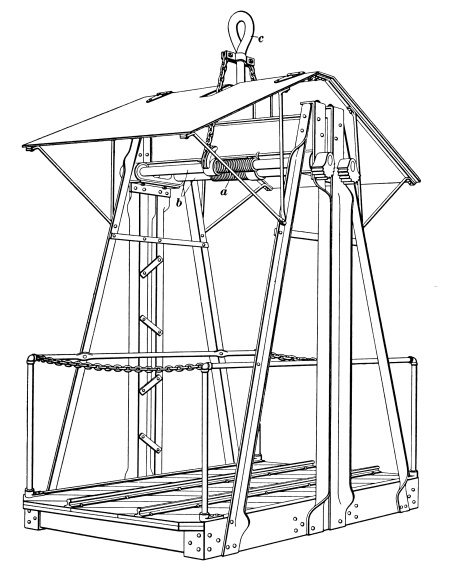

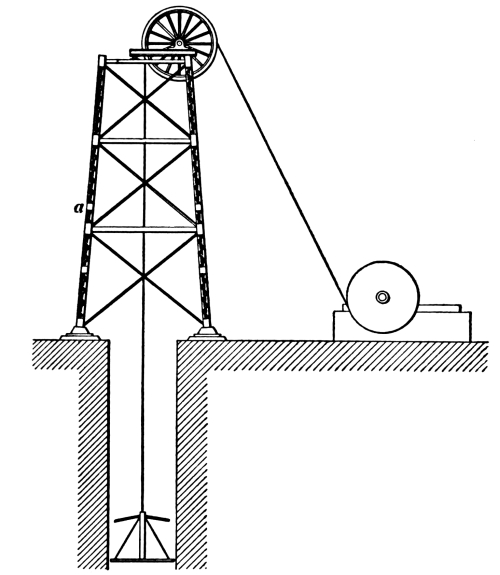

Fig. 1

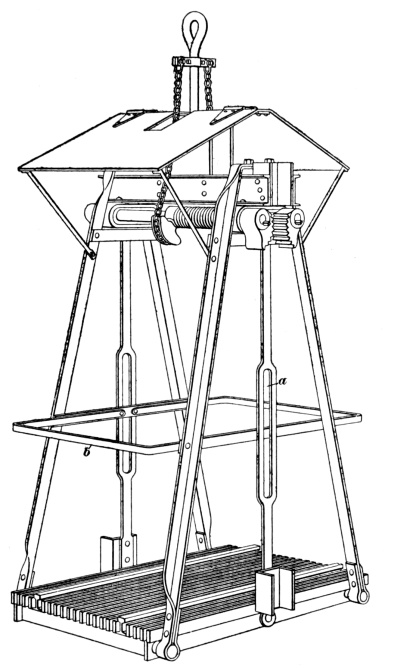

Fig. 2

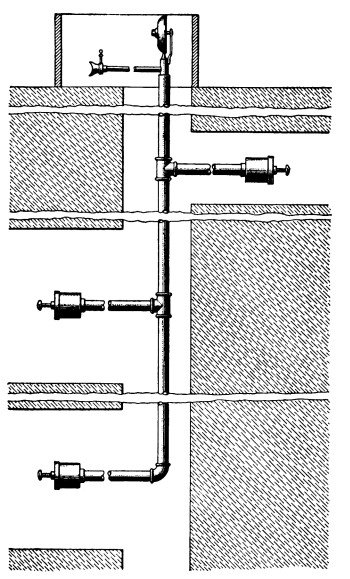

By

I.C.S. STAFF

HOISTING

Parts 3-4

447

Published by

INTERNATIONAL TEXTBOOK COMPANY

SCRANTON, PA.

Hoisting, Parts 3 and 4:

Copyright, 1906,

by International Textbook Company.

Entered at Stationers’ Hall, London

All rights reserved

Printed in U. S. A.

International Textbook Press

Scranton, Pa.

Note.—This book is made up of separate parts, or sections, as indicated by their titles, and the page numbers of each usually begin with 1. In this list of contents the titles of the parts are given in the order in which they appear in the book, and under each title is a full synopsis of the subjects treated.

| HOISTING, PART 3 | |

| Pages | |

| Hoisting Appliances | 1-43 |

| Hoist Indicators | 1-5 |

| Column indicators; Dial indicators; | |

| Special indicators. | |

| Drums and Reels | 6-20 |

| Cylindrical Drums | 7-8 |

| Conical Drums | 9-16 |

| Hoisting with cylindrical drums; | |

| Hoisting with conical drums; | |

| Comparison of cylindrical and conical drums. | |

| Flat Rope Reels | 17-20 |

| Rope Wheels | 21-26 |

| Koepe system; Whiting system; | |

| Modified Whiting system. | |

| Rope Fastenings | 27 |

| Clutches | 28-31 |

| Jaw clutch; Band friction clutches; | |

| Beekman friction clutch. | |

| Brakes | 32-43 |

| Block brake; Post brake; Strap brake; | |

| Differential brake; Power for brakes; | |

| Differential lever; Power brakes; | |

| Crank brake. [Pg iv] | |

| HOISTING, PART 4 | |

| Hoisting Appliances | 1-51 |

| Sheaves | 1-5 |

| Cast-iron sheave; Wood-lined sheaves; | |

| Diameter of sheave; | |

| Rollers and carrying sheaves. | |

| Cages for Vertical Shafts | 6-11 |

| Construction of cage; Safety catches; | |

| Multiple-deck cages. | |

| Automatic Dumping Cages | 12-16 |

| Definition; Slope, or inclined shaft | |

| hoisting; Slope carriage. | |

| Skips, or Gunboats | 17-22 |

| Definition; Method of loading skips; | |

| Method of dumping skips; Skip cage. | |

| Buckets | 23 |

| Car Locks | 23-24 |

| Cage Guides | 25 |

| Landing Fans, or Keeps | 26-28 |

| Common forms of fans; Hydrostatic fans; | |

| Pneumatic fans; Cage chairs. | |

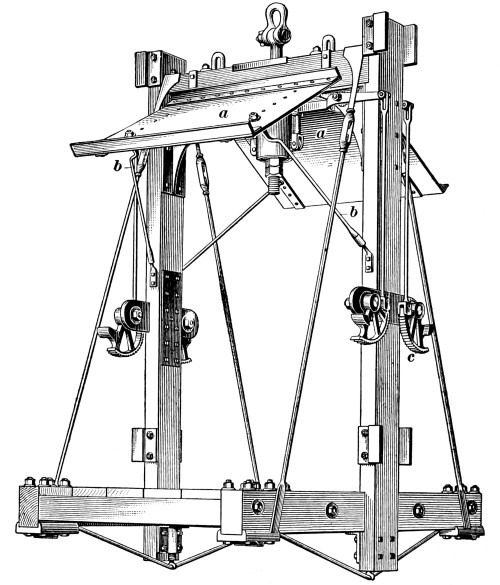

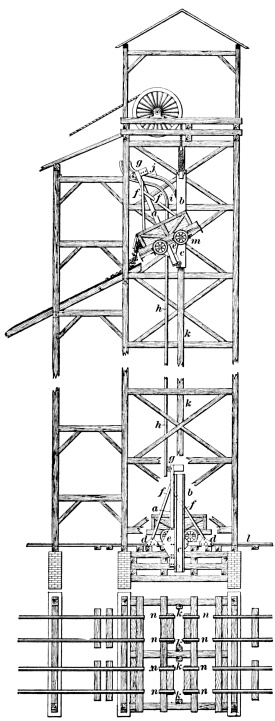

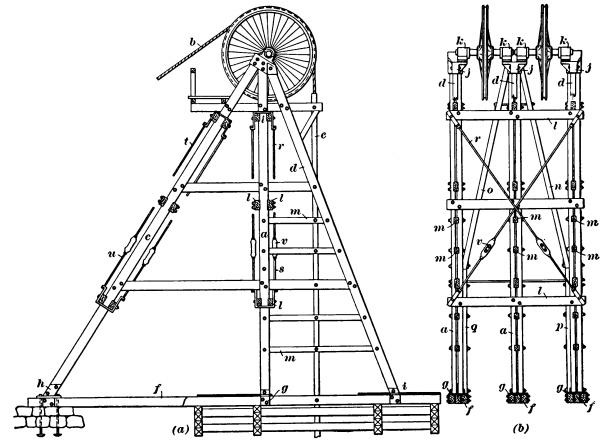

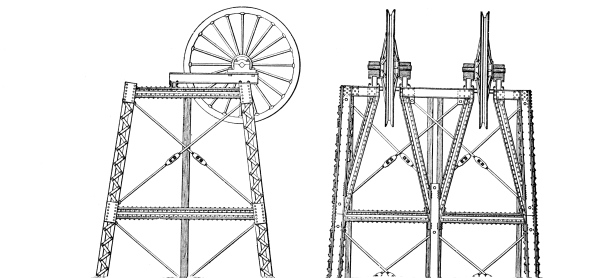

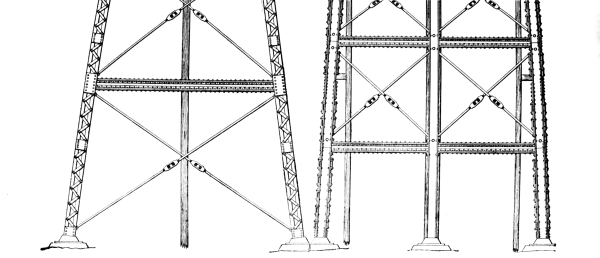

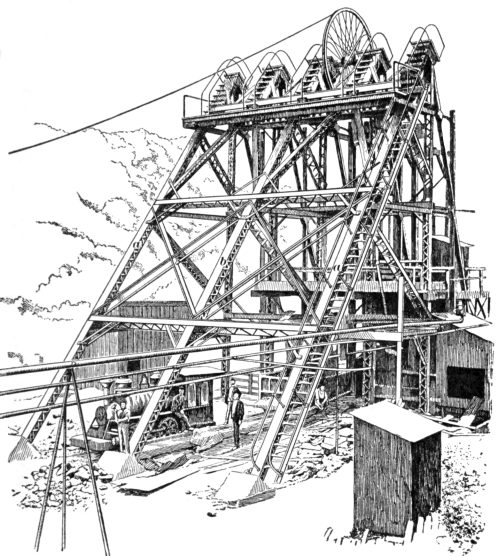

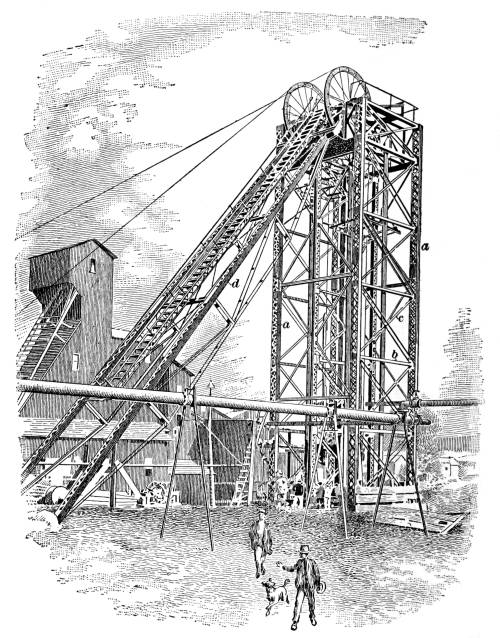

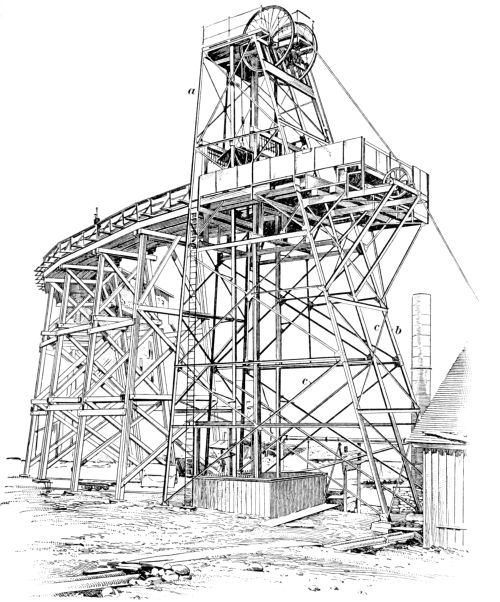

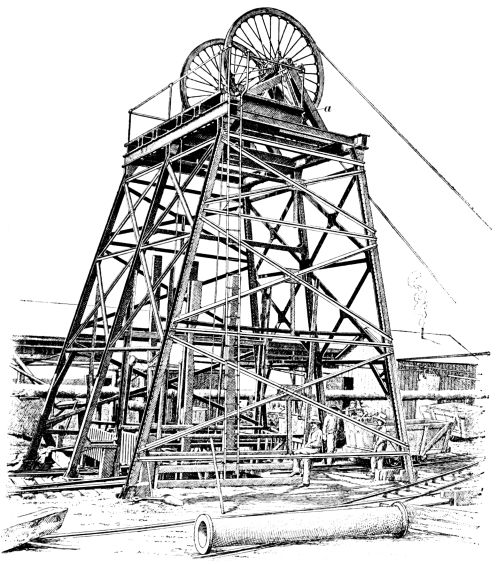

| Head-Frames | 29-45 |

| Head-frames in general; Types of head-frames; | |

| Examples of various types; | |

| Head-frame specification. | |

| Detaching Hooks | 46-47 |

| Signaling | 48-51 |

| Hammer-and-plate signal; Electric bells; | |

| Speaking tubes; Pneumatic gong signal; | |

| Telephones. | [Pg 1] |

HOISTING

(PART 3)

Serial 851C Edition 1

1. The hoist indicator is a mechanism attached to the drum shaft of a hoisting engine to show the hoisting engineer the position of the cage or skip in the shaft throughout the time of hoisting. The use of such indicators is sometimes required by law, but there is a great diversity of opinion as to the advisability of using them. The objections to them are that they are liable to get out of order, and that in general the use of any automatic device that tends to relieve the hoisting engineer of responsibility and constant attention to his engine is not to be commended. A hoisting engineer, however, depends for his stopping point mainly on a mark made on the rope, or on the drum, or on both, and uses an indicator mostly as a guide for the position of the cage during the hoist.

TYPES OF INDICATORS

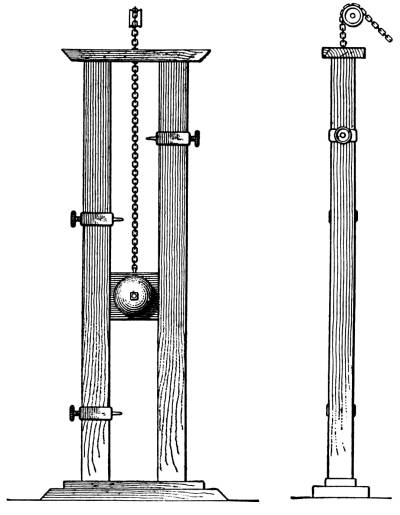

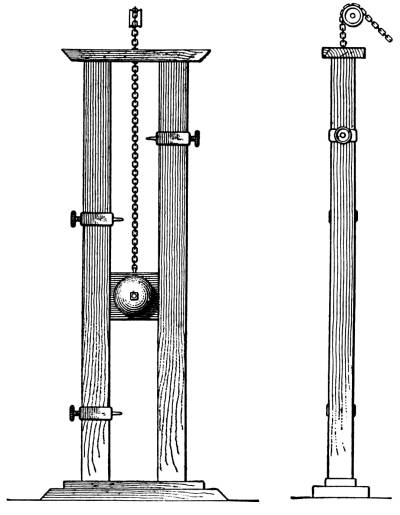

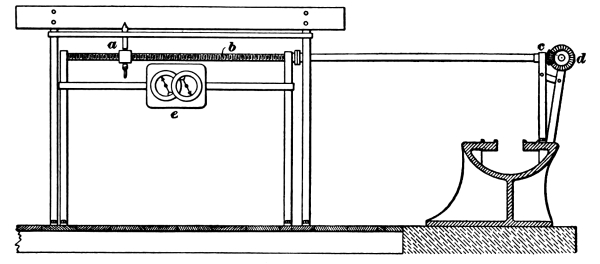

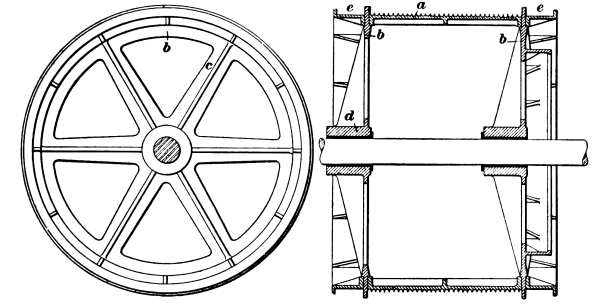

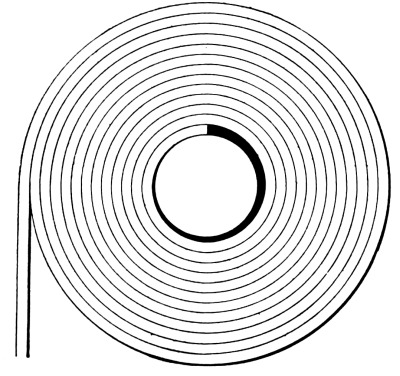

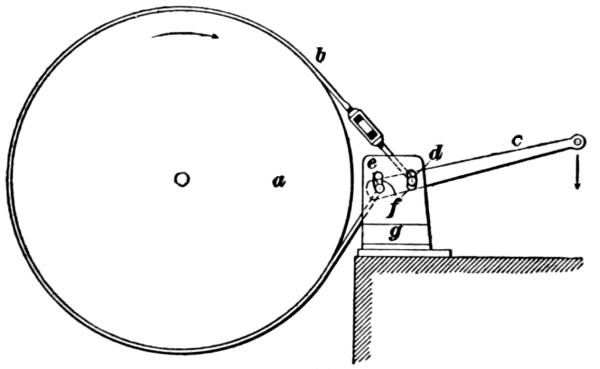

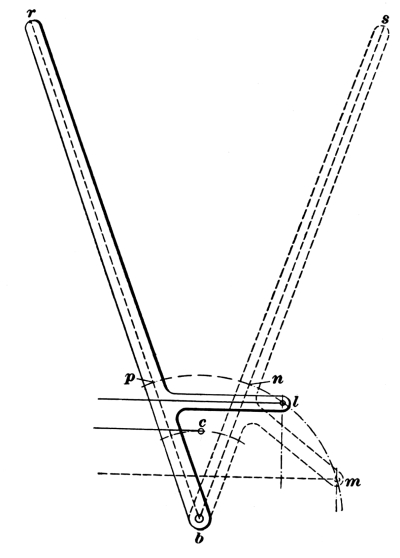

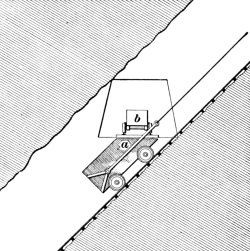

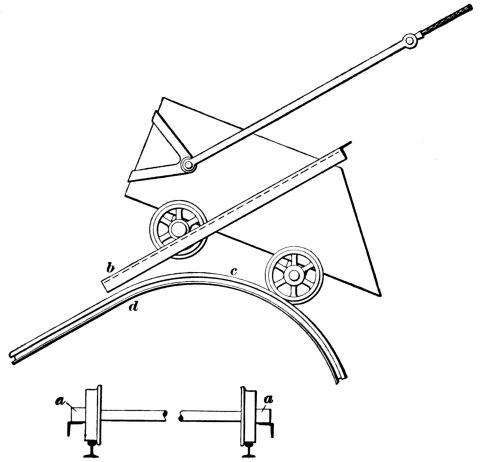

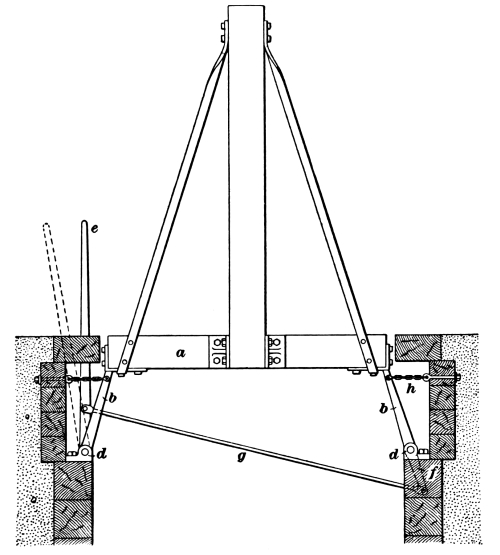

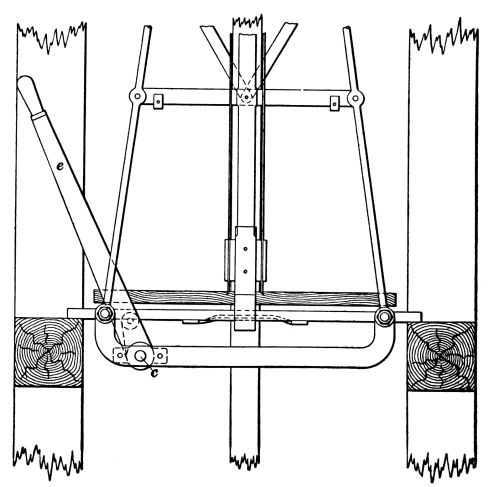

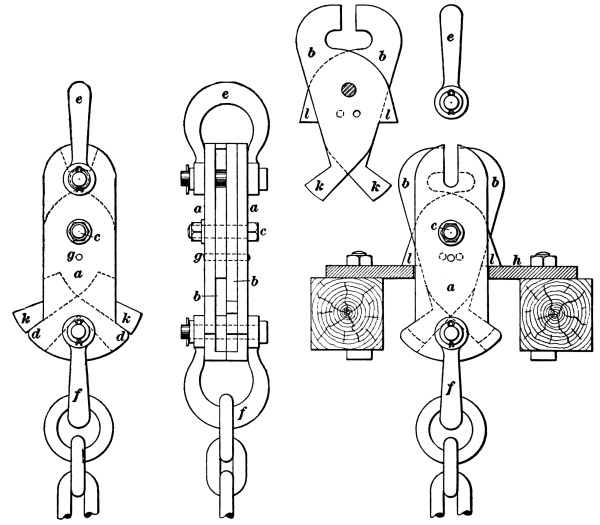

2. Column Indicators.—A very simple indicator, and one that was formerly very commonly used, is made by inserting a pin into the center of the end of the drum shaft and using this as a miniature drum on which to wind and unwind a chain or cord, which corresponds to the hoisting rope as the pin corresponds to the drum. This chain or cord is led over a pulley placed at the top of a pair of guides, [Pg 2] representing the shaft, and carries at its end a weight, pointer, or gong, representing the cage or car, as shown in Fig. 1.

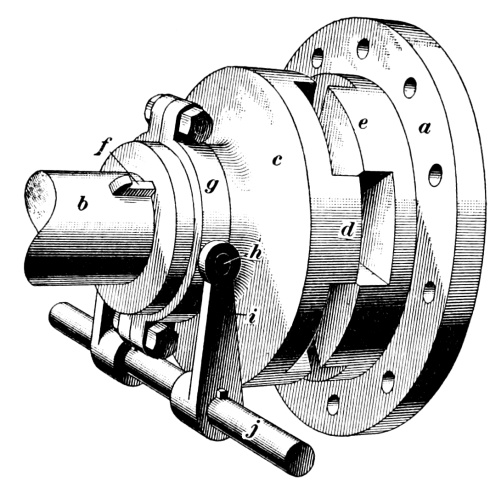

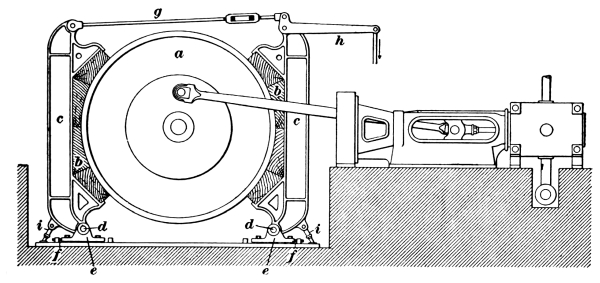

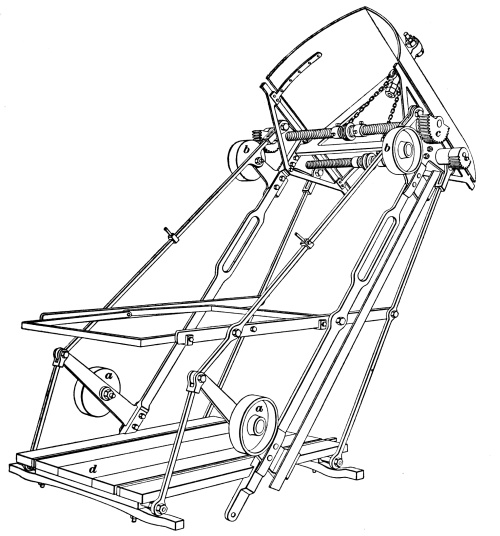

Fig. 1

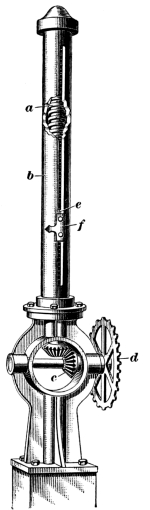

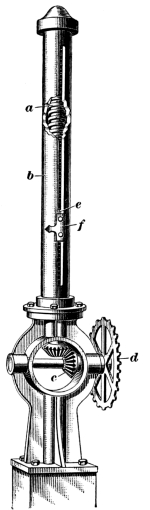

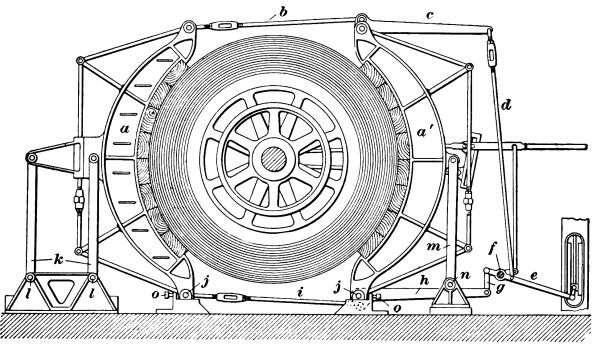

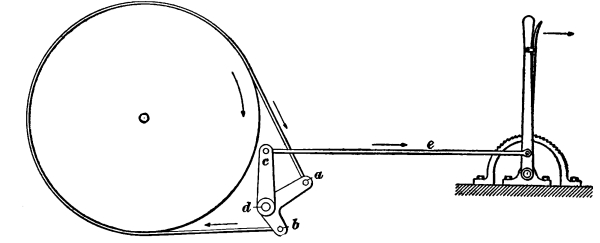

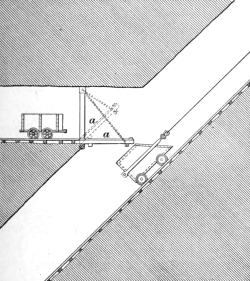

Fig. 2

The different landings in the shaft are marked on the guide; and as the pointer or gong rises and falls it indicates the position of the cage in the shaft. If a gong is used, pointer also may be added and the gong so arranged that it will ring at a point some distance before the landing is reached and thus attract the engineer’s attention. Indicators of this kind, though cheap and easily constructed, are not reliable, for the cord and chain may stretch or they may overlap in winding on the pin, or may bind in the pulley and thus indicate a wrong position of the cage.

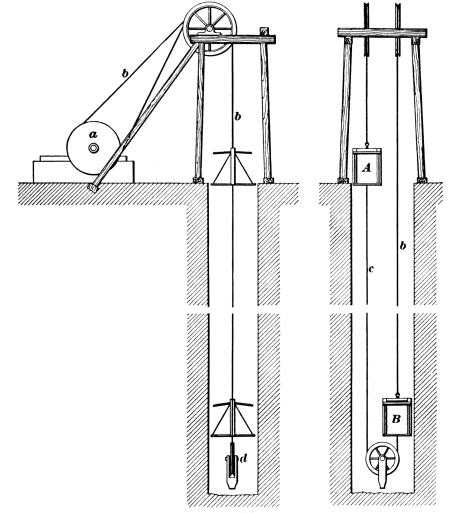

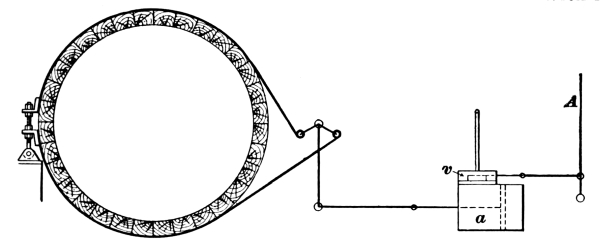

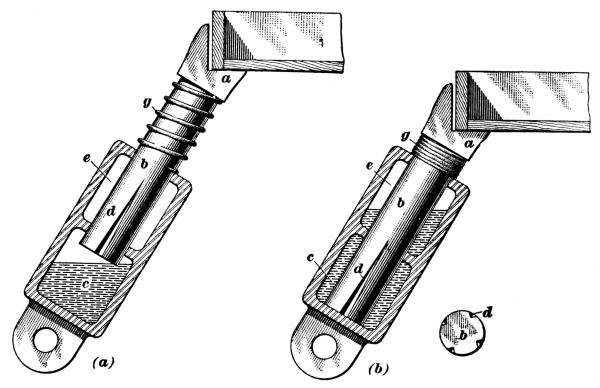

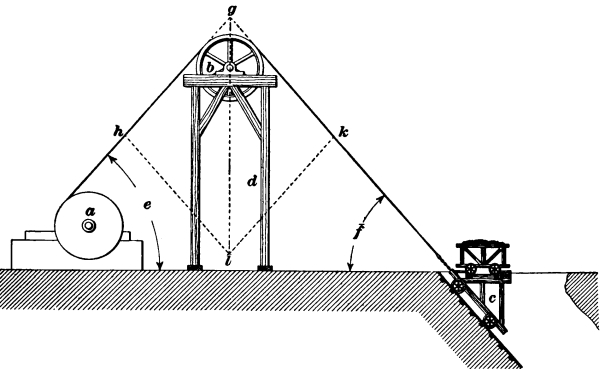

3. An indicator should have a positive motion and be driven by gearing or by link belts. Fig. 2 shows a column indicator that consists of a screw a working inside of a slotted pipe b, which may be of any length necessary. This screw is revolved by means [Pg 3] of the gears c, which are rotated by the sprocket wheel d. A nut e travels up and down the screw a and the pointer f attached to the nut indicates the position of the cage in the shaft. The pipe standard b is usually painted a dead black and the different levels may be marked on it with chalk or white paint. Chalk marks are not safe, as they may be tampered with and the engineer thus misled.

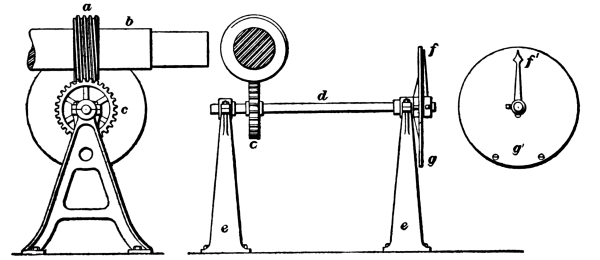

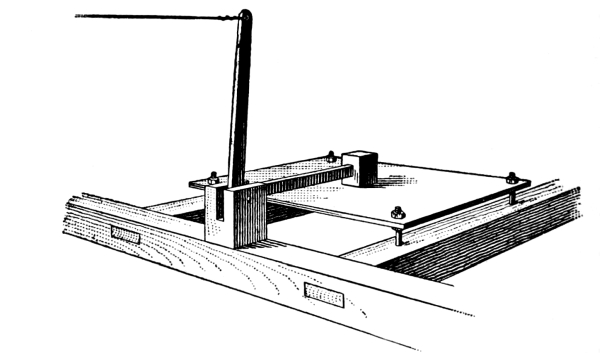

Fig. 3

The pointer a, Fig. 3, is moved by the rotation of the screw shaft b, which is revolved by the bevel gears c and d. This indicator also registers the number of hoists by means of the dials e, for at each hoist the lower end of the pointer a engages a ratchet wheel behind the two dial faces shown and thus registers on the dial.

Fig. 4

4. Dial Indicators.—Fig. 4 shows a positive-motion indicator that is operated as follows: A worm a on the drum shaft b [Pg 4] engages with the worm-wheel c on the small shaft d that is supported by the bearings e. The pointer f is rigidly attached to the shaft d and revolves in front of the properly marked dial g.

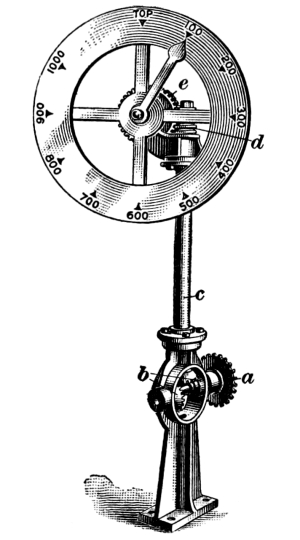

5. Fig. 5 shows a dial indicator attached to drum hoists where the speed of rope is constant for each revolution. The wheel a of this indicator may be a worm-wheel working in a worm on the drum shaft, as described in connection with the indicator shown in Fig. 4, or it may be a sprocket wheel driven by a link belt from a sprocket wheel on a drum, or it may be a gear-wheel driven directly from another gear-wheel on the drum. The gear-wheels b revolve a vertical shaft c fitted at the upper end with a worm d that drives the worm-wheel e placed on the end of the pointer spindle. The different levels from which hoisting is to be done may be painted on the dial, or better, they may be placed on movable targets that are clamped to the dial and can thus be moved as occasion requires.

Fig. 5

Example.—An indicator is desired for a shaft 800 feet deep at which the drum of the hoisting engine to be used is 10 feet in diameter; what ratio of gearing must be used so that the pointer will make one revolution during the hoist?

Solution.—The circumference of the drum is 31.42 ft. (πD = 10 × 3.1416 = 31.416 ft.); hence, the revolutions per hoist are 800 ÷ 31.42 = 25.46 revolutions. Then, if the pointer is to make one revolution per hoist, the ratio of the gearing will be 25.46 to 1. Ans.

6. Special Indicators.—One fault of nearly all indicators is that they give a regular movement throughout the winding, and the space over which the pointer travels is too small to enable the engineer to land the cage accurately. Indicators have been made with a differential motion to the pointer, the motion being greater at the time of landing and less during the middle of the hoist. They are also made [Pg 5] with two pointers, one operating like the dial indicator above described and the other remaining stationary during all the hoist but the last few feet, when it moves around its circle.

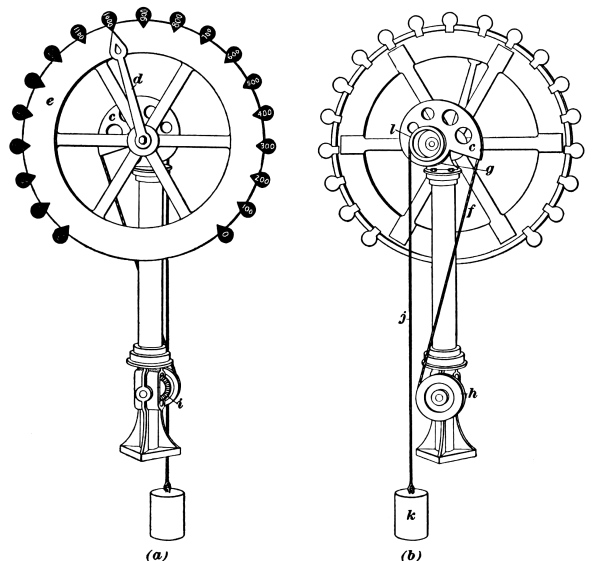

Fig. 6

7. Where flat ropes are used or where round ropes wind on a conical drum, the length of rope wound or unwound is different for each turn of the drum. With all the indicators thus far described, while the speed with which the indicator moves is proportional to the speed at which the drum and the drum shaft revolve, it is not proportional to the speed of the rope when winding and unwinding on a conical drum or on a flat rope reel. Fig. 6 (a) and (b) shows two views of a compensating dial indicator. By means of the spiral form of sheave c, the hand d is made to move equal distances around the [Pg 6] disk e for equal distances of cage movement in the shaft. The rope f passes about the spiral sheave and one end is attached at the small end g of the spiral, while the other end is fastened to the periphery of the sheave h, which takes its motion from the drum shaft or crank-shaft of the hoisting engine by means of the bevel gear i. Consequently, while the sheave h has a regular motion dependent directly on the revolution of the hoisting drum, the pointer d moves irregularly, depending on the position of the spiral sheave c; that is, whether a small or large diameter of the spiral is presented to the rope. The rope j carrying the counterweight k is attached to a small circular drum l that is on the same shaft as the spiral sheave. The purpose of this cord and counterweight is to keep the indicator line f taut and to bring the indicator back to position as the cord f unwinds from the sheave h.

8. In order that the pointer may not stand at exactly the same point on the dial when the cage is at the top and at the bottom, and so that the engineer may be able to distinguish between the top and the bottom positions of the cage by the pointer, the ratio of the gearing is usually increased by allowing one or two extra teeth on the worm-wheel. In the example in Art. 5, assume a ratio of 27: 1; that is, if a worm-gear is used, the worm-wheel will have 27 teeth.

If the pitch of the teeth is ¾ inch, the circumference of the pitch circle will be ¾ × 27 = 20.25 inches and the diameter 6.44 inches.

The pitch of the worm will, of course, be the same as that of the wheel, and its diameter will be whatever is necessary to give sufficient strength outside of the shaft, since it bears no relation to the ratio of the gearing.

9. The drum, or reel, of a hoisting engine is the part on which the rope winds. It is either keyed fast to the engine shaft or is connected to the shaft by means of a clutch, the shaft being made extra heavy to carry the strain due to the weight of the drum and the pull of the rope. [Pg 7]

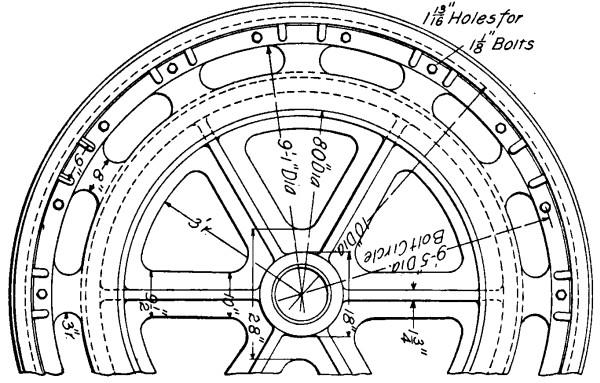

10. The outer part, or shell, of a drum a, Fig. 7, is supported on rims b, and these rims are connected by arms or spiders c with the hubs d. The brake rings e are for the band brakes, of which there may be one or two. The part a may be lagged with strips of wood bolted to the rims b, the heads of the bolts being countersunk. Fig. 8 shows the detailed dimensions of a drum 8 feet in diameter having a 4-foot face designed to carry heavy loads and a large amount of rope. The shell is of boiler plate and the spiders of cast-steel.

Fig. 7

11. The shell may be cast in one piece for small drums or built up in sections for large drums, as in Figs. 7 and 8. The shell may have a smooth surface, Fig. 8, or it may have grooves, Fig. 7, for the rope to lie in as it is wound on the drum. On an iron drum without grooves, the rope will chafe sidewise; and furthermore if the rope winds on a hard flat surface it bears here and there on a single wire and tends to flatten, causing internal wear between the wires; while, in the case of a rope winding in a groove, it is supported on about one-quarter of its circumference, bringing many more wires to bear on the drum and dividing the pressure between them. A wooden-lagged drum causes less [Pg 8] wear on a rope than an ungrooved iron-shell drum, as grooves are gradually worn in the lagging, but is not so good as a grooved iron drum. It is not good practice to allow a rope to wind on itself, and the drum should be long enough to take the full length of the rope required for the hoist. At least two turns of the rope should be on the drum when the load is at the bottom, as the friction between the rope and drum thus greatly lessens the strain coming on the rope at the point where it is fastened to the drum. Allowance for two or three additional turns of the rope should also be made so that the cage may be hoisted above the landing.

Fig. 8

The shell usually has a flange at each end, as shown in Figs. 7 and 8, but it may have a flange at one end only, or may be without flanges entirely. If, however, the flanges are not used, the drum must be extra long to prevent the rope running off the end. If the drum is very long, a third spider is added midway between the other two to stiffen it against collapse. [Pg 9]

Example.—Find the length of a drum 6 feet 3 inches in diameter necessary to hold 1,000 feet of 1¼-inch wire-rope.

Solution.—The diameter from center to center of the rope when wound on the drum is 6 ft. 3 in. plus 1¼ in., or 6 ft. 4¼ in., which is equal to 19.96 ft. (approximately 20 ft.) of circumference. Then, to wind 1,000 ft. will require ¹,⁰⁰⁰/₂₀ = 50 turns on the drum. Allowing two turns of the rope to protect the fastening and three turns in case of overwinding, gives fifty-five turns to be allowed for on the drum. If the drum is of iron with grooves turned in it, ¼ in. must be left between adjacent parts of the rope, or 1½ in. from the center of one turn to the center of the next. Then, 55 × 1½ = 82½ in. plus ¾ in. at each end = 84 in., or 7 ft. for the length of the drum between the flanges. Ans.

If the drum has wooden lagging, clearance need not be allowed between two adjacent coils of rope, as in this case the rope winds against itself and so takes up only 1¼ in. It will then be 55 × 1¼ in. = 68¾ in., or 5 ft. 8¾ in. long (say 5 ft. 9 in.). Ans.

12. In hoisting in balance from deep shafts with cylindrical drums, if no tail-rope is used, or in hoisting from a single shaft with an unbalanced cage, the hoisting engine is not loaded equally at different points of the hoist owing to the gradually changing weight of the unbalanced rope. The following illustrations will further explain this.

13. Hoisting With a Cylindrical Drum.—Suppose that, from a single-compartment vertical shaft 1,000 feet deep, it is required to hoist each trip a load, including friction, of 11,000 pounds made up as follows:

| Pounds | |

| Weight of material | 4,000 |

| Weight of car | 3,000 |

| Weight of cage | 3,000 |

| Friction, 10 per cent. | 1,000 |

| Total | 11,000 |

If a 1⅜-inch cast-steel rope weighing 3 pounds per foot is used, winding about a drum 7 feet in diameter, the weight of rope is then 3 × 1,000 = 3,000 pounds and the load on the rope, when the cage is at the bottom, is 11,000 + 3,000 = 14,000 pounds, while at the top the load on the rope is only 11,000 pounds. The moment of the load at the bottom [Pg 10] is then the load 14,000 multiplied by the radius 3½, or 14,000 × 3½ = 49,000 foot-pounds; and at the top, 11,000 × 3½ = 38,500 foot-pounds. This shows that the load against the engine is much greater at the beginning than at the end of the hoist.

14. Take now a double-compartment vertical shaft of the same depth as in Art. 13 and assume the same amount of material hoisted at a trip, in the same mine car and on the same cage; but that an empty car and cage are lowered in one compartment while the loaded car and cage are hoisted in the other. The two cars and the two cages will balance each other, and the loads will be as follows: At the beginning of the hoist, when the loaded car and cage are at the bottom, the gross load is 14,000 pounds, made up as follows:

| Pounds | |

| Weight of material | 4,000 |

| Weight of mine car | 3,000 |

| Weight of cage | 3,000 |

| Friction, 10 per cent.of above | 1,000 |

| Weight of rope | 3,000 |

| Total | 14,000 |

Multiplying this by the radius of the drum, the gross turning moment is 14,000 pounds × 3½ feet = 49,000 foot-pounds, as before, but there is a counterbalancing load of 6,000 pounds, made up as follows:

| Pounds | |

| Weight of mine car | 3,000 |

| Weight of cage | 3,000 |

| Total | 6,000 |

| Less friction, 10 per cent. | 600 |

| 5,400 |

This means a counterbalancing load moment of 5,400 pounds × 3½ feet = 18,900 foot-pounds. The net load moment to be overcome by the engine at the beginning of the hoist is, therefore, 49,000-18,900 = 30,100 foot-pounds. [Pg 11]

At the end of the hoist there is a gross load on the loaded side of 11,000 pounds, made up as follows:

| Pounds | |

| Weight of material | 4,000 |

| Weight of mine car | 3,000 |

| Weight of cage | 3,000 |

| Friction, 10 per cent. | 1,000 |

| Total | 11,000 |

This is equal to a gross load moment of 11,000 pounds × 3½ feet = 38,500 foot-pounds, but there is a counterbalancing load of 8,100 pounds, made up as follows:

| Pounds | |

| Weight of mine car | 3,000 |

| Weight of cage | 3,000 |

| Weight of rope | 3,000 |

| Total | 9,000 |

| Less friction, 10 per cent. of 6,000 | 600 |

| 8,400 |

This is equal to a counterbalancing load moment of 8,400 pounds × 3½ feet = 29,400 foot-pounds, and leaves a net load moment against the engine of 38,500-29,400 = 9,100 foot-pounds. In other words, the load moment that the engine has to overcome varies from 30,100 foot-pounds at the beginning of the hoist to 9,100 foot-pounds at the end of the hoist.

15. Hoisting With Conical Drums.—Conical drums are designed to make the work of the engine as nearly uniform as possible throughout the hoist. To accomplish this, when the cage is at the bottom of the shaft, and the load is therefore heaviest, the rope winds on that part of the drum having the smallest diameter. As hoisting continues, the rope winds on a gradually increasing diameter of drum, and when the cage is at the top of the hoist, and the load therefore least, the rope is winding on that part of the drum having the greatest diameter; in this way, the moment of the load at every point of the hoist is approximately the same. The great difference in the loads at different [Pg 12] parts of the hoist is due mainly to the variation in the weight of the rope hanging from the drum; hence, the less the weight of the rope in proportion to the total load on the engine, the more nearly uniform is the load on the engine.

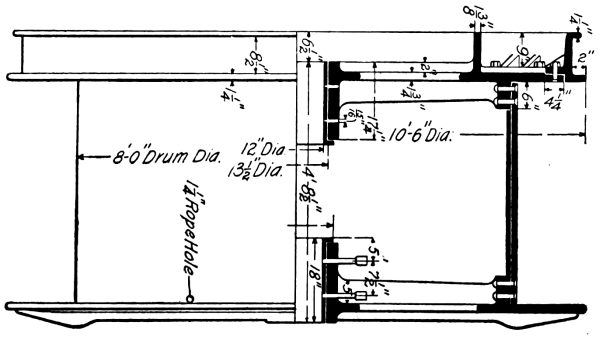

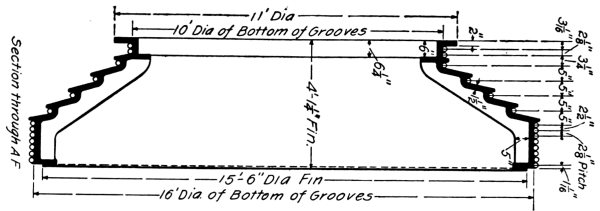

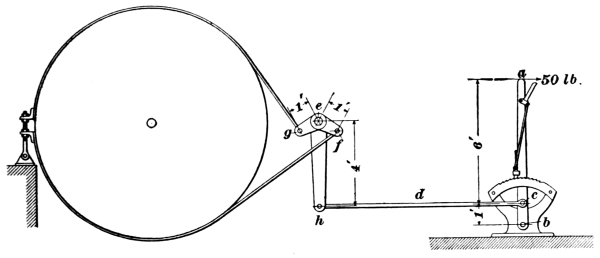

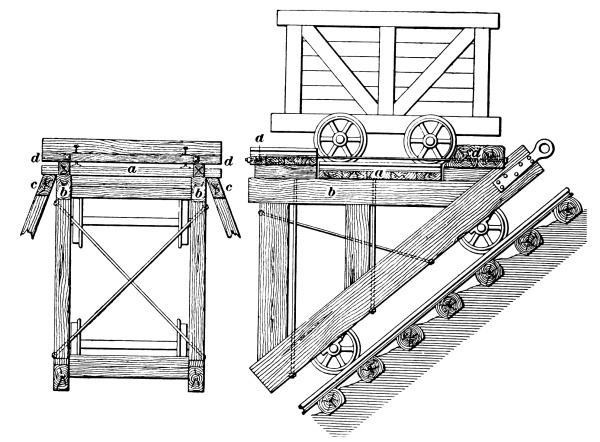

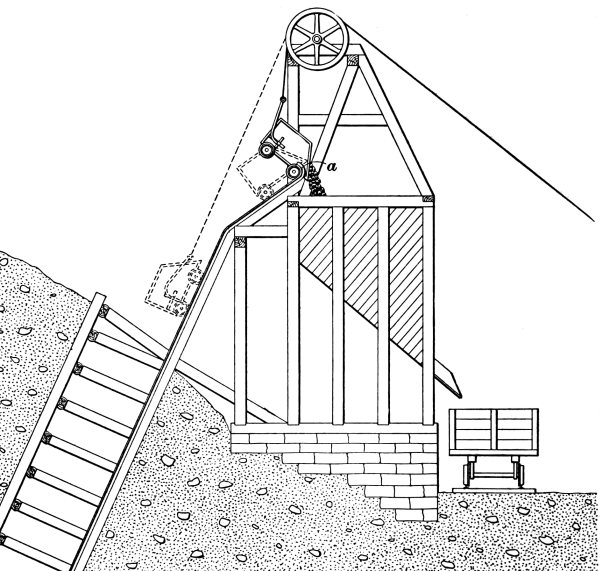

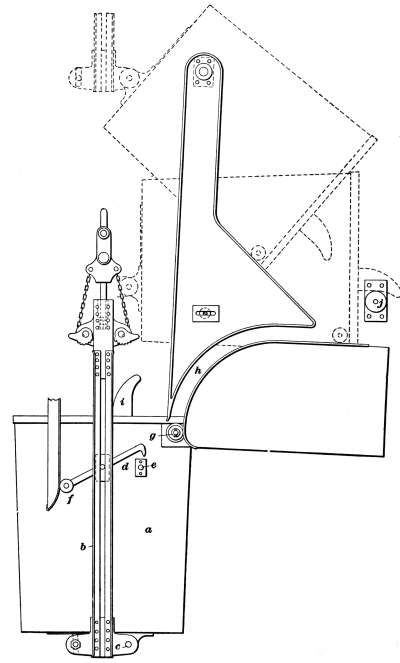

Fig. 9

16. Fig. 9 (a) shows the condition at the beginning of the hoist when conical drums are used. Cage a is at the bottom and carries a loaded car; cage b is at the top and carries an empty car. The net moment that the engine must overcome is the sum of the weight of the material to be hoisted, weight of the cage and car at a, and the weight of the rope attached to a, multiplied by the small radius r of the drum, minus the weight of the car and cage at b, multiplied by the large radius R of the drum.

Fig. 9 (b) shows the condition of things at the end of the hoist, when the cage a is at the top and cage b at the bottom. The loaded car and cage a, whose rope in Fig. 9 (a) [Pg 13] was winding on the smallest diameter of the drum, is now at the top and the rope is winding on the largest diameter of the drum. The cage b with the empty car is now at the bottom and the rope is unwinding from the smallest diameter of the drum. The net moment that the engine must overcome in this position is equal to the sum of the weight of the material hoisted, the weight of the cage a and the car, multiplied by the larger radius R of the drum, minus the sum of the weights of the cage b, the car, and the rope, multiplied by the small radius r of the drum.

17. If the moment of the load against the engine at the beginning of the hoist is to equal that at the end of the hoist, it is possible to determine what relative diameters of drum will produce such an effect, as follows:

| Let | Wₘ | = | weight of material hoisted; |

| Wₖ | = | weight of cage and car; | |

| Wᵣ | = | weight of rope; | |

| R | = | large radius of drum; | |

| r | = | small radius of drum. |

The load moment may be calculated by including friction as ⅒ of the total weight hoisted, except the weight of the rope, as shown in Art. 14; or the friction may be disregarded without serious error. Then, under the conditions shown in Fig. 9 (a), and disregarding friction,

Load moment = (Wₘ + Wₖ + Wᵣ)r - WₖR (1)

and under the conditions shown in Fig. 9(b),

Load moment = (Wₘ + Wₖ)R - (Wₖ + Wᵣ)r (2)

Placing formula 1 = formula 2,

(Wₘ + Wₖ)R - (Wₖ + Wᵣ)r

= (Wₘ + Wₖ + Wᵣ)r - WₖR,

and

| (Wₘ + 2Wₖ + 2Wᵣ) | ||

| R = | r ———————— | (3) |

| (Wₘ + 2Wₖ) |

Since the diameter of a drum is generally given instead of the radius, it follows that if D = larger diameter, d = smaller diameter, and then, since D = 2R and d = 2r, formula 3 may be written

| (Wₘ + 2Wₖ + 2Wᵣ) | ||

| D = | d ———————— | (4) |

| (Wₘ + 2Wₖ) |

[Pg 14] Formula 4 gives only approximate results, which are, however, sufficiently accurate for the mine superintendent’s use, and for this reason friction has been omitted, as it would make the formula much more complex. It may be expressed as a rule as follows:

Rule.—To find the large diameter of a conical drum, multiply the small diameter by the sum of the weight of the material to be hoisted, twice the weight of the cage and car, and twice the weight of the rope; divide this product by the sum of the weight of the material, and twice the weight of the cage and car.

Fig. 10

Applying this rule to the problem given in Art. 14 and omitting friction,

| 7(4,000 + 12,000 + 6,000) | ||

| D = | ———————————— | = 9.6 feet |

| (4,000 + 12,000) |

The drum would then be 7 feet in diameter at the small end and 9 feet 7¼ inches at the larger end. [Pg 15]

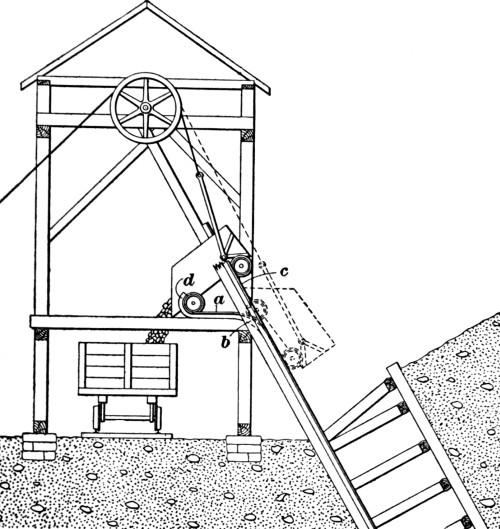

18. Fig. 10 shows a special form of combined conical and cylindrical drum designed for hoisting a total balanced load of 25 tons through a vertical height of 550 feet.

Fig. 11 shows a combined conical and cylindrical drum; an unusual feature is the rope reel shown at each end of the drum, which permits of properly storing a few hundred feet of extra rope, allowing the rope to be lengthened, when needed, without splicing.

Fig. 11

19. Comparison of Cylindrical and Conical Drums. The disadvantages of the cylindrical drum lie entirely in the fact that the load on the engines is variable, but it is possible to overcome this disadvantage by adding a tail-rope to the cages to balance the weight of the rope. This system gives its best results where hoisting is done from one level only, but in deep hoisting it is impracticable because of the extra weight added and because of possible excessive swaying of the rope.

The conical drum has two strong points in its favor: first, the load on [Pg 16] the engine may be nearly equalized during the entire hoisting period; and, second, the starting of the engines with the load requires less power.

The disadvantages of the conical drum are as follows: To maintain a certain average speed of hoisting, the speed toward the end of the hoist is of necessity higher than the average and comes at a time when a slowing up should be taking place, so that more care must be exercised when making the landing. To prevent the rope from being drawn out of the grooves, the latter must be made deep and with a large pitch, thereby increasing the width of the face or length of the drum. In making a landing, when the rope is on the conical face, the rope must be kept taut, as any slackness will permit the rope to leave the groove, with the result that all the rope will pile up in the bottom grooves of the drum allowing the cage to drop into the mine, unless it is resting on the chairs. If there are several levels to be hoisted from, the equalizing of the load on the engines can only be realized for one level; for all other levels this advantage will be lost. For large depths, conical drums become very long and require correspondingly long leads from head-frame to drum. To hold the same amount of rope, conical drums are heavier than cylindrical ones, and as a result, the power required in starting the load is somewhat increased owing to the greater inertia of the rotating parts.

Some of these disadvantages have been overcome by making a combination of cone and cylindrical drums. The drums are so designed that the landing takes place only when the rope is on the cylindrical portion of the drum. For deep hoisting, the greater diameter of the drum and its length must be inconveniently large if the load is equalized. The length and diameter can be reduced by making one-half of the drum cylindrical and by having the rope from each end wind on the same cylindrical portion of the drum. In all cases, however, these modifications are made at the expense of the equalization of the load on the engines, and it is not possible to obtain the latter without including some serious disadvantage.

There are certain objections to both cylindrical and conical drums: [Pg 17] their great size and weight, for large hoists, make them very expensive; their width necessitates placing the engines far apart, which adds to the cost of the engines, foundations, and buildings; the great weight of the drums is also objectionable, because it forms a large part of the mass to be put in motion and brought to rest at each hoist.

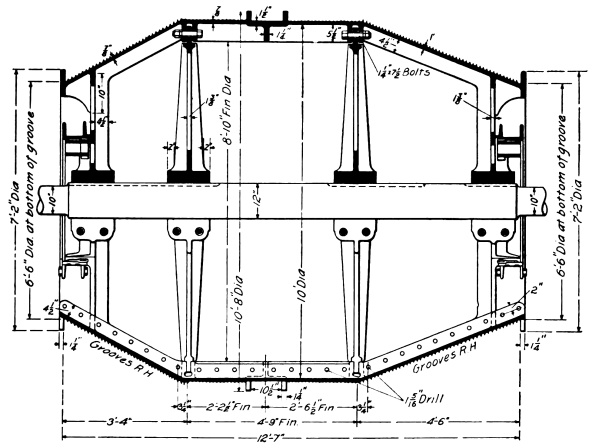

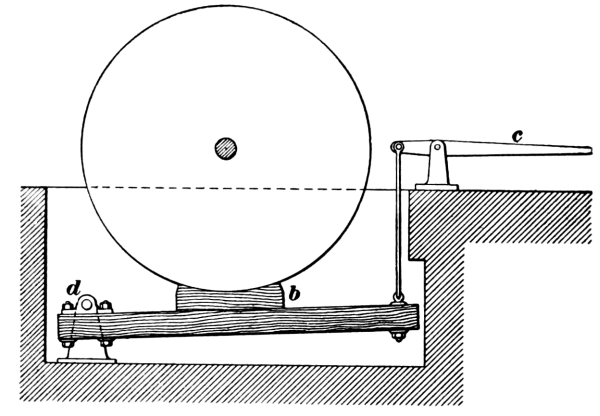

20. To overcome the objections to conical and cylindrical drums, several other systems of hoisting have been tried, among them being one that uses a reel, Fig. 12, and a flat rope. The hub a is increased in diameter, above what is necessary for strength, to such a size as is suitable to wind the rope on. It is then cored out from the inside, so as not to contain too great a mass of metal.

Fig. 12

The arms b of the reel extend radially from the hub to confine the rope laterally when it is all wound on the drum. These arms are connected at their outer ends by a continuous flange c, which flange is flared out, as shown at d, so as to take in the rope easily, if it is deflected at all sidewise.

In the larger-sized reels, the arms are bolted to the hub, and often the outer rim connecting the arms is omitted. Hardwood lining was [Pg 18] formerly used on the arms under the impression that the wear on the rope would be less than with bare iron arms, but sand and grit become embedded in the wood and grind the rope. Polished iron arms with rounded corners and lubricated with oil or tar are best. The end of the rope is fastened in a pocket e provided for it in the hub.

The rope winds on itself, so that the diameter of the reel increases as the hoist is made and as the load due to the weight of the rope decreases. This serves to equalize the load due to the rope in the same manner as the conical drum. Two reels are generally put on the same shaft, and while one is hoisting from one compartment of the shaft the other is lowering into another compartment. The periphery of the hub where the rope winds should not be round but of gradually increasing radius, for if a flat rope be wrapped about a round hub the rope will have to abruptly mount itself at the end of the first revolution and so on for every revolution. The radius of the hub should increase at such a rate as to raise the rope an amount equal to its thickness in the first wrap, so that it will wind on itself without jar at the point of attachment, as well as on succeeding wraps.

21. In America, it is customary to wind on reels of small diameter, that is, starting at 3 or 5 feet and increasing to 8 or 12 feet; but several large plants have been built with reels starting at 8 feet and increasing to 19 feet. In England, reels have been made starting at 16 feet and increasing to 20 or 22 feet. Such large reels are easier on the rope but require large engines, as hoisting in balance is used to only a slight extent. The large reel is easy on the rope, both from the fact that it bends the rope but little and also gives less pressure on the bottom wraps, as each wrap adds to the pressure. These reels are driven by means of plain jaw or friction clutches.

The wear of a flat rope is excessive and the rope itself costs more than a round rope of the same strength, does not last as long, and requires more care and attention.

22. Calculating Size of Flat Rope and Reel.—The calculation of [Pg 19] the size of a flat rope for given work is not so simple as that of a round rope, as there is a variable factor in the width and thickness of the rope that must be taken into account. To illustrate the method of calculation, suppose that it is required to hoist 5,000 pounds of material in a 3,000-pound skip from a vertical two-compartment shaft 2,000 feet deep under conditions requiring a factor of safety of about 9 for the rope.

The determination of the size of the rope and the small and large diameters of the reels must proceed together. The latter calculations are performed in much the same manner as for conical drums.

Referring to Table relating to flat wire ropes in Hoisting, Part 2, it is found that a flat steel rope 6 inches by ½ inch in size and with a breaking strength of 150,000 pounds weighs 5.1 pounds per foot; hence, 2,000 feet of it weighs 2,000 × 5.1 = 10,200 pounds. The total load on the rope will then be 19,000 pounds, made up as follows:

| Pounds | |

| Weight of material | 5,000 |

| Weight of skip | 3,000 |

| Friction, 10 per cent. | 800 |

| Weight of rope | 10,200 |

| Total | 19,000 |

This rope gives a factor of safety of 150,000/19,000 = 7.8, which is not quite enough when figured from the dead load without that due to acceleration.

An 8" × ½" rope with a breaking strength of 200,000 pounds weighs 6.9 pounds per foot; hence, 2,000 feet of it weighs 2,000 × 6.9 = 13,800 pounds. The load on the rope will then be 22,600 pounds, made up as follows:

| Pounds | |

| Weight of material | 5,000 |

| Weight of skip | 3,000 |

| Friction, 10 per cent. | 800 |

| Weight of rope | 13,800 |

| Total | 22,600 |

This rope gives a factor of safety of 200,000/22,600 = 8.8.

Substituting the foregoing weights of material, skip, and rope in formula 4, in Art. 17, gives

| d(5,000 + 6,000 + 27,600) | |

| D = | ———————————— |

| (5,000 + 6,000) |

Hence, the equation of moments is D = 3.5d. In other words, the large diameter, or that of the last coil of rope, should be 3.5 times the small diameter, or that of the reel hub.

23. Fig. 13 represents a coil of flat rope whose greater diameter D and smaller diameter d are to be determined. The area of the hub about which the rope is to coil is (¼)πd², while the area included by the outer coil of rope is (¼)πD² hence, the area of annular space occupied by the rope is

(¼)πD² - (¼)πd² = (¼)π(D² - d²).

Such values for D and d must be chosen that the equation of moments in Art. 22 is satisfied, while the area (¼)π(D²-d²) must correspond to the space occupied by the given rope when rolled.

Fig. 13

Illustration.—2,000 feet of rope ½ inch thick requires

| 2,000 × 12 | |

| ————— | = 12,000 |

| 2 |

square inches in which to be coiled. To satisfy the equation of moments, D must equal 3.5 d; hence, to satisfy both these conditions

(¼)π[(3.5d)² - d²] = 12,000;

The dimensions of the reel will then be: diameter of hub 3 feet 1 inch; width between flanges, 8½ inches, allowing ¼ inch on each side of the rope for clearance; diameter of the flanges where they flare, 10 feet 9½ inches.

Fig. 14

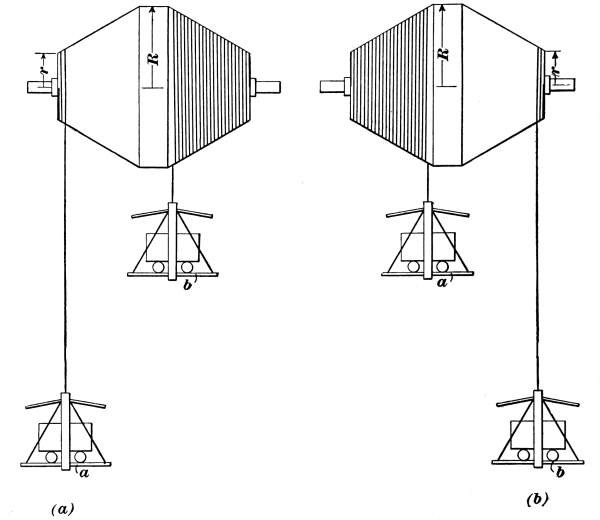

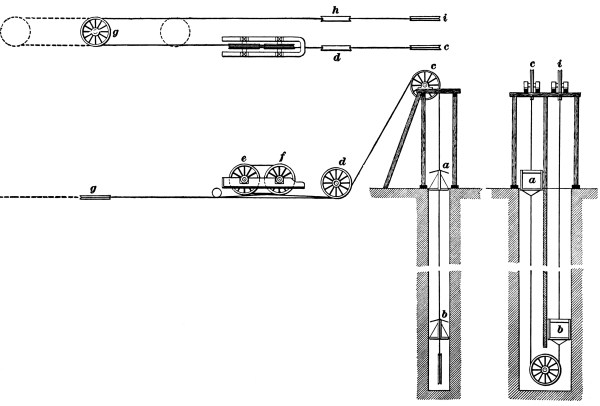

24. Koepe System.—In its lightest form, a drum requires a large amount of power to set it in motion, which power is absorbed by the brake and lost when it is brought to rest again. Furthermore, with deep shafts requiring long drums, the fleet, or angle that the rope makes with the head-sheave due to its traveling from one end of the drum to the other, is not only a disadvantage and possible cause of accident, but it is a source of wear. To overcome these objections and also the great cost of large cylindrical or conical drums, the Koepe system of hoisting, shown in Fig. 14, was devised by Mr. Frederick [Pg 22] Koepe. A single grooved driving sheave a is used in place of a drum. The winding rope b passes from one cage A up over a head-sheave, thence around the sheave a and back over another head-sheave, and down to a second cage B; it encircles a little over half the periphery of the driving sheave and is driven by the friction between the sheave and rope. A balance rope c beneath the cages and passing around the sheave d gives an endless-rope arrangement with the cages fixed at the proper points. The driving sheave is stronger than an ordinary carrying sheave, as it has to do the driving and is usually lined with hardwood, which is grooved to receive the winding rope, the depth of the groove being generally equal to twice the diameter of the rope. Instead of being placed parallel, the head-sheaves are placed at an angle with each other, each pointing to the groove in the driving sheave, thus reducing the side friction of the rope on the sheaves.

The system has been in successful operation since 1877, and experiments made on it have determined that, with a rope passing only one-half turn around the drum sheave, the coefficient of adhesion with clean ropes is about .3. If the ropes are oiled, the adhesion becomes less, and sometimes slippage occurs, producing not only wear of the driving sheave lining but giving an incorrect reading of the hoist indicator and thus possibly producing overwinding, unless the position of the cage is indicated by marks on the rope, or unless the engineer can see the cage.

At the end of the hoist, if the upper cage is allowed to rest on the keep, its weight and the weight of the tail-rope are taken from the hoisting rope, and there is then not enough pull on the hoisting rope to produce sufficient friction with the drum sheave to start the next hoist. To prevent this trouble, the keeps are dispensed with, or the rope is made continuous and independent of the cage. To do this, crossheads are placed above and below each cage and connected by ropes or chains outside of the cages. The bridle chains are then hung from the top crosshead, and when the cage rests on the keeps, the weight of the winding and tail-ropes remains on the driving sheaves. [Pg 23]

25. Advantages and Disadvantages of the Koepe System.—With this system, only one driving sheave is necessary for the operation of two compartments, and it is light, inexpensive to build, and very narrow, admitting of a short sheave shaft and small foundations. This system permits a perfect balance of rope and cage, so that the work to be done by the engine is uniform, except for the acceleration, and consists only in lifting the material and overcoming the friction. There is no fleeting of the rope between the driving sheaves and the head-sheaves.

The system has the following disadvantages, which prevent its being used to any considerable extent: Liability to slippage of the rope on the drum; if the rope breaks, both cages may fall to the bottom; hoisting from different levels cannot be well done, for, since the cages are at fixed distances from each other, the length of the rope is such that when one cage A is at the top, the other cage B is at the bottom. If hoisting is to be done from the bottom, this is satisfactory, but if hoisting is to be done from some upper level, cage B, which is at the bottom, must be hoisted to that level to be loaded before it can go to the top. Then, when cage B goes to the top with its load, cage A must go to the bottom, wait there while cage B is being unloaded, and then be hoisted to the upper level to receive its load. For each trip, therefore, the time required for a cage to go from the bottom to the upper level and be loaded is lost; and two movements of the engines are necessary for a hoist instead of one.

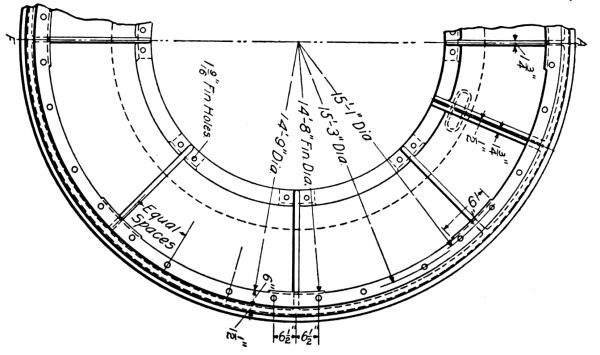

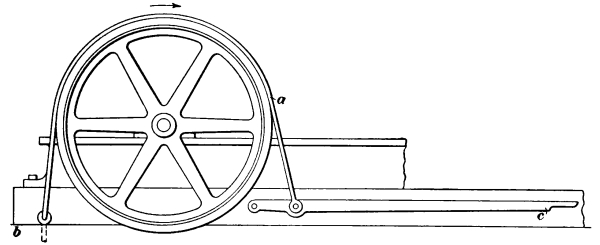

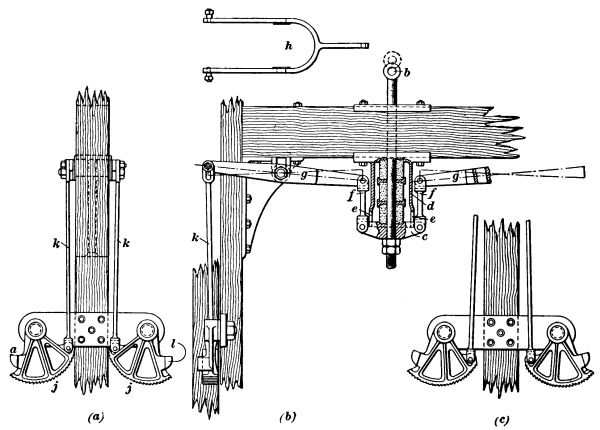

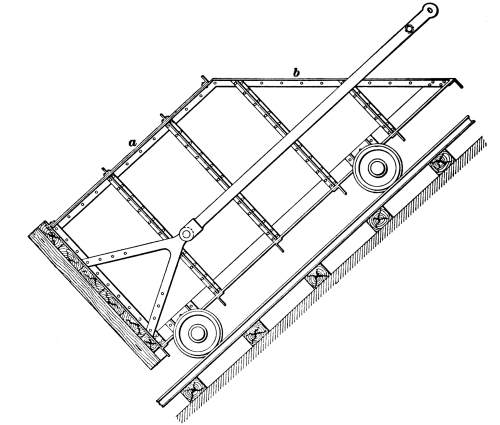

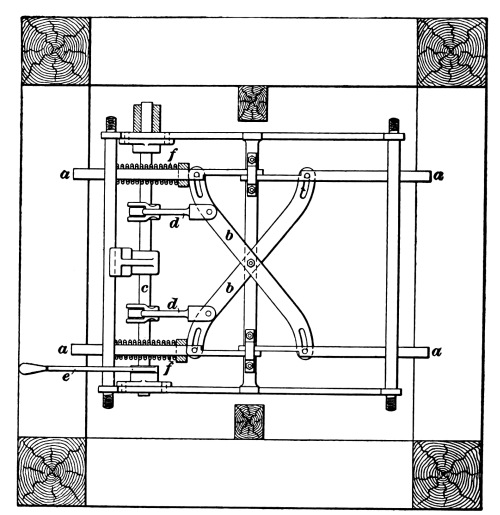

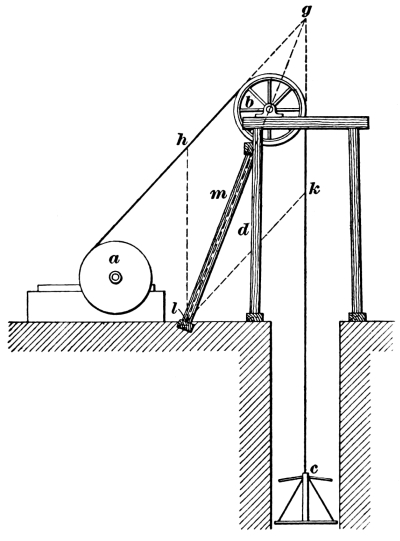

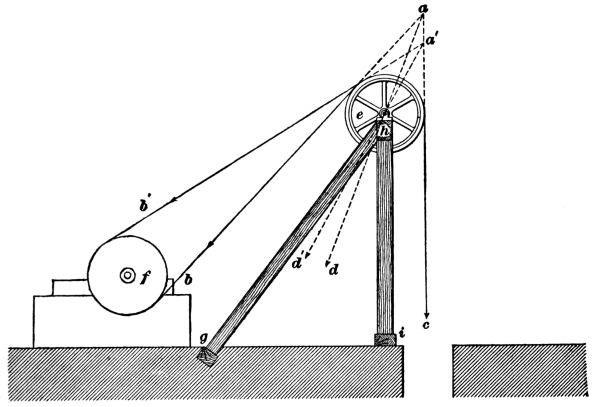

26. The Whiting System.—This is a system of hoisting with round ropes, in which two rope wheels placed tandem are used in place of cylindrical or conical drums. As shown in Fig. 15, for a two-compartment shaft the rope passes from one cage a up over a head-sheave c, down under a guide sheave d, and is then wound three times about the rope wheels e and f, to secure a good hold, then around a fleet sheave g, and back under another guide sheave h, up over another head-sheave i, and down to the other cage b. When the system is to be used for a single-compartment shaft, one end of the rope carries the cage and the other end carries a balance weight, which is run up and down in a corner of the shaft. A balance rope below the cages, as shown, is generally used, though it is not essential to the working of the system, as it is in the Koepe system. When sinking a shaft, a balance rope cannot be used as it interferes with the work at the bottom of the shaft. [Pg 24]

Fig. 15

[Pg 25] The drums or wheels e, f are light, inexpensive, and narrow, thus permitting short sheave shafts and small foundations. They are lined with hardwood blocks, each lining having three rope grooves turned in it. The main wheel e is driven by a hoisting engine, which may be either first or second motion. The following wheel f is coupled to the main wheel by a pair of parallel rods, one on each side, like the drivers of a locomotive. As the rope wraps about the wheels e, f three times, there are six semi-circumferences of driving contact with the rope, as compared with the one semi-circumference in the Koepe system, and there is no slipping of the rope on the wheels. The following wheel f is best tilted or inclined from the vertical an amount equal, in the diameter of the wheels, to the pitch of the rope on the wheel, so that the rope may not run out of its groove and may run straight from one wheel to the other without any chafing between the ropes and the sides of the grooves.

The capacity of the wheels e, f is unlimited, while grooved cylindrical drums, conical drums, and reels will hold only the fixed length of rope for which they are designed.

As shown by the dotted lines, the fleet sheave g is arranged to travel backwards and forwards, in order to change the working length of the rope from time to time to provide for an increased depth of shaft, and for the changes in the length of rope due to stretching and when the ends are cut off to resocket the rope. The fleet sheave g is moved a distance equal to half the change in the length of rope.

27. Hoisting from intermediate levels can be readily done with the Whiting system; for instance, if the cage a is at the top and cage b at the bottom, and hoisting is to be done from some upper level, it is only necessary to run the fleet sheave g out, [Pg 26] and thus shorten the working length of the rope until cage b comes up to the upper level. It can then be loaded and go to the top. While cage b goes to the top, cage a descends to the same level, where it can be loaded while cage b is being unloaded, and can then go directly to the top without any of the lost time, as is the case in the Koepe system.

The system permits a perfect balance of rope and cage, so that the work to be done by the engines is uniform, except for the acceleration, and consists only in lifting the material and overcoming the friction.

There is no fleeting of the rope, so the rope wheels can be placed as close to the shaft as may be desired.

28. This system was tried as early as 1862 in Eastern Pennsylvania, but it was not used extensively because hoisting from great depths was not necessary, since, for depths of less than 1,000 feet, cylindrical and conical drums are quite satisfactory. In the Lake Superior copper region, there are now three Whiting hoists, two of which are probably the largest hoisting plants in the world. Each plant consists of a pair of triple-expansion, vertical, inverted-beam engines, driving direct a pair of 19-foot drums. The high-pressure cylinders are 20 inches in diameter, the intermediate cylinders 32 inches, and the low-pressure cylinders 50 inches, and all six of them have a 72-inch stroke. The rope used is a 2¼-inch plow-steel rope and hoists 10 tons of material at a trip, in one case from a depth of 4,980 feet, the deepest shaft in the world. Several plants on the Whiting system have been built in England, and two or more are working in South Africa.

29. Modified Whiting System.—A modification of the Whiting system is sometimes used in which a large drum keyed to the crank-shaft replaces the small tandem drums, and even the slight probability of the rope slipping in the Whiting system is thus obviated. One rope is fastened to one end of the drum, and the other rope to the other end in such a way that while one is winding on the other will be winding off [Pg 27] the drum. One rope passes directly to the head-sheave while the other passes first around a fleet sheave, similar to that used for the Whiting system, but preferably placed horizontal, and thence to the head-sheave. This system possesses the same advantages as the Whiting system except that the depth of hoist is limited by the size of the drum, and that there is a fleet of the rope. Up to the limiting depth, as determined by the size of the drum, this system can be used with equal economy for any depth. This hoist, as well as the Whiting, is therefore especially suitable for a place where one mining company operates several mines, for it enables the company to select one size for all their permanent work, with all the advantages that come from duplicate machinery.

Fig. 16

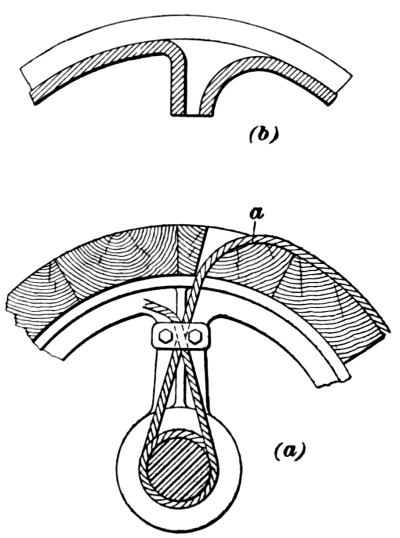

30. A common method of fastening a rope to a drum, Fig. 16 (a), is to pass the rope through a hole in the drum rim and then around the shaft, clamping the end to the rope between the shaft and shell, as shown. Care should be taken to make the radius of curvature of the hole at a as large as possible so that the rope will not be bent any sharper than is necessary. When an iron drum is used, the thickness of the rim does not afford enough depth in which to bend the rope and it is necessary to build in a pocket for the purpose, as shown at Fig. 16 (b). It is well to make both sides of this pocket with a long radius to avoid damaging the rope in case all the rope is accidentally unwound and the drum backed so as to bring the rope against the other side of the pocket. [Pg 28]

31. It is often desired to have the drum of a hoisting engine run loosely on the engine shaft, so that it may run independently of the engine. With such loose-running drums, the engine generally runs only in the direction required to hoist the load, while the cage is lowered entirely by means of the brake. In this way, one engine provided with several drums may be used for hoisting from several shafts or from several levels in the same shaft at the same time. Such a loose-running drum is connected to the engine shaft when a load is to be hoisted by means of a clutch, of which there are two forms commonly used for hoisting machinery: jaw or piston clutches and friction clutches.

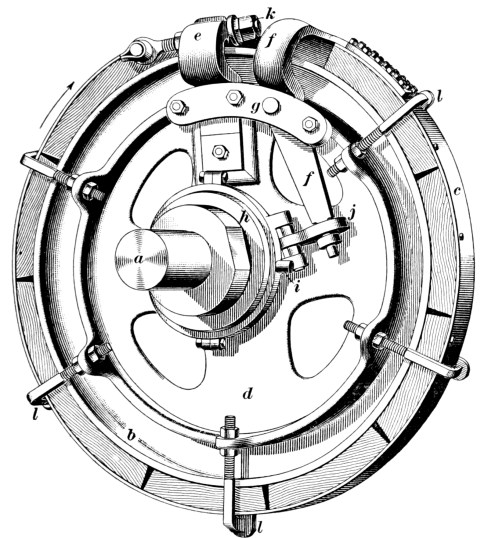

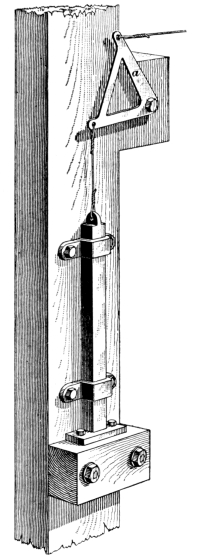

Fig. 17

32. Jaw Clutch.—Fig. 17 shows a jaw clutch, one-half a of which is shown ready to be bolted to a drum or flat rope reel, which is loose on the shaft b. The other half c of the clutch is moved back so that the jaws d are not in contact with the jaws e on the part a. The half c slides freely on a feather key f, which is driven tightly into a deep key seat in the shaft b; a collar g, fitting loosely in a groove in the hub of c, is provided with trunnions h on each side; levers i connect these trunnions with the lever j attached to a suitable handle, by means of which the clutch is made to slide endwise on the shaft so that the jaws d engage or disengage the jaws e and thus connect or disconnect the drum or reel from the clutch. There are generally four or six jaws d that engage the same number of jaws e on the drum, and it is necessary to have little or no play between d and e when [Pg 29] the clutch is connected or there will be too much shock. The clutch is about 2 feet in diameter, and the jaws are 3 or 4 inches deep for the average 20" × 48" first-motion hoisting engine. Instead of the clutch being fastened to the shaft by feather keys, the shaft may be hexagonal where the clutch slides on it and the clutch is machined to match. Jaw clutches are made of either cast-iron or cast-steel, and should be in halves, for convenience of repair, and securely bolted together.

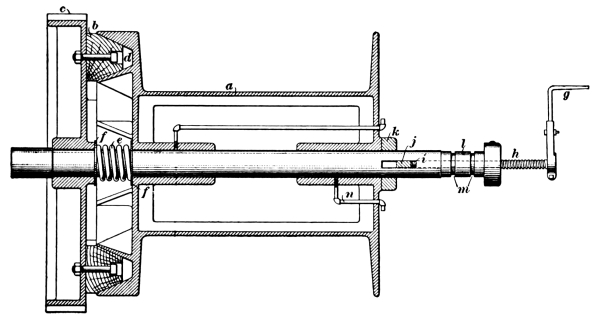

Fig. 18

33. Band Friction Clutches.—Fig. 18 shows a band friction clutch that is attached to and revolves with the shaft a. The winding drum runs loosely on the same shaft and has a driving-band ring or seat b on one end; when the ring c of the clutch is tightened by means of the mechanism shown, the clutch and driving [Pg 30] band become practically one piece and the drum revolves with the clutch. The clutch is constructed as follows: The driving disk d keyed to the driving shaft a is connected to one end of the ring c by a fixed arm e, which is bolted firmly to the disk d and revolves with it; a movable arm f that connects with the other end of the band c turns on the pin g. When the band c is loose, it can revolve about the seat b without touching it, but the band can be tightened and made to clamp b either when revolving or standing still, as follows: The sliding sleeve h may be caused to slide about 6 inches along the hub of the disk d by levers (not shown) that take hold of trunnions i on a ring on the sliding sleeve; this sleeve is connected to the movable arm f by a link j, and when the sleeve is on the end of the hub the link stands at an angle of about 60° with the shaft; by sliding the sleeve toward the disk d, the link is made to move the arm f about 1½ inches at its outer end and to thus tighten the driving-band c, so that it grips the ring b. The adjusting nuts k take up the wear of the wooden blocks with which the ring c is lined. Band lifters l hold the band clear of the ring when it is loose. The clutch shown is built to run in the direction indicated by the arrow, but such clutches may be built to run in either direction; they should always be run in the direction for which they are designed, so that the load may always come on the fixed arm. If the band be tightened slowly, there will be no sudden start or jerk on the rope, as the slip of the band will prevent the entire force of the grip taking effect at once; and after the drum reaches full speed, there is little or no slipping of the driving-band. It is best to keep the band only just tight enough to do the work, for should the car get off the track, or be overwound, or should a cage stick in the shaft for any reason, the band will slip and thus become a safety appliance, and not strain or break the rope, shaft timbering, or machinery, as would be the case if a positive clutch, Fig. 17, were used.

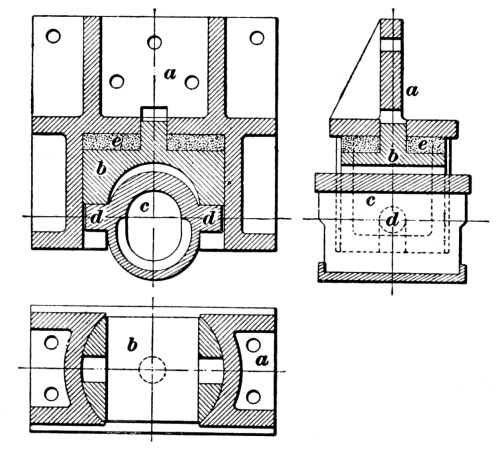

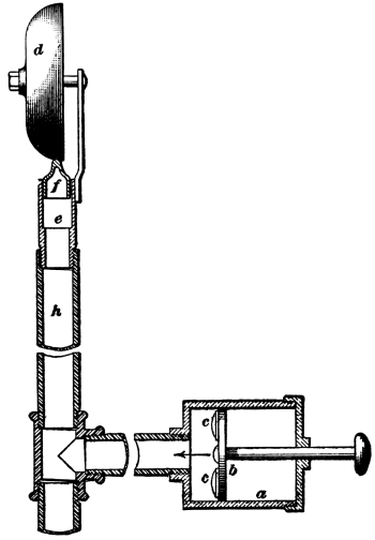

34. The Beekman Friction Clutch.—A simple friction clutch is [Pg 31] shown in Fig. 19, in which a is a section of the drum shell. The wooden blocks b bolted to the side of the gear-wheel c are made of suitable shape to conform to the V-shaped groove d in the side of the drum. The steel spring e between the two steel washers f, f disengages the clutch, as soon as the pressure is relieved, by reversing the motion of the lever g and screw h from the opposite end of the drum. When the lever g is turned, the screw h is forced against the end of the pin i, which, in turn, presses the cross-key j against the collar k, forcing the drum against the blocks b and frictionally engaging the gear-wheel c. This drum shaft is prevented from moving endwise by means of the collar l and the grooves m in the babbitted pillow-block. The wide bearings of the drum on its shaft are lubricated by means of the pipes n.

Fig. 19

A clutch is often used to change the length of the hoisting rope when hoisting from two or more lifts or levels. In this case the shaft carries two drums, one of which is fixed to the shaft, while the other is provided with a friction clutch. When it is desired to change the length of the rope, the cage attached to the loose drum is brought to, say, the upper landing. The cages both resting on the wings, the clutch is loosened and the other cage attached to the fixed drum is now brought to the desired level, when the clutch is again tightened and hoisting proceeds. The change is made in 2 or 3 minutes. [Pg 32]

35. A brake is a device by means of which the motion of a hoisting drum may be retarded or stopped. This is accomplished by friction of the brake against the circumference of the brake wheel. There are three types of brakes, known as block brakes, post brakes, and strap brakes.

Fig. 20

36. The Block Brake.—The block brake, Fig. 20, consists of one or more wooden blocks or shoes b attached to a lever having a fulcrum at d, and connected by a rod to the lever c. Block brakes are objected to mainly because they throw a great load on the journals of the drum when they are applied; they cannot be relied on when there is a heavy load on the drum, and they require the application of great force to the lever c for a given braking power. They are, however, cheap and easily applied to a drum, and the shoe is readily replaced when worn.

37. The Post Brake.—The post brake, Fig. 21, is composed practically of two block brakes applied at two places on the drum diametrically opposite each other, thus equalizing the pressure on the journals. The blocks are generally somewhat longer than in the block brake, or about one-quarter of the circumference of the drum on each side. In Fig. 21, a is the drum; b are wooden brake blocks; c are the posts which in the brake shown are of massive, built-up, steel construction; d are the fulcrums on the plates e, which plates are adjustable by means of the nuts f; by means of these nuts, the fulcrums may be brought closer together as the wooden blocks b wear away; g is a tension rod generally [Pg 33] furnished with a turnbuckle to adjust its length as the wooden blocks wear away. Power is applied at the end of the bent lever h, as shown by the arrow.

Fig. 21

The stops i are adjusted so that the blocks b on each side are equally distant from the drum when the brake is off. The fulcrums d should be some distance below the drum and brake ring, for if they are too near the drum it will be difficult to swing the lower end of the wooden blocks far enough to clear the drum.

Fig. 22

38. Improved Post Brake.—In order to have an equal clearance at [Pg 34] top and bottom, and to have a more powerful leverage than in the ordinary post brake, the posts may be made movable at both top and bottom, Fig. 22. The tops of the posts a a′ are moved, as in Fig. 21, by the tension rod b and the lever c, the latter being connected by rod d to lever e. This lever is pivoted at f and motion is transmitted to the fulcrums j by the link g, the lever h, and the tension rod i. The back post a is supported by the uprights k, which are pivoted at l and swing backwards and forwards like a parallel ruler. The front post a′ is supported by the single upright m, pivoted at n. The setscrews o regulate the motion of the bottom of the posts so as to give equal clearance to the bottom and top of the posts.

An objection to both the block and the post brake is the fact that, if the drum surface to which the brake is applied is not perfectly round, the resistance of the brake will not be uniform when applied while the drum is in motion.

39. The Strap Brake.—A strap brake consists of a wrought-iron band or strap that partly encircles the drum and is connected at its free ends to levers with which the band may be tightened on the brake wheel and the drum thus firmly held. The iron or steel band either lies directly against the wooden lagging of the drum or on wooden blocks bolted to the drum; or else it has bolted to it a lining of wooden blocks that bear on the drum when the band is tightened.

The most efficient forms of strap brakes are those in which the strap or straps are in contact with 270° or more of the circumference of the drum. The greater the arc of contact, the more securely is the drum held by the brake. A single strap is sometimes used, but this is only satisfactory with small drums, say 8 feet or less in diameter; on large drums two straps are generally used, each extending half way around the drum. The levers for transmitting the power from the hand lever or treadle to the brake strap are variously arranged. In some cases, the force is multiplied by several short levers; in others, by one long [Pg 35] lever. The treadle or foot-lever, however, has been replaced almost entirely by the hand lever.

Fig. 23

40. The simplest form of strap brake, Fig. 23, consists of a single strap a, with one end anchored at b and the free end attached to the brake lever c. This brake acts on the same principle as the block brake and is open to the objection that it brings an undue load on the journals, but it is more efficient and holds the drum more firmly under a heavy load than a block brake.

Fig. 24

Block brakes are usually run dry, but in band brakes and post brakes with ample surfaces and proper leverage the wood may be occasionally [Pg 36] slightly oiled with black oil, which greatly adds to the durability of the blocks without unduly lessening the power of the brake.

41. A two-strap brake is shown in Fig. 24. One end of each strap a, b is fastened to the pedestal c by either of the methods shown in Fig. 24 (a), (b), and (c). In the method shown in Fig. 24 (a) and (b), the forgings d, d′, drawn out to the form of bolts, are riveted to the ends of the straps and passed through a casting c that is secured to the foundation. The object in giving one bolt to one strap and two bolts to the other strap is to allow the straps to pass each other and yet have their lines of action intersect. The bolts are fastened to c by four nuts on each bolt, i. e., two principal nuts and two locknuts. This gives a means of adjustment in the length of the strap to take up the wear.

A second method of securing or anchoring the back ends of the straps is shown at (c). In this case, a wrought-iron angular piece is riveted to each strap, and these pieces are passed over the bolt e that takes the place of the casting of the former arrangement. Nuts are used, as shown, to adjust the straps for wear. The bolt should be short and stiff, so as to be well able to stand up to its work when the drum is moving or tending to move in the direction shown by the arrow.

When the brake is applied, the friction between the brake strap and the circumference of the brake wheel produces a great strain on the pedestal c, which must be securely anchored.

The front ends of the straps are worked into eyes, as shown at f, and by these eyes and suitable pins passing through them the ends are fastened to the brake lever g. This lever is supported on and rotates about a pin h, so that when the braking force is applied at i, in the direction of the arrow, the brake lever rotates, pulling down on strap a and up on strap b; and, if the straps are held firmly at the back end, the more force that is applied at i the tighter will the drum be gripped by a and b.

The ends of the straps should be brought in as close to the drum as is [Pg 37] practicable, both front and back, so as to give the greatest amount of contact between the drum and the straps and to get the best effect from the force applied. The springs j are used with straps that are not stiff enough to clear the drum when the brake is released.

42. The rotation of the drum may assist or retard the action of the lever in applying the drop brake. For instance, if, in Fig. 23, the drum revolves in the direction indicated by the arrow, the pull of the drum at the brake strap is in the same direction as the pull of the lever when applying the brake and the action of the lever is then assisted by the motion of the drum. On the other hand, if the drum is revolving in the opposite direction, it opposes the action of the lever and a greater force must be applied to the lever to overcome this opposing pull of the drum. Hence, in the case of strap brakes, if possible, that end should be anchored which will cause the revolution of the drum to assist the lever in applying the brake and throw the strain on the anchor bolt instead of on the lever.

Fig. 25

43. If a brake is required to work with the drum running in either direction, there are several ways of bringing the strain due to the load on the anchorage in whichever way the drum runs. One of the simplest of these is shown in Fig. 25, where a is a drum with a strap brake b embracing nearly the entire circumference; c is a lever bar that is attached to the ends of the brake strap by pins d and e, which work in the slots f in the iron anchor plates g. One anchor plate is on each side of the lever, and both are bolted to the foundation. If the band is kept of the proper length, then, no matter which way the drum is turning, the pull of the drum will come on the anchorage, and the pull on the lever [Pg 38] need be only sufficient to take up the slack end of the band. To illustrate: If the drum is turning in the direction indicated by the arrow, the pin e holding the lower end of the band will be on the bottom of its slot and the pin d will be free in its slot and engaged in tightening the slack end of the band through the motion of the lever c. Were the drum running the other way, the pin d connected with the upper half of the band would move to the upper end of its slot and take the main load, while the pin e at the lower end of the band would only have to take up the slack. The outer, or long, end of the lever moves downwards in all cases to tighten the band. Provision must be made to lift the band clear of the drum when slack, but no anchorage other than at g should be attempted.

Fig. 26

44. The Differential Brake.—The differential brake has both ends of the brake strap attached to short lever arms operated by the brake lever, but these arms are of different lengths and are so arranged that as the longer arm tightens the brake strap the shorter arm yields and loosens the strap. The tightening, however, is more than the loosening or yielding and, as a result, the brake band is tightened about the brake wheel. The form of the lever arm is immaterial so long as the differential principle is retained, that is, that the shorter arm yields when the longer pulls, when the brake is thrown into action. This principle is illustrated in Fig. 26. In this brake, no provision is made for anchoring either end of the brake strap, but the entire load is thrown on the lever arms a and b. These lever [Pg 39] arms are connected with the arm c, which revolves on the same shaft d and is operated by the reach rod e. The revolution of the drum is thus resisted by the shaft d.

This brake is self-acting when the drum revolves so as to pull on the shorter arm, as indicated by the arrows; that is, the motion of the drum helps to set the brake when the latter is once applied. When, however, the drum revolves in the opposite direction, the action of the brake is opposed, instead of being assisted, by the motion of the drum. As a consequence, this particular form of brake is not adapted to hoisting drums that revolve in opposite directions at each alternate hoist. Differential brakes are not generally used.

Fig. 27

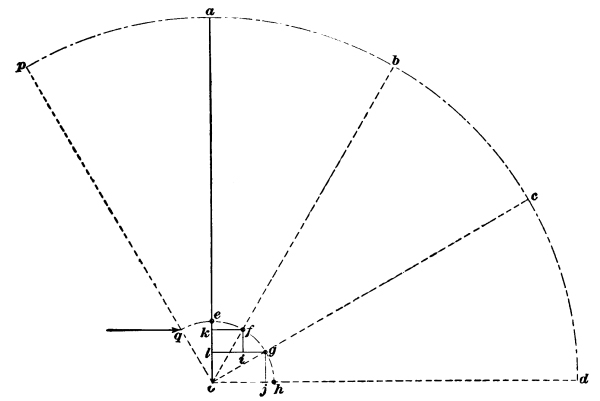

45. Power for Brakes.—For small drums and light loads, the brakes are usually applied by hand power through suitable lever connections. The force that a man can exert can be multiplied indefinitely by levers and combinations of levers; but while the force is multiplied, the distance through which it can act is divided in the same ratio. A certain amount of motion is required to free the brake band from the drum, when the brake is off; this, then, limits the leverage that a man can use. Suppose, for instance, that with a strap brake the band moves from the drum ½ inch, thus increasing the diameter 1 inch, or the circumference about 3 inches. Then, supposing that a man can exert his force to advantage through 3 feet, or 36 inches, the available leverage is ³⁶/₃ = 12. That is, if a man can pull 50 pounds [Pg 40] on his hand lever, he can exert 50 × 12 = 600 pounds circumferentially on the brake band, with simple levers. If any form of differential levers is used, the ratio by which the force applied at the hand lever can be increased will be considerably larger. A diagram will explain this more clearly.

46. In Fig. 27, a is the hand lever, with a fulcrum at b and a pin at c by which it takes hold of a reach rod or connection d. This rod is connected to the end h of the brake lever e, which is connected by pins at f, g to the brake bands. If the leverage of the hand lever a is made 6 to 1, that is, if

| ab | 6 | |

| —— | = | —— |

| cb | 1 |

and a force of 50 pounds is applied at a, a pull of 300 pounds will be exerted at the pin c and, consequently, along the rod d to the end of the brake lever e. Then, if the brake lever is made with a ratio of 4 to 1, that is, if

| eh | 4 | eh | ||

| —— | = | —— | = | —— |

| eg | 1 | ef |

a pull of 300 pounds × 4 = 1,200 pounds will be exerted at the pin f or g. This total pull must be divided equally between the arms eg and ef, giving 600 pounds pull on each. According to the principle of the lever, the distances through which these forces act are inversely proportional to the forces acting. It is assumed that the brakeman can exert the force of 50 pounds through 36 inches; if this is the motion of the end of the hand lever a, one-sixth of this, or 6 inches, will be the motion at c and, therefore, at h; one-fourth of 6 inches or 1½ inches will be the motion at f and g; that is, f will increase its half of the brake band 1½ inches in circumference, and g will do likewise with its half, making the total circumference 3 inches more, or the diameter 1 inch more, and thereby moving the band away from the drum ½ inch radially. The levers are all shown in mid-position to make the figure more simple, but the relative leverages remain the same at all points in the motion.

This is an example of simple levers, but the force applied at the hand lever may be increased in a much greater ratio by the use of a device known as a differential lever. [Pg 41]

Fig. 28

47. The Differential Lever.—The principle of the operation of the differential lever with which a constantly increasing force can be applied to the brake strap is illustrated in Fig. 28. Let a o represent a straight lever whose fulcrum is at o; and let the reach rod be attached at e. In this position, if

| a o | 6 | |

| —— | = | —— |

| e o | 1 |

the effective lever is 6 to 1. If, now, the lever is moved through 30° to the position b o, the force applied at a moves through the distance a b, and the reach rod through the horizontal distance k f, so that the effective leverage is increased a small amount e k and the ratio of the arms becomes

| a o |

| —— . |

| k o |

When the lever is moved another 30° to the position c o, the reach rod moves a distance i g, which is less than k f, so that the effective leverage is increased by the amount k l and the ratio of the arms becomes

| a o |

| —— . |

| l o |

Again, moving the lever 30° more to the position d o, the reach rod moves through the still shorter distance j h, which is less than i g, and the effective leverage becomes very great. It is evident from this that the farther the lever is moved toward d [Pg 42] the greater becomes the effective leverage. In practice, it would be impossible to move the lever through the entire quadrant to advantage, and there would also be more movement of the reach rod at the beginning of the stroke and less at the end than is needed to produce the desired effect.

Fig. 29

From the principle just given, it is plain that, if p o, Fig. 28, represents a brake lever with the reach rod attached at q, a smaller pull will be exerted on the brake band if the lever is moved to the position b o than would be exerted if a lever were moved through the same angle from b o to d o. The movement from p o to b o is a convenient and easy one for the engineer to make, while the movement from b o to d o is inconvenient. To overcome the inconvenience and still to obtain the advantage of this latter movement, the differential lever shown in Fig. 29 is used. By means of an arm placed on the lever, the point of attaching the reach rod is at l instead of p; hence, when the handle r b is moved to the position s b, the point l moves to m, thus securing a greater and gradually increasing pull with the easier movement of the handle.

A differential lever may be advantageously used in connection with any band or post brake and on a drum running in either direction. Such levers are considered by many preferable to the differential brake.

48. Power Brakes.—Large drums and heavily loaded drums [Pg 43] cannot be controlled by hand-power brakes, and in such a case some other form of power, such as steam, compressed air, or water, must be used.

Fig. 30

Fig. 30 shows, in outline, how such power is applied. The movements of the hand lever A, instead of being directly communicated to the lever operating the brake, merely control the valve v connected with the cylinder a. By means of this valve, steam, compressed air, or water is admitted to either end of the cylinder and this moves the piston in the direction necessary to apply or release the brake. There are a number of varieties of such power brakes, differing in structural details, but the action of all is essentially the same. With steam or air power, the brake would be applied with its full force almost instantaneously, thus subjecting the various parts of the mechanism to very severe and objectionable strains, unless the valves were modified so as to regulate the admission of the steam or air. One method of controlling this action is the use of a valve that requires a long travel to give it a full opening. Such a valve can be opened a little, so as to allow the steam to leak through and thereby increase the pressure in the cylinder gradually. As the motion is difficult to regulate, a better method is by means of a floating valve, described in Hoisting, Part 1.

49. Crank Brake.—In addition to the brake applied to the drum and intended for use mainly in emergencies, many hoisting engines are also fitted with a strap brake applied to the crank-disk. In some states, crank-brakes are required by law. In order to give a large bearing surface, the crank-disk is made very large. [Pg 1]

HOISTING

(PART 4)

Serial 851D Edition 1

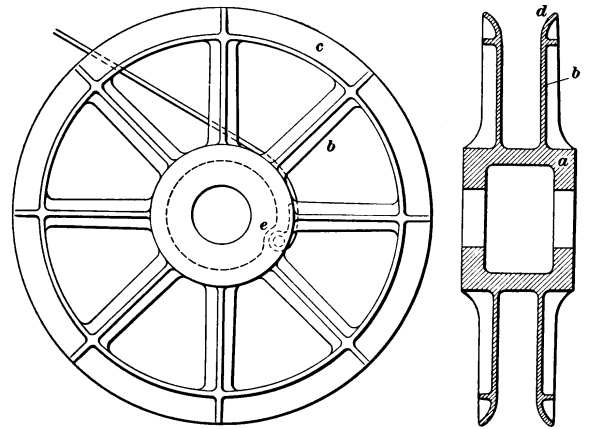

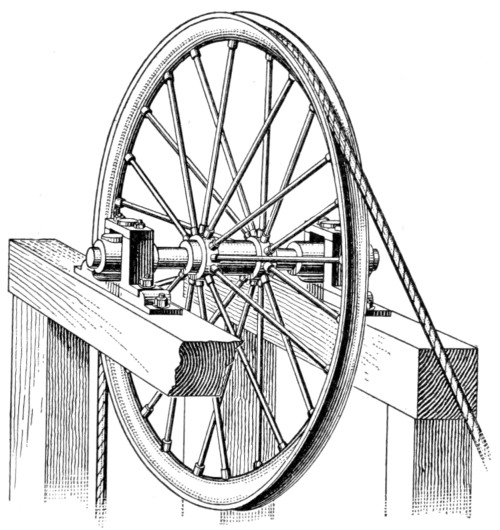

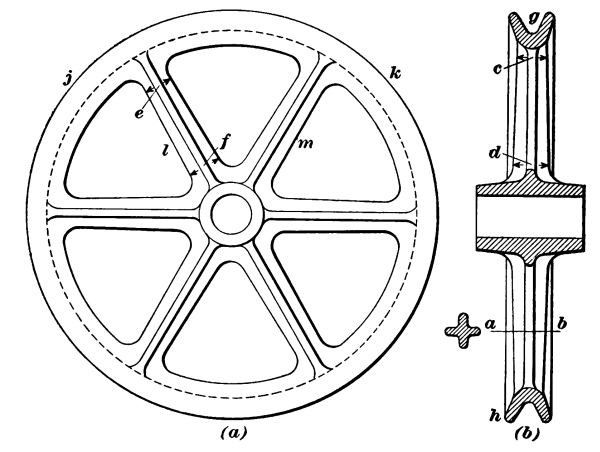

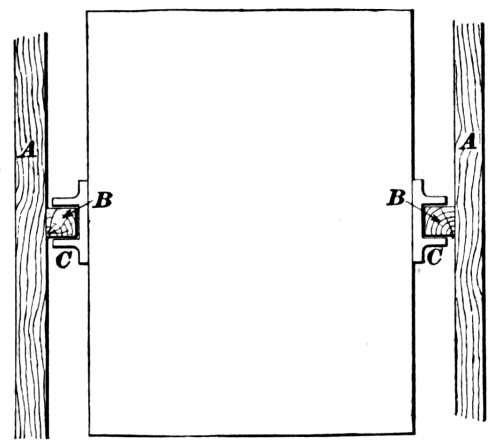

1. Sheaves are grooved iron or steel wheels used to carry or guide a rope. The general method of mounting them on a frame for hoisting light loads is shown in Fig. 1. The journal boxes are so constructed as to be easily taken apart for inspection or repair. For hoisting heavy loads, the timbers must be braced, as is explained under the heading Head-Frames in this Section. Sheaves are of two styles—those composed entirely of cast-iron and those with cast-iron hubs and rims and wrought-iron or soft-steel arms or spokes.

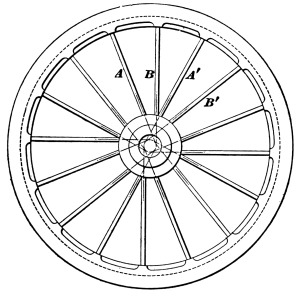

Fig. 1

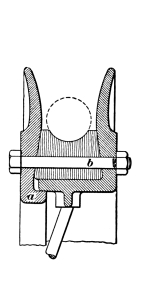

2. The cast-iron sheave, Fig. 2, has arms with a cross-section, as shown at a b, and with the flanges of the arms [Pg 2] tapering from the hub to the rim; that is, d is greater than c and f is greater than e. The bottom of the groove g in the rim should be a circular arc, whose radius is a little larger than that of the rope used over the sheave, to allow for the angling of the rope due to its fleeting on the drum. The flanges h are made quite deep to prevent the rope jumping off.

This sheave is cheaper than a combined cast-iron and wrought-iron or steel sheave, and for many purposes it is entirely satisfactory. Its great weight is an objection, because it adds to the weight on the journals and also offers considerable resistance to being set in motion and stopped.

Fig. 2

If a sheave is merely used to carry the rope or to deflect it only a little, the contact and pressure between the rope and the sheave is small; consequently, the power of the rope to turn the sheave will be slight. In such a case, when the rope starts or stops quickly, as it usually does in modern hoisting plants, the heavier the sheave the more will it lag behind the rope and the greater will be the wear on the rope due to slipping.

3. The sheave with a cast-iron hub and rim and wrought-iron or soft-steel spokes, Fig. 3, is an excellent and extensively [Pg 3] used sheave, especially the larger diameters. The spokes are screwed into the hub and rim and are carried to the right and to the left of the hub alternately, as shown in Fig. 3 (b), so as to take hold of the opposite ends of the hub, thereby giving stiffness to the sheave against any side stress.

Fig. 3

With a sheave having cast-iron arms, the load from the rope is transmitted to the shaft by a compressive stress through the arms directly under the load; that is, if a rope runs over the sheave, Fig. 2, putting a load on it from j to k, this load will be transmitted as a compressive stress through the arms l and m to the hub and the shaft. Of course, a part of this load is carried around the rim to the lower arms and is supported by them in tension, but these lower arms are not considered in designing the sheave because cast-iron is of comparatively little value in tension, whereas it is of great value in compression. In the case of the sheave with wrought-iron arms, or spokes, Fig. 3, the load is transmitted around the rim to the side opposite its point of application and is carried from there to the hub and shaft by the tension of the spokes; in fact, from the method of construction, the spokes in this sheave act only by tension. The sheave is strong and rigid, and much lighter than [Pg 4] a cast-iron sheave of the same strength, so that there is less wear between it and the rope due to any slipping action when it is started or stopped.

Fig. 4

Fig. 5

4. Sometimes, the spokes, instead of being radial as in Fig. 3, are made tangent at the center of the wheel, Fig. 4, to an imaginary circle, which is about 2 inches in diameter for a 10-foot sheave. Alternate pairs of spokes are made tangent to the opposite sides of the circle, so that they pull against each other, and this makes the sheave rigid in both directions. That is, spoke A is tangent to the right side of the tangent circle and A′ to the left side, while spoke B is tangent to the right side of the circle and B′ to the left side. The pair B B′ is joined to one end of the hub, while the pair A A′ is joined to the other end, thus giving lateral stiffness to the sheave. This arranges the spokes in groups of four, so that the total number must be some multiple of four. The tangential direction of the spokes is often necessary in very large sheaves carrying heavy loads, because with such a sheave it requires considerable force to turn the shaft in its bearings, and while radial spokes act only as long levers in turning the shaft, with tangential spokes there is also a direct pull to do it.

5. Wood-Lined Sheaves.—The rims of all sheaves are made [Pg 5] either solid or with wooden lining, as shown in section in Fig. 5. One flange a of the rim is a separate piece that is held on by bolts b. The wooden lining is in the form of blocks placed with the grain of the wood running radially and held securely by clamping together the two flanges with bolts, as shown. With such a sheave, there is much less wear on the rope than there is with one that has a plain cast-iron rim. The wear of the sheave proper is also avoided, because as the blocks wear down they are taken out and replaced by new ones.

6. Diameter of Sheave.—The size of a sheave about which a rope bends is determined generally by the size of the rope to be used, as explained under Wire Ropes in Hoisting, Part 2; but, if the rope is simply to be supported in a straight line, the space available for setting the sheave and its cost and weight usually determine the size used. The minimum allowable diameter of sheave should not be used unless it is necessary to do so, for the larger the sheave the less will be the wear of the rope due to the bending, and the longer the life of the rope, but the cost of the sheave, which increases with the size, puts a limit in the other direction.

7. Rollers and Carrying Sheaves.—Wooden or iron rollers are sometimes used for rope carriers or guides, instead of light sheaves, when the rope has merely to be supported and there is no bending of the rope, excepting the slight amount due to the sagging between the rollers. The diameter of the rollers is of little importance in such cases so far as the rope is concerned. If they are for use on a slope to keep the rope from dragging on the ground, they must be small, because the cars must run over them, and mine cars are usually made low because of restricted headroom in the mine. Rollers and carrying sheaves are fully described and illustrated in Haulage.

If a hoisting rope changes its course from a straight line, even if the deflection is only a small amount, a roller is not advisable and a sheave should be used, if possible. [Pg 6]

CAGES

8. A cage is a carriage used for hoisting mine cars and their contents, men, timber, etc., in both vertical and inclined shafts. Cages are built of wood strengthened with iron or steel, or entirely of iron or steel.

Fig. 6

9. The cage shown in Fig. 6 is much used in the anthracite region of Pennsylvania. It is made largely of oak strengthened with [Pg 7] iron and the size varies to suit the shaft, being sometimes as large as 6 feet wide by 12 feet long. The general construction of the cage is evident from the figure, but several appliances that should be common to all cages in some form or other require detailed explanation.

A covering a, called a bonnet, protects persons on the cage from objects falling down the shaft, and is required by law in some States. This bonnet is made of steel plate with flanges or angle irons to stiffen it, and is usually inclined. To prevent objects of moderate size from wedging between the edge of the bonnet and the shaft lining, the former is sometimes made shorter than the cage, so that a space of about a foot is left between its lower edge and the shaft lining. A short bonnet of this character does not, however, fully protect persons on the cage. The upper part of the bonnet is fastened to the upper cross-bar of the cage by two hinges and is held up by rods b that are attached to the bonnet and have sockets at their lower ends, which fit over pins bolted to the uprights of the cage. By raising the rods from the pins the bonnet can be lowered so that pipes or long timbers may be lowered on the cage.

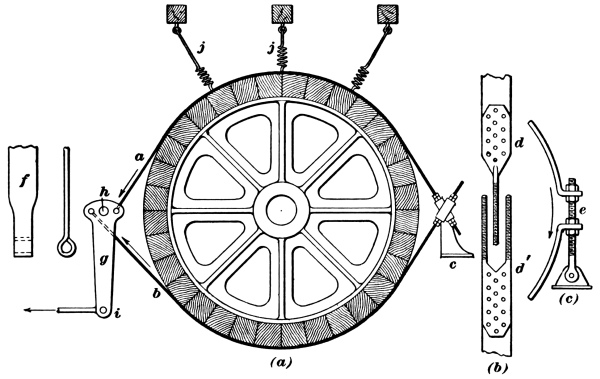

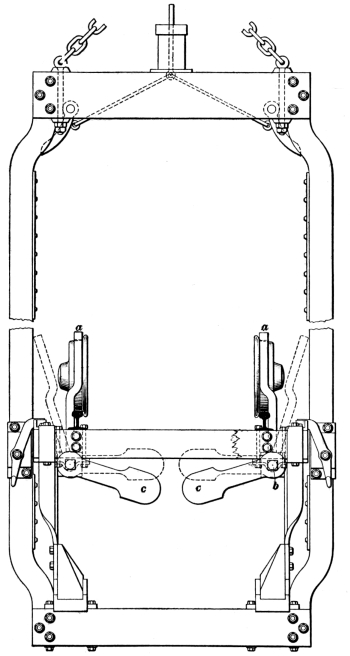

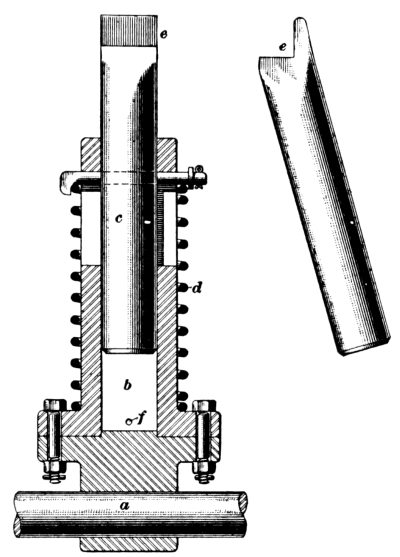

10. Safety catches are intended to prevent a cage falling in case the hoisting rope breaks. A common form, shown at c, Fig. 6, and in detail in Fig. 7, consists of a pair of toothed cams j, Fig. 7, fastened on each side of the cage near the shaft guides. The drawbar b to which the rope is attached extends through the top cross-piece of the cage and through the cylinder d, at the bottom of which is a plate c supplied with lugs for the rods f that connect it with the levers g. Inside the cylinder are three powerful rubber springs, which are in compression so long as the cage hangs from the rope, but are extended if the rope breaks, drawing the rods f down and with them the ends of the levers g to which they are attached; and, since the levers are pivoted, their other ends are moved upwards and with them the rods k. The cams j are each attached to one end of the rods k in such a manner that as the rods move upwards they rotate the cams inwards until they come in contact with the shaft [Pg 8] guides. The teeth of the cams grasp the wooden shaft guides and stop the descent of the cage. The cams are provided with projections a and l that strike the guide and thus prevent the cams turning entirely around. Fig. 7 (a) shows the springs extended and the dogs j just about to grasp the shaft guides, while Fig. 7 (c) shows the position of the dogs when the springs are compressed as they are when hoisting. At e in cylinder d, Fig. 7 (b), there are slots for the lugs of plate c to move up and down as the spring is compressed or extended. Instead of rubber springs, helical steel springs are sometimes used, and with a somewhat different design flat steel springs are used.

Fig. 7

Fig. 8

The cams, or dogs, may be placed at any point along the upright post of the cage, and in some cases two sets of cams are used on each side, one set at the top and another in the middle, both sets being connected by rods so that they work together. Practical tests of these catches, made by allowing the cage to drop, show that they are, as a rule, very efficient devices. The cams usually take hold at once, the cage [Pg 9] dropping only a few inches, or, at most, a few feet if the guides are dry and free from oil. When the guides are very greasy or wet, the cage may drop several feet before the cams take a firm hold and stop it, and with ice-covered guides, instances are given where the cage has fallen 15 feet before the cams ploughed their way through the ice and took firm [Pg 10] hold of the guides; but in so doing the momentum the cage acquired was so great that the guides were destroyed. Fortunately for the utility of safety catches, ropes are usually broken while a loaded cage is being raised, and the cage has an upward momentum; if a rope breaks when the cage is descending at a speed of 30 or 40 feet a second, its momentum is so great that either the catches or guides break. The catches generally hold and either the guides or cage suffer more or less injury under such circumstances. Instead of being placed near the top of the cage the dogs are frequently placed near the center, or near the bottom; in some cases two sets of dogs have been used, one set being at the top and the other at the bottom. Instead of being cam-shaped with a number of small teeth on the rim of the cam, as shown in Fig. 7, the dogs are now frequently made consisting of one or more strong straight teeth on each side of the guide. These teeth are operated similarly to those shown in Fig. 7, and are driven into the guides if the rope breaks, thus holding the cage more firmly than the cam-shaped guides, particularly where the guides are wet.

TABLE I

| Platform | Guides | Safe Load Pounds |

Weight Pounds |

||||

|---|---|---|---|---|---|---|---|

| Width | Length Feet |

Size Inches |

Distance Between | ||||