Transcriber’s Note: This ebook was created in honor of Distributed Proofreaders’ 20th Anniversary.

The symbol ‡ denotes an illustration description that is not part of the original work.

Pop-Corn, the Grain and its Handling

The Right Way to Handle the Batch

What to do with Corn that Does Not Pop

COMPILED BY

E. R. KNOTT

PUBLISHED BY

E. R. KNOTT MACHINE CO.

BOSTON, MASSACHUSETTS

Copyrighted, 1920

By E. R. KNOTT

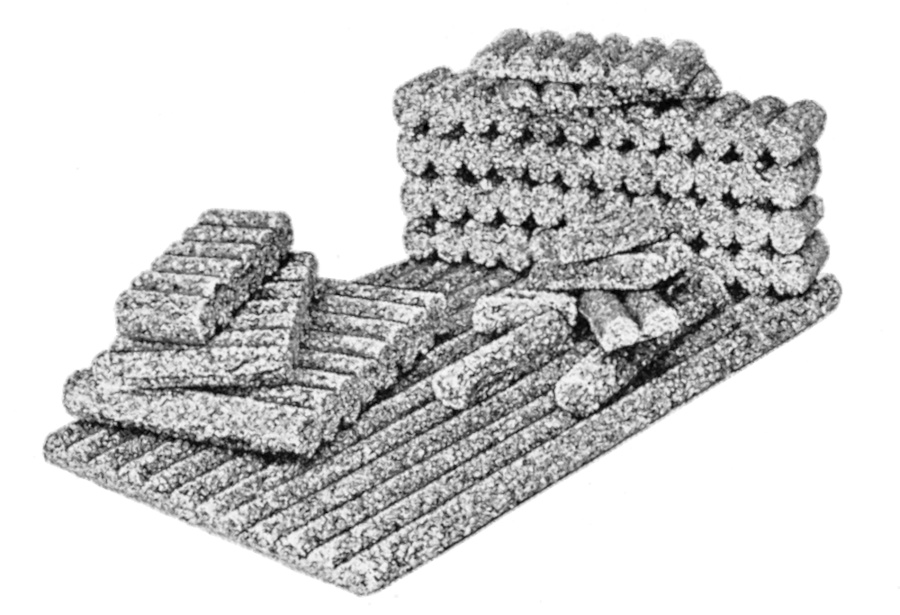

You see a few of the many attractive styles in which you can put up pop-corn made on Knott’s Pop-Corn Machines.

The top package, a pop-corn brick, is extensively sold from Maine to New Jersey along the Atlantic coast at beaches and parks in summer.

The center picture of bar pop-corn, either ground or whole, is a New England favorite. The top bar has the paper folded back as it is held while eating by biting off the bar.

The lower left is a package of whole corn fritters or crispettes, while at the right is shown a crispette on top of some ground corn fritters.

The center upper piece is called “two-fers” because it sells two for a penny. It is a New England piece. The lower center is a penny cake.

These last four pieces are winter goods.

The flavors are Molasses (yellow), Chocolate (brown), Vanilla (white), Checkerberry or Wintergreen (pink).

(1) Because now is the time to enter into the manufacture of pop-corn.

(2) Because every district will soon have its pop-corn factory.

(3) Because your customers will realize that only goods of local manufacture and high quality, under your trade-mark, are dependably fresh and wholesome.

(4) Because people are buying more pop-corn than ever before.

(5) Because the demand for pop-corn ground and whole, in squares, bars, fritters, etc., in New England is as substantial as the demand for crackers.

(6) Because pop-corn has great possibilities.

(7) Because pop-corn may be put before the public in many ways.

(8) Because if one style is not salable in a certain locality there are enough that will be, as there are plenty of styles to choose from.

(9) To show that you should trade-mark your goods.

(10) To show that the “price toboggan” had better coast empty.

(11) To give you guidance, so that no matter what may be your problem you may eventually achieve success.

(12) Because pop-corn makers are scarce as compared to the demand for them, and it is hoped that this will assist in the training of capable men.

(13) Because pop-corn made on quality builds business.

(14) Because we want to increase the consumption of pop-corn.

This is the kind of a book that you get properly balanced in your mind if you READ IT THREE TIMES, one after the other. Even after the third time you will find something that you passed over without noticing at the other readings.

AFTER every man, woman and child gets to know its pleasant taste and its food value, the world consumption of pop-corn is going to be something tremendous.

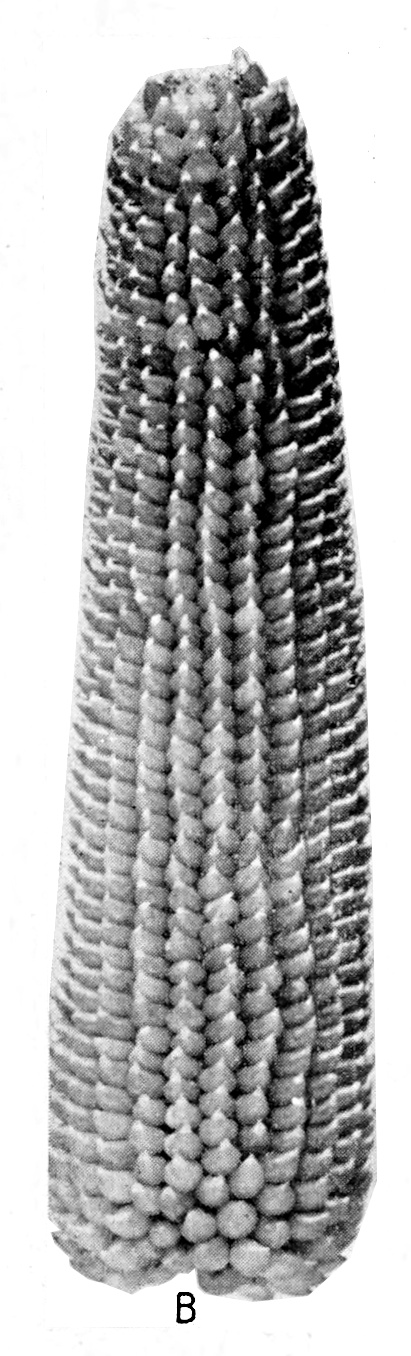

The ear

Consider that pop-corn contains the whole of the grain, and that the grain is thoroughly cooked. It is a healthful, nourishing food. It is pure. It is a poor man’s confection and food combined. It is too palatable for the rich man to ignore. It is considered by “Uncle Sam” to be such a valuable article that through the United States Agricultural Department, he has published two pamphlets for free distribution, Farmers’ Bulletins No. 553, “Pop-corn for the Home,” and No. 554, “Pop-corn for the Market.” By permission of the department we avail ourselves of some of the information there given.

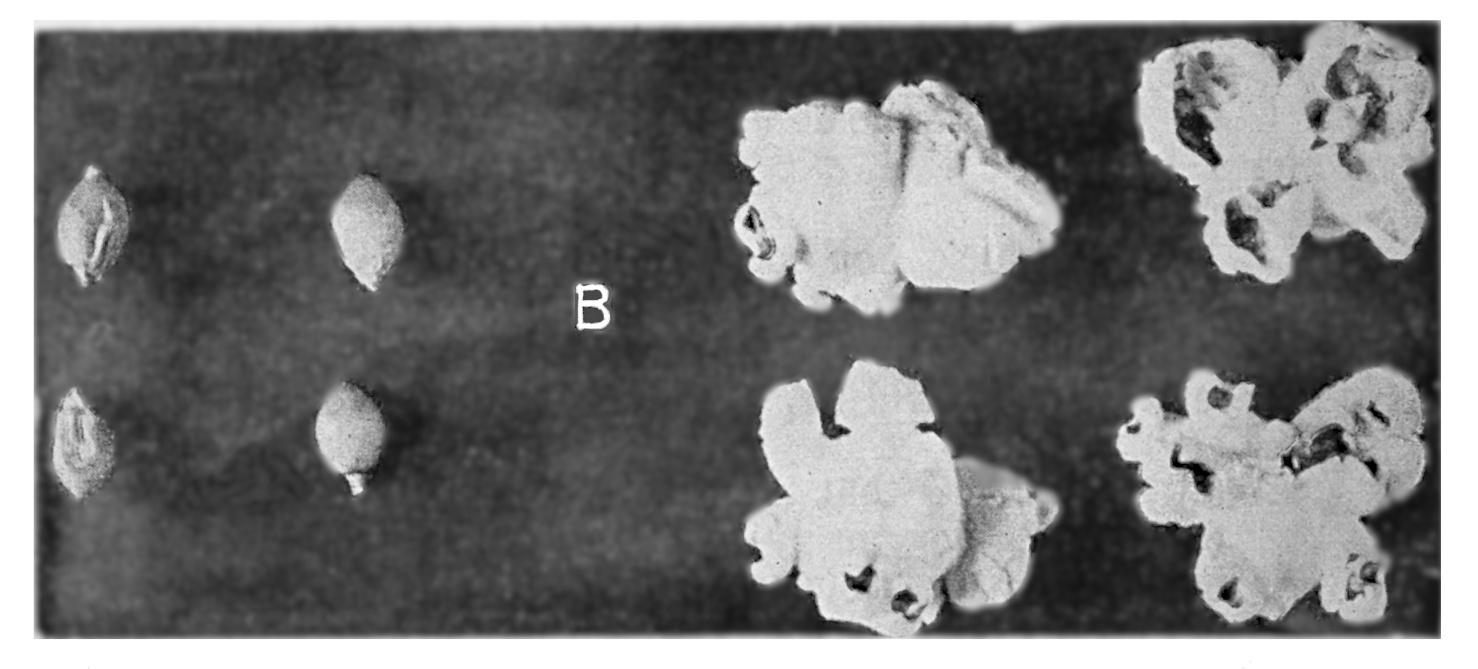

Unpopped Kernels and Popped Kernels of White Rice Pop-Corn

(With Permission of the U. S. Department of Agriculture.)

Out of the more than twenty varieties of pop-corn you are advised to use White Rice, as that makes the largest popped kernel compared to the size of the raw kernel, and it is the most common commercial pop-corn.

As it is the expanding of the moisture in pop-corn by turning into steam that explodes and cooks the grain, it is necessary to have the right quantity of moisture, about twelve per cent., and to have that moisture evenly distributed throughout the kernel, and the kernel otherwise in fit condition for popping.

Some of the things that spoil the popping quality of corn are:

Seed from which the crop is raised not being acclimated to the locality in which it is planted.

Other kinds of corn growing near the pop-corn.

Picking before the pop-corn has fully ripened, or picking after the coming of frost.

Not sufficient ventilation while curing.

Too much drying out; shelled corn dries out faster than corn on the cob.[p. 7]

Shelling the corn too long before popping.

Defects in the kernel itself.

Damage from moths which produce weevils.

Insufficient heat, giving poor popping results.

You see that it is really a delicate proposition to deliver pop-corn to you that will give you the best results. Therefore, it is not safe for you to buy pop-corn of any but reliable dealers.

Seventy pounds of ears, air-dried, constitute a bushel.

Fifty-six pounds of shelled pop-corn make a bushel.

One hundred pounds of ears should give eighty pounds of shelled pop-corn.

There are the same number of food units in:—

To be more accurate, here is the percentage of proteid, fat, carbohydrates and the number of calories in one pound of each of the foods noted.

| Proteid | Fat | Carbo- hydrates |

Calories | |

|---|---|---|---|---|

| Peanuts, | 25.8 | 38.6 | 24.4 | 2560 |

| Sugar, | 00 | 00 | 100 | 1857 |

| Pop-corn, | 11 | 11 | 78 | 1860 |

| Cocoanut, | 4 | 77 | 19 | 2800 |

| Raisins, | 3 | 9 | 88 | 1600 |

| Oatmeal (boiled), | 18 | 7 | 75 | 300 |

| Roast Beef, | 18 | 82 | 00 | 1800 |

| Eggs, | 32 | 68 | 00 | 760 |

| Roast Lamb, | 40 | 60 | 00 | 900 |

| Milk, | 19 | 52 | 29 | 300 |

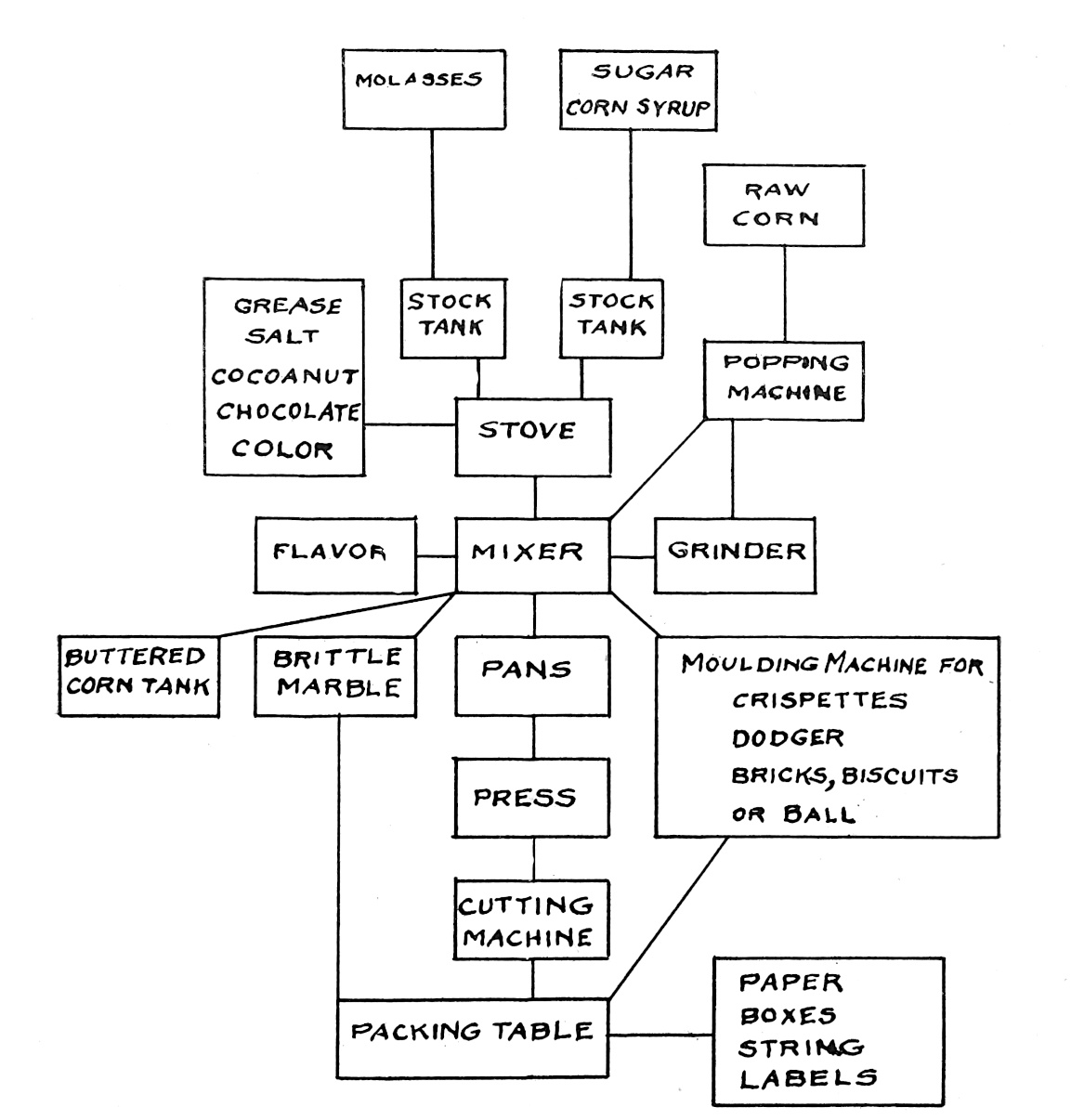

This chart of manufacturing process shows at what point each ingredient enters the batch.

It shows the arrangement of operations.

It shows what type of goods is the easiest to make and what takes the most machinery to complete. It condenses on one page the underlying principles of pop-corn confection manufacture.

Study it carefully. In this chart you will find the answer to your question of how to arrange your factory—at what point in the work a certain material is added to the confection.

It shows what materials are required to manufacture pop-corn confection and shows what set of machines are necessary to make a particular type of corn confection.

It shows what machines are the essential ones in the business.

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Salted Pop-Corn | × | × | ||||||||||||||||

| Buttered Pop-Corn | × | × | × | × | × | |||||||||||||

| Crispettes, various colors and flavors | × | × | × | × | × | × | × | × | ||||||||||

| Dodgers, various colors and flavors | × | × | × | × | × | × | × | × | × | |||||||||

| Biscuits, various colors and flavors | × | × | × | × | × | × | × | × | × | × | ||||||||

| Penny Squares and Bars | × | × | × | × | × | × | × | × | × | × | ||||||||

| Bricks | × | × | × | × | × | × | × | × | × | × | × | |||||||

| Sticks | × | × | × | × | × | × | × | × | × | × | ||||||||

| Brittle | × | × | × | × | × | × | × |

| A | Popper No. 2002-3 Page 19 |

| B | Sifter No. 112 Page 20 |

| C | Two Stock Tanks No. 2013-1 Page 25 |

| D | Measure 2 qt. Graduated |

| E | Paddle No. 2006-1 Page 41 |

| F | Stove No. 113-1 Page 25 |

| G | Mixer No. 114-2 Page 29 |

| H | Crispette Machine S F 3 Page 38 |

| I | Grinder No. 109-1 Page 22 |

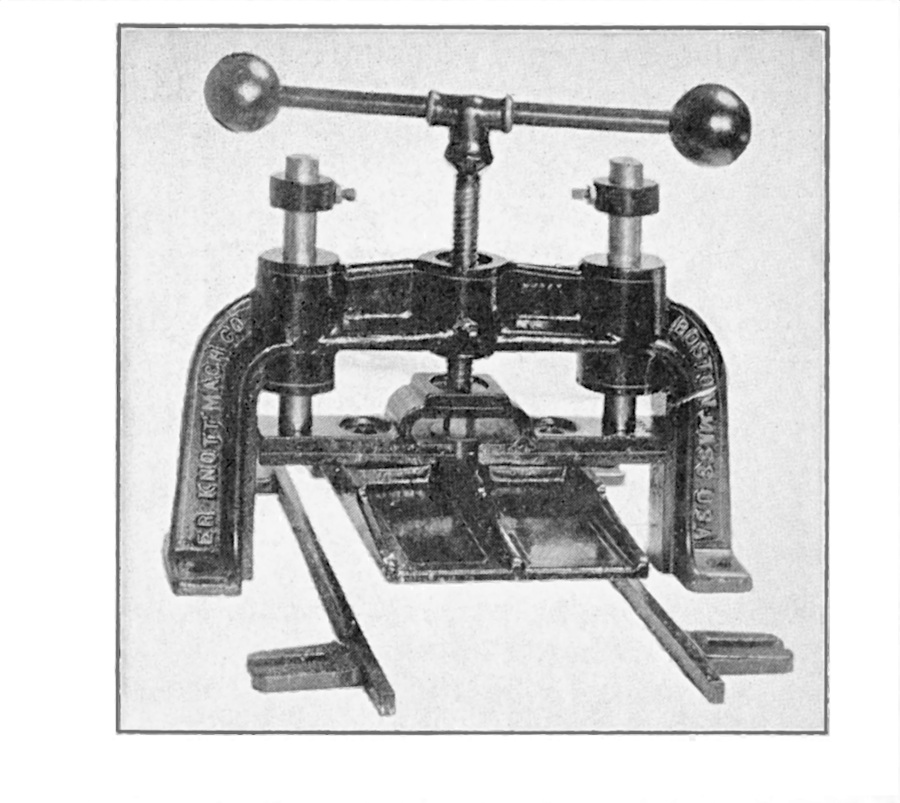

| J | Press No. 110-1 Page 33 |

| K | {Cutting Machine No. 111 Page 35 {Cutting Machine No. 115 Page 37 |

| L | Buttered Corn Tank No. 2019-1 Page 41 |

| M | Wrapping Form Page 31 |

| N | Biscuit Mould No. 2002-1 Page 31 |

| O | 5 Biscuit Pans No. 2007-2 Page 31 |

| P | 5 Stick Pans No. 2007-3 and Mould No. 2002-4 Page 39 |

| Q | 5 Pans No. 2007-1 Page 31 |

| R | 5 Transfer Racks No. 2022-1 Page 35 |

This schedule illustrates in a different way from the “Chart of Manufacturing Procedure” on page 9 what you require as an equipment for the manufacture of any one of the regular types of Pop-Corn Confection.

Pop-Corn Bars, “Penny Squares and Bars” as the line is called, requires as you see by the ×’s, these machines—Popper, Sifter, Stock Tanks, Measure, Stove, Mixer, Grinder, Press, Cutting Machine, 5 Pans—thus you get a definite list of the tools for a complete plant, for the particular product.

YOU, when you first tasted a delicious brittle kernel of Pop-corn, coated thinly with candy, you did not think of the skill attained by practise, the skill that was necessary in order that your piece of pop-corn confection might have the right amount of candy on each kernel of pop-corn and the kernel be of its original full-sized fluffiness.

It is an operation that appeared to you as simple and easy of accomplishment when you first saw it performed in the hands of an expert. Then when you tried it? Well, you had “An experience.”

You found that somehow the corn did not act for you the same as for him.

It did just what you did not expect it to do. It formed into one big ball of condensed pop-corn. Or it became cold before you got it really mixed and you could not then mould it into confection; or instead of the kernels being of their natural large, fluffy nature, you probably found you had ground them to one-half their natural bulk. In other words, you found you had something to learn and you were up against a man’s job. No, you did not give up, but you “cleared for action,” or in other words you stripped off the coat from your mind as well as from your back and studied and tried, studied and tried, until you had the principles, then by practise you acquired speed.

Pop-corn confection is made from the starting of a batch to the completed confection while the original heat is in that batch. A batch of candy is solid compared to a batch of pop-corn, so that a batch of candy may be held to a working temperature by keeping the batch near a fire, while pop-corn cannot be so handled, it must be worked in small batches at a speed to reach the finished confection while the original heat lasts. The working of candy and the heat in it has a tendency to turn the candy back to sugar—that is, to grain it. Candy coated pop-corn, to get the brittle, perfect confection—that is not grained—must be finished confection, while the candy coating is still hot. You see, then, the great advantage to be realized in using the quickest method. Knott’s machines are recognized as the best for the speed that produces quality.

As one item in the process of manufacture, consider the mixing of the corn and candy.

Hot air rises and cold air descends; you know that, but did you ever consider that it has a lot to do with your results in making pop-corn?

You know that popped corn is light and fluffy and air passes through the collection of kernels easily. Think of how hot a kernel must be to pop and yet you know that it is hardly any time at all before the kernel is cold. The air surrounding the kernel is heated by the hot kernel: that air rises and is replaced by cooler air which in turn extracts the heat from the kernel and so the process continues with speed until the kernel is the same temperature as the air.

You have often used the pouring of a liquid to more rapidly cool it. You have lifted spoonful after spoonful of coffee letting it run off the spoon to cool it. Did it ever occur to you that the pouring of the hot, boiling syrup onto the pop-corn in a mixing tank is a cooling process? Because[p. 12] of hot air ascending and cool air descending, that candy that you would thus pour onto the pop-corn will cool at a most rapid rate while you are getting the candy kettle out of the way and your paddle down into the batch to mix the corn and candy. The doing away with this pouring of the candy is necessary to the production of the best goods. You can eliminate it by cooking the candy in a deep kettle and pouring the pop-corn into that kettle on top of the candy and mixing the batch in that kettle.

To coat a kernel of pop-corn with candy is not only for the purpose of tickling the sense of taste, but by the use of that thin covering of candy you keep the dampness out of the kernel. To be most effective, the coating must completely enclose each kernel and yet for the confection to be of the most delicate and brittle texture you must have but the least film of a coating of candy covering each kernel and every kernel the same as every other. To get the best results, you must use the one best method of manufacture.

If without any time passing, that is, instantaneously, you could distribute the candy at the instant it reached the point to which you boil it, the candy then being at its most liquid state, if you could distribute the candy thus instantly over the kernels, you would have the ideal thin coating of candy over each kernel of pop-corn. You would have the most delicious piece of confection you ever set your teeth into.

When mixing by hand, one-half of the time is used in the down stroke of the paddle, which, of course, is necessary before you can make the up stroke, or lift the paddle to mix the corn. Yet, of course, that uses[p. 13] valuable time during which the batch is cooling. A machine so constructed as to have a rotating paddle always under the corn to lift the corn up the sides of the kettle and guiding it to fall down the center of the kettle, such a machine uses no time in return strokes and mixes the batch almost instantaneously.

At this point in our consideration of the subject, let us see what we have learned.

It is best to mix the candy and pop-corn in the way that will be the quickest, the quickest way being to boil the candy in a deep kettle and mix the batch in that same kettle by the use of a pop-corn mixing machine.

Now suppose you use this method for mixing the batch, what size batch will produce the greatest profit?

You know with pop-corn confection, the lighter it is, the better it is. Of course the lighter it is the less material to the piece and the greater[p. 14] the profit. The size of batch you make has an important effect on the lightness of the confection.

Candy coating of the pop-corn must be soft when the cakes are pressed in order to have the cake well held together when cooled. You are cooking above 280 degrees, so your candy must be at a high temperature when the cakes are pressed to attain the result. At that temperature, the candy changes quickly from a plastic to a brittle condition. A batch is too large when the last of it to be moulded is too cool to produce good light confection.

The batch may be kept from cooling so fast by keeping it enclosed in a heated tank, but watch the results and don’t expect this to help much. You must have the tank open to take out the corn to fill the moulds and while it is open there is bound to be a rush of hot air out of the tank and a rush of cold air into it on the principle discussed in the first part of this article. This movement of air takes the heat out of the batch at a fast rate so that it counteracts the effect of the heating of the tank.

One good way is to use the hot kettle you mix your batch in to hold the batch while you scoop the corn out onto the moulds. The quickest way if you are using a set of moulds is for you to arrange the moulds on the bench, make a batch just the right size, dump the batch on top of the moulds and fill them. Then put them through the press. This has the advantage of getting the corn into the moulds at once while the candy coating is soft.

When the candy coating of the kernels is too cool when put in the moulds and pressed, the whole kernels will be broken and you will get so much corn into each mould that the cake will be solid, hard to bite into and heavy.

You see it pays better to run small batches. Your cakes will be light and fluffy and therefore better liked by the consumer. Your materials will make more goods. A day’s work on this plan will show the greatest profit.

Consider the utensils used by this method.

Only two kettles, so you have one on the fire while you are mixing in the other. You have no jacket tank to clean, to grease, with the cost of the grease, to heat by gas, with the cost of the gas. The use of the pop-corn mixing machine in this method assures the same sized cakes being made of less material. The same material produces at least 20 per cent. more finished confection because of the quick and complete mixing.

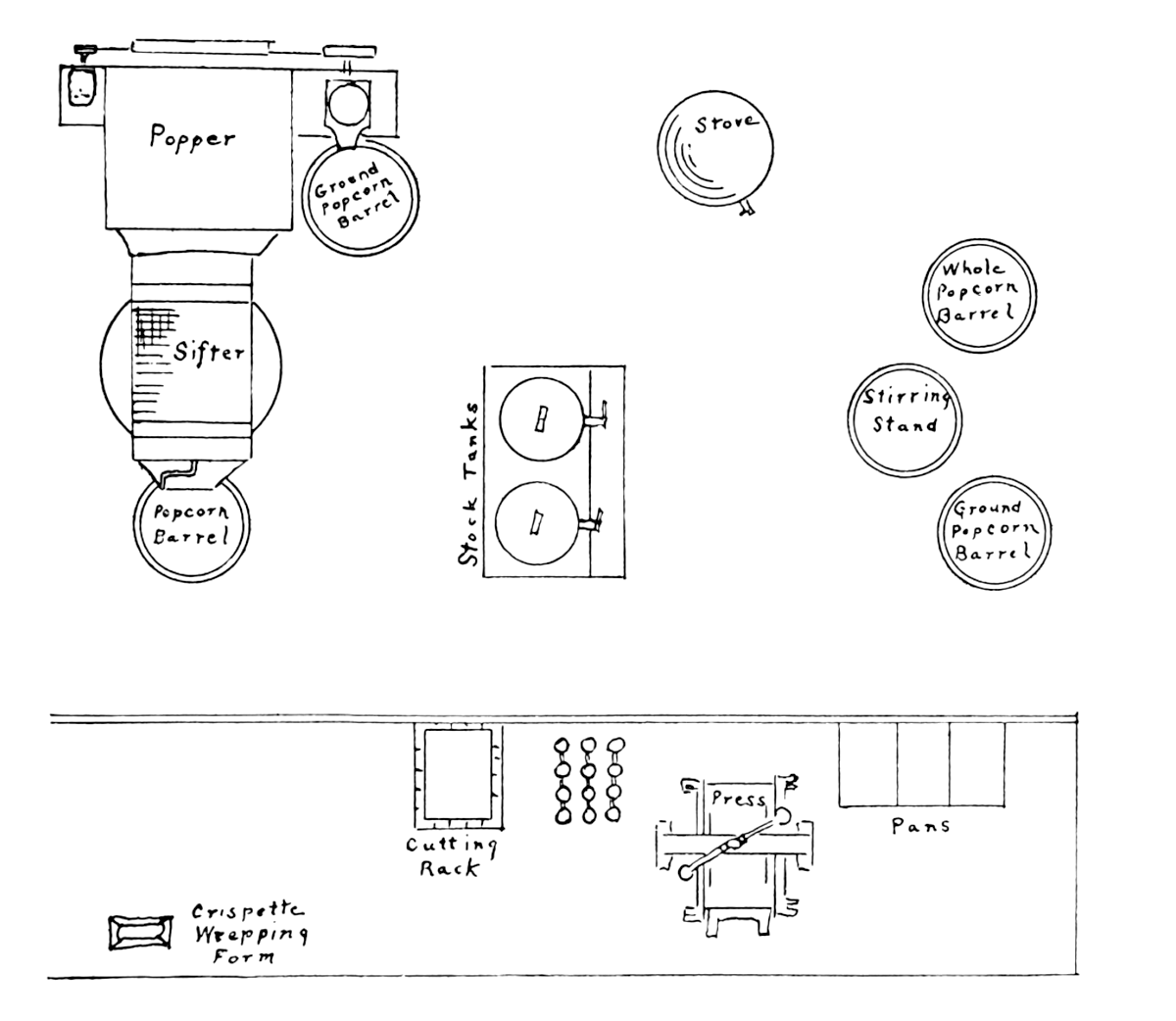

YOU will agree with me that unless you have your outfit arranged right you will be wasting steps, and that one worker will be in the way of another.

The best way is to have the room arranged so that the raw corn starts down one side of the room and the finished goods come back on the other, so that the process of manufacture passes around the room in a continuous progress toward the shipping point.

This sketch gives you an arrangement to consider. You should make your Popper and Mill Stand, Stock Tank Stand, Kettle Stirring Stand and Bench so that you can move them, and thus try various distances and arrangements to fit the particular line of goods that becomes your leader.

It is just as bad to have machines too close together as to have them too far apart, even when arranged in good working order. In the plan above, room is left for barrels to stand in front of the popper, at the side of and in front of the mill and room for two at the Kettle Stirring Stand, one for whole corn and one for ground corn.

Several conditions of manufacture are changed as the quantity of production is increased.

You should pop your corn in a separate room from the place in which the cooking is done. The heat from the poppers—even with the windows open in summer—is very uncomfortable and the escaping gas and burning dust makes the air very unhealthy. Have your poppers so arranged that the bad air will rise and escape without disturbing the workers. Ordinary windows are not enough. Put a ventilator over the poppers. Place a hood, or canopy over your stoves connected by pipe to outdoors, so that when any syrup or molasses gets on the stove and creates a smoke, it will pass off without making the workers uncomfortable.

The arrangement of your factory space as to the location of the doors, windows, stairs and elevator will effect your placing machinery.

Whether you use individual motor drive, or shaft driven machines, will effect the arranging of your plant.

What you intend to manufacture and what machines you buy will also determine how you use your floor space to the best advantage.

Individual motor drive enables you to locate your machines to better manufacturing advantages.

As your business changes in what you make, as you increase or change your goods and as you add more machines, you can more easily move machines to keep the best manufacturing arrangement.

As to cost of operation, it is hard to say under modern conditions whether one way is cheaper than another. With separate motor to each machine, you have no overhead shafts and belts to drop oil and dust and compel you to locate by them. You are not liable to have your plant idle because the one motor is out of order, or one belt has parted, you can keep making something if one machine is out of order, for all the others will be running.

Many manufacturers make a stand for their popper out of three-quarter inch gas pipe, which is fireproof, clean, simple and cheap. It is best to have three pipes for the popper to rest on, one across near the front and two across near the back. These two project to the right twelve inches for the shelf for mill (Stock No. 2001-1). By the use of elbows, tees, flanges and piping you can make a stand to rest on the floor or hang from the ceiling and bring the popper to the right height for your barrels. When hung from the ceiling it leaves the floor clear, and in every way is to be preferred if you make the construction rigid. Determine the height of the barrel you are to use under your Knott Rotary Sifter (Stock No. 112) and have the top of the stand for popper twelve and one-half inches higher than that.

Use an iron box or barrel under the popper to catch the unpopped kernels. In that way you risk no fire should a blazing kernel fall into it. A blaze in pop-corn is easily smothered by stirring up the corn.

You are urged to use an iron barrel under the Knott Rotary Sifter (Stock No. 112) to catch the siftings.

Order your popper made ready to attach Knott’s Rotary Sifter, it costs no more.

Remove the pop-corn popper cylinder.

See that the valves are closed.

Use only the best gasoline.

Do not fill the tank while the burners are lighted, nor remove the tank to fill it. Do not let the tank run dry.

If gasoline burners should leak at any time at the hexagon stuffing box on the valve stem, tighten with pliers. Repeat this operation if any further trouble occurs from this source. If this doesn’t overcome the trouble remove the stuffing box and wrap some cotton cord or linen thread well saturated with common soap around the valve stem. Then tighten stuffing box.

To prevent smoking up the cylinder you are recommended to use alcohol (denatured or wood) in generating cups; light and allow to burn out, then turn on gasoline and light at the perforated cone at top of burner; turn low.

If you are not used to gasoline burners, get some one who knows how to show you.

It is essential to have an uninterrupted and sufficient supply of gas.

Do not use a rubber tube to carry gas to the popper if you can connect the popper directly by pipe. The tubing greatly reduces the pressure. Run a three-quarter-inch pipe to a small sized Popper; and an inch pipe to the large sized Poppers. See that the gas comes to this through no smaller pipe.

Light the burner and turn low.

The distance the pop-corn cylinder is away from the burner is very important. If your cylinder is too near the burner, your corn will be really under the heat and not in it. If the cylinder is too far away from the burner, the corn will be too far away from the hottest part of your fire. This will show by your corn being roasted instead of popped and by your popped kernels being small. The distance between cylinder and the burner should be about 1 inch. This does not mean ¼ inch or ½ inch, neither does it mean 1¼ inch or 1½ inch. The pressure of the gas may require that you make a new adjustment of the burner up or down to get absolutely the best results with the gas you must use.

Make yourself thoroughly familiar with the motions of operating the popper with raw corn without fire before trying to pop corn.

A power-driven machine should have the power turned on before the burner is lighted. This prevents the liability of your forgetting to keep the cylinder revolving over the fire. If the cylinder is not in motion, the fire will burn a hole in it or get it out of shape.

Having oiled the shaft with heavy oil, replace the cylinder.

Put in a scoopful of corn.

This illustrates method of placing corn in cylinder

Turn up the fire and revolve the cylinder clockwise, eighteen or twenty revolutions to the minute.

The popping should begin in one and one-half to two and one-half minutes.

After the popper has been running a little while and becomes thoroughly warmed up, popping may begin in one and one-half minutes.

When the popping is about two-thirds completed, if you are using gasoline fuel, turn down the inside burner only. When gas is used turn the valve off about half-way.

In case pop-corn catches fire in the cylinder, put in a scoop of raw corn, which will extinguish the blaze.

After a little practice you will know from the discharging corn just what moment to turn the cylinder slowly backward and stop to dump the unpopped kernels. On the power machines you must draw the bolt on the crank before you can turn it backwards.

Put in another scoopful of corn.

Turn up the burner, and if you are using gasoline, first the outside and then the inside one, so that the lighting will be from the outside.

Proceed as before.

This machine may be used as a peanut roaster by using a special peanut cylinder in place of the pop-corn cylinder. These cylinders are carried in stock at the factory and will fit your popper.

Open the slide, insert the funnel and put in peanuts until the cylinder is three-quarters full. Then close the slide; remove the pop-corn cylinder; light the burners; put the peanut cylinder in the machine, then revolve the cylinder at the same speed as the pop-corn cylinder, about eighteen to twenty revolutions per minute.

Test the peanuts by running a tryer in the hole in the cylinder.

It will require twenty to thirty minutes to roast.

Empty the cylinder by drawing it part way out, turning it hole downward and swaying it back and forth.

Stock No. 2003-2. Kingery Popper: “The One Liked the Best”

Stock No. 2003-2. Capacity, 12 bushels per hour. Dimensions of body, 37 inches high, 28 inches wide, 14 inches deep; gas machine, 18 inches deep.

Smaller machines or machines arranged in series.

We recommend this machine, we know it is right.

Kingery poppers are generally used in factory production because of their efficiency. The best popper is Kingery No. 58, arranged with gas fuel, electric motor and a blower that forces air into the burner, which mixing with the gas gives a much cleaner, hotter fire with less gas. A fire that pops corn into larger kernels, pops a larger per cent. of the corn and does it in a shorter time.

About fifty, more or less, of unpopped kernels will be blown out by the popping corn or carried out with it at each popping.

These must be sifted out of the popped corn before you make up your confection. You do not want to bite down on a hard kernel and break a tooth, so that it is necessary for you to make certain that every hard kernel is eliminated.

The pop-corn cannot get by without being sifted and every hard kernel is taken out.

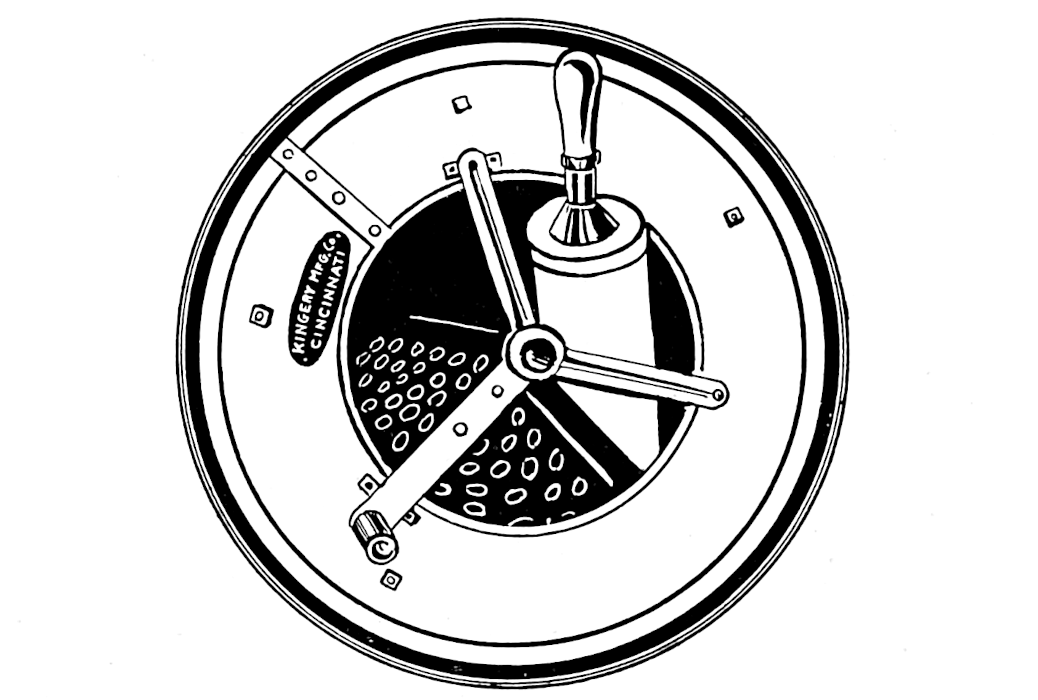

The screen does not clog because it turns over twenty times a minute. No pop-corn kernels are broken, as the pop-corn tumbles over and over in a veritable cascade seven times in passing from the hopper through the cylinder.

By a long series of experiments the construction was determined that positively took out every hard kernel.

With the sifter and driving parts as shown on page 20 you receive drills and tap for bit-stock so you may put up the machine yourself by following the direction sheet.

Screen 12 inches in diameter by 19 inches long with baffle plates that compel the corn to travel in a cascade over 21 feet of screen before it gets out, the pop-corn tumbling over itself so there is nothing to break it up.

Built on cast iron frame, rigid construction, cannot clog, ample capacity, cannot choke, does not break up pop-corn, you can take it away and put it back while popper is running.

Ample capacity to handle pop-corn from large popper.

Siftings must all fall inside of your barrel whether it be 18 inches or 21 inches in diameter.

The power it takes is so small you need not think of it.

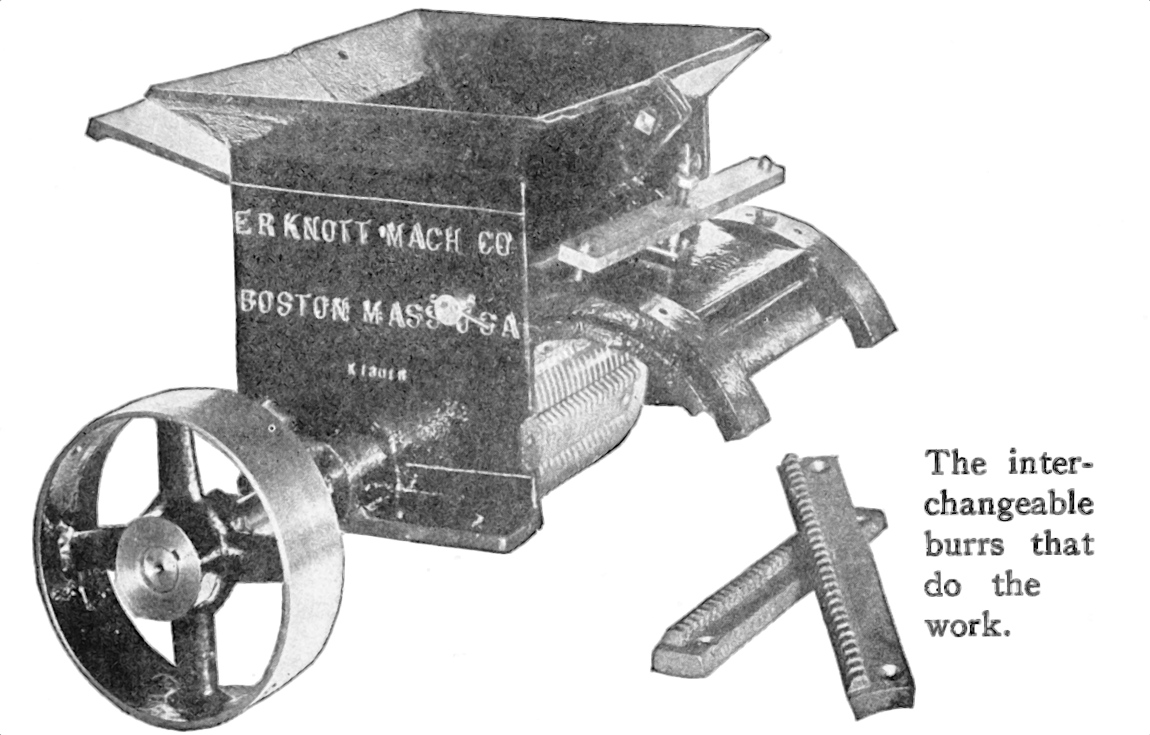

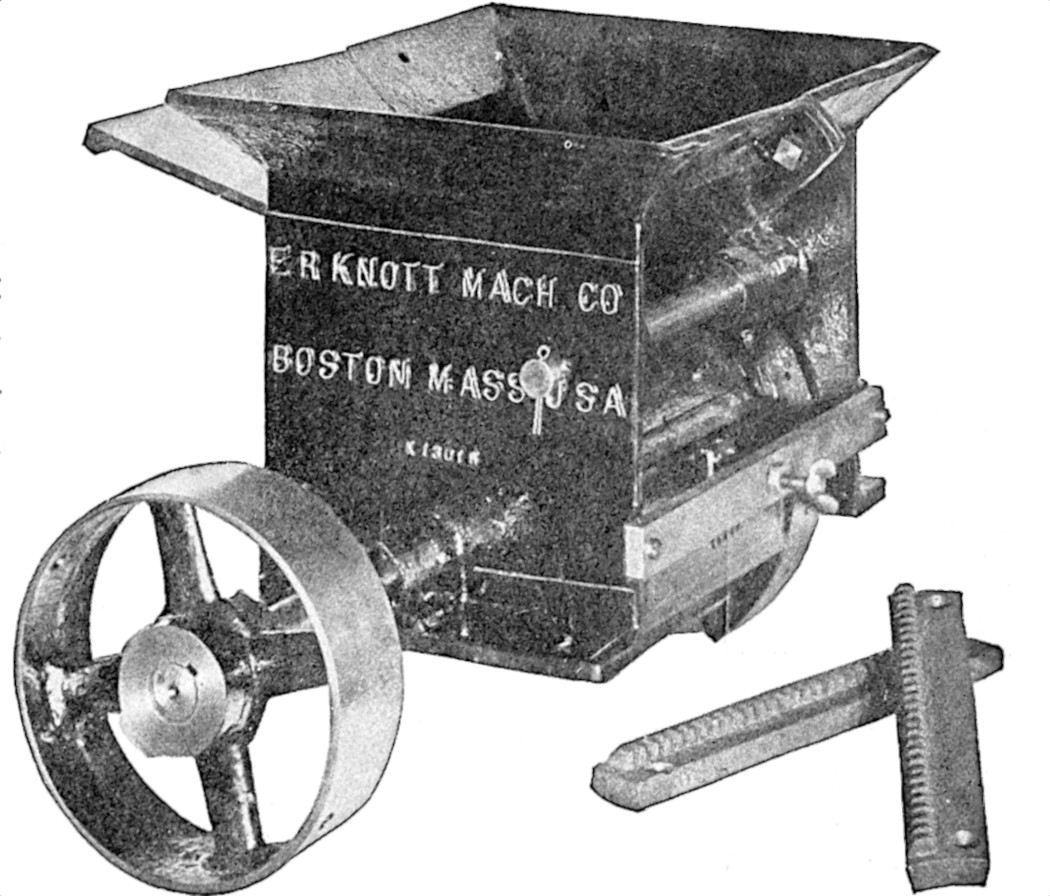

Grinding pop-corn is not the same as crushing raw grain. Pop-corn should be torn apart when it is ground and not mashed, as it is the fluffy, light texture you desire to maintain.

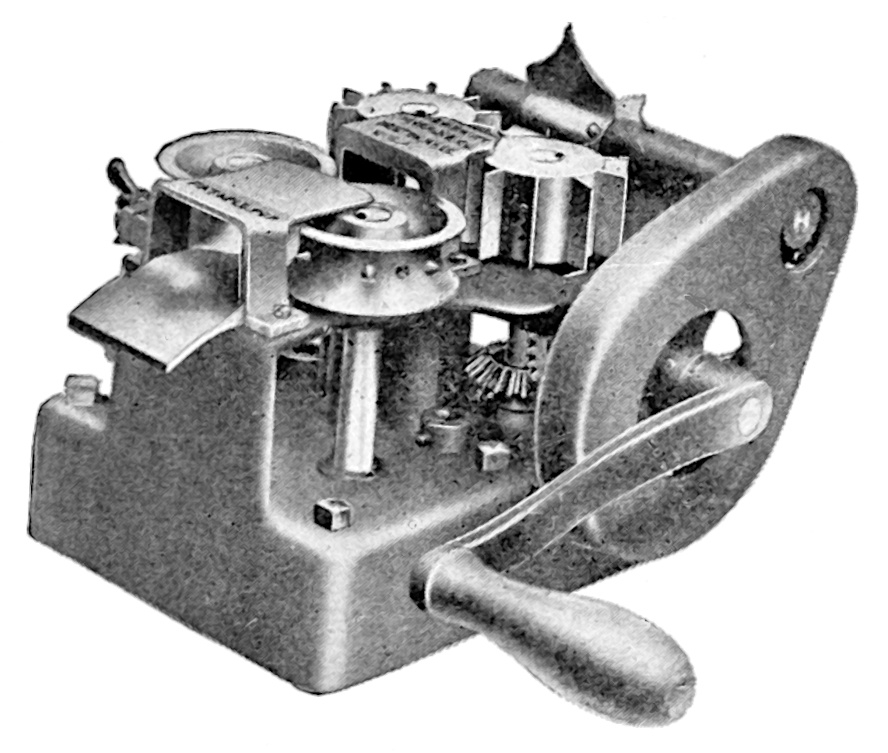

Knott’s Mills (Stock No. 2001 and Stock No. 109) accomplish the same work in different ways, but the former is of disc construction and the latter of the cylinder type. The former is slower but uses much less power.

In case of Mill, Stock No. 2001-1 (see page 24), which is power-driven, the construction is such that it will make no great difference whether the pop-corn is put in before or after the mill is started.

Adjustment is made by the thumb screw in the hub of the pulley. Turning in causes the mill to grind finer.

In case the pop-corn does not feed in the hopper a stick run down in the Hopper (Stock No. 2020-1) or a common knife stuck in between the machine and the Hopper will cause the machine to start grinding again.

Hopper (Stock No. 2020) for this mill holds a bushel of pop-corn.

Knott’s Grinder, Stock No. 109 is the machine for efficient work. Every last bit of pop-corn put in the hopper will be ground without attention.

Never open the slide to let the pop-corn to the grinder until after the power is on. If the power is put on after the pop-corn is let into the machine it will choke, in which case you will have to shut the slide and turn the machine over by hand to clear it.

Adjustment is made by the thumb screw on the side of the machine. Screwing it in causes finer grinding. By tightening up the lock nut on the adjusting screw you lock the adjustment.

Illustrations on page 23 show how the stationary burr bracket is swung out to drop out nails or gravel.

Use this grinder with legs to straddle a barrel and hopper that holds a barrel of pop-corn and place on the stand by the side of the grinder an electric motor totally enclosed type Stock No. 2016-5, No. 2016-6, No. 2016-11, No. 2016-12.

Stock No. 109-4—Knott’s Pop-Corn Grinder

This shows the stationary burrs swung out to drop out nails or gravel, without changing the grinding adjustment.

Your pop-corn is pulled apart—not mashed. Adjustable; no dust. Uniform grinding. All metal. Will last a lifetime. Large quantity capacity.

Stock No. 109-4—Knott’s Pop-Corn Grinder

Showing stationary burr in position for grinding.

| CAPACITY | 10 bbls. per hour |

|---|---|

| POWER | ½ H.P. |

| SPEED | 500 R.P.M. |

| PULLEY | 7″ × 2″ |

| MEASUREMENTS | 11½″ × 16½″ × 10″ |

| THROAT | 7¼″ × 1½″ |

| WEIGHT | 75 lbs. |

Use our motors either Stock No. 2016-5, or No. 2016-6, or No. 2016-11, or No. 2016-12.

Your pop-corn is pulled apart—not mashed. Adjustable. No dust. Uniform grinding. All metal. Will last a lifetime. Small quantity capacity.

| CAPACITY | 2 bbls. per hour |

|---|---|

| POWER | ⅙ H.P. |

| SPEED | 500 R.P.M. |

| PULLEY | 7″ × 1½″ |

| MEASUREMENTS | 12″ × 8½″ × 17¼″ |

| THROAT | 3″ × 2″ |

| WEIGHT | 45 lbs. |

May be driven with one of our Stock No. 2016-1, or No. 2016-2, or No. 2016-7, or No. 2016-8 electric motors.

For greater output consider our Stock No. 109 Mill.

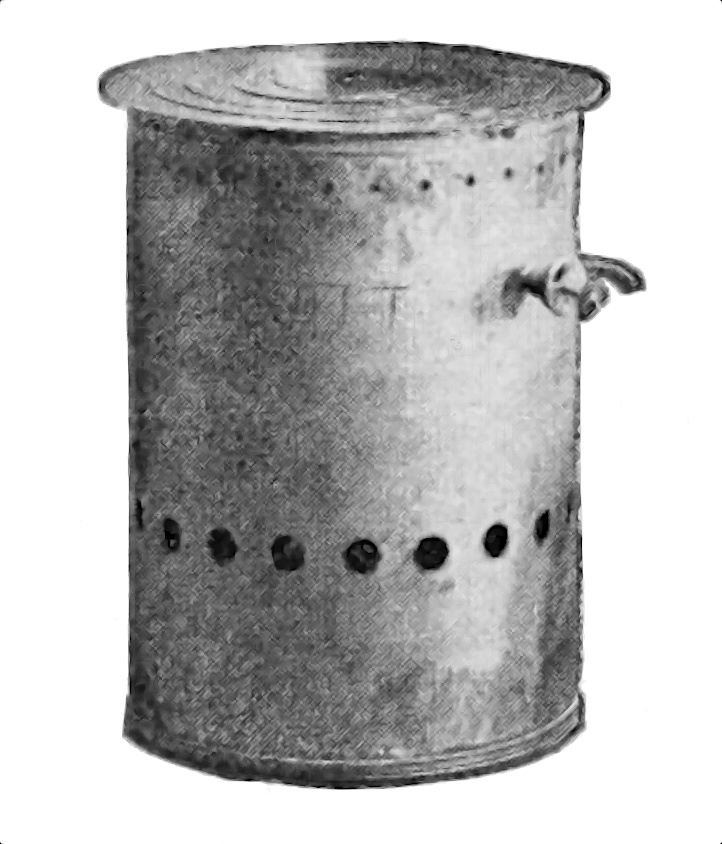

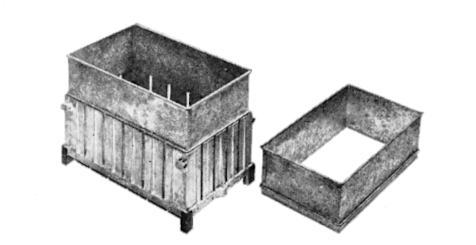

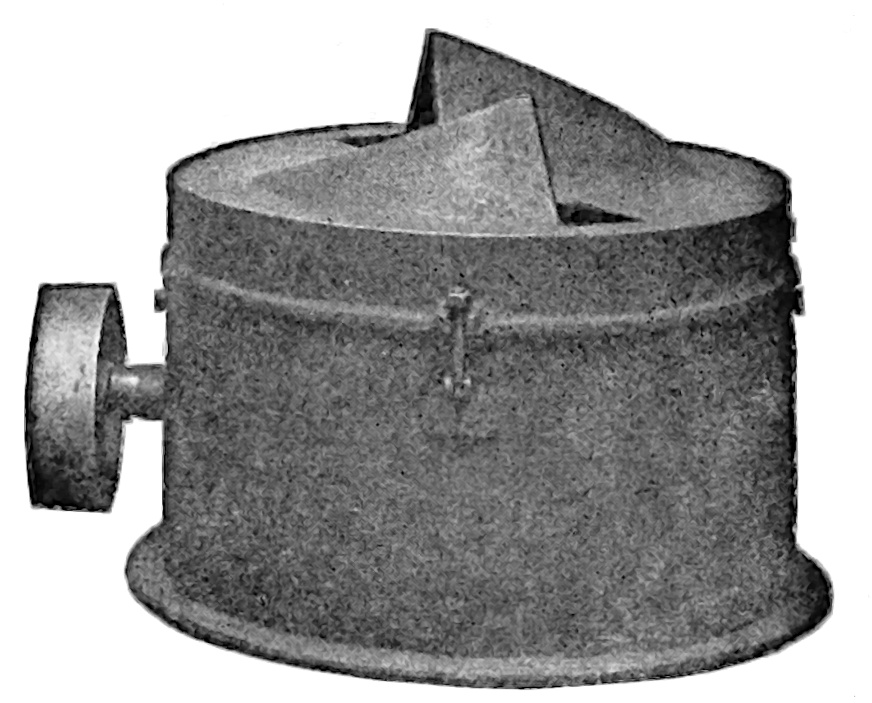

The time saver, clean way, heavy sheet steel, with steel band top and bottom, electric welded, galvanized after manufacture; Stebbins’ side-opening molasses gate, screwed in; 14 inches in diameter and 17 inches deep.

You make the stand so your two quart measure (Stock No. 2010-1) may be stood on a shelf under the gate, thus giving clean, quick method of filling measure.

One tank is for the purpose of holding molasses and the other you should have for syrup made by melting, just bringing to a boil your sugar and corn syrup in the proportions the recipes you are using call for. Use a thermometer and see that it registers 220 degrees, no more or less.

Placing the syrup right off the stove in the covered tank causes it to hold the heat so as you draw it for each batch, you start each batch with hot syrup, which saves time in cooking and accuracy in measuring, aids much toward uniform products.

Stock No. 113-1

Stove top of seven rings, drum of heavy sheet steel, with steel band top and bottom.

Burners of ample capacity and interchangeable.

19 inches in diameter, 25 inches high and weighs 57 pounds.

The Knott Pop-corn Stove is made to be used especially with the Knott Pop-corn Kettle (Stock No. 2004-2) which fits into just the right position so that the fire may boil the syrup for a batch in a few minutes.

These stoves are made so that if you want the other fuel burner you can get it from us and put it in by the aid of a screw-driver.

Read the directions under Pop-corn Popper for generating the gasoline burners and follow them in using gasoline stoves.

The gas stove burner you can regulate for air supply and for gas. This burner is a special one which we recommend because the heat is drawn to the center in a revolving shape like a whirlwind, concentrating the heat on the bottom of the kettle where you want it.

The Electric Blower Stove gives a much hotter fire and the cost of running it is small.

Copper kettle, 19 inches in diameter by 17 inches deep, with single grip handles.

Special sizes. If you want them tell us.

Made light for lifting, but especially strong and durable to stand the stirring of pop-corn.

Weight about 14½ pounds.

Knott’s kettle is the right one to use for all around factory pop-corn work. It is the style used in the pop-corn factories of New England, because they find this method requires the least labor and because it uses less candy to cover the corn. It enables you to cook the candy higher than other methods and thus increases the keeping quality of the pop-corn confection.

You boil your syrup in this kettle. Because you are boiling for each batch less than a gallon of stock, it is not convenient when working fast to use a thermometer. Pop-corn makers use one of four tests, according to their experience in the business. 1.—The so-called “water test,” half a teaspoonful of syrup dropped in cold water. 2.—The test by the color of the syrup. 3.—The test by how it leaves the paddle when scooped up on it. It will string off or come off in lumps, so-called “ragging off the paddle.” 4.—A test by the steam or smoke which rises from the kettle.

You are advised to get a confectioner’s thermometer and make the other tests at the same time you use the thermometer, doing it with syrup over a slow fire and in that way learn how the syrup you finally determine to use will act at the temperature you require.

Practical experience is the one way to learn. Do not expect to make a good batch the first time nor the third time, but you need have no discouragement if you have not reached perfect results on your twelfth batch.

In beginning, you are likely to cook candy too high to be easily worked into shape.

Efficient pop-corn making is not to be learned very easily; it comes with practice.

When you are running on one kind of pop-corn as a specialty so that you want to get out one batch after another as fast as possible, it is well to use two fires and two kettles. One kettle with syrup may be warming up while you are boiling the other.

You will find it well to use a cover on your kettle, part of the time, one of Stock No. 2005-1, or one that you can make yourself out of thin wood. The object is to let the condensing steam run down and thus clean the sides of the kettle.

Copper or wood covers are best, an iron cover rusts out quickly.

These covers will last you a long time because they are of heavy material and handle riveted with copper rivets.

Take the kettle off of the fire and set it in your stirring stand. The stirring stand may be made of a band of iron supported on three or four angle iron legs, or you can cut off a barrel to fit your height and use that as a stirring stand. Put some stones or sand in the bottom to steady it.

Stirring pop-corn is not as easy as it looks. A beginner’s courage is tested sometimes by giving him a batch to stir in which there is no grease. He makes no start at all. Again he may be tried on a wintergreen-flavored batch with an extra dose of flavor. His eyes run so with water that usually he does not finish the batch.

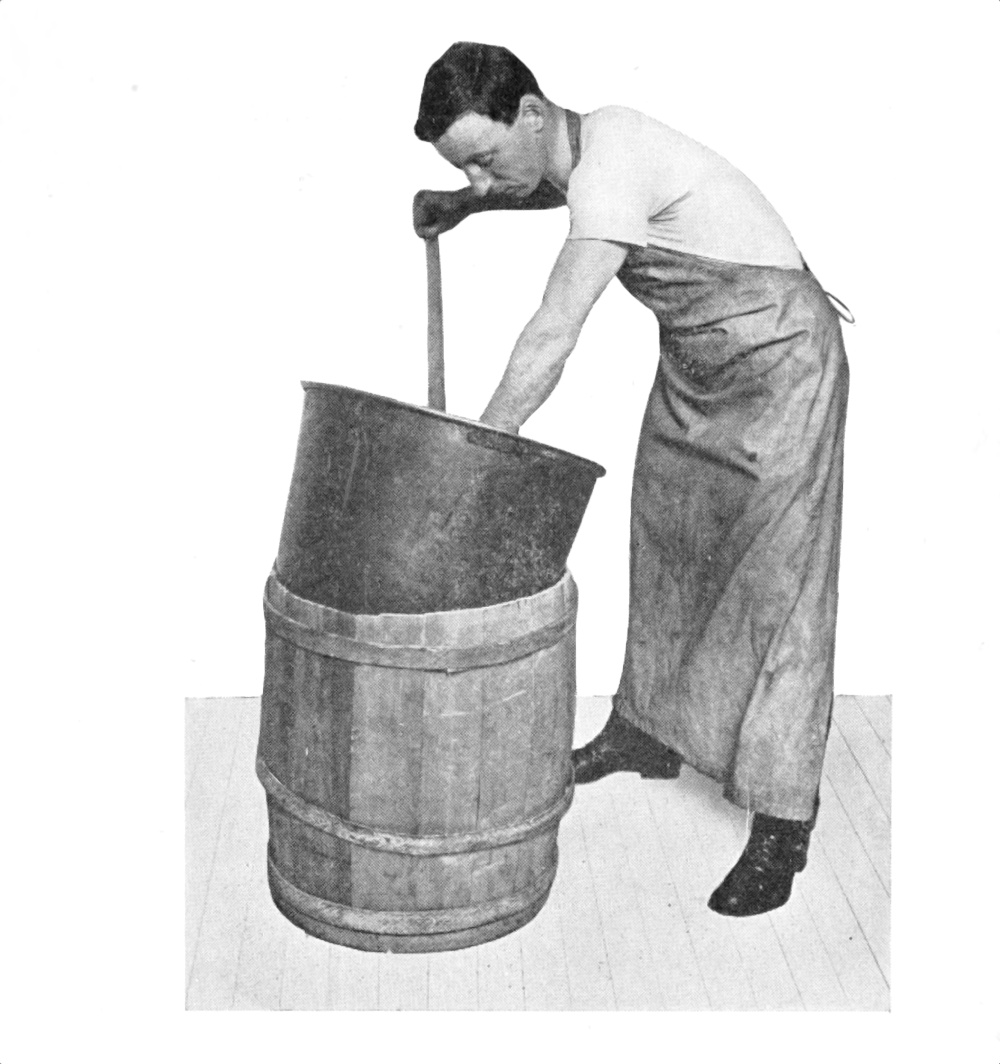

Try this plan: Put the corn in the kettle, then with your left hand on the middle of the paddle (Stock No. 2006-1) and your right hand over the end, make strokes down against the side of the kettle and up through the middle of the batch, at the same time walking around the kettle. Efficient stirring will come with practice.

Stir the pop-corn quickly, but have the batch light, not soggy.

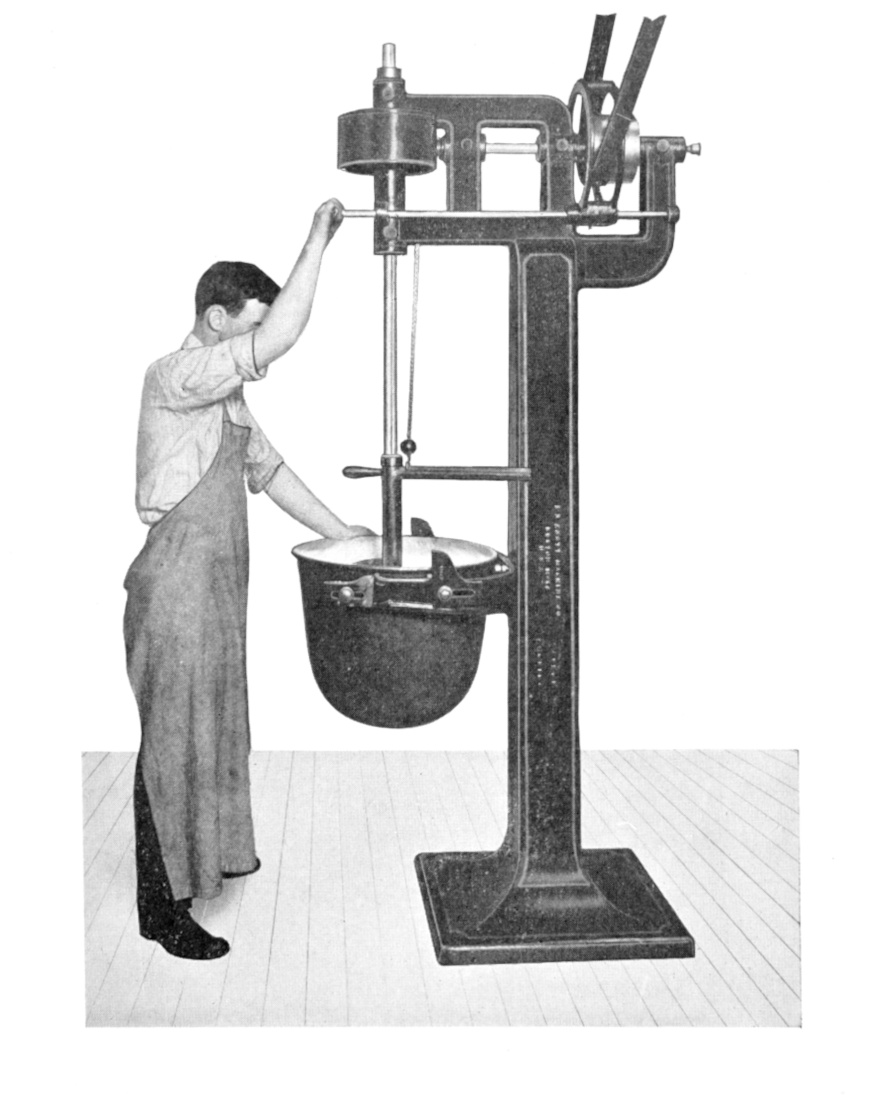

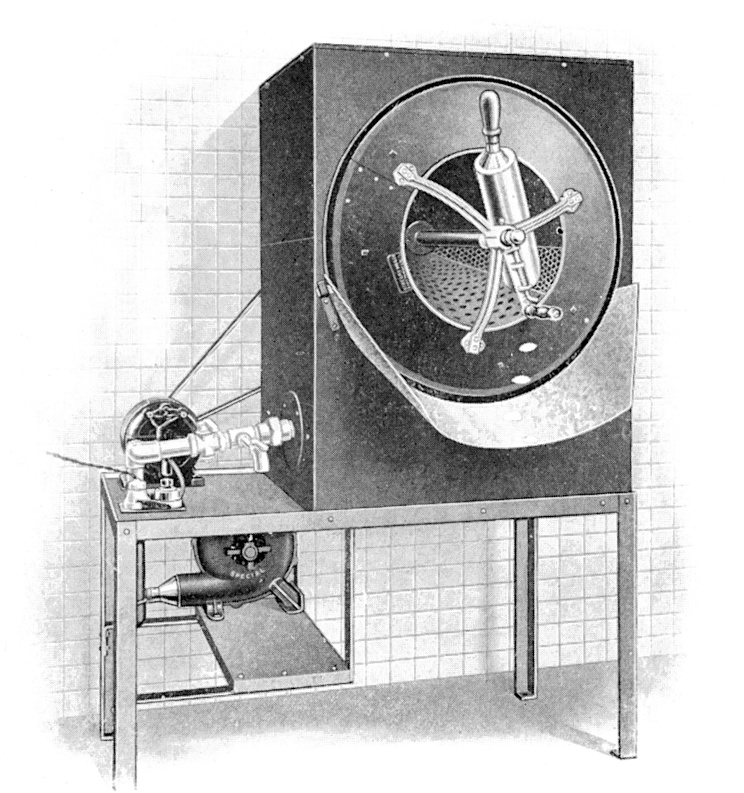

The use of the Knott Pop-Corn Mixing Machine has been well considered and yet the mechanical mixing of pop-corn cannot be emphasized too much.

Many failures in the pop-corn confection business are due to poor mixing. Soggy confection, “hot spot,” that is spots in the confection where there is much more candy than anywhere else. Uneven appearance and texture to the confection, due to slow mixing.

See that you make the best, and only by using Knott’s Pop-Corn Mixing Machine can the best be made.

You must realize that a dough mixer is not a cake mixer, is not an egg beater, is not a concrete mixer, is not a pop-corn mixer.

You know the materials are not alike and the result wanted in each case is different.

You see why you should use a machine specially developed for pop-corn, to distribute the hot syrup quickly and evenly over the pop-corn and give a light fluffy mixture.

Knott’s Pop-Corn Mixing Machine is made specially for Pop-corn, to give the result you want.

Use this method for quality and economy. Mix your Pop-corn in the hot kettle, in which you have just boiled your syrup, and use Knott’s Pop-corn Mixing Machine.

You mix all kinds of pop-corn on this machine better than it can be done any other way.

Whole pop-corn is mixed without breaking the kernels.

Goods are mixed up light, fluffy, thoroughly, evenly.

You distribute the syrup so quickly over the pop-corn that you can cook it higher.

The goods eat better.

You do away with hand mixing entirely.

Make more goods with less labor.

Not so many containers.

The cook makes no difference.

You get more cakes from the same batch; that is, you save in any case more than fourteen per cent. on your bills for material.

Stirs a bushel of pop-corn without throwing any out of the kettle.

Mixes different kinds of batches without any change of adjustment of either paddles or speed.

Nothing to wear the kettles.

So quickly is the syrup distributed that it takes less syrup to cover the pop-corn.

| CAPACITY | One bushel |

|---|---|

| POWER | ½ H.P. |

| SPEED | Pulley 500 R.P.M. Paddle 125 R.P.M. |

| BELT | 2″ Belt 7″ dia. Pulley |

| MEASUREMENT | 9 ft. of Head Room 24″ wide 43″ deep |

| WEIGHT | 700 lbs. net 800 lbs. crated |

Showing the easy way

In regard to swinging the kettle to dump the batch. Pop-corn kettle (Stock No. 2004-2) is not heavy, weighing but fourteen and one-half pounds, and with the pop-corn batch in it, it weighs but a few pounds more. The kettle is swung away from the face thus: take hold of the two handles, swing the kettle underneath from left to right, upward, still keeping the left hand away from yourself and the right hand near you, until the kettle is more than half-way up. Then hold the two handles the same distance away from you. That rotates the kettle upon its center axis while you are swinging up the rest of the way to the top position, at which you stop to dump the batch. You will notice by this motion that the kettle bottom comes nowhere near your face. During the swinging you are moving the kettle so that when you stop the batch falls out right upon the bench or machine just where you want it.

The first two or three times you try this feat, all the pop-corn may not go where you want it, but after that you will have no difficulty.

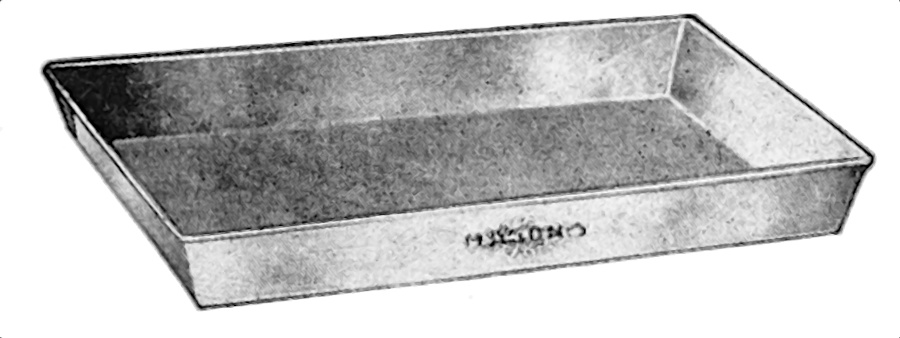

You see, in making square corn cakes, bricks or bars, there are three operations: panning, pressing and cutting; each quickly performed, but the tools used must be right in detail in their dimensions or the greatest difficulty will be experienced, even to the point that you will not be able to make the goods at all.

The kettle of pop-corn, all stirred, yet hot, is dumped into the pans arranged together on the bench. You pan the corn evenly and quickly by hand. Now turn each pan of corn upside down on the bench. Take off the pan and slip it under the pop-corn. The pop-corn is then in the pan bottom-side up so as to present a more even surface to the pressing plate in the press.

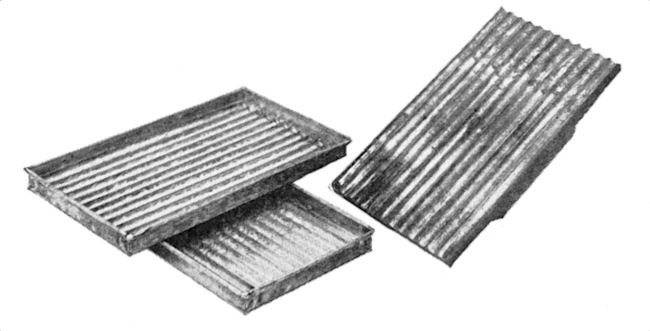

Stock No. 2007-1 pans are the right size for you to pan the corn, by moving your two hands toward you across the pan, with a side motion of your wrists, leaving an even pan of corn and taking to the next pan whatever surplus comes over in your hands. This is certainly the quickest pan to use.

These pans are made from heavy galvanized sheet steel with heavy wired rim. The clearance of the sides is right. This is the pan that will stand considerable usage.

Stock No. 2007-1

Place a paper wrapper across the top of the form and put the crispettes, four, five or six, in the paper into the form. Bring the paper together over the corn, fold it a couple of times, then tuck down the ends, fold them in and crease the bottom to hold them. See illustration in colors.

Arrange moulds side by side on bench, dump your mixed batch on the moulds, fill the moulds with the corn. Slide moulds under the press. The number of moulds used for each batch is determined by the space you have to work in and the quantity you want to make.

This hand press is rugged, simple and efficient.

You bolt it to a bench with the arch twenty inches from the front edge of the bench. Slip in the plate for pan work, and fasten it in place by means of cap screw. Slide a pan under and screw down plate into pan. This locates the pan so that you can bring against it the three guides, two sides and back; tighten them in place so that you can slide the pan in between them and bring the press down without danger of the plate coming down on the edge of pan.

Do not press your pop-corn too solid; it does not eat as well and takes more stock per box.

Put the three sets of round cake plungers on the press cross-bar, locating them by putting the mould plate under the press and fastening them by tightening the cap screws. Adjust and clamp the guides each side and at the back of mould plate, so that when you fill it you can slide it in and bring the plungers down without their striking on the edges.

You may put a block under each end of the press cross-bar against the inside of the arch as a stop to regulate the thickness of your cakes.

Three plunger castings are made with small cap screws to fasten them on top of the bench.

Use them to push the cakes out of the mould plate, by pushing this plate down over them.

The press that does not hesitate.

| PULLEY | 7 inches |

|---|---|

| BELT | 2-inch flat |

| SPEED | 500 R.P.M. |

| POWER | ½ H.P. |

| WEIGHT | 350 lbs. |

[p. 34] You will find this press is durable and easily operated. It is adjustable as to thickness of cake from zero inches to two inches.

The press is started and stopped by the treadle on the floor; putting down your foot starts the press, lifting your foot stops it. A positive lock is arranged so that when the treadle is released the machine locks against operation, preventing accidents.

Power press may be driven by our motor (Stock No. 2016-13, No. 2016-14, No. 2016-15, or No. 2016-16.)

Speed, twenty-five strokes per minute.

Capacity. It will take our 16 × 9-inch or 18 × 12-inch pans of pop-corn and press the corn without hesitating.

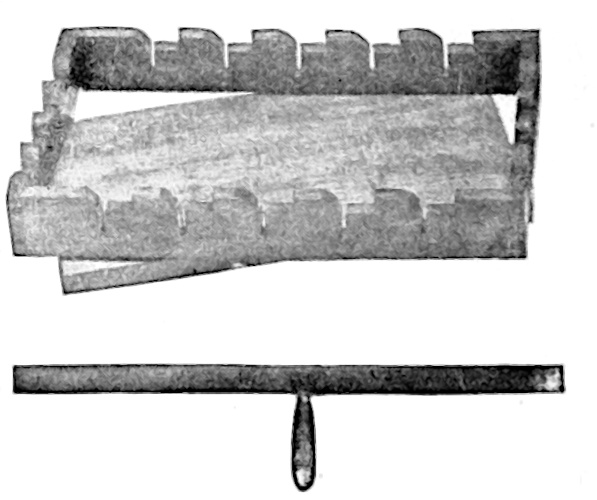

Stock No. 2008-1

These are the very best style of hand cutting rack you can use, made of maple. Nickel-plated handle on straight edge. This rack is made to stay in shape and give long service.

On the bench, about two feet to the right of the press, fasten a board two feet long to the edge, letting it project an inch above the bench.

Place your cutting rack frame against this board on the bench with the bottom board in it and the end toward you.

Take the pan of pressed corn, and turn it upside down on the bench between the press and this cutting rack. A sharp rap will drop the corn out of the pan.

Lift this sheet of corn, put the back end into the cutting rack, bend the sheet into a bow shape so that the front end will go into the rack. Then press down the center.

Hold the straight edge by the handle in the left hand and draw quickly a well sharpened knife (Stock No. 2009-1) toward you along the straight edge to make the cut, passing it through the slots in the sides of the rack. To cut the other way, turn the rack around.

[p. 35]To remove the pop-corn from the rack, lift up the rack frame, leaving the bottom board. The corn will fit tight enough to be lifted with the frame. Set the frame down on the bench to the right. Place your right hand on the pop-corn and lift off the rack with your left hand.

Showing cutting rack with transfer rack on it and showing transfer rack separate

Special Cutting Racks for cutting 16 × 9-inch pans into any size cakes made to order.

This gives the pop-corn brick finished for wrapping, five cakes of different flavors all cut together, making a much better package than hand cutting.

Cuts five sheets in the time it takes to cut one by hand. Pushes five sheets out of rack in one-eighth time that it takes to push five sheets out of hand cutting rack and register one on top of the other for bricks.

Does away with the hand tiring work of cutting with a knife.

Cut your corn with machine accuracy.

Save seventy-five per cent. of your cutting labor.

Increase output per day of pop-corn bricks one hundred per cent.

Drive this by belting from overhead or from motor under the bench. Made with tight and loose pulleys and belt shipper.

| MEASUREMENTS | 63 in. × 27 in. plus overhang of 18 in. |

|---|---|

| PULLEY | 12 in. |

| BELT | 2½ in. flat |

| SPEED | 500 R.P.M. |

| POWER | 1 H.P. |

| WEIGHT | 450 lbs. |

In the making of assorted flavor bricks of pop-corn, you run five batches and fill five pans out of each batch.

First batch, white, vanilla flavor. Second batch, molasses. Third batch, chocolate. Fourth batch, molasses. Fifth batch, pink with wintergreen flavor.

You use five transfer racks and put them in a row on the bench. Turn a pressed pan of corn right from the press upside down on the table to get out the sheet of corn; take the sheet of corn and put it in the transfer rack by putting the back end down first, bend sheet in the middle, put the front end down and then press down the middle. You have five sheets, or pans from a batch; put one in each transfer rack. Do the same with each of the five batches. Sheets being made each one inch thick, the transfer racks will be just filled.

Place a full transfer rack of pop-corn in place on the cutting rack and push the pop-corn down into the cutting rack. Remove the transfer rack. Now run the full cutting rack of pop-corn under the knife in the cutting machine.

The push-out stand should be placed conveniently on the bench, so that you put the cutting rack of cut pop-corn on this push-out stand. As the rack goes down over the stand, the bottom board goes up with the corn on it, so it may be lifted off and the corn slid off onto the packing table.

In the manufacture of penny-pop-corn, it is good to cut them one sheet at a time, then when the goods have become cold pack them. It is necessary to cut them while warm. When the sheets are piled up and cut together as in the Brick and Bar cutting machine, Stock No. 111, they stick together and in the case of the assorted brick, that is just what is wanted. When cutting penny goods, the cakes are wanted separated.

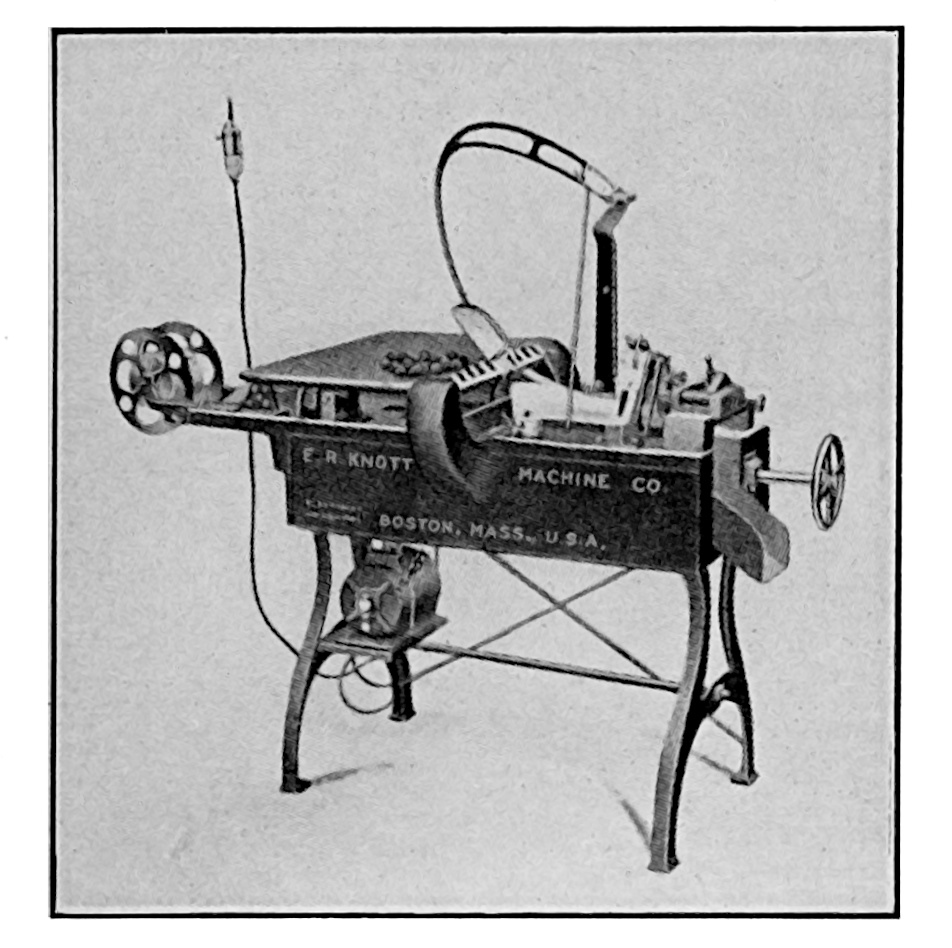

This machine cuts one sheet at a time, but at many times the speed of hand cutting. The sheet is put in the rack and passed through one way, cutting the corn in strips, then the rack is turned and passed through the second part of the machine, which completes the cutting by severing the strips into blocks.

You arrange this machine on your bench in the position as above in the picture. It is best to drive it from a motor on the bench by a chain, but it may be driven from a shaft overhead by belt.

| MEASUREMENTS | 48″ × 80″ |

|---|---|

| PULLEY | 5″ |

| BELT | 2″ |

| SPEED | 500 R.P.M. |

| POWER | 1 + 1 H.P. |

| WEIGHT | 200 lbs. |

Machine complete with 5 racks as shown, may be made to handle sheets of corn 12 inches × 18 inches, Stock No. 2007-2 12-inch pans, and cut the corn 2, 3, 4, 5 or 6 divisions on the 12-inch side and 2, 3, 4, 5, 6, 7 or 8 divisions on the 18-inch side. You see a large variety of sizes are possible by having racks for each.

The machine may be made to cut 9 × 16 sheets, pan 2007-1.

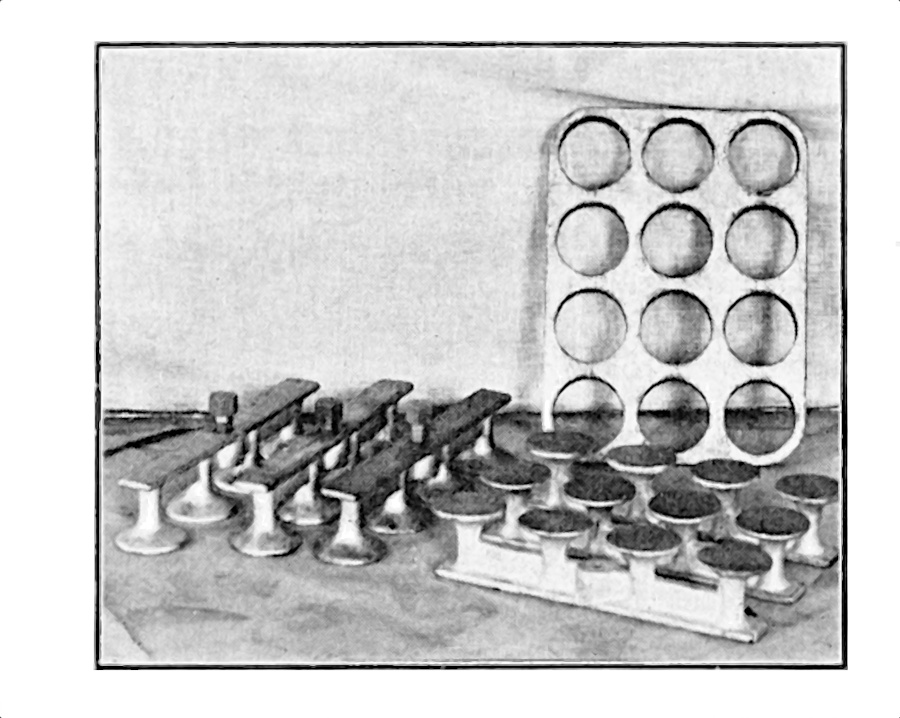

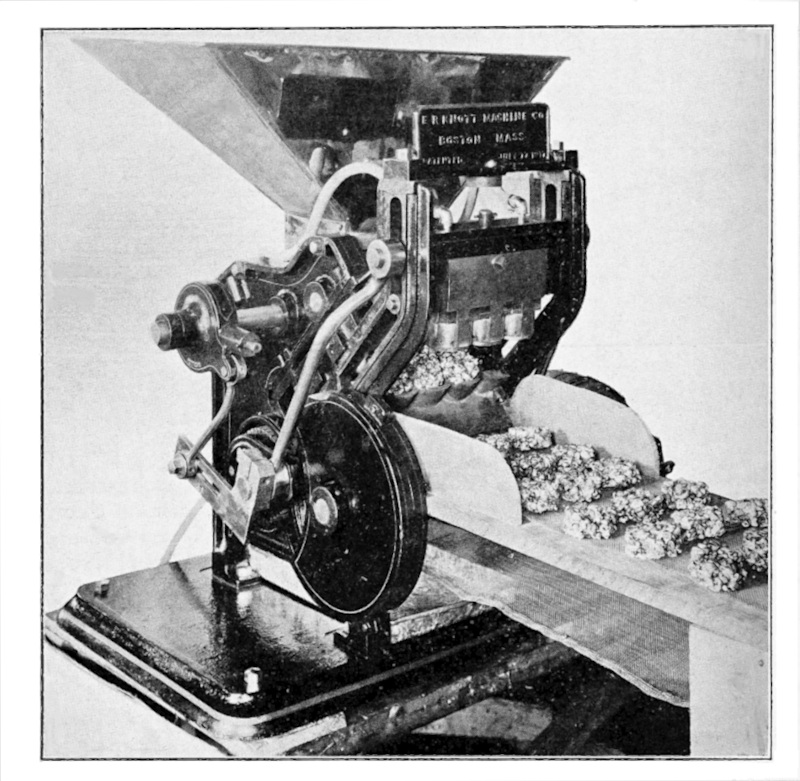

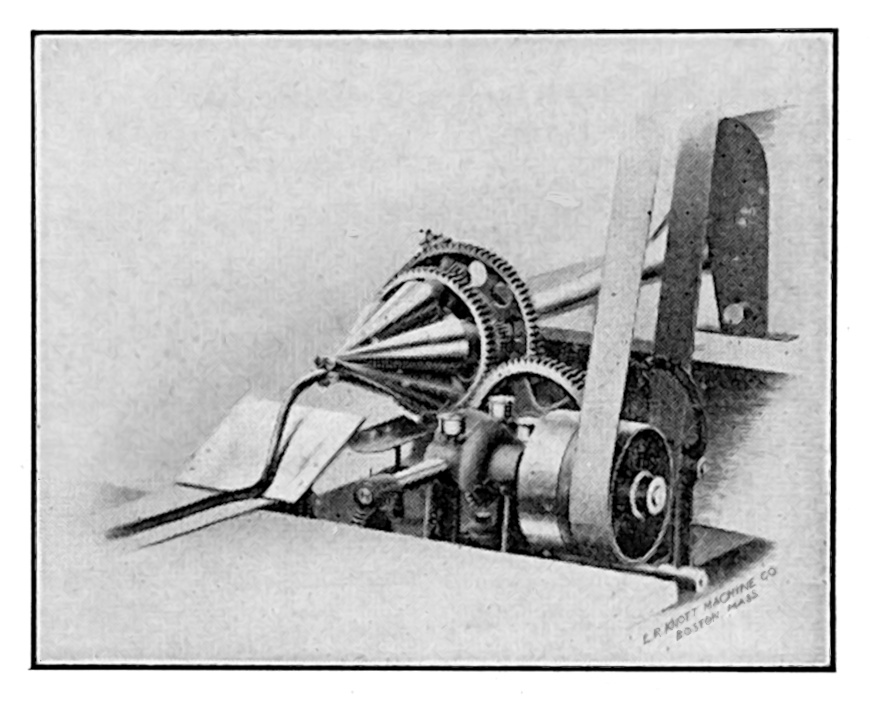

S. F. 3 Machine Making Crispettes

Driven by one-horse motor, then no belt is in the way.

S. F. 3 Machine makes three crispettes at a stroke, 50 strokes per minute, 150 cakes per minute, 2 5-16 inch diameter cakes with the thickness of cake adjustable.

S. F. 6 Machine makes six crispettes at a stroke, 50 strokes per minute, 300 cakes per minute, 2 5-16 inch diameter cakes with the thickness of cake adjustable.

Specify what electricity your motor should be and how long you want the conveyor. 20 feet is good length.

You see at last we have a machine that will make the mixed corn into cakes faster than you can get the batches to it. No longer need you blister your hands filling corn into moulds and make your cakes too solid, or have the batch get cold before all are moulded. As the name says, this machine is a “self filling” machine. You simply place the freshly mixed corn in the hopper on the feed rolls and the machine lays the finished cakes on the conveyor.

Not alone is this machine making in many places the round whole corn fritters, but it works well on ground pop-corn.

[p. 39] It is made up special for cakes of square and oblong shape. It is also used in putting out strips of corn marked to be broken into penny pieces. In fact new applications of this machine are being found constantly. Even a ball of pop-corn is one of the products this machine can be made to produce.

With this automatic means of moulding corn, you can now make at a profit small and thin cakes of corn that could not be made by hand.

The Dainty Pop-Corn Confection

Moulds for Making Brittle Bitts

Use formula No. 5 on page 51 of Knott’s Pop-Corn Book for the syrup in your stock tank.

To make a batch to fill five pans, Stock No. 2007-1 for half round shape, try 1¼ quarts stock and ¾ peck of Ground Pop-Corn, then vary the proportions the next time to suit you.

To make a batch to fill five pans Stock No. 2007-3 for round shape, try 2½ quarts stock and 1½ pecks of Ground Pop-Corn, then vary the proportions the next time to suit you.

Each pressed sheet of Brittle Bitts is 9 inches wide by 16 inches long and composed of 12 sticks 16 inches long.

You may cut them into any length that will divide into 16 inches without waste. Thus, you cut 16 pieces 1 inch long, or 4 pieces 4 inches long.

You can break them apart so as to have each cake made up of two sticks, three sticks or four sticks without waste.

The mechanical handling of sheet Pop-Corn is well described elsewhere in Knott’s Pop-Corn Book.

Popping, Page 6; Sifting, Page 20; Grinding, Page 21; Boiling, Page 48; Mixing, Page 28; Panning, Page 30; Pressing, Page 34; Cutting, Page 34. Look at index, Page 60.

BRITTLE BITTS

Water jacketed, gas burner, galvanized sheet steel

Retail business where buttered pop-corn is sold fast must handle the making in the way to produce the best buttered pop-corn at the lowest price for materials.

Make by recipe on page 49. Mix on Knott’s Pop-corn Mixing Machine and sell from the buttered corn tank where the buttered corn is kept hot by the hot water jacket.

From the time the kettle comes off of the fire to the time the corn is buttered ready for customers, is twelve (12) seconds. That is why this method makes the best, every kernel of pop-corn has a drop of butter on it. Delicious, why, you cannot refuse coming back for more.

This paddle is turned and finished from one piece of stock of straight and close grain. Made to our special design, you will find it will take less strokes to mix your batch than is possible with any other.

This is the knife to use with racks (Stock No. 2008-1) for cutting the corn into Bricks, Bars, etc.

It is a quality product. Hand forged from the best grade of cast steel, hand ground and carefully tempered.

Individual Motor Drive is the most flexible and economical method of driving pop-corn machines. No shafting, no belts, no dirt or grease.

We have found by experience that this type of motor can be relied on at all times. Cheaper motors may be bought, but they are not cheap to run. Here are the motors you should have:

Also three phase Motors

MEASURE your raw materials accurately for every batch. Have your color, flavor, salt, butter, etc., put up in bottles or wax paper, the measured quantity for each batch, and thus maintain uniform quality. Buy these of a Confectioners’ Supply House.

Pop-Corn.—Use only the best, for in the end that is cheapest at any cost. That does not mean that you must pay high prices, nor that high prices assure the best quality. You must judge the quality of the goods by testing them.

Write the E. R. Knott Machine Company for a list of Pop-corn dealers.

Use the best of White Rice Pop-Corn. Secure samples from the dealers and test them in your popper for quality in size of popped kernels, for quantity popped from a scoopful, for length of time it takes to pop, for the amount of waste or unpopped kernels.

Pop-corn of one year’s crop should not be used before the next June and pop-corn from that crop should be used up by the following June. The corn maintains its popping quality best by being kept on the cob, so that corn ought not to be shelled long before it is popped.

Pop the day’s supply of corn the same day you intend to use it.

Use the best. Keep your barrels covered and clean.

Corn Syrup is used not only because it is cheaper than sugar but principally to prevent the candy from graining. The amount of dextrine in it will have a direct effect upon the graining results. Corn syrup varies in the amount of dextrine it contains, ranging from zero per cent. to forty per cent. Twenty-five per cent. at least is required in corn syrup in order to use it with sugar and stop graining, that is, to prevent the syrup from turning back to sugar. Too great a proportion of corn syrup will cause the candy to be tough.

For various kinds of goods and for the same goods in different seasons and climates you will vary the proportion of corn syrup.

You must experiment with the materials that you have available, but you may take this as a basis to start from: seventy-five per cent. of sugar and twenty-five per cent. or less of corn syrup. This will grain and not be sticky or tough, and you may use water on your tools to prevent sticking.

Seventy-five per cent. of sugar and twenty-five per cent. or more of corn syrup will not grain.

Wet your hand before picking up corn syrup so that it will not stick. This method works well in cold weather, but in warm weather use a dipper or let the corn syrup run out of the barrel.

Nothing will spoil the quality of your goods so quickly as a low quality of butter. Exercise great care to see that the butter is fresh, pure and sweet. Put the butter into your candy in the kettle with your syrup.

There are substitutes for butter that may be used in some goods with good results, but be careful, for the keeping quality of the goods is important, as well as the taste when freshly made. Many a business has been a failure because quality was neglected. Quality means freshness, appearance, keeping value, wholesomeness, and the power to stand heat or cold.

Some brands of salt create chemical action and the result is poor goods. Do not use any low-grade salt.

Use salt every batch. Most candy and pop-corn makers do not use enough salt.

Different grades of molasses will give different flavors to the product. “New Orleans” is good. After once adopting a grade be sure to hold to it and not disturb your trade by radically changing the flavor of your goods. Molasses is graded by its sugar content.

This does not receive the attention which it should.

You know that the chemical analysis of water from two local situations, not to mention water from distant points, often varies widely. Therefore, water certainly has considerable to do with the quality of your candy.

Some manufacturers do not use water in their recipes because they say it all has to be boiled out and that the chemical action is not good.

Cream of tartar is used to prevent the sugar returning to sugar or graining, as it is called. A cream of tartar killed batch is short and dry.

Soda used with molasses makes the candy a lighter color by generating gas, which expands it.

The pure food law requirements must be followed and you can secure from your supply dealer the right articles.

You may add your coloring to the batch in the kettle on the fire. Put up in measured amounts beforehand just what you want to use in your batches, then all batches will be alike.

Use the best. By putting it into small bottles, each containing enough for a batch, your goods will all be alike.

There are several styles of raisins to be had; seeded and seedless, and of course, several brands of each. Don’t consider using raisins with seeds in them, as these will not please your trade. Try the different kinds to be found in your local market.

Not enough raisins is better than too many.

Peanuts are to be preferred to other kinds of nuts for mixing with pop-corn. Use the small, well-cleaned, roasted entire nuts with whole or medium ground pop-corn. The small quantity of nuts will make the separate pieces stand out and one poor nut spoils the appearance of the cake and box. A bad nut will make a customer refuse your brand.

Peanuts broken up or ground to the size of half a pea is suggested as one good way to use them.

Care must be exercised in the purchase of cocoanut to see that you are getting quality. Cocoanut may be had either grated, shredded, thread and sliced.

Use the bitter cake-chocolate and cut it up into small pieces.

Crispette wrapping paper is eleven inches long by twelve inches wide. The best paper we know of for this purpose is a forty pound manila wax paper, seventy sheets to the pound. Have it printed at the mill before it is waxed, otherwise the printing will fade, or rub off. A good method is to use a large type label to put inside to show through the plain waxed paper.

Bricks are wrapped in wax paper, size 9 × 12 inches wide, and then a blue paper band with your name upon it is put around to hold the wax paper in place. The wax paper weighs one hundred and twenty-eight sheets to the pound.

Bars are wrapped in wax paper measuring 7 × 16 inches. One hundred and ninety sheets to the pound.

Layer paper, to be put into the boxes between unwrapped pop-corn, may be had. Grade forty pound manila comes in sheets 24 × 36 inches, or cut to the size you want. Twelve sheets 24 × 36 inches weigh one pound. Write E. R. Knott Machine Co. for a list of Wax Paper Makers.

The size of your box must be determined by what you want to put in it.

Penny goods are packed 50, 72, 100, 144, etc., in a box; five-cent package goods 20, 24, 50, 100 in a box.

Buy your boxes of some local supply.

If that is not possible, buy your boxes flat from the nearest convenient maker and use a Corner Box Stitcher to put them together.

Boxes take up less storage space. You make them up as you need them. Boxes are stronger. Other pop-corn manufacturers find this the best way, so you should investigate the method.

Cans, with covers to keep out moisture or the cover put on with a piece of wax paper under it, to exclude moisture, may be used to good advantage by a retailer to protect his stock or by the manufacturer in order to insure the keeping qualities of his corn in the retailer’s hands.

Cases for shipping boxes of pop-corn may be made of corrugated paper or fiber board. Use that which is the cheaper in your own locality.

Crates made of wood may be the best method for your shipping.

Put 10, 12, 20 or 24 boxes in a case or crate.

POP-CORN must form the base of the confection; it is not a material that can be added to a confection with any improving result.

The public when it buys a nut bar, wants a nut bar, and when it buys a pop-corn bar, wants a pop-corn bar, and not a bar made up half and half.

In the use of cocoanut, raisins, or nuts in pop-corn, let the quantity of these be very small in proportion to the pop-corn.

Sell your partly popped and unpopped kernels for chicken or pig feed at one cent a pound. Do not harm your confectionery business by trying to use them in that.

You can grind that product in your mill (Stock No. 2001) as fine as coffee. Sell it as a breakfast food to be served with cream and sugar or to be cooked and served like oatmeal. It will take more power to grind it than it takes to grind pop-corn, so do not expect your popper motor to do it.

An excellent breakfast dish is made by putting a little milk upon a molasses fine pop-corn cake. Try it.

Grind sifted pop-corn to make your fine corn cakes, not the siftings.

If you desire to put up an extra fine grade of buttered pop-corn, or pop-corn brittle, you may use a wire screen size one and one-third to the inch and separate the largest popped kernels for these high-grade goods.

You will find that a small amount of cocoanut will add to the quality of pop-corn when made up in vanilla or molasses syrup in the form of brittle or cakes.

Ground, shredded, thread or flaked cocoanut may be used to increase variety and please various trade. In fact, all three styles of cocoanut added to one style of pop-corn is a good thing.

The use of cocoanut in winter and in summer and its use in pop-corn in different climates with the risk of its becoming rancid are to be considered.

Fresh cocoanut will make a better tasting piece of confection, for it gives a flavor all its own. You must cut it up, grate it and use it in your confection on the same day in order to insure the quality of your goods. If the cocoanut is enclosed in a coating of the candy it will keep as well as the pop-corn.

Dried cocoanut will not become rancid, and will add to the quality of your confection. You need not be afraid of its becoming rancid when you do not get it completely incased with candy.

As to whether the cocoanut is ground, shredded or flaked, makes no difference as far as its use is concerned, but it gives a different flavor and appearance to the confection.

Butter should be cooked into the candy to get the best results.

Use a heaping tablespoonful of cream of tartar to ten pounds of sugar to stop graining when you use no corn syrup. Cook it in the candy.

A little Konut cooked in the candy for coating whole pop-corn makes it stir more easily. Use half as much as the recipe calls for butter.

This is the most important operation. If you do it wrong nothing done afterwards can correct it.

Boiling is to take out the water from your syrup.

The proportions of ingredients will affect the amount of boiling required.

The higher the altitude at which the boiling is done the lower is the degree required to boil it, and the degree will vary to which the candy must be cooked to have it harden in cold water.

You must cook your syrup higher in summer than in winter to attain the same keeping qualities.

Sometimes it is advisable, especially in warm weather, to cook your syrup high and then add molasses, which will set it back. Then boil to your test.

Cooking your candy high may prevent you having time before it hardens to get it well spread over the corn. At the same time you must carry the various operations through as fast as possible so you may be able to use high cooked candy.

Any time you let a batch cook too high you can set it back by adding a little syrup or water.

The degree of cooking alone does not regulate the keeping. The proportion of the materials also has to do with the keeping qualities.

If you are using too small a proportion of corn syrup to the sugar the resulting candy will turn back to sugar, that is, it will grain just the same, no matter to what degree you cook it, unless you use cream of tartar.

In some kinds of ground pop-corn penny goods, it is desirable to let the candy grain in order to prevent stickiness. This is attained by the use of a smaller proportion of corn syrup to sugar and by not letting the goods cool off entirely before boxing. Boxing while warm induces graining.

Candied pop-corn that it is intended should grain a little, may be kept from sticking to the machines and tools by wiping them with a wet rag or sponge. You can easily tell whether to use water or butter when the other will not prevent sticking.

Grease is used in the candy to give the required elasticity and make it less moisture attracting.

The coating of pop-corn with candy is done to keep the pop-corn from absorbing moisture. Consequently the candy must be as moisture proof as possible. And each kernel of pop-corn should be entirely enclosed in a candy casing.

A recipe containing corn syrup and sugar may be boiled to a higher degree than a recipe with molasses in it. Also a clear sugar batch may be boiled to a higher degree than any other. It takes an expert to boil sugar to 345 degrees over an open fire and not burn it. If you use a lot of molasses you cannot boil high enough to prevent sticking and spoiling. Use light molasses, New Orleans molasses. It costs more, but gives quality.

Cooking to a high degree dries out the candy so that it attracts moisture more unless other ingredients, such as grease, are put in to counteract it.

Days when the air is heavy with moisture and the weather warm, it is better not to make candy or make only what you cannot get along without, for the reason that it becomes sticky so quickly that you cannot wrap it before it is in condition to stick to the paper.

You see that you cannot be told just what proportions of materials, cooked to a certain test, will result in a candy that will keep in your territory. You must find that out for yourself. This book merely points out the way.

When measuring pop-corn for these recipes a peck is a heaping peck measureful.

Put one pound of best creamery butter into the pop-corn kettle (No. 2004-2) and set it on the stove. Melt and boil the butter. Considerable steam will rise from it. When that steam has cleared away, which will be in a very short time, the butter is boiled enough. Take the kettle off the fire, set it on top of a barrel, and stir in a handful of salt. Dump two pecks of whole pop-corn into the kettle. Mix it by a motion of stirring and lifting the paddle (No. 2006-1) up through it. After thoroughly mixing, bag from the kettle or put the corn in a water jacketed buttered corn tank (No. 2019-1) from which it is sold hot. After a batch or two you can make the proportions to suit your trade. This article should be made fresh and sold retail at five cents for a ½ pound bag holding a pint. Use Knott’s Pop-Corn Mixing Machine and put in four pecks of pop-corn to one pound of butter.

Never sell buttered corn made the day before. It will drive trade away.

This is made in three flavors and put up in seven different styles. It is sold extensively in Philadelphia and that section of the country. It is generally made in three colors and flavors. Chocolate, white with vanilla flavor, and pink with wintergreen flavor. Other flavors may be made with colors to correspond, such as orange, lemon and sassafras. When put into ¼-pound glacine bags to sell for five cents, or when put into gelatine-covered boxes, so the corn will be protected but still visible, you can have it in single flavors or any desired combinations.

Here is the way to make it:

Put in your kettle (No. 2004-2) on the stove (Stock No. 113) 25 pounds sugar (12½ quarts), 2½ pounds corn syrup (1¼ quarts), 3 quarts water. Bring to a boil and pour into syrup stock tank (Stock No. 2013-1). Put in kettle on fire 2 quarts syrup and ½ ounce butter. Boil until it hardens in cold water; set kettle on Mixing Machine; add a little vanilla for flavor. Dump in one peck of whole pop-corn; stir until it separates; add your chocolate or color over the fire and add the flavor after the kettle is set on the stirring stand.

This may be made in different flavors and colors: chocolate, vanilla, wintergreen, molasses, etc.

[p. 50]Use soda only in molasses brittle. The most common is molasses brittle with cocoanut.

Place your kettle (Stock No. 2004-2) on the stove with 48 pounds sugar (24 quarts), 18 pounds corn syrup (9 quarts), 2 gallons water (8 quarts), 1 quart molasses. Bring to a boil and pour into syrup stock tank (Stock No. 2013-1).

Put in kettle (Stock No. 2004-2) 3 quarts syrup and ¾ pound butter and heaping teaspoonful salt. Boil 320 degrees. Before entirely cooked put in half a pound of long thread cocoanut.

Set the kettle on the Mixing Machine and stir in a heaping teaspoonful of baking soda. Dump in two pecks of whole pop-corn. Stir well. Dump on table while hot and spread out in open thin style to cool.

Put up in ½-pound, 1-pound bags, 5-pound, 10-pound boxes, or in barrels.

Place in your kettle (Stock No. 2004-2) 48 pounds sugar (24 quarts), 16 pounds corn syrup (8 quarts), 2 handfuls of salt (¼ quart), 2 gallons of water (8 quarts), 2 quarts of molasses. Bring to a boil and pour into syrup stock tank (Stock No. 2013-1).

Put in your kettle (Stock No. 2004-2) 1 quart of syrup, Konut half size of a hen’s egg (Konut is a butter substitute) and butter size of a large hen’s egg. Boil to 300 degrees. Set kettle on Mixing Machine. Dump in two pecks of whole pop-corn. Stir thoroughly.

Scoop out onto crispette mould and proceed as instructed, page 31.

Put into the kettle 18 pounds corn syrup (9 quarts), 1 gallon molasses (4 quarts), 1 gallon water (4 quarts), 4 pounds butter, 4 pounds parasub (a butter substitute), 10 pounds “C” (a grade of brown) sugar. Bring to a boil. Melt in 40 pounds white sugar. Pour this in syrup stock tank. Letting this syrup stand over night seems to season it so it uses better.

Put in the kettle 1 quart of syrup. Boil to 300 degrees. Drop in a tablespoonful of salt just as you take the kettle off the fire. Put kettle on Mixing Machine. Dump in two pecks of whole pop-corn. Stir thoroughly.

Scoop out onto crispette moulds and proceed as instructed, page 31.

The maker of this recipe claims that cooking the salt in the batch makes the candy sticky.

Put in kettle (Stock No. 2004-2) 75 pounds (37½ quarts) sugar, 25 pounds (12½ quarts) corn syrup. Bring to a boil and pour into syrup stock tank (Stock No. 2013-1.)

Take ¾ quarts of stock in kettle on fire. Add ¼ quart molasses, ¼ pound Konut, parasub or other good butter substitute. Put in ⅛ pound butter and a tablespoonful of salt. Boil to 285 degrees. Set kettle on Mixing Machine and put in pinch of soda. Dump in one peck of sifted whole pop-corn. Stir thoroughly and quickly. Scoop out to fill[p. 51] crispette moulds or dump batch on three pans and proceed as instructed on page 30.

Put in kettle (Stock No. 2004-2) 60 pounds sugar (30 quarts), 2 gallons water (8 quarts). Bring to a boil and pour into syrup tank (Stock No. 2013-1).

Put in kettle on fire 1 quart stock, ⅛ quart molasses, ¼ pound butter, 1 even teaspoonful cream of tartar. Boil until hard in cold water. Set kettle on Mixing Machine. Dump in two pecks whole pop-corn. Stir thoroughly and quickly; dump while hot on pans or fill moulds.

This may be made up in round sticks, bars, bricks, blocks, round cakes and balls, any shape. Many flavors and colors may be used. The white pop-corn yields well to using colors to represent various flavors.

Chocolate is its own color. Use pink color with wintergreen flavor, vanilla with the natural white color of the pop-corn, molasses is its own color, orange color with the orange flavor, etc. These five colors, each in eight shapes, give forty varieties of pop-corn packages.

Use 60 pounds sugar (30 quarts), 40 pounds corn syrup (20 quarts), 2 gallons water (8 quarts). Bring to a boil and pour into syrup stock tank (Stock No. 2013-1). Put in your kettle 1½ quarts of this stock. The color, or chocolate, you may put in the batch on the fire, the flavor (wintergreen, orange, vanilla, etc.) you must add to the batch when you take the kettle off the fire, otherwise the flavor will boil away. Add chocolate just before you take kettle off the fire. Put in a teaspoonful of salt and a piece of butter size of half an egg. Boil to 286 degrees. Take kettle off fire and set on Mixing Machine; add flavor. Dump in one peck of sifted whole pop-corn and stir thoroughly. Fill crispette moulds or dump on pans and proceed as instructed, page 30.

Remember that a handful of fresh ground flaked or shredded cocoanut adds a variety to the goods; also raisins and peanuts. Add these at the time you set the kettle off the fire onto the stirring stand. These increase the number of styles under this recipe over two hundred and forty.

Follow the foregoing recipe for making fine or medium ground pop-corn cakes.

Make pop-corn in sheets three-eighths or one-half inches thick. Between two sheets put peanut butter, whole peanuts, raisins, etc. The particular likes of your neighborhood may be catered to by the filling you put into these sandwiches. You can cut them into various sizes, even as small as a caramel if you wish.

Make five batches: first, molasses; second, vanilla; third, chocolate; fourth, wintergreen; fifth, molasses. Fine pop-corn. Each batch is panned, pressed one inch thick and cut up in rack; make as many piles[p. 52] as you run pans; place the vanilla on top of the molasses. The cutting rack has a beveled edge so that it will easily slip over the previous sheet to register the cut cakes one on top of the other. When the five sheets are piled you can easily separate the bricks for wrapping. Use Knott’s Brick and Bar Cutting Machine, it does the best work.

Sugar in the shape of the good old white granulated sugar is not in sight sometimes (as in 1919, or in the year 1917 all through the Eastern States).

Consider brown sugar. Remember that brown sugar is not to be used in white goods. It can be used in place of combined white sugar and molasses; weight of brown sugar for weight of white sugar, plus molasses, with nearly same results. There are several grades of brown sugar and the price increases as the grade improves. If you use brown sugar, where formerly you used white, reduce by from 10 to 20 per cent. the quantity of corn syrup to a batch.

Then get some grape or corn sugar. You will have to work out new formulas, yes; but that is oftentimes better than going out of business.

Corn syrup? Yes, even get along without it. Before corn syrup was on the market cream of tartar was used to cut the grain of sugar.

It needs more accurate handling of the batch and requires working with cleaner kettles than is required with corn syrup. Try using an invert sugar, or corn sugar. Water will cut the grain in sugar if enough is used.

Without cane sugar and without corn syrup, how is pop-corn to be made? Do not forget there is honey, corn, or grape sugar, maple sugar, molasses and sugar substitutes on the market. Molasses alone cooked as high as it will go without burning will make a good winter corn cake. Honey is a very fine flavor and of high sugar content.

Pop-corn cakes can be made, even without sugar or corn syrup and be mighty nice in flavor and wholesome. When you do not get sugar, others do not have it and if you can deliver goods, you make the price to cover any increase in cost of materials.

BE afraid to have accounts receivable as well as accounts payable. Well-made pop-corn keeps about as well as crackers. You can, therefore, follow the cracker manufacturers’ distribution methods somewhat, the taking of orders and delivery by wagon to retail stores, the packing in tin cans, the wrapping in wax paper sealed packages, etc.

You must depend on the consumer to keep your factory in operation, so always let the consumer take up most of your mind.

The methods used in getting your goods to the consumer will be chosen according to where the consumers you want to serve are located.

You have the mail order method which will enable you to reach a large market. You get the retail price for your goods, you can do your business where rents are low, you can get the goods to the customer fresh. However, you must secure a way of getting orders that will not take all the profit. The package to insure delivery of the pop-corn in perfect, wholesome condition must not be unreasonable as to its cost.

You may sell at retail over a store counter. Your sales in this case depend on your location and your advertising to draw trade to the store. Best locations in cities require the payment of big rent, which pop-corn will not warrant. A good location in a center of population at a fair rent, then advertising to your prospective customers with samples is the best, but be sure your advertising is consistent with your prospects. Now, in addition to this, send out pedlers on a commission basis. Have your goods on sale at the moving-picture theatre entrances, at the band concerts, at the ball games, at every picnic. In fact, every time a crowd collects have your goods sold. When displaying goods on counter, or when using cans or boxes to store the goods, be sure the oldest goods are at the top of the can, or at the top of the pile on the counter so that those will be sold first. Use tins to keep pop-corn in; it keeps better.

Remember the consumer must get your goods under your trade-mark when they are fit, to make him want more.

Besides making your goods so they will keep as long as possible, and packing them so as to exclude dampness, you should endeavor to know about the goods in the dealers’ hands so that the consumer may buy nothing stale.