Project Gutenberg's Milch Cows and Dairy Farming, by Charles Louis Flint

This eBook is for the use of anyone anywhere in the United States and

most other parts of the world at no cost and with almost no restrictions

whatsoever. You may copy it, give it away or re-use it under the terms

of the Project Gutenberg License included with this eBook or online at

www.gutenberg.org. If you are not located in the United States, you'll

have to check the laws of the country where you are located before using

this ebook.

Title: Milch Cows and Dairy Farming

Comprising the Breeds, Breeding, and Management, in Health

and Disease, of Dairy and Other Stock, The Selection Of

Milch Cows, With A Full Explanation Of Guenon's Method;

The Culture Of Forage Plants

Author: Charles Louis Flint

Release Date: January 1, 2019 [EBook #58592]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK MILCH COWS AND DAIRY FARMING ***

Produced by MWS, Bryan Ness, Harry Lamé and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive/American Libraries.)

Please see the Transcriber’s Notes at the end of this text.

The cover image has been created for this e-text, and is in the public domain.

WITH A TREATISE UPON THE

DAIRY HUSBANDRY OF HOLLAND;

TO WHICH IS ADDED

HORSFALL’S SYSTEM OF DAIRY MANAGEMENT.

By CHARLES L. FLINT,

SECRETARY OF THE MASSACHUSETTS STATE BOARD OF AGRICULTURE;

AUTHOR OF “A TREATISE

ON GRASSES AND FORAGE PLANTS,” ETC.

LIBERALLY ILLUSTRATED.

BOSTON:

PHILLIPS, SAMPSON AND COMPANY,

13 WINTER STREET.

1859.

Entered according to Act of Congress, in the year 1858, by

CHARLES L. FLINT,

In the Clerk’s Office of the District Court of the District of Massachusetts.

Stereotyped by

HOBART A ROBBINS,

New England Type and Stereotype Foundery,

BOSTON.

PRINTED BY R. M. EDWARDS.

TO

THE MASS. STATE BOARD OF AGRICULTURE,

THE

MASS. SOCIETY FOR THE PROMOTION OF AGRICULTURE,

AND THE VARIOUS

AGRICULTURAL SOCIETIES OF THE UNITED STATES,

WHOSE EFFORTS HAVE CONTRIBUTED SO LARGELY TO IMPROVE THE

DAIRY STOCK OF OUR COUNTRY

This Treatise,

DESIGNED TO ADVANCE THAT HIGHLY IMPORTANT INTEREST,

IS RESPECTFULLY DEDICATED,

BY

THE AUTHOR.

| PREFACE. | vii |

| CHAPTER I. INTRODUCTORY.—THE VARIOUS RACES OF PURE-BRED CATTLE IN THE UNITED STATES. | 9 |

| The Ayrshires—The Jersey—The Short-horns—The Dutch—Herefords—The North Devons | |

| CHAPTER II. AMERICAN GRADE OF NATIVE CATTLE.—THE PRINCIPLES OF BREEDING. | 49 |

| CHAPTER III. THE SELECTION OF MILCH COWS. | 79 |

| CHAPTER IV. FEEDING AND MANAGEMENT OF DAIRY COWS. | 113 |

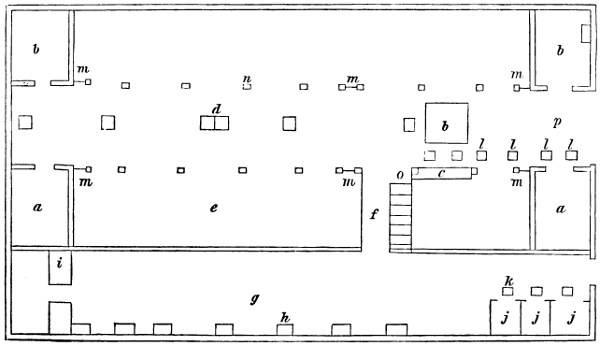

| Soiling—Milking—The Barn | |

| CHAPTER V. THE RAISING OF CALVES. | 155 |

| CHAPTER VI. CULTURE OF GRASSES AND OTHER PLANTS RECOMMENDED FOR FODDER. | 169 |

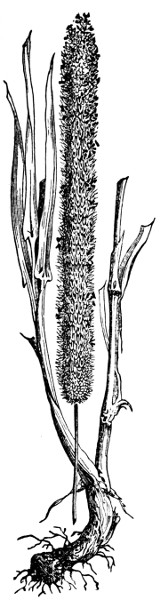

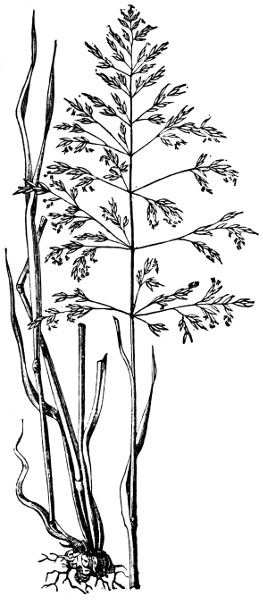

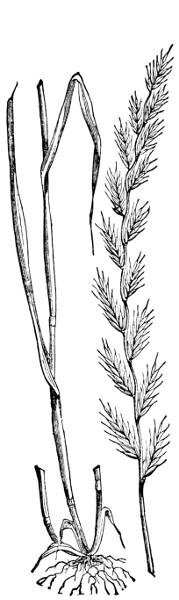

| Timothy grass—June grass—Meadow Foxtail—Orchard grass, or Rough Cocksfoot—Rough-stalked Meadow grass—Fowl Meadow grass—Rye grass—Italian Rye grass—Redtop—English Bent—Meadow Fescue—Tall Oat grass—Sweet-scented Vernal grass—Hungarian grass, or Millet—Red Clover—White Clover—Indian Corn—Common Millet (Panicum miliaceum)—Rye—Oats—Chinese Sugar-Cane—The Potato (Solanum tuberosum)—The Carrot (Daucus carota)—Turnip (Brassica rapa)—Mangold Wurzel—Parsnip (Pastinaca sativa)—Kohl Rabi (Brassica oleracea, var. caulorapa)—Linseed Meal—Rape-Cake—Cotton-seed Meal—Manures | |

| CHAPTER VII. MILK. | 199 |

| CHAPTER VIII. BUTTER AND THE BUTTER-DAIRY. | 217 |

| CHAPTER IX. THE CHEESE-DAIRY. | 241 |

| Cheshire Cheese—Stilton Cheese—Gloucester Cheese—Cheddar Cheese—Dunlop Cheese—Dutch Cheese—Parmesan—American Cheese | |

| CHAPTER X. THE DISEASES OF DAIRY STOCK. | 271 |

| Garget—Puerperal or Milk Fever—Simple Fever—Typhoid Fever—Hoove or Hoven—Choking—Foul in the Foot—Red Water—Hoose—Inflammation of the Glands—Inflammation of the Lungs—Diarrhœa—Dysentery—Mange—Lice—Warbles—Loss of Cud—Diseases of Calves—Diarrhœa, Purging, or Scours—Constipation or Costiveness—Hoove—Canker in the Mouth | |

| CHAPTER XI. THE DAIRY HUSBANDRY OF HOLLAND. | 295 |

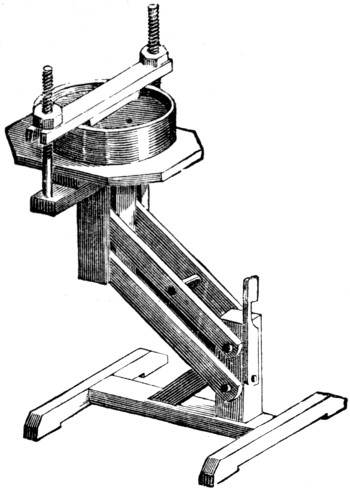

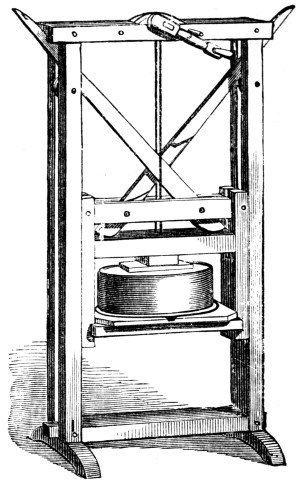

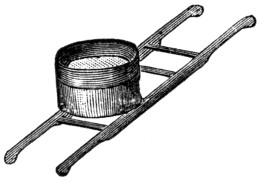

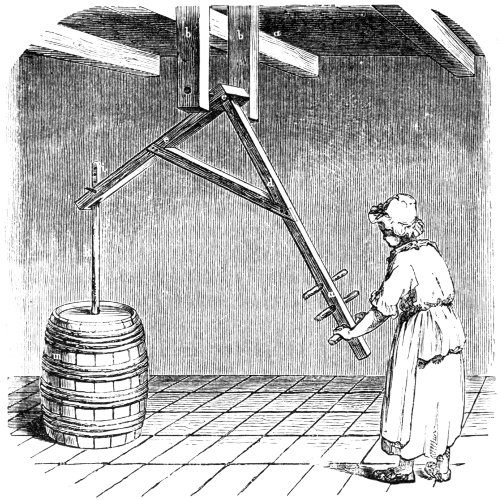

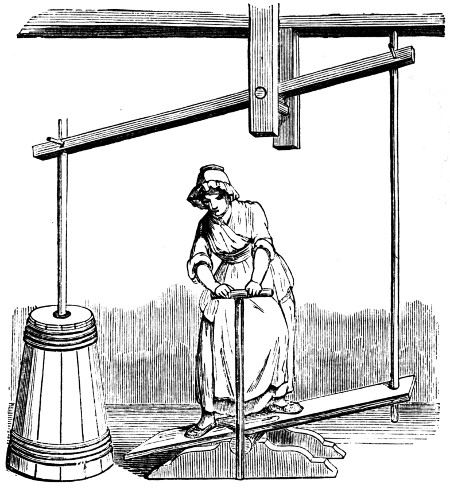

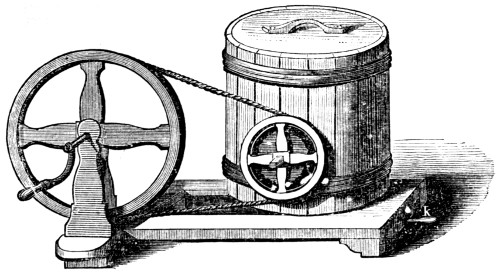

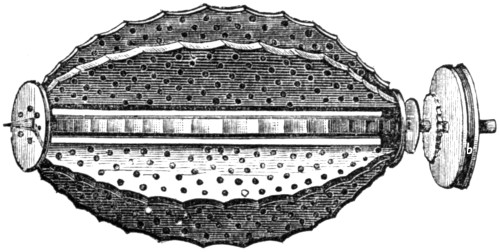

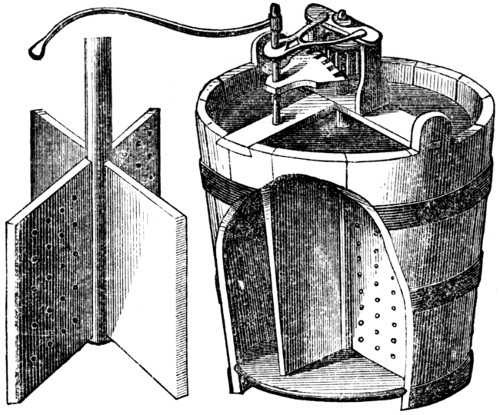

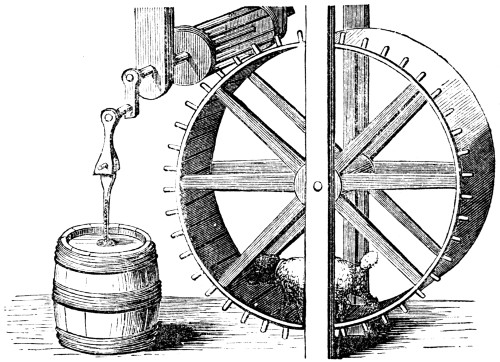

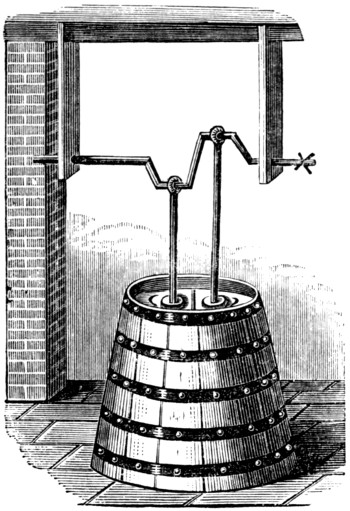

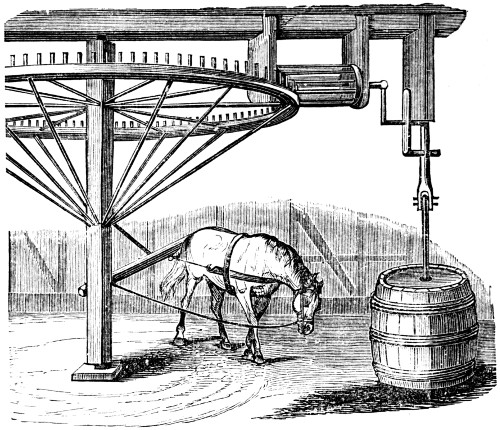

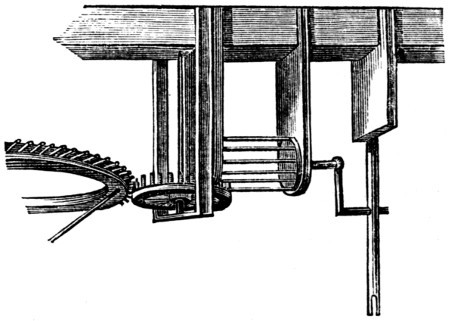

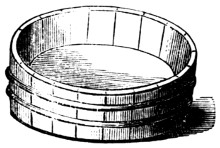

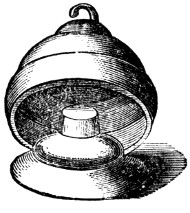

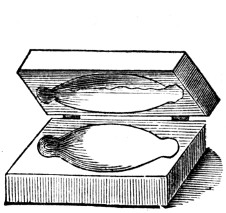

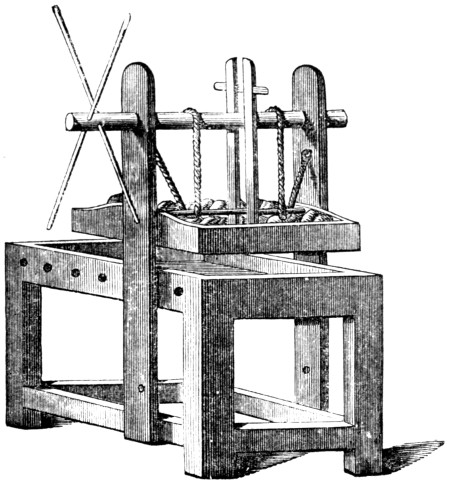

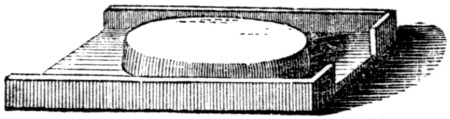

| Milking and Treatment of Milk.—Determination of the Milking Qualities of the Cows—Treatment of Milk for Butter—Methods of Churning—Churning in the Common Churn—The Lever Churn—Churning with an Elastic Rod—Churning with the Treadle Lever—Churning by Horse-power—Duration of the Churning—Working and Treatment of Butter—The Form of Fresh Butter—The Packing of Butter in Firkins and Barrels—Coloring of Butter—Use of the Butter-milk—The Manufacture of the different kinds of Dutch Cheese—Cheese-making in South Holland—Manufacture of Sweet Milk Cheese in South Holland—The Use of the Whey of Sweet Milk Cheese—May Cheese—Jews’ Cheese—Council’s Cheese—New Milk’s Cheese—Cheese-making in North Holland—The Utensils used in Cheese-making in North Holland—Variety of North Dutch Cheeses, and the Trade in them—Making of Edam Cheese—The Red Color of Edam Cheese—Use of the Whey of the North Dutch Sweet Milk Cheese | |

| CHAPTER XII. LETTER TO A DAIRY-WOMAN. | 355 |

| CHAPTER XIII. THE PIGGERY AS A PART OF THE DAIRY ESTABLISHMENT. | 361 |

| APPENDIX. | 365 |

| Gain or Loss of Condition ascertained by weighing Cattle Periodically—Richness of Milk and Cream—Comparison of different methods of Feeding Dairy Cows—Quality of Butter | |

| INDEX. | 411 |

[vii]

This work is designed to embody the most recent information on the subject of dairy farming. My aim has been to make a practically useful book. With this view, I have treated of the several breeds of stock, the diseases to which they are subject, the established principles of breeding, the feeding and management of milch cows, the raising of calves intended for the dairy, and the culture of grasses and plants to be used as fodder.

For the chapter on the diseases of stock, I am largely indebted to Dr. C. M. Wood, Professor of the Theory and Practice of Veterinary Medicine, and to Dr. Geo. H. Dadd, Professor of Anatomy and Physiology, both of the Boston Veterinary Institute. If this chapter contributes anything to promote a more humane and judicious treatment of cattle when suffering from disease, I shall feel amply repaid for the labor bestowed upon the whole work.

The chapter on the Dutch dairy, which I have translated from the German, will be found to be of great practical value, as suggesting much that is applicable to our American dairies. This chapter has never before, to my knowledge, appeared in English.

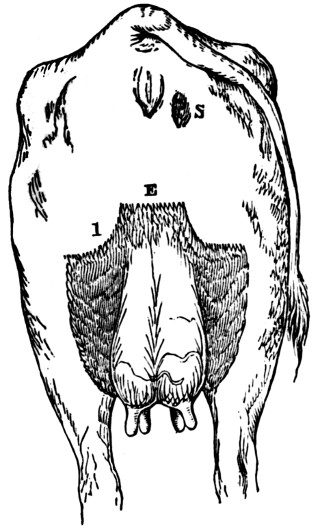

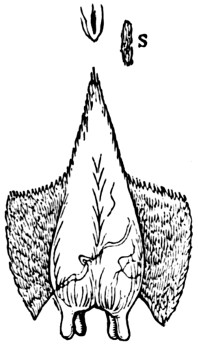

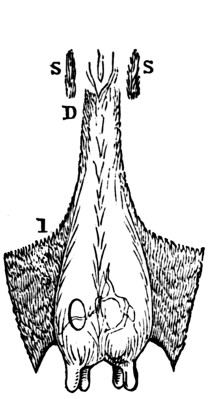

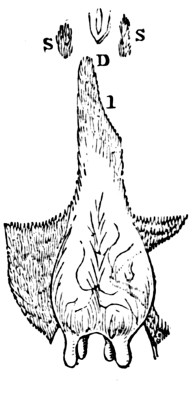

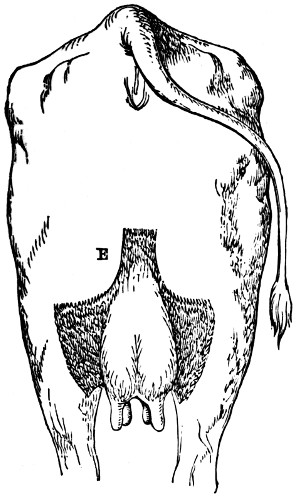

The full and complete explanation of Guénon’s method of judging and selecting milch cows,—a method originally regarded as theoretical, but now generally admitted to be very useful in practice,—I have translated from the last edition of the treatise of M. Magne, a very sensible French writer, who has done good service to the agricultural public by the clearness and simplicity with which he has freed that system from its complicated details.

[viii]

The work will be found to contain an account of the most enlightened practice in this country, in the statements those actually engaged in dairy farming; the details of the dairy husbandry of Holland, where this branch of industry is made a specialty to greater extent, and is consequently carried to a higher degree of perfection, than in any other part of the world; and the most recent and productive modes of management in English dairy farming, embracing a large amount of practical and scientific information, not hitherto presented to the American public in an available form.

Nothing need be said of the usefulness of a treatise on the dairy. The number of milch cows in the country, forming so large a part of our material wealth, and serving as a basis for the future increase and improvement of every class of neat stock, on which the prosperity of our agriculture mainly depends; the intrinsic value of milk as an article of internal commerce, and as a most healthy and nutritious food; the vast quantity of it made into butter and cheese, and used in every family; the endless details of the management, feeding, and treatment, of dairy stock, and the care and attention requisite to obtain from this branch of farming the highest profit, all concur to make the want of such a treatise, adapted to our climate and circumstances, felt not only by practical farmers, but by a large class of consumers, who can appreciate every improvement which may be made in preparing the products of the dairy for their use.

The writer has had some years of practical experience in the care of a cheese and butter dairy, to which has been added a wide range of observation in some of the best dairy districts of the country; and it is hoped that the work now submitted to the public will meet that degree of favor usually accorded to an earnest effort to do something to advance the cause of agriculture.

[9]

DAIRY FARMING

The milking qualities of our domestic cows are, to some extent, artificial, the result of care and breeding. In the natural or wild state, the cow yields only enough to nourish her offspring for a few weeks, and then goes dry for several months, or during the greater part of the year. There is, therefore, a constant tendency to revert to that condition, which is prevented only by judicious treatment, designed to develop and increase the milking qualities so valuable to the human race. If this judicious treatment is continued through several generations of the same family or race of animals, the qualities which it is calculated to develop become more or less fixed, and capable of transmission. Instead of being exceptional, or peculiar to an individual, they become the permanent characteristics of a breed. Hence the origin of a great variety of breeds or races, the characteristics of each being due to local circumstances such as climate, soil, and the special objects of the breeder, which may be the production of milk, butter and cheese, or the raising of beef or working cattle.

A knowledge of the history of different breeds, and[10] especially of the dairy breeds, is of manifest importance. Though very excellent milkers will sometimes be found in all of them, and of a great variety of forms, the most desirable dairy qualities will generally be found to have become fixed and permanent characteristics of some to a greater extent than of others; but it does not follow that a race whose milking qualities have not been developed is of less value for other purposes, and for qualities which have been brought out with greater care. A brief sketch of the principal breeds of American cattle, as well as of the grades or the common stock of the country, will aid the farmer, perhaps, in making an intelligent selection with reference to the special object of pursuit, whether it be the dairy, the production of beef, or the raising of cattle for work.

In a subsequent chapter on the selections of milch cows, the standard of perfection will be discussed in detail, and the characteristics of each of the races will naturally be measured by that. In this connection, and as preliminary to the following sketches, it may be stated that, whatever breed may be selected, a full supply of food and proper shelter are absolutely essential to the maintenance of any milking stock, the food of which goes to supply not only the ordinary waste of the system common to all animals, but also the milk secretions, which are greater in some than in others. A large animal on a poor pasture has to travel much further to fill itself than a small one. A small or medium-sized cow would return more milk in proportion to the food consumed, under such circumstances, than a large one.

In selecting any breed, therefore, regard should be had to the circumstances of the farmer, and the object to be pursued. The cow most profitable for the milk-dairy[11] may be very unprofitable in the butter and cheese dairy, as well as for the production of beef; while for either of the latter objects the cow which gave the largest quantity of milk might prove very unprofitable. It is desirable to secure a union and harmony of all good qualities, so far as possible; and the farmer wants a cow that will milk well for some years, and then, when dry, fatten readily, and sell to the butcher for the highest price. These qualities, though often supposed to be incompatible, will be found to be united in some breeds to a greater extent than in others; while some peculiarities of form have been found, by observation, to be better adapted to the production of milk and beef than others. This will appear in the following pages.

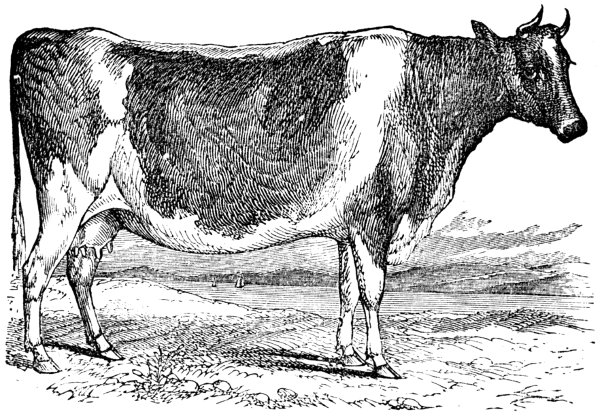

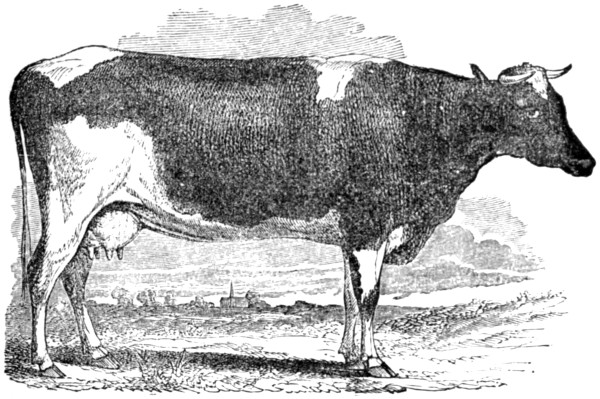

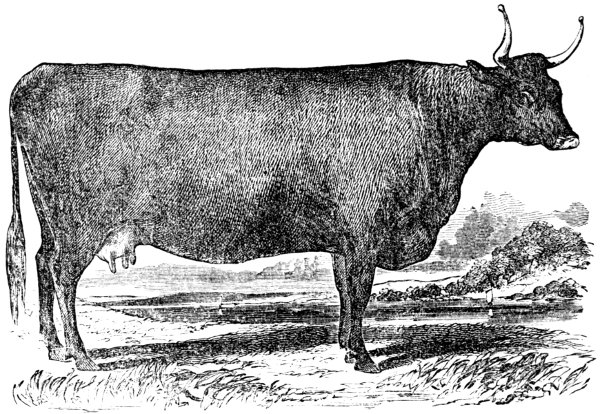

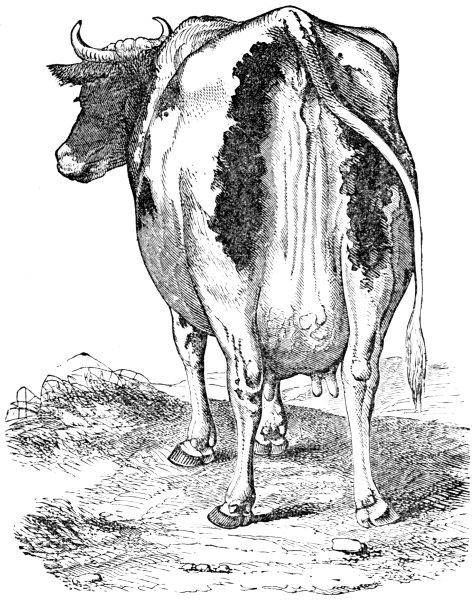

Fig. 1. Ayrshire Cow, imported and owned by Dr. Geo. B. Loring, Salem, Mass.

are justly celebrated throughout Great Britain and this country for their excellent dairy qualities. Though the most recent in their origin, they are pretty distinct from the other Scotch and English races. In color, the pure Ayrshires are generally red[12] and white, spotted or mottled, not roan like many of the short-horns, but often presenting a bright contrast of colors. They are sometimes, though rarely, nearly or quite all red, and sometimes black and white; but the favorite color is red and white brightly contrasted, and by some, strawberry-color is preferred. The head is small, fine, and clean; the face long, and narrow at the muzzle, with a sprightly yet generally mild expression; eye small, smart, and lively; the horns short, fine, and slightly twisted upwards, set wide apart at the roots; the neck thin; body enlarging from fore to hind quarters; the back straight and narrow, but broad across the loin; joints rather loose and open; ribs rather flat; hind quarters rather thin; bone fine; tail long, fine and bushy at the end; hair generally thin and soft; udder light color and capacious, extending well forward under the belly; teats of the cow of medium size, generally set regularly and wide apart; milk-veins prominent and well developed. The carcass of the pure-bred Ayrshire is light, particularly the fore quarters, which is considered by good judges as an index of great milking qualities; but the pelvis is capacious and wide over the hips.

On the whole, the Ayrshire is good-looking, but wants some of the symmetry and aptitude to fatten which characterize the short-horn, which is supposed to have contributed to build up this valuable breed on the basis of the original stock of the county of Ayr; a county extending along the eastern shore of the Frith of Clyde, in the south-western part of Scotland, and divided into three districts, known as Carrick, Cunningham, and Kyle: the first famous as the lordship of Robert Bruce, the last for the production of this, one of the most remarkable dairy breeds of cows in the world. The original stock of this county, which undoubtedly formed the basis of the[13] present Ayrshire breed, are described by Aiton, in his Treatise on the Dairy Breed of Cows, as of a diminutive size, ill fed, ill shaped, and yielding but a scanty return in milk. They were mostly of a black color, with large stripes of white along the chine and ridge of their backs, about the flanks, and on their faces. Their horns were high and crooked, having deep ringlets at the root,—the plainest proof that the cattle were but scantily fed; the chine of their backs stood up high and narrow; their sides were lank, short, and thin; their hides thick, and adhering to their bones; their pile was coarse and open; and few of them yielded more than six or eight quarts of milk a day when in their best plight, or weighed when fat more than from twelve to sixteen or twenty stones avoirdupois, at eight pounds the stone, sinking offal.

“It was impossible,” he continues, “that these cattle, fed as they then were, could be of great weight, well shaped, or yield much milk. Their only food in winter and spring was oat-straw, and what they could pick up in the fields, to which they were turned out almost every day, with a mash of weak corn and chaff daily for a few days after calving; and their pasture in summer was of the very worst quality, and eaten so bare that the cattle were half starved, and had the aspect of starvelings. A wonderful change has since been made in the condition, aspect, and qualities, of the Ayrshire dairy stock. They are not now the meagre, unshapely animals they were about forty years ago; but have completely changed into something as different from what they were then as any two breeds in the island can be from each other. They are almost double the size, and yield about four times the quantity of milk that the Ayrshire cows then yielded. They were not of any specific breed, nor uniformity of shapes or color;[14] neither was there any fixed standard by which they could be judged.”

Aiton wrote in 1815, and even then the Ayrshire cattle had been completely changed from what they were in 1770, and had, to a considerable extent, at least, settled down into a breed with fixed characteristics, distinguished especially for an abundant flow and a rich quality of milk. A large part of the improvement then manifested was due to better feeding and care, but much, no doubt, to judicious crossing. Strange as it may seem, considering the modern origin of this breed, “all that is certainly known is that a century ago there was no such breed as Cunningham or Ayrshire in Scotland. Did the Ayrshire cattle arise entirely from a careful selection of the best native breed? If they did, it is a circumstance unparalleled in the history of agriculture. The native breed may be ameliorated by careful selection; its value may be incalculably increased; some good qualities, some of its best qualities, may be for the first time developed; but yet there will be some resemblance to the original stock, and the more we examine the animal the more clearly we can trace out the characteristic points of the ancestor, although every one of them is improved.”

Aiton remembered well the time when some short-horn or Dutch cattle, as they were then called, were procured by some gentlemen in Scotland, and particularly by one John Dunlop, of Cunningham, who brought some Dutch cows—doubtless short-horns—to his byres soon after the year 1760. As they were then provided with the best of pasture, and the dairy was the chief object of the neighborhood, these cattle soon excited attention, and the small farmers began to raise up crosses from them. This was in Cunningham, one of the districts of Ayrshire, and Mr. Dunlop’s were,[15] without doubt, among the first of the stranger breed that reached that region. About 1750, a little previous to the above date, the Earl of Marchmont bought of the Bishop of Durham several cows and a bull of the Teeswater breed, all of a brown color spotted with white, and kept them some time at his seat in Berwickshire. His lordship had extensive estates in Kyle, another district of Ayrshire, and thither his factor, Bruce Campbell, took some of the Teeswater breed and kept them for some time, and their progeny spread over various parts of Ayrshire. A bull, after serving many cows of the estates already mentioned, was sold to a Mr. Hamilton, in another quarter of Ayrshire, and raised a numerous offspring.

About the year 1767, also, John Orr sent from Glasgow to his estate in Ayrshire some fine milch cows, of a much larger size than any then in that region. One of them cost six pounds, which was more than twice the price of the best cow in that quarter. These cows were well fed, and of course yielded a large return of milk; and the farmers, for miles around, were eager to get their calves to raise.

About the same time, also, a few other noblemen and gentlemen, stimulated by example, bought cattle of the same appearance, in color brown spotted with white, all of them larger than the native cattle of the county, and when well fed yielding much larger quantities of milk, and their calves were all raised. Bulls of their breed and color were preferred to all others.

From the description given of these cattle, there is no doubt that they were the old Teeswater, or Dutch; the foundation, also, according to the best authorities, of the modern improved short-horns. With them and the crosses obtained from them the whole county gradually became stocked, and supplied the neighboring[16] counties, by degrees, till at present the whole region, comprising the counties of Ayr, Renfrew, Lanark, Dumbarton, and Stirling, and more than a fourth part of the whole population of Scotland, a large proportion of which is engaged in manufactures and commercial or mechanical pursuits, furnishing a ready market for milk and butter, is almost exclusively stocked with Ayrshires.

The cross with larger cattle and the natives of Ayrshire produced, for many years, an ugly-looking beast, and the farmers were long in finding out that they had violated one of the plain principles of breeding in coupling a large and small breed so indiscriminately together, especially in the use of bulls proportionately larger than the cows to which they were put. They did not then understand that no crosses could be made in that way to increase the size of a race, without a corresponding increase in the feed; and many very ill-shaped animals were the consequence of ignorance of a natural law. They made large bones, but they were never strong and vigorous in proportion to their size. Trying to keep large animals on poor pasture produced the same effect. The results of first crosses were therefore very unsatisfactory; but gradually better feeding and a reduction in size came to their aid, while in the course of years more enlightened views of farming led to higher cultivation, and consequently to higher and better care and attention to stock. The effect of crosses with the larger Teeswater or short-horn was not so disastrous in Ayrshire as in some of the mountain breeds, whose feed was far less, while their exposure on high and short pastures was greater.

The climate of Ayrshire is moist and mild, and the soil rich, clayey, and well adapted to pasturage, but difficult to till. The cattle are naturally hardy and active, and capable of enduring severe winters, and[17] of easily regaining condition with the return of spring and good feed. The pasture-land of the county is devoted to dairy stock,—chiefly for making butter and cheese, a small part only being used for fattening cows when too old to keep for the dairy. The breed has undergone very marked improvements since Aiton wrote, in 1815. The local demand for fresh dairy products has very naturally taxed the skill and judgment of the farmers and dairy-men to the utmost, through a long course of years; and thus the remarkable milking qualities of the Ayrshires have been developed to such a degree that they may be said to produce a larger quantity of rich milk and butter in proportion to the food consumed, or the cost of production, than any other of the pure-bred races. The owners of dairies in the county of Ayr and the neighborhood were generally small tenants, who took charge of their stock themselves, saving and breeding from the offspring of good milkers, and drying off and feeding such as were found to be unprofitable for milk, for the butcher; and thus the production of milk and butter has for many years been the leading object with the owners of this breed, and symmetry of form and perfection of points for any other object have been very much disregarded, or, if regarded at all, only from this one point of view—the production of the greatest quantity of rich milk.

The manner in which this result has been brought about may further be seen in a remark of Aiton, who says that the Ayrshire farmers prefer their dairy bulls according to the feminine aspect of their heads and necks, and wish them not round behind, but broad at the hook-bones and hips, and full in the flanks. This was more than forty years ago, and under such circumstances, and with such care in the selection of bulls and cows with reference to one specific object, it is not[18] surprising that we find a breed now wholly unsurpassed when the quantity and quality of their produce is considered with reference to their proportional size and the food they consume. The Ayrshire cow has been known to produce over ten imperial gallons of good milk a day.

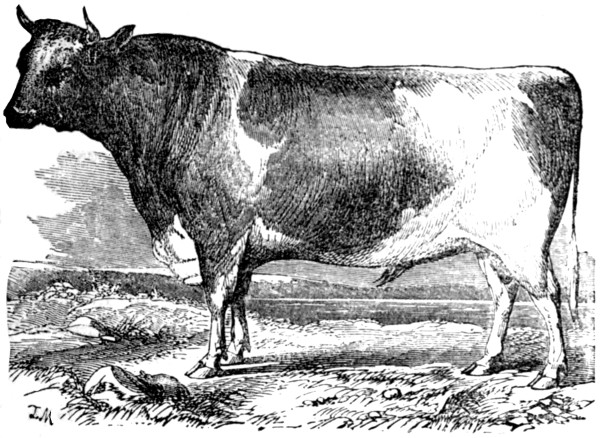

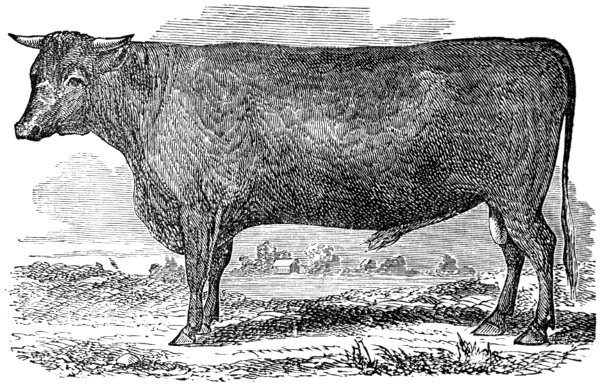

Fig. 2. Ayrshire Bull “Albert,”

Imported and owned by the Mass. Soc. for Promoting Agriculture.

A cow-feeder in Glasgow, selling fresh milk, is said to have realized two hundred and fifty dollars in seven months from one good cow; and it is stated, on high authority, that a dollar a day for six months of the year is no uncommon income from good cows under similar circumstances, and that seventy-five cents a day is below the average. But this implies high and judicious feeding, of course: the average yield, on ordinary feed, would be considerably less.

Youatt estimates the daily yield of an Ayrshire cow, for the first two or three months after calving, at five gallons a day, on an average; for the next three months, at three gallons; and for the next four months, at one gallon and a half. This would be 850 gallons as the[19] annual average of a cow; but allowing for some unproductive cows, he estimates the average of a dairy at 600 gallons per annum for each cow. Three gallons and a half of the Ayrshire cow’s milk will yield one and a half pounds of butter. He therefore reckons 257 pounds of butter, or 514 pounds of cheese, at the rate of 24 pounds to 28 gallons of milk, as the yield of every cow, at a fair and perhaps rather low average, in an Ayrshire dairy, during the year. Aiton sets the yield much higher, saying that “thousands of the best Ayrshire dairy-cows, when in prime condition and well fed, produce 1000 gallons of milk per annum; that in general three and three quarters to four gallons of their milk will yield a pound and a half of butter; and that 271⁄2 gallons of their milk will make 21 pounds of full-milk cheese.” Mr. Rankin puts it lower—at about 650 to 700 gallons to each cow; on his own farm of inferior soil, his dairy produced an average of 550 gallons only.

One of the four cows originally imported into this country by John P. Cushing, Esq., of Massachusetts, gave in one year 3864 quarts, beer measure, or about 966 gallons, at ten pounds to the gallon, being an average of over ten and a half beer quarts a day for the whole year. It is asserted, on good authority, that the first Ayrshire cow imported by the Massachusetts Society for the Promotion of Agriculture, in 1837, yielded sixteen pounds of butter a week, for several weeks in succession, on grass feed only. These yields are not so large as those stated by Aiton; but it should, perhaps, be recollected that our climate is less favorable to the production of milk than that of England and Scotland, and that no cow imported after arriving at maturity could be expected to yield as much, under the same circumstances, as one bred on the spot where the trial is made, and perfectly acclimated.

[20]

In a series of experiments on the Earl of Chesterfield’s dairy farm, at Bradley Ball, interesting as giving positive data on which to form a judgment as to the yield, it was found that, in the height of the season, the Holderness cows gave 7 gallons 1 quart per diem; the long-horns and Alderneys, 4 gallons 3 quarts; the Devons, 4 gallons 1 quart; and that, when made into butter the above quantities gave, respectively, 381⁄2 ounces, 28 ounces, and 25 ounces.

The Ayrshire, a cow far smaller than the Holderness, at 5 gallons of milk and 34 ounces of butter per day, gives a fair average as to yield of milk, and an enormous production of butter, giving within 41⁄2 ounces as much from her 5 gallons as the Holderness from her 7 gallons 1 quart; her rate being nearly 7 ounces to the gallon, while that of the Holderness is considerably under 6 ounces.

The evidence of a large and practical dairyman is certainly of the highest value; and in this connection it may be stated that Mr. Harley, the author of the Harleian Dairy System, who established the celebrated Willowbank Dairy, in Glasgow, and who kept, at times, from two hundred and sixty to three hundred cows, always using the utmost care in selection, says that he had cows, by way of experiment, from different parts of the united kingdom. He purchased ten at one Edinburgh market, of the large short-horned breed, at twenty pounds each, but these did not give more milk, nor better in quality, than Ayrshire cows that were bought at the same period for thirteen pounds a head; and, on comparison, it was found that the latter were much cheaper kept, and that they improved much more in beef and fat in proportion to their size, than the high-priced cows. A decided preference was therefore given to the improved Ayrshire breed, from seven to[21] ten years old, and from eight to twenty pounds a head. Prime young cows were too high-priced for stall feeding; old cows were generally the most profitable in the long run, especially if they were not previously in good keeping. The cows were generally bought when near calving, which prevented the barbarous practice called hafting, or allowing the milk to remain upon the cow for a considerable time before she is brought to the market. This base and cruel custom is always pernicious to the cow, and in consequence of it she seldom recovers her milk for the season. The middling and large sizes of cows were preferred, such as weighed from thirty-five to fifty stone, or from five hundred to eight hundred pounds.

According to Mr. Harley, the most approved shape and marks of a good dairy cow are as follows: Head small, long, and narrow towards the muzzle; horns small, clear, bent, and placed at considerable distance from each other; eyes not large, but brisk and lively; neck slender and long, tapering towards the head, with a little loose skin below; shoulders and fore quarters light and thin; hind quarters large and broad; back straight, and joints slack and open; carcass deep in the rib; tail small and long, reaching to the heels; legs small and short, with firm joints; udder square, but a little oblong, stretching forward, thin-skinned and capacious, but not low hung; teats or paps small, pointing outwards, and at a considerable distance from each other; milk-veins capacious and prominent; skin loose, thin, and soft like a glove; hair short, soft, and woolly; general figure, when in flesh, handsome and well proportioned.

If this description of the Ayrshire cow be correct, it will be seen that her head and neck are remarkably clean and fine, the latter swelling gradually towards the[22] shoulders, both parts being unincumbered with superfluous flesh. The same general form extends backwards, the forequarters being light, the shoulders thin, and the carcass swelling out towards the hind quarters, so that standing in front of her it has the form of a blunted wedge. Such a structure indicates very fully developed digestive organs, which exert a powerful influence on the exercise of all the functions of the body, and especially on the secretion of the milky glands, accompanied with milk-veins and udder partaking of the same character as the stomach and viscera, being large and capacious, while the external skin and interior walls of the milk-glands are thin and elastic, and all parts arranged in a manner especially calculated for the production of milk.

A cow with these marks will generally be of a quiet and docile temper, which greatly enhances her value. A cow that is of a quiet and contented disposition feeds at ease, is milked with ease, and yields more than one of an opposite temperament; while after she is past her usefulness as a milker she will easily take on fat, and make fine beef and a good quantity of tallow, because she feeds freely, and when dry the food which went to make milk is converted into fat and flesh. But there is no breed of cows with which gentleness of treatment is so indispensable as with the Ayrshire, on account of her naturally nervous temperament. If she receives other than kind and gentle treatment, she will often resent it with angry looks and gestures, and withhold her milk; and if such treatment is long continued, will dry up; but she willingly and easily yields it to the hand that fondles her, and all her looks and movements towards her friends are quiet and mild.

As already remarked, the Ayrshires in their native country are generally bred for the dairy, and no other[23] object; and the cows have obtained a just and world-wide reputation for this quality. The oxen are, however, very fitly as working cattle, though they cannot be said to excel other breeds in this respect. The Ayrshire steer may be fed and turned at three years old, but for feeding purposes the Ayrshires are greatly improved by a cross with the short-horns, provided regard is had to the size of the animals. It is the opinion of good breeders that a high-bred short-horn bull and a large-sized Ayrshire cow will produce a calf which will come to maturity earlier, and attain greater weight, and sell for more money, than a pure-bred Ayrshire. This cross, with feeding from the start, may be sold fat at two or three years old, the improvement being especially seen in the earlier maturity and the size. Even Youatt, who maintains that the fattening properties of the Ayrshires have been somewhat exaggerated, admits that they will fatten kindly and profitably, and that their meat will be good; while he also asserts that they unite, perhaps, to a greater degree than any other breed, the supposed incompatible qualities of yielding a great deal of milk and beef.

In the cross with the short-horn, the form becomes ordinarily more symmetrical, while there is, perhaps, little risk of lessening the milking qualities of the offspring, if sufficient regard is paid to the selection of the individual animals to breed from. It is thought by some that in the breeding of animals it is the male which gives the external form, or the bony and muscular system of the young, while the female imparts the respiratory organs, the circulation of the blood, the mucous membranes, the organs of secretion, &c.

If this principle is true, it follows that the milking qualities come chiefly from the mother, and that the bull can not materially alter the conditions which[24] determine the transmission of these qualities, especially when they are as strongly marked as they are in the Ayrshire or the Jersey races. Others, however, maintain that it is more important to the perfection of their dairy to make a good choice of bulls than of heifers, because the property of giving much milk is more surely transmitted by the male than the female. Others still maintain that both parents are represented in the offspring, but that it is impossible to say beforehand what parts of the derivative system are to be ascribed to the one parent and what to the other, and that there is a blending and interfusion of the qualities of both which prevent the body of their progeny being mapped out into distinct regions, or divided into separate sets of organs, of which we can say, “This is from the father, that from the mother.”

Till this question is settled, it is safe, in breeding for the dairy, to adhere to the rule of selecting only animals whose progenitors on both sides have been distinguished for their milking qualities. But where the history of either is unknown, a resort to a well-known breed, remarkable for its dairy qualities, is of no small importance; since, though the immediate ancestors of a male may not be known, if he belongs to a dairy breed, it is fair to presume that his progenitors were milkers. A study and comparison of the size and form of the milk mirror, and other points, indicated by Guénon, on a subsequent page, are worthy of careful consideration in selecting animals to breed from for the dairy, not only among pure-bred animals, but especially in crossing. In the scale of points adopted in England and this country as the standard of perfection for an Ayrshire cow, the udder, on which Guénon placed so much reliance, is valued at twelve times as much as[25] that of the Devon, “because,” as the judges affirm, “the Ayrshires have been bred almost exclusively with reference to their milking properties.”

We must conclude, then, that “for purely dairy purposes the Ayrshire cow deserves the first place. In consequence of her small, symmetrical, and compact body, combined with a well-formed chest and a capacious stomach, there is little waste, comparatively speaking, through the respiratory system; while, at the same time, there is very complete assimilation of the food, and thus she converts a large proportion of her food into milk. So remarkable is this fact, that all dairy farmers who have any experience on the point agree in stating that an Ayrshire cow generally gives a larger return of milk for the food consumed than a cow of any other breed. The absolute quantity may not be so great, but it is obtained at a less cost; and this is the point upon which the question of profit depends.”

I have dwelt thus at length upon this race for the reason that it is preeminently a dairy breed, surpassing all other pure breeds in the production of rich milk and butter on soils of medium fertility, and admirably adapted, in my opinion, to raise the character of our stock to a higher standard of excellence. The best milkers I have ever known, in the course of my own observations, were grade Ayrshires, larger in size than the pure bloods, but still sufficiently high grades to give certain signs of their origin. I have owned several such, which were all good cows. This grade would seem to possess the advantage of combining, to some extent, the two qualities of milking and adaptation to beef; and this is no small recommendation of the stock to farmers situated as American farmers are, who wish for milk for some years and then to turn over to the butcher.

[26]

cattle have now become widely known in this country. Many of them have been imported from an island of the same name in the British Channel, near the coast of France, and they may now be considered, I think, as fully acclimated. They were first introduced over thirty years ago, from the channel islands Alderney, Guernsey, and Jersey.

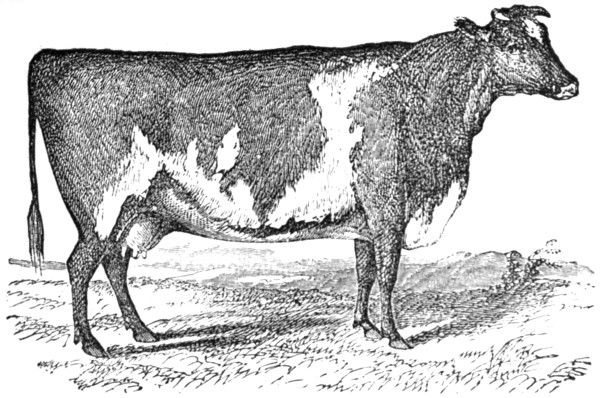

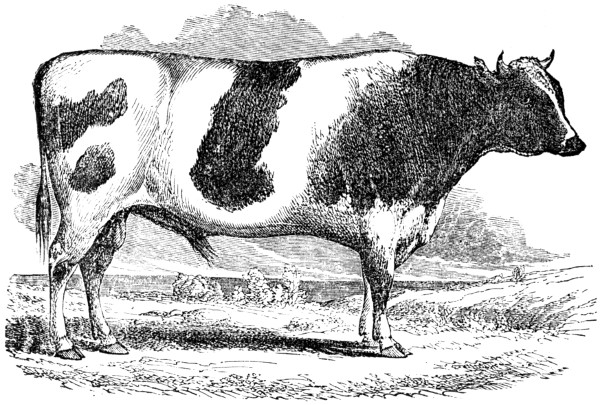

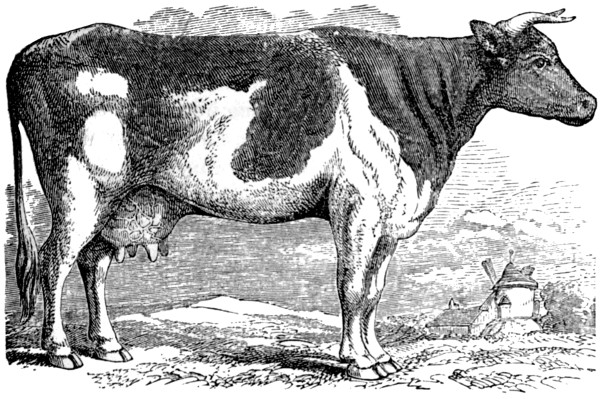

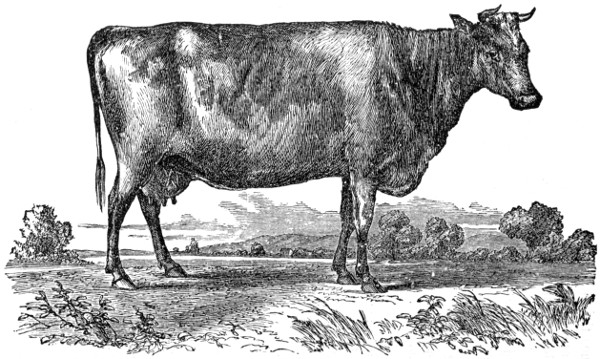

Fig. 3. Jersey Cow.[1]

The opinions of practical men differ widely as to the comparative merits of this race, and its adaptation to our climate and to the wants of our farmers. The most common decision, prevailing among many even of the best judges of stock, appears to be, that, however desirable the cows may be on the lawn or in a gentleman’s park, they are wholly unsuited to the general wants of the practical farmer. This may or may not be the case. If the farmer keeps a dairy farm and sells only milk, the quantity and not the quality of which is his chief care, he can satisfy himself better with some other breed. If otherwise situated,—if he devotes his time[27] to the making of butter for the supply of customers who are willing to pay for a good article,—he may very properly consider whether a few Jerseys, or an infusion of Jersey blood, may not be desirable. Haxton calls the Jersey cow the cheese and butter dairyman’s friend when her milk is diluted with that of ten or a dozen ordinary cows, and his enemy if he should attempt to make either cheese or butter solely from her produce, as, from the excessive richness of the milk, neither will keep long; and, finally, an ornament to the rich man’s lawn, yet in aspect altogether devoid of those rounded outlines which constitute the criterion of animal beauty.

The Jersey race is supposed to have been derived originally from Normandy, in the northern part of France. The cows have been long celebrated for the production of very rich milk and cream, but till within a quarter of a century they were comparatively coarse, ugly, and ill-shaped. Improvements have been very marked, but the form of the animal is still far from satisfying the eye. The head of the pure Jersey is fine and tapering, the cheek small, the throat clean, the muzzle fine and encircled with a light stripe, the nostril high and open; the horns smooth, crumpled, not very thick at the base, tapering, and tipped with black; ears small and thin, deep orange color inside; eyes full and placid; neck straight and fine; chest broad and deep; barrel hooped, broad and deep, well ribbed up; back straight from the withers to the hip, and from the top of the hip to the setting on of the tail; tail fine, at right angles with the back, and hanging down to the hocks; skin thin, light color and mellow, covered with fine soft hair; fore legs short, straight and fine below the knee, arm swelling and full above; hind quarters long and well filled; hind legs short and straight below[28] the hocks, with bones rather fine, squarely placed, and not too close together; hoofs small; udder full in size, in line with the belly, extending well up behind; teats of medium size, squarely placed and wide apart, and milk-veins very prominent. The color is generally cream, dun, or yellow, with more or less white, and the fine head and neck give the cows and heifers a fawn-like appearance, and make them objects of attraction in the park; but the hind quarters are often too narrow to look well, particularly to those who judge animals from the amount of fat they carry. We should bear in mind, however, that a good race of animals is not always the most beautiful, as that term is commonly understood. Beauty in stock has no fixed standard. In the estimation of some, it results mainly from fine forms, small bones, and close, compact frames; while others consider that structure the most perfect, and therefore the most beautiful, which is best adapted to the use to which it is destined. According to the latter, beauty is relative. It is not the same in an animal designed for beef and in one designed fer the dairy or for work. The beauty of a milch cow is the result of her good qualities. Large milkers are very rarely cows that please the eye of any but a skilful judge. They are generally poor, because their food goes mainly to the production of milk, and because they are selected with less regard to form than to good milking qualities. We meet with good milkers of all forms, from the round, close-built Devon to the coarsest-boned scrub; but, with all their varieties of form and structure, good cows will usually possess certain points of similarity and well-known marks by which they are known to the eyes of the judge.

It is asserted by Colonel Le Couteur, of the island of Jersey, that, contrary to the general opinion here, the[29] Jersey cow, when old and no longer wanted as a milker, will, when dry and fed, fatten rapidly, and produce a good quantity and excellent quality of butcher’s meat. An old cow, he says, was put up to fatten in October, 1850, weighing 1125 pounds, and when killed, the 6th of January, 1851, she weighed 1330 pounds; having gained 205 pounds in ninety-eight days, on twenty pounds of hay, a little wheat-straw, and thirty pounds of roots, consisting of carrots, Swedes, and marigold wurzel, a day. The prevailing opinion as to the beauty of the Jersey is based on the general appearance of the cow in milk, no experiments in feeding exclusively for beef having been made, to my knowledge, and no opportunity to form a correct judgment from actual observation having been furnished; and it must be confessed that the general appearance would amply justify the hasty conclusion.

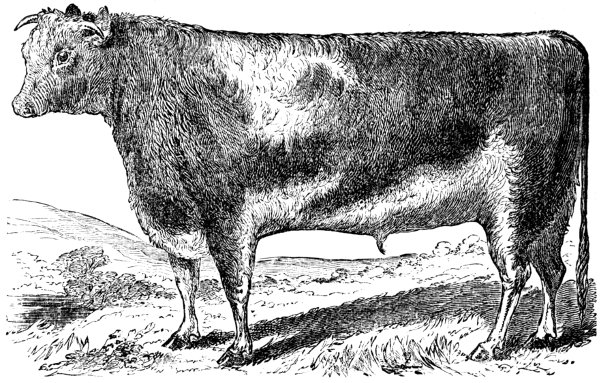

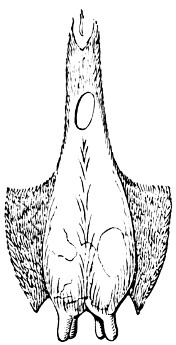

Fig. 4. Jersey Bull.

The bulls are usually very different in character and disposition from the cows, and are much inclined to[30] become restive and cross at the age of two or three years, unless their treatment is uniformly gentle and firm. The accompanying figure very accurately represents one of the best animals of the race in the vicinity of Boston, which has been pronounced by good judges a model of a bull for a dairy breed.

The beautiful Jersey cow “Flirt,” figured on page 26, received the first prize at the Fair of the Massachusetts State Board of Agriculture in 1857, which brought together the largest and finest collection of Jersey cattle ever made in this country. She is well-shaped, and a very superior dairy cow. Her dam, Flora, was very remarkable for the richness of her milk and the quantity of her butter, having made no less than five hundred and eleven pounds in one year, without extra feeding.

From what has been said it is evident that the Jersey is to be regarded as a dairy breed, and that almost exclusively. It is evident, too, that it would not be sought for large dairies kept for the supply of milk to cities; for, though the quality would gratify the customer, the quantity would not satisfy the owner. The place of the Jersey cow is rather in private establishments, where the supply of cream and butter is a sufficient object, or, in limited numbers, to add richness to the milk of large butter dairies. Even one or two good Jersey cows with a herd of fifteen or twenty, will make a great difference in the quality of the milk and butter of the whole establishment; and they would probably be profitable for this, if for no other object.

Other breeds are somewhat noted in Great Britain for their excellent dairy qualities, and among them might be named the Yorkshire and the Kerry; but they have never been introduced into this country to any[31] extent; or, if they ever were, no traces of them as a distinct breed can now be found here.

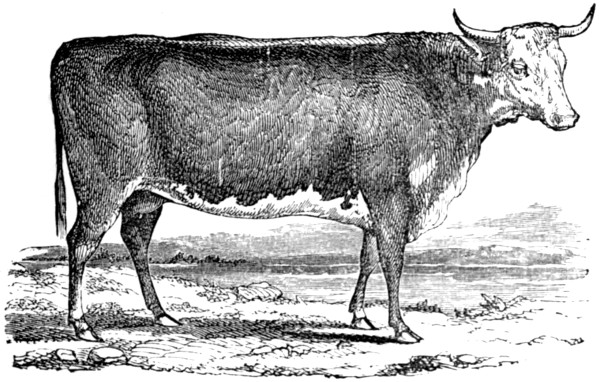

Fig. 5. Short-horn Cow

—No breed of horned cattle has commanded more universal admiration during the last half-century than the improved Short-horns, whose origin can be traced back for nearly a hundred years. According to the best authorities, the stock which formed the basis of improvement existed equally in Yorkshire, Lincolnshire, Northumberland, and counties adjoining; and the preëminence was accorded to Durham, which gave its name to the race, from the more correct principles of breeding which seem to have prevailed there.

There is a dispute among the most eminent breeders as to how far it owes its origin to early importations from Holland, whence many superior animals were brought for the purpose of improving the old long-horned breed. A large race of cattle had existed for many years on the western shores of the continent of Europe. At a very early date, as early as 1633, they[32] were imported from Denmark into New England in considerable numbers, and thus laid the foundation of a valuable stock in this country. They extended along the coast, it is said, through Holland to France. The dairy formed a prominent branch of farming at a very early date in Holland, and experience led to the greatest care in the choice and breeding of dairy stock. From these cattle many selections were made to cross over to the counties of York and Durham. The prevailing color of the large Dutch cattle was black and white, beautifully contrasted.

The cattle produced by these crosses a century ago were known under the name of “Dutch.” The cows selected for crossing with the early imported Dutch bulls were generally long-horned, large-boned, coarse animals, a fair type of which was found in the old “Holderness” breed of Yorkshire,—slow feeders, strong in the shoulder, defective in the fore quarter, and not very profitable for the butcher, their meat being “coarse to the palate and uninviting to the eye.” Their milking qualities were good, surpassing, probably, those of the improved short-horns. Whatever may be the truth with regard to these crosses, and however far they proved effective in creating or laying the foundation of the modern improved short-horns, the results of the efforts made in Yorkshire and some of the adjoining counties were never so satisfactory to the best judges as those of the breeders along the Tees, who selected animals with greater reference to fineness of bone and symmetry of form, and the animals they bred soon took the lead, and excited great emulation in improvement.

The famous bull “Hubback,” bred by Mr. Turner, of Hurworth, and subsequently owned by Mr. Colling, laid the foundation of the celebrity of the short-horns, and it is the pride of short-horn breeders to trace back[33] to him. He was calved in 1777, and his descendants, Foljambe, Bolingbroke, Favorite, and Comet, permanently fixed the characteristics of the breed. Comet was so highly esteemed among breeders, that he sold at one thousand guineas, or over five thousand dollars. Hubback is thought by some to have been a pure short-horn, and by others a grade or mixture.

Many breeders had labored long previous to the brothers Charles and Robert Colling, especially on the old Teeswater short-horns; yet a large share of the credit of improving and establishing the reputation of the improved short-horns is generally accorded to the Collings. Certain it is that the spirit and discrimination with which they selected and bred soon became known, and a general interest was awakened in the breed at the time of the sale of Charles Colling’s herd, October 11, 1810. It was then that Mr. Bates, of Kirkleavington, purchased the celebrated heifer Duchess I., whose family sold, in 1850, after his decease, at an average of one hundred and sixteen pounds five shillings per head, including young calves. Many representatives of the Duchess family, which laid the foundation of Mr. Bates’ success as a breeder, have been brought to this country. They may, perhaps, be regarded as an exception to the modern improved short-horns, their milking qualities being generally very superior.

The sale referred to, and those of R. Colling’s herd, in 1818, and that of Lord Spencer, in 1846, as well as that of the Kirkleavington herd, in 1850, and especially that of the herd of Lord Ducie, two years later, are marked eras in the history of improved short-horns; and through these sales, and the universal enthusiasm awakened by them, the short-horns have become more widely spread ever Great Britain, and more generally fashionable, than any other breed. They have also been largely[34] introduced into France by the government, for the improvement of the various French breeds by crossing, and into nearly every quarter of the civilized world.

Fig. 6. Short-horn Bull “Double Duke,”

(14511⁄2 Am. H. Book,)

Owned by Harvest Club, Springfield.

Importations have been frequent and extensive into the United States within the last few years, and this famous breed is now pretty generally diffused over the country.

The use of the early-imported short-horn bulls and native cows led to the formation of many families of grades, some of them bred back to the sire, and others crossed high up, which have attained a very considerable local reputation in many sections. As instances of this, may be mentioned the Creampot stock, obtained by Col. Jaques from a short-horn bull, Cœlebs, and a superior native cow. A family of fine milkers still exists in Massachusetts, known by the name of the “Sukey breed,” supposed to have been derived from “Denton,” a very superior animal imported by Mr. Williams, of Northboro’, some forty years ago. Many of the best milkers of that section can be traced back to[35] him. The Patton stock, originally imported into Maryland and Virginia, in 1783, and thence to Kentucky, may be classed in the same category. A part of these were at first known as the “milk breed,” and others as the “beef breed:” the first short-horns, at that time good milkers, and the latter long-horns, of large size and coarse in the bone. In Kentucky they were all known as the Patton stock.

The high-bred short-horn is easily prepared for a show, and, as fat will cover faults, the temptation is often too great to be resisted; and hence it is common to see the finest animals rendered unfit for breeding purposes by over-feeding. The race is susceptible of breeding for the production of milk, as several families show, and great milkers have often been known among pure-bred animals; but it is more common to find it bred mainly for the butcher, and kept accordingly. It is, however, a well-known fact that the dairies of London are stocked chiefly with short-horns and Yorkshires, or high grades between them, which, after being milked as long as profitable, feed equal, or nearly so, to pure-bred short-horns.

It has been said, by very high authority, that “the short-horns improve every breed they cross with.”

The desirable characteristics of the short-horn bull may be summed up, according to the judgment of the best breeders, as follows: He should have a short but fine head, very broad across the eyes, tapering to the nose, with a nostril full and prominent; the nose itself should be of a rich flesh-color; eyes bright and mild; ears somewhat large and thin; horns slightly curved and rather flat, well set on a long, broad, muscular neck; chest wide, deep, and projecting; shoulders fine, oblique, well formed into the chine; fore legs short, with upper arm large and powerful; barrel round, deep,[36] well ribbed home; hips wide and level; back straight from the withers to the setting on of the tail, but short from hip to chine; skin soft and velvety to the touch; moderately thick hair, plentiful, soft, and mossy. The cow has the same points in the main, but her head is finer, longer, and more tapering, neck thinner and lighter, and shoulders more narrow across the chine.

The astonishing precocity of the short-horns, their remarkable aptitude to fatten, the perfection of their forms, and the fineness of their bony structure, give them an advantage over most other races when the object of breeding is for the shambles. No animal of any other breed can so rapidly transform the stock of any section around him as the improved short-horn bull.

But it does not follow that the high-bred short-horns are unexceptionable even for beef. The very exaggeration, so to speak, of the qualities which make them so valuable for the improvement of other and less perfect races, may become a fault when wanted for the table. The very rapidity with which they increase in size is thought by some to prevent their meat from ripening up sufficiently before being hurried off to the butcher. The disproportion of the fatty to the muscular flesh, found in this to a greater extent than in races coming slower to maturity, makes the meat of the thorough-bred short-horn, in the estimation of some, both less agreeable to the taste and less profitable to the consumer, since the nitrogenous compounds, true sources of nutriment, are found in less quantity than in the meat of animals not so highly bred.

But the improved short-horn is justly unrivalled for symmetry of form and beauty. I have never seen a picture or an engraving of an animal which gave an adequate idea of the beauty of many specimens of this race, especially of the best bred in Kentucky and Ohio,[37] where many excellent breeders, favored by a climate and pastures eminently adapted to bring the short-horn to perfection, have not only imported extensively from the best herds in England, but have themselves attained a degree of knowledge and skill equalled only by that of the most celebrated breeders in the native country of this improved race.

In sections where the climate is moist and the food abundant and rich, some families of the short-horns may be valuable for the dairy; but they are most frequently bred exclusively for beef in this country, and in sections where they have attained the highest perfection of form and beauty so little is thought of their milking qualities that they are often not milked at all, the calf being allowed to run with the dam.

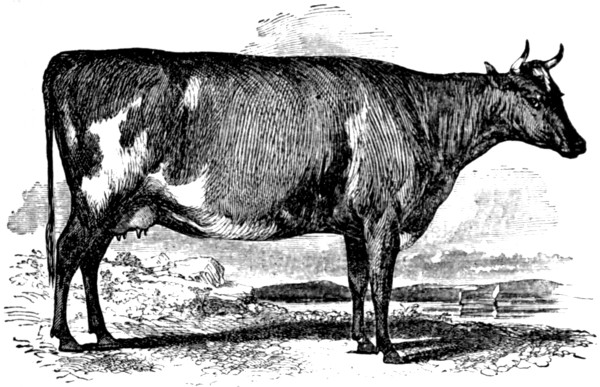

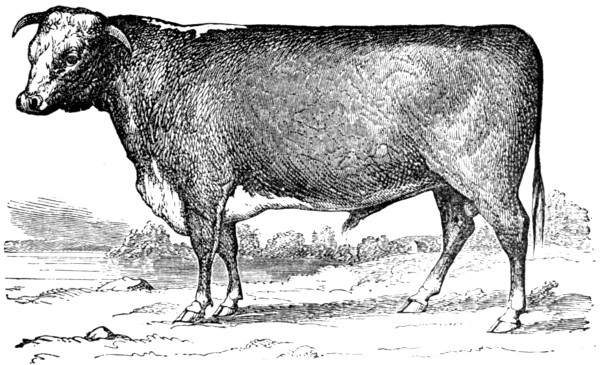

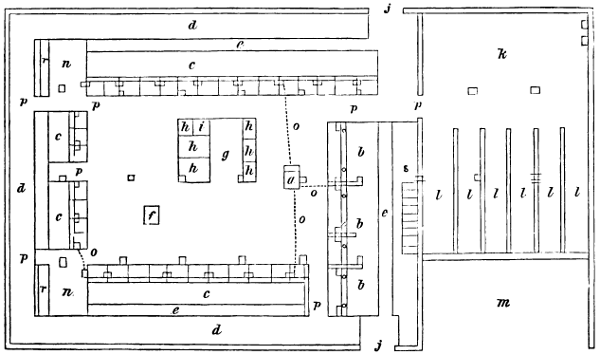

Fig. 7. Imported Dutch Cow.

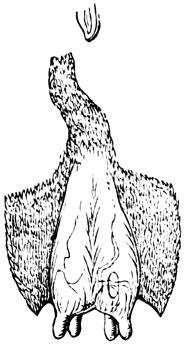

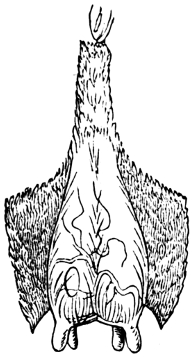

is a short-horned race of cattle, which, in the opinion of many, as I have already remarked, contributed largely, about a century ago, to build up the Durham or Teeswater stock. It has been bred with[38] special reference to dairy qualities, and is eminently adapted to supply the wants of the dairy farmer.

Fig. 8. Imported Dutch Bull.

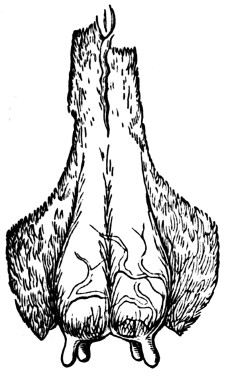

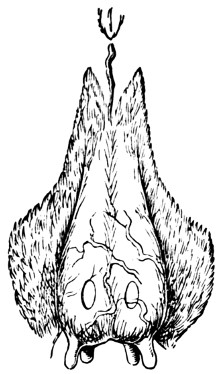

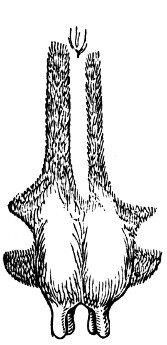

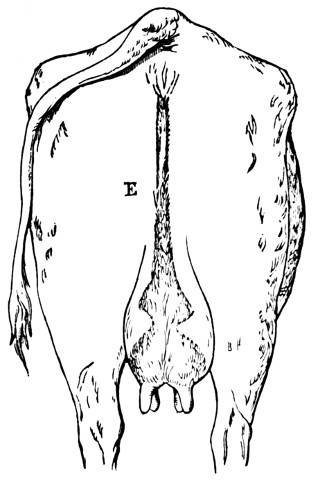

The cow, Fig. 7, was bred in North Holland, and imported by Winthrop W. Chenery, Esq., of Watertown, in 1857. The bull, Fig. 8, was also imported by Mr. Chenery at the same time, from near the Beemster, in the northerly part of Purmerend. Both animals are truthfully delineated, and give a correct idea of the points of the North Dutch cattle. For a more detailed description of this celebrated dairy race, see pages 51 and 301.

Fig. 9. Hereford Cow.

—The Hereford cattle derive their name from a county in the western part of England. Their general characteristics are a white face, sometimes mottled; white throat, the white generally extending back on the neck, and sometimes, though rarely, still further along on the back. The color of the rest of the body is red, generally dark, but sometimes light. Eighty years ago the best Hereford cattle were mottled or roan all over; and some of the best herds, down to a[39] comparatively recent period, were either all mottled, or had the mottled or speckled face. The expression of the face is mild and lively; the forehead open, broad, and large; the eyes bright and full of vivacity; the horns glossy, slender, and spreading; the head small, though larger and not quite so clean as that of the Devons; the lower jaw fine; neck long and slender; chest deep; breast-bone large, prominent, and very muscular; the shoulder-blade light; shoulder full and soft; brisket and loins large; hips well developed, and on a level with the chine; hind quarters long and well filled in; buttocks on a level with the back, neither falling off nor raised above the hind quarters; tail slender, well set on; hair fine and soft; body round and full; carcass deep and well formed, or cylindrical; bone small; thigh short and well made; legs short and straight, and slender below the knee; as handlers very excellent, especially mellow to the touch on the back, the shoulder, and along the sides, the skin being soft, flexible, of medium thickness, rolling on the neck and the[40] hips; hair bright; face almost bare, which is characteristic of pure-bred Herefords. They belong to the middle-horned division of the cattle of Great Britain, to which they are indigenous. They have been improved within the last century by careful selections, the first step to this end having been taken by Benjamin Tomkins, of Herefordshire, who began about 1766, with two cows possessing a remarkable tendency to take on fat. One of these was gray, and the other dark red, with a mottled or spotted face.

Taking these as a foundation, Mr. Tomkins went on to build up a large herd, from which he sold to other breeders, from time to time, till at his decease, in 1819, the whole herd was disposed of at auction—fifty-two animals, including twenty-two steers and two heifers, varying in age from calves to two-year-olds, bringing an aggregate of four thousand six hundred and seventy-three pounds, fourteen shillings, or four hundred and forty-five dollars, thirty-seven and a half cents, a head. A bull was sold to Lord Talbot for five hundred and eighty-eight pounds, while several cows brought from a thousand to twelve hundred dollars a head.

Hereford oxen are excellent animals, less active but stronger than the Devons, and very free and docile. The demand for Herefords for beef prevents their being much used for work in their native county, and the farmers there generally use horses instead of oxen. A recent writer in the Farmer’s Magazine makes the following remarks on this head: “It is allowed on all hands, I believe, that the properties in which Herefords stand preëminent among the middle-sized breeds are in the production of oxen and their superiority of flesh. On these points there is little chance of their being excelled. It should, however, be borne in mind that[41] the best oxen are not produced from the largest cows; nor is a superior quality of flesh, such as is considered very soft to the touch, with thin skin. It is the union of these two qualities which often characterizes the short-horns; but the Hereford breeders should endeavor to maintain a higher standard of excellence,—that for which the best of the breed have always been esteemed,—a moderately thick, mellow hide, with a well-apportioned combination of softness with elasticity. A sufficiency of hair is also desirable, and if accompanied with a disposition to curl moderately it is more in esteem: but that which has a harsh and wiry feel is objectionable.”

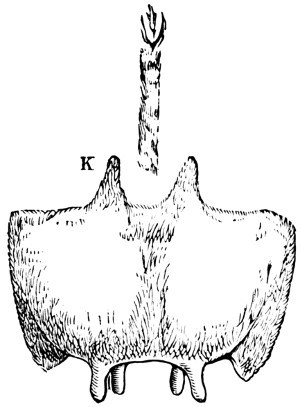

Fig. 10. Hereford Bull.

In point of symmetry and beauty of form, the well-bred Herefords may be classed with the improved short-horns, though they arrive somewhat slower at maturity, and never attain such weight. Like the improved short-horns, they are chiefly bred for beef, and their beef is of the best quality in the English markets, commanding the highest price of any, except, perhaps, the West Highlanders.

[42]

In an experiment carefully tried in 1828, for the purpose of arriving at the comparative economy of the short-horns and Herefords, the latter gained less by nearly one fourth than the former, which had consumed more food. The six animals, three of each breed, were sold after being fed, in Smithfield market, the Herefords bringing less by only about five dollars than the short-horns, while the cost of food consumed by the latter was greater, and the original purchase greater than that of the former.

The short-horn produces more beef at the same age than the Hereford, but consumes more food in proportion. “In all the fairs of England,” says Hillyard, “except those of Herefordshire and the adjoining counties, short-horn heifers are more sought after and sell at higher prices than the Hereford; but it is not so with fat cattle, for, with the exception of Lincolnshire and some of the northern counties, they much prefer the Herefords. Then at Smithfield, where the quality of the beef passes its final judgment, the pound of Hereford beef pays better than the pound of short-horn beef. Short-horn beeves produce at the same age a greater weight, it is true, but they also consume more food. I can easily conceive why, in the magnificent pastures of Lincolnshire, and some of the northern counties of England, they may prefer the short-horns; and that is, that they may keep a less number on a given quantity of land, and only the short-horn could, under these conditions, produce a greater weight of beef per acre. It is very difficult to decide which of the two races in England (the two best in the world) is the most profitable for stock-raisers and for the community.” There are, even in Lincolnshire, many good feeders who prefer the Herefords to the short-horns. One of these, when visited the past season, had thirty head of cattle[43] feeding for the butcher, and only one short-horn. When asked the reason of this, he replied, “I am a farmer myself, and have to pay high rent, and I must feed the cattle that pay me best. Perhaps you think it would be more in fashion to cover my fields with short-horns; but I must look to the net profit, and I get much better with the Herefords. The short-horns are too full of fat and make too little tallow, and they consequently sell too low in the Smithfield market. Our Herefords are better, and they sell better.”

The Herefords are far less generally spread over England than the improved short-horns. They have seldom been bred for milk, as some families of the short-horns have; and it is not very unusual to find pure-bred cows incapable of supplying milk sufficient to nourish their calves. This system was pursued especially by Mr. Price, a skilful Hereford breeder, who sacrified everything to form, disregarding milking properties, breeding often from near relations, and thus fixing the fault incident to his system more or less permanently in the descendants of his stock.

The Herefords have been brought to this country, to some extent, and several fine herds exist in different sections; the earliest importations being those of Henry Clay, of Kentucky, in 1817. The figures of the two animals of this breed presented in this connection represent a bull and cow bred at the State Farm, in Massachusetts, and are good specimens of the breed.

The want of care and attention to the udder, soon after calving, especially if the cow be on luxuriant grass, often injures her milking properties exceedingly. The practice in the county of Hereford has generally been to let the calves suckle from four to six months, and bull-calves often run eight months with the cow. But their dairy qualities are perhaps as good as those[44] of any cattle whose fattening properties have been so carefully developed; and, though it is probable that they could be bred for milk by proper care and attention, yet, as this change would be at the sacrifice of other qualities equally valuable, it would evidently be wiser to resort to other stock for the dairy.

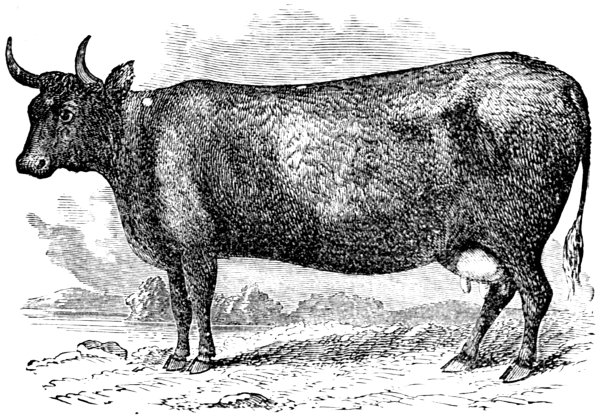

Fig 11. Devon Cow.

Owned by William Buckminster Esq., Framingham Mass.

—The last of the pure-bred races which it will be necessary to describe as prominent among our American cattle is the Devon, a middle-horned breed, now very generally distributed in some sections of the country.

This beautiful race of cattle dates further back than any well-established breed among us. It goes generally under the simple name of Devon; but the cattle of the southern part of the county, from which the race derives its name, differ somewhat from those of the northern, having a larger and coarser frame, and far less tendency to fatten, though their dairy qualities are superior.

[45]

The North Devons are remarkable for hardihood, symmetry, and beauty, and are generally bred for work and for beef rather than for the dairy. The head is fine and well set on; the horns of medium length, generally curved; color usually bright blood-red, but sometimes inclining to yellow; skin thin and orange-yellow; hair of medium length, soft and silky, making the animals remarkable as handlers; muzzle of the nose white; eyes full and mild; ears yellowish, or orange color inside, of moderate size; neck rather long, with little dewlap; shoulders oblique; legs small and straight, and feet in proportion; chest of good width; ribs round and expanded; loins of first-rate quality, long, wide, and fleshy; hips round, of medium width; rump level; tail full near the setting on, tapering to the tip; thighs of the bull and ox muscular and full, and high in the flank, though in the cow sometimes thought to be too light; the size medium, generally called small. The proportion of meat on the valuable parts is greater, and the offal less, than on most other breeds, while it is well settled that they consume less food in its production. The Devons are popular with the Smithfield butchers, and their beef is well marbled or grained.

As working oxen, the Devons perhaps excel all other races in quickness, docility, and beauty, and the ease with which they are matched. With a reasonable load, they are said to be equal to horses as walkers on the road, and when they are no longer wanted for work they fatten easily and turn well.

As milkers, they do not excel, perhaps they may be said not to equal, the other breeds, and they have a reputation of being decidedly below the average. In their native country the general average of a dairy is one pound of butter per day during the summer.

They are bred for beef and for work, and not for the[46] dairy; and their yield of milk is small, though of a rich quality. I have, however, had occasion to examine several animals from the celebrated Patterson herd, which would have been remarkable as milkers even among good milking stock. They had not, to be sure, the beautiful symmetry of form and fineness of bone which characterize most of the modern and highly improved pure-bred North Devons, and had evidently been bred for many years with special reference to the development of the milking qualities, great care having been taken to use bulls and cows as breeders from the best milking stock, rather than of the finest forms. The use of bulls distinguished only for symmetry of form, and of a race deficient in milk-secreting qualities, will be sure to deteriorate, instead of improving, the stock for the dairy.

Fig. 12. Devon Bull.

On the whole, whatever may be our judgment of this breed, the faults of the North Devon cow can hardly be overlooked from our present point of view. The rotundity of form and compactness of frame, though they contribute to her remarkable beauty, constitute an[47] objection to her as a dairy cow, since it is generally thought that the peculiarity of form which disposes an animal to take on fat is somewhat incompatible with good milking qualities, and hence Youatt says: “For the dairy the North Devons must be acknowledged to be inferior to several other breeds. The milk is good, and yields more than the average proportion of cream and butter; but it is deficient in quantity.” He also maintains that its property as a milker could not be improved without probable or certain detriment to its grazing qualities.

But the fairest test of its fitness for the dairy is to be found in the estimation in which distinguished Devon breeders themselves have held it in this respect. A scale of points of excellence in this breed was established, some time ago, by the best judges in England; and it has since been adopted, with but slight changes, in this country. These judges, naturally prejudiced in favor of the breed, if prejudiced at all, made this scale to embrace one hundred points, no animal to be regarded as perfect unless it excelled in all of them. Each part of the body was assigned its real value in the scale: a faultless head, for instance, was estimated at four; a deep, round chest, at fifteen, &c. If the animal was defective in any part, the number of points which represented the value of that part in the scale was to be deducted pro rata from the hundred, in determining its merits. But in this scale the cow is so lightly esteemed for the dairy, that the udder, the size and shape of which is of the utmost consequence in determining the capacity of the milch cow, is set down as worth only one point, while, in the same scale, the horns and ears are valued at two points each, and the color of the nose, and the expression of the eye, are valued at four points each. Supposing, therefore, that[48] each of these points were valued at one dollar, and a perfect North Devon cow was valued at one hundred dollars; then another cow of the same blood, and equal to the first in every respect except in her udder, which is such as to make it certain that she can never be capable of giving milk enough to nourish her calf, must be worth, according to the estimation of the best Devon breeders, ninety-nine dollars! It is safe, therefore, to say that an animal whose udder and lacteal glands are regarded, by those who best know her capacities and her merits, as of only one quarter part as much consequence as the color of her nose, or half as much as the shape and size of her horns, cannot be recommended for the dairy. The improved North Devon cow may be classed, in this respect, with the Hereford, neither of which has well-developed milk-vessels—a point of the utmost consequence to the practical dairyman.

The list of pure-bred races in America may be said to end here; for, though other and well-established breeds, like the long-horns, the Galloways, the Spanish, &c., have, at times, been imported, and have had some influence on our American stock, they have not been kept distinct to such an extent as to have become the prevailing stock of any particular section, so far as I am aware, and hence a notice of them properly comes in the next chapter.

[49]

We have dwelt thus far mainly upon the prominent breeds of cattle known among us, and especially those adapted to the dairy. But a large proportion—by far the largest proportion, indeed—cannot be included under any of the races alluded to.

The term breed, properly understood, applies only to animals of the same species, possessing, besides the general characteristics of that species, other characteristics peculiar to themselves, which they owe to the influence of soil, climate, nourishment, and habits of life to which they are subjected, and which they transmit with certainty to their progeny. The characteristics of certain breeds or families are so well marked, that if an individual supposed to belong to any one of them were to produce an offspring not possessing them, or possessing them only in part, with others not belonging to the breed, it would be just ground for suspecting a want of purity of blood.

If this definition of the term breed be correct, no grade animals, and no animals not possessing fixed peculiarities or characteristics which they share with all other animals of the class of which they are a type, and which they are capable of transmitting with certainty to their descendants, can be recognized by breeders as belonging to any one distinct race, breed, or family.

[50]

The term “native,” or “scrub,” is applied to a vast majority of our American cattle, which, though born on the soil, and thus in one sense natives, do not constitute a breed, race, or family, as properly understood by breeders. They do not possess characteristics peculiar to them all, which they transmit with any certainty to their offspring, either of form, size, color, milking or working properties. But, though an animal may be made up of a mixture of blood almost to infinity, it does not follow that for specific purposes, it may not, as an individual animal, be one of the best of the species. And for particular purposes individual animals might be selected from among those commonly called natives in New England, and scrubs at the West and South, equal, and perhaps superior, to any among the races produced by the most skilful breeding. There can be no impropriety in the use of the term “native,” therefore, when it is understood as descriptive of no known breed, but only as applied to the common stock of the country, which does not constitute a breed. But perhaps the whole class of animals commonly called “natives” would be better described as grades, since they are well known to have sprung from a great variety of cattle procured in different places and at different times on the continent of Europe, in England, and in the Spanish West Indies, brought together without any regard to fixed principles of breeding, but only from individual convenience, and by accident.

The first importations to this country were doubtless those taken to Virginia previous to 1609, though the exact date of their arrival is not known. Several cows were carried there from the West Indies in 1610, and the next year no less than one hundred arrived there from abroad.

The earliest cattle imported into the Plymouth colony,[51] and undoubtedly the earliest introduced into New England, arrived in 1624. At the division of cattle which took place in 1627, three years after, one or two are distinctly described as black, or black and white, others as brindle, showing that there was no uniformity of color. Soon after this, a large number of cattle were brought over from England for the settlers at Salem. These importations formed the original stock of Massachusetts.

In 1625 the first importation was made into New York from Holland, by the Dutch West India Company, and the foundation was then laid for an exceedingly valuable race of animals, which subsequent importations from the same country, as well as from England, have greatly improved.

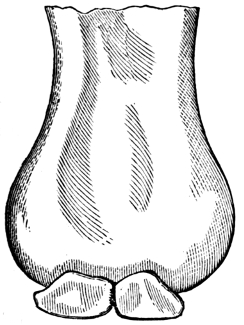

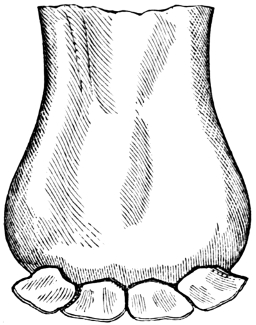

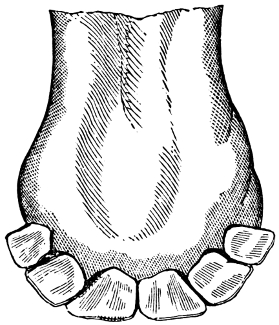

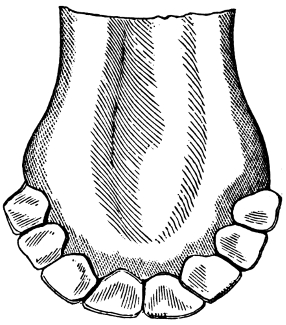

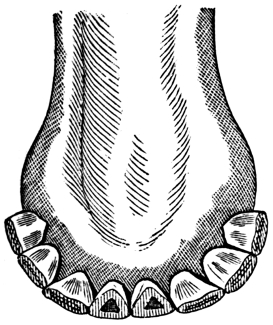

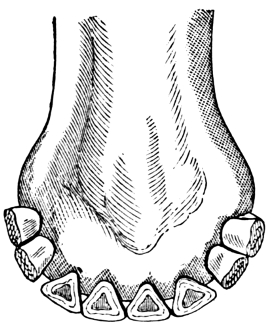

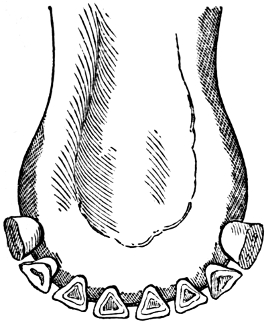

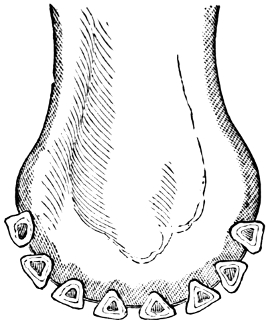

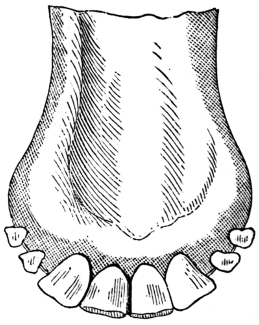

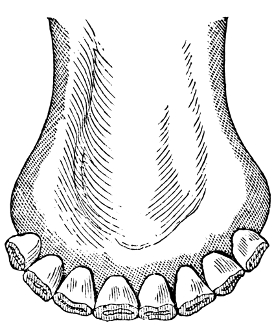

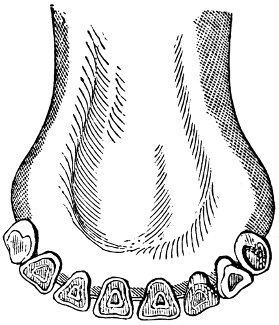

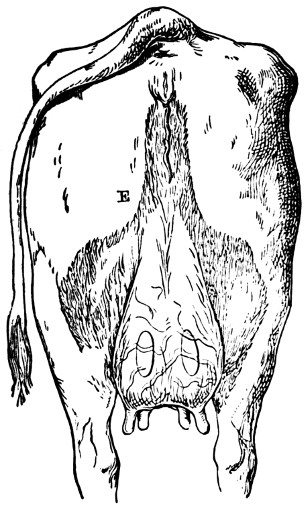

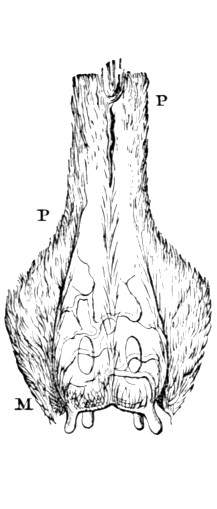

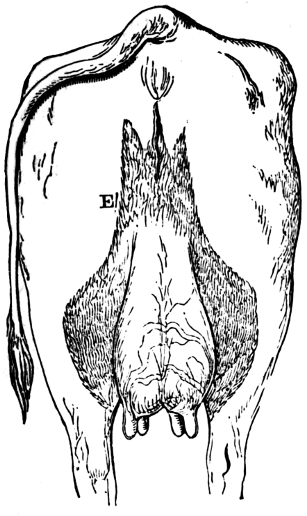

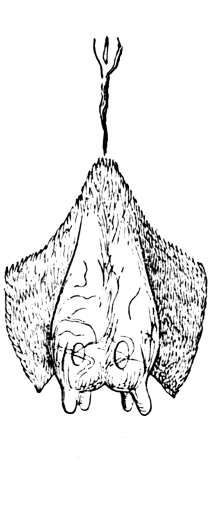

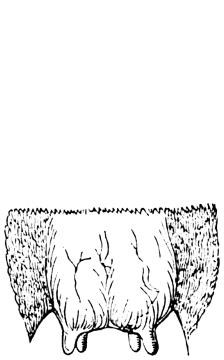

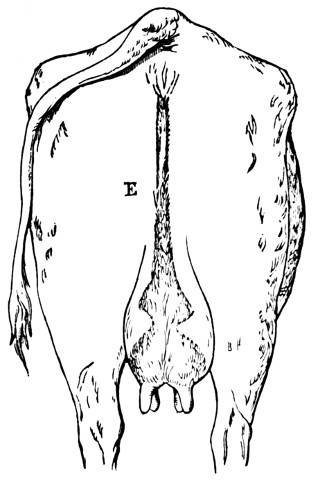

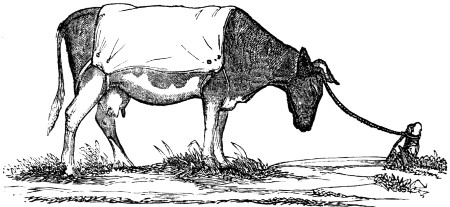

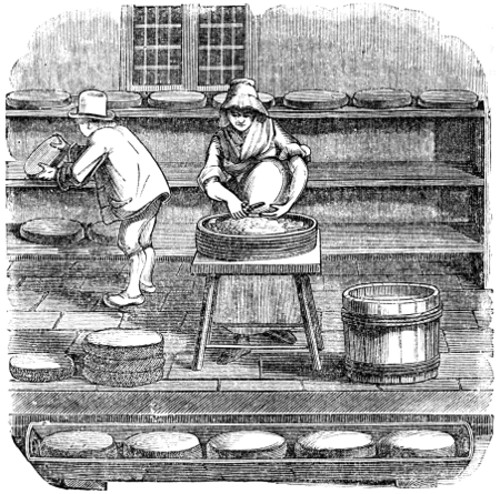

Dairy farming in some parts of Holland, it may be remarked in passing, became a highly important branch of industry at a very early date, and a large and valuable race of dairy cattle existed there long before the efforts of modern breeders began in England. The attention of farmers there is at the present time devoted especially to the dairy, and the manufacture of butter and cheese. They support themselves, to a considerable extent, upon this branch of farming; and hence it is held in the highest respect, and carried to a greater degree of exactness and perfection, perhaps, than in any other part of the world. They are especially particular in the breeding, keeping, and care of milch cows, as on them very much of their success depends. The principles on which they practise, in selecting a cow to breed from, are as follows: She should have, they say, considerable size—not less than four and a half or five feet girth, with a length of body corresponding; legs proportionally short; a finely-formed head, with a forehead or face somewhat concave; clear,[52] large, mild, and sparkling eyes, yet with no expression of wildness; tolerably large and stout ears, standing out from the head; fine, well-curved horns; a rather short than long, thick, broad neck, well set against the chest and withers; the front part of the breast and the shoulders must be broad and fleshy; the low-hanging dewlap must be soft to the touch; the back and loins must be properly projected, somewhat broad, the bones not too sharp, but well covered with flesh; the animal should have long, curved ribs, which form a broad breast-bone; the body must be round and deep, but not sunken into a hanging belly; the rump must not be uneven, the hip-bones should not stand out too broad and spreading, but all the parts should be level and well filled up; a fine tail, set moderately high up and tolerably long, but slender, with a thick, bushy tuft of hair at the end, hanging down below the hocks; the legs must be short and low, but strong in the bony structure; the knees broad, with flexible joints; the muscles and sinews must be firm and sound, the hoofs broad and flat, and the position of the legs natural, not too close and crowded; the hide, covered with fine glossy hair, must be soft and mellow to the touch, and set loose upon the body. A large, rather long, white and loose udder, extending well back, with four long teats, serves also as a characteristic mark of a good milch cow. Large and prominent milk-veins must extend from the navel back to the udder; the belly of a good milch cow should not be too deep and hanging. The color of the North Dutch cattle is mostly variegated. Cows with only one color are no favorites. Red or black variegated, gray and blue variegated, roan, spotted and white variegated cows, are especially liked.

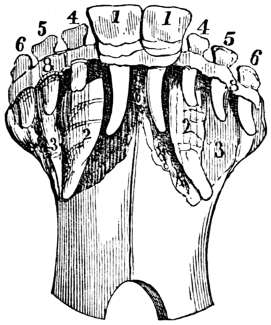

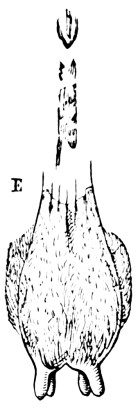

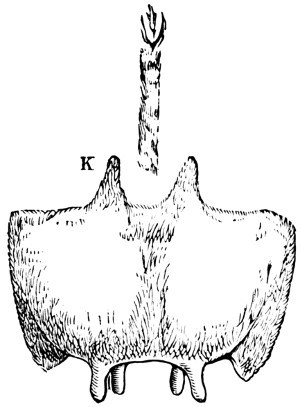

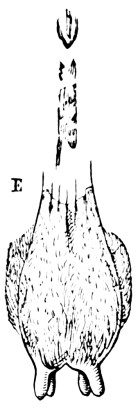

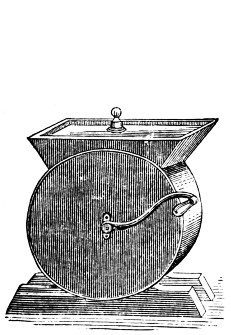

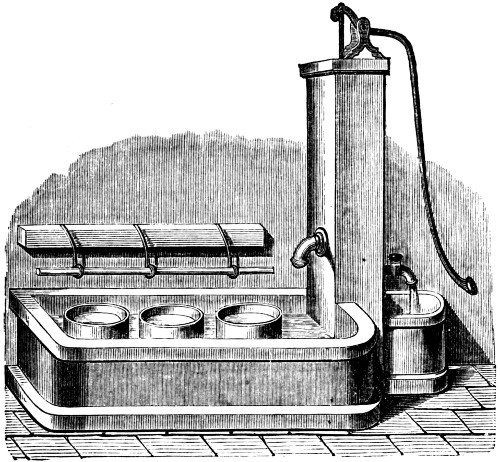

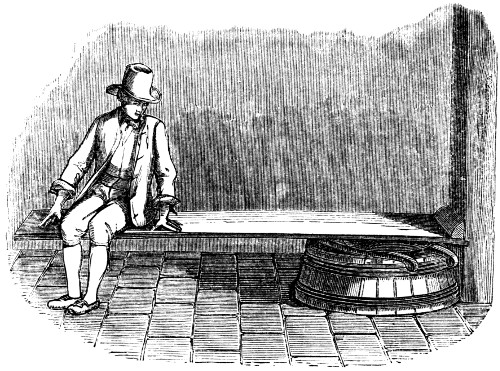

The annexed cut gives a correct idea of the cow most esteemed in Holland; the type of the race so noted for[53] the production of milk, and of the excellent round Dutch cheeses.

Fig. 13. Dutch Dairy Cow.