The Project Gutenberg eBook of Tinting and toning of Eastman positive motion picture film, by Anonymous

Title: Tinting and toning of Eastman positive motion picture film

Second edition--revised

Author: Anonymous

Release Date: March 31, 2023 [eBook #70417]

Language: English

Produced by: Bob Taylor, Charlene Taylor and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive/American Libraries.)

Price $2.50

Second Edition—Revised

Eastman Kodak Company

Rochester, N. Y.

1918

Owing to the difficulty of obtaining foreign made dyes, a revision of the first edition of this publication has been made necessary.

As the result of an exhaustive series of tests of the products of the National Aniline & Chemical Company, Incorporated, New York City, it is now possible to recommend a number of American made dyes suitable for the tinting of motion picture film, and those recommended in this book are in most cases equal in every respect to those previously obtained abroad.

To date, it has not been possible to obtain a thoroughly satisfactory blue dye, film tinted with the Cine Blue recommended being too red, especially before drying. A more suitable dye will no doubt be available in due course.

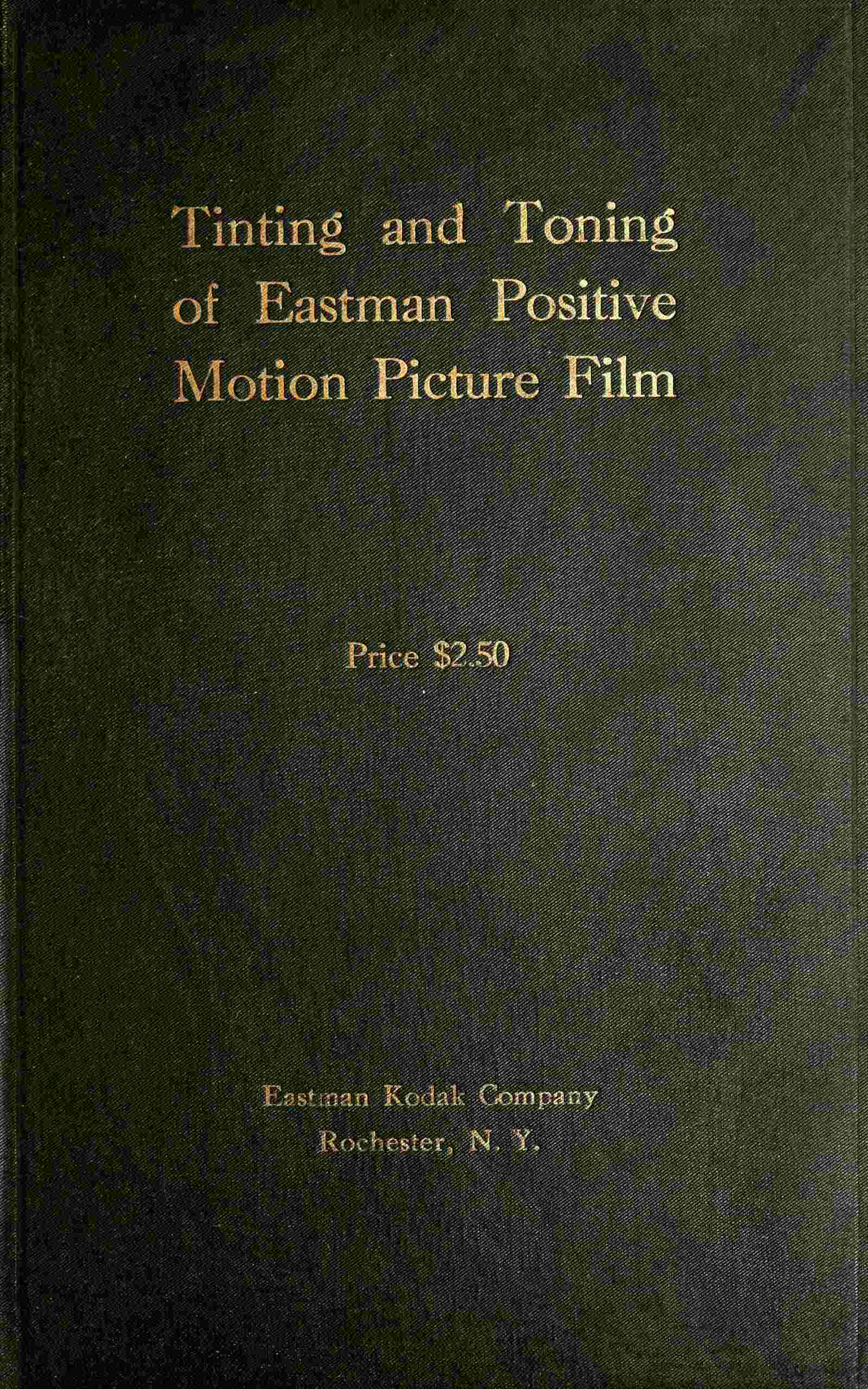

The number of sample tints has been curtailed to twelve, and these are given merely for guidance. It is intended that the various formulas should be altered to suit individual requirements.

The chapter on toning has been thoroughly revised, a number of tones having been eliminated and others substituted. The formula for the copper tone has been improved, while the formulas for green tones requiring the use of vanadium chloride have been eliminated in view of the expense and difficulty of obtaining satisfactory vanadium chloride. With the samples at present on the market it has not been possible to prepare a single-solution toning bath which would keep for any reasonable length of time.

Attention is drawn to the new method of dye toning[1] recently worked out in our Research Laboratory. This consists in first treating the film in the copper toning bath and then immersing the washed film in a solution of a basic dye, the dye attaching itself to the image and leaving the gelatine clear. Although specific directions are given for obtaining five tones only by this method, as further dyes are available, those suitable for toning purposes will be published in due course.

The method of producing sulphide tones has been changed to one of simple re-development with sodium sulphide, the addition of hypo to the sulphide solution having been eliminated. By commencing with thin positive film of the correct density, and using a plain solution of sodium sulphide for re-development, satisfactory transparent tones are obtainable with precision.

The formulas for the iron and uranium tones are the same as in the first edition.

EASTMAN KODAK COMPANY,

Rochester, N. Y.

August, 1918.

[1] The patent rights to this method are being secured by us, but it may be freely used for toning motion picture film manufactured by the Eastman Kodak Company.

[Pg 5]

Tinting and Toning of Eastman

Positive Motion Picture

Film

In the production of motion picture film it is becoming more common to vary the color of the film either by toning or tinting or by a combination of the two processes. Toning consists in either wholly or partially replacing the silver image of the positive film by some colored compound, the clear portions or highlights of the image, consisting of plain gelatine, remaining unaffected and colorless. Tinting, on the other hand, consists of immersing the film in a solution of dye which colors the gelatine itself, causing the whole picture on the screen to have a veil of color over it.

In “tinting” the following factors must be taken into consideration:

Nature of the Dye Employed

Dyes are chemically of two different types, acid and basic; so-called acid dyes are the alkali salts of organic acids, while basic dyes are the chlorides, sulphates, etc., of organic bases.

For the tinting of film only “acid” dyes have been considered since it is not possible to make a complete selection from basic dyes alone, which would necessitate the use of acid and basic dyes in admixture—a procedure highly undesirable and in many cases impossible.

[Pg 6]

Any dye suitable for admixture with others to produce intermediate tints should possess the following properties:

A. The dye should be inert and not attack the gelatine or support. This is of fundamental importance as the gelatine coating of dyed film in many cases has a tendency to lose its flexibility, giving rise to what is known in the trade as “brittleness.”

Several dyes when employed at a concentration of 1% attack gelatine readily at 70 degrees F. and vigorously at 80 degrees F., especially in presence of small amounts of acid, producing a marked softening and often partial dissolution of the film. The effect is roughly proportional to the concentration of the dye and to the temperature, and varies with each individual dye.

Experience has shown that the gelatine coating of film which has been softened in this way by the dye becomes “brittle” on subsequent projection.

The actual factors in the production of brittleness are:

1. The hydrolysing action of acid which in many cases is added to assist dyeing. In case a solid acid is employed the heat encountered during projection will greatly accelerate this hydrolysis.

2. The corrosive action of the dye itself. Dyes vary considerably in this respect according to their particular composition. So far, it has not been possible to make any general classification of dyes in this connection, though nitro compounds appear to be particularly corrosive in their action.

3. The presence of impurities in the dye. These take the form of excessive amounts of loading material such as sodium sulphate or chloride, or small traces of iron, the latter having a tendency to harden the film considerably.

In all the above cases, the physical nature of the gelatine is altered, whereby it loses its property of remaining resilient under normal conditions of temperature and humidity, resulting in “brittleness.”

A suitable test as to whether a dye has any propensity to produce brittleness is to incubate a sample of film, half of which has been dyed, for about 48 hours at 212 degrees F. If any difference in brittleness is noticeable between the[Pg 7] dyed and the undyed portions so treated after the film has been allowed to stand in the air for some time, the dye is unsuitable for tinting.

Apart from the above, most dyes when used at a concentration of 1% and at 80 degrees F. produce more or less softening of the gelatine, which may be prevented by:

(a) Use of only dilute solutions. Except in very special cases, a dye solution stronger than 0.5% is seldom required, the usual strength employed being about 0.2%, at which concentration softening is unusual.

(b) Use of a minimum amount of volatile acid in the dye-bath or omission of the same whenever possible.

(c) By working at temperatures not higher than 70 degrees F.

(d) By slight hardening of the film before dyeing and subsequent softening by glycerine, as described below:

B. The dye should not “bleed” to any considerable extent when the film is washed; in other words, the rate of removal of the dye should be slow and only a slight amount should wash out in a period of, say, five minutes.

In tinting, bleeding is of very considerable importance, since, during the periods between rinsing after dyeing and the placing of the film on the drying rack, any drops of water on the surface of the film become more or less saturated with dye, and these after drying remain as spots and irregular markings which are very apparent on the screen.

It is possible in some cases to modify this bleeding by an acid “stop bath,” or by adding acid to the dye-bath; though it may be considered a general rule that the bleeding of a dye is a property peculiar to itself. In making a selection of dyes therefore, it is necessary to choose only those whose propensity for bleeding is a minimum.

C. The rate of dyeing should be only slightly affected by the addition of acid to the dye-bath, although most acid dyes are more or less sensitive to acid.

In case the rate of dyeing is appreciably affected by the addition of acid it is possible to take advantage of this fact since a much weaker dye solution may be employed to obtain a given tint, while an apparently exhausted bath may be revived by adding a small trace of acid.

[Pg 8]

Only a volatile acid such as acetic acid should be used since this will evaporate on drying, while the strength of the acid in the dye-bath should not exceed .05% or one part in 2000, otherwise softening of the gelatine is liable to occur, especially if the temperature exceeds 70° F.

In the case of a bath containing a mixture of dyes, owing to the fact that acid affects some dyes more than others, as the dye-bath becomes exhausted and the acid content changes, the tint obtained will gradually change also. It is only possible therefore to use acid with any degree of certainty in the case of dye-baths containing a single dye.

D. The dyes should not fade on exposure to heat or light and should not be “dichroic” or change color on dilution.

Moreover, the wear and tear of the film should not be impaired in any way after dyeing, and even after incubating for 48 hours at 212 degrees F., afterwards allowing the film to humidify, no difference should be discernible between dyed and undyed film so treated.

E. The dye should not be affected by the acid fixing bath since any fixing solution accidentally splashed thereon, would destroy the dye immediately.

In view of the large number of tints required in commercial work, it is undesirable to keep a separate dye-powder for the preparation of each particular bath, but rather to prepare the same by admixture of three or more dyes. If three only are employed, mixing must be conducted with great precision in order to reproduce any given tint, but this difficulty is removed by the use of intermediate colors.

The following six standard dyes have been chosen as fulfilling the above conditions as nearly as possible, and by suitably mixing solutions of these, almost any desired tint may be obtained.

| Name Used in Formula | Commercial Name |

| Cine Red | Serichrome Blue R |

| ” Scarlet | Crocein Scarlet MOO |

| ” Orange | Orange A Concentrated |

| ” Yellow | Niagara Fast Yellow |

| ” Green | Ammaco Acid Green L |

| ” Blue | Buffalo Fast Blue R |

[Pg 9]

These dyes are obtainable from the National Aniline & Chemical Co., Inc., New York City.

The strength of the dyes may vary slightly from batch to batch, but this variation is usually so small as not to materially affect the nature of the tint obtained from any particular formula.

The Cine Blue dye appears much redder by artificial light than by daylight, especially before drying the film, as do all tints containing Cine Blue.

The following formulas are given merely for guidance and should be altered to suit individual requirements.

When matching any color view only by artificial light.

Formulas for Tinting at 65° F.

| Tint Number on Chart | Avoirdupois | Metric | Time of Tinting | |||

| 1. | Cine Red | 8 | ozs. | 250 | grams | |

| Acetic Acid (Glacial) | 3½ | ozs. | 100 | grams | ||

| Water | 50 | gals. | 200 | liters | 5 minutes | |

| 2. | Cine Red | 8 | ozs. | 250 | grams | |

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 3. | Cine Scarlet | 8 | ozs. | 250 | grams | |

| Acetic Acid (Glacial) | 3½ | ozs. | 100 | grams | ||

| Water | 50 | gals. | 200 | liters | 5 minutes | |

| 4. | Cine Orange | 8 | ozs. | 250 | grams | |

| Acetic Acid (Glacial) | 3½ | ozs. | 100 | grams | ||

| Water | 50 | gals. | 200 | liters | 4 minutes | |

| 5. | Cine Orange | 1 | lb. | 500 | grams | |

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 6. | Cine Yellow | 8 | ozs. | 250 | grams | |

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 7. | Cine Yellow | 4 | ozs. | 125 | grams | |

| Cine Green | 8 | ozs. | 250 | grams | ||

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 8. | Cine Green | 13 | ozs. | 400 | grams | |

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 9. | Cine Green | 8 | ozs. | 250 | grams | |

| Cine Blue | 8 | ozs. | 250 | grams | ||

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 10. | Cine Blue | 8 | ozs. | 250 | grams | |

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 11. | Cine Blue | 4 | ozs. | 125 | grams | |

| Water | 50 | gals. | 200 | liters | 10 minutes | |

| 12. | Cine Blue | 8 | ozs. | 250 | grams | |

| Cine Red | 4 | ozs. | 125 | grams | ||

| Water | 50 | gals. | 200 | liters | 10 minutes | |

[Pg 10]

Method of Mixing

Dissolve the solid dyes in as small an amount of hot water as possible, and filter through fine muslin. Pour hot water over any residue remaining, which should only be slight, in order to ensure thorough solution of the dye, and dilute the solution in the tank to the required volume at 65 degrees F.

Nature of Positive Film

Only good snappy positive film may be successfully tinted, since tinting tends to reduce contrast.

The depth of the tint obtained depends on the following factors:

Nature and Strength of the Dye-bath

Except in special cases such as fire scenes, sunset and moonlight effects, and the like, it is very undesirable to employ strong tints, since apart from the displeasing effect and irritation to the eye, the dyes produce a slight softening of the gelatine film when used at 80 degrees F. in 1% solution.

Should it be necessary to employ concentrated baths in summer, either cool the dye-bath or use a suitable hardener. This will be unnecessary if hardener is employed in the fixing bath after development, but otherwise if formalin (40%) be added to the dye-bath to the extent of 1 volume to 400 volumes of dye solution, no trouble will be encountered. During the winter months, when it is advisable to treat all film after developing and fixing, with glycerine, the latter may be incorporated with the dye-bath, thereby eliminating an extra operation. The strength of the glycerine should be 2%, or two volumes per one hundred volumes of dye solution. In most cases, however, the addition of glycerine considerably retards the rate of dyeing, so that in order to obtain the same degree of tinting within a period of ten minutes, the concentration of the dye-bath should be increased accordingly.

When delicate tints are employed, the effect is both to remove the contrasty black and white effect, and to add a touch of warmth to the black deposit of silver, even in cases where the highlights are insufficiently stained to be noticeable. The result in many cases is equal to that obtained by partial toning, for example, tint No. 11 gives the effect of a blue-black tone.

[Pg 11]

Temperature of Dye-bath

Although temperature has little effect on the rate of dyeing with the dyes recommended, when used without the addition of acid it is advisable in all cases to work at 65 to 70 degrees F. in order to produce uniform results and remove any danger of softening the film.

Time of Dyeing

In order to duplicate any particular tint with a given dye-bath the film may be dyed either by time or by inspection. Dyeing by time is reliable if the dye-bath does not contain acid, though if acid is present, in time the acidity decreases, causing a slowing down of the rate of dyeing so that it becomes necessary to judge the progress of dyeing by inspection.

If two or more tints of the same color are required, in order to reduce the number of individual dye-baths to a minimum, it is better to vary the time of dyeing rather than to vary the dilution of the bath, providing the time of dyeing for the lighter tint is not less than one minute, which time is considered a minimum for the production of uniform results and for complete control of the dyeing operations.

The time of dyeing also depends somewhat on the previous handling of the film. Film which has been fixed in a bath containing ordinary, or chrome alum, dyes more quickly than that treated with plain hypo and hardened with formalin.

It is probable therefore, that small traces of alum are left in the film even after prolonged washing, which serve as a mordant for the dye.

The film samples herewith shown were fixed in the regular acid hypo bath, so that if for any reason the tints indicated are not obtained in the time stated, then either the time of dyeing or the dilution of the dye-bath should be altered accordingly.

Should the film for any reason be over-dyed, a small portion of the dye may be removed by washing for 10 to 15 minutes, though the nature of the dyes will permit only slight mistakes to be rectified in this manner.

[Pg 12]

Life of the Dye-baths

This averages about 40,000 feet per 50 gallons of dye-bath. The baths may be revived at intervals by the addition of more dye, though this procedure is uncertain and it is generally advisable to mix fresh solution.

The addition of a trace of acetic acid (1 part in 1000) will revive an apparently exhausted bath though as stated above, it is only advisable to do this in the case of baths containing a single dye.

Method of Procedure

Either the “drum” or “rack” method may be employed, and in either case after dyeing for ten minutes (during which time the drum or rack should be agitated to ensure even dyeing and prevent accumulation of air bubbles) the film should be given a thorough rinse in plain water.

Before drying films on racks it is advisable to set the rack at a slight angle for a few minutes, to enable the surplus water to drain off more readily through the perforations. If drums are used for drying it is advisable to remove the surplus water by whirling the drum previous to drying.

If uniform results are to be obtained, film should never be passed through the projector before either tinting or toning.

How to Obtain Intermediate Tints

The twelve tints above are given merely as examples; other tints may be readily obtained by making a trial with a small amount of solution on a short length of film, taking care to match the tint in artificial light and not by daylight, since any dye containing Cine Blue appears redder by artificial light than by daylight.

When matching think of the tint as being made up of one or more of the colors, red, yellow, and blue. Colors such as orange are made by mixing yellow and red, violet by mixing red and blue, and green by mixing yellow and blue. Browns are obtained by mixing all three colors red, yellow, and blue.

[Pg 13]

When comparing any two particular tints, it is usual to say that one is redder, yellower or bluer than the other, and the two may therefore be matched accordingly.

Choice of Tint

Almost any tint if delicate may be employed with advantage, though for general use those ranging through pink, rose, orange, yellow, pale green and pale blue are to be recommended; others are for special purposes.

It is always desirable to obtain harmony in color, especially when combining tinting with toning, so that the combination is pleasing to the normal eye.

For local tinting and hand coloring, the above dyes are likewise satisfactory.

Troubles in Tinting

Streaks and Uneven Coloring

Cause

a. Grease on the film. Never project film before tinting.

b. Slight bleeding and insufficient squeegeeing when on the drying rack. Always carefully remove any surface moisture from the film with a damp chamois, before drying.

Sludge in the Dye-bath

This is due to the precipitation of the dye by small traces of alum or iron in the water supply. In many localities water is purified by adding alum, and only the smallest trace need be present to throw some of the dye out of solution.

Frothing of the Dye-bath

This occurs only when tinting on the drum with Cine Scarlet, Cine Orange, and Cine Green, but no inconvenience will be caused if the drum is revolved slowly.

[Pg 15]

As distinct from tinting, a toned image consists of a color image embedded within a layer of colorless gelatine, so that while the highlights are clear, the shadows are colored.

The coloring matter may consist of an inorganic colored compound or a dye, or of a mixture of both, and by wholly or partially replacing the black and white silver image by one or more of these substances, a colored image is produced.

It is, of course, important that the colored compound should be as transparent as possible so that the full tone will be apparent on projection. In this respect, while some samples of toned film appear colored in the hand, they produce a substantially black and white image on projection, so that when judging any particular tone, it is absolutely necessary to view the image on the screen.

Of the various inorganic colored compounds, the metallic ferrocyanides are the most suitable for toning purposes of which:

Iron (ferric) ferrocyanide is blue,

Copper ferrocyanide is red, and

Uranium ferrocyanide is reddish brown.

It is the object in toning to replace the metallic silver composing the image more or less by one of the above compounds or by a mixture of these. In this way intermediate tones are obtained.

Toning may be effected either by a single solution process or a two solution process.

Two Solution Process

This consists of first converting the silver image into silver ferrocyanide by a suitable bleaching bath, thoroughly washing, and acting upon the ferrocyanide image with a metallic salt, usually in presence of an acid, the metallic[Pg 16] ferrocyanide being produced by double decomposition. The reaction, however, is never complete, so that the image is mixed with undecomposed silver ferrocyanide which tends to make the image opaque, but at the same time it also adds “body” to the latter. Providing allowance is made in the original positive for this intensification, good tones are obtained. (See Tone G.)

Single Solution Process

Instead of the two separate baths used above, a single solution may be employed consisting of a metallic ferricyanide dissolved in a suitable solvent (say, an alkali salt of citric, tartaric, or oxalic acids) in presence of an acid and certain other salts.

On immersion of the positive film in this solution the silver image is converted to silver ferrocyanide, while the colored ferrocyanide is formed simultaneously and combined with it.

In either of the above cases in view of the fact that the metallic ferrocyanide is deposited in a colloidal condition in presence of the gelatine of the film, its state of division and the nature of the tone are usually affected by the presence of certain salts, changes of temperature, concentration of the baths and other factors which must be maintained constant in order to obtain uniform results. With such single baths it is possible to secure tones which are unobtainable by a two solution process, though as such single solutions are sensitive to light and rapidly attack foreign metals which may be present in the shape of faucets, etc., such solutions are comparatively unstable and require care in their use.

Owing to the limited number of colored inorganic compounds available for toning purposes, it is possible to obtain only a limited range of tones by the above methods.

In view of the possible wide range of colors obtainable by the use of dyes, it has long been considered that a satisfactory method of producing a dye image would be the ideal method for toning purposes.

As a result of recent work in our Research Laboratory, it is now possible to recommend such a method of toning which depends upon the fact that certain inorganic compounds, including copper ferrocyanide, have the property[Pg 17] of mordanting certain basic dyes, so that when they are immersed in a solution of the dye the latter attaches itself to the mordant, which in turn becomes colored.

The most suitable dyes for dye toning are those which do not readily dye gelatine so that on immersing, say, a sample of copper toned film in a weak solution of the dye containing a little acid, the dye becomes mordanted to the image, while the highlights consisting of clear gelatine remain colorless, the resulting tone being a combination of the color of the toned film and the dye.

Full particulars are given under tones J, K, L, M and N.

Nature of the Positive to be Toned

Since most toning processes either intensify or reduce the original image, in order to obtain uniform results, commence toning with positive film of the correct density.

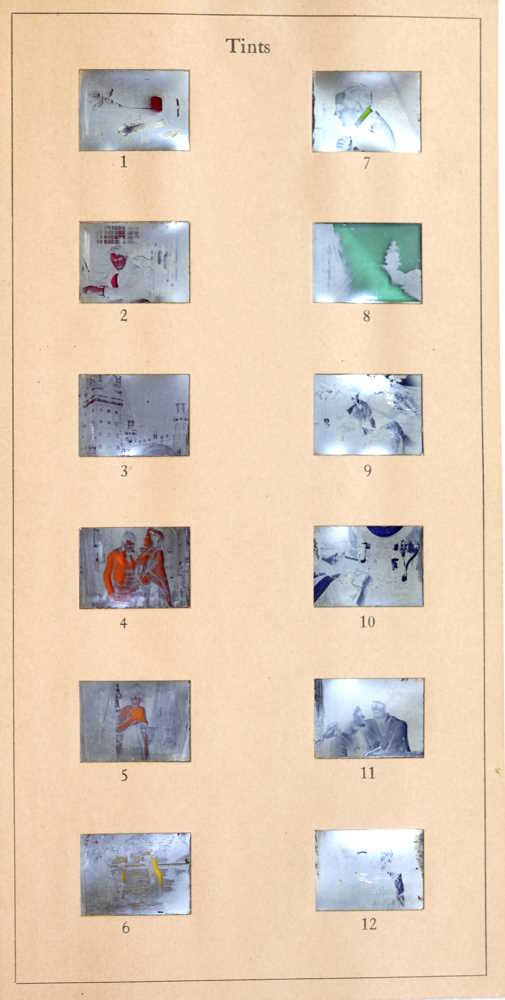

Three standards of positive film have been chosen: Thin, Medium and Normal. (See chart.) The “Thin” and “Medium” standards are obtained by giving a slight overexposure and a shorter time of development.

The exact degree of intensification which takes place in any particular case will soon be learned after a few trials.

Nature of the Developer

Any good Elon-Hydrochinon, Kodelon-Hydrochinon, or straight Hydrochinon formula will give satisfactory tones, though in the case of Tone G an Elon-Hydrochinon developer is essential in order that a rich olive color may be obtained.

For toning, it is necessary that the developed film should be entirely free from fog, since a thin veil becomes intensified in most of the toning processes. Fog may be caused by:

(a) Oxidation of the developer, noticeable by the brown coloration produced after continued use. The remedy is to renew the developer.

(b) Carelessness in compounding the developer. The usual mistake consists in adding the carbonate to the Elon and Hydrochinon without previously adding a portion of sulphite to prevent oxidation. It is not advisable, however, to add the whole of the sulphite to the Elon and Hydrochinon in the first place, otherwise the Elon may precipitate.[Pg 18] Mixing the developer with water which is too warm will often cause fog.

(c) The presence of copper, brass, and tin, the fumes from sodium sulphide, etc., in the developing baths are to be strictly avoided. A salt of copper if present only to the extent of one part in 10,000 will produce fog on cine positive film.

Fixing

This operation should be complete and, if possible, carried out in two consecutive baths and followed by thorough washing, otherwise uneven coloring will result.

In order to eliminate any possibility of uneven toning it is always advisable to tone immediately after washing and before drying.

Control in Toning

As in the case of tinting, the nature of the tone obtained with the various solutions depends on the following factors:

a. The nature and dilution of the toning solutions. Except in those cases where it is recommended to revive the bath by adding more acid, it is not advisable to modify the composition or dilution of the various solutions, as these have been adjusted to give the best results.

b. Temperature of toning.

In most cases a change of temperature from 60 to 70 degrees F. has merely the effect of changing the time of toning. It is advisable, however, to maintain the temperature of the various solutions between 65 degrees and 70 degrees F.

c. Time of toning.

Except in the case of tones F and G when toning proceeds to a limit, the nature of the tone produced varies with the time of toning, reaching a limit in from 10 to 15 minutes, so that in a shorter time intermediate tones are produced. Since most of the toning processes intensify the original image, if an intermediate tone is required, it is usually necessary to commence toning with denser film than when toning is to be carried to the limit. See tones B, C and D.

When producing intermediate tones, it is therefore possible either to tone in the normal bath for a given time[Pg 19] or in a diluted bath for a longer time. In order to reduce the number of individual toning baths to a minimum it is recommended to vary the time of toning rather than to vary the dilution of the bath and to judge the tone by inspection. Since the strength of the toning bath falls off with use, inspection is necessary in all cases except Tones F and G.

Before commencing work with any bath, it is advisable to make a test on a short length of film.

Permanency of Tones

The permanency of the tones produced largely depends on the care exercised throughout the various operations.

The silver sulphide image may be considered permanent, though in the other cases, where more or less silver ferrocyanide is present, the toned image is not absolutely permanent, being somewhat soluble in hypo and affected by fumes of sulphuretted hydrogen.

In the case of the iron and uranium tones, the colored ferrocyanides are dissolved by alkali such as sodium carbonate, so that the toned film should not be washed for too long a time in water which is at all inclined to be alkaline.

In no case however, if the instructions are carefully followed will the toned image deteriorate during the active life of the film. Moreover, so far as can be ascertained, the wear and tear of film which has been toned by the methods recommended is in no way impaired, though by virtue of the hardening action of most of the toning baths on the gelatine it is advisable, especially during the winter months, to immerse the film for three or four minutes in the usual 2% glycerine bath after toning.

Should film have to be stored for long periods of time, toning is inadvisable, nor is it advisable to tone valuable film unless duplicates are available.

The life of the toning bath has been carefully investigated in each case, the term “life” being considered as the total length of film capable of being toned by a given volume of fresh solution when toning is conducted continuously and without interruption.

In all cases it is false economy to exhaust a toning bath to the limit and thus obtain inferior tones, since the cost of the chemicals employed is insignificant compared with the value of the film being treated.

Since the figures given represent the capacity of the bath[Pg 20] for toning under the best conditions, they only apply providing the baths are kept covered as far as possible when not in use, to exclude light, and providing no foreign metallic surface, however small, is allowed to come into contact with the solution.

As mentioned above, single solution baths are not intended for occasional use. In such cases two-solution methods should as far as possible be employed, although it has only been possible to recommend the latter for the production of sulphide and blue-green tones.

Stability of the Solutions

All toning solutions containing potassium ferricyanide are sensitive to light, the ferricyanide being reduced to ferrocyanide. Therefore when not in use the tanks should be carefully covered so as to screen the solutions from sunlight.

It is also very important that no metallic surface however small should come in contact with the solutions; any metal pegs on the racks or pins used to hold the film together will gather the tone in preference to the film, causing the formation of sludge. Plain wooden racks with or without wooden pegs should be used, and metal faucets replaced by wooden plugs.

If any considerable amount of sludge forms in the tank at any time, it is due either to incorrect mixing, the action of light, or to the presence of foreign metallic substances.

Tone A Red (Copper)

Positive Employed—Normal

After immersion of the well washed film in water for one minute, bathe in the following:

| Avoirdupois | Metric | ||

| Copper sulphate | 1 lb. 11 ozs. | 800 | grams |

| Ammonium citrate (neutral) | 5 lbs. 3 ozs. | 2500 | ” |

| Potassium ferricyanide | 1 lb. 11 ozs. | 800 | ” |

| Ammonium carbonate | 13 ozs. | 400 | ” |

| Water to | 50 gals. | 200 | liters |

Dissolve each ingredient separately in as little water as possible, mix the filtered solutions so obtained in the order given, and dilute to the required volume. The solution obtained should be light green in color and perfectly clear. The ammonium carbonate should be almost transparent and free from white powder, and should be dissolved in cold[Pg 21] water, while the ammonium citrate employed should be neutral. Most samples contain acid, which acid would neutralize the ammonium carbonate and affect the resulting tone. The free acid is usually citric acid, and should be neutralized with a solution of ammonia using litmus as indicator.

Temperature of Toning—To obtain the best results the temperature of the bath should be from 65 degrees to 70 degrees F.

Time of Toning—Five to ten minutes.

Time of Washing—10 minutes.

Life of Bath—With use the bath precipitates a brown sludge of copper ferrocyanide, and in consequence becomes weaker by virtue of the loss of copper, though 50 gallons of the solution will tone about 10,000 feet of film.

It is necessary to keep the film entirely submerged in the tank, or constantly in motion when on the drum, otherwise if the film is frequently examined, especially during the first few minutes of toning, streaks are liable to occur.

Tone B Red (Uranium)

Positive Employed—Thin.

Immerse the well washed film in the following:

| Avoirdupois | Metric | ||

| Uranium Nitrate (Neutral) | 16½ ozs. | 500 | grams |

| Potassium Oxalate (Neutral) | 16½ ozs. | 500 | grams |

| Potassium Ferricyanide | 6½ ozs. | 200 | grams |

| Ammonium Alum | 2½ lbs. | 1200 | grams |

| Hydrochloric Acid 10% | 1 quart | 1000 | cc. |

| Water to | 50 gals. | 200 | liters |

Mix in the order given. The solution obtained should be perfectly clear and pale yellow in color.

In view of the fact that the nature of the tone is influenced largely by the acid content, it is very important that the uranium nitrate should contain no free acid, and this may be assured by neutralizing a solution with dilute ammonia until a slight permanent precipitate is obtained.

It is convenient to keep stock solutions of the above (say, 10% solutions) from which a new bath may be expeditiously compounded. A 10% hydrochloric acid solution is one containing 10 parts by volume of the concentrated acid per 100 volumes of the final solution.

[Pg 22]

Temperature of Toning—65 degrees to 70 degrees F.

Time of Toning—Ten minutes.

Since this and the following single solution methods of toning produce a marked intensification of the silver image—which intensification increases with the time of toning—it follows that the nature of the tone changes with time also.

The composition of the bath has been so adjusted that the maximum effect is produced in about 10 minutes, the tone passing through a series of changes from brown to red during this time.

It is therefore possible to obtain intermediate tones by withdrawing the film from the bath at shorter intervals, though in such cases the contrast of the original black and white film should be adjusted accordingly, since with slight toning very little intensification takes place. (See tones C and D.)

Time of Washing—Ten to fifteen minutes.

The highlights will become clear in the above time, though a thin yellowish brown veil may remain in the clear gelatine as a result of the intensification of minute traces of fog, but this has no effect on projection. If the bath is working correctly the yellowish veil is only just perceptible, but if appreciably visible, then either the film was fogged during development, or the bath was not compounded correctly. Washing should not be carried out for too long a period, especially with water inclined to be alkaline, because the toned image is soluble in alkali.

Life of Bath

Fifty gallons of solution will tone about 5000 feet of film without any appreciable change in the tone, after which the rich tone tends to flatness as a result of a deficiency of acid in the bath. At this point the bath may be revived by the further addition of acid to the extent of the original amount, when a further 5000 feet may be toned. At this stage the richness of tone falls off rapidly and the bath should be thrown away.

Used intermittently over a period of several days the life of the bath is approximately the same.

With continued use a slight brownish flocculent precipitate may form in the bath, but this should only be slight, otherwise it is caused by incorrect mixing, the action of light, or by contact with a metallic surface.

[Pg 23]

Tone C—Red Brown (Uranium)

Positive Employed—Medium

The toning formula employed and the instructions to be followed are the same as for Tone B, the time of toning being about 5 minutes at 65 degrees to 70 degrees F.

Tone D—Brown (Uranium)

Positive Employed—Normal

The toning formula employed and the instructions to be followed are the same as for Tone B, the time of toning being about 3 minutes at 65 degrees to 70 degrees F.

Tone E—Sepia (Uranium and Iron)

This particular tone is obtained by suitable mixture of red and blue toning solutions. By varying the proportions of these baths, tones varying from red to sepia may be obtained.

The following is only one of the many tones produced by this method. Increase in the proportion of the iron bath makes the tone colder, and vice versa.

Positive Employed—Medium

Immerse the well washed film in

Solution for tone B (red brown) 5 vols.

Solution for tone H (blue) 1 vol.

Time of Toning 3 to 4 minutes at 65 degrees to 70 degrees F.

The instructions regarding method of procedure, life of bath, etc., are exactly the same as for tone B.

Tone F (Sulphide)

Positive Employed

With a thin positive a warm brown tone is obtained, while with denser film the effect is that of a blue-black tone.

| Avoirdupois | Metric | ||||

| A. | Potassium Ferricyanide | 8 | lbs. 5 ozs. | 4000 | grams |

| Potassium Bromide | 2 | lbs. 2 ozs. | 1000 | grams | |

| Water to | 50 | gals. | 200 | liters | |

| B. | Sodium Sulphide (crystal) | 2 | lbs. 2 ozs. | 1000 | grams |

| Water to | 50 | gals. | 200 | liters | |

[Pg 24]

A trace of iron in the sodium sulphide will do no harm providing the solution is boiled and the precipitated iron sulphide allowed to settle before use. The well washed positive is thoroughly bleached in A, washed for 5 minutes, and immersed in solution B until the film is thoroughly toned.

Temperature of Toning—65 degrees to 70 degrees F.

Time of Toning—Four to five minutes.

Time of Washing—Ten to fifteen minutes.

Life of Baths

The toning baths A and B are comparatively stable and will keep until exhausted.

Tone G—Olive Green (Iron)

Positive Employed—Thin to medium.

The best tones are only obtainable on film developed in an Elon-Hydrochinon developer. Thoroughly bleach the well washed film in:

| Avoirdupois | Metric | |||

| A. | Potassium Ferricyanide | 20 lbs. 12 ozs. | 10,000 | grams |

| Ammonia (concentrated .89) | ½ gal. | 2 | liters | |

| Water to | 50 gals. | 200 | liters | |

Time of Bleaching—Two to five minutes.

After washing for 10 to 15 minutes, tone in the following at 65 degrees to 70 degrees F.:

| Avoirdupois | Metric | ||||

| B. | Ferric Alum (Ferric Ammonium Sulphate) | 4 | lbs. 2 ozs. | 2000 | grams |

| Potassium Bromide | 2 | lbs. 2 ozs. | 1000 | grams | |

| Hydrochloric Acid (concentrated) | 13 | ozs. | 400 | cc. | |

| Water to | 50 | gals. | 200 | liters | |

Time of Toning

Toning should be complete in from 3 to 5 minutes.

Time of Washing—Ten to fifteen minutes.

If the highlights are stained blue, or if the image will not completely tone in the shadows, this is due to insufficient washing after bleaching. When bleaching, it is important to examine the film as little as possible, otherwise streaks are liable to be produced due to the action of the air at those parts where the solution drains off the film. It is also important to tone immediately after bleaching and washing.

[Pg 25]

Life of Baths

Bleach A.

Providing the solution is screened from the light and kept covered to prevent the undue escape of ammonia, the bath keeps fairly well, but if it shows any signs of weakening, it should be revived by the addition of a further quantity of ammonia equal in amount to that originally used. If so revived at intervals, 50 gallons will bleach 40,000 feet of film before exhaustion.

Solution B.

Fifty gallons of solution B will tone 30,000 feet of film without further addition of acid, when it should be thrown away.

Tone H Blue (Iron)

Positive Employed Thin or Medium, according to result desired.

Tone in the following:

| Avoirdupois | Metric | |||

| Potassium Bichromate | 75 | grains | 5 | grams |

| Ferric Alum (Ferric ammonium sulphate) | 8 | ozs. 85 grs. | 250 | grams |

| Oxalic Acid | 1 | lb. 4 ozs. | 600 | grams |

| Potassium Ferricyanide | 6½ | ozs. | 200 | grams |

| Ammonium Alum | 2 | lbs. 2 ozs. | 1000 | grams |

| Hydrochloric Acid 10% | 6½ | ozs. | 200 | cc. |

| Water to | 50 | gals. | 200 | liters |

The method of compounding this bath is very important. Each of the solid chemicals should be dissolved separately in a small quantity of warm water, the solutions allowed to cool, filtered into the tank strictly in the order given, and the whole diluted to the required volume. If these instructions are followed, the bath will be a pale yellow color, perfectly clear, and will remain so for a considerable period.

Time of Toning—Five to ten minutes at 70 degrees F.

Time of Washing

Wash for ten to fifteen minutes until the highlights are clear. A very slight permanent yellow coloration of the clear gelatine will usually occur, but should be only just perceptible, when it will have no effect on projection. If the highlights are stained blue, then either the film was fogged during development or the bath was not compounded correctly. Washing should not be carried out for too long a[Pg 26] period, especially with water inclined to be alkaline, because the toned image is soluble in alkali.

Life of Bath

If the acid is renewed to the extent of the original amount after toning each 5000 feet, the bath is capable of toning 15,000 feet per 50 gallons of solution.

If even after revival, the tone remains flat, the bath is exhausted and should be thrown away.

After continued use, a slight bluish sludge will collect in the bath, but this is not harmful. Should this form, however, to any appreciable extent, it is due either to incorrect mixing, the action of light, or to contact with metallic surfaces.

Tone I—Pale Blue (Iron)

The instructions are as for Tone H with the following modifications:

Positive Employed—Normal.

Time of Toning—Two to four minutes according to depth of tone desired.

Tone J—Red (Dye Tone)

By first toning in Tone A, washing, and then immersing the copper toned film in an acid solution of a basic dye, the dye is mordanted to the toned image, thus modifying the color.

Nature of Positive—Medium

Tone for five to ten minutes in solution as for Tone A, and after washing for ten minutes immerse in the following dye-bath.

| Avoirdupois | Metric | |||

| Safranine A (National Aniline and Chemical Co., Inc.) | 7 | ozs. | 200 | grams |

| Acetic Acid (Glacial) | 32 | ozs. | 1000 | cc. |

| Water to | 50 | gals. | 200 | liters |

[Pg 27]

Time of Toning

Five to ten minutes, according to depth desired.

Temperature of Toning—65 degrees to 70 degrees F.

Time of Washing

Usually only a slight rinse in water is necessary. If the highlights are stained, the film should be washed for five or ten minutes or until clear. Stained highlights are caused either by insufficient washing after toning, too strong a dye-bath, or an incorrect amount of acid in the dye-bath.

Tone K—Orange (Dye Tone)

The instructions are exactly as for Tone J, substituting the following dye-bath.

| Avoirdupois | Metric | |||

| Chrysoidin 3R (National Aniline and Chemical Co., Inc.) | ||||

| or Chrysoidin Y (Extra) | 2 | ozs. 320 grs. | 80 | grams |

| Acetic Acid (Glacial) | 32 | ozs. | 1000 | cc. |

| Water to | 50 | gals. | 200 | liters |

Tone L—Violet (Dye Tone)

The instructions are exactly as for Tone J, substituting the following dye-bath:

| Avoirdupois | Metric | |||

| Methyl Violet (National Aniline and Chemical Co., Inc.) | 2 | ozs. 320 grs. | 80 | grams |

| Acetic Acid (Glacial) | 32 | ozs. | 1000 | cc. |

| Water to | 50 | gals. | 200 | liters |

Intermediate Dye Tones

The depth of the dye tone is determined by the time of immersion both in the copper toning bath and in the dye-bath. Pale tones may therefore be obtained either by giving a short bath in Tone A and fully dyeing, or by toning for a longer time and giving a short immersion in the dye-bath.

By mixing the dye-baths J, K, and L in varying proportions intermediate colors may be obtained just as in tinting.

[Pg 28]

Tone M—Pale Red (Dye Tone)

Positive Employed—Normal

Tone for one to two minutes in Tone A, wash for ten minutes and then immerse in the following dye-bath.

Dye solution for Tone J, one volume.

Dye solution for Tone K, one volume.

When the desired tone is obtained rinse until the highlights are clear.

Compound Tones

Tone N—Copper-Iron-Dye Tone.

By first partially toning the black and white film (Medium) in Tone A for three to four minutes at 65 degrees to 70 degrees F., so that the half-tones are completely toned but the shadows only partially, washing for ten minutes and then completing the toning process in the blue toning bath H, the residual silver in the shadows is toned blue. In this way a double tone is obtained, the shadows appearing dark blue and the half-tones reddish brown.

By immersing the film toned in this manner in the Chrysoidin dye-bath as given under Tone K, the dye is mordanted to the half-tones which contain copper ferrocyanide, producing the effect indicated.

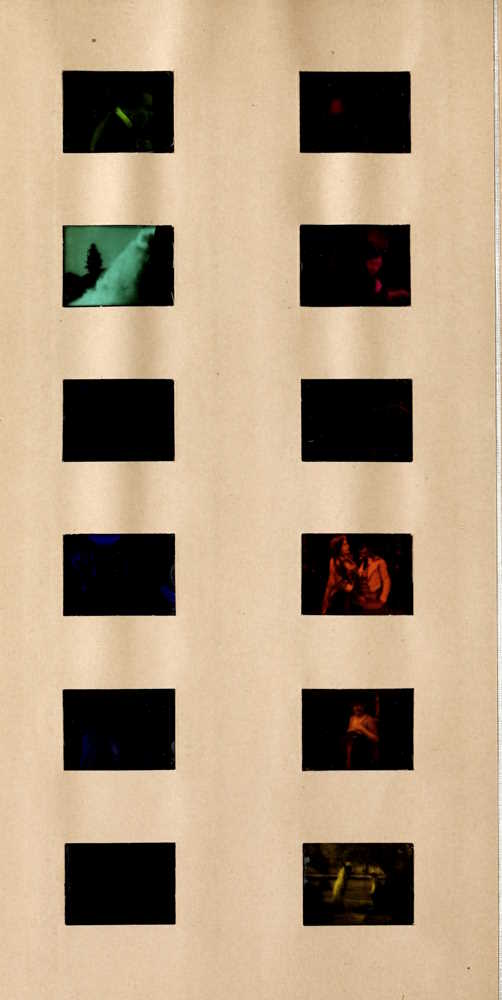

Combined Tinting and Toning

In many cases pleasing effects may be obtained by tinting film which has already been toned, the result being that the clear portions or highlights assume the color of the dye, while the shadows and half-tones project a tint intermediate between that of the dye and the toned deposit.

Considerable judgment is necessary, however, in choosing suitable tints to blend with any given tone.

The most successful combination of toning with tinting is in the production of sunset and moonlight effects over water, by first toning blue and then tinting orange, red or yellow.

[Pg 29]

The following combinations will cover most cases required:

Tones A, B, C, D, E, F, J, K, L. Tints Nos. 2, 5, 6.

Tones G, H, I. Tint almost any delicate shade.

It is considered unnecessary to illustrate every combination of tone and tint above, so that only typical examples are given. It must be noted that toned film (except tones A and F) absorbs the dye more quickly than untoned film, so in order to duplicate appended samples, the dye-baths should be diluted accordingly.

Very pleasing effects may also be obtained by locally tinting toned film, the color being applied either by hand with a brush, or by stencilling.

Equipment

The equipment necessary for systematic tinting and toning is essentially the same as that required for development, consisting of the usual tanks and racks or small drums, only it is advisable that they should be used for this purpose exclusively and, if possible, occupy a separate room to exclude any possibility of contaminating the developing solutions by the copper or sulphiding bath, which would cause development fog immediately.

The “drum” system, on account of the expense involved in apparatus and the larger space required for manipulation, is not to be recommended for tinting and toning operations, though for operation on a small scale, a small wooden drum revolving in a shallow wooden tank is most efficient and economical.

When the tank and rack system is employed, the tanks should be of slate or other resistive material, and have an outlet at the bottom in the form of a hard-rubber stopcock or a plain wooden plug. The racks or drums may be of wood, but if metal pegs are employed on the racks they should be coated with acid-resisting paint such as asphalt, since the presence of any metallic surface in the toning baths will cause contamination and effect a precipitation of sludge. The frames should not be interchanged but kept separate either for tinting or toning to prevent contamination of one bath with racks previously employed in another. This also applies to the small drum system. For instance, a pink tint would be ruined by using a rack which had previously been immersed in a deep blue dye-bath, unless that particular[Pg 30] rack had been thoroughly washed. In the case of delicate tinting, however, no harm is done providing the racks have been previously coated with the following waterproof varnish:

| Avoirdupois | Metric | |||

| Hard paraffin | 3½ | lbs. | 1600 | grams |

| Carbon tetrachloride | 10 | gals. | 40 | liters |

Before treatment it is preferable to immerse the racks which have been previously used for developing, in a 1% solution of hydrochloric acid for two or three minutes, wash for fifteen minutes and thoroughly dry. The well-dried racks are then dipped in the above solution and the excess liquid drained off, when the varnish dries almost immediately. The varnishing should be repeated at intervals.

Mixing Solutions

Developers, toning solutions and dyes should be mixed in crocks of glazed earthenware or enameled iron, using warm water where necessary and ensuring thorough solution by stirring with a wooden paddle, which should be thoroughly washed after each operation. Having thus dissolved the chemicals in as small a quantity of warm water as possible, filter through fine muslin and make up the bath with cold water, so that the final solution will be at approximately the correct temperature.

The chemicals employed should be pure (for the samples, “EKCo.” tested chemicals were used), and in cases where a good water supply is not available, only distilled water should be used.

Troubles in Toning

Most difficulties met with in toning may be traced to one or more of the following causes:

Uneven Toning

This may be due to:

a. Grease on the film. Never project film before tinting or toning.

b. Drying spots on untoned film. If possible, always tint or tone film immediately after washing and before drying.

c. Examination of the film too frequently during toning, causes an oxidation of the toning solution in places where the solution fails to drain from the film.

[Pg 31]

d. Insufficient or uneven washing of the film after bleaching and before toning (Tones F and G).

White Spots

White spots are produced by particles of hypo or carbonate dust or splashes of a solution of these, settling on the toned film. The toned image consists of silver together with more or less silver ferrocyanide and the ferrocyanides of uranium, iron and copper as the case may be. Silver ferrocyanide is soluble in hypo while uranium and iron ferrocyanides are soluble in a solution of sodium carbonate, strong ammonia, etc., so that the white spots indicate those parts where the toned image has been dissolved away.

Irregular white spots may also be formed if the film is imperfectly squeegeed after washing and before drying, especially if the wash water is slightly alkaline. When a spot of water on the toned film evaporates, the small amount of alkali present in the water becomes more concentrated and finally dissolves away more or less of the tone, leaving a white spot on the film.

White spots due to these causes may be prevented by immersing the film for a few seconds in a .5% solution of glacial acetic acid after toning and before placing on the drying rack.

Stained Highlights

Are caused by:

a. Traces of fog on the film before toning.

b. An improperly compounded toning bath. All solutions when new should be perfectly clear.

c. Premature exhaustion of the bath. This is due either to the action of light or to the presence of some metal in the tank in the shape of screw heads, faucets, pins, etc., which gather the tone and cause the formation of sludge.

It is important to keep all solutions containing potassium ferricyanide exposed as little as possible to daylight, to use only wooden racks with wooden pegs, and to cover all metal parts very carefully with acid resisting paint.

d. In dye-toning, stained highlights are due either to insufficient washing after toning with copper, too strong a dye-bath, or an incorrect amount of acid in the dye-bath.

[Pg 33]

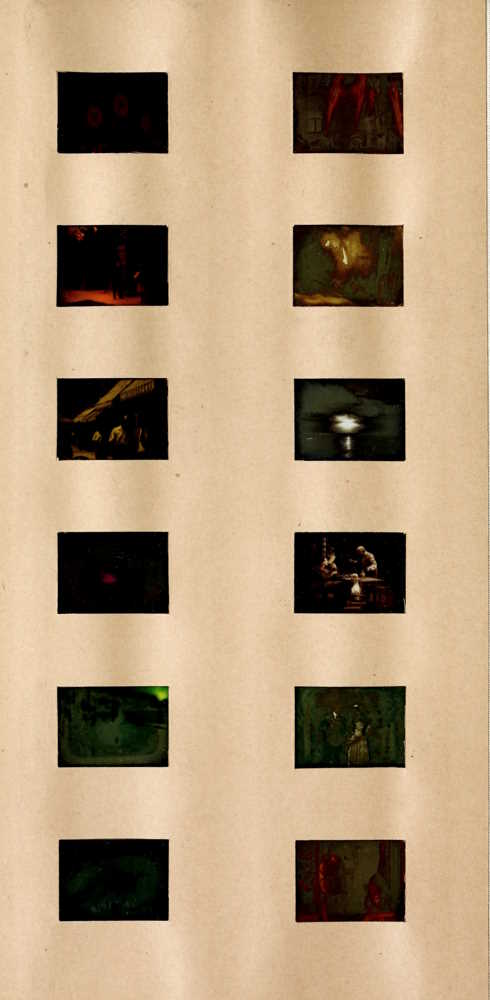

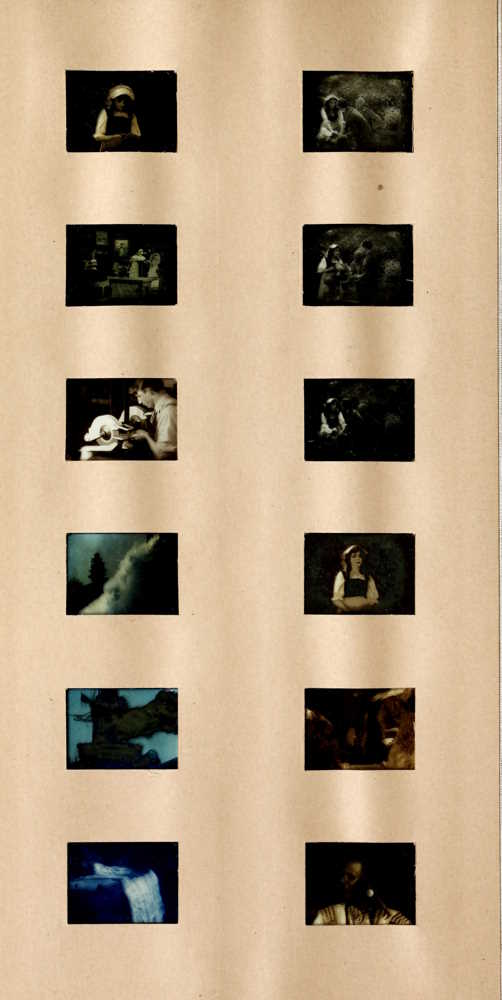

Tints

1-12

Back of Tints

[Pg 34]

1-12

[Pg 35]

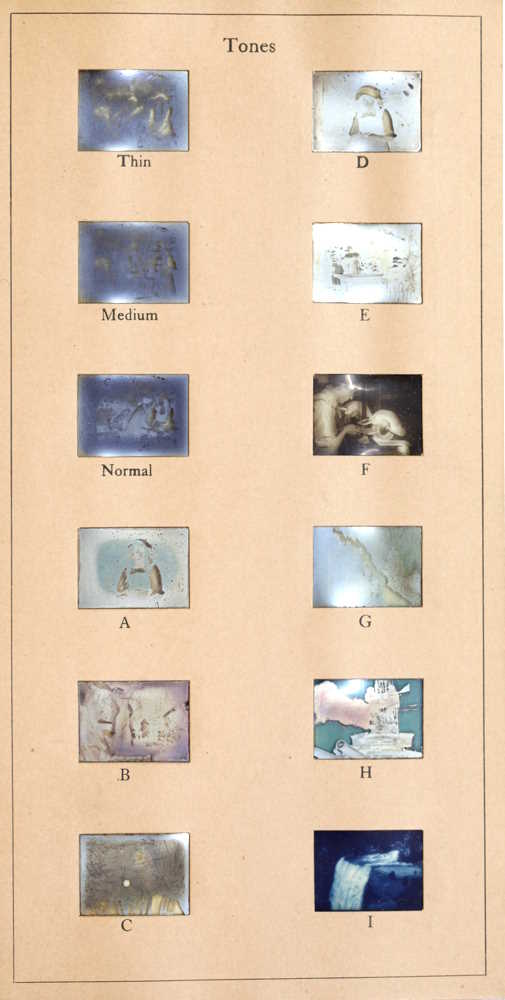

Tones

Thin, Medium, Normal, A-I

[Pg 36]

Back of Tones

Thin, Medium, Normal, A-I

[Pg 37]

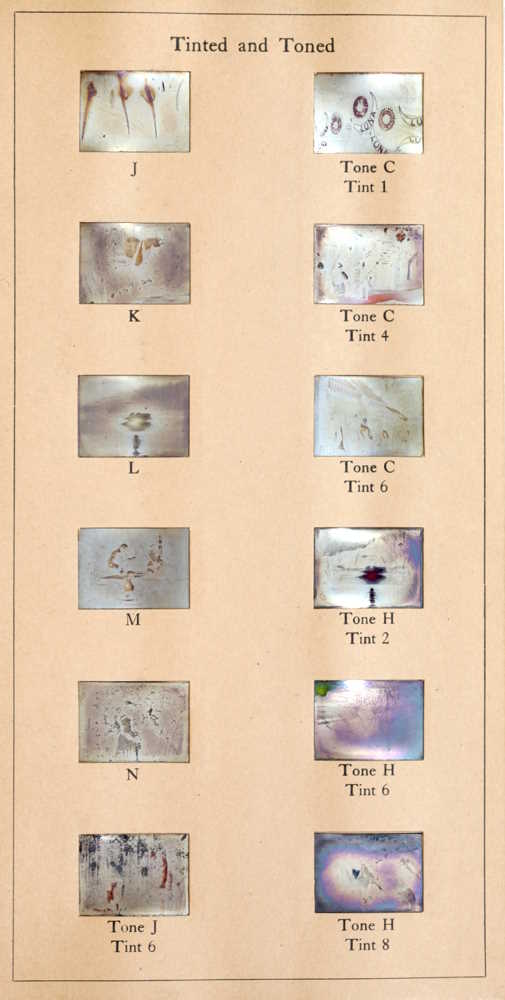

Tinted and Toned

J-N, Tone J Tint 6, Tone C Tint 1, Tone C Tint 4, Tone C Tint 6, Tone H Tint 2 Tone H Tint 6, Tone H Tint 8

[Pg 38]

Back of Tinted and Toned

J-N, Tone J Tint 6, Tone C Tint 1, Tone C Tint 4, Tone C Tint 6, Tone H Tint 2 Tone H Tint 6, Tone H Tint 8

This eBook is for the use of anyone anywhere in the United States and most other parts of the world at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org. If you are not located in the United States, you will have to check the laws of the country where you are located before using this eBook.