Please see the Transcriber’s Notes at the end of this text.

“LEARN TO DO A THING BY DOING IT.”—OLD PROVERB

SELF-HELP

MECHANICAL DRAWING

AN EDUCATIONAL TREATISE

BY

N. HAWKINS, M. E.

Author of Handbook of Calculations, etc.

New York: THEO. AUDEL & CO.,

Publishers

1902

Copyrighted

by

Theo. Audel & Co.

New York

1902

This work

is

most kindly and

respectfully dedicated to

THE COMING MAN

who at the present time

is undoubtedly devoting

a goodly share of

his spare time to

the study of

drawing.

[13]

It is because of a personal and practical experience of the advantage to be gained by the possession of a knowledge of drawing, that the author is prompted to undertake the rather pleasant task of producing a self-help book relating to the subject.

Since the days of youthful endeavor, the author has passed through an extended experience of mechanical life, and scarcely ever without chalk, pencil or instrument in hand, to illustrate by sketch or drawing, the tools to be employed, or to picture the finished product; accordingly, throughout this work, words of explanation and the drawings will go together to aid the diligent student.

It has been said by an eminent writer, that “one workman is superior to another—other circumstances being the same—directly in proportion to his knowledge in drawing, and those who are ignorant of it must in many respects be subservient to others who have obtained that knowledge.”

It has been also said that no man is fitted to be foreman of a shop who cannot draw, and it is generally true that no one will be appointed to that position, except temporarily, who does not possess some knowledge of the art, either “freehand” or instrumental.

[14]

It is a question how far a good working knowledge of drawing can be attained without a teacher; it is true that but few have become proficient without such aid, but it is equally true that “self-help” has been the key note to all advancement.

The author received personal instruction in several ways and times, at home, in school, in an architect’s office, and under an experienced mechanical engineer, but it was in the early morning hours of a bright summer time—lang syne—that he made his first serious attempt to master the art of mechanical drawing. It was a struggle and a battle to hold himself down to “the board” to the finish, but it was a victory—one, won over slothfulness and impatience, and of such a nature as to warrant the use of the term “self-help” to the encouragement of others.

In conclusion two sentiments may be added; if a good working knowledge of drawing is “worth the while” then, 1, the student should be thoroughly in earnest in acquiring it; 2, he should be willing to take sufficient time and give much hard study to gain the skill necessary for success.

This persistence is not irksome. It carries its own reward, and the results are definite and sure.

[15]

Drawing is one of the arts; art relates to something to be done, and art in the industrial and mechanical sense aims chiefly at utility, and is governed by exact rules; hence mechanical drawing—so-called—tends first to be useful and helpful, and second to accuracy in execution, including most minute details; it aspires to the perfection of nature in adaptability of the means to the end.

Drawing constitutes a universal language, to acquire which is a matter of importance, for by its use one is able to illustrate the form and dimensions of an object, device, or utility, in very much less time, and far more clearly, than by a verbal description.

To a person who may not be able perfectly to understand the language of a country, to be able to draw is an aid and a safeguard; to use the words of Sir Joshua Reynolds, “the pencil speaks the language of every land.”

In extensive iron works and metal-working establishments the designer and draughtsman is always in demand. His services are indispensable and his position is a highly responsible one. It becomes his pecial[16] province to design improvements, to furnish sketches and to make finished drawings; to calculate strains, strength, power, motion, weight, friction and durability. All this and much more is the professional draughtsman’s work.

In “directory” classification, he who accomplishes such comprehensive results as above described is termed a “Draughtsman,” but the word has as wide a meaning as “Engineer,” which takes in civil, mechanical, naval, sanitary, steam and other engineering specialists. So, in drafting, it includes the office boy employed in making blue prints, it embraces the copyists, tracers and assistants, as well as the head draughtsman and chief engineer.

Consequently the range is wide, and the line hard to draw between draughtsmen who work with their hands, and those who work with their brains. It may be added that the best men are too frequently undervalued, owing to the unavoidable difficulty in distinguishing the difference in true worth, between the two widely separated classes.

It may be remarked that they only draw well who draw intelligently; aptness in this, as in many other virtues, is a matter of slow growth, “here a line and there a line”—it’s the proper direction, not the rate of progress, that counts in the end.

There are several methods of drawing—1, Free-hand; 2, Instrumental; 3, Geometrical; 4. Perspective. In the first the work, also termed sketching, is executed by pencil, pen, crayon, or even paint-brush; in the second the result is attained by the use of rule, tee-square, drawing pen, etc.; this method is also denominated mechanical drawing, and suggests the title of this volume.

The great usefulness, not to say necessity, of readiness in executing accurately, drawings “to scale,” is[17] emphasized by the fact that now, more than ever, is all machinery designed, and it may almost be said, is “built,” in the draughting room—this is a valuable hint relating to “reading” drawings.

It is wise, as well as easy, to begin at the beginning of things; thus, it is altogether the good part to mount a ladder by the first and second rounds rather than to attempt it by taking the third, sixth, ninth, etc.—especially are first and second rounds the very best to start upon; “Chalk-work,” is the first subject introduced, next, that of “Free-hand.” These are the first steps leading upward in this most agreeable attainment—skill in illustrating and designing of objects, tools, and utilities.

A single word of advice before introducing the elementary work connected with mechanical drawing: if the student should experience difficulty in mastering the diagrams and curves abounding in this book, let him consult an experienced draughtsman or teacher, who, by a few strokes of a lead pencil, can easily make them plain; that knowledge—which cannot be printed or self-taught—termed the Craftsman’s Art, is communicated largely by personal telling and showing, from man to man; in drawing, this help should be thankfully availed of, when necessity arises.

Note.—Sketching is often in demand because there is no time for finished or careful drawings, and the one who can draw a few lines in a moment to let a sudden necessity be known, is the man of the hour. All candidates for First Class Engineer’s Certificates in marine service in the navy have to undergo an examination in rough drawing; this is intended not so much as a proof of the applicant possessing the capability of a draughtsman, but in the event of any injury to the engines in his charge, so that he may be able to send to his Superintendent a rough drawing of the particular part, properly dimensioned, so that it could be worked from, and time saved on the arrival of the ship at the port where the repairs are to be done.

[18]

[19]

[20]

“No matter how thorough our education may have been

at the first, rules and formulas will slip from the

memory, and every day’s experience gives additional

evidence of the truth of the old adage that ‘THE

KEY THAT RESTS, RUSTS.’”—Simpson Ballard.

[21]

The purpose or scope of this work may be briefly stated: It is to aid the aspiring student in making the first advance towards a thorough and useful knowledge of drawing in its several divisions, as elsewhere defined.

The method to be followed in presenting the subject will be the natural order clearly and simply defined, as “from the less to the greater.”

The first subject to be discussed comes under the heading of chalk-work, i. e., such drawings as can be executed on a blackboard, a floor, or even on more primitive surfaces, such as a smooth stone or board.

This is indeed a lowly beginning, but the author is quite confident it will awaken as much interest as any part of the book—even in the most experienced in the art of drawing, as to them it will revive the ambitions and first crude attempts made in the golden days of their youth.

Let it be clearly understood by all, and especially by those who wish to learn drawing, that the study of this delightful art does not require any special qualification. We need only ask one question: Have you learned to write? If so, be assured you may learn to draw, but to all the same rule applies, first the elements of the art, and afterwards the more advanced study.

It is not expected that all should exhibit a decided taste for drawing, for the possession of this is rather a gift of nature than the result of education; but a knowledge of principles and a certain amount of executive ability[22] may be obtained by every one of average capacity, and whatever the natural power may be, it will be increased and developed by exercise; if the progress is steady and continuous and in the right direction, success is sure to crown the work.

The second division of the book will be free-hand drawing, i. e., that which is executed without instruments. Nothing to instruct has been spared in this important step in the path of advancement.

The illustrations accompanying the two opening sections have been made designedly elementary, for there are many who have a taste for drawing and who have a desire to learn, who from place of residence or other circumstances have not the opportunity of receiving the assistance of a master. To such this book presents itself as a friend directing to the right road, talking, reasoning, and explaining by the way.

The “chalk-work” and “free-hand” sections of the book relate to the foundations upon which all must rest who seek the aid to be derived from the art; hence, the following pages are written with a view to encourage all, and those who are prepared to follow the directions given in them may look forward to the possession of sufficient drawing power to add to their usefulness in after life.

At this point of attainment there arises a need to know the meaning of many words and phrases used by draughtsmen; these are grouped alphabetically from A to Z under the heading of,——

Useful Terms and Definitions: Memorizing these few pages will be of benefit, as an intimate knowledge of the language of the drawing office stamps a man as worthy of a hearing, and assures attention to anything which he may write or say pertaining to the art.

[23]

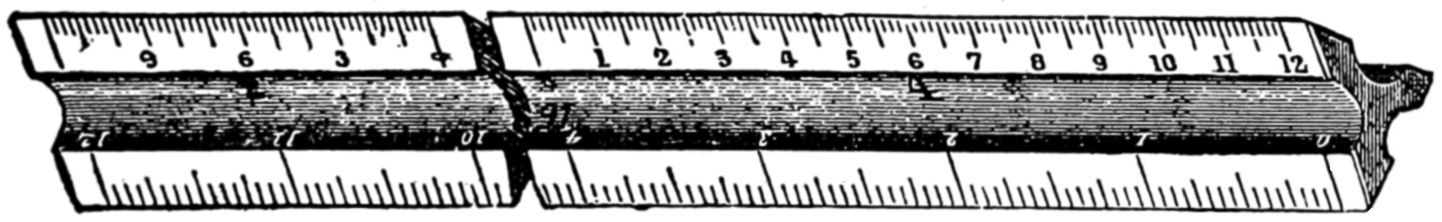

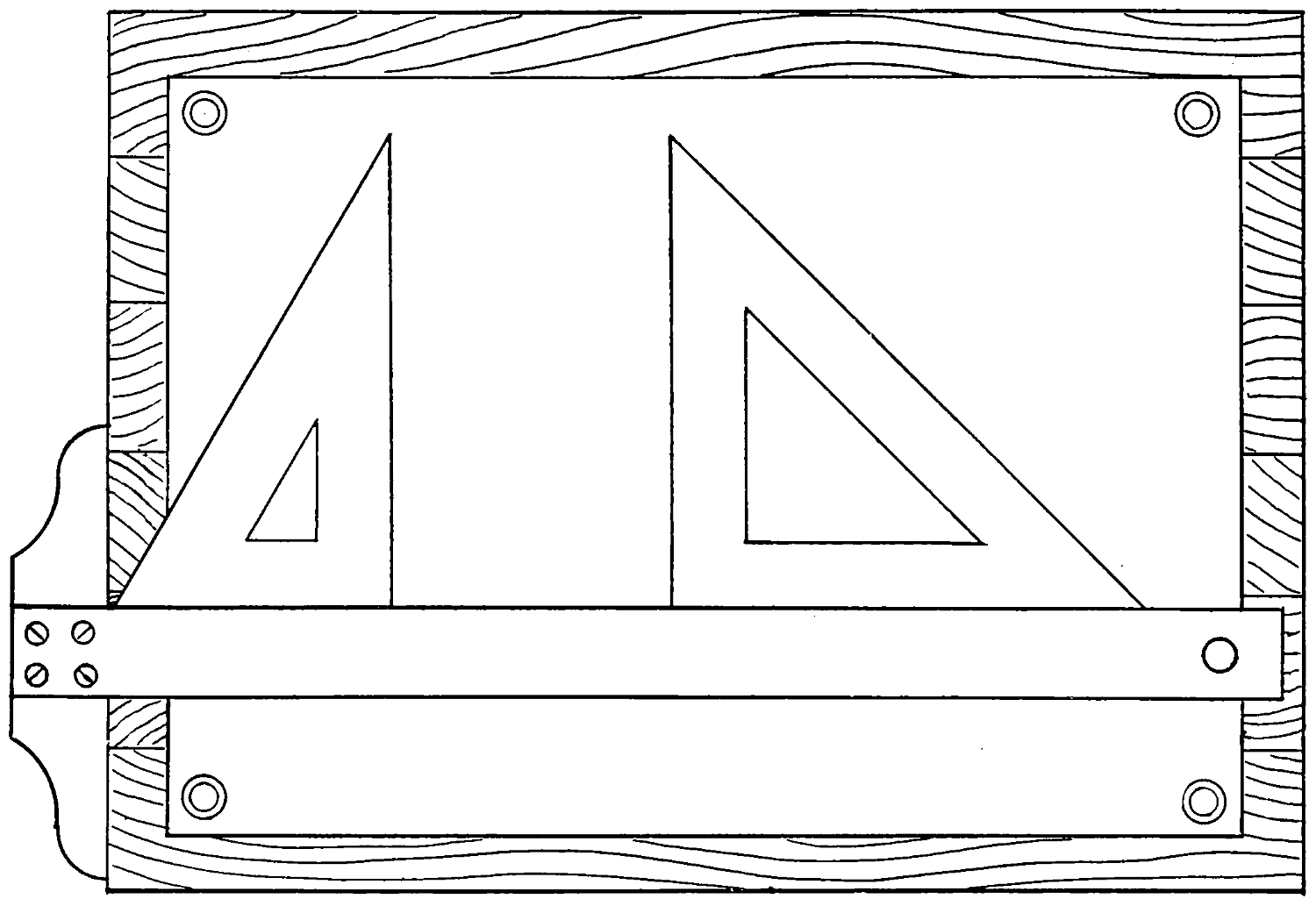

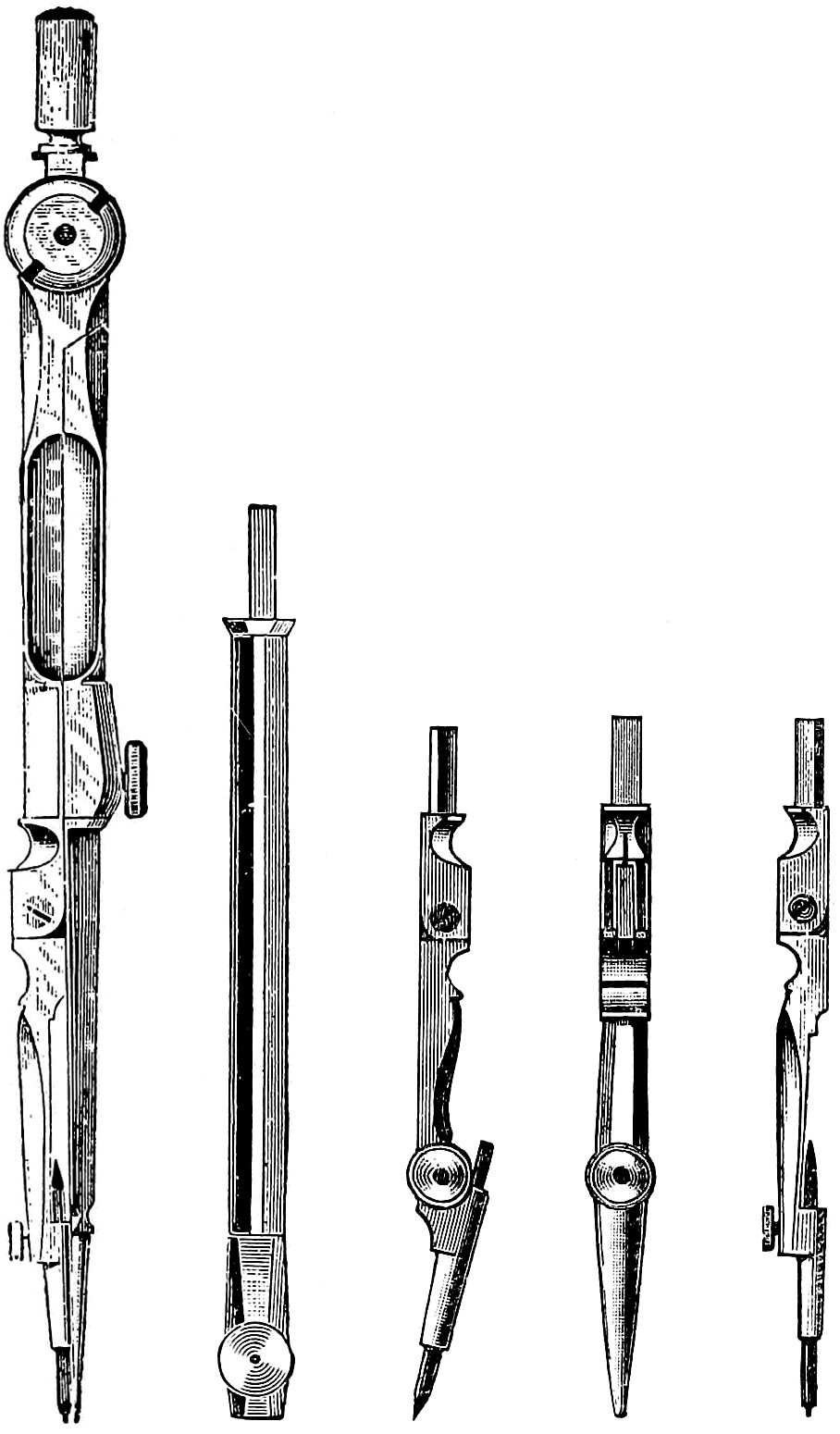

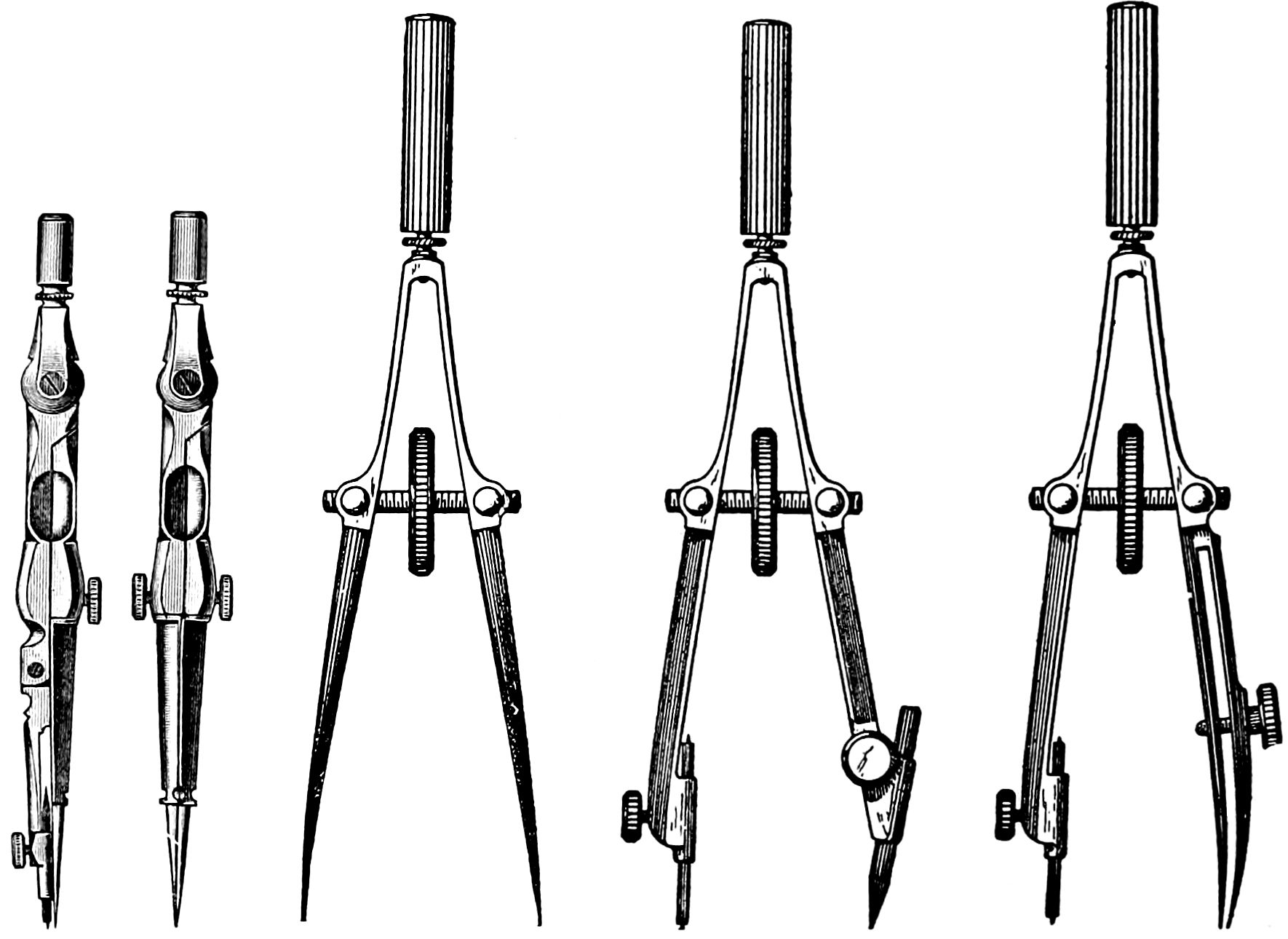

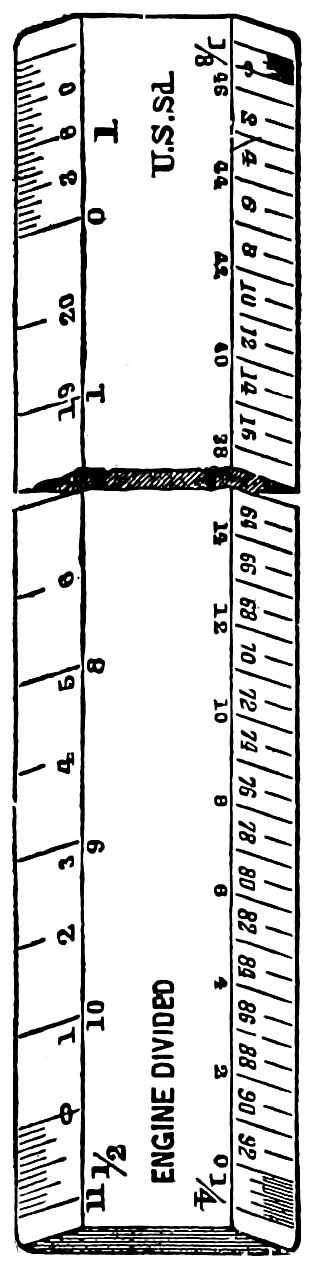

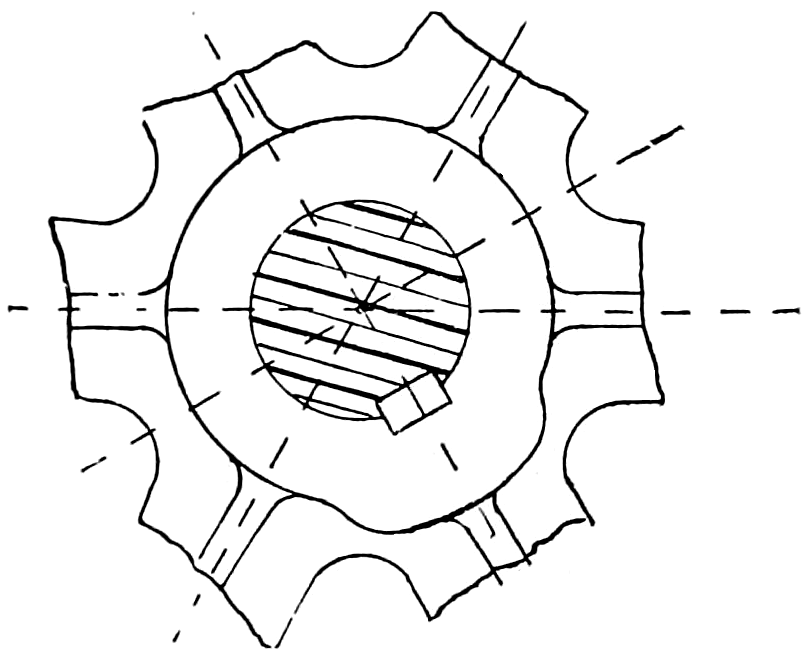

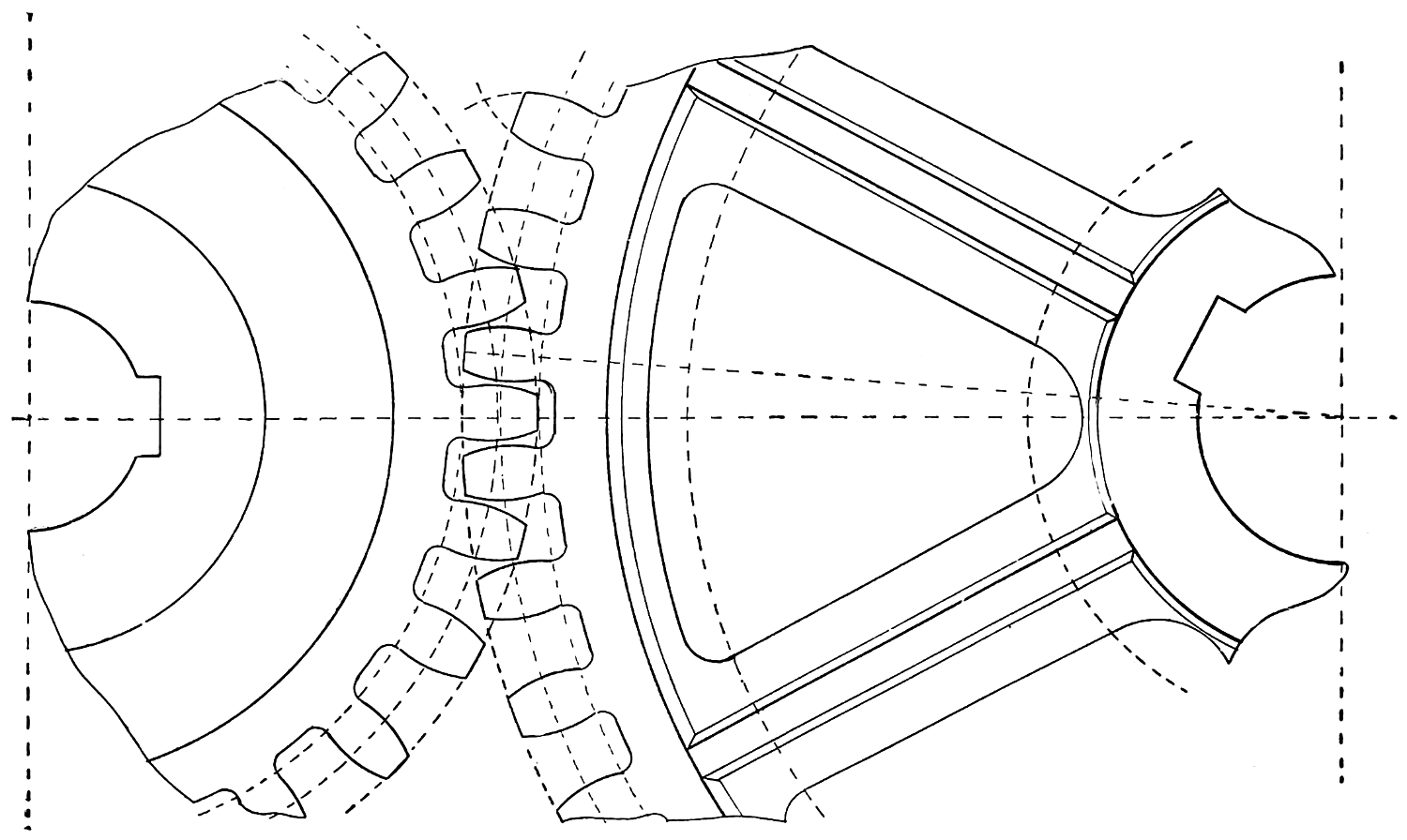

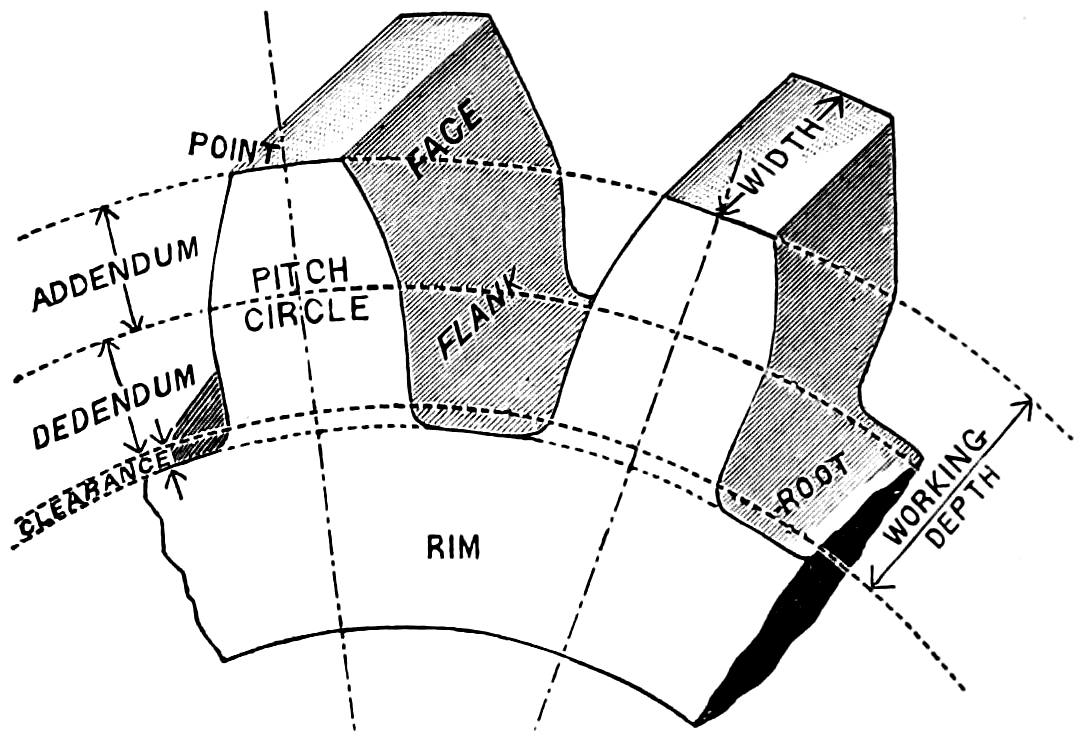

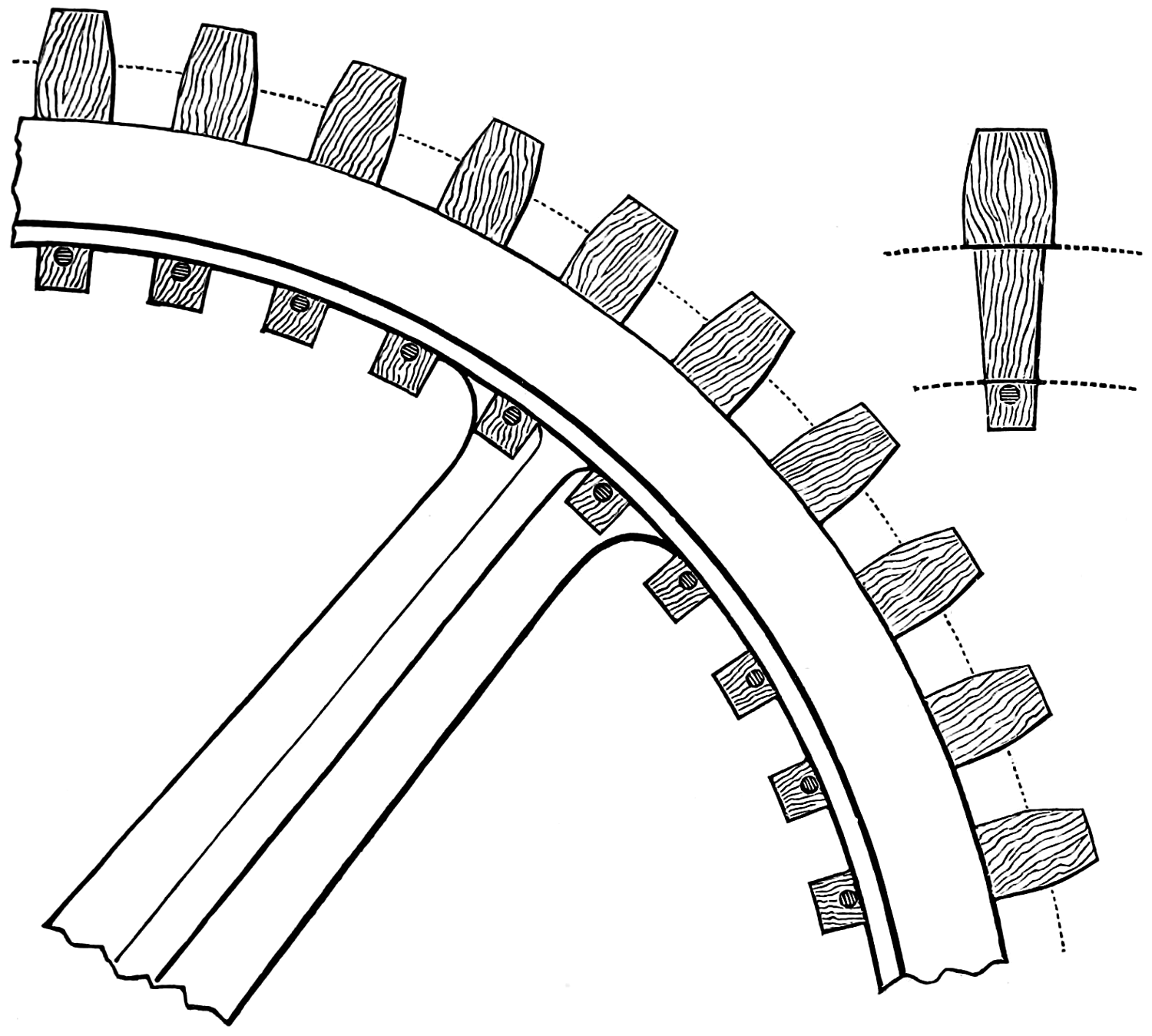

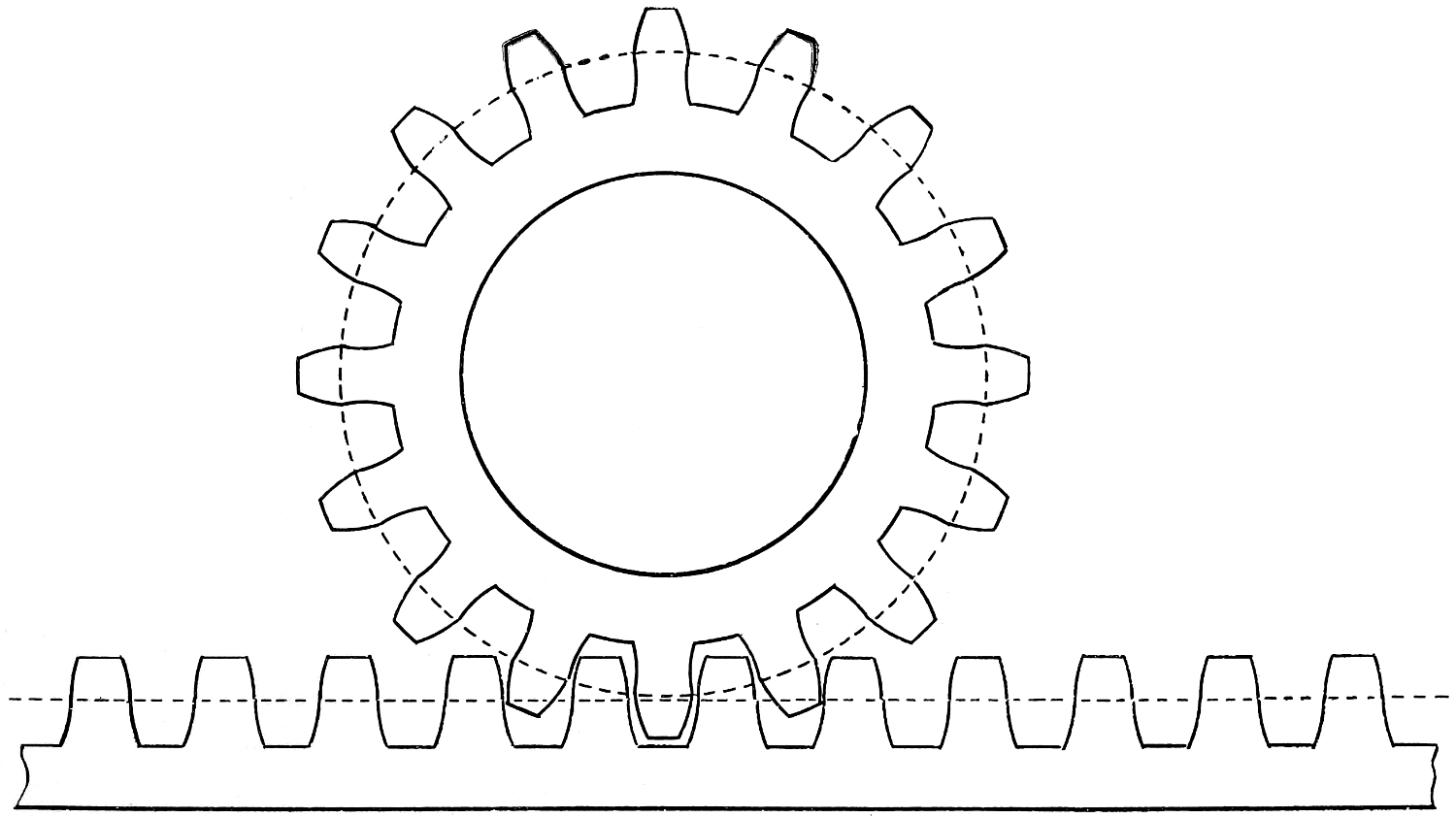

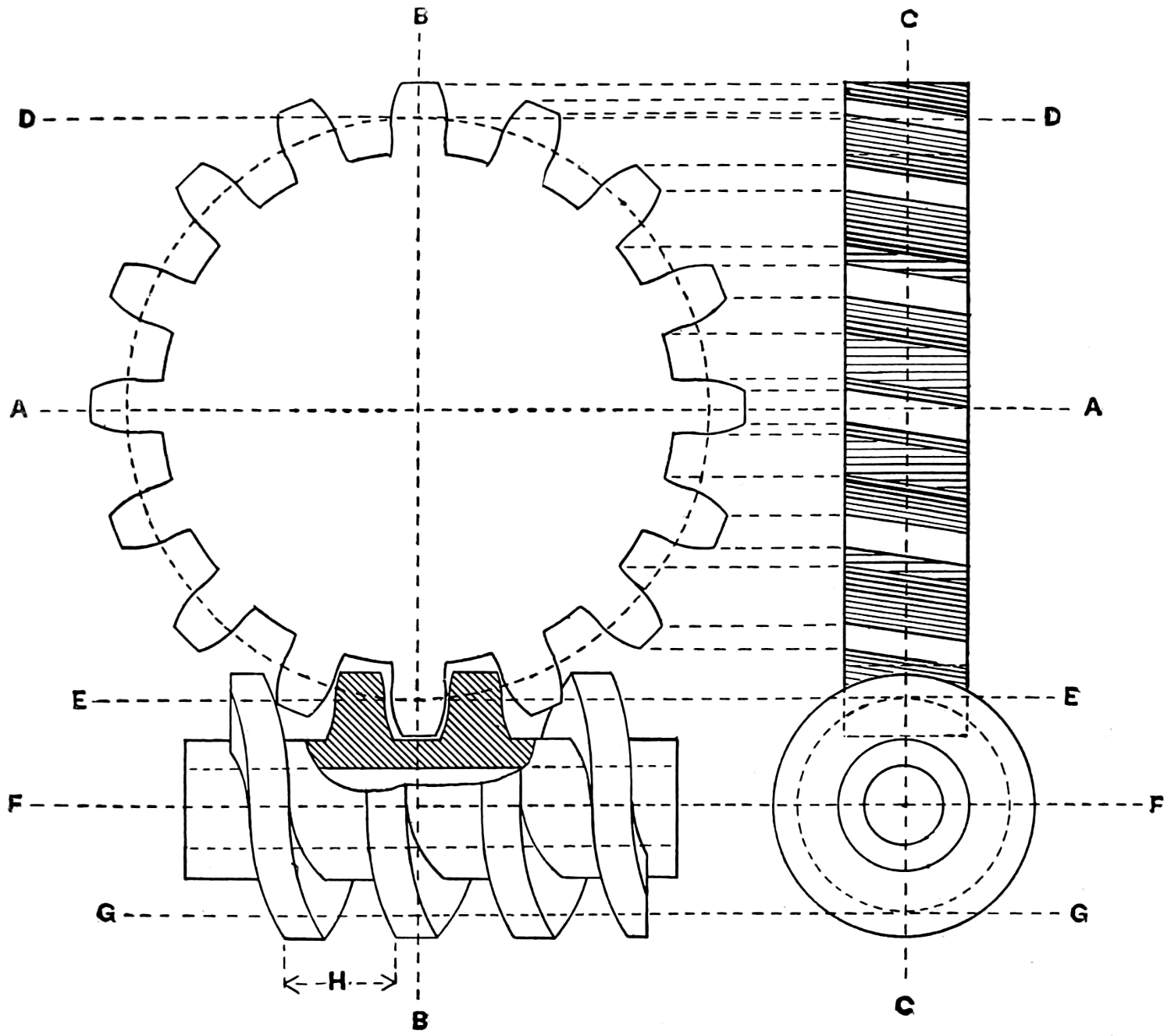

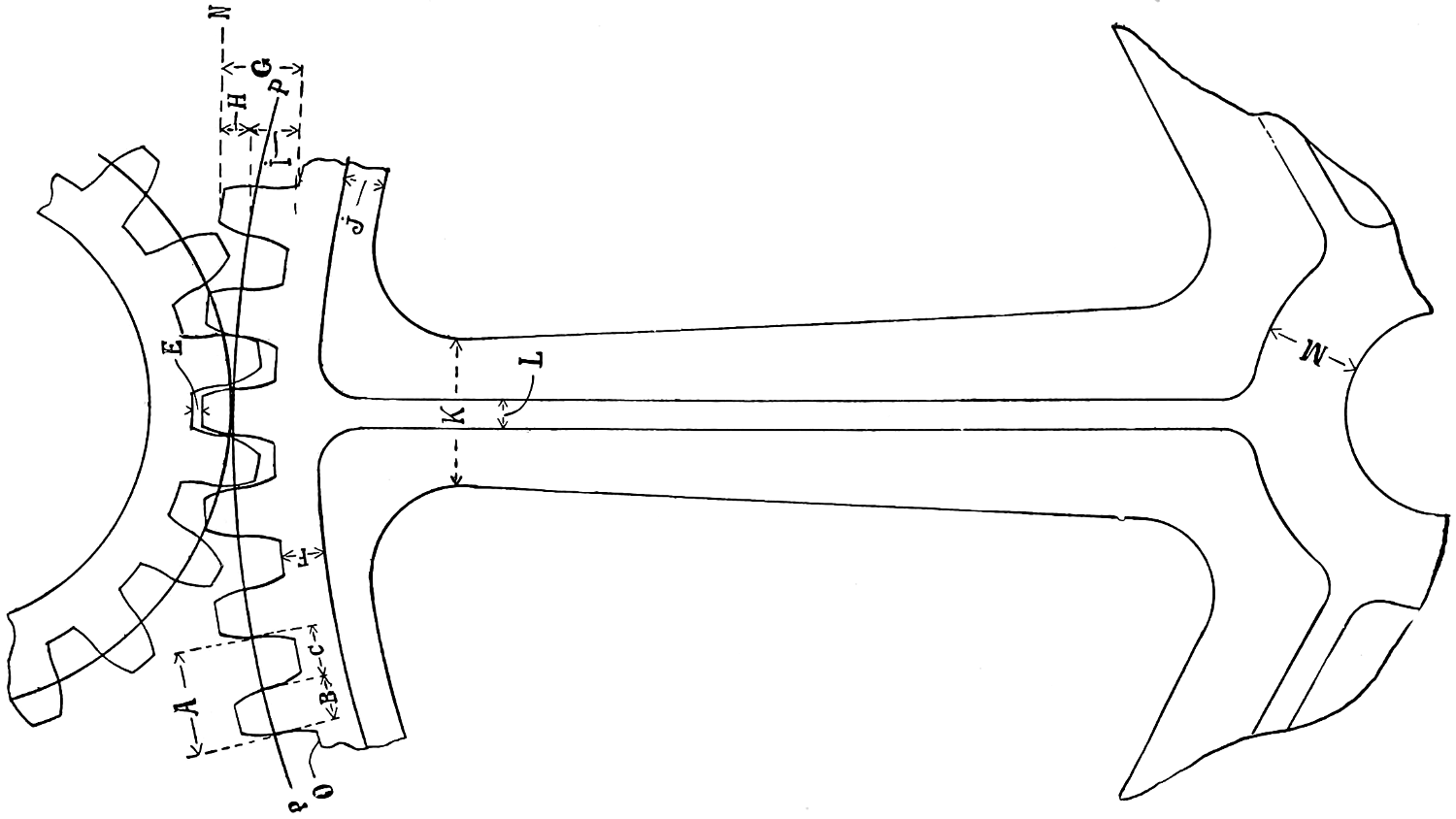

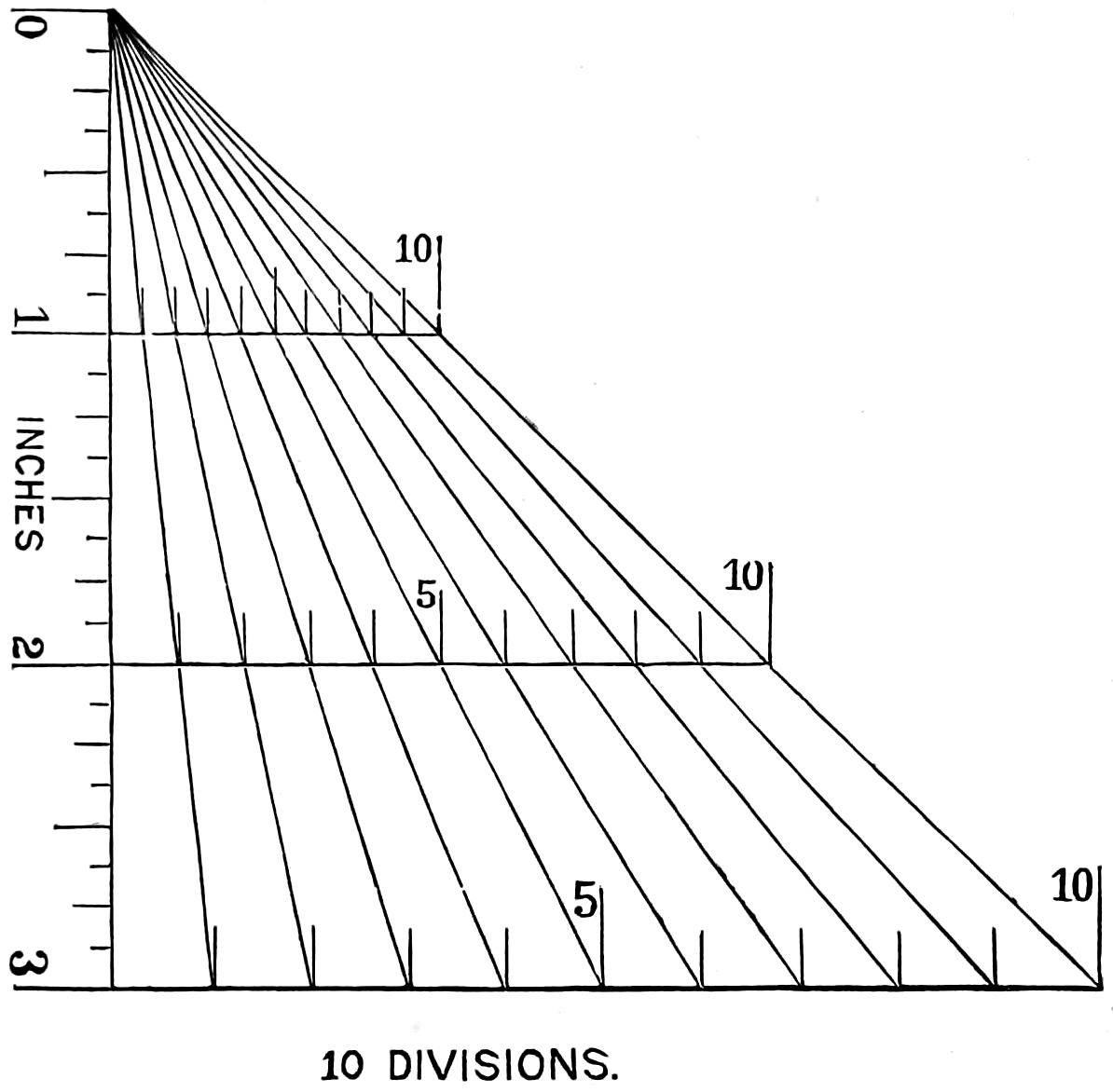

After the Definitions the subject explained will be the Instruments and Materials used in mechanical drawings; following in due course appear Geometrical and Mechanical Drawing, Gearing, Linear Perspective, Projection, Shading, Tracing, Lettering, Drawing Office Rules, Reading Drawings, Useful Tables and a General Index, to which the student is referred. A careful reading is requested to the following helpful note.

Grateful acknowledgment is made to George Perrott, Esq., M. E., for practical and technical assistance throughout the work, and to Theo. Lucas, Engineer, for text and illustrations in the portions of the book relating to Linear Perspective and Projection.

Note.—In Machinery Prof. Chas. H. Benjamin says, referring to drawing, under heading “How and what to study,” “... I have so far said nothing about drawing, for I do not think it of much use to learn that, until you know what you want of it. All this time that you have been studying mechanism you should have had a sketch book or pad of note paper, and made free hand sketches of mechanical movements which interested you and of various machine details. You should accustom yourself to use drawing as a means of expressing ideas, just as you use written words, so that it becomes a second nature to you to sketch anything you wish to remember or describe. If you work from blue-prints in the shop, or if you can borrow some to study, this will help you to understand how a drawing is made. You can get some drawing instruments at any time and begin to practice on drawing straight lines and circles, so as to become familiar with the instruments. And here it will be of great benefit to you if you can attend an evening drawing school for one night in the week at least.

“When you have become sufficiently familiar with the principles of drawing, a book on mechanism will tell you how to draw gear teeth and cams, and how to design various link motions. Make up your own problems from what you see in the shop and make your drawing a means to an end and not the principal thing; it is of little use to be able to make a nice drawing unless you know what to draw and why.

“Drawing is a convenient tool as an aid in expressing to others the ideas which you wish to convey; in all cases take the problems and the ideas from your every-day work and that which is around you; your success will depend upon the close connection which you keep at all times between your acquired knowledge and your practical work.”

[24]

| Introduction, | 1-24 |

| Chalk Work, | 25-38 |

| Preliminary Terms and Definitions, | 39-52 |

| Freehand Drawing, | 53-78 |

| Geometrical Drawing, | 79-100 |

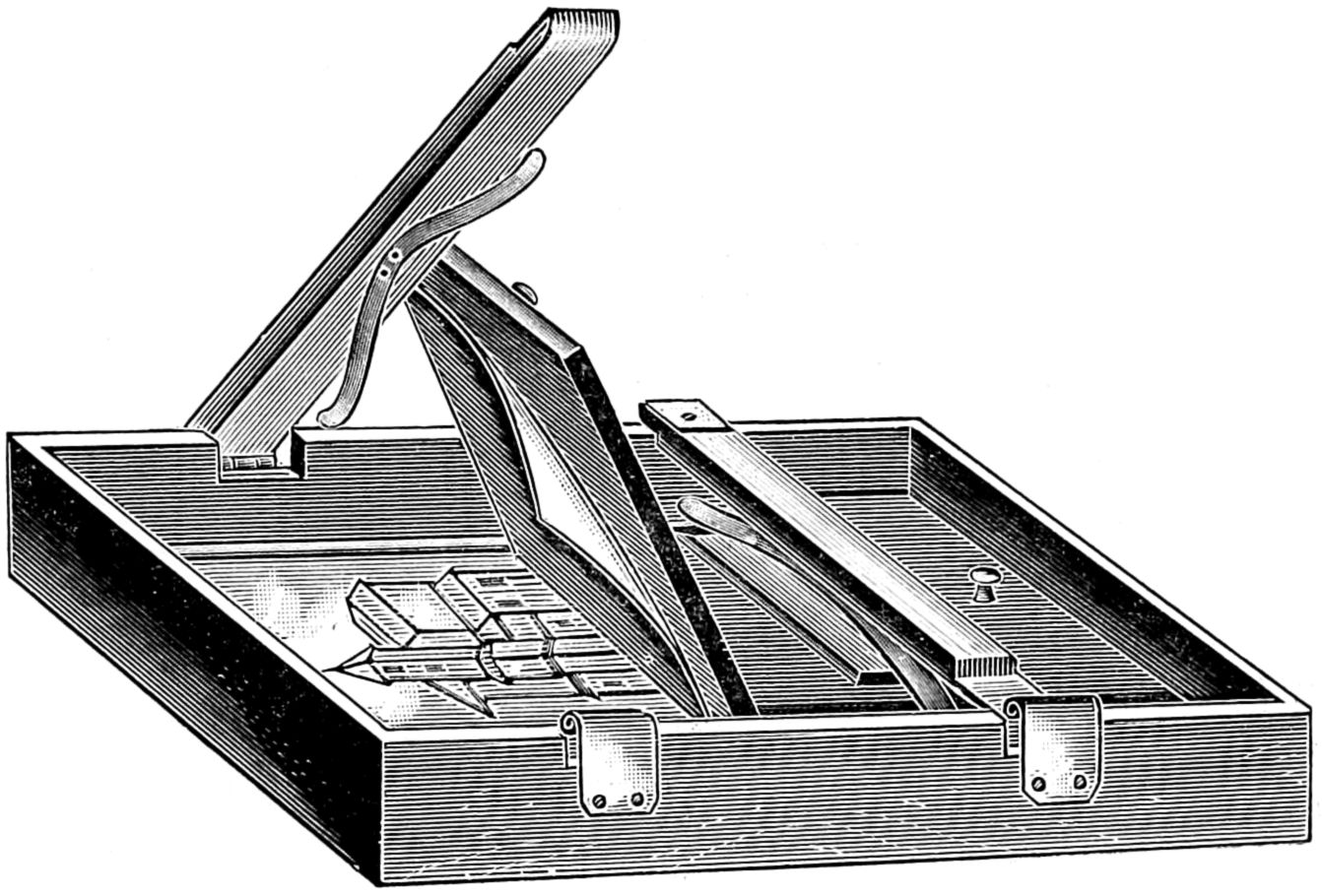

| Drawing Materials and Instruments, | 101-134 |

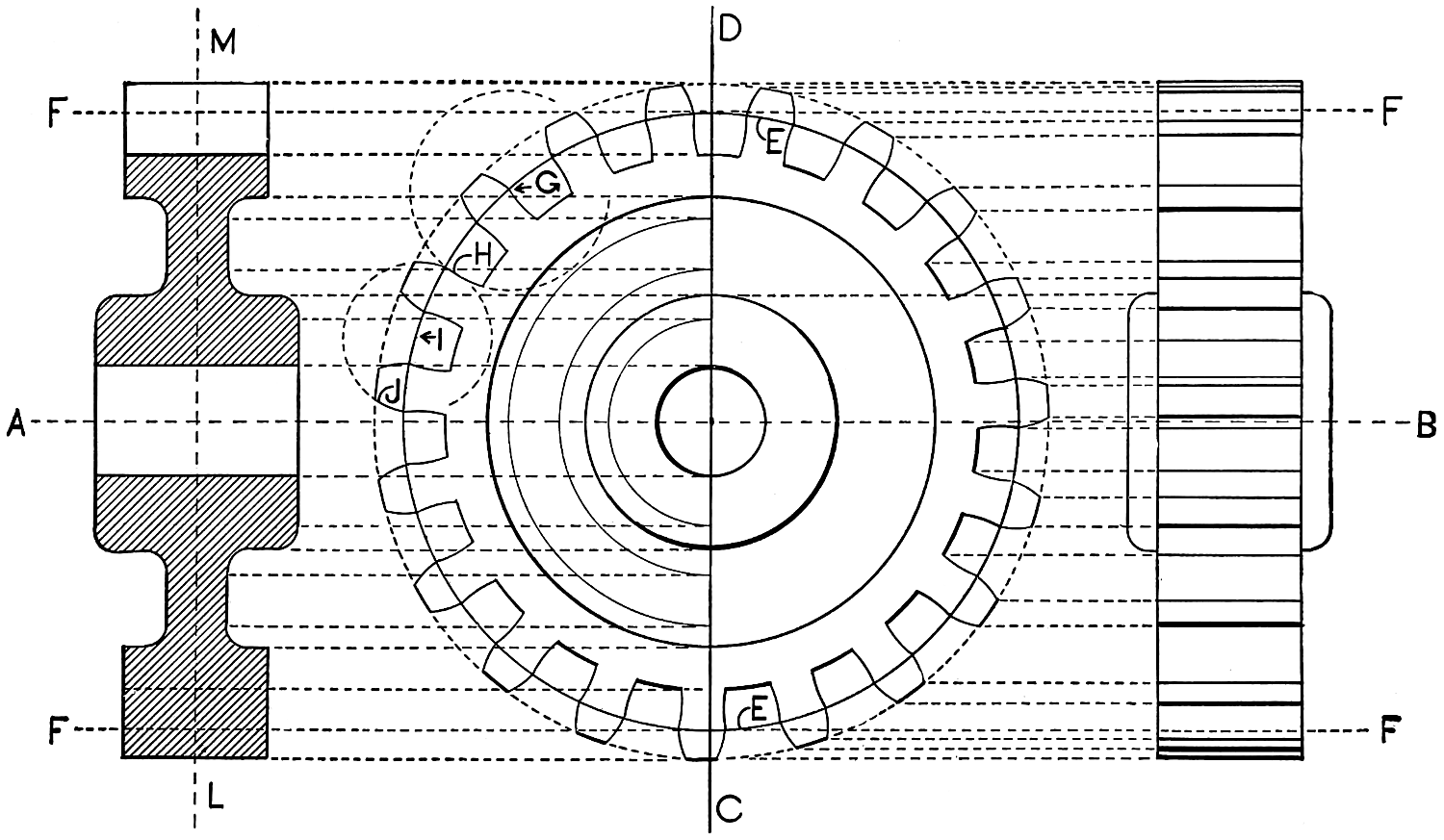

| Mechanical Drawing, | 135-188 |

| Penciling, | 139-147 |

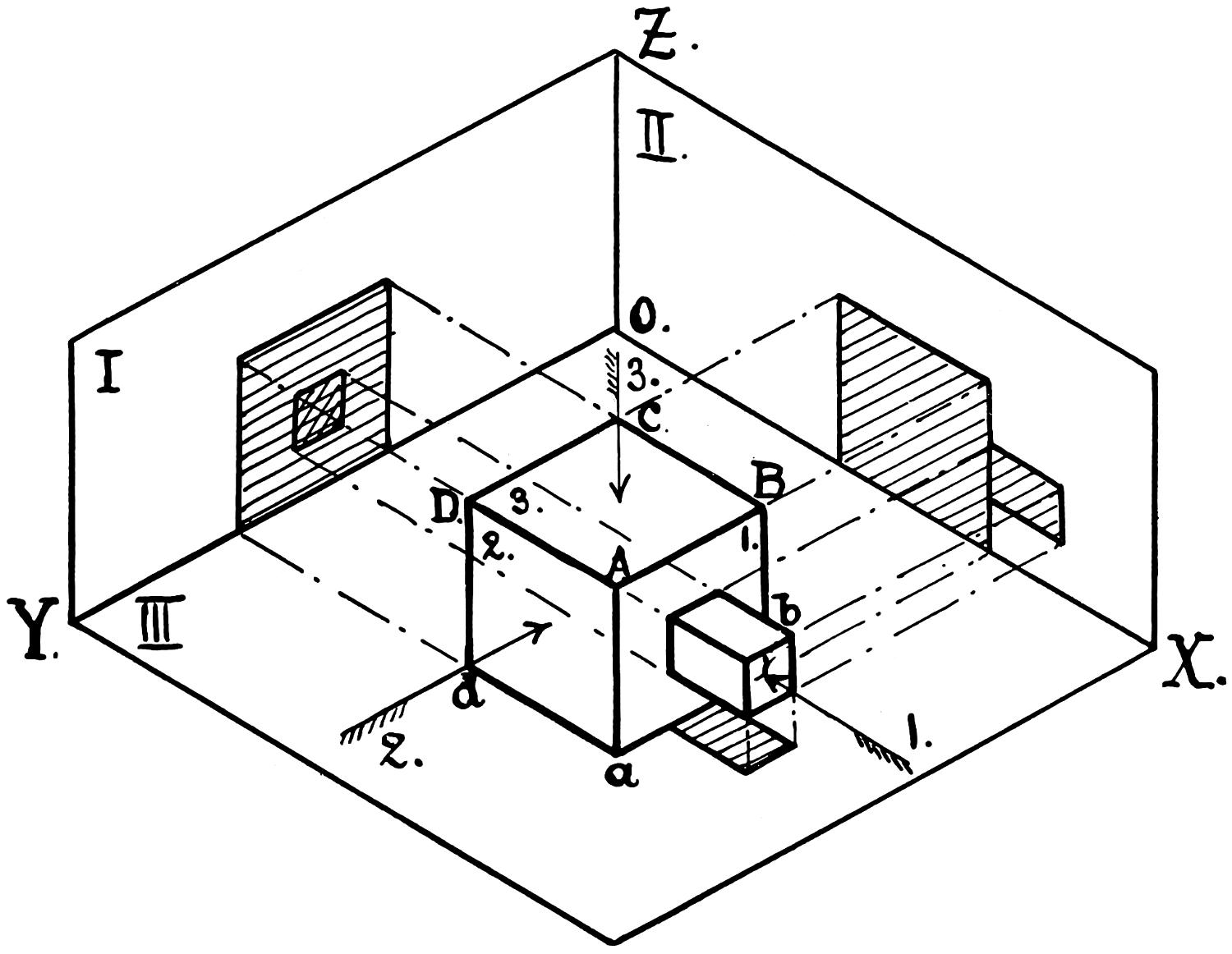

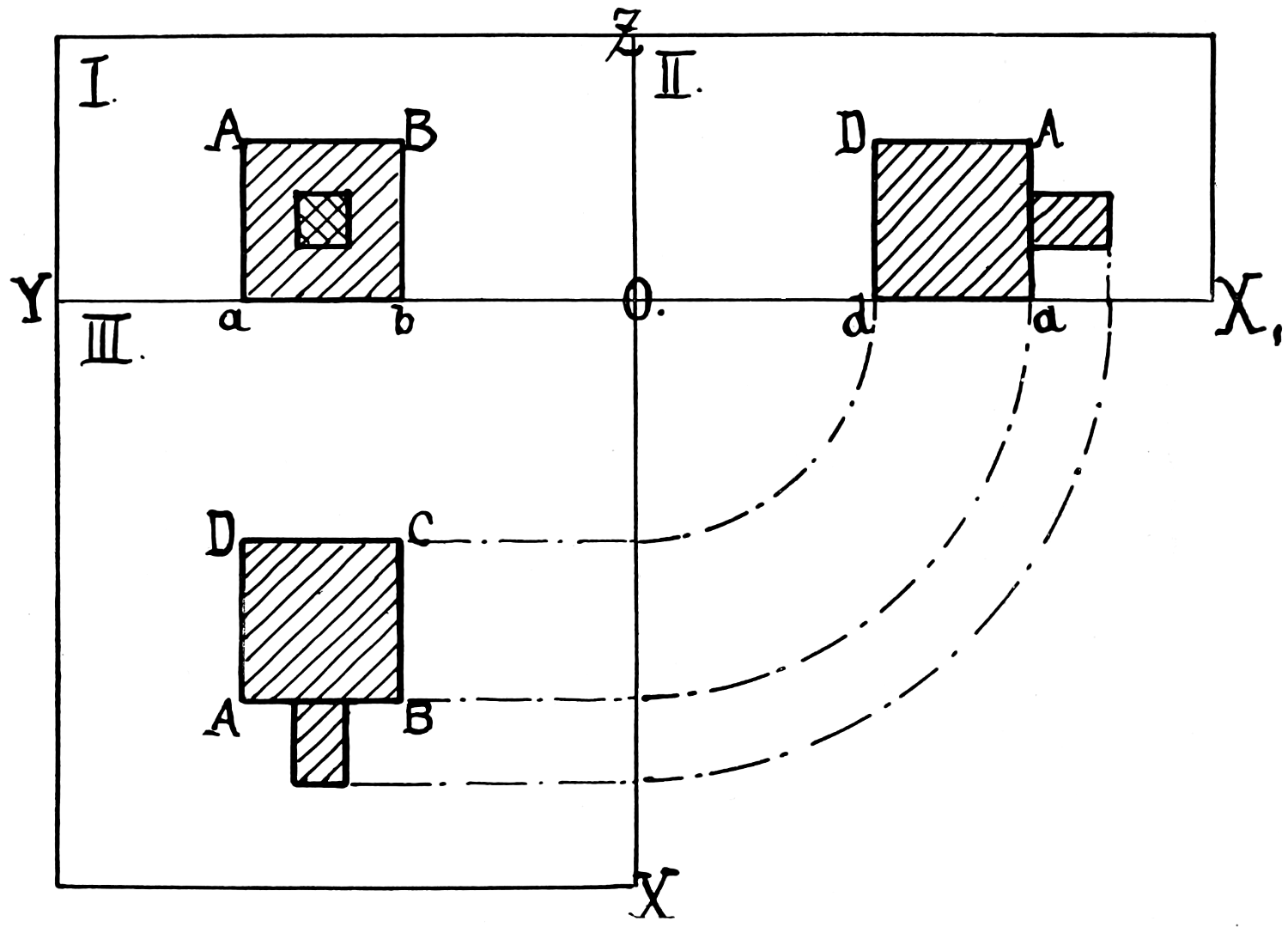

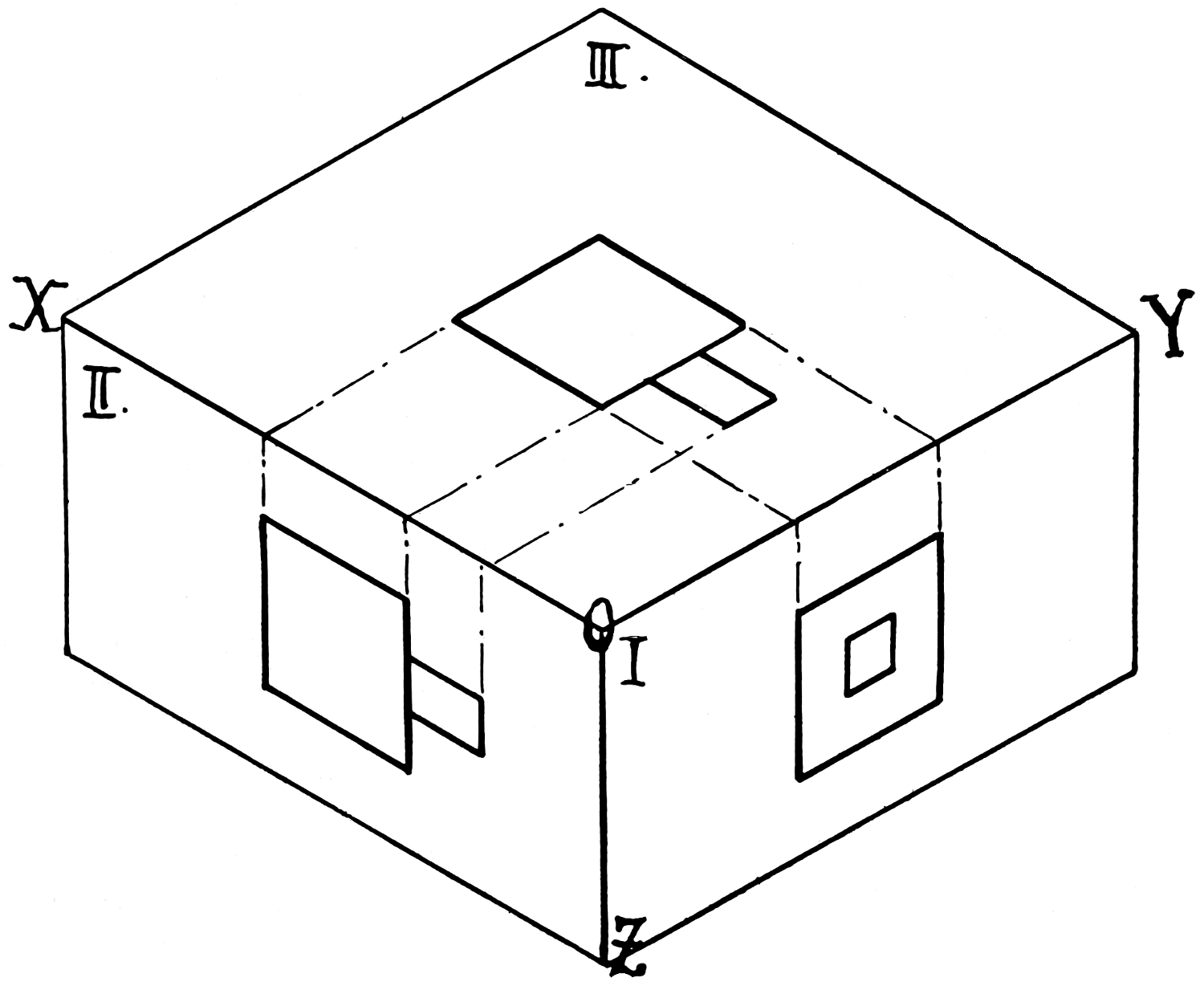

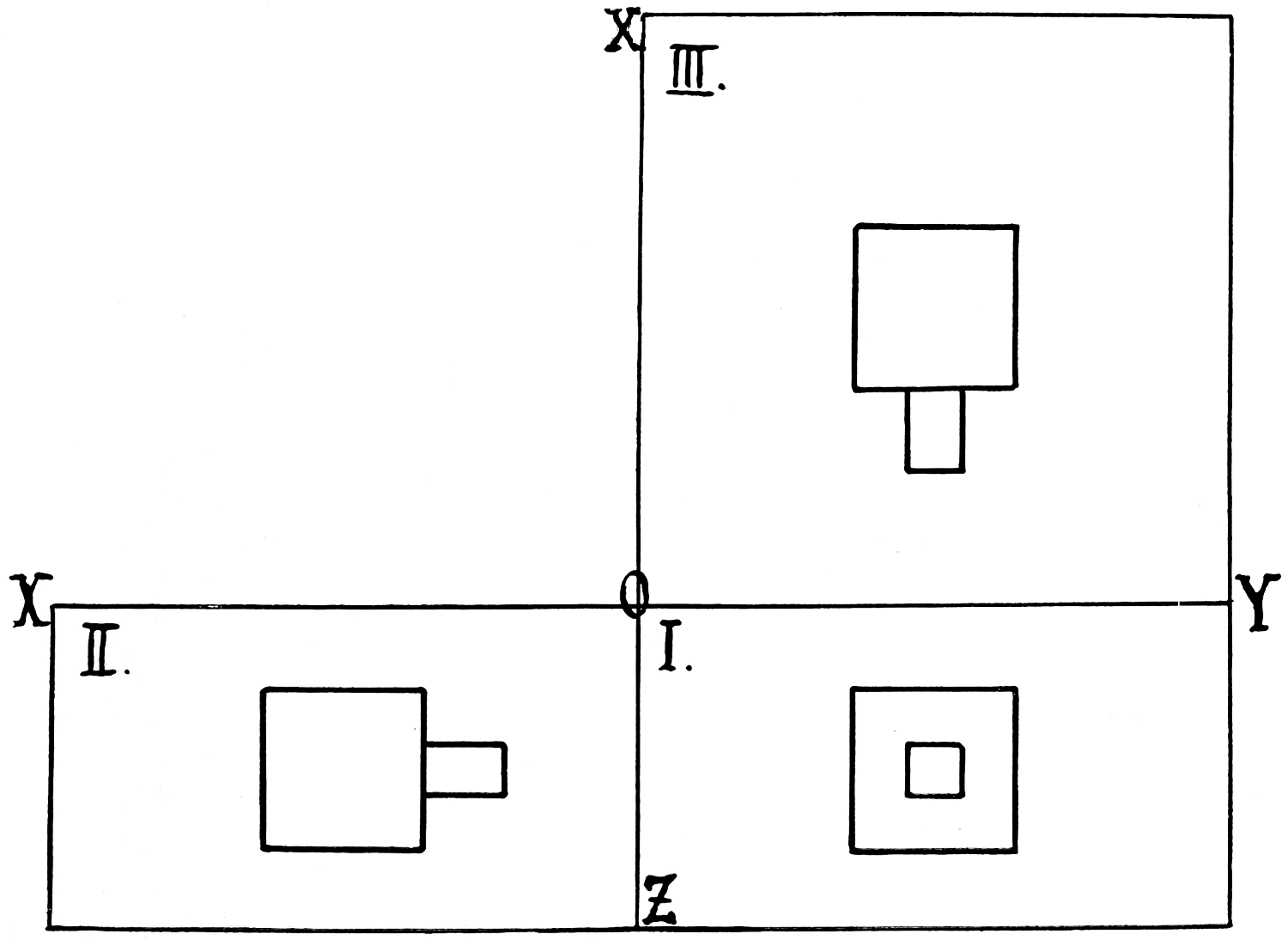

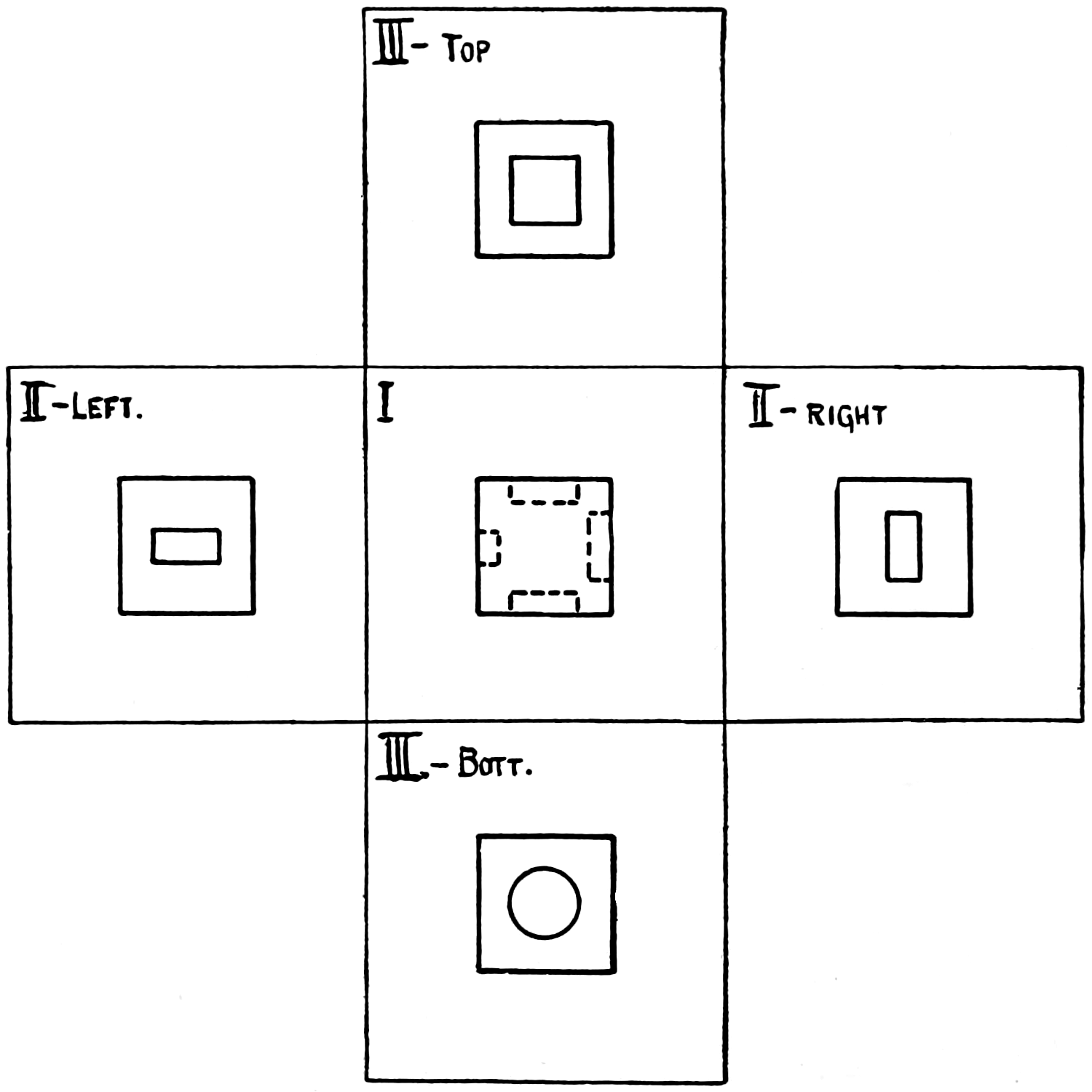

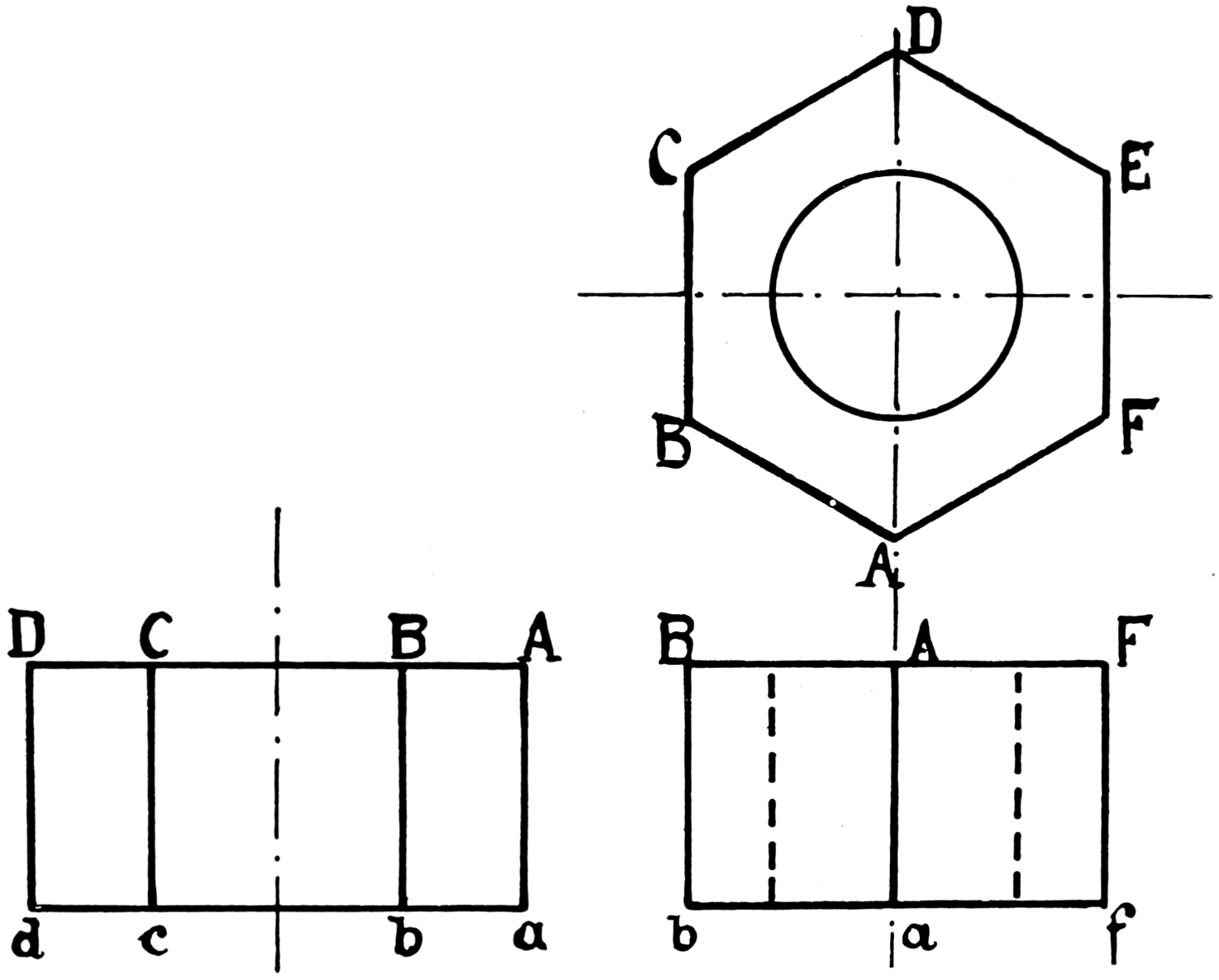

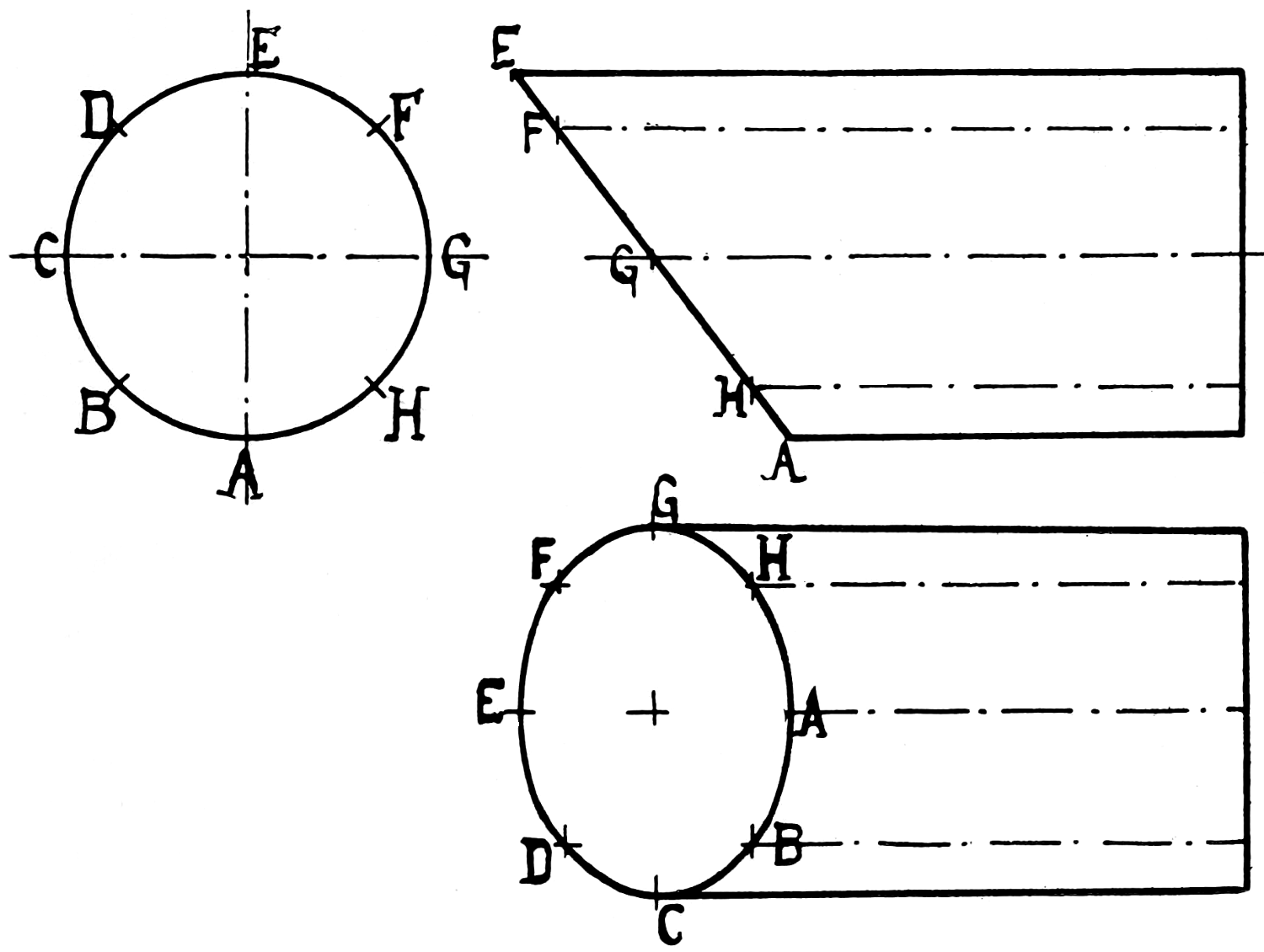

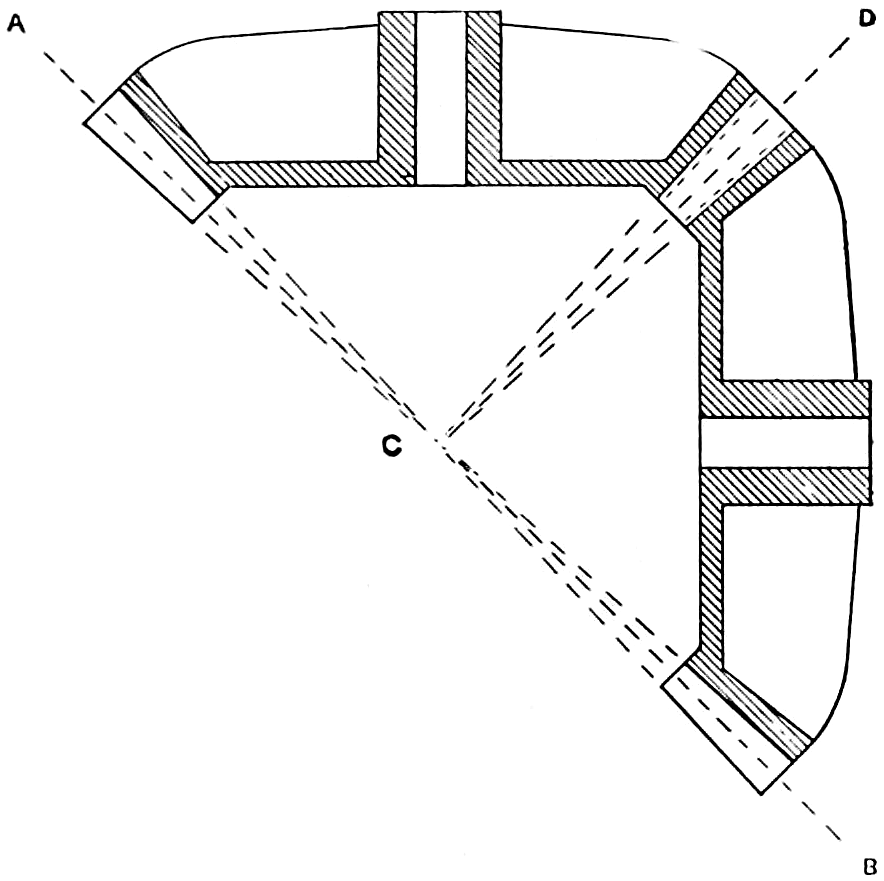

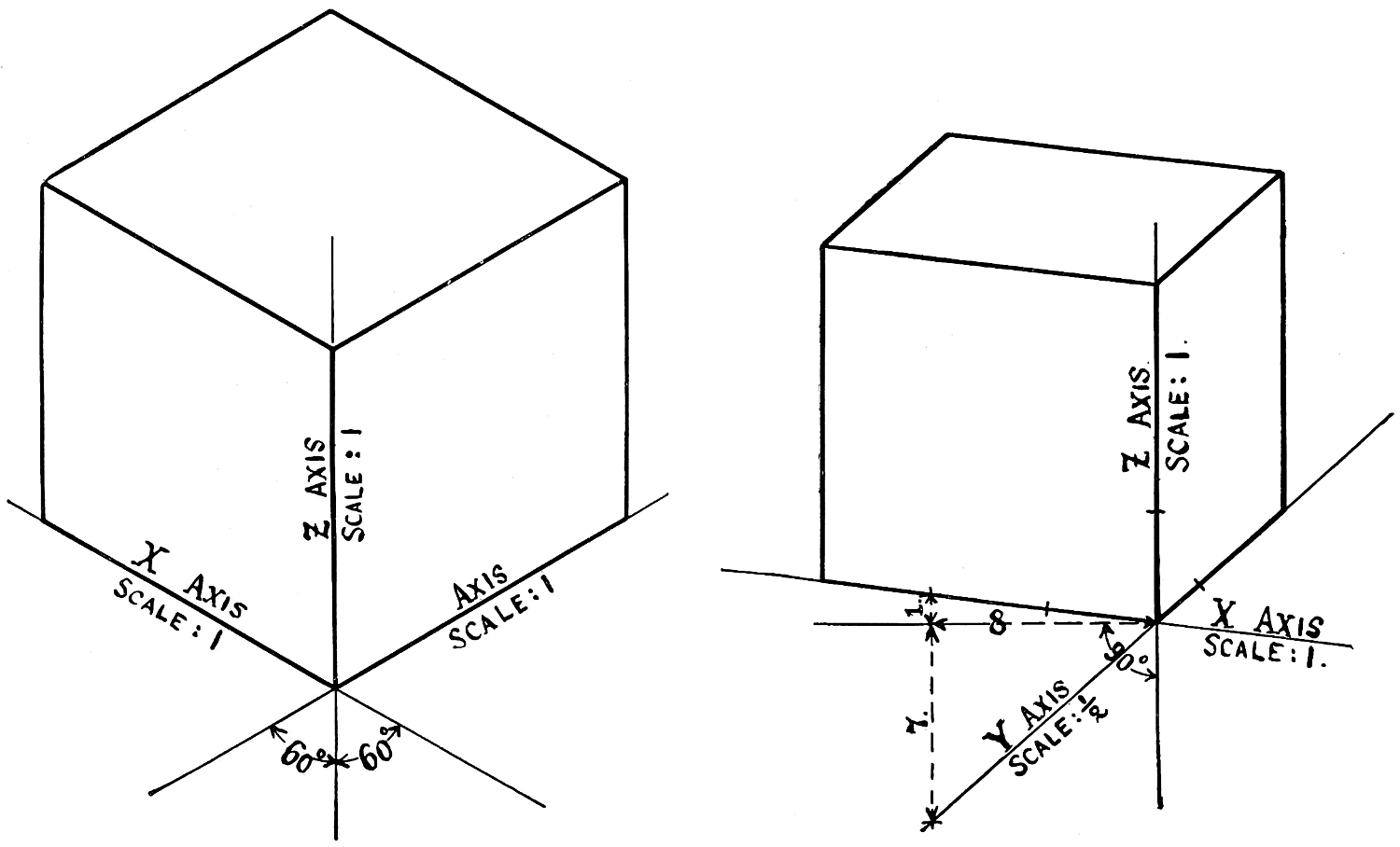

| Projection, | 148-164 |

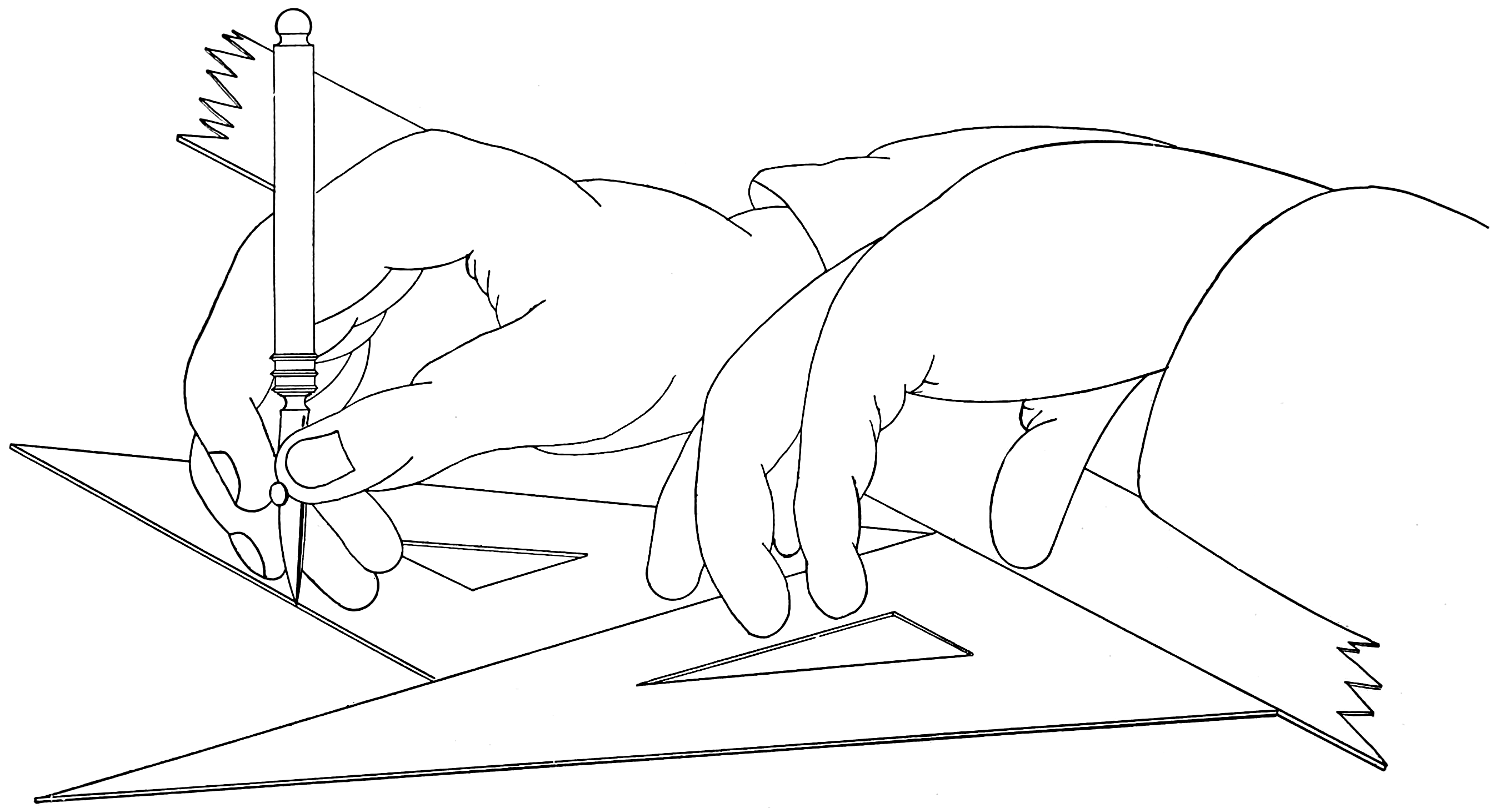

| Inking in Drawings, | 167-170 |

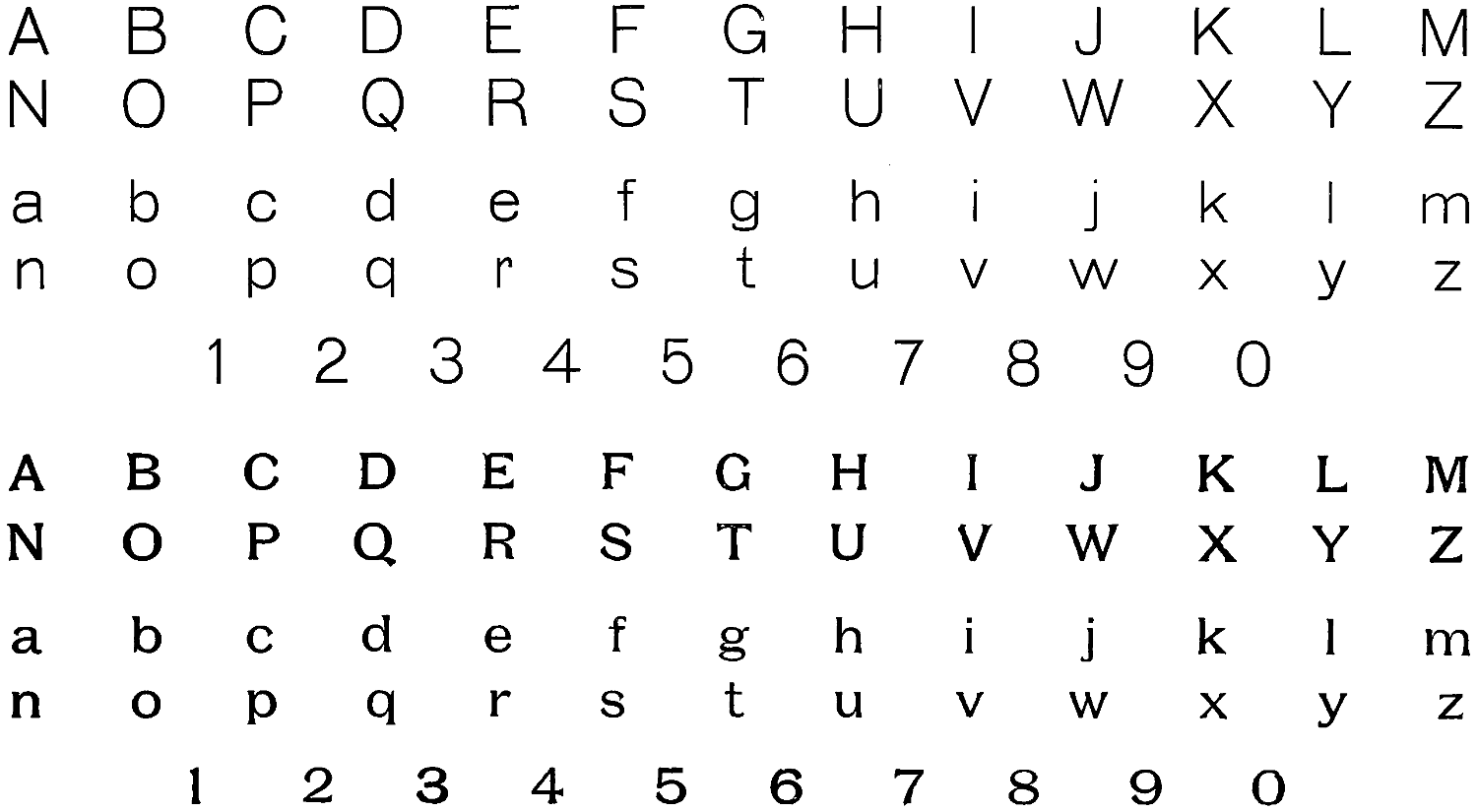

| Lettering Drawings, | 171-175 |

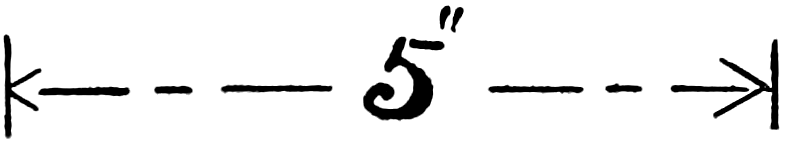

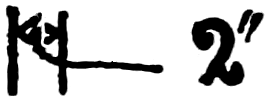

| Dimensioning Drawings, | 176-179 |

| Shading Drawings, | 180-181 |

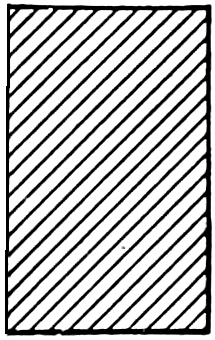

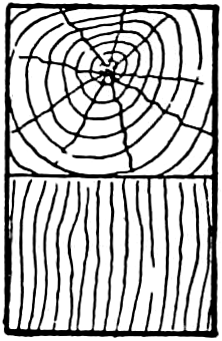

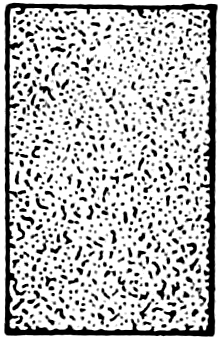

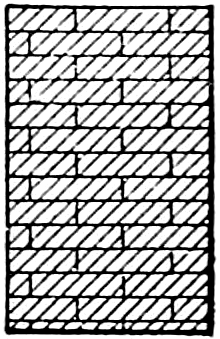

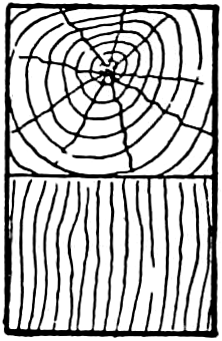

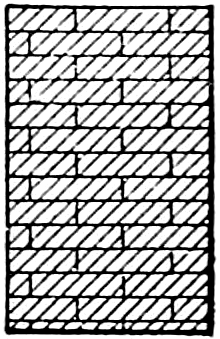

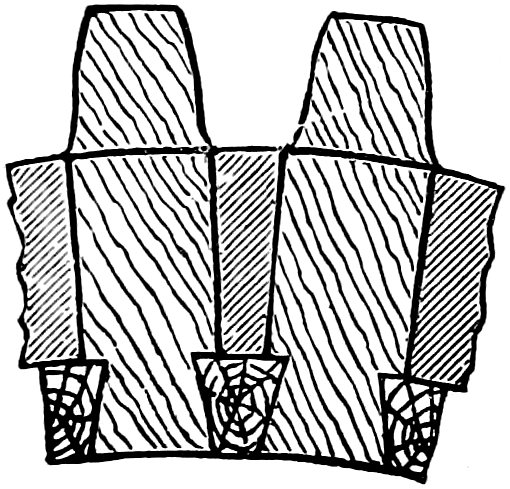

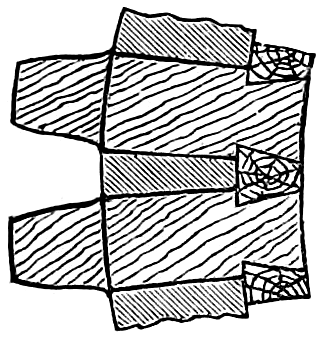

| Section Lining and Colors, | 182-185 |

| Reproducing Drawings, | 186-188 |

| Drawing Office Rules, | 189-195 |

| Gearing, | 197-208 |

| Designing Gears, | 209-216 |

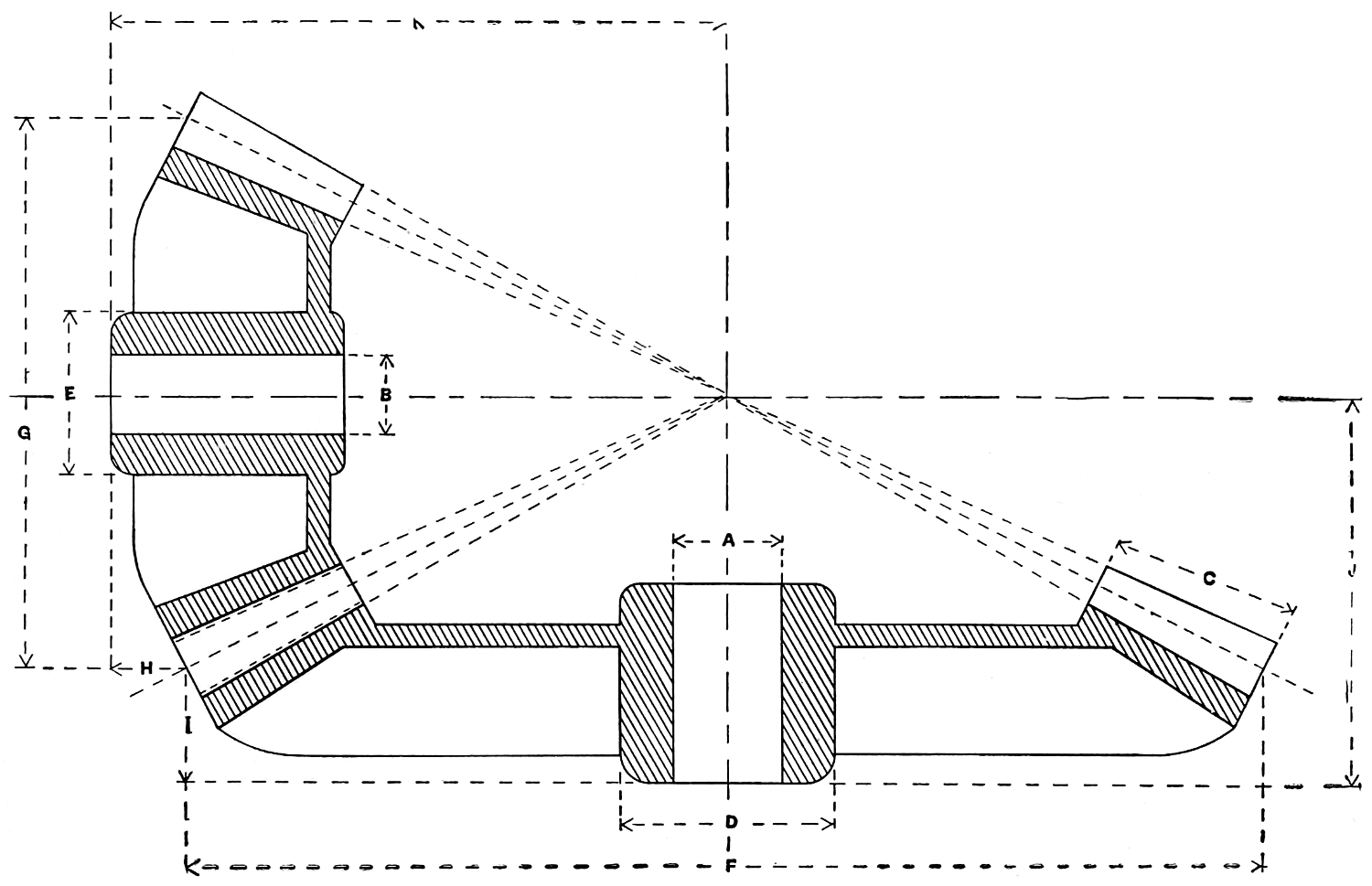

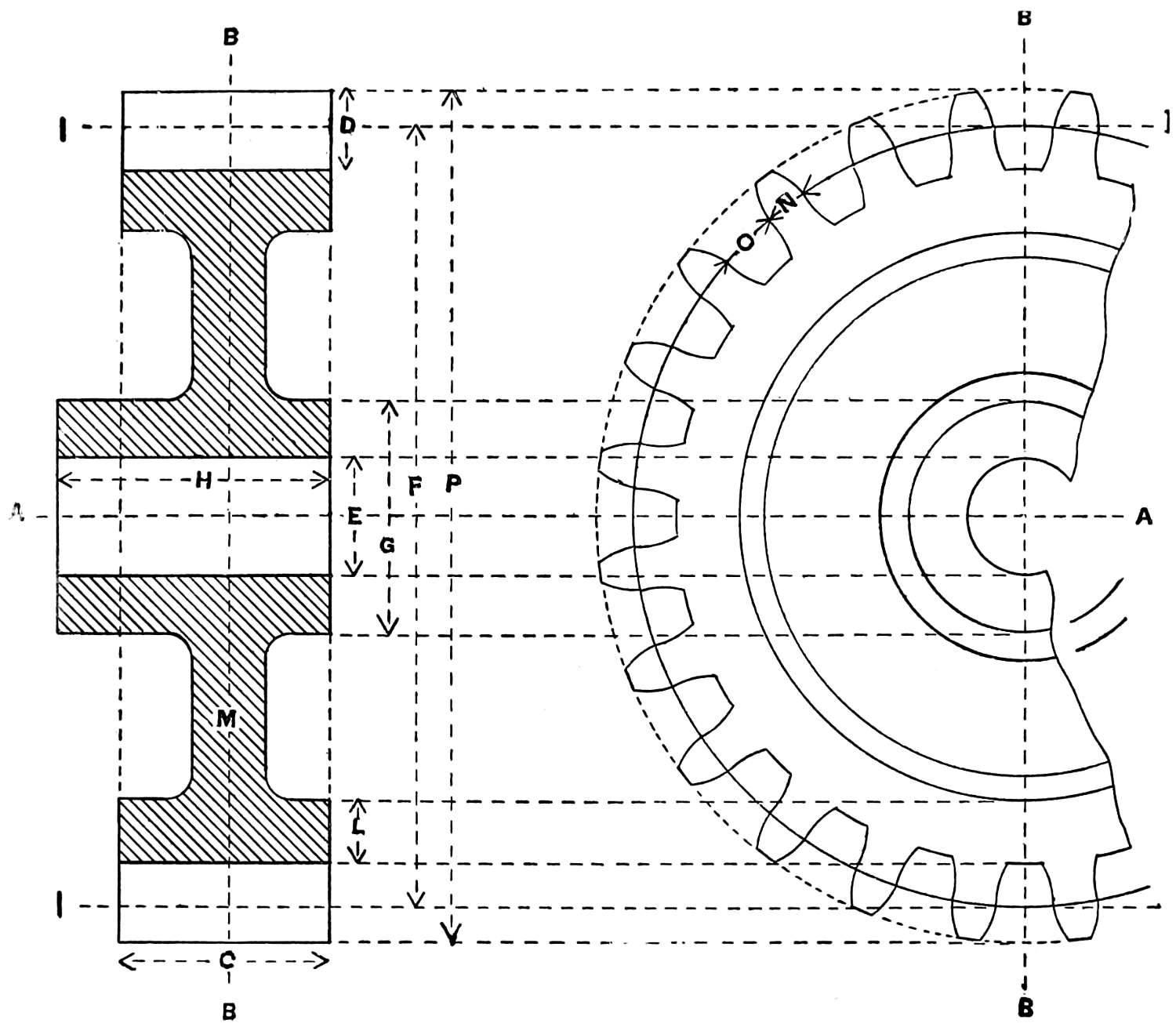

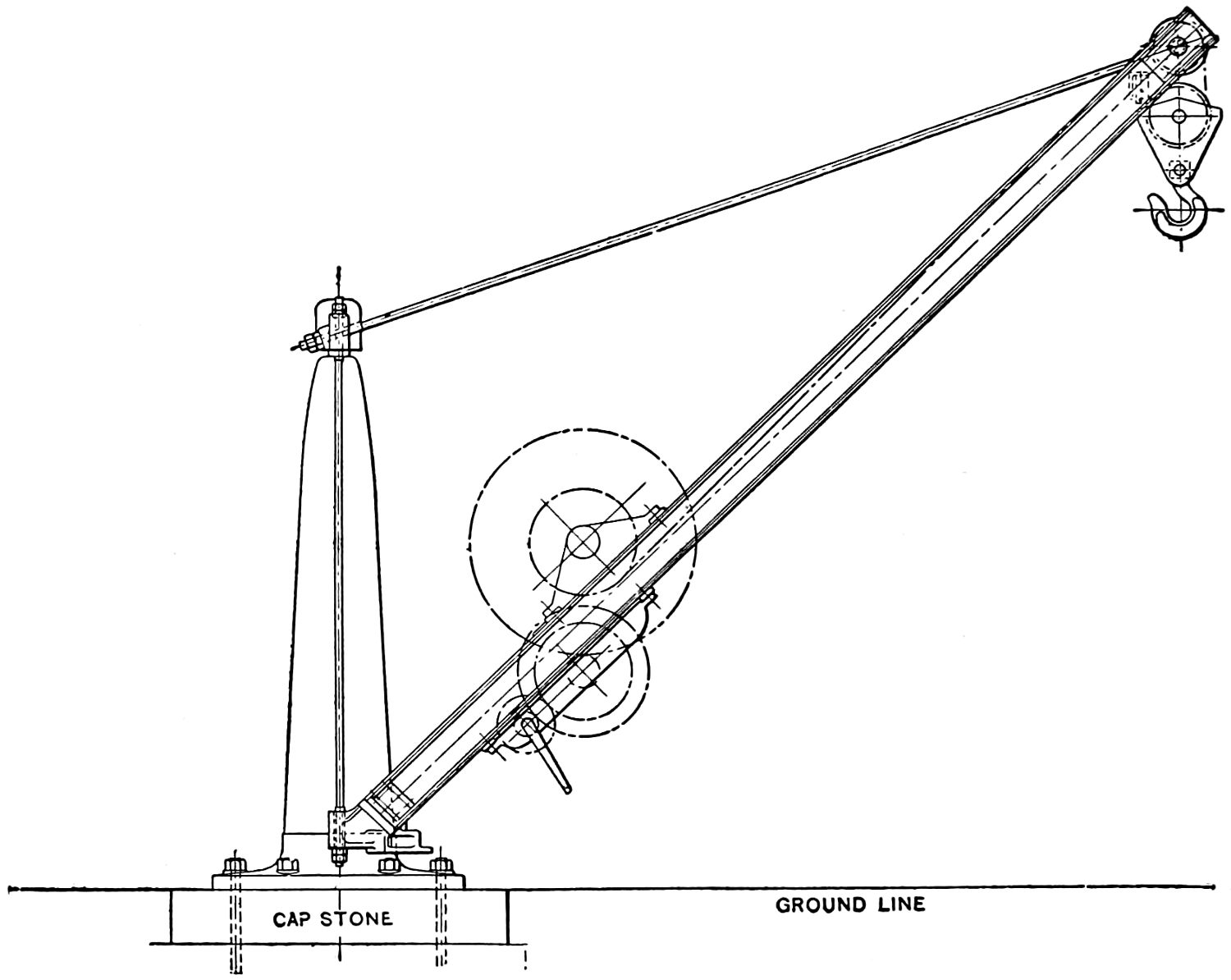

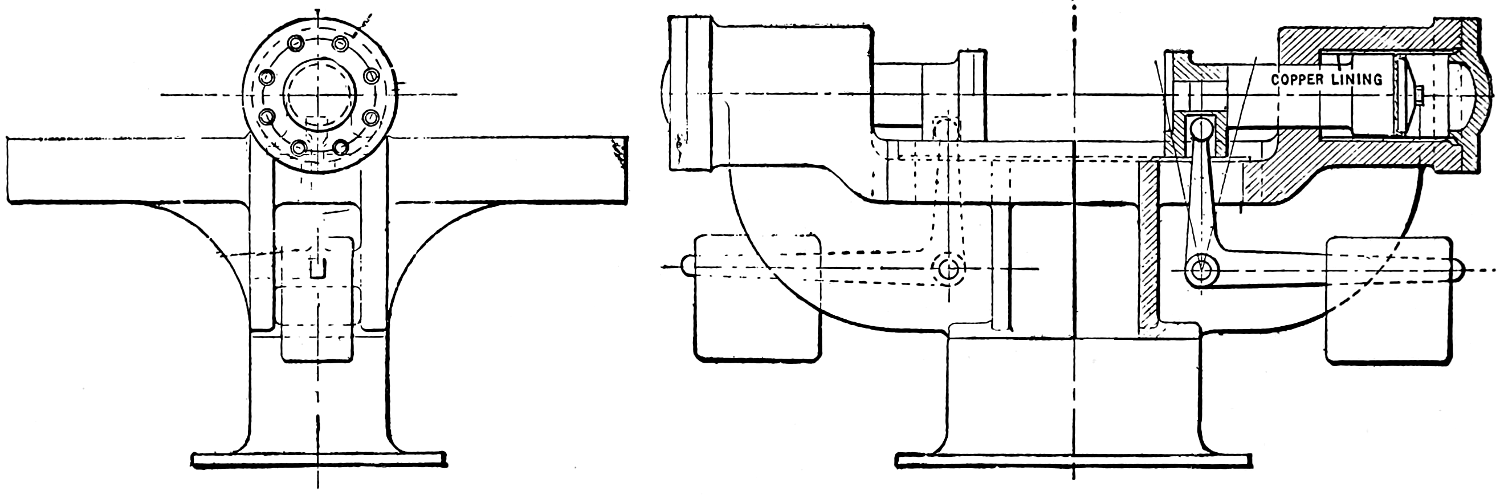

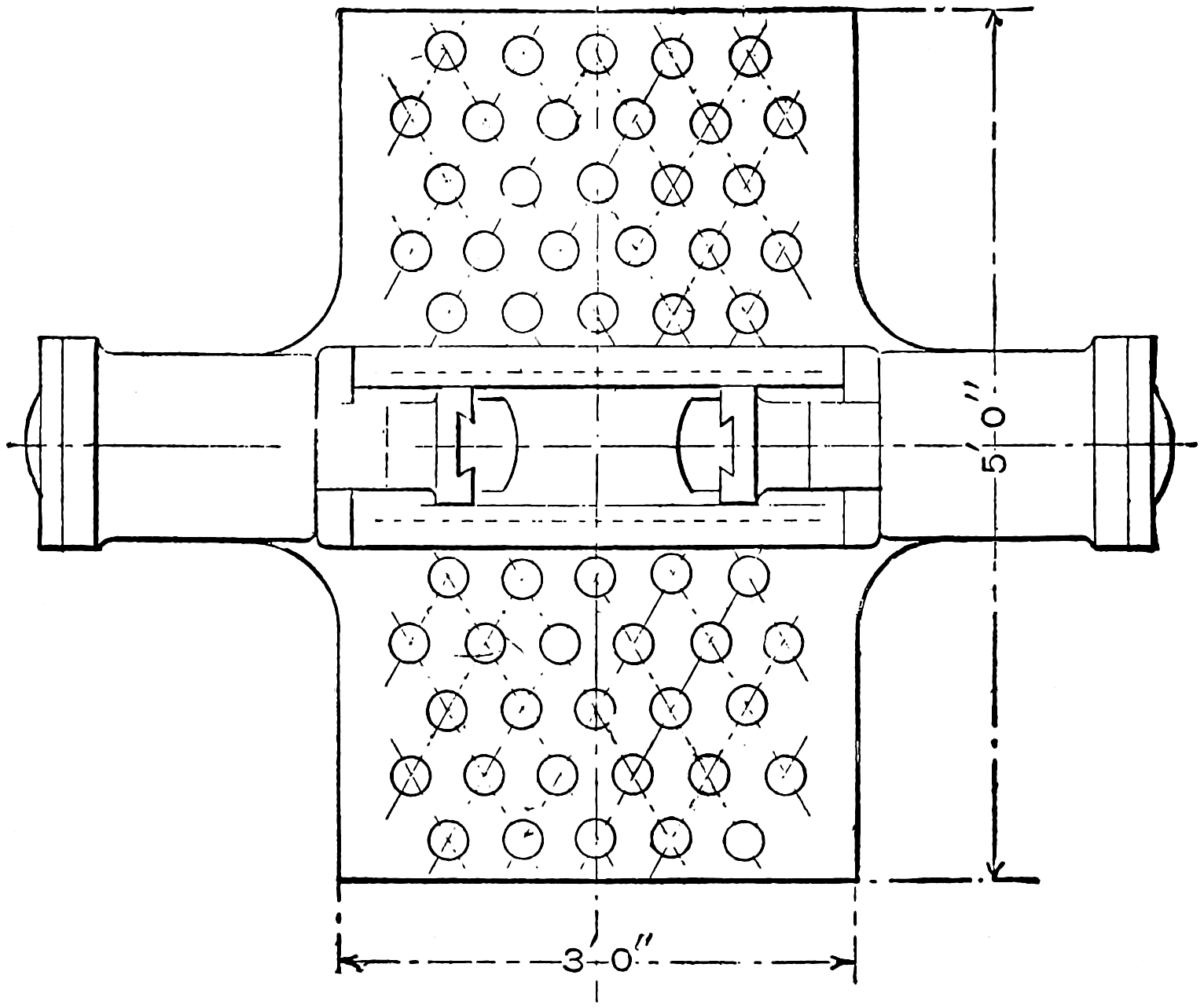

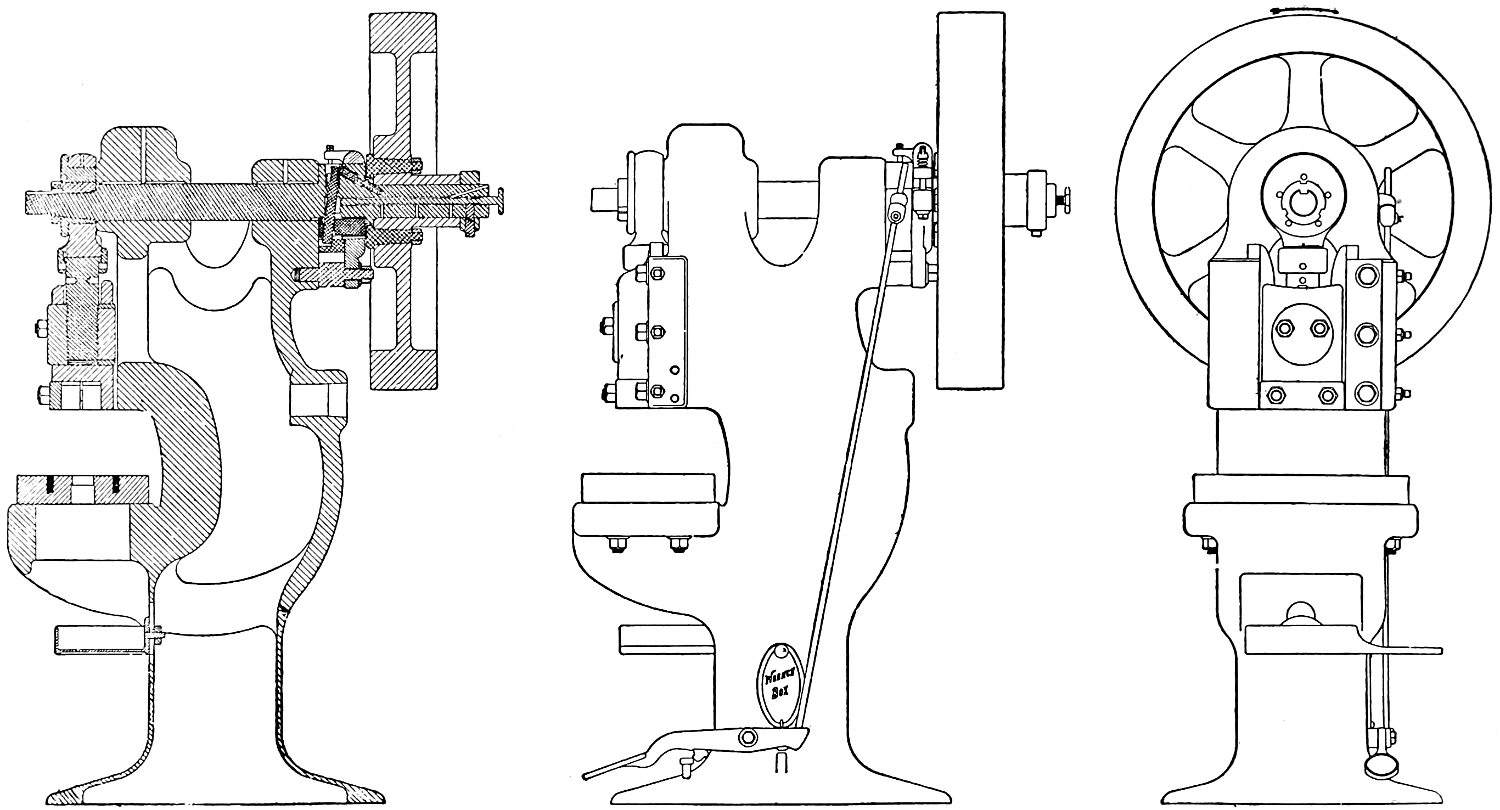

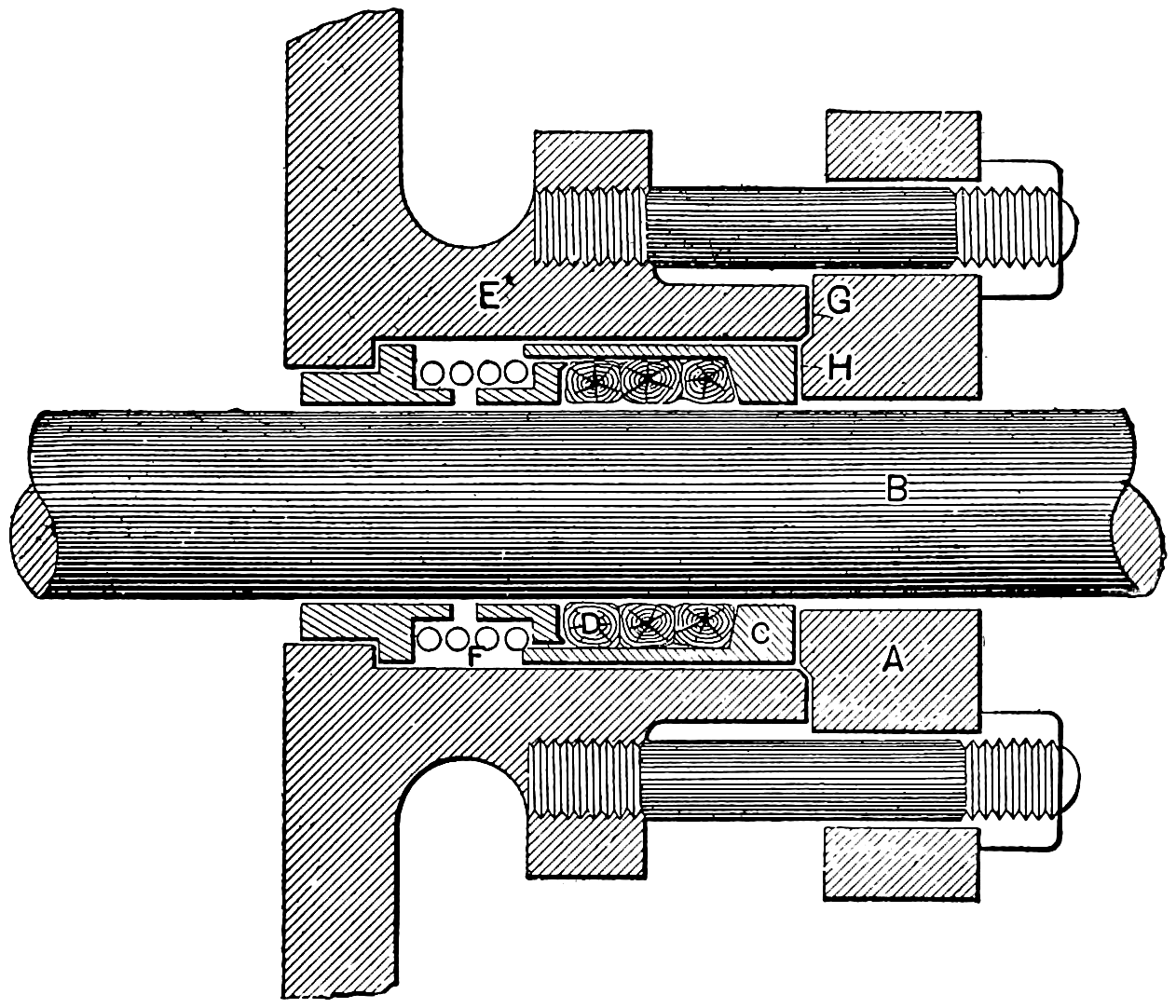

| Working Drawings, | 219-227 |

| Reading Working Drawings, | 228-230 |

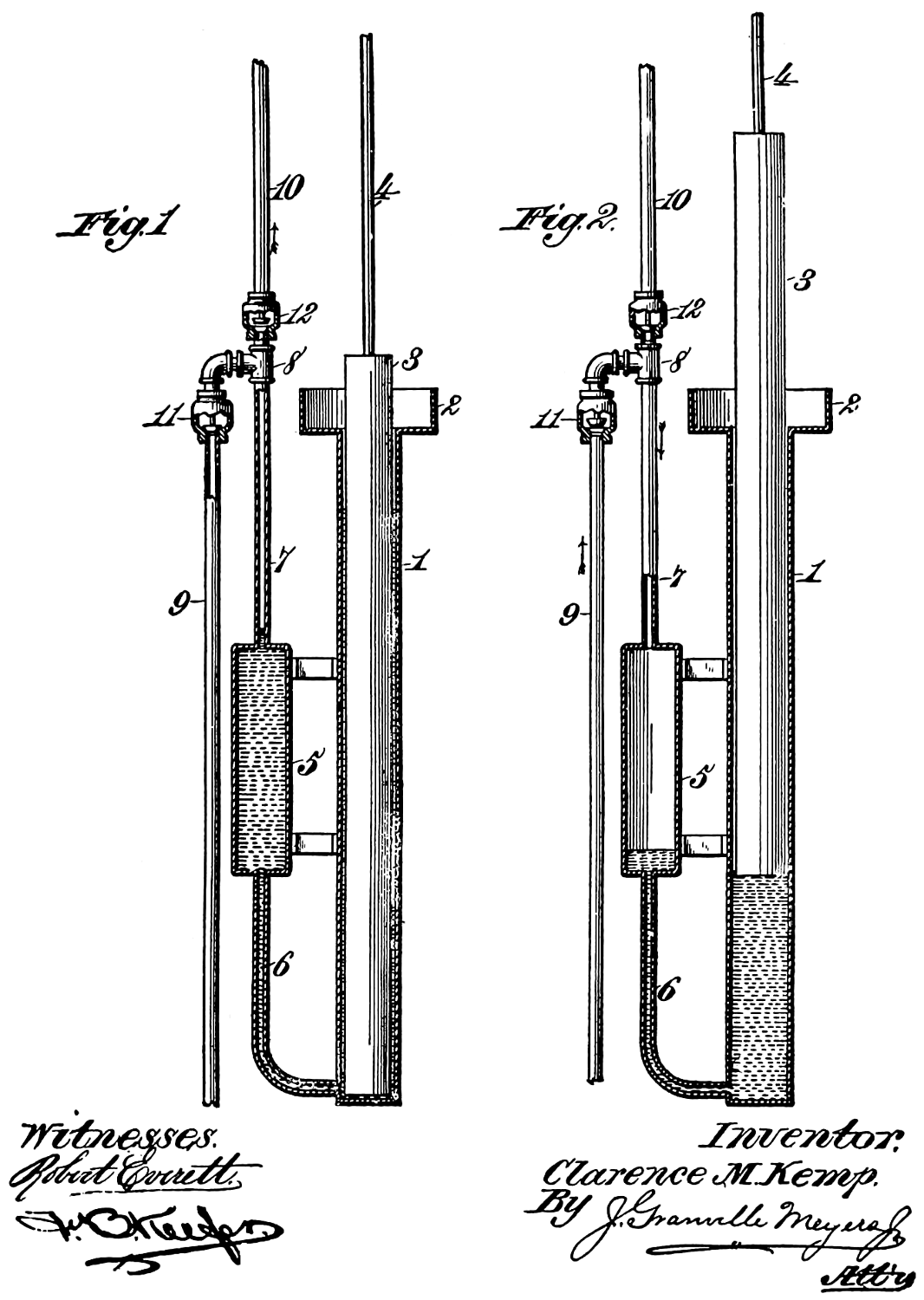

| Patent Office Rules for Drawings, | 231-236 |

| Useful Hints and “Points,” | 237-244 |

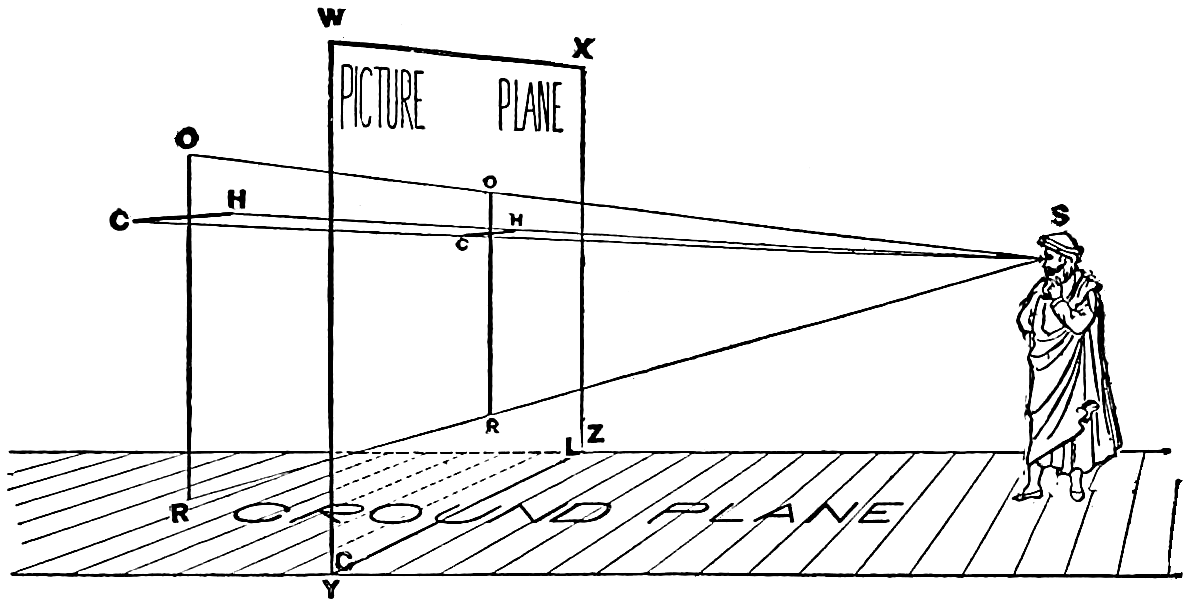

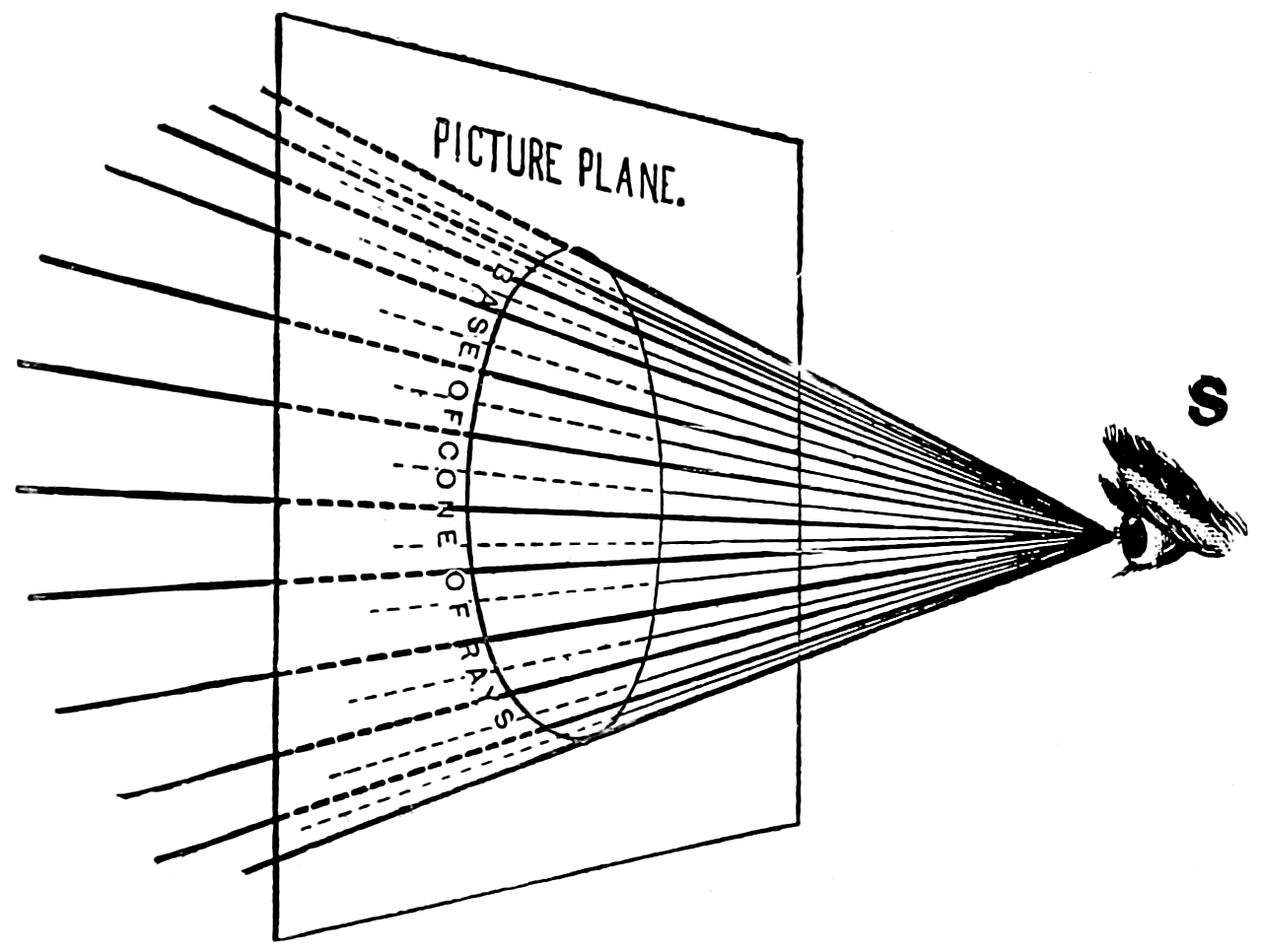

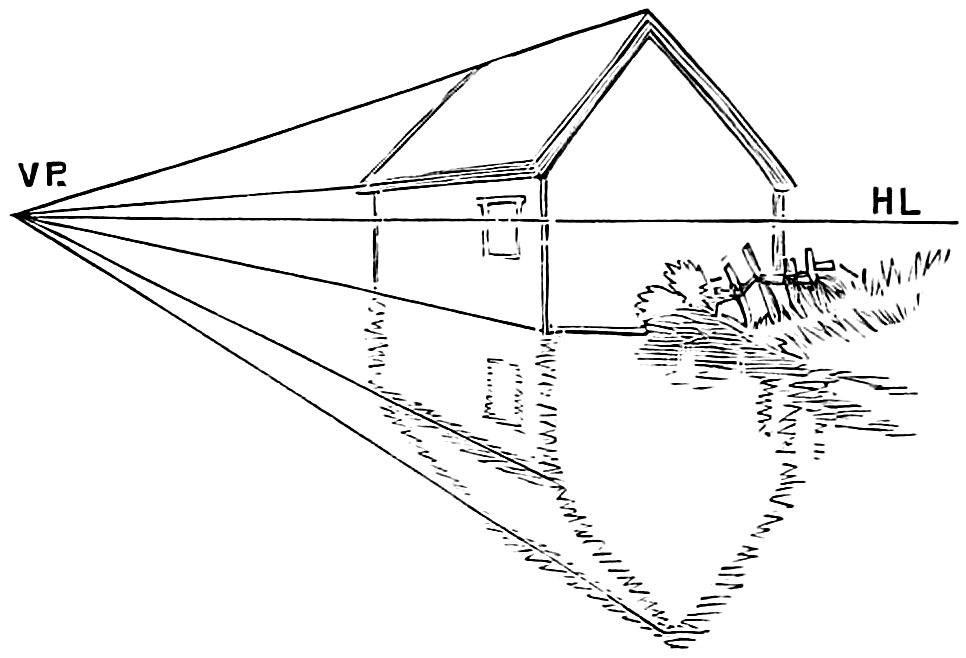

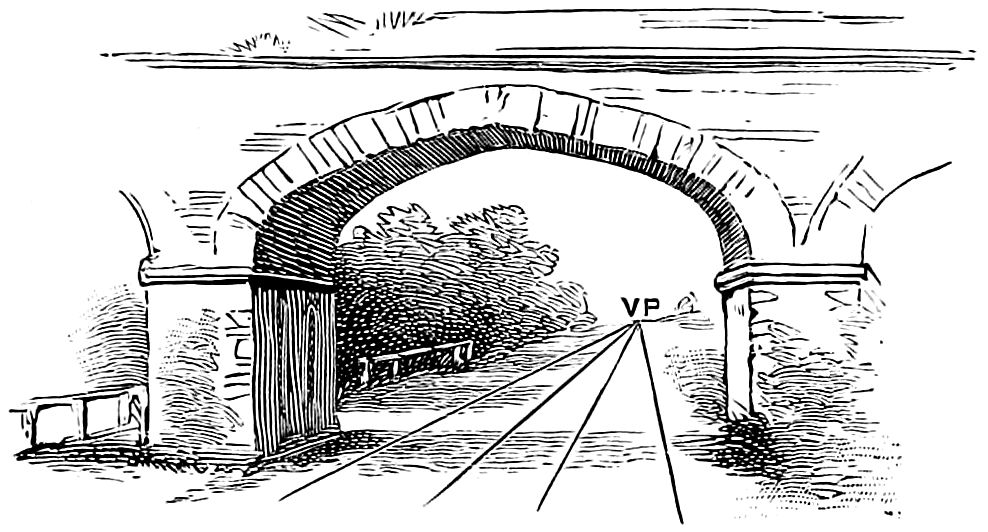

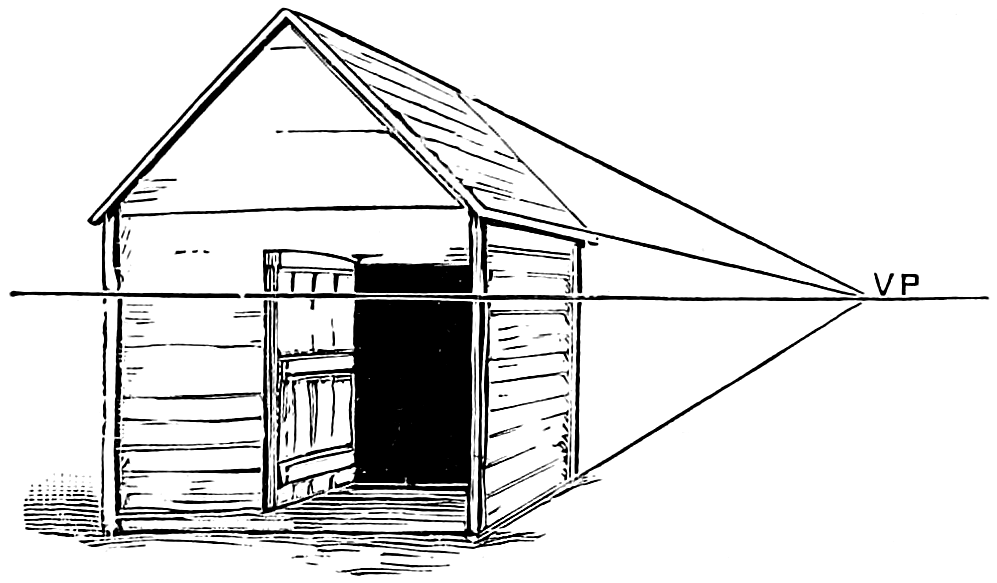

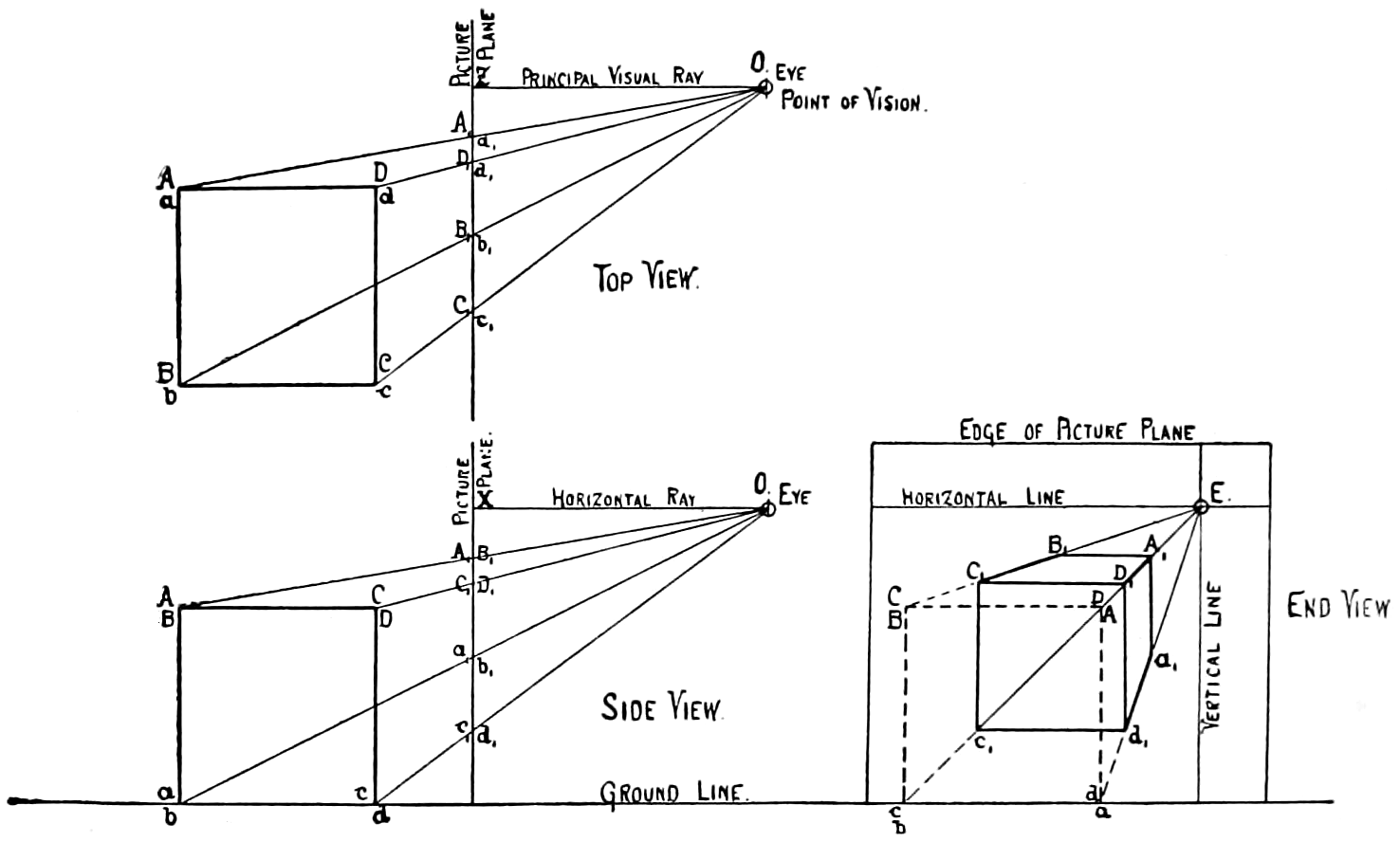

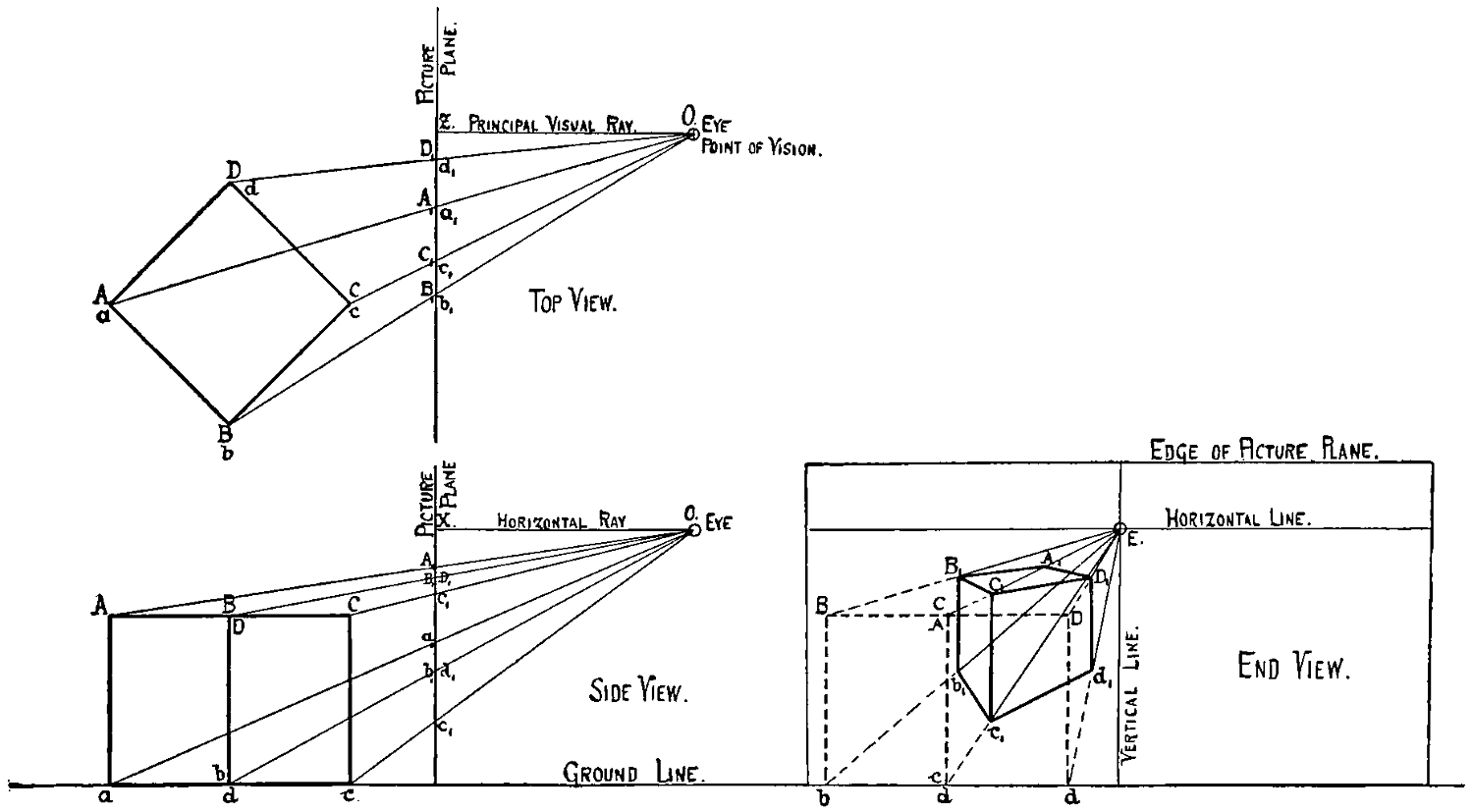

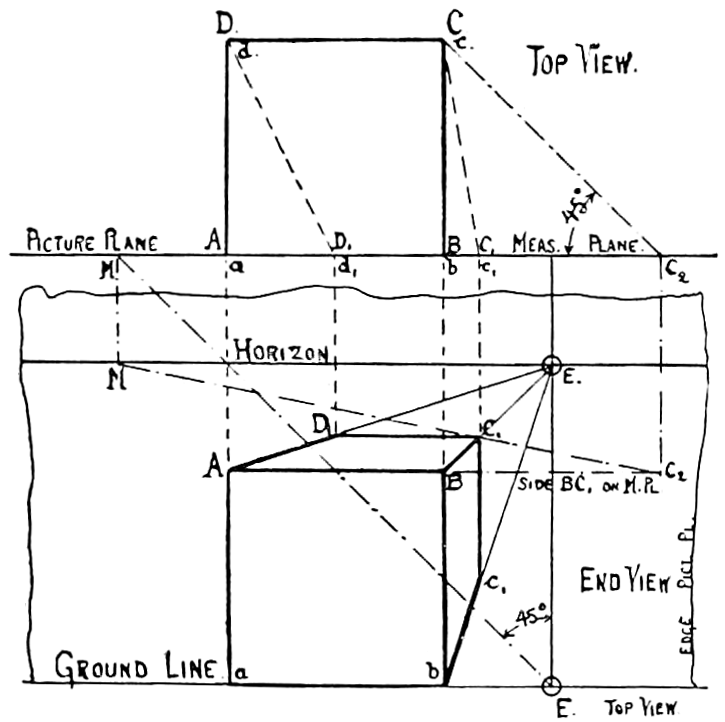

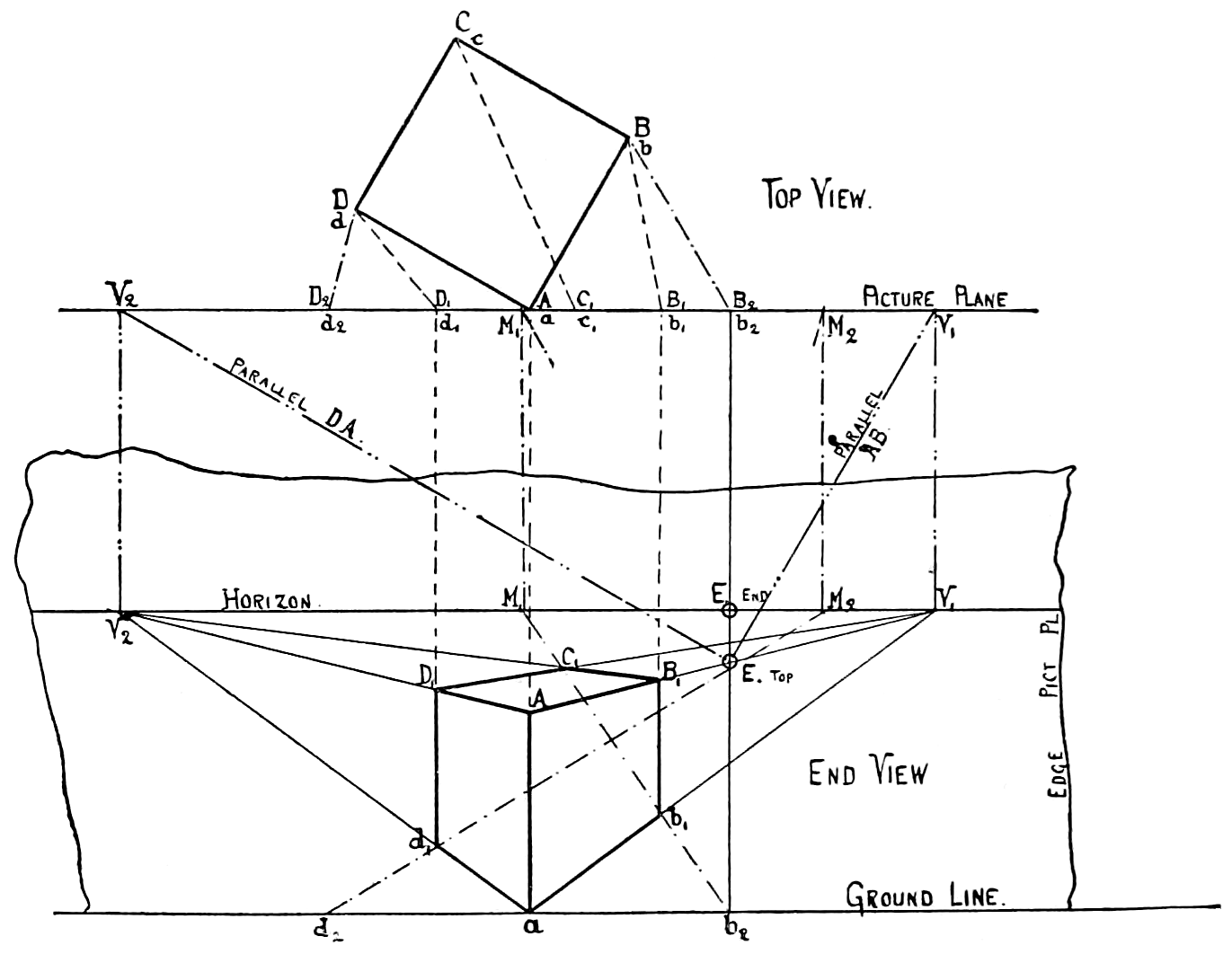

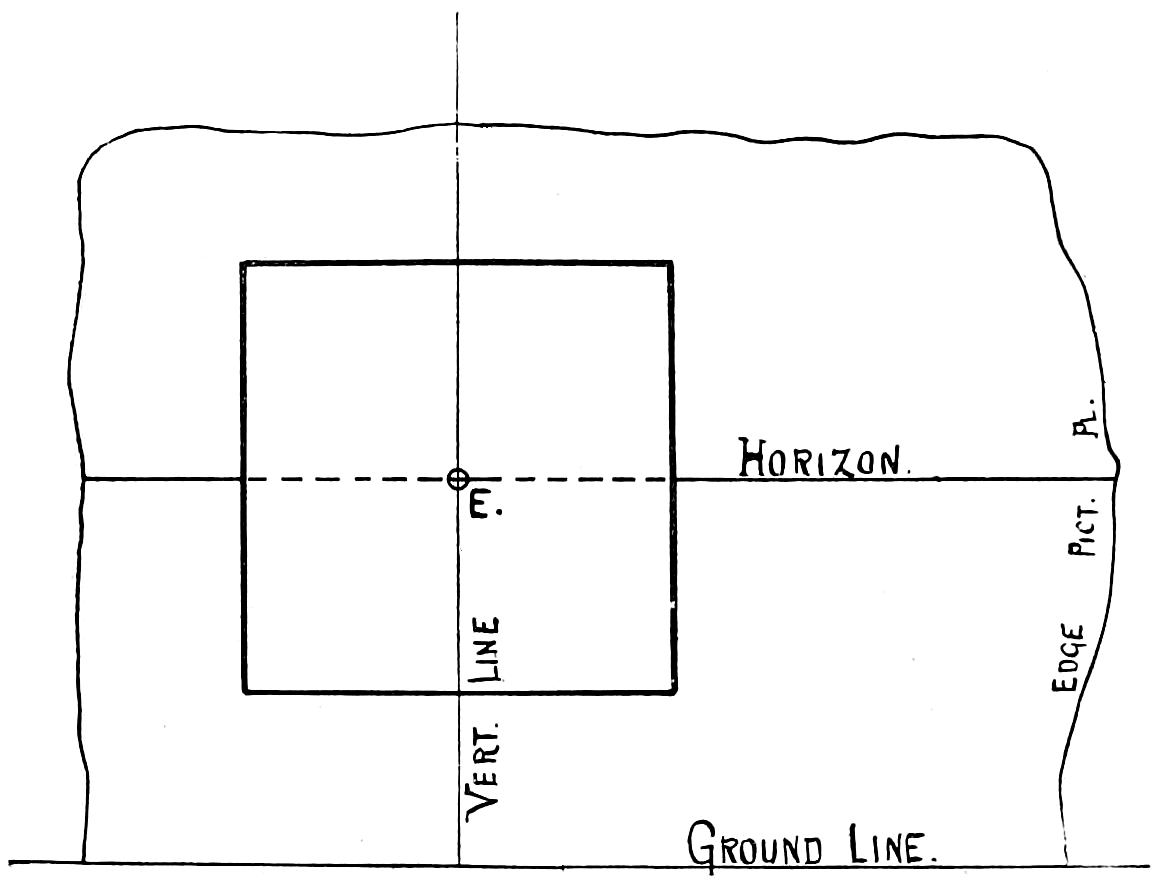

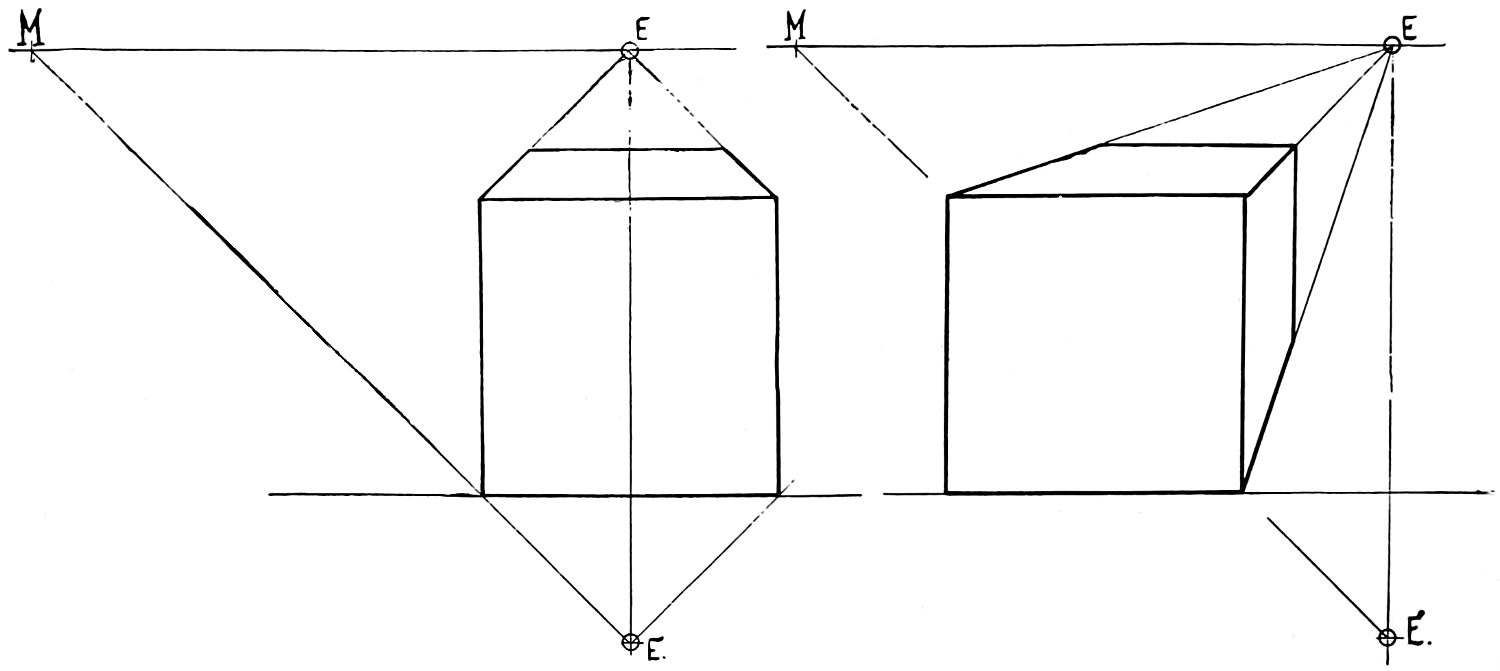

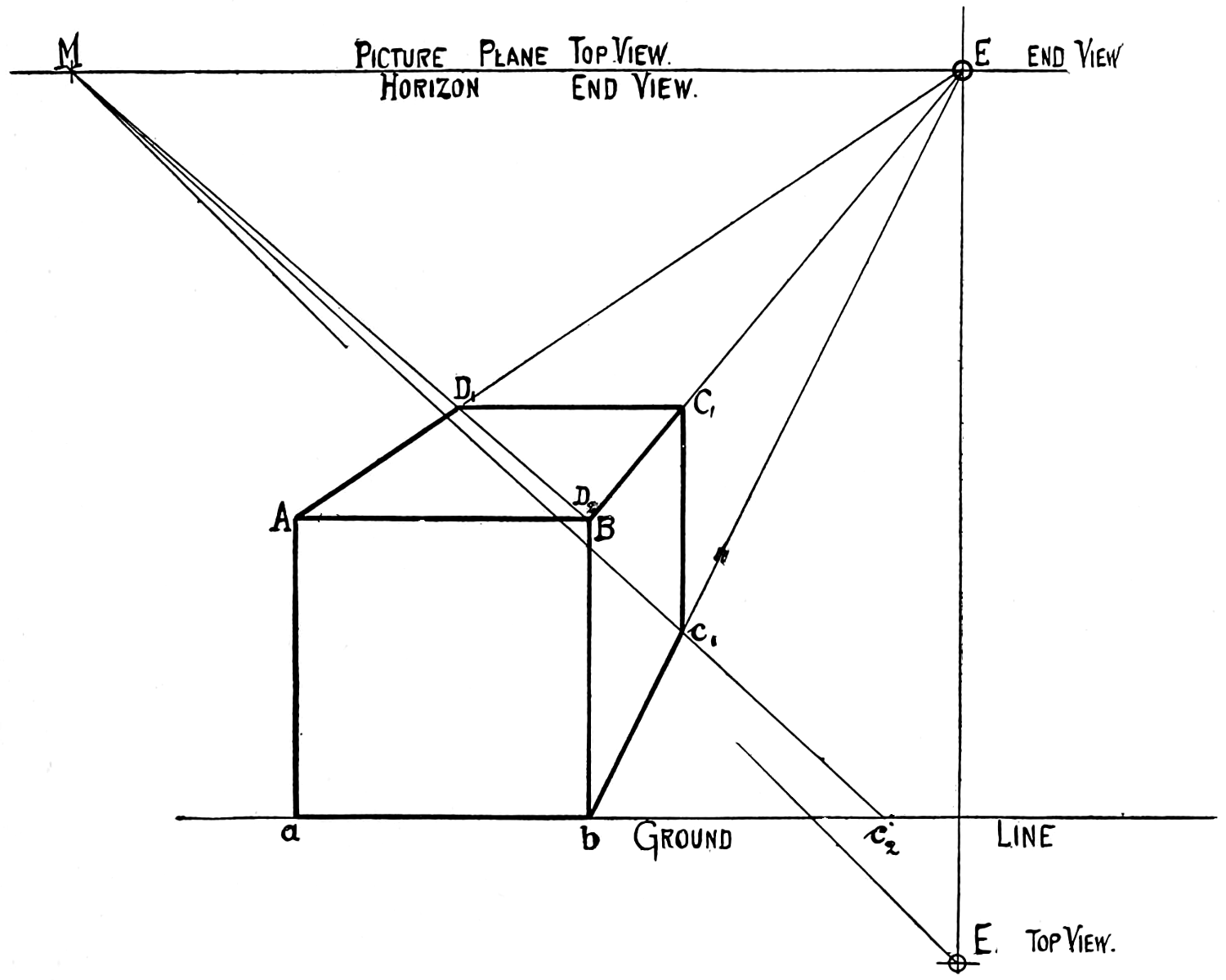

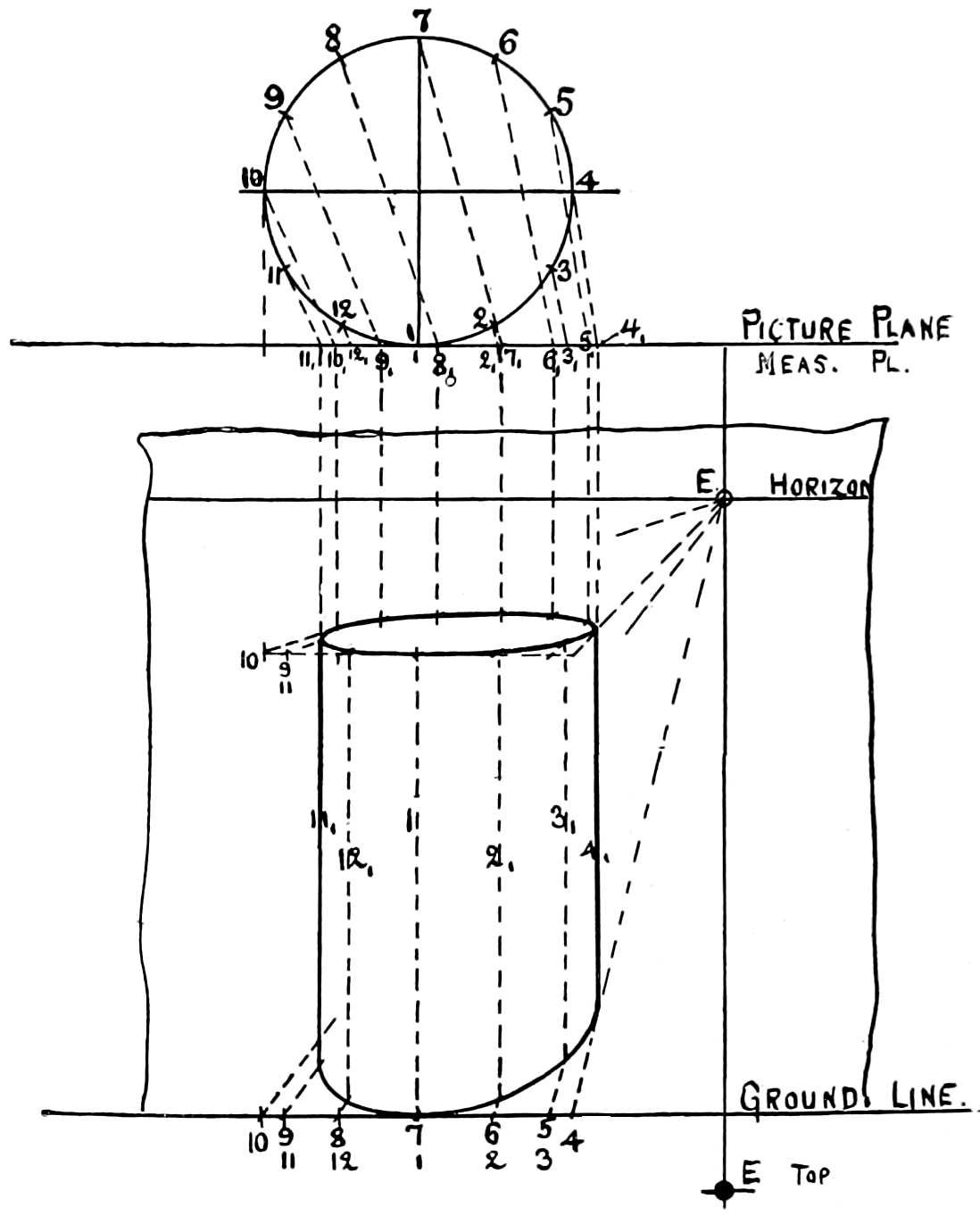

| Linear Perspective, | 245-265 |

| Personal, by the Editor, | 281 |

| Useful Tables, | 269-280 |

| Reference Index, | 283 |

[25]

[26]

| The peculiarity of all art is that it cannot | ||||

| be communicated in writing alone, craft is a | ||||

| term which is synonymous with art; a craft | ||||

| requires manual dexterity which cannot be | ||||

| taught in books. | ||||

[27]

The blackboard has been well called the great weapon of the modern educator; this is especially true in reference to instruction in an art dealing with lines, curves and figures.

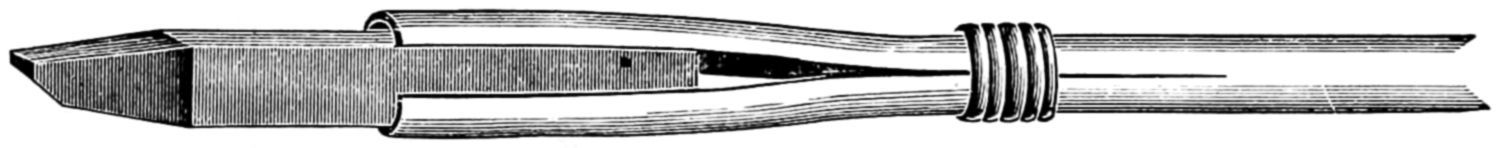

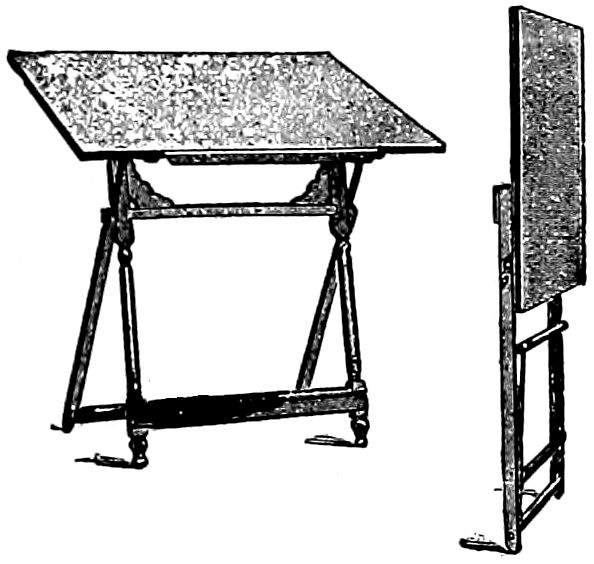

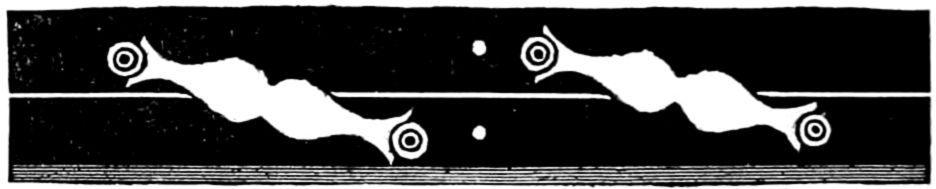

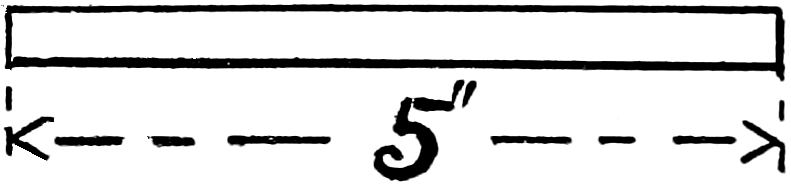

Fig. 6.

Many a man can chalk out on a blackboard, or on a piece of sheet-iron, or on the floor, just what he wants to show, and make his meaning very plain; hence, in every workshop, and many other places, a blackboard is more than useful, and it has been said that no draughting office is complete without one.

Fig. 6 represents a chalk-crayon.

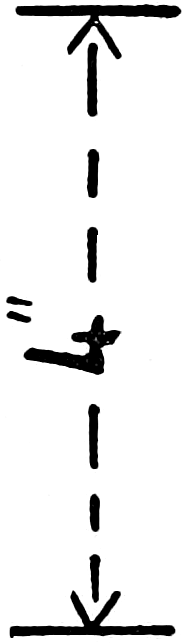

Fig. 7.

Fig. 8.

[28]

Figs. 7 and 8 need no explanation, as they represent two forms of the well-known blackboard.

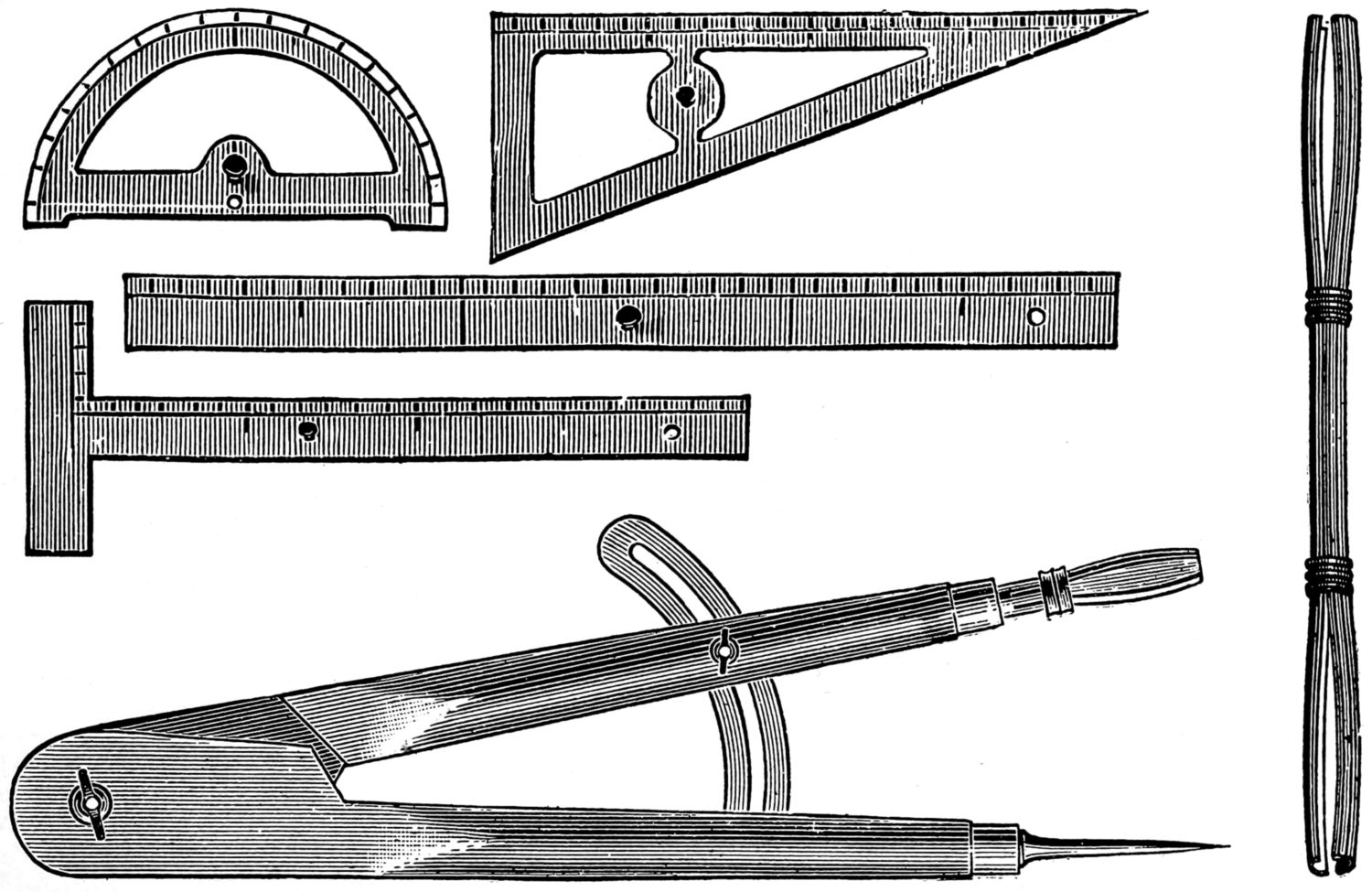

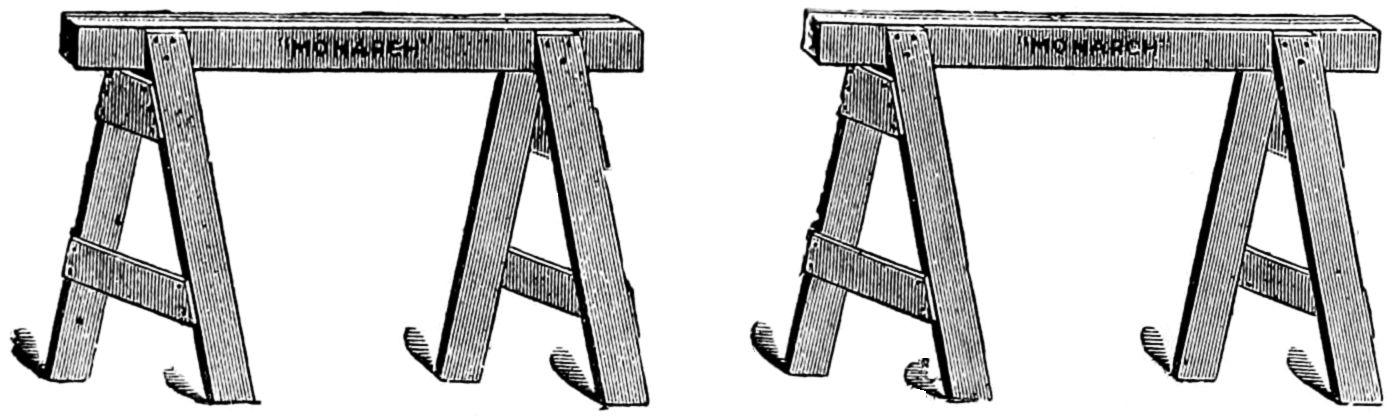

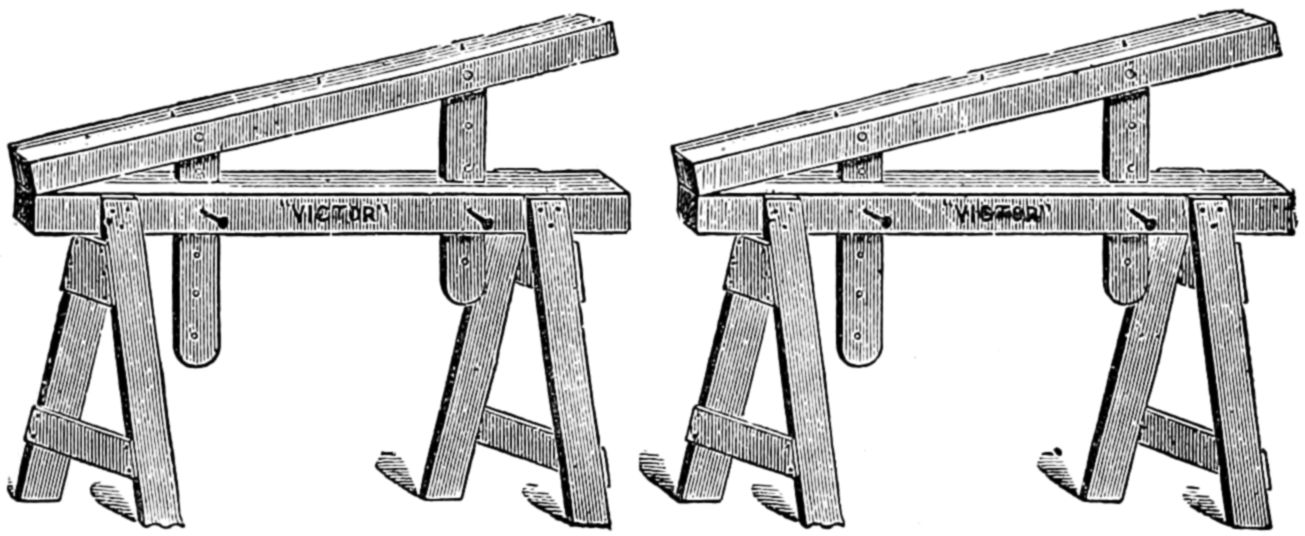

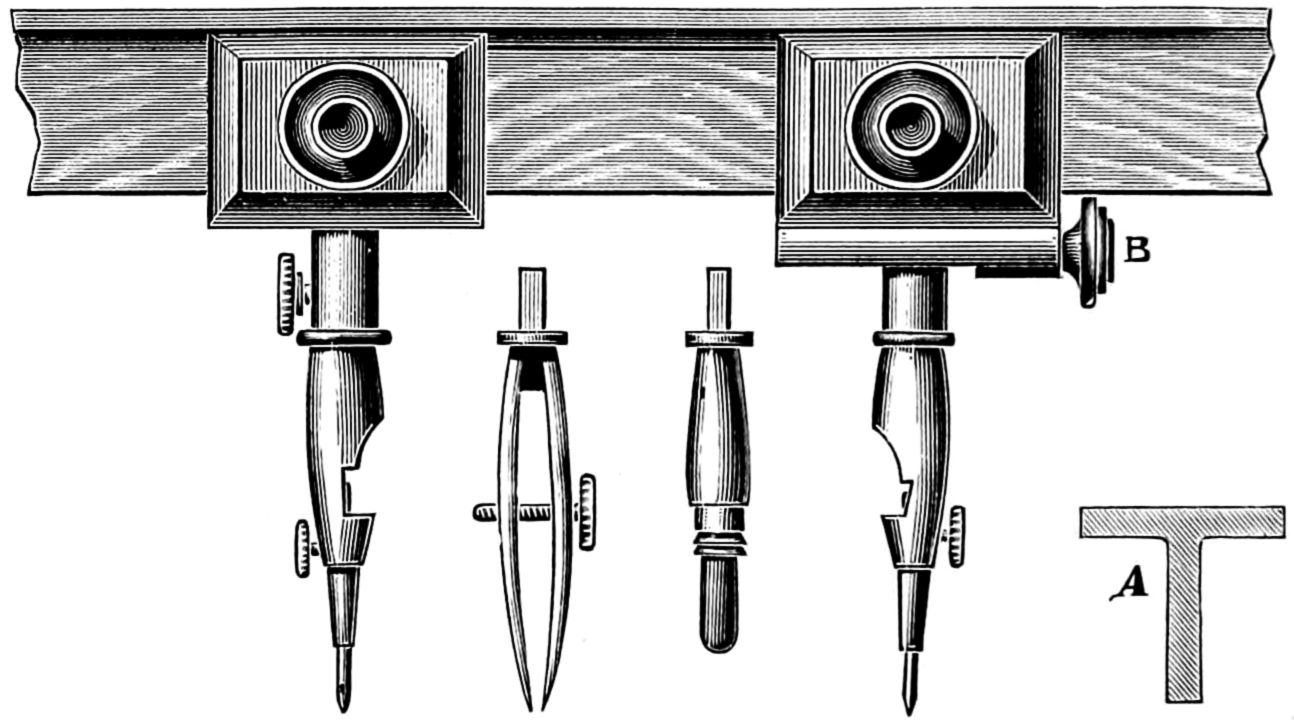

Chalk lines have this advantage—they are easily altered or rubbed out when not needed any longer. The work executed upon a blackboard is mostly done by hand, without aid from instruments; a few tools, however, are useful—such as, 1, large wooden blackboard compasses holding a crayon, which are made and sold by the trade in size twelve inches to thirty inches in length; 2, a straight-edge; and 3, some crayons. With the compasses circles and part of the circle can be made, and with the straight-edge the larger lines can be drawn.

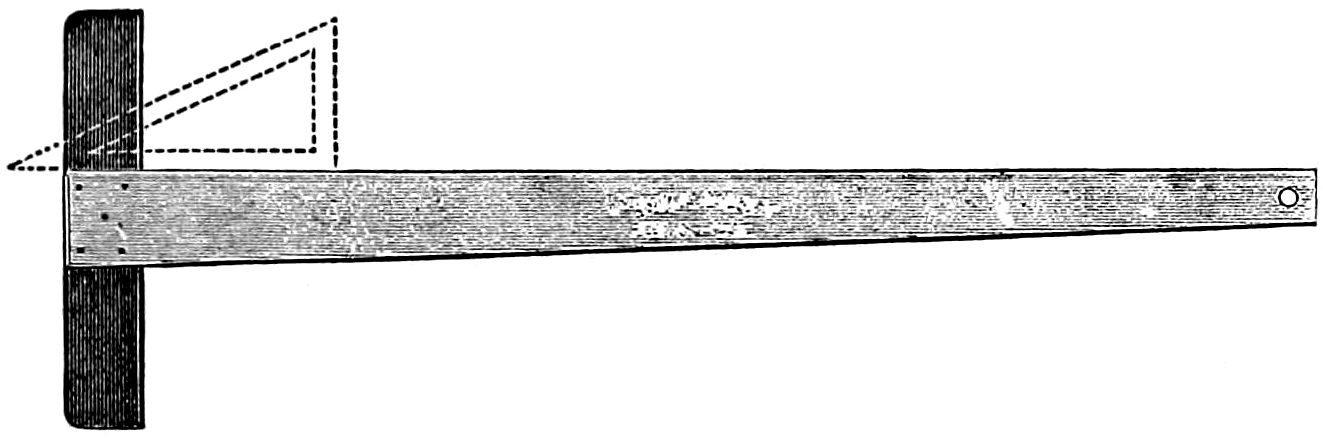

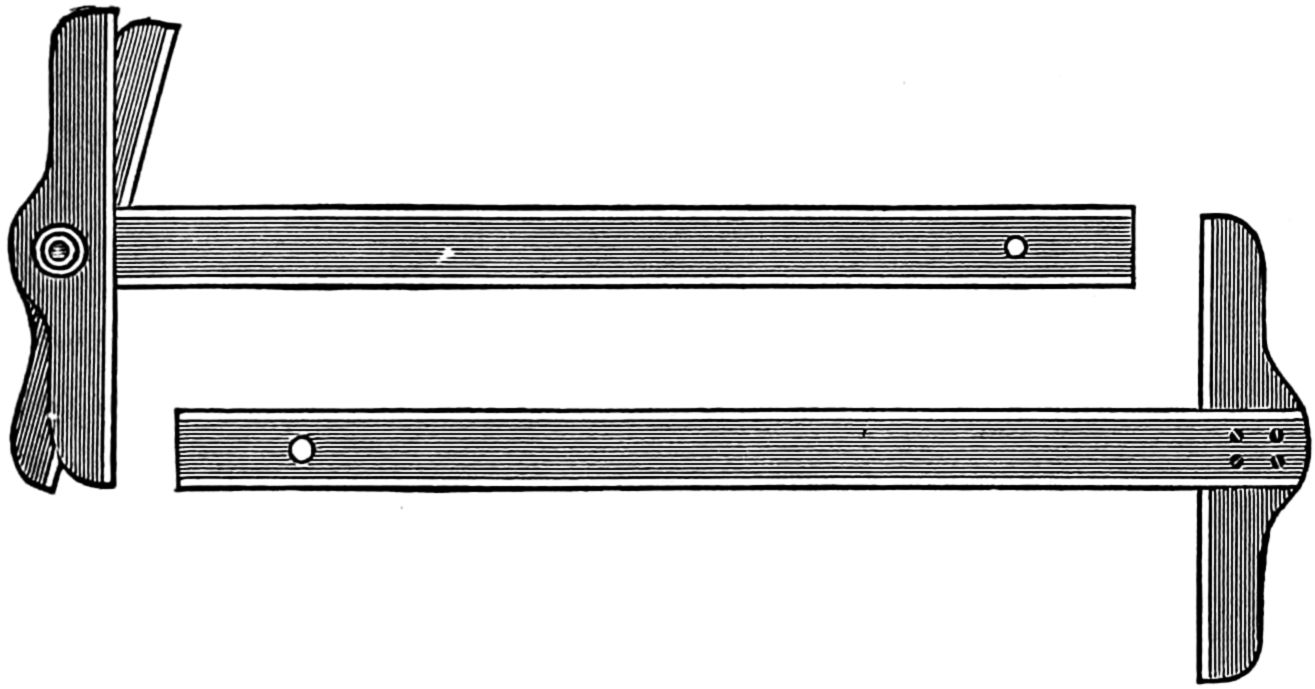

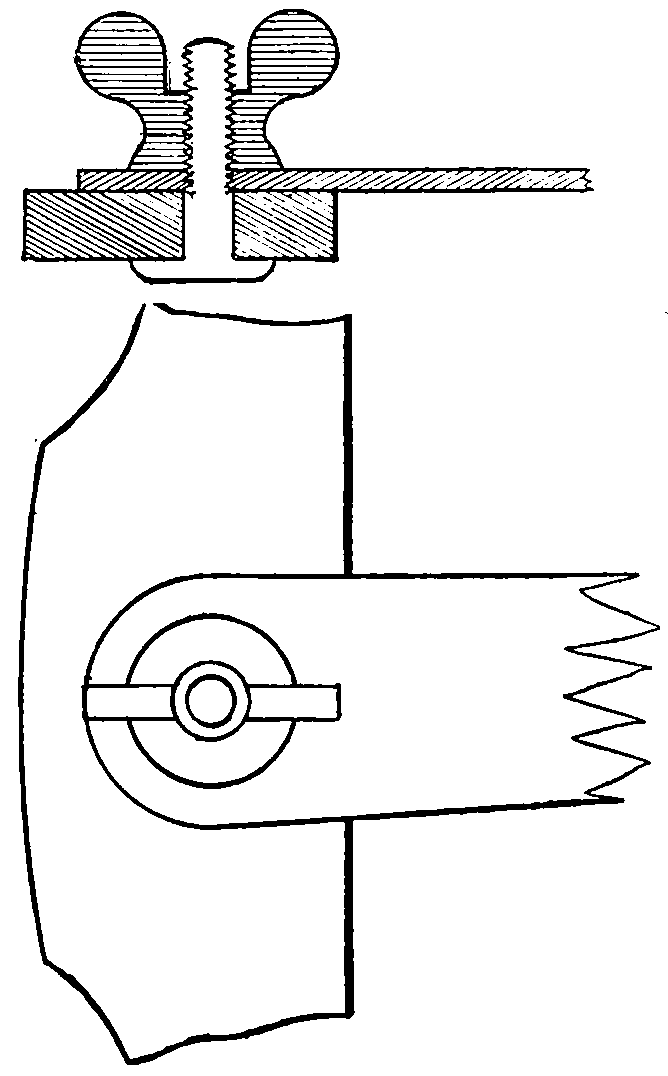

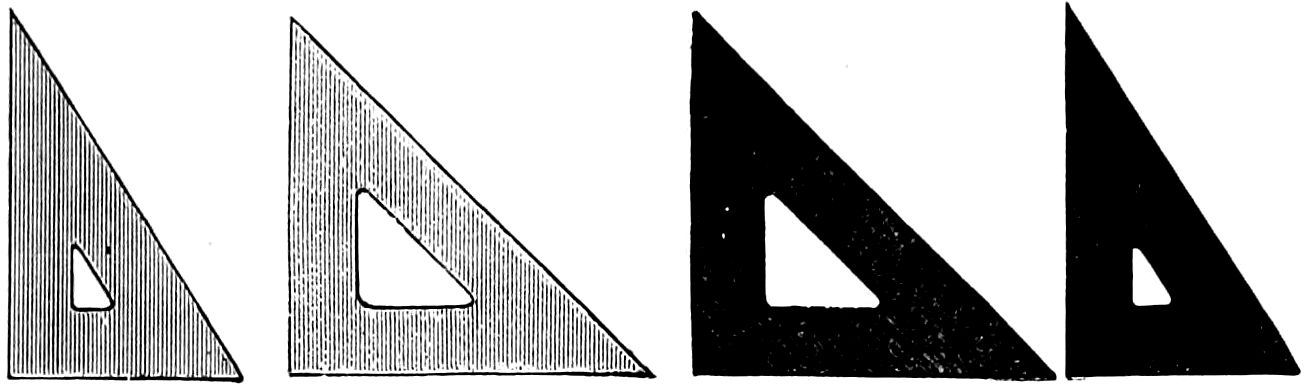

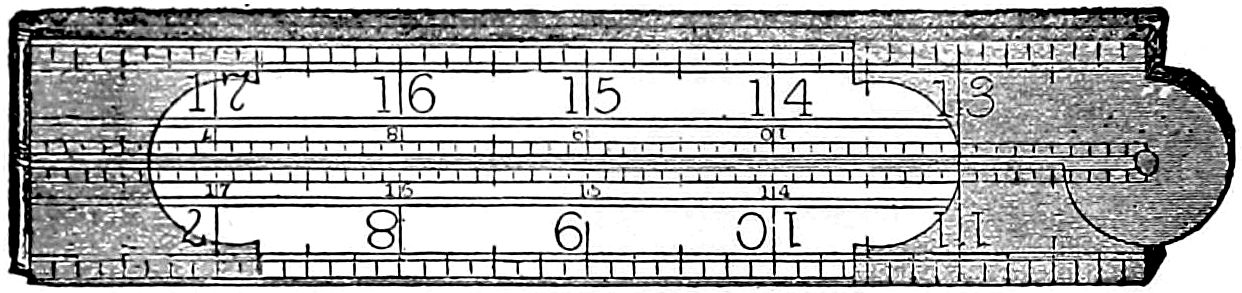

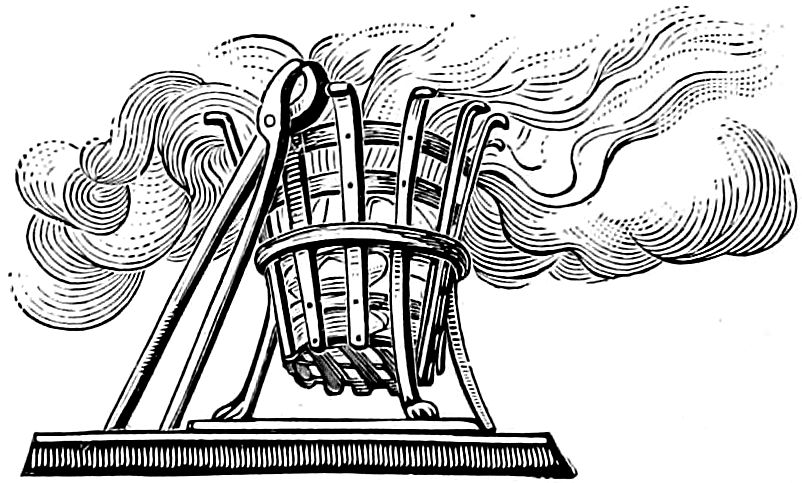

These instruments are shown on page 29, and are, 1, compasses, for holding chalk for making circles; 2, a tee-square; 3, a straight-edge; 4, a protractor for measuring angles; 5, a triangle 60° and 30°; 6, a brass holder for crayons.

Blackboard Drawing.—The use of a blackboard comes principally and properly under the head of[29] free-hand drawing, but its importance is such that a separate division of the volume is assigned to it.

[30]

Thus, chalk-work may be considered the first lesson in “free-hand,” as all the examples can also be most profitably practiced with pencil and paper.

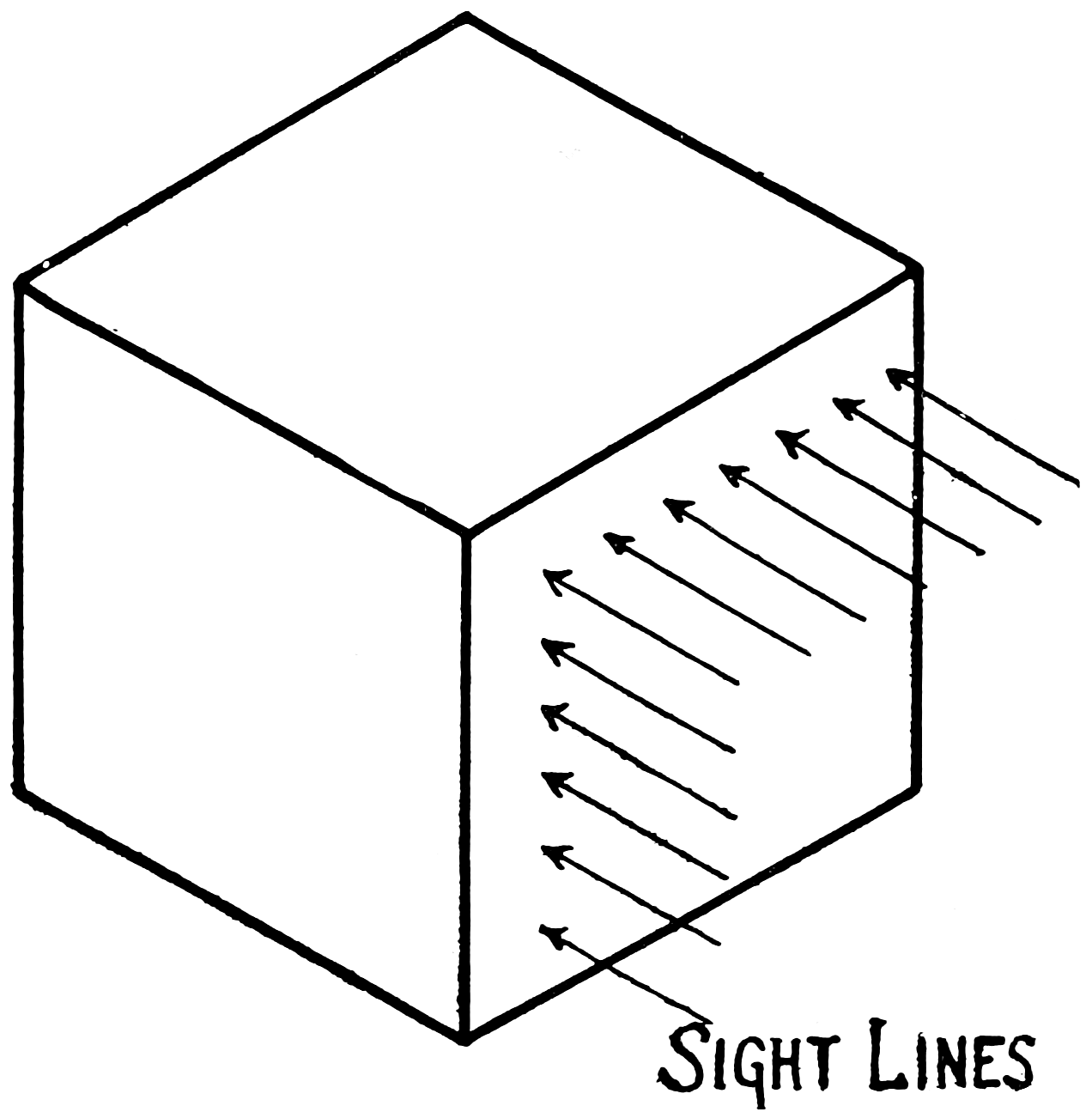

Very rapid drawing upon the board should not be encouraged, as it is likely not to be accurate enough; again, the board should be entirely free from grease. Cloths, sponges or chamois skin rubbers may be used to erase or change the chalk marks. Vertical lines should be drawn from above downward; short lines should be drawn with the fingers alone, those somewhat longer with the hand, using the wrist-joint; the still longer lines with the forearm, using the elbow-joint; those longer yet with the whole arm, using the shoulder-joint; lines should always be drawn with a uniform motion, slow enough for the eye to follow.

Practice in chalk-work should alternate with sketching in a sketchbook and with geometrical drawing—to be hereafter described. The student should practice a short time on the board, at least once a week; large sizes are the most profitable for the representations to be made; when drawing in different directions the hand should be turned, not the paper or board; the hand should never be allowed to obstruct the sight, hence the hand and fingers should be held in a position of freedom—with fingers not nearer than 11⁄2 or 2 inches from the board.

Note.—The first lesson of any kind the author received in drawing was to make a straight line; this was effected by holding the pencil nearly erect and guiding it along by the aid of the little finger held pressed against the edge of a board; this was a useful item of knowledge, as proved by passing years.

A well-known artist, in telling his early experience, said: “The first thing I was taught was to draw a line, divide it, erect a perpendicular from its center, and afterwards to divide the angle made by the perpendicular.” In answer to a question asking how long he was kept at the lines, he replied, “about two months—or a month or two,” indicating that even the longer time would have been well spent in learning to draw a straight line.

Every visible object is bounded by lines which enable the observer to determine its shape. If these[31] lines are straight or curved, the shape of the object is regular; if broken, the shape of the object is irregular.

The elements, then, of form are lines, straight, curved, or broken, and these, therefore, furnish the beginning of all instruction in free-hand or mechanical drawing.

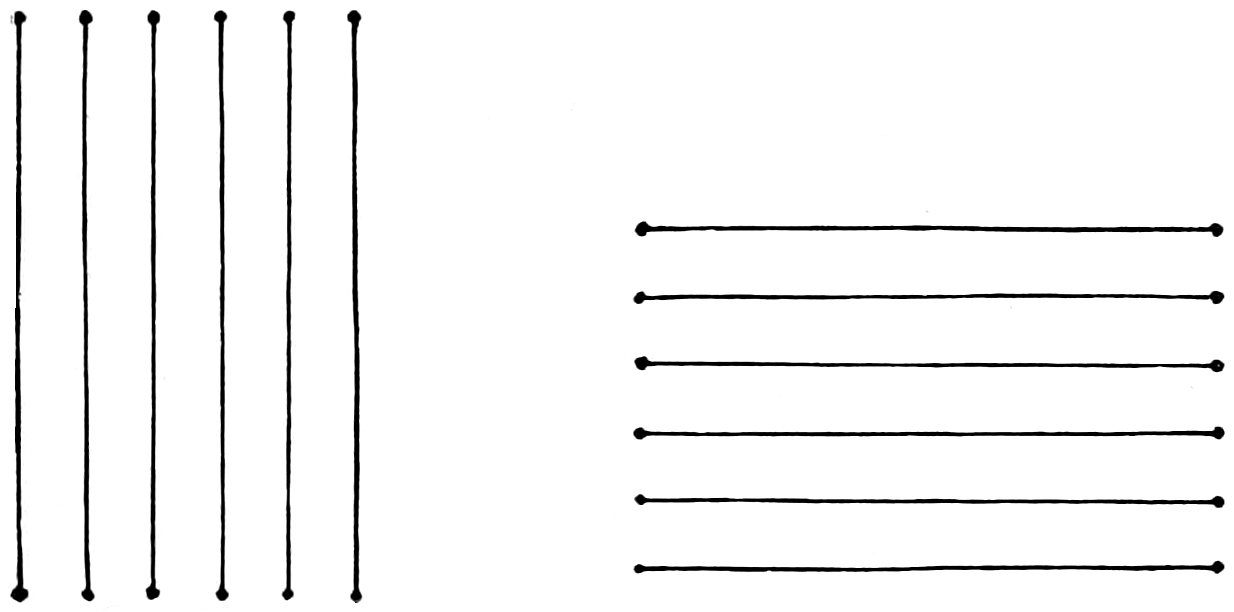

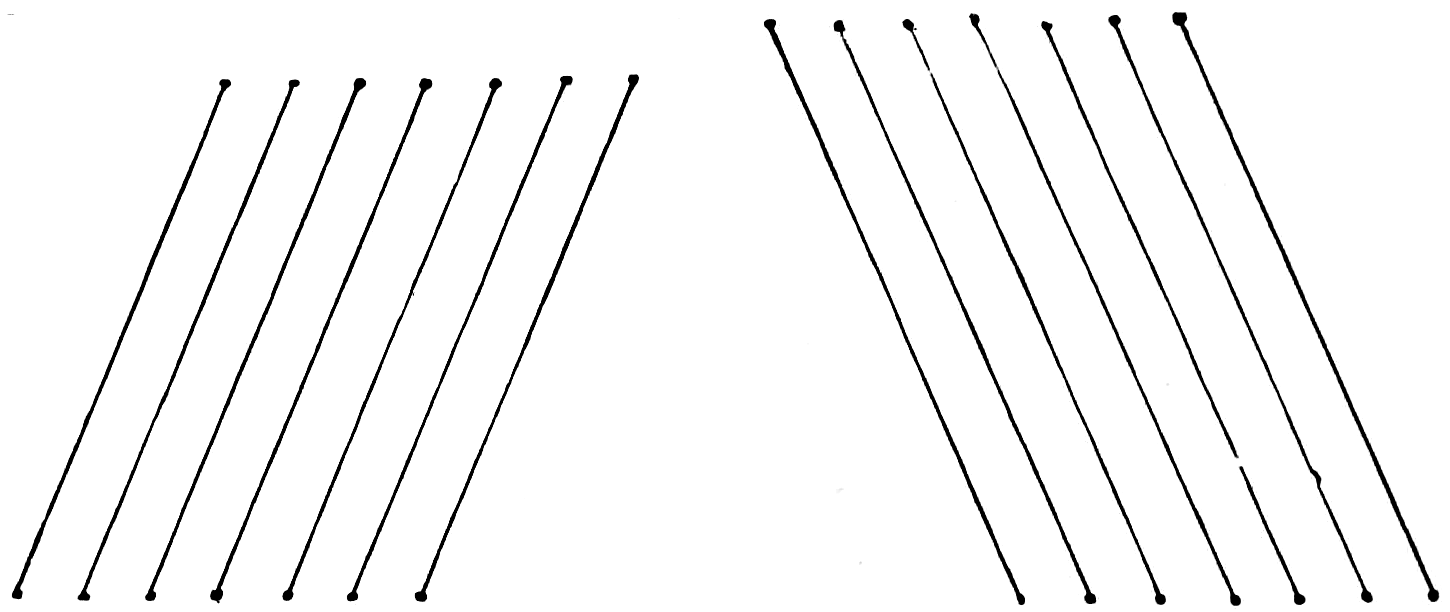

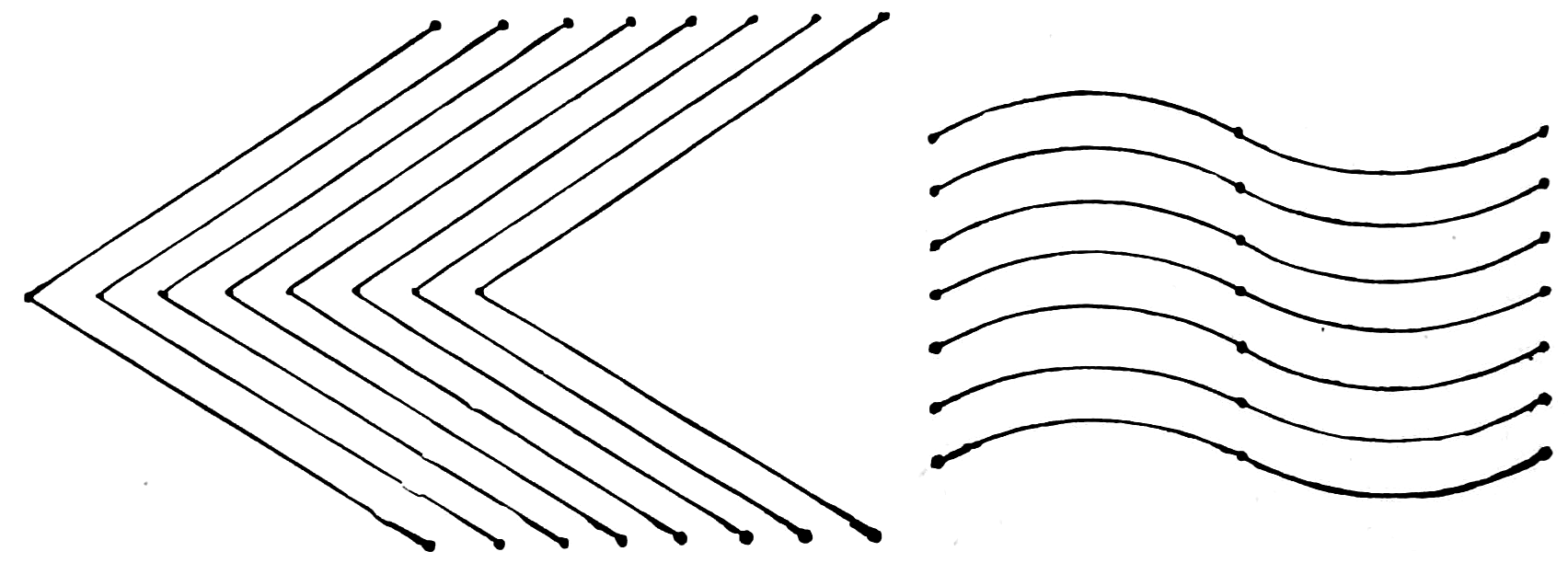

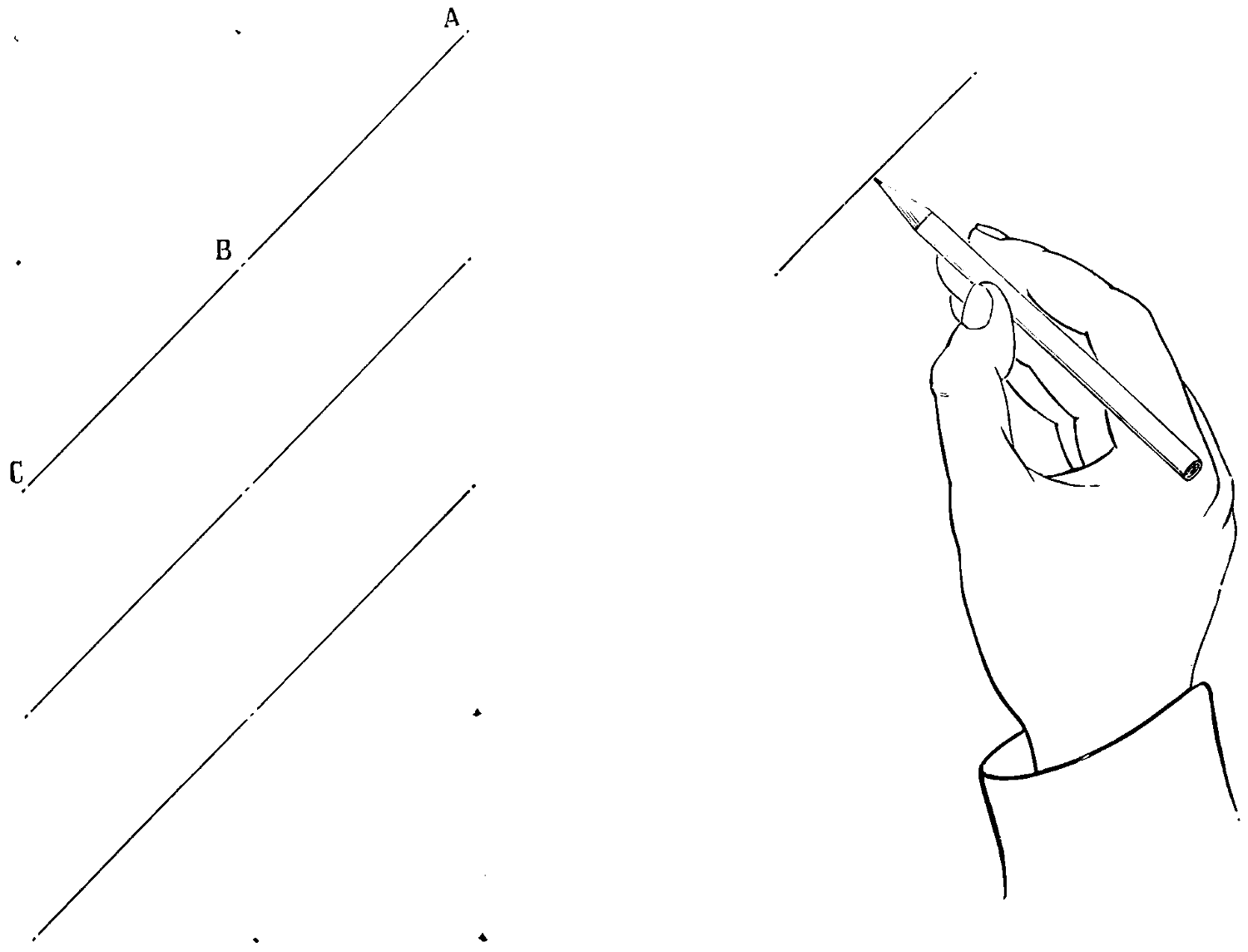

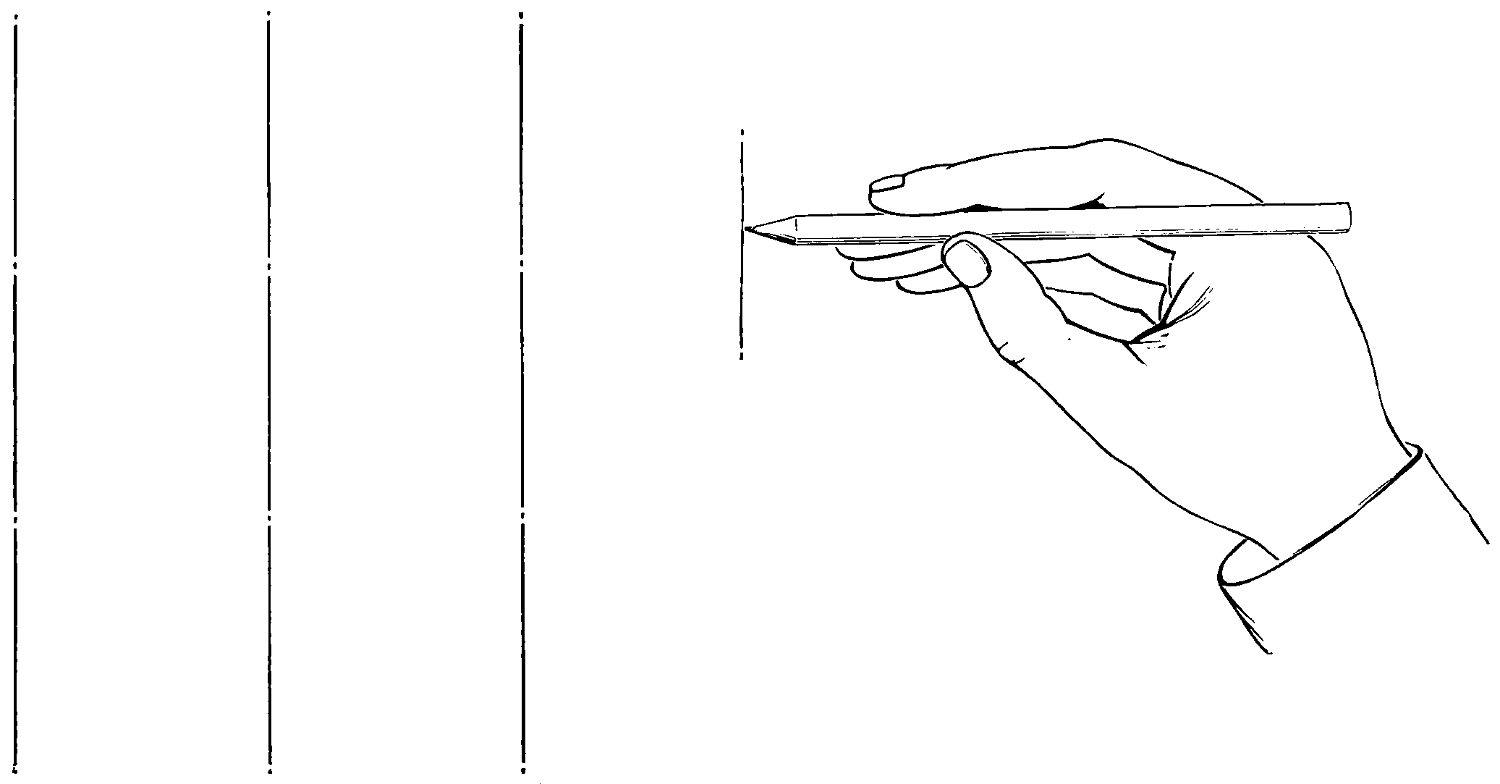

Fig. 15 shows six lines—upright and perpendicular, with points or “dots” indicated at the top and bottom of each line; to draw these, proceed thus:

Fig. 15.

Fig. 16.

The learner should stand with his right shoulder opposite the board, and the weight of the hand and the arm should be allowed to fall naturally; now, make on the board two points, one being six inches above the other, these being merely “dots,” shown at the ends of the lines, figs. 15, etc., and made with two motions; the line between the points should now be drawn not too quickly from the upper to the lower point; three movements of the hand and arm complete the line; to draw the other five lines the movements have simply to be repeated.

If the student pronounces to himself “one,” “two,” “three,” at each motion, it will be helpful; in this exercise, fig. 15, the aim is to make six lines, each line being parallel to the first. Again, in the example, it is intended that the lower point should be made first, next the upper, and lastly the line drawn from the upper to the lower point, but the order may be reversed; at one the upper point, at two the lower, at three the stroke upwards to complete the line.

[32]

To make these as shown in fig. 16, proceed as follows: With the word one make a point, with two another point six inches at the left, with three draw a straight line from the left point to the right. All added lines should be parallel: for practice, reverse the process thus, one, make a “point,” at two another point at the right, at three draw line to the left.

The student will note that the two motions—at the words one and two—are to fix the positions of the ends of the lines; this practice will be found useful in the most advanced examples and an item of elementary practice never to be forgotten—like the help to be derived by the first round of a ladder.

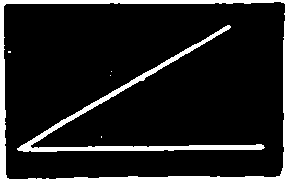

Fig. 17.

Fig. 18.

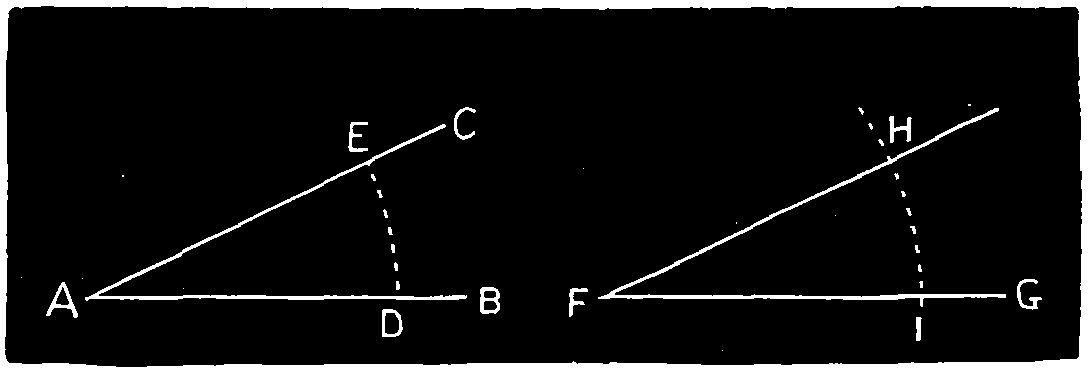

In drawing oblique straight lines as shown in fig. 17, at the word one let the student make the lower point; at the word two the upper, a little to the[33] right of the lower; at the word three draw a line quickly from the upper to the lower point. In pronouncing the words one, two, three, let the student make the additional parallel lines.

As shown in fig. 18, at the word one make the lower point; at the word two the upper point, a little to the left; at the word three draw a line rapidly from the upper to the lower point, and “timing” the process by repeating one, two, three, make the additional parallel lines.

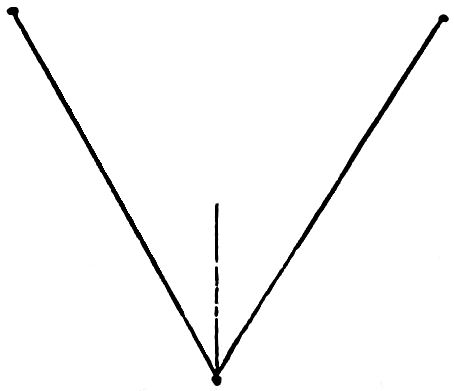

Fig. 19.

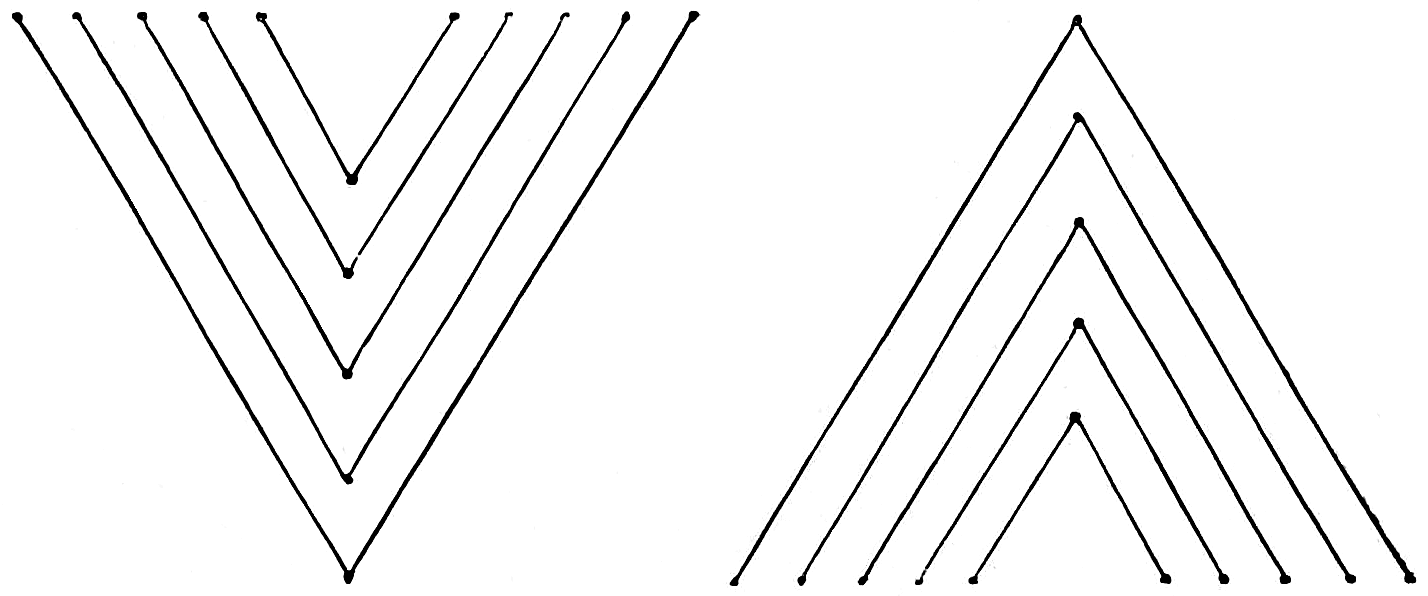

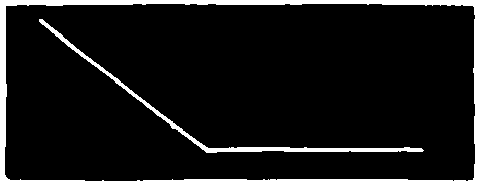

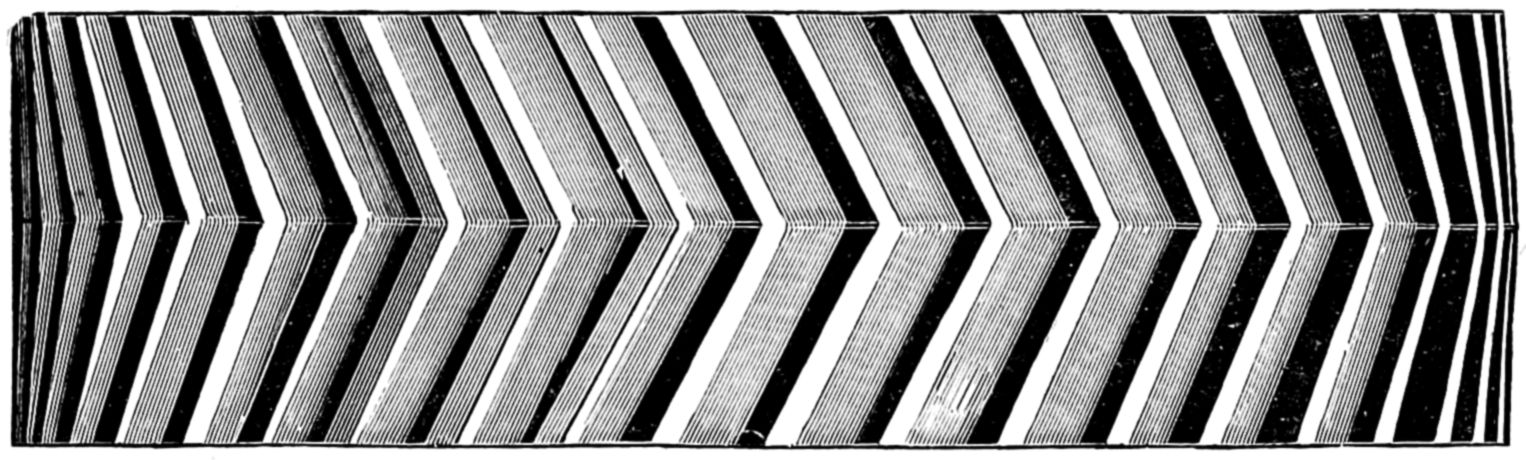

A broken line is composed of two or more straight lines at angles to each other (see fig. 19). To draw them begin (saying) one, make a point; two a point below at the left; three, a point above at the left; four, draw a line from the left hand point to the lower point; at the word five, from the lower point to the upper right hand point. For practice draw numerous lines in the same way, keeping them parallel to each other, as shown in fig. 20.

Fig. 20.

Fig. 21.

[34]

Fig. 22.

Fig. 24.

Fig. 23.

Fig. 25.

[35]

In example, fig. 21, the arrangement of the points is changed—let the student draw at the words, as follows: One, a point; two, a point above at the left; three, a point below at the left; four, draw from the point at the left to the upper point; five, from the upper point to the lower right hand point; continue to add parallel lines to complete the figure as shown.

Figs. 22 and 23 are given as examples to practice, making first the points and then the connecting lines and afterward the parallel lines to complete the figures.

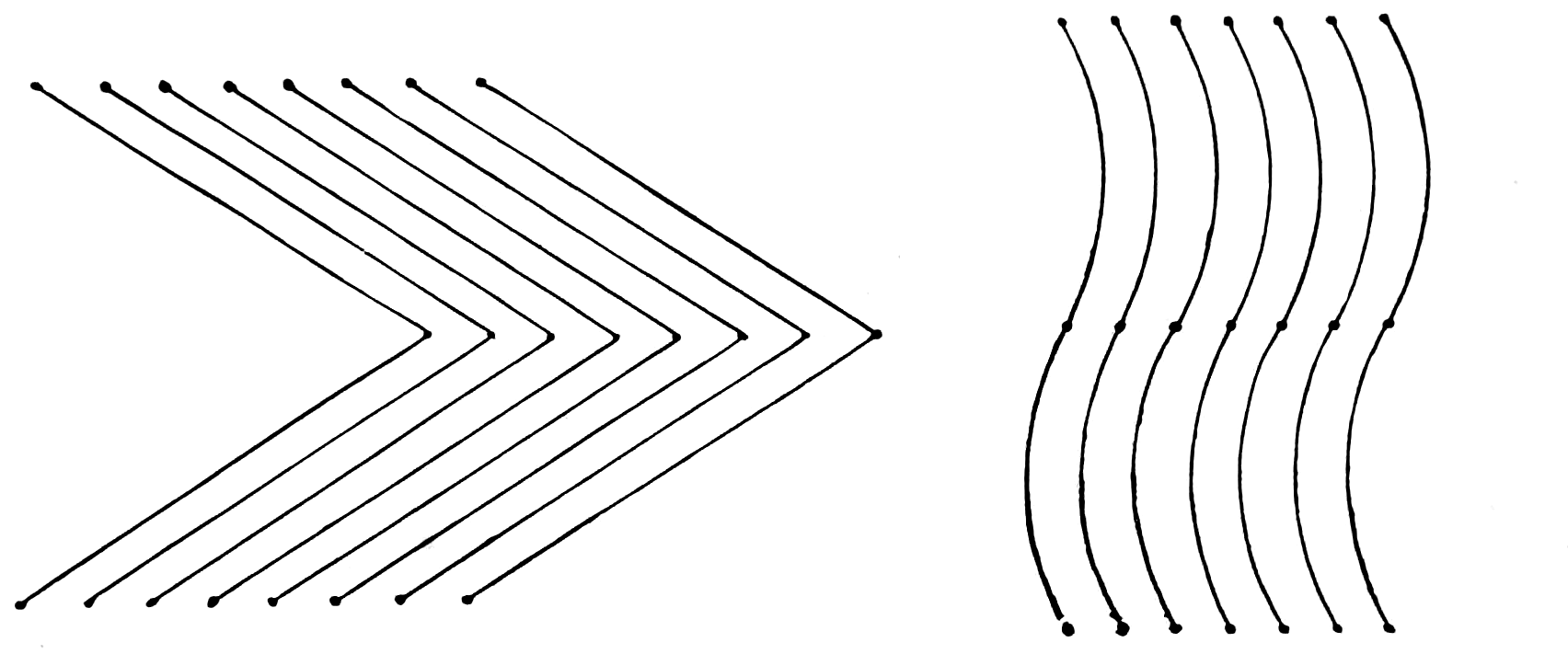

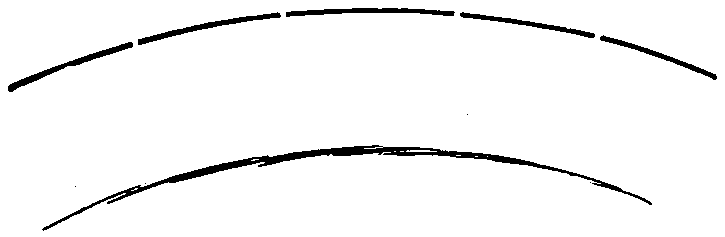

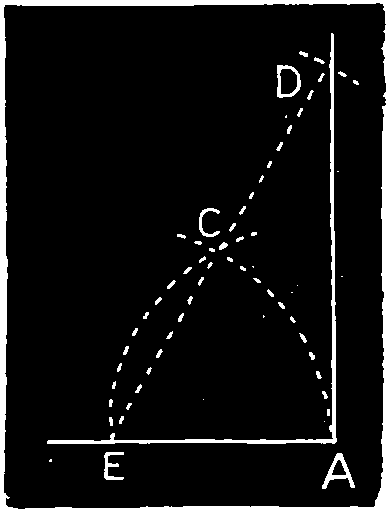

To draw curved lines, as shown in fig. 24. At the word one, point; at the word two, point three inches directly above; three, at the same distance above again make a point; now draw a curve as shown, joining the middle point and the upper point; now draw the curve as shown below it; finally complete figure as shown.

Fig. 26.

Fig. 27.

Fig. 28.

[36]

Fig. 29.

Fig. 30.

Figs. 25 to 30 are to be practiced, making first the points and then connecting them by the curves to complete the figures.

When two or more students are working together, with each having a blackboard, the counting may be in concert—or a teacher could count for a class. In these line examples care should be used in making them of uniform length. There is a difference to be noted between a crooked line and a broken line, the latter being a straight line and the former deviating from it.

Square chalk crayons are the best for hand work, as lines of an even or uniform width can be drawn with them.

A very fine effect is produced by using two thicknesses of chalk, one being double the thickness of the other; the heavy lines being used on the shade side of objects will produce a good effect, giving thickness and body to the object.

Round chalk crayons are used in the compasses to draw circles, but hand lines drawn with them are not so neat as those produced with the square-shaped chalk.

To obliterate or remove the construction, or false lines made on the blackboard, a wooden handle two inches in diameter with a cone end 3 or 4 inches long, covered with chamois skin or soft cloth tightly wrapped round the cone and fastened with a tack or drawing pin, makes the best implement to erase lines not required, the point of the cone will remove these without destroying the lines or curves which meet them.

[37]

Sponges, chamois skin or cloth rubbers are used to rub out the chalk drawings and clean the blackboard.

The best height for a diagram on the blackboard is not higher than the head, nor lower than the elbow.

Horizontal lines should be made from the left to the right; the body and arm being moved with the hand, and kept in the same relative position with it, will steady the hand.

Curved lines to the left should be drawn first, enabling the eye to take in not only the curve in process of formation but that already made.

Passing the crayon in the hand, over the intended curve previous to marking it, will guide the eye and give confidence to the hand in chalking the curve.

A proper distance from the blackboard is essential, the face being about two feet away from it.

Draw with the whole arm extended from the shoulder-joint, not from the elbow or wrist.

Fig. 31.

[38]

| “There are more ways than one of telling things: by speech, by writing, by printing, also by pictures and drawings.” Knowles |

||

[39]

[40]

ELECTRA.

[41]

Like all the arts, drawing has a nomenclature of its own, and nothing can be more helpful to the beginner than to know the name of things relating to the art of drawing. This is a language almost peculiar to itself, and used daily and hourly by many thousands of superintendents, foremen and master mechanics, as well as by owners, designers and draughtsmen, hence its introduction at this early stage.

ALTITUDE.—This is the elevation of an object above its base, or the perpendicular distance between the top and bottom of a figure.

Fig. 33.

Fig. 34.

Fig. 35.

Fig. 36.

Fig. 37.

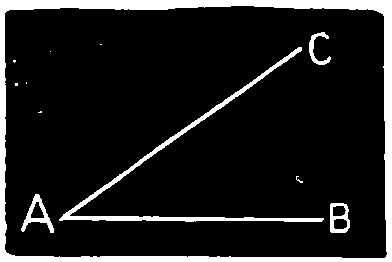

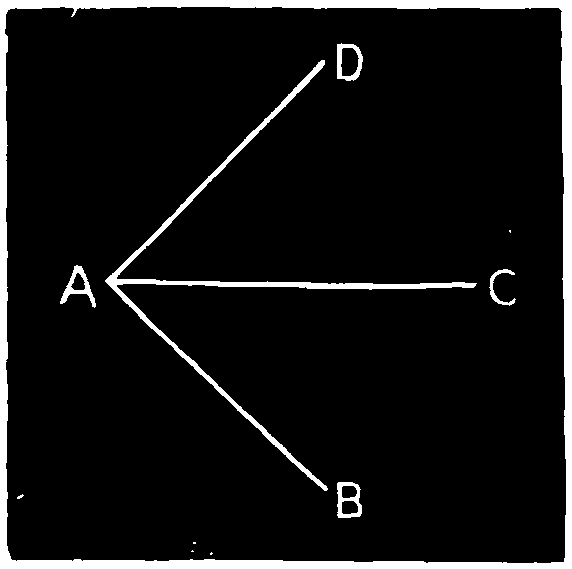

ANGLE is the difference in the direction of two lines which meet or tend to meet. The lines are called the sides and the point of meeting, the vertex of the lines.

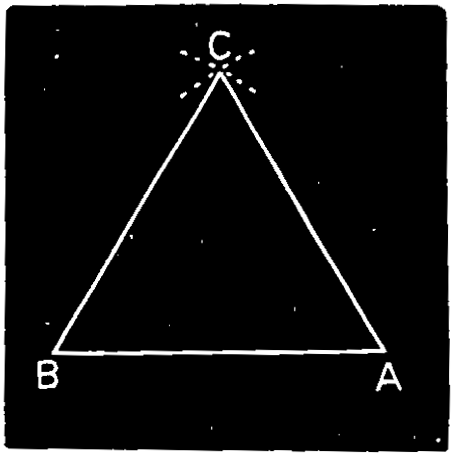

To make an angle apparent, the two lines must meet in a point, as A B and A C, which meet in the point A, as shown in fig. 33.

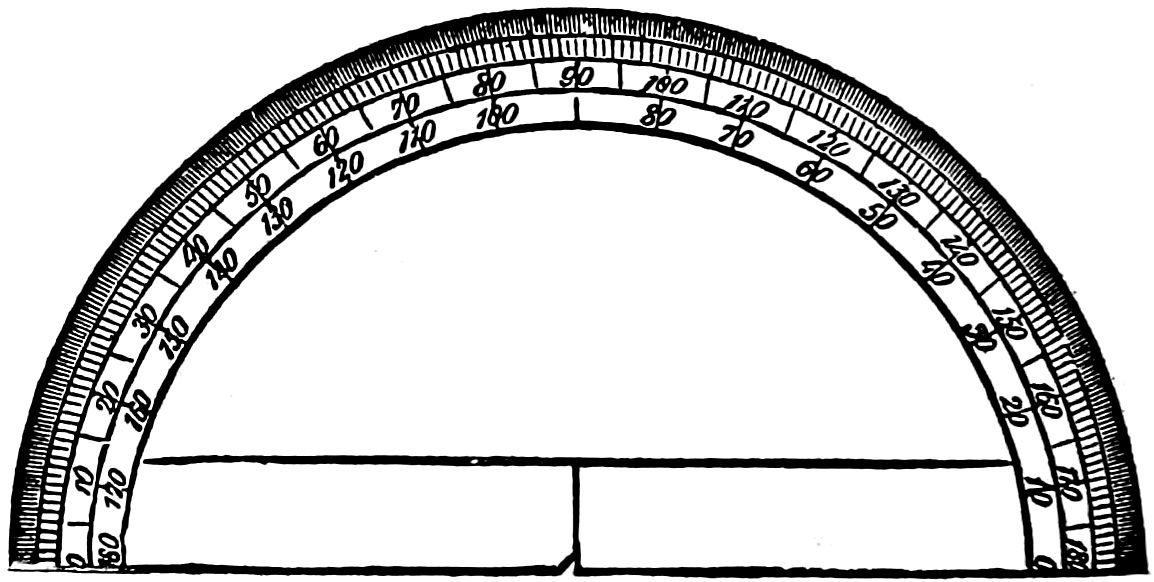

Angles are measured by degrees.

A Degree is one of the three hundred and sixty equal parts of the space about a point in a plane.

Angles are distinguished in respect to magnitude by the terms Right, Acute and Obtuse Angles.

[42]

A Right Angle is that formed by one line meeting another, so as to make equal angles with that other.

The lines forming a right angle are perpendicular to each other.

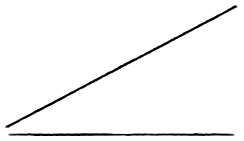

An Acute Angle is less than a right angle. See Fig. 35.

An Obtuse Angle is greater than a right angle. See Fig. 36.

Obtuse and acute angles are also called oblique angles; and lines which are neither parallel nor perpendicular to each other are called oblique lines.

The Vertex or Apex of an angle is the point in which the including lines meet.

An angle is commonly designated by a letter at its vertex; but when two or more angles have their vertices at the same point, they cannot be thus distinguished.

For example, when the three lines A B, A C, and A D in fig. 37 meet in the common point A, we designate either of the angles formed, by three letters, placing that at the vertex between those at the opposite extremities of the including lines. Thus, we say, the angle B A C, etc.

APEX.—The summit or highest point of an object.

ARC.—See circle.

AXIS OF A SOLID.—An imaginary straight line passing through its center.

[43]

AXIS OF A FIGURE.—A straight line passing through the center of a figure, and dividing it into two equal parts.

BASE.—The base of a solid figure is that on which it stands—the lowest part.

BISECT.—To divide into two equal parts.

BISECTOR.—A line which bisects.

Fig. 38.

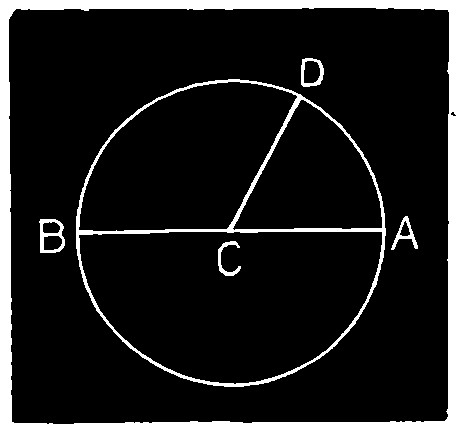

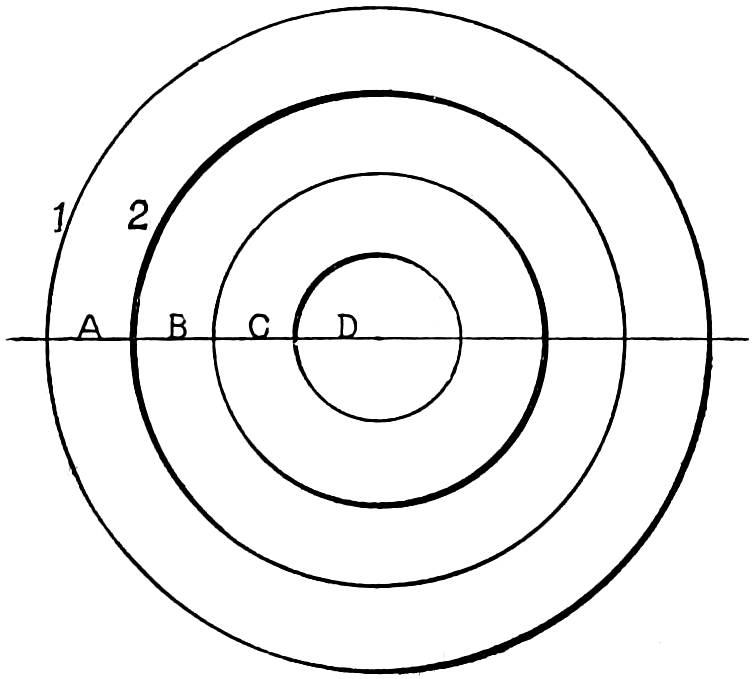

CIRCLE.—A Circle is a plane figure bounded by one uniformly curved line, all of the points in which are at the same distance from a certain point within, called the Center.

The Circumference of a circle is the curved line that bounds it.

The Diameter of a circle is a line passing through its center, and terminating at both ends in the circumference, as A C B.

The Radius of a circle is a line extending from its center to any point in the circumference. It is one-half of the diameter. All the diameters of a circle are equal, as are also all the radii C D, C B and C A.

An Arc of a circle is any portion of the circumference, as B D and A D.

Semi-Circle.—Half a circle formed by bisecting it with a diameter, as A C B. Fig. 38.

An angle having its vertex at the center of a circle is measured by the arc intercepted by its sides. Thus, the arc A D measures the angle A C D, and in general, to compare different angles, we have but to compare the arcs, included by their sides, of the equal circles having their centers at the vertices of the angles.

CIRCUMSCRIBE.—To draw a line of figures about or outside, such as a circle drawn around a square touching its corners or angles.

[44]

Inscribe.—To draw a line or figure inside or on the interior, such as a circle drawn within a square touching its sides.

CONCAVE.—Curving inwardly.

CONE.—A solid body or figure having a circle for its base, and its top terminated in a point or vertex.

CONSTRUCTION.—The making of any object.

CONTOUR.—The outline of the general appearance of an object.

CONVERGENCE.—Lines extending towards a common point.

CONVEX.—Rising or swelling into a round form—the opposite to concave.

CORNER.—The point of meeting of the edges of a solid, or the two sides of a plane figure.

CROSS-HATCHES.—In free-hand drawing the use of lines crossing each other to produce light and shade effects.

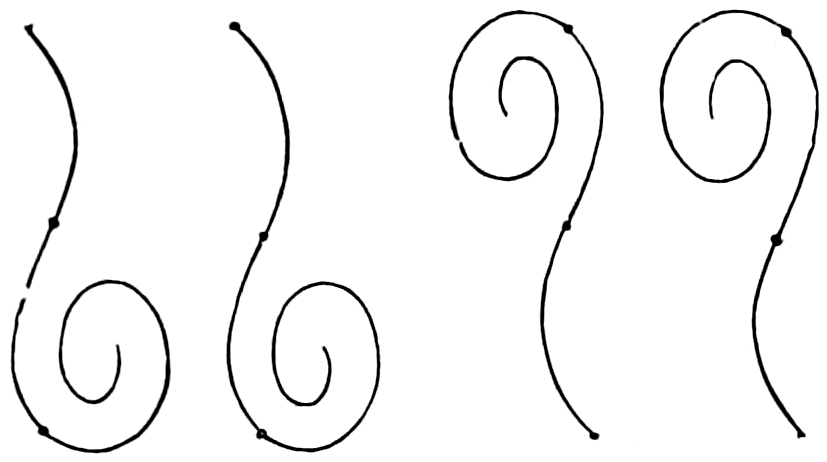

CURVE.—A line of which no part is straight.

Reversed Curve.—One whose curvature is first in one direction and then in the opposite direction.

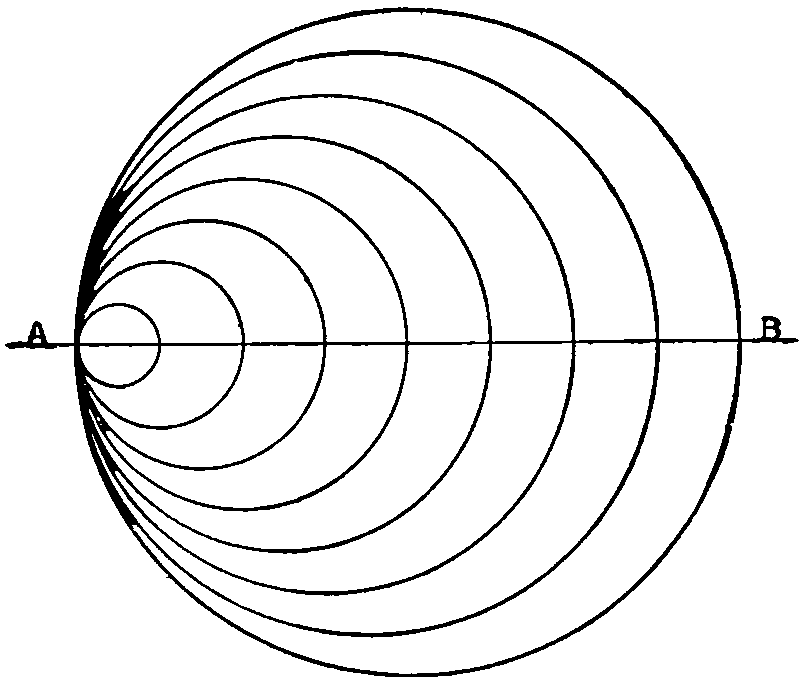

Spiral Curve.—A plain curve which winds about and recedes, according to some law, from its point of beginning, which is called its center.

CYLINDER.—A solid bounded by a curved surface and by two opposite faces called bases; the bases may be any curved figures and give the name to the cylinder; thus a circular cylinder is one whose bases are circles.

CYLINDRICAL.—Having the general form of a cylinder.

DEGREE.—The 360th part of a circle.

DESCRIBE.—To make or draw a curved line; to draw a plan.

DESIGN.—Any arrangement or combination to produce desired results in industry or art. To delineate a form or figure by drawing the outline—a sketch.

[45]

DEVELOP.—To unroll or lay out.

DIAGONAL.—A right line drawn from angle to angle of a quadrilateral or many angled figure and dividing it into two parts.

DIAMETER.—A right line passing through the center of a circle or other round figure terminated by the curve and dividing the figure symmetrically into two equal parts.

EDGE.—The intersection of any two surfaces.

ELEVATION.—The term elevation, vertical projection and front view—applied to drawings—all have the same meaning.

FACE.—One of the plane surfaces of a solid; it may be bounded by straight or curved edges.

FINISHING.—Completing a drawing whose lines have been determined by erasing unnecessary lines and strengthening and accentuating where this is needed.

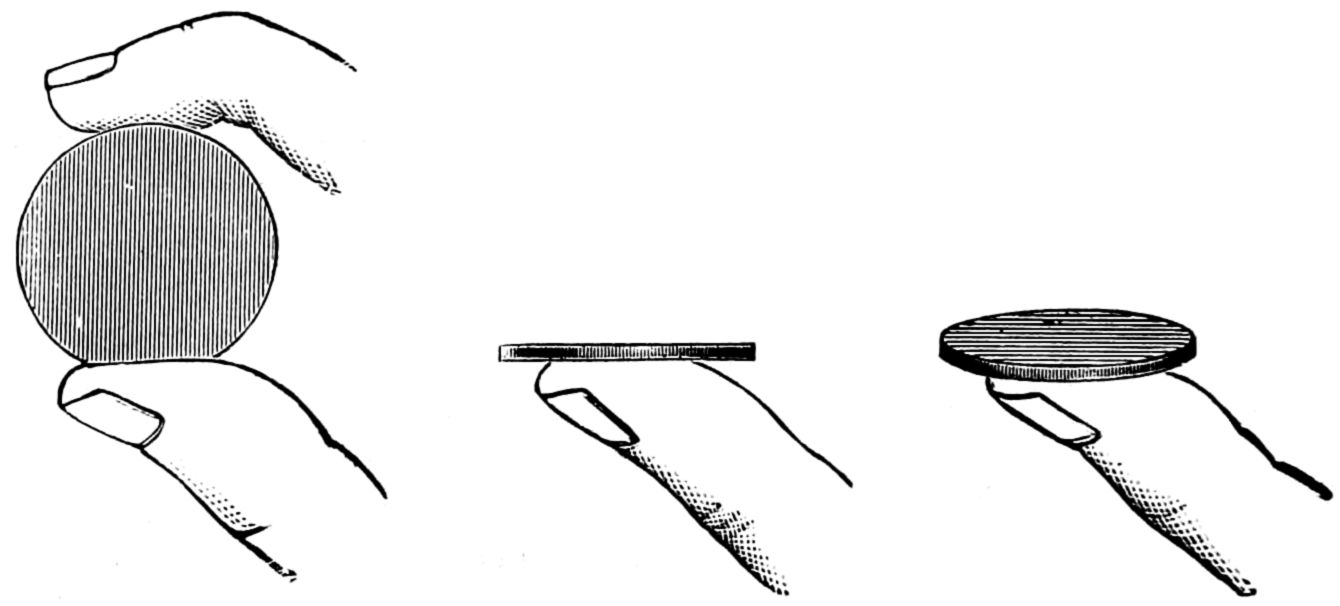

FORESHORTENING.—Apparent decrease in length, owing to objects being viewed obliquely; thus a wheel, when seen obliquely, instead of appearing round, presents the appearance of an ellipse.

FREE-HAND.—Executed by the hand unaided by instruments.

GENERATED.—Produced by.

GEOMETRIC.—According to geometry.

HALF-TINT.—The shading produced by means of parallel equidistant lines.

HEMISPHERE.—Half a sphere obtained by bisecting a sphere by a plane.

HORIZONTAL.—Parallel to the surface of smooth water. In drawing, a line drawn parallel to the top and bottom of the sheet is called horizontal.

INSCRIBE.—See circumscribe—its opposite.

INSTRUMENTAL.—By the use of instruments.

[46]

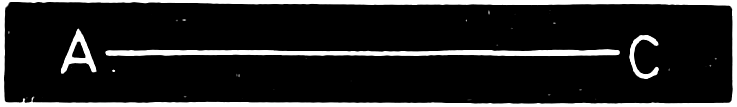

LINE.—A line has length, only, as A C; a right line is a straight line, the shortest line that can be drawn between two points, A——C.

Straight. One which has the same direction throughout its entire length.

Curved. One no part of which is straight.

Broken. One composed of different successive straight lines.

Mixed. One of straight and curved lines.

Center. A line used to indicate the center of an object.

Construction. A working line used to obtain required lines.

Dotted. A line composed of short dashes. - - - - - -

Dash. A line composed of long dashes. — — —

Dot and Dash. A line composed of dots and dashes alternating. — · — · —

Dimension. A line upon which a dimension is placed.

Full. An unbroken line, usually representing a visible edge. ———

Shadow. A line about twice as wide as the ordinary full line.

A straight line is often called simply a line, and a curved line a curve.

LONGITUDINAL.—In the direction of the length of an object.

MODEL.—A form used for study.

OBLIQUE.—Neither horizontal nor vertical.

OBLONG.—A rectangle with unequal sides.

OVAL.—A plane figure resembling the longitudinal section of an egg; or elliptical in shape.

OVERALL.—The entire length.

PARALLEL.—Having the same direction and everywhere equally distant.

PATTERN.—That which is used as a guide or copy in making things.

Flat. One made of paper or other thin material.

[47]

Solid. One which reproduces the form and size of the object to be made.

PERIMETER.—The boundary of a closed plane figure.

PERPENDICULAR.—At an angle of 90°.

PERSPECTIVE.—View; drawing objects as they appear to the eye from any given distance and situation, real or imaginary.

PLAN.—Plan, horizontal projection and top view have the same meaning.

PLANE FIGURE.—A part of a plane surface bounded by straight or curved lines, or by both combined.

Fig. 39.

POLYGON.—A plane figure bounded by straight lines called the sides of the polygon. The least number of sides that can bound a polygon is three. Polygons bounded by a greater number of sides than four are denominated only by the number of sides.

A polygon of five sides is called a Pentagon; of six, a Hexagon; of seven, a Heptagon; of eight, an Octagon; of nine, a Nonagon, etc.

Diagonals of a polygon are lines joining the vertices of angles not adjacent.

The Perimeter of a polygon is its boundary considered as a whole.

The Base of a polygon is the side upon which the polygon is supposed to stand.

The Altitude of a polygon is the perpendicular distance between the base and a side or angle opposite the base.

Fig. 40.

A Quadrilateral is a polygon having four sides and four angles.

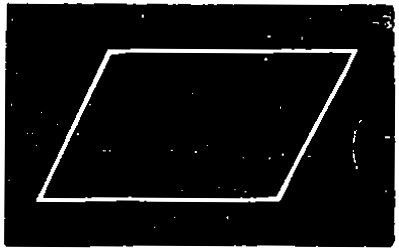

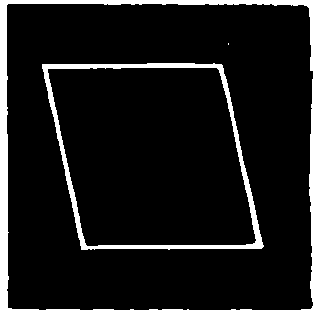

A Parallelogram is a quadrilateral which has its opposite sides parallel.

The side upon which a parallelogram stands and the opposite side are called respectively its lower and upper bases.

[48]

A Rectangle is a parallelogram having its angles right angles.

A Square is an equilateral rectangle, fig. 41.

Fig. 41.

Fig. 42.

Fig. 43.

Fig. 44.

Figs. 45-49.

A Rhomboid is an oblique-angled parallelogram.

A Rhombus is an equilateral rhomboid, fig. 42.

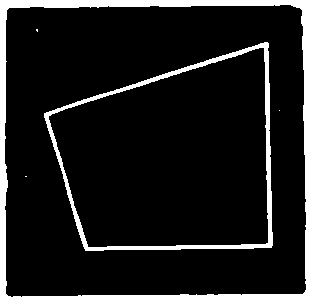

A Trapezium is a quadrilateral having no two sides parallel, fig. 43.

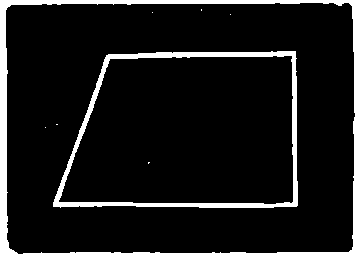

A Trapezoid is a quadrilateral in which two opposite sides are parallel, and the other two oblique, fig. 44.

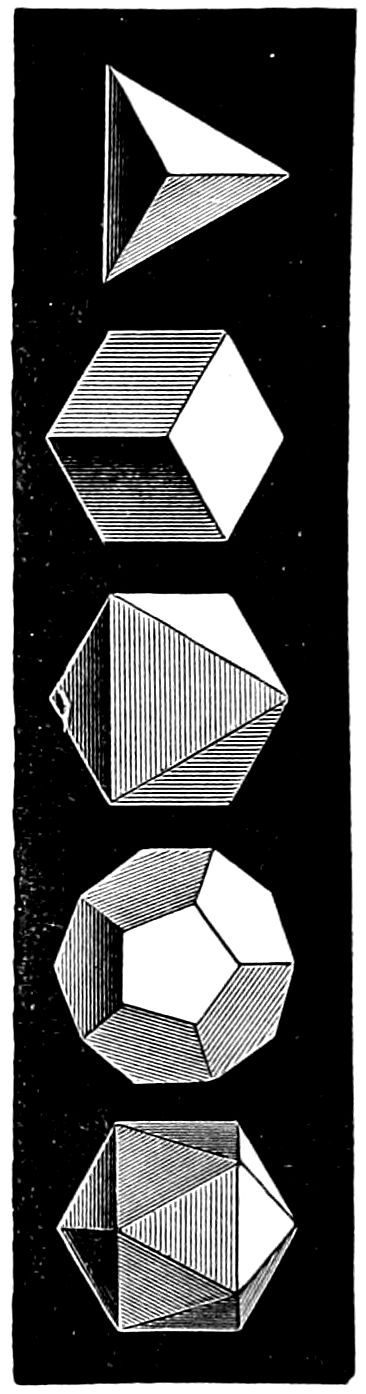

A POLYHEDRON is a solid bounded by planes. There are five regular solids which are shown in figs. 45, 46, 47, 48 and 49. A regular solid is bounded by similar and regular plane figures.

Fig. 45.—The tetrahedron, bounded by four equilateral triangles.

Fig. 46.—The hexahedron, or cube, bounded by six squares.

Fig. 47.—The octahedron, bounded by eight equilateral triangles.

Fig. 48.—The dodecahedron, bounded by twelve pentagons.

Fig. 49.—The icosahedron, bounded by twenty equilateral triangles.

[49]

PRISM.—A solid whose bases or ends are very similar plane figures, and whose sides are parallelograms; prisms are called triangular, square, etc., according as the bases are triangles, squares, etc.

PRODUCE.—To continue or extend.

PROFILE.—An outline or contour.

PROJECTION.—The view of an object obtained upon a plane by projecting lines perpendicular to the plane.

QUADRANT.—The fourth part; a quarter; the quarter of a circle.

QUADRISECT.—To divide into four equal parts.

SECTION.—A projection upon a plane parallel to a cutting plane which intersects any object. The section generally represents the part behind the cutting plane, and represents the cut surfaces by diagonal lines.

SECTIONAL.—Showing the section made by a plane.

SHADOW.—Shade and shadow have about the same meaning.

SOLID.—A solid has three dimensions—length, breadth and thickness.

SPHERE.—A solid bounded by a curved surface every point of which is equally distant from a point within called the center.

SURFACE.—The boundary of a solid. It has but two dimensions—length and breadth. Surfaces are plane or curved.

A Plane Surface is one upon which a straight line can be drawn in any direction.

A Curved Surface is one no part of which is plane.

The surface of the sphere is curved in every direction, while the curved surfaces of the cylinder and cone are straight in one direction.

The surface of a solid is no part of the solid, but is simply the boundary of the solid. It has two dimensions only, and any number of surfaces put together will give no thickness.

[50]

Fig. 50.

Fig. 51.

Fig. 52.

Fig. 53.

Fig. 54.

SYMMETRY.—Design. A proper adjustment or adaptation of parts to one another and to the whole.

TRISECT.—To divide into three equal parts.

TRIANGLE.—A triangle is a polygon having three sides and three angles. Tri is a Latin prefix signifying three; hence a Triangle is literally a figure containing three angles.

A Scalene Triangle is one in which no two sides are equal. See fig. 50.

An Isosceles Triangle is one in which two of the sides are equal. See fig. 51.

An Equilateral Triangle is one in which the three sides are equal. An Equiangular Triangle is one having its three angles equal. An Acute-Angled Triangle is one in which each angle is acute.

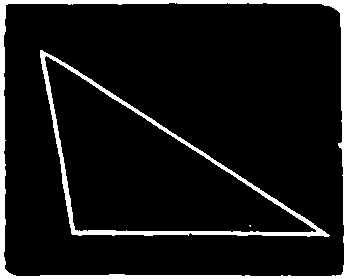

A Right-Angled Triangle is one which has one of the angles a right angle. See fig. 53.

An Obtuse-Angled Triangle is one having an obtuse angle. Fig. 54.

Equiangular triangles are also equal sided, and vice versa.

[51]

VERTICAL.—Upright or perpendicular. Vertical and perpendicular are not synonymous terms.

VERTEX.—See Angle, Quadrilateral, Triangle. The vertex of a solid is the point in which its axis intersects the lateral surface.

VIEW.—See Elevation. Views are called front, top, right or left side, back, or bottom, according as they are made on the different planes of projection. They are also sometimes named according to the part of the object shown, as edge view, end view, or face view.

WORKING DRAWING.—One which gives all the information necessary to enable the workman to construct the object.

[52]

[53]

[54]

Fig. 55.

[55]

A free-hand drawing is executed with the unaided hand and eye, without guiding instruments or other artificial help. It is necessary to be known that all drawing required cannot possibly be done by rule and compass, but that some portions must be drawn “free-hand,” trusting to the eye alone.

Hence, it is important that the student should be able to sketch at sight from objects he may see, or to draw roughly, with a piece of chalk or a pencil, pieces of mechanism required to be represented.

Practice in free-hand should go along with mechanical drawing as progress is made, and thus cultivating both branches equally.

“A simple sketch will often,” as has been rather roughly said, “express more than yards of talk.”

Even a slight sketch refreshes the memory, and in the case of the preparation of a complete set of drawings, with a view to the making of a thoroughly finished mechanical drawing, the proper course to pursue is, to make a general sketch, letter the various parts for reference, and then prepare a series of detailed sketches, similarly lettered, and diffuse with dimensions.

Everyone, whatever his specialty, feels to-day that the ability to sketch rapidly and clearly is among the absolute necessities for correct and prompt transactions of business, in giving and executing orders and doing business with persons outside his profession.

[56]

Mistakes and misunderstandings may be averted by means of rough sketches taken at the time and shown for confirmation; this also saves assistants from getting into trouble, especially if they pin the sketch to the order, for reference, in case of the arising of any dispute. These are a few of the advantages of knowing how to sketch quickly and correctly.

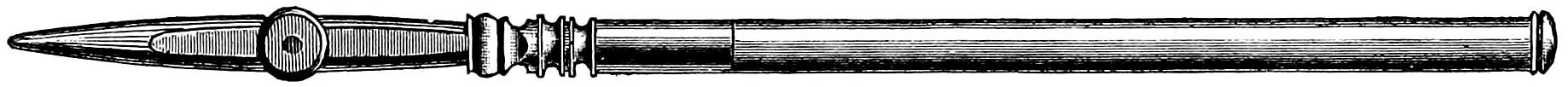

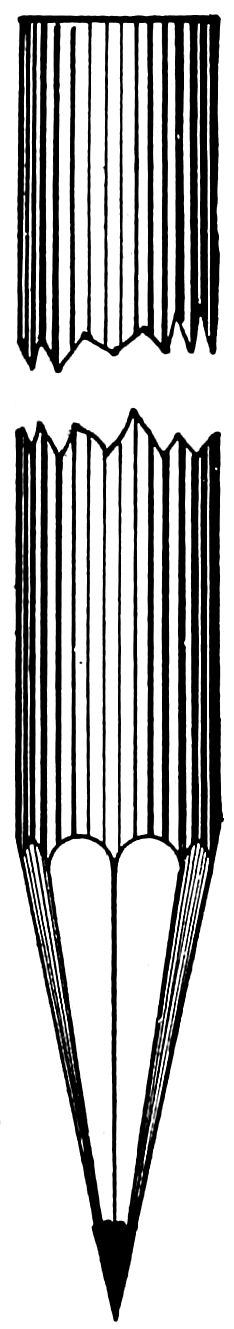

In “free-hand” any sort of pencil is better than none, but there is a considerable advantage in having a good serviceable article—a pencil not too soft nor too hard, and one which will retain its point for some little time.

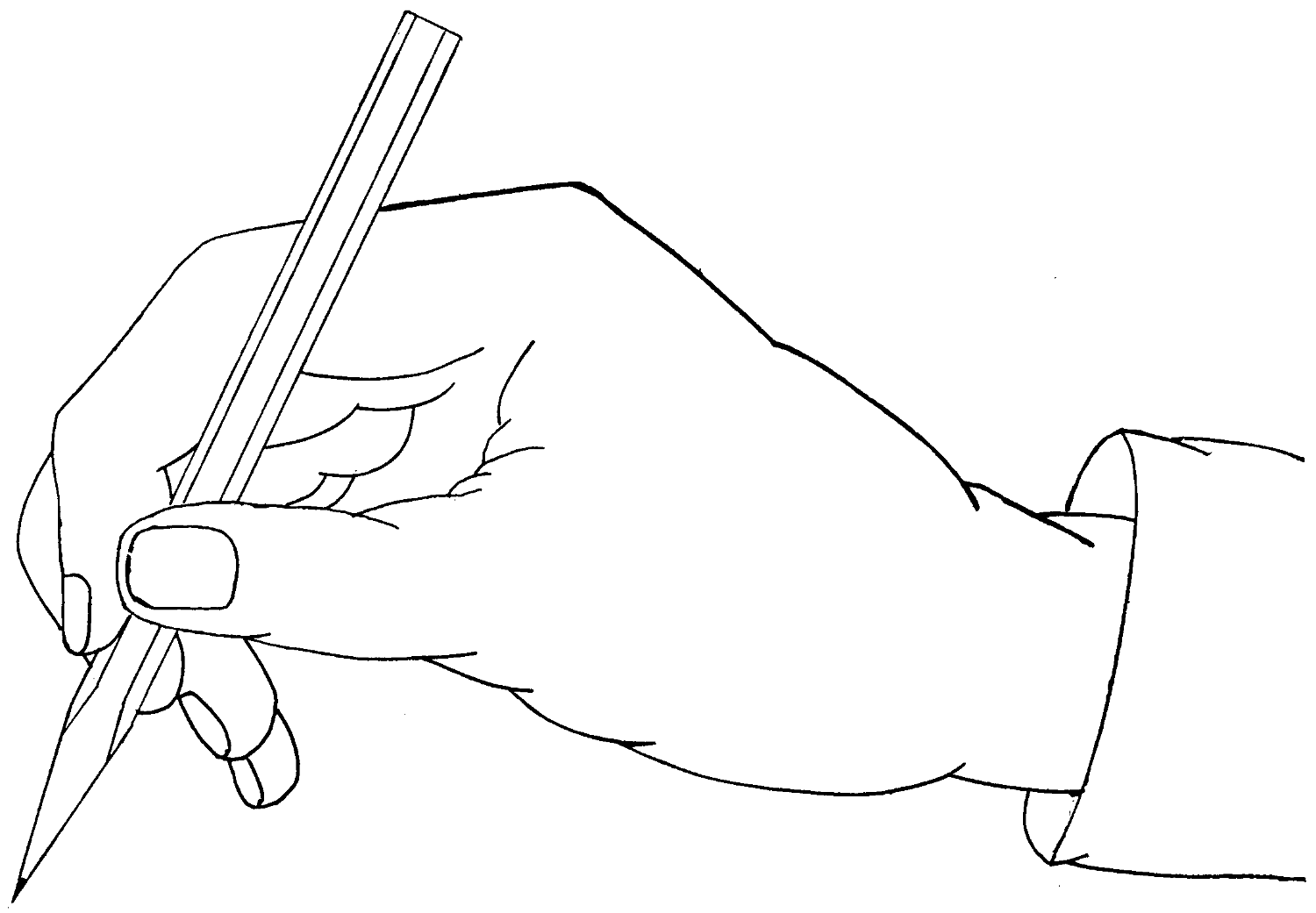

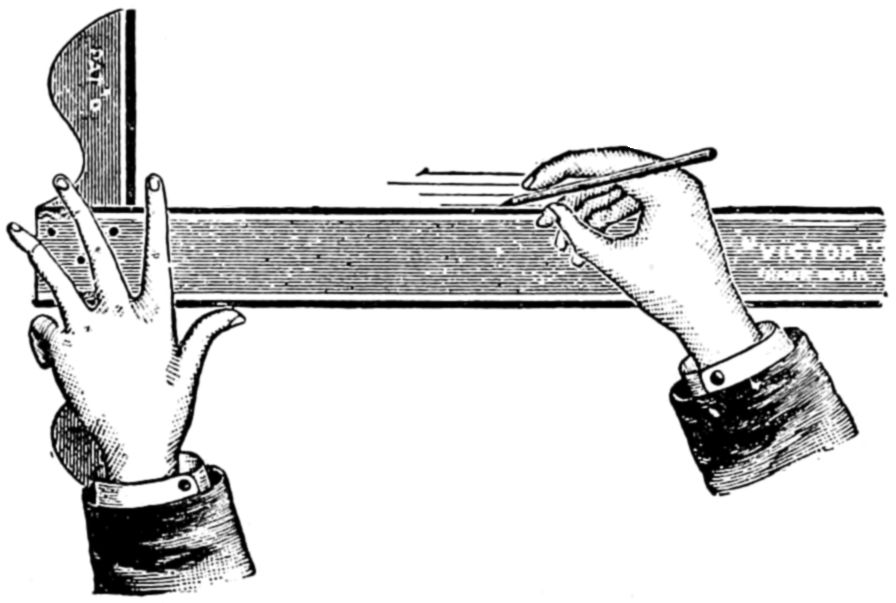

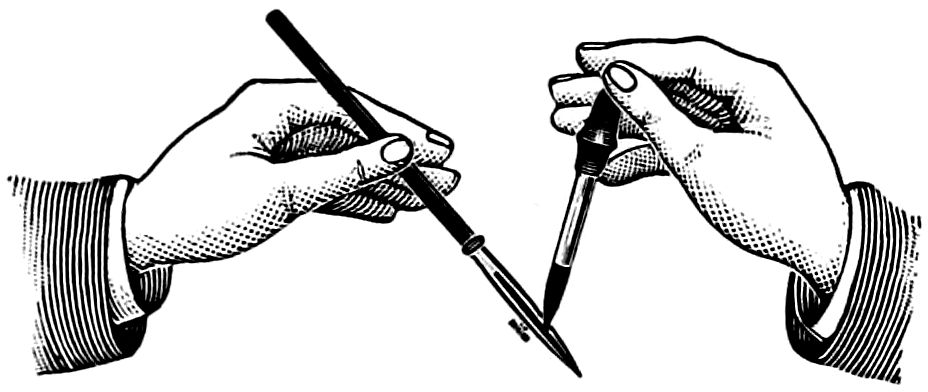

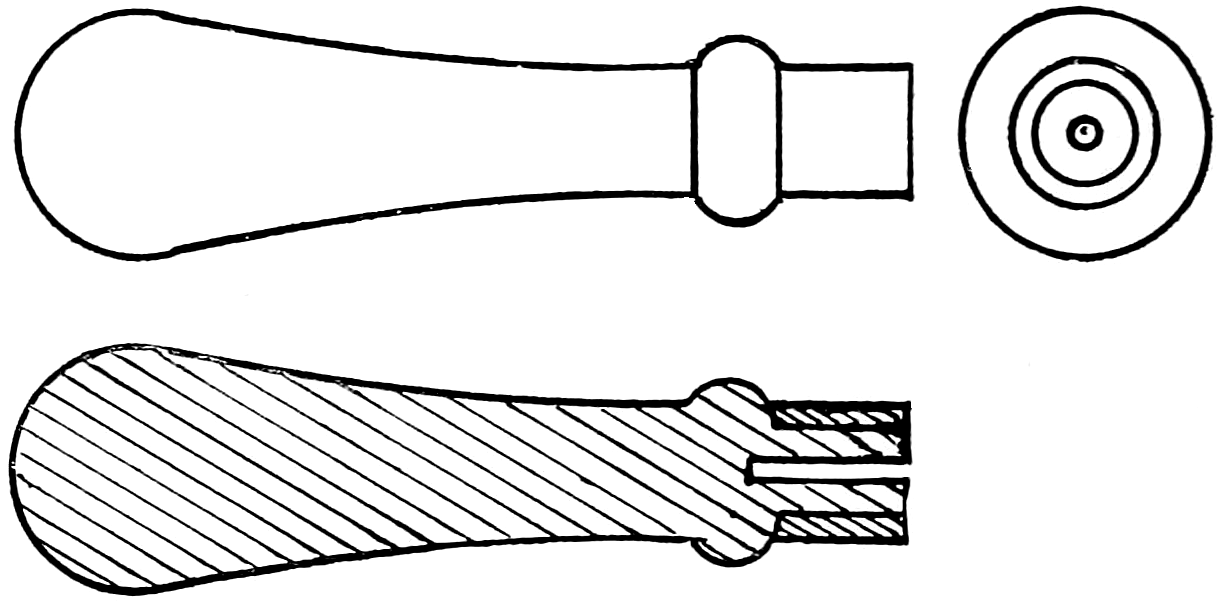

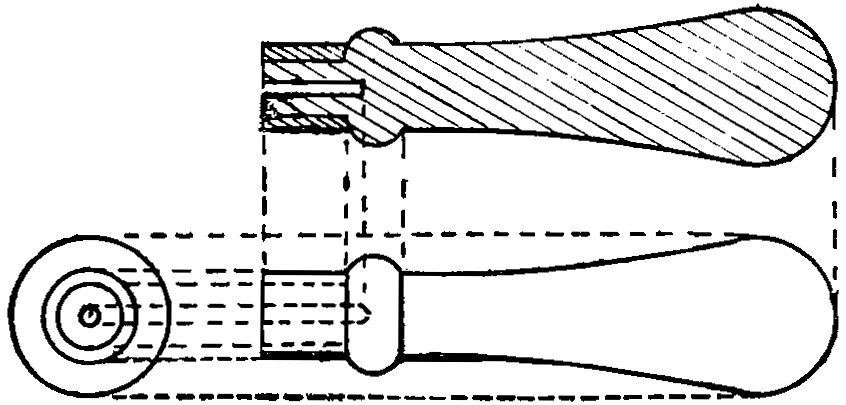

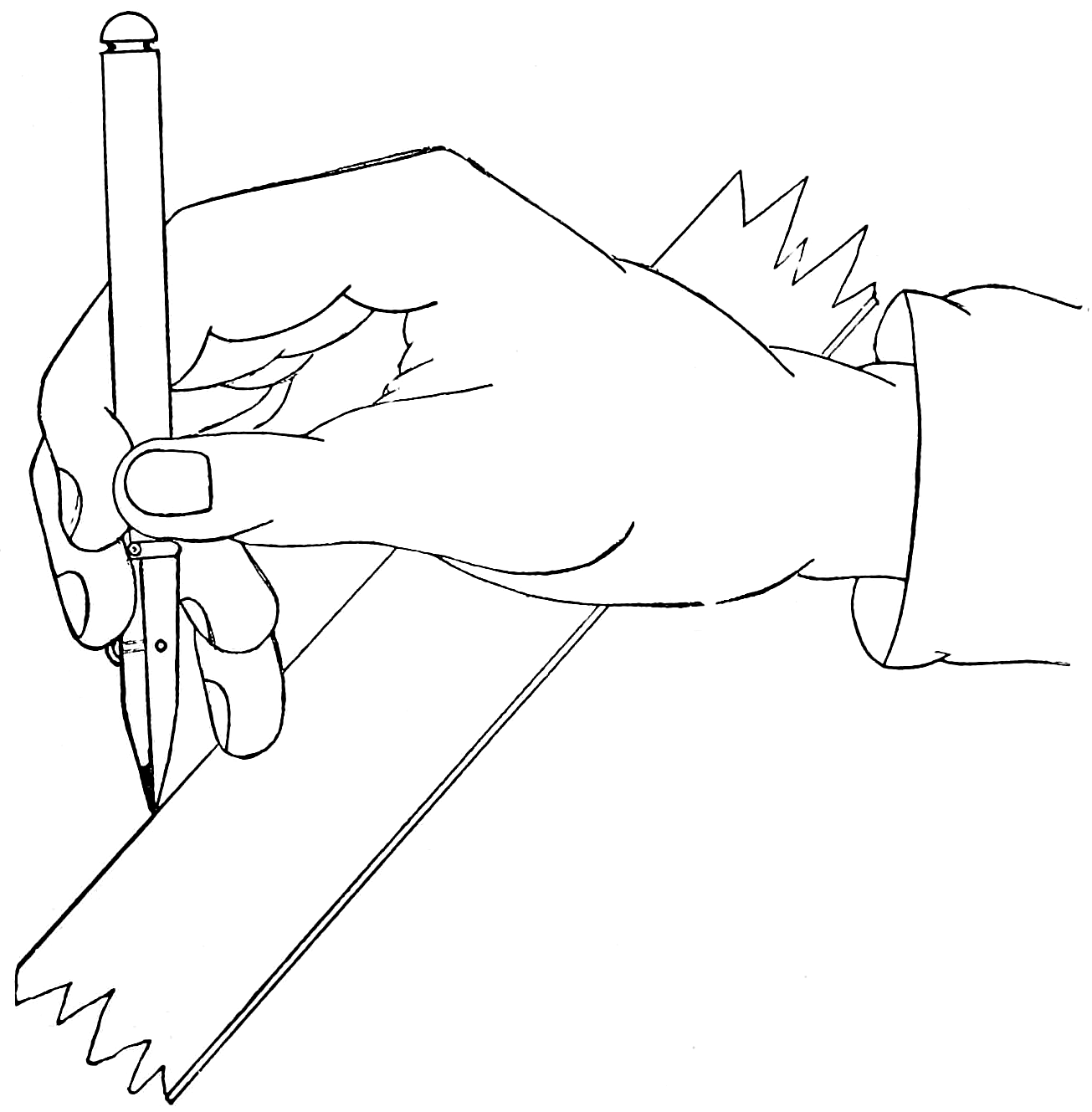

Fig. 55 shows the approved position in which the pencil should be held while sketching. The pencil should be held firmly between the thumb and first finger of the right hand; press the second finger against the pencil at the opposite side to the thumb pressure, so that the pencil is firmly held by the contact of the thumb and two fingers—the third and fourth fingers just coming into easy reach of the paper surface—the wrist or ball of the hand resting lightly on the surface of the work—the arm resting on the desk or drawing-board for steadiness.

The motion of the pencil is produced from the movement of the fingers and thumb, principally in the vertical strokes, and the horizontal strokes are produced by fingers and thumb, combined with a wrist or elbow motion; the oblique lines and curves are produced with a free movement, with nothing cramped or confined about the finger joints.

It should be observed that nothing is more prejudicial to good execution than the habit of leaning over the paper, which ought to be placed on a surface sufficiently inclined to bring every portion equally under the eye, thus obviating the necessity of leaning forward. All support to the figure should be obtained by resting on the left arm, the right being left free for work. By attention to these rules that awkwardness of position,[57] so detrimental to a good figure, will be avoided. It is better to have the light on the left hand, as in this direction the shadow of the pencil does not interfere with the view of the drawing.

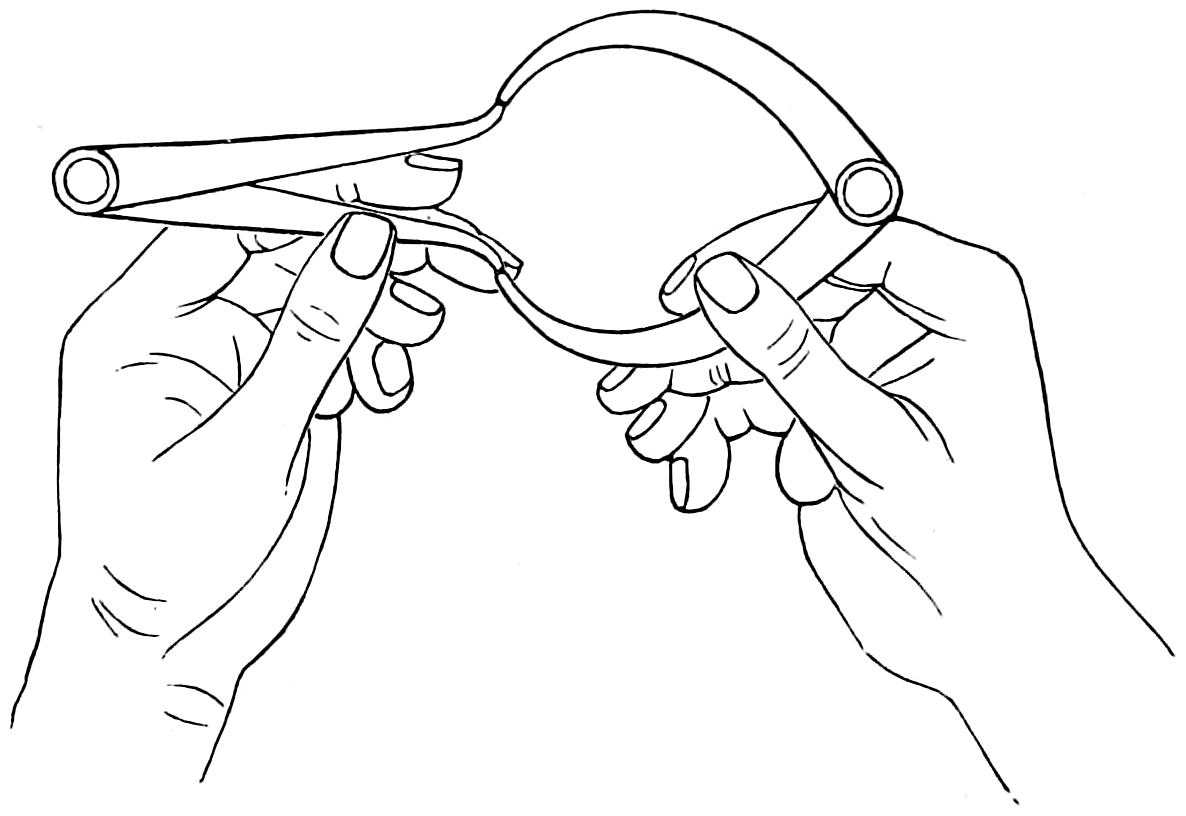

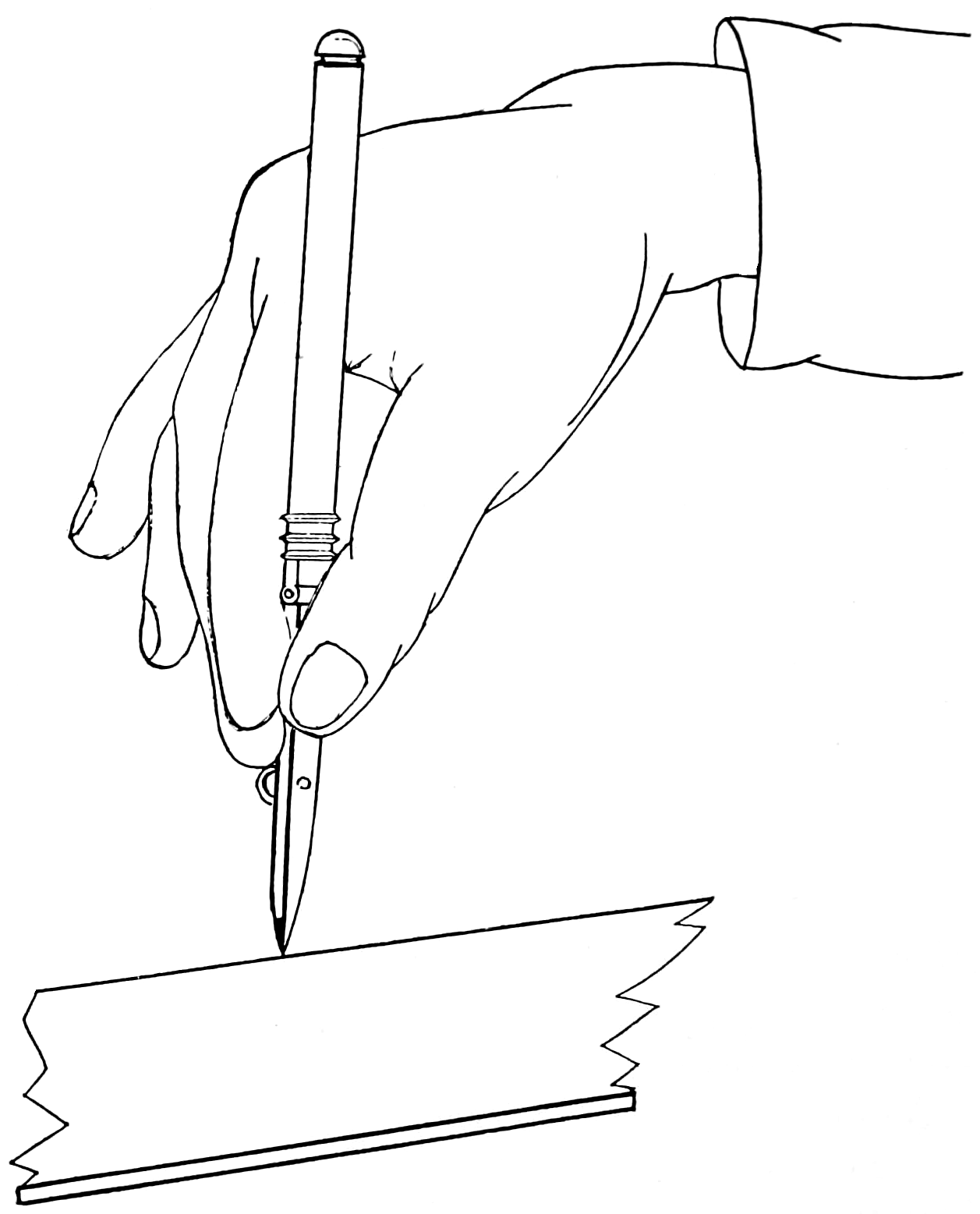

Fig. 56.

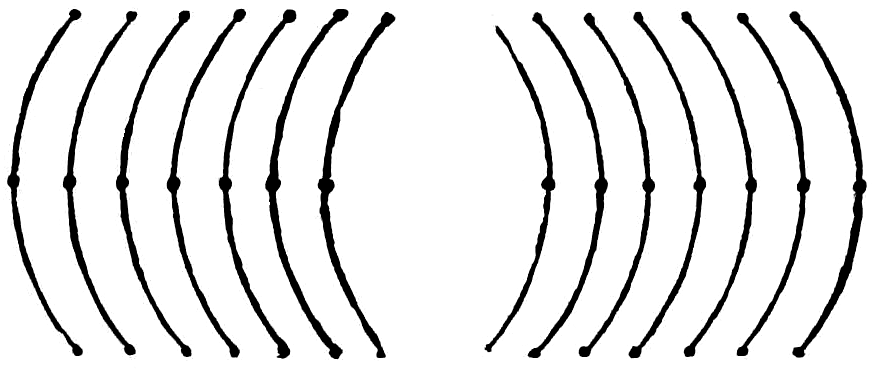

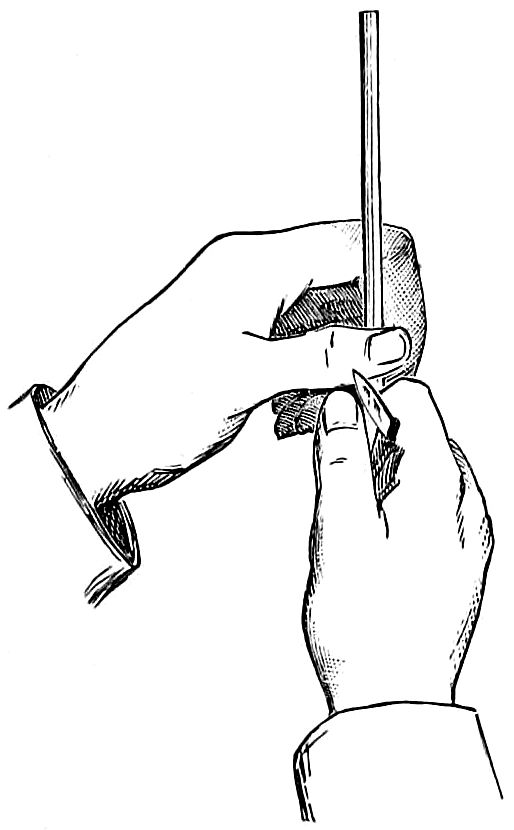

Hold the pencil firmly in the left hand, as in the drawing, allowing about an inch to project beyond the fingers, and turn it gradually as the knife removes the wood. The knife should be held so that the blade alone projects beyond the fingers, and the part of it nearest the handle used for cutting. The pencil should be placed against the inside of the thumb of the right hand, as in the drawing (fig. 56), and the wood removed by slight shaving. The lead should not be cut at the same time as the wood, but rested on the thumb and pared gently afterwards; by attention to these directions the pencil will be economized.

Before a line is drawn, the point at which it is to commence and the point where it is to end, should be known; and let it be distinctly understood that this judgment of the eye, and placing of points, should invariably precede the drawing of every line.

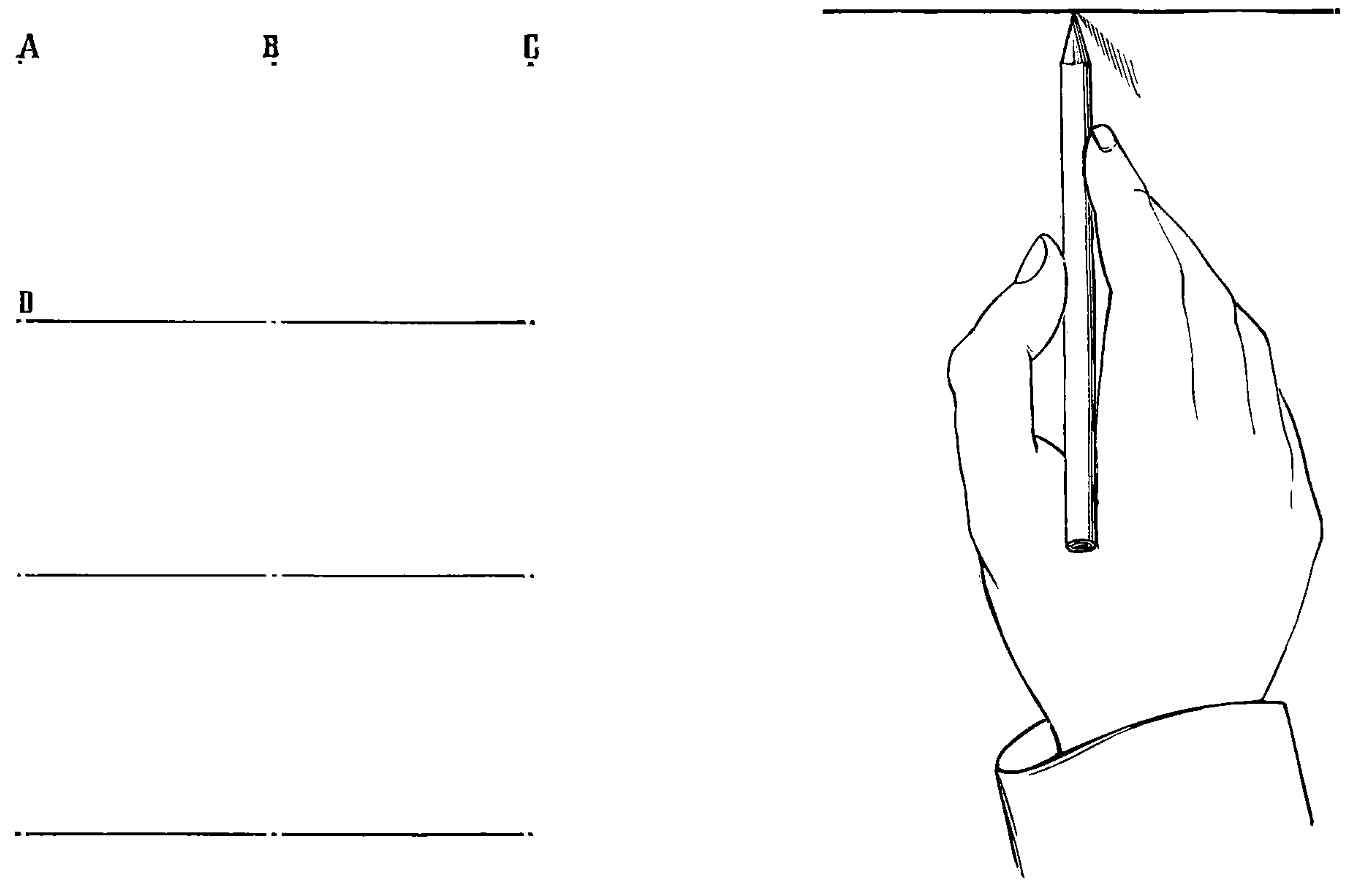

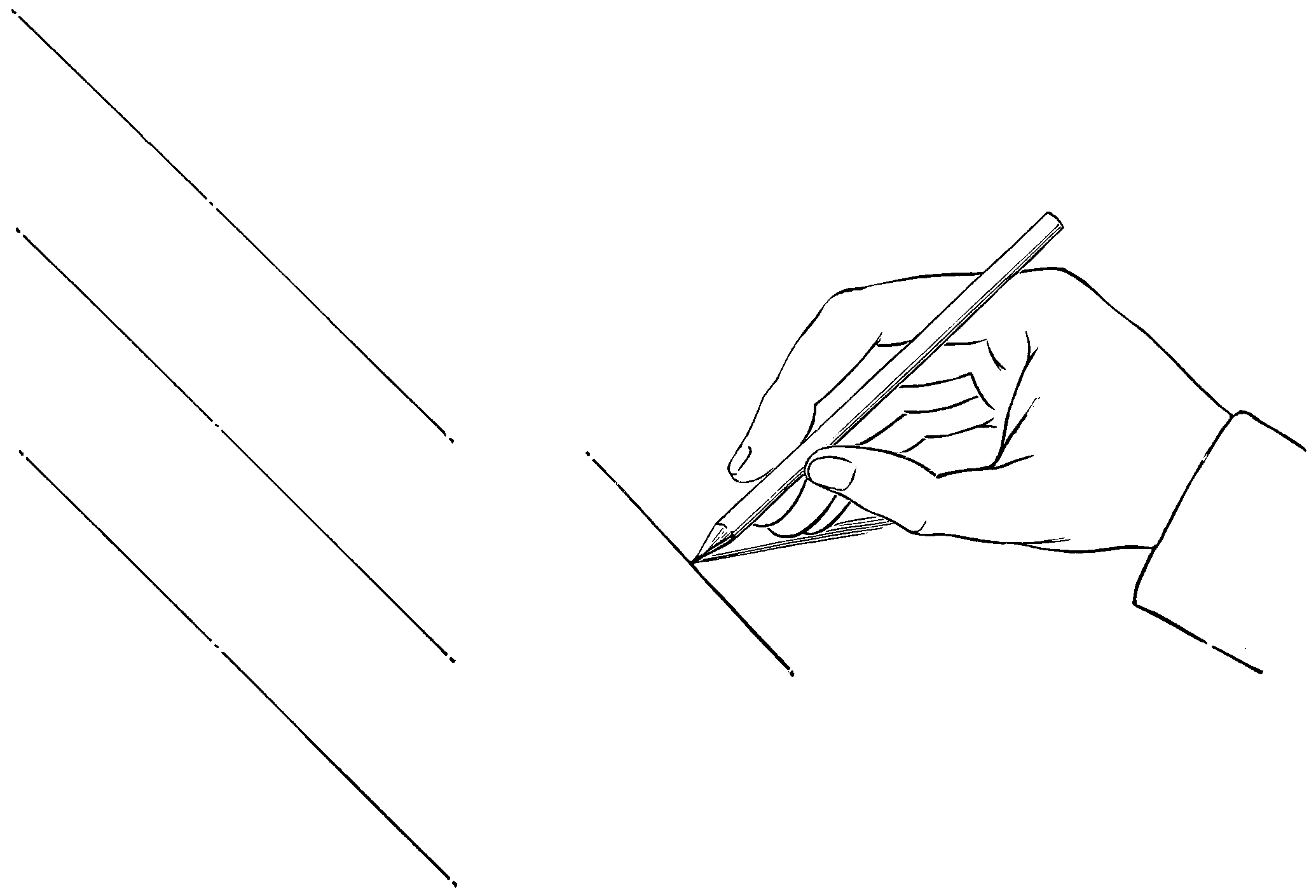

The first effort should, therefore, be to produce a line of points exactly parallel with the upper edge of the paper, and at equal distances from each other. Commence with point A and place the point B carefully level with it, now place a slip of paper against these points in the original, mark their distance apart, and see if the same proportion has been given in your copy; if not, make the necessary correction. Proceed with the next point, examine it, and so on to the end of[58] the line. When this is complete, examine each point in succession, to try if it is at the same distance from the top of the paper; when this is correct, proceed to draw the first level line. Hold the pencil as in the drawing, fig. 57, keeping the elbow near the side; join A to B by one light, steady stroke, produced by a movement of the wrist, and add stroke upon stroke until the line is of the required depth. Continue this process to the end of the line of points. Now place the point D at the right distance below the A, proceed with the points for another line as before, and continue the lines until the paper is covered. In producing the stroke the pencil should not be jerked, or any stop be made between the points, but the movement should be even throughout, and it is much better to produce each line by several soft strokes, as the repetition of delicate lines induces lightness of touch and freedom of hand; and it is also no small advantage that lines thus produced are more easily removed by the India rubber, should they require correction.

Prepare three rows of points down the side of the paper, on the left hand; examine them to see that they are at equal distances from the side and from each other; hold the pencil as in the drawing, fig. 58, move the elbow a little from the side, and join the points A and B with one light line, produced by a movement of the fingers and thumb, repeating the strokes until the line is of the requisite depth; proceed to join B to C, taking care previously to bring the hand a little down the paper, as the line from A to C is too long to be produced from one position. When the three rows of points are filled, make another set, examine them and proceed as before. By these means the paper will be covered with oblique lines, and if the points have been placed exactly, the sheet will have a neat and regular appearance.

Note.—The drawings of hands are introduced to show the positions for holding the pencil, and are not intended for copying.

[59]

Fig. 57.

[60]

Fig. 58.

[61]

It is a common, and at the same time highly injurious habit, to draw this line by a movement of the wrist, the fingers remaining rigid. This may be detected by watching the action of the thumb; if it bends as the line is produced, all is right; but if it does not the wrist is at work.

This line demands the greatest attention, and any care bestowed upon it will be amply repaid in the after studies.

Commence by placing a line of points down the side of the paper, examine them very carefully to see that they are all the same distance from its edge, hold the pencil as in the drawing, fig. 59, move the elbow well out from the side, and join the points by a movement of the fingers and thumb. When one line is complete, place the points for the next, and examine them from the edge of the paper, not from the line just drawn. Proceed in this manner until the paper is covered.

There is in most cases a tendency to place the points for this line in a slightly inclined direction, as in writing, though in some instances the tendency is the opposite, a thoroughly correct eye in this respect being a rare gift: and it may be useful to suggest that the paper be so placed that the line of points to be produced may be exactly in front of the eye.

Prepare three rows of points down the side of the paper, examine them for correctness of position, hold the pencil as in the drawing, fig. 60, remove the elbow as far as possible from the side, and join the points by a movement of the fingers and thumb, and continue the exercise until the paper is covered.

[62]

Fig. 59.

[63]

Fig. 60.

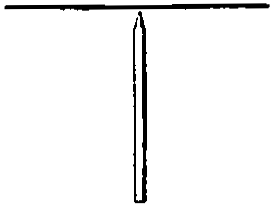

It will be noticed that each change in direction of the line to be drawn, has been accompanied with a[64] corresponding change in the position of the elbow and wrist. The following simple rule will assist the memory when placing the hand for any given line; the pencil should be held so that it may form a T with the line to be drawn:

For the horizontal line, elbow near the side.

For the first oblique, elbow a little removed.

For the perpendicular, elbow more removed.

For the second oblique, elbow most removed.

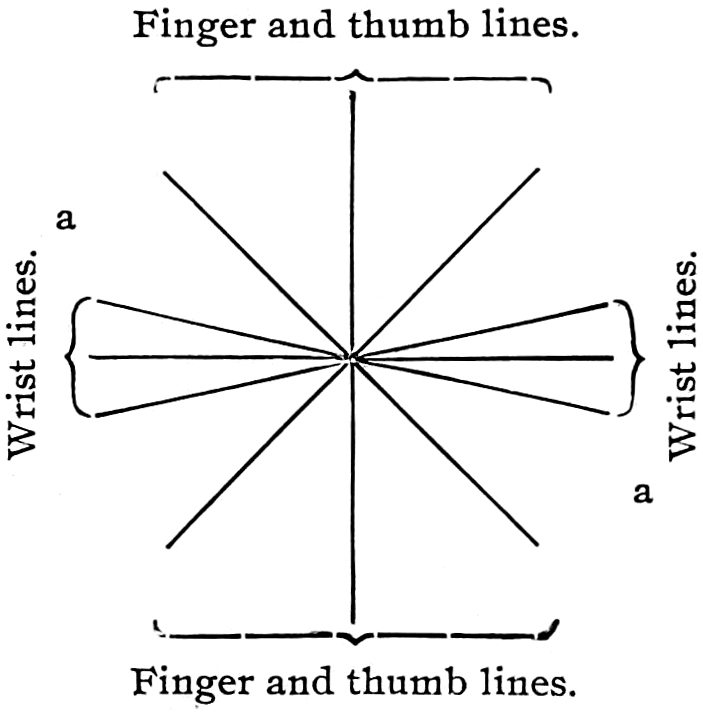

Finger and thumb lines.

W

r

i

s

t

l

i

n

e

s

.

W

r

i

s

t

l

i

n

e

s

.

Finger and thumb lines.

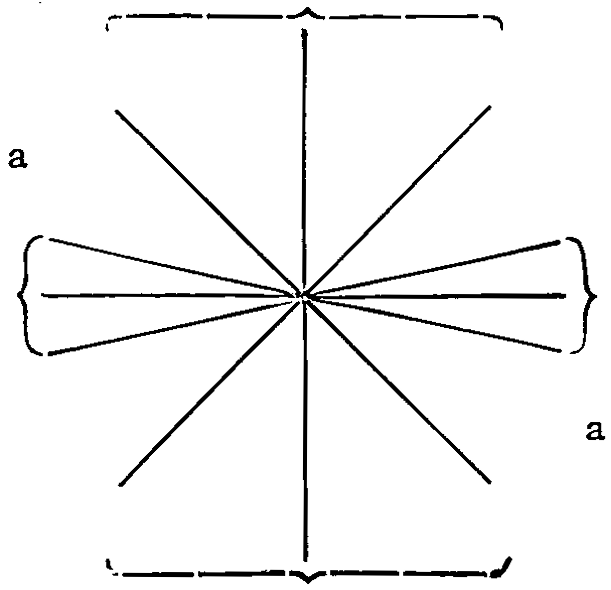

It may also be interesting to notice, with regard to the movements by which lines are produced, that they are divided into two systems; the first is that of the wrist, which includes the horizontal, and lines in nearly the same direction; the second is that of the fingers and thumb, by which all other lines are formed. The following diagram exhibits the two systems and their various lines grouped, and it will be observed that there is a space marked (a) between the two sets, which may be considered neutral ground. Lines in this direction may be produced by either movement, as may be most convenient, but it will always be found that these lines are the most trying to the hand.

[65]

Before commencing this subject, let it be clearly understood that future success will, in a great measure, depend upon the amount of care bestowed upon it. The aim should be to obtain absolute accuracy, and for this end the copies should be tested by the most careful measurements, and corrected until they are true with the originals, but it should be distinctly understood that these measurements are only to be made after the eye and hand have done their best.

Note.—To some it may appear that too much time and care has been bestowed on mere lines, but let it be understood that a good system of line drawing is the basis of all education—the slightest outline by a hand thus trained has a bold, free and masterly character; and with regard to shading, which is simply an aggregation of good lines, it is only by such a practiced hand its most charming effects can be produced.

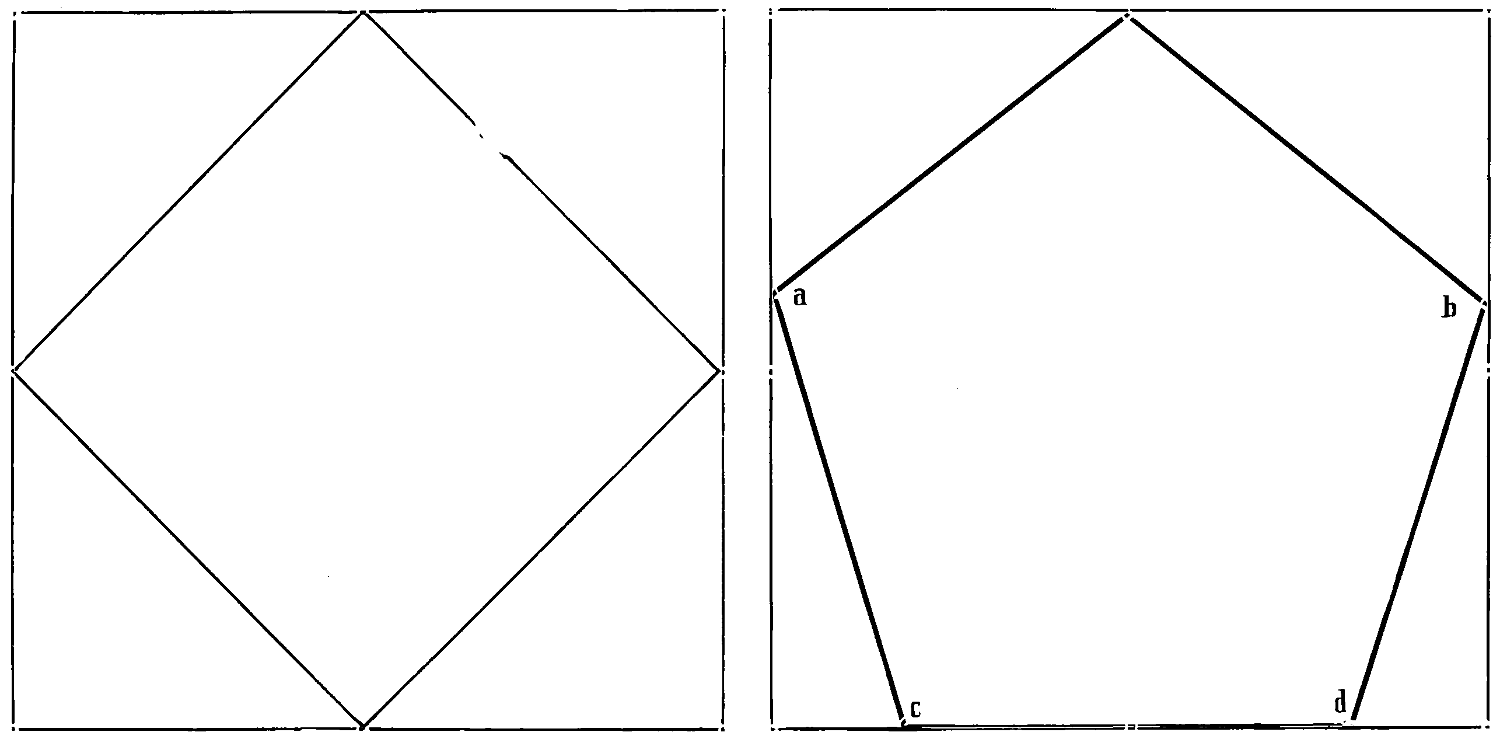

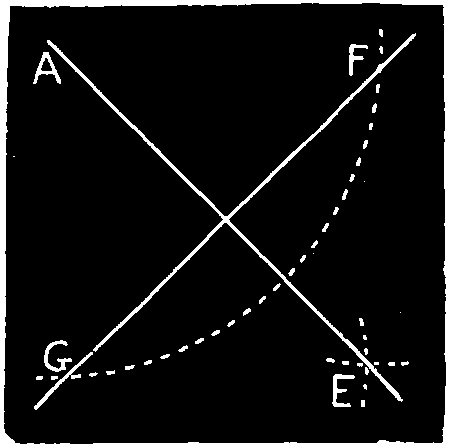

Fig. 66: Place the points A, B. Examine them to see that they are the same distance apart as in the original, and that they are level; place the point C exactly under A, and make A C equal in distance to A B; now place the point D opposite C and under B; try the distances between each point to see that they are the same; divide each side by a point half way, and then draw the lines.

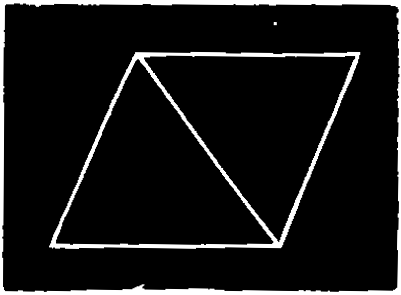

Fig. 67: Repeat the last figure and add the lines A and B, taking great care that the points for them are correctly placed.

Fig. 68: Commence with the square as before; then join the half-way points.

Fig. 69: After the square is drawn, place the points A and B at the right height above the half-way points, and C, D at the proper distance from the corners, then draw the figure.

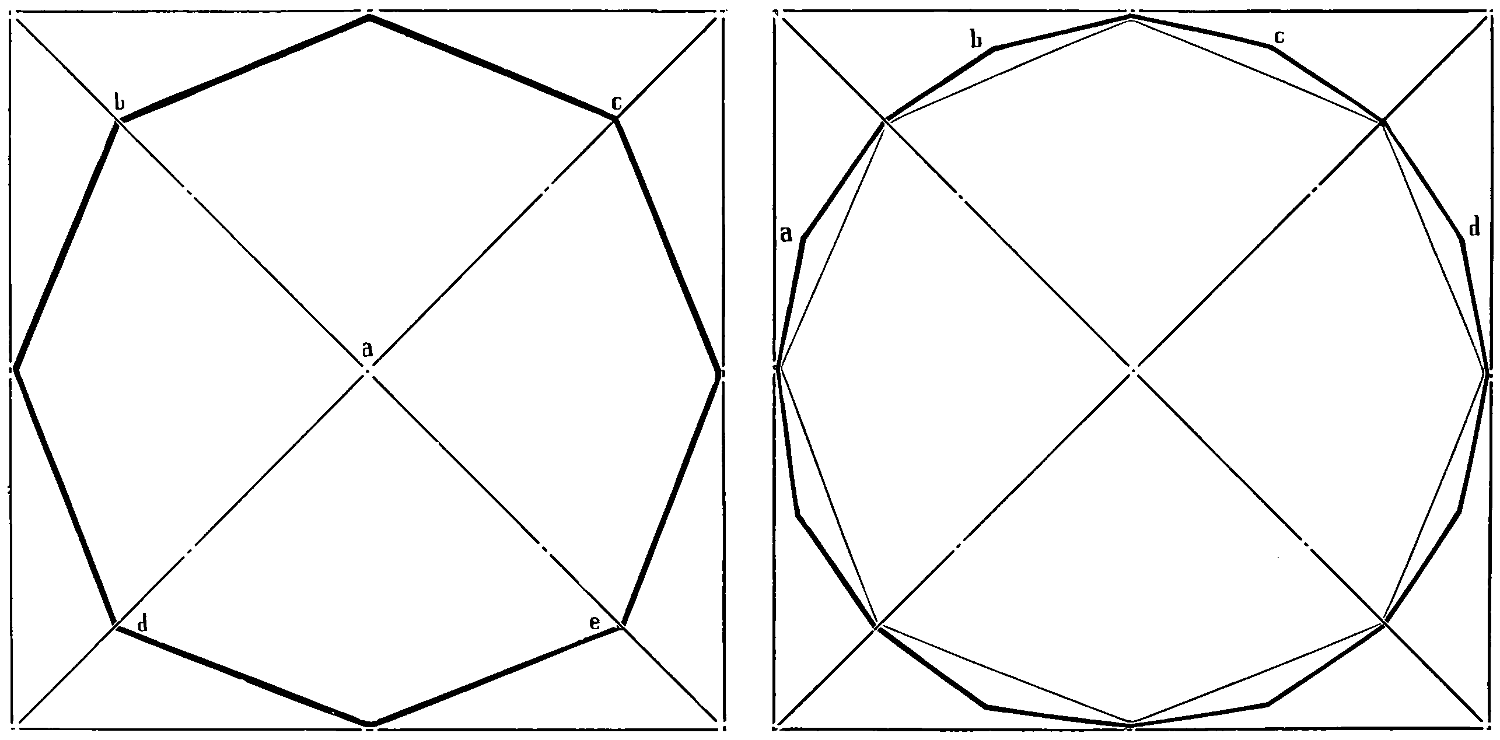

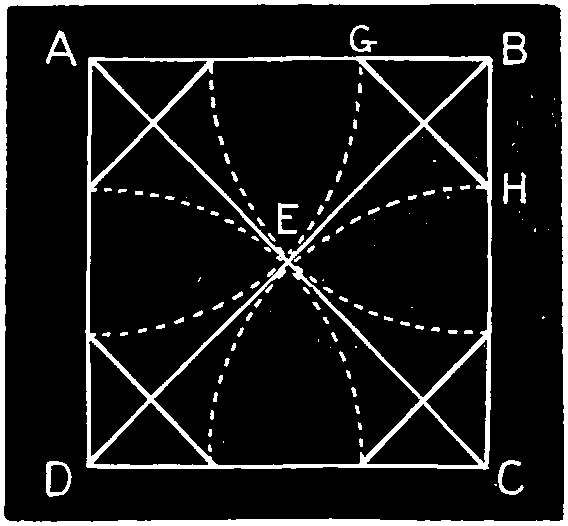

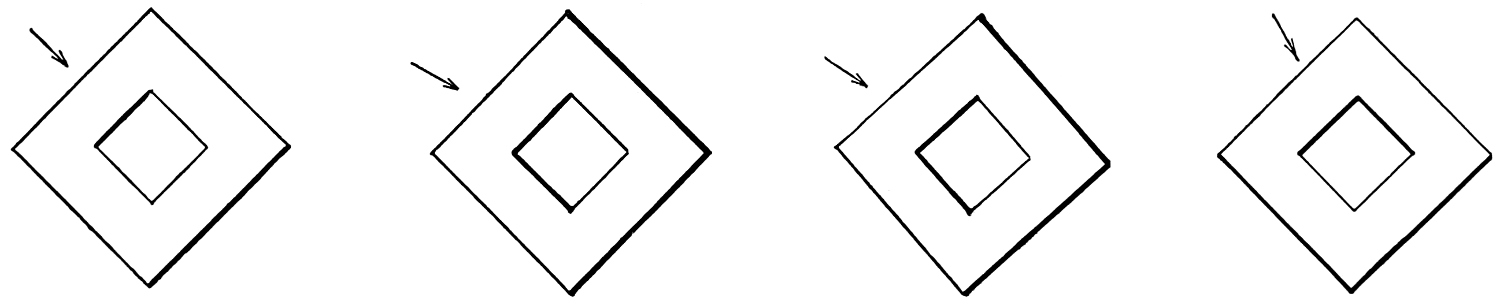

Fig. 70: The greatest care should be taken with the squares for this and the following figure, as the slightest error in them will destroy the symmetry of the drawing within; when the square is completed, join the opposite corners, and place on the crossed lines the points B, C, D, E; examine these to see that they are each at the same distance from the centre A, and that this distance is equal to the space from A to the sides of the square; when all are proved to be correct, complete the figure.

[66]

Fig. 66.

Fig. 67.

[67]

Fig. 68.

Fig. 69.

[68]

Fig. 70.

Fig. 71.

[69]

Fig. 71: Repeat the last drawing with, if possible, greater exactness, and outside the octagon place the points A, B, C, D, etc.; examine each of these points to see that they are all at the same distance from the centre, and then complete the figure.

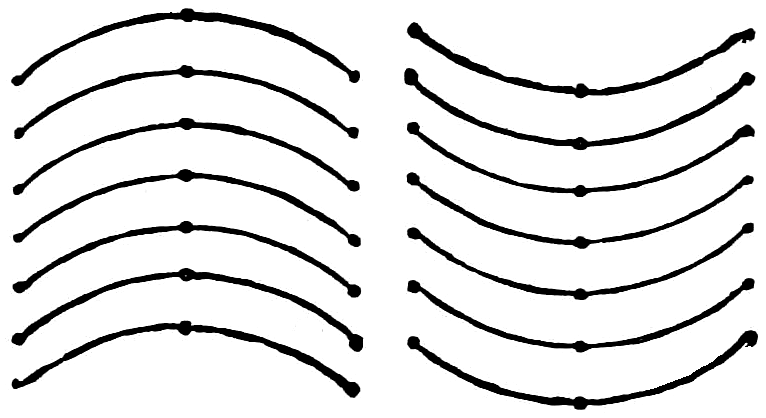

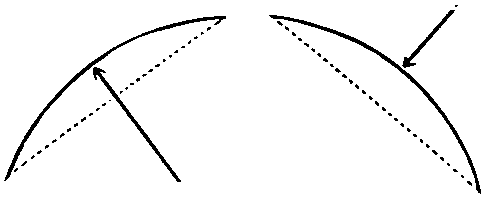

The right position of the hand for drawing any curved line is that required for a straight line which would touch the extremities of the curve. The straight lines given in the exercises are valuable, not only as a guide to the position of the hand, but as an assistance to the eye when forming the curves or examining them after they are produced.

The direction given for drawing a straight line was to form it by one steady movement from point to point, without any jerk or stop by the way. This instruction requires to be changed for the curve, which is better produced by several short strokes, thus:

or by overlapping lines, any outside bits being cleared away with India rubber.

These exercises will test the drawing power and try the patience of the pupil, but they are worthy of all the care which can be bestowed, which in future efforts will meet with its full reward.

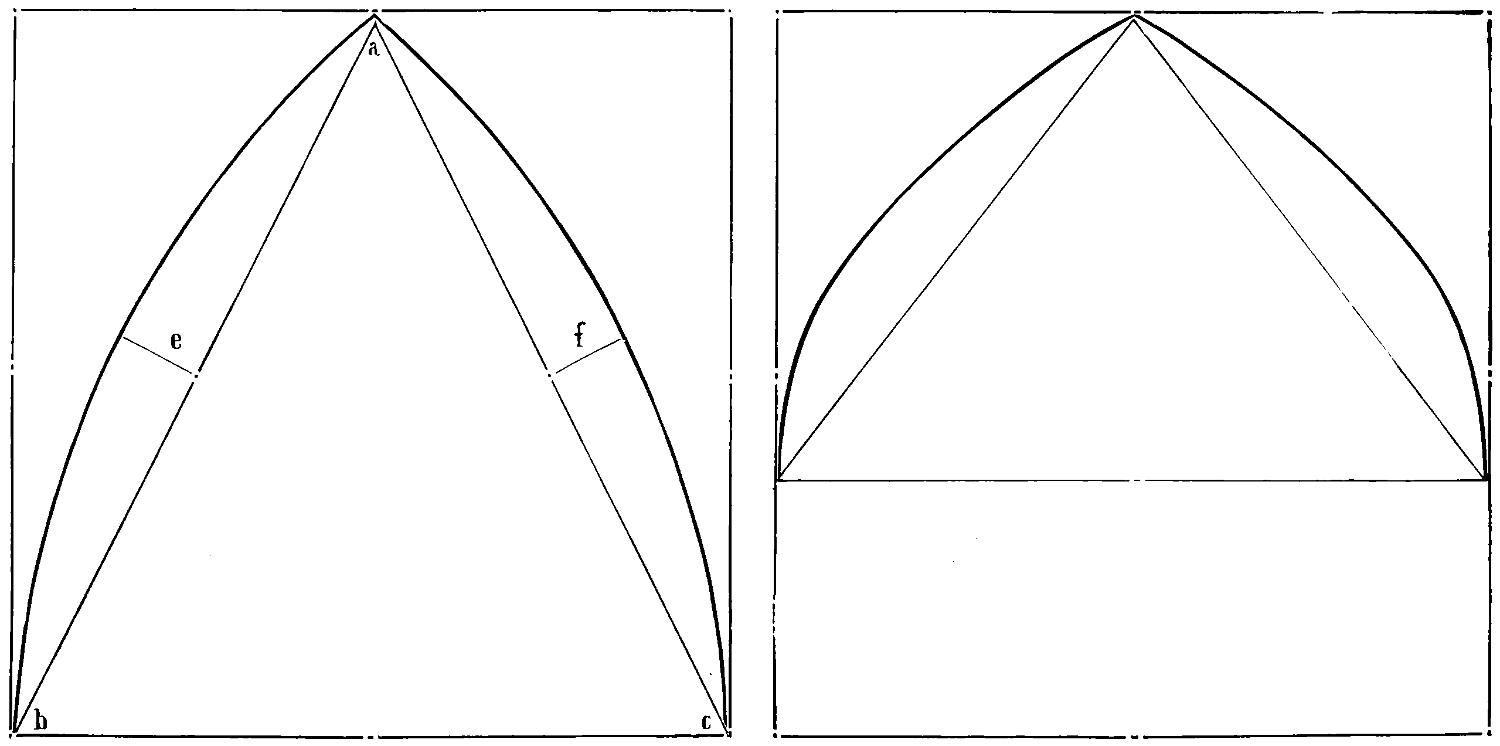

Fig. 76: Draw first the square as directed in the previous lesson, join the points A, B, C and add the short lines at E and F, proceed with the curve A B, drawing it with faint lines at first, and adding stroke upon stroke until the required depth is obtained; the curve A C is more difficult to produce, in consequence of the formation of the hand; it should, therefore, be drawn in shorter pieces, joining them together afterwards by over strokes.

[70]

Fig. 76.

Fig. 77.

[71]

Fig. 77: Draw the square and straight lines first, then add the curves, taking care to give the greatest fullness at the right place.

Fig. 78: Draw the square and straight lines, proceed with the curves, taking care to make each of the same proportion.

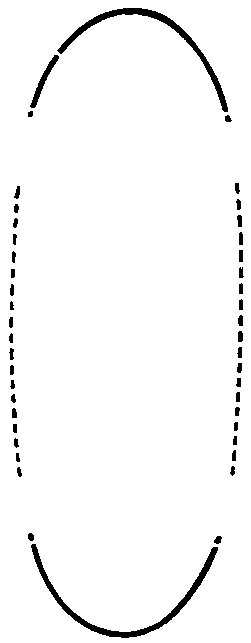

Figs. 79 and 80: The ovals contained in these figures are simply foreshortened circles, and as such forms are of frequent occurrence in sketching from objects, in bridges, wheels, ends of timber, etc., they should be carefully studied; the greatest difficulty is to turn the narrow ends, and prevent their looking like corners. For this purpose it is better to draw the short curves first, thus:

and then join the longer sides to them.

Fig. 81: If this figure can be drawn correctly, a great success has been achieved; the circle is a most difficult form to delineate, and without system could not be accomplished. Draw the square and straight lines within it with great care, examine each point of the octagon to see that it is at the same distance from the centre, and then draw the circle.

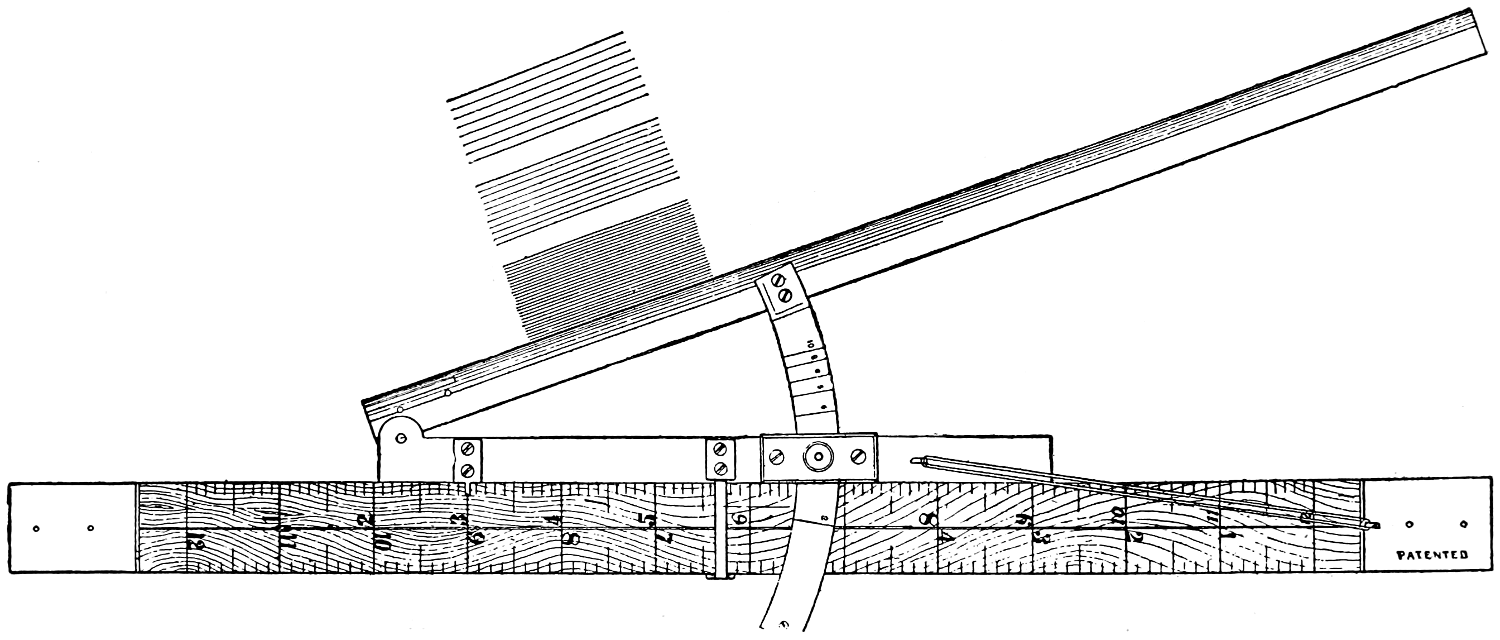

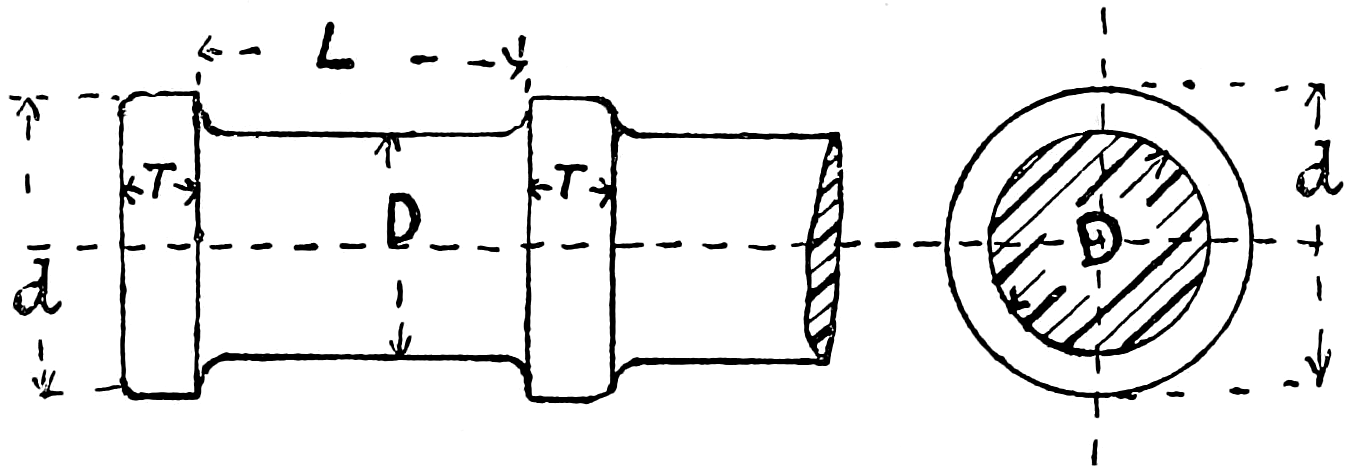

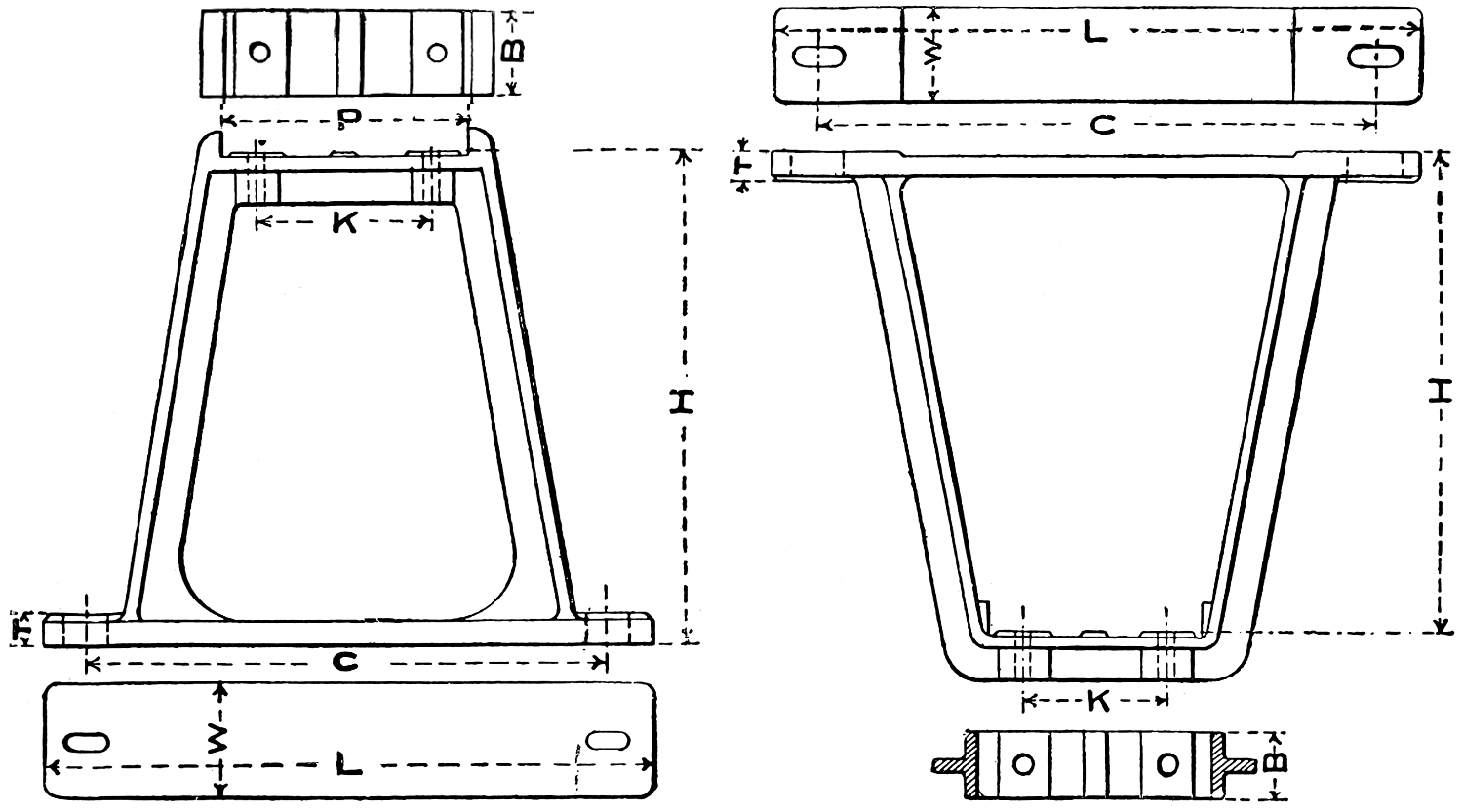

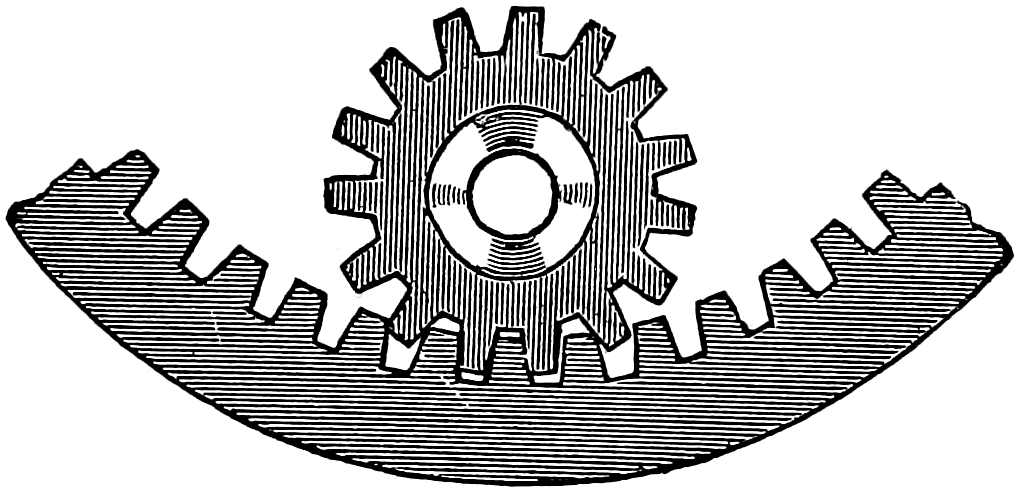

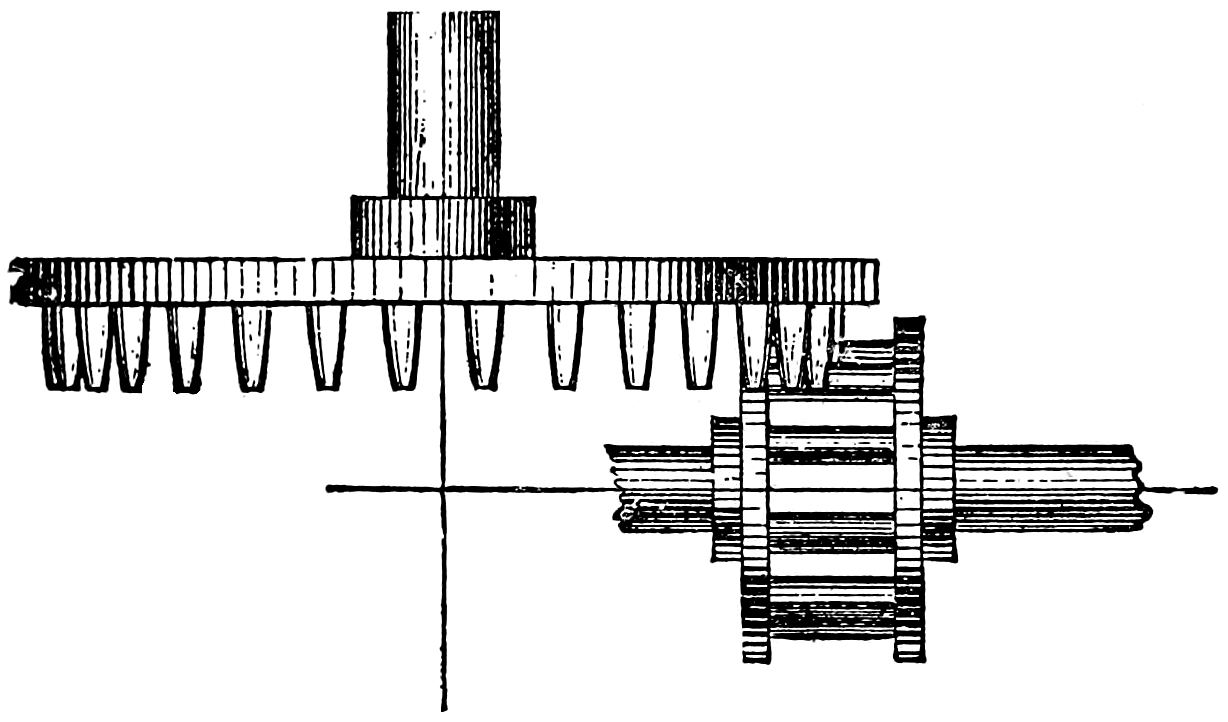

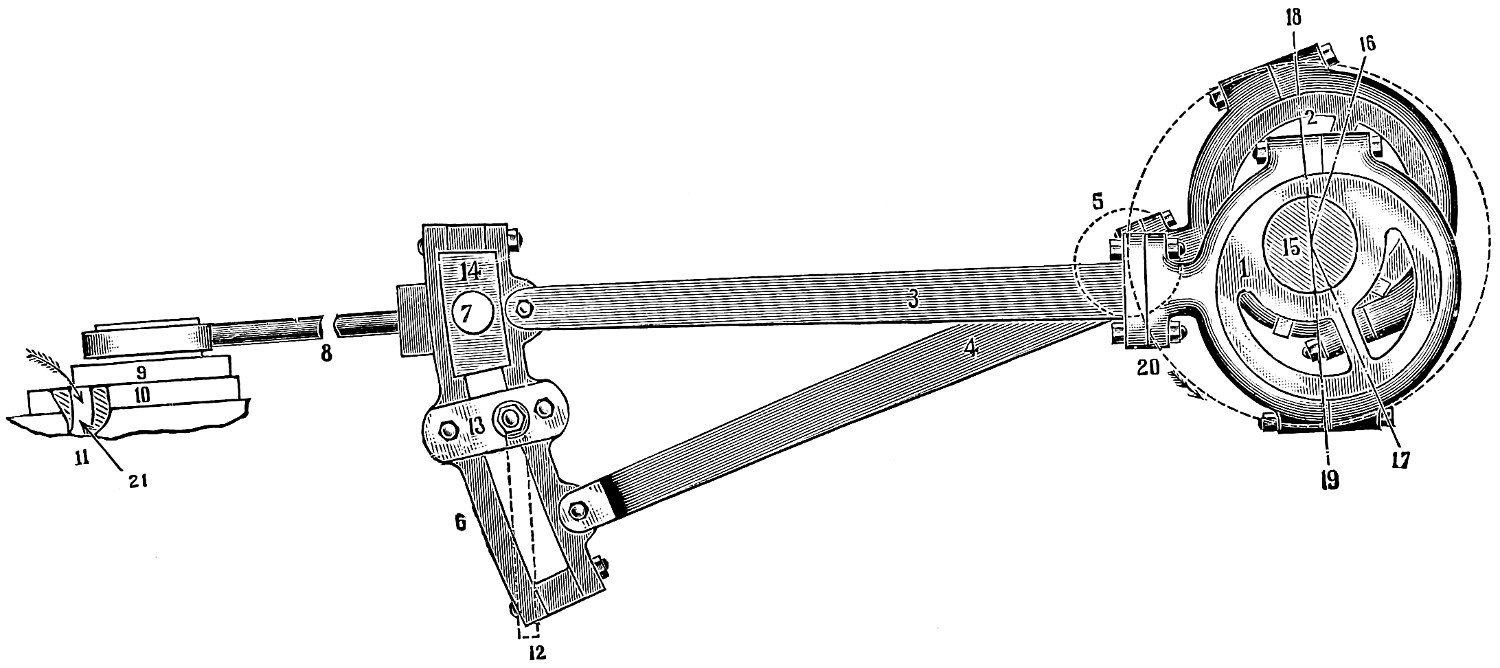

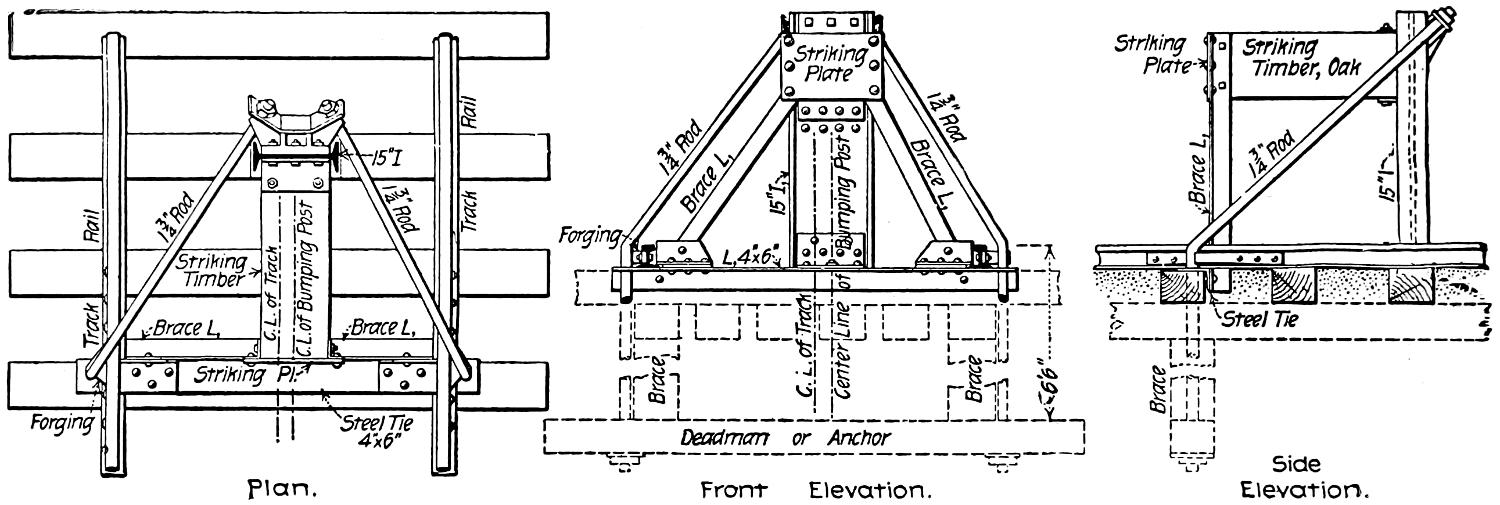

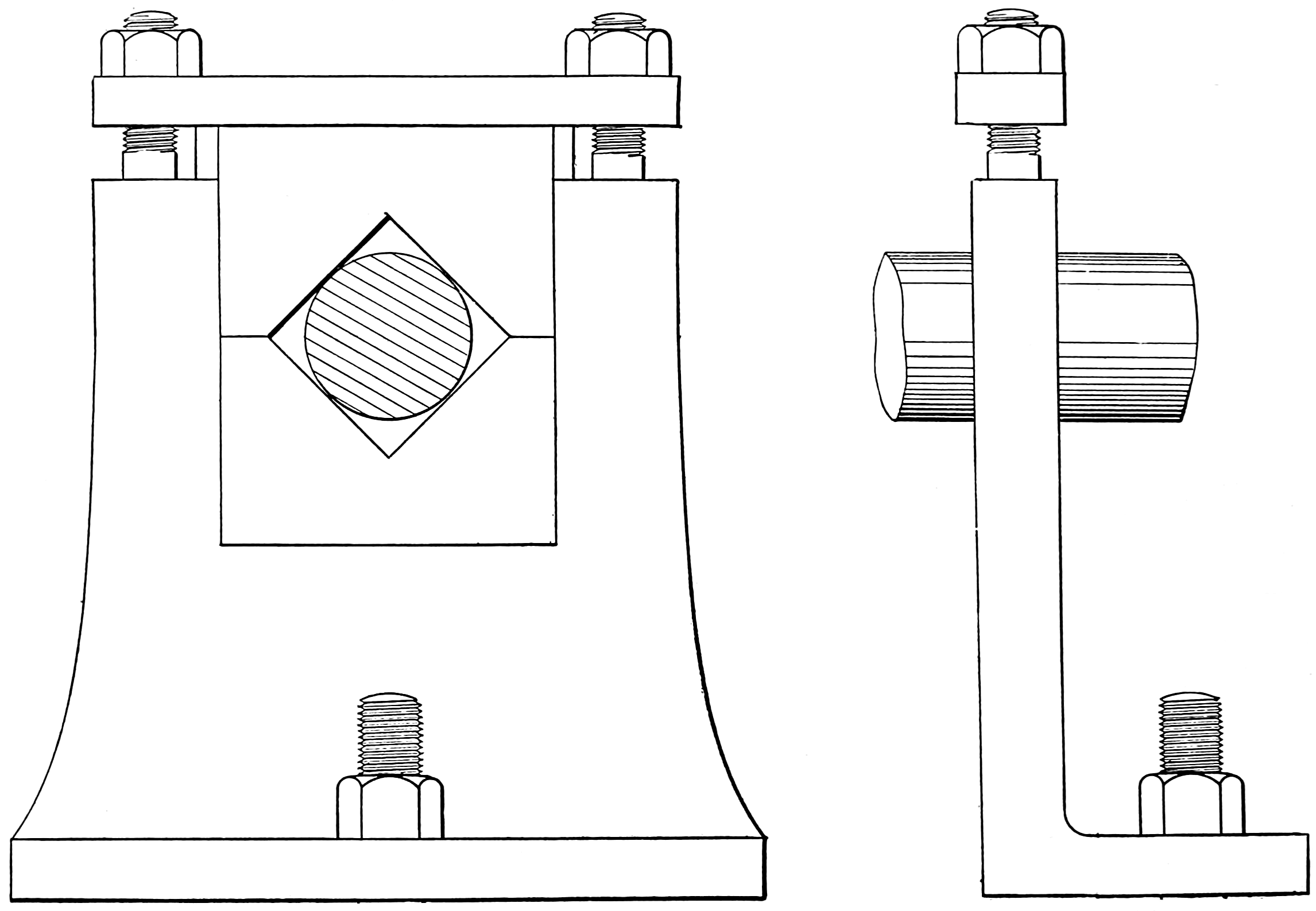

Several figures, 83 to 96, representing more or less familiar parts of machines, utilities, etc., are introduced for practice in free-hand, but—

It must be noted that even in free-hand the wise student will occasionally use the straight edge and compasses, so as to make his first attempts fairly creditable. Many good draughtsmen have begun by simply copying such figures and illustrations as are used throughout this volume and other similar sources; perhaps there is nothing better for practice or training than the copying and reproducing of samples of good mechanical drawings, yet it must always be remembered that advancement in free-hand must be made in the line of less to greater efforts, and that the why and wherefore will be constantly asked by the aspiring student; that good and correct drawings are to be aimed for at all times in every line and dimension—never forgetting the law of proportion in the smallest outlines of objects to be represented.

[72]

Fig. 78.

Fig. 79.

[73]

Fig. 80.

Fig. 81.

[74]

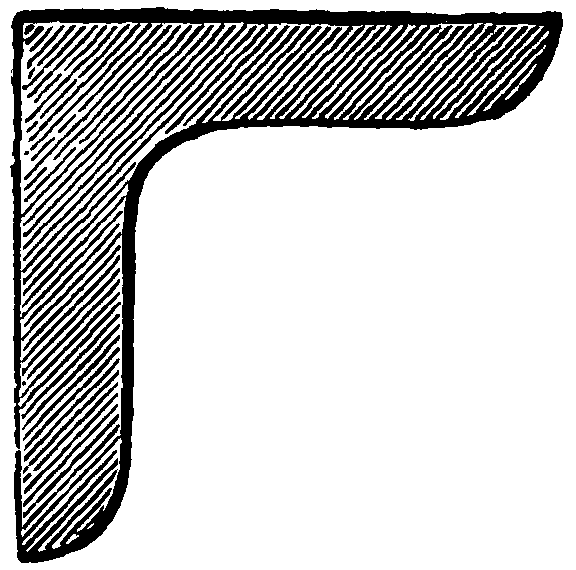

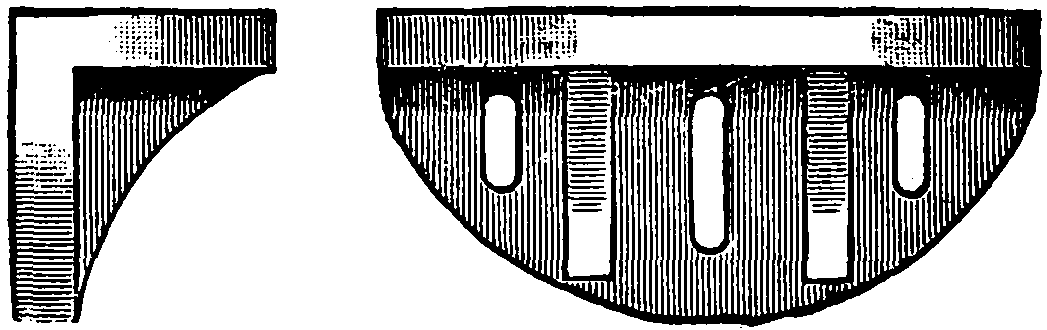

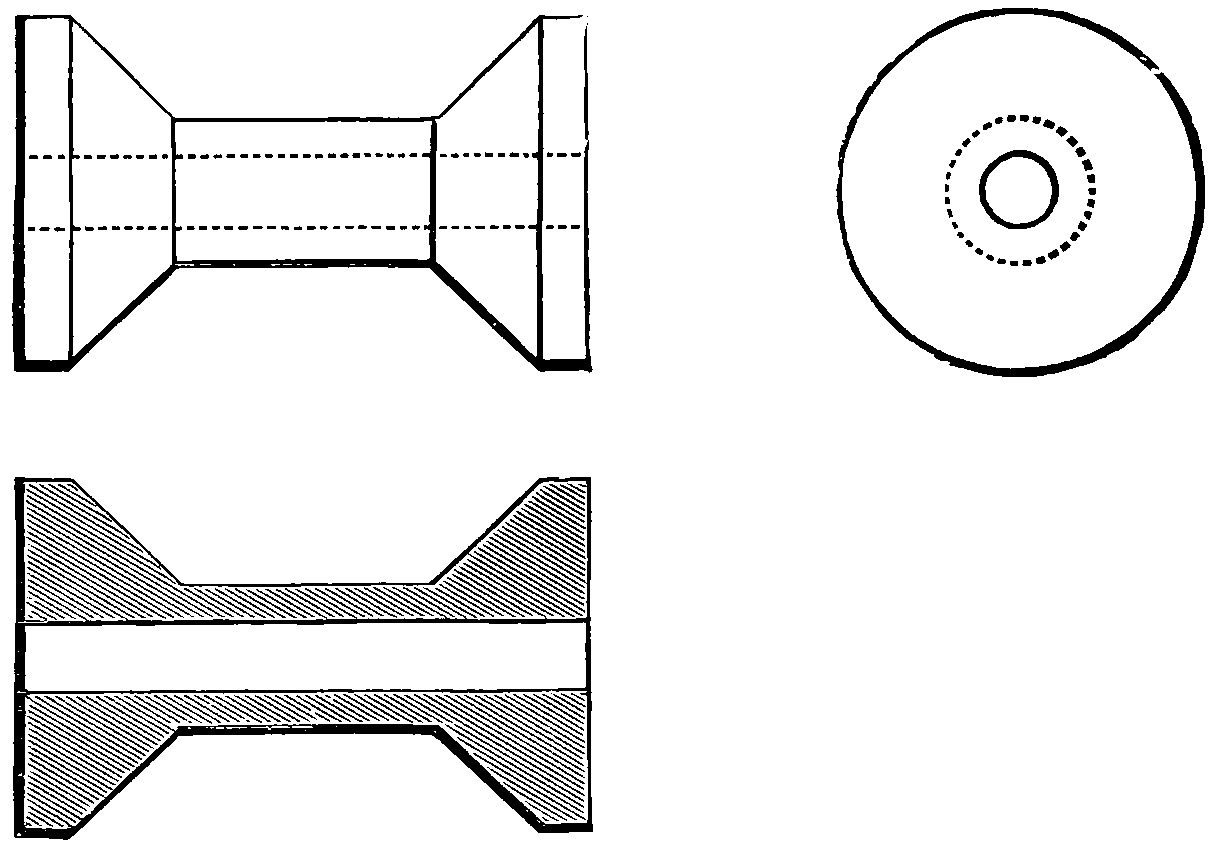

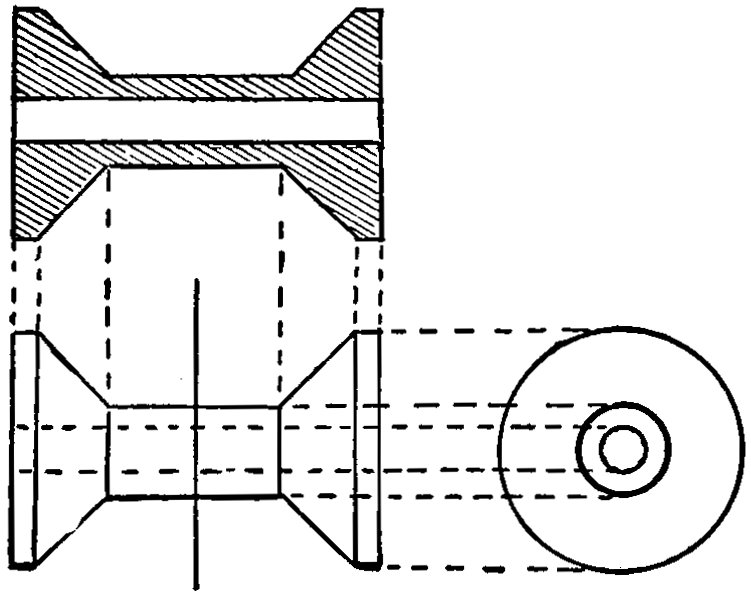

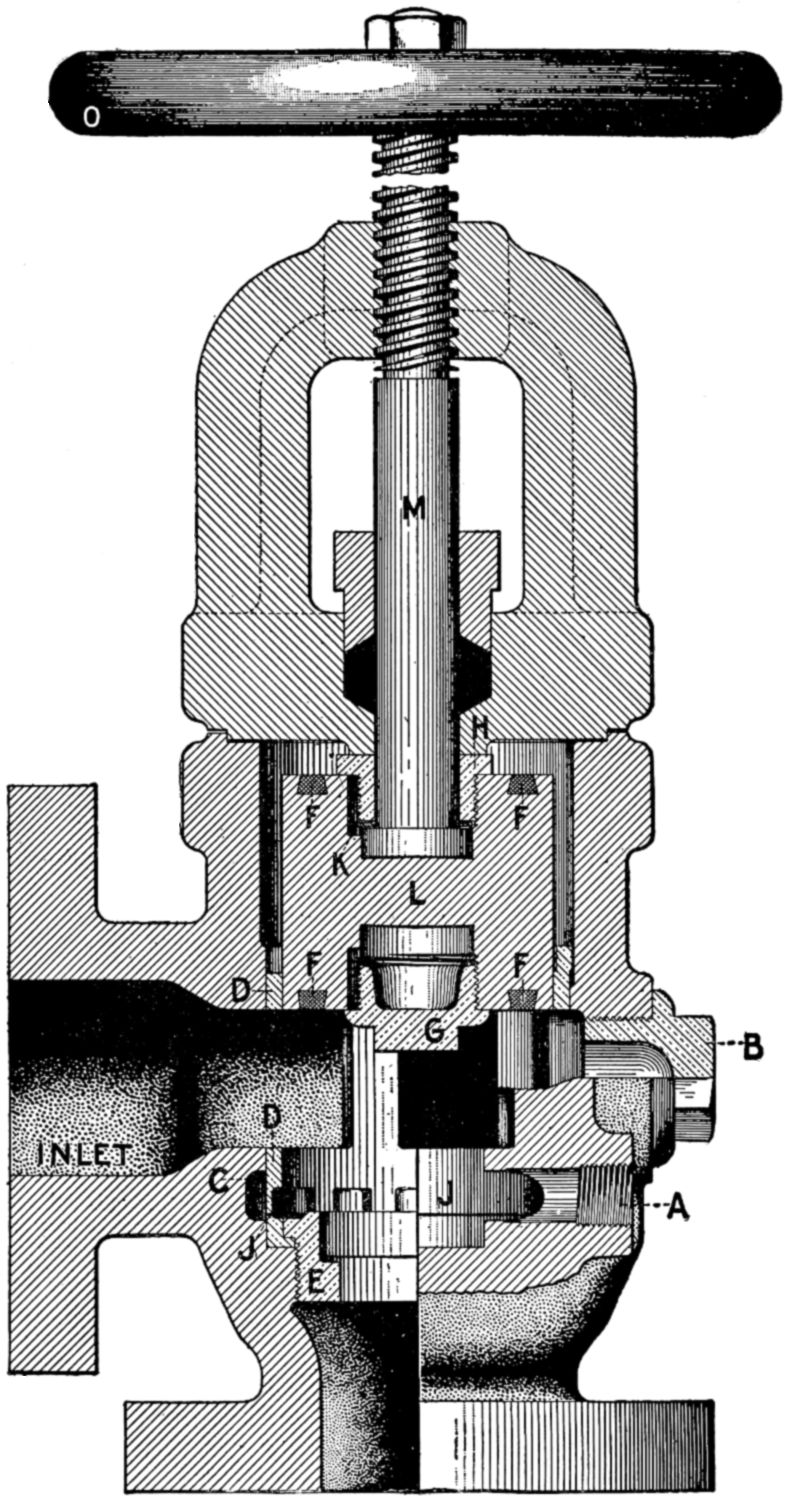

Fig. 83 is a section, or end view of a bar of angle iron; the student will find helpful practice in attempting this figure; he may be allowed to use a straight-edge in drawing the lines, but no measurements; the work should be tested on completion by a rule, or better by penciling from the original on tracing paper, and comparing the free-hand with the copy, when the defective proportions, if any, will be clearly exhibited.

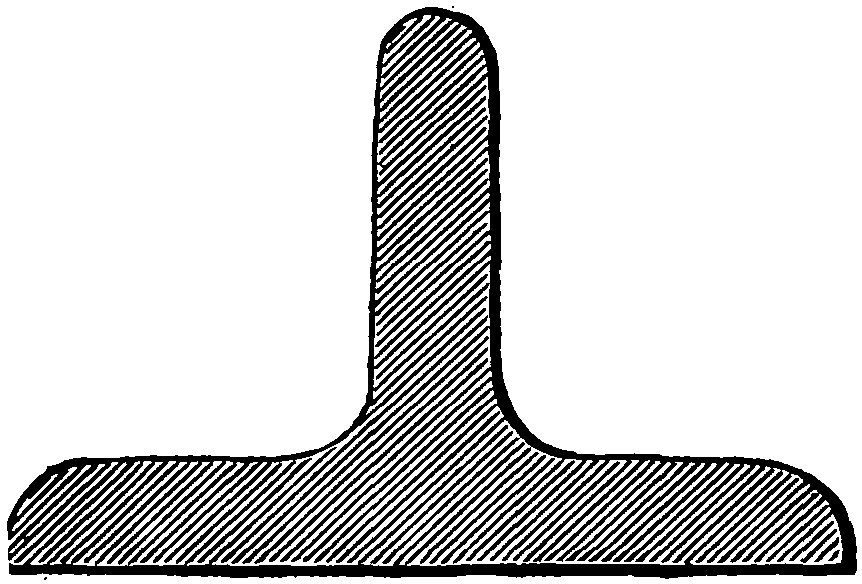

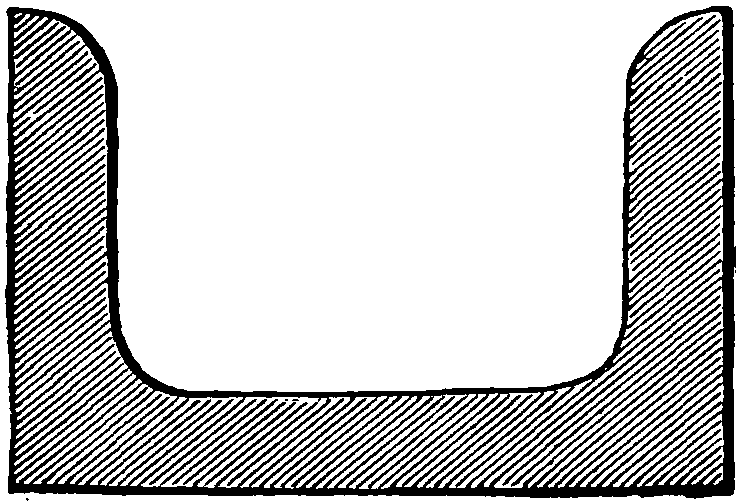

Fig. 84 is a section of tee iron, and fig. 85 is a section of channel iron. These three figures on page 75 should be practiced alternately, although seeming similar in shape.

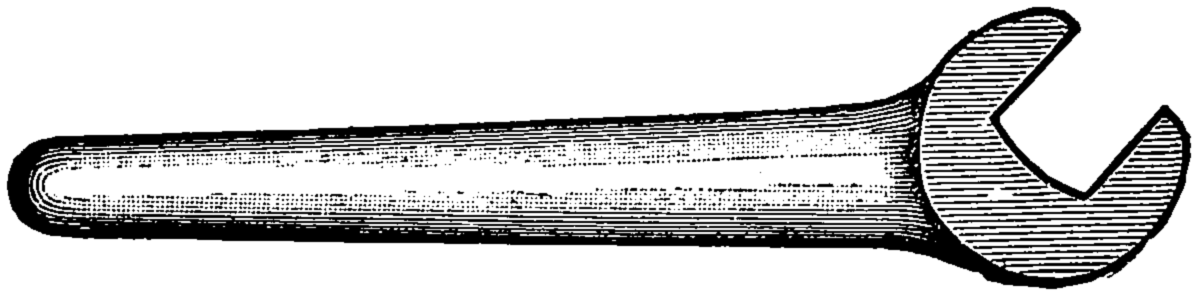

Fig. 86 is a side and end view of an angle plate shaded. Fig. 87 is a wrench shaded.

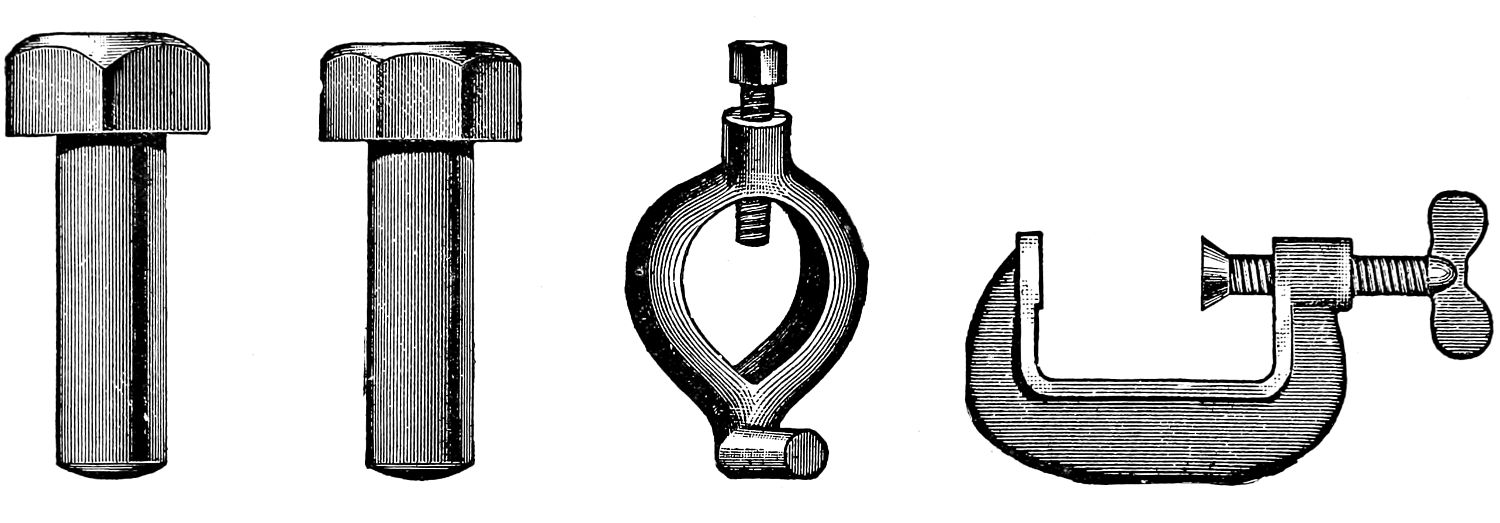

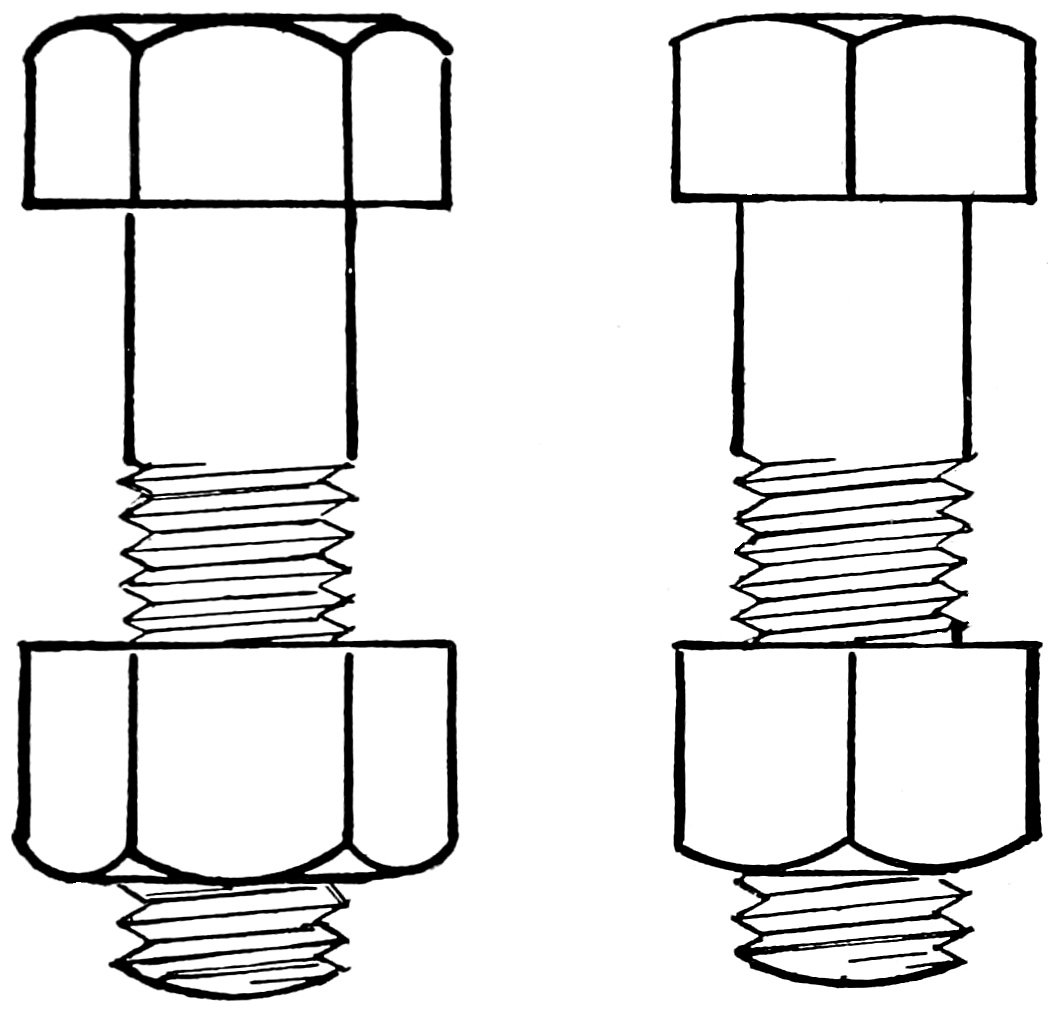

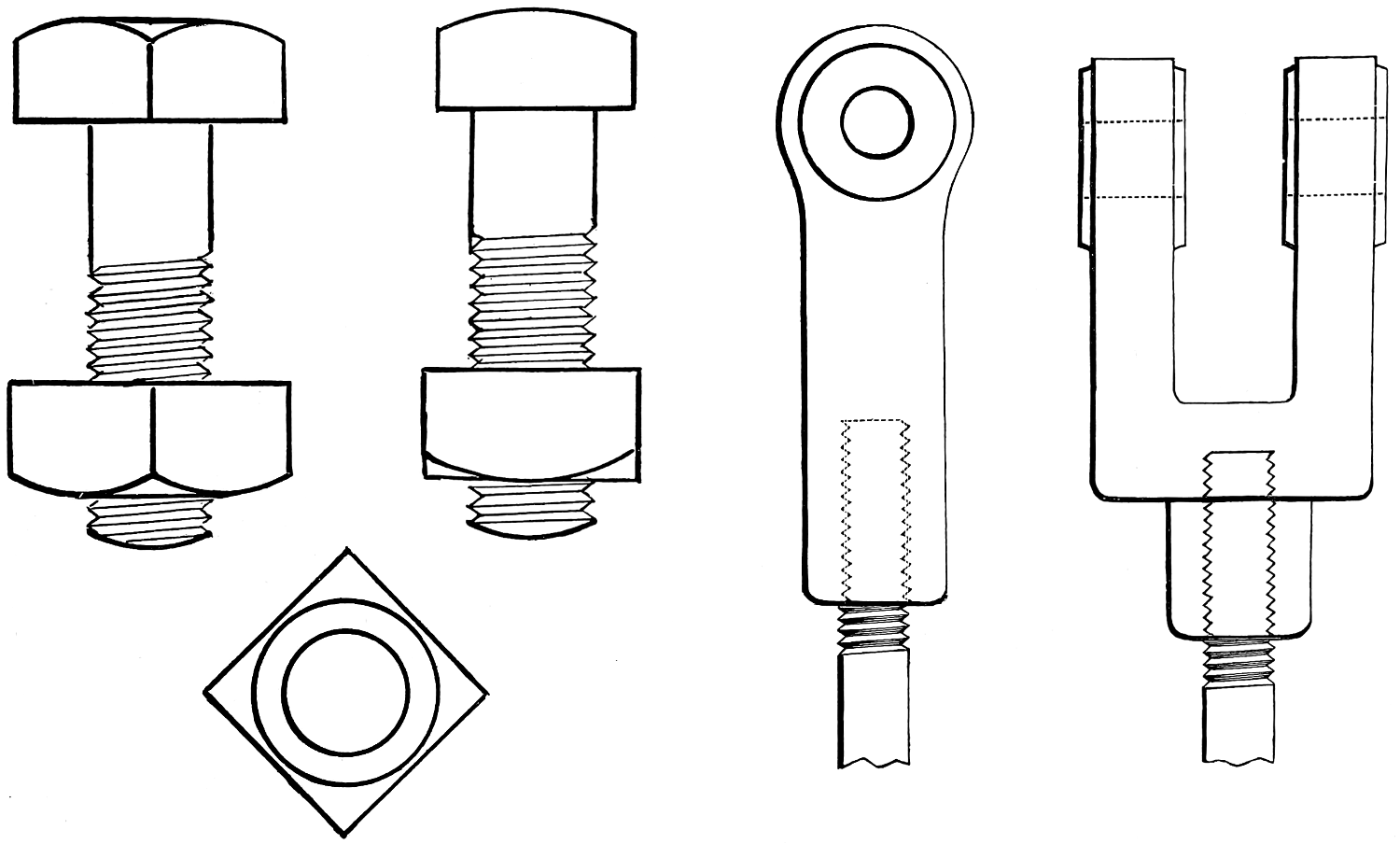

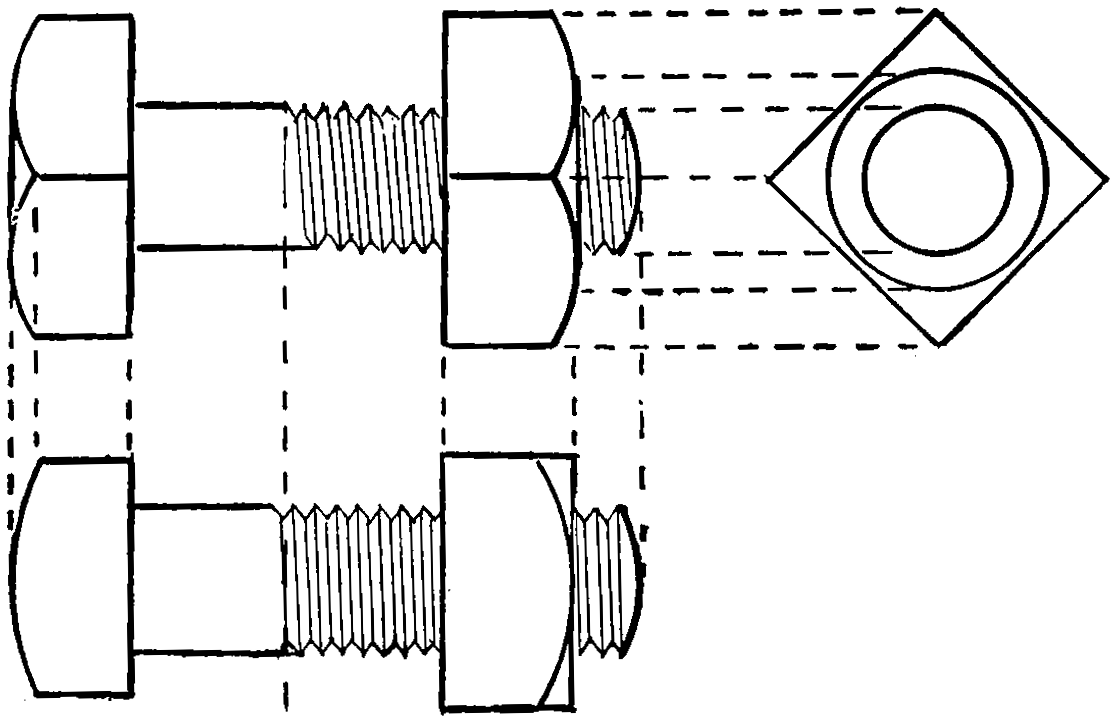

Examples of bolt ends are shown in the two next numbers; fig. 88 exhibits the common square-head bolt, and fig. 89 the hexagon or six-sided bolt-head; these are also examples of straight-line shading. Fig. 90 is a lathe-dog, and shows an example of curved shading; fig. 92 is an engine crank, and an example of straight and curved shading; fig. 91 is a screw clamp.

Fig. 93 is a section of boiler plates riveted together; a caulking tool is also shown.

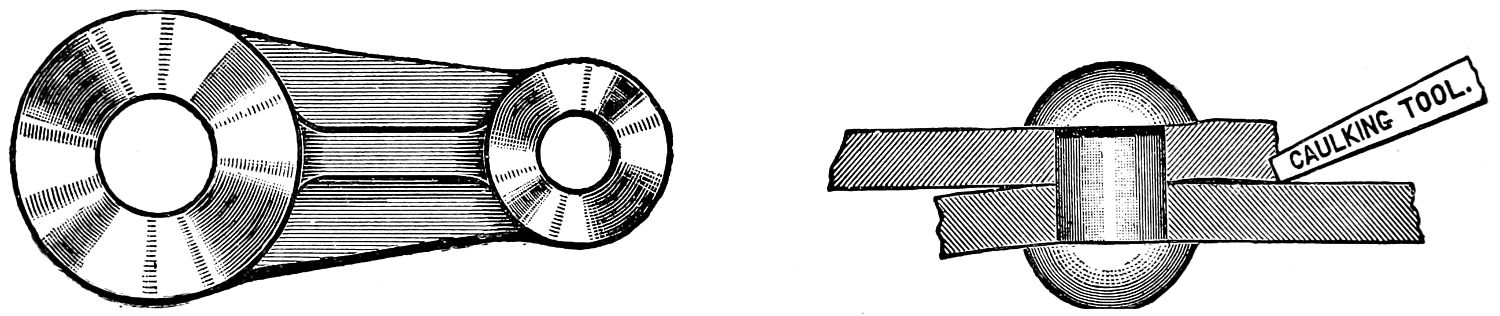

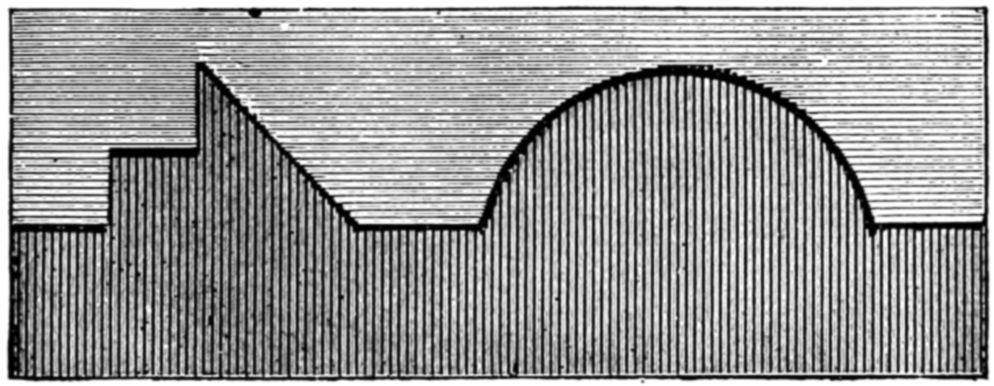

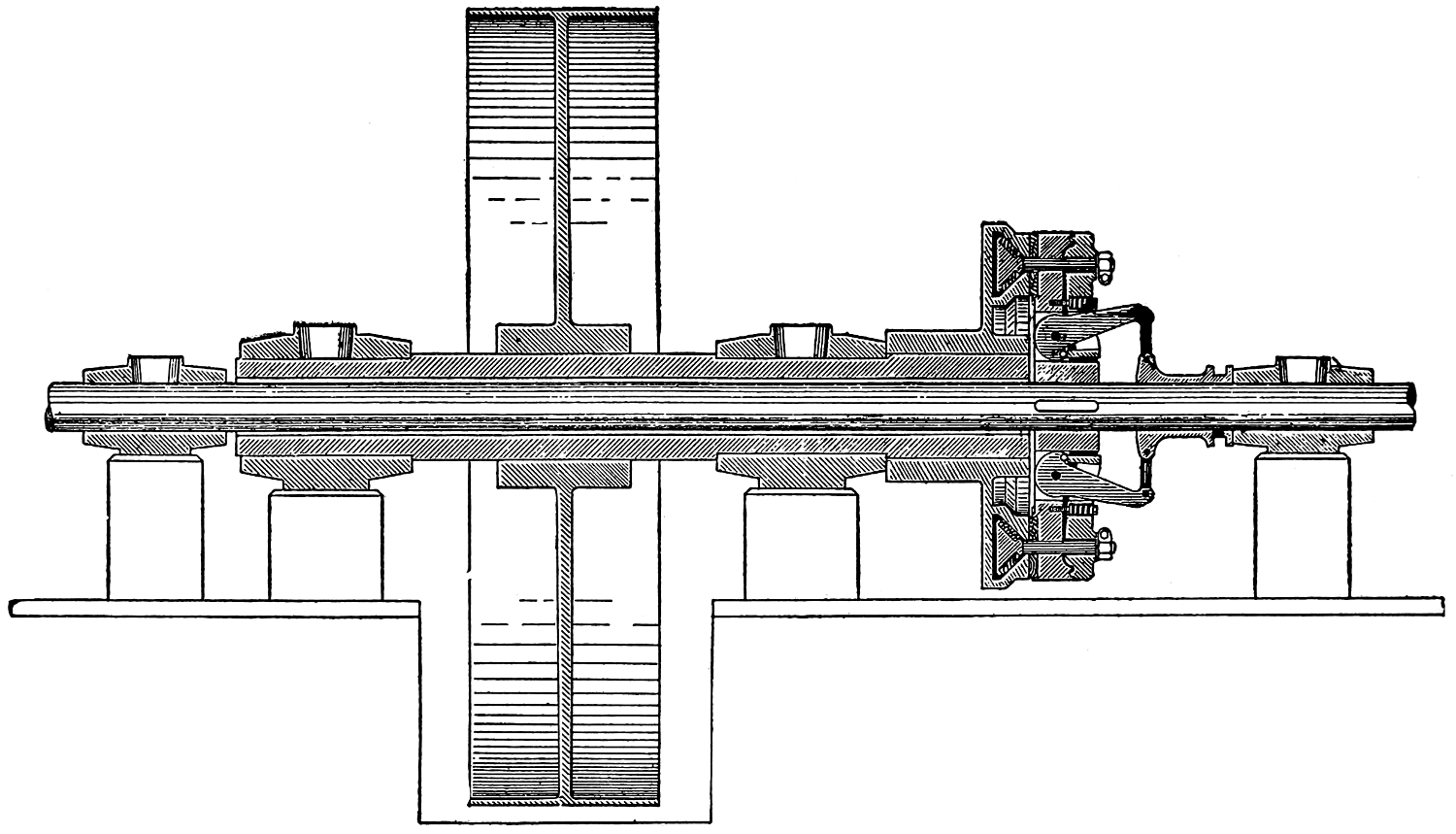

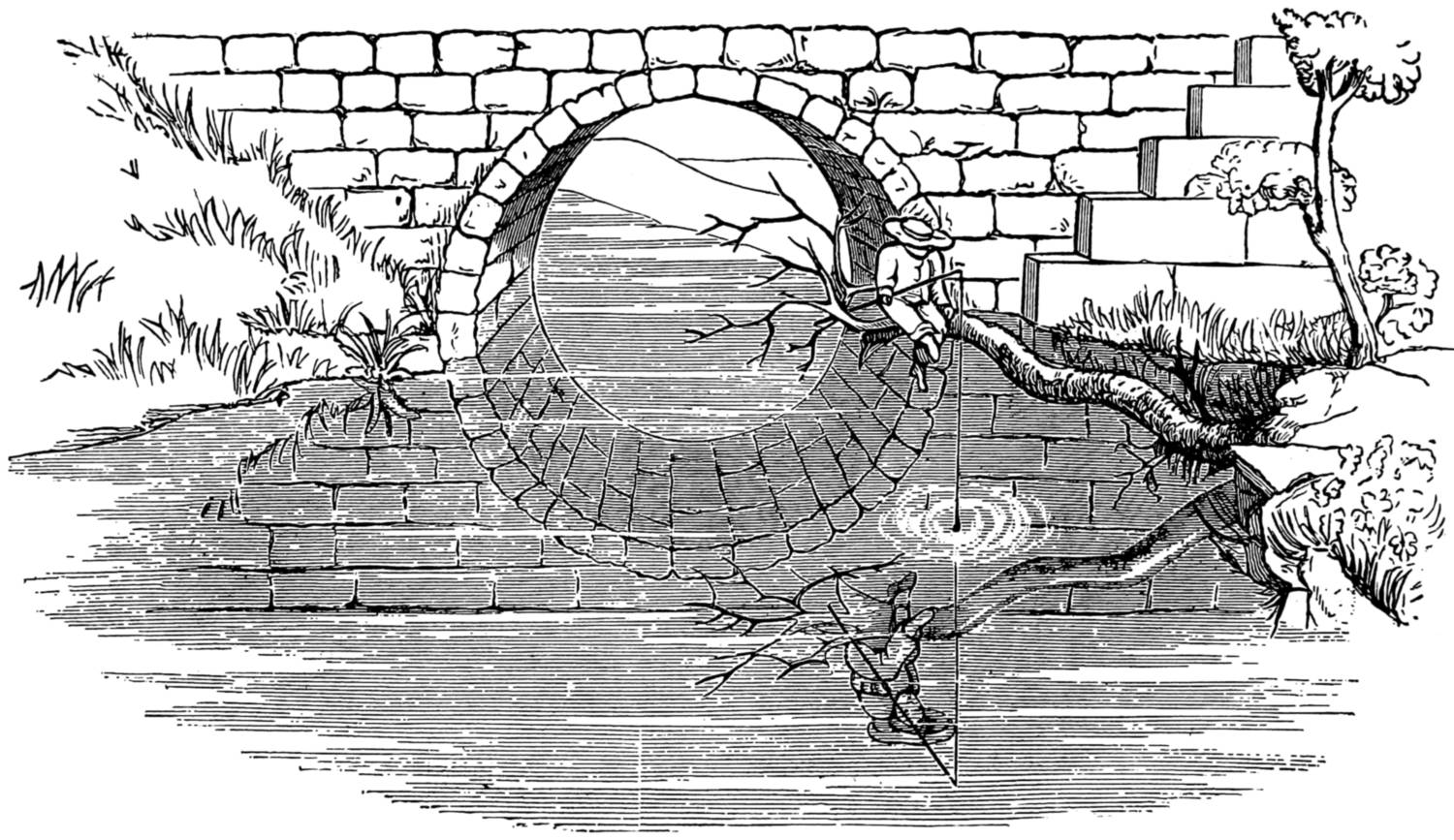

In the example, fig. 94—a hand-wheel—the principal difficulty, even for the most advanced student in free-hand, will be in drawing the circles; a coin, if convenient, can be used to scribe about, in drawing these; the other parts can afterwards be filled in around the circle. Fig. 96 is introduced for practice in penciling and shading; the figure represents a water-wheel on a stone pier.

The familiar oil can is shown in fig. 95. These all are excellent objects for practice.

[75]

Fig. 83.—Fig. 84.—Fig. 85.

Fig. 86.

Fig. 87.

[76]

Fig. 88.—Fig. 89.—Fig. 90.—Fig. 91.

Fig. 92.

Fig. 93.

[77]

Fig. 94.

Fig. 95.

[78]

Fig. 96.

[79]

[80]

[81]

Geometry is the science of measurement; it has been known for more than three thousand years; many lives have been devoted to its development, and it exists to-day as the foundation of all mathematics.

Geometrical drawing is the art of representing, to the eye, the problems “worked out” by geometricians, and the importance of a knowledge of geometrical drawing is paramount. The student will find that the figures delineated and explained in the next few pages constantly occur in mechanical drawing. Says Walter Smith, State Director of Art Education in Massachusetts, “I have never known a case where a student did not progress more satisfactorily in his studies after a course of practical geometry.”

The elementary conceptions of geometry are few:

1.—A point.

2.—A line.

3.—A surface.

4.—A solid, and

5.—An angle.

All of which elements are used in mechanical drawings.

From these, as data, a vast number of mathematical problems have been deduced; of which a few of the most elementary will be illustrated in this work; but these few will repay the attention of the student.

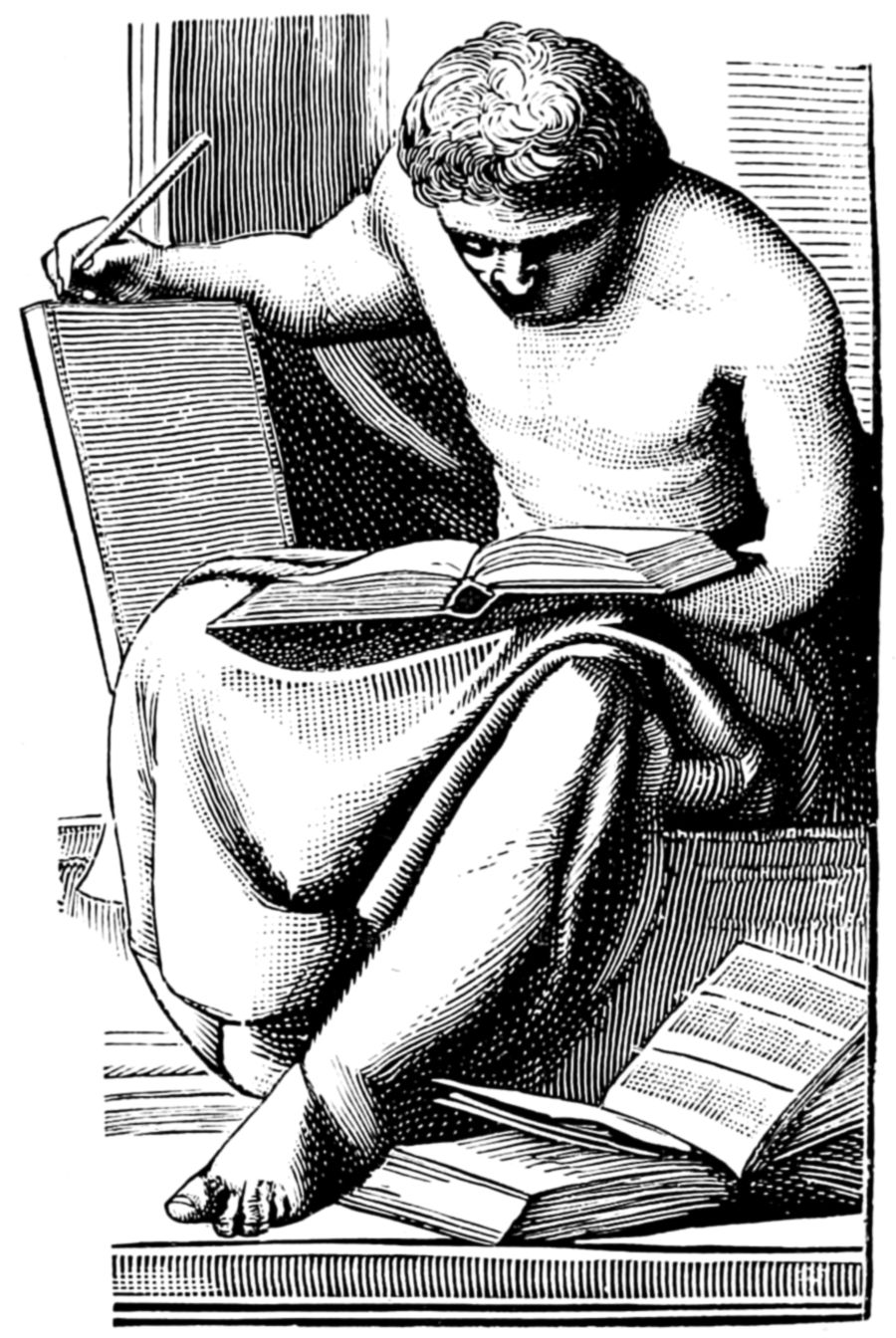

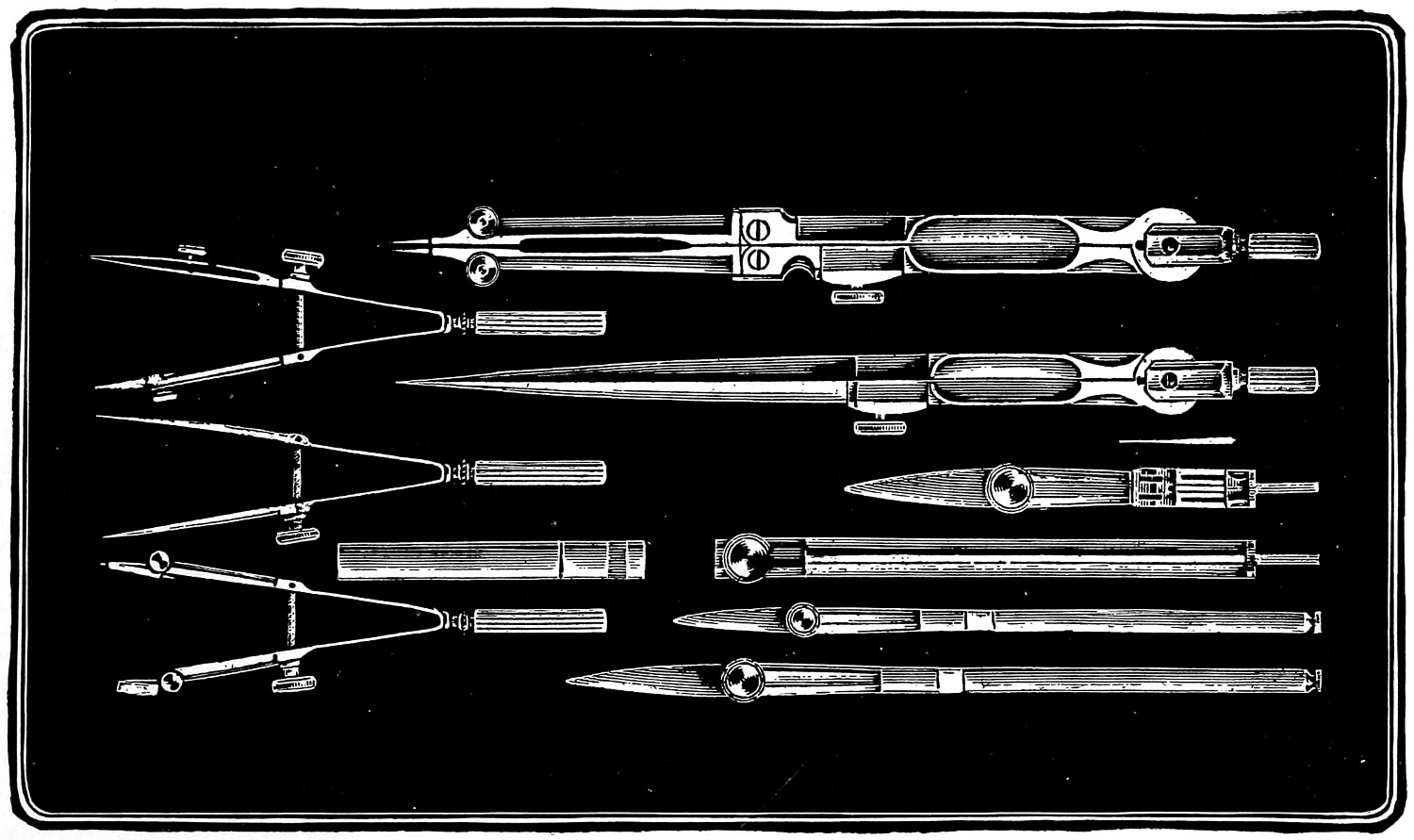

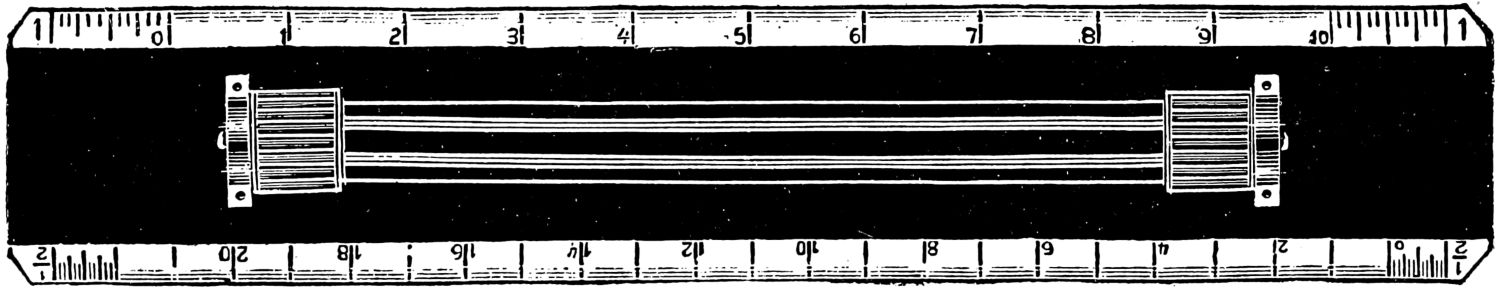

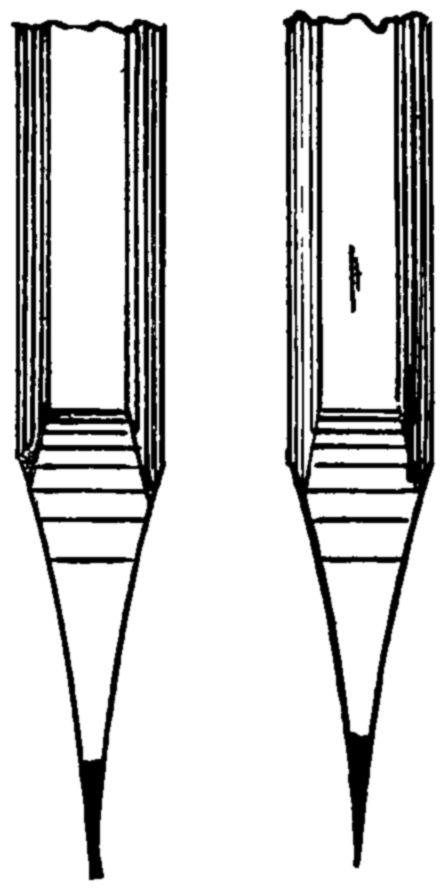

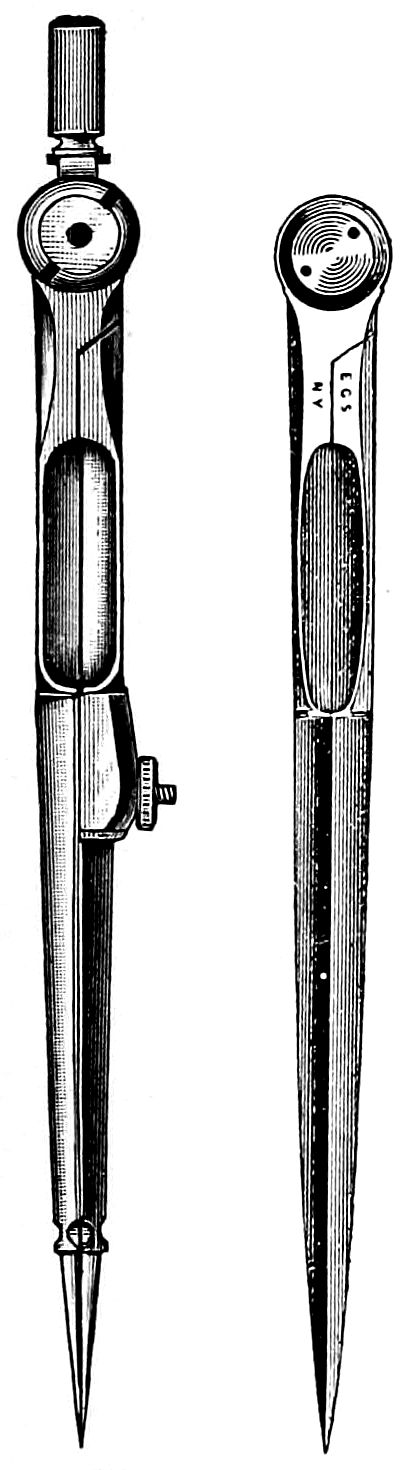

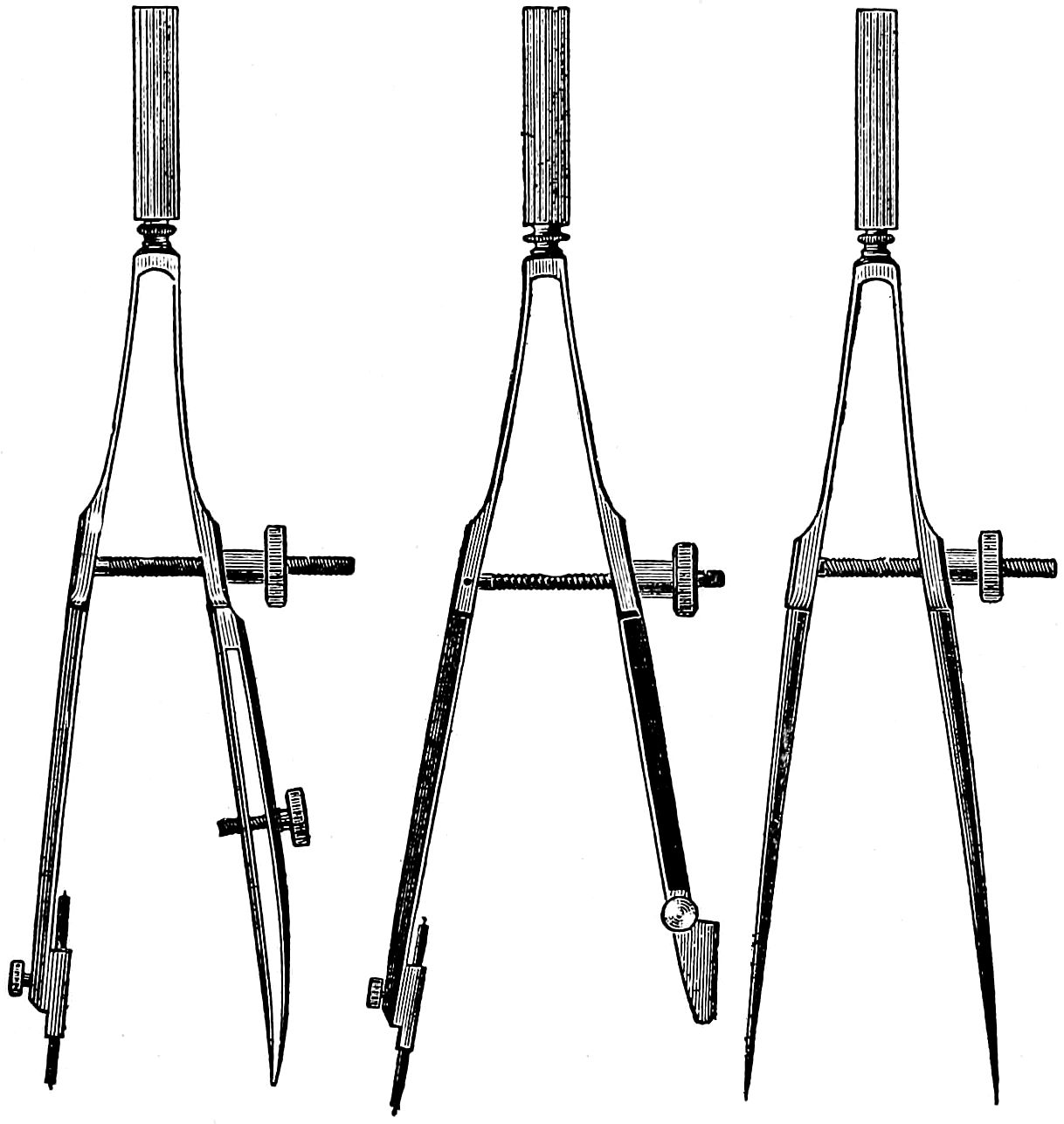

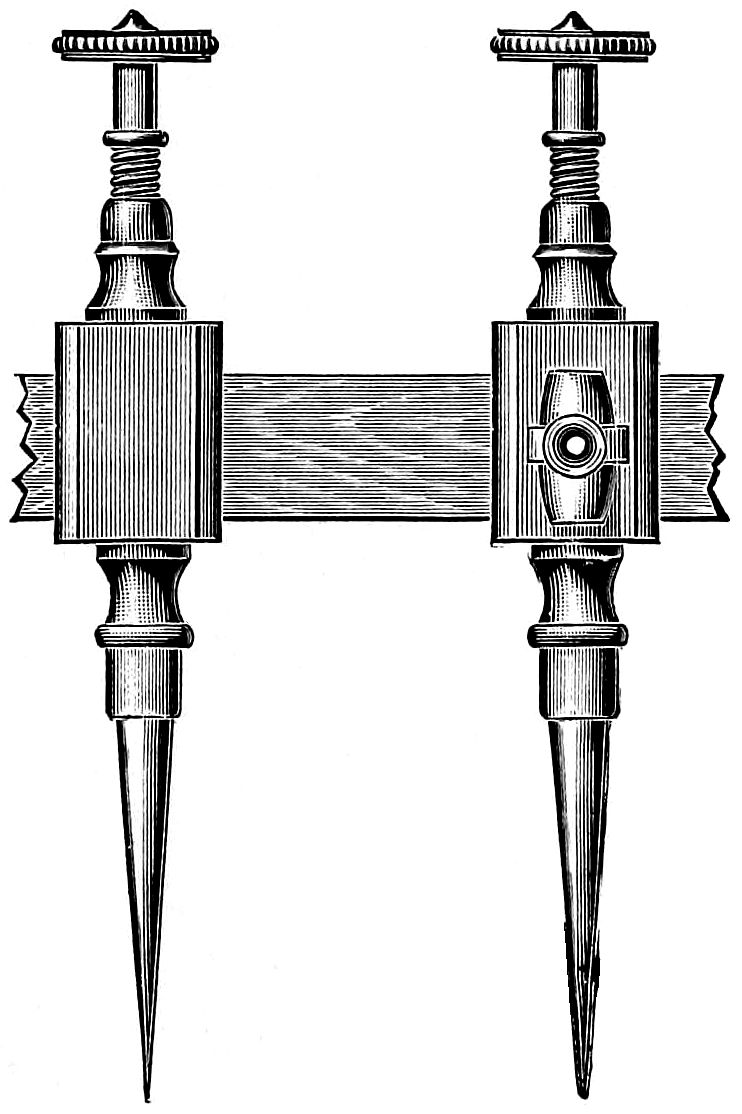

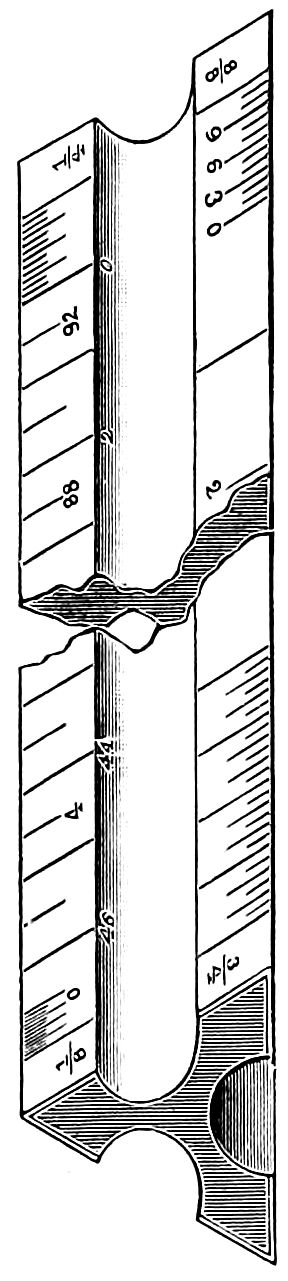

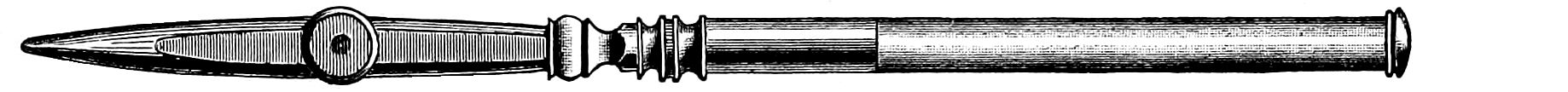

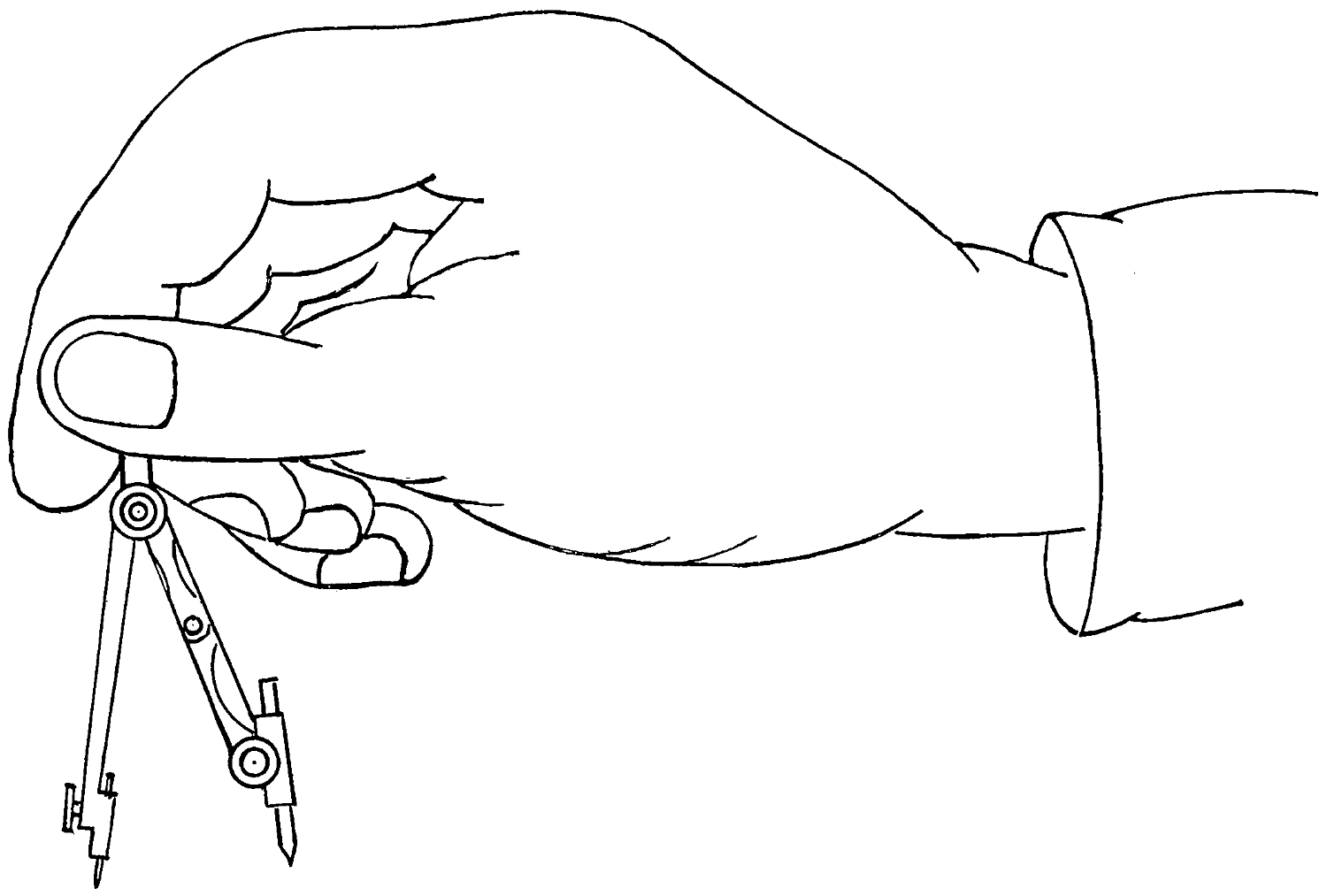

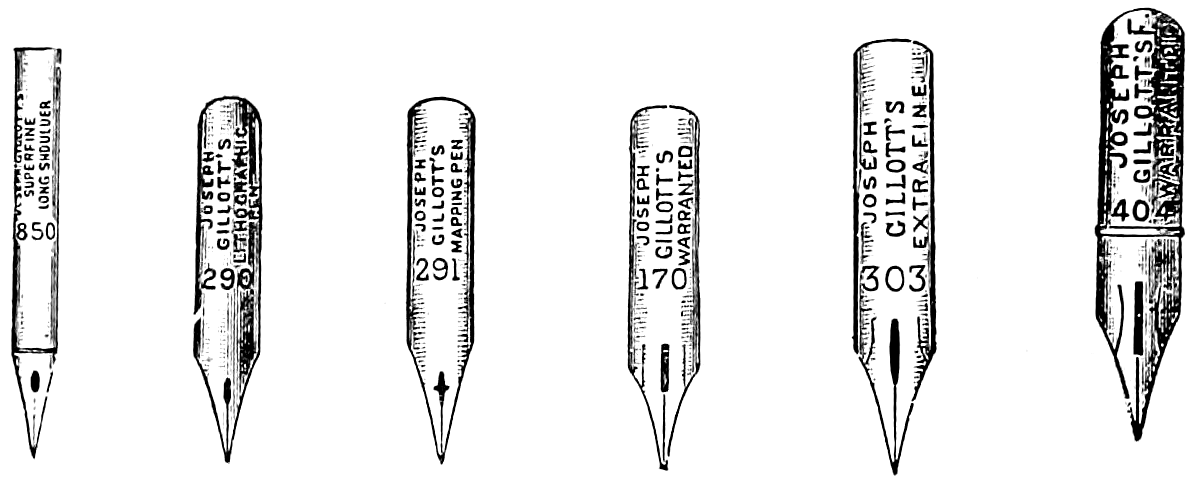

In “freehand” drawing the crayon and pencil are used; in geometrical drawings the dividers, as[82] shown in illustration, fig. 97, together with a rule, are all that is necessary to accomplish the work.

A problem is something to be done, and geometry has been defined as the science of measurement; the relation between geometry and mechanical drawing is very close, hence the term “geometrical problem.”

Fig. 97.

Fig. 98.

Before proceeding with the examples, a few elementary statements belonging to the science of geometry are presented; these will be useful to the student, not only while “doing” the problems, but in many cases of every-day—future—experience.

Geometry is one of the oldest and simplest of sciences; it may be defined as the science of measurement; geometry is the root from which all regular mathematical calculations issue. It has claimed the best thought of practical men from the times of the Greeks and Romans two thousand years ago; they derived their knowledge of the science from the Egyptians, who in turn were indebted to the Chaldeans and Hindoos in times beyond any authentic history; hence it was under the operations of the laws explained in geometry, that the pyramids of Egypt and the temples of Greece were constructed, as well as the engines of war and appliances of peace of ancient times.

A point is mere position, and has no magnitude.

A line is that which has extension in length only. The extremities of lines are points.

A surface is that which has extension in length and breadth only.

[83]

A solid is that which has extension in length, breadth and thickness.

An angle is the difference in the direction of two lines proceeding from the same point.

Lines, Surfaces, Angles and Solids constitute the different kinds of quantity called geometrical magnitudes.

Parallel lines are lines which have the same direction; hence parallel lines can never meet, however far they may be produced; for two lines taking the same direction cannot approach or recede from each other.

An Axiom is a self-evident truth, not only too simple to require, but too simple to admit of demonstration.

A Proposition is something which is either proposed to be done, or to be demonstrated, and is either a problem or a theorem.

A Problem is something proposed to be done.

A Theorem is something proposed to be demonstrated.

A Hypothesis is a supposition made with a view to draw from it some consequence which establishes the truth or falsehood of a proposition, or solves a problem.

A Lemma is something which is premised, or demonstrated, in order to render what follows more easy.

A Corollary is a consequent truth derived immediately from some preceding truth or demonstration.

A Scholium is a remark or observation made upon something going before it.

A Postulate is a problem, the solution of which is self-evident.

Let it be granted—

III. That a straight line can be drawn from any one point to any other point;

[84]

III. That a straight line can be produced to any distance, or terminated at any point;

III. That the circumference of a circle can be described about any center, at any distance from that center.

The common algebraic signs are used in Geometry, and it is necessary that the student in geometry should understand some of the more simple operations of algebra. As the terms circle, angle, triangle, hypothesis, axiom, theorem, corollary and definition are constantly occurring in a course of geometry, they are abbreviated as shown in the following list:

| Addition is expressed by | + |

| Subtraction is expressed by | - |

| Multiplication is expressed by | × |

| Equality and Equivalency are expressed by | = |

| Greater than, is expressed by | > |

| Less than, is expressed by | < |

| Thus B is greater than A, is written | B > A |

| Thus B is less than A, is written | B < A |

| A circle is expressed by | O |

| An angle is expressed by | L |

| A right angle is expressed by | R. L |

| Degrees, minutes and seconds are expressed by | ° ′ ″ |

| A triangle is expressed by | △ |

| The term Hypothesis is expressed by | (Hy.) |

| The term Axiom is expressed by | (Ax.) |

| The term Theorem is expressed by | (Th.) |

| The term Corollary is expressed by | (Cor.) |

| The term Definition is expressed by | (Def.) |

| The term Perpendicular is expressed by | ⊥ |

| The difference of two quantities, when it is not known which is the greater, is expressed by the symbol | ~ |

| Thus, the difference between A and B is written | A ~ B |

1. Things which are equal to the same thing are equal to each other.

2. When equals are added to equals the wholes are equal.

[85]

3. When equals are taken from equals the remainders are equal.

4. When equals are added to unequals the wholes are unequal.

5. When equals are taken from unequals the remainders are unequal.

6. Things which are double of the same thing, or equal things, are equal to each other.

7. Things which are halves of the same thing, or of equal things, are equal to each other.

8. The whole is greater than any of its parts.

9. Every whole is equal to all its parts taken together.

10. Things which coincide, or fill the same space, are identical, or mutually equal in all their parts.

11. All right angles are equal to one another.

12. A straight line is the shortest distance between two points.

13. Two straight lines cannot enclose a space.

[86]

Fig. 99.

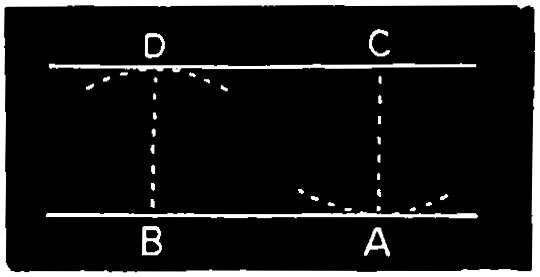

Example 1.—To bisect (cut in two) a straight line or an arc of a circle, Fig. 99. From the ends of A B as centers, describe arcs cutting each other at C and D, and draw C D, which cuts the line at E or the arc at F.

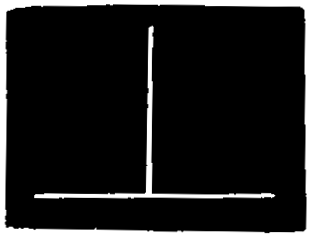

Ex. 2.—To draw a perpendicular to a straight line, or a radial line to a circular arc, Fig. 99. Operate as in the foregoing problem. The line C D is perpendicular to A B; the line C D is also radial to the arc A B.

Fig. 100.

Fig. 101.

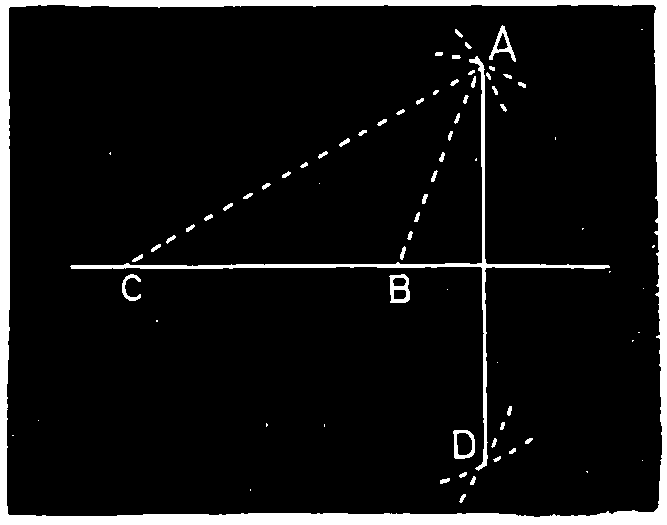

Ex. 3.—To draw a perpendicular to a straight line, from a given point in that line, Fig. 100. With any radius from any given point A in the line B C, cut the line at B and C. Next, with a longer radius, describe arcs from B and C, cutting each other at D, and draw the perpendicular D A.

[87]

Second Method, Fig. 101. From any center F above B C, describe a circle passing through the given point A, and cutting the given line at D; draw D F, and produce it to cut the circle at E; and draw the perpendicular A E.

Fig. 102.

Third Method, Fig. 102. From A describe an arc E C, and from E, with the same radius, the arc A C cutting the other at C; through C draw a line E C D and set off C D equal to C E, and through D draw the perpendicular A D.

Fig. 103.

Fig. 104.

Ex. 4.—To draw a perpendicular to a straight line from any point without it, Fig. 103. From the point A with a sufficient radius cut the given line at F and G; and from these points describe arcs cutting at E. Draw the perpendicular A E.

If there be no room below the line, the intersection may be taken above the line; that is to say, between the line and the given point.

[88]

Second Method, Fig. 104. From any two points B C at some distance apart, in the given line, and with the radii B A, C A, respectively, describe arcs cutting at A D. Draw the perpendicular A D.

Fig. 105.

Fig. 106.

Ex. 5.—To draw a parallel line through a given point, Fig. 105. With a radius equal to the given point C from the given line A B, describe the arc D from B, taken considerably distant from C. Draw the parallel through C to touch the arc D.

Second Method, Fig. 106. From A, the given point, describe the arc F D, cutting the given line at F; from F, with the same radius, describe the arc E A, and set off F D, equal to E A. Draw the parallel through the points A D.

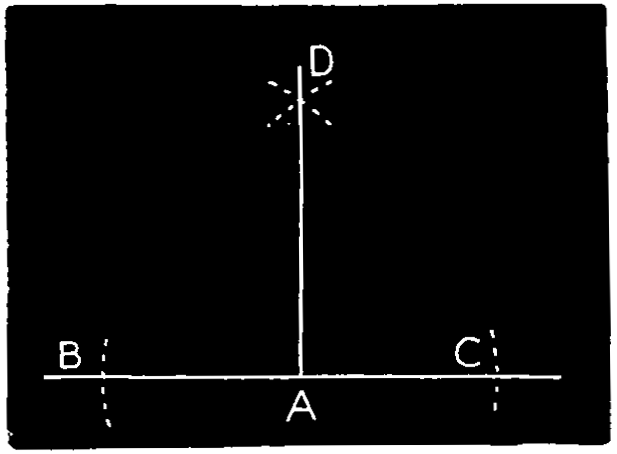

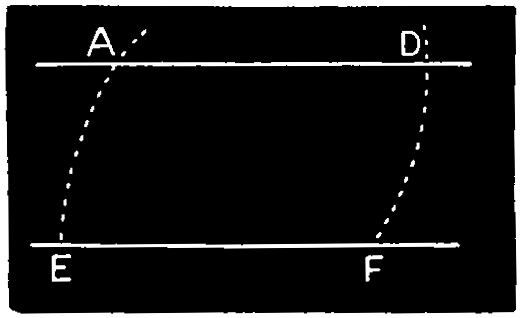

Fig. 107.

When a series of parallels are required perpendicular to a base line A B, they may be drawn as in fig. 107 through points in the base line set off at the required distances apart. This method is convenient also where a succession of parallels are required to a given line C D, for the perpendicular may be drawn to it, and any number of parallels may be drawn on the perpendicular.

[89]

Fig. 108.

Fig. 109.

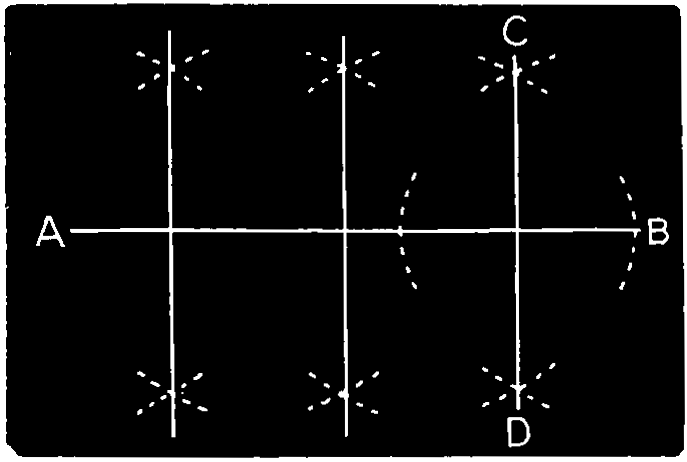

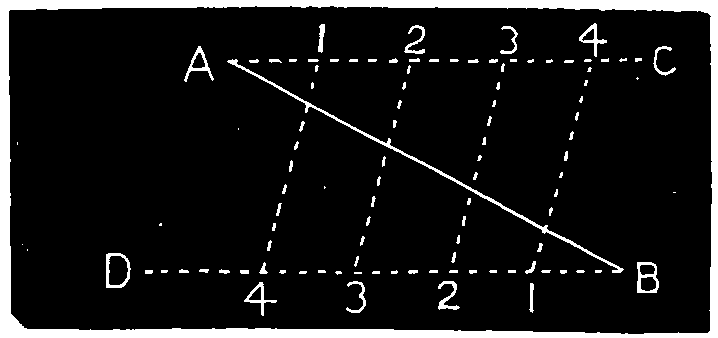

Ex. 6.—To divide a line into a number of equal parts, Fig. 108.

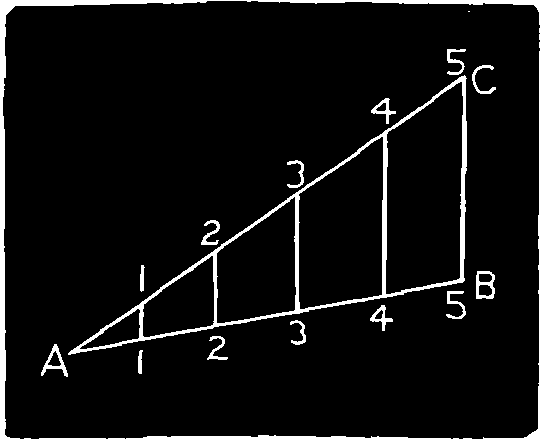

To divide the line A B into, say, five parts. From A and B draw parallels A C, B D on opposite sides; set off any convenient distance four times (one less than the given number), from A on A C, and on B on B D; join the first on A C to the fourth on B D, and so on. The lines so drawn divide A B as required.

Second Method, Fig. 109. Draw the line at A C, at an angle from A, set off, say, five equal parts; draw B 5, and draw parallels to it from the other points of division in A C. These parallels divide A B as required.

Fig. 110.

Ex. 7.—Upon a straight line to draw an angle equal to a given angle, Fig. 110. Let A be the given angle and F G the line. With any radius from the points A and F, describe arcs D E, I H, cutting the sides of the angle A and the line F G.

Set off the arc I H, equal to D E and draw F H. The angle F is equal to A as required.

Fig. 111.

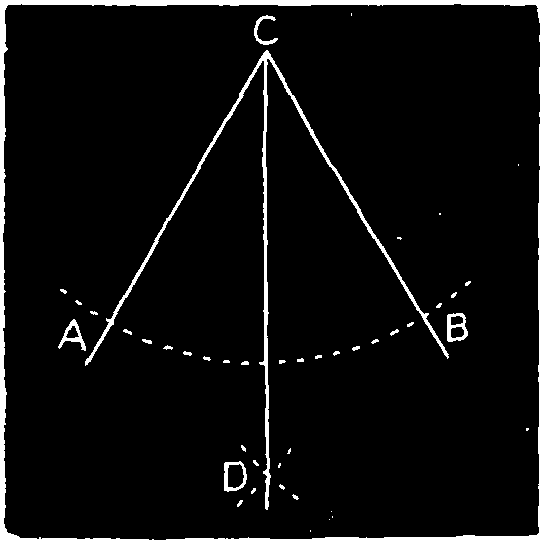

Ex. 8.—To bisect an angle, Fig. 111. Let A C B be the angle; on the center C cut the sides at A B. On A and B as centers describe arcs cutting at D dividing the angle into two equal parts.

[90]

Fig. 112.

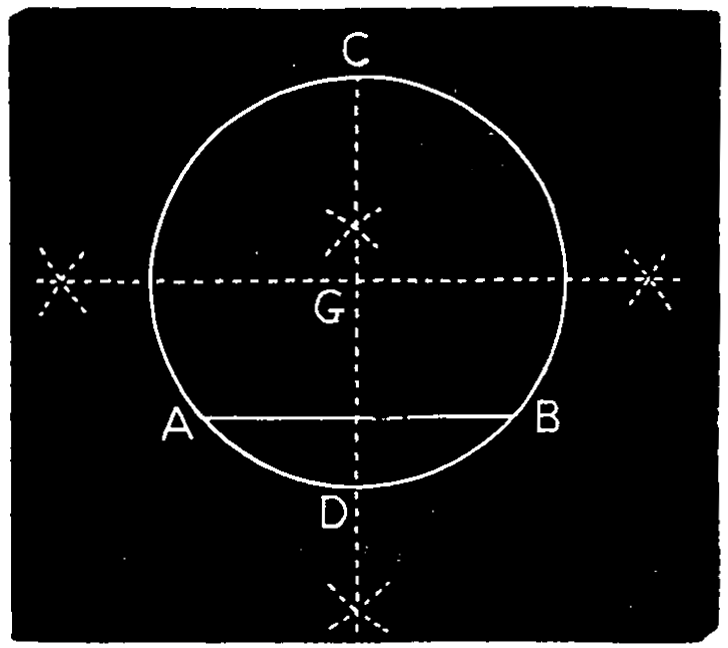

Ex. 9.—To find the center of a circle or of an arc of a circle. Fig. 112. Draw the chord A B, bisect it by the perpendicular C D, bounded both ways by the circle; and bisect C D for the center G.

Fig. 113.

Fig. 114.

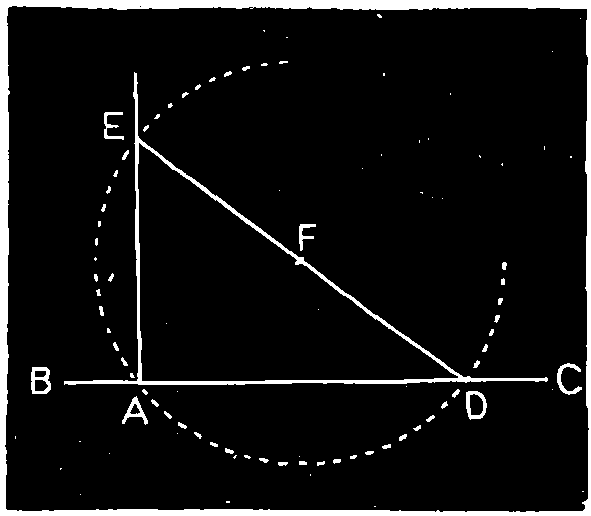

Ex. 10.—Through two given points to describe an arc of a circle with a given radius, Fig. 113. On the points A and B as centers, with the given radius, describe arcs cutting at C; and from C, with the same radius, describe an arc A B as required.

Second, for a circle or an arc, Fig. 114. Select three points A, B, C in the circumference, well apart; with the same radius describe arcs from these three points cutting each other, and draw two lines D E, F G, through their intersections according to Fig. 107. The point where they cut is the center of the circle or arc.

Ex. 11.—To describe a circle passing through three given points, Fig. 114. Let A, B, C be the given points and proceed as in last problem to find the center O, from which the circle may be described.

This problem is variously useful; in finding the diameter of a large fly-wheel, or any other object of large diameter when only a part of the circumference is accessible; in striking out arches when the span and rise are given, etc.

[91]

Fig. 115.

Ex. 12.—To draw a tangent to a circle from a given point in the circumference, Fig. 115. From A set off equal segments A B, A D, join B D and draw A E, parallel to it, for the tangent.

Fig. 116.

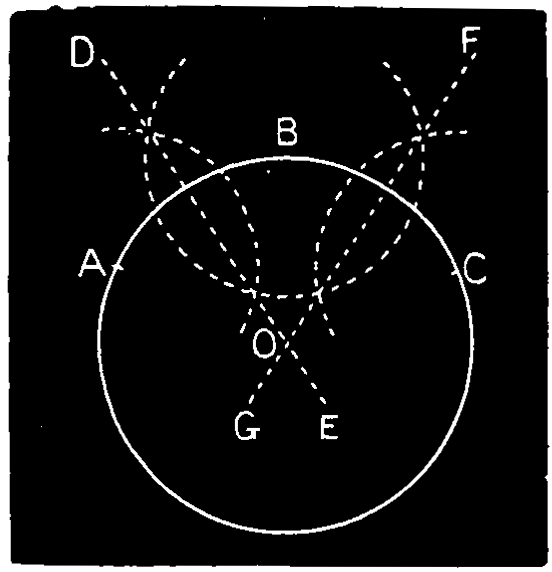

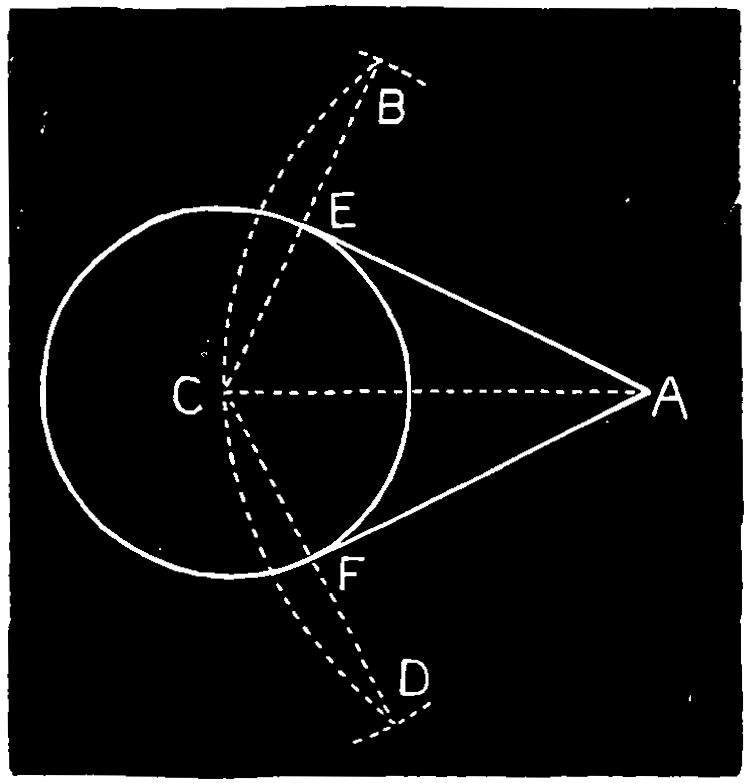

Ex. 13.—To draw tangents to a circle from points without it, Fig. 116. From A with the radius A C describe an arc B C D, and from C with a radius equal to the diameter of the circle, cut the arc at B D, join B C, C D, cutting the circle at E F, and draw A E, A F, the tangents.

Fig. 117.

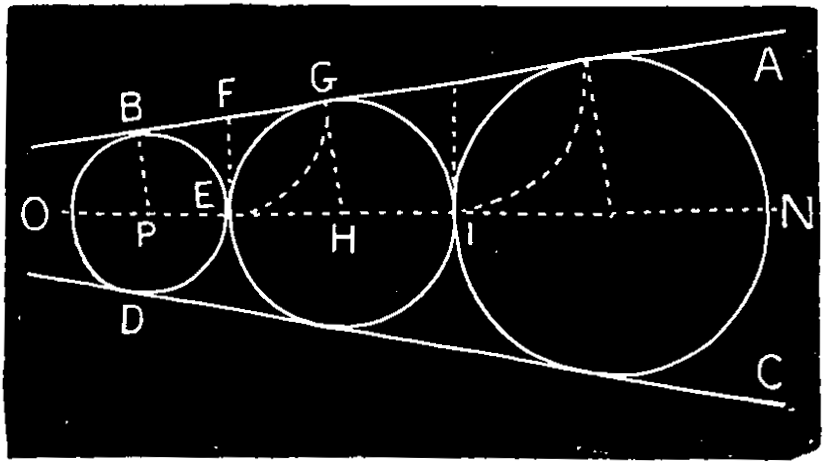

Ex. 14.—Between two inclined lines to draw a series of circles touching these lines and touching each other, Fig. 117. Bisect the inclination of the given lines A B, C D by the line N O. From a point P in this line draw the perpendicular P B to the line A B, and on P describe the circle B D, touching the lines and cutting the center lines at E. From E draw E F perpendicular to the center line, cutting A B at F, and from F describe an arc E G, cutting A B at G. Draw G H parallel to B P, giving H, the center of the next circle, to be described with the radius H E, and so on for the next circle, I N.

[92]

Fig. 118.

Fig. 119.

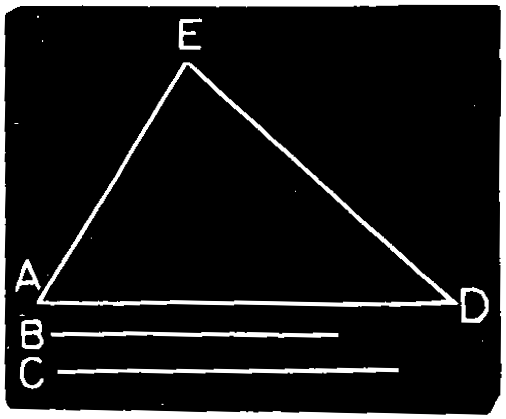

Ex. 15.—To construct a triangle on a given base, the sides being given.

First. An equilateral triangle, Fig. 118. On the ends of a given base A B, with A B as a radius describe arcs cutting at C, and draw A C, C B.

Second. Triangle of unequal sides, Fig. 119. On either end of the base A D, with the side B as a radius describe an arc; and with the side C as a radius, on the other end of the base as a center, describe arcs cutting the arc at E; join A E, D E.

This construction may be used for finding the position of a point C or E at given distances from the ends of a base, not necessarily to form a triangle.

Fig. 120.

Fig. 121.

Ex. 16.—To construct a square rectangle on a given straight line.

First. A square, Fig. 120. On the ends B A as centers, with the line A B as radius, describe arcs cutting at C; on C describe arcs cutting the others at D E; and on D and E cut these at F G. Draw A F, B G and join the intersections H I.

Second. A rectangle, Fig. 121. On the base E F draw the perpendiculars E H, F G, equal to the height of the rectangle, and join G H.

[93]

Fig. 122.

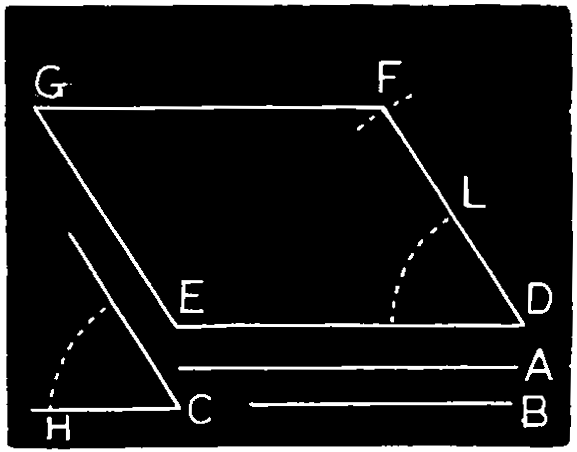

Ex. 17.—To construct a parallelogram of which the sides and one of the angles are given, Fig. 122. Draw the side D E equal to the given length A, and set off the other side D F equal to the other length B, forming the given angle C. From E with D F as radius, describe an arc, and from F, with the radius D E cut the arc at G. Draw F G, E G. Or, the remaining sides may be drawn as parallels to D E, D F.

Fig. 123.

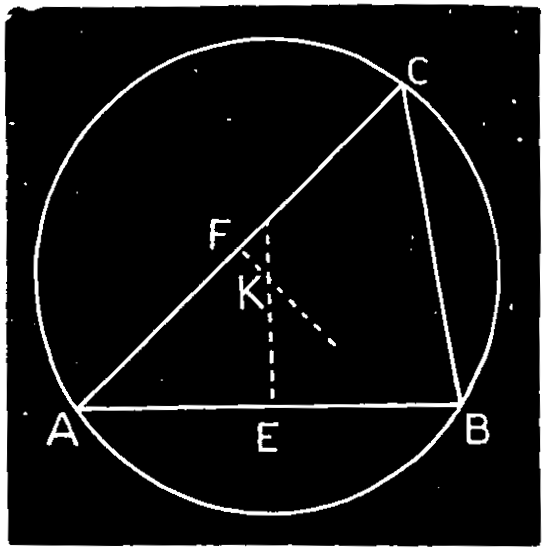

Ex. 18.—To describe a circle about a triangle, Fig. 123. Bisect two sides A B, A C of the triangle at E F, and from these points draw perpendiculars cutting at K. On the center K, with the radius K A draw the circle A B C.

Fig. 124.

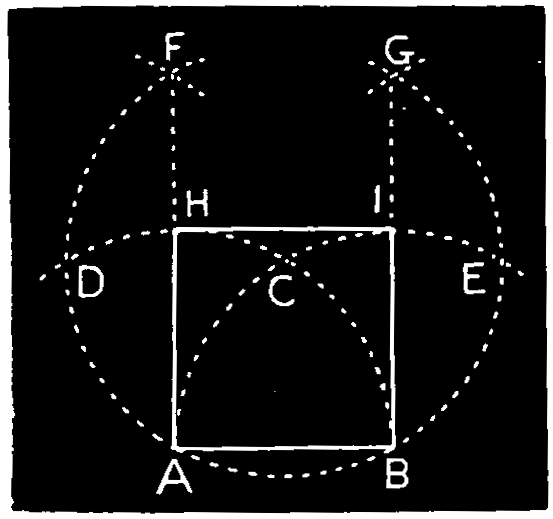

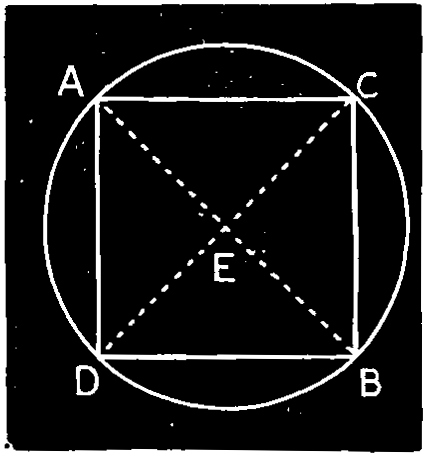

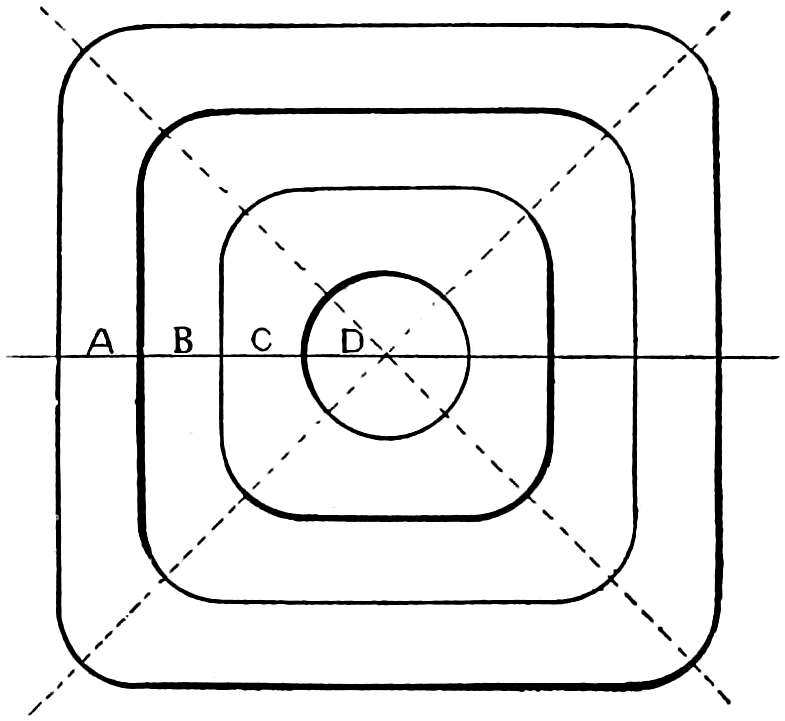

Ex. 19.—To describe a circle about a square, and to inscribe a square in a circle, Fig. 124.

First. To describe the circle. Draw the diagonals A B, C D of the square, cutting at E; on the center E with the radius E A describe the circle.

Second. To inscribe the square. Draw the two diameters A B, C D at right angles and join the points A B, C D to form the square.

In the same way a circle may be described about a triangle.

[94]

Fig. 125.

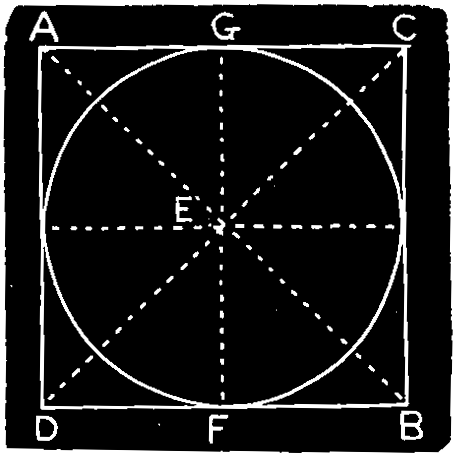

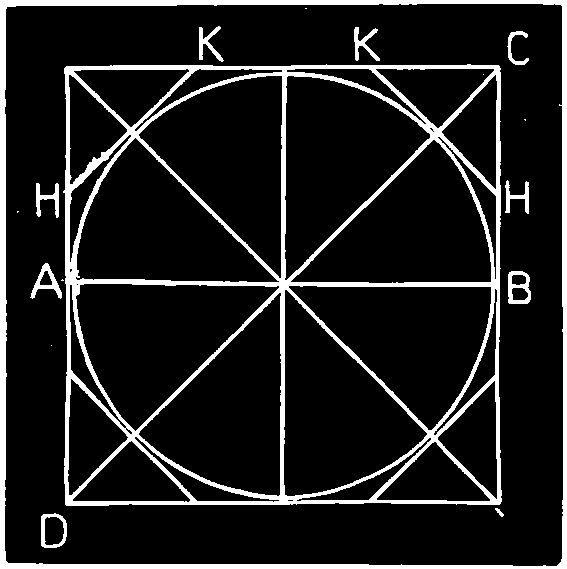

Ex. 20.—To inscribe a circle on a square, and to describe a square about a circle, Fig. 125.

First. To inscribe the circle. Draw the diagonals A B, C D of the square, cutting at E; draw the perpendicular E F to one side, and with the radius E F describe the circle.

Second. To describe the square. Draw two diameters A B, C D at right angles, and produce them; bisect the angle D E B at the center by the diameter F G, and through F and G draw perpendiculars A C, B D, and join the points A D and B C where they cut the diagonals to complete the square.

Fig. 126.

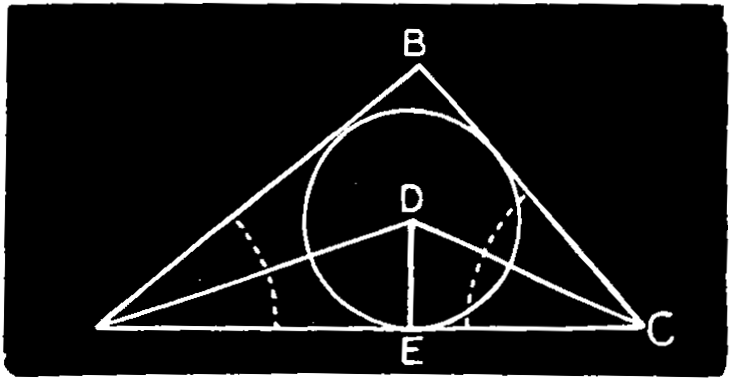

Ex. 21.—To inscribe a circle in a triangle, Fig. 126. Bisect two of the angles A C of the triangle by lines cutting at D; from D draw a perpendicular D E to any side, and with D E as radius describe a circle.

Fig. 127.

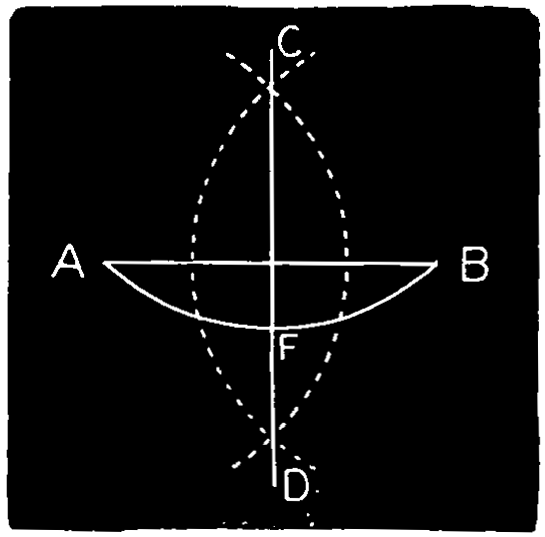

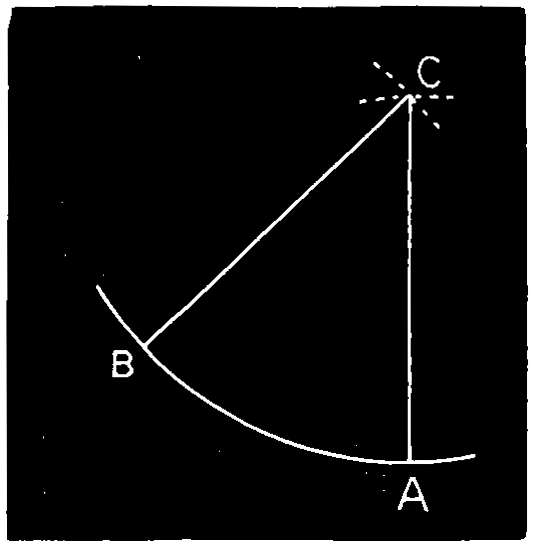

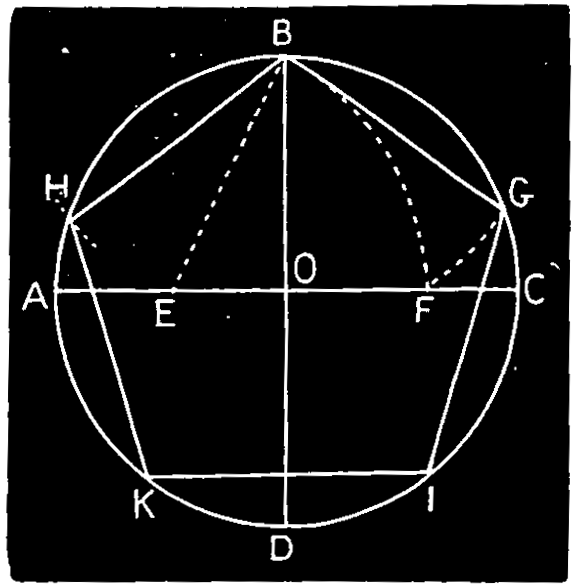

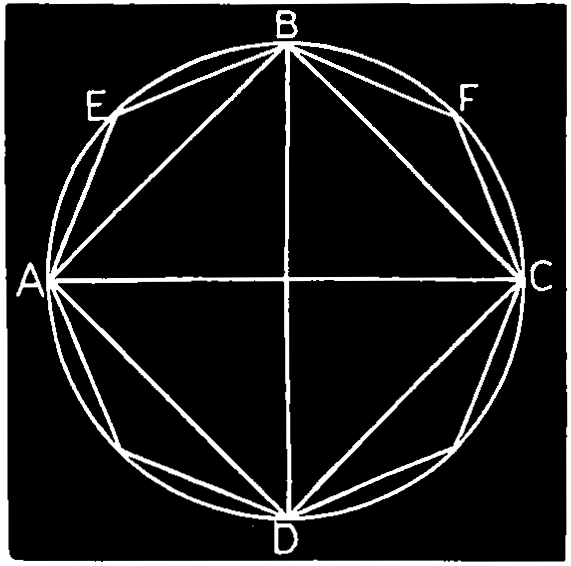

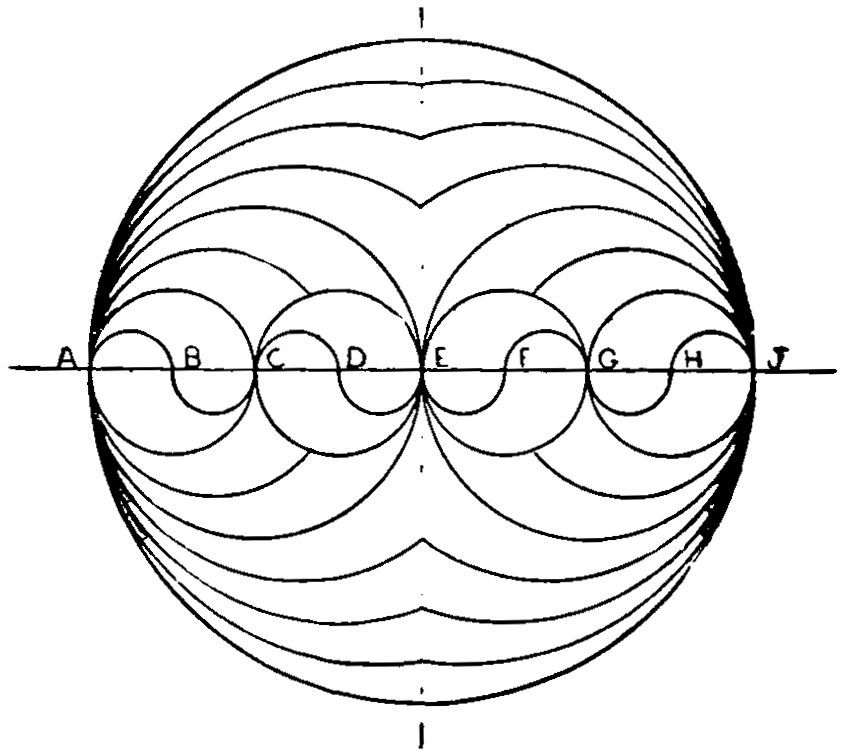

Ex. 22.—To inscribe a pentagon in a circle, Fig. 127. Draw two diameters A C, B D at right angles cutting at O; bisect A O at E, and from B with radius B E cut the circumference at G H and with the same radius step round the circle to I and K; join the points to form the pentagon.

[95]

Fig. 128.

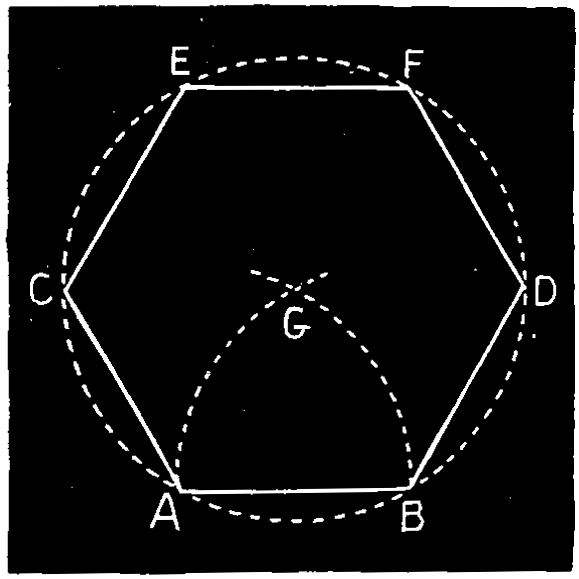

Ex. 23.—To construct a hexagon upon a given straight line, Fig. 128. From A and B, the ends of the given line, describe arcs cutting at G; from G with the radius G A describe a circle. With the same radius set off the arcs A C, C F and B D, D E; join the points so found to form the hexagon.

Fig. 129.

Ex. 24.—To inscribe a hexagon in a circle, Fig. 129. Draw a diameter A C B; from A and B as centers, with the radius of the circle A C cut the circumference at D, E, F, G, and draw A D, D E, etc., to form the hexagon. The points D E, etc., may be found by stepping the radius (with the dividers) six times round the circle.

Fig. 130.

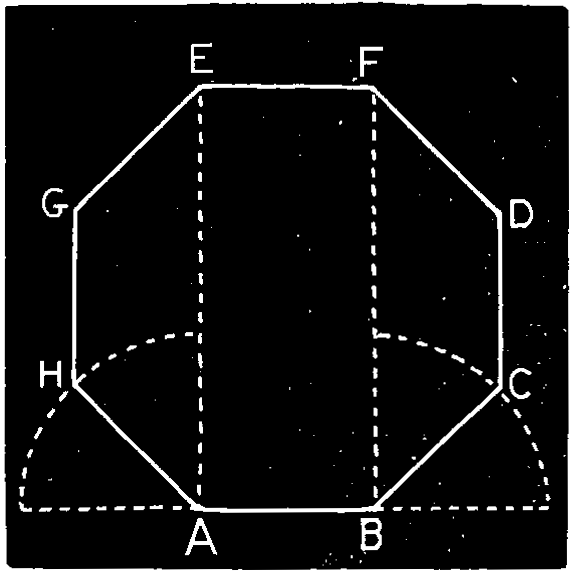

Ex. 25.—To describe an octagon on a given straight line, Fig. 130. Produce the given line A B both ways and draw perpendiculars A E, B F; bisect the external angles A and B by the lines A H, B C, which make equal to A B. Draw C D and H G parallel to A E and equal to A B; from the center G D, with the radius A B, cut the perpendiculars at E F, and draw E F to complete the hexagon.

Fig. 131.

Ex. 26.—To convert a square into an octagon, Fig. 131.—Draw the diagonals of the square cutting at E; from the corners A, B, C, D, with A E as radius, describe arcs cutting the sides at G, H, etc., and join the points so found to complete the octagon.

[96]

Fig. 132.

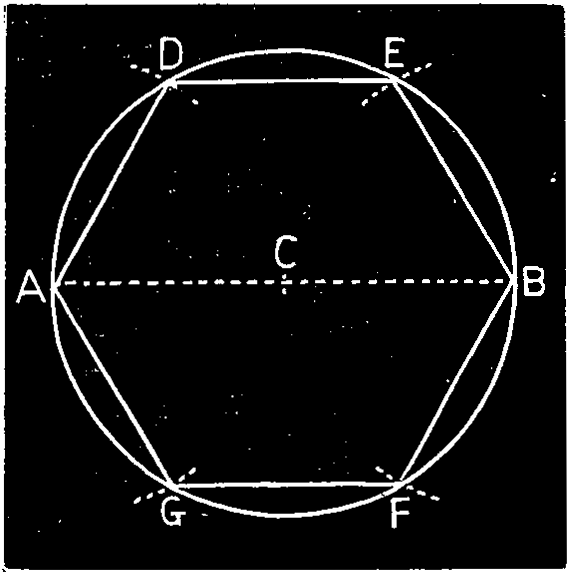

Ex. 27.—To inscribe an octagon in a circle, Fig. 132. Draw two diameters A C, B D, at right angles; bisect the arcs A B, B C, at E, F, etc., to form the octagon.

Fig. 133.

Ex. 28.—To describe an octagon about a circle, Fig. 133. Describe a square about the given circle A B, draw perpendiculars H and K, to the diagonals, touching the circle to form the octagon. Or, the points H, K, etc., may be found by cutting the sides from the corners, by lines parallel to the diagonals.

Fig. 134.

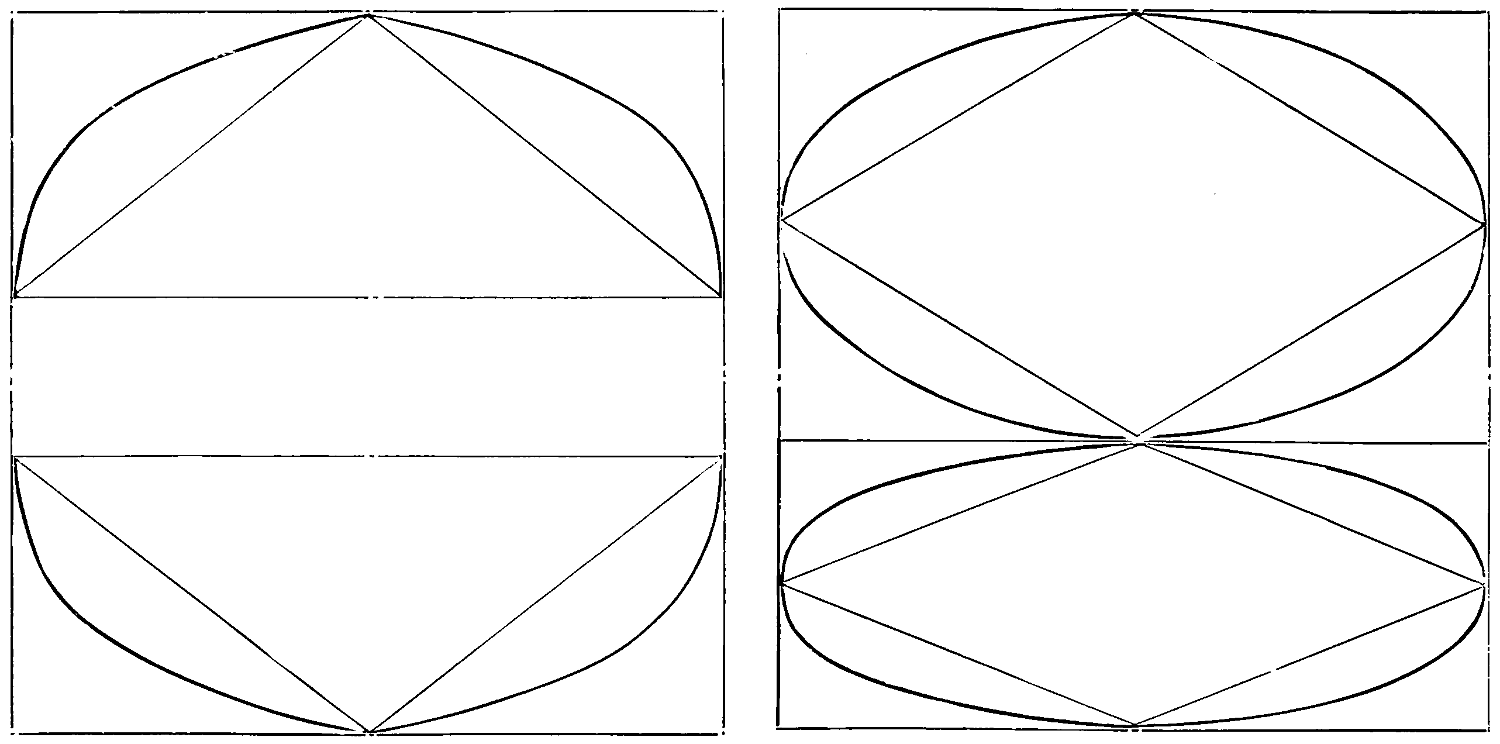

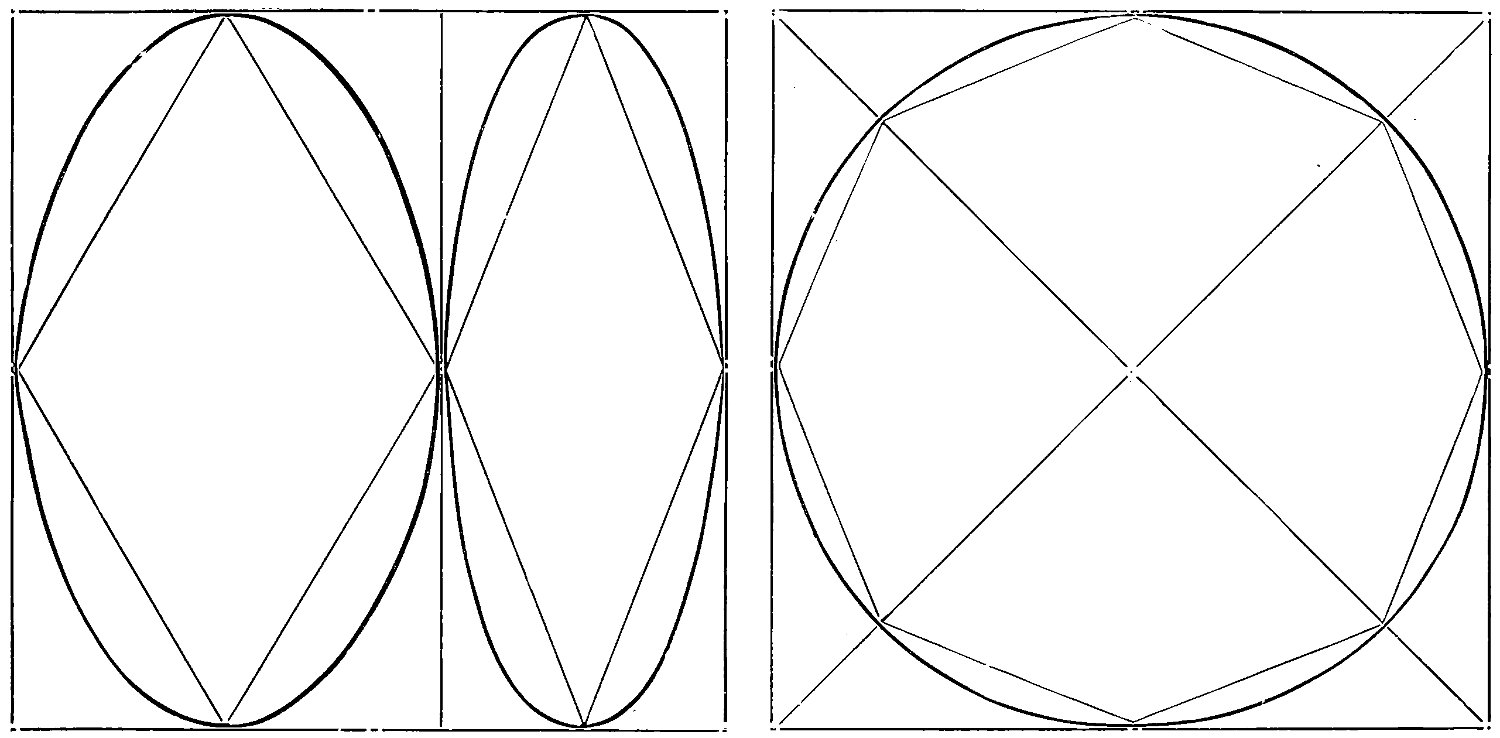

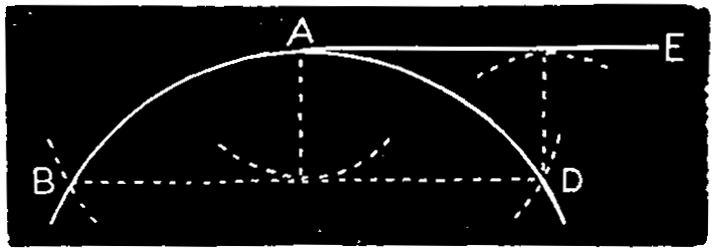

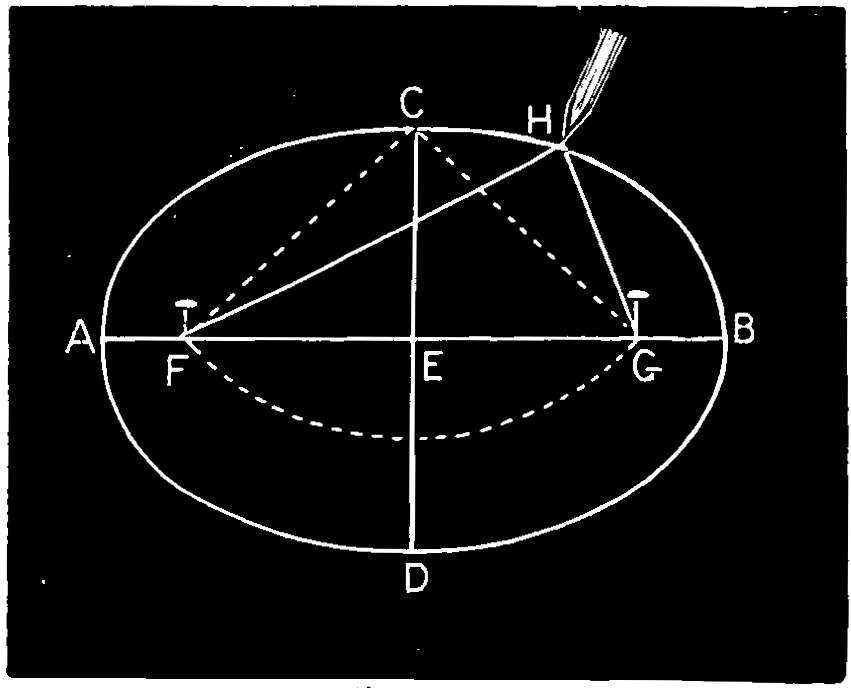

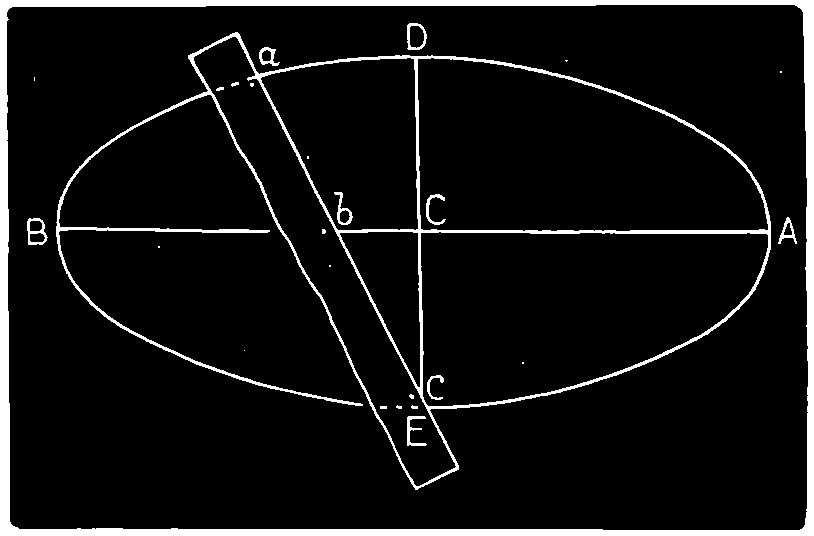

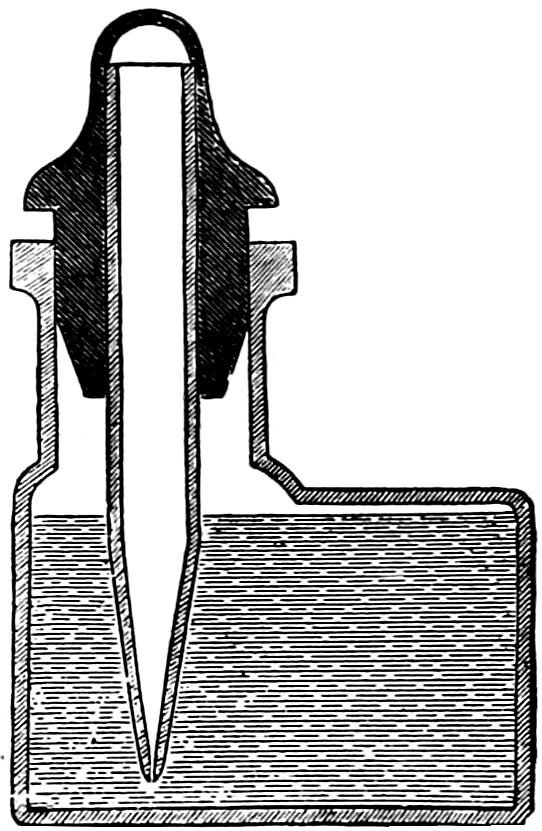

Ex. 29.—To describe an ellipse when the length and breadth are given, Fig. 134. On the center C, with A E as radius, cut the axis A B at F and G, the foci, fix a couple of pins into the axis at F and G, and loop on a thread or cord upon them equal in length to the axis A B, so as when stretched to reach the extremity C of the conjugate axis, as shown in dot-lining. Place a pencil or drawpoint inside the cord, as at H, and guiding the pencil in this way, keeping the cord equally in tension, carry the pencil round the pins F, G, and so describe the ellipse.

Note.—The ellipse is an oval figure, like a circle in perspective. The line that divides it equally in the direction of its great length is the transverse axis, and the line which divides the opposite way is the conjugate axis.

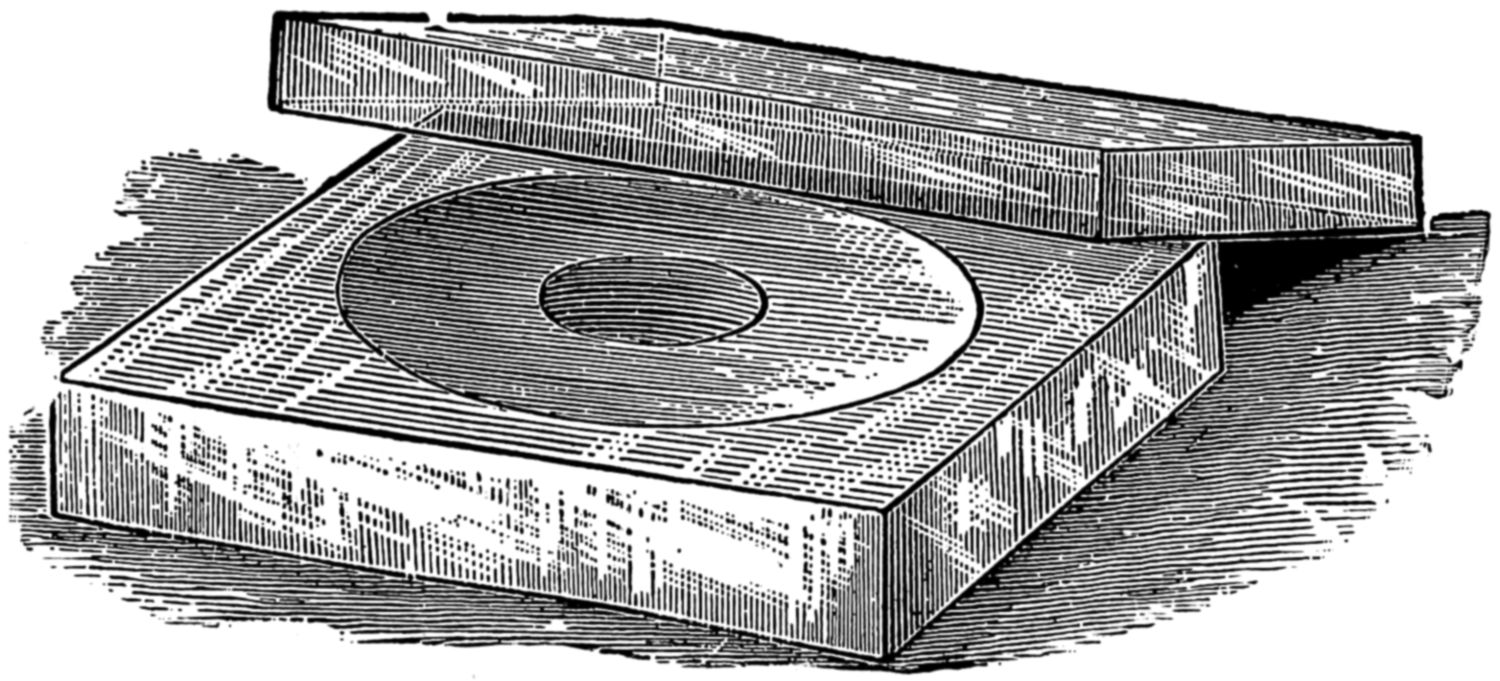

[97]

Second Method. Along the straight edge of a piece of stiff paper mark off a distance a c equal to A C, half the transverse axis; and from the same point a distance a b equal to C D, half the conjugate axis. Place the slip so as to bring the point b on the line A B of the transverse axis, and the point c on the line D E; and set off on the drawing the position of the point a. Shifting the slip, so that the point travels on the transverse axis, and the point c on the conjugate axis, any number of points in the curve may be found, through which the curve may be traced. See fig. 135.

Fig. 135.

[98]

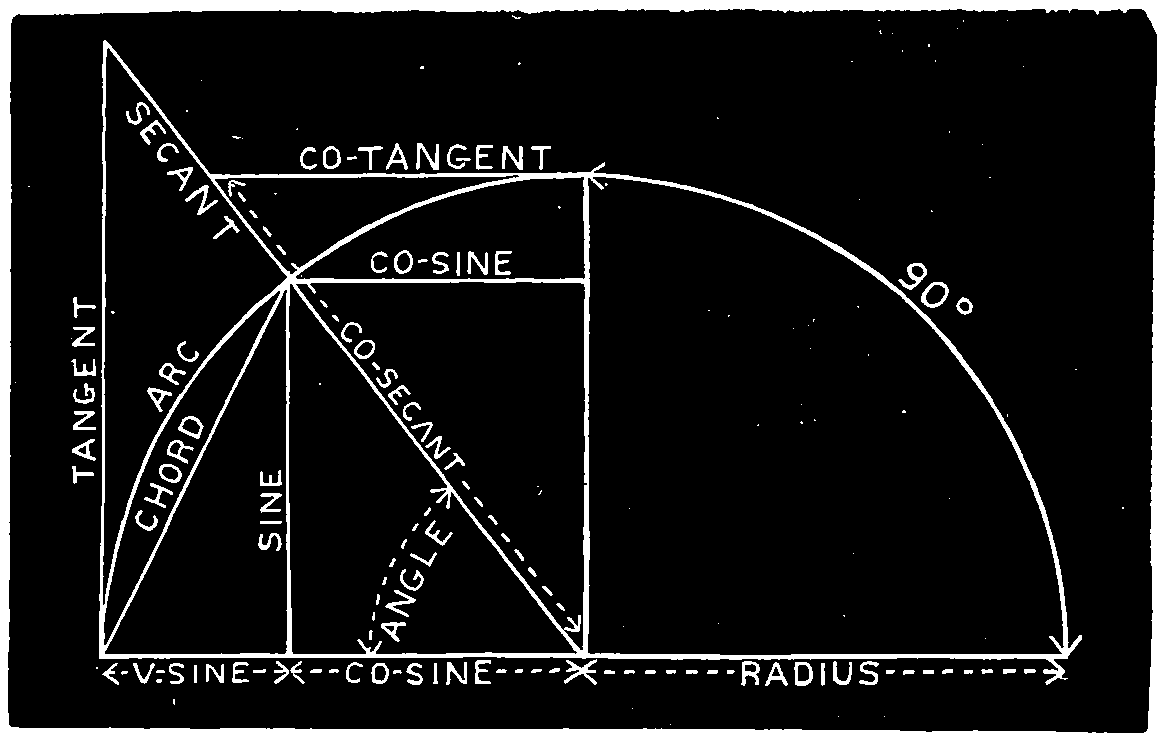

Trigonometry is that portion of geometry which has for its object the measurement of triangles. When it treats of plane triangles, it is called Plane Trigonometry; and as the engineer will continually meet in his studies of higher mathematics the terms used in plane trigonometry, it is advantageous for him to become familiar with some of the principles and definitions relating to this branch of mathematics.

The circumferences of all circles contain the same number of degrees, but the greater the radius the greater is the absolute measures of a degree. The circumference of a fly wheel or the circumference of the earth have the same number of degrees; yet the same number of degrees in each and every circumference is the measure of precisely the same angle.