*** START OF THE PROJECT GUTENBERG EBOOK 50927 ***

Link to Contents.

Link to Classified Index of Advertisements.

Link to Colored plates.

Link to Index.

Scientific American

Architects and Builders edition.

No. 26

With Two Supplements consisting of

Two Plates in Colors and One Large Sheet of Details.

DECEMBER, 1887 Single Copies, 25 Cents.—$2.50 a Year

Copyrighted, 1887, By Munn & Co.

New York: Published by MUNN & CO., 361 Broadway, corner Franklin Street.

ii

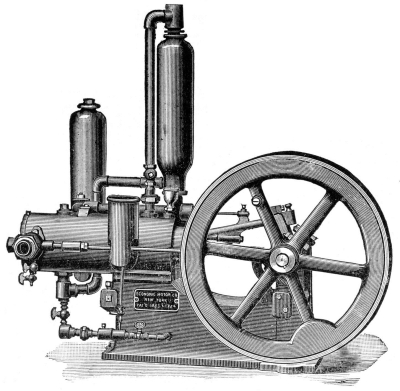

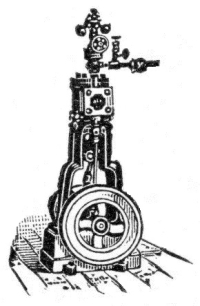

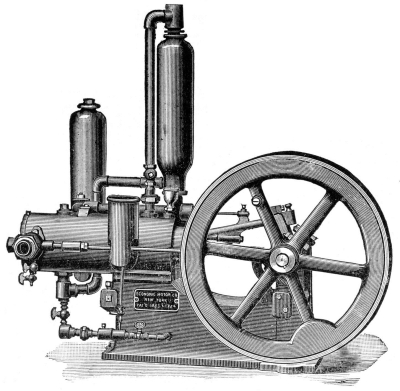

Economic ✠ Gas ✠ Engines.

Best in principle, workmanship, and materials. An unequalled small

Motor adapted to all uses. When the Motor is not at work, the expense

of running it ceases. Simple, Safe, Economical, Durable. No extra

Insurance required.

PLUMBERS’ GAS ENGINE.

Especially adapted for pumping water in Private and Apartment

Houses, Flats, Small Hotels, and many other places.

No. 6.1 Man.

Capacity 250 Gallons, 50 feet high, per hour.

LARGER SIZES.

No. 7. One‐Half Horse, 600 Gallons, 50 feet High, per Hour.

No. 8. One Horse, – 1,500

„

„

„ „

GASOLINE GAS ENGINES.

No. 15. One Man, – 300 Gallons, 50 feet High, per Hour.

No. 16. One‐Half Horse, 600

„

„

„ „

No. 18, One Horse, – 1,500

„

„

„ „

Four Sizes, from Motor for Sewing Machine or Dental Engine to One Horse

Power.

Our Gas Engines will work satisfactorily when attached to Gasoline

Machines.

SEND FOR ILLUSTRATED CATALOGUE.

Economic Gas Engine Co.,

Office and Salesroom, 34 DEY ST., NEW YORK.

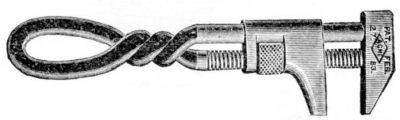

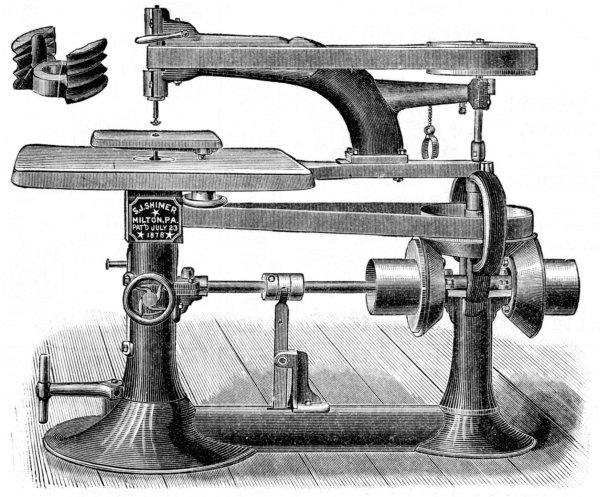

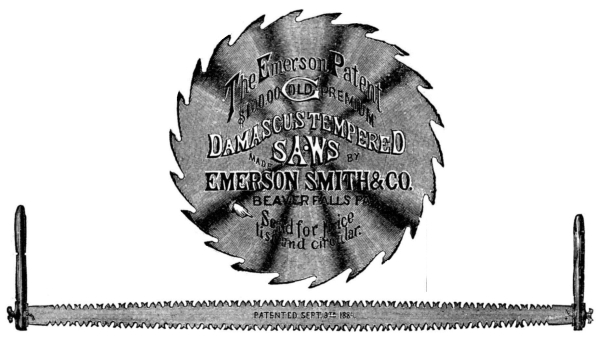

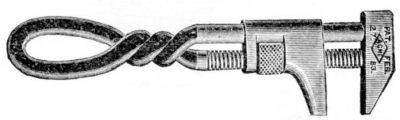

STAR HACK SAW.

No. 2.

This Saw is much harder than a file, and will cut iron almost as fast

as it will wood. One saw blade will cut off a bar of half‐inch round

iron one hundred times. The blade is eight inches long, and will do

most of the sawing required about a house, shop, or farm. The Patent

Frame is made of steel, polished and nickel plated. It will face the

saw in four directions, as desired. Frame and twelve Saw Blades sent

by mail, postage prepaid, on receipt of $1.50. Hardware dealers will

furnish them at the same price. All genuine goods are marked with a

star and bear our name. We also have full control of the Star Bracket

Saws, and warrant them to be better than any imported blades.

MILLER’S FALLS CO., 93 Reade Street, New York.

A

FIRST CLASS

OFFICE BUILDING

SHOULD BE Furnished With

A

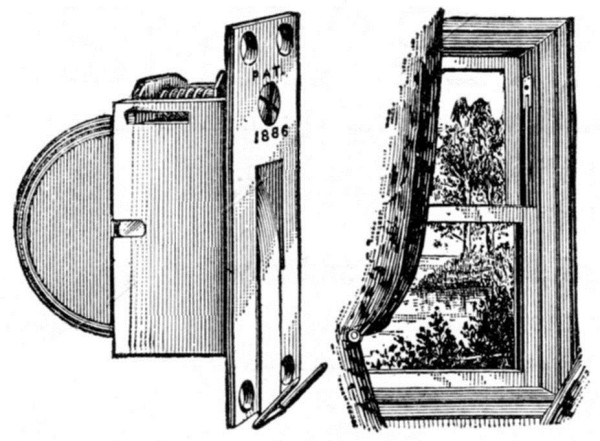

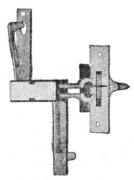

U. S. MAIL CHUTE

(PAT’D.) Connecting EVERY STORY with

THE U. S.MAIL BOX.

ADDRESS FOR CIRCULARS, &c.,

CUTLER MF’G. CO.

“A NECESSITY.” Sole Makers, ROCHESTER, N. Y.

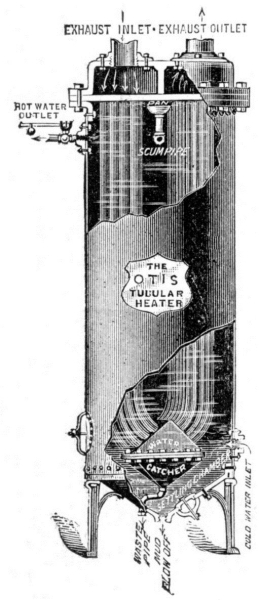

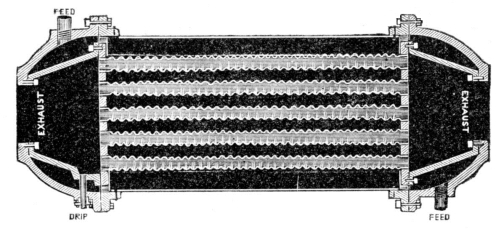

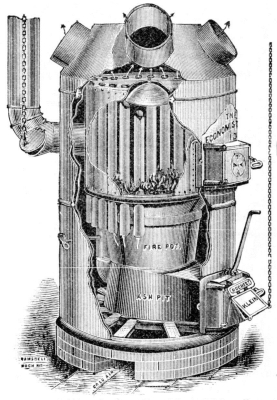

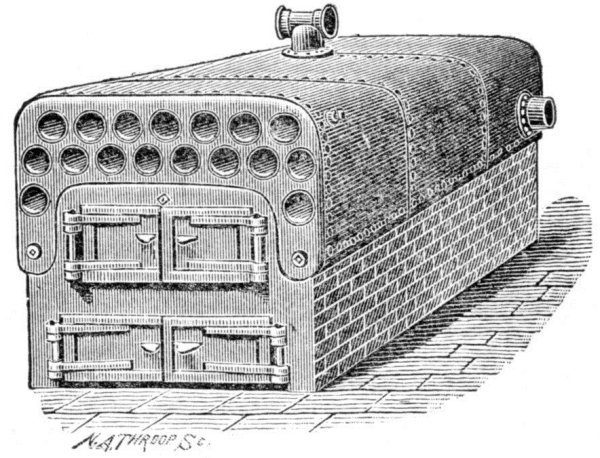

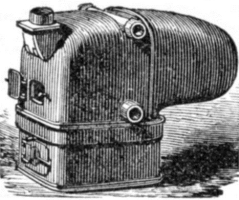

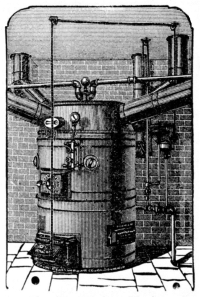

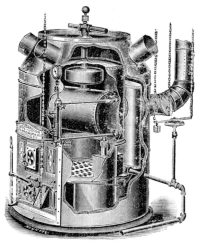

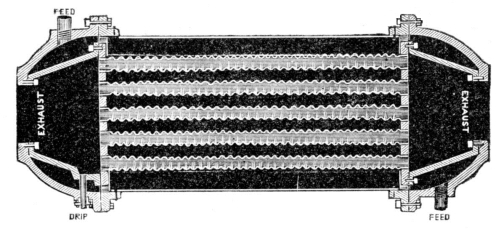

THE OTIS TUBULAR FEED WATER HEATER

With Seamless Brass Tubes and the most recent improvements.

Specially adapted for utilizing the exhaust steam of

ELEVATOR

PUMPS,

both Passenger and Freight, to heat the Feed Water for the boilers.

We guarantee one square foot of heating surface per horse power.

We can give reference from Heaters already in operation under the same

conditions, giving the best of satisfaction.

MANUFACTURED

BY

Stewart Heater

COMPANY,

40 & 42 Clinton Street,

BUFFALO, N. Y.

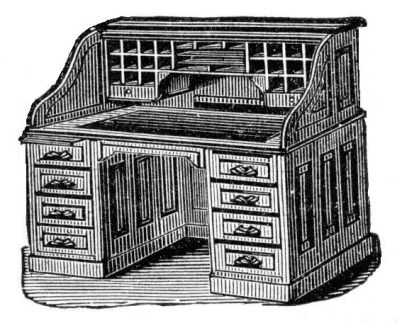

DESKS

—AND—

OFFICE

FURNITURE

In Great Variety

MANUFACTURED BY

T. G. SELLEW,

111 Fulton Street,

NEW YORK.

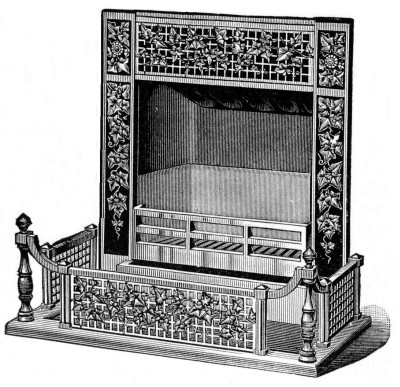

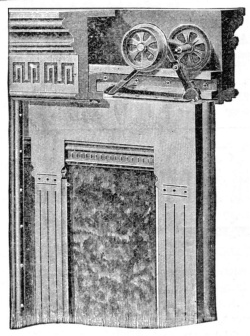

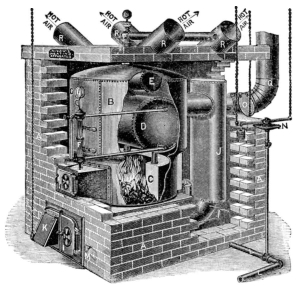

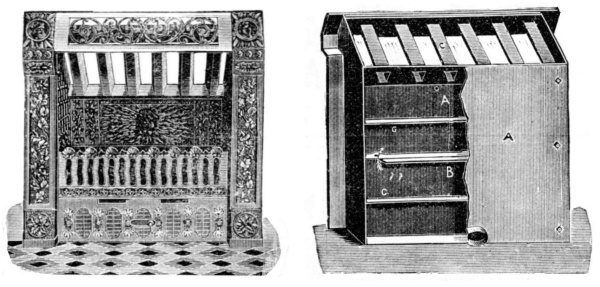

THE JACKSON

Heat‐Saving & Ventilating Grate

COMBINED

GRATE and FURNACE.

HEATING

on ONE or TWO Floors.

Greatest variety of rich and chaste designs in plain or oxidized Iron,

Steel, Nickel‐Plate, Electro‐Bronze, Solid Brass or Bronze. Largest

rooms in coldest climates thoroughly heated. Out‐door air warmed by

the heat wasted in ordinary grates, and introduced, producing perfect

ventilation and equable temperature, without drafts. In use everywhere. Illustrated Catalogues.

EDWIN A. JACKSON & BRO., 77 Beekman St., New York.

ARCHITECTS, BUILDERS!

ATTENTION IS CALLED TO

ADVERTISEMENT ON PAGE iii.

FRANK B. MALLORY.

SPECIFICATIONS SHOULD INCLUDE

Folsom’s Patent Roof Snow‐Guards

——300,000 IN USE.——

Address, JOHN H. HILLER, 1408 Tremont St., Boston.

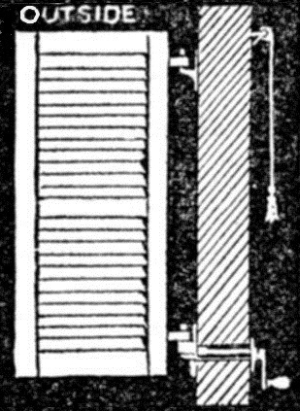

Solid Braided Cotton Sash Cord.

The “SAMSON” Window Line does not wear out. Save the annoyance

of broken cords. Samples free on application to the manufacturers.

J. P. TOLMAN & CO., 164 High Street, Boston, Mass.

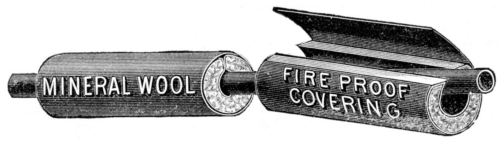

THE

Asbestos Packing Co.

ASBESTOS REMOVEABLE COVERING

BOSTONITE

ASBESTOS FLOORING FELT &c.

No. 1 WAREPROOF SHEATHING

THE A. P. Co. 3 PLY ROOFING

ASBESTOS CEMENT FELTING

ROOFING PITCH

OFFICES:

169 Congress St., Boston.

33 John St., New York.

BRUSH

Electric Lights.

Incandescence Lights for Apartment Houses and Residences furnished by

THE BRUSH ELECTRIC COMPANY,

CLEVELAND, OHIO.

NEW YORK OFFICE: No. 36 Union Square.

CHICAGO OFFICE: No. 130 Washington Street.

ST. LOUIS OFFICE: No. 404 Market Street.

DETROIT OFFICE: No. 88 Griswold Street.

SEND FOR CATALOGUE No. 8.

SCHUMACHER & ETTLINGER,

LITHOGRAPHERS,

32, 34 and 36 Bleecker and 311 Mott Streets,

NEW YORK.

FINE COLOR WORK A SPECIALTY.

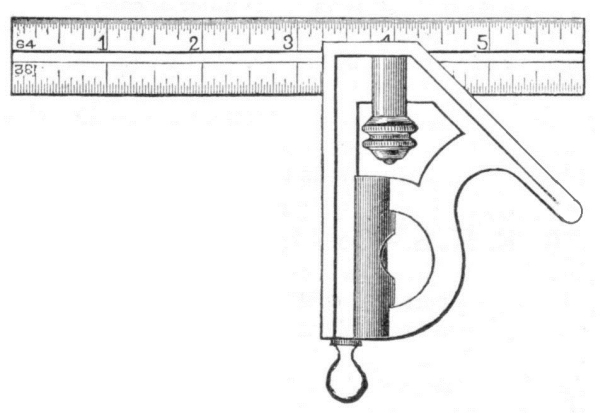

STANLEY RULE & LEVEL CO.,

MANUFACTURERS OF

IMPROVED

CARPENTERS’ TOOLS.

FACTORIES:

NEW BRITAIN,

CONN.

SOLD BY ALL

HARDWARE DEALERS.

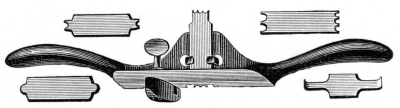

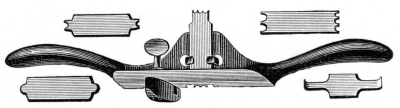

Stanley’s Universal Hand Beader.

For Beading, Reeding or Fluting, and for all kinds of light Routering,

this tool is invaluable to wood‐workers.

Seven superior steel cutters go with each tool. Both ends are

sharpened, thus embracing six ordinary sizes of Beads, four sets of

Reeds, two Fluters and a double Router Iron (⅛ and ¼ inch).

No. 66 Iron stock with seven Steel Cutters, $1.00.

119

Scientific American

ARCHITECTS AND BUILDERS EDITION

NEW YORK, DECEMBER, 1887.

Entered at the Post Office of

New York as Second Class Matter.

Vol. IV.Subscription, $2.50 a Year.

Single Copies, 25 Cents.

No. 6.

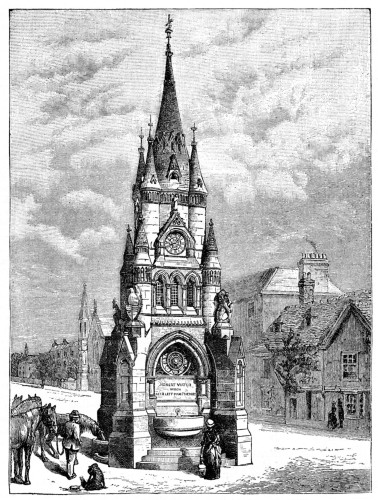

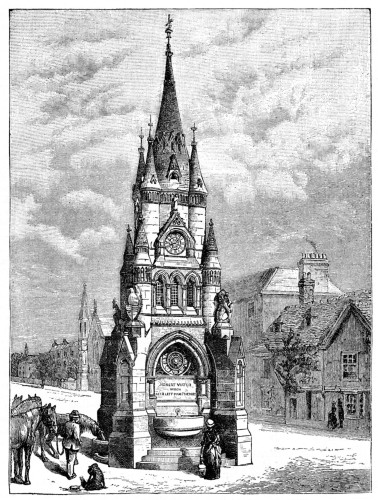

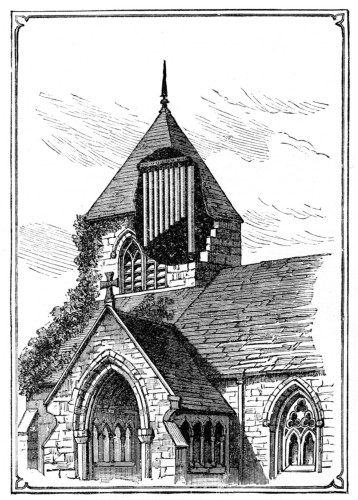

THE SHAKESPEARE MEMORIAL AT STRATFORD‐UPON‐AVON.

The American veneration for the birthplace of Shakespeare is well

known, and it has just taken practical shape by the presentation to

the town of a public drinking fountain and clock tower, the gift

of an American citizen, Mr. George W. Childs, of Philadelphia, in

commemoration of the jubilee of Queen Victoria. The memorial has

been erected in Rother Street, a broad open space near the center of

the town, where several thoroughfares converge, and where the annual

statute fairs or “mops” take place. The structure is handsome and

imposing, and is built of Peterhead granite (for the fountain) and

of hard freestone (for the clock tower). The base of the tower is

square, with projecting buttresses at the four corners, terminating

in acutely pointed gablets, surmounted by a lion bearing the arms of

Great Britain alternately with the American eagle and the stars and

stripes. Appropriate inscriptions are engraved on the four sides of

the memorial. The tower terminates in a spire, beneath and surrounding

which are smaller spires and turrets. The whole height of the structure

is fifty feet. The architect is Mr. Jethro A. Cossins, of Birmingham.

The ceremony of inaugurating the fountain was performed on Monday,

October 17, by Mr. Henry Irving, in the presence of the Mayor (Sir

Arthur Hodgson, K.C.M.G.), the corporation, and a distinguished

company of visitors. Sympathetic letters were read from Mr. J. Russell

Lowell and Mr. Whittier; and speeches were delivered by Mr. Irving,

by Mr. Phelps, the American Minister, Mr. Walter, of the Times, Sir

Theodore Martin, and others.—London Graphic.

THE SHAKESPEARE MEMORIAL AT STRATFORD‐UPON‐AVON

Larger image (211 kB)

Optical Refinements in Architecture.

Many architects look upon all refinements of line and curve as so much

waste time, and would as soon think of referring to the original Latin

of Vitruvius for rules in proportioning their rooms as to consult and

apply the corrections of the Parthenon to their buildings. In sketching

out his design to a small scale on a sheet of Whatman’s drawing paper,

the architect does so without any further thought than to produce

a convenient plan or a well grouped elevation. Any infinitesimal

correction to the straight line or entasis would be inappreciable to

the naked eye on the surface of paper the inequalities of which would

render it worthless; nor does he take much trouble in the proportions

of his rooms, so long as they look right and fit well. If such

refinements are to be made, they should be shown in large drawings,

or set out to the full size on the works by proper rules and other

instruments. The task is laborious and troublesome, and contract prices

are little in sympathy with such niceties of adjustment. Even of the

more practicable mode of adopting certain ratios and proportions, the

architect does not avail himself very much.

We do not say that every horizontal beam—such as an entablature

supported by columns at intervals—ought to be “corrected” by the

application of a parabolic curve, or that every string course and

cornice should be arranged to curve or bend upward; but we contend that

these refinements ought to be made in interiors wherever the lines

are long, and contrasting lines and surfaces occur in juxtaposition;

that they are, in truth, applying precisely the same principle of

correction as the colorist or decorator would apply when he takes care

to juxtapose two colors or shades which shall be complementary to or

harmonize with each other.

It is painful to witness in modern buildings a perfect ignoring of

these principles of design. We go into a public hall or concert room,

and take our seat. The flat coffered ceiling appears to be literally

bending or falling upon our heads. To make the impression still more

apparent, the architect has introduced a circular or flatly curved arch

over the orchestral recess. If the ceiling is a flat curve, as it often

is, the trusses are, perhaps, brought down below and incased, their

lower edges being made perfectly horizontal, the two lines serving

to increase the difference between them; in other words, to make the

trusses look as if they were deflecting.

Mr. Pennethorne, some years ago, showed that the masses of the temples

of Athens and Rome were designed on perspective principles—that is

to say, the masses and many of the details were designed as they

were intended to be viewed. The point of sight was always before the

architect—that is to say, he studied the effect of his entablatures,

abaci, and other masses of details from points of view that were

likely to be frequented. It is well known that the various sections

through the Doric capitals, the mouldings, and other parts of Athenian

buildings, were composed of different arcs of the conic sections.

Mr. Pennethorne says that the Greek entablature is perspectively

proportioned and arranged to suit the given points of sight thus: The

apparent height of entablature is measured in seconds upon the arc of

a great circle. “Then, dividing this whole apparent height into some

given number of aliquot parts, measured also in seconds, the apparent

height of the architrave, of the frieze, and cornice will, in each

case, be a multiple of this given modulus. Again, by dividing the first

modulus into a given number of apparent aliquot parts, a second modulus

is obtained, by which the apparent heights of all the details of the

cornice of architrave and frieze will be regulated, and the true lineal

heights are then all determined by trigonometrical calculations.” In

short, all the visible heights of features are, upon this principle,

regulated from a given point, the real elevational height of each part

being afterward found.

This system of proportion would probably entail too much labor upon

the architect to work out with any accuracy, and may be looked upon as

chimerical. But we see instances every day of positive ignorance of

these principles, especially in the designing of mouldings, projecting

features, and towers. If the architect is too impatient to make nice

corrections in the manner we have pointed out, he ought at least to

take the trouble necessary to regulate his heights and masses before

inking in his elevations. Sketching in perspective is a valuable

auxiliary in designing roughly the masses of a building; but some more

accurate method is required in perspectively setting out the heights of

stories, entablatures, parapets, towers, and other features. This can

only be done by adjusting all heights from a given point of sight, or

upon the arc of a circle described from the said point. An elevation is

misleading, as every architect knows who has suffered disappointment

after the building is finished. It only gives vertical heights, which

may be very much curtailed or foreshortened in the actual view of the

building from the opposite side of the street, for example.

Many towers and spires have been spoiled by designing them in elevation

instead of at the angle. In broach spires we find a want of care in

one particular above the others. The broach is designed on the level.

The hips of the broach are made to look gentle in elevation, but when

raised above the eye 60 or 100 feet, they become so depressed as to

give a very ungraceful and abrupt springing to the spire.

We may instance the want of entasis to spires and columns. Every one

who has a critical sense of vision must have observed the apparent

weakness there is in a spire that has perfectly straight sides, when

compared with one which has been entasised, and the same with all

columns. Here also the method to insure the correction can be easily

applied. The more important of these refinements are capable of being

made at the initial stage of design, without recourse to decimals

of two or three removes from the decimal point, or to mathematical

calculations.—Abstract from the Building News.

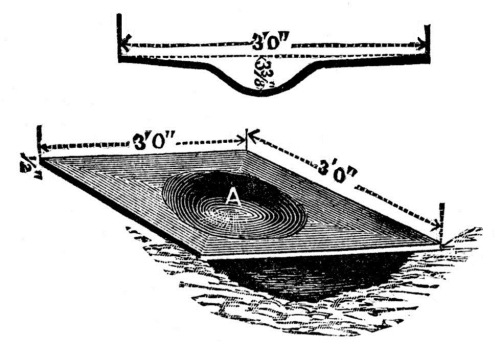

Testing Pile‐Protecting Compounds.

In 1882 several piles, coated with various patent anti‐teredo

coverings, were driven in the harbor of San Francisco for the purpose

of testing them. Recently Engineer Manson began pulling up the piles in

order to see the result of the experiments. A pile coated with Pearce’s

compound, composed of paraffine, limestone, kaolin, etc., was found

to be completely honeycombed by the teredos. The eucalyptus and cedar

piles were also nearly destroyed. In 1884 the two piles incased by A.

W. Von Schmidt in sewer pipe and cement, the twenty‐three coated by

Frank Shay with asphalt and wire cloth, the ten of McKeon & Co., coated

with warm cement containing a poisonous substance, and those of W. H.

Hayes, coated with Portland cement, etc., were examined by Colonel

Mendel and Mr. Manson. All showed signs of having proved failures. The

insect is ahead of the inventors up to date.

A Tower on the Mount of Olives.

The tower which is being erected by the Russians on the highest point

of the Mount of Olives is already several stories high, but one

more is to be added. The object is to make it so high that both the

Mediterranean and the Dead Sea may be seen from the top. A number of

bells will be placed in the tower. In digging the foundation, several

Christian graves were found, together with an inscription in Greek, in

which the word “Stephanus” could yet be deciphered.

120

Scientific American.

ESTABLISHED 1845.

Munn & Co., Editors and Proprietors,

No. 361 BROADWAY, NEW YORK.

O. D. MUNN.A. E. BEACH.

NEW YORK, DECEMBER, 1887.

THE

SCIENTIFIC AMERICAN,

ARCHITECTS AND BUILDERS EDITION.

$2.50 a Year, Single Copies, 25 cents.

This is a Special Edition of The Scientific American, issued

monthly. Each number contains about forty large quarto pages, forming,

practically, a large and splendid Magazine of Architecture,

richly adorned with elegant plates in colors and with fine

engravings; illustrating the most interesting examples of modern

Architectural Construction and allied subjects.

A special feature is the presentation in each number of a variety of

the latest and best plans for private residences, city and country,

including those of very moderate cost as well as the more expensive.

Drawings in perspective and in color are given, together with full

Plans, Specifications, Costs, Bills of Estimate, and Sheets of Details.

No other building paper contains so many plans, details, and

specifications regularly presented as the Scientific American.

Hundreds of dwellings have already been erected on the various plans we

have issued, and many others are in process of construction.

All who contemplate building or improving homes, of erecting structures

of any kind, have before them in this work an almost endless series

of the latest and best examples from which to make selections, thus

saving time and money.

Many other subjects, including Sewerage, Piping, Lighting, Warming,

Ventilating, Decorating, Laying Out of Grounds, etc., are illustrated.

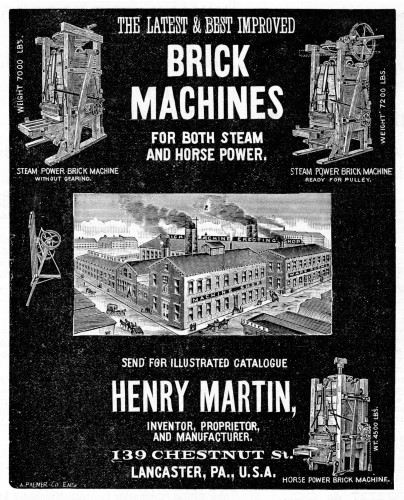

An extensive Compendium of Manufacturers’ Announcements is also given,

in which the most reliable and approved Building Materials, Goods,

Machines, Tools, and Appliances are described and illustrated, with

addresses of the makers, etc.

The fullness, richness, cheapness, and convenience of this work

have won for it the Largest Circulation of any Architectural

publication in the world.

An Increase of Trade will necessarily accrue to all

Manufacturers and Dealers whose establishments are conspicuously

represented in this important edition of The Scientific

American. Terms for advertising very moderate. A card of rates

sent on application.

Bound Volumes.—Two volumes are published annually. Volumes

1, 2, 3, and 4, which include all the numbers of this work from

commencement to close of 1887, may now be obtained at this office

or from Booksellers and Newsdealers. Price, bound in paper, $1.50

per volume. These volumes contain all the colored plates, sheets

of details, specifications, and all the other interesting matter

pertaining to the work. They are of great permanent value. Forwarded to

any address.

MUNN & CO., Publishers,

361 Broadway, New York.

For additional information concerning any of the plans or buildings

illustrated in these pages, address Munn & Co., as above.

CONCERNING AGENTS.

Customers who pay money to subscription agents or brokers do so

at their own risk. Care should be taken to deal only with known,

responsible, and reliable parties. We send no papers until we receive

the subscription price; and no person is authorized to represent us,

act for us, or receipt for us.

Munn & Co., Publishers, 361 Broadway, New York.

CONTENTS

Of the December number of the Architects and Builders Edition

of Scientific American.

| (Illustrated articles are marked with an asterisk.) |

| Arch construction | 131 |

| Architectural era | 129 |

| Architecture, optical refinements in | 119 |

| Ash, white | 125 |

|

Bamboo tree | 123 |

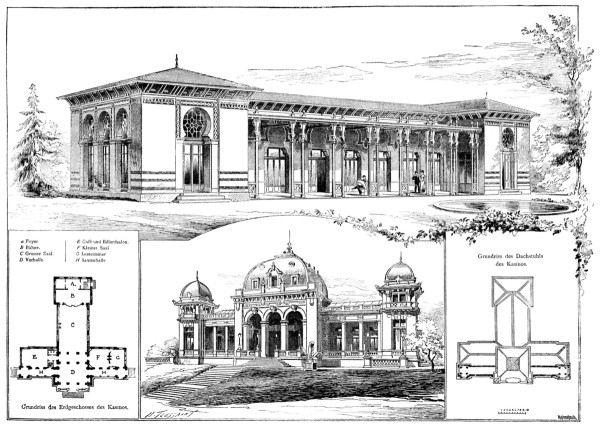

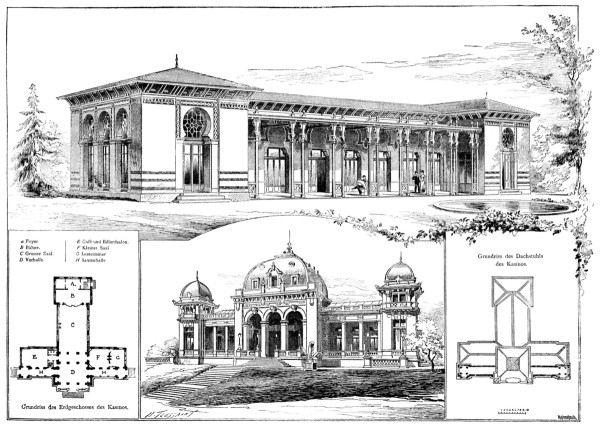

| Bathing establishment and casino in Vittel (Vosges)* | 134 |

| Beams, iron, in place of wood | 133 |

| Board, sounding, in St. Paul’s Cathedral | 142 |

| Books for architects, builders, etc | xiii |

| Bricks, fire | 126 |

| Building, a great | 140 |

| Cement, Portland | 126 |

| Charleston, S. C., building in | 139 |

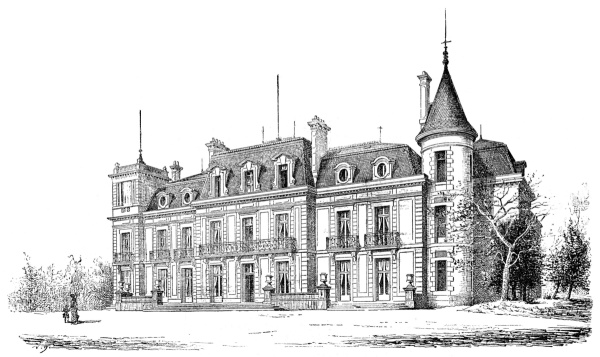

| Chateau at Castelnaudary* | 130 |

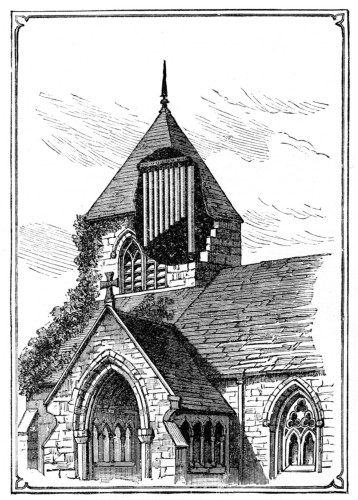

| Chimes for churches, new form of* | 132 |

| Chimes, tube | 132 |

| Chimneys, removal of | 132 |

| Church, unsafe | 126 |

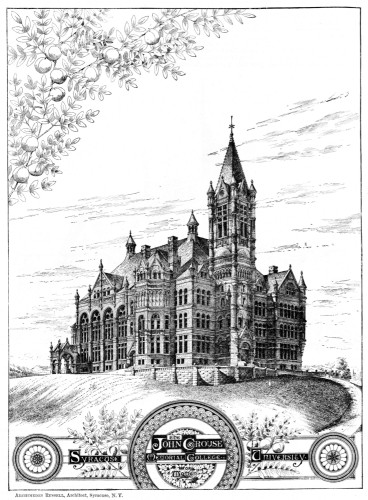

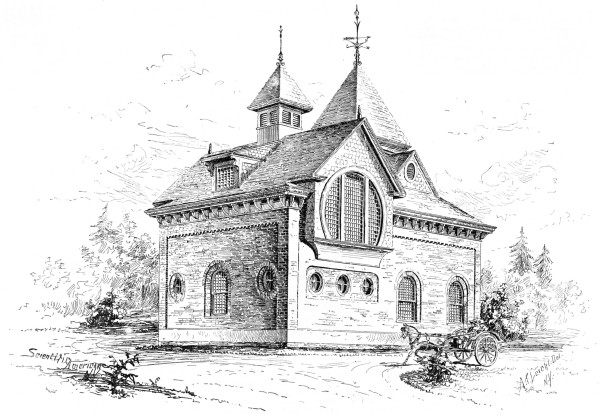

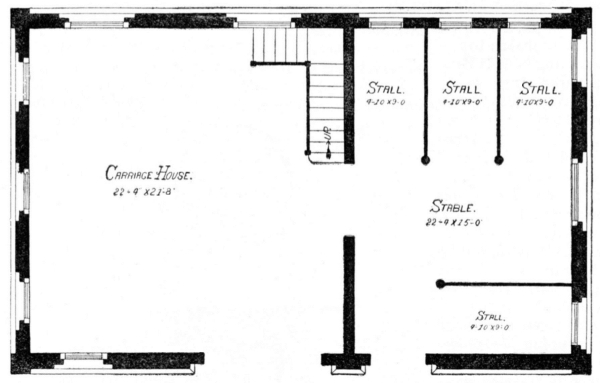

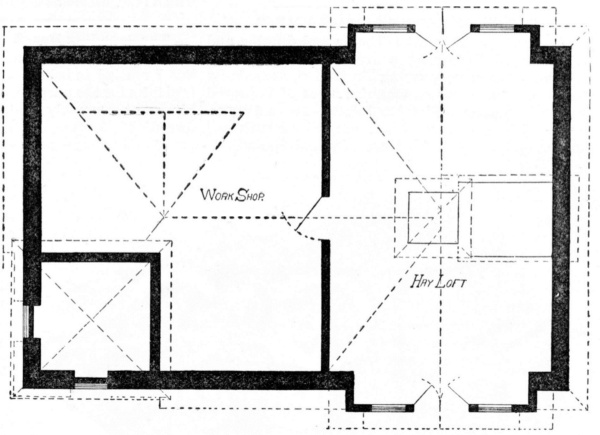

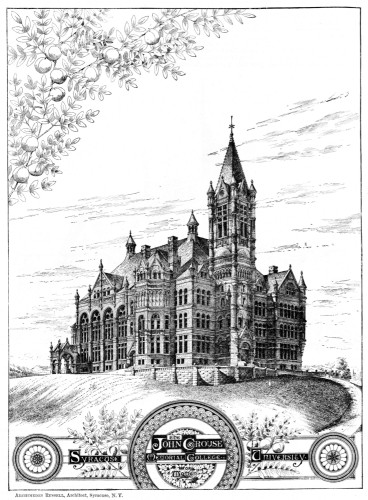

| College for women, the John Crouse memorial* | 139 |

| Compounds, pile protecting, testing | 119 |

| Correction, a | 120 |

| Cottage, a French* | 122 |

| Cottage for $4,200* | 136, 140 |

| Cottage, sketch for a* | 135 |

| Drain pipes and wells | 130 |

| Dwelling, a $4,200* | 138 |

| Dwelling of moderate cost* | 120 |

| Dwellings at Glenridge* | 126 |

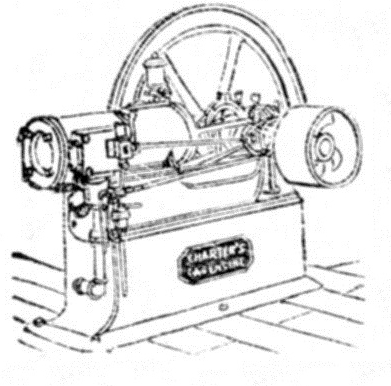

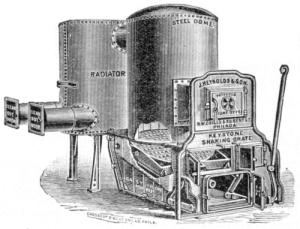

| Engine, Charter gas and gasoline | 142 |

| Fever, typhoid, carried by well water | 126 |

| Fireproof structures* | 124 |

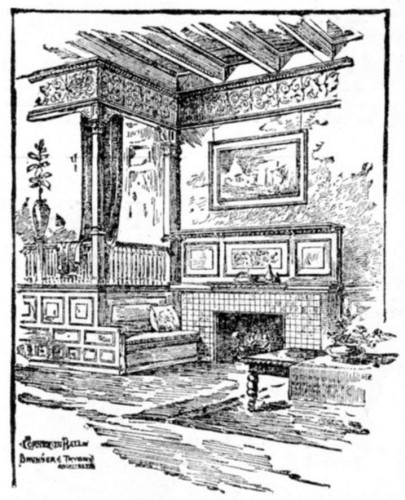

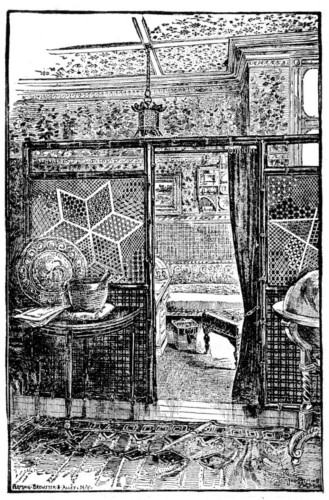

| Fireside, cheerful, how to make* | 142 |

| Flues, chimney, construction of | 124 |

| Forestry problem, our | 122 |

| Foundations in wet ground | 142 |

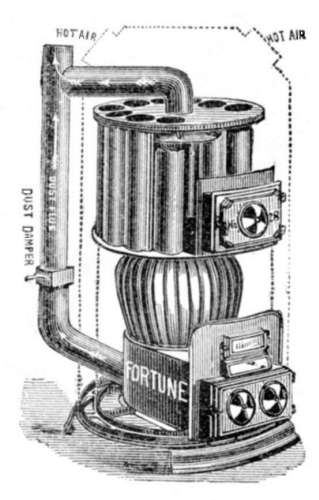

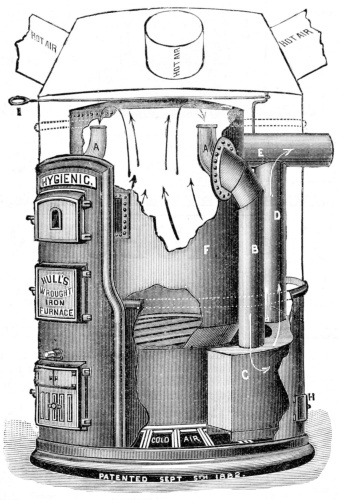

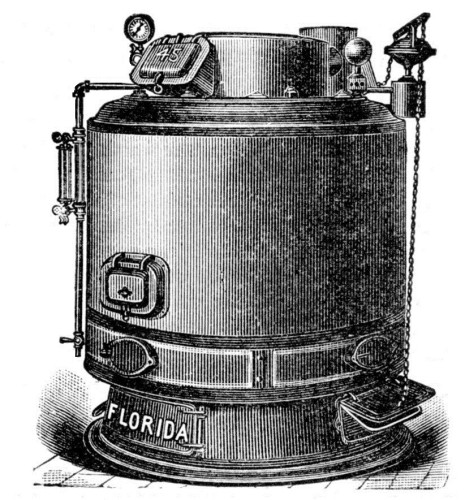

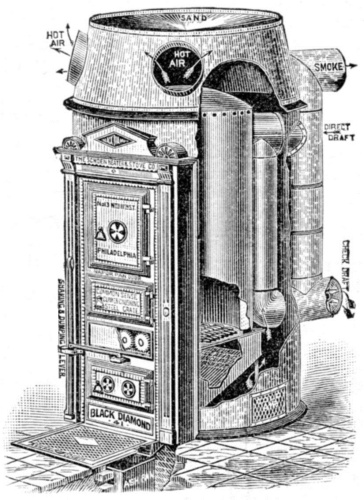

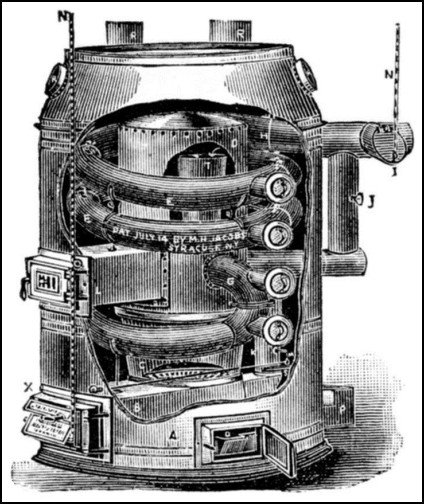

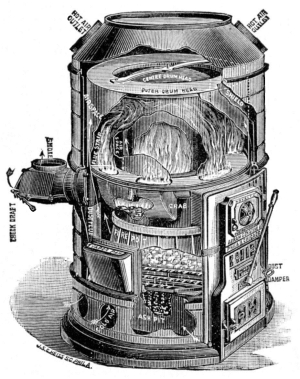

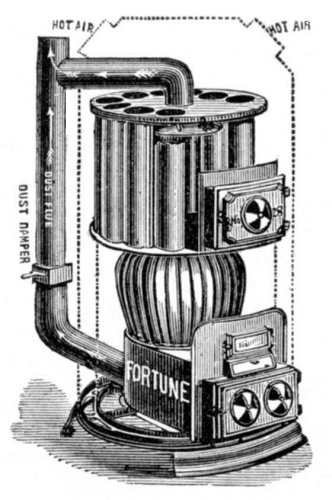

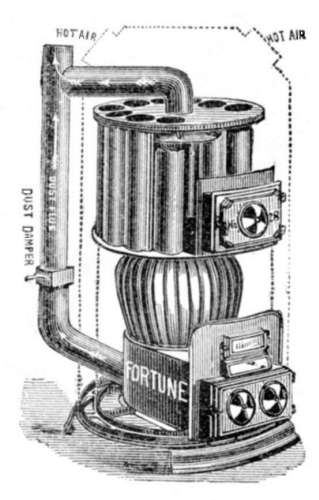

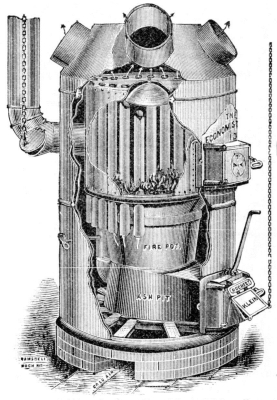

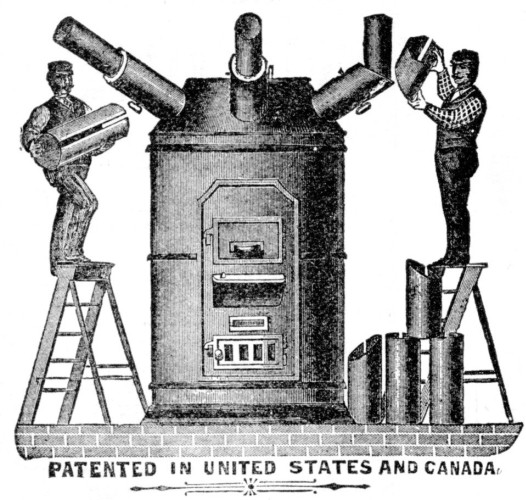

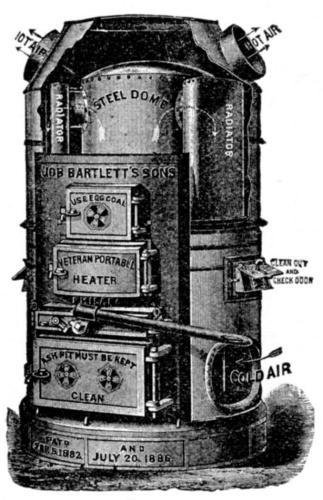

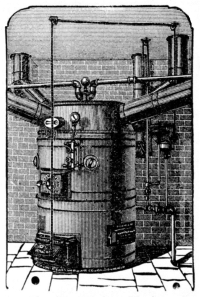

| Furnace, hot air, the “Fortune”* | 142 |

| Gangways vs. staircases | 133 |

| Grown, how we have | 135 |

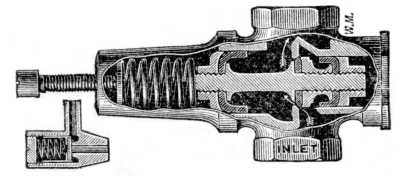

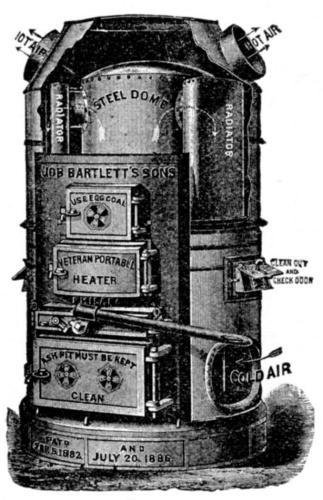

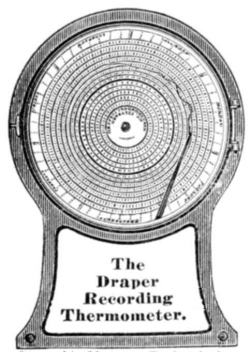

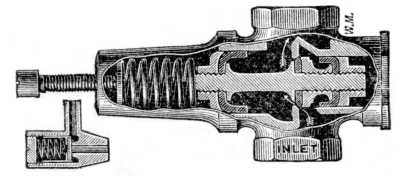

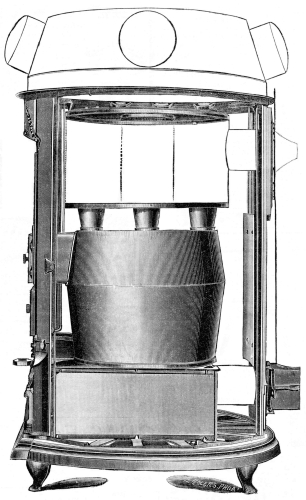

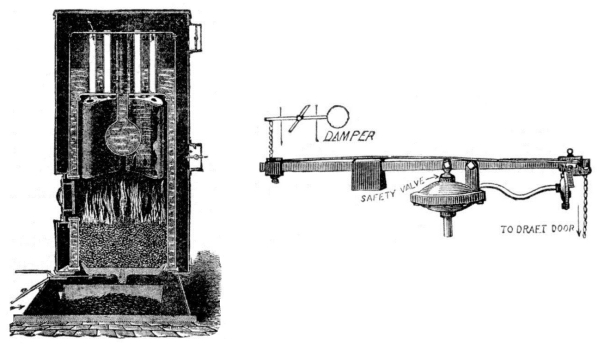

| Heater, Wainwright* | 142 |

| Hemlock | 127 |

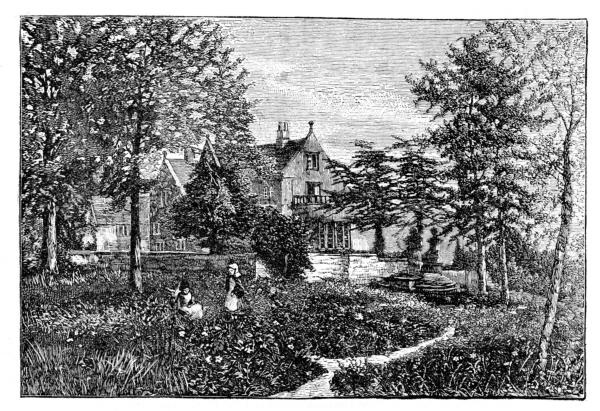

| Home, Florence Nightingale’s* | 132 |

| Homes of factory operatives* | 133 |

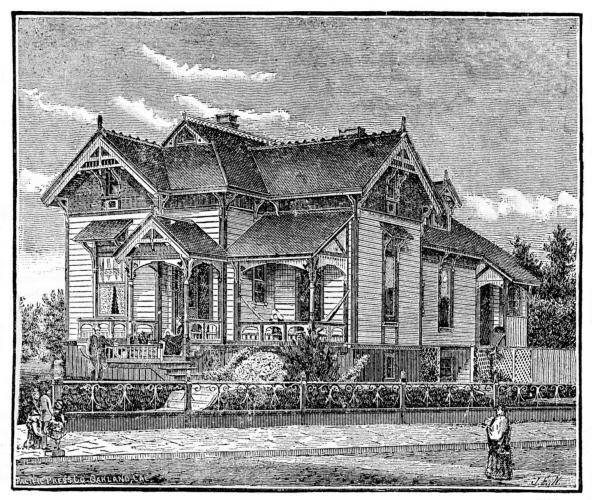

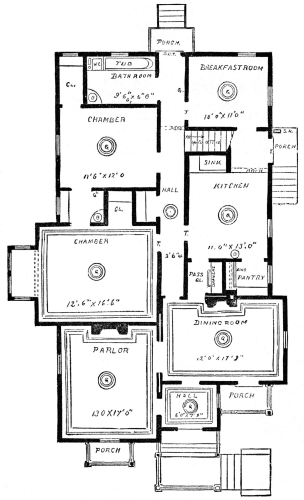

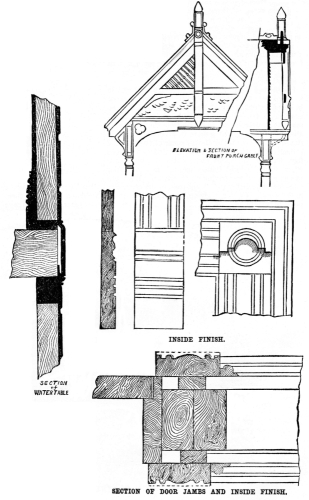

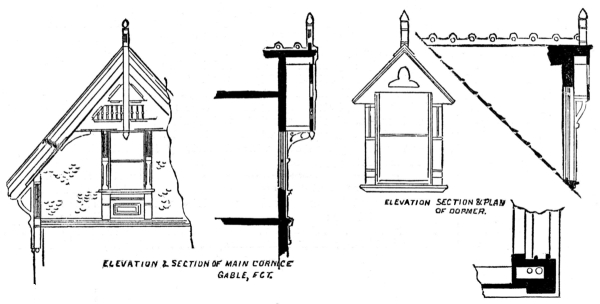

| House, $2,500 California* | 128 |

| Ice house, how to build | 130 |

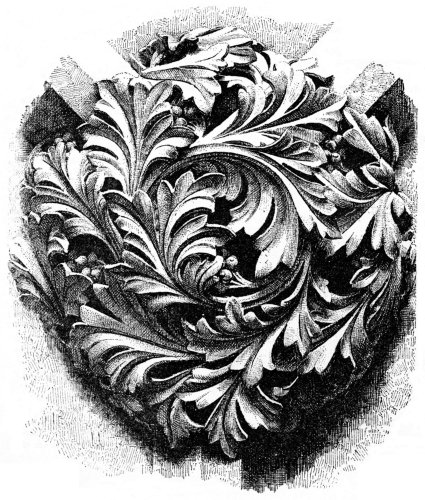

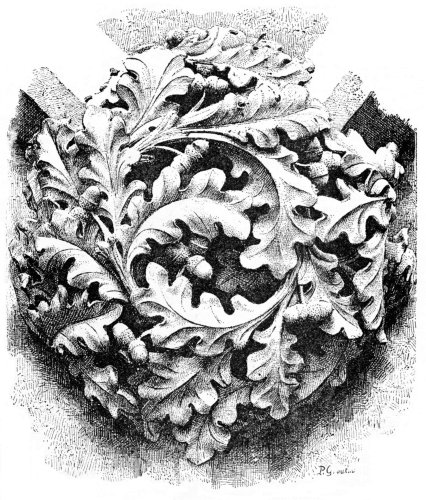

| Ink, marking, blue | 129 |

| Keystones, ornamental* | 125 |

| Library, curious | 138 |

| Memorial, Shakespeare, at Stratford‐upon‐Avon* | 119 |

| Mortar, sugar | 122 |

| Nails | 130 |

| Notes and queries | vi, x |

| Painting | 132 |

| Pavements, cedar | 127 |

| Pine woods | 134 |

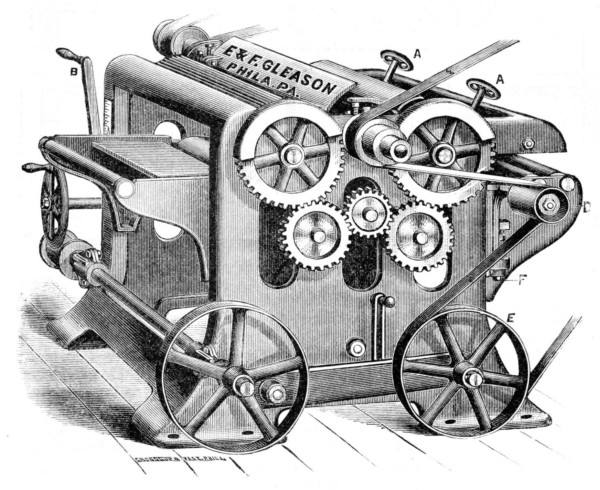

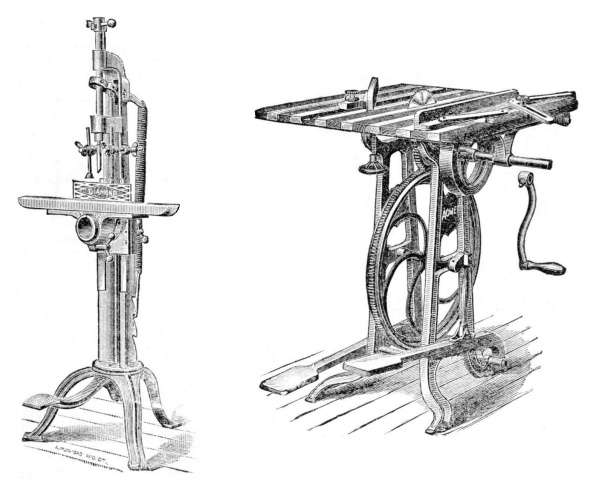

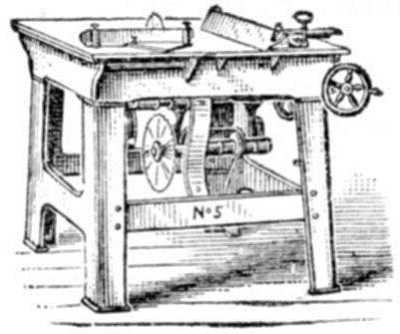

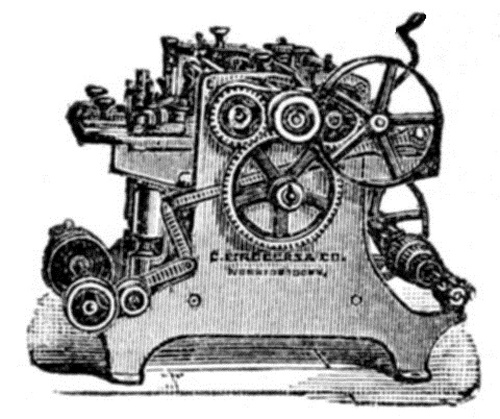

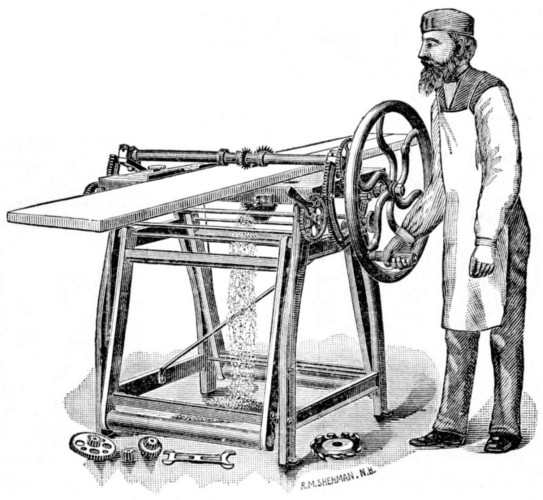

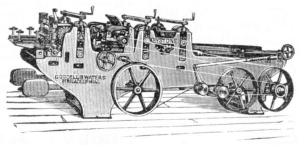

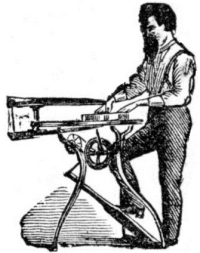

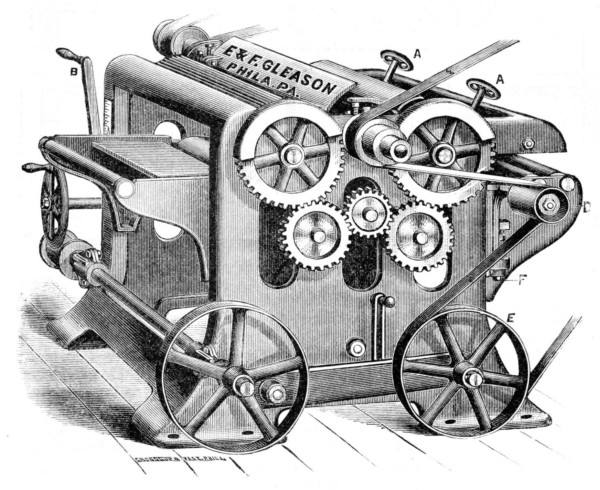

| Planer, improved double surface* | 142 |

| Plants for room decoration | 141 |

| Plate, roofing, a large contract for | 120 |

| Plumbing, not defective | 142 |

| Protection, fire | 140 |

| Rabbit remedy | 130 |

| Readers and patrons, to our | 120 |

| Residence, a suburban* | 121 |

| Residence for $5,000* | 137, 140 |

| Residence for $8,000* | 123 |

| Roburite—a new explosive* | 133 |

| Roofing plate, contract for, large | 120 |

| Rooms, proportions of | 140 |

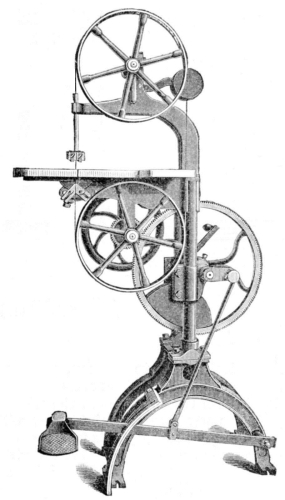

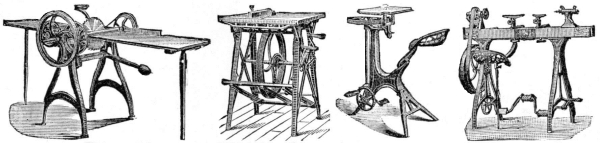

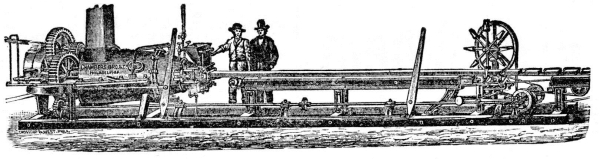

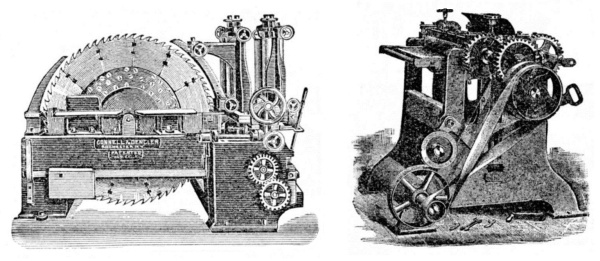

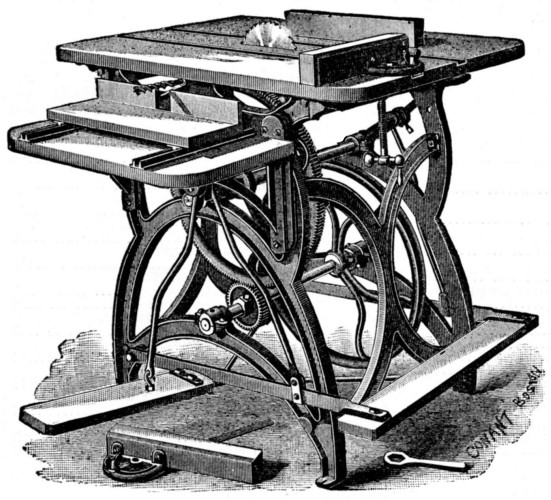

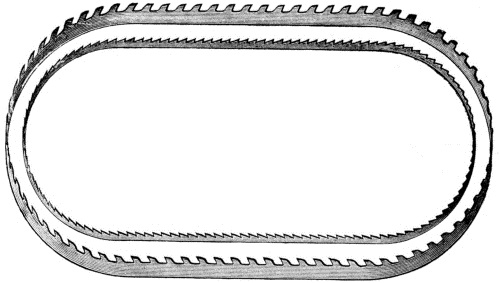

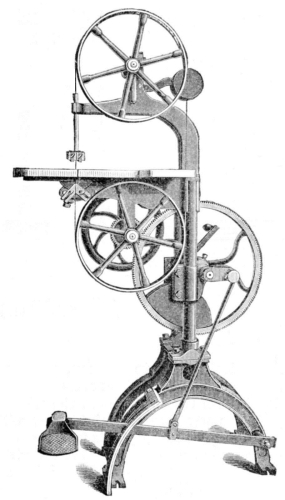

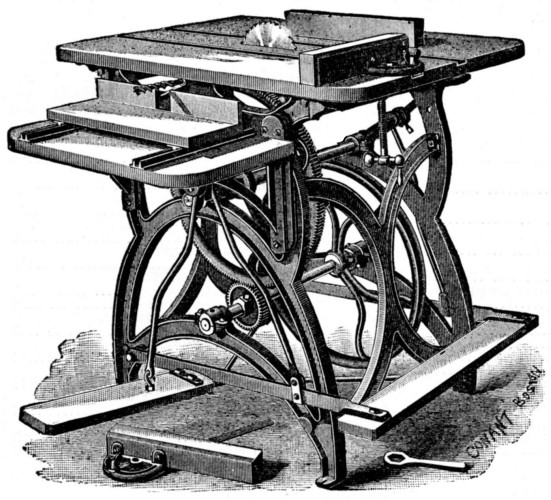

| Saw, band, hand and foot power* | 142 |

| Sawdust | 125 |

| Stable costing $5,500* | 140 |

| Statue, marble, how made | 139 |

| Suggestion, a good | 135 |

| Temple, Egyptian | 124 |

| Tower on the Mount of Olives | 119 |

| Trees, roadside, in Belgium | 124 |

| Victory, tower of | 135 |

| Walls of burning buildings, collapse of | 127 |

| Walter, Thomas Ustick | 134 |

| Yard, back, the | 134 |

TO OUR READERS AND PATRONS.

The present number closes our fourth volume and brings us to the end of

another year. Many subscriptions now terminate, and we ask our patrons

to be prompt in sending their renewals, thus avoiding the loss of any

numbers. The terms are only $2.50 a year.

Considering the wealth of illustration, the variety and value of

information presented, this work is by far the cheapest of anything in

the same line.

To builders, and those contemplating the erection of dwellings or other

structures, our paper has proved to be of great value.

With every number, during the past two years, we have given plates

in colors of many new buildings, with specifications, accompanied by

extra special sheets of details. In most cases these have been so

complete as to enable the builder and contractor to proceed at once

with the construction; and on the plans thus presented, thousands of

new buildings have been erected in all parts of the country. In almost

every town in the land attractive dwellings are now to be seen, which,

on inquiry, will be found to have been built from Scientific

American plans.

No architectural publication in the world presents to its patrons

so many practical specifications and drawings without cost, except

the merely nominal subscription rate of $2.50 a year. It is hardly

necessary to remind the builder that he would be obliged to pay several

hundred dollars if the same number of plans were to be specially

prepared for him.

In addition to the colored plates, details, and specifications, we have

furnished a large number of other new architectural illustrations and

many pages of valuable information. In all, the past year’s volumes

include about one thousand engravings.

We remind our readers of these items with the hope they will mention

them to their friends, and, if possible to secure a new subscription,

to send it in with the renewal of their own.

Our aim is to improve and enlarge the sphere of work, rendering it more

and more valuable. To this end we need the support and encouragement of

as many subscribers as possible. If each one of our friends will do a

little for us in this direction, all the parties concerned will derive

benefit.

If any of readers have inquiries to be answered, or suggestions to

make, relating to subjects or features they would like to see treated

in our paper, we shall, at all times, be pleased to hear from them.

Architects and builders who desire to see their plans reproduced in our

pages are also invited to communicate with the editor.

A CORRECTION.

In our November number an error was made in the estimate given for the

$2,500 house illustrated in our colored plate. The cost should have

been stated at $3,400. In some way the bill for mason work and painting

was omitted. These additions and other modifications bring the cost up

to the above sum.

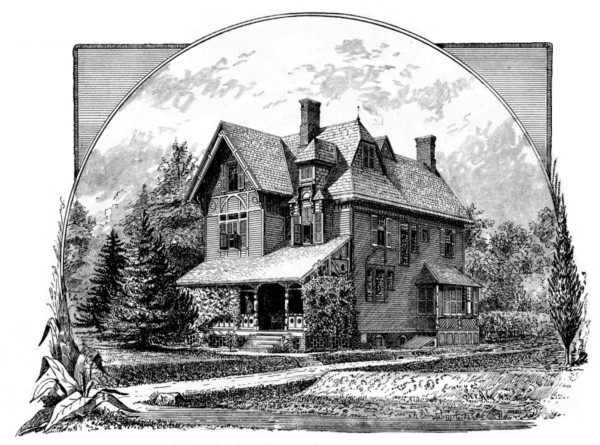

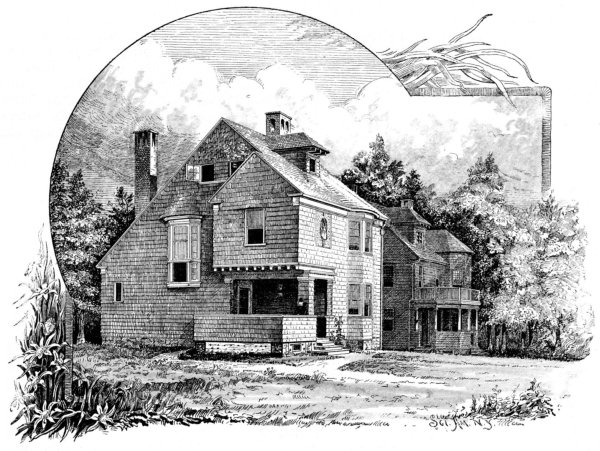

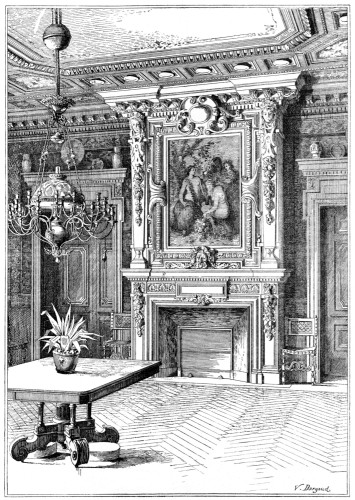

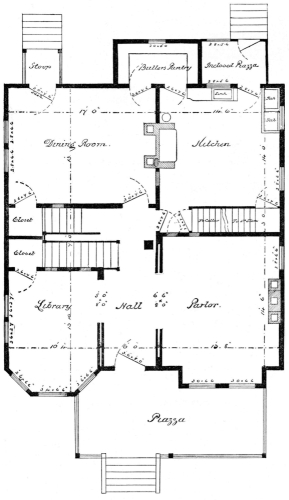

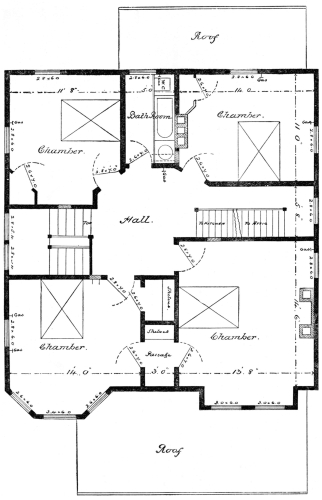

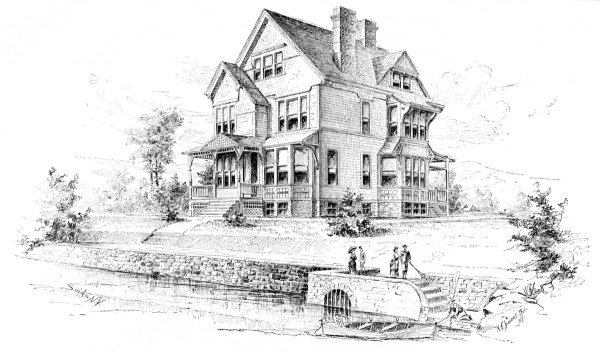

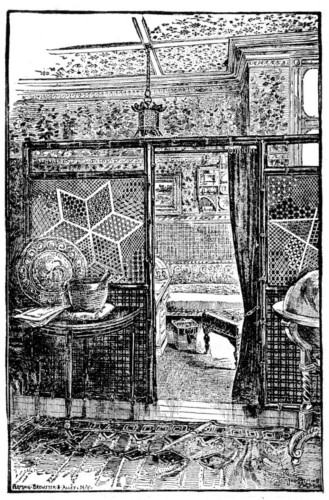

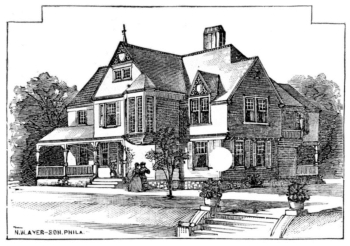

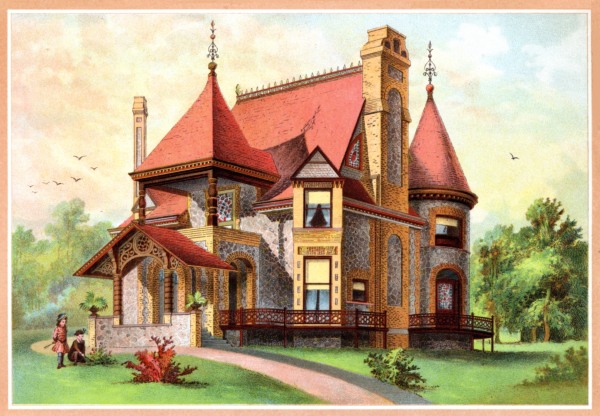

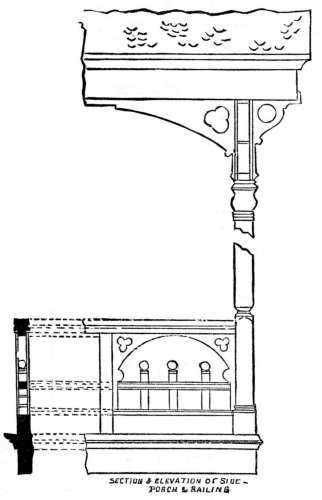

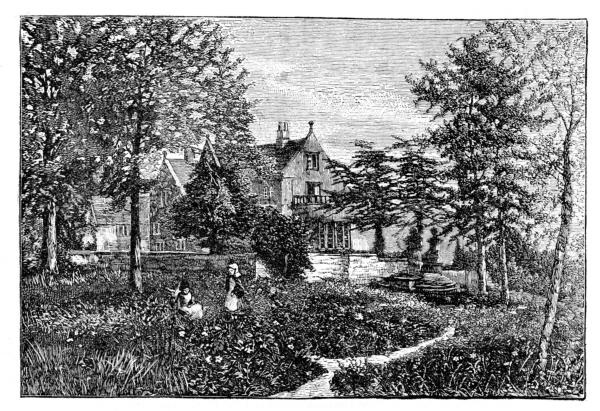

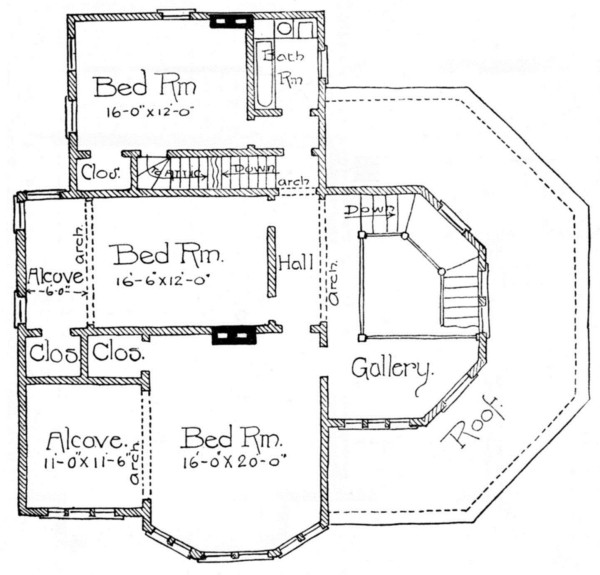

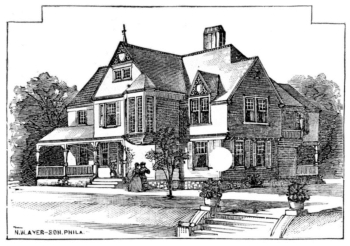

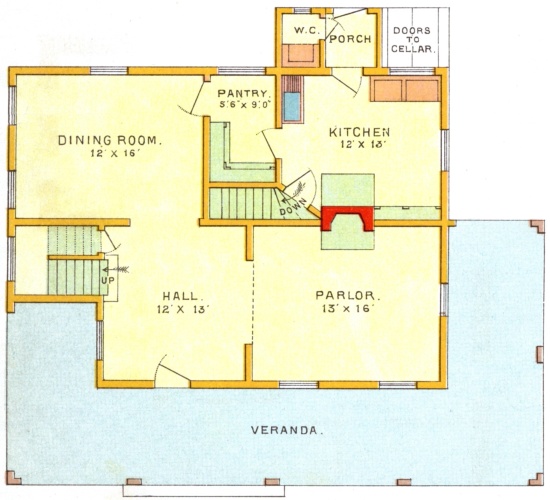

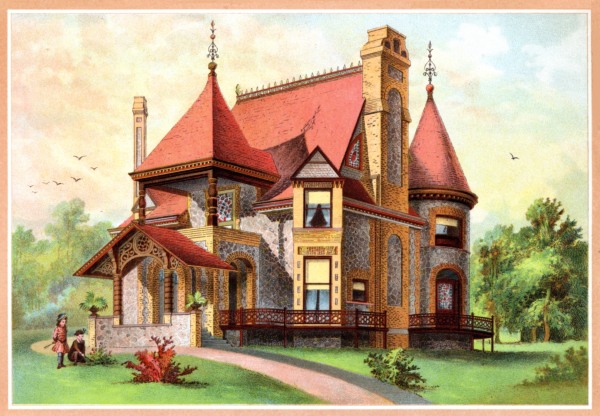

A SUBURBAN RESIDENCE.

One of our colored plates this month represents a suburban dwelling

built of dark trap rock, trimmed with buff brick, and roofed with

ornamental stamped iron plates. It is now being constructed in New

Jersey, by days’ work, at a cost of about $9,250. The following is an

abstract from the

Specifications.

mason work.

Excavating.—Excavation under the entire house to a depth of about 4′.

Cellar Walls.—Cellar walls built of good sized trap rock. All

necessary bluestone sills, cellar steps, and copings, fine tooled

brownstone steps for stoops, also fine tooled brownstone sills for the

doors and windows above cellar.

Walls.—All stone walls above cellar are medium sized trap rock and

well selected, pointed with black mortar.

Brick Trimmings.—Buff brick used for trimmings, as shown on the

plans, laid in mortar same color as brick.

Chimneys.—Chimneys built of trap rock and buff brick, and topped out

as shown on the plans.

Fireplaces.—Fireplaces built where shown, of white fire brick, and

the hearths laid in tile.

Stone Steps.—Stone steps from main entrance to ground.

Porch Floor.—Porch floor is cemented with Portland cement.

Cementing.—The entire cellar bottom is cemented 3” thick with

concrete and Portland cement.

Plastering.—The entire first and second stories are plastered

three‐coat work, hard finished. Cornices in principal part of first

story and second story hall. Center pieces in rooms to correspond.

CARPENTRY.

Timber.—Timber all well seasoned spruce. Floor timbers, 2″ × 10″,

12″ on centers. Studding, 3″ × 4″. Main rafters, 2″ × 8″, 24″ on center.

Cornice.—The cornice is formed of wood heavily moulded.

Roof.—The rafters are covered with hemlock boards, then covered with

ornamental iron plates laid on tar felt. Valleys and gutters, XX tin.

Leaders, galvanized iron. The ridge is ornamental iron work.

Floors.—The floors throughout are double. The upper floors are

narrow white pine, except hall and kitchen. The hall is narrow oak, the

kitchen narrow white maple, the bath rooms are white maple. The main

hall is paneled wainscot, 4′ high. Kitchen and bath rooms wainscoted

with narrow beaded strips of maple. The trimmings throughout, except

main hall, will be selected white pine. Hall to be of white oak. Doors

to be six paneled. Main stairs and balustrade to be white oak. Others

stairs white pine, with Georgia pine treads. Inside blinds throughout.

Plain bronze hardware on principal part of first story. Jet and bronze

for balance.

Painting.—The wood and iron work on the outside will be painted

three coats. The inside will be wood filled and have two coats of hard

oil.

Plumbing.—The apparatus for plumbing work located as shown on the

plans. To be piped and arranged for water pressure.

Range.—The kitchen to have an approved low down range, fitted in

fireplace.

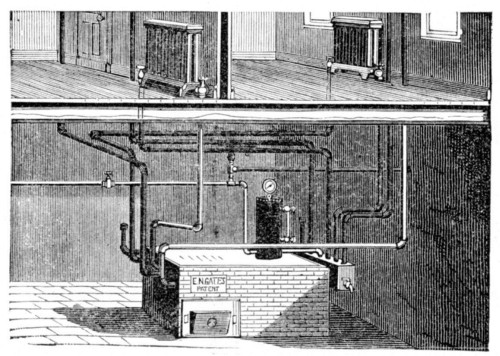

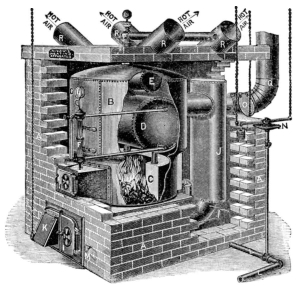

Heater.—There will be placed in the cellar a No. 14 combination

steam and hot air heater.

| ESTIMATE OF COST. |

| Mason work, complete | $4,400 |

| Carpenter and roof work | 3,400 |

| Painting | 200 |

| Plumbing, gas pipes, etc. | 650 |

| Steam heating | 600 |

| | $9,250 |

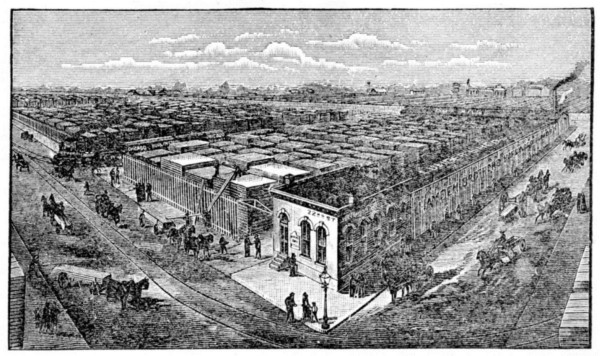

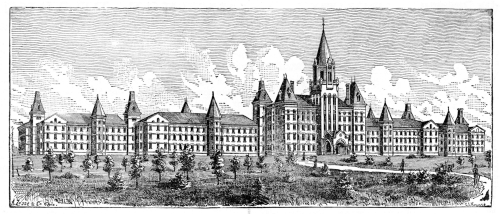

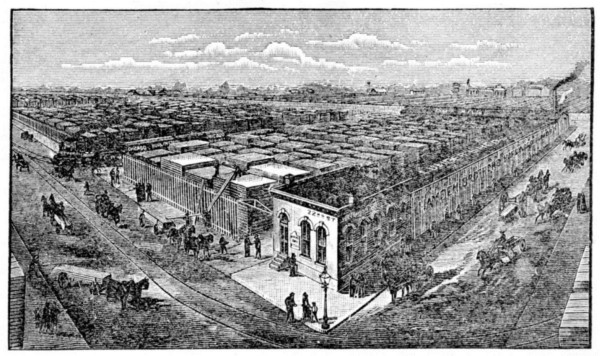

A LARGE CONTRACT FOR ROOFING PLATE.

The interesting picture of the Western Tennessee Hospital for the

Insane, at Bolivar, in that State, which will be found in our

advertising pages, will command the attention of humanitarians and

administrators everywhere. Such buildings, devoted to such purposes,

are not frequently to be met with. The announcement made in connection

therewith, that the Alderly brand of square Terne plate was selected by

the commissioners for the roof, gutters, and valleys of the structure,

requiring over 1,000 boxes of roofing plate, presents, in a forcible

way, the claims of that article. It is manufactured and sold by Messrs.

Gummey, Spering, Ingram & Co., of Philadelphia, Pa., and Liverpool,

England.

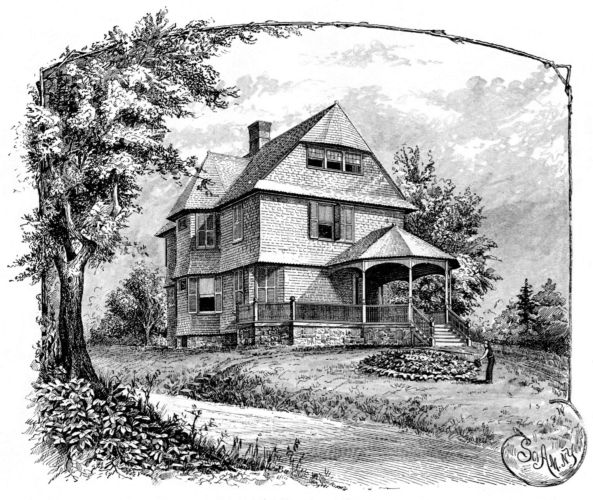

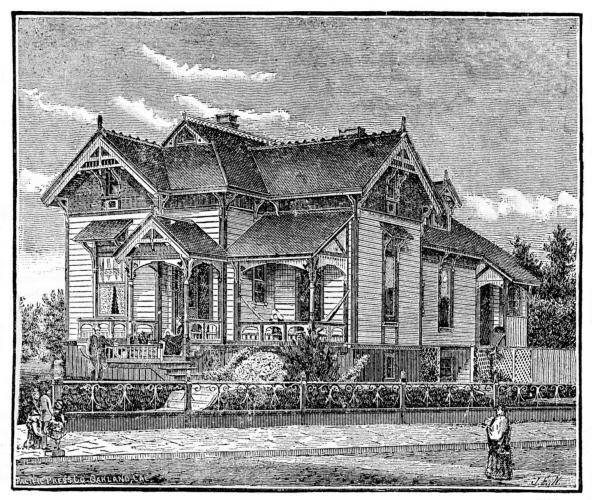

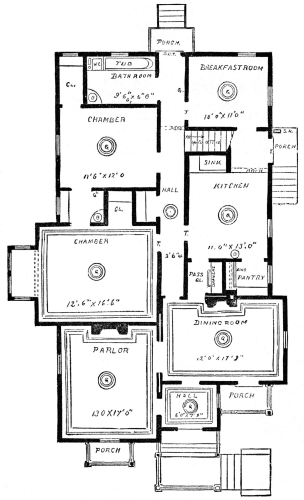

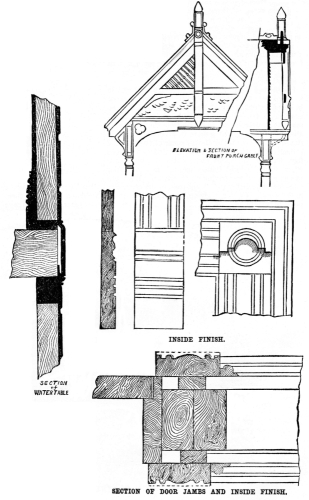

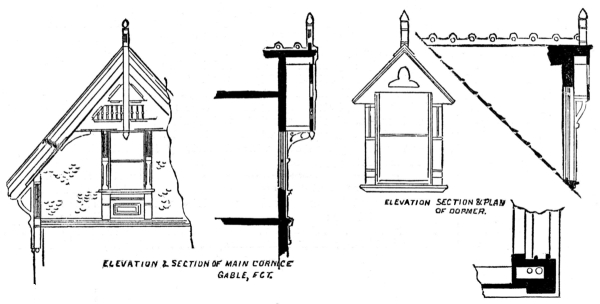

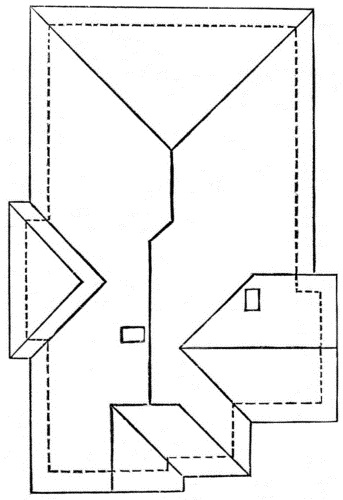

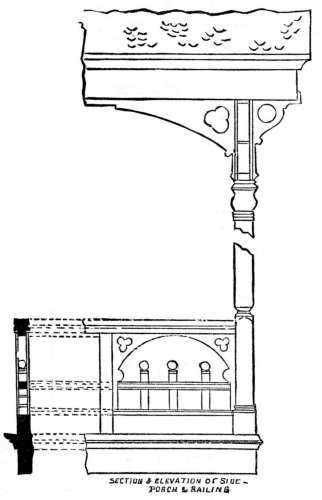

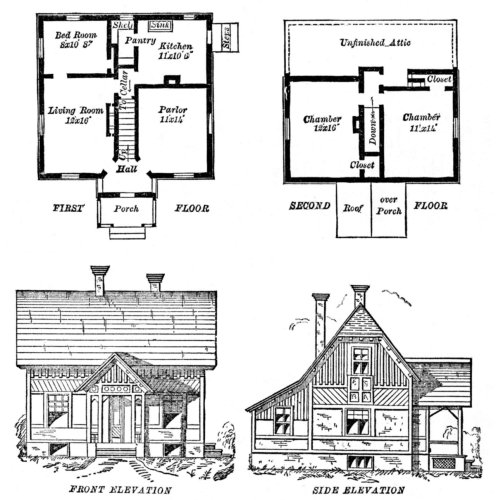

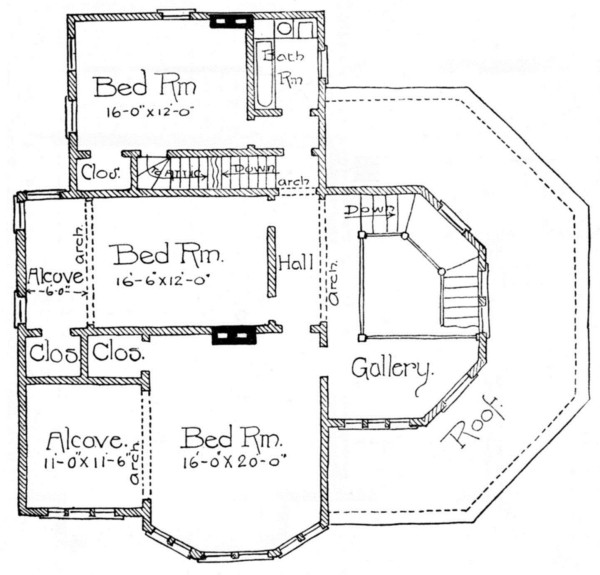

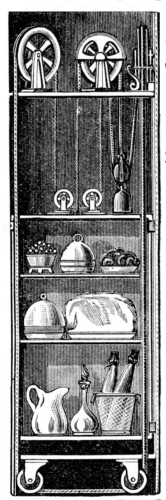

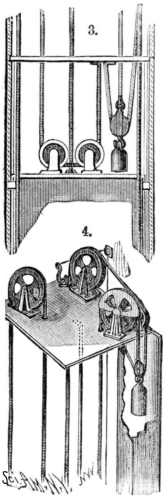

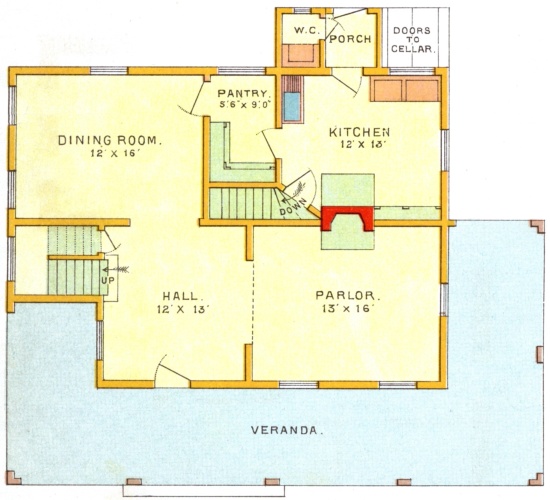

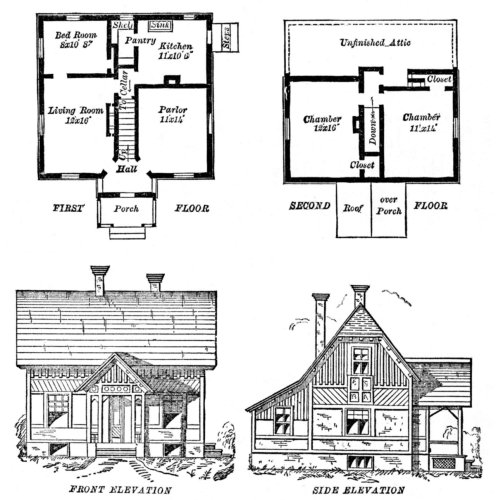

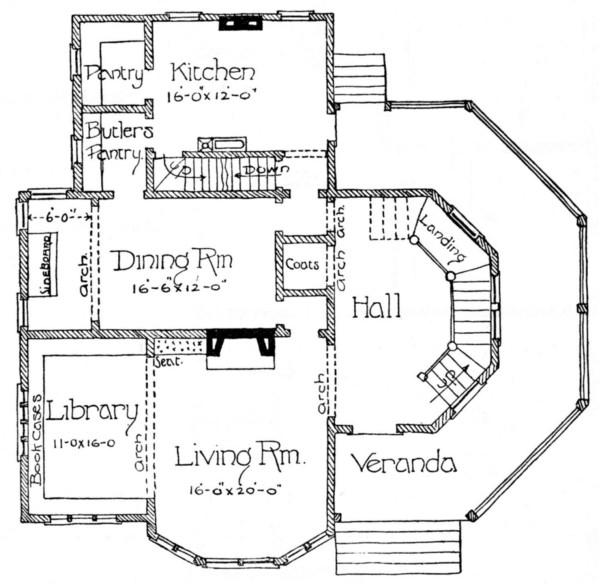

A DWELLING OF MODERATE COST.

This cottage is built in Plymouth Park, Buzzard’s Bay, near Wareham,

Mass., one of the most charming locations on the New England coast.

From the veranda a beautiful view is obtained of the bay and coast.

The cottage is erected on one of the knolls (which is one of the

features of the park), and has for a background a grove of pine and

oak trees. The shingles are treated with “Cabot’s creosote stains” of

the following colors: On roofs, a steel gray, and on sides, sienna.

The clapboards are painted a light olive green and trimmed with bronze

green and Indian red. The studs of hall, dining room, and parlor are

exposed, and together with underboarding and beams overhead are planed

and sand‐papered, and all woodwork is given two coats of shellac of

light finish. The second floor is plastered (sand finish). The contract

price for cottage was $2,800 complete. The architect is Chas. E.

Miller, 149 Broadway, N. Y.

Specification.

general conditions.

The contractor is to give his personal superintendence to the work,

and to furnish all transportation, labor, materials, apparatus,

scaffolding, and utensils needful for performing the work in the

best workmanlike manner, according to the true intent and meaning

of the drawings and these specifications, which are intended to be

co‐operative, and when anything is shown on plans and not mentioned in

specification, or vice versa, the same is to be furnished as though

it were both shown and specified. This specification and the drawings

annexed are intended to include everything requisite to the proper

and entire finishing of carpenter’s, mason’s, and plumber’s work, and

the same shall be furnished, notwithstanding every item necessarily

involved in the above words is not particularly mentioned.

All work when finished is to be delivered up in an undamaged state,

without exception, except where otherwise specified, all materials to

be of their respective kinds, and all labor to be done in the best

workmanlike manner, to the full satisfaction of owner. Should the

contractor introduce, at any time, materials different from the sort

and quality herein specified, the same shall be removed and made good

at the contractor’s expense.

The contractor will be held responsible for all portions of the work

let to him.

The contractor shall make no alterations of the drawings or

specification, but should any error or inconsistency appear in these,

it shall be the duty of the contractor121 to duly notify architect, who

will make proper adjustment. The contractor is to give to the proper

authorities all requisite notices of the work in his charge, obtain

official permits and licenses for temporary obstructions and pay all

proper fees for the same, and to be solely answerable for all damage

to neighboring premises or to the person or property of the public by

himself or his men or through any operatives under his charge, whether

in contract or extra work. Contractor is to protect his work from frost

until building is finished, and is to cart away all rubbish and leave

the whole broom clean. All drawings, etc., are to be returned to the

architect, and are not to be used for any other building.

CARPENTER.

Scantling.—Sills over piers 6″ × 8″, sills that rest on stone wall

4″ × 6″, all to be halved and pinned at angles. Plates 4″ × 4″, posts

4″ × 6″, girts 4″ × 4″, braces 2″ × 4″, studding 2″ × 4″. The studding

of hall, parlor, and dining room to be planed and chamfered.

Partition caps 2″ × 4″ to be planed in the above rooms. Soles 2″ × 4″

as well. First floor beams 2″ × 8″, 16″ on centers. Second floor 2″

× 8″, 16″ on centers, and to be dressed when exposed in above rooms.

Attic beams 2″ × 8″, 16″ on centers. All beams under partitions to be

doubled and spiked. Trimmers ditto.

Main Roof.—Rafters 2″ × 8″, 2′ on centers. Valley rafters 3″ × 10″.

Veranda.—Girders 4″ × 8″, floor beams 2″ × 6″, 2′ on centers.

Rafters 2″ × 6″ (dressed). Posts constructed of studs. Hemlock boards

and shingles. Veranda roof timber will be exposed and dressed, floor to

be merchantable yellow pine, free from large loose knots, shakes, or

sap. Balcony floors to be covered with heavy canvas and slushed over

with metallic paint, to be graded away from wall of house.

Framing.—The house to be framed and braced in a perfect and

substantial manner, and to be perfectly plumb and true. All beams to be

spiked together where practicable, so as to form tie across building.

All framing of beams to be with tenon and tusk. Roofs strongly framed

and cross bridges, first and third tier of beams. Gutters on roof to be

hung of galvanized iron. Veranda to be built in and lined with Merchant

& Company’s roofing tin (or plates). There will be three 4″ galvanized

iron leaders for main roof, and one in front for veranda. (See plans.)

Gables.—Construct gables as shown.

Roofing.—Cover all roofs with sawed pine shingles 6″ × 18″, three

shingles to the lap. On main roofs these to be nailed on shingle laths;

on veranda roofs, on spruce boards, underside dressed (as specified).

Flashing of Merchant & Company’s old method roofing plates. Flash

around chimney, valleys, and junction of roofs with walls of house.

Walls.—The walls of hall, dining room, and parlor to be covered with

good ⅞″ pine boards dressed on exposed side; all other underboarding

to be of hemlock of even thickness. Over this cover walls with felt

paper, and then on first story cover paper with clear pine clapboards

5″ to weather. Above felt cover paper with 6″× 16″ sawed pine shingles

not more than 6″ to weather. Between partitions of hall, dining room,

and parlor fit ⅞″ pine boards, dressed on both sides, with ¼ round

mould to keep panel in place; the sheathing on other sides of room

dressed on one side; boards not more than 5″ wide.

Bases.—Form base as shown of 1½″ thick pine.

Casings.—1¼″ thick and 2″ wide.

Furring.—Fur out the walls of stairs to cellar (corner boards to be

4″ wide, 1¼″ thick; put on angle beads where necessary).

Outside Step.—⅞″ thick riser, 1¼″ thick tread.

Flooring.—First and second floors to be made of good T. and G.

yellow pine in rooms over hall, parlor, and dining room; to be dressed

on both sides; third floor spruce; all to be not more than 5″ wide.

Partitions.—Set the partitions between hall, parlor, dining room,

pantry, kitchen, and cellar stairs with 2″ × 4″ spruce, studs dressed

and chamfered. (Note.—This is to be done so as to make a uniform

appearance in hall, dining room, and parlor.) Studs of all other

partitions of hemlock. Construct woodwork between piers, as shown.

Interior Stock.—All the stock for inside finish to be best quality,

well seasoned, smoothed, and sand‐papered, and, unless otherwise

specified, of white pine. Hardwood saddles for all hearths and door

openings.

Architraves.—All doors and windows to have ⅞″ × 5″ plain

architrave with moulding and bead on ends. No splicing allowed.

Doors.—Front door to be 2″ thick, of design shown (cherry). All

other doors to have 1⅝″ thick four paneled stock door (local

manufacture), and, unless otherwise shown, to be 2′ 6″ × 7′ 6″. The

openings from hall to parlor and dining room to be: hall and parlor, 7′

× 7′ 6″; hall and dining room, 6′ × 7′ 6″. Bases 6″ high, moulded (in bed

rooms, closets, and pantries).

Door Frames.—All door frames to have 1⅛″ thick jamb, with stops

nailed on.

Window Frames.—All windows, unless otherwise shown, to have box

frames with pockets; sills to have sub‐sill, upper sill, plowed, etc.,

and given proper pitch.

Sashes.—All sashes to be 1⅝″ thick, with lights as shown, and to

have moulded sash bars. All sliding sashes to be double hung, the best

steel axle pulleys, hemp sash cords, and iron weights. Cellar windows

to have plank frame hinged at top. Casements to be hinged and have

spring catches.

Bath Room.—Sheathe up sides of bath tub, riser of water closet and

basin, with clear white pine ⅝″ thick; wainscoating of bath room of

same stuff 4′ 6″ high with neat mould on top. Make a batten door under

basin with catch, etc. Door in riser of and in top of water closet and

bath to be black walnut put on with brass screws.

Closets.—Fit up closets, except as otherwise specified, with one

shelf, and cleat under for books. Bed room in attic to be furred as

shown.

Dressers.—Fit up dresser in kitchen of clear white pine, glass doors

at top and drawers and cupboards under; dressers in pantry to be the

same.

Blinds.—Provide and hang to all windows of first and second floors

1¼″ outside blinds of two folds properly hinged, and having rolling

slats.

Base Knobs.—To all doors, and to have rubber tips.

Hardware.—Butts.—All doors to be properly hung with japanned butts

of requisite sizes. Locks.—The front door to be supplied with brass

faced mortise, patent reversible front door knob lock with night work,

with two keys to each combination, and brass striking plate. All other

doors (except closets) to have 4″ mortised locks, brass face and brass

striking plate. Closets to have rim locks. All locks to have brass

keys. Knobs.—The front door to have a plain 2½″ round bronze knob,

with bronze rose and drop escutcheon to match. All other knobs to be

(black) terra cotta with bronze iron mounting, etc. Bell pulls.—The

bell pull to front door to be bronze, to match front door hardware.

Bolts.—The rear door to kitchen to have two barrel bolts; door to

cellar one, doors to bulkhead to have brass padlock with staples,

etc. Drawer pulls.—Drawers to have bronzed iron drawer pulls. Sash

fasts.—All double hung windows on first floor to have Morris patent

self‐locking sash fasts, to be of bronzed iron. Put on patent fasts to

all casements, windows. Hooks.—Put heavy, triple hooks of japanned

cast iron to all closets, 8″ apart. Screws.—All hinges, etc., to

be securely put in place with steel screws of proper size. Bell

hanging.—Put in a large gong for front door, properly connect with

wire, etc.

Stairs.—Main stairs to have an open string moulded and nosing to

return on ends and carried around well. Risers ⅞″ thick, tread 1½″

thick: tread and risers housed into wall string and treads plowed into

risers; risers plowed into the underside of the tread. The outer string

to be 1″ thick, and beaded on lower edge. All to be of clear pine.

The stairs to have cherry newel, 5″ × 5″, turned. Cherry rail, 2″ ×

3″. Balusters, 3 on each tread, 1⅛ × 1⅛; all to be solidly put

together and wedged. Cellar stairs to have 1½″ thick strings, sawed

to receive 1¼ treads; all of spruce. Attic stairs to have 1¼″

strings, plowed to receive risers and treads; all of spruce.

PAINTING.

All shingles of walls and roof to be stained with Cabot’s best creosote

stains, of colors selected by architect. The clapboards to receive two

coats of best white lead and linseed oil finish, in colors as directed.

Hardwood.—The newel, rail, and balusters to be filled with three

coats of hard oil, rubbed to a dead finish. The studs and beams

overhead in dining room, parlor, and hall to have two coats of shellac

(or Wheeler’s hard finish). All other woodwork the same.

Glazing.—All glass to be double thick American, of number of lights

shown; all to be well puttied and tacked, thoroughly cleaned, and left

whole and perfect. All small lights to have cathedral glass, selected.

MASON.

Excavation.—Excavate for all cellar wall piers, etc., as shown. Dump

the earth where directed, and leave the premises clear after building

is finished. Piers 3′ below surface.

Cement, Lime, and Sand.—All lime used in the mason’s work to be

extra No. 1 Rockland lime. Cement, best quality Rosendale of approved

brand. Sand to be clean and sharp, and all to be used in proper

proportions.

Foundations.—Furnish all materials and build walls, unless otherwise

shown, 1′ 6″ thick of stone laid in lime and cement mortar in equal

portions, and clean, sharp sand in proper proportion; the whole to be

well bonded and trowel jointed inside and out.

Hearths.—Hearths to be of Portland cement, with lampblack to give

color.

Bluestone.—Chimney cap to be of bluestone in one piece, holes for

flues cut in. Cellar stairs as shown.

Brickwork.—Brickwork of chimney to be selected, on exposed places

jointed in red mortar, all to be hard, well burned brick. Build in

register flue in kitchen breast where directed and 6″ C. I. thimble

where shown. Build in breast of chimney on second floor 5″ C. I.

thimble, 2′ 6″ from floor.

Trimmer Arches.—Turn trimmer arches over all fireplace openings.

PLASTERER.

Laths.—Laths to be best seasoned pine, free from all imperfections,

laid ⅜″ apart and breaking joint.

Plaster.—Plaster will be two coat work, the second to be white sand

finish, well floated. The first coat to be best Rockland lime and clean

sharp sand, well mixed with long cattle or goat hair, to be thoroughly

worked and stacked, all to be well troweled and made perfectly true.

Patch up and repair all plastering at completion of building.

PLUMBER.

Lead Pipes.—The lead pipes through to be AA lead pipe. The waste

pipes to be heavy; all joints between lead pipes to be heavily wiped,

and joints between lead and iron pipes to be made with brass ferrules

wiped into lead pipe and calked into iron pipe with molten lead and

oakum.

Iron Pipes.—Iron pipes to be heavy C. I. soil pipe, free from all

imperfections, and of uniform thickness; thoroughly coated inside and

out with coal tar. All joints to be calked tight with molten lead and

oakum.

Drain Pipe.—From point marked on plans run a four inch C. I. pipe

to roof, making all proper branches for water closets, baths, basins,

tubs, sinks, and at roof to be capped with Smith’s patent ventilating

cap. At foot of this place a 4″ running trap, with hole for cleaning

out, and an inlet to run out under servants’ water closet. All branches

to be Y branches, 4″ for water closet, and 2″ for basins, sink, etc.

Plumber to make connections with street pipe.

Lead Supply Pipe.—Run from point marked on plans a ¾″ lead pipe.

Place at the beginning of this a rough round way lever handle, stop and

waste cock. Connect with main supply. From the ¾ lead pipe make all

proper connections for water closets, tubs, baths, and sink with ⅝″

pipe, all to be graded so as to empty at stock cock. In kitchen, over

sink, put two cocks (lever handle), so as to control supply of hot and

cold water to second floor, the same to empty in the sink.

Boiler.—Furnish and set where shown in kitchen a heavy 30 gallon

galvanized iron boiler with stand complete. The boiler to be supplied

with water through a branch of ⅝″ lead pipe, and connect with water

tank of range with a ⅝″ extra strong lead pipe, the other part of

boiler to be fitted up with ⅝″ strong lead pipe with ⅝″ sediment

cock, and the required length of light lead pipe to empty into sink

trap (boiler to have a safety attachment). Furnish and put on to supply

to boiler in the most convenient place a ⅝″ finished lever handled

stop cock to control supply to boiler. From head of boiler run lines of

⅝″ lead pipe to supply sink and tubs in kitchen, basin, and bath tub

on second floor.

Sink.—Furnish and set up (and of size shown) a plain C. I. sink

with slate back. To be set on C. I. legs, to be supplied with hot and

cold water through ⅝″ lead pipe, drawn through ⅝″ compression bibb

cocks, one hose, the other plain, wasted through heavy lead S trap

calked into iron pipe as specified.

Tubs.—Furnish and set up tubs of size shown, supplied and wasted the

same as sink, but to have brass plugs and safety chains. Tubs of wood

well dovetailed.

Wash Basin.—Furnish and fit up (of size shown) in bath room a 1¼″

thick Italian marble slab, counter‐sunk and moulded on edges, backs 10″

high, the slab to be fitted with a 12″ marble pattern basin (overflow)

well fitted to slab, with brass clamps, etc. The basin to be supplied

with hot and cold water through silver plated compression basin bibb

cocks (⅝), wasted through 2″ lead pipe and S trap, silver plated

basin plug and safety chain.

Bath.—Furnish and fit up bath of size shown, 14 ounce copper tinned

and planished, tub to be supplied with hot and cold water through ⅝″

lead pipe, and drawn through ⅝″ bath silver plated compression cocks.

Wasted through 2″ lead S trap. Silver plated plug and safety chain.

Note.—All lead S traps to have brass trap screws for cleaning.

Water Closet.—Water closet in bath to be a Demarest or Manhattan

patent long oval flushing rim earthenware hopper, automatic seat, all

complete, with waste preventing cistern, to be copper lined; supply

through ⅝″ lead pipe connected to main supply; to have heavy last

lead trap, properly connected with soil pipe. Connect from cistern to

hopper with 1¼″ light lead pipe so as to get good flush. The water

closet for servants to be enameled iron hopper with cistern, etc., as

above.

It is said that the ova of tapeworms are frequently deposited in the

wrinkles of a lettuce leaf and near the mid rib of a cabbage leaf, and

so it behooves those wishing uncooked leaves of any kind to have them

carefully washed.

122

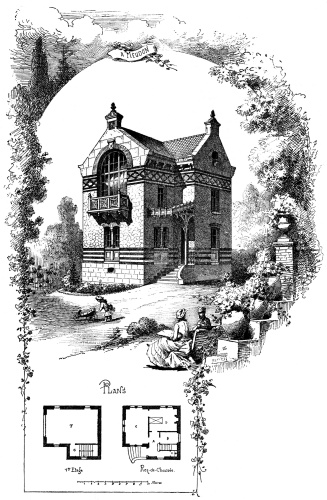

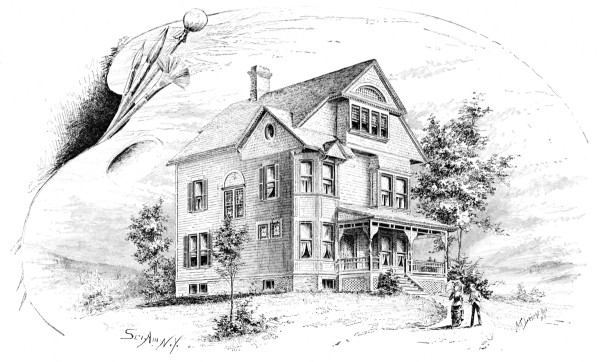

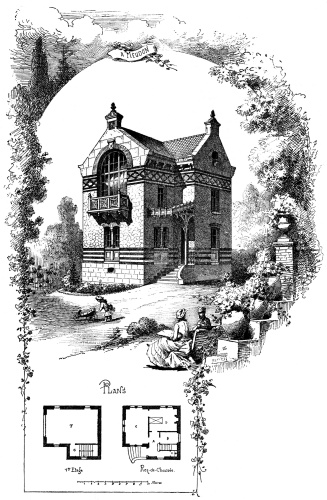

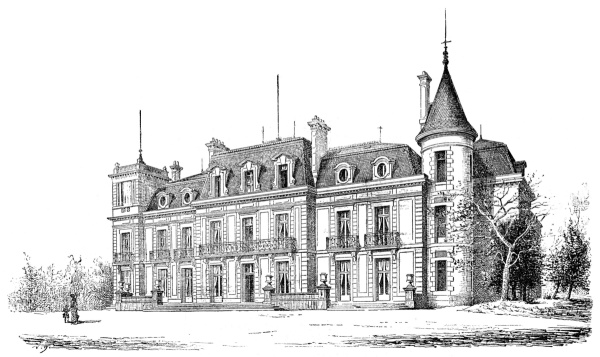

A FRENCH COTTAGE.

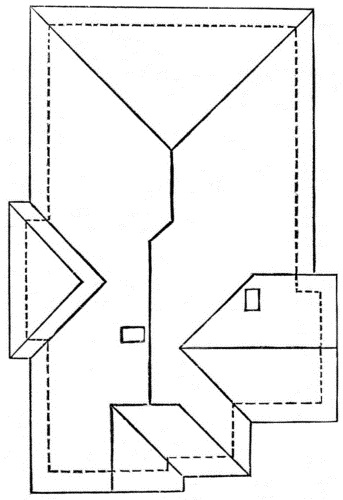

We publish herewith the plans for a house designed by M. A. Fatalot

and erected by M. Valette, architect. It is built on the side of the

terrace (Rue Babie), on the green hills which overlook the Seine.

A FRENCH COTTAGE—HOTEL DE PEINTRE, A MEUDON.

Larger image (230 kB)

The construction is very simple. The architect was, in fact, asked

to use the strictest economy. The first floor, built over a cellar,

consists simply of a vestibule, A, which opens into a dining room, C,

a bed room, D, a kitchen, B, the water closets, E, and the stairway.

The latter is constructed of wood and leads to the second story, which

serves as both studio and drawing room. This room is lighted by the

large window shown in our perspective view. The walls of the building

are of stone—stone from Meudon, nicely colored—and Bourgogne bricks

of different shades form the design of the frieze. The basement is of

dressed stone; the pediments of the gables and the cornice are covered

with a plaster of sand and mortar colored in imitation of stone. The

tops of the pediments are decorated with Parvillee faience. The perron

is of Bagneux stone and the mullions and supports of Euville stone.

| The following is a detailed list of the expenses: |

| Masonry | $1,480 |

| Carpenter work | 265 |

| Plumbing, etc. | 166 |

| Joiner’s work | 462 |

| Locksmith’s work | 315 |

| Heater, etc. | 74 |

| Painting and glazing | 92 |

| | $2,854 |

| Salaries | 200 |

| | $3,054 |

Our Forestry Problem.

According to latest estimates, we consume yearly, with our present

population of sixty millions, not less than twenty billion cubic feet

of wood. The amount is made up, in round figures, in the following

manner:

2,500,000,000 feet for lumber market and wood manufactures;

360,000,000 feet for railroad construction;

250,000,000 feet for charcoal;

500,000,000 feet for fence material, etc.;

17,500,000,000 feet for fuel.

To this it will be safe to add, for wasteful practices and for the

destruction by yearly conflagrations, at the least, twenty‐five per

cent.

The average yearly growth of wood per acre in the well stocked and well

cared for forests of Germany has been computed at fifty cubic feet.

Applying this figure to our present requirements, we should have an

area of not less than five hundred million acres in well stocked forest

to give us a continual supply of all kinds for our present needs. Now,

a careful canvass made four years ago developed the result that the

existing forest area in the United States, excluding Alaska and Indian

Territory, comprised almost five hundred million acres (489,280,000);

but it is well known to everybody who is acquainted with our forests

that they cannot compare in yield with the average European Continental

forests under systematic management. Much of what is reported as forest

is useless brush land or open woods, and depreciated in its capacity

for wood production by annual fires, by which the physical structure of

the leaf mould is destroyed, and thus, too, its capacity for storing

the needful moisture, reducing wood production, and killing all young

growth.

Without care, without management, and left to the kind but uneconomical

work of nature, interfered with, in addition, by rude and ignorant

action of man, it is doubtful whether, on the existing area, one

half the amount of wood is produced yearly which we now require. We

have, therefore; beyond doubt, reached—if not passed—the time when

increased drain means squandering of capital, and when regard to

husbanding, to careful management, to recuperation of our forests,

and planting of new forests is required for the purpose of merely

furnishing raw material; and it should not be forgotten that to

reproduce the quick growing white pine of an acceptable quality and

sufficient size requires not less than eighty to one hundred years,

and for the long leaved pine two hundred years; that, altogether, wood

crops are slow crops; that nothing of size can be grown under a quarter

of a century at the best.

That this is a business requiring intelligent national consideration

is apparent. Not less so if we appreciate the magnitude of the values

resulting from it. The total value of forest products in the census

year was placed at $700,000,000, or ten times the value of the gold

and silver production, five times the value of all coal and mineral

production, and exceeding every one of the agricultural crops, corn and

wheat not excepted; and representing in value about thirty per cent. of

the total agricultural production.

Of injuries wrought locally by the reckless clearing of hill sides and

of deterioration of the soil due to inconsiderate action of man, I

could entertain you by the hour. The country is full of examples. Any

one who wishes to study the effect of such denuding of hill sides upon

the soil, the water flow, and agricultural conditions, need not go to

France, Spain, Italy, Greece, or Palestine. The Adirondack Mountains

are within easier reach, where the thin cover of earth exposed to

the washing rains is carried into the rivers, leaving behind a bare,

forbidding rock and desolation, while at Albany the Hudson River is

being made unnavigable by the debris and soil carried down the river.

The government has spent more than ten million dollars, I believe, and

spends every year a goodly sum, to open out a passage over the sand bar

thus formed.

Go to the eastern Rocky Mountains, or to Southern California, and you

can gain an insight into the significance of regulated water supply for

the agriculture below, and also learn how imprudently we have acted

and are acting upon the knowledge of this significance by allowing the

destruction of mountain forests in the most reckless and unprofitable

manner. Along the shores of Lake Michigan, and along the sea coast, we

are creating shifting sands by the removal of the forest cover, to make

work for the ingenuity of our children in devising methods for fixing

these sands again. The vegetable mould with which the kind forest had

covered the alluvial sands of the southern coast plain we are taking

pains to burn off in order to replace it with expensive artificial

fertilizers.

That the great flood of the Ohio, which cost the country more than

twenty million dollars, was entirely due to deforestation, I will

not assert; but it must have been considerably aggravated by the

accumulation of minor local floods, due to the well known reckless

clearing of the hill sides, which sent their waters down into the river

in torrents. At the season when the winter snows are melting, watch the

newspapers, and you will find an almost daily mention of the disastrous

ravages of brooks and streams, many of which injuries could have been

prevented by avoiding the creation of their distant and indirect cause.

Thus we may multiply examples all over the country, showing harmful

local influences upon agricultural conditions due to forest devastation.

That the vast stretches of land in the Northwest, from which the white

pine has been cut and burned off, present the aspect of a desolation

which sickens the heart, you may hear from every one who has seen these

deserts unnecessarily wrought by man. Every traveler in this country,

be it to the White Mountains, to the Adirondacks, along the Alleghany

Mountains, be it through the Rockies or the redwoods of California,

cannot but be startled by the desolate, sad aspect of many of these

once beautifully clad mountain crests.

And we are a nation hardly a hundred years old, with over thirty acres

per capita to spread ourselves upon. What will become of us when we

must live upon five acres per head? We are far enough advanced in our

recklessness of disregarding the indirect significance of forest areas

to have learned a lesson at home, and to feel the necessity of being

more careful in the utilization of the forest, so as not to lose its

protection for our agricultural and general interests.

The means for its solution I may only briefly indicate. They are

education, example, encouragement, legislation. Some of these are

of slow effect. Others can be made to give results at once. Let the

United States government, which still holds some seventy million acres

of the people’s land in forests, mostly on the Western mountains,

where its preservation is most urgently needed—let the government

set aside these otherwise valueless lands, and manage them as a

national forest domain, and then the first effective step, a feasible

and not a forcible one, is made. Let the military reservations on

the Western treeless plains, which are still in the hands of the

general government, be planted to forests and managed as such. This

would be no doubtful experiment, would interfere with nobody, would

enhance the value of the surrounding country—and education, example,

and encouragement are provided, as far as it is in the legitimate

province of the general government. And such example, instead of

costing anything to the country, can be made self‐sustaining—nay,

productive—and would add appreciably to the people’s wealth.—B. E.

Fernow.

Mortar containing sugar has been employed in building the new Natural

History Museum in Berlin, and has proved far superior to common mortar.

It sets almost with the firmness of a good cement, while mortar made

with molasses became soft and brittle after a time. In Madras a mortar

is used with which either sugar, butter or buttermilk, shellac and eggs

are mixed. It holds well and takes a marble‐like polish.

123

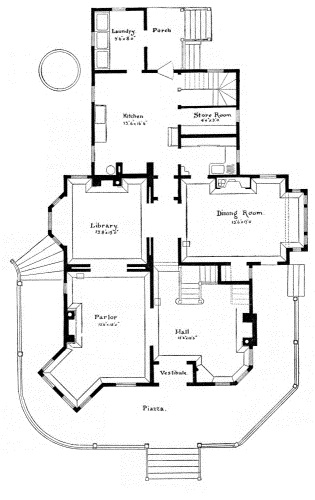

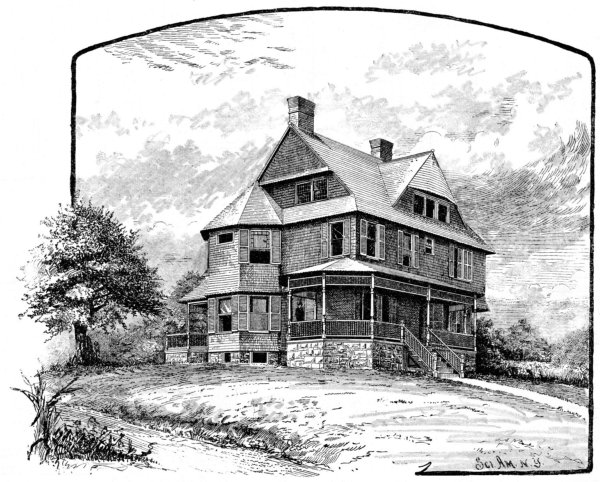

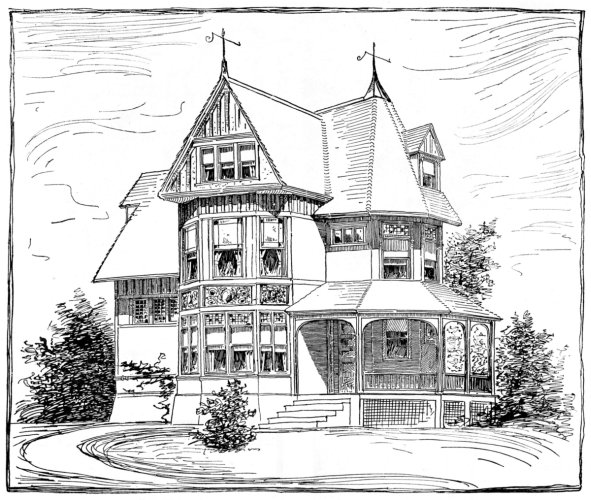

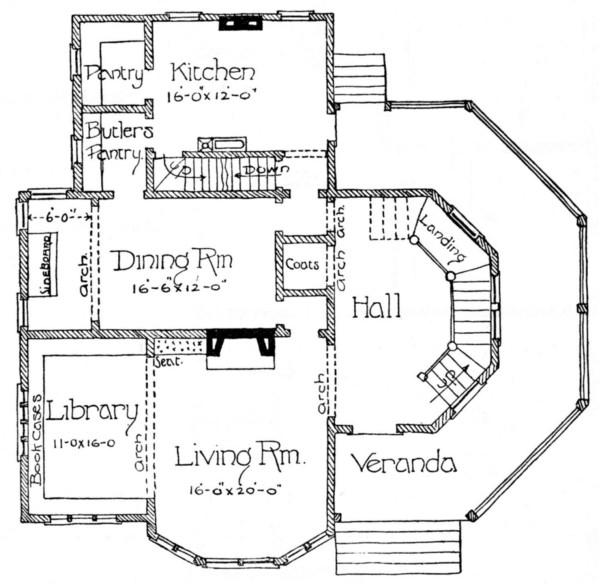

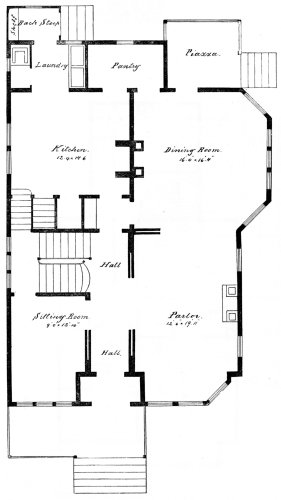

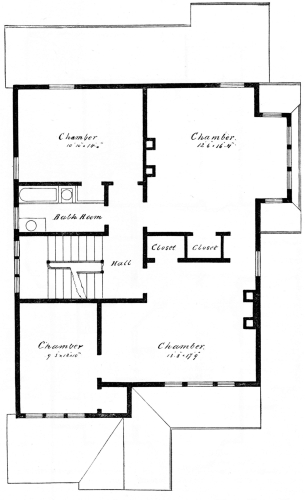

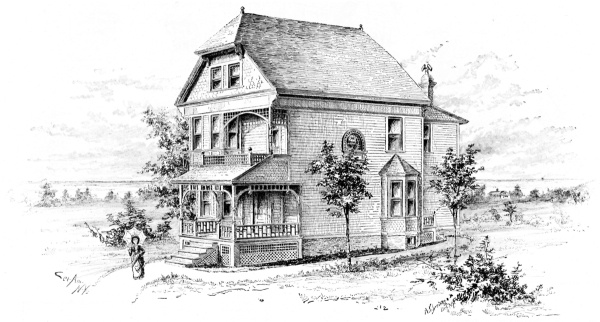

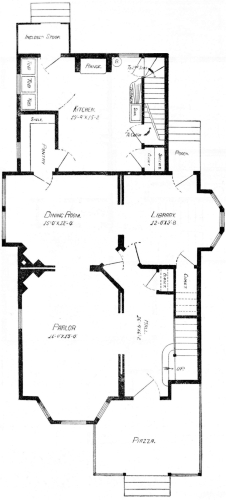

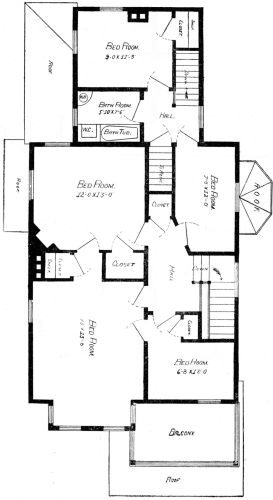

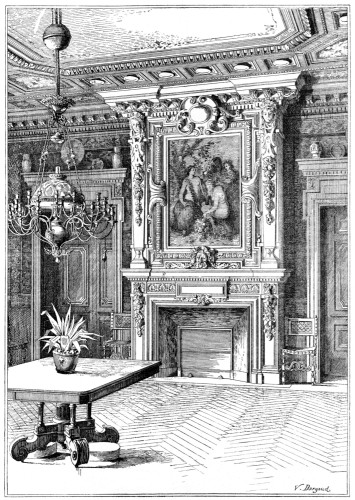

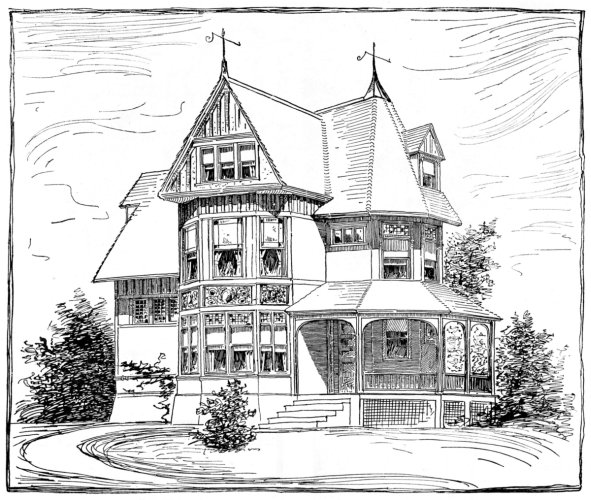

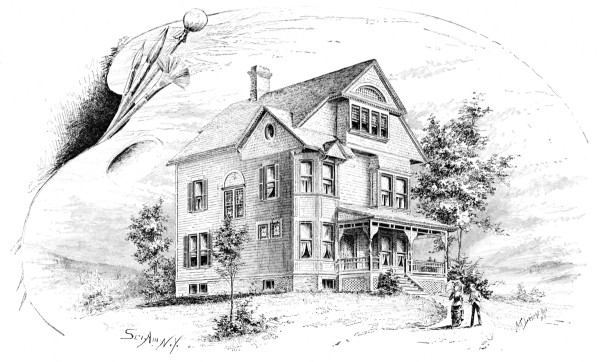

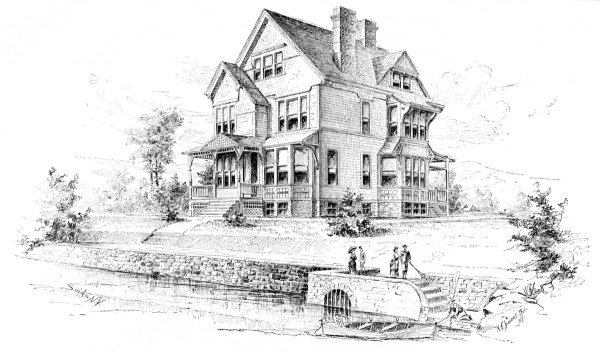

A RESIDENCE FOR $8,000.

The perspective and plans herewith presented are from the designs

of Mr. S. W. Whittemore, architect, East Orange, N J. The general

dimensions are: Front, 36 feet, exclusive of bay windows; side, 51

feet, exclusive of piazza and laundry. Height of stories: Cellar, 7

feet; first story, 10 feet; second story, 9 feet 6 in.; attic, 8 feet.

Materials.—Foundation, stone; first and second stories, clapboards;

roof, shingles.

Cost.—$8,000.

Fireplaces are provided in the dining room, library, parlor, and hall.

The attic is finished throughout. Cellar under the whole house except

laundry.

Bamboo Tree.

Writing from China, a correspondent says that the Chinese have

developed the culture of the bamboo tree very wonderfully. They can

produce a perfectly black as well as a yellow bamboo. The Emperor of

China has one officer whose duty is to look after his bamboo gardens.

This valuable tree is found in all tropical and sub‐tropical regions,

both in the eastern and western hemispheres. An attempt has been made

in England, and with some success, to raise a dwarf species found at

an altitude of 12,000 feet in the Himalaya mountains. The new world

furnishes bamboo of the greatest diameter. The stems are usually very

slender, but in the northwestern part of South America is found one

species with a diameter of 16 inches. The Chinese put this plant to a

greater variety of uses than any other people. Some kinds of it when

it first shoots up from the ground are used as a vegetable as we use

124asparagus, or it can be pickled in vinegar or made into delicious

sweetmeats. The plant has to be 30 years old to blossom, and then it

bears a great profusion of seeds and dyes. These seeds may be used like

rice, and a kind of beer may be made from them. In 1812 severe famine

in portions of China was prevented by the sudden blossoming of a great

number of bamboo trees. The stems of all the varieties are remarkably

silicious. One kind found in Java is so hard that it strikes fire

when the hatchet is applied to it. This has only a very slender stem,

which is polished and used as stems for tobacco pipes. This Protean

tree furnishes material for houses, boats, cordage, sails of boats,

telescopes, aqueduct pipes, water‐proof thatching, clothing, water

wheels, fences, chairs, tables, book cases, boxes, hats, umbrellas,

shields, spears, and paper. The pith is used for lamp wicks, so there

is no part of it that cannot be used for something. From some of it

exquisite carvings inlaid with gold and silver are cut, that exceed

in beauty the ivory carvings for which the Chinese are so famed.

Recently it has been put to another use. Mr. Edison has found that

the carbonized fibers of the bamboo furnish the best material for the

incandescent electric lamp, and has made use of it in his system of

lighting. In Burmah and Siam whole cities are built from bamboo. These

houses are made in pieces, lashed together, and raised on posts several

feet high.—The Lumber World.

FIREPROOF STRUCTURES.

An article recently published by us apropos of the Opera Comique

catastrophe has brought us several interesting communications, and,

among them, one from Mr. Hennebique, one of the designers of the 948

foot Belgian tower. Mr. Hennebique has established the fact that

structures in which iron is used in the flooring do not arrest the

ravages of fire, but fall even more quickly than those in which wood is

employed.

In fact, the beams that support the ceiling joists, flooring,

and laths, naturally combustible materials, are raised to a high

temperature, and, becoming red hot, bend under their own weight, and at

the same time shove the walls outwardly.

The flooring of Mr. Hennebique’s invention, which is composed of a

cement made of coal ashes, plaster rubbish, and hydraulic lime, is

refractory enough to resist the heat developed by combustion.

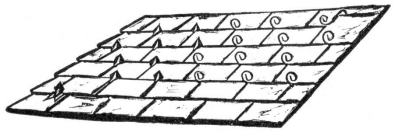

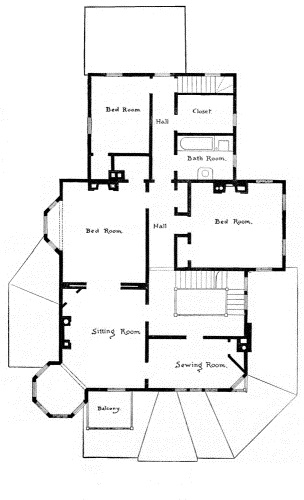

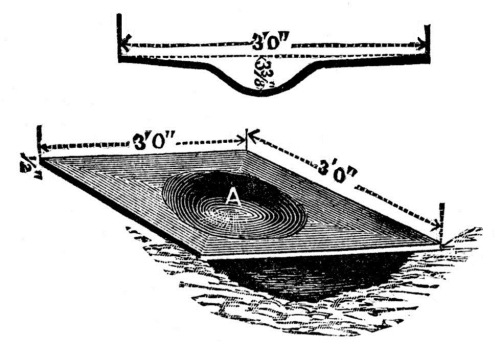

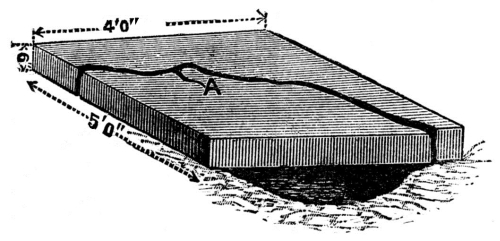

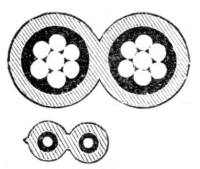

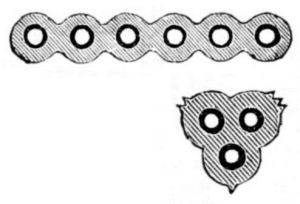

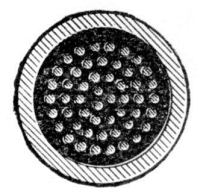

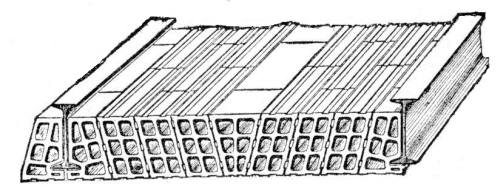

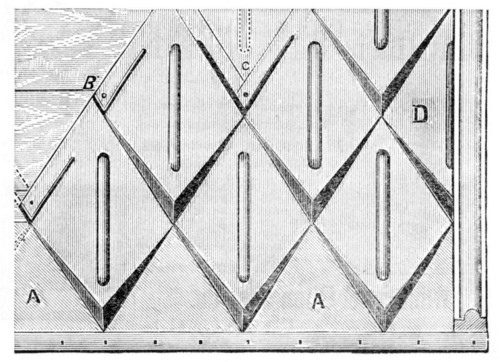

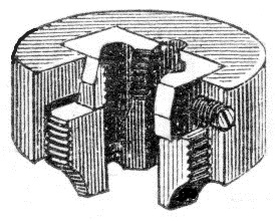

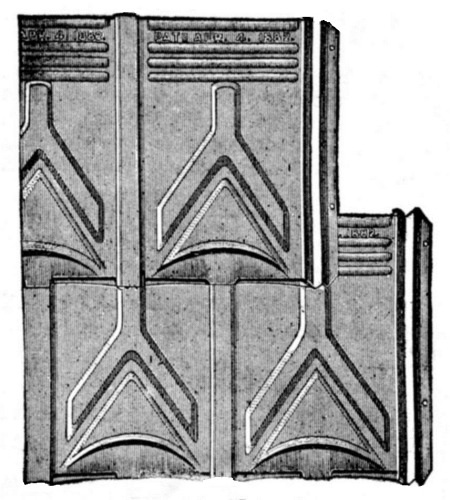

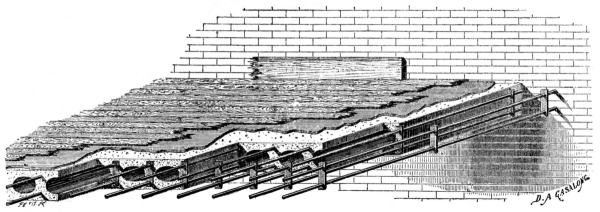

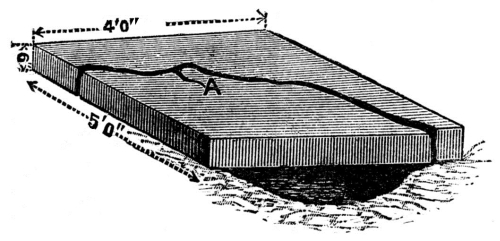

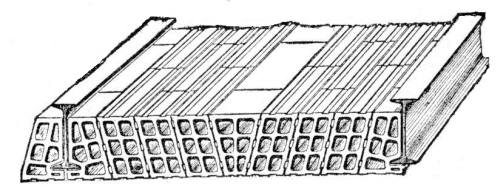

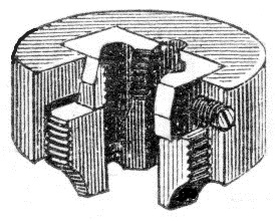

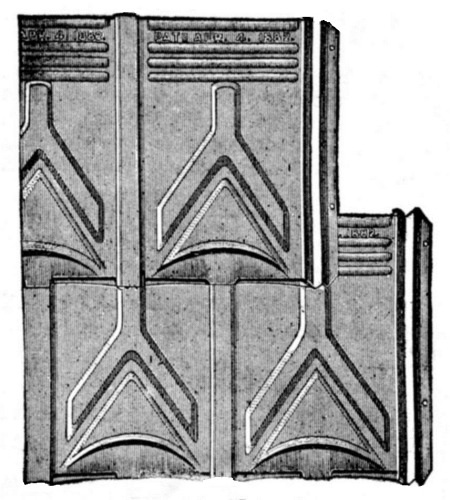

As may be seen from the figure, this flooring consists of tubular

girders resting upon very simple metallic anchorages. These girders

are of the composition above described, and thus constitute a sort

of monolith upon which any sort of a floor can be laid—terra cotta,

marble, wood, etc.

Aside from its being nearly completely incombustible, this sort of

flooring presents a great advantage, from an economical standpoint, in

consequence of the rational utilization of the materials employed. It

is unnecessary to say that the metal is perfectly protected against

oxidation.

Another advantage of this flooring is that it almost entirely prevents

the propagation of sound.

HENNEBIQUE’S FIREPROOF FLOORING.

As may be readily seen, this mode of construction is applicable to

different uses and to every possible sort of decoration, such as

cornices, compartment ceilings, girders of various styles, as well as

pillars, pilasters, columns, and supports of every shape and every

resistance.—Chronique Industrielle.

Construction of Chimney Flues.

In a letter to the Insurance World Mr. Thomas Boyd, architect, of

Pittsburg, Pa., gives the following practical information:

I have had considerable experience in examining buildings burned by

fire, having been associated with my father for eleven years, and

during that time have examined hundreds of buildings destroyed by fire.

I have traced more fires to the cause of defective flues than to any

other source, and I could refer you to buildings, not only in this

city but in others, where fires have occurred from this cause, and the

insurance men and the public in general stated that the fire occurred

from “unknown causes,” as it was first seen many feet away from the

flues.

In seventy‐five cases in one hundred where fires occur from “unknown

causes,” it can be traced to defective brickwork. Ordinarily, an

architect specifies that the brickwork shall be well slushed, and that

the flues shall be well pargeted or plastered on the inside. This is

a great error, as no flues should be plastered on the inside, and no

walls having flues in them should be slushed, as the term is generally

understood.

The flues should in all cases be built smooth on the inside, and all

the joints should be filled full of mortar, the vertical joints as

well as the bed joints. The lining of the flue or the four inches

surrounding the flue should always be kept in advance of the brickwork,

and the brick adjoining the lining and the second and third brick, and

so on, should be shoved in soft mortar up against each other. This will

fill all the vertical joints from bottom to top as laid. The slushing

that is ordinarily put in from the top only goes down into the joint

about ½ inch, thus leaving an opening the entire length of the wall,

and in some cases an opening which a mouse could crawl through. As it

is only a question of time when all the plastering that can be put on

the inside of a flue will fall off, it will leave these vertical joints

between the bricks open into the flue, and as the joists cross through

these joints in the brickwork, fire is liable to take place ten or

twenty feet away from the flue. I have taken down many old buildings in

which these joints were filled with carbon or soot.

If the flues are built as above described, any competent builder

or architect can find out whether the mechanics doing the work are

slighting it or not; but if the inside of the flue is plastered or

lined with terra cotta or any other material, you cannot tell whether

the wall is properly built or not until this plastering falls off,

which it will in the course of a few years. Thus all buildings erected

with plastered flues are liable to burn at any time.

I have made a practice for a number of years of building flues without

lining them, and then when the house is built, or as each story is

erected, I put a dense smoke in the flue and close the opening at the

top. If there is a hole the size of an ordinary pin head, the smoke

will find it and penetrate into the interior of the wall adjoining the

flue.

Roadside Plantations of Trees in Belgium.

The roadside planting of trees is carried out on a most extensive

scale in Belgium, forming a marked feature in the landscape of that

country. According to the report of M. J. Houba, State Head Bailiff

or Ranger of Woods and Rivers in Belgium, recently published in the

Revue Horticole, the total length of the highroads of Belgium in 1881

amounted to 4,227 miles, classified, as regards tree planting, in the

following manner:

| | Miles. |

| Roads already planted | 2,417 |

| „ still to be planted | 264 |

| „ which cannot be planted | 1,546 |

| | 4,227 |

From this it will appear that, at the date mentioned, more than half

the entire length of the Belgian highroads had been planted, and that

the proportion would soon reach two‐thirds.

The number of trees used in forming these plantations amounted

to 871,685, representing in 1881 a money value of £415,986, the

average cost of each tree when planted having been about 2s. 6d. The

plantations had therefore at this date increased in value to nearly

four times the amount of the capital originally expended upon them.

The trees principally employed in these roadside plantations (already

made) are: Elms, 371,621; oaks, 130,828; poplars, 80,853; ash,

73,893; beech, 32,970; maples, 27,755; service trees, 24,630; Norway

spruce, 43,767; larch, 41,699. It will be seen from this list that

coniferous trees are largely used in Belgium for roadside planting. On

the other hand, the report only gives 897 plane trees, 976 acacias,

and 672 cherry trees, apple trees, and pear trees, showing that

while the Belgian authorities fully recognize the great utility of

these roadside plantations in other respects, they especially aim

at the production of timber of good quality in a commercial point of

view.—The Garden.

An Egyptian Temple.

An Egyptian temple appears to have been one of the most imposing

assemblages of buildings that can be well conceived. Avenues lined

with hundreds of sphinxes on each side led the worshiper to the

sacred precinct for the distance of thousands of feet, and thus the

mind, even when remote from the vicinity of the temple, received an

impression calculated to excite veneration. This avenue was terminated

by a stupendous mass of pyramidal form, above 200 feet wide and about

80 feet high, whose enormous proportion was naught diminished by the

vastness of the plain in which it stands, nor by contrast with the

mountains that overhung it. In the center of this propyleum is a door,

flanked in advance by an obelisk on each side, about 90 feet high,

and beside which are figures of colossal dimensions, 45 feet high,

sitting as guardians of the sacred portal. The effect of the whole

is gigantic, and calculated to impress the coming worshiper with the

fullest notions of his insignificance in the scale of material nature.

The triumphal gateway being passed, a magnificent court meets the eyes

of the beholder, having on each side a colonnade. And this court led

to a densely columned hall or vestibule, under the shades of which

the crowds of Egypt’s sons and daughters reposed to recover from the

exhaustion and fatigue caused by their journey under a burning sun to

the fane of their creature god. And here the mind also dwelt awhile on

the first impressions produced by the contemplation of the overpowering

majesty of the gorgeous mass. For the huge propylea, which inclosed

either end of the court, and the hall, with its forest of clustered

columns, which the eye could not number, and the playful variety

and copiousness of channeled hieroglyphics which left not a space

uncovered, and the brilliancy of the pigment which gave an endless

variety to the shafts and capitals of the columns, to the beams, the

walls and ceilings, bewildered the attention, and left not a moment of

repose to the wondering stranger. A lofty central avenue of columns,

above 60 feet high, forming, as it were, a triumphal way, leads under

a third portal, of dimensions by no means inferior to the others

just mentioned, and marked with what care and with what sanctity the

priests guarded every approach to the inner parts of the temple. But

this gateway passed, and a scene the most sublime burst upon the view.

An ample peristyle much larger than the one already passed, presented

itself to the eye, probably planted with trees, crowded with metaphoric

statues.

On either hand a double avenue of columns, less for convenience than

dignity of effect. In the center uprose the portico of the mass of

building, that formed the temple itself—the columns in dimension

more lofty, in decoration more rich, in proportion more graceful than

those of the courts. The dynasties that had ruled over the country

up to the period of the erection of this temple have their histories

graven on the walls and on the columns. The same pyramidal form gives

an appearance of endless durability to the mass, which is surmounted

by an immense hollowed cavetto having the center occupied by the

sculptured form of the agatho demon, or winged globe and serpents,

with outstretched wings extending over the center intercolumniation of

the facade, and seemingly a being of another world. Admitted beneath

this porch, the minds of the worshipers are prepared for the gloomy

inner penetralia, where every object was mysterious and emblematic.

Numerous doorways closed by curtains succeeded each other, and led from

vestibule to vestibule, which hindered the eye from penetrating with

sacrilegious gaze into the inmost sanctuary, all access to it being

forbidden to the multitude.

To these vestibules the light of day was denied, and the mind was

subdued by the gloom of the spot, for the attention was absorbed by

the contemplation of the sacred mysteries of the place and by the

effects produced on the attention by the huge incongruous figures of

granite—monstrous reflections of the gloomy minds of the religious

inhabitants of the sacred precinct, who sought to deify matter and the

animal instincts.—T. L. Donaldson.

125

The White Ash.

“About twenty years ago, Prof. J. L. Budd, of Ames, Iowa, advised

keeping the seeds of the ash through the winter in kegs or boxes, mixed

with clean moist sand, taking care that they become neither too wet

nor too dry. Freezing will do no harm. The ground should be marked and

prepared as for corn, and planting at the intersections, placing four

to six seeds in the hill. They should be carefully cultivated, and the

next spring thinned to one plant in each hill, the vacancies being

supplied. By planting thus thickly, the young trees get a straight

growth. At the end of six years every alternate row north and south

should be thinned out, and at the end of ten years every alternate tree

in each row. When twelve years old, on good soil and proper culture

the first four years the grove would have 12,000 trees on ten acres,

averaging eight inches in diameter. By cutting the stumps close to the

ground, and covering with a light furrow on each side, a second growth

is obtained in eight or ten years, more valuable than the first.”

Prof. C. S. Sargent, in speaking of this timber, says: “To develop

its best qualities, the white ash should be planted in a cool, deep,

moist, but well drained soil, where it will make a rapid growth. That

the plantation may be profitable as early as possible, the young trees

should be inserted in rows three feet apart, the plants being two feet

apart in the rows. This would give 7,260 plants to the acre, which

should be gradually thinned until 108 trees are left standing, twenty

feet apart each way. The first thinning, which might be made at the end

of ten years, would give 4,000 hoop poles, which at present price would

be worth $400.

“The remaining thinnings, made at different periods up to 25 or 30

years, would produce some three thousand trees more, worth at least

three times as much as the first thinnings. Such cutting would pay all

the expenses of planting, the care of plantation, and the interest

on the capital invested, and would leave the land covered with trees

capable of being turned into money at a moment’s notice, or whose value

would increase for a hundred years, making no mean inheritance for the

descendants of a Massachusetts farmer. The planting of the white ash

as a shade and roadside tree is especially recommended, and for that

purpose it ranks, among our native trees, next to the sugar maple.”

Prof. B. G. Northrop says in reference to this tree: “One of the

most valuable of our native trees is the white ash, and, all things

considered, it is one of the most profitable for planting. Combining

lightness, strength, toughness, elasticity, and beauty of grain in

a rare degree, it is in great and growing demand for farming tools,

furniture, interior finishing of houses and railroad cars, the

construction of carriages, for oars and pulley blocks, and many other

purposes. The excellence of our ash is one secret of the preference

given abroad to American agricultural implements. It is hardy, will

bear the bleakest exposure, is a rapid grower and attains large size,

but will not thrive on poor lands. It is every way superior to the

European ash, much as that has been cultivated and lauded abroad. It

is now found widely in the nurseries and young plantations attached

to the forest schools of Europe. Director General Adolfo di Beranger,

president of the Royal Instituto Forestale, at Vallombrosa, pointed me

to his plantations of Fraxinus Americana with a tone which implied

that is the tree of which Americans may well be proud.

“The ash is a fine ornamental tree for private grounds, public parks,

or for the wayside. When planted closely for timber they grow straight

and free from low laterals, and early reach a size that makes the

thinnings valuable for poles and fencing.

“The seeds of the white ash are abundant, ripening by the first of

October. They may be easily gathered after the first frost. If sown in

the fall, they should be covered with three inches of straw. If to be

sown in the spring, the seed may be mixed with damp sand.”

Sawdust.