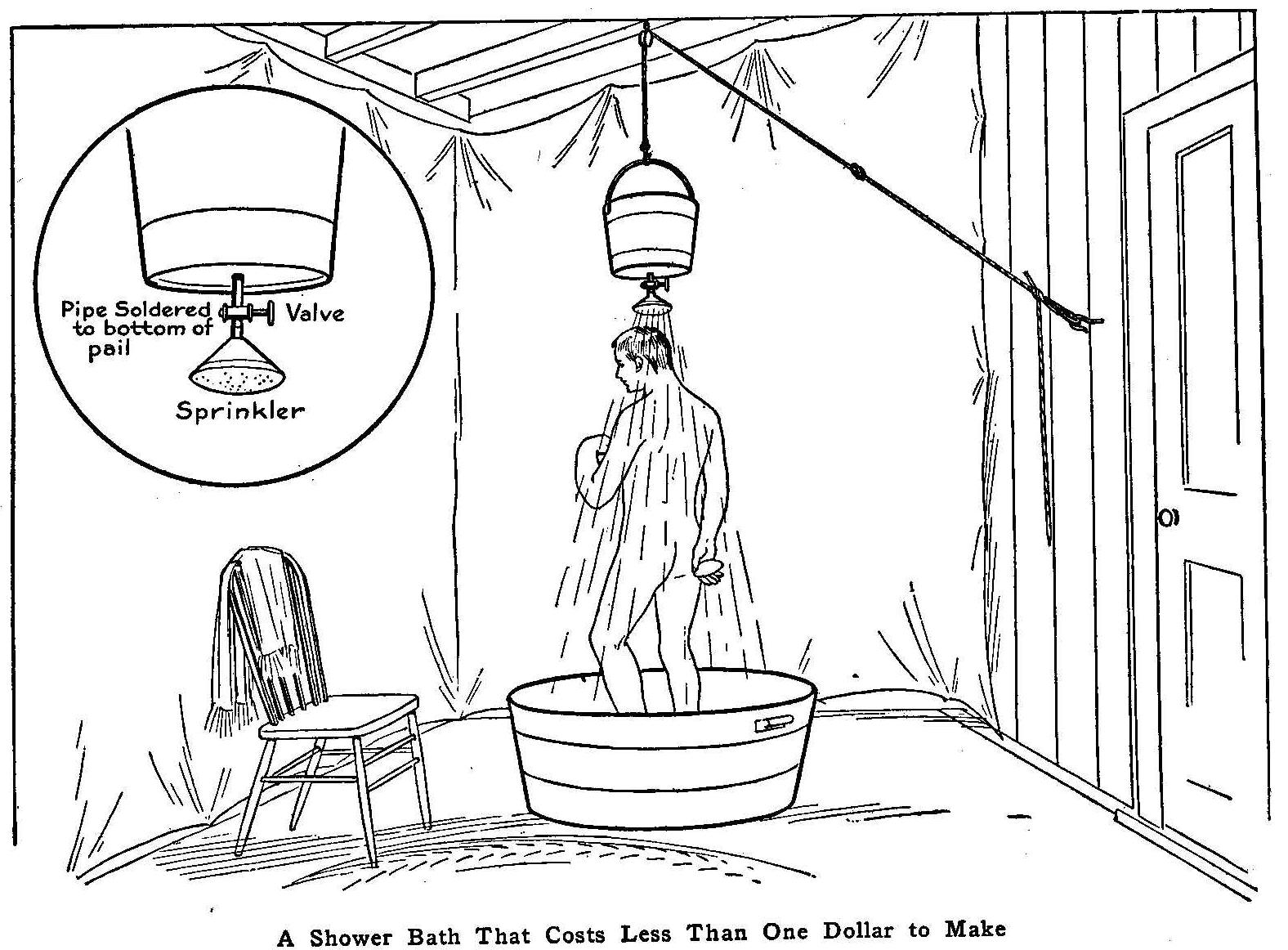

A Shower Bath That Costs Less Than One Dollar to Make

While in the country during vacation time, I missed my daily bath and devised a shower bath that gave complete satisfaction. The back porch was enclosed with sheeting for the room, and the apparatus consisted of a galvanized-iron pail with a short nipple soldered in the center of the bottom and fitted with a valve and sprinkler. The whole, after filling the pail with water, was raised above one's head with a rope run over a pulley fastened to the roof of the porch, and a tub was used on the floor to catch the water. A knot should be tied in the rope at the right place, to keep it from running out of the pulley while the pail is lowered to be filled with water, and a loop made in the end, which is placed over a screw hook turned into the wall. If the loop is tied at the proper place, the pail will be raised to the right height for the person taking the shower bath.

The water will run from 10 to 15 minutes. The addition of some hot water will make a splendid shower bath.

Contributed by Dr. C. H. Rosenthal, Cincinnati, O.

As I needed several small sprocket wheels and had none on hand, I made them quickly without other expense than the time required, from scrap material. Several old hubs with the proper size bore were secured. These were put on an arbor and turned to the size of the bottom of the teeth. Hole were drilled and tapped to correspond to the number of teeth required and old stud bolts turned into them. The wheels were again placed on the arbor and the studs turned to the required size. After rounding the ends of the studs, the sprockets were ready for use and gave perfect satisfaction.

Contributed by Charles Stem, Phillipsburg, New York.

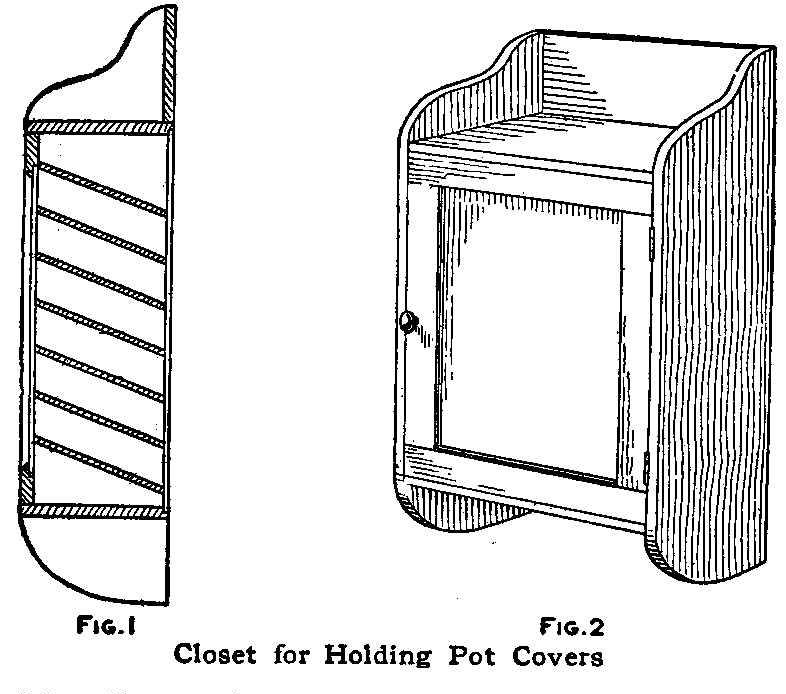

FIG. 1

FIG. 2

Closet for Holding Pot Covers

The sides of the cover closet are cut as shown in Fig. 1 and shelves are nailed between them at a slight angle. No dimensions are given as the space and the sizes of the covers are not always the same. The back is covered with thin boards placed vertically. The front can be covered with a curtain or a paneled door as shown.

Contributed by Gilbert A. Wehr, Baltimore, Md.

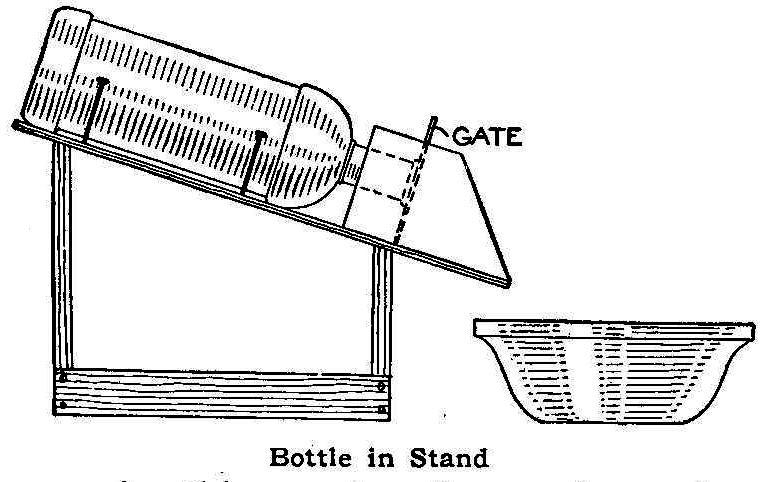

Bottle in Stand

Some cooks find it a very difficult matter to prepare salad dressing, principally mayonnaise dressing, as the constant stirring and pouring of oil and liquids are required in the operation. The simple homemade device shown in the accompanying sketch greatly assists in this work. It consists of a stand to hold a bottle, the mouth of which rests against a small gate directly in the rear of the attached tin trough. The weight of the bottle and the contents against the gate serves as a check or stopper. If the gate is raised slightly, it will permit a continuous flow of liquid of the desired amount.

In using developing papers, either for contact printing or enlargements, you are, by all rules of the game, entitled to a certain number of overexposed prints, says a correspondent of Camera Craft. But there is no reason why you should lose either the paper or the time and trouble expended in making these prints. By using the following method, you can turn these very dark prints into good ones.

First: these overexposed prints must be fully developed. Do not try to save them by rushing them out of the developer into the short-stop or fixing bath. The results will be poor, and, if you try to tone them afterward, the color will be an undesirable, sickly one. Develop them into strong prints, thoroughly fix, and wash until you are sure all hypo is removed. In my own practice, I carry out this part of the work thoroughly, then dry the prints and lay aside these dark ones until there is an accumulation of a dozen or more, doing this to avoid too frequent use of the very poisonous bleaching solution. The bleacher is made up as follows and should be plainly marked "Poison."

| Cyanide of potassium | 2 oz. |

| Iodide of potassium | 20 gr. |

| Water | 16 oz. |

Place the dry print, without previous wetting, in this solution. It will bleach slowly and evenly, but, when it starts to bleach, transfer it to a tray of water, where it will continue to bleach. When the desired reduction has taken place, stop the action at once by immersing the print in a 10-per-cent solution of borax. The prints may be allowed to remain in this last solution until they are finished. A good final washing completes the process. This washing must be thorough and a sponge or a tuft of cotton used to clean the surface of the print.

{17}With a little practice, this method of saving prints that are too dark becomes easy and certain. The prints are lightened and at the same time improved in tone, being made blue-black with a delicate and pleasing quality that will tempt you to purposely overexpose some of your prints in order to tone them by this method for certain effects. The process is particularly valuable to the worker in large sizes, as it provides a means of making quite a saving of paper that would otherwise be thrown away.

Stand Attached to Table

An ordinary ironing board is cut square on the large end and a slot cut 1-1/2 in. wide and 4 in. long to admit the angle support. The support is placed against the table and the board is pressed down against the outer notch which jams against the table, thus holding the board rigid and in such a position as to give free access for ironing dresses, etc.

Contributed by T. L. Gray, San Francisco, Cal.

Fig 3 Paper Corners for Blotter Pads

Procure four sheets of blotting paper, preferably the colored kind, as it will appear clean much longer than the white. The size of the pad depends on the size of the blotting paper.

Fold four pieces of ordinary wrapping paper, 5 by 15 in. in size, three times, to make it 5 by 5 in. Fold each one from corner to corner as shown in Fig. 1 and again as in Fig. 2. Paste the last fold together and the corner holders are complete. Put one on each corner of the blotting paper. They can be fastened with a small brass paper fastener put through the top of the holder. The blotting paper can be easily changed by removing the holders and fasteners. Corners complete are shown in Fig. 3.

Contributed by J. Wilson Aldred Toronto, Canada.

Wires Attached to a Lavatory

A very handy article is an attachment on wash basins or lavatories for holding the sleeves back while washing the hands. It is very annoying to have the sleeves continually slip down and become wet or soiled. The simple device shown herewith can be made with bent wires or hooks and attached in such a way that it can be dropped out of the way when not in use.

Contributed by L. J. Monahan, Oshkosh, Wisconsin.

A pencil eraser will remove the tarnish from nickel plate, and the ink eraser will remove the rust from drawing instruments.

Fig. 1 Fig. 2

The Pattern and the Finished Bookmark

Secure a piece of brass of No. 20 gauge, having a width of 2-1/4 in. and a length of 5 in. Make a design similar to that shown, the head of which is 2 in. wide, the shaft 1 in. wide below the head and the extreme length 4-1/2 in. Make one-half of the design, as shown in Fig. 1, freehand, then trace the other half in the usual way, after folding along the center line. Trace the design on the metal, using carbon paper, which gives the outline of the design Fig. 2.

Drilling and Sawing the Metal

With the metal shears, cut out the outline as indicated by the drawing. With files, smooth off any roughness and form the edge so that it shall be nicely rounded.

The parts of the design in heavy color may be treated in several ways. A very satisfactory treatment is obtained by etching, then coloring. Clean the metal thoroughly with pumice stone and water or with alcohol before the design is applied. Cover all the metal that is not to be lowered with a thick coating of asphaltum. Allow this to dry, then put on a second coat. After this has dried, thoroughly immerse the metal in a solution composed as follows: 3 parts water, 1 part sulphuric acid, 1 part nitric acid.

Allow the metal to remain in this solution until the exposed part has been eaten about 1/32 in. deep, then remove it and clean off the asphaltum, using turpentine. Do not put the hands in the solution, but use a swab on a stick.

For coloring olive green, use 2 parts water to 1 part permuriate of iron. Apply with a small brush.

The lines at A and B will need to be cut, using a small metal saw. Pierce a hole with a small drill, Fig. 3, large enough to receive the saw and cut along the lines as in Fig. 4. A piece of wood with a V-shaped notch which is fastened firmly to the bench forms the best place in which to do such sawing. The teeth of the saw should be so placed that the sawing will be done on the downward stroke. The metal must be held firmly, and the saw allowed time to make its cut, being held perpendicular to the work.

After the sawing, smooth the edges of the metal with a small file and emery paper. The metal clip may be bent outward to do this part of the work.

The cover from a cheesebox can be converted into a tea tray that is very dainty for the piazza, or for serving an invalid's breakfast.

{19}First sandpaper the wood until it is smooth, then stain it a mahogany color. The mahogany stain can be obtained ready prepared. After the stain has dried, attach brass handles, which can be obtained for a small sum at an upholsterer's shop. A round embroidered doily in the bottom adds to the appearance of the tray.

Contributed by Katharine D. Morse, Syracuse, New York.

Drill a 1/2-in. hole through a block of pine or other soft wood 2 in. thick. Tack over one end of the hole a piece of pasteboard in which seven coarse sewing-machine needles have been inserted. The needles should be close together and pushed through the pasteboard until the points show. The hole is then filled with melted babbitt metal. When this is cold, the block is split and the pasteboard removed. This tool makes neat pierced work and in making brass shades, it does the work rapidly.

Contributed by H. Carl Cramer, East Hartford, Conn.

Knife Attached to the Board

Cooks can slice, chop or mince vegetables and various other food rapidly by placing the little device, as shown, on a chopping board. Ii is an ordinary staple, driven in just far enough to allow a space for the end of an ordinary pointed kitchen knife to fit in it. The staple is driven in the edge of the chopping board. The knife can be raised and lowered with one hand, as the material is passed under the blade with the other. Great pressure can be applied and the knife will not slip.

Contributed by M. M. Burnett, Richmond, Cal.

Sew straps to the sides of mattresses and they can be handled much easier.

Round Stick In a Spool

The home workshop can be supplied with a carpenter's gauge without any expense' by the use of a large spool and a round stick of wood. The stick should be dressed to fit the hole in the spool snugly and a small brad driven through one end so that the point will protrude about 1/16 in.

The adjustment of the gauge is secured by driving the stick in the hole in the direction desired. A better way and one that will make the adjusting easy is to file the point end of a screw eye flat and use it as a set screw through a hole in the side of the spool.

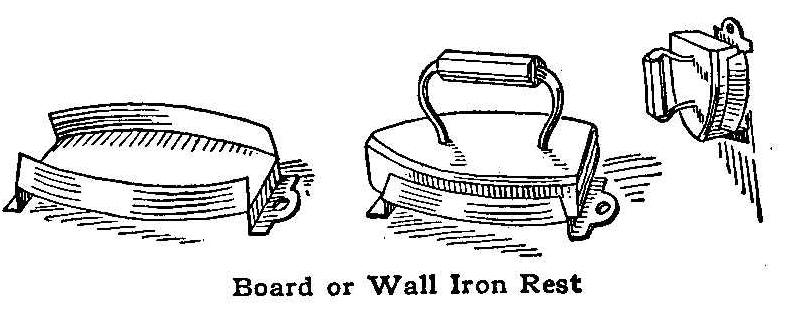

Board or Wall Iron Rest

The iron rest and wall hanger shown in the sketch is made of sheet iron. The upturned edges of the metal are bent to fit the sloping sides of the iron. The holder and iron can be moved at the same time.

Contributed by W. A. Jaquythe, Richmond, Cal.

When groceries are delivered, save the paper bags and use them for staring bread and cakes. Tie the neck of the bag with a string and it will keep the contents fresh and clean.

Contributed by Mrs. L. H. Atwell, Kissimmee, Florida.

If a little chalk is rubbed on a file before filing steel, it will keep the chips from sticking in the cuts on the file and scratching the work.

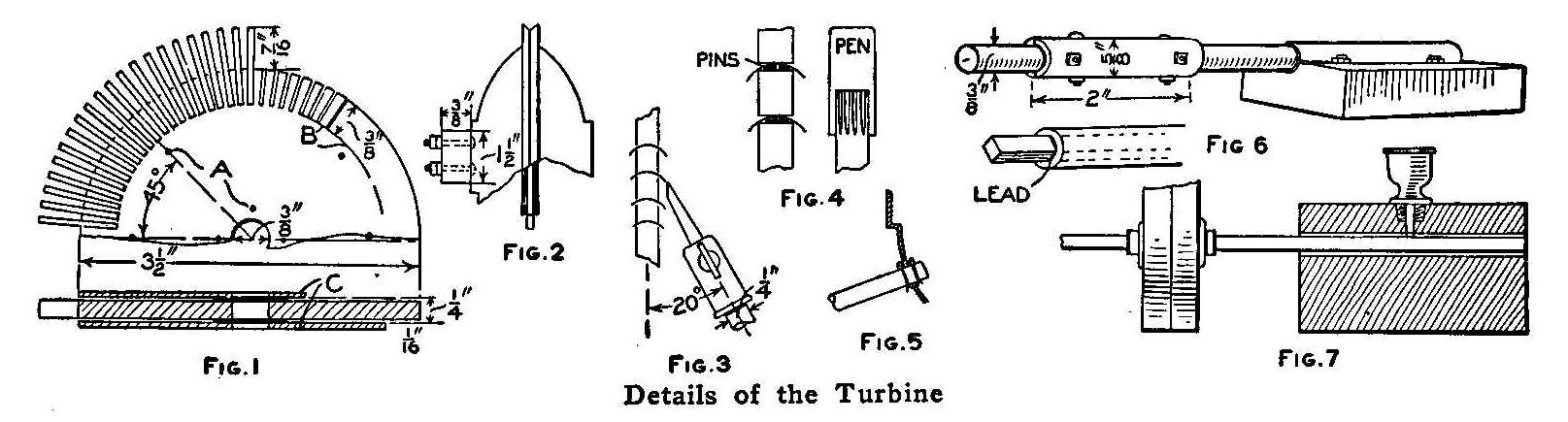

Details of the Turbine

Procure some brass, about 3/16 in. thick and 4 in. square; 53 steel pens, not over 1/4 in. in width at the shank; two enameled, or tin, saucers or pans, having a diameter on the inside part of about 4-1/2 in.; two stopcocks with 1/8 in. holes; one shaft; some pieces of brass, 1/4 in. thick, and several 1/8-in. machine screws.

Lay out two circles on the 3/16-in. brass, one having a diameter of 3-1/2 in. and the other with a diameter of 2-3/4 in. The outside circle is the size of the finished brass wheel, while the inside circle indicates the depth to which the slots are to be cut. Mark the point where a hole is to be drilled for the shaft, also locate the drill holes, as shown at A, Fig. 1. After the shaft hole and the holes A are drilled in the disk, it can be used as template for drilling the side plates C.

The rim of the disk is divided into 53 equal parts and radial lines drawn from rim to line B, indicating the depth of the slots. Slots are cut in the disk with a hacksaw on the radial lines. A small vise is convenient for holding the disk while cutting the slots. When cutting the disk out of the rough brass, sufficient margin should be left for filing to the true line. The slots should be left in their rough state as they have a better hold on the pens which are used for the blades. The pens are inserted in the slots and made quite secure by forcing ordinary pins on the inside of the pens and breaking them off at the rim, as shown in Fig. 4.

When the pens are all fastened two pieces of metal are provided, each about 1 in. in diameter and 1/32 in. thick, with a 3/8-in. hole in the center, for filling pieces which are first placed around the shaft hole between the disk and side plates C, Fig. 1. The side plates are then secured with some of the 1/8-in. machine screws, using two nuts on each screw. The nuts should be on the side opposite the inlet valves. The shaft hole may also be filed square, a square shaft used, and the ends filed round for the bearings.

The casing for the disk is made of two enameled-iron saucers, Fig. 2, bolted together with a thin piece of asbestos between them to make a tight joint. A 3/4-in. hole is cut near the edge of one of the saucers for the exhaust. If it is desired to carry the exhaust beyond the casing, a thin pipe can be inserted 1/4 in. into the hole. Holes are drilled through the pipe on both inside and outside of the casing, and pins inserted, as shown in Fig. 5. Solder is run around the outside pin to keep the steam from escaping. At the lowest point of the saucer or casing a 1/8-in. hole is drilled to run off the water. A wood plug will answer for a stopcock.

If metal dishes, shaped from thick material with a good coating of tin, can be procured, it will be much easier to construct the casing than if enameled ware is used. The holes can be easily drilled and the parts fitted together closely. All seams and surfaces around fittings can be soldered.

{21}Nozzles are made of two stopcocks having a 1/8-in. hole. These are connected to a 3/8-in. supply pipe. The nozzles should be set at an angle of 20 deg. with the face of the disk. The nozzle or stopcock will give better results if the discharge end is filed parallel to the face of the disk when at an angle of 20 deg. There should be a space of 1/16 in. between the nozzle and the blades to allow for sufficient play, Fig. 3.

The bearings are made of 1/4-in. brass and bolted to the casing, as shown, with 1/8-in. machine screws and nuts. Two nuts should be placed on each screw. The pulley is made by sliding a piece of steel pipe on the engine shaft and fastening it with machine screws and nuts as shown in Fig. 6. If the shaft is square, lead should be run into the segments.

The driven shaft should have a long bearing. The pulley on this shaft is made of pieces of wood nailed together, and its circumference cut out with a scroll saw. Flanges are screwed to the pulley and fastened to the shaft as shown in Fig. 7.

The bearings are made of oak blocks lined with heavy tin or sheet iron for the running surface. Motion is transmitted from the engine to the large pulley by a thin but very good leather belt.

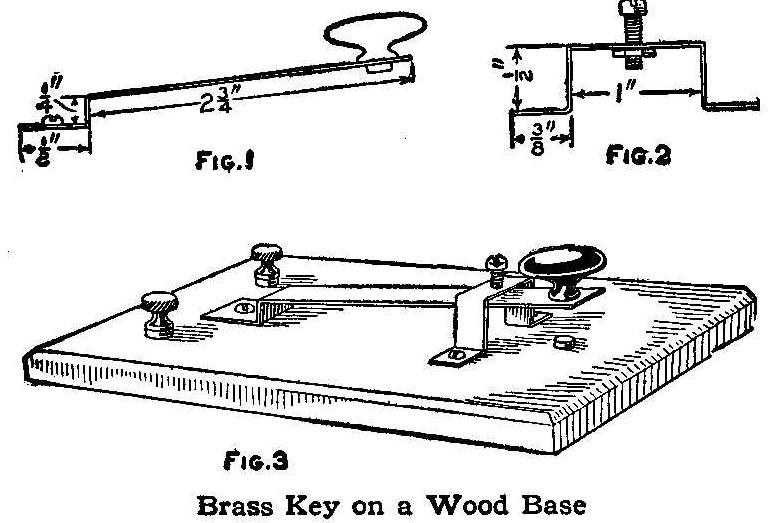

Brass Key on a Wood Base

A simple and easily constructed telegraph key may be made in the following manner: Procure a piece of sheet brass, about 1/32 in. thick, and cut out a strip 3-1/2 in. long by 3/4 in. wide. Bend as shown in Fig. 1 and drill a hole for the knob in one end and a hole for a screw in the other. Procure a small wood knob and fasten it in place with a small screw. Cut a strip of the same brass 2-3/4 in. long and 5/16 in. wide and bend as shown in Fig. 2. Drill two holes in the feet for screws to fasten it to the base, and one hole in the top part for a machine screw, and solder a small nut on the under side of the metal over the hole.

Mount both pieces on a base 4-1/4 by 2-3/4 by 1/4 in., as in Fig. 3, and where the screw of the knob strikes the base when pressed down, put in a screw or brass-headed tack for a contact. Fasten the parts down with small brass wood-screws and solder the connections beneath the base. Binding posts from an old battery cell are used on the end of the base. The screw on top of the arch is used to adjust the key for a long or short stroke.

Contributed by S. V. Cooke, Hamilton, Canada.

Camps and suburban homes located where ice is hard to get can be provided with a cooling arrangement herein described that will make a good substitute for the icebox. A barrel is sunk in the ground in a shady place, allowing plenty of space about the outside to fill in with gravel. A quantity of small stones and sand is first put in wet. A box is placed in the hole over the top of the barrel and filled in with clay or earth well tamped. The porous condition of the gravel drains the surplus water after a rain.

The end of the barrel is fitted with a light cover and a heavy door hinged to the box. A small portion of damp sand is sprinkled on the bottom of the barrel. The covers should be left open occasionally to prevent mold and to remove any bad air that may have collected from the contents.

Contributed by F. Smith, La Salle, Ill.

Secure a cheese box about 12 in. high and 15 in. or more in diameter. It will pay you to be careful in selecting this box. Be sure to have the cover. Score the wood deeply with a carpenter's gauge inside and out 3-1/2 in. from the top of the box. With repeated scoring the wood will be almost cut through or in shape to finish the cut with a knife. Now you will have the box in two pieces. The lower part, 8-1/2 in. deep over all, we will call the basket, and the smaller part will be known as the tray.

Remove the band from the cover and cut the boards to fit in the tray flush with the lower edge, to make the bottom. Fasten with 3/4-in brads. The kind of wood used in making these boxes cracks easily and leaves a rough surface which should be well sandpapered.

The four legs are each 3/4-in. square and 30-1/2 in. long. The tops should be beveled to keep them from splintering at the edges. With a string or tape measure, find the circumference of the tray or basket and divide this into four equal parts, arranging the lap seam on both to come midway between two of the marks. When assembling, make these seams come between the two back legs.

The tray is placed 1-1/4 in. from the top end and the basket 6-3/4 in. from the bottom end of the legs. Notch the legs at the lower point about 1/8 in. deep and 1-1/4 in. wide to receive the band at the lower end of the basket. Fasten with 3/4-in. screws, using four to each leg, three of which are in the basket. Insert the screws from the inside of the box into the legs.

Stain the wood before putting in the lining. If all the parts are well sandpapered, the wood will take the stain nicely: Three yards of cretonne will make a very attractive lining. Cut two sheets of cardboard to fit in the bottom of the tray and basket. Cover them with the cretonne, sewing on the back side. Cut four strips for the sides from the width of the goods 5-1/2 in. wide and four strips 10 in. wide. Sew them end to end and turn down one edge to a depth of 1 in. and gather it at that point,—also the lower edge when necessary. Sew on to the covered cardboards. Fasten them to the sides of the tray and basket with the smallest upholsterers' tacks. The product of your labor will be a very neat and useful piece of furniture.

Contributed by Stanley H. Packard, Boston, Mass.

Paper Aeroplanes in Draft

A novel and attractive aeroplane window display can be easily made in the following manner: Each aeroplane is cut from folded paper, as shown in the sketch, and the wings bent out on the dotted lines. The folded part in the center is pasted together. Each aeroplane is fastened with a small thread from the point A as shown. A figure of an airman can be pasted to each aeroplane. One or more of the aeroplanes can be fastened in the blast of an electric fan and kept in flight the same as a kite. The fan can be concealed to make the display more real. When making the display, have the background of such a color as to conceal the small threads holding the aeroplanes.

Contributed by Frederick Hennighausen, Baltimore, Md.

Fig.2 Fig.3

The Stone Chipped into Shape

If you live where flints abound, possess the requisite patience and the knack of making things, you can, with the crudest of tools and a little practice, chip out as good arrowheads as any painted savage that ever drew a bow. Select a piece of straight-grained flint as near the desired shape as possible. It may be both longer and wider than the finished arrow but it should not be any thicker. The side, edge and end views of a suitable fragment are shown in Fig. 1. Hold the piece with one edge or end resting on a block of wood and strike the upper edge lightly with a hammer, a small boulder or anything that comes handy until the piece assumes the shape shown in Fig. 2.

The characteristic notches shown in the completed arrow, Fig. 3, are chipped out by striking the piece lightly at the required points with the edge of an old hatchet or a heavy flint held at right angles to the edge of the arrow. These heads can be made so that they cannot be distinguished from the real Indian arrowheads.

Contributed by B. Orlando Taylor, Cross Timbers, Mo.

Handle on Cover

A stamp pad is a desk necessity and the cleanliness of one depends on keeping it closed when it is not in use. The opening and closing of a pad requires both hands and consequently the closing of a pad is often neglected in order to avoid soiling the fingers. This trouble can be avoided if the pad is fitted with a small handle as shown in the sketch. Take the ordinary pad and work the hinge until it opens freely. If necessary apply a little oil and spread the flanges of the cover slightly.

Saw off the top of a common wood clothespin just above the slot, saving all the solid part. Fasten this to the cover near the back side in an upright position with a screw. A tap on the front side of the pin will turn it over backward until the head rests on the desk thus bringing the cover up in the upright position. When through using the pad, a slight tap on the back side of the cover will turn it down in place.

Contributed by H. L. Crockett, Gloversville, N. Y.

Finished Kennel

Concrete Forms

The kennel shown in the illustration is large enough for the usual size of dog. It is cleanly, healthful and more ornamental than the average kennel. This mission style would be in keeping with the now popular mission and semi-mission style home, and, with slight modifications, it could be made to conform with the ever beautiful colonial home. It is not difficult to build and will keep in good shape for many years.

{24}The dimensions and the manner of making the forms for the concrete, and the location for the bolts to hold the plate and rafters, are shown in the diagram.

Contributed by Edith E. Lane, El Paso, Texas.

Photograph in the Shell

Split an English walnut in the center, remove the contents, and scrape out the rough parts. Make an oval opening by filing or grinding. If a file is used, it should be new and sharp. After this is done, take a small half round file and smooth the edges into shape and good form.

The photograph print should be quite small—less than 1/2 in. across the face. Trim the print to a size a little larger than the opening in the shell, and secure it in place with glue or paste. It may be well to fill the shell with cotton. Mount the shell on a small card with glue, or if desired, a mount of different shape can be made of burnt woodwork.

Contributed by C. S. Bourne, Lowell, Mass.

Spoon Holder

In making marmalade and jellies the ingredients must be stirred from time to time as the cooking proceeds. After stirring, some of the mixture always remains on the spoon. Cooks often lay the spoon on a plate or stand it against the cooking utensil with the handle down. Both of these methods are wasteful. The accompanying illustration shows a device made of sheet copper to hold the spoon so that the drippings will return to the cooking utensil. The copper is not hard to bend and it can be shaped so that the device can be used on any pot or kettle.

Contributed by Edwin Marshall, Oak Park, Ill.

Some time ago I received two gramophone records that were cracked in shipment but the parts were held together with the paper label. As these were single-faced disk records, I used the following method to stick them together: I covered the back of one with shellac and laid the two back to back centering the holes with the crack in one running at right angles to the crack in the other. These were placed on a flat surface and a weight set on them. After several hours' drying, I cleaned the surplus shellac out of the holes and played them.

As the needle passed over the cracks the noise was hardly audible. These records have been played for a year and they sound almost as good as new.

Contributed by Marion P. Wheeler, Greenleaf, Oregon.

An amateur mechanic who had been much annoyed by the insects which were attracted to his electric lights found a solution in the pneumatic moth trap described in a recent issue of Popular Mechanics. He fixed a funnel to the end of the intake tube of a vacuum cleaner and hung it under a globe. The insects came to the light, circled over the funnel and disappeared. He captured several pounds in a few hours.

Contributed by Geo. F. Turl, Canton, Ill.

In filtering a large amount of solution one usually desires some means other than a large funnel and something to make the watching of the process unnecessary. If a considerable quantity of a solution be placed in a large bottle or flask, and a cork with a small hole in it inserted in the mouth, and the apparatus suspended in an inverted position over a small funnel so that the opening of the cork is just below the water level in the funnel, the filtering process goes on continuously with no overflow of the funnel.

As soon as the solution in the funnel is below the cork, air is let into the flask and a small quantity of new solution is let down into the funnel. The process works well and needs no watching, and instead of the filtrate being in a large filter paper, it is on one small piece and can be handled with ease.

Contributed by Loren Ward, Des Moines, Iowa.

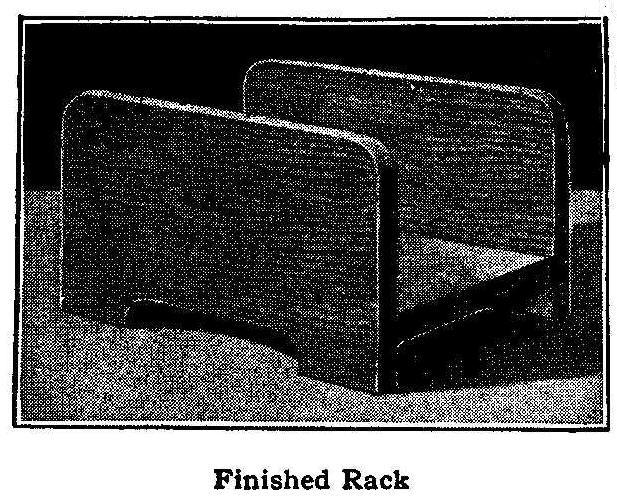

Finished Rack

Details of the Rack

The illustration shows a rack for postcards. Those having houses with mission-style furniture can make such a rack of the same material as the desk, table or room furnishings and finish it in the same manner.

The dimensions are given in the detail sketch. The two ends are cut from 1/4-in. material, the bottom being 3/8 in. thick. Only three pieces are required, and as they are simple in design, anyone can cut them out with a saw, plane and pocket knife.

Contributed by Wm. Rosenberg, Worcester, Mass.

A good substitute for a shoe horn is a handkerchief or any piece of cloth used in the following way: Allow part of the handkerchief or cloth to enter the shoe, place the toe of the foot in the shoe so as to hold down the cloth, and by pulling up on the cloth so as to keep it taut around the heel the foot will slide into the shoe just as easily as if a shoe horn were used.

Contributed by Thomas E. Dobbins, Glenbrook, Conn.

In building a photographic dark room, it is necessary to make it perfectly light-tight, the best material to use being matched boards. These boards are tongued and grooved and when put together effectually prevent the entrance of light.

The next important thing to be considered is to make it weather-tight, and as far as the sides are concerned the matched boards will do this also, but it is necessary to cover the roof with felt or water-proof paper.

The best thickness for the boards is 1 in., but for cheapness 3/4 in. will do as well, yet the saving is so little that the 1-in. boards are preferable.

The dark room shown in the accompanying sketch measures 3 ft. 6 in. by 2 ft. 6 in., the height to the eaves being 6 ft. Form the two sides shown in Fig 1, fixing the crosspieces which hold the boards together in such positions that the bottom one will act as a bearer for the floor, and the second one for the developing bench. Both sides can be put together in this way, and both exactly alike. Keep the ends of the crosspieces back from the edges of the boards far enough to allow the end boards to fit in against them.

One of the narrow sides can be formed in the same way, fixing the crosspieces on to correspond, and then these three pieces can be fastened together by screwing the two wide sides on the narrow one.

Lay the floor next, screwing or nailing the boards to the crosspieces, and making the last board come even with the ends of the crosspieces, not even with the boards themselves. The single boards can then be fixed, one on each side of what will be the doorway, by screwing to the floor, and to the outside board of the sides. At the top of the doorway, fix a narrow piece between the side boards, thus leaving a rectangular opening for the door.

The roof boards may next be put on, nailing them to each other at the ridge, and to the sides of the room at the outsides and eaves. They should overhang at the sides and eaves about 2 in., as shown in Figs. 3 and 4.

One of the sides with the crosspieces in place will be as shown in Fig. 2 in section, all the crosspieces and bearers intersecting around the room.

The door is made of the same kind of boards held together with crosspieces, one of which is fastened so as to fit closely to the floor when the door is hinged, and act as a trap for the light. The top crosspiece is also fastened within 1 in. of the top of the door for the same reason.

Light traps are necessary at the sides and top of the door. That at the hinged side can be as shown at A, Fig. 5, the closing side as at B, and the top as at C in the same drawing. These are all in section and are self-explanatory. In hinging the door, three butt hinges should be used so as to keep the joint close.

The fittings of the room are as shown sectionally in Fig. 6, but before fixing these it is best to line the room with heavy, brown wrapping paper, as an additional safeguard against the entrance of light.

The developing bench is 18 in. wide, and in the middle an opening, 9 by 11 in., is cut, below which is fixed the sink. It is shown in detail in Fig. 7, and should be zinc lined.

The zinc should not be cut but folded as shown in Fig. 8, so that it will fit inside the sink. The bench at each side of the sink should be fluted (Fig. 9), so that the water will drain off into the sink. A strip should be fixed along the back of the bench as shown in Figs. 6 and 9, and an arrangement of slats (Fig. 10), hinged to it, so as to drop on the sink as in Fig. 6, and shown to a larger scale in Fig. 11.

{27}

Details of the Dark Room

A shelf for bottles and another for plates, etc., can be fixed above the developing bench as at D and E (Fig. 6) and another as F in the same drawing. This latter forms the bottom of the tray rack, which is fixed on as shown in Fig. 13. The divisions of the tray rack are best fitted loosely in grooves formed by fixing strips to the shelves and under the bench and sink as in Fig. 13.

Extra bearing pieces will be wanted for the shelves mentioned above, these being shown in Fig. 14. The window is formed by cutting an opening in the side opposite the door, and fixing in it a square of white glass with strips of wood on the inside and putty on the outside, as in Fig. 15. A ruby glass is framed as shown at G, Fig. 16, and arranged to slide to and fro in the grooved runners H, which makes it possible to have white light, as at I, or red light as at K, Fig. 16. The white glass with runners in position is shown at L in the same drawing, but not the red glass and frame. Ventilation is arranged for by boring a series of holes near the floor, as at M, Fig. 6, and near the roof as at N in the same drawing, and trapping the light without stopping the passage of air, as shown in the sections, Fig. 17.

The finish of the roof at the gables is shown in Fig. 18, the strip under the boards holding the felt in position when folded under, and the same is true of the roll at the top of the roof in Fig. 19.

The house will be much strengthened if strips, as shown in Fig. 20, are fastened in the corners inside, after lining with brown paper, screwing them each way into the boards.

The door may have a latch or lock with a knob, but should in addition have two buttons on the inside, fixed so as to pull it shut tightly at top and bottom. A waste pipe should be attached to the sink and arranged to discharge through the floor. A cistern with pipe and tap can be fastened in the top of the dark room, if desired, or the room may be made with a flat roof, and a tank stand on it, though this is hardly advisable.

It is absolutely necessary that the room be well painted, four coats at first is not too many, and one coat twice a year will keep it in good condition.

A brick foundation should be laid so that no part of the room touches the ground.

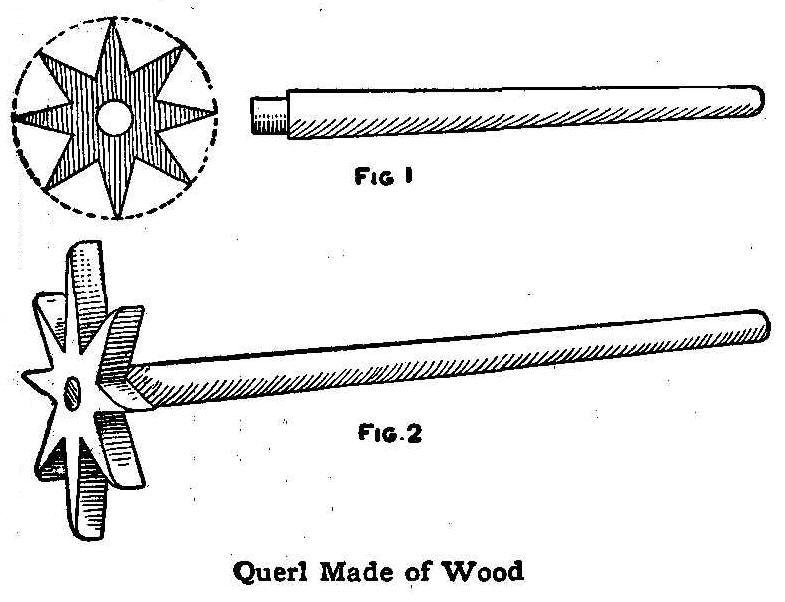

Querl Made of Wood

"Querl" is the German name for a kitchen utensil which may be used as an egg-beater, potato-masher or a lemon-squeezer. For beating up an egg in a glass, mixing flour and water, or stirring cocoa or chocolate, it is better than anything on the market.

This utensil is made of hardwood, preferably maple or ash. A circular piece about 2 in. in diameter is cut from 1/2-in. stock and shaped like a star as shown in Fig. 1, and a 3/8-in. hole bored in the center for a handle. The handle should be at least 12 in. in length and fastened in the star as shown in Fig. 2.

In use, the star is placed in the dish containing the material to be beaten or mixed and the handle is rapidly rolled between the palms of the hands.

Contributed by W. Karl Hilbrich, Erie, Pennsylvania.

Occasionally one finds a piece of soldering to do which is impossible to reach with even the smallest of the ordinary soldering irons or coppers. If a length of copper wire as large as the job will permit and sufficiently long to admit being bent at one end to form a rough handle, and filed or dressed to a point on the other, is heated and tinned exactly as a regular copper should be, the work will cause no trouble on account of inaccessibility.

Contributed by E. G. Smith, Eureka Springs, Ark.

Collar Button Ends In Wood Stick

When an ink line is erased the roughened surface of the paper should be smoothed or polished so as to prevent the succeeding lines of ink from spreading. A convenient desk accessory for this purpose can be made of a short piece of hardwood and two bone collar buttons.

File off the head of one button at A and the base from another at B. Bore a small hole D and E in each end of the wood handle C and fasten the button parts in the holes with glue or sealing wax. The handle can be left the shape shown or tapered as desired. The small end is used for smoothing small erasures and the other end for larger surfaces.

Hairpin In Stick

An ordinary hairpin is driven part way into a small round piece of wood, about 3/8 in. in diameter and 2 or 2-1/2 in. long, for a handle, as shown in the sketch. The hairpin should be a very small size. To operate, simply insert the wire loop into the cherry where the stem has been pulled off and lift out the seed.

Contributed by L. L. Schweiger, Kansas City, Mo.

Shape of Tenon and Mortise

The illustration shows an unusual dovetail joint, which, when put together properly is a puzzle. The tenon or tongue of the joint is sloping on three surfaces and the mortise is cut sloping to match. The bottom surface of the mortise is the same width at both ends, the top being tapering toward the base of the tongue.

Contributed by Wm. D. Mitchell, Yonkers, New York.

Base Made of Corks

The many forms of round-bottomed glass bottles used in chemical laboratories require some special kind of support on which they can be safely placed from time to time when the chemist does not, for the moment, need them. These supports should not be made of any hard material nor should they be good conductors of heat, as such qualities would result in frequent breakage.

A French magazine suggests making the supports from the large corks of glass jars in which crystal chemicals are usually supplied from the dealers. The manner of making them is clearly shown in the sketch. Each cork is cut as in Fig. 1 and placed on a wire ring (Fig. 2) whose ends are twisted together and the last section of cork is cut through from the inner side to the center and thus fitted over the wire covering the twisted ends, which binds them together. The corks in use are shown in Fig. 3.

Artistic Flower Boxes

Instead of using an ordinary green-painted window box, why not make an artistic one in which the color does not clash with the plants contained in it but rather harmonizes with them.

Such a window box can be made by anyone having usual mechanical ability, and will furnish more opportunities for artistic and original design than many other articles of more complicated construction.

The box proper should be made a little shorter than the length of the window to allow for the extra space taken up in trimming and should be nearly equal in width to the sill, as shown in Fig. 1. If the sill is inclined, as is usually the case, the box will require a greater height in front, to make it set level, as shown in Fig. 2.

The box should be well nailed or screwed together and should then be painted all over to make it more durable. A number of 1/2-in. holes should be drilled in the bottom, to allow the excess water to run out and thus prevent rotting of the plants and box.

Having completed the bare box, it may be trimmed to suit the fancy of the maker. The design shown in Fig. 1 is very simple and easy to construct, but may be replaced with a panel or other design. One form of panel design is shown in Fig. 3.

Trimming having too rough a surface will be found unsuitable for this work as it is difficult to fasten and cannot be split as well as smooth trimming. It should be cut the proper length before being split and should be fastened with brads. The half-round hoops of barrels will be found very useful in trimming, especially for filling-in purposes, and by using them the operation of splitting is avoided. After the box is trimmed, the rustic work should be varnished, in order to thoroughly preserve it, as well as improve its appearance.

To the owner of a garden in a town where squirrels are protected by law, life in the summer time is a vexation. First the squirrels dig up the sweet corn and two or three replantings are necessary. When the corn is within two or three days of being suitable for cooking, the squirrels come in droves from far and near. They eat all they can and carry away the rest. When the corn is gone cucumbers, cabbages, etc., share the same fate, being partly eaten into. At the risk of being arrested for killing the squirrels I have used a small target rifle morning and night, but during my absence the devastation went on steadily. Last year they destroyed my entire corn crop. Traps do no good; can't use poison, too dangerous. But I have solved the difficulty; it's easy.

Shake cayenne pepper over the various vegetables which are being ruined, and observe results.

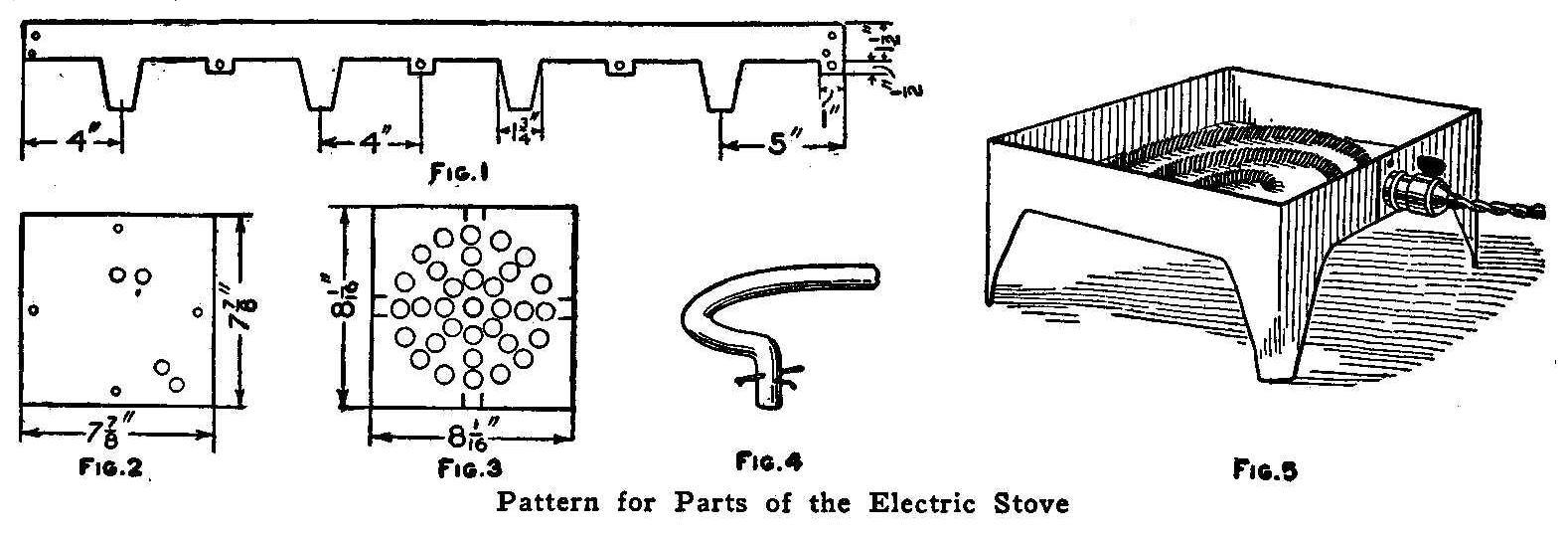

Pattern for Parts of the Electric Stove

The construction of an electric stove is very simple, and it can be made by any home mechanic having a vise and hand drill. The body is made of sheet or galvanized iron, cut out and drilled as shown in Fig. 1.