Fig. 2,583.—General Electric simultaneous record of three waves with common zero.

THE THOUGHT IS IN THE QUESTION THE INFORMATION IS IN THE ANSWER

QUESTIONS

ANSWERS

&

ILLUSTRATIONS

A PROGRESSIVE COURSE OF STUDY FOR ENGINEERS,

ELECTRICIANS, STUDENTS AND THOSE DESIRING TO

ACQUIRE A WORKING KNOWLEDGE OF

ELECTRICITY AND ITS APPLICATIONS

A PRACTICAL TREATISE

by

HAWKINS AND STAFF

THEO AUDEL & CO. 72 FIFTH AVE. NEW YORK.

COPYRIGHTED, 1915,

BY

THEO. AUDEL & CO.,

New York.

Printed in the United States.

TABLE OF CONTENTS

GUIDE No. 8

| WAVE FORM MEASUREMENT | 1,839 to 1,868 | |

Importance of wave form measurement—methods: step by step; constantly recording—classes of apparatus: wave indication; oscillographs—step by step methods—Joubert's; four part commutator; modified four part commutator; ballistic galvanometer; zero; Hospitalier ondograph—constantly recording methods: cathode ray; glow light; moving iron; moving coil; hot wire—oscillographs—moving coil type; construction and operation; production of the time scale; oscillograms—falling plate camera; its use. |

||

| SWITCHBOARDS | 1,869 to 1,884 | |

General principles: diagram—small plant a.c. switchboard—switchboard panels; generator panel; diagram of connections—simple method of determining bus bar capacity—feeder panel—diagrams of connection for two phase and three phase installations. |

||

| ALTERNATING CURRENT WIRING | 1,885 to 1,914 | |

Effects to be considered in making calculations—induction; self- and mutual; mutual induction, how caused—transpositions—inductance per mile of three phase circuit, table—capacity; table—frequency—skin effect; calculation; table—corona effect; its manifestation; critical voltage; spacing of wires—resistance of wires—impedance—power factor; apparent current; usual power factors encountered; example—wire calculations—sizes of wire—table of the property of copper wire—drop; example—current—example covering horse power, watts, apparent load, current, size of wire, drop, voltage at the alternator, and electrical horse power. |

||

| POWER STATIONS | 1,915 to 1,988 | |

Classification—central stations; types: a.c., d.c., and a.c. and d.c.; reciprocating engine vs. turbine—location of central stations; price of land; trouble after erection; water supply; service requiring direct current—size of plant; nature of load; peak load; load factor; machinery required; example; factors of evaporation; grate surface per horse power—general arrangement of station; belt drive with counter shaft; desirable features of belt drive; conditions, suitable for counter shaft drive; location of engine and boilers; the steam pipe; piping between engine and condenser; number and type of engine; superheated steam; switchboard location; individual belt drive; direct drive—station construction—foundations—walls— roofs—floors—chimneys; cost of chimneys and mechanical draft; high chimneys ill advised—steam turbine; types: impulse and reaction; why high vacuum is necessary; the working pressure—hydro-electric plants—water turbines; types: impulse, reaction—isolated plants—sub-stations; arrangement; three phase installations; reactance coils in sub-stations; portable sub-stations. |

||

| MANAGEMENT | 1,989 to 2,114 | |

The term "management"—selection; general considerations—selection of generators; efficiency of generators; size and number; regulation—installation; precautions; handling of armatures; assembling a machine; speed of generators; calculation of pulley sizes; gear wheels—belts; various belt drives; horse power transmitted by belts; velocity of belt; endless belts—switchboards; essential points of difference between single phase and three phase switchboard wiring; assembling a switchboard; usual equipment. Operation of Alternators—alternators in parallel; synchronizing; lamp methods; action of amortisseur winding; synchronizing three phase alternators; disadvantage of lamp method—cutting out alternator; precautions; hunting—alternators in series. Transformers; selection; efficiency; kind of oil used; detection of moisture; drying oil; regulation; transformers in parallel; polarity test—motor generators; various types and conditions requiring same—dynamotors; precautions—rotary converters; objections to single phase type; operation when driven by direct current, by alternating current; most troublesome part; efficiency; overload; starting; starting current. Electrical measuring instruments; location; readings; station voltmeters; points relating to ammeters; attention necessary; usual remedies to correct voltmeter—how to test generators; commercial efficiency; various tests. Station Testing: resistance measurement by "drop" method—methods of connecting ammeter voltmeter and wattmeter for measurement of power—motor testing: single phase motor—three phase motor, voltmeter and ammeter method; two wattmeter method; polyphase wattmeter method; one wattmeter method; one wattmeter and Y box method—three phase motor with neutral brought out; single wattmeter method—temperature test, three phase induction motor—three phase alternator testing: excitation or magnetization curve test—synchronous impedance test—load test—three phase alternator or synchronous motor temperature test—direct current motor or generator testing: magnetization curve—(shunt) external characteristic—direct current motor testing; load and speed tests—temperature test, "loading back" method—compound dynamo testing: external characteristic, adjustable load—transformer testing: external characteristic, adjustable load—transformer testing: core loss and leakage or exciting current test—copper loss—copper loss by wattmeter measurement and impedance—temperature—insulation—internal insulation—insulation resistance—polarity—winding or ratio tests. |

||

The great importance of the wave form in alternating current work is never denied, though it has sometimes been overlooked. The application of large gas engines to the driving of alternators operated in parallel requires an accurate knowledge of the wave form, and a close conformation to a sine wave if parallel operation is to be satisfactory. It is also important that the fluctuations in magnetism of the field poles should be known, especially if solid steel pole faces be used.

If an alternator armature winding be connected in delta, the presence of a third harmonic becomes objectionable, as it gives rise to circulating currents in the winding itself, which increase the heating and lowers the efficiency of the machine.

That the importance of having a good wave form is being realized, is proved by the increasing prevalence in alternator specifications of a clause specifying the maximum divergence allowable from a true sine wave. It is however perhaps not always realized that an alternator which gives a good pressure wave on no load may give a very bad one under certain loads, and the ability of the machine to maintain a good wave form under severe conditions of load is a better criterion of its good design than is the shape of its wave at no load.

The question of wave form is of special interest to the power station engineer. Upon it depends the answer to the questions: whether he may ground his neutral wires without getting large circulating currents; whether he may safely run any combination of his alternators in parallel; whether the constants of his distributing circuit are of an order liable to cause dangerous voltage surges due to resonance with the harmonics of his pressure wave; what stresses he is getting in his insulation due to voltage surges when switching on or off, etc. 1840 It has been shown by Rossler and Welding that the luminous efficiency of the alternating current arc may be 44 per cent. higher with a flat topped than with a peaked pressure wave, while on the other hand it is well known that transformers are more efficient on a peaked wave. Also the accuracy of many alternating current instruments depends upon the wave shape.

In making insulation breakdown tests on cables, insulators, or machinery, large errors may be introduced unless the wave form at the time of the test be known. It is not sufficient even to know that the testing alternator gives a close approximation to a sine wave at no load; since if the capacity current of the apparatus under test be moderately large compared with the full load current of the testing alternator, the charging current taken may be sufficient to distort the wave form considerably, thus giving wrong results to the disadvantage of either the manufacturer or purchaser.

The desirability of a complete knowledge of the manner in which the pressure and current varies during the cycle, has resulted in various methods and apparatus being devised for 1841 obtaining this knowledge. The apparatus in use for such purpose may be divided into two general classes,

1. Wave indicators;

2. Oscillographs.

and the methods employed with these two species of apparatus

may be described respectively as,

1. Step by step;

2. Constantly recording.

that is to say, in the first instance, a number of instantaneous

1842

values are obtained at various points of the cycle, which are

plotted and a curve traced through the several points thus

obtained. A constantly recording method is one in which an

infinite number of values are determined and recorded by the

machine, thus giving a complete record of the cycle, leaving no

portion of the wave to be filled in.

Figs. 2,585 and 2,586.—Oscillograms (from paper by Morris and Catterson-Smith, Proc. I. E. E., Vol. XXXIII, page 1,023), showing how the current varies in one of the armature coils of a direct current motor. Fig. 2,585 was obtained with the brushes in the neutral position, and fig. 2,586 with the brushes shifted forward.

The various methods of determining the wave form may be further classified as: 1843

| ❴ Joubert's method; | |

| ❴ Four part commutator method; | |

| ❴ Modified four part commutator method; | |

| 1. Step by step | ❴ Ballistic galvanometer method; |

| ❴ Zero method; | |

| ❴ By Hospitalier ondograph. |

Fig. 2,587.—Oscillogram by Bailey and Cleghorne (Proc. I.E.E., Vol. XXXVIII), showing the sparking pressure or pressure between the brush and the commutator segment at the moment of separation. The waves fall into groups of three owing to the fact that there were three armature coils in each slot.

| ❴ cathode ray; | ||

| ❴ by use of various types | ❴ glow light; | |

| 2. constantly recording | ❴ of oscillograph, | ❴ moving iron; |

| ❴ such as | ❴ moving coil; | |

| ❴ hot wire. | ||

Fig. 2,588.—Various wave forms. The sine wave represents a current or pressure which varies according to the sine law. A distorted wave is due to the properties of the circuit, for instance, the effect of hysteresis in an iron core introduced into a coil is to distort the current wave by adding harmonics so that the ascending and descending portions may not be symmetrical. A peaked wave has a large maximum as compared with its virtual value. A peaked wave is produced by a machine with concentrated winding.

Joubert's Method.—The apparatus required for determining the wave form by this step by step method, consists of a galvanometer, condenser, two, two way switches, resistance and adjustable contact maker, as shown in fig. 2,589. 1844

The contact maker is attached to the alternator shaft so that it will rotate synchronously with the latter. By means of the adjustable contact, the instant of "making" that is, of "closing" the testing circuit may be varied, and the angular position of the armature, at which the testing circuit is closed, determined from the scale, which is divided into degrees.

A resistance is placed in series with one of the alternator leads, such that the drop across it, gives sufficient pressure for testing.

Ques. Describe the method of making the test.

Ans. For current wave measurement switch No. 1 is placed on contact F, and for pressure wave measurement, on contact G, switch No. 2 is now turned to M and the drop across the resistance (assuming switch No. 1 to be turned to contact F) measured by charging the condenser, and then discharging it through the galvanometer by turning the switch to S. This is repeated for a number of positions of the contact maker, noting each time the galvanometer reading and position of the contact maker. By plotting the positions of contact maker as abscissæ, and the galvanometer readings as ordinates, the curve drawn through them will represent the wave form. 1845

The apparatus is calibrated by passing a known constant current through the resistance.

Fig. 2,590.—Four part commutator method of wave form measurement. The contact device consists of two slip rings and a four part commutator. One slip ring is connected to one terminal of the source, the other to the voltmeter, and the commutator to the condenser. By adjusting R when a known direct current pressure is impressed across the terminals, the voltmeter can be rendered direct reading.

Fig. 2,591.—Modified four part commutator method of wave form measurement (Duncan's modification). By this method one contact maker can be used for any number of waves having the same frequency. Electro-dynamometers are used and the connections are made as here shown. The moving coils are connected in series to the contact maker, and the fixed coils are connected to the various sources to be investigated, then the deflection will be steady and by calibration with direct current can be made to read directly in volts.

Fig. 2,592.—Diagram illustrating the ballistic galvanometer method of wave form measurement. The test may be made as described in the accompanying text, or in case the contact breaker is belted instead of attached rigidly to the shaft, it could be arranged to run slightly out of synchronism, then by taking readings at regular intervals, points will be obtained along the curve without moving the contact breaker. If this method be used, a non-adjustable contact breaker suffices. In arranging the belt drive so as to run slightly out of synchronism, if the pulleys be of the same size, the desired result is obtained by pasting a thin strip of paper around the face of one of the pulleys thus altering the velocity ratio of the drive slightly from unity.

Ballistic Galvanometer Method.—This method, which is due to Kubber, employs a contact breaker instead of a contact maker. The distinction between these two devices should be noted: A contact maker keeps the circuit closed during each revolution for a short interval only, whereas, a contact breaker keeps the circuit open for a short interval only.

Fig. 2,592, shows the necessary apparatus and connections for applying the ballistic galvanometer method. The contact breaker consists of a commutator having an ebonite or insulating segment and two brushes. 1847

In operation the contact breaker keeps the circuit closed during all of each revolution, except the brief interval in which the brushes pass over the ebonite segment.

The contact breaker is adjustable and has a scale enabling its various positions of adjustment to be noted.

Ques. Describe the test.

Ans. The contact breaker is placed in successive positions and galvanometer readings taken, the switch being turned to F, fig. 2,592, in measuring the current wave, and to G in measuring the pressure wave. The results thus obtained are plotted giving respectively current and pressure waves.

Figs.. 2,593 and 2,594.—Two curves representing pressure and current respectively of a rotary converter. Fig. 2,593, pressure wave V, fig. 2,594 current wave C. These waves were obtained from a converter which was being driven by an alternator by means of an independent motor. The rotary converter was supplying idle current to some unloaded transformers and the ripples clearly visible in the pressure wave V, correspond to the number of teeth in the armature of the rotary converter.

Ques. How is the apparatus calibrated?

Ans. By sending a constant current of known value through the resistance R. 1848

Zero Method.—In electrical measurements, a zero method is one in which the arrangement of the testing devices is such that the value of the quantity being measured is shown when the galvanometer needle points to zero.

In the zero method either a contact maker or contact breaker may be used in connection with a galvanometer and slide wire bridge, as shown in figs. 2,595 and 2,596.

Fig. 2,595.—Diagram illustrating zero method of wave measurement with contact maker. The voltage of the battery must be at least as great as the maximum pressure to be measured and must be kept constant.

Ques. What capacity of battery should be used?

Ans. Its voltage should be as great as the maximum pressure to be measured.

Ques. What necessary condition must be maintained in the battery?

Ans. Its pressure must be kept constant.

Ques. How are instantaneous values measured?

Ans. The bridge contact A is adjusted till the galvanometer 1849 shows no deflection, then the length AS is a measure of the pressure.

The drop between these points can be directly measured with a voltmeter if desired.

Ques. How did Mershon modify the test?

Ans. He used a telephone instead of the galvanometer to determine the correct placement of the bridge contact A.

Fig. 2,596.—Diagram illustrating zero method of wave measurement with contact breaker. The voltage of the battery must be at least as great as the maximum pressure to be measured and must be kept constant.

Ques. How can the instantaneous values be recorded?

Ans. By attaching to the contact A, a pencil controlled by an electro-magnet arranged to strike a revolving paper card at the instant of no deflection, the paper being carried on a drum.

Hospitalier Ondograph.—The device known by this name is a development of the Joubert step by step method of wave form measurement, that is to say, the principle on which its 1850 action is based, consists in automatically charging a condenser from each 100th wave, and discharging it through a recording galvanometer, each successive charge of the condenser being automatically taken from a point a little farther along the wave.

Fig. 2,597.—Diagram of Hospitalier ondograph showing mechanism and connections. It represents a development of Joubert's step by step method of wave form measurement.

As shown in the diagram, fig. 2,597, the ondograph consists of a synchronous motor A, operated from the source of the wave form to be measured, connected by gears B to a commutator D, in such a manner that while the motor makes a certain number of revolutions, the commutator makes a like number diminished by unity; that is to say, if the speed of the motor be 900 revolutions per minute, the commutator will have a speed of 899. 1851

The commutator has three contacts, arranged to automatically charge the condenser cc' from the line, and discharge it through the galvanometer E, the deflection of which will be proportional to the pressure at any particular instant when contact is made.

In fig. 2,597, GG' are the motor terminals, HH' are connected to the condenser cc' through a resistance (to prevent sparking at the commutator) and I, I' are the connections to the service to be measured.

A permanent magnet type of recording galvanometer is employed. Its moving coil E receives the discharges of the condenser in rapid succession and turns slowly from one side to the other.

Fig. 2,598.—View of Hospitalier ondograph. In operation, a long pivoted pointer carrying a pen and actuated by electro-magnets, records on a revolving drum a wave form representing the alternating current, pressure or current wave.

The movable part operates a long needle (separately mounted) carrying a pen F, which traces the curve on the rotating cylinder C. This cylinder is geared to the synchronous motor to run at such a speed as to register three complete waves upon its circumference.

By substituting an electromagnetic galvanometer for the permanent magnet galvanometer, and by using the magnet coils as current coils and the moving coil as the volt coil, the instrument can be made to draw watt curves. Fig. 2,598 shows the general appearance of the ondograph.

1852 Cathode Ray Oscillograph.—This type of apparatus for measuring wave form was devised by Braun, and consists of a cathode ray tube having a fluorescent screen at one end, a small diaphragm with a hole in it at its middle, and two coils of a few turns each, placed outside it at right angles to one another. These coils carry currents proportional to the pressure and current respectively of the circuit under observation.

Fig. 2,599.—General Electric moving coil oscillograph complete with tracing table. The tracing table is employed for observing the waves, and by using a piece of transparent paper, the waves under observation appear as a continuous band of light which can be traced, thus making a permanent record. This is not, however, to be regarded as a recording attachment, and can not be used where instantaneous phenomena are being investigated. The synchronous motor for operating the synchronous mirror in connection with tracing and viewing attachment is wound for 100 to 115 volts, 25 to 125 cycles, and should, of course, be run from the same machine which furnishes power to the circuit under observation. A rheostat for steadying and adjusting the current should be connected in series with the motor. The beam from the vibrator mirrors striking this synchronous mirror moves back and forth over the curved glass, and gives the length of the wave; the movement of the vibrator mirror gives the amplitude, and the combination gives the wave complete. An arc lamp or projection lantern produces the image reflected by the mirrors upon the film, tracing table or screen. For the rotation of the photographic film, a small direct current shunt wound motor is ordinarily used.

1853 The ray then moves so as to produce an energy diagram on the fluorescent screen.

Fig. 2,600.—General Electric moving coil oscillograph. The moving elements consist of single loops of flat wire carrying a small mirror and held in tension by small spiral springs. The current passing down one side and up the other, forces one side forward and the other backward, thus causing the mirror to vibrate on a vertical axis. The vibrator elements fit into chambers between the poles of electro-magnets, and are adjustable, so as to move the beam from the mirror, both vertically and horizontally. A sensitized photographic film is wrapped around a drum and held by spring clamps. The drum, with film, is placed in a case and a cap then placed over the end, making the case light, when the index is either up or down. The loading is done in a dark room. A driving dog is screwed into the drum shaft, and which, when the drum and case are in place, revolves the film past a slot. When an exposure is to be made, the index is moved from the closed position, thus opening the slot in the case and exposing the film to the beam of light from the vibrating mirrors when the electrically operated shutter is open. The slot is then closed by moving the index to "Exposed." A slide with ground glass can be inserted in place of the film case or roll holder to arrange the optical system when making adjustments. The shutter operating mechanism is arranged so as to hold the shutter open during exactly one revolution of the film drum. There are two devices connected to the shutter operating mechanism; one opens the shutter at the instant the end of the film passes the slot; the other opens immediately, at any part of the film, and both give exposure during one revolution. The first is useful when making investigations in which the events are either recurring, or their beginnings known or under control, and the second when the time of the event is not under control, such as the blowing of fuses or opening of circuit breakers.

The instrument is much used in wireless telegraphy, as it is capable of showing the characteristics of currents of very high frequency. 1854

Fig. 2,601.—General Electric moving coil oscillograph with case removed, showing interior construction and arrangement of parts. The oscillograph is furnished complete with a three element electro-magnet galvanometer, optical system, shutter and shutter operating mechanism, film driving motor and cone pulleys, photographic and tracing attachments, 6 film holders, and the following repair parts, for vibrators: 6 extra suspension strips; 6 vibrator mirrors; 1 box gold leaf fuses; 1 bottle mirror cement; 1 bottle damping liquid.

Fig. 2,602.—Oscillogram showing the direct current pressure of a 25 cycle rotary converter (below), and (above) the pressure wave taken between one collector ring and one commutator brush. The 12 ripples per cycles in the direct current voltage are due to a 13th harmonic in the alternating current supply.

1855 Glow Light Oscillograph.—This device consists of two aluminum rods in a partially evacuated tube, their ends being about two millimeters apart. When an alternating current of any frequency passes between them a sheath of violet light forms on one of the electrodes, passing over to the other when the current reverses during each cycle. The phenomenon may be observed or photographed by means of a revolving mirror.

Fig. 2,603.—Curves by Morris, illustrating the dangerous rush of current which may occur when switching on a transformer. The circuit was broken at F and made again at G. The current was so great as to carry the spot of light right off the photographic plate due to the fact that a residual field was left in the core after switching off, and on closing the switch again the direction of the current was such as to tend to build up the full flux in the same direction as this residual flux. The dotted lines have been drawn in to show how the actual waves were distorted from the normal.

Moving Iron Oscillograph.—This type is due to Blondel, to whom belongs the credit of working out and describing in considerable detail the principles underlying the construction of oscillographs.

The moving iron type of oscillograph consists of a very thin vane of iron suspended in a powerful magnetic field, thus forming a polarized magnet. Near this strip are placed two small coils which carry the current whose wave form is to be measured.

The moving iron vane has a very short period of vibration and can therefore follow every variation in the current.

Fig. 2,604.—Siemens-Blondel moving coil type oscillograph. The coil is in the shape of a loop of thin wire, which is suspended in the field of an electro-magnet excited by continuous current. The current to be investigated is sent through this loop, which in consequence of the interaction of current and magnetic field, begins to vibrate. The oscillations are rendered visible by directing a beam of light from a continuous current arc lamp onto a small mirror fixed to the loop. The light reflected by the mirror is in the form of a light strip, but by suitable means this is drawn out in respect of time, so that a curve truly representing the current is obtained. The loop of fine wire is stretched between two supports and is kept in tension by a spring. As the spring tension is considerable, the directive force of the vibrating system is large, and its natural periodicity very high. The mirror is fixed in the center of the loop, and has an area of 1 square mm. In order to protect the loops from mechanical injury they are built into special frames. The mirrors are of various sizes, the loop for demonstration purposes (projection device) being provided with the largest mirror and the most sensitive loop with a mirror of the smallest dimensions.

Attached to the vane is a small mirror which reflects a beam of light upon some type of receiving device.

The Siemens-Blondel oscillograph shown in fig. 2,604, is of the moving coil type, being a development of the moving iron principle.

Moving Coil Oscillograph.—The operation of this form of oscillograph is based on the behaviour of a movable coil in a magnetic field.

Figs. 2,605 and 2,606.—Oscillograms reproduced from a paper by M. B. Field on "A Study of the Phenomena of Resonance by the Aid of Oscillograms" (Journal of E. E., Vol. XXXII). The effect of resonance on the wave forms of alternators has been the subject of much investigation and discussion; it is a matter of vital importance to the engineer in charge of a large alternating current power distribution system. Fig. 2,605 shows the pressure curve of an alternator running on a length of unloaded cable, the 11th harmonic being very prominent. Fig. 2,606 shows the striking alteration produced by reducing the length of cable in the circuit and thus causing resonance with the 13th harmonic.

It consists essentially of a modified moving coil galvanometer combined with a rotating or vibrating mirror, a moving photographic film, or a falling photographic plate. The galvanometer portion of the outfit is usually referred to as the oscillograph as illustrated in figs. 2,608 to 2,612, representing diagrammatically the moving system.

In the narrow gap between the poles S, S of a powerful magnet are stretched two parallel conductors formed by bending a thin strip of phosphor bronze back on itself over an ivory pulley P. A spiral spring attached to this pulley serves to keep a uniform tension on the strips, and a guide piece L limits the length of the vibrating portion to the part actually in the magnetic field. 1858

A small mirror M bridges across the two strips as shown. The effect of passing a current through such a "vibrator" is to cause one of the strips to advance while the other recedes, and the mirror is thus turned about a vertical axis.

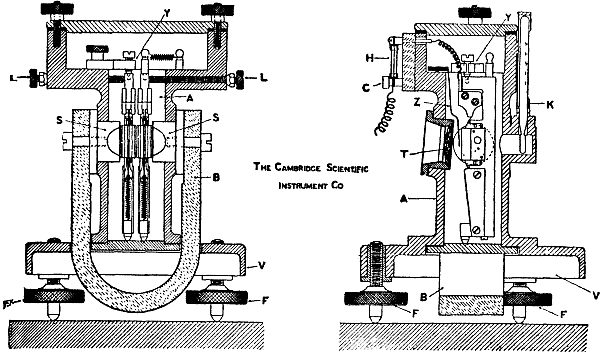

Fig. 2,607.—General view of electro-magnet form of Duddell moving coil oscillograph, showing oil bath and electro-magnet. This instrument is specially designed to have a very high natural period of vibration (about 1/10,000 of a second) so as to be suitable for accurate research work. It is quite accurate for frequencies up to 300 per second. In the figure, A is the brass oil bath in which two vibrators are fixed; B, core of electro-magnet which is excited by two coils, one of which, C, is seen. The ends of these two coils are brought out to four terminals at D, so that the coils may be connected in series for 200 volt, or in parallel for 100 volt circuits. The bolts, E,E, hold the oil bath in position between the poles of the magnet. F,F,F (one not seen), are levelling screws; G,G, terminals of one vibrator; H, fuse; K, thermometer with bulb in center of oil bath.

Figs. 2,608 to 2,612.—Vibrator of Duddell moving coil oscillograph and section through oil bath of electro-magnet oscillograph. The vibrator consists of a brass frame W, which supports two soft iron pole pieces P,P. Between these, a long narrow groove is divided into two parts by a thin soft iron partition, which runs up the center. The current being led in by the brass wire U, passes from an insulated brass plate to the strip, which is led over an ivory guide block, down one of the narrow grooves and over another guide block, the loops round the ivory pulley O, which puts tension on the strip by the spring N, back to the guide block again, up the other narrow groove, and out by way of the insulated brass plate and lead U. Halfway up the grooves the center iron partition R is partially cut away to permit of a small mirror M, bridging across from one strip to the other, being stuck to the strips by a dot of shellac at each corner. The figure illustrates one type of vibrator in which P is removable from W for ease in repairing. In type 1, these pole pieces P,P are not removable. The vibrators are placed side by side in the gap between the poles S,S of the electro-magnet, see fig. 2,610. Each vibrator is pivoted about vertical centers, the bottom center fitting in the base of the oil bath, and the one at the top being formed by a screw in the cock piece Y. It can thus be easily turned in azimuth, its position being fixed by the adjusting screw L, a spiral spring serving to keep the vibrator always in contact with this screw. Since each cock piece can be independently moved forward or backward, each vibrator can be tipped slightly in either of these directions so that complete control over the mirrors is obtained and reflected spots of light may be made to coincide with that reflected from the fixed zero mirror, which latter is fixed to a brass tongue in between the two vibrators. A plano-convex lens of 50 cm. focal length is fixed on the oil bath in front of the vibrator mirrors to converge the reflected beams of light. It will be noticed that this lens is slightly inclined so that no trouble will be given by reflections from its own surface. The normal distance from the vibrator mirrors to the scale of photographic plate is 50 cm., and at this distance, a convenient working deflection on each side of the zero line is 3 to 4 cm. This is obtained with a R.M.S. current through the strips of from .05 to .1 of an ampere according to wave form, etc. The maximum deflection on each side of the zero line should not exceed 5 cm. while the maximum R.M.S. current through the strips should in no case exceed .1 ampere.

Each strip of the loop passes through a separate gap (not shown in the figure). The whole of the "vibrator," as this part of the instrument is called, is immersed in an oil bath, the object of the oil being to damp the movement of the strips, and make the instrument dead beat. It also has the additional advantage of increasing by refraction the movement of the spot of light reflected from the vibrating mirrors.

The beam of light reflected from the mirror M is received on a screen or photographic plate, the instantaneous value of the current being proportional to the linear displacement of the spot of light so formed.

With alternating currents, the spot of light oscillates to and fro as the current varies and would thus trace a straight line.

To obtain an image of the wave form, it is necessary to traverse the photographic plate or film in a direction at right angles to the direction of the movement of the spot of light.

Fig. 2,613.—Duddell moving coil oscillograph with projection and tracing desk outfit. The outfit is designed for teaching and lecture purposes. In operation, after the beam of light from the arc lamp has been reflected from the oscillograph mirrors, it falls on a vibrating mirror which gives it a deflection proportional to time in a direction at right angles to the deflection it already has and which is proportional to the current passing through the oscillograph. It is therefore only necessary to place a screen in the path of the reflected beam of light to obtain a trace of the wave form. Since the vibrating mirror is vibrated by means of a cam on the shaft of a synchronous motor, which motor is driven from, or synchronously with, the source of supply whose wave form is being investigated, the wave form is repeated time after time in the same place on the screen, and owing to the "persistence" of vision, the whole wave appears stationary on the screen. The synchronous motor with its vibrating mirror, mentioned above, is located underneath the "tracing desk." When used in this position a wave a few centimeters in amplitude is seen through a sheet of tracing paper which is bent round a curved sheet of glass. A permanent record of the wave form can thus easily be traced on the paper. A dark box which is designed to hold a sheet of sensitized paper in place of the tracing paper, can be fitted in place of the tracing desk. Thus an actual photographic record of the wave form is obtained. If the synchronous motor be transferred from its position underneath the tracing desk to the space reserved for it close to the oscillograph, the beam of light is then received on a large mirror which is placed at an angle of about 45 degrees to the horizontal and so projects the wave form onto a large vertical screen which should be fixed about two and a half meters distant. Under these conditions a wave form of amplitude 50 cm. each side the zero line may be obtained which is therefore visible to a large audience.

Ques. How are the oscillograms obtained in the Duddell moving coil oscillograph?

Ans. In all cases the oscillograms are obtained by a spot of light tracing out the curve connecting current or voltage with time. 1861 The source of light is an arc lamp, the light from which passes first through a lens, and then, excepting when projecting on a screen, through a rectangular slit about 10 mm. long by 1 mm. wide. The position of the lamp from the lens is adjusted till an image of the arc is obtained covering the three (two moving, one fixed) small oscillograph mirrors. The light is reflected back from these mirrors and, being condensed by a lens which is immediately in front of them, it converges till an image of the slit is formed on the surface where the record is desired. All that is necessary now to obtain a bright spot of light instead of this line image is to introduce in the path of the beam of light a cylindrical lens of short focal length.

Figs. 2,614 and 2,615.—Sectional view of permanent magnet form of Duddell moving coil oscillograph. This instrument has a lower natural period of vibration (1/3000 second) than the type shown in fig. 2,612, and therefore is not capable of accurately following wave forms of such high frequency, but it is sufficiently quick acting to follow wave forms of all ordinary frequencies with perfect accuracy. It is easier to repair, and more portable owing to the fact that the magnetic field is produced by a permanent magnet instead of an electro-magnet. This also renders the instrument suitable for use on high tension circuits without earth connection, as, owing to the fact that no direct current excitation is required, the instrument is more easily insulated than other types.

Ques. What is the function of the mirrors on the vibrating vane? 1862

Fig. 2,616.—Diagram of connections of Duddell oscillograph to high pressure circuit. The modification necessary for high pressure circuit only applies to the vibrator which gives the pressure wave and consists in adding two more resistances, R4 and R5. Referring to fig. 2,617, it will be seen that in case fuse f2 blows, or the vibrator be accidentally broken, the full supply voltage is immediately thrown on the instrument itself. This is not permissible in high voltage work and therefore the resistance R5 is introduced as a permanent shunt to the oscillograph vibrator. The resistance R4 is an exact duplicate of R2 being a 21 ohm plug resistance box for adjusting the sensitivity of the vibrator to an even figure. In practice R5 is usually a part of R1, and in most of the high voltage resistances, two taps are brought out near one end to serve as R5. One of these taps is usually 50 ohms distant from the end terminal and the other only 5 ohms from the end. The use of these taps is as follows: The large resistance consisting of R1 + R5 is so chosen with respect to the voltage of the circuit under investigation that the current through R1 is about .1 ampere. It should never be more than this continuously. Then R4 is connected to the 50 ohm tap, and since the resistance of the oscillograph vibrator circuit is variable from about 5 to 26 ohms by means of R4, the current can be controlled through the oscillograph from about .066 to .091 of an ampere, enabling an open wave form to a convenient scale to be obtained. If it now be desired to record large rises of pressure, such as may occur in cases of resonance, the height of the wave must be reduced in order to keep these rises on the plate. This is accomplished by disconnecting R4 from the 50 ohm tap and connecting it to the 5 ohm tap, when the current through the vibrator will be from .05 to .016 of an ampere according to whether the resistance R4 is in or out of circuit. When, instead of using the falling plate, the cinematograph camera is being used, it becomes necessary always to work on the 5 ohm tap since the width of the film is much less than that of the plate, and the current must therefore be less. In experiments where sudden rises of voltage are expected it is often advisable to keep R1 as great as possible. That end of the resistance R1 referred to as R5 in the diagram should be securely connected to the supply main and no switch or fuse used. A switch may, if desired, be used in series with R1, provided it be inserted at the point where R1 joins the supply main remote from R5. It will be seen that fuses f1 and f2 are shown. Provided that the connections are always made in accordance with the diagram, and the vibrators are always shunted by R5 or R3 respectively, there is not much objection to the use of these fuses, but on general principles it is wise to avoid fuses in high tension work and accordingly with each permanent magnet oscillograph, dummy fuses are supplied, which can be inserted in place of the ordinary fuses when desired. The remark previously made about keeping both vibrators and the frame of the instrument at approximately the same pressure applies with additional emphasis in high pressure work.

1863 Ans. They simply control the direction of a beam of light in a horizontal plane in such a manner that its deflection from a zero position depends on the current passing through the instrument, and it is therefore evident that the oscillograph is not complete without means of producing a time scale.

Fig. 2,617.—Diagram of connections of Duddell oscillograph to low pressure circuit, R1 is a high non-inductive resistance connected across the mains in series with one of the vibrators. S2 is a switch, and f2, the fuse (on the oscillograph in this circuit). The resistance of R1 in ohms should be rather more than ten times the voltage of the circuit, so that a current of a little less than .1 of an ampere will pass through it. The vibrator will then give the curve of the circuit on an open scale. (For the projection oscillograph, the resistance R1 should be only twice the supply voltage, since .5 of an ampere is required to give full scale deflection on a large screen.) To obtain the current wave form, the shunt R3 is connected in series with the circuit under investigation and the second vibrator is connected across this shunt. Here also f1 is a fuse, S1 a switch, and R2 an adjustable resistance box. The switch S1 is however unnecessary if the plug resistance box supplied for R2 be used, since an infinity plug is included in this box. The shunt R3 should have a drop of about 1 volt across it in order to give a suitable working current through the vibrator. The resistance R2 is not absolutely essential, but it is a great convenience in adjusting the current through the vibrator. It is a plug resistance box, the smallest coil being .04 of an ohm and the total 21 ohms. Being designed to carry .5 ampere continuously it can be used with any other type of Duddell oscillograph, and by its use the sensitiveness of the vibrator can be adjusted so that a round number of amperes in the shunt gives 1 mm. deflection. This adjustment is best made with direct current. It should be noted in connecting the oscillograph in circuit, that the two vibrators should be so connected to the circuit that it is impossible that a higher pressure difference than 50 volts should exist between one vibrator and the other, or between either vibrator and the frame. To ensure attention to this important point, a brass strap is provided which connects the two vibrators together and to the frame of the instrument. This does not mean that this point must necessarily be earthed since the frame of the instrument is insulated from the earth. It is advisable, however, to earth it when possible.

Figs. 2,618 and 2,619.—Two curves obtained with the falling plate camera and illustrating the discharge of a condenser through an inductive circuit. When taking curve A the resistance in the circuit was very small compared to the inductance, while before taking curve B an additional non-inductive resistance was inserted in the circuit so that the oscillations were damped out much more rapidly although the periodic time remained approximately constant.

Ques. How is the time scale produced?

Ans. Either the surface on which the beam of light falls may be caused to move in a vertical plane with a certain velocity, so that the intersection of the beam and the plane surface traces out a curve connecting current with time (a curve which becomes a permanent record if a sensitized surface be used); or, the surface may remain stationary and in the path of the horizontally vibrating beam may be introduced a mirror which rotates or vibrates about a horizontal 1865 axis, thus superposing a vertical motion proportional to time on the horizontal vibration which is proportional to current, and causing the beam of light to trace out a curve connecting current and time on the stationary surface.

Ques. What kind of recording apparatus is used with the Duddell oscillograph?

Ans. A falling plate camera, or a cinematograph film camera.

Fig. 2,620.—Synchronous motor with vibrating mirror as used with Duddell moving coil oscillograph. Since the motor must run synchronously with the wave form it is required to investigate, it should be supplied with current from the same source. The motor can be used over a wide range of frequencies (from 20 to 120). When working at frequencies below 40, it is advisable to increase the moment of inertia of the armature, and for this purpose a suitable brass disc is used. The armature carries a sector, which cuts off the light from the arc lamp during a fraction of each revolution, and a cam which rocks the vibrating mirror. It makes one revolution during two complete periods, and the cam and sector are so arranged that during 1½ periods, the mirror is turning with uniform angular velocity, while during the remaining half period, the mirror is brought back quickly to its angular position, the light being cut off by the sector during this half period.

1866 Ques. Explain the operation of the falling plate camera.

Ans. In this arrangement a photographic plate is allowed to fall freely by the force of gravity down a dark slide. At a certain point in its fall it passes a horizontal slit through which the beams of light from the oscillograph pass, tracing out the curves on the plate as it falls.

Figs. 2,621 to 2,623.—Interior of cinematograph camera as used on Duddell moving coil oscillograph for obtaining long records. The loose side of case is shown removed and one of the reels which carry the film lying in front. The spool of film which is placed on the loose reel A, passes over the guide pulley B, then vertically downward between the brass gate D (shown open in the figure), and the brass plate C. The exposure aperture is in the plate C and can be opened or closed by a shutter controlled by the lever M. The groove in the plate C, and the springs which press the gate D flat on the plate C, prevent the film having any but a vertical motion as it passes the exposure slit. E is the sprocket driving pulley which engages with the perforations on the film and unwinds it from the reel A to reel H. Outside the case on the far side of it is secured to the axle G a three speed cone pulley. This is driven by a motor of about 1/7 horse power, which also drives, through the gears shown, the sprocket pulley E. Close to the grooved cone pulley is a lever carrying a jockey pulley L, and a brake, which latter is normally held onto the cone pulley by a spring and so causes the loose belt to slip. By pressing a lever which is attached to the falling plate camera case, the brake can be suddenly released and at the same time the jockey pulley caused to tighten the belt onto the grooved cone pulley, so that the starting and stopping of the film is controlled independently of the driving motor, and being quickly accomplished avoids waste of film. Both reels are alike and each is made in two pieces. The upper reel is loose on its axle and its motion is retarded slightly by a friction brake. The lower reel is also loose on its axle, but it is driven by means of a friction clutch, the clutch always rotating faster than the reel so that the used film delivered by the sprocket pulley E is wound up as fast as delivered. K is the front face of one reel, the boss on it pushes into the tube on the other half H, which serves not only to unite the two halves, but also to secure the end of the film which is doubled through J.

The mean speed of the plate at the moment of exposure is about 13 feet per second. This speed is very suitable for use with frequencies 1867 of from 40 to 60 periods per second. A cloth bag is used to introduce the plate to the slide.

A catch holds the plate until it is desired to let it fall. Inside the case, is a small motor, 100 or 200 volts direct current, driving four mirrors which are fixed about a common axis with their planes parallel to it.

Fig. 2,624.—Portion of oscillograph record taken with cinematograph film camera, showing the rush of current and sudden rise of voltage at the moment of switching on a high pressure feeder.

By looking through a small slot in the end of the camera into these rotating mirrors, the observer sees the wave form which the oscillograph is tracing out and is thus able to make sure that he is obtaining the particular wave form or other curve desired before exposing the plate.

Fig. 2,625.—Portion of oscillograph record taken with a cinematograph film camera showing the effect of switching off a high pressure feeder and illustrating the violent fluctuations produced by sparking at the switch contacts.

The plate falls into a second red cloth bag which is placed on the bottom of the slide. The plates used are "stereoscopic size", 6¾" × 3¼" (17.1 × 8.3 cm.).

Ques. For what use is the cinematograph camera adapted?

Ans. For long records. 1868

For instance, in investigations, such as observation on the paralleling of alternators, the running up to speed of motors, and the surges which may occur in switching on and off cable, etc. The cinematograph camera fits on to the falling plate case and by means of which a roll of cinematograph film can be driven at a uniform speed past the exposure aperture, enabling records up to 50 metres in length to be obtained. An interior view of the cinematograph camera is shown in fig. 2,621.

Fig. 2,626.—Curves reproduced from an article by J. T. Morris in the Electrician. "On recording transitory phenomena by the oscillograph."

Fig. 2,627.—First rush of current from an alternator when short circuited, showing unsymmetrical initial wave of current, becoming symmetrical after a few cycles. 25 cycles.

Fig. 2,628.—Pressure wave obtained from narrow exploring coil on alternator armature, indicating distribution of field flux. The terminal voltage of the alternator is very nearly a sine wave, 60 cycles; about 17 volts.

1869 SOME OSCILLOGRAPH RECORDS

Fig. 2,629.—The waves of voltage and current of an alternating arc. A, voltage wave; B, current wave showing low power factor of the arc without apparent phase displacement. 60 cycles.

Fig. 2,630.—Rupturing 650 volt circuit. A, current wave; B, 25 cycle wave to mark time scale.

Fig. 2,631.—First rush of current from alternator when short circuited, showing unsymmetrical current wave, also wave of field current caused by short circuit current in armature. Upper curve, armature current; lower curve, field current.

Fig. 2,632.—Mazda (tungsten) lamp, showing rapid decrease to normal current as filament heats up. 25 cycles.

Fig. 2,633.—Current wave in telephone line corresponding to sustained vowel sound "i," as in machine; voice pitched at A 110.

Fig. 2,635.—Short circuit current on direct current end of rotary converter, 21,500 amperes maximum. Upper curve, direct current voltage; lower curve, direct current amperage. Duration of short circuit about .1 second.

General Principles of Switchboard Connections.—The interconnection of generators, transformers, lines, bus bars, and switches with their relays, in modern switchboard practice is shown by the diagrams, figs. 2,636 to 2,645. The figures being lettered A to J for simplicity, the generators are indicated by black discs, and the switches by open circles, while each heavy line represents a set of bus bars consisting of two or more bus bars according to the system of distribution. It will be understood, also, in this connection, that the number of pole of the switches and the type of switch will depend upon the particular system of distribution employed.

Diagram A, shows the simplest system, or one in which a single generator feeds directly into the line. There are no transformers or bus bars and only one switch is sufficient.

In B, a single generator supplies two or more feeders through a single set of bus bars, requiring a switch for each feeder, and a single generator switch.

In C, two generators are employed and required and the addition of a bus section switch.

D, represents a number of generators supplying two independent circuits. The additional set of bus bars employed for this purpose necessitates an additional bus section switch, and also additional selector switches for both feeders and generators.

E, shows a standard system of connection for a city street railway system having a large number of feeders.

1873 This arrangement allows any group of feeders to be supplied from any group of generators.

Fig. 2,646.—Fort Wayne switchboard panel for one alternator and one transfer circuit. Diagram giving dimensions, arrangement of instruments of board, and method of wiring. The different forms of standard alternating current switchboard panels for single phase circuits made by the Fort Wayne Electric Works are designed to fulfill all the usual requirements of switchboards for this class of work. The line includes panels equipped for a single generator; for one generator and two circuits; one generator and one transfer circuit; one generator, an incandescent and an arc lighting circuit; and also feeder panels of different kinds.

It also permits the addition of a generator switch for each generator.

F, represents the simplest system with transformers.

It requires a single generator transformer bank, switch and line. The arrangement as show at F is used where a number of plants supply the same system.

G, represents a system having more than one line.

In this case a bus bar and transformer switch is used on the high tension side.

H, shows a number of generators connected to a set of low tension bus bars through generator switches, and employing a low tension transformer switch. 1874

I, shows the connections of a system having a large number of feeders supplied by several small generators. In this case, the plant is divided into two parts, each of which may be operated independently.

J, represents the arrangement usually employed in modern plants where the generator capacity is large enough to permit of a generator transformer unit combination with two outgoing lines. By operating in parallel on the high tension side only, any generator can be run with any transformer. The whole plant can be run in parallel, or the two parts can be run separately.

Fig. 2,647.—General Electric small plant alternating current switchboard, designed for use in small central stations and isolated plants. They are for use with one set of bus bars, to which all generators and feeders are connected by means of single throw lever switches or circuit breakers, suitable provision being made for the parallel operation of the generators.

Fig. 2,648.—Crouse-Hinds voltmeter and ground detector radial switch, arranged for mounting on the switchboard. The switch proper is placed on the rear of the board with hand wheel, dial, and indicator only on the front side. The current carrying parts are of hard brass, with contact surfaces machined after assembling. The contact parts are of the plunger spring type, and the cross bar has fuse connections. Ground detector circuits are marked G+ and G- for two wire system, and G+, G-, GN+ and GN- for three wire system. When the voltmeter switch is to be used as a ground detector, two circuits are required for a two wire system, and four circuits for a three wire system, that is, a six circuit voltmeter and ground detector switch for use on a two wire system has two circuits for ground detector and four circuits for voltmeter readings. A six circuit voltmeter and ground detector switch, for use on a three wire system, has four circuits for ground detector and two circuits for voltmeter readings.

Switchboard Panels.—The term "panel" means the slab of marble or slate upon which is mounted the switches, and the indicating and controlling devices. There are usually several panels comprising switchboards of moderate or large size, these panels being classified according to the division of the system that they control, as for instance: 1876

1. Generator panel;

2. Feeder panel;

3. Regulator panel, etc.

In construction, the marble or slate should be free from metallic veins, and for pressures above, say, 600 volts, live connections, terminals, etc., should preferably be insulated from the panels by ebonite, mica, or removed from them altogether, as is generally the case with the alternating gear where the switches are of the oil type.

Figs. 2,649 and 2,650,—Wiring diagrams of Crouse-Hinds voltmeter and ground detector switches. Fig. 2,649 voltmeter switch; fig. 2,650 voltmeter and ground detector switch. A view of the switch is shown in fig. 2,648; it is designed for use on two or three wire systems up to 300 volts.

The bus bars and connections should be supported by the framework at the back of the board, or in separate cells, and the instruments should be operated at low pressure through instrument transformers.

The panels are generally held in position by bolting them to an angle iron, or a strip iron framework behind them.

1877 Generator Panel.—This section of a switchboard carries the instruments and apparatus for measuring and electrically controlling the generators. On a well designed switchboard each generator has, as a rule, its own panel.

Figs. 2,651 to 2,653.—Diagrams of connections for generator panels. Key to symbols: A, ammeter; A.S., ammeter switch; C.T., current transformer; F., fuse; F.A., direct current field ammeter; F.S., field switch; G.C.S., governor control switch; L.S., limit switch (included with governor motor); O.S., oil switch; P.I.W., polyphase indicating wattmeter; P.W.M., polyphase watthour meter; P.R., pressure receptacle; P.P., pressure plug; Rheo., rheostat; S., shunt; S.R., synchronizing receptacle; S.P., synchronizing plugs; T.B., terminal board for instrument leads; V, alternating current voltmeter.

Figs. 2,654 and 2,655.—Diagrams illustrating a simple method of determining bus capacity as suggested by the General Electric Co. Fig. 2,654 relates to any panel; the method is as follows: 1. Make a rough plan of the entire board, regardless of the number of panels to be ordered. The order of panels shown is recommended, it being most economical of copper and best adapted to future extensions. 2. To avoid confusion keep on one side of board everything pertaining to exciter buses, and on other side everything pertaining to A. C. buses. 3. With single lines represent the exciter and A. C. buses across such panels as they actually extend and by means of arrows indicate that portion of each bus which is connected to feeders and that portion which is connected to generators. Remember that "Generator" and "Feeder" arrows must always point toward each other, otherwise the rules given below do not hold. Note also that the field circuits of alternator panels are treated as D. C. feeders for the exciter bus. 4. On each panel mark its ampere rating, that is, the maximum current it supplies to or takes from the bus. For A. C. alternator panels the D. C. rating is the excitation of the machines. 5. Apply the following rules consecutively, and note their application in fig. 2,654. (For the sake of clearness ampere ratings are shown in light face type and bus capacities in large type.) A. Always begin with the tail of the arrow and treat "generator" and "feeder" sections of the bus separately. B. Bus capacity for first panel = ampere rating of panel. C. Bus capacity for each succeeding panel = ampere rating of panel plus bus capacity for preceding panel. (See sums marked above the buses in fig. 2,654.) D. For a panel not connected to a bus extending across it, use the smaller value of the bus capacities already obtained for the two adjoining panels. (See exciter bus for panel C.) E. The bus capacity for any feeder panel need not exceed the maximum for the generator panels (see A. C. bus for panel G) and vice versa (see exciter bus for panel B). Hence the corrections made in values obtained by applying rules B and C. The arrangement of panels shown in fig. 2,654 is the one which is mostly used. The above method may, however, be applied to other arrangements, one of which is shown in fig. 2,655. Here the generators must feed both ways to the feeders at either end of the board so that in determining A. C. bus capacities it is necessary to first consider the generators with the feeders at one end, and then with the feeders at the other end as shown by the dotted A. C. buses. The required bus capacities are then obtained by taking the maximum values for the two cases.

Fig. 2,656.—End view showing general arrangement of switchboards for 240, 480, and 600 volt alternating current. The cut shows a single throw oil switch mounted on the panel.

In the case of a dynamo, a good representative panel would have mounted upon it a reverse current circuit breaker, an ammeter, a double pole main switch (or perhaps a single pole switch, since the circuit breaker could also be used as a switch) a double pole socket into which a plug could be inserted to make connection with a voltmeter mounted on a swinging bracket at the end of the board; a 1880 rheostat handle, the spindle of which operates the shunt rheostat of the machine, the rheostat being placed either directly behind the spindle, if of small size, or lower down with chain drive from the hand wheel spindle, if of larger size, a field discharge switch and resistance, a lamp near the top of the panel for illuminating purposes, a fuse for the voltmeter socket, and, if desired, a watthour meter. If the dynamo be compound wound, the equalizing switch will generally be mounted on the frame of the machine, and in some cases the field rheostat will be operated from a pillar mounted in front of the switchboard gallery. If the generator be for traction purposes, the circuit breaker is more often of the maximum current type, and a lightning arrester is often added, without a choke coil, the latter as well as further lightning arresters being mounted on the feeder panels.

Figs. 2,657 and 2,658.—Two views of a feeder panel, showing general arrangement of the devices assembled thereon. A, circuit breaker; B, ammeter; C, voltmeter; D, switches.

In the case of a high pressure alternating current plant of considerable size, the bus bars oil switches, and the current and 1881 pressure transformers are generally mounted either in stoneware cells, or built on a framework in a space guarded by expanded metal walls, and no high pressure apparatus of any sort is brought on to the panels themselves.

Figs. 2,659 to 2,666.—Diagram of connections for three phase feeder panels. Key to symbols: A, ammeter; A.S., three way ammeter switch; B.A.S., bell alarm switch; C.T., current transformer; F, fuse; O.S., oil switch; P.I.W., polyphase indicating wattmeter; P.W.M., polyphase watthour meter; T.B., terminal board; T.C., trip coils for oil switch.

Feeder Panel.—The indicating and control apparatus for a feeder circuit is assembled on a panel called the feeder panel.

The most common equipment in the case of a direct current feeder panel comprises an ammeter, a double pole switch, and double pole fuses or instead of the fuses, a circuit breaker on one or both poles; in the case of a traction feeder a choke coil and a lightning arrester are often added. 1882

Figs. 2,667 and 2,668.—Diagrams of connections for two phase and three phase installations: A and A1, ammeter; C.C., constant current transformer; C.T., current transformer; D.R., discharge resistance; F, fuse; F.S., field switch; L.A., lightning arrester; O.S., oil switch; P.P., pressure plug; P.R., pressure receptacle; P.T., pressure transformer; S and S1, plug switches; T.C., oil switch trip coil; V, voltmeter.

The equipment of a typical high pressure three phase feeder panel is an ammeter (sometimes three ammeters, one in each phase) operated by a current transformer, and oil break switch with two overload release coils, or three if the neutral of the circuit be earthed, the releases being operated by current transformers.

Fig. 2,669.—Crouse-Hinds radial ammeter switch, arranged for mounting directly on the switchboard. It is designed for use with external shunt ammeters of any make or capacity, and in connection with the required number of shunts, makes possible the taking of current readings of a corresponding number of circuits by means of one ammeter. The wiring diagram is shown in fig. 2,670.

The switch when on a large system is often in a cell some distance behind the panel, and is then controlled by a system of levers, or by a small motor which is started and stopped by a throw over switch on the panel, in which case there is generally a lamp or lamps on the panel to show whether the switch is open or closed. 1884

Air brake switches or links are placed between the bus bars and the oil switch to allow of the latter being isolated for inspection purposes, and as a general rule no apparatus carrying high pressure current is allowed on the front of the panel. With both direct and alternating current feeders, a watthour meter is often added to show the total consumption of the circuit.

Fig. 2,670.—Wiring diagram for Crouse-Hinds radial ammeter switch as illustrated in fig. 2,669. The switch proper is on the rear of the switchboard, and the hand wheel dial and indicator on the front.

A typical three phase generator panel is provided with three ammeters, one in each phase, operated from three current transformers, one to each ammeter, a volt meter, a power factor indicator, and an indicating watthour meter, all operated from one or more pressure transformers, and the necessary current transformers, the operating handle of the oil switch, which is connected to the switch itself by means of rods, two maximum releases operated by current transformers, or a reverse relay for automatically tripping the switch, lamps for indicating when the switch is tripped, a socket for taking the plug which makes connection between the secondary of a pressure transformer and the synchronizer on the synchronizing panel, and a lamp for illuminating purposes, while on the base of the panel or on a pillar at the front of the gallery is mounted the gear for the field circuit. This consists of a double pole field switch and a discharge resistance, an ammeter, a handle for the rheostat in the generator field, and (if each alternator have its own direct coupled exciter) possibly also a small rheostat for the exciter field.

NOTE.—In some cases where the capacity of the plant is not very great, the oil switch is mounted on the back of the panel, and the bus bars, current transformers, &c., on the framework, also just at the back of the panel, but under no circumstances, in good modern practice, is high pressure apparatus permitted on the front of the board. Where the capacity of the plant is very large, the oil switches are operated electrically by means of small motors, and in this case the small switch gear for starting and stopping this motor is mounted on the generator panel, also the lamp or lamps to indicate when the switch is open, and when closed.

In the case of alternating current, because of its peculiar behaviour, there are several effects which must be considered in making wiring calculations, which do not enter into the problem with direct current.

Accordingly, in determining the size of wires, allowance must be made for

1. Self-induction;

2. Mutual-induction;

3. Power factor;

4. Skin effect;

5. Corona effect;

6. Frequency;

7. Resistance.

Most of these items have already been explained at such length, that only a brief summary of facts need be added, to point out their connection and importance with alternating current wiring.

Induction.—The effect of induction, whether self-induction or mutual induction, is to set up a back pressure of spurious resistance, which must be considered, as it sometimes materially affects the calculation of circuits even in interior wiring.

Self-induction is the effect produced by the action of the electric current upon itself during variations in strength.

1886 Ques. What conditions besides variations of current strength governs the amount of self-induction in a circuit?

Ans. The shape of the circuit, and the character of the surrounding medium.

If the circuit be straight, there will be little self-induction, but if coiled, the effect will become pronounced. If the surrounding medium be air, the self-induction is small, but if it be iron, the self-induction is considerable.

Figs. 2,671 to 2,676.—The effect of self-induction. In a non-inductive circuit, as in fig. 2,672, the whole of the virtual pressure is available to cause current to flow through the lamp filament, hence it will glow with maximum brilliancy. If an inductive coil be inserted in the circuit as in fig. 2,674, the reverse pressure due to self-induction will oppose the virtual pressure, hence the effective pressure (which is the difference between the virtual and reverse pressures), will be reduced and the current flow through the lamp diminished, thus reducing the brilliancy of the illumination. The effect may be intensified to such degree by interposing an iron core in the coil as in fig. 2,676, as to extinguish the lamp.

Ques. With respect to self-induction, what method should be followed in wiring?

Ans. When iron conduits are used, the wires of each circuit should not be installed in separate conduits, because such arrangement will cause excessive self-induction.

The importance of this may be seen from the experience of one contractor, who installed feeders and mains in separate iron pipes. 1887 When the current was turned on, it was found that the self-induction was so great as to reduce the pressure to such an extent that the lamps, instead of giving full candle power, were barely red. This necessitated the removal of the feeders and main and re-installing them, so that those of the same circuit were in the same pipe.

Ques. What is mutual induction?

Ans. Mutual induction is the effect of one alternating current circuit upon another.

Fig. 2,677.—Measurement of self induction when the frequency is known. The apparatus required consists of a high resistance or electrostatic a.c. voltmeter, d.c. ammeter, and a non-inductive resistance. Connect the inductive resistance to be measured as shown, and close switch M, short circuiting the ammeter. Connect alternator in circuit and measure drop across R and across Xi. Disconnect alternator and connect battery in circuit, then open switch M and vary the continuous current until the drop across R is the same as with the alternating current, both measurements being made with the same voltmeter; read ammeter, and measure drop across Xi. Call the drop across Xi with alternating current E, and with direct current Ei, and the reading of the ammeter J. Then L = √E2 + Ei2 ÷ 2π f I. If the resistance Xi be known, and the ammeter be suitable for use with alternating current, the switch and R may be dispensed with.

Then L = √E2 - Xi2 Ii2 ÷ 2π f I, where Ii is the value of the alternating current. The resistance of the voltmeter should be high enough to render its current negligible as compared with that through Xi.

Ques. How is it caused?

Ans. It is due to the magnetic field surrounding a conductor cutting adjacent conductors and inducing back pressures therein.

This effect as a rule in ordinary installations is negligible. 1888

Transpositions.—The effect of mutual induction between two circuits is proportional to the inter-linkage of the magnetic fluxes of the two lines. This in turn depends upon the proximity of the lines and upon the general relative arrangement of the conductors.

Fig. 2,679.—Transposition diagram for three phase, three wire line, transposing at the vertices of an equilateral triangle. The line is originally balanced and becomes unbalanced on transposing, a procedure which should be resorted to only to prevent mutual induction.

Fig. 2,680.—Transposition diagram of three phase, three wire line, with center arranged in a straight line.

The inductive effect of one line upon another is equal to the algebraic sum of the fluxes due to the different conductors of the first line, considered separately, which link the secondary line. 1889

The effect of mutual induction is to induce surges in the line where a difference of frequency exists between the two currents, and to induce high electrostatic charges in lines carrying little or no current, such as telephone lines.

| Size B.&S. | Diam. (inches) |

Distance d (inches) |

Self Inductance L (henrys) |

|---|---|---|---|

| 0000 | .46 | 12 | .00234 |

| 18 | .00256 | ||

| 24 | .00270 | ||

| 48 | .00312 | ||

| 000 | .41 | 12 | .00241 |

| 18 | .00262 | ||

| 24 | .00277 | ||

| 48 | .00318 | ||

| 00 | .365 | 12 | .00248 |

| 18 | .00269 | ||

| 24 | .00285 | ||

| 48 | .00330 | ||

| 0 | .325 | 12 | .00254 |

| 18 | .00276 | ||

| 24 | .00293 | ||

| 48 | .00331 | ||

| 1 | .289 | 12 | .00260 |

| 18 | .00281 | ||

| 24 | .00308 | ||

| 48 | .00338 | ||

| 2 | .258 | 12 | .00267 |

| 18 | .00288 | ||

| 24 | .00304 | ||

| 48 | .00314 | ||

| 3 | .229 | 12 | .00274 |

| 18 | .00294 | ||

| 24 | .00310 | ||

| 48 | .00351 | ||

| 4 | .204 | 12 | .00280 |

| 18 | .00300 | ||

| 24 | .00315 | ||

| 48 | .00358 | ||

| 5 | .182 | 12 | .00286 |

| 18 | .00307 | ||

| 24 | .00323 | ||

| 48 | .00356 | ||

| 6 | .162 | 12 | .00291 |

| 18 | .00313 | ||

| 24 | .00329 | ||

| 48 | .00369 | ||

| 7 | .144 | 12 | .00298 |

| 18 | .00310 | ||

| 24 | .00336 | ||

| 48 | .00377 | ||

| 8 | .128 | 12 | .00303 |

| 18 | .00325 | ||

| 24 | .00341 | ||

| 48 | .00384 | ||

| 9 | .114 | 12 | .00310 |

| 18 | .00332 | ||

| 24 | .00348 | ||

| 48 | .00389 | ||

| 10 | .102 | 12 | .00318 |

| 18 | .00340 | ||

| 24 | .00355 | ||

| 48 | .00396 |

1890 This effect may be nullified by separating the lines and by transposing the wires of one of the lines so that the effect produced in one section is opposed by that in another. Of two parallel lines consisting of two wires each, one may be transposed to neutralize the mutual inductance.

Fig. 2,678 shows this method. The length L' should be an even factor of L so that to every section of the line transposed there corresponds an opposing section.

Fig. 2,681.—Capacity effect in single phase transmission line. The effect is the same as would be produced by shunting across the line at each point an infinitesimal condenser having a capacity equal to that of an infinitesimal length of circuit. For the purpose of calculating the charging current, a very simple and sufficiently accurate method is to determine the current taken by a condenser having a capacity equal to that of the entire line when charged to the pressure on the line at the generating end. The effect of capacity of the line is to reduce the pressure drop, that is, improve the regulation, and to decrease or increase the power loss depending on the load and power factor of the receiver.

Fig. 2,682.—Capacity effect in a three phase transmission line. It is the same as would be produced by shunting the line at each point by three infinitesimal condensers connected in star with the neutral point grounded, the capacity of each condenser being twice that of a condenser of infinitesimal length formed by any two of the wires. The effect of capacity on the regulation and efficiency of the line can be determined with sufficient accuracy in most cases by considering the line shunted at each end by three condensers connected in star, the capacity of each condenser being equal to that formed by any two wires of the line. An approximate value for the charging current per wire is the current required to charge a condenser, equal in capacity to that of any two of the wires, to the pressure at the generating end of the line between any one wire and the neutral point.

The self inductance of lines is readily calculated from the following formula:

L = .000558 {2.303 log (2A ÷ d) + .25} per mile of circuit

where

L = inductance of a loop of a three phase circuit in henrys.

Note.—The inductance of a complete single phase circuit = L × 2 ÷ √3.

A = distance between wires;

d = diameter of wire.

| Size B.&S. | Diam. (inches) |

Distance d (inches) |

Capacity C (μfarads) |

|---|---|---|---|

| 0000 | .46 | 12 | .0226 |

| 18 | .0204 | ||

| 24 | .01922 | ||

| 48 | .01474 | ||

| 000 | .41 | 12 | .0218 |

| 18 | .01992 | ||

| 24 | .01876 | ||

| 48 | .01638 | ||

| 00 | .365 | 12 | .0124 |

| 18 | .01946 | ||

| 24 | .01832 | ||

| 48 | .01604 | ||

| 0 | .325 | 12 | .02078 |

| 18 | .01898 | ||

| 24 | .01642 | ||

| 48 | .01570 | ||

| 1 | .289 | 12 | .02022 |

| 18 | .01952 | ||

| 24 | .01748 | ||

| 48 | .0154 | ||

| 2 | .258 | 12 | .01972 |

| 18 | .01818 | ||

| 24 | .01710 | ||

| 48 | .01510 | ||

| 3 | .229 | 12 | .01938 |

| 18 | .01766 | ||

| 24 | .01672 | ||

| 48 | .01480 | ||

| 4 | .204 | 12 | .01874 |

| 18 | .01726 | ||

| 24 | .01636 | ||

| 48 | .01452 | ||

| 5 | .182 | 12 | .01830 |

| 18 | .01690 | ||