Please see the Transcriber’s Notes at the end of this text.

Frontispiece

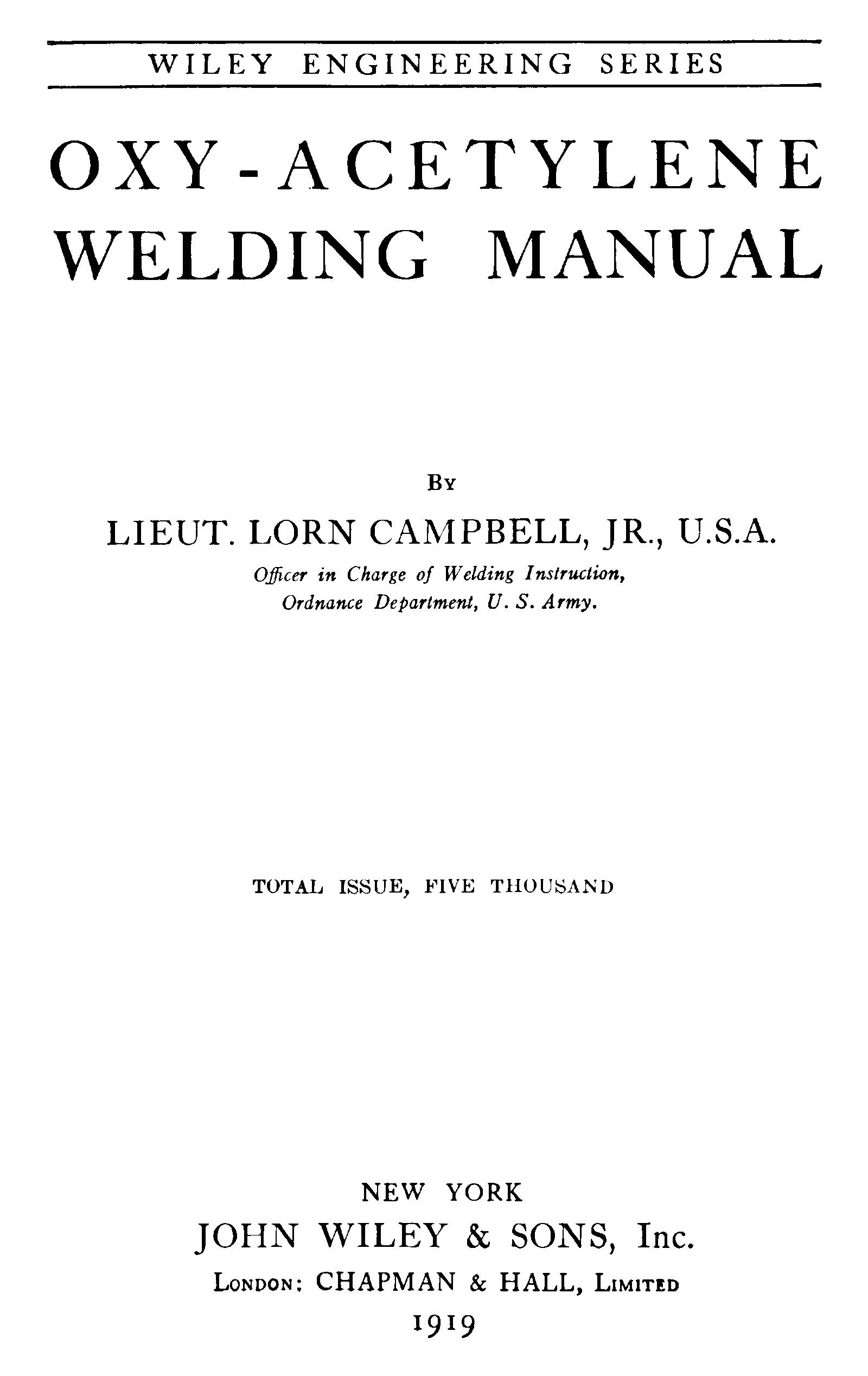

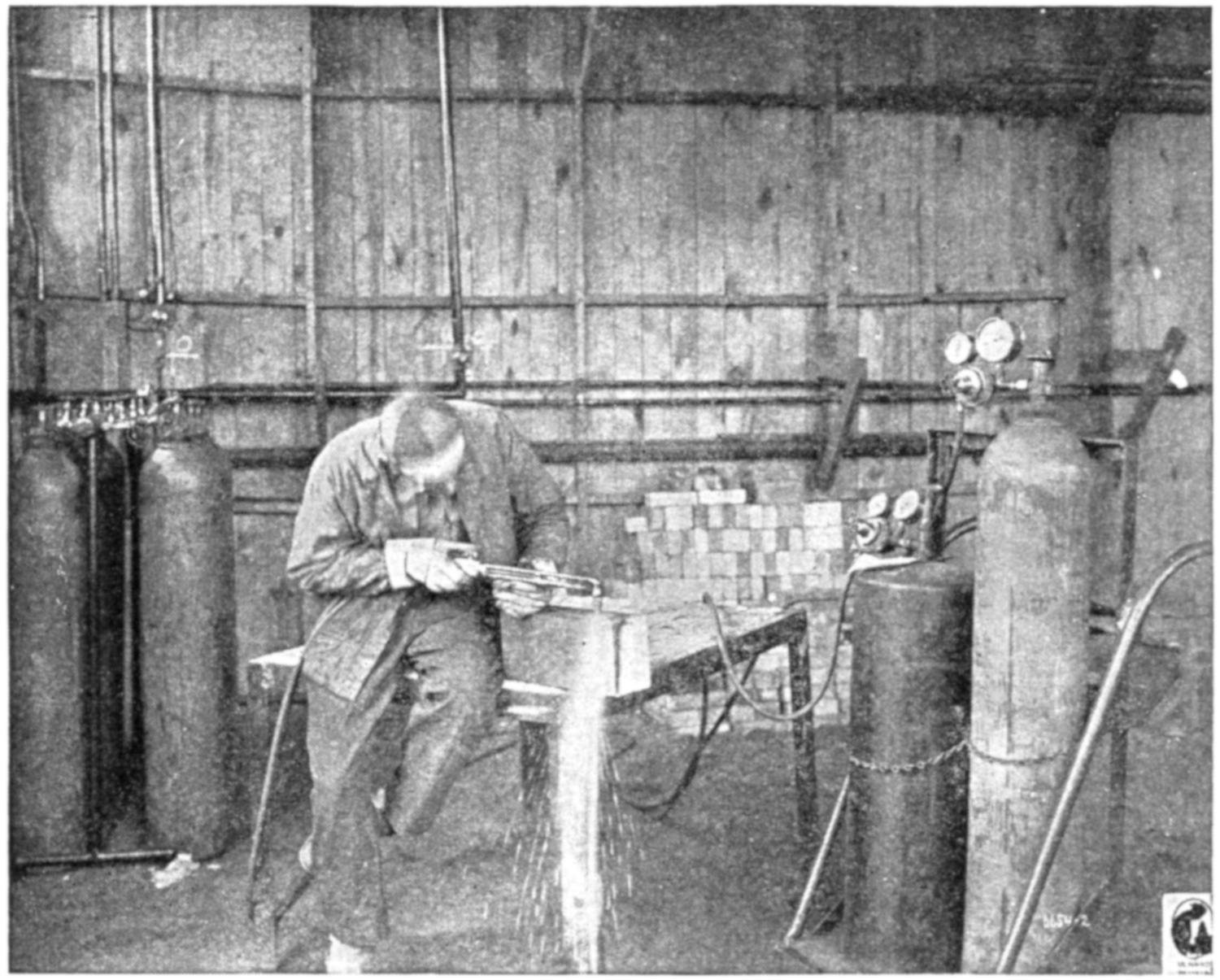

Welding School, Ordnance Department, United States Army, Peoria, Ill.

WILEY ENGINEERING SERIES

By

LIEUT. LORN CAMPBELL, JR., U.S.A.

Officer in Charge of Welding Instruction,

Ordnance Department, U. S. Army.

TOTAL ISSUE, FIVE THOUSAND

NEW YORK

JOHN WILEY & SONS, Inc.

London: CHAPMAN & HALL, Limited

1919

Copyright, 1919

BY

LORN CAMPBELL

Copyrighted in Great Britain

PRESS OF

BRAUNWORTH & CO.

BOOK MANUFACTURERS

BROOKLYN, N. Y.

[v]

(1) The oxy-acetylene method of welding and cutting metals has of late been receiving considerable attention. Its tremendous power of creating, repairing and destroying the work of man has been but recently recognized in its broadest sense, and the demand for operators, skilled in the manipulation of this apparatus, which always has been far in excess of the supply, now knows no limit. Many authorities have set forth their views and theories upon this subject, in America and also in foreign countries. These have been published from time to time in many of the leading periodicals and magazines, as well as in book form. It seems the purpose of most of these works has been to advance the operators who already have a smattering knowledge of this art, or to present to the purchaser of apparatus a set of operating instructions.

(2) It is singular indeed that a school manual, devoted exclusively to the instruction of the beginner, which will serve as an aid to the instructor as well as to the student, has not yet been put forth. It cannot be said that there is not a demand for such. Recently there seems to have been a mushroom growth of welding classes. The majority of the vocational schools, colleges, night schools, and automobile schools have all entered the instruction in oxy-acetylene welding on their rolls and each is attempting to instruct in an entirely different manner from the other.[vi] There can be no question as to the expediency of affording the educational institutions a systematic as well as a standardized method of instructing. But the books and articles of the nature mentioned are not suited to this purpose, and were not designed for it. A school-book is wanted; something to be used in the classroom, to be employed as a reference in the shop practice, to be studied for what it contains, and to indicate further lines of research, where such are required.

(3) To meet this demand, the present “Manual” has been written to serve the instructor as well as the student. In its preparation many books, both well-known and obscure, have been examined and the methods of shop instruction have been carefully studied by the author.

(4) It has been found that regardless of how fast the ground may be covered in the lecture room, the average student’s power of assimilation is limited and considerable time has been spent in determining this ratio and applying it between the lecture subjects and shop work.

(5) It must be remembered that while the chapters comprising the theoretical part of this welding manual follow in the order given, the actual shop practice, as previously mentioned, is the most important.

(6) Kindly aid has been received from many sources. Granjon & Rosemberg, Kautney, M. Keith Dunham, S. W. Miller, Henry Cave, C. J. Nyquist, P. F. Willis, Ben K. Smith, and others have embodied in their writings many excellent ideas, which have assisted the author in bringing out certain points advantageously. The following manufacturers are to be given credit for many of the illustrations:

The Oxweld Acetylene Co., Newark, N. J.

The United States Welding Co., Minneapolis, Minn.

The Bastian Blessing Co., Chicago, Ill.[vii]

The Linde Air Products Co., New York City.

The General Welding & Equipment Co., Boston, Mass.

The Messer Manufacturing Co., Philadelphia, Pa.

The Alexander Milburn Co., Baltimore, Maryland.

The Torchweld Equipment Co., Chicago, Ill.

The Davis-Bournonville Co., Jersey City, N. J.

The K. G. Welding Co., New York City.

The Chicago Eye Shield Co., Chicago, Ill.

The Commercial Acetylene Supply Co., New York City.

The Welding Engineer, Chicago, Ill.

The Journal of Acetylene Welding, Chicago, Ill.

Note.—Lieut. Campbell offers his services without charge to anyone interested in this method of welding and may be addressed care of John Wiley & Sons, Inc., Publishers, 432 Fourth Avenue, New York City.

[viii]

The Wiley Engineering Series will embrace books devoted to single subjects. The object of the Series is to place in the hands of the reader all the essential information regarding the particular subject in which he may be interested. Extraneous topics are excluded, and the contents of each book are confined to the field indicated by its title.

It has been considered advisable to make these books manuals of practice, rather than theoretical discussions of the subjects treated. The theory is fully discussed in text-books, hence the engineer who has previously mastered it there, is, as a rule, more interested in the practice. The Wiley Engineering Series therefore will present the most approved practice, with only such theoretical discussion as may be necessary to elucidate such practice.

[ix]

| PAGE | ||

| Introduction | 1 | |

| I. | Apparatus | 19 |

| II. | Operation | 27 |

| III. | Shop Equipment | 39 |

| IV. | Apparatus Repairs | 44 |

| V. | Preheating Agencies | 51 |

| VI. | Part One—Welding of Cast Iron | 58 |

| Part Two—Welding of Cast Iron | 67 | |

| Part Three—Welding of Cast Iron | 70 | |

| Part Four—Welding of Cast Iron | 75 | |

| VII. | Part One—Steel Welding | 81 |

| Part Two—Steel Welding | 87 | |

| Part Three—Steel Welding | 92 | |

| Part Four—Steel Welding | 97 | |

| VIII. | Brass Welding | 106 |

| IX. | Part One—Aluminum Welding | 109 |

| Part Two—Aluminum Welding | 113 | |

| Part Three—Aluminum Welding | 118 | |

| X. | Welding of Malleable Iron | 120 |

| XI. | Oxy-acetylene Cutting | 125 |

| XII. | Carbon Burning | 135 |

| Glossary | 145 | |

| Lectures | 149 | |

| Index | 167 | |

[1]

Oxy-Acetylene Welding Manual

(1) When choosing a life vocation, one generally views the possibilities it has to offer and delves deeply into these, previous to making a decision. It is therefore thought advisable at this time to present the student with an idea of what is meant by oxy-acetylene welding and cutting; how it is applied; the possibilities and advantages attached to such an art.

(2) Acetylene gas, when burned with a proper portion

of oxygen gas, produces an extremely hot flame, in fact,

the hottest flame known. Its temperature is over 6000

degrees Fahrenheit. With this flame it is possible to bring

any of the so-called commercial metals, namely: cast iron,

steel, copper, and aluminum, to a molten state and cause

a fusion of two pieces of like metals in such a manner that

the point of fusion will very closely approach the strength

of the metal fused. If more metal of like nature is added,

the union is made even stronger than the original. This

method is called oxy-acetylene welding and differs from

what the average layman considers welding in the blacksmith’s

forge, insomuch that there is no blow struck to

assist fusion in this process. And while the forge method

is limited to wrought iron and steel which is detachable[2-

3]

and of restricted size and shape, the oxy-acetylene process

has, practically speaking, no such limitations.

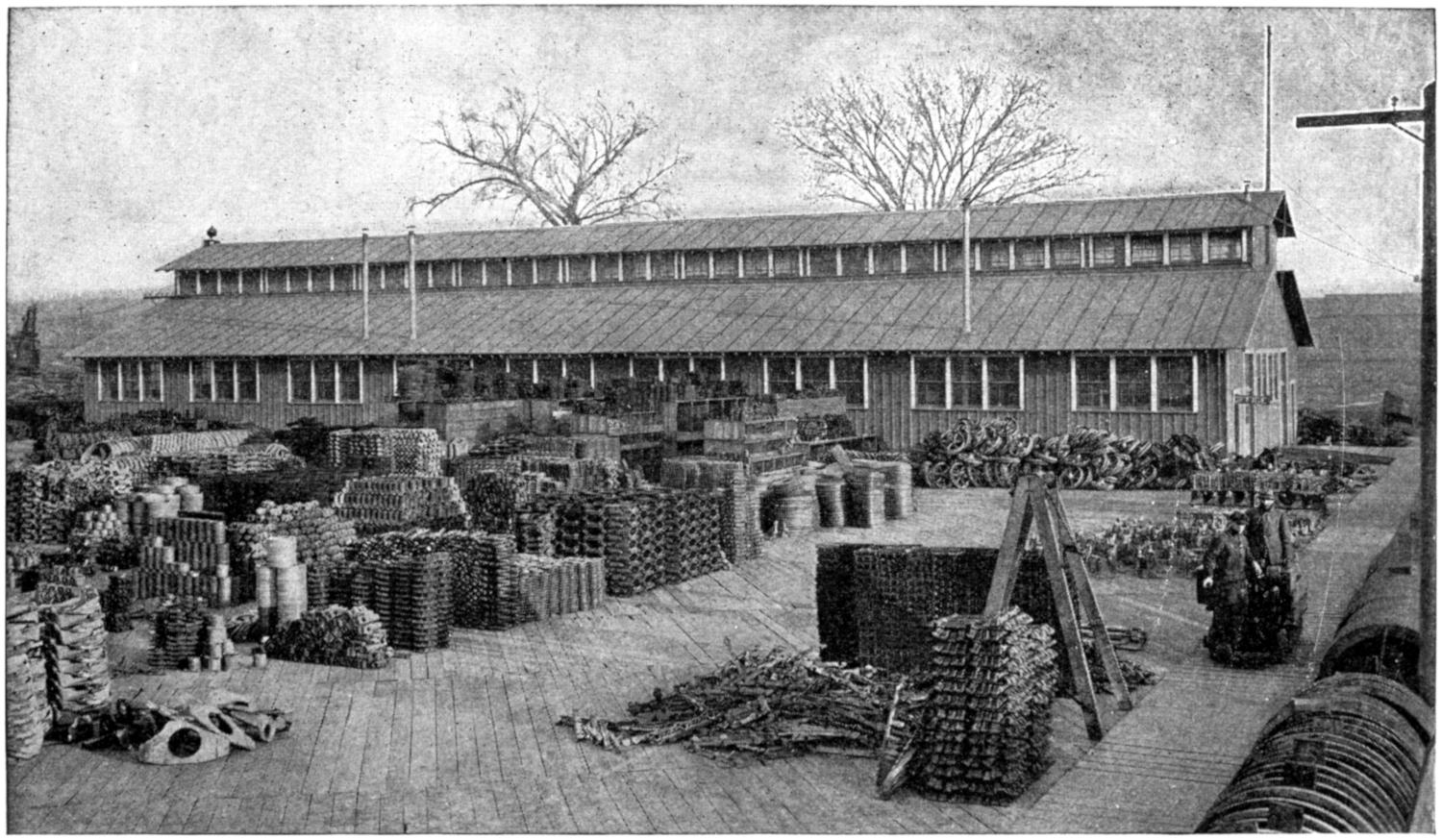

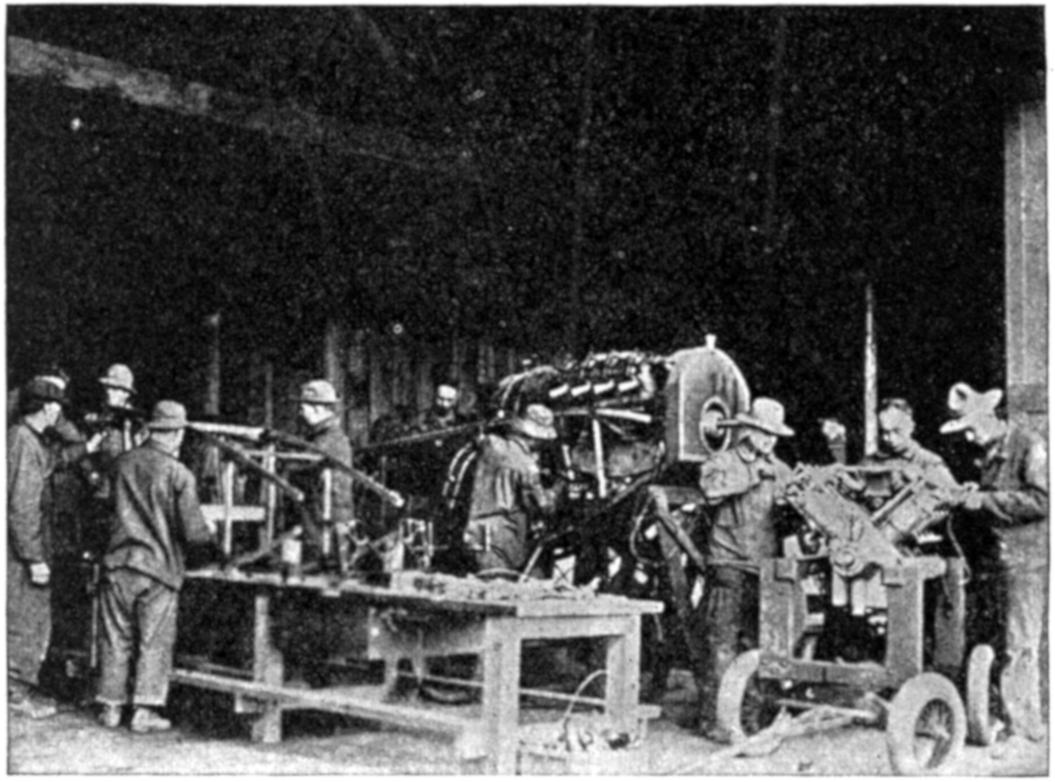

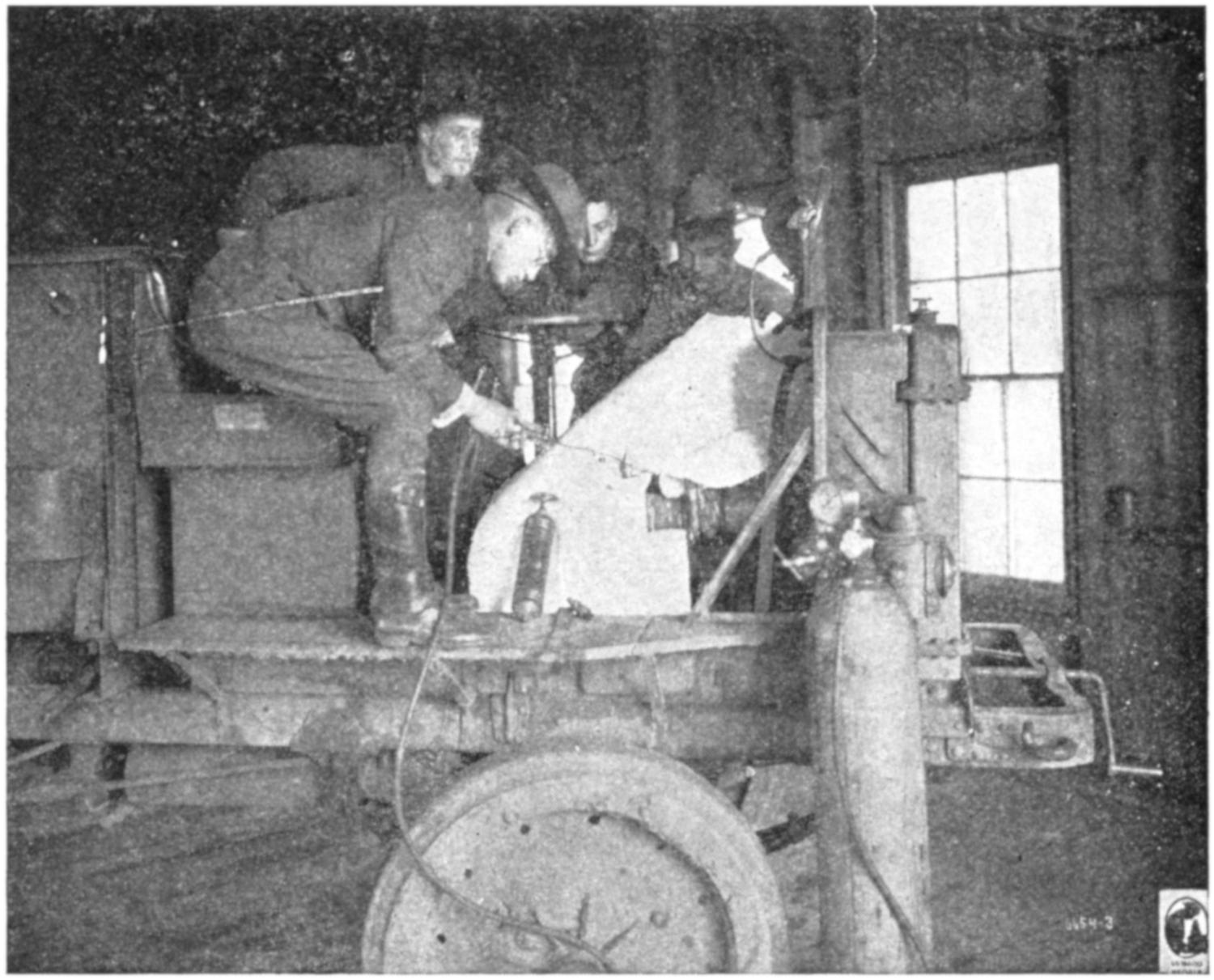

(Courtesy of Acetylene Journal Publishing Co.)

Fig. 1.—Welders on an Ordnance Mobile Repair Unit in Action.

(Courtesy of the Oxweld Acetylene Co.)

Fig. 2.—In Enameled Products for the Kitchen the Weld is Fast Replacing the Riveting, Brazing, and Soldering of the Light Sheet Metal Seams.

(3) Manufacturers in the metal-working world were very slow to grasp the real significance of this important process, until the operators began demonstrating some of its possibilities. At the present time, however, there is hardly a metal barrel or tank manufacturer who has not discarded the old method of producing costly leaky, riveted drums and containers, for this modern fusing process. The manufacturers of fire-proof doors and windows, cooking utensils, seamless pipe and tubing, office furniture and what not, are now virtually dependent upon the welding torch at every turn.

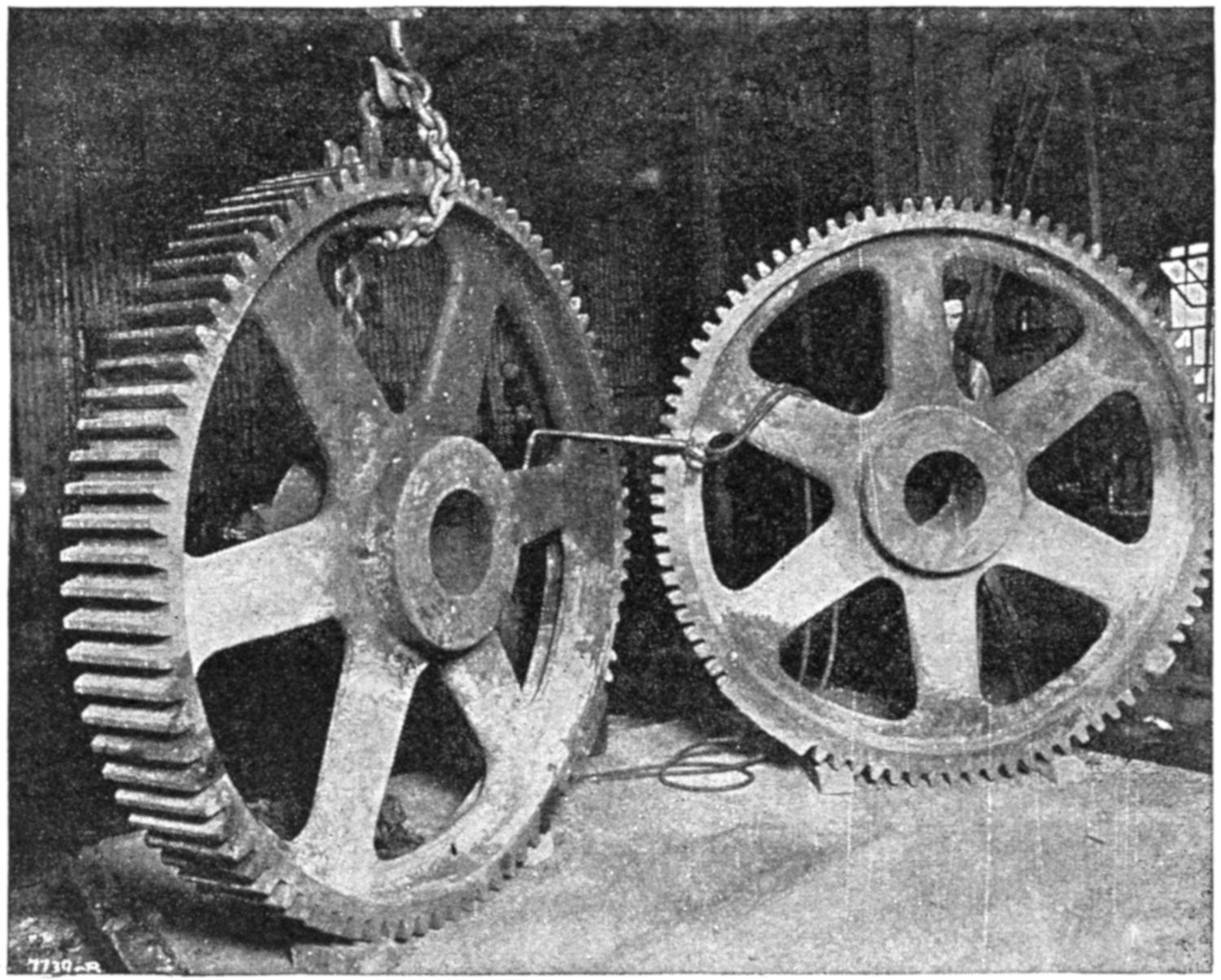

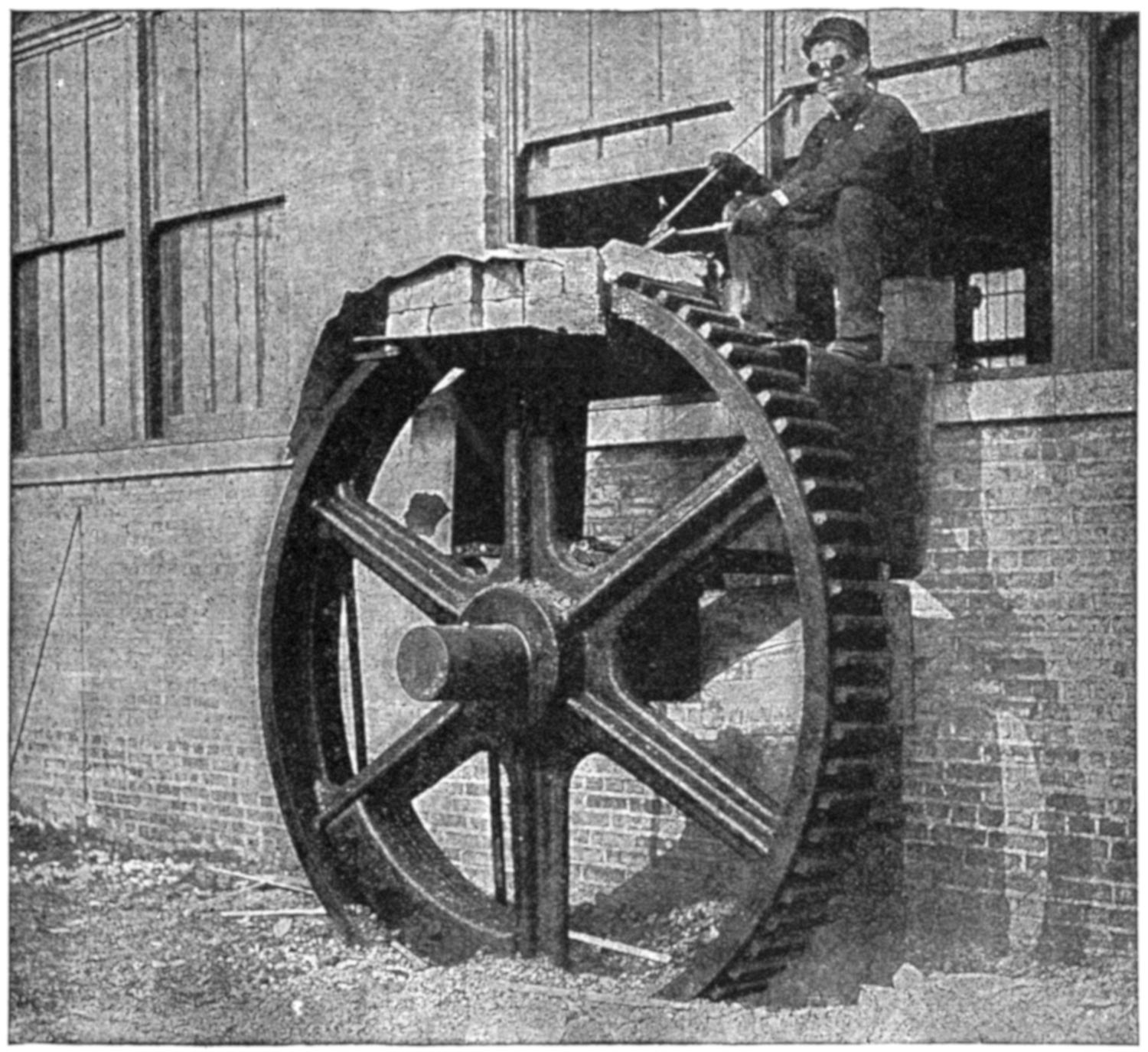

(4) As a repairing agent, the welding torch has no rival. Whether it is a casting of iron, steel, brass, or aluminum that has broken; a boiler or tank that has worn away in spots, or an error on the part of engineer, foundryman or machinist, the part can generally be reclaimed and made stronger than originally. To-day practically no manufacturing concern that is dependent upon metallic machinery could think of being deprived of its oxy-acetylene apparatus, once having learned its worth. In the not far distant past, were a gear or some casting to break, it probably meant closing[4] down the entire plant until a new part could be obtained, which, whether the source of supply were near or at a long distance, would mean costly delay. With oxy-acetylene equipment and an efficient operator on hand, almost every emergency is provided for.

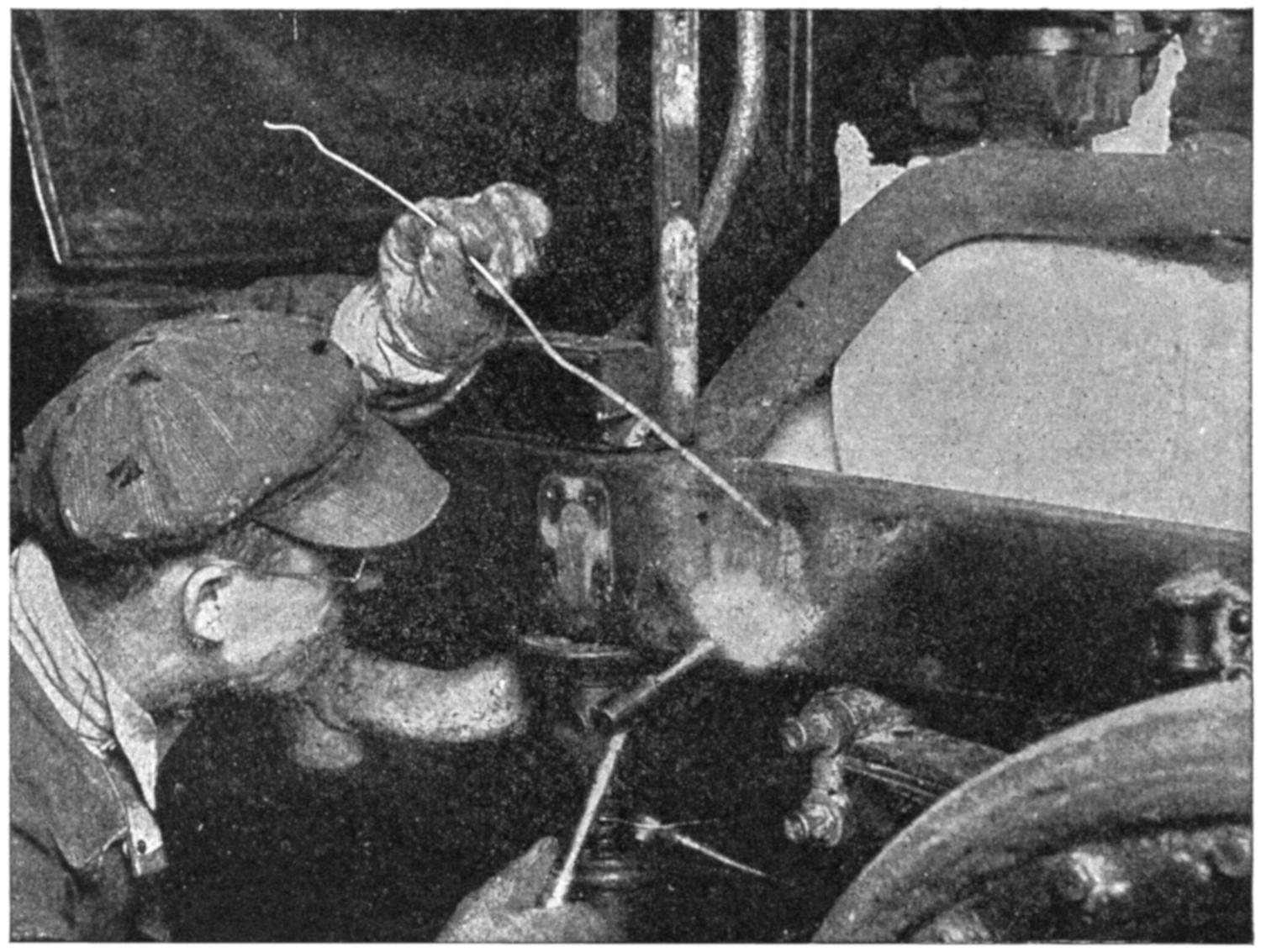

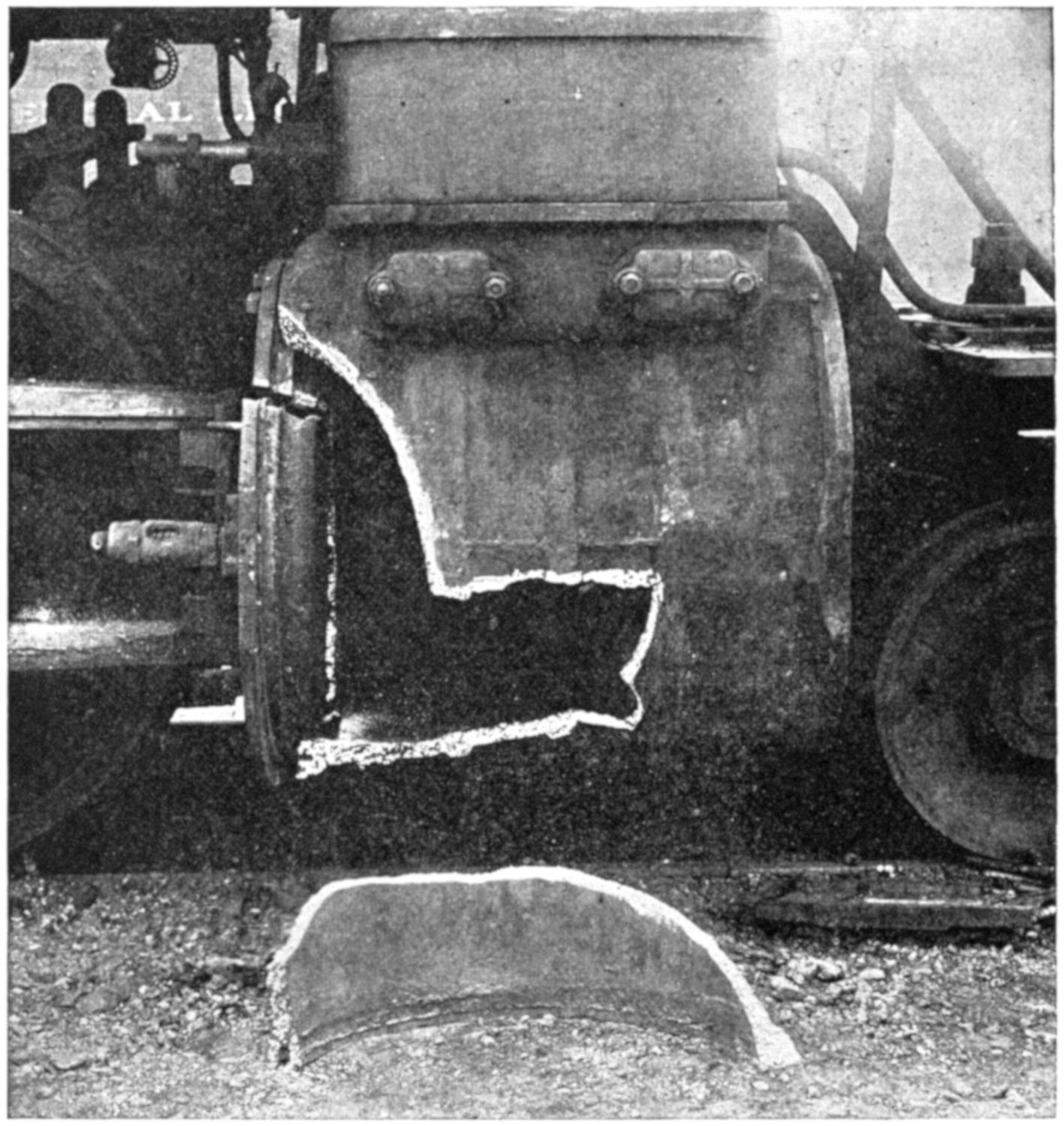

(Courtesy of the Oxweld Acetylene Co.)

Fig. 3.—Welding Broken Frame of 5-ton Automobile Truck.

(5) If an automobile owner breaks a frame, he does not consider replacing it with a new one, as the labor alone for stripping his machine and setting it up again, not to mention the cost of the new frame and the time required for this operation, is prohibitive. Rather, he has his car taken to the nearest welder or his portable apparatus to the car and the job is completed within thirty or forty minutes, with the frame at the point of the break made stronger than ever. Locomotive frames are handled in much the[5] same manner, only more time is required and perhaps extra operators, but the important point to be brought out is the fact that on many jobs no dismantling is required and the repair is permanently and quickly executed.

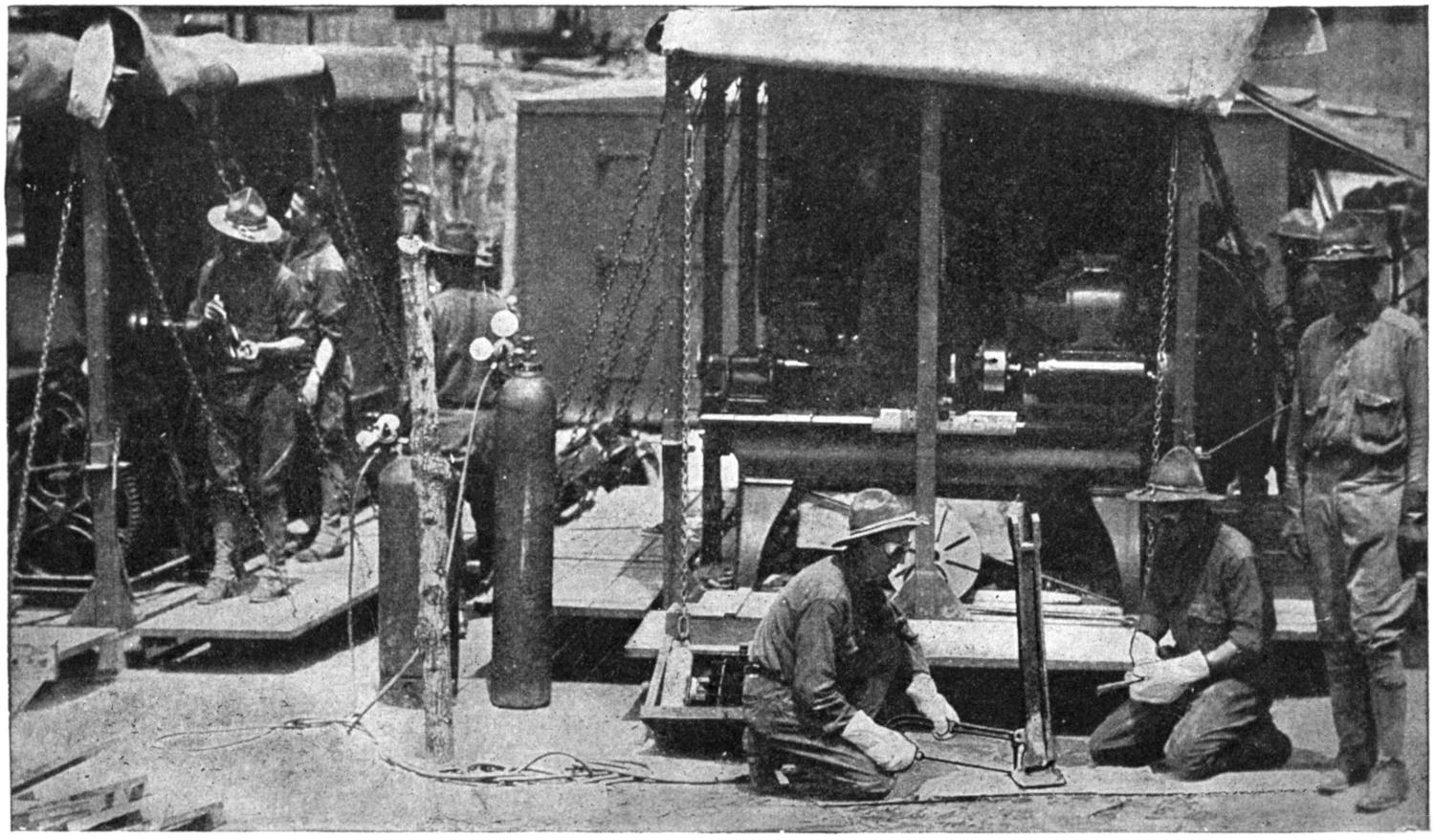

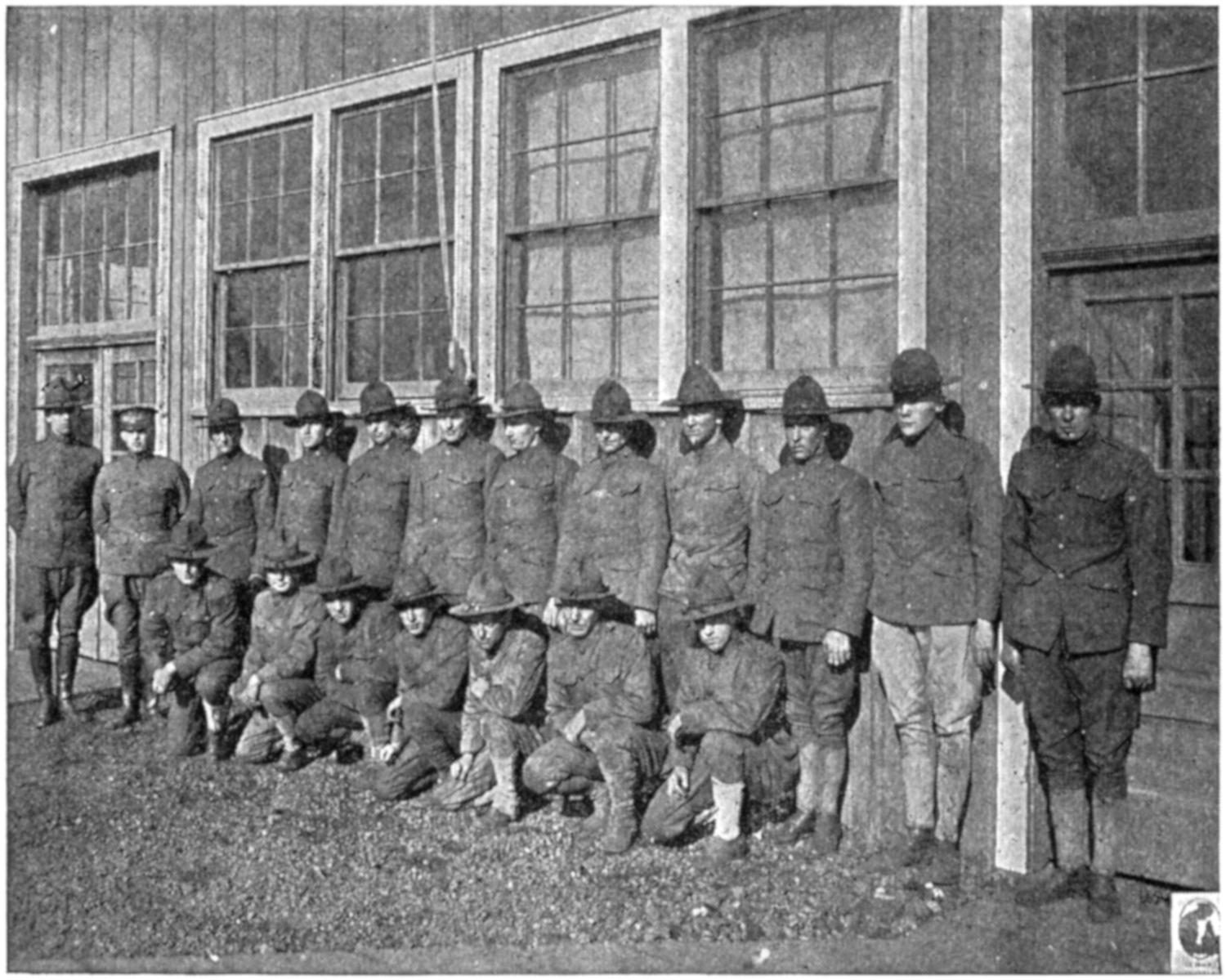

Fig. 4.—Staff of Instructors at the Ordnance Welding School, U. S. A.

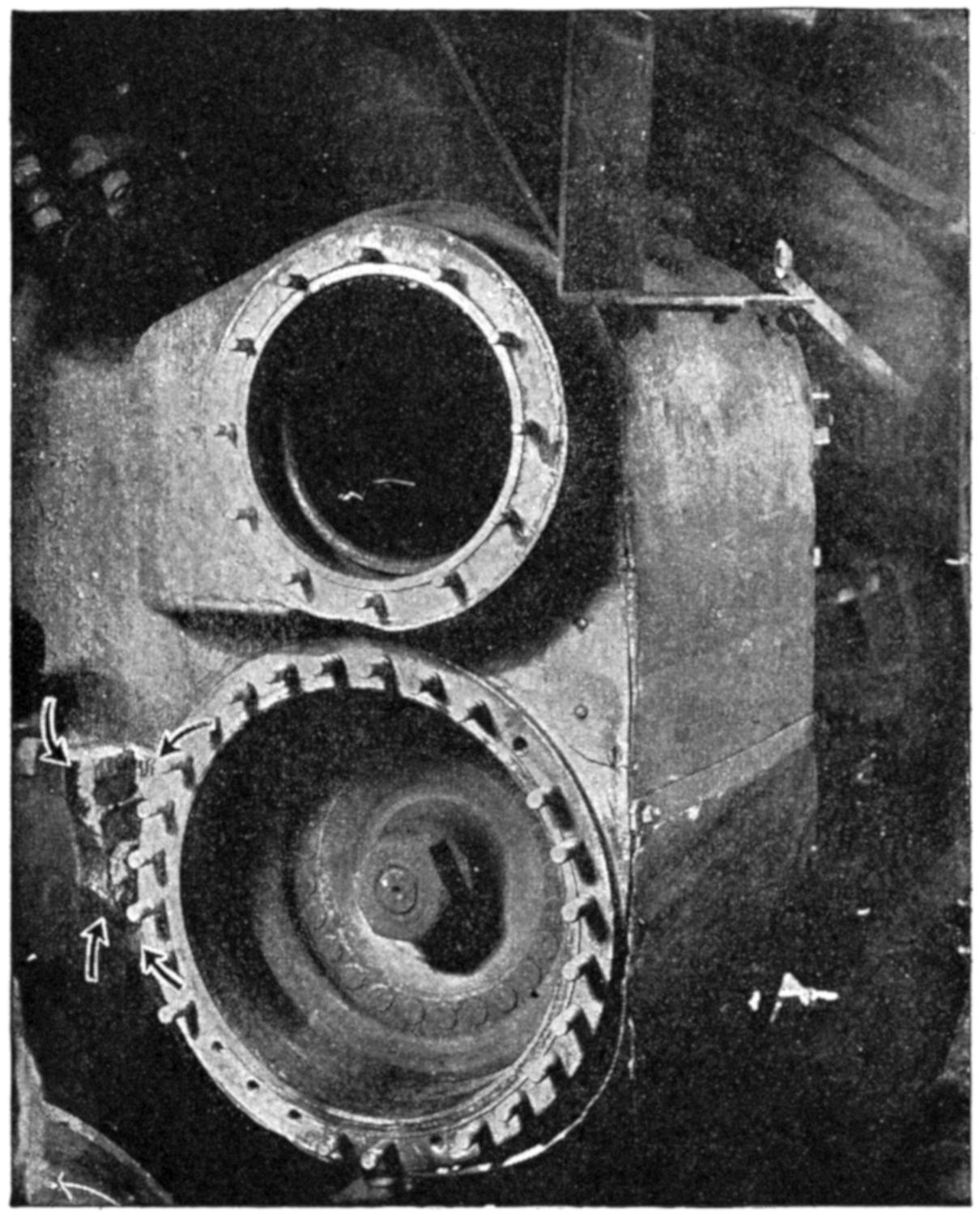

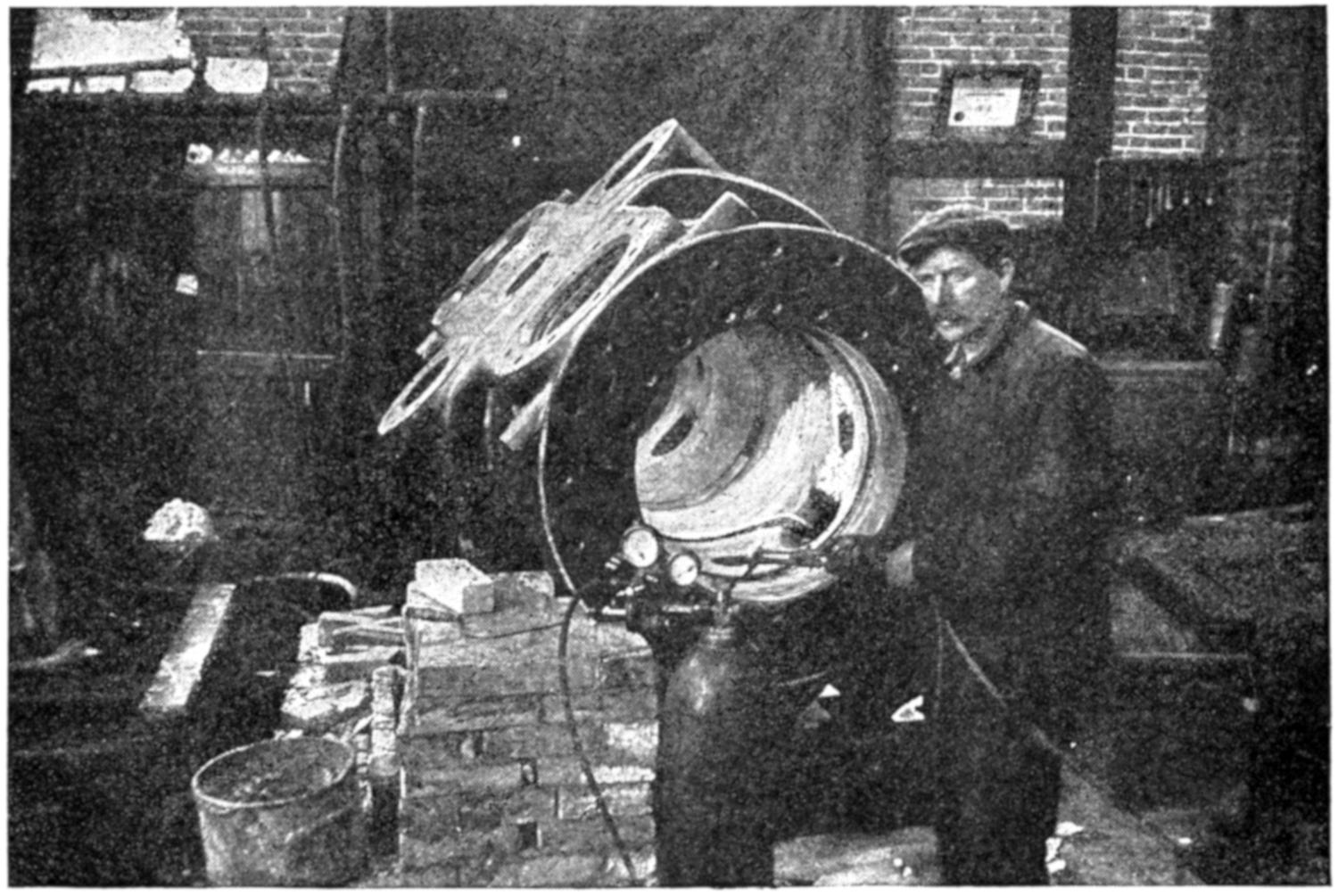

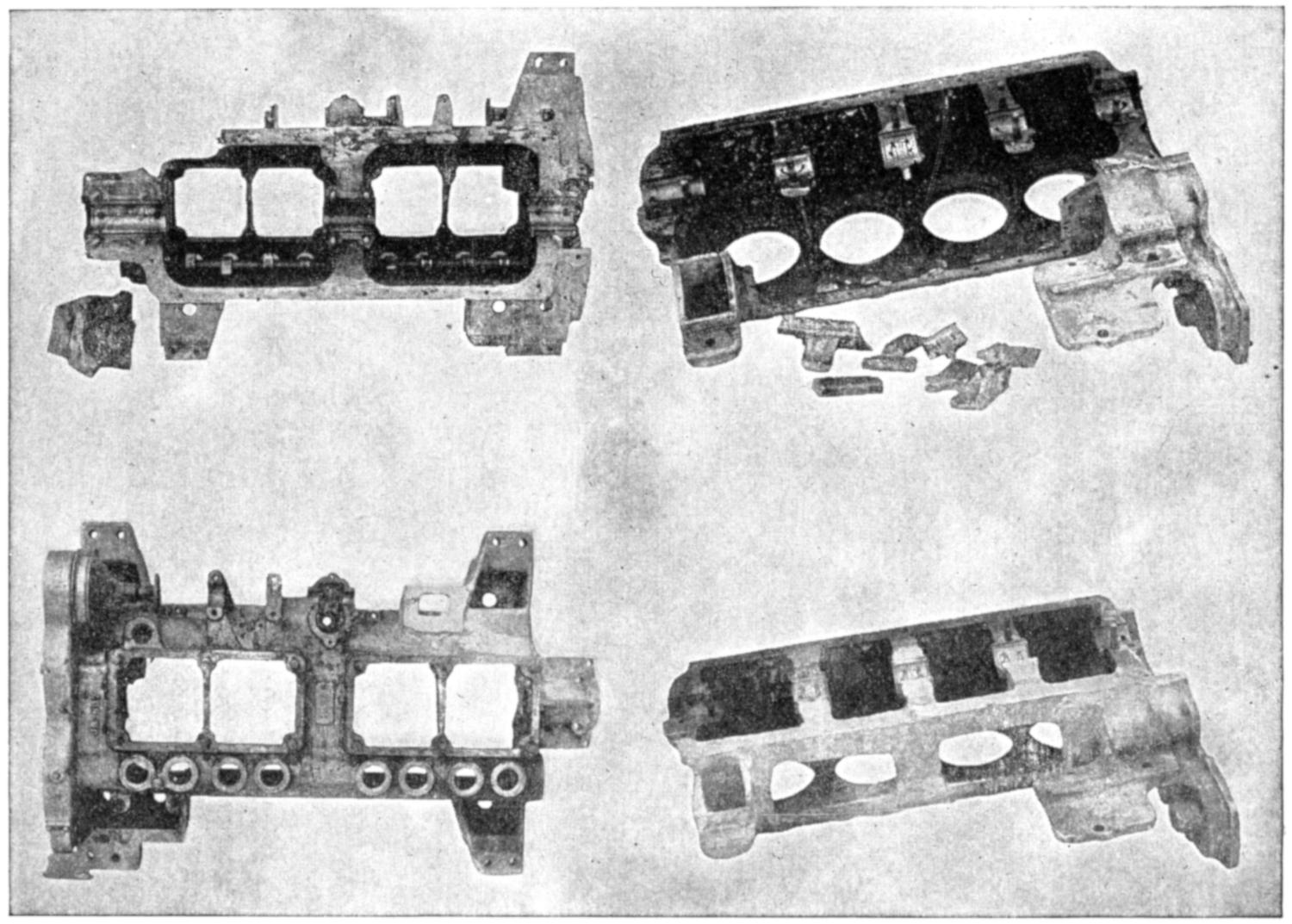

(6) An interesting example of the true worth of welding was brought to the attention of the public when the United States entered the European War, and all the interned German vessels, which had been greatly damaged by the orders of their commanding officers, were restored to working condition with the oxy-acetylene and electric welding process. This was considered impossible by many engineers not familiar with the process, insomuch as they looked upon oxy-acetylene welding as applicable only to small parts and[6] here some of the sections which had been blown or struck out of the cast cylinders, etc., weighed many hundreds of pounds. In many instances the ribs of these same vessels were cut most of their depth, but these were restored to working order in a remarkably short time and the results were more convincing than any words.

(7) Cutting with the oxy-acetylene process is just the opposite from that of welding. The latter might be considered constructive and the former destructive. In the case of welding, two parts are brought to a molten condition along the line to be joined and both fused together. Whereas in cutting, one piece of metal, when brought to a red heat, is cut in two by an oxidizing flame. Cutting has not the wide scope that welding has, for it can only be applied successfully at the present day to wrought iron, rolled and cast steel. While it is limited in its scope, the speed of this process in severing large masses of metal is very spectacular and appeals forcibly to the observer.

(8) Probably the world’s first awakening to the real meaning of oxy-acetylene cutting came when the U. S. battleship “Maine,” was being taken from Havana Harbor. All the heavy armor plate and seemingly immovable wreckage was cut into small sections which could be handled easily. This was all accomplished with the cutting torch, which seems to eat its way through metal with the same ease that a hot knife goes through butter.

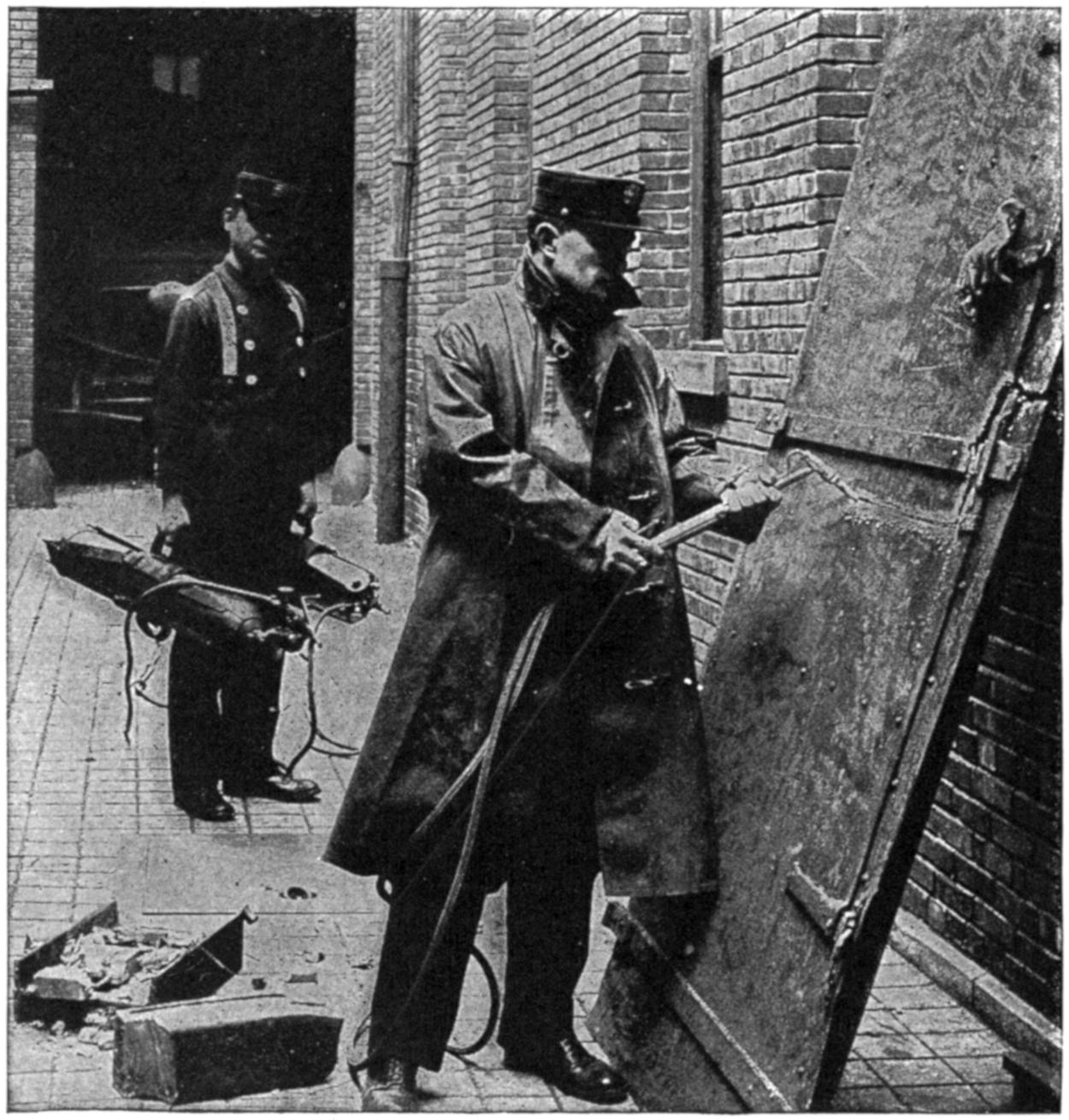

(Courtesy of the Oxweld Acetylene Co.)

Fig. 5.—Fireman Cutting ¹⁄₄-inch Steel Fire Door with Portable Apparatus.

(9) Before and since the time of the “Maine,” the cutting torch has been accomplishing wonderful feats. In every scrap yard, old boilers and the like are being cut into furnace size; speeding up the production in answer to the world’s cry for more metal. The wreckage on railroads and buildings using steel reinforcements is being cleared in hours, with the aid of the cutting torch, where it required days by other methods. Most of the fire departments in[7] the larger cities now carry the cutting torch as part of their equipment, and to it has been credited the saving of many lives, by its timely cutting away of steel doors, bars or barriers which prevented escape. Much of the plate in this country’s shipbuilding yards is being cut to size right on the job, and the function of this torch in cutting off risers measuring from one to thirty-six inches in diameter in the foundry seems only to be of secondary importance in comparison with[8] some of its other uses. In order to transport some of the largest inland lake boats which were much too long to pass through the locks, to the sea, they were cut in parts, transported, and later welded together and placed in service.

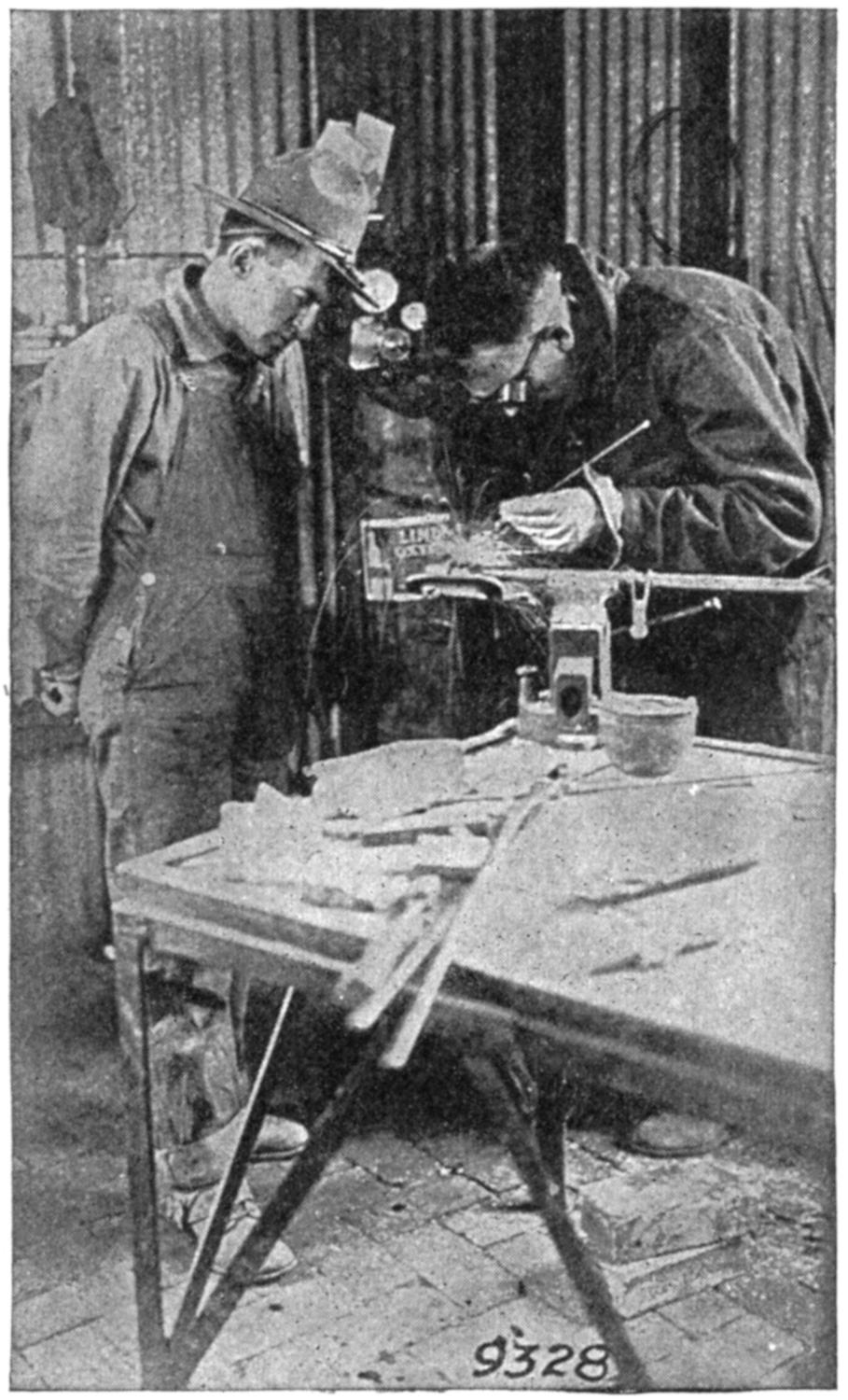

(Courtesy of the Acetylene Journal Publishing Co.)

Fig. 6.—Welders of the Signal Corps, U. S. Army, in Action.

(10) It is not only possible to keep a cutting torch burning under water, but it can also be made to cut. Contracting companies are cutting off their piling under water and it has been known that in European ports cutting has been successfully accomplished at a depth of thirty feet. A special torch is employed by submarines to cut nets under water.

(11) In reviewing the oxy-acetylene welding and cutting process, we find that its growth is one of the most remarkable the world has ever witnessed. About 1907 saw its industrial birth and since that time it has advanced by leaps and bounds, rivaling the automobile industry in its progress,[9] despite the opposition and criticism levied at it by workers of other trades and its careless and unskilled manipulation.

(Courtesy of the Acetylene Journal Publishing Co.)

Fig. 6a.—Welders of the Signal Corps, U. S. Army, in Action.

(12) It is quite impossible to present anything like a complete list of the applications of this process, but a few of its general uses are here enumerated:

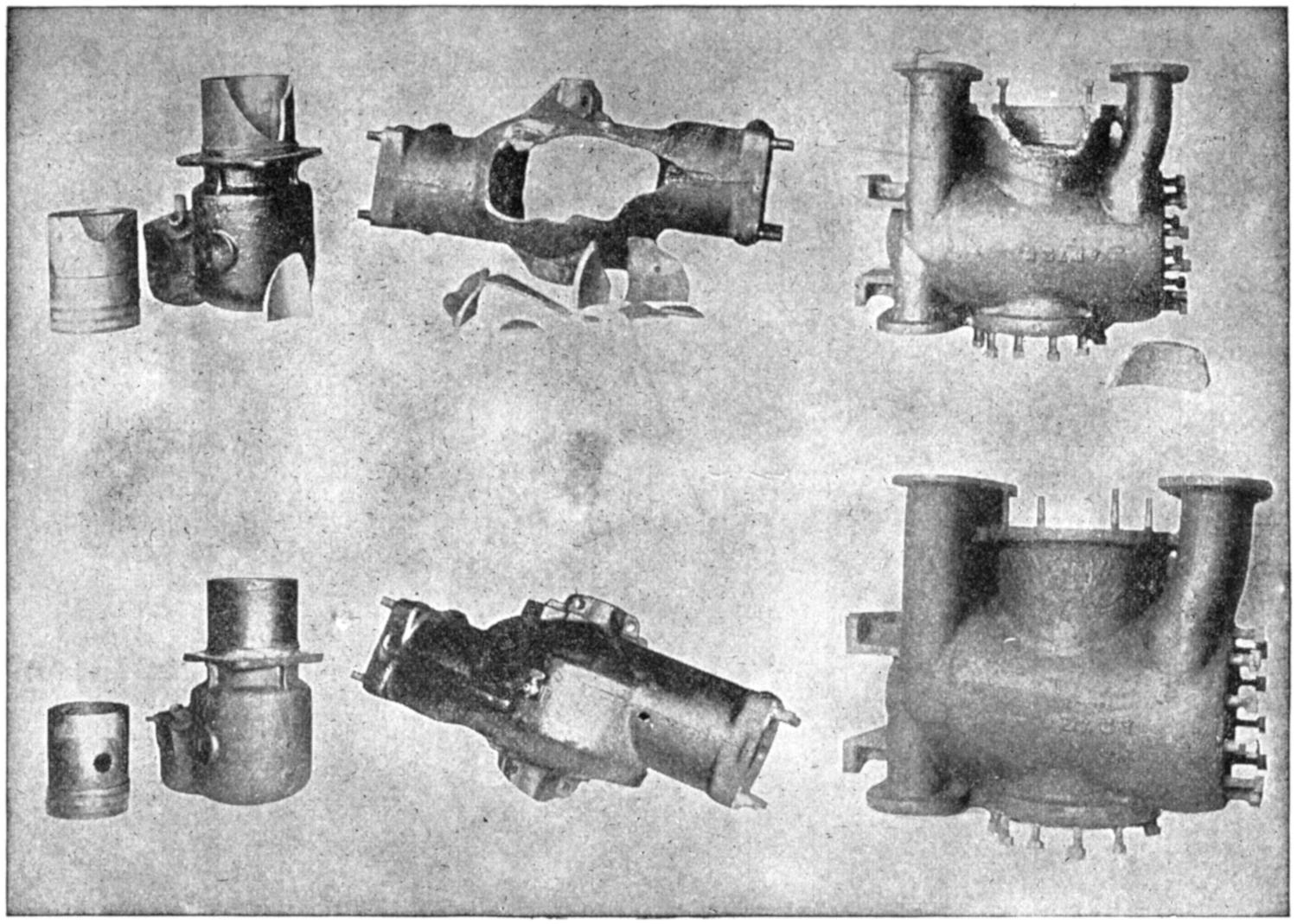

(A) Airplane Construction.—Welding of frames, sockets, water and gasoline tanks, water jackets and valve cages to[10] cylinders, intake and exhaust manifolds and connections, spark plug thimbles and the repair of aluminum crank cases, etc.

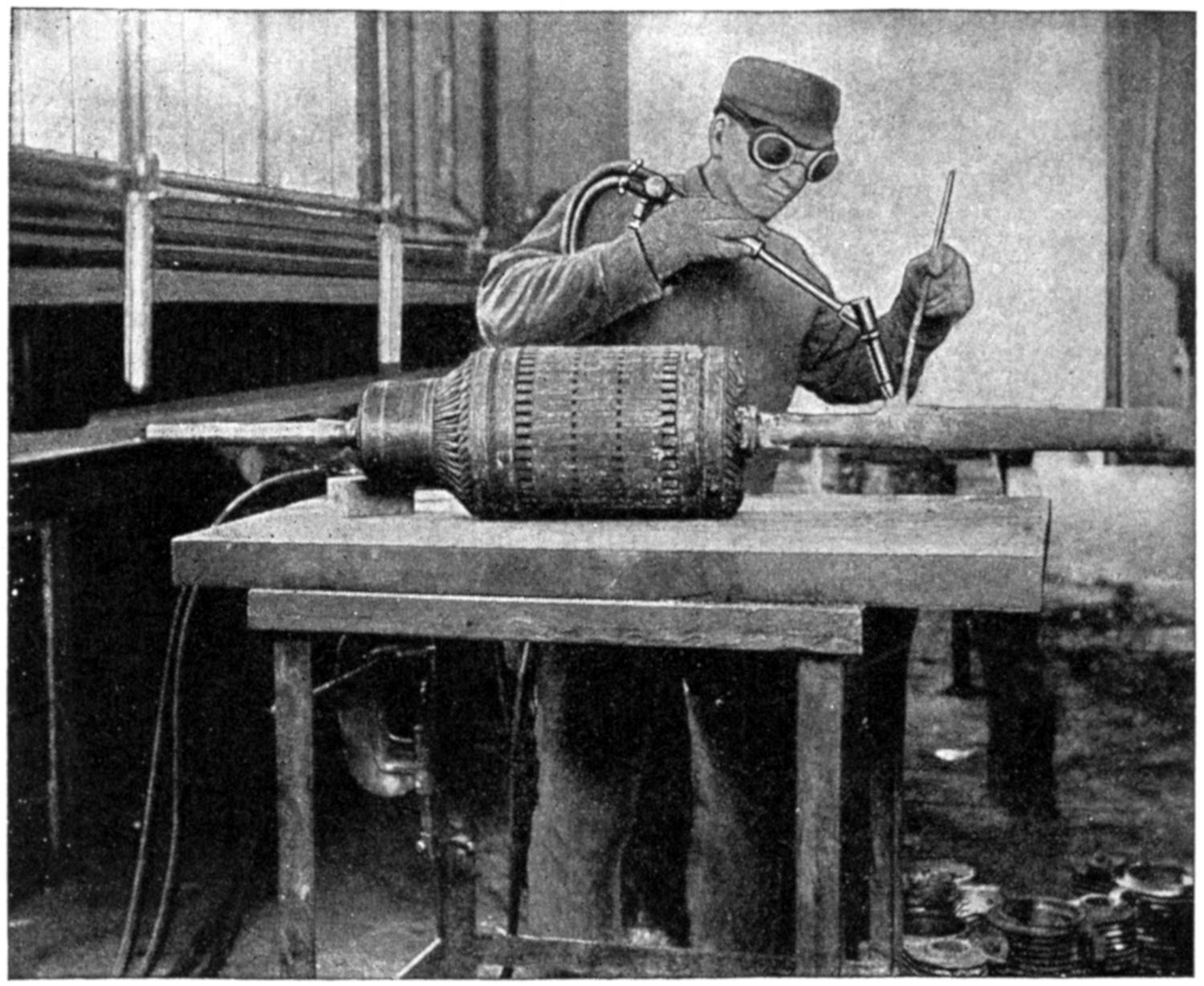

(Courtesy of the Oxweld Acetylene Co.)

Fig. 7.—Welding a 2-foot Length of New Shafting on the End of a Motor Shaft 2 Inches in Diameter.

(B) Automobile Manufacture.—Welding of steel and aluminum bodies, transmission and rear axle housings, crank-shafts, cylinders, gears, manifolds, pinions, crank cases, valves, rims, mufflers, frames, fenders, wind-shield tubings, and uprights, etc.

(C) Boiler Shops.—Welding and building up worn spots around hand-hold plates, repairing cracks and checked portions of fire boxes, retipping flues, connections, etc.

(D) Brass and Copper.—Welding kettles, vats, tanks,[11] stills, floats, cooking utensils, manifolds, water jackets, electrical and chemical wares, etc.

(E) Commercial Welding.—Reclamation service on all kinds of metals, quick and permanent repairs on all broken parts of machinery.

(F) Electric Railway.—Welding air receivers on air-brake systems, building up shafts, bonding the rails, motor housings, worn boxes, reclaiming gears and broken trucks, steel trolley wires, etc.

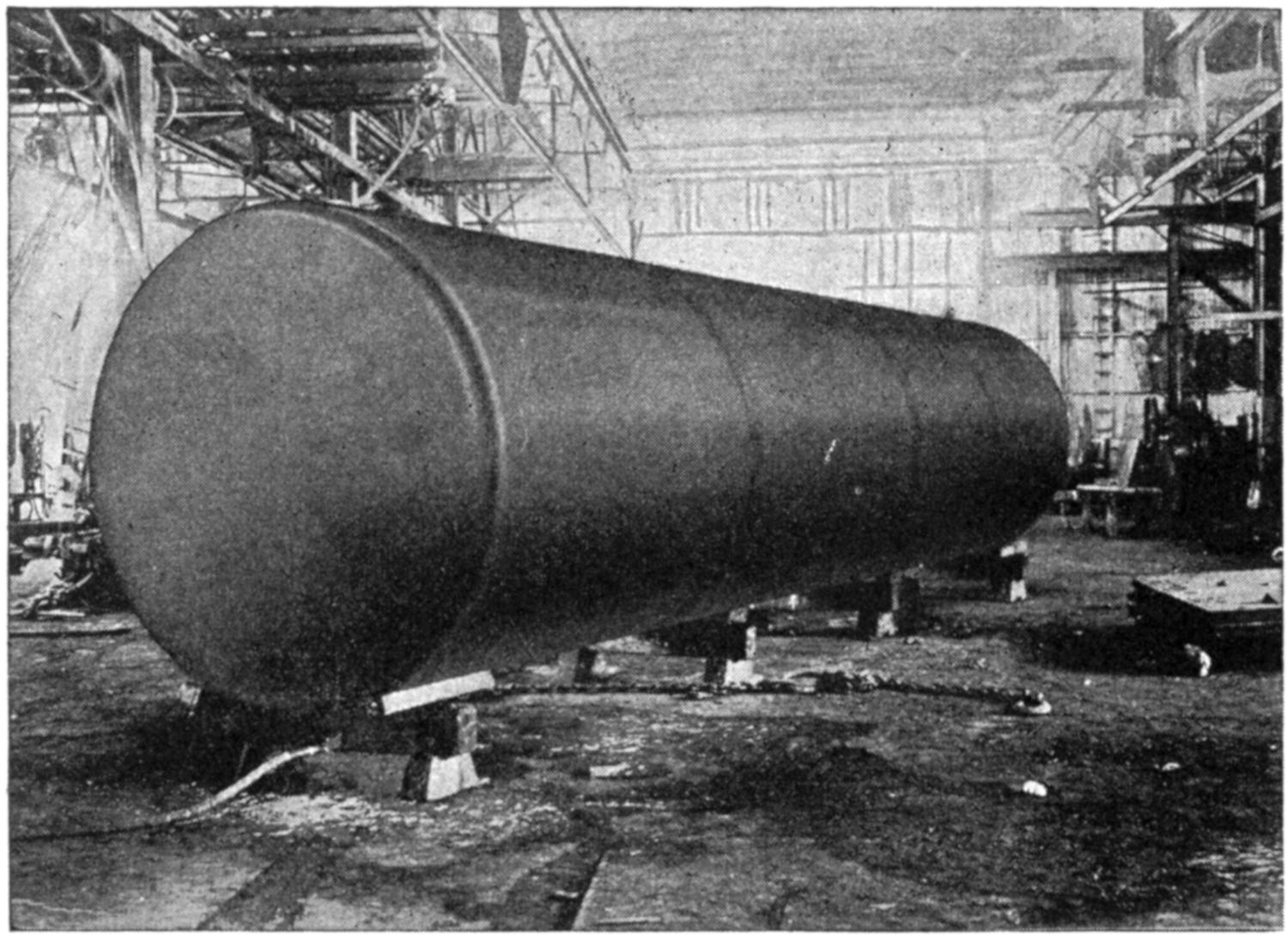

(Courtesy of the Torchweld Equipment Co.)

Fig. 8.—This is a Steel Tank, Made of ³⁄₈-inch Plate, which Measures 30 Feet Long and 8 Feet in Diameter, Fused into One Piece by the Welding Torch.

(G) Forge Shop.—Welding complicated parts which can not be conveniently handled in the forge.

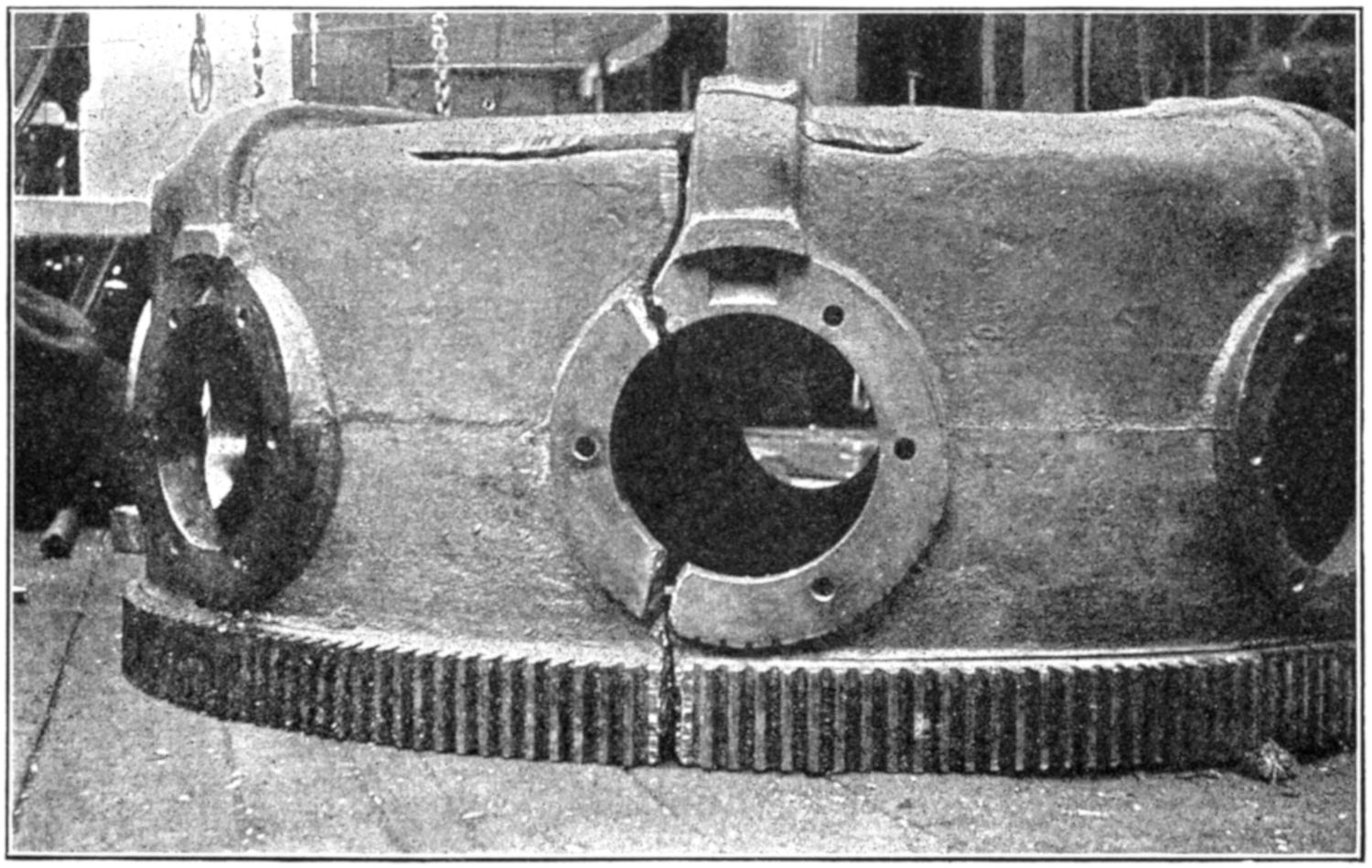

(H) Foundries.—Welding up blowholes, porous spots, and reclaiming castings in general. The cutting off of risers, gates, and heads on steel castings.

[12]

(I) Lead Burning.—Lead pipe joints, storage battery connections and repairs, lead linings in vats, etc.

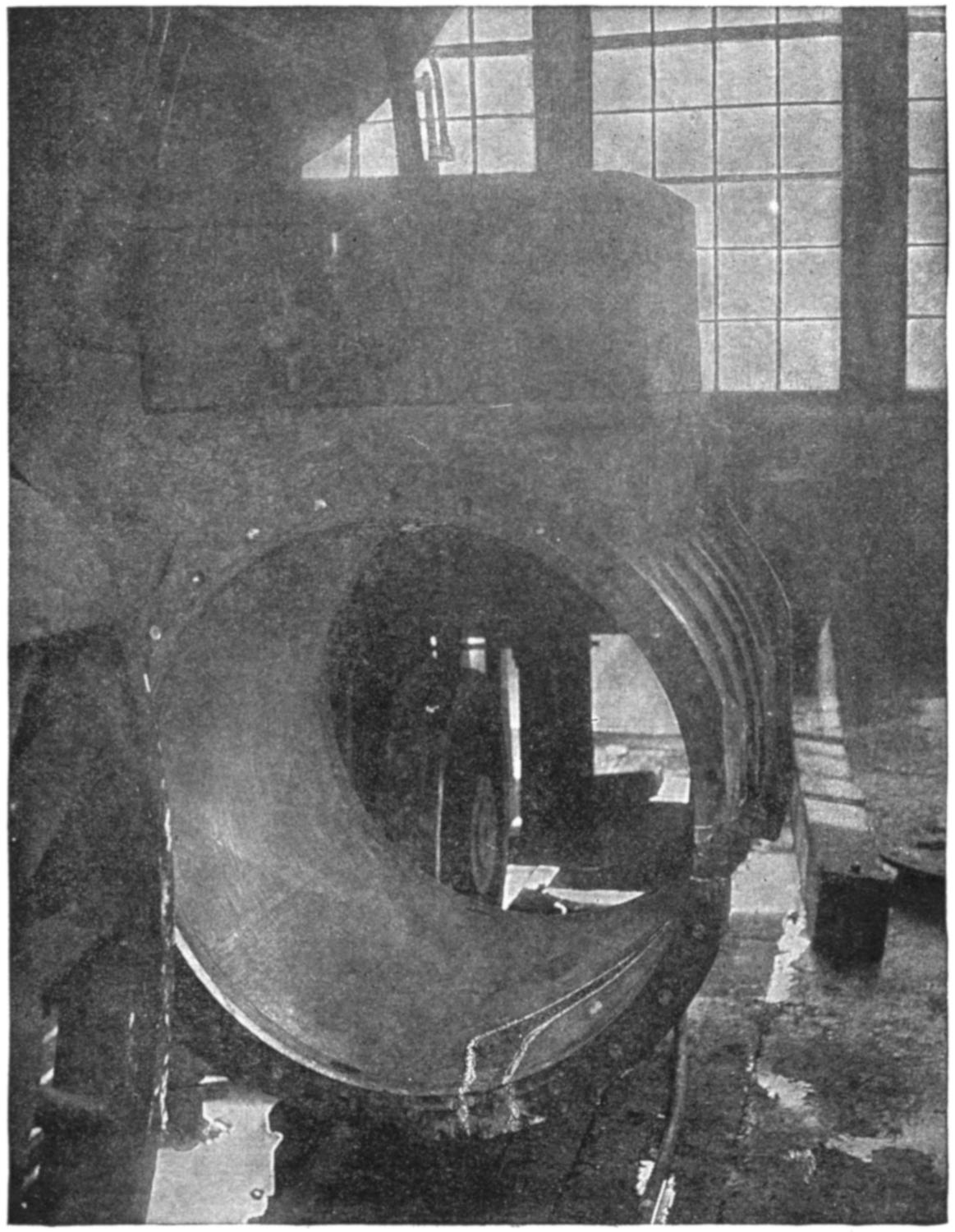

(Courtesy of Ben K. Smith, U. S. Welding Co.)

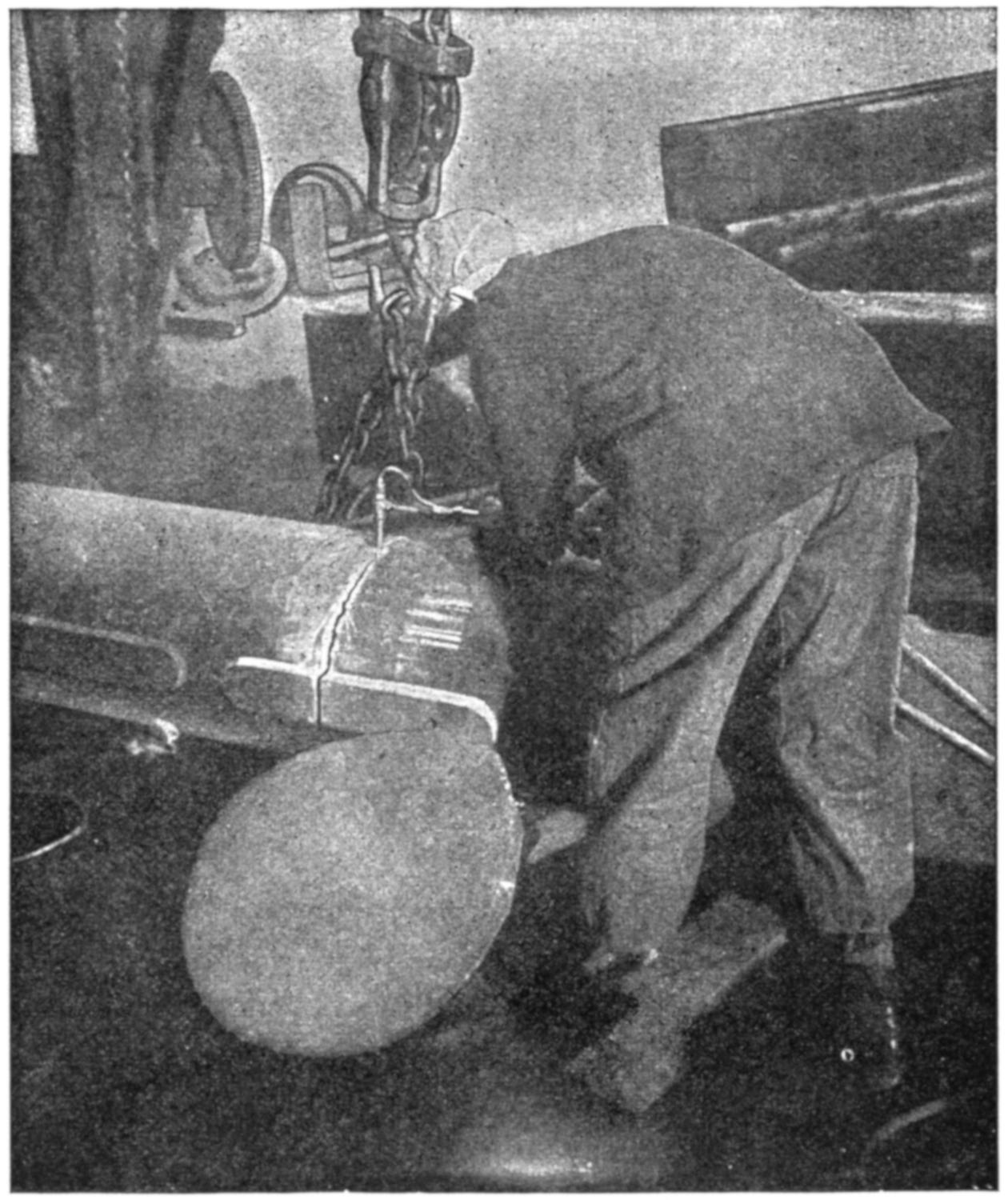

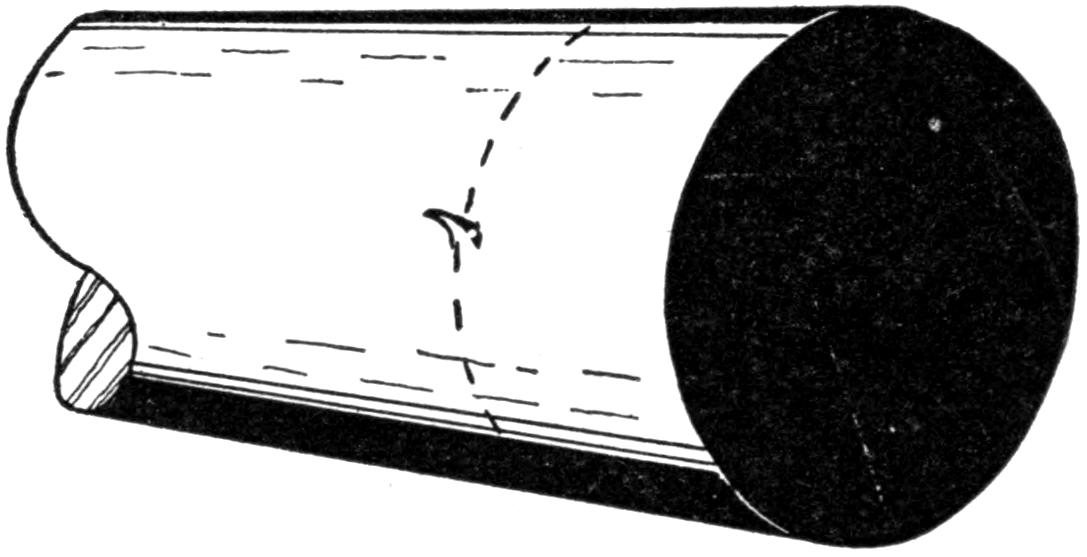

Fig. 9.—Locomotive Cylinder to be Welded in Place.

(J) Lumber Mills.—Building up worn shafts, repairing gears, chains, and broken parts.

(K) Machine Shops.—Rectifying errors on part of machinists and engineers. A “putting-on” tool in every respect.

(L) Manufacturers.—Welding spouts and handles on[13] cooking utensils, fire-proof doors and window sashes, office files and furniture, chains, etc.

(M) Mines.—Repairing pipe lines, boilers, broken shafts, gears, and building up worn parts on dippers, etc. The cutting torch is used for clearing away wreckage in case of accidents.

(N) Pipe Work.—Welding of water, gas, and oil, steam and air lines. High-pressure refrigeration systems are cut and welded in place.

(Courtesy of the Oxweld Acetylene Co.)

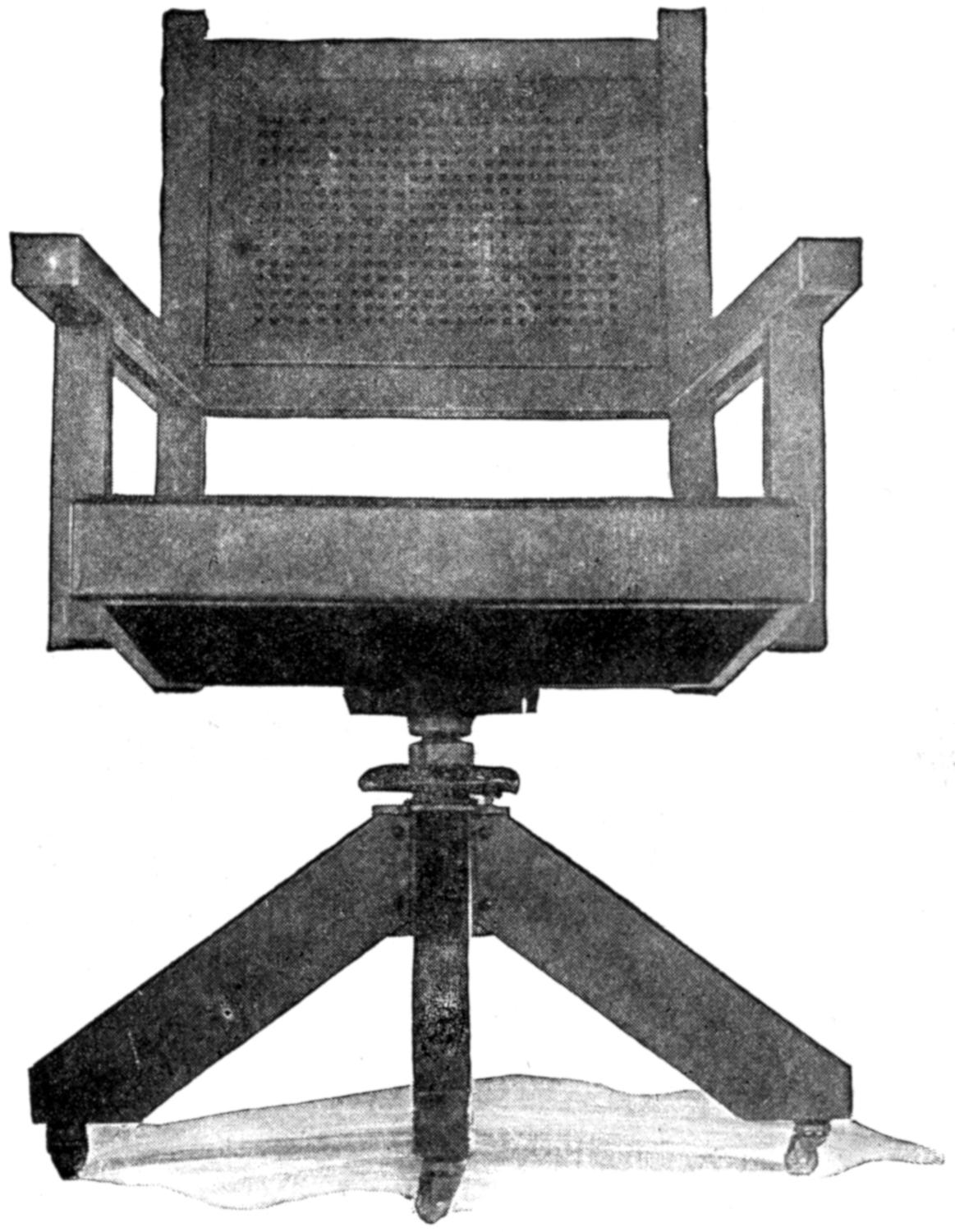

Fig. 10.—Steel Roll Top Desk—all Joints and Seams Welded. An Excellent Example of High-grade Welded Metal Furniture.

(O) Plate Welding.—Tanks for oil, steam driers, digesters, vats, chemical receivers, generators, etc.

(P) Power Plants.—Welding of steam, air, and water-lines, of pump castings, cylinders, pistons, worn or broken parts, etc.

(Q) Railroad Work.—Reclaiming bolsters, couplings, slotting[14] forged engine rods, building metal cars, repairing fire-boxes, patching and replacing side sheets, flue welding, building up frogs and crossings, cutting off rails, mud rings, welding cracked cylinders, cross-heads, steam-chests, building up worn spots on wheels, rims and pins, welding spokes and locomotive frames, etc.

(Courtesy of the Oxweld Acetylene Co.)

Fig. 11.—Office Chair. Welded at all Joints.

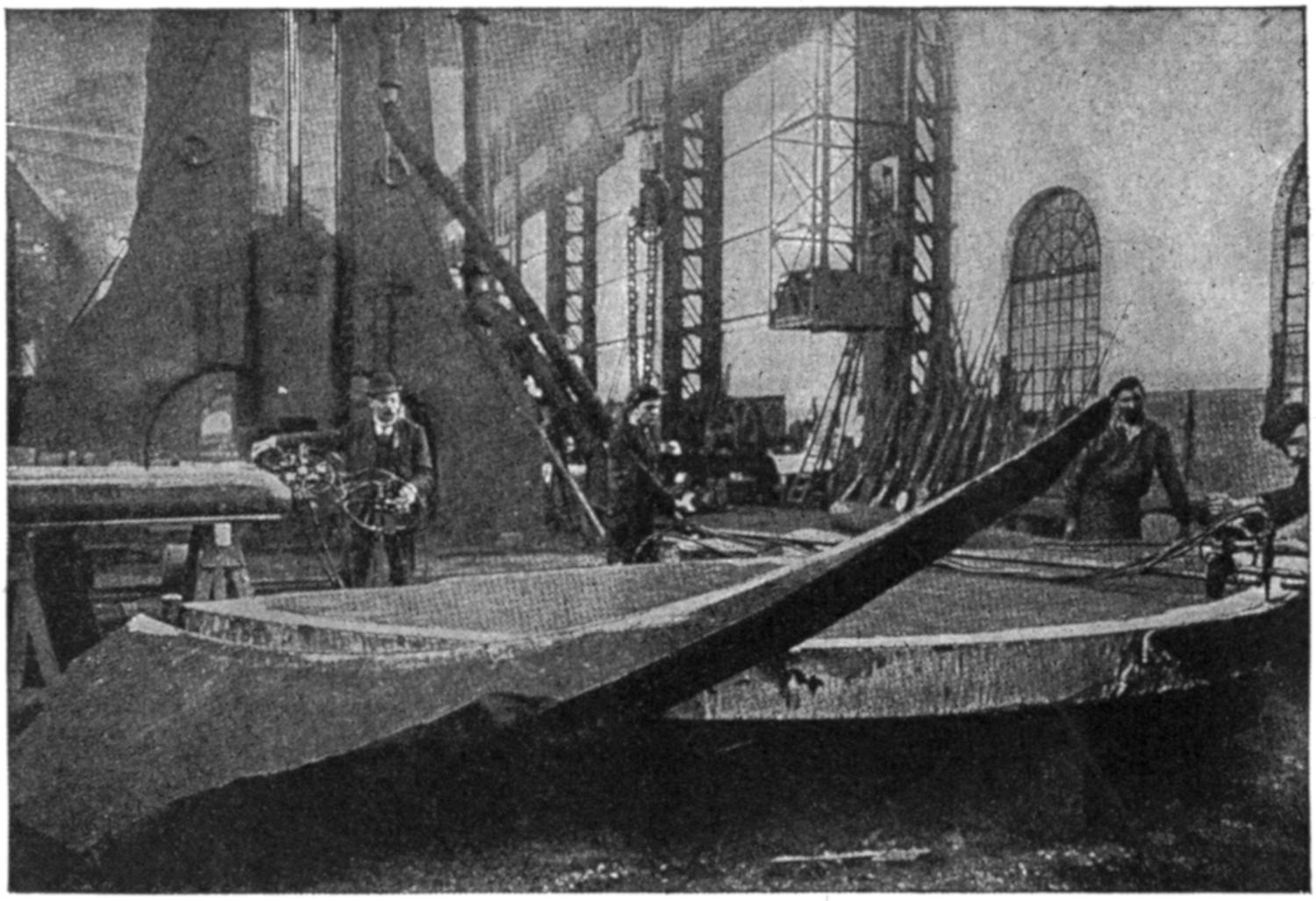

(R) Rolling Mills.—Fabricating “open-hearth,” water jacket doors, cutting up “lost heats,” scrap plates and bar stock billets. General repairs of furnace equipment, hot beds, rolls, gears, engines, plates, etc.

[15]

(S) Sheet Metal.—Manufacture of tubing, oil-storage barrels, metallic furniture, range boilers, etc.

(T) Shipyards.—Cutting off plates and irregular shapes of steel, channels, special sections. Building up of worn shocks, building and patching hulls, stringers and the reclamation of propellers, posts and broken parts of machinery, etc.

(U) Structural Steel.—Cutting holes for rivets, gussets and splice plates, and wrecking. Welding up misdrilled holes and machinist’s errors. Cutting channels, I beams, and other shapes for coping, splicing and fitting rails, welding reinforcing rods for concrete work of any desired length and structural parts where bolting and riveting is difficult or impossible.

(Courtesy of the British Oxygen Co.)

Fig. 12.—Cutting Armor Plate by the Oxy-acetylene Process.

(V) Scrap Yards.—Cutting up scrap boilers, tanks and other large work to mill size, wrecking structural buildings, and reducing to small size, reservoirs, tanks and boilers,[16] which are housed in buildings to remove them without damage to the structures.

(W) Tractor Industry.—Cutting and welding frames, track and wheel guards, water, gasoline, and oil tanks; welding up of blowholes, porous spots and misdrilled holes in castings of all kinds.

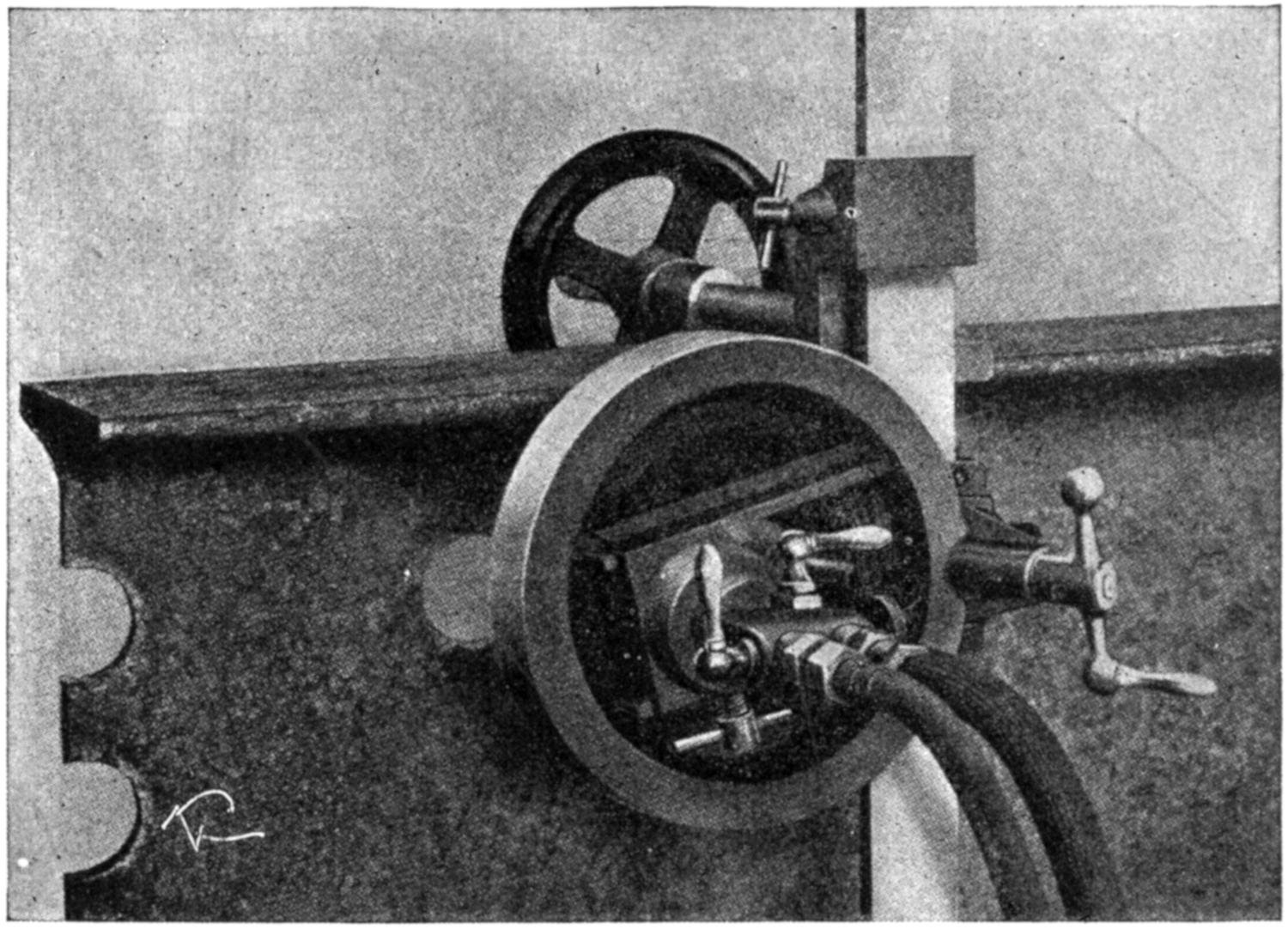

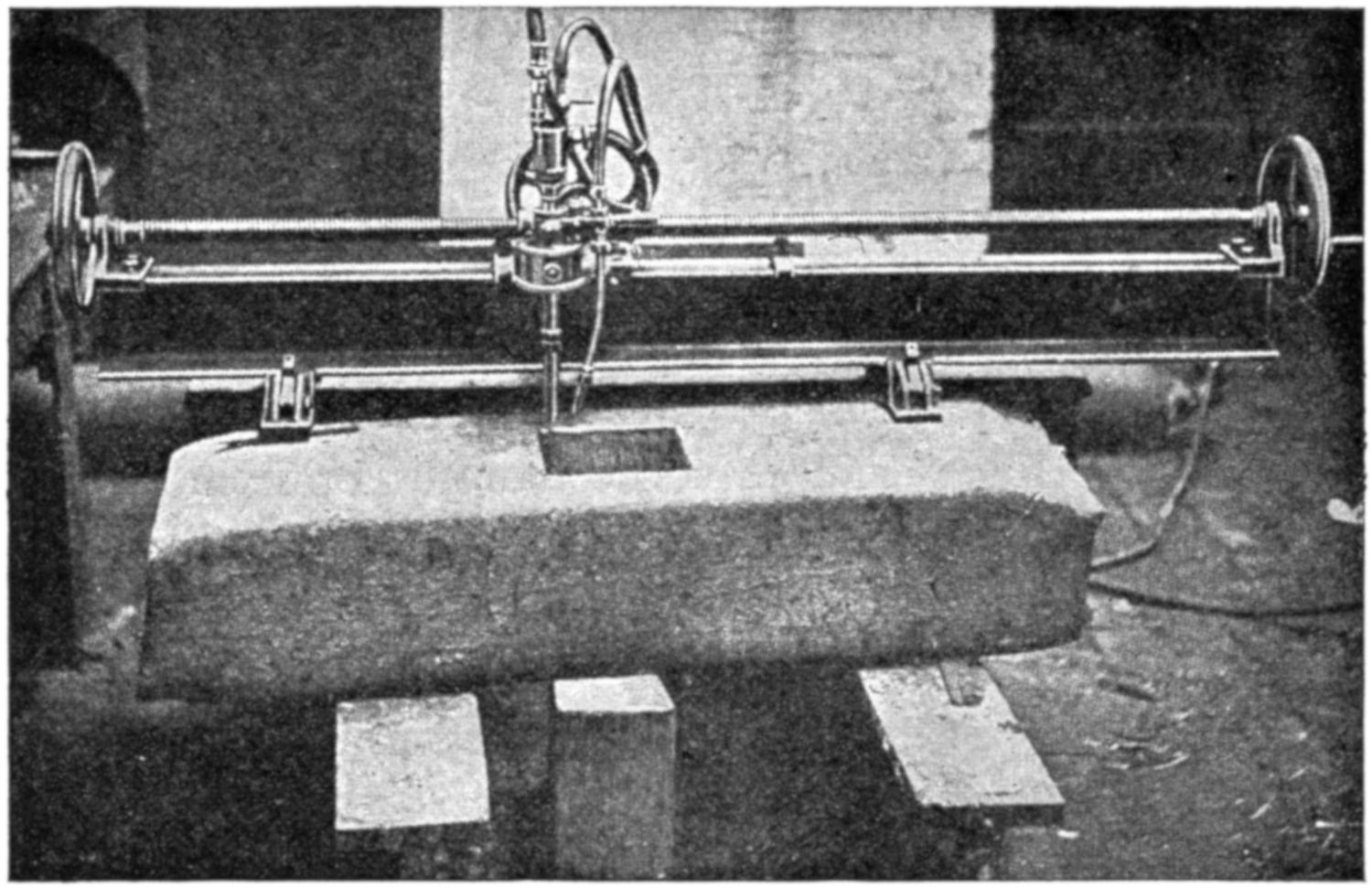

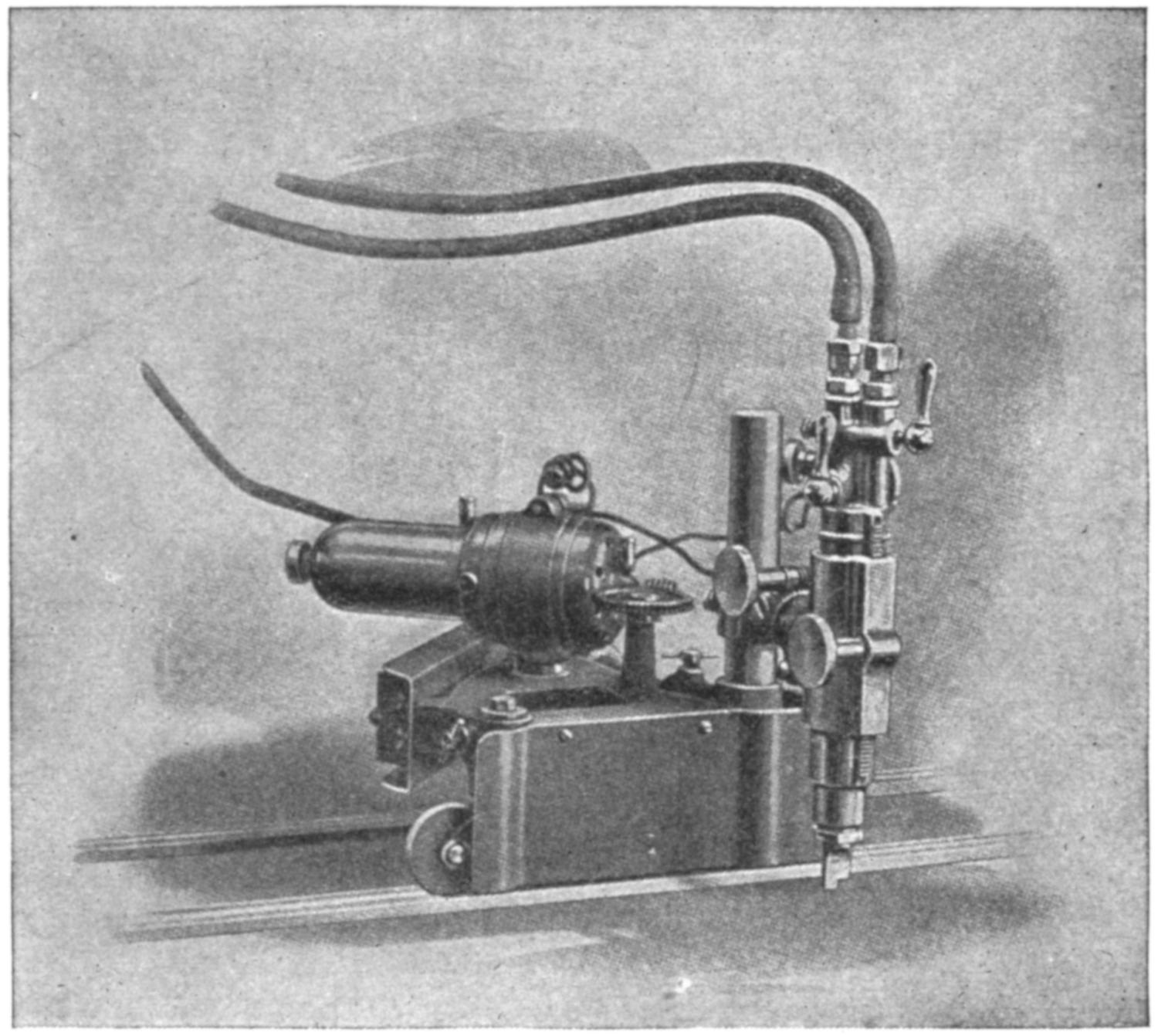

(Courtesy of the Davis-Bournonville Co.)

Fig. 13.—Here is Illustrated an Oxy-acetylene Machine for Cutting Holes in the Web of Rails, or in Structural Iron, of not more than ³⁄₄ Inch in Thickness. It can be Quickly Attached and Accurately Adjusted to Pierce through the Iron Instantly, without any Previous Drilling, and it will Cut Smooth Round Holes, from ¹⁄₂ to 2 Inches in Diameter in from 30 to 60 Seconds. It is Particularly Adapted for Railroad Work, and Enlarging or Cutting Holes in Building and Bridge Work.

(13) The foregoing, as previously stated, is but a partial list of some of the applications of the oxy-acetylene welding and cutting process to various industries. What has the[17] future in store for it? Almost daily, some new application is found for it and at the present time experiments are under way in boiler construction, the results of which are not difficult to foresee. Giant hulls of seagoing vessels are being fused together by welding and the limits of this wonderful process which is now practically in its infancy are difficult to forecast.

(14) During the World War many manufacturers of non-essentials shut down and others turned their entire production over to the government, changing their machinery and in most instances their entire plant. What, then, are those who are operating machines and apparatus, produced by these firms before the war, going to do for replacements? There is but one answer, have their broken or worn out parts welded.

(15) Oxy-acetylene operators have always numbered far less than the demand, a point which was clearly brought out by the government when its immense Army and Navy were being formed. There were so few men familiar with the oxy-acetylene process that it at once took measures to establish its own schools where men could be trained, a thing that the commercial world had been THINKING of doing for some years. As the demand for operators continues to increase, it behooves a man, even though he is not a metal worker, to think and apply himself, in order that he may “carry on,” to the best advantage when opportunity knocks.

(16) The methods of instruction herein set forth are very simple and while differing in many respects from those used by the trade, have been most successfully employed in producing efficient operators. Certain principles are instilled in the beginner and some of the exceptions which are of minor importance are overlooked to avoid confusion. Criticism is expected from those who have never engaged[18] in instruction of this kind on a large scale. There are many differences to be expected on account of this very fact, for there are few who have gone further than the instruction of very small classes where individual attention may be given.

(17) All history of the process, gas manufacture and the like have been omitted in order to give greater detail to the actual shop practice and to have the operator become familiar with his apparatus and thereby operate it with all due respect and intelligence.

(18) Oxy-acetylene welding cannot be learned by watching others work, although observation may at times assist the beginner. Actual torch practice, brain work and a power of “I will,” produce the most efficient operators. For those who earnestly apply themselves to the instructions which follow, there is every reason to believe that success will be theirs.

[19]

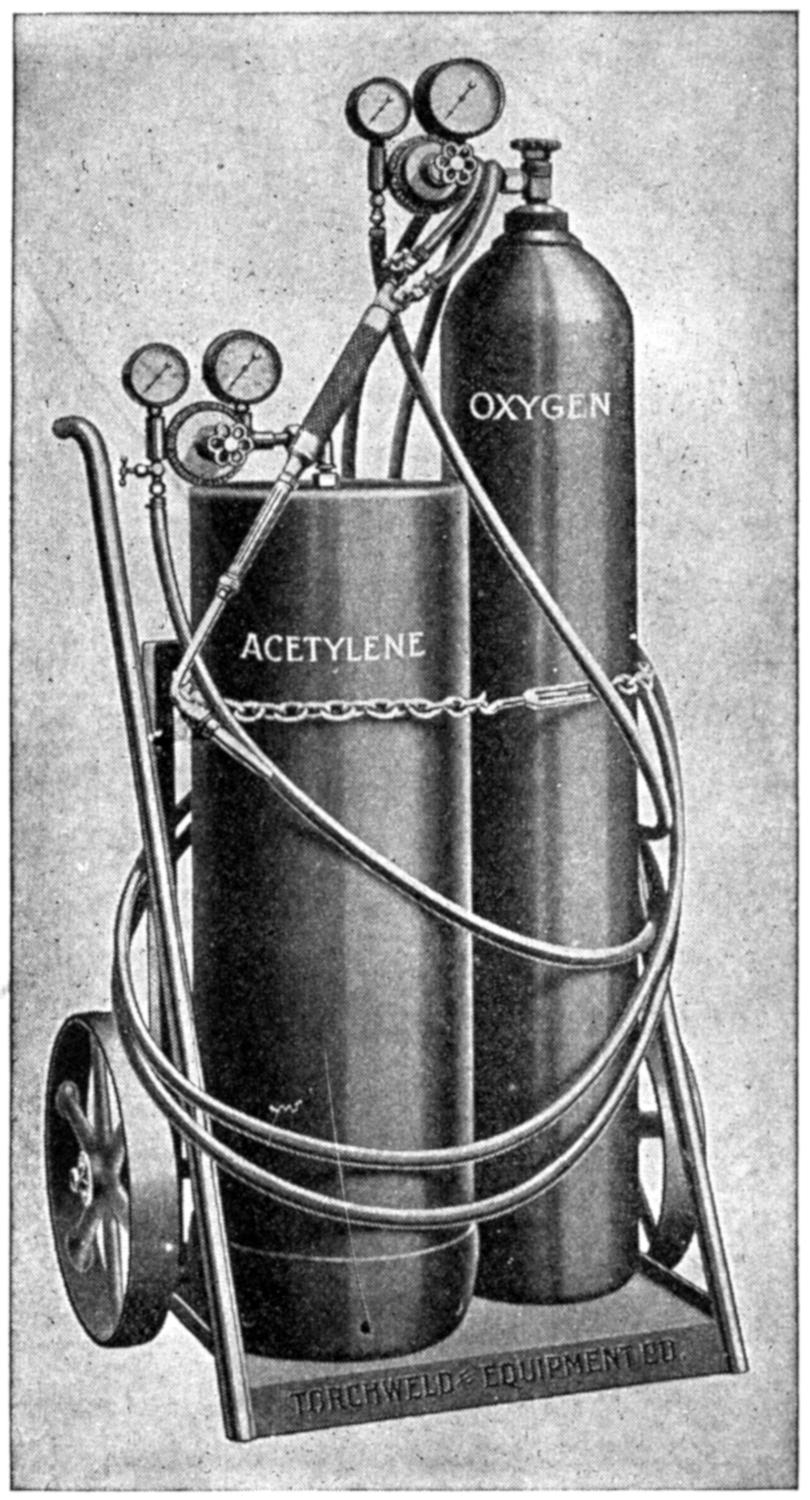

(19) Welding apparatus in general consists of two regulators equipped with pressure gauges, two lengths of hose, and a welding torch. The regulators are attached to cylinders of acetylene and oxygen and are used to reduce and maintain a uniform pressure of these gases for use at the torch. The gases at reduced pressure are conveyed to the torch by the hoses. The regulators should each have a high-pressure gauge to indicate the contents of the cylinder, and also a line or working-pressure gauge to show the gas pressure on each hose. When the gases reach the torch they are there mixed and combustion takes place at the welding tip, which is fitted to the torch. Such an apparatus is called portable, on account of its movability. There are other equipments wherein one or both of the gases are generated, but these will not be discussed here.

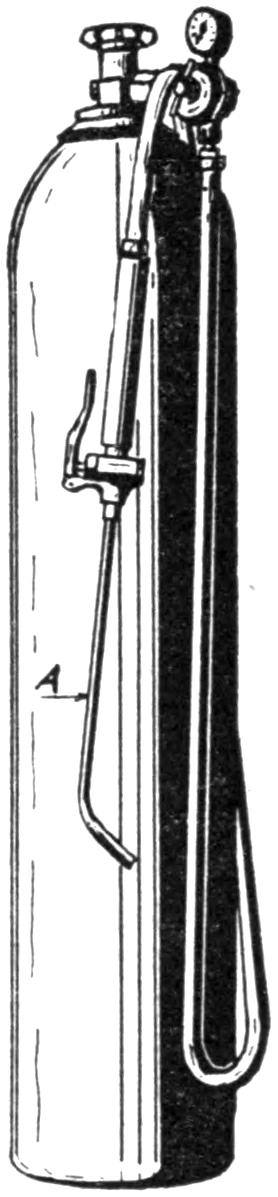

Fig. 14.—A Portable Welding Unit.

(20) For convenience oxy-acetylene welding apparatus may be divided into three classes, depending upon the principles used in securing the fuel gas or acetylene for the flame. Low-pressure, medium-pressure and high-pressure apparatus generally use about the same pressure of oxygen and it will be called a constant. The acetylene gas is a variable and in the low-pressure type only enough pressure is required to overcome the friction of the line until it reaches the oxygen injector, located in the torch, which acts as a syphon, drawing the acetylene gas to the point of ignition. In a medium-pressure type about three-fourths as much pressure[20] is required on the acetylene line as on the oxygen. This type is apt to verge on the injector type, as it depends to some extent upon the oxygen under pressure carrying acetylene gas to the point of ignition. In the high-pressure type equal pressure on each line is used. To further make this classification clear, a certain sized tip using, perhaps, 12[21] pounds of oxygen pressure can be used as an example. In a low-pressure type perhaps 2 pounds pressure or less will be needed on the acetylene line. On the medium-pressure approximately 9 pounds will be required, while on the high-pressure an equal amount, or 12 pounds will be needed.

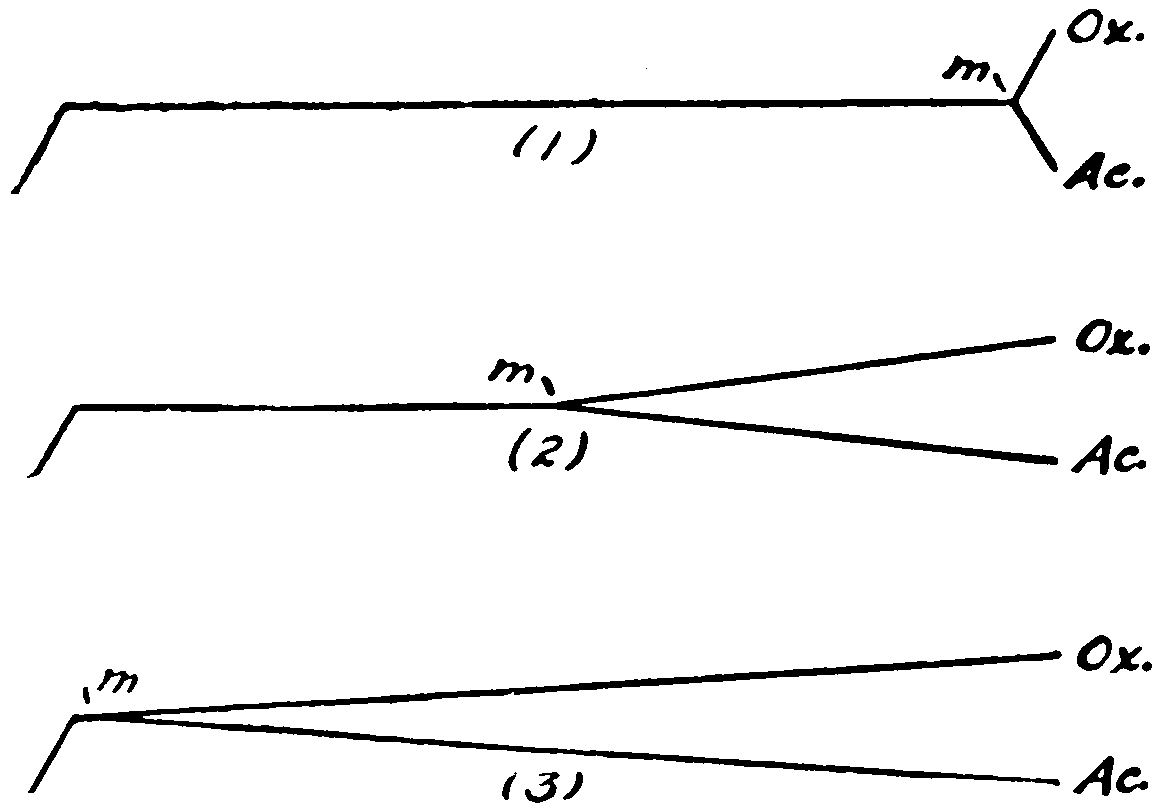

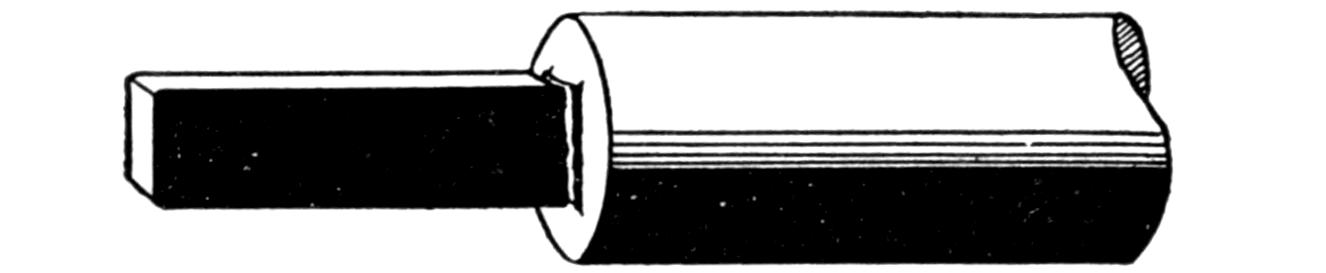

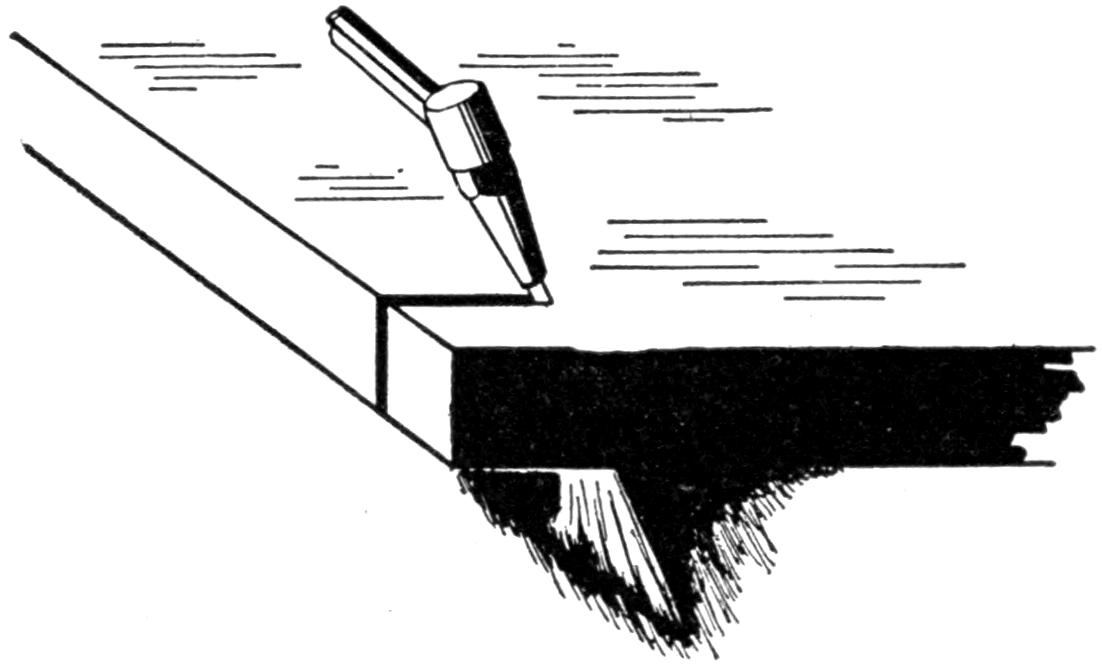

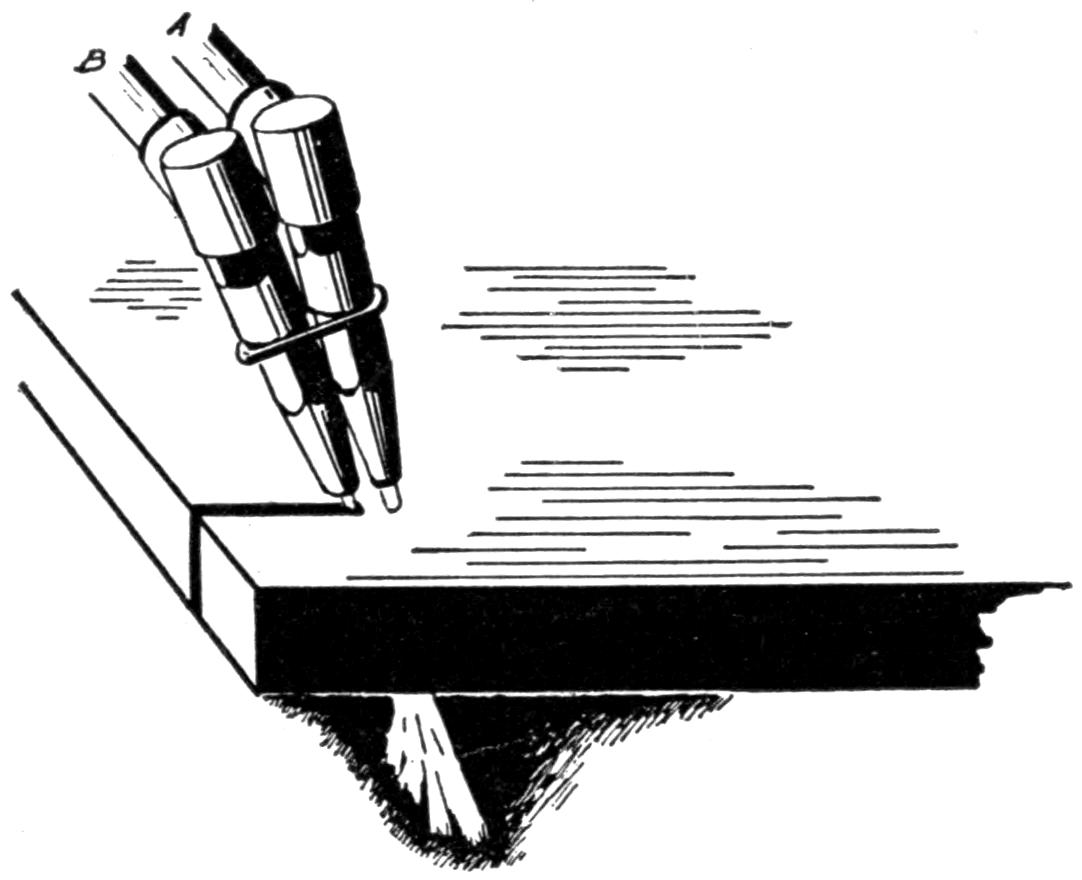

Fig. 15.—Location of Mixing Chambers in Welding Torches.

(1) Shows gases mixing in the handle. (2) Has the mixing chamber in the middle of the torch. (3) Illustrates how the gases are kept separate until the head of the torch is reached. Ox. represents oxygen gas; Ac. acetylene gas; and m mixing chamber.

(21) The mixing chambers for the gases may be located in the head; in the middle of the torch, or in the handle. By mixing chambers reference is made to that portion of the torch where the two gases are brought together and mixed. As can be seen with three different types of welding torches and three different locations for the mixing of the gases, the manufacturers can find a large range for producing oxy-acetylene apparatus. Some undoubtedly will fill certain requirements better than others. Much, too, will depend upon the ability of the operator in handling a torch.

(22) Flashbacks are caused by the improper mixture of the gases, which increases the rate of flame propagation to such an extent that the flame will flash back to the mixing chamber. Acetylene in a pure state will burn very much slower than when mixed with equal parts of oxygen. When[22] more oxygen is introduced the flame propagation is much greater, so that when an excess of oxygen is used, there is bound to be considerable trouble from backflashing. When sufficient acetylene is introduced to the mixing chamber, there is absolutely no chance for this lean mixture to occur. If the flame flashes back to the mixing chamber, both gases should be closed off immediately, at the torch, the oxygen first, and then the acetylene gas.

(23) In some torches the heating of the mixing chamber will cause a flashback and with these it is necessary to shut off the acetylene and leave the oxygen valve just cracked and immerse the torch head in water, dipping it slowly, so as not to cause too great a strain. The oxygen will bubble out and prevent the water backing up in the tip. If the flashback deposits enough soot on the inside of the tip and the head to impair the working quality of the torch, the soot should be removed by using a soft wire, preferably of copper, or some other material which will not mar the tip.

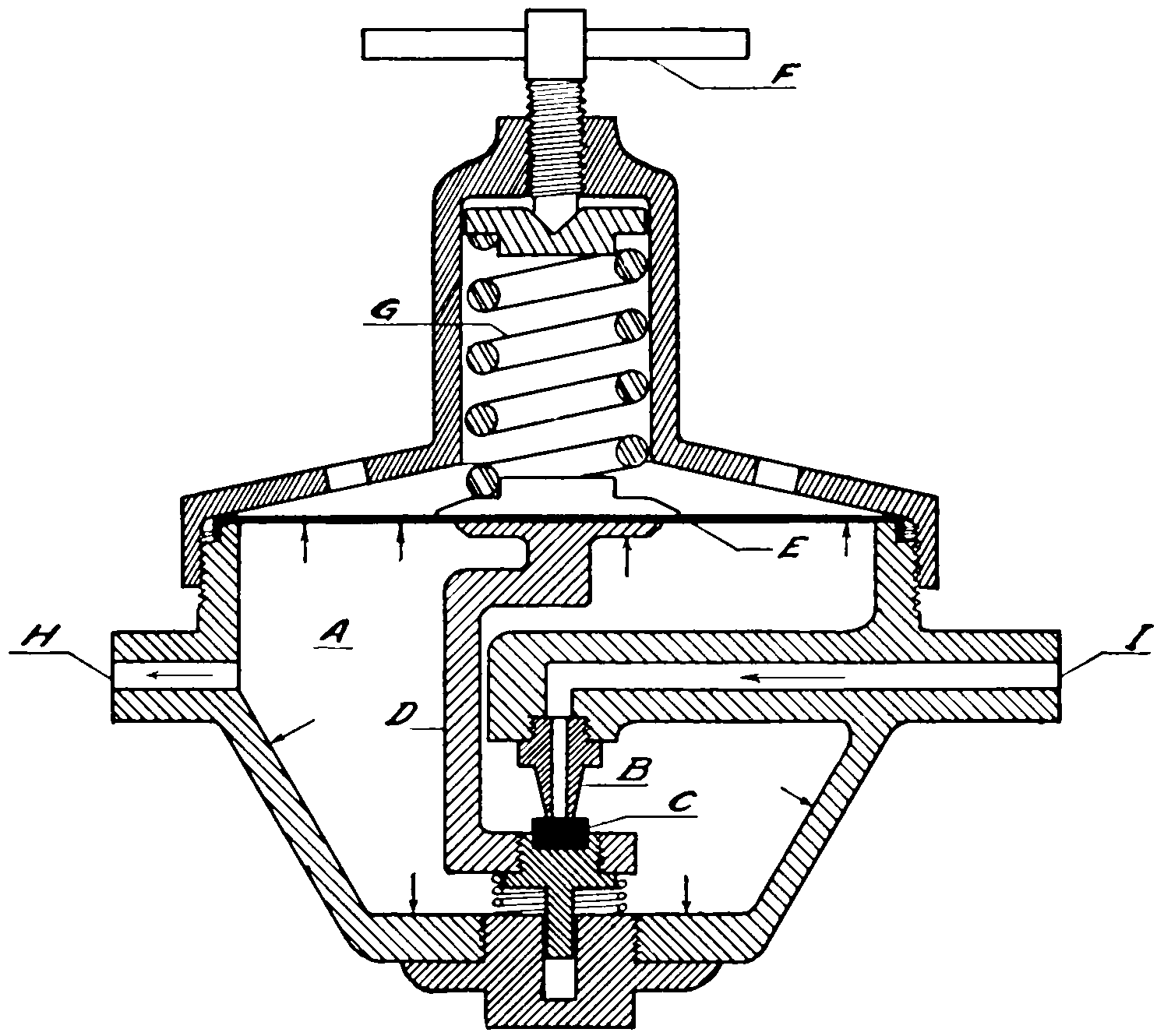

Fig. 16.—Cross-section of Regulator.

A, chamber; B, nozzle; C, seat; D, seat arm; E, diaphragm; F, cross-bar, or adjusting screw; G, diaphragm springs; H, gas outlet; I, gas inlet.

(24) It is interesting to note the action of a regulator, used to reduce the cylinder pressure on both gases. The gas from the cylinder, at high pressure, comes directly into the body of the regulator or chamber (A), Fig. 16, through a fine nozzle (B). A seat of gallilith, casenite, or fiber (C), attached to an arm (D), presses against this nozzle. Arm (D), in turn, is attached to a very sensitive diaphragm (E) and is moved every time there is a pressure exerted on the latter. The movement of this diaphragm is controlled by a handle or a screw, with a “cross-bar” attached to its end as is shown at (F). This screw bears upon the diaphragm through the medium of the springs (G). As this screw is forced inward the springs force the diaphragm in, and thereby move the seat away from the nozzle of the regulator. The gas, entering under high pressure, exerts an equal force on all parts of the chamber and the diaphragm[23] receives its share. Now the chamber walls are made of a solid material, usually a bronze or brass, and cannot be changed, but this diaphragm can be moved and as this pressure is increased, the diaphragm is forced out and the nozzle (B) is automatically closed by having the seat (C) brought in contact with it. When gas is drawn off through the line (H), the pressure within the chamber will naturally drop and as it does so, the springs will force the diaphragm inward, permitting a replacement of the gas drawn off. Although not noticeable, there is a continual movement of this diaphragm whenever the gas is being used. It can be readily seen that the amount of pressure within the regulator can be accurately set by the tension of the spring against the diaphragm which is controlled by the screw carrying the “cross-bar.”

[24]

(25) There are two types of regulators manufactured for the reduction of gases under high pressure, depending upon the nature of work to be done. The high-pressure regulator is employed for heavy work where a great deal of gas is used and the regulator must pass it without much effort, to prevent its freezing. This type of regulator is used on cutting or on large welding work. It differs from the low-pressure or ordinary type in four distinct features. Generally it contains a much heavier diaphragm which is smaller in diameter, making it stiffer in every respect. The tension springs which act upon this diaphragm are much heavier. The nozzle which presses against the seat is much larger, to permit the passage of a greater amount of gas. Then, too, a larger working pressure gauge must be used, in order to read this high pressure. In the welding of metals, especially in steel, the adjustment of the flame is a very important matter, and absolutely dependable regulation must be had. This is not possible with a high-pressure regulator and is not intended to be so. The larger the diaphragm, the more sensitive the regulator, and this point should be borne in mind, and no small welding work attempted with the high-pressure regulator. The reverse form of reasoning may be applied to low-pressure regulators which have been used in cutting. They are very likely to be strained and satisfactory results cannot be expected, for they are not made for that purpose. Acetylene regulators are constructed much more sensitively than the oxygen regulators, to take care of the lower pressure of gas and in a sense might be called weaker, insomuch that the larger nozzle which passes the gas is closed or regulated by springs which are not nearly as strong as in the oxygen regulator. For this reason acetylene regulators cannot be interchanged with oxygen regulators for they will not stand the pressure demanded in the first place, and in the second place, were a small quantity of[25] acetylene gas left in the regulator and oxygen introduced, an inflammable mixture would be formed which is not advisable to have present, on account of its explosiveness. In many instances oxygen regulators are put out with the copper diaphragms, whereas another metal must be used on the acetylene regulators, because acetylene gas attacks copper and usually a German silver or rubber diaphragm is used. On account of the lower pressures used in charging the acetylene cylinders, lower pressure gauges are used than on oxygen regulators.

(26) All tension should be removed from the diaphragm springs by screwing out on the “cross-bar” (that is, to the left), before admitting gas under pressure to the regulator to avoid abusing the seat. If a matter of 1800 pounds pressure were admitted suddenly into any regulator that had the seat removed from the nozzle, there would be a sudden exertion upon the diaphragm, which would draw the regulator seat up very violently against the nozzle, and if it did not crack the seat it would undoubtedly groove it to such an extent that it would leak and a trouble known as “creeping regulator” would result. If this occurs, good work cannot be expected because the flame will not remain steady, and it is therefore necessary to take steps to rectify this abuse. If there is a welding company available, the regulator should be sent to it for repairs, but if the operator is in an isolated district when this occurs, and must have some means of continuing work, it will be possible for him to remove the seat by unscrewing the back of the regulator. If the seat has become grooved, and he thinks that this is the trouble, many times the seat can be turned over and the machined surface on the other side used. If the seat is cracked, however, about the quickest way of making an emergency repair is to turn out a new seat from hard rubber or fiber on a lathe.

[26]

(27) In acetylene cylinders an absorbent called acetone is generally used, which gives up the gas as required. A full cylinder can be used for some time without any noticeable difference in the gauge reading, and then, as it nears the empty point, the gauge reading will drop very perceptibly. It is therefore impossible to depend upon a high-pressure acetylene gauge as an index to the contents of the cylinder. The only method known to correctly check the amount of acetylene gas on hand is to weigh the cylinder. There are 14¹⁄₂ cubic feet of acetylene gas to the pound, and when the net weight of the cylinder is given the contents can readily be figured. A tag bearing the net weight or figures which will permit its computation is generally found attached to each acetylene cylinder. In the case of oxygen cylinders, there being no absorbent used, the contents of the cylinder is indicated on the high-pressure gauge. On the latest type gauge the contents will be shown by cubic feet, by pounds pressure and by atmospheric pressure, to facilitate the computation of costs by the operator.

(28) Occasionally a needle valve on a torch will begin to leak and it will be found necessary to grind it. Realizing that oil and grease are not to be used where oxygen is in evidence, the question is often brought up as to the proper lubricant to be used in doing this kind of work. Glycerine is used by most manufacturers, together with powdered glass or flour emery. In doing work of this kind the finished job is thoroughly washed with ether. Occasionally when piping oxygen lines through the shop, a screwed coupling will leak and there is a temptation to calk the same with white lead, but this should never be done, rather use lead oxide mixed with the glycerine for this purpose as it forms a paste which sets very rapidly and forms a hard, tough compound.

[27]

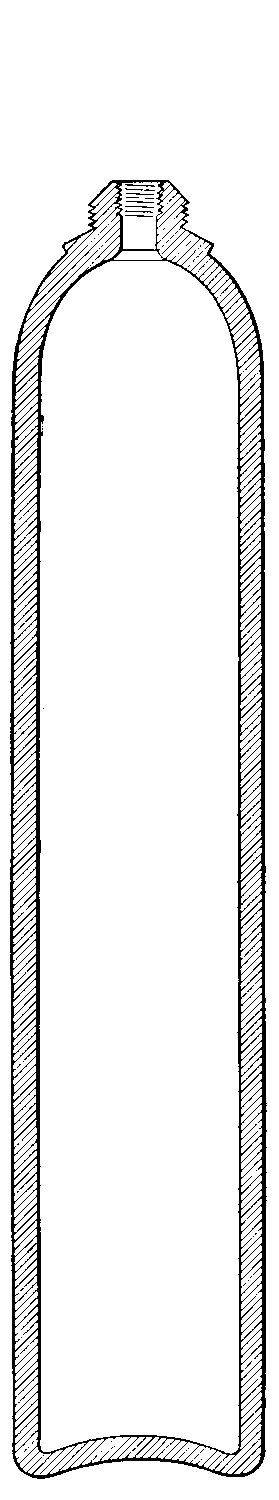

(29) In oxy-acetylene welding there are two gases used, as the name would indicate, namely, oxygen and acetylene. The first is used to intensify the flame and can in nowise be likened to the inflammable nature of the second. There is a great deal of oxygen present in the air we breathe. It is an odorless, tasteless, and colorless gas, as most of us are aware. In the commercial world oxygen is manufactured by the decomposition of water into its elements, oxygen and hydrogen, by the electrolytic process or is taken from the air by a reduction process and is stored in steel-drawn cylinders. These cylinders are drawn out of one piece of steel and are of considerable thickness throughout, having absolutely no seams, welded or otherwise. There is no filler nor absorbent used on the inside of these cylinders, as pure oxygen under pressure is not considered dangerous. The standardized sized oxygen cylinder is one which contains 200 cubic feet of gas fully charged. Oxygen is compressed in these cylinders at a pressure of 1800 pounds, at normal temperature, and this pressure does not vary to any great extent with change in temperature (as shown by table on page 29). There is attached to the tip of the steel cylinder, or “bottle,” as some workers call it, a double seating valve which has one seat operate when the cylinder is closed, and the other when the cylinder is wide open. A regulator is attached to this valve when working.

[28]

Fig. 17.—Sectional View of Oxygen Cylinder without Valve.

(Courtesy of the Linde Air Products Co.)

Fig. 18.—A Standard 200-foot Oxygen Cylinder.

[29]

TABLE SHOWING THE DIFFERENT PRESSURES OF OXYGEN—AT VARIOUS TEMPERATURES

| Temp. Deg. Fahr. |

Press. Lb. Per Deg. |

Temp. Deg. Fahr. |

Press. Lb. Per Deg. |

Temp. Deg. Fahr. |

Press. Lb. Per Deg. |

Temp. Deg. Fahr. |

Press. Lb. Per Deg. |

|---|---|---|---|---|---|---|---|

| 0 | 1568 | 25 | 1654 | 50 | 1739 | 75 | 1824 |

| 1 | 1572 | 26 | 1657 | 51 | 1743 | 76 | 1828 |

| 2 | 1575 | 27 | 1660 | 52 | 1746 | 77 | 1831 |

| 3 | 1579 | 28 | 1664 | 53 | 1749 | 78 | 1835 |

| 4 | 1582 | 29 | 1667 | 54 | 1753 | 79 | 1838 |

| 5 | 1585 | 30 | 1671 | 55 | 1756 | 80 | 1842 |

| 6 | 1589 | 31 | 1674 | 56 | 1760 | 81 | 1845 |

| 7 | 1592 | 32 | 1678 | 57 | 1763 | 82 | 1848 |

| 8 | 1596 | 33 | 1681 | 58 | 1766 | 83 | 1852 |

| 9 | 1599 | 34 | 1684 | 59 | 1770 | 84 | 1855 |

| 10 | 1603 | 35 | 1688 | 60 | 1773 | 85 | 1859 |

| 11 | 1606 | 36 | 1691 | 61 | 1777 | 86 | 1862 |

| 12 | 1609 | 37 | 1695 | 62 | 1780 | 87 | 1865 |

| 13 | 1613 | 38 | 1698 | 63 | 1784 | 88 | 1869 |

| 14 | 1616 | 39 | 1701 | 64 | 1787 | 89 | 1872 |

| 15 | 1620 | 40 | 1705 | 65 | 1790 | 90 | 1876 |

| 16 | 1623 | 41 | 1708 | 66 | 1794 | 91 | 1879 |

| 17 | 1626 | 42 | 1712 | 67 | 1797 | 92 | 1883 |

| 18 | 1630 | 43 | 1715 | 68 | 1800 | 93 | 1886 |

| 19 | 1633 | 44 | 1719 | 69 | 1803 | 94 | 1889 |

| 20 | 1637 | 45 | 1722 | 70 | 1807 | 95 | 1893 |

| 21 | 1640 | 46 | 1725 | 71 | 1811 | 96 | 1895 |

| 22 | 1643 | 47 | 1729 | 72 | 1814 | 97 | 1900 |

| 23 | 1647 | 48 | 1732 | 73 | 1818 | 98 | 1903 |

| 24 | 1650 | 49 | 1736 | 74 | 1821 | 99 | 1906 |

| 100 | 1910 |

Fig. 19.

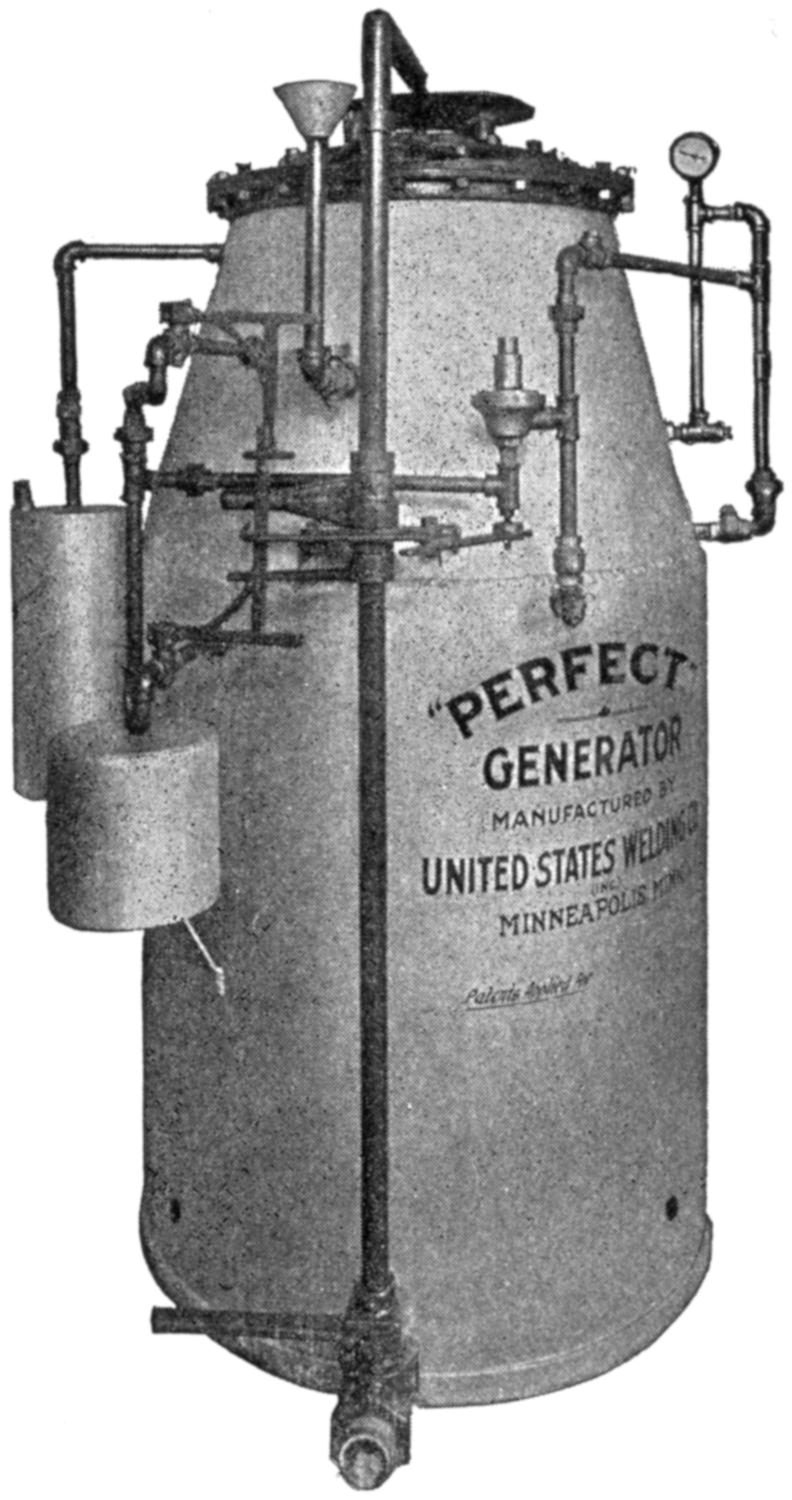

(30) Acetylene is the fuel gas, and is one of the greatest containers of heat known. Burning in a free state, its carbon content is so rich that complete combustion is impossible, and stringy black particles will be noticed floating through the air. In order to fully combust this gas, oxygen is introduced under pressure and a temperature of over[30] 6000 degrees Fahrenheit is obtained. (Acetylene contains about five times as many B. T. U.’s (British Thermal Units) as hydrogen.) This gas, unlike oxygen, becomes very dangerous when in a free state it is subjected to an excessive pressure. The slightest jar may cause its disintegration and a violent explosion follows. On account of this danger, acetylene is not stored in a free state; neither is it subjected to very high pressures. Its cylinders are put[31] out by various manufacturers to comply with the laws and regulations of the Interstate Commerce Commission. Some of these cylinders have been welded, but the most modern method is to make them of one piece of drawn steel. They are then filled with an absorbent of some kind to take up the gas and prevent any portion of it being left in a free state. Acetone is the popular absorbent, and is a liquid capable of absorbing twenty-five times its own volume of acetylene gas at normal pressure. The filling material varies with each of the manufacturers, but charcoal, asbestos and mineral wool are in very common use. Acetylene is obtained from calcium carbide brought in contact with water, or vice versa, and is compressed and then stored in the cylinders at a pressure varying from 150 to 250 pounds. When fully charged this pressure will vary almost directly with any change of temperature. Acetylene cylinders for welding are available in 100, 200, 225, and 300 cubic foot sizes.

Fig. 20.—A Generator for Producing Acetylene under Pressure.

(31) In setting up apparatus for the first time, the regulator containing the 3000-pound gauge is attached to the taller of the cylinders, which holds the oxygen gas, and the other regulator is fastened to the shorter cylinder. The hoses, which should be cleared of all powder or scale on their interior, are then added. The black hose should connect the oxygen regulator to the torch valve, marked “OX” and the red hose, the acetylene regulator to the torch valve stamped “AC.” In attaching regulators to full cylinders the “cross-bar” on the regulator should always be turned out, that is to the left, until it turns freely, to insure all pressure being released from the diaphragm, before the cylinder pressure is turned on. Another precaution that should be observed is the “cracking” of the cylinder valves, before attaching the regulator, in order to blow out any dirt or foreign particles that may be lodged there, otherwise they will be carried into the regulator seat,[32] or lodged in some small passage, which will impair the working of the apparatus. Then too, if no truck or clamping device has been provided, both the oxygen and acetylene cylinders should be securely clamped or wired together, a rule which should be insisted upon at all times, whether in a job shop, manufacturing concern, or training school, or any place where top-heavy oxygen cylinders are being used. No particular harm results if these cylinders are turned over, which is very easily done on account of their rounded base, if no regulator is attached, but very frequently regulators are attached and the hose connecting the same to torch is found in the operator’s way. The slightest pull or tripping on this hose will upset the cylinder, usually demolishing the regulator and expensive gauges and at times causing much confusion among the workmen, on account of the loud hissing noise given off by the escaping gas. Always secure the drums or the cylinders in a safe manner.

(32) In turning on the gas, the oxygen valve is opened wide until seated and the acetylene valve is only partially opened. Often the question is raised as to where the operator should stand, especially when dealing with high-pressure oxygen. It is recommended that the operator should stand at the side and towards the rear when performing this operation, for sometimes an unreliable gauge may be attached, which if bursting, would send the glass into the operator’s face.

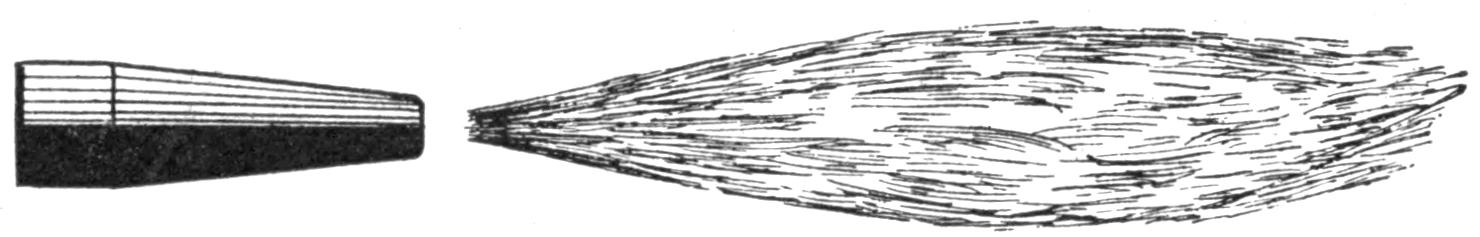

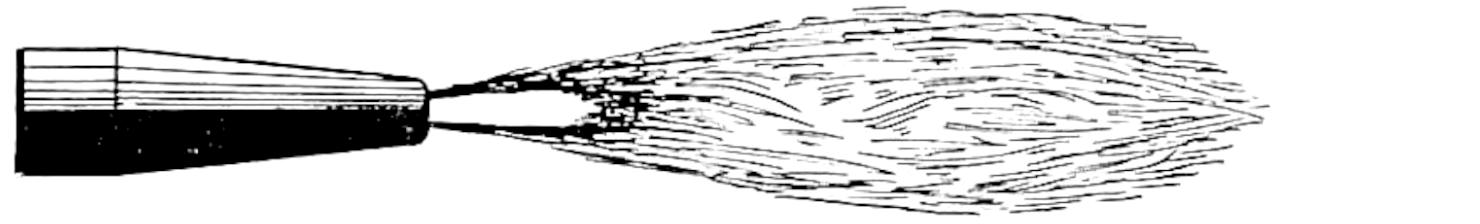

Fig. 21.—Acetylene Flame Blowing away from Tip.

Fig. 22.—Addition of Oxygen to Acetylene Flame.

Fig. 23.—More Oxygen Pressure Applied. Flame Contains Slight Excess of Acetylene, and is Known as “Carbonizing.”

Fig. 24.—“Neutral” Flame. Correct Proportions of Oxygen and Acetylene Gases.

Fig. 25.—“Oxidizing” Flame. Too much Oxygen Present.

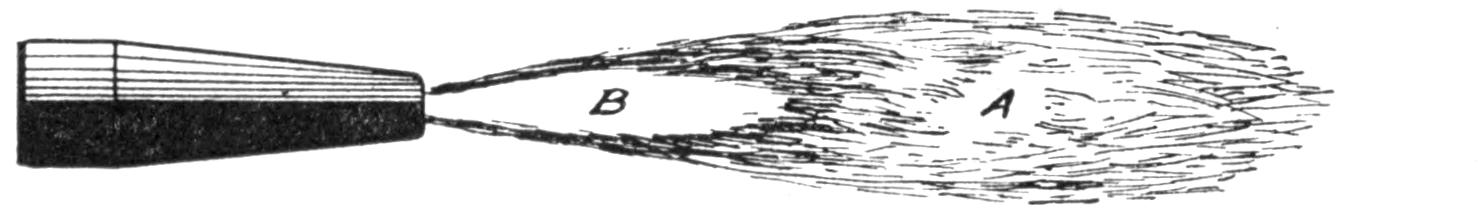

(33) As soon as an operator has gas pressure in his regulators, he begins wondering how much pressure should be placed on his line, that is, the portion between the regulator and the torch. Of course, this depends upon the size of the tip, but the operator should have some means of approximating this pressure without going to his manufacturer’s chart every time. A neutral flame, that is, theoretically equal parts of oxygen and acetylene, is desired for welding.[33] Now in lighting, the flame should stand away from the tip a slight distance, in torches other than the low-pressure type, while in these there will only be a good full flame issue from the tip. Enough oxygen must be in evidence to bring this acetylene flame down to the neutral point. If not enough pressure is used, this result cannot be obtained, and of course, more pressure must be introduced. It is better to have too much pressure than not enough on the line, for the operator may use his torch valve to again regulate this pressure and is always sure of enough gas. Theoretically, all adjustments should be made at the regulator, but in practice this is very seldom carried out. The accompanying cuts will illustrate the five conditions which every welder should be familiar with, in the flame adjustment. Fig. 21 shows the acetylene turned on full; no oxygen has as yet been introduced. The flame has a yellow appearance and is very rich in carbon, as can be seen by the soot given off. In Fig. 22 we see the oxygen being turned on; the yellow flame (A) is gradually giving way to a white part at (B). In this condition we say that a feather flame exists. Fig. 23 shows slightly more oxygen pressure. In Fig. 24 we have the neutral flame, which can be readily recognized on account of its bluish white color and well-defined outline,[34] appearing like the end of an unused piece of chalk, only, of course, much smaller. In Fig. 25 can be seen an excess or too much pressure of oxygen. It will be noticed that the neutral flame assumes a more bluish color, is a little pointed, and a very noticeable hissing sound is in evidence. This is what is called an oxidizing flame and will be again referred to. Too much oxygen is used. Operators who attempt to turn on the oxygen first and then light it, will find that it does not burn, and their efforts will be useless. In picking up a torch for the first time, any operator can turn on one valve and detect by the odor of the gas, whether it is oxygen or the fuel gas, and can light it in accordance. Some operators, however, attempt to turn on a little of each gas and light. This is not to be recommended, for flashbacks may occur. When the welder accustoms himself to turning on enough pressure to accommodate whatever sized tip he may have, he will find that there is no great need for paying attention to the pressure gauges on his regulators[35] except to check up on the full drums of oxygen, and to tell whether he has enough gas left to complete a certain piece of work.

(34) A neutral flame is theoretically composed of equal parts of oxygen and acetylene ignited, but this ratio is very seldom worked out in practice. There is usually an excess of oxygen in evidence. A neutral flame is generally spoken of as being over 6000 degrees Fahrenheit, and this does not vary with the different sized tips as most welders think. Of course there are different quantities of heat between a very small tip and a large sized one, but the temperature of the flame is the same.

(35) If too much acetylene gas is used, a feather flame such as was seen in Fig. 23 will appear. This has a carbonizing effect on the weld, for it introduces carbon and causes the weld to become very brittle.

(36) If too much oxygen gas is used, the effect shown in Fig. 25 will take place, and the weld will have oxygen introduced, which is a very detrimental feature, and is particularly noticeable in working on steel, for it raises a white foam over the surface of the melted metal, which sometimes is worked right into the weld itself. An experienced welder will always know just what kind of a flame action he is obtaining on his weld, not because he takes the flame away every time he wishes to look at it, but he can tell by the action of his metal exactly the nature of his flame.

(37) Infra-red (heat) and ultra-violet (light) rays present to a small extent in the neutral flame are injurious to the naked eye. Colored glasses or goggles are used to shield the eyes when working with this flame. Too dark a glass should not be used, as it will cause a strain upon the eyes more injurious than the flame. Exposed metal frames should be avoided too, as they hold the heat and burn the operator.

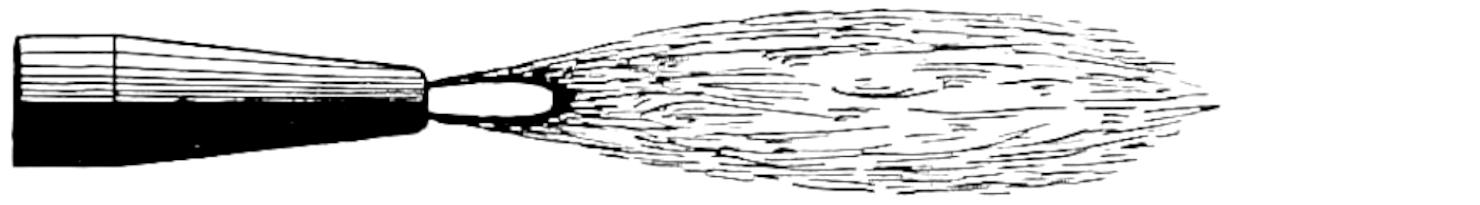

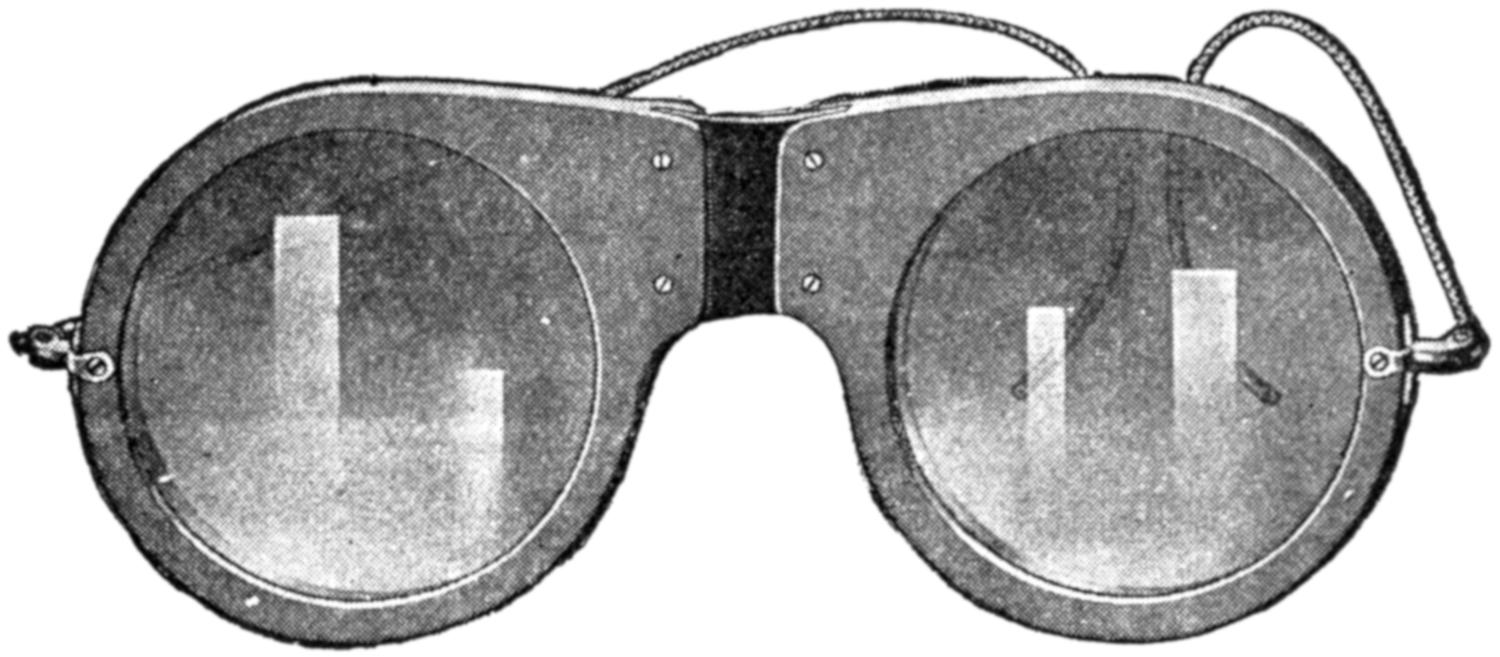

(Courtesy of the Chicago Eye Shield Co.)

Fig. 26.—A Spectacle Made for Welders, having a Frame of Fiber and Arranged so that Lenses may be Replaced.

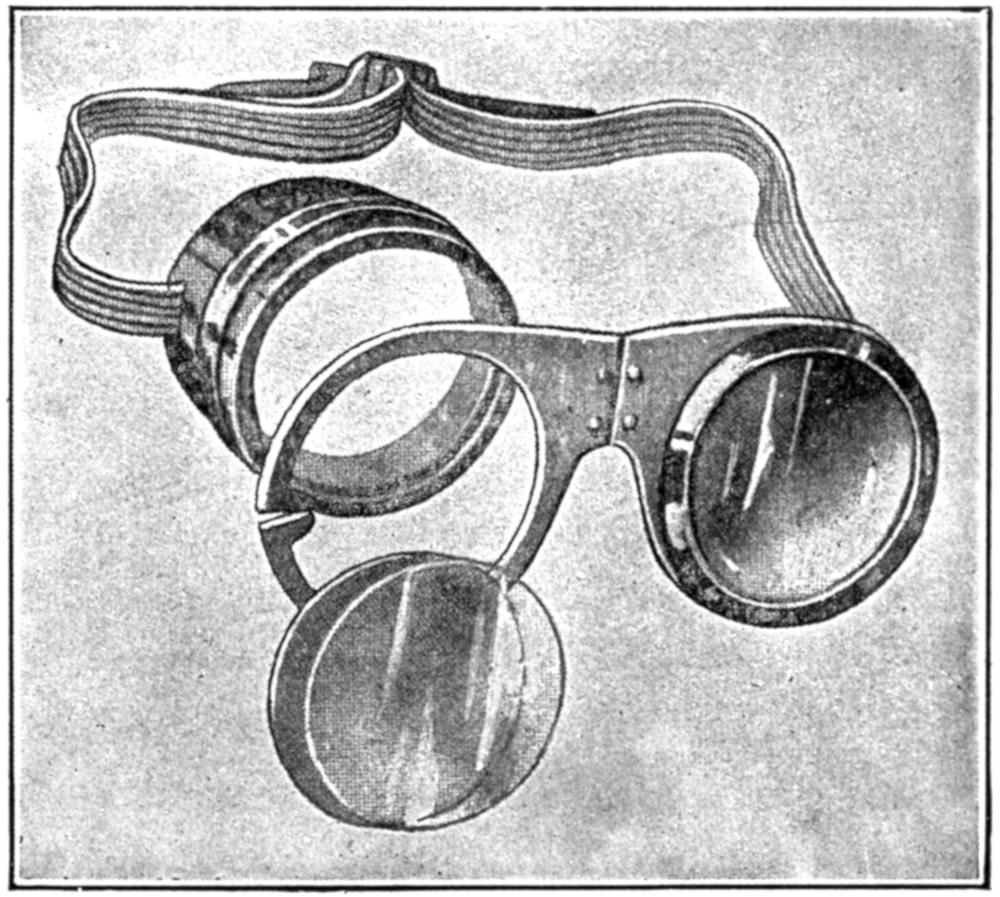

(Courtesy of the Chicago Eye Shield Co.)

Fig. 27.—Showing Cover Glass which Protects the Colored Lens and the Replaceable Features of a Modern Goggle.

(38) To shut off the apparatus for several hours or so,[36] it is best to relieve all pressure from the lines, such as hose and so forth, and to do this close both tank valves; open the torch valves; release the tension on the regulator, by screwing the “cross-bar” to the left, and finally, close the torch[37] valves. It is quite necessary that these torch valves closed, for quite frequently, if a small tip is in the torch and an excess of oxygen pressure comes through the line, when both torch valves are open, much of the oxygen may back up the acetylene line and cause a serious flashback when lighting up. This can be avoided by keeping both torch valves closed when not in use.

(39) If a valve on an empty acetylene cylinder is left open the acetylene gas will escape, and mixing with the air, which is a supporter of combustion, a very inflammable mixture will be formed. If any fire is present, such as might be smouldering in a forge, possibly not used for several hours or so, or a match lighted, or a flame started in any way, an explosion is likely to occur. When an acetylene cylinder is exhausted, as far as possible, in a moderately high atmospheric temperature, then shut off for a while and the temperature drops, air will be drawn into the vacuum thus formed when the valve is again opened. In this manner an explosive mixture forms in an empty acetylene cylinder and is certainly to be avoided. Care should be taken, especially in winter, to guard against such occurrences, as in some outlying shops a decided change in temperature takes place between closing time and starting up time the following morning. Acetylene tanks should always be securely closed when empty, not only for the above reasons but insomuch that each contains acetone, which is likely to escape if the tank is thrown around. Acetone is very costly and used extensively in the manufacture of smokeless powder, so that at times it is hard to replenish.

(40) Oxygen has an affinity for oils and greases, and should not be allowed to come in contact with them, especially in confined places, as a spontaneous combustion may result. Oils and greases should never be used around oxy-acetylene welding apparatus and on nearly every apparatus on the[38] market the words “Use no oil,” will be found. Despite this precaution, however, many times ignorant operators will be found squirting oil into the holes around the regulator cap, and through the gauges, in order, as they say, to allow them to work easier. This use of oil should be discouraged, and the sooner the better.

[39]

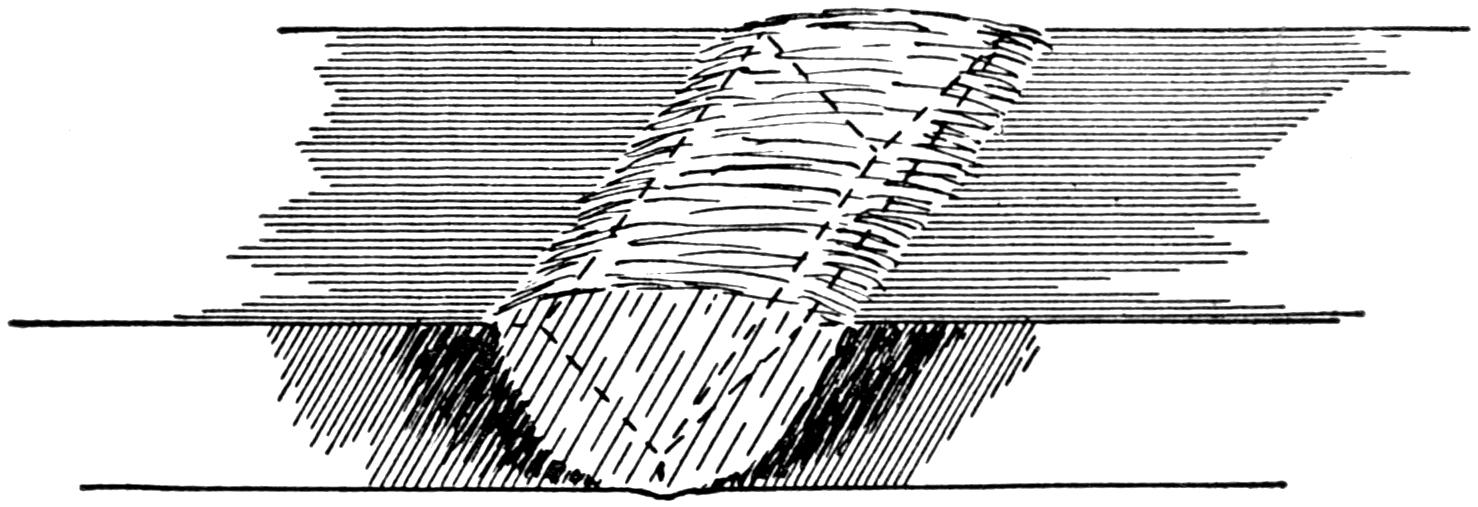

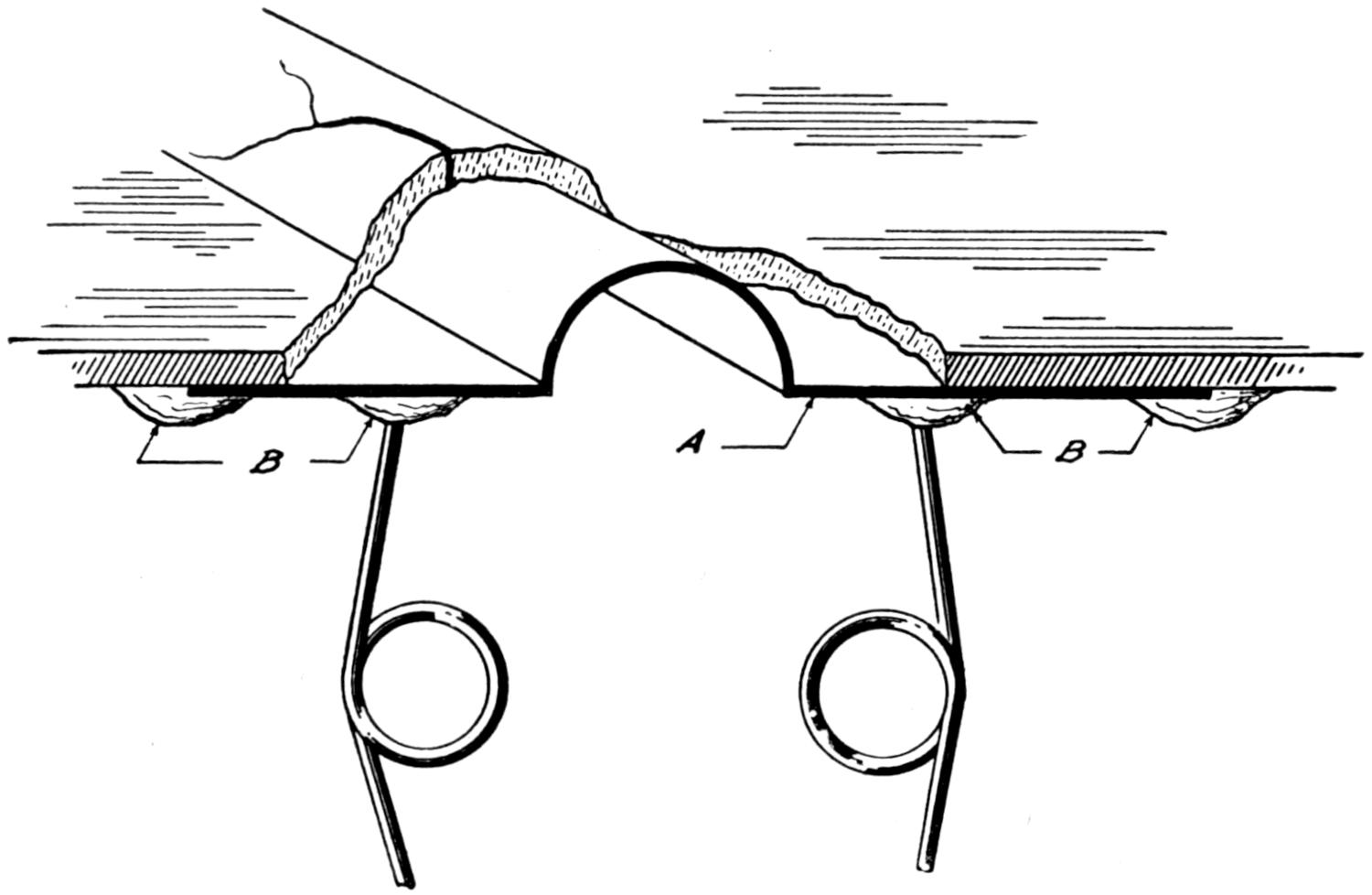

(41) In equipping a shop for welding, in addition to the welding apparatus, the operators are many times undecided whether it is advisable to have a planed metal or a brick top table to use for welding purposes; each has its advantages, but were there a choice of one or the other, it is suggested that the brick-top table be used. The theory of having a planed metal top for lining up work does not prove as satisfactory in actual practice as might be expected, for the simple reason that the average welder generally places his metal in direct contact with this cold top, and much of the heat which is supposed to go into the weld is conducted away by the table top, producing a hard, brittle weld. In the case of cast iron, these welds are generally porous. Then too, the operator to a large extent depends upon the table top for lining up his work and does not study his contraction and expansion as thoroughly as he might. The result is that many of his pieces warp in cooling. To rectify the first objection it is advisable to cover the table top with asbestos paper as shown in Fig. 28. In the second place, sometimes clamps are used to hold the work in position. Preheating without a layer of bricks on a metal-topped table is not to be recommended.

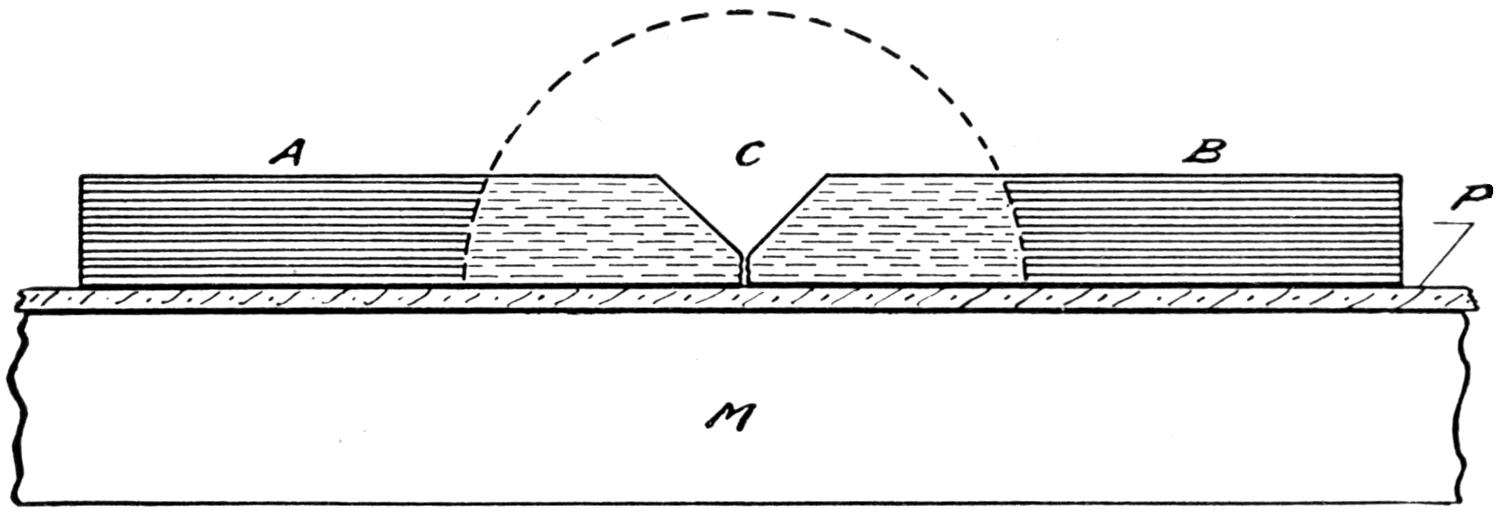

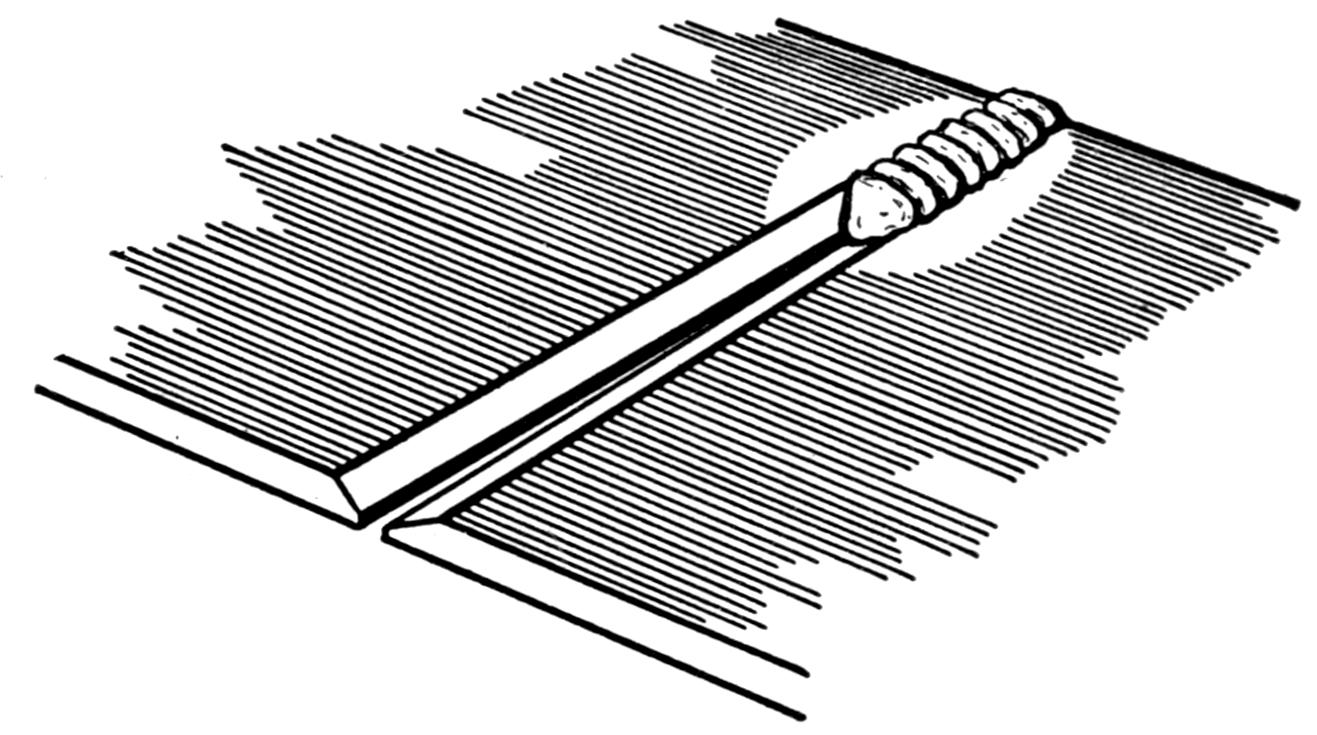

Fig. 28.—Method of Holding Heat when Welding on Metal Top Tables.

Asbestos paper, P, is laid upon the metal top, M, and the pieces, A and B, placed upon P in such a manner that the weld can be made at C. The asbestos paper prevents too much heat escaping from the bottom of the weld.

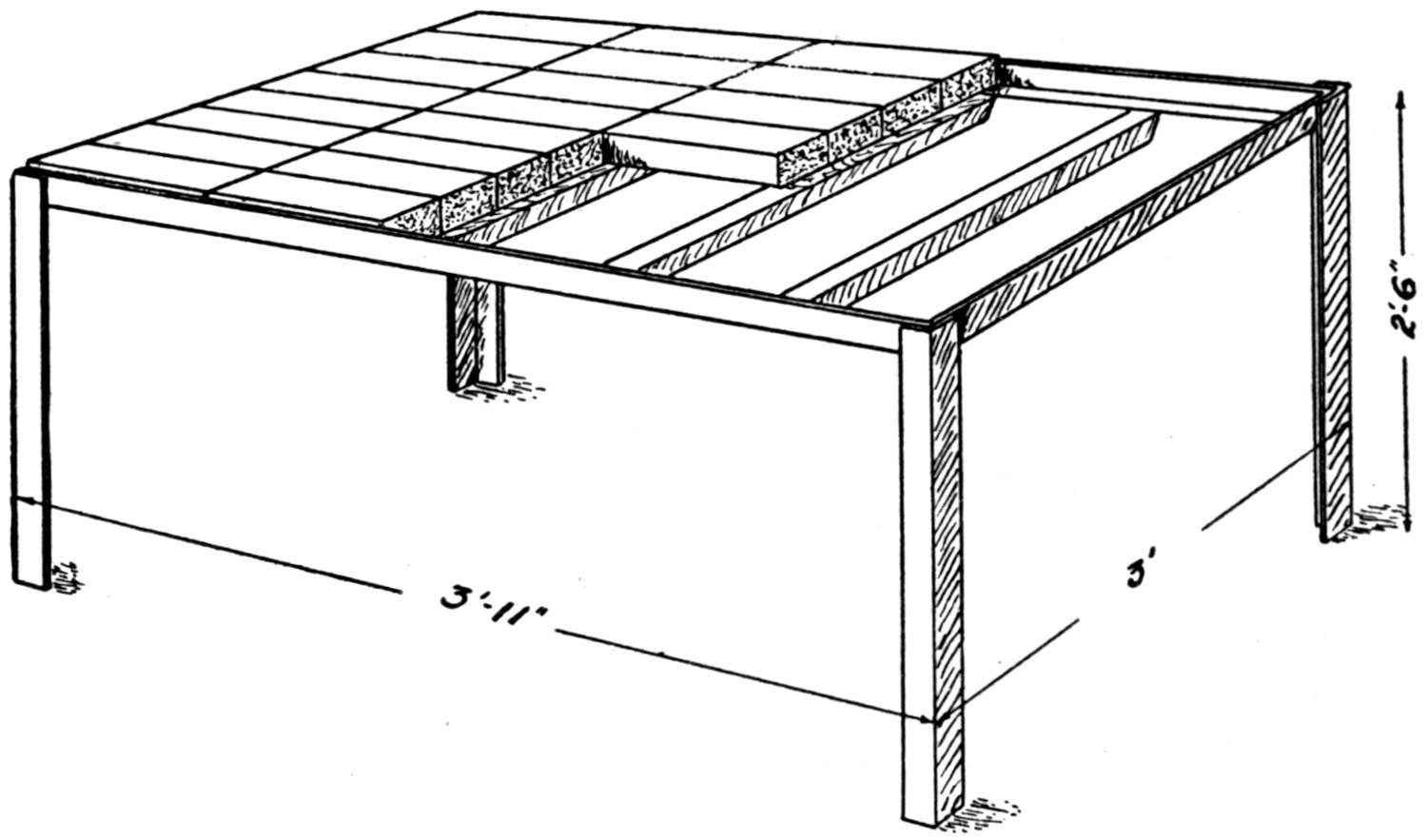

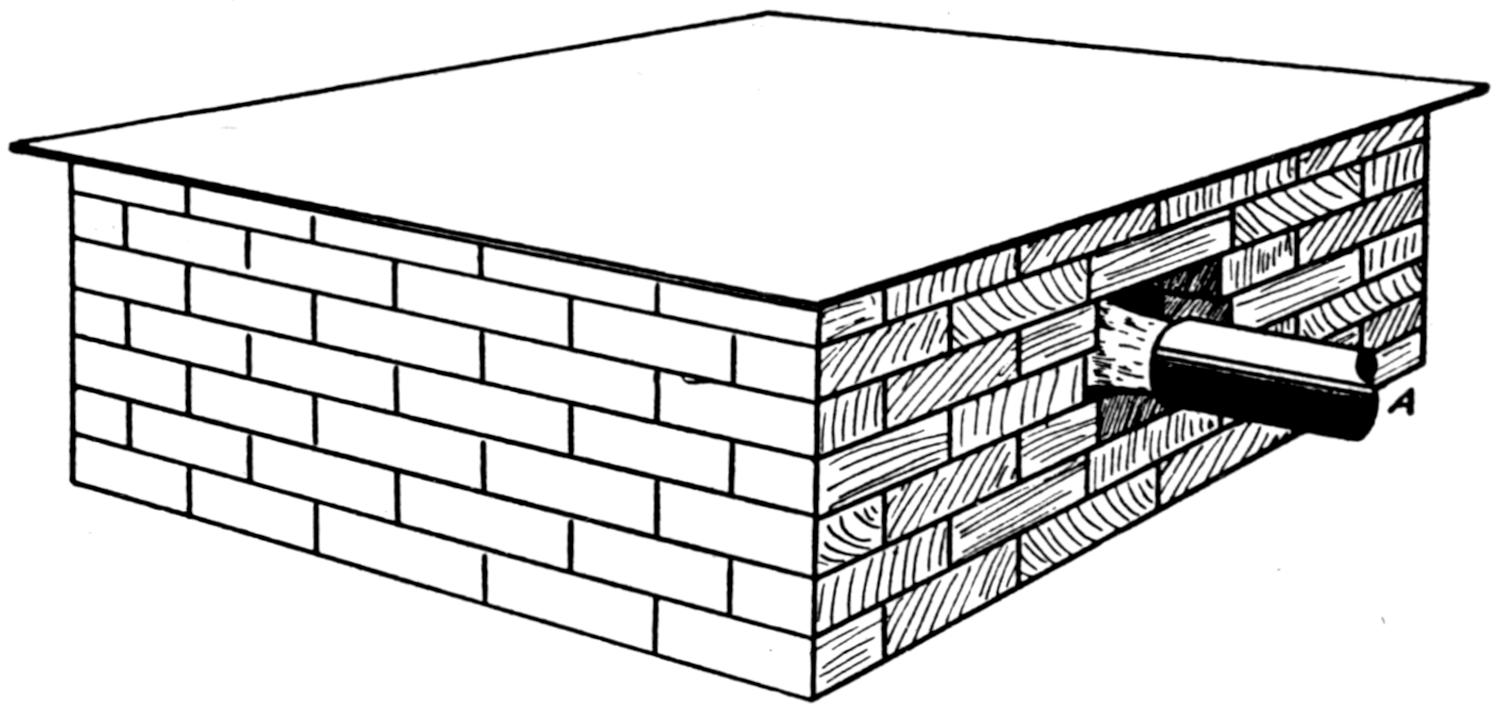

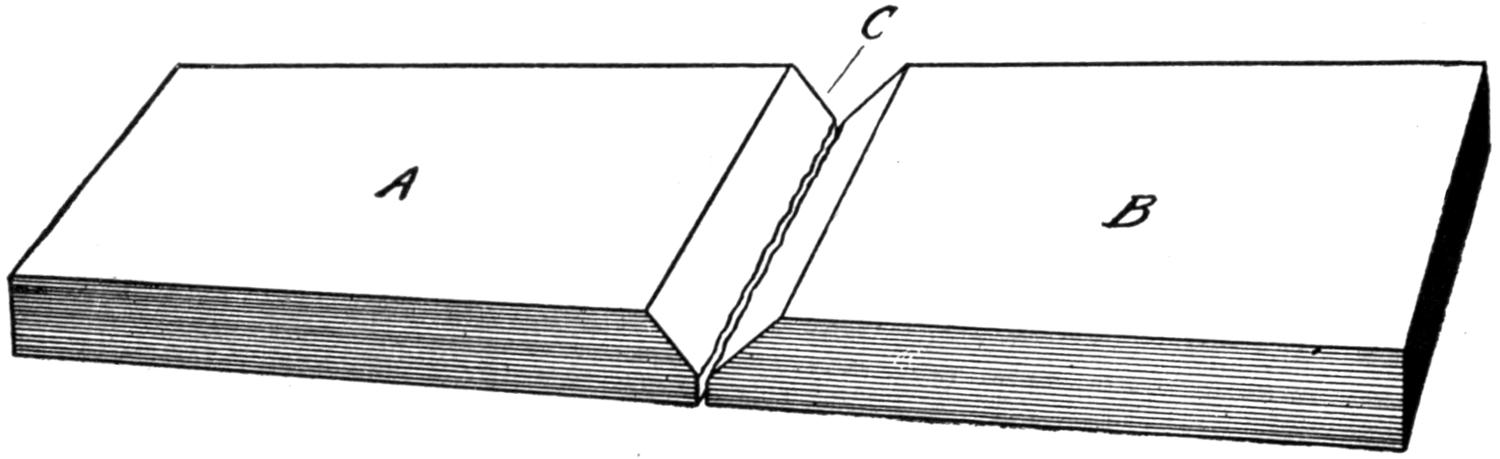

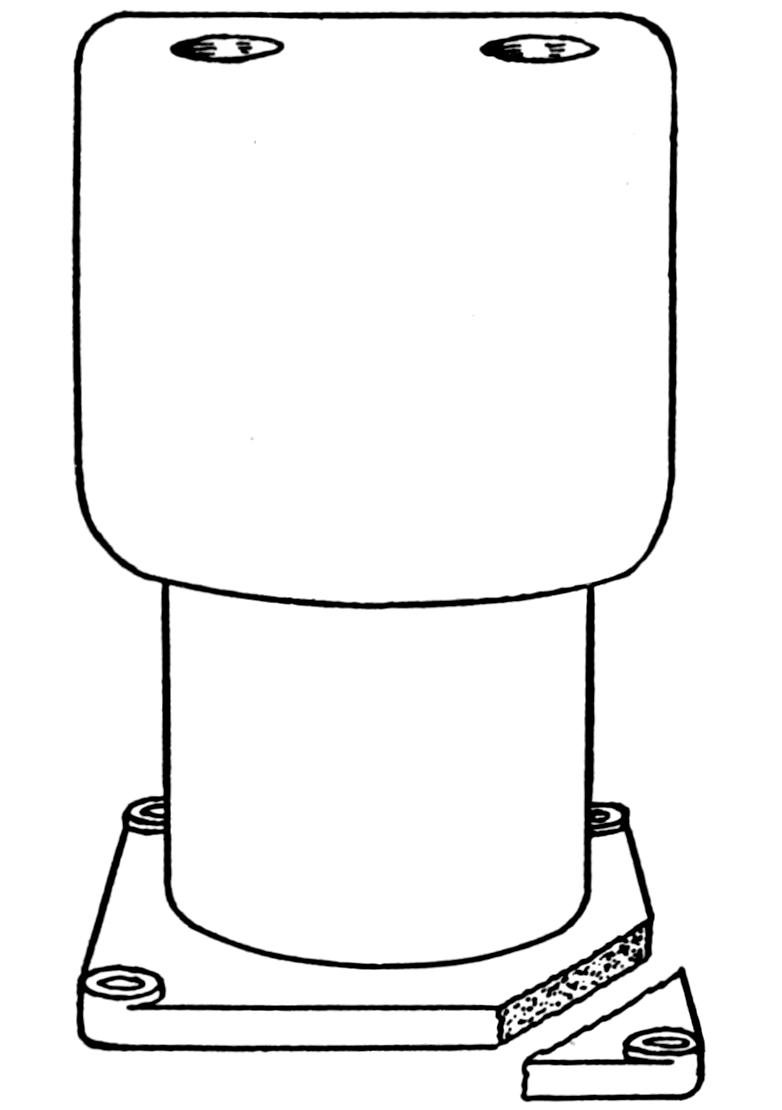

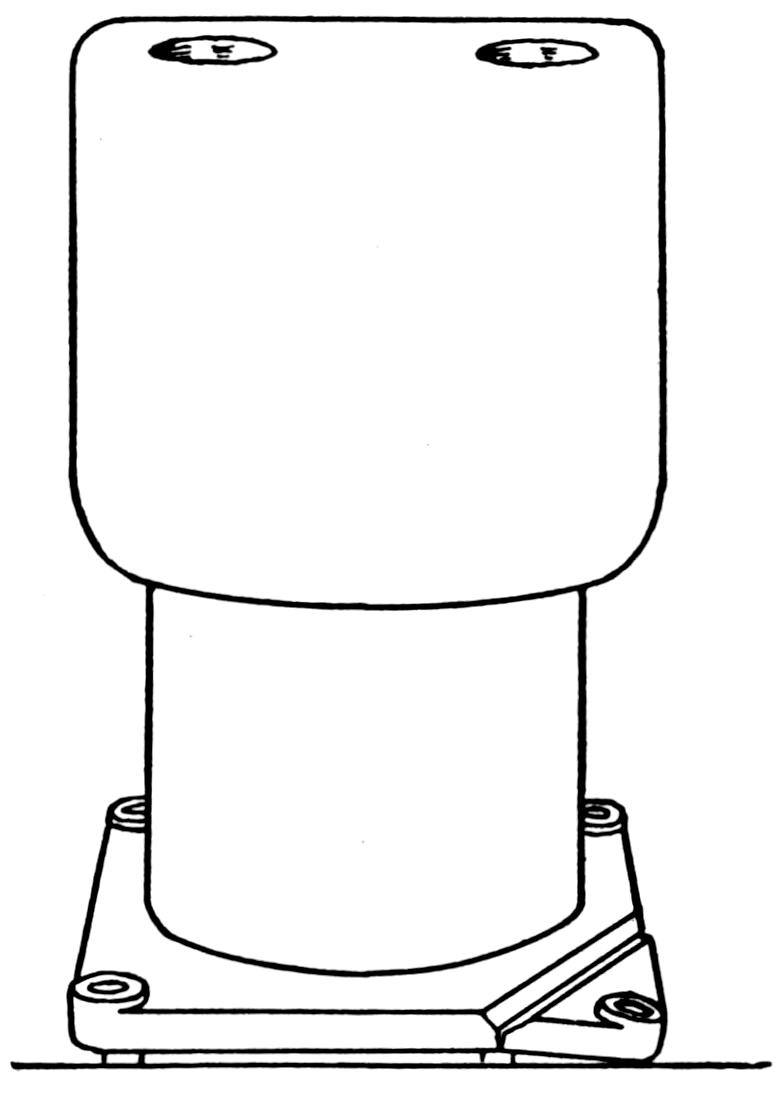

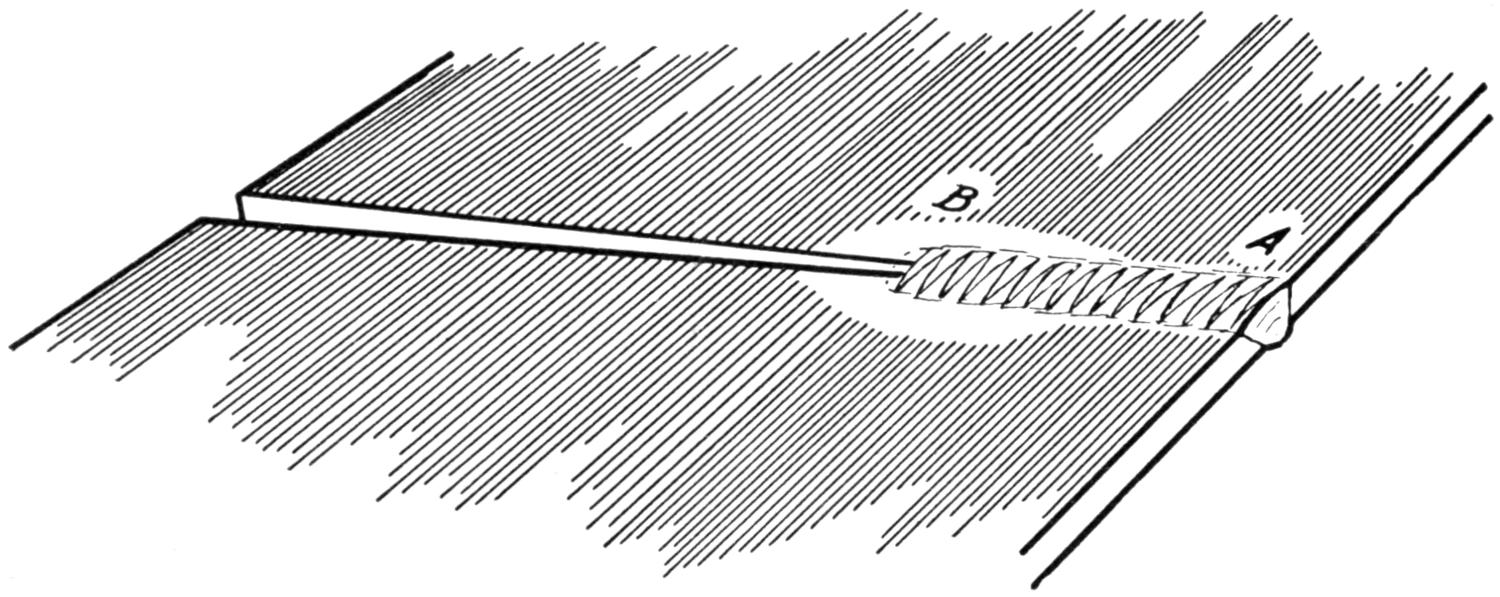

Fig. 29.—A Fire-brick Table for Welding.

Angle iron measuring 2 by 2 by ¹⁄₄ inches is welded together in the manner shown and covered with fire-bricks which measure 2¹⁄₂ by 4¹⁄₄ by 9 inches.

(42) A fire-brick table, made up along the lines shown in Fig. 29, is very easily constructed and can be used for all sorts of jobs. It is well to have everything clear around the legs and have no braces to cut the operator on the shins[40] or to interfere in any way with his work. The best fire bricks obtainable should be used. A large number of extra bricks should always be on hand for they come in very handy in most of the welding operations, and in fact to conduct a welding shop without fire bricks could almost be likened to a blacksmith’s shop without an anvil. Besides being used for table tops, preheating furnaces of a[41] temporary nature may be built and the bricks used to jack up and align many jobs which could not be handled otherwise.

(43) An emery wheel plays a very important part in a commercial welding shop, insomuch that rust, scale, and unnecessary metal can be removed in a very short time by its use. A flexible shaft attachment should be on hand, if possible, or a portable grinder of some kind, for in many cases where the casting, or the piece being worked upon is too heavy to bring to the emery wheel, the wheel can be brought to it and many places ground down by its use that would be impossible with a stationary grinder.

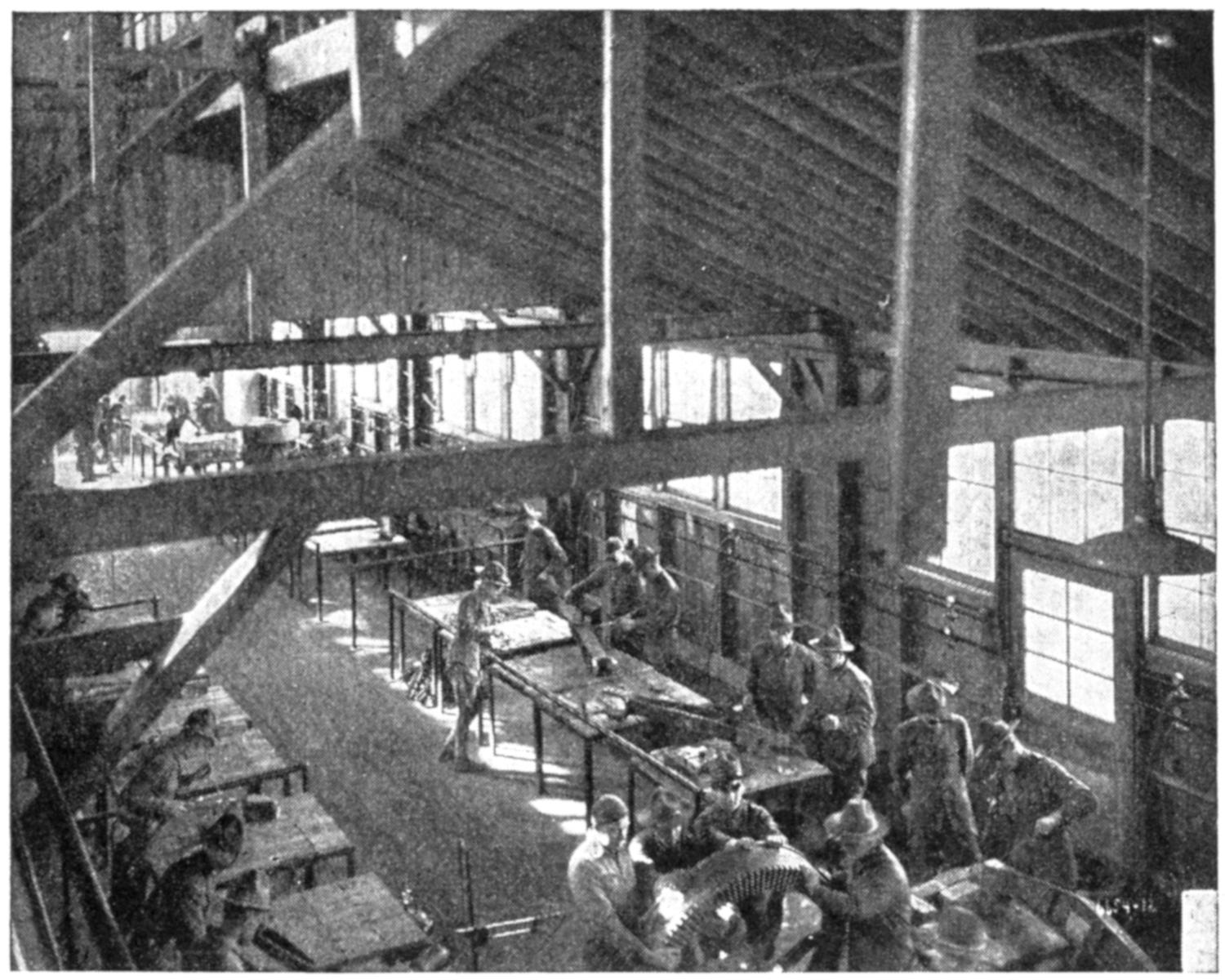

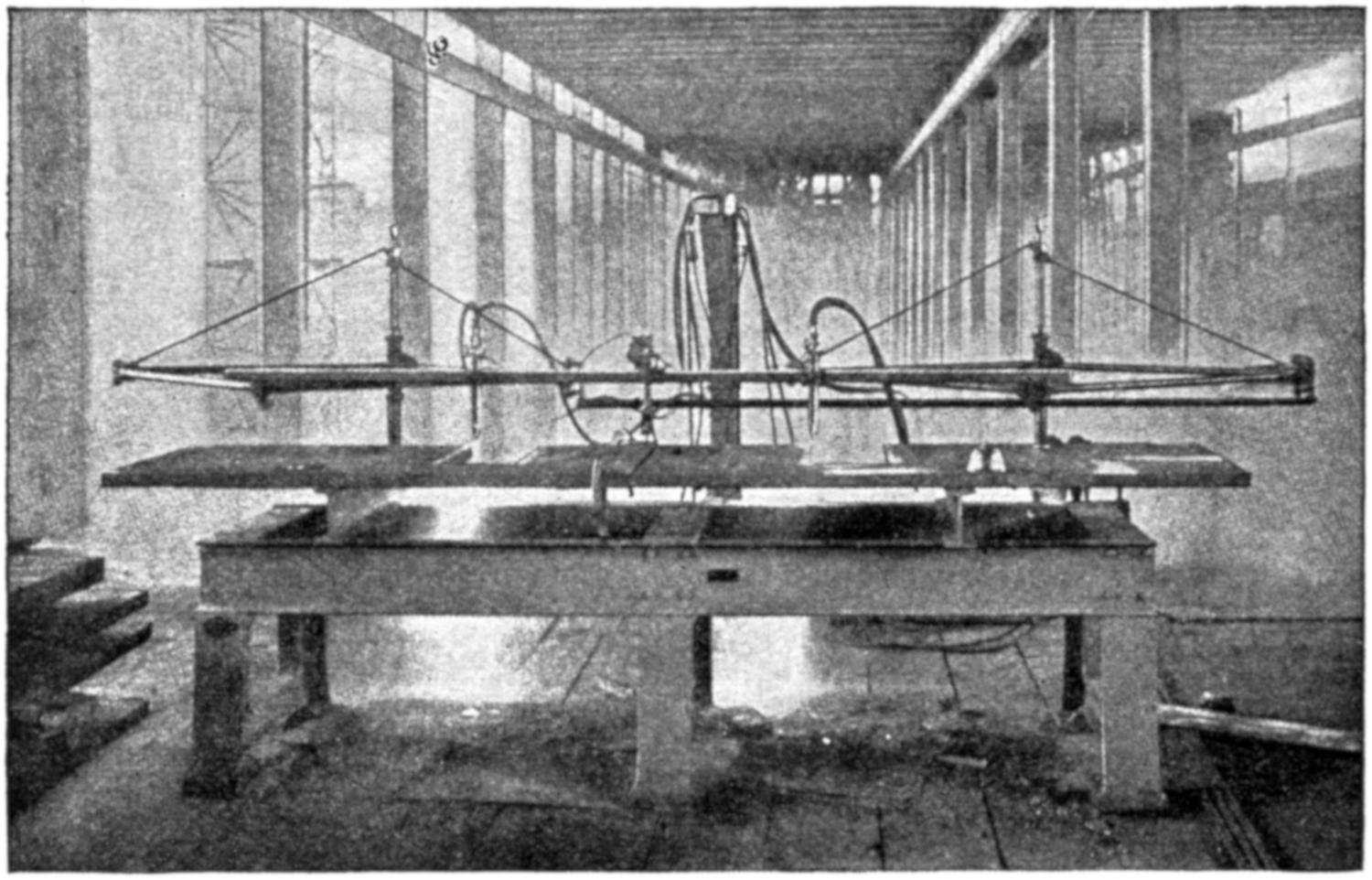

Fig. 30.—One Shop in which Instruction in Steel is being Given, at the Ordnance Welding School.

Note the construction of the welding tables. Two or more may be placed together, to give as large a surface as desired.

(44) Many times when working near a hole which may be threaded, the welder has much difficulty in keeping his[42] metal from entering the hole. At other times it is necessary to back up preheated work such as aluminum, to prevent its collapsing. Ordinary clay or putty cannot be used for this purpose. The simple reason being that when metal is heated it expands and the clay or putty in giving off its moisture contracts, showing two opposite reactions. Retort cement is a name given furnace cement mixed with shredded asbestos, this, as well as carbon flour, has been found to be very satisfactory for filling in holes and backing up pre-heated work. Retort cement is purchased in airtight containers, hardening very quickly when brought in contact with the air, so at all times it should be kept in containers similar to those in which it is purchased. It cannot be reclaimed once it is hardened.

(45) A blacksmith forge will be the medium of saving much valuable gas and time in a welding shop. It will heat up parts to be welded in very short order and while in this condition they may be welded and then thrown back into the forge and allowed to cool very slowly.

(46) Several pails of water should always be located where welding is being done to prevent fire from flying sparks; to cool the torch tips and filler-rods, when working on large jobs; to keep certain parts of work being welded cool, and to harden or temper other parts.

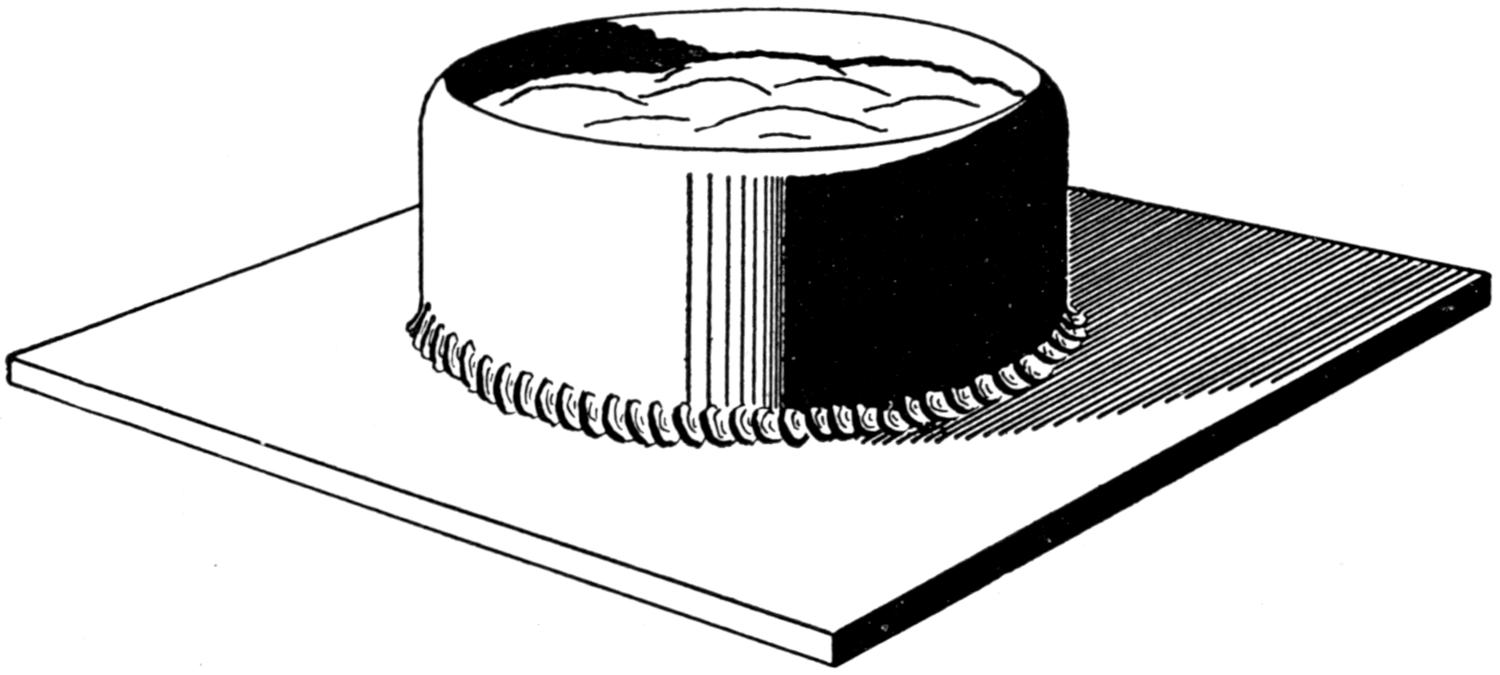

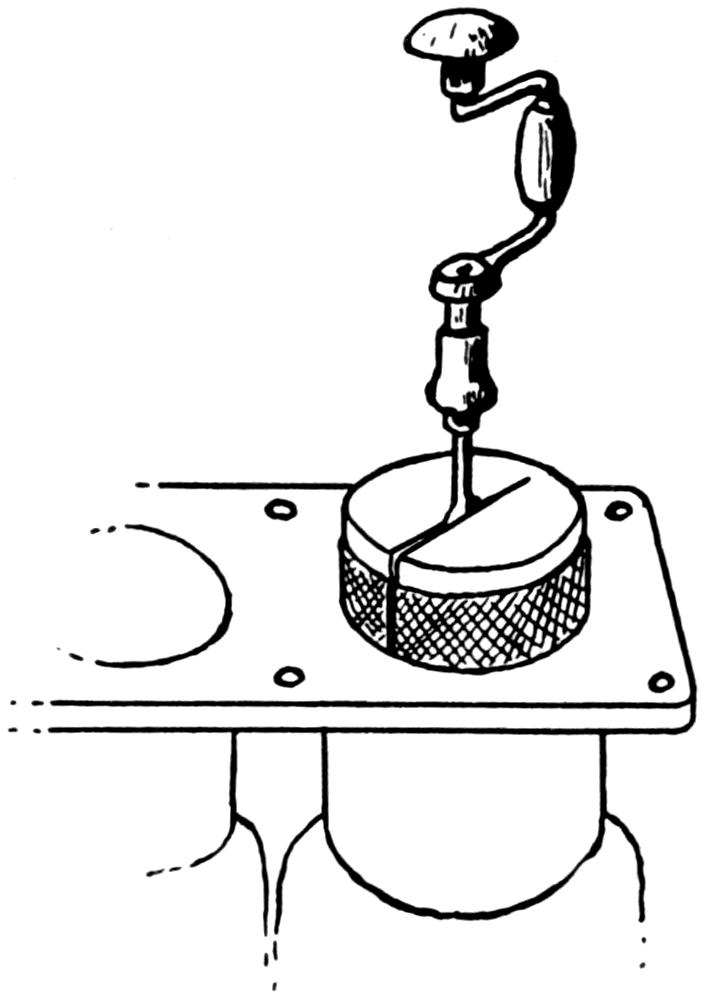

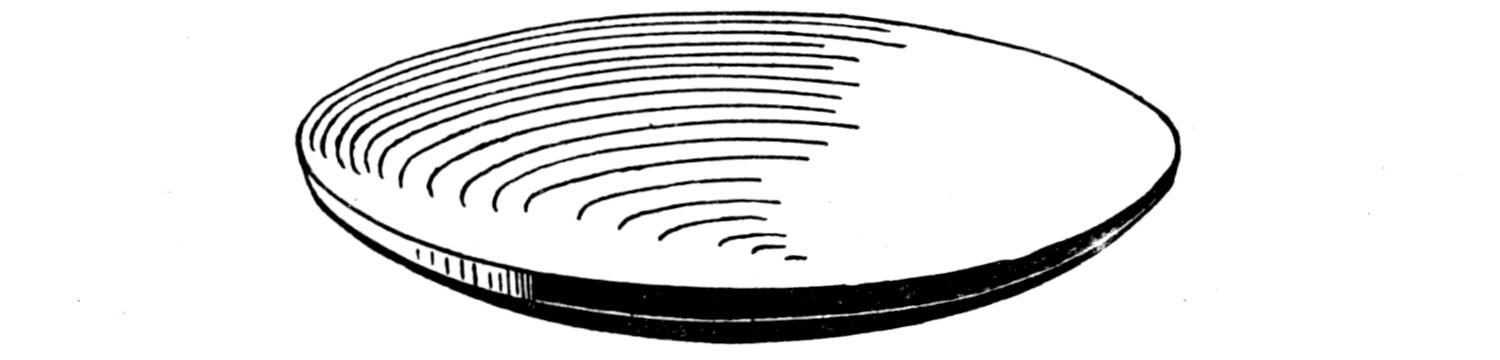

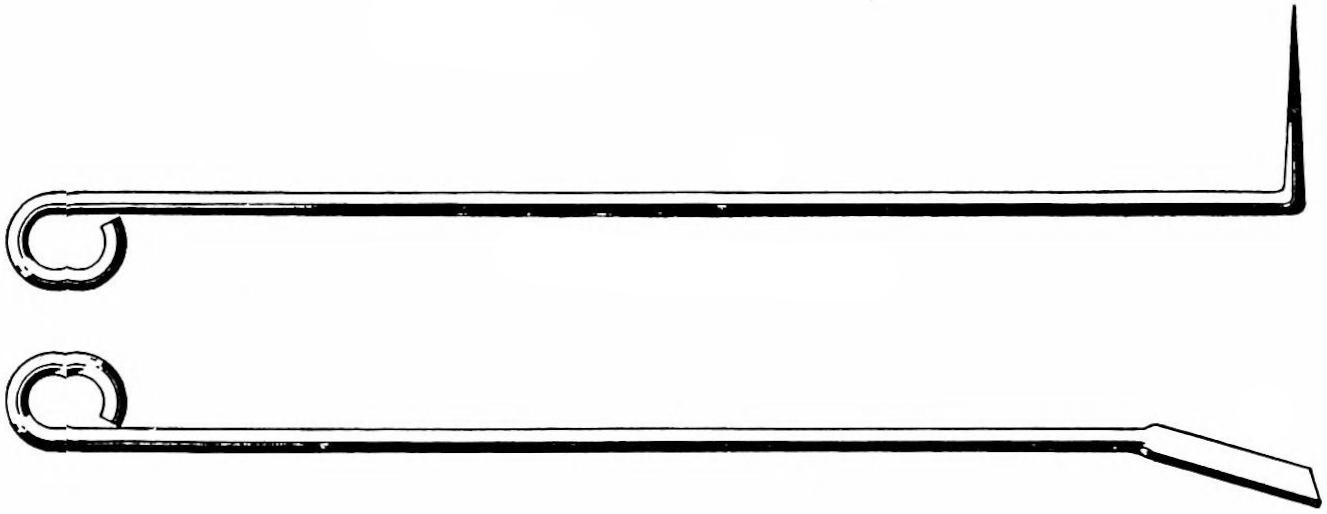

(47) A simple and efficient manner of handling flux in the welding shop has puzzled many welders, on account of the flux containers being easily upset, their inaccessibility and the action of the air upon large quantities of flux. A simple method of overcoming this is to cut in two, a two and one-half or three-inch pipe coupling and mount it by welding on a square piece of one-eighth inch plate, as shown in Fig. 31. This type of container is very hard to upset; may be used when working on preheated jobs; is easy to get at on account of its shallow nature, and, as it only holds a[43] small amount of flux, it can be cleaned out frequently and a fresh flux will always be available.

Fig. 31.—A Good Flux Container for the Welding Table.

(48) Additional equipment beneficial to the welder will be a quantity of various sized carbon rods and blocks; asbestos paper; goggles; V-blocks for lining up shafts and an assortment of mechanics’ tools, such as wrenches, hammers, chisels, hack-saws, and other things which might be used in dissembling or assembling various kinds of machinery.

(49) Another important item which is generally overlooked in the average welding shop is the question of ventilation. Although the welding flame itself contains no objectionable gases, those from fresh charcoal preheating fires, those given off when some of the alloys of the filler-rods are melted when brass, copper, and other metals are being worked on, and from gas engine exhausts are not desirable. At times they will give the operators violent headaches unless means are taken to carry them off. The ventilation should be such that it will not directly affect the work. Drafts are to be avoided as much as possible, for many times they will warp pieces being preheated if allowed to come in direct contact with them. It is a good thing to remember that indirect ventilation and plenty of it is a prime requisite in a good welding shop.

[44]

(50) Occasionally in setting up a welding apparatus, a leak may be noticed along the lines, some time after the plant is in operation. Leaks on either the oxygen or acetylene lines are to be considered dangerous as well as costly and therefore to be avoided at all times. When the cylinder valves are closed on the drums containing the gases, and the hands on the low-pressure gauges of each regulator are seen to drop or reduce their pressure when the torch valves are shut off and allowed to remain so, this is an indication that there is a leak between the regulator and the torch. It is not desirable to use a match or a flame of any kind in testing for leaks. There are various methods employed by the cautious welder, but about the best of these is a soapy solution of water, which is kept in a can at all times and is applied with a paint brush. If this solution is applied to any leaky part, bubbles will form immediately and the leak will be located.

(51) At times, when working in isolated places, where repairs cannot be had, and no means have previously presented themselves for testing out the cylinders or the apparatus as a whole, it may be found that the threads or ground seat on the cylinder valve of the regulator which is connected will be in such a condition that a leak is in evidence. Or it may be that the threads will not permit the seat being drawn up sufficiently to make it airtight. In cases of this kind, the welder must find some means of proceeding[45] with his work, and while it will be impossible for him to use white lead or any oily substance with safety, he may stop the leak with litharge or lead oxide mixed with a small quantity of glycerine. A string soaked in this solution may be wound around the main connection and the swivel nut screwed up to the seat as far as it will go. If allowed to harden for a short time, the litharge will set and a very satisfactory temporary repair will be effected.

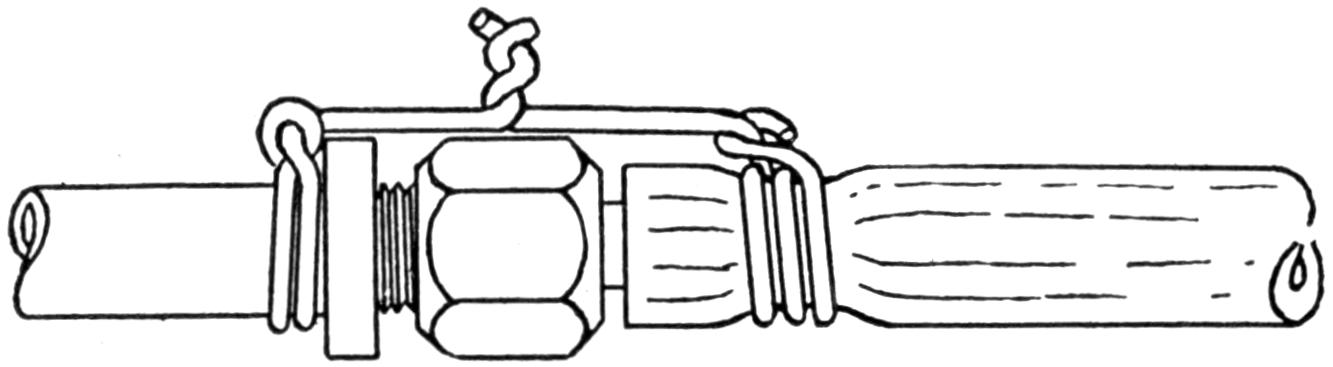

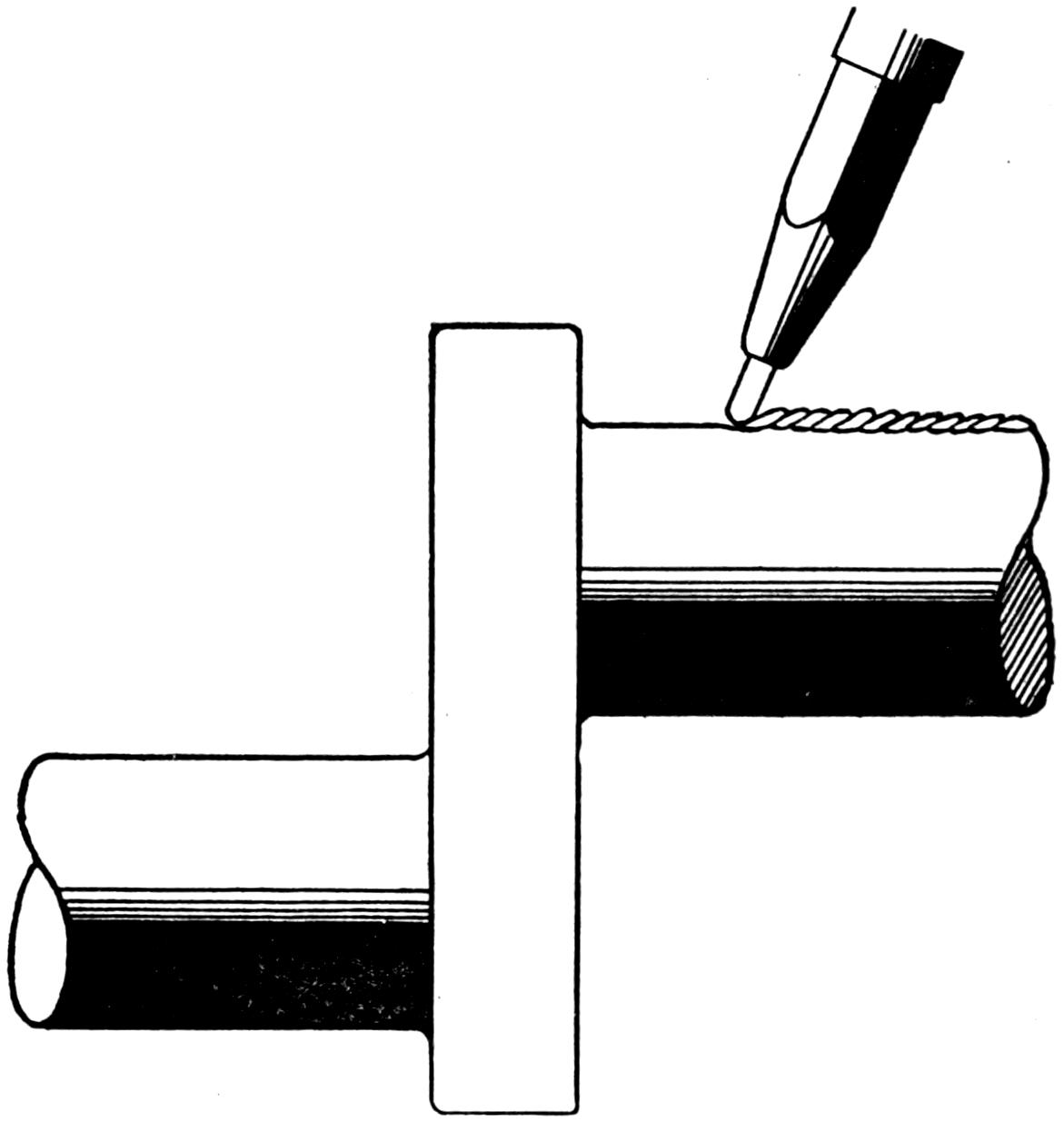

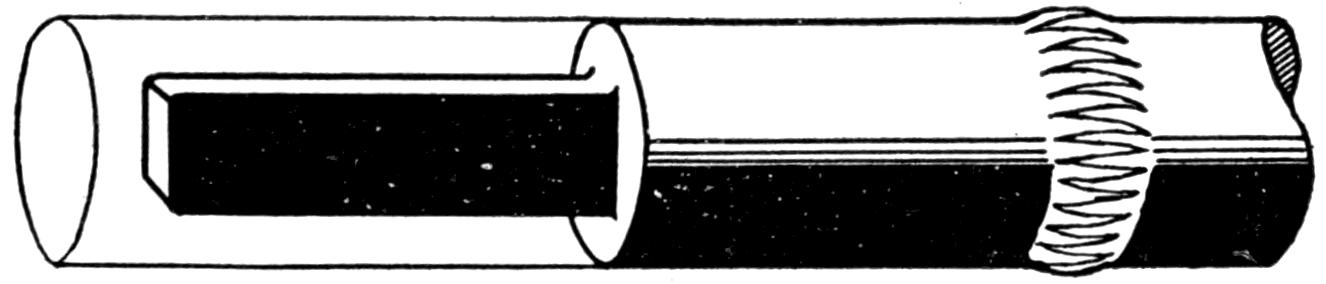

Fig. 32.—Method of Attaching Hose to Connection so it cannot Pull or Blow off.

(52) The method shown in Fig. 32 of attaching connections to hoses so that they will not blow off when pressure is applied is a very simple and effective means of overcoming this difficulty. Undoubtedly it will assist some operators in solving the trouble that has been occasioned by the ordinary hose clamps, especially when doing cutting or heavy welding work where the gas pressure is considerably higher than usual. The wire used should be large enough to prevent cutting the fabric in the hose.

(53) An injured hose which may leak should never be used after the leak is noticed unless some means are taken to repair it. The use of tape in trying to repair hose on an oxy-acetylene welding outfit should never be permitted. The most efficient way of overcoming an injury of this kind is to cut the hose at this part and insert a piece of pipe. The ends of the hose are then wired to this pipe and a union is thereby effected which will generally outlast the life of the hose. Special connections for this purpose are put out by most welding companies, so that a supply may be on hand if hose trouble is expected.

[46]

(54) When transporting welding apparatus, occasionally the “cross-bar” on the regulator is lost and many times the operators do not know what is to be done. The purpose of the “cross-bar,” as we have already seen, is only to apply pressure on the diaphragm springs, so that if a set screw of the same diameter and same thread as those of the “cross-bar” can be found and screwed into its place with a wrench, a section of filler-rod can be welded across the top of it and the use of the regulator will not be impaired. If a special thread is used by any particular company, a piece of brass or iron can be turned down in a lathe to fit.

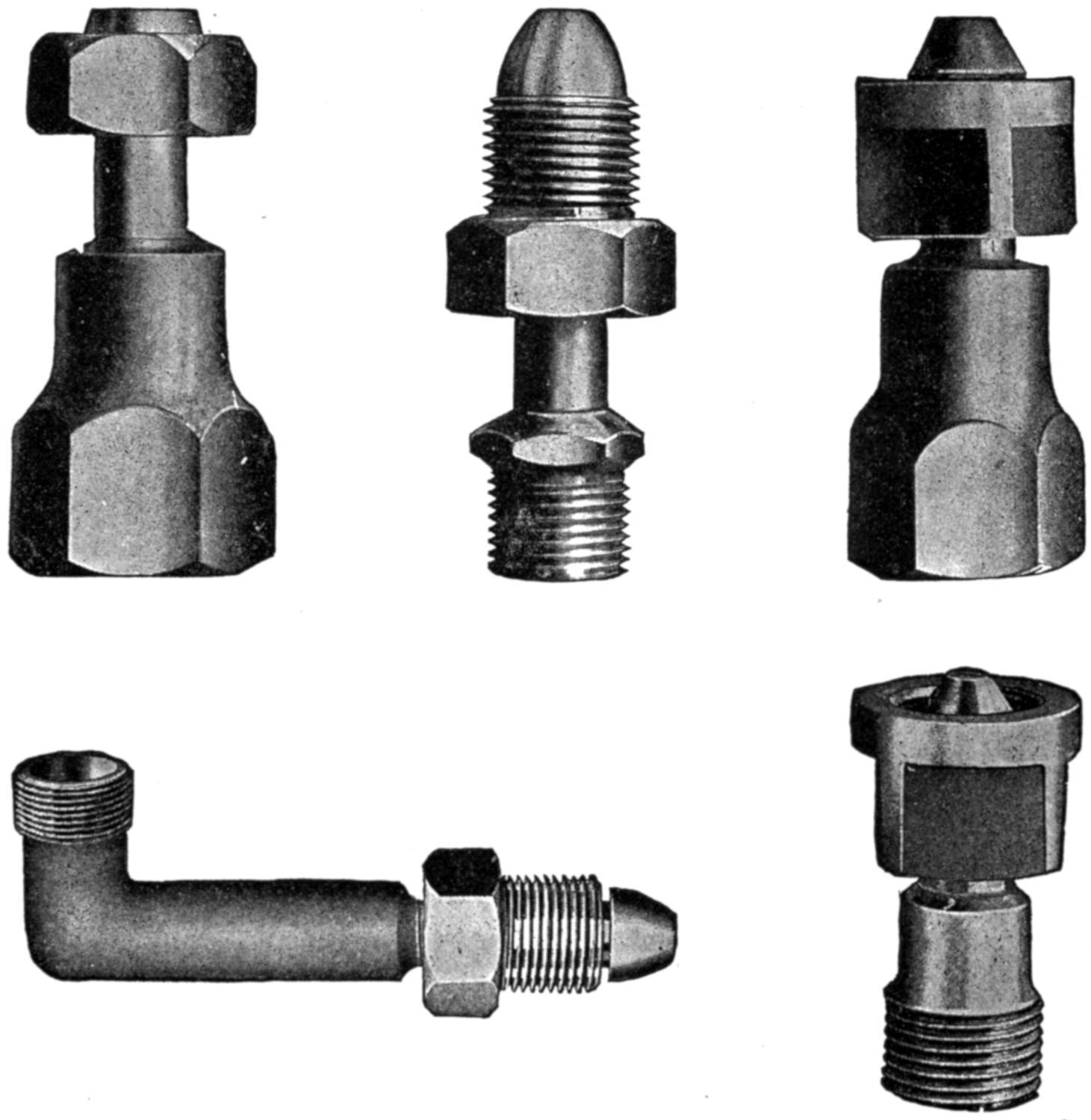

(Courtesy of the Bastian-Blessing Co.)

Fig. 33.—Various Types of Adaptors Used to Connect Regulators to Cylinders having Different Connection.

(55) The manufacturers of practically all regulators use the quarter-inch tapered pipe thread in attaching the cylinder connections to the regulator and do not depend upon the threads being gas-tight, so they solder them in. There are various types of cylinder connections put out by different manufacturers of the gases and occasionally it may be necessary to use a cylinder of gas which contains a different connection than is supplied on the regulator. Various adapters, such as shown in Fig. 33, are supplied to overcome this difficulty, but at times the operator is confronted with the very embarrassing situation, of having a cylinder of gas and his regulator of different connections, but no adapter suitable. This predicament is usually found when some very important work is to be done and sometimes far from a supply depot. At times the operator may have an adapter which will fit the cylinder but not the regulator. If this is the case, his difficulty can be very easily overcome, for generally all adapters are made of two parts, “sweated” together, and have the same quarter-inch tapered thread as used in the cylinder connections on the regulator. The adapter can be separated, the tank connection removed and the correct connection “sweated” into the regulator.

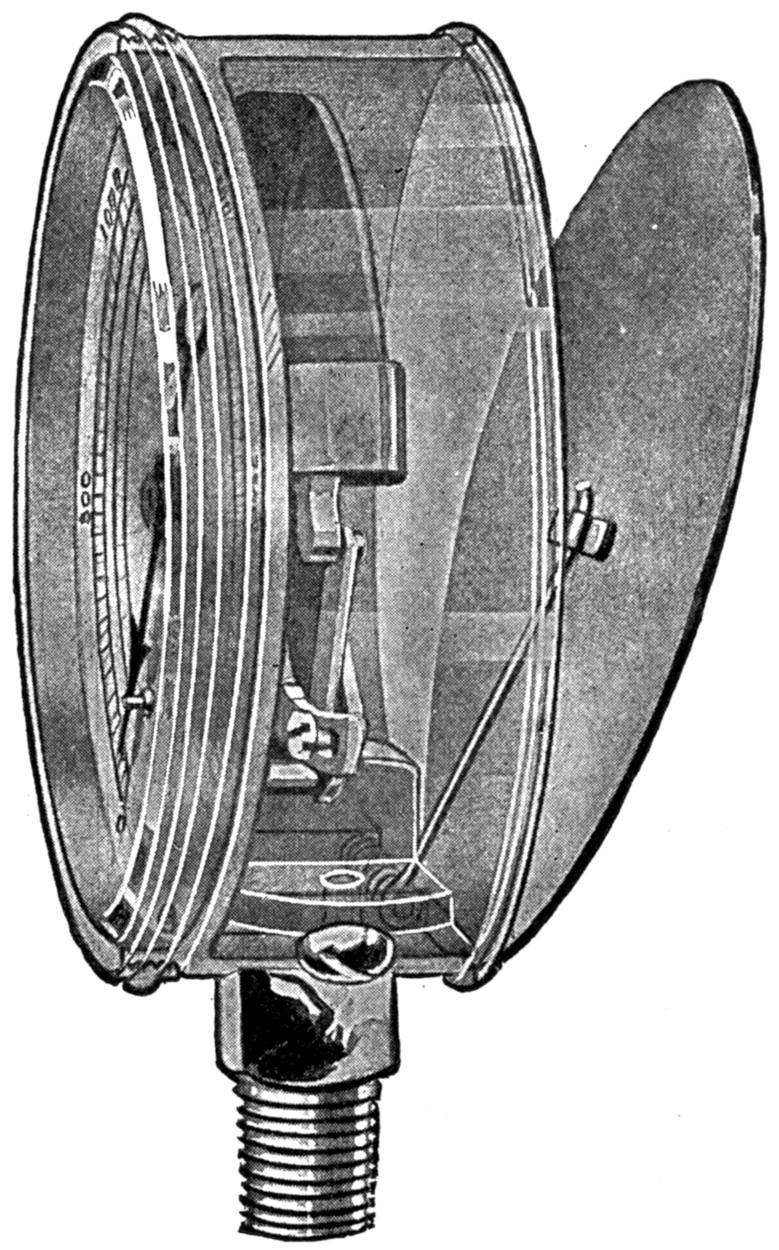

(Courtesy of the U.S. Gauge Co.)

Fig. 34.—Showing Solid-front and Hinged-back Features of a “Safety-first” High-pressure Oxygen Gauge.

(56) Most gauges used in the oxy-acetylene industry to[47] indicate gas pressure are of the Bourbon type. The most recent types of the oxygen high-pressure gauges are constructed with a hinged back and a solid front, which means that should an oil or foreign matter enter the gauge from any source whatsoever and tend to burst it, the back would be blown off and there would be no glass that could possibly fly around. This is a safety device which has been welcomed with much enthusiasm on the part of the oxy-acetylene industry.[48] When leaks occur in gauges, it is always best to remove the gauge from the regulator, stopping the hole temporarily with a pipe plug and return the gauge to the manufacturers for repair. These gauges are very delicately constructed and can be rendered useless if handled by the inexperienced. A great many times after the case of the gauge has been jarred or loosened, the screws connecting this case to the inside working mechanism are tightened up, breaking the soldered connection holding the spring tube on the inside of the gauge. This causes a leak which can[49] be repaired quite easily if the operator is able to solder it. It must be remembered, however, that if the flame is brought in contact with any of the springs that their tension will be lost and that the gauge may not operate correctly after this repair is made unless great care is exercised.

Fig. 35.—A 3000-pound High-pressure Oxygen Gauge.

(57) Undoubtedly there are many welders who in beginning to operate their welding apparatus conclude that their gauges must be at fault when they show a reading after apparently all pressure has been released in closing down the apparatus. It is to avoid the impression that the gauge is at fault that time is here taken to show that even though the cylinder valve is closed and the “cross-bar” on the regulator screwed out that when the torch valves are opened to drain the lines there will still be a reading on the high-pressure[50] gauge if the regulator seat is in good working order. It is simply a case of gas being trapped between the regulator and the cylinder valve. To reduce this reading it is only necessary to screw in the “cross-bar,” thus opening the regulator seat. This could be avoided if the cylinder valve were closed first and the torch valves opened while the regulator “cross-bar” were still screwed in, then as soon as the gas had left the line, the torch valves could be closed and the “cross-bar” on the regulator could be screwed out until free.

[51]

(Courtesy of the Messer Mfg. Co.)

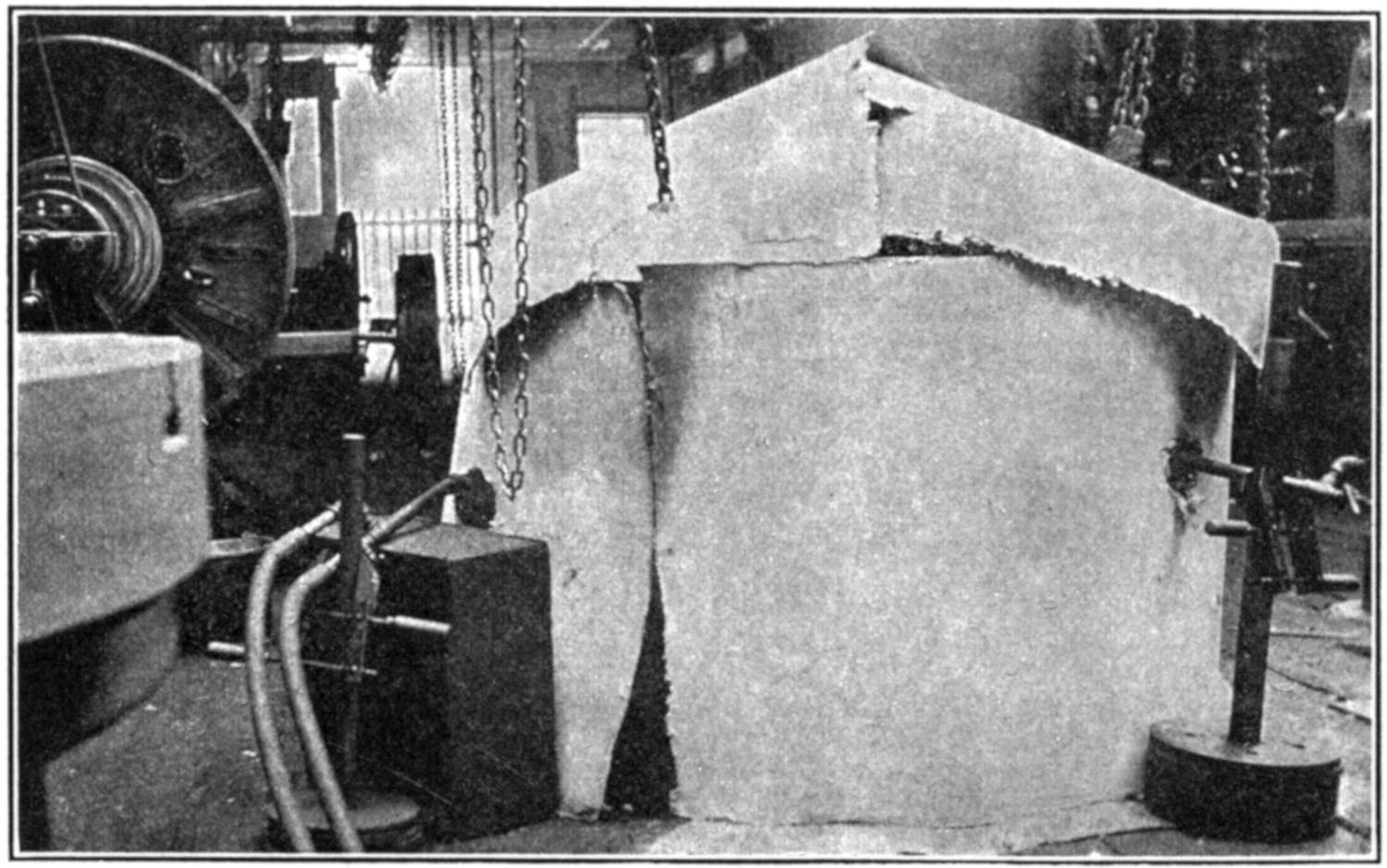

Fig. 36.—A Large Job Prepared for Welding.

(58) Preheating, as applied to oxy-acetylene welding, means the application of heat to the article to be welded in some manner which is usually different than by the welding flame itself. Charcoal, coke, kerosene, crude oil, coal and natural gas are used for this purpose. The principal reasons for pre-heating parts to be welded are: To take care of the effects of contraction and expansion on the confined ends; to save time, gas, and material; and to make[52] a better weld by making it quicker and with less chance of burning up the metal.

(Courtesy of the Messer Mfg. Co.)

Fig. 37.—Showing how Large Work can be Covered with Asbestos Paper when Preheating.

(59) On account of the ductile qualities of steel, there is not quite as much heat used in preheating, to take care of the contraction and expansion, as in cast iron. On brass work a very dull red heat is considered sufficient, or otherwise the alloys might burn out. When preheating aluminum, there will be no change in color as the heat is introduced, so other methods are used to determine the correct temperature. Three methods are used for this purpose by most welders. “Half-and-half” soldering wire will usually melt when applied to the surface of aluminum which is preheated to the proper state; the puddle stick when drawn smartly across the heated surface should scrape off the oxide and leave a clear blue streak if the work is in condition[53] to be welded; and if a medium-sized tip is brought down so that the neutral flame just touches the surface for a second or two, the metal will sweat, if at the proper temperature, and small globules which have the appearance of mercury will stand out on the surface.

(60) The beginner must study contraction and expansion in order that he may know when and where to apply it in figuring out his work. Many welding jobs have turned out to be failures through lack of knowledge in this respect. Take, for example, a water-cooled cylinder block of the ordinary gas engine; the water jacket may be broken when the water is allowed to freeze in it. This problem has certainly confined ends, but some welders have attempted to weld such jobs cold, that is, without preheating, and possibly have succeeded in executing what they thought was a very fine weld, but upon examination, have discovered that the cylinder walls, which are very accurately machined, have been warped to such an extent that the block is rendered useless. This is strictly a “preheating” job, and the cylinder should be brought to a dull red heat if the best results are to follow.

As has been stated elsewhere in this volume, the weld should not be considered successful unless the piece worked upon can be returned to a usable state.

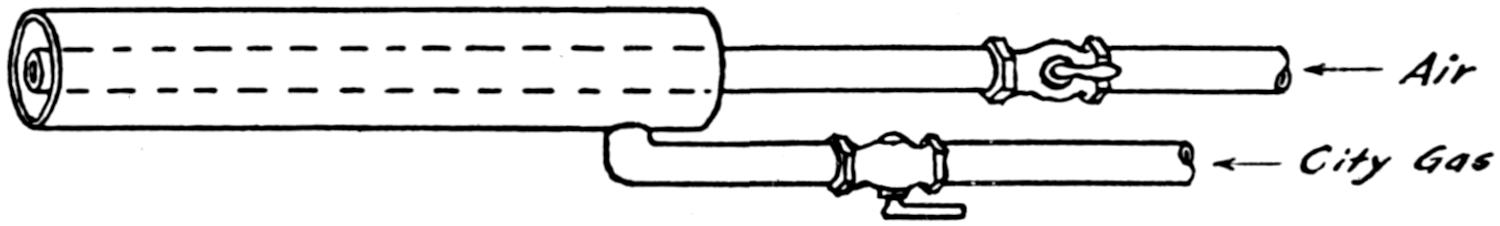

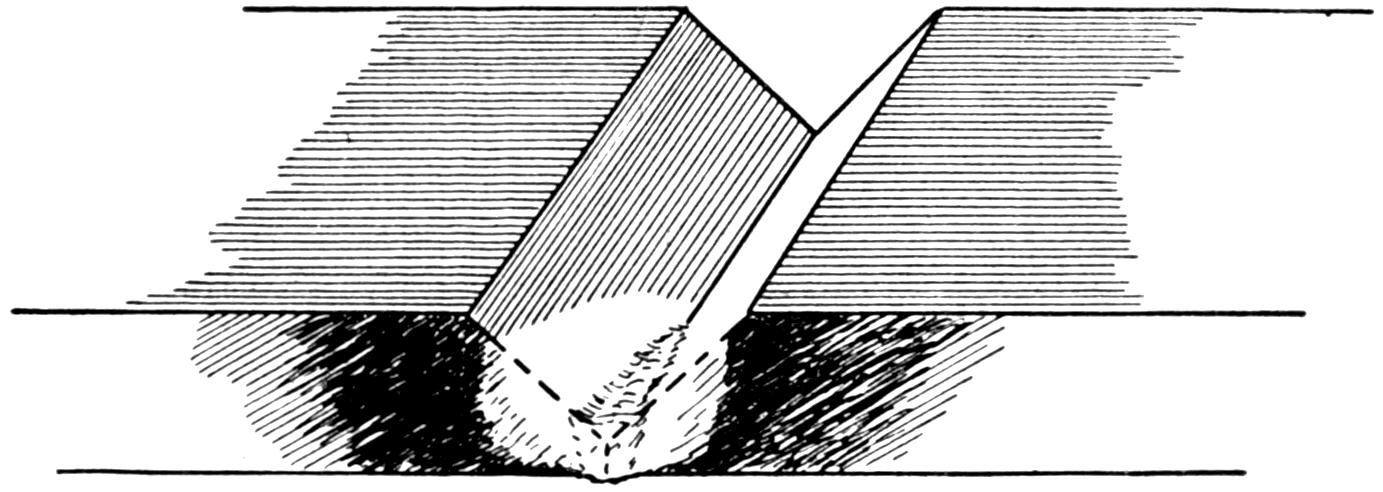

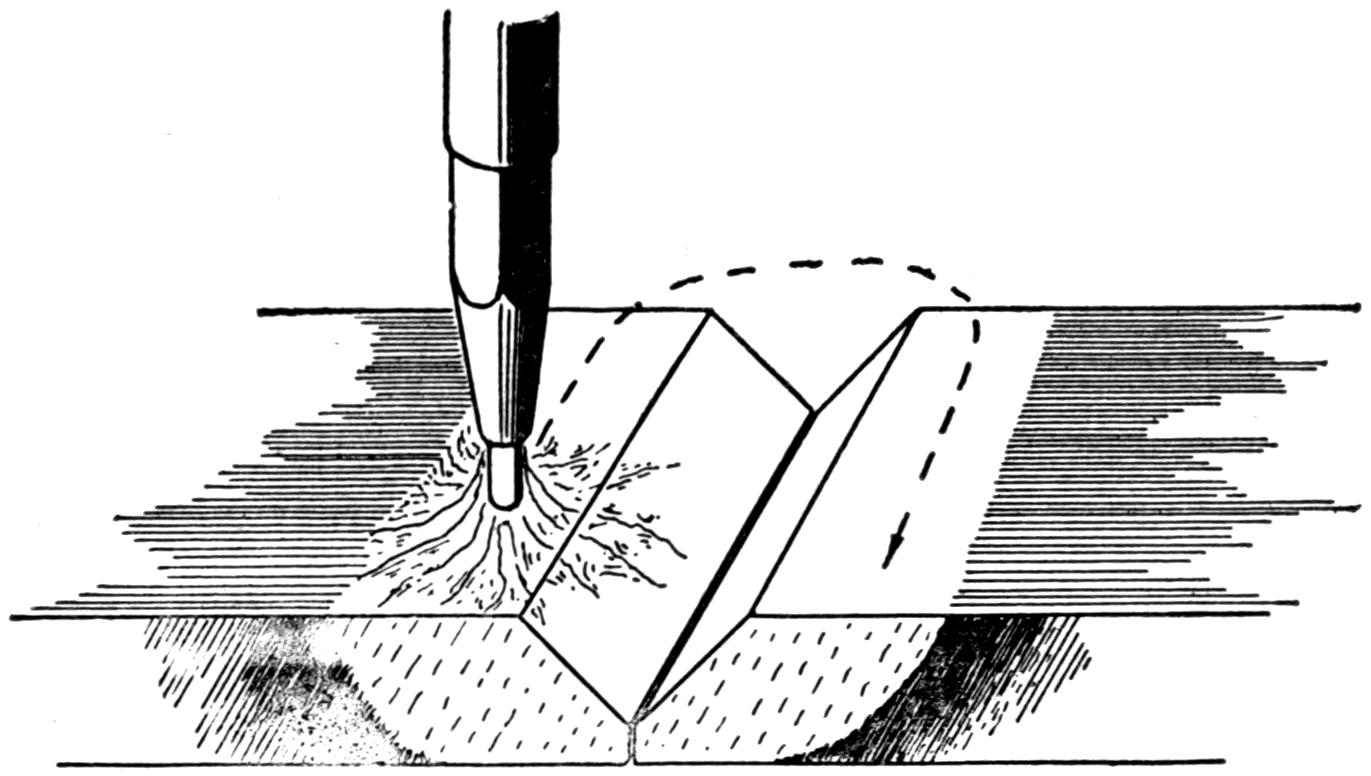

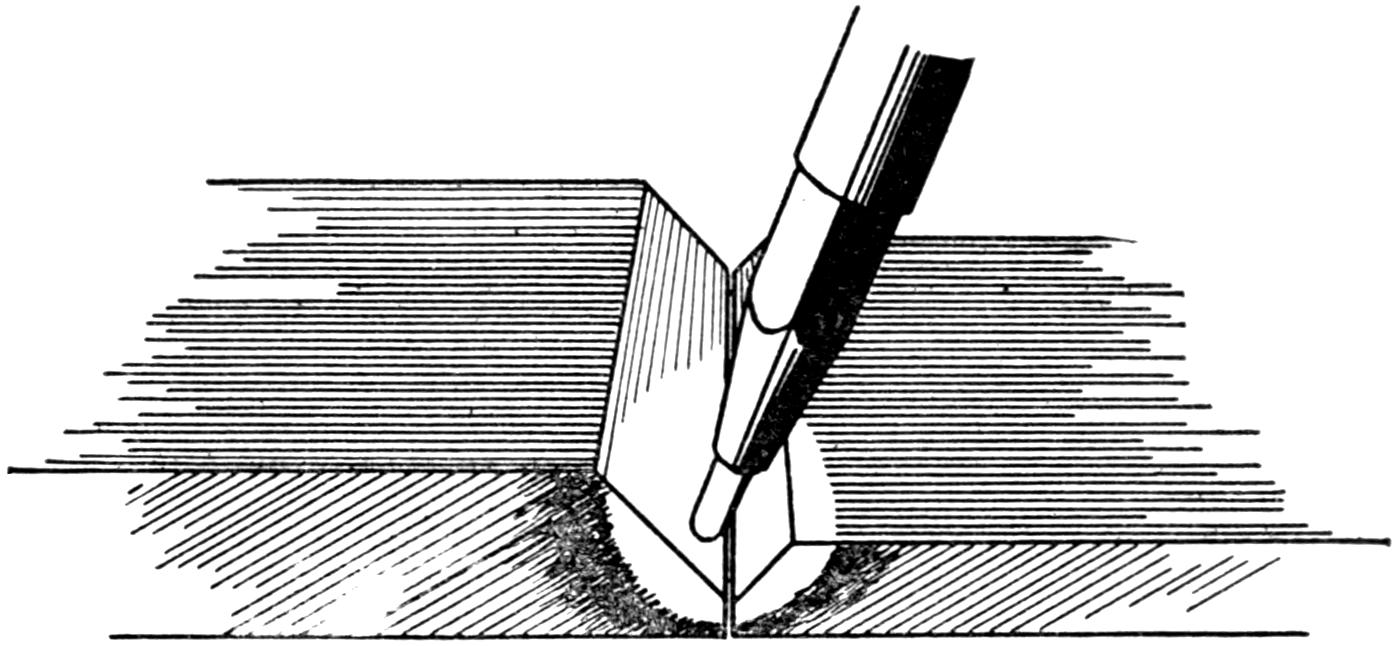

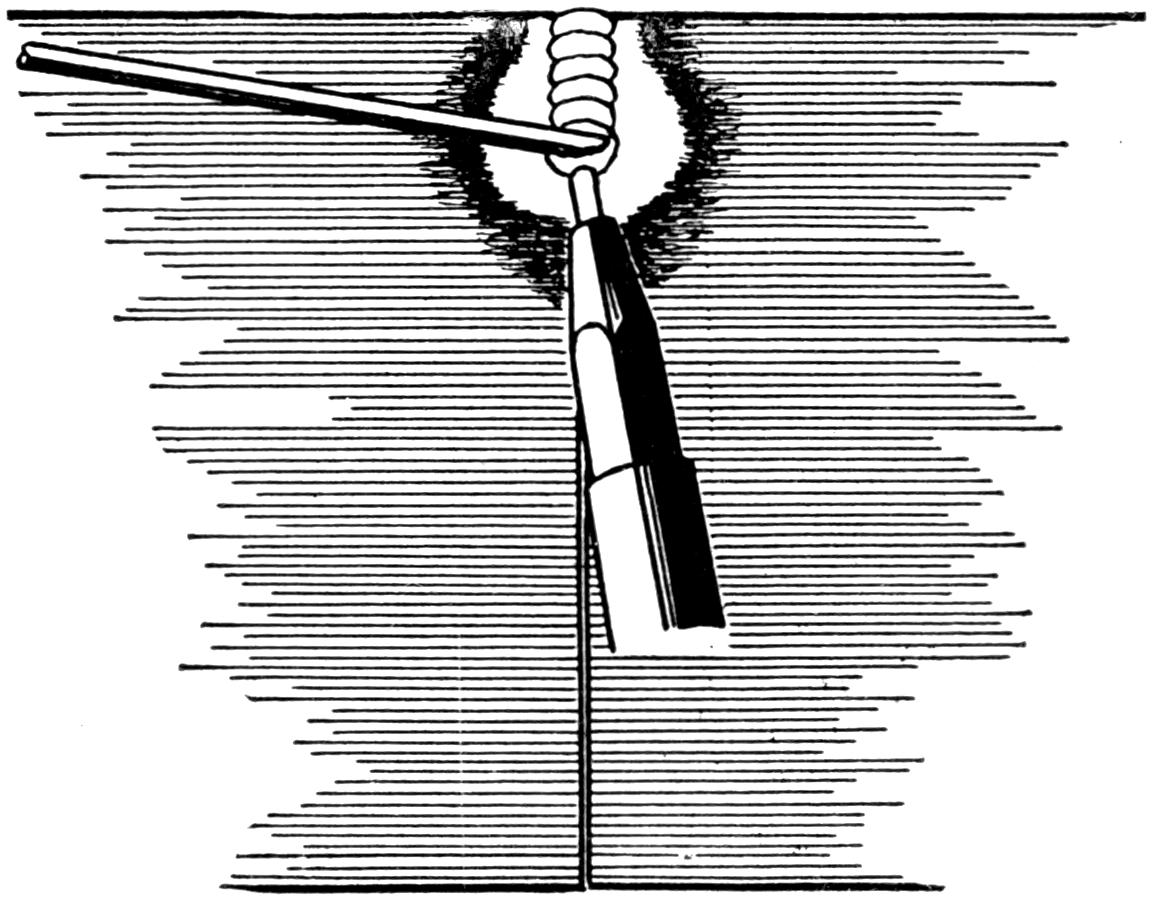

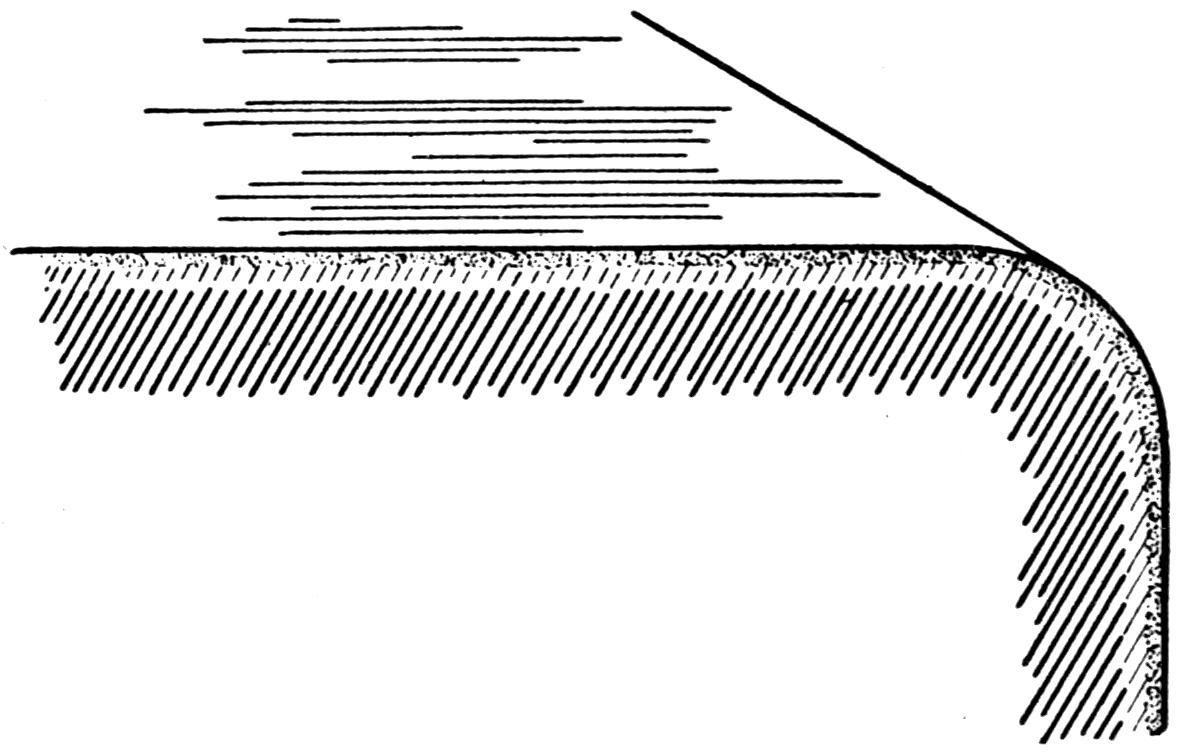

(61) Several different fuels have been mentioned, all of which can be used for preheating purposes. Charcoal is considered the best agent for general welding, as it gives off a very steady heat which will gradually be absorbed by the article worked upon, bringing it to the heat desired and holding it there throughout the welding operation. It will then permit very gradual cooling, as this sort of fire takes a long time in dying—a desirable asset in work of this kind. On account of the scarcity of charcoal and its high price, other agencies are used and chief among them are torches using kerosene, crude oil, or city gas, as a fuel. These usually[54] heat up the work more quickly, but care in their manipulation is necessary. A preheating torch to be used in conjunction with city gas can be very easily constructed, if the details of Fig. 38 are observed. This proves to be a very efficient and cheaply constructed apparatus.

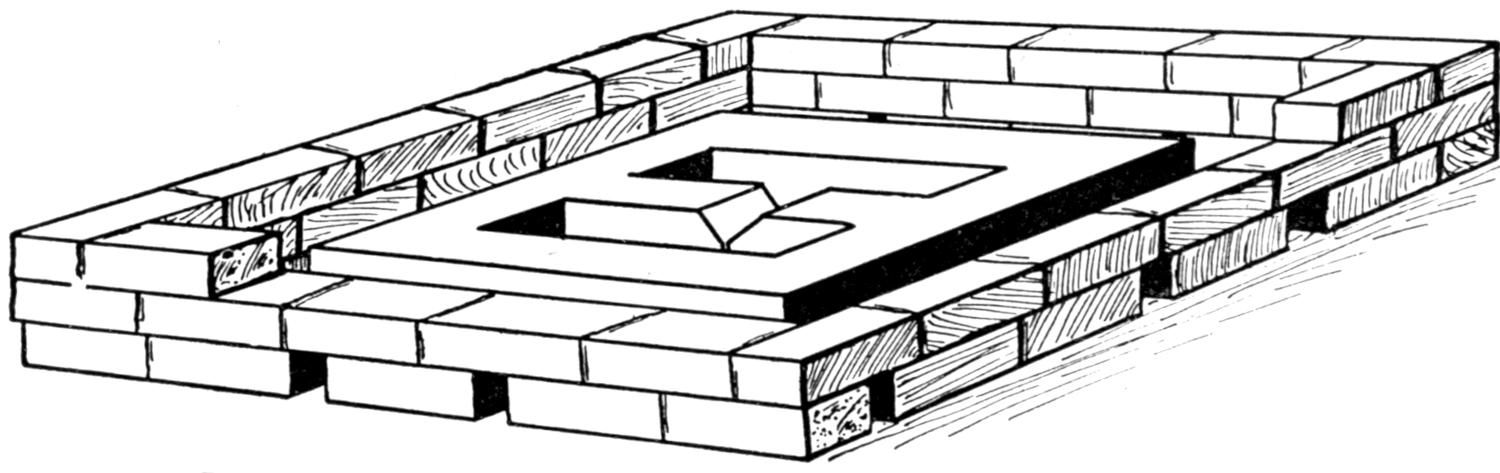

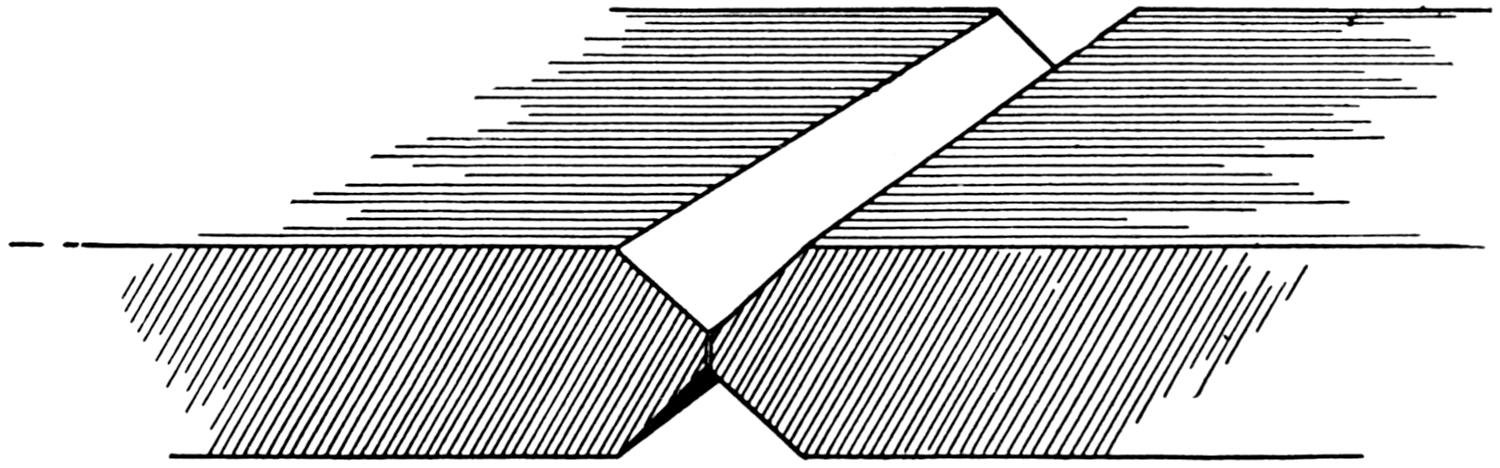

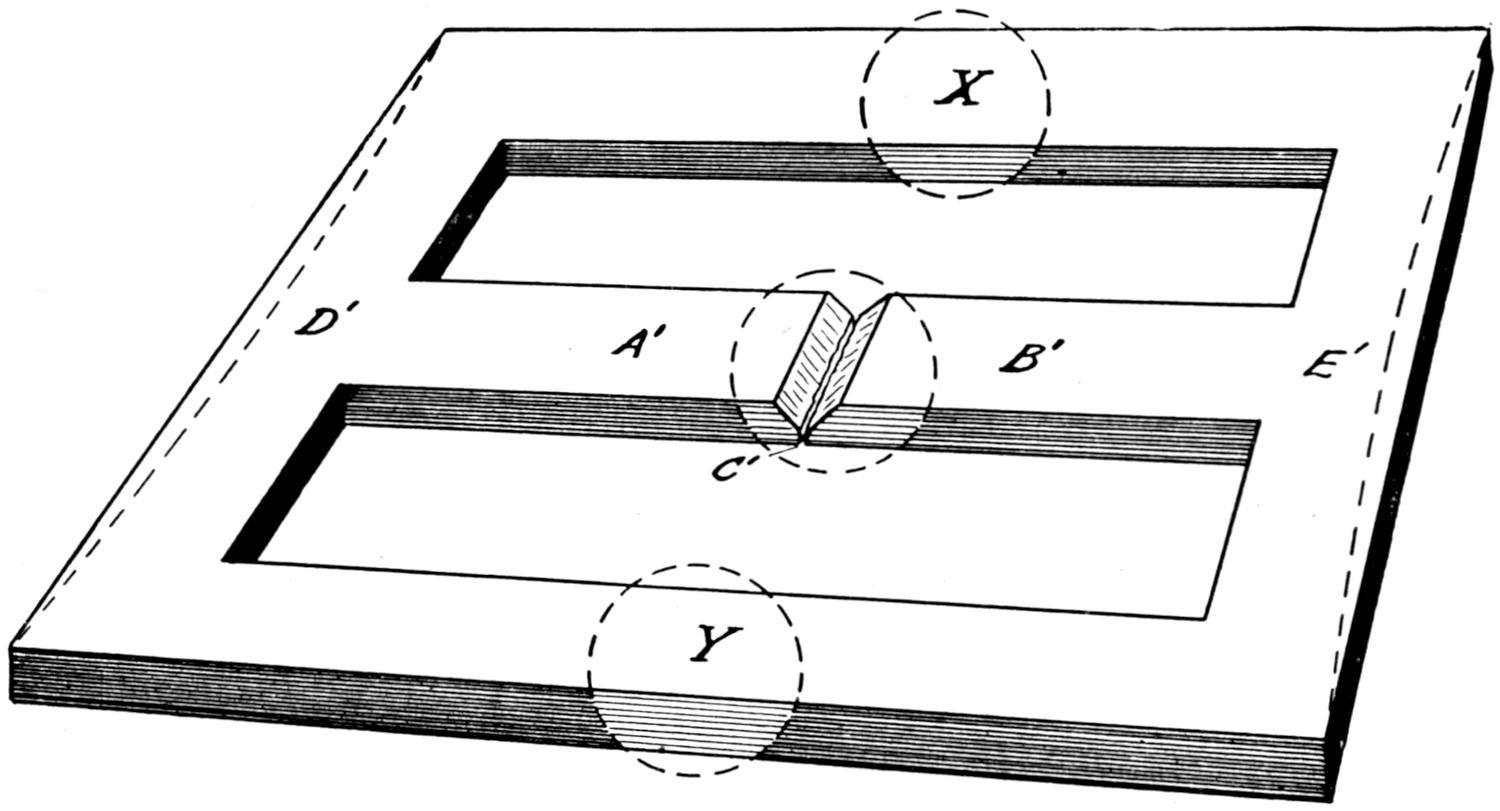

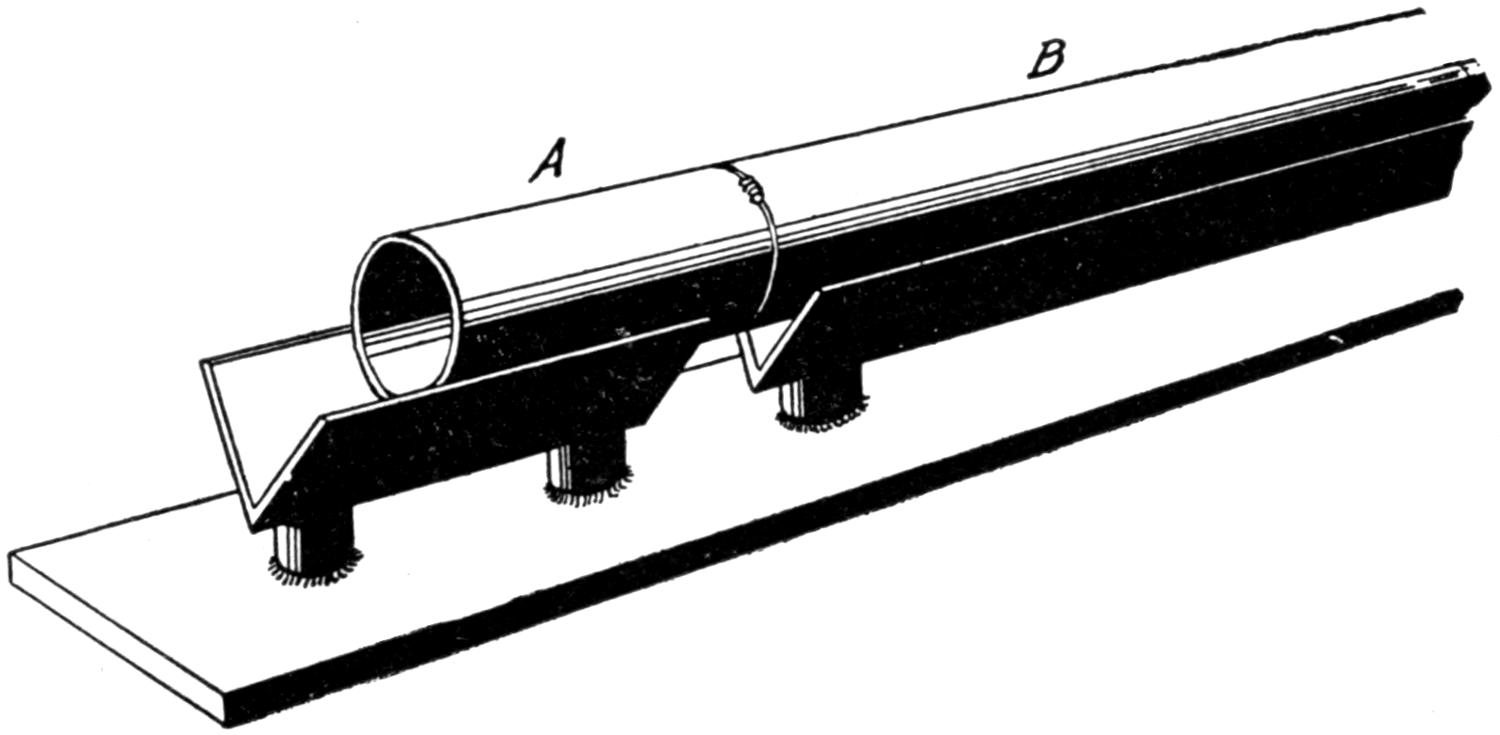

Fig. 38.—Preheating Torch, Constructed of Black Iron Pipe, for Burning City Gas.

(62) When work is being preheated, it is best to have it protected from all drafts, to prevent warping. Possibly the most extensively used material for building up temporary ovens to hold the heat and protect the work from the air currents is fire brick and with it asbestos paper. When setting up an ordinary casting for preheating, these bricks are built up in builder’s fashion, about four inches away from the piece itself, as shown in Fig. 39, and practically level with the top of the piece. If charcoal is to be used, draft spaces are left in the first row of bricks as shown, and the charcoal ignited through the openings with the welding torch. The work to be welded should have the line of weld at the top if possible and be set up from the floor, or the surface[55] upon which the oven is resting, on one or two fire bricks, in order that the full benefit of the heat will be received. Asbestos paper is then laid across the top, and the oven will appear as in Fig. 40. When starting the fire, a layer of charcoal, a matter of two or three inches thick, is at first used, but as the chill is taken off the piece the oven can be filled to the top, and usually this is enough to complete the work.

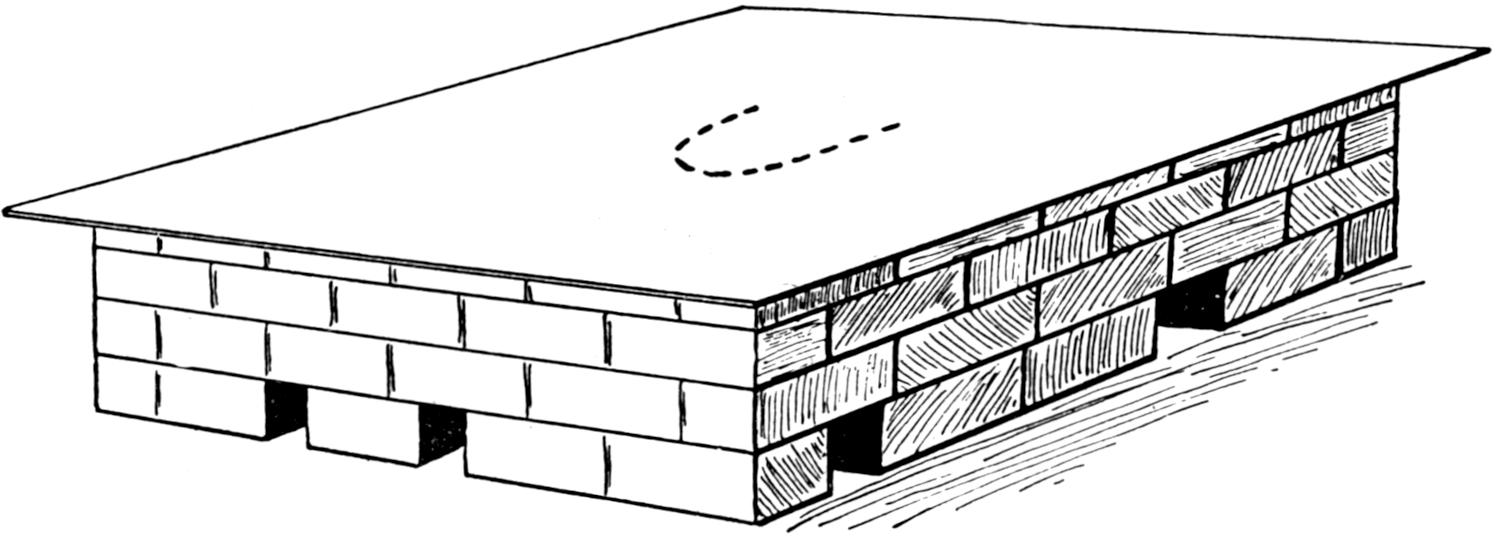

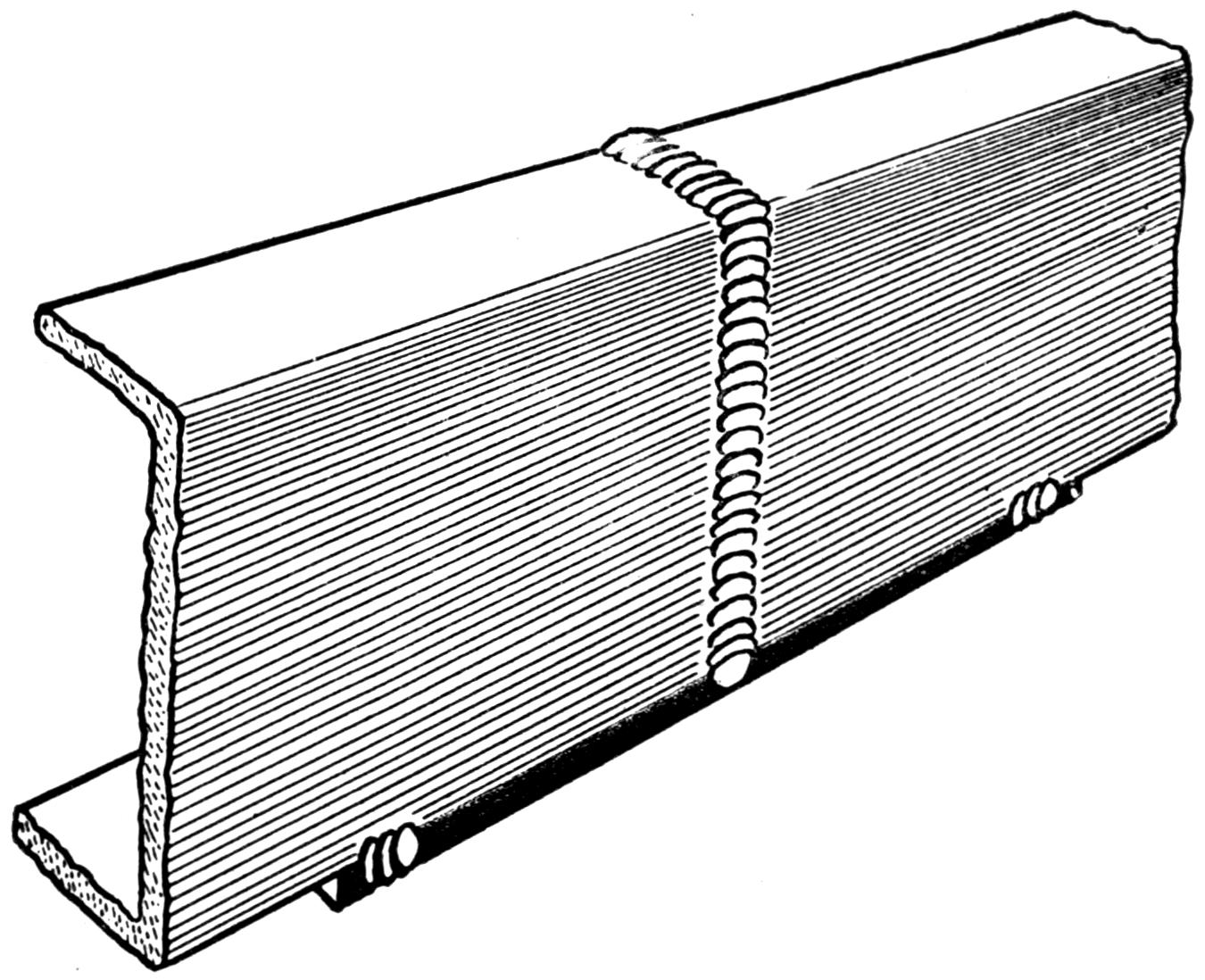

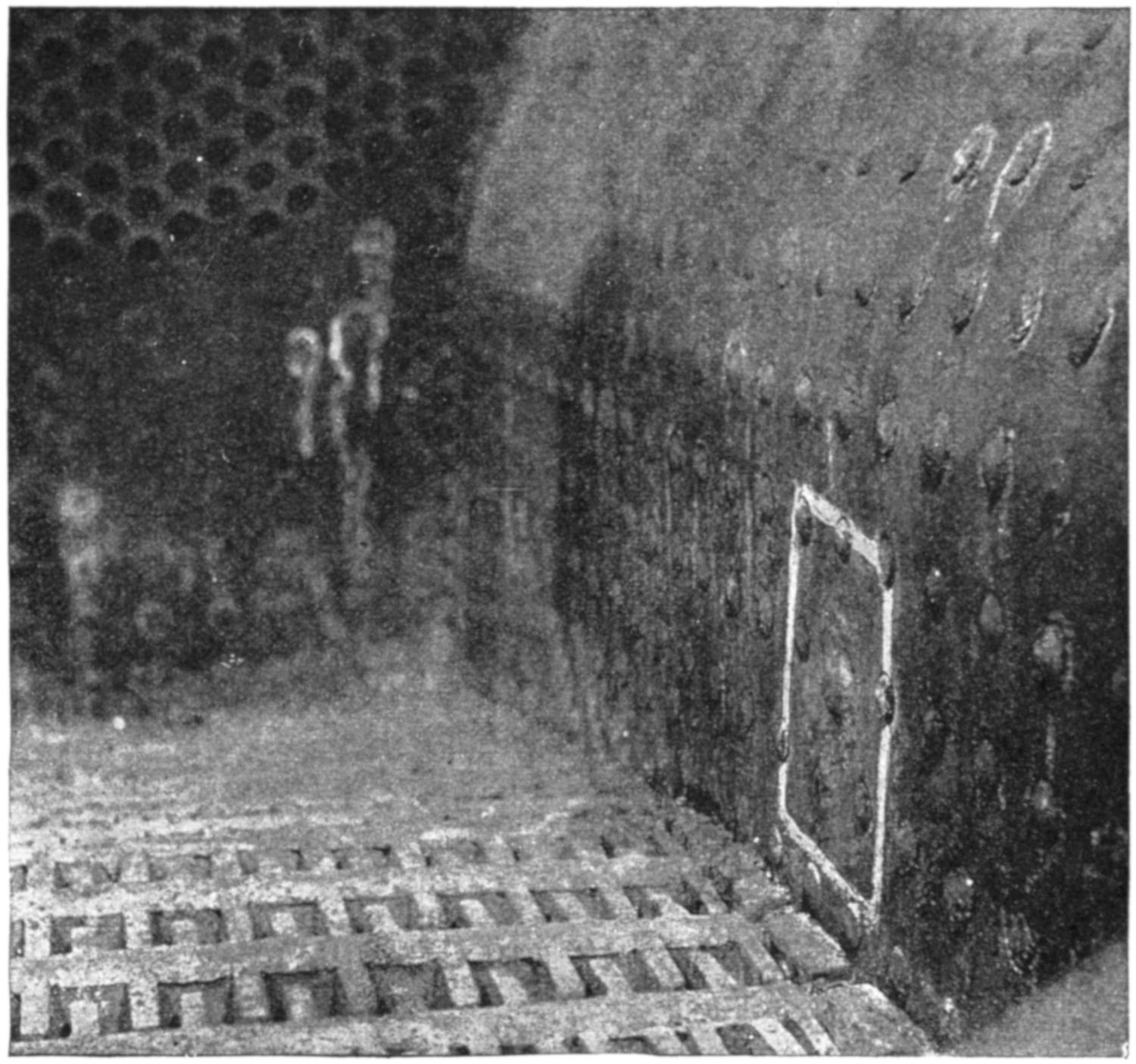

Fig. 39.—Temporary Preheating Oven, Built of Fire Brick.

Fig. 40.—Temporary Preheating Oven of Fire Bricks Covered with Asbestos Paper.

(63) In order to protect the operator, when working over hot fires, it is recommended that the asbestos covering be left on, and that only a small section immediately in the vicinity of the weld be removed, which can be accomplished by cutting a “U” in the paper as shown by the dotted lines in Fig. 40. This can be turned back, exposing the place which is to be welded, and at the same time protecting the operator, to a large extent, from the unnecessary heat. When the weld is finished, this lap can be turned back and the piece allowed to cool. On pieces which require turning and must be welded in several different positions, the preheating oven, as it is called, should be built considerably larger, to provide for handling the work. It must be remembered that during the entire operation, the piece should be left inside the oven and should not be removed to a welding[56] table. Some beginners make the mistake of doing this. When welding with the charcoal in closed rooms, during the winter months, the fumes will be found to be very disagreeable and means should be taken to provide indirect ventilation, otherwise the welders will be troubled with headaches and smarting eyes.

Fig. 41.—Showing How Oven is Built when Preheating Torch is to be Used. Torch is Shown at (A).

(64) When using preheating torches, the ovens are built much closer to the work and do not have the openings along the bottom row of bricks. They are made as tight as possible, and in some cases it will be found advisable to build up the walls with two layers of bricks, with asbestos paper between them, in order to hold the heat and cause the work to heat up in a more uniform manner. A hole is left in one end of the oven, through which the flame of the preheating torch is introduced as shown in Fig. 41. It is not thought best to have the torch flame come in direct contact with the work which is being preheated, and a baffling plate of metal or brick is placed directly in front of the flame, in order to spread it around the oven. Judgment will have to be used in all such work.

(65) The setting up of the work, when preheating, is an important point overlooked by many welders, especially so in the case of aluminum. Care should be taken to see that the[57] work has a good solid setting and is braced at a sufficient number of points, to prevent its sagging when in a preheated condition. Many times when working on rough surfaces, a few firebricks distributed around the bottom of the oven with a dab of putty, clay, or retort cement, placed upon them, will form an excellent cushion upon which the work can rest and the operator may feel confident that no sagging will occur.

[58]

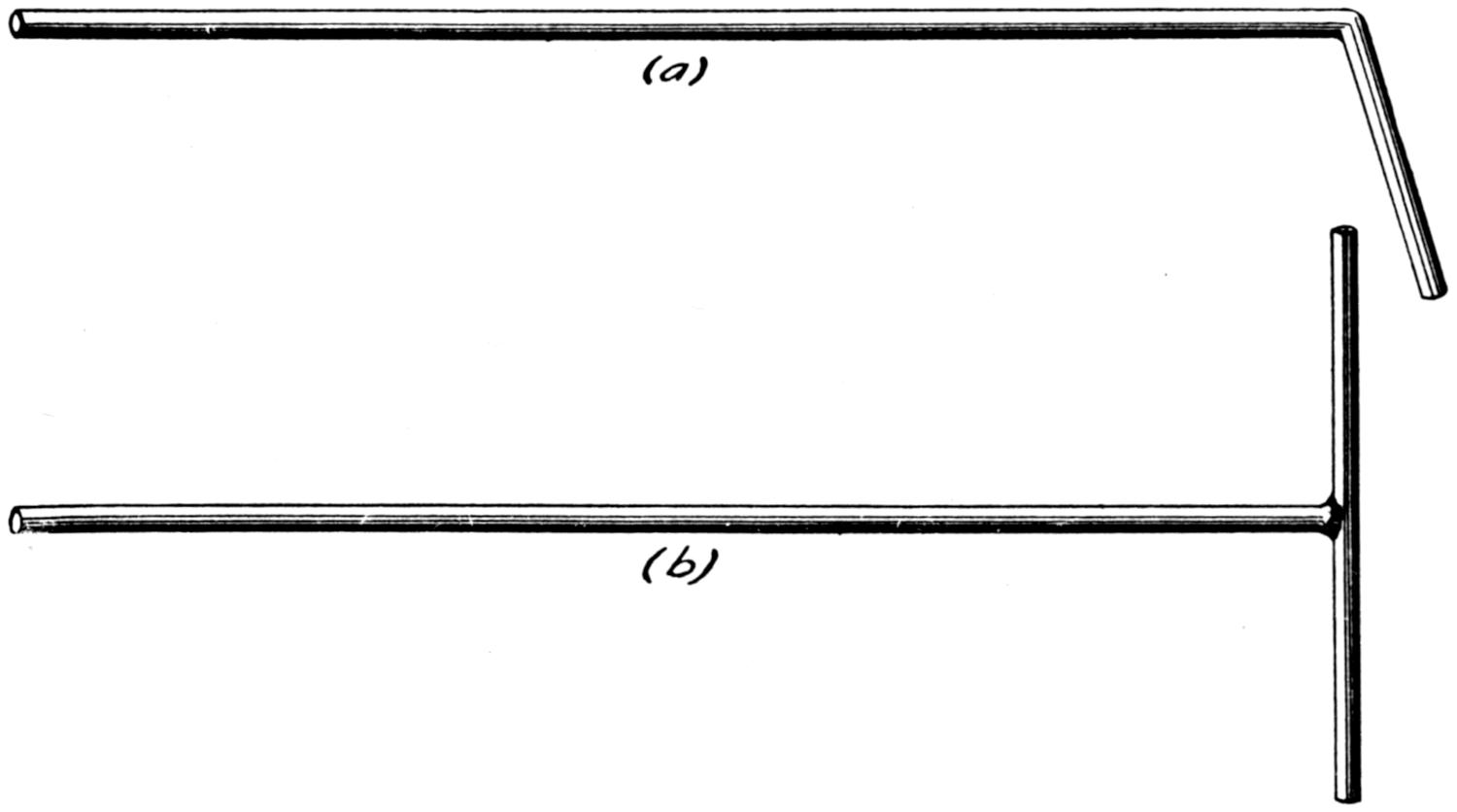

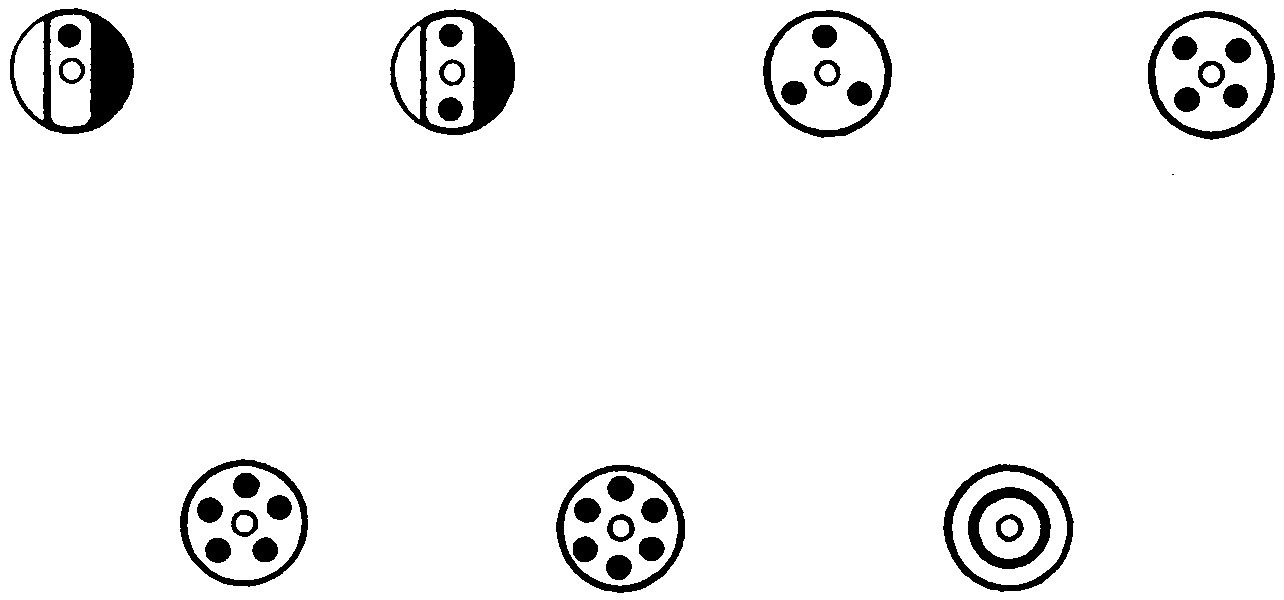

(66) In order to know how to weld, it is quite imperative that the operator first know the kind of metal he is to work on. It is surprising to find how few welders know their metals thoroughly. An incident might be cited where some welders depend upon the sparks given off by the emery wheel in determining the kind of metal they are about to weld. They will approach the wheel; grind off their work, noting the sparks; return to their welding table; choose their filler rods and do their welding without any delay whatsoever, much to the consternation of their fellow workers. There are four simple ways in common use to distinguish between cast iron, malleable iron, and steel; they are: By the cross-section of a fresh break, by application of the welding torch, by the sparks given off when applied to the emery wheel and by the chisel test.

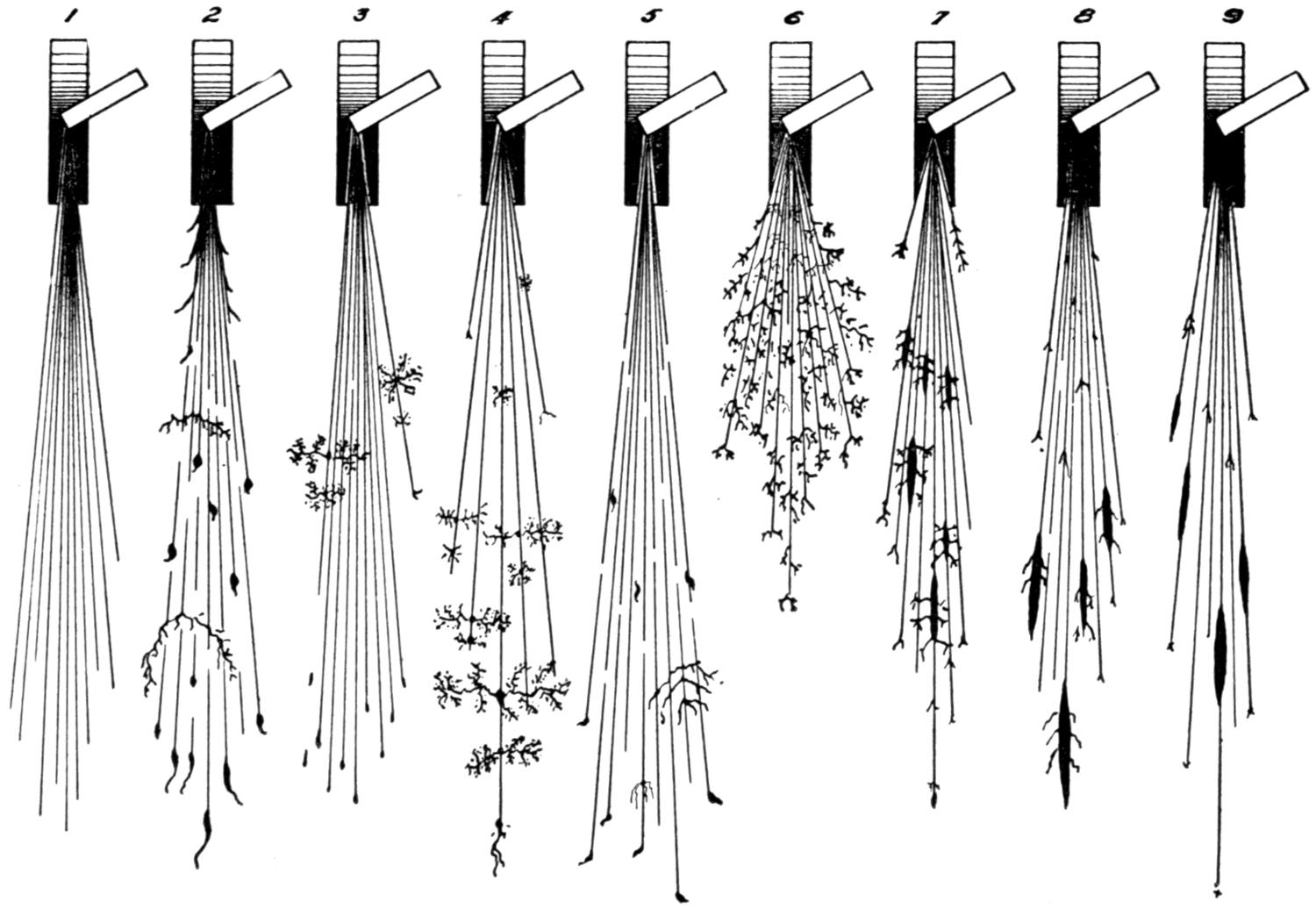

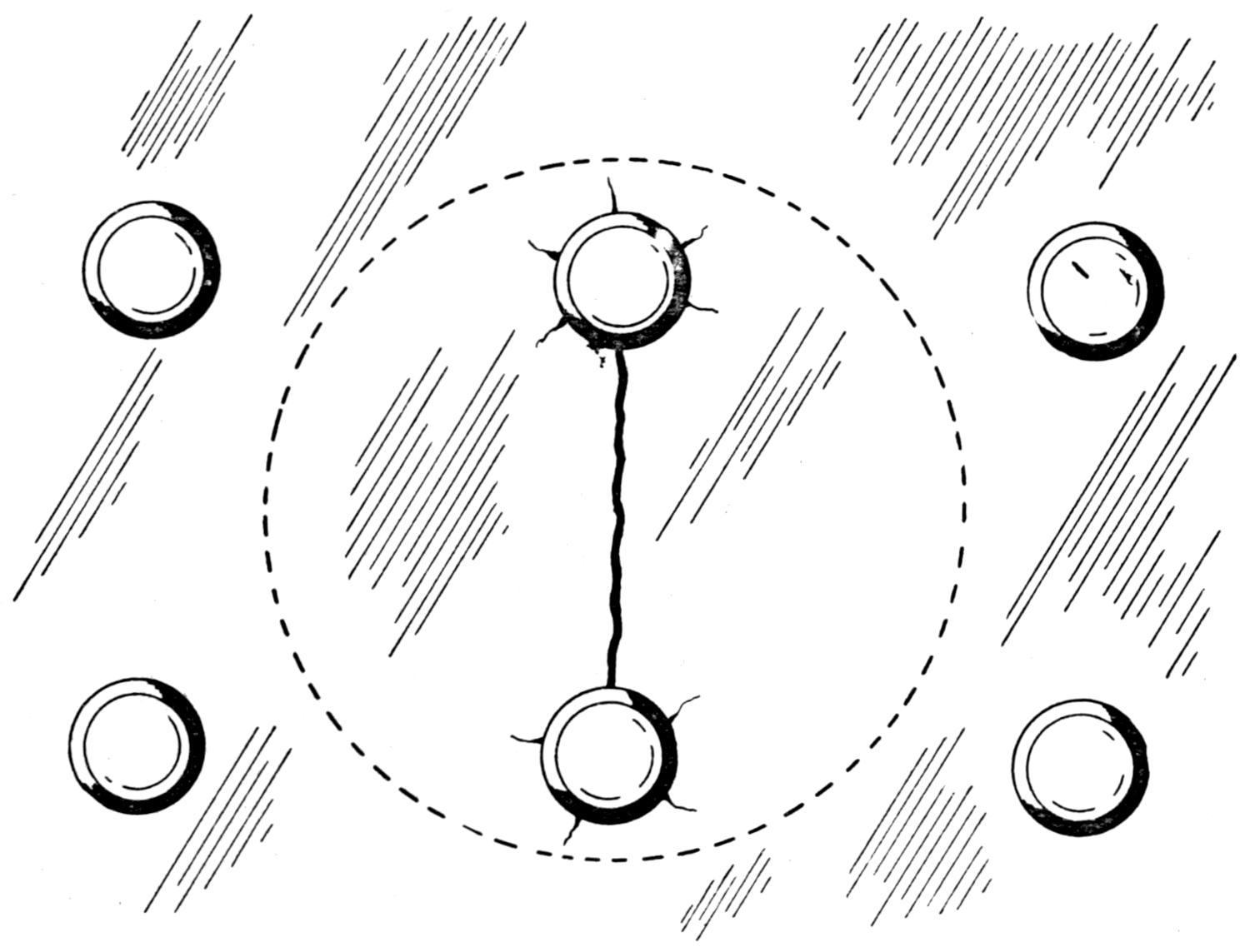

Fig. 42.—Characteristic Sparks of Different Irons and Steels Thrown off by an Emery Wheel. Wheel should be Clean Cutting and Run about 7000 Feet per Minute.

(1) Shows cast iron. No sparks unless impurities are present.

(2) Is wrought iron almost free from carbon. Heated particles thrown from wheel follow straight line. These become broader and more luminous some distance from their source of heat.

(3) Illustrates mild steel action. Small amount of carbon present causes a division or forking of the luminous streak.

(4) Shows the effect of increasing the carbon from 0.50 to 0.85 per cent in mild steel. The iron spark lines diminish: the forking of the luminous streak occurs more frequently, being subdivided by re-explosions from smaller particles.

(5) Is a piece of carbon tool steel. The iron lines are practically eliminated with the increase of the explosions and subdivisions, causing display of figures.

(6) Gives the spark of high-speed steel, containing in addition to 65 per cent carbon, other alloying elements, chiefly tungsten and chromium.

(7) Represents a manganese spark. (Occasionally found in cast iron.)

(8) Shows spark thrown from old grade of “Mushett” steel.

(9) Represents a magnet steel spark.

(67) Externally cast iron usually has some sand on its surface and its cross-section shows the grain to be fine, even, and to have a dull grayish color. The surface of malleable iron contains no sand and its grain is very fine, such as cast iron, but slightly darker in color. A very fine steel veneer is on all surfaces of malleable iron, which is much lighter in color. When the welding torch is applied to cast iron, no sparks are given off, but when applied to malleable iron a bright spark is thrown off which breaks in falling, showing that the outside material is steel. These sparks soon cease and the metal which is molten is covered by a heavy oxide[59] or skin which recedes or draws away from the flame slightly, showing a very porous cast-iron interior. When brought in contact with the emery wheel steel sparks, which are very luminous and break in falling, are given off first in the case of malleable iron, but they soon change to the dull red spark[60] of cast iron. When a chisel is applied to cast iron, the iron chips off; when applied to malleable iron the edge will curl up, then chip off when the cast iron is reached. The cross-section of cast steel shows a bright, coarse, silvery gray grain. When the torch is applied a distinctively steel spark which is luminous and breaks in falling is thrown off. When applied to the emery wheel steel sparks are thrown off; when the edge is chipped by a chisel it will curl up.

METHODS OF DISTINGUISHING METALS

| Here are five methods, any one or all of which may be used to learn the nature of common castings which might confuse the welder. | ||||

| No. | Test. | Malleable Iron. | Cast Steel. | Cast Iron. |

|---|---|---|---|---|

| 1 | Outside Appearance. | Generally smooth and free from all sand, weighs about same as cast iron. | Rough surface with sand in evidence, weighs much more than cast iron. | Surface fairly smooth but generally shows some sand. |

| 2 | Cross-section Test. | Ring of bright steel crystals outside, with darker iron crystals inside. | Large, bright, luminous, silver crystals. | Fine, uniform, dark gray, crystals. |

| 3 | Emery Wheel Test. | Few steel sparks and then iron sparks from interior. | Bright, luminous sparks that break in falling. | Dull red sparks that do not break. |

| 4 | Chisel Test. | Surface will curl and interior break off. | Will curl before breaking. | Will chip off. |

| 5 | Torch Test. | Gives way before flame and delivers few sparks. Metal becomes porous. | Gives forth bright sparks that break in falling. | Gives no sparks except where there are impurities. |

Fig. 43.

[61]

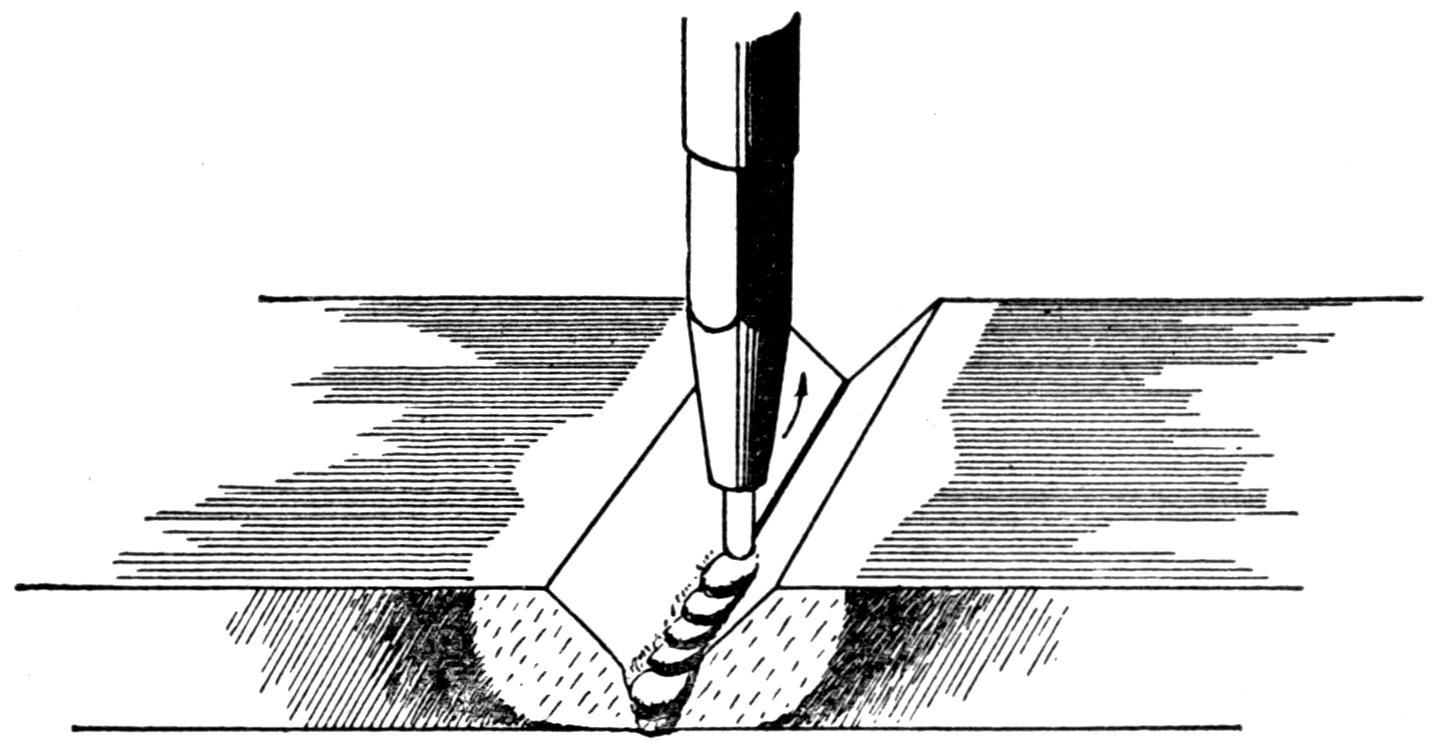

(68) The metal in the filler-rod should be the same in practically all cases as the metal to be welded. There are few exceptions to this rule, but the principal one is that of malleable iron. The cast iron in the rods is of a very good grade and generally much better than the piece to be worked upon. To permit the ready flow of the rod and eliminate oxidation, as much as possible, three per cent of silica is generally used in the casting of filler-rods for cast iron welding. Piston rings and other scrap iron should not be used for filler-rods, as they contain many impurities such as core-sand, dirt, grease, etc., which will ruin the weld. It is disheartening to see some operators attempt to economize on the filler-rod. It is not an uncommon sight to see several dollars’ worth of gas and the same amount of the welder’s time, together with a few cents’ worth of filler rods all lost, and the operator’s reputation ruined. This, because an attempt is made to save the few cents involved in the filler-rods by substituting a rod of a very poor grade.