The Project Gutenberg EBook of A Text-book of Paper-making, by

C. F. Cross and E. J. Bevan

This eBook is for the use of anyone anywhere in the United States and most

other parts of the world at no cost and with almost no restrictions

whatsoever. You may copy it, give it away or re-use it under the terms of

the Project Gutenberg License included with this eBook or online at

www.gutenberg.org. If you are not located in the United States, you'll have

to check the laws of the country where you are located before using this ebook.

Title: A Text-book of Paper-making

Author: C. F. Cross

E. J. Bevan

Release Date: March 4, 2018 [EBook #56679]

Language: English

Character set encoding: UTF-8

*** START OF THIS PROJECT GUTENBERG EBOOK A TEXT-BOOK OF PAPER-MAKING ***

Produced by Chris Curnow, RichardW, and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

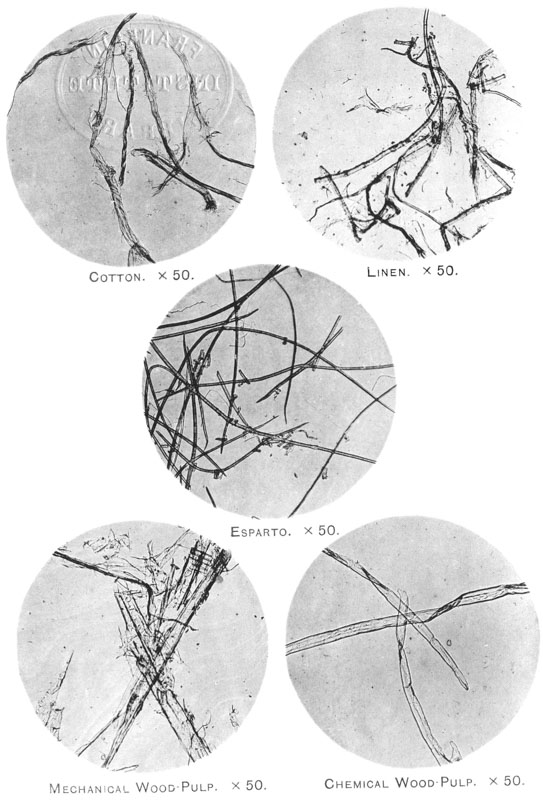

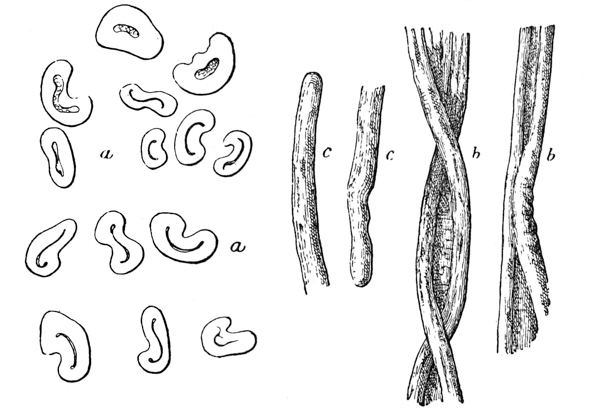

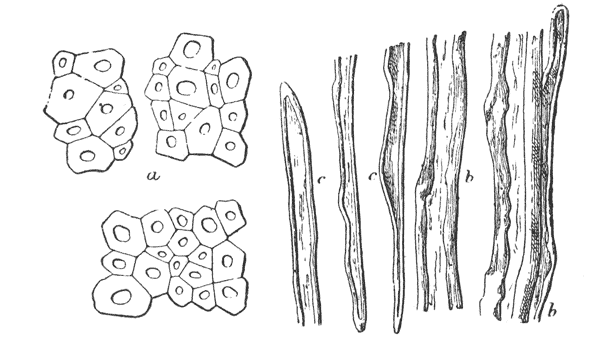

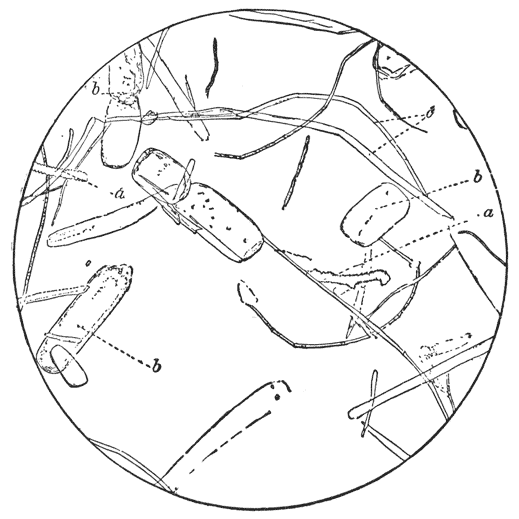

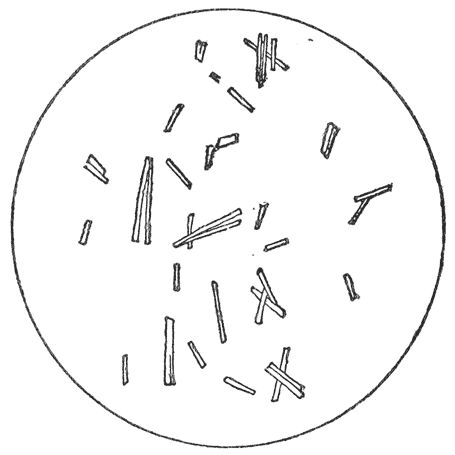

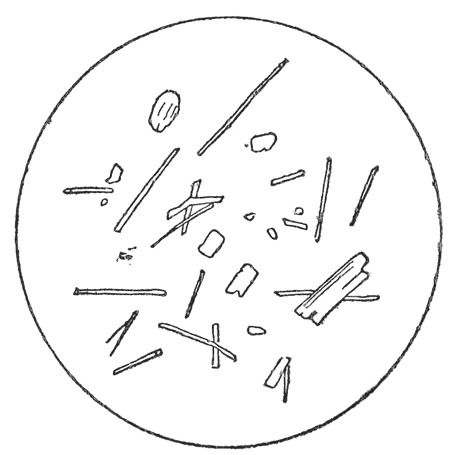

| Cotton. × 50. | Linen. × 50. |

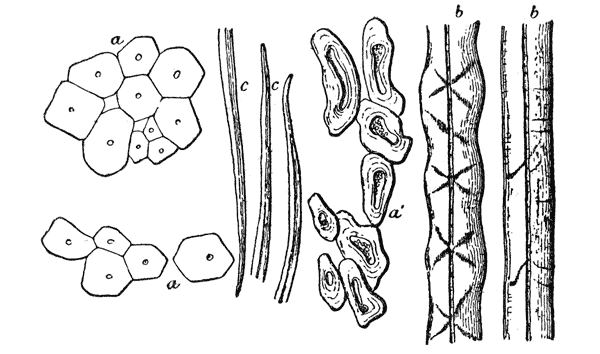

| Esparto. × 50. | |

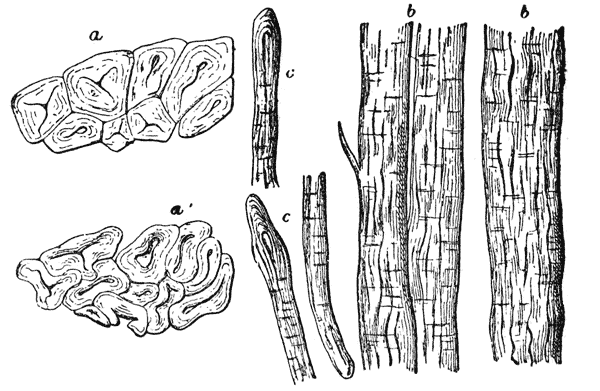

| Mechanical Wood-pulp. × 50. | Chemical Wood-pulp. × 50. |

The practical portion of the present work has in part already appeared as an article, by one of the authors, in ‘Spons’ Encyclopædia of the Industrial Arts.’ Since its publication, however, many and important improvements have been introduced in this, as in other branches of the art of paper-making, which necessitated considerable additions to the original article. It has at the same time been to a great extent re-written, and, as the authors hope, improved.

Our object in writing this book has been to bring before students and others the principles upon which scientific paper-making should be conducted, a concise exposition of which has not, we believe, been hitherto attempted.

Considerable prominence has been given to this aspect of the subject, possibly at the expense of what some may consider more essential details.

A belief in the importance of a thorough scientific training for paper-makers has dictated the style and purpose of the book.

We have not thought it necessary to enter into minute details respecting the construction of machinery, &c.; for these the reader is referred to such works as Hofmann’s Treatise on the Manufacture of Paper.

Much of the scientific portion is here published for the first time. Part of it has already appeared in the form of papers read before various societies.

The chapter relating to the Treatment of Wood formed the subject of an essay, which obtained the prize offered by the Scottish Paper-makers’ Association, in connection with the Edinburgh Forestry Exhibition, 1884.

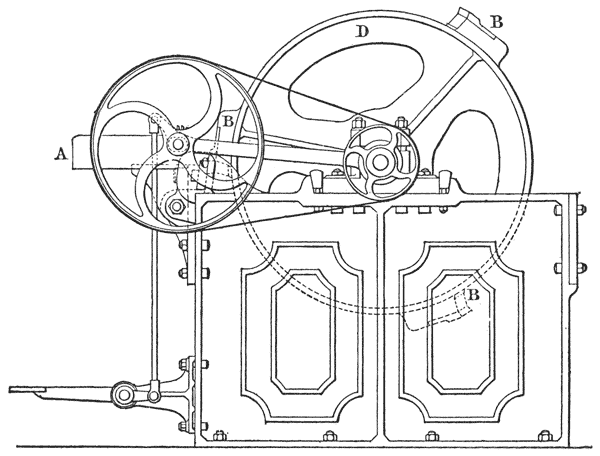

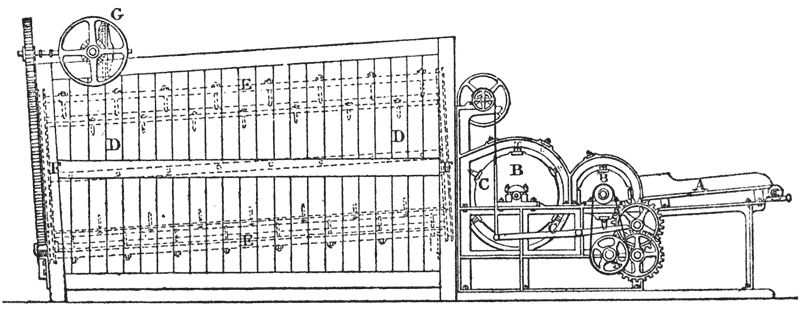

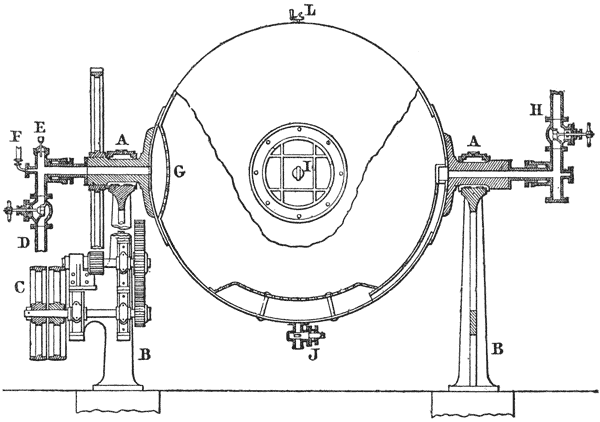

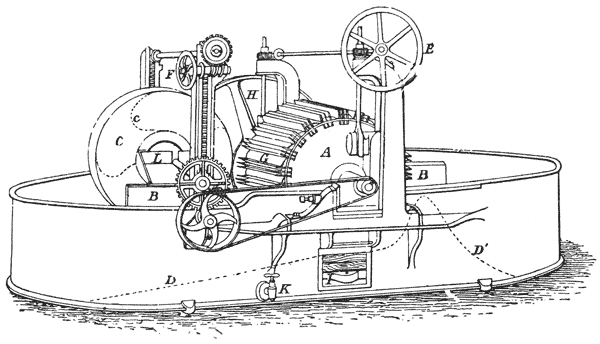

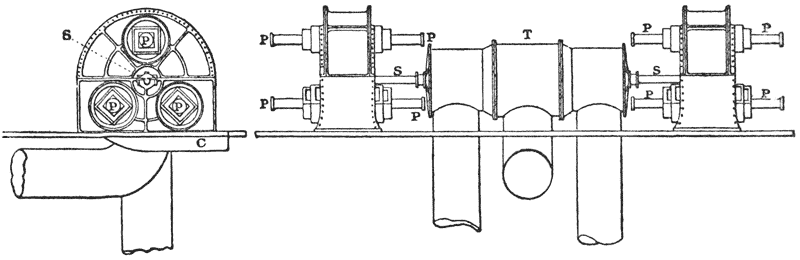

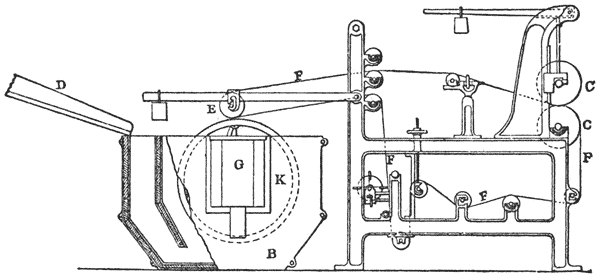

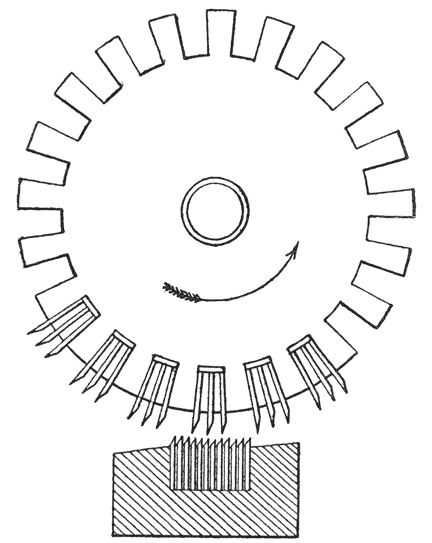

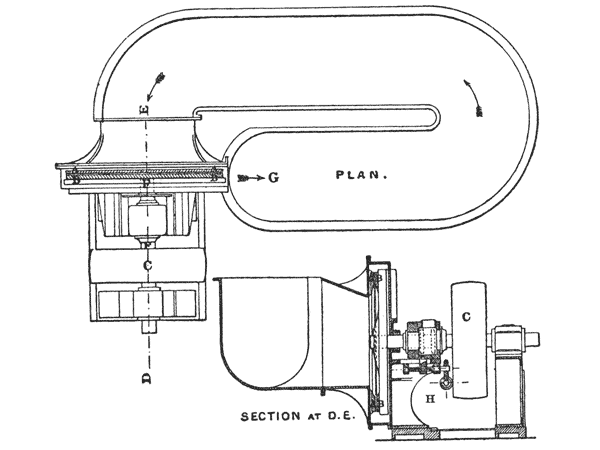

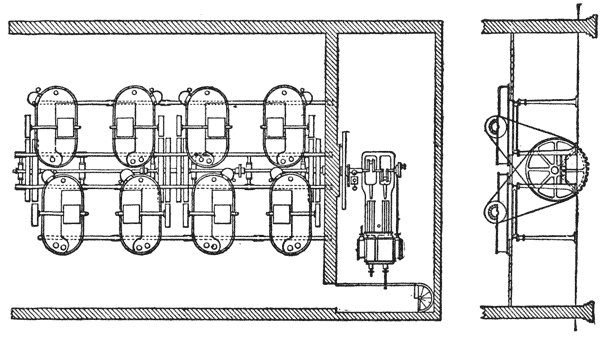

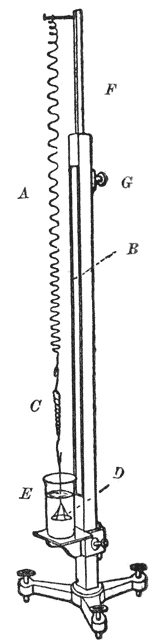

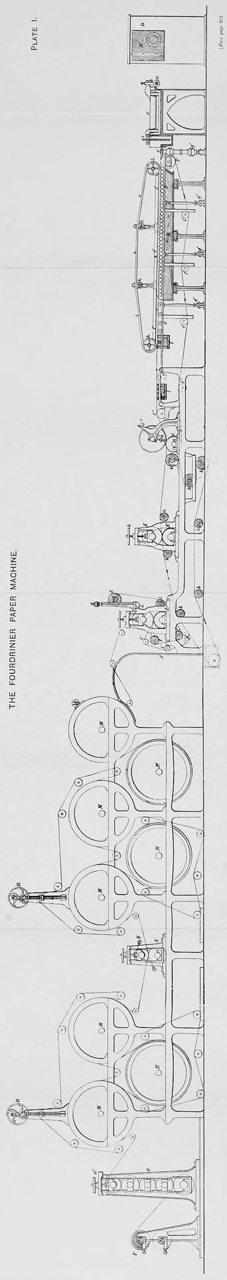

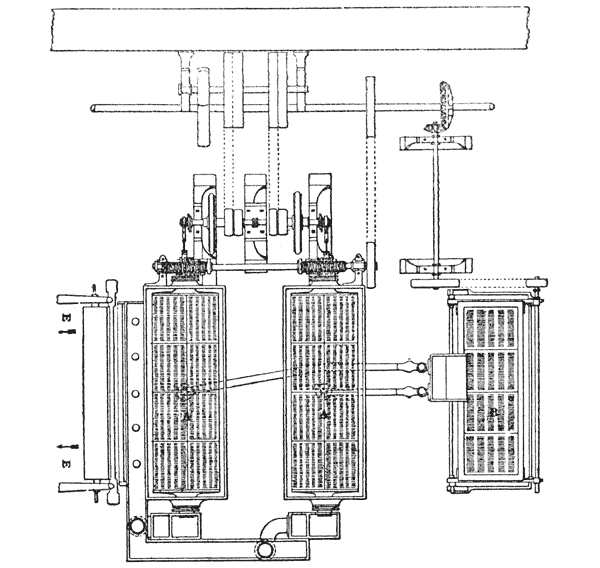

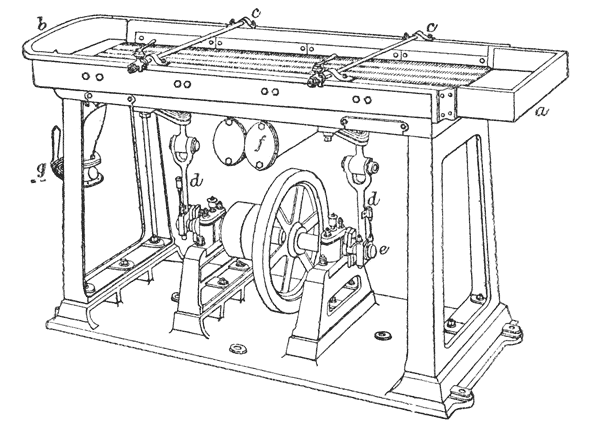

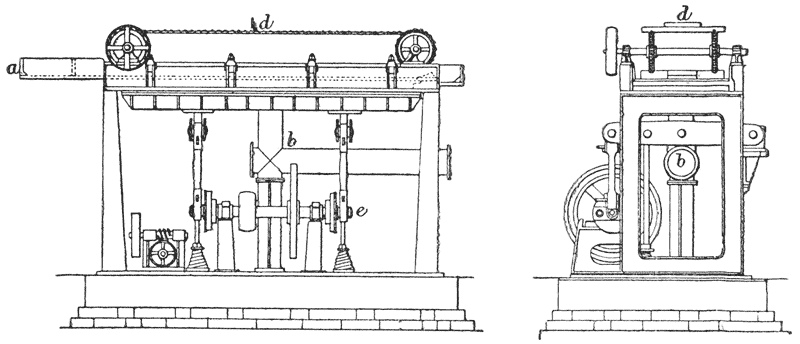

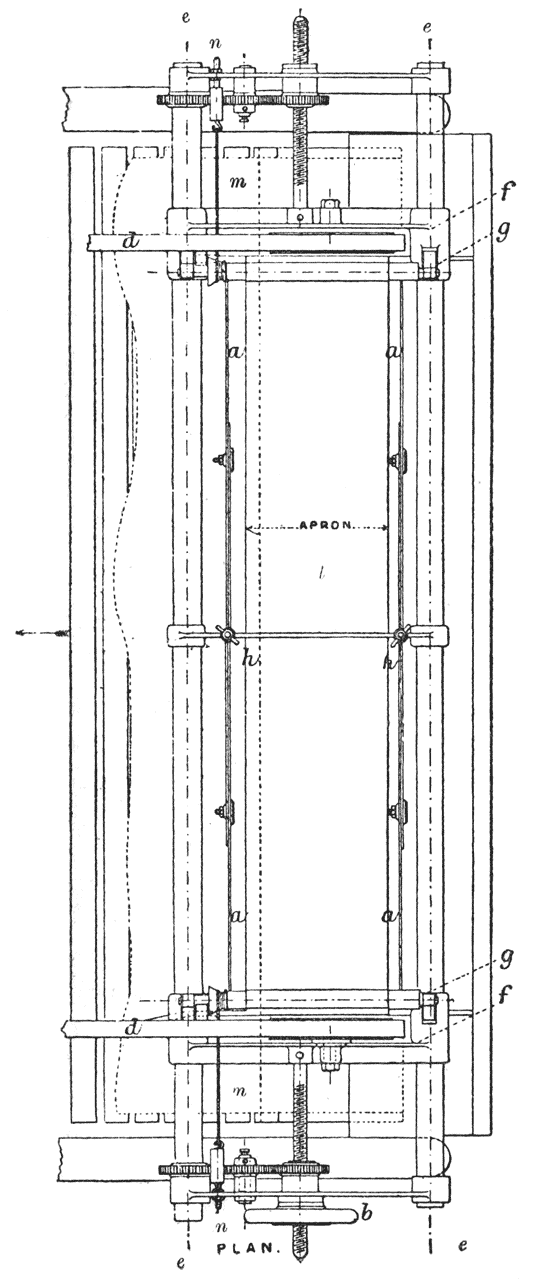

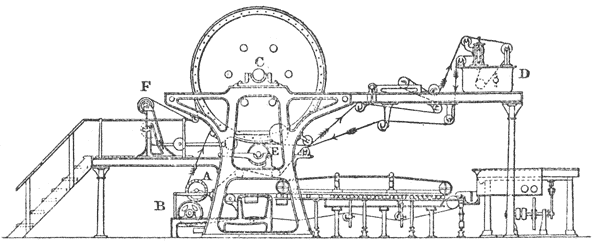

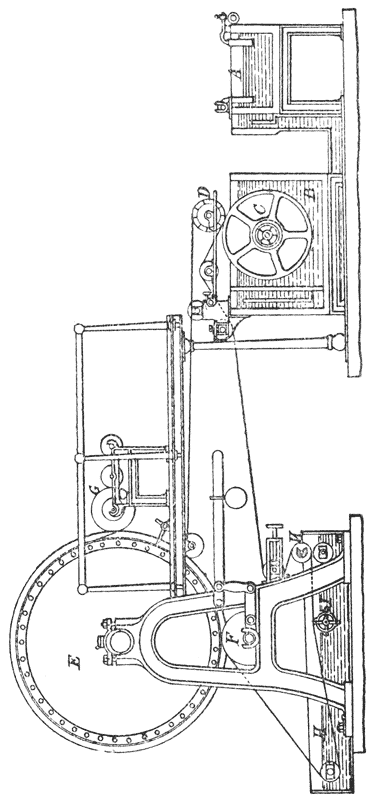

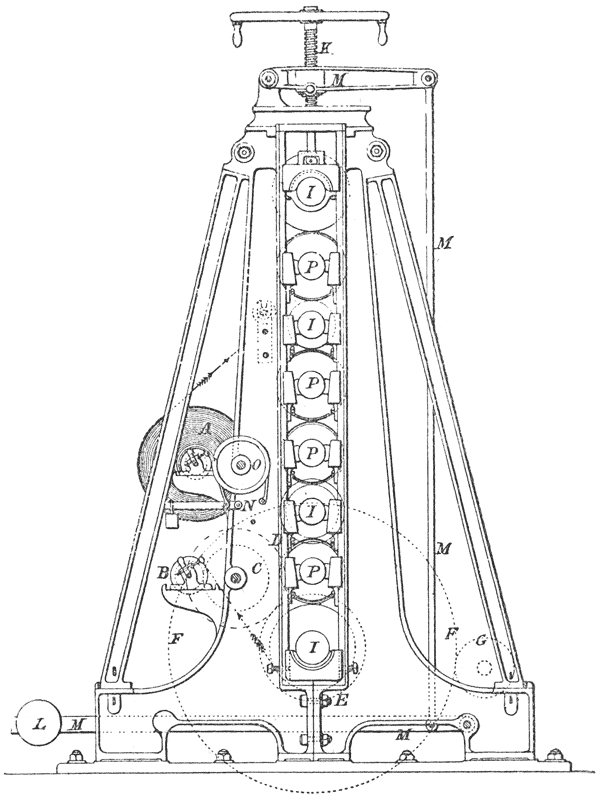

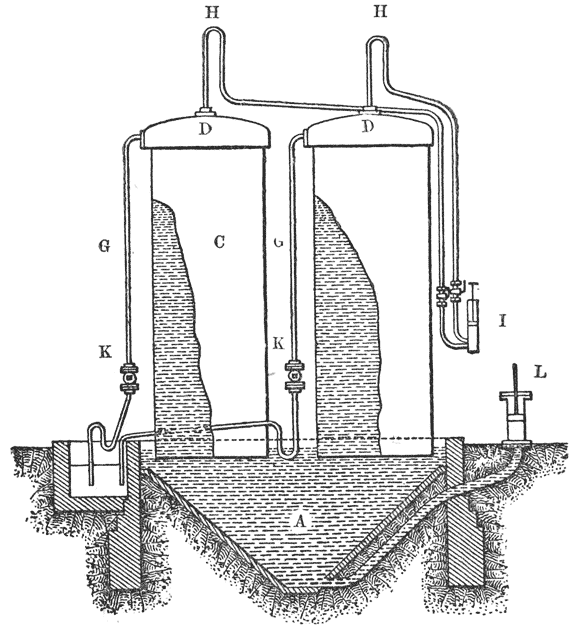

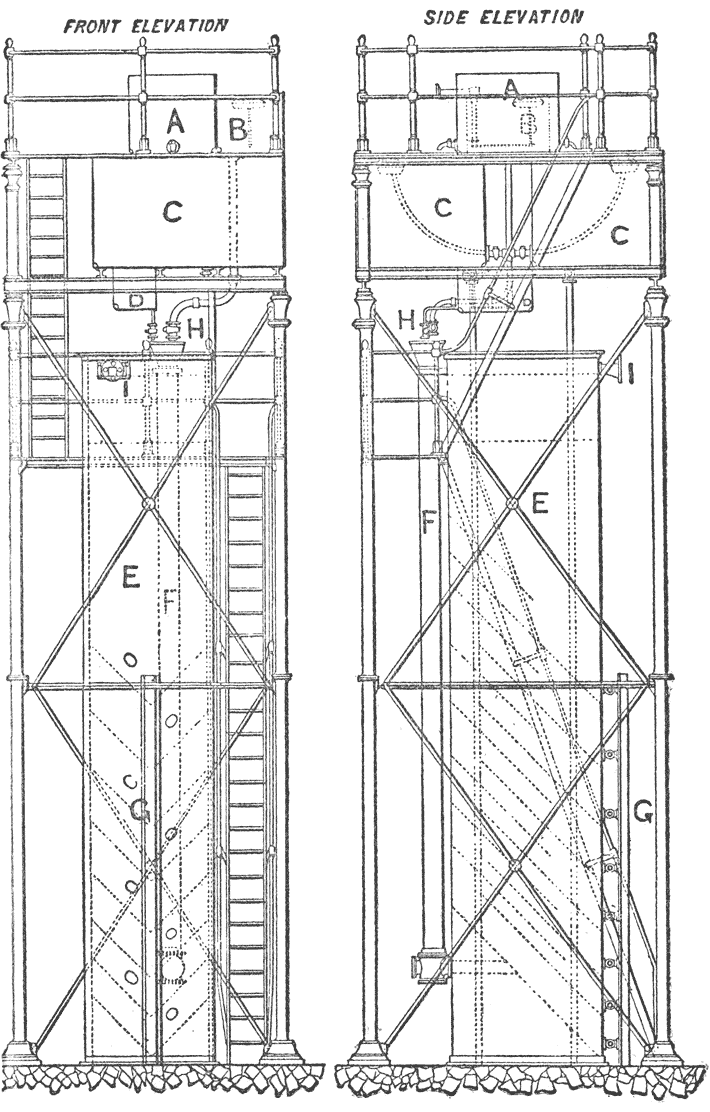

We would here express our obligations to Messrs. G. and W. Bertram, Messrs. Masson, Scott, and Bertram, Messrs. Rœckner and Co., and others, for their courtesy in furnishing us with the drawings from which the illustrations were prepared; to Dr. C. R. A. Wright, F.R.S., who kindly communicated the substance of the chapter on the Action of Cuprammonium on Cellulose; to Mr. Carl Christensen, for drawings and information regarding the manufacture of mechanical wood-pulp; also to the following friends, among others, who have, in various ways, rendered us important assistance:—Messrs. R. C. Menzies, C. M. King, G. E. Davis, A. Beckwith, and C. Beadle.

Finally, we would tender our thanks to Mr. C. G. Warnford Lock for the care he has bestowed on the editing of the book. The indexing and the Chapter on Statistics are entirely his production.

4, NEW COURT, LINCOLN’S-INN, W.C.

CONTENTS.

|

|

|---|---|

INTRODUCTORY

NOTE |

|

CHAPTER I.

CELLULOSE—THE

CHEMICAL

PROPERTIES

OF

TYPICAL

MEMBERS

OF

THE

CELLULOSE

GROUP,

WITH

REFERENCE

TO

THEIR

NATURAL

HISTORY |

|

CHAPTER II.

PHYSICAL

STRUCTURE

OF

FIBRES—MICROSCOPICAL

EXAMINATION |

|

CHAPTER III.

CHEMICAL

ANALYSIS

OF

PLANT

SUBSTANCES |

|

CHAPTER IV.

AN

ACCOUNT

OF

THE

CHEMICAL

AND

PHYSICAL

CHARACTERISTICS

OF

THE

PRINCIPAL

RAW

MATERIALS |

|

CHAPTER V.

PROCESSES

FOR

ISOLATING

CELLULOSE

FROM

PLANT

SUBSTANCES |

|

CHAPTER VI.

SPECIAL

TREATMENT

OF

VARIOUS

FIBRES—BOILERS,

BOILING

PROCESSES,

&C. |

|

CHAPTER VII.

BLEACHING |

|

CHAPTER VIII.

BEATING |

|

CHAPTER IX.

LOADING,

SIZING,

COLOURING,

&C. |

|

CHAPTER X.

PAPER

MACHINES,

HAND-MADE

PAPER |

|

CHAPTER XI.

CALENDERING,

CUTTING,

&C. |

|

CHAPTER XII.

CAUSTIC

SODA,

RECOVERED

SODA,

&C. |

|

CHAPTER XIII.

THE

TESTING

OF

PAPER,

MECHANICAL,

CHEMICAL,

AND

MICROSCOPICAL |

|

CHAPTER XIV.

GENERAL

CHEMICAL

ANALYSIS

FOR

PAPER-MAKERS |

|

CHAPTER XV.

SITE

FOR

PAPER-MILL—WATER

PURIFICATION |

|

CHAPTER XVI.

ACTION

OF

CUPRAMMONIUM

ON

CELLULOSE—WILLESDEN

PAPER |

|

CHAPTER XVII.

STATISTICS |

|

CHAPTER XVIII.

BIBLIOGRAPHY |

|

CHAPTER XIX.

ADDENDA |

|

INDEX |

The raw materials of the paper-maker are primarily the vegetable fibrous substances; in addition to these there are various articles which are employed as auxiliaries, either in the preparatory or finishing processes to which these fibrous materials, or the web of paper are subjected. The latter class are of subsidiary importance, more especially from our present point of view.

In insisting upon the recognition of first principles, we cannot overrate the importance of a thorough grasp of the constitution of the plant fibres, as the necessary foundation for the intelligent conduct of paper-making, and to this subject we will at once proceed.

Careful study of a mature plant will show that it is made up of structural elements of two kinds, viz. fibres and cells, which, to use a rough parallel, we may liken in function to the bricks and mortar of a house. It is the former which admit of the many extended uses, with which we are familiar, in the arts of spinning and weaving, and which constitute the fabrics which are the most indispensable to our civilised life. For the most part, as we know, fibres and cells are aggregated together into compound tissues, and a process of separation is therefore a necessary preliminary to the utilisation of the former. The cotton fibre is the only important exception to this general condition of distribution. Here we have the seed envelope or perisperm, converted into a mass {2} of fibres, and these by a spontaneous process accompanying the ripening, so isolated as to be immediately available. Next in order in point of simplicity of isolation, are those fibrous masses, or tissues, which, although components of complex structures, exhibit a greater cohesion of their constituent fibres than adhesion to the contiguous cellular tissues with which they go to build up the plant. Into such a tissue the “bast,” or inner bark layer of shrubs and trees, more especially those of tropical and sub-tropical regions, frequently develops, and it is, in fact, this bast tissue, graduating in respect of cohesion of its constituent fibres, from a close network such as we have spoken of, to a collection of individual fibres or fibre-bundles disposed in parallel series, which supplies the greater part of the more valuable of the textile and paper-making fibres; we may instance flax, hemp, and jute, each of which is the basis of an enormous industry. According to the degree of adhesion of the bast to the contiguous tissues, or, in another aspect, according to its lesser aggregate development, so is the difficulty of isolation and the necessity of using processes auxiliary to the mechanical separation of the tissue.

It is worthy of note here that the Japanese paper with which we are in these times so familiar, is prepared by the most primitive means from the bast of a mulberry (Broussonetia papyrifera); the isolated tissue, consisting of a close network of fibres, is simply cut and hammered to produce a surface of the requisite evenness, and the production of a web of paper is complete. In isolating the bast fibres employed in the textile industries, a preliminary partial disintegration of the plant stem is brought about by the process of steeping or retting, by which the separation of fibre from flesh or cellular tissue is much facilitated.

Last in order of simplicity of distribution, we have the fibres known to the botanist as the fibro-vascular bundles of leaves and monocotyledonous stems, these bundles being irregularly distributed through the main cellular mass, and consequently, by reason of adhesion thereto, much more {3} difficult of isolation. For this and other reasons, more or less in correlation with natural function, we shall find this class of raw material lowest in value to the paper-maker.

It is necessary at this stage to point out that the work of the paper-maker and that of the textile manufacturer are complementary one to the other, and the supply of fibrous raw material is correspondingly divided: it may be said, indeed, that the paper industry subsists upon the rejecta of the textile manufactures. The working up of discontinuous fibre elements into thread, which is the purpose of the complicated operations of the spinner, is conditioned by the length and strength of these ultimate fibres. Paper-making, on the other hand, requires that the raw material shall be previously reduced to the condition of minute subdivision of the constituent fibres, and therefore can avail itself of fibrous raw material altogether valueless to the spinner, and of textile materials which from any cause have become of no value as such. To the raw materials of the paper-maker, which we have briefly outlined above, we must therefore add, as a supplementary class, textiles of all kinds, such as rags, rope, and thread.

Having thus acquired a general idea of the sources of our raw materials, we must study more closely the substances themselves, and first of all we must investigate them as we should any other chemical substance, i.e. we must get to understand the nature and properties of the matter of which the vegetable fibres are composed. While these exhibit certain variations, which are considerable, the substances present a sufficient chemical uniformity to warrant their being designated under a class name: this name is cellulose. The prototype of the celluloses is the cotton fibre.

Plants are so far built up of cellulose that it may be called the material basis of the vegetable world. Plant tissues, however, seldom, if ever, consist of pure cellulose, but contain besides, other products of growth either chemically combined with the cellulose or mechanically bound up with the tissue, which are, according to the nature of their union, removable either by means of fundamental chemical resolution or by the application of simple solvents. A general method for the isolation of cellulose consists in exposing the moist tissue to the action of chlorine gas or of bromine water in the cold, and subsequently boiling in dilute ammonia; repeating this treatment until the alkaline solution no longer dissolves anything from the tissue or fibre. The cellulose is then washed with water, alcohol, and ether, and dried. Obtained in this way, or in the form of bleached cotton, or of Swedish filter paper, it is a white substance, more or less opaque, retaining the microscopic features of the tissue or fibre from which it has been isolated. Its sp. gr. is 1·25–1·45. Its elementary composition is expressed by the percentage numbers (Schulze)

| C | 44·0 | 44·2 |

| H | 6·3 | 6·4 |

| O | 49·7 | 49·4 |

or by the corresponding empirical formula, viz. C6H10O5.

These numbers represent the composition of the ash-free cellulose. Nearly all celluloses contain a certain proportion, {5} however small, of mineral constituents, and the union of these with the organic portion of the fibre or tissue is of such a nature that the ash left on ignition preserves the form of the original. It is only in the growing point of certain young shoots that the cellulose tissue is free from mineral constituents. (Hofmeister.)

As already indicated, cellulose is insoluble in all simple solvents; it is, however, dissolved by certain reagents, but only by virtue of a preceding chemical modification. An exception to this is to be found, perhaps, in the ammoniacal solution of cupric oxide (Schweitzer’s reagent), in which it dissolves without essential modification, being recovered by precipitation, in a form which is chemically identical with the original, though differing, of course, in being structureless, or amorphous. This reagent may be employed in a variety of forms, but the following method of using it is to be recommended as the most certain in its results. The substance to be operated upon is intimately mixed with copper turnings in a tube which is narrowed below and provided with a stopcock. Strong ammonia is poured upon the contents of the tube and, after being allowed to stand for some minutes, is drawn off and returned to the tube; the operation is several times repeated until the solution of the substance is effected. In order to facilitate the oxidation of the copper by the atmospheric oxygen, a current of air may be aspirated through the apparatus. The solution of the oxide prepared in this way is more effective in its action on cellulose than that obtained by dissolving the precipitated hydrate in ammonia. Cellulosic tissues in contact with this reagent are seen to undergo a disaggregation of their fibres, which swell up, become gelatinous, and disappear in solution. On adding an acid to the viscous solution, a precipitate of the amorphous cellulose is obtained in the form of a jelly resembling hydrated alumina; after washing and drying, it forms a brownish, brittle, horny mass. The cellulose is also precipitated upon simply diluting the viscous solution with water and allowing it to stand {6} 8–10 days in a closed vessel. From this observation it was inferred by Erdmann that the cellulose could not be considered as dissolved in the strict sense of the word, but the experiments of Cramer upon the osmotic properties of the solution proved this inference to be unfounded, and that cellulose is actually dissolved by the ammoniacal solution of copper oxide.

On treating the ammonio-cupric solution of cellulose with metallic zinc, this metal precipitates the copper, replacing it in the solution, and producing the corresponding ammonio-zincic solution of cellulose, which is colourless. Some of these solutions are lævo-gyrate.

Cellulose, in those forms to which the application of the term has been hitherto restricted, is a comparatively inert substance, and its reactions are consequently few. One of these is available for the identification of cellulose, and is chiefly used in the microscopical examinations of tissues: this is its reaction with iodine. Cellulose is not coloured blue by a solution of iodine excepting under the simultaneous influence of hydriodic acid, potassium iodide, sulphuric acid, phosphoric acid, or zinc iodide or chloride. The solution is prepared in the following way: zinc is dissolved to saturation in hydrochloric acid, and the solution is evaporated to sp. gr. 2·0; to 90 parts of this solution are added 6 parts potassium iodide dissolved in 10 parts of water; and in this solution iodine is dissolved to saturation. By this solution cellulose is coloured instantly a deep-blue or violet. For the identification of cellulose in the gross, mere inspection is usually sufficient; confirmatory evidence is afforded by an observation of the action of the ammonio-copper reagent, and of the absence of reaction with chlorine water. (See p. 18.)

Cellulose in its earlier stages of elaboration has no action upon light; but with age it acquires the property of double refraction, not, as has been shown by experiment, by virtue of its state of aggregation, but of its molecular constitution (Sachs). {7}

| Temp. | Time. | Weight absorbed. | |

|---|---|---|---|

| H2SO4 | 4° C. (39° F.) | 3 min | 0·00495 |

| HCl | „ | „ | 0·00733 |

| NaOH | „ | „ | 0·02020 |

The molecular ratio of the absorption, in the two latter, is 3 HCl : 10 NaOH, and it is noteworthy that the same ratio was observed for silk.

Cellulose removes barium hydrate from its solution in wafer to form with it an insoluble compound. On adding lead acetate to the solution of cellulose in the ammonio-copper reagent, so prepared as to contain no carbonate, a {8} precipitate is obtained consisting of a compound of cellulose with lead oxide, but in variable proportions. The compound C6H10O5PbO is formed by the action of finely-divided lead oxide upon the above solution. Quite recently it has been shown (O’Shea, Chem. News, May 28th, 1886) that when dilute solutions of lead are passed through ordinary filter paper, a certain amount is retained which cannot be removed by washing.

Cellulose does not combine with metallic salts, a fact which has been established incidentally to researches upon the mode of action of mordants.

The combinations of cellulose with acid radicles (ethereal salts) are both definite and stable.

Triacetyl Cellulose [C6H7 (C2H3O)3 O5] is formed by treating cellulose with six times its weight of acetic anhydride at 180° C. (356° F.). The product of the reaction is a syrupy solution from which the compound in question separates on dilution with water as a white flocculent precipitate.

Triacetyl cellulose is insoluble in alcohol and in ether, but soluble in glacial acetic acid. It is easily saponified by boiling with a solution of potassium hydrate, the cellulose being regenerated. No derivative containing more than three acetyl groups has been obtained; but a mixture of the mono-and di-acetyl cellulose is formed in treating cellulose with only twice its weight of acetic anhydride, the formation of these bodies being unattended by their solution.

Whenever cellulose, in any form, is brought into contact with strong nitric acid at a low temperature, a nitro product, or a nitrate, is formed. The extent of the nitration depends upon the concentration of the acid, on the time of contact of the cellulose with it, and on the state of the physical division of the cellulose itself.

Knop, and also Kamarsch, and Heeren, found that a mixture of sulphuric acid and nitric acid also formed nitrates of cellulose; and still later (1847), Millon and Gaudin employed a mixture of sulphuric acid and nitrates of soda or potash, which they found to have the same effect. {9}

Several well characterised nitrates have been formed, but it is a very difficult matter to prepare any one in a state of purity, and without admixture of a higher or lower nitrated body.

The following are known:—

Hexa-nitrate, C12H14O4(NO3)6,* gun cotton. In the formation of this body, nitric acid of sp. gr. 1·5, and sulphuric acid of sp. gr. 1·84 are mixed, in varying proportions, about 3 of nitric to 1 of sulphuric (sometimes this proportion is reversed), and cotton is immersed in this at a temperature not exceeding 10° C. (50° F.) for 24 hours: 100 parts of cellulose yield about 175 of cellulose nitrate. The hexa-nitrate so prepared is insoluble in alcohol, ether, or mixtures of both, in glacial acetic acid or in methyl alcohol. Acetone dissolves it very slowly. This is the most explosive gun-cotton. It ignites at 160°–170° C. (320°–338° F.). According to Eder the mixtures of nitre and sulphuric acid do not give this nitrate. Ordinary gun cotton may contain as much as 12 per cent. of nitrates soluble in ether-alcohol. The hexa-nitrate seems to be the only one quite insoluble in ether-alcohol.

* To represent the series of cellulose nitrates so as to avoid fractional proportions, the ordinary empirical formula is doubled and the nomenclature has reference to this double molecule.

Penta-nitrate, C12H15O5(NO3)5. This composition has been very commonly ascribed to gun-cotton. It is difficult, if not impossible, to prepare it in a state of purity by the direct action of the acid on cellulose. The best method is the one devised by Eder, making use of the property discovered by de Vrij, that gun-cotton (hexa-nitrate) dissolves in nitric acid at about 80°–90° C. (176°–194° F.) and is precipitated, as the pentanitrate, by concentrated sulphuric acid after cooling to 0° C. (32° F.); after mixing with a larger volume of water, and washing the precipitate with water and then with alcohol, it is dissolved in ether-alcohol, and again precipitated with water, when it is obtained pure.

This nitrate is insoluble in alcohol, but dissolves readily {10} in ether-alcohol, and slightly in acetic acid. Strong potash solution converts this nitrate into the di-nitrate, C12H18O8 (NO3)2.

The tetra- and tri-nitrates (collodion pyroxyline) are generally formed together when cellulose is treated with a more dilute nitric acid, and at a higher temperature, and for a much shorter time (13 to 20 minutes), than in the formation of the hexa-nitrate. It is not possible to separate them, as they are soluble to the same extent in ether-alcohol, acetic ether, acetic acid or wood spirit.

On treatment with concentrated nitric and sulphuric acids, both the tri-and tetra-nitrates are converted into penta-nitrate and hexa-nitrate. Potash and ammonia convert them into di-nitrate.

Cellulose di-nitrate, C18H13O8 (NO3)2 always results as the final product of the action of alkalis on the other nitrates, and also from the action of hot, somewhat dilute, nitric acid on cellulose. The di-nitrate is very soluble in ether-alcohol, acetic ether, and in absolute alcohol. Further action of alkalis on the di-nitrate results in a complete decomposition of the molecule, some organic acids and tarry matters being formed. The reactions and resolution products of this body have, however, been but slightly studied, and apparently not at all with the view to elucidate anything respecting the constitution of cellulose itself.

| 12 hours’ exposure. | 24 hours’ exposure. | |

|---|---|---|

| C | 43·78 43·47 | 43·00 42·90 |

| H | 5·85 6·13 | 6·28 6·18 |

| O | 50·37 50·40 | 50·72 50·92 |

Other oxidising agents produce similar results; even by exposure to air and light, cellulose is slowly converted into these oxidised derivatives.2 From their mode of formation, they have been termed oxycelluloses, and to distinguish them from a series of more highly oxidised derivatives, produced by the action of nitric acid upon cellulose, which they nevertheless resemble in many of their characteristics, the prefix α is employed. The following are the distinguishing features of the α oxycelluloses as represented by the more extreme of the above mentioned products. It reduces Fehling’s solution at the boiling temperature, and the cuprous oxide is deposited upon the fibre in a state of intimate union, producing the effect of an orange dye. It attracts the basic colouring matters from their solutions and is dyed to a full shade, the depth of colour being proportionate to the amount of oxidation to which the cellulose has been subjected. See also p. 43. Treated with a warm solution of phenylhydrazine salts in water, it is coloured a bright lemon-yellow. Its most remarkable property is its attraction for the vanadium compounds, which is so powerful that combination may be proved to take place when this element in the form of chloride is presented to the oxycellulose in an aqueous solution containing not more than 1 in 1,000,000,000,000 parts.

2 Witz. Bull. Soc. Ind. Rouen, X. 416, and XI. 189.

The β oxycellulose resulting, as already indicated, from the action of dilute nitric acid upon cellulose, will be subsequently considered, under the head of the decompositions of cellulose, to which the reaction which we have been considering may be regarded as transitional. {12}

The modification of cellulose, which occurs on the conversion of unsized paper into the so-called parchment paper, by exposure for a short time to the action of strong sulphuric acid, and subsequent washing and drying, consists doubtless in a superficial conversion of the cellulose into amyloid, or a body closely resembling it.

The action of zinc chloride solution upon cellulose is similar to that of sulphuric acid.

Cellulose in contact with iron, and in presence of air and moisture, is converted into a sugar and a gummy substance, which latter is converted into a sugar on boiling with dilute acids. Oxidised by potassium permanganate or bichromate in presence of acetic acid, it is converted into glucose, dextrin, and formic acid.

* Cross and Bevan, Chem. Soc. Journ., xliii. p. 23.

4 The action of alkaline substances dissolved from the glass must be taken into account in this decomposition.

The most important part which ulmic substances play in the economy of nature, is in the composition of soils. It is doubtful whether they act directly as fertilisers, but by their action upon the mineral constituents of soils they contribute to the supply of these necessary elements of growth to the plant.

The process of cellulosic fermentation may be represented by the equation:

A similar transformation takes place under the influence of certain fatty seeds, e. g. those of rape and colza; and it is probable that the formation of cellulose in living plants may take place at the expense of saccharose and under the influence of ferments. In support of this it has been established that in the sugar-cane, the formation of wood—i.e. cellulose—is accompanied pari passu by a decrease in saccharose. More recently, A. Brown (Chem. Soc. Journ., 432, 1886) has investigated the formation of cellulose by the “vinegar plant” growing in solutions of the carbo-hydrates, e. g. dextrose in yeast-water. The cells elaborate an extra-cellular fibrin, which acts as a “cell-collecting medium,” and they possess therefore a two-sided activity, i.e. the property above mentioned, in addition to their strictly fermentative activity. The cellulose film in question was found to contain 50 to 60 per cent. of pure cellulose. It is noteworthy that in a solution of levulose the growth of the “plant” is unattended by fermentative action, 33 per cent. of the substance being, on the other hand, transformed into cellulose.

Like cellulose, jute dissolves in cuprammonia, and is similarly acted upon by the concentrated acids. By nitric acids it is converted into nitric ethers, which are yellow coloured, but in other respects closely resemble the pyroxylins. They are entirely soluble in acetone.

Jute differs from cellulose in the following respects: its percentage composition (excluding ash) is

| C | 47·0 | 48·0 | per cent. |

| H | 5·9 | 5·7 | „ |

| O | 47·1 | 46·3 | „ |

It is harsher to the touch, and its colour varies from grey to brown; it combines directly with the greater number of the organic colouring matters, removing them from solution, i.e., becoming dyed with them; it is coloured deep yellow by immersion in a solution of aniline sulphate; moistened with a solution of phloroglucol and afterwards with hydrochloric acid, it gives a deep red coloration; with pyrrol also in presence of hydrochloric acid it gives a deep carmine colour; it is attacked and partially converted into soluble products by a number of reagents which have no action, under similar conditions, upon cellulose. Certain of these we must consider more in detail.

After dissolving away this compound by exhaustive treatment with alcohol, the fibre still gives a brilliant reaction with sodium sulphite, showing that a portion is still held back in combination with the cellulose, or cellulose residue. On treating the residual fibre with boiling nitric acid, a considerable quantity of chloropicrin CCl3NO2 is formed, and it is probable that the union of the molecule C19H18Cl4O9 with the cellulose may be effected by the aldehyde5 molecule CCl3COH; each group being contained in the original lignocellulose, the action of the chlorine tending to disturb the atomic equilibrium and to rearrange the atoms into groups, which in their modified form have less mutual coherence. If the chlorinated fibre be directly boiled with the sodium sulphite solution, its resolution into cellulose and soluble non-cellulose derivatives is complete: and this treatment constitutes the most simple and rapid method of estimating the cellulose in lignified tissues. It is only necessary finally to wash the cellulose with hot water containing a little acetic acid (when placed in a funnel it acts as its own filter), and then with, alcohol, when it may be dried and weighed. In order to ensure the resolution of the fibre by a single chlorination (in the case of jute, and the like), it must, previously to exposure to the gas, be boiled in a dilute (1 per cent.) solution of potassic hydrate. In the case of wood and other more resistant structures, it will be necessary to repeat the chlorination.

5 Furfural may also be isolated from the chlorinated jute; the survival of this aldehyde is noteworthy.

The percentage of cellulose yielded by this method is, in the case of jute, usually 2–3 per cent. higher than by the bromine method. Moreover, if the temperature be maintained at 0° C. (32° F.), by placing the fibre, which is to be exposed to the action of the gas, in contact with pounded ice, the percentage may be still further increased, amounting {20} in some cases to 80–82. Corresponding to this increased yield, the cellulose is obtained in long filaments. It will be seen, therefore, that the cellulose isolated by chemical treatment from a compound cellulose is affected both in character and quantity by the process employed, and it is affected in a much greater degree than the cellulose itself exposed to the same treatment, after isolation. The composition of the cellulose obtained in this way differs from that of celluloses, such as cotton, which exist in the plant in an isolated and more fully formed condition; it contains 43 per cent. C and 6 per cent. H, corresponding to the formula n [3 C6H10O5H2O.] The composition of this cellulose will be seen to be identical with that of certain of the oxycelluloses previously described; and its properties are, moreover, those of an oxycellulose. These facts go to show that the jute fibre substance, and the substances allied to it, are compounds of cellulose with other molecules, i.e. they are compound celluloses. They may be conveniently grouped under the term ligno-cellulose.

Schulze’s method of isolating cellulose from wood, and from the ligno-celluloses generally, consisted in macerating them for 12 to 14 days with 8⁄10 their weight of potassium chlorate dissolved in 12 parts by weight of nitric acid (sp. gr. 1·10), and completing the resolution by afterwards boiling with dilute ammonia. By the action of a more concentrated acid, 50 per cent. HNO3, at 80° C. (176° F.), a soluble derivative is obtained which has the composition (C25H40NO25). It is a syrupy, highly acid body, dyeing animal fibres a deep yellow shade, and giving with the earthy bases salts of the formula (C25H32NO25M4), which are precipitated by alcohol from their aqueous solution in the form of bright yellow flocks that dry to a yellow powder.

| C | 64·4 |

| H | 4·4 |

| O | 31·2 |

The solution yields on distillation furfural and acetic acid.

The increase in weight resulting from the fixation of the {23} nitric acid residue is approximately equal to that of cotton “nitrated” under the same conditions.

They are freely soluble in acetone. On examination they prove to be homogeneous. If the fibre be warmed with the mixture after the first reaction is completed, it dissolves. The solution is found to contain oxalic, succinic, and suberic acids, but no aromatic nitro-derivatives, whereas if ligno-cellulose contain a benzene nucleus, as has been supposed, such derivatives could not fail to be formed under these conditions.

The coals themselves may be regarded as pseudo-carbon derivatives of celluloses, formed by a process of molecular condensation, the true nature of which remains a matter of speculation. In this view, the whole of our vast series of aromatic or benzene compounds, derived as they are from the products of the destructive distillation of coals, may be traced back to a cellulose origin.

Pseudo-carbons are obtained as products of the action of various reagents upon the celluloses, and other of the so-called carbo-hydrates. These reagents, such as sulphuric acid, act in virtue of their dehydrating power; and the recognition of this fact, together with the supposed “carbonaceous” {25} character of the product, led to the erroneous conclusion that the carbohydrates are in such decompositions simply resolved into carbon and water; a conclusion which seems to derive additional warrant from the peculiar numerical relationship which exists between the C, H, O atoms of all the members of the group. Their relation is expressed in the general formula Cn H2(n−m) O(n−m), and in the somewhat misleading term carbohydrate, which is applied to the whole group. We now know that the removal of water from these bodies by the action of dehydrating agents—including heat—follows the ascertained laws of chemical dehydration, involving molecular condensations and rearrangement, and that the pseudo-carbons are the extreme terms of a series of such condensations or cumulative resolutions. The matter, however, is not as yet sufficiently investigated to enable us to state with any preciseness the mechanism of these changes. Still this general statement will enable us to avoid many of the erroneous views which have existed on the subject, and in a measure to anticipate the results of future investigation.6

6 It is worthy of mention that by the action of chlorine in presence of water, and by the action of concentrated nitric acid upon the cannel coals, substitution derivatives are formed resembling those obtained by the action of these reagents respectively upon the ligno-celluloses.

| C | 65·7 |

| H | 8·3 |

| O | 24·5 |

| N | 1·5 |

Cork, however, unlike the jute fibre, is by no means chemically simple, but can be resolved by the action of mere solvents into a number of proximate constituents, such as acids, a variety of fatty bodies, nitrogeneous bodies, &c.

Cuticular tissues, such as constitute the covering of fruits, are more simple in composition; the cuticle of the apple after purification, has the following percentage composition:

| C | 73·66 |

| H | 11·37 |

| O | 14·97 |

The cuticular substance of cotton, straw, esparto, &c., are doubtless similar bodies. These numbers point to a {27} remarkable similarity in composition to the fats, and, indeed, from the results of his study of this tissue, Frémy concluded that it was a fat in everything but its physical properties, of which we may mention insolubility in alcohol and in ether, and infusibility. This tissue, however, as also cork, contains a cellulose residue, which may be isolated by any of the methods of treatment given for ligno-cellulose. Under the action of boiling nitric acid these tissues are resolved into cellulose on the one hand, and a series of fatty acids or products of their decomposition, suberic and adipic acids, &c., on the other; the latter amounting in the case of cork to 40 per cent. of the weight of the substance treated. The cellulose obtained by this treatment is but 2–3 per cent.; this number, however, represents only the amount which has survived a treatment which we know to be destructive to cellulose. If, on the other hand, cork be resolved by treatment with sodium sulphite solution at 100lb. pressure, or 166° C. (331° F.), a soft mass is obtained, preserving the structural features of the original cork, until subjected to slight pressure, when it falls to a cellular mass. From this, cellulose is isolated by any of the less drastic processes above described, and is found to amount to 9–10% of the original cork. As in ligno-cellulose, we have evidence of a transition from cellulose to the tannins, so in cork and cuticular tissue we have evidence of the metamorphosis of cellulose into fats, a fact indicated in the term adipo-cellulose, which we have applied to the compound celluloses constituting these protective plant tissues. This metamorphosis is doubtless a very complex process, and would appear to involve the formation of tannins also, at least as a subsidiary result. Still, the essential feature of the change is the production of the peculiar fat-like substances which have been described; and with due regard to the limitation pointed out, the views here advanced represent the results of the investigations of the subject as far as they have proceeded.

It may be observed that the general characteristics of the {28} adipo-celluloses as of the ligno-celluloses are those of a complex aldehyde.

| 43·7 | per cent. | C. |

| 5·9 | „ | H. |

On boiling with an alkali it loses in weight about 20 per cent., the substance dissolved being identical in properties with Frémy’s pectic acid, a substance containing 42 per cent. C and 4.8 per cent. H = C16H22O15. Many other bast fibres, as well as cellulose tissues, exhibit similar properties, and although this branch of the subject has been but little investigated, there is sufficient evidence for constituting a special class of compound celluloses under this term, pecto-cellulose, having properties indicated in the type selected above.

In addition to pectic acid there exists in, or can readily be obtained from certain plants, a series of bodies of a similar nature, such as pectose, pectin, parapectic acid and metapectic acid. The most important of these are pectic acid and metapectic acid.

Pectic acid, though it rarely exists ready-formed in the plant, can readily be obtained from it by the action of weak alkalis. It is best procured by boiling the pulp of turnips with a 10 per cent. solution of sodium carbonate for about half an hour. If an acid be added to the filtered liquid, pectic acid is precipitated as a transparent colourless jelly, which {29} dries up to a transparent horny mass. By the prolonged action of alkalis or acids, pectic acid is converted into metapectic acid (C8H14O9), which may be obtained as a syrupy, strongly acid liquid.

From what we know of the properties of the members of the pectic group, and therefore of the pecto-celluloses, it will be readily seen that the latter are very liable under the action of alkalis to undergo conversion into soluble derivatives.

Conversely, a study of the action of alkalis upon plant substances, enables us to determine to what extent the latter partake of the nature of the pecto-cellulose, the importance of which to the practical paper maker we need hardly point out. For a further development of this idea (see p. 43).

We now have to treat of the fibrous raw materials from the point of view of form or structure, which is, of course, a very important factor in determining the quality of the paper or other fabric into which they are manufactured. It is sufficiently evident that the strength of paper is primarily due to the cohesion of its constituent fibres. When paper is torn, the edges present a fibrous appearance, and observation teaches us that, other things being equal, the greater the manifestation of fibrous structure the stronger will be the paper. If a paper be thoroughly wetted, its tensile strength is reduced to a minimum, and if subjected to a slight strain we get, not a tearing, but a pulling asunder of the fibres. If this be performed under a lens, the structure of the paper is more clearly seen, and it will be appreciated to what extent the qualities of a paper are the aggregate of the qualities of its constituent fibres. A more careful dissection of the paper shows that these fibres, which are the ultimate fibres of the plant, as distinguished from the bundles of these, or filaments, which the spinner employs, are interlaced in all directions. To produce this effect of interweaving, and to insure that uniformity which is an essential feature of good paper, we have among others the following contributory causes: (1) the deposition of the fibres from suspension in water; (2) the composition of the pulp with regard to the reduction of the fibrous bundles, and the isolation of the individual fibres; and (3) the structure of these ultimate fibres. It is with the last that we are chiefly concerned at present.

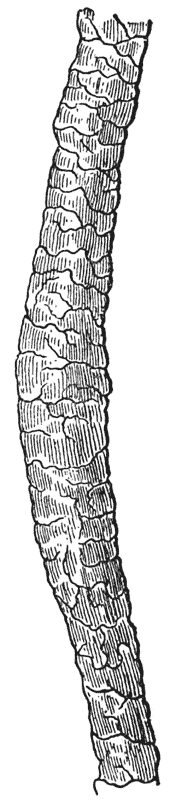

To convey a general notion of the influence of the structure {31} of fibres upon fabrics, we shall with advantage travel outside our immediate province to consider briefly the woollen and silk manufactures in relation to this point. Wool is, as we know, a discontinuous fibre, and its structure is that represented in Fig. 1, the most conspicuous feature being its broken surface, consisting apparently of imbricated scales.

The silk fibre, on the other hand, is a dual cylinder, spun by the worm in a continuous length, and with a perfectly smooth surface. Now, it would not be to our purpose to point out that in starting from a discontinuous simple fibre, to produce a continuous, therefore necessarily compound one, a very different treatment or process of spinning is required from that which the opposite condition renders practicable. We will rather consider the influence of structure upon materials manufactured from these fibres. It is obvious that the wool fibres, brought into contact with one another, tend to interlock; whereas silk fibres if rubbed or pressed together, simply slide over one another; the result in the fabric is by multiplication of the effect, a shrinking or contracting in length and breadth. This interaction of the fibres, and the phenomena to which it gives rise, is known as the felting of wool and woollen goods; this tendency, for the contrary reason, is not seen in silk fabrics. The production of paper from a disintegrated fibrous mass or pulp introduces similar considerations. That paper will be the stronger in which the constituent fibres are the better felted, and the degree in which felting takes place will depend to a great extent upon the form or microscopic peculiarities of the fibres. This is only one of the more obvious inferences to be drawn from the structure of fibres to the qualities of the papers which they compose. Other {32} equally important practical bearings will be seen to attach to the microscopic study of our fibrous raw materials, and to the consideration of this branch of the subject, we now ask the careful attention of the student.

It is impossible for us to deal specially with the subject of the microscope and its manipulation. The microscope, as a revealer of natural wonders is one thing; as an instrument of scientific discovery, quite another. For the latter, the student must train himself by systematic work, and should especially concentrate his attention upon some one branch of natural history, however restricted.

We shall assume, in our treatment of the subject, a knowledge of the microscope as an instrument of research, such as can be easily acquired in a few weeks of work under the guidance of a teacher or of one of the excellent manuals which now abound. We also assume a certain acquaintance with the elements of vegetable physiology, which it will be seen is necessary for a full grasp of the subject. Such an acquaintance, also, may be easily acquired, under direction, in a few weeks of work.

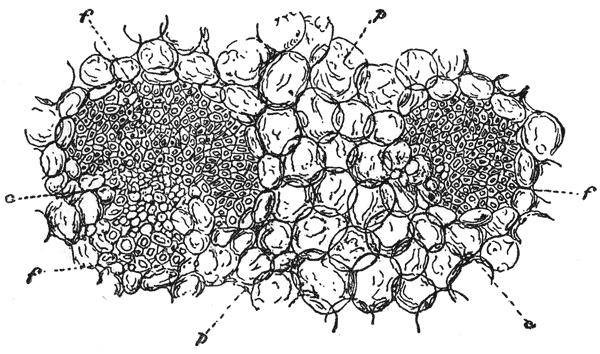

We have before alluded to the differences presented by {33} mono and dicotyledonous stems in regard to the distribution of their fibrous constituents. In illustration of this, we may cite Figs. 2, 3, which represent, (2) a section of the aloe, (3) a section of the jute plant. The available fibres are in (2) the fibro-vascular bundles (f), which are irregularly distributed throughout the main mass of cellular tissue, and {34} in (3) the bast fibres (f), which constitute a definite and separate tissue. We have already alluded to the practical consequences of this typical difference of distribution, in regard to processes of separating these fibres on the large scale.

This process we have explained is necessarily simpler in the case of a fibrous tissue, definitely localised; and this may be demonstrated by a superficial examination of a young branch of an exogen. As we know, the bark tissues are easily stripped from the underlying wood. If now we work up the former in a mortar, with a little water, we soon perceive the separation of the compound tissue into cellular matter on the one hand and fibres, the latter being more or less long and silky, according to the plant from which isolated. They vary in length from one millimetre to several centimetres, and are aggregated together in the plant in such a way as to constitute bundles, often of very considerable length; the general arrangement being comparable with that of the tiles in the roof of a house. It is important to distinguish the fibre-bundles from the elementary or normal fibres, and to this end they are designated by the term filament. Bast fibres are flexible and fusiform, terminating gradually in a point at either end, as represented in Fig. 4; bast filaments, built up of these fibres, containing often as many as twelve in the bundle, are usually cylindrical, but exhibit the widest differences in regard to the aggregation, in degree as well as number of their constituents. It is obvious that while the spinner has to do with these filaments, the paper maker works up the ultimate fibre constituents or fibres. It is also an obvious corollary from this distinction that a fibrous material which from “weakness” is unavailable for textile application, may yet be perfectly “strong” from the paper maker’s point of view; in other words, the individual fibres may be strong, but have little cohesion in the filaments. As we proceed, the student will see more and more the practical bearings of this branch of the study, and will perceive the inferences to be drawn from the investigation of {35} minute relationships to manufacturing processes and their products.

We shall say but little as to the necessary equipment. (1) A dissecting microscope, for dissecting under a lens, magnifying the object to 40 or 50 diameters. (2) An ordinary student’s microscope with lenses for magnifying to 100 and 300 diameters. This is adequate to the work, though of course, it may be an advantage in certain cases, to be provided with higher powers. (3) A glass slide, carrying an engraved scale of centimetres and millimetres for measuring the lengths of objects, and a micrometer, divided into 1⁄10 mm. for measuring diameters. It is also important to be able to determine the degree of enlargement under any particular combination of lenses, and for this purpose to possess a micrometer eye-piece, with a millimetre scale divided into hundredths. (4) An effective microtome and the usual mounting accessories.

A very important feature in the diagnosis of fibres, more especially in regard to the composition of the fibre substances, is the effect produced by treatment with various reagents. Certain of these reactions we have already {36} indicated. We shall now give the details of composition of the several solutions which will be required.

The accessory solution, dilute sulphuric acid, which is employed to determine the reaction between the cellulose and the iodine, is prepared as follows:—2 volumes of concentrated glycerin are mixed with 1 volume water, and to the mixture an equal volume of oil of vitriol (1·78 sp. gr.), is slowly added, so as to prevent as far as possible a rise of temperature. The effect of the glycerin is very remarkable in preventing the distortion of the objects under the action of the acid, which in other respects remains uninfluenced.

By way of verification of this iodine test, which is somewhat capricious, it is advisable to test the reagents with a standard substance. The best for the purpose is a linen yarn which has been partially bleached. Under the action of the reagents the fibres composing this yarn, which must, of course, be suitably “teazed out” for mounting, are coloured a light blue, the centre, however, showing a yellow line, {37} marking the distribution in the interior canal of a non-cellulose fibre constituent. Should these effects not appear, it may be concluded that the acid requires to be strengthened. On the other hand, too great a concentration is equally to be avoided; it is evidenced by causing a distortion of the fibre, easily recognised by comparison with the fibre mounted in a neutral medium.

The employment of the aniline sulphate solution, as well as of the solutions of the aniline colours, presents no difficulties, and therefore needs no detailed description. The former strikes a more or less deep yellow with lignose; the aniline colours stain or dye the tissue or fibre more or less deeply, according to its composition, and, as it is a reciprocal action, {38} according also to the composition of the colouring matter. In following up this subject, the student will require to consult works on vegetable histology.

Sections of the filaments are prepared by cutting in a microtome, the filaments being previously agglutinated into a stiff bundle by means of any of the usual stiffening solutions, and after drying, embedded in wax in the usual way. Sections of fresh stems and tissues are cut with a “section” razor.

Having prepared the objects, their examination under the microscope necessarily divides itself into:—(1) the determination of external features; (2) the diagnosis of chemical composition. The fibres themselves will be individually considered in regard to microscopic features.

There is one aspect of these structural features, however, which admits of more general treatment, and in respect to this we may anticipate with advantage, viz., the dimensions or simple elements of form. The importance of the determination of the length and diameter of both filaments and fibres will be readily appreciated by an inspection of the following table, in which the numbers are given for several of the more important.

A careful study of this table in relation to the application of these several fibres, will show that the correlation of the latter with these ultimate dimensions is close and essential. {39}

| Length of Filament. | Length of Fibres. | Diameter of Cells. | ||||

|---|---|---|---|---|---|---|

| Extreme. | Normal. | |||||

| cm. | cm. | 1⁄100mm. | 1⁄100mm. | |||

| A. Seed hairs. Filaments composed of individual cells. | ||||||

| Cottons. | ||||||

| Gossypium barbadense (Sea Island) | 4·05 | 4·05 | 1·92–2·79 | 2·52 | ||

| Gossypium acuminatum | 2·84 | 2·84 | 2·01–2·99 | 2·94 | ||

| Gossypium arboreum | 2·50 | 2·50 | 2·00–3·78 | 2·99 | ||

| Bombax heptaphyllum | 2–3 | 2–3 | 1·9–2·9 | .. | ||

| B. Bast fibres. Filaments or fibre bundles, made up of individual fibre-cells aggregated together. | ||||||

| Flax. | ||||||

| Linum usitatissimum | 20·140 | 2·0–4·0 | 1·2–2·5 | 1·6 | ||

| Hemp. | ||||||

| Cannabis sativa | 100–300 | .. | 1·5–2·8 | 1·8 | ||

| China Grass. | ||||||

| Boehmeria nivea | .. | 22·0 | 4·0–8·0 | 5·0 | ||

| Ramie. | ||||||

| Boehmeria tenacissima | .. | 8·0 | 1·6 | .. | ||

| Jute. | ||||||

| Corchorus capsularis | 150–300 | ·8 | 1·0–2·0 | 1·6 | ||

| Corchorus olitorius | 150–300 | ·8 | 1·6–3·2 | 2·0 | ||

| Paper mulberry. | ||||||

| Broussonetia papyrifera | .. | ·7–2·1 | .. | 3·6 | ||

| Linden bast. | ||||||

| Tilia grandifolia | .. | 1·1–2·6 | .. | 1·5 | ||

| C. Fibro-vascular bundles | ||||||

| New Zealand Flax. | ||||||

| Phormium tenax | 80–110 | 2·5–5·6 | ·8–1·9 | 1·3 | ||

| Aloe. | ||||||

| Aloe perfoliata | 40–50 | 1·3–3·7 | 1·5–2·4 | .. | ||

| Esparto. | ||||||

| Stipa tenacissima | 10–40 | 0·5–1·9 | ·9–1·5 | .. | ||

A very important point in the diagnosis of a raw material, and next in order of treatment, is the degree of purity of the substance, in so far as this is related to structure. The fibres may be associated with cellular tissue, or with cellular debris, if they have undergone the retting process or other treatment for separation; or with “encrusting and intercellular substances” in various proportions. In the latter case the association with the fibres is usually much more intimate; they are in fact essential constituents of the fibre bundles {40} (bast-fibres, fibro-vascular bundles), whereas the former we may regard as “foreign matter.” We may, however, distinguish between the normal incrustation of the fibre-cells, and such an incrustation of the filaments as would be described as a loose adhesion of non-fibrous matter. The latter is seen in such tissues as the bast of the adansonia, and the fibro-vascular bundles of the aloes. These are points with which observation alone can familiarise the student; as experience grows he will find it increasingly easy to follow general distinctions, and in proportion as he uses his own faculties, so he will be able to generalise for himself. He will find this equally true of the second section of the microscopic examination, i.e., the micro-chemical diagnosis of fibres. Under this head is included the observation of the behaviour of fibres towards the various reagents above described. In addition to their microscopical employment it is useful to note their effect on fibres in the gross, both in their natural state and after treatment with bleaching agents.

In applying the iodine reaction, attention must be paid to the following details of manipulation. Place the object (dry) upon the glass slide, moisten with a few drops of the iodine solution, cover with a glass slip and examine under the microscope. Note the effects, which are those of the iodine alone. Then remove the iodine solution by means of blotting paper, and introduce the sulphuric acid by the method of “irrigation.” The colouration of the cellulose (blue-violet) is immediate; it has the effect moreover, of bringing out more clearly a number of the structural details of the fibre.

We have already treated of the resolution of the raw fibres into cellulose and non-cellulose constituents by processes which convert the latter into soluble derivatives. The student will derive much instruction from following up the attendant structural disintegration with the aid of the microscope. The chemical dissection of lignified fibres by the alternate action of bromine water and alkalis, should be studied by mounting specimens of the fibre at all stages and {41} carefully noting all the changes which occur. The more drastic action of chlorine should also be studied by mounting the chlorinated fibre (in water) and then irrigating with the alkaline solvent (caustic alkali or sulphite) and noting the stages in the completion of the disintegration.

It will be convenient at this point to present to the reader a general scheme for the chemical analysis of fibrous raw material.

We have already discussed (p. 4) the methods for the determination of cellulose in fibrous substances. This is to the paper-maker the most important constituent, and is that upon which his calculations of the value of a raw material are based. Not only, however, is it of the greatest importance for him to be able accurately to determine the amount of cellulose, but it is necessary to be able to form some idea of the nature of the cellulose and also the ease with which it can be obtained from the fibre. This latter point can only be properly established by direct trial of the fibre under the conditions existing in the factory. It should also be borne in mind that these conditions influence to a considerable degree the amount of cellulose, actually obtained in practice, and that therefore the percentage shown by a careful determination in the laboratory should only be taken as an indication of the amount likely to be realized. The student will be able, from what has been said before of the properties of the different celluloses, to apply his knowledge to a determination of any particular specimen. In order to supplement this knowledge, it may be well at this particular point to cite the chief results of an investigation bearing upon this point by Webster (Chem. Soc. Journ., 1883, p. 23).

His method of investigation consisted in (1) estimating {43} the cellulose; (2) determining the loss sustained by the fibre when boiled for 5 minutes, and also for 60 minutes, with an alkaline solution (caustic soda 1 per cent. Na2O), the former being taken to represent the purely solvent action, the difference between the two amounts being an indication of the degrading action of the soda; (3) determining the ultimate composition (C H and O) of the fibre substance. It should be observed that the specimens were carefully averaged and purified by boiling in glacial acetic acid and in alcohol. On carefully considering the following table it will be seen that the chief points brought out by Webster’s investigation are (1) the association of a low carbon percentage with pectous properties and considerable degrading action on long boiling in alkali. The bearing of this will be better understood in connection with a discussion of the properties of pectic acid (p. 28) and the oxycelluloses (p. 13). (2.) The influence of the composition of the original fibre on the isolated cellulose.

The solutions of aniline sulphate and of the aniline colours give valuable aid in a diagnosis of plant substances. Webster observed, as was to be expected, that the yellow colour produced could be taken as an indication of the amount of lignification, those fibres which were of a pectous nature showing little or no colour. On the other hand, when the fibres were treated with a neutral solution of the so-called alkali-blue it was found that the converse took place, highly pectous fibres being dyed much more deeply than those which were lignified. (Compare the action of aniline colours on oxycellulose, p. 11.)

| Agave Americana. | Yucca gloriosa. | Ananassa sativa (Pine Apple.) | Musa paradisiaca (Manilla). | Phormium tenax (New Zealand Flax). | ||

|---|---|---|---|---|---|---|

| 1. Yield of cellulose by chlorine method | 81·2 | 80·8 | 76·3 | 62·8 | 86·3 | |

| 2. Character of isolated cellulose | Fibres free. | Fibres free. | Fibres agglutinated. | Fibres agglutinated. | Fibres partially agglutinated. | |

| 3. Loss in boiling 1 per cent. caustic soda (5 minutes) | 9·9 | 14·5 | 9·6 | 18·6 | 5·8 | |

| 4. Ditto (60 minutes) | 14·6 | 16·5 | 19·0 | 31·7 | 9·9 | |

| 5. Ash | 1·0 | 1·3 | 1·0 | 1·6 | 0·9 | |

| 6. Elementary composition | ||||||

| C. | 45·9 | .. | 42·5 | 42·6 | 44·4 | |

| H. | 6·1 | .. | 5·6 | 5·6 | 5·9 | |

| 7. Lignified or otherwise. Aniline sulphate reaction | Lignified. | Lignified. | Lignified. | Lignified. | Lignified. | |

| Boehmeria Puya. | Urtica heterophylla (Nilgherry Nettle). | Crotolaria juncea (Sunn). | Hibiscus strictus. | Linum usitatissimum (Flax). | Corchorus capsularis (Jute). | ||

|---|---|---|---|---|---|---|---|

| 1. Yield of cellulose by chlorine method | 83·8 | 95·0 | 76·9 | 63·0 | 82·0 | 75·0 | |

| 2. Character of isolated cellulose | Fibres partially agglutinated. | Fibres free. | Fibres free. | Fibres partially agglutinated. | Fibres free. | Fibres free. | |

| 3. Loss in boiling 1 per cent. caustic soda (5 minutes) | 15·6 | 2·6 | 5·3 | 13·7 | 7·8 | 17·2 | |

| 4. Ditto (60 minutes) | 24·1 | 7·3 | 10·7 | 25·5 | 16·6 | 18·6 | |

| 5. Ash | 3·7 | 1·0 | 0·9 | 2·0 | 1·7 | 1·1 | |

| 6. Elementary composition | |||||||

| C. | 41·8 | 42·9 | .. | .. | 43·7 | 47·1 | |

| H. | 6·0 | 5·9 | .. | .. | 5·9 | 5·9 | |

| 7. Lignified or otherwise. Aniline sulphate reaction | Not lignified. | Not lignified. | Lignified. | Lignified. | Not lignified. | Lignified. | |

If the student require more precise knowledge of the nature of a fibrous material than that afforded by a determination of the cellulose, the following method of analysis will prove of service.

About two grms. are taken and dried at 110–115° C. until the weight remains constant: the loss represents water. The fibre is then treated with a hot mixture of benzene and alcohol, dried as before and weighed: the loss is fat, wax, {45} &c. The residue from this treatment is then repeatedly exhausted with boiling water and again dried at 110–115° C. and weighed: the loss is put down as aqueous extract. The exhausted fibre is then treated for cellulose by either of the methods given on p. 19. The ash is determined in a separate portion.

This chapter contains the results obtained from an investigation of the different plant fibres by the methods indicated in the two previous chapters.

In the following table the fibres are classified according to the reactions which they give with iodine solution.

| A. Seed Hairs. | B. Dicotyledonous Bast Fibres. | C. Monocotyledonous Fibres corresponding to Bast Fibres. | |

|---|---|---|---|

| Blue reaction | Cotton. | Linen. | Straw. |

| Hemp. | Esparto. | ||

| China grass. | Pine apple. | ||

| Paper mulberry | |||

| Sunn. | |||

| Yellow reaction | Jute. | New Zealand flax. | |

| Yucca. | |||

| Hibiscus. | Aloe. | ||

| Manilla hemp. |

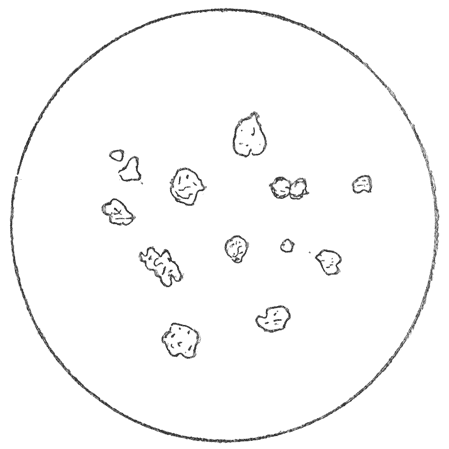

Microscopic features.—Fibres simple, opaque, flattened, always more or less twisted upon itself, side wall membranous, showing striæ. {47}

Sections.—Simple, oval, irregular, central cavity often containing granules.

Micro-chemical reaction.—Blue with iodine solution.

General chemical characteristic.—Pure cellulose basis with slight admixture of colouring matters, &c.

| Church. | Müller. | |

|---|---|---|

| Cellulose | 91·15 | 91·35 |

| Fat | 0·51 | 0·40 |

| Aqueous extract (containing nitrogeneous substances) | 0·67 | 0·50 |

| Water | 7·56 | 7·00 |

| Ash | 0·11 | 0·12 |

| Cuticular substance (by difference) | .. | 0·63 |

E. Schunck in his investigation of cotton bleaching (Chem. News, 17, p. 11) finds that in boiling with sodium carbonate solution the fibre loses 5 per cent. in weight. Some portion of the dissolved substances is precipitated on acidifying and is found to contain a wax, brown resinous and colouring matters, and pectic acid. {48}

Forms in which employed.—Fibrous refuse from the decortication of the seeds; spinning waste, threads, rags, new and old.

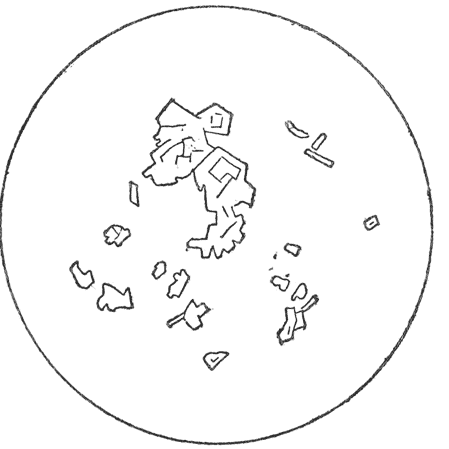

Microscopic features.—Fibres transparent, regular, with tapered ends, side walls thick, consequently central canal small, smooth externally, sometimes slightly striated. Filaments easily split up into fibres.

Sections.—Polygonal, regular, angles more or less acute, lumen represented by point; slight indications of concentric arrangement of fibre substance.

Micro-chemical reaction.—Blue with iodine solution.

General chemical characteristic.—Pecto-cellulose.

Composition of raw fibre.—This varies with the different species, and is doubtless also influenced by variations in the {49} processes of retting. The following are the analyses of two samples of Belgian flax (heckled):—

| Müller. | ||

|---|---|---|

| Cellulose | 81·99 | 70·55 |

| Fat and wax | 2·37 | 2·34 |

| Aqueous extract | 3·62 | 5·94 |

| Pectous substances | 2·72 | 9·29 |

| Water | 8·60 | 10·56 |

| Ash | ·70 | 1·32 |

The chemistry of the flax fibre has been investigated by Kolb.

Forms in which employed.—Scutching refuse, spinning waste, threads, rags, new and old.

Microscopic features.—Compact bundles. Fibres show striæ and fissures, and often fibrillæ, detached or adherent. The central canal almost obliterated, ends of fibres large and flattened. The bundles show fine transverse markings. {50}

Section.—Well marked concentric zones of fibre substance, irregular in outline.

Micro-chemical reaction.—Blue and yellow reaction with iodine solution, the joint result showing green colouration.

General chemical characteristic.—Pecto-cellulose.

| Müller. | |

|---|---|

| Cellulose | 77·13 |

| Fat and wax | ·55 |

| Aqueous extract | 3·45 |

| Pectous substances | 9·25 |

| Water | 8·80 |

| Ash | 0·82 |

Forms in which employed.—Scutching refuse, spinning waste, threads, cuttings and rope ends.

Microscopic features.—Generally similar to those of hemp.

Micro-chemical reactions.—With iodine various, from blue to yellow. With aniline sulphate, slight yellow.

General chemical characteristics.—Pecto-cellulose (with some ligno-cellulose).

The following are the results of analysis of the raw fibre (H. Müller):—

| Cellulose | 80·01 |

|---|---|

| Fat and wax | ·55 |

| Aqueous extract | 2·82 |

| Pectous substances | 6·41 |

| Water | 9·60 |

| Ash | 0·61 |

This fibre, exported from India and the Sunda Islands, has found employment in Spain and Portugal, but up to the present has not been adopted to any extent in other parts of Europe.

Microscopic characteristics.—Irregular in form and length; often conspicuous in respect of latter (see Table, p. 39); fibre sometimes cylindrical, either smooth or striated, sometimes flattened; central canal well developed, often containing granules; extremities of fibres rounded, spatulated or lance-shaped. Sections marked by numerous concentric layers, often showing radiating striæ.

Micro-chemical reaction.—Blue to violet, with iodine solution.

General chemical characteristics.—Pecto-cellulose.

Composition of raw fibre (H. Müller):—

| Cellulose | 75·83 | 62·50 |

|---|---|---|

| Fat and wax | ·20 | 0·56 |

| Aqueous extract | 6·29 | 9·76 |

| Pectous substances | 6·07 | 12·00 |

| Water | 8·74 | 9·55 |

| Ash | 2·87 | 5·63 |

Forms in which employed.—Up to the present the price has been prohibitive. Has been the subject of successful {52} experiments; imparts great tensile strength to paper. The portions available will be as in flax.

The fibres of this plant were, in the olden times, separated in the same way as flax, and worked up into cloth. At present it has no practical interest to the paper-maker, but deserves attention at the hand of the student, as the most easily accessible for the purpose of study. It is, moreover, possible that, under cultivation, it may yet become a source of raw material for paper-making.

Microscopic features.—Compact bundles; fibres smooth.

Micro-chemical reactions.—Yellow brown, with iodine; yellow, with aniline sulphate; bright yellow, with chlorine water; changed to carmine by treatment with sodium sulphite solution. {53}

General chemical characteristic.—Ligno-cellulose. The chemistry of jute as the type of ligno-cellulose has been treated on p. 17.

Composition of raw fibre (Müller):—

| 1st Quality. | Cuttings or Butts. (Root ends). | |

|---|---|---|

| Cellulose | 63·76 | 60·89 |

| Fat and wax | 0·38 | ·44 |

| Aqueous extract | 1·00 | 3·89 |

| Non-cellulose, or lignin | 24·32 | 20·98 |

| Water | 9·86 | 12·40 |

| Ash | ·68 | 1·40 |

Forms in which employed.—Threads, butts, bagging.

The fibres give a yellow colouration with aniline sulphate, but they contain only a small proportion of lignose. The following are the results of analyses of this bast:—

| Cellulose | 49·35 | 58·82* |

|---|---|---|

| Fat and wax | 0·94 | 0·41 |

| Aqueous extract | 13·57 | 7·08 |

| Pectous substances | 19·05 | 15·19 |

| Water | 10·90 | 13·18 |

| Ash | 6·19 | 4·72 |

* Made up of 13·75 cellulose from medullary tissue, 45·07 cellulose of fibres.

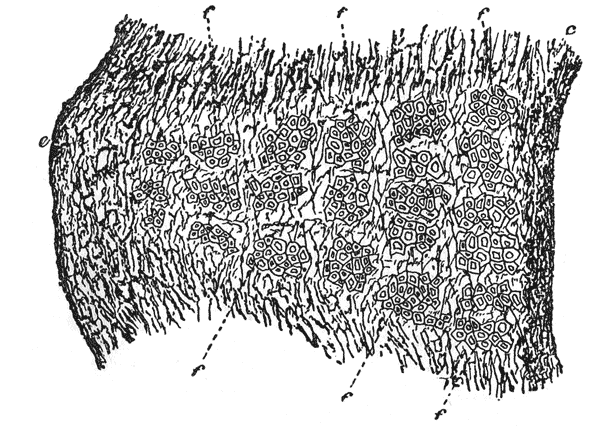

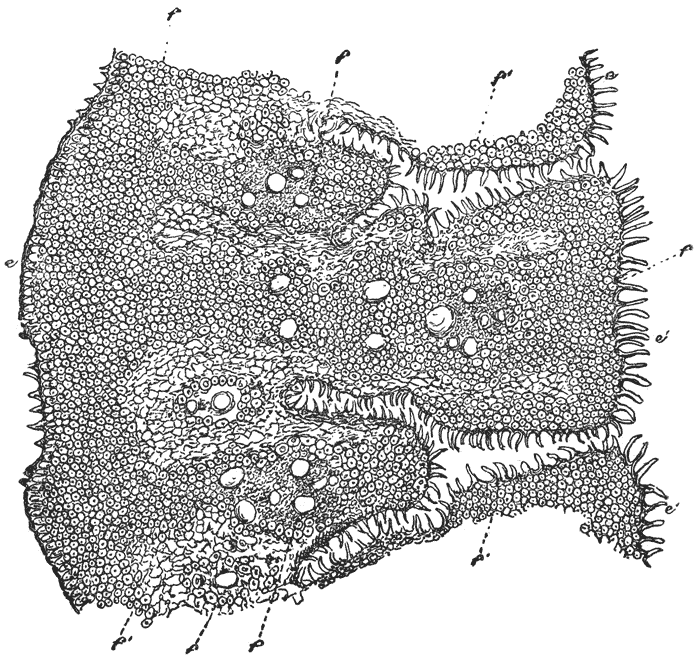

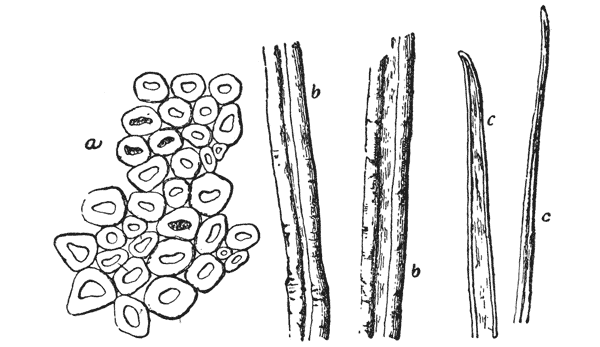

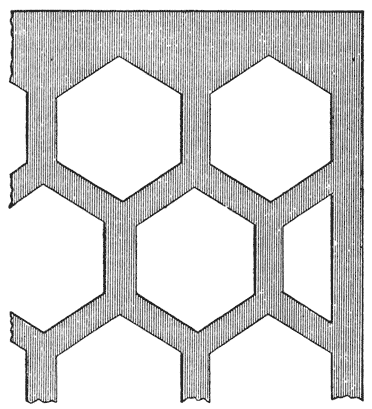

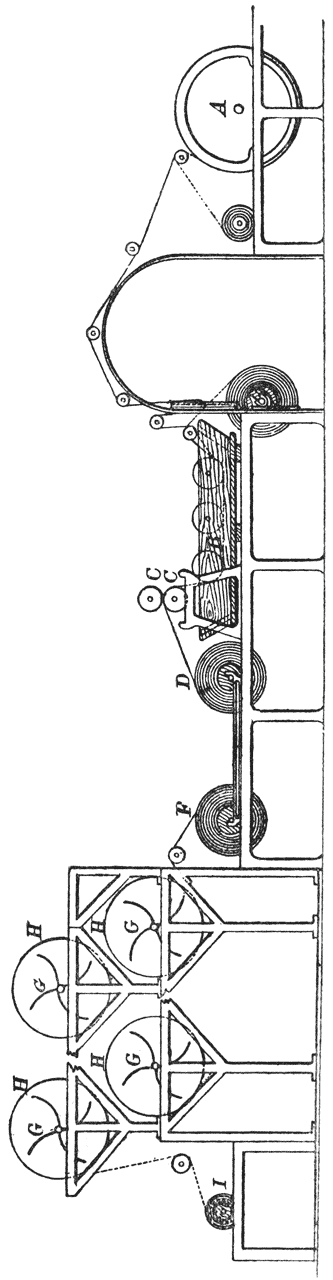

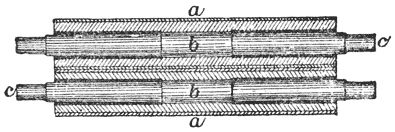

Order, Gramineæ. Bast fibres of fibro-vascular bundles. Length, 1·5 mm.; diameter, 0·012 mm.; ratio, 125. Illustrated in Figs. 10, 11. In Fig. 10, the fibro-vascular {56} bundles f are seen spread throughout the interior of the leaf, but the intervals, instead of being occupied by parenchyma, with large cells and thin walls, are filled with a compact mass of fine solid fibres f ′ ; e, external epidermis; e′, internal epidermis; mag. 100. In Fig. 11, a is a section of a group of fibres; b, fibres seen longitudinally; c, ends; mag. 300.

Microscopic features.—Short, smooth, cylindrical, uniform in diameter, central canal very small, extremities rounded, truncated and bifurcated.

Section.—Minute, generally oval, sometimes polygonal; central cavity represented by a point.

Micro-chemical reaction.—Both blue and yellow with iodine solution.

In examining a paper containing esparto under the microscope, the pulp will be found to contain, in addition to the fibres of the fibro-vascular bundles, a certain number of the cuticular cells (see Fig. 12), together with some of the fine hairs which are seen in the section (Fig. 10). These are very characteristic.

General chemical characteristics.—Pecto-cellulose mixed with some ligno-cellulose. {57}

Composition (Hugo Müller):—

| Spanish. | African. | |

|---|---|---|

| Cellulose | 48·25 | 45·80 |

| Fat and wax | 2·07 | 2·62 |

| Aqueous extract | 10·19 | 9·81 |

| Pectous substances, &c. | 26·39 | 29·30 |

| Water | 9·38 | 8·80 |

| Ash | 3·72 | 3·67 |

Microscopic features.—Generally similar to those of esparto. There are, however, differences of shape and dimensions of the serrated cuticular cells, which differentiate the various kinds of straw from each other and from esparto.

In Fig. 12 are shown these cells, from maize-straw (a and b); from rye-straw (c) and from esparto (d). The {58} following table gives the dimensions of the cells from different kinds of straw:—

| Length. | Breadth. | |||

|---|---|---|---|---|

| Barley | 0·103–0·224 | mm. | 0·012–0·014 | mm. |

| Rye | 0·086–0·345 | „ | 0·012–0·016 | „ |

| Wheat | 0·152–0·449 | „ | 0·018–0·024 | „ |

| Oats | 0·186–0·448 | „ | 0·012–0·017 | „ |

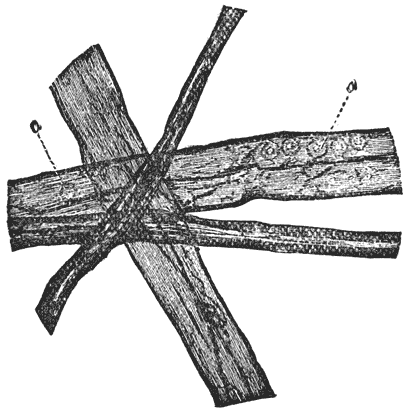

Another distinctive feature of straw-fibre is the presence in it of a number of oval cells, derived from the pithy matter attached to the inside of the stem. These are clearly shown at b (Fig. 13), which represents the general appearance of straw pulp.

General chemical characteristics.—Both ligno-cellulose and pecto-cellulose.

The following are the results of analyses of straws (Hugo Müller):— {59}

| Winter Wheat. | Winter Rye. | |

|---|---|---|

| Cellulose | 46·60 | 47·69 |

| Fat and wax | 1·49 | 1·93 |

| Aqueous extract | 8·07 | 0·05 |

| Non-cellulose or lignin | 28·49 | 26·75 |

| Water | 9·85 | 11·38 |

| Ash | 5·50 | 3·20 |

From the close botanical relationship of these products to the stems of the gramineæ of our own climate, their microscopic features are, as might be expected, similar to those of straw. The similarity is further shown by the chemical composition (Hugo Müller):—

| Air-dried | |

|---|---|

| Cellulose | 50·13 |

| Fat and wax | ·78 |

| Aqueous extract | 10·56 |

| Lignin and pectous substances | 24·84 |

| Water | 8·56 |

| Ash | 5·13 |

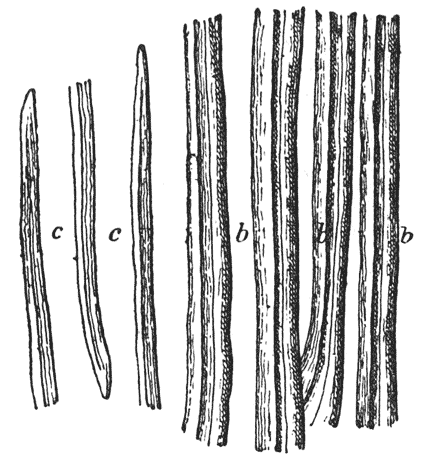

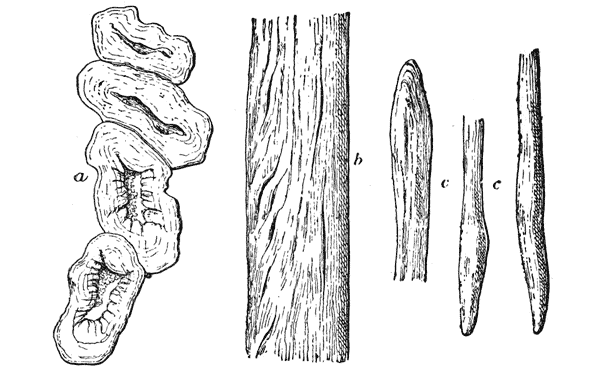

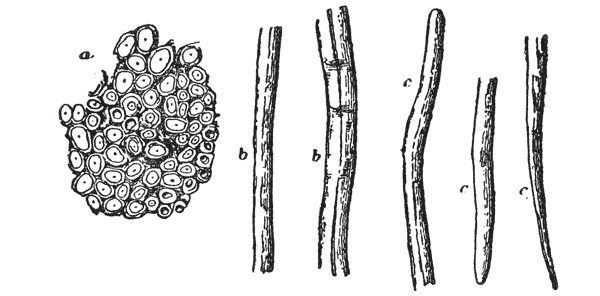

Microscopic characteristics.—Length of fibres, 9 mm., diameter 0·016 mm., ratio, 560. Fibres are fine, regular and smooth; the walls are uniform, central canal small, extremities vesicular. The fibres have little cohesion in the bundle. Sections round or polygonal. Illustrated in Fig. 4, p. 35.

Micro-chemical reaction.—Yellow, with iodine solution. Characteristic deep red colouration with concentrated nitric acid (Müller).

General chemical characteristic.—Ligno-cellulose. It contains 86·3 per cent. of cellulose.

Microscopic characteristics.—Length of fibres, 6 mm.; diameter, ·024 mm.; ratio, 250. Fibres, white lustrous; the walls are uniform; central cavity large and very apparent. Fibres easily detached. {60}

Sections round or polygonal. Illustrated in Fig. 14: a, section of bundle of fibres; b, fibres seen longitudinally; c, ends; mag. 300.

Micro-chemical reaction.—Yellow with iodine solution.

Composition (Hugo Müller):—

| Cellulose | 64·07 |

|---|---|

| Fat and wax | ·62 |

| Aqueous extract | ·96 |

| Lignin and pectous substances | 21·60 |

| Water | 11·73 |

| Ash | 1·02 |

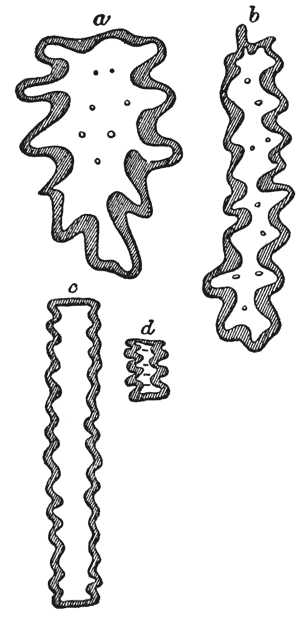

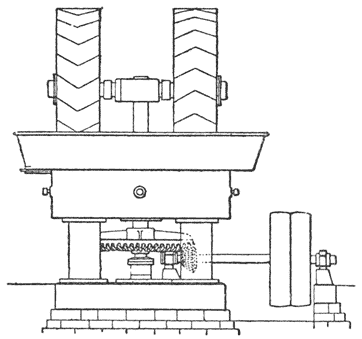

In America, however, poplar and other woods are largely employed. The coniferæ yield a larger proportion of pulp than most other woods, the individual fibres, moreover, are longer, and for these reasons it is generally preferred. On the other hand, however, poplar is more readily acted upon by reagents. Fig. 15 gives the microscopic appearance of {61} the fibre of the common white fir. It is characterised by the presence of numerous pitted vessels (Fig. a).

Pine wood consists essentially of a compound cellulose, resembling in most of its properties the jute fibre (see p. 16). With iodine solution it gives a deep yellow colour. The chemical composition of some of the more important woods will be seen from the following analyses. (Müller.)

| Birch. | Beech. | Lime. | Pine. | Poplar. | |

|---|---|---|---|---|---|

| Cellulose* | 55·52 | 45·47 | 53·09 | 56·99 | 62·77 |

| Resin | 1·14 | 0·41 | 3·93 | 0·97 | 1·37 |

| Aqueous extract | 2·65 | 2·41 | 3·56 | 1·26 | 2·88 |

| Water | 12·48 | 12·57 | 10·10 | 13·87 | 12·10 |

| Lignin | 28·21 | 39·14 | 29·32 | 26·91 | 20·88 |

The above results are calculated on the ash-free wood. The ash varies from about 0·3 to 0·7 per cent.

We are now in a position to discuss generally the various methods by which the paper-maker obtains cellulose from the different raw materials. The special treatments necessary for each of the more important of these will be given more fully subsequently. These methods, though they vary considerably with the different materials to be treated, may be roughly divided into two groups—the alkaline and the acid processes. The former, which we will call a, comprises all processes in which caustic soda, carbonate of soda and lime, or mixtures of these are employed; the latter, b, the various processes which have been introduced of late years, involving the use of sulphurous acid, either alone or in combination with a base, such as lime or magnesia.

The processes in group a may be applied to the treatment of every known fibrous vegetable material; those in group b are at the present time applied exclusively to the preparation of pulp from wood.

Group a may be conveniently subdivided according to the nature of the materials operated upon.

It is obvious that those materials, such as bleached cotton and linen threads and rags, which have already undergone treatment by the textile manufacturer, and are therefore more or less already in the state of pure cellulose, require but little chemical treatment at the hands of the paper-maker, whose attention is therefore chiefly directed to the removal of such adventitious matters as size, grease, &c. This can generally be effected by the employment of weak solutions of caustic soda, or even of lime at a low pressure. {63}

We now have to consider the treatment of those materials which consist of the compound celluloses.

All methods for the isolation of cellulose from the compound celluloses depend upon a hydrolytic resolution of their constituents, i.e. a splitting up by combination with water into cellulose on the one hand, and a series of soluble derivatives on the other. This, as will be shown, may to a certain extent be accomplished by the action of water itself at a high temperature. As, however, the products of such an action are acid bodies, which, if allowed to remain in contact with the cellulose, would injuriously affect it, and would induce the production of complicated bodies, the removal of which from the cellulose would become increasingly difficult, it is necessary to have present a body such as caustic soda, which by combining with these acid bodies, removes them as such from the sphere of action.

In certain raw materials, such as straw and esparto, we have, in addition to the compound celluloses which form, so to speak, the groundwork, a certain proportion of fatty and resinous bodies, whose removal is brought about by the action of the caustic soda converting them into soaps.

The compound celluloses may be divided, as we have seen, into three classes—pecto-celluloses, ligno-celluloses, and adipo-celluloses. The last-named being present in only a few paper-making materials, and then only in very small proportion, is without any practical interest. We are concerned therefore with the two former only.

(1) Pecto-celluloses.—From what we have seen of the nature of the pecto-celluloses, it follows that for their resolution a tolerably simple treatment with soda will be sufficient.

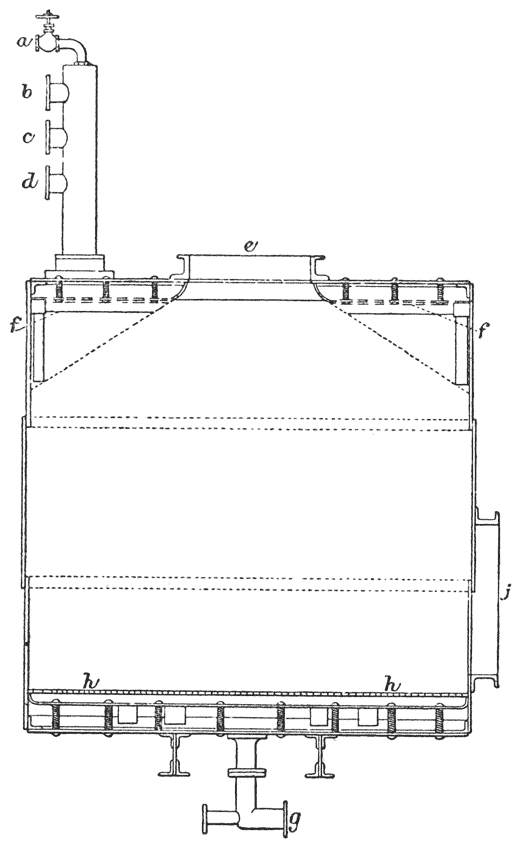

The chief members of this group in which the paper-maker is interested, are esparto and straw. The former being but very slightly lignified, its resolution can be effected at a very low pressure; in fact it is even possible by using tolerably strong solutions to do it by boiling in open vessels.

Straw, on the other hand, though it possesses certain features in common with esparto, is more lignified, and in {64} consequence, necessitates a much more energetic action to complete its resolution. It is therefore usual to boil it at somewhat high pressures (40–70 lb.), and with larger quantities of soda than are demanded in the case of esparto. It is, moreover, essential, so to regulate the treatment, that even the most resistent portions of the straw, such, for example, as the knots, shall be completely resolved, otherwise unbleached portions are liable to find their way into the finished paper. By increasing the quantity of soda, it is possible to boil under reduced pressure, and vice versâ; this may be taken as a general principle applicable in all other cases.

We now come to the second class of celluloses, that is to say, the ligno-celluloses. Of these, perhaps the most important are jute, manilla, and wood.

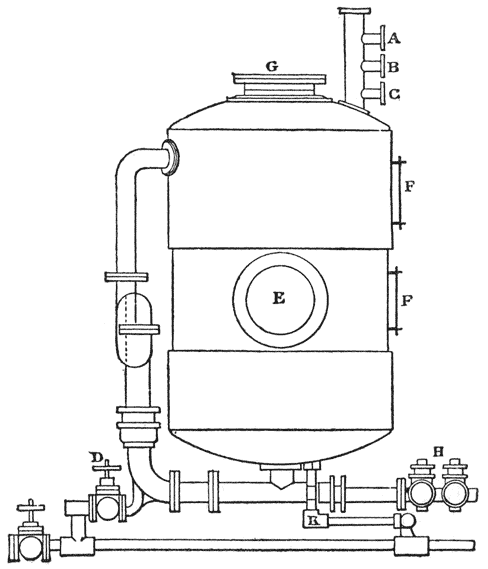

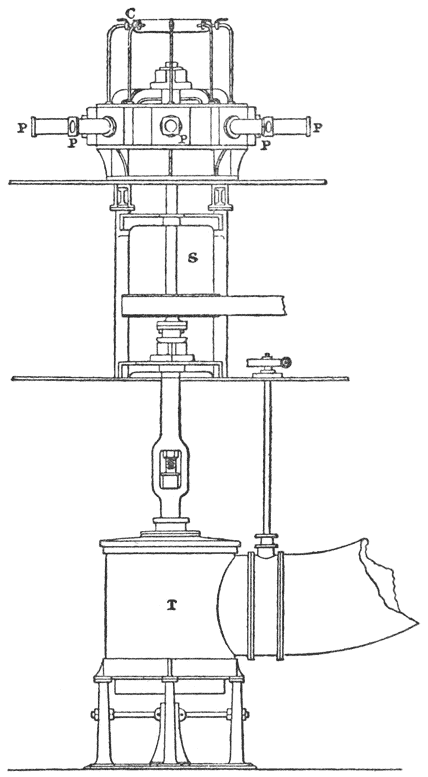

For their complete resolution, it is imperative to employ very strong solutions at very high temperatures and pressures; thus in the case of wood it is necessary to boil at temperatures corresponding to a pressure of 100–120 lb. per square inch.