Please see the Transcriber’s Notes at the end of this text.

New original cover art included with this eBook is granted to the public domain.

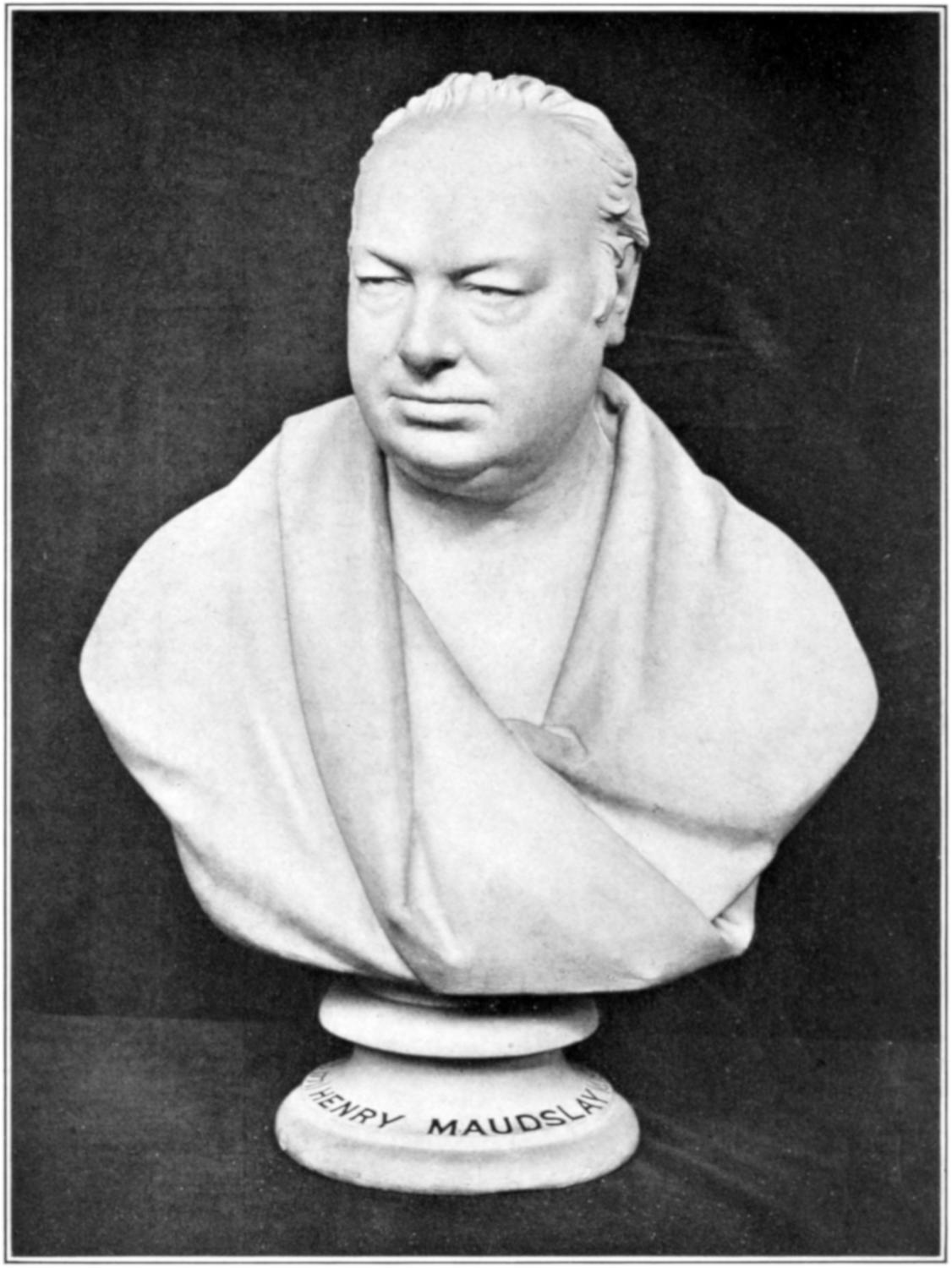

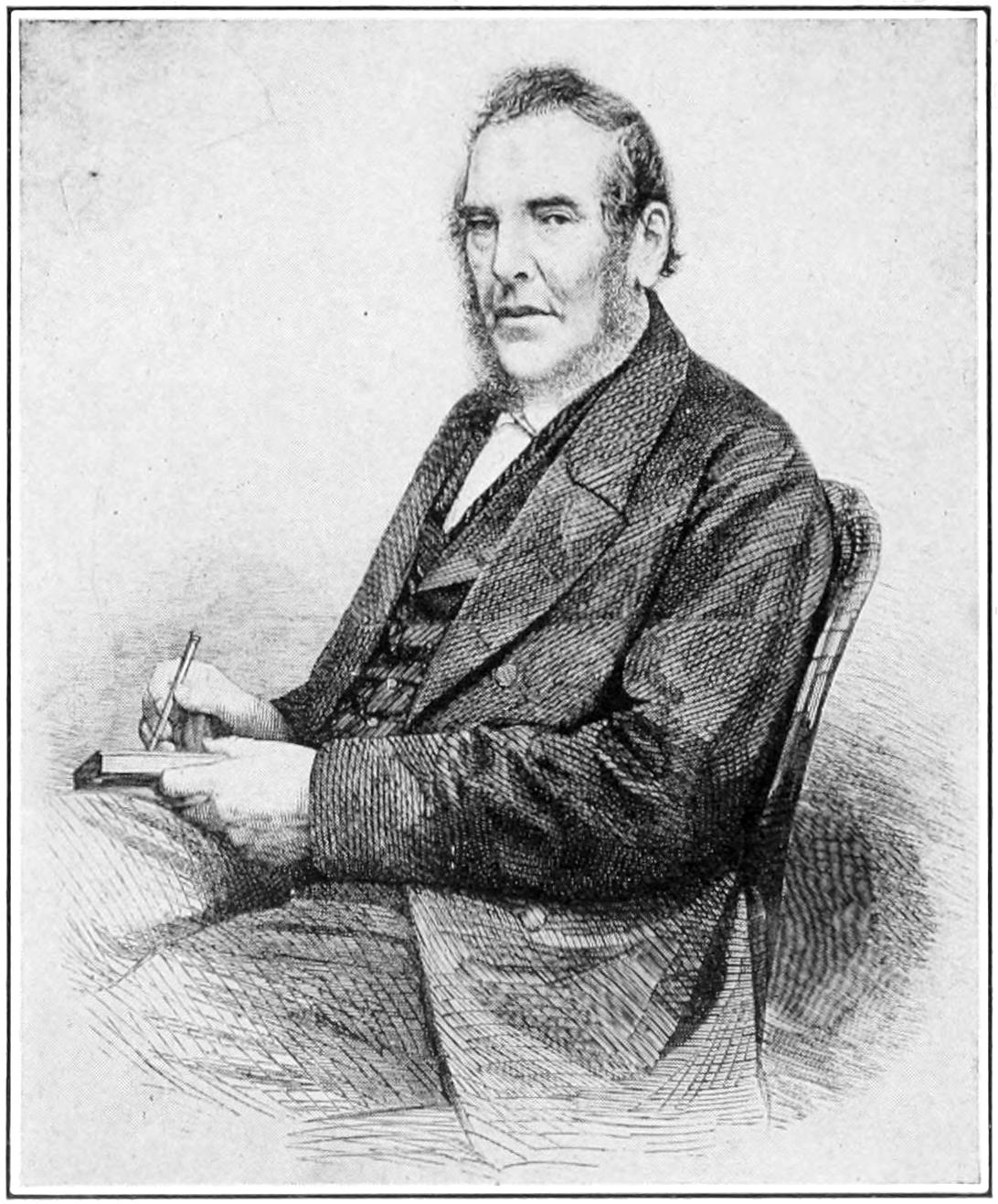

Henry Maudslay

English and American

Tool Builders

By

JOSEPH WICKHAM ROE

Museum of the Peaceful Arts, City of New York,

Professor of Industrial Engineering,

New York University

First Printed in 1916

Reprinted in 1926

McGRAW-HILL

BOOK COMPANY, Inc.

NEW YORK: 370 SEVENTH AVENUE

LONDON: 6 & 8 BOUVERIE ST., E. C. 4

1926

Copyright, 1916

BY

Joseph Wickham Roe

First published May, 1916

Republished March, 1926

[v]

“Man is a Tool-using Animal. Weak in himself, and of small stature, he stands on a basis, at most for the flattest-soled, of some half-square foot, insecurely enough; has to straddle out his legs, lest the very wind supplant him. Feeblest of bipeds! Three quintals are a crushing load for him; the steer of the meadow tosses him aloft, like a waste rag. Nevertheless he can use Tools, can devise Tools: with these the granite mountain melts into light dust before him; seas are his smooth highway, winds and fire his unwearying steeds. Nowhere do you find him without Tools; without Tools he is nothing, with Tools he is all.”

Carlyle: “Sartor Resartus,” Chap. IV.

The purpose of this book is to bring out the importance of the work and influence of the great tool builders. Few realize that their art is fundamental to all modern industrial arts. Without machine tools modern machinery could not be built. Little is known by the general public as to who the great tool builders were, and less is known of their lives and work.

History takes good care of soldiers, statesmen and authors. It is even kind to engineers like Watt, Fulton and Stephenson, who have conspicuously and directly affected society at large. But little is known, even among mechanics, of the men whose work was mainly within the engineering profession, and who served other engineers rather than the general public. The lives and the personalities of men like Maudslay, Nasmyth and Eli Whitney, can hardly fail of interest to the mechanic of today. They were busy men and modest, whose records are mainly in iron and steel, and in mechanical devices which are used daily with little thought of their origin.

In following the history of English and American tool builders, the query arises as to whether there might not have been important contributions to tool building from other countries. Others have contributed to some degree, but practically all of the creative work in tool building has been done in these two countries. Although the French were pioneers in many mechanical improvements, they have always shown an aptitude for refinements and ingenious novelties rather than for commercial production on a large scale. They have[viii] influenced other nations more through their ideas than through their machinery. The Swiss are clever artisans, particularly in fine work, but they have excelled in personal skill, operating on a small scale, rather than in manufacturing. Germany has, under the Empire, developed splendid mechanics, but the principal machine tools had taken shape before 1870, when the Empire began. The history of English and American tool building, therefore, covers substantially the entire history of the art.

Almost the only book upon tool builders and their work is Samuel Smiles’ “Industrial Biography,” which is out of print and little known. It is an admirable and interesting book, and a mine of information upon the English tool builders down to about 1850. The writer has used it freely and would urge those who are interested in the subject to go to it for further information on the early mechanics. It was written, however, over fifty years ago and contains nothing about modern developments or about the American tool builders who have contributed so much.

The writer has tried to trace the origin and rise of tool building in America and to give something of its spread in recent years. The industrial life of the United States is so vast that a comprehensive history of even a single industry, such as tool building, would run far beyond the limits of one volume. This book, therefore, is confined to the main lines of influence in tool building and to the personalities and cities which have been most closely identified with it. The later history of American tool building has never been written. For this the writer has had to rely largely upon personal information from those who are familiar with it, and who have had a part in it.

[ix]

Part of the material contained in this book has appeared from time to time in the American Machinist, and the writer would acknowledge his indebtedness most of all to Mr. L. P. Alford, the editor of that journal. His help and counsel have given these pages much of such value as they possess. So many have helped with information, corrections and suggestions that acknowledgments can be made only to a few. The writer would particularly thank Mr. L. D. Burlingame, Mr. Ned Lawrence, Mr. James Hartness, Mr. Coleman Sellers and Mr. Clarence Bement.

If these pages serve to stimulate interest in the lives and work of the tool builders, to whom we owe much, they will fulfill the hope of the writer.

Sheffield Scientific School,

Yale University,

October, 1915.

In reprinting this book certain minor corrections have been made. In the later chapters references occur here and there to the “present” condition of various plants and firms. After careful consideration, it seems wise to let these statements stand as they were written in 1915. Interest in this subject centers chiefly on the early history of the plants and firms rather than on recent changes. To revise the statements, bringing them up to date, would add little. With the ever shifting status of a live industry, the statements, so revised, would remain correct for only a short time. Therefore, when a reference is made to present conditions[x] it should be understood to cover those at the beginning of the World War, which is a natural dividing point in our industrial history.

The general predictions made in the last two paragraphs of the book have been borne out by the developments in American toolbuilding since that time.

Museum of the Peaceful Arts,

City of New York,

February, 1926.

[xi]

| PAGE | |||

| Chapter | I. | Influence of the Early Tool Builders | 1 |

| Chapter | II. | Wilkinson and Bramah | 11 |

| Chapter | III. | Bentham and Brunel | 22 |

| Chapter | IV. | Henry Maudslay | 33 |

| Chapter | V. | Inventors of the Planer | 50 |

| Chapter | VI. | Gearing and Millwork | 63 |

| Chapter | VII. | Fairbairn and Bodmer | 71 |

| Chapter | VIII. | James Nasmyth | 81 |

| Chapter | IX. | Whitworth | 98 |

| Chapter | X. | Early American Mechanics | 109 |

| Chapter | XI. | The Rise of Interchangeable Manufacture | 128 |

| Chapter | XII. | Whitney and North | 145 |

| Chapter | XIII. | The Colt Armory | 164 |

| Chapter | XIV. | The Colt Workman—Pratt & Whitney | 173 |

| Chapter | XV. | Robbins & Lawrence | 186 |

| Chapter | XVI. | The Brown & Sharpe Manufacturing Company | 202 |

| Chapter | XVII. | Central New England | 216 |

| Chapter | XVIII. | The Naugatuck Valley | 231 |

| Chapter | XIX. | Philadelphia | 239 |

| Chapter | XX. | The Western Tool Builders | 261 |

| Appendix A | 281 | ||

| Appendix B, The Jennings Gun | 292 | ||

| A Partial Bibliography on Tool Building | 295 | ||

| Henry Maudslay | Frontispiece | |||

| Fig. | 1. | Smeaton’s Boring Machine, Carron Iron Works, 1769 | Facing page | 2 |

| Fig. | 2. | French Lathes of about 1772 | Facing page | 2 |

| Fig. | 3. | French Slide-Rest, 1772 | Facing page | 6 |

| Fig. | 4. | French Lathe for Turning Ovals, 1772 | Facing page | 6 |

| Fig. | 5. | Genealogy of the Early English Tool Builders | page | 7 |

| Fig. | 6. | John Wilkinson | Facing page | 14 |

| Fig. | 7. | Wilkinson’s Boring Machine | Facing page | 14 |

| Fig. | 8. | Eminent Men of Science Living in 1807-8 | Facing page | 20 |

| Fig. | 9. | Sir Samuel Bentham | Facing page | 22 |

| Fig. | 10. | Sir Marc Isambard Brunel | Facing page | 26 |

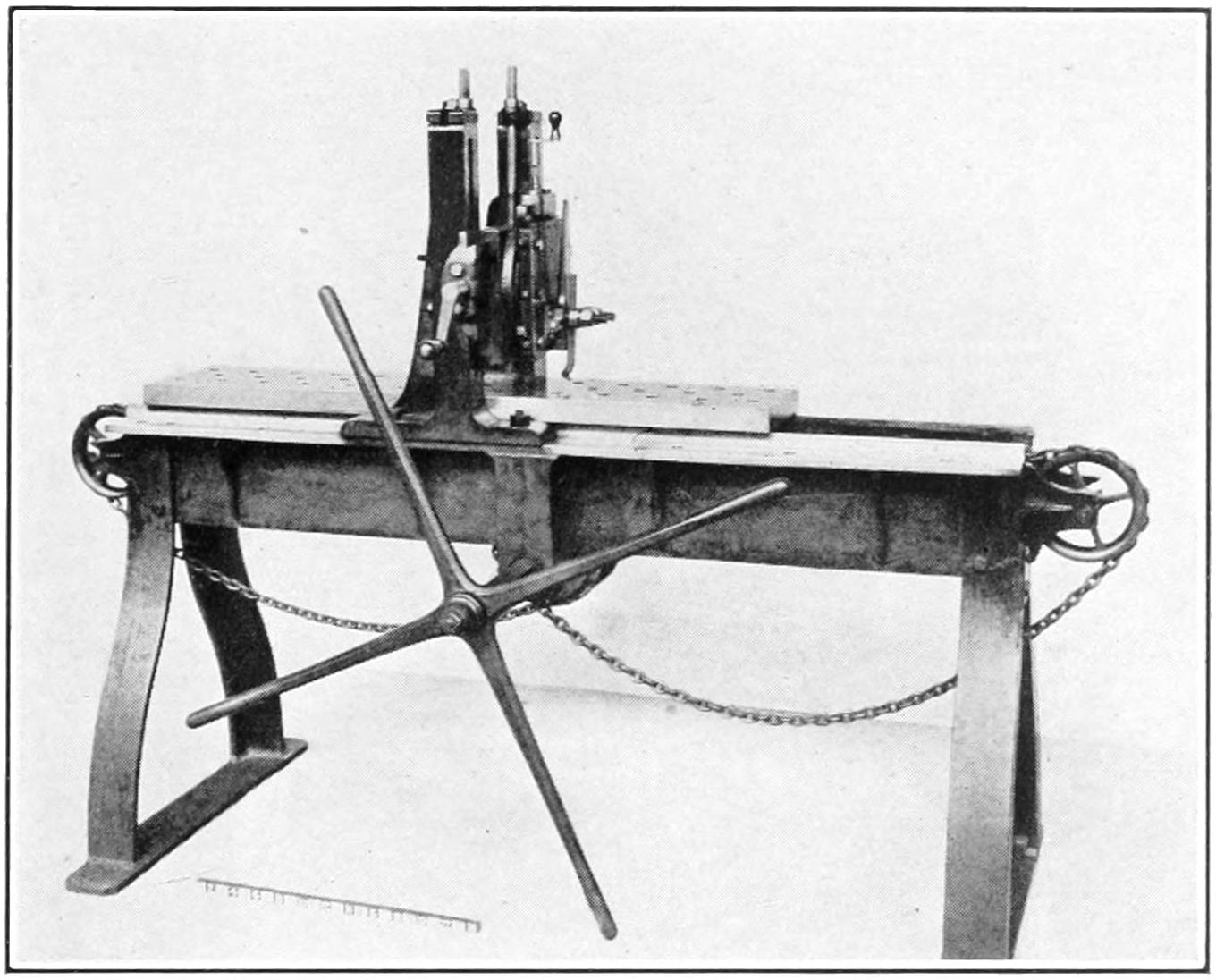

| Fig. | 11. | Brunel’s Mortising Machine | Facing page | 30 |

| Fig. | 12. | Brunel’s Shaping Machine | Facing page | 30 |

| Fig. | 13. | French Screw-Cutting Lathe, Previous to 1569 | page | 37 |

| Fig. | 14. | French Screw-Cutting Lathe, about 1740 | page | 37 |

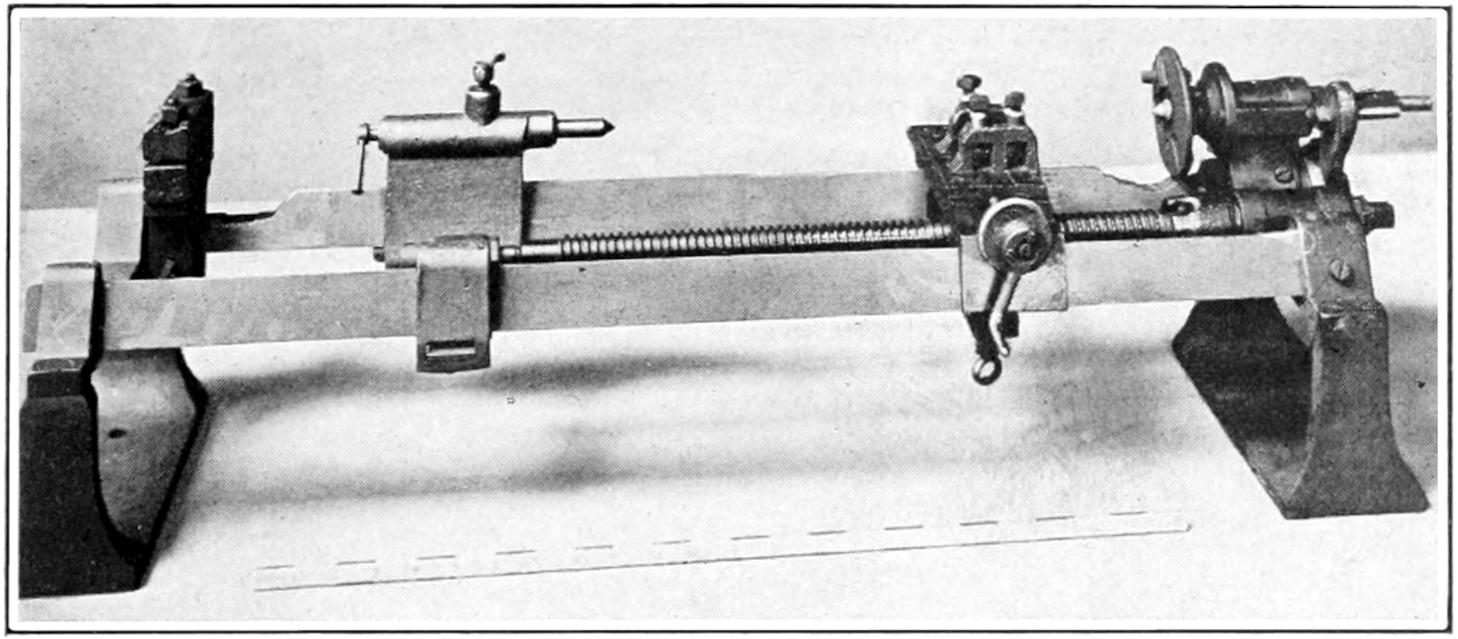

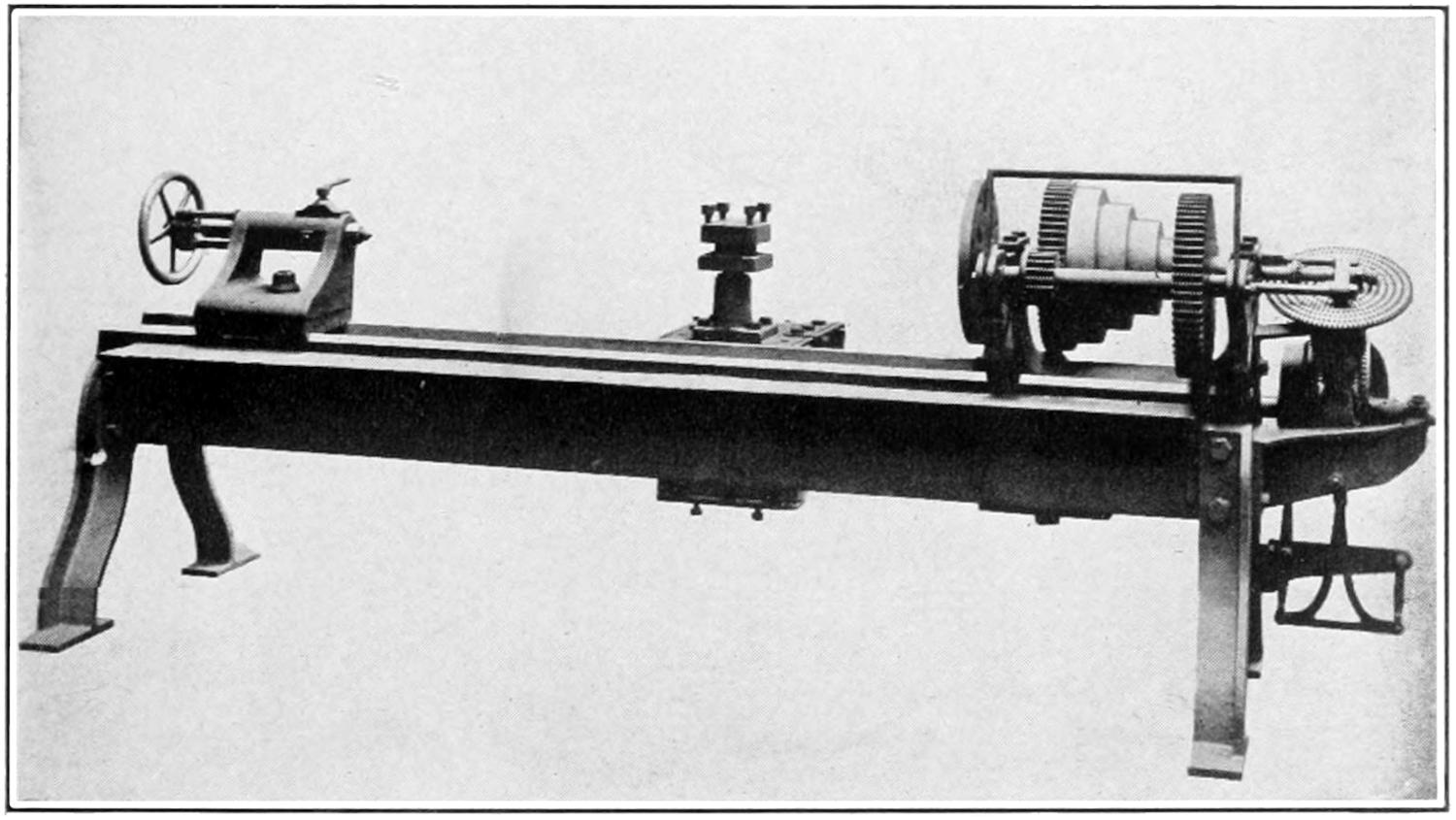

| Fig. | 15. | Maudslay’s Screw-Cutting Lathe, about 1797 | Facing page | 42 |

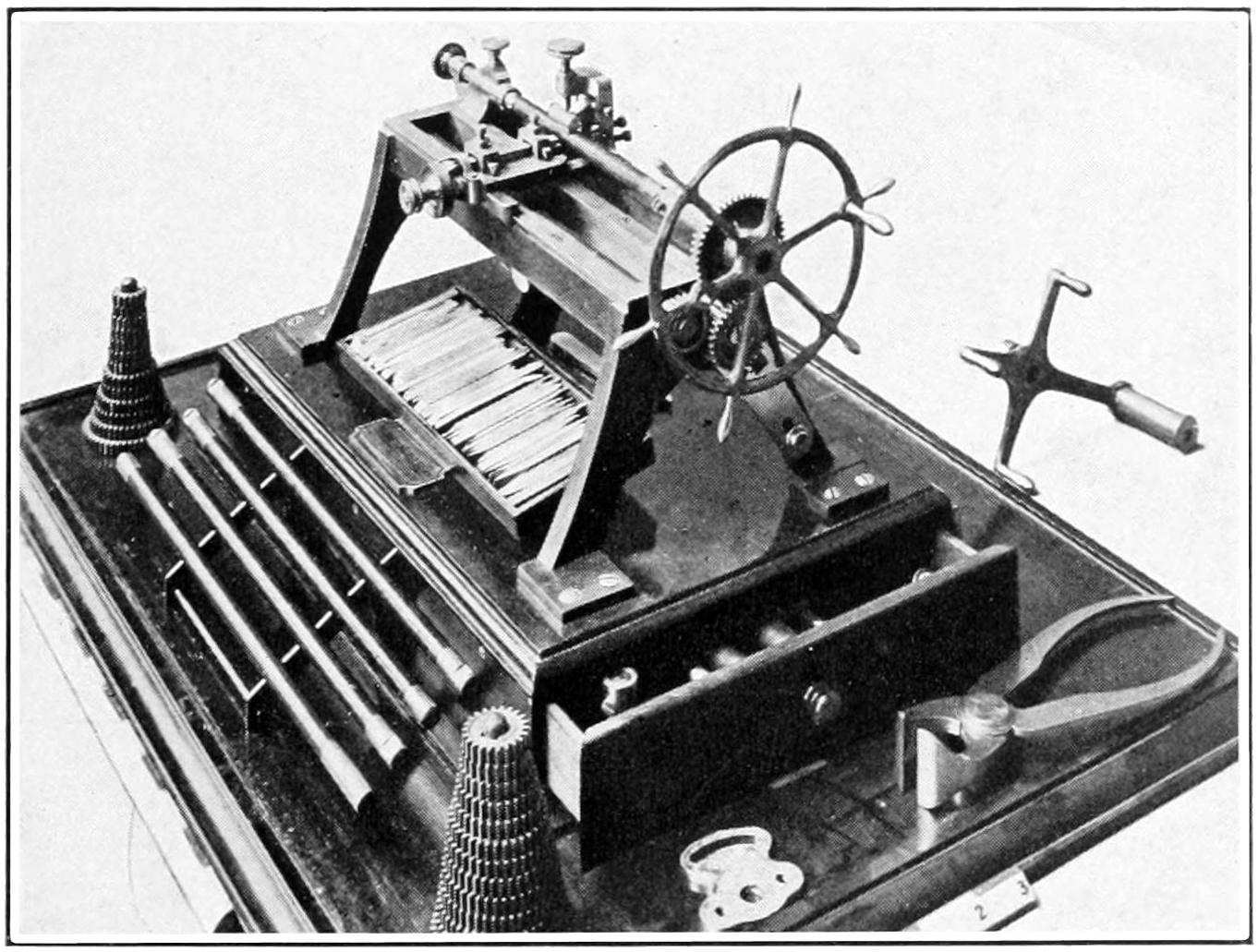

| Fig. | 16. | Maudslay’s Screw-Cutting Lathe, about 1800 | Facing page | 42 |

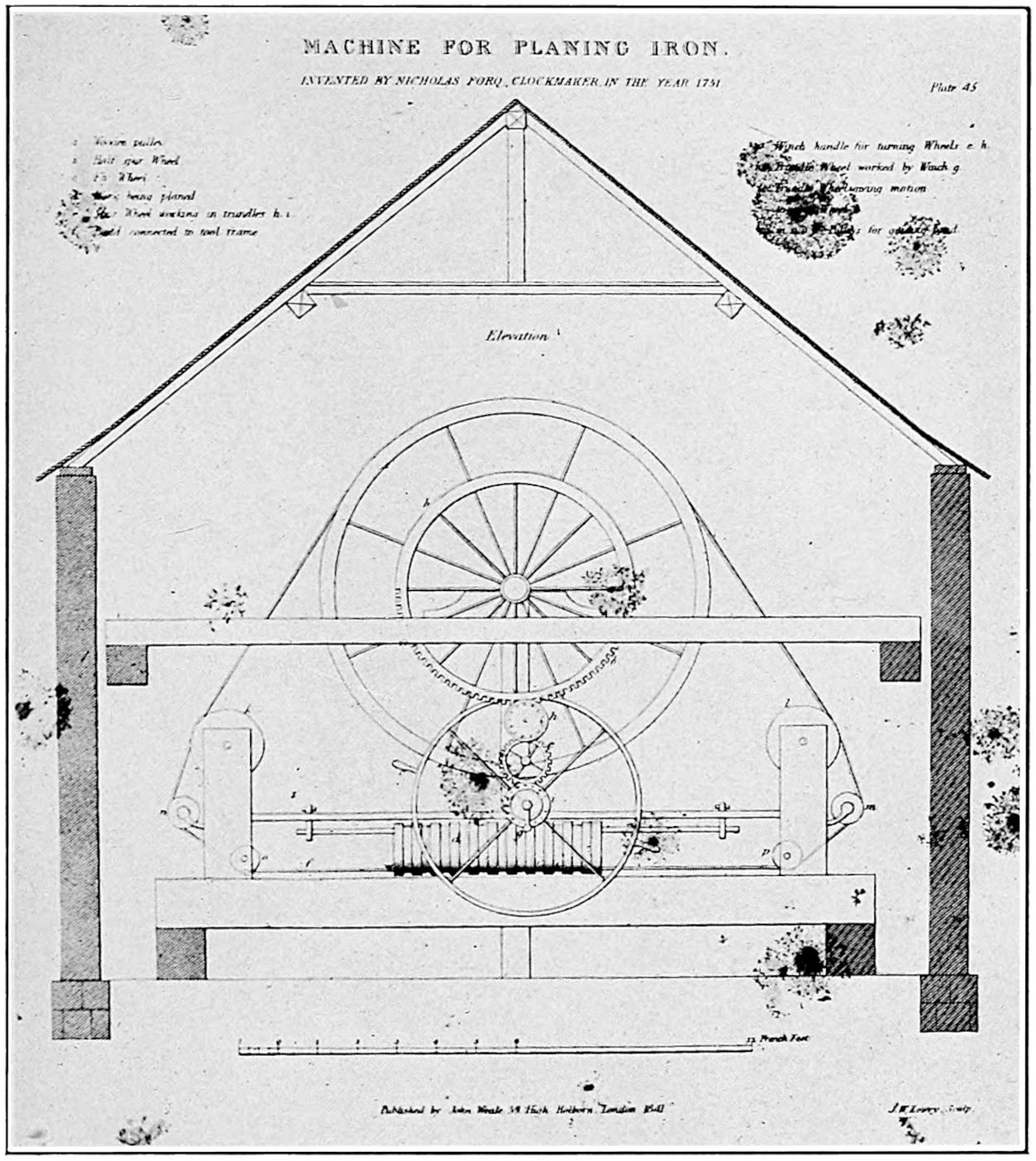

| Fig. | 17. | French Planing Machine by Nicholas Forq, 1751 | Facing page | 50 |

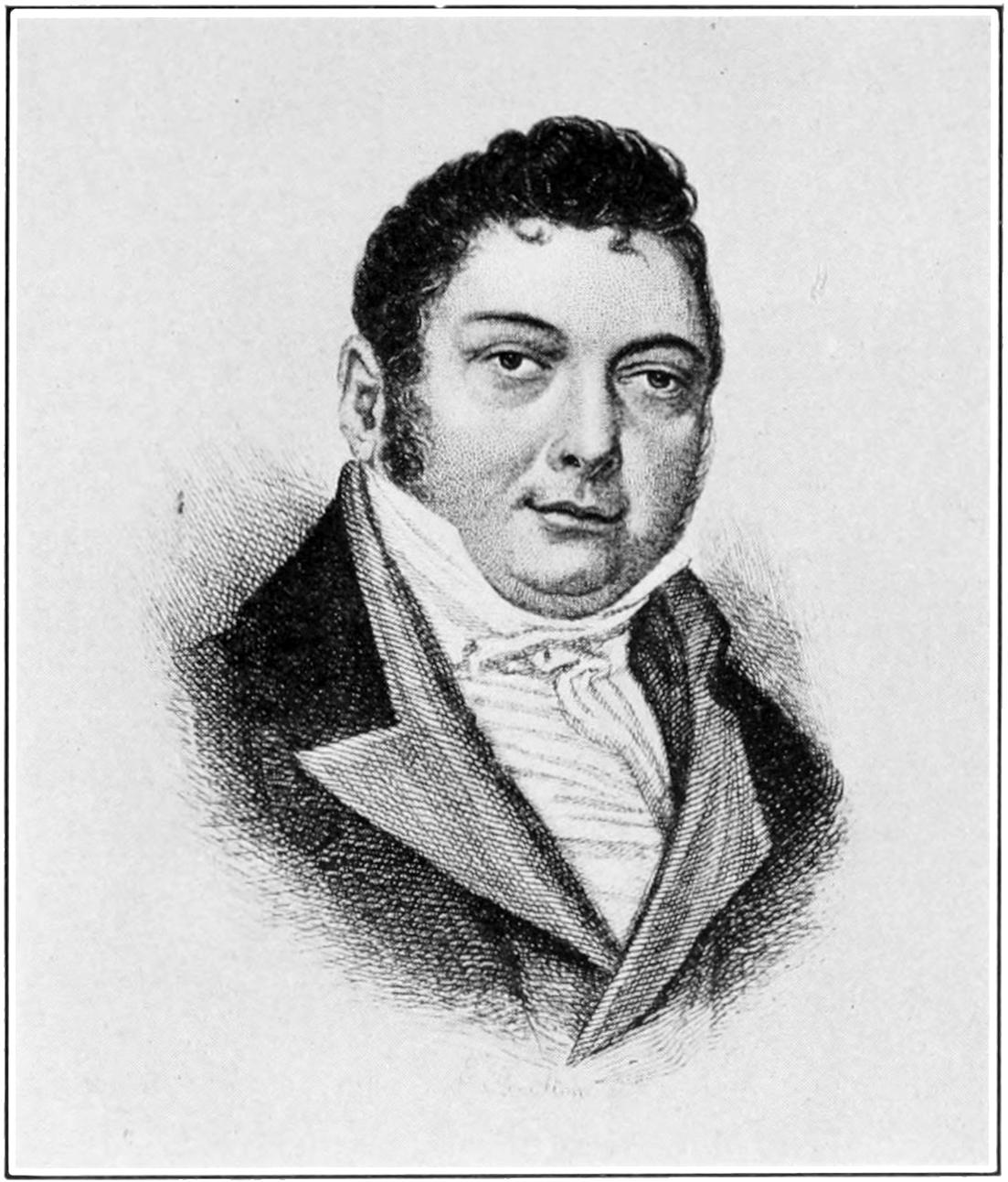

| Fig. | 18. | Matthew Murray | Facing page | 58 |

| Fig. | 19. | Richard Roberts | Facing page | 58 |

| Fig. | 20. | Roberts’ Planer, Built in 1817 | Facing page | 60 |

| Fig. | 21. | Roberts’ Back-Geared Lathe | Facing page | 60 |

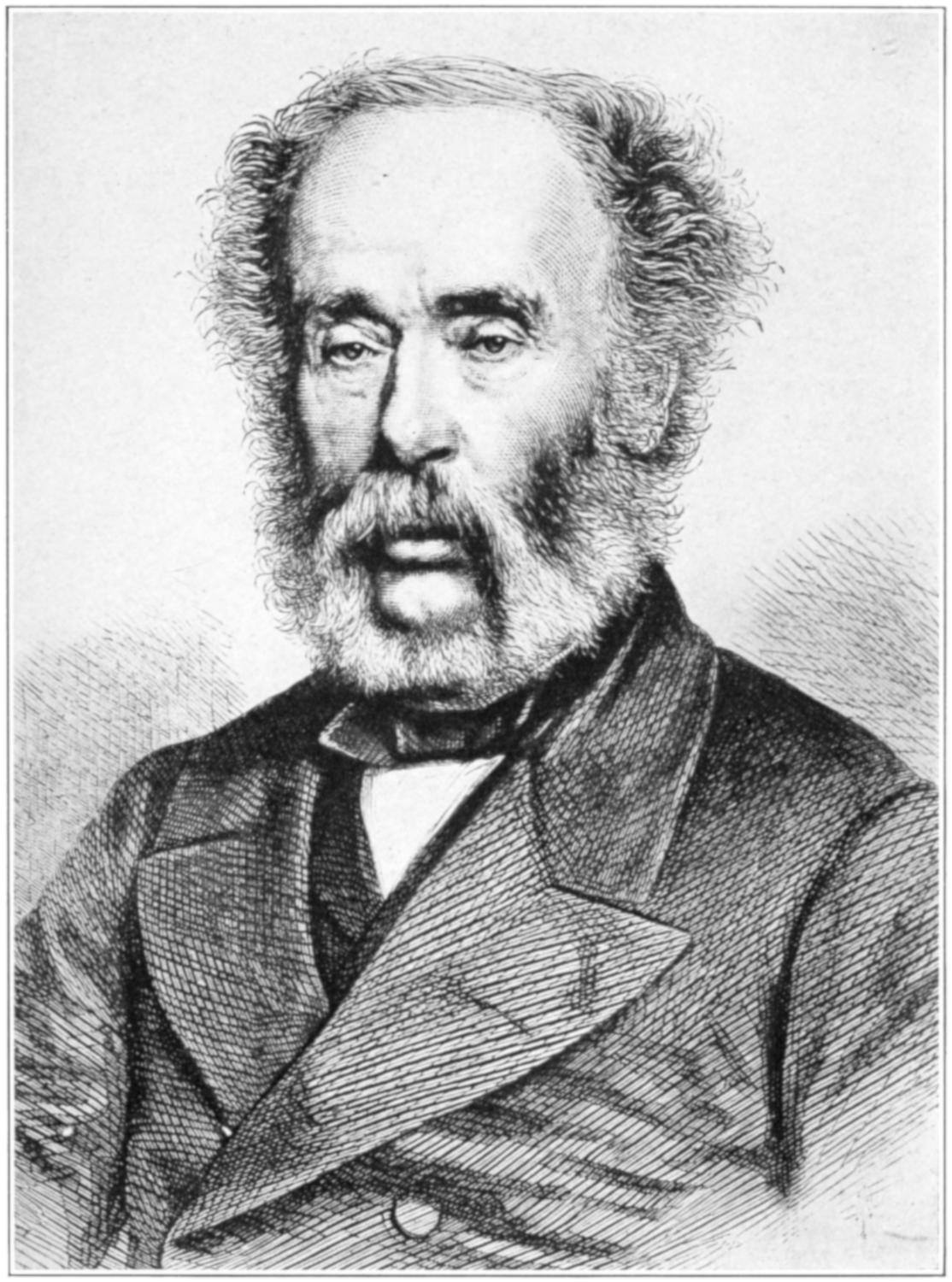

| Fig. | 22. | James Nasmyth | Facing page | 82 |

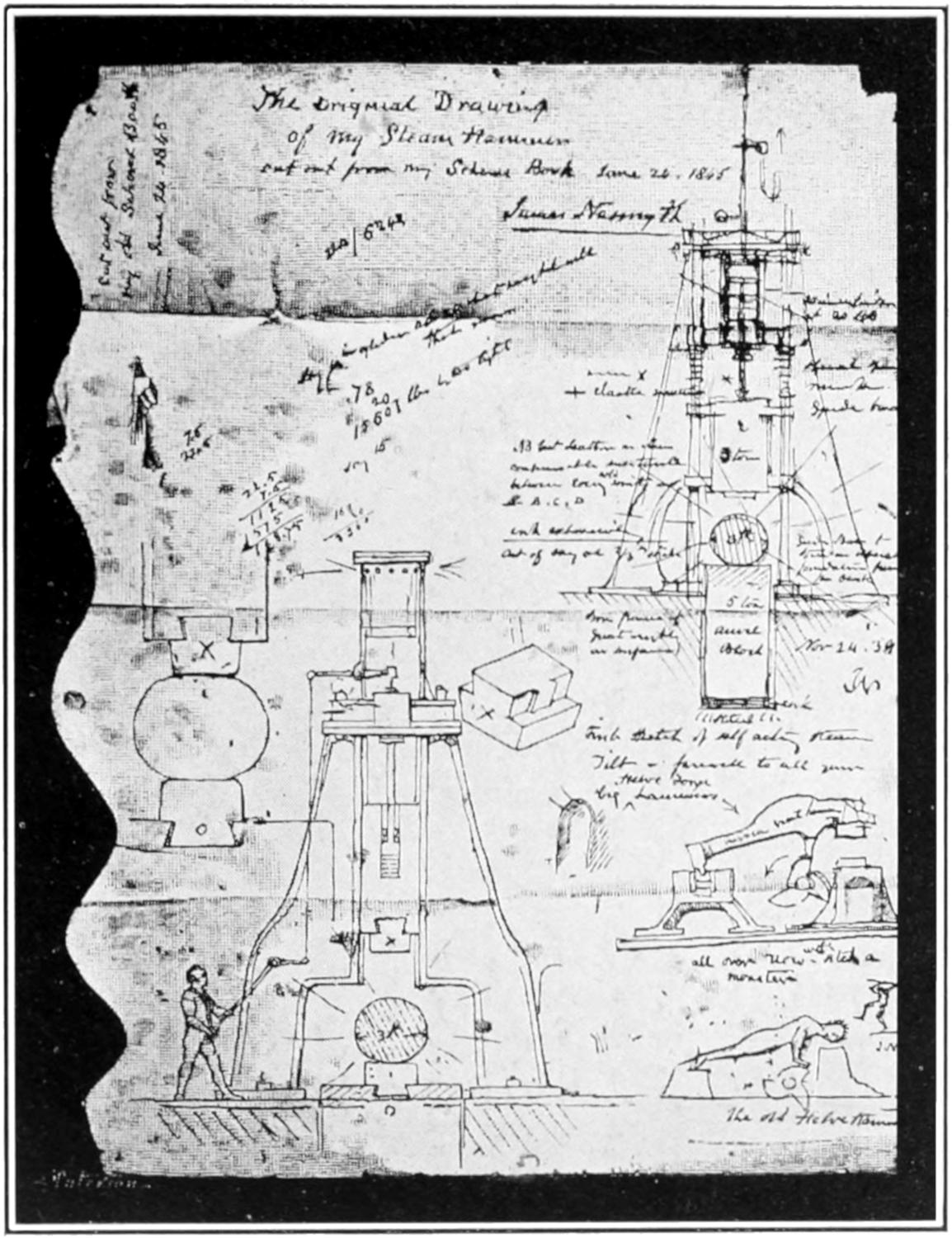

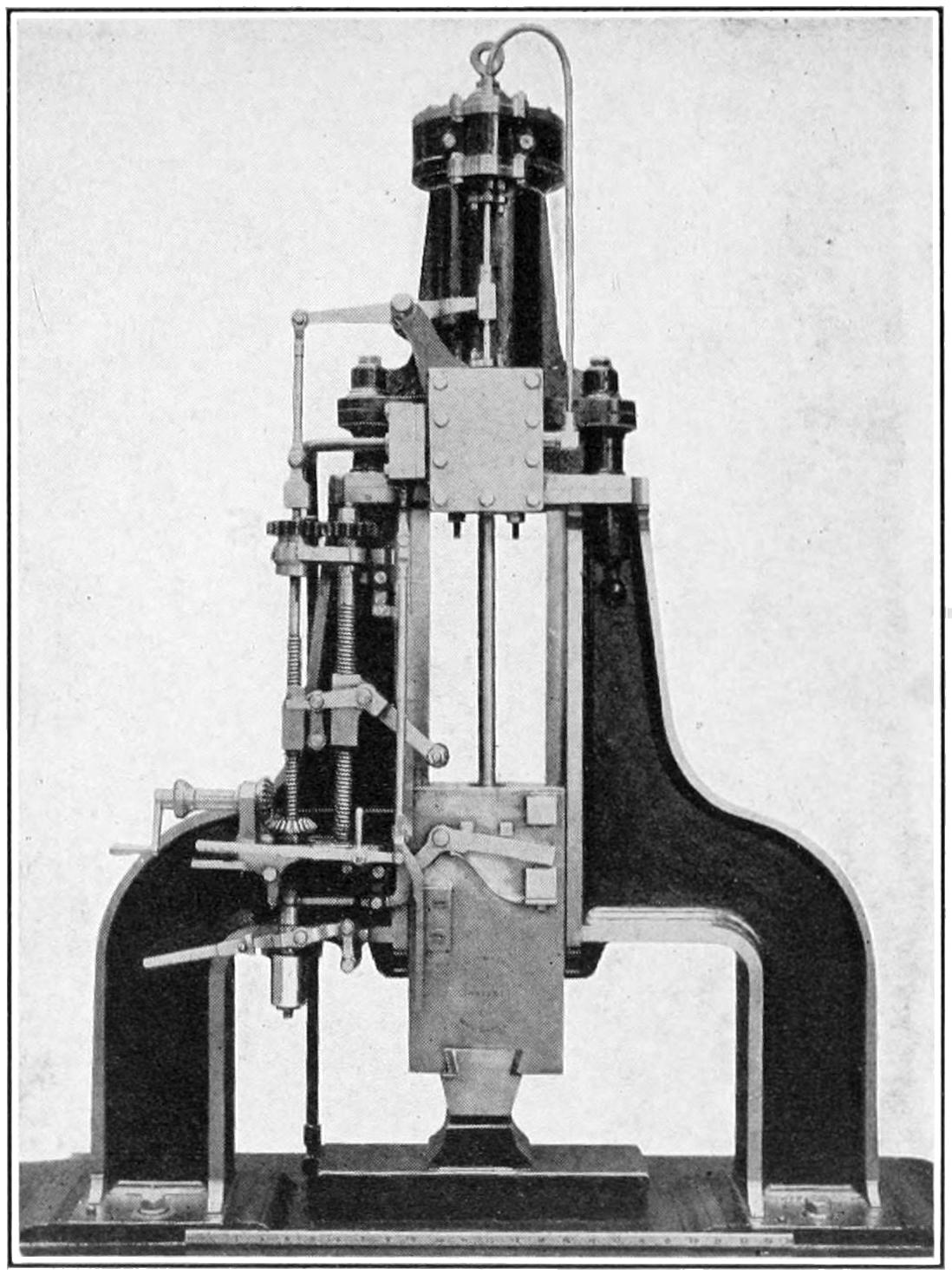

| Fig. | 23. | First Sketch of the Steam Hammer, November 24, 1839[xiv] | Facing page | 94 |

| Fig. | 24. | Model of the First Steam Hammer | Facing page | 94 |

| Fig. | 25. | Sir Joseph Whitworth | Facing page | 102 |

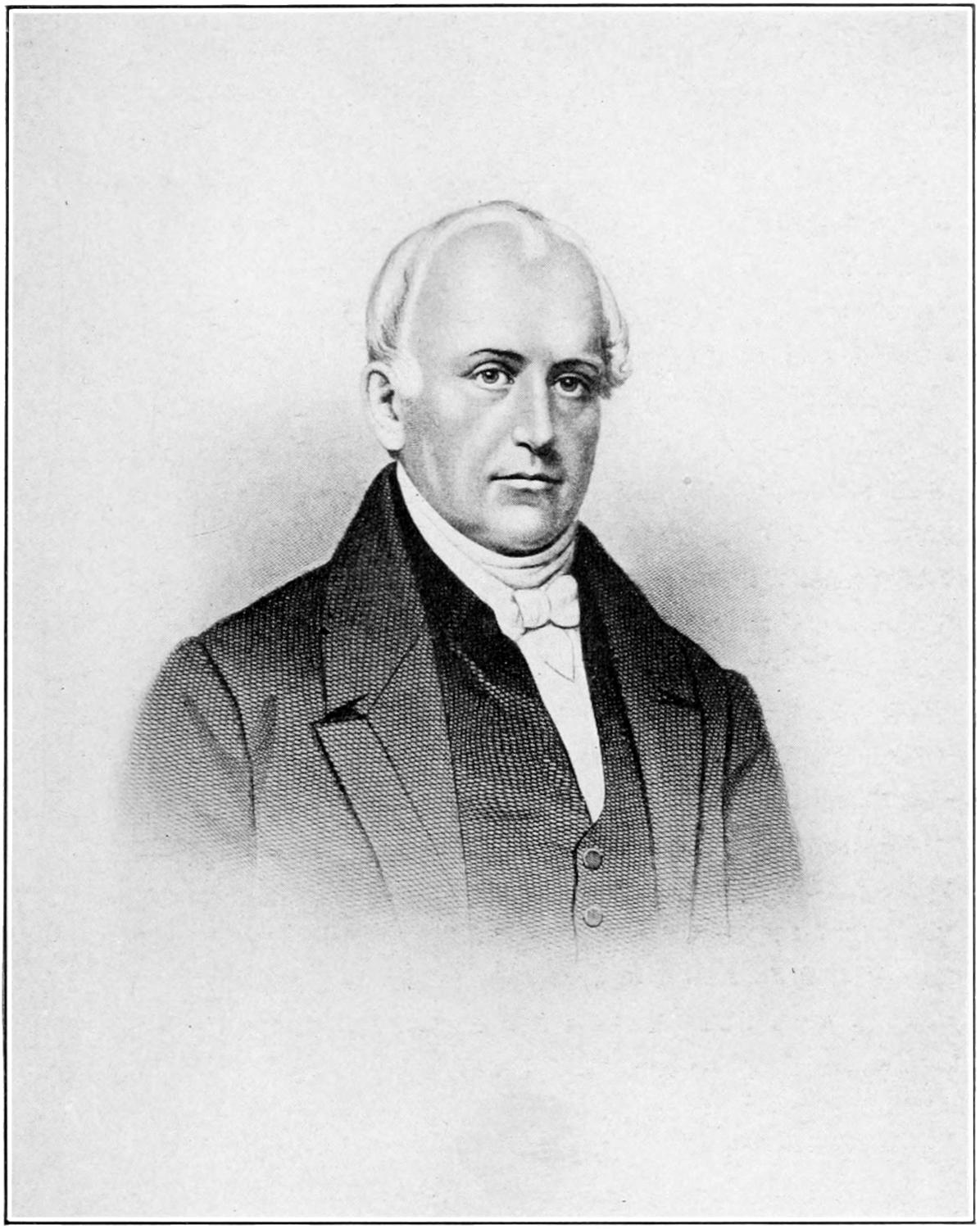

| Fig. | 26. | Samuel Slater | Facing page | 122 |

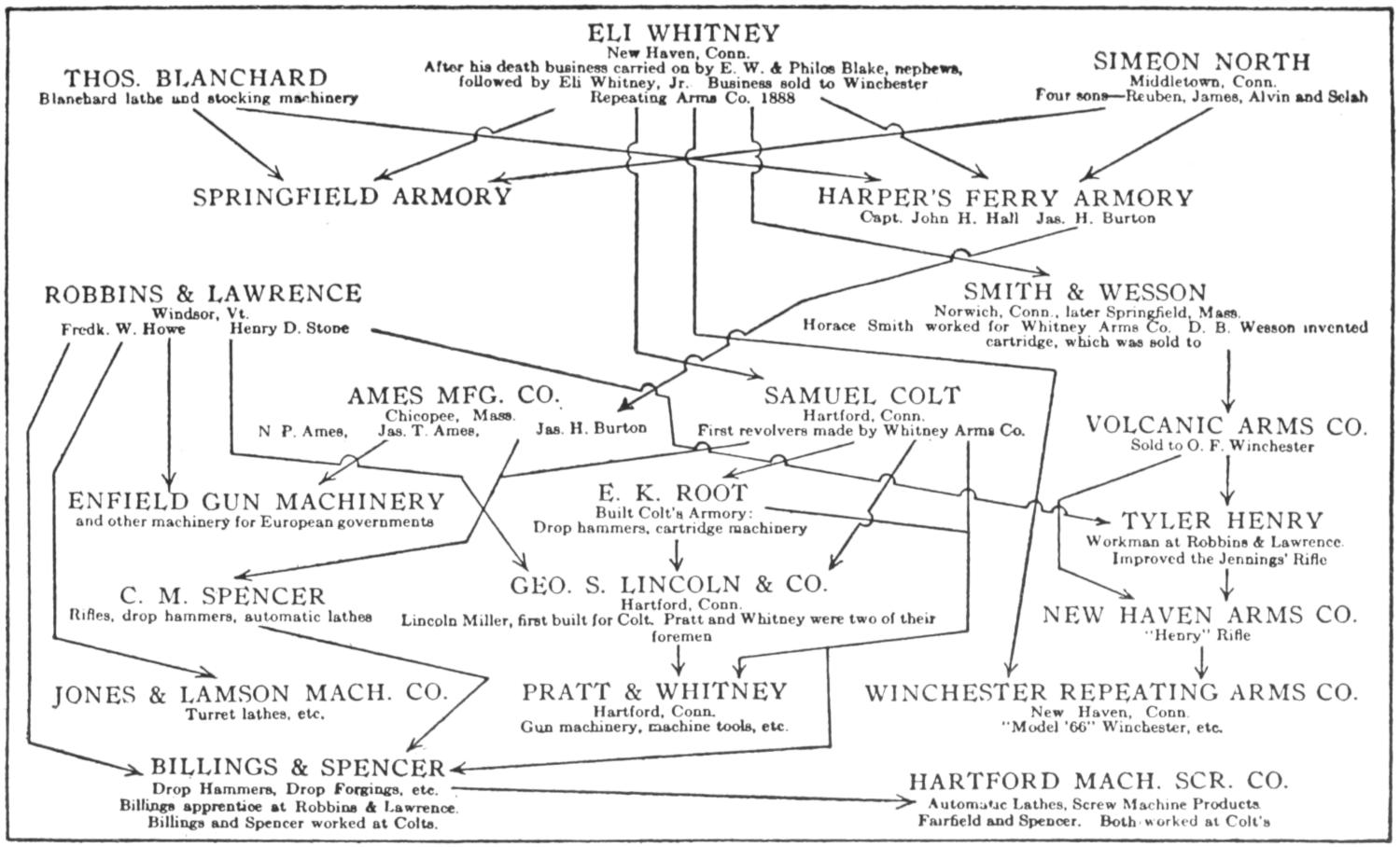

| Fig. | 27. | Genealogy of the New England Gun Makers | page | 139 |

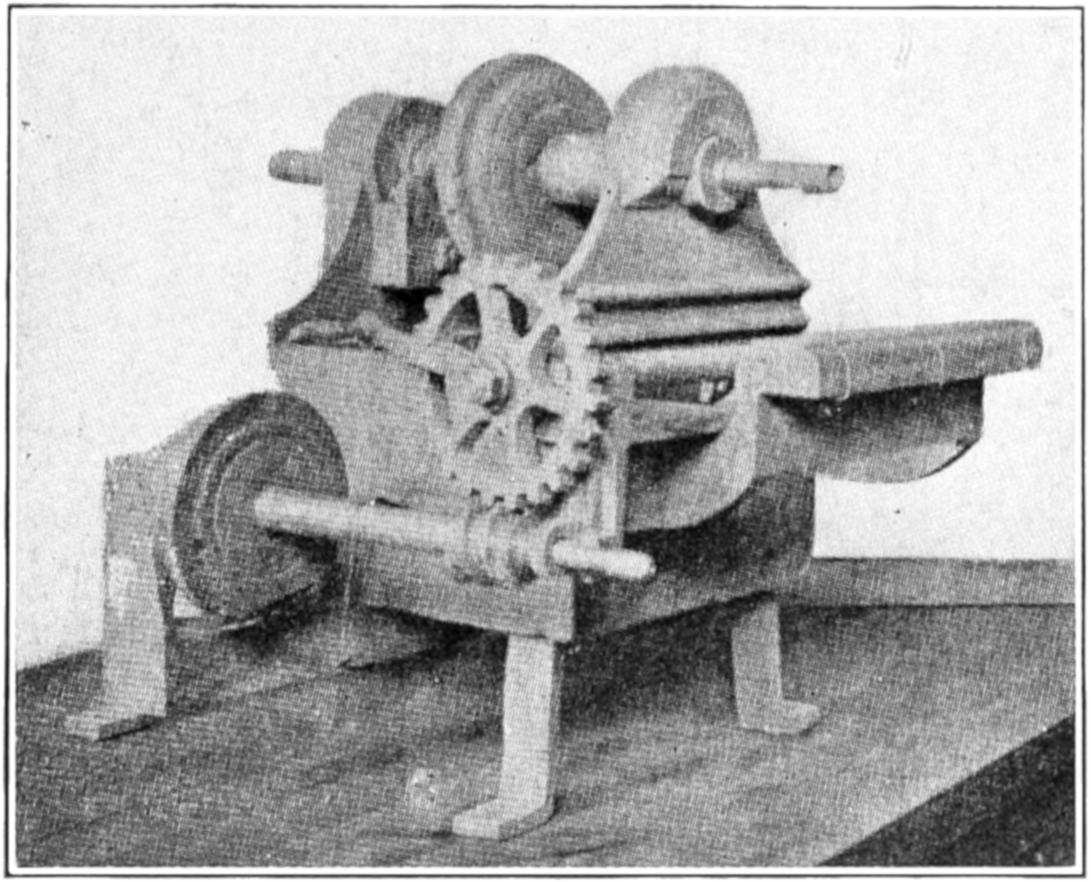

| Fig. | 28. | The First Milling Machine, Built by Eli Whitney about 1818 | Facing page | 142 |

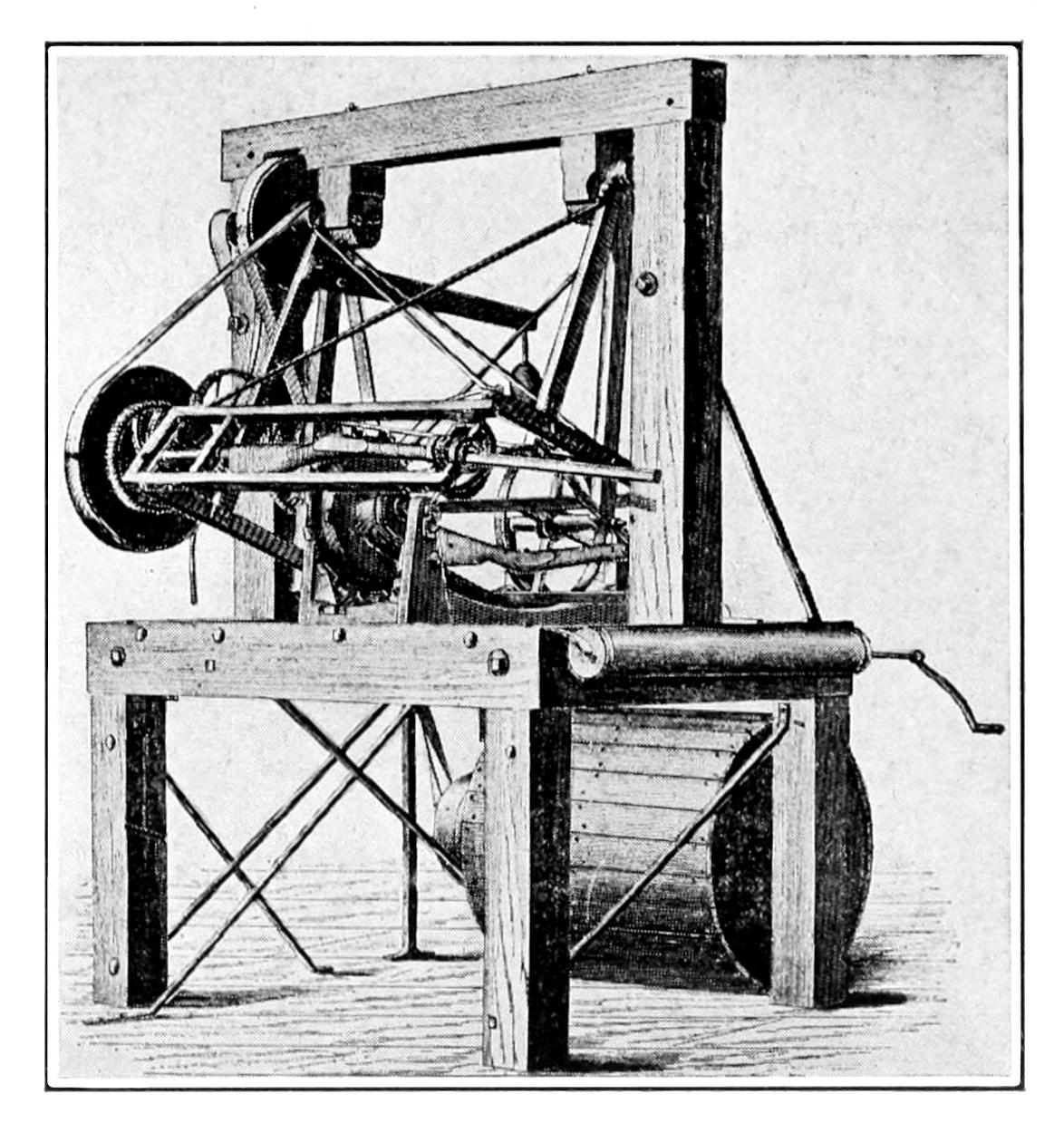

| Fig. | 29. | Blanchard “Gun-Stocking” Lathe, Built in 1818 for the Springfield Armory | Facing page | 142 |

| Fig. | 30. | Eli Whitney | Facing page | 152 |

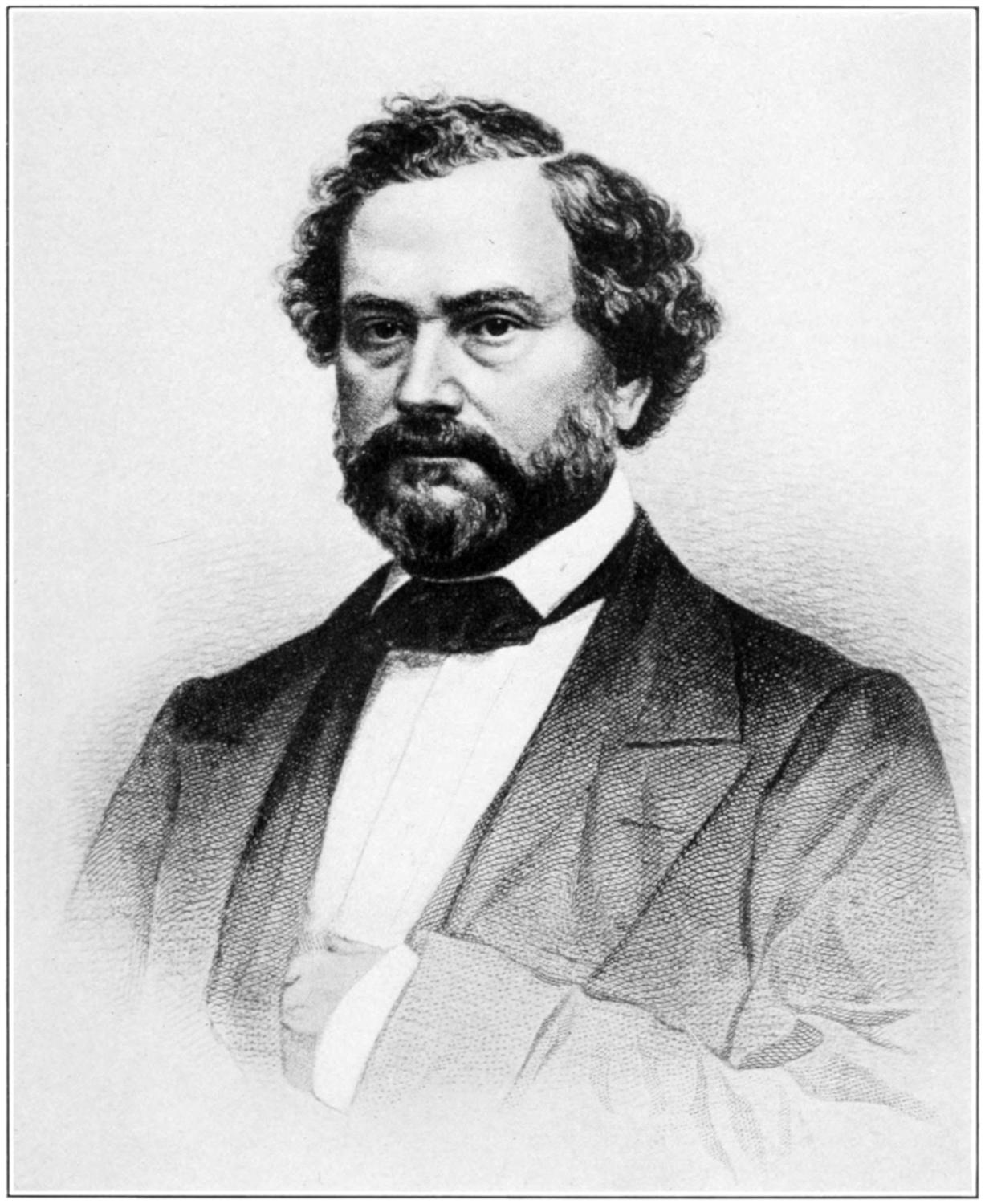

| Fig. | 31. | Samuel Colt | Facing page | 164 |

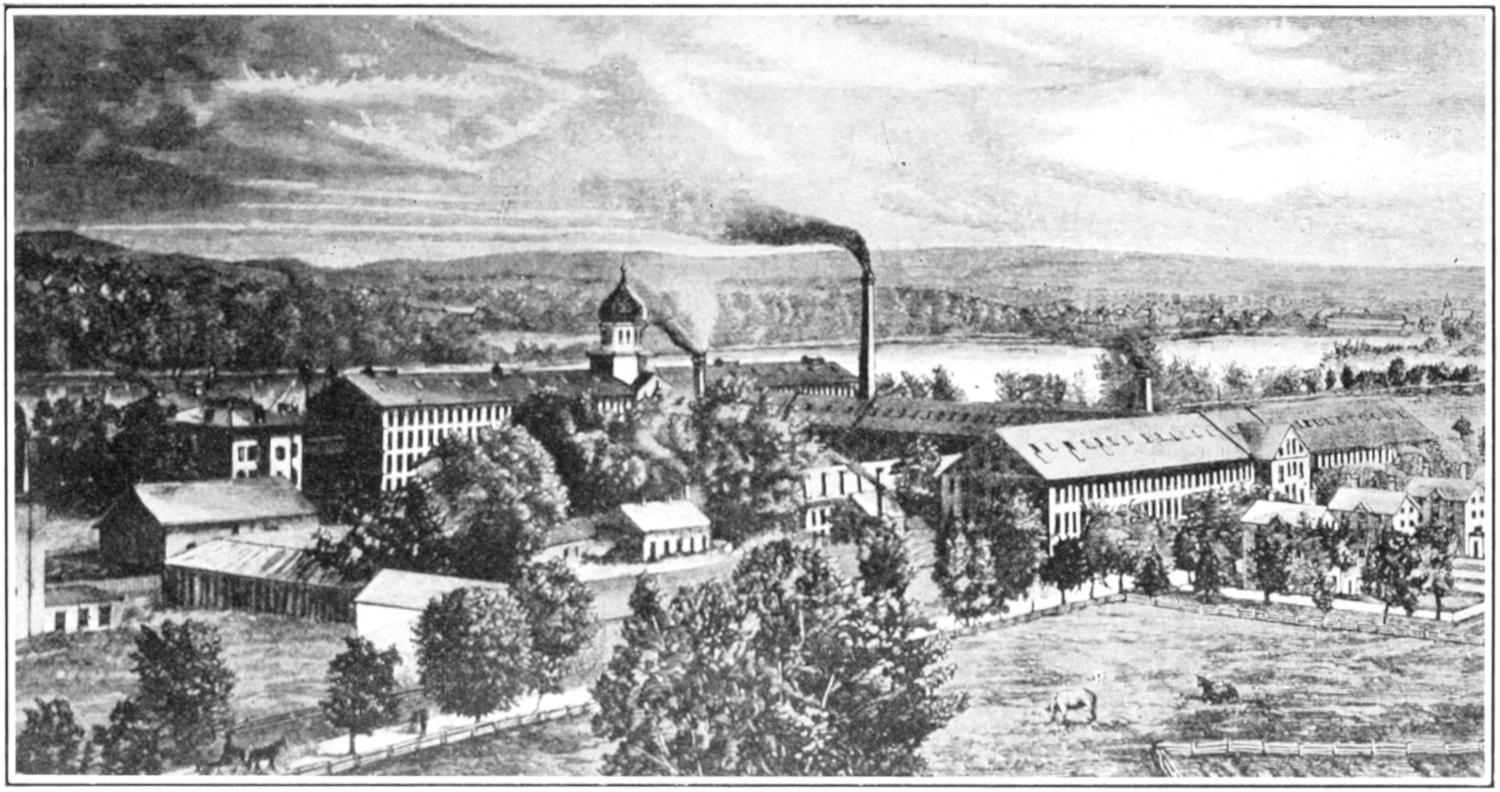

| Fig. | 32. | The Colt Armory | Facing page | 168 |

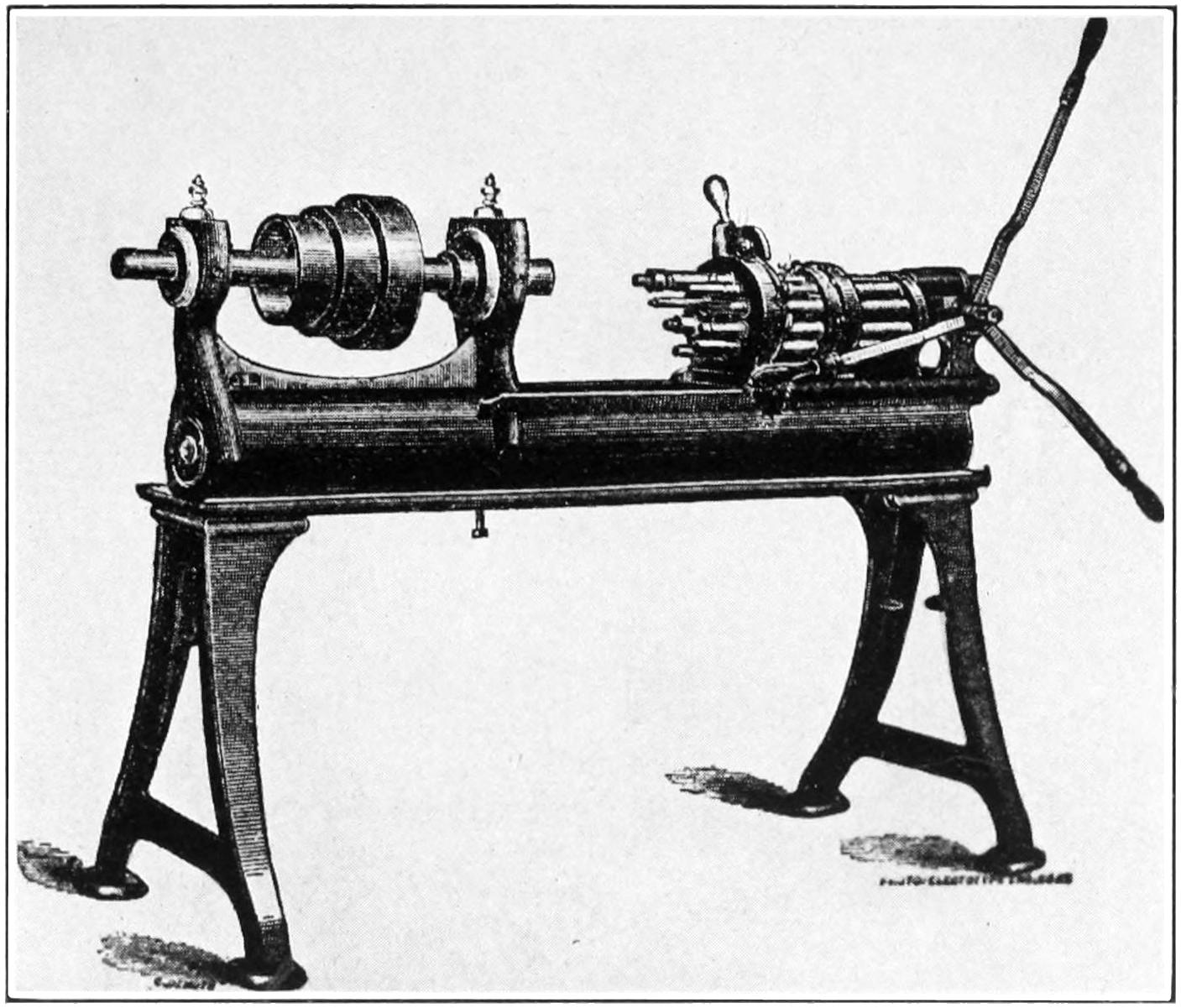

| Fig. | 33. | Root’s Chucking Lathe, about 1855 | Facing page | 170 |

| Fig. | 34. | Root’s Splining Machine, about 1855 | Facing page | 170 |

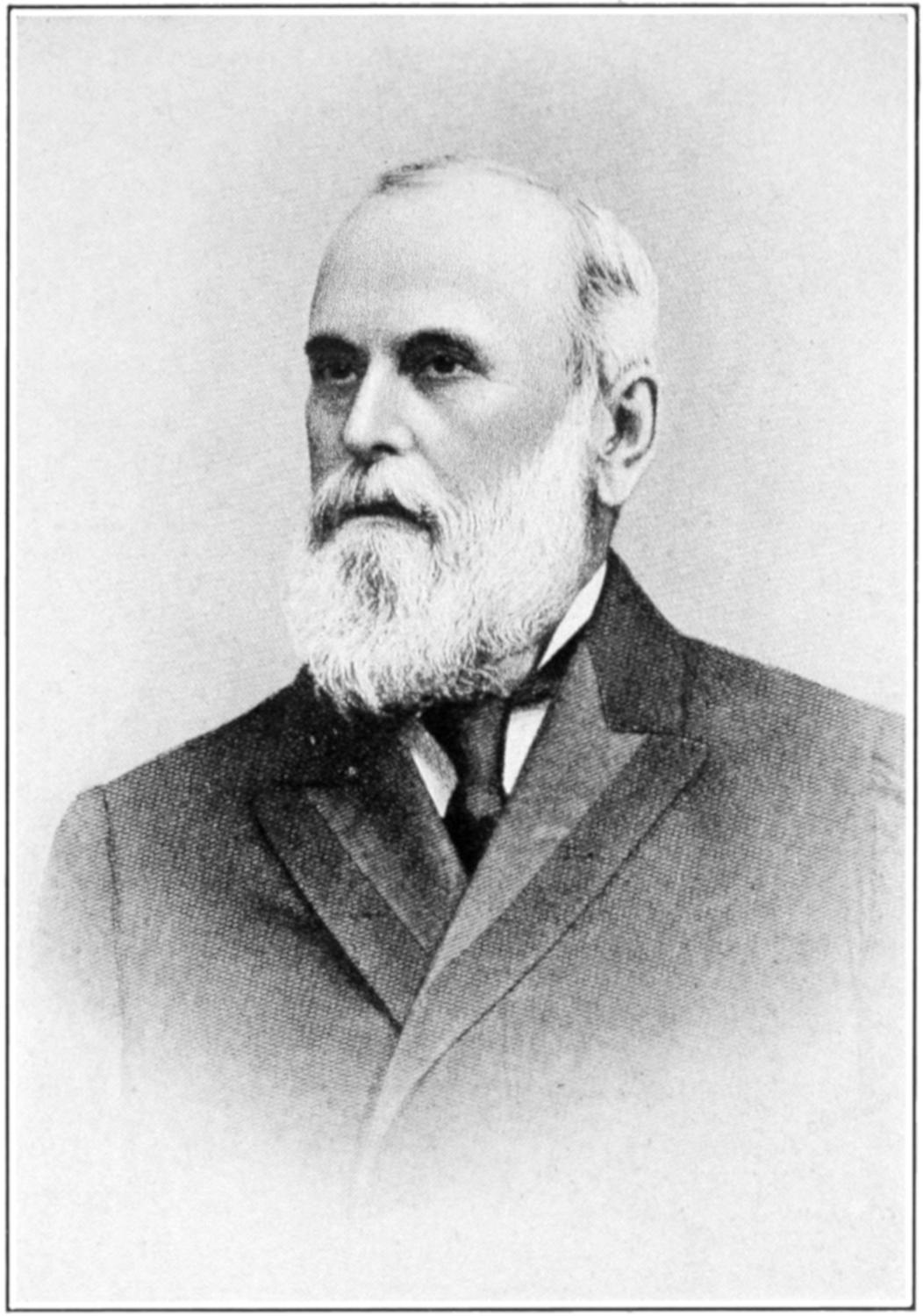

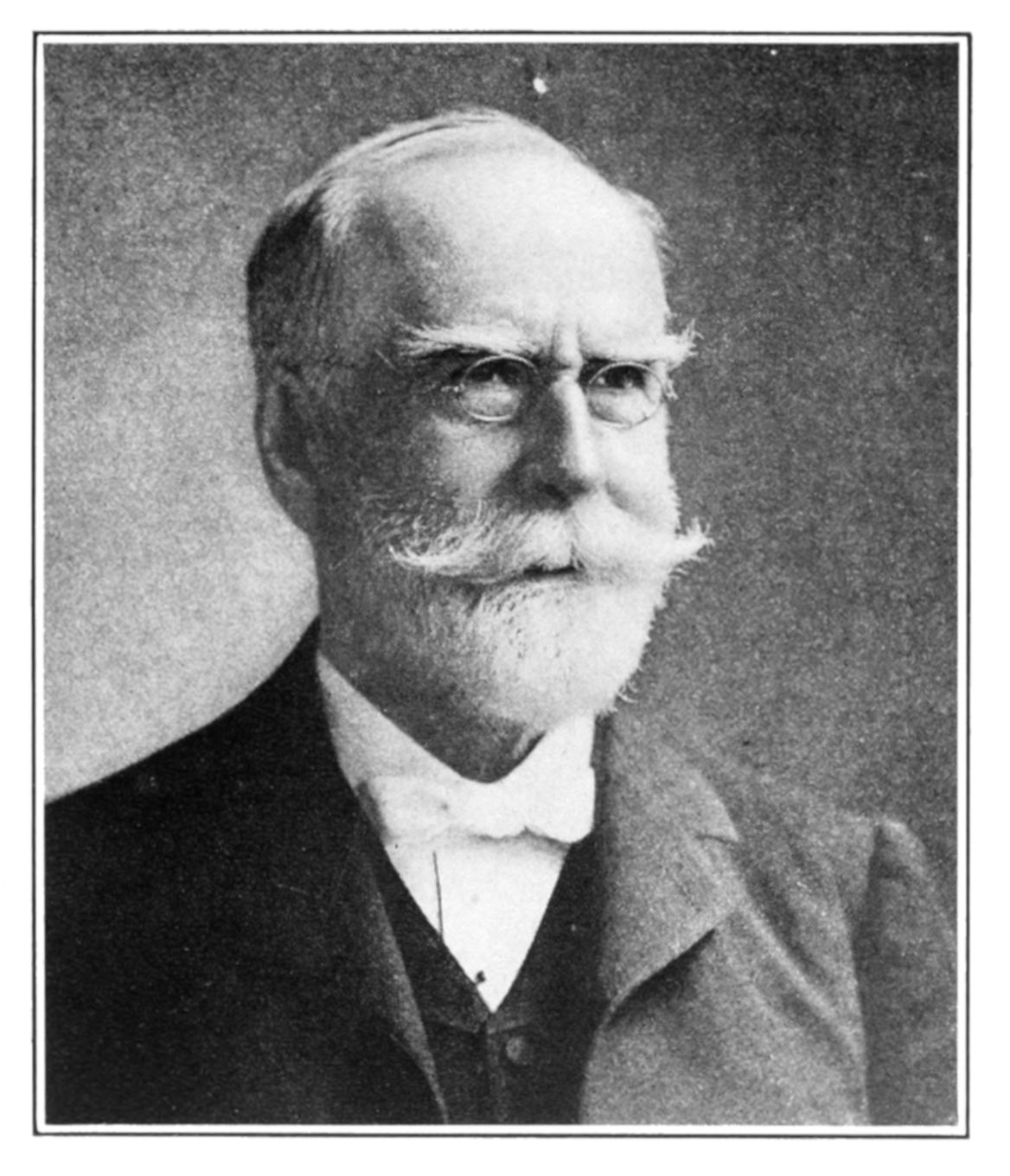

| Fig. | 35. | Francis A. Pratt | Facing page | 178 |

| Fig. | 36. | Amos Whitney | Facing page | 178 |

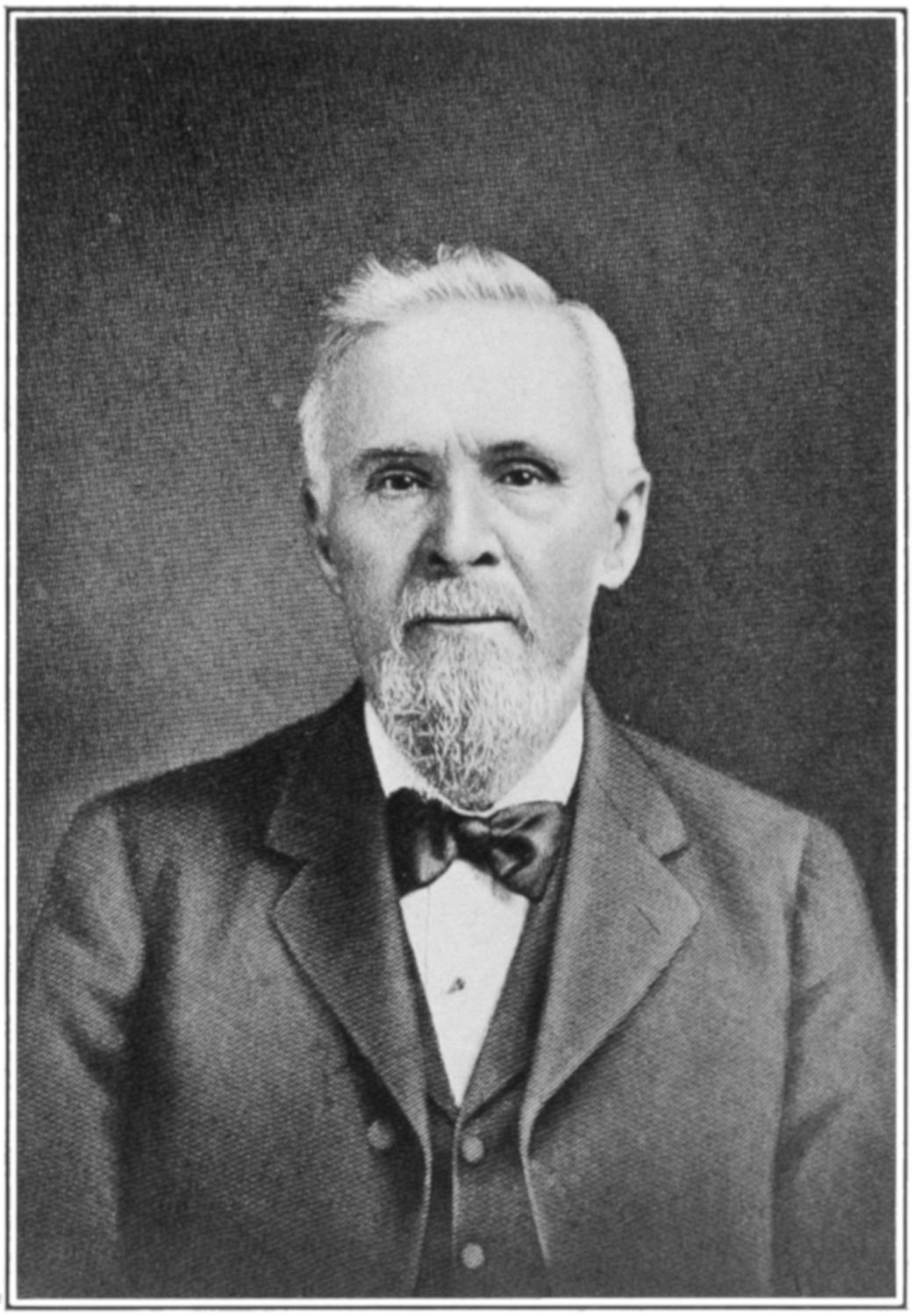

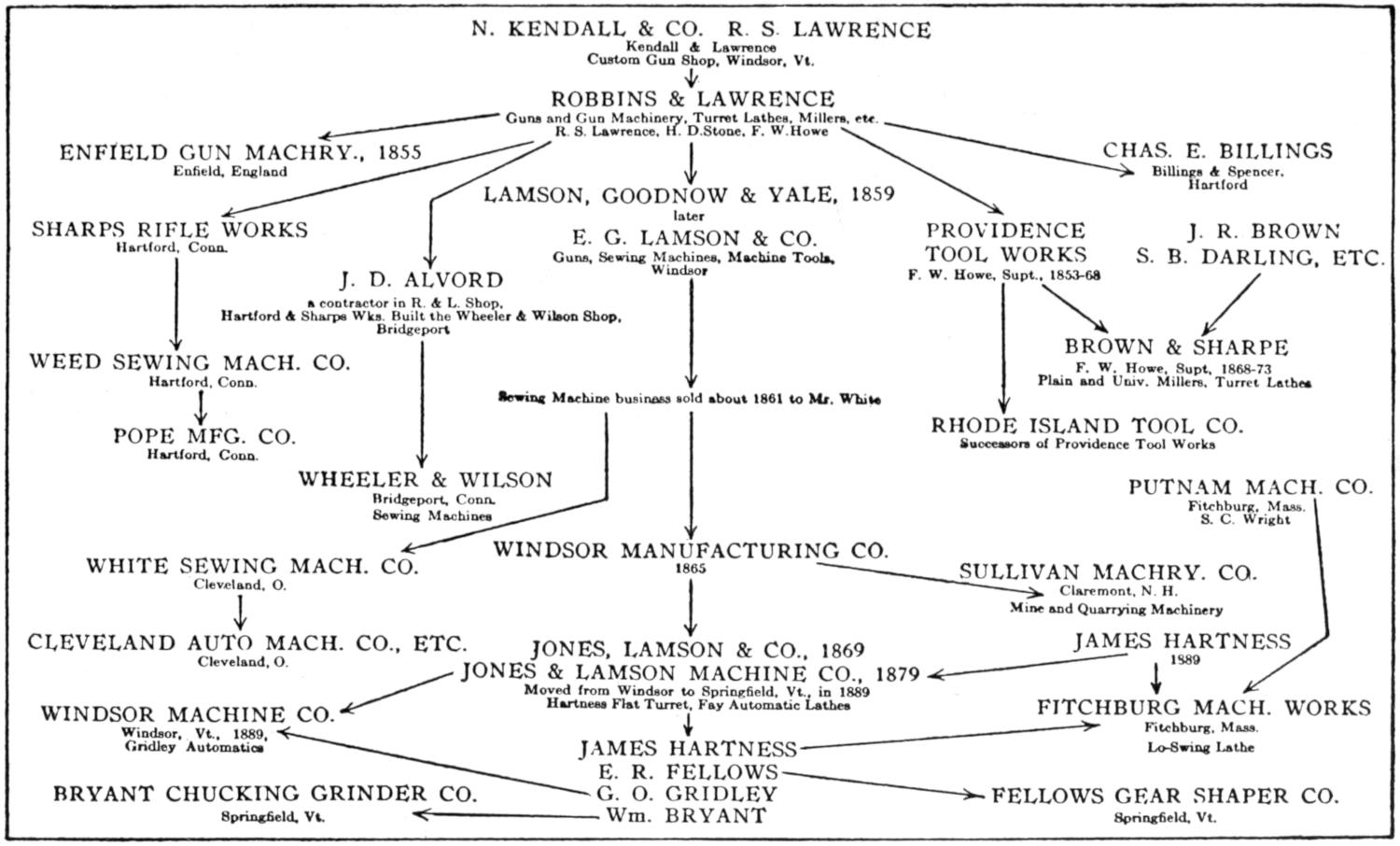

| Fig. | 37. | Genealogy of the Robbins & Lawrence Shop | page | 187 |

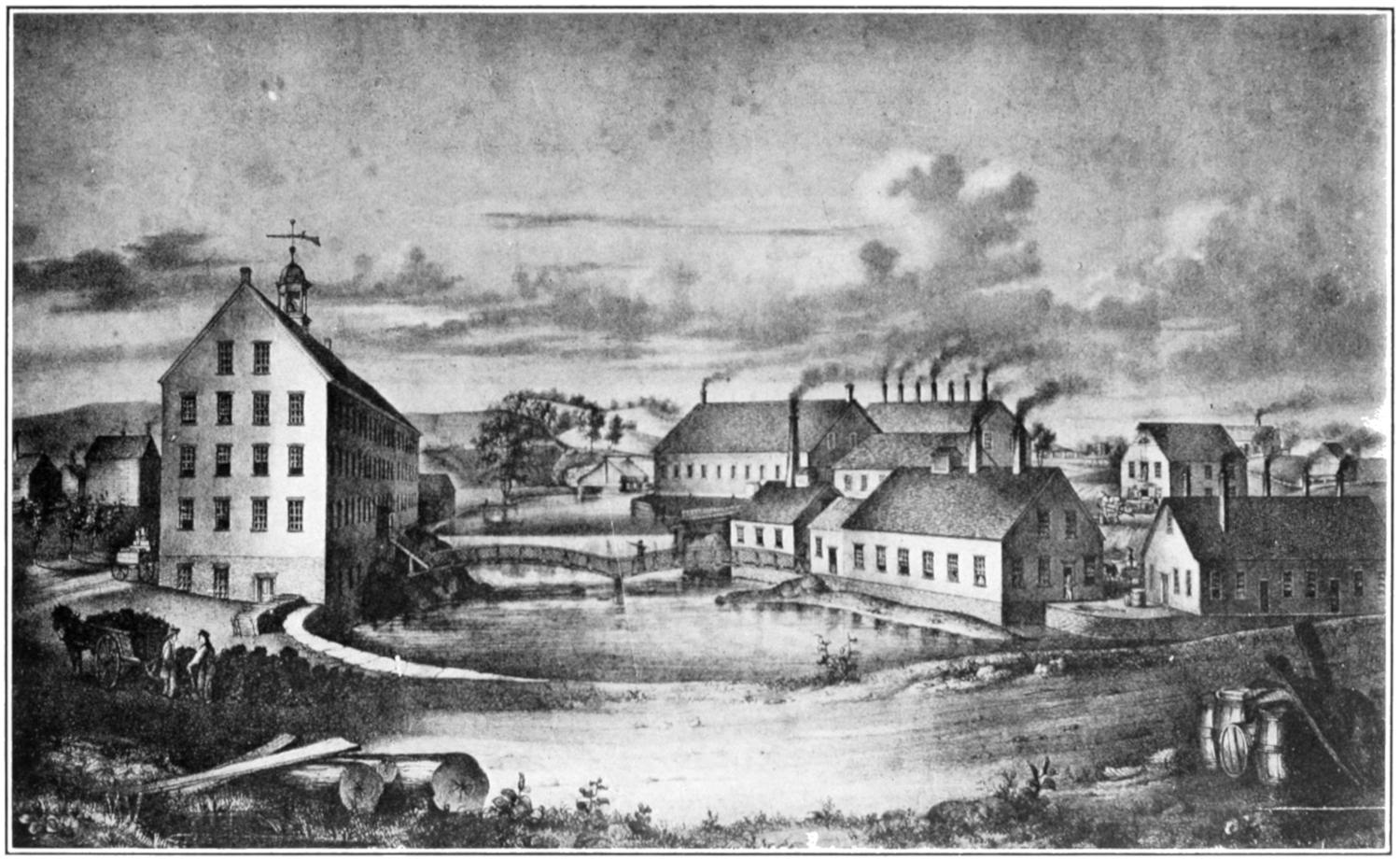

| Fig. | 38. | Robbins & Lawrence Armory, Windsor, Vt. | Facing page | 190 |

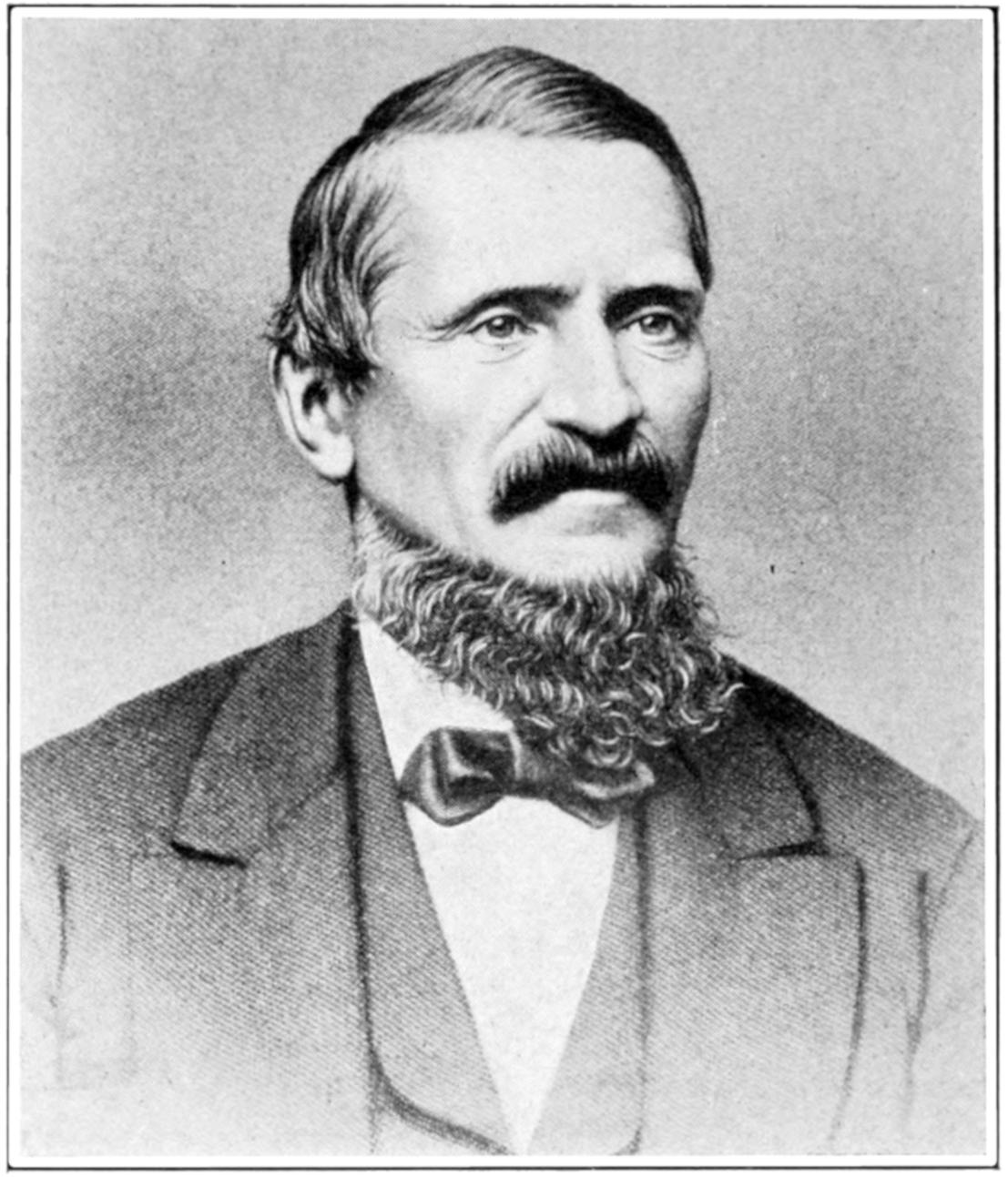

| Fig. | 39. | Frederick W. Howe | Facing page | 196 |

| Fig. | 40. | Richard S. Lawrence | Facing page | 196 |

| Fig. | 41. | James Hartness | Facing page | 198 |

| Fig. | 42. | Joseph R. Brown | Facing page | 202 |

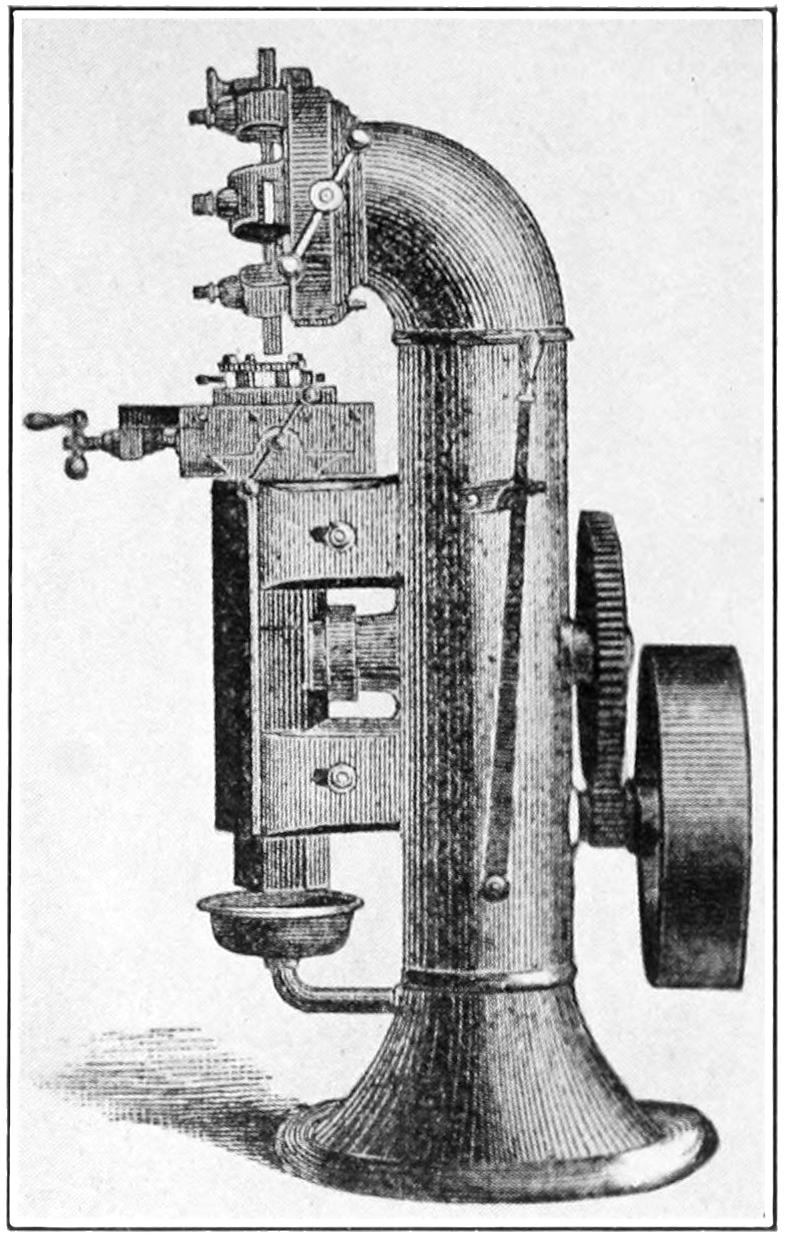

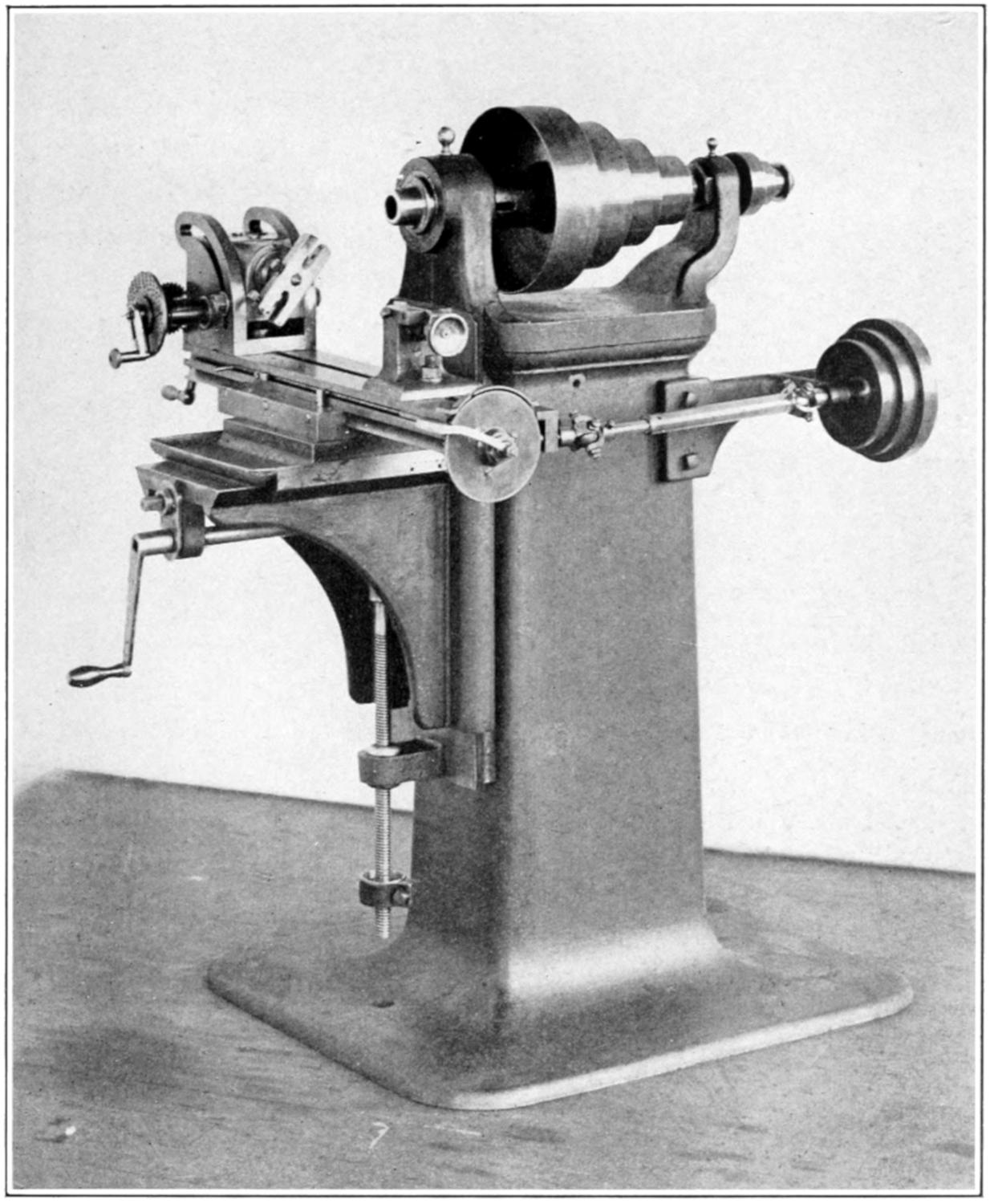

| Fig. | 43. | First Universal Milling Machine, 1862 | Facing page | 208 |

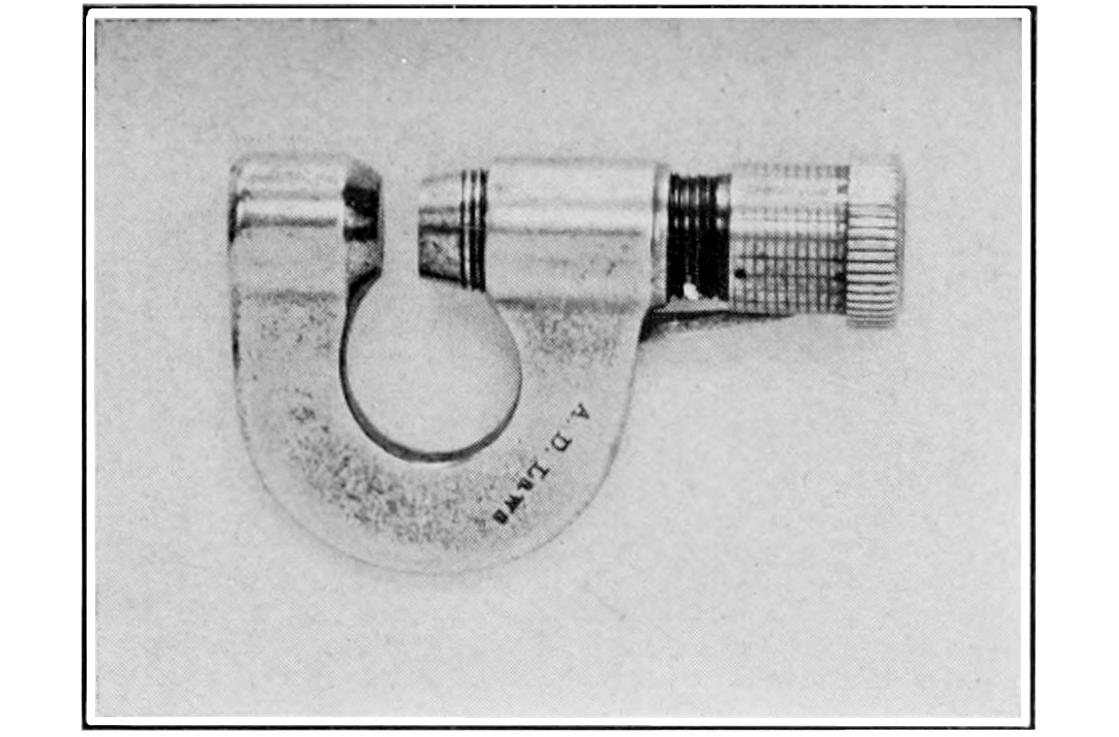

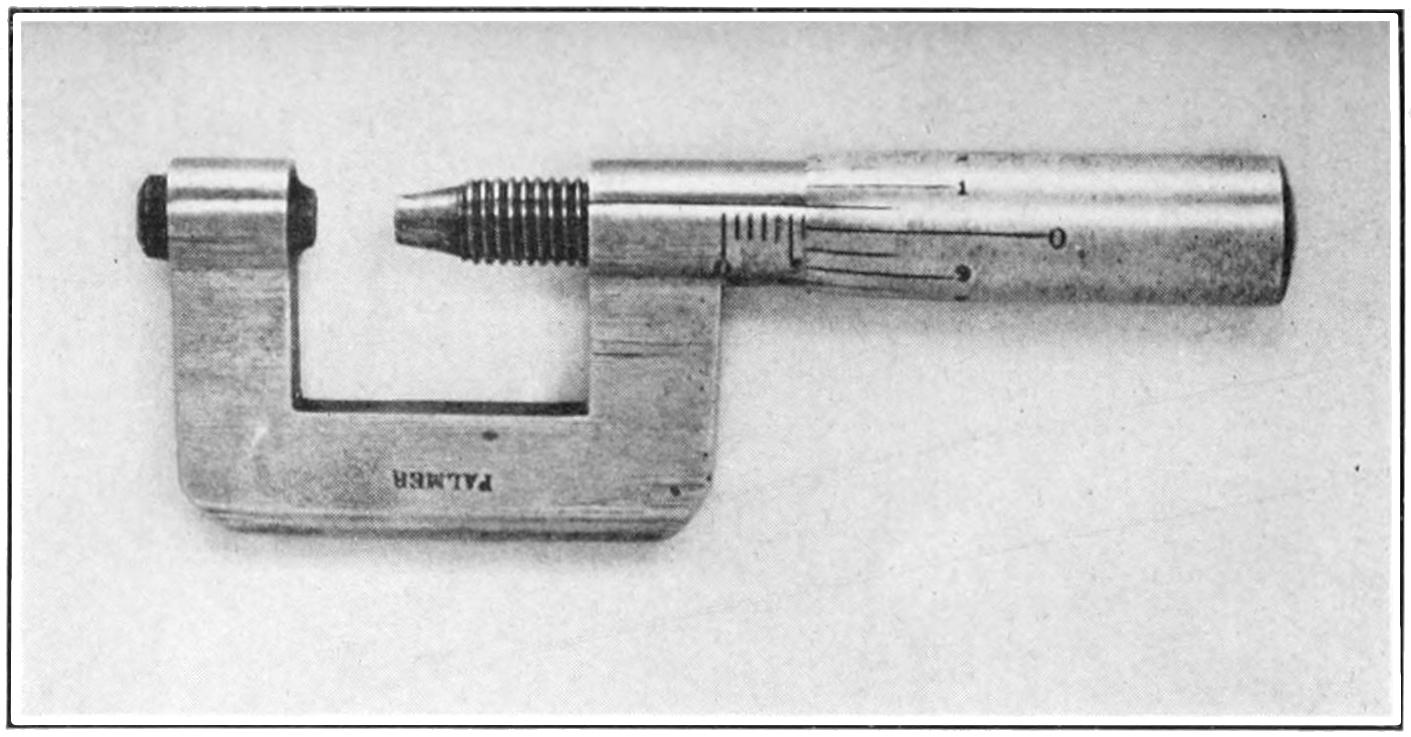

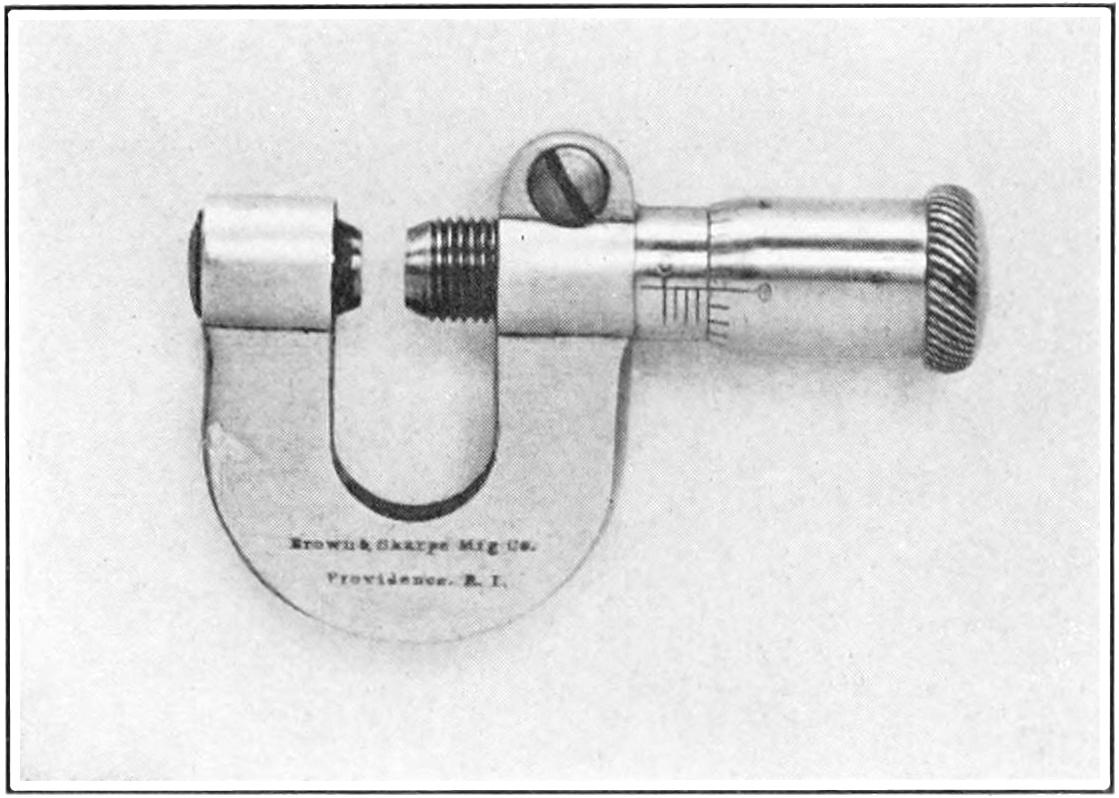

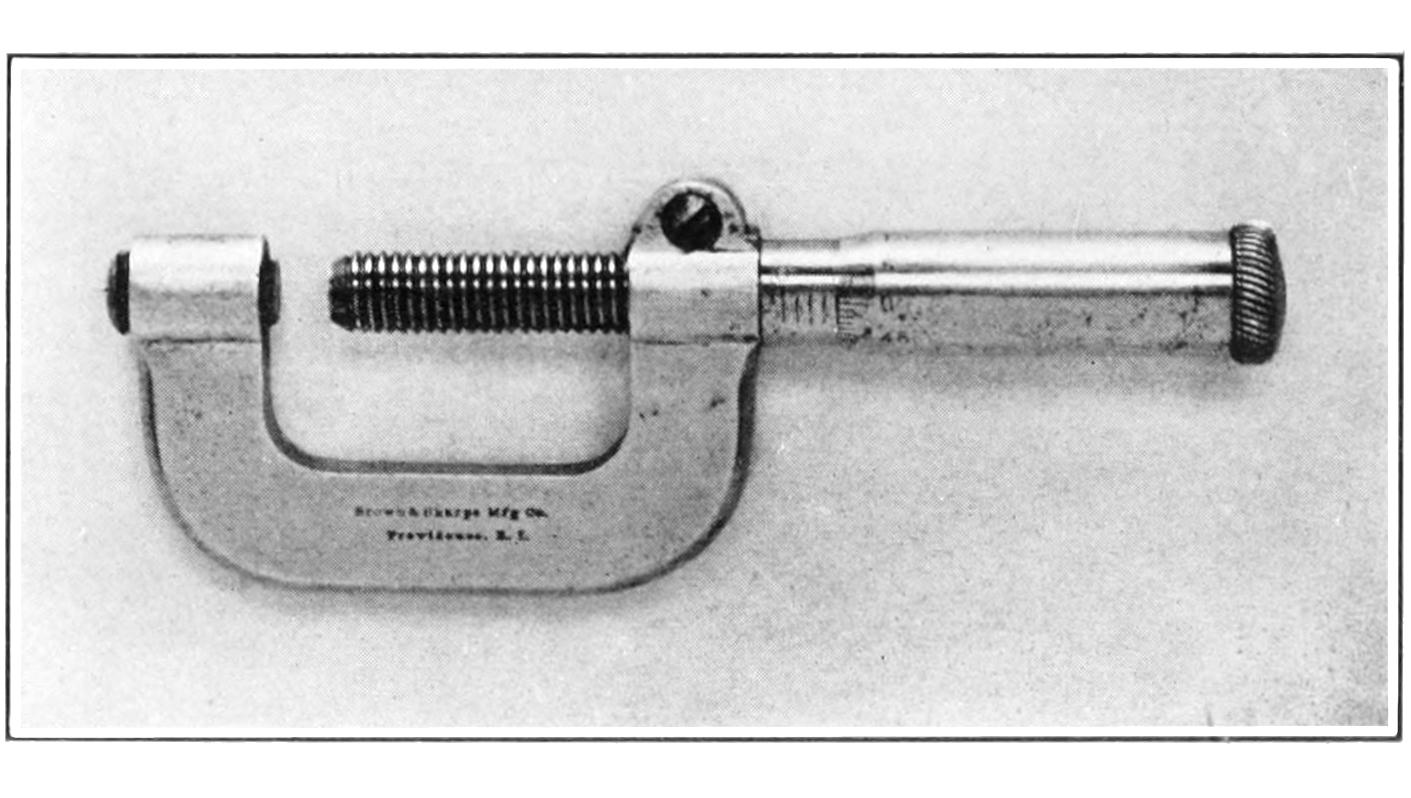

| Fig. | 44. | Early Micrometer Calipers | Facing page | 212 |

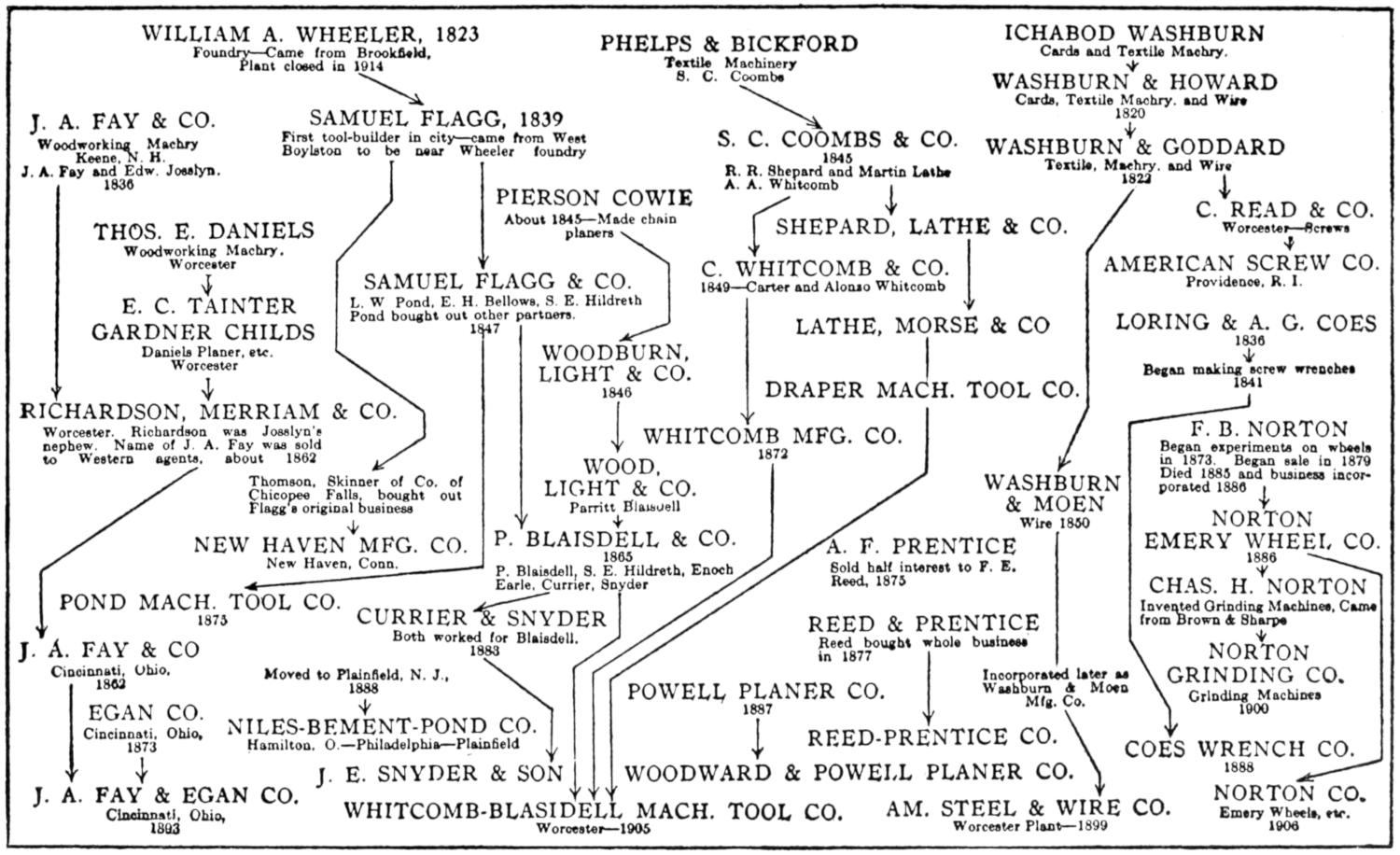

| Fig. | 45. | Genealogy of the Worcester Tool Builders | page | 223 |

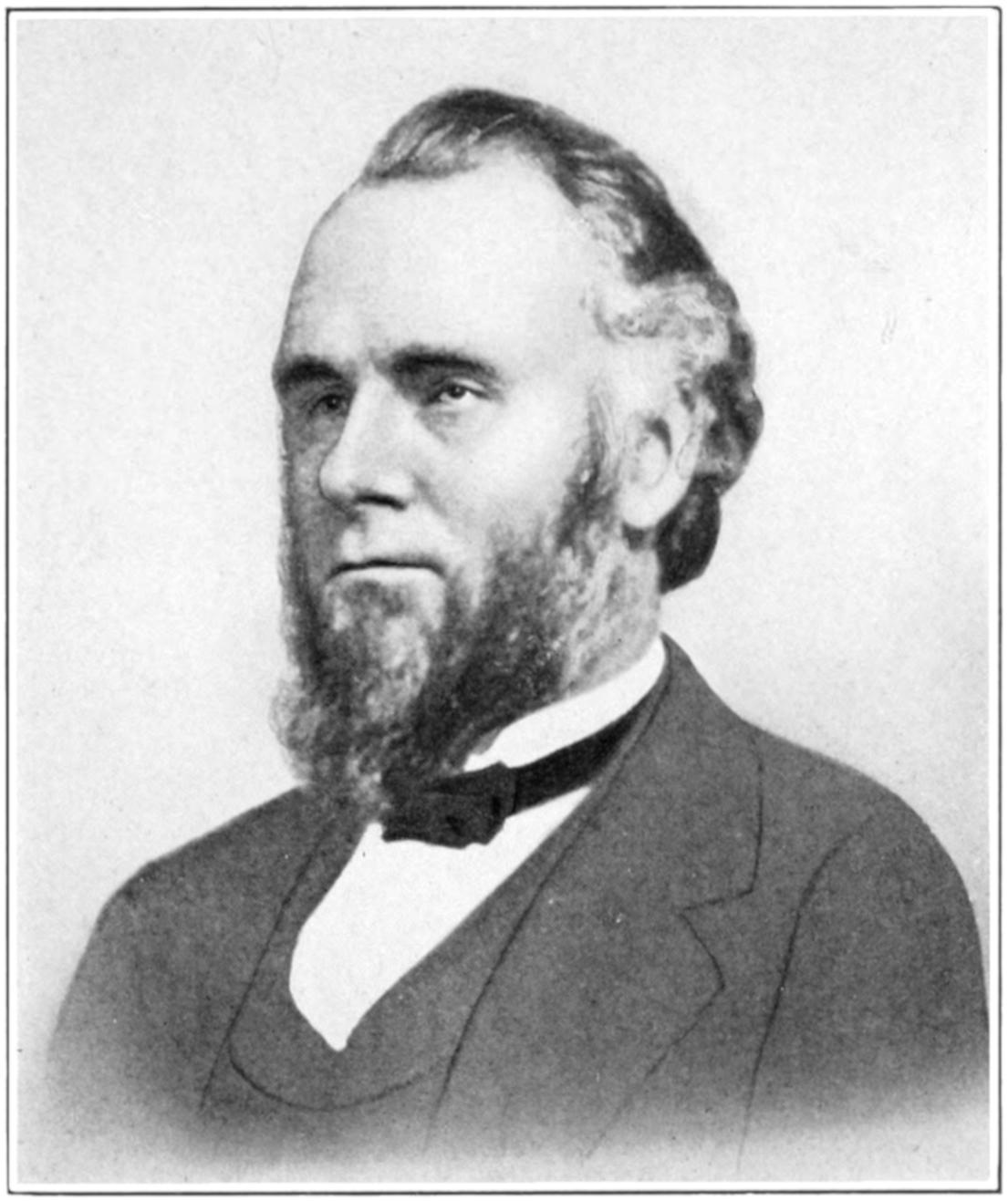

| Fig. | 46. | Lucius W. Pond | Facing page | 228 |

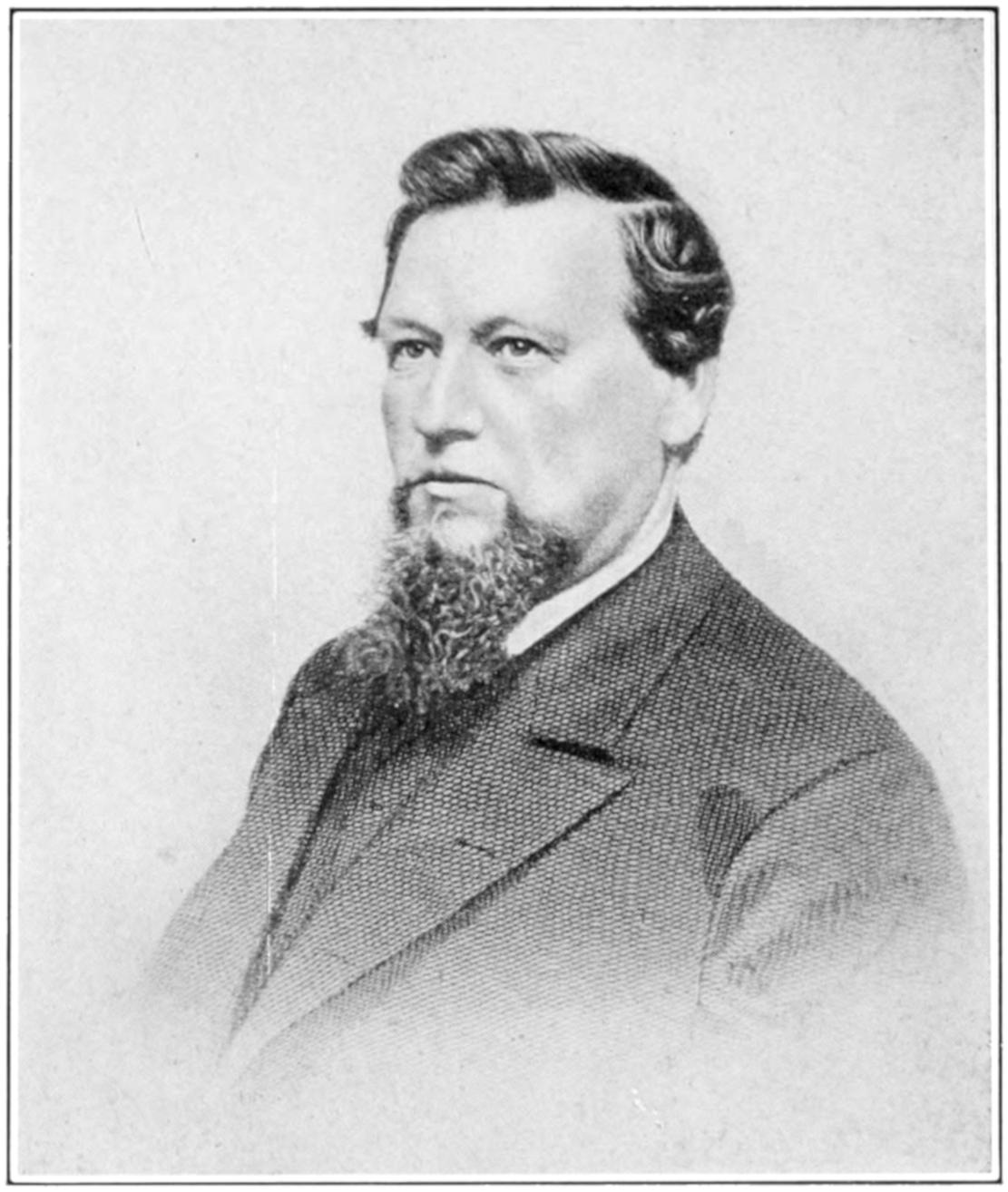

| Fig. | 47. | Salmon W. Putnam | Facing page | 228 |

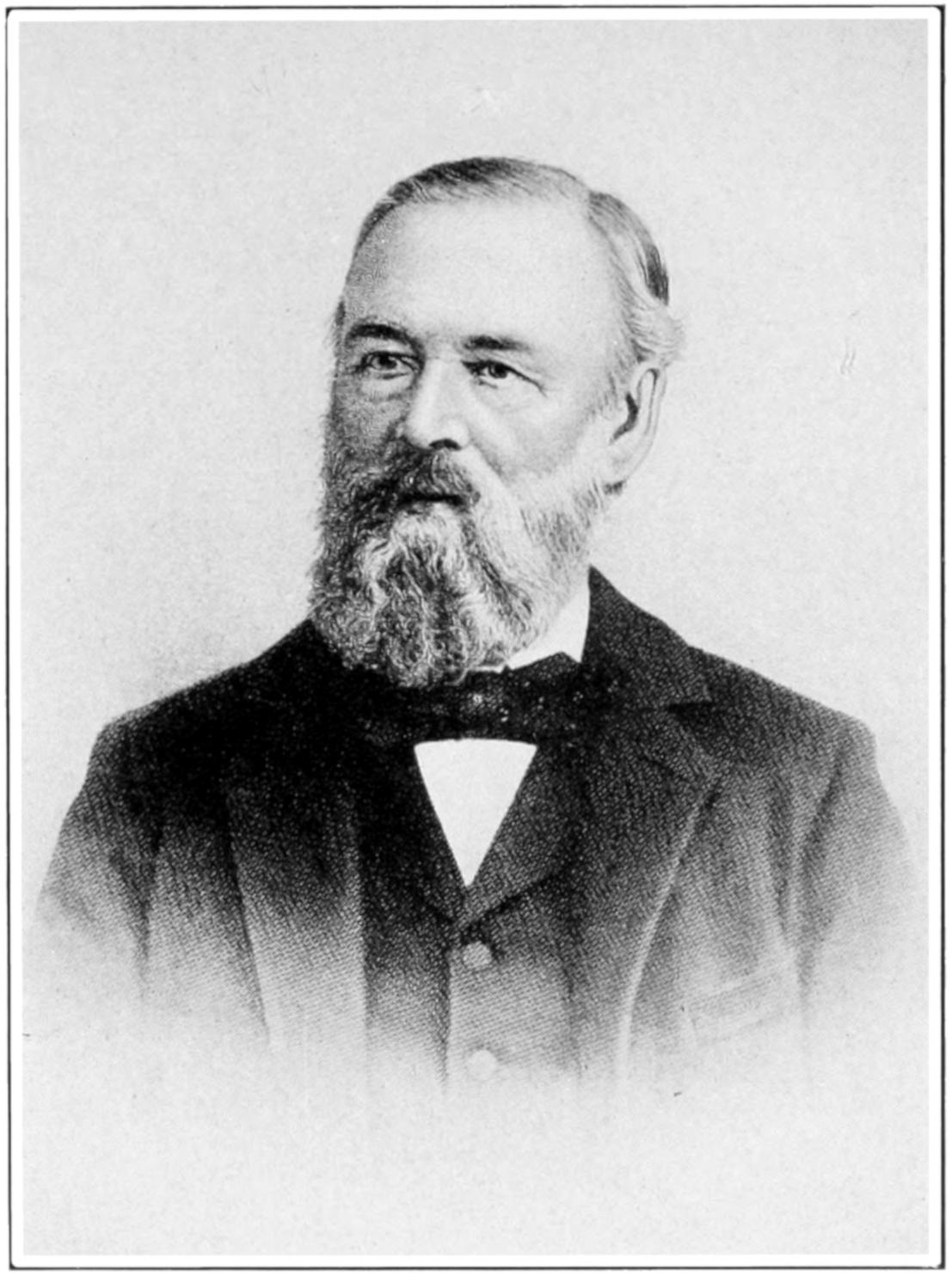

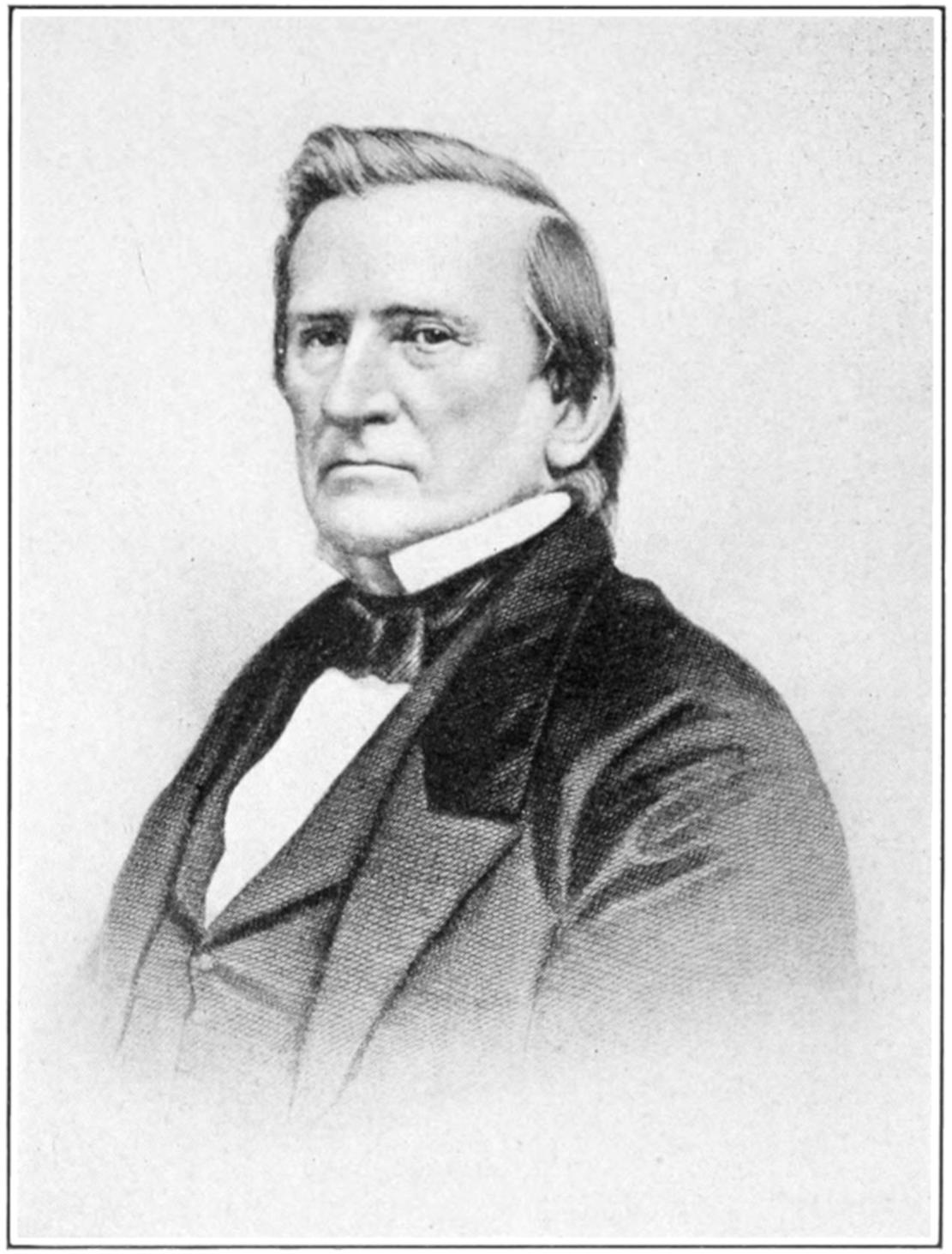

| Fig. | 48. | Hiram W. Hayden[xv] | Facing page | 232 |

| Fig. | 49. | Israel Holmes | Facing page | 232 |

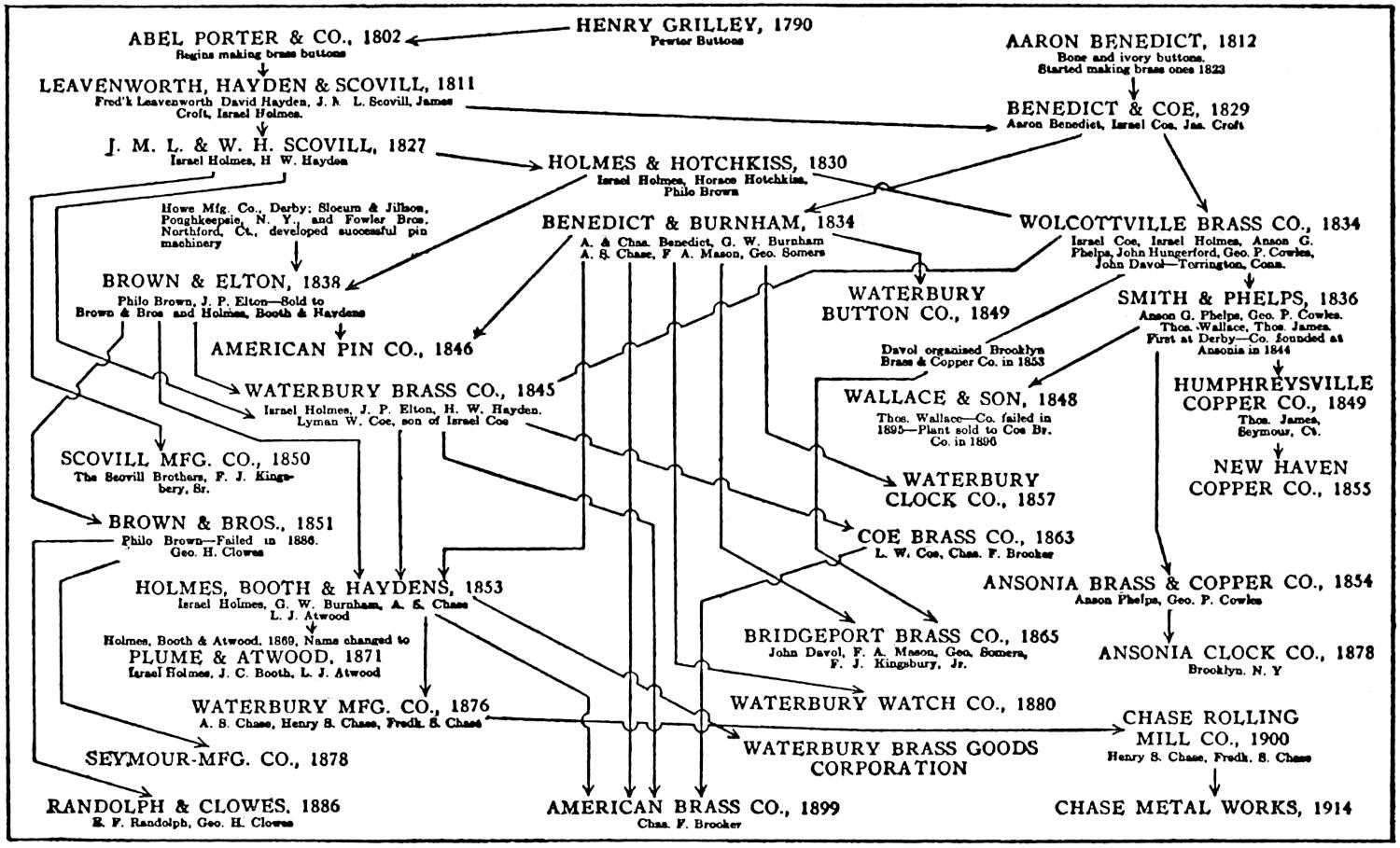

| Fig. | 50. | Genealogy of the Naugatuck Brass Industry | page | 235 |

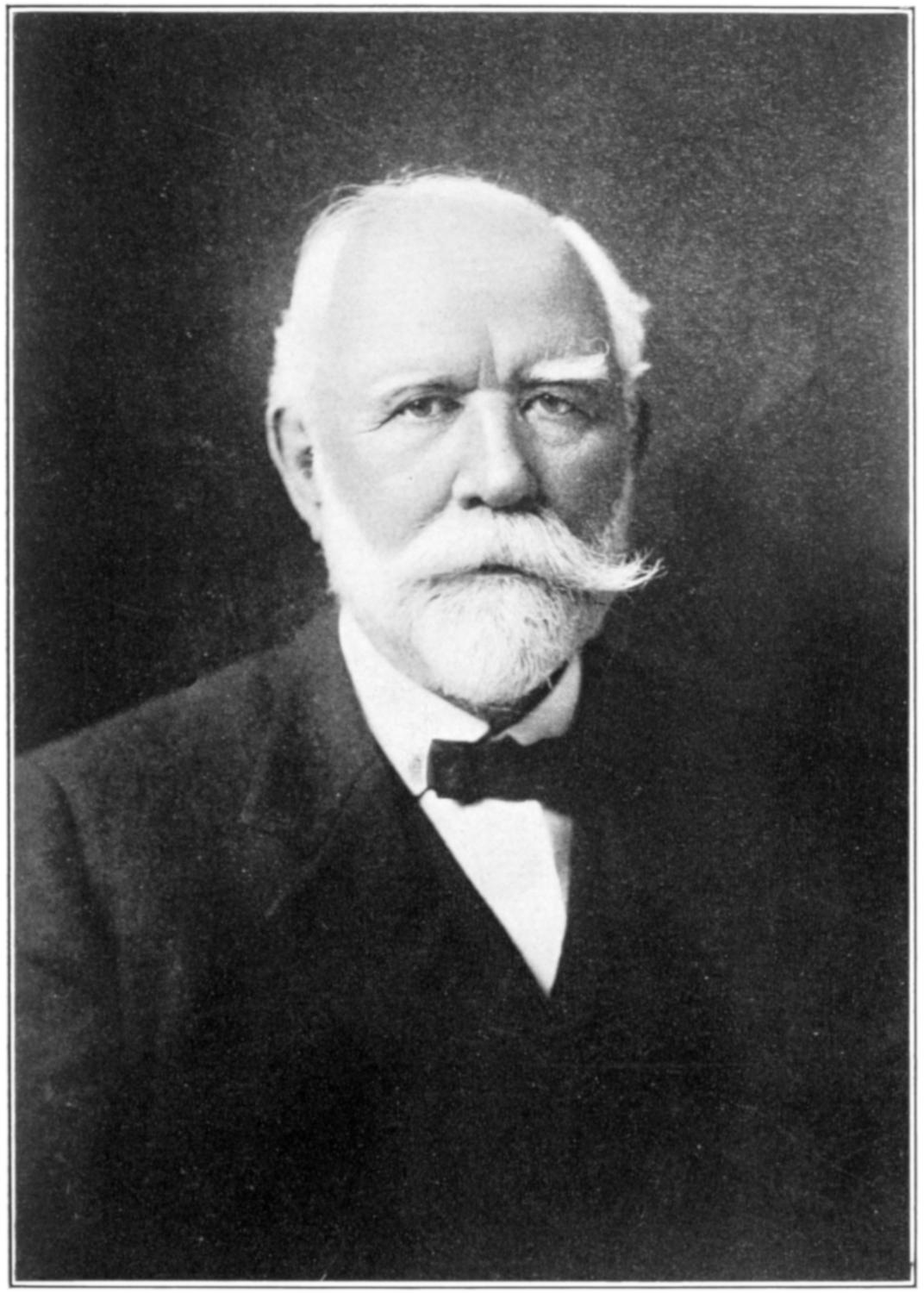

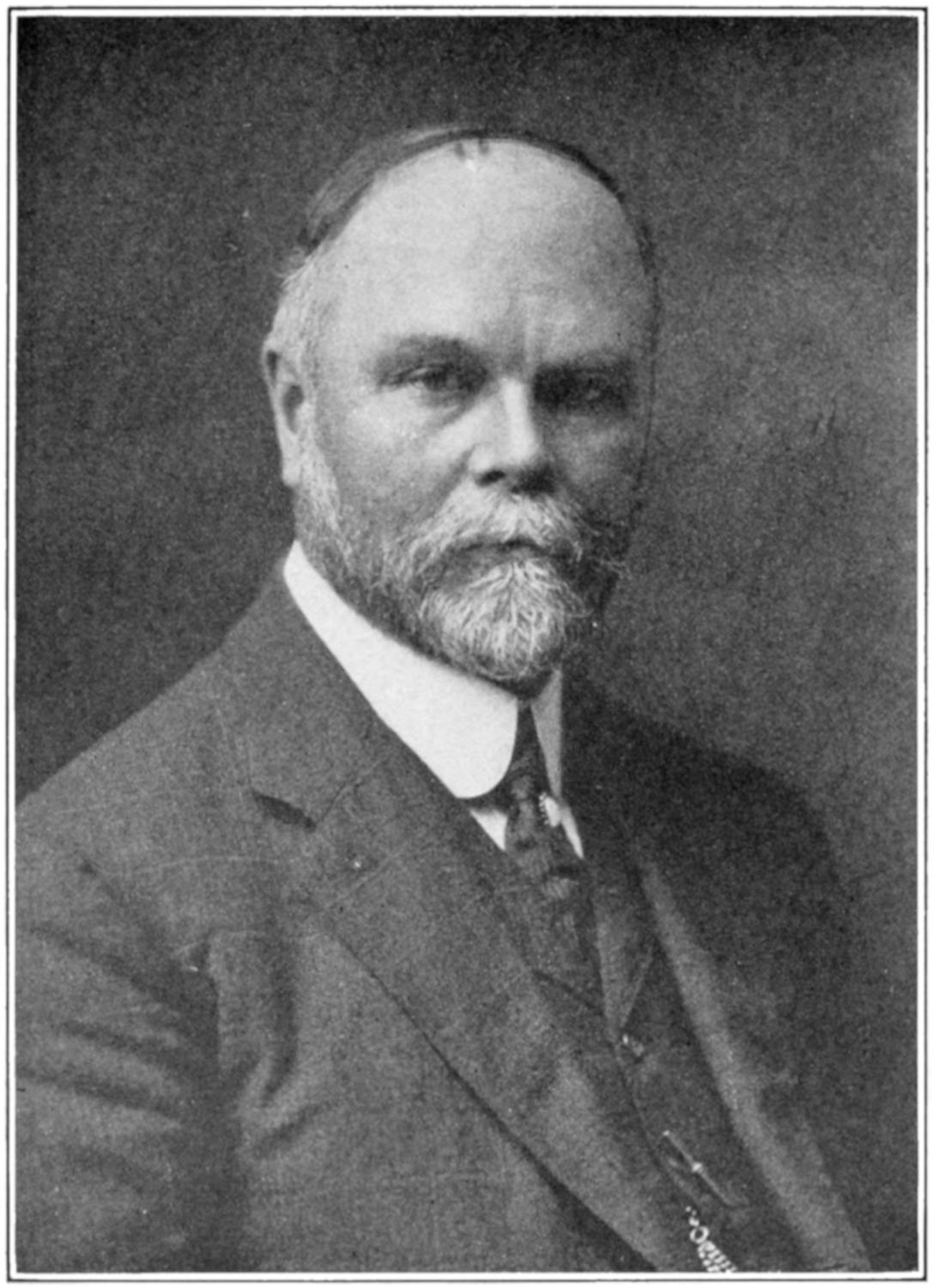

| Fig. | 51. | William Sellers | Facing page | 248 |

| Fig. | 52. | Coleman Sellers | Facing page | 252 |

| Fig. | 53. | William B. Bement | Facing page | 252 |

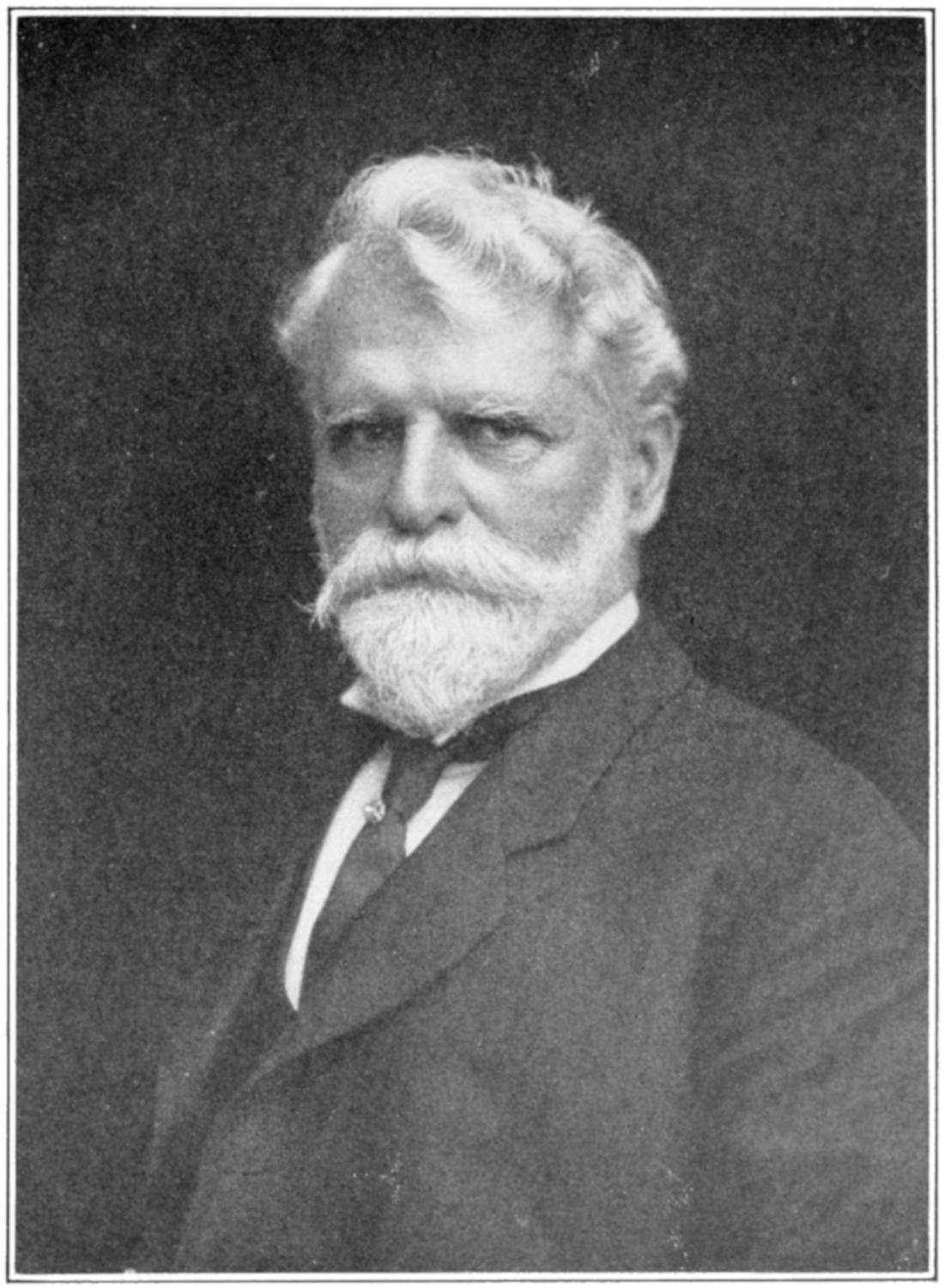

| Fig. | 54. | Worcester R. Warner | Facing page | 262 |

| Fig. | 55. | Ambrose Swasey | Facing page | 262 |

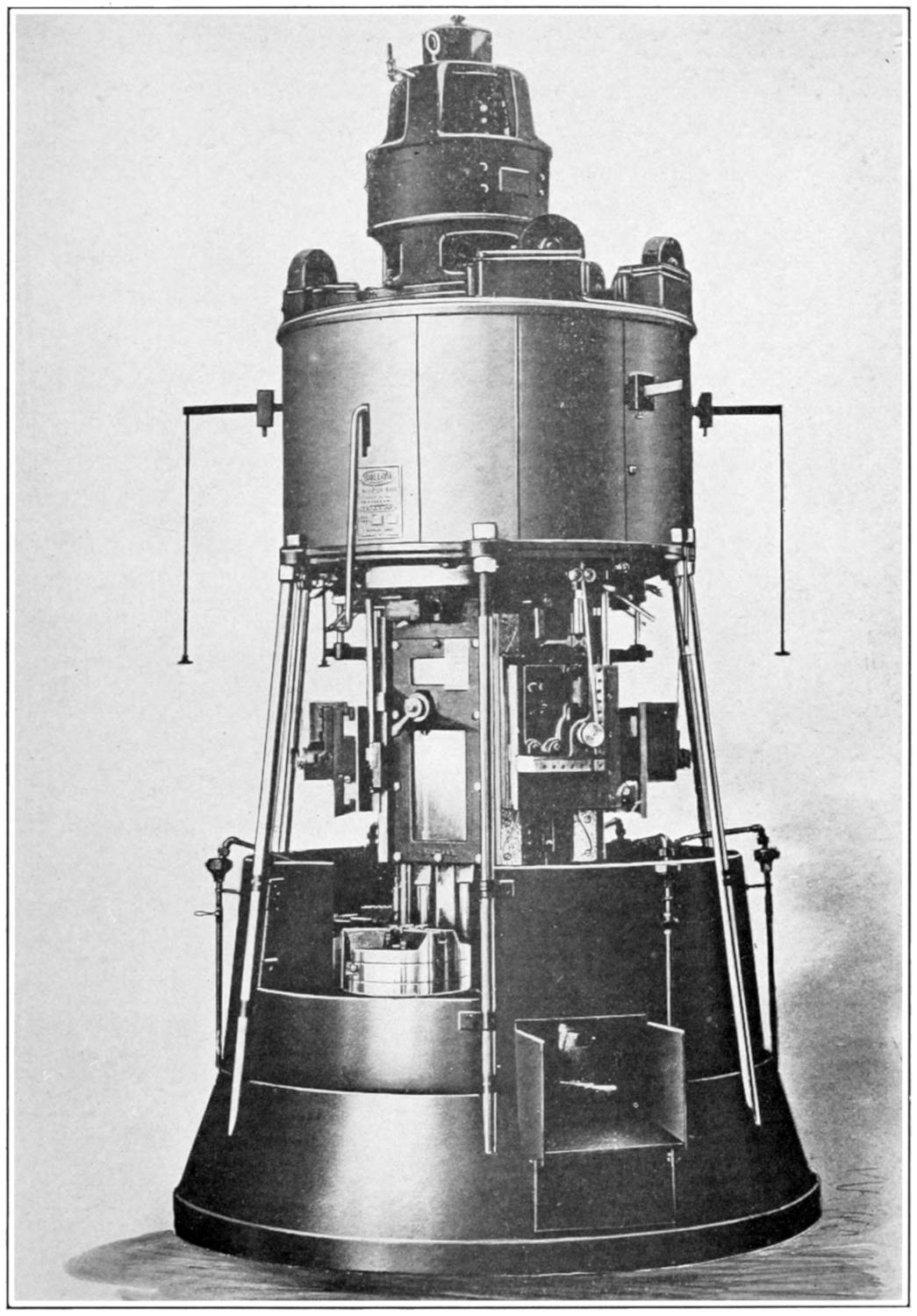

| Fig. | 56. | The “Mult-au-matic” Lathe, 1914 | Facing page | 276 |

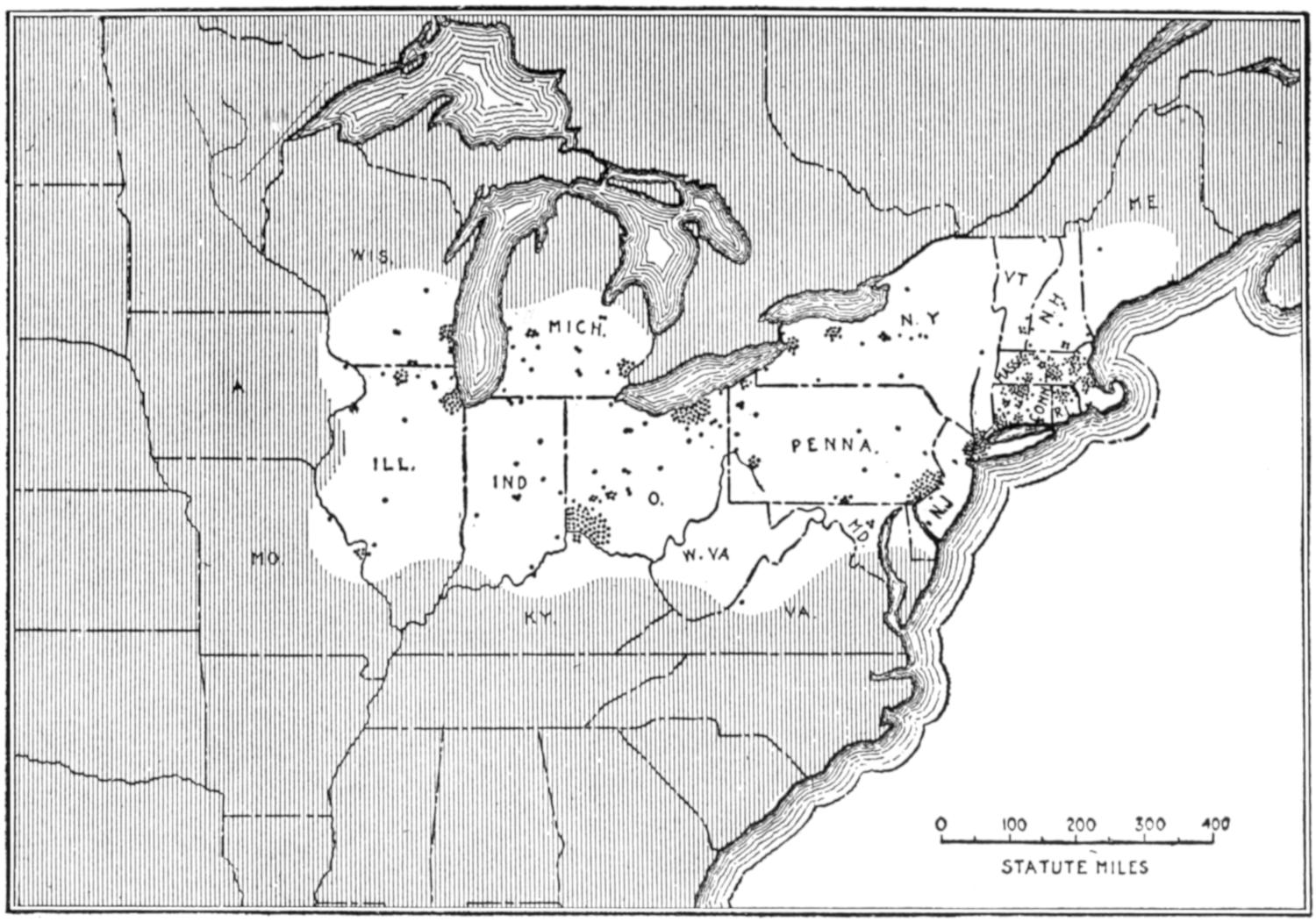

| Fig. | 57. | Machine Tool Building Area of the United States, 1915 | page | 279 |

[1]

ENGLISH AND AMERICAN TOOL BUILDERS

Well-informed persons are aware of the part which machinery in general has had on modern industrial life. But the profound influence which machine tools have had in that development is scarcely realized, even by tool builders themselves.

Three elements came into industrial life during the latter part of the eighteenth century. First, the development of modern banking and the stock company brought out the small private hoards from their hiding places, united them, and made them available for industrial undertakings operating on the scale called for by modern requirements. Second, Watt’s development of the steam engine and its application to the production of continuous rotative motion gave the requisite source of power. But neither the steam engine itself nor the machinery of production was possible until the third element, modern machine tools, supplied the means of working metals accurately and economically.

It is well to glance for a moment at the problems which were involved in building the first steam engine. Watt had been working for several years on the steam engine when the idea of the separate condenser came to him on that famous Sunday afternoon walk on the Glasgow Green, in the spring of 1765, and, to use his own words, “in the course of one or two days the invention was thus far (that is, as a pumping engine) complete in[2] my mind.”[1] He was a skilled instrument maker and his first small model was fairly successful, but when he undertook “the practice of mechanics in great,” his skill and all the skill of those about him was incapable of boring satisfactorily a cylinder 6 inches in diameter and 2 feet long; and he had finally to resort to one which was hammered. For ten weary years he struggled to realize his plans in a full-sized engine, unable to find either the workmen or the tools which could make it a commercial success. His chief difficulty lay in keeping the piston tight. He “wrapped it around with cork, oiled rags, tow, old hats, paper, and other things, but still there were open spaces left, sufficient to let the air in and the steam out.”[2] Small wonder! for we find him complaining that in an 18-inch diameter cylinder, “at the worst place the long diameter exceeded the short by three-eighths of an inch.” When Smeaton first saw the engine he reported to the Society of Engineers that “neither the tools nor the workmen existed that could manufacture so complex a machine with sufficient precision.”[3]

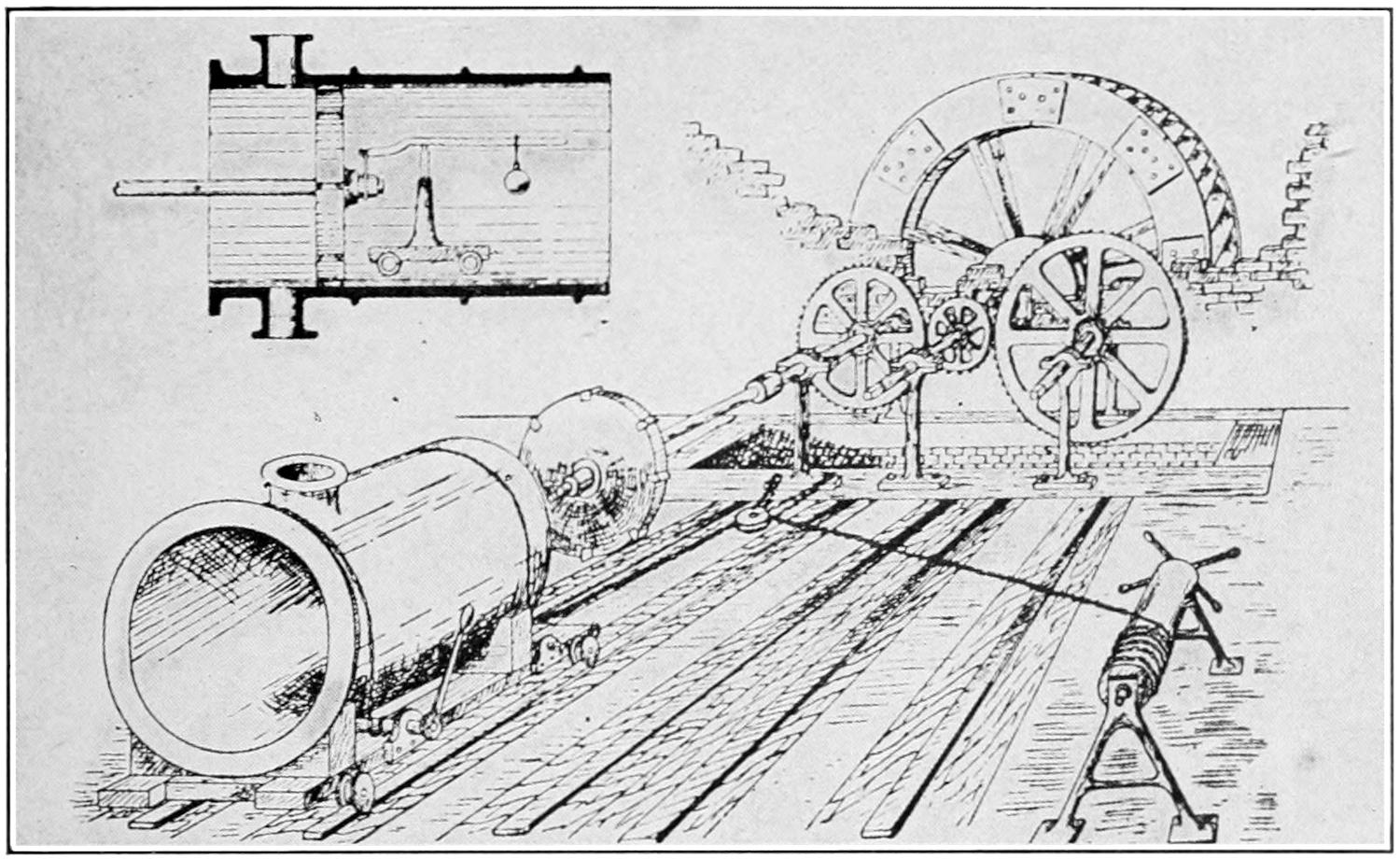

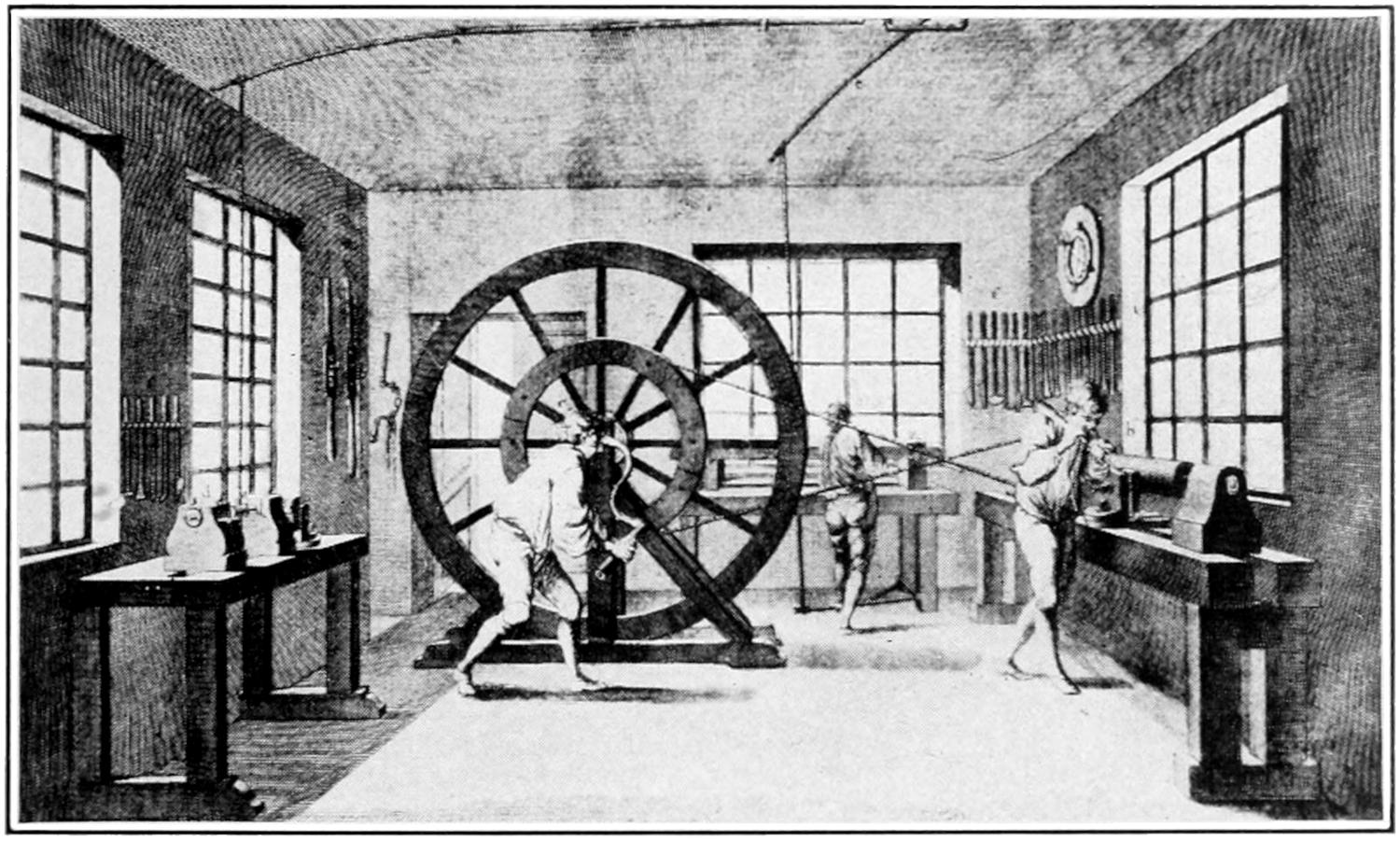

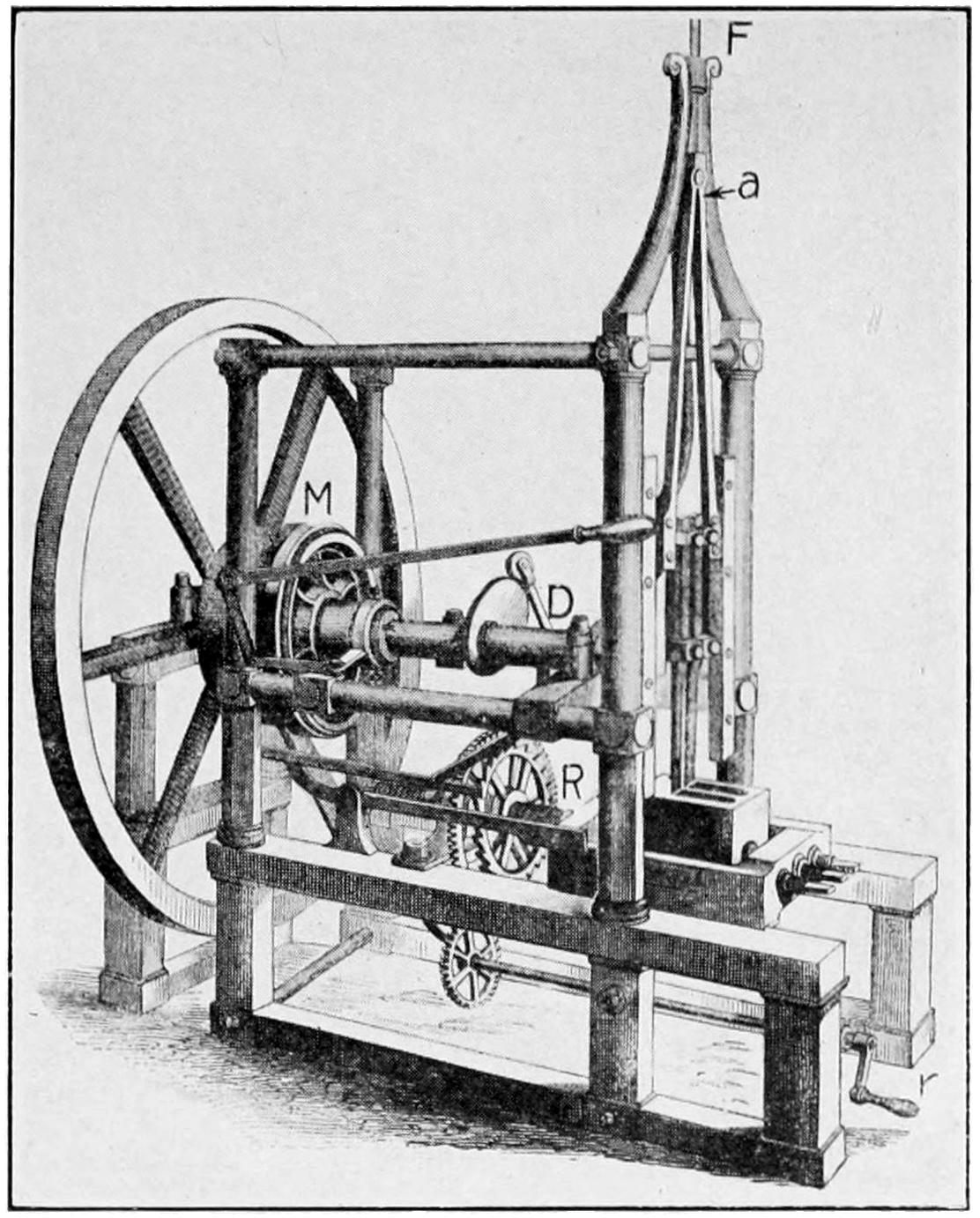

Smeaton himself had designed a boring machine in 1769 for the Carron Iron Works for machining cannon, an illustration of which is given in Fig. 1.[4] It consisted of a head with inserted cutters mounted on a long, light, overhung boring bar. The work was forced forward on a rude carriage, as shown. The method of supporting the cutter head, indicated in the section, shows an ingenious attempt to obtain a movable support from an inaccurate surface. One need hardly say that the work resulting was inaccurate.

[4] “Engineer,” London, March 4, 1910; p. 217. Drawn from the description given in Farey’s “Treatise on the Steam Engine.”

Figure 1. Smeaton’s Boring Machine

Carron Iron Works, 1769

Figure 2. French Lathes of about 1772

[3]

Fortunately, in 1774, John Wilkinson, of Bersham, hit upon the idea, which had escaped both Smeaton and Watt, of making the boring bar heavier, running it clear through the cylinder and giving it a fixed support at the outboard end as shown in Fig. 7. The superiority of this arrangement was at once manifest, and in 1776 Boulton wrote that “Mr. Wilkinson has bored us several cylinders almost without error; that of 50 inches diameter, which we have put up at Tipton, does not err the thickness of an old shilling in any part.”[5] For a number of years, Wilkinson cast and bored all the cylinders for Boulton & Watt.

[5] Farey: “Treatise on the Steam Engine,” p. 328. 1827.

The importance to Boulton & Watt of the timely aid of Wilkinson’s boring machine can hardly be overestimated. It made the steam engine a commercial success, and was probably the first metal-working tool capable of doing large, heavy work with anything like present-day accuracy.[6]

[6] Watt’s beautiful parallel motion, invented in 1785, was made necessary by the fact that there were no planers to machine a crosshead and guides. Planers were not developed until thirty years later.

We hardly realize the crudity of the tools available in the eighteenth century. In all machinery the principal members were of wood, as that could be worked by the hand tools then in use. The fastenings and smaller parts only were of metal, and consisted of castings and forgings fitted by hand. There were some lathes of the very simplest type. Most of them were “pole” lathes, operated by a cord reaching from a foot treadle, around the work itself, and up to a pole or wooden spring attached to the ceiling. The work rotated alternately forward and backward, and was caught with a hand tool each time as it came forward. Two are shown in Fig. 2, one at the back and one at the left. Only the very best forms had continuous motion from a direct drive on the[4] live spindle, as shown at the right of the same figure. This figure is reproduced from the French Dictionnaire des Sciences, published in 1772. Such lathes were almost useless for metal cutting, as they lacked both the necessary power and a holding device strong enough and accurate enough to guide a tool. The slide-rest, while it had been invented, had not been put into practical form or come into general use. There were a few rude drilling and boring machines, but no planing machines, either for metal or wood. The tool equipment of the machinist, or “millwright,” as he was called, consisted chiefly of a hammer, chisel and file. The only measuring devices were calipers and a wooden rule, with occasional reference perhaps to “the thickness of an old shilling,” as above. Hand forging was probably as good as or better than that of today. Foundry work had come up to at least the needs of the time. But the appliances for cutting metal were little better than those of the Middle Ages.

Such was the mechanical equipment in 1775; practically what it had been for generations. By 1850 it was substantially that of today. In fact, most of this change came in one generation, from about 1800 to 1840. Since that time there have been many improvements and refinements, but the general principles remain little changed. With so wonderful a transformation in so short a time, several questions arise almost inevitably: Where did this development take place, who brought it about, and why was it so rapid?

The first question is fairly simple. England and America produced the modern machine tool. In the period mentioned, England developed most of the general machine tools of the present day; the boring machine, engine lathe, planer, shaper, the steam hammer and standard taps and dies. Somewhat later, but partially coincident with this, America developed the special[5] machine tool, the drop hammer, automatic lathes, the widespread commercial use of limit gauges, and the interchangeable system of manufacture.

In a generalization such as this, the broad lines of influence must be given the chief consideration. Some of the most valuable general tools, such as the universal miller and the grinder, and parts of the standard tools, as the apron in the lathe, are of American origin. But, with all allowances, most of the general machine tools were developed in England and spread from there throughout the world either by utilization of their design or by actual sale. On the other hand, the interchangeable system of manufacture, in a well-developed form, was in operation in England in the manufacture of ships’ blocks at Portsmouth shortly after 1800; and yet this block-making machinery had been running for two generations with little or no influence on the general manufacturing of the country, when England, in 1855, imported from America the Enfield gun machinery and adopted what they themselves styled the “American” interchangeable system of gun making.[7]

The second question as to who brought this change about is not so simple. It is not easy to assign the credit of an invention. Mere priority of suggestion or even of experiment seems hardly sufficient. Nearly every great improvement has been invented independently by a number of men, sometimes almost simultaneously, but often in widely separated times and places. Of these, the man who made it a success is usually found to have united to the element of invention a superior mechanical skill. He is the one who first embodied the invention in such proportions and mechanical design as to make it commercially available, and from him its permanent influence spreads. The chief credit is due to[6] him because he impressed it on the world. Some examples may illustrate this point.

Leonardo da Vinci in the fifteenth century anticipated many of the modern tools.[8] His sketches are fascinating and show a wonderful and fertile ingenuity, but, while we wonder, we smile at their proportions. Had not a later generation of mechanics arisen to re-invent and re-design these tools, mechanical engineering would still be as unknown as when he died.

[8] American Machinist, Vol. 32, Part 2, pp. 821 and 868.

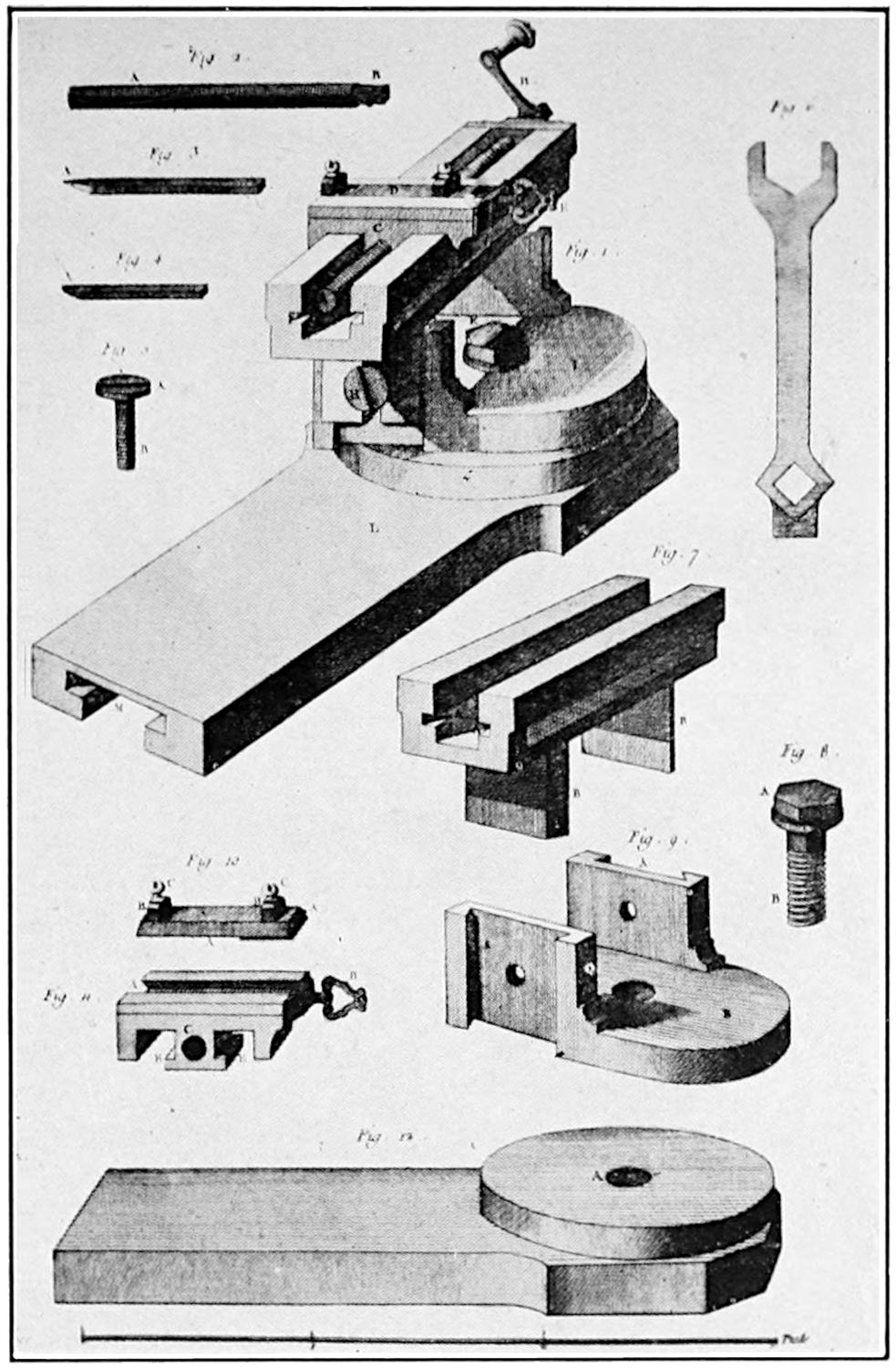

Take the slide-rest. It is clearly shown in the French encyclopedia of 1772, see Fig. 3, and even in an edition of 1717. Bramah, Bentham and Brunel, in England, and Sylvanus Brown,[9] in America, are all said to have invented it. David Wilkinson, of Pawtucket, R. I., was granted a patent for it in 1798.[10] But the invention has been, and will always be, credited to Henry Maudslay, of London. It is right that it should be, for he first designed and built it properly, developed its possibilities, and made it generally useful. The modern slide-rest is a lineal descendant from his.

Blanchard was by no means the first to turn irregular forms on a lathe. The old French rose engine lathe, shown in Fig. 4, embodied the idea, but Blanchard accomplished it in a way more mechanical, of a far wider range of usefulness, and his machine is in general use to this day.

Figure 3. French Slide-Rest, 1772

Figure 4. French Lathe for Turning Ovals, 1772

The spindle swings sidewise under the influence of the two cams which bear against the upright stops

[7]

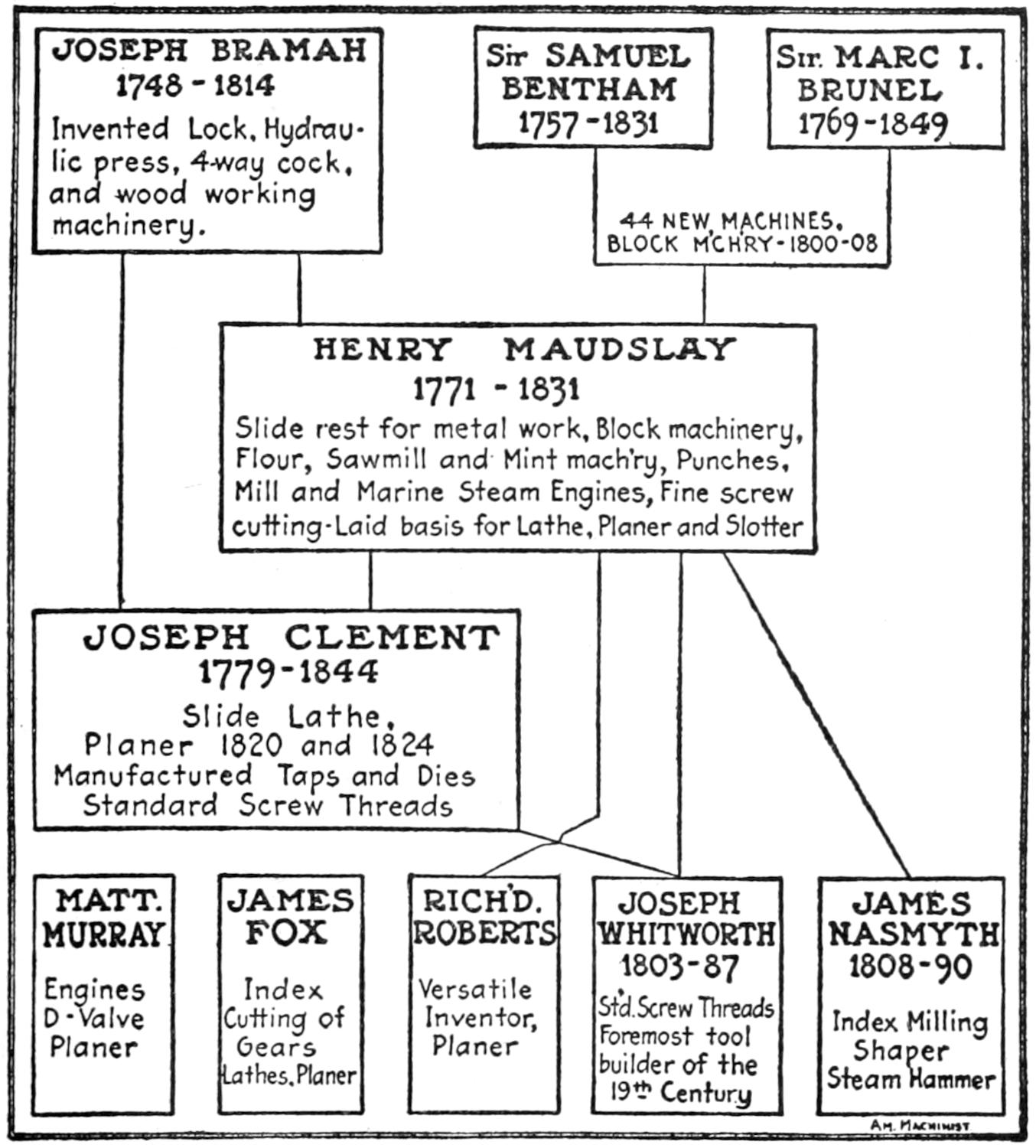

| JOSEPH BRAMAH 1748-1814 Invented Lock, Hydraulic press, 4-way cock, and wood working machinery. |

Sir SAMUEL BENTHAM 1757-1831 |

Sir MARC I. BRUNEL 1769-1849 |

|||||||||

| 44 NEW MACHINES. BLOCK M’CHRY-1800-08 |

|||||||||||

| HENRY MAUDSLAY 1771-1831 Slide rest for metal work, Block machinery, Flour, Sawmill and Mint mach’ry, Punches, Mill and Marine Steam Engines, Fine screw cutting. Laid basis for Lathe, Planer and Slotter |

|||||||||||

| JOSEPH CLEMENT 1779-1844 Slide Lathe, Planer 1820 and 1824 Manufactured Taps and Dies Standard Screw Threads |

|||||||||||

| MATT. MURRAY | JAMES FOX | RICH’D. ROBERTS | JOSEPH WHITWORTH 1803-87 |

JAMES NASMYTH 1808-90 |

|||||||

| Engines D-Valve Planer | Index Cutting of Gears Lathes, Planer | Versatile Inventor, Planer | Std. Screw Threads Foremost tool builder of the 19th Century | Index Milling Shaper Steam Hammer | |||||||

| Am. Machinist | |||||||||||

Figure 5. Genealogy of the Early English Tool Builders

[8]

To the third question as to why this development when once begun should have been so rapid, there are probably two answers. First, an entirely new demand for accurate tools arose during these years, springing from the inventions of Arkwright, Whitney, Watt, Fulton, Stephenson and others. The textile industries, the steam engine, railways, and the scores of industries they called into being, all called for better and stronger means of production. While the rapidity of the development was due partly to the pressure of this demand, a second element, that of cumulative experience, was present, and can be clearly traced. Wilkinson was somewhat of an exception, as he was primarily an iron master and not a tool builder, so his relationship to other tool builders is not so direct or clear. But the connection between Bramah, Maudslay, Clement, Whitworth and Nasmyth, is shown in the “genealogical” table in Fig. 5.

Bramah had a shop in London where, for many years, he manufactured locks and built hydraulic machinery and woodworking tools. Maudslay, probably the finest mechanician of his day, went to work for Bramah when only eighteen years old and became his foreman in less than a year. He left after a few years and started in for himself, later taking Field into partnership, and Maudslay & Field’s became one of the most famous shops in the world.

Sir Samuel Bentham, who was inspector general of the British navy, began the design of a set of machines for manufacturing pulley blocks at the Portsmouth navy yard. He soon met Marc Isambard Brunel, a brilliant young Royalist officer, who had been driven out of France during the Revolution, and had started working on block machinery through a conversation held at Alexander Hamilton’s dinner table while in America a few years before. Bentham saw the superiority of Brunel’s plans, substituted them for his own, and commissioned him to go ahead.

In his search for someone to build the machinery, Brunel was referred to Maudslay, then just starting in for himself. Maudslay built the machines, forty-four in all, and they were a brilliant success. There has been[9] considerable controversy as to whether Bentham or Brunel designed them. While Maudslay’s skill appears in the practical details, the general scheme was undoubtedly Brunel’s. In a few of the machines Bentham’s designs seem to have been used, but he was able enough and generous enough to set aside most of his own designs for the better ones of Brunel.

Of the earlier tool builders, Maudslay was the greatest. He, more than any other, developed the slide-rest and he laid the basis for the lathe, planer and slotter. His powerful personality is brought out in Nasmyth’s autobiography written many years later. Nasmyth was a young boy, eager, with rare mechanical skill and one ambition, to go to London and work for the great Mr. Maudslay. He tells of their meeting, of the interest aroused in the older man, and of his being taken into Maudslay’s personal office to work beside him. It is a pleasing picture, the young man and the older one, two of the best mechanics in all England, working side by side, equally proud of each other.

Joseph Clement came to London and worked for Bramah as chief draftsman and as superintendent of his works. After Bramah’s death he went to Maudslay’s and later went into business for himself. He was an exquisite draftsman, a fertile inventor, and had a very important part in the development of the screw-cutting lathe and planer. Joseph Whitworth, the most influential tool builder of the nineteenth century, worked for Maudslay and for Clement and took up their work at the point where they left off. Under his influence machine tools were given a strength and precision which they had never had before. Richard Roberts was another pupil of Maudslay’s whose influence, though important, was not so great as that of the others.

We have an excellent example of what this succession[10] meant. Nasmyth tells of the beautiful set of taps and dies which Maudslay made for his own use, and that he standardized the screw-thread practice of his own shop. Clement carried this further. He established a definite number of threads per inch for each size, extended the standardization of threads, and began the regular manufacture of dies and taps. He fluted the taps by means of milling cutters and made them with small shanks, so that they might drop through the tapped hole. Whitworth, taking up Clement’s work, standardized the screw threads for all England and brought order out of chaos.

Some account of the growth of machine tools in the hands of these men will be given later. Enough has been said here to show the cumulative effect of their experience, and its part in the industrial advance of the first half of the nineteenth century. Similar successions of American mechanics will be shown later.

Writing from the standpoint of fifty years ago, Smiles quotes Sir William Fairbairn: “‘The mechanical operations of the present day could not have been accomplished at any cost thirty years ago; and what was then considered impossible is now performed with an exactitude that never fails to accomplish the end in view.’ For this we are mainly indebted to the almost creative power of modern machine tools, and the facilities which they present for the production and reproduction of other machines.”[11]

[11] Smiles: “Industrial Biography,” p. 399.

[11]

In the previous chapter it was stated that John Wilkinson, of Bersham, made the steam engine commercially possible by first boring Watt’s cylinders with the degree of accuracy necessary, and that his boring machine was probably the first metal-cutting tool capable of doing large work with anything like modern accuracy. Although Wilkinson was not primarily a tool builder but an iron master, this achievement alone is sufficient to make him interesting to the tool builders of today.

He was born in 1728. His father made his financial start by manufacturing a crimping iron for ironing the fancy ruffles of the day. John Wilkinson first started a blast furnace at Belston and later joined his father in an iron works the latter had built at Bersham, near Chester. By developing a method of smelting and puddling iron with coal instead of wood-charcoal, he obtained an immense commercial advantage over his rivals and soon became a powerful factor in the iron industry. Later, he built other works, notably one at Broseley, near Coalbrookdale on the Severn.

One of the important branches of his work was the casting and finishing of cannon. It was in connection with this that he invented the boring machine referred to. He bored the first cylinder for Boulton & Watt in 1775. Farey, in his “History of the Steam Engine,” says:

[12]

In the old method, the borer for cutting the metal was not guided in its progress,[12] and therefore followed the incorrect form given to the cylinder in casting it; it was scarcely insured that every part of the cylinder should be circular; and there was no certainty that the cylinder would be straight. This method was thought sufficient for old engines; but Mr. Watt’s engines required greater precision.

Mr. Wilkinson’s machine, which is now the common boring-machine, has a straight central bar of great strength, which occupies the central axis of the cylinder, during the operation of boring; and the borer, or cutting instrument, is accurately fitted to slide along this bar, which, being made perfectly straight, serves as a sort of ruler, to give a rectilinear direction to the borer in its progress, so as to produce a cylinder equally straight in the length, and circular in the circumference. This method insures all the accuracy the subject is capable of; for if the cylinder is cast ever so crooked, the machine will bore it straight and true, provided there is metal enough to form the required cylinder by cutting away the superfluities.[13]

[13] Farey: “Treatise on the Steam Engine,” p. 326. 1827.

Wilkinson’s relations with Boulton & Watt became very intimate. He showed his confidence in the new engine by ordering the first one built at Soho to blow the bellows of his iron works at Broseley. Great interest was felt in the success of this engine. Other iron manufacturers suspended their building operations to see what the engine could do and Watt himself superintended every detail of its construction and erection. Before it was finished Boulton wrote to Watt:

Pray tell Mr. Wilkinson to get a dozen cylinders cast and bored from 12 to 50 inches in diameter, and as many condensers of suitable sizes; the latter must be sent here, as we will keep them ready fitted up, and then an engine can be turned out of[13] hand in two or three weeks. I have fixed my mind upon making from 12 to 15 reciprocating, and 50 rotative engines per annum.[14]

[14] Smiles: “Boulton & Watt,” p. 185. London, 1904.

This letter is interesting as showing Boulton’s clear grasp of the principles of manufacturing. Later, when Boulton & Watt were hard pressed financially, Wilkinson took a considerable share in their business and when the rotative engine was developed he ordered the first one. He consequently has the honor of being the purchaser of the first reciprocating and the first rotary engine turned out by Watt. Later, when Watt was educating his son to take up his work, he sent him for a year to Wilkinson’s iron works at Bersham, to learn their methods.

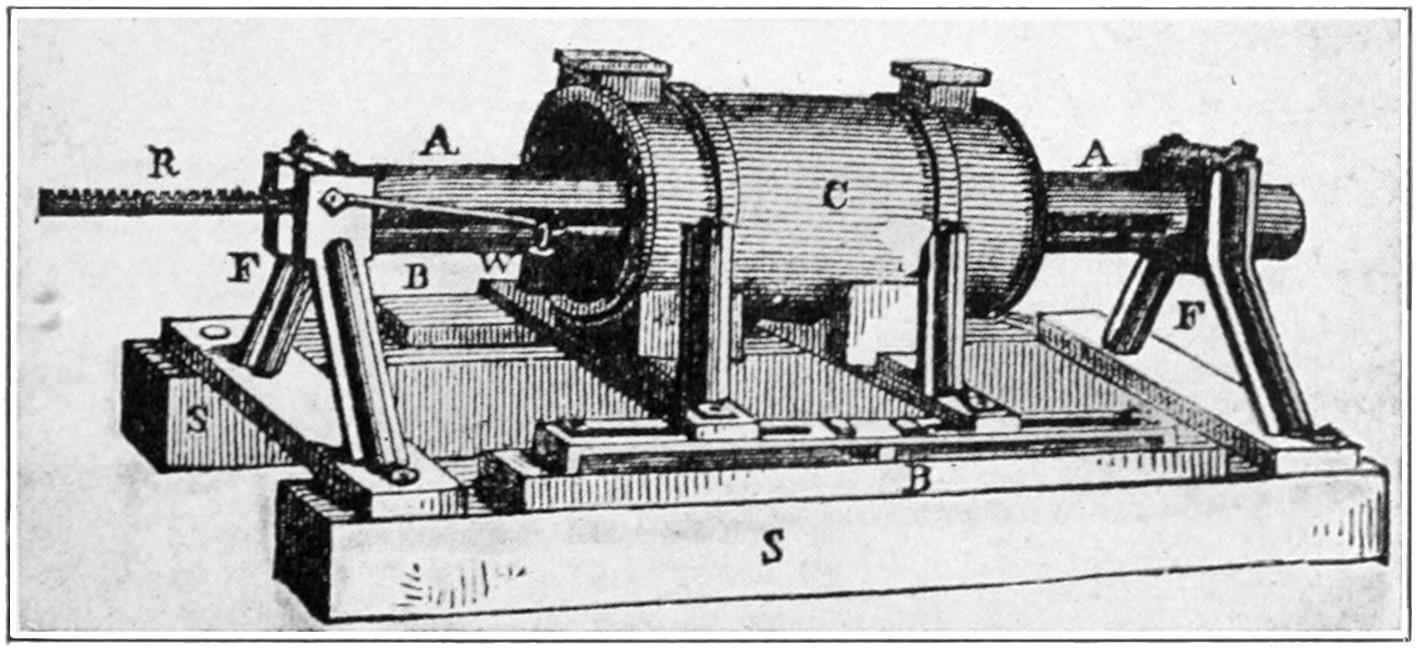

Fig. 7, taken from an old encyclopedia of manufacturing and engineering, shows the boring machine used for boring Watt’s steam cylinders.

On two oaken stringers SS, frames FF were mounted which carried a hollow boring bar A driven from the end. The cylinder to be bored was clamped to saddles, as shown. The cutters were carried on a head which rotated with the bar and was fed along it by means of an internal feed-rod and rack. In the machine shown the feeding was done by a weight and lever which actuated a pinion gearing with the rack R, but later a positive feed, through a train of gears operated by the main boring-bar, was used. Two roughing cuts and a finishing cut were used, and the average feed is given as ¹⁄₁₆ inch per revolution. While this machine may seem crude, a comparison with Smeaton’s boring machine, Fig. 1, will show how great an advance it was over the best which preceded it.

Wilkinson was a pioneer in many lines. He built and[14] launched the first iron vessel and in a letter dated July 14, 1787, says:

Yesterday week my iron boat was launched. It answers all my expectations, and has convinced the unbelievers who were 999 in a thousand. It will be only a nine days wonder, and then be like Columbus’s egg.[15]

[15] “Beiträge zur Geschichte der Technik und Industrie,” 3. Band. S. 227. Berlin, 1911.

In another letter written a little over a year later, he says:

There have been launched two Iron Vessels in my service since Sept. 1st: one is a canal boat for this [i.e., Birmingham] navigation, the other a barge of 40 tons for the River Severn. The last was floated on Monday and is, I expect, at Stourport with a loading of bar iron. My clerk at Broseley advises me that she swims remarkably light and exceeds my expectations.[16]

[16] Ibid., 3. Band. S. 227.

In 1788 William Symington built and ran a steam-operated boat on Dalswinton Loch in Scotland, which was a small, light craft with two hulls, made of tinned sheet-iron plates.[17] It has been erroneously claimed that this was the first iron boat. It was at best the second. Although of no commercial importance, it is of very great historical interest as it antedated Fulton’s “Clermont” by many years.

[17] Autobiography of James Nasmyth, p. 30. London, 1883.

Twenty-three years later, in 1810, Onions & Son of Broseley built the next iron boats, also for use upon the Severn. Five years later Mr. Jervons of Liverpool built a small iron boat for use on the Mersey. In 1821 an iron vessel was built at the Horsley works in Staffordshire, which sailed from London to Havre and went up the Seine to Paris.[18] Iron vessels were built from time to time after that, but it was fully twenty-five years before they came into general use.

[18] Smiles: “Men of Invention and Industry,” pp. 51-52. New York, 1885.

Figure 6. John Wilkinson

Figure 7. Wilkinson’s Boring Machine

Used for Machining the Cylinders of Watt Engines

[15]

With Abraham Darby, 3d, Wilkinson has the honor of having built, in 1779, the first iron bridge, which spanned the Severn at Broseley. This bridge had a span of 100 feet 6 inches, and a clear height of 48 feet, and is standing today as good as ever.[19] He invented also the method of making continuous lead pipe.

[19] Smiles: “Industrial Biography,” p. 119. Boston, 1864. Also, Beiträge, etc., 3. Band. S. 226.

He was a man of great ability, strong and masterful. Boulton wrote of him to Watt:

I can’t say but that I admire John Wilkinson for his decisive, clear, and distinct character, which is, I think, a first-rate one of its kind.[20]

[20] Smiles: “Boulton & Watt,” p. 438. London, 1904.

There is a note of qualification in the last clause. With all his admirable qualities Wilkinson was not always amiable and he was in constant feud with the other members of his family. He became very wealthy, but his large estate was dissipated in a famous lawsuit between his heirs.

Forceful and able as Wilkinson was, another man, Joseph Bramah, living in London about the same time, had a much more direct influence on tool building. Bramah was a Yorkshire farmer’s boy, born in 1748, and lame.[21] As he could not work on the farm he learned the cabinet maker’s trade, went to London, and, in the course of his work which took him into the well-to-do houses about town, he made his first successful invention—the modern water-closet. He patented it in 1778 and 1783, and it continues to this day in substantially the[16] same form. In 1784 he patented a lock, which was an improvement on Barron’s, invented ten years before, and was one of the most successful ever invented. For many years it had the reputation of being absolutely unpickable. Confident of this, Bramah placed a large padlock on a board in his shop window in Piccadilly and posted beneath it the following notice:

“The artist who can make an instrument that will pick or open this lock shall receive two hundred guineas the moment it is produced.”

[21] The best account of Bramah is given in Smiles’ “Industrial Biography,” pp. 228-244. Boston, 1864.

Many tried to open it. In one attempt made in 1817, a clever mechanic named Russell spent a week on it and gave it up in despair. In 1851 Alfred C. Hobbs, an American, mastered it and won the money. He was allowed a month in which to work and the Committee of Referees in their report stated that he spent sixteen days, and an actual working time of fifty-one hours, in doing it. This gave Hobbs a great reputation, which he enhanced by picking every other lock well known in England at that time, and then showing how it was done.

This started up the liveliest kind of a controversy and gave everyone a chance to write to the Times. They all began first picking, then tearing each other’s locks. Headlines of “Love (Hobbs?) Laughs at Locksmiths,” “Equivocator” and other like terms appeared.[22]

[22] Price: “Fire and Thief-proof Depositories, and Locks and Keys.”

It was finally recognized that any lock could be picked by a skillful mechanic with a knowledge of locks, if he were given time enough. The old Bramah lock, made, by the way, by Henry Maudslay himself, did not fare so badly. Hobbs had unmolested access to it for days with any tools he could bring or devise; and though he finally opened it, a lock probably sixty years old which could[17] stand such an assault for fifty hours was secure for all ordinary purposes.[23]

[23] Anyone who is interested can find an account of the affair in Price’s “Fire and Thief-proof Depositories, and Locks and Keys,” published in 1856, and Mr. Hobbs has given his own personal account of it, explaining how the work was done, in the Trans. of the A. S. M. E., Vol. VI, pp. 248-253.

When Bramah began manufacturing the locks he found almost immediately that they called for a better quality of workmanship than was available, with even the best manual skill about him. A series of machine tools had to be devised if they were to be made in the quantities and of the quality desired. He turned first to an old German in Moodie’s shop who had the reputation of being the most ingenious workman in London; but while he, with Bramah, saw the need, he could not meet it. One of his shopmates, however, suggested a young man at the Woolwich Arsenal named Henry Maudslay, then only eighteen years old.

Bramah sent for him and Maudslay soon became his right-hand man, and was made superintendent of the works at nineteen. The work of these two men in developing the tools needed laid the foundation for the standard metal-cutting tools of today. The most important improvement was the slide-rest. Nasmyth later said that he had seen the first one, made by Maudslay, running in Bramah’s shop and that “in it were all those arrangements which are to be found in the most modern slide-rest of our own day” (i.e., fifty years later). Other parts of the metal-cutting lathe also began to take shape; it has been said that parts of the lock were milled on a lathe with rotary cutters, and that the beginnings of the planer were made. How much of this work was Bramah’s and how much Maudslay’s it would be hard to say. Bramah was a fertile, clever inventor; but Maudslay was[18] the better general mechanic, had a surer judgment and a greater influence on subsequent tool design.

About this time Bramah invented the hydraulic press. As he first built it, the ram was packed with a stuffing-box and gland. This gripped the ram, retarded the return stroke, and gave him a lot of trouble until Maudslay substituted the self-tightening cup-leather packing for the stuffing-box, an improvement which made the device a success.

Bramah’s restless ingenuity was continually at work. He invented a very successful beer-pump in 1797, the four-way cock, a quill sharpener which was in general use until quills were superseded by steel pens, and he dabbled with the steam engine. He was a bitter opponent of Watt and testified against him in the famous suit of Boulton & Watt against Hornblower. He maintained the superiority of the old Newcomen engines and said that the principle of the separate condenser was fallacious, that Watt had added nothing new which was not worthless, and that his so-called improvements were “monstrous stupidity.”

In 1802 Bramah obtained a patent for woodworking machinery second only in importance to that granted Bentham in 1791. Like Bentham, he aimed to replace manual labor “for producing straight, smooth, and parallel surfaces on wood and other materials requiring truth, in a manner much more expeditious and perfect than can be performed by the use of axes, saws, planes, and other cutting instruments used by hand in the ordinary way.” His tools were carried in fixed frames and driven by machinery. In his planing machine, one of which was running in the Woolwich Arsenal for fifty years, the cutter-head, which carried twenty-eight tools, was mounted on a vertical shaft and swept across the work in a horizontal plane. He used this same method[19] in planing the metal parts for his locks, which corresponds, of course, to our modern face-milling. He provided for cutting spherical and concave surfaces and used his device for making wooden bowls.

In 1806 he devised an automatic machine which the Bank of England used many years in numbering their banknotes, eliminating error and saving the labor of many clerks.

Maudslay was in his employ from 1789 to 1797. He was getting as superintendent 30s. ($7.50) a week. A growing family and “the high cost of living” rendered this insufficient and he applied for more. He was refused so curtly that he gave up his position and started in for himself in a small workshop on Oxford Street in London. Later he took Field in as partner under the firm name of Maudslay & Field.

In 1813 Bramah engaged another man who later had a great influence, Joseph Clement. Clement soon became his chief draftsman and superintendent. Salaries had gone up somewhat by that time and he had an agreement for five years starting on the basis of three guineas a week with an advance of four shillings each year. At Bramah’s death not long after, his sons took charge of the business, and soon grew jealous of Clement’s influence. By mutual consent the contract was terminated and he went at once to Maudslay & Field as their chief draftsman. Later he, too, set up for himself and had an important part in the development of the screw-cutting lathe, the planer and standard screw threads. Whitworth was one of his workmen and Clement’s work on taps and dies formed the basis of the Whitworth thread.

Bramah died in 1814, at the age of sixty-six. He was a man of widely recognized influence, a keen and independent thinker, a good talker, and, though it might not appear from what has been said, a cheery and always[20] welcome companion. He left a reputation for absolute business integrity and the quality of his workmanship was unrivaled until his later years, when he was equaled only by those he had himself trained. He gave the world some great and valuable devices and paved the way for others. His influence on modern tools can probably never be accurately judged, but Smiles’ tribute to him is as true today as when it was written, two generations ago:

From his shops at Pimlico came Henry Maudslay, Joseph Clement, and many more first-class mechanics, who carried the mechanical arts to still higher perfection, and gave an impulse to mechanical engineering the effects of which are still felt in every branch of industry.[24]

[24] Smiles: “Industrial Biography,” p. 244.

Bramah had an invincible dislike for sitting for his portrait and consequently none exists. A death-mask was made by Sir Francis Chantrey, who executed the Watt statue in Westminster Abbey, but it was unfortunately destroyed by Lady Chantrey. The complete catalog of the National Portrait Gallery in London[25] gives Bramah’s name. The reference, however, directs one to Walker’s famous engraving of the “Eminent Men of Science Living in 1807-1808,” which shows about fifty distinguished scientists and engineers grouped in the Library of the Royal Institution. This engraving is the result of four years’ careful study. It was grouped by Sir John Gilbert, drawn by John Skill, and finished by William Walker and his wife. Bramah’s figure, No. 6, appears in this group, but with his back turned, the only one in that position. It is a singular tribute to Bramah’s influence among his generation of scientists that this picture would have been considered incomplete without him. As no portrait of him existed he was included, but with his face turned away. The figure was drawn in accordance with a description furnished by Bramah’s grandson, E. H. Bramah.

[25] Cust’s.

Figure 8. Eminent Men of Science Living in 1807-8

From Walker’s Engraving in the National Portrait Gallery, London

Group originated by William Walker. Designed by Sir John Gilbert. Engraved by Walker and Zobel.

[21]

The engraving includes many other men of interest whose names are indicated. Some of them have already been considered; others, while famous as engineers, worked in fields other than the one we are considering.

[22]

In the genealogical table shown in Fig. 5, Sir Samuel Bentham and Sir Marc I. Brunel are indicated as having originated the famous “Portsmouth Block Machinery,” which was built by Maudslay and which first gave him his reputation as a tool builder. While Bentham was primarily a naval administrator and Brunel a civil engineer, they were among the first to grasp the principles of modern manufacturing and embody them successfully. Both were men of distinction and each had an interesting career.

Samuel Bentham, Fig. 9, was a brother of Jeremy Bentham, the famous English publicist and writer on economics, and a step-brother of Charles Abbott, speaker of the House of Commons. He was born in 1757, went to the Westminster School, and later was a naval apprentice in the Woolwich Arsenal. His tastes and his training led him toward the administrative and constructive work of the navy, and for this he had the best education available at that time. He went to sea after a final year at the Naval College at Portsmouth; and in 1780, in consequence of his abilities, was sent by Earl Howe, then first Lord of the Admiralty, to visit the various ports of northern Europe. He went through the great ports of Holland and the Baltic, eastward to St. Petersburg, and was introduced at the Russian court by the British ambassador.

Figure 9. Sir Samuel Bentham

From an Old Miniature

[23]

The Russians took to him kindly, as he was handsome, tall, and distinguished in manner, inspired confidence, and made and held friends. He was well received by the Empress Catherine, and soon became a favorite of Prince Potemkin. He traveled over a greater part of the empire from the Black Sea to the Arctic and as far east as China, examining mining and engineering works. On his return to St. Petersburg he fell in love with a wealthy heiress of the nobility. The parents objected; but though the empress, who was interested, advised an elopement, he gave it up as dishonorable and went away to Critcheff in southern Russia as a lieutenant-colonel of engineers in the Russian army. While there he took charge of Potemkin’s grossly mismanaged factories in order to put them on a sound basis, an undertaking suggestive of the twentieth-century efficiency engineer. In this he was not wholly successful. In 1787 he built and equipped a flotilla of ships, and in the following year distinguished himself in a naval battle with the Turks, in which John Paul Jones was also engaged. One of the vital elements in the fight was the use of the large guns built by Bentham, which fired shells for the first time in naval warfare. Nine Turkish ships were burned or sunk and 8000 men were killed or taken prisoners. For his part in this battle Bentham was knighted and made a brigadier-general.

There were few skilled artisans in Russia and almost none available in the southern provinces—a Danish brass founder, an English watchmaker and two or three sergeants who could write and draw were all he had. This set Bentham at work on the problem of “transferring skill” by means of machines, so that unskilled workmen might be made to produce the same results as skilled labor.

While Bramah and Maudslay were working in London[24] on their metal-cutting tools for making locks, Bentham, in Russia, was thinking out substantially the same problem in woodworking machinery. He returned to England in 1791 and that year took out his first patent. Certain suggestions which he made to the Admiralty about the introduction of machinery into the dockyards led to his making an extended inspection of the dockyards throughout the kingdom, and he reported that immense savings were possible. The office of inspector general was created for him and authority given him to put his recommendations into effect.

For the next eighteen years he served the British navy. When he took hold it was honeycombed with inefficiency and worse. His business-like methods, his skill as an engineer and naval designer, and his fearless integrity were elements in the preparedness of the British navy in the Napoleonic wars. He was an intrepid enemy of red tape and graft and soon made cordial enemies; but he was a good fighter, with no weak spots in his armor, and it took many years to bring him down. In 1805 he was sent to St. Petersburg, and kept there on various pretexts for two years. It was remarked by some about the Admiralty office, that so high was their opinion of his talents they would be glad to give him £6000 ($30,000) a year if by that means they would never see him again. He returned in 1807 to find his office abolished and its functions transferred to a board, of which he was made a member at an increased salary. Here his power was diluted somewhat, but even this solution was too strong and he was retired on a pension in 1812. For the next fifteen years he lived in retirement in France. The years abroad softened the rancor of his enemies and from his return to England in 1827 until his death, Bentham was in frequent and friendly consultation with the[25] navy officials. Bentham may well be considered as one of the first and greatest of “efficiency experts.”[26]

[26] See the biography of Bentham, by William Lucas Sargant: “Essays of a Birmingham Manufacturer,” Vol. I, No. V. London, 1869. Also, “Memoirs of the late Brigadier-General Sir Samuel Bentham,” by Mary S. Bentham, in “Papers and Practical Illustrations of Public Works.” London, 1856.

The patent of 1791 referred to is not important, but it was followed by another in 1793 in which was set forth the whole scheme of woodworking machinery which had been maturing in Bentham’s mind. This has been characterized as one of the most remarkable patents ever issued by the British Patent Office. More than fifty years after, one of the Crown judges said of it in summing up a case before him involving woodworking machinery, that “the specification of his (i.e., Bentham’s) patent of 1793 is a perfect treatise on the subject; indeed, the only one worth quoting that has to this day been written on the subject.”

Jeremy Bentham had revolutionized the prison system of England, and had introduced the system of labor in penitentiaries which has become an essential element in all modern penal systems. Woodworking was the most available field of work, but the greater part of the prisoners were of course unskilled, and Samuel Bentham was called upon to devise machines to meet the need. The two brothers established a factory and began making woodworking machinery for the prisons and dockyards.

The work for the dockyards soon took definite form. Pulley blocks formed one of the important supplies of the navy. A single full-rigged frigate used about 1500 and the Admiralty were purchasing at that time about 100,000 yearly. This formed a large business in itself and one in which the interchangeability that Bentham[26] was continually urging was especially desirable. On Bentham’s recommendation, a government factory organized on a manufacturing basis and utilizing machinery had been begun at Portsmouth and a few machines of his design already installed, when Brunel, who had been working independently on block machinery, was introduced to him.

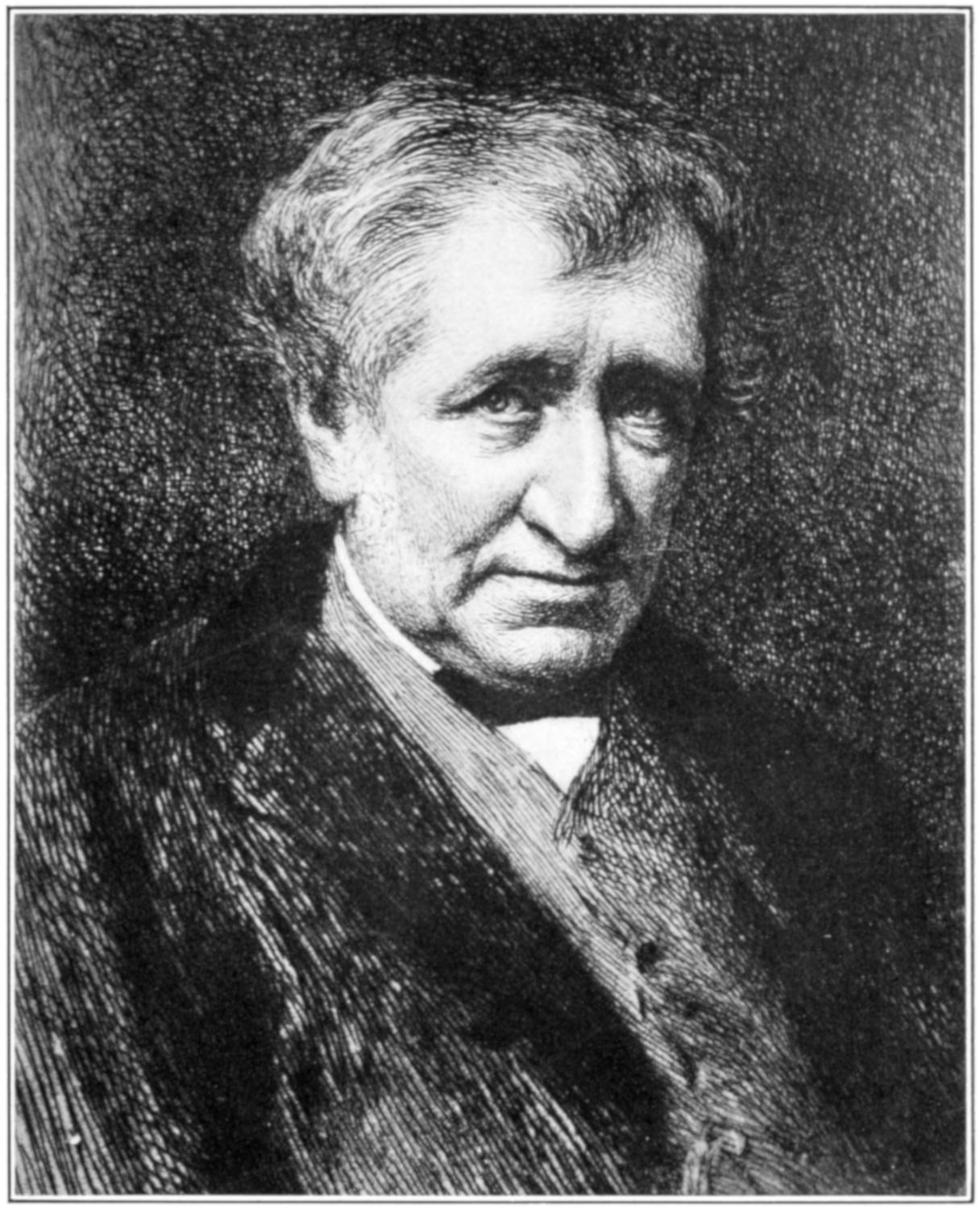

Marc Isambard Brunel, Fig. 10, was a Norman Frenchman, born in 1769, who was the despair of his father because he would not study to be a priest and would persist in drawing and in making things. As a family compromise he received a naval training and served as an officer for six years. In 1793, his ship being paid off, he was in Paris. His outspoken loyalty in one of the cafés on the very day when Louis XVI was sentenced to the guillotine brought down upon him the anger of the republicans present. He escaped in the confusion, spent the night in hiding, and leaving Paris early the next morning, made his way to Rouen. Here he hid for a time with M. Carpentier, the American consul, in whose home he met a young English girl whom he afterwards married. Six months later he sailed from Havre on a forged passport, under the nose of a frigate searching for suspects, and landed in New York only to find a French republican squadron lying in port. As he was personally known to many of the officers and in danger of being recognized, arrested and condemned as a deserter, he left the city at once and went to Albany in the vague hope of finding M. Pharoux, a friend who was undertaking the survey of a large tract of wild land in the Black River valley, east of Lake Ontario. Brunel found him by good chance, joined the party, and soon became its real leader. They showed the capacity, which the French have always had, of working in friendly relationship with the Indians, and their work was successfully accomplished. Fifty years later there were still traditions among Indians in the valley of a wonderful white man named “Bruné.”

Figure 10. Sir Marc Isambard Brunel

From a Photograph by Walker, Ltd., of the Portrait in the National Gallery, London

[27]

Brunel remained in America for over five years and was naturalized as a citizen in 1796. During this time he was engaged on the Hudson-Champlain canal and various river improvements. He was a friend of Major L’Enfant, who planned the city of Washington and he submitted one of the competitive designs for the original Capitol. He also designed and built the old Park Theater in New York, which was burned in 1821. He was appointed chief engineer of New York, built a cannon foundry and had a part in planning the fortifications of the Narrows in New York harbor.

He was gay, refined and a favorite among the emigrés who enlivened New York society in the closing years of the eighteenth century. It was at Alexander Hamilton’s dinner table that the first suggestion of the block machinery came to him. He had been invited to meet a M. Delabigarre, who had just arrived from England. M. Delabigarre had been describing the method of making ship’s blocks and spoke of their high and increasing cost. Brunei listened with attention and then pointed out what he considered the defects of the method and suggested that the mortises might be cut by machinery, two or three at a time. The shaping machine he afterward used was conceived while he was at Fort Montgomery in the highlands of the Hudson. Brunel left America for England early in 1799 and remained in England the rest of his life. His marriage soon after his arrival to Miss Kingdom, the girl whom he had met at Rouen, doubtless gives the reason for this change.

Two months after reaching England, he took out a patent for a writing and duplicating machine and he also invented a machine for twisting cotton thread. Meantime[28] he was working on the drawings for a complete set of block machinery, and by 1801 he had made a working model of the mortising and boring machines. He offered his plans to Fox & Taylor, who held the navy contract for blocks. Mr. Taylor wrote in reply that his father had spent many years developing their existing methods of manufacture and they were perfectly satisfied with them. He added, “I have no hope of anything better ever being discovered, and I am convinced there cannot.”

Brunel, through introductions brought from America, then laid his plans before Lord Spencer, of the Admiralty, and Sir Samuel Bentham. Bentham, as we have seen, was already working on the same problem. He saw at once the superiority of Brunel’s plans and, with the freedom from jealousy and self-interest which characterized his whole career, he recommended their adoption, with the result that Brunel was commissioned to build and install his machines.

About sixty years ago there was a sharp controversy over the origin of this Portsmouth machinery. Partisans of Bentham and Brunel each claimed the entire credit for all of it. The fact is that some of Bentham’s machines were used for the roughing out, but all the finishing work was done on Brunel’s, and there is little doubt that the definite plan of operations and all the more intricate machines were his. Bentham conceived the enterprise and had it well under way. His broad-minded and generous substitution of Brunel’s plans for his own was quite as creditable to him as the execution of the whole work would have been.

While Brunel was a clever and original designer, he was not a skilled mechanic. His plans called for a large number of refined and intricate machines which were wholly new and he no sooner began actual work than he felt the need of a mechanic capable of building them.[29] Maudslay had just started in for himself and was working in his little shop on Oxford Street, with one helper. M. Bacquancourt, a friend of Brunel’s, passed his door every day and was interested in the beautiful pieces of workmanship he used to see from time to time in the shop window. At his suggestion Brunel went to Maudslay, explained to him his designs, and secured his help. There could hardly have been a better combination than these two men. Maudslay’s wonderful skill as a mechanic and his keen, practical intuition supplied the one element needed and together they executed the entire set of machines, forty-four in all.[27]

[27] For a description of the Portsmouth Block Machinery, see Tomlinson’s “Cyclopedia of Useful Arts,” Vol. I, pp. 139-146. London, 1852. Also, Ure’s “Dictionary of Arts, Manufactures, and Mines,” Vol. I, pp. 398-402; Seventh Edition. London, 1875; and Rees’ “Cyclopedia,” article “Machinery for Manufacturing Ship’s Blocks.”

The machinery was divided into four classes.

First. Sawing machines, both reciprocating and circular, for roughing out the blocks.

Second. Boring, mortising, shaping and “scoring” machines for finishing the blocks.

Third. Machines for turning and boring the sheaves, for riveting the brass liner and finish-facing the sides. In the larger sizes small holes were drilled on the joint and short wire pins riveted in to prevent slipping between the liner and block.

Fourth. The iron pins on which the sheaves turned were hand forged in dies, turned and polished.

In addition to these there were several machines for forming “dead eyes,” or solid blocks without sheaves, used in the fixed rigging. A detailed description of the entire set would be too long. A brief description of one or two of the machines will serve to give some idea of the others.

[30]

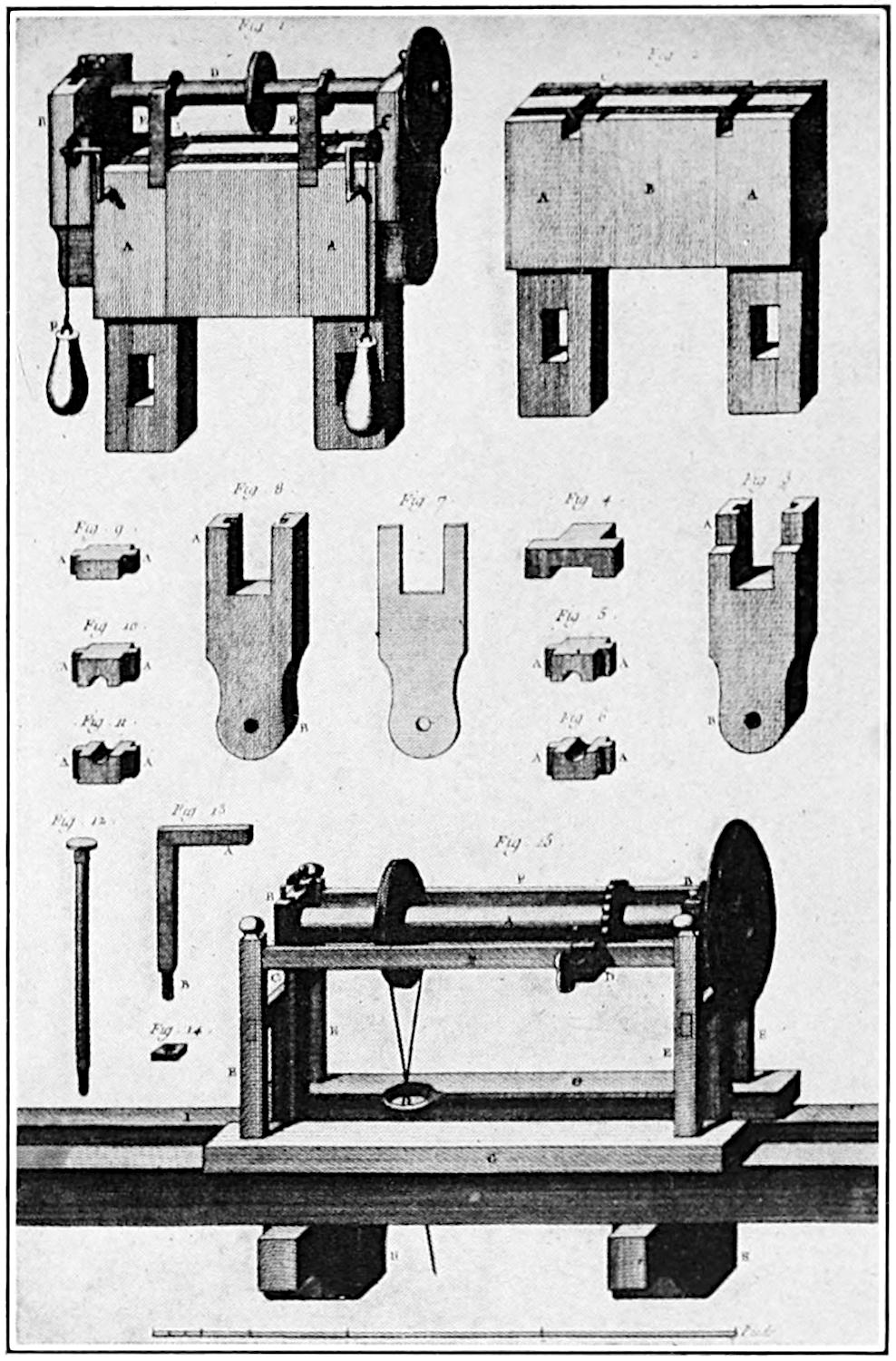

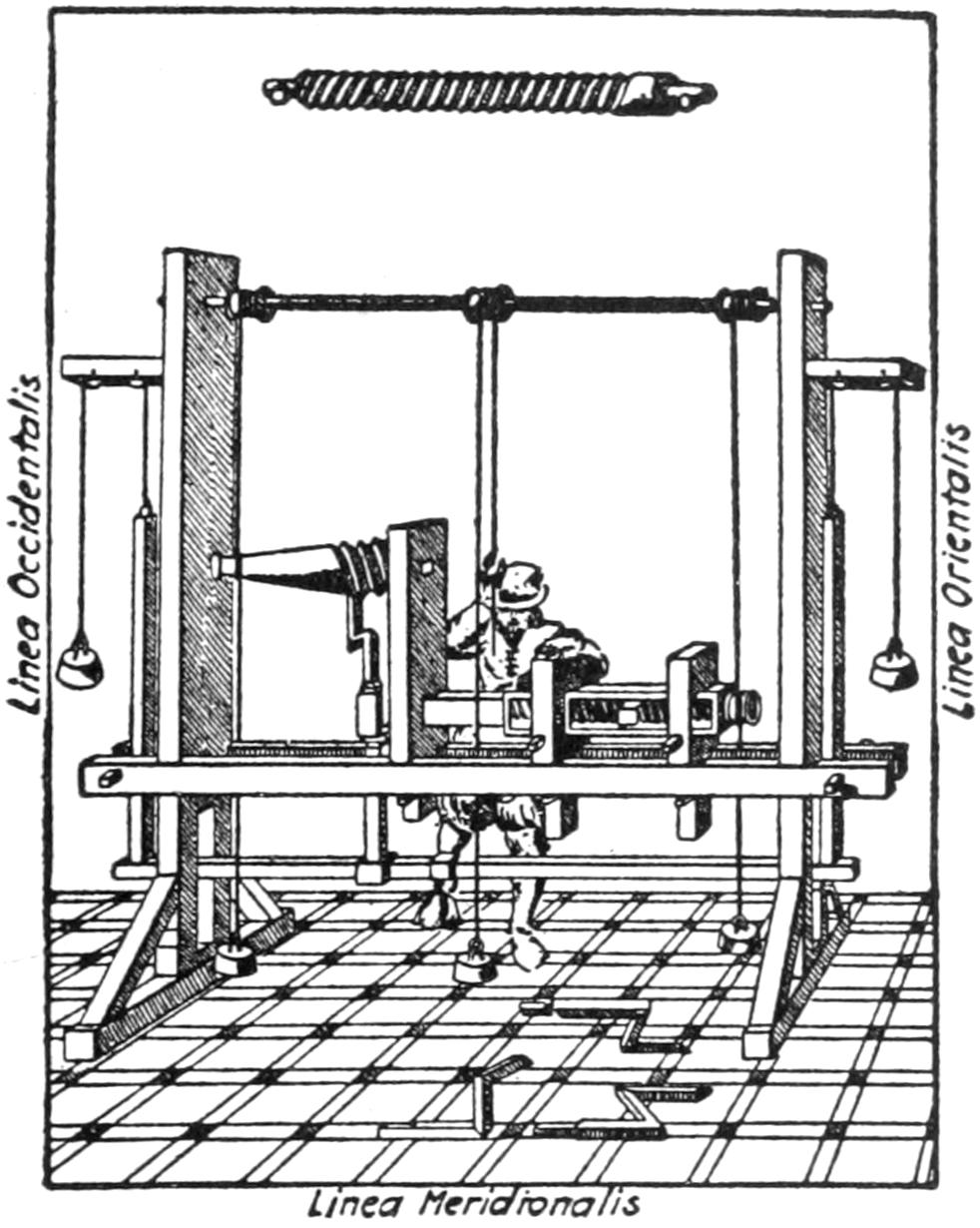

Fig. 11 is taken from an old wood-cut of the mortising machine.[28] A model of it is shown in the background of the portrait of Brunel in the National Gallery, reproduced opposite page 26. A pulley and flywheel are connected by a cone clutch M to a shaft D. At the front end of this a crank and connecting-rod drive the reciprocating cutter head from a point a. The chuck carrying the block, movable forward and backward on guides, was operated by the feed screw R, a cam, and the ratchet motion shown. A system of stops and weighted levers on the side threw out the ratchet feed at the end of the cut, and the carriage was returned by hand, using the crank r. The crosshead had two guiding points, a double one below the driving point and a single one above it at F, and made 150 strokes per minute. The chuck could take either one or two blocks at a time.

[28] Tomlinson: “Cyclopedia,” Vol. I, p. 141.

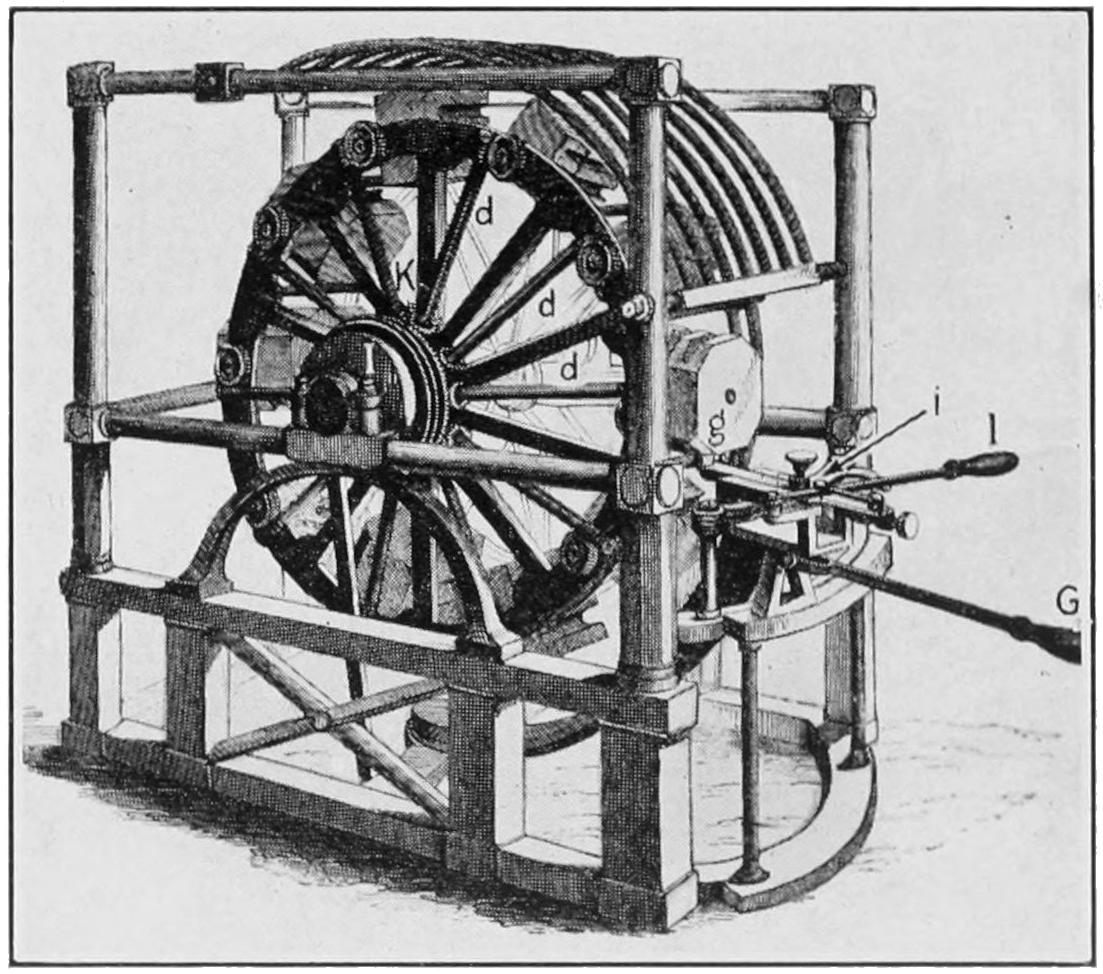

Fig. 12 shows the shaping machine.[29] Ten blocks were chucked between two large, circular frames, the same working points being used as in the last machine. The principle of establishing and adhering to working points seems to have been clearly recognized. A cutter g was moved across the face of the blocks as they revolved, its motion being governed by the handles l and G and a former i. One side of each of the ten blocks was thus finished at a time. The blocks were then indexed 90° by revolving the bevel K, which turned the wormshafts d and rotated all the chucks simultaneously. The blocks were then faced again in their new positions and the operation continued until the four sides were finished. The strong curved bars at the top were provided to protect the workman in case one of the blocks should let go. As the momentum of the frame and blocks was considerable, a spring brake was provided between the bearing and bevel-gear to bring them to rest quickly.

[29] Ibid., Vol. I, p. 144.

Figure 11. Brunel’s Mortising Machine

Figure 12. Brunel’s Shaping Machine

[31]

Another well-designed machine “scored” the outside of the blocks for the ropes or straps. Two disks with inserted steel cutters grooved the blocks which were chucked on a swinging frame. The depth and path of cut were governed by a steel former against which a roller on the cutter shaft bore. In the metal working machines, under the fourth group, cutters were used in which a short, round bar of tempered steel was held by a binding screw in a holder of the lathe-tool type. From the sketch of it shown by Holtzapffel, the whole device might almost be used as an advertisement for a modern tool-holder for high-speed steel cutters.

Enough has been said to show that these machines were thoroughly modern in their conception and constituted a complete range of tools, each performing its part in a definite series of operations. By this machinery ten unskilled men did the work of 110 skilled workmen. When the plant was in full running order in 1808 the output was over 130,000 blocks per year, with a value of over $250,000, an output greater than that previously supplied by the six largest dockyards. It continued for many years to supply all the blocks used by the Royal Navy, and was in fact superseded only when wooden blocks themselves largely made way for iron and steel ones.

Brunel devised other woodworking tools, but none so successful as these. He started a mill at Battersea which burned down; his finances became involved and he was thrown into prison for debt. He was freed through a grant of $25,000 which friends secured from the government. His later work was in the field of civil engineering—the most famous work being the Thames[32] tunnel. He was given the Legion of Honor in 1829, was knighted in 1841, and died in 1849.[30]

[30] For fuller information, see the biography of Sir Marc Isambard Brunel by Richard Beamish, F.R.S. London, 1862.

His son, Sir Isambard K. Brunel, was also one of the foremost engineers of England, a bridge and ship builder, railway engineer and rival of Robert Stephenson. At the age of twenty-seven he was chief engineer of the Great Western Railway, and built the steamer “Great Western” to run from Bristol to New York as an extension of that railway system. This was the first large iron ship, the first regular transatlantic liner, and the first large steamship using the screw propeller. Its success led to the building of the “Great Eastern” from his designs. This ship was about 700 feet long and for nearly fifty years was the largest one built. She was a disastrous failure financially and after a varied career, which included the laying of the first transatlantic cable, she was finally broken up. Brunel was a strong advocate of the broad gauge and built the Great Western system with a 7-foot gauge, which was ultimately changed to standard gauge. While a number of his undertakings were failures financially, his chief fault seems to have been that he was in advance of his generation.

[33]

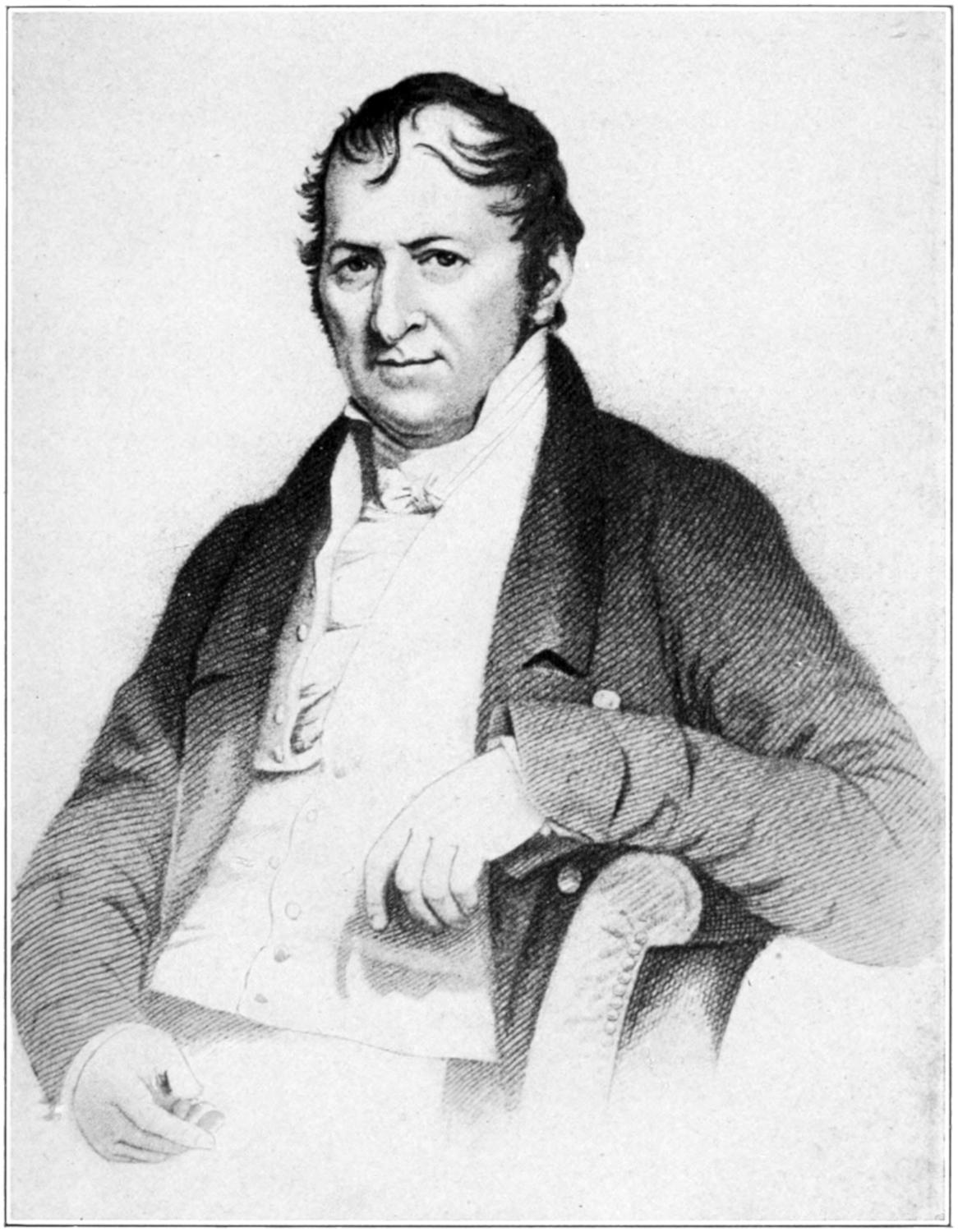

We have mentioned Henry Maudslay frequently. In fact, it is hard to go far in any historical study of machine tools without doing so.[31]

[31] For best accounts of Maudslay, see Smiles’ “Industrial Biography,” Chap. XII, and “Autobiography of James Nasmyth.”

Maudslay was born in Woolwich in 1771. He was the son of an old soldier working in the arsenal, and had but little schooling. At twelve he was at work in the arsenal, first as a “powder monkey” filling cartridges, later in the carpenter shop and smithy. Young as he was, he soon became the leader among the workmen. He was a born craftsman and his skill was soon the pride of the whole shop. To dexterity he added an intuitive power of mechanical analysis and a sense of proportion possessed by few men, and from the beginning he showed a genius for choosing the most direct and simple means for accomplishing his purpose. He was a great favorite among his fellows from his fine personal appearance, his open-heartedness and complete freedom from conceit.

In the chapter on Bramah we have seen how Bramah, seeking someone to help him devise tools to manufacture his locks, turned first to an old German mechanic in Moodie’s shop. One of the hammer men in Moodie’s shop suggested Maudslay, apologizing for his youth, but adding that “nothing bet him.” When Bramah saw Maudslay, who was only eighteen, he was almost ashamed to lay his case before him. Maudslay’s suggestions,[34] however, were so keen and to the point that the older man had to admit that the boy’s head at least was old enough. He adopted the suggestions and offered him a job in his shop at Pimlico, which Maudslay gladly accepted. As he had served no apprenticeship, the foreman had doubts of his ability to work among experienced hands. Without a moment’s hesitation Maudslay pointed to a worn-out bench vice and asked whether he could take his rank among the other workmen if he could fix it as good as new before the end of the day. He was told to go ahead. He resteeled and trued the jaws, filed them up, recut and hardened them, and before the time set had it together, trimmer and in better shape than any of its neighbors. It was examined, admired and accepted as his diploma as a journeyman.

His advancement was rapid, and in about a year, while still only nineteen, he was made general foreman and maintained his leadership without the slightest difficulty. He remained with Bramah for eight years, during which time the two laid the foundation for many of the modern machine tools, more especially the slide-rest and screw-cutting lathe. We have already considered Maudslay’s work done in connection with Bramah and little need be added here in regard to it. During this time Bramah invented the hydraulic press, but the cup-leather packing which is so essential a part of it was suggested by Maudslay.

He left the Pimlico shop because Bramah would not give him more than 30 shillings ($7.50) a week, and with a single helper started a little blacksmithing and jobbing shop on his own account near Wells and Oxford streets in London.

His first customer was an artist who gave him an order for an iron easel. Business prospered and he found plenty of work. His reputation was established, however,[35] in connection with the Portsmouth block machinery, which was described in the last chapter. The building of this machinery occupied about eight years, from 1800 to 1808. The design was substantially Brunel’s, but Mr. Nasmyth says that “every member of it was full of Maudslay’s presence and the mechanical perfection of its details, its practicability and adaptability show his handiwork at every turn.”

Soon after this work was undertaken, Maudslay moved his shop to Margaret Street, near Cavendish Square. During the building of the block machinery Maudslay had met Joshua Field, who had been engaged as a draftsman in the Portsmouth dockyards under Sir Samuel Bentham and had worked with him in the development of the machinery. Field was transferred to General Bentham’s office at the Admiralty in 1804, and a year later joined Maudslay. Five years later they moved to Lambeth on the south side of the Thames and bought an old riding school on Westminster Road on what was formerly a swampy marsh. Here the firm of Maudslay & Field continued its long and famous career. Few firms have influenced mechanical development more, and for many years it was one of the leading machine shops of the world. Here Maudslay did his life work as one of the leaders in the development not only of machine tools but of the steam engine, both stationary and marine. After his death in 1831 the business was continued by Mr. Field, who outlived him many years, and by Maudslay’s son and grandson, both of whom were fine mechanics and men of great influence.

It was in connection with the slide-rest and screw-cutting lathe that Maudslay is best known. Too much value cannot be placed on the slide-rest and its combination with a lead screw, operated by change gears. It is[36] used in some form in almost every machine tool and is one of the great inventions of history.

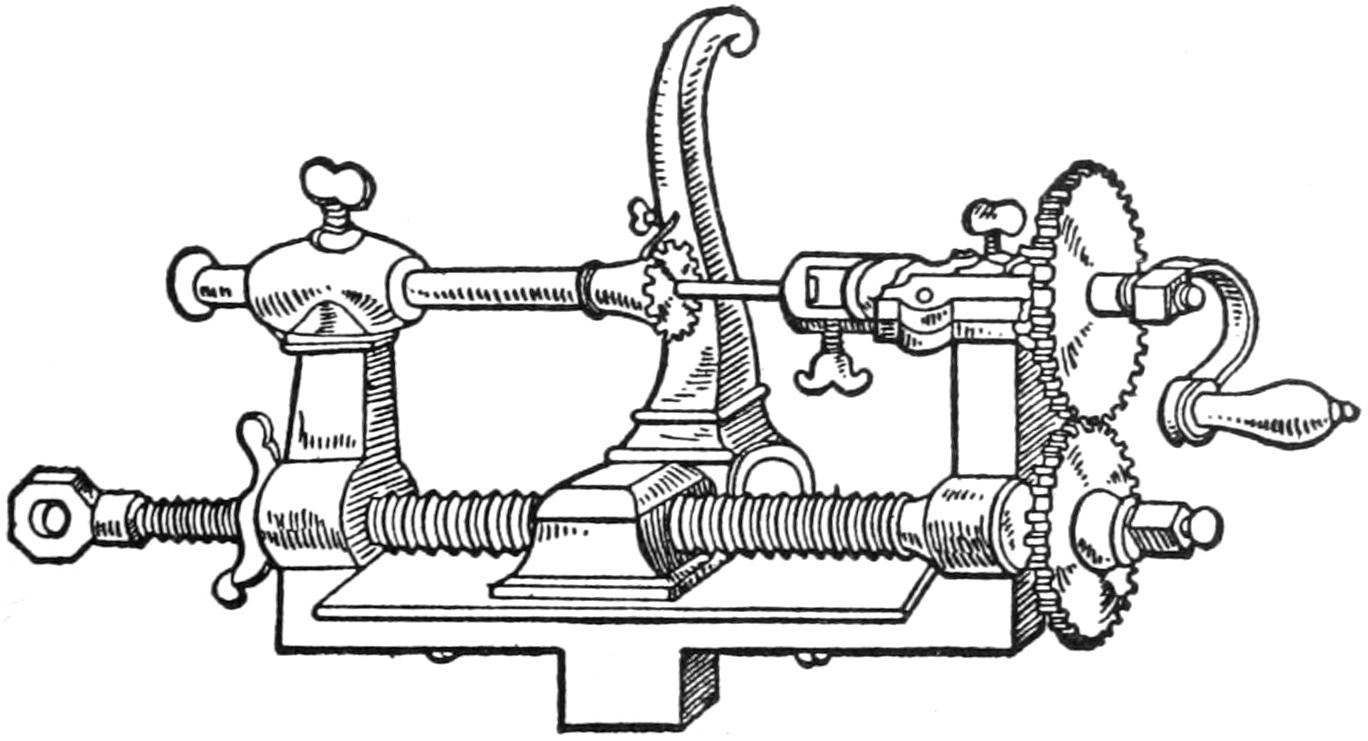

Like most of the great inventions, it was the work of many men. In crude applications, parts of it date back to the Middle Ages. Leonardo da Vinci caught an inkling of it. French writers in the sixteenth and seventeenth centuries describe and illustrate devices which involve the parts of it. Fig. 13, reproduced from an illustration in the old work of Besson, first published in 1569,[32] shows a lead screw. The copy from which this illustration was taken is printed in Latin and is in the Astor library, New York. The upper shaft had three drums; the middle one carried the rope which was manipulated by the operator. Of the drums at the ends, the one at the left operated a lead screw and the one on the right, the piece being cut. The two outer weights held the follower up against the lead screw. The cutting was, of course, intermittent, as in all the earlier types of lathes. The idea of the lead screw occurs in other French works of the seventeenth and eighteenth centuries. In the lathe shown in Fig. 14, from a French book published in 1741,[33] gears instead of ropes were used to connect the rotation of the lead screw with that of the work, but if the idea of change gears was contemplated, it was not developed.

[32] “Des Instruments Mathématiques et Méchaniques, &c., Inventées par Jacques Besson.” First Latin and French Edit., 1569. Plate 9. Two later editions were published at Lyons, one in 1578 and one in 1582. The same copper plates were used in the three editions.

[33] Holtzapffel: “Turning and Mechanical Manipulation,” Vol. II, p. 618. London, 1847.

[37]

Figure 13. French Screw-Cutting Lathe, Previous to 1569

Figure 14. French Screw-Cutting Lathe, about 1740

[38]

The slide-rest was also known. An illustration of a French slide-rest, published long before Maudslay’s time, is reproduced in Fig. 3. In Bramah’s original “slide-tool,” the tail-stock and slide-rest were combined.[34] It was made about 1795 by Maudslay while still his foreman. How much of the design was Bramah’s and how much Maudslay’s we cannot tell. It was a light, flimsy affair and very different from the slide-rests Maudslay was making only a few years later.

[34] Buchanan: “Practical Essays on Mill Work and Other Machinery.” London, 1841. Volume of Plates.

In none of these was the slide-rest combined with change gears and a power-driven lead screw. It was this combination which formed Maudslay’s great contribution, together with improvements in proportion and in mechanical design which raised the device from an ingenious but cumbersome mechanical movement to an instrument of precision and power. Jesse Ramsden, a famous instrument maker, is said to have made a small lathe in 1775, which had change wheels and a sliding tool holder moved by a lead screw. The writer has been unable to find any illustration or description of it, and if such a lathe existed, it certainly did not exert a very wide influence. The combination was anticipated in Bentham’s famous patent of 1793. In this patent Bentham says: “When the motion is of a rotative kind, advancement (of the tool) may be provided by hand, yet regularity may be more effectually insured by the aid of mechanism. For this purpose one expedient is the connecting, for instance, by cogged wheels, of the advancing motion of the piece with the rotative motion of the tool.”[35] This patent contained no drawings, and the suggestion was not, so far as is known, embodied in any definite construction.

[35] See the British patent records. Patent No. 1951, dated April 23, 1793.

Many men were working at the problem of generating an accurate screw thread. The use of dies was quite well known, but their design and workmanship was of the crudest order and their product of the same character;[39] and they were inadequate for the making of any large threads. Holtzapffel’s book on “Turning and Mechanical Manipulation,” published in London, 1847, describes some of the attempts of the earlier mechanics to devise other means.[36] At the famous Soho works in Birmingham a workman by the name of Anthony Robinson cut a screw 7 feet long and 6 inches in diameter with a square, triple thread. After the cylinder had been turned, paper was cut and fitted around it, removed, marked in ink with parallel oblique lines, then replaced on the cylinder and the lines were pricked through with a center punch. The paper was again removed and dots connected by fine lines with a file. The alternate spaces between the lines were then cut out with a chisel and hammer and smoothed by filing. A block of lead and tin, as a temporary guide nut, was then cast around the partially formed screw. Adjustable cutters were fixed upon this guide nut and it was used as a kind of tool-holding slide-rest, being rotated around the screw by hand levers, thereby cutting the finished thread. In other words, a lead screw was cut on the piece itself and the temporary nut was used as a tool holder to finish the work.

[36] Holtzapffel. Vol. II, pp. 635-655.

One method used for some purposes was to coil two wires around a core in close contact with each other. One of these was then removed, leaving a space corresponding to the hollow of the thread. The core and remaining wire were then dipped in melted tin and soldered together. In some cases they were actually used in this form as the desired screw thread. In others, the helical wire was used to guide a sleeve nut which controlled a tool used to cut a thread located farther up on the length of the core.

Another method resorted to was that of grooving a smooth cylinder by a sharp-edged cutter standing at the[40] required pitch angle and relying on the contact of the knife-edge to produce the proper traverse along the cylinder as it was rotated, thus developing the screw. This method is not so crude as it seems and was one of those used by Maudslay himself. He also used a flat steel tape wound about a cylindrical bar, but he found the inclined knife method more satisfactory. The device which he used was a mechanism of considerable refinement. He employed cylinders of wood, tin, brass and other soft metals accurately mounted to revolve between centers. The hardened knife was crescent-shaped, nearly fitting the cylinder, and fixed at the required angle with great precision by means of a large graduated wheel and tangent screw. A chasing tool carried by a small, adjustable slide cut the thread as the stock moved forward under the incisive action of the inclined knife edge. Hundreds of screws, both right and left, were made by this device, and their agreement with each other is said to have been remarkable. This was the way in which Maudslay generated his first lead screws.

With the best of the screws so obtained Maudslay made the first screw-cutting lathe a few years prior to 1800, shown in Fig. 15,[37] which had two triangular bars for a bed, and was about three feet long. The headstock carried a live spindle, which was connected with a lead screw by a pair of gears, and a slide-rest ran upon the triangular bars under control of a lead screw having four square threads per inch. In this machine he at first used different lead screws for different pitches. The inner end of the lower spindle in the headstock had a two-jawed driving device, which might be disconnected and into which various lead screws might be fitted. Later he added change gear wheels.

[37] No. 1601 in South Kensington Museum, London. Cat. M. E. Collection, Part II, p. 266.

[41]