| Note: | Images of the original pages are available through Internet Archive. See https://archive.org/details/rudimentarytreat00hobb |

Please see the Transcriber’s Note at the end of this text.

LONDON:

PRINTED BY LEVEY, ROBSON, AND FRANKLYN,

Great New Street and Fetter Lane.

[iii]

RUDIMENTARY TREATISE

ON THE

CONSTRUCTION OF LOCKS.

EDITED BY

CHARLES TOMLINSON.

“Il n’y a point de machines plus communes que les serrures: elles sont assez composées pour mériter le nom de machine; mais je ne sais s’il y en a qui soient aussi peu connues par ceux qui les emploient. Il est rare qu’on sache en quoi consiste la bonté d’une serrure, le degré de sûreté qu’on peut s’en promettre. Leur extérieur est presque la seule chose à quoi l’on s’arrête. Les usages importans auxquels elles sont employées devraient cependant exciter la curiosité à les connaître, si la curiosité était toujours excitée raisonnablement.”—M. de Réaumur, “Des Serrures de toutes les espèces,” forming the fifth chapter of M. Duhamel’s Treatise “Art du Serrurier,” in the “Descriptions des Arts et Metiers faites ou approuvées par Messieurs de l’Académie Royale des Sciences.”

LONDON:

JOHN WEALE, 59 HIGH HOLBORN.

MDCCCLIII.

[iv]

“There are no machines more common than locks: they are sufficiently complex to merit the name of machine; but I know of no others the structure of which is so little understood by those who use them. It is rare to find any one who knows wherein the goodness of a lock consists, or the degree of security that he can attach to it. The outside of a lock is usually all that attracts attention. Doubtless the important uses to which locks are applied would excite curiosity respecting their structure, if curiosity were always excited for worthy objects.”—M. de Réaumur.

[v]

The reader is entitled to know the origin of the small work which he holds in his hands.

In August 1852, being about to write a short article on Locks for a Cyclopædia of Useful Arts, of which I am the editor, I consulted my esteemed and lamented friend, the late Professor Cowper, of King’s College, as to the desirability of explaining to the general reader the defects of some of our English locks, which, previous to the celebrated “lock controversy” of 1851, had borne a high character for skilful construction, beauty of workmanship, and undoubted security. Professor Cowper expressed his strong conviction that by exposing the defects of our locks, the cause of mechanical science, as well as the public in general, would be benefited; that if our locks were defective, inventors would be stimulated to supply the defects, and the art of the locksmith would be raised accordingly. He considered that Mr. Hobbs had made a considerable step in advance in the constructive details of his art, not only in having detected the weak points of some of our best English locks, but also in having introduced two or three new locks, which appeared to be more secure than any of those previously produced. Professor Cowper gave me an introduction to Mr. Hobbs, who placed at my disposal a variety of literary materials relating to the history and construction of locks, and stated his intention at some future time of bringing out a small book on the subject, if he could meet with a publisher. I recommended him to offer the work to Mr. Weale, for insertion in his series of Rudimentary Works. This was accordingly done, and I was invited to prepare the work; but as my engagements did not leave me sufficient leisure to write the book, I requested my friend Mr. George Dodd to put the materials together, and to search for[vi] more. Mr. Dodd acceded to my request; and having completed his part of the work, I subjected it to a careful revision, and added various details which seemed to be necessary to completeness, at least so far as the narrow limits of a small rudimentary work would admit of completeness. The manuscript was then sent to press: each sheet as it was received from the printer was submitted to Mr. Hobbs, who read it with care, and made his annotations and corrections thereon. Mr. Hobbs and I then had a meeting, when the additions and corrections were read and discussed, and admitted or rejected as the case might be. The sheet having been thus corrected was sent to press.

It should also be stated that, during the progress of the work, Mr. Weale, at my request, wrote to Messrs. Bramah, and also to Messrs. Chubb, informing them that a Rudimentary Treatise on the Construction of Locks was being prepared, and requesting them to state in writing what alterations or improvements they had made in their locks since the date of the Great Exhibition. The communications which we have received from these celebrated firms are inserted verbatim, in their proper places, in the present work.

Such is the mode in which this small volume has been prepared. I have endeavoured to perform an editor’s duty conscientiously, without entertaining the feeling of a partisan in the matter. My chief object in superintending the production of this book (an object in which the Publisher fully participates) is to advance the cause of mechanical science, and to supply a deficiency in one of the most interesting portions of its English literature.

C. TOMLINSON.

Bedford Place, Ampthill Square,

July 1853.

[vii]

The first edition of this volume, though at the date of its appearance co-ordinating with the state of knowledge of the period, and containing matter well arranged and lucidly described—as must have been expected from the reputation of its author—had, through the lapse of the few intervening years, inevitably become somewhat behind the state of the art of which it treats—one which is daily receiving the attentive consideration of many skilful men, and occasional marked improvements. Amongst those of later years none are more noteworthy than the locks patented by Mr. Fenby, of Birmingham; of these an account, with accurate illustrations, for which the drawings are supplied by the inventor, is now added,—together with a brief essay upon the important but popularly ill-understood subject of iron safes.

ROBERT MALLET.

April, 1868.

[viii]

In reference to Mr. Smyth’s letter, which is given at pp. 130, 131, that gentleman is desirous to state that it was in consequence of the defects there pointed out that Mr. Hobbs was enabled to pick the Bramah lock operated upon, which had been manufactured forty years previously, when the sliders were made of iron instead of steel as they now are, and yet, notwithstanding that and the other defects pointed out, it took Mr. Hobbs sixteen days to pick it. In proof of the security of the Bramah lock, Mr. Smyth mentions that Mr. Hobbs’s best workman failed in picking an ordinary 3-inch Bramah box lock; and that a person in the employ of Messrs. Johnson and Ravey, of Conduit Street, failed also in his attempt to pick a 6-inch cellar-door lock, though he had the lock in his possession for twelve months, employing his evenings in making instruments and trying to pick it. Mr. Smyth contradicts the statement made at page 128, that the new lock was removed from the window through any fear of its being opened. On the contrary, it was put up especially to afford an opportunity for Mr. Hobbs to make, if he thought fit, another trial, and it remained in the window four months. The sole cause of its removal was to stop the impertinent applications of men and boys, which interfered too much with the general business of the firm.

[ix]

| CHAP. | PAGE | |

|---|---|---|

| I. | On Locks and Lock-literature | 1 |

| II. | Ancient Locks: Grecian, Roman, Egyptian | 8 |

| III. | Lock classification. The Puzzle-Lock and the Dial-Lock | 16 |

| IV. | Warded Locks, with their varied appendages | 27 |

| V. | On Tumbler or Lever Locks | 43 |

| VI. | The Bramah Lock | 64 |

| VII. | American Locks | 82 |

| VIII. | The Lock Controversy: previous to the date of the Great Exhibition | 102 |

| IX. | The Lock Controversy: during and since the time of the Great Exhibition | 115 |

| X. | Effects of the Great Exhibition of 1851 in improving English Locks | 140 |

| XI. | The Lock and Key Manufacture | 154 |

| XII. | English Patents for Locks. Aubin’s Lock Trophy. Conclusion | 164 |

| Appendix. | ||

| XIII. | On an Improved Construction of Lock and Key: Fenby’s Adytic Lock | 176 |

| XIV. | Fenby’s Stop Lock | 193 |

| XV. | Note upon Iron Safes | 201 |

[1]

ON THE

CONSTRUCTION OF LOCKS.

The manufacture of locks, and a consideration of the mechanical principles involved in their construction and security, have never yet been treated with any degree of fulness in an English work. Lock-making has occupied a large amount of ingenuity, and lock-patents have been obtained in considerable number, though not always, we are satisfied, with a commensurate return for the expense incurred,—but lock-philosophy (if so it may be designated) has not been largely attended to.

And yet it may safely be said that much which is both mechanically and commercially important is comprised in a lock. Every improvement in the manufacture of iron, steel, and brass—that is, in the tool-making and machine-making processes—may be made to reflect its light on the lock-manufacture; the stamping, the casting, the planing, the slotting, the screw-cutting, the polishing of metals,—all, in proportion as they are improved, impart some of their aid to the lock-maker. Then, in the finer kinds of locks, the works are so delicate as to approach to the nicety of clockwork; thereby combining the manipulative skill of a talented[2] artisan with the rougher mechanical work of the smith. The principles of mechanical science are also appreciated by many lock-makers. The lever, the inclined plane, the eccentric, the cam, the screw, the wheel and pinion, the ratchet, the spring,—all are brought to bear on the internal mechanism of locks, frequently in many novel combinations.

The commercial importance of locks—though of course never seriously questioned when once fairly brought before one’s attention—has been recently rendered so apparent as to have risen to the position of a public topic. If a strong room, containing gold and silver, notes and bills, books and papers—if such a room be necessarily shielded from intrusion, it becomes no less necessary that the shield should be really worthy of its name, trusty and reliable: a good lock is here nearly as indispensable as a faithful cashier. And without dwelling on such an auriferous picture as a room fall of gold, we shall find ample proof of the commercial importance of lock-making in the ordinary circumstances by which we are every day surrounded. Until the world becomes an honest world, or until the honest people bear a larger ratio than at present to the dishonest, the whole of our movables are, more or less, at the mercy of our neighbours. Houses, rooms, vaults, cellars, cabinets, cupboards, caskets, desks, chests, boxes, caddies,—all, with the contents of each, ring the changes between meum and tuum pretty much according to the security of the locks by which they are guarded.

A commercial, and in some respects a social, doubt has been started within the last year or two, whether or not it is right to discuss so openly the security or insecurity of locks. Many well-meaning persons suppose that the discussion respecting the means for baffling the supposed safety of locks offers a premium for dishonesty, by shewing others how to be dishonest. This is a fallacy. Rogues are very keen in their profession, and know already much more than we can teach them respecting their several kinds of roguery. Rogues knew a good deal about lock-picking long before locksmiths discussed[3] it among themselves, as they have lately done. If a lock—let it have been made in whatever country, or by whatever maker—is not so inviolable as it has hitherto been deemed to be, surely it is to the interest of honest persons to know this fact, because the dishonest are tolerably certain to be the first to apply the knowledge practically; and the spread of the knowledge is necessary to give fair play to those who might suffer by ignorance. It cannot be too earnestly urged, that an acquaintance with real facts will, in the end, be better for all parties. Some time ago, when the reading public was alarmed at being told how London milk is adulterated, timid persons deprecated the exposure, on the plea that it would give instructions in the art of adulterating milk; a vain fear—milkmen knew all about it before, whether they practised it or not; and the exposure only taught purchasers the necessity of a little scrutiny and caution, leaving them to obey this necessity or not, as they pleased. So likewise in respect to bread, sugar, coffee, tea, wine, beer, spirits, vinegar, cheap silks, cheap woollens—all such articles as are susceptible of debasement by admixture with cheaper substances—much more good than harm is effected by stating candidly and scientifically the various methods by which such debasement has been, or can be produced. The unscrupulous have the command of much of this kind of knowledge without our aid; and there is moral and commercial justice in placing on their guard those who might possibly suffer therefrom. We employ these stray expressions concerning adulteration, debasement, roguery, and so forth, simply as a mode of illustrating a principle—the advantage of publicity. In respect to lock-making, there can scarcely be such a thing as dishonesty of intention: the inventor produces a lock which he honestly thinks will possess such and such qualities; and he declares his belief to the world. If others differ from him in opinion concerning those qualities, it is open to them to say so; and the discussion, truthfully conducted, must lead to public advantage: the discussion stimulates curiosity, and the[4] curiosity stimulates invention. Nothing but a partial and limited view of the question could lead to the opinion that harm can result: if there be harm, it will be much more than counterbalanced by good.

The literature of lock-making is, as we have implied, very scanty, both in England and America. The French and Germans, though far below our level as lock-makers, are very superior to us in their descriptions of the construction and manufacture of locks. Take, for instance, the French treatise published more than eighty years ago by the Académie des Sciences, and forming part of a folio series of manufacturing treatises, illustrated very fully by engravings. It is worth while to examine this work, to see how minutely and faithfully the writers of such treatises performed their task nearly a century ago. The Art du Serrurier, with the distinguished name of M. Duhamel du Monceau as the author or editor, was published in 1767. It occupies 290 folio pages, and is illustrated by 42 folio plates. The first chapter gives us an introduction and general principles, in which the choice and manipulation of materials are touched upon; the different qualities of iron and steel; and the processes of forging, founding, welding, stamping, filing, polishing, &c. In the copper-plates representing these smiths’ operations and the tools employed,[1] there is a smithy, with about a dozen smiths engaged in all these various occupations, with stockings down, and a due amount of workshop slovenliness. The next chapter takes us into what may perhaps be called “smith’s work in general,” or at least it treats of the manufacture of various kinds of ironmongery for doors, windows, and house-fittings generally. Then the third chapter treats of “smith’s work which serves for the security of houses,” consisting of railings, palings, bars, and gates of various kinds—such at least as are made of iron. In chapter four we have a notice of such kinds of[5] smith’s work as relate to the fastenings for doors, windows, closets, chests, &c.; such as hinges, hasps, latches, bolts, and other contrivances less complex than an actual lock. This brings us, by a natural transition, to locks in general, which form the subject of chapter five, to which is attached the illustrious name of M. de Réaumur as the author. Here are given a hundred folio pages of description, illustrated by twenty folio plates relating to locks, lock-making, and locksmiths. The sixth chapter relates to the iron-work of carriages, or the labours of the coachsmiths; while chapter seven, to wind up the work, relates to bell-hanging.

[1] It is worthy of remark, that the tools described are the same as those which are used by the locksmith at the present day; shewing how little improvement has been made in the means of producing locks.

That chapter of the work which has reference to locks is the only one with which we have to do here. It is arranged in a systematic manner, beginning with the simpler locks, without wards or tumblers, and proceeding thence to others of more complex construction. The period at which the work was written was too early to lead us to expect to find a tumbler-lock described and delineated: there are, however, numerous examples of single tumbler-locks, many of them of great ingenuity. The use of multiple bolts, that is, of many bolts shot at once by one action of the key, seems to have been familiar enough to the locksmiths of those days. One lock represented is remarkable; it is attached to a strong and ponderous coffer or chest. The chest is open; and the whole under or inner surface of the cover is seen to be occupied by a lock of intricate construction; there are no less than twelve bolts, three on each long side, one on each short side, and one in each corner; these bolts are so placed as to catch under a projecting rim fixed round the top of the coffer. The collection of keys, exhibited on a separate plate, is remarkable for the great variety of forms given to them. We shall by and by copy some of the drawings of this curious work.

It was to be expected that in the Encyclopédie Méthodique, published in the same country and in the same century, the locksmith’s art would be treated at some such length as in the work just described. Among the two hundred volumes of[6] which the Cyclopédie consists, several are devoted to arts and manufactures; and one of them contains the article in question. It occupies 168 quarto pages, and is illustrated by 35 copper-plate engravings, shewing in detail not only the parts of various locks, but the tools used by the lockmaker. It is proper, however, to remark, that much of the letterpress and many of the plates relate to smith’s work generally, and not exclusively to lock-work; the French name serrurerie being applied not only to lock-making, but to most of the smith’s work required in dwelling-houses. This affords, indeed, a striking illustration of the fact, that until lately a lock-maker has been regarded rather as a smith than as a machinist, rather as a forger and filer of pieces of iron, than as a fabricator of delicate mechanism. One of the most curious features in this treatise is a vocabulary, containing, in alphabetical arrangement, a minute account of all the French technical terms employed in the locksmith’s art. This vocabulary alone occupies 38 quarto pages.

The Germans, like the French, bestow great attention on their treatises relating to the manufacturing arts. Some of these are, indeed, worked up to a degree of minuteness which would seem superfluous, where little distinction is drawn between the importance of fundamental principles and that of mere technical details. Locks have had their due share. The article on locks in Prechtl’s Technological Encyclopædia written by Karmarsch, and published in 1842, occupies about 140 pages. Locks are very minutely classified by the author, according to their purposes and their modes of action, and are illustrated by many plates. One of his classifications is into German, French, and Bastard locks, referring in part to the extent to which the key turns round in the lock; and the last of the three having an intermediate character between the other two. After treating of the ordinary warded locks, he comes to the combination principle; and it is profitable here to notice, how well the works of our machinists are understood on the continent, when they have[7] any thing to recommend them; there are a dozen closely printed pages devoted to a minute description of Bramah’s invention, with all the separate parts illustrated by copper-plate engravings. After this comes a more general account of the details and manufacture of locks, similarly illustrated by engravings.

Whatever may be the merits of the different articles relating to locks in the various English cyclopædias, there are none approaching in length to the article in Prechtl’s work. But when we consider that Prechtl devotes twenty large volumes to technological or manufacturing subjects, he is of course able to devote a larger space to each article than is given in English works. Both in England and in America, men are more disposed to do the work than to describe it when done. In the Encyclopædia Britannica, in Rees’ Cyclopædia, in Hebert’s Engineers’ and Mechanics’ Cyclopædia, in the Encyclopædia Metropolitana, in the Penny Cyclopædia, and in other similar works, locks are described as well as can be expected within the limits assigned to the articles. Mr. Bramah’s essay on locks, and on his own lock in particular, is one of the few English pamphlets devoted expressly to this subject. An excerpt from the proceedings of the Institute of Civil Engineers, in 1851, gives an interesting paper on locks by Mr. Chubb; and shorter reports of papers and lectures have been published in various ways. Perhaps the best account of locks which we have, considering the limited space within which a great deal of information is given in a very clear style, is that contained in Mr. Tomlinson’s Cyclopædia of Useful Arts.

[8]

Locks and door-fastenings have not, until modern times, been susceptible of any classified arrangement according to their principles of construction. They have been too simple to require it, and too little varied to permit it. That some such fastenings must be employed wherever doors of any kind are used is sufficiently apparent; and there is a little (though only a little) information obtainable, which shews the nature of the fastenings adopted in early times. The bolt, the hasp, the chain, the bar, the latch, the lock, all were known, in one or other of their various forms, in those ages which we are accustomed to consider classical. Travellers, generally speaking, do not descend to locks, or rather they do not think about them; otherwise they might have collected much that would have been novel and applicable to the present work; and, indeed, there is some ground for the assertion, that a notice of the door-fastenings of all nations would reveal to us something of the social and domestic habits of various members of the great human family. Be this as it may, however, we may profitably make a little inquiry into the locks of ancient times.

In the volumes of Lardner’s Cyclopædia relating to the “Manners and Customs of the ancient Greeks and Romans,” we do not find any mention of the kinds of locks used by those nations; but the author, while describing the houses, says:—“Doors turned anciently upon large pivots in the centre, let into sockets in the lintel and threshold, so that one of the sides opened inwards, the other outwards; and Plutarch gives the following curious reason why persons were to knock and[9] alarm the porter, viz. lest the visitor entering unawares should surprise the mistress or daughter of the family busy or undressed, or servants under correction, or the maids quarreling.” As the visitors had thus the power (if permitted so to do) to open the outer door of a house, it would appear that very little in the nature of a lock was employed under ordinary circumstances, unless indeed it were a mere latch. In respect to Roman houses it is stated, that “the doors revolved upon pivots, which worked in a socket below, and were fastened by bolts which hung from chains.” There is no mention of locks here. Mr. St. John, in his work on the same subject, says: “The street-door of a Grecian house, usually, when single, opened outwards; but when there were folding-doors they opened inwards, as with us. In the former case it was customary, when any one happened to be going forth, to knock, or call, or ring a bell, in order to warn passengers to make way.” After describing the various kinds of wood of which the doors were made, he proceeds: “The doors at first were fastened by long bars passing into the wall on both sides; and by degrees smaller bolts, hasps, latches, and locks and keys, succeeded. For example, the outer door of the thalamos in Homer was secured by a silver hasp, and a leathern thong passed round the handle, and tied, perhaps, in a curious knot.”

Mr. Yates, in a learned article on this subject in Smith’s Dictionary of Greek and Roman Antiquities, collects numerous details scattered through various early writers. We will string together a few of these details, so far as they have any relation to the fastenings of doors. The outer door of a Roman house was generally called janua; whereas the inner doors were called ostia. The doorway, when complete, consisted of four indispensable parts—the threshold or sill, the lintel, and the two jambs. The threshold, on which the feet trod, was often regarded with a kind of superstitious reverence; the lintel, which crossed the doorway at the top, having a considerable superincumbent weight to bear, was usually made of one piece of timber or stone of great strength; the jambs, or side[10] uprights, were also made in one piece each. The doorway, in every building of the least importance, contained two doors folding together; even the internal doors had their bivalve construction. But in every case each of the two valves was wide enough to allow persons to pass through without opening the other; in some cases even each valve was double, so as to fold like our window-shutters. These doors, or valves, were not hinged to the side-posts, as with us, but were, as has already been stated, pivoted to the lintel above and the threshold below. The fastening usually consisted of a bolt placed at the base of each valve or half-door, so as to admit of being pushed into a socket made in the sill to receive it. The doorways in some of the houses at Pompeii still shew two holes in the sill, corresponding to the bolts in the two valves. At night, the front door of the house was further secured by means of a wooden and sometimes an iron bar placed across it, and inserted into sockets on each side of the doorway; hence it was necessary to remove the bar in order to open the door. Chamber-doors were often secured in the same manner. In the Odyssey there is mention of a contrivance (adverted to by Mr. St. John) for bolting or unbolting a door from the outside; it consisted of a leather thong inserted through a hole in the door, and by means of a loop, ring, or hook, capable of taking hold of the bolt so as to move it in the manner required. We have here evidently the elements of a more complete mechanism; for the bolt was a rude lock in the same degree that the thong was a rude key. That the Romans afterwards had real locks and keys is clear; for the keys found at Herculaneum and Pompeii, and those attached to rings, prove that a kind of warded lock must have been well known.[2] There are the remains of a tomb at Pompeii, the door of which is made of a single piece of marble, including the pivots, which were encased in bronze, and turned in sockets of the same metal; it is three feet high, two feet nine inches wide, and[11] four and a quarter inches thick; it is cut in front to resemble panels, and thus approaches nearer in appearance to a modern wooden door; and it was fastened by some kind of lock, traces of which still remain.

[2] An examination of the Roman keys in the British Museum sufficiently attests this fact.

The same facts frequently become more clear when described in different words by different writers. We shall make use of this circumstance. Mr. Donaldson, in his Essay on Ancient Doorways, presents us with details which illustrate many of the foregoing remarks. “Homer describes the treasures and other valuable objects (mentioned in the Odyssey) as being kept in the citadel, secured merely by a cord intricately knotted. This, of course, was soon found to be a very insufficient protection, and therefore a wooden bar was adopted inside the doors of houses, to which it was attached by an iron latch, fastened or removed by a key adapted to it; this key was easily applied from within; but in order to get at it from without, a large hole was made in the door, allowing the introduction of the hand, so as to reach the latch and apply the key. The lock called the Lacedæmonian, much celebrated by ancient writers, was invented subsequently; it was especially fitted for the inner chambers of houses, the bar fastenings continuing to be employed for closing the outer doors of dwellings and the entrance-gates to cities. The Lacedæmonian lock did not require a hole to be made in the door, for it consisted of a bolt placed on that side of the entrance-door which opened, and on the inside of a chamber-door. When a person who was outside wished to enter, it was necessary for him to insert the key in a little hole and to raise the bolt; and in time this species of fastening was improved by the insertion of the bolt in an iron frame or rim permanently attached to the door by a chain, and fastening the door by the insertion of the hasp, through the eye of which was forced the bolt inside the lock by applying the key.” After quoting a Latin sentence from Varro in elucidation of his subject, Mr. Donaldson proceeds to observe, that for the most part the locks of the ancients were different in principle from those of modern days, not being inserted[12] or mortised into the doors, nor even attached except by a chain; they were, in fact, padlocks.

One of the passages in the Odyssey alluding to the primitive mode of fastening the valves or folding-doors of a house runs thus:—

Most of the other great nations of antiquity resembled either the Egyptians or the Greeks and Romans, more or less closely, in their domestic and domiciliary arrangements; or, at any rate, so far as such humble matters as locks and keys are concerned, we need not seek far from those nations for examples. The Nineveh and other Assyrian explorations have, however, revealed many curious and unexpected facts; from the temples and the palaces we may by and by penetrate into the houses and rooms of the citizens sufficiently to know how their doors were fastened. In the mean time ancient Egypt awaits our notice.

Sir J. Gardner Wilkinson, in his Manners and Customs of the Ancient Egyptians, gives the following information concerning the doors and door-fastenings of that remarkable people, on the authority of models, sculptures, and paintings, still existing. The doors were frequently stained so as to imitate foreign and rare woods. They were either of one or two valves, turning on pieces of metal, and were secured within by a bar or by bolts. Some of these bronze pins have been discovered in the tombs of Thebes; they were fastened to the wood with nails of the same metal, the round heads of which served also as ornaments. In the stone lintels and floors behind the thresholds of the tombs and temples are still frequently to be seen the holes in which the pivot-pins turned, as well as those of the[13] bolts and bars, and the recess for receiving the opened valves. The folding-doors had bolts in the centre, sometimes above as well as below; a bar was placed across from one wall to the other.

In many of the ancient Egyptian doors there were wooden locks fixed so as to fasten across the centre at the junction where the two folds of the door met. It is difficult, by mere inspection of the bas-reliefs and paintings, to decide whether these locks were opened by a key, or were merely drawn backwards and forwards like a bolt; but if they were really locks, it is probable that they were on the same principle as the Egyptian lock still in use. For greater security, these modern locks are occasionally sealed with a mass of clay; and there is satisfactory evidence that the same custom was frequently observed among the ancient inhabitants of that country. Sir J. G. Wilkinson gives a representation of an iron key, now in his possession, which he procured among the tombs at Thebes, and which looks very much like a modern burglar’s picklock. In relation to keys generally, and after mentioning the use of bronze for their manufacture, he says: “At a later period, when iron came into general use, keys were made of that metal, and consisted of a straight shank about five inches in length, and a bar at right angles with it, on which were three or more projecting teeth. The ring at the upper extremity was intended for the same purpose as that of our modern keys; but we are ignorant of the exact time when they were brought into use; and the first invention of locks distinct from both is equally uncertain; nor do I know of any positive mention of a key, which, like our own, could be taken out of the lock, previous to the year 1336 before our era; and this is stated to have been used to fasten the door of the summer parlour of Eglon, the king of Moab. The description here adverted to is that contained in Judges iii. 23-25: ‘Ehud went forth through the porch, and shut the doors of the parlour upon him, and locked them ... his servants ... took a key, and opened them.’”

[14]

The curious and ingenious wooden lock of ancient Egypt is still in use in Egypt and Turkey. In Eton’s Survey of the Turkish Empire, published towards the close of the last century, the locks then and there in use are thus described: “Nothing can be more clumsy than the door-locks in Turkey; but their mechanism to prevent picking is admirable. It is a curious thing to see wooden locks upon iron doors, particularly in Asia, and on their caravanserais and other great buildings, as well as upon house-doors. The key goes into the back part of the bolt, and is composed of a square stick with five or six iron or wooden pins, about half an inch long, towards the end of it, placed at irregular distances, and answering to holes in the upper part of the bolt, which is pierced with a square hole to receive the key. The key being put in as far as it will go, is then lifted up; and the pins, entering the corresponding holes, raise other pins which had dropped into these holes from the part of the lock immediately above, and which have heads to prevent them falling lower than is necessary. The bolt, being thus freed from the upper pins, is drawn back by means of the key; the key is then lowered, and may be drawn out of the bolt. To lock it again, the bolt is only pushed in, and the upper pins fall into the holes in the bolt by their own weight.” Mr. Eton, probably seeing how well the tumbler-principle is here understood, says: “This idea might be improved on; but the Turks never think of improving.” The locks on the doors of modern houses in Cairo seem to be of this long-established form, except where iron locks have been imported from Europe.

A letter was inserted in the Journal of Design for July 1850 from Mr. W. C. Trevelyan; in which, after adverting to the Egyptian lock, he says: “It is remarkable that the locks which have been in use in the Faröe Islands, probably for centuries, are identical in their construction with the Egyptian. They are, lock and key, in all their parts made of wood; of which material, if I mistake not, they have also[15] been found in Egyptian catacombs; and so identical with the Faröese in structure and appearance, that it would not be easy to distinguish one from the other.”

fig. 1.

fig. 2.

fig. 3.

fig. 4.

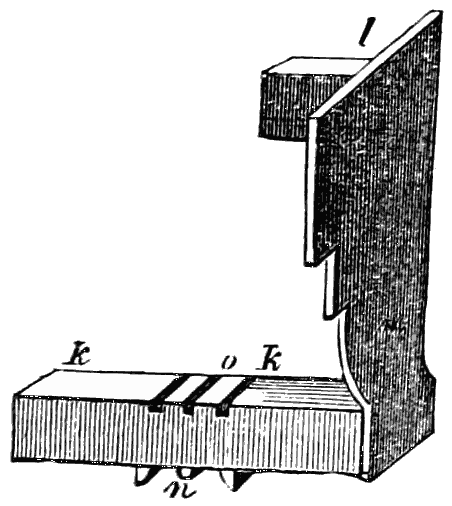

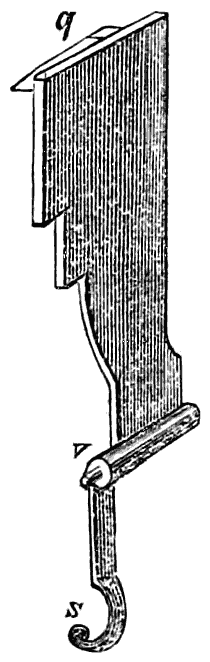

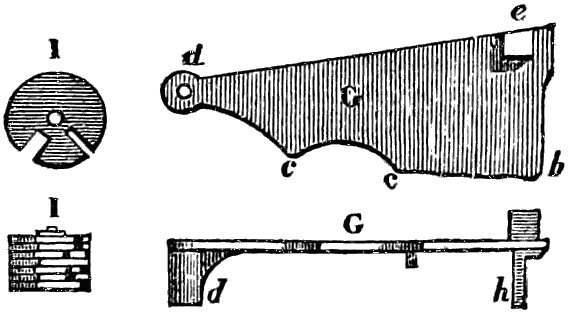

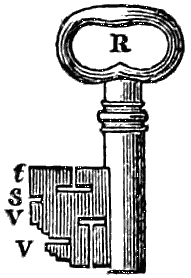

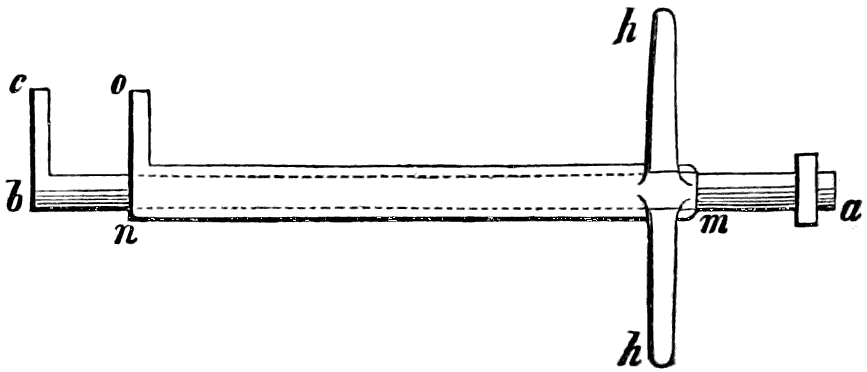

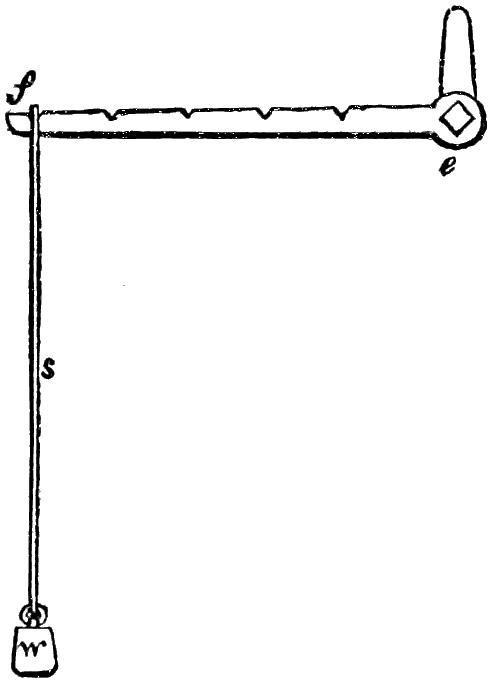

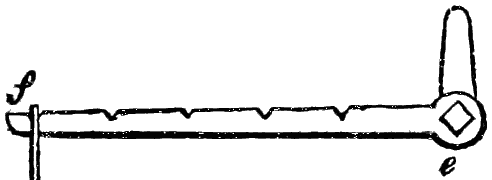

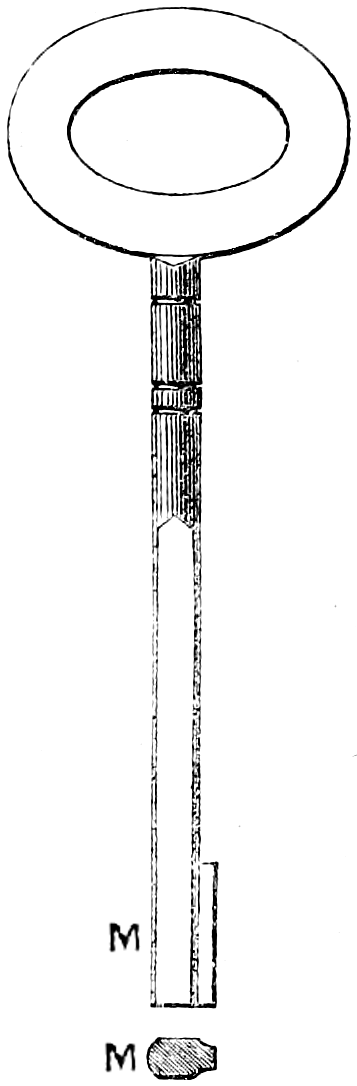

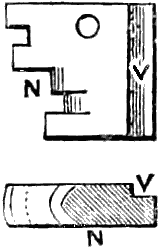

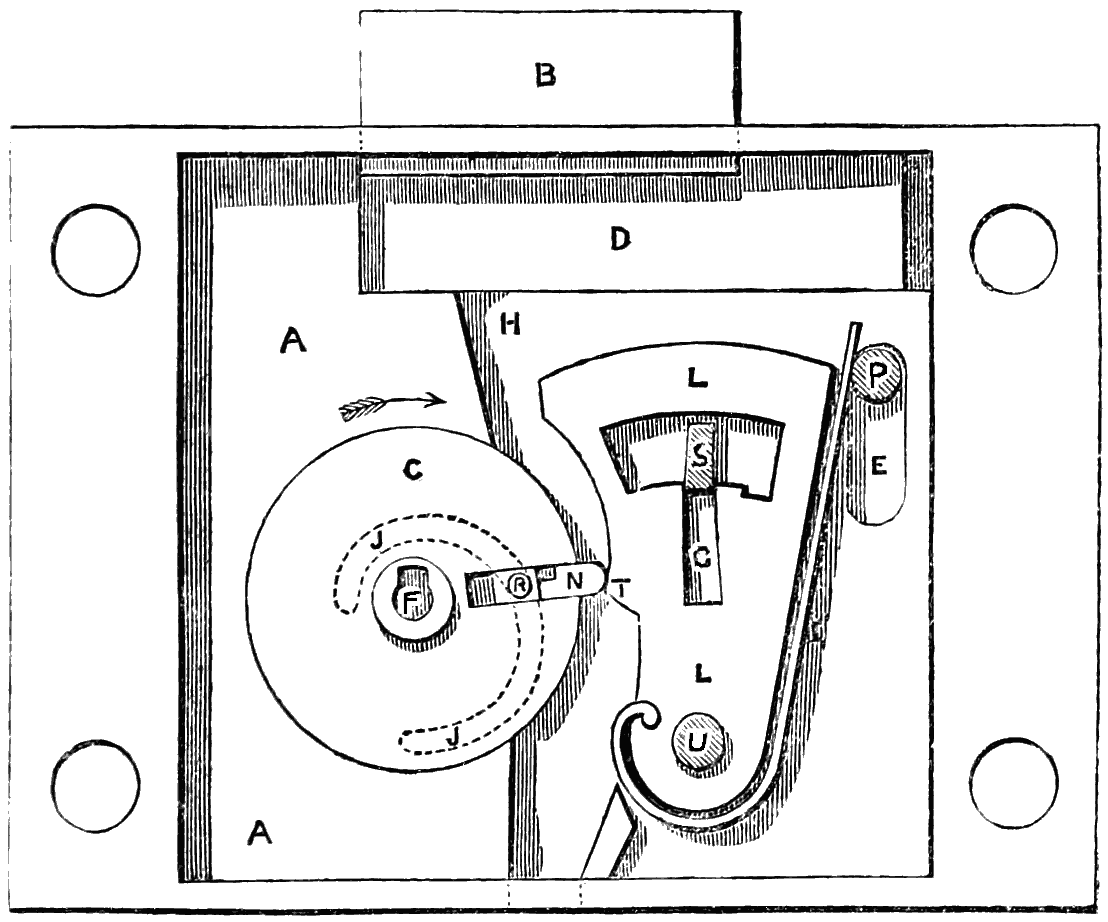

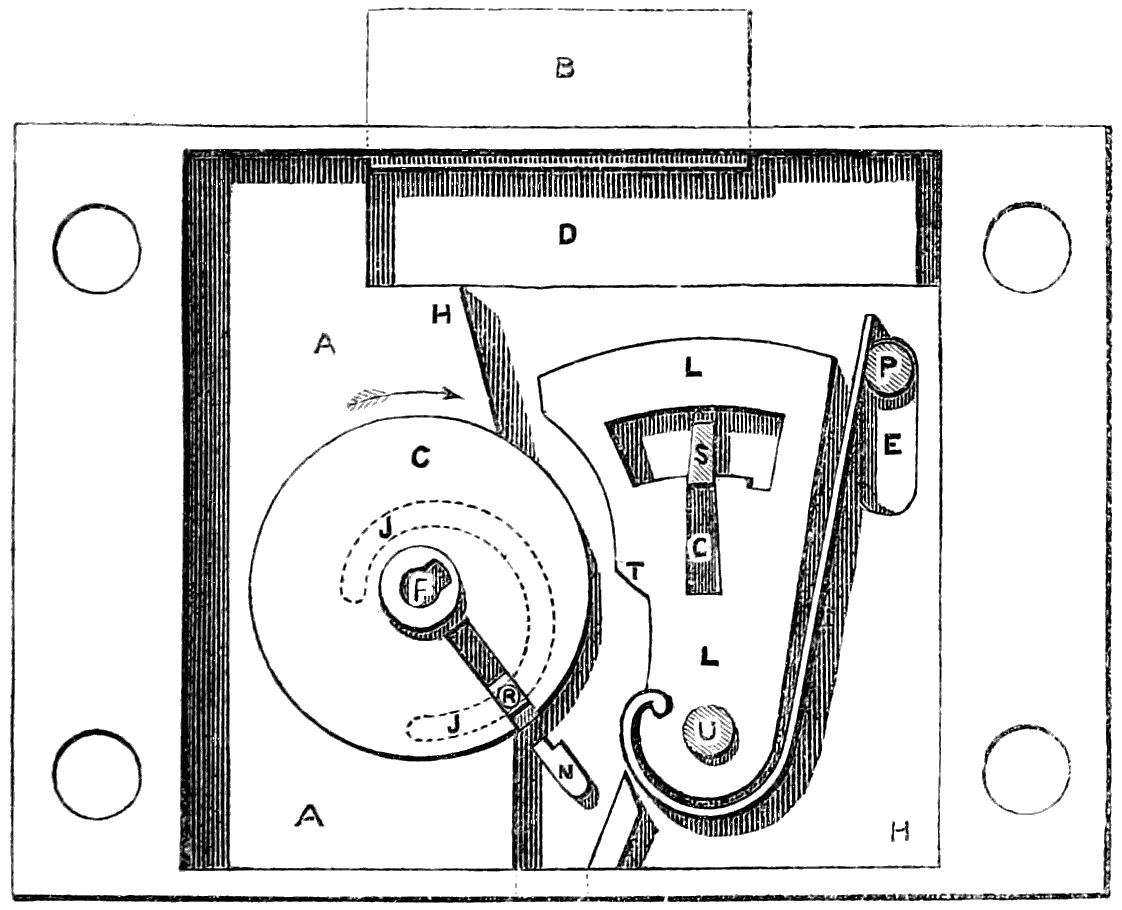

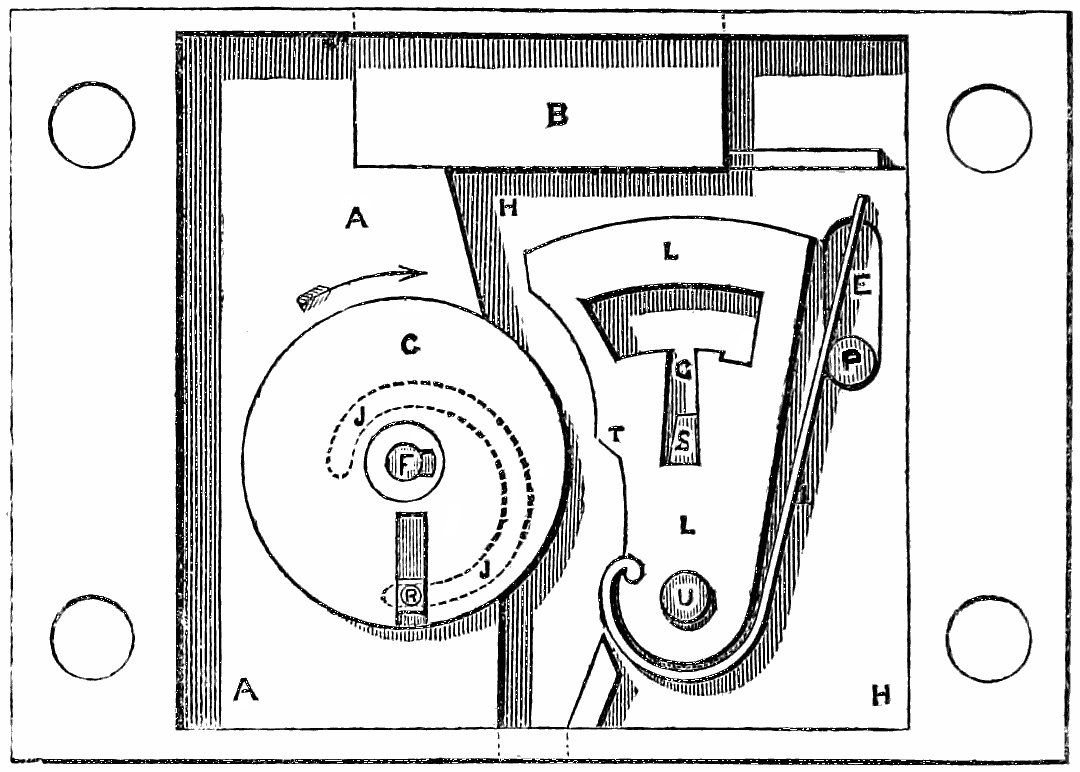

The construction of this remarkable Egyptian or pin-lock will be understood from the accompanying engravings. The quadrangular portion, a a fig. 1, is the case of the lock, screwed or otherwise fastened to the door, having a wooden bolt, b b, passing horizontally through a cavity in it. In the part of the case above the bolt are several small cells containing headed pins, arranged in any desired form; and in the top of the bolt itself are an equal number of holes similarly arranged. The effect of this arrangement is such that, when brought into the right positions, the lower ends of the headed pins drop into the corresponding holes in the bolt, thereby fastening the bolt in the lock-case. A large hollow, or cavity, is made at the exposed end of the bolt, the cavity extending as far as and beyond the holes occupied by the pins. The key consists of a piece of wood (shewn in two positions, figs. 3 and 4,) having pins arranged like those in the lock, and projecting upwards just to a sufficient distance to reach the upper surface of the bolt. This being the arrangement, whenever the key is introduced and pressed upwards, its pins exactly fill the holes in the bolt, and by so doing dislodge those which had fallen[16] from the upper part of the case. The bolt may, under these circumstances, be withdrawn (as shewn in fig. 2), leaving the headed pins elevated in their cells, instead of occupying the position shewn by the dotted lines in fig. 1. The cavity in the bolt must of course be high enough to receive the thickness of the key, and also the length of the pins protruding from the key.

This primitive lock comprises many of the best features of the tumbler or lever-locks of later days, as will be seen in a future chapter. There will also be opportunities of shewing how the pin-action has been applied in other ways in some of the modern locks.

In approaching the subject of modern locks it becomes necessary to decide upon some method of treating the widely-scattered and diverse materials which are presented to our notice. One plan would be to trace the subject chronologically, by describing, in the order of their invention, the most important locks which have been presented to public notice. But this would be attended with some disadvantages: the peculiar characters of the several locks would not be brought out with sufficient distinctness; and the result, so far as the reader is concerned, would rather tend to confusion than to a clear appreciation of the subject. There are more advantages belonging to a classification of locks under certain headings, according to some marked peculiarities in their modes of action. This is a convenient plan, but it is not an easy one to put in execution; for inventors have not sought to place their locks in any particular class, but rather to call attention to their merits. Moreover,[17] many locks embody two or three distinct principles so equally, that it will often be difficult to decide in which class to place them. This, nevertheless, may be done with an approach to correctness. It is necessary first, however, to explain certain technical terms by which locks are distinguished one from another.

Locks, in truth, admit of an immense variety, which, however important to be known to locksmiths, carpenters, and others employed on them, need only be glanced at very cursorily by the general reader. Some locks are named according to the purposes to which they are to be applied; others according to their shape, or the principles of their construction. In the first place, there is the distinction between in-door and out-door locks. Of in-door locks, one principal kind is the draw-back lock, for street-doors, in which the bolt is capable of maintaining any one of three positions: it may be locked by the key, or left half-way out by the pressure of a spring, or be drawn back by a handle. In the first position, it can only be withdrawn by the key; in the second, it closes the door, but can easily be withdrawn by the handle; and in the third, it leaves the door unfastened. If these locks are made of iron and carefully finished, they are further called iron-rim; but if made of wood, suitable for back-doors and inferior purposes, they are spring-stock. For the doors of rooms, there are the iron-rim, the brass-case, and the mortise lock; the second supplants the first, and the third the second, as we advance in the elegance of the door-fittings. Other designations for room-locks depend on the number of the bolts: thus, if there be only one bolt, it is a dead lock or closet lock; if there be a second bolt, urged by a spring and drawn back by a handle, it is a two-bolt lock; and if there be also a third, a private bolt acting only on one side of the door, it is a three-bolt lock. Again, according to the kind of handle employed, it may be a knob lock or a ring lock. According to which edge of the door it is to be fixed, it becomes a right-hand or a left-hand lock. If the wards of the lock are of somewhat superior quality, and[18] bend round nearly to a circle, the lock is one-ward round, two-ward round, and so forth. If the lock has no wards at all, it is plain; if the wards are of common character, they are often called wheels, and then the lock becomes one-wheel, two-wheel, &c. Sometimes the lock is named from certain fancied resemblances in the shape of the ward, as the L-ward, T-ward, or Z-ward. If the wards are cast in brass, instead of being made of slips of iron or copper, the lock is termed solid ward.

Of the numerous but smaller varieties known by the collective name of cabinet locks, there are the cupboard, the bookcase, the desk, the portable desk, the table, the drawer, the box, the caddy, the chest, the carpet-bag, and many other locks. All these locks are further called straight, when the plate is to be screwed flat against the wood-work; cut, when the wood is to be so cut away as to let in the lock flush with the surface; and mortise, when a cavity is excavated in the edge of the door for the reception of the lock.

Out-door locks are usually wooden stock locks, for stables, gates, &c.; comprising many varieties of Banbury, bastard, fine, &c. There are D locks and P locks, for gates, designated from their shapes; and there are the numerous kinds of padlocks.

The above terms are employed chiefly between the makers of the locks and the persons who fix them in their places; but there are other terms and names, more familiarly known, which will come under notice in future pages.

It is scarcely worth while to descant upon the “middle age” of lock-making—to impart to the subject so much of dignity as to be susceptible of regular historical treatment. True, we know that wards were employed before tumblers (unless, indeed, the pins of the Egyptian lock be considered as tumblers—a character to which they present considerable claim), and that wards may be taken as the representative of the medieval period of lock-making; but it may be more profitable to proceed in our notice of the different kinds of locks in an order which will in itself partake somewhat of the historical character.

[19]

Apart from all the warded and tumbler locks are the very curious puzzle or letter-locks; a construction which we propose to dismiss out of hand in the present chapter, before treating of those which have more commercial importance.

The puzzle-lock is generally in the form of a padlock, which is opened and closed without the use of a key, and which has certain difficulties thrown in the way of its being opened by any one who is not in the secret of the person who closed it. It is, in fact, one of the locks in which the doctrine of permutation is made to contribute to the means of security. The key to open it is a mnemonic or mental one, instead of one of steel or iron. Two centuries ago, the puzzle-lock attracted far more attention than any other. It has always certain movable parts, the movement of which constitutes the enigma. Some of these very curious and out-of-the-way locks are so formed as to receive the name of dial-locks; but the chief among them are ring-locks—a name the meaning of which will be presently understood.

The puzzle or letter-lock of the ring kind, then, consists essentially of a spindle; a barrel, encompassing the spindle; two end-pieces, to keep the spindle and barrel in their places; and the shackle, hinged to one of these end-pieces. To unfasten the lock, one of the end-pieces must be drawn out a little, to allow the shackle or horse-shoe to be turned on its hinge; and the question arises, therefore, how this end-piece is to be acted upon. This is effected in a very ingenious way: there are four studs or projections in a row on the spindle, and as the spindle fits pretty closely in the barrel, the former cannot be drawn out of the latter unless there be a groove in the interior of the barrel, as a counterpart to the studs on the exterior of the spindle; four rings fit on the barrel, on the interior of each of which there is a groove; and unless all these four grooves coincide in direction, and even lie in the same plane as the groove in the barrel, the studs will not be able to pass, and the spindle cannot be drawn out. Each ring may be easily made to work round the barrel by means of the[20] fingers, and to maintain any position which may be given to it. There are outer rings, one over each of the rings just described, with the letters of the alphabet (or a considerable number of them) inscribed on each; and these outer rings, by means of notches on the inside, govern the movements of the inner rings.

The action is, therefore, as follows: when the padlock is to be locked, the rings are so adjusted that all the grooves shall be in a right line; the spindle is thrust in, the end-piece is fixed on, and the shackle is shut down. The padlock is now fastened; but a reverse order of proceeding would as easily open it again, and therefore the “safety” or “puzzle” principle is brought into requisition. The outer rings are moved with the finger, so as to throw the various interior grooves out of a right line, and thus prevent the withdrawal of the spindle. As each ring may be turned round through a large or a small arc, and all turned in different degrees, the variations of relative position may be almost infinite. The letters on the outer rings are to assist the owner to remember the particular combination which he had adopted in the act of locking; for no other combination than this will suffice to open the lock. There may, for instance, be the four letters L O C K in a line, which line is brought to coincide with two notches or marks at the ends of the apparatus; and until all the four outer rings are again brought into such relative position as to place the letters in a line, the lock cannot be opened.

There are many allusions to locks, apparently belonging to the letter or puzzle principle, in authors who flourished two or three centuries ago. Thus, in Beaumont and Fletcher’s play of the Noble Gentleman, written in the early part of the seventeenth century, one of the characters speaks of

And in some verses by Carew, written about the same time, there is an analogy drawn, in which one of the things compared is—

[21]

In the Memorabilia of Vanhagen von Ense, written about the middle of the seventeenth century, a commendatory notice is given of a letter-lock, or combination-lock, invented by M. Regnier, Director of the Musée d’Artillerie at Paris. “Regnier,” we are told, “was a man of some invention, and had taken out a patent for a sort of lock, which made some noise at the time. Every body praised his invention, and bought his locks. These consisted of broad steel rings, four, five, or eight deep, upon each of which the alphabet was engraved; these turned round on a cylinder of steel, and only separated when the letters forming a particular word were in a straight line with one another. The word was selected from among a thousand, and the choice was the secret of the purchaser. Any one not knowing the word might turn the ring round for years without succeeding in finding the right one. The workmanship was excellent, and Regnier was prouder of this than of the invention itself. The latter point might be contested. I had a vague recollection of having seen something of the sort before; but when I ventured to say so, my suspicions were treated with scorn and indignation, and I was not able to prove my assertion; but many years afterwards, when a book, which as a boy I had often diligently read, fell into my hands, Regnier’s lock was suddenly displayed. The book was called Silvestri a Petrasancta Symbola Heroica, printed at Amsterdam in 1682. There was an explanation at p. 254, attached to a picture; these were the words:—Honorius de Bellis, serulæ innexæ orbibus volubilibus ac literatis circumscripsit hoc lemma—Sorte aut labore.[3] However, neither luck nor labour would have done much more towards discovering the secret of opening Regnier’s locks, from the variety of their combinations; and their security seemed so great, that[22] the couriers’ despatch-boxes were generally fastened with them.”

[3] “Honorius de Bellis wrote this inscription,—By chance or by labour,—round a lock composed of revolving rings graven with letters.”

This curious extract, which was brought forward by Mr. Chubb, in a paper on locks and keys (read before the Institution of Civil Engineers in 1850), seems to take away the credit from one (Regnier) with whose name the letter-lock has been most intimately associated. We shall presently explain, however, what it was that Regnier effected towards perfecting the letter-lock. In the meantime it may be interesting to note that the British Museum contains a copy of the work mentioned by Vanhagen. At the page indicated there is an engraving (a fac-simile of which is given in fig. 5) containing a drawing of a veritable puzzle or letter-lock; the lock consists of a cylinder or barrel, on which seven rings work; each of these rings is inscribed with letters, and the ends of the cylinder are grasped by a kind of shackle.

fig. 5. Puzzle-lock of the seventeenth century.

It was a natural result of the arrangement of the letter-lock, as invented (conjecturally) by Cardan, that only one particular word or cipher or key could be used in each lock; and it was to increase the puzzle-power of the lock that Regnier[23] doubled all the rings, making each pair concentric, and enabling the user to vary the cipher at pleasure.

The principle of the letter-lock, when applied to doors, requires that sort of modification which renders it what is termed a dial-lock. There are to such a lock one or more dials, with a series of letters or figures stamped on them; there is to each dial a hand or pointer connected by a spindle with a wheel inside the lock; on the wheel is a notch which has to be brought to a certain position before the bolt can be moved. There are false notches, to add to the difficulty of finding the true notch in each wheel. To adjust the notches to their proper position, a nut on the back of the wheel is loosened, and the pointer is set at any letter or figure chosen by the user. The pointers and the dials perform the part of the outer rings, the wheels that of the inner rings; and it is easy to see that the same leading features prevail in the two kinds of lock, however they may differ in detail.

These dial-locks have not been numerous; they require wheel and pinion work within the body of the lock, which gives delicacy and complication to the mechanism. The letter padlock, be its merits great or small, is strong and durable, not liable to get out of order; and in so far as it requires no key or key-hole, it occupies rather a special position among locks. One of our great “merchant-princes” has been a letter-lock inventor, as the following will shew.

Early in 1852, Mr. William Brown, the distinguished member for South Lancashire, read a paper before the Architectural and Archæological Society of Liverpool, of much interest in relation to our present subject. His object was to describe a letter-lock which he had invented, and which had up to that time given high satisfaction. We cannot do better than transcribe the paper, as reported in one of the Liverpool Journals, with a few abridgments.

“As your society are desirous of seeing any improvements or attempts at them, I send you a stock-lock for inspection. The idea for its construction I took from a letter-padlock.[24] I had a lock of this description made by Mr. Pooley twenty-five years ago, which has been in use ever since on Brown, Shipley, and Co.’s safe....

“Its advantages I conceive to be—First, it cannot be picked, for there is no key-hole. Second, it cannot be blown up by gunpowder, for the same reason. Third, you cannot drill through the door so as to reach the lock, for you are intercepted by a steel plate on which your tools will not act: thus you cannot introduce gunpowder that way to force the lock off. Fourth, you cannot bounce off the wheels in the interior with a muffled hammer, for vulcanised India-rubber springs resist this. Fifth, you cannot drill the spindles out, as their heads are case-hardened. Sixth, you cannot drive them in, for they are countersunk in the door about half-way through....

“Now let us set the lock to the word W O O D (any other four letters might be used). When you set the lock, make a private record of them, so that you may not forget them. If parties do not know your letters, nothing but violence, applied by some means or other, can enable them to get into your safe; for the lock will not open to any thing but its talisman. Take off all the large wheels and open the lock: you will see that the large wheels have a number of false chambers; if you get the spurs of the bolt into three real chambers and one false, you are as fast as ever, for all four must be right.

“Having placed your key and pointer outside the door to point to W on brass-plate No. 1, the small wheel inside obeys the same impulse; then maintain your small wheel steadily on this point, and the large wheel No. 1 will only fit on at the right place, the true opening compartment being opposite the spur of the bolt. It being necessary at the time you set your lock that it should be open, proceed with Nos. 2 and 3 in the same way, your pointer standing steadily at O. No. 4 is the same, the pointer being held steadily at D. You should then shoot your lock two or three times, to be sure you have[25] made no mistake. Every time you shoot your bolts out, turn your wheels away from the true chamber, and see when you again turn your pointers to W O O D that your lock opens freely; it is the proof that you have made no mistake, and you may now venture to lock your safe. When you unlock the door, and find it necessary to leave it open for a time, you should shoot the bolts as if locked, and turn the wheels, so that no one may find what your real letters are; and again adjust them to their proper places, in order that the bolt may go back and enable you to re-lock. Once having locked the door and turned the wheels from your real letters, you need not trouble yourself with carrying the key, but leave it in any place beside the lock.

“I believe two wheels would make a perfectly safe lock; three would be quite so. I adopted four to make security doubly sure, as it would be impossible in any given time to work the changes. On two wheels by chance the lock might open; you can, however, calculate the chances against this; and also three or four, the false compartment on the outer rim being taken into calculation. ***

“If this lock is of any value, it should be known; if it has weak points, let them be pointed out, and they may admit of a remedy; for we ought not to be led to believe a lock is safe which is not so.”

In relation to the “first advantage” which Mr. Brown not unreasonably supposed to be possessed by his lock—viz. that “it cannot be picked, because it has no keyhole”—we shall have something to say in a future page, where certain fallacies on this subject will be noticed. In the meantime we may remark, that it is not a little creditable that a leading Liverpool merchant should have invented a lock worthy of occupying a position on his own safe for a quarter of a century; for we may be quite certain that he would not have allowed the lock to maintain that post of honour unless it had really (so far as experience had then gone) served worthily as a safeguard to his treasures. And if it were possible to[26] collect all the by-gone specimens of lock-oddities, we should probably find among them many highly-ingenious letter-locks; for supposing a man to have a mechanical turn of mind, a lock is by no means an unworthy medium for displaying it; the pieces of metal are so small as to be easily manageable at a small work-bench in a small room. The fondness for this sort of employment evinced by the unfortunate Louis XVI. of France led to the common remark, “He is a capital locksmith, but a very bad king.”

In an amusing article in the Observer, during the progress of the “lock controversy,” was the following paragraph relating to combination-locks of the letter or puzzle kind: “The French, in their exposition of 1844, availing themselves of the permutation principle, produced some marvels in the art; but the principle has not been adopted in this country. The Charivari had an amusing quiz upon these locks when they first came out. It said the proprietor of such a lock must have an excellent memory: forget the letters, and you are clearly shut out from your own house. For instance, a gentleman gets to his door with his family, after a country excursion, at eleven o’clock at night, in the midst of a perfect deluge of rain. He hunts out his alphabetical key, and thrusts it into his alphabetical lock, and says A Z B X. The lock remains as firm as ever. ‘Plague take it!’ says the worthy citizen, as the blinding rain drives in his eyes. He then recollects that that was his combination for the previous day. He scratches his head to facilitate the movement of his intellectual faculties, and makes a random guess B C L O; but he has no better success. In addition to his being well wet, his chances of hitting on the right combinations and permutations are but small, seeing that the number is somewhere about three millions five hundred and fifty-three thousand five hundred and seventy-eight. Accordingly, when he comes to the three-hundredth he loses all patience, and begins to kick and batter the door; but a patrol of the National Guard passes by, and the disturber of the streets is marched off to the watch-house.”

[27]

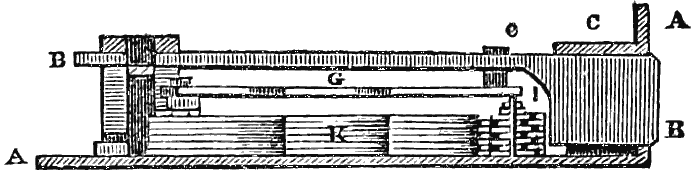

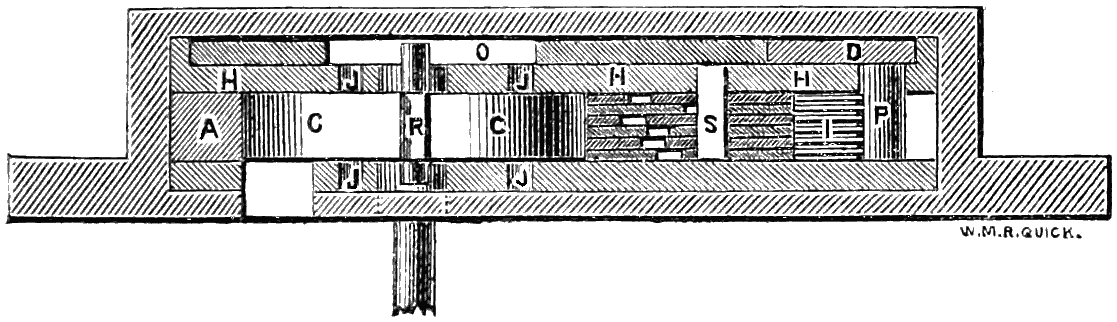

The more ordinary locks are of an oblong quadrangular shape. In nearly all of them, either a bolt shoots out from the lock, to catch into some kind of staple or box, or a staple enters a hole in the edge of the lock, and is there acted upon by the bolt. A common room-door lock will illustrate the first of these kinds, a tea-caddy lock the second. The key, as is well known, enters a receptacle made for it; and the shaft of the key generally serves as a pivot or axis around which the web or flat part of the key may move in a circular course. During this movement the web acts directly or indirectly on the bolt, driving it in or out according to the direction in which the key is turned; the key impels the bolt one way, certain springs act upon it in another, and the balance between these two forces determines the locking and unlocking of the bolt. Wards, or wheels, are contrivances for rendering the opening difficult without the proper key; and it is of warded locks that we shall chiefly treat in this chapter.

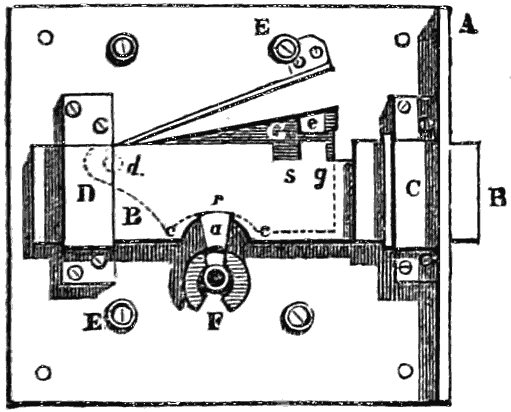

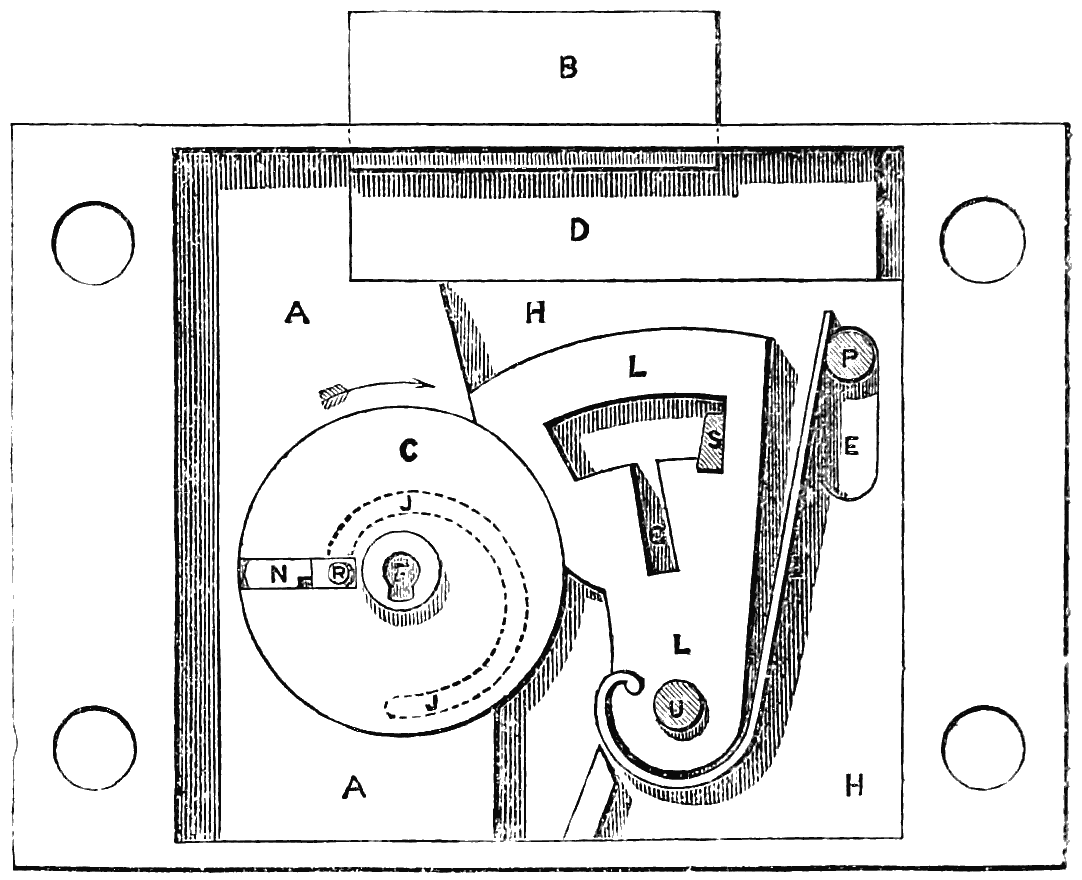

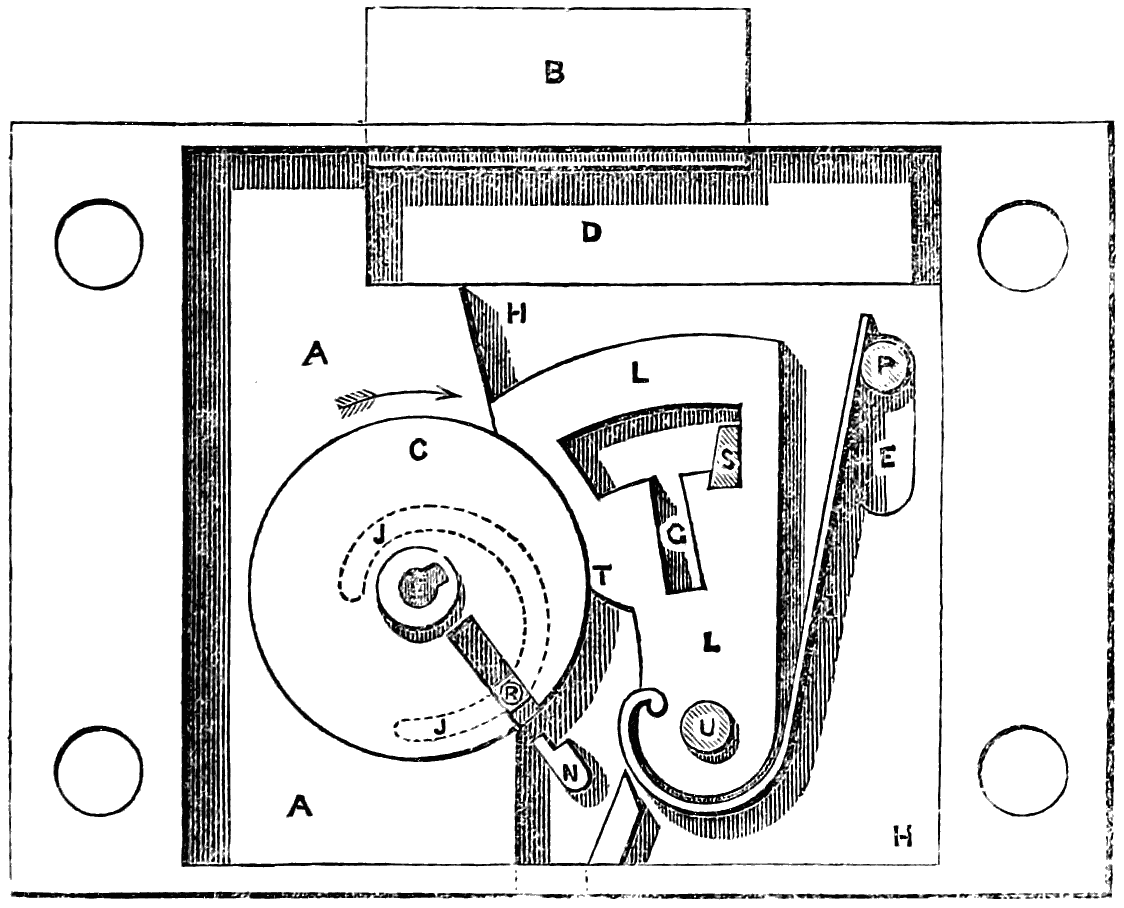

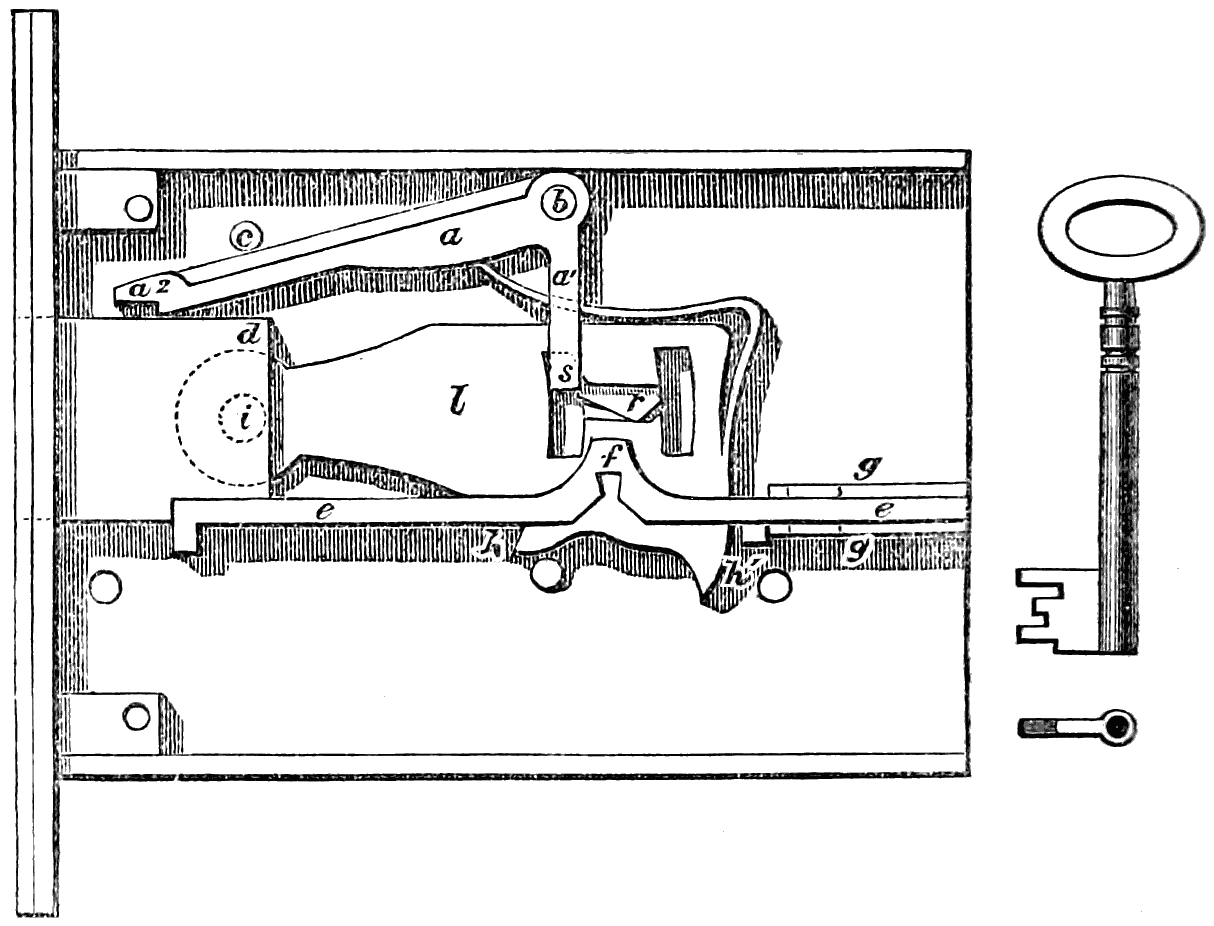

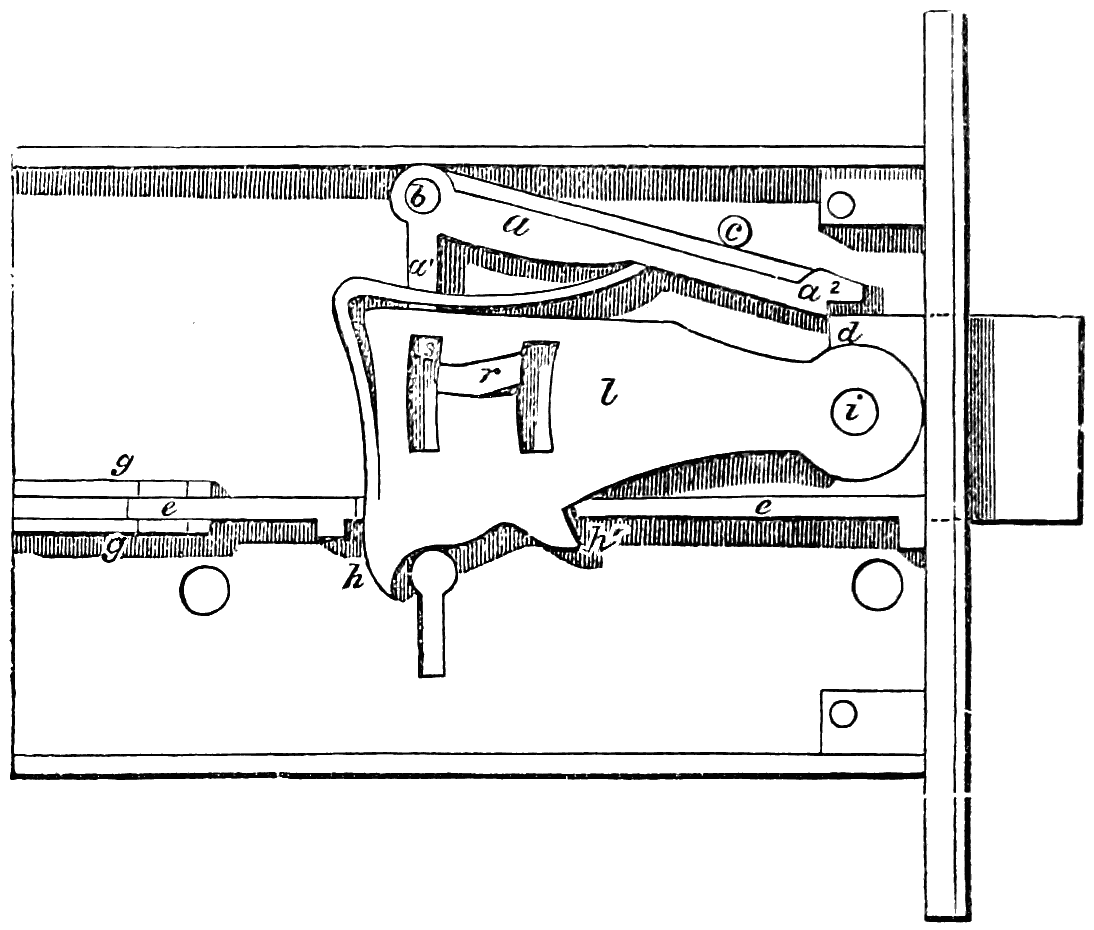

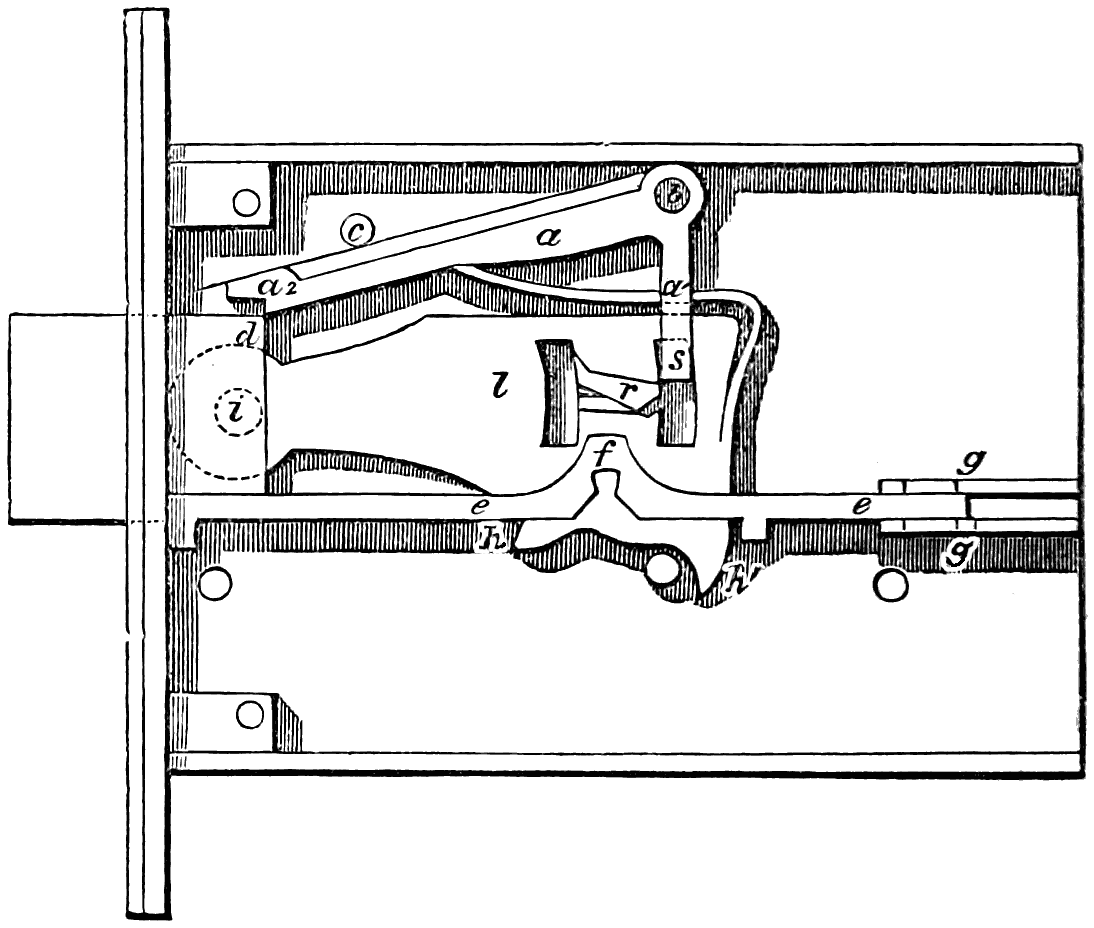

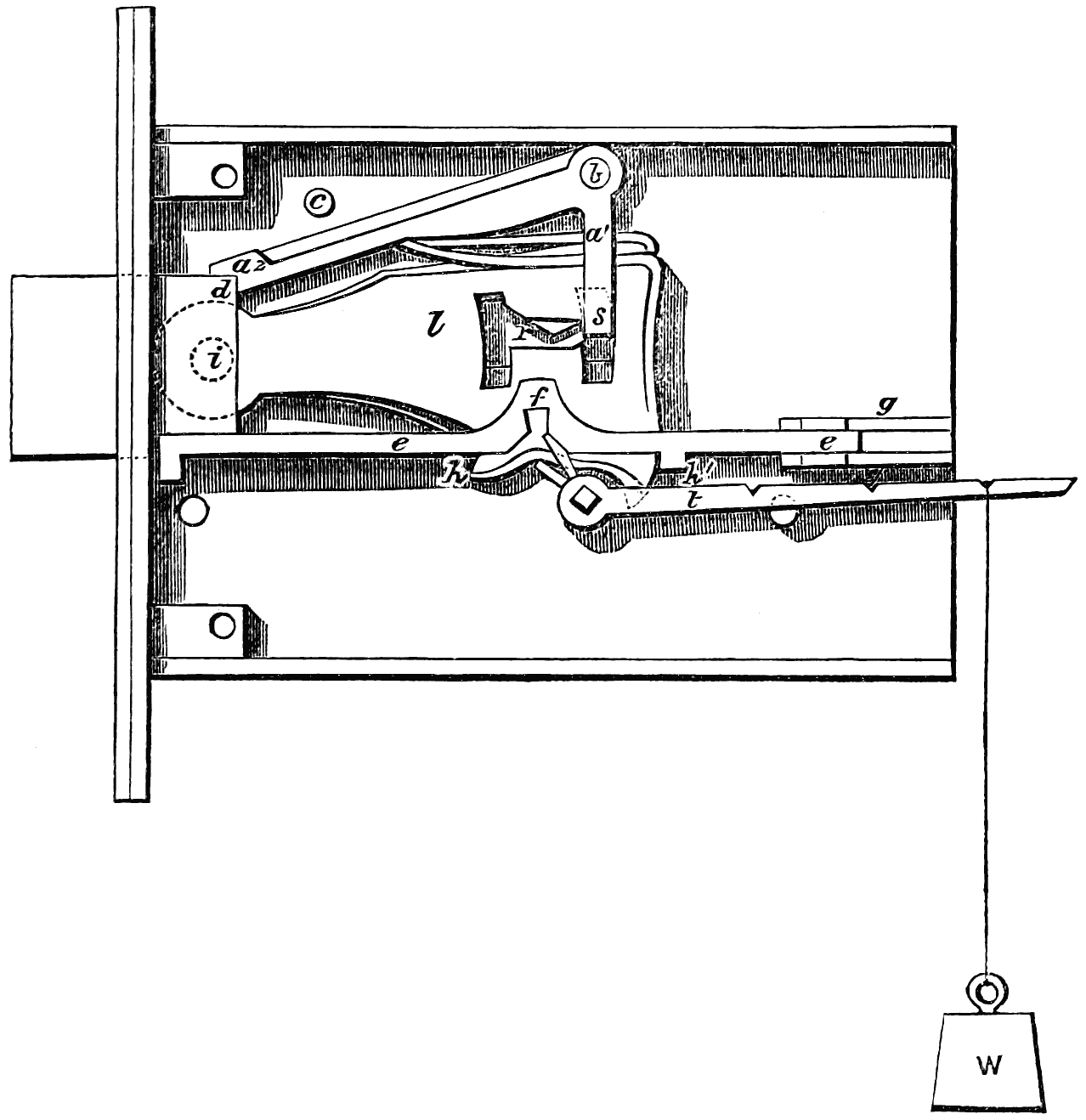

fig. 6. Interior of a back-spring warded lock.

The annexed cut, fig. 6, represents the interior of an ordinary back-spring lock, without tumblers. Such a lock may[28] usually be known from a tumbler-lock by this simple circumstance, that it emits a smart snapping noise during the process of locking, occasioned by the pressure of the spring when the bolt is in a particular position. In the woodcut the bolt is represented half out, or half shot. At a a are two notches on the under side of the bolt connected by a curved part; b is the back spring, which becomes compressed by the passage of the curve through a limited aperture in the rim c c of the lock. When the bolt is wholly withdrawn, one of the notches a rests upon the rim c c; and the force with which the notch falls into this position, urged by the spring b, gives rise to the snapping or clicking noise. When the bolt is wholly shot, the other notch rests in like manner upon the edge of the aperture in the rim.

It must be obvious at a glance, that this back-spring lock is objectionable on the score of security, on account of the facility with which the bolt may be forced back by any pressure applied to its end, a pressure which may often easily be brought to bear. At the centre of the lock is seen the end of the key acting on a notch in the bolt, and surrounded by wards.

fig. 7. Section to shew the action of wards.

It is not at a first glance that the relation between the clefts in a key and the wards of a lock can be duly appreciated; because the wards present themselves to view as portions of circles to which nothing in the key seems to correspond; but if it be borne in mind that the key has a rotary[29] motion within the key-hole around the pipe or barrel as an axis, the circular form of the wards will be accounted for, and their section will be regarded as exhibiting the looked-for relation to the wards of the key. In the annexed cut, for example (fig. 7), which represents a portion of the interior of a warded lock, the curved pieces of metal are the wards (two in this case); and there are two clefts in the bitt of the key to enable the latter to take its circular course without interruption from the wards. If the clefts were other than they are, either in number, position, or size, this freedom of the key’s movement could not be obtained.

fig. 8. End sections of keys.

When once the opinion became established that a lock is rendered secure by virtue of its wards, (a theory which we shall have to discuss in a later page,) much ingenuity was displayed in varying the wards of the lock, the clefts of the key, and the shape of the keyhole. Even if the two former were unchanged, a change in the latter might add to the puzzlement of the arrangement. For instance, in the annexed cut (fig. 8), all the six keys represented may have clefts or cuts exactly alike, all alike adapted to the wards of one particular lock; yet the differences in the thickness of the web are such, that if the keyholes were shaped in conformity therewith, each keyhole would be entered by one of these keys; b and c differing from a in the relative thickness at different points, and d, e, and f having certain curvatures and cavities not to be found in the other three.

fig. 9. Examples to shew the action of “master,” or “skeleton keys.”

But without waiting for the detailed examination of the relative security and insecurity of locks, we may at once shew how simple is the principle which renders the warded system[30] fallacious. In fig. 9 we shall be able to illustrate this. Numbers 1, 2, and 3, all appear very different keys, and it is quite true that neither one would open a lock adapted for either of the other two; and yet the very simple arrangement No. 4 would open all three. This No. 4 is called a skeleton-key; and the relation which it bears to the others may be expressed in the form of a proposition thus: at any point where there is solid metal in all the keys, there must (or may) be solid metal in the corresponding part of the skeleton-key; but at any point where there is a vacancy or cavity in any of the keys, there must be a cavity in the corresponding part of the skeleton-key. If Nos. 1, 2, 3, 4, be examined, this proposition will be found to be borne out; there is so much cavity in No. 4 that it avoids the wards in all the three locks, nothing being required but the tongue of metal to move the bolt. Sometimes, to add to the safety, wards are attached to the front as well as the back plate of the lock; and then there may be a double series of notches required in the key, such as in No. 5; but if this be compared with Nos. 9, 10, 11, it will be found that although no one of the four would open a lock[31] adapted for either of the other three, yet the skeleton-key No. 12 would master them all, having cavities wherever any of the others have cavities. This is the theory of the master-key, by which one key may be made to command many locks. Nos. 6 and 7 have complicated wards; but the key is so much cut up as to be weakened more than is desirable. No. 8 enables us to point out the difference between two distinct classes of keys. Keys with pipes or barrels fitting on a pin or pipe-shaft can only open a lock on one side of the door or box; but a key with a solid stem, as No. 8, has the clefts so cut as to open the lock from either side, as in a street-door lock: it is, in fact, two warded keys fixed end to end, only half of which is employed at one time in opening the lock.

fig. 10. Wards of an old French lock.

Some of the warded locks of the last century are curious. While the idea prevailed that a complicated ward gave security, there was room for the exercise of ingenuity in varying the shape of the wards. Fig. 10 is copied from the great French work. It represents the cuts in the key, and also (seen perspectively) the complicated forms of the pieces of metal which constitute the wards corresponding with those cuts. The aperture in the key at 16 fits upon the metal surrounding the keyhole at 18; and the M-shaped cuts at 17 fit in like manner upon the similarly-shaped metal pieces at 19.

Another example of a similar kind is shewn in fig. 11, where an anchor appears to have been the favourite form. The[32] anchor cuts in the key are shewn at 26; while in the wards the bottom of the anchor is near the keyhole at 28, and the top at 29.

fig. 11. Wards of an old French lock.

fig. 12. Wards of an old French lock.

A similar illustration occurs in fig. 12, where the star-like cuts at 34 on the key correspond with the star-like wards at 33.

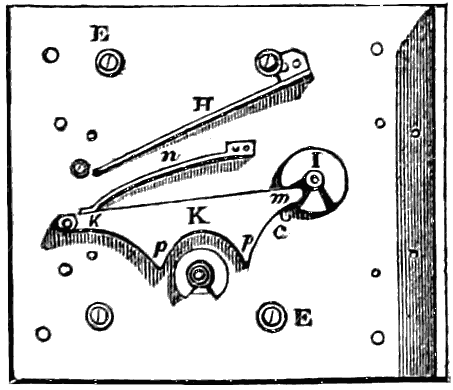

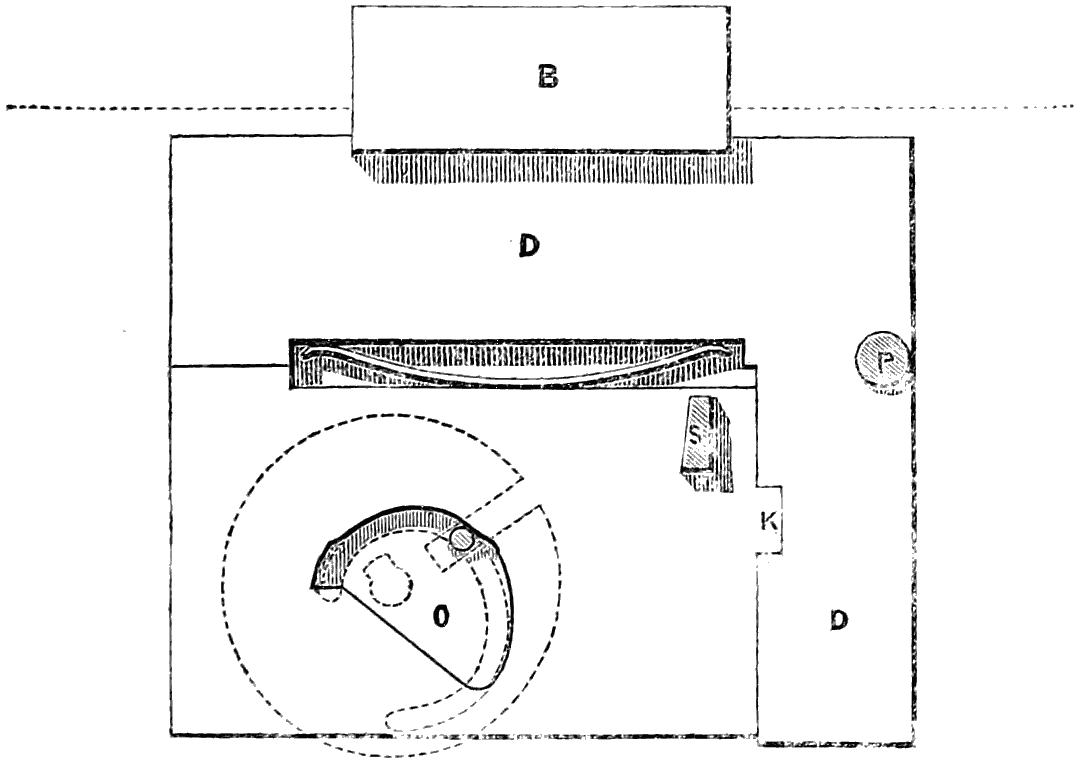

fig. 13. Exterior of an old secret lock.

fig. 14. The same, with a portion of the front let down, shewing the key-hole.

From the fifteenth to the eighteenth centuries locks were made in France, on which a vast amount of care and expense was bestowed. They were, in an especial degree, decorative appendages as well as fastenings. They were of three kinds: room-locks, buffet-locks, and chest-locks; they were fixed on the outside of the door or lid, so as to be fully visible. The key had a multitude of perforations which bore no particular relation to the wards of the lock, but which were regarded as tests of the workman’s skill. The honorary distinctions awarded to apprentices and aspirants in the art depended very much on the number and fine execution of these perforated keys. The locks, considered as fastenings, had slender merit; although usually throwing four bolts, they were not very secure. Fig. 13 represents the exterior of a lock made about the year 1730, by Bridou, a celebrated Parisian locksmith. It was a lock belonging to a coffer or strong[33] chest; all the works being sunk below the level of a carved architectural moulding or ornament. There is a secret opening near the part C, forming a portion of the ornamental design; it allows a bolt, shewn at D, fig. 14, acted on by the spring E, to be touched, by which a doorway opens upon the hinges at B B. A A are a sort of pilasters, which aid in forming a hold for the bolts. The little ornament at C is drawn down by the hand, opening the secret door and revealing the key-hole G. S S, O O, Z Z, are ornaments fastened on at b c d, fig. 14, by nuts and screws, intended to display the skill of the workman.[34] The lock itself, access to the keyhole of which is obtained within the secret door, has nothing very remarkable about it.

fig. 15. Examples of true and false keys.

Mr. Chubb, in his paper read before the Institute of Civil Engineers, illustrated the insecurity of the warded lock by the example of one which had actually been placed in the strong-room of a banking house, and which is represented in the annexed cut (fig. 15). The wards are here shewn, surrounding the central key-pin; and from the appearance of the key, shewn at a, it is evident that these wards must have been rather complex. But the uselessness of the wards was proved by the result. A burglar employed an instrument, shaped like that at b, having on one of its faces, or sides, a layer of wax and yellow soap; this instrument, being introduced through the keyhole and turned a little way round, brought the soft composition in contact with the ends of the wards, and these ends thus left their impress on the composition. A false key was then made, as at c, which, however clumsy it may appear, has a cavity, or vacuity, where there is a cavity in the true key; and by such a surreptitious instrument was the lock opened. Even so rude an instrument as d, by passing round the wards, might open such a lock.

We are somewhat anticipating the full consideration of this[35] subject; but it is desirable at once to explain how and why an improvement on the warded lock was sought for.

In connexion with the fanciful eighteenth-century locks, lately adverted to, we may remark, that no less a man than Louis XVI. was an amateur workman in this department of mechanical art—or at least in smith’s work, which in France is generally considered to include lock-making. Sir Archibald Alison says, in his History of Europe:—“He had an extraordinary fondness for athletic occupation and mechanical labour; insomuch that he frequently worked several hours a-day with a blacksmith of the name of Gamin, who taught him the art of wielding the hammer and managing the forge. He took the greatest interest in this occupation, and loaded his preceptor in the art with kindness; who returned it by betraying to the Convention a secret iron recess which they had together worked out in the walls of the cabinet in the Tuileries, wherein to deposit his secret papers during the storms of the Revolution.” There are not wanting indications that the unfortunate monarch wrought upon locks, as well as upon safes and strong-rooms.

Besides wards, there have been numerous other contrivances for adding to the security of locks—including screws, escutcheons, spiral springs, wheel-and-pinion work, alarums, and multiple bolts. As these are not of sufficient importance to be treated in separate chapters, we shall here give just so much notice of them as will illustrate their general character. Some of them are found combined with the “tumbler” principle, presently to be described; but all of them, it is now well known, were employed in various, ways when the tumbler lock was but little understood, and when the warded lock was held in esteem.

The Marquis of Worcester, whose curious Century of Inventions, written nearly two hundred years ago, contains so many suggestions which ingenuity has since developed into practical completeness, gives four of his inventions in the following words:—

[36]

69. “A way how a little triangle screwed key, not weighing a shilling, shall be capable and strong enough to bolt and unbolt, round about a great chest, an hundred bolts, through fifty staples, two in each, with a direct contrary motion; and as many more from both sides and ends; and, at the self-same time, shall fasten it to the place beyond a man’s natural strength to take it away; and in one and the same turn both locketh and openeth it.

70. “A key with a rose-turning pipe and two roses pierced through endwise the bit thereof, with several handsomely contrived wards, which may likewise do the same effects.

71. “A key, perfectly square, with a screw turning within it, and more conceited than any of the rest, and no heavier than the triangle screwed key, and doth the same effects.

72. “An escutcheon, to be placed before any of these locks, with these properties: First, the owner, though a woman, may with her delicate hand vary the ways of causing to open the lock ten millions of times beyond the knowledge of the smith that made it, or of me that invented it. Second, if a stranger open it, it setteth an alarum a-going, which the stranger cannot stop from running out; and besides, though none shall be within hearing, yet it catcheth his hand as a trap doth a fox; and though far from maiming him, yet it leaveth such a mark behind it as will discover him if suspected; the escutcheon or lock plainly shewing what money he hath taken out of the box to a farthing, and how many times opened since the owner had been at it.”

Mr. Partington, in his edition of the marquis’s singular work, makes a few comments on these lock-and-key contrivances. He says that the lock is evidently intended to operate on the principle of applying a screw for the purpose of moving the bolt, instead of using a key as a lever for this purpose. That such a plan might be applied to locks generally, he observes, there can be no doubt; and by a similar contrivance the large keys at present in use for outer doors, iron chests, &c. might be advantageously reduced by this means. By[37] employing the escutcheon mentioned by the marquis, much additional security would be obtained. It must be confessed, however, that many of the marquis’s statements are difficult to credit.

The escutcheon has been a favourite resource with lock-makers. Mr. Mordan’s escutcheon, for instance, introduced before the Society of Arts in 1830, is a contrivance to be placed temporarily over the keyhole of a door, to prevent the picking of the lock during the owner’s absence. The escutcheon, or “protector,” has a short pipe which, after the door has been locked, is thrust into the keyhole; attached to the pipe is a small lock, on Bramah’s or any other convenient principle, so contrived that, on turning its key, two lancet-shaped pieces fly out laterally and bury themselves in the wood. The escutcheon cannot be removed until the small key has reacted upon the small lock; and until this removal has taken place, the large key cannot reach the keyhole.

A curious application of the escutcheon principle attracted some attention among locksmiths about seventy years ago. One of the first premiums awarded by the Society of Arts, after the commencement of their “Transactions,” was to Mr. Marshall, for a “secret escutcheon,” in 1784. In his description of his new invention, he adverts to the marquis of Worcester’s wonderful escutcheon, and to the many attempts which have since been made to produce an apparatus which should realise the marquis’s description. He supposes that the letter padlock originated as one among many varieties of these imitative inventions; but this may be doubted. Mr. Marshall’s contrivance, however, was in effect an endeavour to improve upon the letter-lock. He considered it an objection that, in ordinary locks of this kind, the letter-rings admit of no variation of place; and he sought to remedy this defect. It is not so much a new lock, as an escutcheon for a lock, which he produced. There is a studded bar passing through a barrel; there are five rings which work concentrically on this barrel; there are letters on the outer surfaces of the rings,[38] and notches on the inner surface; but when, by the usual puzzle-action of the rings, the notches in them have been brought into a right line with the studs of the bar, the result is, not that the hasp of a padlock is raised, but that the escutcheon is removed from the keyhole of an ordinary lock. Mr. Marshall’s contrivance, therefore, is not so much a ring padlock, as a puzzle-ring security for the escutcheon of a fixed lock.

Some locks work by a screw and a spiral spring, instead of an ordinary key. Mr. W. Russell received a silver medal from the Society of Arts, about thirty years ago, for a new mode of locking the cocks of liquor-casks. Under ordinary circumstances, as is well known, the cock of a barrel or cask is in no way secure from the action of any one who can approach near enough to touch it; and different methods have been adopted of obtaining this security or secrecy. One plan is to employ a perforated cap, soft-soldered to the barrel of the cock, immediately over the grooved plug, the top of which plug is formed to the shape of the perforation, and a socket-key of the same form is introduced to turn the plug or open the lock. Another plan is to employ an iron saddle or staple, passing over the plug and below the bottom of the cock, through which a bolt is put, and a pendent padlock attached. The first method is very inefficient; the second is much superior, and has been largely adopted for locking the cocks of coppers, stills, vats, and other large vessels. But Mr. Russell thought some further improvement wanted. He caused a hole to be bored through the barrel, and to some depth into the plug when the latter is in the position for closing the cock. A stud works into this hole in such a way, that when the stud is driven home, the plug cannot be turned or the lock opened. The stud is attached at its other end to a spiral spring connected with a screw; a key is employed, the hollow pipe of which has an internal screw; and when this key is inserted in the cock-barrel and turned twice round, it draws back the stud, and allows the plug to be turned round in the proper way for opening the cock.

[39]