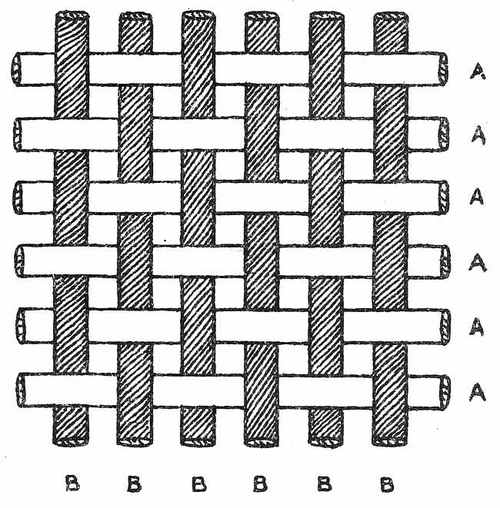

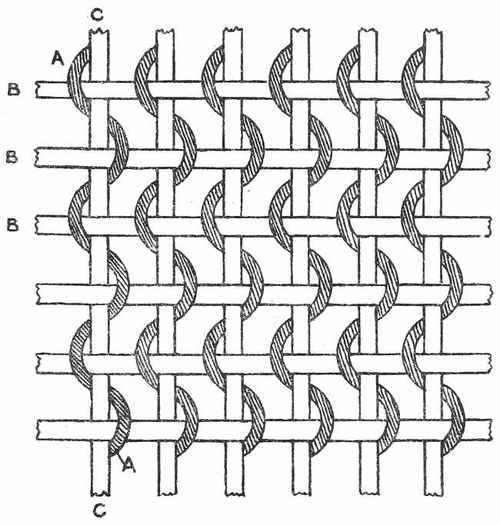

PLAIN WEAVE.

A. Weft threads.

B. Warp threads.

Figure 1 shows the simplest manner of interlacing warp and weft threads. This style of weave is called plain, calico, or "one-over and one-under" weave.

TRANSCRIBER'S NOTE

The cover image was created by the transcriber and is placed in the public domain.

Obvious typographical errors and punctuation errors have been corrected after careful comparison with other occurrences within the text and consultation of external sources. More detail can be found at the end of the book.

PIECE GOODS

MANUAL.

FABRICS DESCRIBED; TEXTILE, KNIT GOODS, WEAVING TERMS, ETC., EXPLAINED; WITH NOTES ON THE CLASSIFICATION OF SAMPLES.

Compiled and Illustrated, as an Aid to Members of the Chinese Maritime Customs Service,

BY

A. E. BLANCO,

Second Assistant, A, Chinese Maritime Customs.

SHANGHAI:

STATISTICAL DEPARTMENT

OF THE

INSPECTORATE GENERAL OF CUSTOMS.

1917.

The following pages represent an attempt to compile, primarily for the benefit of members of the Chinese Maritime Customs Service, descriptions of cotton, woollen, and other fabrics, their weaves and finishes, etc., together with other information concerning terms currently used in the piece goods trade which are likely to be met with in invoices, applications, or contracts.

This manual does not embrace all textiles known to the trade, but it does cover all those enumerated in the "Revised Import Tariff for the Trade of China," as well as many others. As far as possible the commonly accepted trade name has been used. It should, however, be borne in mind that many fabrics are known in the trade by a variety of names, so that one branch of the trade may not recognise a name applied to the same fabric by another branch.

The descriptions have been built up from information obtained first hand from practical weavers, manufacturers, wholesale and retail merchants, buyers, etc., as well as from personal visits to mills in the Manchester and Huddersfield districts, and from standard works on weaving. To Mr. G. W. Shaw, of Botham Hall, Huddersfield, I am indebted for introductions to the principal manufacturers in that district, enabling me to go through such mills as those of Mr. A. Whitwam and Messrs. Godfrey Sykes, where every phase of manufacture from raw material to finished goods was shown and explained with characteristic Yorkshire thoroughness. I am indebted for either information or actual samples, or both, to:—

Mr. A. F. H. Baldwin, American Commercial Attaché, London.

John Bright & Bros., Limited, Rochdale.

Mr. A. J. Brook, Huddersfield.

Mr. C. W. Bunn, Deputy Appraiser, New York.

Mr. F. Chitham, Director, Selfridge & Co., Limited, London.

Mr. W. E. Dale-Shaw, Huddersfield.

Drey, Simpson, & Co., Limited, Stockport.

"Dry Goods Economist," New York.

W. & C. Dunlop, Bradford.

Fisher & Co., Huddersfield.

Mr. W. R. Gandell, Board of Trade, London.

Horrockses, Crewdson, & Co., Limited, Preston.

W. G. Humphreys & Co., London.

Mr. A. F. Kendrick, Board of Education, London.

The London Chamber of Commerce.

McCaw Allan & Co., Lurgan.

Selfridge & Co., Limited, London.

Mr. A. Sutton, Piece Goods Expert, Board of Trade, London.

Tanner Bros., Greenfield.

Mr. F. Walker, Huddersfield.

William Watson & Co., London.

Alfred Young & Co., Limited, London.

The Board of Trade (through their Piece Goods Expert, Mr. A. Sutton), John Bright & Bros., Limited, and Selfridge & Co., Limited, realising the value of classified information concerning descriptions of piece goods, have very kindly supplied me with ranges of samples.

The following works have been consulted, and their contents have materially assisted me. I take the opportunity of acknowledging my indebtedness to their authors, as well as to those of any other works consulted but which may have been omitted from this list:—

"Analysis of Woven Fabrics," by A. F. Barker and E. Midgley.

Bennett's "Glossary of Fabrics."

"Cotton," by R. J. Peake.

"Cotton Goods in China," by Ralph M. Odell, U.S. Commercial Agent.

"How to Buy and Judge Materials," by H. B. Heylin.

House of Representatives Document No. 643 (Report of Tariff Board on Schedule 1 of the Tariff Law).

"Silk," by L. Hooper.

"Textiles," by William H. Dooley.

"Textiles," by Paul H. Nystrom, Ph.D.

"The Cotton Weaver's Handbook," by H. B. Heylin.

The Cotton Year Book.

"The Draper's Dictionary," by S. William Beck.

The Wool Year Book.

"Wool," by J. A. Hunter.

I wish specially to acknowledge my indebtedness to Mr. A. Sutton, Piece Goods Expert to the Board of Trade, London, for having perused the manuscript of the "Piece Goods Manual" and for the painstaking manner in which he pointed out where modifications were advisable. His suggestions have enabled me to revise definitions so as to make them agree with accepted trade interpretations.

A. E. BLANCO.

London, 1915-16.

| Plain Weave | Figure | 1. |

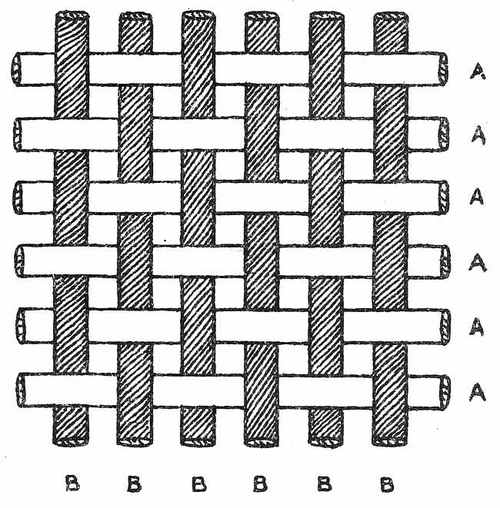

| Three-end Twill Weave | " | 2. |

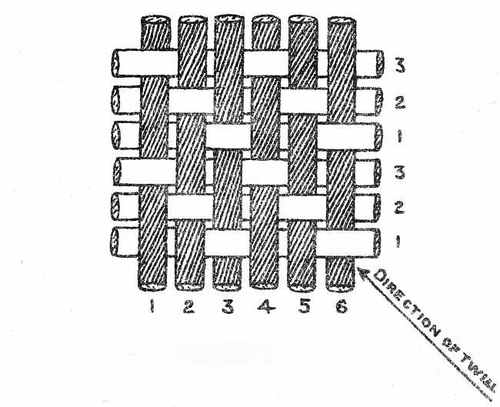

| Four-end Twill Weave | " | 3. |

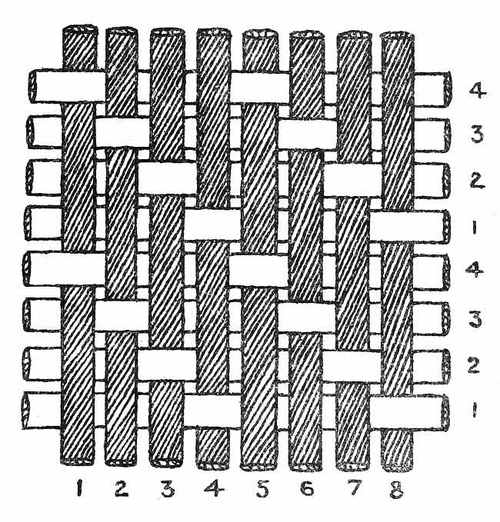

| Four-end Weft Twill Weave | " | 4. |

| Two-and-two Twill Weave | " | 5. |

| Irregular Twill Weave | " | 6. |

| Five-end Warp Sateen Weave | " | 7. |

| Five-end Weft Sateen Weave | " | 8. |

| Simple Plain Gauze Weave | " | 9. |

| Weft-pile Weave | " | 10. |

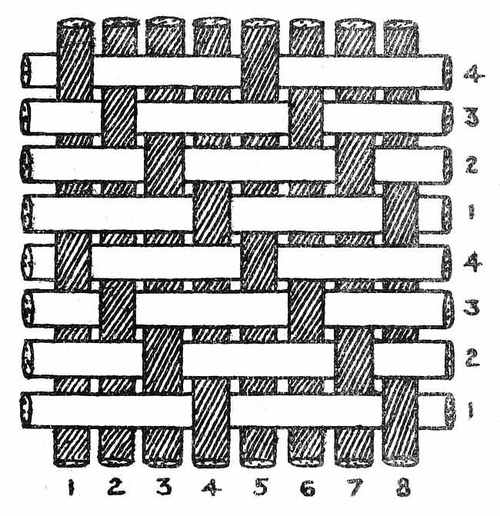

Figure 1 shows the simplest manner of interlacing warp and weft threads. This style of weave is called plain, calico, or "one-over and one-under" weave.

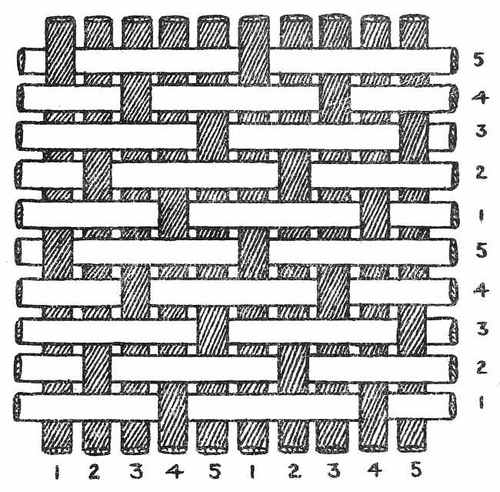

This figure illustrates the interlacing of warp (shaded) and weft (white) threads, so as to produce a regular "three-end twill" weave. It also shows the direction of twill. In this figure the warp threads are shown interlaced with the weft threads in three distinct positions. There is a distinct predominance of warp threads thrown to the surface by this style of interlacing, and a fabric woven on this system would be "warp-faced." This weave is called a two-warp and one-weft regular twill, also Regatta and Galatea weave.

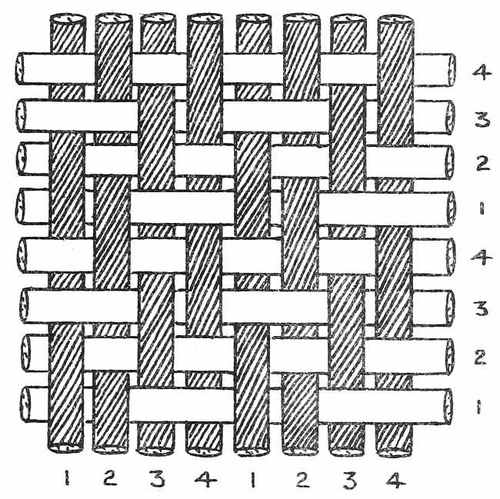

This figure illustrates a four-end, three-warp and one-weft, regular twill, also known as a Florentine twill, or a "three-up and one-down twill." The twill produced by this style of interlacing is well marked. The warp (shaded) predominates, and for this reason a cloth woven on this system of interlacing would be termed "warp-faced," or warp twill.

This figure, in which the weft threads predominate on the surface, illustrates a four-end, one-warp and three-weft, regular weft twill, in which three-quarters of the weft threads are thrown to the surface and the remaining quarter is warp. It is the reverse of Figure 3.

This figure illustrates a four-end, two-warp and two-weft, regular twill. Neither warp nor weft predominates on the surface. This style of twill is known as Harvard twill.

This figure illustrates a broken or irregular twill, also known as a broken Harvard or Stockinette weave.

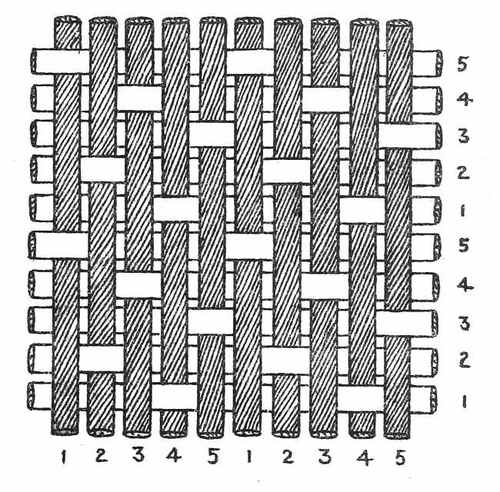

This figure illustrates the method of interlacing warp (shaded) and weft threads so as to produce a five-end warp sateen, or satin twill. This weave, in which the warp predominates on the surface, is reversed in Figure 8.

This figure illustrates a five-end weft sateen. Sateen weaves are virtually a form of broken or rearranged twill. The weft sateen weave, represented by this figure, shows weft predominating on the face: it is practically the reverse of the weave shown by Figure 7.

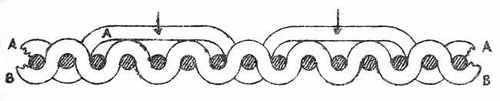

In this figure A are threads known as crossing threads and are typical of gauze weave; they are binding threads holding B (weft threads) and C (warp threads) firmly together. It will be noticed that B and C do not interlace to form a plain weave. If crossing threads A were removed, no fabric would remain. These crossing threads in this figure are shown as always passing over the weft threads B and always under the warp threads C. This style of weave, when combined with a few "plain-weave" picks, produces Leno.

In this figure A is a weft-pile pick or flushing thread; B is a backing or ground cloth pick; the dots show cross section of warp threads. It will be seen that the ground picks B, together with the warp threads (shown cut through), form the foundation fabric. Pile thread A is shown bound into the fabric by the second, eighth, and fourteenth warp thread. Pile threads are cut after leaving the loom at a point indicated by the arrows; the pile produced is then sheared level and suitably finished.

Actual.—The terms "actual" and "nominal" are used in the trade to indicate (1) that the width should be taken as stated or (2) that a certain amount of allowance should be made. "Actual" implies that the width is not less than stated. "Nominal" means that the width of the cloth may vary as much as half an inch below width given on contract.

Agaric.—A cotton fabric of loop yarn construction, having a surface somewhat similar to a fine Turkish Towelling.

Albatross.—A dress fabric of worsted warp and worsted filling of open texture and fancy weaves. When the name is applied to a cotton fabric it is used to designate a plain-woven all-cotton fabric, soft, fine, and free from ornamentations, made in imitation of the worsted fabric of the same name. It has a fleecy surface, is generally sold in white, black, or solid colours, being used instead of Bunting for flags. Not often used for printing, for which purpose it is not well adapted.

Alhambra Quilt.—An all-cotton counterpane woven with a coarse waste weft known as Candlewick. A loosely woven coloured warp yarn is used for the figuring and a grey "sticking" warp for securing the weft in position.

Alpaca.—This name is given to a fabric woven with a cotton warp and an alpaca wool weft. The fabric is classed as a lustre fabric, this being due to the predominance of the lustrous weft. Generally plain woven with a simple one-over and one-under weave, Alpaca is, when solid coloured, a cross-dyed fabric, i.e., one in which the cotton warp yarns were dyed prior to weaving and the piece of fabric piece-dyed after leaving the loom. Similar to Lustre Orleans, Mohair Brilliantine, and Mohair Sicilian, which are typical lustre fabrics.

Alpaca Wool is the fleece of the Peruvian sheep, which is a species of llama. The staple is of good length and soft, but is not quite as lustrous as mohair. The natural colours are white, black, brown, and fawn.

Alpacianos.—Nothing seems to be recorded in any modern book dealing with textiles or in any technical dictionary concerning any fabric known by the name of Alpacianos. The name, however, appears in the Revised Import Tariff for the trade of China, from which it would appear to be an all-cotton fabric, piece-dyed after leaving the loom, probably averaging between 28 and 31 inches in width and about 25 yards in length. The name is probably of South American origin.

American Sheetings.—A rather coarse make of plain-woven grey cloth, woven from coarse yarns (about 20's counts), 48 threads of warp and the same number of weft picks to the inch, and generally woven with "twist way" weft. Another name for this material is Cabot. Average width, 36 inches; length, 40 yards per piece. Weight varies. The use of the name Sheeting, as applied to this class of material, is now firmly established but incorrect, Sheetings originally being a two-and-two twill fabric having a width of as much as 120 inches.

Angola.—This name is used to designate a plain or twill weave fabric having a cotton warp and a weft made from cotton and wool scribbled together prior to being spun. The proportion of wool to cotton varies. This scribbled wool and cotton yarn, or Angola Wool as it is called, generally contains about 20 per cent. of cotton and 80 per cent. of wool.

Angola Yarn or Wool.—A yarn spun from a mixture of 80 per cent. wool and 20 per cent. cotton.

Angora.—Angora is the name of a species of goat which yields a wool commercially known as Mohair. This kind of wool enters largely into the classes of goods known as Astrakhan, Crépon, Plushes, Brilliantine, Zibelines, fine Cashmeres, and other fabrics usually sold as all wool. It enters into the manufacture of very high-grade fabrics in combination with silk. More lustrous than wool, it has not, however, the warmth-retaining properties of the latter.

Angora Goat.—A species of goat originally bred in Asia Minor, producing Mohair fibre. From the long silky hair of this goat was made Turkish Yarn or Camel Yarn. The name Camel Yarn has led to mistakes; it has no reference to the camel, but is derived from the Arabic word chamal, fine.

Animalised Cotton.—To increase the affinity of cotton for dye-stuffs and at the same time increase its lustre, cotton is sometimes treated with solutions of wool, silk, or gelatine in such[3] a manner that when the solvent has evaporated the coated surface remains sufficiently pliable not to crack under normal conditions.

Armure.—A weave which produces a fine pebbled surface.

Artificial Silk.—In the making of artificial silk, cellulose prepared from wood or cotton is turned into a nitro-cellulose by treatment with nitric acid. This nitro-cellulose is made liquid by dissolving it in ether and alcohol, then forced under pressure through very fine tubes, or forced through holes of about 1/250th of an inch pierced in a platinum plate, in the form of very fine threads, from which the ether and alcohol evaporate readily, leaving the nitro-cellulose as a fine lustrous fibre. Artificial silk is often used in the ornamentation of figured fabrics. It bears a very deceptive resemblance to true silk, but the individual fibres are coarser and burn very quickly, without the typical smell of true silk and without the hard bubble of ash. Its value is about a third of that of the best silk, but as an offset to this must be taken its higher specific gravity. If of equal thickness, the length of thread, weight for weight, is only from half to two-thirds that of real silk.

Astrakhan.—A fabric having a curly, wavy surface resembling Astrakhan fleece. There are three varieties of this kind of fabric, each produced on a different principle: (1) on the weft principle, in which, owing to shrinkage of the ground texture, the pile weft is thrown up and forms a curly loop; (2) on the warp texture principle, in which a thick curly warp yarn is brought over wires to form the necessary loops; and (3) the cheapest form, as a knitted fabric.

Astrakhan varies as regards the size of the loop which goes to make the curl. The lustre yarn that is used is curled before use, the curl being fixed by heat. The ground texture is cotton. Width varies from 48 to 50 inches; weight from 19 to 36 ounces per yard of the 50-inch wide material. The heavier grades run 35 to 40 yards per piece, the lighter grades from 50 to 55 yards. Generally met with in solid black or a grey produced by blending black and white fibres, also in solid white. Astrakhans have generally an uncut pile, but are sometimes finished with part of the loop curls cut, say, 50 per cent., which gives the fabric the appearance of woolly fur with complete curls at intervals.

Back Cloth.—An unbleached, reinforcing, all-cotton cloth, plain woven, used in printing fabrics to support the fabric which is being printed.

Backed Cloth.—To add weight to certain single texture fabrics, extra threads running either in the direction of the warp, i.e., lengthways of the piece, or weftways across the piece, are stitched on to the back of the fabric. Fabrics having such extra threads stitched on to them are called Backed Cloths.

Baffetas.—Plain-woven cloth, bleached or dyed blue.

Baize.—A coarse, harsh, loosely woven woollen fabric of plain weave, having a long nap on both sides like flannel. Baize is generally dyed in bright colours and is known under the name Bayetas. Average width 66 to 67 inches, length 30 to 45 yards per piece.

Balbriggan.—Named after the town of Balbriggan, Ireland. First applied, in 1845, to full-fashioned hosiery made from unbleached cotton. About 1860 the term was applied to knit underwear of the same material. It was originally used only on high-class goods, but now covers everything in light-weight flat underwear made of yarn stained to the shade of Egyptian cotton.

Bale of Cotton.—The standard bale of cotton, according to the usage of the trade in England and America and generally accepted elsewhere, weighs 500 pounds. The following is the average weight and density of cotton bales:—

| Weight. | Density per Cubic Foot. | ||

| —— | —— | ||

| Egyptian | about | 700 lb. | 34 lb. |

| American | " | 500 " | 24 " |

| East Indian | " | 400 " | 30 " |

| Brazilian | " | 250 " | 20 " |

Baline.—A coarse canvas, mostly made of better grades of jute, flax, and hemp, used for upholstery purposes, interlinings, tailoring purposes, etc.

Balzarine Brocades, Dyed.—The cotton variety of this class of fabric would be an all-cotton fabric having a gauze weave and net-like appearance which had been embellished by the addition of certain figures or designs woven into the fabric either by means of combination of the warp and weft threads or by means of an additional thread or threads. But Lappet or Swivel figured Balzarines would not be considered Brocades in the true sense, as such style of figuring is not brocaded. Dyed Balzarine Brocades are piece-dyed after leaving the loom.

Balzarines.—Very few books of reference make mention of this kind of fabric. Of "uncertain origin," this name is said to have been given to "a light-weight mixed fabric of cotton and wool for women's dresses commonly used for summer gowns before the introduction of barége (or barrège)." Barége was, for the name seems to have fallen into disuse, "an open fabric resembling gauze, but more open in texture and stouter in thread. It was made of various materials but is best known as made of silk warp and worsted weft. It was first employed as ornament for the head, especially for sacred ceremonies, as baptism and marriage." It would appear, therefore, from the above that Balzarines—of the cotton variety—would be a gauze weave or net-like fabric woven from cotton warp and cotton weft. They may have been either bleached, dyed, printed, or brocaded. The exact difference between Balzarines and other gauze fabrics does not appear in any modern works dealing with textiles. The fabric probably approximates 30 inches in width and from 28 to 30 yards in length per piece. Unless specially designated as such, Balzarines are free from brocaded ornamentation; but from the fact that they are found associated with Lenos, they may, like these, have some plain weave combined with the main gauze structure—probably running in stripes lengthways of the piece.

Bandanna is a term applied to materials that have been dyed in a somewhat unusual manner, the cloth being tied in knots prior to being dipped into the dye-stuff. A peculiar clouded effect is produced, as the dye-stuff does not reach the knotted parts equally with the rest of the surface. This term is met with most frequently in connexion with a large handkerchief, of which great quantities were imported into India for sale to the natives.

Barré.—A striped or barred design, woven or printed, running from selvedge to selvedge.

Basket Cloth.—A plain-woven all-cotton fabric woven with two or more warp threads grouped together without twisting and woven as a unit of matt weave.

Batiste.—A fabric of French origin; the term has come to mean commercially a light, sheer cloth, made of fine quality of yarns and woven with a plain weave. A light fabric, with a Swiss finish, in distinction from a Nainsook, and usually wider and heavier than the latter fabric. In 32-inch widths and up a line of Batistes runs 14 to 16 square yards to the pound. There are bleached and unbleached cotton Batistes, also linen and coloured Batistes. The cotton are largely ecru, and the linen are most[6] commonly in the grey. There is a gradual variation in qualities ranging from a comparatively coarse to a very fine Batiste. There are also wool Batistes.

Bayadère.—Applied to fabrics in which the stripe, whether woven or printed, runs crosswise, that is, from selvedge to selvedge.

Bayetas.—The Spanish for Baize, which is a coarse, harsh, loosely woven woollen fabric having a long nap on both sides like flannel. Bayetas are generally dyed in bright colours and have an average width of 66 to 67 inches and a length of 30 to 45 yards per piece.

Beavers.—A heavy cloth manufactured of fine wool with a finish on face made to imitate the appearance of the beaver's fur. When the surface is made with a long and dense nap this fabric becomes known as Fur Beaver.

Beaverteen.—A heavy, twill-weave, all-cotton fabric of the fustian or uncut pile variety, usually dyed in shades of grey or tan and generally used for garments having to withstand rough wear.

Bedford Cords.—Fabrics having cords or ribs running in the direction of the length of the cloth, produced by interweaving the weft, in plain or twill order, with alternate groups of warp threads. The ribs may be emphasised by the addition of wadding or stuffing warp threads. Bedford Cords may be woven as either an all-cotton, all-wool, or wool and cotton fabric. The ribs of Bedford Cords are but slightly separated from each other. Cotton Bedford Cords closely resemble a wide-welt Piqué. See Welt.

Beige.—A dress fabric, generally twilled weave, made of yarns spun from wool which has been dyed in the stock prior to being spun, mostly met with in greys, browns, and mottled or mixed effects. In America the term is used to designate a dress fabric of fine texture woven from yarns in which two threads of different colours are twisted together or wherein printed yarns are employed.

Bengal Stripes.—An all-cotton plain-woven fabric of the striped Gingham variety. Warp yarns partially white, balance dyed indigo blue.

Bengaline.—A silk fabric having thick threads or cords at intervals, from selvedge to selvedge. Frequently the cord is of wool, covered with silk in the process of weaving, or cotton and[7] silk are combined together to produce this kind of material. When made of all cotton and known as a cotton Bengaline, it is generally mercerised. The warp yarn is often of two-ply. Bengaline has much the appearance of Poplin.

Silk or part-silk Bengalines are often treated to an embossing process, which method presses a figure upon the fabric very similar in appearance to a Jacquard woven effect. A common name for Reps, also similar to Poplin, but generally of a heavier corded appearance with the cord running transversely across the face of the fabric.

Binding Cloth.—A muslin dyed and stamped or embossed, used to cover books by bookbinders.

Bleached.—This term is used to designate either raw cotton, cotton yarn, or more often cotton fabrics which have been rendered white. The most generally used agent for bleaching is chloride of lime. The process of bleaching varies according to whether the fibres being bleached are in the loose, the yarn, or the woven state. Prior to being bleached fabrics are said to be in the "grey"; after bleaching they are said to be "white."

Bleached Domestics.—A term commonly used referring to the cheaper grades of bleached cotton cloths, either plain or twilled.

Bombazine.—Bombazine is the name given to a twilled fabric of which the warp is of silk and the filling is worsted.

Book-fold Muslin.—A trade designation meaning muslin put up in 24-yard lengths, folded in such a way as to open book-wise from the centre, the various folds resembling the leaves of a book.

Botany.—A term applied to worsted yarns made from Botany wool. It is considered the finest of all worsted yarns and is used for making fine fabrics of close texture. The name Botany is commonly used to designate a fine grade of Australian wool.

Bouclé.—Having knots, loops, or curls on the surface; usually employed for cloakings. Imitation Astrakhan is a type of the kind of fabric coming under the heading Bouclé.

Bourette.—A rough-surfaced effect produced by introducing lumpy, knotted yarns at intervals in the weaving.

Broadcloth.—Broadcloth is a soft, closely woven material made with an all-wool warp and filling having a satin finish. The beauty of Broadcloth depends on its even, nappy, lustrous surface. The three main points that go towards fixing its value are the quality of the wool used, the uniformity of the nap, and the perfection of finish. It is most often twill woven, double plain, but it is also met with in a plain weave.

Brocade.—The ordinary cotton Brocade is a figured fabric of single texture. More elaborate Brocades, used for dress and upholstery purposes, may have several wefts, in which case the cloth is one-sided, the warp forming the ground on the face, and the wefts appearing only where required to produce figure. Soft-spun wefts are often used in Brocades and similar kinds of cloths, the better to fill and throw up the figure used in their ornamentation. It is a term commonly applied to fabrics of different weaves or combinations of weaves in which the design appearing on the surface of the fabric is of a fancy figured or floral effect, usually of elaborate design; also used as an adjective to denote "woven figured."

Brocatelle.—The real Brocatelle is a rich upholstery fabric, which has a raised figure of silk warp and weft interwoven in satin order, on a ground formed by a linen weft and a special binder warp. The name is also applied to quilts having a coarse white weft and two colours of warp, which latter change places for figuring purposes.

Broché.—The French term for Brocade. Elaborate figures woven on the surface of the fabric.

Brown Sheeting.—This term is the equivalent of "plain grey cloths" and covers all weights of cotton goods in the grey or unfinished condition.

Brown Shirting.—The term is restricted usually to mean such grey cotton cloths as have a width of 40 inches or less from selvedge to selvedge.

Bugis.—This name is given to a fine make of cotton sarong having only one side decorated with a border design. It is used by sewing two pieces together plain edge to plain edge, thus converting it into a sarong with both edges ornamented.

"Bump" Yarns.—Cotton yarns of coarse numbers below 3's, used for weft purposes in counterpanes and other coarse fabrics, are termed "Bump" Yarns. Sometimes the term Candlewick is used for very coarse counts. The counts in the case of "Bump" Yarns are denoted by the number of yards weighing 1 ounce.

This kind of weft is extensively used for coarse and heavy goods, such as bagging, Alhambra quilts, etc.

Example.—A yarn weighing 60 yards to the ounce would be termed 60's "Bump."

Bunting.—A plain, loose, even-thread weave of Mohair wool or worsted, used mostly for making flags. Bunting, which is a material having to be dyed, is made of wool and not cotton or other vegetable fibre for the reason that wool has a greater affinity for dye-stuffs than cotton and retains them better. There is, however, a cotton fabric woven from low-count yarns, generally known as either Butter Muslin or Cheese Cloth, which is sometimes called Bunting.

Burlaps.—A plain-woven, coarse, and heavy fabric made from jute, flax, or hemp, used for wrappings, upholstery, etc.

Butcher's Linen.—A coarse, heavy, plain-weave linen.

Cabled Yarns.—Cabled Yarns are produced by folding together "two-fold" threads. Under the heading "Folded Yarn" it will be seen that when two single threads of 60's count yarn are twisted together they produce a two-fold 60's, written thus: 2/60. When three such two-fold yarns are twisted together they produce a six-fold 60's thread. Sewing cottons, known in the trade as Spool Cotton, are good examples of Cabled Yarns.

Cabot.—A Levant term for a rather coarse make of plain grey cloth, woven from coarse yarns (about 20's counts); 48 warp threads and the same number of picks to the inch.

Lancashire-made Cabots are usually heavily sized. Considerable quantities of this cloth are made in South Carolina mills in 36-inch width and shipped to China under the name of American Sheetings.

Calico.—This name is used to designate most plain-woven cotton fabrics which have simple designs printed on their face in either one or more colours. Calicoes are usually in two colours, that is, one colour for the ground and the other for the figure or design. The ground colour is generally effected by piece-dyeing the fabric in some solid colour. After the cloth is dyed the design[10] is printed on the cloth. Being cheap fabrics, Calicoes are generally given a "cheap common dye"—by this is meant that the colours are not fast and will run or fade when washed. The printing of Calicoes is done by the aid of a machine whose main feature is a revolving cylinder on which the design has been stamped or cut out. Such machines are capable of printing several colours in one design. Calico is woven with a plain one-over and one-under weave. As a textile term it is applied to cheaper grades of plain cotton cloth, and the name is rightly applied when such cloths are printed. In the Manchester district and in Great Britain generally the term Calico is used only to designate a plain grey or white shirting or sheeting free from any ornamentation.

Camel's Hair.—A loosely woven fabric of long-fibre wool. The term in its original sense is used to describe the soft downy fibre from the haunches and under parts of the camel.

Camlets (Woollen).—An all-wool plain-woven fabric free from any ornamentation of weave produced either by combination of weave or extra warp or weft threads. It is invariably woven with the plain one-over and one-under weave from worsted yarns, which make the fabric somewhat lustrous. In width averaging 30 to 31 inches and in length 60 to 61 yards. Camlets are only divisible into two kinds, Dutch and English. The former variety appears to be no longer made, and one manufacturer states that practically 99 per cent. of the Camlets imported into China are of the English variety. Not unlike an Alpaca in feel, though somewhat less lustrous, Camlets may be compared to a very fine wool Bunting.

Camlets, Dutch (Woollen).—This heading apparently covers a type of material which has almost disappeared from the market. Originally a rough cloth made from camel's hair, it was known as either Camlet or Camelot. A somewhat ancient description is "a rough fabric composed of wool and cotton, or hair and silk with a wavy or variegated surface." A firm of manufacturers in Bradford, written to for information under this heading, writes as follows: "This is a very ancient heading, and Camlets now are only made in this country, and although there are about three qualities shipped to China, practically speaking, 99 per cent. are in the quality of the sample shown." The sample in question shows the fabric to be a plain, all-wool, fairly loosely plain-woven fabric dyed a bright vermilion. Both warp and weft are of worsted yarn and hence it is a somewhat lustrous fabric; in width it averages between 30 and 31 inches, in length from 60 to 61 yards, and its average value during the 10 years 1904-14 was 40s. 5d. per piece. Camlet somewhat resembles a fine Bunting and has a harsh handle; somewhat stiff, it has the feel of an Alpaca fabric.

Camlets, English (Woollen).—This fabric is described under Camlets, Dutch. A typical sample of English-made Woollen Camlets showed the fabric to be a plain, all-wool, fairly loosely plain-woven fabric dyed a bright vermilion. Both warp and weft are of worsted yarn, and hence it is a somewhat lustrous fabric, averaging 30 to 31 inches in width and 60 to 61 yards in length. Average value of the quality generally imported into China was for the 10 years 1904-14 40s. 5d. per piece. Somewhat harsh of handle, it resembles a fine Bunting with the stiff feel of an Alpaca.

The earliest mention of English Camlets is to be found in Camden's "Brittania," 1610, where, speaking of Coventry, it is said: "Its wealth, arising in the last age from the woollen and camblet manufacture, made it the only mart of this part." In the next century those of Brussels are said to exceed all other Camlets for beauty and quality, those of England being reputed second.

Caniche.—Name given to a curled wool fabric showing the effect of the coat of the caniche, or French poodle.

Canton Flannel.—This term is used to designate an all-cotton flannel, first made for and exported to Canton. Canton Flannel will be found more fully described under "Cotton Flannel." It is a narrow heavy fabric, twill woven, showing twill on one side and having a long, soft, raised nap on the other. Woven as a four-shaft twill for winter weights and as a three-shaft twill for the summer weight. Width from 27 to 30 inches. Canton Flannel is taken direct from the loom, measured, napped, and folded, and packed for shipment. The yarn used to make this class of cloth is spun from low-grade cotton of from three-fourths to 1 inch in length of staple, generally dyed in bright colours.

Canvas.—Canvas is a coarse plain-weave fabric woven from yarn which is hard twisted. It is often woven from folded yarn, and this may readily be seen in what is known as embroidery canvas. Canvas used for sails is generally a stout strong-built cloth woven with "double warp coarse flax yarns." A term applied to heavy, plain, unbleached, dyed or yarn-dyed fabric, of different grades or weights properly made of ply yarns, although the term more frequently applies to fabrics of such similar appearance made without or partially of ply yarn. Various sorts of Canvases are known in different trades, such as Embroidery Canvas, Duck, Dress Canvas, Mercerised Canvas, etc. Dress fabrics, the principal part of which are of such a construction, are still termed Canvas in the distributing trade when they contain stripes or fancy effects of other weaves.

Carbonising.—All-wool cloths and even raw wool very often contain a certain amount of vegetable matter, such as burrs, the chemical composition of which is similar to that of cotton, and as it is at times very desirable to extract this vegetable matter, the cloth or fibre is for this purpose subjected to a process known as carbonising. The material is passed through a bath containing sulphuric acid of a suitable strength and temperature. Upon drying, the acid concentrates upon the vegetable matter, converting it into hydrocellulose, which, being in the form of a powder, is easily removed, while the wool, not being acted upon by the acid to any considerable extent, remains intact. This system would be employed to test the percentage of cotton in any union fabric: by carefully weighing the sample prior to treatment and again after all the vegetable matter had been carbonised the proportion of cotton to wool can readily be ascertained.

Casement cloth.—A plain-woven fabric used for casement window curtains and usually white or cream-coloured. Casement Cloth is made from either mohair, alpaca, or cotton. The cotton variety is made from high-class yarns, well woven, and is mercerised before bleaching or dyeing.

Cashmere.—A cloth made from the hair of the Cashmere goat. The face of the fabric is twilled, the twills or diagonal lines being uneven and irregular owing to the unevenness of the yarn. Cashmere was originally made from hand-spun yarn. In the knitted goods trade the word Cashmere, when applied to hosiery or underwear, means goods made of fine worsted yarns spun from Saxony or other soft wools.

Cashmere has been described as being a lightly woven woollen fabric of twilled construction and soft finish, having the twill on the "right" side, i.e., on the face of the fabric. It is sometimes woven with a cotton warp and fine Botany wool weft. An all-cotton variety, woven in the same way as the true Cashmere, is also met with: it is known as Cotton Cashmere.

Cashmere Double.—A Cashmere cloth having as a distinctive feature a twill face and a Poplin-corded effect on the reverse.

Cashmere Wool is the fine, extremely soft, grey or white fur of the Cashmere goat, which is bred in Tibet. There are two kinds of fibre obtained: one, which is really the outer covering, consisting of long tufts of hair, beneath which is found the other, the true Cashmere Wool of commerce, a soft downy wool of brownish grey tint having a fine silky fibre.

Castor.—A heavy cloth, manufactured of fine wool with a finish on the face made to imitate the fur of the beaver. This cloth differs from Beaver Cloth only in its weight, Castor cloth being lighter than Beaver.

Cellular Cloth.—A plain Leno fabric having an open cellular structure, which is specially suited for shirtings and underwear. Cellular Cloth is also found with stripes of different weave, though still a form of Leno weave to the rest of the fabric.

Ceylon or Ceylon Flannel.—A coloured striped cloth woven with a cotton and wool mixture weft. The warp threads which form the stripes are dyed in the yarn prior to weaving.

Challis.—The name is given to a light-weight plain or figured material made either of cotton or wool or a mixture of both. An all-wool Challis has, when plain woven, the appearance of a Muslin Delaine. Usually printed.

Chambray.—Chambray is a staple fabric of many years standing, being next in line of the cotton goods after the better grades of Gingham. It is a light-weight single cloth fabric, always woven with a plain weave and a white selvedge. It is woven from warp and weft which may be either all cotton, cotton and silk, or all silk: it has an average width of 27 or 30 inches and weighs 2 to 3½ ounces per finished yard. When made as an all-cotton fabric it is finished in the same way as a Gingham.

Charmeuse.—A light-weight satin having a high natural lustre.

Checks.—Fabrics having rectangular patterns formed by crossing the threads of a striped warp with weft threads of the same order. "Mock" Checks are produced by combining weave effects.

When Checks are woven without a highly variegated colouring they are known as Ginghams.

Cheese Cloth.—A very open and lightly constructed thin cotton fabric of light weight and low-count yarns, woven with a plain weave, weighing from 9 to 12 yards to the pound. Cheese Cloth is often used for Bunting, by which name it is sometimes known. The Cheese Cloth used for wrapping round cheese and butter after they have been pressed is a bleached cloth.

Cheviot.—Most stout woollen fabrics which have a rough or shaggy face are described as Cheviots, which has become a term denoting more a class of goods than a particular fabric. It has a slightly felted, short, even nap on the face, and is often made of "pulled wool," which is the wool taken from the pelts of dead sheep.

Mungo, shoddy, and a fair percentage of cotton enter into the composition of the yarn from which it is made. Irrespective of the quality of the yarn used, however, Cheviots are finished either with a "rough" or a close finish. The weave may either be plain or twill.

Chiffon.—A sheer silk tissue of plain weave and soft finish. The word is often used to indicate light weight and soft finish, as Chiffon Velvet.

Chinchilla.—A fabric made of fine wool, having a surface composed of small tufts closely united. The name is Spanish for a fur-bearing animal of the mink species, and the fabric is an imitation of the fur.

Chiné.—Warp-printed: a fabric wherein the design, being printed on the warps, appears somewhat faintly and in indefinite outline. The weft is not printed, but is generally in the white. Some varieties, occasionally met with, have a coloured weft. This class of fabric is also known as a Shadow Cretonne, when the designs are of the variety generally used in Cretonne fabrics.

Chintz.—When this name is applied to a fabric other than a printed Chintz it is used to designate a woven Chintz, which is a fabric on the warp threads of which, before being woven into cloth, various coloured designs have been printed. Many silk ribbons are Chintz woven. Where the colours seem to have run in the pattern the name Chene is sometimes used. Warp-printed Chintz is also known as Shadow Cretonne, from the softness of the design due to the white weft blurring the sharpness of the design printed on the warp.

Clip Spots.—Figured Muslins ornamented by small detached figures of extra warp or weft, the floating material between the spots being afterwards clipped or sheared off.

Coated Cotton Cloths.—This name is given to a cloth having one or both surfaces coated with paint, varnish, pigments, or other substances. Examples of coated cloths are Tracing Cloth, Bookbinder's Cloth, Imitation Vellum, Oilcloths, and Oilskins.

Collarette.—A wide knitted neckband used on men's undershirts in lieu of binding.

Coloured.—This term, when applied to textile fabrics, is used to show that the fabric which is designated as "coloured" has been dyed in the yarn and not dyed subsequently to having been woven, i.e., it has been woven from coloured yarns.

Coloured Crimp Cloth.—Like all other fabrics that are designated as "coloured," Coloured Crimp Cloth is dyed in the yarn and not piece-dyed. Coloured Crimp Cloth is essentially a Crimp Cloth which has been woven from previously dyed yarn; apart from this difference it answers the description given under Crimp Cloth, Plain or Crimps.

Coloured Lists.—All serges, etc., that are dyed in the wool or yarn, as against those dyed in the piece, have coloured lists or edging. The word "list" is another name for selvedge.

Coloured Woollen and Worsted Yarns.—The most important coloured woollen and worsted yarns are: (a.) Mixtures, (b.) Mélanges, (c.) Marls, and (d.) Twists.

(a.) Mixtures.—A mixture yarn is one composed of fibres of two or more colours which have been thoroughly blended. In woollens the wool is dyed after scouring and the mixing accomplished during the carding process.

(b.) Mélange.—This is a fine mixture yarn produced from a top-printed sliver. The result is obtained by printing at regular intervals the required colours on the top of the sliver. The mixing of the fibres and colours is brought about during the drawing and spinning processes. As a rule only long fibres such as Mohair are subjected to this method of treatment. In these yarns, on many fibres two or more colours may be clearly seen under the microscope.

(c.) Marls.—A term sometimes applied to three-fold twist yarns, but more correctly applied to a yarn which is between a twist and the mixture yarn. It is produced by combing two or more slivers of different colour in the later drawing operations, and in consequence the colours are not so thoroughly blended as in the case of mixture yarns.

(d.) Twists.—This class of yarn is produced by simply twisting or folding together two or more yarns of different colours.

Corduroy.—Corduroy, like many other low-grade cotton fabrics woven with a pile weave, such as Cotton Velvets, Velveteens, Moleskins, is really a Fustian. The pile surface of[16] Corduroys does not cover the surface of the fabric uniformly, as in the case of Velveteens, for instance, but runs in straight lines or ribs, which may be of different sizes and have round or flat tops. When a Corduroy has a twill back it is known as a "Genoa" backed Corduroy; when, as in the lighter makes, the back shows a plain weave it is known as "Tabby" backed.

Corduroy is a cotton fabric with the ribs running lengthways of the piece. The pile is a weft pile. Corduroys are made in many varieties—known as Fine Reed, Eight Shafts, Thicksets, Constitution, Cables, etc. Constitution and Cables have broad floats or races which are some distance apart. The term Corduroy, when applied to hosiery, is used to designate stockings which are commonly known as two-and-two rib, or two ribs alternating on face and back of children's stockings.

Côtelé.—A ribbed weave in flat, rather wide effect.

Cotton.—Cotton is the most used of all vegetable fibres for the manufacture of textiles. Length and fineness of individual fibres go towards making quality; shortness and coarseness of fibre make for low qualities.

The chief classes of cotton are known as Sea Island, Egyptian, American, Brazilian, Peruvian, East Indian, the first mentioned being the highest and the last the lowest quality. Qualities are designated in each class as follows:—

| 1. Fair. | 5. Low Middling. |

| 2. Middling Fair. | 6. Good Ordinary. |

| 3. Good Middling. | 7. Ordinary. |

| 4. Middling. |

East Indian type of cotton fibres measure on an average but half an inch, as compared with 2 inches in Sea Island type.

Cotton Duck.—Duck being a fabric which is sometimes woven in linen, to refer to it simply as Duck might be misleading; hence, although when used by itself the term Duck is generally recognised to mean a cotton fabric, to differentiate between the two the word Cotton or Linen is used. This fabric is described under "Duck."

Cotton Flannel.—As the name implies, Cotton Flannel is a material woven in cotton in imitation of the real all-wool flannel. It is either a plain or a twill woven fabric which has had the weft on one or both sides of the fabric "raised" or "napped." This is done by passing the fabric, whilst it is tightly stretched, over a revolving cylinder, the surface of which is covered with small steel hooks or teasels; these, scratching as they do the surface of the fabric, tear up very slightly the short fibres and cover the fabric[17] with a "nap," which is afterwards cut down uniformly. Cotton Flannel was first made for the Canton market. Cotton Flannels may be either "single raised" or "double raised"; in the first only one side of the fabric is raised, in the second both sides are raised. Whilst Cotton Flannel clearly shows that the fabric is a cotton one, the term Flannelette does not necessarily mean that it is a purely cotton fabric identical with Cotton Flannel. Flannelette may contain wool, even if only in very small percentage, but by trade usage the name is used to designate only an all-cotton fabric.

Cotton Plush.—The term Plush being a generic term applied to cut-pile fabrics having the pile deeper than ordinary Velvet, Velveteen, etc., it follows that Cotton Plush is essentially a cotton-pile fabric with a somewhat deeper pile than Velveteen. Cotton Plushes may be woven with either plain or twill back, the plain-backed variety being known as a "Genoa" Plush and the twill-backed variety as a "Tabby" Plush.

Cotton Yarn Measures.—

| 54 | inches | = | 1 thread (or circumference of wrap reel). | |

| 4,320 | " | = | 80 threads = 1 lea. | |

| 30,240 | " | = | 560 " = 7 lea = 1 hank. | |

| 1 hank | = | 840 yards. | ||

| 1 bundle is usually 10 lb. in weight. | ||||

The French system of numbering Cotton Yarns is as follows:—

| 1,000 | metres | weighing | 500 | grammes | = | No. 1's. |

| 1,000 | " | " | 250 | " | = | No. 2's. |

| 1,000 | " | " | 50 | " | = | No. 10's. |

| 1,000 | " | " | 25 | " | = | No. 20's. |

The count is therefore arrived at by dividing the number of metres reeled by twice the number of grammes they weigh.

Counts.—The size of yarn is technically called the "count," and it is based upon the number of hanks, "cuts," or "runs" of a given length which are required to weigh 1 pound. The standard length of the hank varies according to the nature of the yarn. Cotton Yarn measures 840 yards per hank; Worsted Yarn measures 560 yards per hank; Woollen Yarn measures 256 or 300 yards per "cut," "run," or hank, according to district; Linen measures 300 yards per lea; and Spun Silk, 840 yards per hank. The number of such "cuts," "runs," hanks, or leas required to weigh 1 pound avoirdupois equal the number of the count. When Woollen Yarn is in gala cuts of 300 yards the number of such cuts required to weigh 24 ounces equal the count: this becomes equivalent to the number of 200 yards required to weigh 1 pound.

Coutil.—French for Drill. A strong three-thread twill cloth with herring-bone stripes dyed drab or French grey and used for corset-making.

Covert.—A wool or worsted cloth, usually in fine twill weave, in small mixture effect. There are various grades of Coverts and they all have as a distinctive feature neutral tones of colour. The real Covert cloth is always made from double and twist warp yarns and single fillings. The weave is such that the filling yarn does not show on the face of the cloth, therefore almost any shade similar in general tone to the warp may be used as filling. Cheap grades are made as a piece-dyed union mixture containing up to 30 per cent. cotton. They are also known as Venetian Coverts when they have a pronounced whipcord effect. The weave is a sateen weave of the warp-face variety.

Crabbing.—One of the many processes through which cloth goes from the time it leaves the loom on its way to being turned out as a finished fabric. The object of crabbing is to fix or set the cloth at the width it has to be as a finished fabric. The actual operation of crabbing consists of running the cloth at a tension on to a steaming or boiling roller. The axle or core of the roller is hollow and perforated; the cloth having been tightly wound round, steam is forced through the perforations and right through the mass of tightly wound cloth. The superheated steam sets the cloth.

Crape Cloth, Plain.—Plain Crape Cloth is an all-cotton fabric, plain woven from hard-twisted cotton yarns and is free from any woven or printed ornamentation. The nature of the hard-twisted yarn is such that it readily shrinks or curls in length when not kept at a high tension; this, together with subsequent finishing operations, causes a considerable contraction to take place, resulting in an uneven crinkled surface, which is the chief characteristic of Crape. The crinkled surface in true Crape is obtained in several ways: (1) by combination of materials; (2) by weave combination; (3) by combination of (1) and (2); (4) by mechanical arrangements during weaving; (5) by subjecting fabrics specially constructed to a special chemical process during finishing. The cheaper grades of Crape have the crinkled effect produced by suitably prepared rollers through which the cloth is passed, and the crinkled effect in cotton Crapes is not always the result of true Crape weaving, which relies on the irregularity of the interweaving of threads to produce the Crape effect. In width Crape seldom exceeds 30 inches, but is made up in pieces of varying length.

The name is also applied to a thin, transparent, "crisp" or crumpled silk material, usually black, which is used in mourning, as well as to a sort of thin worsted material of which the dress of the clergy is sometimes made.

Crash.—A coarse plain-weave linen material in which the unevenness of the weft yarns gives a rough surface to the cloth. There are various grades of Crash, of which the coarser and more irregular kinds are used for towelling, whilst the finer are dress materials. Some Crash fabrics are woven from waste cotton.

Cravenette.—A waterproofing process applied to fabrics made of silk, wool, or cotton. Not a fabric.

Crêpe de Chine.—A sheer silk having a minute crape effect in the weave. The name in its correct acceptance applies to an all-silk fabric, but there are also cotton and silk mixed fabrics which bear this name, and at times even all-cotton fabrics have been so designated—by the retailer, at least. All the materials which are known by this name are of comparatively light weight. In practically all these fabrics the lustre is imparted by the warp yarns, which are likely to be of better silk than the filling. The filling yarns are twisted harder than for ordinary cloth. The hard twisting of any yarn will so curl up the fibres that they will not lie parallel and so will not reflect light and give lustre. All-silk Crêpe de Chine fabrics have a width of about 40 inches, whilst all-cotton and cotton and silk mixtures average 27 inches in width. The all-cotton variety is most often simply designated as Crêpe.

Crêpe Meteor.—A lustrous silk Crêpe.

Crepoline.—A fabric of a warp rib character in which the regular order of the weave is so broken as to give a "rib crape" effect.

Crépon.—A dress fabric of silk or wool in which the design is produced by using yarns having a different degree of stretch, so that portions of the fabric are crisped, crinkled, or apparently blistered, either irregularly or in set designs.

Cretonne.—This fabric is essentially a printed cotton fabric woven either with a plain twill satin or oatmeal weave. The weft is generally made from waste and is not very regular. Cretonnes, being used mainly for curtains, hangings, or furniture coverings, are generally printed with large, bold, and highly coloured designs. It is woven with a bleached or grey cotton warp and filling in widths ranging from 25 to 36 inches, and for curtains in widths[20] up to 50 inches. Their main feature is their large bright-coloured floral designs, and their value depends to a great extent upon the artistic merits of these designs. Sometimes a fancy weave or small brocaded effect may occur in this class of fabric, but it is seldom met with, and it is not representative of the true Cretonne fabric. Flax also is said to be used in the manufacture of certain grades of Cretonnes, without, however, taking them out of the class to which Cretonne fabrics belong.

Crimp Cloth, Plain, or Crimps.—Crimps are plain-woven all-cotton fabrics which have as their distinctive feature "cockled" striped effects. These "crimped" or "cockled" stripes are produced by dividing the warp threads into two separate "beams," one of which is under greater tension than the other; that is to say, the warp threads from one of the beams will be tight and the others slack. These slack threads in the process of weaving are "taken up" more rapidly and form the "crimped" stripes. Crimps may also be produced by subjecting fabrics specially constructed to a special chemical process during finishing, or by passing the material through suitable rollers which will stretch the material in some places more than in others and thus artificially produce the "cockled" stripe. Crimps are made up in widths seldom exceeding 30 inches; the length of pieces, however, may vary considerably. It is also known as Seersucker or Crinkle.

Crinkle, or Seersucker.—Names given to striped fabrics of the Crimp type. Seersucker originally meant a silk fabric.

Cross-dyed.—Cross-dyed goods may be described as fabrics woven with black or coloured cotton warps and wool or worsted fillings and afterwards dyed in the piece. This process is resorted to because the warp and filling of a fabric woven with a cotton warp and a wool filling, and then piece-dyed, would not become identical in colour, as cotton and wool have not the same attraction for dye. Cross-dyeing is generally used in mohair, alpaca, and lustre fabrics, and the principal cloths in this classification are cotton warp figured Melroses, Florentines, Glacés, Brilliantines, Lustres, Alpacas, and Mohairs. See Union Cloth.

Crossover.—This name is given to fabrics having stripes, of either colour or weave effect, extending across the width of the cloth from selvedge to selvedge.

Cut Goods.—Underwear made of either ribbed or flat webbing knitted into long rolls and cut to the proper lengths and sections for garments, after which the various parts are sewed together.

Cuttling.—Plaiting cloth in folds; used in the same sense as lapping and folding, as opposed to rolling into bolts.

Damask.—The name Damask is technically applied to certain classes of fabrics richly decorated with figures of foliage, fruits, scrolls, and other ornamental patterns, usually of a large and elaborate character. The weaves usually employed are twills (mostly satin twills), and the figures in the fabric are made by alternately exchanging warp for weft surface or vice versa. The materials employed vary according to the purpose to which the fabrics are to be applied. In the manufacture of upholstery cloth for hangings and furniture covering, silk or worsted is used; while for table covers, towels, napkins, etc., linen is generally employed, except in the cheapest grades, when cotton is the material used. Damask was originally applied only to silken fabrics whose designs were very elaborately woven in colours and often with either gold or silver threads. Although in the majority of Damask fabrics nothing but satin twill weaves are employed (principally five and eight shaft), very good effects are obtained by combining other weaves with satin twills. Where Damasks are made all of one colour, as in white linen table covers, the effect is given by the threads lying at right angles to each other; the light falling upon them brings the pattern in bold relief and makes it easily visible.

Damassé.—Applied to fabrics having a rich woven design. Similar to Damask.

Delaine.—A term applied to plain-woven materials made "of wool." The term probably originated in France and was applied there to all plain-woven fabrics of light weight made of wool. As used at present, the term may be combined with another name, and then purely designates the nature of the material used in the manufacture of the fabric, such as in Muslin Delaine.

Denim.—A stout cotton warp-faced twill cloth, generally woven as a four-end twill. The warp is dyed either blue or brown before weaving, whilst the weft is grey; they are both of coarse counts. Denim, being a warp-faced material, has the warp on the surface; and as the warp is made of coloured yarns, the cloth when woven shows a solid coloured surface. The back of the fabric shows the bulk of the weft threads, and these, being in the grey, give the back of the cloth a distinctive lighter colour than the face of the cloth. Like all warp-faced twill weave, the back of the cloth shows a plain-weave effect. Denims have generally a white edging forming the selvedge; they range from medium to heavy weight and are largely used in the manufacture of workmen's overalls.

Derby Rib.—Applied to hosiery having six ribs on the face alternating with three on the back.

Diagonal.—This name is applied to plain or figured twills of bold character and originates in the twill effect, which, in relation to the length of the fabric, runs in a diagonal direction. This twill effect is produced by raising warp threads in groups in a progressive order, the filling thus making them stand out in ridges or heavy twill.

Diaper.—This term as applied to fabrics is used to describe two distinct styles, the first of which consists of a small diamond weave, while the second and true Diaper has rectangular figures or dice interwoven on the Damask principle. In cotton fabrics it is confined to diced or diamond reversible patterns on a small scale. The weave is produced by the interchanging of warp and weft. In linen fabrics, also, it is used to produce diced, diamond, and bird's-eye patterns, and also small reversible Damask patterns. In some districts the names Dorneck and Diced are used instead of Diaper.

Dimity.—A fine cotton fabric, plain or printed, having a cord design running lengthways of the piece. The figures are often arranged in alternate stripes and appear as if embossed, this effect being due to the coarse weft "flushes." A cheaper kind is sometimes made by arranging a reversed woven stripe of warp-face and weft-face twill on a plain ground texture.

Discharge Printing.—In what is known as the "discharge" style of printing, the cloth is first impregnated throughout its whole substance by being either vat-dyed or pad-dyed; then the cloth is dried, but the colour is not fixed. It is next passed through the printing machine, and chemicals having the property of preventing the development are printed on it, either alone or in combination with other colouring matters. The ground colour is then developed by steaming, and the printed pattern, white or coloured, is obtained upon a coloured ground.

Dobbie, or Dobby.—This name is used to describe a type of loom used for the production of certain classes of figured fabrics which have a great many points of similarity with fabrics produced by means of a Jacquard loom. The distinctive feature of a Dobby loom is the series of lattices into which pegs are inserted, which control the lifting of heald shafts in their proper order, so as to form the shed, the heald shafts being pulled down again by means of springs after having been lifted up to form a shed.

Domestics.—This term is used in the textile producing districts of Great Britain to denote a class of medium and heavy weight grey cloths, plain or twill woven, the better qualities of which are not exported but used for home or domestic consumption.

Domet.—A strong, heavy, twill-woven cotton fabric resembling Canton or Cotton Flannel, having a raised or napped surface on both sides of the fabric. Domet may be either in the grey or white and is a plain fabric.

Double Cloth Weave.—Where two single cloths are so woven that they are combined together and make but one, it becomes known as a Double Cloth and is the result of double-cloth weaving.

Double Cloth is woven either to obtain two well-defined and finished faces or to allow of a heavy material being made with a good quality face and with the back made up of a cloth composed of inferior material. This style of weaving is resorted to when the object is to produce certain kinds of bulky or heavy overcoating.

Double Sole, Heel, and Toe means an extra thread added to hosiery at points mentioned. Strictly speaking, "double" applies only to single-thread goods.

Double Warps.—The name double warp is used to designate various kinds of fabrics of good quality in which the warp threads consist of two-fold yarn. Not to be mistaken as designating two-ply or double-weave fabrics.

Drap d'Été.—Allied to Cashmere in weave, but heavier.

Dresden.—A small unobtrusive design in pastel colourings.

Drills.—Drills are strong, heavy, warp-faced fabrics woven from yarns of good quality with a three (two warp and one weft), four (three warp and one weft), or five (four warp and one weft) end twill weave. When so woven they are known as Florentine Drills, of which the khaki Drill so often met with in the Colonies is a good example. Drills are also woven with a warp sateen weave which have—as the twill effect is done away with—a smooth surface.

Drills may be either linen or cotton fabrics, grey or white, bleached or dyed, printed or striped. They average 40 yards in length per piece and vary in weight from under 10 to 12¾ pounds[24] or over per piece and 31 inches in width. The name is from the Latin trilex, of three threads, and is applied to a "three-thread twilled cloth." Cotton Drill is a medium weight single cloth weighing from 4 to 6 ounces and composed of all-cotton yarns, warp, and filling, and is generally woven as a three-end twill-weave fabric.

Drillette.—This is a cotton fabric, finer and lighter in make than the ordinary cotton Drill. Drillette of 30-inch width is imported into Colonial markets, where it is largely used for linings and pocketing.

Duchesse.—A satin fabric having the back woven in flat twills, with a smooth surface.

Duck.—Duck is a heavy single-cloth cotton fabric made of coarse two-ply yarn of plain weave. Lighter than Canvas, Duck is woven on the same principle as Canvas. Duck on leaving the loom is finished by washing and sizing, drying and pressing; this gives the finished material a peculiar, hard, stiff feel. There are linen Ducks, but they are specially designated as Linen Ducks, the term Duck being used to denote the cotton variety.

Better qualities of Duck, such as are used for tropical suitings, are woven with a two-and-two matt dice or Hopsack weave. The term "two-and-two" means that two weft threads pass alternately under and over two warp threads, exactly as if a plain weave had been doubled and the weave worked with two threads instead of one; the plain weave is often termed a one-and-one weave. See Cotton Duck.

Dungaree.—A stout cotton warp-faced twill cloth woven as a four-end twill from coarse-count warp and weft. The only difference between this fabric and a Denim is that in the latter the weft is grey, whereas in a Dungaree both the warp and the weft have been dyed prior to weaving. Dungaree, being a warp-faced material, has the warp on the surface, and as both warp and weft are dyed yarns, the cloth, when woven, shows a solid coloured surface.

Duplex Prints.—Fabrics which have one set of patterns printed on the face of the cloth and another different pattern or design printed on the reverse side are generally styled Duplex Prints. They differ from fabrics which have been printed in colour on one face, but in such a manner that the printed pattern has soaked through and shows—though less sharply—on the back of the fabric. The Duplex Print is the result of two distinct printing operations, first on one side, then on the[25] other side, of a fabric. This being the essential condition for a Duplex Print, it follows that the two patterns need not be different. Fabrics printed on one side only, but in such a way that the design shows equally or nearly so on both sides, are not Duplex Prints.

Dyeing.—This term is used to describe the colouring of materials to enhance their value and appearance. There are five methods of producing colour in the fabric:—

| 1. Raw material dyeing. | 4. Mixed dyeing. |

| 2. Yarn dyeing. | 5. Piece dyeing. |

| 3. Cross dyeing. |

Unless the process is specially mentioned when a fabric is spoken of as "dyed," it can be taken that what is meant is that the fabric was "piece-dyed," i.e., dyed in the piece after being taken off the loom. A dyed fabric is one which has been impregnated with some colouring matter and this irrespective of the means adopted to so impregnate it. Whether the fabric once woven has been allowed to—

1º. Remain in a dye vat soaking up dye, or

2º. Whether it has been drawn through a series of troughs containing dye (Continuous or Pad-dyeing process) with a view to its absorbing the dye—

is immaterial. Where both sides of a fabric are equally coloured, and where a fabric shows that there has been thorough saturation, that fabric is said to be dyed.

Dyed and Printed.—This term is used to designate any fabric which has been first impregnated with colouring matter either by being vat-dyed or pad-dyed, and which in addition has been ornamented by having certain designs impressed on the surface of the fabric in either one or more colours. This is known as direct printing. Fabrics may be dyed and printed by various styles of printing, such as "Discharge," which consists of printing chemicals upon dyed fabrics in designs, the chemicals causing the dye to come out wherever applied, leaving the printed design either white or in a different colour from that of the dyed ground. "Resist" or "Reserve" style of printing is a process used to obtain white figures on a coloured ground. In this process the designs are printed in substances that are impervious to the dye into which the cloth is subsequently placed. The cloth is dyed, but all parts covered by the resist agent remain white.

Dyed Alpacianos.—This fabric is found grouped in the Revised Import Tariff for the Trade of China under "Dyed Cottons."

Alpacianos, as the name of a fabric, seems to have fallen into disuse and is probably a very old name. Dyed Alpacianos would appear to be an all-cotton fabric piece-dyed after leaving the loom, probably averaging between 28 and 31 inches in width and about 25 yards in length per piece.

The particular weave of Alpacianos is not described in any modern book of reference dealing with textiles. Names of fabrics vary, come into fashion, and die out. Few connected with modern textile industries could describe, say, fabrics such as "Durant," "Tammy," or "Everlasting Webster," yet not so very long ago there were fabrics currently sold under these names.

Dyed Balzarines.—The cotton variety of this somewhat ancient fabric was an all-cotton light-weight open fabric resembling gauze, approximating 30 inches in width and 30 yards in length per piece, piece-dyed in solid colours after leaving the loom. See Balzarines.

Dyed Cambrics.—Real Cambric is essentially a plain-woven linen fabric of light weight and soft finish, but the kind of Cambric most often met with is a cotton fabric of similar weave. Dyed Cotton Cambrics are piece-dyed after leaving the loom and, like White Cambrics, are generally finished with a smooth glazed surface. The differentiation between Cotton Cambrics and Muslins is somewhat difficult, as the term Cambric is often applied to what are in reality Muslins.

Dyed Corduroys (Cotton).—The term is used to describe a pile-weave ribbed cotton fabric which has been coloured in the piece with a view to enhance its value and appearance.

Dyed Cotton Lastings.—This fabric is a plain all-cotton twill or kindred weave material firmly woven from hard-twisted yarns and piece-dyed after weaving. Lastings enter largely into the manufacture of uppers for boots and shoes.

Dyed Cotton Spanish Stripes.—A plain-woven all-cotton fabric woven with a plain weave, having both surfaces raised, giving the fabric the general appearance of Flannelette; being a dyed fabric, it is piece-dyed after leaving the loom. As a distinctive feature, Spanish Stripes have a list or edge of different colour to the main body of the fabric. The warp threads are finer and harder twisted than the filling threads, which are soft and full to facilitate the raising during the process of finishing. In width this fabric may vary between 28 and 64 inches, and in length it[27] averages 25 yards. A similar fabric woven from dyed yarns would be a coloured woven fabric and would not belong to the dyed cotton variety.

Dyed Crimp Cloth.—An all-cotton fabric having the distinctive "cockled" striped effect of Crimp Cloth. This cockled effect is produced by greater tension in some of the warp threads than in others. Dyed Crimp Cloth is piece-dyed after leaving the loom and is distinguishable from coloured woven Crimp Cloth, which is woven from coloured yarns. This material seldom exceeds 30 inches in width, the length per piece varies.

Dyed Drills.—A heavy twill-woven all-cotton fabric, the weave of which is described under "Drills," which has been dyed in the piece, i.e., impregnated with a Uniform colour over its whole surface.

Dyed Figured Cottons.—Under this heading may be grouped all such fabrics which (a) are made of all cotton, (b) are figured by having any design, large or small, woven or embossed, on their surface, (c) are dyed in any colour, and (d) are not otherwise enumerated. The fabrics coming under this heading include both fabrics which have not been subjected to any special process of finishing and those which have been so treated, irrespective of the style of finish. The ribs or reps of such fabrics, which are known as "Reps" or "Ribs," do not in themselves constitute figures. Printing produces a style of ornamentation which does not rightly belong to this class of goods, in which it must only be the result of weaving or embossing.

Dyed Figured Cotton Italians.—This name is used to designate an all-cotton fabric having the characteristic even, close, smooth surface of the plain Italian Cloth, but which, in addition, has had its surface ornamented with any figures, floral or geometrical effects, etc., this figuring having been produced either by means of extra threads, or by combining the warp and weft threads, or by having the pattern or outline of the design impressed, stamped, or embossed in the fabric, which, as it is a "dyed" fabric, has been coloured after leaving the loom.

Dyed Figured Cotton Lastings.—This fabric is essentially an all-cotton twill or kindred weave material firmly woven from hard-twisted yarn, which has been figured or ornamented in the weaving by the introduction of a small floral or geometrical design. The fabric, being a "dyed fabric," is piece-dyed. Like Plain Lastings, this material enters largely into the manufacture of uppers for boots and shoes.

Dyed Figured Cotton Reps.—This name is used to designate an all-cotton material which is primarily a Rep fabric. It combines the prominent reps or ribs running transversely across the face of the cloth, which is the distinctive feature of a Plain Rep fabric, with certain small figures, floral or geometrical effects, etc., which are introduced for the purpose of ornamentation. This figuring may be produced either by means of extra threads on the surface of the cloth, by the mode of interlacing the warp and the weft threads on the surface of the cloth, or by having the pattern or outline of the design impressed or stamped in the fabric, which, as it is a dyed fabric, has been coloured after leaving the loom. This kind of material averages 32 inches in width and 32 yards in length per piece.

Dyed Figured Ribs.—This name is used to designate a fabric which is primarily a rib material having the characteristic rep or rib running from selvedge to selvedge, or, in some cases, lengthways of the fabric, but which, in addition, has had its surface ornamented with any figures, floral or geometrical designs. This ornamentation constitutes the figuring and is produced either by means of extra threads or by having the pattern or outline of the design impressed, stamped, or embossed in the fabric, which, as it is a dyed fabric, has been coloured after leaving the loom. A Dyed Figured Cotton Rib would be an all-cotton material with an average width of 32 inches and averaging 32 yards to the piece.

Dyed Fustians.—Fustians embrace two classes of finished goods, some of which are characterised in finishes by a nap raised on the fabric, such as Moleskins, Beaverteens, etc. The other class comprises cut pile fabrics, variously known in the trade by distinctive names, such as Velveteen and Corduroy. Fustians are essentially all-cotton fabrics. Dyed Fustians are piece-dyed fabrics and not woven from coloured yarns.

Dyed Imitation Turkey Reds.—The fabric of which this class of goods is an imitation is generally a twill-faced all-cotton cloth piece-dyed with a cochineal dye, which is fast to light and washing. The Dyed Imitation Turkey Red is similar in construction of fabric, but depends for its colouring upon a chemical or synthetic dye which, while it resembles cochineal, has not the same qualities of fastness.

Dyed Imitation Turkey Reds are piece-dyed fabrics averaging in width 32 inches and in length 25 yards per piece. Fabrics coming under this heading are invariably plain, i.e., unornamented either through weave combination, printing, or embossing.

Dyed in the Piece or Piece-dyed.—These terms virtually explain themselves. When a fabric is impregnated with a uniform colour over its whole surface it is said to be dyed in the piece or piece-dyed.

Piece-dyeing is open to produce cloud spots, stains, etc., which would not appear if the yarn had been dyed previously to being woven, for in that case even if the yarn had in parts got stained it would not show as a clearly defined stain in the fabric once woven. Piece-dyed fabrics may sometimes be distinguished from yarn-dyed fabrics by unravelling threads of each kind. In the case of yarn-dyed fabrics, the dyestuff has penetrated through the yarn, while in the case of piece-dyed fabrics the dye-stuff has not the same chance of penetrating yarn as completely. The term "dyed in the grey" (see under Union Cloth) has a similar meaning to "dyed in the piece" or "piece-dyed."

Dyed Lawns are plain-woven light-weight cotton fabrics of soft finish which have been piece-dyed, i.e., impregnated with a uniform colour over their whole surface after leaving the loom. They vary in weight from 1¼ to 2¼ ounces per square yard and in width from 27 to 46 inches. They answer to descriptions of White Lawns (which see), and differ from them only in regard to the fact that they are piece-dyed.

Dyed Lenos.—This fabric or class of fabric is an all-cotton material woven with a gauze and Leno weave and subsequently piece-dyed. The description of Leno fabrics given in a United States Government publication reads: "A term frequently used where various weaves or combination of weaves also have warp threads crossing over one or more warp threads instead of lying parallel to one another throughout the fabric. The warp threads which thus appear in a zig-zag way either on the surface or closely interwoven in the fabric, are, in addition to interlacing with the filling threads, also crossing their neighbouring warp threads that continue in a parallel line with the selvedges."

Leno fabrics generally show stripe effects, the exception to this being the All-over Leno, which resembles in weave the ordinary Cellular Cloth.

Dyed Leno Brocade.—This term is used to designate a fabric woven in the Leno style, that is to say, in a combination of "gauze weaving" and any other style of weave, and the term Brocade shows that it is a figured fabric having a figure chiefly constructed by weft threads floating on the surface of the material. As in this class of fabric the threads are not dyed prior to weaving, the term "dyed" shows that the material has been dyed after it has left the loom. See also Lenos.

Dyed Muslins.—Dyed Muslin is an all-cotton fabric of light weight, plain woven, which has been piece-dyed, i.e., impregnated with a uniform colour over its whole surface. There is a difficulty in describing Muslins, for the term Muslin, according to one Government publication, is "a generic term for thin plain-woven cotton cloth. The name, however, is frequently used in conjunction with such names as dotted, fancy, figured, spot, check, Swiss, etc., which in each case would denote some combination weave, or as containing stripes or checks, but the fabric still preserving a light weight." From this, however, it seems clear that a Muslin is a plain non-figured fabric of light weight.