Boston National Historical Park

Massachusetts

Produced by the

Division of Publications

National Park Service

U.S. Department of the Interior

Washington, DC

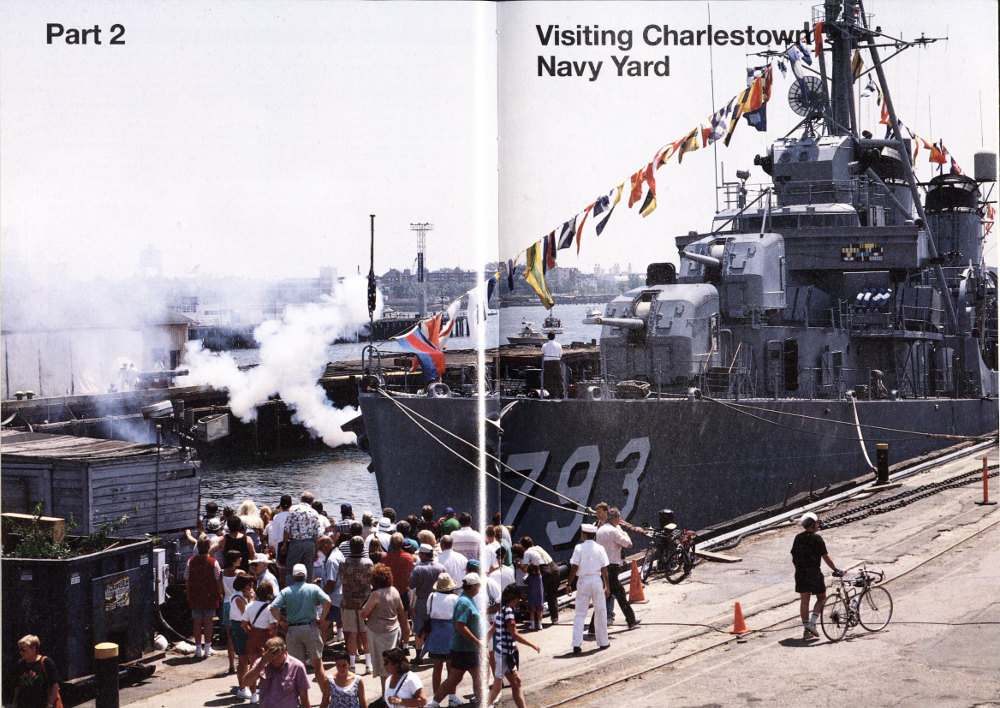

Deep within Boston Harbor, Charlestown Navy Yard was birthplace, repair center, outfitting base, and port of refuge for thousands of U.S. naval vessels. This is the story of the yard, the ships it served, and the people who kept them seaworthy.

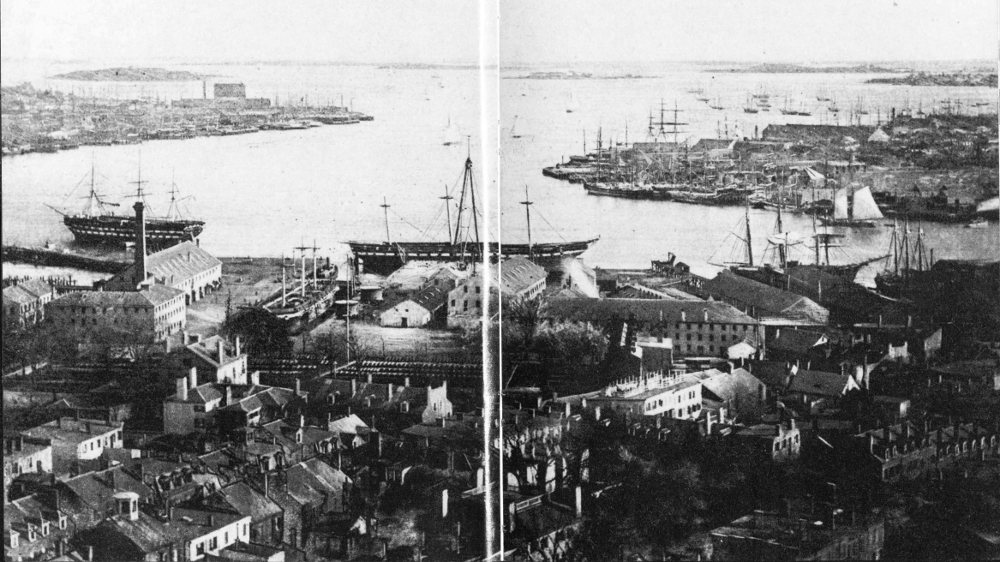

Boston Harbor; about 1870. Visible in the foreground are Charlestown Navy Yard’s timber dock (left) and dry dock (center left, with docked vessel). The ships anchored off the navy yard piers are (left) U.S.S. Ohio, the yard’s receiving ship (for housing recruits and sailors transferring between vessels), and U.S.S. Wabash “in ordinary” (that is, out of commission and in storage).

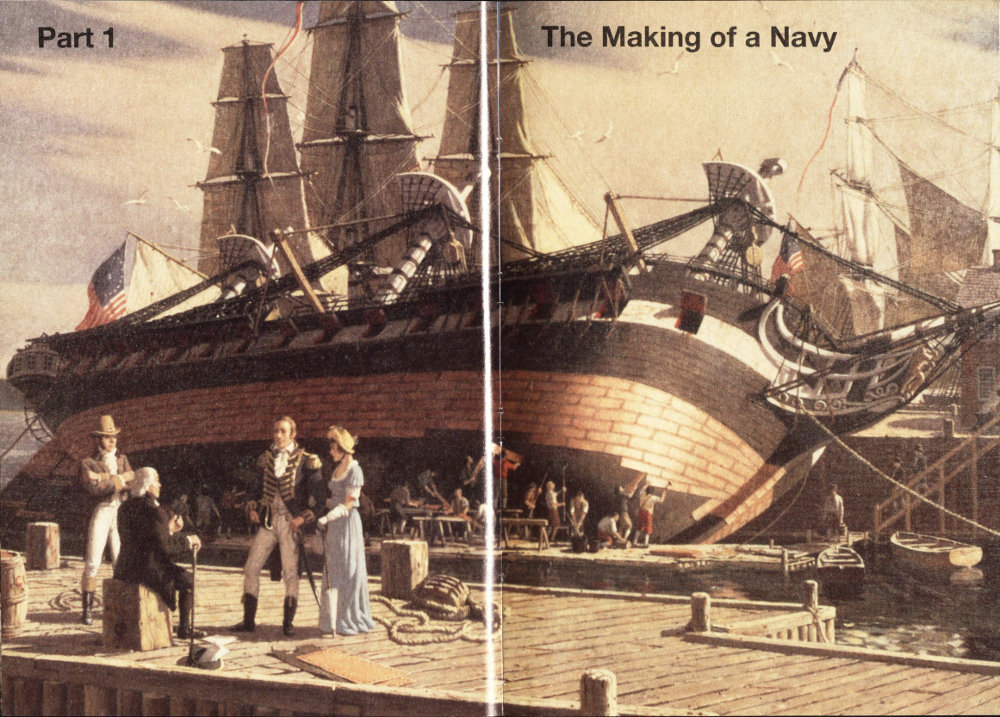

In 1803, U.S.S. Constitution was careened at a Boston wharf for recoppering before sailing for the Mediterranean to confront the Barbary States.

U.S. Naval Shipyards

The U.S. government established Charlestown Navy Yard as the newly-formed republic was meeting early challenges to its merchant shipping. In the decade after gaining independence, the young nation kept no standing navy. But continuing raids on U.S. commerce by Barbary pirates and French privateers in the 1790s spurred Congress to authorize the construction of new warships.

Realizing that existing private shipyards were inadequate for the increasingly ambitious shipbuilding program, the Secretary of the Navy established in 1800-1801 six federal yards to build, outfit, repair, and supply naval vessels. These facilities at Portsmouth, N.H.; Boston; New York; Philadelphia; Washington, D.C.; and Norfolk, Va., were the nucleus of the naval shipyard system. Except during the Civil War, they launched most of the Navy’s vessels until the advent of steel hulls in the 1880s, when private yards began building them in greater numbers.

As with the first six, later naval shipyards were sometimes created to fill an immediate military need. The War of 1812, for instance, prompted the building of the two Great Lakes yards. The Mound City yard was established during the Civil War, strategically located near the confluence of the Mississippi and Ohio Rivers to build and repair Union gunboats. Although U.S. naval vessels are today built in private shipyards, four navy yards still actively serve the fleet.

1833 view of one of the yard’s wharves, by William Bennett. Beyond, decommissioned Independence and Columbus are roofed over for protection.

When Captain William Bainbridge arrived in Boston aboard U.S.S. (United States Ship) Constitution in February 1813, he had reason to be satisfied. While the U.S. Army faltered early in the War of 1812, a string of naval victories over British ships was boosting public confidence. Two months earlier, the big frigate commanded by Bainbridge had engaged H.M.S. (His Majesty’s Ship) Java off the coast of Brazil. Java was the faster ship, but Constitution had heavier guns. By skillful maneuvering. Constitution kept them trained on the British frigate, pounding Java with broadsides until its colors came down.

Crew and commander were met with parades in Boston, but Bainbridge had little time to enjoy the acclaim. He was immediately faced with a task that, if not as exciting as a sea battle, was nevertheless formidable. He had temporarily relinquished command of the Charlestown Navy Yard when he sailed on Constitution. While he was gone, Navy Secretary Paul Hamilton charged the yard with building one of the nation’s first ships-of-the-line—the battleships of their day. As things now stood, that was an impossibility: Charlestown simply lacked the facilities for such an undertaking.

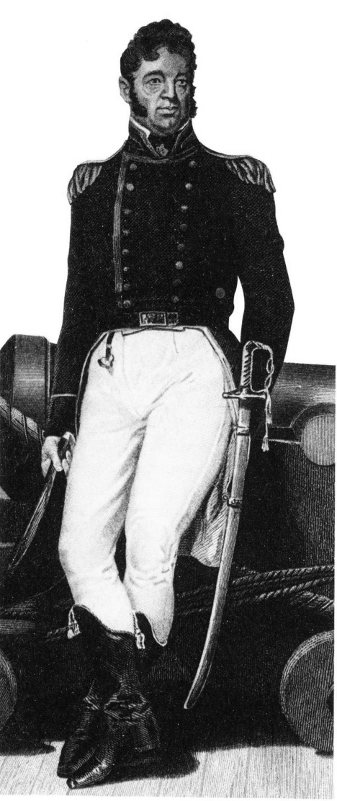

Bainbridge, who at 37 had already seen extensive naval action and been imprisoned by Barbary pirates, wrote soon after becoming commandant in 1812: “No period of my naval life has been more industrious or fatiguing.” He was shorthanded and hampered by bad weather, conditions that must have sorely tested the endurance of a man with his temperament: aggressive, 12 volatile, not noted for his patience. When he took command of the Charlestown yard, Bainbridge pressed the Washington bureaucracy to authorize improvements to a facility that suffered, in his words, from “mismanagement and neglect.”

Captain William Bainbridge was the Charlestown yard’s second commandant (1812-15) and captain of the first ship built there, U.S.S. Independence.

Years later, Bainbridge was typically blunt in depicting for the Secretary of the Navy what he saw as the Herculean task assigned him in 1812. The yard had been “in a state of perfect chaos. The public property in a state of ruin and decay ... a boat could not approach at certain periods of the tide within five hundred feet of the shore ... it was even exposed to the inroads of the cattle from [the] highway.”

Even allowing for Bainbridge’s penchant for the dramatic, his description was accurate. The buildings were too few, too small, and in need of repair. The timber needed to complete the repair of the frigate Chesapeake was decayed beyond use. But most pressing was the need for a large stone wharf and building slip. Here was a naval shipyard that could not service a sloop-of-war, let alone build a large frigate or ship-of-the-line. Small vessels could tie up at the modest wooden wharf, but the yard had to rent private wharves for repairing warships. Chesapeake had been languishing since 1809 in a rented berth at $1500 a year.

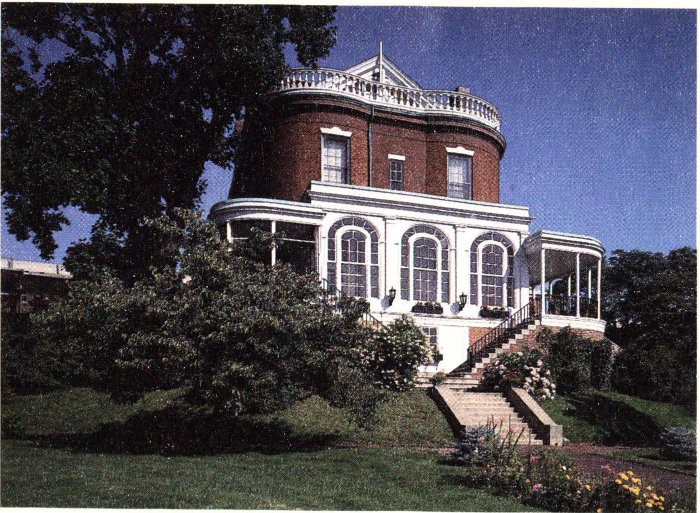

The commandant’s hilltop house surveyed 25 acres of scattered buildings and grassy tidal flats directly across the “stream” (the Charles River) from Boston. There was a marine barracks, a parade ground, carpenter and blacksmith shops, a timber shed, a small hospital, a saltwater timber dock, and piles of cannon, shot, iron, and ballast. The facility Bainbridge took over in 1812 was in truth more supply depot than shipyard.

So why, after his exploits aboard Constitution, when another ship command and the chance for further glory were his for the asking, did Bainbridge return to 13 Charlestown? Because he had also asked to command the powerful 74-gun ship-of-the-line the yard would build, and he wanted to oversee construction.

On resuming command in March 1813 he lobbied again for a wharf and building slip. As a well-known ship’s captain he was used to getting the attention of the Navy Department. But his sphere of activity had shifted from quarterdeck to desktop, and he had to watch coveted funds go to ships bound for sea. He was not, however, one to hold his tongue. He bombarded the Secretary of the Navy with letters (the tone of which, in this and other matters, sometimes bordered on sarcasm) until the wharf and slip were finally begun in April 1813. After the laying of the 74’s keel in May, Bainbridge was relentless in his requests for more improvements—a navy store, capstans for hauling out ships, “shears” (a simple crane) for installing masts, a ropewalk.

But his real passion was the great ship he could watch taking shape from his window. He even suggested the name: Independence. Bainbridge chafed to “give John Bull an opportunity of testing the strength of an American 74”—especially after Chesapeake had finally left the yard in June only to be captured practically within sight of Boston by the British frigate Shannon.

The combative commandant was rarely put off by obstacles—or someone else’s reputation. Having clashed with workers over compensation they demanded for days lost to bad weather, he shut out the source of trouble by ordering a shiphouse 210 feet long and 50 feet high built over the 74’s building slip. To oversee ship construction Bainbridge hired Edmund Hartt and his son Edward—well-regarded Boston shipbuilders in whose yard was built the hugely successful Constitution. But in a dispute with Edward Hartt the angry Bainbridge grabbed him “by the shoulder and carried him out of my office.” Hartt’s father quit in protest, whereupon Bainbridge quickly engaged another shipbuilder to finish the job.

Bainbridge’s other main duty as commander of the yard was the defense of Boston Harbor—the importance of which was underscored by the Shannon-Chesapeake engagement. By spring of 1814 British warships were raiding the New England coast almost at will, and the Boston citizenry (many of whom vigorously opposed the war) was anxious over an anticipated attack on the city. The rising 74, Bainbridge knew, made a tempting target while it was unarmed and immobile on the ways. He asked for the New England Guards, a Boston militia company, to stand ready at the yard as Independence neared completion.

Guarding United States property at the Charlestown yard was normally the responsibility of the U.S. Marines, stationed there since 1802. But it was a small detachment, not enough to defend the yard and its ships against a serious attack. Bainbridge, who earlier protested the vulnerability of the yard, had other problems with the marines. Though they were under naval command while at sea, on shore the Navy had no authority over them. Bainbridge deplored this situation, complaining that his inability to mete out the same corporal punishment to marines as was used on sailors was “productive of insubordination.”

In any case Independence was ready for launching by June 1814. But the much-anticipated ceremony on the 18th was an embarrassing failure. Independence hung up halfway down the launching ways, much to the satisfaction of a Federalist quoted in the Boston Gazette: “It was no wonder she stuck ... the war itself sticks.” The next day, when workers attempted to move the vessel by winch with the New England Guards pitching in to haul on the lines, a block flew apart and killed master joiner William Champney.

U.S.S. Independence, built at Charlestown in 1815, was the nation’s first ship-of-the-line. On its maiden voyage the 74-gun vessel served as flagship of the Mediterranean squadron in the Barbary Wars. After the Charlestown yard removed one gun deck in 1835, turning the slow 74 into a fast, powerful frigate (above), Independence served as flagship of the Brazil and Pacific squadrons. The frigate spent the last 60 years of its career as receiving ship (temporary sailors’ quarters) at Mare Island Navy Yard near San Francisco Bay, where it ended a century of service in 1914.

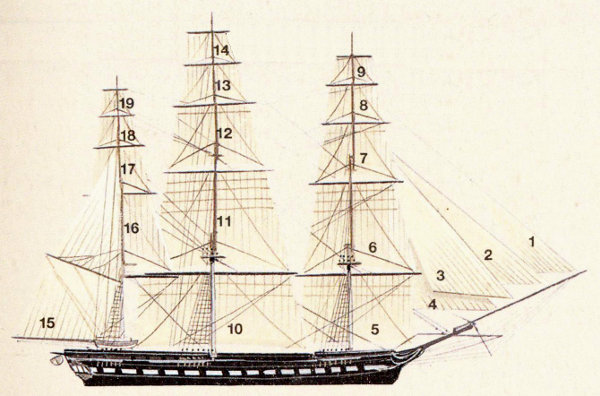

Ships-of-the-Line were the battleships of their day, carrying 64 to 100 guns or more on two or three gun decks (below the open decks). Ship-rigged (square sails on three masts), these warships took their place in the line of battle in huge fleet actions.

Frigates had 22 to 44 guns on one gun deck. They were ship-rigged counterparts of today’s cruisers, excelling in single engagements and as commerce destroyers. Frigates also did convoy duty and served as scouts for battle fleets.

Sloops-of-War had 8 to 24 guns on an open deck and were ship-rigged. Fast and versatile—the destroyers of their day—sloops provided escort protection and harassed enemy shipping. Their shallow draft made them useful in coast defense and in lake squadrons.

Brigs-of-War had about 20 smaller guns on an open gun deck and carried square sails on two masts. Designed as small, fast cruisers, they served as scouts, blockade runners, commerce raiders, and in anti-piracy and slaveship patrols.

Then, to worsen an already grim situation, the British warships that had blockaded Boston Harbor for over a year became an immediate threat. A raiding party from the frigate Nymphe rowed into the harbor in the early morning darkness of the 21st and burned a small sloop within a mile of the yard. The next day, with the charred remains of the vessel tied up at a Charlestown wharf, the leader of the raid publicly taunted Bainbridge. In an open letter in the Boston Patriot, Bainbridge was warned to better defend his “unfledged Independence.”

On the afternoon of June 22, under the eye of the Guards, the vessel finally slid down the ways into Boston Harbor. The launching was celebrated by a gun salute from Constitution and cheers from a crowd of 20,000. Bainbridge’s friend, the author Washington Irving, couldn’t attend but wrote Bainbridge that he would drink a “potation bottle ... to the success of your first cruise.” In the same spirit Bainbridge entertained with food and drink 300 mechanics and laborers who had, he said, “worked cheap, and done their work most faithfully.”

But the war he wanted so badly to join remained out of Bainbridge’s reach. Desertions, along with financial and outfitting delays, held up the vessel until 1815, by which time peace with England had been concluded.

Another opportunity soon presented itself. The predatory corsairs of the North African Barbary States—Tunisia, Tripolitania, Algeria, and Morocco—had long been a thorn in the side of American merchant shipping. Bainbridge, with Independence as his flagship, won command of a squadron whose mission was to display to the Barbaries the new power of the U.S. Navy. The assignment was particularly attractive to Bainbridge, who earlier in his career had surrendered a ship to the Tripolitans and had another commandeered by the Algerians. But a second squadron under Captain Stephen Decatur beat Bainbridge across the Atlantic and defeated the Algerians in battle. His role was thus reduced to persuading the other Barbaries at gunpoint to end their extortionist ways. The suppression of the Barbary pirates was nevertheless satisfying to Bainbridge. As senior officer, he had the honor of commanding the squadron that initiated a permanent U.S. presence in the Mediterranean—the first of the Navy’s “distant station” squadrons.

Upon Bainbridge’s return to Boston he attempted to regain command of the yard from his replacement, Captain Isaac Hull. Unsuccessful, he was instead appointed Port Captain (“commander afloat” of all naval vessels in Boston Harbor), with Independence designated station flagship. Bainbridge settled down to a career as a senior officer, serving as commandant at the yard twice more in the 1820s and ’30s. He had helped put Charlestown on the map as the builder of a major warship. More significantly, after the War of 1812 the yard began building a reputation as an important repair and supply facility.

The Charlestown yard, and the U.S. Navy itself, owed their existence in part to the same Barbary pirates who occasioned Independence’s first cruise. The severing of ties with Britain during the Revolution also meant the loss of protection from the Barbaries long provided by the Mother Country’s powerful navy and by the “tribute” Britain paid them. The United States had no navy to protect its seaborne commerce—so essential to a coastal nation dependent on overseas trade—and the treasury could not bear the tribute payments or the ransom demands for captured ships and sailors.

Thus after independence the Mediterranean trade had been virtually closed to the United States. There was much unresolved debate about the problem, but when the pirates spilled out into the Atlantic in 1793 and took 11 American vessels in a few months, Congress took action. The following year it authorized six frigates, three of which were launched in 1797: United States, Constellation, and Constitution.

Congress was spurred to finish the job by the actions of Revolutionary France during its war with Britain. French commerce raiders so terrorized American neutral shipping that in 1798 an angry U.S. government created the Navy Department and prepared for war. (There were a number of engagements at sea, but war was never declared.) Congress authorized funds to build, borrow, or accept as gifts 49 vessels, ranging from galleys to six 74-gun ships-of-the-line.

The 74s were never built, but while the program was still alive, naval shipyards to build them were established in Portsmouth, Boston, New York, Philadelphia, Washington, and Norfolk. Boston, wrote Secretary of the Navy Benjamin Stoddert to President John Adams, from “the natural strength of its situation [meaning its large, deep, and defensible harbor], the great number of ship carpenters in its vicinity, and of its seamen, must always remain a building place and place of rendezvous for our navy of the first importance.” Thus in 1800 the Charlestown Navy Yard was established.

For most of its history Charlestown’s primary mission was to keep the fleet sailing. That is not to say the yard wasn’t a shipbuilder; it built more than 200 warships over its 174 years of operation. But most of the new ships were built to meet the immediate demands of war. (Three quarters of them were launched during World War II alone.) For fully half of those years no new ships came down the ways. The pattern established in the yard’s early years was one of ongoing repair, outfitting, supply, and conversion work punctuated by occasional new launchings.

The classes of ships that came down the ways at Charlestown and other naval yards were the outcome of strategic and political deliberations in Washington. U.S. naval policy devised during the first half of the 19th century had its roots in the War of 1812. Before the British blockade bottled up its warships, the tiny U.S. Navy had successfully fought a brief guerre de course against Britain, using a strategy that emphasized single ship actions and raids on enemy shipping with relatively small, fast frigates and sloops-of-war. The early naval successes prompted Congress in 1813 to authorize six new frigates (three of which were built) and six sloops. These, and the nine frigates authorized in 1816 and laid down in the 1820s (including the Charlestown-built Cumberland), formed the backbone of the Navy until just before the Civil War.

But the War of 1812, which helped shape a practical role for the 19th-century Navy, also led lawmakers into an expensive attempt to compete with European navies on their terms. Using the argument that large, powerful ships were essential to the defense of the nation’s shores (and perhaps remembering the crucial role of French 74s at Yorktown), Congress also authorized four 74-gun ships-of-the-line in the 1813 act.

While ships-of-the-line were traditionally used in fleet actions with set lines of battle (hence their name), they were also deployed to break blockades and to “show the flag”—that is, remind other nations of the United States’ military reach. Postwar nationalism, a popular navy still basking in the nation’s praise, and the country’s demonstrated vulnerability 17 to blockade prompted appropriations in 1816 for additional 74s.

Between 1813 and 1822 fourteen 74s were laid down, including Independence (1813), Vermont (1818), and Virginia (1822) at Charlestown. But in the decade after the war strategists cast a skeptical eye on such large ships. The expensive, provocative, and easily outmaneuvered behemoths, they said, were only a drag on the Navy—inappropriate for a young nation that wanted to stay out of European conflicts. By 1825 only five 74s had gone into service.

In 1835 Independence took a turn in its career that was emblematic of naval policy. The 74 had lain idle at Charlestown for 13 years. It was a sluggish sailer, and its great weight and design flaws brought the lower lee guns too close to the water to be useful during combat. So Independence was “razeed,” cut down from three decks to two, and transformed from an unsuccessful ship-of-the-line into a very good 54-gun frigate—the largest and one of the fastest in the Navy.

Only a few present at its 1837 recommissioning realized that Independence was also among the last of its kind. Fast approaching was a technology that would displace naval sail; steam would drive the Navy of the future. In 1839 the Navy’s first commissioned steamer—the two-year-old harbor battery Fulton II—arrived at Charlestown for repairs. A local paper called it “the oddest looking fish we have ever set our eyes on.” Four towering stacks spouting black smoke rose from the deck, on which were mounted engine cylinders four feet in diameter. The sidewheel covers, likened to “immense fungi,” barely cleared the sides of the dry dock.

With the dock and other improvements, the Charlestown yard had by the 1840s taken shape as an important repair and shipbuilding facility. The dry dock (see pages 40-41), five years abuilding, had opened in 1833 amid much ceremony. Vice President Martin Van Buren and other dignitaries watched as the already-venerable Constitution, stripped and demasted, inaugurated the dock. Much of the tidal flats had been reclaimed behind a granite quay (the yard would triple its original size by 1869), and the rest of the yard’s uneven grounds had been leveled. A high stone wall, built to help stop pilfering and protect the ships, stretched between the Charles and Mystic rivers.

The yard had become more self-sufficient. The boilers for the dry dock pump engines also provided steam for the new sawmill and blockmaking and armorer’s shops. In 1837, the yard’s ropewalk (also steam-powered) and tar house had been completed (see pages 20-21). The yard now made its own paint in the “oil house,” while hardware was supplied by a large smithy with 12 forges.

Other significant additions: masting shears looming over the new shear wharf; a sparmaker’s shed, masthouse, and sail loft; new timber docks; a steam chest for bending wood; an armory with thousands of muskets, bayonets, and swords; and neat ranks of guns, shot, and anchors in their respective “parks.” Hundreds of elm trees planted by order of Commodore Bainbridge softened the yard’s industrial setting.

Anchored out in the harbor were several vessels “in ordinary.” A vessel in ordinary was out of service and in storage with a skeleton crew until recommissioned. The ship was demasted, salted to retard dry rot, whitewashed inside, tightly caulked, and its sides and decks “payed” with a thick coat of varnish and tar. Tubular windsails directing air belowdecks and holes cut in the bulkheads insured good air circulation. Some vessels in ordinary at Charlestown had protective wood and 18 canvas sheds over their decks, an innovation of Captain Hull.

Vermont, Virginia, and the frigate Cumberland, begun in 1825, had become permanent fixtures in their great shiphouses. They were still officially under construction and near completion, but were really in ordinary. (Virginia was something of an ill-starred vessel. Over the years at least three people had died in accidents around the ship, and its reputation was reconfirmed in 1845 when a visitor fell to his death from its scaffolding.) Construction on Virginia and Vermont had slowed to a standstill after critics questioned the strategic value of ships-of-the-line. But economic considerations played at least as big a role; ordinary was a cheap way to keep expensive-to-sail vessels, including big frigates like Cumberland (launched in 1842), ready for war.

In 1848 Vermont was finally launched to “a vast concourse of people and the firing of cannons.” But the day of the big 74s was over. Neither Vermont nor New Hampshire (built at Portsmouth Navy Yard), the last two ships-of-the-line completed by the Navy, ever saw service as a commissioned warship. In fact most 74s had short careers of little strategic consequence. Independence, first of the class, was the only one still serving as a warship at mid-century, but it had been cut down to a frigate.

The launching of Vermont also closed a chapter in the yard’s history. The second ship laid down at Charlestown 30 years before, Vermont was the last all sail-powered warship launched there—obsolescent even as it came down the ways.

Although this was a U.S. Navy Yard run by naval officers, throughout its history those wielding the caulking mallets and rivet guns were civilians working for civilian foremen. During the first half of the 19th century the yard’s workforce steadily increased from 89 in 1822 to 370 in 1853. At mid-century the records show most of them were born in New England—half from Massachusetts. Some 15 percent were Irish, the majority working as laborers.

So complicated an undertaking as the building of a warship required an array of specialized occupations falling under the general label of “mechanics”: carpenters, sawyers, joiners, sparmakers, blockmakers, painters, gun carriage makers, armorers, sailmakers, blacksmiths, caulkers, riggers, boatbuilders, coopers, ropemakers, masons, machinists, plumbers, and coppersmiths. A force of unskilled laborers was at times supplemented by the ordinary crews and by the sailors stationed at the yard.

Each shop had its master, quartermen (leaders of several crews), leadingmen (crew leaders), and crews of mechanics, apprentices, laborers, and a few boys (before child labor laws eliminated such positions). In the early years, when the yard’s facilities were sparse, it was not unusual for the master to have his own shop outside of the yard. The commandant would in effect contract with the master to do the work there with his own men. In the 1840s and ’50s the Navy tightened the regulations, giving the masters less leeway in hiring and ordering supplies. By the Civil War they were all yard employees.

A look at the young men in the apprenticeship program, started in 1817, gives a clearer picture of the yard employees they would become. Those applying for the program—generally at age 16—had to show good character and be physically able to perform the tasks of their trade. They had to demonstrate the ability to read, write, and do simple math. The terms of the five-year indenture (later reduced to four) were generally clear: in return for exhibiting growing mastery of his trade, the apprentice received from the Navy room and board, increasing pay, and continuing education in reading, writing, arithmetic, and theories of the trade. But because the indenture was technically a personal contract between the boy’s parents or guardian and the master, not the Navy, questions of obligation sometimes arose when a new man became master. At the end of the apprenticeship—usually at age 21—the boy became a yard employee.

Continues on page 22

During the early 19th century, Charlestown’s shipyard bell called several hundred civilian tradesmen and laborers to work each morning. Laboring from sunrise to sunset under the supervision of naval officers and civilian shop masters, these yard employees built, repaired, and supplied United States warships for naval duty around the globe. Fluctuating government budgets, changing seasons, and the uneven demands of war and peace made navy yard work intermittent and unpredictable.

A navy yard rigger tightens a warship’s mast shrouds.

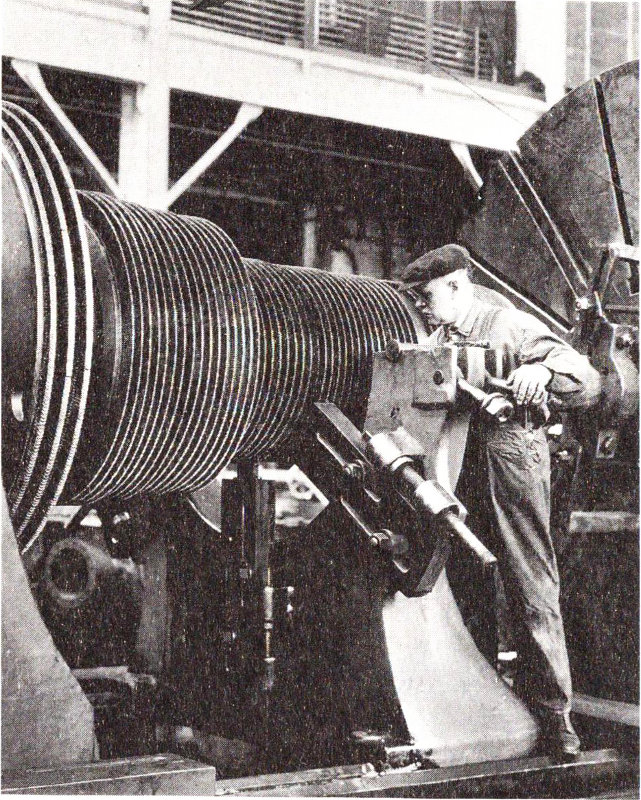

Several factors enticed the U.S. Navy into constructing its only ropemaking facility at the Charlestown Navy Yard in the 1830s: skilled labor, access to raw materials, and technical expertise. The port of Boston already boasted more than a dozen ropewalks employing many skilled artisans. Perhaps most importantly, the Navy was eager to take advantage of newly developed labor-saving machines like those already in use in New England’s textile mills. Because rope had to be twisted in a straight line, the maximum length that could be produced was determined by the length of the ropewalk (so called because workers spinning the hemp fibers by hand walked the length of the building). The Charlestown ropewalk’s quarter-mile length allowed production of rope up to 1200 feet long. Designed by architect Alexander Parris (best known for Boston’s Quincy Market), the ropewalk complex included the rope “laying” area running the length of the building, spinning and preparing machine rooms, the hemp house, and the tar house. The complex was powered by massive steam engines and tended by men and boys. The Navy’s move to mechanized rope production came at a critical time, as machine-spun rope began to replace intricate hand-spinning techniques. The hand spinners’ resistance inspired contests in the 1840s, in which they challenged the quality of machine-made rope. The results of such a challenge to the Charlestown ropewalk were somewhat ironic. Though its machine-made rope proved to be stronger and cheaper to produce, hand-spun rope was superior in the smaller sizes, and the mechanized ropewalk began producing some hand-spun rope, doing so until the end of the 19th century.

Spinning Combed bundled fibers called “roving” are fed from a can onto the spinning frame. At the spindle they are spun counterclockwise into yarn, which is wound on a bobbin.

Forming the Strand Bobbins are mounted on the twisting frame. The yarns are threaded through the register plate to equalize tension and tied to a rotating hook on the rolling “jack.” The jack pulls yarns from the bobbins and twists them clockwise into a strand.

Laying the Rope Three or four strands are tied to a rotating hook on the jack. While clockwise tension is kept on the other ends by rotating hooks, the strands are twisted counterclockwise into rope.

Budget-minded Naval Commissioners in Washington allowed the commandant to pay just enough to hold on to his workers. He generally matched the rates of private shipyards in the area to keep workers from being lured away. The daily rates thus fell with the coming of cold weather and the slowing of work, since the workers were then in low demand elsewhere. The Navy defended this hard-nosed practice, maintaining that with fewer daylight hours (workers mustered at sunrise and were dismissed at sunset), the yard got less work out of the men. The niggardly pay policies sometimes backfired: in 1821 the low-paid sailmakers left en masse to work at private yards.

More than the skilled craftsmen, the laborers’ jobs depended on the amount of work at the yard, but most of the workforce awaited the coming of cold weather with some anxiety. The yard’s practice was to retain only as many people as it could keep working, and bad weather sharply reduced the volume of work. The completion of a new ship or of a major repair job also meant the letting go of large numbers of workers, at least until the next job. In effect many in the workforce were not given permanent jobs, but only hired on to perform seasonal work, much like house carpenters, or to complete a single project.

Though the situation was normally weighted in favor of the employer, the scales could occasionally tip the other way, especially for skilled workers. In 1825, when the coming of spring coincided with a surge in building brought on by a recent Boston fire, Commandant William Crane was forced to raise wages to compete for skilled workers. He sent his Master Builder Josiah Barker up the coast as far as Portland to recruit mechanics.

At times skilled workers attempted to force the Navy’s hand, organizing to protest conditions. When the caulkers struck for higher wages in January 1835, the commandant, Commodore Jesse Elliott, fired them and quickly found others willing to work at the established rate. Two days later the “refractory caulkers,” unable to find work in the middle of the winter, asked to be rehired at their old wages. Wanting to remain on good terms with his employees, Elliott allowed the men to return.

Sometimes the walkout worked. Yard workers considered unreasonable a change in their working hours made in 1852. By this time they were working a straight 10-hour day. But under the new policy, they had to work sunrise to sunset if that period contained even a minute less than 11 hours, thus adding up to an hour to their day during the winter. They walked off the job, forcing the Navy to rescind the policy.

These actions represent a period when the yard workers, though not yet unionized, could strike—an option later denied to government employees. While workers were generally forced to accept the prevailing pay and conditions at the yard, they were not completely without power.

In the Charlestown Navy Yard’s first half-century, world events, U.S. politics, and sectional rivalries affected the ebb and flow of work and the hiring and firing of men. The yard was born in the midst of a world at war and grew to prominence in a time of relative calm—in retrospect, the lull before the storm of civil war.

Sloop-of-war (U.S.S. Decatur or Dale) dry docked in Charlestown has its rigging tarred and its hull sheathed with copper, about 1852.

Continues on page 29

The creation of a wooden warship began in the mold loft. There carpenters translated specifications from standard plans for each class of vessel into full-sized wooden patterns. These were used to fashion hull members, for which white oak or live oak were the favored woods. (Some 2,000 trees were required for a 74-gun ship-of-the-line.) On the slightly inclined building ways, joiners first laid the keel, the great spine of the ship running along the bottom of the hull. Then they attached the stem and the stern post to the keel and raised the frames—the vessel’s ribs. The frames formed the contours of the hull and, together with horizontal deck beams and vertical stanchions beneath the beams, provided a strong skeleton. After 1829, iron and copper bolts and spikes replaced many of the wooden “treenails” that secured the structural members and fastened the deck and hull planking. The rudder was hung, the hull caulked and sheathed with copper to protect it from teredo worms, and the ship was launched. Riggers then “stepped” masts to the keelson, a lengthwise beam bolted to the keel (see page 19). After they rigged the horizontal spars, cordage, and sails, the new warship was ready for outfitting.

Expanding U.S. interests in the Pacific spurred Congress in 1825 to authorize a new class of sloop-of-war to protect those interests. Charlestown Navy Yard constructed three of them between 1825 and 1827.

The first three warships ordered for the infant U.S. Navy in 1794—one of them the Boston-built Constitution—were frigates unlike any others. Naval strategists knew the nation could afford to build only a few vessels, so they had to be formidable warships. They were inspired by French “razees,” ships-of-the-line (see page 14) that had one gun deck removed, transforming them into large, heavily armed frigates. The sharp lines of Constitution’s hull gave it a frigate’s speed, but in size and stoutness it was comparable to a small ship-of-the-line. (Its heavy oak frames, spaced close together and sheathed with thick planking, proved virtually impenetrable in battle—hence the name “Old Ironsides.”) The theory was that Constitution would be powerful enough to fight any frigate, quick enough to flee anything bigger. The British, though, scorned the new frigates, asserting that they lacked the tactical strengths of either frigates or ships-of-the-line: too slow to engage the former, too weak to stand up to the latter. But Constitution more than lived up to U.S. expectations in the War of 1812, when it bested two British frigates in separate battles, escaped two more, and captured a frigate and a sloop-of-war in a third engagement. Constitution fought no more battles, but served honorably for another 40 years. Throughout its career Constitution has been closely associated with the Charlestown Navy Yard, undergoing several overhauls there. The first was in 1833, when the frigate inaugurated the yard’s dry dock. In 1992-95 it was serviced in the same dock. Since 1897 the yard has been home port for Constitution, the Navy’s oldest commissioned warship.

The 24-Pounder Long Gun

A gun crew of 6 to 14 men wrestled with this 5,600-pound gun. To adjust elevation, a crew member placed a handspike on one of the steps (A) and levered the breech (B) up or down; the gun captain slid the quoin (C) in or out.

U.S.S. Constitution

High-resolution Map

Constitution’s Sails

Sail area, with studding sails (not shown), was more than 43,000 sq. ft.

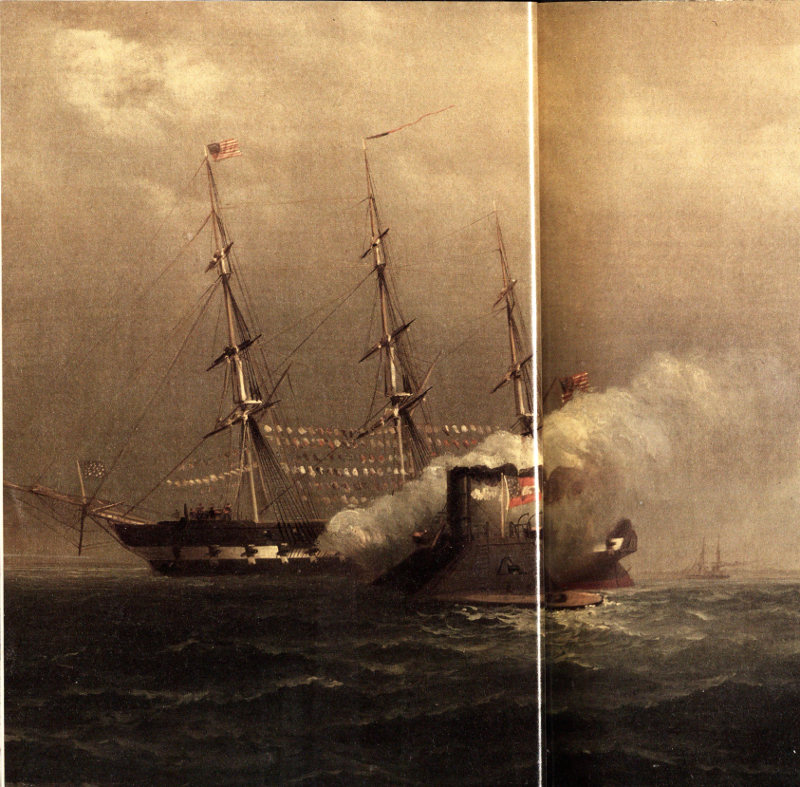

Sinking of Union sloop Cumberland by Confederate ironclad Virginia (ex-U.S.S. Merrimack) in 1862, by Alexander C. Stuart.

Merrimack, Virginia, Cumberland: names that point up the ironies of war. As the steam frigate Merrimack was being launched in July 1855 (see pages 32-33), the partially built ship-of-the-line Virginia lay in another part of the yard. It had been laid down and named in the 1820s, a more harmonious time. Even if the old 74 had finally come down the ways, it is not likely that, amidst the sectional acrimony of the 1850s, it would have kept the old name—and certainly not after the secession of the state whose namesake it was.

A year after Merrimack’s launching, the frigate was back in the yard after going aground during its shakedown cruise (when the crew becomes familiar with a ship and problems are ironed out). While workers replaced damaged coppering and repaired the propeller on the big warship, a smaller sail frigate waited its turn.

Launched 13 years earlier, Cumberland had served as flagship of the African Squadron, whose mission was to suppress slave running. Now back home, Cumberland moved into the dry dock soon after Merrimack was towed out. It was cut down to a fast sloop-of-war with one gun deck of 28 guns and a crew of 376.

Cumberland’s worth as a leaner warship was proven in the first months of the Civil War. Assigned to the Atlantic Blockading Squadron, the vessel took eight Confederate prizes in three weeks. But the next year Cumberland, among the last sailing ships launched by the Navy, came up hard against the future.

On March 8, 1862, Cumberland and other vessels were on blockade duty in Hampton 30 Roads, Virginia, when the men on deck sighted a bizarre new war machine steaming out of Norfolk. Approaching them was a dark, monolithic vessel—decks awash, no masts, no sails, no sailors. C.S.S. (Confederate States Ship) Virginia, the much-rumored ironclad blockade-breaker, had finally taken the stage.

Architect’s rendering of the Charlestown machine shop’s “Great Chimney,” 1858.

It was a slow, clumsy vessel, but menacing nevertheless. Using a full mile to gather momentum, Virginia steamed steadily towards the Union vessels. It passed the frigate Congress and headed straight for Cumberland, its sloping iron casement shedding the Union ships’ barrage of heavy shot and explosive shell as if they were “peas from a pop-gun,” in the words of a Cumberland sailor. But Cumberland, though clearly outmatched, could not avoid engagement. It was at anchor in a dead calm, the crew’s wash drying in the rigging. The Union sailors could only take the punishing return fire, clear the decks for battle, and wait for the inevitable.

Longer than Cumberland by half, with a submerged iron ram projecting from its bow, the approaching vessel looked to the Union ship’s pilot like a “huge, half-submerged crocodile.” Virginia tore into Cumberland’s bow below the waterline (see pages 28-29), then backed off, leaving its ram imbedded in a seven-foot hole. Both vessels now loosed volleys at point-blank range; dozens of Cumberland’s crew were maimed or killed.

As the vessel listed and began to sink, the crew abandoned ship, but 121 men—already dead, too hurt to save themselves, or firing guns to the end—went down with Cumberland. (As water flooded the gun deck, a young gun crew officer barely saved himself by squeezing through a gun-port. He was Lieutenant Thomas Selfridge, who in 1890 became commandant of the Charlestown Navy Yard.) Before darkness ended the fighting, the ironclad also riddled Congress, killing more than a hundred 31 men and setting the vessel on fire. Congress burned on into the night and finally exploded.

The frightening weapon that had handed the U.S. Navy its worst defeat began its career as the hull of a wooden steam vessel. A week after the surrender of Fort Sumter, the loss of the important Gosport Navy Yard at Norfolk to rebel troops became inevitable. Evacuating Union forces—under cover of Cumberland—burned and scuttled several warships to keep them from falling into Confederate hands. But some were salvageable, including a large steam frigate on which everything below the waterline was intact. Southern engineers converted the vessel into an advanced warship, removing the masts and topping the hull with a rooflike iron shell. The original name of the vessel they retrieved and transformed: U.S.S. Merrimack.

Merrimack’s reincarnation as Virginia embodied two technologies—steam and iron (and then steel)—that were advanced during the Civil War and that eventually defined the modern Navy. Steam engineering had traveled a long road of acceptance in the conservative Navy. By 1850, the year the Charlestown Navy Yard built its first steamer, Great Britain had built or converted from sail some 25 propeller and paddlewheel steam warships. The U.S. Navy had launched only seven. Steam engines were still considered novelties by many old Navy men—at best auxiliary power, at worst dirty and undependable nuisances that called for machine tenders rather than sailors.

Their resistance was not entirely unjustified. There was the problem of range: Merrimack, for instance, could cruise only about 17 days with its coal bunker full. American steamers far from home had to depend on French or British coaling stations and machine shops in places like Hong Kong and Shanghai. Unlike self-reliant sail, steam alone could not meet the demands of distant squadrons. And in the early days of steam, it was no faster than sail: in fact it was often slower. More crucial, early steam engines were inefficient and unreliable, so captains would not trust them in combat. And coal took up valuable space needed for supplies, crew, and ammunition.

But the main problem was that early steamers were driven by big, ungainly sidewheels that caused captains no end of problems (see page 35). They so harmed a vessel’s sailing qualities that steam was of necessity the primary power source on sidewheelers—but the Navy wanted to use steam only as auxiliary power.

Another way of employing steam power for propulsion was needed. The propeller (called a “screw”) was the answer, allowing naval steam to come into its own. Construction of the prototype screw sloop Princeton began in 1841, before America’s first sidewheel warships even went into service. The Navy built only eight more deepwater sidewheelers before the famous 1854 class of six screw steamers (led by the Charlestown-built Merrimack) made the cumbersome vessels a footnote in naval history. With the advent of the propeller, enough problems were solved that auxiliary steam power became feasible in warships. On an 1858 cruise from Honolulu to Acapulco, Merrimack steamed only three days out of 32.

Merrimack, whose subsequent adventures we have already followed, was in the tradition of large American frigates like Constitution. While its engines were never very dependable, Merrimack was an excellent sailer, powerfully armed, and on its inaugural European cruise inspired Britain to build similar vessels with better engines.

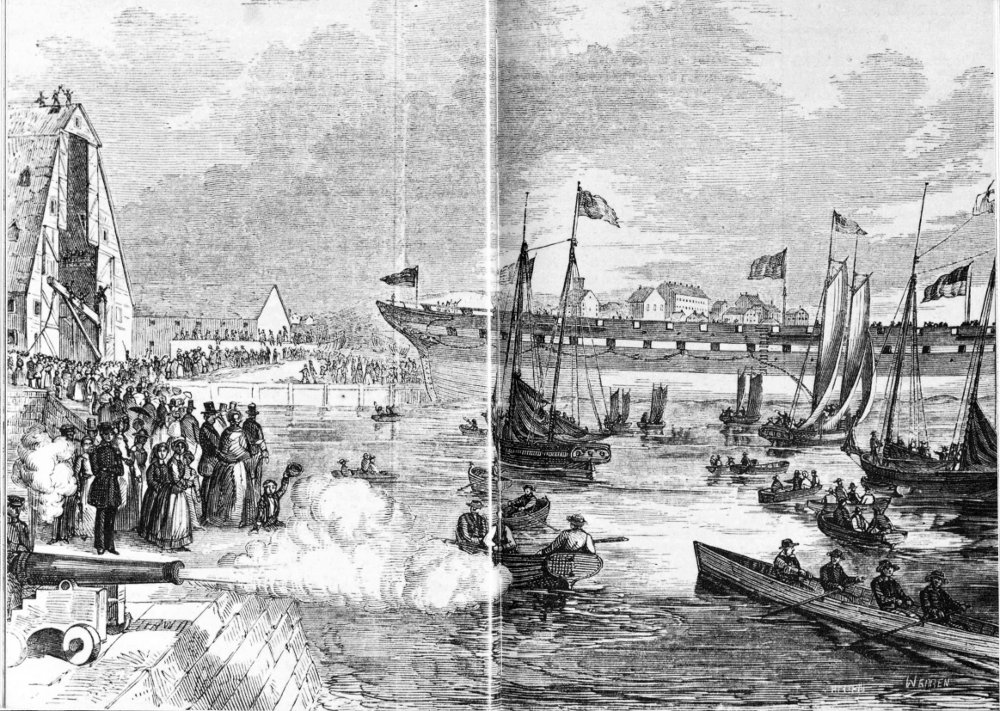

Merrimack is launched at Charlestown in 1855; Cumberland was built in the same shiphouse in 1842.

The screw sloop Hartford, launched at Charlestown in 1858, was one of a follow-up class of steamers. (These and other screw steamers of the ’50s were all frigates and sloops; no steam ship-of-the-line was built at Charlestown or any other yard. As we have seen, the era of such large wooden ships was over by the time the Navy was converting to steam.) These were smaller vessels with a shallower draft—better suited to coastal and river operations. As Rear Admiral David G. Farragut’s flagship in victories at New Orleans and Mobile Bay, Hartford was perhaps the most celebrated steamer in the Union Navy.

With propellers, even the most hidebound captains could appreciate the better maneuverability steam gave them during combat. Gradually the tactical roles of steam and sail were reversed, with increasingly efficient and dependable steam engines officially becoming the primary power source and sail the auxiliary. As a matter of economy, however, American vessels continued to use sail whenever possible on long-distance cruises.

Steam technology demanded a whole new set of skills of Charlestown’s mechanics. When the steam battery Fulton II docked there in 1839, the yard could repair only the vessel’s wooden components, having to contract work on the engine to local companies. But by 1845 yard personnel could fully service the screw sloop Princeton. While some carpenters may have made the transition, it is more likely that most of those working with steam machinery had a background in the field.

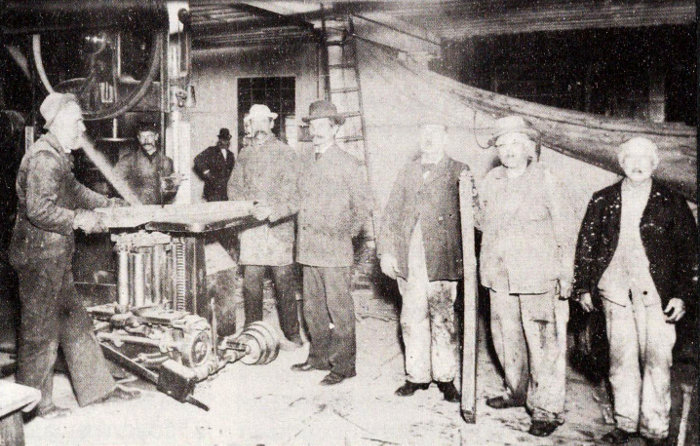

As the yard adapted to the new age, it underwent a decade of modernization and quickened production preceding the Civil War. The dry dock was lengthened; gas lights were installed; the yard began manufacturing wire rope in 1857. But the most important improvement was a state-of-the-art machine shop—its 240-foot stack long a landmark at the yard—that replaced the old smithery in 1859. It contained such equipment as a machine that could plane a metal surface 10 feet square and a huge lathe capable of handling iron propeller shafts 35 feet long. The facility also helped the yard to incorporate a new technology dramatized (though not introduced) by C.S.S. Virginia: ironcladding.

Sinking of large warships had rarely occurred in naval battle. Solid shot either bounced off thick wooden hulls or left a small, patchable hole. So warships normally just blasted away at each other until one of them, casualties mounting and its deck and rigging a shambles, hauled down its colors. Yet Virginia had sunk or caused to eventually sink two of them in two hours. Its ironcladding allowed it to get close enough to Cumberland to use an ancient but still effective technique, ramming, and close enough to Congress to pound the ship at close range with its broadside shot and big rifles. While ramming would not remain a tactical option, ironcladding was universally adopted as every naval power raced to design hulls that could withstand ever more powerful explosive shells fired from rifled guns (see pages 42-43).

As in every war, technology helped shape strategy in the Civil War and strategic considerations helped determine how new technologies were applied. The Navy’s major role in the war effort was to blockade some 3,500 miles of Southern coastline. The South’s blockade runners were typically the most advanced examples of British shipbuilding, steam-powered sidewheelers that were often iron- or steel-hulled. In the first year of the war, only about one in eleven of these runners were caught (partly because sidewheelers were still faster than screw steamers), and the Union Navy continued to build, borrow, and buy every vessel it could to strengthen the blockade.

Continues on page 36

When steam was introduced as an auxiliary naval power source in the 1820s, paddle-wheels were the initial method of propulsion. In the late 1830s engineers began working with propellers—“screws” in naval terminology. Each technology had its partisans: the sidewheel provided greater combat maneuverability, was suited to riverine warfare, and presented no problems of leakage, as did the screw’s underwater shaft hole. However, the exposed wheels were vulnerable during combat, ate up deck space needed for guns, hindered sail handling, and created more drag than a screw when the vessel was under sail. The launching of the screw warships H.M.S. Rattler in Britain and U.S.S. Princeton in the United States in 1843 signaled the coming ascendancy of screw propulsion. In the historic 1845 tug-of-war between Rattler and an otherwise-identical sidewheeler, the greater efficiency of the screw was publicly confirmed.

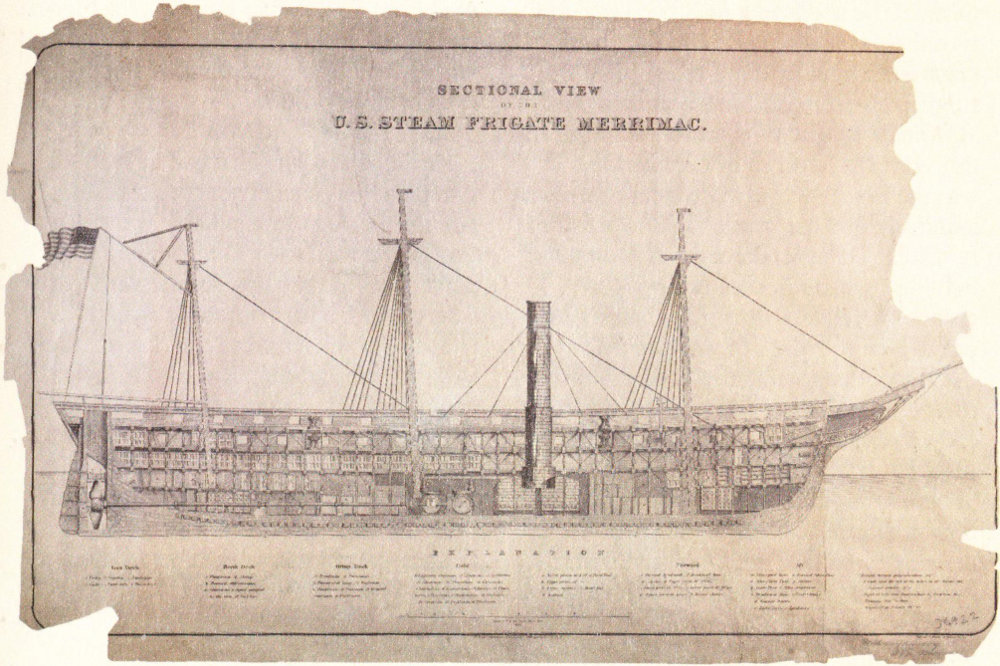

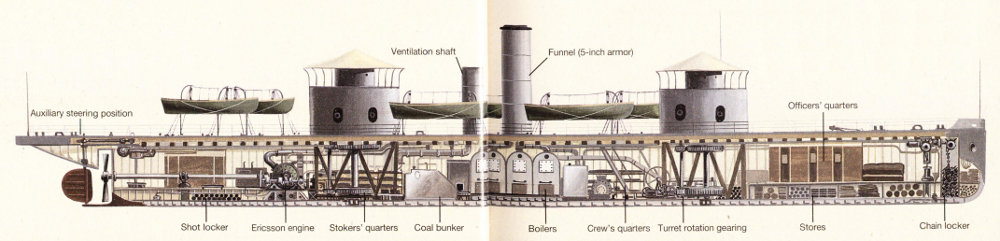

SECTIONAL VIEW OF THE U.S. STEAM FRIGATE MERRIMAC.

1857 inboard plan of screw frigate Merrimack. Screw could be hoisted into a well to reduce drag when the vessel was under sail.

Sidewheels: good maneuverability, but vulnerable above the water.

The screw: more efficient, and protected below the waterline.

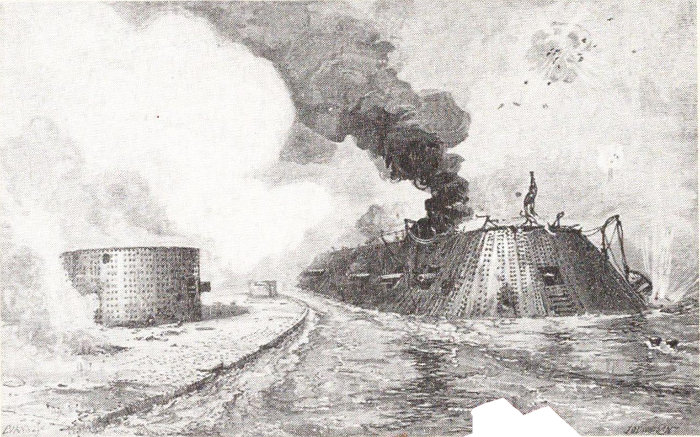

Thus when naval officers learned of the conversion of Merrimack into an armored blockade-breaker, they were understandably worried. In the debate over the type of vessel the Navy should develop to counter the Southern threat, John Ericsson’s proposal for a turreted, shallow-drafted coastal ironclad won out over larger, oceangoing designs with traditional broadsides. His ironclad, called U.S.S. Monitor, was the prototype of the turreted ironclad class named after it. (While monitors and Virginia-type ironclads continued to meet the needs of a mostly coastal and riverine naval war, two broadside ironclads were built by the Union. One of them, New Ironsides, was quite effective.)

Monitor fought Virginia to a standoff the day after the latter sank Cumberland. It was the first clash between steam-powered ironclads, and the world took notice. Captain John Dahlgren, creator of Monitor’s two big guns, put it succinctly: “Now comes the reign of iron—and cased sloops are to take the place of wooden ships.”

It did not happen immediately: Monitor-class iron hulls were not very seaworthy. (Monitor sank in late 1862 while being towed during a storm off Cape Hatteras.) Wooden ships under both sail and steam power continued to fight the Civil War’s deepwater battles, but Dahlgren’s words came true after the war. The evolving iron, and then steel, warship incorporated elements from both ironclads: the deeper hull and superstructure of Virginia and, rather than multiple-gun broadsides, a few large guns in revolving Monitor-type turrets that allowed the guns to be trained without turning the entire vessel.

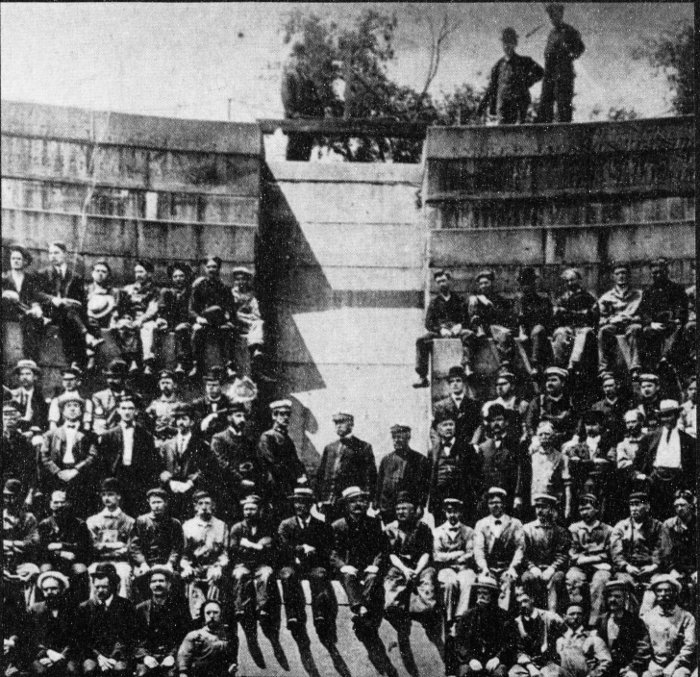

Only four monitors were built by navy shipyards, but officers considered them the best produced during the war. Monadnock, a double-turreted monitor built at Charlestown, was generally thought the best of the lot and the only one of this class to see action. After the war, it proved its unusual seaworthiness by voyaging around Cape Horn to San Francisco.

Other than Monadnock, ironcladding work at the Charlestown yard was performed on vessels built elsewhere, although the workers clad with iron the bulwarks of some of the double-ended sidewheelers built there. These vessels, a temporary reprieve for naval sidewheel technology, were designed for the narrow, shallow rivers of the South, allowing the “brown-water” Navy to reverse direction without turning around. The Charlestown yard built five double-enders—the biggest class constructed there during the war and, with those built at other yards, the biggest class of ships produced in the United States before World War I.

The Charlestown yard had in 1858 initiated its first machinist apprenticeship, acknowledging the inevitable transformation of the yard’s work. Steam had somewhat prepared the way for the yard’s artisans to work with iron: those already trained as boilermakers could adapt their skills to ironcladding. But increasingly the trades related to steam machinery and ironcladding were formalized with titles and apprenticeships. Through the 1850s and ’60s, machinists, iron moulders, and boilermakers accounted for an increasingly large part of the workforce: from a total of 26 (3 percent) in 1854 to 371 (19 percent) in 1866. But even though such trades were necessary in the yard by the mid-1860s, they were still in the minority and were paid less, considered less exacting and more easily mastered than the old wooden ship trades.

Samuel Cochran, a longtime employee at Charlestown, recalled later in life that when he arrived at the yard as a young man during the Civil War “the majority of the men employed were ship carpenters and joiners and most of the tools they used were cross cut saws and axes.” His own job was to turn the grindstone on which they were sharpened.

Cochran went on to paint a vivid picture of the yard during the war years when some 3,000 workers held jobs there: the 37 ordnance workers who had the dangerous job of retrieving powder from the magazine, donning canvas slippers to reduce the chance of sparks; the clandestine barrels of liquor in cellars, complete with drinking straws; the yard “politicians” who owed their jobs to patronage; sawyers in their six-foot-deep sawpits; the sailors (“Jackies”) on the receiving ships finding new ways to get extra grog on board.

A minor labor grievance in 1861 illustrates how the exigencies of war changed the working atmosphere at the yard and reduced the workers’ leverage. As it had in 1852, the government decided that yard employees should work sunrise to sunset from September to March, thus bringing their hours in line with those of private yard workers. Again the workers protested, although they continued to work, stating in their petition that they had no desire to hinder the government’s campaign to “crush out a foul rebellion.” This time the Navy made no concessions. Two strikes in 1862 over the same issue were half-hearted and futile; the longer hours remained in effect.

The sense of urgency and focus engendered by war and the accelerated pace of technological change pushed the yard to extraordinary levels of production. So it was not surprising that with the coming of peace the activity here and at other yards fell off. But the drop was precipitous. At war’s end, in sheer numbers and in engine technology, the U.S. fleet compared favorably with those of the European powers. In the weeks after Appomattox, however, the fleet shrank dramatically and continued to decline thereafter. In the postwar economic and political climate, the government’s priorities shifted. Massive funds were needed for reconstruction of the southern states and for war-deferred developments of the nation’s interior. The Navy would have to wait.

European navies, though, were riding the new wave of technology. In the 1870s their warships began to shed their sailing rigs as steam power became routine technology. But in America the old guard reasserted itself in peace, and there was a reaction against steam. After 1869, all naval vessels, steam or not, were required to have “full sail power,” and captains were on notice that they would pay for any coal they consumed other than for emergencies. Four-bladed propellers were replaced with two blades to reduce drag when under sail—with a corresponding loss of steaming efficiency.

As the British and European navies rapidly converted to lighter and stronger iron and then steel hulls on their largest ships, virtually all U.S. vessels built in the 1860s and ’70s were wooden-hulled (although some of these contained iron bracing). Even as late as 1885, the Army and Navy Journal asserted that “a staunch, fast wooden vessel is still the best for cruising purposes.” But while wooden-hulled U.S. naval vessels were generally acknowledged to be fine examples of their kind, many were well past their prime: Independence, for example, flagship of the first Mediterranean squadron, had been a receiving ship at Mare Island Navy Yard in California since 1857.

It was not only romantic tradition that kept naval shipbuilding in its antebellum condition. Burning coal in warships cost money; the wind, if not as dependable, was free. Sails continued to make good sense on long-distance cruises. America still had no foreign coaling stations to support a distant steam fleet, and isolationist sentiment hindered their acquisition.

Marines guard the entrance to Charlestown Navy Yard in 1874. The gate no longer exists, but the building at right, dating to 1813, still stands.

Workers in the gun park, 1890s, load cannon and cannonballs onto a cart. Dry dock and carpenter shop can be seen in the background.

A baseball team of yard workers poses for its picture in front of the machine shop, about 1905.

For the same political and strategic reasons, America’s was a cruising navy, made up of ships not intended for naval battle but for scouting, showing the flag, and commerce raiding. Wooden hulls sufficed for such roles. The government and private enterprise continued to look inland, and iron was used instead for rails and bridges to speed westward expansion. In any case, American metallurgy lagged behind that of Britain, while diminishing timber supplies made British designers look to alternate hull materials—not the case in the United States.

If the Navy in general and navy yards in particular declined in the 1870s, Charlestown’s relative position was strong. From after the war to the early ’80s, Charlestown was the second most productive yard after New York. A large number of vessels came to the yard for repair—mostly wooden vessels with steam engines. To service these ships, Charlestown in the 1870s continued to hire more machinists, engineers, boilermakers, and patternmakers while retaining a solid contingent of wooden ship tradesmen.

Few new vessels were launched from any yard in this period. In the last three decades of the century Charlestown constructed three—all in 1874. The screw sloops Vandalia and Adams were launched on successive days, the latter (constructed at the yard by a private shipbuilder) being the last wooden warship laid down by the Navy. A few months earlier the yard had launched its first iron-hulled vessel, the torpedo ram Intrepid. But it was not part of a general transition to iron. The Navy built only four other iron-hulled vessels, none of them major warships. The 1874 launchings at the Charlestown yard reflected the U.S. Navy’s lukewarm and indecisive response to changing naval technology.

The yard by 1880 had changed little since the improvements of the ’50s. It had greater capacity now with four shiphouses and two building ways, but the physical plant also reflected the technological limbo into which the Navy had settled. There was a coaling wharf to service steamers and a new rolling mill for iron plate. But the large sail loft and wet timber dock were still very much in use, and oxen still pulled the timbers from dock to sawmill.

The dry dock was occupied by Hartford in 1879-80. It was receiving new engines after long tours in the 1860s and ’70s on Far Eastern stations. Its two-year stay in the dock—longer than normally needed for such a job—testified to the general state of affairs. The shrinking fleet had reduced the work load and slowed the pace at the yard. Under such conditions it was cheaper to use a smaller crew and take longer to do the work.

That the Navy was willing to give this much attention to so honored a ship as Hartford is understandable. But it symbolized the fact that it was only putting off the inevitable—modernization. By the early 1880s the U.S. Navy floundered in the wake of Europe’s navies—the victim of limited funds, tradition-bound officers, political neglect, and popular indifference. There were but 48 decaying vessels in commission, most at a Civil War or even prewar level of technology. On top of the other problems, the corruption associated with the administration of Ulysses S. Grant had touched the Navy—including the Charlestown yard—in the late 1870s. Here, as at other yards, politicians found jobs for men who were then expected to vote as they were told. It is easy to see why one historian has characterized this period as the “low water mark” of the Navy.

There were rumors of yard closings. Nothing happened immediately, but less and less work came to Charlestown. Then, in 1883, the Navy suspended all repair and construction work at the yard and reduced its role to manufacturing. So began hard times at Charlestown Navy Yard, during which it came perilously close to shutting down altogether.

Continues on page 45

Before dry docks came into use in the 16th century, the only way to service a ship’s hull was to “careen” it—heave it over on its side, still floating (see pages 6-7), or laying in the mud at low tide. It was difficult and time-consuming and put great strain on the hull. The answer was the dry dock. The concept is simple: float the vessel into a three-sided basin, then close the seaward end and remove all the water. The vessel settles on a cradle, its hull accessible. To undock: reflood the basin, open the seaward end and float the vessel out. But the concept’s execution required a finely-engineered complex of masonry, engines, pumps, reservoir, tunnels, culverts, valves, and gates—in effect a huge well-coordinated machine. The Charlestown dry dock and the one built concurrently at Norfolk, Va., were the first such naval structures in the country. Six years under construction, the Charlestown dock was inaugurated in 1833 with the docking of Constitution. It was 305 feet long (extended in 1856 to 370 feet and again in 1948 to 398 feet), 60 feet wide, and 30 feet deep—the Navy’s largest dry dock until the 1890s. It took the original eight pumps four to five hours to empty the tremendous basin. Other operations were to some extent governed by Boston Harbor’s 10-foot tide. After the dock was enlarged the water level did not rise as rapidly as the tide during filling, so it took two high tides to do the job. For emptying and filling, the caisson was filled with water and sunk in place between grooves in the dock walls. For docking and undocking, the caisson was emptied and floated out of the way on the high tide (see inset). It took 24 men working hand pumps for an hour and a half to expel the water from the caisson. The original wooden caisson lasted until 1901, when the steel caisson still in use today was completed.

1. After its 1858 launching, U.S.S. Hartford is docked for installation of its steam engine. To empty the dock, workers opened the discharge gates (A), releasing water to flow (red arrows) down discharge culverts (B) (on both sides of dock) to fill the reservoir (C).

2. The pumphouse (D), its steam engine driving two pumps in underground wells (E), pumped the water from the dock via the reservoir and sent it through an underground culvert back to the harbor.

3. To fill the dock, the discharge gates were closed and the filling gates (F) were opened. Water flowed (green arrows) first to wells (G), then into the dock through the same culverts used to empty it.

The clash of ships at sea embodies the ongoing technological battle between arms and armor: between deploying ever more destructive weapons and contriving ways to withstand them. As long as solid shot was the only way to attack a ship’s hull, heavy timbers were usually armor enough. Big wooden warships were rarely sunk by even the heaviest shot. (Constitution is a particularly good example.) But the rules of the game changed with the coming of more powerful and more accurate guns, and especially with the development of the practical explosive shell in the 19th century. A shell could open a gaping hole in a heretofore impervious wooden hull. By 1860 France and then Britain had begun building ironclads. In Britain, especially, the rising cost of diminishing timber supplies was another incentive to experiment with iron, both as armor and for structural elements of the hull. But in the United States, wood was still cheaper than iron. Also, though the country had earlier experimented with ironcladding, the Navy resisted the new technology, putting emphasis on speed rather than armor. But it quickly made up for lost time after the beginning of the Civil War. The Confederacy took the lead, for the same reason that the United States had built “super-frigates” at the end of the 18th century. A country that could afford only a small navy had to build state-of-the-art warships. The blockade-breaker C.S.S. Virginia showed the lethal effectiveness of its ironcladding on its first outing (see page 28). The next day U.S.S. Monitor fought Virginia to a draw in the first battle between ironclads (right). The encounter spurred European navies to accelerate their ironclad programs, but new breech-loading rifled guns were demonstrating greater armor-piercing ability. In response iron, and then steel, armor was made thicker and harder, leading to still more powerful guns. The gun designers generally stayed a step ahead, with the biggest guns able to penetrate the thickest armor.

Inside a Turret

The monitor Monadnock (all turreted ironclads were designated monitors) was built at the Charlestown yard in 1862-63. The only monitor built there, it was quite successful, described by Admiral David Dixon Porter as “the best monitor afloat.”

Layers of Protection

Light battleship U.S.S. Maine on its first cruise in 1895. Maine, part of the new steel navy, blew up in Havana Harbor in 1898 under circumstances still unclear. The resulting Spanish-American War ended Spain’s days as a colonial power and made a popular hero of Theodore Roosevelt, who resigned as Assistant Secretary of the Navy to serve in Cuba.

On first looking into the cavernous interior of Shiphouse I, a visitor during the winter of 1884 would have gotten the impression that Charlestown was a busy shipyard. Workers crawled over the almost completed ship-of-the-line Virginia, swinging hammers, sawing, pumping hydraulic jacks—apparently applying the finishing touches. But behind the house, growing piles of four-foot lengths of wood told a different story. The workers were breaking up the old 74. Virginia had occupied the shiphouse for more than 60 years, through all but the first two of the yard’s launchings. Back in 1824, Virginia had been within two months of making its own trip down the ways. Now its day had passed, and its great timbers were being reduced to firewood and sold at auction.

Outside the shiphouse, very few workers could have been found among the silent buildings. Charlestown was a moribund yard, barely functioning since its repair and construction duties had been suspended the year before. Only the manufacturing divisions still showed signs of life. In 1886 the yard would be officially converted to a facility that manufactured equipment—especially rope—for vessels built and repaired elsewhere.

The yard was also stripped of much of its equipment and ordered to sell the vessels in ordinary. Repair work fell to an all-time low: between the 1883 docking of the Charlestown-built double-ender Talapoosa and 1890, the dry dock was used exactly five times to do repair work for the U.S. Navy—once on the yard tug and four times on the floating gate for the dry dock.

Joiner Shop foreman George W. Burroughs, about 1901.

New construction was out of the question. The yard had known for years that the vessels already in the shiphouses and on the building ways (labeled “Rotten Row” by a local newspaper in 1882) would never be launched. So it came as no surprise that the order closing the yard also condemned Virginia, two wooden steamers, and a monitor—the latter three laid down during the Civil War. Still, it was disheartening that in the early 1880s a yard that had built and repaired ships was reduced to taking them apart.

At least the dismantling of vessels provided employment for the workers, who at this point felt quite vulnerable. Throughout the 1880s, “suspension” (being laid off) was always hanging over their heads. More than 500 men were employed at the yard when work was halted in mid-1883. There were around 300 by the end of the year and their ranks continued to thin, averaging less than 200 until 1888—most of them ropemakers, machinists, laborers, and watchmen.

Until World War I, jobs connected with supply would remain more stable than those related to construction and repair. In the late 1880s and ’90s, managers found ways to transfer men in the latter trades to other divisions within the yard in order to keep their services on call. But in the early ’80s the yard could find virtually no work for men skilled in the craft of wooden shipbuilding—formerly the elite of the workforce. After Virginia and the other vessels had been turned into stacks of wood, those who had done the work were sent home.

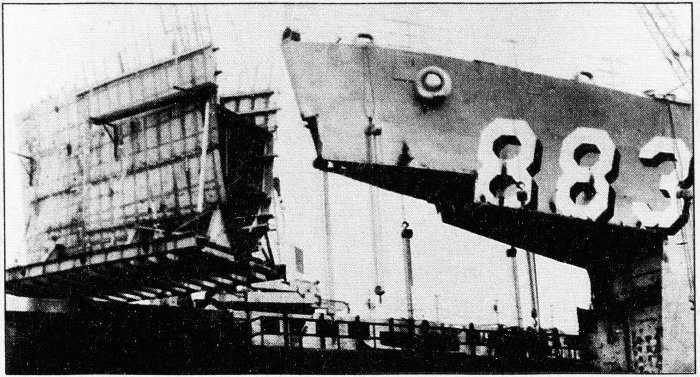

Now let us look ahead some three decades to 1917, by which time we find a yard dramatically transformed. Eleven wharves described a great arc at the confluence of the Charles and Mystic Rivers. The familiar old shiphouses had been replaced by a large shipbuilding ways and steel plate storage yards. The timber basin that had 47 long dominated the center of the yard was gone, replaced by a new dry dock twice as long as the first one. The other timber basin at the east end of the yard had been filled in and was now the site of gas and oil tanks, a locomotive shed, and a gas plant for acetylene torches.

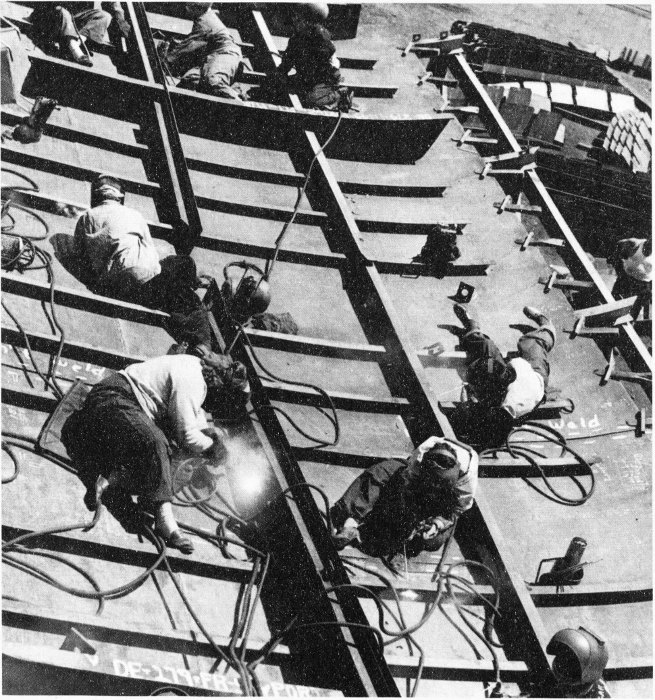

It was a vital place, showing an intensity not seen since the Civil War. In fact it was again a wartime yard: after almost three years of neutrality the United States had entered the global conflict that was later called World War I. Some 4,500 workers worked two ten-hour shifts or around the clock in three eight-hour shifts, answering to a steam whistle instead of the bell that had summoned 19th-century yard workers. The wharves and docks were crowded with three- and four-stacker steel ships, some carrying the towering cage masts that were a short-lived experiment of the period. On the building ways, workers had laid the keel of the fuel ship Brazos.

Electric lights illuminated the thousands of men working on ships through the night. Vessels under repair were alive with the flare of welding torches and the tattoo of pneumatic rivet guns. Over them moved the arms of great cranes, including a 150-ton floating derrick and a colossus that traveled on tracks between dry docks. Materials and equipment were transported by yard locomotives that had replaced the oxen (although horses still did service). A mechanized coaling plant near the old dry dock helped ease the dirty and arduous task of fueling ships. But it was apparently undependable, and at times ships were coaled the old way.

Charlestown’s main responsibility was repairing the warships of a greatly enlarged fleet: steel destroyers, armored cruisers and battleships, submarines, and wooden sub chasers. The yard also outfitted and commissioned new vessels, converted civilian vessels to wartime use, armed merchantmen, and altered seized German passenger liners to transport U.S. troops to France.

More work came to the yard in 1917-18 than in any other comparable period in its history before World War II. Some 450 vessels were serviced during those two years. In addition Charlestown was a supply depot and embarkation point. In all, an average of 50 ships a day arrived at or departed from the yard during the war.

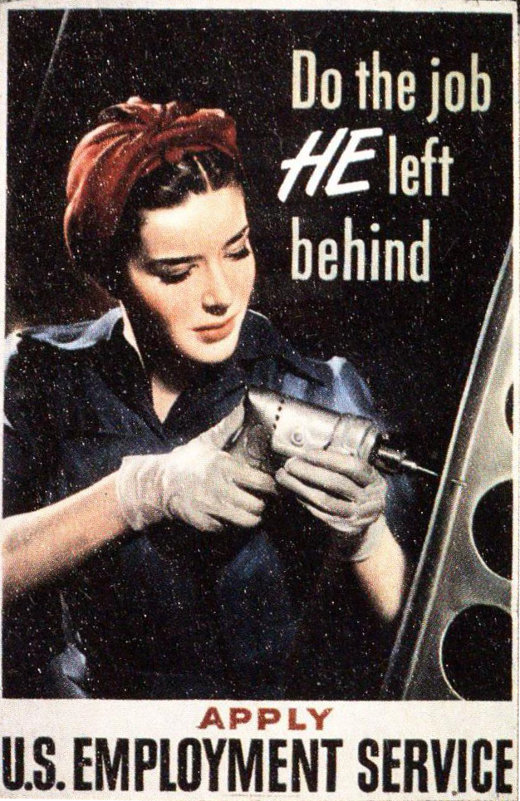

By 1918 some 10,000 skilled workers, laborers, and clericals worked at Charlestown. Reflecting the growth of the labor movement over the last three decades, many of them belonged to trade unions (although they could neither strike nor be represented by the unions in wage negotiations). Women working at the yard were mostly naval yeomen, but a few worked as radio and telephone operators, radio electricians, and ropewalk machine tenders.

Yard employees worked in 17 trade shops, the names of which characterized the needs of modern steel shipbuilding: Shipfitters (including riveters, drillers, welders, sheet metal workers); Electrical; Pattern (for cast metals); Chain; Copper/Pipefitting; and other skills employed in raising a steel ship.

Some of the old familiar shops survived in reduced or altered roles. The sail loft now produced mostly canvas bags, pea jackets, and hammocks. The riggers loft had become a versatile shop responsible for an array of shipyard tasks. They still worked aloft on stacks and steel masts; directed dry docking and crane operations; prepared shipways for launchings; dove beneath ships in hardhat diving suits; and continued to do the traditional rigger’s handiwork, such as the braided rope fenders that protected ships’ hulls and the fancy leatherwork and ropework still common on naval vessels. The workers in the joiner shop worked on the small wooden boats built at the yard, but spent much of their time making shipboard furniture. The ropewalk continued to turn out the large quantities of rope still needed on steel ships.

These young women were working as civilian clerks for the Navy when the U.S. entered World War I. Overnight they became Yeomen-F (female) naval personnel. (Yeomen is the naval term for clerical workers.)

Joiners were skilled workers in wood and traditionally the elite of the yard workforce. Even in the early days of steel ships, they remained among the highest paid of the workers. Here joiners are photographed in their shop, about 1897.

Yard’s floating crane, shown here in 1913, could lift 150 tons. Dry Dock 1 is visible in left background.

The traditional shipyard hierarchy was virtually unchanged: the crews of mechanics, apprentices, and laborers were headed by leadingmen; several leadingmen were supervised by quartermen; and the quartermen were under a chief quarterman or they answered directly to the master who headed the shop.

Unlike the hard times of the 1880s, the employees at Charlestown had reason to feel secure. Civil Service reforms of the ’90s had already gone a long way toward making merit, not political advantage, the criterion for hiring and firing. And now, in the hour of war, the Navy wanted to keep its shipyard workers. In the months before the United States entered the conflict, officials had worried that employees swept up in the popular sentiment for preparedness would enlist. Secretary of the Navy Josephus Daniels declared it the “patriotic duty” of the workers to remain at the yard, asserting that “their services to their country ... [are] as important as if they were actually in the field.”

When the draft was initiated in 1917, the Navy responded by gaining exemptions for crucial classes of yard workers such as supervisors, draftsmen, and skilled mechanics and their helpers. The military draft gave new meaning to the yard’s “six-muster” rule, by which any worker missing six successive roll calls for any reason could be fired. One week after any worker was dismissed, the yard informed his draft board.

The demand for workers and the boosted war economy drove up wages. No doubt prompted by this incentive and by the exemption policy, some 240,000 men applied for work at the yard in 1917-18. But while Charlestown didn’t lack for applicants, filling the most skilled positions was a continuing problem. To remedy this (and to help workers gain exemptions), the yard cut a year from the term of apprenticeship and established a trade school to train unskilled workers as mechanics.

While World War I sped up Charlestown’s evolution from naval backwater to modern shipyard, other factors had set the process in motion. Time and expected technological advances accounted for some of it. But the transition was accelerated at the yard by a larger transformation of the Navy, prompted by the country’s position in a changing world and completed on the stage of the Spanish-American War.

Historians have tagged this transformation the “New Navy.” If we simply compare the numbers of the 1880 Navy, when its aging fleet of wooden vessels ranked 12th in the world, to that of the 1900 Navy, when there were in commission or on the stocks 17 steel battleships and a number of armored cruisers, the label “new” is certainly accurate. But there was more to this than simply building new steel ships to catch up to Europe. The Navy’s mission underwent a strategic shift in this 20-year period.

The early phase involved a strengthening of the Navy’s capacity to carry out its mission. For a century its job had been to defend the shores and to ensure that other navies allowed American merchant vessels free trade anywhere in the world. Its tactical traditions were one-on-one engagements and hit-and-run commerce raiding. But it was clear by the early 1880s that the U.S. Navy was inadequate for even these limited operations. Reformers could point to obvious deficiencies as European navies converted to armored steel hulls in the 1870s and ’80s. The old wooden navy had become a disgrace.

Powerful voices were raised in the House Naval Affairs Committee, and in 50 1883 Congress appropriated money for the steel cruisers Atlanta, Boston, and Chicago, and the dispatch vessel Dolphin. These vessels could still spread a large area of sail, and by European standards were not formidable, but the so-called “ABCD” ships were the core of the New Navy, the first small step towards making the United States a true sea power.

For Charlestown, they were a mixed blessing. The New Navy’s need for maintenance and repair bode well for the future, but the immediate effect was devastating. For the same legislation that authorized new ships also established a new criterion for repairing existing vessels. Only repairs that cost less than 30% (later reduced to 20%) of the cost of a new ship of the same size could be performed. This freed up funds to build the new ships, but it also meant so little work for shipyards that both repair and construction work at Charlestown and three other yards was suspended.

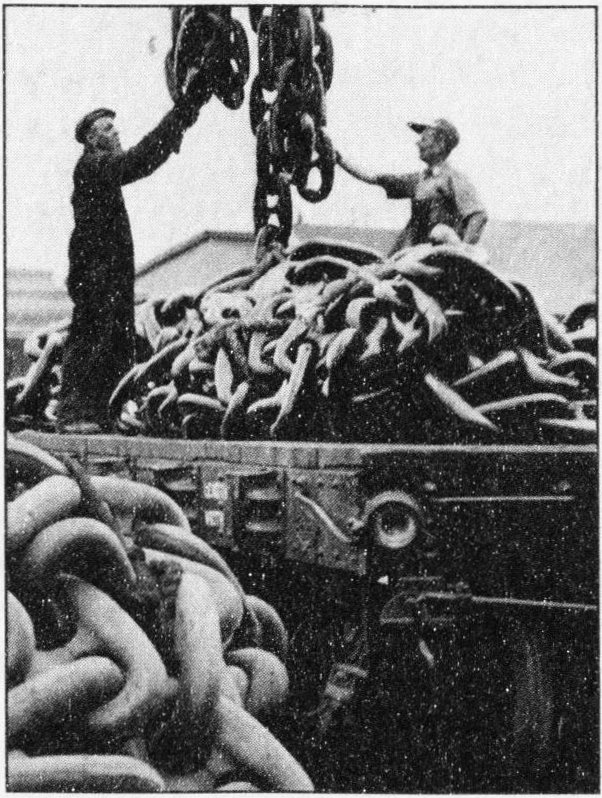

In its new role as manufacturing center, the yard kept the ropewalk, rigging loft, and sail loft open. The forge began producing chain and anchors for the new steel ships. But even these activities were sporadic until later in the decade. A survey done one March day in 1884 showed that the ropewalk was spinning rope for Dolphin—literally the only thing done that day to help put warships to sea.

During the worst years of the 1880s the ropewalk almost singlehandedly kept the yard alive. It made itself an indispensable facility by supplying virtually all of the Navy’s rope. Other shops followed its lead, and by 1890 the Charlestown yard had become an important general manufacturing center, the only naval shipyard producing rope, sail, anchors, and chain. It was still unable to service ships, however. In August 1890 Chicago was directed to the yard for repairs, only to turn back because the old dry dock wasn’t in good enough condition to accept the steel cruiser. “Repairs to engine bolts” for Boston typified the kind of task the yard could perform.

But 1890 also marked the beginning of the yard’s rebirth. Congress appropriated $152,000 for new machine tools and modernization of Charlestown’s crumbling facilities. It wasn’t enough to remake the yard, but it was a start. It was also the year that Commander Alfred Thayer Mahan, president of the Naval War College and one-time aide to the Charlestown Navy Yard commandant, published The Influence of Sea Power Upon History, 1660-1783. This important book helped to stimulate the world-wide buildup of naval forces prior to World War I. His thesis (greatly simplified) was as follows: A combination of geography, population size, and “national character” makes a great seafaring nation. Essential to the continued well-being of such a nation is a government that actively promotes a vigorous maritime commerce. “Sea power”—command of the sea lanes—protects this commerce. Only large concentrated fleets of capital ships able to engage and destroy the enemy’s navy can create and maintain sea power.