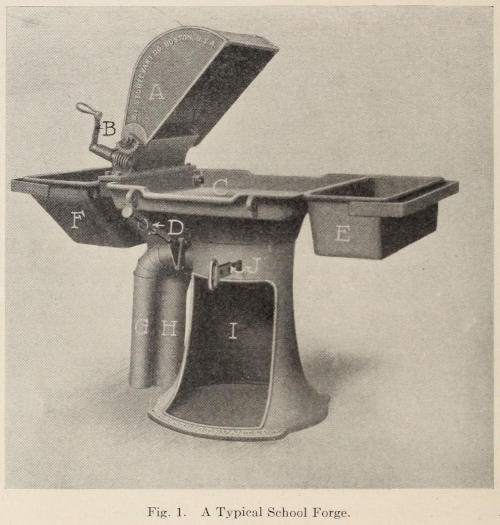

Fig. 1. A Typical School Forge.

The Project Gutenberg eBook of Practical forging and art smithing, by Thomas F. Googerty

Title: Practical forging and art smithing

Author: Thomas F. Googerty

Contributor: Edward J. Lake

Release Date: December 6, 2022 [eBook #69488]

Language: English

Produced by: deaurider and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

THOMAS F. GOOGERTY

Milwaukee, Wis.

The Bruce Publishing Company

Copyright, 1915

The Bruce Publishing Company

The present demand for school instruction in the industrial arts has made it necessary for the teachers of industries to have that knowledge of materials and methods which can only result from long and careful experience with the materials of industry.

This book is the result of a life of such experience by a man who is now recognized as a master craftsman in wrought metal.

The author’s work in wrought iron is comparable in design and finish to the best work that has been produced in that material.

Some pieces of the best German work are before me as I make this statement and tho more intricate they are no better in execution and far less suitable to the material in design than the pieces illustrated in this book which I have seen in process of execution and in the finished form.

The author has moreover been a teacher of wrought metal work for many years.

This experience is reflected in the sequence of difficulty presented by the exercises and the clear, simple statement of the text.

With such clear and exact statement and with such profuse illustration it is evident that the metal worker can gather much of the author’s long experience from this book and take many a short cut to success in an accomplishment to which there can be no royal road.

But the effectiveness of an applied art is measured best by its expression of purpose within the limitations of the material used.

The artistic success of this book lies in the evident fact that the work represented appears “Hand wrought and fashioned to beauty and use.”

I predict for it increasing usefulness in setting right the practice of forging in school shops and as an inspiration to teachers, craftsmen and tradesmen.

EDWARD J. LAKE.

| Page | |

| CHAPTER I. | |

| The Forge—Forge Tools—The Anvil—Anvil Tools—Making the Fire—Cleaning the Fire—Welding—Flux and Its Uses | 7 |

| CHAPTER II. | |

| Electric Welding—Oxy-acetylene Gas Welding—The Fagot Weld—The Separate Heat Weld—Scarfing—Upsetting—Making the Weld—Lap Welding without Scarfing—Jump Welding—Butt Weld—Split Welding—Corner Weld—T-Weld | 22 |

| CHAPTER III. | |

| Corner Weld—Brazing—Fagot Weld—Fuming a Loose Eye—Hammock Hook—Finishing Wrought Iron—S-Link—Welded Eye Pin | 36 |

| CHAPTER IV. | |

| Staples—Open Links—Welded Chain Lines—Punching—A Grab Hook | 46 |

| CHAPTER V. | |

| Bolts—Cupping Tool—Gate Hook—Hay Hook—Welded Ring—Expansion of Heated Iron | 54 |

| CHAPTER VI. | |

| Making Tongs—Pig Iron—Puddling—The Bessemer Process—The Open Hearth Process—Crucible Steel—The Cementation Process—Tempering | 60 |

| CHAPTER VII. | |

| Making a Flat Cold Chisel—Spring Tempering—Welding Steel—Case Hardening—Coloring Steel—Annealing—Making a Scratch Awl—Making a Center Punch—Making a Hand Punch—High Speed Steel—Annealing High Speed Steel | 70 |

| ART SMITHING | |

| CHAPTER VIII. | |

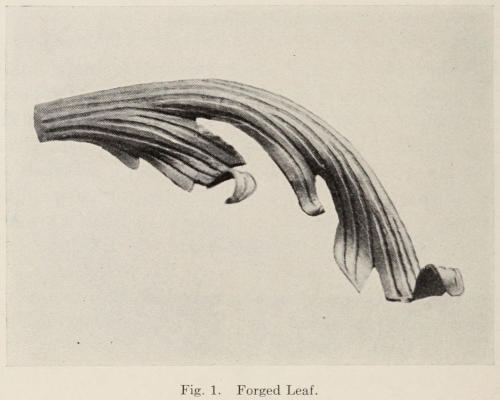

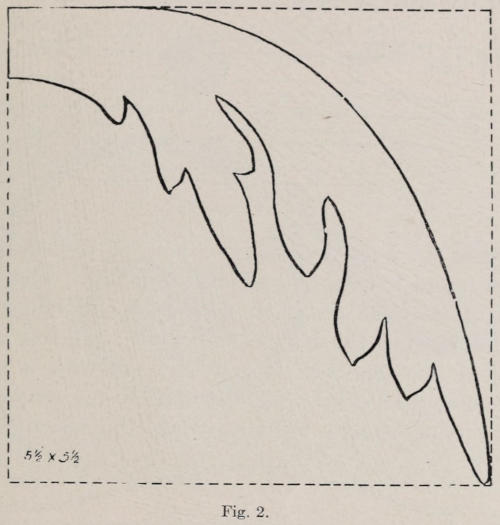

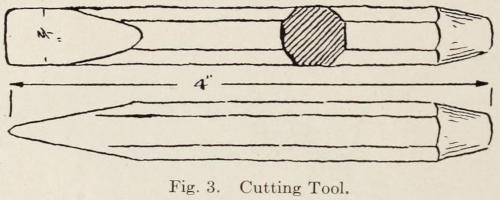

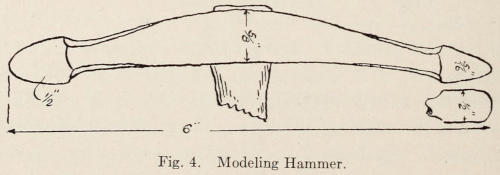

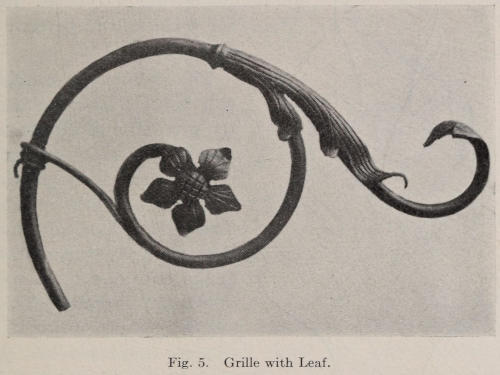

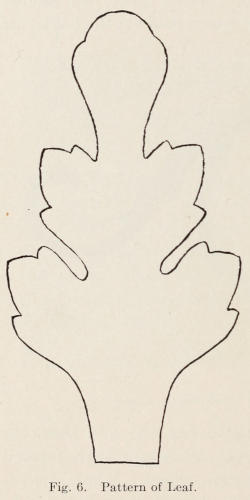

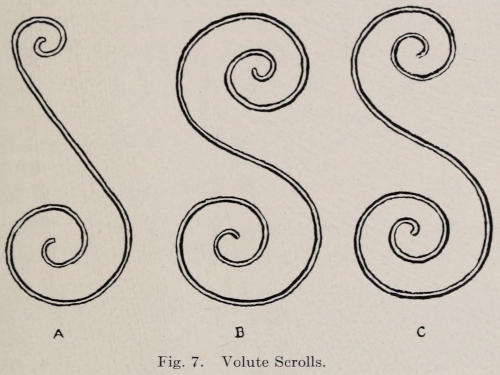

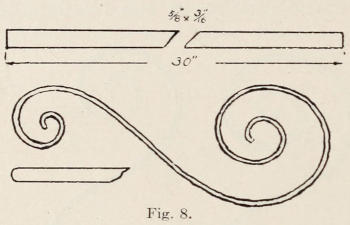

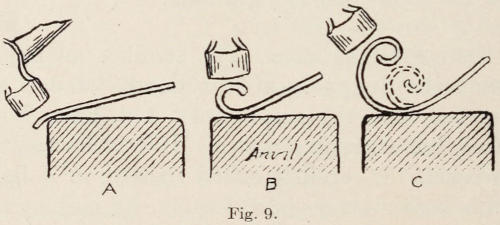

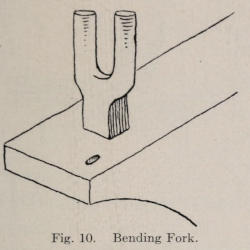

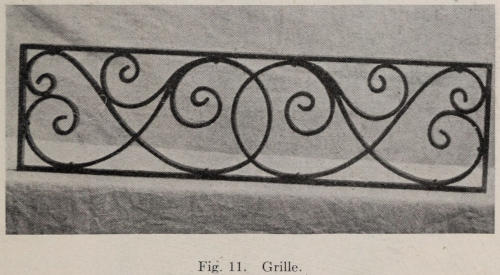

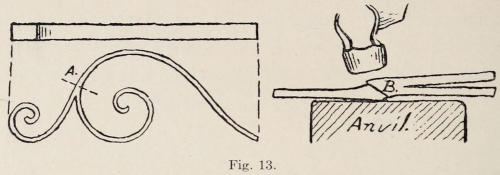

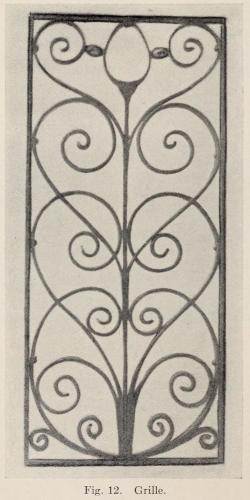

| Wrought Iron Work—Making a Wrought Iron Leaf—Making a Volute Scroll—Grilles | 83 |

| CHAPTER IX. | |

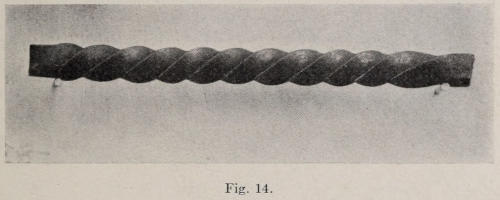

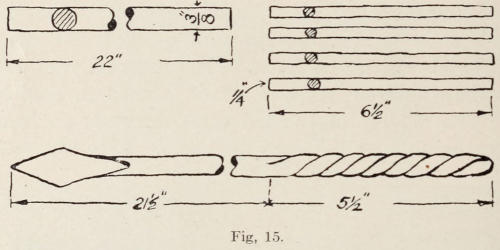

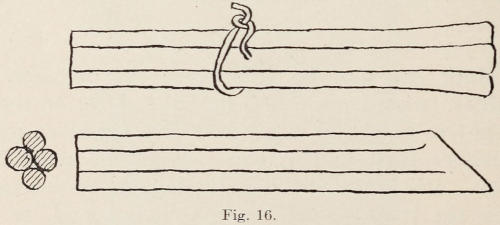

| Twisting—Braiding—Making a Fire Shovel | 93 |

| CHAPTER X. | |

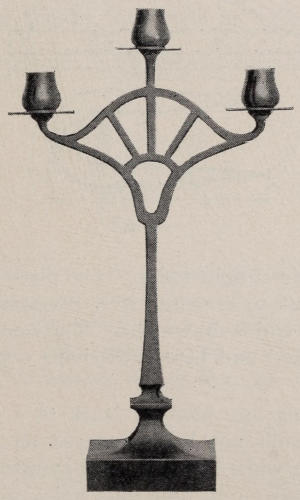

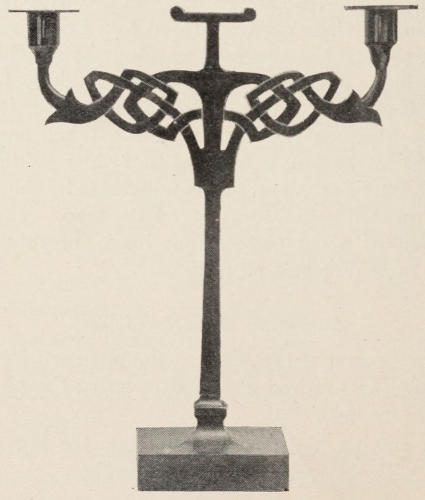

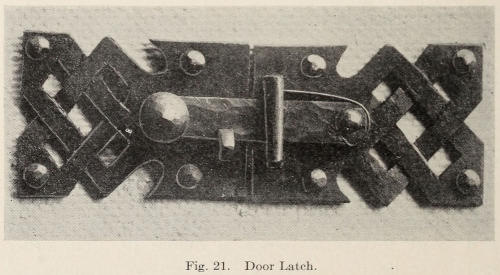

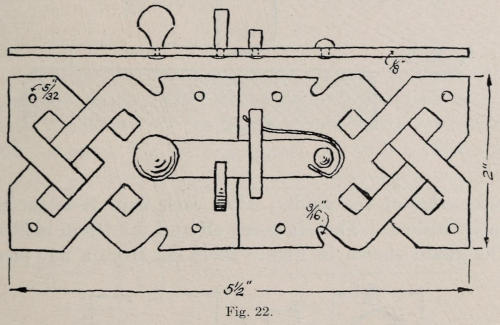

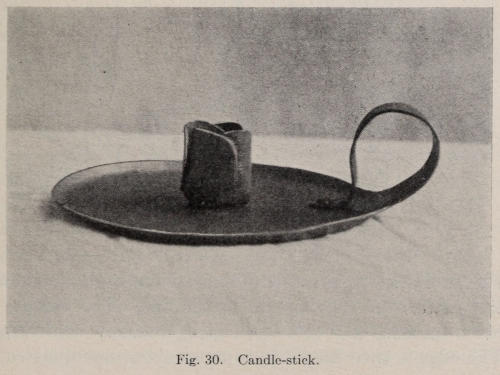

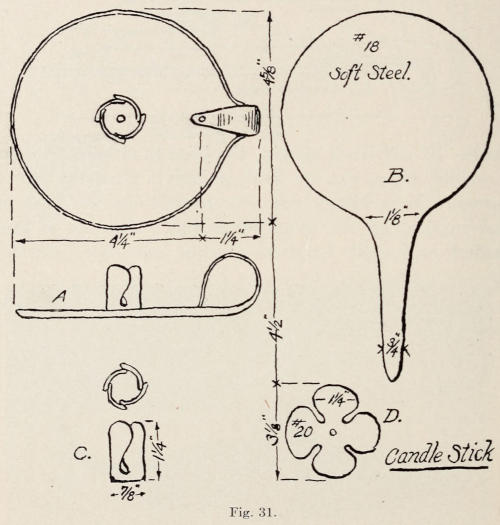

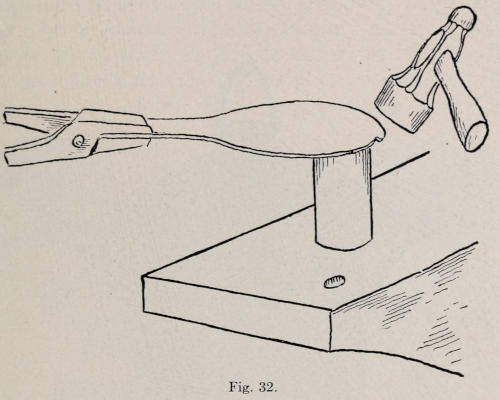

| Making a Door Latch—Making a Hinge—Making a Candle Stick | 99 |

| CHAPTER XI. | |

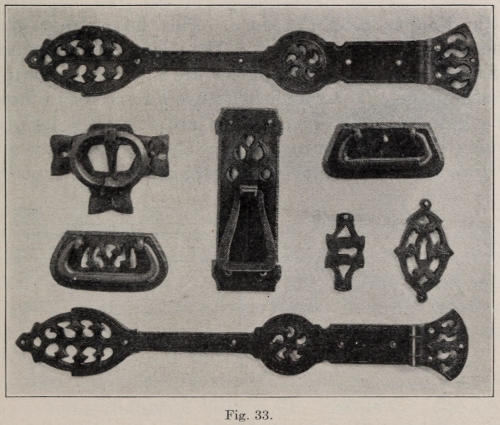

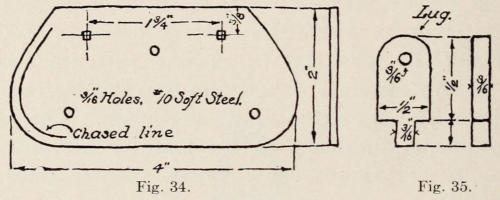

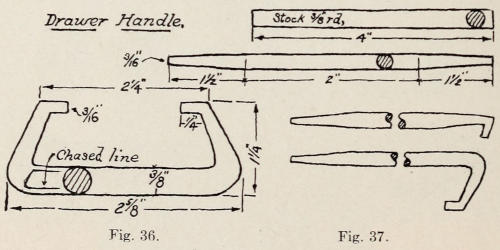

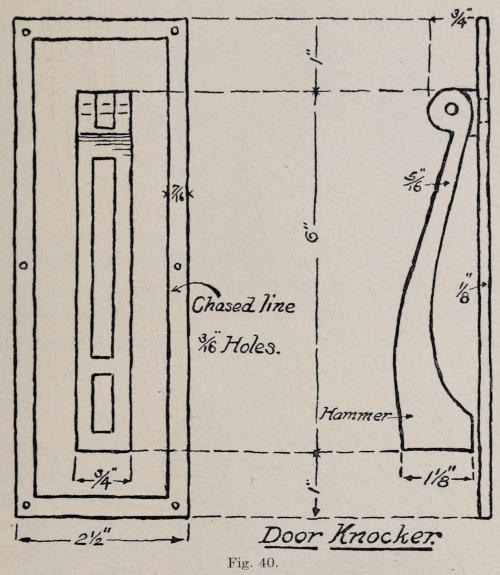

| Making a Drawer Pull—Chasing—Making a Door Knocker—Repousse—Perforated Decoration | 107 |

| CHAPTER XII. | |

| Making a Hat and Coat Hook—A Fuller—Jump Welding—Making a Wall Hook | 117 |

| CHAPTER XIII. | |

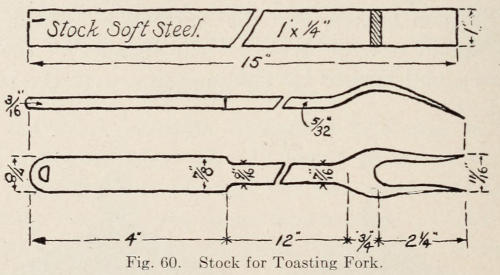

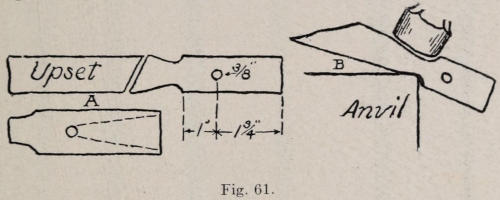

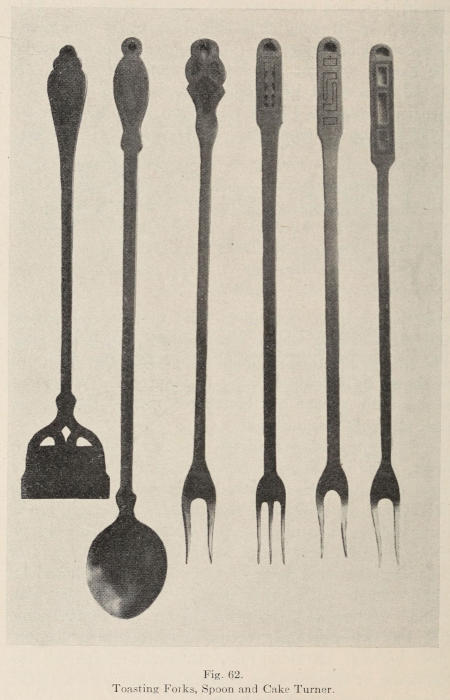

| Making a Toasting Fork—Inlaying | 124 |

| CHAPTER XIV. | |

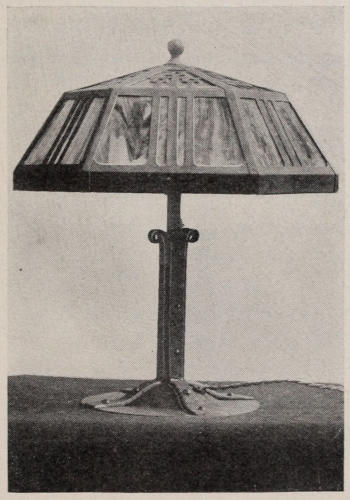

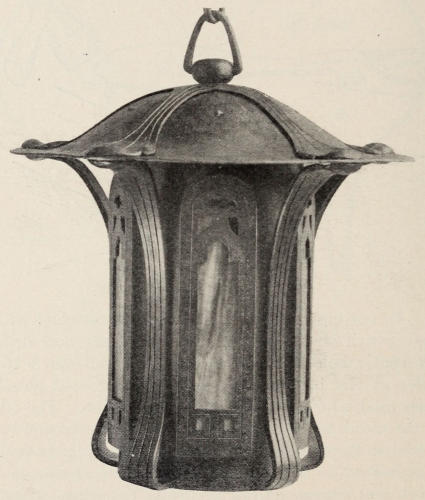

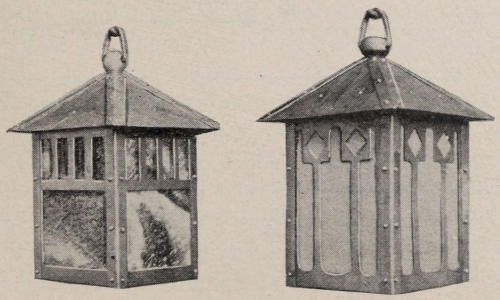

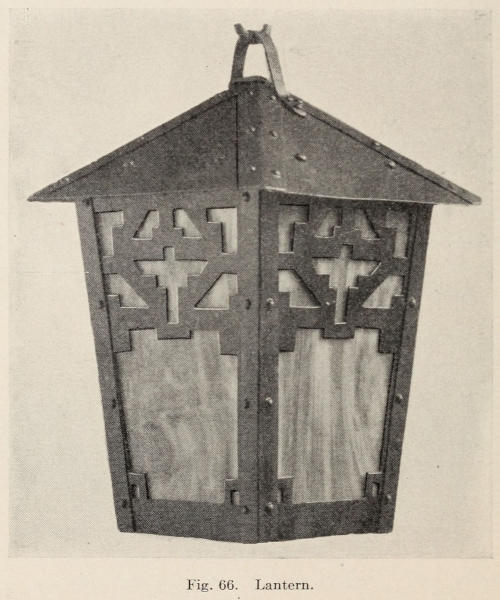

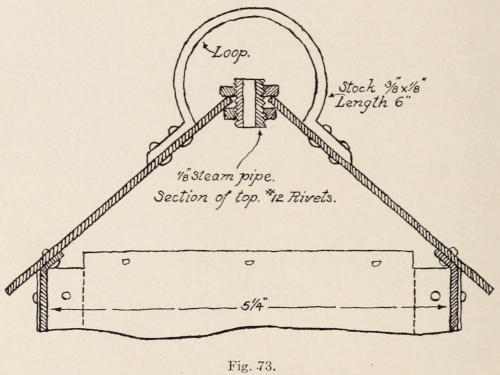

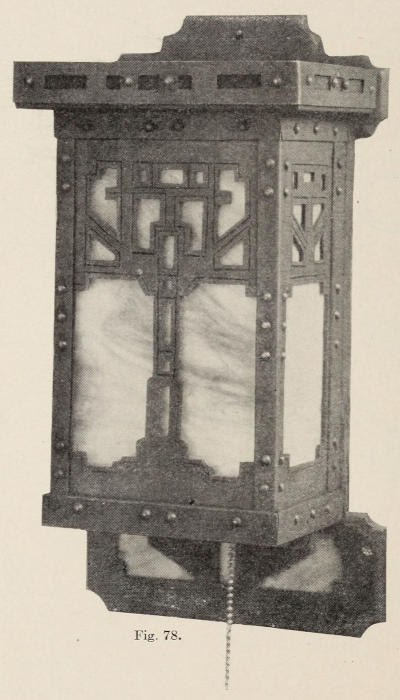

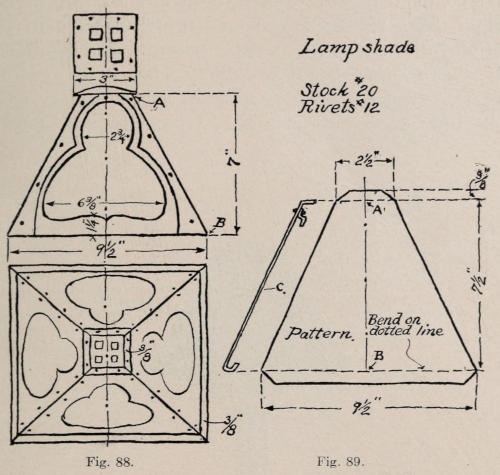

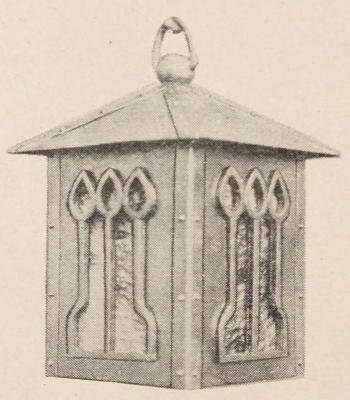

| Making a Lantern—Making a Wall Lamp | 130 |

| CHAPTER XV. | |

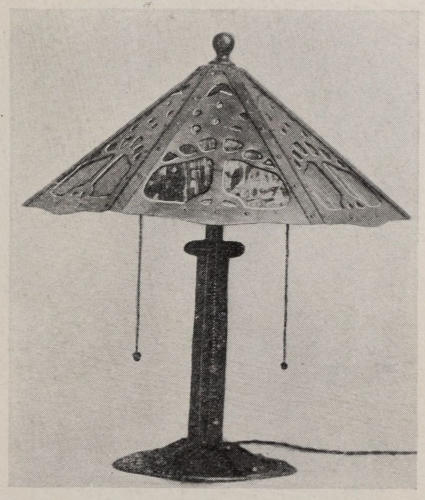

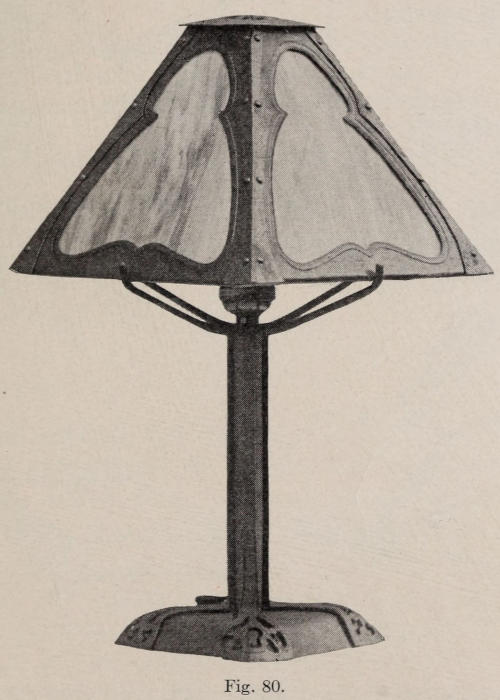

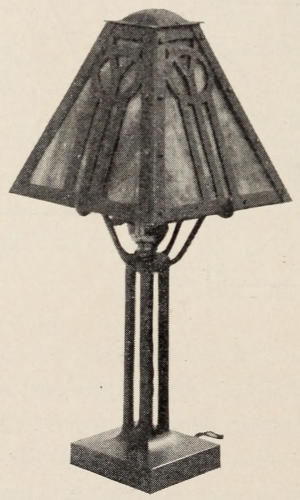

| Making a Portable Lamp | 139 |

The Forge—Forge Tools—The Anvil—Anvil Tools—Making the Fire—Cleaning the Fire—Welding—Flux and Its Uses.

One of the most essential things in the school forge shop is a good forge and fire; half the work is then mastered. A few years ago nearly all of the small commercial shops running from one to six or more fires were equipped with brick or iron forges. The blast was furnished either with a bellows or fan which had to be turned by hand. This method was a great drawback, which resulted in much loss of time. It was impossible to do much work without the aid of a helper. Work that required two men in those days is being done now by one. Modern invention has played an important part in simplifying the labors of the workers in iron and steel. At the present time there are various kinds of forges in use that lessen the work of the smith. The most successful factories are now equipped with modern forges and appliances in order that they may be able to do work quickly.

In our manual training schools, where the pupils have such short periods in which to do work, it is necessary that the shops be equipped with modern tools so that they can produce work quickly. This will give the individual pupil more practice in a shorter length of time, which simply means more knowledge. Our schools should not be hampered by using forges that have been out-of-date for years.

The best forge for manual training and trade schools is the down draft with power driven fans, thus[8] eliminating all pipes overhead and doing away with the dust and dirt. A boy, working at this kind of a forge, can use both hands in the handling of the work being heated in the fire; this is a great advantage over the old way of turning a crank. Another good feature of the mechanical draft forge is that it teaches a boy early how to avoid over-heating or burning his iron. This is the first thing one must learn in working at forging, as one who cannot heat the metal properly cannot work it. One must become acquainted with the material, and the burning heat must be understood.

Fig. 1. A Typical School Forge.

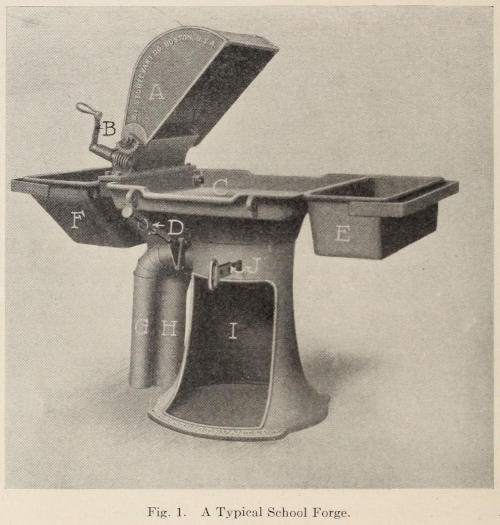

Fig. 2. Fire Tools.

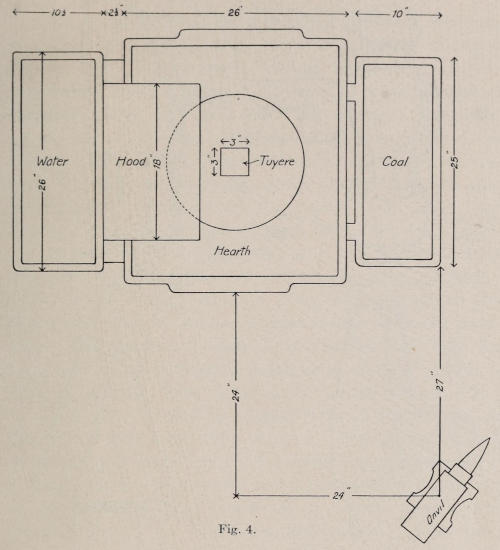

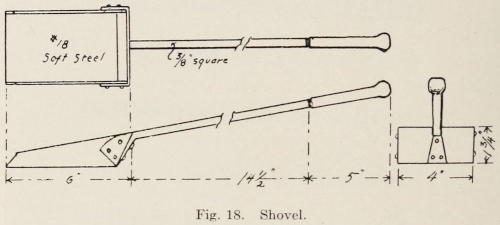

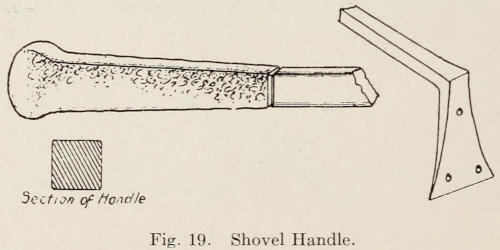

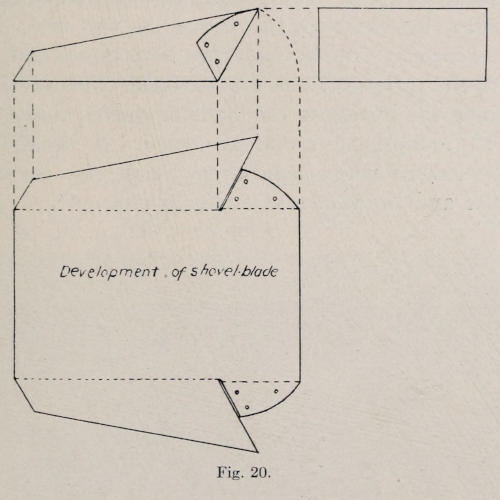

Figure 1 shows an illustration of a down draft forge suitable for schools; it is made of cast iron. A pressure fan furnishes the blast for the fire and an exhaust fan takes away the gas and smoke thru an opening at the bottom of the hood, and thru a large pipe which continues under the floor and out thru a flue. The hood represented at A, can be moved backward and forward to catch the smoke. The hood is moved with a crank and worm gear as shown at B. The hearth is shown at C; a hole in the center is called the tuyere. This is where the fire is built and is the outlet for the wind. The amount of air needed for the fire is regulated by a valve that is moved with a rod shown at D. The coal box is always at the right hand of any forge and is shown at E. The water box is represented at F. At G is shown the pressure pipe and at H the exhaust pipe. Notice the large opening under the forge at I. Thru this opening any nut or screw under the tuyere can be tightened with ease. Notice the slide-rod at J. This rod, when pulled, dumps the cinders out of the tuyere, and a bucket may be set under the hearth to catch them.[10] In school shops these forges are generally set in pairs in order to save room. Figure 2 shows three fire-tools needed for the forge fire. These tools consist of a poker made from ⅜-inch round stock, 26 inches long with a loose eye turned on one end for a handle; a shovel with a flat blade 4 by 6 by ¹⁄₁₆ inches with a handle riveted to the blade, and a tool called a scraper. This scraper is made from the same stock as the poker and is made with an eye at one end and a flat hook at the other. It is used to scrape the coal and coke onto the fire, and to move pieces of coke or coal, so that the iron may be seen while heating.

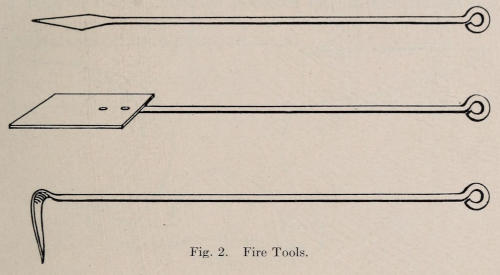

Fig. 3. Anvil.

The anvil should be of wrought iron with a steel face, weighing about 125 pounds. This is large enough for any work being done in manual training schools. In the school shop the anvils should all be of the same size and weight so that any tool used with them will fit into any square hole. In factories where anvils are made, they are forged from wrought iron or soft steel, with a carbon steel face welded on; some are cast steel thruout and others are cast iron with a steel face. The face is generally three-quarters inch thick, and is hardened[11] to resist heavy blows from the hammer and sledge. (See drawing Figure 3 of anvil.) The anvil should be fastened with iron straps, on a 10 by 10-inch block, set into the ground about 3½ feet. From the top of the anvil to the floor should measure 26 inches. The proper place to set the anvil in relation to the forge is shown in the drawing, Figure 4. The smith should stand between the forge and the anvil, with the horn of the anvil at his left when facing it. The anvil edge farthest from the smith is called the outer edge and the one nearest the smith is called the inner edge.

Fig. 4.

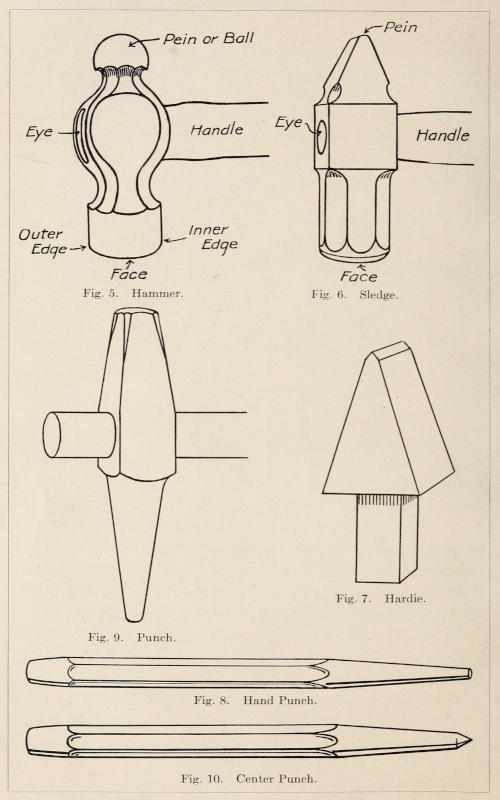

Fig. 5. Hammer. Fig. 6. Sledge.

Fig. 9. Punch. Fig. 7. Hardie.

Fig. 8. Hand Punch.

Fig. 10. Center Punch.

Every anvil should have two ball hammers weighing about 1½ and 2 lbs. each. (See drawing of hammer, Figure 5.) The hammers should be numbered corresponding with a number on the anvil. All the hammers should be kept in a rack when not in use. When the pupils come into the shop to work, they should be assigned to a certain forge and held responsible for the care of tools. A ten-pound sledge hammer should also be included, perhaps one for every two forges; the handle should be 26 inches long. (See Figure 6.)

A piece of tool steel fitted into the square hole of the anvil and sharpened at the top, is called a hardie. It is used in cutting iron. A piece of iron is set on the sharpened edge of the hardie and struck with the hammer. The sharpened edge of the hardie cuts into the iron, and in this manner it is cut deep enough so that it may be broken. (See drawing of hardie, Figure 7.)

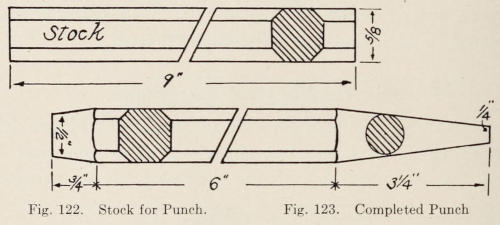

If a piece of steel is pointed on one end, it can be hammered thru a flat piece of iron. This is one method of punching holes in iron; a steel punch so made is called a hand punch. Ordinarily hand punches are made out of ½-inch to ¾-inch hexagonal tool-steel bars about eleven inches long. (See drawing Figure 8.) For heavy punching, a short, thick punch with a hole thru it, (called the eye) to receive a wooden handle, is used. This kind of punch is struck on with a sledge hammer. (See drawing Figure 9.)

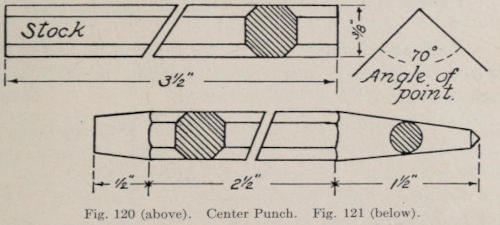

A center punch is used to make depressions in metal so that a drill may be started in a given place. It is used also to mark places or distances on the surface of metal when the metal is to be bent at a certain place. Center punches are made from hexagonal tool steel about 4 by ½-inch, drawn to a point and ground to a short angle. (See Figure 10.)

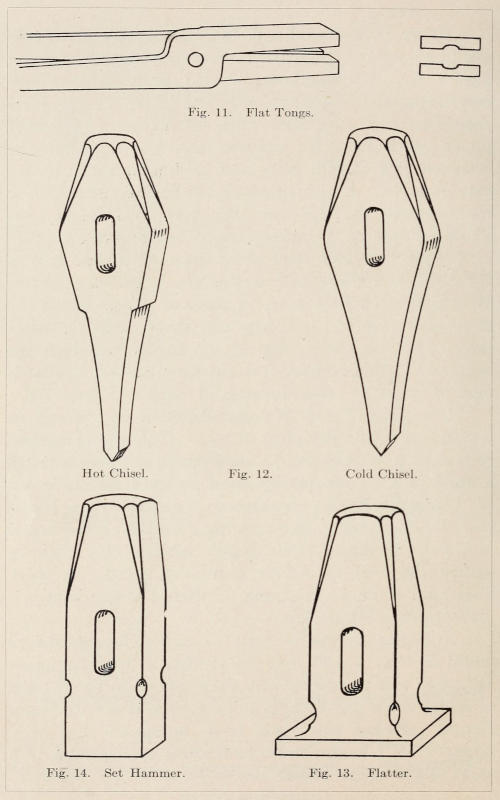

Fig. 11. Flat Tongs.

Fig. 12. Hot Chisel. Cold Chisel.

Fig. 13. Flatter. Fig. 14. Set Hammer.

In heating and handling short pieces of stock, tongs are used (see Figure 11) which are made from Swedish iron or mild steel; they are made in various sizes and shapes according to use. They are called pick-ups, flat, round-nose, and bolt tongs according to the shape of the lips. Tongs should always be made to fit the piece being forged. One cannot hold a piece of iron properly with tongs that do not fit the piece. They may be heated and fitted to the stock when occasion demands. One important reason why tongs should fit the piece being hammered, is that when turning and striking the piece there is danger of the piece being knocked out of the tongs in a whirling motion and the flying piece of hot iron is liable to strike someone; this danger must be closely watched. Tongs should not be heated red hot and cooled in water; this destroys them.

Hot and cold chisels are used in cutting stock. The blade of the hot chisel is made very thin, while the cold chisel is made blunt to stand the heavy strain in cutting. They are generally made with a hole thru them, called the eye, to receive a wooden handle. These chisels are struck on with a sledge hammer. (See Figure 12.)

Iron and steel are sometimes smoothed with a tool called a flatter. This tool is struck on with a sledge, and should not be used to stretch iron. Its purpose is only to give the work a smooth finish. Figure 13 shows a flatter, and Figure 14 a set-hammer. The set-hammer is always used to smooth and draw stock. All of these tools are made from tool-steel.

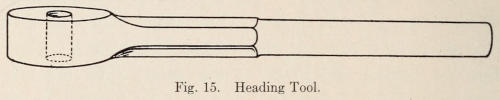

A heading tool is made from a flat piece of soft steel with a hole in one end. Sometimes a carbon steel face is welded on. The heading tool is used mostly[16] in heading bolts. Heading tools are made with different sized holes. (See Figure 15.)

Fig. 15. Heading Tool.

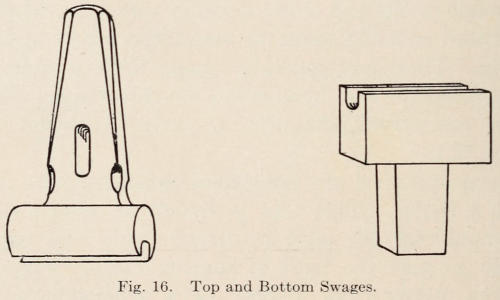

Fig. 16. Top and Bottom Swages.

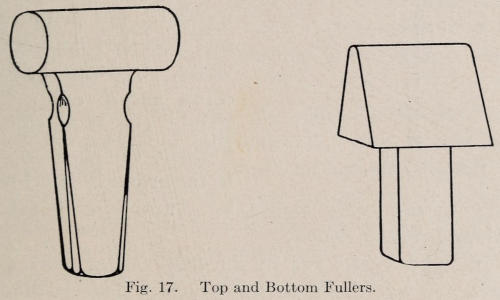

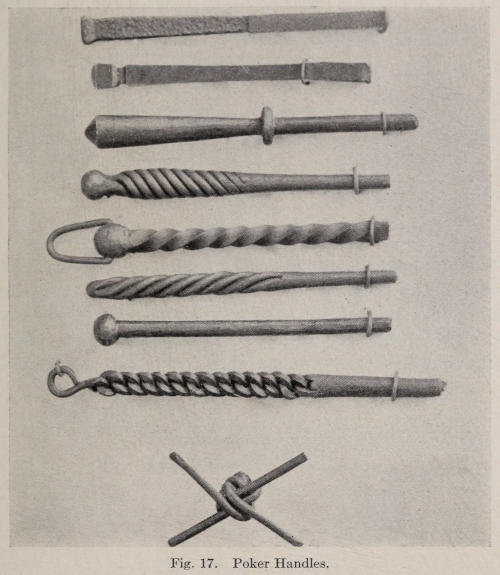

Swages and fullers are used to smooth and form iron into various shapes. The swages generally have half round depressions in them. They are made in pairs called top and bottom swage. The bottom one fits the square hole of the anvil; the top one has a hole for a wooden handle. (See drawing Figure 16.) The fullers are also made in pairs called top and bottom fullers. They are used to make depressions in metal. (See drawing Figure 17.) When referring to swages, fullers, and other tools of this character, blacksmiths speak of anvil tools. Special anvil tools are used in doing various kinds of forging, and are made when needed. The anvil tools should be kept in a tool rack next to the anvil. These tools should be made from tool-steel of about 75-point carbon, or they may be[17] purchased from a dealer. Some tools, such as swages, that do not require continuous service, are made of soft steel.

The anvil tool should have a buggy-spoke for a handle. The handle should stick thru the eye of the hole about one inch and should never be wedged. If the handle is wedged it is more liable to be broken when the tool is struck a glancing blow with the sledge hammer. This is very often the case. The reason the spoke should stick thru the tool is that if it should begin to work off the handle when struck with the sledge hammer, the movement can be seen.

Fig. 17. Top and Bottom Fullers.

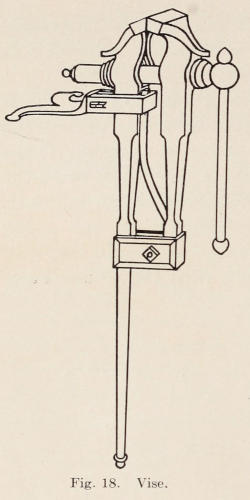

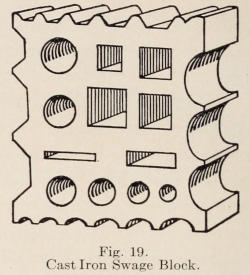

Figure 18 shows a wrought vise suitable for school work. A cast iron machinists’ vise should not be used excepting, perhaps, for bench work. Figure 19 shows a cast-iron swage block with various sized holes, and depressions around the edge for forming iron.

The stock used in a forge shop should be kept in a rack built for the purpose. The different kinds of stock, such as soft and tool-steel, common and Swedish iron, should be partly painted with a distinguishing[18] color, so that there will be no trouble finding what is wanted. For instance, all soft steel should be painted white, tool-steel another color, and so on. There should also be in the shop a shears to cut iron. One of the ordinary hand-power shears in use today would be suitable and may be purchased from a dealer.

Fig. 18. Vise.

Fig. 19. Cast Iron Swage Block.

In lighting the fire in the forge all of the cinders are cleaned out down to the tuyere. This is done by scraping them to the sides of the fire-place with the shovel. All clinkers should be picked out with the hands and put under the forge. It is a good plan to pick out some of the best pieces of coke and set them to one side on the forge, to be used later on. The slide rod that controls the ash dump at the bottom of the tuyere, is now pulled to allow the cinders and ashes to drop thru. Do not allow a boy to pull the valve after the fire is started, as this wastes the coke and is a bad habit to get into.

When the tuyere is clean, some shavings are lighted in the bottom and when well burned, the coke is raked back on the fire. A little wind is then turned on. Wet coal is banked around the sides and back of the fire. When the fire is well started and loosened up in front with the poker and most of the smoke burned, it is ready for heating. The coal in the box should be thoroly mixed with water before putting it on the fire, for the reason that it cokes better, and packs in around the sides of the fire, keeping it from breaking thru. The coal box is always at the right of the worker when he is facing the fire. The box on his left, and between the down draft forges, is to hold water—not coal. There should be a water cup of some sort hanging on a hook so that when water is needed for fire or coal it may be handled with the cup.

A fire, when not properly handled becomes hollow, due to the center burning out. If iron is heated in this kind of a fire, it will become oxidized, that is to say, a dirty scale will form over the metal. Iron cannot be properly heated, and it is impossible to get the welding heat with a fire in this condition. The reason a fire becomes hollow is that it may be filled with clinkers, or too much blast may have been used, and when it comes in contact with the pieces being heated causes them to cool and oxidize. Sometimes the fire will not be directly over the hole in the tuyere; which is one cause of poor heating. This is a common fault with boys working at the forge. Always have the fire over the hole in the tuyere, and not to one side.

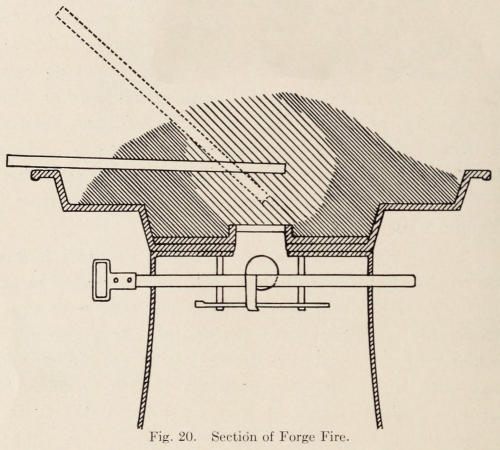

When the fire becomes hollow and dirty, clean it by picking out the clinkers with the poker or scraper, then move the sides of the fire towards the center of the[20] tuyere with the shovel, keeping the well-coked inner sides near the center of the tuyere, and having the center of fire over the hole in the tuyere. Wet coal is now banked around the outer sides. Always have a thick bed of coke under the piece being heated and regulate the blast so as not to burn out the center of the fire at once. See drawing of fire with piece about on the same plane with bottom of hearth; notice dotted lines representing the wrong way to put stock in the fire. (Fig. 20.)

Fig. 20. Section of Forge Fire.

If two pieces of iron are placed in the fire and heated, they will become gradually softer until they reach a state where the metal has become sticky. If touched together the two pieces will stick. This is what is known as welding heat. If they were taken to the anvil and hammered while in this condition they would unite and become one piece. This would be called welding. All metals cannot be welded. Iron, soft steel, low-carbon tool steel and spring steel can be welded.

A flux is used in welding steel—this excludes the air and forms a pasty surface on the metal which is squeezed out from between the surfaces of the metal when hammered. Borax and the many welding compounds are used. Very seldom is it necessary to use a flux on iron. Clean sand, which is good, is used by many. Borax or welding compound is sometimes used on very thin stock. For ordinary welding, such as is being done in school shops, borax should never be used. It is poor practice, unnecessary, and a useless waste.

In heating iron, if it is brought beyond the welding heat, it will become softer and softer until it will finally burn. This may be known by the great number of little explosive sparks coming from the fire. These little sparks are particles of iron separating from the bar and burning. As the heat gradually rises, the metal separates. If the bar were now placed on the anvil and struck a hard blow with a hammer, it would fly to pieces. Therefore, judgment must be used in striking the first blow on any welding heat—it should be light. The succeeding blows should be made gradually harder. A hard blow at the start might make the metal fly to pieces, or make the upper piece slip away from the under piece. If lighter blows were struck, the weld might be made in good shape.

The principal thing in welding is to have a clean fire. All of the clinkers must be kept out. The fire should be a well burned one, without much smoke or gas, and never any green coal near the pieces being heated. Well burned pieces of coke around the metal should always be used in raising the welding heat. In raising the welding heat very little blast should be used at first. Heat the pieces slowly so as to get them hot thruout.

Electric Welding—Oxy-acetylene Gas Welding—The Fagot Weld—The Separate Heat Weld—Scarfing—Upsetting—Making the Weld—Lap Welding Without Scarfing—Jump Welding—Butt Weld—Split Welding—Corner Weld—T Weld.

A rapid blast on the start, not only heats the outer part of the metal first and not the center, but it also burns out the fire and makes it become hollow before the metal has the welding heat. There is a right and a wrong way of taking a welding heat from the fire to the anvil. The pieces must be lifted clear up out of the fire, and must not be dragged thru the dirt and cinders on the inner edge of the fire. Iron will not unite when dirty. It is very easy to get a clean heat if one will pay attention to having the fire clean. Do not attempt to get the welding heat in a dirty fire; this is one thing that must be impressed upon the mind of one working at the forge. The skillful worker in iron always pays particular attention to the fire, for he knows by experience that it must be clean, in order to do good work.

Welding is also done with an electric welding machine. The pieces to be welded are clamped and held in bronze clamps. The clamps are adjusted so that the ends of the pieces to be welded touch. They can be moved so as to bring the pieces into close contact or separate them. When the pieces are in close contact, the current is turned on. The pieces are then separated a little so that the current jumps across the space between them, forming an electric arc. This heats the[23] ends to a welding heat, and by forcing them together they are welded.

Another form of welding is by the oxy-acetylene gas method. It is being used extensively at present, and has been found very valuable and economical in making the lighter welds. It is possible to weld steel, iron, cast-iron, copper, brass and aluminum by this process. The apparatus consists of a specially designed blow pipe, an acetylene tank and an oxygen tank under pressure.

The method of welding is to heat the pieces to be welded with the blow pipe until they reach the fusion point. For instance, in welding cast-iron, the pieces are clamped together, a V shape is cut nearly thru the joint, the metal is heated to the fusion point, and a feeder, which is a small cast-iron rod, is melted into it. In welding steel, the feeder is a steel rod; for copper or brass welding, a rod of copper or brass is used. Nowadays this method is extensively used in automobile work, in repairing cracked cylinders.

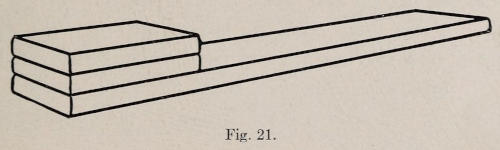

Fig. 21.

A very simple weld to make by heating in the forge, is what is known as the fagot weld. In doing this, two or three pieces are welded by simply laying one piece on top of the other, or a bundle of pieces of iron of various sizes and shapes are bound together, heated and welded. For example, if a bar of flat iron is heated and cut half thru in several places, doubled over and over, one piece[24] on top of the other and then welded in order to make a large piece of stock this would be called a fagot weld.

In Figure 21, the pieces are represented ready to make a fagot weld.

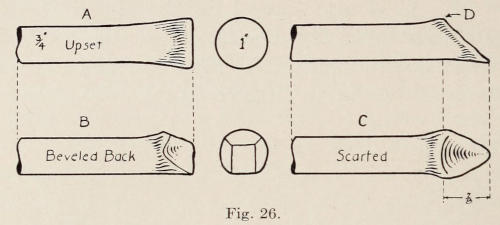

The welding of two pieces of stock by scarfing and lapping is known as a separate-heat-weld, so called because the pieces are detached while the heat is taken. In making any kind of a weld there is more or less stock wasted in the raising of the welding heat, therefore the parts to be lapped and welded are always upset or thickened and then scarfed. The word “scarfed” means the shaping of the ends of the bars so that when heated and lapped one on top of the other, they will fit and make a splice, leaving the stock when hammered about its original size.

The method of upsetting is to heat the ends of the bar, then set the hot end on the anvil with the bar vertical and hammer on the other end. This thickens the heated end. If it is a long heavy bar, the worker churns the bar up and down striking the hot end on the anvil. A bar may also be heated on the end, then fastened in a vise and the hot part hammered to thicken it. In upsetting, the bar must be kept straight as hammering will bend it where heated; if not kept straight, it will not thicken.

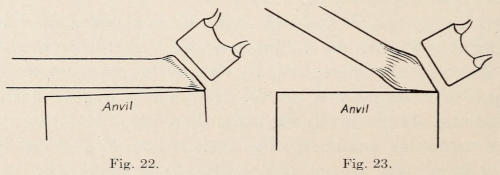

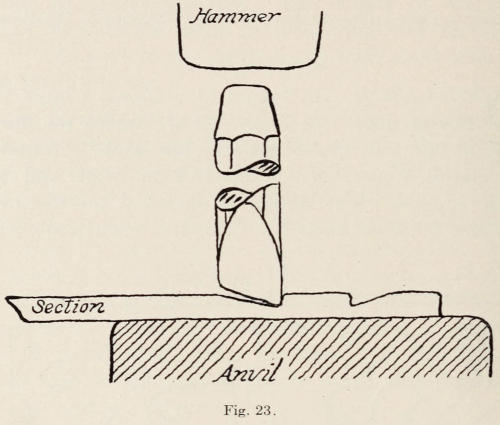

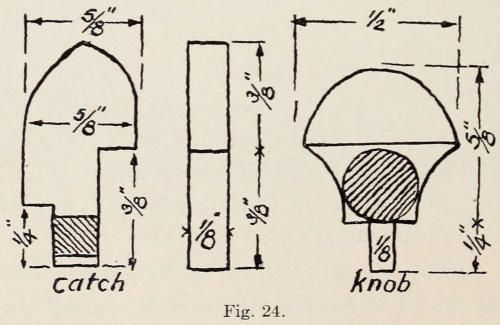

Fig. 22. Fig. 23.

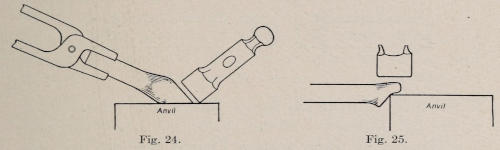

When a piece is upset about one inch in diameter for a three-quarter inch, round bar, it is scarfed by setting the hot end on and near the outer edge of the anvil. It is then driven back on a bevel by hammering. See Figure 22. It is also turned on the side and beveled on both sides to nearly a point. See Figure 23. The scarf must not be hammered when the piece is held in the center of the anvil, (Figure 24), for the reason that the edge of the hammer comes in contact with the anvil, pecking dents in it or breaking out pieces from the hammer.

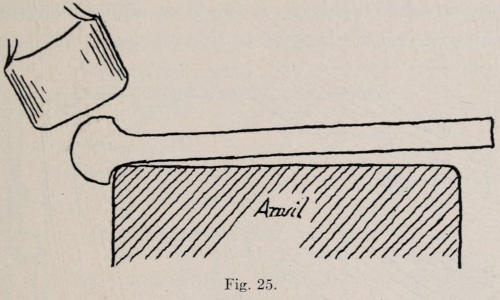

Fig. 24. Fig. 25.

Another method of scarfing is to hammer the end partly back as previously explained, then set the piece on the inner edge of the anvil and hammer it as shown in Figure 25. After each blow, it is drawn away from the edge of the anvil just a little; this tapers it with a series of little steps, not for the purpose of making notches in the scarfs to fit together and hold while hammering, but simply because the edge of the anvil leaves it in this condition when tapered. It is also drawn pointed by hammering on the outer edge of the anvil.

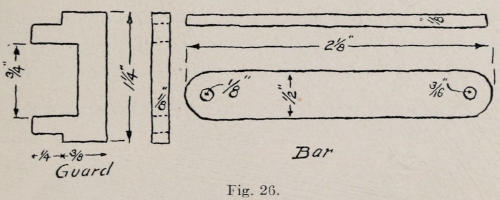

Theory teaches that the scarf should be made with the beveled part convexed. However, in practice, it is made to look like the drawing in Figure 26. Note the raised parts at “D”. This is forced up when the scarf is first driven back with the hammer as shown at “B”.

The reason that the high part should be on the scarf, is, that when lapped it gives an additional amount of stock at this part of the laps to be hammered. If the scarfs are made flat, when hammered, they are not liable to finish up without having the pieces thin, or the point of the lap exposed. If the scarfs are made concave, it is claimed by some workers of iron that dirt will deposit there and result in a poor weld. This is true to some extent. However, dirt will deposit on any scarf unless the fire is clear. With a concaved scarf when lapped, there is not stock enough to be hammered without leaving the pieces thin, or the lapping too long when welded. Scarfs should not be made concave.

Fig. 26.

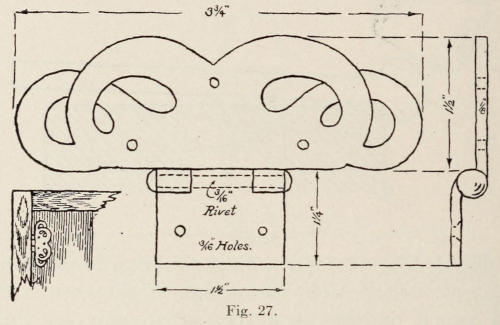

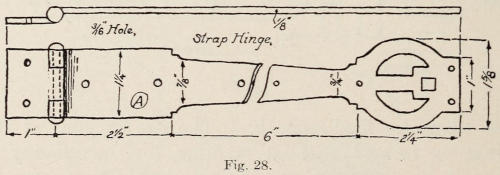

Fig. 27. Fig. 28.

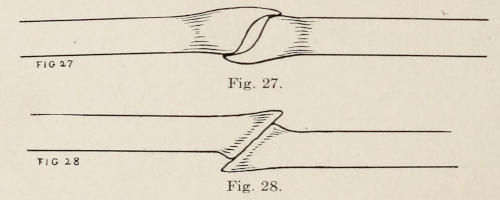

Notice in Figure 27, the incorrect way of scarfing and in Figure 28, the correct way.

The scarfs must not be made too long; this is a common fault with all beginners and one to avoid.[27] The scarfs should be made a little longer than the thickness of the iron, perhaps 1½ times the thickness.

In raising the welding heat, the pieces must be placed in the fire with the scarfs, or beveled part, down. The fire must be a clean one. A well burned fire is best. A new fire is not a good one to raise the welding heat in, as there is too much smoke and green coal that comes in contact with the metal. The hammer should be placed on the anvil about over the square hole, so it will be handy to reach when making the weld. The anvil should also be clean. A heavy hammer should be used in welding. The proper way to hold the hand hammer is with the fingers around the handle and the thumb protruding along the side and near the top. The thumb should never grip around the handle, but lie along the side to guide and direct the blows. When using the sledge hammer, stand in front of the anvil and not at its side, and let the first blow be a light one.

In heating a slow blast is maintained. When the pieces begin to get about yellow, more blast is used. The pieces can be watched without removing them from the fire. They should be turned over occasionally, moving them nearer to the surface of fire to see how the heat is progressing, and then under the coke again. Care must be taken to get both pieces heated alike. If one piece should get hotter than the other, it can be moved over in the fire a little, and the cool one put in its place. Perhaps the fire is hotter in one spot than another. If one piece is heating much faster than the other, lift it clear up and out of the fire for a few seconds to cool and give the other piece a chance to become hotter. If the points of the scarf are heating too fast for the body, the pieces must be pushed thru the fire a little farther.

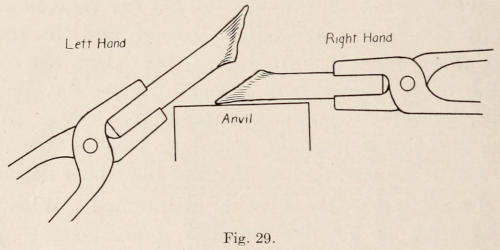

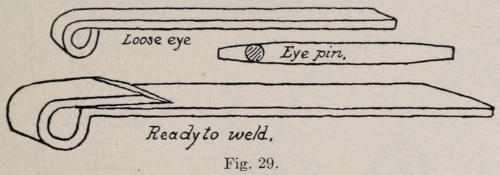

It is a good plan sometimes, when the pieces are about a yellow heat to shut off the wind for a moment, to let the pieces and fire even up and give the heat a chance to soak thru them. As the pieces become nearly white, the blast is increased. Welding heat is about 1900°-2000° Fahrenheit, and can only be determined by experience. When the temperature of the pieces reaches the welding heat, they are lifted up and out of the fire and taken by the smith to the anvil, without the aid of a helper. The smith raps them against one another or against the anvil to dislodge any dirt that may be on the scarfs. The piece in the left hand is set against the inner edge of the anvil. The piece in the right hand is now moved across the anvil until it comes under the top one. See Figure 29. The piece in the left hand is then placed on the under one, by simply raising the hand, teetering the piece on the edge of the anvil, and holding it firmly by pressing down. This is important. The smith lets go of the piece in his right hand, and taking the hammer strikes lightly until the two are stuck, after which he welds them together with solid blows, first on one side, then on the other and finally on the corners.

Fig. 29.

It requires some practice to be able to take two pieces from the fire and place them in position on the anvil to be welded. This should be practiced by the pupil under the eye of the teacher, perhaps a dozen or more times, with the cold pieces before he undertakes to get the welding heat. If one cannot take the pieces out and place them in position, he cannot make a weld of this kind.

Two boys should not be allowed to work together on this weld. One can do it much better than two. It is a one-man job. There is nothing difficult about it, after the method is learned by deliberate and persistent practice with the cold iron. There is no need of hurrying when taking the pieces out of the fire to the anvil.

If the scarfs are too long, they will overlap one another too far and cannot be welded down quickly enough. If too short, they hammer down too quickly to make a good job, and the weld will be thin.

If the scarfs are the right length and about the same size, which is important, the weld will finish down in good shape and make a smooth job, providing the ends are clean. When the pieces being heated, look as tho they are covered with grease, you may be sure the fire is dirty, or is too new.

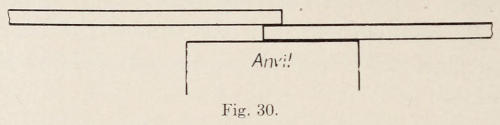

A lap weld is sometimes made without scarfing the ends. For instance, pieces of 1″ × ¼″ iron are to be welded by the lap method. They are brought to a welding heat without upsetting; taken to the anvil as previously explained for the scarf weld, lapped about ⁵⁄₁₆-inch, as shown in Figure 30, and welded. This form of welding is used in a hurry-up job where there is no great amount[30] of strain on the work. It is impossible to make a strong weld this way. Very thin stock, either iron or steel, can be welded to advantage in this manner by hammering on the flat sides. The edges, instead of being hammered, are cut off with a chisel, then ground or filed smooth. In welding very thin stock, a little flux is used. Always weld by separate heats, and do not rivet or split the stock to hold both ends in place. This is not necessary. Try to make the weld with one heat. All good welds are made in one heat.

Fig. 30.

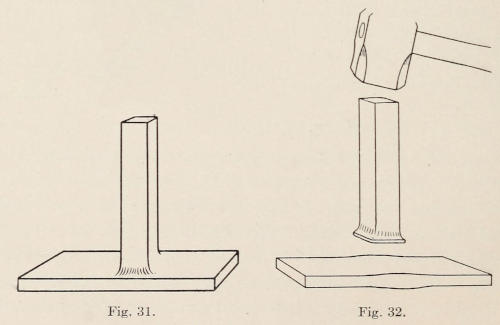

Fig. 31. Fig. 32.

For example, a piece like the one shown in Figure 31, is to be made by welding. The pieces should be prepared as shown in Figure 32. The square piece is 1″ by 1″ by 6″, the flat one 1½″ by ½″ by 8″. The square piece is heated directly on one end. If the heat[31] cannot be taken short enough, it may be cooled in water so as to upset it with a lip or projection, as shown. This lip can be worked out afterwards with a fuller, or it may be driven into a heading tool which has the top corners of the hole rounded. This will leave the corners of the lip round as shown. The bar at the end should also be made slightly convex, so that the center part comes in contact with the flat piece first. The flat piece is also upset in the center.

In welding, separate heats are taken. With the square bar, handled with the right hand, the pieces are brought to the anvil by the smith. The square bar is set on top of the flat one, and a helper strikes the top piece with the sledge, driving it down into the bottom one. The edge of the lip is then welded fast with a hand-hammer; or a fuller or set hammer is used, the helper striking with a sledge.

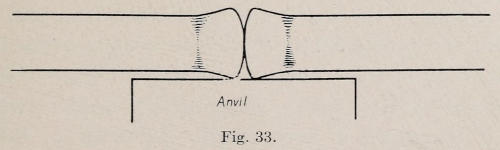

Fig. 33.

Iron may be welded by butting the ends together. In doing this, the bars must be long enough so that they can be handled without tongs. For instance, two bars of one-inch round stock, one five feet long and the other shorter are to be welded. This size is about as light as can be welded with this method. The ends are heated and upset a little making them a little high in the center so that when they are placed together, the contact is in[32] the center. A short heat is taken on the end of each bar. The smith takes out the long bar and the helper the short one, butting the ends together on the anvil, as shown in Figure 33. The helper hammers on the end of the short piece with a heavy hammer while the smith holds the long one firmly, and hammers on the joint, at the same time turning the bar so as to hammer the joint all around. In welding heavier stock, a sledge should be used requiring more helpers. This method makes a good weld, providing the heats are clean.

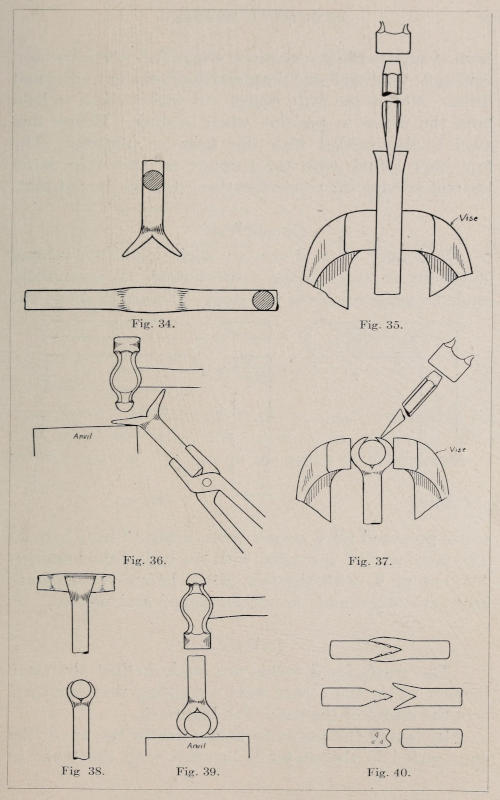

Figure 34 shows a drawing of round stock prepared for a split weld. In making this weld, one piece is heated on the end, caught in a vise and split with a thin chisel. See Figure 35.

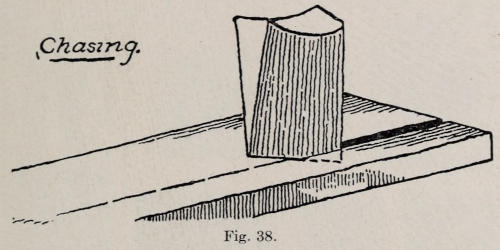

These prongs are then spread and scarfed on the inside with the ball of the hammer letting them become fan shape and as wide as possible. See Figure 36. The other piece is upset and both pieces are caught in the vise. The scarf is then hammered tight and the ends are cut so as not to have them too long. See Figure 37. The cutting of the scarf, and partly into the bar, helps to bind the pieces firmly while the heat is being taken. See drawing of piece ready to be welded, Figure 38.

Fig. 34. Fig. 35.

Fig. 36. Fig. 37.

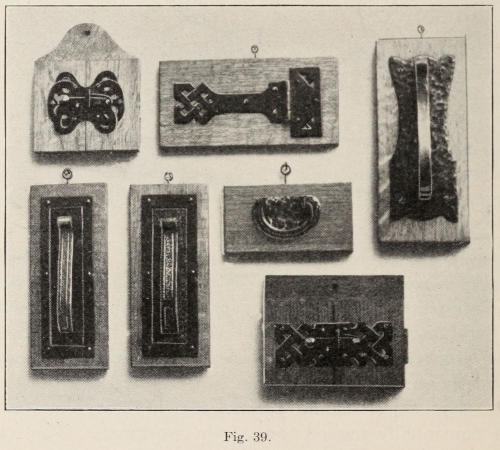

Fig. 38. Fig. 39. Fig. 40.

A heat is now taken, using a little sand or welding flux, if the stock is very small. In welding, the first blow is struck on the end of the split piece to drive it down tight and weld it in the center. See Figure 39. The sides are next hammered to weld the laps. It is then finished. On heavy work, the heats are taken separately and placed on the anvil by the smith, in the same manner as described for a jump weld. Another form of split welding is shown in Figure 40. This method is used in welding heavy iron and steel, such as picks and drills. Notice the little beards cut with a chisel to help hold the pieces in position when heating. Heavy tool steel is also welded with this form of splitting. The first blow struck with the hammer on this weld, is on the end, forcing the pieces together; then on the flat part.

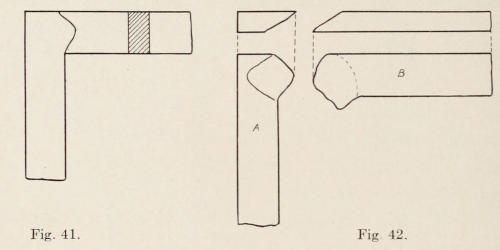

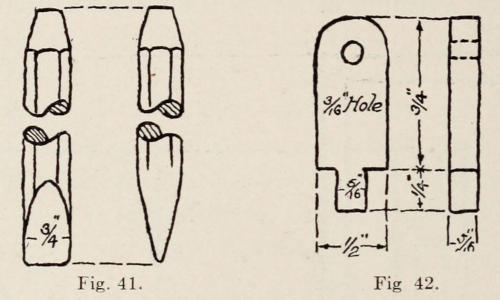

In Figure 41 is shown an angle made by welding on the corner; this is called a corner weld. It is generally made by using square or flat stock. Figure 42 shows the scarfs prepared for a corner weld, using 1″ by ½″ stock. The piece at “A” is scarfed with the ball of the hammer. The one at B, with the face of the hammer. Separate heats are taken and the pieces lapped and welded.

Fig. 41. Fig. 42.

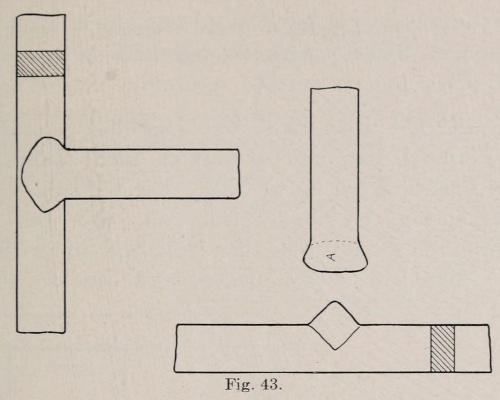

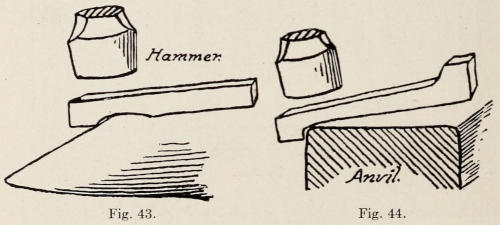

The scarfs for T-welds are made in just the same manner as for the corner weld, excepting that one scarf is in the center of the bar. See Figure 43.

In taking the pieces from the fire to the anvil, the one scarfed in the center is handled with the tongs in[35] the left hand. The one scarfed on the end is handled with the right hand, letting it under the other, and then hammered. Notice how wide the scarf is made on the end piece at “A”. This is done to cover the other scarf. All flat “T” scarfs are made in this manner.

Fig. 43.

Corner Weld—Brazing—Fagot Weld—Turning a Loose Eye—Hammock Hook—Finishing Wrought Iron—S Link—Welded Eye Pin.

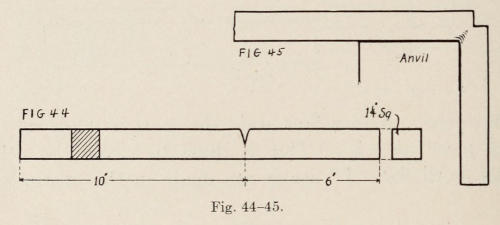

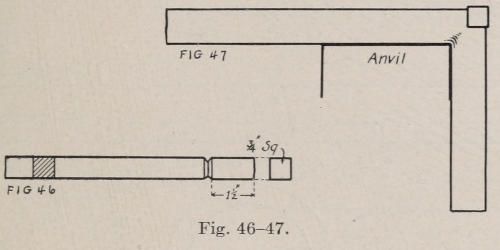

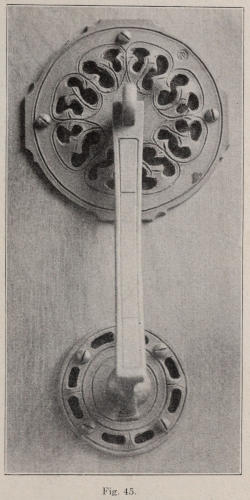

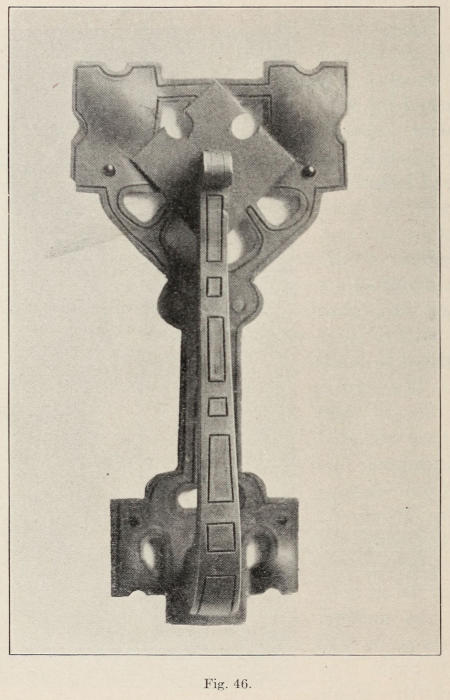

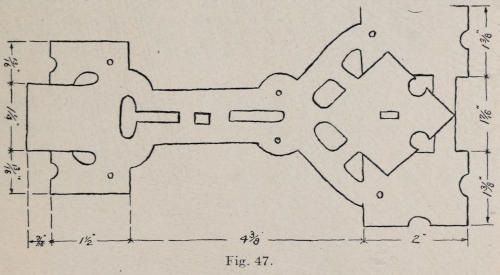

A corner weld made by using heavy stock, for example, one and one-fourth inch square, is to have a square corner by welding. See Figure 44. With the dimensions six inches from one end, the bar is heated and cut about half thru from one side with a hot chisel. The bar is then heated and bent to about a right angle, as shown in Figure 45. A piece of ¾-in. square stock is cut on four sides as shown in Figure 46. This piece is welded into the corner as shown in Figure 47. The heat is separate, and the smith takes both pieces to the anvil when hot. He places them in position as shown in the drawing, the helper doing the welding. The long part of the bar is then broken off, another heat is taken and the corner is finished up by the smith.

Fig. 44-45.

Iron and steel can be fastened together by brazing. In doing this, the ends are tapered or dove-tailed together[37] and bound with wire or a rivet to hold them in position. They are then placed in the fire and brought to a red heat. Some borax and spelter are put on and the heat is raised until the brass flows. The work is then taken out of the fire and let cool; then it is finished with a file, or by grinding. Spelter is an alloy of copper and zinc, and may be purchased from dealers. Brass wire may also be used in brazing, and sometimes copper.

Fig. 46-47.

In teaching boys forging, the writer feels that it is a waste of time to give a beginner little pieces to make, such as staples, hooks, etc. A boy cannot learn to handle his hammer, or to heat a piece of stock by making small things. What the beginner in forging needs is some work that he can swing a hammer on without danger of spoiling it. Very few boys on entering a shop can handle a hammer, and they certainly do not learn about heating metal in a forge, by working at staples, etc. The first exercise should be a fagot weld.

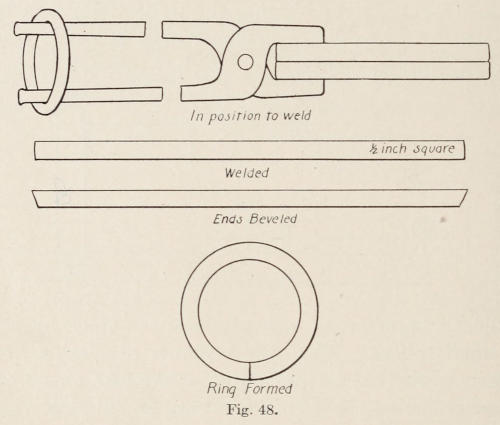

In doing this, two pieces of iron ½ in. square and 6 in. long are used. The instructor demonstrates the welding of these two pieces before the class. In making the weld, one piece is laid on top of the other and both are caught at one end with a pair of tongs. The tongs[38] should fit the pieces nicely; a ring is placed over the ends of handles to bind the jaws firmly on to the pieces. A heat is then taken on about one-half of the length of the stock; the pieces are welded and at the same time drawn to ½ in. square. The pieces are now turned around in the tongs and the balance is heated and welded. While drawing stock always have the bar at right angles with the long side of the anvil. If the bar is not so held, it will twist on the slightly rounded face of the anvil.

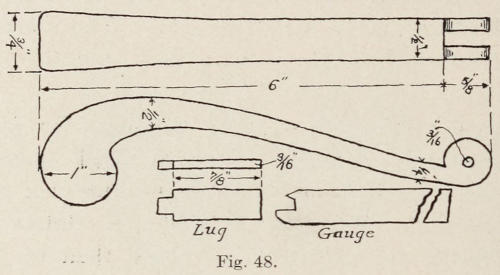

Fig. 48.

There will be more or less iron burned by the boys in making this fagot weld; but this is necessary, for a boy can never learn how to work iron until he can heat it properly. He must over-heat and burn iron in order to understand the heat limitations of the metal.

After the weld is made and the bar is drawn to the original size, the ends must be squared by upsetting[39] them. The bar when finished should be ½ in. square thruout its length, and straight with the ends squared.

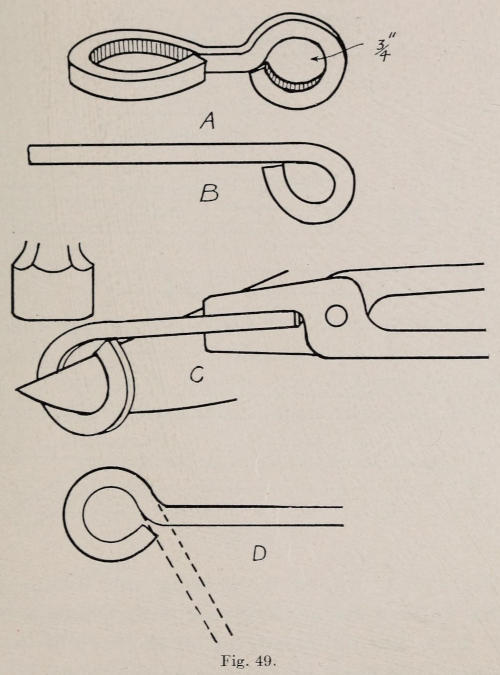

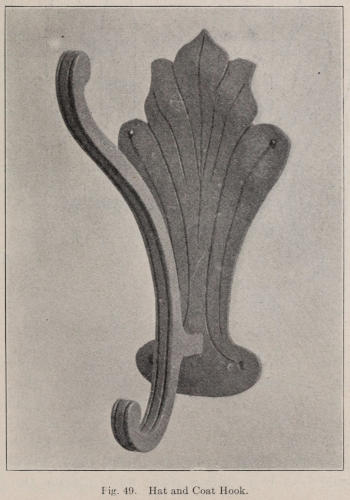

Fig. 49.

It is then formed into a loose ring by hammering it over the horn of the anvil and not on a ring mandrel. In forming the ring, the ends are upset on an angle, so that when bent into ring form, they will fit together nicely. See Figure 48.

This exercise will be made in the same manner as number one, excepting that the bar is finished to ⁷⁄₁₆ in. square, and a ring is turned on each end. See Figure 49.

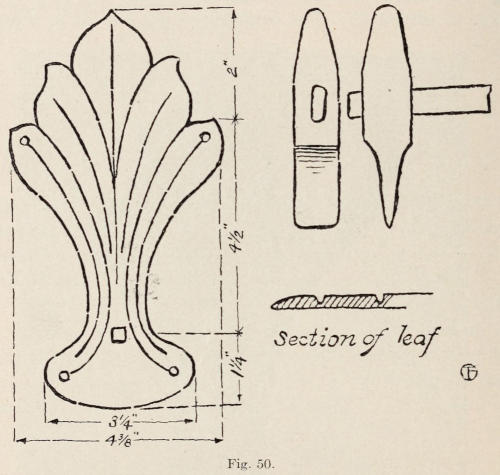

Fig. 50.

The eye is formed by heating and hammering it over the horn of the anvil, giving it the shape as shown at B. It is then reheated, set on the horn of the anvil and hammered close to the eye as shown at C, which bends it central with the shank as shown at D.

In turning loose eyes of any size stock or dimensions, on the end of a bar, the ring is first turned into a circle of the desired size. It is then sprung central[41] with the shank. With this method, no figuring of stock is required.

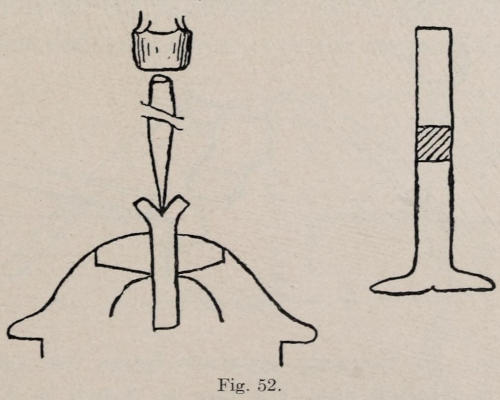

Fig. 51. Fig. 52.

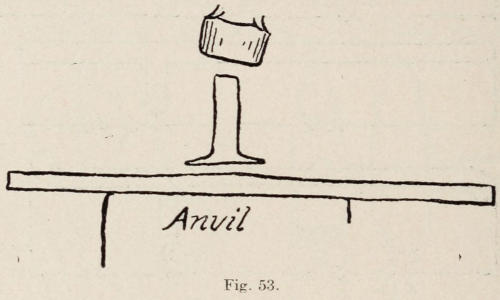

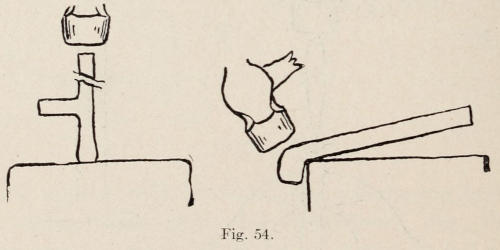

Fig. 53. Fig. 54.

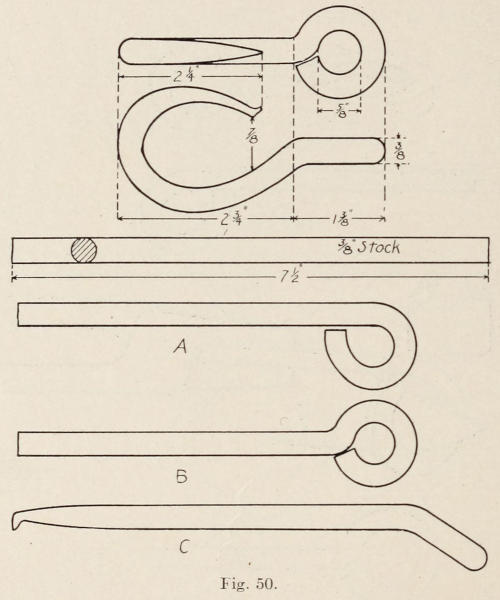

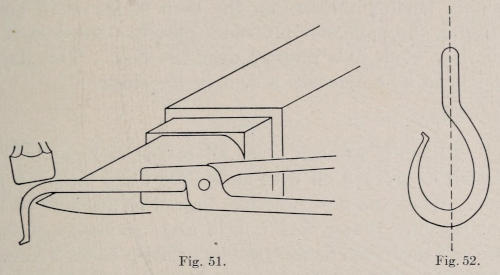

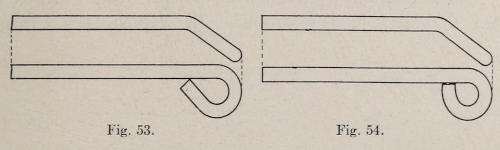

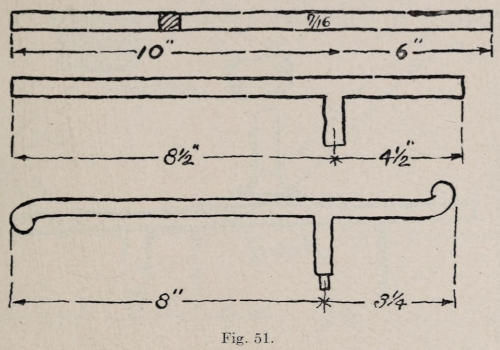

In making a hammock hook, the stock should be soft steel, which may be purchased for about the same price as iron. It will stand the bending strains better than iron. The size of the stock is 7½ in. by ⅜ in. round. The end is heated and a loose eye formed. The other end is drawn to a taper with ¼ in. of the end turned up as shown. See drawing of hook, Figure 50, and the different steps in forming the eye at A, B and C. The hook is formed over the horn of the anvil as shown in Figure 51. Figure 52 shows the finished hook with a dotted line drawn thru the center, indicating where the pull should come. In Figure 53 is shown a common fault when turning a loose ring at the end of[42] a bar, in not bending the extreme end first. Notice Figure 54, where the end is bent as it should be.

The expert worker in iron is very careful not to hammer mark and destroy the section of a bar. One should remember that bending a ring or iron hook is simply holding the bar on the horn of the anvil and striking the part that protrudes past it. Never strike the bar when it is directly over the horn. This does not bend it, but makes a dent in the stock.

To finish wrought iron, all of the scale and dirt should be scraped off with an old file while the piece is hot. When the iron is cooled, linseed or machine oil is rubbed on. If the work is held over the smoke of the fire and then oiled, it will take on a darker color. Never paint iron work. This destroys the texture of the metal. Do not file work bright. It should be dark—filing is not forging.

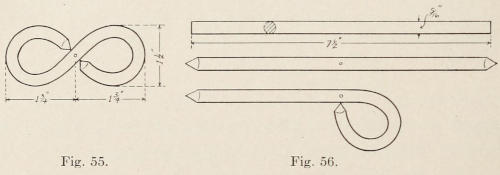

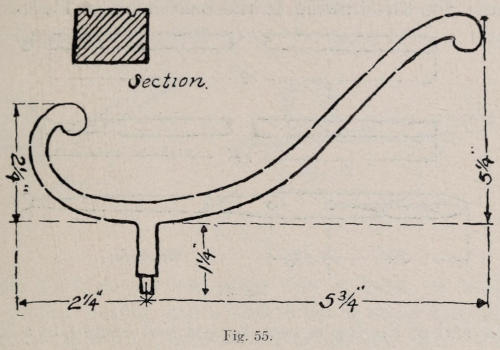

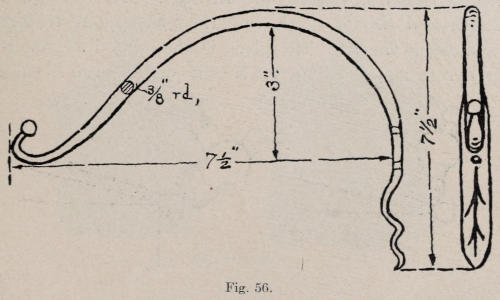

Fig. 55. Fig. 56.

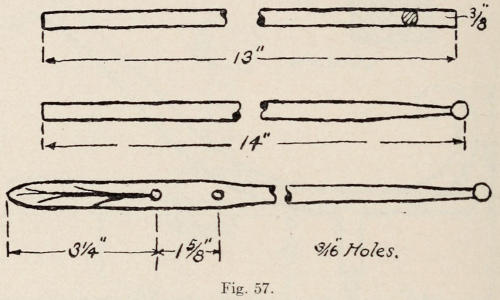

Figure 55 shows a drawing of an S-Link, which is used to splice broken chains. In Figure 56 is shown he length and size of the stock. The ends are drawn to a short point and the center of the bar is marked with a center punch. One-half of the link is then formed, bringing the point at the center punch mark and using[43] one-half of the bar. This is a simple link to make. The only thing to be careful about is to not destroy the section of the bar with hammer marks. This may be avoided if one does not strike the hook directly over the horn of the anvil, but to one side of the horn. See in Figure 57, the correct blow.

Fig. 57.

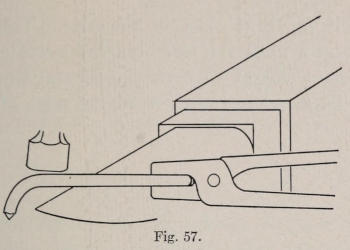

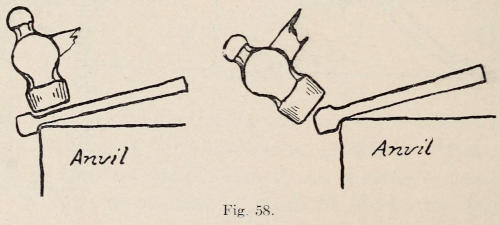

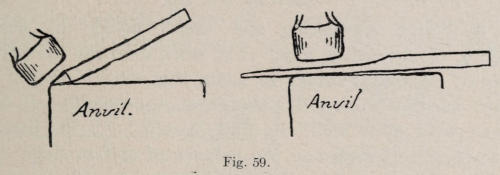

Figure 58 shows a drawing for a welded Eye Pin. The eye may be made any size for practice. In making the ring, the bar is heated in the center and hammered over the outer edge of the anvil, as shown in Figure 59. The piece is now turned end for end, and jogged down again with the ball of the hammer. See Figure 60. The piece should now look like the drawing in Figure 61. The center of the piece is heated and hammered over the horn of the anvil to make the ring round and to bring the shanks together. See Figure 62.

Fig. 58.

Fig. 59 (above). Fig. 60 (below).

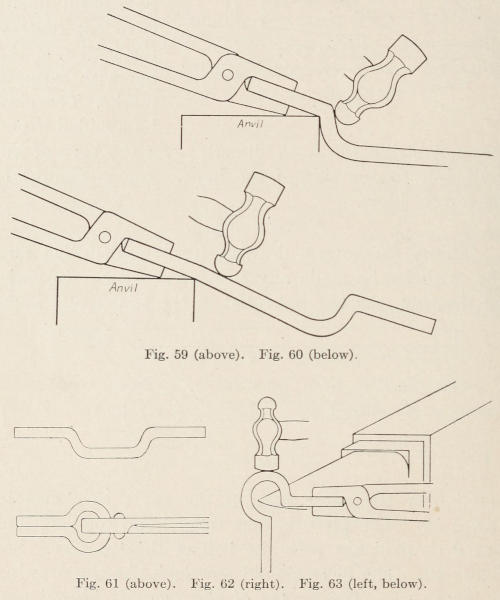

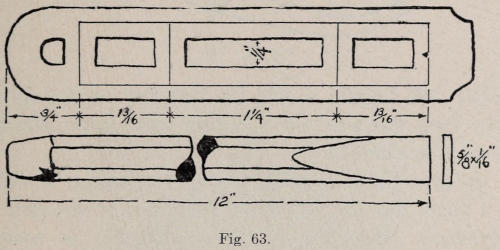

Fig. 61 (above). Fig. 62 (right). Fig. 63 (left, below).

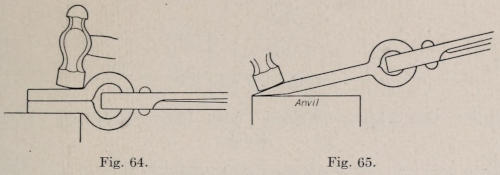

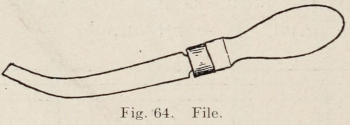

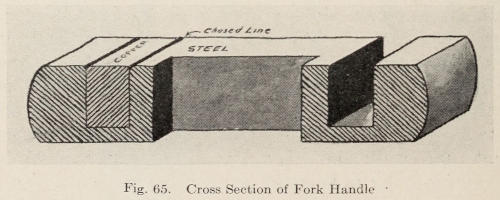

In welding, the piece is caught by the ring with a flat pair of tongs. See Figure 63. It is now placed in[44] the fire so as to get the heat close to the ring. The tongs are then removed, until the piece reaches a white heat; the piece is again caught with the tongs, and the heat is raised. It is taken out and set on the edge of the anvil and hammered as shown in Figure 64. The first blow struck is close to the ring in order to weld that part first. If it cannot be all welded in one heat, it should be reheated at once. Do not hammer unless[45] the heat is a welding heat, as the stock will become too thin before it is welded. Do not heat the tongs red as this destroys them and the piece cannot be held with hot tongs. When the ring is welded, the end is drawn to a square point. See Figure 65.

Fig. 64. Fig. 65.

Staples are used for hasps, gate hooks, and for various other purposes. They are made from all sizes of stock, depending on the use to which they are put. On account of its pliability, soft steel is the best stock to use in making staples.

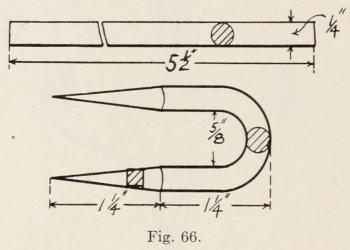

Fig. 66.

The length to cut stock is shown in the drawing of the staple in Figure 66. The stock is caught at one end with a pair of light tongs. The piece is then heated and drawn out to a point; it is reversed in the tongs and the other end is drawn out. The center of the piece is then reheated and bent into shape over the horn of the anvil.

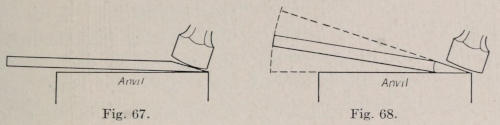

In drawing any piece of stock to a tapered point, the taper should not be hammered on one side continuously and, when turned over, hammered back again. To have a taper on all four sides alike, the bar must be[47] raised the proper distance and not laid flat on the anvil. Figure 67 illustrates the wrong way and Figure 68, the correct way.

Fig. 67. Fig. 68.

Fig. 69.

Fig. 70. Fig. 71.

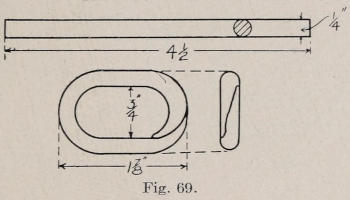

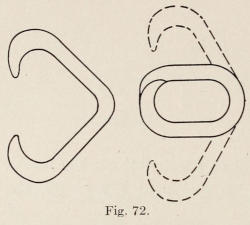

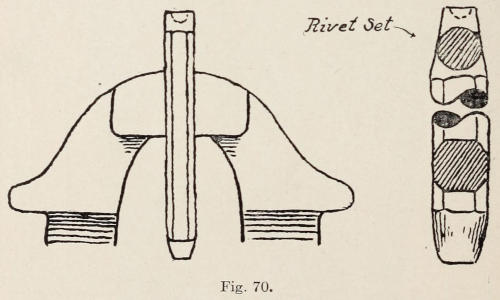

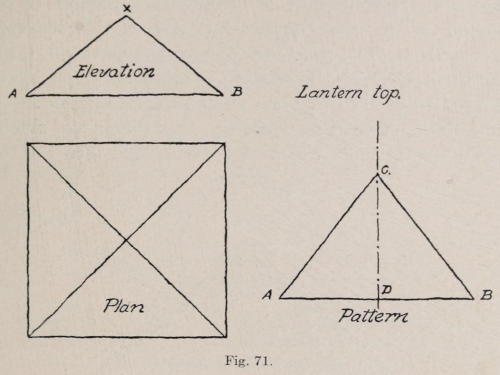

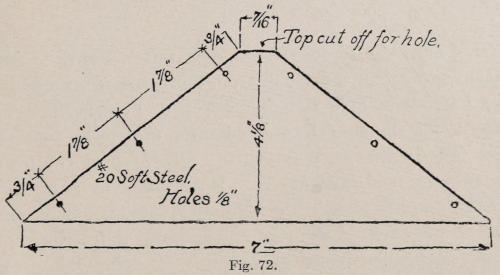

In Figure 69 is shown a drawing of an open link. Open links are used in the splicing of broken chains. In splicing a chain, the link is opened by driving a chisel between the laps, or it is opened when made. These laps are hooked into links of broken chain and then driven together. In making the link, one end is drawn to a flat point and a hook is hammered on it. See Figure 70. The other end is heated and drawn out as in Figure 71. The center of the piece is now heated and bent over the horn of the anvil to the desired shape.[48] See Figure 72. Notice in the drawing that the hooks at the open end of the link are not very long. They should not be made longer than shown.

Fig. 72.

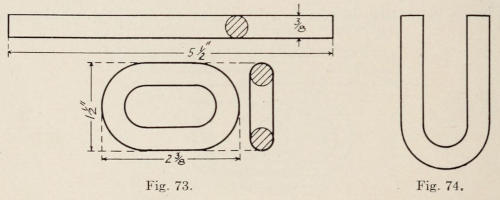

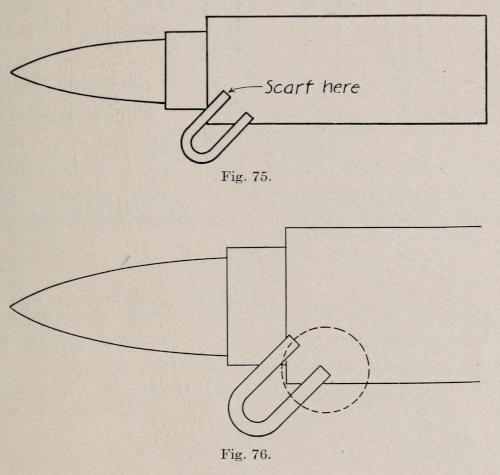

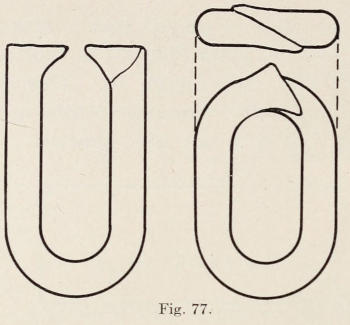

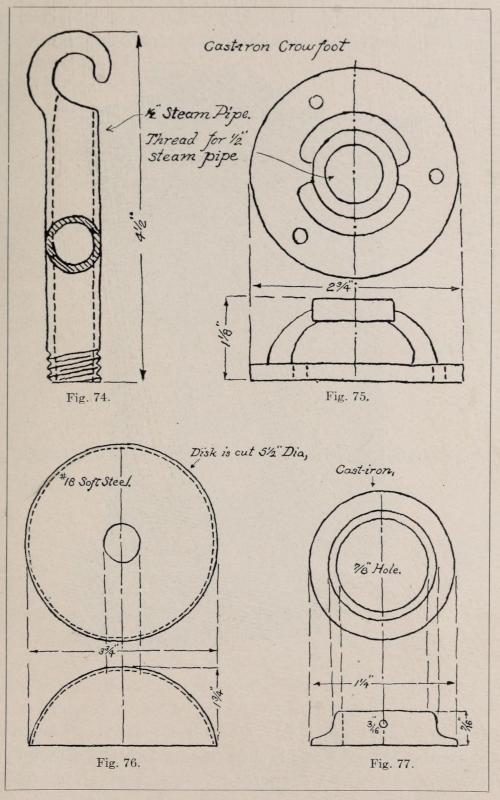

The form and length of the stock for this exercise is shown in Figure 73. The link may be made from iron or soft steel. After the stock is cut, it is heated in the center and bent over the horn of the anvil into a “U” shape. See Figure 74. The ends are now heated and scarfed by setting them on the anvil as shown in Figure 75. The iron is then struck on top with the hand hammer. After each blow, it is moved away from the anvil just a little, giving the end a bevel, so that, when finished, the scarf consists of a series of slanting notches.

Fig. 73. Fig. 74.

In scarfing, both ends of the links are set on the anvil. The end of the one on the right hand side must not be moved when scarfing the other. After each[49] blow of the hammer, the piece is moved just a little. If it is moved too far and the other end of the link is fixed it will describe an arc. See Figure 76. This is the method used in scarfing links. Sometimes they are welded without scarfing, but it is not good practice.

Fig. 75. Fig. 76.

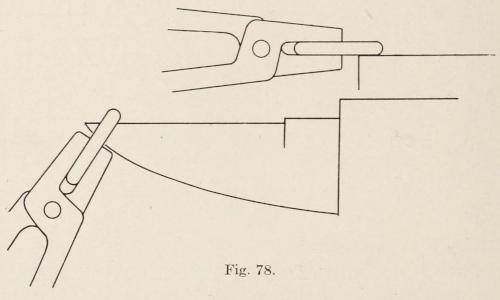

Figure 77 shows the link scarfed, lapped and ready to be welded. In welding, the heat is taken directly on the end of the lap and not on the sides, so as not to burn the stock above the laps. When the link has the welding heat, it is taken to the anvil and hammered on the flat sides, then set on the horn of the anvil, and hammered on the corners. See Figure 78. The shape of the link at the weld should be just a little pointed for a strong link.

Fig. 77.

In making chains, do not weld two single links and then one between them. Weld a link on the end of the chain and keep repeating until finished.

Fig. 78.

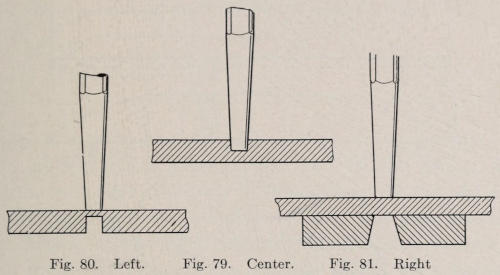

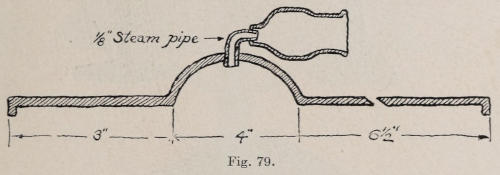

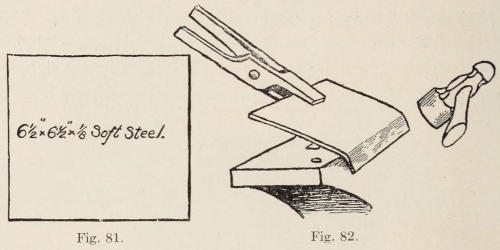

Punching holes thru hot iron is not a difficult exercise. For instance: A ⅜-in. hole is to be punched thru a flat piece of iron or steel. The piece is heated, taken to the anvil and a punch set on the spot to be punched. The punch is struck three or four blows with the hand hammer driving it into the metal as shown in Figure 79. The piece is then turned over and the punch is set over the dark spot which is caused by the former blows, and is driven thru. See Figure 80. Square and other shaped holes are punched in the same manner. Thin stock is punched cold. In doing this, the piece[51] to be punched is set on the punch block and the punch driven thru the metal into the hole of the block. A punch-block is a round or square block of steel with one or more tapered holes thru it. See Figure 81.

Fig. 80. Left. Fig. 79. Center. Fig. 81. Right.

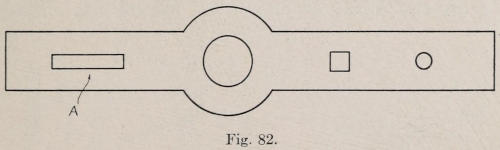

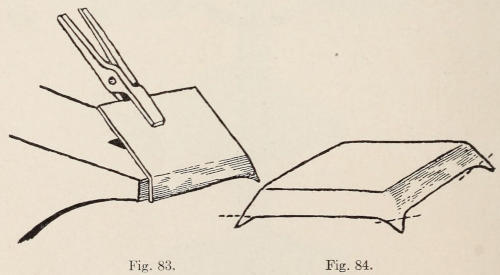

Figure 82 shows some holes that could be punched while the metal is hot. A hole like the one shown at A, is made with a punch of that shape; the next hole is made with the same punch. Afterwards the hole is upset or shortened by heating and cooling each side of the hole. The bar is then hammered on the end. This shortens and spreads the metal. The hole is made true by driving a round punch thru it. The stock used for this exercise should be soft steel.

Fig. 82.

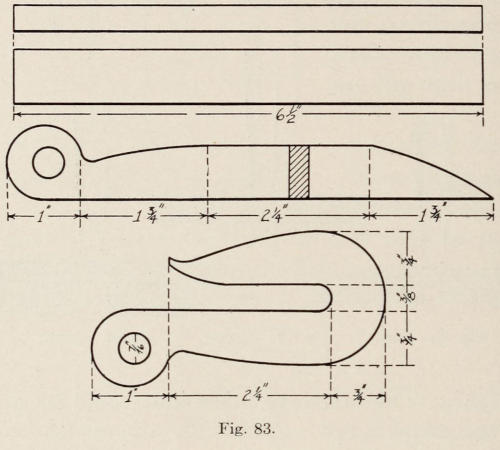

Fig. 83.

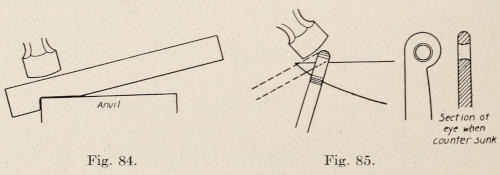

Fig. 84. Fig. 85.

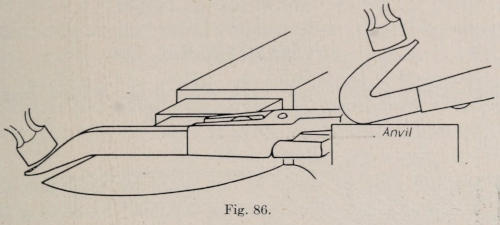

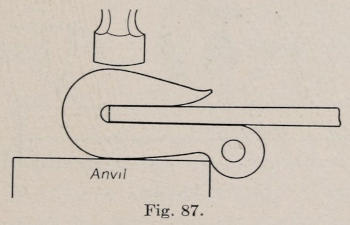

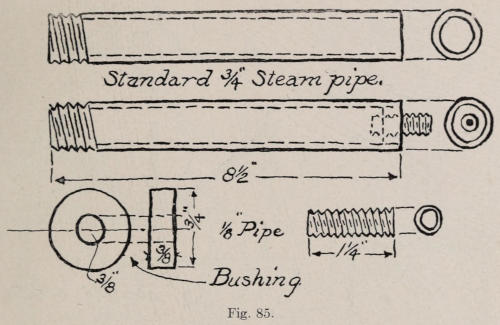

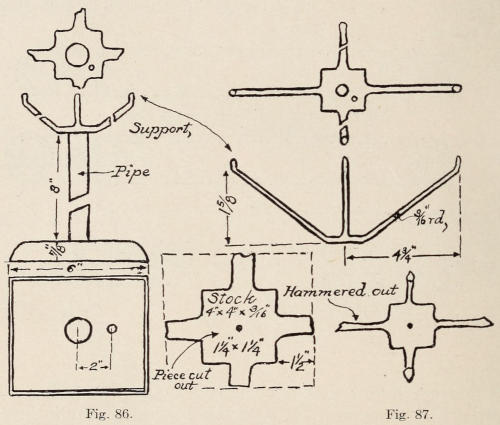

Figure 83 shows a drawing of the hook with size of stock to be used. The stock should be mild steel, 6½ by ¾ by ⅜ inches. To form the eye one end is heated and shouldered back one inch from the end, by hammering it on the anvil as shown in Figure 84. The eye is then rounded with the hammer and the hole punched with a hand punch. The hole is countersunk by hammering it on the horn as shown in Figure 85. The[53] point is next drawn out and then the hook is heated in the center. It is cooled each side of the center and hammered over the horn to bend, then on the anvil as shown at Figure 86. A piece of ⅜-in. flat iron is set on the inside of the hook and the hook hammered to fit the iron. This leaves the opening of the hook uniform and just the size required. See Figure 87.

Fig. 86.

Fig. 87.

Bolts may be made in one piece by upsetting the end of a bar, then squaring the head by driving the piece into a heading tool. A bolt may also be made by welding a collar around the end of a bar after which the head is squared.

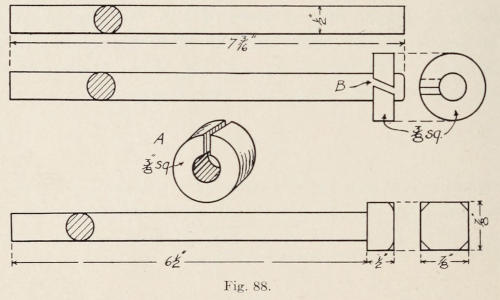

Fig. 88.

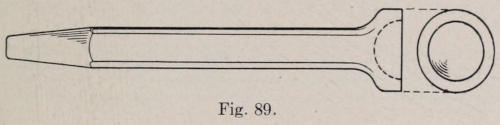

Figure 88 shows a welded bolt head. After the stock is cut to proper length, the collar for the head is made. It is heated and hammered over the horn of the anvil to make it round. The end of the collar is now cut off on the hardie, cutting clear thru from one side and giving it a bevel. The other end is cut from the opposite side giving it a bevel also. See drawing at A. The collar is driven on the end of the bar while[55] the collar is cold and the bar is hot. When the collar is hammered on the end of the bar, there should be about ⅛-in. crack. See drawing at B. The reason is that, in welding, the collar is lengthened. Hammering stretches the metal, and it must have end room. When the collar is ready the bar is heated on the end and upset just a little. A heat is then taken, and the collar is welded by striking it on four sides, letting the opening form one of the corners. The bolt is then inserted into a ½-in. hole in a heading tool to smooth the end of the head with a hammer. A cupping tool is next set on to the head and given a few good blows with the hammer. This bevels the top corners of the square head. A cupping tool is a piece of tool steel with a half round depression in one end. See Figure 89.

Fig. 89.

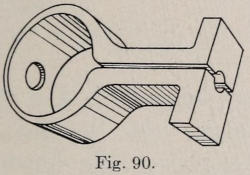

Fig. 90.

The heads of bolts can be beveled with the hammer, instead of with a cupping tool. Figure 90 shows a tool to be used in the vise to make heads on light rods. The rod is heated and inserted into the hole; then the vise is tightened after which the ends are hammered down.

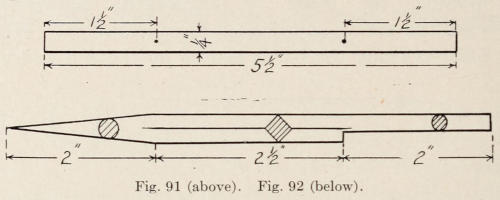

Figure 91 shows the length and size of stock which should be of soft steel. One and one-half inches from each end of the bar is marked with a center punch.[56] One end is drawn round to a point. The other is hammered round for the eye. See Figure 92. In the drawing Figure 93, the eye and the hook are shown turned. The center part of the hook is square and is to be twisted. This is done by heating the square part to a uniform heat and cooling each end. The hook is then twisted with two pairs of tongs, or it may be caught in a vise and twisted with one pair of tongs. See drawing of the finished hook, Figure 94.

Fig. 91 (above). Fig. 92 (below).

Fig. 93. Fig. 94.

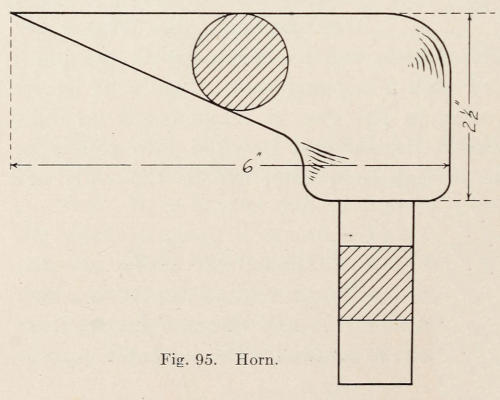

Fig. 95. Horn.

Figure 95 shows a tool called a horn; it fits into the square hole of the anvil. It is used to turn very small eyes at the end of a bar. A[57] piece of 1½-in. round soft steel is used in making it, by drawing the end square to fit the hole in the anvil. It is afterwards bent over and the taper drawn as shown.

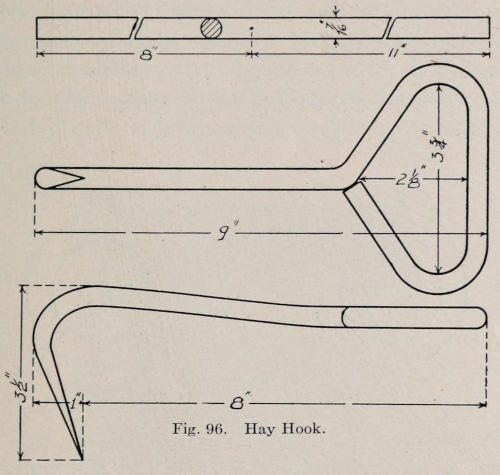

Figure 96 shows the stock which should be soft steel, to be used in making a Hay Hook. The eye is first turned, using 11 inches of the bar. The end is then heated and drawn to a point after which it is bent as shown in the drawing.

Fig. 96. Hay Hook.

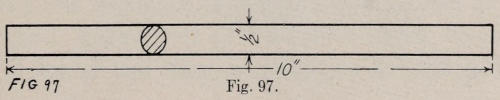

Fig. 97.

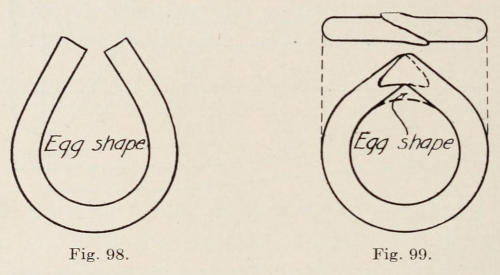

Figure 97 shows a drawing for a ring to be made from ½-in. round stock cut 10 inches long. The whole[58] is heated red at one time and then formed into shape by hammering it over the horn as shown in Figure 98. The ends are now heated and scarfed in the same manner as described for the welded link. When they are lapped and ready for welding, they should look like Figure 99. Notice that the ring is made egg shape so that a heat may be taken directly on the ends of the scarfs and not at the sides. The ring when welded is formed round.

Another method of welding rings is to upset the ends and then form the rings. It is scarfed as explained above. This is seldom done in practical work because it is too slow, and the other method is about as strong.

Fig. 98. Fig. 99.

In welding the ring, it is handled in the same manner as in welding links. To find the amount of stock for rings, the inside diameter plus the thickness of stock is multiplied by 3.1416 or 3⅐. To this is added enough stock for the lap of the weld. For example a ring is required of one-inch stock. The inside measure is 10 inches. Solution: (10 + 1) × 3⅐ = 11 × 3⅐ = 34⁴⁄₇ + ½ inch for welding.

In heating a piece of iron to be formed into a ring, it should never be heated to the welding heat. A welding heat on any piece of work that is not to be[59] hammered destroys the texture of the metal. Any piece of work to be formed, should be heated evenly and not too hot.

Iron when heated expands. For example, if a piece of stock 12 by 1 by ⁵⁄₁₉ in. is heated red its entire length and then measured, it will be about 12¼ in. long. When the piece is cooled it will go back to its original length of twelve inches.

In making bands or tires for wagons, they are made a little short, then heated and put on, letting them shrink to their original size, which makes them tight.

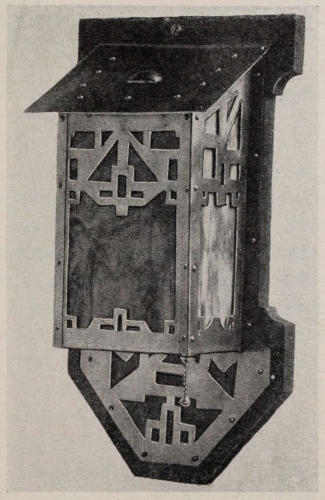

Wrought Iron Lantern.

Marking Tongs—Pig Iron—Puddling—The Bessemer Process—The Open Hearth Process—Crucible Steel—The Cementation Process—Tempering.

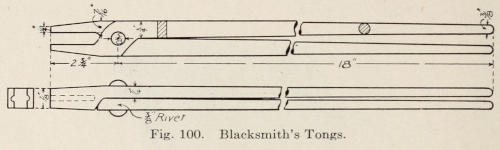

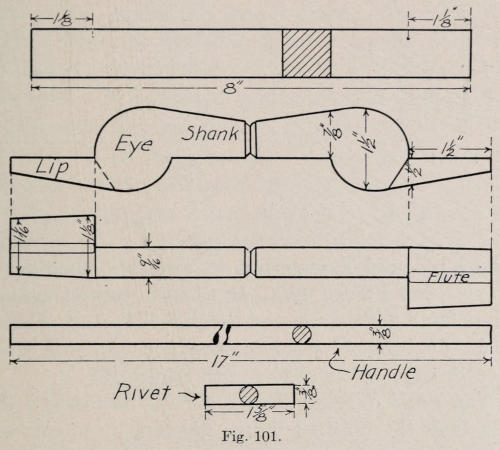

In forging tongs, stock ⅞-in. square of Norway or Swedish iron may be used, as it is much easier for a beginner in welding the handle on to the jaws. Soft steel may be used later on if desired. Figure 100 shows the drawing of a finished pair of flat tongs. Figure 101 shows the size of stock used and the dimensions of the rough forgings. It is not intended that the dimensions given are to be accurately followed, but they are given as an idea of what may be forged from this size of stock. In forging the jaws, no helper is required to handle a sledge hammer after the piece is cut from the bar for the reason that it is time lost for the one who handles it, besides one man can do it.

Fig. 100. Blacksmith’s Tongs.

Fig. 101.

Fig. 102. Fig. 103.

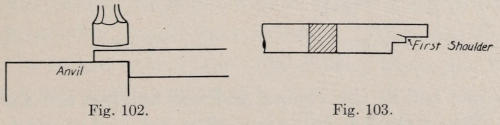

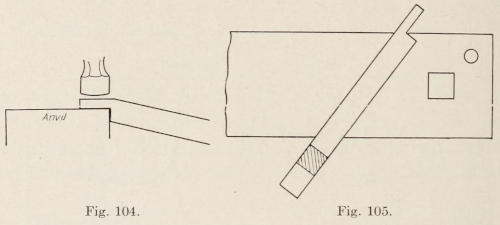

In forging the jaws a heavy hand hammer is used, and the bar is heated to the welding heat, or near it. One and one-eighth inch of the bar is set on the inner edge of the anvil and the lip is hammered as shown in Figure 102. The lip must not be turned and hammered[61] on its edge. Let it get as wide as it will, and do not hammer it too thin. After the shoulder has been started for the length of the lip, it must not be moved. A common fault is to start the shoulder and then to find that the lip is not long enough and proceed to make another shoulder. The result of the second shoulder is that when nearly finished a crack will be discovered. The reason that second shoulder starts a crack is that the metal stretched over the first shoulder. This is called a cold shut. See Figure 103. Another common fault is to lower the bar when making the lip.[62] This pulls the lip on an angle with the bar and when it is straightened, another crack is formed in the corner. See Figure 104. The bar must be on the same plane with the anvil face at all times. When the lip is made, the bar is turned to the left, setting it on the outer edge of the anvil and hammering to form the shoulder for the eye. See Figure 105. It is then turned again to the left hand and hammered down for the last shoulder.

Fig. 104. Fig. 105.

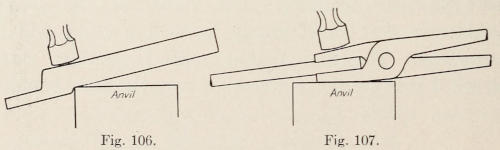

At this time the stock required for the eye is beyond the outer edge of the anvil. See Figure 106.

Fig. 106. Fig. 107.

The rough forging should always be made a little larger than the finished tongs; finishing it to size when the handle is welded on. When both jaws are forged, they are cut in the center and the handles are welded on. When the handles are well upset and scarfed, the shanks of the jaws are drawn to equal size. Care must be taken in having the scarfed ends equal in size or a[63] poor weld will result. The handles at the weld are drawn square with the corners tapered off. The jaws are now drawn and fitted to size. Notice that the lip tapers on the edge, also on the flat part. A small flute is fullered lengthways on the inside of the lip so that round as well as flat iron may be held. The hole is next punched thru the eye with a hand punch. A piece of ⅜-in. rod of soft steel is cut to the proper length and used for a rivet. It is heated and inserted into the holes in the jaws and hammered on both sides with hard blows. The jaws of the tongs are now heated red and worked back and forth to loosen the rivet in the eye. The jaws are fitted to the size of the stock they are to handle as in Figure 107. The regular stock rivets should not be used in tongs. The ⅜-in. round piece headed from both sides fits the holes thru the eye best.

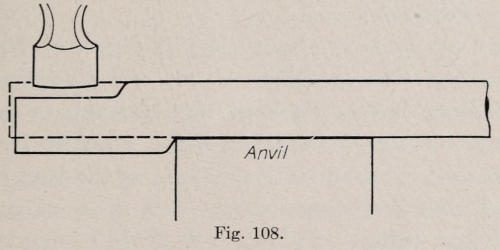

Fig. 108.

In making tongs to hold a larger piece of stock, the square bar should have an offset. The jaws should then be forged as in Figure 108. Notice where the hammer strikes the bar to offset it.

In forging tongs, the handles should be welded to the jaws to give practice in welding.

Pig iron is made by smelting the iron ore in a blast furnace. The ore is charged in a furnace mixed with lime stone as a flux, and melted by using coke or coal as fuel. The resulting metal is called pig iron. It contains from three to five per cent of carbon, two to four per cent of silicon and various small amounts of sulphur, phosphorus and manganese.

Wrought iron is made by melting the pig iron in a puddling furnace; about one-half ton is charged at a time. After it is softened, it is stirred with large iron hooks by the puddler and his helper. It is kept kneaded to expose every part to the action of the flame, so as to burn out all of the carbon. All the other impurities separate from the iron and form what is known as the puddle clinker.

Pig iron melts at about 2100° F., steel at 2500° F., and wrought iron at 2800° F., so the temperature of the puddling furnace is kept high enough to melt pig iron but not hot enough to keep wrought iron in a liquid state. Consequently, as soon as the iron becomes pure it forms a spongy mass. This mass of sponge is divided into lumps of about 100 or 150 pounds which are taken to a squeezer and formed into blocks. In the operation of squeezing the greater proportion of impurities left in the iron after the puddling, are removed. While these blocks are still hot they are rolled into flat musk bars. The bars are now cut and heated to white heat in a furnace, taken to the rolls, welded and rolled into merchant bars. In the welding and rolling the cinder coated globules of iron are forced close[65] together as the iron is welded. This gives the iron a fibrous structure increasing its strength.

In making steel by the Bessemer process, the pig iron is put into a large pear shaped vessel called the converter. The bottom is double; the inner casing is perforated with holes called tuyeres, to admit air forced under pressure. From ten to fifteen tons of molten iron at one time are poured into the converter while it is lying on its side. The compressed air is now turned into the double bottom as the converter rises to a vertical position. The air has sufficient pressure to prevent the metal from entering the tuyeres, and it passes up and thru the metal, burning out the carbon. After the blast which lasts about ten minutes, the metal is practically liquid wrought iron. The converter is now laid on its side and the blast is shut off. A certain amount of molten spiegeleisen (white cast iron containing much carbon or ferromanganese) is added so as to give the steel the proper amount of carbon and manganese to make it suitable for its purpose. The steel is then poured into ingots and rolled into rails, girders, etc. Carbon is pure charcoal; manganese is a chemical element very difficult to fuse, but easily oxidized.

The open hearth process of steel manufacturing is similar to the puddling process. The carbon is removed by the action of an oxidizing flame of burning gas. The furnace has a capacity of forty or fifty tons and is heated with gas or oil. The gas and air needed for its combustion are heated to a temperature of over[66] 1000° F. before entering the combustion chamber, by passing thru so-called regenerative chambers. Owing to the preheating of the gas and air a very high temperature can be maintained in the furnace so as to keep the iron liquid after it has parted with the carbon. The stirring up of the metal is not done with hooks as in puddling furnace but by adding certain proportions of iron scales or other oxides the chemical reaction of which keeps the metal in a state of agitation. With the open hearth process the metal can be tested from time to time. When it contains the proper amount of carbon it is drawn off thru the tapping hole at the bottom of the hearth, leaving the slag at the top. As steel is produced in a liquid form, from which impurities have been removed in the form of slag that rises and floats at the top, the metal is homogeneous and practically without grain. Wrought iron will outlast steel when exposed to the weather.

Crucible steel, or tool steel, also called cast steel, is made by using high grade, Swedish, wrought iron and adding carbon which is low in phosphorus content. The oldest method is called the “Cementation Process.” The iron bars were packed in air-tight retorts with powdered charcoal between them. They were put in a cementation furnace, heated red and kept at this temperature for several days. The bars, in this way, absorbed the carbon from the charcoal. The carbonized bars (called “blister steel”) were then cut into small pieces, remelted in a crucible, poured in ingots and rolled into bars.

The newer method is to melt small pieces of Norway or Swedish iron base with charcoal in a graphite or clay crucible. It is then poured into moulds and made into ingots, after which it is forged or rolled into bars.

The crucible process enables the manufacture of steel to almost exact analysis and insures a clean and pure material. It also absorbs the carbon much faster than steel made the old way.

In the school forge shop, the tool steel used should be of an inexpensive kind. High priced steel should not be used as more or less is wasted by the pupils in working. A carbon steel should be used for all forge shop tools. About 75 to 95 point is suitable. High-speed tool steel should be used only to give the pupils instruction in its handling and use, and to familiarize them with the different kinds of steel and their treatment.

To the steel maker, temper means the percentage of carbon in the steel. The word point means one-hundredth of one per cent, thus 10 point carbon means ten one-hundredths of one per cent. One hundred and fifty point carbon contains one and one-half per cent. This is about as high as is generally made. One hundred and fifty point is known as high temper; low temper is about 40 point. Steel containing less than 40 point does not harden to advantage and is classed with machinery steel. There is a range of tempers between high and low point which are used for different kinds of tools.

In the forge shop the term temper means the degree of hardness given to a piece of tool steel. As an example, a piece of steel is heated to a dark red color and cooled in water or oil. This is called hardening. If this piece is too hard for the purpose intended, it is then tempered to reduce some of its hardness, and to give the steel elasticity and strength. In doing this, it is subjected to heat, (the more heat the softer the piece[68] becomes). In the forge shop, in tempering steel, the metal is polished bright after hardening. If it is a small piece, it is then held on or near a piece of hot iron. As the piece becomes heated, the steel heated in the air assumes colors; at first a very faint yellow and gradually darker, until all of the color has disappeared leaving the steel without any trace of hardness.

These different colors as they appear on the surface of hardened steel represent different degrees of hardness. The following simple list of colors applies to the different tools and carbon to use:

Light straw—430° F. Lathe tools—130 point carbon.

Dark straw—470° F. Taps and dies—120 point carbon.

Purple gray—530° F. Chisels and blacksmiths’ tools, 75 to 95 point carbon.

Of course there are other colors than these. As the heat advances every few degrees the color keeps changing to a darker which indicates the tool is becoming softer.

The hardening heat is about 1300 to 1400 degrees Fahrenheit, or a cherry red. About 400 degrees Fahrenheit relieves the strain in a hardened piece of steel; 600 degrees leaves a trace of hardness and is about right for springs.

In order to know the results of heating and cooling steel one should take a small bar and cut nicks in it with a chisel every half inch. The bar is then heated from a white heat at the end to a very dark red some inches back. It is then cooled in water, the pieces broken and the grain noted. The heat that leaves the steel file hard and a very fine grain is the hardening[69] heat of that steel. The hardening heat is a dark red. The hotter it was when cooled the coarser the grain shows on the end of the broken pieces.

In further demonstrating hardening and tempering of tool steel, the making of a flat cold chisel will be considered. The principles involved are about the same in all hardening and tempering.

Making a Flat Cold Chisel—Spring Tempering—Welding Steel—Case Hardening—Coloring Steel—Annealing—Making a Scratch Awl—Making a Center Punch—Making a Hand Punch—High Speed Steel—Annealing High Speed Steel.

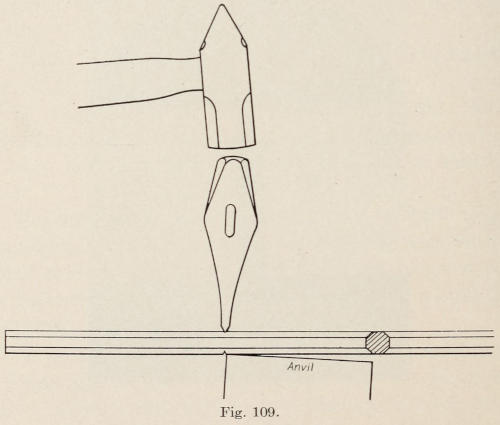

Fig. 109.

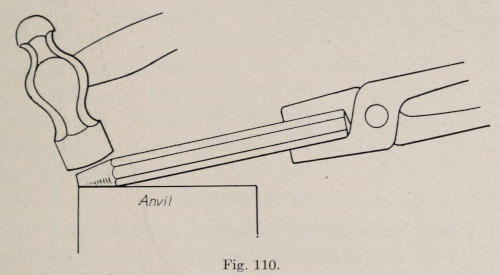

A good cold chisel is an indispensable tool in a shop, and one that is very much abused. Therefore, it should be made with the greatest care. In the forging of a good chisel a piece of ⅝-in. octagonal tool steel, from 75 to 95 point carbon, is used. The piece is cut six inches long. In doing this the bar may be nicked with a chisel. The nicked part is then set over the outer edge of the anvil. A chisel with a handle is set on the nicks and given a good blow with a sledge hammer, shearing the piece from the bar. See Figure 109.[71] This method of cutting is quite dangerous, so care must be taken. Perhaps, a less dangerous method, tho not so practical, is to heat the bar red and cut the piece off with a hot chisel and sledge, or on the hardie, if one has no helper. The end is then hammered. See Figure No. 110.

Fig. 110.

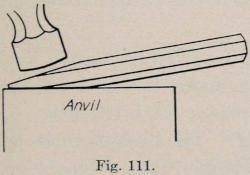

When cut off and hammered round on one end, the piece is caught with a fluted-lip pair of tongs that will hold it firmly and a ring is placed on the ends of the reins to bind them. The end is now heated in a well burned fire, letting the heat soak in slowly, and not forcing it with too much blast. If the fire is lively hardly any blast is used on the start. The piece is brought to a heat somewhat beyond what is commonly called cherry heat. It is then taken to the anvil and drawn out square with hard blows of the hammer, to a long taper, and nearly to a point. This taper should be about 1¾ inches long. See Figure No. 111.

Fig. 111.

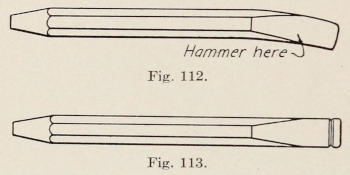

Hammering must cease before the red heat has left the steel. It is again heated and hammered on two sides; in drawing the chisel bends edgewise. Do not strike it on the edge; it will fracture the grain of the steel. To straighten the blade, it should be hammered on the flat side near the concave edge. See Figure No. 112. This stretches the metal and straightens the blade. Care must be taken in hammering not to make the chisel wider in one place than in another.

Fig. 112. Fig. 113.

When finishing the chisel, it is hammered lightly until the red is nearly but not quite gone. This hammering packs the grain and makes it fine. The end of the chisel is set on a hardie and cut half thru, so that when it is hardened and tempered it may be broken to note its grain and also require less grinding in sharpening. See Figure No. 113. The chisel is now heated very slowly to a dark red and set in a dry place on the forge to anneal. This annealing relieves the strain in the tool due to hammering.

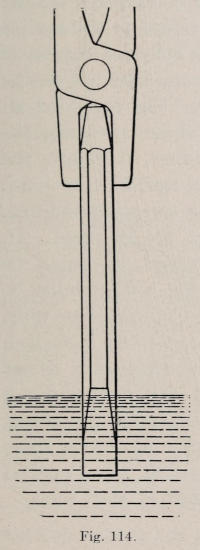

When the chisel is cold it is reheated to harden and temper. Over-heating does not make the tool harder when cooled in water, but increases its brittleness, so care must be taken when heating. The heating must be very slow, and to a dark red, 2½ inches long. The chisel should be cooled as the heat is going up. A common practice of heating the steel more than a cherry red and holding it out of the forge until the heat goes down, before dipping, is wrong. When properly heated the[73] chisel is held in a vertical position and dipped about 1½ inches into 16 gallons of salt and water, heated from 60° to 70° F. See Figure 114. The tool is kept in motion when dipped. When cooled it is removed, and the hardened part is rubbed bright with an emery stick or sand paper. This is done so that the temper colors may be seen. Tempering increases the tool’s elasticity and strength, and reduces the brittleness. The temper color will show just a faint yellow against the edge of the remaining heat that was left in the tool after hardening.

Fig. 114.

In hardening the tool, it is heated 2½ inches of its length and 1½ inches is cooled in water to harden. The remaining heat gradually runs thruout the whole chisel and may be noted by the faint yellow color on the bright part of the tool traveling towards the cutting end. This faint yellow temper color, due to the heat and air, is followed with darker colors; if let run too much all of the hardness would be taken out of the tool. Four hundred and thirty degrees Fahrenheit would be about a light straw color, leaving the steel very hard. About 600° F. would be the darkest color, nearly black. This is as hot as steel can be made and still leave a trace of hardness. This temper is too soft for a chisel but about right for springs; therefore when[74] the very dark purple temper color covers the whole bright part of the chisel the point is dipped in water. The chisel is then set in a dry place on the forge to cool slowly. The temper color must run to the end of the chisel very slowly. The reason for this is that if the temper color comes slow, the chisel is tempered farther back from the point. The temper colors on the surface of the bright steel are obtained by different degrees of heat, as it travels from the remaining heat left in the tool when the piece was hardened. The less heat allowed to travel toward the end of chisel, the paler the temper color and the harder the chisel; therefore, the faint yellow color indicates that the steel is very hard. The darker the temper color becomes the softer the tool.

The best chisels are those that are file proof. If, after hardening and tempering a chisel, it cannot be cut with a file, it is too hard and the temper must be run out more. If the grain of steel is very fine when broken the chisel had the proper heat when quenched, but if it looks coarse the tool was too hot when cooled and must be annealed, rehardened and tempered. A little judgment will enable one to determine the proper hardness for all tools of this character by noting these temper colors. The above explanation in a general way applies to the working of all carbon steel tools.

There are many kinds of springs that are hardened and tempered. The methods of handling are about the same with all. As an example, a piece of spring steel 5 by 1 by ¹⁄₁₆ inches is to be tempered. In doing this, the piece is caught at one end with a pair of light tongs. The steel is heated to a dark red and dipped into a can[75] of sperm oil, or equal parts of lard and tallow. When cool it is held over the fire until the surplus oil takes fire and blazes off. It is redipped in the oil, and the oil is burned three times in all. It is then partly cooled in the oil and set on the forge until cool, when it is ready for use. Steel is manufactured especially for springs. It is called spring steel. It is made in a different way from tool steel, by the open hearth process. It differs in quality and cannot be absolutely guaranteed. The steel is never free from all foreign elements which might be detrimental to its quality.

In hardening thin pieces of steel such as knives, very thin milling cutters, etc., there is always difficulty in preventing warping after hardening. Two heavy surface plates, planed on one side, are used. On one of these plates equal parts of tallow and lard are spread ¼ inch thick. The knife is heated in a steam pipe with one end plugged and having fire under and over it. When an even red heat is reached, the knife is brought out and set on the oil and at the same time the top plate is set onto the knife until cool. This hardens the blade and keeps it from springing. The knife is brightened and the temper is drawn to a dark straw color by holding it on a hot iron.

Very small pieces of steel are packed into an iron pipe or box surrounded with charcoal. The whole is then heated red and the pieces are dumped out and cooled in water. To draw temper, they are put in an iron ladle filled with lard oil that is heated on the fire.

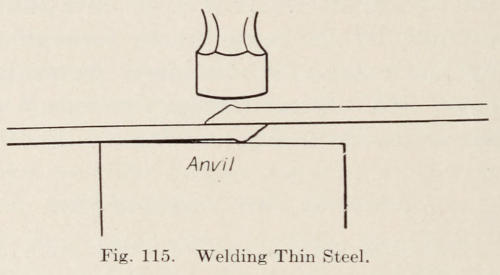

All small pieces of tool and spring steel should be welded with separate heats. A little practice and a clean fire, with some good welding compound, are necessary. In separate heat welding of flat steel, the flat sides of the scarfs are put together instead of the beveled ones. The scarfs are shown in Figure No. 115. The method of riveting and splitting small pieces of flat steel to hold them together while taking the heat is not to be recommended because after they are put together in this manner the lap is double thick, and in raising the heat there is always danger of over-heating each side of the lap. Separate heats and a clean fire is the best method to use to make a good weld, unless the steel is heavy. In this case, it is split and forked as previously explained.

Fig. 115. Welding Thin Steel.

The difference between wrought iron and tool steel lies in the absence of carbon in the iron. Tool steel can be hardened because it contains carbon, and when heated and suddenly cooled becomes hard thruout. The surface of wrought iron or mild steel can be carbonized and then made very hard. This is called case hardening because about ¹⁄₁₆ inch or less of the[77] outside of the bar is made hard while the center is soft. There are several methods. One is to place the articles in a tight cast iron box and surrounded with ground bone before placing in a furnace. The box is then brought to a high heat of about 1700 degrees Fahrenheit. It is held at this heat for several hours and then let cool. When cool, the pieces are reheated and dipped in salt water to harden them or they may be cooled with the first heating. By another method the pieces are placed in an iron ladle with cyanide of potassium and heated. Iron may be heated red and rolled in the cyanide, then reheated and plunged into water. Care must be taken in handling cyanide as even the fumes are poisonous.

Very bright pieces of soft steel can be case hardened and colored at the same time. In doing this, cyanide is heated in an iron box, and the steel articles are put into it. When heated they are removed and dipped into a solution of water and salt peter to cool and harden them. This gives them a mottled effect with many colors. A pint of salt peter to about four gallons of water makes a solution strong enough. This bath becomes poisoned from the cyanide. It should be kept clean and labeled “Poison.”

A piece of metal of any kind is said to be “annealed” when made very soft. Steel should be annealed before it is filed, drilled, or machined, as it is a very hard metal to work when cold. The method of annealing is first to heat the piece to a red heat. It is then covered with warm, slacked lime so that the air will[78] not come in contact with it until cool. A simple way to anneal, when in a hurry, is to heat the steel red, setting it in a dry place on the forge until black. It is then plunged into water quickly and brought out. This operation is repeated until the piece is cool. Steel is also annealed by heating the piece red and setting it on the forge until cool. The slower steel is cooled, the softer it becomes. Wrought iron and mild steel forgings should always be annealed when used in work where there is danger of breaking them.

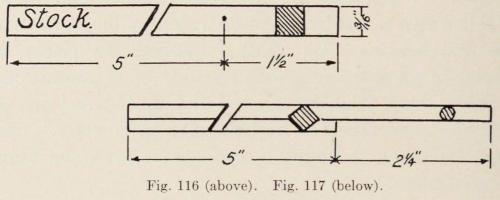

Fig. 116 (above). Fig. 117 (below).

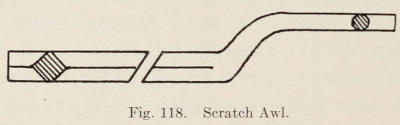

Fig. 118. Scratch Awl.

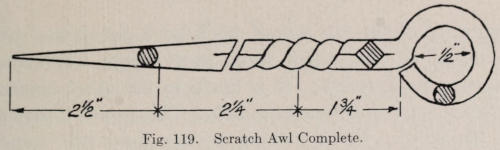

This tool is used to scratch holes on the surface of metal, and also to lay out shapes on metal. Figure 116 shows the dimensions of stock. The piece should be carbon steel. One and one-half inches from one end, the bar is drawn out until it measures 2¼ inches in length, as shown in Figure 117. It is then bent on an angle as shown in Figure 118. This part is now heated and hammered over the horn of the anvil to form the[79] eye or ring. It is then twisted by catching one end in the vise and twisting to the right. The point is next drawn out as shown in Figure 119. The point is then ground or filed and the awl tempered hard.

Fig. 119. Scratch Awl Complete.