*** START OF THE PROJECT GUTENBERG EBOOK 55541 ***

[i]

SKETCH OF DRY ROT FUNGUS

On basement floor joist in house, at Greenwich, near London

Feb 1875.

END OF JOIST

Crumbled into fine red powder, with slight rubbing.

TOP OF JOIST.

Portion of fungus near the edge was torn away on removal of floor boards,

the undersides of which were covered with fungus, as well as the sides of nearest joist 10ins. distant.

Portion of fungus near the edge was torn away on removal of joist.

Fungus covered top and sides of sleeper joist.

Colours of fungi. White, yellow, green, purple, and rusty red.

[ii]

A TREATISE

ON THE

ORIGIN, PROGRESS, PREVENTION, AND CURE

OF

DRY ROT IN TIMBER.

WITH REMARKS ON

THE MEANS OF PRESERVING WOOD FROM DESTRUCTION BY

SEA WORMS, BEETLES, ANTS, ETC.

BY

THOMAS ALLEN BRITTON,

LATE SURVEYOR TO THE METROPOLITAN BOARD OF WORKS, AND SILVER MEDALLIST OF THE

ROYAL INSTITUTE OF BRITISH ARCHITECTS IN 1854, 1856, AND 1870.

LONDON:

E. & F. N. SPON, 48, CHARING CROSS.

NEW YORK: 446, BROOME STREET.

1875.

[iii]

[iv]

THIS VOLUME

IS

Dedicated to

GEORGE VULLIAMY, Esq.,

VICE-PRESIDENT

OF THE

ROYAL INSTITUTE OF BRITISH ARCHITECTS;

AND

ARCHITECT

OF

THE METROPOLITAN BOARD OF WORKS;

AS A SLIGHT ACKNOWLEDGMENT

OF HIS

COUNSEL, SYMPATHY, AND FRIENDSHIP,

DURING MANY YEARS.

[v]

PREFACE.

In preparing this treatise on Dry Rot, the author has

endeavoured to place in as condensed a form as was consistent

with the nature of the subject, the knowledge and

information dispersed through a numerous collection of

writers who have treated thereon; he has also availed

himself of the assistance of professional friends, builders,

timber-merchants, foremen and carpenters; and, by so

doing, has been enabled to record several instances of the

progress and cure of dry rot. He has consulted many

valuable papers published during the last thirty years, in

the various professional journals in England, America,

France, and Germany, upon this important subject, and

has also obtained much useful information from the works

of Evelyn, Nicholson, Tredgold by Hurst, Papworth, Burnell,

Blenkarn, and other English writers upon timber;

Silloway, of North America; Porcher, of South America;

Du Hamel, De Moray, and De Lapparent, of France; and

several writers whose works will be referred to.

It is many years since a separate and complete work on

dry rot has been published, and those who are desirous of

inquiring into the matter are frequently at a loss where

to obtain any information. Existing works on the subject

are out of print, and although they can be seen at a few[vi]

professional institutes, they are beyond the reach of the

general public.

It has been the aim of the author in preparing this

treatise to give a fair hearing to every patentee, and he

has endeavoured to be as impartial as possible in recording

instances of failure and success. If he has erred in

any particular case, he will be happy, should this work

reach a second edition, to make any necessary correction.

The reader will probably find some things repeated in

the course of the work; this is in many cases unavoidable,

and in some advisable; for if by a little tautology important

truths can be impressed upon the mind of the

reader, the author will feel that his labour in preparing

this work has not been altogether in vain.

Modern authorities have been relied upon in preference

to ancient ones: the following sentence, written by the

late Sydney Smith, is quoted as a reason for so doing:

“Those who come first (our ancestors) are the young

people, and have the least experience. We have added

to their experience the experience of many centuries;

and, therefore, as far as experience goes, are wiser, and

more capable of forming an opinion than they were.”

20, Limes Grove, Lewisham,

May 14th, 1875.

[vii]

CONTENTS.

| CHAPTER I. |

| On the Nature and Properties of Timber |

Page 1 |

| CHAPTER II. |

| On the Gradual Rise and Development of Dry Rot |

14 |

| CHAPTER III. |

| On Felling Timber |

51 |

| CHAPTER IV. |

| On Seasoning Timber by Natural Methods, viz. Hot and Cold Air;

Fresh and Salt Water; Vapour; Smoke; Steam; Boiling; Charring

and Scorching, &c. |

63 |

| CHAPTER V. |

| On Seasoning Timber by Patent Processes, &c. |

105 |

| CHAPTER VI. |

| On the Means of Preventing Dry Rot in Modern Houses |

171 |

| CHAPTER VII. |

| On the Means of Preservation of Wooden Bridges, Jetties, Piles,

Harbour Works, &c., from the Ravages of the Teredo navalis and

other Sea-worms |

203 |

| [viii]CHAPTER VIII. |

| On the Destruction of Woodwork in Hot Climates by the Termite or

White Ant, Woodcutter, Carpenter Bee, &c.; and the Means of

Preventing the Same |

240 |

| CHAPTER IX. |

| On the Causes of Decay in Furniture, Wood Carvings, &c.; and the

Means of Preventing and Remedying the Effects of such Decay |

262 |

| CHAPTER X. |

| Summary of Curative Processes |

283 |

| CHAPTER XI. |

| General Remarks and Conclusion |

288 |

| Index |

295 |

ILLUSTRATIONS.

| Dry Rot on Floor Joist |

Frontispiece |

|

To face page |

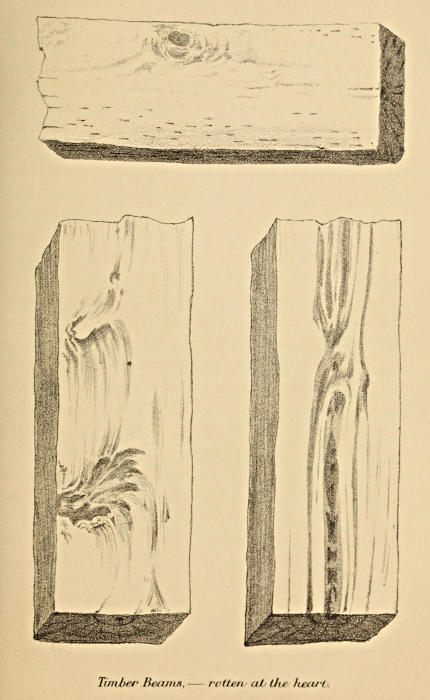

| Timber Beams—Rotten at the Heart |

34 |

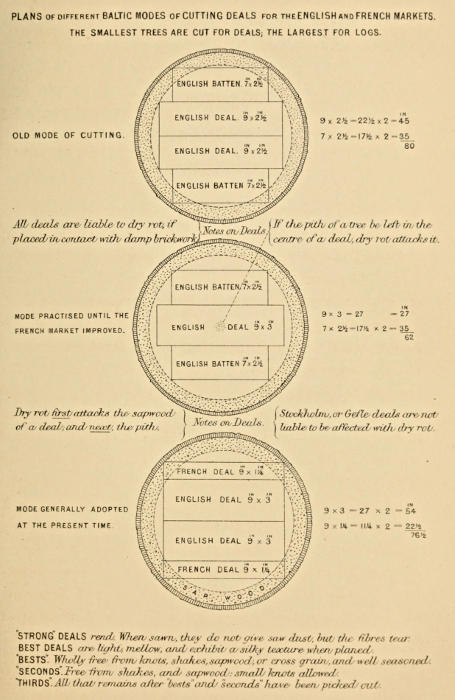

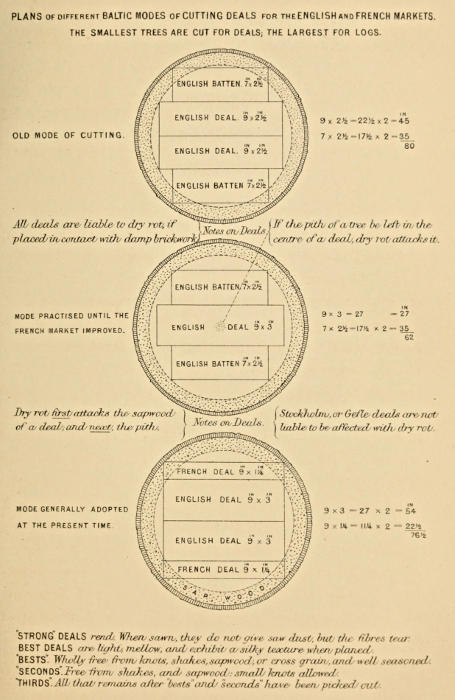

| Baltic Modes of Cutting Deals |

64 |

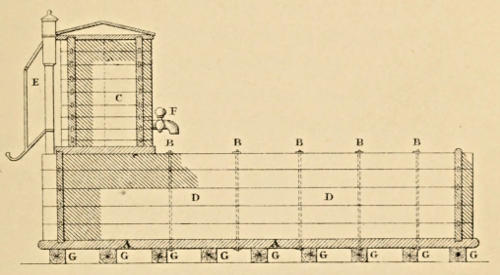

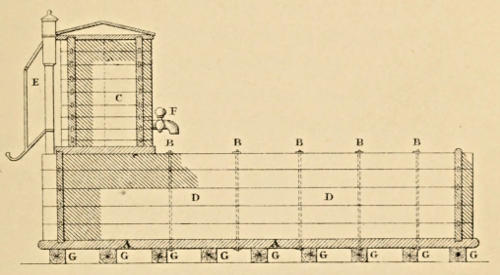

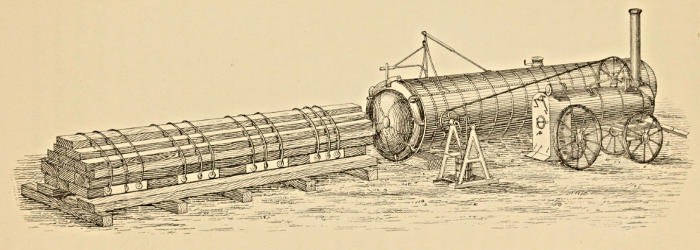

| Mr. Kyan’s Timber Preserving Tank |

126 |

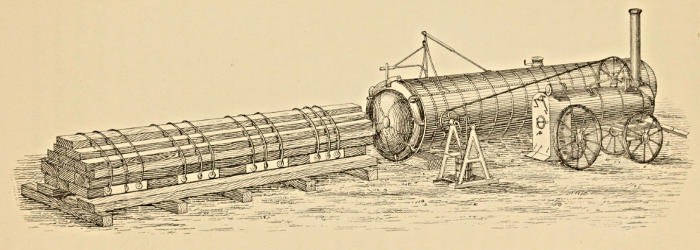

| Messrs. Bethell and Co.’s Timber Preserving Apparatus |

136 |

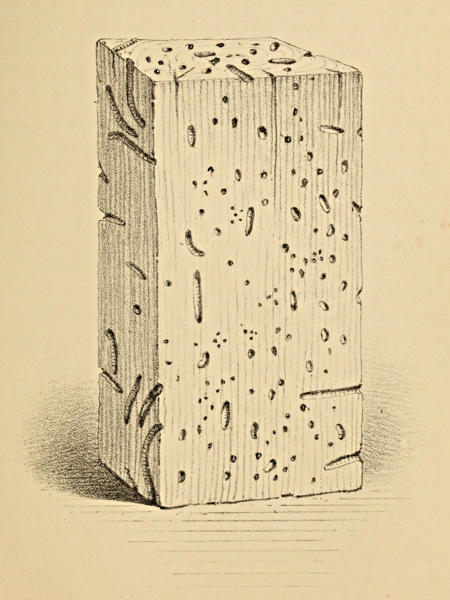

| Timber Piles from Balaclava Harbour |

208 |

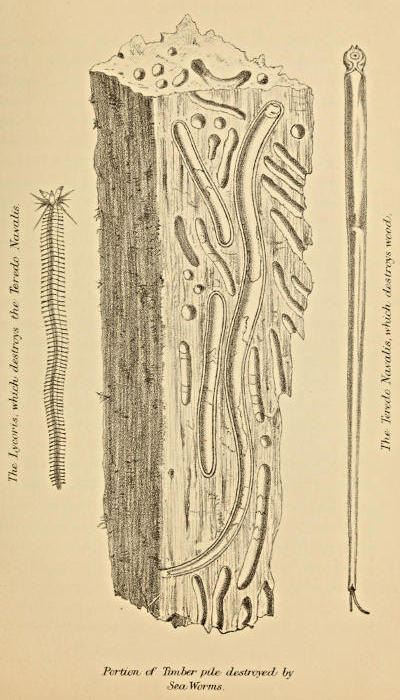

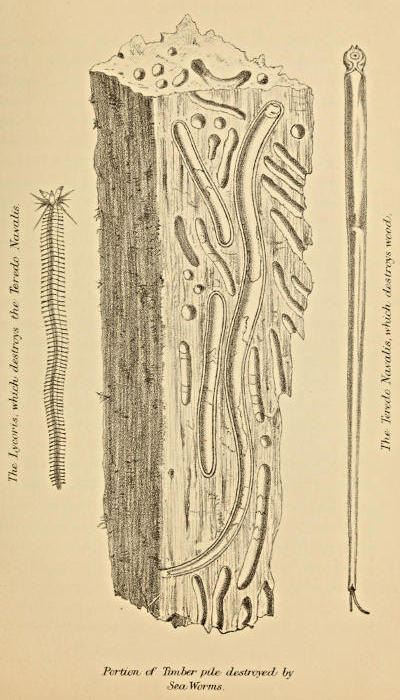

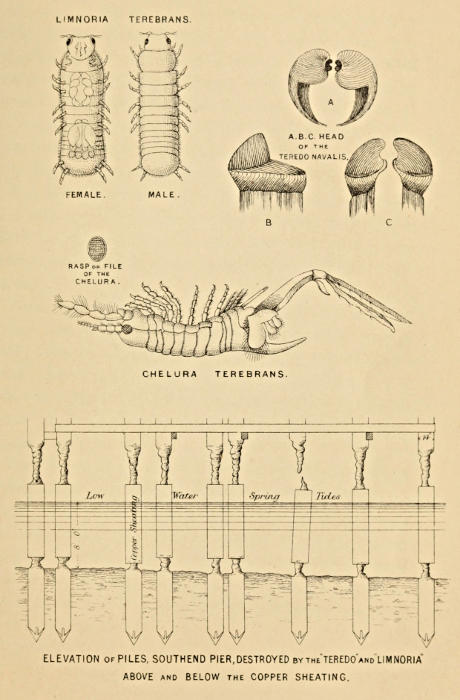

| Destruction of Timber Pile by Teredo |

212 |

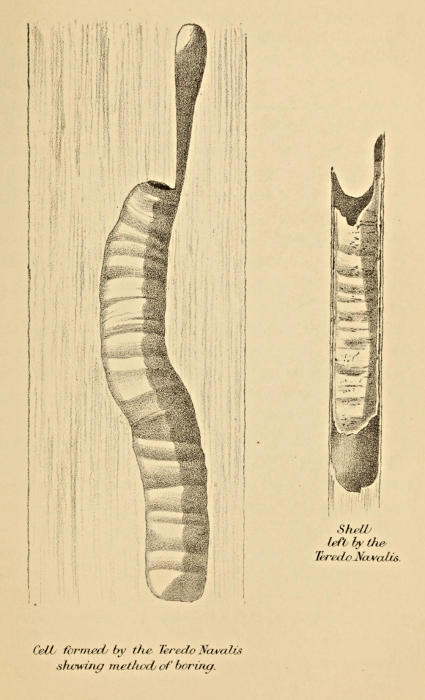

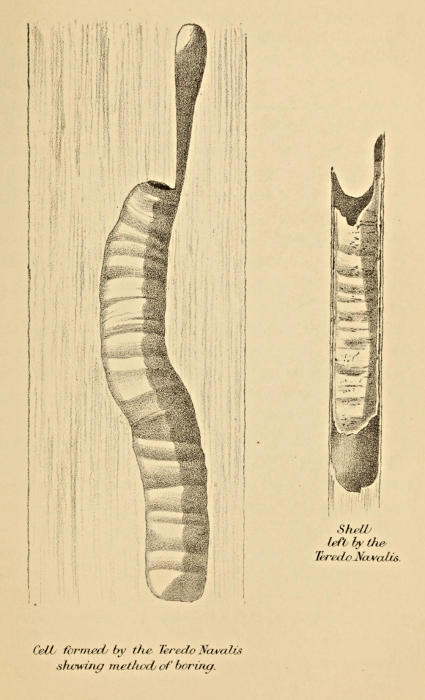

| Shell and Cell of Teredo navalis |

216 |

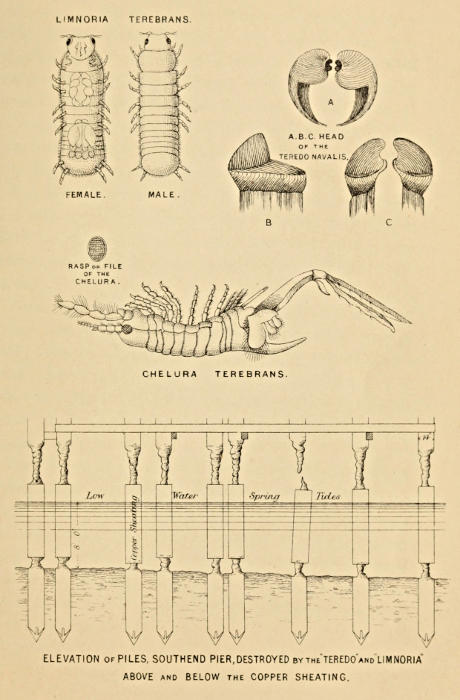

| Piles, Southend Pier; Limnoria, &c. |

220 |

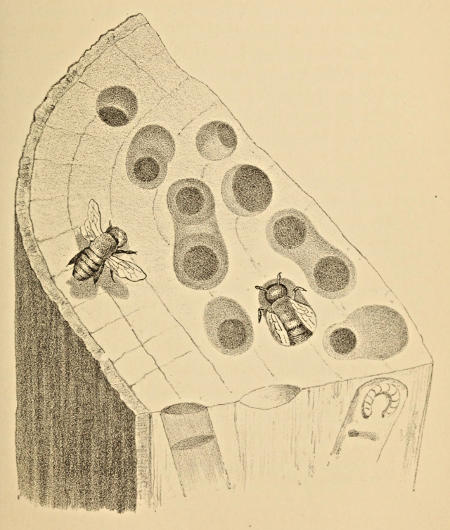

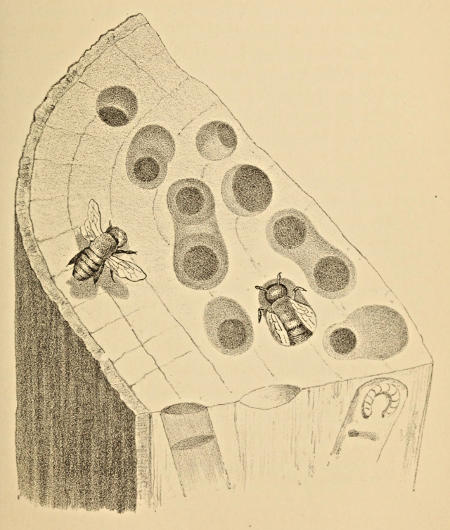

| Carpenter Bees at Work |

260 |

[1]

A TREATISE ON DRY ROT IN TIMBER.

CHAPTER I.

ON THE NATURE AND PROPERTIES OF TIMBER.

In considering the subject of Timber trees, we commence

with their Elementary Tissues, and first in order is the

Formative Fluid, which is the sole cause of production of

every tissue found in trees. It is semi-fluid, and semi-transparent,

and in this condition is found abundantly

between the bark and the wood of all trees in early spring;

and thus separates those parts so as to permit the bundles

of young wood to pass down from the leaves, and thus

enable the tree to grow. It is under these conditions

that the woodman strips the bark from trees which are to

be cut down, since then it does not adhere to the wood.

The first step in the formation of any tissue from the

formative fluid is the production of a solid structureless

fabric called Elementary Membrane, and a modification of

that fabric termed Elementary Fibre.

The structures which are produced from the above-mentioned[2]

“raw material” are very varied in appearance,

and are called Cellular Tissues, to signify that they are

made up of hollow cells. The spaces between the cells are

called Intercellular Spaces, which are of vital importance,

as they contain air. Woody fibre constitutes the mass of

the stems of our forest trees. Its peculiar characteristic

is that of great tenacity, and power of resistance, and for

this its structure is admirably adapted: it consists of

bundles of very narrow fibres, with tapering extremities,

and is so placed from end to end, that the pointed ends

overlap each other. Each fibre is very short, and the partitions

which result from the apposition of the fibres, end to

end, do not interfere with the circulation through them.

The tube is not composed of simple thin membranes only;

but in addition has a deposit within it, which, without

filling the tube, adds very greatly to the strength of the

fibre: an arrangement whereby the greatest strength and

power of resistance and elasticity shall be obtained; and,

at the same time, the functions of circulation uninterruptedly

maintained. The strength is mainly due to the

shortness of each fibre, the connection by opposite ends of

many fibres, almost in one direct line, from the root upwards;

and lastly, to the deposit on the inner side of the

membrane. The uses of woody fibre are very varied and

most important; it is the chief organ of circulation in all

wooded plants, and, for this purpose, pervades the plant

from the root to the branches. The current in this tissue

is directed upwards from the shoot, through the stem to

the leaves, and downwards from the leaves through the

bark to the root. Thus, its current has a twofold tendency;[3]

the ascending and chief one being for the purpose

of taking the raw, or what is called the common sap, from

the ground to be digested in the leaves, and the descending

being devoted to the removal from the leaves of the

digested, or what is termed the proper sap, to be applied

to the purposes of the tree, and also of the refuse matter

to be carried to the roots, and thence thrown out into the

soil as a noxious material. The proper sap differs considerably

in different trees; it is always less liquid, and

contains a much greater proportion of vegetable matter

than the common sap. It is very probable that trees of

the same kind produce proper sap of different qualities in

different climates.

Woody Fibre may be considered the storehouse of the

perfected secretions. It is well known that as trees advance

in life, the wood assumes a darker colour, and more

particularly that lying near to the centre of the stem.

This is due to the deposit of the perfected juices in the

woody fibre at that point; and where age has matured the

tree, it is probable that the woody fibre so employed is no

longer fitted for the circulation of the sap; and, also, that

the perfected sap, when once deposited, does not again join

in the general circulation. The dark colour of the heart

of oak, as contrasted with oak of very recent growth, is an

illustration of this fact, as is also the deep colour which is

met with in ebony and rose-wood. Technically, the inner

wood is called the heart-wood, and the outer or younger

wood the sap-wood. Of these, the former contains little

fluid, and no vegetable life, and, being the least liable to

decay, is therefore the most perfect wood; the latter is[4]

soft and perishable in its nature, abounding in fermentable

elements; thus affording the very food for worms,

whose destructive inroads hasten its natural tendency to

decay.

The proportion of sap-wood in different trees varies very

much. Spanish chestnut has a very small proportion of

sap-wood, oak has more, and fir a still larger proportion

than oak; but the proportions vary according to the situation

and soil, and according to the age at which they have

been felled: for instance, the teak tree in Malabar, India,

differs from teak in Anamalai, South India. This subject

has been very fully treated by Mr. Patrick Williams, in

his valuable work on Naval Timber.

Wooded Stems are divided into two great and well-defined

classes, according to their internal conformation,

viz. such as grow from without (exogenous), and such as

enlarge from within (endogenous). The former are more

common in cold, and the latter in hot climates.

Exogenous Stems.—On examining a section of a stem

of an oak, or any other of our forest trees, we observe the

following parts: first, the pith, or its remains in the centre;

second, the bark on the outside; third, a mass of wood

between the two, broken up into portions by the concentric

deposition of the layers, and by a series of lines which pass

from the centre to the circumference. Thus, there are

always pith, bark, wood, and medullary rays. Each stem

has two systems, the cellular or horizontal, and the

vascular or longitudinal, and the parts just mentioned

must belong to one or other of those systems. Thus,

the pith, medullary rays, and bark belong to the horizontal[5]

system; and the wood constitutes the longitudinal

system.

The Pith occupies the centre of the stem, and remains

throughout the period of growth of some trees, as of the

elder; or is abstracted after a few years, as in the oak,

and almost all large trees. In the latter class of trees,

there are some remains of the pith for many years after

the process of absorption has commenced, but at length no

vestige can be detected, and its position is known only

by the central spot around which the wood is placed in

circles. In the old age of the tree the pith frequently

assumes a colour which it has obtained from the juices

which have been deposited. The connections of the pith

are extremely important. Firstly, it is in direct connection

with every branch, and is the structure which first conveys

fluids to, and receives fluids from every new leaf. It

thence becomes the main organ of nutriment, and, at the

same time, the chief depository of the secretions. Secondly,

it is in equally direct and unbroken connection with the

bark, through the medium of the medullary rays; and so

becomes the centre of all the movements of sap which

proceed in the horizontal system.

The mode in which the ultimate disappearance of the

pith occurs has been a matter of speculation. That the

circulation in the heart-wood ceases after a certain

number of years, and that the connection between it and

the bark becomes broken, is proved by the fact that

numbers of trees may be found in tolerably vigorous

growth within the bark, whereas at the heart they are

decayed and rotten. It appears clear that it is not converted[6]

into wood, and there are facts against the opinion

that it is gradually compressed by the wood; but since it

is known that in the growth of the tree much compression

of the previously formed wood must occur, and since this

compression is a likely theory by which to account for the

disappearance of the less resisting pith, it is now generally

considered to be one of the causes of this occurrence. As

a general rule, the pith, so long as it exists, is not mingled

with other than cellular structures; but, in certain

instances, wooden fibre has been found with it, and, in

others, spiral vessels have been detected.

Medullary Sheath.—Immediately surrounding the

pith of all exogenous plants, there is a layer of longitudinal

tissue, which has received the name of medullary

sheath. This sheath has no special walls, but is bounded

by the pith on the inner, and the wood on the outer side.

It is in this situation that ducts of various kinds and

spiral vessels may be found, and in all cases it conveys the

longitudinal structure from the root, direct to each leaf.

The integrity of this structure is therefore highly necessary

to the life of the tree.

Medullary Rays.—These structures come next in

order, and, as has been previously intimated, belong to

the horizontal cellular system of the stem; they constitute

the channel of communication between the bark and the

pith, and are composed of a series of walls of single cells

resting upon the root, and proceeding to the top of the

tree, and radiating from the centre. They lie between

the wedge-like blocks of wood, and as they have a lighter

colour than the wood, they are evident on an oblique section[7]

of any stem, and are called the silver grain. Their

colour and number suffice to enable anyone to distinguish

various kinds of wood, and greatly increase their beauty.

They cannot, of course, exist before the wood is formed,

and are therefore not met with in very young trees. They

commence to exist with the first deposited layers of wood,

and continue to grow outwardly, or nearest to the bark, so

long as the wood continues to be deposited. In those

woods which possess in abundance the silver grain,

another source of ornament exists, viz. a peculiar damask

or dappled effect, somewhat similar to that artificially

produced on damask linens, moreens, silks, and other

fabrics, the patterns on which result from certain masses

of the threads on the face of the cloth running lengthways,

and other groups crossways. This effect is observable

in a remarkable degree in the more central planks of

oak, especially in Dutch wainscot.

The Bark.—As the medullary rays terminate in the

bark, on their outer side, the consideration of that part

next follows. It forms the sheath of the tree, and its

more immediate use is that of giving protection to the

wood. If bark did not exist, there would be no formative

fluid, and without formative fluid there could not be

any deposit of woody fibre.

Wood.—We find wood occupying nearly the whole

body of the trunk of the tree, and arranged, as a rule, in

a very regular manner. On taking up any piece of wood,

but more particularly the entire section of a stem, we

first notice a series of circles, which increase in diameter

and separate by wider intervals as we approach the bark.[8]

In this manner the trunk is composed of numerous zones

enclosed within each other. Again, in almost all trees,

the medullary rays before mentioned may be observed

passing in straight lines from the centre to the circumference;

and, as the circle of the stem at the bark is much

larger than any circle near to the centre, it follows that

the medullary rays will be wider apart at the bark than

at the pith. On this view of the subject it may be stated

that the stem is composed of a series of wedge-shaped

blocks, which have their edges meeting at the centre.

The combination of these two views gives the correct idea

of the arrangement of the wood, viz. a series of wedges,

each divided into segments of unequal width by circular

lines passing across them. From this description it must

not be imagined that these various portions are detached

from each other; for although the medullary rays and the

circular mode of deposition both tend to a less difficult

cleavage of the wood, they yet bind the parts very closely

to each other.

The explanation of the occurrence of distinct zones of

wood is, that each zone is the produce of one year, and

that in our climate, more so than in tropical climates, the

period of growth of wood ceases for many months between

the seasons, and this induces a distinction in appearance

between the last wood of a former, and the first wood of a

succeeding year. This distinction is maintained throughout

each year, and throughout a long series of years.

The enclosure of zone within zone, is owing to the

mode in which the wood is produced, and the position in

which it is deposited. Wood is formed by the leaves[9]

during the growing season, and passes down towards the

root between the bark and the wood of the previous year;

and, as the leaves more or less surround the whole stem,

the new layer at length completes a zone, and perfectly

encloses the wood of all former years. This is the explanation

of the term exogenous, which is derived from

two words signifying to grow, outwardly, for the stem

increases in thickness by successive layers on the outer

side of the previously formed wood.

The thickness of the zone for the year is rarely equal

around the whole circumference of the stem, and this is

due to the lesser abundance of leaves on the branches of

one side than on the other, or to the prevalence of winds,

or some other physical cause, acting in that direction in

opposition to the growing process. It should be observed

that there is not in timber any appearance of a gradual

change from alburnum to perfect wood. On the contrary,

in all cases the division is most decided; one concentric

layer being perfect wood, and the next in succession sap-wood.

The age of trees has been inferred, when a section of

the whole stem could be examined, by counting the

number of rings of wood which have been deposited

around the pith. In tropical countries, however, this

method cannot be always relied upon.

Woods are variable in quality according to the nature

of the climate, and of the soil, as also in a considerable

degree to the aspect in which they are situated. Trees

grown slowly in open, dry, and exposed situations are

more fine and close in their annual rings, and more substantial[10]

and durable, than those which are grown in close

and shady forests, or rapidly reared in moist or sappy

places, the latter being soft and broad in their rings, and

very subject to decay; and their pith is not always quite

in the centre, for the layers are variable also.

The waggon maker takes care to combine toughness

and durability by selecting his wood from trees of second

growth, or from trees of first growth that from infancy

have stood alone, or far apart. If the soft wood trees have

stood alone, and are very large (as is often the case with

some of the pines), and most of the branches are near the

top, the wood near the base of the trunk is sometimes

found to be shaky. This defect is produced by the action

of heavy winds on the top of the tree, which wrenches or

twists the butt, and thus cleaves apart the fibres of the

wood. If the main-top (couronnement, of French writers)

of a tree dies while the tree is yet standing, it indicates

that water has found its way into the trunk, and that the

tree is in a state of decay.

The fir which grows on very dry marl, forms very

narrow yearly rings; if on rich or damp marl, they are

wide; and when on wet soil, they are again smaller. The

common fir on moor soil, has even smaller yearly rings

than if on dry sand or marl. From this it is evident

that too wet or too dry a soil is not suitable for this tree.

The alder and the willow grow best on wet soil, and

thrive but poorly when standing dry.

The weight of wood is of great importance, because its

hardness, resistance, and its heating power, as well as

other valuable properties, are all more or less depending[11]

upon it. In the first place, we must consider that even

wood which has been forested very light will become

heavy, when put for some time into water, but in such

timbers the sap is already given to dissolution. If the

fibre were the only substance in the wood, then the specific

weight would depend upon the number of pores contained

in its body; the pores are, however, filled with a substance

such as resin, die, &c. Some years since, when the Indian

railways were being formed, the native wood-cutters were

so well aware of the above-mentioned fact, that they used

to cut down the soft and inferior woods in the forests; soak

them in water for a certain time; and then endeavour to

pass them to the railway contractors as sound, heavy, and

good railway sleepers, and the latter, not being acquainted

with the Indian woods, were, at first, often deceived.

The hardest, and heaviest woods come from the hotter

climates; the only exception is the pine, which thrives considerably

better, and furnishes heavier timber, when it has

grown in colder regions, or upon high mountains.

Trees grown on northern slopes furnish lighter timber

than if grown on southern or western. The soil has great

influence upon the width of the yearly rings, and from

this we are able to come to a conclusion in regard to the

specific weight. In the fir and larch trees the wood is

heaviest when their rings are smallest.

The difference in the strength of timber between the

south and the north side is attributable to the grain being

closer on the north side, as the sap does not rise in the

same proportion as upon the south. In forest-grown

wood the difference is almost imperceptible, as the sun[12]

cannot act upon the trunk of the tree; in open-grown

timber, the difference is really perceptible. It is well

known that all woods do not lose strength by being open

grown, or, in other words, that the south side is not always

weaker than the north; that theory only applies to the

coniferæ species. In ash it is the opposite, as the south

side is the strongest. In soft-wooded trees, as the acer

species, the difference is not perceptible, as the annual

rings, and the intervening cellular tissues, are so close

akin as to render the wood so compact in its grain that

there is no difference in its strength. The coniferæ

species, or the pines, are the only classes of woods that

are stronger on the north side than on the south: it is

well known that the difference originates in the wood

being more open in the grain on the south side than on

the north.

An influence upon the specific weight is exercised by

the resin, and the die, which are contained in the interior

of the wood. On level dry ground, or deep sandy soil,

we find the fir beautifully red inside; but when we look

at it on lias soil, it shows broad yearly rings, and hardly

any colour at all. The larch tree, again, in such soil,

develops itself well with a rich colour. The cause for

these appearances must therefore rest with the chemical

condition of the soil, and its effect upon the individuality

of the fir: it is probably the nature of the soil that causes

the difference of character between Honduras and Spanish

mahogany; Honduras being full of black specks, and

Spanish of minute white particles, as if it had been

rubbed over with chalk. Oaks generally furnish good[13]

timber when grown slowly in dry ground, whilst those

from wet soil appear comparatively spongy; similar results

are obtained with other trees.

Many persons constantly employed on wood are of

opinion that it becomes harder if it is worked or barked

whilst green.

It is not safe to condemn timber, merely because long

cracks are visible on the surface. Such openings are

frequently only superficial, and do not penetrate deeply

into the wood: in such cases it is very little weakened

thereby. It is difficult to obtain timber of large scantling

without some defects of this kind, but care should be

taken to ascertain if they are of a serious nature.

Trees arrive at an age when their wood becomes ripe,

and then they are fit for felling; but as upon the proper

method and time for doing this, the prevention of dry rot

frequently hinges, a separate chapter is devoted to this

part of the subject.

[14]

CHAPTER II.

ON THE GRADUAL RISE AND DEVELOPMENT OF

DRY ROT.

The opinion generally received has drawn a line of discrimination

between the decay accompanied by a vegetable

spreading on the surface of the timber, and that which is

effected by an animal existing within it, which decay is

frequently denominated the worm in timber; but as each

is equally entitled to the dreaded appellation, they might

more justly be distinguished as the animal and vegetable

rot.

The dry rot in timber derives its name from the effect

produced, and not from the cause: it is so called in opposition

to the wet rot, which is properly denominated, as

this exists only in damp situations, and is applied to the

decomposition which takes place in timber containing sap,

and exposed to moisture: but although the dry rot is

usually generated in moisture, in some cases it will flourish

independent of extraneous humidity. Dry rot differs

from wet rot in this respect, that the former takes place

only when the wood is dead, whereas the latter may begin

when the tree is standing.

Wet rots are composed of porous fibre running from the

rot into the trunk of the tree. This rot is of a brown

colour, and has an offensive smell. The evil is often[15]

found with white spots, the latter of watery substance:

when it has yellow flames, it is very dangerous.

A large quantity of the vegetable kingdom consists

of plants differing totally from the flowering plants in

general structure, having no flowers and producing no

seed properly so called, but propagating by means of

minute cellular bodies, called spores. These highly organized

vegetables are known to botanists as Cryptogamia.

Fungi are plants in which the fructifying organs are so

minute, that without the aid of a powerful microscope

they cannot be detected. To the naked eye, the fine dust

ejected from the plant is the only token of reproduction;

this dust, however, is not truly seed, for the word seed

supposes the existence of an embryo, and there is no such

thing in the reproductive bodies of fungi. The correct

terms are spores, when the seeds are not in a case; sporidia

when enclosed in cases. The spores or sporidia are placed

in or upon the receptacle, which is of very various forms

and kinds, but how different soever these may be, it is the

essential part of the fungus, and in many cases constitutes

the entire plant. That portion of the receptacle in which

the reproductive bodies are imbedded is called the

hymenium: it is either external, as in the Agaric, where

it forms gills; or included, as in the puff-balls. The

pileus of fungi is the entire head of the plant, not a

mere head covering.

Some naturalists have insisted upon the spontaneous

production of fungi, while others maintain that they are

produced by seed, which is taken up and supported in the

air until a soil proper for its nourishment is presented, on[16]

which being deposited it springs up of various appearances

according to the principle of the seed, and the nature of

the recipient.

It is extremely difficult to give a logical definition of

what constitutes a fungus. It is not always easy with a

cursory observation under the microscope, to determine

whether some appearances are produced by fungi, insects,

or organic disease; experience is the safest guide, and

until we acquire that we shall occasionally fail.

In the ‘Index Fungorum Britannicorum,’ 2479 species

of British fungi are enumerated: any detailed account of

the arrangement of this extensive family of plants, or

of the character of even its principal sections would be

impossible within the limits of this volume; all that can

be attempted will be a general description of the fungi

causing dry rot.

If dry rot shows itself in a damp closet or pantry, the

inside of the china or delf lying there will be coated

with a mould, or a fine powder like brick-dust. This

excessively fine powder is no other than unaccountable

myriads of the reproductive spores or seeds of the fungus;

they are red in colour, and are produced on the surface

of the fungus in millions. Certain privileged cells on the

face of the fungus are furnished each with four minute

points at their apex, each four bearing a single brick-red,

egg-shaped spore; so that the fruit is spread over the

surface of the fungus in groups of fours. To see the

form of these spores the highest powers of the microscope

are required, and then they can only be viewed as transparent

objects. If these excessively minute bodies be[17]

allowed to fall on wet flannel, damp blotting-paper, or

wet wood, they immediately germinate and proceed to

reproduce the parent fungus. The red skin of the spores

cracks at both ends, and fine mycelial filaments are sent

out: this is the “mould,” spawn, or mycelium from

which the new fungus (under favourable conditions of continued

moisture) appears.

It matters little where we go: everywhere we are

surrounded with life. The air is crowded with birds and

insects; the waters are peopled with innumerable forms,

and even the rocks are blackened with countless mussels

and barnacles. If we pluck a flower, in its bosom we see

many a charming insect. If we pick up a fallen leaf,

there is probably the trace of an insect larvæ hidden in

its tissue. The drop of dew upon this leaf will probably

contain its animals, visible under the microscope. The

very mould which covers our cheese, our bread, our jam,

or our ink, and disfigures our damp walls, is nothing but

a collection of plants.

The starting point of life is a single cell-that is to say

a microscopic sac filled with liquid and granules, and

having within it a nucleus, or smaller sac. From this

starting point of a single cell, this is the course taken:

the cell divides itself into two, the two become four, the

four eight, and so on, till a mass of cells is formed.

The researches of Pasteur show that atmospheric dust

is filled with minute germs of various species of animals

and plants, ready to develop as soon as they fall into a

congenial locality. He concludes that all fermentation is

caused by the germination of such infinitesimal spores.[18]

That they elude observation does not seem strange, when

we consider that some infusoria are only ⅟240000 of an

inch in length.

It is ascertained that fungi produce seed which contains

the properties of germination; and that vegetable corruption

is suited to effect it. When we contemplate the

fineness and volatility of the germs, the hypothesis will

not appear unreasonable that they are conveyed by the

rains into the earth, and are absorbed by vegetables;

that with the sap they are disseminated throughout the

whole body, and begin to germinate as soon as the

vegetable has proceeded to corruption. Whatever, therefore,

may be the appearance or situation of the fungus

producing the dry rot, or from whatever substance it

originates, that substance must be in a corrupt state.

Fungi result from, or are attendant on, vegetable corruption,

assisted by an adequate proportion of heat and

moisture. The sap, or principle of vegetation, brought

into activity, is, according to the ‘Quarterly Review,’

No. 15, the cause of dry rot, in as far as it is favourable

to the growth of fungi, as it would seem to be when in a

state of fermentation.

Vegetable corruption invariably presupposes fermentation.

Fermentation is a state of vegetable matter, the component

parts of which have acquired sufficient force to

produce an intestinal motion, by which the earthy saline,

the oily and aqueous particles therein contained, exert

their several peculiar attractive and repulsive powers,

forming new combinations, which at first change, and at[19]

length altogether destroy the texture of the substance

they formerly composed.

There are two things essential towards creating and supporting

the intestinal motion, namely, heat and humidity;

for without heat, the air, which is supposed to be the

cohesive principle of all bodies, cannot be so rarefied as to

resume its elasticity; and without humidity there can be

no intestinal motion.

According to Baron Liebig, the decay of wood takes

place in the three following modes:—First, oxygen in the

atmosphere combines with the hydrogen in the fibre, and

the oxygen unites with the portion of carbon of the fibre,

and evaporates as carbonic acid: this process is called

decomposition. Second, we have to notice the actual decay

of wood which takes place when it is brought in contact

with rotting substances; and the third process is called

putrefaction. This is stated by Liebig to arise from the

inner decomposition of the wood in itself: it loses its

carbon, forms carbonic acid gas, and the fibre, under the

influence of the latter, is changed into white dust.

The fungus occasioning the dry rot is of various appearances,

which differ according to the situation in which it

exists. In the earth, it is fibrous and perfectly white,

ramifying in the form of roots; passing through substances

from the external surface, it somewhat differs

from that form; here it separates into innumerable small

branches.

Mr. McWilliam observes, “If the fungi proceed from

the slime in the fissures of the earth, they are generally

very ramous, having round fibres shooting in every[20]

direction. If they arise from the roots of trees, their first

appearance is something like hoar frost; but they soon

assume the mushroom shape.”

Hence it appears that we frequently build on spots of

ground which contain the fundamental principle of the

disease, and thus we are sometimes foiled in our endeavours

to destroy the fungus by the admission of air. In

this case the disease may be encouraged by the application

of air as a remedy. When workmen are employed

in buildings which contain dry rot, and when they are

working on ground which contains the symptoms of this

disease, their health is often affected. A London builder

informs us, that a few years since, while building some

houses at Hampstead his men were never well: he afterwards

ascertained that the ground was affected with rot,

and that within one year after the house was erected, all

the basement floor was in a state of premature decay.

Sir Robert Smirke, architect, remarked in 1835, that he

had noticed “there are certain situations in which dry rot

prevails remarkably.”

The fungus protruded in a very damp situation is fibrous,

of moderate thickness, feels fleshy. From the spot whence

it arises it extends equally around, wholly covering the

area of a circle. This form would possibly continue in

whatever situation it might vegetate, if the air had no

motion, and every part of the substance on which it grew

were equally supplied with a matter proper to encourage

the expansion. The surface of this fungus is pursed, and

of various colours, the centre is of a dusky brown, mixed[21]

with green, graduated into a red, which degenerates into

yellow, and terminates in white.

One of the most formidable of the tribe of fungi is the

Merulius lachrymans (often called the Dry Rot) of which

the following description is given by Dr. Greville: “Whole

plant generally resupinate, soft, tender, at first very light,

cottony, and white. When the veins appear, they are of a

fine yellow, orange, or reddish brown, forming irregular

folds, most frequently so arranged as to have the appearance

of pores, but never anything like tubes, and distilling,

when perfect, drops of water.” Hence the term lachrymans,

from lacrymo, Lat., I weep: the Merulius lachrymans is

often dripping with moisture, as if weeping in regret for

the havoc it has made. In the genus Merulius, the texture

is soft and waxy, and the hymenium is disposed in porous

or wavy toothed folds. Berkeley, in his ‘Fungology,’

gives the following description, which is similar to Dr.

Greville’s: “Large, fleshy but spongy, moist, ferruginous

yellow, arachnoid and velvety beneath; margin tomentose,

white; folds ample, porous, and gyroso-dentate.” The

Merulius is found in cellars and hollow trees, sometimes

several feet in width, and is the main cause of dry rot.

Another formidable fungi, which attacks oak in ships,

is the Polyporus hybridus (the dry rot of our oak-built

vessels). It is thus described by Berkeley: “White,

mycelium thick, forming a dense membrane, or creeping

branched strings, hymenium breaking up into areæ, pores

long, slender, minute.”

From the slow progress dry rot makes in damp situations,[22]

it appears that excessive damps are inimical to the

fungus, for its growth is more rapid in proportion as the

situation is less damp, until arrived at that certain degree

of moisture which is suited both to its production and

vegetation. When further extended to dry situations, its

effects are considerably more destructive to the timber on

which it subsists: here it is very fibrous, and in part

covered with a light brown membrane, perfectly soft and

smooth. It is often of much greater magnitude, projecting

from the timber in a white spongeous excrescence, on the

surfaces of which a profuse humidity is frequently observed:

at other times, it consists only of a fibrous and thin-coated

web irregularly on the surface of the wood. Excrescences

of a fungiform appearance are often protruded amidst those

already described, and are evidences of a very corrupt

matter peculiar to the spots whence they spring. According

to the situation and matter in which they are produced,

they are dry and tough, or wet, soft, and fleshy, sometimes

arising in several fungiforms, each above the other, without

any distinction of stem; and when the matter is differently

corrupted, it not unfrequently generates the small acrid

mushroom.

Mr. McWilliam observes, “The fungi arising from oak

timbers are generally in clusters of from three to ten or

twelve; while those from fir timber are mostly in single

plants: and these will continue to succeed each other

until the wood is quite exhausted.”

Damp is not only a cause of decay, but is essential to

it; while, on the other hand, absolute wet, especially at a

low temperature, prevents it. In ships this has been particularly[23]

remarked, for that part of the hold of a ship

which is constantly washed by the bilge-water is never

affected with dry rot. Neither is that side of the planking

of a ship’s bottom which is next the water found in a

state of decay, even when the inside is quite rotten, unless

the rot has penetrated quite through the inside.

It matters little whether wet is applied to timber before

or after the erection of a building. Timber cannot resist

the effect of what must arise in either case; viz. heat and

moisture, producing putrid fermentation; for instance, in

basement stories with damp under them, dry timber is but

little better than wet, for if it is dry it will soon be wet;

decay will only be delayed so long as the timbers are

absorbing sufficient moisture, therefore every situation

that admits moisture is the destruction of timber.

In a constancy and equality of temperature timber will

endure for ages. Sir Christopher Wren, in his letter to

the Bishop of Rochester, inserted in Wadman’s ‘History

of Westminster Abbey,’ notices “That Venice and

Amsterdam being both founded on wooden piles immersed

in water, would fall if the constancy of the situation of

those piles in the same element and temperature did not

prevent the timber from rotting.” Nothing is more

destructive to woodwork than partial leaks, for if it be

kept always wet or always dry, its duration is of long continuance.

It is recorded that a pile was drawn up sound

from a bridge on the Danube, that parted the Austrian

and Turkish dominions, which had been under water 1500

years.

The writer of an article on the decay of wood, in the[24]

‘Encyclopædia Britannica,’ 1855, observes, “If a post of

wood be driven into the ground, the decay will commence

at the surface of the ground; if driven into the earth

through water, the decay will commence at the surface of

the water; if used as a beam let into a damp wall, rot

will commence just where the wood enters the wall.”

Humboldt observes in his ‘Cosmos,’ with reference to

damp and damp rooms, that anyone can ascertain whether

a room is damp or not, by placing a weighed quantity of

fresh lime in an open vessel in the room, and leaving it

there for twenty-four hours, carefully closing the windows

and doors. At the end of the twenty-four hours the lime

should be reweighed, and if the increase exceeds one per

cent. of the original weight, it is not safe to live in the room.

Decay of timber will arise from the effects of continued

dryness or continued wetness, under certain conditions; or

it may also arise from the effect of alternate dryness and

moisture, or continued moisture with heat.

At one time dry rot appears to have made great havoc

amongst the wooden ships of the British Navy. In the

Memoirs of Pepys, who was Secretary to the Admiralty

during the reigns of Charles II. and James II., reference

is made to a Commission which was appointed to inquire

into the state of the navy, and from which it appears that

thirty ships, called new ships, “for want of proper care

and attention, had toadstools growing in their holds as big

as one’s fists, and were in so complete a state of decay,

that some of the planks had dropped from their sides.”

In the ‘European Magazine’ for December, 1811, it is

stated that, “about 1798, there was, at Woolwich, a ship[25]

in so bad a state that the deck sunk with a man’s weight,

and the orange and brown coloured fungi were hanging,

in the shape of inverted cones, from deck to deck.”

Mr. William Chapman, in his ‘Preservation of Timber

from Premature Decay,’ &c., gives several instances of the

rapid decay of the ships of the Royal Navy, about the

commencement of the present century. He mentions

three ships of 74 guns each, decayed in five years; three

of 74 guns each, decayed in seven years; and one of 100

guns, decayed in six years. Mr. Pering, also, in his ‘Brief

Enquiry into the Causes of Premature Decay,’ &c., says

that ships of war are useless in five or six years; and he

estimates the average duration to be eight years, and that

the cost of the hull alone of a three-decker was nearly

100,000l. Mr. Pering was formerly at the dockyard,

Plymouth, and therefore a good authority, if he availed

himself of the opportunities of studying the subject. He

has stated that he has seen fungi growing so strong

betwixt the timbers in a man-of-war, as to force a plank

from the ship’s side half an inch.

No doubt a great deal of this decay was attributable to

the use of unseasoned timber, and defective ventilation;

but there is too much reason to believe that it was principally

owing to the introduction of an inferior species of

oak (Quercus sessiliflora) into the naval dockyards, where,

we imagine, the distinction was not even suspected. The

true old English oak (Quercus robur) affords a close-grained,

firm, solid timber, rarely subject to rot; the other

is more loose and sappy, very liable to rot, and not half

so durable.

[26]

One cause of the decay of wood in ships is the use of

wooden treenails. A treenail is a piece of cleft wood

(made round), from 1 foot to 3 feet 6 inches in length

and 1½ inch in diameter. As the treenails are also

made to drive easy, they never fill the holes they are

driven into; consequently, if ever it admits water at the

outer end, which, from shrinking, it is liable to do, that

water immediately gets into the middle of the plank, and

thereby forms a natural vehicle for the conveyance of

water. The treenail is also the second thing which

decays in a ship, the first, generally, being the oakum.

Should any part of the plank or timbers of a ship be in an

incipient state of decay, and a treenail come in contact

with it, the decay immediately increases, while every

treenail shares the same fate, and the natural consequence

is, the ship is soon left without a fastening. Treenails in

a warm country are sure to shrink and admit water.

Mr. Fincham, formerly Principal Builder in Her

Majesty’s dockyard, Chatham, considers that the destruction

of timber by the decay commonly known as dry rot,

cannot occur unless air, (?) moisture, and heat are all

present, and that the entire exclusion of any of the three

stays the mischief. By way of experiment, he bored a

hole in one of the timbers of an old ship built of oak,

whose wood was at the time perfectly sound; the admission

of air, the third element, to the central part of the

wood (the two others being to a certain degree present)

caused the hole to be filled up in the course of twenty-four

hours with mouldiness, which very speedily became so

compact as to admit of being withdrawn like a stick.

[27]

The confinement of timber under most circumstances is

attended with the worst consequences, yet a partial ventilation

tends to fan the flame of decay.

The admission of air has long been considered the only

means of destroying the fungus, but as it has frequently

proved ineffectual, it must not be always taken as a certain

remedy. If dry air be properly admitted, in a quantity

adequate to absorb the moisture, it will necessarily exhaust

and destroy the fungus; but care should be taken

lest the air should be conveyed into other parts of the

building, for, after disengaging itself from the fungus

over which it has passed, it carries with it innumerable

seeds of the disease, and destroys everything which offers

a bar to its progress. Air, in passing through damps,

will partake of their humidity; it therefore soon becomes

inadequate to the task for which it is designed. Owing

to this circumstance, air has been frequently admitted into

the affected parts of a building without any ultimate

success; too often, instead of injuring the fungus, it has

considerably assisted its vegetation, and infected with the

disease other parts of the building, which would otherwise

probably have remained without injury. The timber,

which is in a state of decomposition by an intestinal

decay, is little affected by the application of air, as this

cannot penetrate the surrounding spongeous rottenness

which generally forms the exterior of such timber, and

protects the action which the humid particles have

acquired in the exterior: as the extent and progress of

the disease is therefore necessarily concealed, it is difficult

to ascertain correctly the effect produced by the admission[28]

of dry air. Under these circumstances of necessity and

danger, it will require considerable skill to effect the

purpose without increasing the disease, and, as each case

has its own peculiar characteristics, it is necessary before

one attempts to admit air as a remedy, to previously estimate

the destructive consequences which may result from

so doing, and ascertain whether it will be injurious or

beneficial to the building. The joists of the houses built

by our ancestors last almost for ever, because they are in

contact with an air which is continually changing. Now,

on the contrary, we foolishly enclose them between a

ceiling of plaster (always very damp to begin with) and

a floor; they frequently decay, and then cause the most

serious disasters, of which it is impossible to be forewarned.

Damp, combined with warmth, is as a destroying agent,

still more active than simple damp alone—the heat being

understood as insufficient to carry off the moisture by

evaporation; and the higher the temperature with a corresponding

degree of moisture, the more rapid the decay.

If the temperature to which wood is exposed, whilst any

sap remains in it, is too elevated, the vegetable fluids

ferment; the tenacity is diminished, and when the action

is carried to its full extent, the wood quickly becomes

affected by the dry rot. Exposure to the atmosphere

in positions where rain can lodge in quantity, contact

with the ground, and application in damp situations

deprived of air, will render wood liable to the wet rot;

and however well seasoned it may have been previously

to being brought within the influence of any of these[29]

causes, it will infallibly suffer. Air should therefore have

free access to the wood in every direction:

… “for without in the wall of the house he made narrowed rests

round about, that the beams should not be fastened in the walls of the

house.”—1 Kings vi. 6.

Rondelet says, “The woodwork of the church of St.

Paul, outside the city walls, which was destroyed by fire

in 1823, was erected as far back as the fifth century.”

Although the atmosphere surrounding the framework was

often at once warm and damp, yet it was never stagnant.

It should be remembered that 500 people in a church

during two hours give off fifteen gallons of water into the

air, which, if not carried away, saturates everything in

the building after it has been breathed over and over

again in conjunction with the impurities it contains collected

from each individual.

Fever, scrofula, and consumption arise in many instances

from defective ventilation.

The signs of decay in timber are, as has been stated,

fungi. Some of them now and then are microscopic, and

owe their existence to the sporules deposited on the

surface; while fermentation, generated by prolonged contact

with warm, damp, and stagnant air, is as a soil where

seeds sow and nourish themselves.

Mr. McWilliam, in his work on dry rot, states that if

the temperature be very low or very high, the effects are

the same with respect to the growth of fungi. At 80° dry

rot will proceed rapidly, at 90° its progress is more slow;

at 100° it is slower still, and from 110° to 120° it will in

general be arrested. It will proceed fast at 50°; it may[30]

be generated at 40°; its progress will be slow at 36°; and

is arrested at 32°, yet it will return if the temperature is

raised to 50°.

Dry rot externally first makes its appearance as a

mildew, or rather a delicate white vegetation, that looks

like such. The next step is a collecting together of the

fibres of the vegetation into a more decided form, somewhat

like hoar frost; after which it speedily assumes the

leathery, compact character of the fungus, forming into

leaves, spreading rapidly in all directions, and over all

materials, and frequently ascending the walls to a considerable

height, the colour variable—white, greyish white,

and violet, light or decided brown, &c.

In the section of a piece of wood attacked by dry rot

a microscope reveals minute white threads spreading and

ramifying throughout its substance; these interlace and

become matted together into a white cottony texture,

resembling lint, which effuses itself over the surface of

the timber; then in the centre of each considerable mass

a gelatinous substance forms, which becomes gradually of

a yellow, tawny hue, and a wrinkled, sinuated porous consistence,

shedding a red powder (the spores) upon a white

down; this is the resupinate pileus, the hymenium being

upwards, of Merulius lachrymans, in its perfect and

matured state. Long before it attains to this, the whole

interior of the wood on which it is situated has perished;

the sap vessels being gradually filled by the cottony

filaments of the fungus; no sooner do these appear

externally than examination proves that the apparently[31]

solid beam may be crumbled to dust between the fingers;

tenacity and weight are annihilated.

Dr. Haller says that seven parts in eight of a fungus in

full vegetation are found by analysis to be completely

aqueous.

The strength of fungi is proportionate to the strength

of the timber the cohesive powers and nutritive juices of

which they absorb; and according to the food they receive

so they are varied and modified in different ways, and

are not always alike. Different stages of corruption produce

food of different qualities, and hence many of the

different appearances of fungi. One takes the process of

corruption up where another leaves it off, and carries it

forward and farther forward to positive putrefaction.

The forms which fungi assume are extremely diversified;

in some instances we have a distinct stem supporting a

cap, and looking somewhat like a parasol; in others the

stem is entirely absent, and the cap is attached either by

its margin, and is said to be dimidiate, or by its back, or

that which is more commonly its upper surface, when it is

called resupinate. In some species the form is that of a

cup, in others of a goblet, a saucer, an ear, a bird’s nest, a

horn, a bunch of coral, a ball, a button, a rosette, a lump

of jelly, or a piece of velvet.

Decomposition takes place without fungus where the

timber and the situation are always moist, as in a

close-boarded kitchen floor, where it is always dry, or

very nearly so, and where it is alternately wet and dry,

cold and hot. When the decomposition is affected with[32]

very little moisture, and no fungus, the admission of air

will generally prevent further contamination; but where

there is abundance of moisture, rottenness, and fungus, a

small quantity of air will hasten the destruction of the

building.

In timber which has been only superficially seasoned

this disease is produced internally, and has been known to

convert the entire substance of a beam, excepting only

the external inch or two of thickness to which the

seasoning had penetrated, into a fine, white, and threadlike

vegetation, uniting in a thick fungous coat at the

ends, the semblance being that of a perfectly sound beam.

In this internal rot a spongy fungous substance is formed

between the fibres. This has often been observed in large

girders of yellow fir, which have appeared sound on the

outside, but by removing some of the binding joists have

been found completely rotten at the heart. An instance

of this kind occurred at Kenwood (the seat of the Earl of

Mansfield) in 1815. Major Jones, R.E., states that on one

occasion he was called upon to report on the state of a

building in Malta; that the timbers had every external

appearance of being sound, but on being bored with an

auger they were found internally in a total state of decay.

It is on this account that the practice of sawing and

bolting beams is recommended, for when timber is large

enough to be laid open in the centre this part is laid open

to season; so that when a tree is large enough to be cut

through to make two or more beams, decomposition is

impeded.

The first symptoms of rottenness in timber are swelling,[33]

discoloration, and mouldiness, accompanied with a musty

smell; in its greater advance the fibres are found to

shrink lengthways and break, presenting many deep

fissures across the wood; the fibres crumble readily to a

fine snuff-like powder, but retain, when undisturbed, much

of their natural appearance.

In whatever way boughs are removed from trees, the

effect of their removal is, however, very frequently to

produce a rotting of the inner wood, which indicates

itself externally by a sudden abnormal swelling of the

trunk a little above the root; sometimes the trunk

becomes hollow at the part affected, and this particular

description of rot will almost invariably be found to exist

in those trees whose roots are much exposed. The rot

itself is either of a red, black, or white colour in the

timber when felled, and when either of the two last-named

colours prevail, it will be found that the decay

does not extend very far into the tree; but if, on the

contrary, the colour of the parts most visibly affected

should be decidedly red, the wood should be rejected for

any building purposes. Sometimes small brown spots,

indicative of a commencement of decay, may be observed

near the butt or root end of trees, and though they do

not appear to be connected with any serious immediate

danger to the durability of the wood, it is advisable to

employ the material so affected only in positions where it

would not be confined in anything like a close, damp

atmosphere.

Great hesitation may be admitted as to the use of

timber which presents large bands of what are supposed[34]

to be indefinitely-marked annual growth, because the

existence of zones of wood so affected may be considered

to indicate that the tree was not in a healthy state when

they were formed, and that the wood then secreted lacked

some of the elements required for its durability, upon being

subsequently exposed to the ordinary causes of decay.

In many cases when timber trees are cut down and

converted for use, it is found that at the junction of some

of the minor branches with the main stem, the roots, as it

were, of the branches traverse the surface wood in the

form of knots, and that they often assume a commencement

of decay, which in the course of time will extend to

the wood around them. This decay seems to have arisen

in the majority of cases from the sudden disruption of

the branch close to its roots, with an irregular fracture,

and with such depressions below the surface as to allow

the sap to accumulate, or atmospheric moisture to lodge in

them. A decomposition of the sap takes place—in fact,

a wound is made in the tree-and what are called “druxy

knots” are thus formed, which have a contagious action

on the healthy wood near them.

There is this particular danger about the dry rot; viz.

that the germs of the fungi producing it are carried easily,

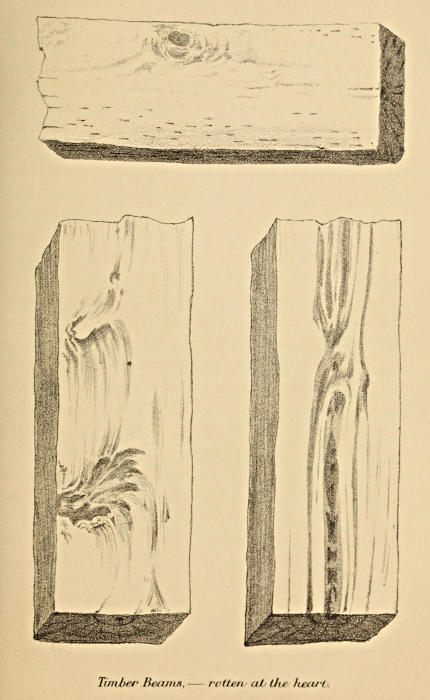

and in all directions, in a building wherein it once displays

itself, without necessity for actual contact between the

affected or the sound wood; whereas the communication

of the disease resulting from the putrefactive fermentation,

or the wet rot, only takes place by actual contact.

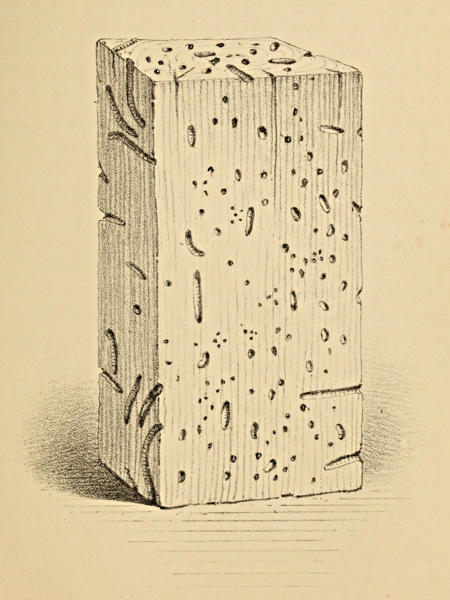

Timber Beams,—rotten at the heart.

Before dry rot has time to destroy the principal timbers

in a building, it penetrates behind the skirtings, dadoes,[35]

and wainscotings, drawing in the edges of the boards, and

splitting them both horizontally and vertically. When

the fungus is taken off, they exhibit an appearance similar

both in back and front to wood which has been charred; a

light pressure with the hand will break them asunder,

even though affected with the rot but a short time; and

in taking down the wainscot, the fibrous and thin-coated

fungus will generally be seen closely attached to the

decayed wood. In timber of moderate length the fungus

becomes larger and more destructive, in consequence of

the matter congenial to its growth affording a more

plentiful supply.

It is a great characteristic of fungi in general that they

are very rapid in growth, and rapid in decay. In a night

a puff-ball will grow prodigiously, and in the same short

period a mass of paste may be covered with mould. In a

few hours a gelatinous mass of Reticularia will pass into

a bladder of dust, or a Coprinus will be dripping into

decay. Many instances have been recorded of the rapidity

of growth in fungi; it may also be accepted as an axiom

that they are in many instances equally as rapid in decay.

In considering the liability of any particular description

of foreign timber to take the dry rot, attention must

be paid to the circumstances under which it is imported.

Sometimes the timber is a long while coming here, whilst

at other times it is imported in a very short period. The

length of time consumed in the voyage has a great deal

to do with its likelihood of taking the rot: it may have a

very favourable passage, or a very wet one, and the ship is

frequently, in some degree, affected with the disease. It[36]

perhaps begins in the ship, and it may often be seen

between the timber or deals, when it will impregnate the

wood to a great depth. Whether it is inherent in the

timber or not, of this we may be certain, that where there

is a fetid atmosphere it is sure to grow. Canadian yellow

wood pine timber is more subject to rot than Baltic or

Canadian red wood timber, although the latter will

sometimes decay in four or five years. Turpentine is a

preventive against dry rot, and Canadian timber is sometimes

largely impregnated with it, especially the red wood

timber; the yellow wood is very subject to dry rot. Very

few cargoes of timber in the log arrive from Canada in

which in one part or other of nearly every log you will

not see a beginning of the vegetation of the rot. Sometimes

it will show itself only by a few reddish, discoloured

spots, which, when scratched by the finger nail to the

extent of each spot, it will be seen that the texture of

the timber to some little depth is destroyed, and will be

reduced to powder; and on these spots a white fibre may

generally be seen growing. If the timber has been

shipped in a dry condition, and the voyage has been a

short one, there may be a few logs without a spot; but

generally speaking very few cargoes arrive from Canada

in which there are many logs of timber not affected. But

if the cargo has been shipped in a wet condition, and the

voyage has been a long one, then a white fibre will be

seen growing over nearly every part of the surface of

every log; and in cargoes that have been so shipped, all

the logs of yellow pine, red pine, and of oak, are generally

more or less affected on the surface.

[37]

Nearly every deal of yellow pine that has been shipped

in Canada in a wet state, when it arrives here is also

covered over with a network of little white fibres, which

are the dry rot in its incipient state. There is no cargo,

even that which is shipped in tolerably dry condition, in

which, upon its arriving here, may not be found some

deals, with the fungus beginning to vegetate on their

surface. If they are deals that have been floated down

the rivers of America or Canada, and shipped in a wet

state, on their arrival here they are so covered with this

network of the fungus, that force is often necessary to

separate one deal from another, so strongly does the

fungus occasion them to adhere. They grow together

again, as it were, after quitting the ship, while lying in

the barges, before being landed. Accordingly, if a cargo

has arrived in a wet condition, or late in the year, or if

the rain falls on the deals before they are landed, and

they are then piled in the way in which Norwegian and

Swedish deals are piled, that is, flatways, in six months

time, or even less, the whole pile of deals become deeply

affected with rot; so that, whenever a flat surface of one

deal is upon the flat surface of another, the rot penetrates

to the depth of ⅛ of an inch. Its progress is then arrested

by repiling the deals during very dry weather, and by

sweeping the surface of each deal before it is repiled: but

the best way is to pile the deals in the first instance upon

their edges; by which means the air circulates freely

around them, the growth of the fungus is arrested, and

the necessity of repiling them prevented. If the ship is

built of good, sound, and well-seasoned oak, the rot would[38]

perhaps not affect it, but in order to prevent its doing so,

the precaution is usually taken to scrape the surface as

soon as the hold is clear of the cargo of timber. Were

the cargo not cleared, and the hold not ventilated, a ship

that was permanently exposed to this fungus would, no

doubt, be affected. It is easy, however, to prevent its

extending by washing the hold with any desiccating

solution.

Anyone who wishes to know how timber is occasionally

shipped to this country should read the report of a trial,

in the ‘Times,’ 22nd Feb., 1875 (Harrison v. Willis),

relative to a cargo of pitch pine shipped from Sapelo, in

the Isthmus of Darien, for Liverpool. This cargo, however,

never arrived at Liverpool: it was lost at sea.

The motto of the Worshipful Company of Shipwrights

is, “Within the ark, safe for ever.” We suggest it should

be altered to, “Within the ark which is free from dry rot,

safe for ever.”

There are two descriptions of European deals very

liable to take the dry rot; viz. yellow Petersburgh deals,

and yellow and white battens, from Dram, in Norway.

When Dram battens, which have been lying a long time

in bond in this country, have not been repiled in time,

they have been found as much affected with the dry rot

as many Canadian deals; though this has not happened

in so short a time as has been sufficient to rot Canadian

deals. The fungus growing on the Petersburgh deals and

Dram battens has all the characteristics and effects of dry

rot as exhibited in the Canadian deals, the detection of

dry rot being in most cases the same.

[39]

It should be remembered that white deal absorbs more

water than yellow; and yellow more water than red; and

the quantity of water absorbed by the white accounts for

its more rapid decay in external situations; as the greater

the quantity of water absorbed the quicker is the timber

destroyed. Mr. John Lingard, in his work on timber

(1842), states that he has proved that 4½ oz. of water can

be driven off from a small piece of fir, weighing only

10 oz. when wet, which is nearly half. This timber was

on a saw-pit, and going to be put into a building.

The most general, and the most fatal cause of decay,

viz. the wet rot, has attracted less attention than the more

startling, but less common evils, the dry rot, and the

destruction by insects.

Sir Thomas Deane, in 1849, related before the Institution

of Civil Engineers of Ireland, an extraordinary

instance of the rapid decay of timber from rot, which

occurred in the church of the Holy Trinity at Cork.

On opening the floors under the pews, a most extraordinary

appearance presented itself. There were flat

fungi of immense size and thickness, some so large as

almost to occupy a space equal to the size of a pew, and

from 1 to 3 inches thick. In other places fungi appeared,

growing with the ordinary dry rot, some of an unusual

shape, in form like a convolvulus, with stems of from a

quarter to half an inch in diameter. When first exposed,

the whole was of a beautiful buff colour, and emitted the

usual smell of the dry-rot fungus.

During a great part of the time occupied in the repairs

of the church, the weather was very rainy. The arches[40]

of the vaults having been turned before the roof was

slated, the rain water saturated the partly decayed oak

beams. The flooring and joists, composed of fresh timber,

were laid on the vaulting before it was dry, coming in

contact at the same time with the old oak timber, which

was abundantly supplied with the seeds of decay, stimulated

by moisture, the bad atmosphere of an ill-contrived

burial-place, and afterwards by heat from the stoves constantly

in use. All these circumstances account satisfactorily

for the extraordinary and rapid growth of the fungi.

Many instances might be mentioned of English oak

being affected with dry rot, under particular circumstances.

There was a great deal at the Duke of Devonshire’s,

at Chiswick, about 60 years ago. Needy builders,

who work for contract, sometimes use American oak, and

call it wainscot: it is a bad substitute for wainscot, being

very liable to warp and to be affected with dry rot. “I

know of one public building,” observed the late Mr. Henry

Warburton, M.P., “in which it has been introduced, and,

I suppose, paid for under that name.”

Another serious instance of the decay of timber from

rot occurred some time since in Old St. Pancras Church,

London. When the dry rot made its appearance, it

spread with amazing rapidity. Sometimes in the course

of a night, a fungus of about the consistence of newly-fallen

snow, and of a yellowish-white unwholesome

colour, would be found to have spread over a considerable

surface. The fungus was without shape, but in some cases

it rose to a height of 2, 3, or 4 inches above the planks

or other surfaces on which it grew. It could be cut with[41]

a knife, leaving a clear edge on each side, and there did

not seem to be any covering or membrane over the outer

or under surface. The smell of those matters was unpleasant,

and seemed like the concentration of the smell

which had pervaded the church for so long a time before;

and, in a short time, beams, planks of flooring, railings, &c.,

were reduced to rottenness: the colour changed, and a

heavy dark-brown dust fell, and represented the once

solid timber. On making an examination with a view of

discovering the cause of the attack, it was found that in

the graveyard, near the church, there were graves, and

several vaults: there were also vaults in the inside of

the church. Most of them were filled, or nearly so, with

water, which had run from the overcrowded graves.

In the interior there were water-logged vaults, and the

walls were saturated with damp. It was also seen that

from want of proper spouts and drains, near the outer

walls, the drip from the large pent roof had fallen into

the foundations. In this situation, when the window

frames were properly arranged, a drain dug round and

from parts of the church, and other alterations, which

should long before have been made, were completed, the

dry rot vanished, and no more complaints of the foulness

of the air have since been heard.

We could quote many cases of rot which have been

caused from the want of proper drains and spouts. Architects

should remember that the feet of Gothic collar roofs

have to bear the whole weight of the roof, and unless well

seasoned, and carefully protected from damp, leaks, &c.,

premature decay and dry rot will be sure to occur. It is[42]

surprising what injury leaks from gutters will sometimes

do. In 1851, Professor T. L. Donaldson stated that “a

brestsummer of American timber was used some time

since at a house in London: after an expiration of three

years cracks began to appear in the front wall. A friend

of mine, an architect, was called in to find out the cause;

and after examining different parts of the house, was

almost giving up his search in despair, when he thought

he would have the shop cornice removed and look at the

brestsummer. He then discovered that some water had

been admitted by accident, and penetrating the brestsummer,

had caused it to rot, and crack the wall.”

Dry rot was found in the great dome of the Bank of

England, London, as originally built by Sir Robert

Taylor: it also existed in the Society of Arts building, in

the Adelphi, London. It was also found in the domes of

the Panthéon, and Halle-au-Blé, Paris; but we hope there

is no dry rot in the dome of St. Paul’s Cathedral, London,