BOTH THE HOUSE FLY AND BLOWFLIES may be captured in traps. The character of the bait used and the location of the traps greatly influence the kind of flies caught. This bulletin tells how to make the flytraps that have been found most effective, where to put them, and how to bait and care for them.

Flytrapping, of course, affords only partial relief. The logical method of fly control is to prevent the multiplication of these pests by proper disposal of or treatment of their breeding places. The reader is therefore referred to Farmers' Bulletin 1408 for further information on house-fly control, to Farmers' Bulletin 1097 for various methods of combating the stable fly, and to Farmers' Bulletin 857 for additional measures to be used against the screw-worm fly and certain other blowflies injurious to livestock.

| Washington, D. C. | Issued June 10, 1916 Revised March, 1930 |

By F. C. Bishopp, Principal Entomologist in Charge,

Division of Insects Affecting Man and Animals, Bureau of Entomology

| Page | |

| Uses and limitations of flytraps | 1 |

| Kinds of flies caught | 1 |

| Types of traps | 2 |

| Trapping the screw-worm fly | 11 |

| Baits for traps | 11 |

| Bait containers | 13 |

| Care and location of traps | 14 |

| Sticky fly papers | 14 |

FLYTRAPS have a distinct place in the control of the house fly and other noxious fly species. There is a general tendency, however, for those engaged in combating flies to put too much dependence on the flytrap as a method of abating the nuisance. It should be borne in mind that flytrapping is only supplementary to other methods of control, most notable of which is the prevention of breeding either by completely disposing of breeding places or by treating the breeding material with chemicals.

It may be said that there are two main ways in which flytraps are valuable: (1) By catching flies which come to clean premises from other places which are insanitary and (2) by capturing those flies which invariably escape in greater or less numbers the other means of destruction which may be practiced. Furthermore, the number of flies caught in traps serves as an index of the effectiveness of campaigns against breeding places.

Flytrapping should begin early in the spring if it is to be of greatest value. Although comparatively few flies are caught in the early spring, their destruction means the prevention of the development of myriads of flies by midsummer.

The various species of flies which are commonly annoying about habitations or where foodstuffs are being prepared may be divided roughly into two classes: (1) Those which breed in animal matter, consisting mainly of the so called blowflies, including the screw-worm fly;[1] and (2) those which breed in vegetable as well as in animal matter. In the latter group the house fly[2] is by far the most important. The stable fly is strictly a vegetable breeder, as are also certain other species which occasionally come into houses and in rare cases may contaminate foodstuffs. The stable fly,[3] which breeds in [ 2 ] horse manure or decaying vegetable matter, and the horn fly,[4] which breeds in cow manure, are blood-sucking species, and can be caught in ordinary flytraps in comparatively small numbers only. The kind of flies caught depends to a considerable extent on the material used for bait. In general, the house fly and other species which breed in vegetable matter are attracted to vegetable substances, while the blowflies will come most readily to animal matter. This rule, of course, is not absolute, as flies are less restricted in feeding than in breeding habits, and, as is well known, the house fly is attracted to a greater or less extent to any moist material, especially if it has an odor.

[1] Cochliomyia macellaria Fab.

[2] Musca domestica L.

[3] Stomoxys calcitrans L.

[4] Haematobia irritans L.

The same general principle is involved in nearly all flytraps in use, though superficially they may appear quite different. The flies are attracted into a cage, as it were, by going through a passage the entrance of which is large and the exit small, so that there is little chance of the flies, once in, finding their way out again. This principle is modified to fit different conditions. For instance, the window trap, devised by C. F. Hodge, catches the flies as they endeavor to enter or leave a building; the garbage-can trap, for which Professor Hodge is also to be credited, catches the flies that have entered garbage cans; and the manure-box trap retains the flies bred from infested manure put into the box or pit.

The attractant used to induce flies to enter traps may consist of (1) food, as in baited traps; (2) odors, as in window traps placed in windows from which odors are emitted; and (3) light, as in traps on manure boxes. Of course, light is an important factor in the success of all traps, for, as is well known, flies have a marked tendency to go toward the light, and they usually enter the trap by flying toward the light after having been attracted beneath it by bait or after entering a room in search of food.

A number of traps of this general type are on the market, but most of these are of small size. Nearly all are constructed with a dome instead of a cone, and on this account the catching power is reduced about one-third. Moreover, the farmer, dairyman, or anyone with a few tools can construct traps at a small fraction of the sale price of ready-made ones.

There are now being made by certain firms in the Southwest traps of the dimensions and with the desirable features discussed in the following pages. These traps are all metal and some are built so that they can be taken apart for shipment.

A trap which appears from extensive tests made by E. W. Laake and the writer to be best for effective trapping, durability, ease of construction and repair, and cheapness may be made as follows:

The trap consists essentially of a screen cylinder with a frame made of barrel hoops, in the bottom of which is inserted a screen cone. The height or the cylinder is 24 inches, the diameter 18 inches, and the cone is 22 inches high, and 18 inches in diameter at the base. Material necessary for this trap consists of four new or secondhand wooden barrel hoops, one barrel head, four laths, 10 feet of strips 1 to inches wide 1½ one-half inch thick (portions of old boxes will suffice), 61 linear inches of 12 or 14 mesh galvanized screening 24 inches wide for the sides of the trap and 41 inches of screening 26 inches wide for the cone and door, an ounce of carpet tacks, and two turn-buttons, which may be made of wood. The total cost of the material for this trap, if all is bought new at retail prices is about $1. In practically all cases, however, the barrel hoops, barrel head, lath, and strips can be obtained without expense. This would reduce the cost to that of the wire and tacks, which would be about 80 cents. If a larger number of traps are constructed at one time, the cost is considerably reduced.

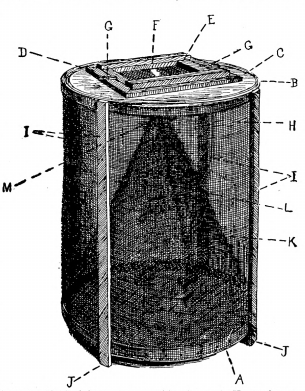

One of these traps is illustrated in Figures 1 and 2. In constructing the trap two of the hoops are bent in a circle (18 inches in diameter on the inside), and nailed together, the ends being trimmed to give a close fit. These form the bottom of the frame (A), and the other two, prepared in a similar way, the top (B). The top (C) of the trap is made of an ordinary barrel head with the bevel edge sawed off sufficiently to cause the head to fit closely in the hoops and allow secure nailing. A square, 10 inches on the side, is cut out of the center of the top to form a door. The portions of the top (barrel head) are held together by inch strips (D) placed around the opening one-half inch from the edge to form a jamb for the door. The door consists of a narrow frame (E) covered with screen (F) well fitted to the trap and held in place (not hinged) by buttons (G). [ 4 ] The top is then nailed in the upper hoops and the sides (H) formed by closely tacking screen wire on the outside of the hoops. Four laths (I) (or light strips) are nailed to the hoops on the outside of the trap to act as supports between the hoops, and the ends are allowed to project 1 inch at the bottom to form legs (J). The legs are made to project inches when the traps are to be used with bait pans 4 inches deep in trapping screw-worm flies. The cone (K) is cut from the screen and either sewed with fine wire or soldered where the edges meet at (L), or a narrow lath may be nailed along these edges. The apex of the cone is then cut off to give an aperture (M) 1 inch in diameter. It is then inserted in the trap and closely tacked to the hoop around the base.

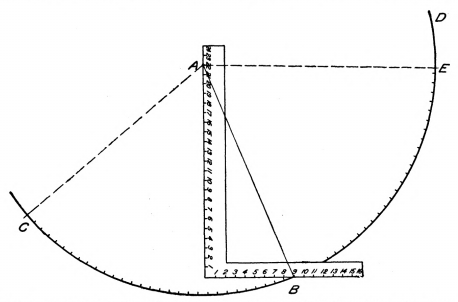

The construction of a cone of any given height or diameter is quite simple if the following method be observed. It is best to cut a pattern from a large piece of heavy paper, cardboard, or tin. Figure 3 illustrates the method of laying out a cone of the proper dimensions for the above trap. An ordinary square is placed on the material from which the pattern is to be cut; a distance (22 inches) equal to the height of the cone is laid off on one leg of the square at A, and a distance (9 inches) equal to one-half of the diameter of the base of the cone is laid off on the other leg at B, and a line is drawn between the points A and B. With the distance [ 5 ] between these points as a radius and with the point A as a center, the portion of a circle, CD, is drawn. With a pair of dividers, the legs of which are set 1 inch apart, or with the square, lay off as many inches on the arc CD, starting at C, as there are inches around the base of the cone, which in this case is about 56½ inches, reaching nearly to the point E. Then add one-half inch for the lapping of the edges of the cone, and one-half inch which is taken up when the cone is tacked in, thus making a total distance from C to E of 57½ inches. Draw a line from A to C and another from A to E, and cut out the pattern on these lines and on the arc from C to E, as shown in Figure 3. The edges AC and AE are then brought together, lapped one-half inch, and sewed with wire or soldered. After the aperture of the cone is formed by cutting off the apex, as previously described, it is ready for insertion in the trap.

In order to figure the distance around the base of a cone of any given diameter, multiply the diameter by 3.1416 or 31⁄7.

The height of the legs of the trap, the height of the cone, and the size of the aperture in the top of the cone, each is of importance in securing the greatest efficiency.

A modification of the previously described trap has been made by D. C. Parman of the Bureau of Entomology. The principal point of advantage in this type is that it can be made more quickly and with fewer tools. The principles and dimensions are the same, the most striking difference being the absence of a wooden top. A single hoop with the thick edge down forms the upper frame of the cylinder and the entire top is made of screen. A circular piece of screen with a diameter about 3 inches greater than the diameter [ 6 ] of the cylinder is cut; a hoop with a diameter equal to the inside of the top of the trap is then made of heavy wire and laid upon the disk of screen and the edges of the screen bent in over it. By folding in and crimping the edges of the wire over the wire hoop it will remain in position without difficulty and the edges of the screen disk are used to lift the top of the trap out for emptying flies. It is important to have the screen top fit the inside of the cylinder very snugly at all points. If there is any space left where flies can escape it is a good plan to bind the edge of the top with a strip of burlap. This not only helps to close the openings but keeps the hoop in place and aids in removing the top. Another difference is that the screen forming the sides of the cylinder is placed on the inside of the hoops and legs, the frame being built first and then the cylinder formed by tacking the wire on the inside of the hoops and nailing in along the upright strips and against the wire short pieces of laths with their upper ends against the lower edge of the hoop forming the top of the trap and extending downward along the legs about two-thirds of their length. These strips hold the wire in place and give rigidity to the trap, and they are thick enough to project beyond the inner surface of the hoop and form a support upon which the edges of the screen top rest.

Conical traps with galvanized-iron frames are satisfactory, but they are less easily rescreened. These, of course, can be constructed only by shops with considerable equipment. Traps constructed with a wooden disk about the base of the cone, and a similar disk around the top to serve as a frame, or those with a square wooden frame at the bottom and top, with strips up the corners, are fairly satisfactory. It should be borne in mind, however, that the factor which determines the number of flies caught is the diameter of the base of the cone, if other things are equal. Therefore, the space taken up by the wooden framework is largely wasted, and if it is too wide it will have a deterrent effect on the flies which come toward the bait. For this reason it is advisable that the wood around the base of the cone should be as narrow as consistent with strength—usually about 3 inches.

Under no condition should the sides or top of the trap be of solid material, as the elimination of light from the top or sides has been found to decrease the catch from 50 to 75 per cent.

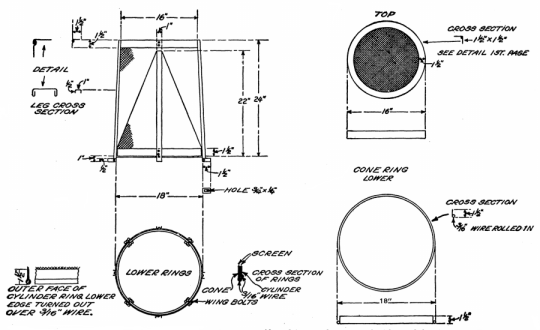

Where large numbers of traps are to be constructed, and especially if they are to be used for trapping screw-worm flies on the range, it is desirable to make them with metal rather than wooden frames. Traps with galvanized-iron frames are now being used extensively on ranches in central and western Texas in combating the screw-worm fly. Mechanics may wish to vary details of construction from those given in the specifications, but the dimensions and general features of the trap should not be altered. The cost of the metal-framed traps varies from about $3.50 to $5 each according to the number ordered, the workmanship, and the kind of materials used. For the guidance of those who desire such traps the following directions, together with a working drawing (fig. 4), are given:

Dimensions—As per working drawing.

Wire—14-mesh galvanized or preferably copper screen wire.

Cylinder—Wire gauze, to be soldered completely around inside of top ring and at intervals of 2 inches or less in groove of bottom ring. Vertical seam to be soldered entire and placed behind one leg. Where shipment of traps is not contemplated the diameter of the top of the cylinder may be the same as that of the bottom.

Top—Wire gauze to be soldered completely around periphery on inside of top ring.

Cone—Wire gauze to be soldered completely around inside of cone ring and vertically along seam. A 1-inch inlet hole shall be formed at apex of cone.

Frame—To be made of 24-gauge galvanized iron. This includes top and bottom rings and legs.

Legs—Galvanized-iron channels made as per detailed drawing and secured to top and bottom rings with four rivets, 1⁄8 inch in diameter, to each leg. First turned and drilled as per drawing.

Bottom cylinder ring—J shaped, with bottom edge of cylinder dropped into J—crimped and soldered to secure. Ends of ring riveted to secure.

Cone ring—Galvanized-iron band with 3⁄16-inch round iron wire rolled into lower edge, as per cross-section drawing of "cone ring."

Wing nuts—Four copper wing bolts and nuts, as per drawing, to hold cone securely in place.

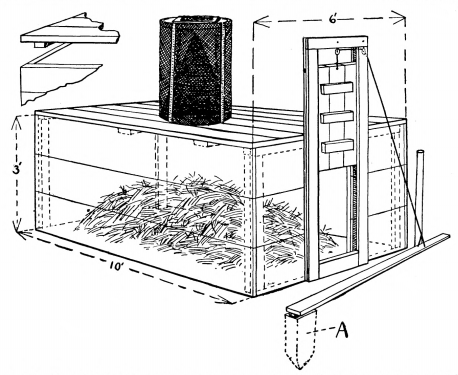

Manure pits or boxes are desirable for the temporary storage of manure, especially in towns and cities. These have been widely advocated, but the difficulty has been that manure often becomes infested before it is put into them, and flies frequently breed out before the boxes are emptied and often escape through the cracks. To obviate these difficulties a manure box or pit, with a modified tent trap or cone trap attached, is desirable. Arthur Swaim, of Florida, has devised a form of manure trap consisting of a series of screen tents with exit holes along the ridges of these, over which is a screen box. The latter retains the flies as they pass through the holes in the tents. The entire trap is removable.

In order to retain the fertilizing value of manure to the greatest extent, it is advisable to exclude the air from it as much as possible and to protect it from the leaching action of rains. This being the case, there is really no necessity to cover a large portion of the top of the box with a trap, but merely to have holes large enough to attract flies to the light and cover these holes with ordinary conical traps with the legs cut off so the bottom of the trap will fit closely to the box. The same arrangement can be made where manure is kept in a pit. In large bins two or more holes covered with traps should be provided for the escape of the flies.

Manure boxes should be used by all stock owners in towns and cities, and they are also adaptable to farms. The size of the manure bin should be governed by the individual needs, but for use on the farm it is desirable to make it large enough to hold all of the manure produced during the busiest season of the year. A box 14 feet long, 10 feet wide, and 4 feet deep will hold the manure produced by two horses during about five months. About 2 cubic feet of box space should be allowed for each horse per day. The bin should be made of concrete or heavy plank. When the latter is used the cracks should be battened to prevent the escape of flies. The bin should have a concrete floor or it may be set in the ground several inches and the dirt closely banked around the outside. For the admission of the manure a good-sized door should be provided in either end of a large bin. A portion of the top should be made easily removable for convenience in emptying the box, or one entire end of the box may be hinged. On account of the danger of the door being left open through carelessness it is advisable to arrange a lift door which can be opened by placing the foot on a treadle as the manure is shoveled in. The door should be heavy enough to close automatically when the treadle is released.

A concrete pit set on a slope so that the manure may be dumped in from a wheelbarrow is convenient for dairy farms. For large stock farms it may be desirable to have a concrete pit so constructed as to permit of the manure being taken directly into it with a litter carrier and doors provided which are large enough to admit a wagon or manure spreader for the removal of the material.

A manure bin with flytrap attached is shown in Figure 5.

Attention is directed to a maggot trap devised by R. H. Hutchison, as described in Farmers' Bulletin 851 of the Department of Agriculture. Where large quantities of manure are produced on a farm, this method of storing the manure on a platform and trapping the maggots which breed out may be more convenient than the manure bin.

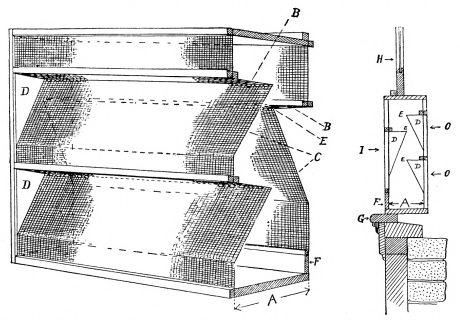

C. F. Hodge has designed a trap which is really a modified tent trap adapted to use in a window. This trap is constructed so as to catch the flies as they enter or leave through the window. It is adaptable to barns which are fairly free from cracks or other places where flies may enter. It may also be used on windows of buildings where foodstuffs are prepared and where flies endeavor to enter through the windows or escape after having gained entrance through other passageways. All openings not provided with traps should be closely screened, and on large buildings traps may be installed in every third window.

This trap is essentially a screen box closely fitted to the frame of a window. (See fig. 6.) The thickness of the box at A should be about 12 inches. Instead of the screen running straight down over the box on either side, it is folded inward nearly to the center of the frame in V-shaped folds running longitudinally across the window. One, two, or even more folds may be made in the screen on either side. The upper side of the fold B should extend toward the center almost at right angles with the side of the trap; that is, parallel with the top and bottom; and the lower side C should slant downward as shown in the drawing. The sides of the frame may be cut out at the proper angle and the pieces D returned after the screen has been tacked along the edges. Along the apex (inner edge) of each fold is punched a series of holes E about one-half inch in diameter and 1 inch apart. The apices of the folds on either side of the window should not be directly opposite. A narrow door F opening downward [ 11 ] on hinges should be made on one side of the trap at the bottom for removal of the dead flies. The entire trap is fastened to the window by hooks so that it may be readily taken off. An additional trapping feature may be added by providing a tent trap fitted in the bottom of the box. A narrow slit is left along the base to allow the flies to enter beneath the tent. Bait may be placed under the tent to attract the flies.

It has been found that the use of these window traps will aid in protecting animals in barns from stable flies and mosquitoes, and in some cases horseflies and other noxious species are caught. They tend to exclude the light, however, and are somewhat cumbersome, especially in thin-walled buildings.

[5] Cochliomyia macellaria Fab.

Recent efforts to reduce the loss to the livestock industry of the Southwest resulting from the ravages of the screw-worm have directed attention to the employment of flytraps in this work.

Mention has been made of the importance of preventing the breeding of flies as a prerequisite to effective control. This is equally true of the screw-worm and other blowflies, which attack animals, and of the house fly. In the case of these blowflies main dependence must be placed on the complete and prompt burning of all carcasses and animal refuse.

Experiments conducted in the range sections of Texas indicate that traps properly baited and set are of material aid in preventing screw-worm injury to livestock. If general trapping is undertaken, at least three or four traps should be maintained on each section of land. These should be located preferably near watering places and where cattle congregate, especially in the so-called hospital pastures or traps, where the screw-worm-infested animals are kept for treatment.

The conical-type traps as described are advised. The traps should be set in broken shade on a board platform about 2 feet square, securely fastened to a tree or on a post where the trap and bait will be the least disturbed by stock or wild animals.

During the latter half of one season over 100 gallons of flies, the vast majority of which were screw-worm flies, were captured in about 25 traps operated on a ranch in west Texas.

The question of the baits best adapted for this species and other points in regard to the operation of the traps are briefly discussed under subsequent headings.

The problem of selecting the best bait for flies is an important one. In choosing a bait it should be remembered that it is largely the fermentation which renders the material attractive, and that baits are most attractive during their most active period of fermentation. As has been indicated, the kind of bait used should be governed by the species of flies the destruction of which is desired. This is most often the house fly.

A mixture of 1 part of a cheap cane molasses (blackstrap or New Orleans) and 3 parts of water is one of the most economical and effective baits for the house fly. Sugar-beet or stock molasses, which is very cheap in regions where produced, when mixed in the foregoing proportions is fairly attractive. Sirup made by dissolving 1 part of ordinary brown sugar in 4 parts of water and allowing the mixture to stand a day or two to induce fermentation is almost equal to molasses and water as a fly bait. If it is desired to use the sirup immediately after making it, a small quantity of vinegar should be added. Honeybees are sometimes caught in large numbers with this bait. When this happens some of the other baits recommended should be used.

On dairy farms probably milk is next choice as a bait to cane-molasses solution, considering its convenience. The addition of ripe bananas or other fruit increases the attractiveness of the milk bait. The curd from milk, with one-half pound of brown sugar added for each pound, and water to make it thoroughly moist, is a very good bait and continues to be attractive for 10 days or longer if Kept moist. A mash consisting of one-half pound of bran, 1 quart of milk, 1 quart of water, 2 tablespoonfuls of brown sugar, and a yeast cake makes an attractive and lasting bait.

The foregoing baits are rendered more attractive by stirring occasionally.

With the baits before mentioned few blowflies will be caught. For use about slaughterhouses, butcher shops, and other places where blowflies are troublesome it has been determined that the mucous membranes which form the lining of the intestines of cattle or hogs are without equal as a bait. This material, which is commonly spoken of as "gut slime," can be obtained from packing houses where sausage casings are prepared. The offensive odor of this bait renders its use undesirable around habitations or materials intended for human consumption.

At the front of and at loading docks of meat-packing establishments, where house flies are troublesome and blowflies are usually not abundant, it is best to bait the traps with one of the house-fly baits listed above. Around meat markets, where both house flies and blowflies abound, one of the combination baits given on page 13 should be employed.

Where rabbits or other wild animals are plentiful they make a very satisfactory bait for use on the ranges; in fact, they are rather better than any other available bait. The animal should be opened up so as to expose the intestines; and when the weather is very dry it is best to keep some water in the pan, as it adds to the attractiveness of the bait. Entrails and other animal refuse may be utilized in a similar way when they are available. In large trapping operations goats or sheep culled from the flock are cut up for bait, from 1 to 2 pounds of meat being used in each bait pan.

The main objection to the use of these meat baits is that some maggots are likely to complete their growth and escape from the bait pans. This can be largely avoided by adding nicotine sulphate to the water in the bait pan in the proportion of one teaspoonful to each gallon of water. This does not check the decomposition enough to reduce the attractiveness of the bait and practically prohibits the escape of any maggots.

As a substitute for wild animals or animal refuse when they are not available, experiments show that fairly satisfactory catches can be secured by utilizing dried "gut slime" or dried whole egg. The former is not generally on the market but can be prepared by packing houses at a moderate cost. Both of these materials are easily carried on a saddle horse, and all that is necessary is to place about one-fourth pound in the bait pan and add 1 gallon of water, after which the mixture should be stirred. The more frequently any of these baits is agitated, the greater the catch which will be secured. If the bait is kept well moistened it will continue attractive for 10 days or longer. These baits should be kept alkaline by the addition, once or twice a week, of a teaspoonful of washing or baking soda.

With a number of the baits before mentioned both house flies and blowflies are captured. This is especially true with the "gut slime" and dried egg. Where both of these kinds of flies are abundant such baits are desirable. Certain other mixtures may also be utilized. A packing-house product known as blood tankage is a good fly bait when used before drying and with molasses and water. Fish scraps or meat scraps, especially with molasses and water added, will attract all kinds of flies. Overripe or fermenting fruit such as watermelon rinds or crushed bananas often gives very satisfactory results. A combination of overripe bananas with milk is much more attractive than either one used separately.

The size of the bait container in relation to the size of the trap is a very important consideration. It has been found that a small pan or a deep pan of bait set in the center under a trap will catch only a small fraction of the number of flies secured by using larger shallow containers. The best and most convenient pan for baits is a shallow circular tin, such as the cover of a lard bucket. Under range conditions it is advisable to use a more substantial bait pan and preferably one 4 inches deep, so that a greater quantity of bait may be used, thus preventing complete drying out between visits to the trap. Its diameter should be about 4 inches less than that of the base of the trap, thus bringing the edge within 2 inches of the outside edge of the trap. For liquid baits the catch can be increased slightly by placing a piece of sponge or a few chips in the center of the bait pan to provide additional surface upon which the flies may alight.

In many cases flytrapping has been rendered ineffectual by the fact that the traps were not properly placed or cared for. In setting traps a location should be chosen where flies naturally congregate. This is usually on the sunny side of a building out of the wind. In hot weather, however, traps should be placed so as to be in shade during midday. It is exceedingly important that the bait containers be kept well filled. This usually requires attention every other day. The bait pans should be washed out at rather frequent intervals. This gives a larger catch and avoids the danger of flies breeding in the material used for bait. Further, it should be borne in mind that traps can not be operated successfully throughout the season without emptying them. Where flies are abundant and the bait pans are properly attended to the traps should be emptied at weekly intervals. Where flies become piled high against the side of the cone, the catching power of the trap is considerably reduced. The destruction of the flies is best accomplished by immersing the trap in hot water or, still better, where a tight barrel is at hand place a few live coals in a pan on the ground, scatter two tablespoonfuls of sulphur over them, place the trap over the coals, and turn the barrel over the trap. All of the flies will be rendered motionless in about five minutes. They may then be killed by using hot water, throwing them into a fire, or burying them. In the operation of flytraps in controlling the screw-worm it has not been found necessary, especially during hot weather, to kill the flies, as they die very rapidly within the traps. In order to empty a trap it may be inverted and the dead flies shaken down. As the living flies will naturally go upward, the door may then be removed and the dead flies shaken out, the door replaced, and the trap set upright without loss of many of the living flies. The location of traps used against the screw-worm fly is briefly discussed on page 11.

Sticky fly papers are of some value in destroying flies which have gained access to houses, but they have marked limitations and numerous objectionable features. For use out of doors traps are much more effective and economical.

Doctor Crumbine, of the Kansas State Board of Health, gives the following method for preparing fly paper:

"Take 2 pounds of rosin and 1 pint of castor oil; heat together until it looks like molasses. Take an ordinary paintbrush and smear while hot on any kind of paper—an old newspaper is good—and place several about the room. A dozen of these may be made at a cost of 1 cent."

Transcriber Note

Minor typos have been corrected. Illustrations were moved to prevent splitting paragraphs. Produced from files generously made available by USDA through The Internet Archive. All resultant materials are placed in the Public Domain.