An Old-Fashioned Shoemaker. Frontispiece.

A MANUAL OF SHOEMAKING

An Old-Fashioned Shoemaker. Frontispiece.

A MANUAL

OF

SHOEMAKING

AND

LEATHER AND RUBBER

PRODUCTS

BY

WILLIAM H. DOOLEY

PRINCIPAL OF THE LOWELL INDUSTRIAL SCHOOL

ILLUSTRATED

BOSTON

LITTLE, BROWN, AND COMPANY

1912

Copyright, 1912,

By Little, Brown, and Company.

All rights reserved.

Published, September, 1912.

The author was asked in 1908 by the Lynn Commission on Industrial Education to make an investigation of European shoe schools and to assist the Commission in preparing a course of study for the proposed shoe school in the city of Lynn. A close investigation showed that there were several textbooks on shoemaking published in Europe, but that no general textbook on shoemaking had been issued in this country adapted to meet the needs of industrial, trade, and commercial schools or those who have just entered the rubber, shoe, and leather trades. This book is written to meet this need. Others may find it of interest.

The author is under obligations to the following persons and firms for information and assistance in preparing the book, and[vi] for permission to reproduce photographs and information from their publications: Mr. J. H. Finn, Mr. Frank L. West, Head of Shoemaking Department, Tuskegee, Ala., Mr. Louis Fleming, Mr. F. Garrison, President of Shoe and Leather Gazette, Mr. Arthur L. Evans, The Shoeman, Mr. Charles F. Cahill, United Shoe Machinery Company, Hood Rubber Company, Bliss Shoe Company, American Hide and Leather Company, Regal Shoe Company, the publishers of Hide and Leather, American Shoemaking, Shoe Repairing, Boot and Shoe Recorder, The Weekly Bulletin, and the New York Leather Belting Company.

In addition, the author desires to acknowledge his indebtedness to the great body of foreign literature on the different subjects from which information has been obtained.

| PAGE | ||

| Preface | v | |

| CHAPTER | ||

| I. | Fundamental Shoe Terms | 1 |

| II. | Hides and their Treatment | 4 |

| III. | Processes of Tanning | 21 |

| IV. | The Anatomy of the Foot | 77 |

| V. | How Shoe Styles are Made | 93 |

| VI. | Departments of a Shoe Factory | 103 |

| VII. | McKay and Turned Shoes | 144 |

| VIII. | Old-fashioned Shoemaking and Repairing | 162 |

| IX. | Leather and Shoemaking Terms | 177 |

| X. | Leather Products Manufacture | 218 |

| XI. | Rubber Shoe Manufacture and Terms | 228 |

| XII. | History of Footwear | 250 |

| Index | 281 |

| An Old-fashioned Shoemaker | Frontispiece |

| Facing Page | |

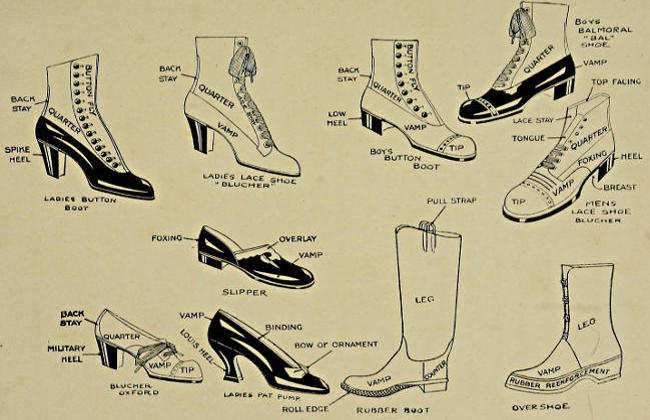

| Names of the Different Parts of Foot Wear | 2 |

| Green-salted Calfskin | 12 |

| Tanning Process | 24 |

| Tanning Process, showing Rotating Drums | 28 |

| Sole Leather Offal | 34 |

| Bones and Joints of the Human Foot | 78 |

| The Different Parts of the Foot and Ankle | 78 |

| A Last in Three Stages of Manufacture | 98 |

| A Modern Shoe Factory | 104 |

| A Skin Divided before Cutting | 112 |

| Cutting Leather | 116 |

| Goodyear Stitching | 116 |

| Stock Fitting Room | 120 |

| Lasting | 124 |

| Welting | 124 |

| Rough Rounding | 128 |

| Edge Trimming | 128 |

| Leveling | 132 |

| [x]Heeling | 132 |

| Sole Scouring | 136 |

| Heel Shaping | 136 |

| Ironing | 140 |

| Packing | 140 |

| Cross Sections of Welt Shoe and McKay Sewed Shoe | 144 |

| Stitching | 148 |

| Tacking | 148 |

| Cross Section of Standard Screwed Shoe | 160 |

| Side of Leather divided as to Quality | 168 |

| Cross Section of McKay Sewed Shoe | 200 |

| Cross Section of Goodyear Welt Shoe | 200 |

| Crude Rubber | 228 |

| Washing and Drying | 232 |

| Calender Room | 234 |

| Cutting Room | 236 |

| Putting together the Parts of a Rubber Shoe | 240 |

| Heel-making Department | 242 |

| Parts of a Rubber Boot | 248 |

| Insole for Hand-sewed Shoe | 264 |

| Hand-sewed Shoe | 264 |

| Stitching Room of a German Shoe Factory | 276 |

Before explaining the manufacture of shoes, it is necessary to fix definitely in our minds the names of their different parts. Examine your shoes and note the parts that are here described.

The bottom of the shoe is called the sole. The part above the sole is called the upper. The top of the shoe is that part measured by the lacing which covers the ankle and the instep. The vamp is that section which covers the sides of the foot and the toes. The shank is that part of the sole of the shoe between the heel and the ball. This name is often applied to a piece of metal or other substance in that part of the sole, intended to give support to the arch of the foot. The[2] throat of the vamp is that part which curves around the lower edge of the top, where the lacing starts.

Backstay is a term used to denote a strip of leather covering and strengthening the back seam of the shoe. Quarter is a term used mostly in low shoes to denote the rear part of the upper when a full vamp is not used. Button fly is the portion of the upper containing the buttonholes of a button shoe. Tip is the toe piece of a shoe, stitched to the vamp and outside of it. The lace stay is a term used to denote a strip of leather reënforcing the eyelet holes. Tongue denotes a narrow strip of leather used on all lace shoes to protect the instep from the lacing and weather.

Names of the Different Parts of Foot Wear. Page 2.

Foxing is the name applied to leather of the upper that extends from the sole to the laces in front, and to about the height of the counter in the back, being the length of the upper. It may be in one or more pieces, and is often cut down to the shank[3] in circular form. If in two pieces, that part covering the counter is called a heel fox. Overlay is a term applied to leather attached to the upper part of the vamp of a slipper. The breast of the heel is the inner part of the heel, that is, the section nearest the shank.

If we examine our shoes, we will find that the different parts are composed of material called leather. The bottom of the shoe is of hard leather, while the part above the sole is of a softer, more pliable leather. This leather is nothing more than the hides of different animals treated in such a way as to remove the fat and the hair.

After the hides have been taken from the dead body of the animal, they are quite heavily salted to preserve them from spoiling. In this salted condition they are shipped to the tanneries.

The process or series of processes by which the hides and skins of animals are converted into leather is called tanning. The process may be divided into three groups of subprocesses as follows:—

Beamhouse process, which removes the hair from the hides and prepares them for the actual process of the tanning or conversion into leather; tanning, which converts the raw hide into leather; and finishing, which involves a number of operations, the objects of which are to give the leather the color that may be desired and also to make it of uniform thickness, and impart to it the softness and the finish that is required for a particular purpose.

Hides are divided roughly in the tannery, according to the size, into three general classes:—

(1) Hides, skins from fully grown animals, as cows, oxen, horses, buffaloes, walrus, etc. These are thick, heavy leather, used for shoe soles, large machinery belting, trunks, etc., where stiffness, strength, and wearing qualities are desired. The untanned hides weigh from twenty-five to sixty pounds.

(2) Kips, skins of the undersized animals[6] of the above group, weighing between fifteen and twenty-five pounds.

(3) Skins from small animals, such as calves, sheep, goats, dogs, etc. This last group gives a light, but strong and pliable leather, which may be used for a great many purposes, such as men’s shoes and the heavier grades of women’s shoes.

The hides, kips, and skins are divided into various grades, according to their weight, size, condition, and quality.

The quality of the hides not only depends upon the kind of animal, but also upon its fodder and mode of living. The hides of wild cattle yield a more compact and stronger leather than those of our domesticated beasts. Among these latter the stall-fed have better hides than the meadow-fed, or grazing cattle. The thickness of the hide varies considerably on different animals and on the parts of the body, the thickest part of the bull being near the head and the middle of the back, while at the belly the hide is thinnest.[7] These differences are less conspicuous in sheep, goats, and calves. As regards sheep, it would appear that their skin is generally thinnest where their wool is longest.

In the raw, untanned state, and with the hair still on, the hides are termed “green” or “fresh.” Fresh, or green hides are supplied to the tanners by the packers or the butchers, or are imported, either dry or salted.

Hides are obtained either from the regular packing houses or from farmers who kill their own stock, and do not skin the animal as scientifically as the regular packing houses, in which case they are called country hides. There are different grades of hides and leather, and these different grades are divided in the commercial world into the five following grades:—

(Raised on plain. Rough side suitable for soles.)

(Green salted)

Hides obtained from steers raised on Western farms are known as native steer hides.

Native cowhide (heavy) is hide weighing from fifty-five to sixty-five pounds, obtained from cows.

Native cowhide (light) is cowhide weighing under fifty-five pounds.

Branded cowhide is hide obtained from cows that are branded on the face of the hide.

Butts is a term applied to the part of the hide remaining after cutting off the head, shoulders, and strip of the belly.

Colorado steer hide is from Colorado steers, which are very light.

Texas steer hide comes in three grades, heavy, light, and extra light. The heavy[10] grade is very heavy because the animal is allowed to graze on the plains. That is the reason why it is heavier than the Colorado steer hide, which is raised on the farm.

Bull hide is divided into two classes, the regular hide and the branded grade. The branded grade usually is one cent a pound less than the regular.

Country hides are of three grades, Ohio Buffs, Ohio Ex., and Southern. The Ohio Buffs weigh from forty to sixty pounds. The Ohio Ex. weighs from twenty to forty pounds. Southern hides have spots without hair and other blemishes on them, due to the sting of insects. This makes the Southern hide inferior to the Ohio, Indiana, Michigan, and Chicago hides that have no such blemishes. Ohio Butt hides are the best, because in Ohio they kill a great many young calves, while in Chicago young cows (that have calved) are killed, causing the hide to be flanky.

The season of the year in which cattle[11] are slaughtered has considerable influence upon both the weight and condition of the hide. During the winter months, by reason of the hair being longer and thicker, the hide is heavier, ranging from seventy-five to eighty pounds, and gradually decreasing in weight as the season becomes warmer and the coat is shed, until in June and July it weighs from seventy down to fifty-five pounds, the hair then being thin and short. The best hides of the year are October hides, and short-haired hides are better for leather purposes than long-haired ones.

A thick hide which is to be used for upper leather is cut into sides before the tanning process is completed. This is performed by passing it between rollers where it comes in contact with a sharp knife-edge, which splits it into two or more sheets. Great care must be exercised in cutting the leather in order to have good “splits” (sheets of leather). A split from[12] a heavy hide is not as good as a whole of a lighter leather.

Butts and backs are selected from the stoutest and heaviest oxhides. The butt is formed by cutting off the head, the shoulder, and the strip of the belly. The butt or back of oxhide forms the stoutest and heaviest leather, such as is used for soles of boots, harness, etc.

Green-Salted Calfskin. Page 12.

Hides and skins are received at the tannery in one of three conditions, viz. green-salted, dry, or dry-salted. Very few hides are received by tanners in fresh or unsalted condition, salt being necessary to preserve them from decay. Green-salted hides are those that have been salted in fresh condition, tied up in bundles, and shipped to the tanner. Dry hides are those that were taken from the carcass and dried without being salted; these are usually stiff and hard. Dry-salted hides are hides that were heavily salted while they were fresh, and then dried. The hides and skins[13] that are received from the slaughterhouses of this country are almost invariably green-salted; those from foreign countries are green-salted, dry, and dry-salted.

It does not matter in what condition the hides are received or the kind of leather into which they are to be tanned; they all require soaking in water before any attempt is made to remove the hair or to tan them. The object of the soaking process, as it is called, is to thoroughly soften the hides and to remove from them all salt, dirt, blood, etc. Ordinary hides are usually soaked from twenty-four to forty-eight hours. Dry hides require much longer. The water should be changed once or twice during the process, since dirty water may injure the hides. Soft water is better than hard for this process. Where the water is hard, it is customary for the tanner to add a quantity of borax to it to increase its cleansing power and to hasten the softening of the hides.

When dry hides have become soft enough to bend without cracking, they are put into a machine and beaten and rolled, then soaked again until they are soft and pliable. It is very important that all the salt and dirt are removed during the process of soaking, as they injure the quality of the leather if they are not removed before the hides are unhaired. When the soaking process is completed, the lumps of fat and flesh that may have been left on by the butcher are removed by hand or by a machine, and the hides are then in condition to be passed along into the next process. The parts that cannot be made into leather, such as tails, teats, etc., are trimmed off before the hides are soaked. Large hides are cut into two pieces or halves, called “sides,” after they have been soaked.

For the purpose of taking the hair from the hides and skins, lime, sulphide of sodium, and red arsenic are used. Lime is sometimes used alone, but usually one[15] of the other two chemicals is mixed with it. The lime is dissolved in hot water, a quantity of either sulphide of sodium or red arsenic is added to it, and the solution is then mixed with water in a vat, the hides being immersed in this liquor until the hair can be easily removed. The action of the unhairing liquor is to swell the hides, then to dissolve the perishable animal portion and loosen the hair so that it can be rubbed or pulled off.

There are several different processes of unhairing the hides. Each tanner uses the process that will help to give the leather the qualities that it should have, such as softness and pliability for shoe and glove leather, or firmness and solidity for sole and belting leather. This is one of the most important in the series of tannery processes, and if the hides are not unhaired properly and not prepared for tanning as they should be, the leather will not be right when it is tanned and finished.

There is also a process of unhairing, called “sweating,” which softens the hide and loosens the hair so that it can be scraped off. In this process the hides begin to decay before the hair is loose; it is therefore a dangerous process to use and must be carefully watched or the hides will be entirely spoiled. Sweating is never used for the finer, softer kinds of leather. It is applied chiefly to dry hides for sole, lace, and belt leather. It is an old-fashioned process and is not used as much nowadays as some years ago.

The pelts of sheep are salted at the slaughterhouses and then shipped to the tannery. Here they are thrown into water and left to soak twenty-four hours to loosen the dirt and dissolve the salt. The pelts are next passed through machines that clean the wool, and any particles of flesh remaining on the inner or flesh side are removed. The pelts are then in condition to have the wool removed. As long as a sheepskin has the wool upon it, it is called[17] a pelt; as soon as the wool has been taken off, it is called a skin or a “slat.”

Each pelt is spread out smoothly on a table with the wool down and the inner or flesh side up. A mixture of lime and sulphide of sodium is next applied uniformly over the skin with a brush. The pelt is then folded up and placed in a pile with others. The solution that was applied penetrates the skin and loosens the wool, which, at the end of twenty-four hours, more or less, can be easily pulled off with the hands or rubbed off with a dull instrument or stick. The workman must be careful not to get any of the solution on to the wool, as it dissolves it and makes it worthless. Since the wool is valuable, the solution must be applied to the flesh side very carefully so that it does no injury. The wool that is removed from the skins is called “pulled wool.”

The slat is now ready to be limed, washed, pickled, and tanned. Heavy skins are[18] often split into two sheets after they have been limed. The part from the wool side is called a skiver, and that from the flesh side is called a flesher.

After the skins have been limed, they are bated and washed, which makes them soft, clean, and white; they are then put into a solution of salt, sulphuric acid, and water, called “pickle,” and after a few hours they are taken out, drained, and tanned.

Large quantities of sheepskins are sold to tanners in the pickled condition by those who make a business of preparing such skins and selling the wool. Pickled skins can be kept an indefinite length of time without spoiling; they can also be dried and worked out into a cheap white leather without any further tanning whatever. Most of such skins, however, are sold to tanners, who tan them into leather. Sheepskins contain considerable grease, which must be removed before the leather can be sold.

For some processes of tanning, calfskins, goatskins, and cattle hides are also pickled the same as sheepskins; for other processes they are not pickled, but are thoroughly bated or delimed, washed, and cleansed. Heavy hides are sometimes split out of the lime; more frequently, however, they are not split until after they have been tanned.

To capitulate, the preparatory processes may be briefly described as follows:—

Soaking, which dissolves the salt, removes the dirt and makes the hides soft and comparatively clean.

Liming and unhairing, which swell the hides and dissolve the perishable animal portion, loosen the hair, and put the hides into proper condition for tanning. Hides tanned without liming, even if the hair is removed by some chemical, do not make pliable leather, but are stiff and hard.

Bating, which removes the lime from the hides.

Pickling, which helps in the tanning later,[20] and keeps the hides and skins from spoiling if they are not tanned at once.

The lumps of fat and flesh that may be on the hides are removed by machinery or by placing the hide over a beam and scraping it with a knife. The hair, when it is loosened by the lime, is removed by a machine or by hand.

The various processes of tanning may be roughly divided into two classes, vegetable chemical and mineral chemical. The first class is often spoken of in tanneries simply as the “vegetable” while the second is called “chemical” process. In the vegetable processes the tanning is accomplished by tannin, which is found in various barks and woods of trees and leaves of plants. In the so-called chemical processes the tanning is done with mineral salts and acids which produce an entirely different kind of leather from that procured by vegetable tanning.

There is also a method of tanning, or, more properly speaking, tawing, in which alum and salt are used. This process makes white leather that is used for many[22] purposes; it is also colored and used in the manufacture of fine gloves. Leather is also made by tanning skins with oil. Chamois skins are made in this way.

The materials that are used to tan hides and skins act upon the hide fibers in such a way that the hides are rendered proof against decay and become pliable and strong. There are many vegetable tans; they are used for sole leather, upper leather, and colored leather for numerous purposes. The bark of hemlock trees is one of the principal tans. The woods and barks of oak, chestnut, and quebracho trees are often used. Palmetto roots yield a good tan. Large quantities of leather are treated with gambier and various other tanning materials that come from foreign countries. Sumac leaves, which are imported from Sicily, contain tannin that makes soft leather suitable for hat sweatbands, suspender trimmings, etc. Sumac is also obtained from the State of Virginia,[23] but the foreign leaves contain more tannin and make better leather than the American.

To a large extent the so-called chemical processes have supplanted the vegetable processes, that is, old tan bark and sumac processes; but in some tanneries both methods are used on different kinds of skins.

In the old bark process the tan bark is ground coarse and is then treated in leaches with hot water until the tanning quality is drawn out. The liquor so obtained is used at various strengths as needed.

In the newer method the tan liquor is displaced by a solution of potassium bichromate, which produces its results with much less expenditure of time.

When the hides or skins are ready for the tanning process, they are put into a revolving drum, known as a “pinwheel,” or into a pit in which are revolving paddles, with a dilute solution of potassium dichromate[24] or sodium dichromate, acidified with hydrochloric or sulphuric acid. If the pinwheel is employed, it is revolved for seven hours or longer; after which time the liquor is drawn off and replaced by an acidified solution of sodium thiosulphate or bisulphite, and then the revolution is continued several hours longer. If the pit is used, the skins are removed to another drum containing the second solution, and kept at rest or overturned for a like period.

In removing the skins from the pinwheel or vat, and in handling them after treatment with lime for the loosening of the hair, the hands and arms of the workmen are seriously injured, becoming raw if not protected by rubber gloves; even with gloves it is difficult to prevent injury, and in some establishments the workmen are relieved by the substitution of a single-bath process, in which the liquor is less harmful to the skin.

The hides are then removed from the[25] pits, washed and brushed, followed by slow drying in the air. When partly dried, they are placed in a pile and covered until heating is induced. They are then dampened and rolled with brass rollers to give the leather solidity. Sole leather is oiled but little. Weight is increased by adding glucose and salt.

Various rapid processes of tanning have been devised in which the hides are suspended in strong liquors or are tanned in large revolving drums. It is claimed that this hastens the process, but the product has been criticized as lacking substance or being brittle.

Chrome tannage has been chiefly developed in this country during the last twenty years and is now in general use. It consists in throwing an insoluble chromium hydroxide or oxide on the fibers of a skin which has been impregnated with a soluble chromium salt—potassium bichromate. Other salts like basic chromium chloride, chromium[26] chromate, and chromic alum are also used. The hydrochloric or sulphuric acid acts by setting free chromic acid.

After several hours, the skin shows a uniform yellow when cut through its thickest part. It is then drained and the skin worked in a solution of sodium bisulphite and mineral acid (to free sulphur dioxide). The chromic acid is absorbed by the fiber and later reduced by sulphur dioxide.

In the making of chrome black leather each tanner has his own method. Contrary to the general belief, there are many different methods of chrome tannage. No two tanneries employ just the same process.

Tanners of chrome leather seek to produce leather suitable for the particular demands made upon it by the peculiarities or characteristics of the varying seasons. Summer shoes require a cool, light leather; at other times a heavier tannage is essential, with some call for a practically waterproof product.

All leathers, whether vegetable-or chrome-tanned, must be “fat liquored.” That is to say, a certain amount of fatty material must be put into the skin in order that it may be mellow, workable, and serviceable. This is very essential in producing calf leather. Fat liquors usually contain oil and soap, which have been boiled in water and made into a thin liquor. The leather is put into a drum with the hot fat liquor; the drum is set in motion, and as it revolves the leather tumbles about in the drum and absorbs the oil and soap from the water. It is the fat liquor that makes the leather soft and strong.

Leather used in shoes is divided into two classes: sole leather and upper leather.

Sole leather is a heavy, solid, stiff leather and may be bent without cracking. It is the foundation of the shoe, and therefore should be of the best material. The hides of bulls and oxen yield the best leather for this purpose.

The hide that is tanned for sole leather is soaked for several days in a weak solution (which is gradually made stronger) of oak or hemlock tan made from the bark. Oak-tanned hide is preferred and may be known by its light color. A chemical change takes place in the fiber of the hide. This is a high-grade tannage, and is distinguished principally by its fine fibers and close, compact texture.

Oak sole leather, by reason of its tough character, and its close, fibrous texture, resists water and will wear well down before cracking. It is by many considered better than other leather for flexible-sole shoes, requiring waterproof qualities.

Sole leather is divided into three classes according to the tanning—oak, hemlock, and union.

Oak tanning is as follows: the hides are hung in pits containing weak or nearly spent liquors from a previous tanning, and agitated so as to take up tannin evenly.[29] Strong liquor would harden the surface so as to prevent thorough penetration into the interior of the hides. After ten or twelve days, the hides are taken out and laid away in fresh tan and stronger liquor. This process is repeated as often as necessary for eight to ten months. At the end of this time the hide has absorbed all of the tannin which it will take up.

Hemlock tanning is similar to the oak tanning in process. The hemlock tan is a red shade. Hemlock produces a very hard and inflexible leather. It is modified by use of bleaching materials which are applied to the leather after being tanned. It is sold in sides without being trimmed, while the oak is sold in backs, with belly and head trimmed off.

Hemlock leather is used extensively and almost principally for men’s and boys’ stiff-soled, heavy shoes, where no flexibility is required or expected. Its principal desirable quality is its resistance to trituration,[30] or being ground to a powder, and its use in men’s and boys’ pegged, nailed, or standard screw shoes is not in any way objectionable to the wearer. In fact, for this class of shoes, it is probably the best leather that can be used. But when hemlock is used in men’s and boys’ Goodyear welt shoes, where a flexible bottom is expected and required, it generally does not give good results. It cannot satisfactorily resist the constant flexing to which it is subjected, and after the sole is worn half through, the constant bending causes it to crack crosswise. On this account it becomes like a sieve, and has no power of resistance in water, and therefore it is not at all suited to flexible-bottomed shoes.

In “union-tanned” hides, both oak and hemlock are used and the result is a compromise in both color and quality. This tan was first used about fifty years ago. Twenty-five years ago the union leather tanners began to experiment with bleaching[31] materials to avoid the use of oak bark, which was becoming scarce and high priced, and eventually developed a system of tanning union leather with hemlock or kindred tanning agents, excluding oak. The red color and the hard texture were modified by bleaching the leather to the desired color and texture. This produces leather which has not the fine, close tannage of genuine oak leather and at the same time lacks the compact, hard character of hemlock leather. Union leather produced in this manner is a sort of mongrel or hybrid leather, being neither oak nor hemlock. On account of its economy in cutting qualities, however, it is largely used in the manufacture of medium-priced shoes where a certain degree of flexibility is required in the sole. This is particularly true of women’s shoes.

Union leather is sold largely in backs and trimmed the same as oak, though not so closely.

Sole leather is also made nowadays by tanning the hides by the chrome or chemical process. This leather is very durable and pliable and is used on athletic and sporting shoes. It has a light green color and is much lighter in weight than the oak or hemlock leather.

Many kinds of hide are used for sole leather. This country does not produce nearly enough hides for the demand, and great quantities are imported from abroad, although most of the imported hides come from South America. Imported hides are divided into two general classes, dry hides and green-salted hides.

Dry hides are of two kinds, the dry “flint,” which are dried carefully after being taken from the animal and cured without salt. These generally make good leather, although if sunburnt, the leather is not strong. “Dry-salted hides” are salted and cured to a dry state. Dry hides of both kinds are used for hemlock leather[33] only, although all hemlock leather is not made from dry hides.

Green-salted hides are used in making oak-tanned leather as well as hemlock, and those used by United States tanners come largely from domestic points; but there is a variable amount imported each year from abroad, principally from Europe and South America. Green-salted hides are of two general classes, those branded and those free of brands.

Cow and steer hides of the branded type are used by tanners of oak and union leather. Those not branded are used more largely for belting and upholstering leathers, a small part finding their way into hemlock leather.

Sole leather remnants, strictly speaking, include such a wide variety of items that it is difficult to cover them all. Few people, however, realize the big range of usefulness of this class of stock. While not exactly a by-product, remnants are often classed as such. Under the class of sole leather[34] remnants are included sole leather offal, such as heads, bellies, shoulders, shanks, shins, men’s heeling, men’s half heeling, men’s and women’s three-and four-piece heeling, etc. Stock that cannot be used in the shoe business goes into the chemical and fertilizer trade, among other outlets. By a special acid process of burning this stock, ammonia is derived from it, which goes into fertilizer; and another by-product is sulphuric acid for the chemical trade. The amount of ammonia obtained is small, being about seven per cent of ammonia to a ton of sole leather scrap. This is mixed with fertilizer and sold mostly in the Southern States, and to a small extent in the West, there being a law in many of the Western States against the use of fertilizer made from leather products, on account of its low grade.

In the disposition of offal, heads are used for taps, top lifts, and under lifts. Shoulders are used for outsoles and inner soles, while[35] bellies are used for medium to heavy taps and counters. Lightweight bellies and shanks are utilized for making box toes and counters.

Shanks are also used for taps and under lifts. This stock is solid and substantial and well suited for these purposes. The bellies, being flexible, are the best part of the hide obtainable for inner soles.

In cutting out soles, the manufacturer accumulates a considerable quantity of solid or center pieces, which are used for small top lifts, also for “Cuban” tops, thereby using up the bulk of the small heavy scrap that ordinarily would be sold for pieced heeling. There is also a demand for similar stock from the hardware trade, where it is used for making mallet and tool handles, also for wagon and carriage washers. Large quantities of men’s and women’s heeling and half heeling go to England, where it is cut up by heel manufacturers into lifts and sectional lifts for[36] the English trade; there being a shortage of this class of offal there.

The shoe manufacturer, after cutting his soles and taps, is obliged to skive them to get the particular iron he needs. This leaves what is known as a “flesh sole shape,” also a “tap shape.” These skivings are pasted together by another class of trade and again used for inner soling and taps in the cheaper grades of shoes. Smaller skivings, or waste, after sorting out the sole and tap shapes, are sold to the leather board trade. This eventually comes back to the shoe trade in the shape of leather board and is cut into heel lifts. The waste after cutting heel lifts is again resold to the leather board trade and makes another round trip to the shoe manufacturer. This illustration, as well as many others in the leather remnant business, demonstrates the scientific principle that nothing is ever entirely lost. In regard to pieced heel lifts, these are made in either two, three, or four[37] sections. This refers to what are known as sectional heel lifts. Scrap leather is also used for shanking for the European trade.

Soles and taps, known as rejects, that is, those thrown out by the high-grade trade, are sold to manufacturers of cheaper lines. A shoe manufacturer cutting his own soles and buying sole leather in sides, after sorting out the soles suited to his own requirements, will sell what he cannot use to remnant dealers, who in turn re-sell them to shoe manufacturers requiring that particular class of stock. The scrap leather, or remnant dealer, thus forms a useful link in the chain of distribution, furnishing a market where shoe and leather manufacturers may dispose of their surplus products to best advantage, and providing a source of supply for buyers who wish any particular article to suit their individual needs.

Upper or dressed leather is made from kips or large calfskins. It is tanned and finished like all other forms of leather by[38] variations of the foregoing process. Thick hides are often split thin by machinery, and the parts retained and finished separately. The parts of the leather from the hair side are most valuable and are called “grain” leather; the inner parts or “flesh splits” are made into a variety of different kinds of leather by waxing, oiling, and polishing.

It is finished by scouring with brushes and then rubbed with a piece of glass, which removes creases and wrinkles and stretches the leather. Then it is stuffed with a mixture of oil, soap, and tallow, which is worked into it by rolling. Various finishes are given to leather, such as seal grain, buff, glove grain, oil grain, satin calf, russet, plain shoe, etc.

Upper leathers are blacked by rubbing with a mixture of lampblack and oil or tallow, or with a solution of copperas and logwood.

No tanning process, no matter how good or thorough, can make firm, serviceable,[39] wear-resisting leather out of all portions of any hide, because nature made some parts of every hide porous, spongy, and lacking in fibrous strength.

Calfskins used by tanners are of several classes. American calfskins, taken off in the United States and Canada, are usually sold green pelted. Farmers raise only a small fraction of the calves born. Each cow must produce a calf in order to insure a maximum flow of milk. Most of the farmers keep cows to produce milk, hence they sell the young calves for veal and use their skins for high-grade calf leather.

In European countries farmers fatten their calves before selling them in order to get a higher price for the veal. The skin is not so valuable for leather as the skin from younger calves, and it is used for lower-value leathers.

Calfskin is not split. A heavier weight skin might be. It is shaved to a uniform thickness.

Calf leather is divided into the following classes, depending upon the finish of the leather:—

Boarded calf (made in both chrome and bark tannage).

Wax calf, finished on the flesh side with a waxy, hard surface.

Box calf is a proprietary name. It is boarded—rubbed with a board to raise the grain. It is known by minute, squarelike lines.

Mat calf is a dull-finished calfskin, used more in topping.

Suede calf is finished on flesh side. Most makes of suede calf are chromed, although there are some vegetable.

Storm calf is a heavy skin, finished for winter wear. Considerable oil is used in finishing.

French calf is finished on flesh side.

Dry hides are obtained from Buenos Ayres, where the cattle are raised on the plains. This city exports a large quantity of[41] hides, dry, salted, and cured by smoking. The hides of cows generally yield inferior grain leather; but South American cowhides may be worked for light sole leather.

Calves’ hides are thinner, but when well tanned, curried, and dressed, they yield a very soft and supple leather for boots and shoes. They are finished with wax and oil on the flesh side, and can also be finished on the hair (grain of skin).

Calves’ skin (green salted).

Paris City calfskins. These are obtained in three grades—light, medium, and heavy.

Light grades run from four to five, or seven to eight pounds; medium grades run from seven to nine pounds; heavy grades run from nine to twelve pounds.

Patent leather may be made from colt, calf, or kid skin. Coltskin is the skin of young horses, or split skins of mature horses.

Patent colt and kid are used for the most part in the medium fine grades, and patent[42] side (cowhide) is used in the medium and cheaper grades. Chrome tanned are used entirely in the manufacture of patent leather.

Patent leather, as it appears in shoes, may be described either as varnished leather, coltskin, or kid, and sometimes the French use calfskin. The process is largely a secret one, although there is no longer any patent on the principle of the same. It is made by shaving the skins on the flesh side or hair side to a uniform thickness. Then it is de-greased to put the skin in condition to receive the finish and protect the same from peeling off. Successive coats of liquid black varnish are applied, the first coats being dried and rubbed down, so as to work the liquid thoroughly into the fibers of the leather. The last coat is applied with a brush, and baked to from one hundred and twenty to one hundred and forty degrees Fahrenheit for thirty-six hours and then allowed to dry in direct sunlight for from six to ten hours, which seems to be essential to remove[43] the sticky feeling. Various ingredients are used in making the different varnishes, the first coating consisting of naphtha, wood alcohol, amyl acetate, etc. The black varnishes consist of linseed oil and various other mixtures, heated in iron kettles. The final coating is a naphtha preparation resembling japanning material. The hide is stretched on a frame during the varnishing operations.

It is almost impossible to tell the difference in quality of shiny leather by appearance, although in general the leather on which the grain shows through the varnish will prove more serviceable than that on which the finish is so thick as to hide the grain. Great care must be exercised in resewing patent leather shoes that have been exposed during the cold weather, as the cold has a tendency to freeze the finish. Patent leather, like all varnished coatings, is liable to crack. No one can guarantee it not to do so. The kid patent leather is more elastic[44] and porous than other kinds. The serious objection to the use of patent leather for a shoe is its air-tightness. This makes it both unhygienic and uncomfortable. The kid patent leather is the only patent leather that has not this objection.

Kid is a term applied to shoe leather made from the skins of mature goats. The skin of the young goat or kid is made into the thin, flexible leather used for kid gloves, which is too delicate for general use in shoes. The goats from which come the supply of leather used in this country for women’s and children’s fine shoes are not the common, domesticated kind known in this country, but are wild goats or allied species partially domesticated, and are found in the hill regions of India, the mountains of Europe, portions of South America, etc.

There are about sixty-eight recognized kinds of goatskins that are imported from all over the world. The Brazilian, Buenos[45] Ayres, Andean, Mexican, French, Russian, Indian, and Chinese are a few of the many kinds that are known as such. Each particular species of goat hide possesses its own peculiarities of texture. The thickness and grain differ according to the environment in which the animal has been raised. It is peculiar that those raised in cold climates do not have as thick skins as those raised in warmer climates, for the long, thick hair apparently takes the strength.

We may wonder where all the skins come from that are made up into glazed kid, mat kid, and suede, at the rate of several thousand dozen every day. The great proportion of the skins are goatskins. These are almost all imported from abroad, where the animals are slaughtered and disposed of much the same as we dispose of beef and veal here. Sheepskins and carbarettas, the hides of animals that are a cross between sheep and goats, are also used.

The finer grades of kid and goatskins[46] which are tanned in large quantities in New England, come from the Far East.

In China there are two great ports from which skins are shipped, Tientsin and Shanghai. Back in the interior, starting from a point about twelve hundred miles from the sea, collectors make their rounds twice a year.

The breeder of goats kills his flock just before the collector is due, skins the animals on the hillside, preserves the meat for food, and with the kidskins, which have been partly dried, wrapped in a bundle carried upon the back, or upon a pack animal, the breeder makes his way to the station. It may be that there are a half hundred breeders awaiting the coming of the collector and he pays them the market price for the skins.

Whenever the collector has a sufficient supply to make it profitable to ship, he bales the skins and then sends them over the thousand mile journey along the river to the seaport.[47] From Tientsin or Shanghai they are taken by tramp steamers, which reach Eastern ports by way of the Suez Canal, and on the trip the steamers make several ports, so that it is from six to ten weeks before the skins reach America.

Another method of importing is to have the raw material shipped across the Pacific and then transferred to a railroad, but the difference in cost to the manufacturer is so great that it is unprofitable.

The China goatskins are rated as among the finest in the world and when tanned they make the highest-grade shoe.

Then there are mocha skins, which come from Tripoli, Arabia, and Northern Africa. In those places the method of collection is practically the same as in China.

The two best-known grades are the Hodieda and the Benghazi. They derive their designations from the exporting cities. Hodieda is located in the southwestern part of Arabia on the Red Sea, while[48] Benghazi is in Barca, one of the provinces of Tripoli.

Other goatskins are produced in India and Russia, and millions of skins are exported annually from Bombay, Madras, and Calcutta. These skins are not brought direct to America, but are transshipped at Marseilles or London.

The jobbers in Europe or India occupy rather a unique position, for according to their practice it is almost impossible for them to suffer financial losses in dealing with an American tanner. The latter, when he wishes to arrange for his year’s supply of raw material, negotiates with an agent in Boston, with whom he signs a contract for so many skins. Then it is necessary for the tanner to either purchase with money equal to the face value or secure by loans letters of credit from Boston banking houses which have European connections.

Before the skins are exported, the jobber has his money from the European banking[49] concerns and the bills of lading are forwarded to the Boston bankers, who turn them over to the tanners, and, when the occasion requires, obtain from the tanners what is known as a deed of trust.

All goatskins are tanned by the same chrome tanning process, whether the finish is to be glazed or mat. The proportions of chemicals vary according to the texture of the skin, and according to the grain.

The process of tanning is quicker than the tanning of heavier hides, and all varieties of tannage are used, the chrome methods having come into very general use. There are many kinds of finish given, such as glazed, dull, mat, patent, etc. One quality that distinguishes goat leather, the “kid” of shoemaking, is the fact that the fibers of the skin are interlaced and interlocked in all directions. The finished skins as they come from the tannery, by whatever process they may be put through, are sorted for size and quality, a number of grades[50] being made. Instead of ripping straight through, like a piece of cloth, or splitting apart in layers, as sheepskin will do when made into leather, the kid holds together firmly in all directions.

Glazed kid is colored after it is tanned by submerging it in the color, a very important process. The glossy surface is obtained by “striking” or burnishing on the grain side. It is made in black and colors, particularly tan, and is known by about as many names as there are manufacturers of it.

Glazed kid is used in the uppers of shoes, making a fine, soft shoe that is particularly comfortable in warm weather, and is said to prevent cold feet in winter, owing to unrestricted circulation.

Mat kid is a soft, dull black kid, the softness being the result of treatment with beeswax or olive oil. It is finished on the grain side the same as glazed kid, and is used principally for shoe toppings. It is very similar in appearance to mat calf and[51] is often used in preference to it, as it is of much lighter weight, and about as strong.

Suede kid is not tanned, but is subjected to a feeding process in an egg solution, called “tawing,” to make it soft and pliable. The skin is stretched and the color is applied by “brushing” (with a brush). The color does not permeate the skin, but is merely on the surface. Suedes are made from carbarettas and split sheepskins. Suedes are used very extensively in making slippers, and come in a great variety of colors.

A castor kid is a Persian lambskin finished the same as a suede, and is used in making very soft, fine-appearing leather—like glove leather. The skin is of such a very light weight that it has to be “backed up” before being made into shoes.

Fancy leathers are used extensively for toppings of shoes having patent leather vamps. Facings are selected from fancy leathers to make the inside of a shoe attractive and to increase its wearing quality.[52] Leathers of dull or glazed finish are used in typical shoe colors.

Miscellaneous kinds of kids are as follows:—

Kangaroo is the skin of the animal of that name.

Buckskin is the skin of certain deer.

Sheepskin is the skin of the familiar domestic sheep.

Chamois is the skin of the animal of that name and by courtesy the specially treated skins of certain domestic animals.

It is a simple matter to recognize a kid-skin among the various kinds of upper leather, because of its very light weight and pliability.

During the winter, leather, in drying, is apt to become frozen, especially where no well-equipped drying loft is provided. Such leather becomes weak and limp if thawed out too rapidly. In freezing, the water in the hides which have been hung up to dry is forced out and stretches apart the hide fiber. The wetter the hides, therefore, the more demoralized they will be by the frost. The treatment of rushing the frozen leather into a warm room is inadvisable; the best method is to allow the hides to hang as they were and to tightly close all openings to the outside air. In case this is impossible, it is best to place the leather in a heap, in a room where the temperature will not fall below the freezing point, and to cover it with a cloth. In case the leather rolls up, it should be moistened before the roll becomes greater than is customary; it will thus become firmer throughout. Some upper leather and especially sheepskins for lining purposes are aided by freezing, since the[54] leather becomes white and plump and also is of a bright color, though the durability is somewhat lessened.

The popularity of white leather for shoes is increasing wonderfully. There is good reason for this. The modern white shoes have a stylish and fashionable appearance which has won the hearts of women of all ages and conditions, and when they want a thing, there is always alertness in supplying it. The new love for white shoes is interesting to trace. Years ago white leather for shoes was made principally from deerskins. But this leather, while attractive when new, would stretch soon after being worn, and take on a yellowish tinge. Besides, the price of such shoes was very high, and it is not surprising that they became supplanted by the cheaper, but attractive and useful, white canvas shoes, which became quick sellers during the season.

It is greatly to the credit of our tanners that they have been able to perfect and[55] put on the market a white leather for shoes which answers all requirements satisfactorily. This leather is made from cowhides; the white color will not fade nor turn yellow, and best of all, the leather can be easily cleaned and made to look good as new. Another advantage is that such leathers can be used in shoes that sell at popular prices.

There are many common, commercial grades of upper leather.

Willow calf is a fine, soft, chrome tannage of calfskin. It is sold in three colors, light tan, ox blood, and olive-brown. The distinguishing features of this leather are its durability and the fact that it always keeps soft and pliable. It is adapted to the highest quality of men’s and women’s shoes.

Box calf is a storm-calf leather of highest quality. It is a waterproof, chrome tannage in a medium tan color, with a dull finish. This is the best leather obtainable for rough, outdoor wear, walking shoes,[56] hunting boots, etc. It is also adapted to men’s and women’s very fine footwear. There is a growing demand for this kind of shoe. In the uppers of the best storm shoes you will always find box calf.

Royal kid is a black chrome calfskin, dull finished with a smooth, natural grain of fine texture, soft and pliable. It is used for vamps and whole shoes of the highest grades for men and women, and is a very popular material for the fall and winter shoe. The desirable qualities of fine calf leather are making the demand for it grow faster than the supply of raw material increases.

Tan royal is a tan color, chrome calf leather, smooth finish, fine grain, excellent cutting qualities, uniform, of medium rich tan shades. Tan calf leather is very attractive and the tan shoe is now a staple product.

Cadet kid is a bright black, smooth-finished, chrome calfskin for men’s and[57] women’s fine shoes. This tannage and finish give a remarkable cutting value. The stability of this stock is entirely unique and makes the finished shoe stand up, keeping its much desired shape through the different tests of manufacturing. It is said to be the best calfskin, by the best judges, the shoe manufacturers.

Bronko patent is distinguished for its fine, coltskin-effect grain. It has a rich and lustrous black patent finish. The results obtained from bronko patent in its workings through the shoe factory and its wearing qualities afterward have never been equaled. Bronko is one of the finest results of the development of chrome patent leather.

Cadet kid side is a chrome side leather that closely imitates the calfskin, called cadet kid. It has a bright, lustrous finish, and a remarkably fine grain. It is surprisingly like fine calf leather in appearance.

Cadet calf sides are similar to cadet kid[58] sides with the exception of a boarded finish. This is another black chrome, side leather which comes very near to a calfskin.

Mat royal chrome side is a special finish, closely resembling calf, used for the tops of men’s and women’s medium fine shoes.

Black hawk patent is a well-tanned, well-finished patent leather for medium-priced women’s shoes and for tipping.

Colored box chrome side, boarded, is a substitute for willow calf.

Black box chrome side, boarded, is a substitute for box calf in medium fine shoes.

Kangaroo kid side is a back-tanned, dull, smooth, black leather nearly like calf, used in the tops of men’s shoes, and men’s and women’s whole shoes.

Waterproof black is a high quality leather of great durability for men’s and boys’ heavy shoes. Waterproof brown is similar to waterproof black, except in color, and is a leather made for hard service.

Amhide black is a soft, dry, high-grade[59] tannage for lightweight, comfortable, sporting, work, and hard-wear shoes.

Amhide russet is like black amhide in everything but color.

Hercules storm chrome is a leather distinguished for its fine grain and good appearance of medium heavy weight.

Boris is a heavy-weight, soft, waterproof leather for men’s medium quality shoes. It is finished in three colors and black.

Zulu is a medium-priced leather, which makes a very fine wearing heavy shoe. It is made in two colors and black.

Bison is a colored or black-finished leather, of a high grade, very comfortable and durable.

Ottawa is of two colors and black finished, and is suitable for high quality, heavy, rough shoes.

Sheboygan calf is a heavily stuffed, soft, waterproof leather. It is of two colors and black.

Dongola calf is a black leather used for[60] durable, medium-priced, heavy, outdoor shoes.

Belt knife splits are sold in several tannages and finishes of the most improved manufacture. These splits are sorted in all weights. Uniform selection is maintained, and the quality in every way is of the highest order.

Oxford calf union splits is one of the highest grades of grain-finished, union splits. It has an extremely soft and fine appearance.

Cambridge calf union splits have a most careful and high-grade finish, but somewhat firmer than Oxford calf.

Flesh splits are sold in two tannages. These are the highest-grade flesh splits that it is possible to make, and they are a long distance ahead of the ordinary flesh splits, their improved finish making them a modern and largely used substitute for satin.

Ottawa black and russet splits include a variety of printed splits, used for shoes[61] in combination with grain leather and for whole shoes. They are selected in many weights.

Flexible splits for Goodyear, gem, McKay inner soles, is leather that offers the greatest advantages to large and small buyers. It is the product of six different tanneries, assorted in all the usual weights. Great care is taken in the manufacture of these splits to adapt them perfectly to the shoe manufacturer’s needs.

Flexible bends are used by manufacturers of Goodyear welt shoes requiring a straight Goodyear or gem inner sole. They find these bends of great advantage on account of the small amount of waste, the strength and desirability of stock. They are made in six tannages.

Chrome flexible splits for inner soles furnish a very strong and durable leather for inner soles, taps, and outer soles.

Ooze gusset splits, colored, give a very low-priced leather suitable for gussets, bellows[62] tongues for high-cut boots, also for the quarter-linings of Oxfords.

Ooze vamp splits, black and colored, are strong, durable, low-priced leathers suitable for cheap work shoes where waterproof qualities are not required.

Chrome-tanned embossed splits, colored, are made in a great variety of patterns for cheap shoes and other work where leather is required. They are durable and low priced.

A native steer about four years old, killed in the month of October, affords the best example of a good hide for belting manufacture, that is, for the transmission of power from pulley to pulley. At this age and at this season the steer is in prime condition.

On account of the great and enormous strain put upon belting, and the necessity for its running true upon the pulley, it[63] should be of the highest grade possible, combining great strength to prevent stretching, and evenness of grain to insure long wear; therefore only hides of selected steers are serviceable, and these in turn are rejected when they contain any blemishes or cuts or other imperfections. After a hide is accepted for belting purposes, it is subjected to a generous trimming, the head, neck, legs, and belly being cut away, leaving only a small and compact section embracing from two to two and a quarter feet on each side of the backbone and extending about six feet along the same from the tail forward. This is the portion of the hide where the fibers are closely and firmly knit together, and where the vitality is the greatest, due to the close proximity of the network of nerves radiating from each side of the spine to all parts of the hide.

The hides of the bull and cow of every breed are inferior for belting purposes to that of the steer. The hide of the bull is[64] coarse and hard, with the neck very heavy and full of wrinkles, causing a variation in the thickness and run of the grain of the leather. The hide of the cow is thin, does not run uniform in thickness, being heavier on the hips than at the shoulder, and is lacking in the firmness necessary in good belting. The sharp angles of the hip bones of a cow also tend to form pockets in the hide.

After the hide has been trimmed, it is subject to the process of “currying.” All membranes or particles of flesh adhering to the hide are removed by a machine which shaves the membrane, etc., off, with lightning rapidity. The leather is then washed and scoured by machine, which removes all dirt still adhering to the hide. After the leather is thoroughly cleaned and while in a damp state, it is placed upon the table, and greases, composed of pure animal oil, are worked into the leather on both the grain and the flesh side with brushes.[65] This is carried on in the cold state. It is then put into a large revolving wheel containing water heated to a high degree, which causes the leather to swell and pores to open. The leather is then taken out and put into another wheel containing heavy mineral oil and heated several degrees greater than the water, and tumbled about in the wheel until the heavy oil fills the distended pores and fibers. After this, the leather is allowed to dry.

The hides are allowed to remain for several months in the tan liquor until the green hide is changed into leather.

After the hide has been changed into leather, it is stretched. To properly stretch the leather for belting purposes, it must first be cut so as to remove that part which shows the markings of the backbone of the steer.

Leather is stretched by placing it in clamps, every part of the piece getting the same pull. (The leather is put into the[66] clamps while damp, as damp leather will give the greatest amount of stretching.)

When the stretching process is completed and the leather has thoroughly dried in stretching clamps, it is released. These pieces of leather are quite dry, very firm, and not very pliable. The leather is now moistened in order that it shall be more pliable as it passes through the finishing processes. After the water has soaked into the leather (called sammied), it becomes very soft. It is then subjected to a roller under heavy pressure to take all the unevenness out of the hide. It is next thoroughly dried, causing the fibers to shrink; then again moistened and put through a polishing machine, which acts on the same principle as the rolling jack.

The sides and centers are now put through a cutting machine, which reduces the leather to strips of different sizes.

Belts are put together by cementing the parts. Belt cement is a most powerful adhesive.[67] It actually governs the strength of the belt, as the belt is as strong as the weakest part of the joint.

Rawhide is used for a great many purposes. After the side of leather has been trimmed of the portions that cannot be used, it is sold to the lace maker. He measures the same in a machine.

The trimmings from the side of the hide may be used for a mallet head or other tools made of leather. The most common products of the strong section of rawhide strings are shoe strings, belting laces, and parts of harnesses. It is also made into leather shoe strings that are used in the logging camps.

When the hide is selected for the rawhide purposes, it is first passed to a de-hairing machine, where all the hair is removed. It is then fleshed; that is, all loose membrane[68] and any flesh that may have adhered to the hide are removed from the flesh side. The rawhide is then placed in a special bath for the purpose of opening the pores, before the oils and greases are added to it. After this bath, it is dried thoroughly in a hot box and then put into wheels which mill the greases into the hide.

The hide, which is made hard by this drying process, is put through breakers, where it is thoroughly worked into soft and pliable form.

The hide is next passed to the setting-out machine, which finishes all forms of leather—by condensing and strengthening the fibers. Special oils are applied to both the grain and flesh side of the hide. It is finished by hand and cut into laces. This hand finishing is usually done in order to reject all parts that are not perfect.

Haired leather is tanned by acid—a quicker method. The hide is split into sides and tanned with the belly stock on[69] them, which is used for car straps, cowbell straps, trunk straps, and riding bridles.

There are a great many by-products in a leather belting factory, all of which are used. The finest strips are used for whip lashes, small pieces are used for the French heel, and the extremely small pieces are used in leather mats.

The by-product from the belting bull, which is about fifty per cent, is used for shoe leather and leather straps. There is considerable leather taken from the belting bull for certain harness work. The belly is thick and porous though not tough, and is used for halters, cow bridles, and other parts of harness where the strain is not great.

Round belt is made from the best belting, but while the strain on round belting is[70] not severe, the leather must be soft and pliable. It is selected from regular stock of native steer hide.

Leather that has been tanned is made up of a great many little bundles of fibers. The coarser and stronger fibers are on the inside, and the very fine and smoothly laid fibers are on the outside. These fibers are so intertwined and so elastic that when the leather bends these bundles play on one another. On account of the smoothness of the surface it may be polished, and beautiful finishes and effects obtained on the leather.

The elasticity of leather (which is due to the elasticity of its fibers) allows it to stretch to a great extent. The tendency to return to its original position is very strong at the beginning, but grows weaker if the strain is continued at any one point.[71] Of course, in stretching the leather, there is always a corresponding drawing in another part of the shoe, which gives it a worn and baggy appearance.

When shoes are removed from the feet, they are oftentimes damp, due to perspiration. The stretched or strained fibers are apt to shrink and return to their original position. In order to avoid this, it is necessary to place shoe-trees in them.

When the linings of shoes are exposed to friction and excretion of perspiration from the feet of some people, they deteriorate. This is due to the fact that the acids of perspiration (acetic, formic and butyric acids) have become so concentrated that they act on the fibers of the leather. These acids exert a burning effect, causing the fibers to lose their elasticity so that they no longer play on one another, but become fastened to each other. The result is that they become hard, and any attempt to bend the leather tears them apart; and[72] once the union of fibers is destroyed it cannot be repaired.

In order to keep the fibers in such a condition (soft and flexible), they should be lubricated often (twice a week) with a liquid followed by a wax paste, usually called shoe dressing. When a brush or a piece of cloth is rubbed over the surface of leather containing the shoe lubricants (shoe polish), it produces a smooth surface called a “shine.”

Compounds which shine without friction produced by brush or cloth should not be used, as they are simply varnishes and one coat on top of the other destroys the leather.

In olden times our fathers and mothers used handmade shoes, and wore them till they had passed their period of usefulness. At that time the consumption did not equal the production of leather. Knowledge of[73] conditions in the great western countries to-day will show that many of the big cattle-raising sections, once famed for their cattle, have been taken up by homesteaders and are now producing grain instead of cattle. But since the appearance of the machine-made shoe, different styles of shoes are placed on the market at different seasons, to correspond to the change of style of clothing, and shoes are often discarded before they are worn out. We have not been able thus far to utilize cast-off leather as the shoddy mill uses wool and silk, etc. The result is that the consumption of leather is above the production, therefore substitutes must be used.

In shoe materials there is at present an astonishing diversity and variety. Every known leather is used from kid to cowhide, and textile fabrics have developed rapidly, especially in the making of women’s and children’s shoes. The satins, velvets, serges,[74] and other fabrics that are used in the manufacture of shoes must be firm and well woven, and are usually supplied with a backing of firm, canvas-like fabric, to give strength.

As to wearing quality the old saying, “There is nothing like leather,” still holds good; but people do not buy shoes for their wearing qualities alone in these days. Style and intrinsic beauty are considered, and have a cash value just as in any other article of apparel.

Each fabric is made of two sets of threadlike yarn woven at right angles to each other. They are called the warp and filling (weft). The warp is composed of yarn running the longest way of the fabric, and filling runs the short way of the fabric. Since the warp is the body of the cloth, it is its strongest part and all fabric in shoes should be placed warpwise across the foot of the wearer, so as to be able to resist the great strain.

Various attempts have been made for legislation to prohibit the treating of leather by chemicals or the use of substances to increase its weight. Complaints have been made by a number of shoe manufacturers that the excessive use of glucose (a form of sugar) in sole leather has resulted in injuring the leather and fabrics composing the uppers of shoes.

Representatives of large leather firms claim that the methods of tanning sole leather have radically changed during the last few years, and that the small quantity of glucose and epsom salts that is used to-day in finishing sole leather is absolutely necessary to its value, and is in no sense an adulterant or weighting material. Shoe manufacturers, on the other hand, claim that in some cases larger amounts of glucose, salt, etc., have been added to the soft leather from the belly of the animal, in order to give it the desired stiffness. On account of the high price of leather, various[76] attempts have been made to find a substitute for it. Most of these substitutes consist of strong cloth treated with some drying oil like linseed, the oil having previously been mixed with other solid substances.

A prize of five thousand francs has been awarded to a Belgian inventor, Louis Gevaert, for his unusually superior artificial leather. The process consists in the more or less intimate impregnation of stout cloth with tannic albuminoid substances. Shoes made of this are said to possess not only the resistance and elasticity of natural leather, but its durability of wear. Moreover, they are much cheaper, costing, including manufacture, only four francs (about eighty cents) and being sold at about six francs per pair.

Very few people, even among those engaged in the shoe industry, know much of the anatomy of the foot. Yet it is evident that they ought to know something about it in order to furnish the foot with a proper covering.

The first thing that strikes a person on looking at the human foot is its large proportion of bone. On pressing its top surface and that of its inner side, the amount of flesh will be found to be very small, indeed. The same is true of the inner and outer ankle. The extreme back of the ankle has scarcely any flesh covering. The most fleshy portions of the foot are its outer side, the base of the heel and the ball of the big toe.

The reason for this disposition of flesh is to protect or cover those parts of the foot that support the body by coming in contact with the ground. They act as pads and lessen the concussion. The abundance of flesh on the outer side of the foot is to protect or act as a shield against danger. The inside of the foot is not exposed as much as the outside.

The foot is divided into three parts, the toes, the waist and instep, and the heel and ankle. The largest bone of the foot is the heel bone (called calcaneum). It is the bone that projects backward from the principal joint and forms the main portion of the heel. When a person is flat-footed, this bone is thrust farther backward than nature intended to have it. The connection between it and the tarsal bones is lost.

The Bones and Joints of the Human Foot.

The Different Parts of the Foot and Ankle. See page 86.

The top bone of the foot is the astragalus, and it forms the main joint upon which the process of walking depends. This bone has a smooth, circular, upper surface that[79] connects it with the main bone of the lower leg. It is absolutely necessary that this bone should be in perfect harmony (relation) with the others in order to insure comfort and health. If the arches of the foot are forced out of position, up or down or sidewise, this joint is not permitted to do its work normally.

Rheumatism is a frequent evil of an injured joint. Hence the necessity of absolutely normal action, unhampered by ill-fitting shoes.

The principal arch of the instep is called the cuneiform or tarsal bone. Persons are troubled with defective insteps to quite an extent. Misshapen joints at this point due to shoes that do not fit and consequently disarrange and throw out of position the delicate, natural structure, work great havoc with the comfort of the foot. Nine joints cluster at this point.

The bones of the toes are called the metatarsal bones and phalanges. There[80] can be no doubt that nature intended mankind to walk in his bare feet, and in that event the phalanges of the foot would occupy a much more important part than is now the case as a result of modern civilization. There are nineteen bones in the foot, and the disturbance of one or more of these will serve to upset the entire foot by throwing out of relationship the general unit of work devolving upon the whole number of joints and bones. Each joint has its accompaniment of muscles, and each lack of alignment of bones and joints provokes discord and lack of harmony in the muscular action.

Muscles are attached to bones, and by their contraction or extension the bones are moved. Very few movements are effected by means of a single muscle. The muscles of the foot in nearly all cases are in combination, and are so complex in their action that the best surgeons find it difficult to describe them satisfactorily.

The chief characteristics of the foot are its spring and elasticity. While the foot has wonderful powers of resistance and adaptability, it is the shoemaker’s duty not to strain the same, but to provide for each action.

The most sensitive part or the one part that is most susceptible of injury is the big toe. This is due to the fact that the tendency of the foot in walking is to travel toward the toe of the boot, and in a word to press into rather than shun danger. The shoemaker provides for this, first, by allowing sufficient length of sole to extend beyond the termination of the toe, and second, by the fit of the upper and the preparation of the sole. In this way, if the toe of the shoe strikes against a hard substance, the big toe of the foot will remain untouched.

Seventy-five per cent of the people have more or less trouble with their feet. Some of these troubles are caused by the manufacturer putting on the market shoes whose[82] lines look handsome and attractive to the eye, but are lacking in any other good features. Shoes that fit properly should have plenty of room from the large toe joint to the end of the toes, and also should have plenty of tread, especially at this point.

A mere glance at our bare foot will show conclusively that pointed-toe boots are false in the theory of design. The toes of a foot when off duty touch each other gently. When they are called on to assist us in walking or in supporting our body, they spread out—although not to any great extent. This, then, being the action, no sensible maker of boots and shoes would attempt to restrain them. Box or puff-toe shoes allow the greatest freedom.

The pointed-toe shoes, which join the vamp to the upper immediately over the big toe joint, exceedingly high heels, and thick waist shoes are not for the best interests of the foot.

The evils of ill-fitting shoes are corns, bunions, and calluses.

Corns are mainly due to pressure and friction. When the layers of skin become hardened, they form a corn, which is merely a growth of dead skin that has become hard in the center. This hardened spot acts like a foreign body to the inflamed parts.

A hard corn is formed more by friction than pressure. It is produced by the constant rubbing of a tight or small shoe against the projecting parts of some prominent bony part, as the last joints on the third, fourth, and little toe. When this action continues, it produces inflammation. Rest—as relieving the feet of the friction—decreases this inflammation, leaving a layer of hardened flesh. Renewed action reproduces the same effects, leaving behind a second layer of hardened flesh. This continued action and reaction brings on a callus, rising above the surface of the skin. This increases from its base. An[84] ordinary hard corn may be removed by scraping up the callous skin around its border, and prying out carefully with a knife. Soft corns are chiefly the result of pressure or friction. These corns are soft and spongy elevations on the parts of the skin subjected to pressure. Soft corns are mostly found on the inner side of the smaller toes. Those on the surface of joints by mechanical action will become hard.

The blood corn is excessively painful. It is the result of an ordinary corn forcibly displacing the blood vessels surrounding it, and causing them to rest upon its surface.

The bunion is an inflammatory swelling generally to be found on the big toe joint. The chief cause of bunions is known to be the wearing of boots or shoes of insufficient length. The foot, meeting with resistance in front and behind, is robbed of its natural actions, the result being that the big toe is forced upward, and subjected to continuous[85] friction and pressure. The wearing of narrow-toe boots that prevent the outward expansion of the toe is another cause.

The comparisons of quantities are often called ratios. The ratios of the different parts of the foot to the height are different in the infant from that of the adult period. Between these two periods the ratios are constantly changing.

There are two series of shoe sizes on the market; the smallest size of shoe for infants (size No. 1) is, or was originally, four inches long; each added full size indicates an increase in length of one third of an inch (sizes 1 to 5). Children’s sizes run in two series, 5 to 8, and 8 to 11; then they branch out into youths’ and misses’; both running 11½, 12, 12½, 13, 13½ and back again to 1, 1½, 2, etc., in a series of sizes that run up into men’s and women’s. Boys’ shoes run from 2½ to 5½; men’s from 6 to 11 in regular runs. Larger sizes usually are made upon special orders. Some few manufacturers[86] go to 12. Women’s sizes run from 2½ to 9. Some manufacturers do not go above size 8. The rate of sizes is sometimes varied from by manufacturers of special lines of shoes. A man’s No. 8 shoe would be nearly eleven inches long. These measurements originated in England and are not now absolute.

A system of French sizes is used which consists of a cipher system of markings to indicate the sizes as well as widths so that the real size may not be known to the customer.